Patents

Literature

45results about How to "Good high temperature characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

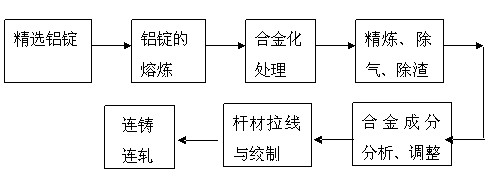

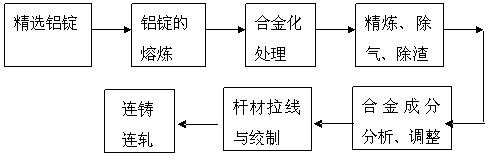

High-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire and production method thereof

InactiveCN102634695ASave construction investmentImproved resistance to overloadIngotUltimate tensile strength

The invention discloses a high-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire and a production method of the high-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire. The high-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire is produced by finely selecting ingredients and contents of aluminum alloy and conducting process control. The specific steps are as follows: selecting Fe, Si, Mg, Cu and Re with different weight percents, melting aluminum ingot with the content not more than 0.03% in a vertical melting furnace, adding alloying elements in a heat insulation furnace, stirring, refining, conducting on-the-spot contents rapid analysis, carrying out content adjustment, and standing, enabling the aluminum ingot and the alloying element into a continuous casting machine for casting, rolling to be a circular aluminum alloy rod on a continuous rolling machine, pulling the circular aluminum alloy rod to be a circular aluminum alloy wire and twisting the circular aluminum alloy wire to be a conductor for aerial power transmission and distribution. According to the application of the aluminum alloy wire and the production method of the aluminum alloy wire, the aluminum alloy wire directly replaces the generally used aluminum conductor steel reinforced and is an energy-saving, environment-friendly and novel wire.

Owner:FAR EAST CABLE

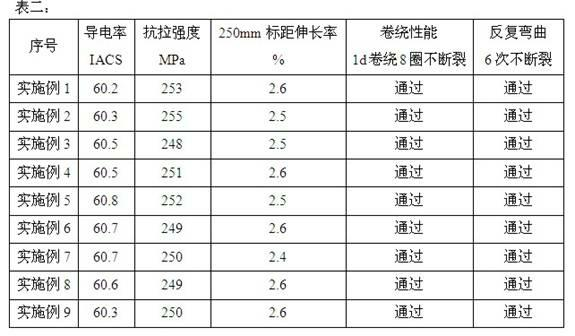

Mud drying system and use method thereof

ActiveCN101618930AHigh drying yieldReduce drying energy consumptionSludge treatment by de-watering/drying/thickeningHeat pumpsSludgeWater circulation

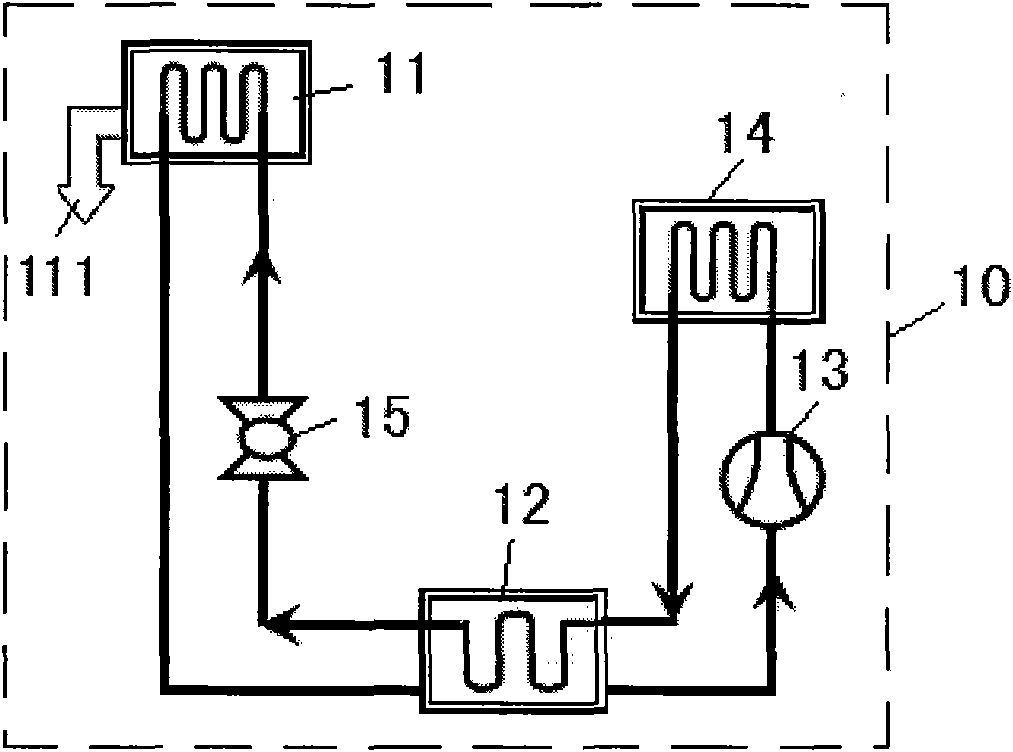

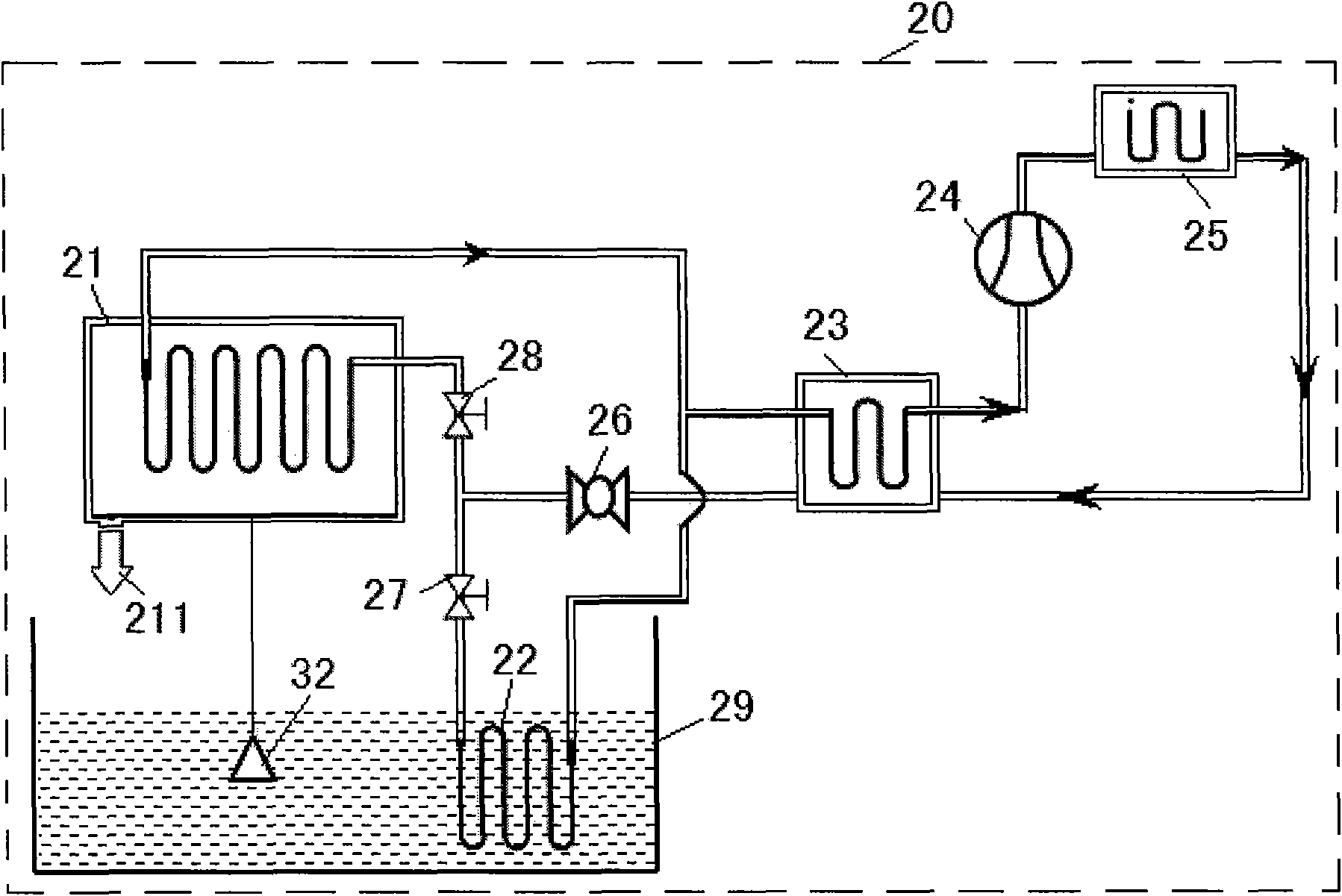

The invention relates to a mud drying system and a use method thereof. The mud drying system comprises a transcritical heat pump auxiliary heat supplying loop, a heat pump auxiliary heat supplying loop, an air heating and waste heat recovering loop and a hot water circulation loop; the transcritical heat pump auxiliary heat supplying loop comprises an evaporator, an internal heat exchanger, a compressor, a gas cooler and a throttle valve; the heat pump auxiliary heat supplying loop comprises an evaporator, a wastewater and waste heat recovering evaporator, an internal heat exchanger, a compressor, a condenser, a throttle valve, two stop valves and a wastewater tank; the air heating and waste heat recovering loop comprises a hothouse, an air compressor, a gas discharging and carrying port, a first evaporator, the other evaporator and a condenser; and the hot water circulation loop comprises a pump, a hothouse and the condenser in the heat pump auxiliary heat supplying loop. The invention adopts the hothouses to obtain solar energy to heat mud and utilizes the transcritical heat pump auxiliary heat supplying loop and the heat pump auxiliary heat supplying loop to recover the sensible heat and the latent heat in humid air to heat mud, thereby lowering the energy consumption for drying the mud. The invention can be widely applied to various mud processing fields.

Owner:TSINGHUA UNIV +3

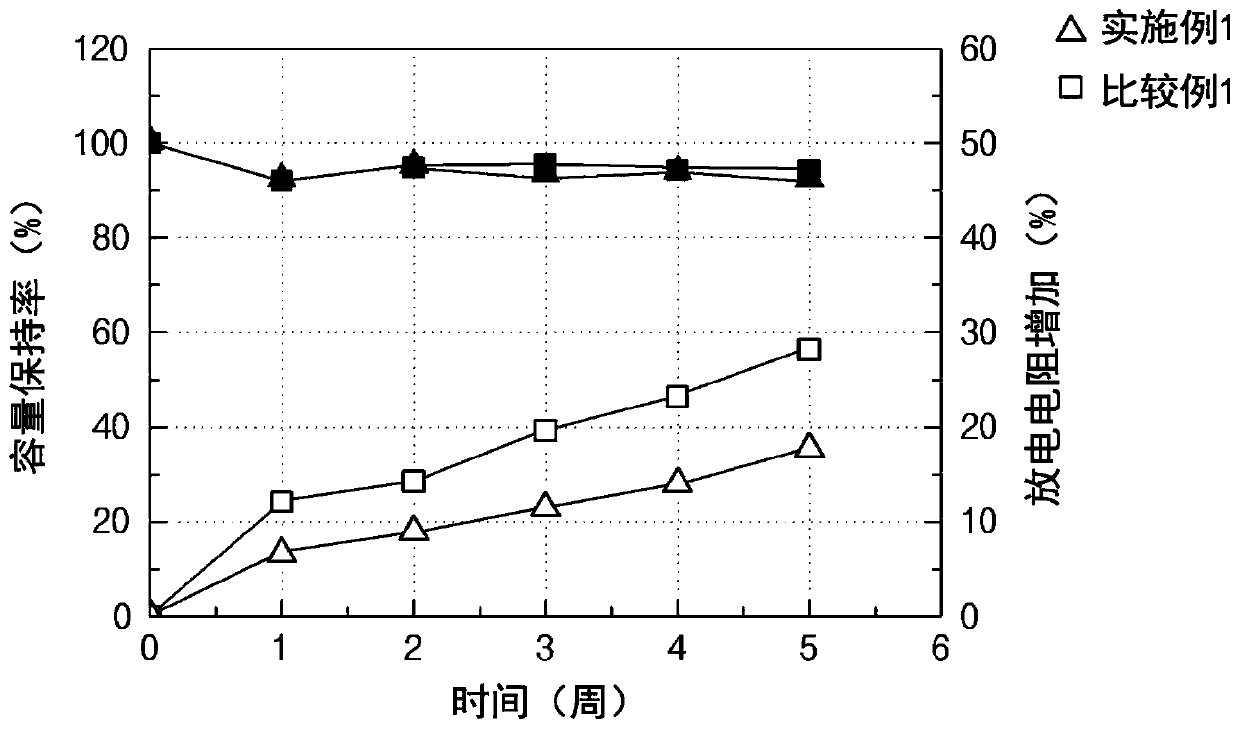

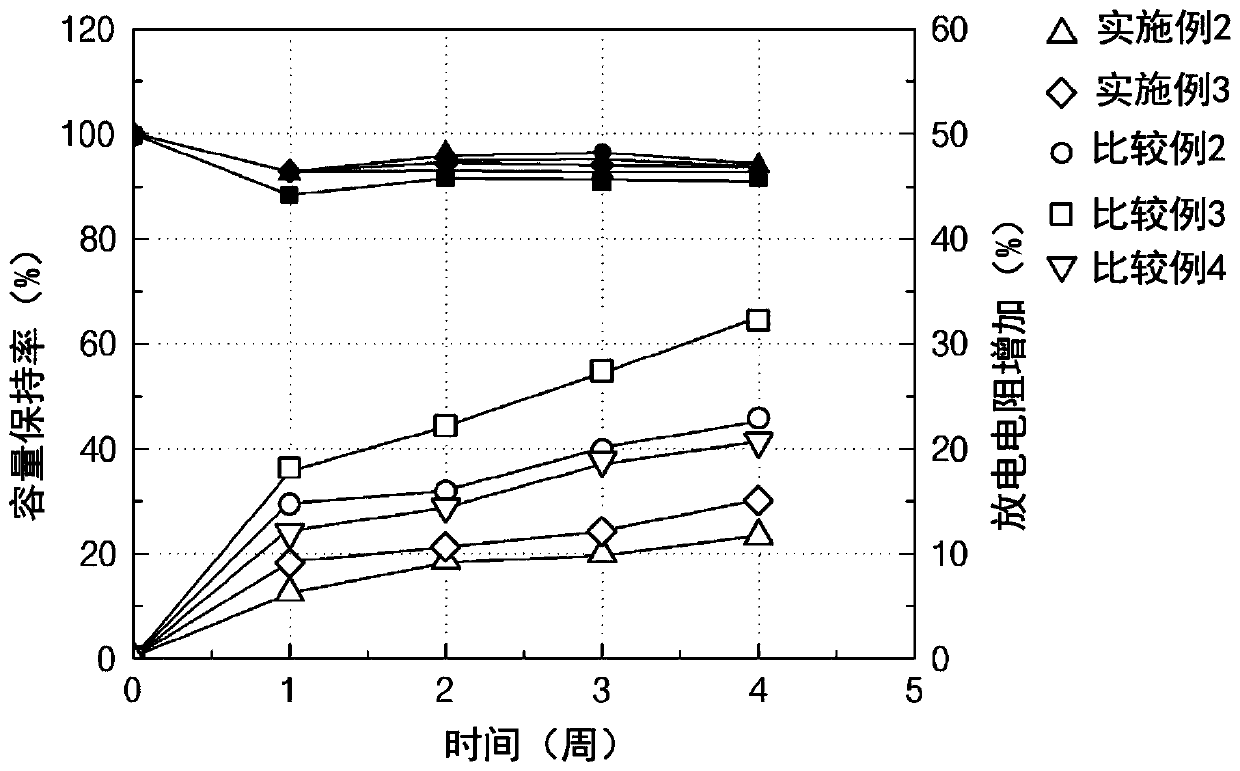

Positive electrode active material and non-aqueous electrolyte secondary battery containing the same

ActiveCN1571194AExcellent lithium ion conductivityGood high temperature characteristicsNon-aqueous electrolyte accumulatorsFixed capacitor electrodesTitaniumNon aqueous electrolytes

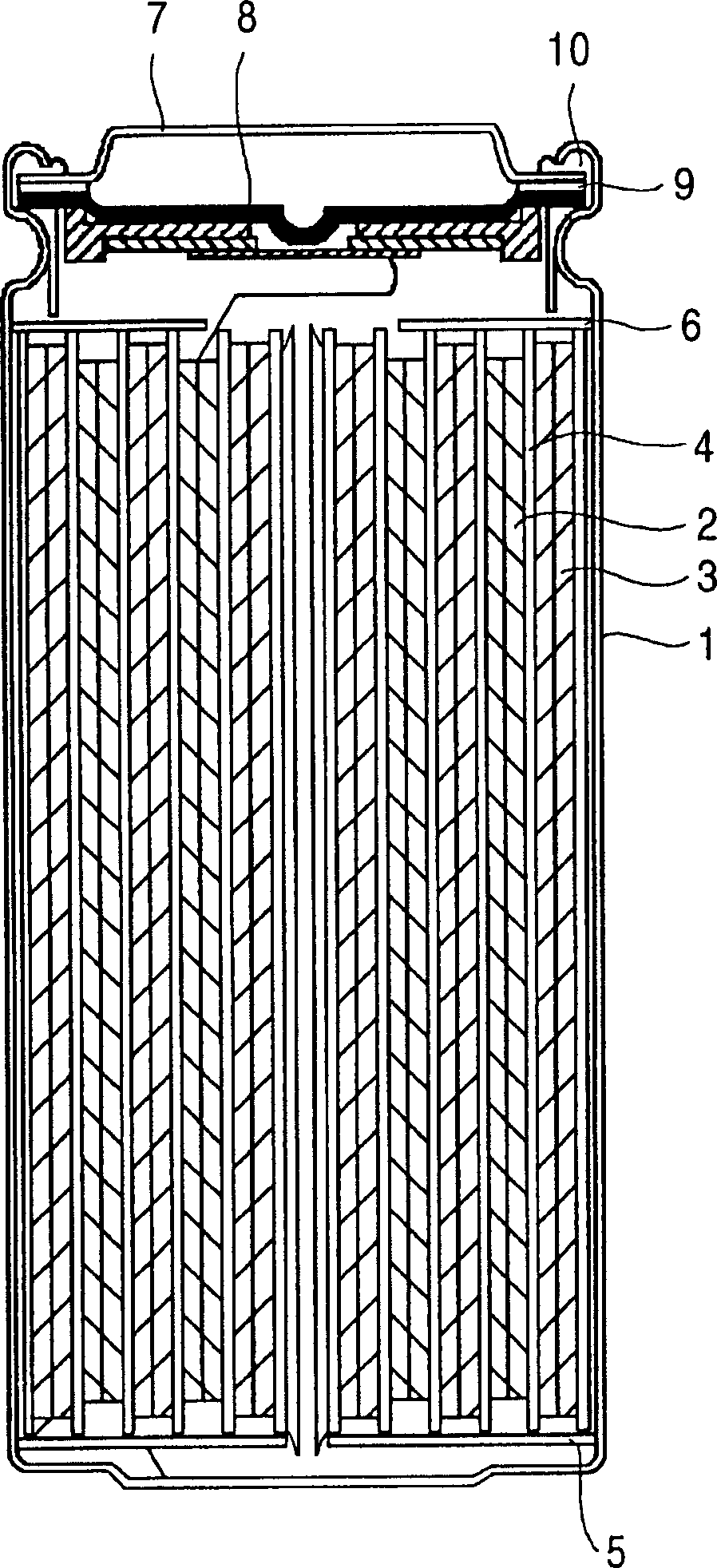

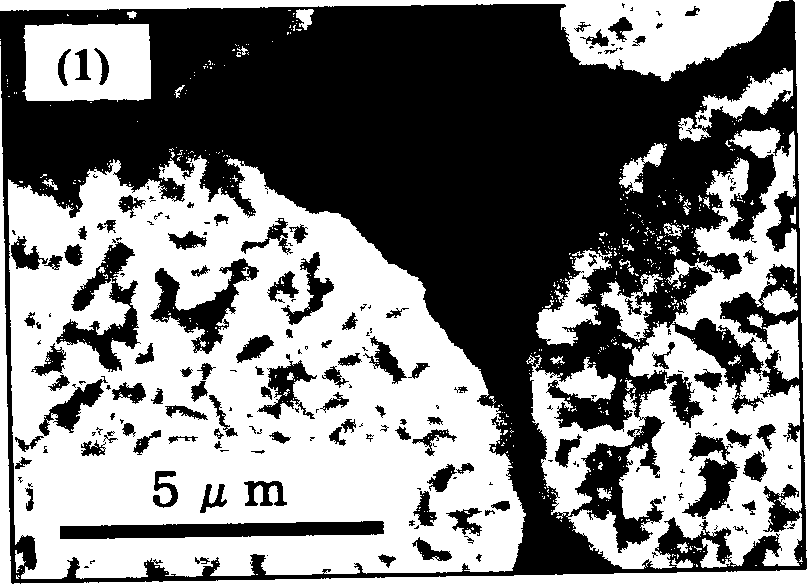

A positive electrode active material includes particles composed of a compound oxide; and coating layers composed of a compound oxide formed on at least parts of the surfaces of the particles. The particles have a layered structure and include a first compound oxide mainly composed of lithium and nickel. The coating layers include a second compound oxide mainly composed of lithium and titanium. The ratio by weight of the first compound oxide to the second compound oxide is between 96:4 and 65:35. The positive electrode active material has a mean particle diameter of 5 to 20 mum.

Owner:MURATA MFG CO LTD

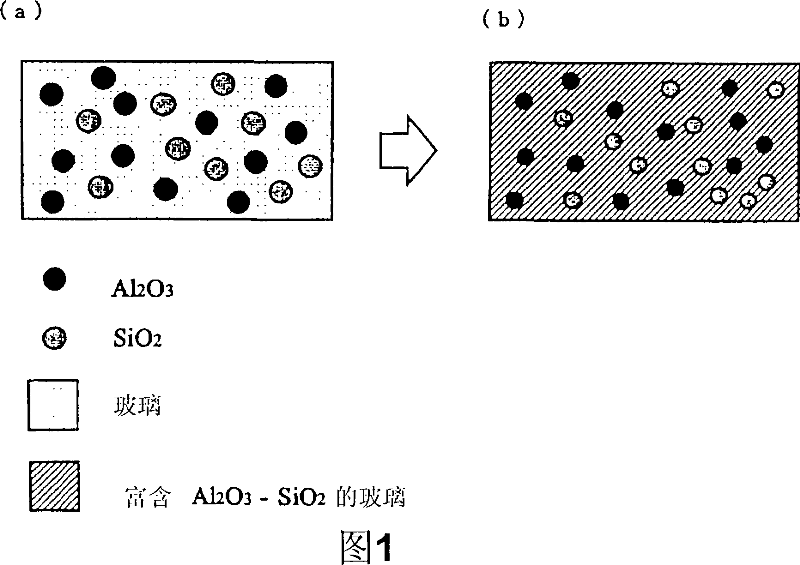

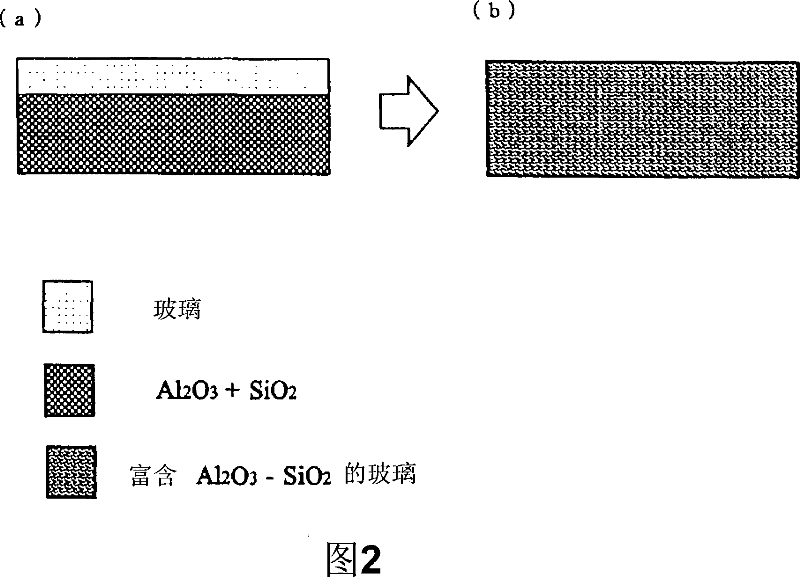

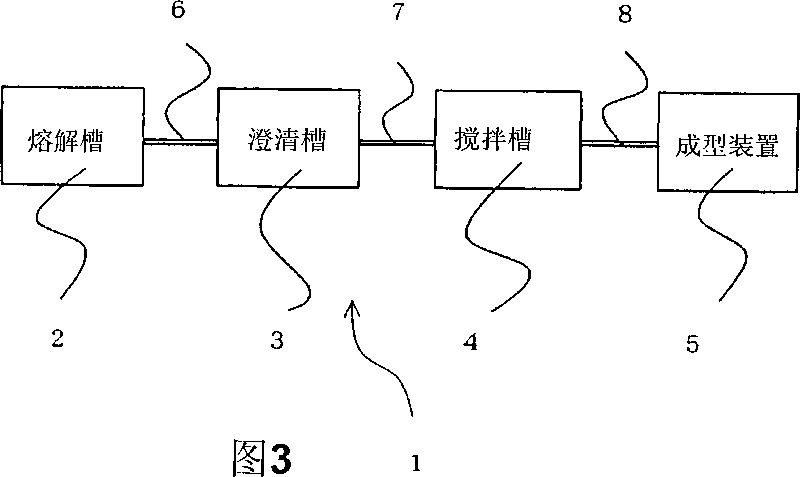

Process of preparing mineral bonding material and its composite material with phosphate and aluminium-silicon material

InactiveCN1673169AHigh low temperature strengthGood high temperature characteristicsClaywaresFiberAlkaline earth metal

The present invention relates to method of preparing mineral bonding material and its composite materials with phosphate and aluminum-silicon material at relatively low temperature. Under relatively low temperature, aluminum-silicon material with reaction activity is made to produce bonding reaction with phosphate to obtain one kind of amorphous solid Al-Si-P mineral bonding material. The Al-Si-P mineral bonding material may be used as basic material to prepare various composite materials with different performance via adding bauxite, silicon powder, flyash, mineral slag, fiber, etc. The said composite materials may be formed through casting or pressing, and the materials have excellent endurance, high mechanical strength and good high temperature performance.

Owner:SOUTH CHINA UNIV OF TECH

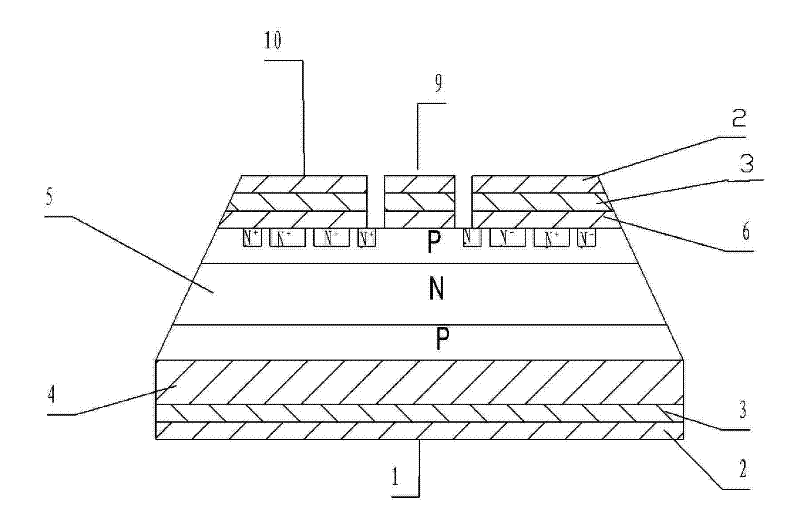

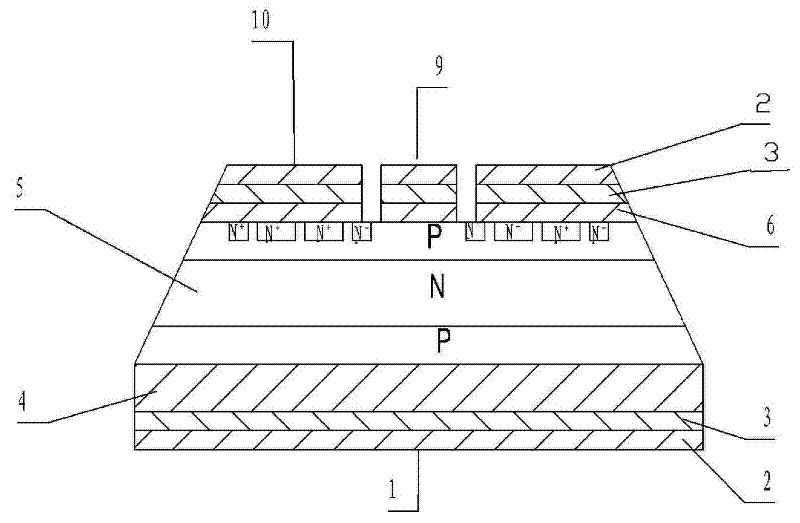

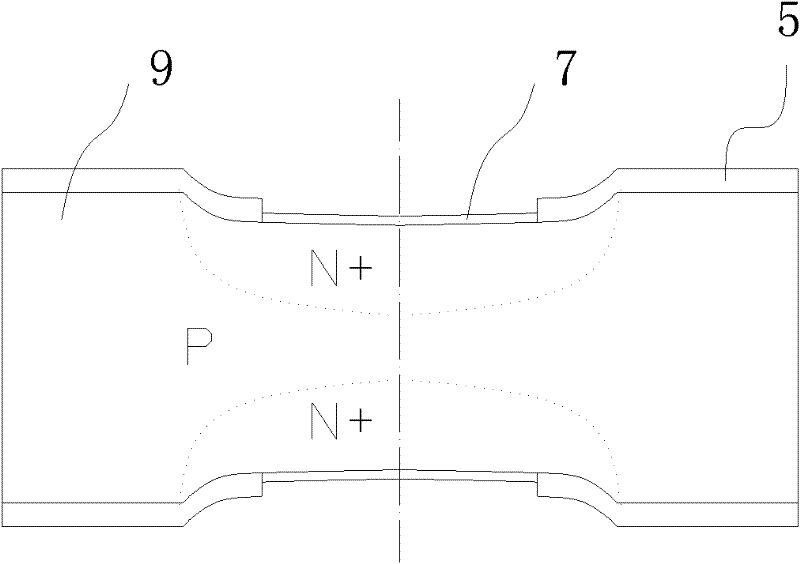

Thyristor core manufacturing process

InactiveCN101752248AImprove welding characteristicsImproved high temperature characteristicsSemiconductor/solid-state device manufacturingEvaporationAlloy

The invention discloses a thyristor core manufacturing process. The manufacturing process is characterized in that the manufacturing process includes the following steps: 1) boron diffusion; 2) oxidization; 3) primary photoetching; 4) phosphorus diffusion; 5) sintering; 6) evaporation; 7) alloying; 8) secondary photoetching; 9) surface treatment-nickeling; 10) surface treatment-silvering; 11) tertiary photoetching; 12) angle grinding; 13) surface corrosion. Primary diffusion-oxidization-photoetching-secondary diffusion are carried out on an original N-type silicon slice so as to form a four-layer (P-N-P-N) structure; sintering and bonding are carried out under the vacuum condition and high temperature; high-purity aluminum is gasified on the surface of a mono-crystalline silicon slice by an electron beam under high temperature so as to form an effective protective film; finally, nickeling and silvering treatments are respectively carried out on a surface layer of a sintered and film-coated thyristor core, and an anode and a cathode which can be welded are led out at the two ends of the thyristor core, so as to prepare the entire thyristor core suitable for both welding encapsulation and pressure-welding encapsulation at the same time as removing a traditional lead evading technology.

Owner:ZHEJIANG SIFANG ELECTRONICS

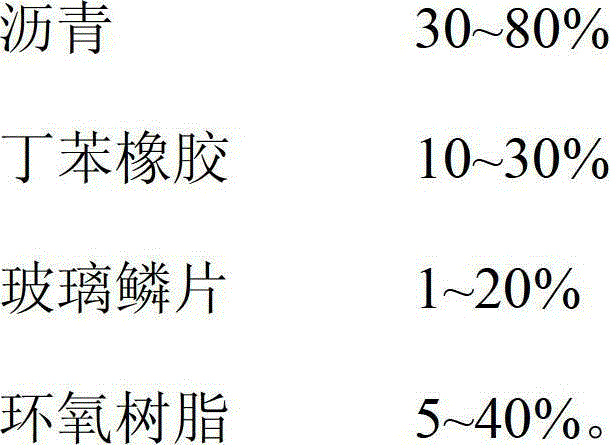

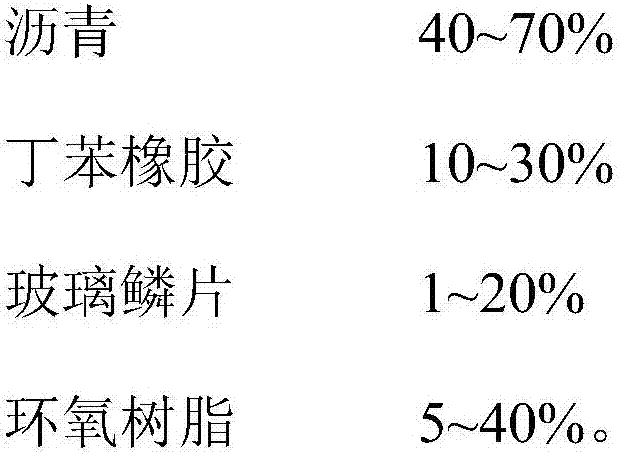

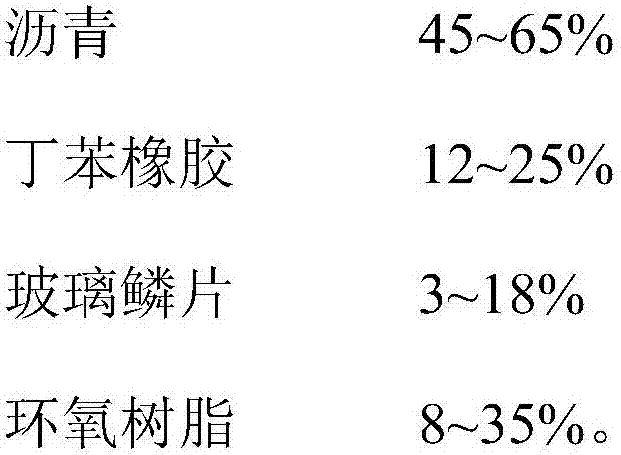

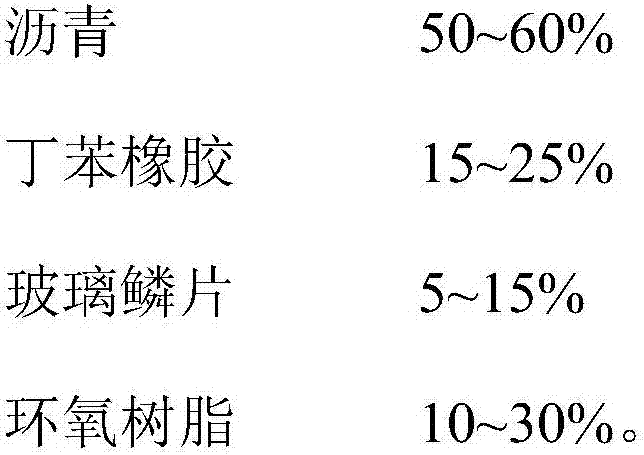

Pipeline coating, application thereof and pipeline coated with same

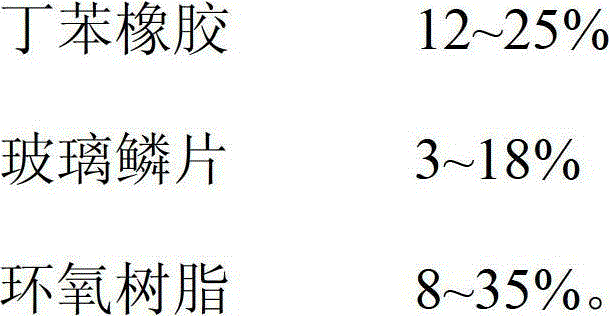

InactiveCN102719195AGood high temperature performanceImprove impact resistanceConjugated diene hydrocarbon coatingsAnti-corrosive paintsButadiene-styrene rubberAsphalt

The invention relates to pipeline coating comprising an asphalt composition. The pipeline coating comprises, by weight, 30-80% of asphalt, 10-30% of butadiene styrene rubber, 1-20% of glass flakes and 5-40% of epoxy resin. The invention further provides a pipeline coated with the pipeline coating, a method using the pipeline coating to coat the pipeline and application of the pipeline coating comprising the asphalt composition. The pipeline coating is simple in manufacture method, has excellent impact resistance and flexibility and further displays excellent high-temperature property and adhesive force.

Owner:TIANCHANG JULONG TRAVEL PAINT

Coating material for platinum material, platinum material coated with such coating material, and glass manufacturing apparatus

InactiveCN101044265ANo volatile lossGood high temperature characteristicsGlass furnace apparatusMetallic material coating processesPlatinumRefractory

Owner:TANAKA PRECIOUS METAL IND +1

Magnesium alloy and magnesium alloy casting

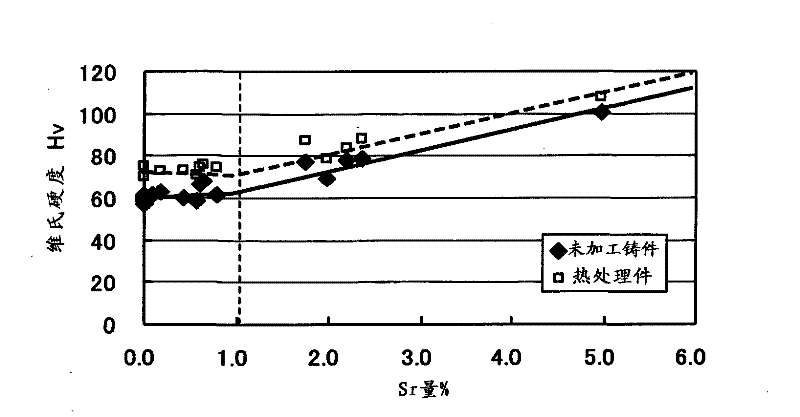

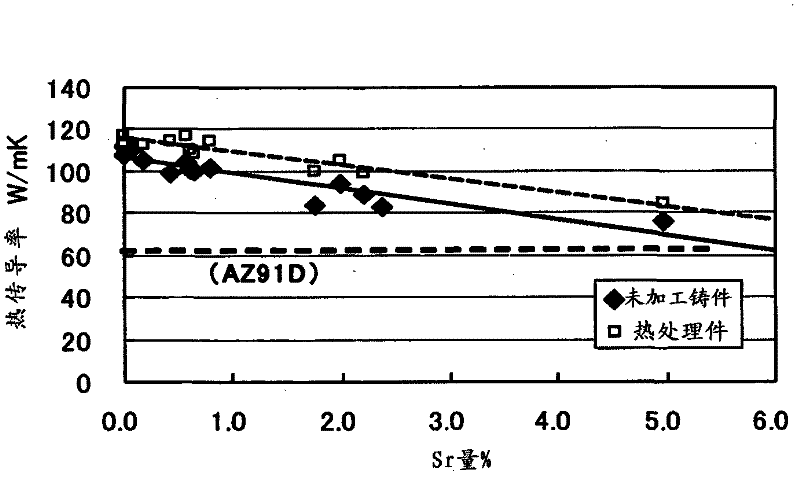

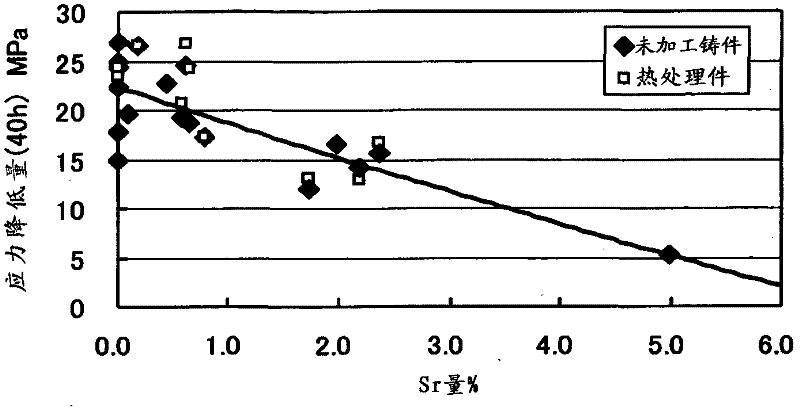

InactiveCN102197153AGood high temperature characteristicsGood castabilityImpurityThermal conductivity

The Mg alloy comprises 2-6% of Al, Ca at a composition ratio (Ca / Al) of 0.5-1.5, 0.1-0.7% of Mn, 1-6% of Sr, and the remainder Mg and inevitable impurities and / or modified elements, when the total is 100 wt%. With this, an Mg alloy with excellent normal-temperature characteristics as well as creep resistance and high-temperature characteristics, such as thermal conductivity, was obtained.

Owner:TOYOTA IND CORP

Method for preparing mineral bonding materials and composite materials thereof from phosphoric acid and aluminium-silicon materials

InactiveCN1721356AHigh low temperature strengthGood high temperature characteristicsClaywaresSilica fumeIon

The present invention relates to one kind of mineral bonding material prepared with phosphoric acid and alumina and silica material at relatively low temperature and its composite material. At relatively low temperature, alumina and silica material with reaction activity and phosphoric acid produce bonding reaction to form one kind of amorphous solid mineral bonding Al-Si-P material. The mineral bonding Al-Si-P material may be used as base material and added with bauxite, silica powder, flyash, mineral slag, fiber, etc to prepare various kinds of composite material with different performances. The composite materials may be cast or pressed to form optionally without needing of introducing alkali earth ions, and the prepared material has high durability, high mechanical strength and good high temperature performance.

Owner:SOUTH CHINA UNIV OF TECH

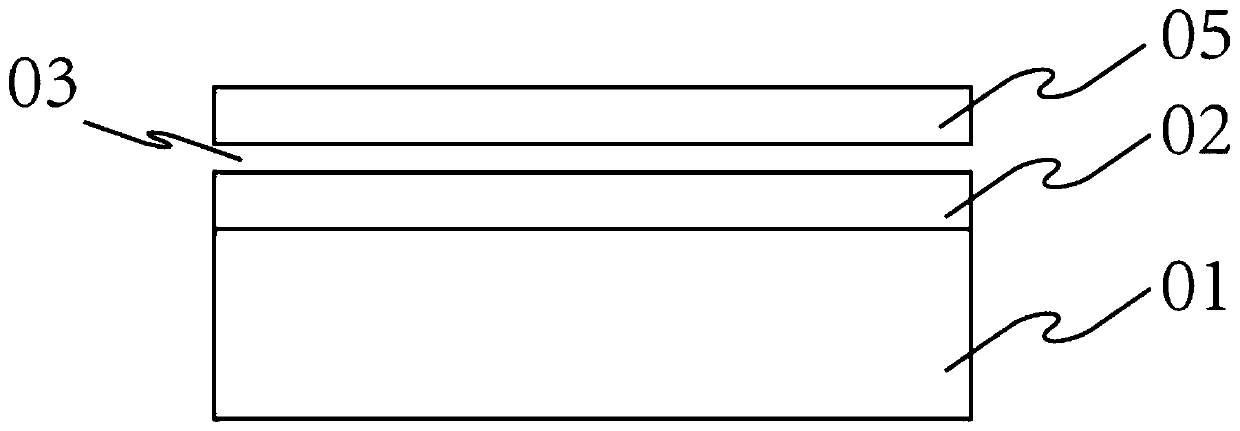

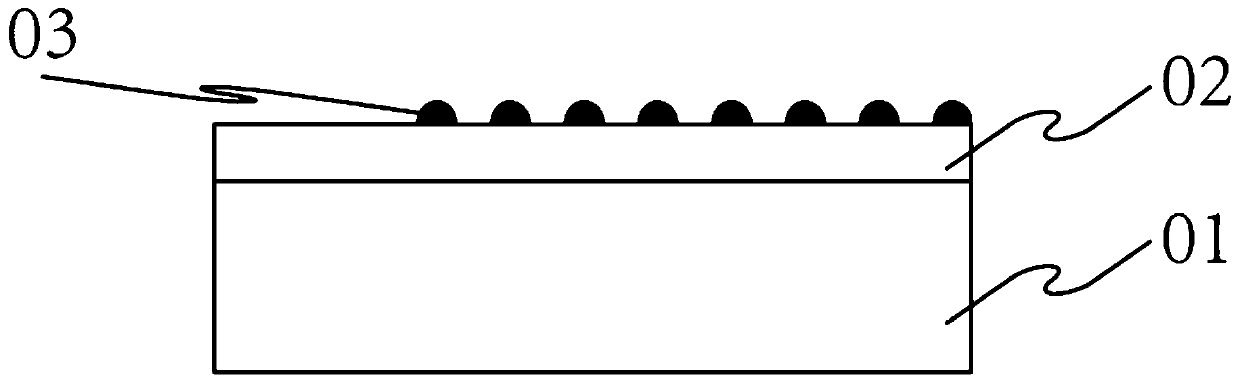

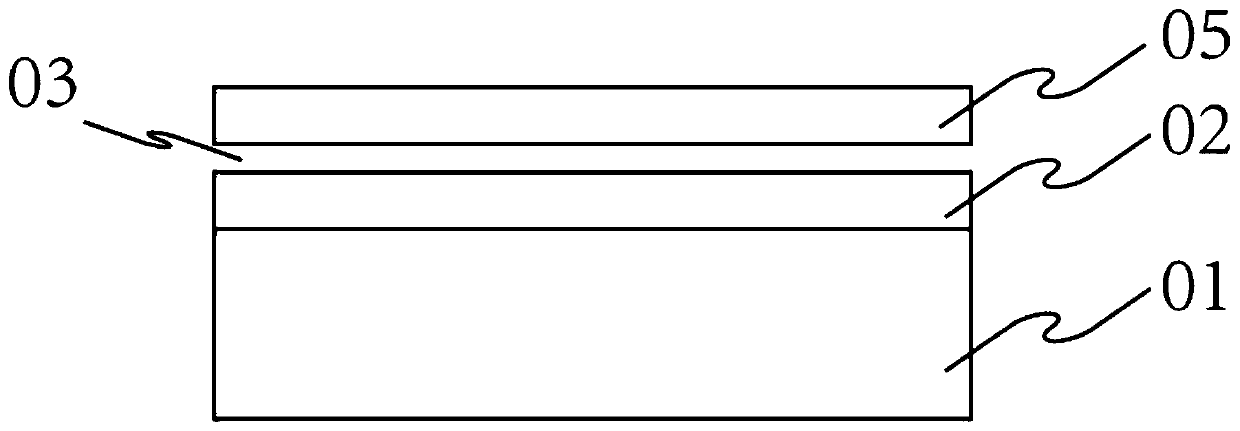

High-speed DFB laser and manufacturing method thereof

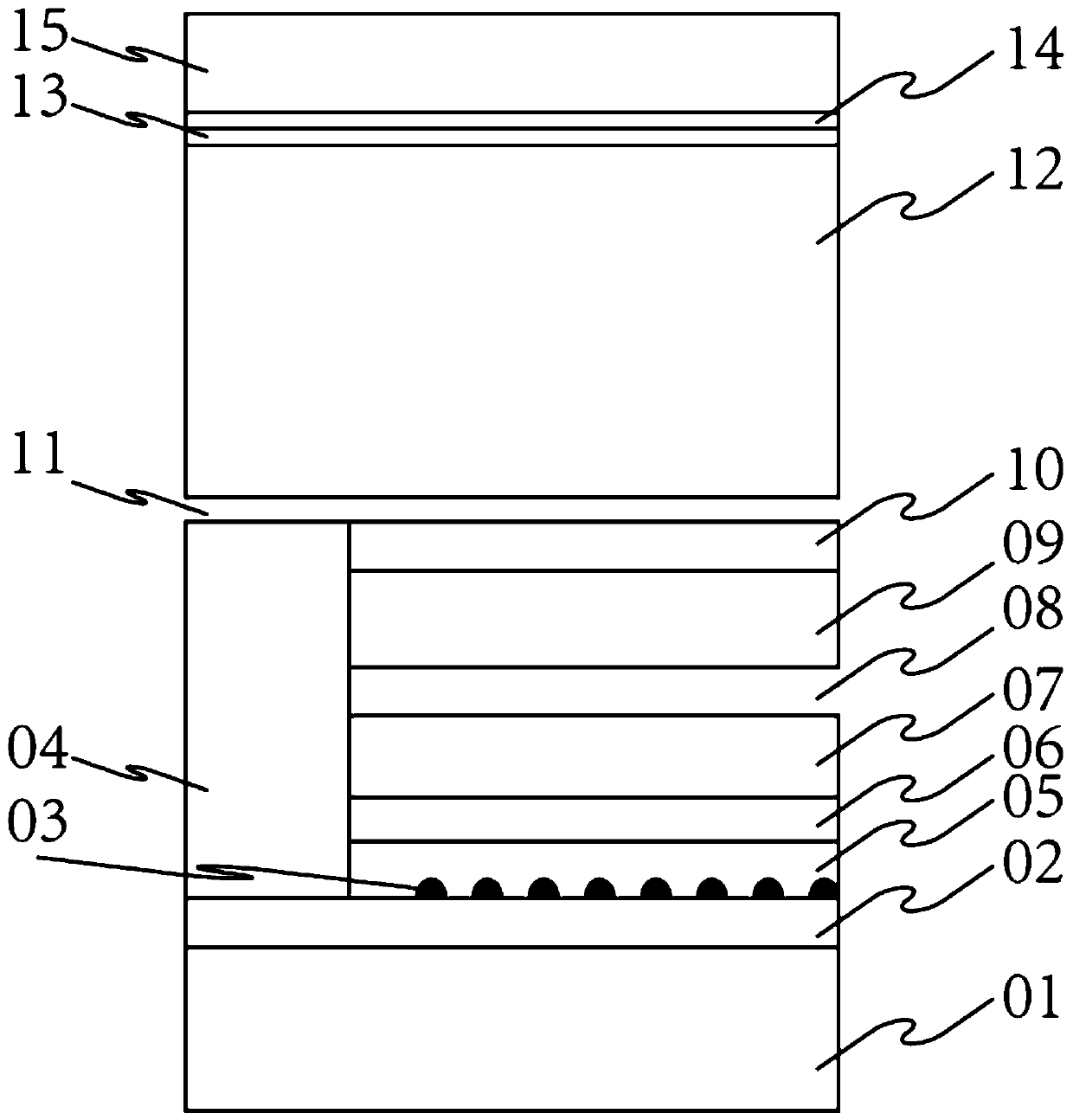

PendingCN110535030AEasy to storeLower the thresholdOptical wave guidanceLaser detailsGratingQuantum well

The invention provides a high-speed DFB laser, and the epitaxial structure thereof comprises an InP substrate. A buffer layer is deposited on the InP substrate. A vertical confinement layer is deposited on the upper left of the buffer layer. A grating layer, a transition layer, a lower confinement layer in an active area, a lower waveguide layer, a quantum well, an upper waveguide layer and an upper confinement layer in the active area are deposited on the upper right of the buffer layer in order from bottom to top. The vertical confinement layer is aligned with the upper end of the upper confinement layer in the active area, and a corrosion barrier layer is deposited above the two layers. A coupling layer, a first barrier gradation layer, a first barrier gradation layer and an ohmic contact layer are sequentially deposited on the corrosion barrier layer. According to the invention, the laser has the advantages of low resistance, fast modulation rate and good lattice matching at high temperature, and is favorable for grating preservation; and during the growth process, pulsed airflow growth is used to grow a microscler nucleus layer first and then an epitaxial layer with a certainthickness, which is beneficial to improve the growth quality of the epitaxial layer.

Owner:全磊光电股份有限公司

High-speed working temperature DFB laser and manufacturing method thereof

PendingCN110535032ALower the thresholdLower resistanceOptical wave guidanceLaser optical resonator constructionGratingQuantum well

The invention provides a high-speed working temperature DFB laser. The epitaxial structure of the laser comprises an InP substrate. A buffer layer is deposited on the InP substrate. A vertical confinement layer is deposited on the upper left of the buffer layer. A grating layer, a transition layer, a lower confinement layer in an active area, a lower waveguide layer, a quantum well, an upper waveguide layer and an upper confinement layer in the active area are deposited on the upper right of the buffer layer in order from top to bottom. The vertical confinement layer is aligned with the upperend of the upper confinement layer in the active area, and a corrosion barrier layer is deposited above the two layers. A coupling layer, a first barrier gradation layer, a first barrier gradation layer and an ohmic contact layer are sequentially deposited on the corrosion barrier layer. An insulating layer is arranged on the surface of the laser. According to the invention, the laser has the advantages of low resistance, fast modulation rate and good high temperature characteristics; an Al-containing material is prevented from being exposed to a water and oxygen environment; the reliability of the device is improved; a large-sized chip structure is adopted; a high-thermal-conductivity material is evaporated on the surface of the chip; and the laser has the advantages of good chip heat dissipation and good high temperature characteristic, and can work in a wide temperature range.

Owner:全磊光电股份有限公司

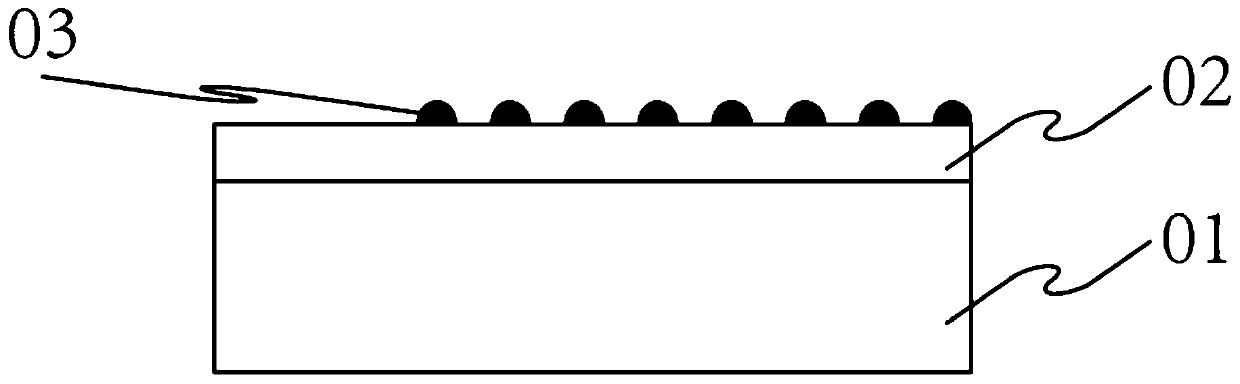

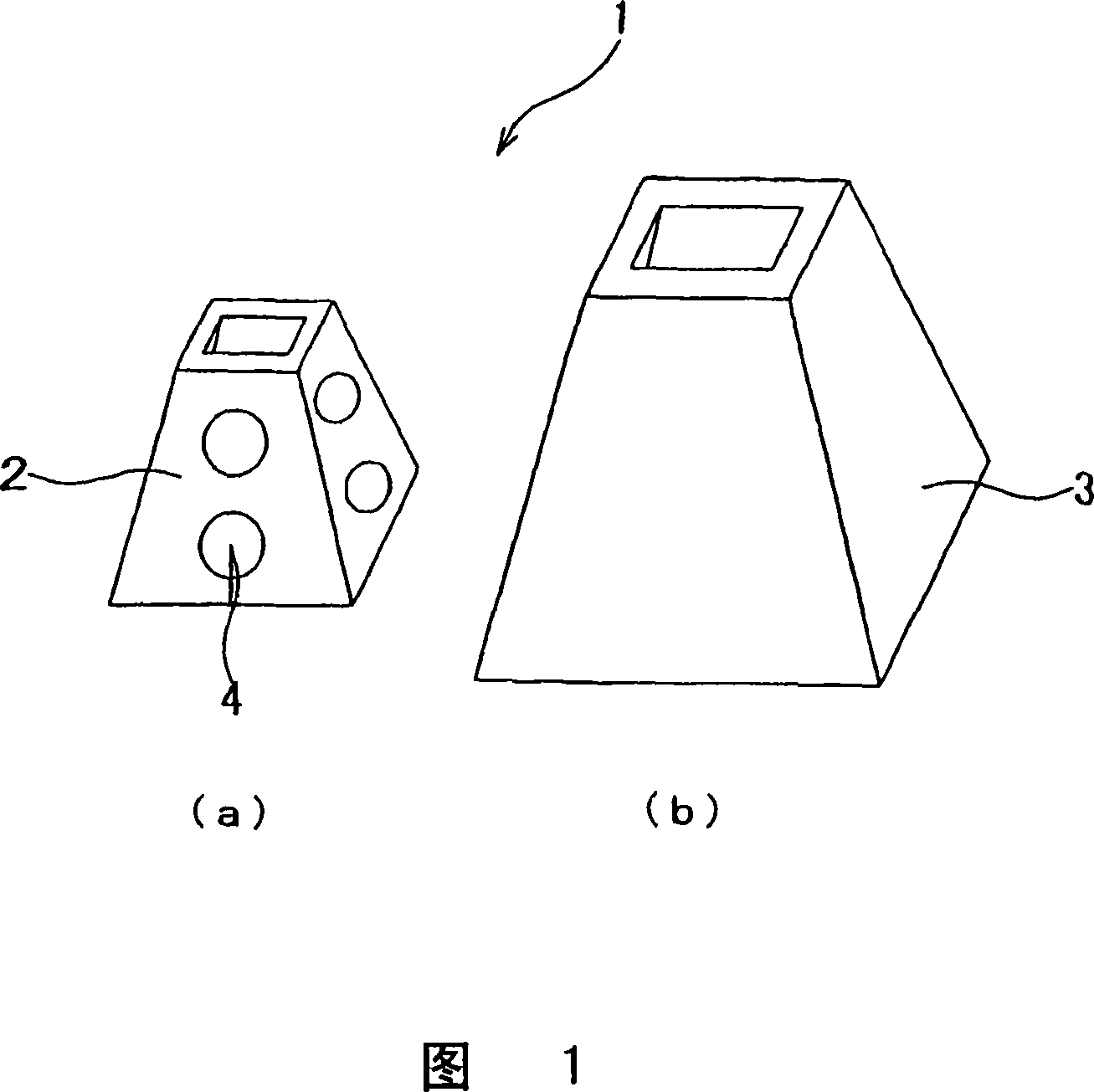

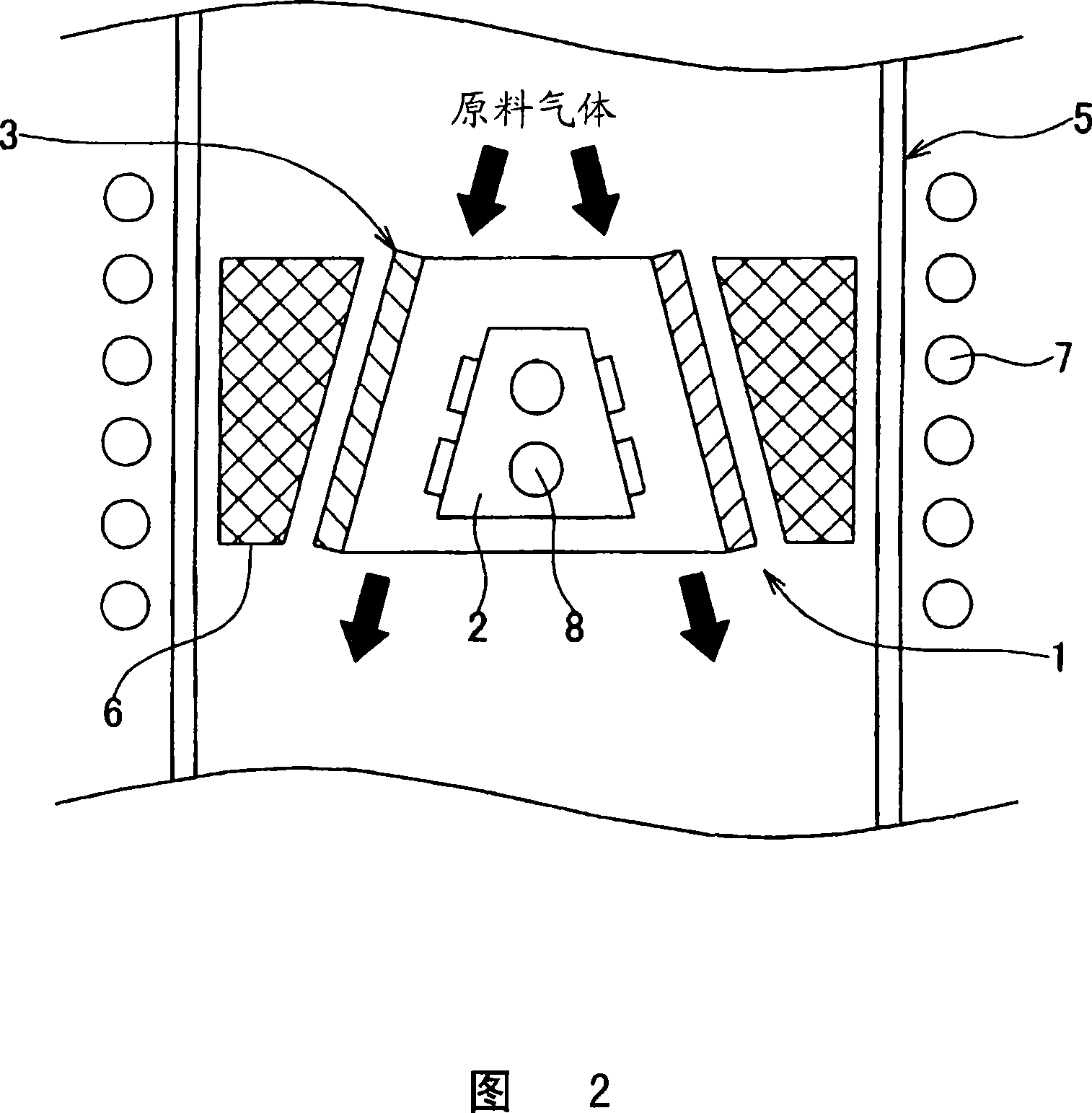

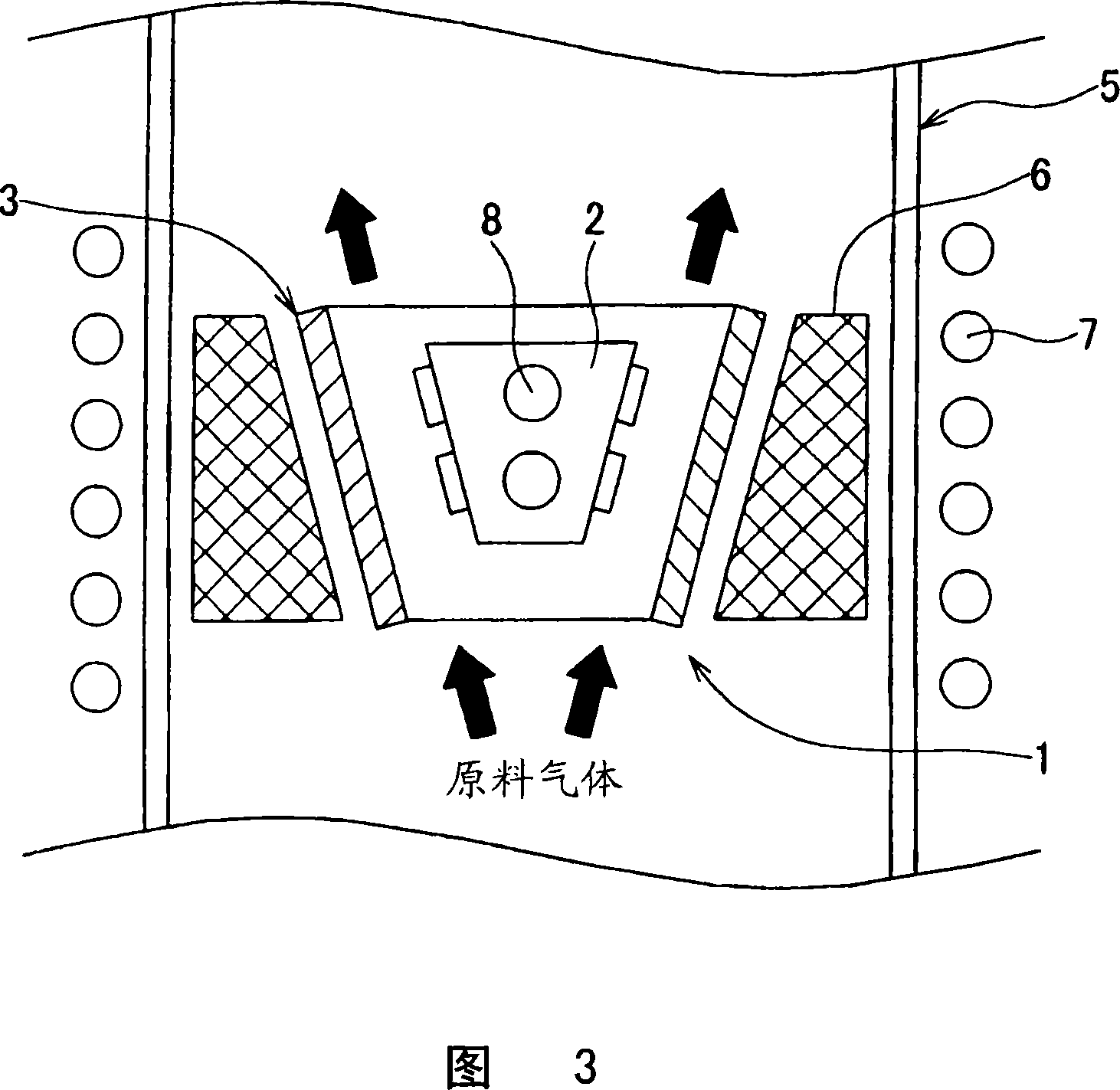

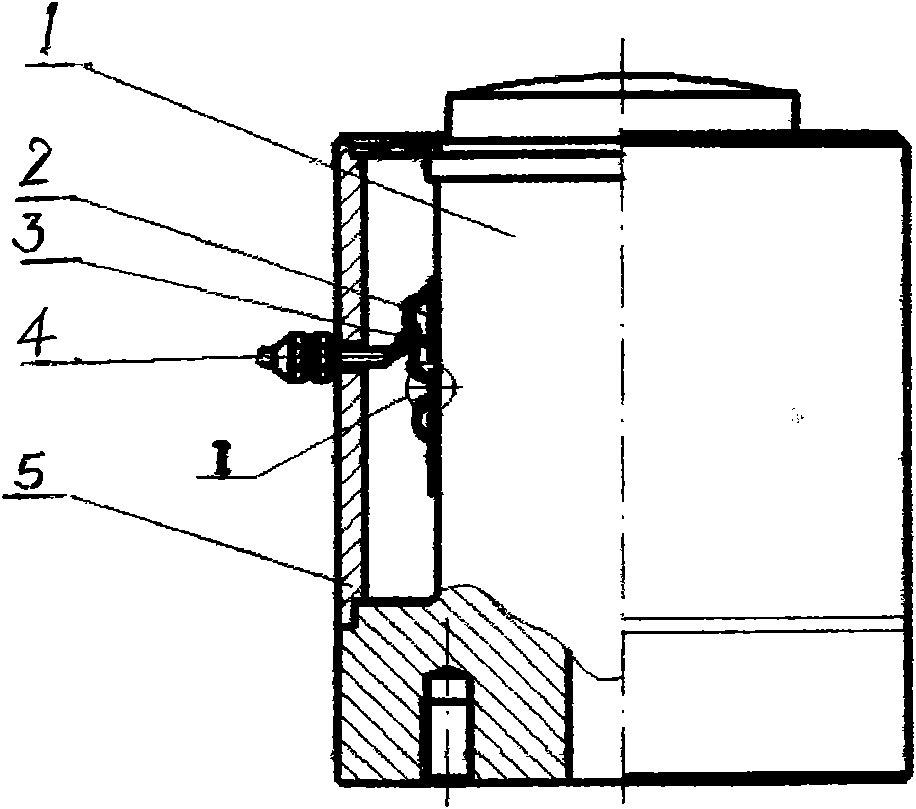

Susceptor

InactiveCN1938822AImprove consistencyInhibition releaseDiffusion/dopingSemiconductor/solid-state device manufacturingSusceptorSemiconductor

A susceptor used for semiconductor epitaxial growth, by which a plurality of highly uniform epitaxially grown films can be obtained at the same time. The susceptor is used for semiconductor epitaxial growth, and is composed of a barrel-type susceptor, which has a plurality of planes whereupon a plurality of substrates can be freely placed on the external side, and a member, which has the barrel-type susceptor inside and has planes arranged to face each of the planes of the barrel-type susceptor by inclining in the same direction. Alternatively, the susceptor is composed of a barrel-type susceptor, which has a plurality of planes whereupon a plurality of substrates can be freely placed on the inner side, and a member, which has the barrel-type susceptor on the outer circumference part and has planes arranged to face each of the planes of the barrel-type susceptor by inclining in the same direction.

Owner:TOYO TANSO KK

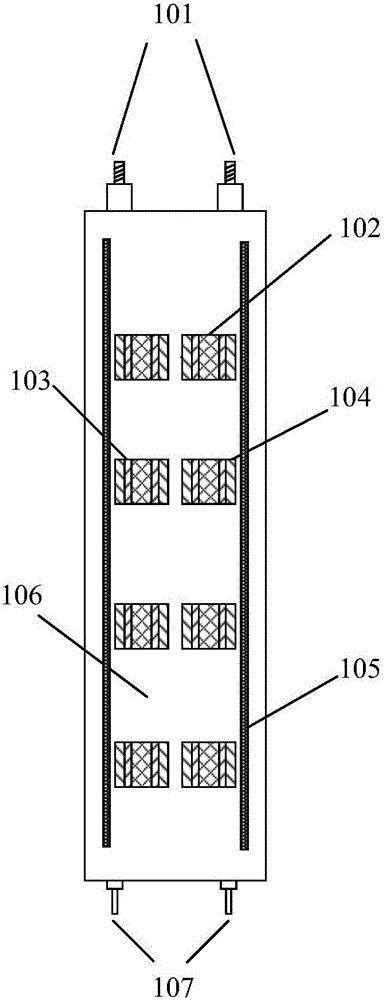

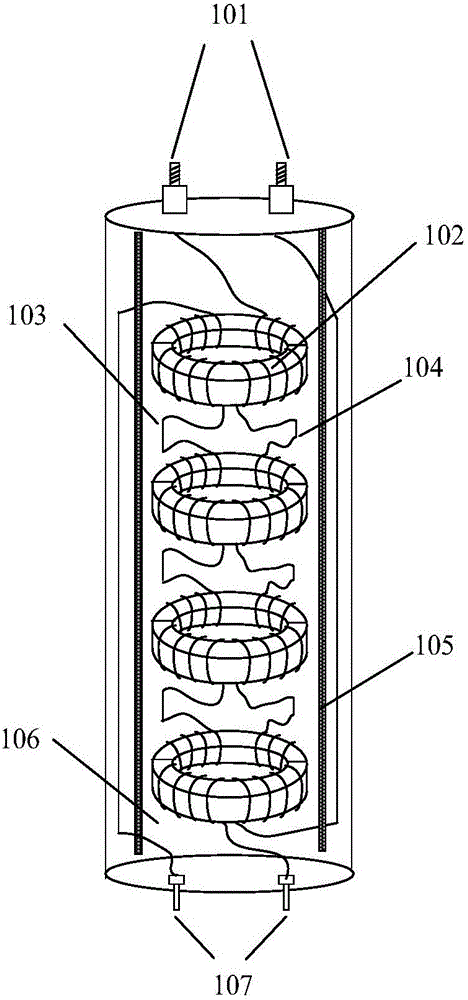

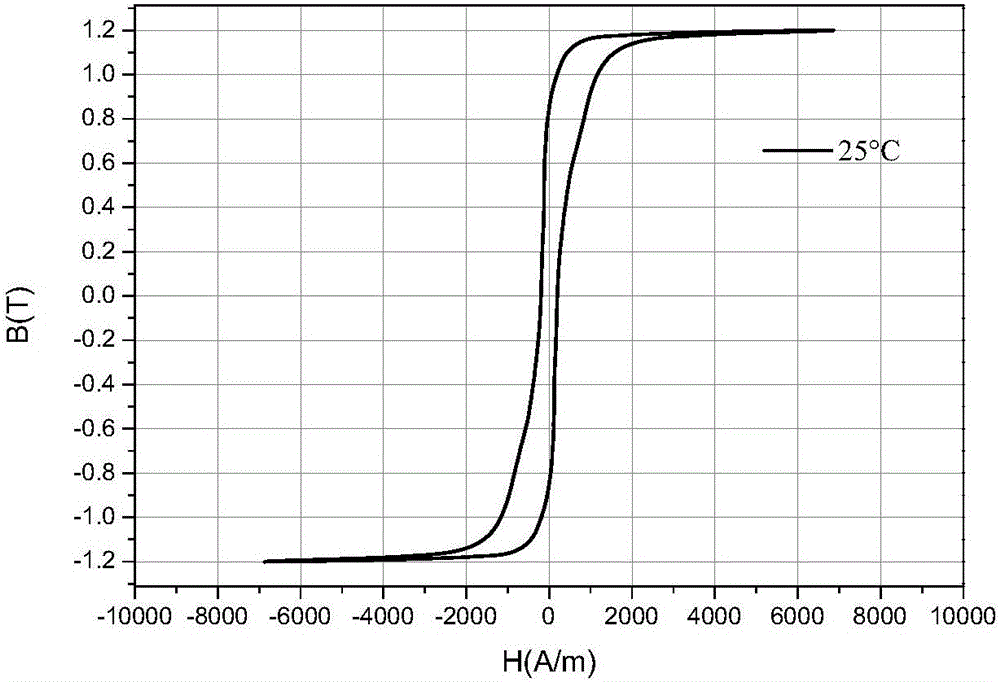

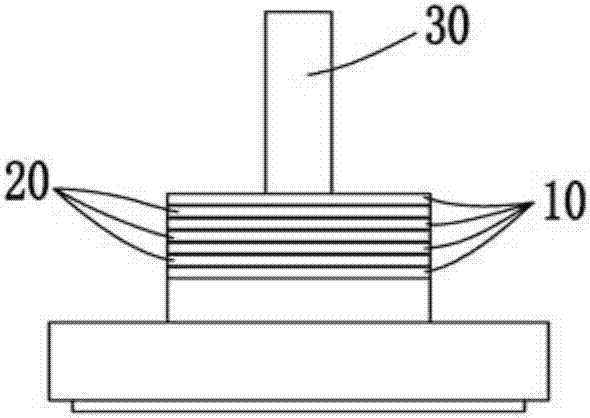

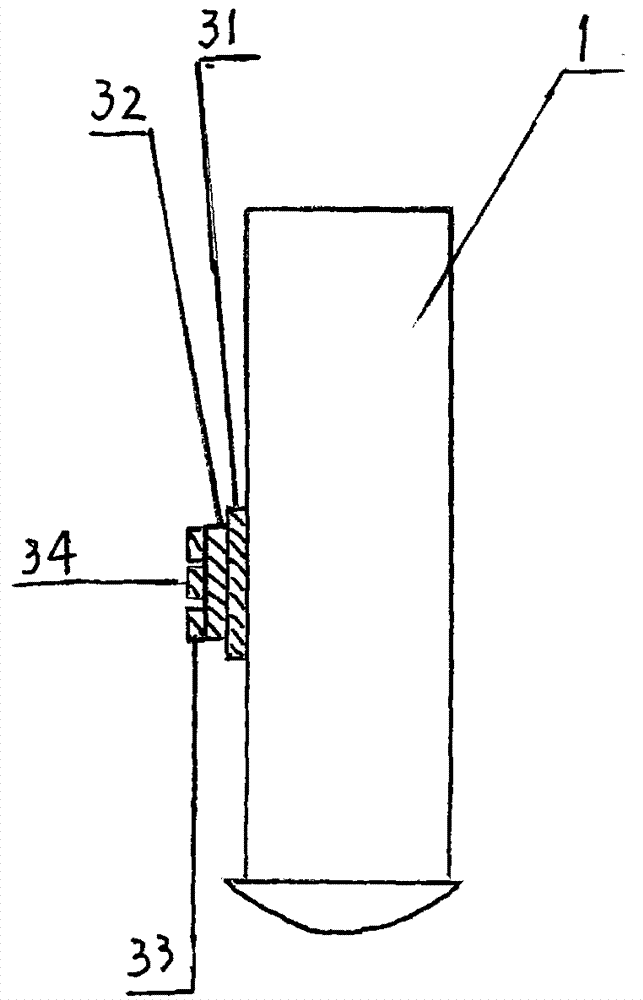

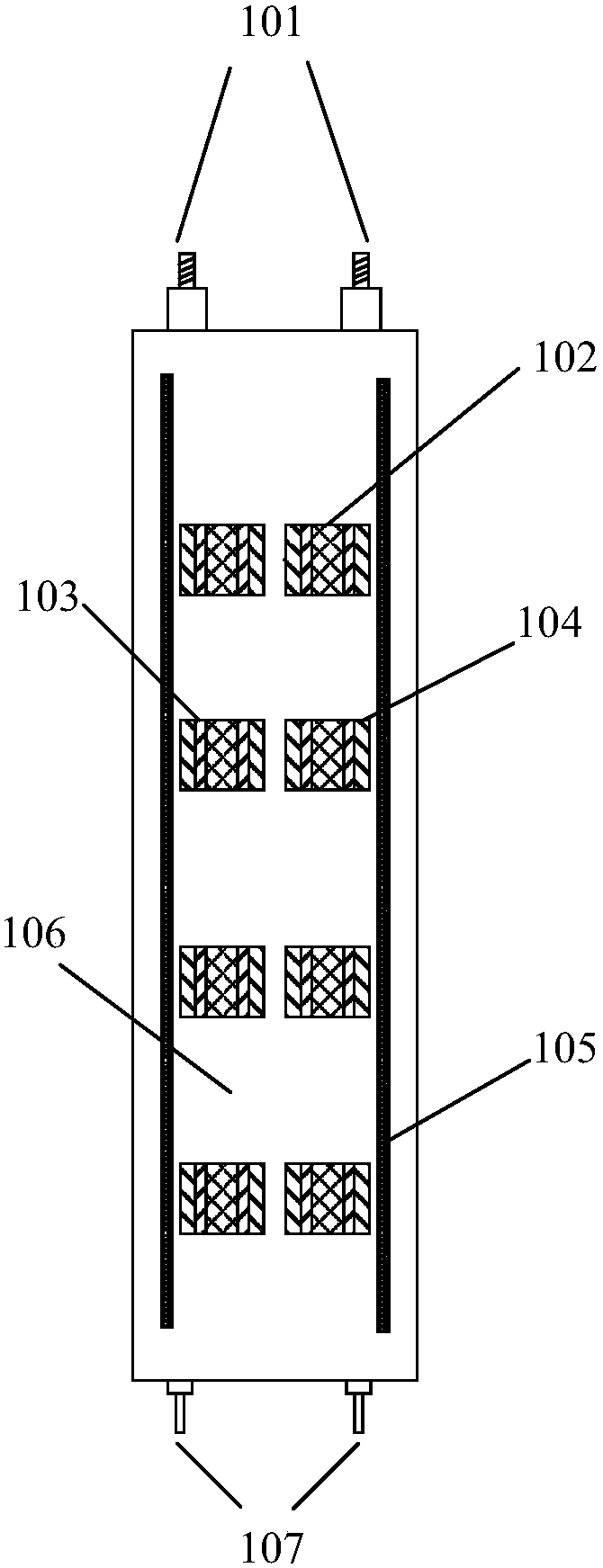

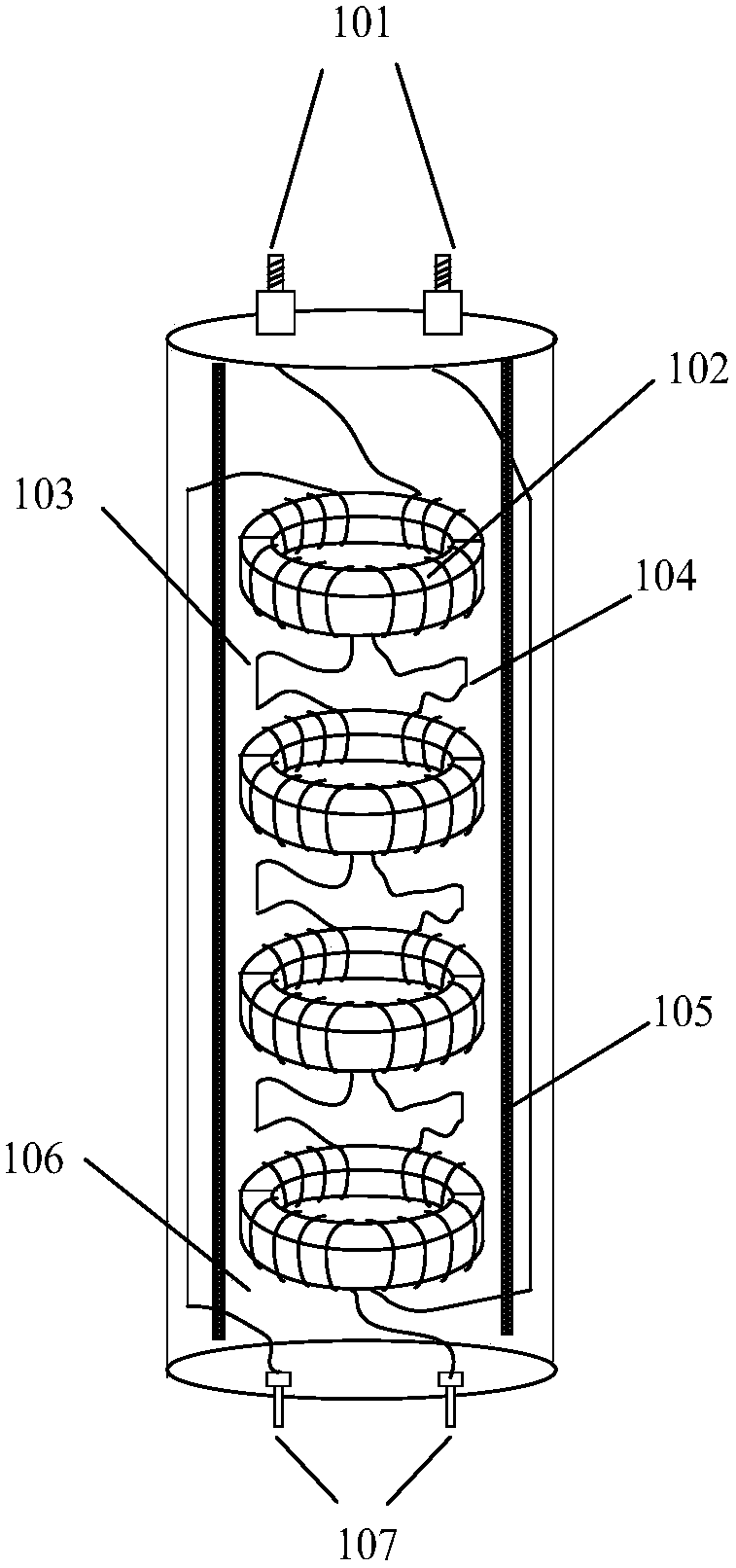

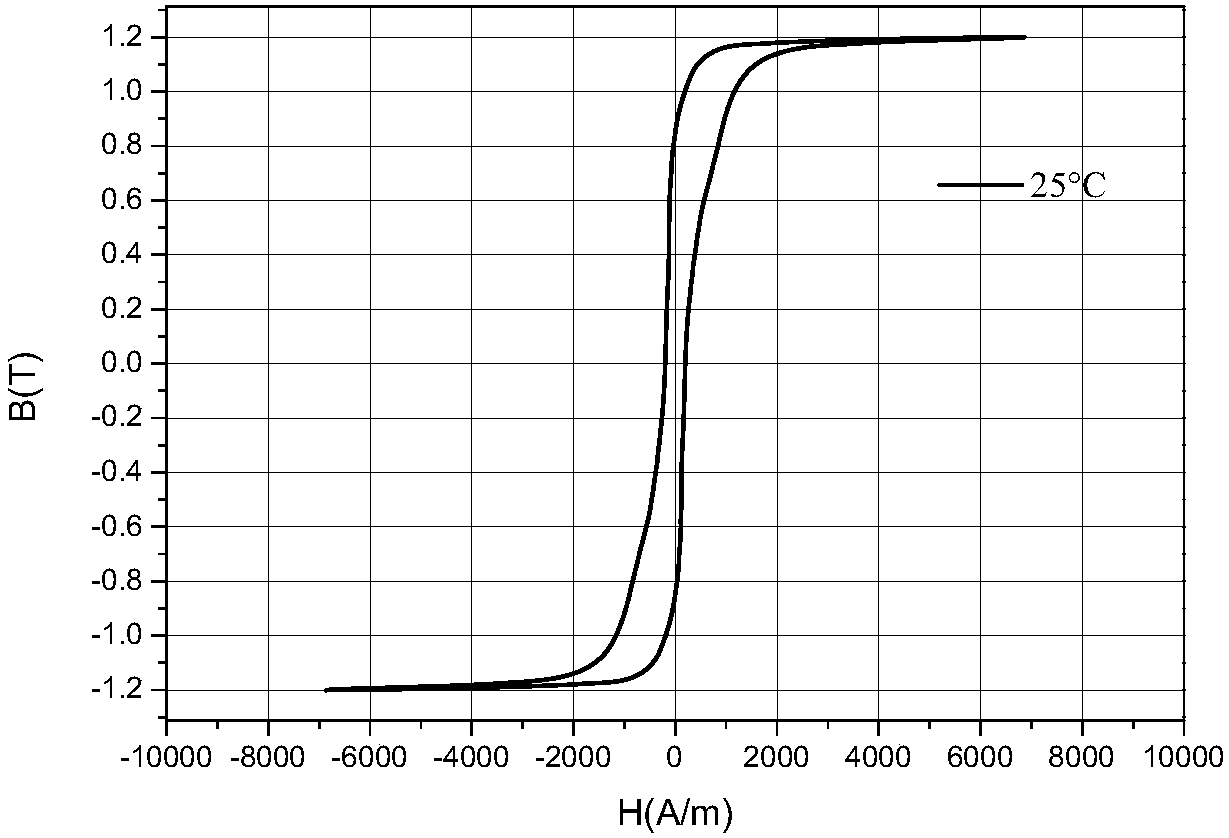

Medium-high-frequency transformer capable of being used in high-temperature downhole environment and parameter acquisition method therefor

ActiveCN105931821AFlexible shape and volumeGood high temperature characteristicsGeometric CADTransformers/inductances casingsSecondary sideElectrical and Electronics engineering

The invention discloses a medium-high-frequency transformer capable of being used in a high-temperature downhole environment and a parameter acquisition method therefor The medium-high-frequency transformer comprises magnetic core units, primary side windings, secondary side windings and a fixed frame, wherein the magnetic cores consist of multiple annular nanocrystalline magnetic cores with high high-temperature characteristics; the windings are uniformly wound around each annular magnetic core; the primary side windings are arranged on the inner layer while the secondary side windings are arranged on the outer layer; the numbers of turns of the primary side windings and the secondary side windings on each annular magnetic core are the same; the primary side windings and the secondary side windings on adjacent two magnetic cores are connected in series; all the magnetic cores and the windings are coaxially and longitudinally arranged, and are fixed on the fixed frame; a certain distance is reserved between adjacent two magnetic cores for radiating; the whole transformer is encapsulated by high-temperature epoxy resin; and the primary side windings are led out through primary side terminals while the secondary side windings are led out through secondary side terminals. The transformer is flexible in size, and can be used reliably in the high-temperature downhole environment.

Owner:HUAZHONG UNIV OF SCI & TECH

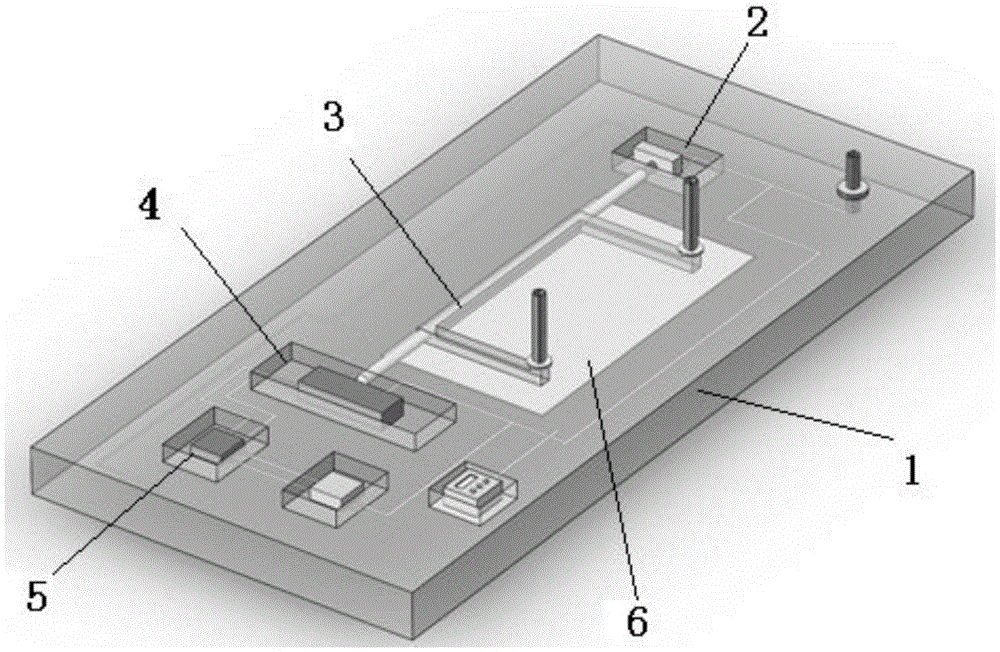

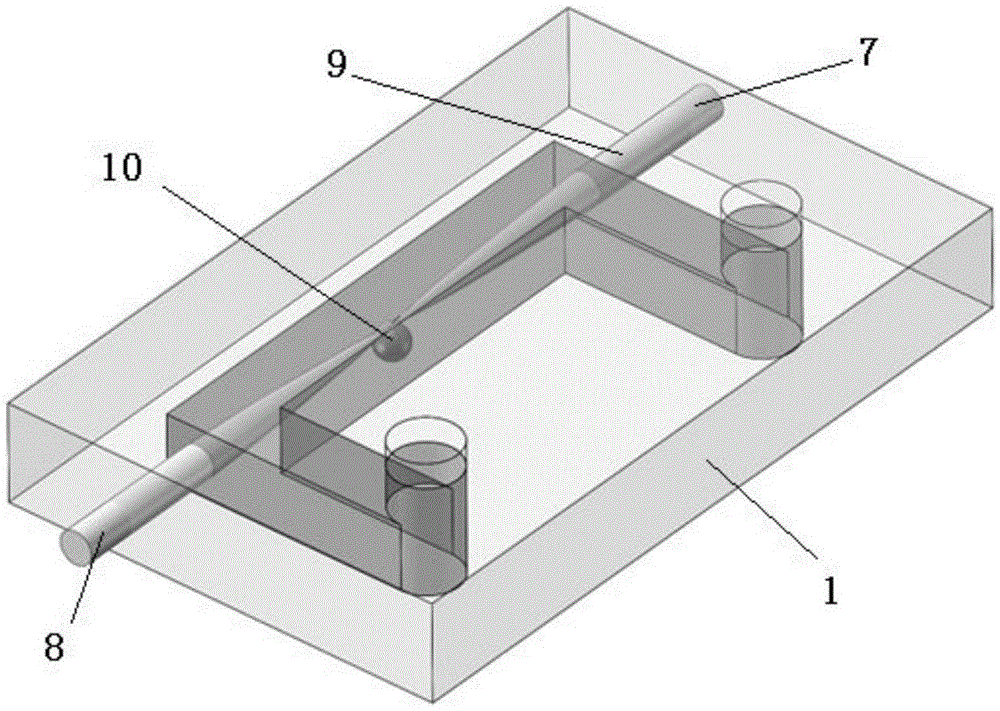

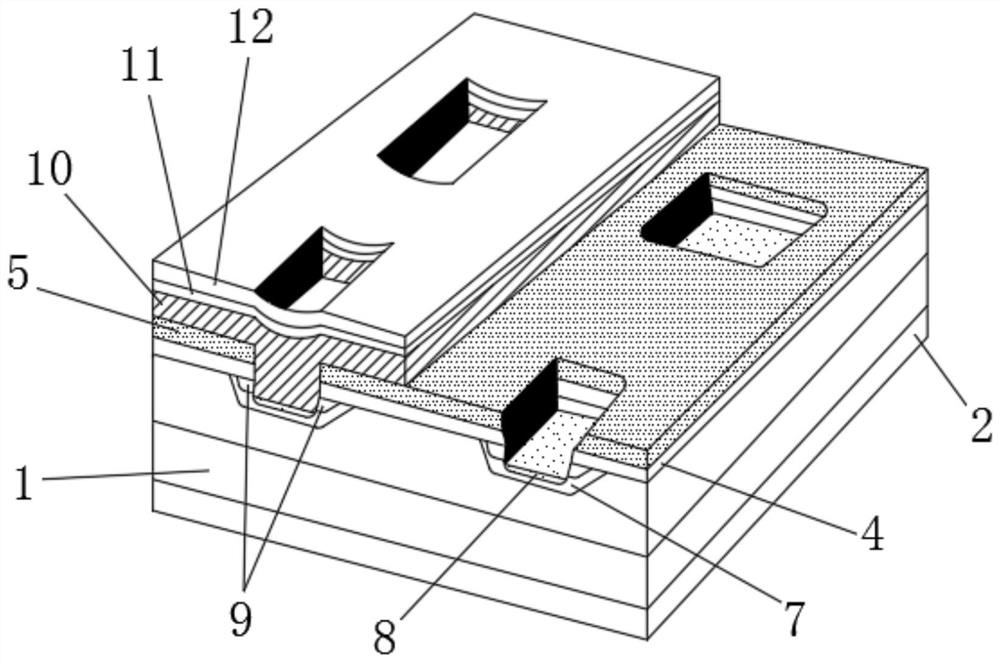

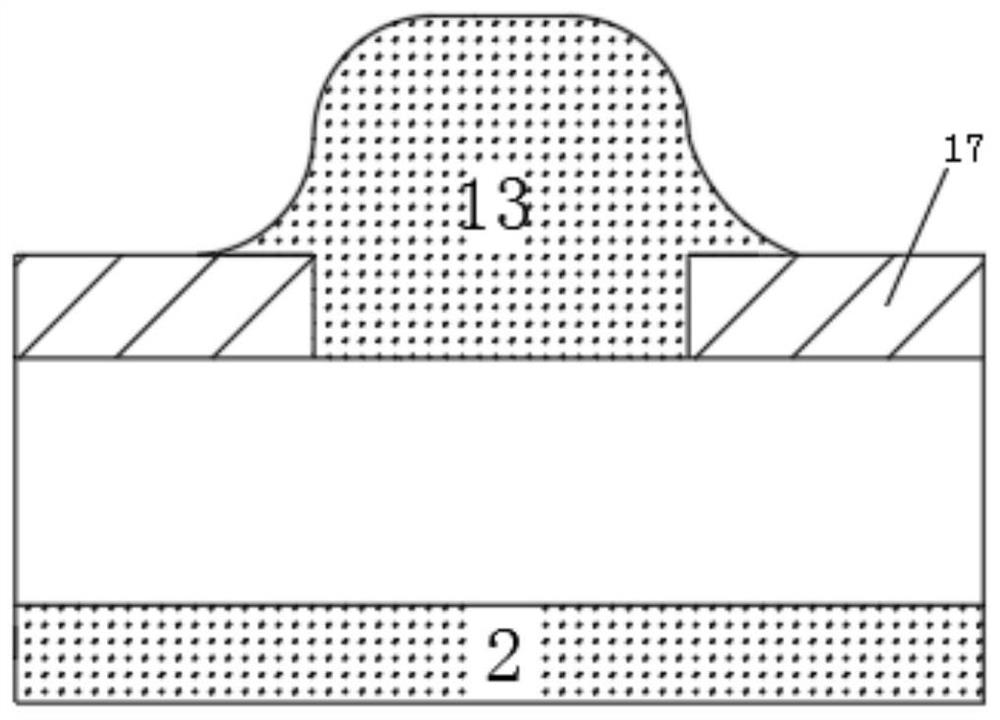

Photon microflow detection chip based on LTCC integration

ActiveCN105583014AEasy to manufactureFast preparationMaterial analysis by optical meansLaboratory glasswaresTemperature controlSignal processing

The invention discloses a photon microflow detection chip based on LTCC integration, and belongs to the field of microsystem sensing detection. The chip integrates a micro light source, an optical fiber system, a photon sensing system, a detector chip, a signal processing chip and a temperature control board on an LTCC monolithic substrate, wherein a microflow channel and the optical fiber system are manufactured in the substrate, and therefore sensing of photons in the monolithic microflow system is achieved. The photon microflow detection chip has the advantages that integrated manufacturing of the optical fiber system and the photon sensing system can be more conveniently achieved in the LTCC substrate; parts such as the light source, the detector and the signal processor which are needed by the detection chip can be integrated on the LTCC substrate through a standard microassembly technology; controllable manufacturing of the microflow detection channel needed by the detection chip on the LTCC substrate can be conveniently achieved; LTCC has the good anti-corrosion characteristic and the high-temperature characteristic and can support the chip to be applied to a severe environment.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Coating and application thereof

InactiveCN107325728AGood high temperature performanceOvercome the disadvantage of poor adhesionConjugated diene hydrocarbon coatingsSpecial surfacesEpoxyMetallurgy

The invention relates to a pipeline coating containing an asphalt composition. The coating is prepared from the following components in percentage by weight: 40 to 70 percent of asphalt, 10 to 30 percent of styrene-butadiene rubber, 1 to 20 percent of glass flake and 5 to 40 percent of epoxy resin. The invention also provides a pipeline coated with the pipeline coating, a method for coating the pipeline by using the pipeline coating and a purpose of the asphalt composition as the pipeline coating. The production method of the pipeline coating provided by the invention is simple; the pipeline coating not only has excellent impact resistance and flexibility, but also shows excellent high-temperature characteristic and adhesive force.

Owner:过春明

Manufacturing method for planar bidirectional trigger diode chip

InactiveCN102522333AHigh rebound voltageReduce Fragmentation RateSemiconductor/solid-state device manufacturingLow leakageOxide

The invention relates to a manufacturing method for a planar bidirectional trigger diode chip. Low leakage current, high breakback voltage and stable quality are ensured, process steps are further reduced, and a qualified rate is increased. A P-type wafer with the thickness of 100 to 300 mu m is taken as a raw material. The method comprises the steps of growing an oxide layer on the surface of the wafer, photoetching a diffusion window and cutting the wafer into chips. Between the steps of photoetching the diffusion window and cutting the wafer into the chips, the method further comprises the following steps of: 1) sinking the diffusion window; 2) performing phosphorus diffusion; 3) removing an inversion layer from the surface; 4) migrating impurities at high temperature, and growing a silicon dioxide passive film layer; 5) photoetching metal electrode windows; and 6) plating gold or nickel. By the method, a thick silicon wafer can be adopted, so that a fragmentation rate can be decreased; and by a planar passivated structure, cutting is performed in scribing channels, and voltage stability and high high-temperature characteristics are ensured.

Owner:佛山益辰电子科技有限公司

Gold alloy

InactiveCN104328302AGood high temperature characteristicsExtended service lifeLong lastingGold jewelry

The invention relates to the technical field of alloys, and particularly relates to a gold alloy. The gold alloy comprises 5-10% of Ag, 3-7% of Zn, 2-5% of Cu, 2-4% of Nb, 0.5-1.5% of Ca, 0.5-1.5% of Zr, 2-4.5% of Er, 0.5-1% of Ho, 1-3% of epoxy resin and the balance of gold and inevitable impurities. The invention also provides a synthetic method of the gold alloy. The gold alloy provided by the invention has the advantages of excellent high-temperature property, very long service life, high-temperature resistance, oxidization resistance and creep resistance; gold jewelry made from the gold alloy has the advantages of low price, high hardness and long-lasting color and luster and can be worn for a long time.

Owner:北海嘉华珠宝有限公司

Preparation method of three-phase ceramic fiber composite heat insulation tile

The invention discloses a preparation method of a three-phase ceramic fiber composite heat insulation tile, belongs to the technical field of high-temperature ceramic materials, and aims at solving the problems that the heat-resistant temperature of an existing ceramic fiber heat insulation tile needs to be increased and the high-temperature volume stability is poor. The preparation method comprises the following steps of: 1, adding boron oxide powder and zirconium oxide powder into silica sol, adding quartz ceramic fibers into the mixed sol, and drying to obtain pretreated quartz ceramic fibers; 2, mixing an opacifying agent, an adhesive composition and a sintering aid, and adding an ethanol solution to obtain mixed slurry; 3, uniformly mixing the pretreated quartz ceramic fibers, siliconcarbide ceramic fibers, alumina fibers and a polyacrylamide aqueous solution to obtain a ceramic fiber mixture; 4, mixing the mixed slurry with the ceramic fiber mixture; 5, pressing to form a ceramic fiber composite dry blank; and 6, carrying out sintering treatment. The quartz ceramic fibers are pretreated, crystallization of the quartz ceramic fibers is inhibited, and the heat insulation performance and the high-temperature stability of the composite heat insulation tile are improved.

Owner:JIAMUSI UNIVERSITY

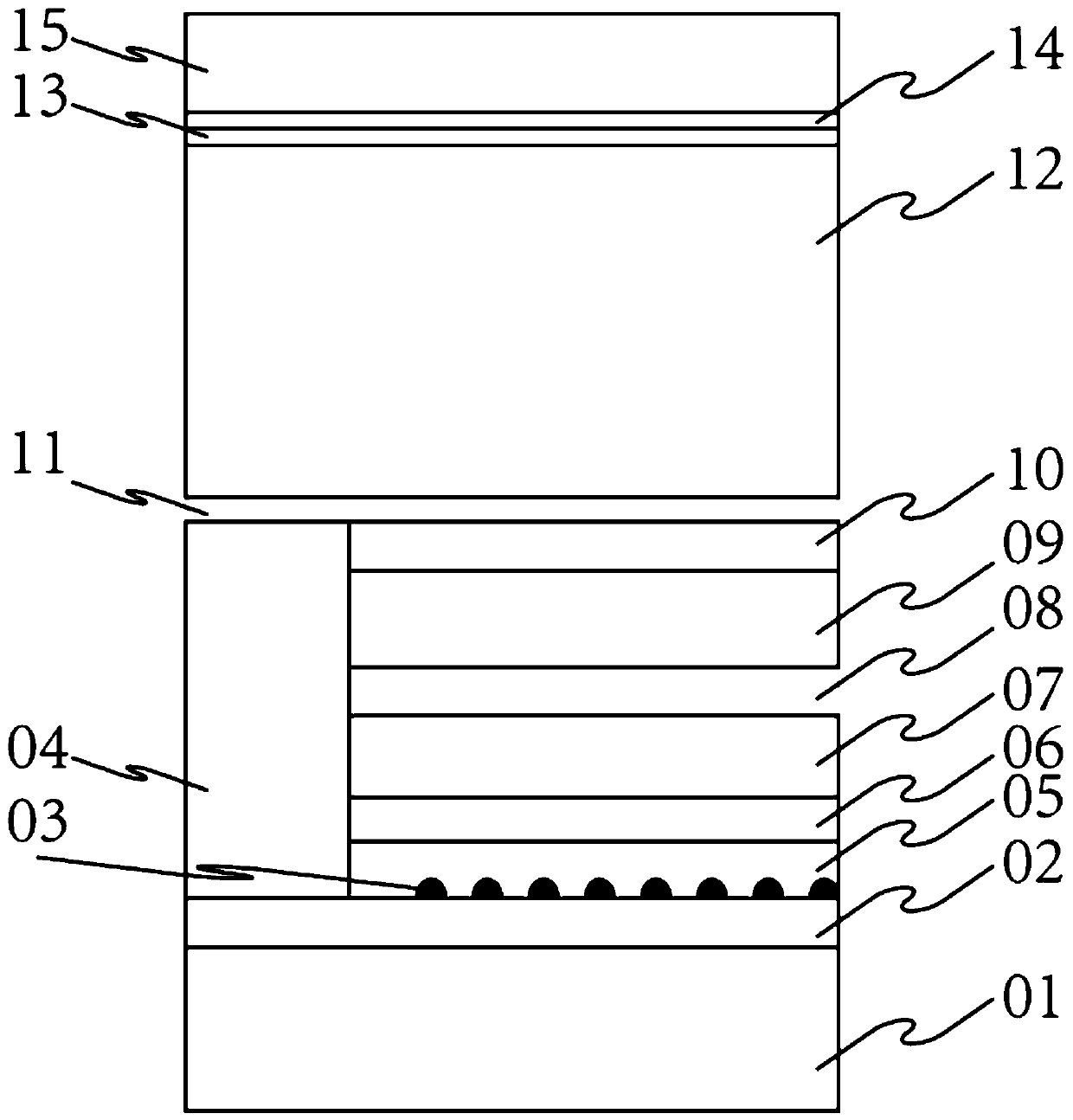

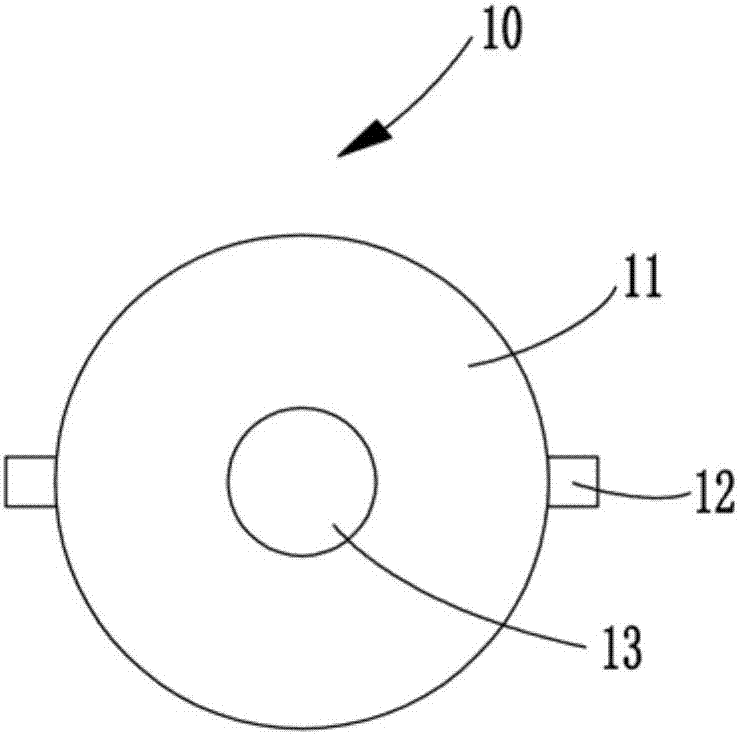

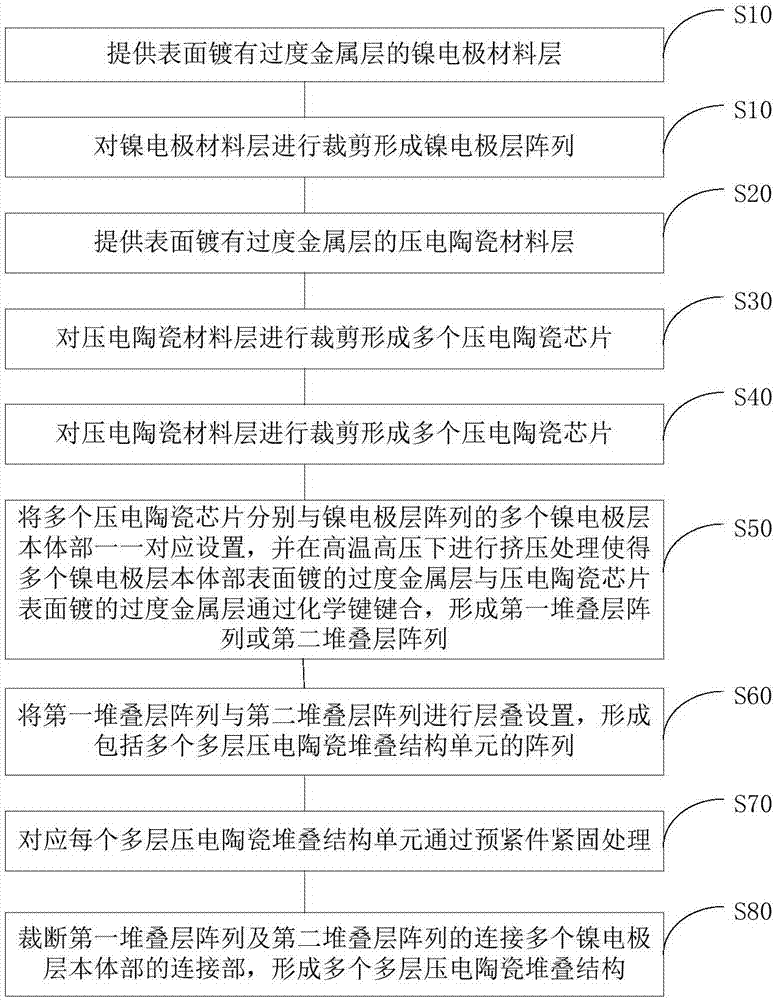

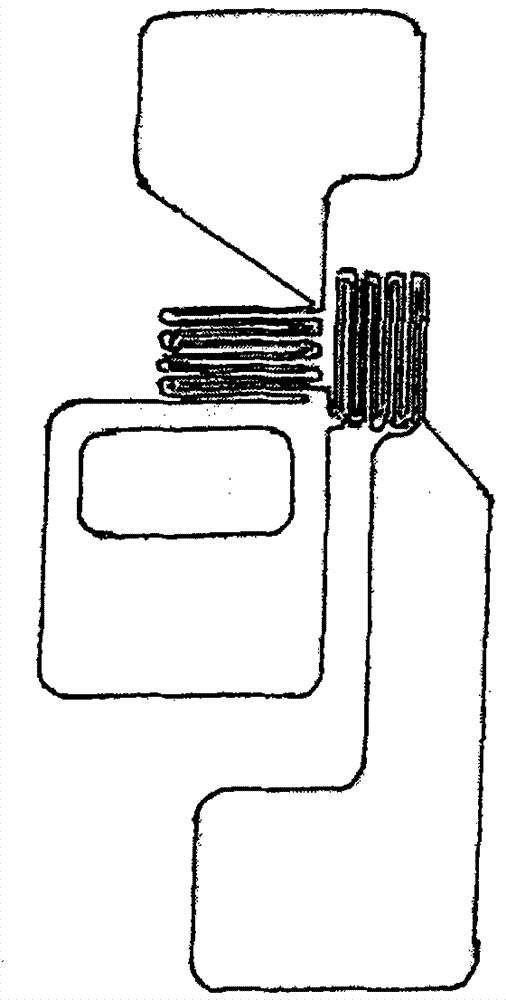

Multilayer piezoelectric ceramic stack structure and preparation method thereof as well as sensor

PendingCN107195769ASimple structureGood high temperature characteristicsSubsonic/sonic/ultrasonic wave measurementUsing electrical meansNickel electrodeCeramic

The invention relates to a multilayer piezoelectric ceramic stack structure and a preparation method thereof as well as a sensor. The multilayer piezoelectric ceramic stack structure comprises a first stack layer and a second stack layer which are stacked; each of the first stack layer and the second stack layer is a composite stack layer formed by bonding material layers through metallic bonds and comprises a piezoelectric ceramic chip and a nickel electrode layer, wherein a transition metal layer is plated on the surface of the piezoelectric ceramic chip; a transition metal layer is plated on the surface of the nickel electrode layer; the transition metal layer plated on the surface of the piezoelectric ceramic chip and the transition metal layer plated on the surface of the nickel electrode layer are bonded through the metallic bonds; and the first stack layer and the second stack layer which are stacked are firmly connected through a pre-tightening piece. The multilayer piezoelectric ceramic stack structure provided by the invention has the advantages of better frequency response characteristic, smaller stress fluctuation at high temperature and simple structure.

Owner:FATRI UNITED TESTING & CONTROL QUANZHOU TECH CO LTD

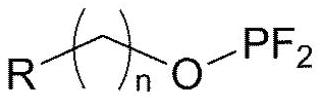

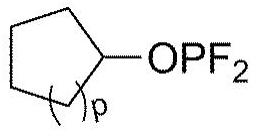

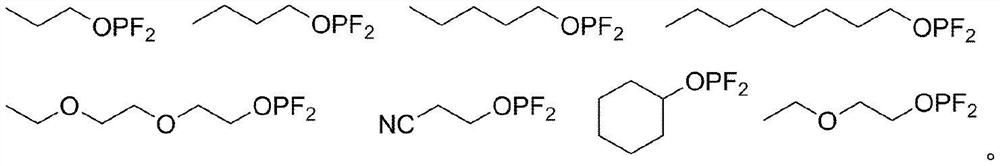

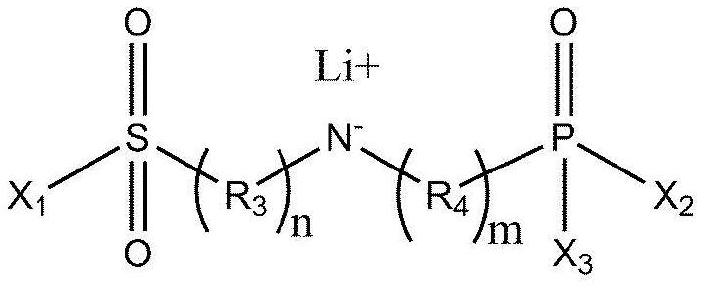

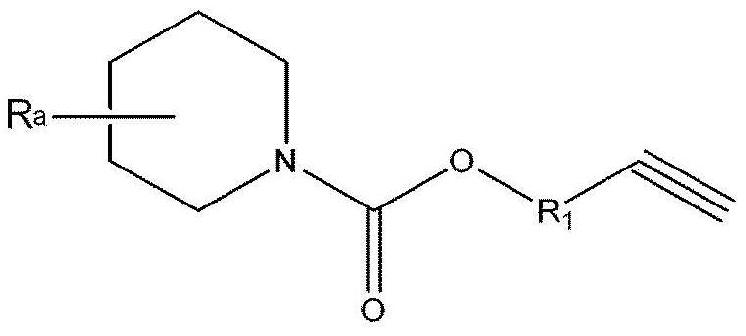

Electrolytic solution for lithium secondary battery, and lithium secondary battery comprising same

PendingCN111788732AIncrease powerImprove life characteristicsPositive electrodesLi-accumulatorsElectrolytic agentElectrical battery

The present invention relates to an electrolytic solution for a lithium secondary battery, and a lithium secondary battery comprising the same. The lithium secondary battery according to the present invention employs the electrolytic solution for the lithium secondary battery, containing a difluorophosphite compound, according to the present invention, and thus has improved characteristics.

Owner:SK ON CO LTD

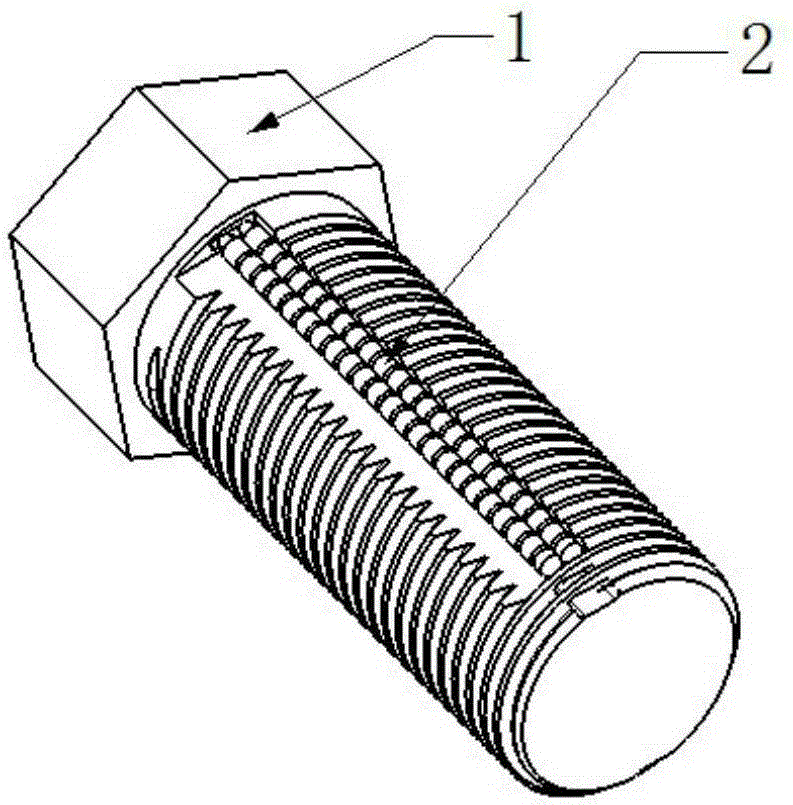

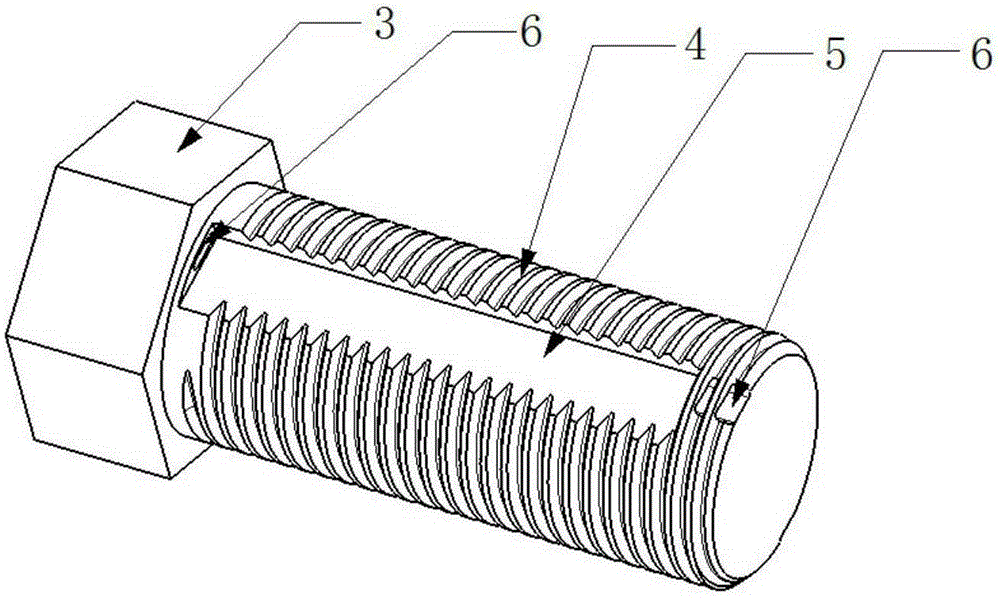

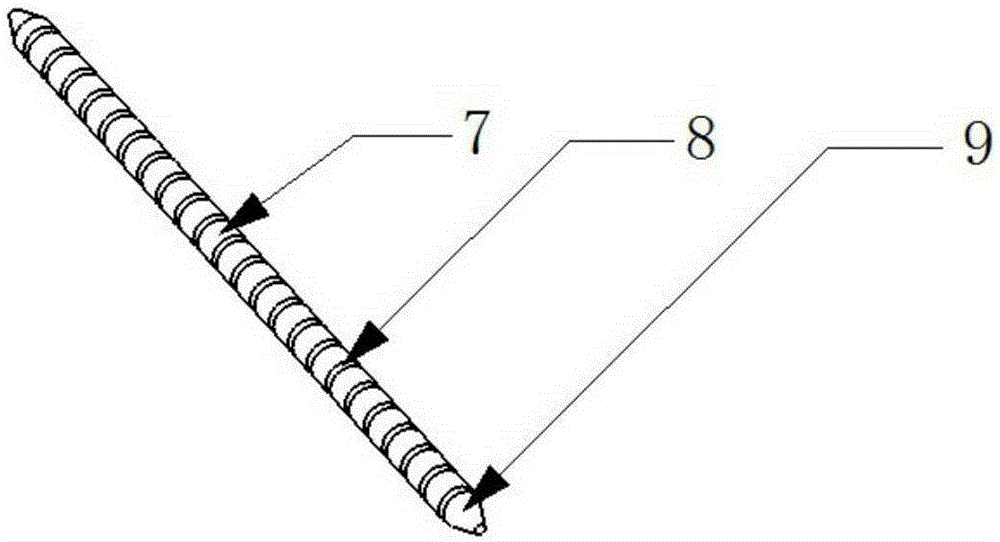

Guide self-locking bolt connecting assembly for blind hole and use method

The invention relates to a guide self-locking bolt connecting assembly for a blind hole. The guide self-locking bolt connecting assembly for the blind hole comprises a self-locking bolt composed of a head and a threaded rod, wherein at least one angle groove extending in the axial direction is formed in the outer wall of the threaded rod; two parallel guide pins are arranged in each angle groove. Each guide pin comprises a flat and straight cylindrical guide pin body, wherein a plurality of annular threaded grooves are formed in the outer wall of the guide pin body, the distance between every two adjacent annular threaded grooves is equal to the thread pitch of the thread on the threaded rod, installation end sockets are arranged at the two ends of the guide pin body, and the depth of the angle grooves is larger than or equal to the diameter of the guide pin body. On the threaded rod, annular groove holes are formed in the two ends of each angle groove, and the installation end sockets at the two ends of each guide pin body are located in the annular groove holes in the two ends respectively. The invention further relates to a use method for the guide self-locking bolt connecting assembly for the blind hole.

Owner:TIANJIN CHENGLI AVIATION TECH CO LTD

High-temperature sapphire weighing sensor

ActiveCN102023047BImprove high temperature resistanceGood high temperature characteristicsWeighing apparatus using elastically-deformable membersWeighing apparatus detailsElastomerElectrical resistance and conductance

The invention relates to a high-temperature sapphire weighing sensor which can maintain long-term stable work in a high-temperature environment. The high-temperature sapphire weighing sensor is provided with a shell with a cable connector; a niobium-based alloy elastic body with a strain zone surface and an external circuit bard which is connected with the connector are installed in the shell; the center of the strain zones at two side surfaces of the elastic body is provided with a sensitive assembly which is connected with the external circuit board; the sensitive assembly sequentially comprises a sapphire base, a strain resistance layer, a welding layer and a passivation protecting layer from inside to outside; and a high-temperature Ni resistor for compensating sensitivity drift caused by temperature change is welded on the external circuit board. The invention adopts advanced approaches, such as ion beam sputtering process, ion beam etching process, electrostatic sealing process, and the like, ensures that the sensor has excellent long-term stability in the high-temperature environment, has the advantages of tiny temperature zero drift and high comprehensive precision and can precisely measure carried weight.

Owner:SHAANXI ELECTRICAL APPLIANCE RES INST

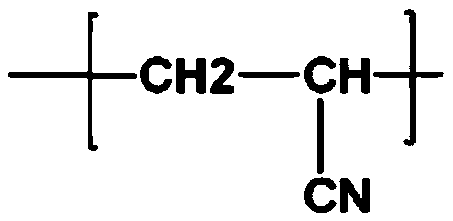

Cathode slurry composition for secondary battery, cathode for secondary battery produced by using same and secondary battery

ActiveCN111095611ADecreased electrode adhesionImprove high temperature storage performancePositive electrodesElectrode collector coatingConductive materialsCopolymer

The present invention relates to a cathode slurry composition for a secondary battery. The cathode slurry composition for the secondary battery comprises a cathode active material; a carbon-based conductive material having a specific surface area (BET) of 100 to 200 m2 / g; a binder; and a nitrile-based copolymer which has an electrolyte swelling degree defined by formula (1) below of 200% or lower,and which does not contain a functional group other than a cyano group. The present invention also provides a cathode for the secondary battery produced by using the cathode slurry composition and the secondary battery. In a Formula (1): electrolyte swelling degree (%) = {(W1-W0) / W0}*100, W0 is the initial weight of a polymer film produced from the nitrile-based copolymer, and W1 is the weight ofthe polymer film measured after storing the polymer film in an electrolyte at 60 DEG C for 48 hours.

Owner:LG ENERGY SOLUTION LTD

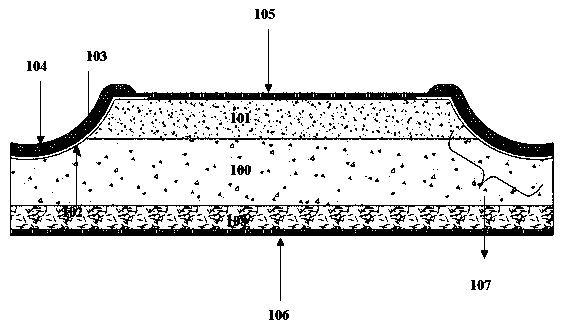

High-reliability rectification device application chip with composite inner passive film single-groove structure

PendingCN110890415AImprove reliabilityImprove stabilitySemiconductor devicesEngineeringSingle crystal

The invention provides a high-reliability rectification device application chip with a composite inner passivation film single-groove structure. A chip mesa adopts a single-groove design, the surfaceof the inner wall of a groove adopts a composite inner passivation layer structure, and a composite inner passivation layer is composed of a polycrystalline silicon film, a bottom layer high-purity nanoscale oxide film, a silicon nitride film and glass. The chip is composed of a single crystal semiconductor body on the middle layer, a chip body with a P-type boron junction region on the upper layer and an N-type phosphorus junction region on the lower layer, a table board, an upper electrode metal layer and a lower electrode metal layer. According to the invention, the problems of poor reliability and poor high-temperature characteristics of a protective film with glass as a passivation layer in a chip groove are solved.

Owner:安徽微半半导体科技有限公司

Diode chip and manufacturing method thereof

InactiveCN113270502AImprove conduction lossHigh frequencySemiconductor/solid-state device detailsSolid-state devicesReverse recoveryEngineering

The invention provides a diode chip and a manufacturing method thereof. The chip comprises a plurality of cells which are connected in parallel, each cell comprises an N+ substrate, the back surface of each N+ substrate is provided with a back metal layer, the front surface of each N+ substrate is provided with an N- epitaxial region, and the front surface of each N- epitaxial region is sequentially provided with a gate oxide layer, polycrystalline silicon and a metallization layer; a P-type base region is embedded in the middle of the front face of the N- epitaxial region, a protruding part is arranged on the back face of the metallization layer, the protruding part is embedded into the P-type base region, an N+ region is arranged around the protruding part, a P+ region is arranged between the end face of the protruding part and the P-type base region, and the front faces of the P-type base region and the N+ region are covered with gate oxide layers. Compared with a PN junction structure, the device has the advantages of lower break-over voltage, shorter reverse recovery time and the like; compared with a Schottky diode, the Schottky diode has the advantages of good high-temperature characteristic, small electric leakage, positive temperature coefficient and the like; the conduction pressure drop is small, the energy consumption is low, the heat yield is small, and the durability is high; and a multi-cell parallel structure is adopted, so that the heat dissipation capability is greatly improved.

Owner:CHINA ZHENHUA GRP YONGGUANG ELECTRONICS CO LTD STATE OWNED NO 873 FACTORY

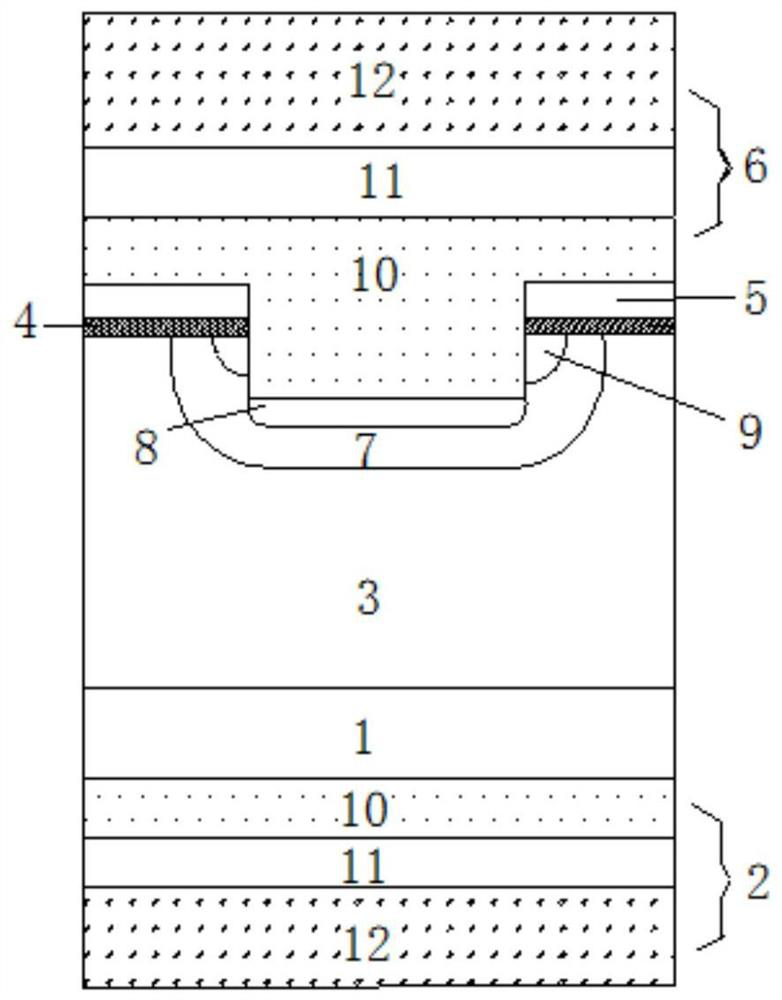

Diaphragm used for lithium-ion storage battery and manufacturing method thereof

The invention discloses a diaphragm used for a lithium-ion storage battery and a manufacturing method thereof. The porosity of the diaphragm is 50%-70%, the average pore size of the diaphragm is 0.1-0.3um, and the largest pore size to the average pore size of the diaphragm is 1.10-1.25. The preparing method of the invention has simple process, and the porosity and the pore size of the diaphragm are controlled through the synergistic effect of plasma discharging processing technology and a nucleating agent, thereby solving the problem that troubles are brought for mixing of melt and uniformityof pore forming as the vast scale of inorganic fillers are added into the diaphragm for increasing the pore size and porosity.

Owner:乐凯胶片股份有限公司

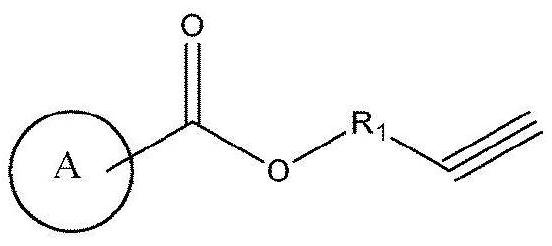

Electrolyte for lithium secondary battery and lithium secondary battery comprising same

PendingCN113728484AIncrease resistanceGuaranteed capacityCell electrodesLi-accumulatorsOrganic solventElectrical battery

The present invention relates to an electrolyte for a lithium secondary battery, comprising lithium salt, an organic solvent and an additive, wherein the additive comprises a compound represented by chemical formula 1 and a compound represented by chemical formula 2; and a lithium secondary battery comprising the electrolyte for the lithium secondary battery.

Owner:LG ENERGY SOLUTION LTD

An underground high temperature medium and high frequency transformer and its parameter acquisition method

ActiveCN105931821BFlexible shape and volumeGood high temperature characteristicsGeometric CADTransformers/inductances casingsEpoxyFixed frame

Owner:HUAZHONG UNIV OF SCI & TECH

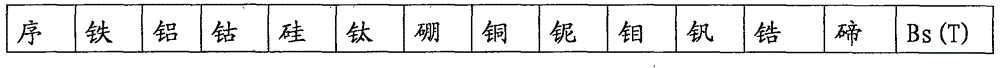

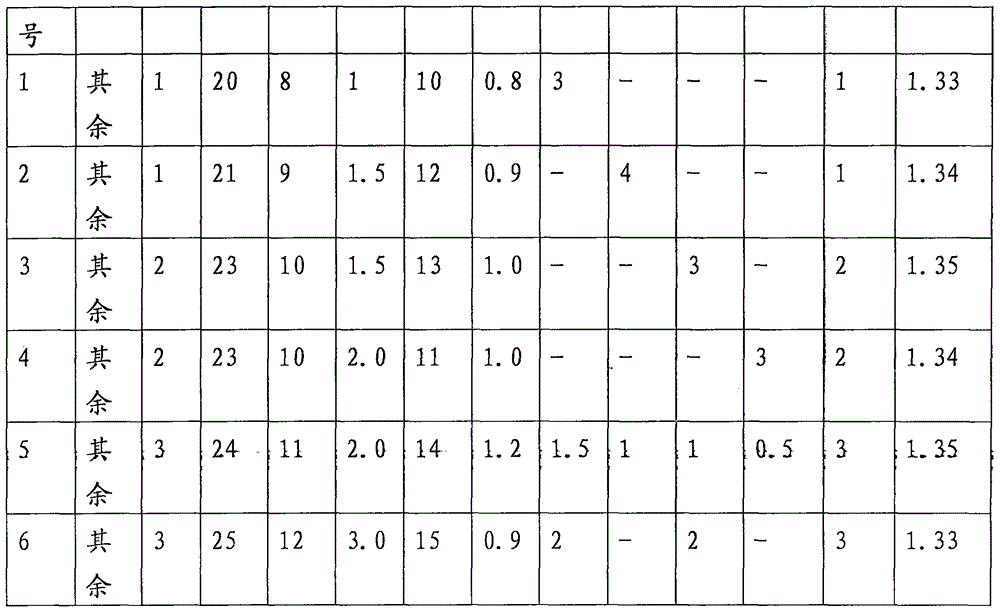

Magnetic alloy material

InactiveCN105118604AGood high temperature characteristicsGood magnetic storage performanceMagnetic materialsAluminiumNiobium

Owner:杨雯雯

a gold alloy

The invention relates to the technical field of alloys, and particularly relates to a gold alloy. The gold alloy comprises 5-10% of Ag, 3-7% of Zn, 2-5% of Cu, 2-4% of Nb, 0.5-1.5% of Ca, 0.5-1.5% of Zr, 2-4.5% of Er, 0.5-1% of Ho, 1-3% of epoxy resin and the balance of gold and inevitable impurities. The invention also provides a synthetic method of the gold alloy. The gold alloy provided by the invention has the advantages of excellent high-temperature property, very long service life, high-temperature resistance, oxidization resistance and creep resistance; gold jewelry made from the gold alloy has the advantages of low price, high hardness and long-lasting color and luster and can be worn for a long time.

Owner:北海嘉华珠宝有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com