Patents

Literature

155results about How to "Reduce airtightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air cleaner

InactiveUS20100186357A1Improve the air environmentPositive pressure effectCombination devicesMechanical apparatusAir volumeAir filter

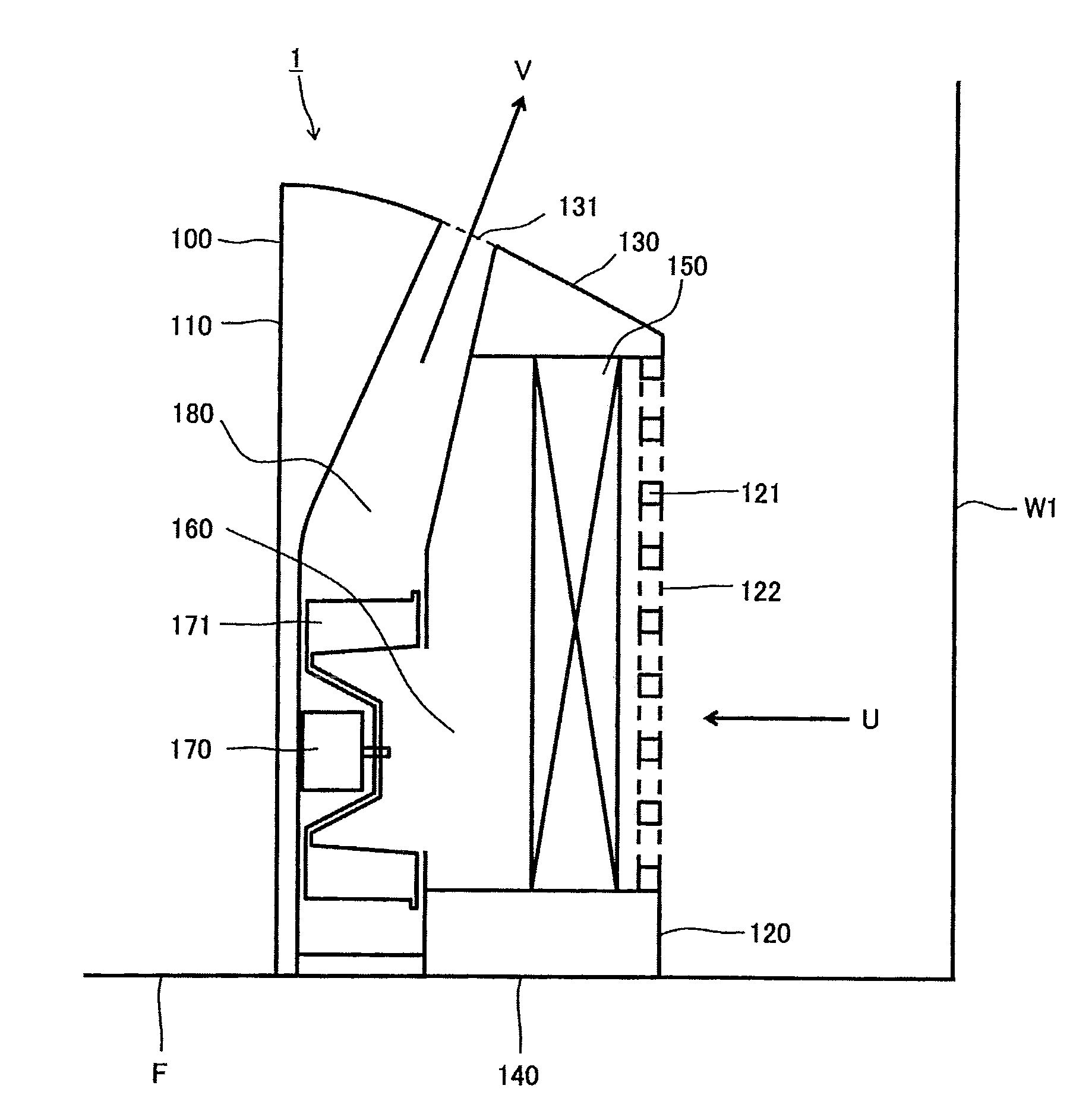

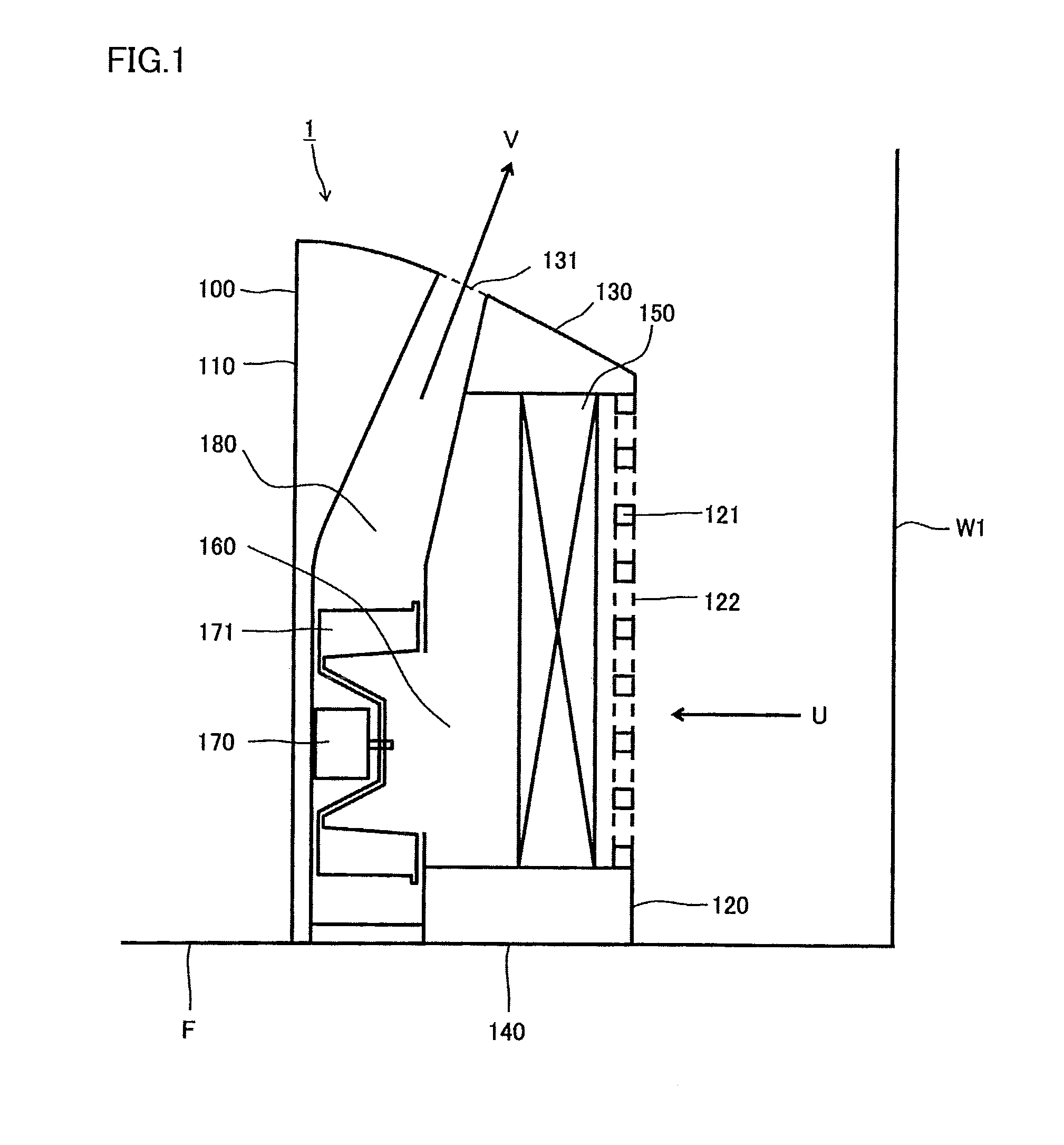

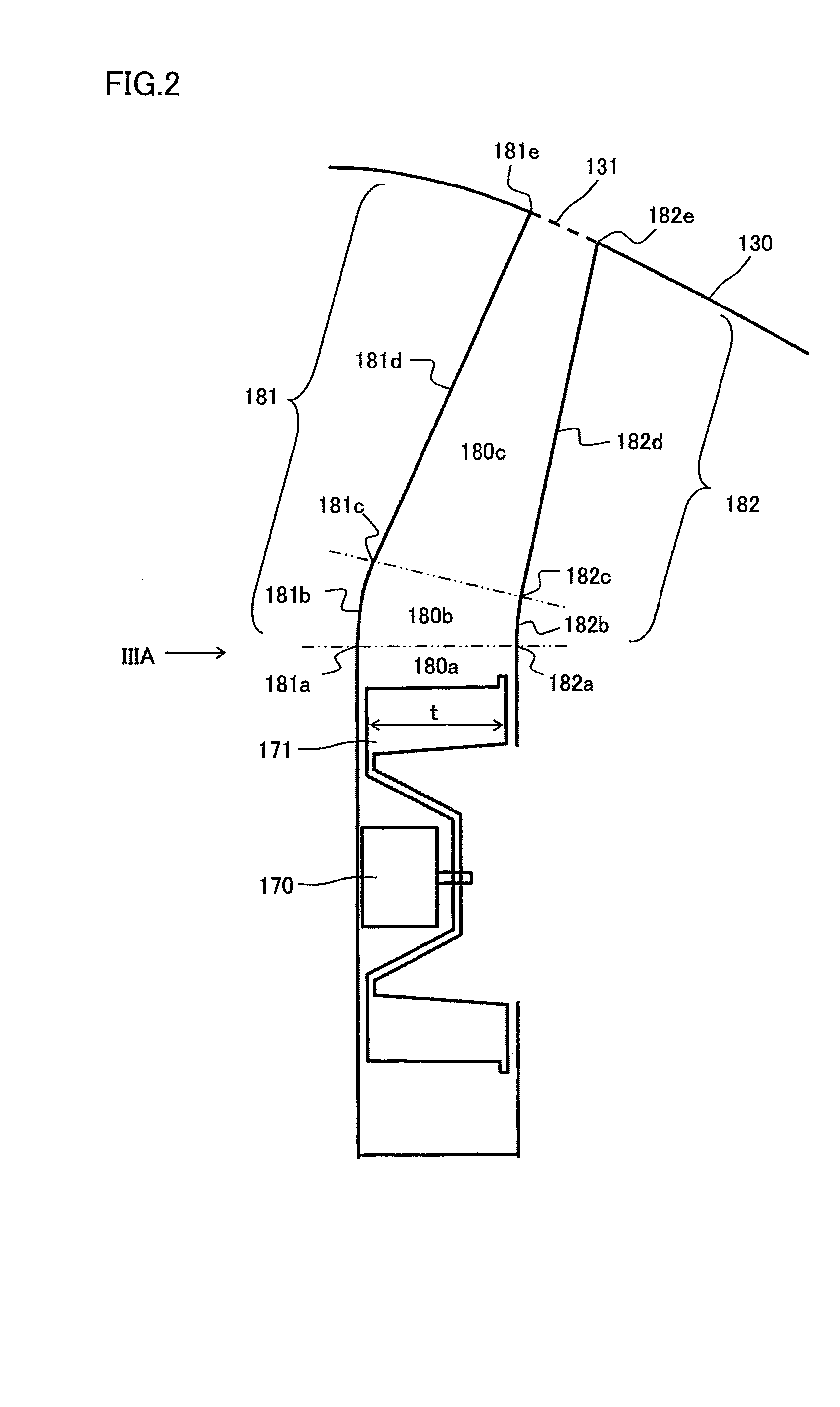

Provided is an air cleaner capable of enhancing an effect of improving an indoor air environment through enhancing an efficiency of circulating an air current without increasing an air flow volume. The air cleaner (1) is placed on a floor surface (F) and used so as to be located in the vicinity of a side wall surface (W1) of a room and comprises a suction port (122), an air filter (150), a blowout port (131), and an air blower (170). When a distance from a middle position of the blowout port (131) to the side wall surface (W1) of the room is supposed to be L [mm], a distance from the middle position of the blowout port (131) to a ceiling surface of the room is supposed to be H [mm], and the air cleaner (1) is placed and used in a position which allows the distance L to be a value selected from among values in a range of 100<L<600, in order to cause the air sent out from the blowout port (131) to first reach the side wall surface (W1) of the room, an angle θ[°] formed between a direction in which the air is sent out from the blowout port (131) and a vertically upward direction is set to be in a range of tan−1(L / H)<θ≦35.

Owner:SHARP KK

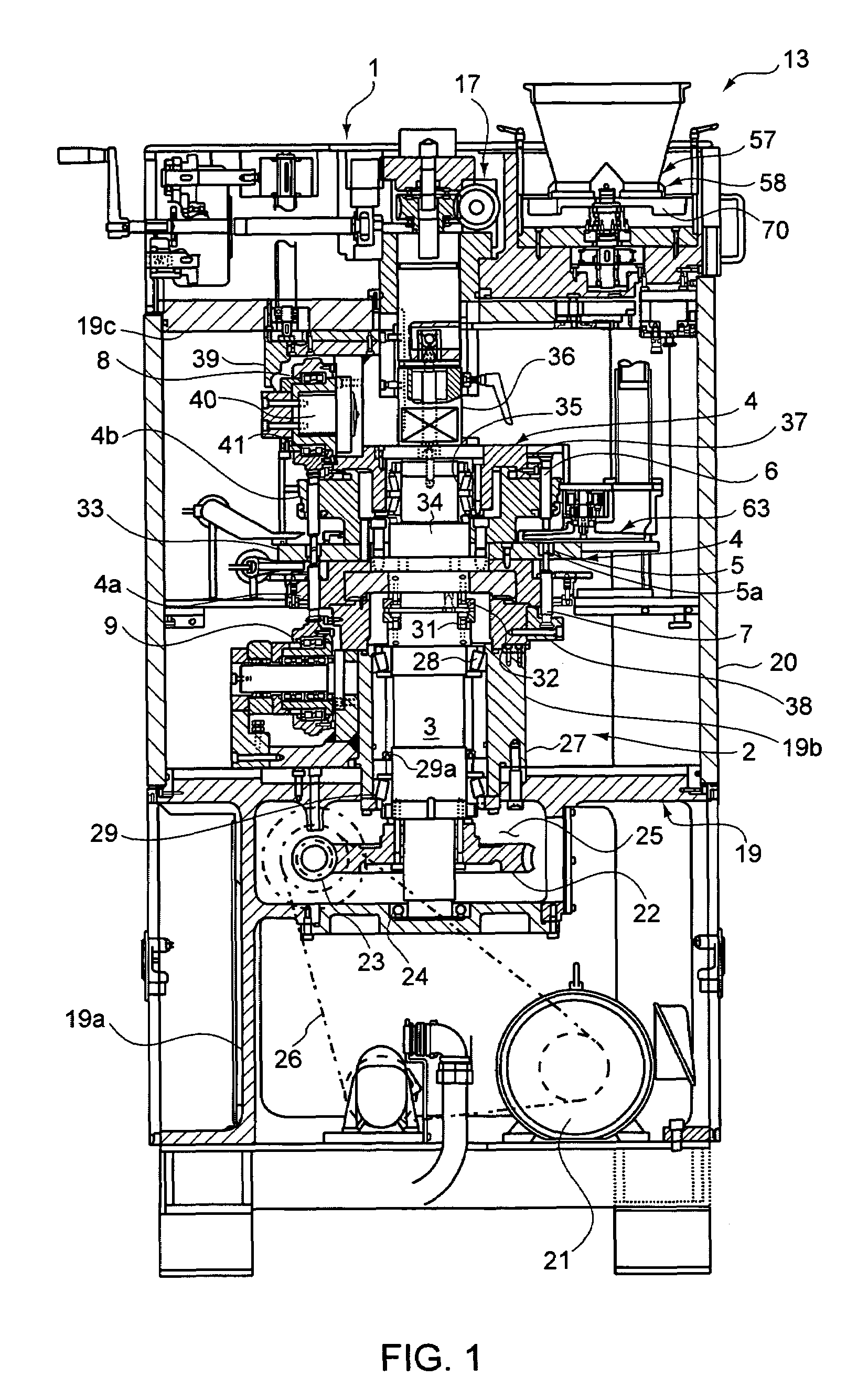

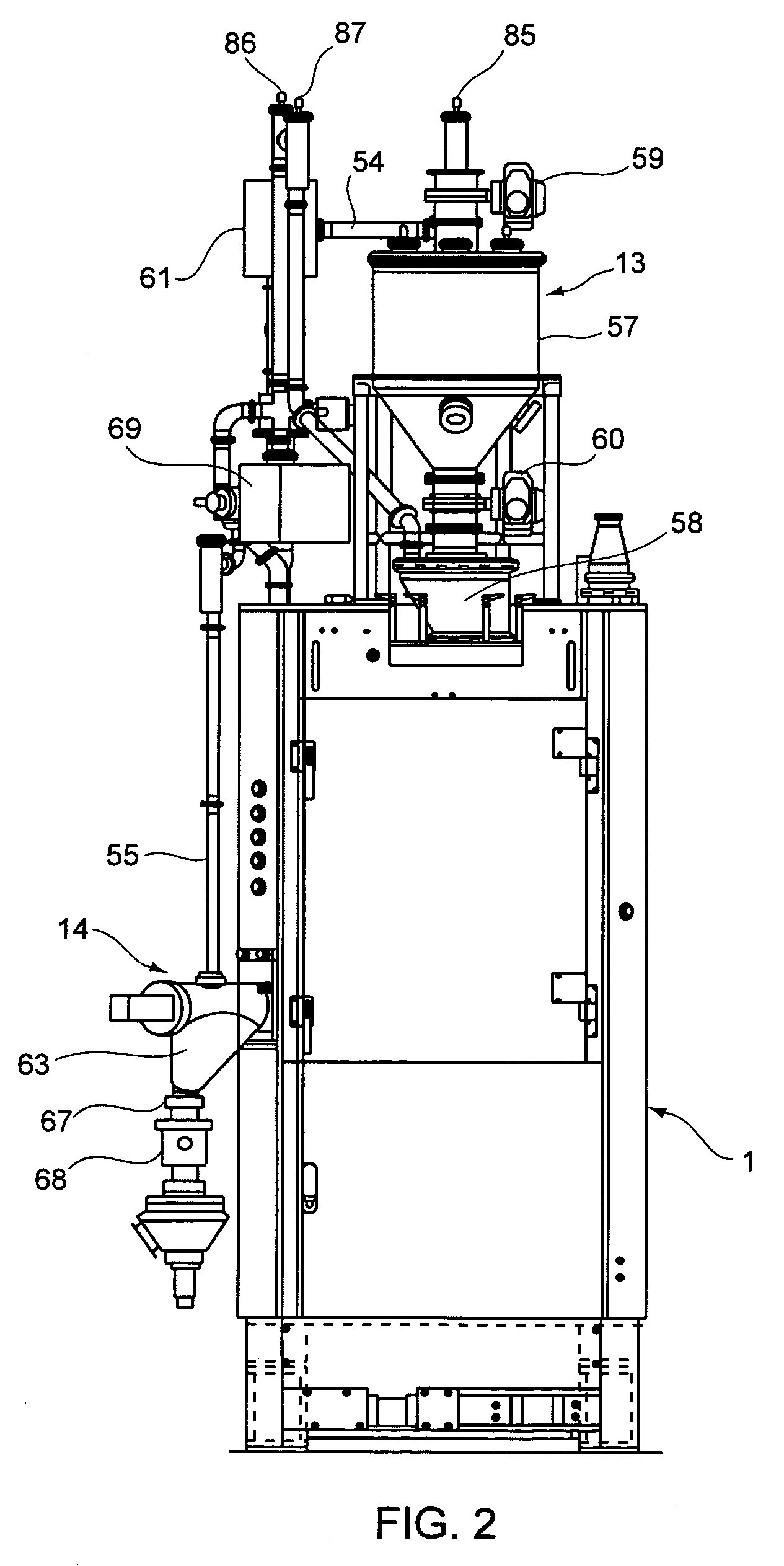

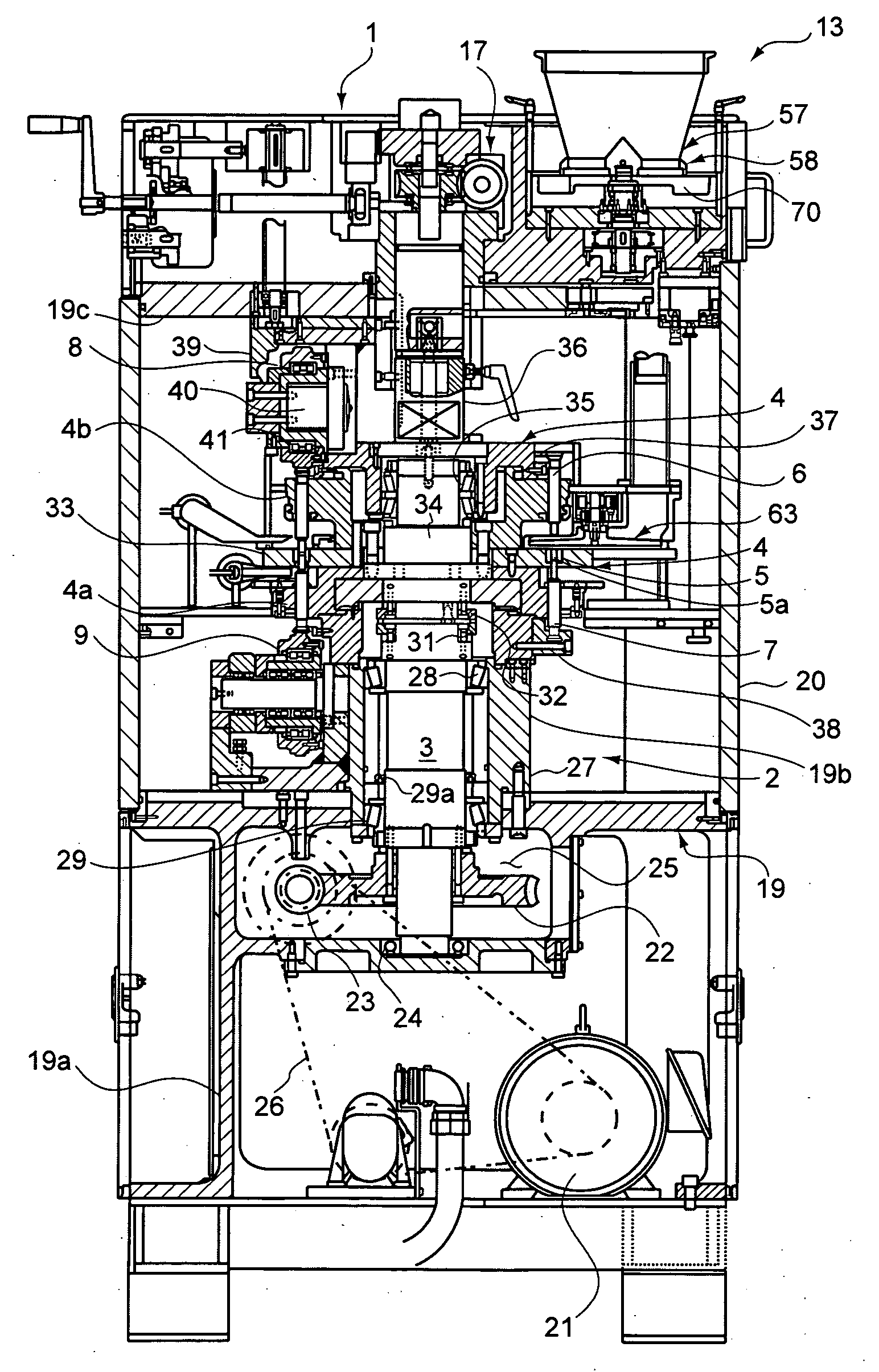

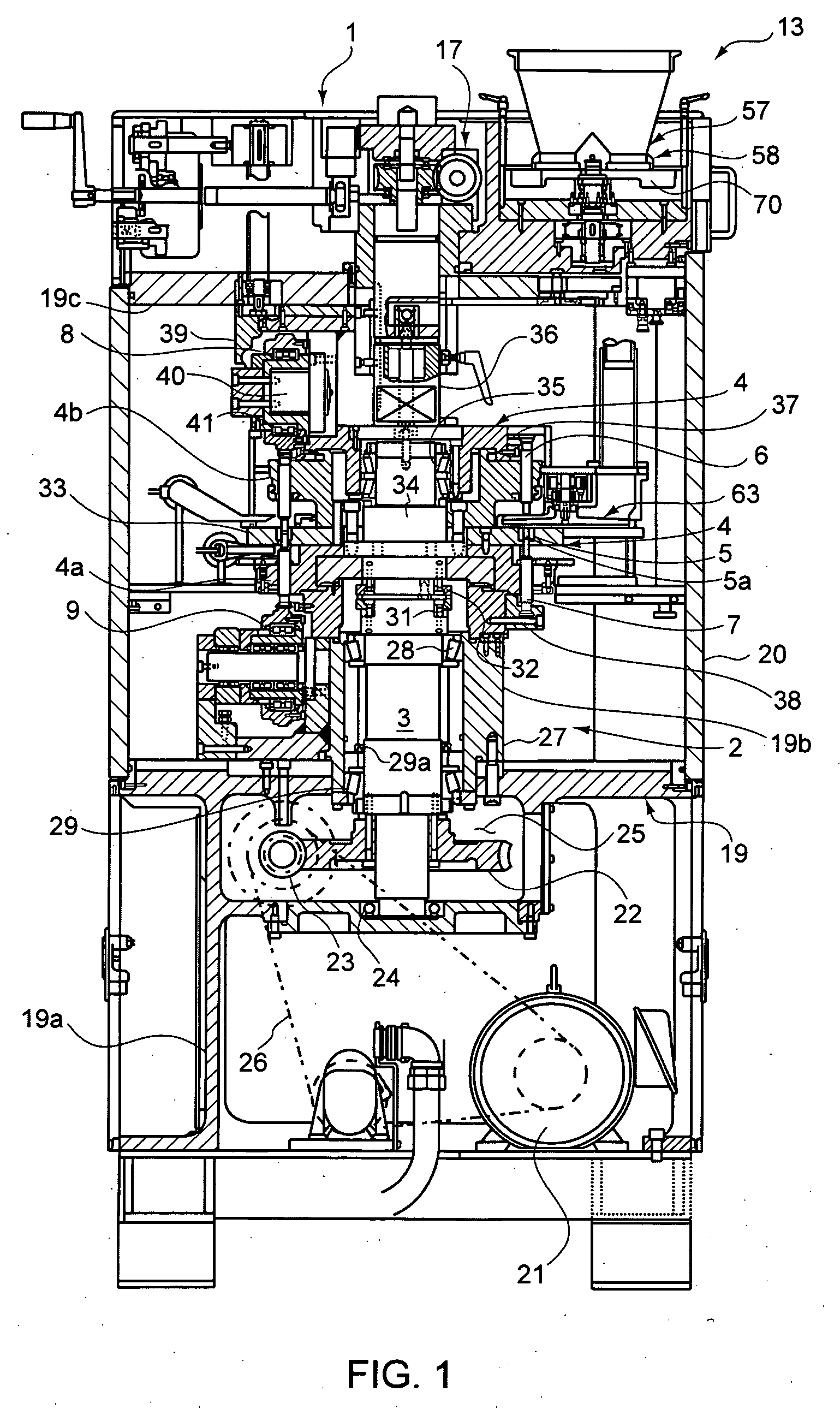

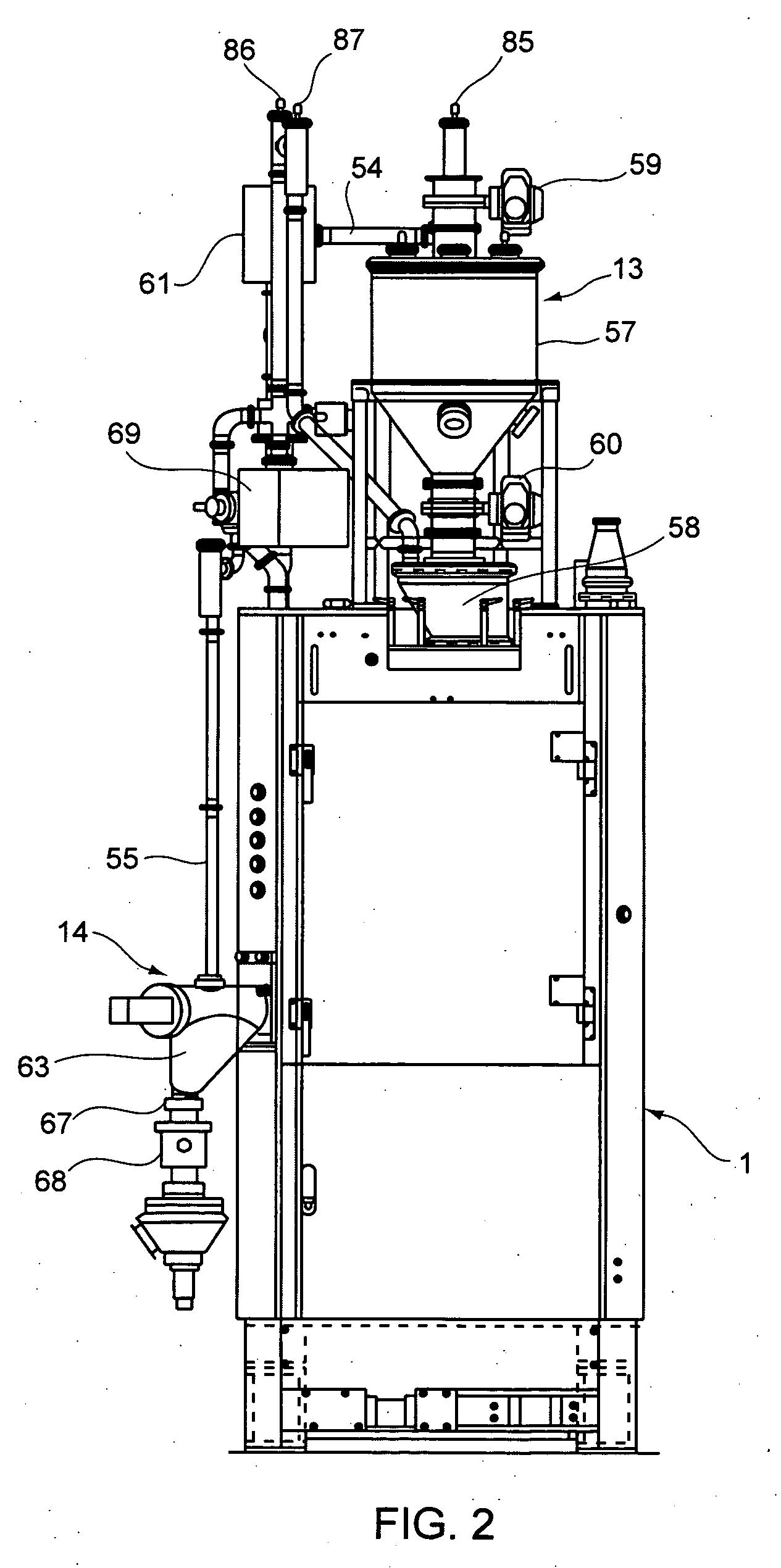

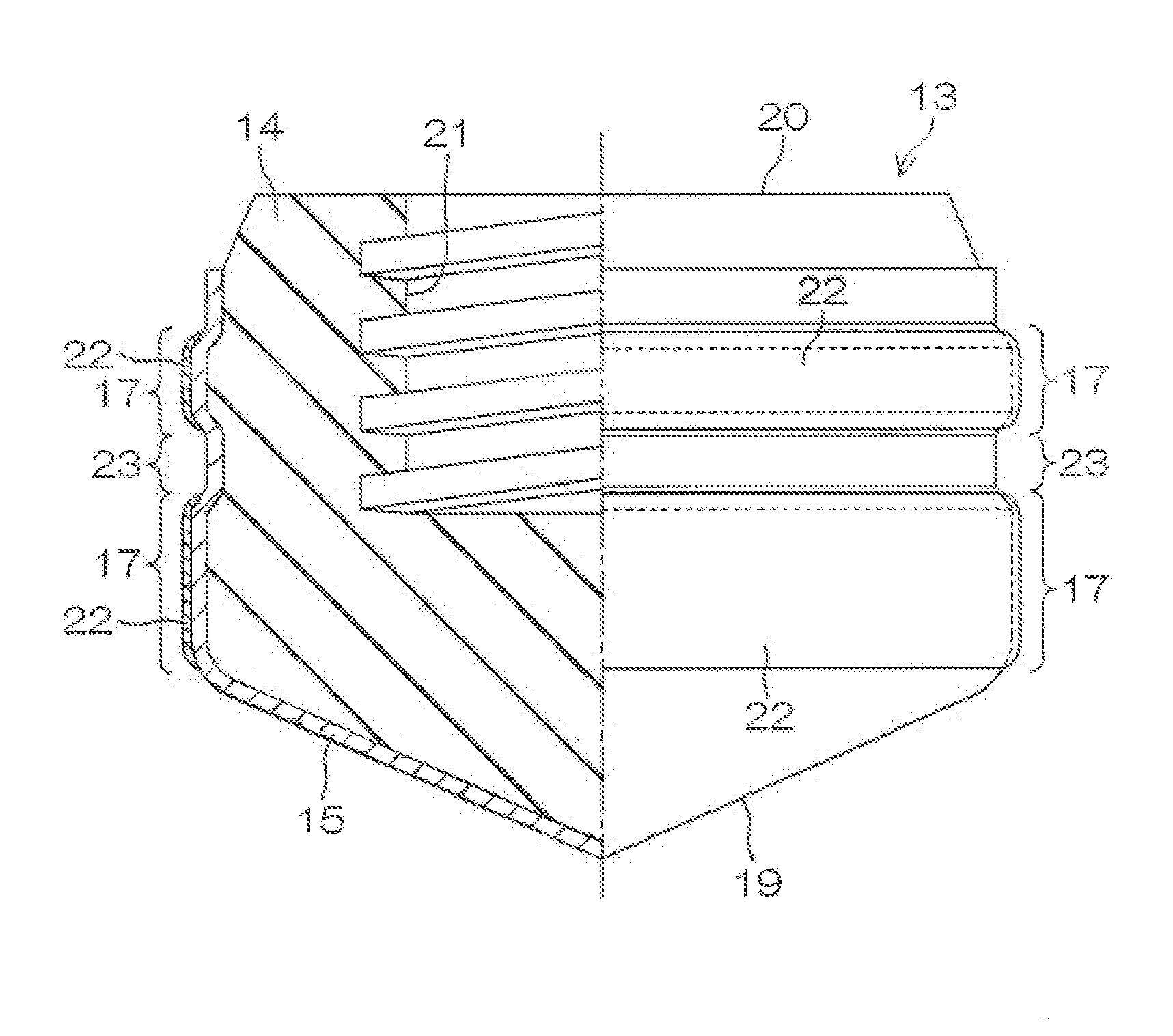

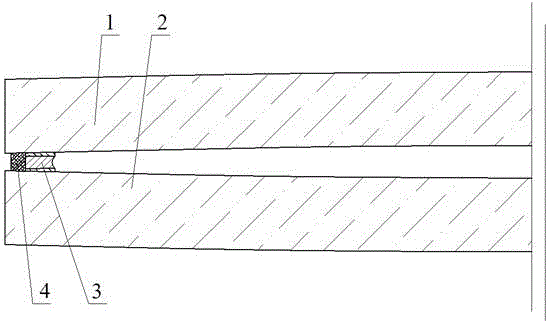

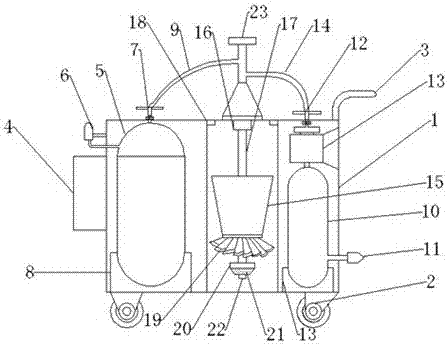

Rotary powder compression molding machine

ActiveUS7381356B2Avoid distractionReduce airtightnessMouldsConfectioneryCompression moldingAtmospheric air

An apparatus is provided for effectively preventing the scattering and the like of powder material, by maintaining a completely sealed condition, from the supply of the powdery material and the discharge of the molded articles to the cleaning of the interior. A housing 1 comprising, connected via a piping system 10, a vacuum device 11 for depressurizing said housing 1 interior; an atmosphere cut-off valve 12 installed on said piping system 10 for cutting off a piping interior atmosphere on said housing 1 side from a piping interior atmosphere on the vacuum device 11 side; a wetdown piping system 72 for wetting, within the atmosphere on the housing 1 side starting from said atmosphere cut-off valve 12, a compression molding mechanism 2 as well as powdery material stuck to the inside of said housing 1; and an outside air introduction mechanism 15 installed on said housing 1 for opening up an airtight condition of the housing.

Owner:KIKUSUI SEISAKUSHO LTD

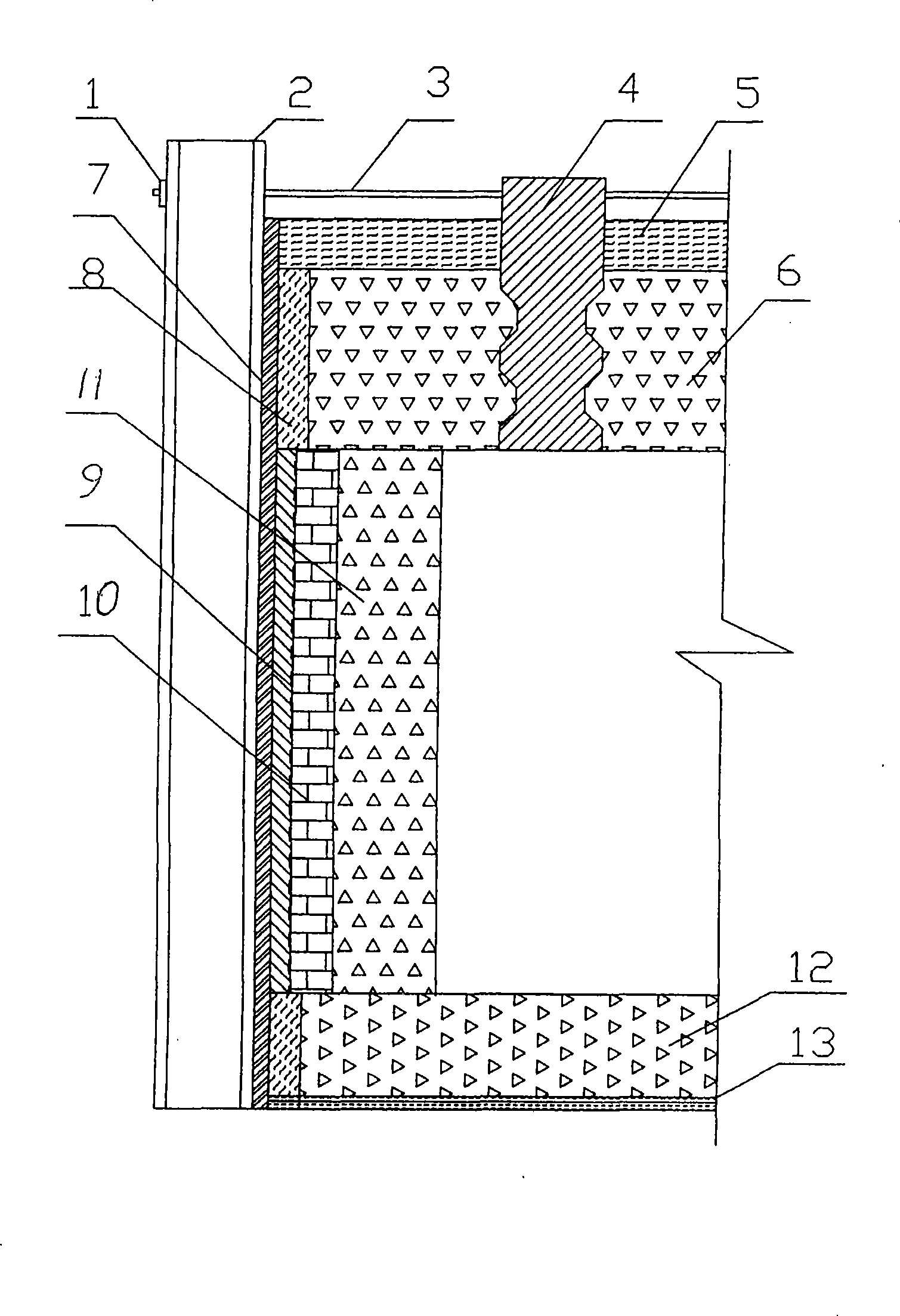

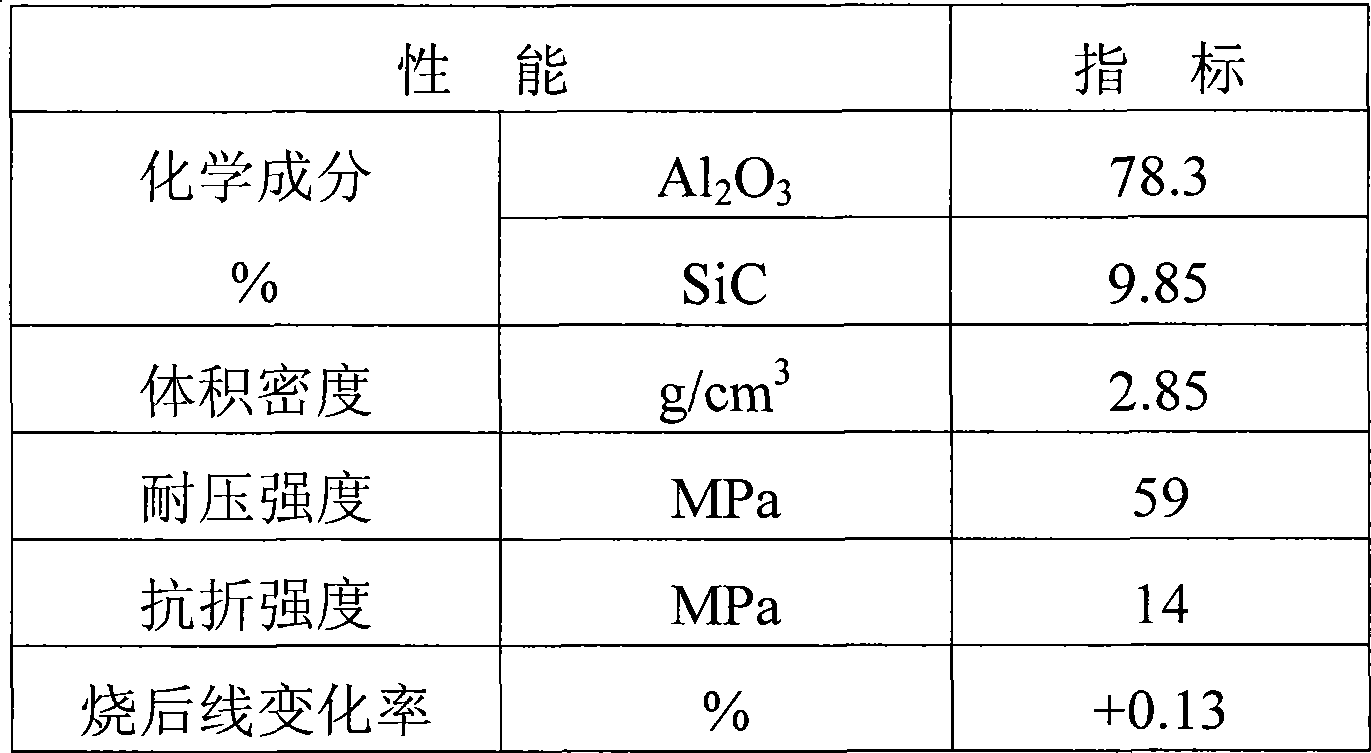

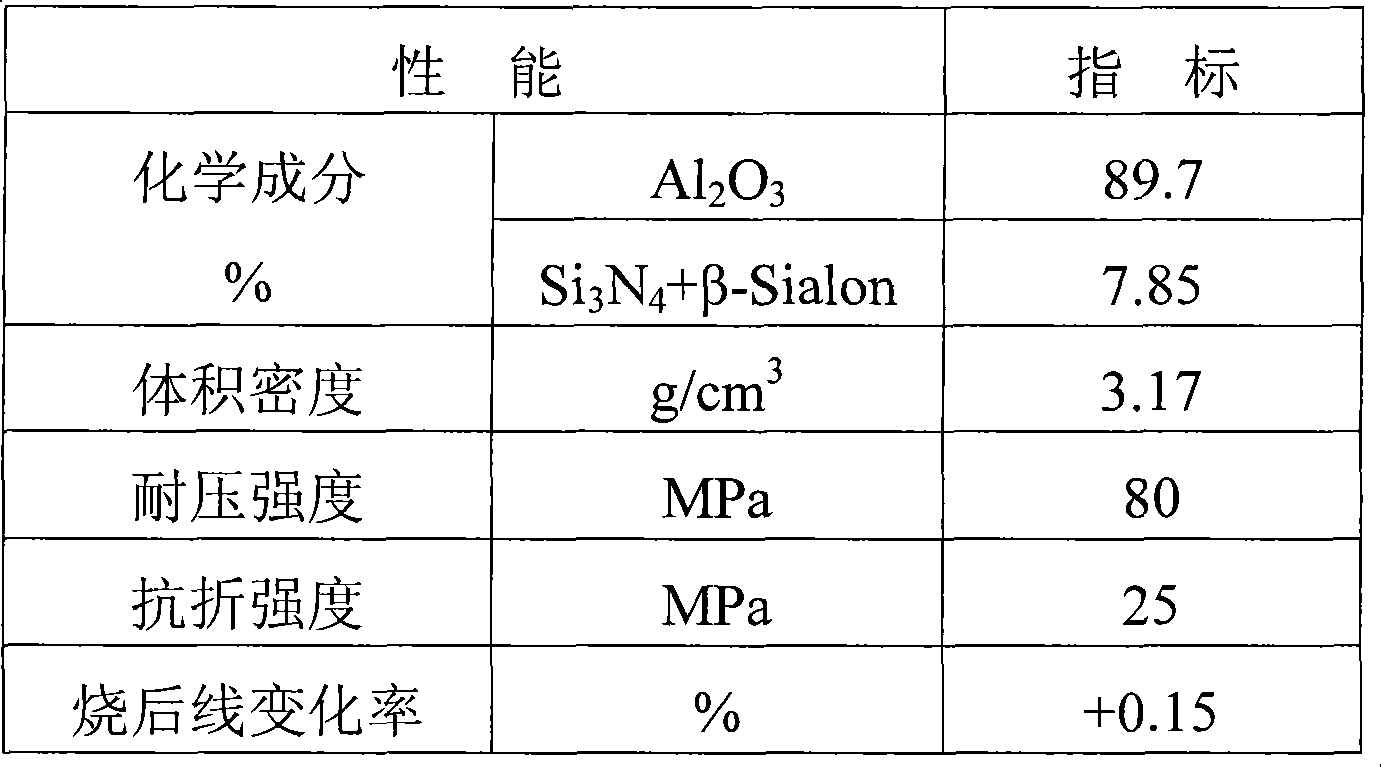

Aluminum melting furnace capable of improving service life and thermal efficiency

InactiveCN101413757AImprove heat radiation abilityGood energy saving effectMonolithic liningsHeating efficiencyThermal efficiency

An aluminum melting furnace capable of increasing service life and heat efficiency comprises a shell body and a lining layer covered on the inner wall of the shell body. The furnace is characterized in that work layers in the lining layer, namely the work layers of the furnace bottom, the furnace wall and the furnace top, are integrally cast from castable refractory and constructed; wherein, the furnace top is in a flattopping structure as well as the integral cast structure with hanging anchorage bricks, the furnace wall is in a composite structure belonging to a straight vertical surface structure. Being fully cast, the lining of the aluminum melting furnace has no seam, smooth surface, high integral strength, good air tightness and stable structure in use, and can greatly reduce radiation loss and improve the heat efficiency; with nonoxides used in the lining casting material, the material does not shrink, crack, aluminize, uneasily adhere with slag and is not eroded by aluminum alloy melt with high thermal shock stability in the state of smelting operation. Compared with the service life of a traditional brick structure, the service life is improved more than 3 times.

Owner:巩义市嘉丰耐火材料有限公司

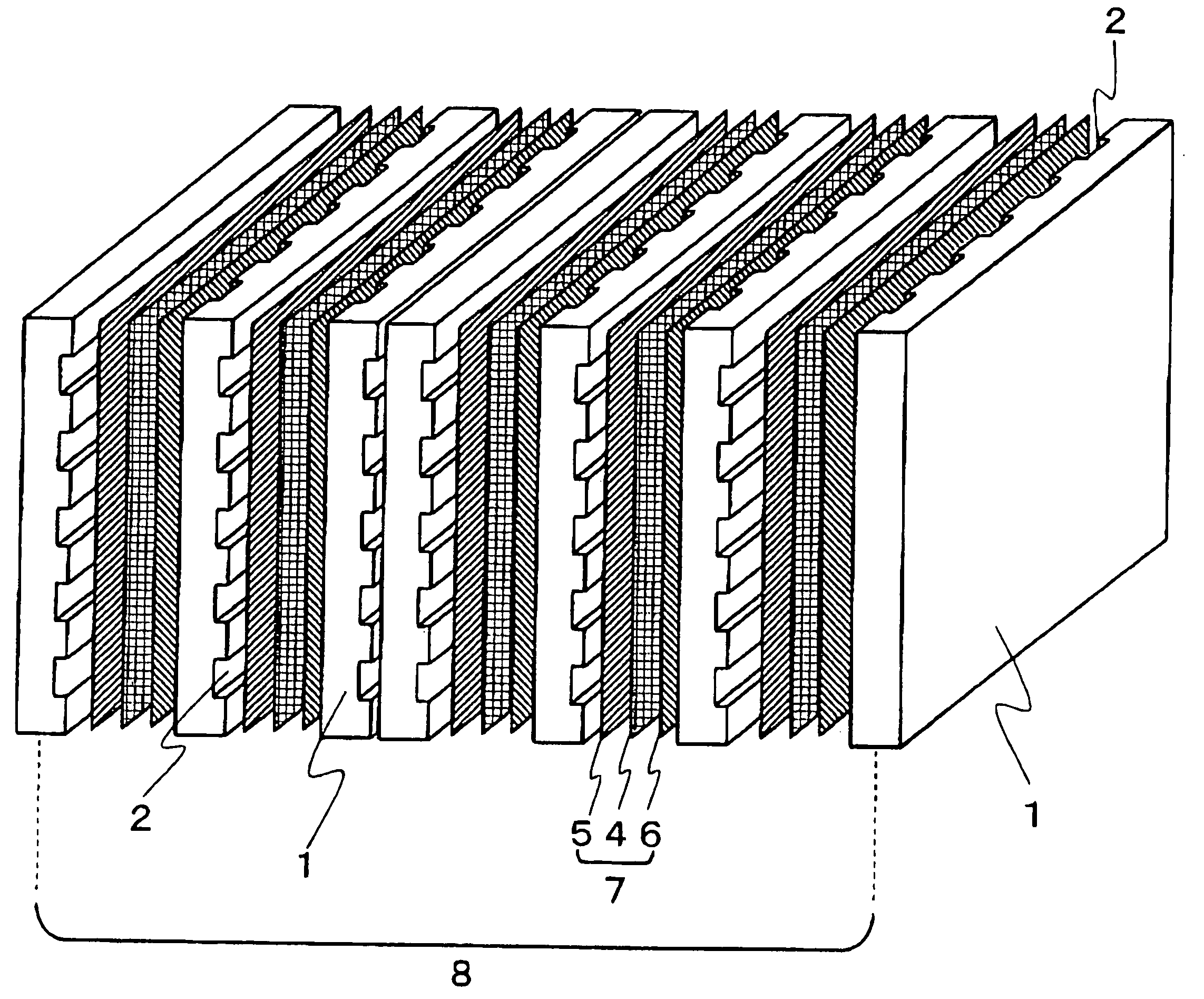

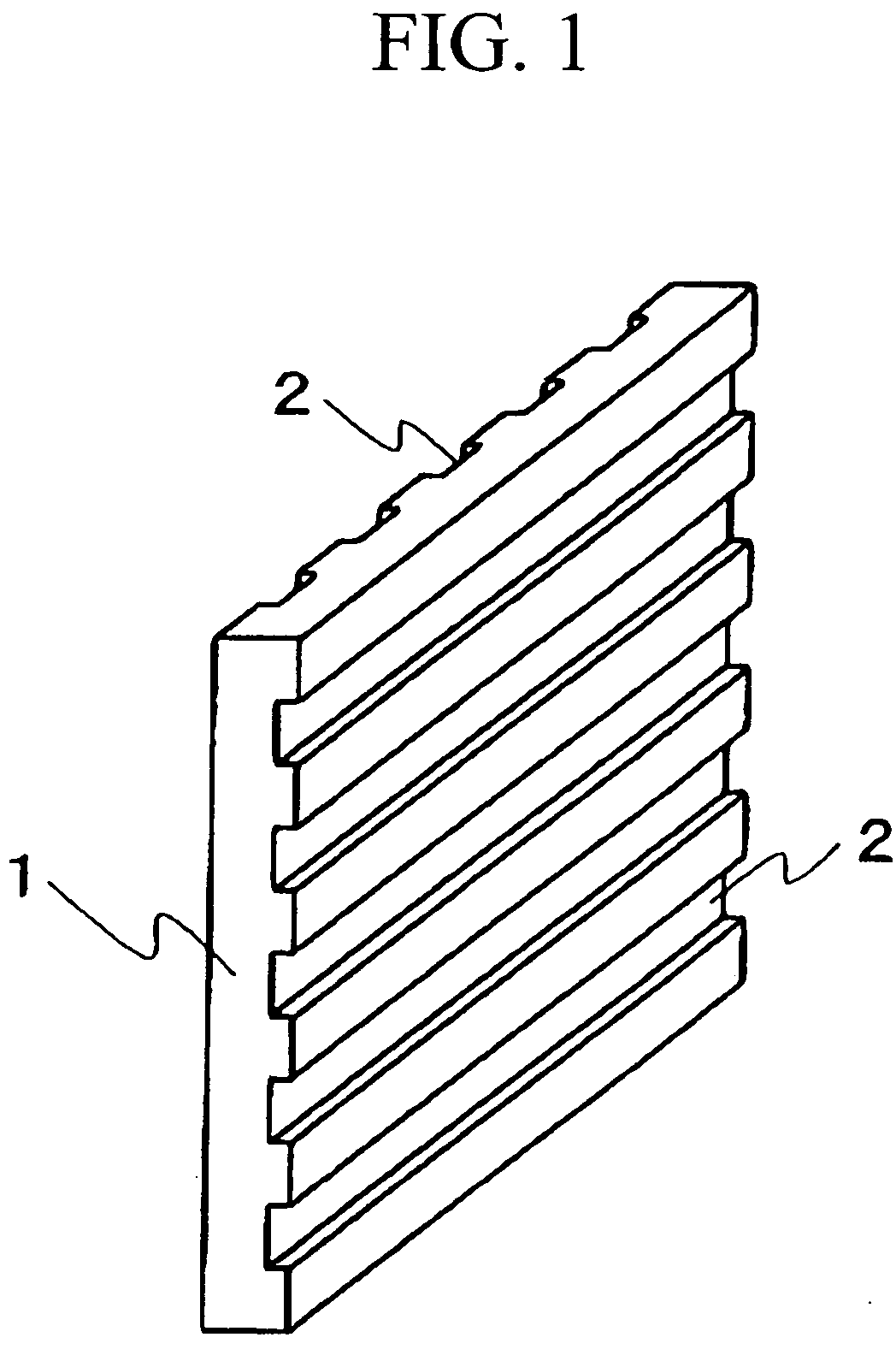

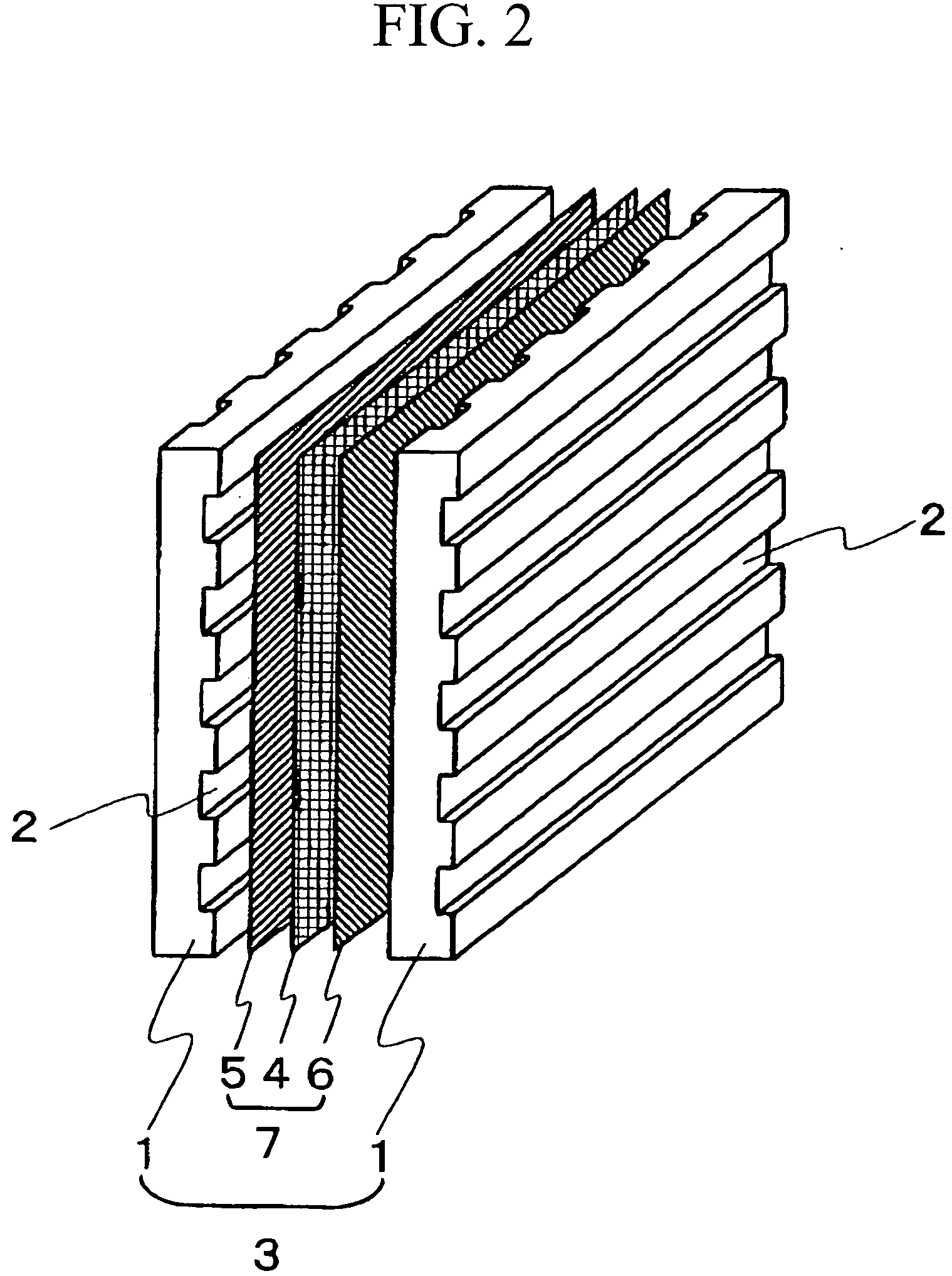

Method for producing separator for fuel cell, separator for fuel cell and fuel cell

InactiveUS20060147780A1Improve power generation efficiencyLittle process complexityNon-metal conductorsFuel cells groupingFuel cellsEngineering

A method for manufacturing fuel cell bipolar plates involves heating and softening a nonwoven fabric including an electrically conductive powder and thermoplastic resin fibers of 0.1 to 20 μm diameter, and shaping the softened nonwoven fabric.

Owner:DAINIPPON INK & CHEM INC

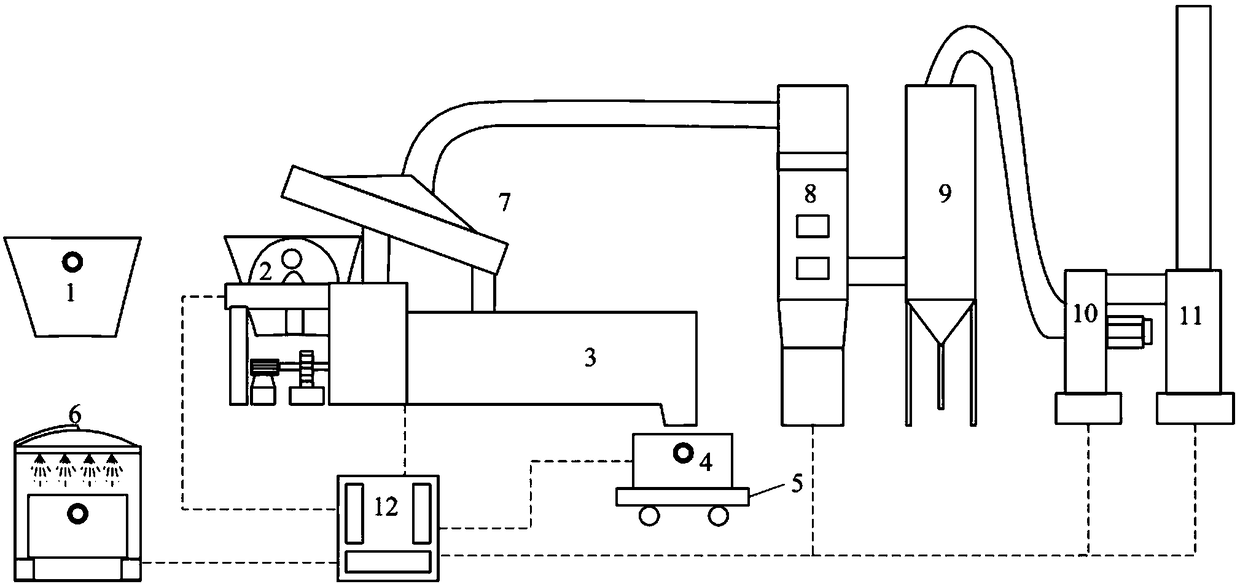

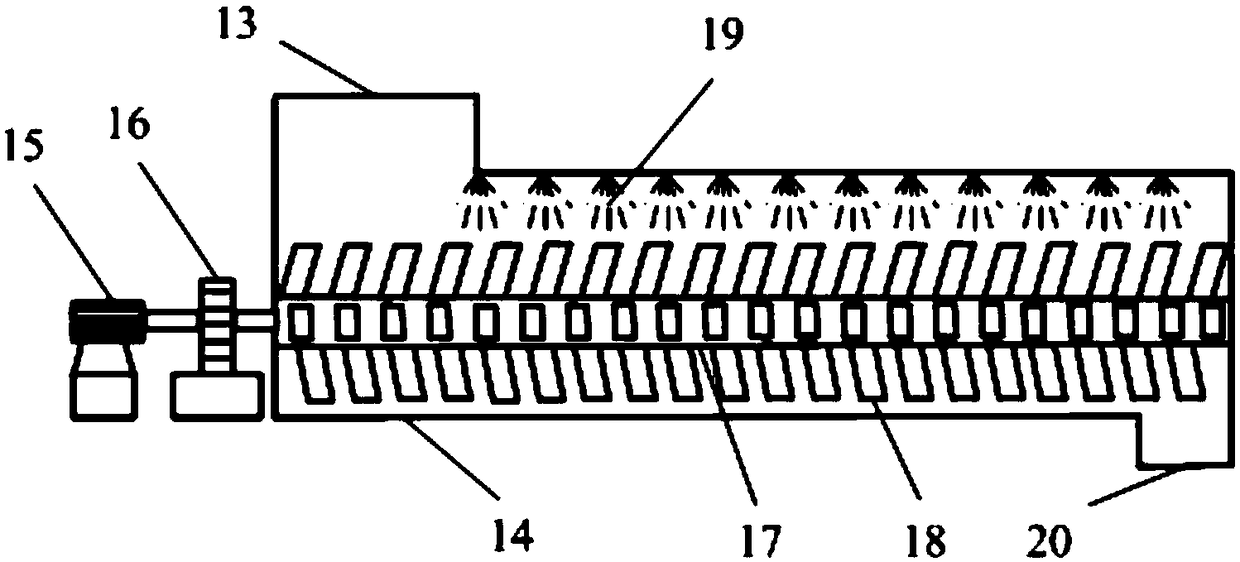

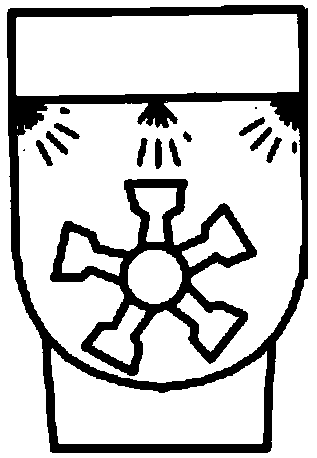

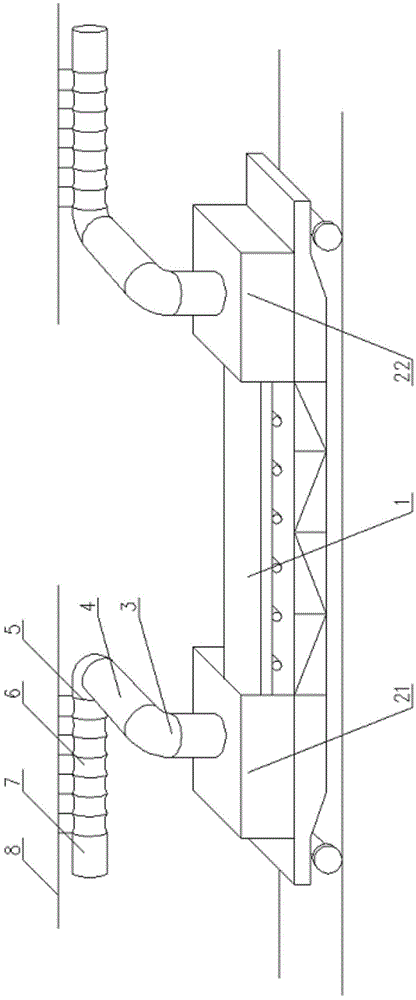

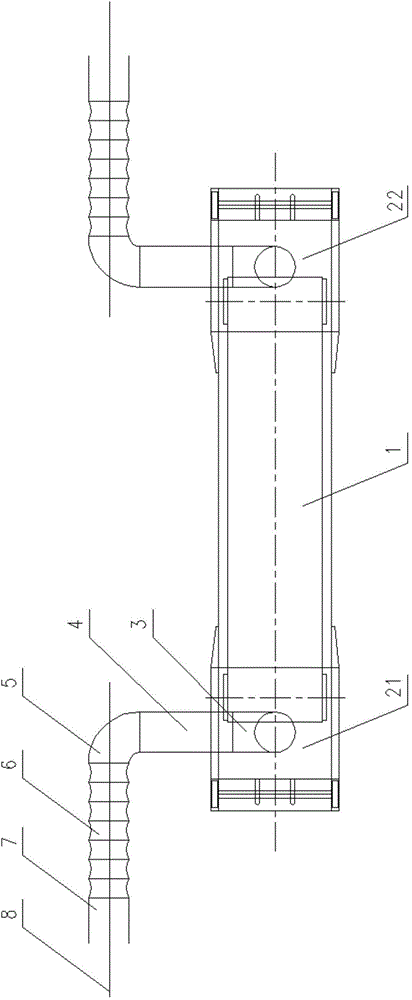

Melted steel dreg spiral crushing device and method

PendingCN109112238AHigh degree of automationGood production continuityRecycling and recovery technologiesBatch productionFlue gas

The invention relates to a melted steel dreg spiral crushing device and method. The melted steel dreg spiral crushing device comprises a dreg tank (1), a rollover machine (2), a spiral crusher (3), aslag groove (4), a dreg discharging machine (5), a hot suffocating tank (6), a flue gas treatment system and a control system (12); the rollover machine is used for pouring dreg; the fixed shaft of the spiral crusher can be used for continuously crushing melted steel dreg; the melted steel dreg can be continuously poured into the spiral crusher; the spiral crusher is used for crushing the steel dreg and driving the steel dreg to a dreg outlet while being rotated according to a certain speed; the device has the advantages that continuous production of steel dreg treatment is realized, a previous batch production manner is changed and the steel dreg treatment efficiency is greatly improved.

Owner:MCC ENERGY SAVING & ENVIRONMENTAL PROTECTION +2

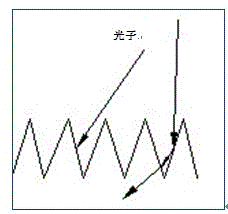

Packaging method for cerium-doped halogenated lanthanum scintillation crystal

ActiveCN102944891AReduce airtightnessReduce penetrationX/gamma/cosmic radiation measurmentScintillation crystalsRefractive index

The invention discloses a packaging method for a cerium-doped halogenated lanthanum scintillation crystal. The packaging method is characterized in that the scintillation crystal sequentially undergoes grinding (to remove a corrosion layer), polishing and surface roughness in a hypoxia dry environment; a reflecting surface of the crystal and a reflection material form a diffuse reflection surface, a light-emitting surface and a high-refraction-rate optical coupling glue form a light-emitting port, and the optimum state of the crystal light-emitting surface is of a sawtooth-shaped optical microstructure; a scintillation crystal packaging structure which is resistant to oscillation, temperature shock and damp is designed; and three layers of composite protecting structures comprising a rigid sleeve pipe, a foaming heat-insulating buffer layer and a casing are arranged. An optical coupling agent at the front end of the crystal and an elastic gasket at the rear end of the crystal are made of soft elastic materials. A gap is reserved between a rear cover and a rigid gasket, the heat-insulating effect is improved, and a double-way compound sealant is adopted to adhere the position of a joint of the casing.

Owner:北京玻璃研究院有限公司 +1

Ceramic small outline package (CSOP) method

InactiveCN101740413AReduce distanceSmall arcSemiconductor/solid-state device manufacturingAviationBonding process

The invention discloses a ceramic small outline package (CSOP) method which comprises a cleaning process, a die bonding process, a bonding process, a before-package baking process, a package process and a printing process. An integrated circuit packaged by adopting the CSOP method has excellent electrical property and thermal property, small volume and light weight. The invention is widely applied to fields of aviation, astrogate and the like. When in application, solder paste is printed on a printed circuit board (PCB) welding pad, and the electrical connection is realized by sintering welding points through reflow welding.

Owner:TIANSHUI 749 ELECTRONICS

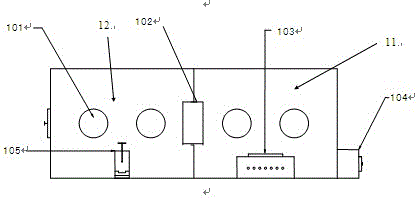

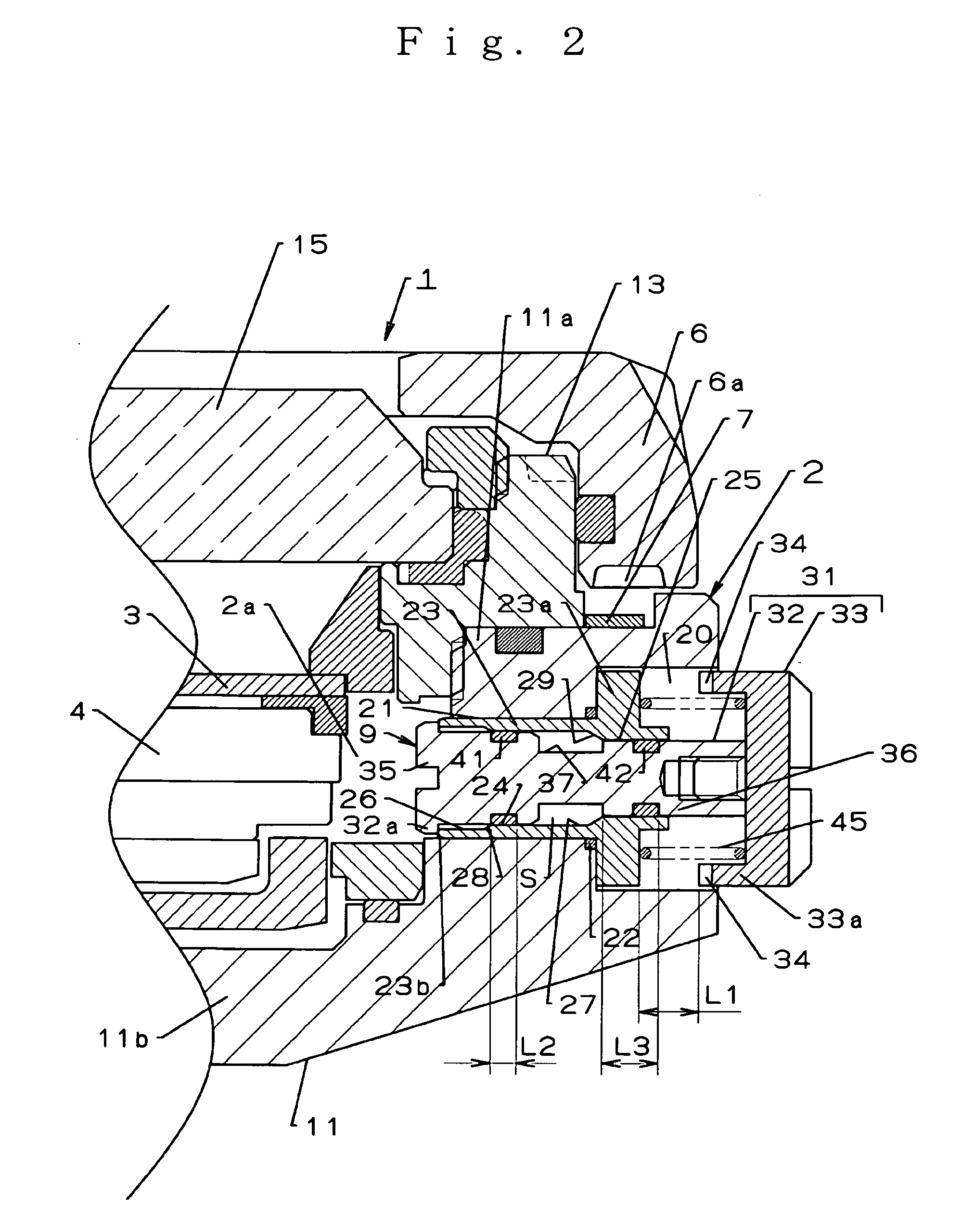

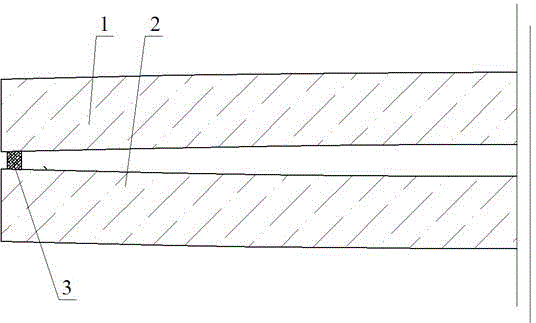

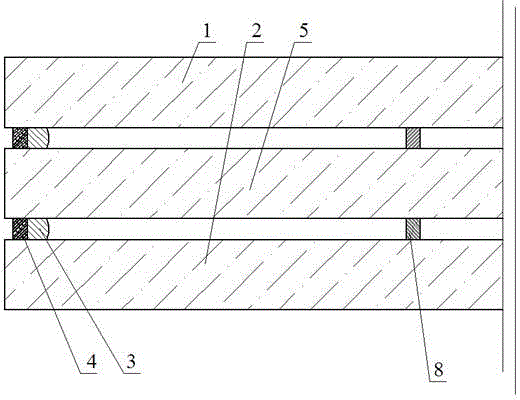

Rotary powder compression molding machine

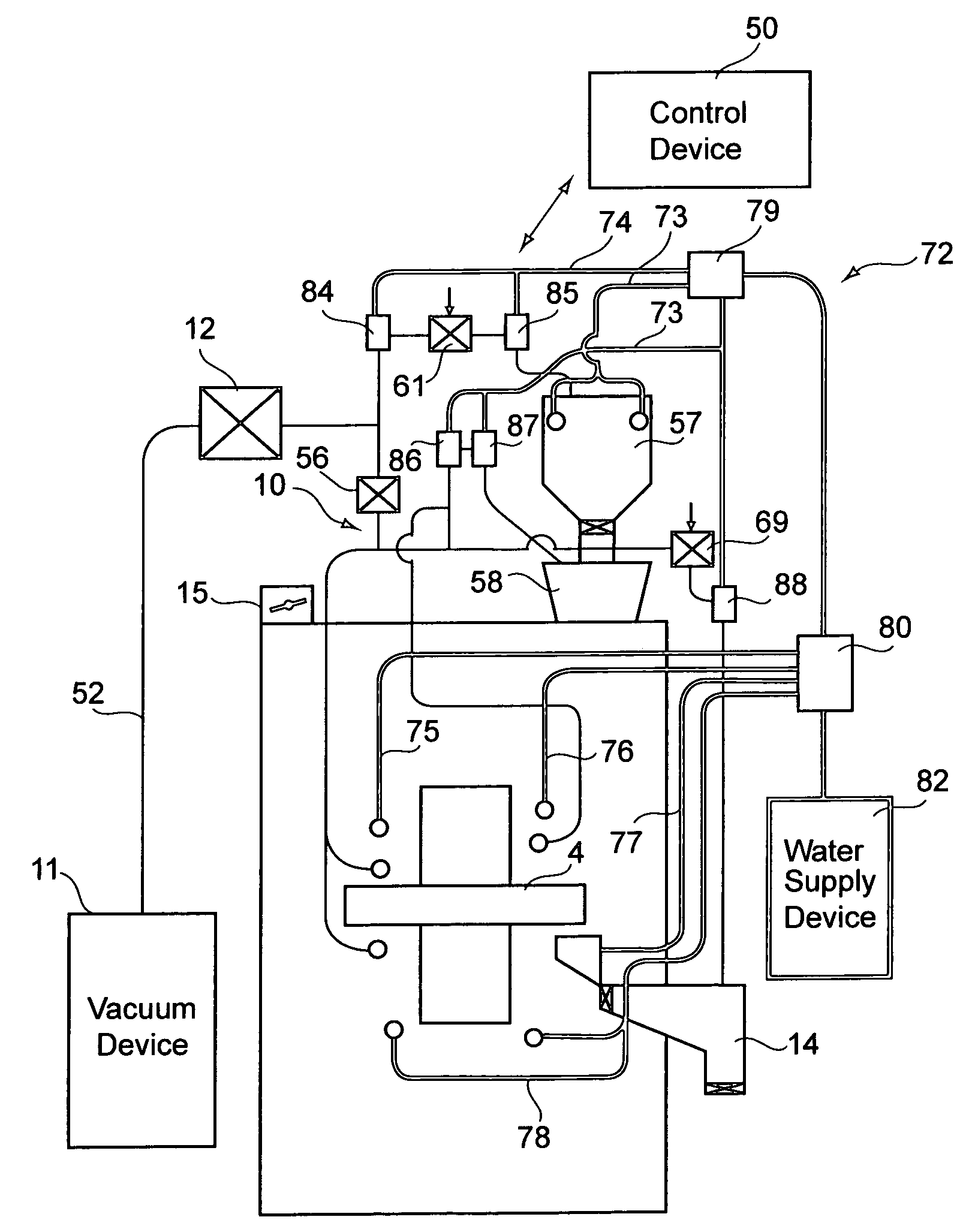

ActiveUS20050151292A1Improve airtightnessAvoid distractionMouldsConfectioneryCompression moldingEngineering

[Problem to be Solved]An apparatus is provided for effectively preventing the scattering and the like of powder material, by maintaining a completely sealed condition, from the supply of the powdery material and the discharge of the molded articles to the cleaning of the interior. [Means of Solving]Said housing 1 comprising, connected via a piping system 10, a vacuum device 11 for depressurizing said housing 1 interior; an atmosphere cut-off valve 12 installed on said piping system 10 for cutting off a piping interior atmosphere on said housing 1 side from a piping interior atmosphere on the vacuum device 11 side; a wetdown piping system 72 for wetting, within the atmosphere on the housing 1 side starting from said atmosphere cut-off valve 12, a compression molding mechanism 2 as well as powdery material stuck to the inside of said housing 1; and an outside air introduction mechanism 15 installed on said housing 1 for opening up an airtight condition of the housing 1.

Owner:KIKUSUI SEISAKUSHO LTD

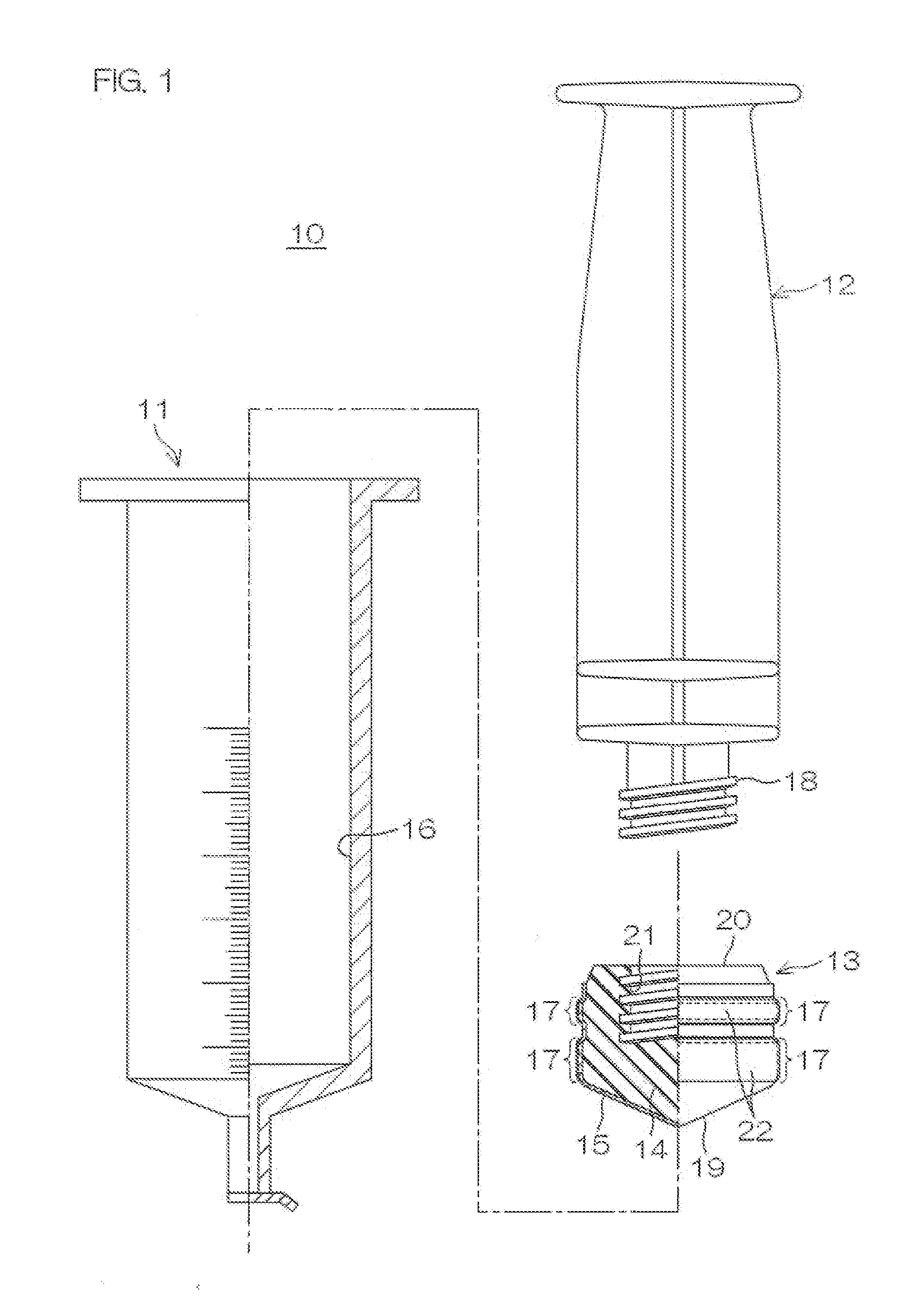

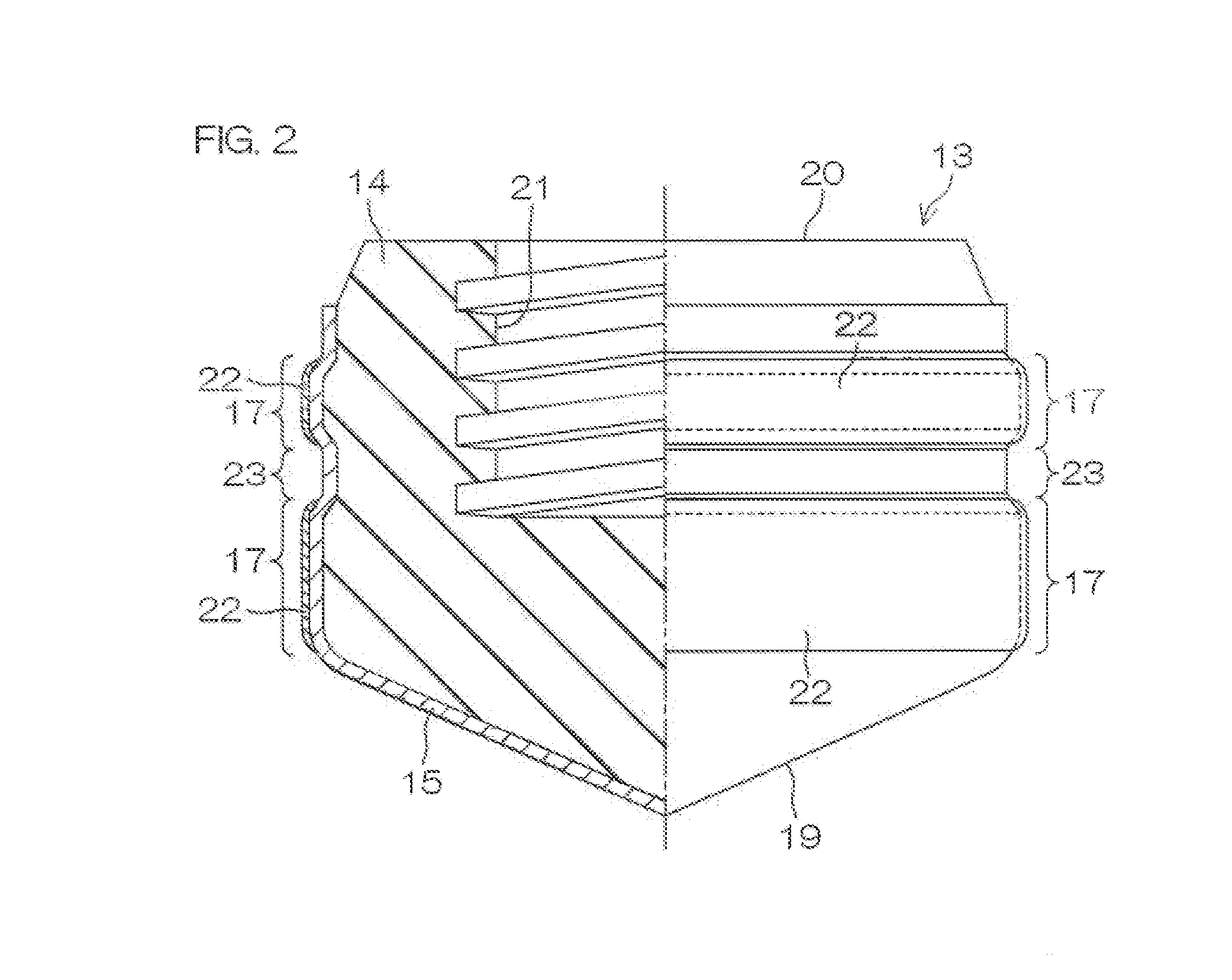

Gasket for prefilled syringe and prefilled syringe

ActiveUS20150231337A1Suppress wrinklesPrevent leakageInfusion syringesSurgeryPrefilled SyringeBiomedical engineering

A gasket for prefilled syringe according to the present invention is a gasket for prefilled syringe that includes a fluid contacting portion, a sliding portion with a circumferential surface, a film layer made of a fluororesin coated on the fluid contacting portion and sliding portion and further, and a coating layer including trimethylsiloxysilicate laminated on the film layer covering the sliding portion.

Owner:SUMITOMO RUBBER IND LTD

Vacuum-glass heat-insulating board and manufacturing method thereof

InactiveCN105669007ASolve the sealing problemSolve the vacuum problemGlass reforming apparatusGlass productionFlat glassAir tightness

The invention relates to a vacuum-glass heat-insulating board. The vacuum-glass heat-insulating board comprises upper glass and lower glass, wherein the periphery of the upper glass and the periphery of the lower glass are connected together through a sealing material in a sealing manner, a closed vacuum layer is formed between the upper glass and the lower glass and contains a low-melting-point or volatile or highly-inspiratory metal, the upper glass and the lower glass are convex glass or flat glass, and the convex surface of the convex glass faces to the outer side. A manufacturing method for the vacuum-glass heat-insulating board disclosed by the invention is simple in process, the sealing effect is good, the air tightness and service life of the vacuum-glass heat-insulating board can be effectively guaranteed, and mechanized, automated and large-scale production can be achieved.

Owner:戴长虹

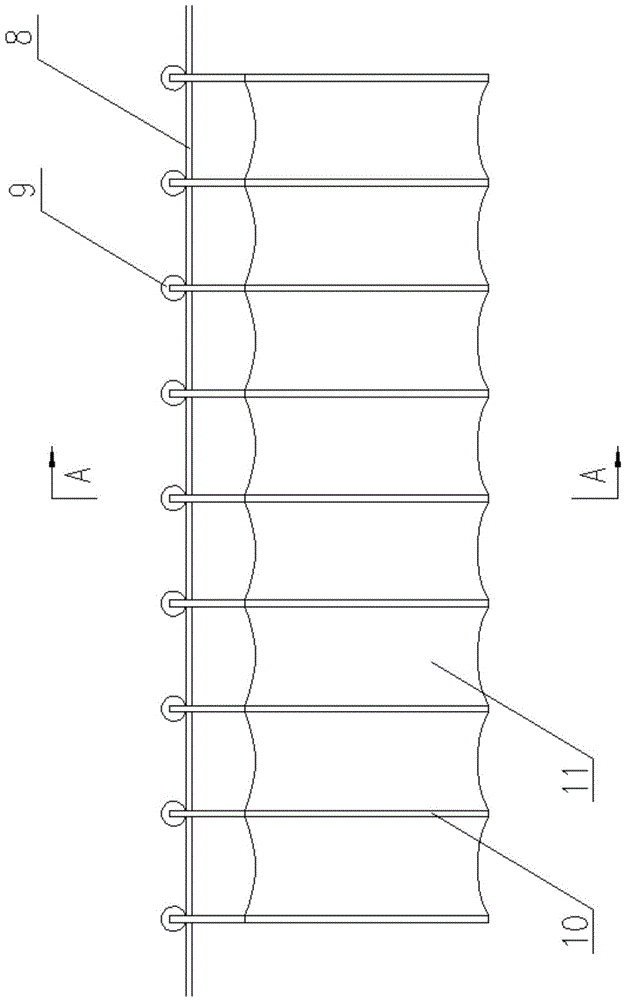

Segmented construction method for troughed bulkhead

The invention discloses a segmented construction method for a troughed bulkhead. The segmented construction method comprises the following steps that S100, according to the ship design requirements, prefabricated steel plates are bent and pressed into Z-shaped bulkhead assemblies; S200, the multiple Z-shaped bulkhead assemblies are assembled and welded into the troughed bulkhead on a jig frame; S300, wall pier assemblies are assembled and formed; S400, the troughed bulkhead and the wall pier assemblies are assembled and formed; S500, anti-accumulating plates are mounted between the troughed bulkhead and the wall pier assemblies; and S600, connecting welding seams between the anti-accumulating plates and the troughed bulkhead as well as between the anti-accumulating plates and the wall pierassemblies are subjected to air tightness inspection. The troughed bulkhead of a ship is split into the multiple Z-shaped bulkhead assemblies for separate machining, then the Z-shaped bulkhead assemblies are assembled and welded into the complete troughed bulkhead on the jig frame, mounting of the anti-accumulating plates is advanced at the construction stage of the troughed bulkhead, thus the using rate of the jig frame of the troughed bulkhead can be increased, the construction efficiency can be improved, and meanwhile, the problem that continuity and safety of operation cannot be ensured due to the narrow and small construction space caused by mounting in the final assembly stage of the ship is solved.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

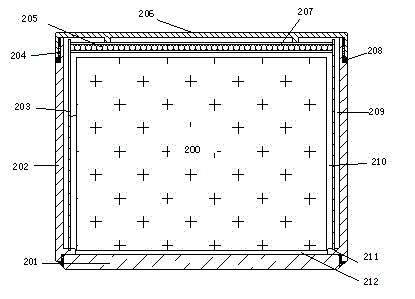

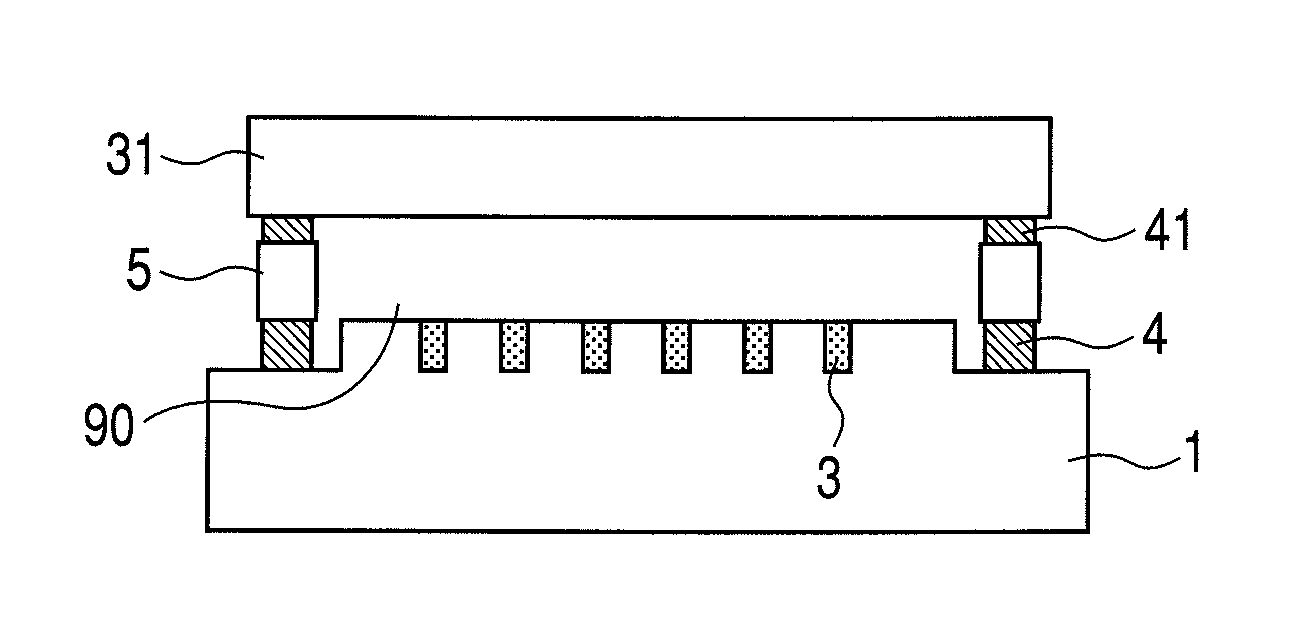

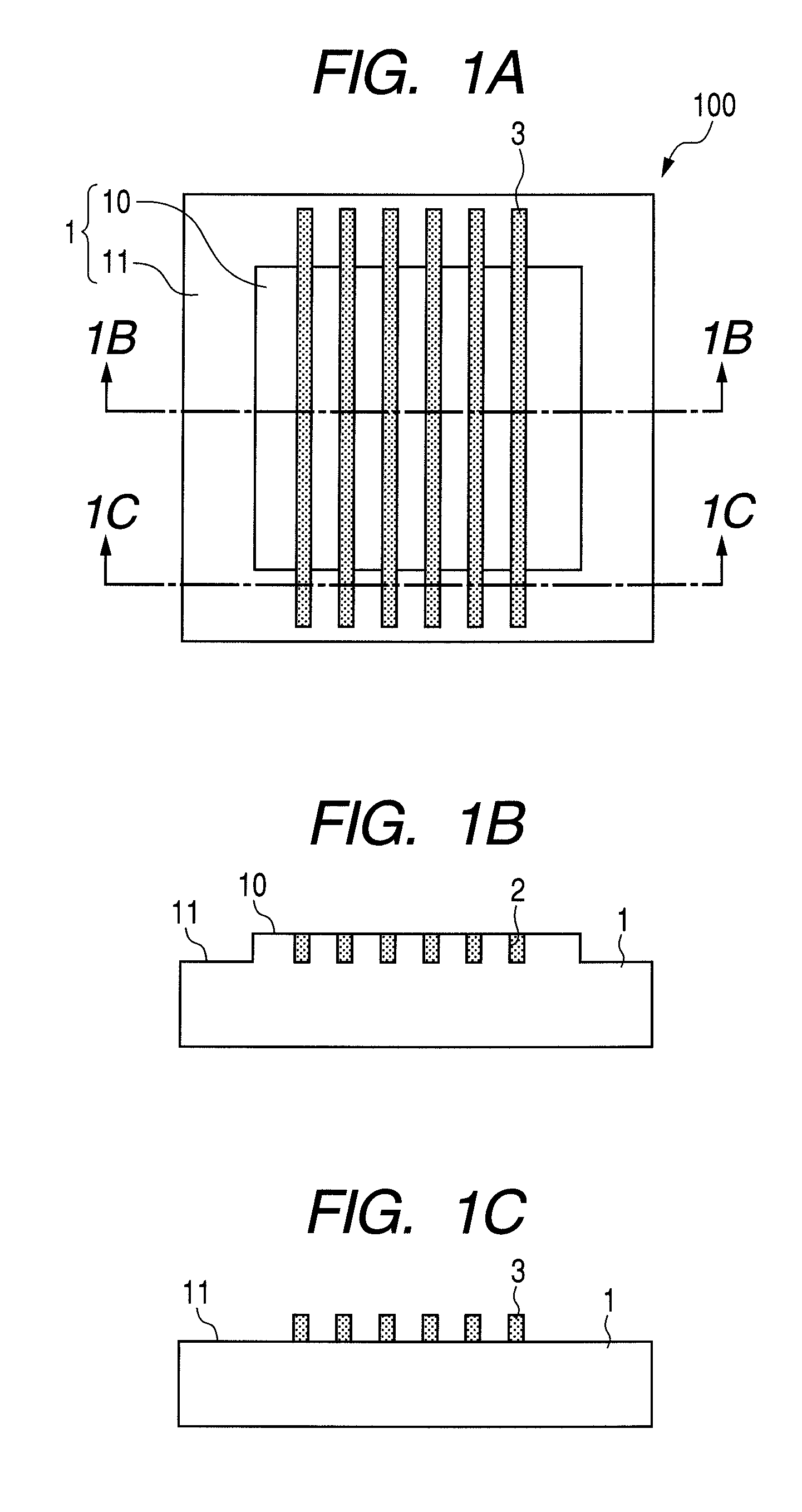

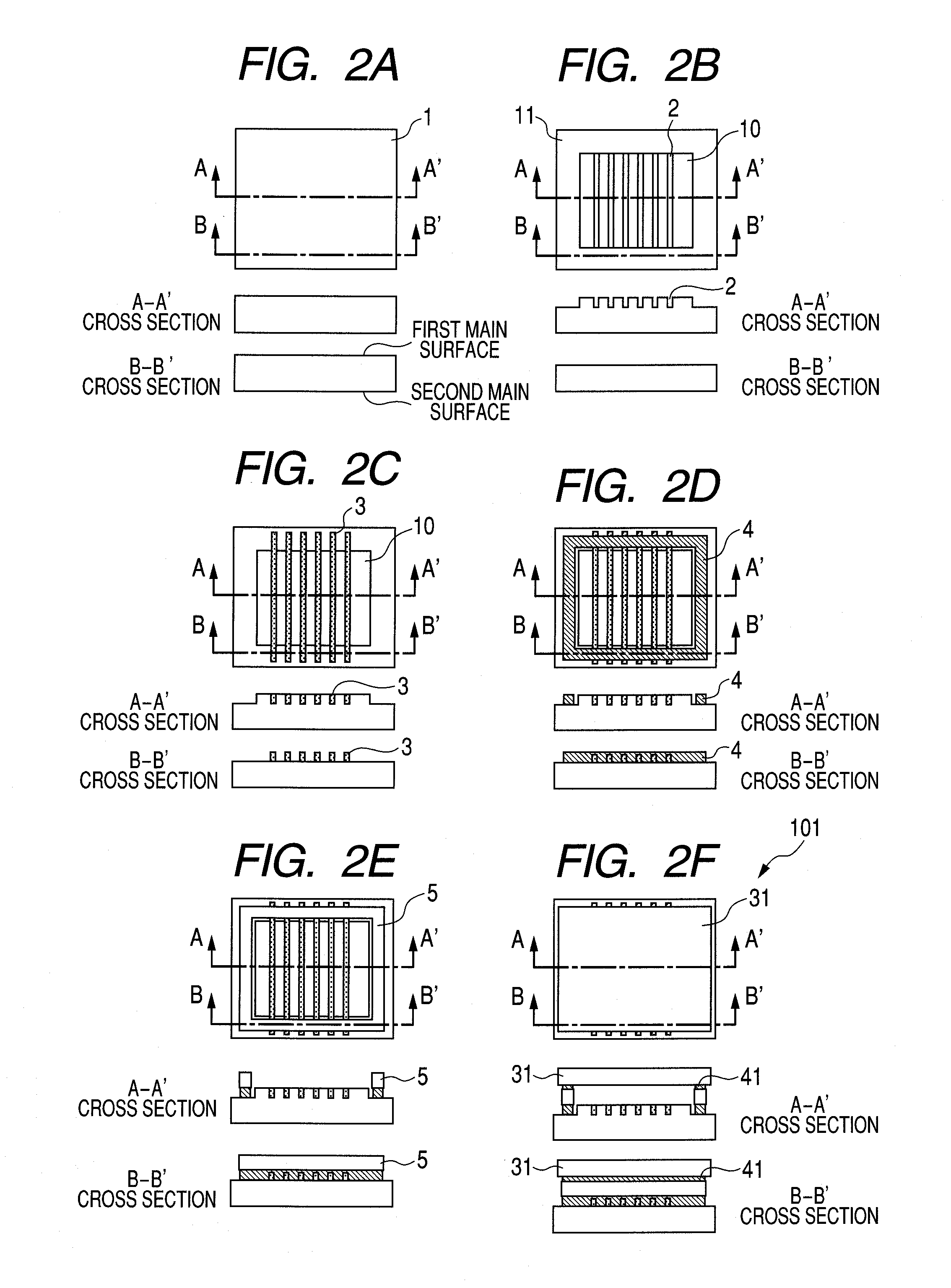

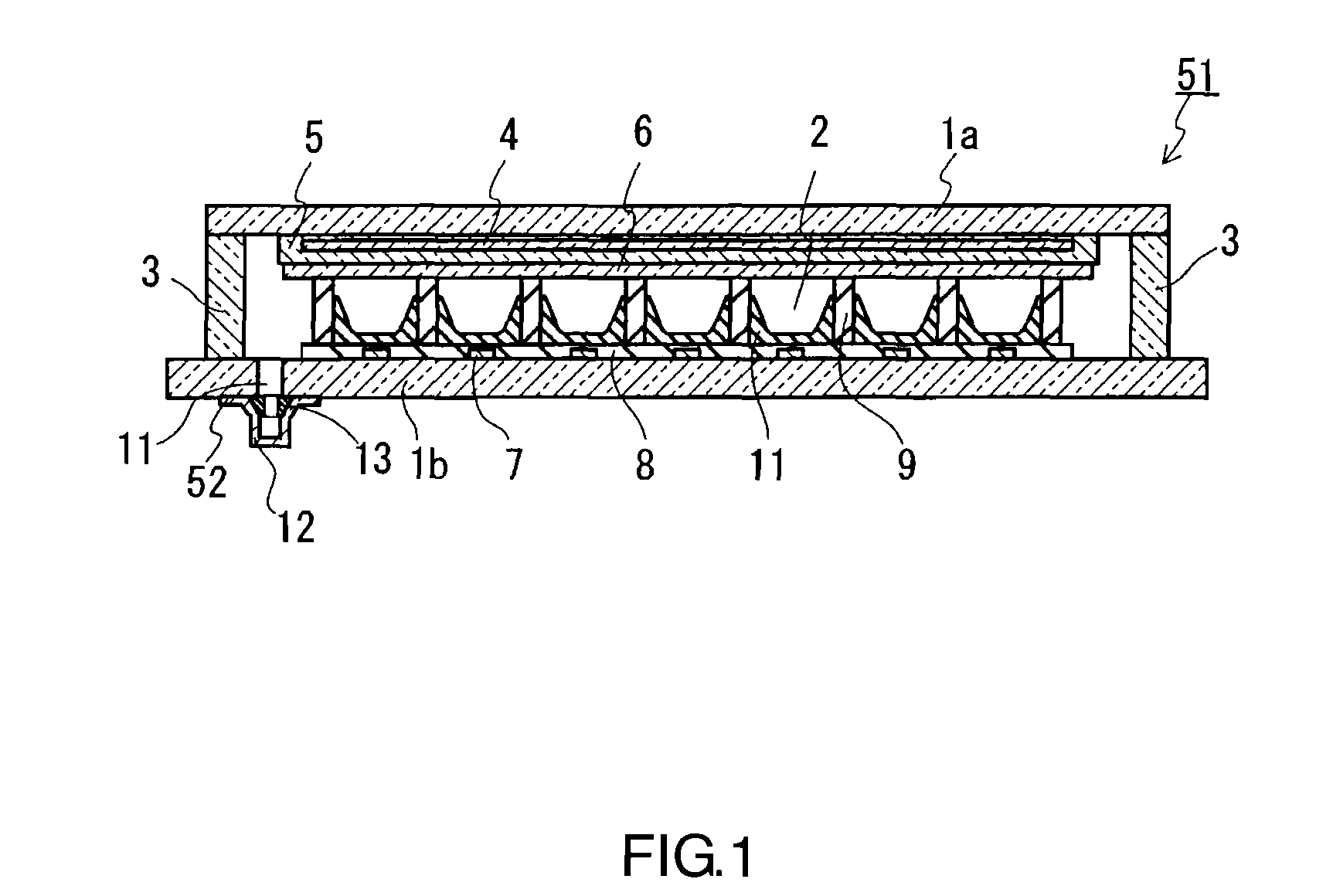

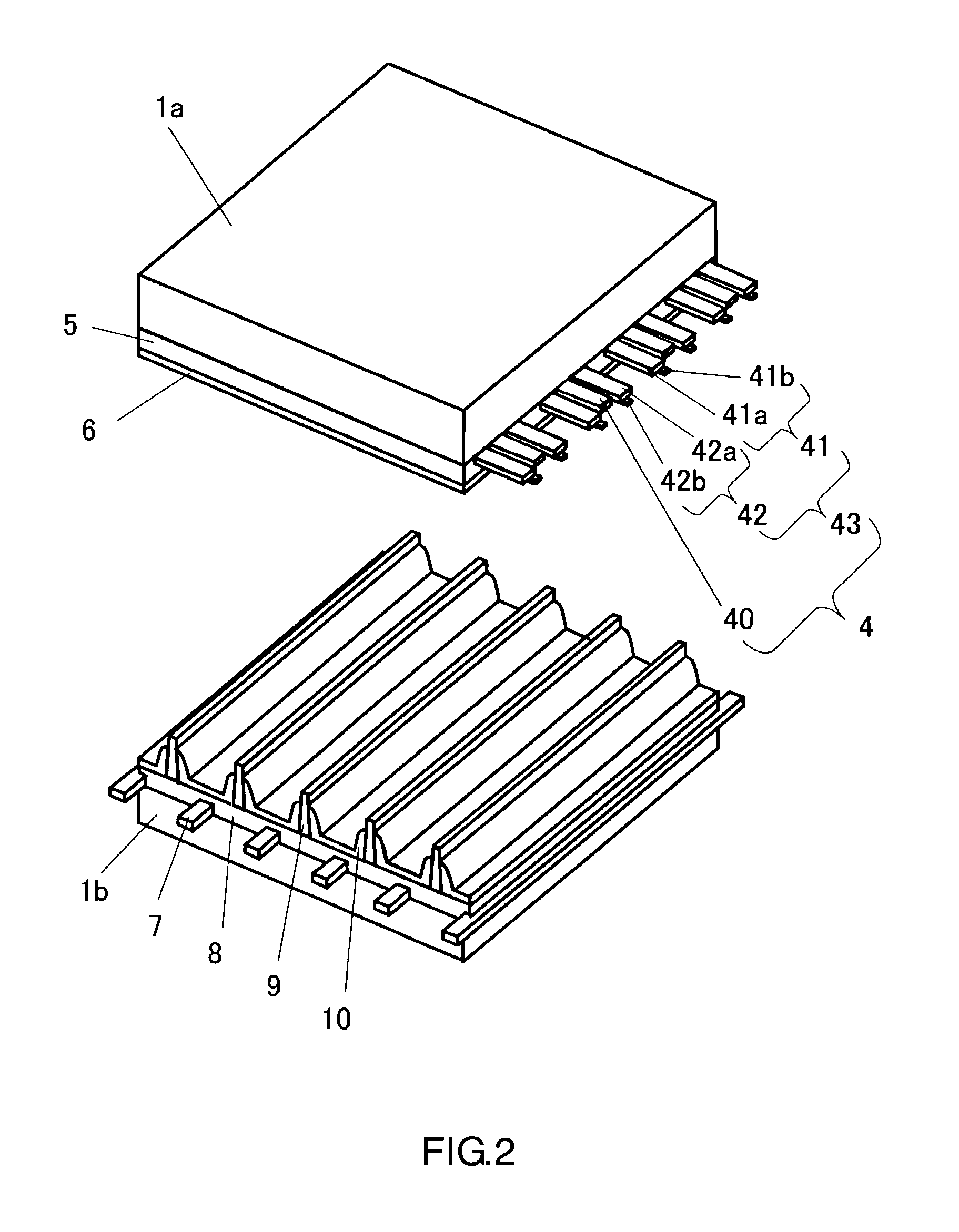

Airtight container and display device using the airtight container, and manufacturing method therefor

InactiveUS7928645B2Reduce airtightnessDischarge tube luminescnet screensCathode-ray/electron-beam tube leading-in arrangementsDisplay deviceEngineering

Owner:CANON KK

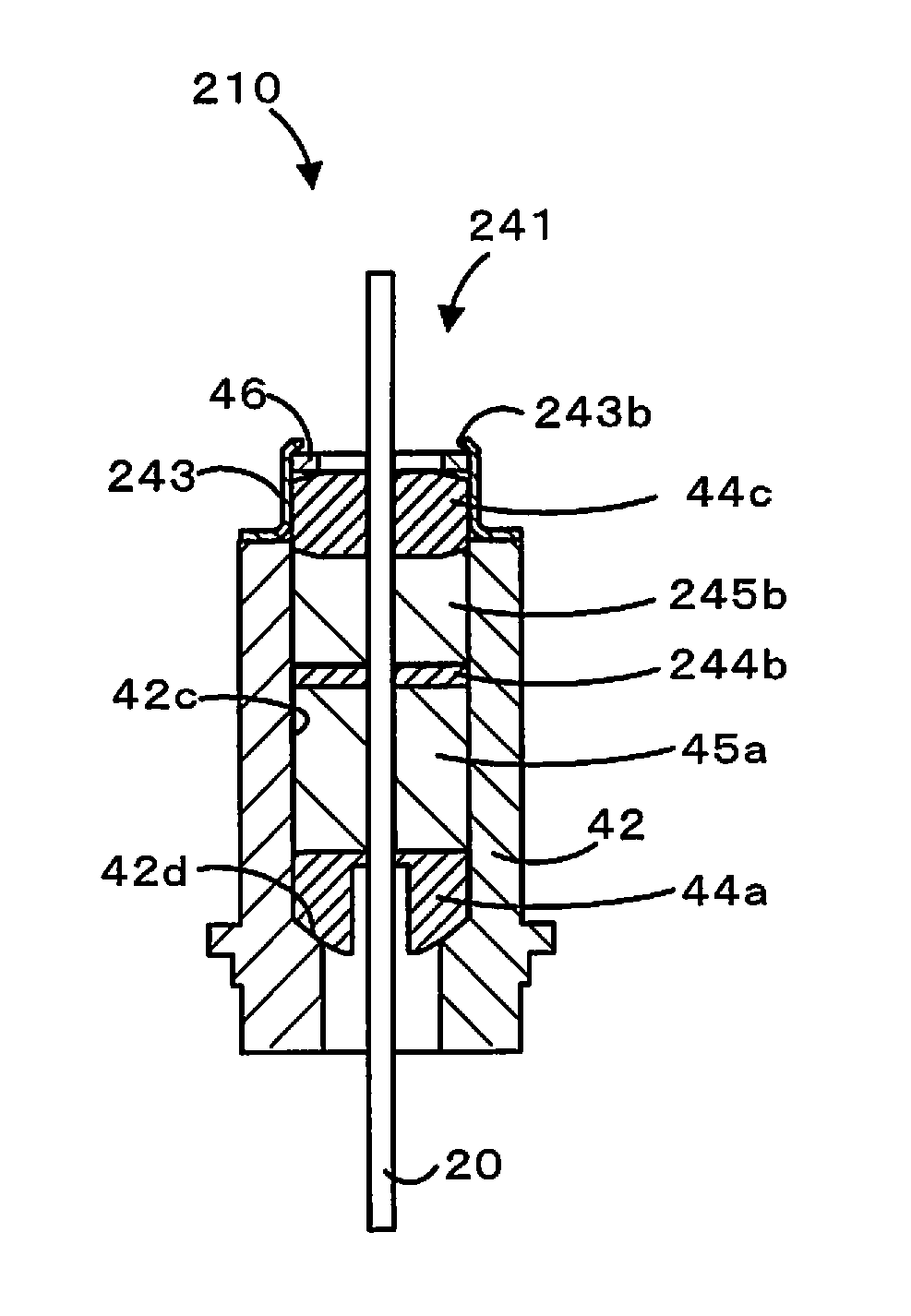

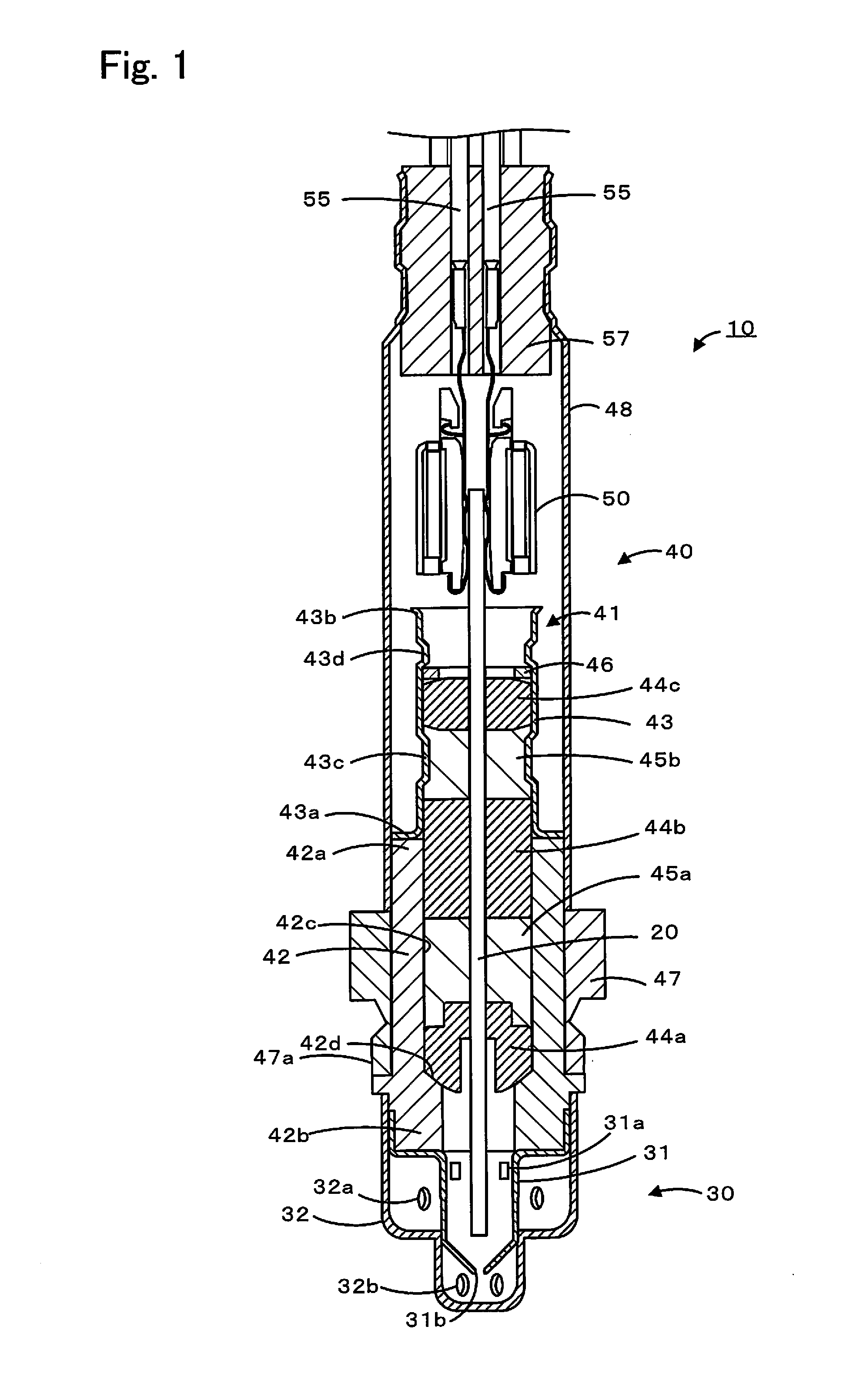

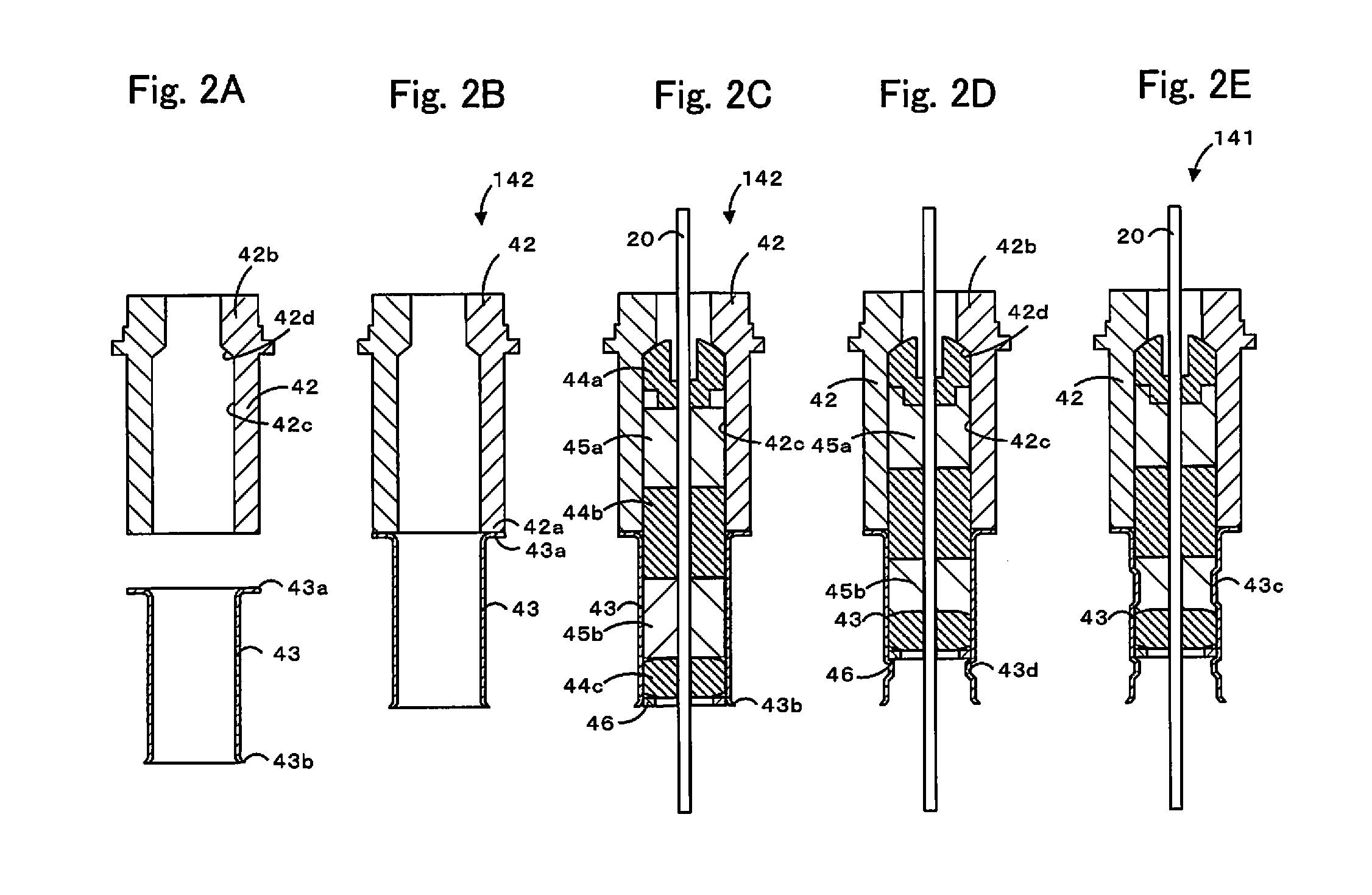

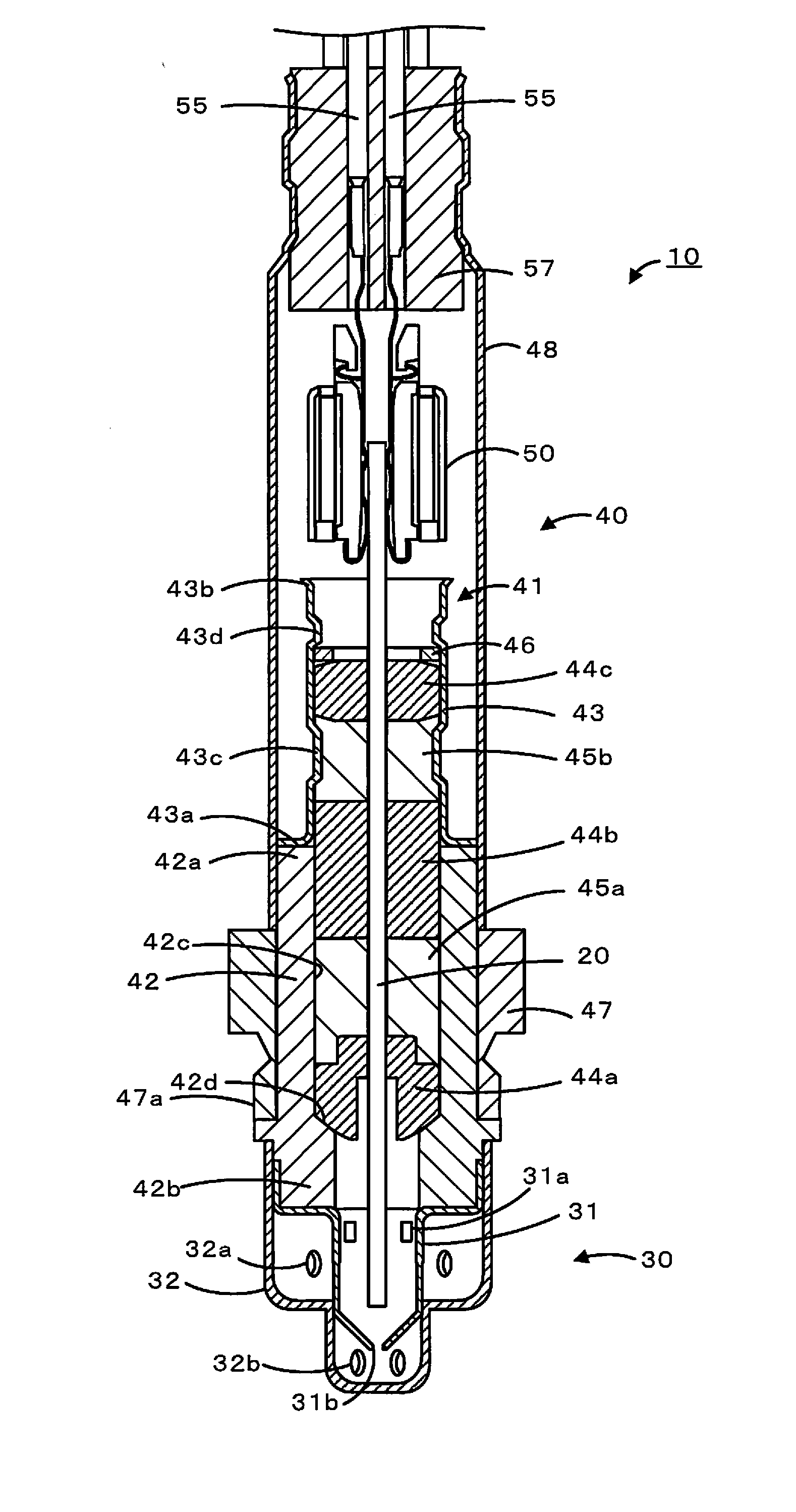

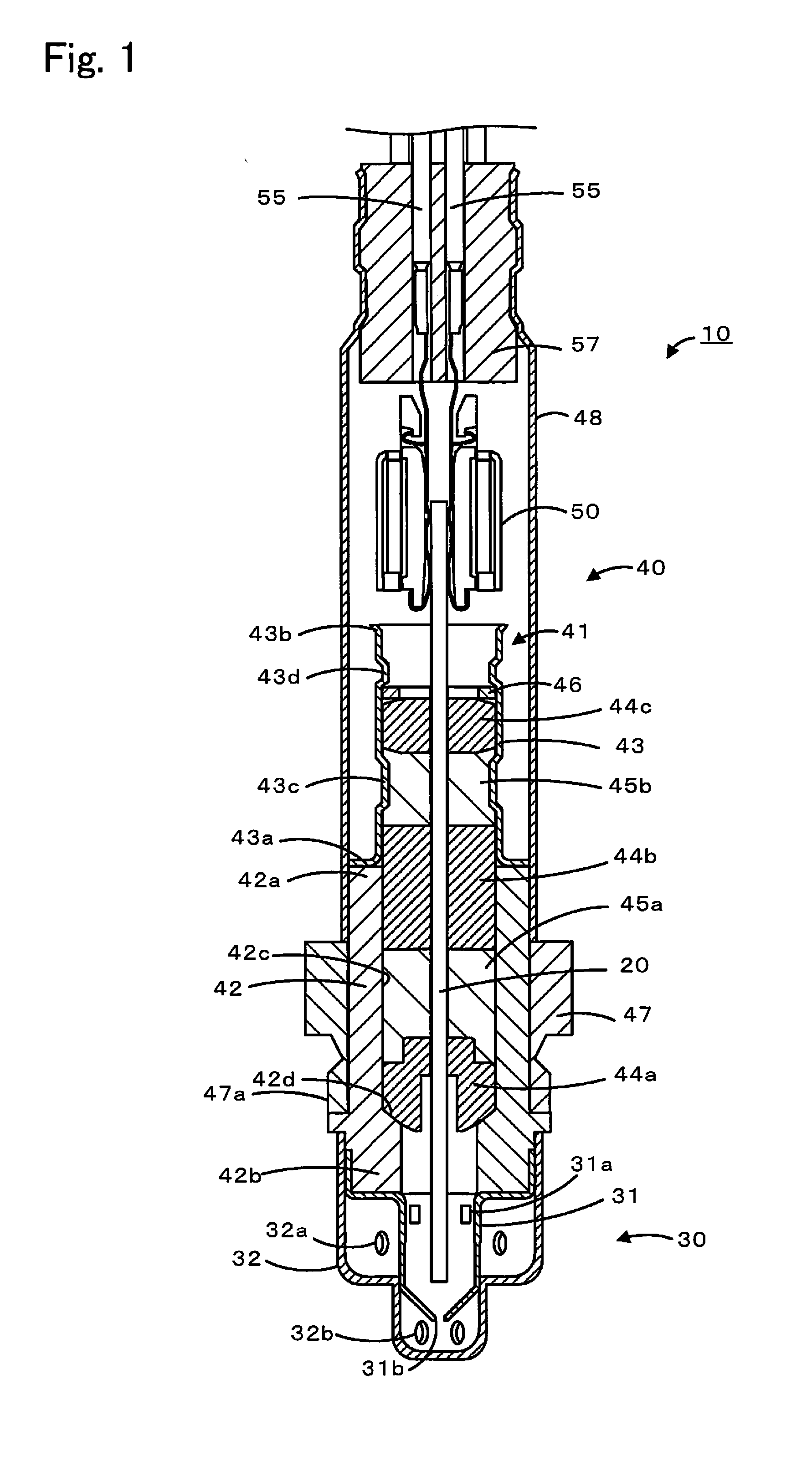

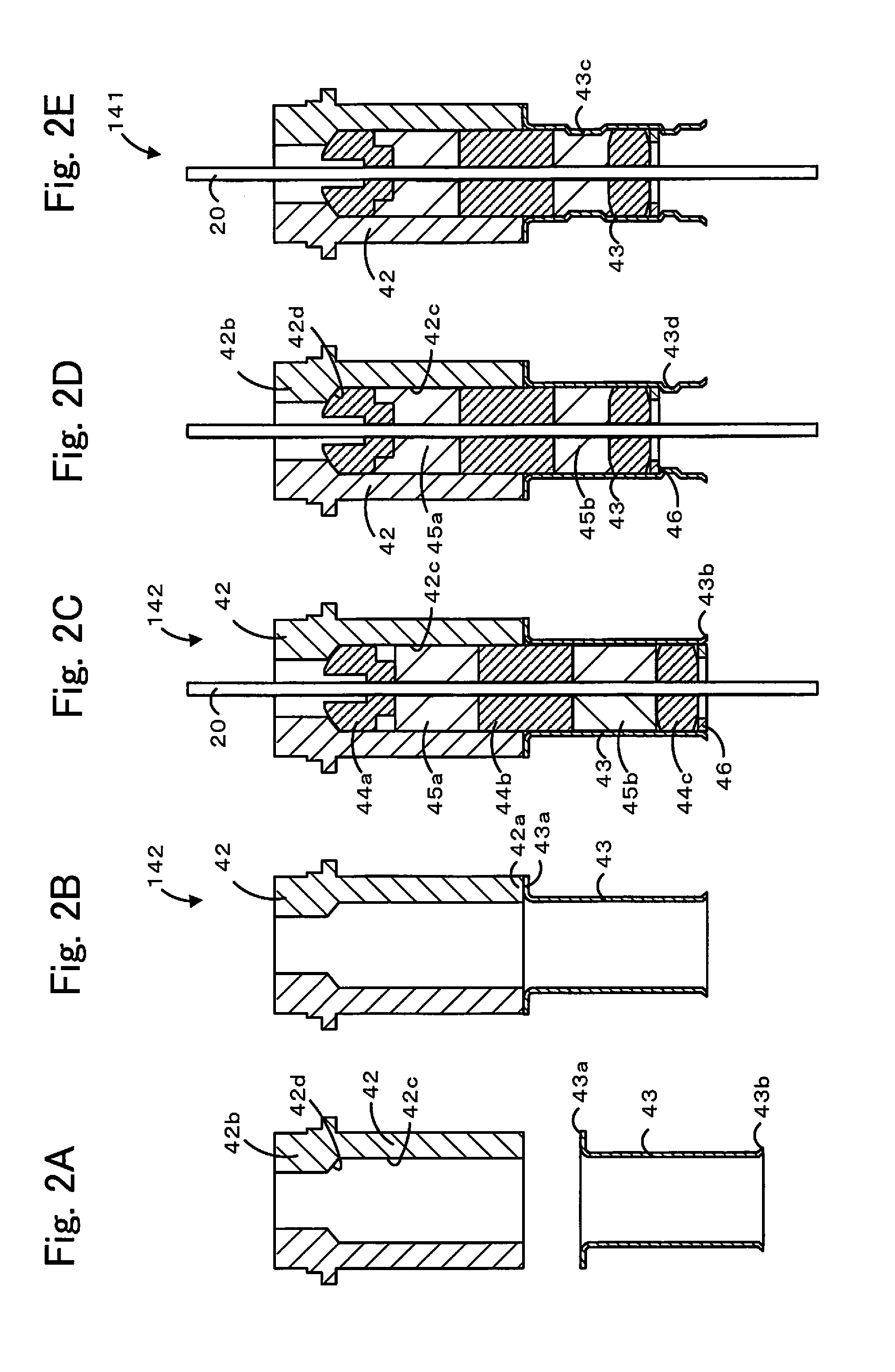

Gas sensor

ActiveUS20150268187A1Gas tightnessReduction in total void spaceMaterial analysis by electric/magnetic meansEngineeringVoid space

In a gas sensor 10, a powder compact 45a seals a void space between an inner peripheral surface 42c of metal-made main hardware 42 and a sensor element 20, and the inner peripheral surface 42c has arithmetic average roughness Ra of 0.5 to 5 μm. The gas sensor 10 includes supporters 44a and 44b, which are arranged in a penetration hole of the main hardware 42, which allow the sensor element 20 to penetrate therethrough, and which press the powder compact 45a in sandwiching relation from both sides in an axial direction. A surface of at least one of the supporters 44a and 44b has the arithmetic average roughness Ra of not more than 0.5 μm.

Owner:NGK INSULATORS LTD

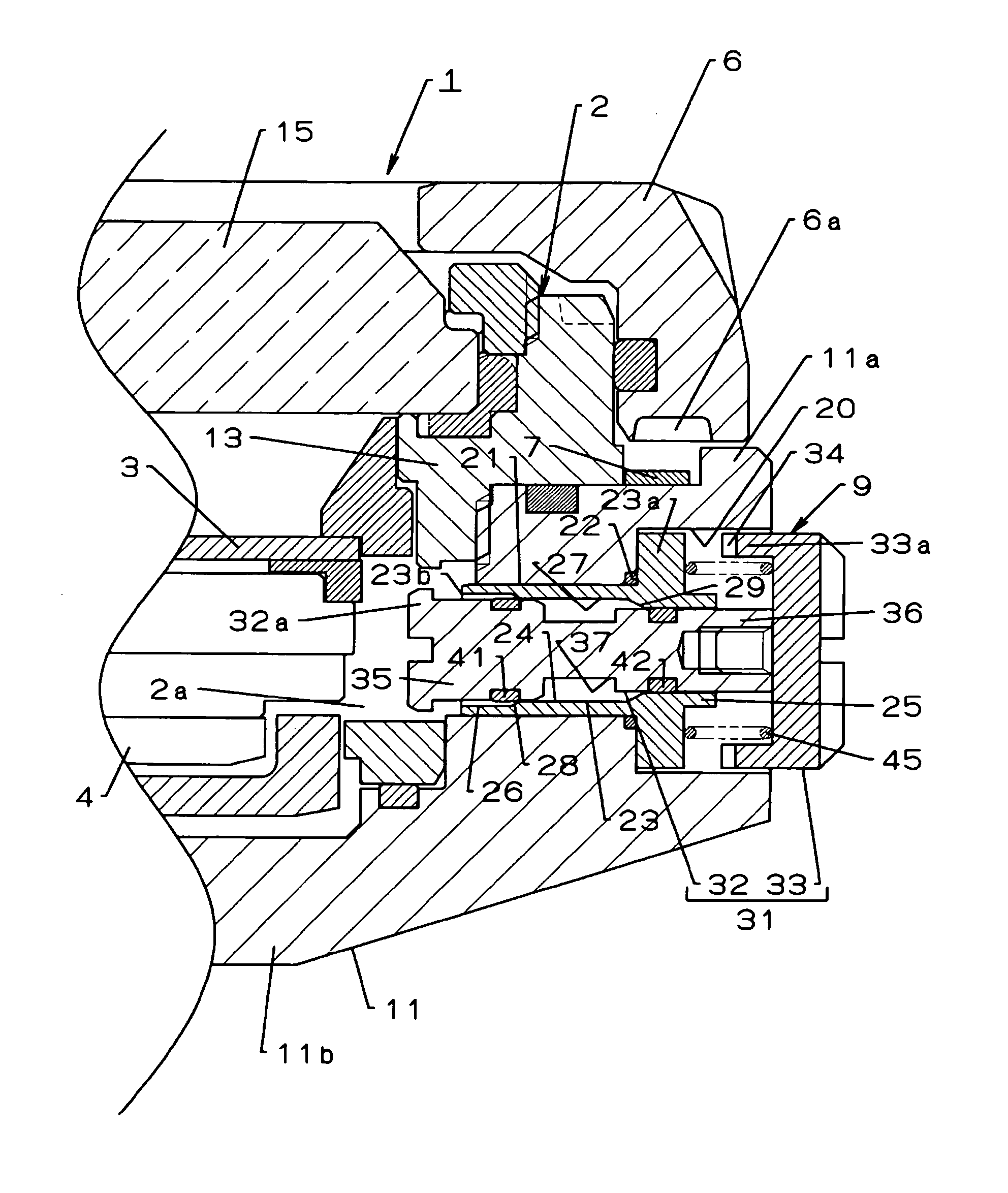

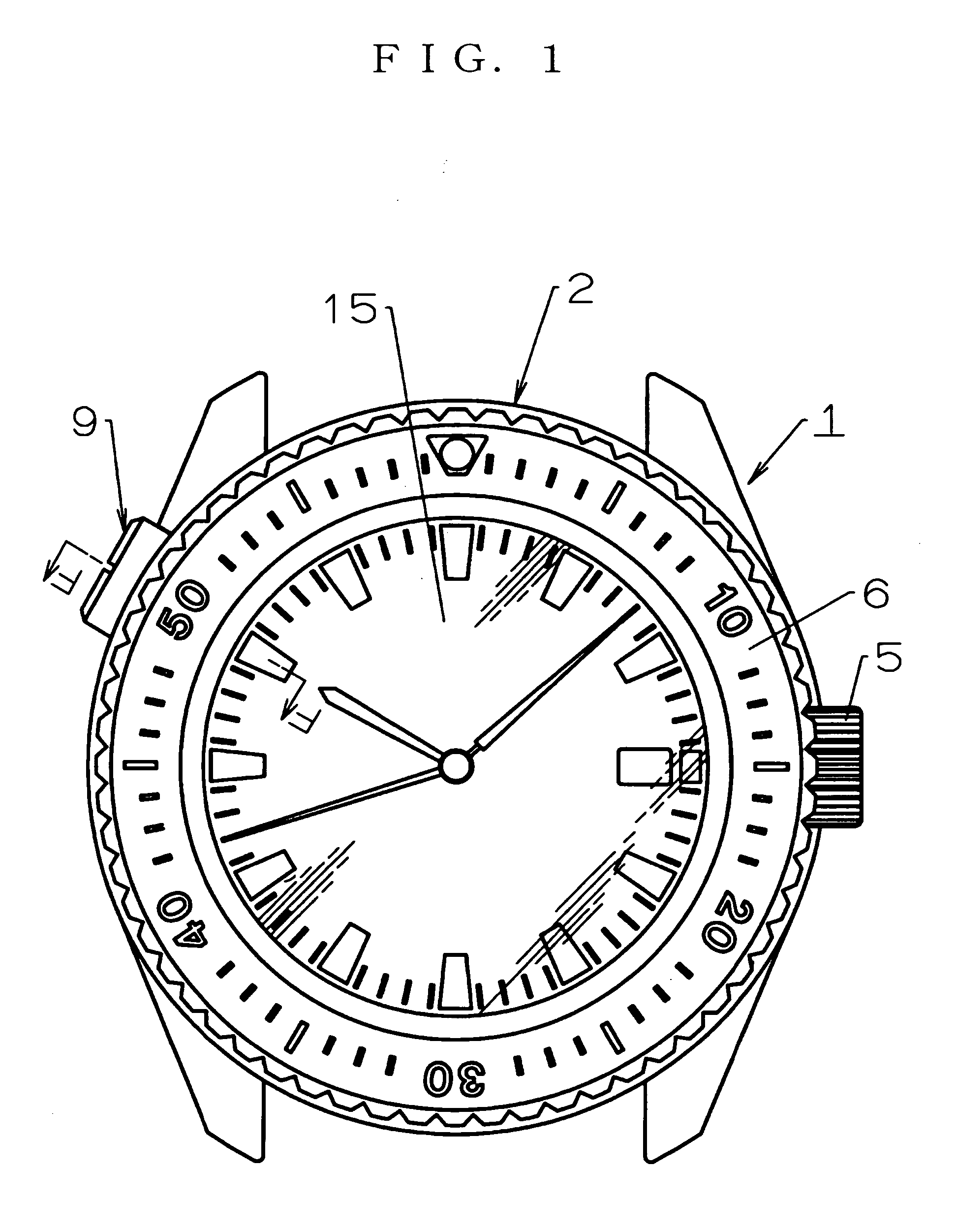

Portable timepiece

ActiveUS20110051570A1Reduce airtightnessIncrease pressureClockwork casesReciprocating motionCoil spring

A wristwatch is equipped with a timepiece exterior assembly, an exhaust button, a coil spring, and seal members. A pipe provided in the exterior assembly so as to establish communication between the interior and exterior thereof has seal surfaces and escape portions. The button is equipped with a shaft portion inserted into the pipe and exhibiting a detachment preventing portion to be caught by a pipe edge portion from within the exterior assembly, and a button portion depressed from the outside of the exterior assembly. The spring, which urges the button in an anti-pushing-in direction, is provided between the button portion and the timepiece exterior assembly. Seal members, mounted to the shaft portion in correspondence with the seal surfaces are moved between a sealing position and an exhaust position through axial reciprocating movement of the button, and, while in contact with the seal surfaces, define a closed space S together with the outer periphery of the shaft portion and an escape portion opposed to this outer periphery.

Owner:SEIKO INSTR INC

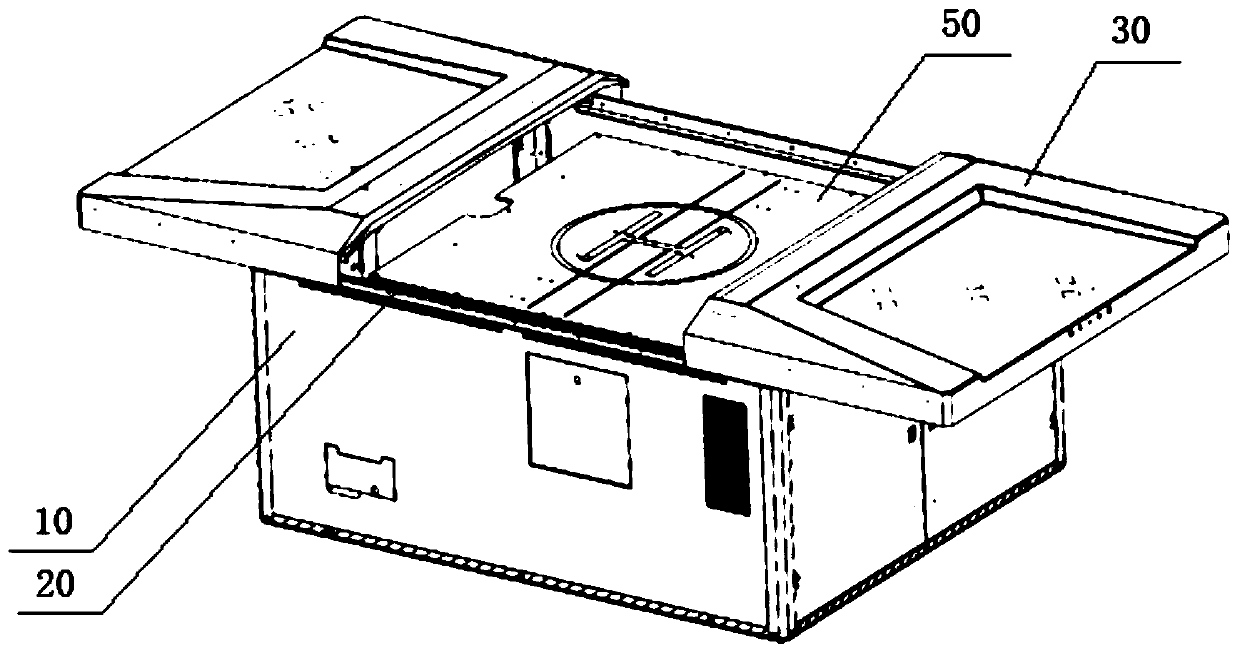

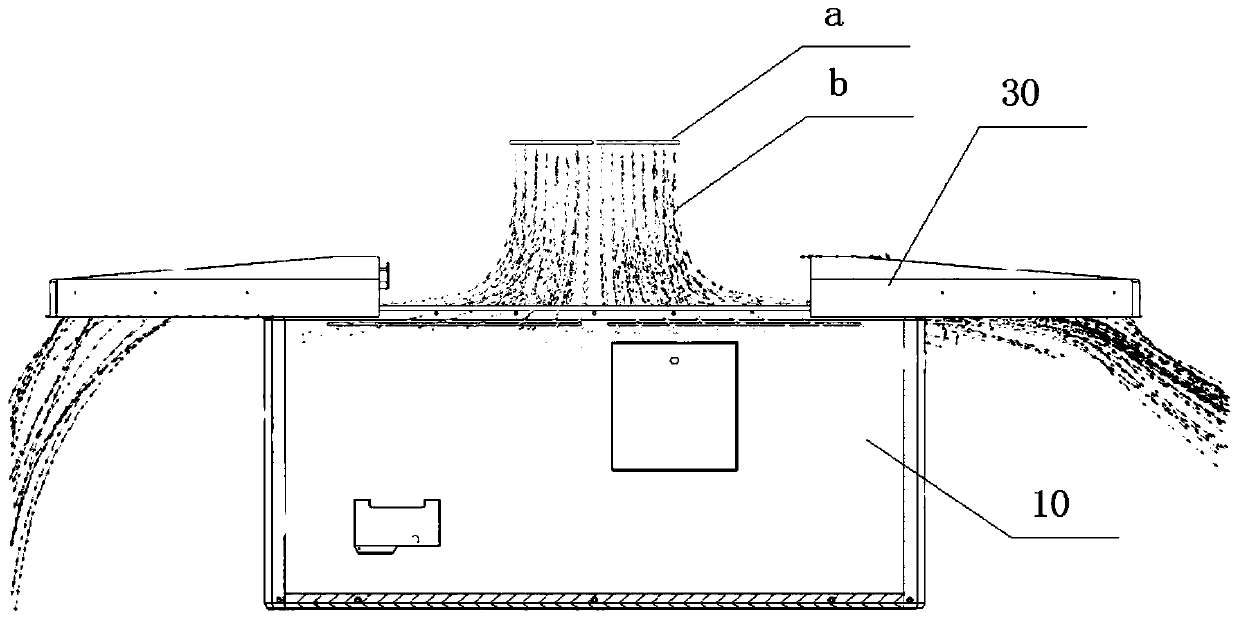

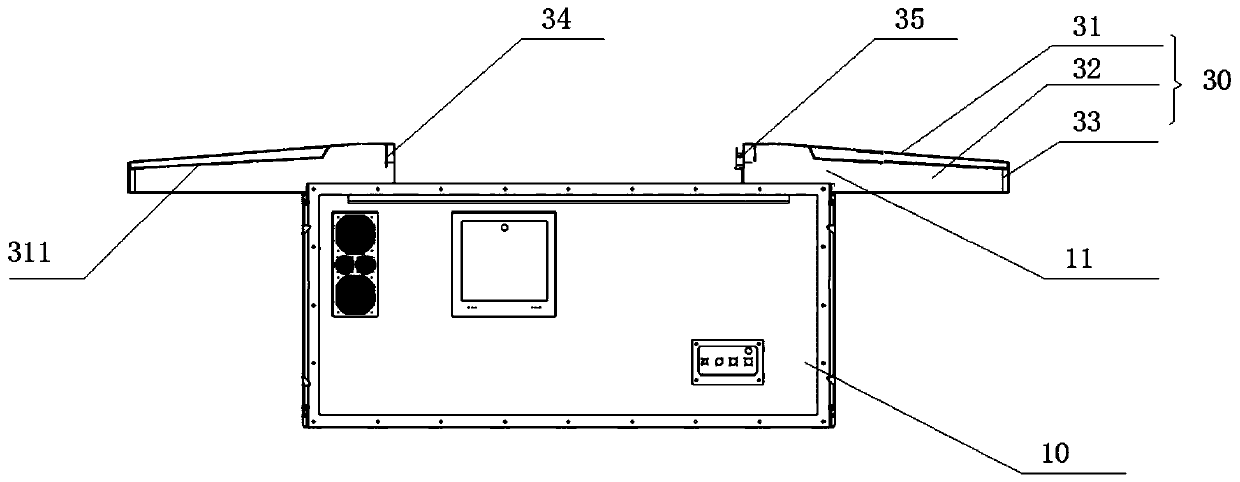

Unmanned aerial vehicle nest

ActiveCN111392054AAvoid unpredictable changesEnsure safetyPortable landing padsMarine engineeringUncrewed vehicle

The invention provides an unmanned aerial vehicle nest. The unmanned aerial vehicle nest comprises a nest body, a guide rail, two cabin doors, a driving device, a parking platform and a lifting device. A nest opening is formed in the top of the nest body; the guide rail is arranged at the machine nest opening; the two cabin doors are arranged at the machine nest opening in an openable and closablemanner, the two cabin doors are movably connected with the guide rail, the two cabin doors relatively slide along the guide rail to open or close the machine nest opening, and the bottoms of the cabin doors and the edge of the nest opening form an air guide opening; the parking platform is arranged in the nest body; the lifting device is arranged in the nest body and drives the parking platform to ascend to the nest opening. According to the unmanned aerial vehicle nest, the cabin doors on the two sides of the unmanned aerial vehicle take-off and landing platform are designed into the structures forming air ducts, so that the ground effect of the unmanned aerial vehicle can be relieved in the take-off and landing processes, unpredictable changes of the unmanned aerial vehicle are avoided,and the safety of the unmanned aerial vehicle and surrounding workers during landing of the unmanned aerial vehicle is guaranteed.

Owner:广州中科云图智能科技有限公司

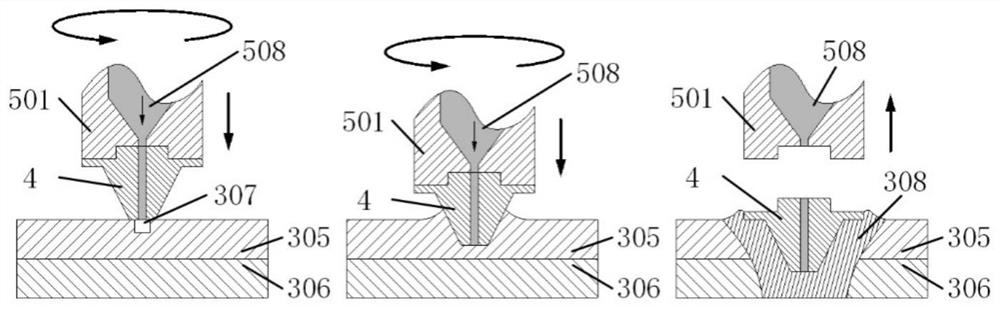

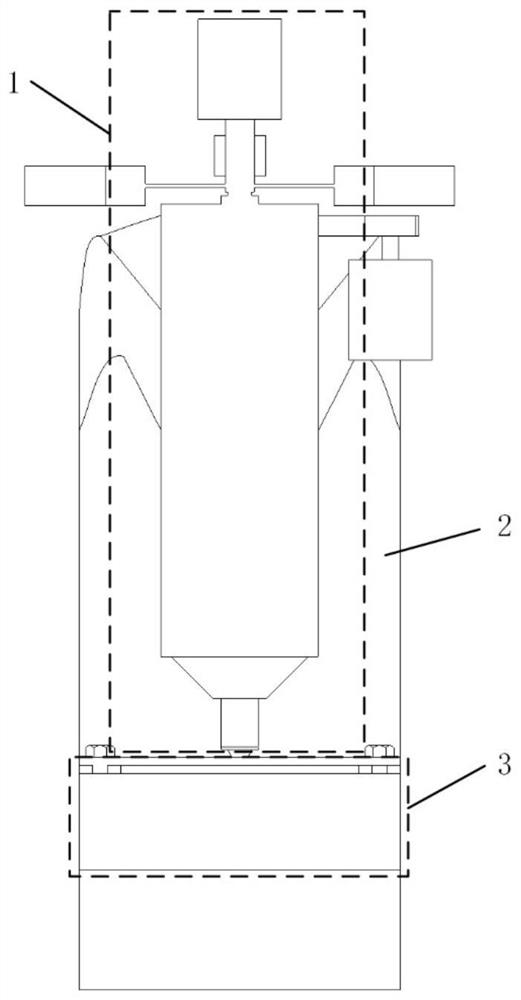

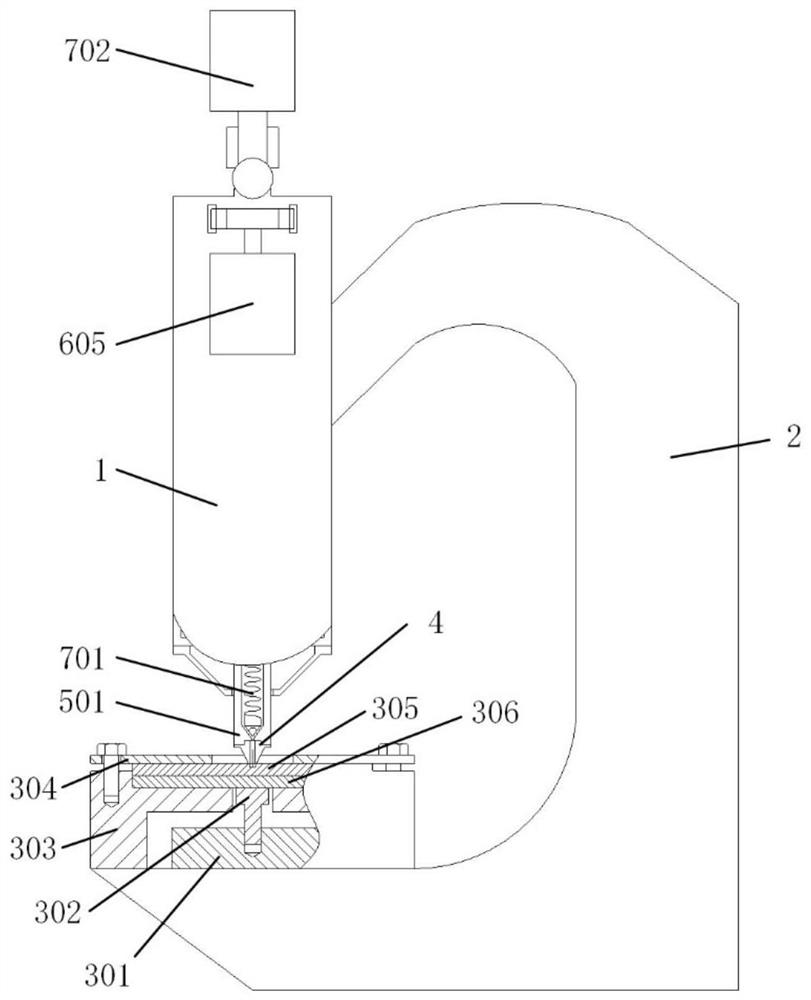

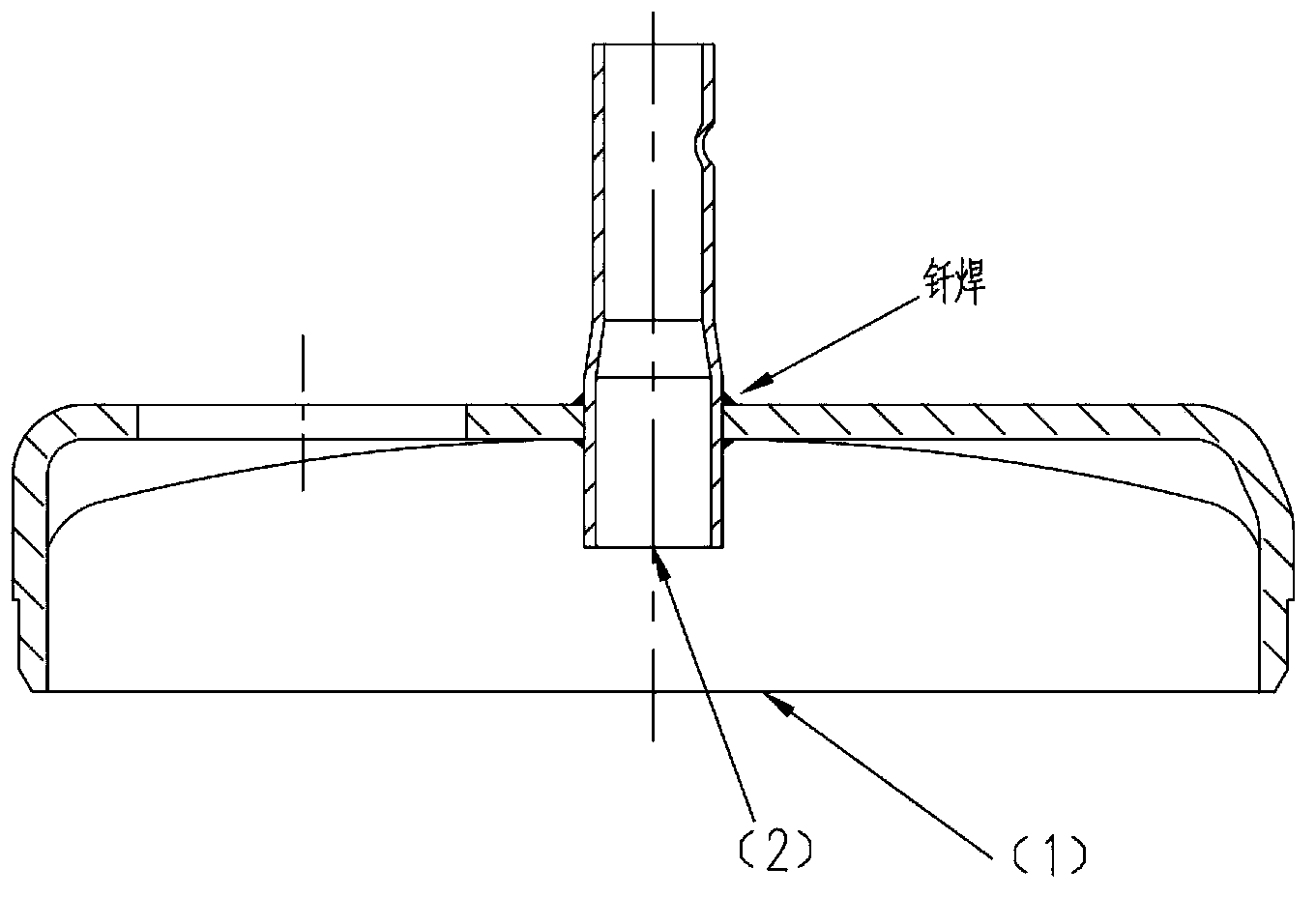

Powder reinforced stirring friction riveting method and device

ActiveCN111805073AImprove air tightnessReduce airtightnessNon-electric welding apparatusEngineeringForce sensor

The invention relates to a powder reinforced stirring friction riveting device. The powder reinforced stirring friction riveting device comprises a stirring friction riveting main shaft, a C-shaped rack and a workbench, wherein the stirring friction riveting main shaft comprises a rotary mechanism, a feeding mechanism, a vibrating / rotating mixing mechanism and a powder feeding mechanism; the stirring friction riveting main shaft is used for realizing the rotary motion and feed motion of a rivet and feeding and mixing powder; the C-shaped rack is used for fixing the stirring friction riveting main shaft and the workbench; and the workbench is mainly composed of a force cell, a sensor head, a tool die and a tool pressing plate and is used for clamping a to-be-riveted workpiece and testing the riveting acting force of the main shaft in real time. According to the powder reinforced stirring friction riveting device, the powder reinforced stirring friction riveting between same or differentlight plates at room temperature can be realized, a riveted stirring friction riveting joint without key hole defects and with good joint forming quality and high connecting strength can be obtained,the required riveting forming force is less than that of traditional riveting, and the powder reinforced stirring friction riveting device has the advantages of high efficiency, simplicity and convenience in operation and low energy consumption.

Owner:XI AN JIAOTONG UNIV

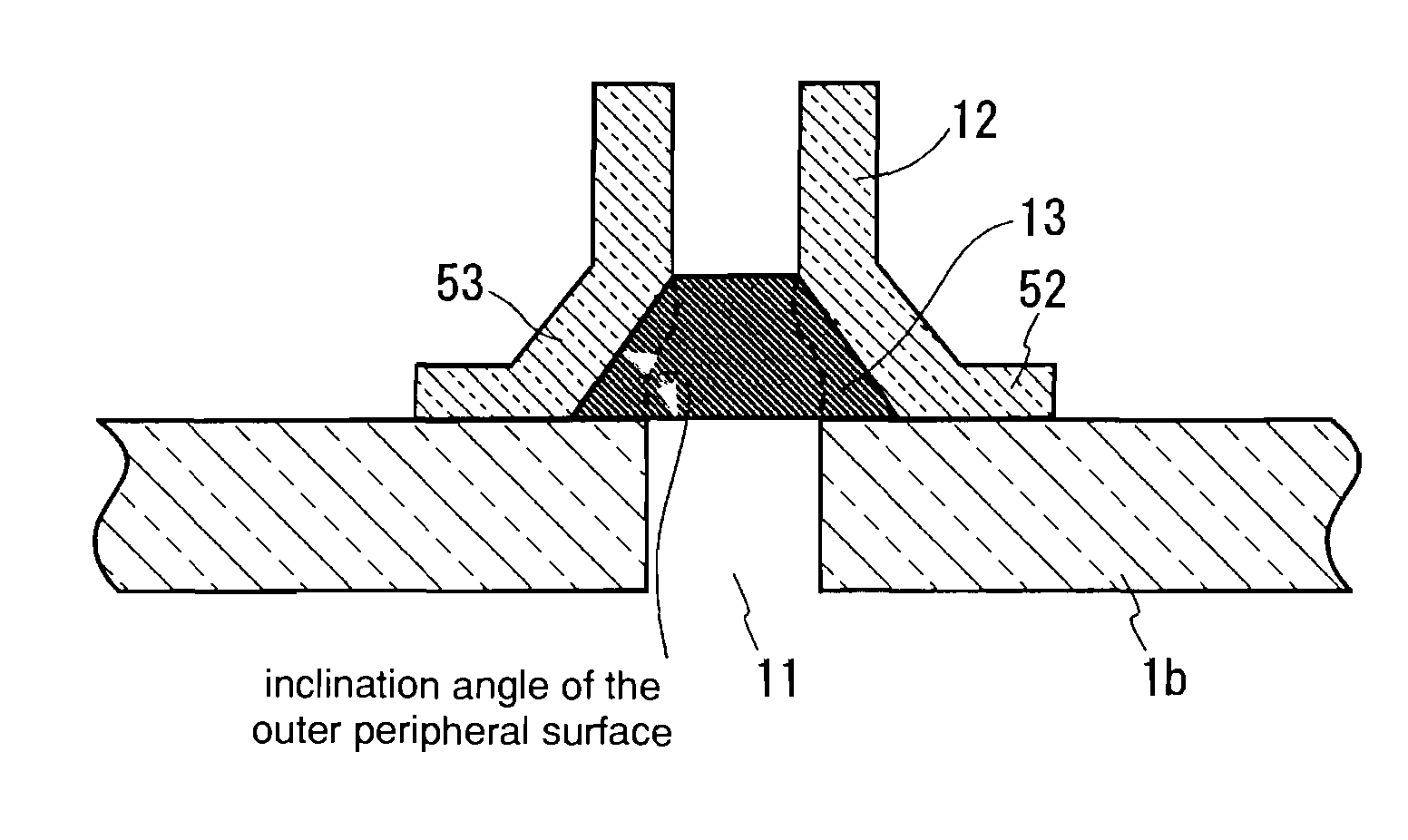

Display device, vent tube with glass ring, phosphate glass ring, and method of producing the same

InactiveUS20090260845A1Reduce airtightnessConvenient lifeCathode ray/electron stream lampsTube/lamp vessels exhaustionDisplay deviceEngineering

The present invention reduces the amount of lead used in a display device and improves its long-term moisture resistance. This display device includes: a panel (1b) provided with a hole (11) formed therein; a phosphate glass member (13); and a tube (12) mounted on the panel (1b) via the glass member (13) so as to cover the hole (11). The glass member (13) is bonded to at least a partial area of the inner wall surface of the tube (12) and to a partial area of the panel (1b), so that the entire periphery of the end face of the tube (12) located on the side of the hole (13) is in contact with the panel (1b).

Owner:PANASONIC CORP

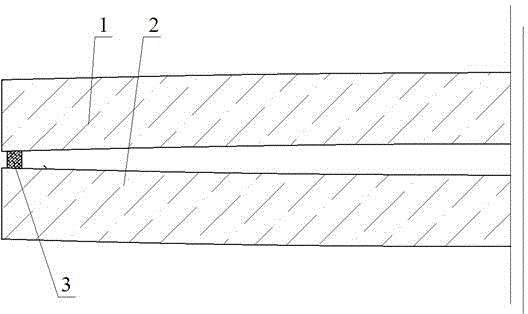

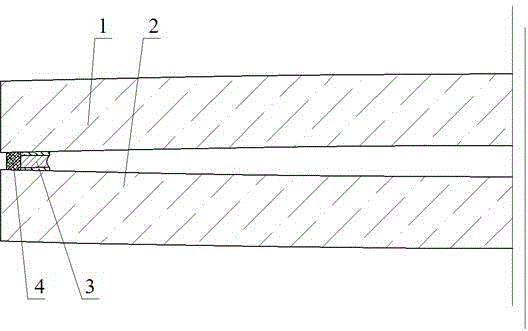

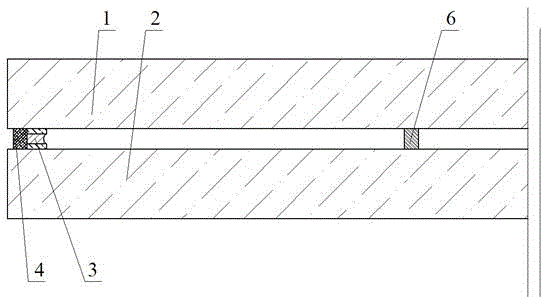

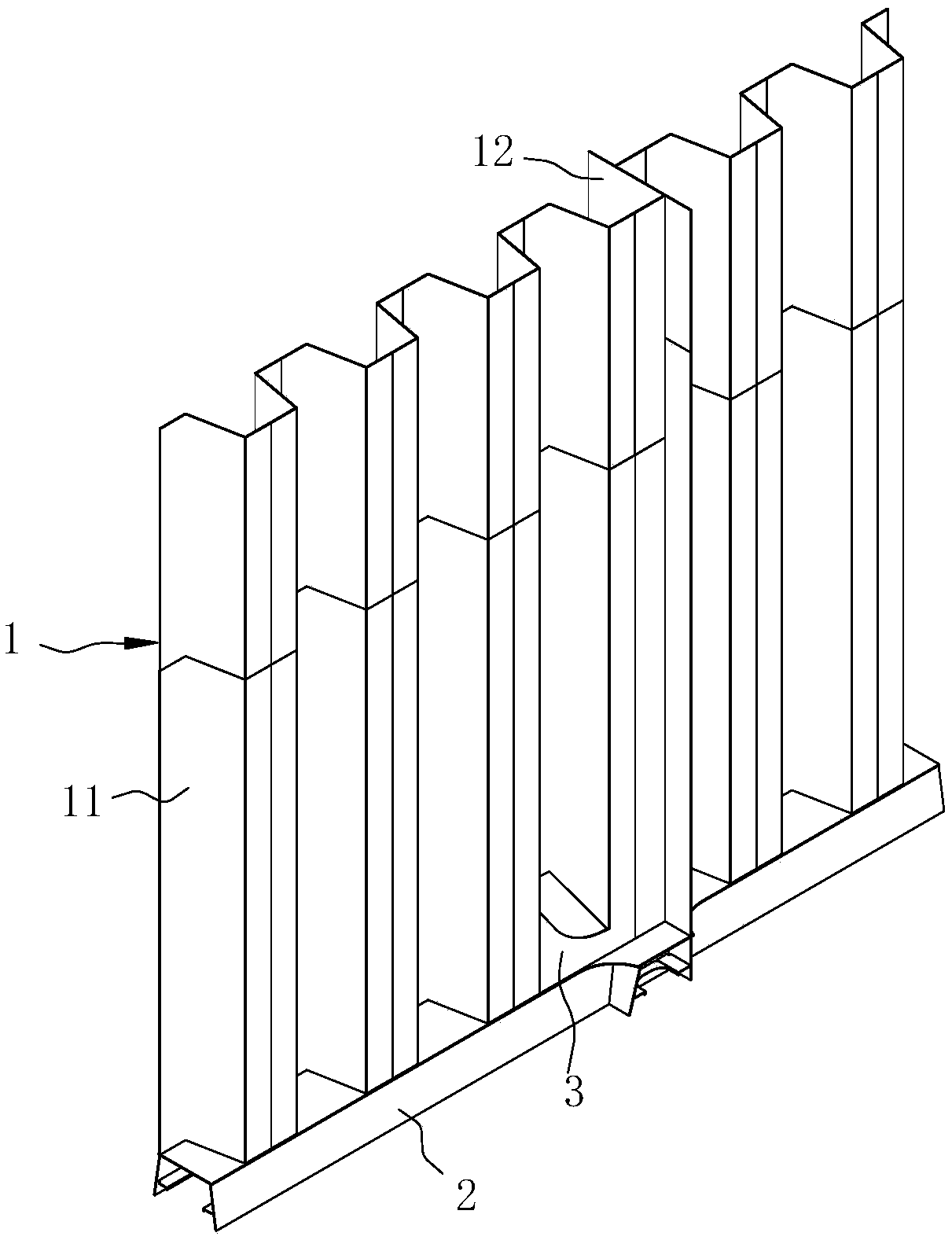

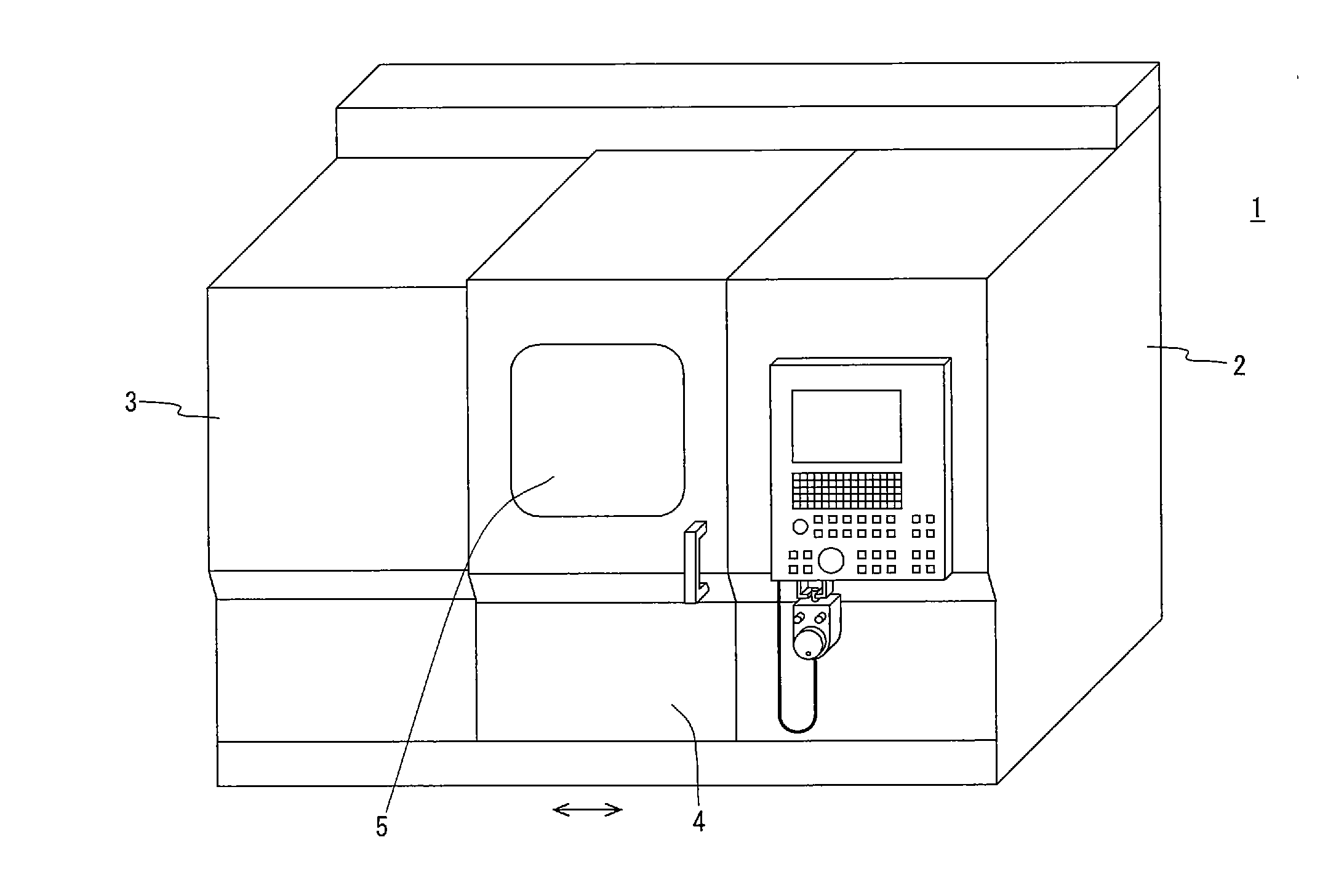

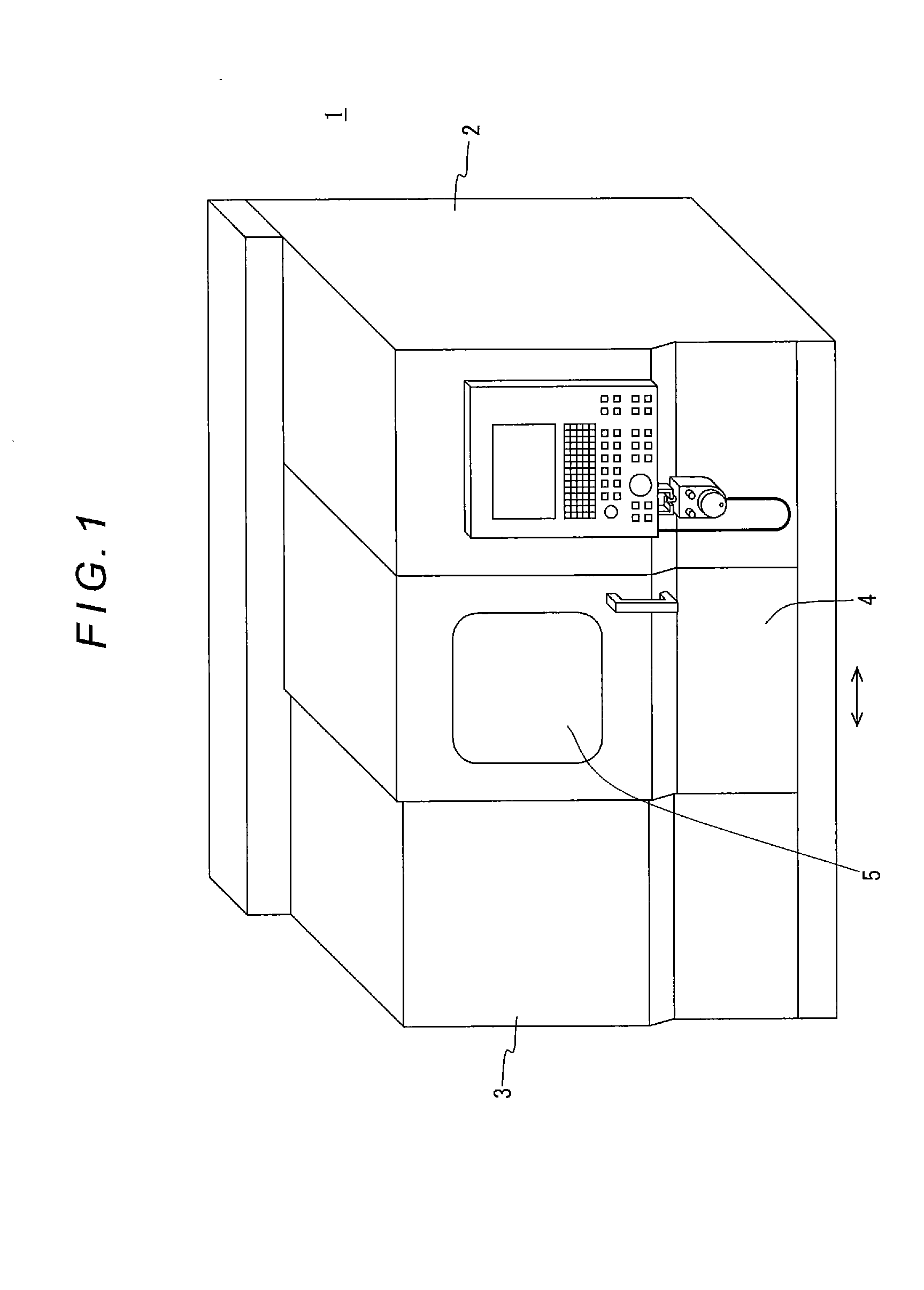

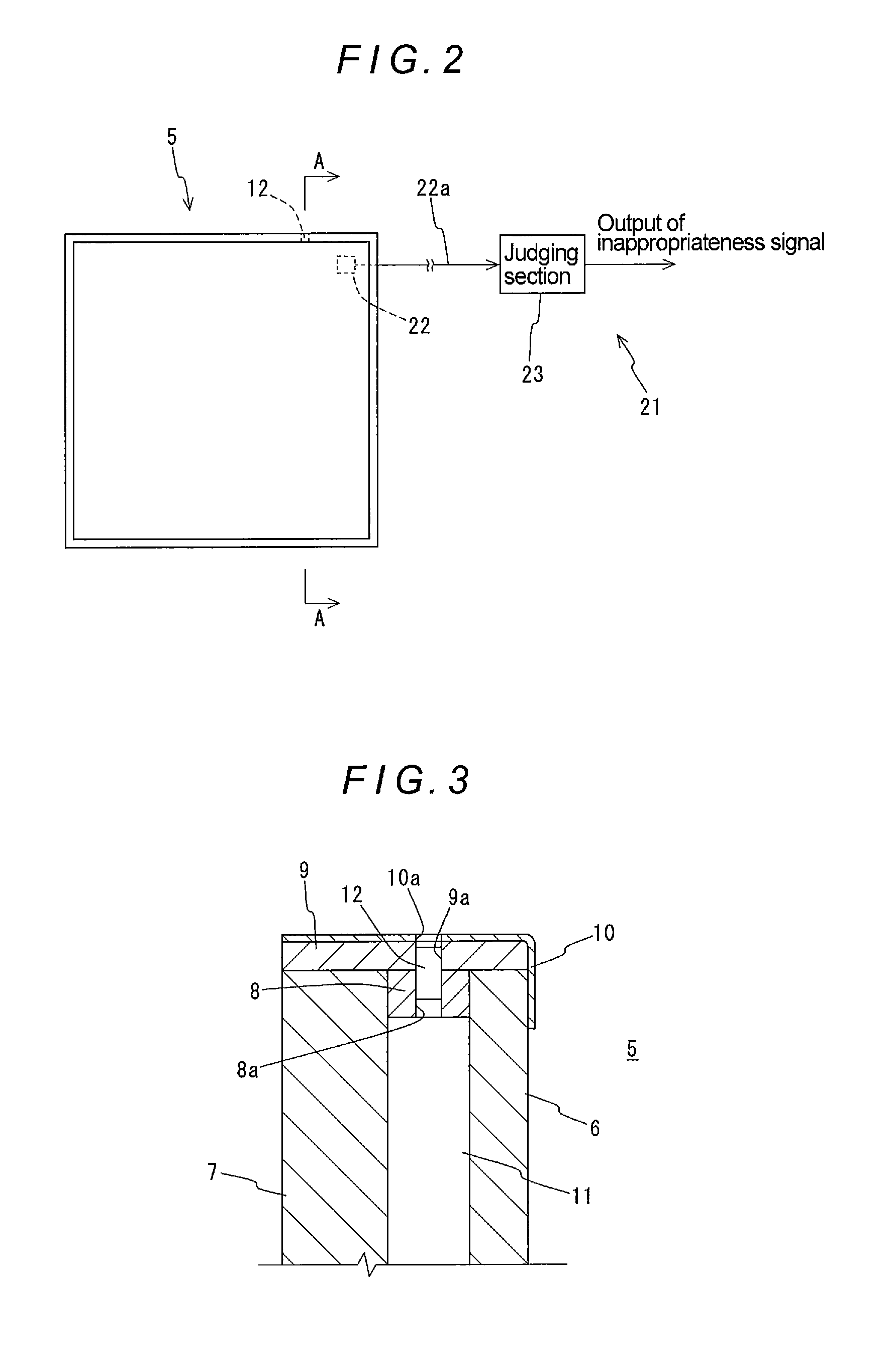

Method and Apparatus for Detecting Airtight State of Machine-Tool Window

ActiveUS20140150533A1High wear resistanceLow resistanceDetection of fluid at leakage pointMaintainance and safety accessoriesEngineeringPressure sensor

Methods and apparatus for detecting machine tool window airtightness includes an airtight state detector, having a sensor detecting the pressure in a space of the window, and a judging section for determining appropriateness of the airtight state of the space based on a pressure value from the pressure sensor and outputting a judgment result. Pressure in the window space, which initially may be pressurized or pressure-reduced, is detected intermittently by the pressure sensor, and the judging section determines appropriateness of the airtight state of the window on the basis of a variation state of the detected pressure.

Owner:DMG MORI SEIKI CO LTD

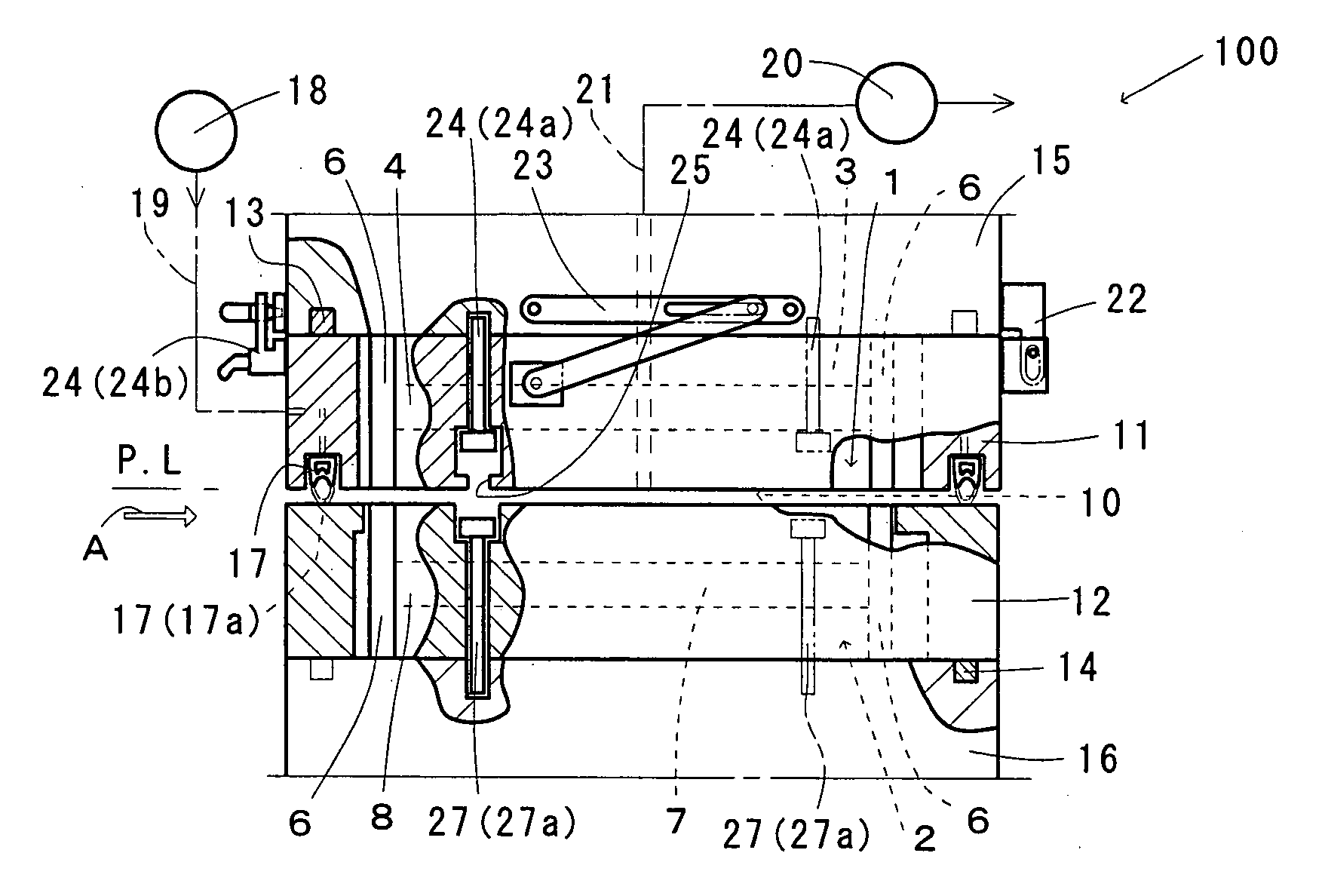

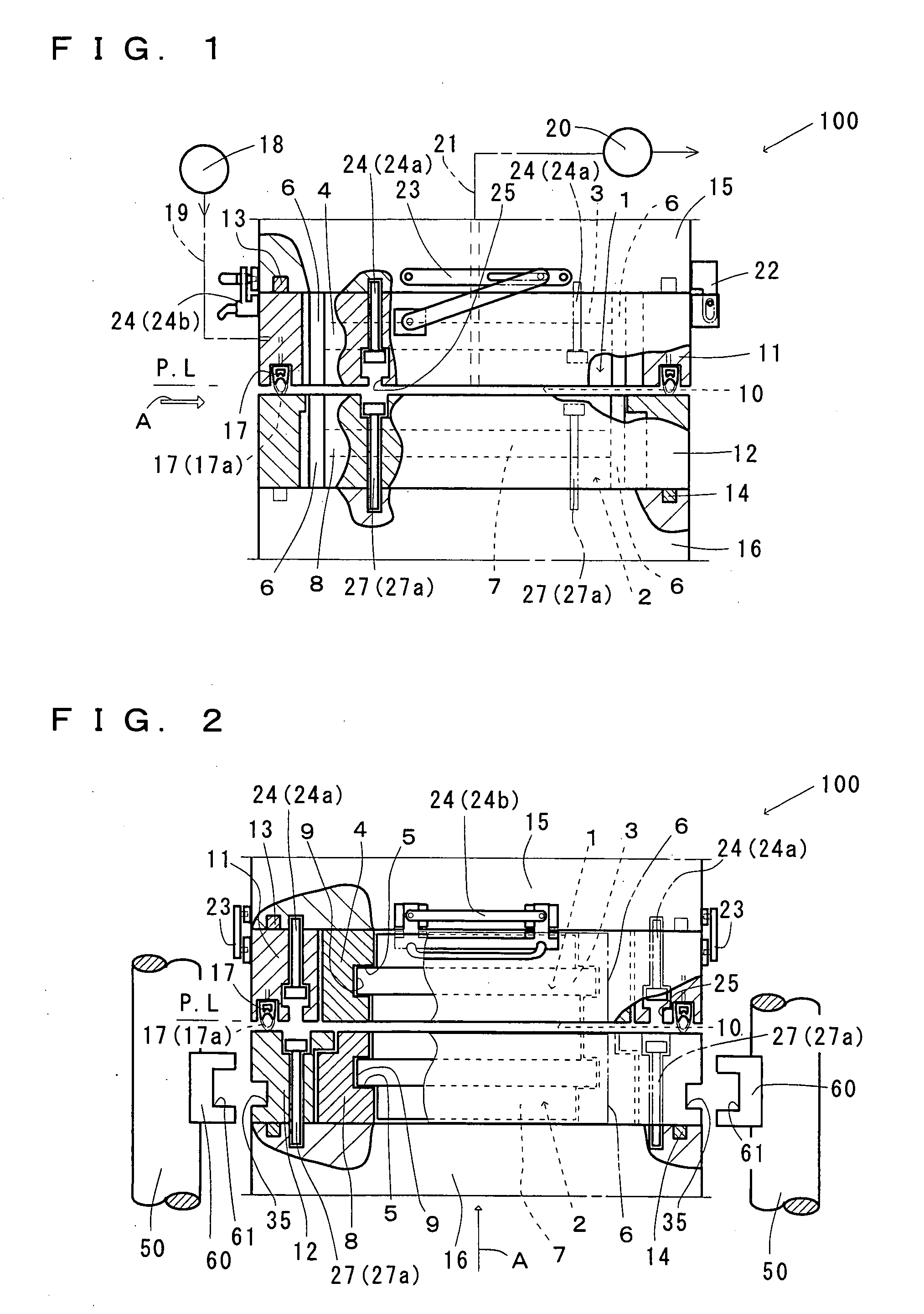

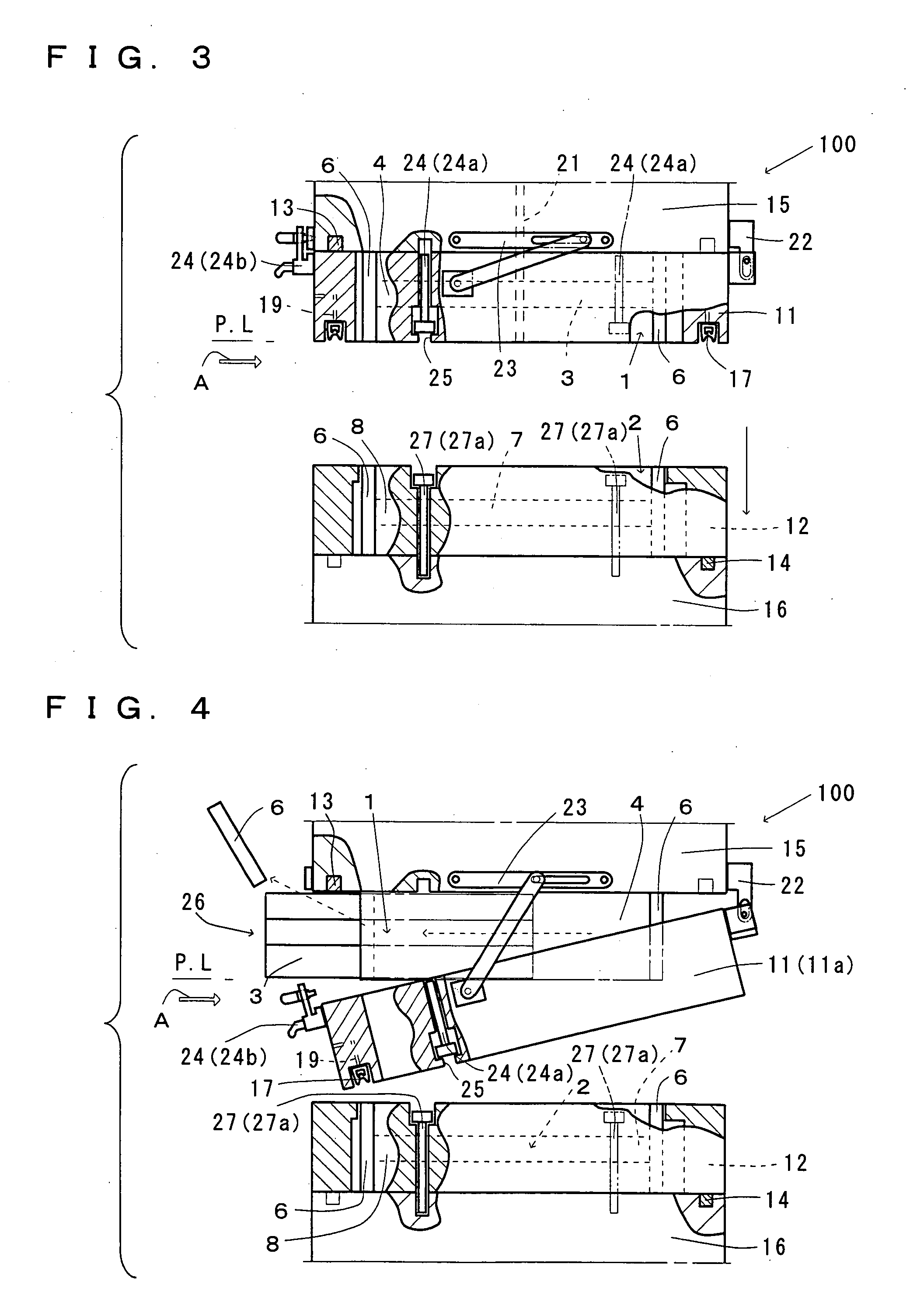

Resin-Sealing and Molding Apparatus with Sealing Mechanism and Method of dismounting Contitiuent Part of Die Assembly Fitted Therein

InactiveUS20090162471A1Reduce airtightnessLow efficiencySolid-state devicesSemiconductor/solid-state device manufacturingShell moldingAmbient air

A resin-sealed molding apparatus furnished with sealing means. The sealing means includes upper-die-side ambient air shutoff member fixed to upper-die-side mount base board so as to surround the lateral side of upper die and lower-die-side ambient air shutoff member fixed to lower-die-side mount base board so as to surround the lateral side of lower die. The upper-die-side ambient air shutoff member is fixed to the upper-die-side mount base board by means of upper-die-side fixing tool. The lower-die-side ambient air shutoff member is fixed to the lower-die-side mount base board by means of lower-die-side fixing tool. The upper-die-side ambient air shutoff member and the upper-die-side mount base board are rotatably connected by means of axis member. Only by dismounting of the lower-die-side fixing tool from the lower-die-side mount base board and the lower-die-side ambient air shutoff member, there can be realized the state in which the lower-die-side ambient air shutoff member can be completely dismounted from the lower-die-side mount base board.

Owner:TOWA

Vacuum glass insulation panel and preparation method thereof

InactiveCN105669003ASolve the sealing problemSolve the vacuum problemGlass reforming apparatusGlass productionFlat glassAdhesive

The present invention discloses a vacuum glass insulation panel. The vacuum glass insulation panel includes an upper glass and a lower glass. The peripheries of the upper glass and the lower glass are sealed and connected together through one, two or multiple sealing materials. The sealing materials comprises a glass solder, a metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or flat glass. The convex surface of the convex glass faces towards the outside. The vacuum glass insulation panel preparation method is simple in processes. The prepared vacuum glass insulation panel and tempered vacuum glass insulation panel overcome the deficiencies in the prior art. The preparation method can effectively ensure the tightness and service life of the vacuum glass insulation panel, and can realize mechanized, automatic and mass productions.

Owner:戴长虹

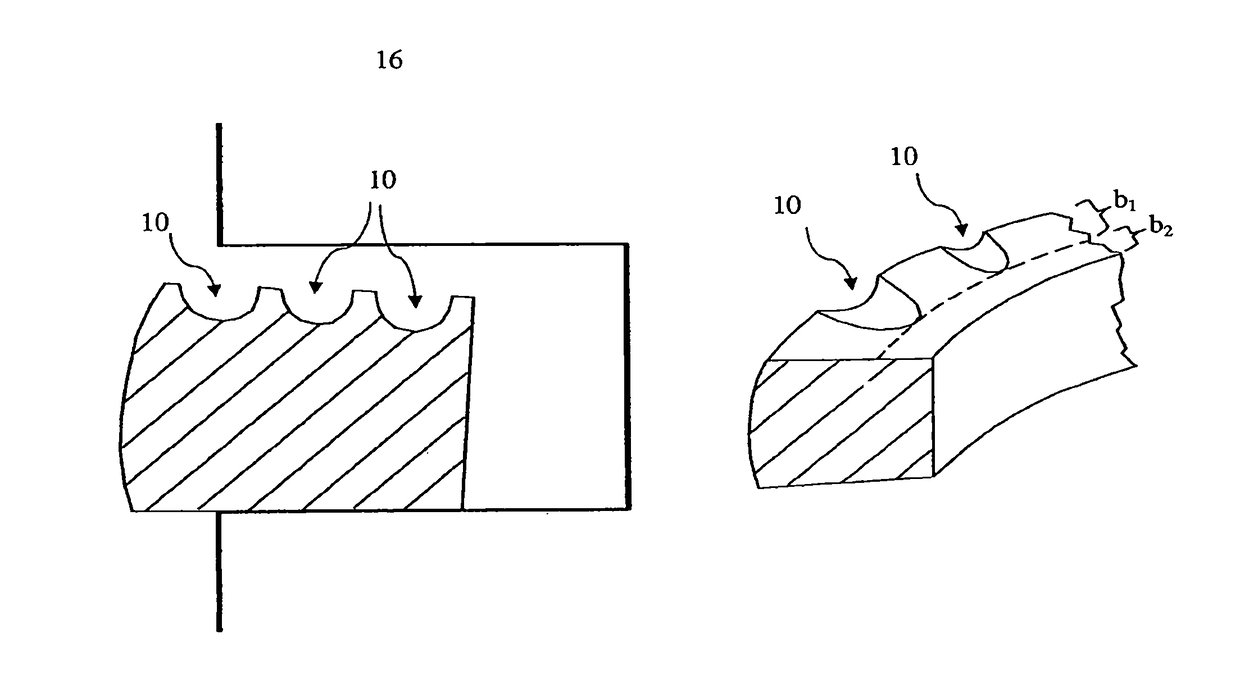

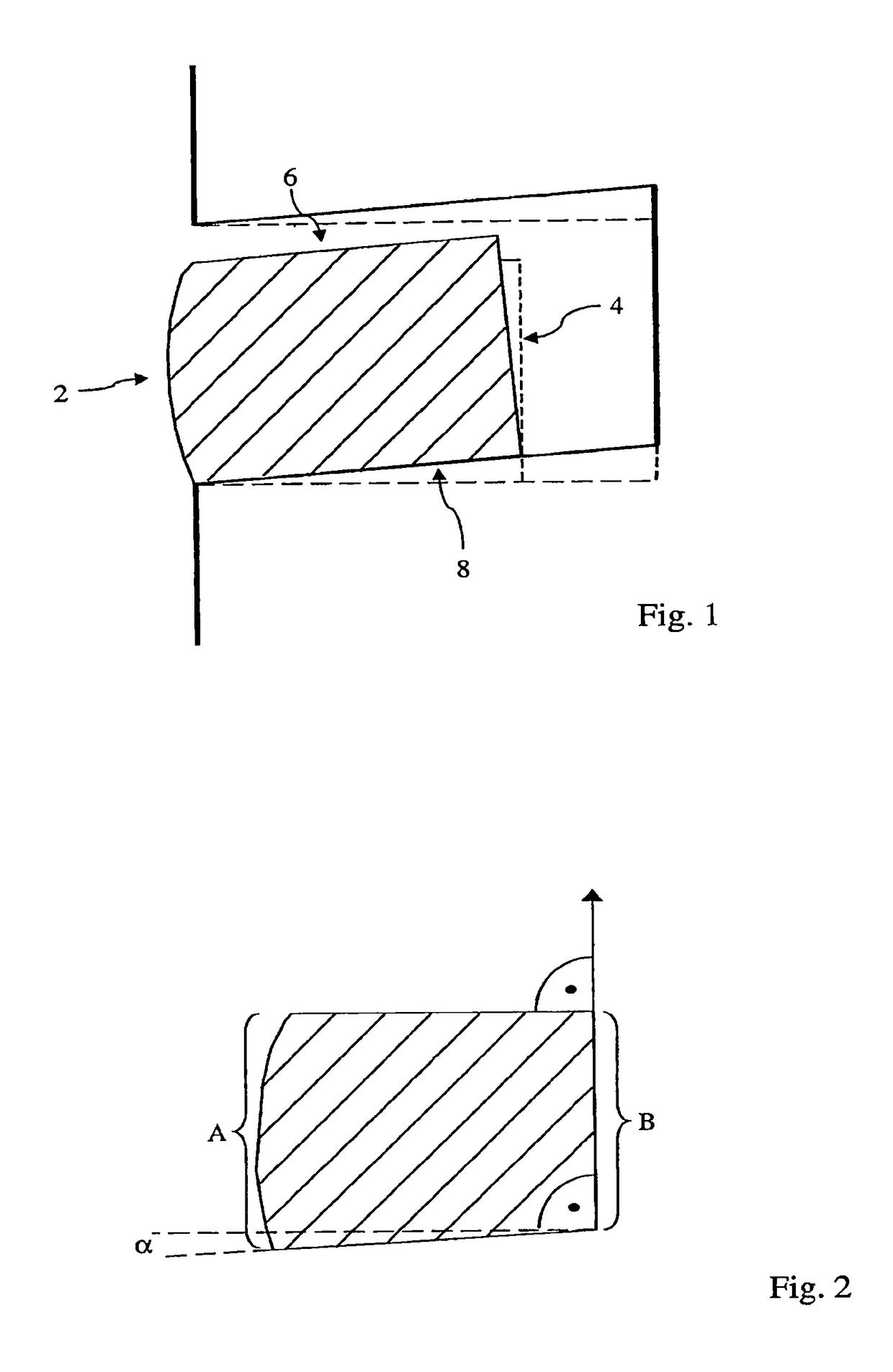

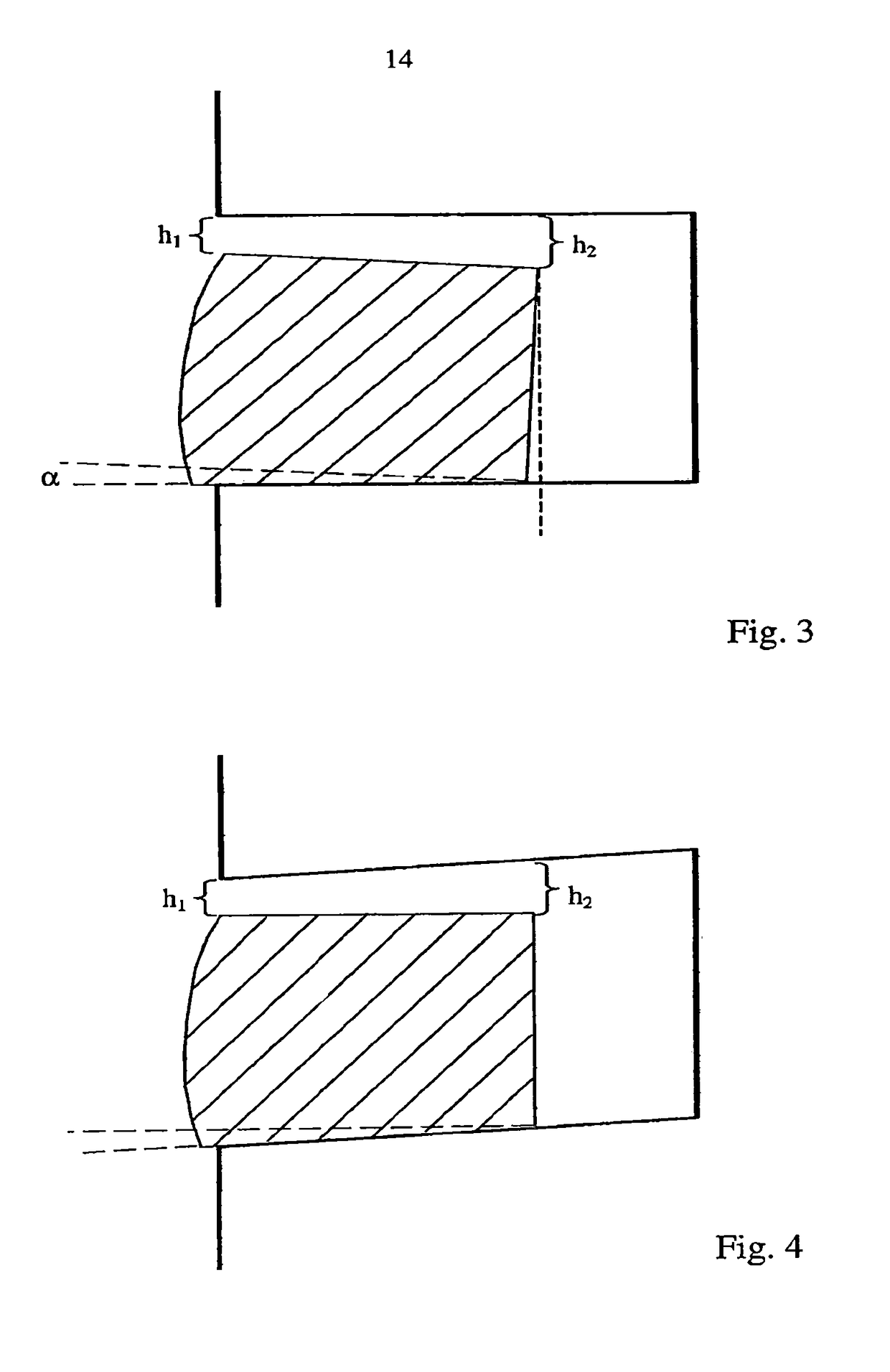

Piston ring

A piston ring for a piston of a piston engine has an external circumferential surface (2), and internal circumferential surface (4), and upper flank (6) pointing in the direction of the piston upper side, and a lower flank (8) pointing in the direction of the piston underside. The lower flank (8) runs obliquely with respect to the upper flank (6), so that axial height (A) of the piston ring is grater at the external circumferential surface (2) than the axial height (B) at the internal circumferential surface (4), and wherein on each side of the thrust of the piston ring at least one recess (10) is provided in the upper flank (6).

Owner:FEDERAL MOGUL BURSCHEID

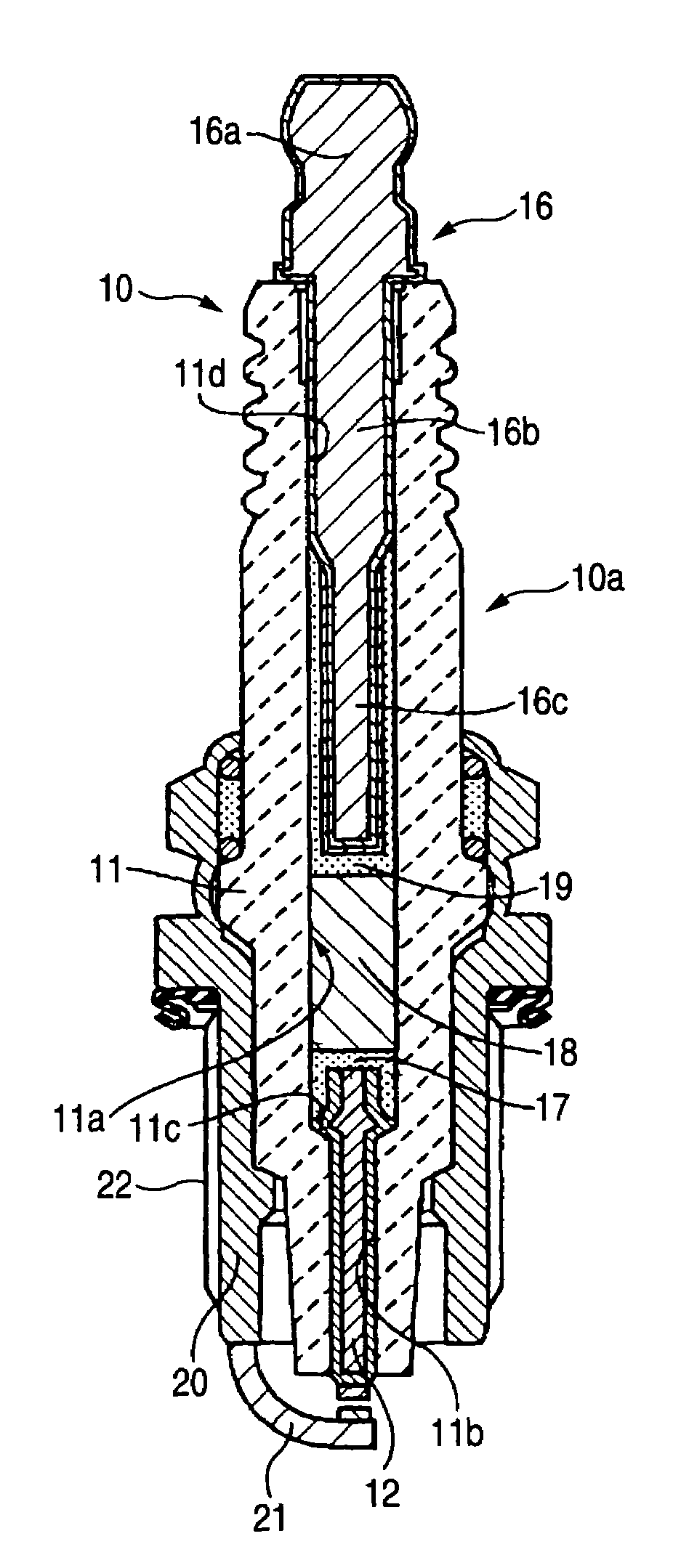

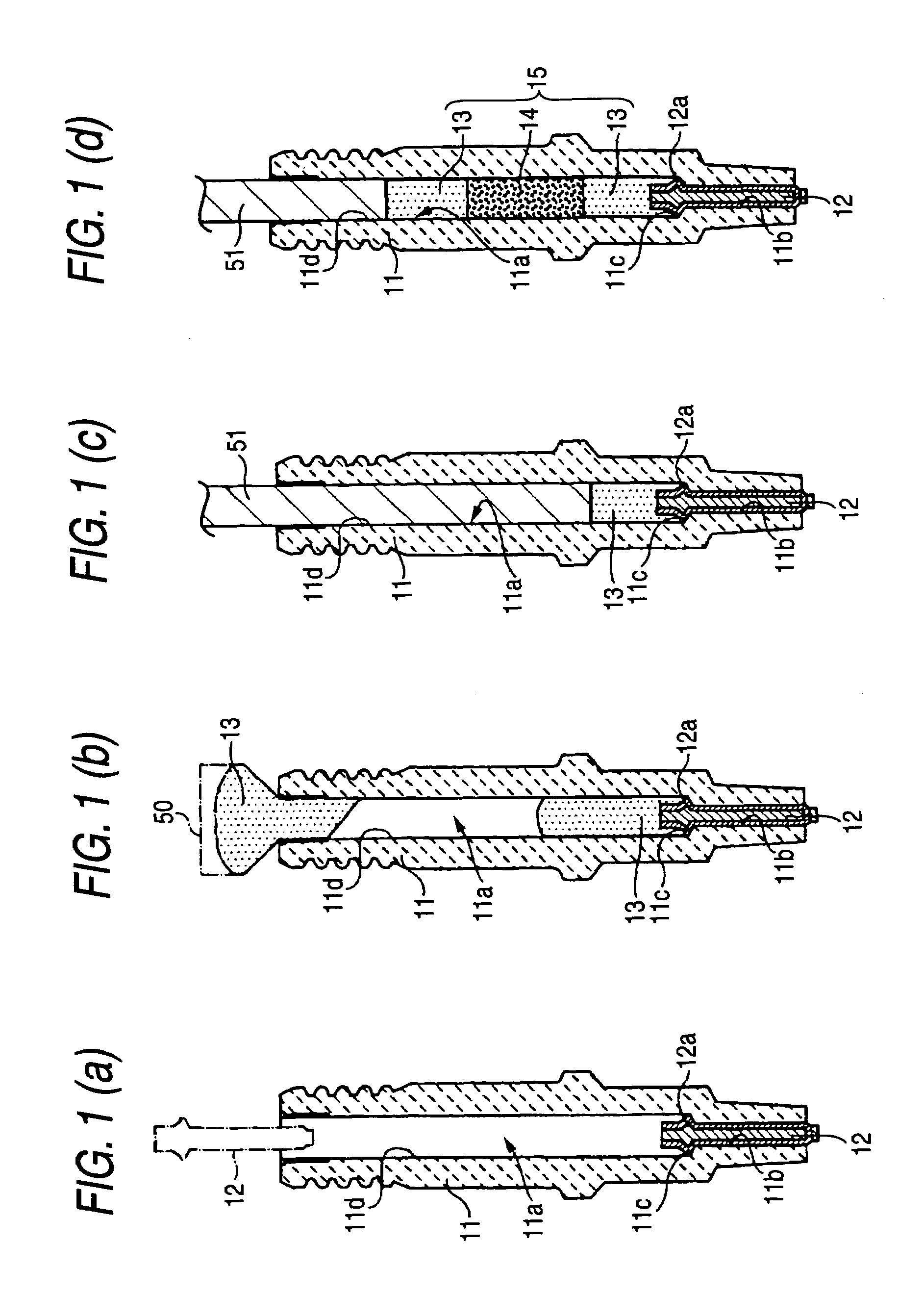

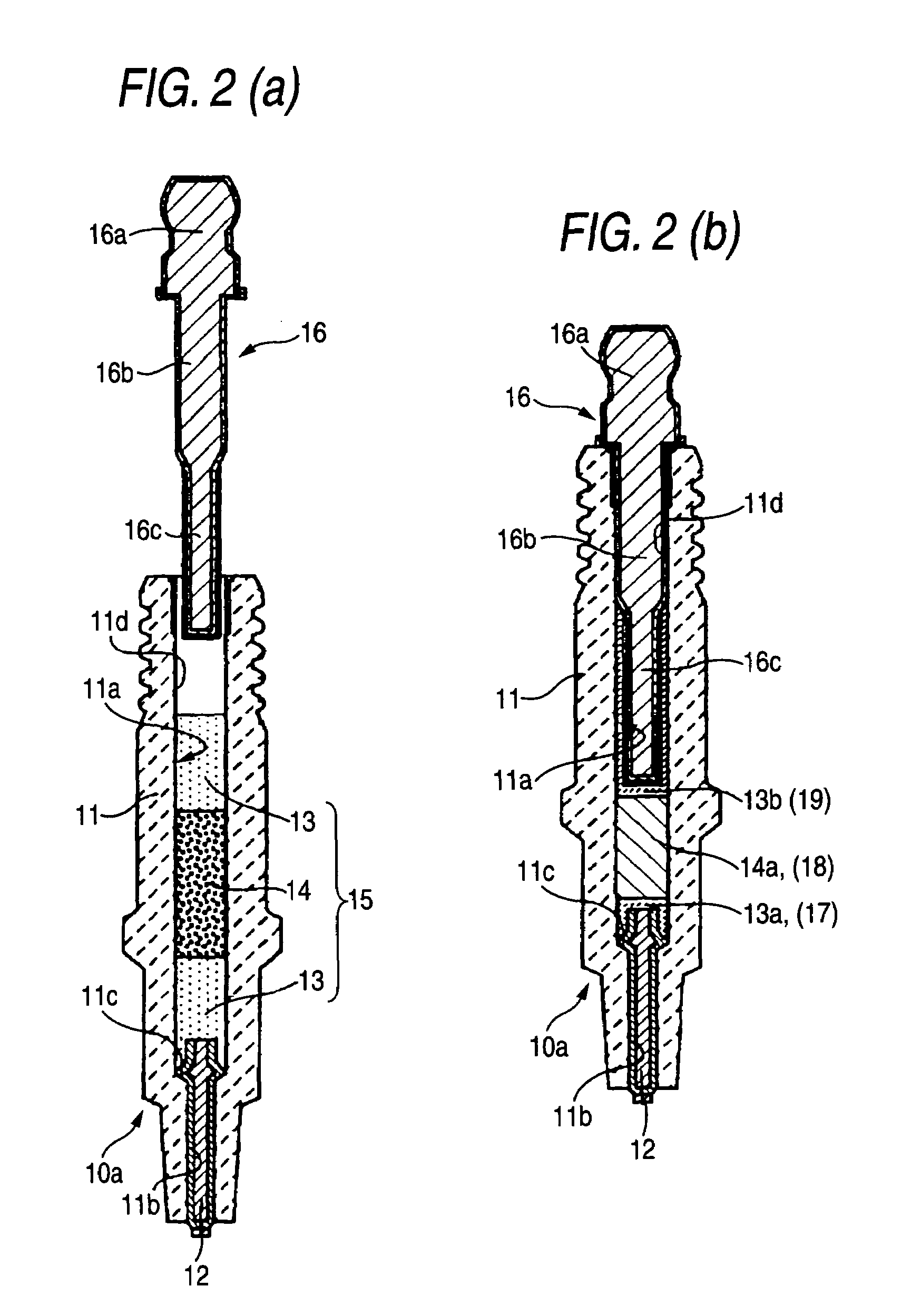

Spark plug with excellent impact resistance conductive seal, and method for producing the same

ActiveUS7626320B2More impact resistantReduce airtightnessFuel injection apparatusMachines/enginesAlloyAir tightness

An object of the present invention is to provide a spark plug which has more excellent impact resistance with electrical conductivity and airtightness kept excellent. In the invention, each of first and second electrically conductive sealing layers (17) and (19) is made of electrically conductive glass containing a glass component and a metal component. The metal component at least contains a Cu—Zn alloy which contains Cu as a first component, and Zn as a second component.

Owner:NGK SPARK PLUG CO LTD

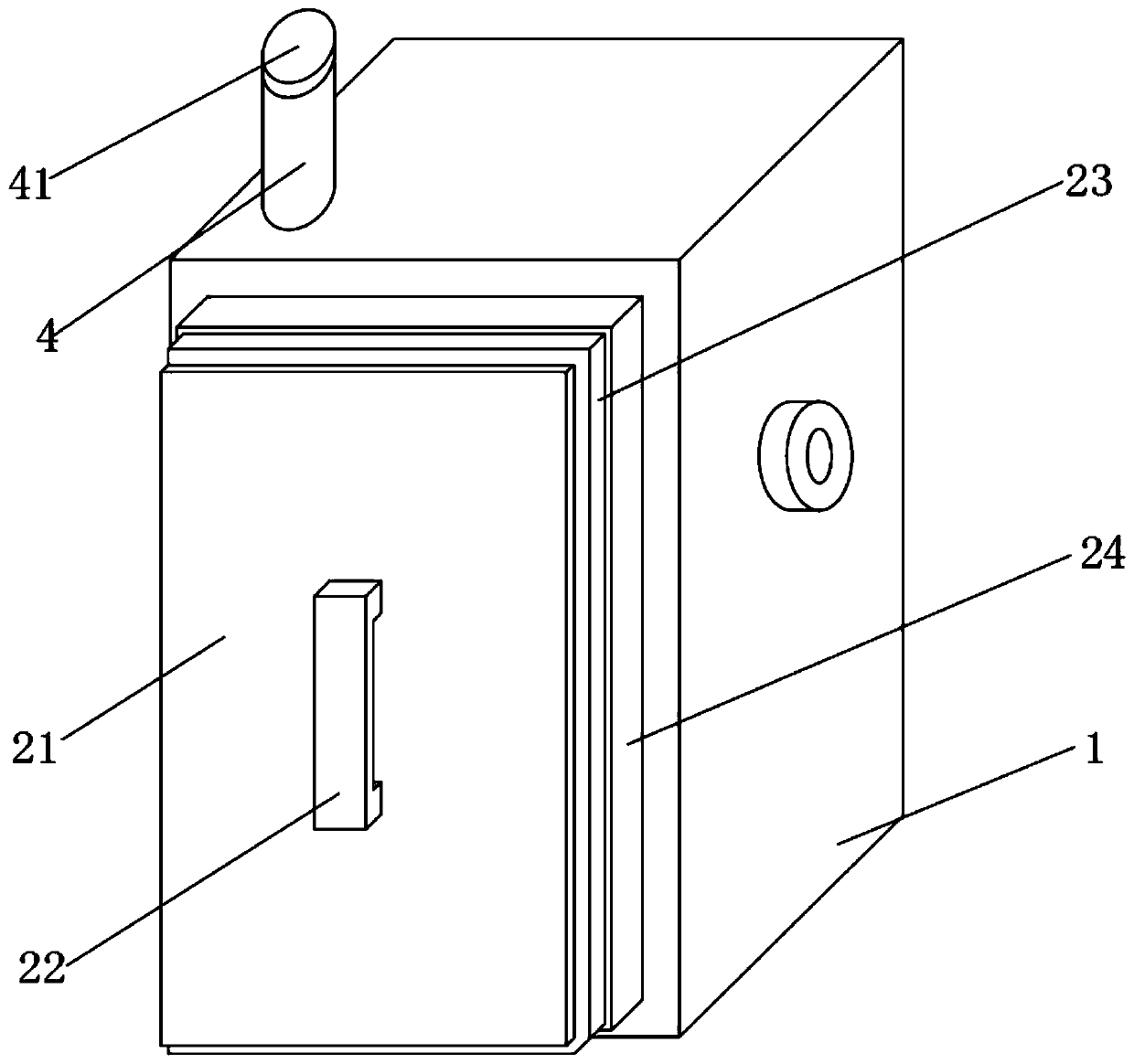

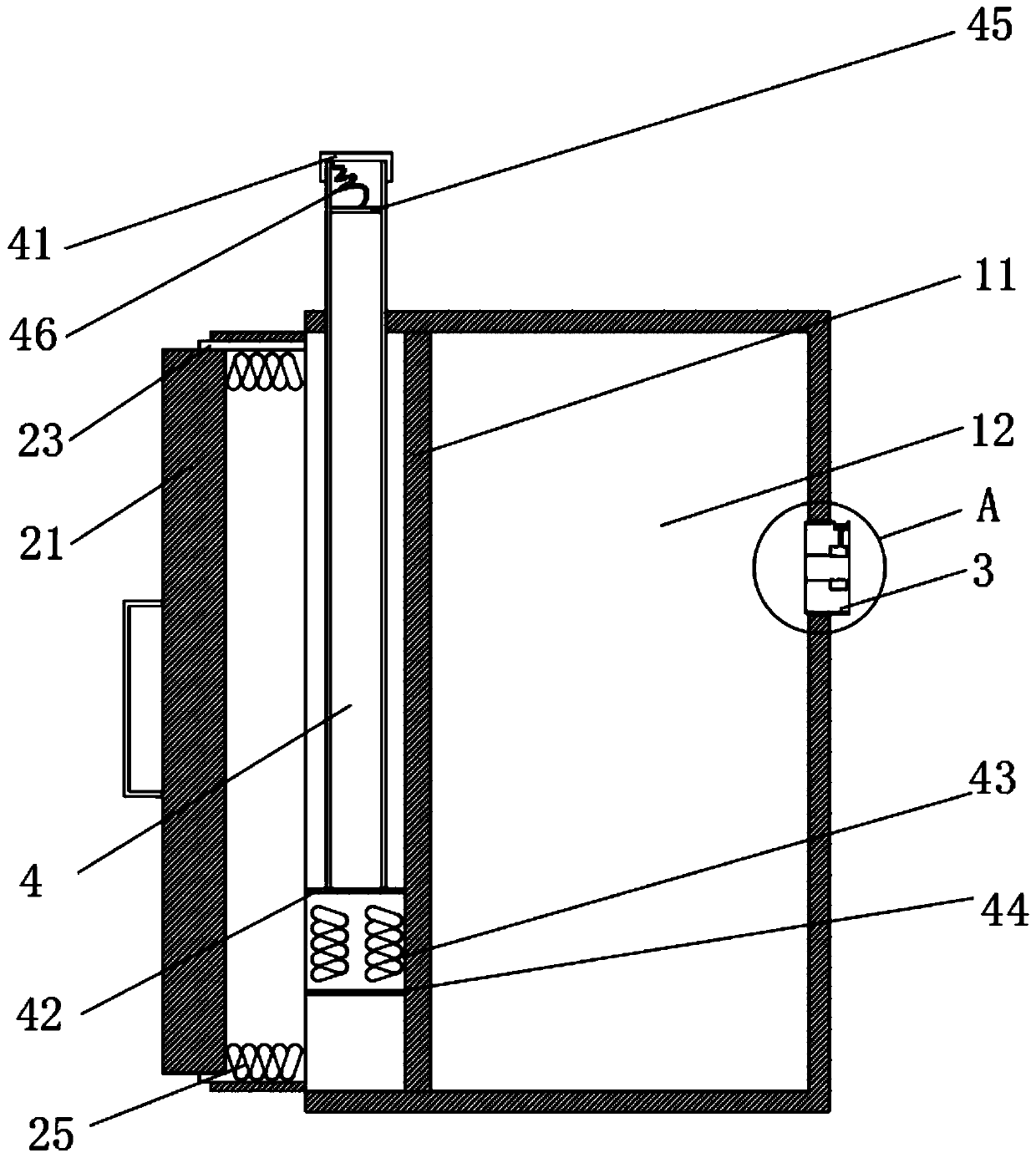

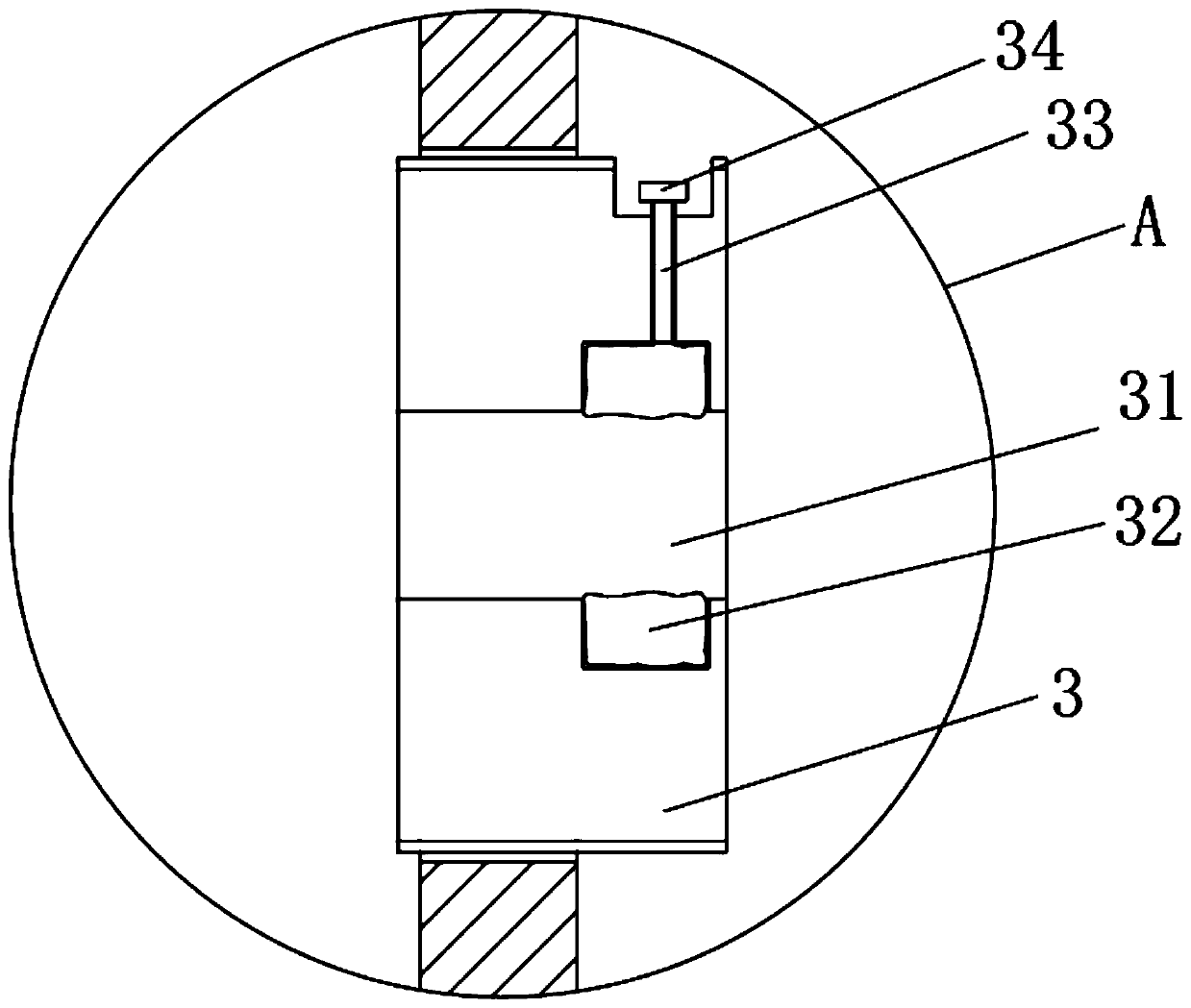

Marine self-protection uninterruptible power supply box

PendingCN109888636AReduce air pressureReduce manufacturing costSubstation/switching arrangement casingsEngineeringUninterruptible power supply

The invention relates to a marine self-protection uninterruptible power supply box. The box comprises a power supply box body, the outer surface of the power supply box body is detachably mounted witha connecting pipe, the connecting pipe is penetrated with a through-wire hole, the through-wire hole communicates with the inside and outside of the power supply box body, the connecting pipe is provided with a sealing mechanism, a wire tube is inserted into the through-wire hole, and then the hole is sealed by the sealing mechanism, and the inside and outside of the power supply box body are isolated. The outer surface of one side of the power supply box body is hingedly connected with a closing door, the outer surface of one side of the closing door away from the power supply box body is provided with a sliding door, a folding belt is fixedly connected between the outer border frame of the sliding door and the inner border frame of the closing door, and a connection spring is fixedly connected between the inner surface of the pulling plate and the closing door. The marine self-protection uninterruptible power supply box has the advantages of simple structure, ingenious design, low preparation cost, good waterproofing and repeated operation, and is easy to popularize and use.

Owner:ANQING MARINE ELECTRIC DEVICE

Gas sensor

ActiveUS20160370312A1Shorten the lengthReduce airtightnessMaterial analysis by electric/magnetic meansEngineeringMetal

In a gas sensor, a powder compact seals a void space between an inner peripheral surface of metal-made main hardware and a sensor element, and the inner peripheral surface has arithmetic average roughness of 0.5 to 5 μm. The gas sensor includes supporters, which are arranged in a penetration hole of the main hardware, which allow the sensor element to penetrate therethrough, and which press the powder compact in sandwiching relation from both sides in an axial direction. A surface of at least one of the supporters has the arithmetic average roughness of not more than 0.5 μm.

Owner:NGK INSULATORS LTD

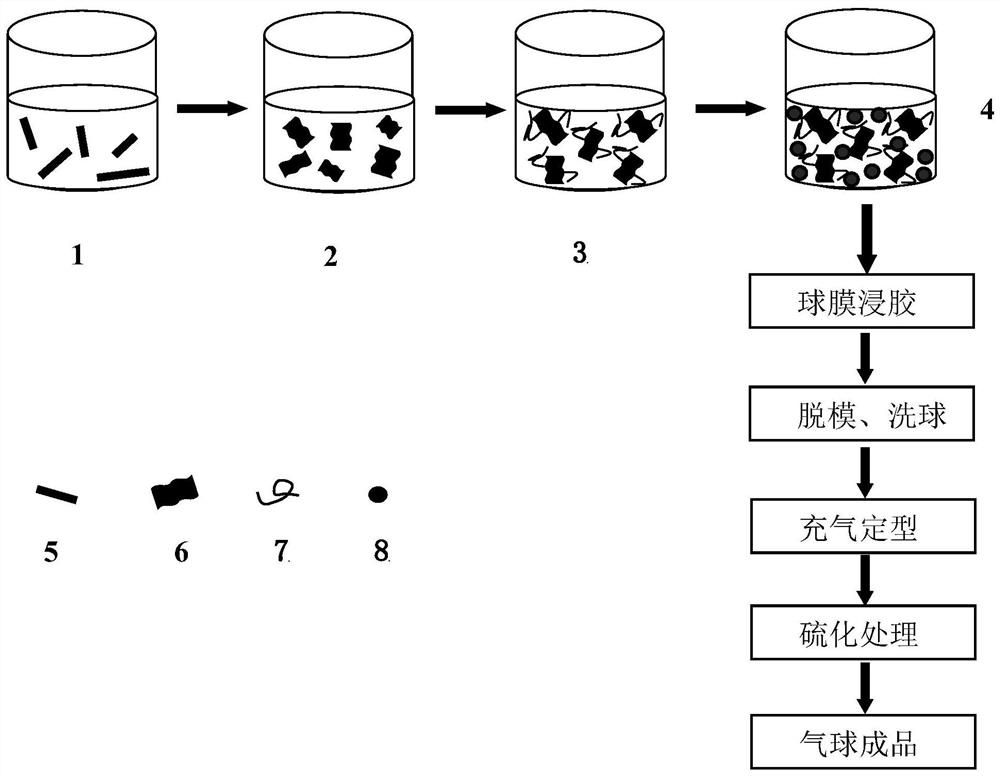

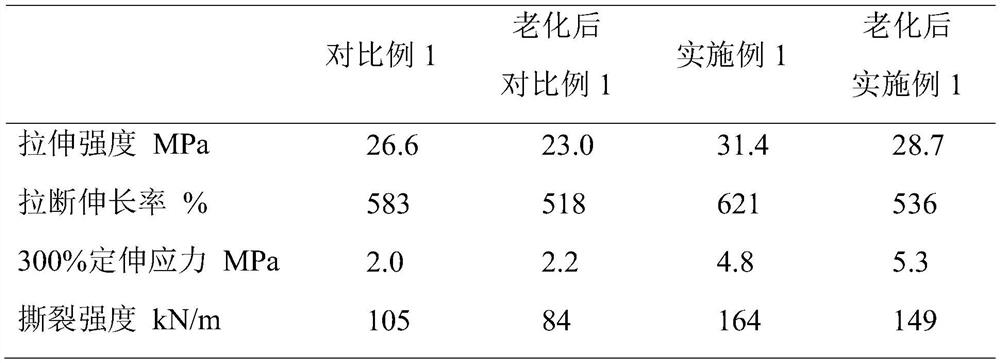

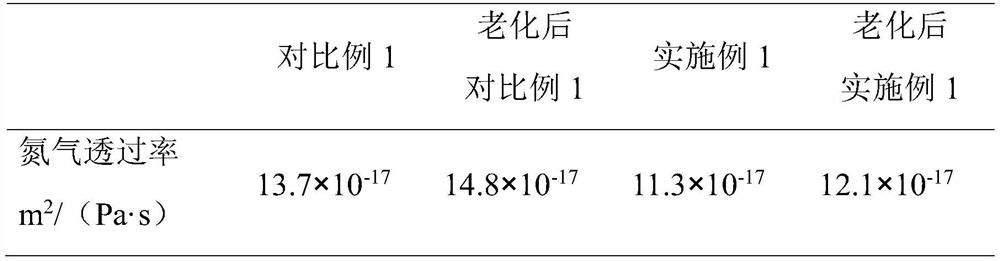

Graphene oxide and/or phyllosilicate natural rubber composite material for space balloons and preparation method of graphene oxide and/or phyllosilicate natural rubber composite material

InactiveCN111621069AImprove mechanical propertiesSmall mechanical propertiesGas balloonGraphite oxide

The invention discloses a graphene oxide and / or phyllosilicate natural rubber composite material for a space balloon and a preparation method of the graphene oxide and / or phyllosilicate natural rubbercomposite material. The composite material comprises the following components in parts by weight: 100 parts of natural rubber, 0.1-10 parts of graphene oxide and / or layered silicate and 0.1-6 parts of a stabilizer, wherein the graphene oxide and the phyllosilicate are pre-modified by an interface agent. Graphene oxide and / or phyllosilicate are / is pretreated through the interface agent, the polarity of graphene oxide and / or phyllosilicate is reduced, good compatibility with natural latex is achieved, and strong interface bonding is achieved. Through nano-compounding of natural latex, grapheneoxide and phyllosilicate, the mechanical property, the radiation aging resistance and the air tightness of the film are greatly improved, and the film can be used as an advanced technology for improving the ball film of the space balloon.

Owner:BEIJING UNIV OF CHEM TECH +1

Reversible mobile belt conveyer

The invention provides a reversible mobile belt conveyer. According to the reversible mobile belt conveyer, a first dust collection device and a second dust collection device are arranged at the machine head discharging end and the machine tail discharging end respectively, the first duct collection device comprises a first hopper which is arranged outside the machine head discharging end in a covering mode, a first dust collection pipeline which can be used for supplying negative pressure is connected to the outside of the first hopper in a sealed mode, the first dust collection pipeline can move along with the first hopper, the second dust collection device comprises a second hopper which is arranged outside the machine tail discharging end in a covering mode, a second dust collection pipeline which can be used for supplying negative pressure is connected to the outside of the second hopper in a sealed mode, and the second air collection pipeline can move along with the second hopper. According to the reversible mobile belt conveyer, the dust collection devices are arranged at the machine heat discharging end and the machine tail discharging end respectively, and thus the dust collection requirement can be met when discharging is conducted at any end; in the whole airtight operating process aiming at raise dust and air carriers of the raise dust, tracking type dust collection can be achieved under different working conditions and in different working states, the air volume is small, and the dust collection effect is good.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

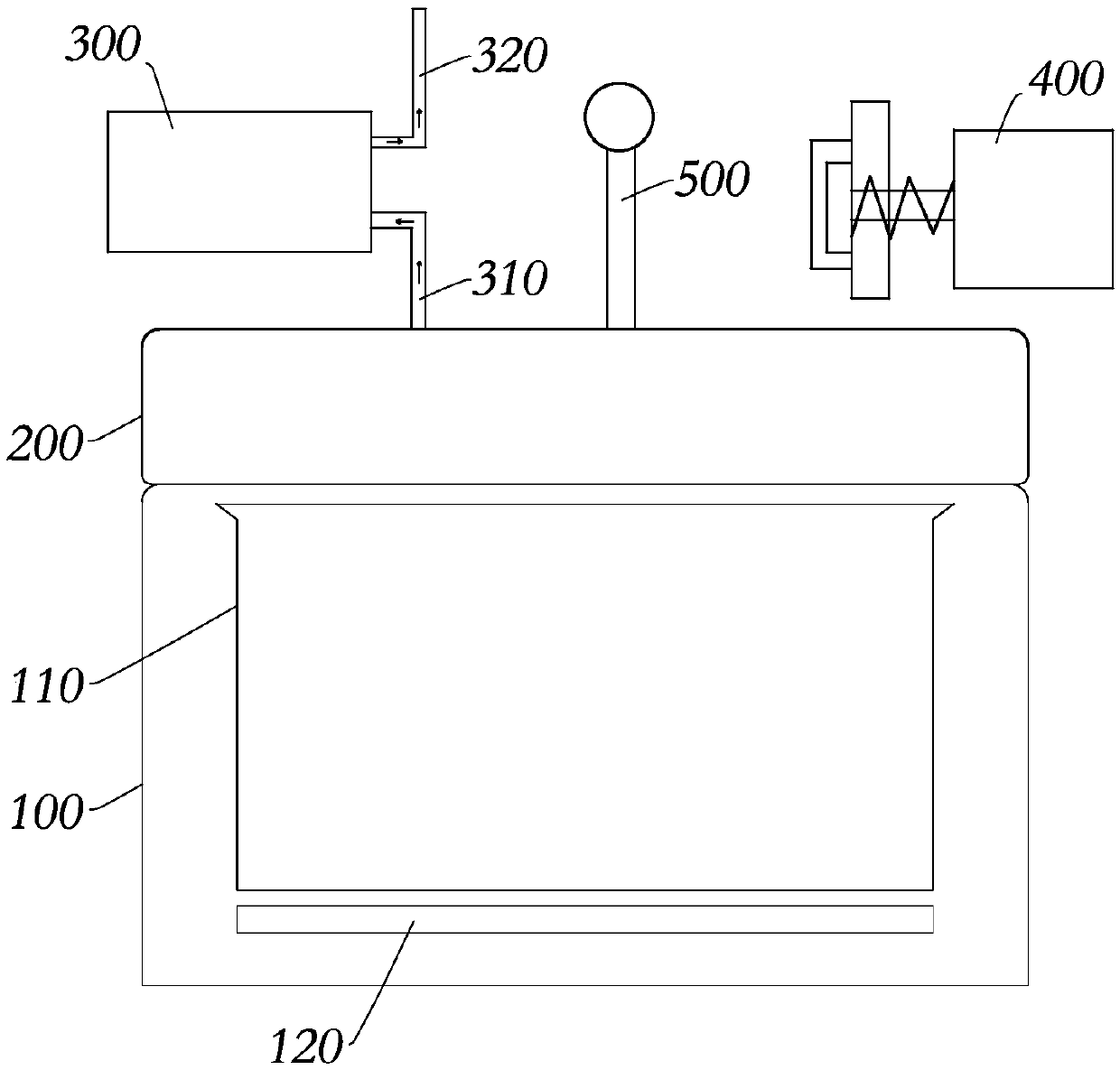

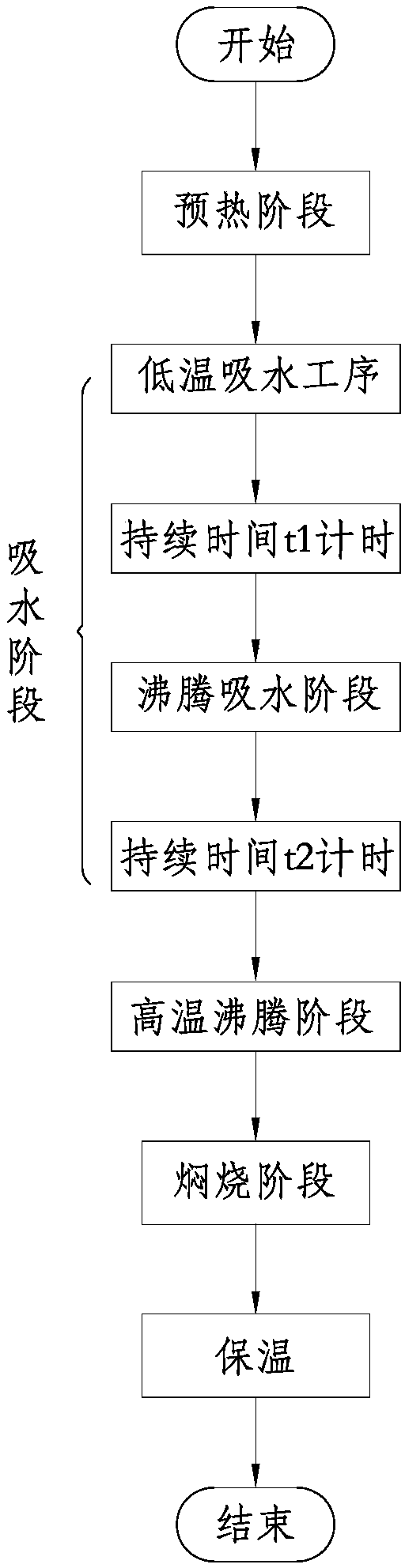

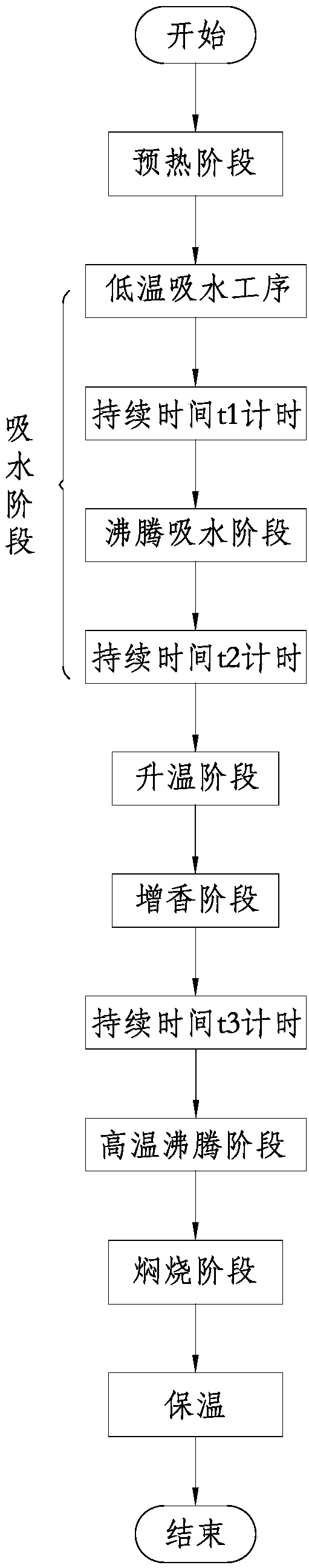

Cooking control method of vacuum electric cooker

InactiveCN111449487ASufficient water absorptionFast water absorptionCooking vesselsThermodynamicsProcess engineering

The invention discloses a cooking control method of a vacuum electric cooker, belongs to the field of kitchen appliances, and solves the problem of overlong cooking time of the existing electric cooker. The cooking control method of the vacuum electric cooker comprises a preheating stage, a water absorption stage and a high-temperature boiling stage, wherein the water absorption stage comprises: alow-temperature water absorption process, wherein food materials in a cooking cavity are kept at a first water absorption temperature T1 for a duration t1; and a boiling water absorption process, wherein an air sucking device works to enable the cooking cavity to be kept at a preset negative pressure, the food materials in the cooking cavity are heated to a second water absorption temperature T2and kept for a duration time t2, and the second water absorption temperature T2 is the boiling point temperature under the preset negative pressure. According to the invention, food materials are boiled in advance in the water absorption stage through the boiling water absorption procedure, so that the purpose of shortening the cooking time is achieved.

Owner:JOYOUNG CO LTD

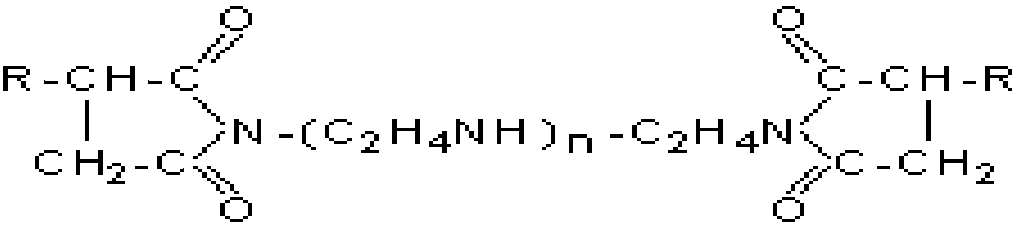

Solder composition and preparing method and application thereof

ActiveCN103506771AReduce manufacturing costGood brazing penetrationWelding/cutting media/materialsWelding/soldering/cutting articlesManganeseExhaust pipe

The invention discloses solder composition and a preparing method and application thereof. The solder composition comprises first metal and second metal. The first metal is at least one of copper, nickel and manganese. The second metal is at least one of zinc, silver, copper, nickel, manganese and chrome. The first metal and the second metal are different. The solder composition does not contain at least one of silicon and phosphorus. The solder composition can be effectively used for connecting objects made of different kinds of metal, and the solder composition is especially suitable for copper-steel brazing of an air sucking pipe and an exhaust pipe of a compressor. Compared with existing silver-based solder, the solder composition is low in production cost, compared with national standard copper zinc solder, the solder composition is good in brazing permeability, high in welding intensity, good in welding filling performance and reliability and strong in corrosion resistance, base metal in an application range is strong in adaptability, and welding reject ratio and airtight leakage rate are low.

Owner:GUANGDONG MEIZHI COMPRESSOR

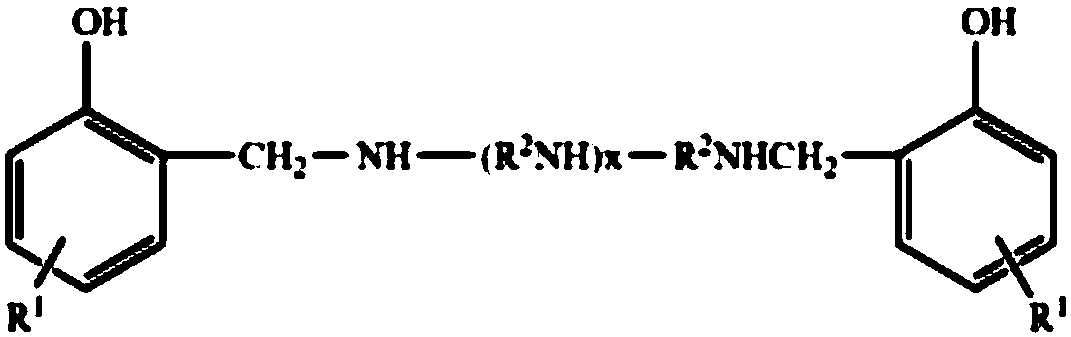

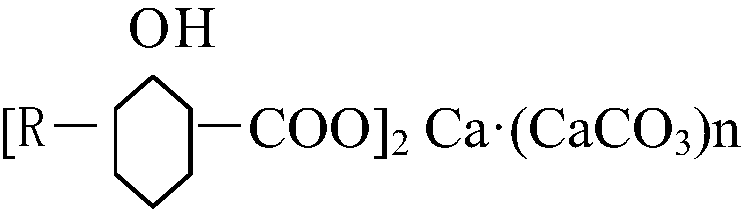

Cleaning agent for engine lubrication system without disassembly

ActiveCN108546583AEasy to cleanImprove adsorption capacityLubricant compositionOil sludgeCarbon deposit

Owner:杭州维客泰美品牌管理有限公司

Sewer dredging device and application method for same

The invention relates to a sewer dredging device which belongs to the technical field of dredging. The sewer dredging device provide by the invention has high adaptability, wherein water is supplied by a water pump and high-pressure water columns are sprayed out by a sprayer, so that the sewer wall can be washed from top to bottom, and thus sludge left on the sewer wall can be washed. In this way, the defect that the sludge on the sewer wall cannot be cleaned up by a suction dredging method can be solved. According to the invention, compressed air is taken as a dredging medium; huge impact force is generated by the blasted-in compressed air; the sludge on the sewer bottom can be impacted and stirred violently; the sludge on the bottom can be lifted by washing and will be lifted along the bottom face of a conical sludge collection bucket; and finally, the sludge falls down under gravity and sludge resistance and falls into the conical sludge collection bucket. Because of the large impact force, even solid objects such as straws and stones with large sizes can be lifted by impact for subsequent collection and cleaning. Hence, the problem that the suction dredging method cannot clean up the solid objects such as straws and stones can be avoided. The device has broad application prospect.

Owner:广东宏丰建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com