Internal combustion engine lubricating oil composition

A lubricating oil composition, composition technology, applied in lubricating compositions, petroleum industry, additives, etc., capable of solving problems such as low phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

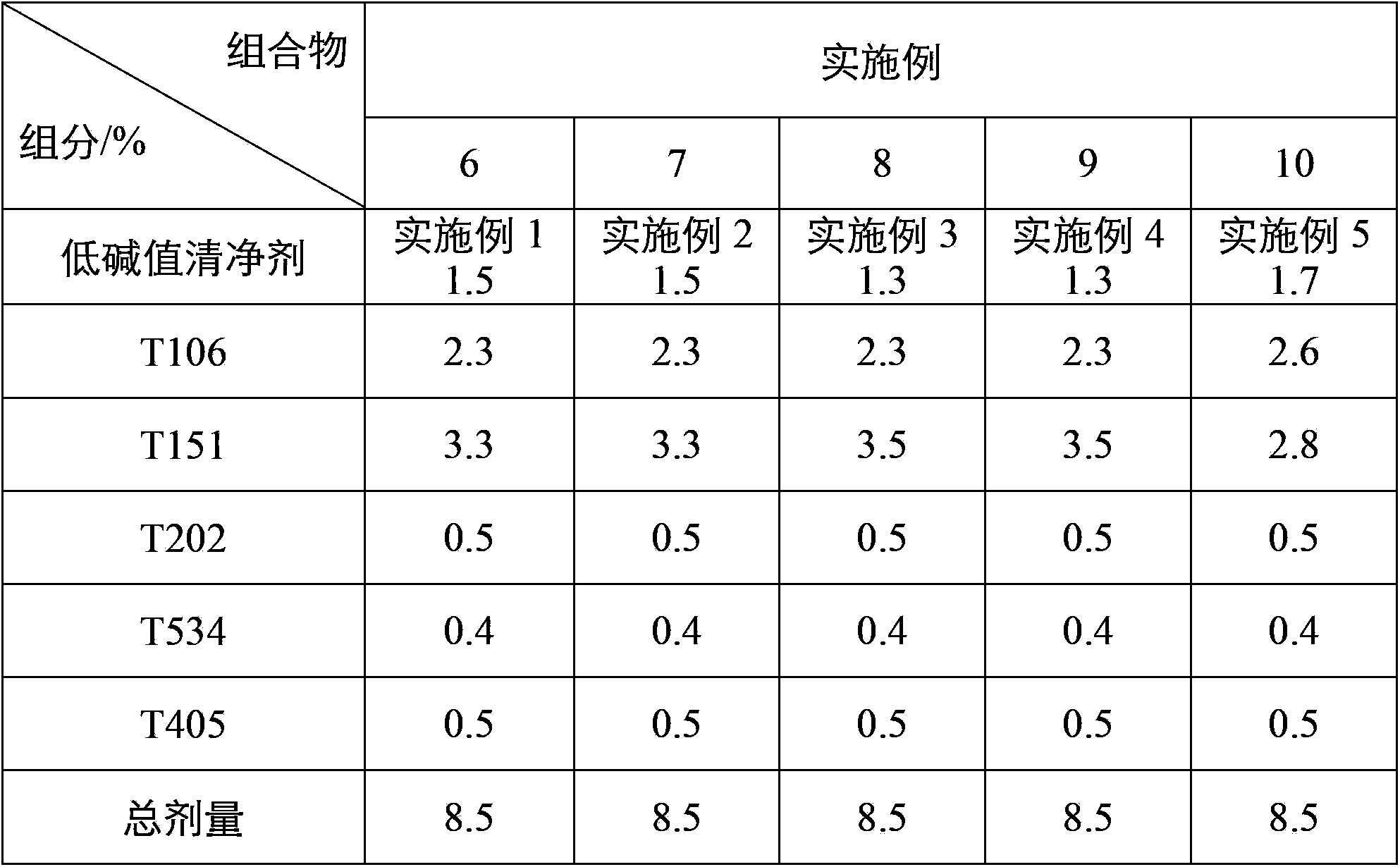

Examples

preparation example Construction

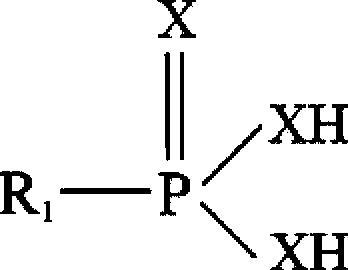

[0079] Preparation of organothiophosphonic acid A

[0080] Add 1000 grams of polyisobutylene with a number average molecular weight of 1000 in a three-necked flask equipped with electric stirring, add P 2 S 5 168 grams, gradually heat up from room temperature to 210°C, the heating rate is 30°C / hour, and react at a constant temperature of 210°C for 12 hours. At this time, the material gradually changes from colorless to brown, and 8.5 grams of water vapor is introduced for reaction and post-treatment . The obtained polyisobutylenethiophosphonic acid had a sulfur content of 5.2% and a phosphorus content of 2.2%, which was recorded as organothiophosphonic acid A.

[0081] Preparation of organothiophosphonic acid B

[0082] Add 1000 grams of polyisobutylene with a number average molecular weight of 2300 in a three-necked flask equipped with electric stirring, add P 2 S 5 158 grams, gradually warming up from room temperature to 225 ° C, the heating rate is 30 ° C / hour, 12 ...

Embodiment 1

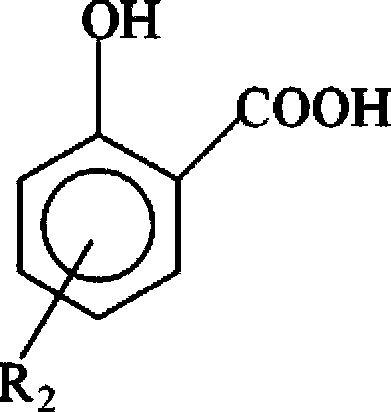

[0084]In Example 1, the molar ratio of the raw material organic thiophosphonic acid A to alkyl salicylic acid was 1:1.5, and the saponification reaction was carried out by adding the raw materials at one time.

[0085] Add organic thiophosphonic acid A60 gram (molecular weight=1112, 0.054mol) and alkyl salicylic acid 62.72 grams (0.081mol) in the 500ml there-necked flask that temperature control system and electric stirring are installed, then add No. 120ml No. 200 solvent gasoline, Stir for 5 minutes, then add 6.4 grams of magnesium oxide (0.16mol), add 5 grams of water (0.278mol), 2.2 grams of 98% concentrated sulfuric acid, and then heat up to 95 ° C for 6.5 hours. At this time, the material becomes a brown liquid. After the reaction Add 85 grams of 150SN dilution oil, then distill out the water, cool the material to 50°C, centrifuge for 30 minutes on a centrifuge with a rotating speed of 2000rpm, and distill after removing the slag to obtain a low-alkaline value detergent M...

Embodiment 2

[0087] In Example 2, the molar ratio of the raw material organic thiophosphonic acid A to alkyl salicylic acid was 1:1.5, and the saponification reaction was carried out by adding the raw material twice.

[0088] In the 500ml there-necked flask that temperature control system and electric stirring are installed, add organothiophosphonic acid A60 gram (molecular weight is 1112, 0.054mol), add No. 200 solvent gasoline of 100ml again, stir 5 minutes, then add 3.3 grams of magnesium oxide ( 0.083mol), add 3 grams of water (0.167mol), stir for 25 minutes, heat up to 95°C for 3 hours, and the material turns into a brown liquid. Then add 62.72 grams (0.081mol) of alkyl salicylic acid and react for 15 minutes, then add 3.1 grams of magnesium oxide (0.078mol), 2 grams of water (0.111mol), 2.2 grams of 98% concentrated sulfuric acid, and control the reaction temperature to be 95 ° C. React for 3 hours, add 85 grams of 150SN diluent oil to the reaction, then distill off the water, cool t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Base value | aaaaa | aaaaa |

| Base value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com