Patents

Literature

76results about How to "Excellent antioxidant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automobile automatic transmission fluid

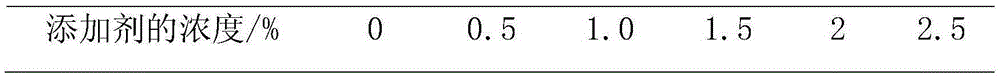

InactiveCN103980984AExcellent antioxidantImprove wear resistanceAdditivesAutomatic transmission fluidViscosity index

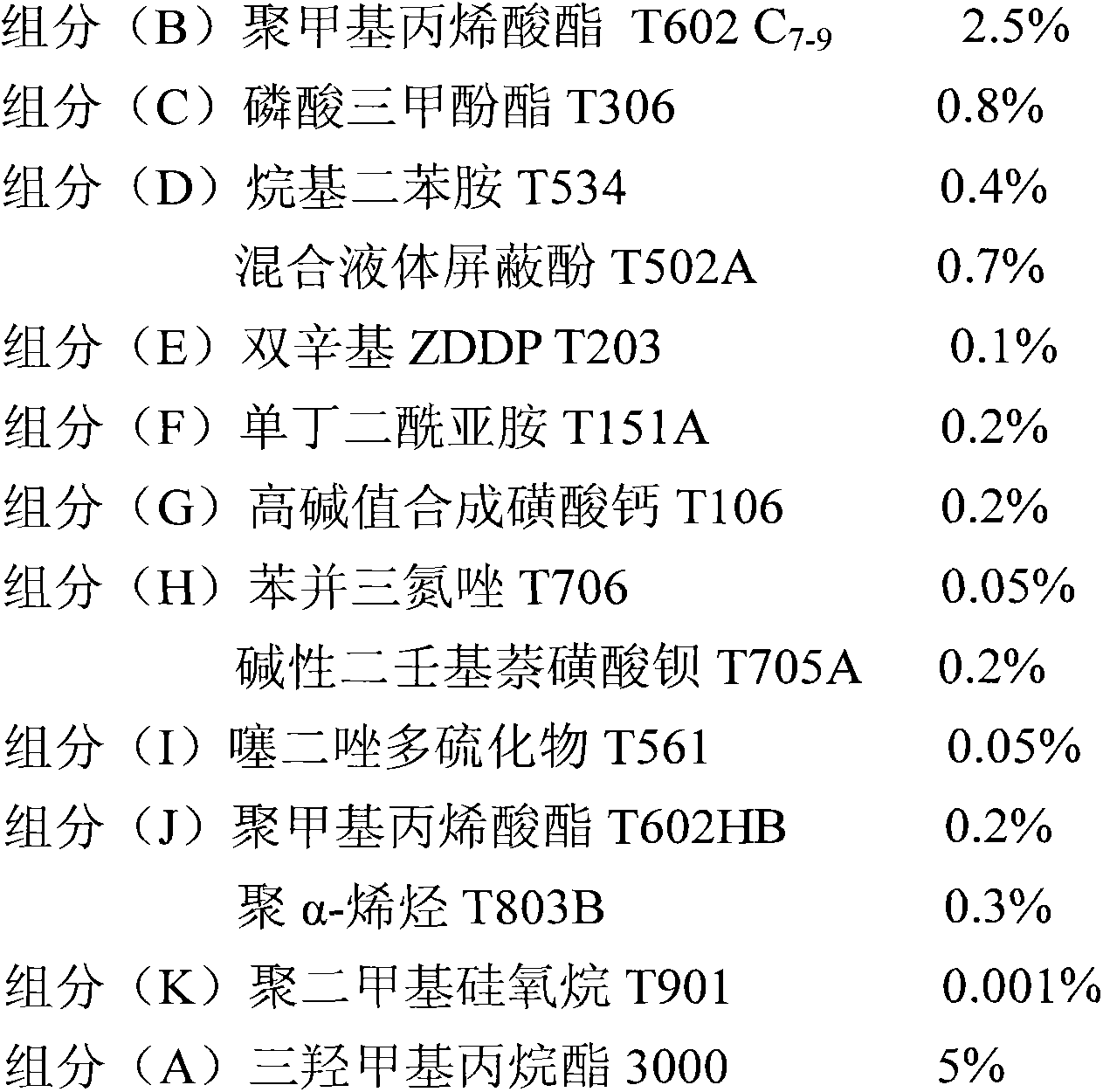

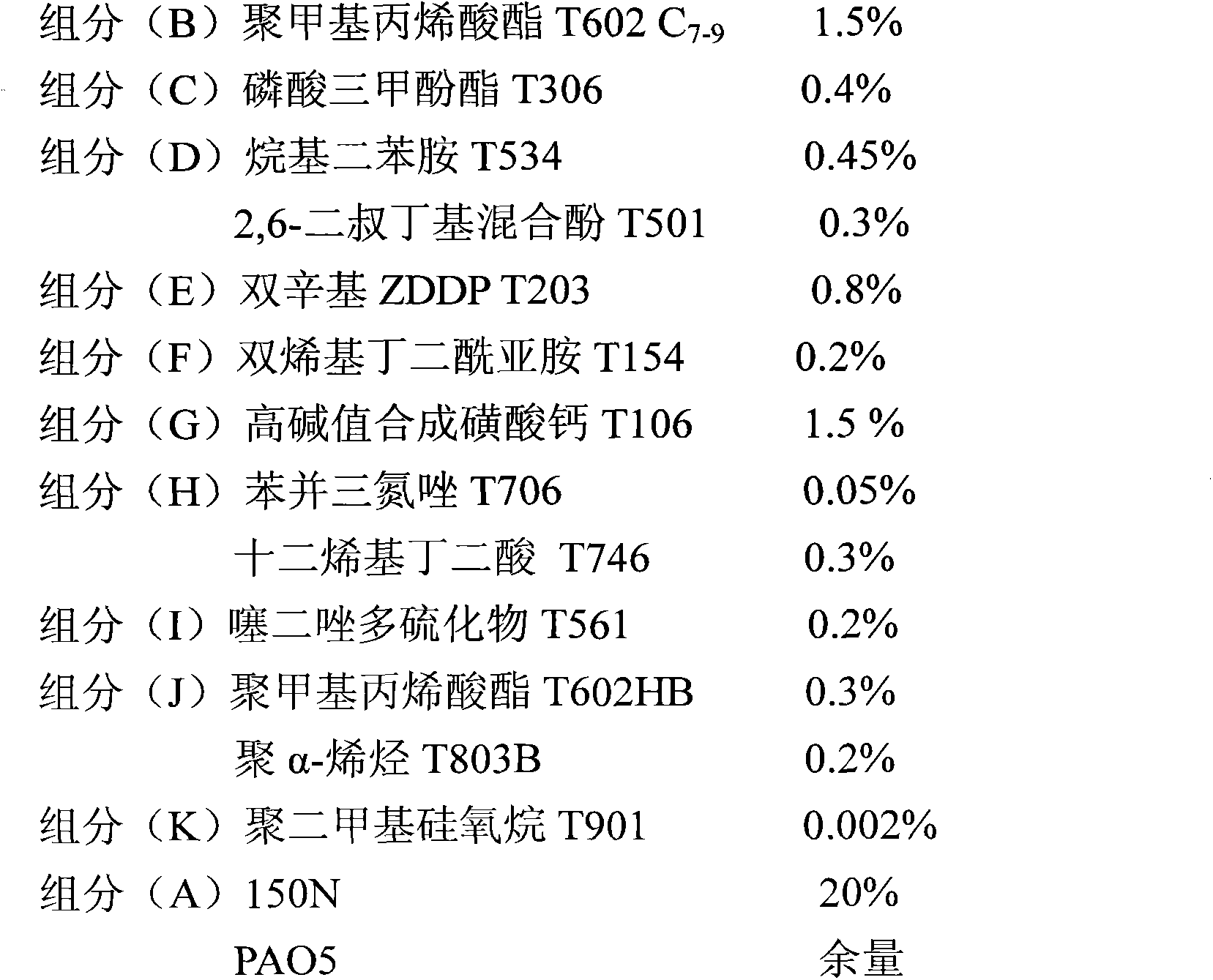

The invention relates to an automobile automatic transmission fluid, and mainly aims at solving the problems of non ideal wear resistance and antioxidant properties of automobile automatic transmission fluids in the prior art. The composition comprises base oil accounting for 85.0 to 97.0% of the total weight; a viscosity index improver accounting for 0.2 to 10.0% of the total weight; an anti-wear reagent at extreme pressure, accounting for 0.2 to 2.0% of the total weight; an antioxidant accounting for 0.05 to 2.0% of the total weight; an antioxidant anticorrosion anti-wear agent accounting for 0.02 to 1.0% of the total weight; a dispersant accounting for 0.1 to 3.0% of the total weight; a detergent accounting for 0.05 to 2.0% of the total weight; an anti rust agent accounting for 0.05 to 3.0% of the total weight; a metal deactivator accounting for 0.02 to 3.0% of the total weight; a pour point depressant accounting for 0.2 to 8.0% of the total weight; and an antifoaming agent accounting for 0.0001 to 0.02% of the total weight. The automobile automatic transmission fluid has the advantages of good antioxidant anticorrosion anti-wear properties.

Owner:LIAONING RUNDI AUTOMOTVE ENVIRONMENTAL PROTECTIONTECH

Rare earth hydroxide catalyst for moderate/low temperature carbonyl sulfur hydrolysis and preparation method thereof

InactiveCN1593751AHigh activity at medium and low temperatureGreat operating flexibilityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCarbonyl groupLow activity

The invention relates to a kind of rare-earth hydroxide catalyst with medium-low carbonyl sulfur hydrolysis and its manufacturing method. The catalyst of the invention is rare earth hydroxide, and chemical molecular formulas of it are: Re(OH)3, on which Re is stood for La, Pr, Nd, Sm, Eu, Gd. Compared with the existing COS hydrolysis catalyst, the catalyst of the invention has the advantages of \ high medium-low activity, great operating elasticity, excellent resistibility of oxygen and sulfur, simple manufacturing method and so on. When the concentration of oxygen in virgin gas is less than 2%, the catalyst activity has no influence; furthermore, when the virgin gas contains oxygen and hydrogen sulfide at the same time, the influence of catalyst activity can be neglected.

Owner:TONGJI UNIV

Ultra-wearable rubber formulation for sports shoes sole

The invention discloses a superwear-resisting rubber formulation of sport sole, and is characterized in that the formulation according to parts by weight comprises 80 parts of polybutadiene rubber, 20 parts of natural gum STR-5L, 1 part of uniform tackiness resin, 45-48 parts of white carbon black, 3.5 parts of softening oil, 3-3.2 parts of coupler, 5.2-5.8 parts of activator, 1 part of zinc stearate, 1 part of antifog agent, 1.9-2.1 parts of sulphur, and 1.65-1.95 part of accelerating agent, an ideal raw material functional combination can be obtained after applying the rubber formulation for sports shoes, which makes the sport shoe rubber sole having superwear resistance which is superior to ordinary rubber sole, and has a plurality of excellent properties such as wet-skid resistance, impact resistance and the like.

Owner:ANTA CHINA

Lubricating oil composition

One lube oil compound with the quality of oxidation resistance, abrasive resistance, and anti-attrition, based on total weight of the compound, includes the following components: (a) zinc salt, ntoquita nantokite, magnesium salts, calcium salt and barium salt of dialkyl phosphorodithioic acid, the content is 0.1-3.5%; (b) compound antioxidant of amine antioxidant and phenolic ester antioxidant, the content is 0.2-3.0%; (c) molybdenum salt of dialkyl dithioic organic acid, the content is 0.05-1.5%; (d) monohydric or polyhydric alcohol ester with abrasive resistance and anti-attrition produced by monohydric alcohol or diatomic alcohol and alkyl, arene or alkyl phenol in place of carboxylic acid, the content is 0.05-1.5%; (e) zinc salt, sodium salt, magnesium salts, calcium salt and barium salt dialkyl dithiocarbamate or dialkyl dithiobenzoic acid, the content is 0.05-1.5%; (f) grease oil, the residue.

Owner:CHINA PETROLEUM & CHEM CORP +1

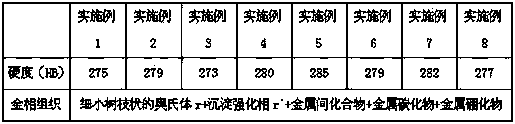

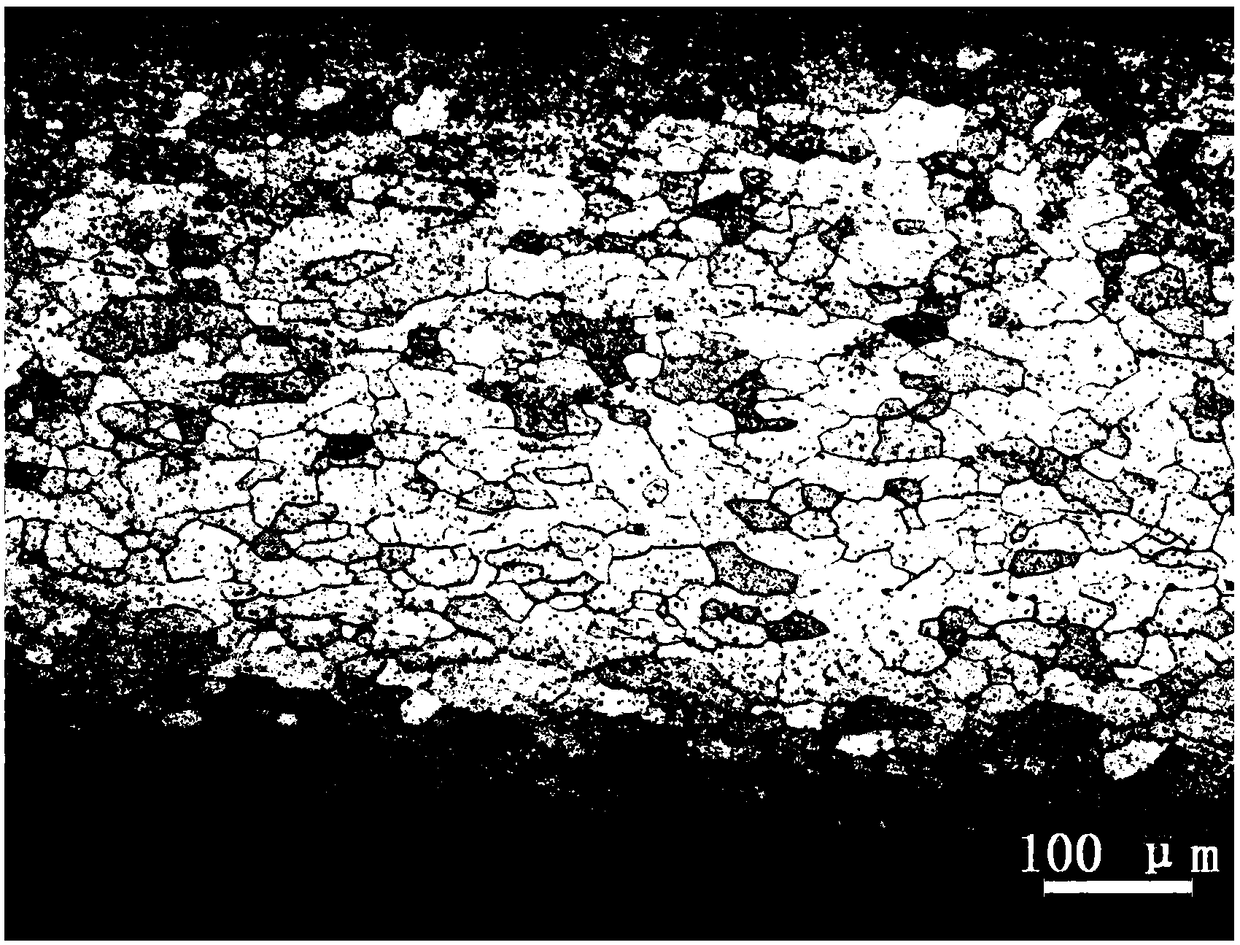

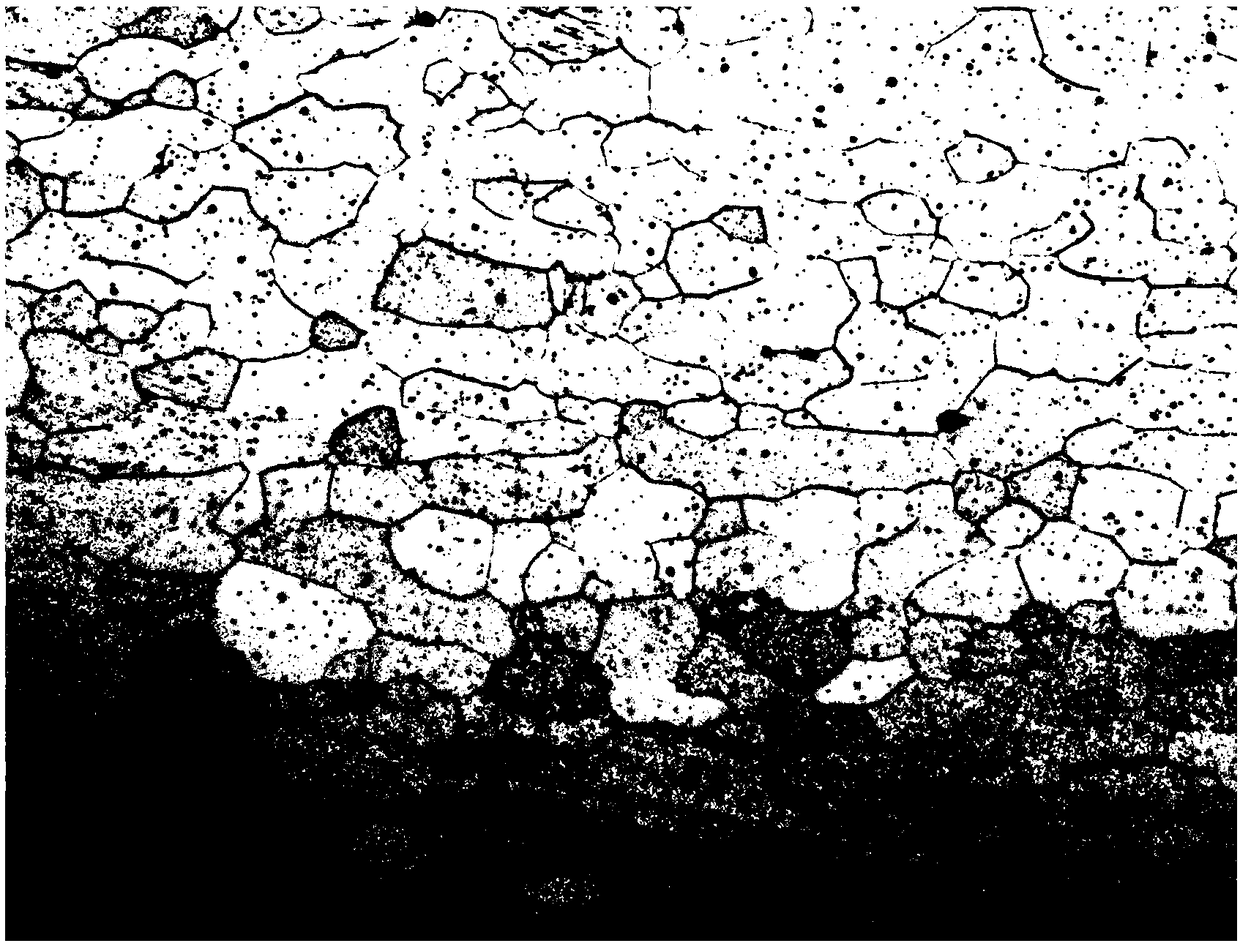

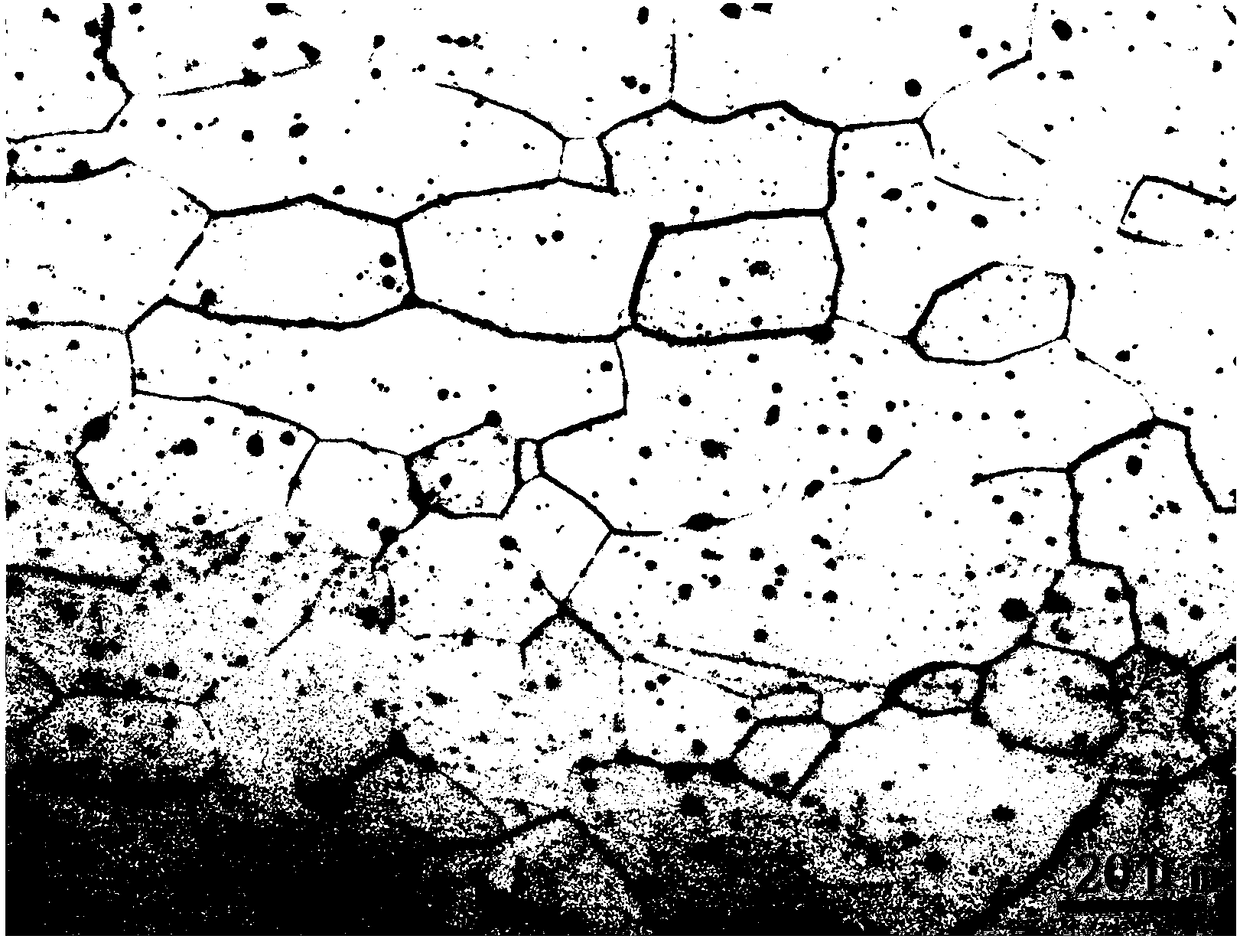

High-temperature-resistant alloy casting and preparation method thereof

ActiveCN104195474AHigh strengthImprove high temperature creep resistanceFoundry mouldsFoundry coresChemical compositionCarbide

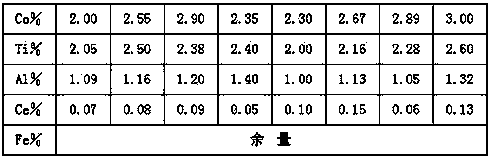

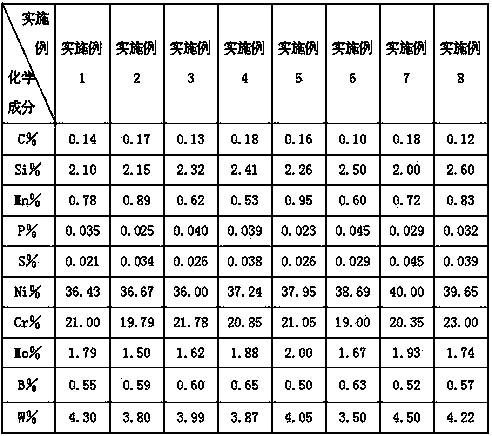

The invention relates to a high-temperature-resistant alloy casting and a preparation method thereof. The alloy casting comprises the following chemical components by mass percent: 0.10% to 0.18% of C, 2.0% to 2.6% of Si, less than or equal to 1% of Mn, less than or equal to 0.045% of P, less than or equal to 0.045% of S, 19% to 23% of Cr, 36% to 40% of Ni, 1.5% to 2.0% of Mo, 0.50% to 0.65% of B, 3.5% to 4.5% of W, 1.0% to 1.4% of Al, 2.0% to 2.6% of Ti, 2% to 3% of Co, 0.05% to 0.15% of Ce and the balance of Fe. The preparation method comprises the following steps of the preparation of a wax mould; the preparation of a mould shell; smelting; and pouring. The as-cast hardness of the alloy casting is HB273-285; and an as-cast metallographic structure of the alloy casting is composed of a fine and small dendritic austenite r, a precipitation strengthening phase r', an intermetallic compound, a metal carbide and a metal boride. The obtained inner core cup casting is strong in high-temperature creep resistance, high-temperature resistance and oxidation resistance and is high in strength and stability under a high-temperature condition, so that the long service life of the casting is realized.

Owner:BAODING FENGFAN PRECISION CASTING

Diesel engine lubricating oil composition, preparation method, and application thereof

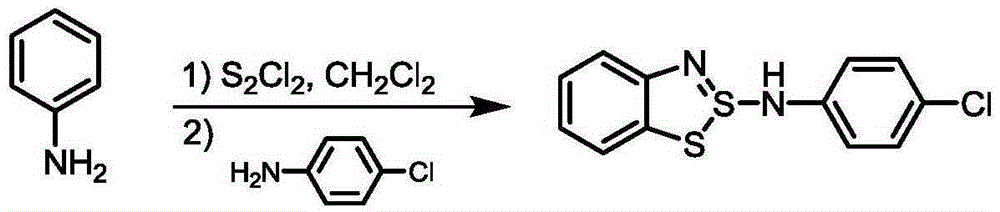

ActiveCN106753701AExcellent antioxidantImprove wear resistanceOrganic chemistryAdditivesSulfonateChemical composition

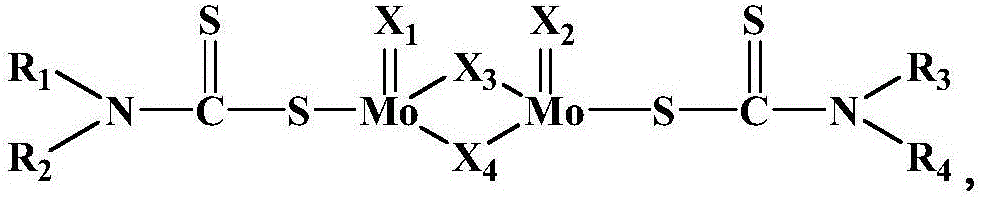

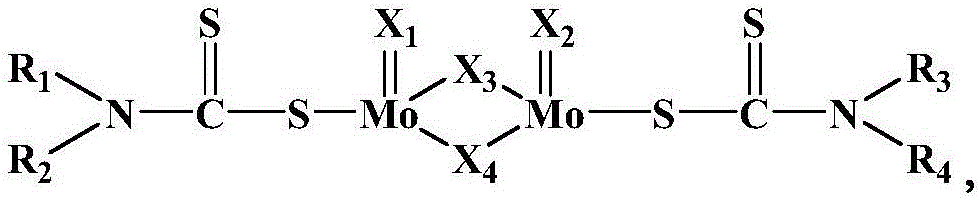

The invention provides a diesel engine lubricating oil composition, a preparation method, and an application thereof. The diesel engine lubricating oil composition includes: A) a multi-functional additive, which is represented as the formula (I); B) a boron-containing anti-oxygen-type polyisobutylene succinimide ash-free dispersant; C) at least one high-molecular-weight polyisobutylene succinimide ash-free dispersant; D) a sulfonate and / or a sulfurized alkylphenol salt; E) at least one dialkyl zinc dithiophosphate; F) an amine-type antioxidant and / or a phenolic ester antioxidant; and G) the balanced being lubricating basic oil. The lubricating oil composition is not higher than 0.09% in content of phosphorus and is not higher than 1% in sulfate ash content, has excellent anti-oxidizing, anti-wear and high-temperature cleaning performances, and can satisfy the demand of high-performance diesel engine lubricating oil at CH-4 and CI-4 grades.

Owner:CHINA PETROLEUM & CHEM CORP +1

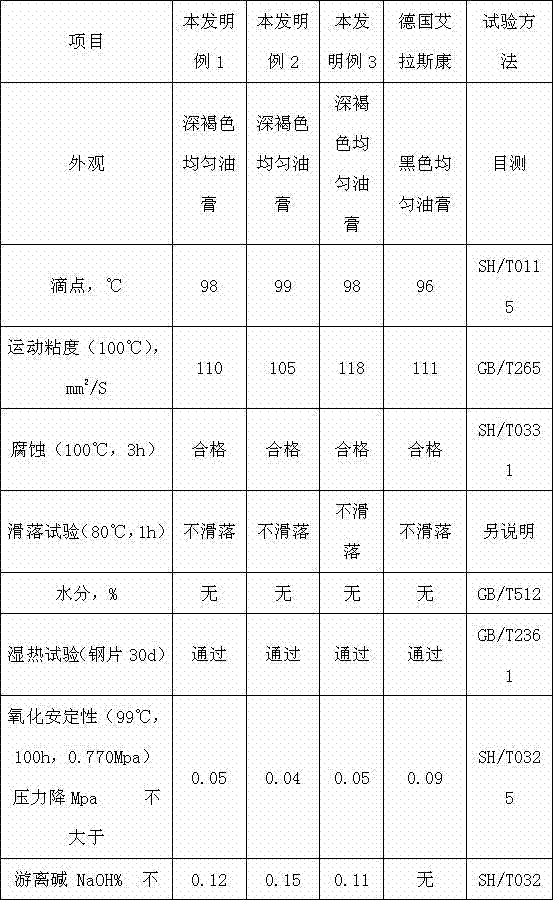

Anti-oxidant and wear-resistant surface protection grease for steel wire ropes

The invention relates to anti-oxidant and wear-resistant surface protection grease for steel wire ropes. The surface protection grease consists of the following components in percentage by weight: 12-16 percent of palm wax, 17-20 percent of Duroc slack wax, 17-21 percent of naphthenic base extract oil, 22-26 percent of paraffin base high-viscosity oil, 2-5 percent of zinc dialkyl dithiophosphate, 1-4 percent of diphenylamine, 6-10 percent of polyisobutene, 7-11 percent of ethylene-propylene copolymer and 0.1-1 percent of calcium sulfonate. Compared with the prior art, the surface protection grease has the advantages of high dropping point, no softening or drain on hot weather, quick coagulation during coating, no waste of raw materials, no pollution on the operation environment (including use), high moving viscosity, high adhesion to the surfaces of steel ropes, and avoidance of the phenomenon of falling in a strong shocking state at a high temperature during operation. The more outstanding characteristic is that the neutral and weakly acid states of the conventional final products (including imported Elaskon) are turned into a weakly alkaline (NaOH is not more than 0.15 percent) state in which metals can pass a corrosion test. As the formation of acid substances can be neutralized effectively, SH / T0325 oxidation stability test and SH / T0332 corrosion test are passed excellently, the service lives of steel wire ropes are prolonged, and the production, storage and use environments are purified.

Owner:GUANGZHOU ROSTON PETROCHEM CO LTD

Solid grounding resistance-reducing agent and method for preparing the same

InactiveCN1542079AGood resistance reductionImprove conductivityOther chemical processesSodium BentoniteGrounding resistance

The present invention relates to low-resistivity earthing agent, and is especially one kind of solid low-resistivity earthing agent with flyash as main material and its preparation process. The solid low-resistivity earthing agent is prepared with flyash as well as additives including bentonite, graphite and hydrated lime and through mixing. Using flyash as main material can reduce environmental pollution and lower cost. The solid low-resistivity earthing agent is superior to available marketable similar product and has resistivity not higher than 0.5 ohm.m, no toxicity, no pollution, no corrosion, compact structure and stable performance. The solid low-resistivity earthing agent may be used widely in work earthing and protecting earthing of various electric apparatus, building, etc.

Owner:许国进

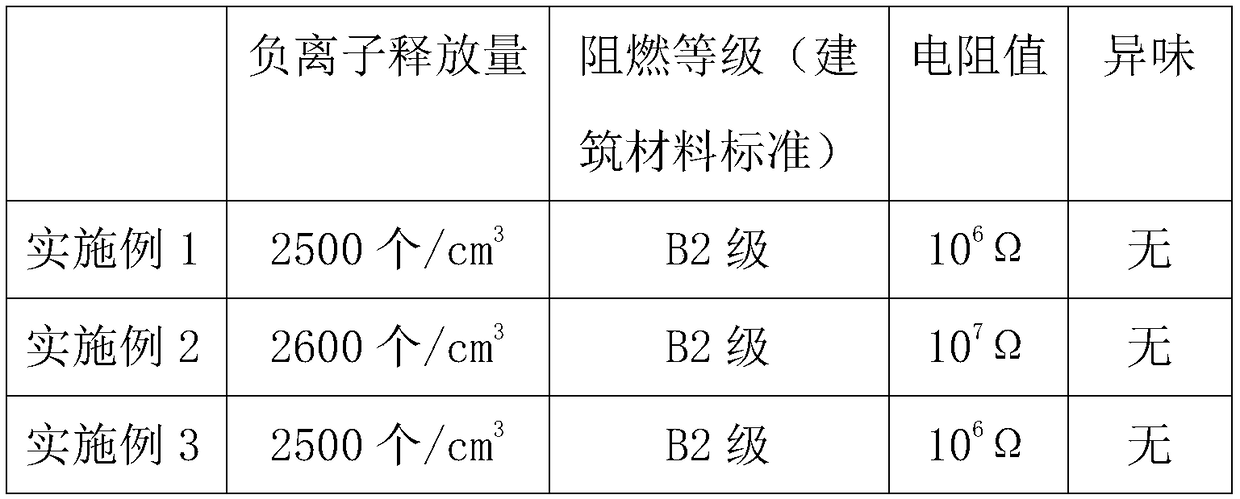

Antistatic wall cloth and production process thereof

ActiveCN109296152ARelatively uniform molecular weightEasy to processCovering/liningsMicroparticleHuman health

The invention discloses the technical field of wall cloths and particularly relates to an antistatic wall cloth and a production process thereof. A material, namely tourmaline powder, included in theantistatic wall cloth is silicate crystals and is powder prepared in the mode that electrical raw ores are subjected to impurity removing, and then smashed and purified, the tourmaline powder can generate electric ions and release negative ions for a long term, the content of the negative ions in the tourmaline powder can reach 80000-100000 per cubic meter, the tourmaline powder enables a face layer to have the effect of releasing the negative ions, and the negative ions can purify air, remove dust, smoke microparticles and bacteria, prevent mould and remove undesirable odors, and is favorableto human health; an antistatic agent has the characteristics of a surfactant and makes combined action with sodium chloride and white carbon black, so that the surface of the face layer of the antistatic wall cloth is combined with moisture to achieve the function of electric conduction and the function of leaking static electricity in time, and through the antistatic agent, the sodium chloride and the white carbon black, the resistance of the face layer of the antistatic wall cloth is kept within the range of 106-107 omega; and the prepared antistatic wall cloth has the good antistatic capability, meanwhile is diverse in function and can meet the requirements of people for indoor wall surface decorating materials.

Owner:路联新材料集团股份有限公司

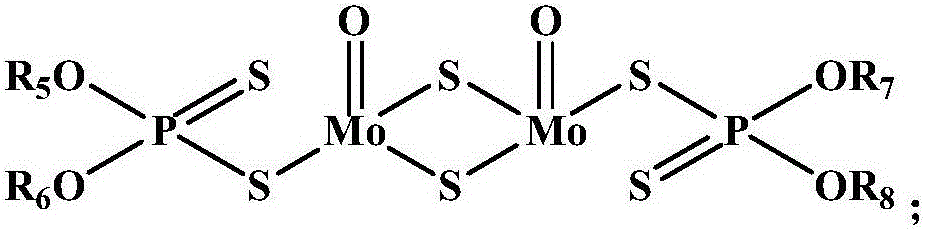

Drilling fluid lubricant and drilling fluid

InactiveCN106010480AImprove the lubrication effectImprove temperature resistanceDrilling compositionWell drillingFresh water

The invention relates to a drilling fluid lubricant and drilling fluid used in oil drilling construction. The drilling fluid lubricant components include: base oil, surfactant, carbon black, molybdenum dialkyl dithiocarbamate and molybdenum dialkyl dithiophosphate; the parts by weight of each component are: base oil 51-86 2-6 parts of surfactant, 0-3 parts of carbon black, 5%-20 parts of molybdenum dialkyldithiocarbamate, 5-20 parts of molybdenum dialkyldithiophosphate. The invention has good lubricating effect in fresh water drilling fluid and composite brine drilling fluid, and has good temperature resistance, oxygen resistance and corrosion resistance.

Owner:中石化石油工程技术服务有限公司

Grounding grid NiP-DLC composite corrosion resisting protection coating and preparing method

InactiveCN103956592AImprove wear resistanceExcellent corrosion resistanceLine/current collector detailsVacuum evaporation coatingGrounding gridChemical plating

The invention discloses a grounding grid NiP-DLC composite corrosion resisting protection coating and preparing method. The coating comprises an NiP alloy coating covering the grounding grid material and a pure carbon type diamond coating covering the NiP alloy coating, wherein the NiP alloy coating is a corrosion resisting coating, and the pure carbon type diamond coating is a high hardness oxidation resistant coating. The coating preparing method comprises the steps that the NiP alloy coating is deposited on the surface of the grounding grid material in a chemical plating mode, and the pure carbon type diamond coating is deposited on the surface of the NiP alloy coating through an anode layer ion source in a vacuum cavity. The coating is more superior in abrasion resistance, corrosion resistance and oxidation resistance, and friendly to the environment. The method is simple in technology and high in deposition efficiency, and the coating is suitable for being produced on a large scale. The thick composite coating can be obtained based on the method, the service life of the coating can be greatly prolonged, and cost can be reduced.

Owner:WUHAN UNIV

Production technology of polypropylene building template

InactiveCN103012958AExcellent impact resistanceExcellent deformation resistanceForming/stuttering elementsConstruction engineeringProcess engineering

The invention provides a production technology of a polypropylene building template, which is the technology for producing the building template by adopting waste plastics as the raw materials. The production technology comprises the steps of pretreating the raw materials, mixing the materials, and carrying out extrusion molding. The raw materials are treated based on a certain ratio and prepared into the product building template under a certain condition. The product building template has the characteristics that the construction quality is high, the building template can be recycled for a plurality of times, the cost is reduced, the benefit is increased, the energy conservation and environment protection are realized, and the residues can be recycled; and the product building template has a large market demand and wide prospect, and is an excellent substitute for steel templates, bamboo plywood and wood plywood.

Owner:HUNAN FENGSHUO TECH

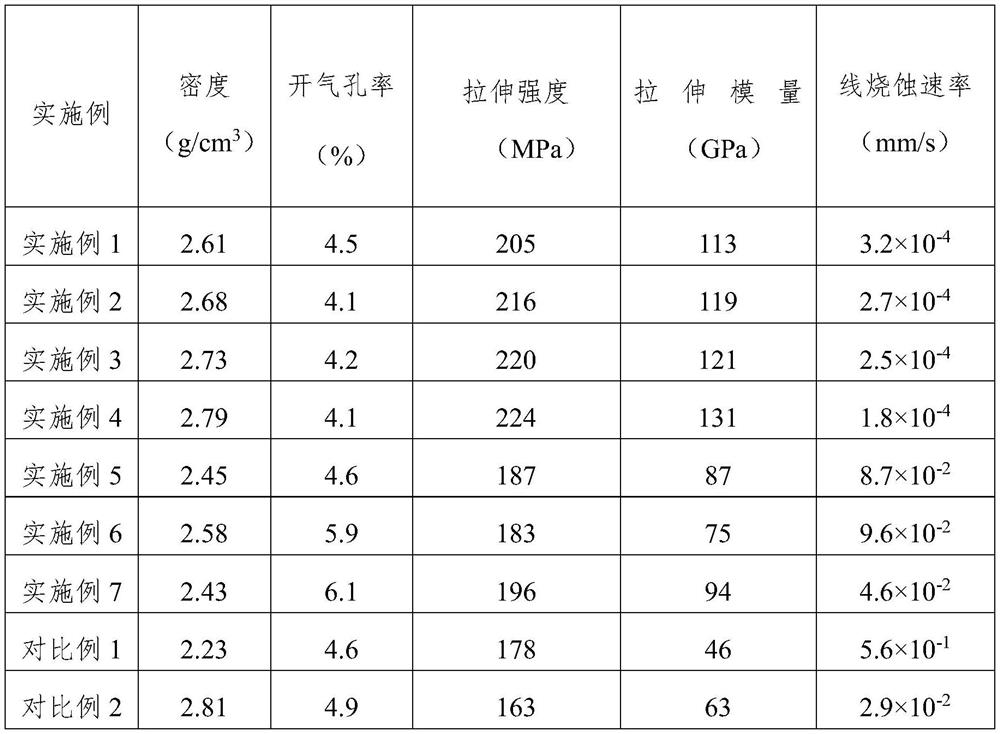

High-entropy ceramic-based composite material and preparation method thereof

ActiveCN113321510AImprove mechanical propertiesImprove high temperature oxidation resistance and ablation resistancePorous carbonSlurry

The invention relates to a high-entropy ceramic-based composite material and a preparation method thereof. The method comprises the following steps: (1) preparing high-entropy ceramic slurry containing (Tix1Zrx2Hfx3Nbx4Tax5)C high-entropy ceramic powder and phenolic resin; (2) impregnating a porous carbon / carbon green body by using the high-entropy ceramic slurry, and then sequentially carrying out the steps of curing and high-temperature cracking to obtain a high-entropy ceramic-based composite material intermediate; and (3) carrying out liquid silicon infiltration reaction on the high-entropy ceramic-based composite material intermediate obtained in the step (2) to prepare the high-entropy ceramic-based composite material. The high-entropy ceramic-based composite material prepared by the method disclosed by the invention comprises a (Tix1Zrx2Hfx3Nbx4Tax5)C matrix and a SiC matrix which are high in modulus and resistant to high temperature, and has excellent mechanical and high-temperature ablation resistance.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Tire bead protective rubber with excellent flexibility

InactiveCN102492187AImprove flex resistanceImprove wear resistanceSpecial tyresRubber materialTire bead

The invention relates to a tire bead protective rubber material with excellent flexibility and a processing process thereof. According to the design scheme provided by the invention, the formation is mainly composed of the following components: natural rubber SMR20, butadiene rubber BR9000, stearic acid, zinc oxide, an antioxidant 4020, an antioxidant RD, protective wax, carbon black N375, white carbon black, reinforced resin PFM-C, aromatic hydrocarbon oil, an accelerating agent NS, an insoluble sulfur IS-6005 and a scorch retarder CTP (N-(cyclohexylthio) phthalimide). In the formation, a crude rubber system in which the natural rubber and the butadiene rubber coexist is adopted, and a novel material namely reinforced resin PFM-C is used; the rubber material is produced according to the formation, and the process is simple and convenient and is low in cost. The invention provides the tire bead protective rubber material with excellent flexibility for production of tires.

Owner:SICHUAN TYRE & RUBBER CO LTD

Oil-resistant rubber

The present invention relates to an oil-resistant rubber. The oil-resistant rubber of the present invention is added with natural rubber, which has the excellent performance of natural rubber. In addition, neoprene is added, and the rubber molecule contains chlorine atoms, which has excellent anti-oxidation and anti-ozone properties. Non-flammable, self-extinguishing after fire, oil resistance, solvent resistance, acid and alkali resistance, aging resistance, and good air tightness; acrylic rubber has good heat resistance and oil resistance, and can be used in lubricants containing sulfur, phosphorus, and chlorine additives. Stable performance, aging resistance, oxygen and ozone resistance, ultraviolet resistance and excellent air tightness. In addition, combined with other auxiliary components, the prepared oil-resistant rubber has good physical and mechanical properties, oil resistance less than 6%, good heat resistance and air tightness. It can fully adapt to the use of automobile oil cylinder seals.

Owner:SHANDONG YONGTAI CHEM GROUP

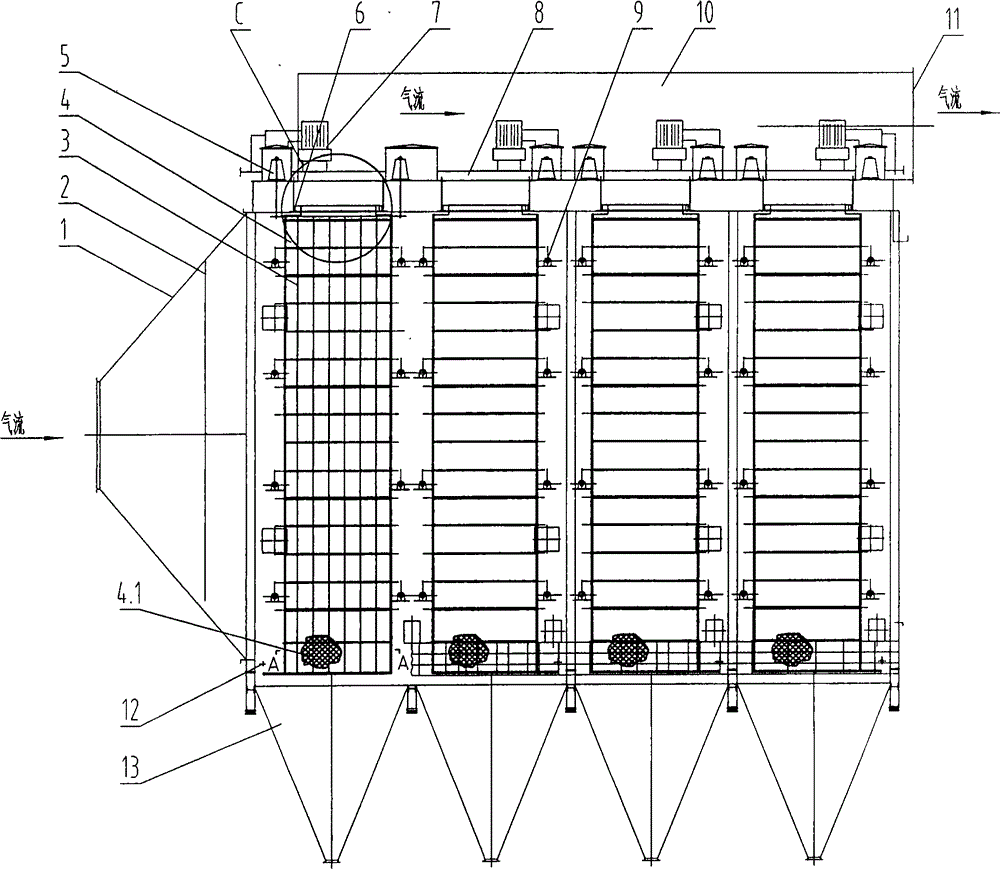

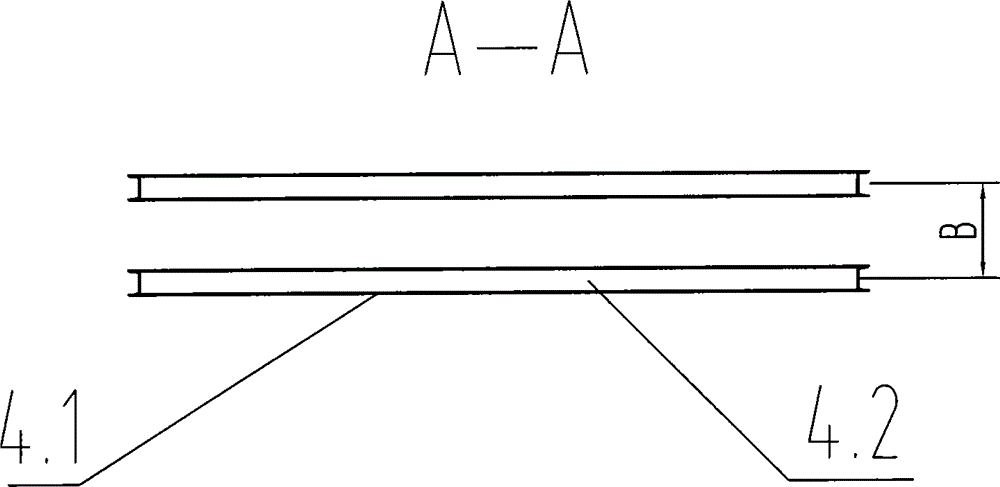

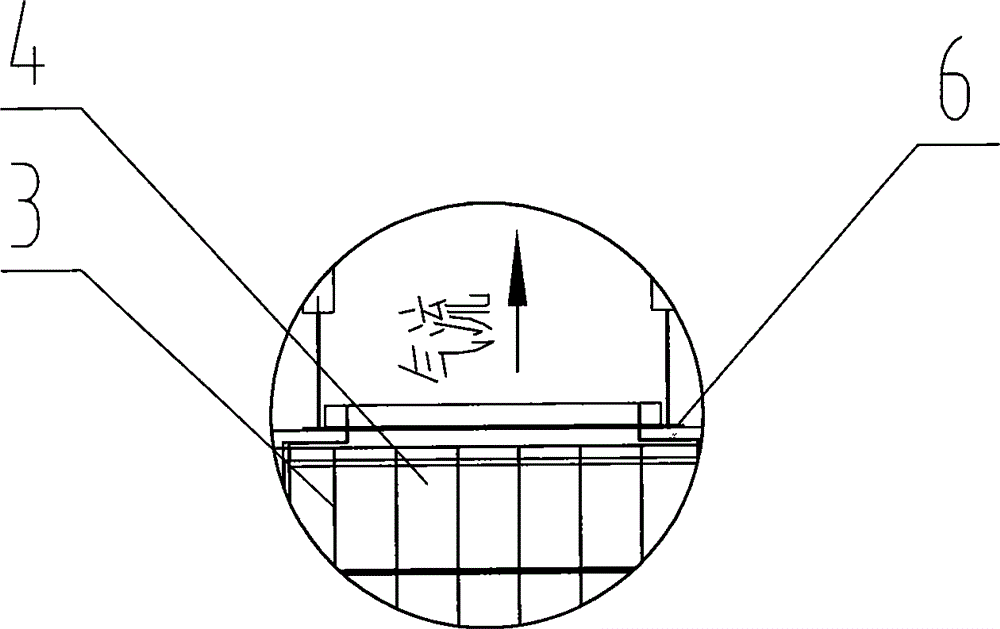

Filter plate type electrostatic precipitator

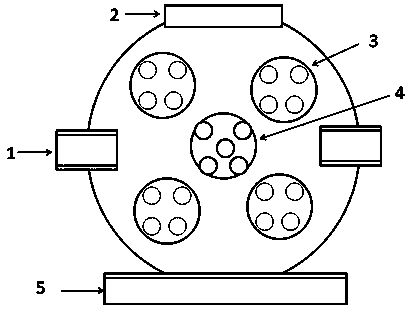

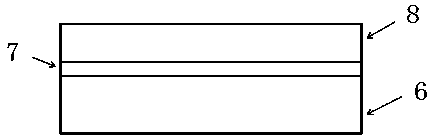

InactiveCN104668096APlay a filtering roleIncrease collection speedElectrode constructionsElectrodes cleaningElectric fieldAirflow

The invention relates to a filter plate type electrostatic precipitator. An anode row of the precipitator consists of a plurality of parallelly arranged box type filter plates; the box type filter plates are suspended on a suspending beam in a precipitator shell and are in alternative arrangement with a discharge electrode row, so that the filter plate box bodies configured in the shell and the discharge electrode row suspended among the filter plates form positive and negative electrode systems of the electrostatic precipitator; rapping devices are arranged at two sides of the cathode row and the anode row for rapping the cathode row configured at the electrode interval B and the filter plate box bodies periodically; upper opening ends of the filter plate air ducts are communicated with the air exhaust channels at the top of the precipitator; an electric field and a metal filter plate form a composite dust precipitation chamber, and dust attached to the outer surface of the filter plate falls into a dust hopper. According to the invention, the bidirectional dust precipitation under the action of electric field power and air flow power does not generate secondary dust flying; the system resistance is relatively low, and is less than or equal to 500Pa; the dust filtering and precipitation speed is improved by 60 times; the service life of a filter cartridge can reach 10 years; the dust precipitation efficiency Eta is greater than or equal to 99.95%; the absorption of fine dust (not greater than 1 micron) can meet the PM2.5 emission requirement.

Owner:BODI WEAPON MAKES

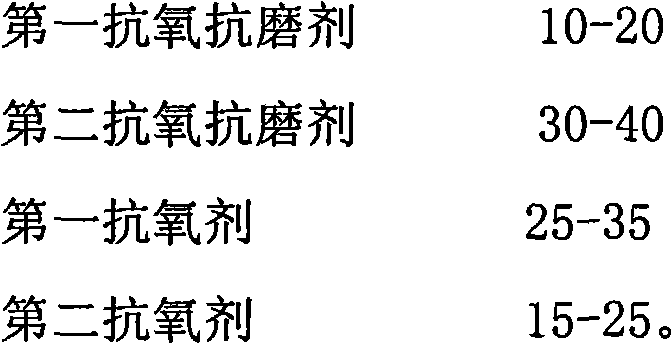

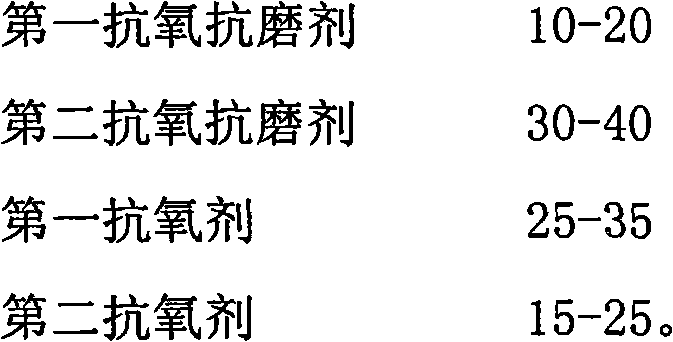

Multifunctional lubricating oil compound additive

InactiveCN102492526AAvoid three-way catalytic poisoningInhibit acidity changesAdditivesParathion methylPropanoic acid

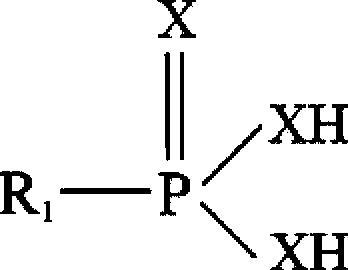

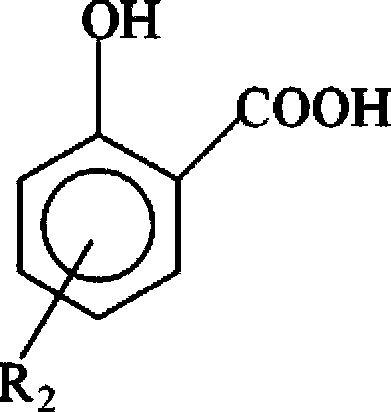

The invention discloses a multifunctional lubricating oil compound additive, which comprises a first antioxidant antiwear agent, a second antioxidant antiwear agent, a first antioxidant agent and a second antioxidant. The first antioxidant antiwear agent is selected from non-parathion-methyl type organic multimetallic compound and / or non-parathion-methyl type organic monometal compound, the second antioxidant antiwear agent is selected from organic boric acid ester compound and / or inorganic oil soluble boric acid salt compound, the first antioxidant agent is selected from dialkyl group diphenylamine and / or biphenols compound, and the second antioxidant is beta-(3,5-dule-tertiary butyl-4-hydroxycyclohexyl phenyl ketone) propionic acid isooctanol ester. The multifunctional lubricating oil compound additive contains no parathion-methyl, avoids ternary catalysis poisoning of automobiles, is environmentally friendly, has good antioxidant and anti-friction performance, can effectively restrain increase of oil product viscosity, prolongs service life of oil products, particularly can effectively restrain acidity change of the oil products, and prolongs long-time stability and service life of the oil products.

Owner:赵醒翩

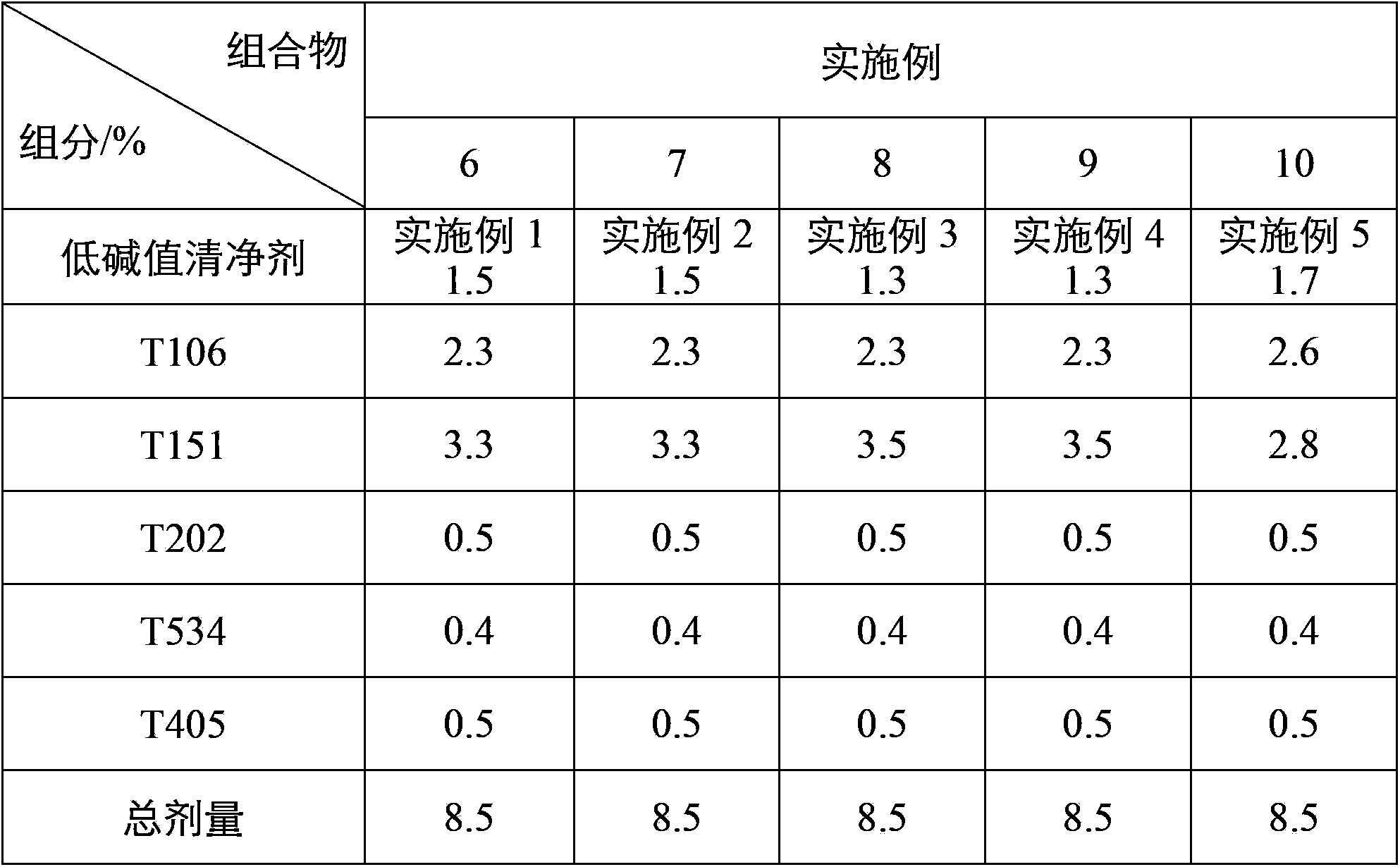

Internal combustion engine lubricating oil composition

The invention provides an internal combustion engine lubricating oil composition, which comprises: A, a low-base number clearing agent accounting for 0.1-5.0% of the total mass of the composition, wherein the preparation method of the low-base number clearing agent comprises saponification reaction of organic thio-phosphoric acid, oxides of alkali metal and / or alkaline earth metal, water, alkyl salicylic acid, and inorganic acid and / or aryl carboxylic acid accelerants together or in sequence, and product collection; B, a high-base number clearing agent accounting for 0.1-6.0% of the total mass of the composition; C, a dispersant accounting for 0.1-6.0% of the total mass of the composition; D, an anti-oxidant accounting for 0.1-2.0% of the total mass of the composition; E, an oiliness agent accounting for 0.01-5.0% of the total mass of the composition; F, a lubricating base oil forming the main component of the composition. The internal combustion engine lubricating oil composition of the invention is low in phosphorus content, has excellent cleaning, dispersion, anti-oxidation and antirust performance, can reduce the generation of low temperature greasy filth, and can meet the specification requirements of API 5W / 30SJ.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of molybdenum alloy, molybdenum alloy and application of molybdenum alloy

ActiveCN108193115AImprove temperature resistanceImprove high temperature strengthStrontiumOxidation resistant

The invention discloses a preparation method of a molybdenum alloy. The preparation method comprises the following steps that molybdenum powder and strontium powder are mixed uniformly and pressed andformed after being subjected to isostatic pessing treatment, and a pressed green body is obtained; then, the pressed green body is placed into a vacuum furnace to be sintered, and the molybdenum alloy is obtained after the pressed green body is cooled along with the furnace, wherein the mass ratio of the molybdenum powder to the strontium powder is 1 : (0.005-0.01), the pressure intensity of isostatic pessing treatment is 400-600 MPa, and time is 30-90 s; and according to the sintering system, heat preservation is performed for 1-1.5 hours at the temperature of 600-800 DEG C, then the temperature is raised to 1100-1300 DEG C, heat preservation is performed for 0.5-1 hour, then the temperature is raised to 1500-1900 DEG C, and heat preservation is performed for 5-6 hours. The invention further discloses the molybdenum alloy prepared through the preparation method and application of the molybdenum alloy. The molybdenum alloy is superior to an ordinary molybdenum alloy on the aspects ofhigh-temperature resistance, high-temperature intensity, oxidation resistance and low-temperature plasticity, can replace pure molybdenum and TZM and is preferred as a thermal equipment material.

Owner:昆山胜典机电科技有限公司

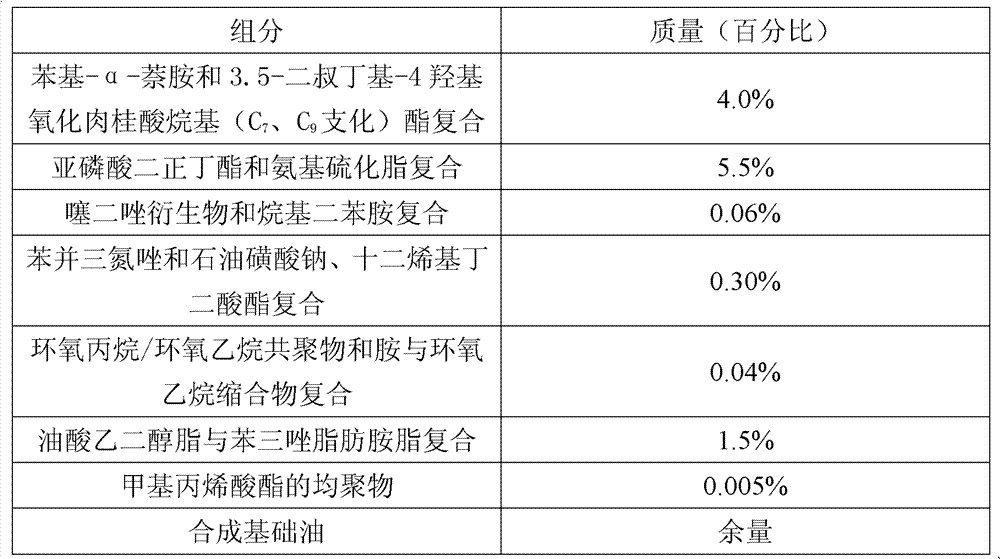

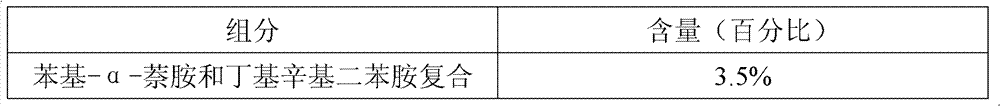

Lubricating-oil composition of speed reducing machine in gas turbine for ship

The invention discloses a lubricating-oil composition of a speed reducing machine in a gas turbine for ship. The lubricating-oil composition comprises the following components in percent by mass: 2-4% of antioxidant, 5-6% of antiwear agent, 0.1-0.4% of antirusting agent, 0.06-0.08% of metal passivating agent, 0.05-0.3% of demulsifying agent, 0.005-0.01% of anti-foaming agent, 1-2% of oiliness agent and the balance of base oil. The lubricating-oil composition has the obvious advantages that the comprehensive performance is good, and all performance indexes meet the use requirements; not only are the antioxygen, anticorrosion and antiwear performances good, but also the antirusting, anti-salt-fog and antifoaming performances are quite excellent; the lubricating-oil composition also meet the use requirements of the gas turbine for ship in the aspects of acid control capability, clean dispersity and rubber adaptability; and the base oil is compounded and synthesized by selecting diester and polyol ester which have excellent performance, so that the base oil assuredly has good heat stability, good viscosity-temperature characteristic, excellent low-temperature mobility, low volatility and good lubricity simultaneously.

Owner:GUANGXI UNIV

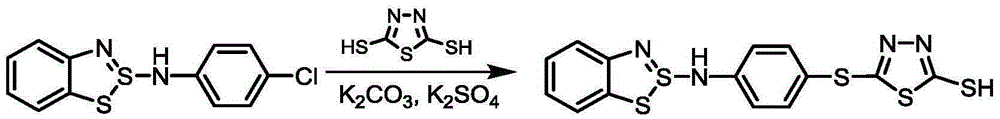

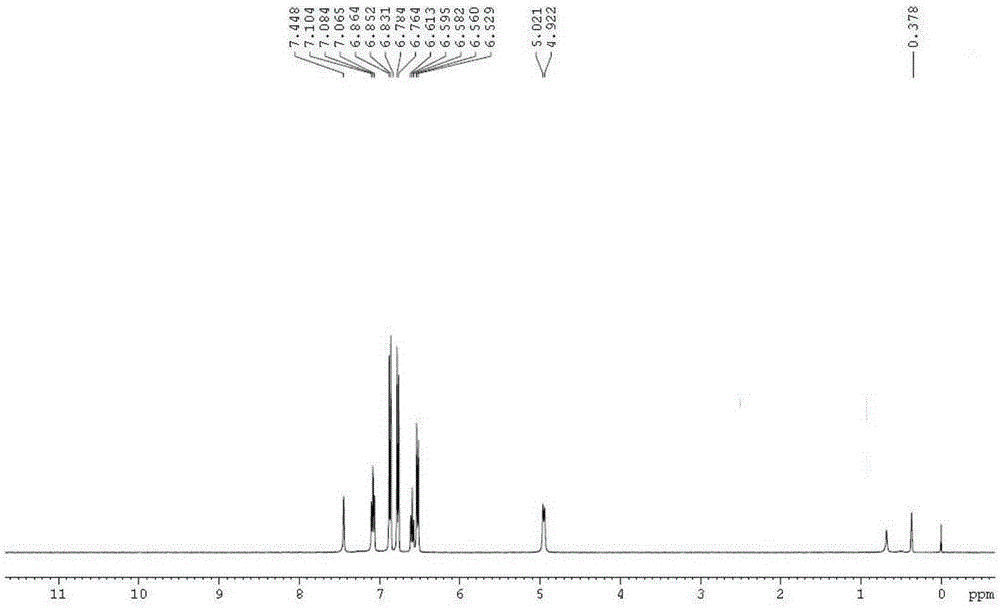

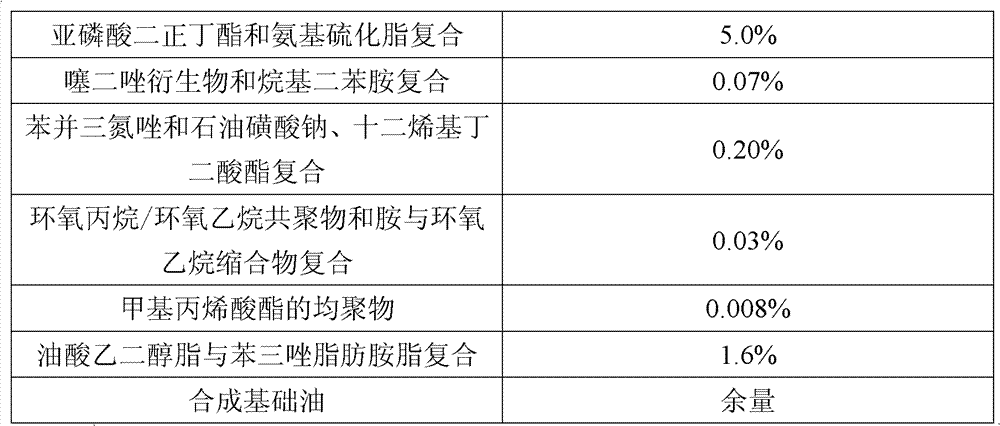

Diesel engine lubricant composition and preparation method and application thereof

ActiveCN106281577AExcellent antioxidantExcellent soot dispersionOrganic chemistryAdditivesAntioxidantSulfate

The invention provides a diesel engine lubricant composition and a preparation method and application thereof. The diesel engine lubricant composition is made from A) antioxidant structurally shown in formula (I); B) antioxidant polyisobutylene succinimide ashless dispersant; C) polyisobutylene mono-succinimide; D) polyisobutylene bis-succinimide; E) a mixture of sulfates and sulfurized alkyphenates; F) zinc dialkyl dithiophosphates; G) a major amount of lubricant base oil. The lubricant composition of the invention has excellent oxidization resistance, soot dispersibility, and high-temperature cleaning performance, and can meet the requirement on high-performance diesel engine lubricants of levels CH-4 and CI-4.

Owner:CHINA PETROLEUM & CHEM CORP +1

Internal combustion engine lubricant composition and method for improving detergency of internal combustion engine lubricant

The invention provides internal combustion engine lubricant composition and a method for improving detergency of an internal combustion engine lubricant. The internal combustion engine lubricant composition is prepared from 1%-5% of an alkylsalicylate detergent, 1%-6% of a high-basic-value sulfonate detergent, 1%-5% of a low-basic-value sulfonate detergent, 1%-6% of an ashless dispersant, 0.1%-2%of an antioxidant, 0.1%-2% of an oiliness agent, 1%-20% of a viscosity index improver and the balance of lubrication base oil. The internal combustion engine lubricant composition has good deterging,dispersing, oxygen-resisting, wear-resisting and rust-resisting properties and contains less phosphorus, formation of low-temperature oily sludge can be reduced, and requirements of API SL for specifications can be met.

Owner:CHINA PETROLEUM & CHEM CORP +1

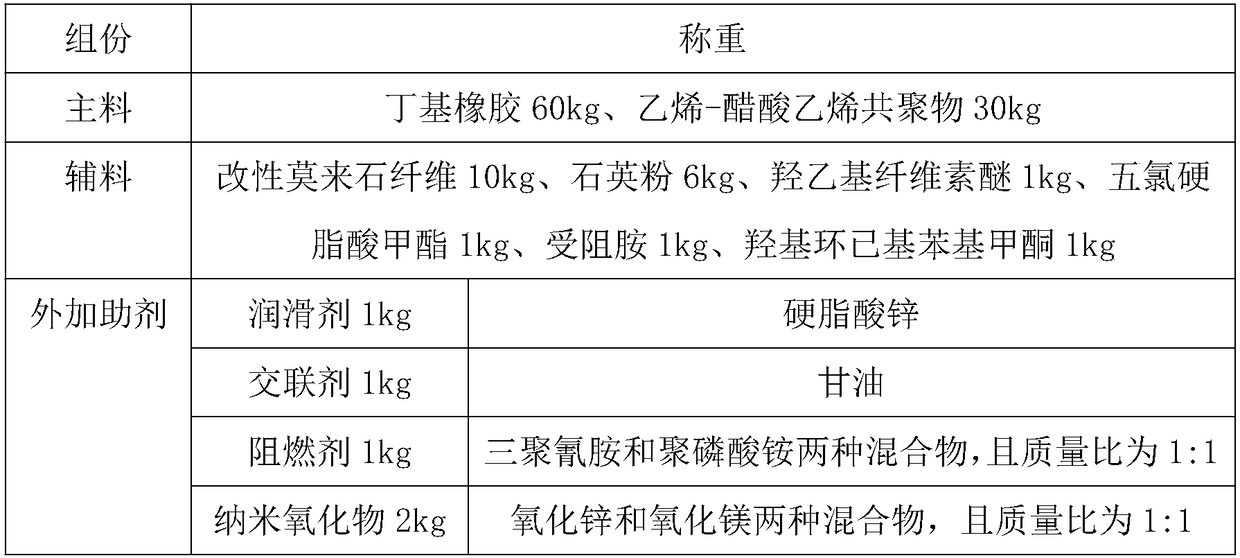

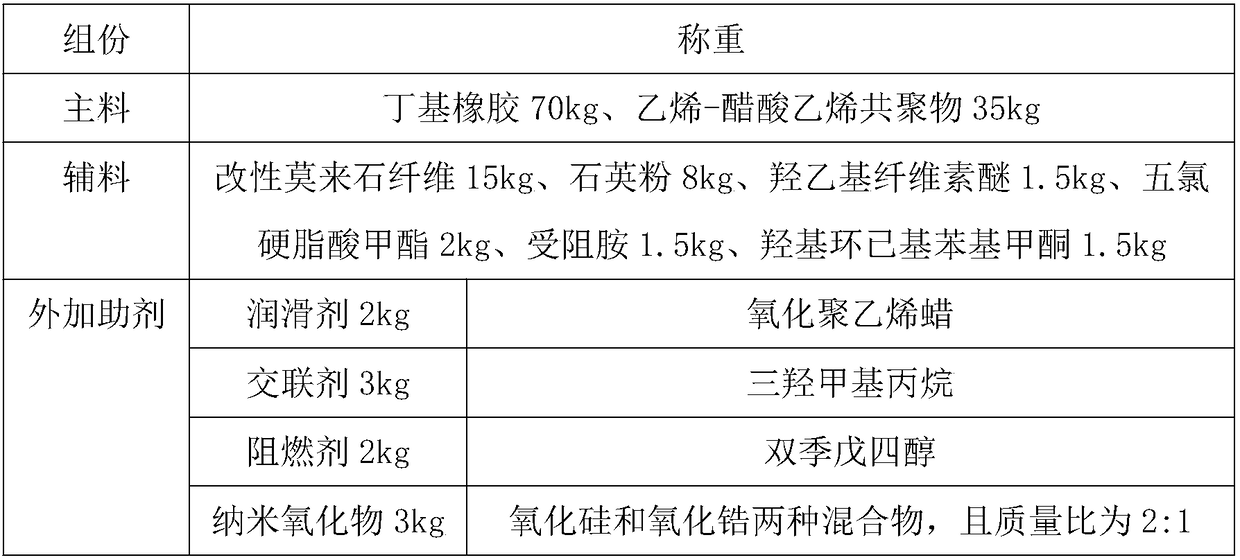

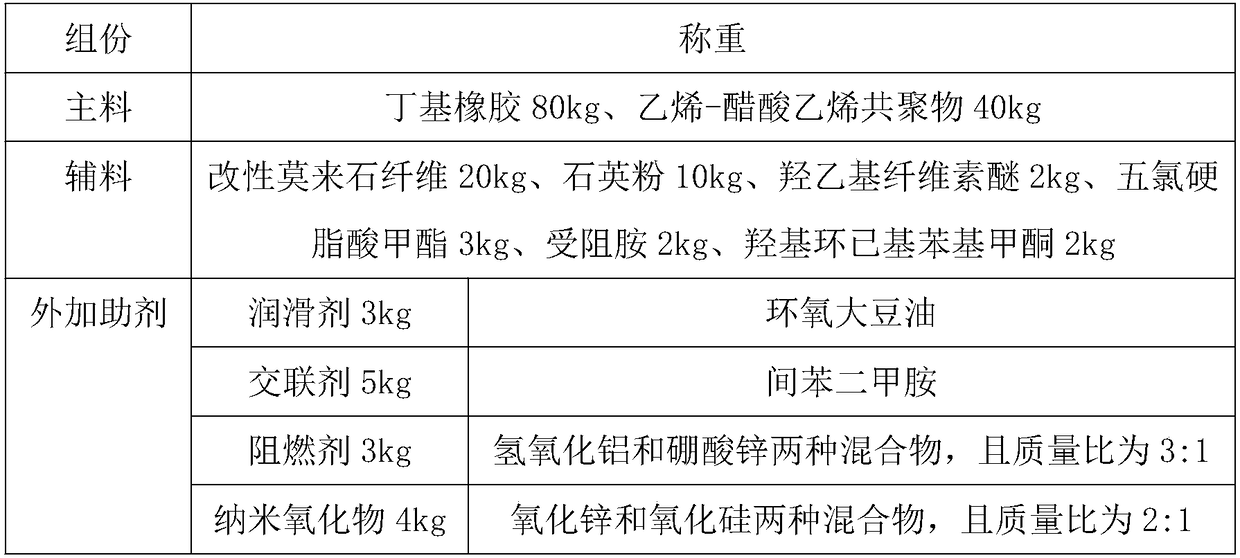

Wear-resistant electric insulating rubber material and preparation method thereof

The invention discloses a wear-resistant electric insulating rubber material and a preparation method thereof, and relates to the technical field of electric insulating materials. The material comprises the following raw materials: butyl rubber, ethylene-vinyl acetate copolymer, modified mullite fiber, quartz powder, hydroxyethyl cellulose ether, methyl pentachlorostearate, hindered amine, hydroxycyclohexyl phenyl ketone, lubricant, crosslinking agent, flame retardant and nano oxide. The preparation method comprises operations of mixing, open milling and the like of the raw materials to prepare the wear-resistant electric insulating rubber material. The rubber material provided by the invention has the characteristics of simple preparation method, wide raw material sources, low cost, excellent comprehensive performance, high electrical insulating property, good mechanical properties, stable physical and chemical properties, oxygen resistance, wear resistance and aging resistance, greatly prolongs the service life of a product, and has broad market prospects.

Owner:HEFEI DAZHUO ELECTRIC POWER CO LTD

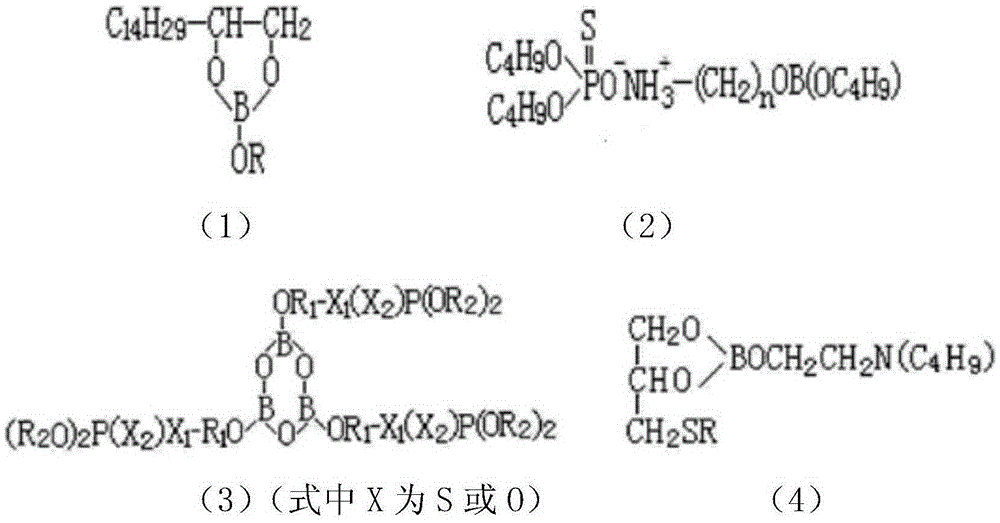

Milt-functional metal surface treatment additive containing boride diethanolamine phosphates and preparation method

ActiveCN105238499AImprove the lubrication effectImprove rust resistanceAdditivesPhosphorus organic compoundsWater basedViscous liquid

The invention relates to a method for preparing a milt-functional metal surface treatment additive containing boride diethanolamine phosphates, which comprises steps: diethanolamine and phosphate esterification agents are added into a reaction kettle to react, are hydrolysed and concentrated to obtain a viscous liquid, a water-carrying agent is added into the viscous liquid, a boriding agent is added to react by stirring, and the water-carrying agent is boiled up by decompressing to obtain a target product. The milt-functional metal surface treatment additive which is prepared through the method comprises 30-60% boride diethanolamine phosphates and 20-60% diethanolamine double phosphate esters. The method for preparing the milt-functional metal surface treatment additive containing the boride diethanolamine phosphates has the beneficial effects that the milt-functional metal surface treatment additive containing the boride diethanolamine phosphates has excellent antifriction, antioxidant, rust-proof and lubrication performance and the like because phosphates which are used as main components in the milt-functional metal surface treatment additive containing the boride diethanolamine phosphates contain active elements such as N, P and B and the like, is strong in anti-hydrolytic property, can improve lubricity and anti-rust property of a water-base metal working fluid by being added into the water-base metal working fluid, also can improve extreme pressure property and prolongs service life of the water-base metal working fluid simultaneously, and is an excellent multi-functional water-soluble additive.

Owner:CHANGZHOU VOCATIONAL INST OF ENG

Synthetic diesel engine oil

InactiveCN110003970AExcellent detergency and dispersibilityGood thermo-oxidative stabilityLubricant compositionBiochemical engineeringOxidation stability

The invention discloses synthetic diesel engine oil. The synthetic diesel engine oil comprises, in percentage by mass, 68%-71% of group III base oil, 14%-16% of high-viscosity group IV base oil, 14%-16% of a compound additive and 0.3% of a pour point depressant. In the diesel engine oil, the group III base oil has good oxidation stability, the shear resistance of lubricating oil is guaranteed without any viscosity index improver, the pressure cannot be reduced in the long oil change period, the oil film strength of the lubricating oil is enhanced by use of high-viscosity synthetic base oil, and strong enough oil film protection can be provided in the long-kilometer driving process of an engine.

Owner:无锡奇比特润滑油有限公司

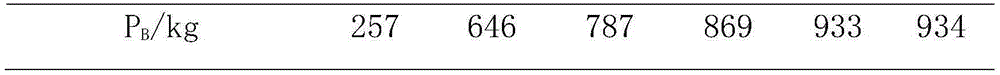

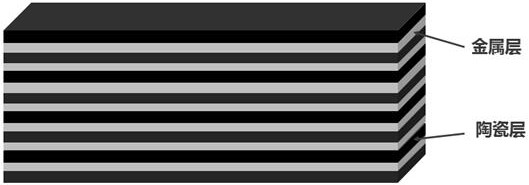

High-strength and high-toughness TaxHf1-xC-based composite material and preparation method thereof

The invention discloses a high-strength and high-toughness TaxHf1-xC-based composite material and a preparation method thereof. According to the TaxHf1-xC-based composite material, TaxHf1-xC ceramic is used as a substrate, and metal Ta is used as a toughening phase; the TaxHf1-xC-based composite material is of a layered structure, the TaxHf1-xC ceramic layer and the metal Ta layer are arranged ina laminated mode, and the upper surface and the lower surface of the TaxHf1-xC-based composite material are both TaxHf1-xC ceramic phases. The preparation method comprises the steps of designing the structure of the TaxHf1xC-based composite material, paving and filling raw materials according to the designed structure, sintering at high temperature and the like. The TaxHf1-xC-based composite material provided by the invention has the characteristics of high strength and high toughness, can be used in an extreme thermal environment, and can be used as a high-temperature valve of a solid rocketengine, a wing leading edge of a hypersonic flight vehicle and other components. The preparation method provided by the invention is simple and convenient in process and large in material structure design space.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method of high-intensity heat-proof long glass fiber/nylon 6/nylon 66 composite material

InactiveCN108047703ASmall mechanical propertiesDelay or inhibit thermo-oxidative degradation to a certain extentGlass fiberNylon 6

The invention discloses a preparation method of a high-intensity heat-proof long glass fiber / nylon 6 / nylon 66 composite material, which is characterized by comprising the following materials: taking 30 to 50 parts by weight of nylon 6, 10 to 20 parts by weight of nylon 66, 0.2 to 0.8 part by weight of high-temperature resistance heat stabilizer, 1 to 3 parts by weight of PP-g-MAH, 0 to 0.8 part byweight of calcium chloride anhydrous and mixing; pouring a mixture into a mixer to stir for 3 to 8min, then adding the obtained product into a double-screw extruder, carrying out melting on the mixture under a screw rotating speed of 200 to 300r / min and at a temperature of 260 to 270 DEG C, adding long glass fibers from a glass fiber inlet of the double-screw extruder, carrying out mixing, extrusion, cooling and grain cutting with the molten mixture and then drying particles to prepare the long glass fiber / nylon 6 / nylon 66 composite material with high-intensity heat-proof performance. The high-intensity heat-proof long glass fiber / nylon 6 / nylon 66 composite material can be used as an engine manifold material and a windscreen wiper base material in the automobile industry and can also be used for electronic appliances and the mechanical industry.

Owner:MIANYANG HONGQI NEW MATERIAL SCI & TECH

Biodegradable machine oil for refrigerating compressor and preparation method thereof

InactiveCN103468373AMeet high performance requirementsEasy to manufactureBase-materialsRefrigeration compressorAntioxidant

The invention provides biodegradable machine oil for a refrigerating compressor and a preparation method thereof. The biodegradable machine oil contains the ingredients in percentage by weight: 91-95% of base oil, 1-2% of antioxidant, 0.5-1% of antifoamer, 0.5-1% of anti-emulsifier, 2-3% of metal passivator and 1-2% of rust preventer. The preparation method of the biodegradable machine oil comprises the steps of (a) preparing the base oil; (b) carrying out heating treatment on the base oil; (c) carrying out additive adding treatment. According to the biodegradable machine oil for the refrigerating compressor and the preparation method thereof, provided by the invention, the biodegradable machine oil is reasonable in proportion and simple and convenient in preparation, has relatively high natural degradability, can be excellently dissolved with a refrigerant of the compressor and has relatively good oxidation, rusting, wearing and hydrolysis resistance, so that the requirements of the refrigerating compressor for high performance are met.

Owner:CHANGSHU MIAOQUAN COMPRESSOR ACCESSORIES

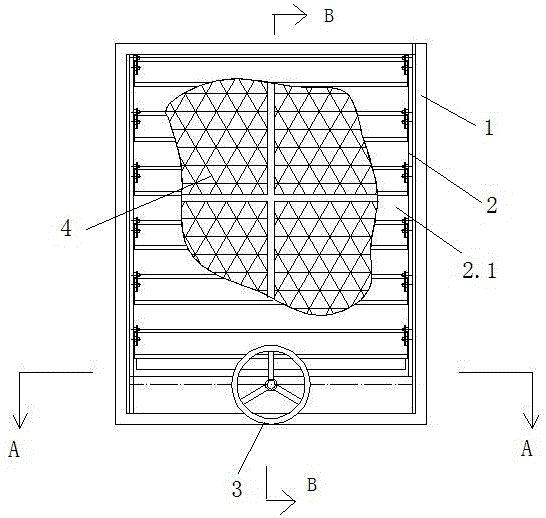

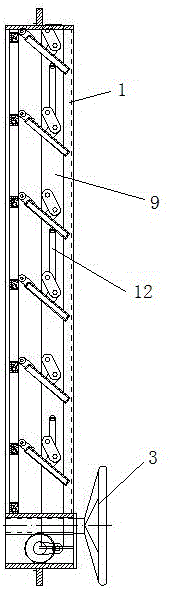

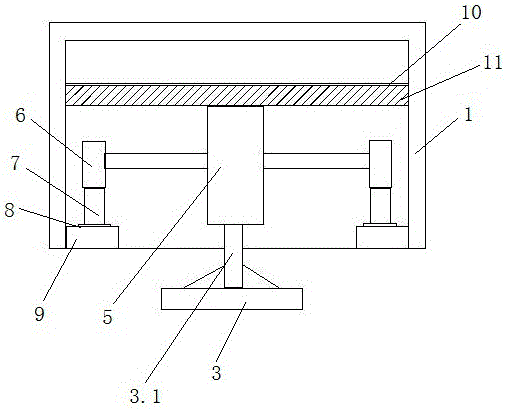

Sealed watertight blind window

InactiveCN106476152AImprove product qualityImprove wet skid resistanceSealing arrangementsForeign matterRadar

The invention relates to a blind window and particularly provides a sealed watertight blind window. The sealed watertight blind window comprises a window frame and a venetian blind arranged in the window frame. The venetian blind is composed of multiple venetian blind vanes which are arranged from top to bottom. The lower sides of the two ends of the venetian blind vanes are connected with longitudinal movable support rods at the two sides through hinges correspondingly. The movable support rods are mounted onto the window frame through shafts. The sealed watertight blind window further comprises a hand wheel arranged outside the window frame. A threaded rod of the hand wheel is connected with a worm wheel arranged on the lower portion inside the window frame in a rotary manner. The worm wheel is in transmission connection with coaxial large gears at the two ends. Each large gear is engaged with a corresponding small gear. Each small gear is engaged with a rack arranged on the corresponding movable support rod. A shielding net is arranged behind the blind window, and a sealing device is arranged in front of the blind window. The sealing device comprises a sealing groove and a sealing strip, wherein the sealing groove is formed in the window frame, and the sealing strip is arranged in the sealing groove in an attached manner. The sealed watertight blind window is good in sealing effect and shielding effect and capable of preventing foreign matter from entering therein and effectively scattering radar waves, and a quite good hiding effect is achieved.

Owner:南京海獭软件有限责任公司

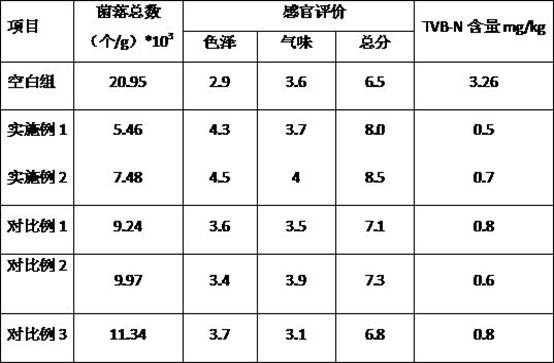

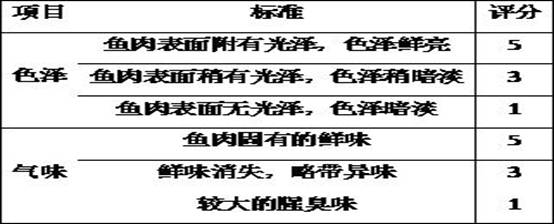

Processing method of prefabricated loach dish

InactiveCN113907293AExtended shelf lifeImprove sensory qualityMeat/fish preservation by heatingBiotechnologyMonosodium glutamate

The invention belongs to the technical field of aquatic product processing, and particularly relates to a processing method of a prefabricated loach dish, which comprises the following steps: unfreezing, cleaning, deodorizing, frying, pickling to be tasty, vacuum packaging and microwave sterilizing. The raw material comprises loach, salt, green onion, ginger, black pepper powder, cooking wine, white spirit, garlic, chili, soybean oil, salad oil, lard, monosodium glutamate, white sugar, vinegar, soy sauce, green and red rice pepper, onion, soybean paste, chilli sauce, minced garlic sauce, amomum tsao-ko, anise, cinnamon, myrcia, netmeg, chive, water, plumeria rubra extract, golden camellia flower extract, rosemary extract and lysozyme. The method has the beneficial technical effects that the loss of nutrient substances caused by high-temperature processing is greatly reduced, active ingredients with nourishing functions in the loaches are reserved, and the product is rich in taste, reasonable and scientific in formula and capable of nourishing the body.

Owner:TIANJIN JINBAODI MANOR FOOD CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com