Cleaning agent for engine lubrication system without disassembly

A technology for lubricating systems and engines, applied in lubricating compositions, petroleum industry, etc., can solve the problems that the cleaning effect of cleaning agents needs to be improved, and achieve the effect of strong cleaning performance and strong adsorption performance

Active Publication Date: 2018-09-18

杭州维客泰美品牌管理有限公司

View PDF7 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Practice has found that the cleaning effect of the existi

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

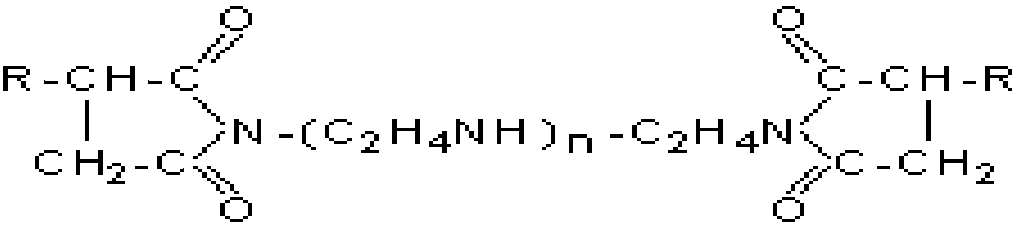

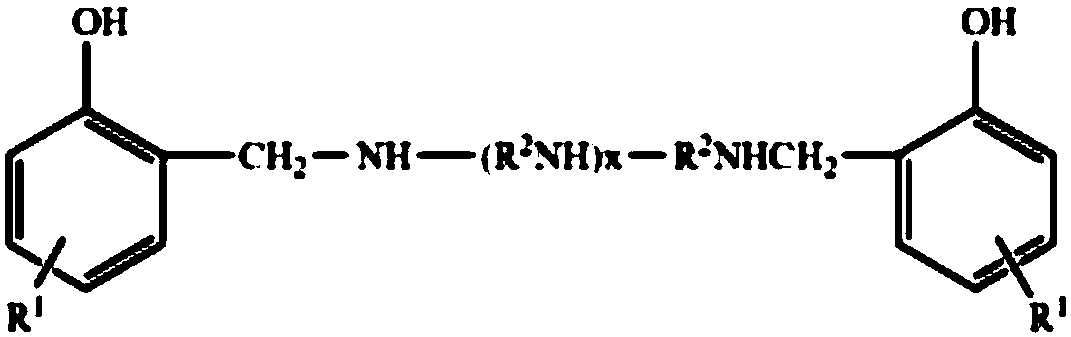

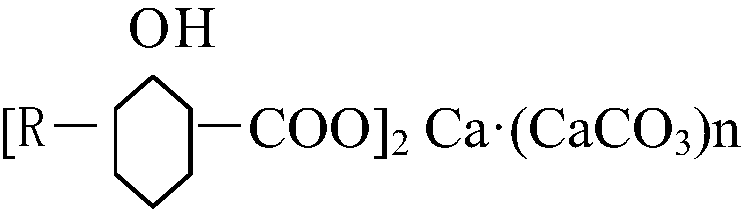

The invention discloses a cleaning agent for an engine lubrication system without disassembly. The cleaning agent is prepared from the following components: polyisobutylene butyldiimide, a Mannich base dispersing agent, calcium alkyl salicylate, calcium sulfonate, calcium naphthenate, long-chain alkyl primary zinc phosphorodithioic acid, octyl-butyl diphenylamine, dimethyl sulfoxide, oil soluble polyether, heavy alkyl benzene, 150N base oil, and T901 methylsilicone oil. The cleaning agent product provided by the invention has a higher cleaning performance on low-temperature oil mud and a higher adsorption performance on generated carbon deposits and paint films, and can be used for washing the paint films and the carbon deposits adsorbed on the part surface away so as to enable the paint films and the carbon deposits to disperse and suspend in oil.

Description

technical field [0001] The invention relates to the technical field of engine lubricating system cleaning agents, in particular to a disassembly-free cleaning agent for engine lubricating systems. Background technique [0002] With the rapid development of the world's automobile technology, highly intelligent control systems for automobile engines have become popular. The engine has stronger power, lower fuel consumption and emissions than before, but it puts forward higher requirements for oil quality and vehicle maintenance. Deposits in key components have posed a serious threat to the operating conditions of the engine. The use of "vehicle non-dismantling cleaning chemicals" to deal with specific faults has become one of the important maintenance methods, and it is also a routine maintenance item to ensure that the engine is always in an ideal operating state. field plays an important role. [0003] The deposits that may exist in the engine lubrication system can be div...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C10M169/04C10N30/04C10N30/06C10N40/10

CPCC10M169/048C10M2203/06C10M2203/1025C10M2207/144C10M2207/16C10M2209/103C10M2215/064C10M2215/28C10M2217/06C10M2219/04C10M2219/044C10M2223/045C10M2229/041C10N2030/04C10N2030/06C10N2040/25C10N2020/02C10N2010/04

Inventor 彭洪斌

Owner 杭州维客泰美品牌管理有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com