Patents

Literature

32results about How to "Improved resistance to overload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

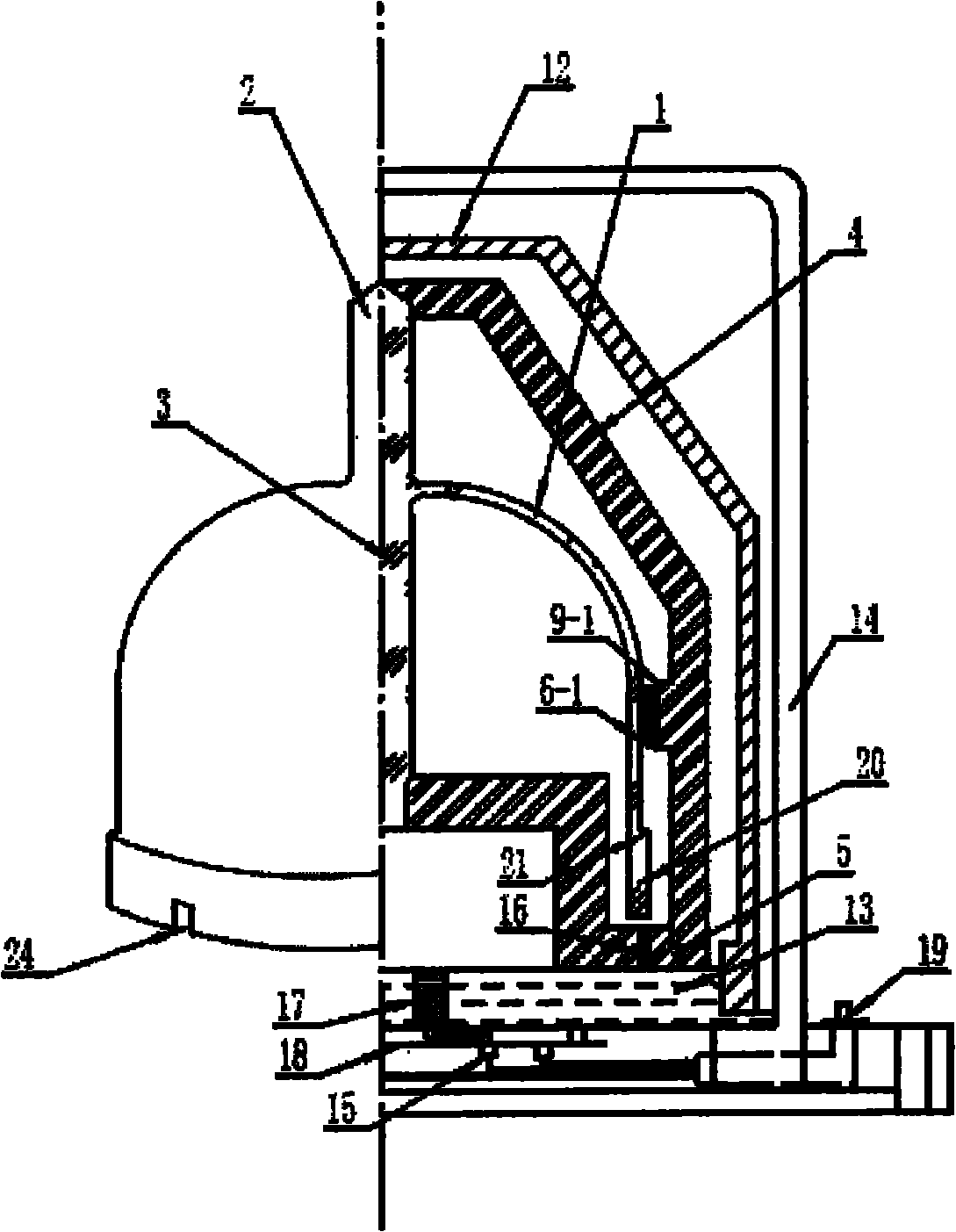

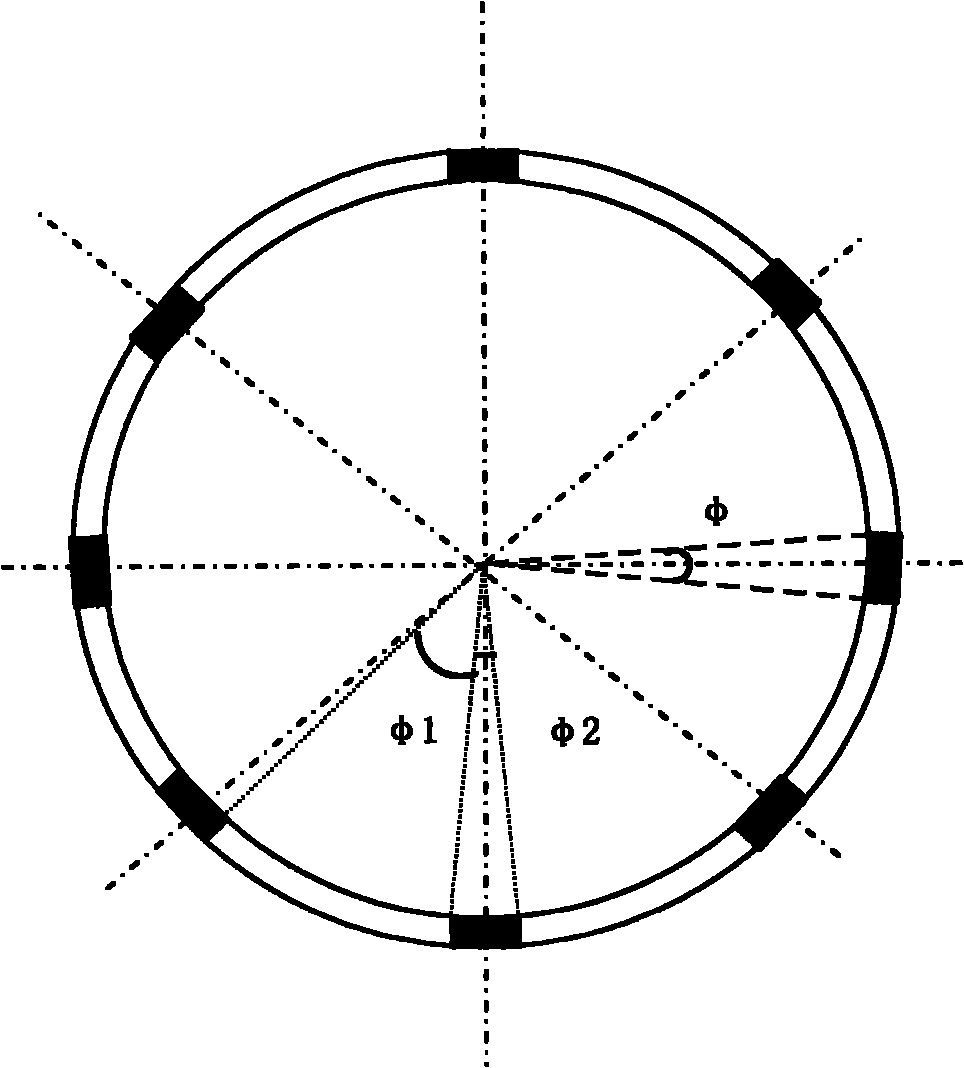

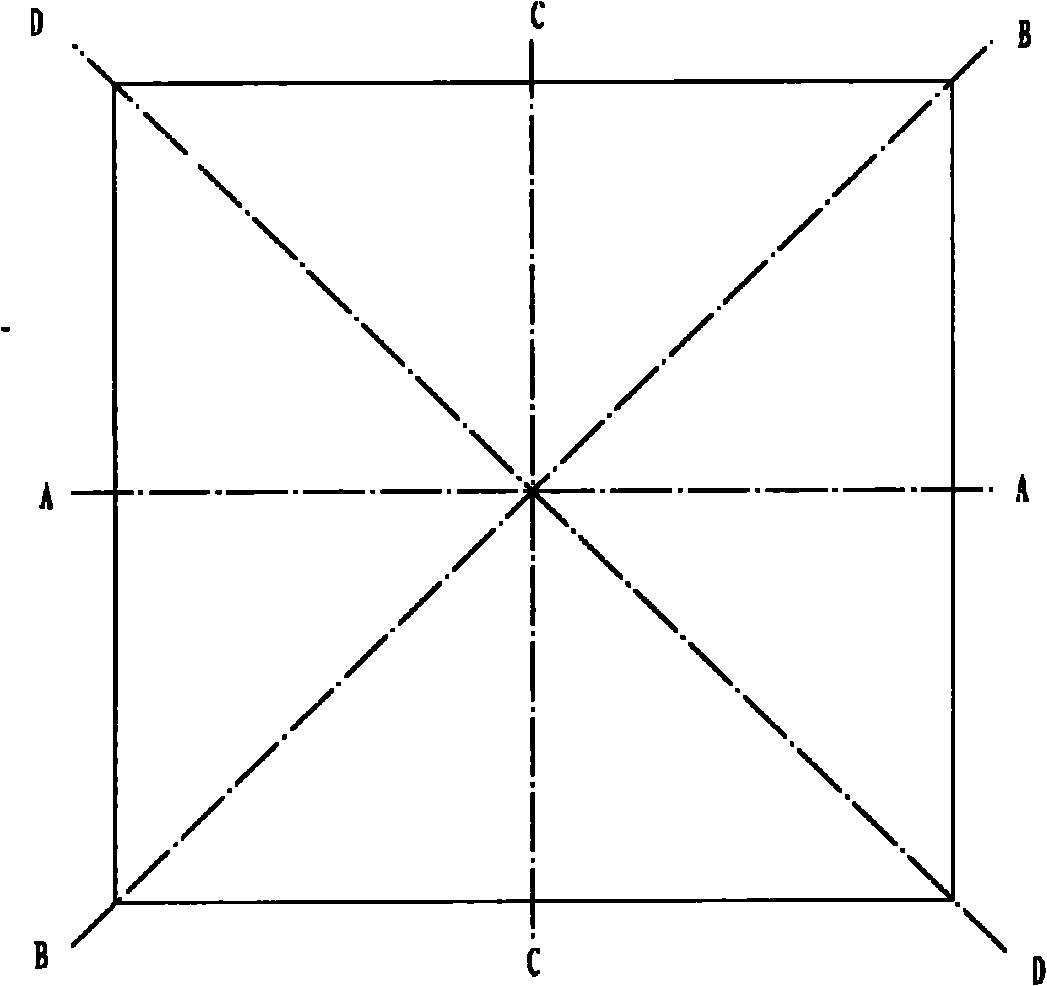

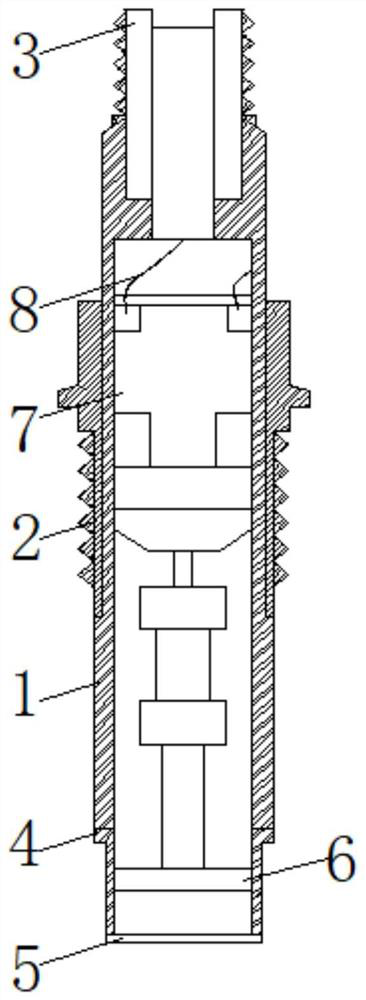

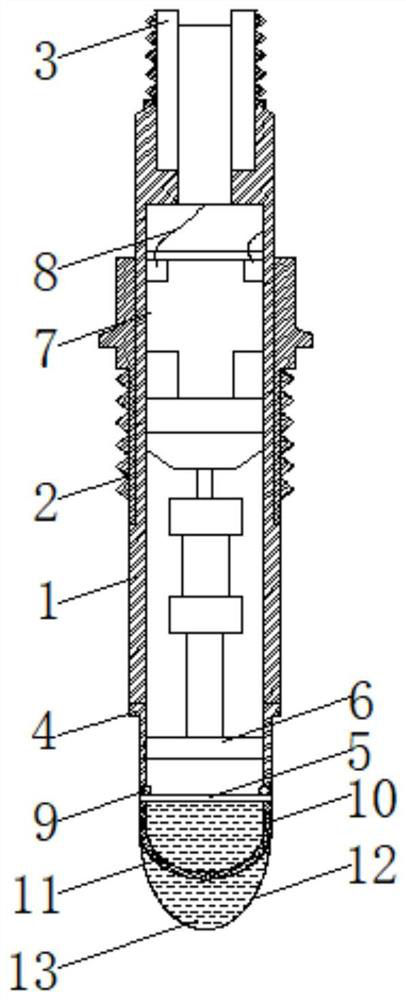

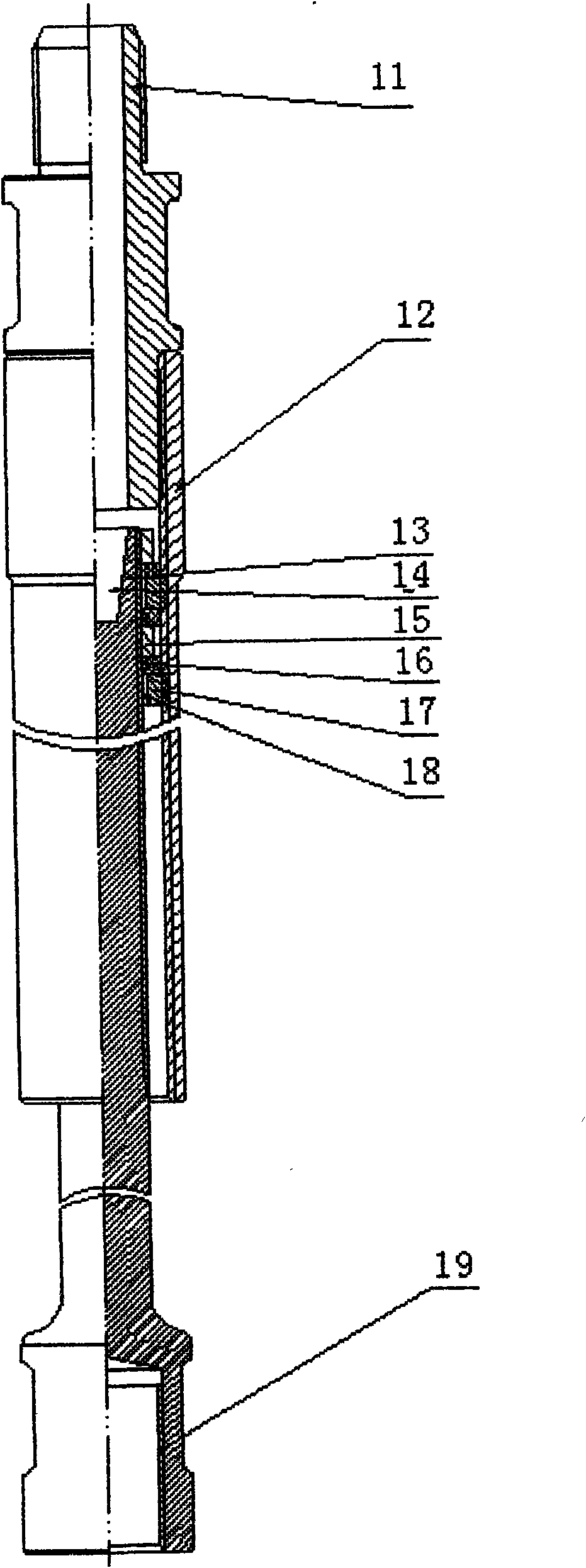

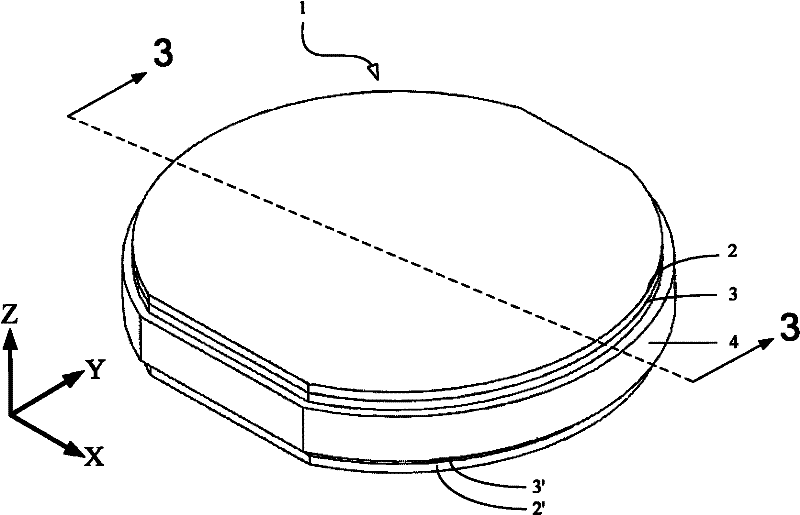

Campaniform oscillator type angular rate gyroscope

InactiveCN101968359AHigh quality factorImprove structural strengthSpeed measurement using gyroscopic effectsTurn-sensitive devicesInterior spaceVariable thickness

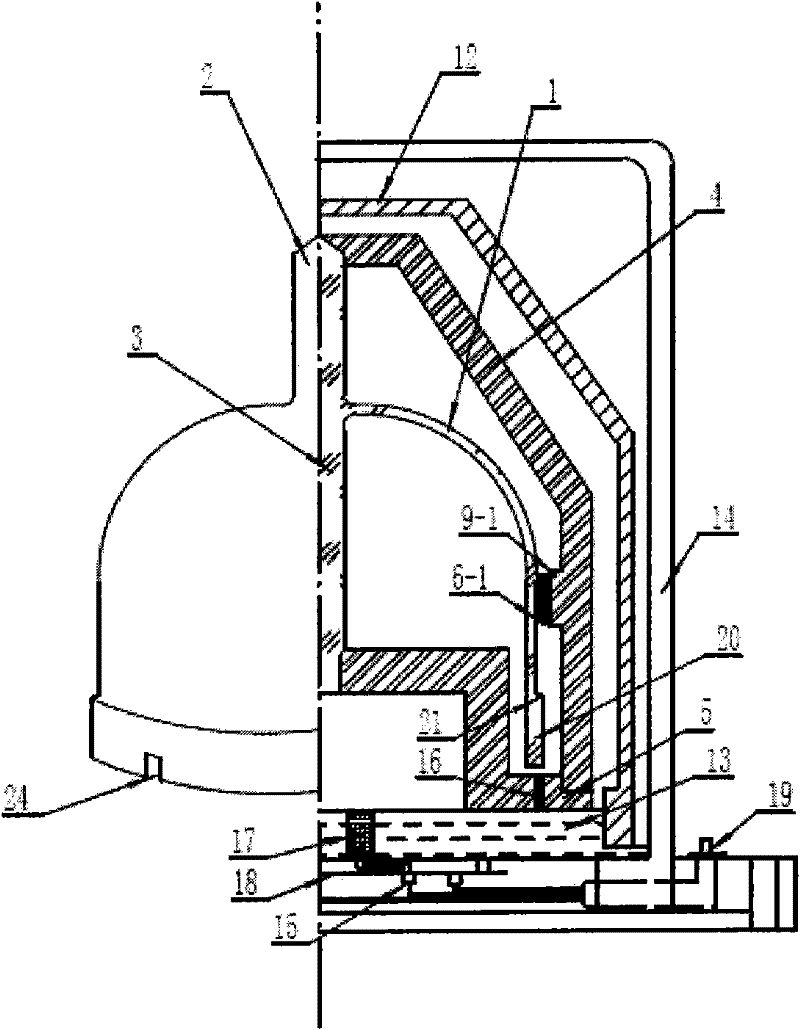

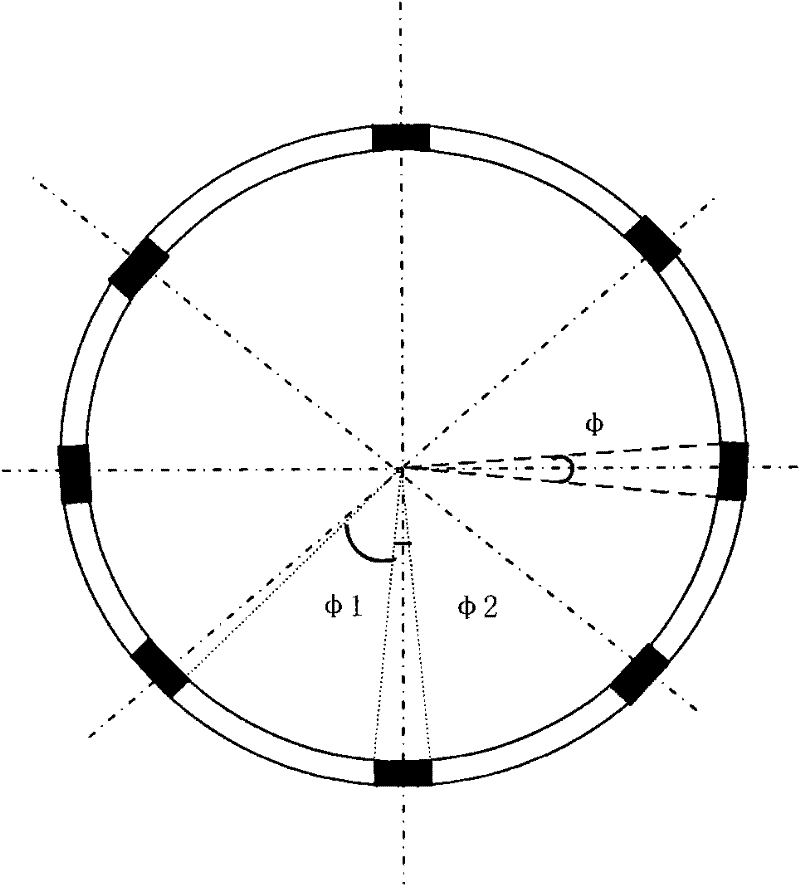

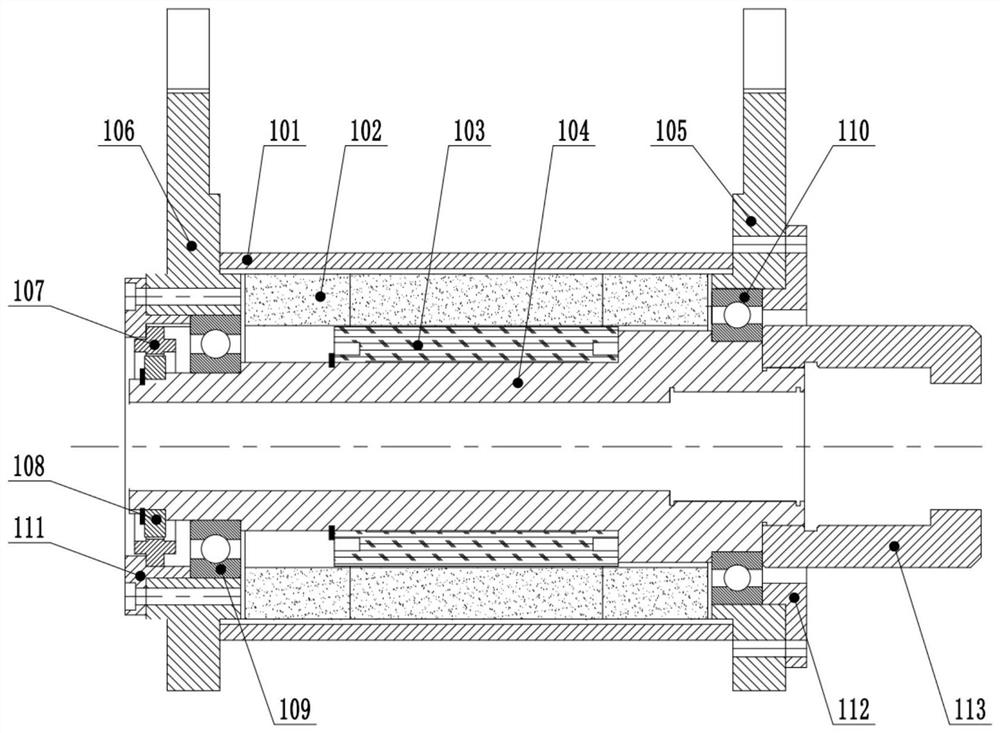

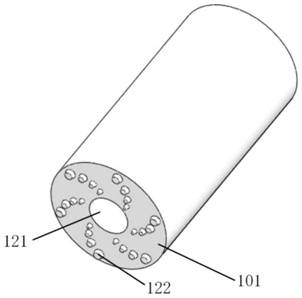

The invention relates to an angular rate gyroscope which has the variable-thickness axisymmetric multi-curved surface fusion structural feature and takes an oscillator with a campaniform structure as a sensitive element. The angular rate gyroscope consists of the oscillator, an oscillator support structure, an airtight cover, a cylindrical outer frame and a system circuit, wherein the oscillator is made of a quartz material and is machined integrally for forming with a phi-shaped support rod; the upper and the lower ends of the support rod are respectively fixed to the top end of a support cover and the central position of a support base plate; a driving electrode and a vibration mode stable electrode are attached to the support cover; a detection electrode is arranged in the inner space of the campaniform oscillator; the airtight cover and the cylindrical outer frame are sequentially arranged outside a support structure; and the system circuit is positioned between the bottom of the airtight cover and the outer frame. The angular rate gyroscope is suitable for the application field of measuring medium and low-precision angular rate in the high dynamic environment, and the oscillator with the campaniform structure has the high quality factors and high overload capacity resistance and has the characteristics of hold facility during power failure, simple structure, suitability for batch production and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +2

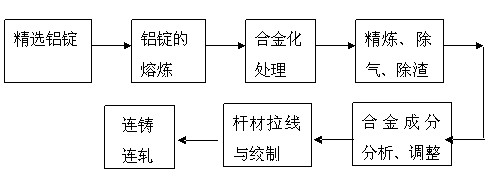

High-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire and production method thereof

InactiveCN102634695ASave construction investmentImproved resistance to overloadIngotUltimate tensile strength

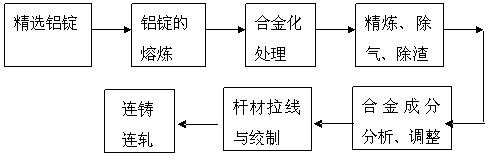

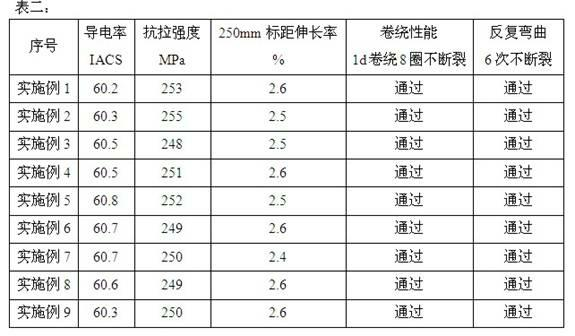

The invention discloses a high-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire and a production method of the high-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire. The high-conductivity non-heat-treatment type moderate-intensity aluminum alloy wire is produced by finely selecting ingredients and contents of aluminum alloy and conducting process control. The specific steps are as follows: selecting Fe, Si, Mg, Cu and Re with different weight percents, melting aluminum ingot with the content not more than 0.03% in a vertical melting furnace, adding alloying elements in a heat insulation furnace, stirring, refining, conducting on-the-spot contents rapid analysis, carrying out content adjustment, and standing, enabling the aluminum ingot and the alloying element into a continuous casting machine for casting, rolling to be a circular aluminum alloy rod on a continuous rolling machine, pulling the circular aluminum alloy rod to be a circular aluminum alloy wire and twisting the circular aluminum alloy wire to be a conductor for aerial power transmission and distribution. According to the application of the aluminum alloy wire and the production method of the aluminum alloy wire, the aluminum alloy wire directly replaces the generally used aluminum conductor steel reinforced and is an energy-saving, environment-friendly and novel wire.

Owner:FAR EAST CABLE

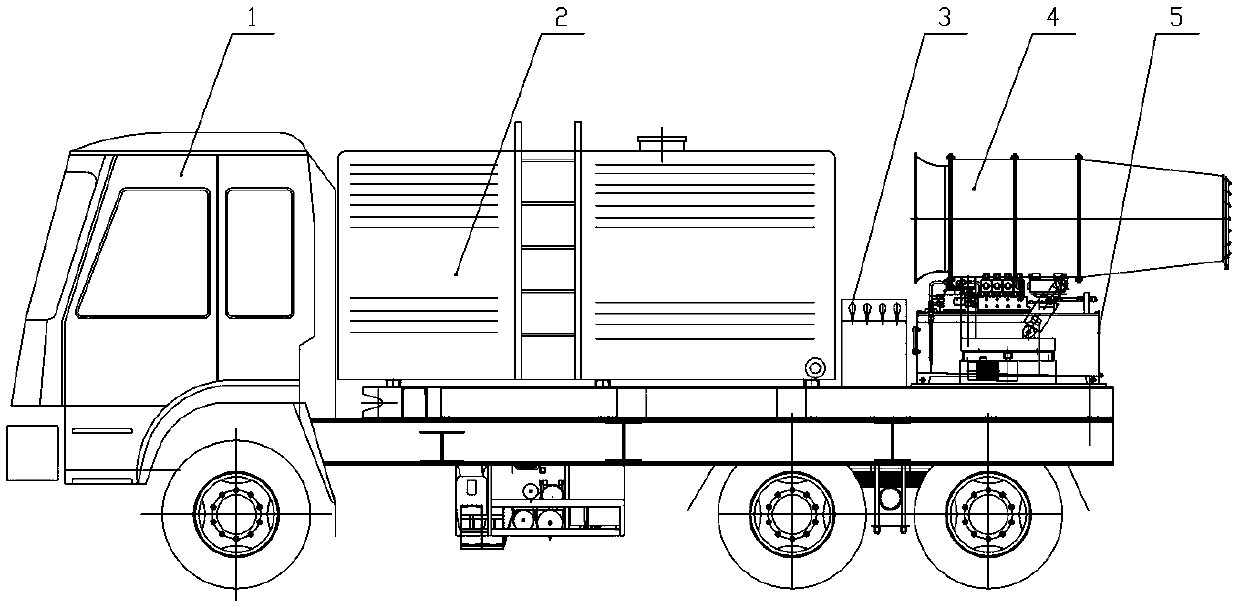

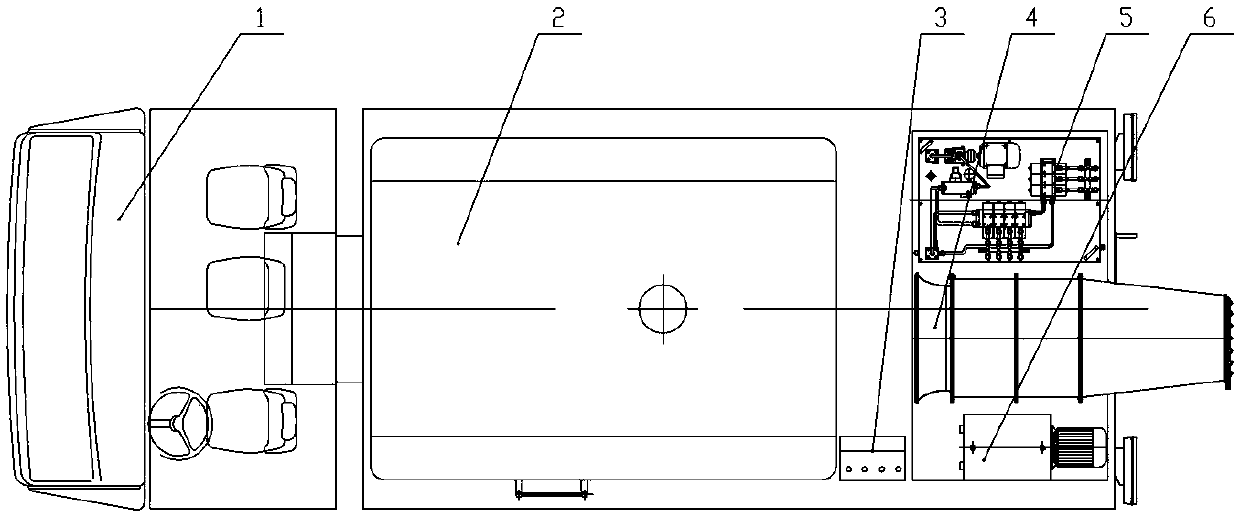

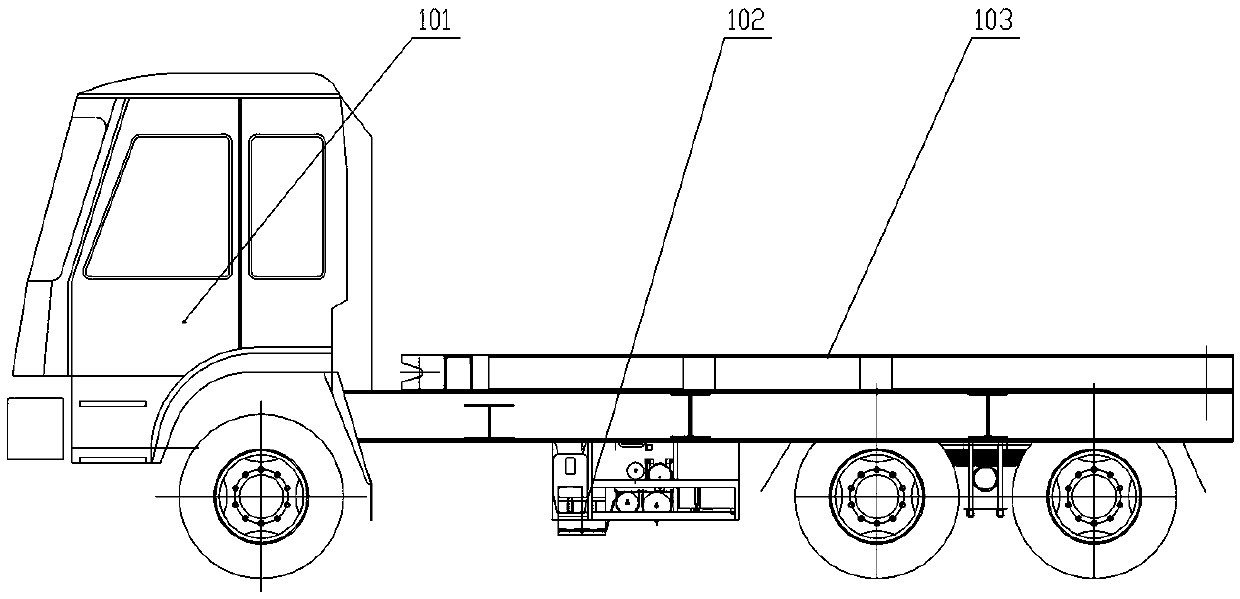

Mobile multi-stage hydraulic-drive pneumatic spray dust-settling truck

ActiveCN103786628AImprove spray distanceIncrease speedSpraying vehiclesLiquid spraying apparatusWater storage tankGear wheel

The invention relates to a mobile multi-stage hydraulic-drive pneumatic spray dust-settling truck, mainly solving technical problems of high investment caused by individual use of spray dust-settling devices and poor effect caused by common use of the spray dust-settling devices due to far distance on conditions of multiple and dispersed dust source points, variable dust source locations and complicated conditions of dust sources. The technical scheme includes that a water storage tank is connected with a high-pressure water pump through a water pipe and high-pressure water is pumped to a spraying assembly; a hydraulic station is connected to a hydraulic motor of a mist spraying device through a high-pressure oil pipe to drive an impeller of axle-flow fans to generate high-pressure air flows, the high-pressure air flows send mist to a dust working face, and high-pressure oil of a hydraulic station is connected to a hydraulic cylinder; the mist spraying device is lifted and then is driven to oscillate around a rotating bearing by a motor and a reduction gearbox via a rotational driving gear; a carriage engine drives a power generator through a double-output transmission in a gear shifting manner so that power required for system running is obtained. The mobile multi-stage hydraulic-drive pneumatic spray dust-settling truck is mainly used for far-distance large-range dust settling and removing and firefighting in fugitive emission fields such as tunnel heading, blast mining, loading, crushing and unloading.

Owner:PINGAN ELECTRICAL

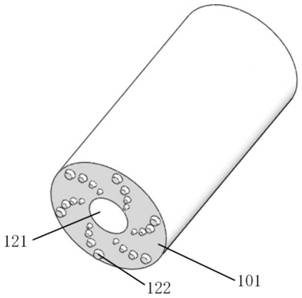

Piezoresistance type accelerometer with high g values

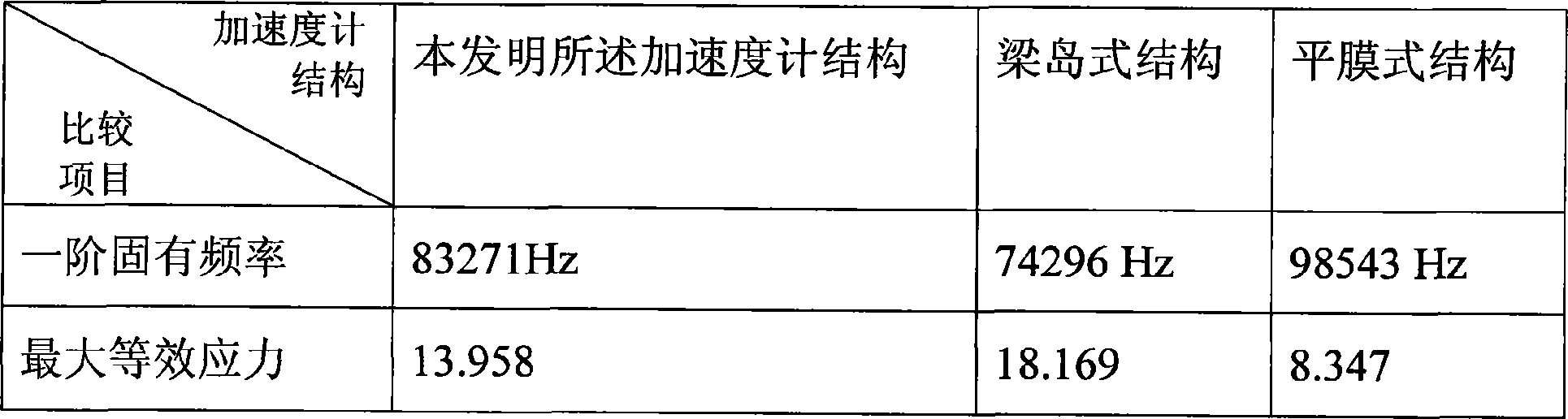

InactiveCN101118249AHigh sensitivityRaise the natural frequencyAcceleration measurement using interia forcesElectrical resistance and conductanceEngineering

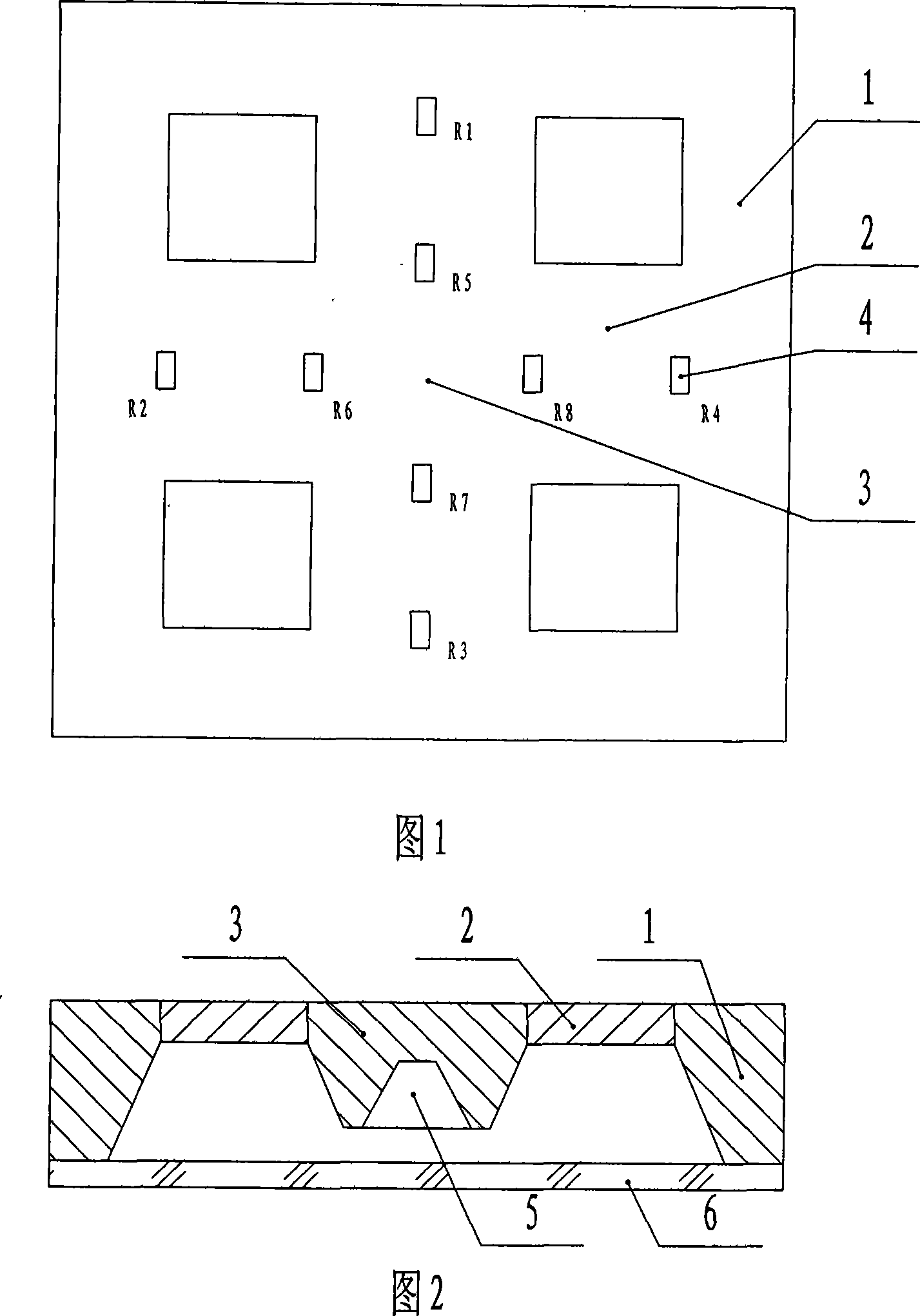

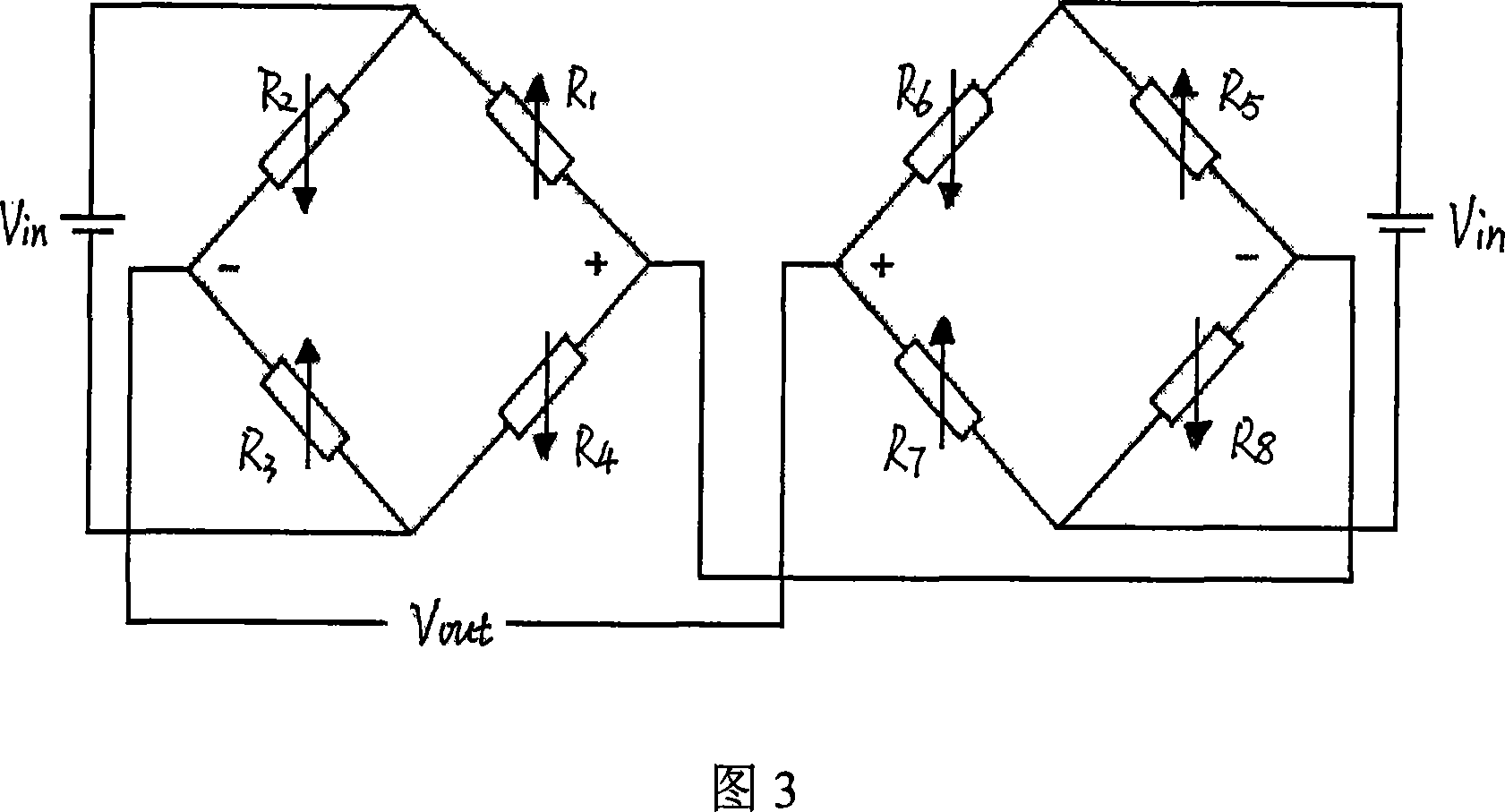

The present invention relates to the technical field of the micro mechanical electronics, in particular to a piezoresistive high g-value accelerometer which resolves the problems that the structure of the existing accelerometer can not meet the demand of properties like high fixed frequencies, high flexibility and high bearing of lateral acceleration at the same time. The accelerometer comprises a Silicon-based frame, an elastic girder, and a quality block that is hung at the middle of the silicon-based frame by dint of the elastic girder; wherein, the end part of the elastic girder is provided with a voltage-dependent resistor that forms a Wheatstone bridge, the width of the elastic girder is the same with the width of the quality block, but the thickness of the elastic girder is smaller than the thickness of the quality block, the backside of the quality block is provided with a concave slot. The present invention has simple reasonable structure and good anti-overloading ability; and avoids being disabled under the circumstance of serious striking. Moreover, the production technique is quite simple, which is suitable for high-range accelerometer.

Owner:ZHONGBEI UNIV

Stirring friction forging additional material manufacturing method and device of nano reinforcing composite materials

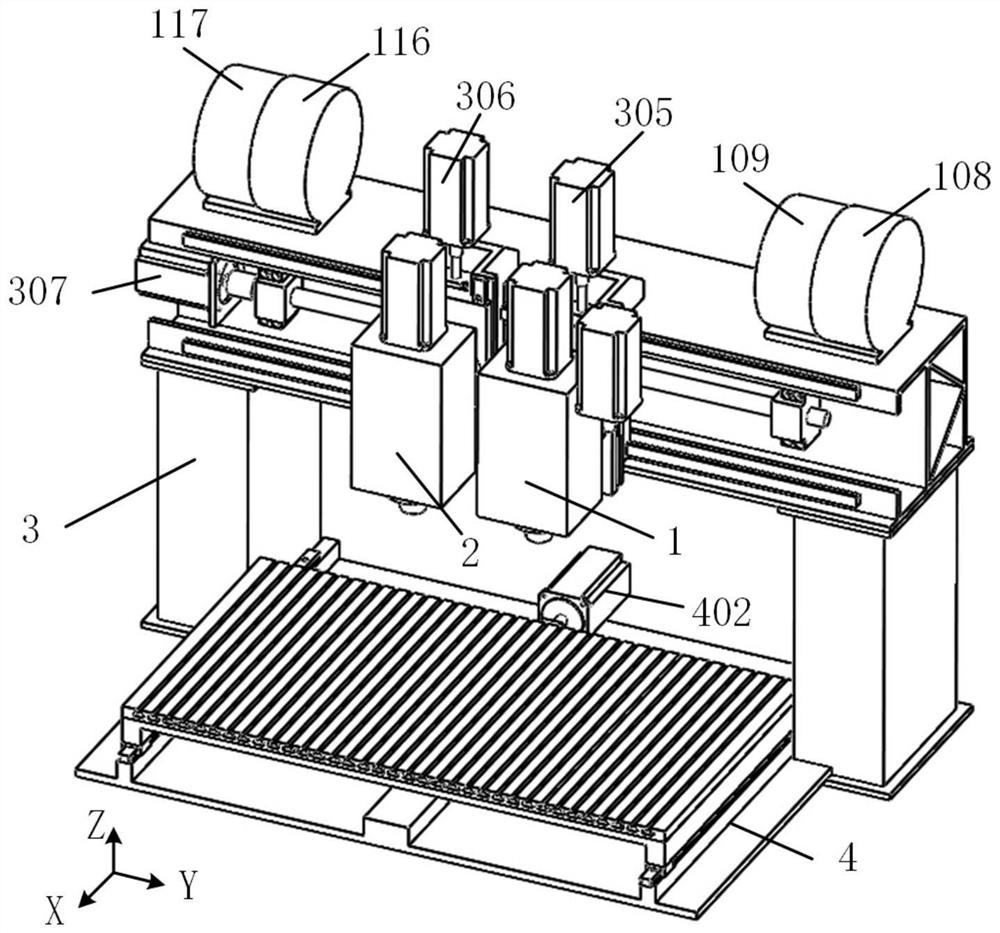

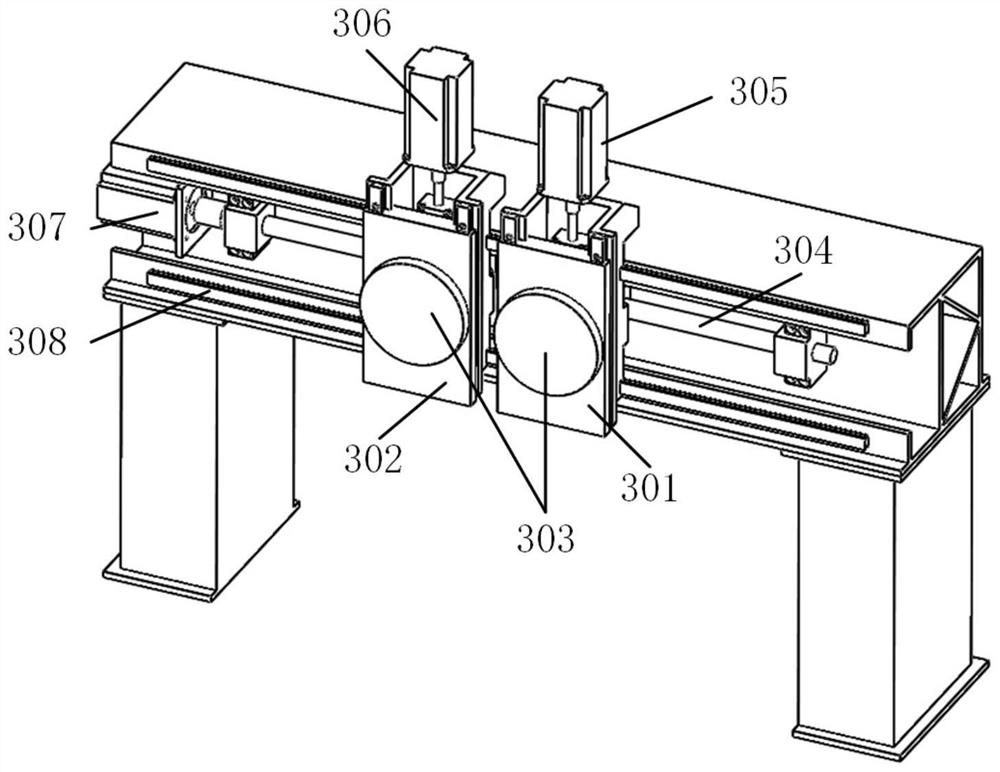

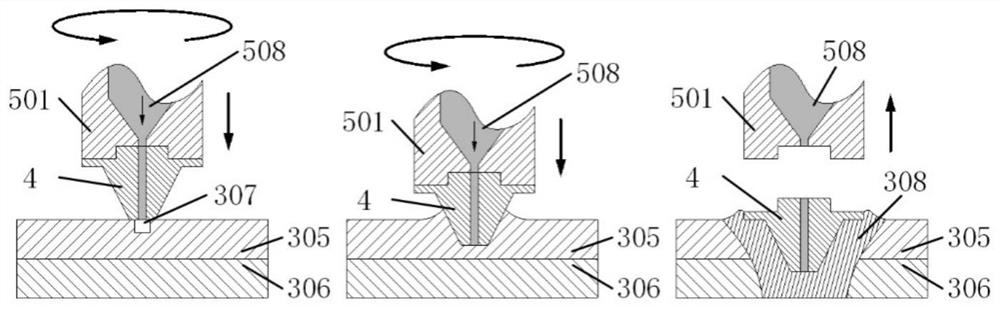

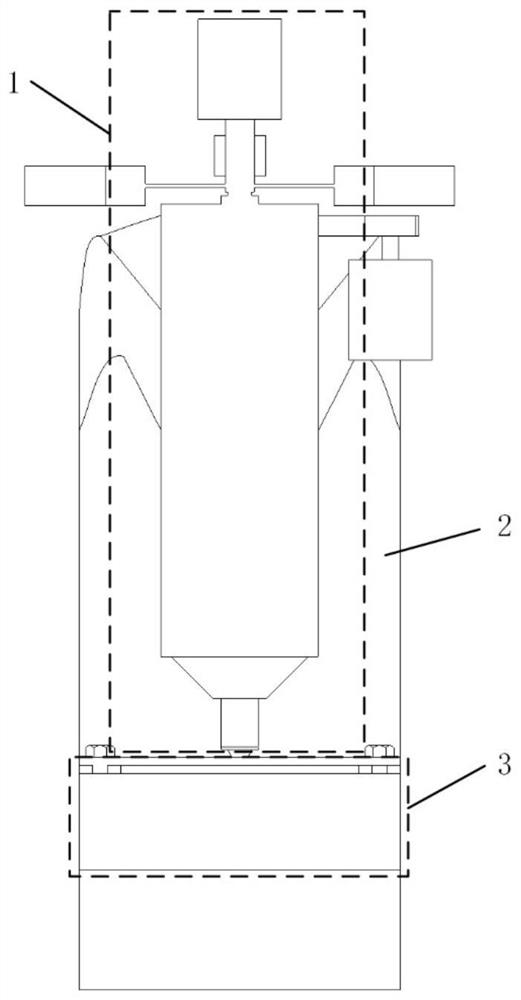

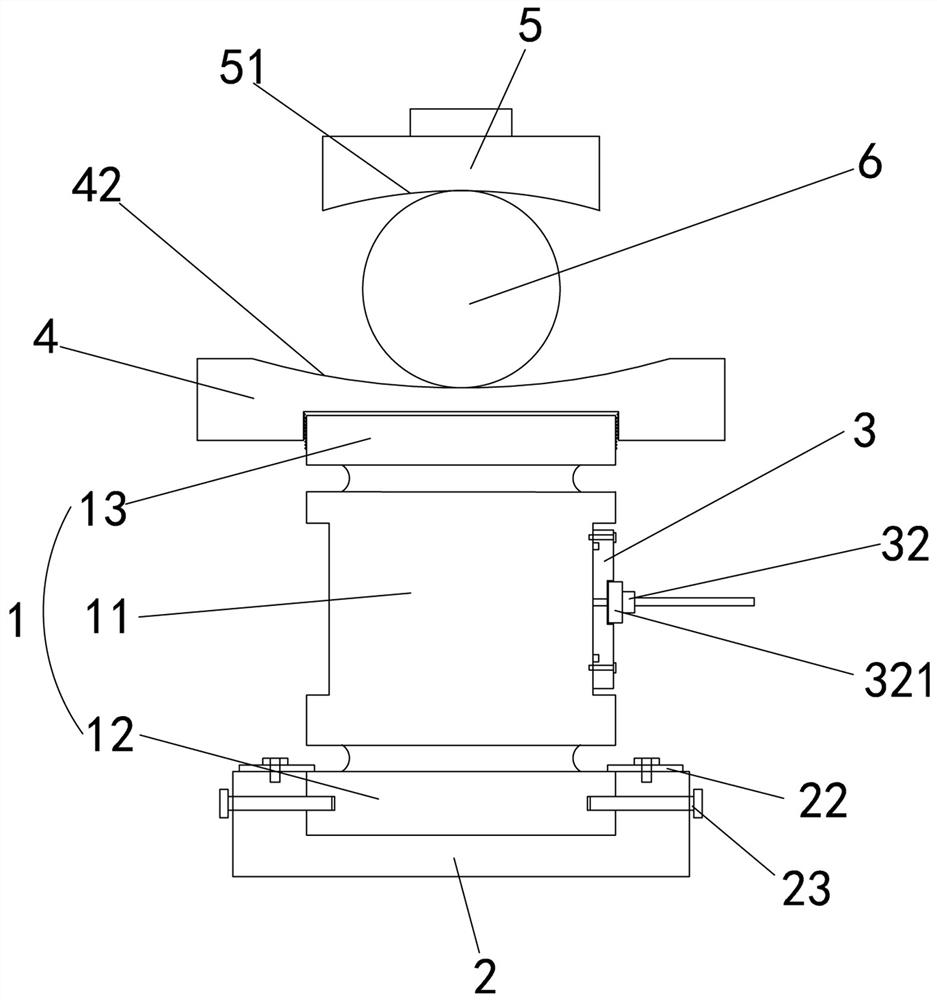

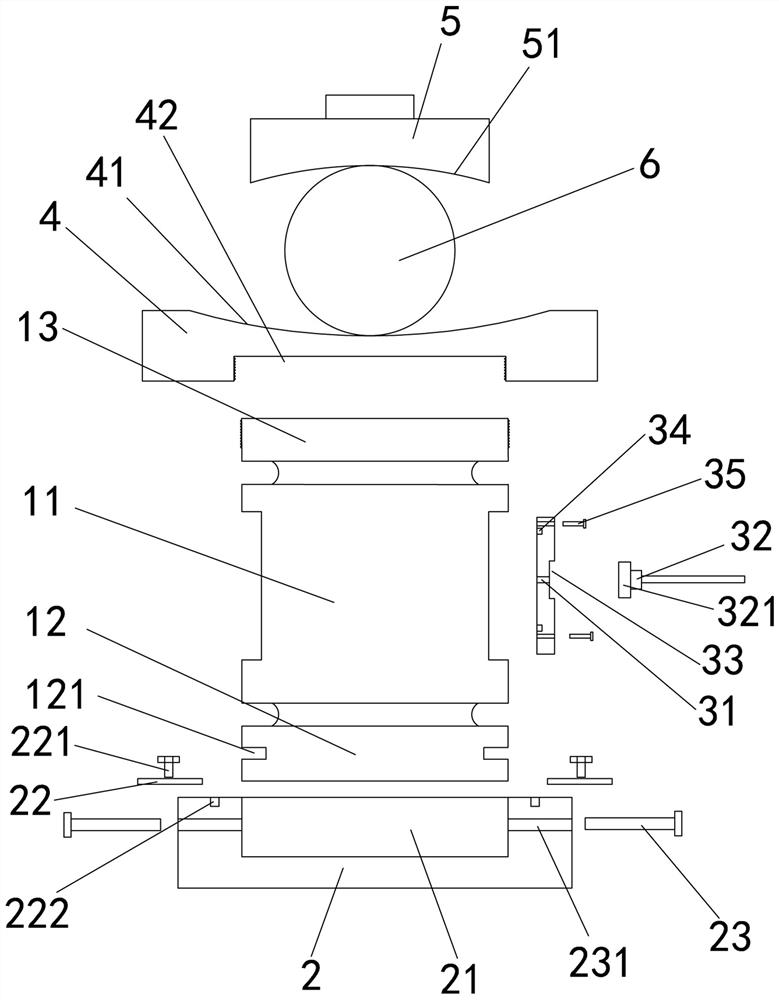

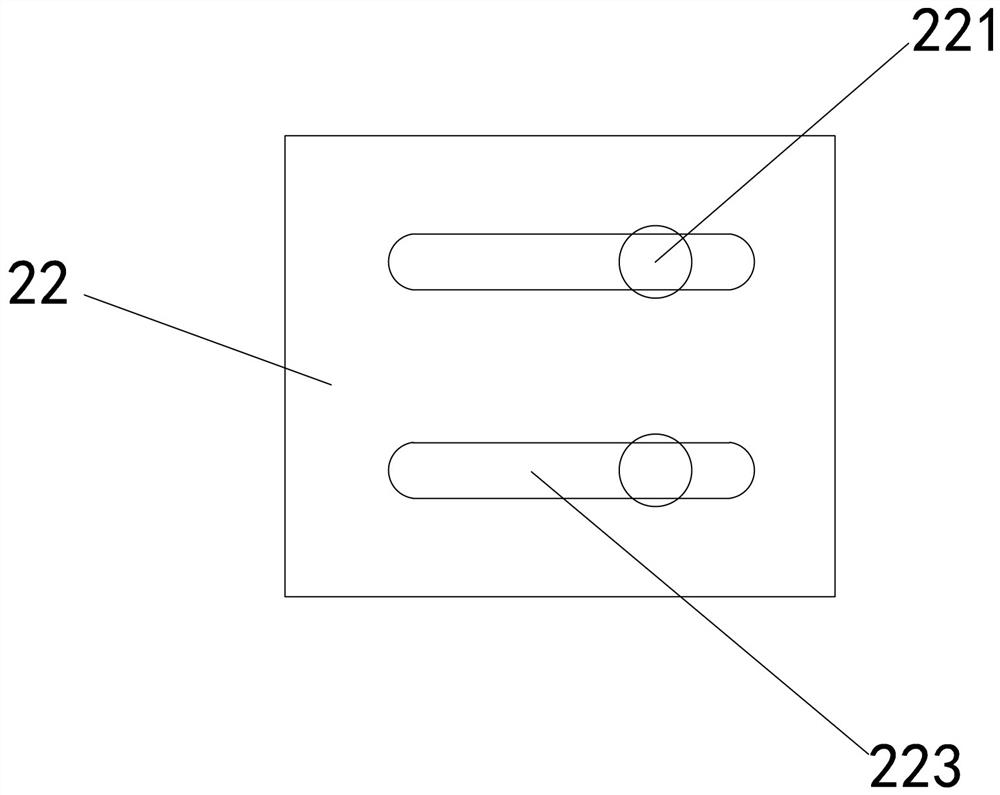

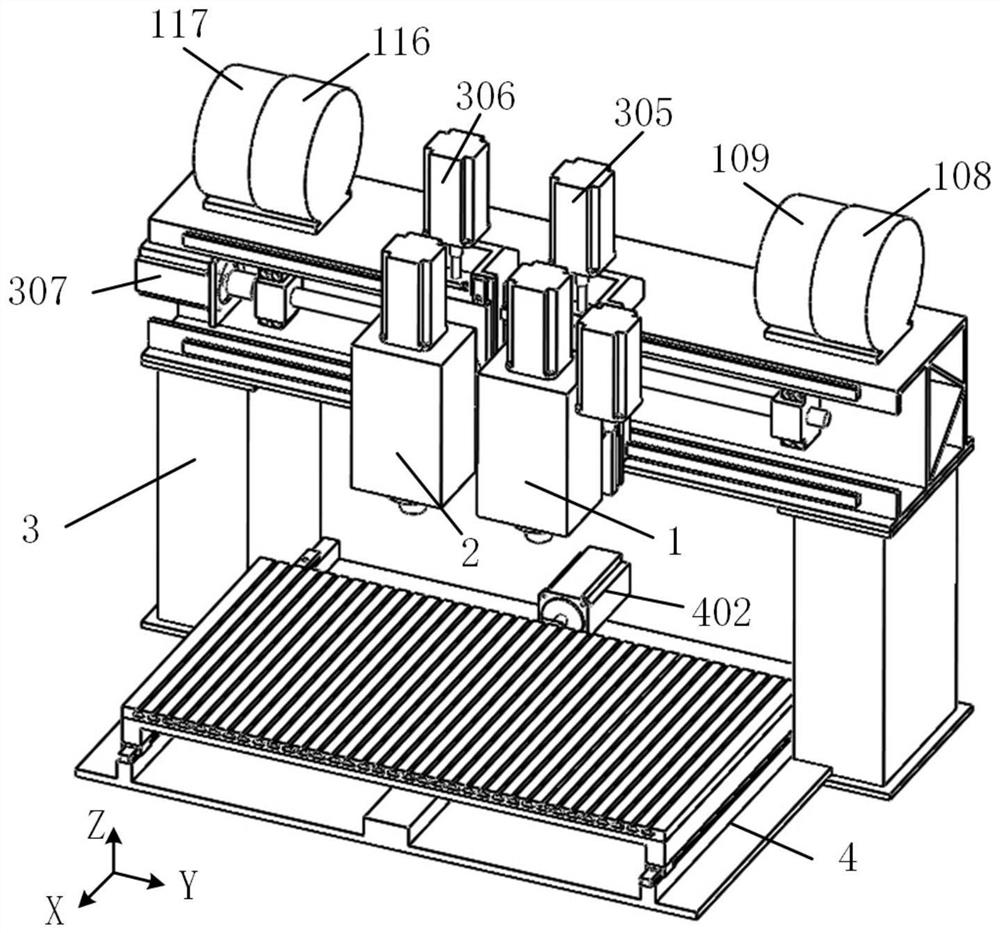

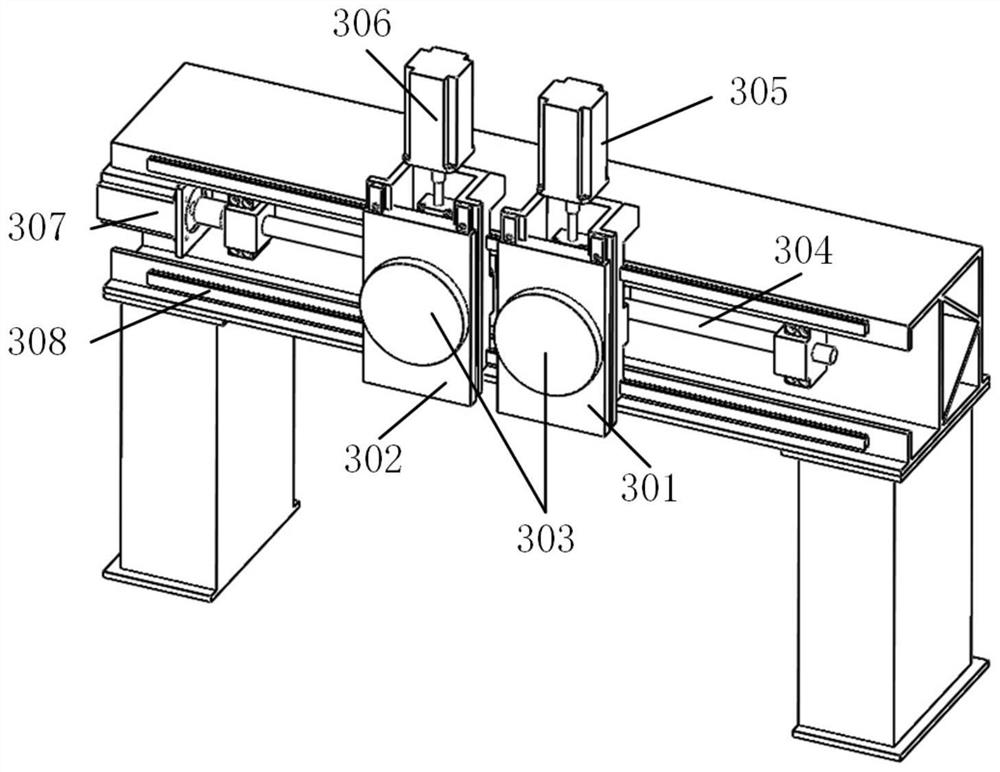

ActiveCN111804910AImprove performanceEfficient Quality Additive ManufacturingAdditive manufacturing apparatusTransportation and packagingMaterial supplyIsothermal forging

The invention relates to a stirring friction forging additional material manufacturing method and device of nano reinforcing composite materials. The device comprises four parts including a stirring friction additional material main shaft, an isothermal forging mechanism, a gantry type rack and a workbench; the stirring friction additional material main shaft is used for realizing mixing, preheating and supplying of powder or granular materials, conducting friction squeezing of materials output from a material supplying hole, and using friction heat and pressure to realize layer-by-layer additional material forming manufacturing; the isothermal forging mechanism is used for realizing isothermal forging and micro reshaping of an additional material layer; the gantry type rack is used for fixing the stirring friction main shaft and the isothermal forging mechanism and for realizing advancing as well as swaying angle adjustment of the stirring friction main shaft and the isothermal forging mechanism along the Y axis and the Z axis; and the workbench is used for fixing a substrate and realizing advancing of the substrate along the X axis. The method and the device can realize high-efficiency and high-quality additional material manufacturing of light alloy powder or granular materials, and have the advantages of higher efficiency, simple and convenient operation and lower energy consumption.

Owner:XI AN JIAOTONG UNIV

Powder reinforced stirring friction riveting method and device

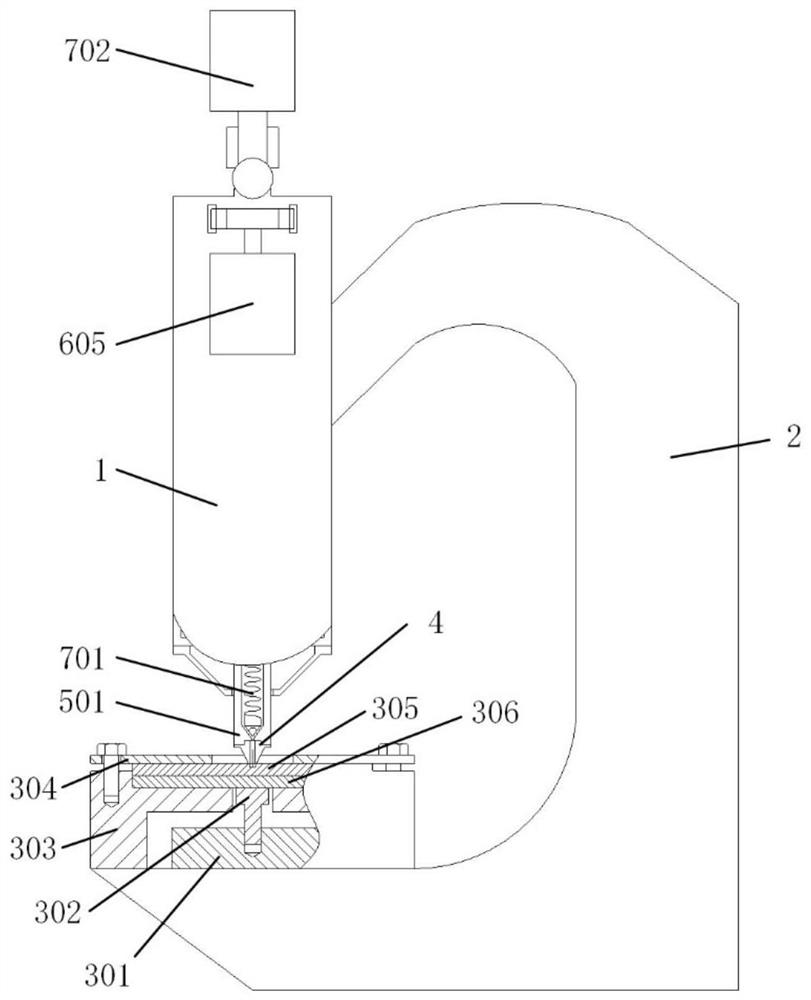

ActiveCN111805073AImprove air tightnessReduce airtightnessNon-electric welding apparatusEngineeringForce sensor

The invention relates to a powder reinforced stirring friction riveting device. The powder reinforced stirring friction riveting device comprises a stirring friction riveting main shaft, a C-shaped rack and a workbench, wherein the stirring friction riveting main shaft comprises a rotary mechanism, a feeding mechanism, a vibrating / rotating mixing mechanism and a powder feeding mechanism; the stirring friction riveting main shaft is used for realizing the rotary motion and feed motion of a rivet and feeding and mixing powder; the C-shaped rack is used for fixing the stirring friction riveting main shaft and the workbench; and the workbench is mainly composed of a force cell, a sensor head, a tool die and a tool pressing plate and is used for clamping a to-be-riveted workpiece and testing the riveting acting force of the main shaft in real time. According to the powder reinforced stirring friction riveting device, the powder reinforced stirring friction riveting between same or differentlight plates at room temperature can be realized, a riveted stirring friction riveting joint without key hole defects and with good joint forming quality and high connecting strength can be obtained,the required riveting forming force is less than that of traditional riveting, and the powder reinforced stirring friction riveting device has the advantages of high efficiency, simplicity and convenience in operation and low energy consumption.

Owner:XI AN JIAOTONG UNIV

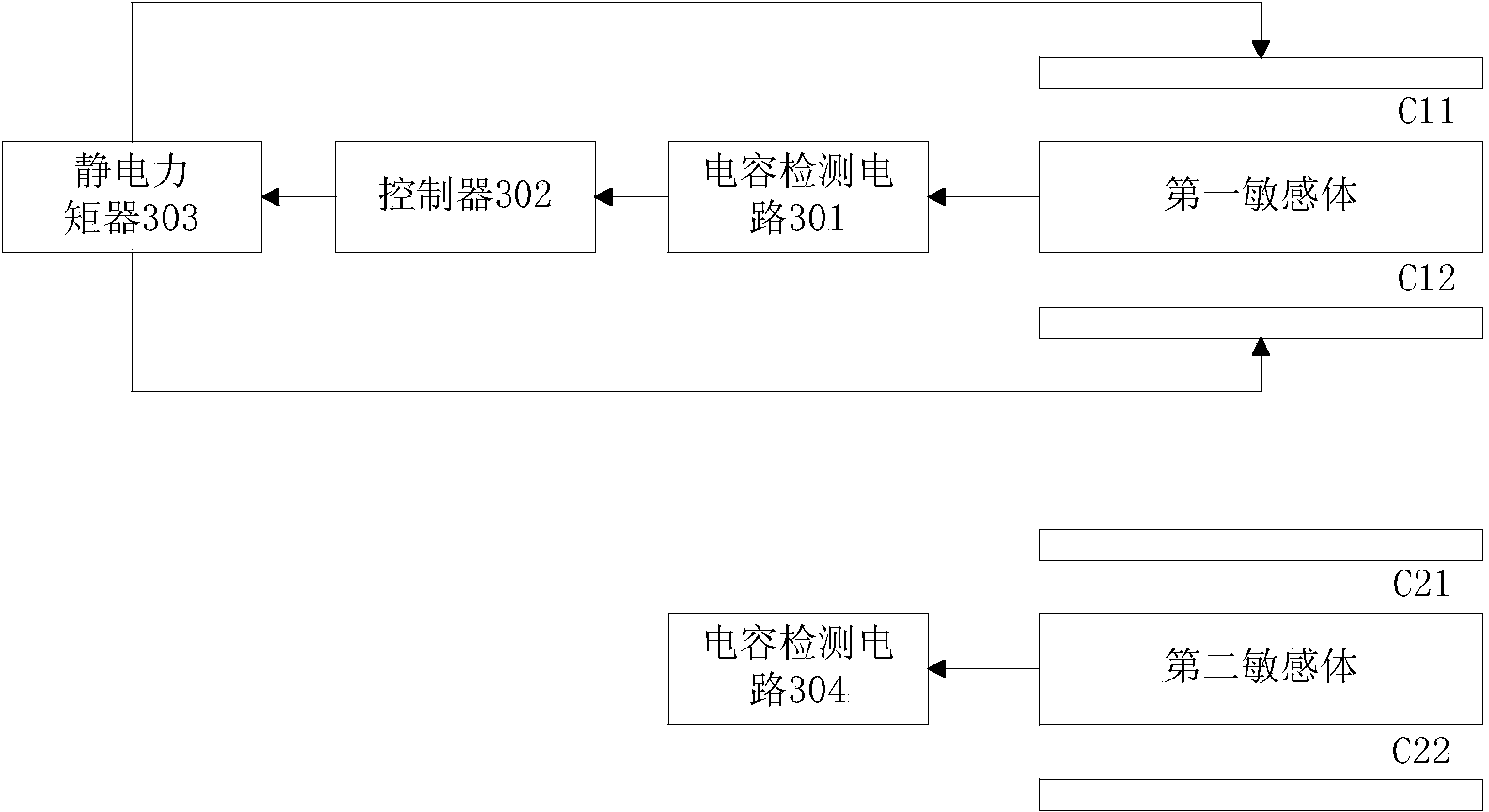

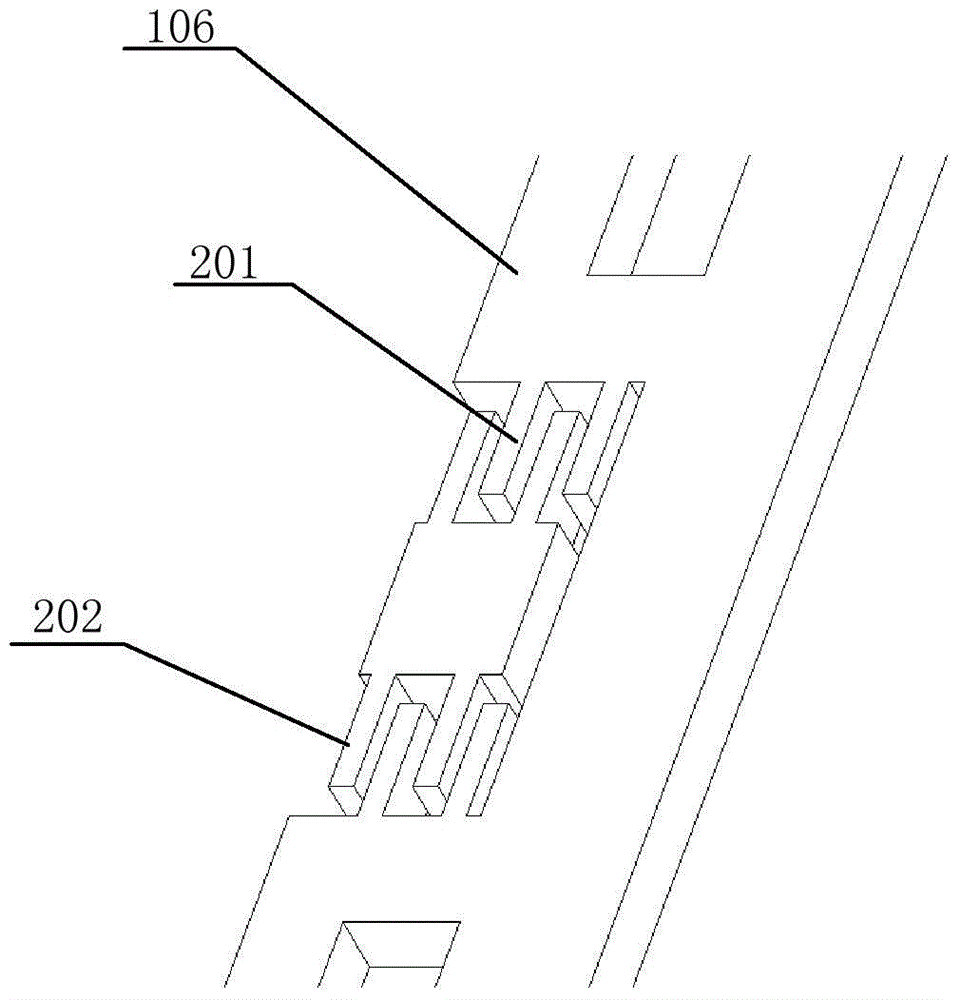

Micromechanics accelerometer

The invention discloses a micromechanics accelerometer which comprises a chip, connection parts, a plurality of sensitive bodies, wherein a first ligand is fixedly arranged on the chip, and the plurality of sensitive bodies are connected with the chip through corresponding connection parts. A plurality of connection parts are different in rigidity, so that the sensitive bodies can measure accelerated speeds in different ranges. The micromechanics accelerometer integrates the sensitive units which are different in ranges and are nested layer by layer, so that accelerated speeds in different ranges can be measured by corresponding sensitive units. Therefore, accuracy and precision of measurement can be increased effectively by means of the measurement mode. Furthermore, the plurality of sensitive units are nested layer by layer. Accordingly, compared with the existing accelerometer, the micromechanics accelerometer is compact in structure and small in size.

Owner:TSINGHUA UNIV

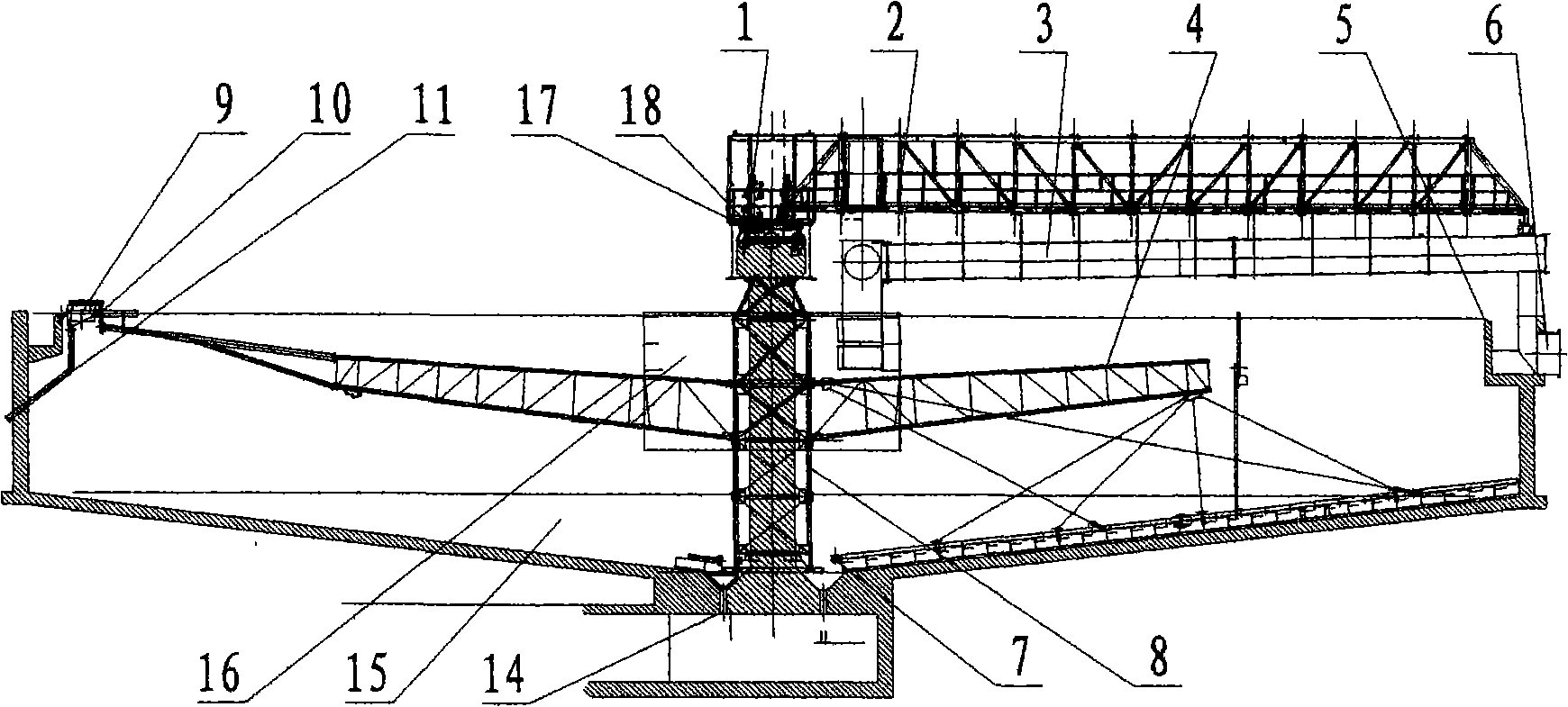

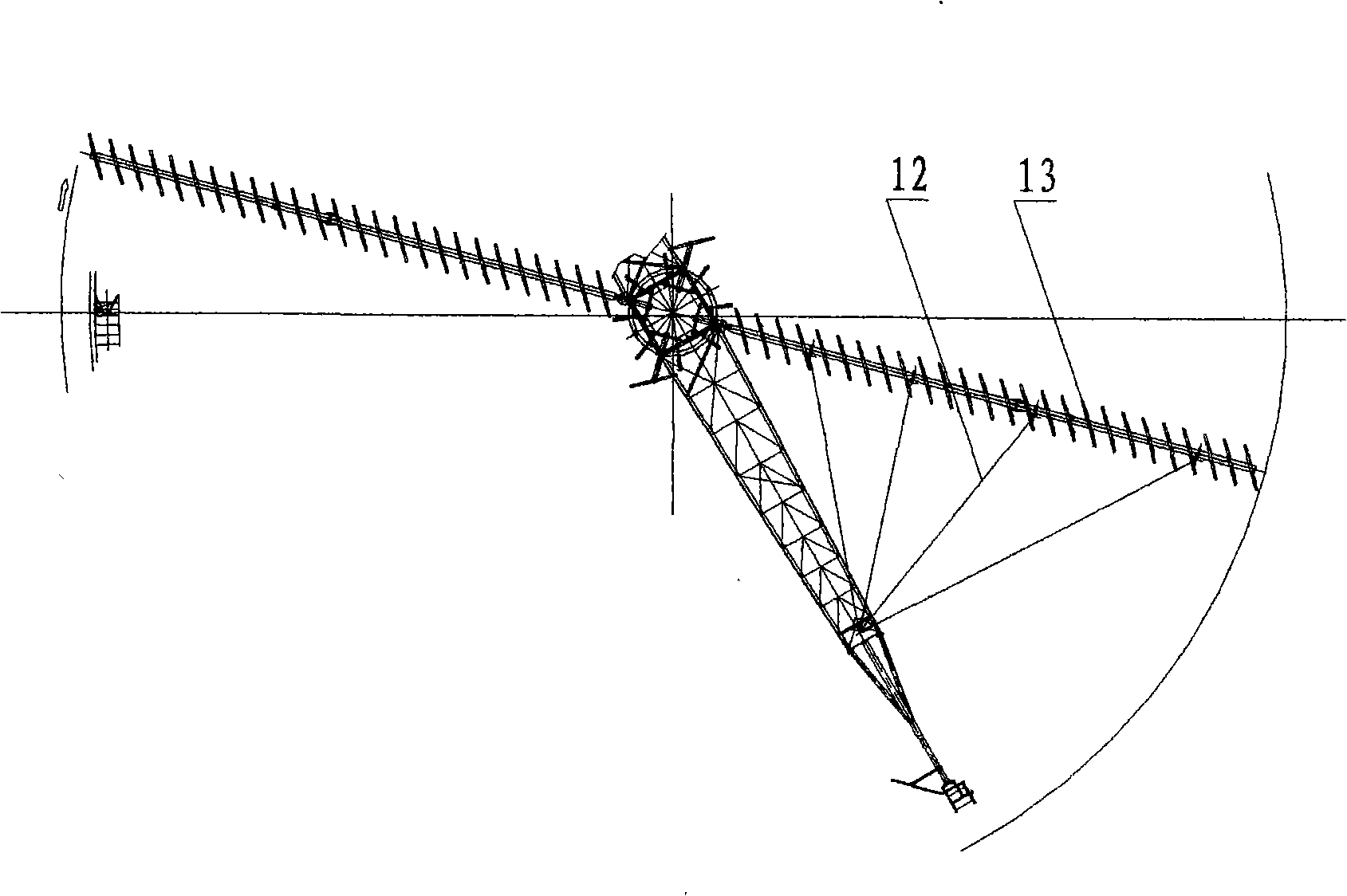

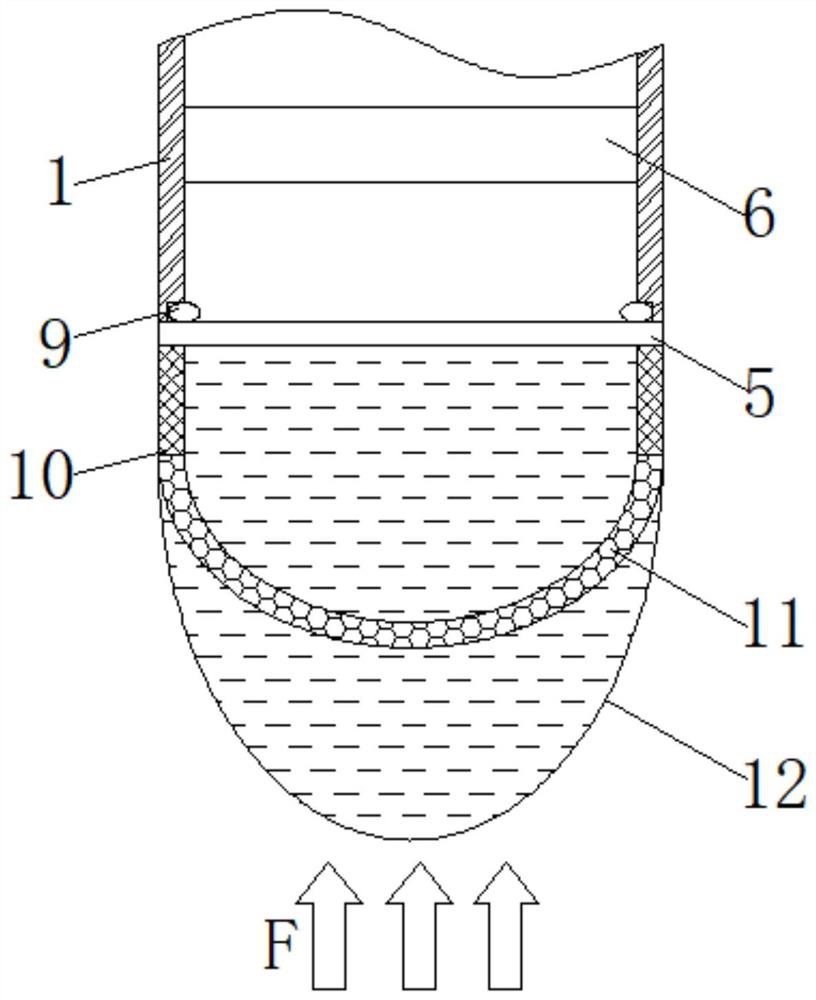

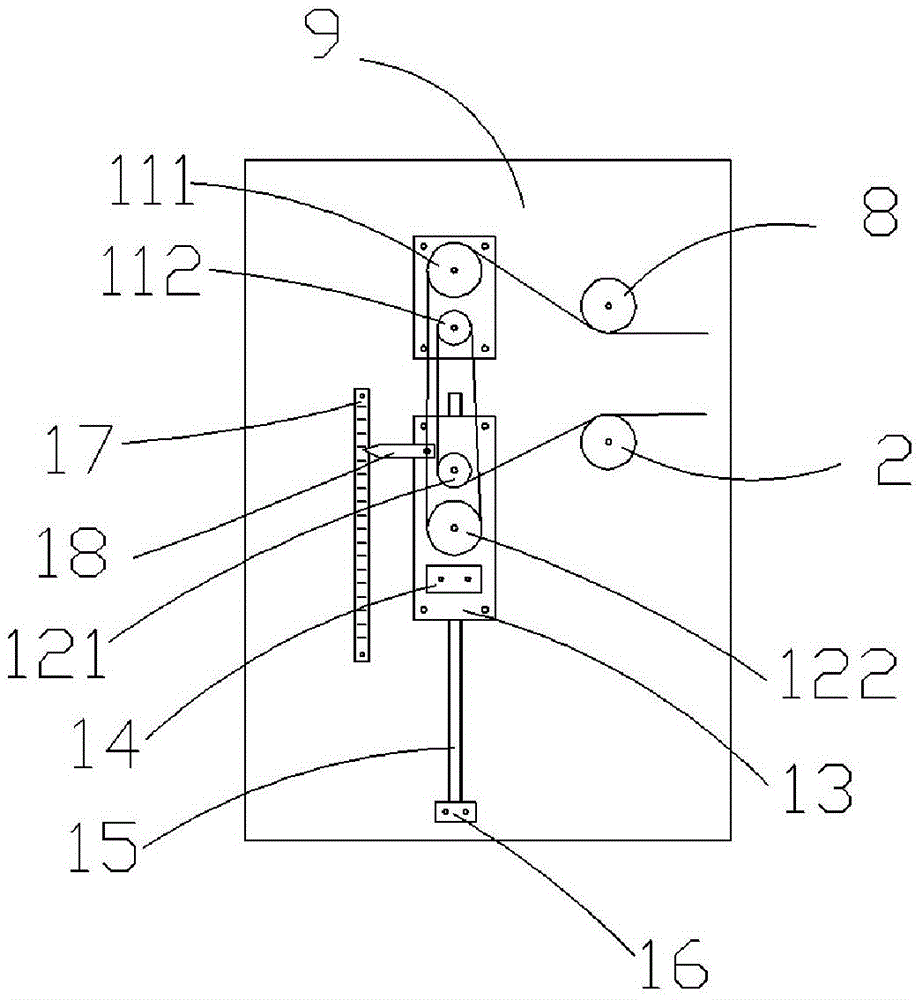

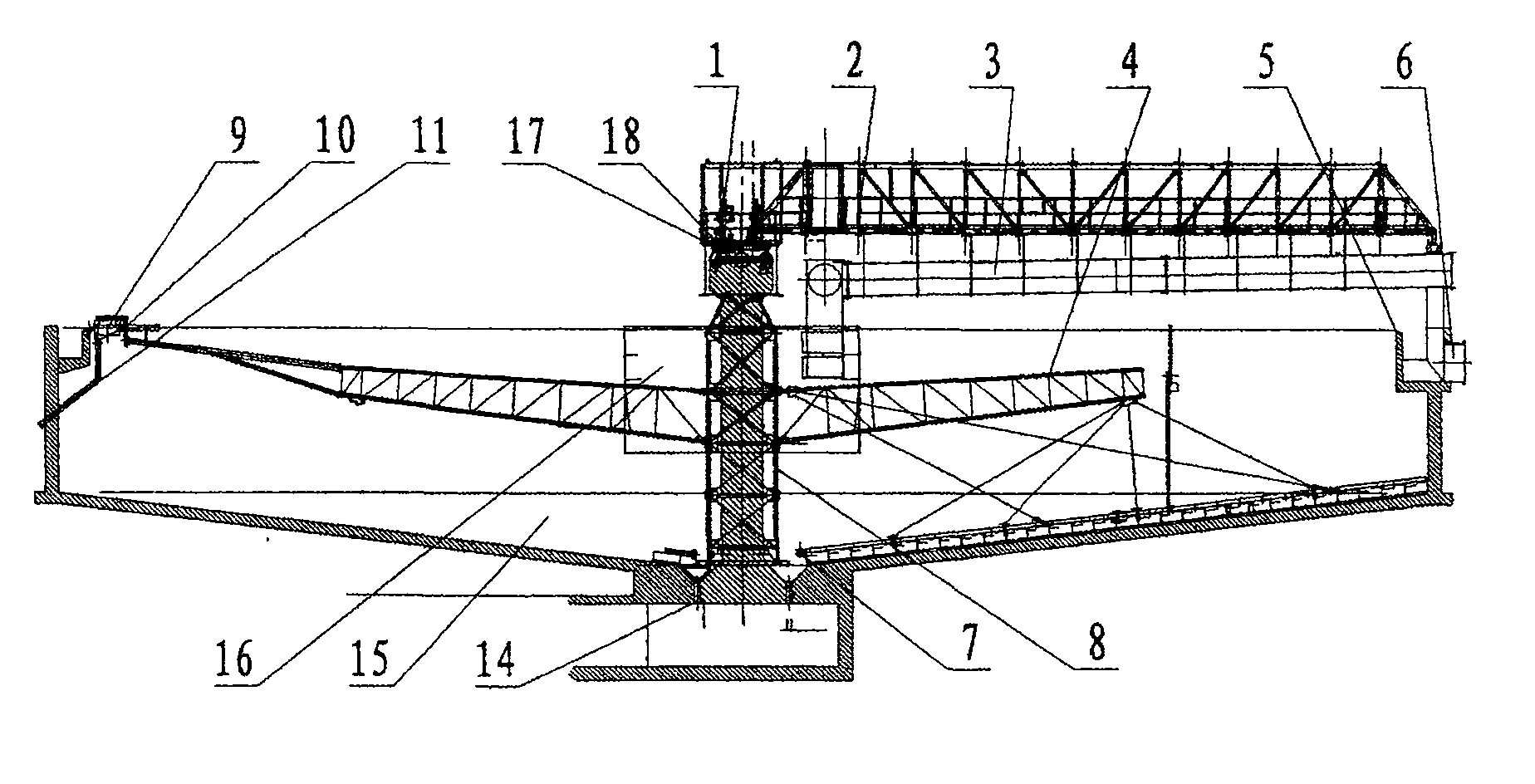

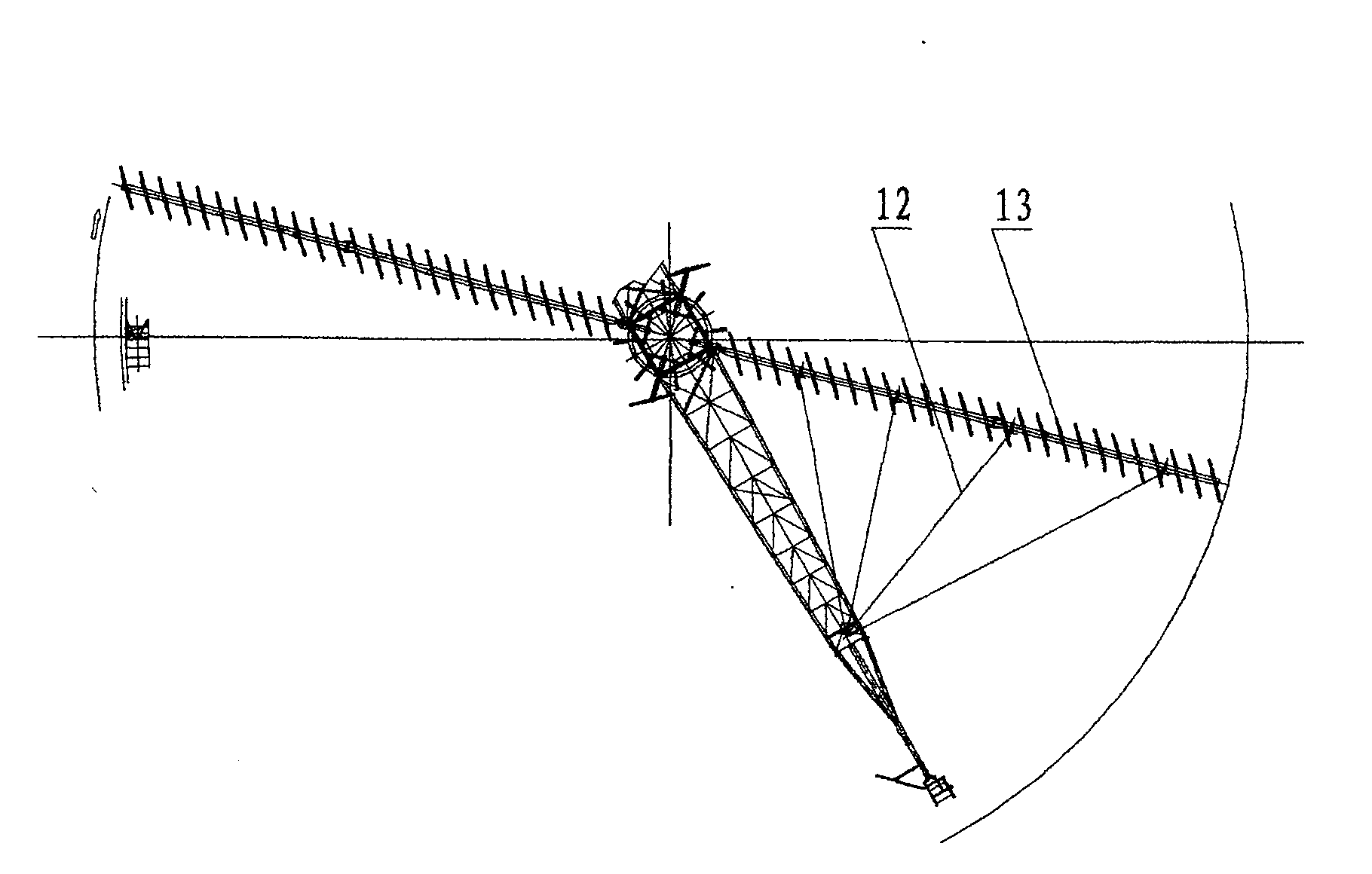

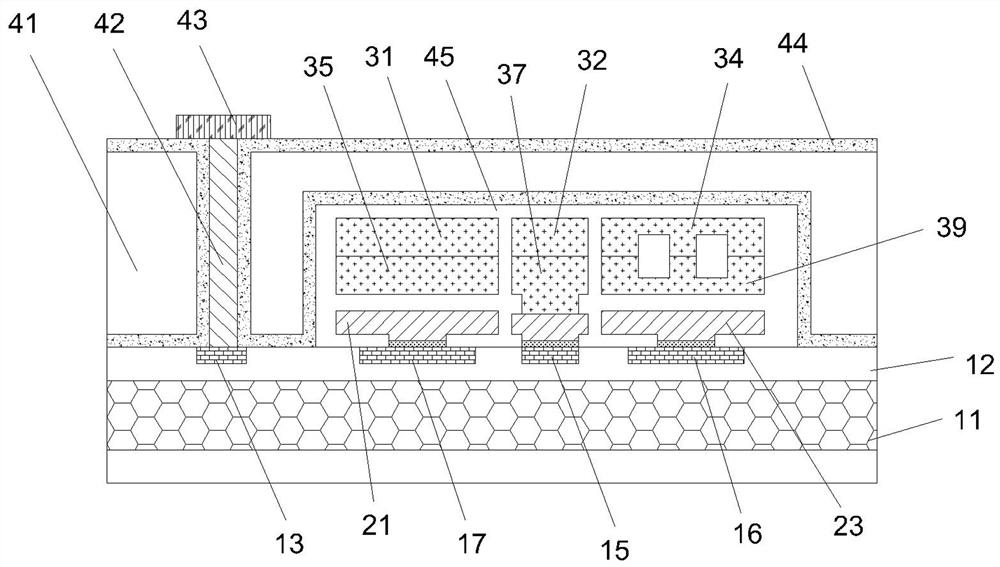

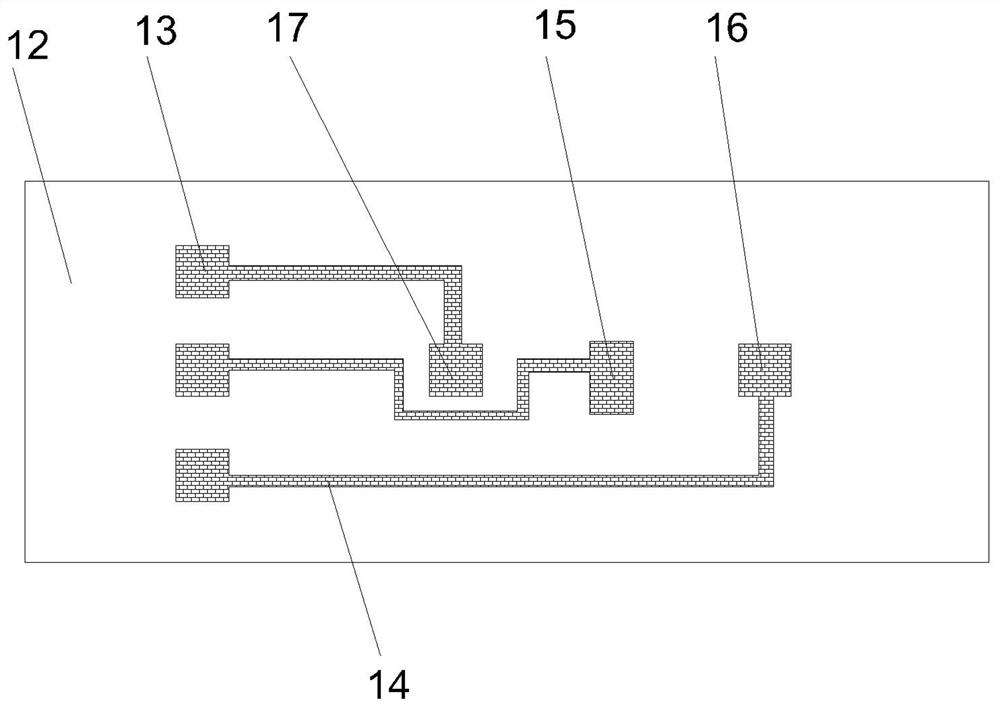

Central transmission mud scraper of large-sized flexible rake lift

InactiveCN101279149AImproved resistance to overloadAvoid disadvantagesWater/sewage treatmentSedimentation separationGear driveSludge

The invention discloses a large central transmission sludge scrapper with flexible lifting rakes, which is used for sludge treatment of environmental protection and essentially comprises a 2 to 4 cycloids planetary gear drive device (1) with overtorque protection and torque display, a truss (2), a water inlet pipe (3), a rotary torque arm (4), an overflow weir (5), an water outlet pipe (6), a hinged joint (7), a central rotary cage (8), an oil collector (9), an oil scrapper rake (10), an oil outlet pipe (11), steel wire ropes (12), a sludge scrapper rake (13), a sludge discharge outlet (14), a truss radical sedimentation basin (15), a feeding steady flow tube (16), a rotary support (17), a pinion wheel (18), etc. The large central transmission sludge scrapper of the invention can realize the transmission of high torque and guarantee the effect of sludge scrapping, high-efficiency and stable operation, and is particularly applicable to a large radial sedimentation basin with the diameter equal to or more than 45 meters.

Owner:丹东北方环保工程有限公司

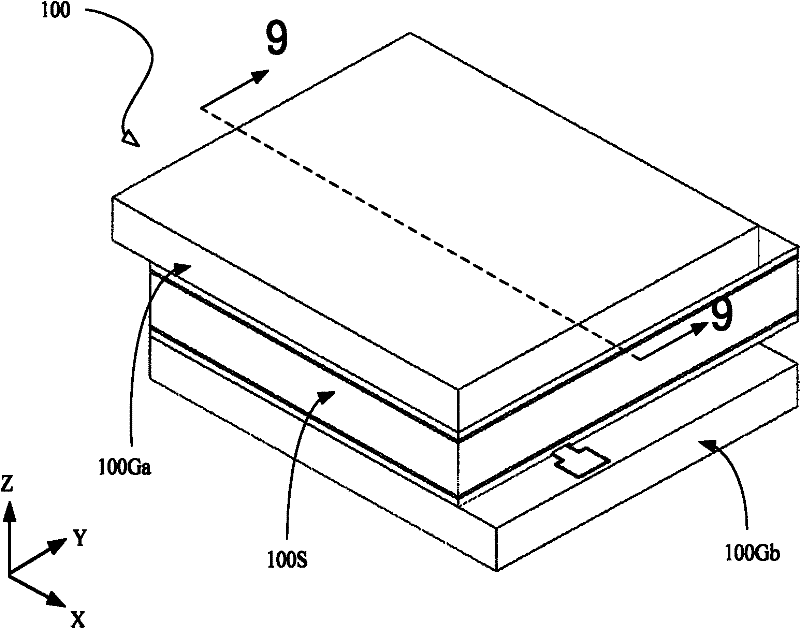

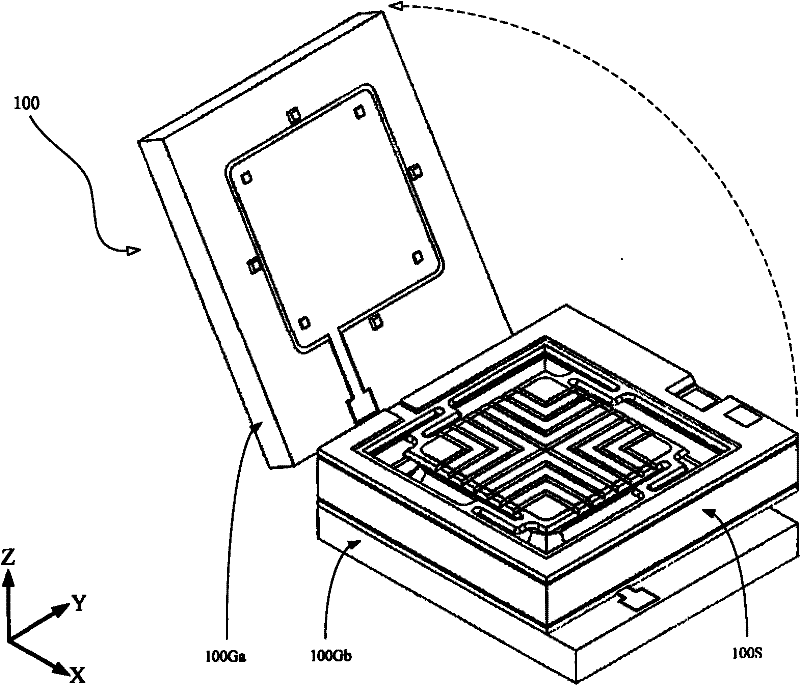

Campaniform oscillator type angular rate gyroscope

InactiveCN101968359BHigh quality factorImprove structural strengthSpeed measurement using gyroscopic effectsTurn-sensitive devicesVariable thicknessGyroscope

The invention relates to an angular rate gyroscope which has the variable-thickness axisymmetric multi-curved surface fusion structural feature and takes an oscillator with a campaniform structure as a sensitive element. The angular rate gyroscope consists of the oscillator, an oscillator support structure, an airtight cover, a cylindrical outer frame and a system circuit, wherein the oscillator is made of a quartz material and is machined integrally for forming with a phi-shaped support rod; the upper and the lower ends of the support rod are respectively fixed to the top end of a support cover and the central position of a support base plate; a driving electrode and a vibration mode stable electrode are attached to the support cover; a detection electrode is arranged in the inner space of the campaniform oscillator; the airtight cover and the cylindrical outer frame are sequentially arranged outside a support structure; and the system circuit is positioned between the bottom of the airtight cover and the outer frame. The angular rate gyroscope is suitable for the application field of measuring medium and low-precision angular rate in the high dynamic environment, and the oscillator with the campaniform structure has the high quality factors and high overload capacity resistance and has the characteristics of hold facility during power failure, simple structure, suitability for batch production and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY +2

Automobile gear shaft and forging method thereof

The invention discloses an automobile gear shaft and a forging method thereof. The gear shaft comprises, by weight, 0.16-0.2% of carbon, 0.15-0.3% of silicon, 0.75-0.90% of manganese, 0-0.015% of phosphorus, 0-0.025% of sulfur, 0.5-1.1% of chromium, 0.01-0.03% of aluminum, 0-0.025% of copper, 0.12-0.28% of nickel, 2.98-3.58% of molybdenum and the balance iron. A raw material blank is subjected tocirculating heating and cooling many times, then subjected to surface treatment, cooled to 1100-1300 DEG C and kept warm; then, upsetting and drawing are carried out to reach the specification required by forge pieces, and the forging temperature is 850-1300 DEG C; the blank is drawn into an octagonal shape and distributed, small head drawing, rolling and finishing are carried out, and then the blank is subjected to thermal treatment and carburizing treatment. The hardness, fatigue resistance and overload resistance of the gear shaft are improved while the application stability of the gear shaft is ensured.

Owner:浙江恒利五金科技有限公司

Stable column type weighing sensor structure

PendingCN112781698ASimple structureReduce volumeWeighing auxillary devicesSpecial purpose weighing apparatusMechanical engineeringSteel ball

The invention provides a stable column-type weighing sensor structure, and relates to the technical field of load-bearing sensors. The stable column type weighing sensor structure comprises an elastic body, a base, a wire outlet plate, an expansion piece, a pressure head and a steel ball, the elastic body comprises a main body, a first connecting piece and a second connecting piece, and the side edge of the first connecting piece is provided with a first insertion hole; the base is provided with a fixing hole, a limiting plate, an anti-rotation pin, a fixing bolt, a first bolt hole and an anti-rotation pin hole, the wire outlet plate is provided with a cable, a cable hole and a cable connector piece, the side, close to the wire outlet plate, of the cable connector piece is provided with a connector, and the wire outlet plate is provided with a second insertion hole through which the connector can penetrate conveniently; and the side, close to the second connecting piece, of the expansion piece is provided with a connecting hole for facilitating insertion of the second connecting piece. The stable column type weighing sensor structure is simple in structure, small in size, light in weight, high in precision, high in toppling resistance, good in self-resetting effect, good in lateral force resistance and high in overload resistance.

Owner:航天南洋(浙江)科技有限公司

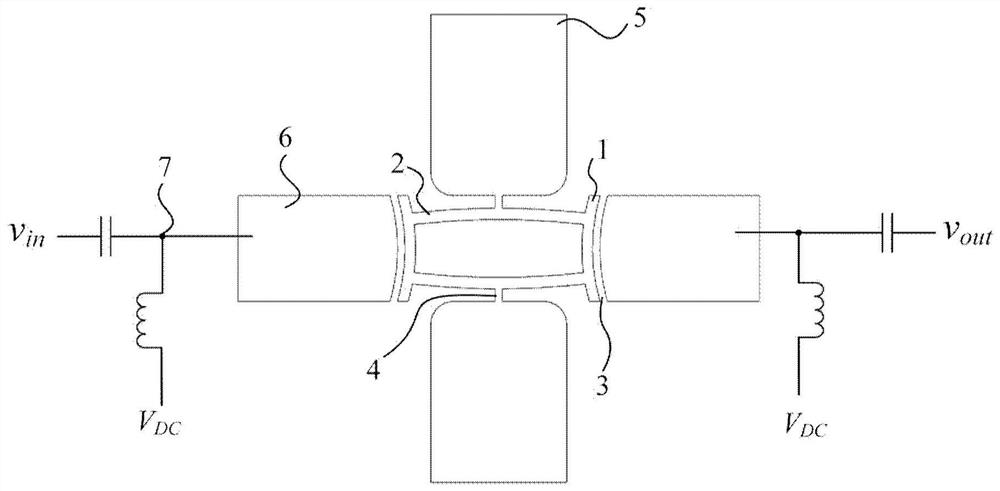

Multi-beam structure combined radio frequency micro electro mechanical system resonator and application

PendingCN112422097AFlexible settingsImprove perceptionImpedence networksCommunications systemRadio frequency microelectromechanical system

The invention relates to a multi-beam structure combined radio frequency micro-electro-mechanical system resonator and an application, wherein the multi-beam structure combined radio frequency micro-electro-mechanical system resonator comprises an electro-mechanical conversion beam unit which is a transduction assembly of the input end and the output end of the resonator; an energy transmission beam which is a connecting structure of the electromechanical conversion beam unit; an electrode for applying a drive excitation; a dielectric layer which is a gap layer between the electromechanical conversion beam unit and the electrode; a base that plays a role in supporting the resonator; and a supporting structure used for realizing the suspension of the resonator. The multiple beam structuresachieve modal coupling through frequency matching, the distortion degree is small, a high Q value can be maintained and flexible setting of multiple resonant frequencies is achieved; so that good impact resistance and overload resistance are achieved, the beam structures can be used for constructing a multi-mode, multi-frequency-band and reconfigurable advanced wireless communication system, and the application potential of the beam structures under complex environment conditions is enhanced; therefore, internet-of-things effect is improved, and the environmental perception ability is enhanced.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

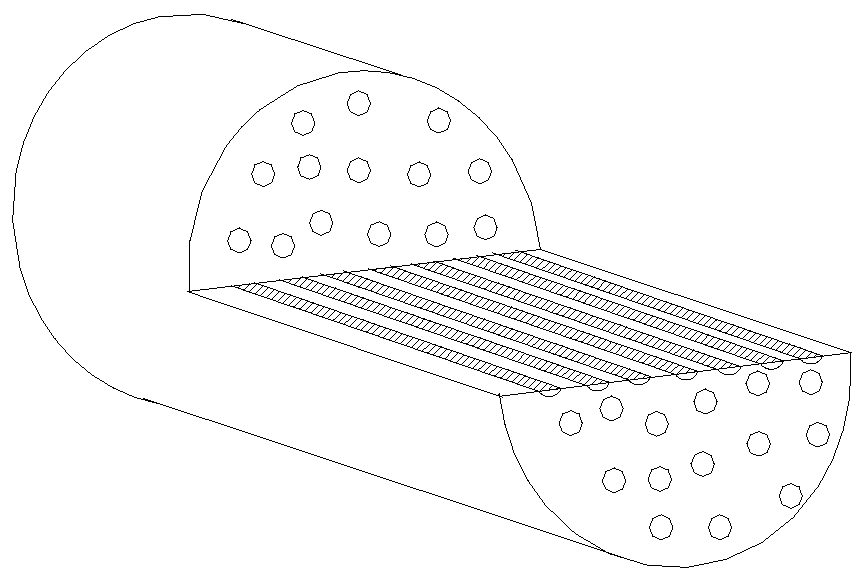

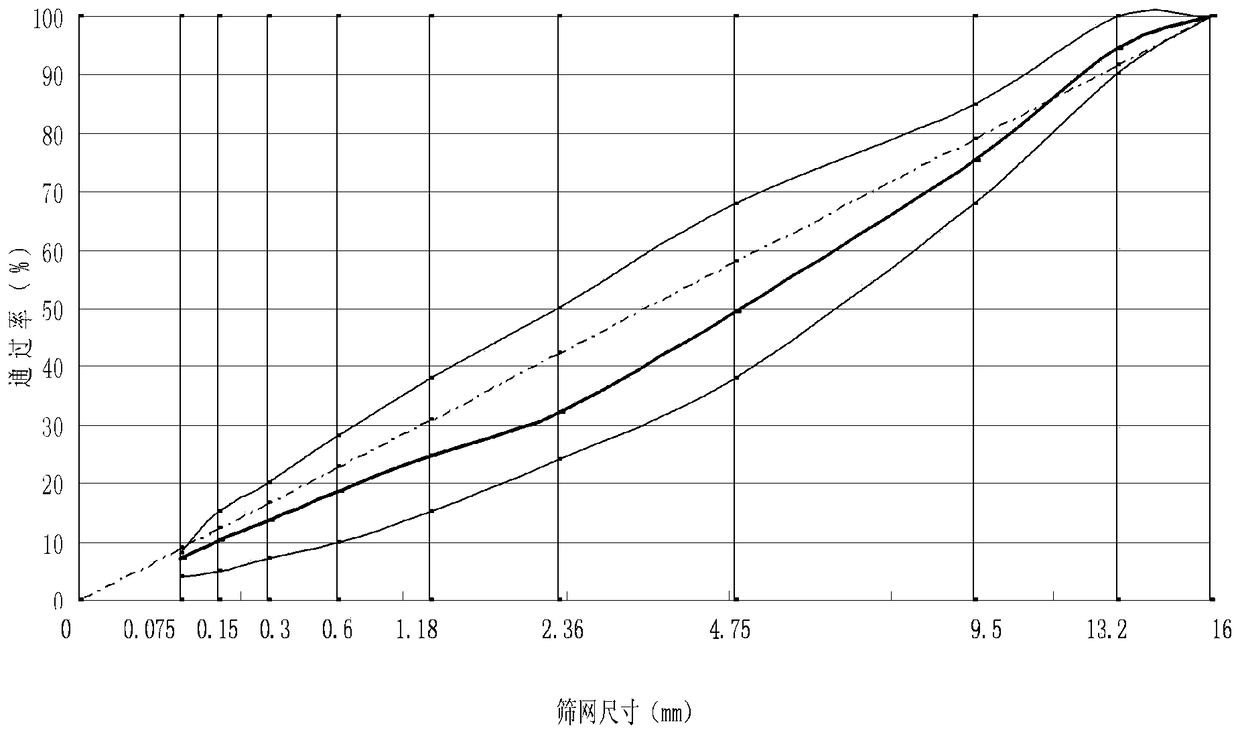

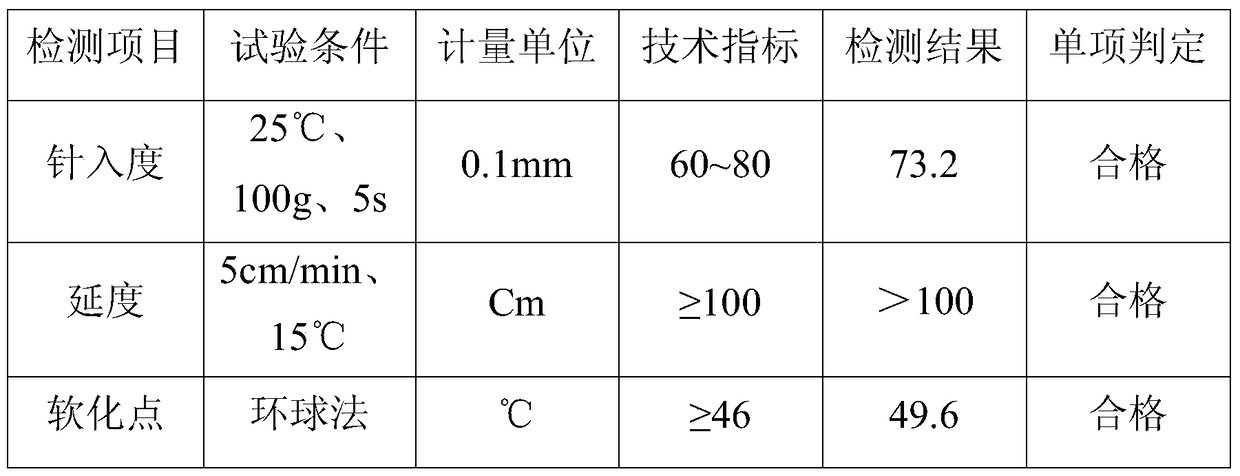

A kind of crude fiber reinforced asphalt mixture

InactiveCN105331128BImprove mechanical propertiesImproved resistance to overloadBuilding insulationsRoad surfaceHeavy load

Owner:余姚市交通规划设计研究院

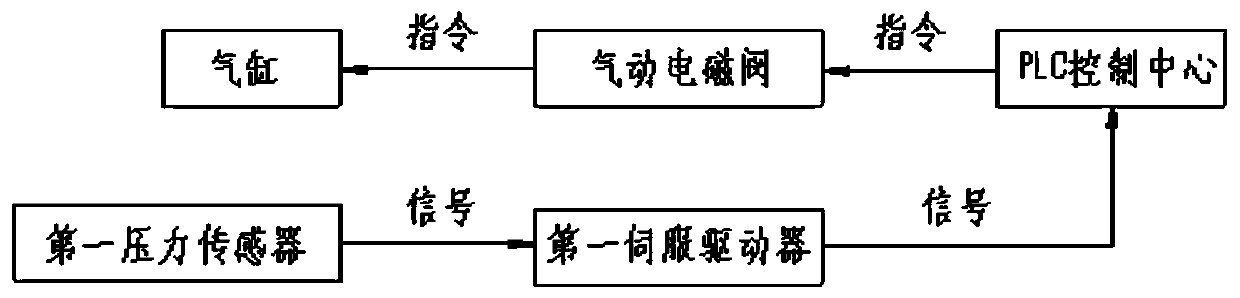

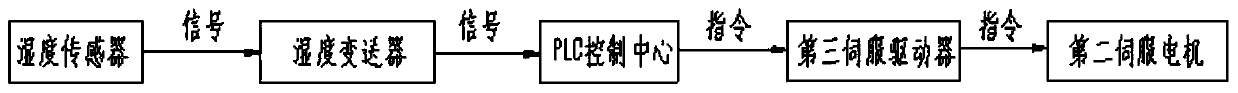

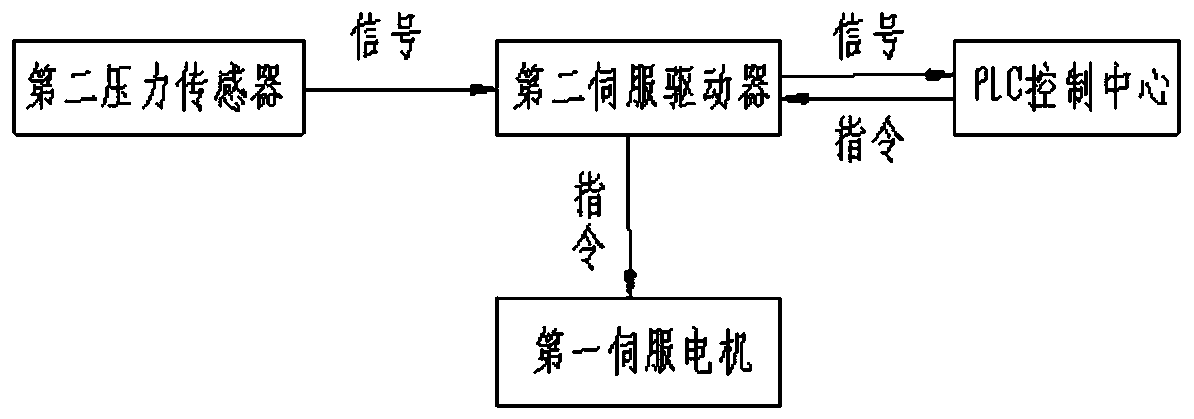

Intelligent system for controlling oil sludge pyrolysis carbonization

InactiveCN109870975AEasy to controlEasy to operateProgramme control in sequence/logic controllersControl engineeringCarbonization

The invention provides an intelligent system for controlling oil sludge pyrolysis carbonization. The intelligent system comprises a discharging control module, a conveying control module, a drying control module, a pyrolysis detection module and an intelligent control center, wherein the discharging control module is connected with the intelligent control center and is used for controlling the quantity of oil sludge in a feeding device; the conveying control module is connected with the intelligent control center, and is used for controlling a conveying device of the oil sludge; the drying control module is connected with the intelligent control center and is used for controlling a drying machine to work; and the intelligent control center is arranged in the intelligent system and is usedfor intelligently controlling the modules. The intelligent control center is used to control the modules, so that the intelligent control of the oil sludge pyrolysis carbonization system is realized;and therefore, the system has the characteristics of being easy to control and simple and stable in operation.

Owner:中科天龙(厦门)环保股份有限公司

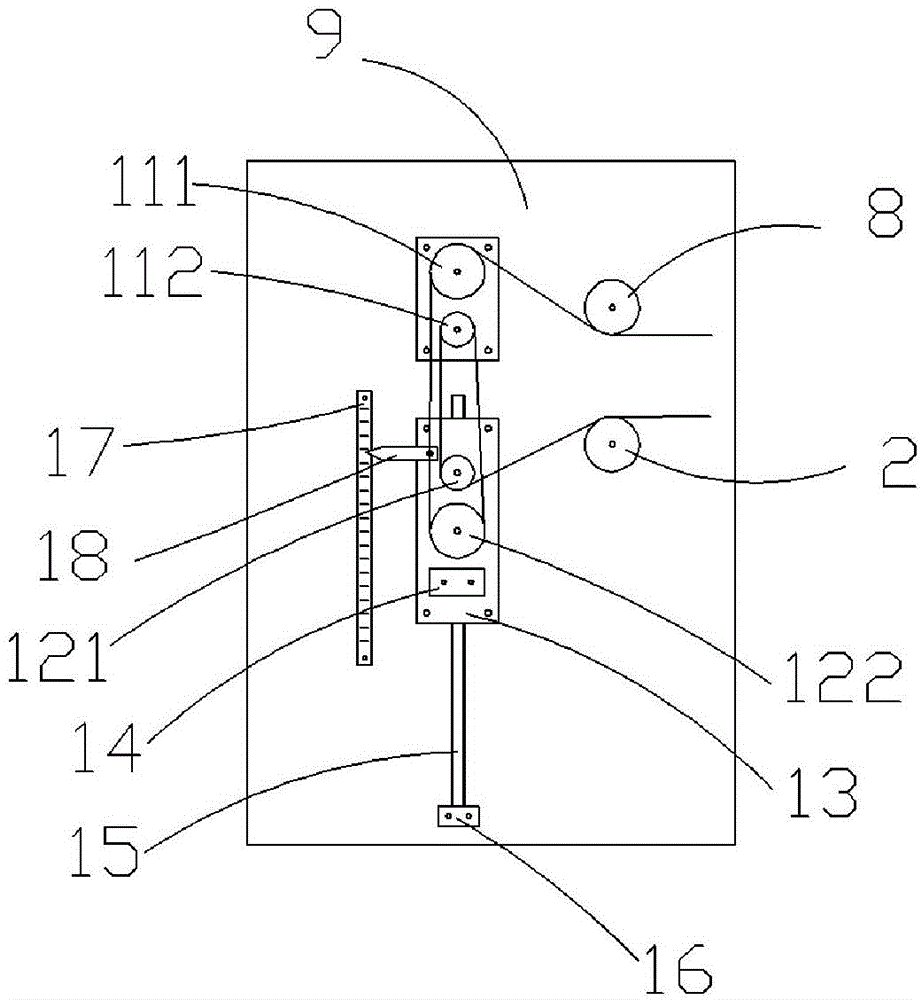

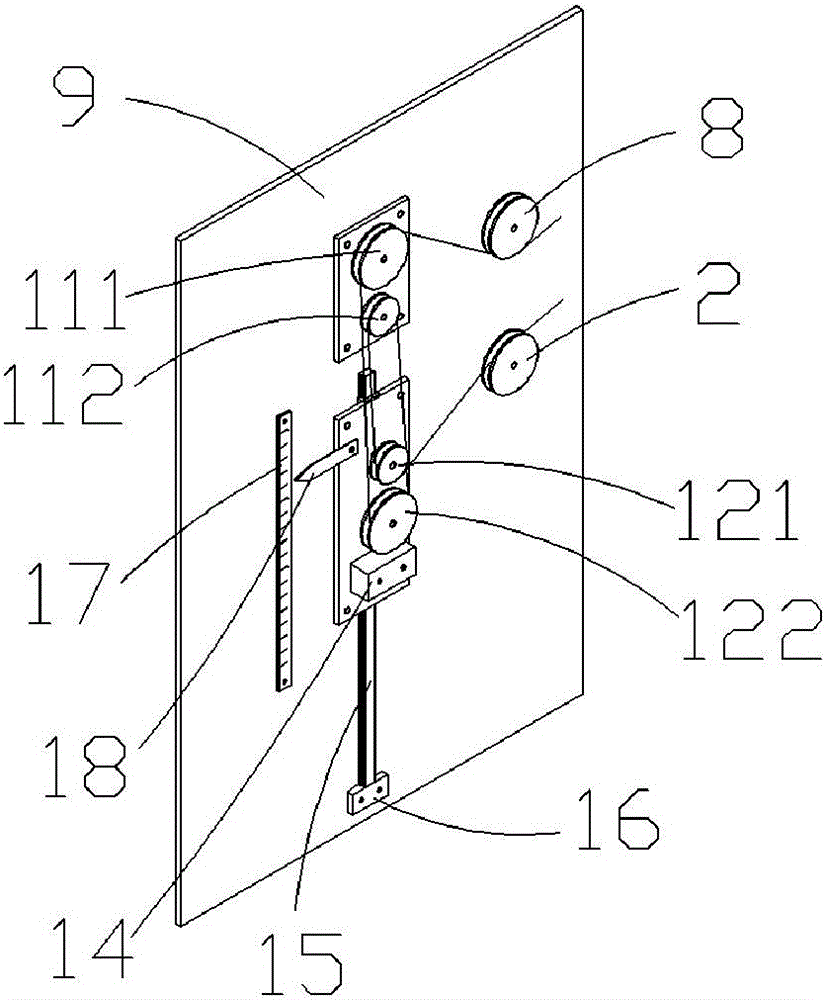

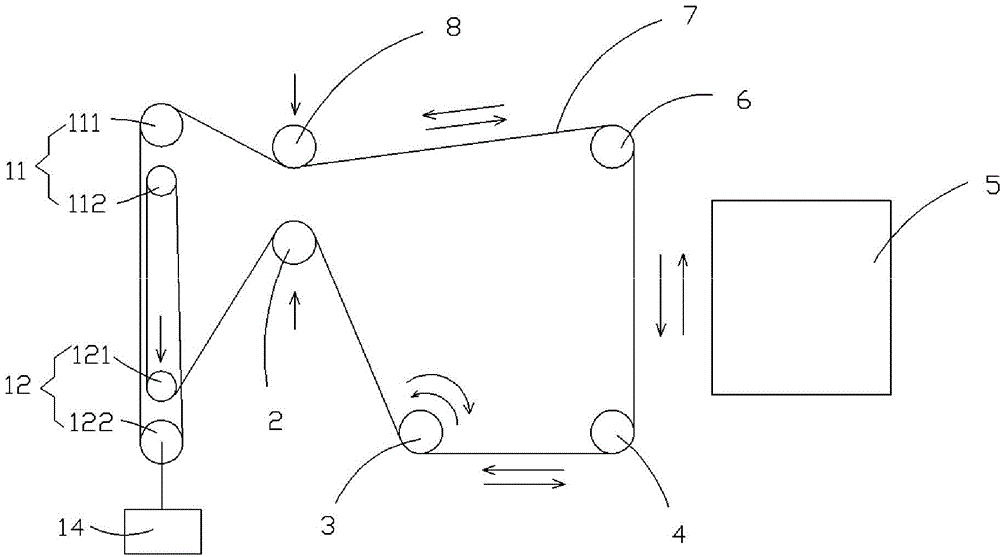

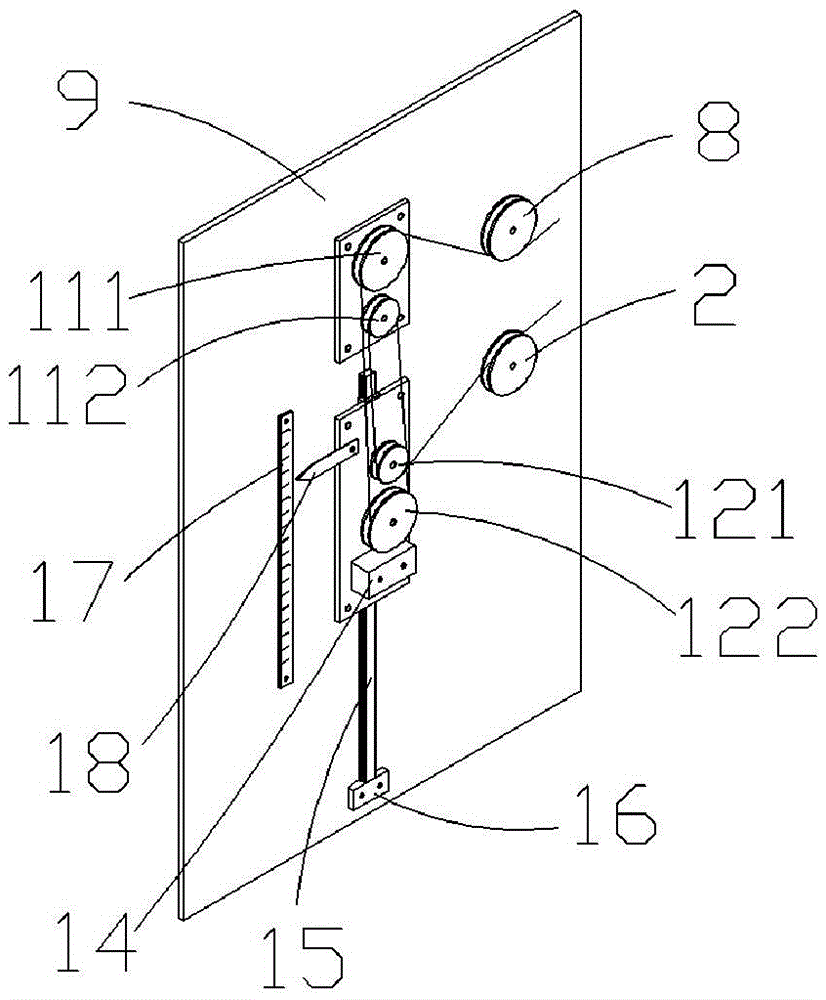

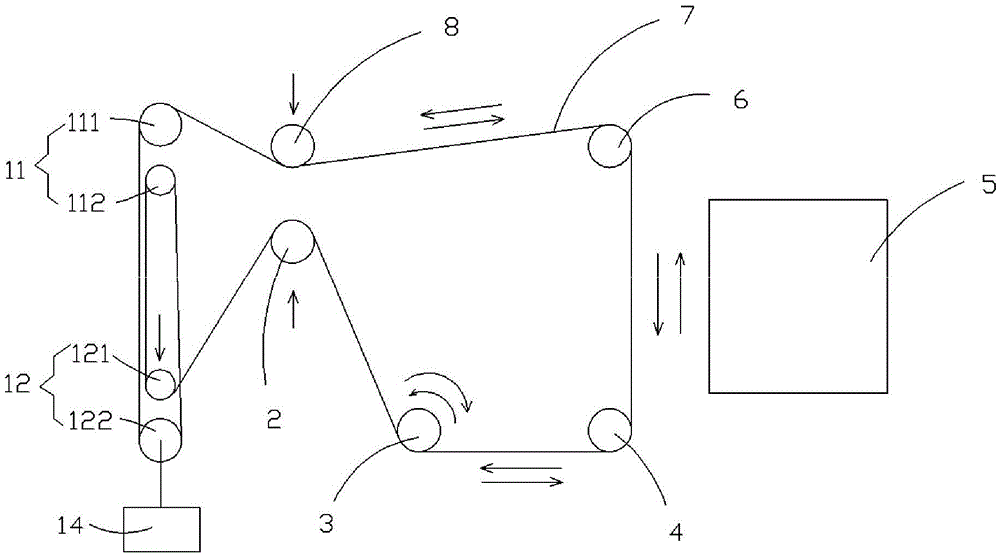

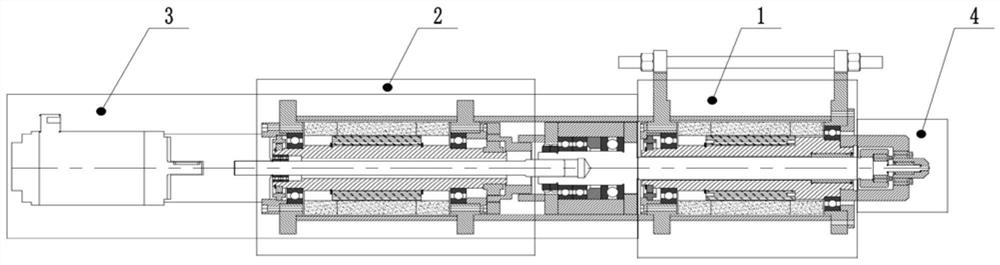

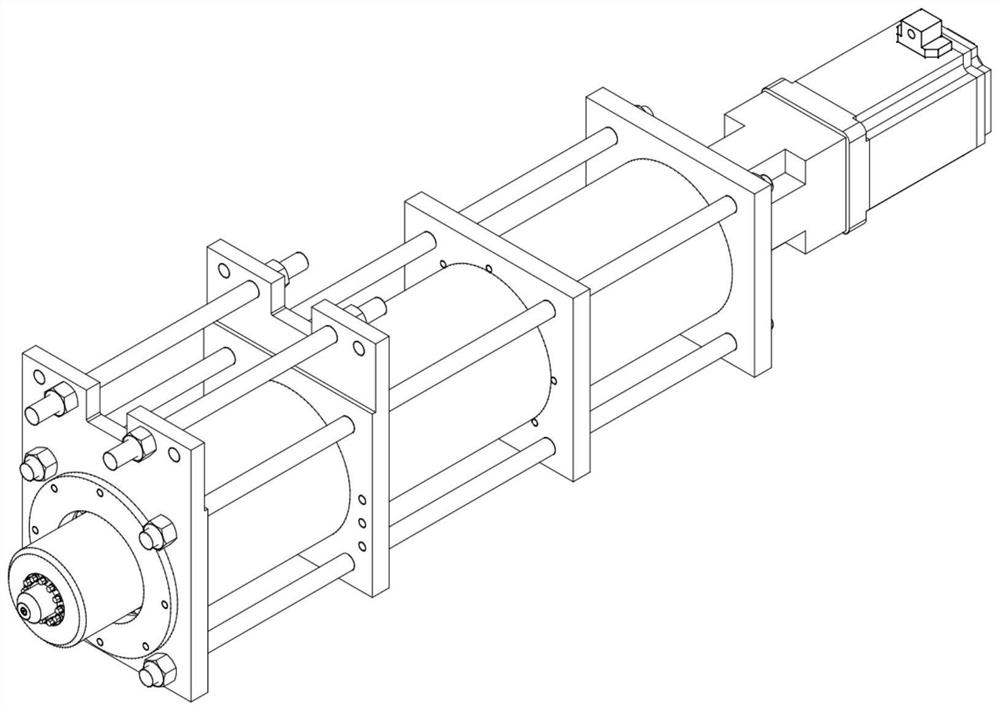

Wire winding mechanism and method of wire cutting machine

InactiveCN103949736AReliable structureLow manufacturing costElectrical-based machining electrodesWire cuttingEngineering

The invention discloses a wire winding mechanism and a wire winding method of a wire cutting machine. The wire winding mechanism comprises a base plate, a wire storage barrel, a first guide wheel, a second guide wheel, a third guide wheel, a fourth guide wheel and a wire electrode, wherein a guide rail device, a pulley block tensioning device, a tension stroke indicating plate and a pointer are arranged on the base plate; the pulley block tensioning device comprises a balancing weight, a fixed pulley block, a movable pulley block, a movable pulley block fixed plate and a guide rail device limit block; the guide rail device comprise a guide rail and a sliding block; the fixed pulley block, the guide rail, the tension stroke indicating plate and the guide rail device limit block are fixed to the bottom plate; the movable pulley block, the balancing weight and the pointer are fixed to the movable pulley block fixed plate; the movable pulley block fixed plate is fixed to the sliding block of the guide rail device; the sliding block is fixed to the guide rail and slides along the guide rail; the guide rail device limit block is arranged at the tail end of the lower part of the guide rail. The wire winding mechanism and the wire winding method of the wire cutting machine have the advantages that the structure is simple, the manufacturing is simple, the cost is lower, the machining precision and the processing efficiency of wire cutting are better improved, and the economic benefits are higher.

Owner:ZHEJIANG SCI-TECH UNIV

Mobile multi-stage hydraulic transmission air-supply spray dust suppression vehicle

ActiveCN103786628BImprove spray distanceIncrease speedSpraying vehiclesLiquid spraying apparatusFar distanceWater storage tank

Owner:PINGAN ELECTRICAL

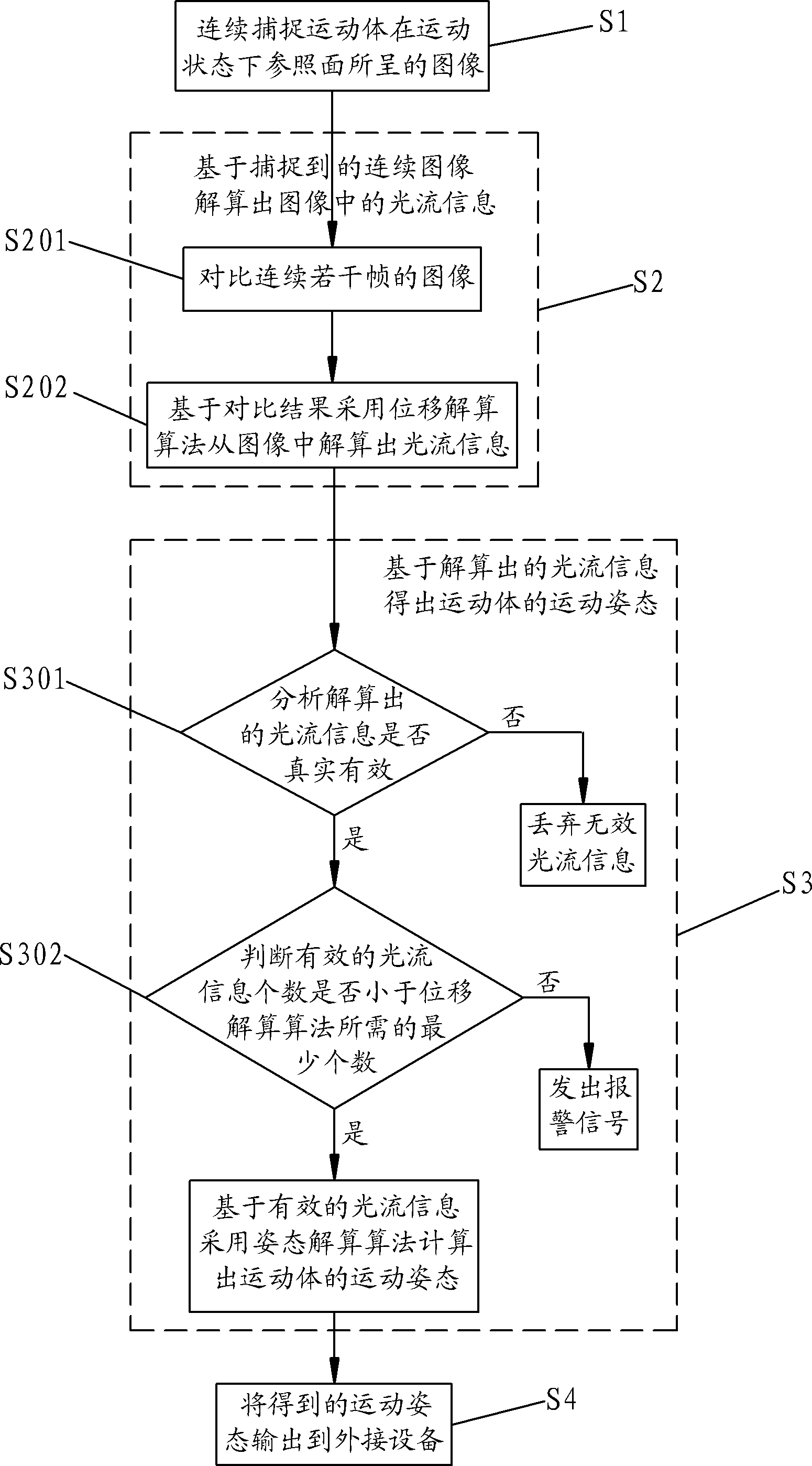

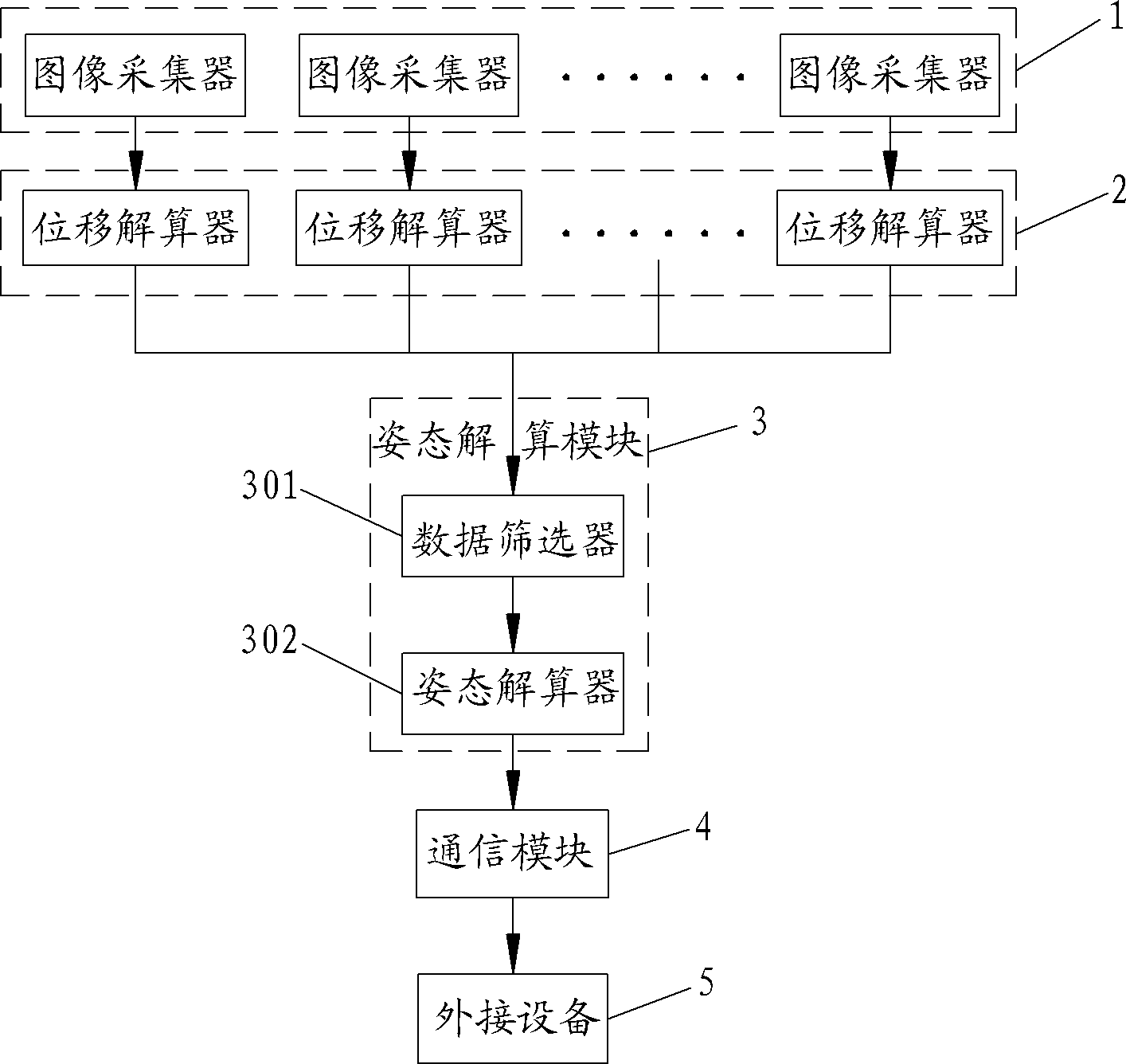

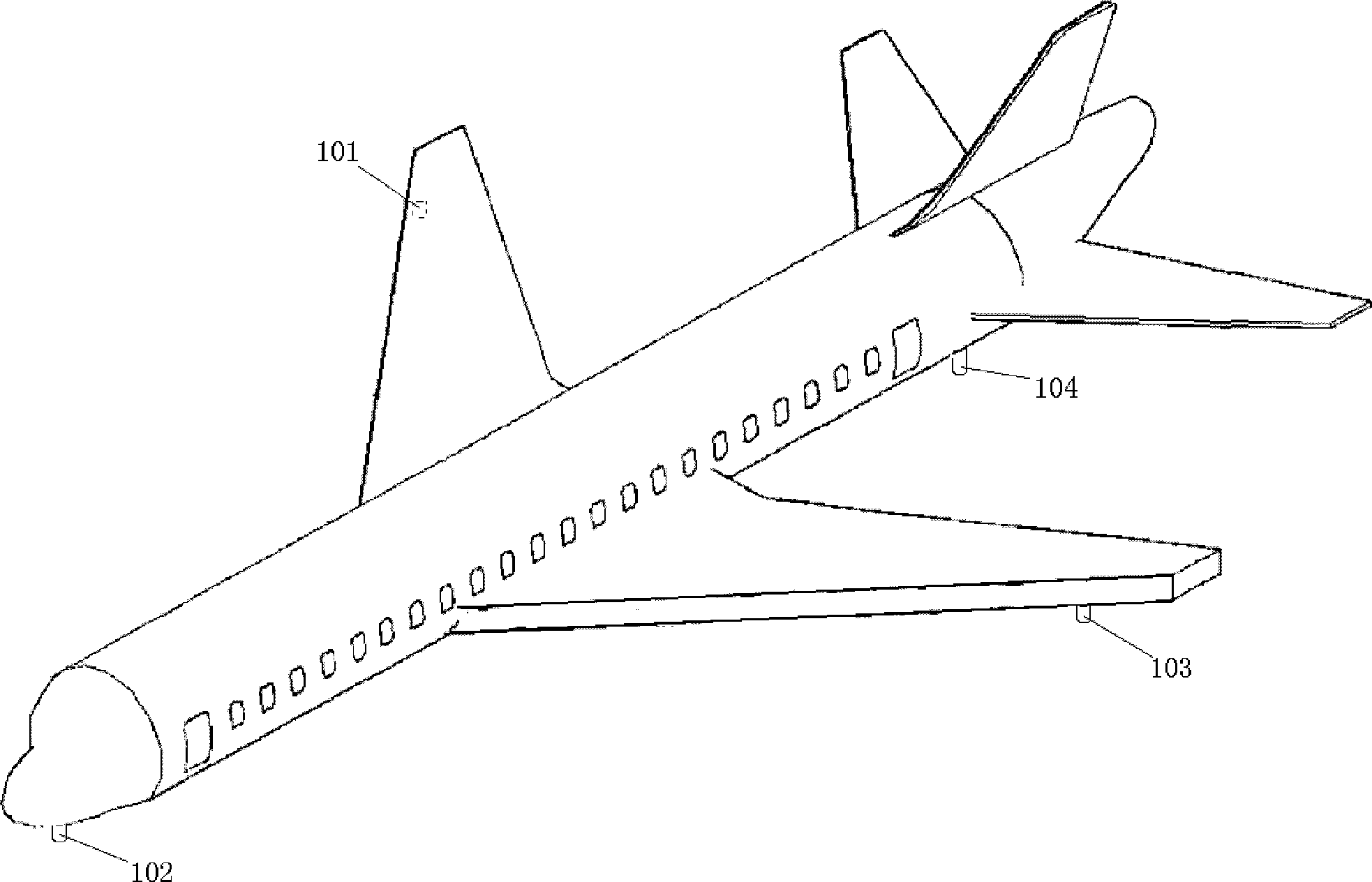

Method and system for sensing motion gestures of moving body

InactiveCN102654917BReduce computational complexitySusceptible to interferenceImage analysisJet aeroplaneTerrain

Owner:TSINGHUA UNIV

A capacitive pressure sensor

ActiveCN110823442BImprove work efficiencyAvoid warpingFluid pressure measurement by electric/magnetic elementsCapacitive pressure sensorSilicone oil

The invention relates to the technical field of electronic devices, and discloses a capacitive pressure sensor, which includes a housing, a diaphragm is fixedly connected to the bottom of the housing, and an O-ring is fixedly connected to the inner wall of the bottom of the housing. A baffle is placed on one side of the diaphragm, an arc-shaped plate is fixedly connected to the bottom of the baffle, and a transfer film is fixedly connected to the outside of the baffle, and liquid is filled between the diaphragm and the transfer film. The capacitive pressure sensor uses silicone oil to make the transfer film and the arc plate have a certain distance, and the silicone oil transmits the force received by the transfer film to the diaphragm, and converts the deformation of the diaphragm into the displacement of the transfer film. The distance between the plate and the transmission film is used to control the deformation of the diaphragm. When the pressure reaches the maximum upper limit of the diaphragm, the transmission film and the arc-shaped plate fit together, and the baffle distributes the force to the shell to prevent the diaphragm from being damaged due to pressure. Exceeding the bearing capacity produces fracture events, thereby improving the overload resistance of the overall device.

Owner:东台市高科技术创业园有限公司

A wire-feeding mechanism and method for a wire-cutting machine

InactiveCN103949736BThe overall structure is simple and reliableReduce manufacturing costElectrical-based machining electrodesBlock and tackleWire cutting

The invention discloses a wire winding mechanism and a wire winding method of a wire cutting machine. The wire winding mechanism comprises a base plate, a wire storage barrel, a first guide wheel, a second guide wheel, a third guide wheel, a fourth guide wheel and a wire electrode, wherein a guide rail device, a pulley block tensioning device, a tension stroke indicating plate and a pointer are arranged on the base plate; the pulley block tensioning device comprises a balancing weight, a fixed pulley block, a movable pulley block, a movable pulley block fixed plate and a guide rail device limit block; the guide rail device comprise a guide rail and a sliding block; the fixed pulley block, the guide rail, the tension stroke indicating plate and the guide rail device limit block are fixed to the bottom plate; the movable pulley block, the balancing weight and the pointer are fixed to the movable pulley block fixed plate; the movable pulley block fixed plate is fixed to the sliding block of the guide rail device; the sliding block is fixed to the guide rail and slides along the guide rail; the guide rail device limit block is arranged at the tail end of the lower part of the guide rail. The wire winding mechanism and the wire winding method of the wire cutting machine have the advantages that the structure is simple, the manufacturing is simple, the cost is lower, the machining precision and the processing efficiency of wire cutting are better improved, and the economic benefits are higher.

Owner:ZHEJIANG SCI-TECH UNIV

Four-motor direct drive type alternating current servo punching and riveting device and punching and riveting machine for friction stir rivet welding of multiple layers of plates

ActiveCN113458584AImprove air tightnessReduce airtightnessNon-electric welding apparatusStampingElectric machine

The invention relates to a four-motor direct drive type alternating current servo punching and riveting device for friction stir rivet welding of multiple layers of plates. The four-motor direct drive type alternating current servo punching and riveting device comprises a stirring sleeve rotating system, a stirring needle rotating system, a stirring needle punching system and a stirring head system. A rotor of a first torque motor directly drives a stirring sleeve chuck through a first hollow main shaft so as to realize rotary motion; a bearing sleeve is used for axially driving an ejector pin; the stirring needle rotating system comprises a first alternating current servo motor and a spline shaft; the alternating-current servo motor drives the spline shaft, and the spline shaft is connected with the ejector pin through a spline pair to achieve rotation of the ejector pin and maintain the axial freedom degree of the ejector pin. According to the four-motor direct drive type alternating current servo punching and riveting device, any cooperation of stirring sleeve rotation, stirring needle rotation and stirring needle stamping can be achieved, a keyhole withdrawing defect left by the friction stir spot welding process can be overcome, mechanical combination is added on the basis of metallurgical combination, and a rivet welding connection point which is high in connection strength, good in appearance quality and tight in connection can be obtained.

Owner:XI AN JIAOTONG UNIV

Friction stir forging additive manufacturing method and device for nano-reinforced matrix composites

ActiveCN111804910BImprove performanceEfficient Quality Additive ManufacturingAdditive manufacturing apparatusTransportation and packagingMechanical engineeringIsothermal forging

The invention relates to a friction stir forging additive manufacturing device for nano-reinforced matrix composite materials, comprising four parts: a friction stir additive spindle, an isothermal forging mechanism, a gantry-type frame and a worktable; the friction stir additive spindle is used to realize powder or Mixing, preheating and feeding of granular materials, and friction extruding the material output from the feeding hole, using friction heat and pressure to achieve layer-by-layer additive manufacturing on the substrate; isothermal forging mechanism is used to realize additive manufacturing. Isothermal forging and micro-shaping of layers; gantry frame is used to fix the friction stir spindle and isothermal forging mechanism and realize the feed and swing angle adjustment of the friction stir spindle and isothermal forging mechanism along the Y and Z axes; the worktable is used for fixing The base body and the realization of the feed of the base body along the X axis. The invention can realize high-efficiency and high-quality additive manufacturing of light alloy powder or granular material, and has the advantages of higher efficiency, simple operation and lower energy consumption.

Owner:XI AN JIAOTONG UNIV

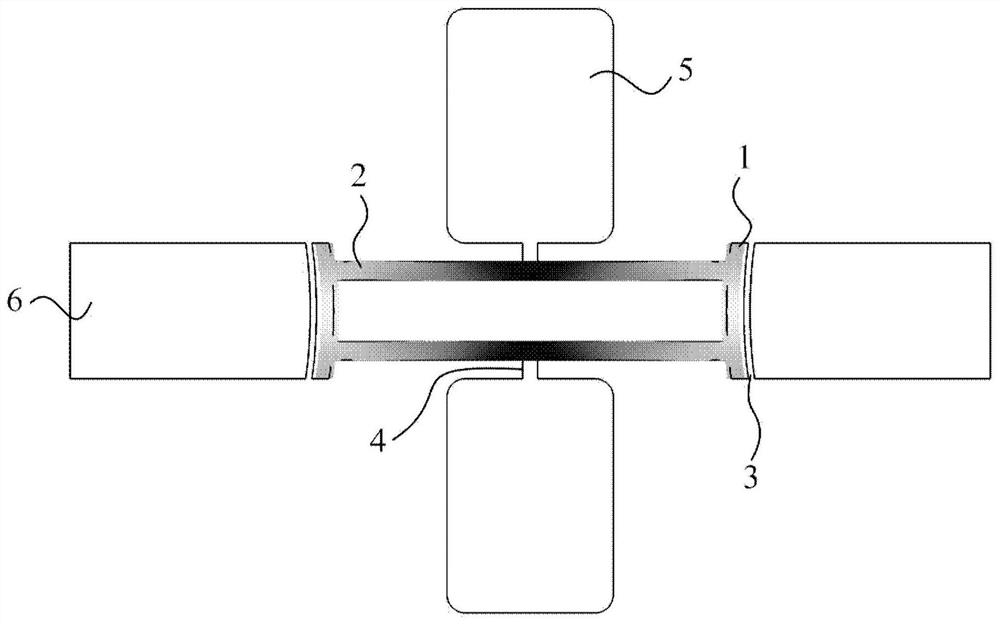

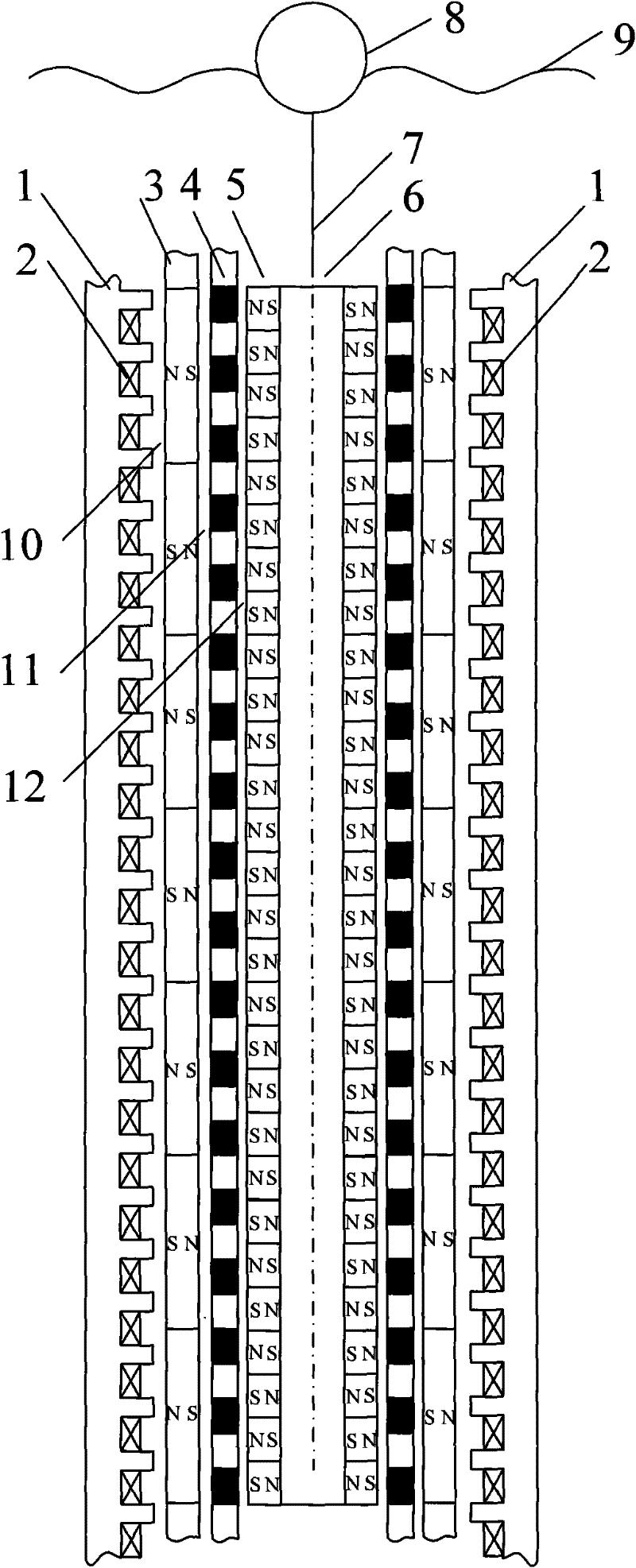

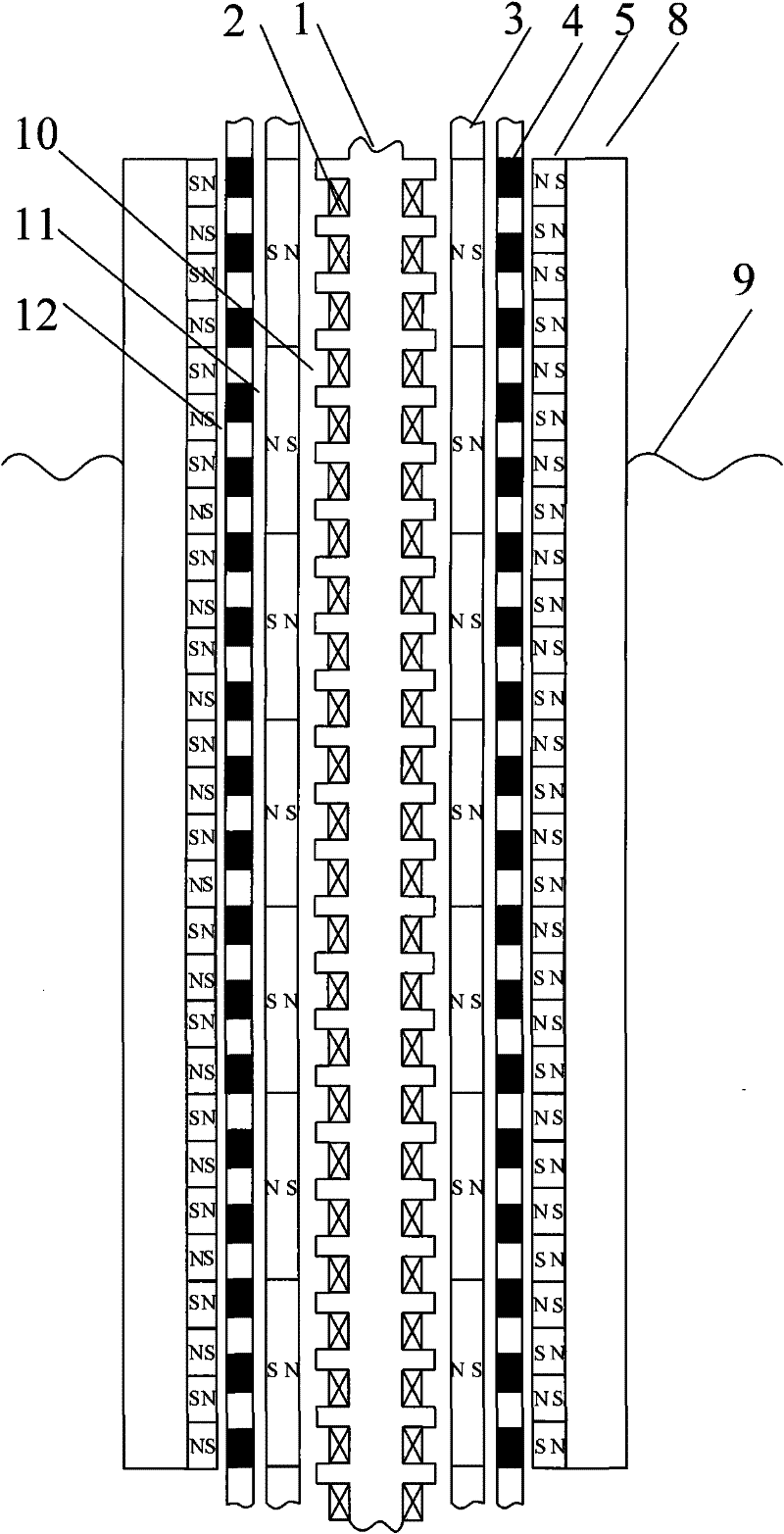

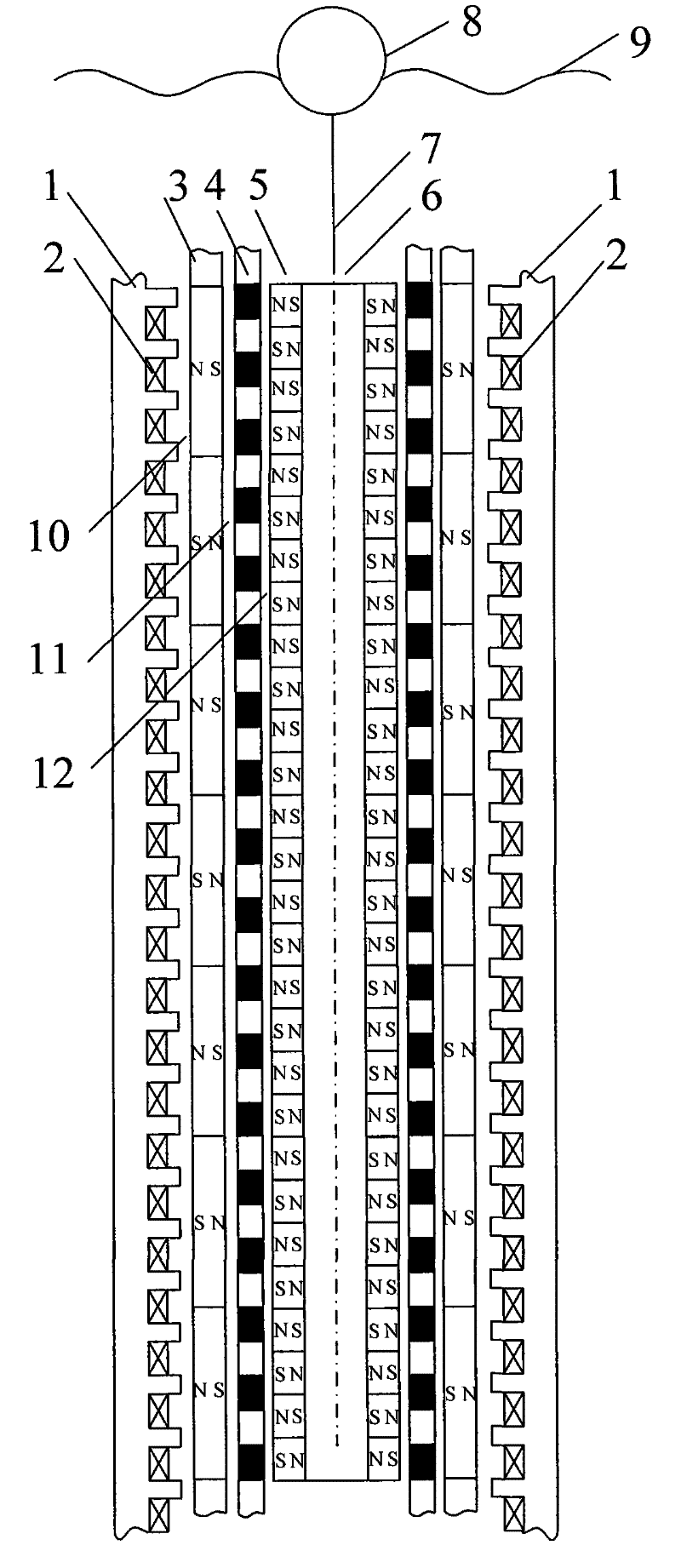

Sea wave linear motor driven by magnetic gear

ActiveCN101660481BNo pollution in the processNo noiseMachines/enginesEngine componentsLow speedElectric machine

The invention relates to a sea wave linear motor which is driven by a magnetic gear, comprising two structures which are both formed by a cylinder type permanent magnet synchronous linear motor and a cylinder type linear magnetic gear. The permanent magnet synchronous linear motor comprises a motor primary and a motor secondary, wherein, the motor primary comprises a primary iron core (1) and a primary winding (2); the primary iron core (1) is fixed at the bottom of the sea; the primary winding is embedded in a wire casing of the primary iron core; the motor secondary comprises a permanent magnet (3); the magnetic gear comprises a high speed side (3), a middle adjusting magnet ring (4), a low speed side (5) and an iron core (6); the magnetic gear high speed side is permanent magnet synchronous linear motor secondary (3); the adjusting magnet ring (4) in the middle part is fixed at the bottom of the sea; the magnetic gear low speed side comprises a permanent magnet (5) and an iron core(6) which are connected with a buoy (8) floating on the sea surface (9); an air gap (10) is arranged between the linear motor primary (1) and the linear motor secondary (3); an air gap (11) is arranged between the linear motor secondary (3) and the magnetic gear adjusting magnet ring (4); and an air gap (12) is arranged between the adjusting magnet ring (4) and the magnetic gear low speed side.

Owner:SOUTHEAST UNIV

Central transmission mud scraper of large-sized flexible rake lift

InactiveCN100546693CImproved resistance to overloadAvoid disadvantagesWater/sewage treatmentSedimentation separationEngineeringPinion

The invention discloses a large-scale flexible rake-lifting center-driven mud scraper for environmental sludge treatment, mainly composed of 2-4 cycloidal planetary gear drive devices (1) truss (2) with over-torque protection and torque display ) Inlet pipe (3) Rotating torque arm (4) Overflow weir (5) Outlet pipe (6) Articulation point (7) Center tumbler (8) Oil collector (9) Oil rake (10) Oil outlet pipe (11 ) steel wire rope (12) mud scraper (13) mud outlet (14) truss radial flow sedimentation tank (15) feeding steady flow cylinder (16) slewing support (17) pinion (18) and other components, which can realize the transmission of large The torque ensures the mud scraping effect, and the operation is efficient and stable. It is especially suitable for large radial flow sedimentation tanks with a diameter of 45 meters and above.

Owner:丹东北方环保工程有限公司

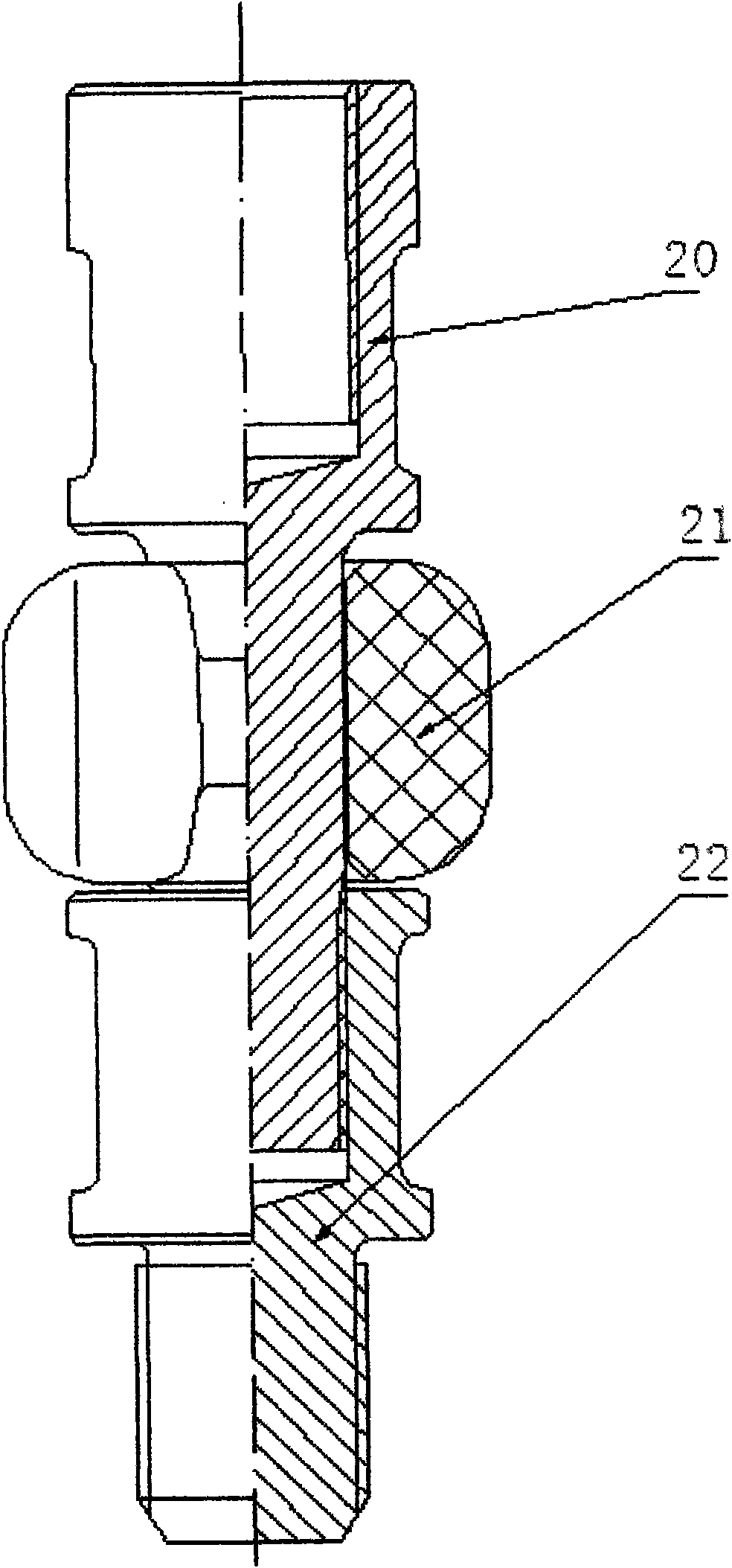

Modulation wave pumping rod electrical-heating oil extraction device

InactiveCN101629482AAvoid destructionImprove temperature riseDrilling rodsFluid removalHeating oilElectrical energy consumption

The invention relates to an oil extraction device, which is used in order to realize extraction or improve recovery when ultra-thick and ultra-high condensate crude oil occurs in the crude oil extraction process, in particular to a modulation wave pumping rod electrical-heating oil extraction device, comprising a 0 to 20Hz modulation wave power, a hollow polish rod, a hollow rod insulating short section, a sucker rod, a sucker rod coupling insulating centralizer, in / out door cables and a sliding contactor; the modulation wave pumping rod electrical-heating oil extraction device is characterized in that the lower end of the hollow polish rod is connected with the hollow rod insulating short section which consists of insulation substance infused between an outer pipe and an inner rod and staggered multi-layer inner and outer compression rings and insulation rings; the device uses the modulation wave power to supply power, has no unbalance loading and little complex pollution on grid, can transfer electrical heat on an ideal carrier, namely the sucker rod, thereby causing the crude oil to get higher and more ideal temperature rise with the same electrical energy consumption; the self reactive loss of the device is low, therefore, the device has good energy-saving effect and anti-overload ability so as to adapt to the needs of different environments.

Owner:曲健

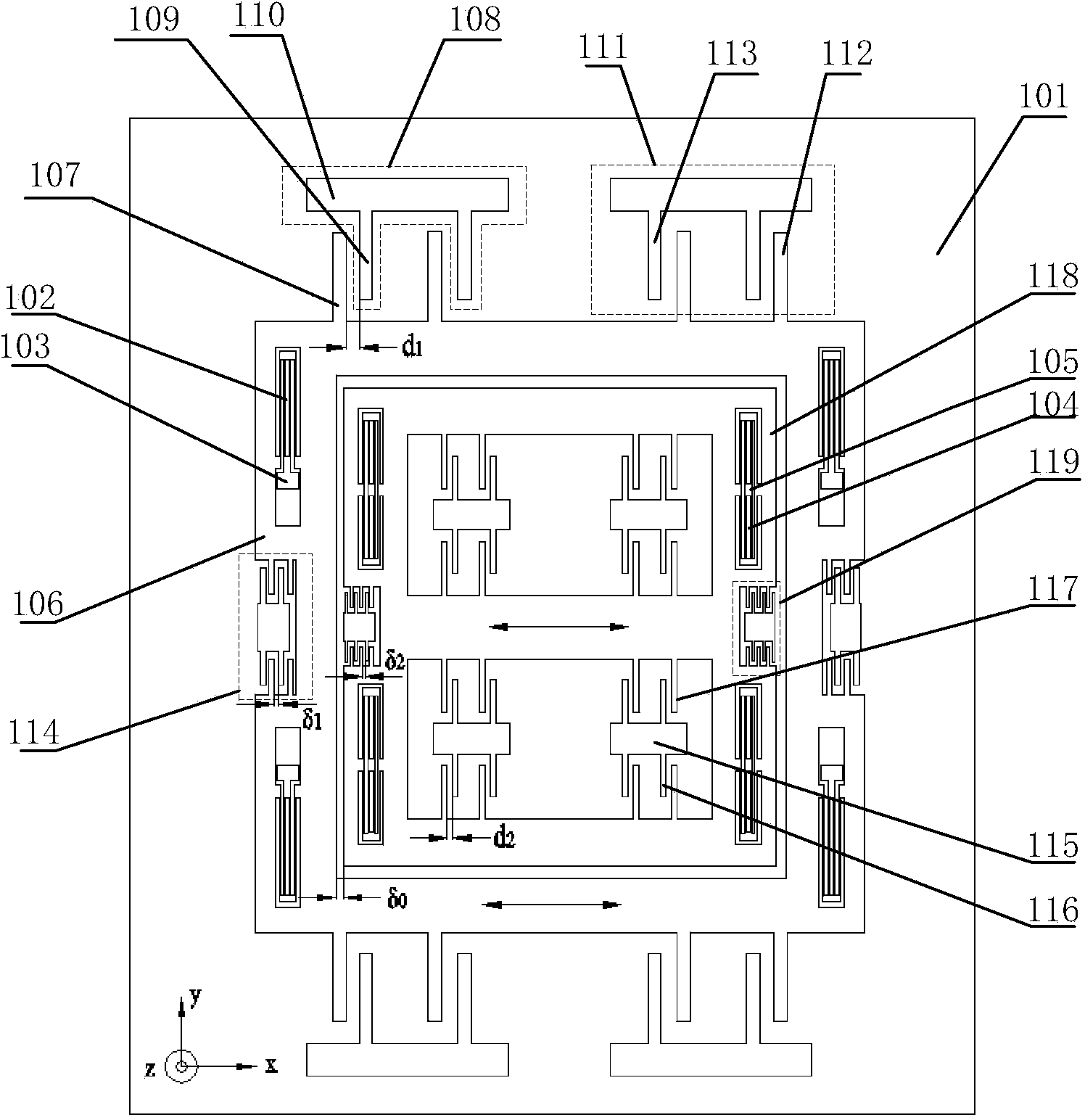

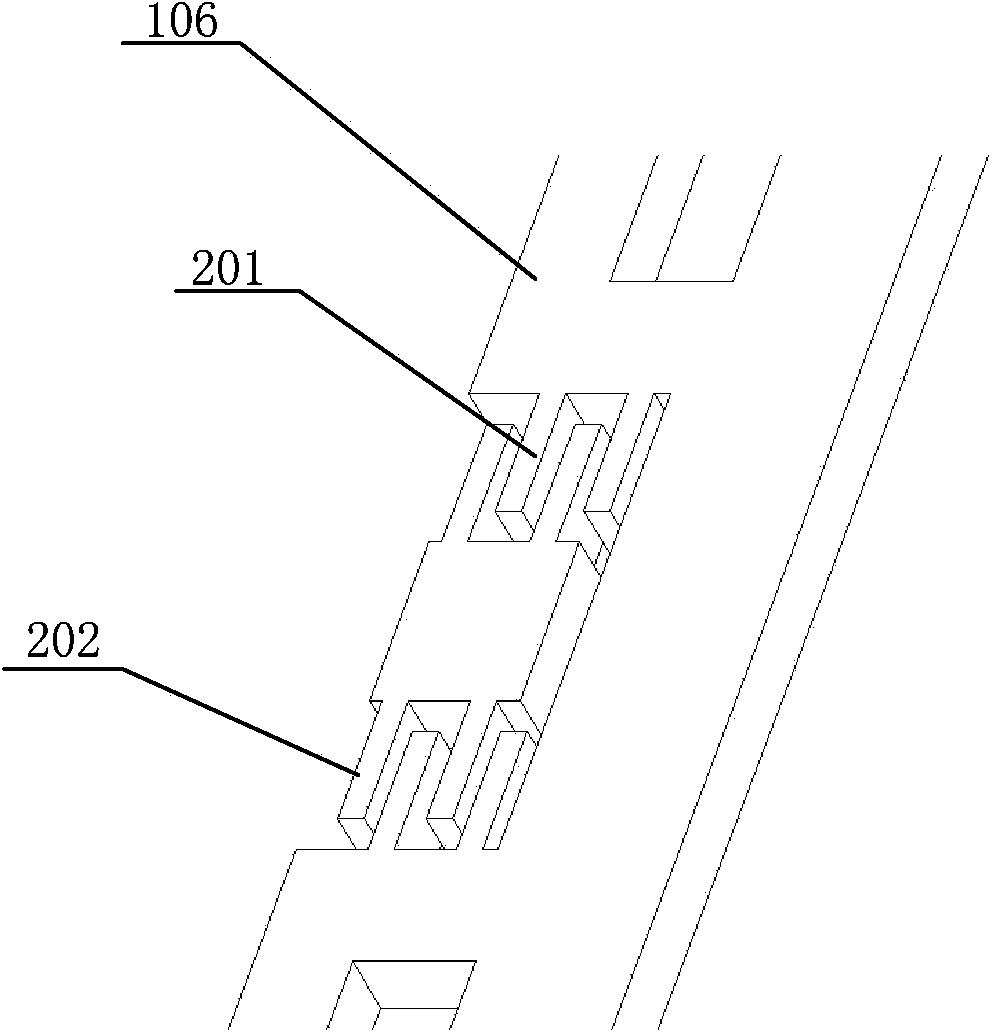

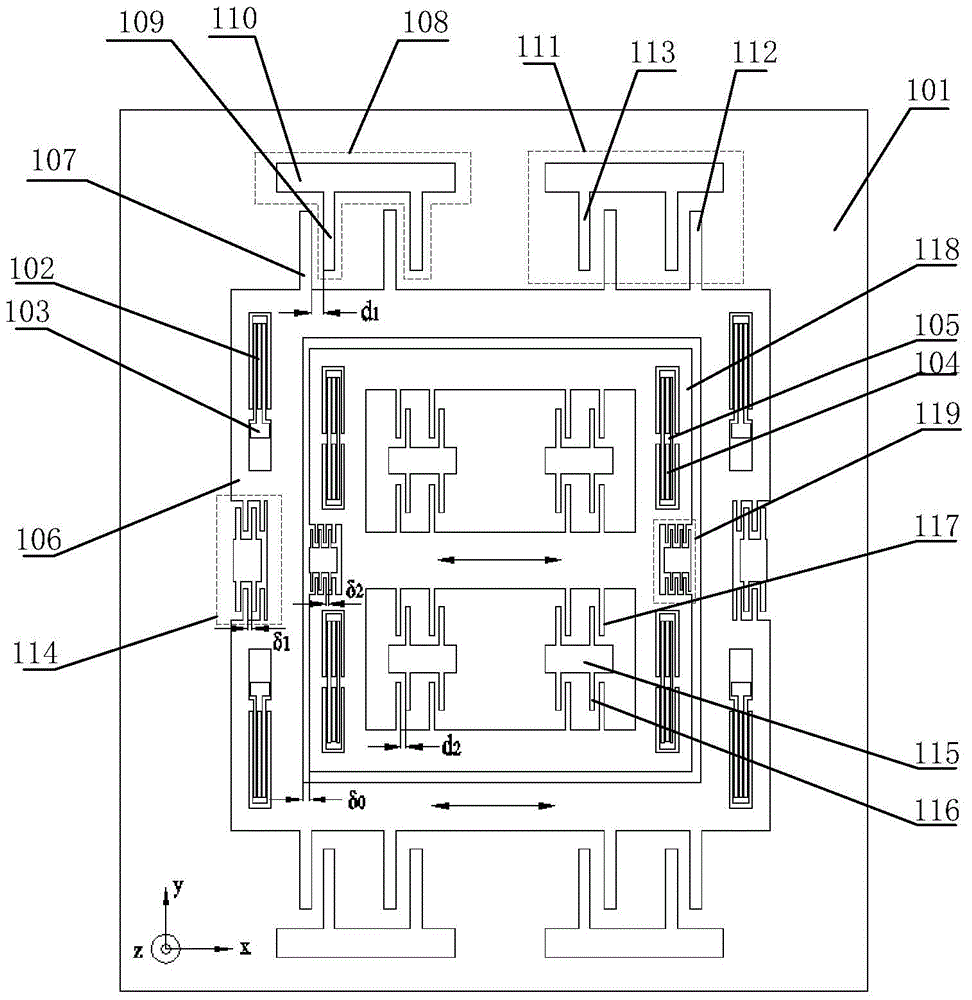

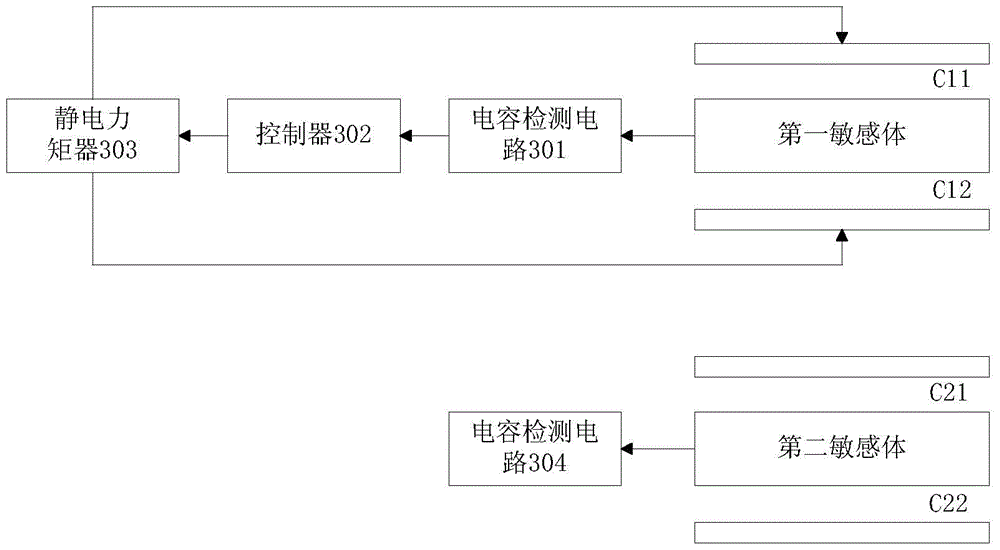

Micro machine differential capacitance accelerometer with symmetrical structure

ActiveCN101625372BFacilitate adjustment of film damping effectFacilitate high-precision detectionTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesCapacitanceAccelerometer

The invention relates to a micro machine differential capacitance accelerometer with a symmetrical structure, which is connected with a movable silicon structure component through an anchoring area along the upper direction and the lower direction. Elastic supporting beams of the silicon structure component are divided into an upper layer and a lower layer and distributed between a movable mass block and a fixedly supported frame as well as connected with the movable mass block and the fixedly supported frame; and the round angle transition is adopted at joints of the movable mass block and the fixedly supported frame as well as the beams; both the upper surface and the lower surface of the movable mass block are provided with gas flow guide grooves; and an electrode cover plate can be made of a silicon material. The gas flow guide grooves distributed on both the upper surface and the lower surface of the mass block are beneficial to regulating the squeeze-film damping effect of the accelerometer so as to structurally improve the dynamic characteristic of the surface separated capacitance detection accelerometer. A plurality of the elastic supporting beams of the accelerometer aremade of single crystal silicon materials with a single doping concentration, thereby eliminating thermal inconsistency stress caused by adopting different materials and the thermal inconsistency stress caused by different single crystal silicon doping concentrations.

Owner:安徽云芯微系统科技有限公司

A micromachined accelerometer

The invention discloses a micromechanics accelerometer which comprises a chip, connection parts, a plurality of sensitive bodies, wherein a first ligand is fixedly arranged on the chip, and the plurality of sensitive bodies are connected with the chip through corresponding connection parts. A plurality of connection parts are different in rigidity, so that the sensitive bodies can measure accelerated speeds in different ranges. The micromechanics accelerometer integrates the sensitive units which are different in ranges and are nested layer by layer, so that accelerated speeds in different ranges can be measured by corresponding sensitive units. Therefore, accuracy and precision of measurement can be increased effectively by means of the measurement mode. Furthermore, the plurality of sensitive units are nested layer by layer. Accordingly, compared with the existing accelerometer, the micromechanics accelerometer is compact in structure and small in size.

Owner:TSINGHUA UNIV

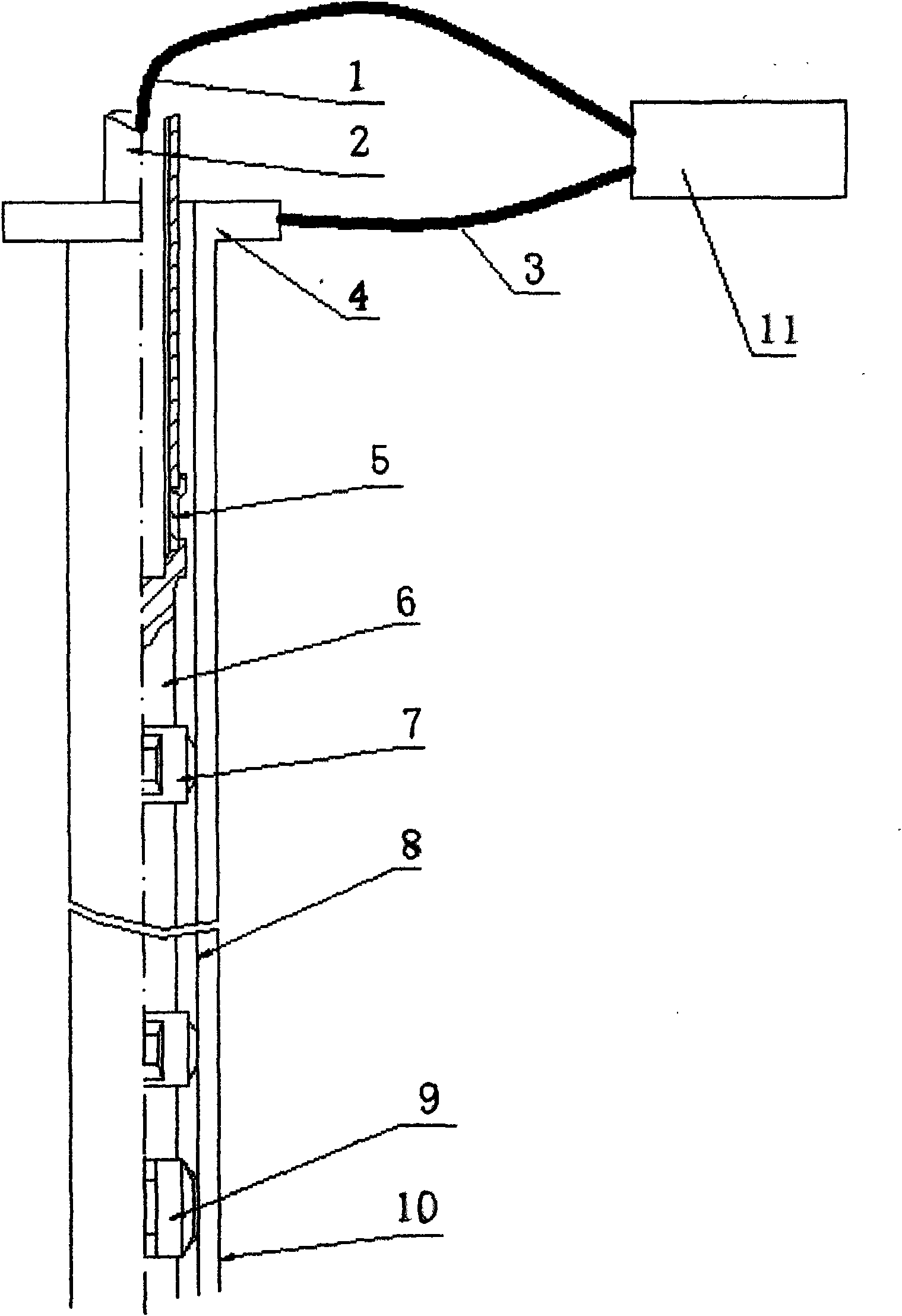

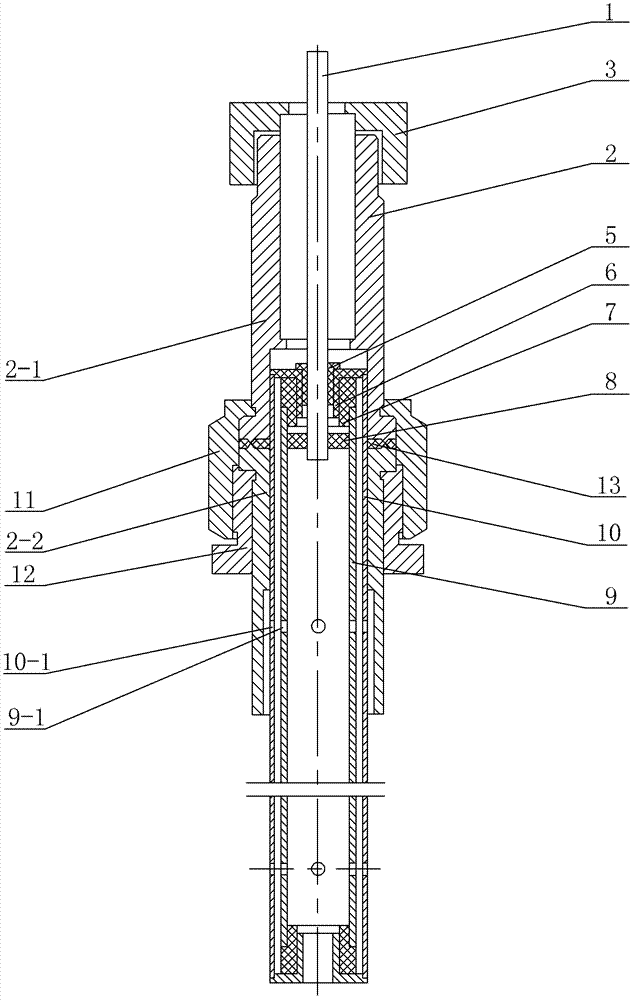

Device for measuring liquid level of liquefied natural gas cylinder

InactiveCN102606877BHigh sensitivityImprove dynamic response characteristicsContainer filling methodsContainer discharging methodsGas cylinderAcoustic wave

The invention discloses a device for measuring a liquid level of a liquefied natural gas cylinder and relates to a liquid level measuring device, in particular to a device for measuring the liquid level of the liquefied natural gas cylinder. The invention aims to solve the problems that an acoustic wave type liquid level meter is complex in structure, high in cost and difficult in maintenance and popularization and a float-type liquid level meter is easily damaged and has low reliability and high maintenance quantity. A binding post is inserted into a shell component; a first insulating sleeve is sleeved on an outer side wall of the binding post; a guide sleeve, a supporting sleeve and a second insulating sleeve are sleeved on an outer side wall of the lower part of the binding post in turn from interior to exterior; an inner tube is sleeved on the second insulating sleeve; an outer tube is sleeved on the inner tube; a plurality of first through holes are arranged on the outer side wall of the inner tube; a plurality of second through holes are arranged on the outer side wall of the outer tube; the lower end of the binding post is provided with a positioning nut; and a pressing nut is sleeved on the outer side wall of the upper end of the shell component. The device is used for measuring liquid level height change in the liquefied natural gas cylinder.

Owner:贾林祥

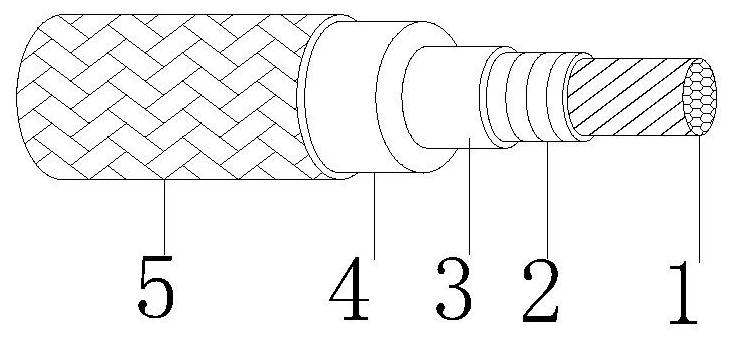

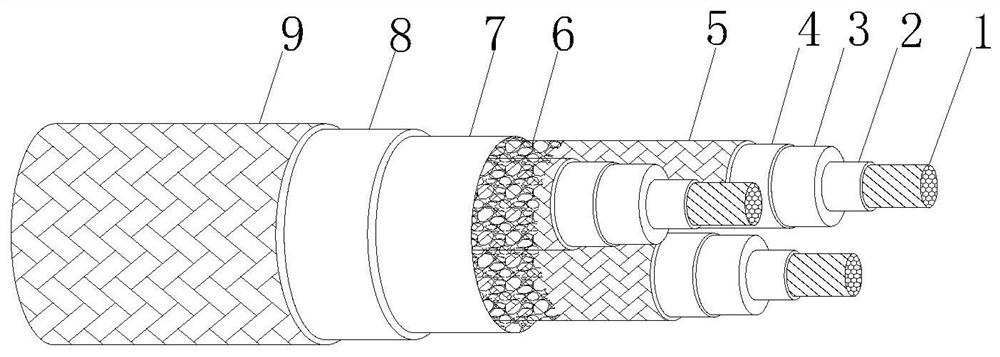

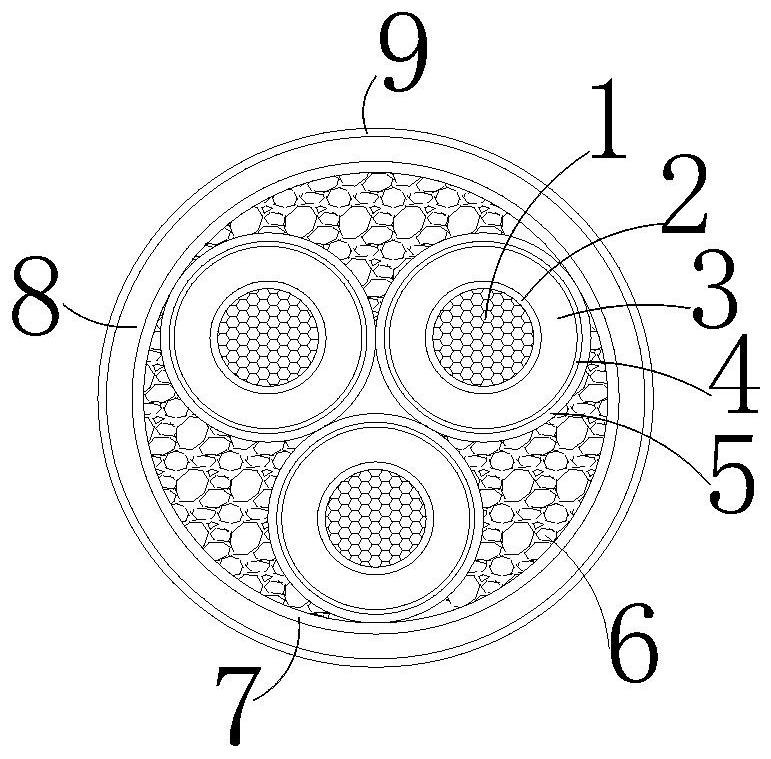

Vehicle-mounted 3KV insulated wire and cable with same

PendingCN111863340AImprove flexibilityLow mass densityPower cables with screens/conductive layersFlexible cablesElectrical conductorIn vehicle

The invention discloses a vehicle-mounted 3KV insulated wire and a cable with the same. The insulated wire comprises a flexible conductor, a semi-conductive insulating tape layer, a semi-conductive shielding layer, an insulating layer and a braided tape layer which are sequentially laminated and coated from inside to outside, wherein the insulating layer is made of a flexible high polymer materialwith withstand voltage of more than 3KV. The cable comprises a cable body formed by twisting and combining a plurality of insulated wires, wherein the outer side of the cable is sequentially coated with a silk floss non-woven fabric layer and a protective sleeve layer. The cable can adapt to various tactical vehicle-mounted mobile application occasions, can be quickly laid in a severe field operation environment, and is convenient to fold and unfold, and meanwhile, the cable has the excellent properties of flexibility, convenience in moving and dragging, oil, acid and alkali corrosion resistance, wear resistance, water resistance, salt mist resistance, ultraviolet resistance, overload resistance, high durability and the like.

Owner:广东吉青电缆实业有限公司

An anti-jamming and overload-resistant mems accelerometer

ActiveCN110568220BGuaranteed symmetryImprove anti-interference abilityAcceleration measurementAccelerometerInterference resistance

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

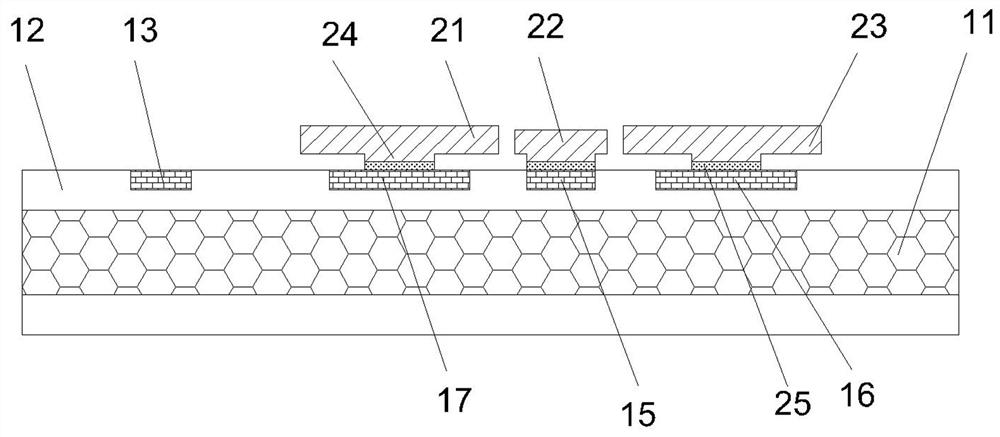

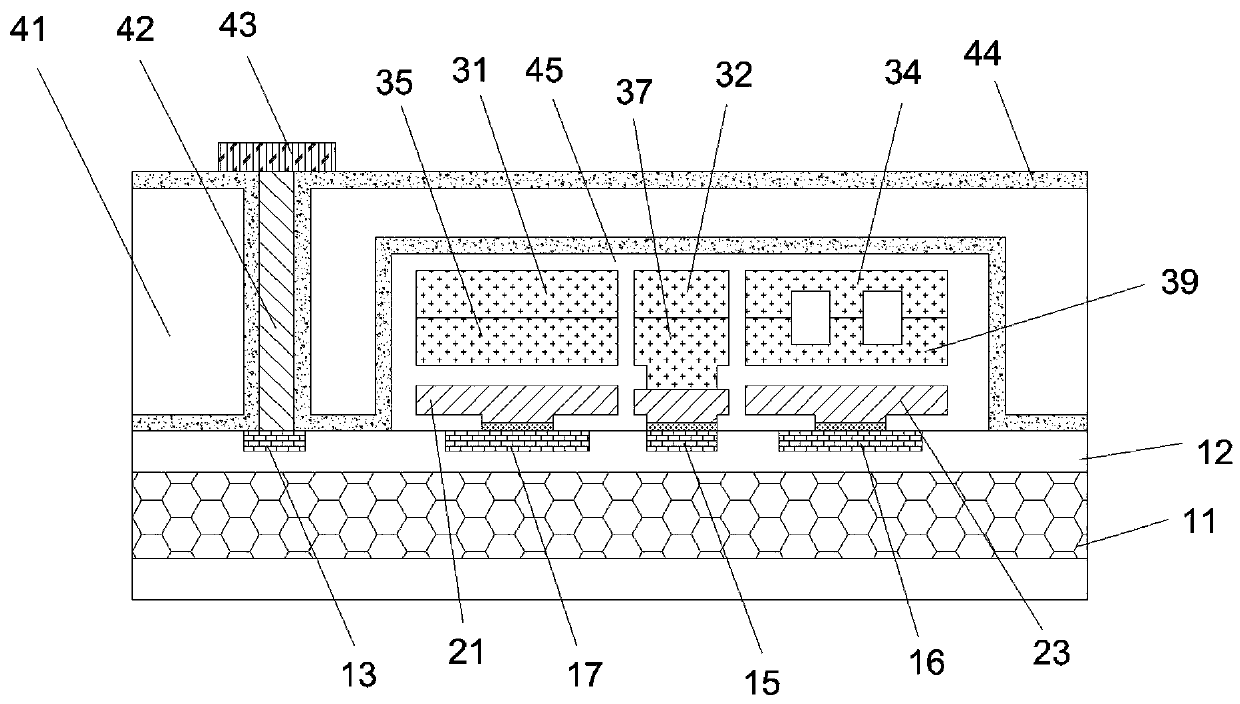

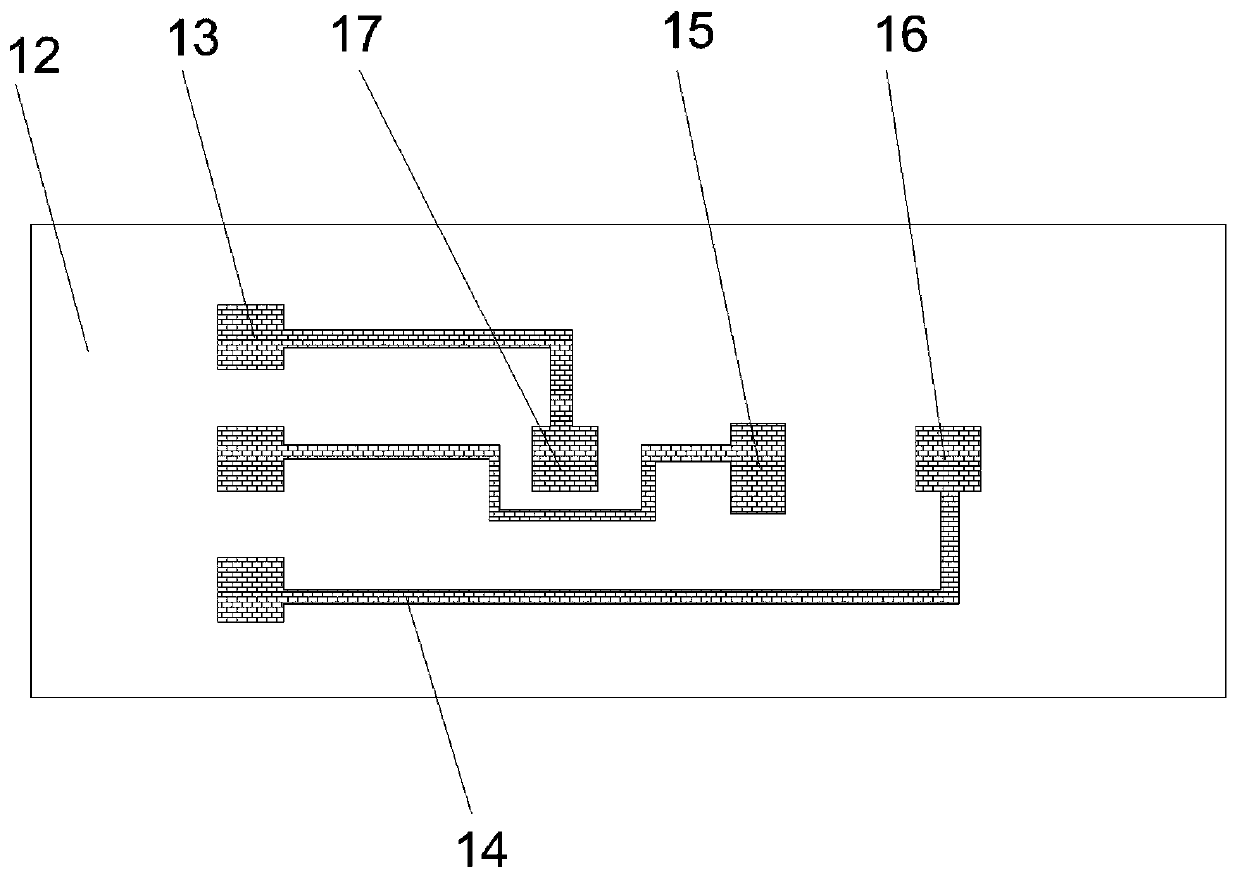

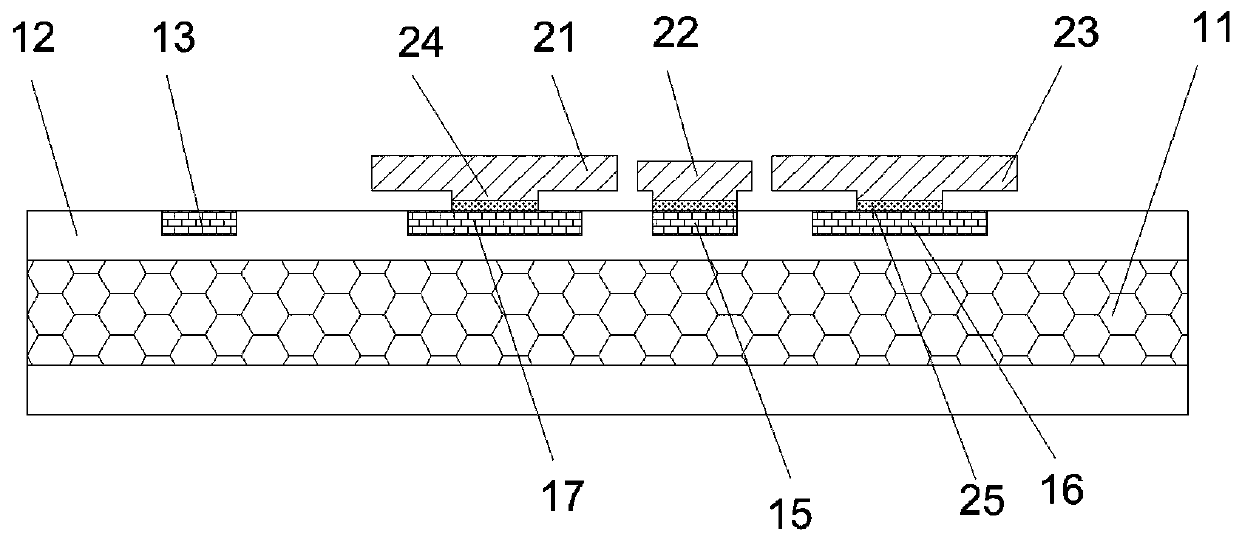

Anti-interference and overload-resistant MEMS accelerometer

ActiveCN110568220AReduce the impactGuaranteed symmetryAcceleration measurementAccelerometerAnchor point

The invention discloses an anti-interference and overload-resistant MEMS (Micro-Electro-Mechanical System) accelerometer. The accelerometer comprises a substrate layer, an induction electrode layer, amovable sensitive structure layer and a cap which are bonded in sequence. The induction electrode layer comprises an induction electrode center anchor point and induction electrodes on the two sides.The movable sensitive structure layer comprises a first movable sensitive structure center anchor point, a first solid movable sensitive structure and a first hollow movable sensitive structure. A silicon support column is arranged at the bottom of each induction electrode. The top end of each silicon support column is connected with the corresponding induction electrode, and the bottom end of each silicon support column is connected with the substrate layer. A second movable sensitive structure central anchor point, a second solid movable sensitive structure and a second hollow movable sensitive structure are respectively and symmetrically bonded above the first movable sensitive structure central anchor point, the first solid movable sensitive structure and the first hollow movable sensitive structure. A closed cavity is formed between the first hollow movable sensitive structure and the second hollow movable sensitive structure. The influence of the external environment on the performance of the device can be reduced, and the reliability of the device can be improved.

Owner:EAST CHINA INST OF OPTOELECTRONICS INTEGRATEDDEVICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com