High-temperature-resistant film and preparation method thereof

A high-temperature-resistant and thin-film technology, applied in the field of high-temperature-resistant thin films and their preparation, can solve the problems of high-temperature resistance, many structural layers, complex parameters, etc., and achieve good injection molding performance, good transparency, and heat-resistant flexure The effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

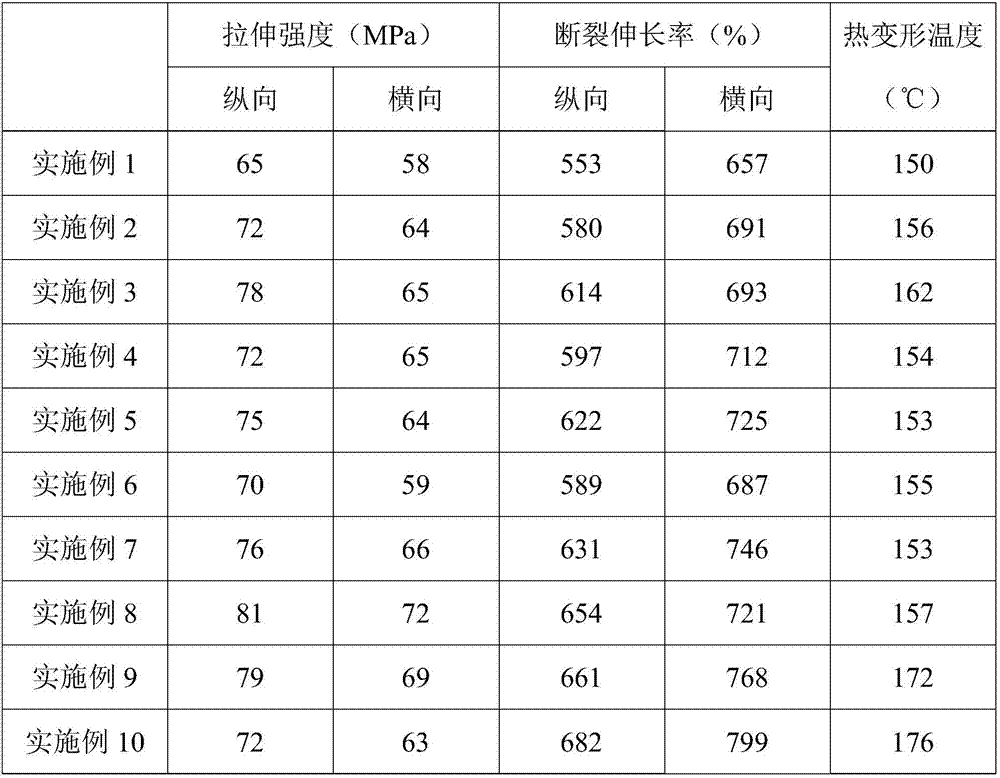

Examples

Embodiment 1

[0028] The high-temperature-resistant film of this embodiment includes three parts: an outer layer, a middle layer and an inner layer. The weight of the outer layer accounts for 10% of the total weight of the film, the weight of the middle layer accounts for 60% of the total weight of the film, and the weight of the inner layer accounts for 30% of the total weight of the film. , where, by weight percentage,

[0029] The raw materials for the preparation of the outer and inner layers are PP M800E;

[0030] The raw material for the middle layer is composed of 80% MDPE 5400 and 20% LDPE TN00.

[0031] The preparation method of the high temperature resistant film of the present embodiment is as follows:

[0032] 1) mixing materials, mixing the preparation raw materials of the middle layer of the formula amount to prepare the middle layer raw material mixture of the high temperature resistant film;

[0033] 2) batching, the middle layer raw material mixture of the high temperature ...

Embodiment 2

[0036] The high-temperature-resistant film of this embodiment includes three parts: an outer layer, a middle layer, and an inner layer. The weight of the outer layer accounts for 30% of the total weight of the film, the weight of the middle layer accounts for 50% of the total weight of the film, and the weight of the inner layer accounts for 20% of the total weight of the film. , where, by weight percentage,

[0037] The raw materials for the preparation of the outer and inner layers are PP M800E;

[0038] The raw material for the middle layer is composed of 60% MDPE 5400 and 40% LDPE TN00.

[0039] The preparation method of the high temperature resistant film of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

Embodiment 3

[0041] The high-temperature-resistant film of this embodiment includes three parts: an outer layer, a middle layer and an inner layer. The weight of the outer layer accounts for 30% of the total weight of the film, the weight of the middle layer accounts for 60% of the total weight of the film, and the weight of the inner layer accounts for 10% of the total weight of the film. , where, by weight percentage,

[0042] The raw materials for the preparation of the outer and inner layers are PP M800E;

[0043] The raw material for the middle layer is composed of 70% MDPE 5400 and 30% LDPE TN00.

[0044] The preparation method of the high temperature resistant film of this embodiment is the same as that of Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com