Patents

Literature

103 results about "Phosphorodithioic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

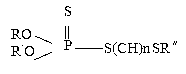

Diethyl dithiophosphoric acid, sometimes mistakenly called diethyl dithiophosphate, is the organophosphorus compound with the formula (C2H5O)2PS2H. It is the processor for production of the organophosphate insecticide Terbufos. Although samples can appear dark, it is a colorless liquid.

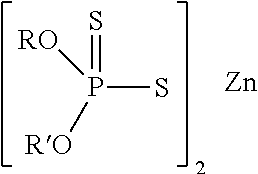

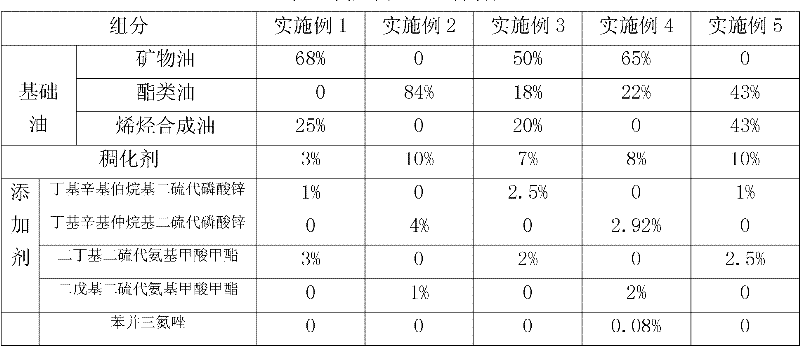

Premium wear resistant lubricant

A premium synthetic lubricant having antiwear properties comprises a synthetic isoparaffinic hydrocarbon base stock and an effective amount of at least one antiwear additive. The antiwear additive is preferably at least one of a metal phosphate, a metal dialkyldithiophosphate, a metal dithiophosphate a metal thiocarbamate, a metal dithiocarbamate, an ethoxylated amine dialkyldithiophosphate and an ethoxylated amine dithiobenzoate. Metal dialkyldithiophosphates are preferred, particularly zincdialkyldithiophosphate (ZDDP). The base stock is derived from a waxy, Fischer-Tropsch synthesized hydrocarbon feed fraction comprising hydrocarbons having an initial boiling point in the range of about 650-750 DEG F., by a process which comprises hydroisomerizing the feed and dewaxing the isomerate. The lubricant may also contain hydrocarbonaceous and synthetic base stock material in admxture with the Fischer-Tropsch derived base stock.

Owner:EXXON RES & ENG CO

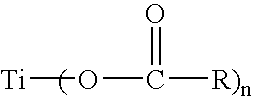

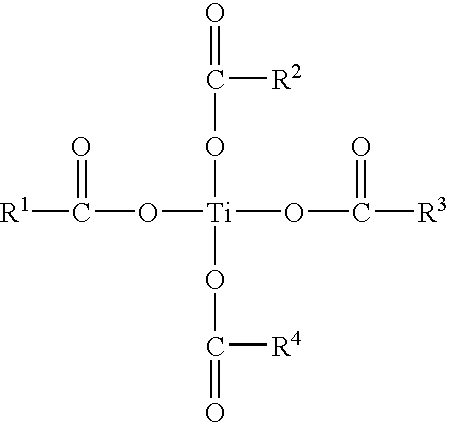

Titanium-containing lubricating oil composition

ActiveUS20070132274A1Improve fuel economyImprove wear characteristicsVehicle seatsWindowsTitanium metalPhysical chemistry

A lubricating oil composition comprising a) an oil of lubricating viscosity having a viscosity index of at least about 95; b) at least one calcium detergent; c) at least one oil soluble titanium compound; d) at least one friction modifier; and e) at least one metal dihydrocarbyldithiophosphate compound. The composition has a Noack volatility of about 15 wt. % or less, and contains from about 0.05 to about 0.6 wt. % calcium from the calcium detergent, titanium metal in an amount of at least about 10 ppm up to about 1500 ppm titanium from the titanium compound, and phosphorus from the metal dihydrocarbyldithiophosphate compound in an amount up to about 0.1 wt. %.

Owner:AFTON CHEMICAL

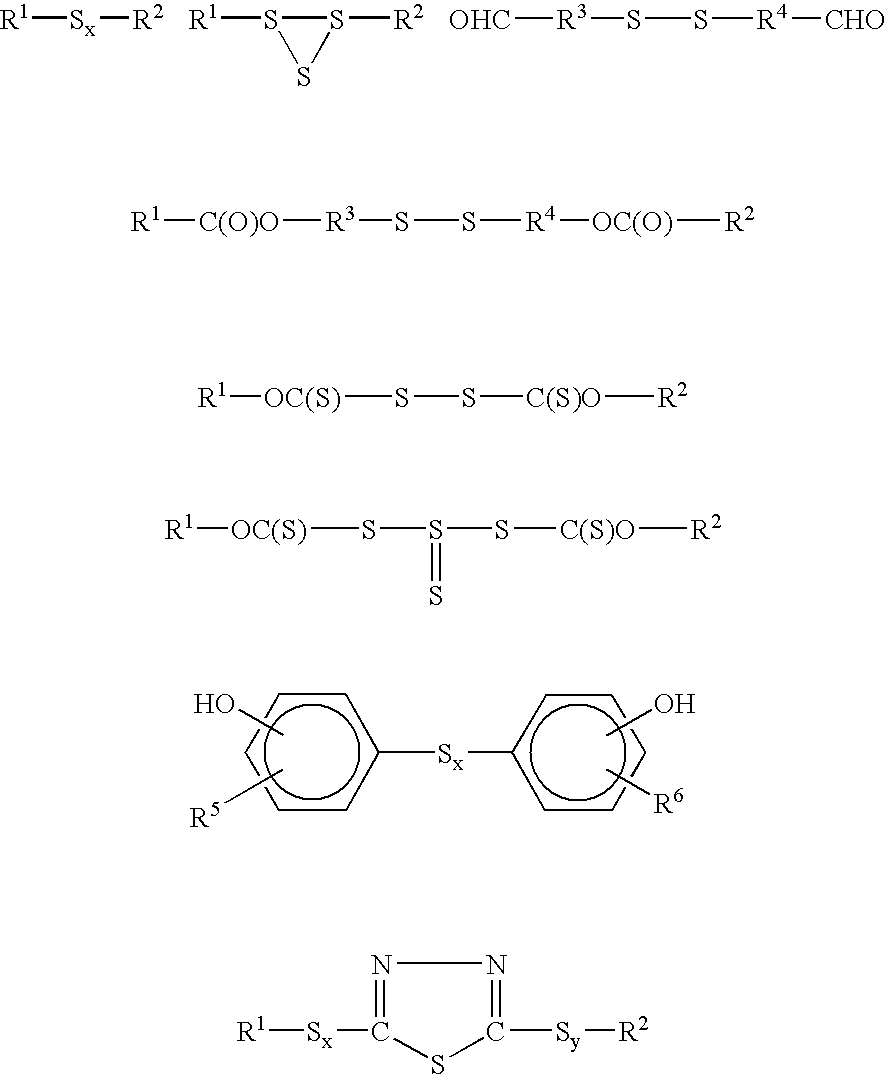

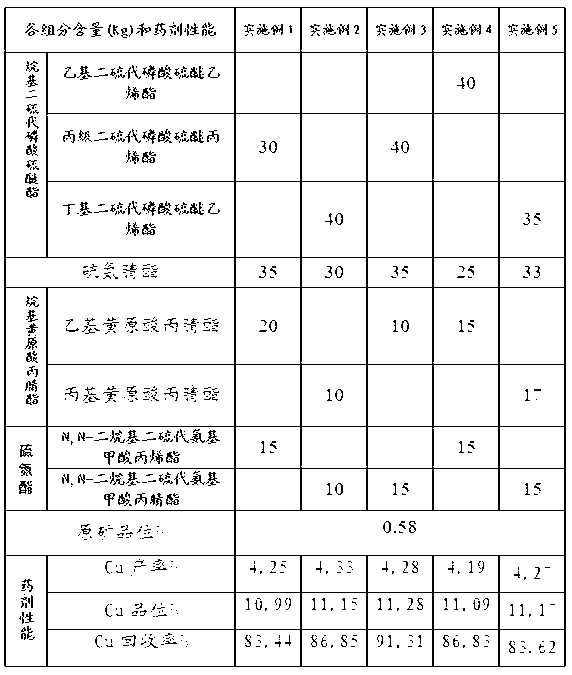

Collecting agent for high-sulfur copper mine

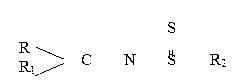

The invention relates to a flotation agent for a copper mine and discloses a high-efficiency collecting agent for a high-sulfur copper mine. The collecting agent comprises the following materials in parts by weight: 30-40 parts of alkyl phosphorodithioic acid thioether ester, 25-35 parts of cyanoethyl diethyl dithionocarbamate, 10-20 parts of alkyl xanthic acid propionitrile ester and 10-15 parts of sulfur-nitrogen ester. The collecting agent for the high-sulfur copper mine has double functions of collecting and foaming, is good in selectivity and high in collecting ability, can realize high-efficiency separation of copper from sulfur in a low pH value (approximately 5) range, can effectively reduce the consumption of lime in the floatation process, can effectively increase the grade and recovery rate of concentrate, and has a wider application scope.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Internal combustion engine oil and composite additive composition

One compound of composite addition agent with oxidation resistance and abrasive resistance applied in internal combustion engine oil contains the following components: (I) phenol antioxidant, the content is 0-35%; (II) amine antioxidant, the content is 0-35%; (IH) sulfur and azote compound, the content is 0-35%; (IV) molybdenum naphthenate or dialkyl molybdenum dithiocarbamate, the content is 10-35%; (V)zinc phosphorodithioic acid, the content is 20-50%; among them, the content of at least one of component (I), (II), (III) is not zero. The above composite addition agent has a content of 1.5-3.5% in the internal combustion engine oil compound. The compound of composite addition agent and internal combustion engine oil provided by this invention has the effects of oxidation resistance, abrasive resistance and extreme pressure, furthermore, with low content of phosphor, which agrees with the demand of SJ gasoline and oil and the standard of the phosphor content for SJ gasoline and oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

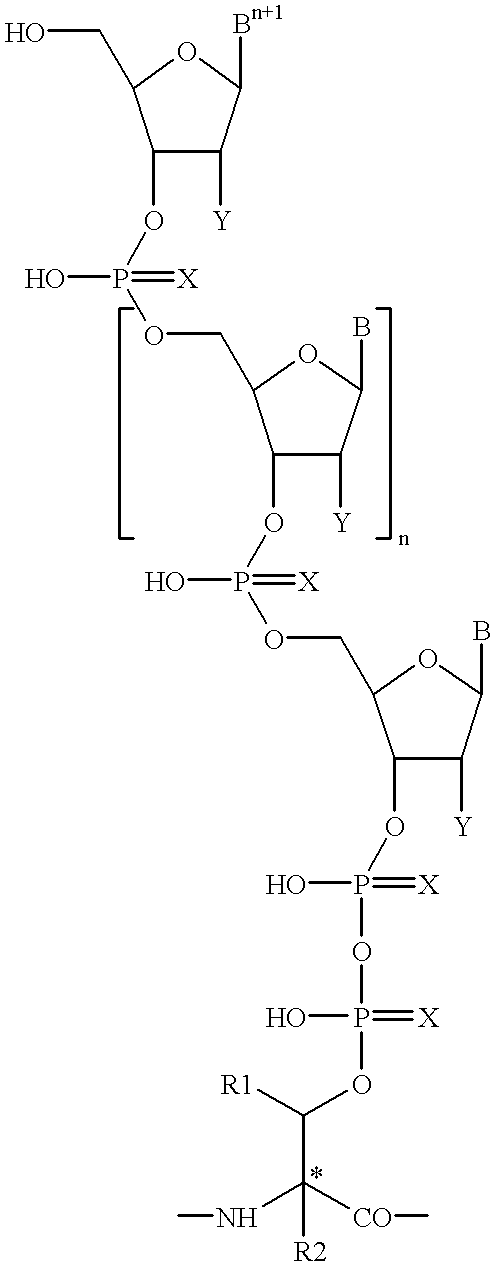

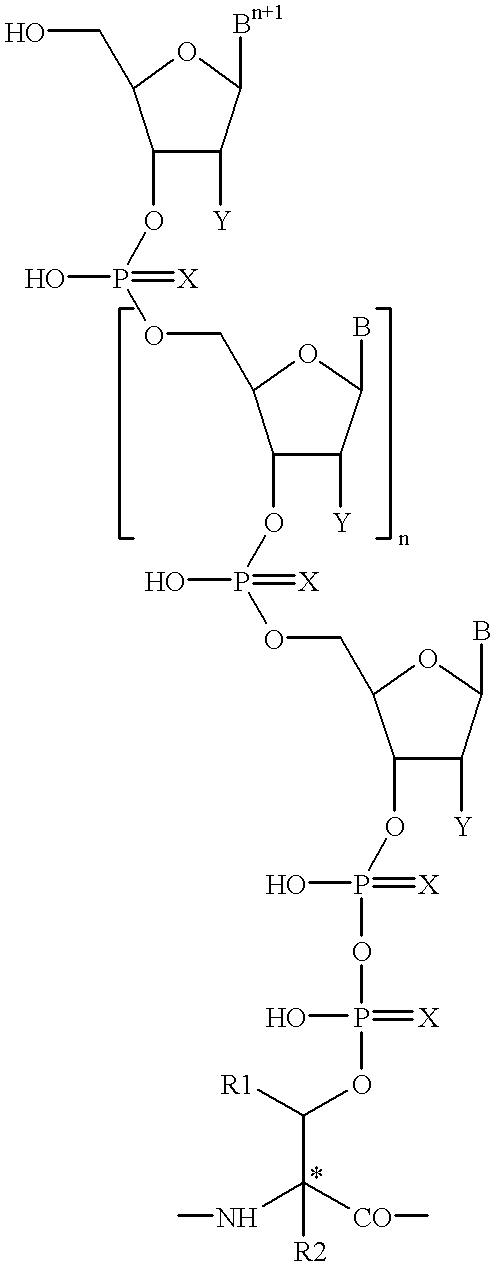

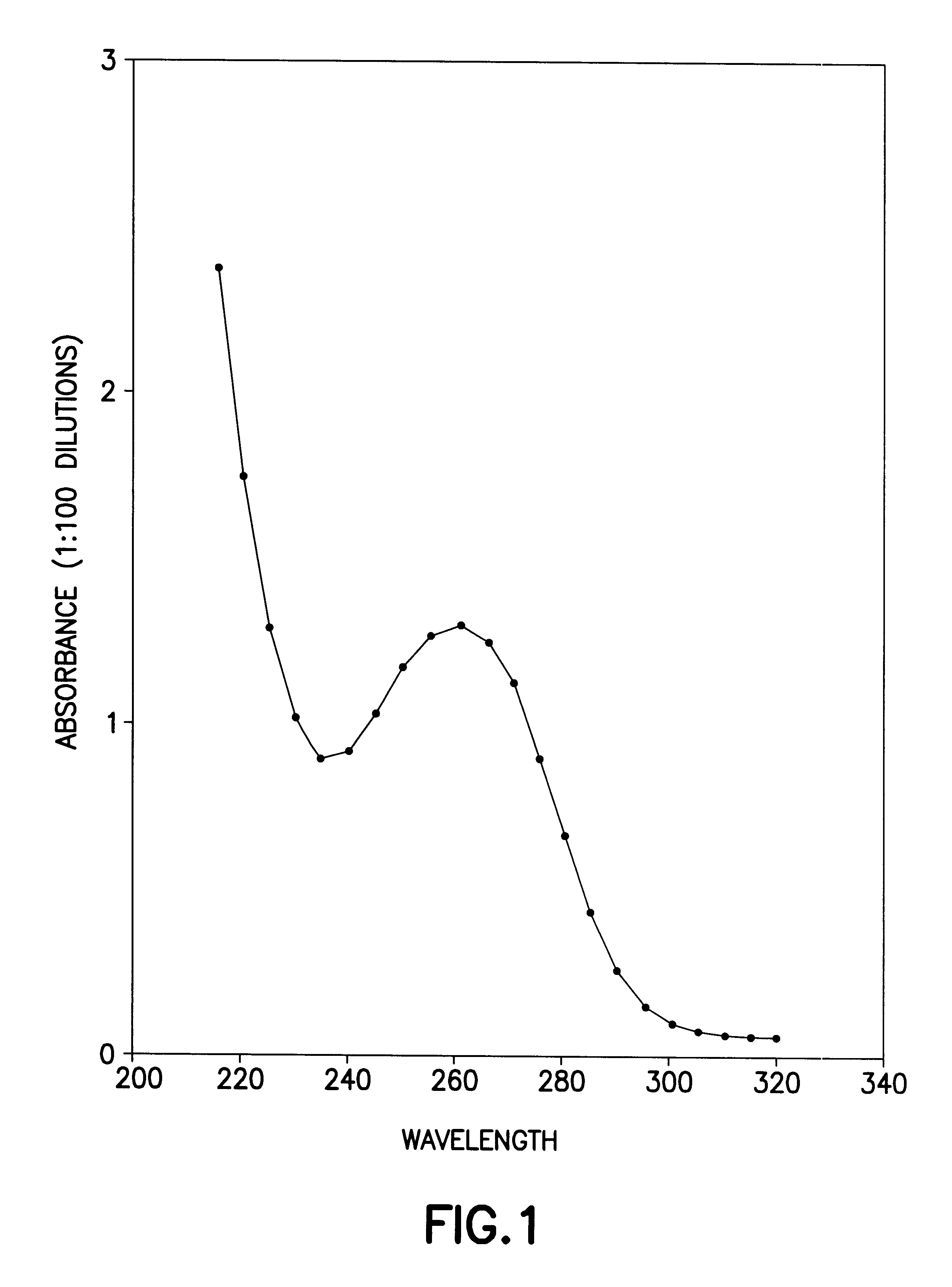

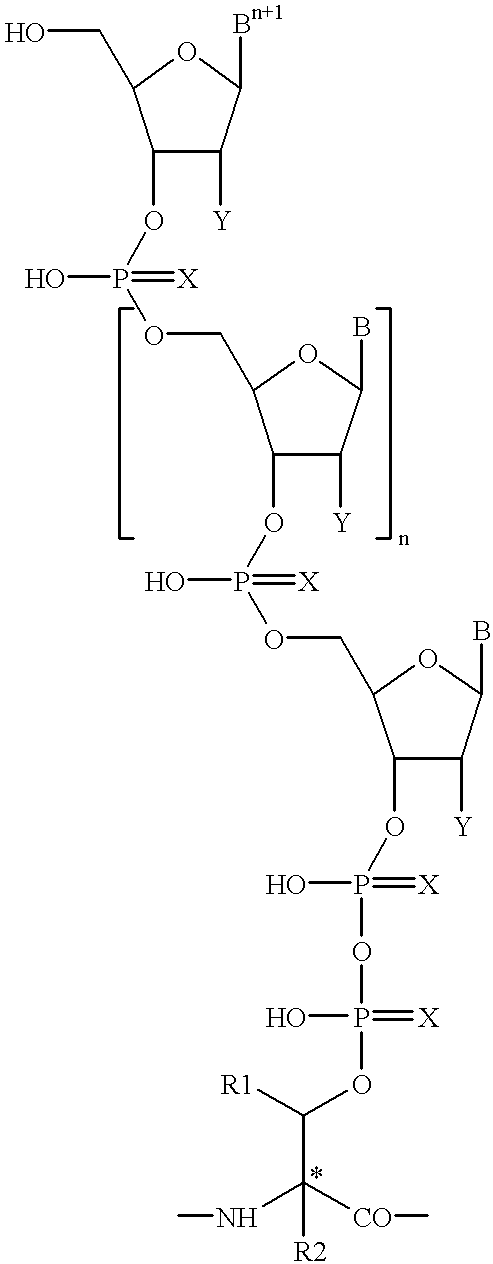

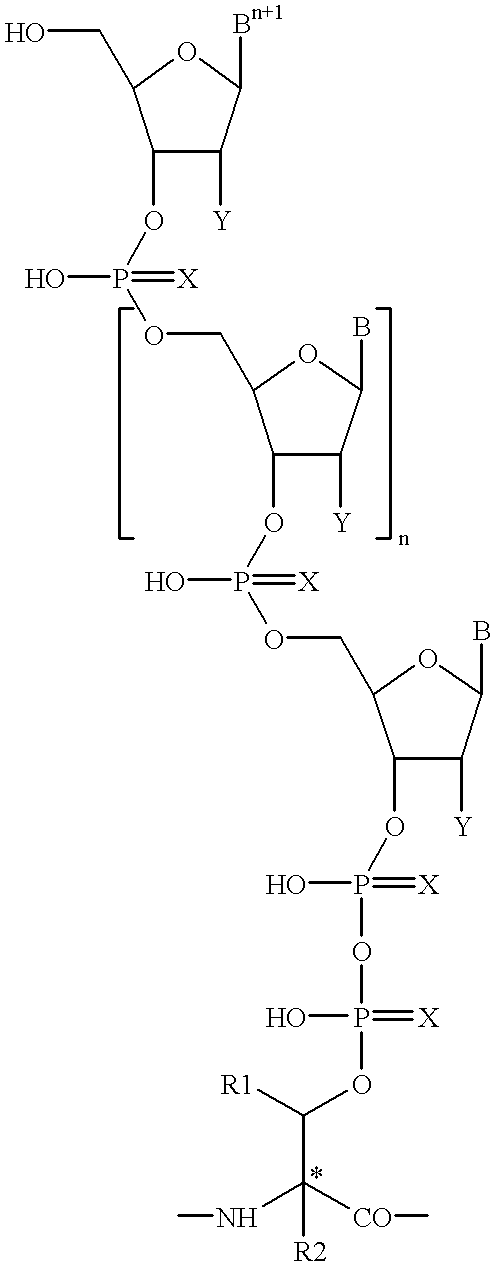

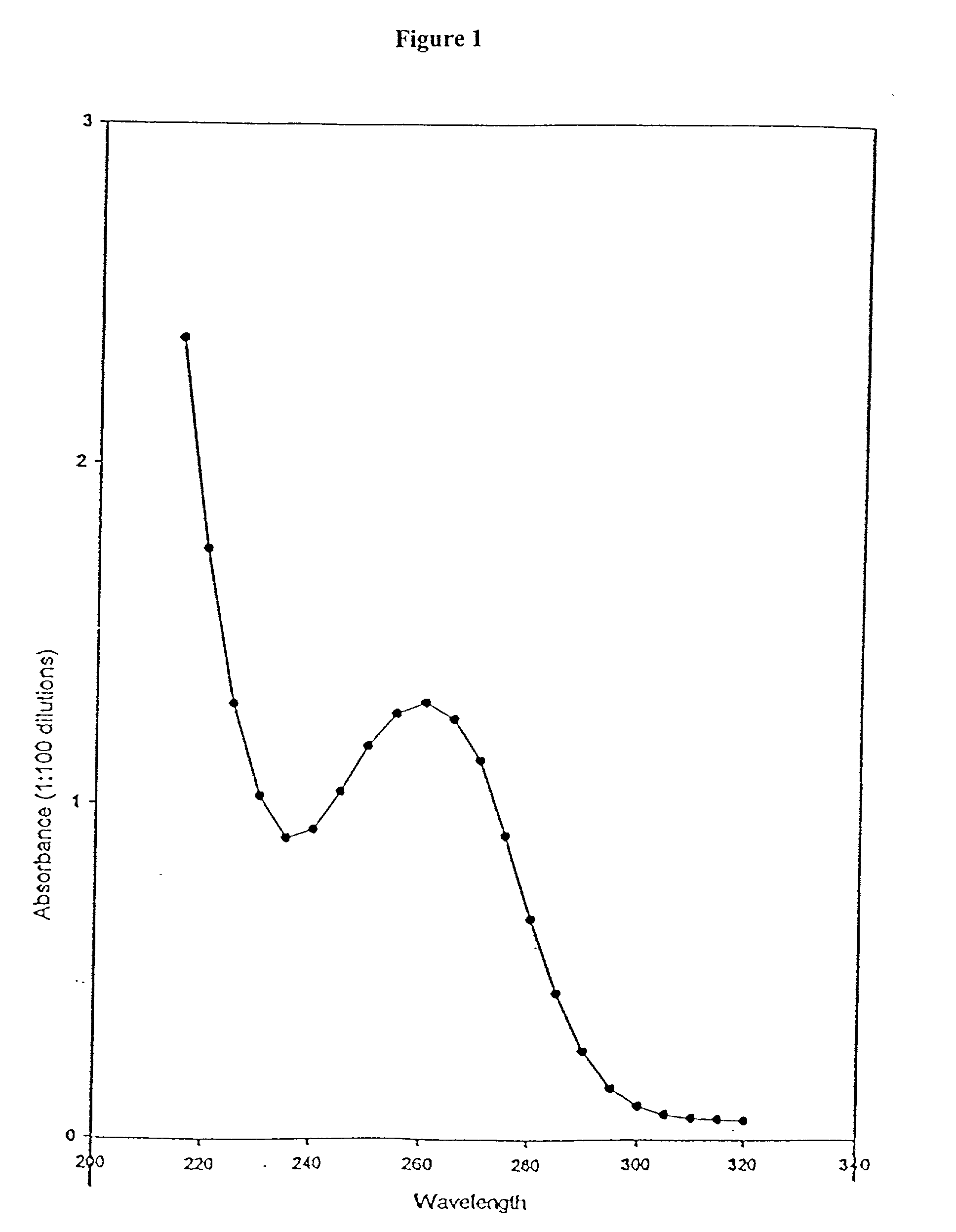

Preparation of a therapeutic composition

Product R, a novel therapeutic composition for treating viral infections and stimulating the immune system, comprises a unique peptide having 31 amino acids and another unique peptide having 21 amino acids and connected with an oligo-nucleotide through a diphosphodiester or diphosphodithioate ester linkage. The composition has a light absorption spectrum with typical absorption ratios of 1.998 at 260 nm / 280 nm and 1.359 at 260 nm / 230 nm.

Owner:BBM HLDG

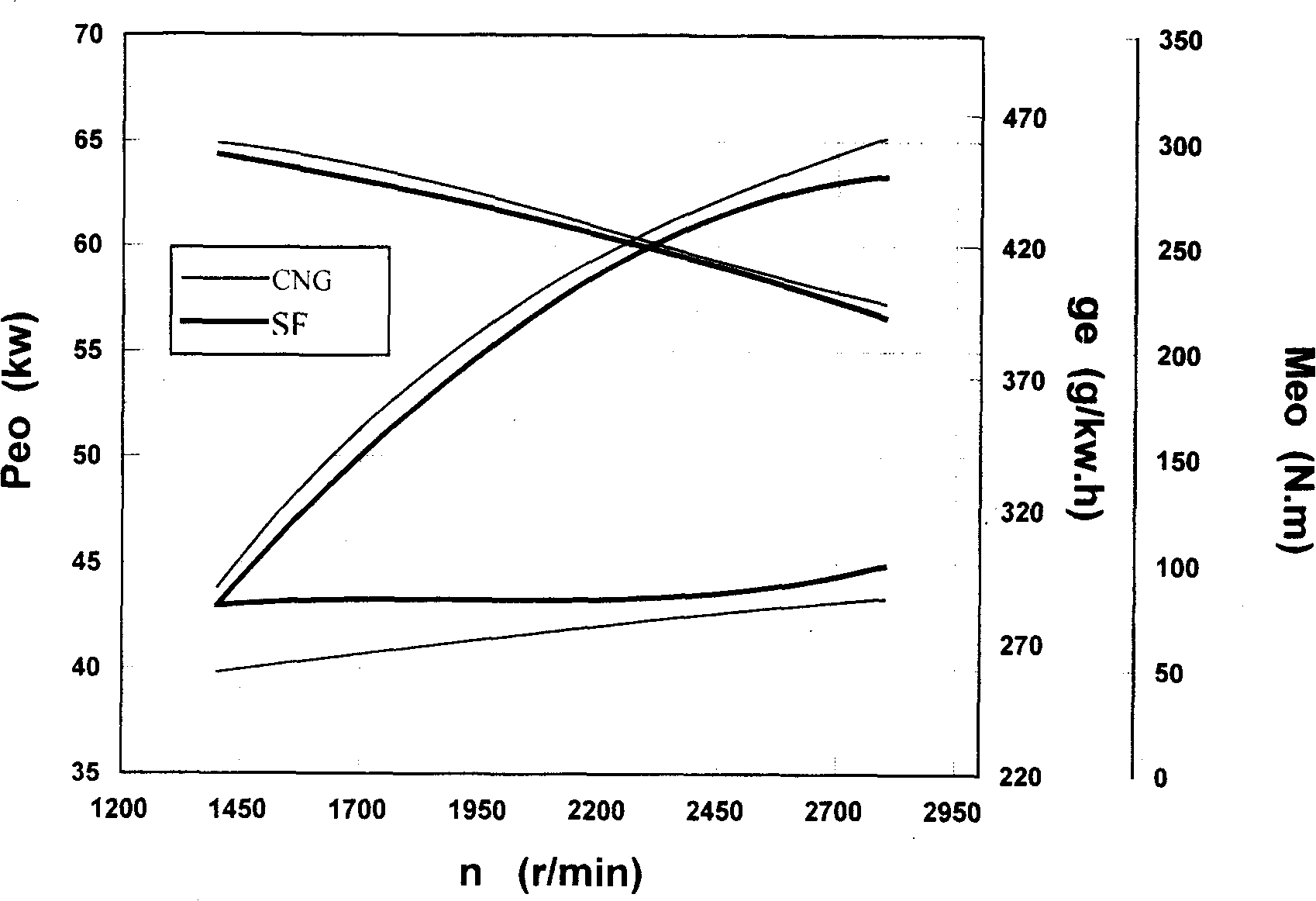

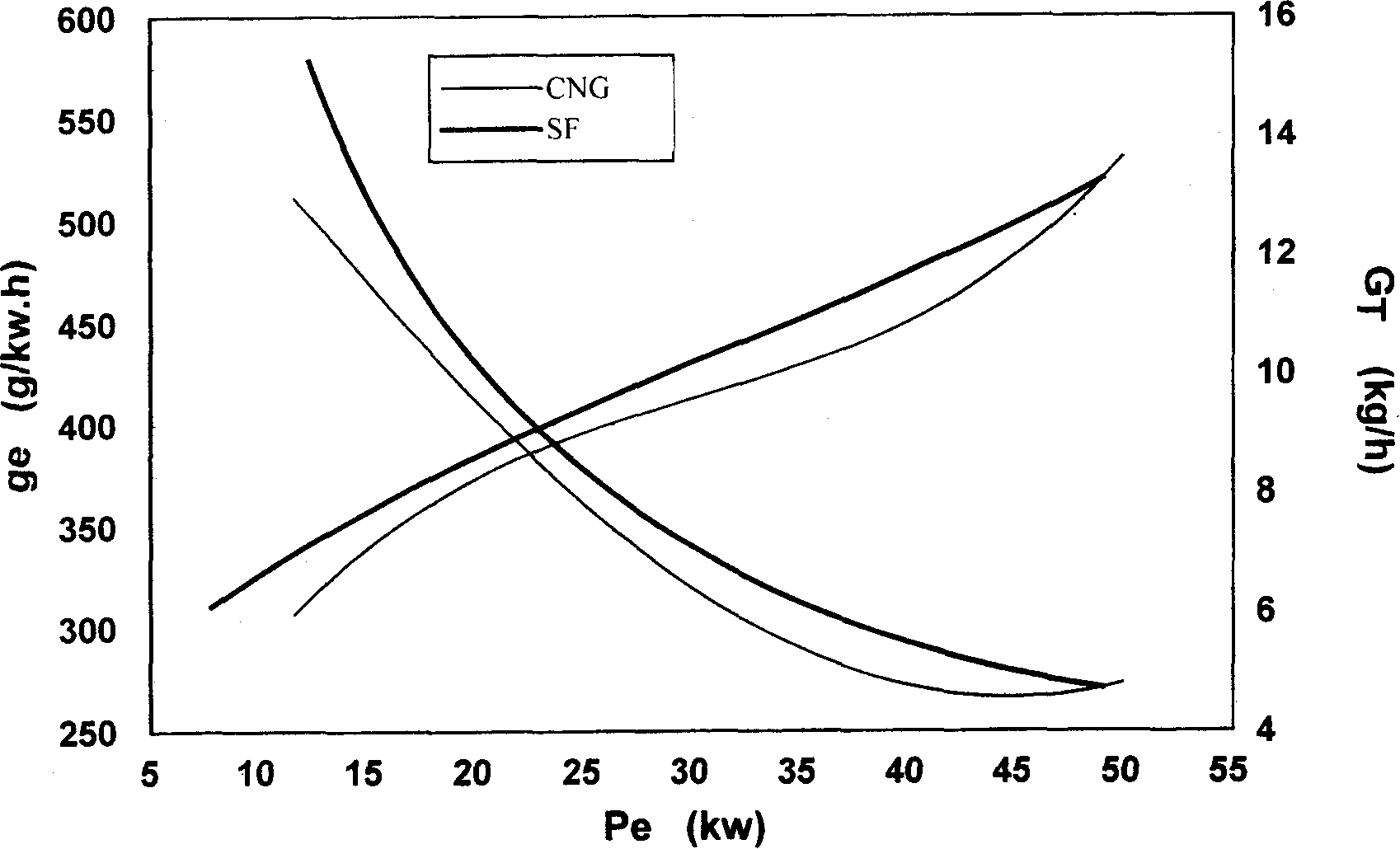

Lubricating oil for natural gas and gasoline dual purpose fuel engine

Owner:CHANGAN UNIV

Premium wear resistant lubricant

Owner:EXXON RES & ENG CO

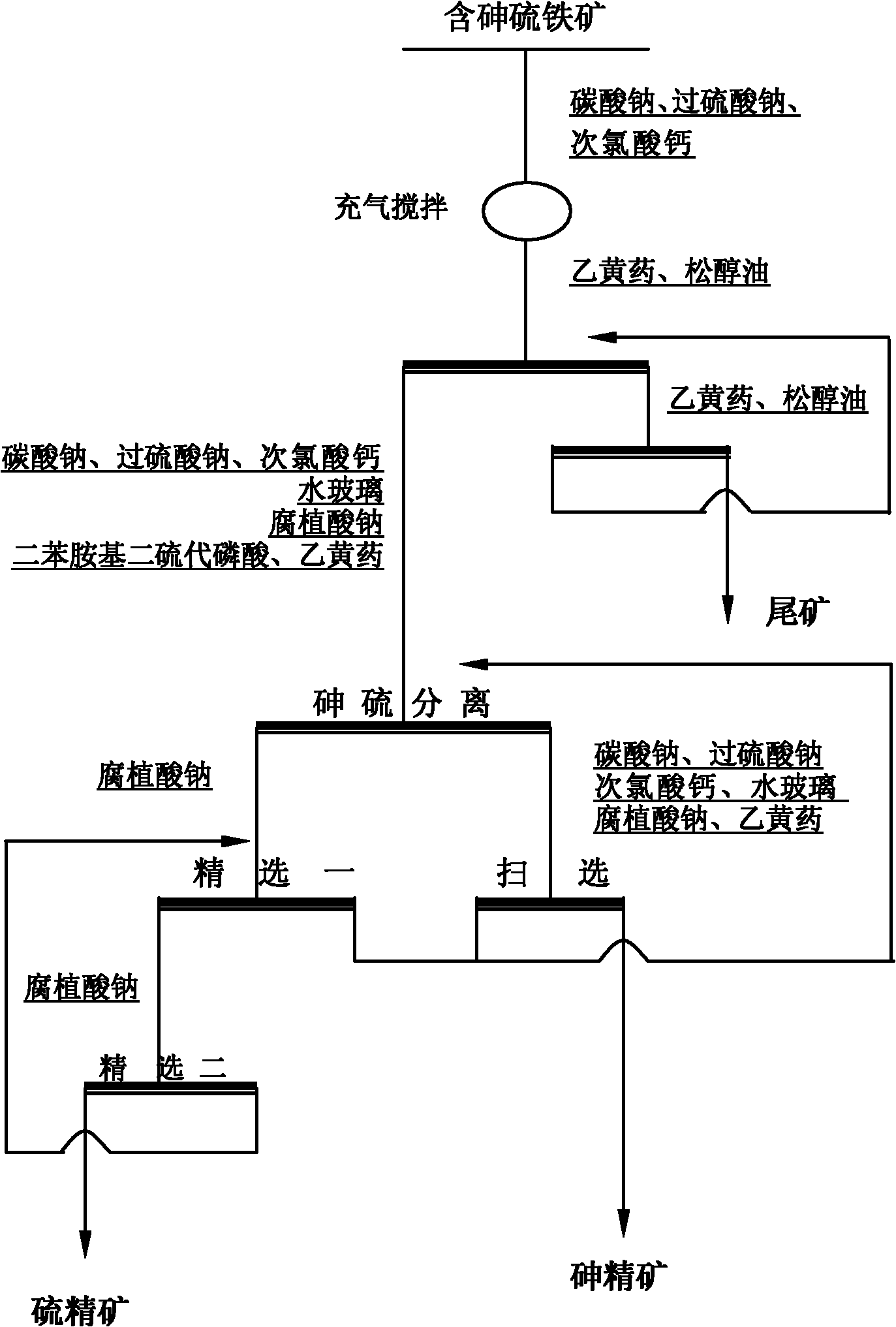

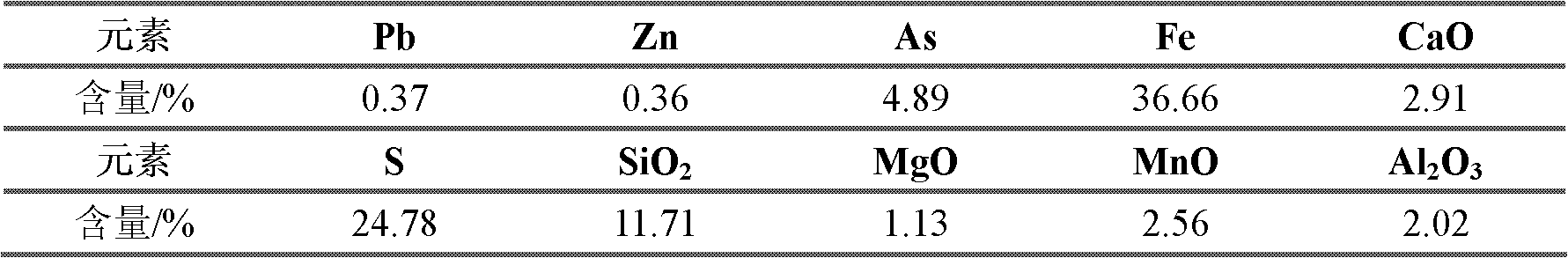

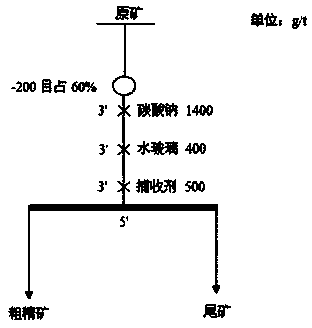

Floatation separation method for pyrites from arsenopyrites

InactiveCN101844108AIncrease oxygen contentElectrochemical conditions for stable flotationFlotationMineral flotationElectrochemistry

The invention aims at floatation separation of arsenic from sulfur in arsenic-containing pyrites. The floatation separation comprises the following steps of: adjusting an ore pulp to keep the pH value of the pulp between 9 and 10; adjusting the potential of the ore pulp to between 350 and 380 millivolts by adding oxidant medicaments of sodium persulfate and calcium hypochlorite; introducing air to increase oxygen content in the ore pulp; and stabilize electrochemical conditions of mineral floatation. During the floatation separation of the pyrites from the arsenopyrites, the potential of the ore pulp is stabilized by adding the oxidant medicaments of sodium persulfate and calcium hypochlorite; the arsenopyrite is suppressed by using a new collector of dianilino dithiophosphoric acid, and regulators of sodium silicate and sodium humate according to a principle of an electrochemical floatation process to make the pyrites such as arsenopyrites, iron pyrites, pyrrhotites and the like acted with a medicament selectively in the subsequent floatation process; and the floatation separation of the pyrites from the arsenopyrites is performed so as to form a sulfur concentrate with low arsenic content.

Owner:CENT SOUTH UNIV +1

Lubricating composition substantially free of ZDDP

InactiveUS20050148477A1Improved engine cleanlinessReduce wearOrganic chemistryLiquid carbonaceous fuelsFriction modifierAnti oxidant

The present invention provides a composition comprising: (a) a metal salixarate; (b) at least one additive selected from the group consisting of (1) an antioxidant; (2) a friction modifier; (3) a dispersant; (4) a viscosity modifier; (5) a dispersant viscosity modifier; and (6) an antiwear agent other than a metal hydrocarbyl dithiophosphate; and (c) an oil of lubricating viscosity, wherein the composition contains 400 ppm or less of phosphorus derived from a metal hydrocarbyl dithiophosphate. The invention further provides a process for preparing the composition and its use.

Owner:THE LUBRIZOL CORP

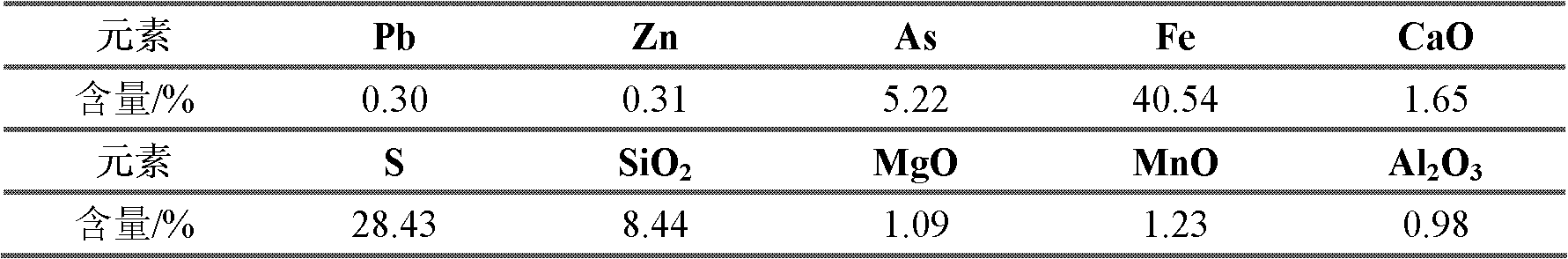

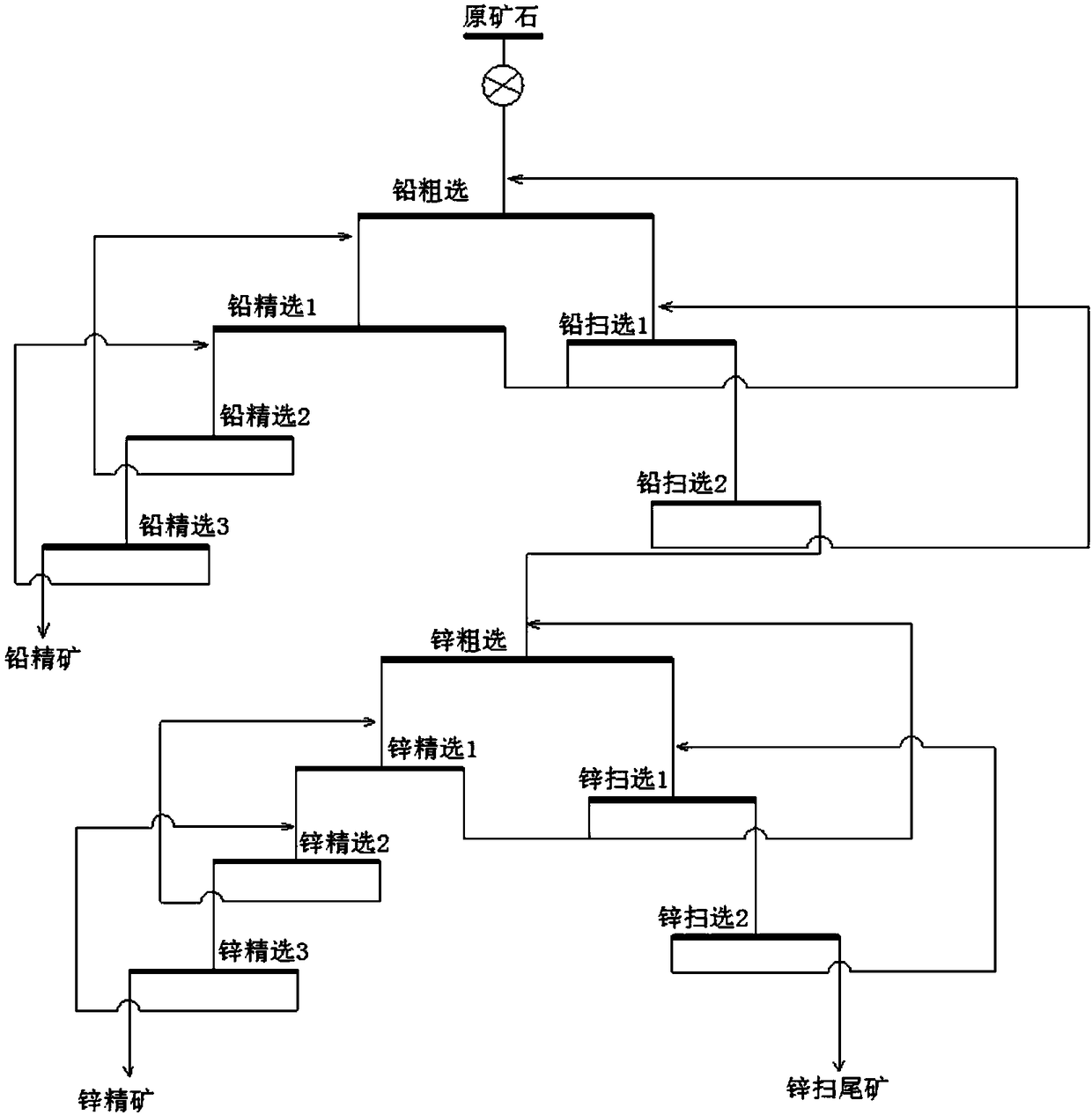

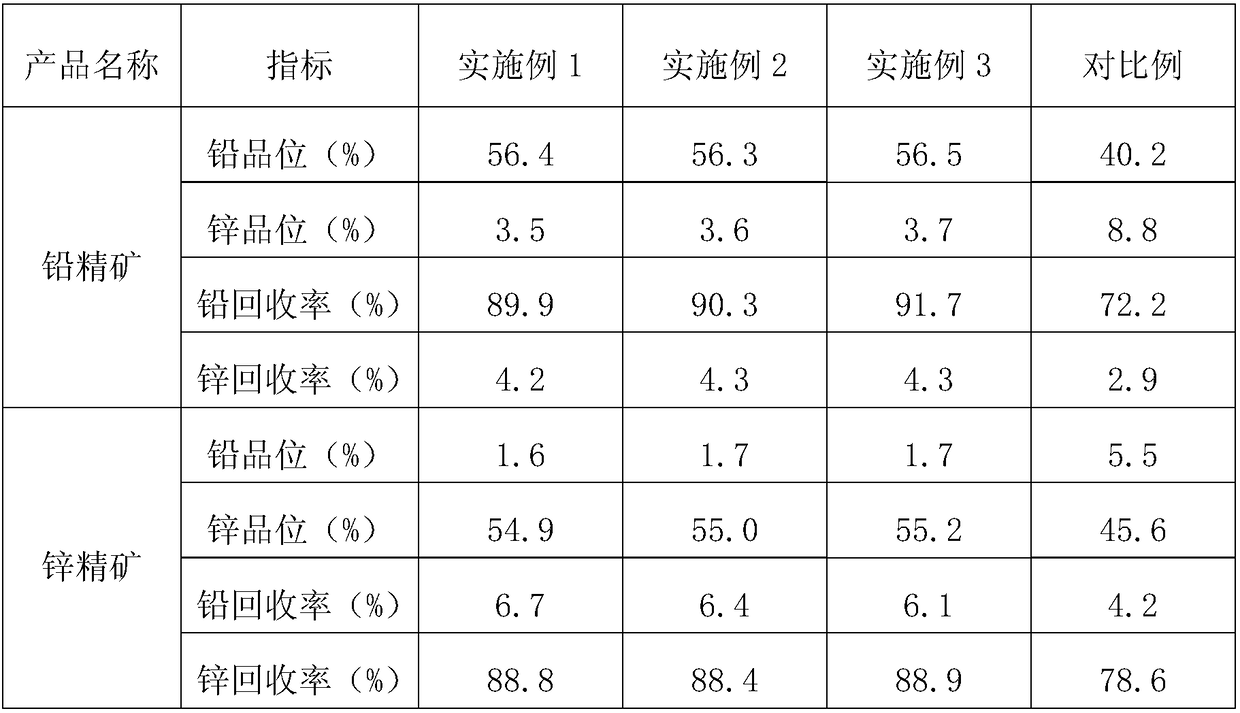

Selection method of lead and zinc sulfide ore

The invention discloses a selection method of lead and zinc sulfide ore, and belongs to the technical field of beneficiation. The selection method comprises the steps of milling of raw ore, flotationof lead and flotation of zinc, wherein during rough flotation of lead, lime, calcium hypochlorite, zinc sulfate, sodium sulfite, sodium sulfide, dimethyl dicarbonate, ethyl thio carbamate, sodium n-butylxanthate, dianilinodithiophosphoric acid, diphenyl amino phosphorodithioic acid and sodium carbonate are added; during fine flotation of lead, lime, zinc sulfate, sodium sulfite and sodium sulfideare added; during scavenging of lead, lime, calcium hypochlorite, zinc sulfate, sodium sulfite, sodium sulfide, dimethyl dicarbonate, ethyl thio carbamate, dianilinodithiophosphoric acid, diphenyl amino phosphorodithioic acid and sodium carbonate are added; during rough flotation of zinc, lime, copper sulfate, ammonium sulfite, sodium n-butylxanthate and terpenic oil are added; during fine flotation of zinc, lime is added; and during scavenging of zinc, lime, copper sulfate, ammonium sulfite, sodium n-butylxanthate and terpenic oil are added. By adoption of the selection method of lead and zinc sulfide ore, the problem that when a traditional flotation method is used for selecting lead and zinc sulfide ore, the recovery rate of lead and zinc is low is solved.

Owner:广西华洋矿源材料有限公司

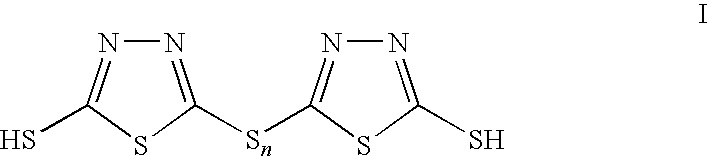

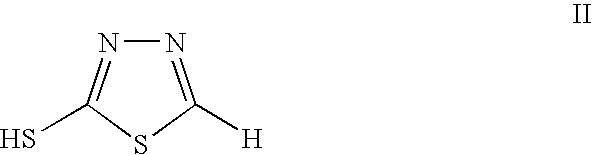

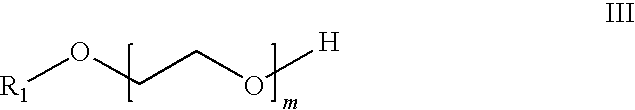

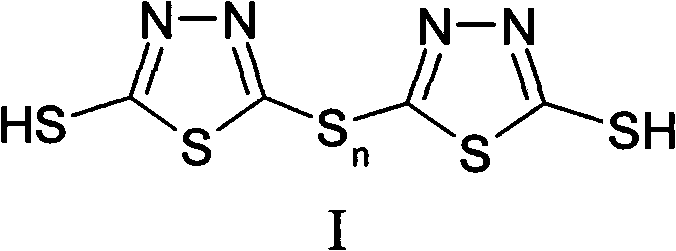

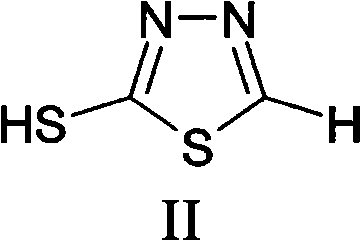

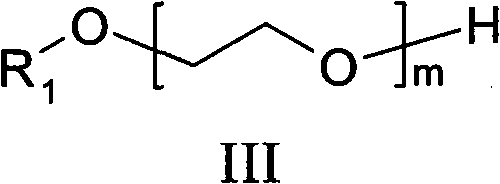

Additive composition for ep greases with excellent antiwear and corrosion properties

A lubricant composition is provided as follows:At least 90% of a base grease;(a) a thiadiazole poly(ether)glycol complex in an amount which provides about 1500 to 3500 ppm sulfur;(b) molybdenum dihydrocarbyldithiophosphate in amount which provides about 77 to 450 ppm molybdenum; and(c) zinc dihydrocarbyldithiophosphate in an amount which provides about 600 to 1000 ppm zinc. An additive composition for grease, consisting of components (a), (b) and (c), is also provided.

Owner:VANDERBILT CHEM LLC

Lubricating oil compositions

InactiveUS20150344812A1Reduce and inhibit corrosionAvoid corrosionLiquid carbonaceous fuelsAdditivesChemical compositionDithiophosphoric acid

A lubricating oil composition having a sulphated ash content of less than or equal to 1.2 mass % as determined by ASTM D874 and a phosphorous content of less than or equal to 0.12 mass % as determined by ASTM D5185, which lubricating oil composition comprises or is made by admixing: an oil of lubricating viscosity, in a major amount; an oil-soluble or oil-dispersible polymeric friction modifier as an additive in an effective minor amount; and, an oil-soluble or oil-dispersible dihydrocarbyl dithiophosphate metal salt as an additive in an effective minor amount.

Owner:INFINEUM INT LTD

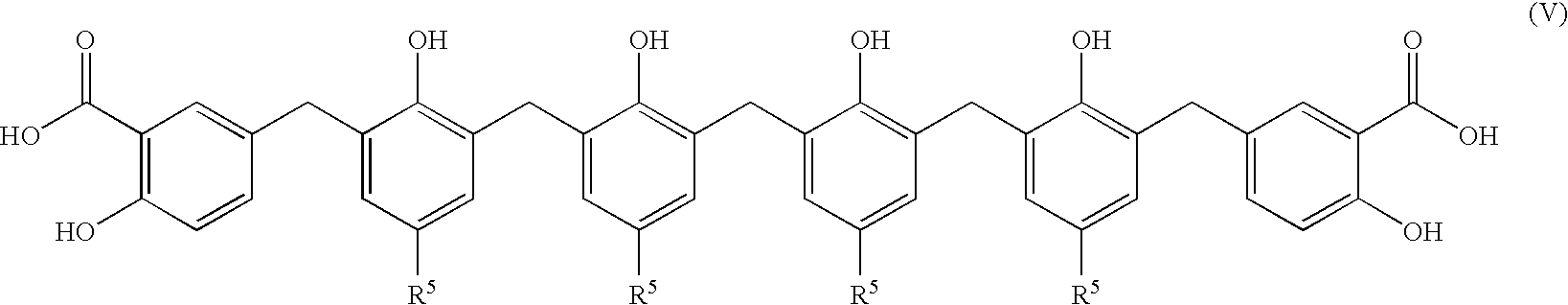

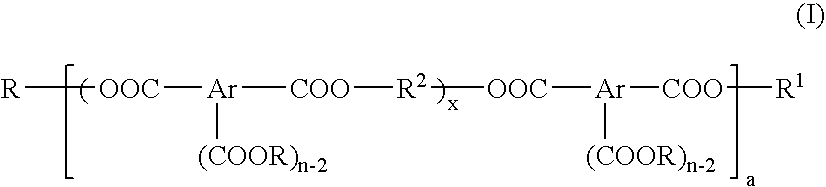

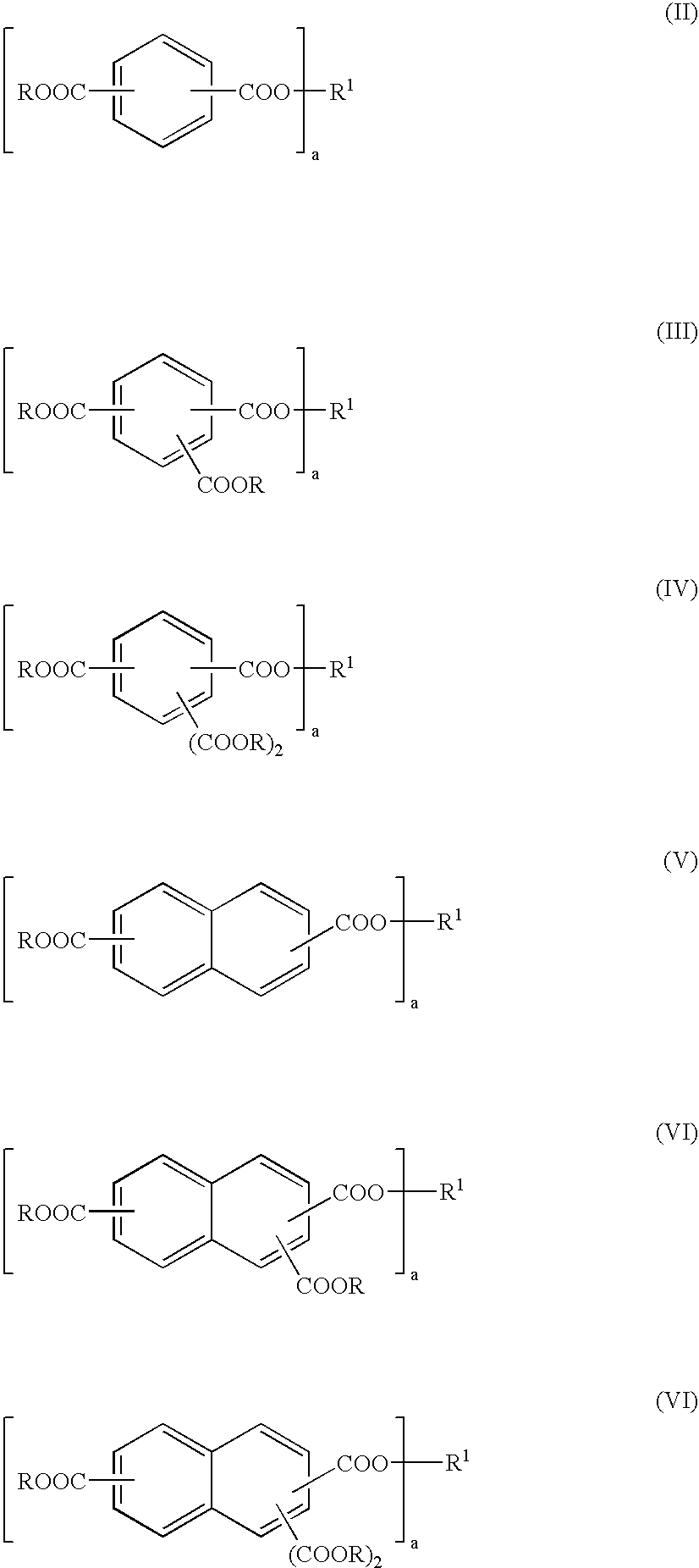

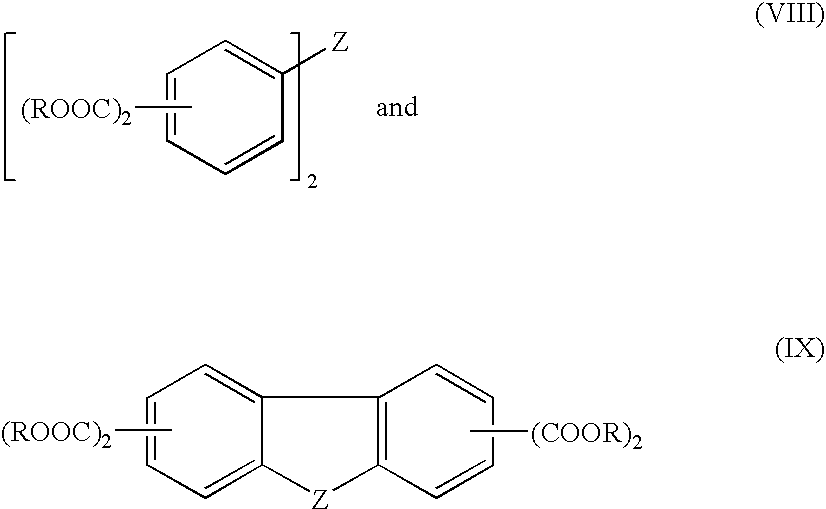

Lubricating Compositions Containing An Ester Of A Polycarboxylic Acylating Agent

InactiveUS20080051307A1Improve fuel economyReduce particulate emissionsNon-fuel substance addition to fuelCombustion enginesArylCarboxylic acid

The invention provides a lubricating composition containing: (a) a major amount of an ester of a polycarboxylic acylating agent; and (b) at least one compound from: (i) a metal hydrocarbyl dithiophosphate, or (ii) a viscosity modifier, wherein the metal hydrocarbyl dithiophosphate contains at least one hydrocarbyl group including an aryl functional group, a substituted-aryl functional group or mixtures thereof. The composition is suitable for high temperature engines, particularly a ceramic containing engine to provide at least one of increased fuel economy, decreased emissions of particulate matter, increased oxidative stability and decreased deposit formation.

Owner:THE LUBRIZOL CORP

Mineral flotation collecting agent for oxidized ores

The invention provides a collecting agent for collecting minerals of oxidized ores such as ilmenite and a preparation method thereof, and belongs to the technical field of mineral flotation collectingagents. The mineral flotation collecting agent for the oxidized ores such as ilmenite is used after ammonium dibutyl dithiophosphate, ethylenediaminetetraacetic acid salt, maleate, sodium oleate andthe like are mixed; and the mineral flotation collecting agent has the characteristics of good water solubility, good dispersion and high selective adsorption ability to objective minerals, and is mainly used for flotation separation of valuable minerals in the oxidized ores such as the ilmenite, scheelite and wolframite. The preparation method of the mineral flotation collecting agent for the oxidized ores is simple in process, operation is easy to control, the prepared collecting agent has the advantages of high selectivity, good dispersion, low agent dosage and high mineral separation comprehensive efficiency, and quite important significance for promoting mineral separation of the minerals such as the oxidized ores is achieved.

Owner:河南天鸿新材料科技有限公司

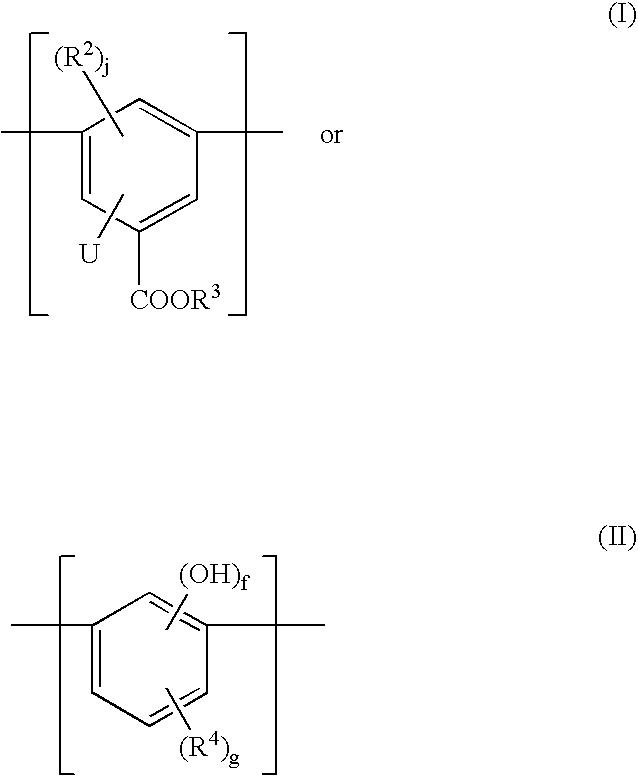

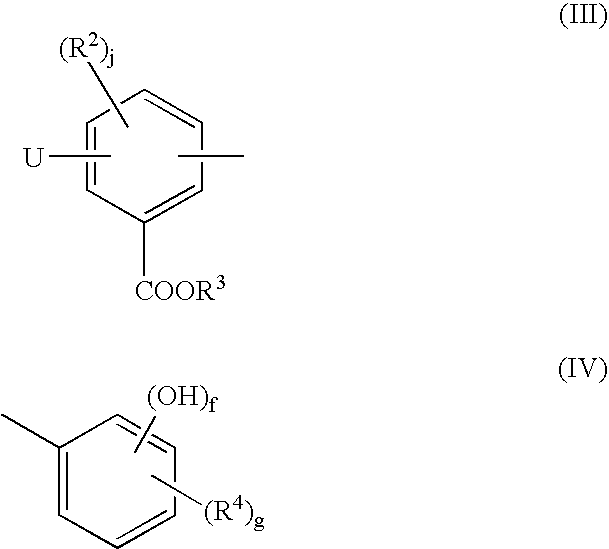

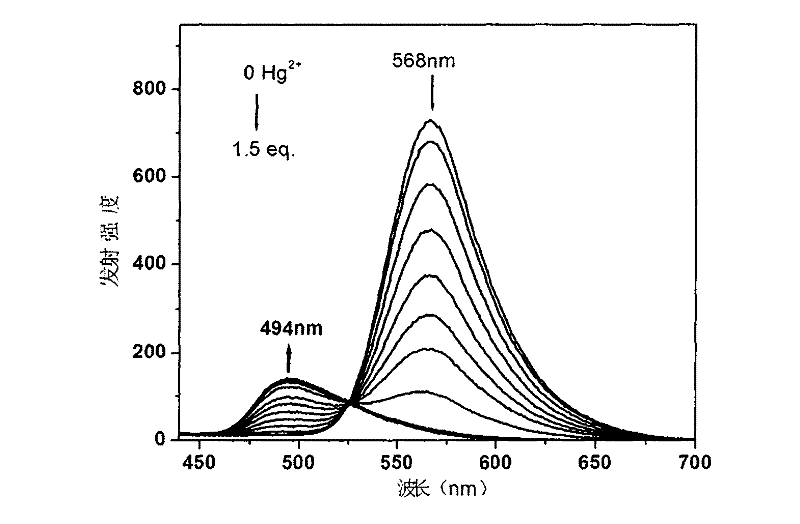

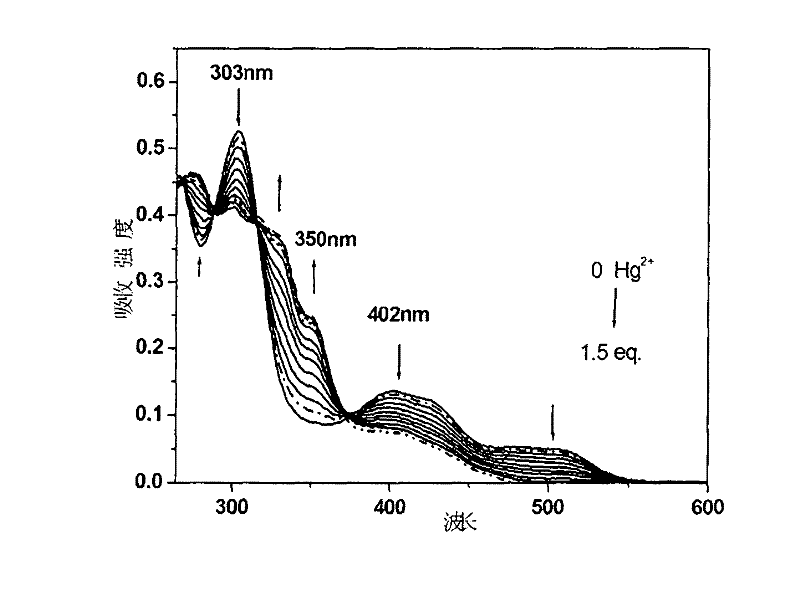

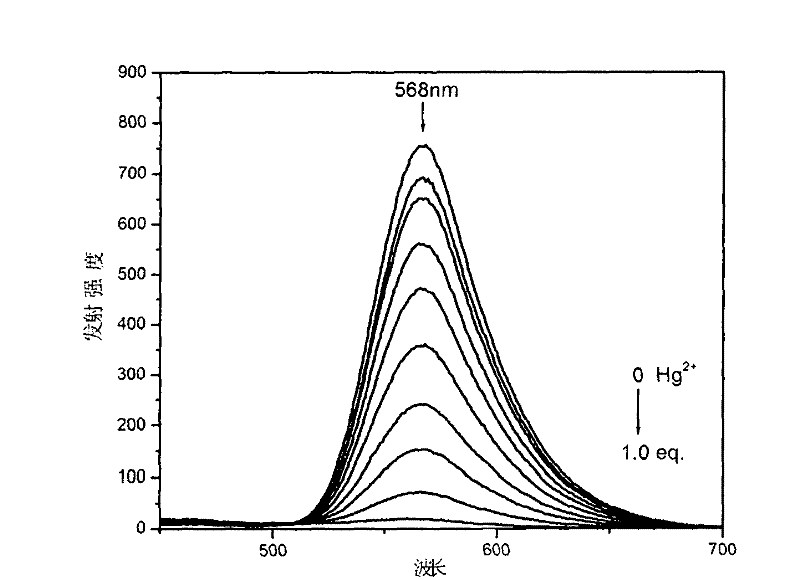

Iridium complex-containing phosphorescent materials, preparation thereof and application method for detecting mercuric ions and acetonitrile

InactiveCN102190685AHigh sensitivityHigh selectivityGroup 8/9/10/18 element organic compoundsChemiluminescene/bioluminescenceIridiumCarbamate

The invention discloses preparation and an application method for iridium complex phosphorescent materials. A series of dithio compounds such as N,N-disubstituted dithio carbamates, or O,O-disubstituted dithio phosphates and alkoxy-substituted dithio formats are subjected to dissociation of dichloro bridged complex of iridium, and iridium complexes shown as a formula (I), a formula (II) or a formula (III) are generated. The iridium complexes can be used for detecting mercuric ions and acetonitrile; and through influence of Hg2+ on physical, electrochemical and sensing properties of the iridium complexes, the iridium complex phosphorescent materials identify the Hg2+ in high selectivity, high sensitivity and quick response, the turn off phenomenon occurs, and a phosphorescent sensor for detecting the Hg2+ can be manufactured. By changing a solvent for detecting, a turn on phenomenon occurs and a novel sensor for detecting acetonitrile can be manufactured.

Owner:NANJING UNIV OF POSTS & TELECOMM

Lubricating oil composition

One lube oil compound with the quality of oxidation resistance, abrasive resistance, and anti-attrition, based on total weight of the compound, includes the following components: (a) zinc salt, ntoquita nantokite, magnesium salts, calcium salt and barium salt of dialkyl phosphorodithioic acid, the content is 0.1-3.5%; (b) compound antioxidant of amine antioxidant and phenolic ester antioxidant, the content is 0.2-3.0%; (c) molybdenum salt of dialkyl dithioic organic acid, the content is 0.05-1.5%; (d) monohydric or polyhydric alcohol ester with abrasive resistance and anti-attrition produced by monohydric alcohol or diatomic alcohol and alkyl, arene or alkyl phenol in place of carboxylic acid, the content is 0.05-1.5%; (e) zinc salt, sodium salt, magnesium salts, calcium salt and barium salt dialkyl dithiocarbamate or dialkyl dithiobenzoic acid, the content is 0.05-1.5%; (f) grease oil, the residue.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation of a therapeutic composition

Product R, a novel therapeutic composition for treating viral infections and stimulating the immune system, comprises a unique peptide having 31 amino acids and another unique peptide having 21 amino acids and connected with an oligo-nucleotide through a diphosphodiester or diphosphodithioate ester linkage. The composition has a light absorption spectrum with typical absorption ratios of 1.998 at 260 nm / 280 nm and 1.359 at 260 nm / 230 nm.

Owner:BBM HLDG

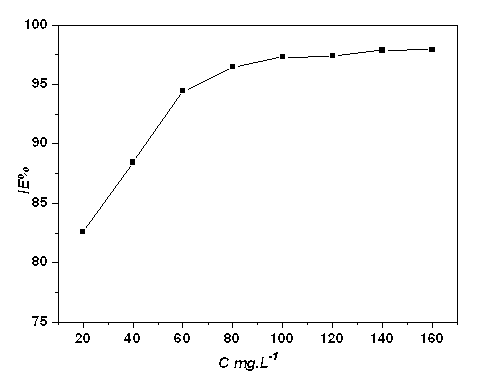

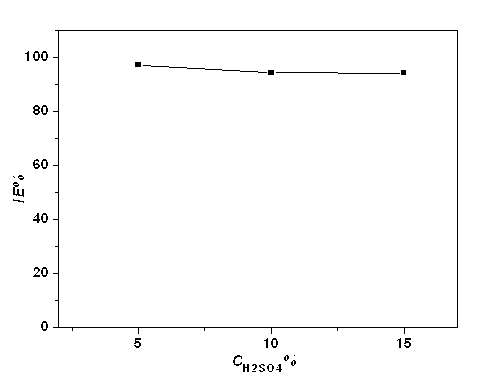

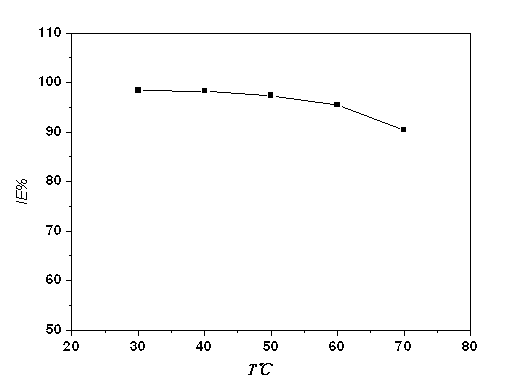

Application of O-O'-dicyclohexyl phosphorodithioic acid-N,N-diethylamine in preparing metal pickle liquor

InactiveCN101736351AGood metal corrosion inhibition effectRaw materials are cheap and easy to getMedicinal chemistryPolymer chemistry

The invention discloses application of O-O'-dicyclohexyl phosphorodithioic acid-N,N-diethylamine in preparing a metal pickle liquor. An effective metal corrosion inhibition effect can be obtained through the step of adding the O-O'-dicyclohexyl phosphorodithioic acid-N,N-diethylamine into pickling mediums with different concentrations to lead the concentration of the pickling mediums to be 20-160 mg / L.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

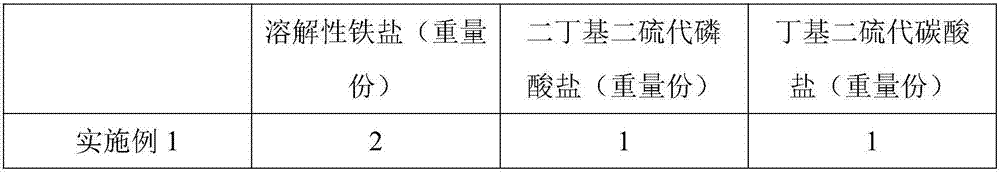

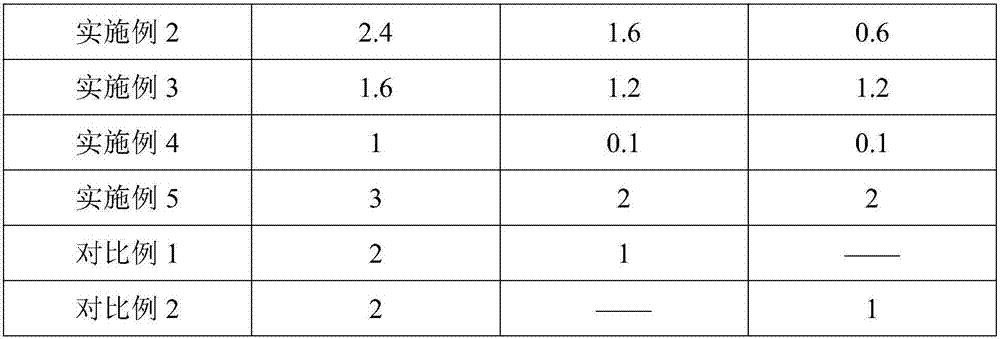

Preparation method and application of heavy metal contaminated soil/bottom mud stabilizer

ActiveCN107446587AImprove stabilityLimited ratioContaminated soil reclamationOrganic fertilisersDibutyl dithiophosphateSolubility

The invention relates to the technical fields of soil remediation and environmental protection, in particular to a heavy metal contaminated soil / bottom mud stabilizer. The heavy metal contaminated soil / bottom mud stabilizer is prepared from soluble ferric salt, dibutyl dithiophosphate and butyl dithiocarbonate in proportion. A heavy metal repair agent is low in cost, can effectively eliminate harm of heavy metal ions in soil, and has relatively good stabilizing effect on arsenic and other heavy metals in arsenic-containing composite heavy metal contaminated bottom mud under an acid condition, so that the defect that an existing product is poor in stabilizing effect on the arsenic-containing composite heavy metal contaminated bottom mud is overcome. The heavy metal contaminated soil / bottom mud stabilizer can be applied to stabilizing treatment of heavy metal contaminated muddy bottom of arsenic, lead, cadmium, copper, zinc and chromium. The heavy metal contaminated soil / bottom mud treated by the stabilizer can be used for roadbed building filler. The heavy metal contaminated soil / bottom mud stabilizer has the effects of protecting the environment, changing waste into things of value and increasing a waste utilization rate, and has a considerable economic value.

Owner:湖南新九方科技有限公司

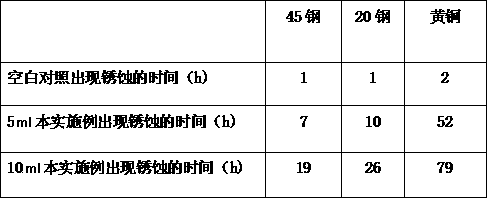

Metal antirust agent containing ammonium molybdate

ActiveCN103031558AGood gas phase anti-rust effectExcellent contact rust resistanceSodium acetateSodium diacetate

The invention discloses a metal antirust agent containing ammonium molybdate. The metal antirust agent is prepared from the materials in parts by weight: 95-105 parts of castor oil, 1.2-2.4 parts of ferrocene, 0.8-1.6 parts of polyisobutene, 1-2 parts of ammonium molybdate, 1.3-2.5 parts of sodium diacetate, 0.8-1.6 parts of 2-methyl imidazoline, 1-1.8 parts of diethanol amine, 0.3-0.9 parts of dialkyl group phosphorodithioic acid, 0.7-1.2 parts of sodium dodecyl benzene sulfonate, 0.9-1.7 parts of polydimethylsiloxane, 5.2-6.4 part6s of film-forming resin and 1-2 parts of modified kaolin. The metal antirust agent has excellent contact antirust performance and good gas phase antirust effect, and has good gas phase antirust effect and contact antirust effect to coppers and brass.

Owner:广州市昌东化工工程材料有限公司

Process of preparing multi-functional additive for lubricant composition form saturated cashew nut shell liquid

InactiveUS20020128159A1Reduce coefficient of frictionImprove the lubrication effectAdditivesPhosphorus organic compoundsPolymer sciencePhosphorus pentasulphide

A process for the preparation of multi-functional additive, amino di(alkylcyclohexyl0) phosphorodithioate, for use as an additive in a lubricant composition so as to impart improved coefficient of friction, wear reduction, antioxidant and extreme pressure properties, including the steps of (a) hydrogenating distilled technical cashew nut shell liquid with palladium or nickel or platinum catalyst; to fully hydrogenate the olefinic chain and aromatic ring of the precursor; (b) reacting fully hydrogenated technical cashew nut shell liquid with phosphorus pentasulfide to obtain unpolymerized hydrogenated cashew nut shell liquid phosphorodithioic acid, the reaction being carried out at a temperature ranging from 20 to 140.degree. C. ; and (c) condensing the unpolymerized fully saturated cashew nut shell liquid phosphorodithioic acid with at least one amine to obtain the amino di(alkylcyclohexyl) phosphorodithioate. A lubricant containing a major proportion of a material selected from the group consisting of an oil of lubricating viscosity and a grease; and remainder an additive including amino di(alkylcyclohexyl)phosphorodithioate prepared by the foregoing process.

Owner:INDIAN OIL CORPORATION

Preparing method of flame-retardant water-borne coating

InactiveCN104140731AImprove the defect of "hot sticky and cold brittle"Improve wear resistanceFireproof paintsSodium molybdateEthyl group

The invention relates to a preparing method of flame-retardant water-borne coating. Water, emulsifier and methyl acrylic acid are added in, the temperature is raised to 50 DEG C, stirring is performed for 25 min, A monomers are added in, and emulsification is performed for 25 min to 45 min; backflow water is led in when the temperature is raised to 75 DEG C, heat preservation is performed when the temperature is raised to 80 DEG C, initiators are dropwise added, the drop time is 1 h to 4 h, and reaction is performed for 4 h to 5 h after dropping is finished; then, di(2-ethylhexyl) molybdenum dithiophosphate is added, stirring reaction is performed for 1 h to 4 h after dropping is finished, and nuclear layer emulsifier is obtained; B monomers and initiators are dropwise added into the obtained nuclear layer emulsifier, the drop time is 1 h to 3 h, stirring reaction is performed at the temperature of 70 DEG C to 85 DEG C for 2 h after the dropping is finished, then, sodium molybdate is added, stirring reaction is performed at the temperature of 75 DEG C to 85 DEG C for 1 h to 3 h, crosslinking agents are added, reaction is performed at the temperature of 70 DEG C to 85 DEG C for 1 h to 2 h, the temperature is lowered to 50 DEG C, dispersion liquid A, zinc dialkyl dithiophosphate and emulsifier are added, the reacting time is 40 min, reduction materials are added in, stirring reaction is performed at the temperature of 75 DEG C to 85 DEG C for 1 h to 3 h, the pH value is adjusted to 7 to 8 by adding ammonia water, and the flame-retardant water-borne coating is obtained. Due to the preparing method, the flame-retardant performance of resin films made from acrylic ester can be substantially improved, and the defect that traditional resin films made from acrylic ester becomes yellow is overcome.

Owner:惠州市正伟涂料有限公司

Plastic base material film for packaging

ActiveCN103012915AImprove barrier propertiesImprove air tightnessFlexible coversWrappersLow-density polyethyleneEpoxy

The invention discloses a plastic base material film for packaging. The film is prepared from the following raw materials in parts by weight: 15-18 parts of low-density polyethylene (LDPE), 40-45 parts of linear low-density polyethylene (LLDPE), 34-40 parts of metallocene linear low-density polyethylene (mLLDPE), 10-15 parts of SG-1 polyvinyl chloride, 3-5 of epoxy linseed oil, 2-3 parts of polyethylene wax powder, 1-2 parts of distearoyl isopropoxy aluminate, 8-12 parts of kieselguhr, 2-4 parts of poly-4-methyl-1-amylene, 5-10 parts of light calcium carbonate, 2-3 parts of phosphorodithioic acid, 1-2 parts of phthalate, 1-2 parts of smoke sheet rubber, 0.5-0.8 parts of zinc stearate, 1-2 parts of 3-aminopropyltrimethoxysilane, 1-2 parts of ferrocene and 1-2 parts of modified wood ashes. The plastic base material film for food packaging has good separation performance and air tightness, good anti-polluting performance, excellent pressure resistance and impact resistance as well as the characteristics of high heat-sealing strength and good heat sealing performance.

Owner:汕头市汇诚包装材料实业有限公司

Antiwear and energy-saving lubricant oil

This invention relates to modified lubricating oil, especially antifriction green lubricating oil, it includes following weight percentage constituents, base oil 86-96%, engine oil complexing agent 3-13.8%, dialkyl phosphorodithioic acid oxygen molybdenum0.2-3%. When the lubricating oil made by production process request used on vehicle engine, it can greatly improve lubricating and fuel oil economical efficiency. The fuel oil is economized, car oil consumption is reduced 12.4%, out car noise reduces 2.4%, and inner car noise reduces 3.4%. The additive is easy to make, cost is low and is easy to extend.

Owner:XINJIANG FUKE OIL PROD CO LTD

Additive composition for ep greases with excellent antiwear and corrosion properties

A lubricant composition is provided as follows: At least 90% of a base grease; (a) a thiadiazole poly(ether)glycol complex in an amount which provides about 1500 to 3500 ppm sulfur; (b) molybdenum dihydrocarbyldithiophosphate in amount which provides about 77 to 450 ppm molybdenum; and (c) zinc dihydrocarbyldithiophosphate in an amount which provides about 600 to 1000 ppm zinc. An additive composition for grease, consisting of components (a), (b) and (c), is also provided.

Owner:VANDERBILT CHEM LLC

Method for preparing flame-retardant core-shell type waterborne acrylate resin coating

ActiveCN104086698AImprove the shortcomings of yellowingImprove wear resistanceCoatingsMANGANESE ACETATEPolymer science

The invention relates to a method for preparing a flame-retardant core-shell type waterborne acrylate resin coating. The method comprises the following steps of adding water, an emulsifier and acrylic acid, raising the temperature to 40 DEG C, stirring for 30 minutes, adding a monomer A, emulsifying for 15-45 minutes, raising the temperature to 70 DEG C, starting to introduce recirculation water, raising the temperature to 80 DEG C, reacting for 2 hours, dropwise adding an initiator for 2-4 hours, and reacting for 1-2 hours; adding manganese amino acid, stirring and reacting for 1-4 hours at 80 DEG C, adding a metal salt to adjust the pH value to be 4, adding manganese acetate, stirring and reacting for 1-2 hours at 60 DEG C to obtain a core layer emulsion; simultaneously dropwise adding a monomer B and an initiator into the core layer emulsion for 1-3 hours, stirring and reacting for 3 hours at 70-85 DEG C, adding a crosslinking agent, reacting for 1-3 hours at 70-90 DEG C, cooling to 40 DEG C, adding molybdenum di(2-ethylhexyl)phosphorodithioate and an emulsifier, reacting for 40 minutes, adding the material B, stirring and reacting for 1-3 hours at 65-85 DEG C and adding aqueous ammonia to adjust the pH value to be 7-8 to obtain the flame-retardant core-shell type waterborne acrylate resin coating. By virtue of the preparation method, the flame resistance of the acrylate resin can be greatly improved and the shortcoming of yellowing of a traditional acrylate resin film can also be improved.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD +1

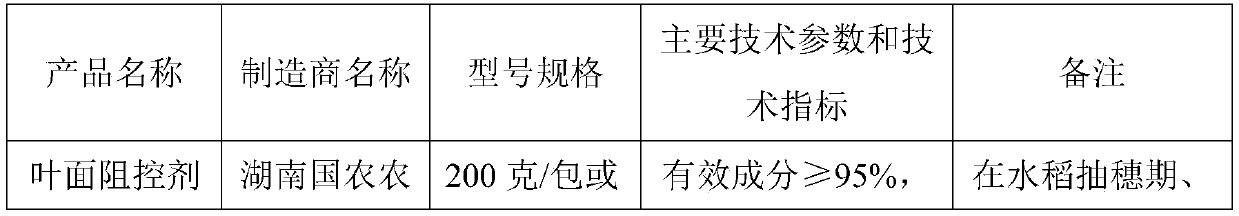

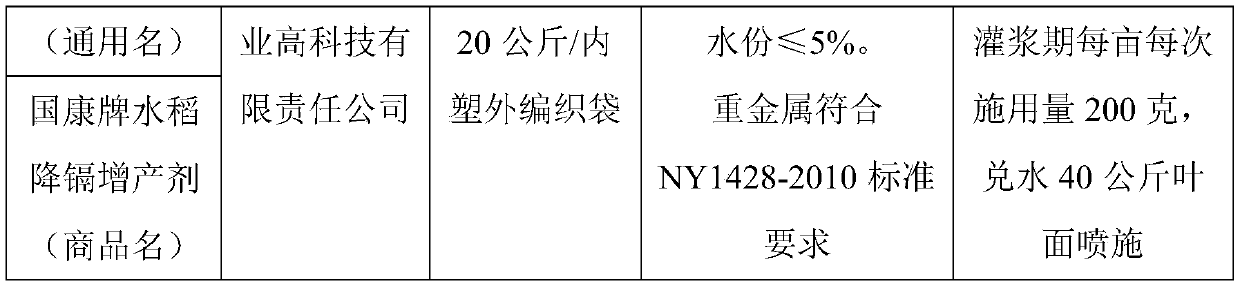

Rice cadmium-reducing and yield-increasing agent and production method thereof

PendingCN110668879ARealization of cadmium reductionReduce cadmium contentFertilising methodsFertilizer mixturesCyclodextrinCopper sulfate

The invention discloses a rice cadmium-reducing and yield-increasing agent. The rice cadmium-reducing and yield-increasing agent is mainly produced by mixing the following components: a component A which is one of or a composition of any two of cyclodextrin and derivatives of the cyclodextrin, a component B which is one of or a composition of any two of zinc sulfate, manganese sulfate, ferrous sulfate and copper sulfate, and a component C which is one of or a composition of any two of dialkyl dithiophosphates; and the mass fractions of the component A, the component B and the component C in the rice cadmium-reducing and yield-increasing agent are 1%-90%, 1%-90% and 1%-98% correspondingly. The invention further provides a production method of the rice cadmium-reducing and yield-increasing agent. The rice cadmium-reducing and yield-increasing agent is small in using amount, treatment is rapid, easy, convenient and not limited by the site, the concentration and the like, long-distance automatic spraying control by an unmanned aircraft can be further achieved, and the rice cadmium-reducing and yield-increasing agent is especially suitable for cadmium-standard-exceeding treatment of rice and emergency treatment of complex heavy metal pollution accidents in case of emergencies and has good application prospects.

Owner:湖南国农农业高科技有限责任公司

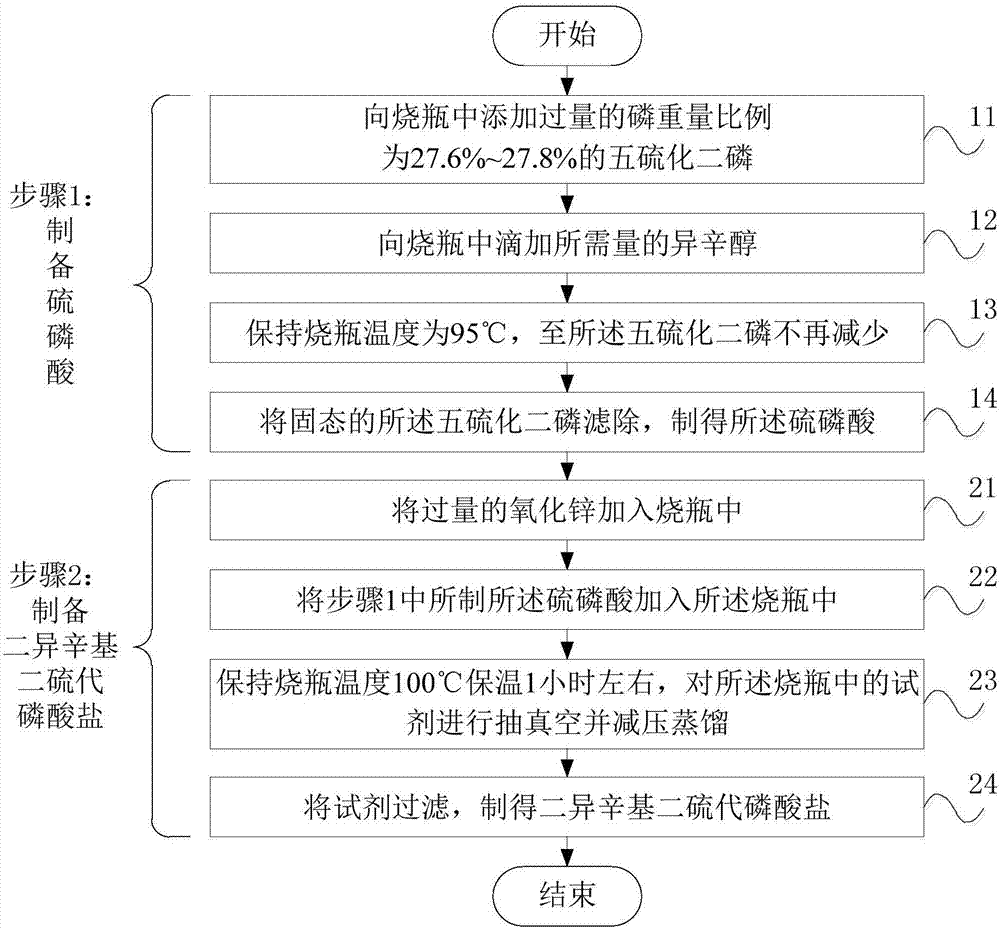

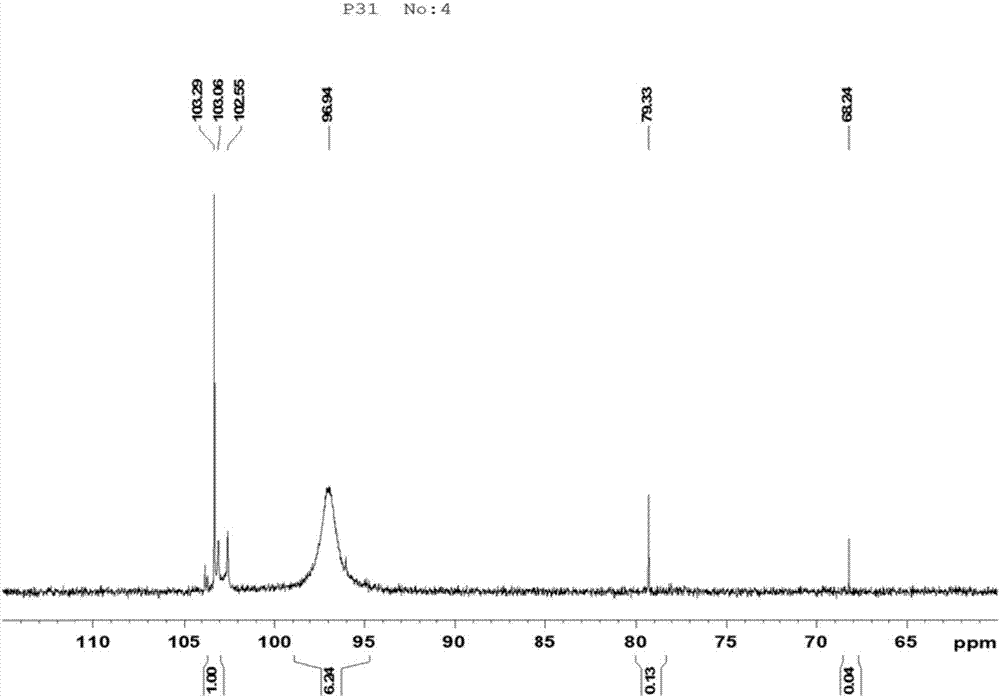

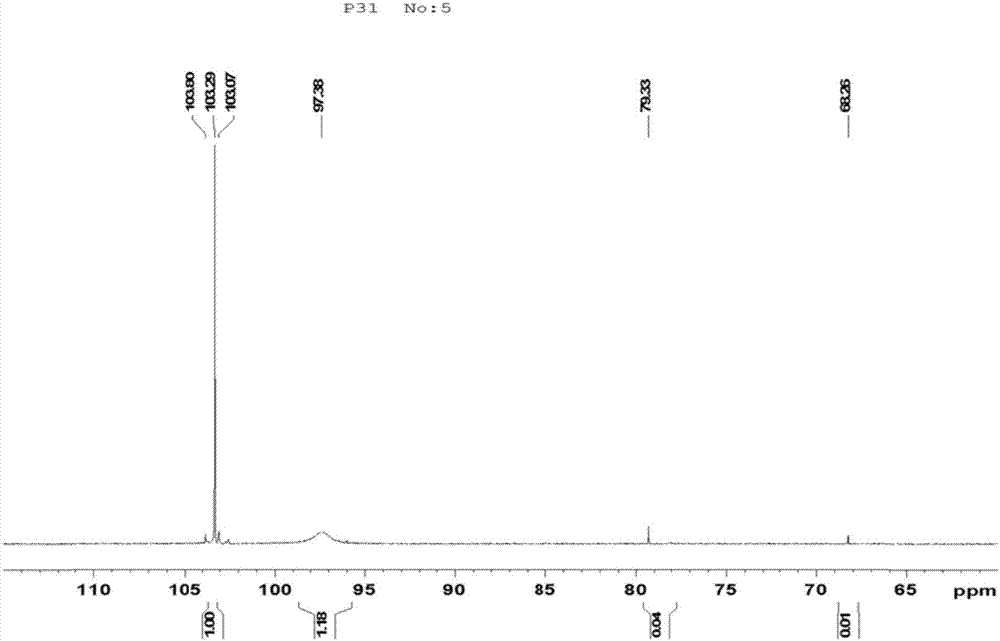

Preparation method of diisooctyl dithiophosphate additive of hydraulic oil

ActiveCN107955035AImprove water separation effectSimple production processGroup 5/15 element organic compoundsAdditivesPhosphorus pentasulfideSulfur

The invention discloses a preparation method of a diisooctyl dithiophosphate additive of hydraulic oil. The preparation method comprises the following steps: adding excessive phosphorus pentasulfide of which the weight ratio of phosphorus is 27.6%-27.8%; dropwise adding a required amount of isooctanol; maintaining the temperature of a flask to be 95 DEG C until complete reacting; filtering out solid phosphorous pentasulphur; adding excessive zinc oxide; adding prepared phosphorodithioic acid; maintaining the temperature of the flask at the temperature of 100 DEG C and insulating for about 1 hour, and vacuumizing and distilling under reduced pressure; and filtering a reagent to obtain diisooctyl dithiophosphate. The zinc oxide comprises 25-30% of direct-method zinc oxide and 70-75% of indirect-method zinc oxide, and the excessive range of the zinc oxide is 5-8%. When the diisooctyl dithiophosphate additive prepared by the technical scheme of the invention is used on the hydraulic oil, the water separation performance of the hydraulic oil is obviously improved, a production process is simple, the use amount of the zinc oxide is reduced, a catalyst is omitted, treatment of wastes in the later period is relieved, and the production cost is reduced obviously.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

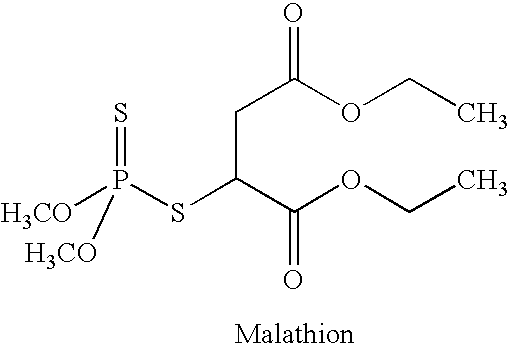

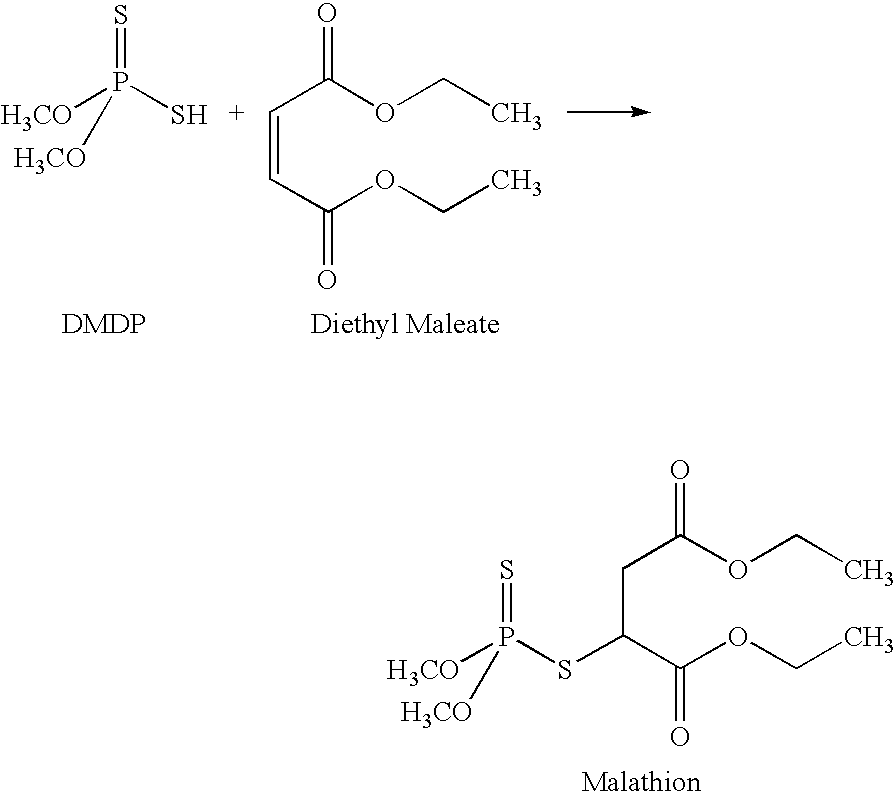

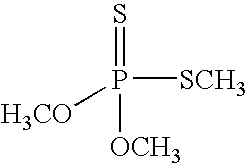

Process for Preparing Malathion for Pharmaceutical Use

ActiveUS20070010496A1Yield maximizationMaximize purityBiocidePhosphorous compound active ingredientsMethyl thiophosphateImpurity

The present invention provides a process for preparing a highly pure form of malathion having a reduced level of toxic impurities. In addition, the malathion prepared by the process of this invention is storage stable. The level of toxic impurities in the malathion, e.g., isomalathion, O,O,S-trimethyl phosphorodithioate (MeOOSPS), O,O,S-trimethyl phosphorothioate (MeOOSPO), O,S,S-trimethyl phosphorodithioate (MeOSSPO), malaoxon, isomalathion, diethyl fumarate, methyl malathion, dimethyl malathion, O,O-methyl,ethyl-S-(1,2-dicarboethoxy)ethyl-phosphorodithioate are lower than that of any other commercial preparation of malathion that may be used for pharmaceutical purposes.

Owner:TARO PHARMA INDS

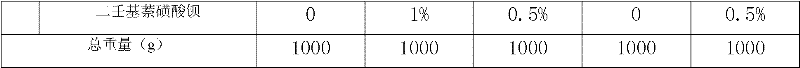

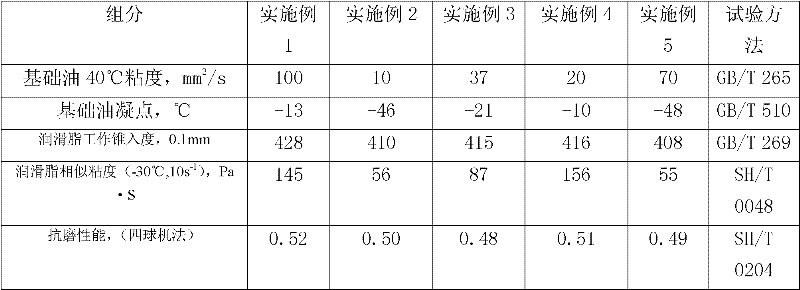

Lubricating grease composition for cotton picker

ActiveCN102250675AGood low temperatureImprove liquidityLubricant compositionBase oilStandard methods

The invention relates to a lubricating grease composition for a cotton picker and mainly solves the problem that the flowability of lubricating grease is poor in the prior art. The lubricating grease composition provided by the invention comprises the following components in percentage by weight: 3-10% of thickening agent, 84-95% of basic oil with a kinematic viscosity which is 10-100 sq.mm / s anda condensation point which is not higher than 10 DEG C below zero and 2-8% of additive comprising 1-4% of dialkyl phosphorodithioic acid (a), 1-3% of dialkyl aminodithioformic acid (b) and 0-1% of antirust additive (c). The lubricating grease manufactured by the invention has good low-temperature flowability and good pumping performance; the similar viscosity at 30 DEG C below zero is detected byusing an SH / T0048 standard method and numerical values are all less than 200 Pa*S, so that the lubricating grease composition has a certain superiority when being used for the cotton picker.

Owner:CHINA PETROLEUM & CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com