Patents

Literature

50results about How to "Reduce solid solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

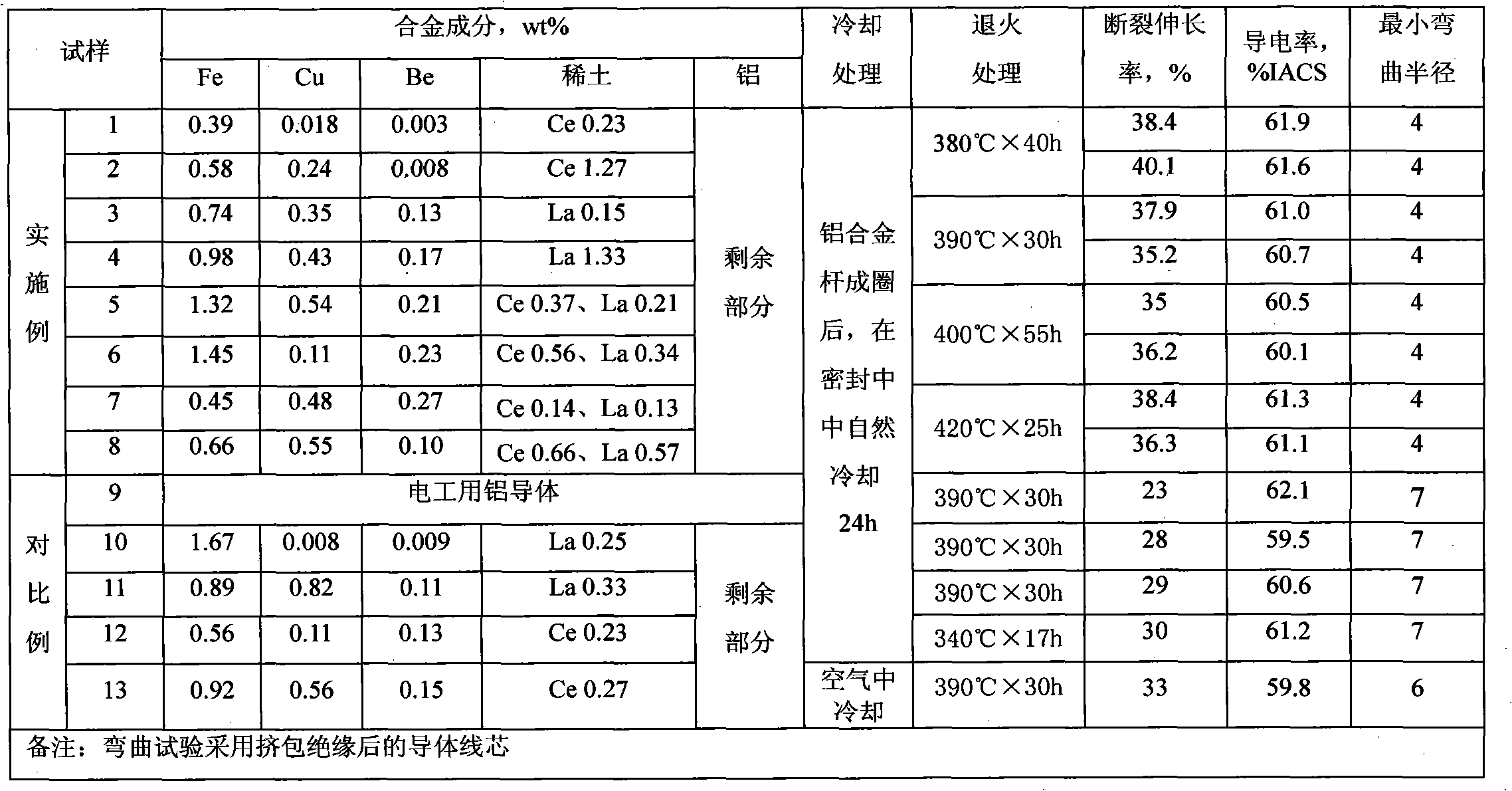

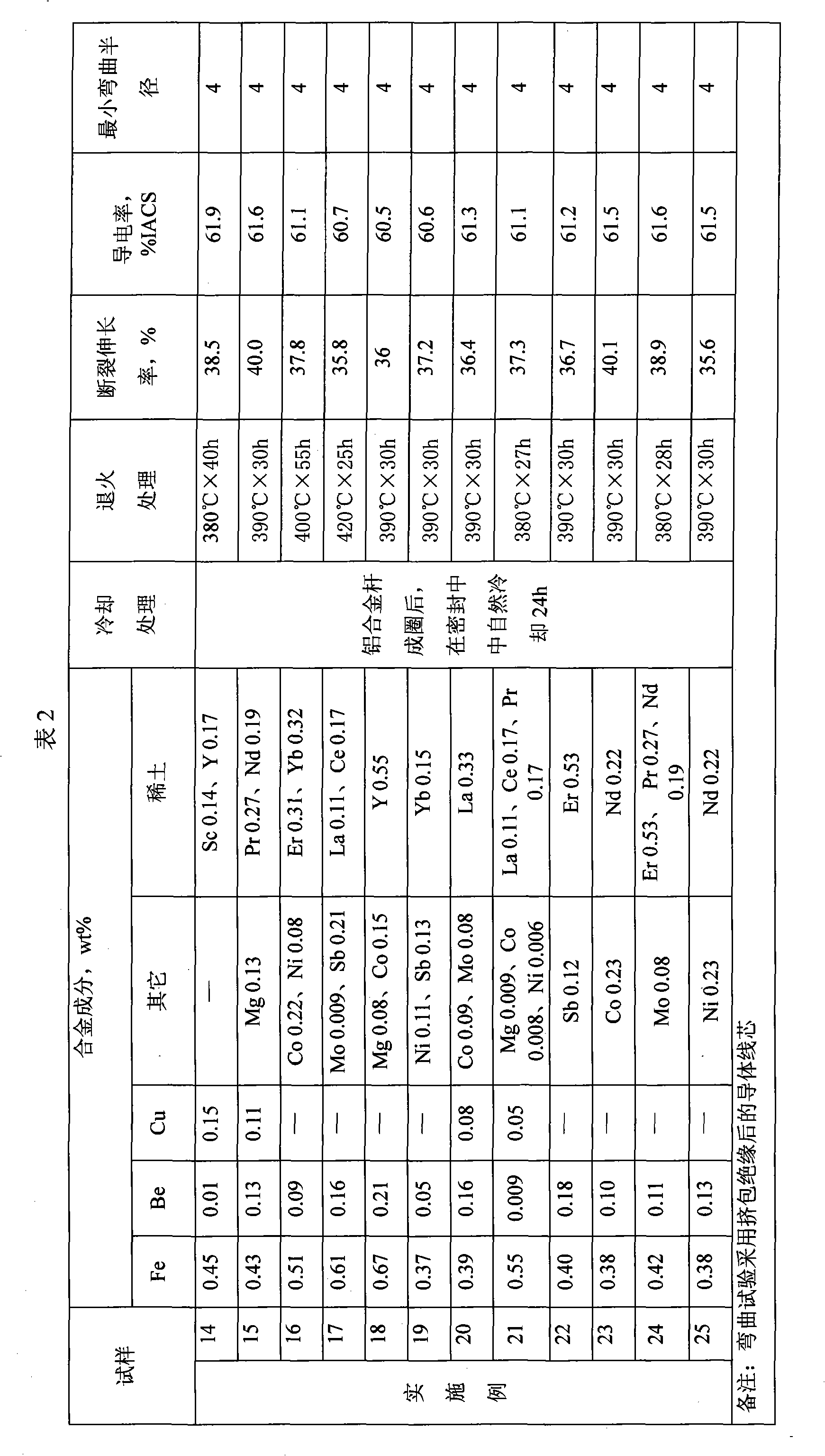

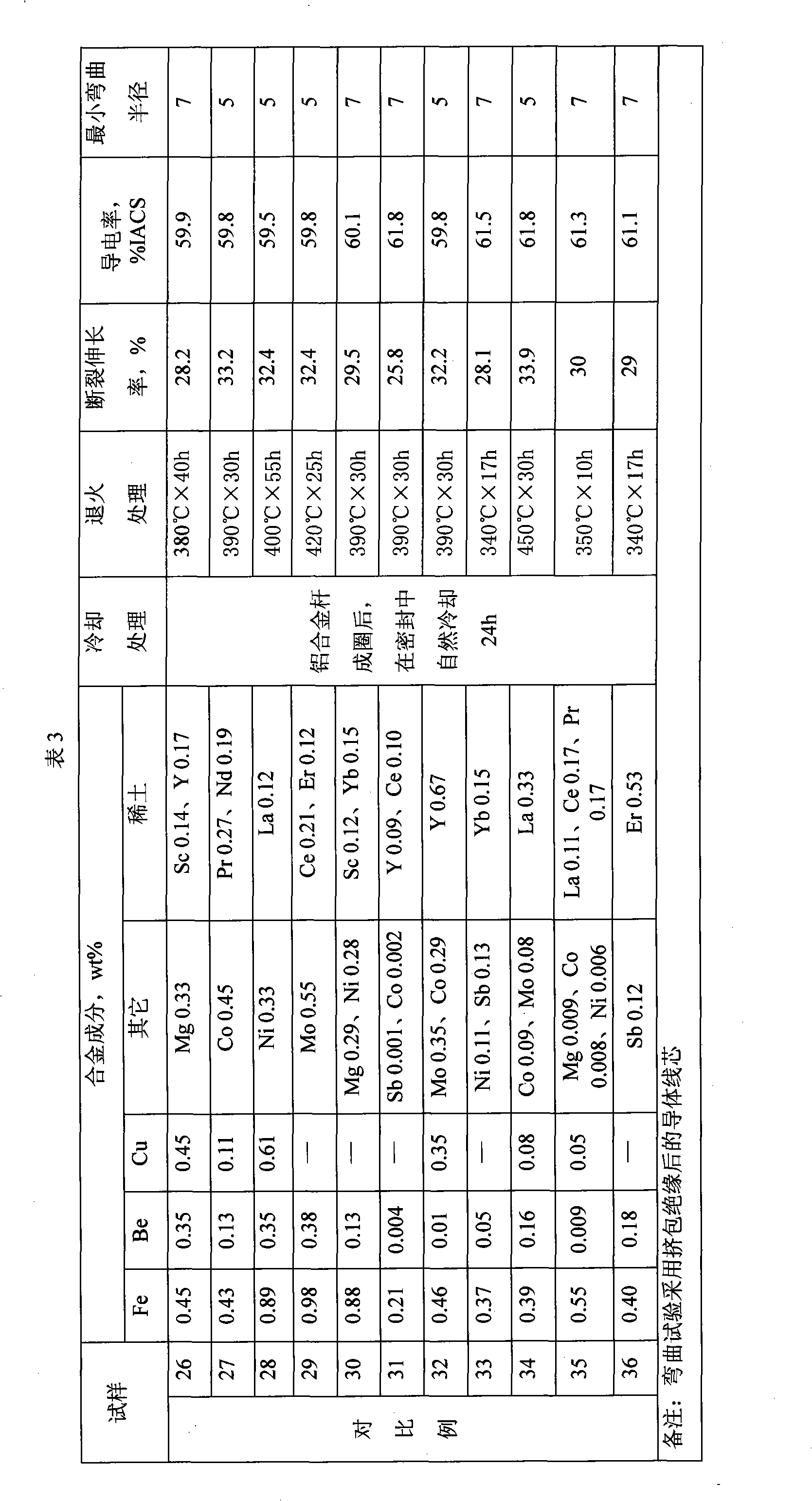

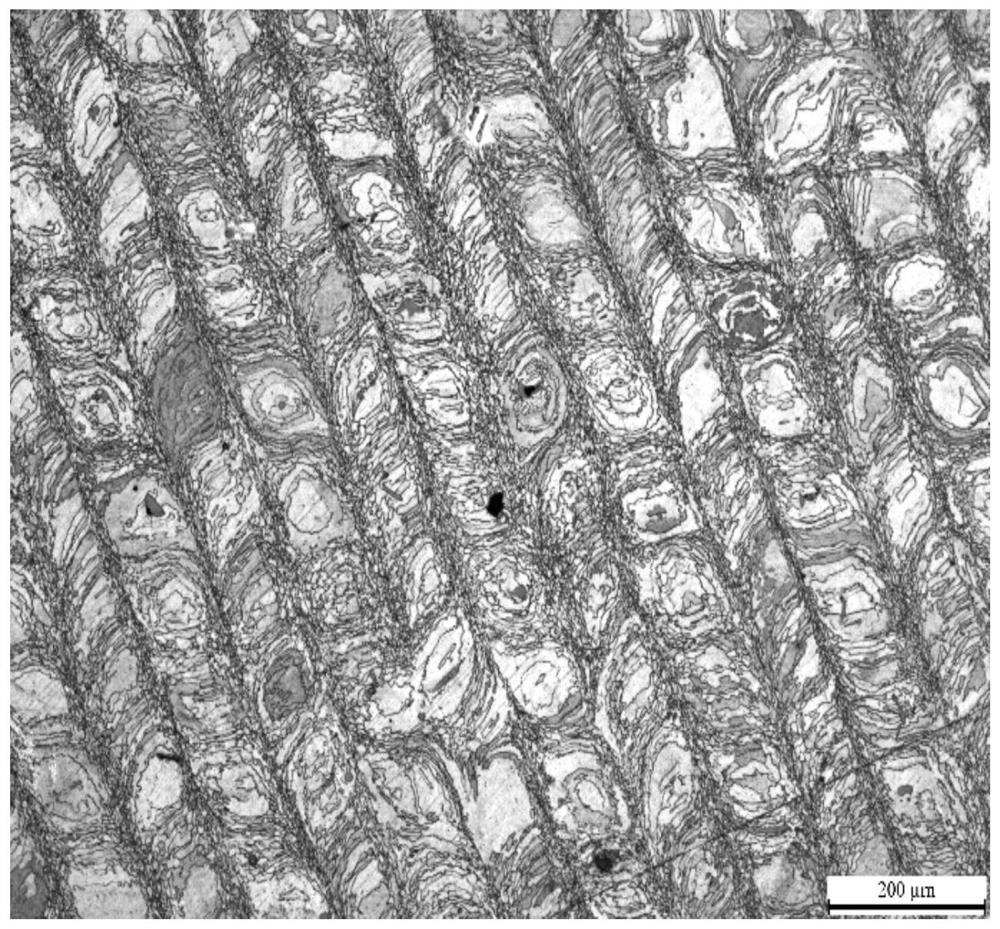

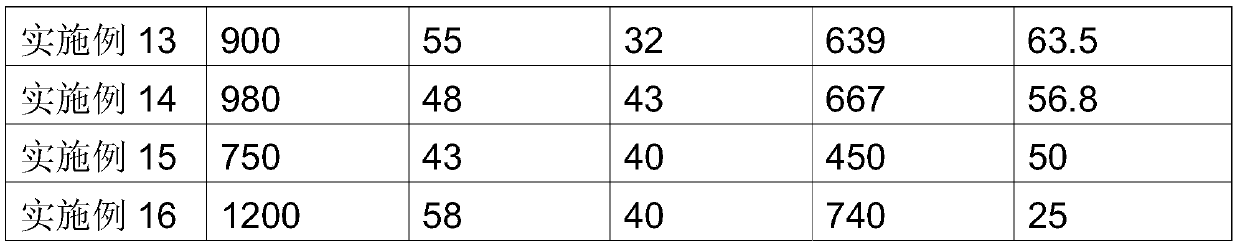

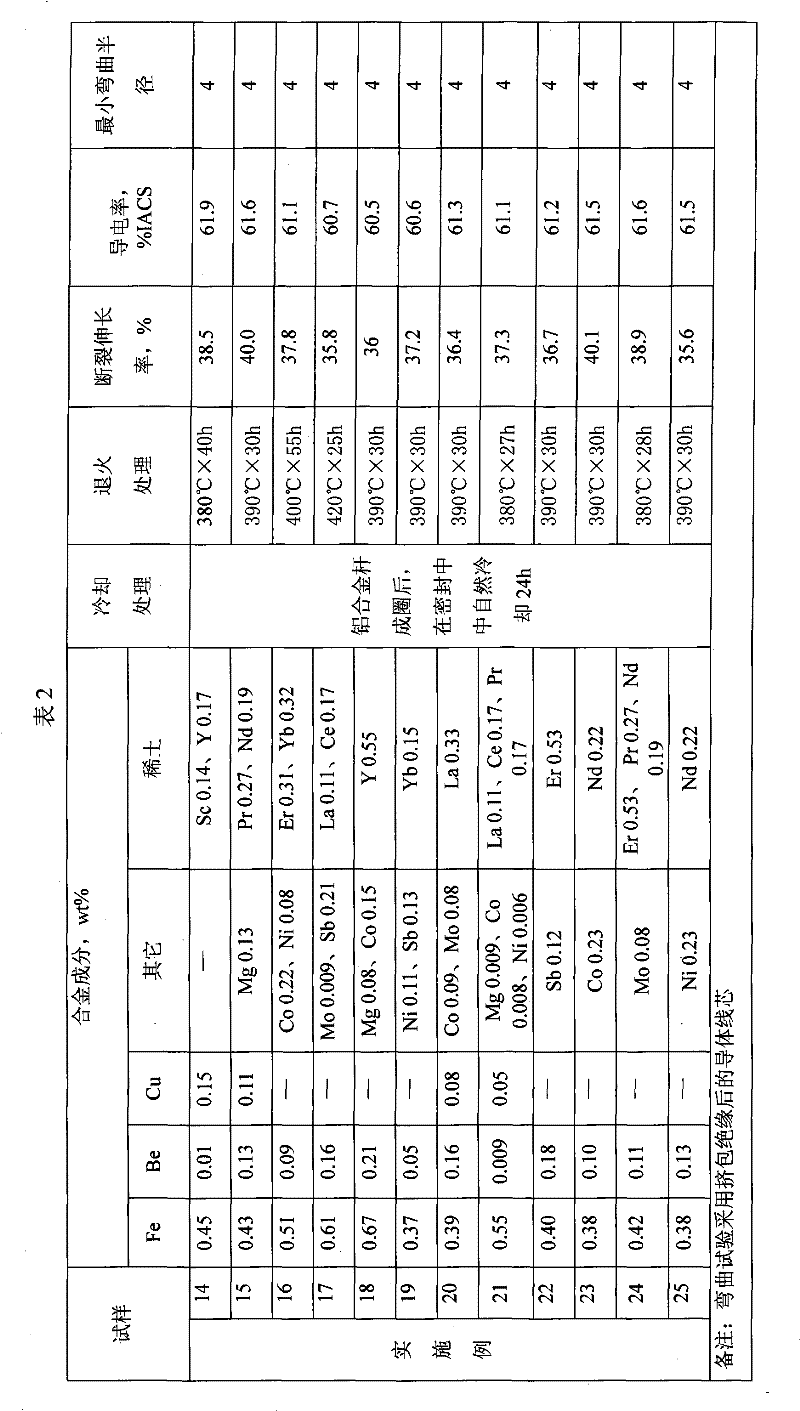

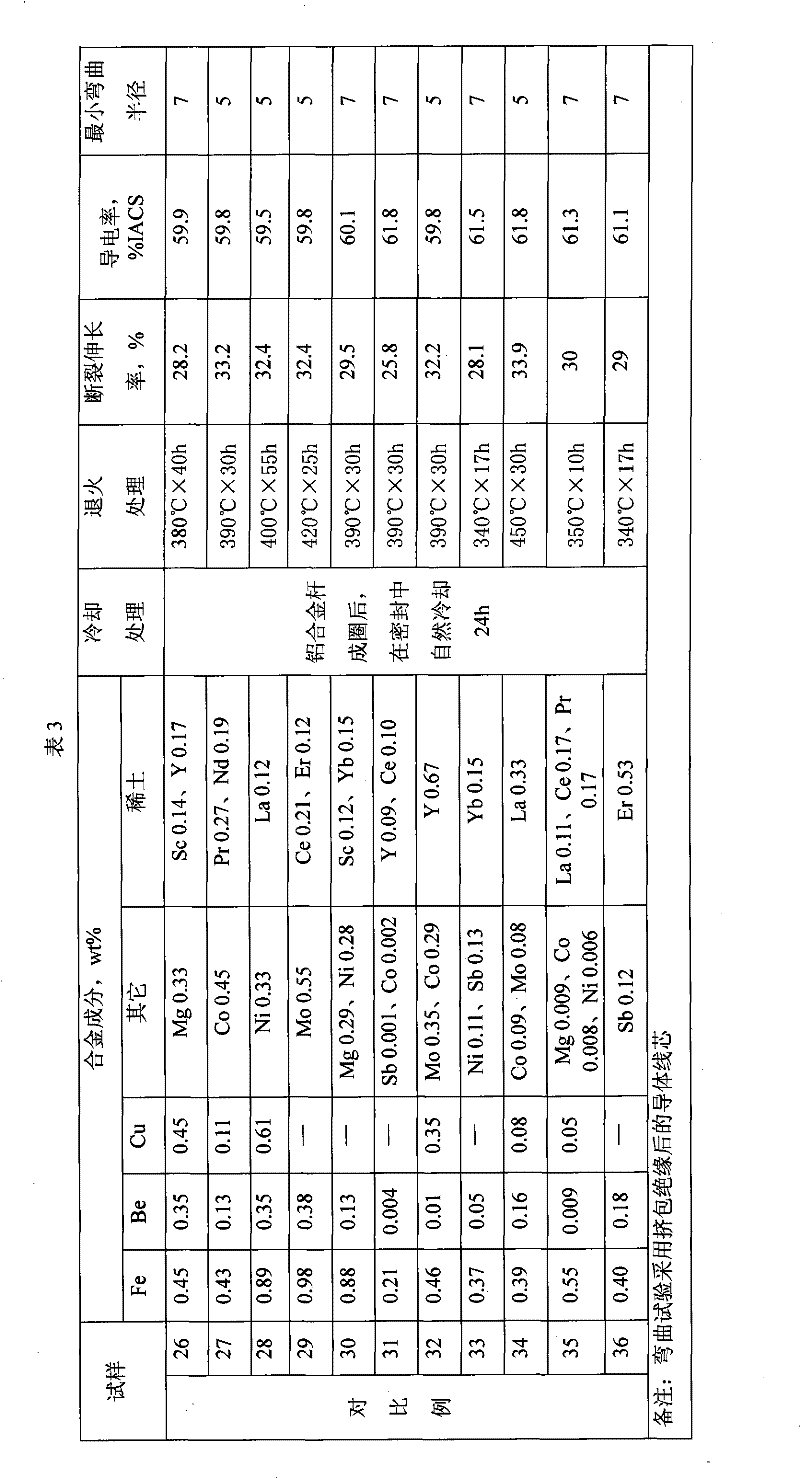

Super-soft aluminum alloy conductor and preparation method thereof

The invention provides a super-soft aluminum alloy conductor and a preparation method thereof. The aluminum alloy conductor comprises the following materials in percentage by weight: 0.3 to 1.5 percent of Fe, 0.001 to 0.3 percent of Be, 0.005 to 0.6 percent of Cu, 0.1 to 1.5 percent of rare earth, less than or equal to 0.08 percent of Si, less than or equal to 0.15 percent of total inevitable impurities, and the balance of aluminum. The aluminum alloy is drawn into an aluminum alloy wire by melting, continuous casting and continuous rolling, and the aluminum alloy wire is put into an annealing furnace and annealed for 20 to 40 hours at the temperature of between 380 and 420 DEG C to form the aluminum alloy conductor, wherein the annealing is performed in a sealed heat insulation device under the protection of nitrogen. The aluminum alloy has extremely good toughness and elongation performance, the coefficient of elongation reaches or exceeds 35 percent and even can reach 40 percent, and the electric conductivity can reach 60 percent IACS.

Owner:ANHUI JOY SENSE CABLE

Preparation method of high-conductivity aluminum alloy

InactiveCN103276261AHigh affinityPlay the role of hydrogen absorption and hydrogen fixationRare-earth elementElectrical conductor

The invention relates to a preparation method of high-conductivity aluminum alloy and belongs to the field of nonferrous metal materials. The preparation method comprises the following steps of: preparing an aluminum ingot comprising the following alloy elements in percentage by weight: 4.5 to 13.5 percent of Si (silicon), 0.1 to 1.5 percent of Mg (magnesium) and not more than 0.1 percent of impurity elements, smelting the aluminum ingot in a furnace, adding 0.1 to 0.3 percent of zirconium which serves as additive for the alloying treatment, uniformly mixing, then adding 0.1 to 1.35 percent of rare-earth element for degeneration, purifying, degassing and deslagging, and covering the surface of aluminum liquid with a solid covering agent; casting to prepare the aluminum alloy conductor material; and carrying out the first-stage aging treatment and the second-stage aging treatment on the aluminum alloy conductor material, discharging and cooling with air. The manufactured aluminum-silicon alloy can meet the requirements on the aluminum alloy material conductivity and the mechanical property; and moreover, the preparation process is simple, the cost is low, and the mass production is easy to realize.

Owner:JIANGSU UNIV

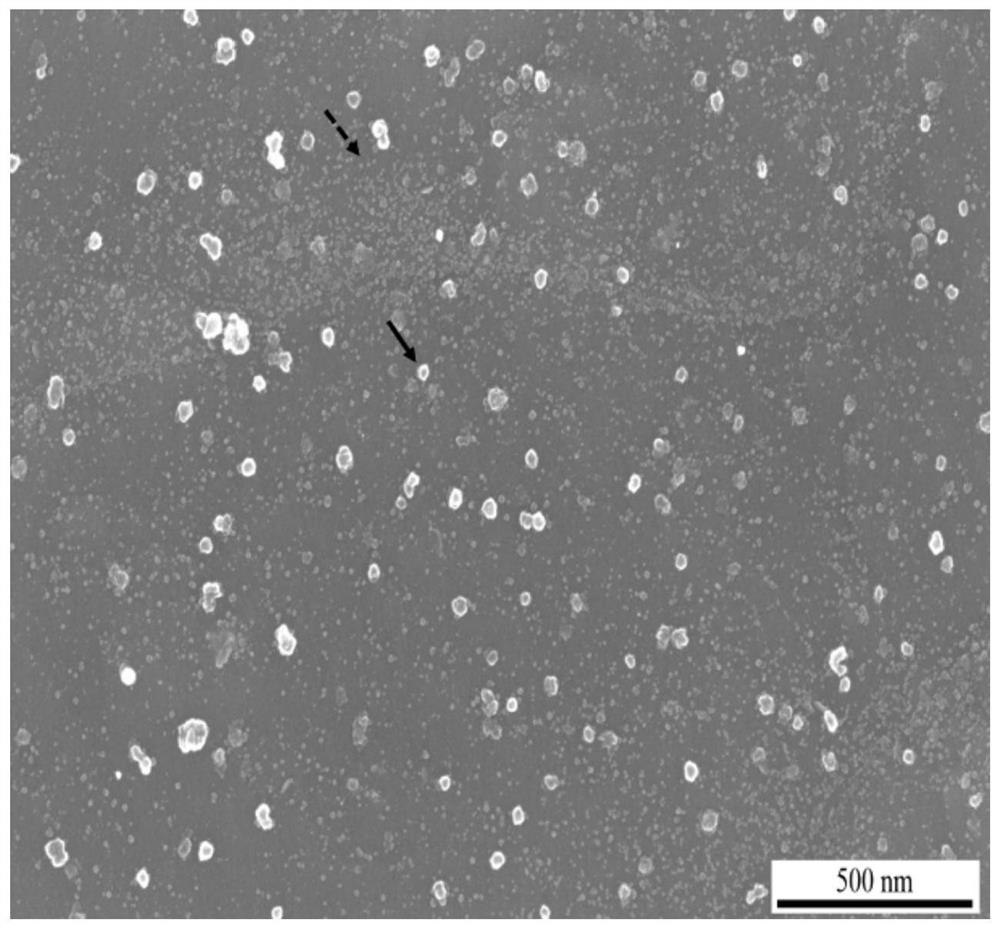

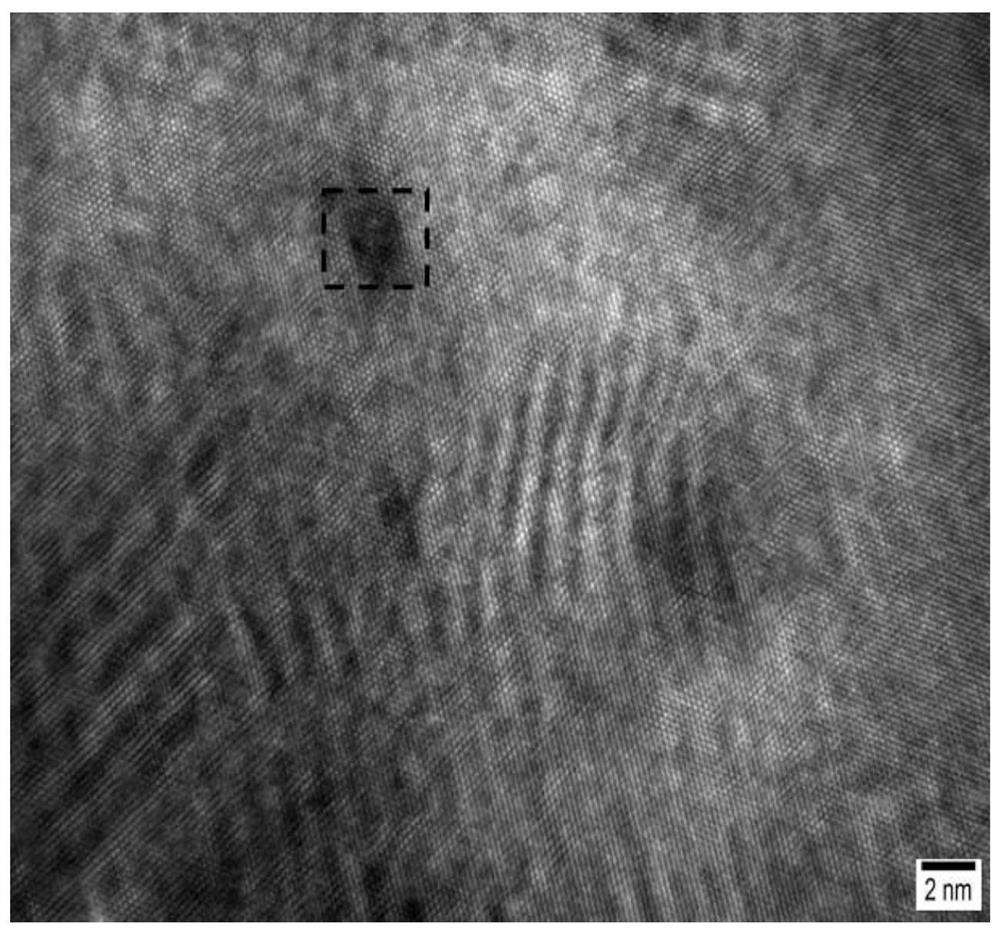

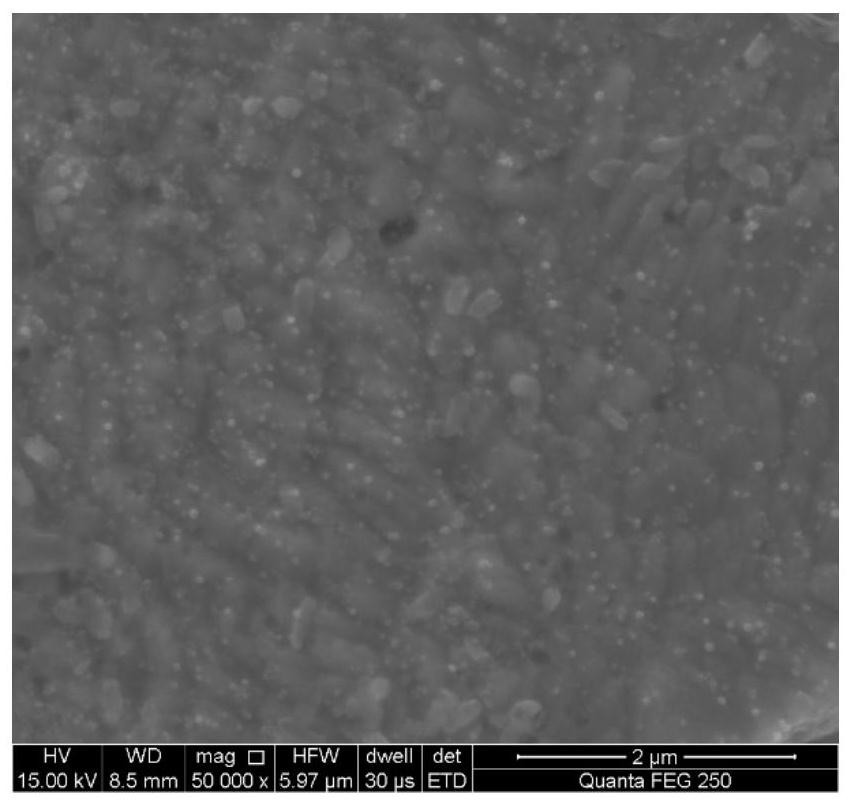

High-strength and high-conductivity Cu-Cr-Nb alloy with double-peak grain size and double-scale nano-phase reinforcing function

ActiveCN112391556AHigh plastic conductivityImprove conductivityAdditive manufacturing apparatusTransportation and packagingElectrically conductiveCopper matrix

The invention provides a high-strength and high-conductivity Cu-Cr-Nb alloy with a double-peak grain size and a double-scale nano-phase reinforcing function, and belongs to the field of additive manufacturing and high-strength and high-conductivity copper alloys. In the designed alloy, the contents of Cr and Nb are 2.0-2.8 at% and 1-1.3 at% correspondingly, the atomic ratio of Cr to Nb is controlled to be slightly greater than 2:1, and a copper matrix is reinforced by nanophases such as a Cr2Nb phase and a Cr phase. According to the alloy, the high-performance Cu-Cr-Nb alloy with the double-peak grain size and the double-scale nano-phase reinforcing function is prepared through the cooperation of selective laser melting and a special heat treatment process. The tensile strength of the prepared Cu-Cr-Nb alloy at room temperature is larger than 800 MPa, the yield strength of the Cu-Cr-Nb alloy is larger than 710 MPa, the microhardness of the Cu-Cr-Nb alloy is not lower than 256 HV, the elongation of the Cu-Cr-Nb alloy is not lower than 25%, and the conductivity of the Cu-Cr-Nb alloy is not lower than 70% IACS. The tensile strength at 700 DEG C is 145-155 MPa.

Owner:CENT SOUTH UNIV

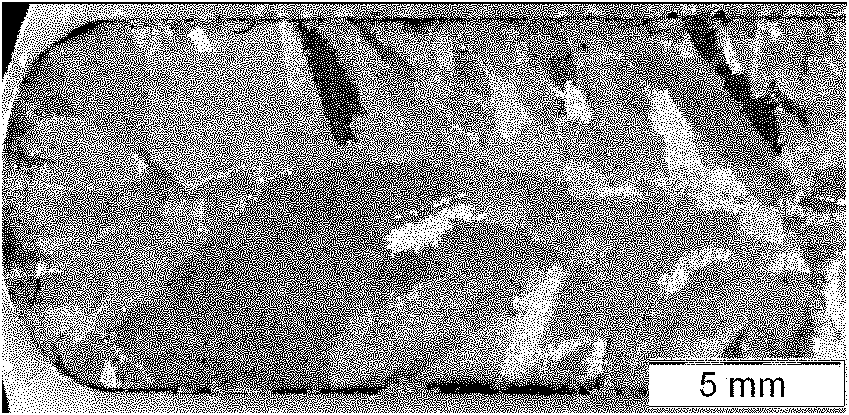

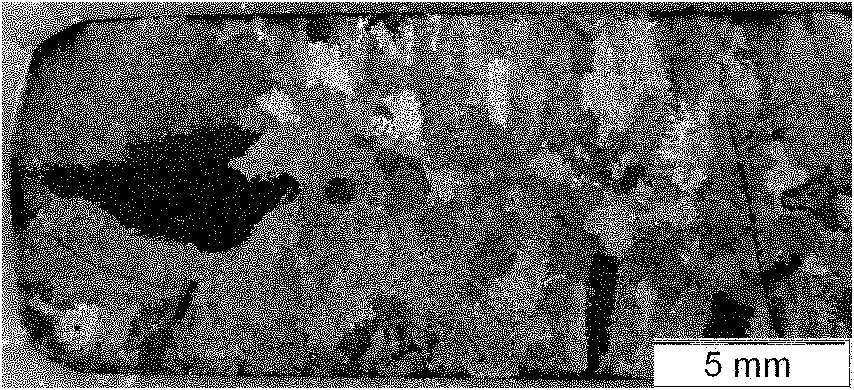

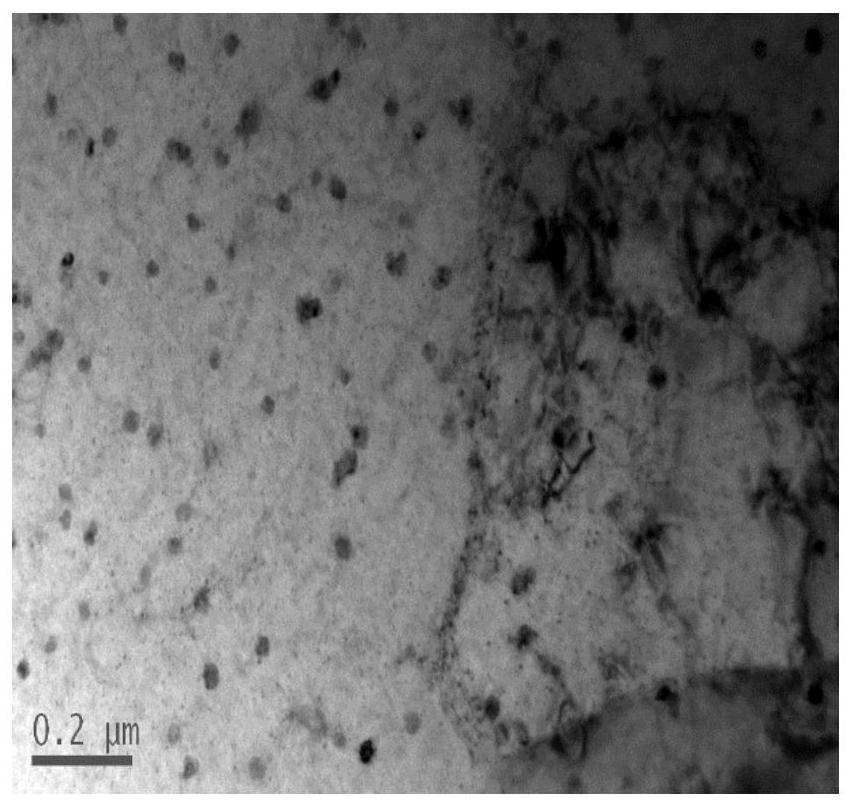

Method for preparing in-situ deformation Cu-Ag composite material by using magnetic field

The invention relates to a method for preparing an in-situ deformation Cu-Ag composite material by using a magnetic field, belonging to the technical field of materials and comprising the following steps of: 1, with oxygen-free copper and electrolyzed silver as raw materials, preparing a Cu-Ag alloy liquid or Cu-Ag alloy ingot; 2, placing the Cu-Ag alloy liquid or Cu-Ag alloy ingot into a vacuum electric furnace, preserving the temperature and then cooling with the furnace, applying a static magnetic field or alternating-current magnetic field to obtain an as-cast Cu-Ag alloy; 3, preserving the temperature of the as-cast Cu-Ag alloy and then thermally forging to prepare a deformation Cu-Ag alloy; 4, drawing the formation Cu-Ag alloy to prepare a deformation Cu-Ag composite material; 5, thermally treating the deformation Cu-Ag composite material in vacuum, then drawing again; and 6, sequentially repeating the step 5 to obtain the in-situ deformation Cu-Ag composite material. The method provided by the invention effectively improves the ultimate tensile strength and the electric conductivity of the Cu-Ag alloy; and the prepared composite material has greatly improved property.

Owner:NORTHEASTERN UNIV

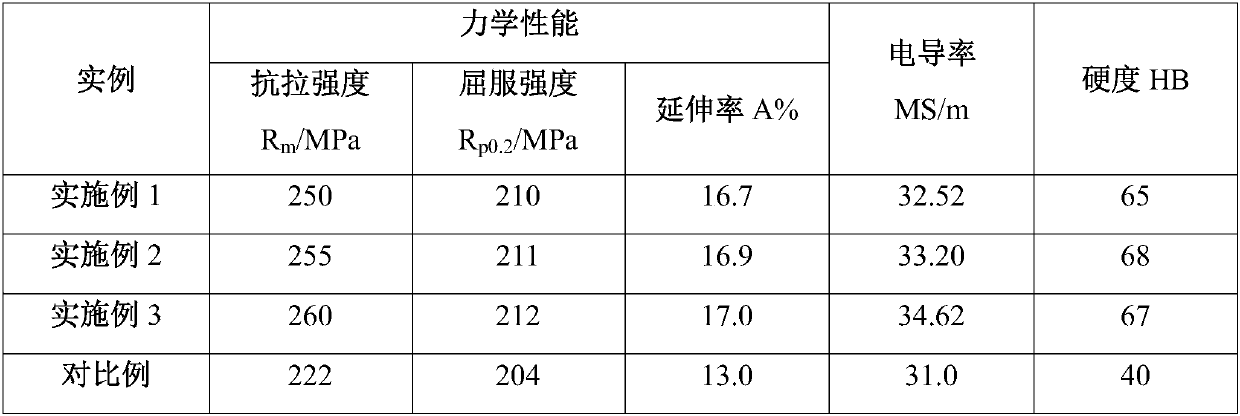

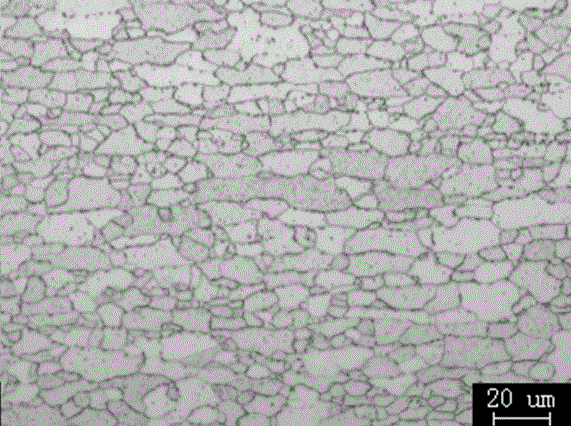

High-conductivity 6 series aluminum alloy and production process therefor

InactiveCN110983124ALow thermal conductivityReduced mechanical propertiesExtrusion control devicesUltimate tensile strengthMechanical property

The invention belongs to the technical field of aluminum alloy production processes, and relates to a high-conductivity 6 series aluminum alloy and a production process therefor. The high-conductivity6 series aluminum alloy is prepared from the following element components in percentage by weight: 0.55%-0.60% of Si, 0.10%-0.15% of Fe, 0.05%-0.08% of Cu, 0.01%-0.02% of Mn, 0.60%-0.65% of Mg, 0.01%-0.02% of Cr, not greater than 0.01% of Ti, 0.05%-0.08% of Zn, not greater than 0.01% of V, 0.15%-0.18% of Gd, 0.015%-0.02% of B, not greater than 0.03% of single impurities, not greater than 0.10% ofimpurities and the balance Al; by improving a formula and the process, the tension strength of the aluminum alloy reaches 250 Mpa, the yield strength reaches 210 Mpa, the percentage elongation afterfracture reaches 16.7%, and the conductivity Gamma is equal to 32.52 MS / m; and the hardness HB is equal to 65, so that the mechanical property and the conductivity of the 6 series aluminum alloy are obviously improved.

Owner:YINGKOU ZHONGWANG ALUMINUM CO LTD

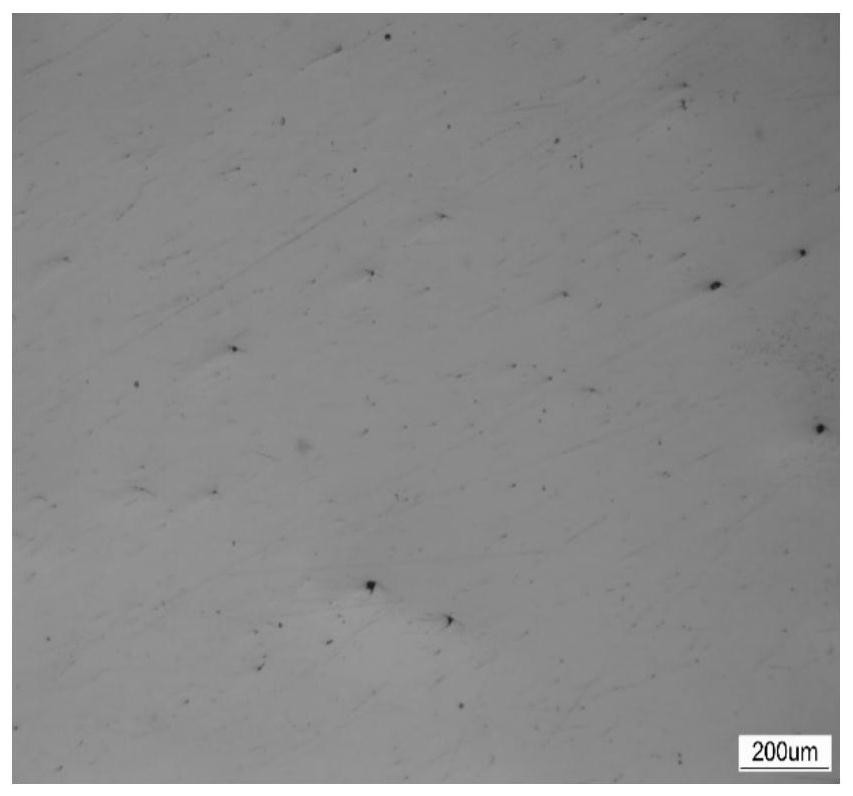

Low carbon cold-rolled steel sheet for LED lead frame and production method thereof

The invention relates to a low carbon cold-rolled steel sheet for a LED lead frame and a production method thereof, and mainly solves the technical problems that the low carbon cold-rolled steel sheet for the LED lead frame in prior art has nonuniform hardness, high surface roughness and bad aging-resistance. The production method comprises the following steps: smelting according to components, molten iron desulphurization, complex top-bottom blowing converter smelting, argon blowing from bottom of a ladle, protective casting with argon blowing in whole course, heating in a slab heating furnace, rough rolling, finish rolling, reeling for obtaining a hot-rolled steel coil, uncoiling, pickling, cold rolling, annealing in a vertical type continuous annealing furnace, flattening, and reeling for obtaining a finished product with a thickness of 0.4-0.5mm; the finishing temperature of the finish rolling is 860-900 DEG C, the reeling temperature of the hot rolling is 620-660 DEG C, the cold rolling reduction is 75-85%, the temperature scope of a soaking zone of the vertical type continuous annealing furnace for a band steel in hard rolled state after cold rolling is 710-730 DEG C, the soaking time for the band steel in the vertical type continuous annealing furnace is 105-120 s, and temper elongation is 1.0-1.4%. The low carbon cold-rolled steel sheet is mainly used for the LED lead frame.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Method for improving strength and conductivity of Cu-Cr-Nb alloy

ActiveCN112317755AIncrease solid solutionInhibit growthAdditive manufacturing apparatusConductive materialHydrogen contentElectro conductivity

The invention provides a method for improving strength and conductivity of a Cu-Cr-Nb alloy. According to the method, Cu-Cr-Nb alloy powder with high sphericity degree and less satellite powder is prepared through argon atomization, nitrogen low-temperature winnowing powder screening is adopted, and packaging is conducted in the reducing atmosphere; SLM forming is conducted in the atmosphere withthe hydrogen content being 1-3% and the balance of argon gas, so that oxygen content in the alloy is effectively reduced, and conductivity of the alloy is improved; and finally, a formed part is placed in a reducing atmosphere to be subjected to two-stage aging treatment, and the Cu-Cr-Nb alloy with high strength, high plasticity and high conductivity is obtained. The room-temperature tensile strength of the Cu-Cr-Nb alloy prepared through the method is not lower than 623 MPa, the elongation is not lower than 27%, the microhardness is not lower than 217 HV, the electric conductivity reaches 84% IACS, and the 700 DEG C high-temperature tensile strength is not lower than 140 MPa. The method has important application value in the field of high-strength and high-conductivity copper alloys.

Owner:CENT SOUTH UNIV

Aluminum alloy strip for battery shell and manufacturing method of aluminum alloy strip

InactiveCN112195373AReduce cooling and solidification speedHigh tissue densityElectrical batteryUltimate tensile strength

The invention discloses an aluminum alloy strip for a battery shell and a manufacturing method of the aluminum alloy strip. The aluminum alloy strip comprises the following components in percentage byweight: 0.55%-0.75% of Fe, 0.20%-0.40% of Si, 0.08%-0.10% of Cu, 0.95%-1.15% of Mn, 0.015%-0.020% of delta Ti and the balance of Al. Delta Ti is the content difference value of Ti in a launder and astanding furnace. The manufacturing method comprises the steps of smelting and refining; continuous casting and rolling; double-stage desolventizing annealing; and cold rolling. The alloy cooling solidification speed in the continuous casting and rolling process is effectively reduced, the solid solution amount of Mn in the alloy is reduced, segregation and unbalanced crystalline structures are eliminated, fine grain structures are formed in the alloy, and the distribution uniformity of alloy elements is improved; and the tensile strength of a finished product of the prepared aluminum alloy strip ranges from 140 MPa to 165 MPa, the yield strength is larger than or equal to 130 MPa, the ductility is larger than or equal to 8%, and the mechanical property is excellent.

Owner:JIANGSU ALCHA ALUMINUM CO LTD

Six-series aluminum alloy template and production process thereof

ActiveCN110983125AImprove mechanical propertiesReduce solid solutionUltimate tensile strengthMaterials science

The invention belongs to the technical field of aluminum alloy production process, and relates to a six-series aluminum alloy template and a production process thereof. The six-series aluminum alloy template is prepared from the following elementary compositions in percentage by weight: 0.50-0.55 % of Si, 0.10-0.15 % of Fe, 0.05-0.10 % of Cu, 0.05-0.10 % of Mn, 0.55-0.60 % of Mg, less than or equal to 0.05 % of Cr, less than or equal to 0.05 % of Zn, less than or equal to 0.05 % of Ti, less than or equal to 0.25 % of La, less than or equal to 0.05 % of other single impurity content, less thanor equal to 0.15 % of total impurity, and the balance of Al. Through the improvement of alloy composition and production process, the final six-series aluminum alloy template has tensile strength of 280 Mpa, yield strength of 255 Mpa and elongation after fracture of 12.5 %, the mechanical properties are significantly improved, and the production needs of customers can be met.

Owner:YINGKOU ZHONGWANG ALUMINUM CO LTD

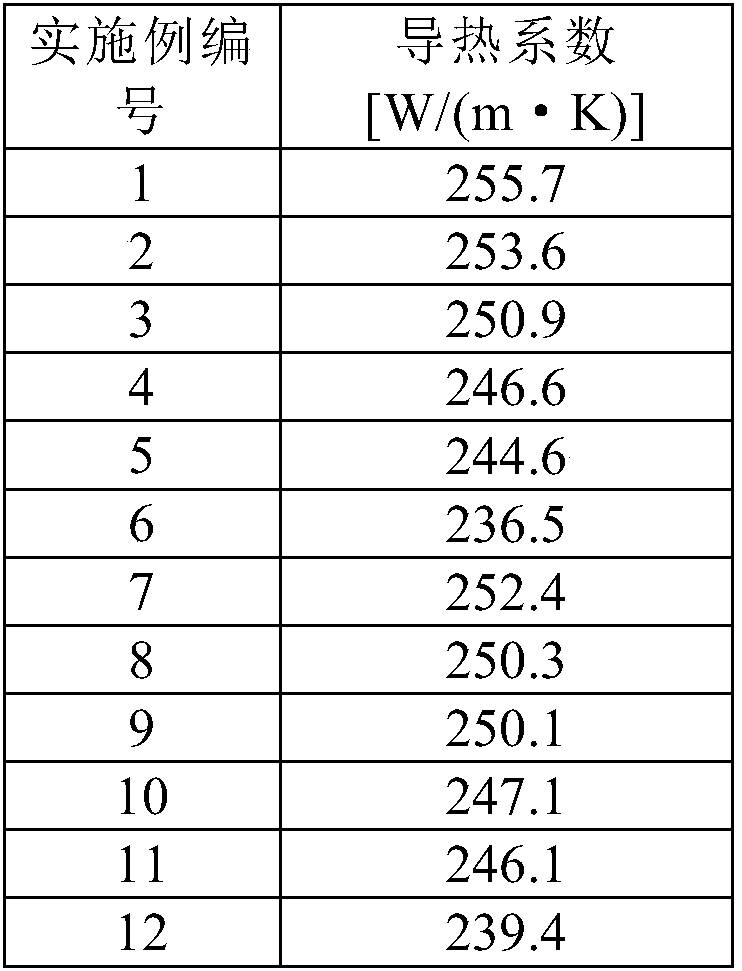

High-thermal conductivity thermal treatment die-casting aluminum alloy and preparation method thereof

InactiveCN109338179AThe degree of lattice distortion is weakenedImprove thermal conductivityHeat conductingDie casting

The invention relates to a high-thermal conductivity thermal treatment die-casting aluminum alloy and a preparation method thereof. The alloy is prepared from the following components: 8.50 wt% to 11.0 wt% of Si, 0.01 wt% to 0.5 wt% of Re, 0.05 wt% to 0.20 wt% of B, 0.20 wt% to 1.00 wt% of Fe, less than 0.5 wt% of Cu, less than 0.5 wt% of Mg, less than 0.05 wt% of other impurities under control and the balance Al. Compared with the prior art, the die-casting aluminum alloy has the beneficial effect that Re and B elements are doped into the aluminum alloy, and heat-conducting property of the die-casting aluminum alloy is greatly improved by utilizing properties of the Re and B elements.

Owner:苏州慧驰轻合金精密成型科技有限公司

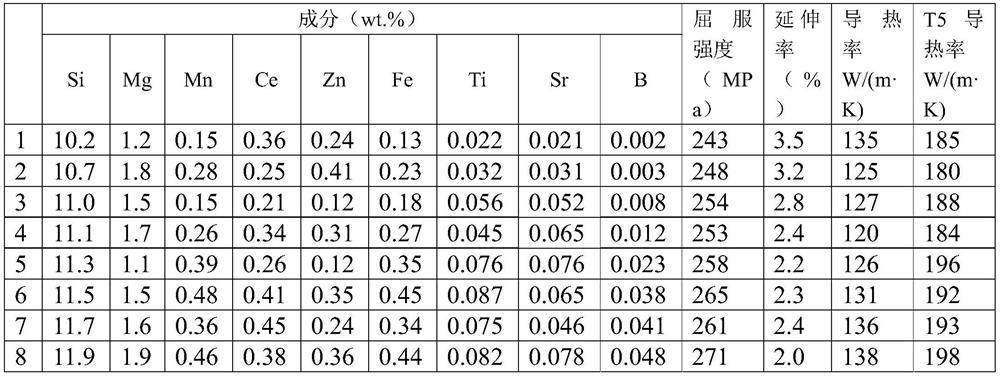

Die-casting alloy material for high-thermal-conductivity high-yield mobile phone middle plate and preparation method thereof

ActiveCN111690845AHigh Yield High Thermal ConductivityReduce lattice distortionUltimate tensile strengthMobile phone

The invention relates to a die-casting alloy material for a high-thermal-conductivity high-yield mobile phone middle plate and a preparation method thereof. The alloy comprises 10-12 wt% of Si, 1.0-2.0 wt% of Mg, less than 0.5 wt% of Mn, less than 0.5 wt% of Ce, less than 0.5 wt% of Zn, 0.1-0.5 wt% of Fe, 0.01-0.1 wt% of Ti, 0.005-0.1 wt% of Sr, 0.002-0.05 wt% of B, and the balance Al, wherein thecontent of other impurities is controlled below 0.01 wt%. Compared with the prior art, the Mn, Si, Mg and Ce are added into the aluminum alloy, a ternary strengthening phase Mg2Si, MnAl6 and Al11Ce3binary precipitation phase is introduced, the yield strength and the elongation rate of the material are remarkably improved, meanwhile, the Ce and B elements are doped into the aluminum alloy, and the thermal conductivity of the die-casting alloy is greatly improved by utilizing the performances of the Ce and B elements.

Owner:苏州慧驰轻合金精密成型科技有限公司

Method for preparing Cu-Fe alloy from Cu cuttings and Fe cuttings

InactiveCN111519063AImprove conductivityAccurate ingredientsTransportation and packagingMetal-working apparatusAlloyMaterials science

The invention provides a method for preparing a Cu-Fe alloy from Cu cuttings and Fe cuttings. The mass ratio of the pure Cu cuttings to the pure Fe cuttings is 4-99:1. The method comprises the steps of uniformly mixing the pure Cu cuttings with the size of (0.1-11) mm*(0.1-4.9) mm*(0.01-1.57) mm and the pure Fe cuttings with the size of (0.1-6.5) mm*(0.1-2.7) mm*(0.01-1.46) mm; pressing the mixedcuttings at 600-890 MPa and indoor temperature for 25-65 s to obtain a cold pressed billet; pressing the cold pressed billet at 650-750 MPa and 900-1000 DEG C for 35-70 s to obtain a hot pressed billet; extruding the hot pressed billet into a bar at the extrusion ratio of 25-36:1 at 800-900 DEG C and extrusion speed of 0.1-0.5 mm / s; conducting multi-pass cold drawing on the bar at indoor temperature to obtain a wire with the percentage of cross-section contraction being 99.75%-99.99%; and finally conducting annealing treatment on the wire at 200-500 DEG C to obtain the high-strength high-conductivity Cu-Fe alloy. According to the Cu-Fe alloy prepared through the method, the melting process is not needed, oxidization and burning loss of a raw material can be effectively avoided, the solid solution rate of Fe in Cu can be greatly reduced, and accordingly, the conductivity of the Cu-Fe alloy is remarkably improved.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

Preparation method of high-conductivity aluminum alloy

InactiveCN103276261BHigh affinityPlay the role of hydrogen absorption and hydrogen fixationRare-earth elementElectrical conductor

Owner:JIANGSU UNIV

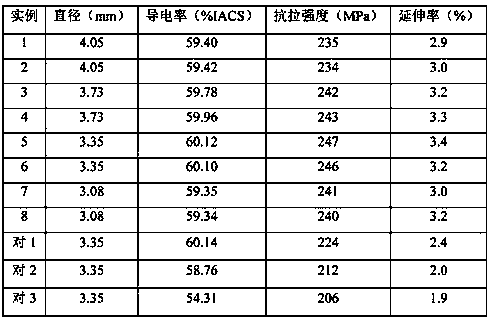

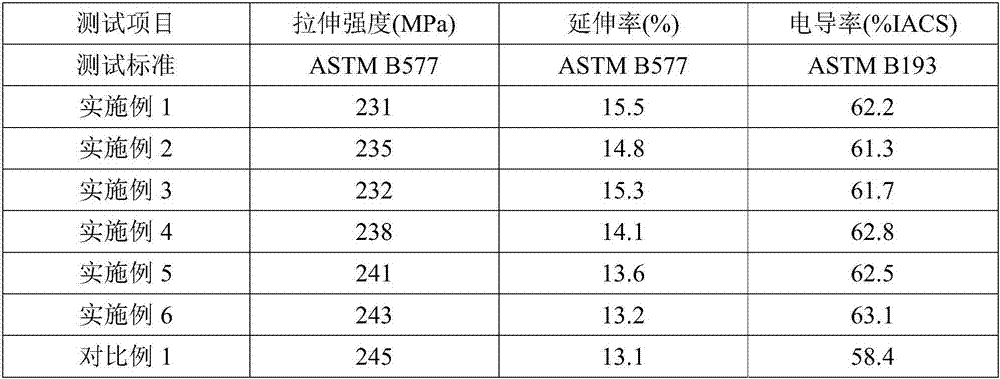

High-conductivity medium-strength aluminum alloy single wire and preparing method thereof

InactiveCN110373584ASave construction investmentLarge draw-to-weight ratioTemperature control deviceMetal rolling arrangementsChemical compositionHigh conductivity

The invention discloses a high-conductivity medium-strength aluminum alloy single wire. The high-conductivity medium-strength aluminum alloy single wire comprises chemical components including, by weight percent, 0.12 to 0.34% of Si, 0.2 to 0.4% of Fe, 0.05 to 0.2% of Cu, 0.3 to 0.42% of Mg, 0.03 to 0.1% of Bi, 0.06 to 0.25% of Sr, 0.01 to 0.05% of B, not larger than 0.01% of Mn+Ti+Cr+V, and the balance Al. The aluminum alloy single wire is made through process steps of smelting, degassing, casting, rolling and wire drawing, the tensile strength of the aluminum alloy single wire is larger thanor equal to 234 Mpa, the electric conductivity is larger than or equal to 59.2% IACS, the ductility is larger than or equal to 2.9%, and the wire has the excellent mechanical and electrical conductance properties.

Owner:XICHUAN COUNTY POWER BUREAU

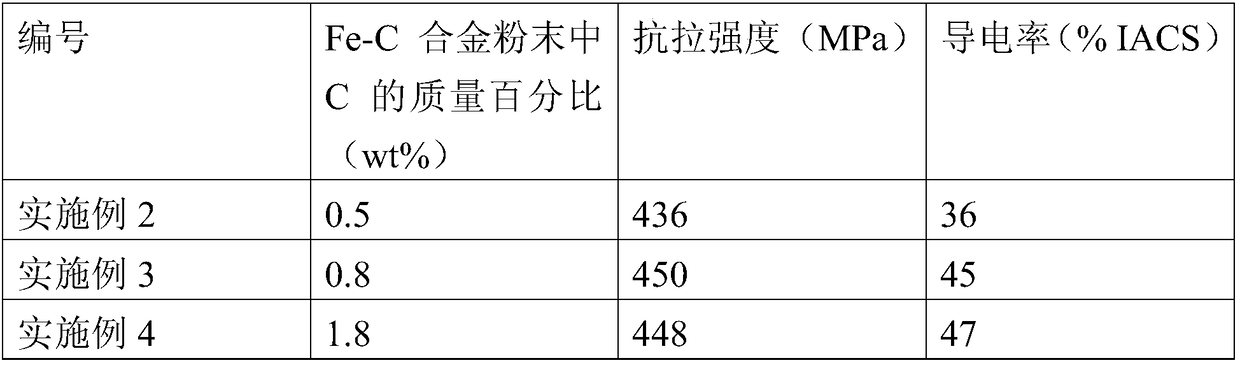

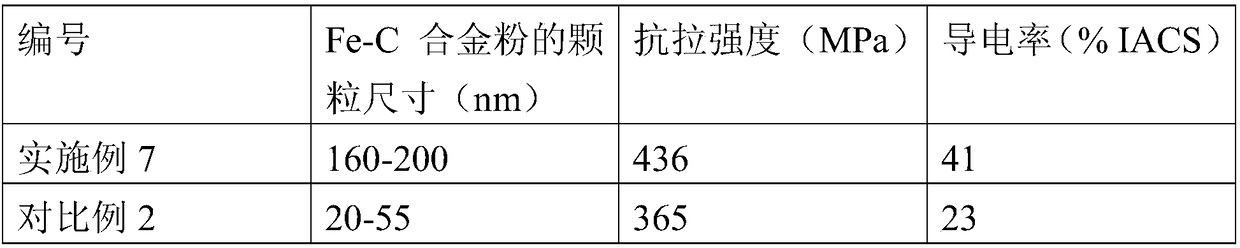

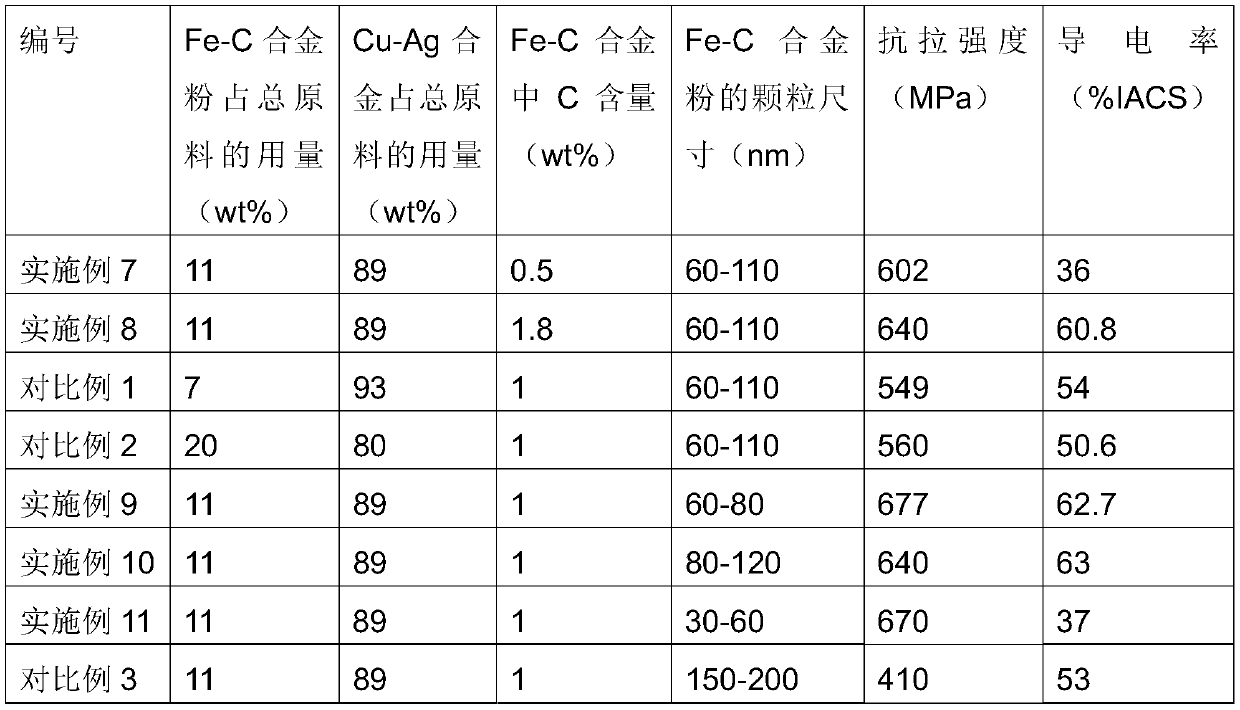

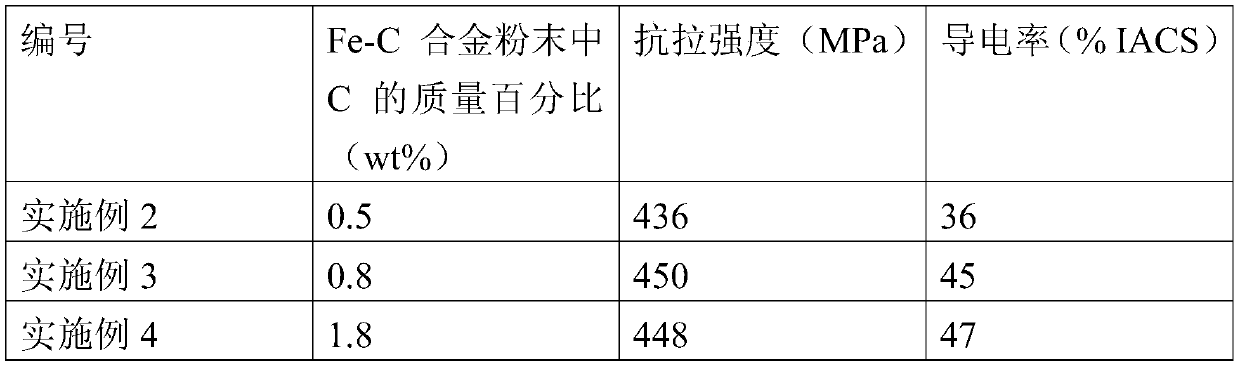

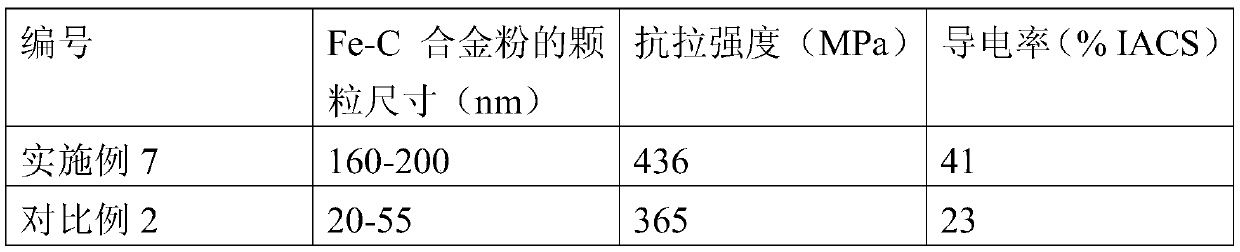

Cu-Fe-C alloy and preparation method thereof

The invention discloses a Cu-Fe-C alloy and a preparation method thereof. The Cu-Fe-C alloy comprises, by mass, 85-90% of Cu and 10-15% of Fe-C alloy. The preparation method comprises the following steps of Cu smelting, adding of the Fe-C alloy, and the rapid solidification, so that alloy particles are uniformly distributed in the Cu-Fe-C alloy in a Cu matrix. According to the method, the conductivity and tensile strength of the Cu-Fe alloy can be improved, the tensile strength of the obtained cast-state alloy is 410-470 MPa, and the conductivity is 30-50% IACS.

Owner:HENAN POLYTECHNIC UNIV

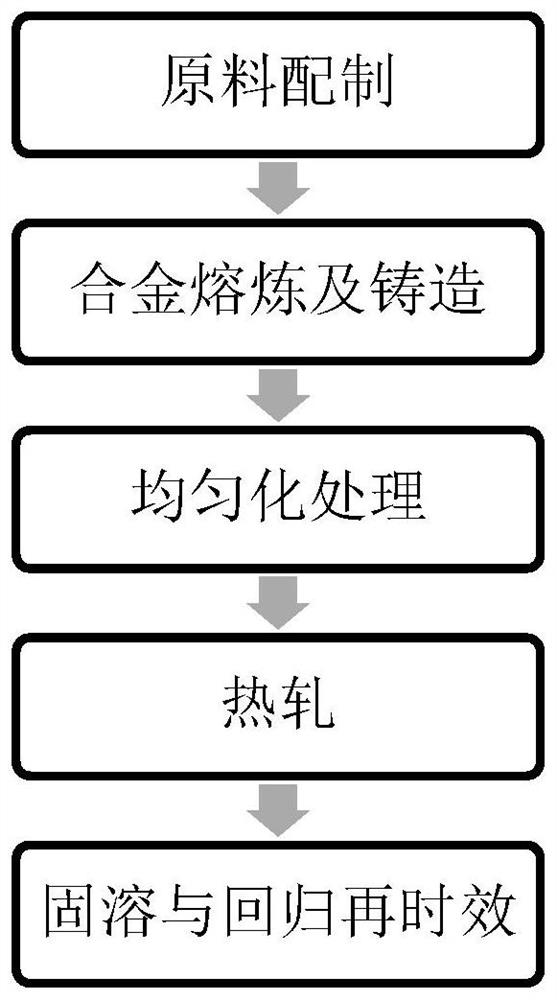

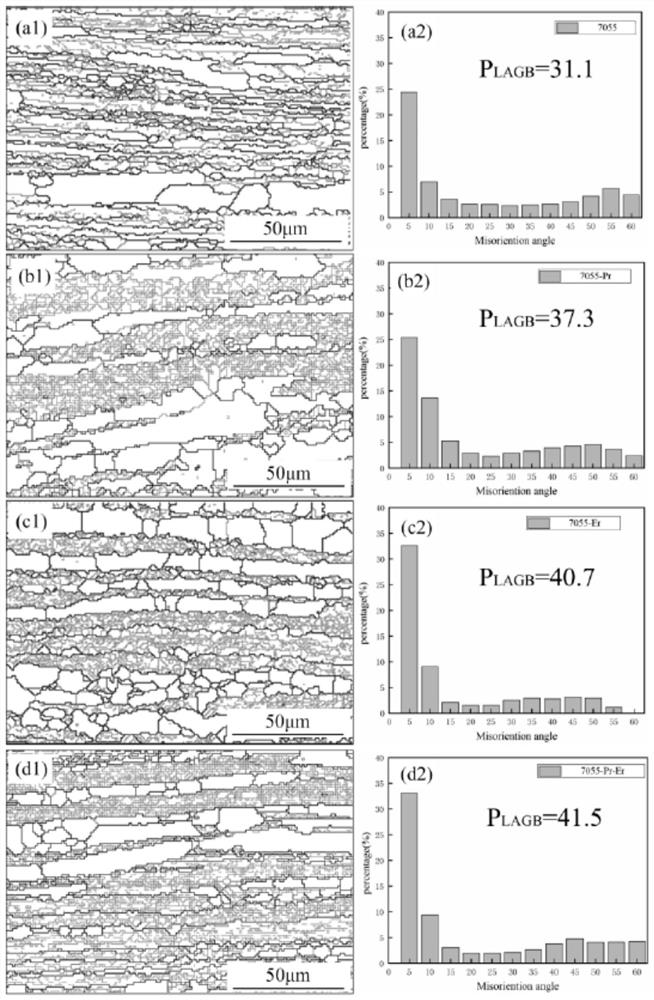

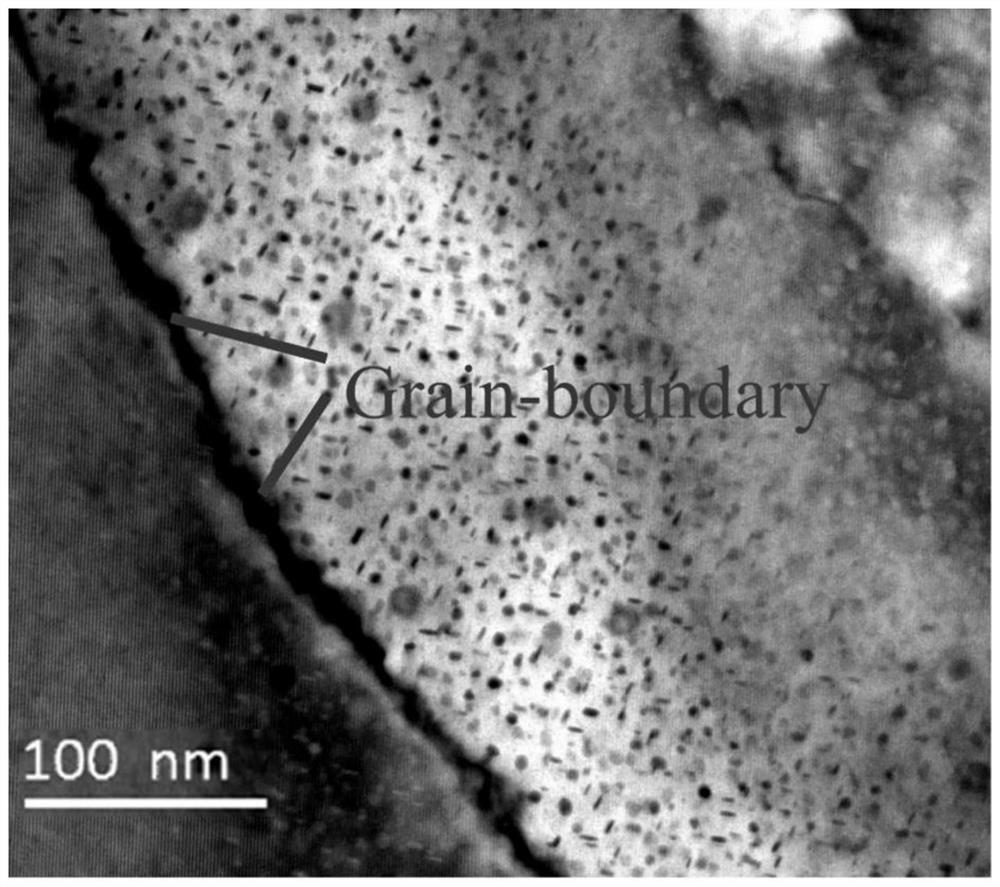

High-strength corrosion-resistant Al-Zn-Mg-Cu alloy added with Er and Pr and preparation method of high-strength corrosion-resistant Al-Zn-Mg-Cu alloy

The invention provides a high-strength corrosion-resistant Al-Zn-Mg-Cu alloy added with Er and Pr and a preparation method of the high-strength corrosion-resistant Al-Zn-Mg-Cu alloy, and belongs to the technical field of metal alloys. The aluminum alloy comprises the following components in percentage by weight: 7.20 to 8.00 percent of Zn, 2.00 to 2.32 percent of Mg, 2.00 to 2.46 percent of Cu, 0.15 to 0.22 percent of Zr, 0.10 to 0.13 percent of Er, 0.15 to 0.20 percent of Pr, less than or equal to 0.1 percent of Si, less than or equal to 0.1 percent of Fe, less than or equal to 0.05 percent of other single impurities, less than or equal to 0.15 percent of total impurities and the balance of Al. Wherein 3.1 < = Zn / Mg < = 4.0, and 0.40% < = Zr + Er + Pr < = 0.55%. The invention further provides a preparation method of the high-strength corrosion-resistant Al-Zn-Mg-Cu alloy, the tensile strength of the produced high-strength corrosion-resistant Al-Zn-Mg-Cu alloy is 620-635 MPa, the yield strength is 395-415 MPa, the ductility is 9.5-11.5%, the conductivity is 34.0-35.0% IACS, and the high-strength corrosion-resistant Al-Zn-Mg-Cu alloy has excellent comprehensive performance and is suitable for being used as a high-strength corrosion-resistant structural part.

Owner:JIANGXI UNIV OF SCI & TECH

Copper-silver composite material preparation method

A preparation method for preparing a copper-silver composite material, which is carried out according to the following steps: (1) use oxygen-free copper and electrolytic silver as raw materials, and make Cu-Ag alloy liquid after melting; (2) place it in a vacuum electric furnace, heat and keep Cool with the furnace and apply a constant magnetic field; (3) keep warm at 700-800°C for 1-3 hours, and then hot forge; (4) draw at room temperature; (5) conduct vacuum heat treatment to obtain copper-silver composite Material. The method of the present invention can achieve the purpose of refining Cu dendrites, can reduce the solid solution of Ag atoms in the Cu matrix, reduce the solid solubility of Ag in the matrix, increase the effective strengthening, and reduce the solid solution scattering of conductive electrons.

Owner:陈广新

Aluminum alloy material, preparation method of aluminum alloy material and application

The invention provides an aluminum alloy material, a preparation method of the aluminum alloy material and application. The aluminum alloy material comprises, by mass, 0.25-0.35% of iron, 0.1-0.25% of copper, 0.2-0.4% of magnesium, 0.05-0.15% of zinc, 0.1-0.3% of silicon, 0.01-0.05% of boron, 0.2-0.35% of scandium, 0.05-0.15% of ruthenium and the balance aluminum. The aluminum alloy material is obtained through the method that aluminum ingots are molten, added with other components of the formula ratio, and then sequentially subjected to melting, pouring, homogenizing treatment, water quenching and aging treatment. Aluminum alloy prepared through the preparation method serves as a guide line material, and has high tension strength, elongation and specific conductance at the same time.

Owner:GUANGDONG OMG TRANSMITTING TECH CO

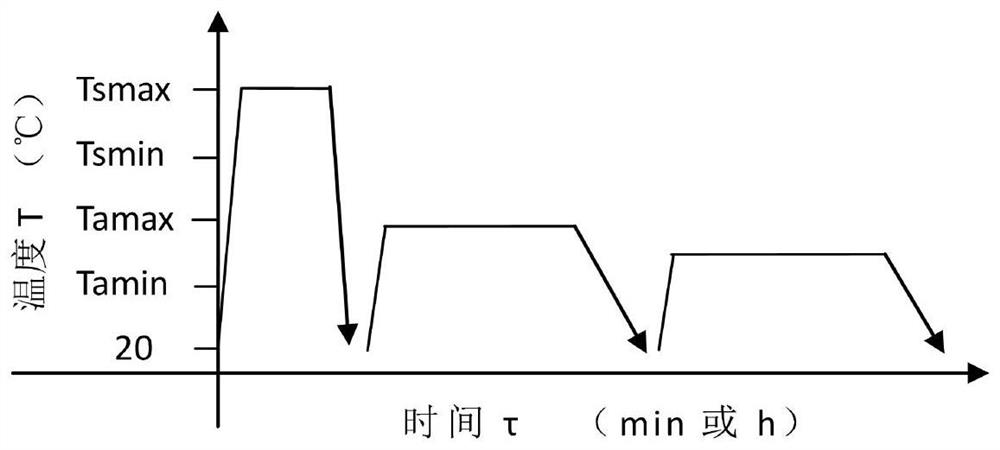

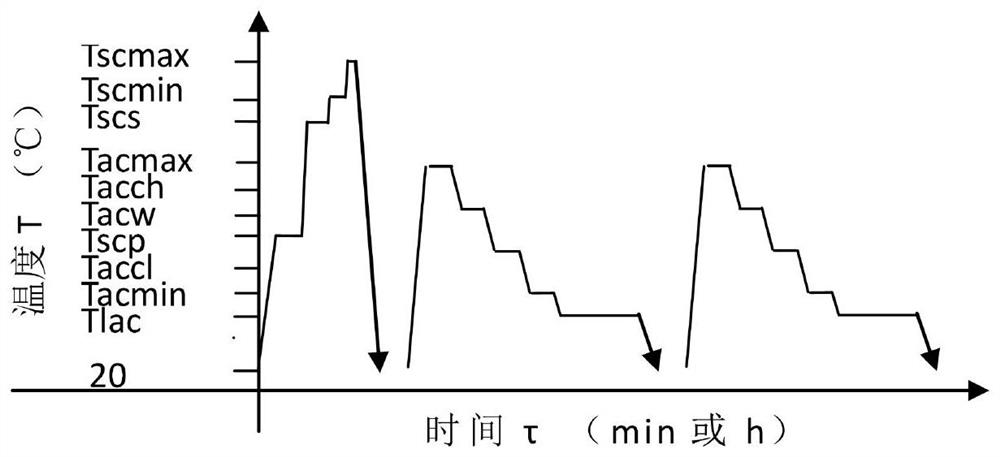

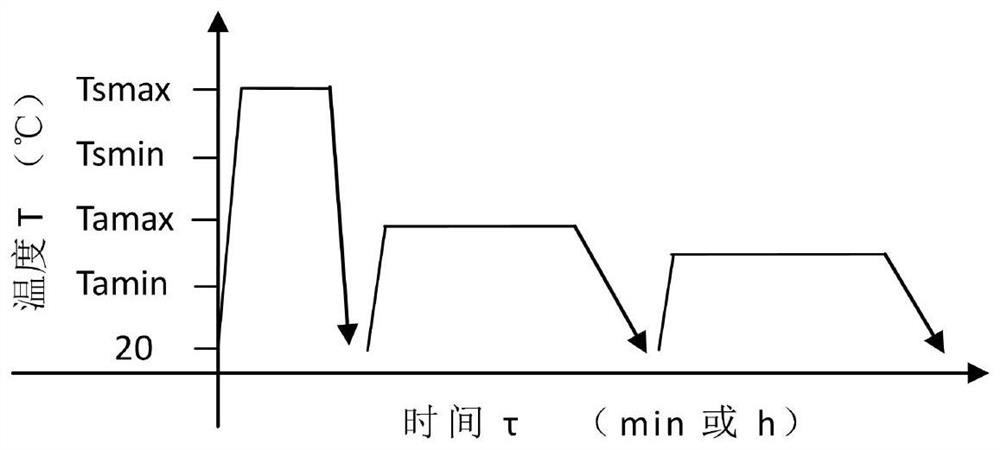

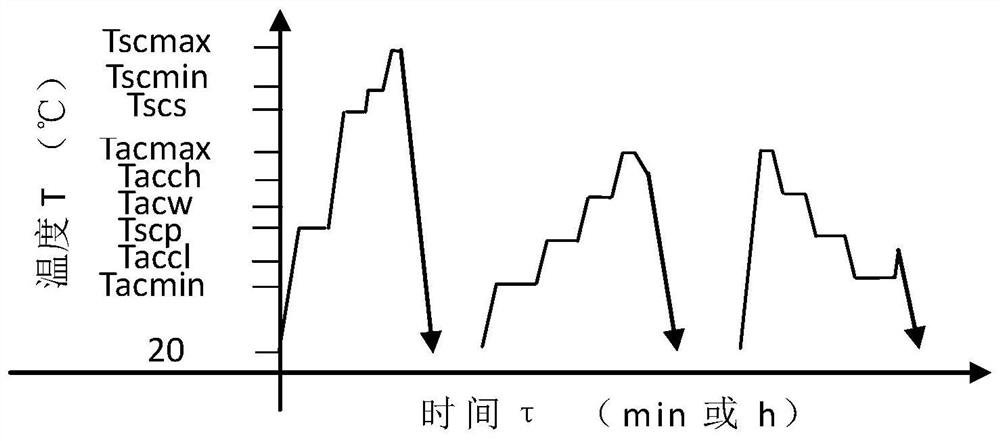

Critical solid solution and critical repeated cooling aging and annealing heat treatment method

The invention provides a critical solid solution and critical repeated cooling aging and annealing heat treatment method which comprises a critical solid solution heat treatment process and a critical repeated cooling aging and annealing heat treatment process. The scheme of the invention has technical feasibility, process adaptability, quality reliability, economic reasonability and use safety, can effectively enhance the advantages and avoid the disadvantages of a conventional mainstream heat treatment method of austenitic stainless steel, fundamentally solves the "one-long one-high four-poor five-low" special heat treatment technical difficult problems of "poor quality stability, low rate of qualified products, low hardness, low mechanical property, poor consistency, poor discoloration and rust corrosion resistance, long heating time, low efficiency, poor heating reliability of heat treatment equipment and low service life and high cost of a high-temperature component" of existing austenitic stainless steel heat treatment, and is particularly suitable for the technical field of heat working engineering such as smelting, steel rolling, forging, heat treatment and the like related to the austenitic stainless steel in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

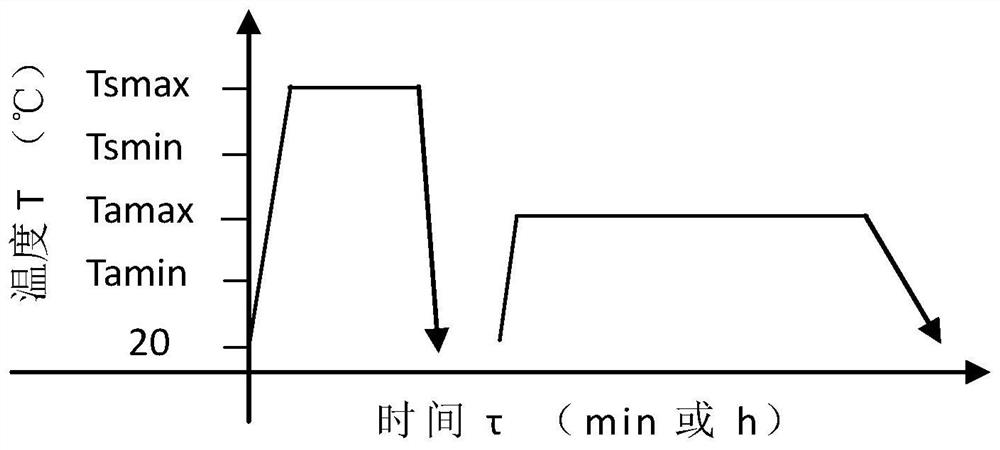

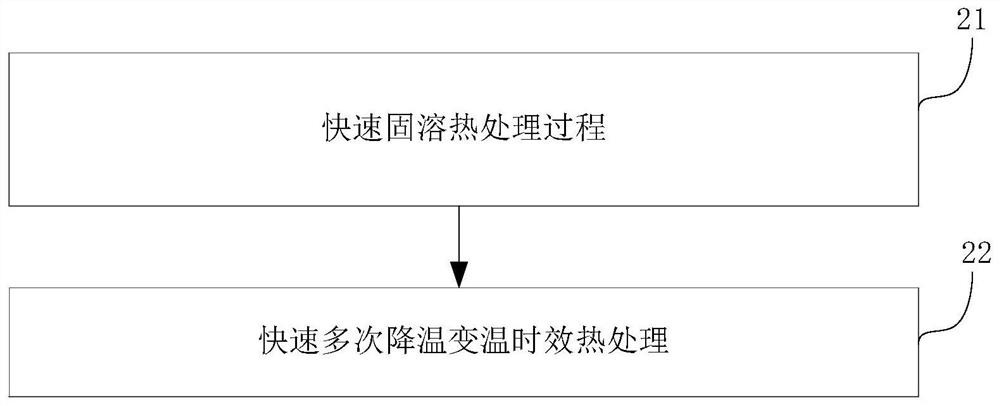

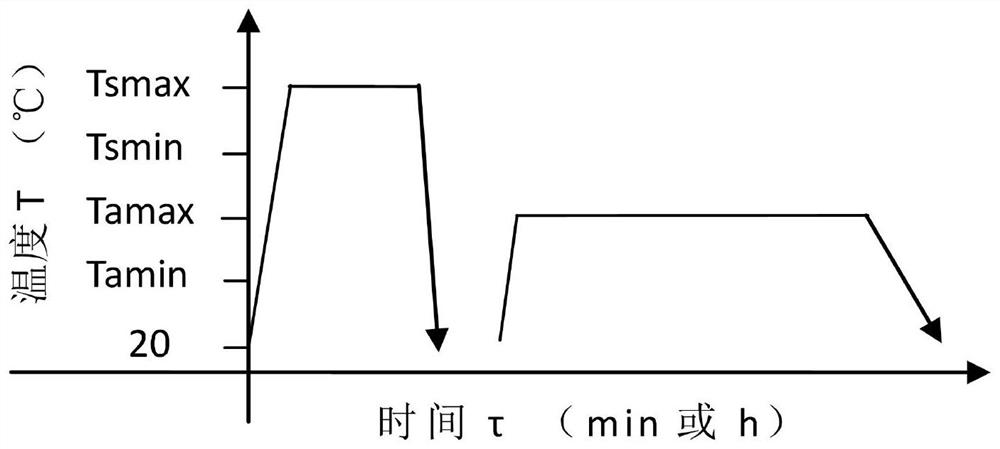

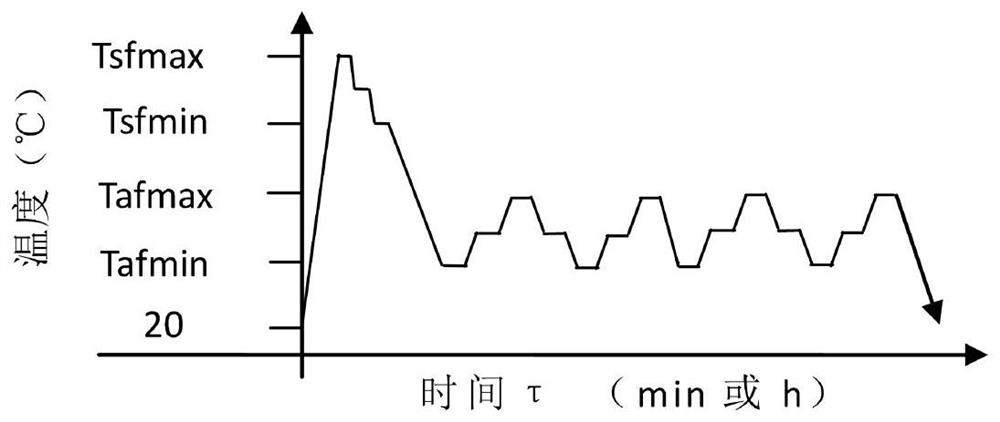

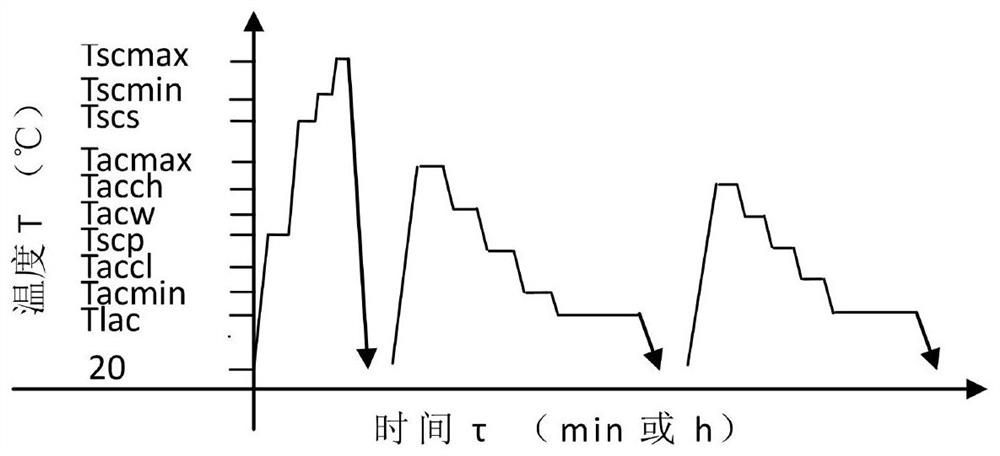

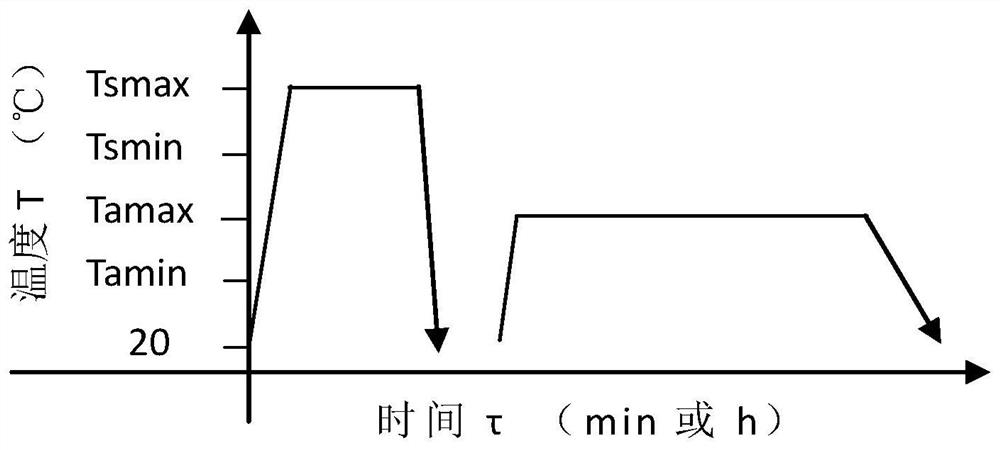

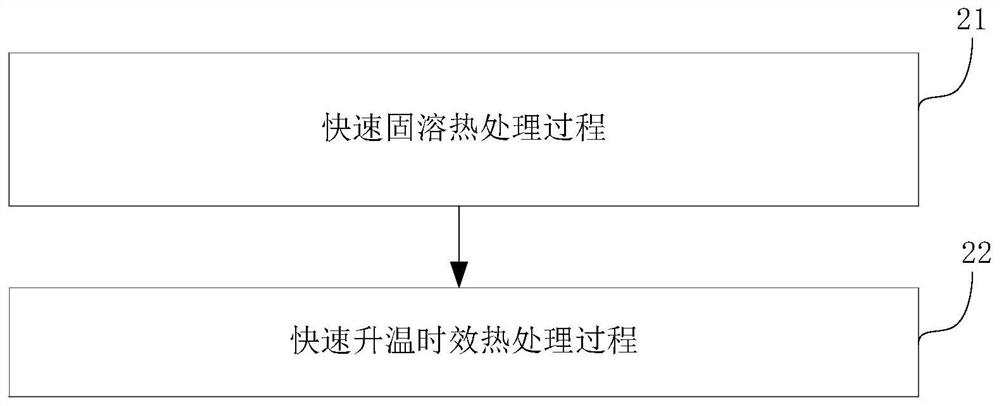

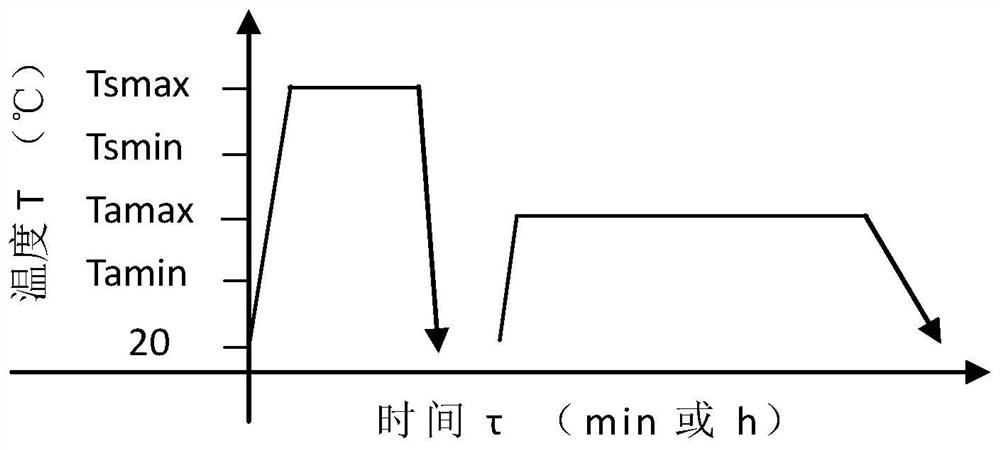

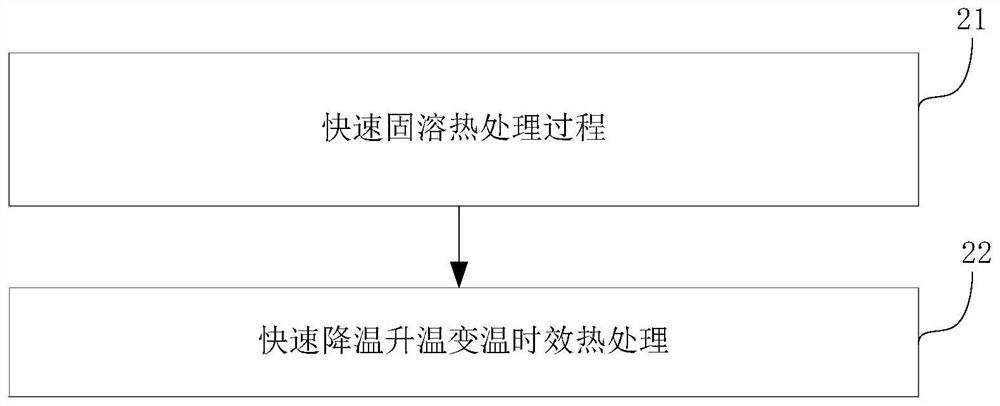

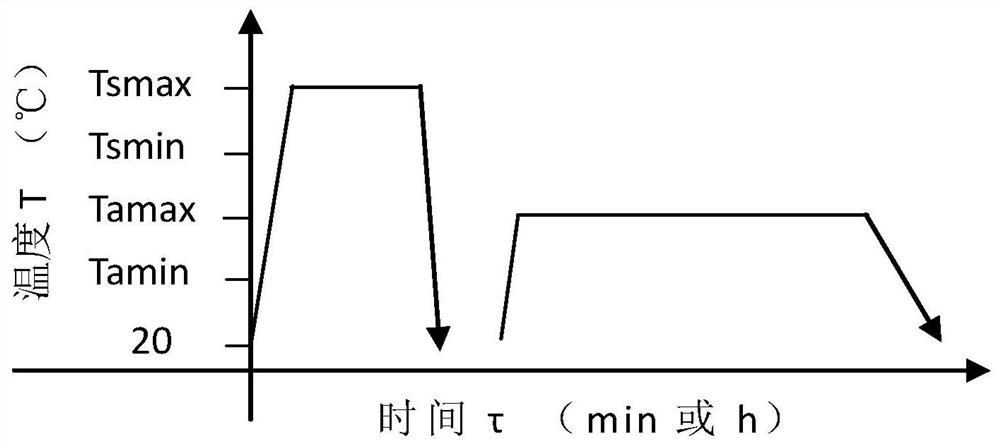

Rapid solid solution and rapid multi-cooling variable-temperature aging heat treatment method

PendingCN112725591AQuality and reliabilityImprove quality stabilityThermodynamicsProcess engineering

The invention provides a rapid solid solution and rapid multi-cooling variable-temperature aging heat treatment method. The rapid solid solution and rapid multi-cooling variable-temperature aging heat treatment method involves a rapid solid solution heat treatment process and a rapid multi-cooling variable-temperature aging heat treatment process. According to the scheme, the special heat treatment technical problems of "one long, one high, three poor and five low", namely, poor quality stability, low qualified product rate, low hardness, low mechanical property, poor consistency, long heating time, low efficiency, poor heating reliability of heat treatment equipment, short service life of high-temperature components, high cost and the like of austenitic stainless steel heat treatment can be solved.

Owner:山西柴油机工业有限责任公司

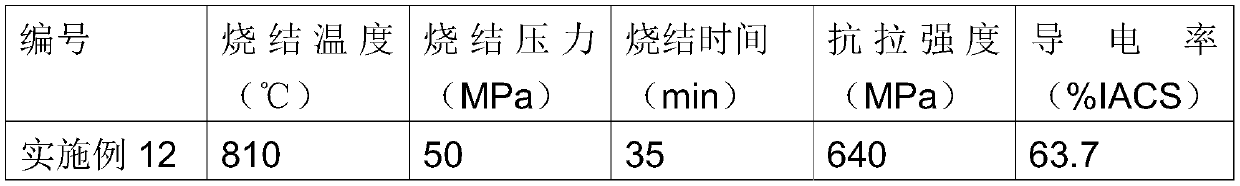

cu-fe-c-ag alloy

The invention provides Cu-Fe-C-Ag alloy. The alloy is prepared through the following steps: (1) preparation of raw materials, wherein the raw materials comprise Cu-Ag prealloy powder, (2) ball-millingmixing: adding grinding balls to perform powder mixing to obtain composite powder, (3) hot-pressure sintering: putting the composite powder obtained in step (2) into a hot-pressure sintering furnaceto sinter, keeping the sintering temperature at 800-1,000 DEG C, the sintering pressure at 45-55MPa and the sintering time of 30-45min to obtain the Cu-Fe-C-Ag alloy. The alloy can be used for improving the electric conductivity and tensile strength of the Cu-Fe alloy.

Owner:HENAN POLYTECHNIC UNIV

Super-soft aluminum alloy conductor and preparation method thereof

ActiveCN101974709BLittle change in performanceReduce solid solutionMetal/alloy conductorsElectrical conductorRare earth

Owner:ANHUI JOY SENSE CABLE

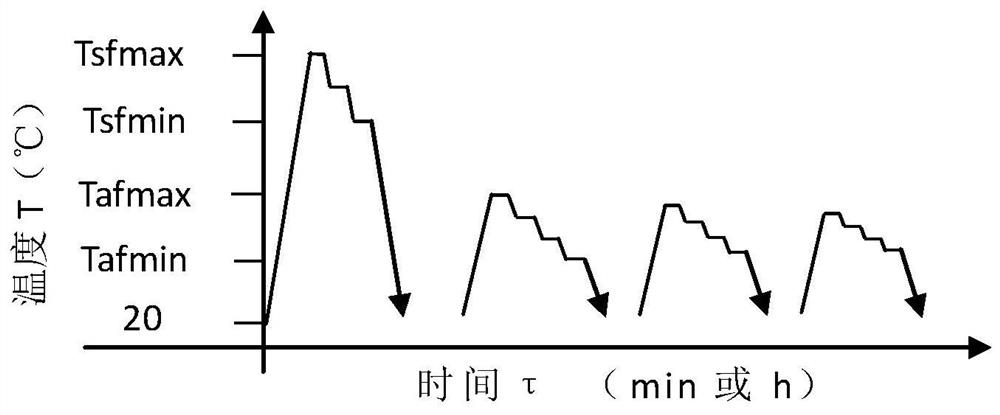

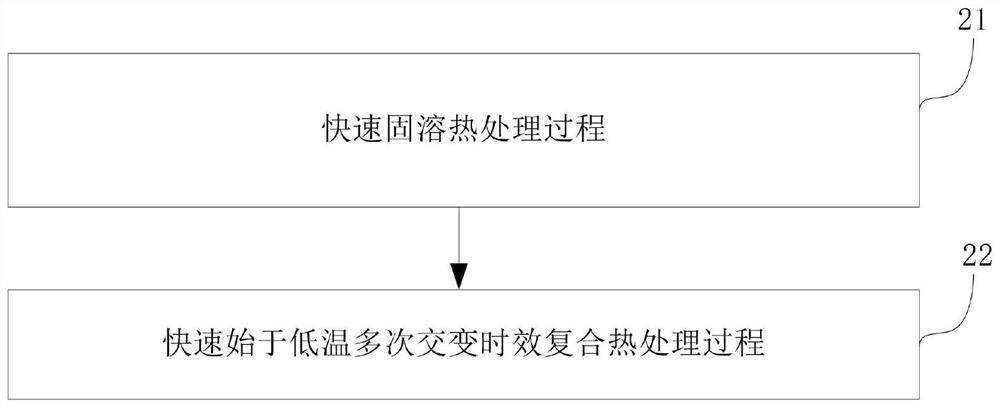

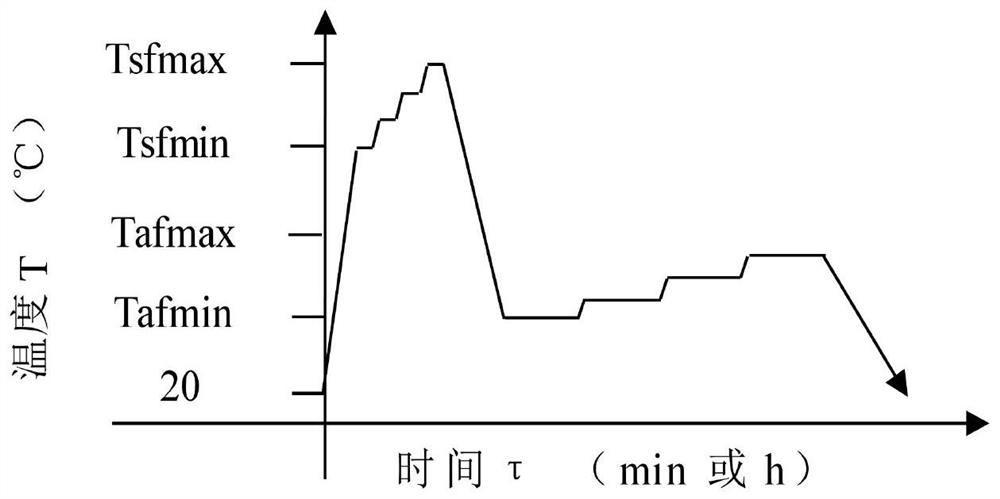

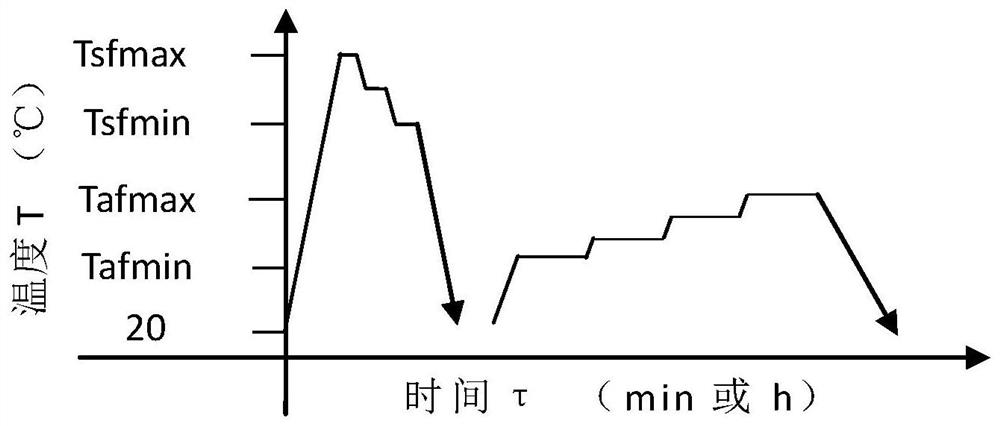

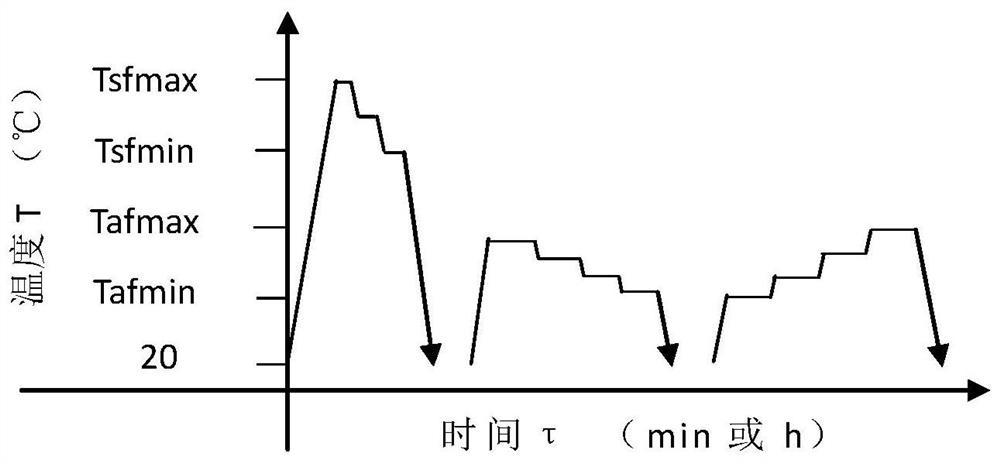

Rapid solid solution and rapid low-temperature multiple alternating aging composite heat treatment method

PendingCN114395684ATechnically feasibleProcess adaptabilityHeat treatment process controlHeating timeHardness

The invention provides a composite heat treatment method for rapid solid solution and rapid starting from low-temperature multiple alternating aging. The composite heat treatment method comprises a rapid solid solution heat treatment process and a composite heat treatment process for rapid starting from low-temperature multiple alternating aging. According to the scheme, the problems that austenitic stainless steel solid solution and aging heat treatment is poor in quality stability, low in qualified product rate, low in hardness, low in mechanical property, poor in consistency, long in heating time, low in efficiency and low in cost can be solved. And heat treatment equipment is poor in heating reliability, high-temperature components are short in service life, the cost is high, and other special heat treatment technology theories and practice problems are solved.

Owner:山西柴油机工业有限责任公司

Sufficient solid solution and sufficient heating aging composite heat treatment method

PendingCN114410931AQuality and reliabilityImprove quality stabilityHeat treatment process controlThermodynamicsHeating time

The invention provides a sufficient solid solution and sufficient heating aging composite heat treatment method. The method comprises a sufficient solid solution heat treatment process and a sufficient heating aging composite heat treatment process. According to the scheme, the specific heat treatment technical problems of'one-long-one-high three-difference five-low 'of existing austenitic stainless steel heat treatment, such as poor quality stability, low qualified rate, low hardness, low mechanical property, poor consistency, long heating time, low efficiency, poor heating reliability of heat treatment equipment, short service life of high-temperature components, high cost and the like, can be solved.

Owner:山西柴油机工业有限责任公司

A kind of Cu-Fe-C series alloy and preparation method thereof

The invention discloses a Cu-Fe-C alloy and a preparation method thereof. The Cu-Fe-C alloy comprises, by mass, 85-90% of Cu and 10-15% of Fe-C alloy. The preparation method comprises the following steps of Cu smelting, adding of the Fe-C alloy, and the rapid solidification, so that alloy particles are uniformly distributed in the Cu-Fe-C alloy in a Cu matrix. According to the method, the conductivity and tensile strength of the Cu-Fe alloy can be improved, the tensile strength of the obtained cast-state alloy is 410-470 MPa, and the conductivity is 30-50% IACS.

Owner:HENAN POLYTECHNIC UNIV

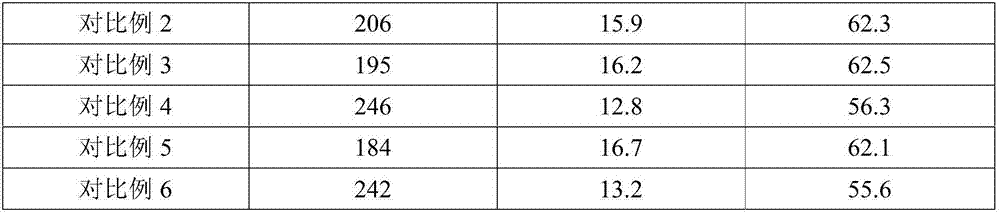

Critical solid solution and critical multi-cooling variable-temperature aging and annealing heat treatment method

The invention provides a critical solid solution and critical multi-cooling variable-temperature aging and annealing heat treatment method. The method comprises a critical solid solution heat treatment process and a critical multi-cooling variable-temperature aging and annealing heat treatment process. The scheme has technical feasibility, process adaptability, quality reliability, economic rationality and use safety, and can effectively enhance the advantages and avoid the disadvantages of a traditional mainstream heat treatment method of austenitic stainless steel, so that the problems that the existing austenitic stainless steel heat treatment is poor in quality stability, low in qualified rate, low in hardness, low in mechanical property, poor in consistency, poor in discoloration and corrosion resistance, long in heating time, low in efficiency, low in cost and the like are fundamentally solved. The critical solid solution and critical multi-cooling variable-temperature aging and annealing heat treatment method is particularly suitable for the technical field of hot working engineering such as smelting, steel rolling, forging and heat treatment related to the austenitic stainless steel in steel mills and manufacturers.

Owner:山西柴油机工业有限责任公司

A method for controlling mottle on the surface of steel plates for welded structures

ActiveCN109174964BGuaranteed pourabilityReduce generationTemperature control deviceWork treatment devicesMolten steelMechanical property

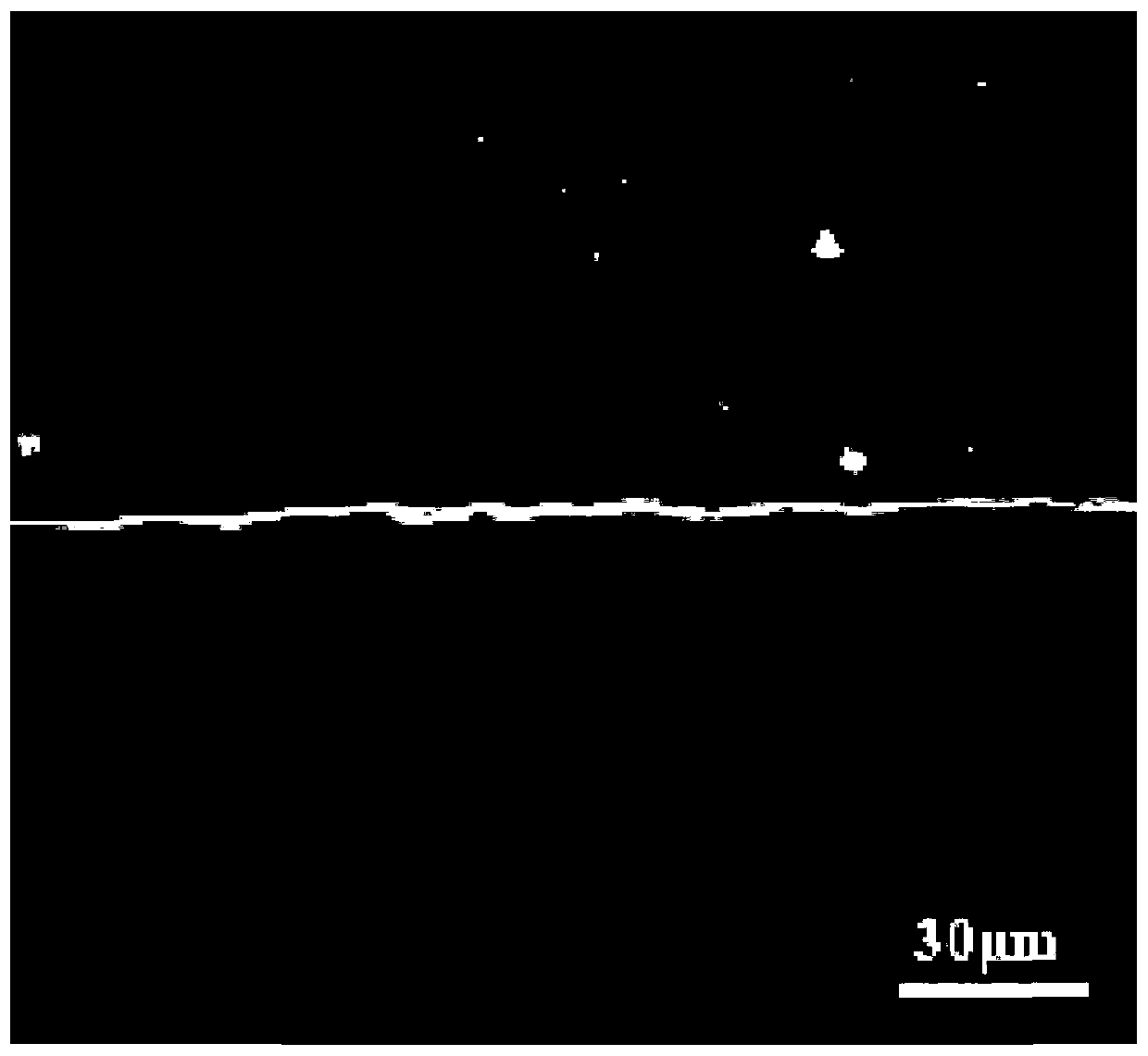

The invention discloses a controlling method of steel plate surface spots for a welding structure. Based on a composition system of steel for the welded structure, the processes of smelting, slab heating, descaling, steel rolling and cooling of molten steel are controlled in a production process, and so that uniform iron oxide sheet is obtained in the production process; and meanwhile, on the basis of ensuring mechanical properties of a steel plate, the thickness of the iron oxide sheet for the steel for the welding structure is effectively controlled, and the damage of the iron oxide sheet isavoided. The method can enable the steel plate surface iron oxide sheet to be dense and uniform, the thickness of the iron oxide sheet is controlled within 30 [mu], and spots defects after shot blasting on the surface of the steel for the welding structure and colour difference watermark defects after spray painting are eliminated.

Owner:NANJING IRON & STEEL CO LTD

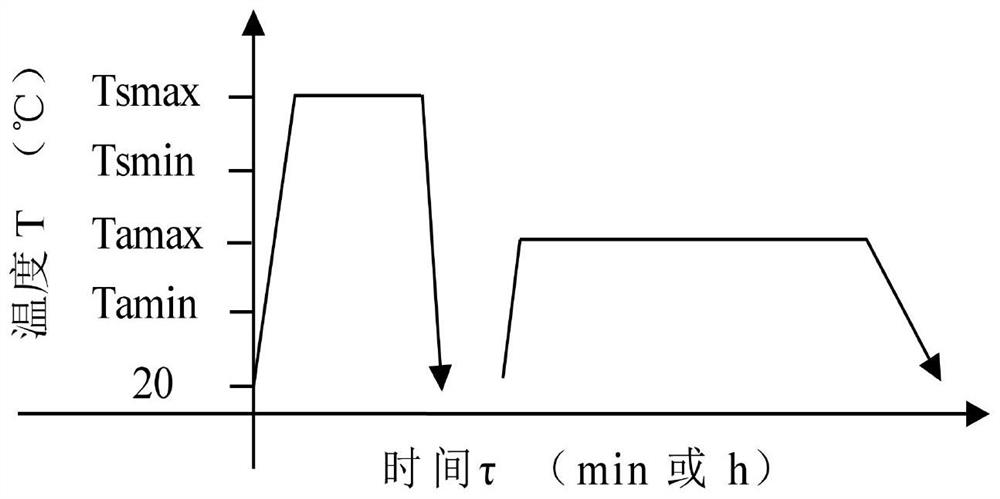

Rapid solid solution and rapid heating aging heat treatment method

The invention provides a rapid solid solution and rapid heating aging heat treatment method. The rapid solid solution and rapid heating aging heat treatment method comprises the steps of a rapid solid solution heat treatment process and a rapid heating aging heat treatment process. According to the scheme, the specific heat treatment technology theory and practice problems of poor quality stability, low qualified rate, low hardness, low mechanical property, poor consistency, long heating time, low efficiency, poor heating reliability of heating equipment, short service life of high-temperature components and high cost and the like of austenitic stainless steel heat treatment are solved.

Owner:山西柴油机工业有限责任公司

Rapid solid solution and rapid cooling, heating and variable-temperature aging heat treatment method

The invention provides a rapid solid solution and rapid cooling, heating and variable-temperature aging heat treatment method. The heat treatment method comprises a rapid solid solution heat treatment process and a rapid cooling, heating and variable-temperature aging heat treatment process. According to the scheme, the specific heat treatment technical problems of low quality stability, qualified rate, hardness, mechanical property and consistency, long heating time, low efficiency, low heating reliability of heat treatment equipment, short service life and high cost of high-temperature components and the like during austenitic stainless steel heat treatment can be solved.

Owner:山西柴油机工业有限责任公司

Aging heat treatment method for critical solid solution as well as critical temperature rise and temperature fall

The invention provides an aging heat treatment method for critical solid solution as well as critical temperature rise and temperature fall. The aging heat treatment method comprises a critical solid solution heat treatment process, a critical temperature rise aging heat treatment process and a critical temperature fall aging heat treatment process. The aging heat treatment method provided by the invention has technical feasibility, process adaptability, quality reliability, economic rationality and use safety; the advantages and disadvantages of a traditional mainstream heat treatment method for austenitic stainless steel can be effectively enhanced and avoided; the specific heat treatment technology problems that in the existing austenitic stainless steel heat treatment process, the quality stability is low, the rate of qualified products is low, the hardness is relatively low, the mechanical performance is low, the consistency is poor, the discoloration and corrosion resisting capacity is poor, the heating time is long, the efficiency is low, the heating reliability of heat treatment equipment is poor, the service life of high-temperature components is short, and the cost is high can be fundamentally solved; and the aging heat treatment method is particularly applicable to the technical fields of hot-working engineering such as smelting, steel rolling, forging and heat treatment of austenitic stainless steel in steel mills and manufacturing plants.

Owner:山西柴油机工业有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com