High-conductivity medium-strength aluminum alloy single wire and preparing method thereof

A medium-strength aluminum alloy, high conductivity technology, used in temperature control, metal rolling, elongation control, etc., can solve the problems of expensive rare earth elements, low tensile strength of aluminum alloy materials, and achieve excellent overload resistance. and fatigue characteristics, uniform internal temperature, and low stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

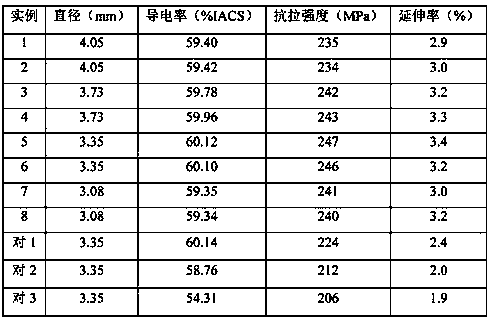

Examples

Embodiment 1

[0034] A medium-strength aluminum alloy monofilament with high conductivity, its chemical composition and weight percentage are: Si: 0.12%, Fe: 0.25%, Cu: 0.1%, Mg: 0.33%, Bi: 0.03%, Sr: 0.1%, B: 0.04%, Mn+Ti+Cr+V≤0.01%, the balance is Al.

[0035] The preparation method of the above-mentioned high-conductivity and medium-strength aluminum alloy monofilament comprises the following steps:

[0036] (1) Smelting: Add aluminum ingots to an intermediate frequency induction furnace to melt at 750°C, add Al-B master alloy, stir for 15 minutes after melting, and let stand for 20 minutes; keep the temperature at 750°C, and continue to add Al-Si, Al-Fe, Al- For Cu, Al-Bi, Al-Sr master alloys, stir for 10 minutes after melting, let stand for 25 minutes, and finally add pure Mg ingot, stir for 20 minutes after melting, let stand for 25 minutes;

[0037] (2) Degassing: Blowing in N 2 Carry out refining, blowing time is 5min, stand still for 20min, remove slag, obtain aluminum alloy liquid...

Embodiment 2

[0046] A medium-strength aluminum alloy monofilament with high conductivity, its chemical composition and weight percentage are: Si: 0.15%, Fe: 0.3%, Cu: 0.05%, Mg: 0.4%, Bi: 0.07%, Sr: 0.06%, B: 0.03%, Mn+Ti+Cr+V≤0.01%, the balance is Al.

[0047] The preparation method of the above-mentioned high-conductivity and medium-strength aluminum alloy monofilament comprises the following steps:

[0048] (1) Smelting: Add aluminum ingots to an intermediate frequency induction furnace to melt at 740°C, add Al-B master alloy, stir for 10 minutes after melting, and let stand for 25 minutes; keep the temperature at 740°C, continue to add Al-Si, Al-Fe, Al- For Cu, Al-Bi, Al-Sr intermediate alloys, stir for 15 minutes after melting, and let stand for 30 minutes, finally add pure Mg ingot, stir for 10 minutes after melting, let stand for 30 minutes;

[0049] (2) Degassing: Blowing in N 2 Carry out refining, blowing time is 8 minutes, stand still for 30 minutes, remove slag, obtain aluminu...

Embodiment 3

[0058] A medium-strength aluminum alloy monofilament with high conductivity, its chemical composition and weight percentage are: Si: 0.18%, Fe: 0.22%, Cu: 0.2%, Mg: 0.36%, Bi: 0.09%, Sr: 0.08%, B: 0.05%, Mn+Ti+Cr+V≤0.01%, the balance is Al.

[0059] The preparation method of the above-mentioned high-conductivity and medium-strength aluminum alloy monofilament comprises the following steps:

[0060] (1) Smelting: Put the aluminum ingot into an intermediate frequency induction furnace to melt at 730°C, add Al-B master alloy, stir for 20 minutes after melting, and let it stand for 30 minutes; keep the temperature at 730°C, and continue to add Al-Si, Al-Fe, Al- For Cu, Al-Bi, Al-Sr intermediate alloys, stir for 15 minutes after melting, and let stand for 25 minutes, and finally add pure Mg ingot, stir for 15 minutes after melting, let stand for 25 minutes;

[0061] (2) Degassing: Blowing in N 2 Carry out refining, blowing time is 6min, stand still for 40min, remove slag, obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com