Patents

Literature

519results about How to "Reduce phosphorus content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

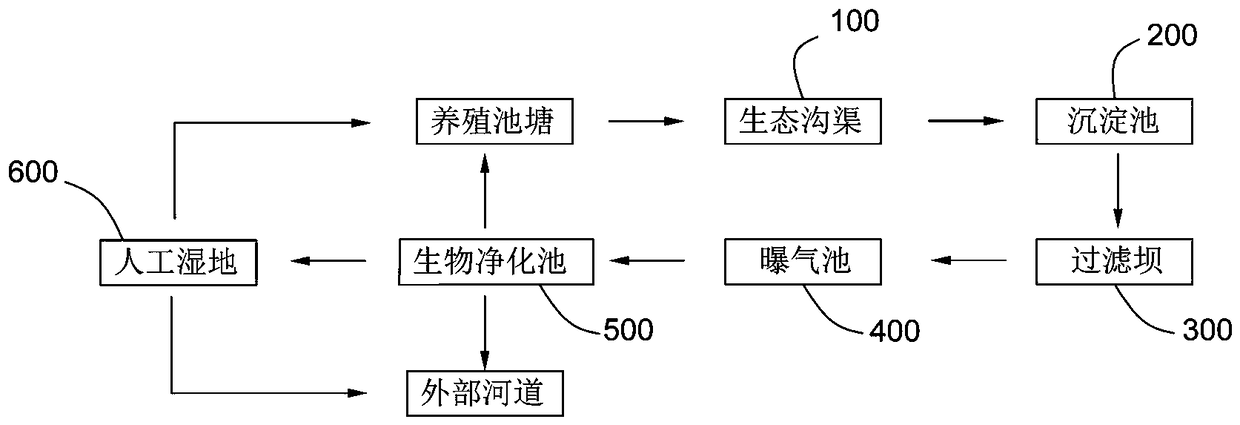

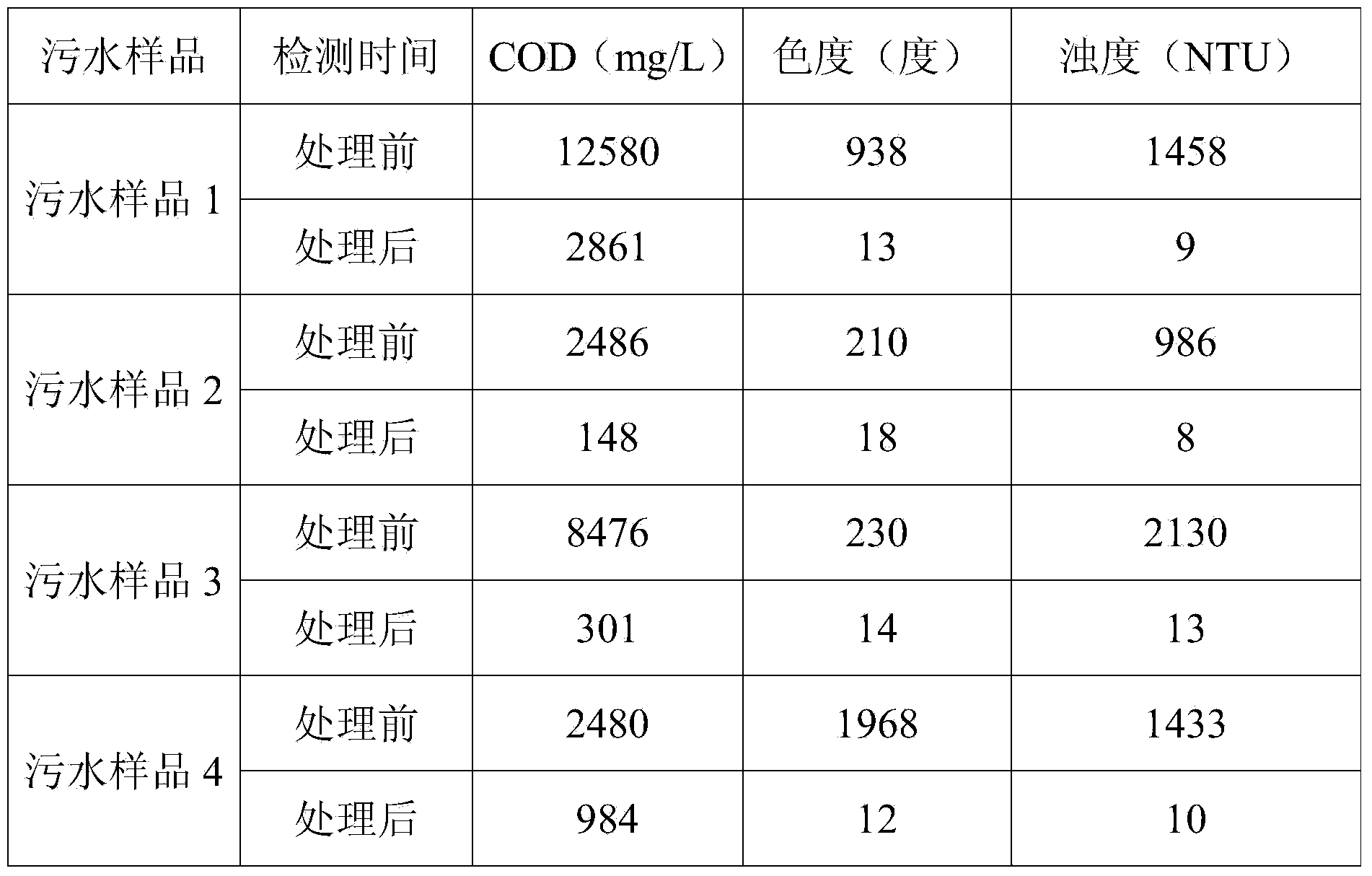

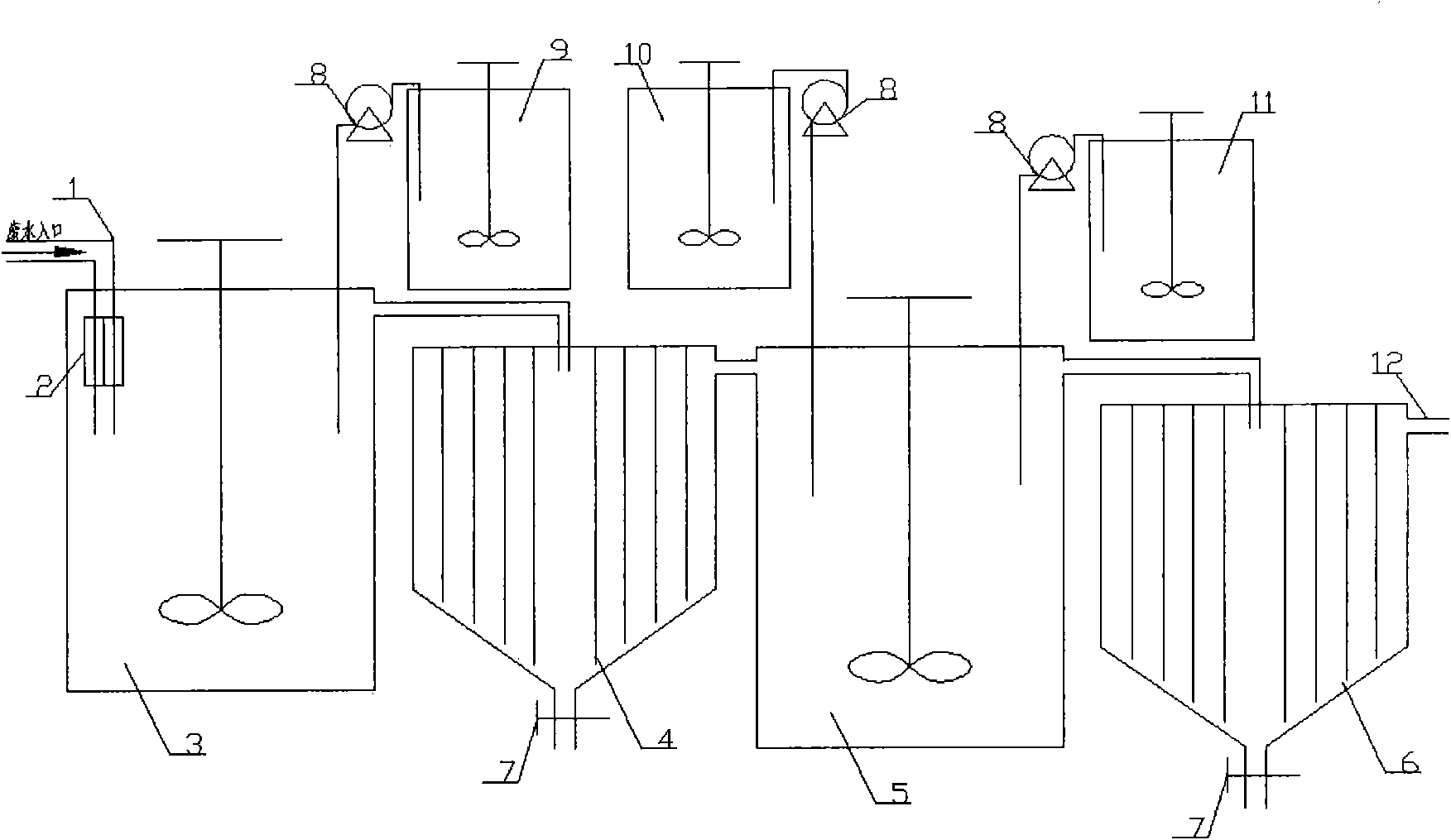

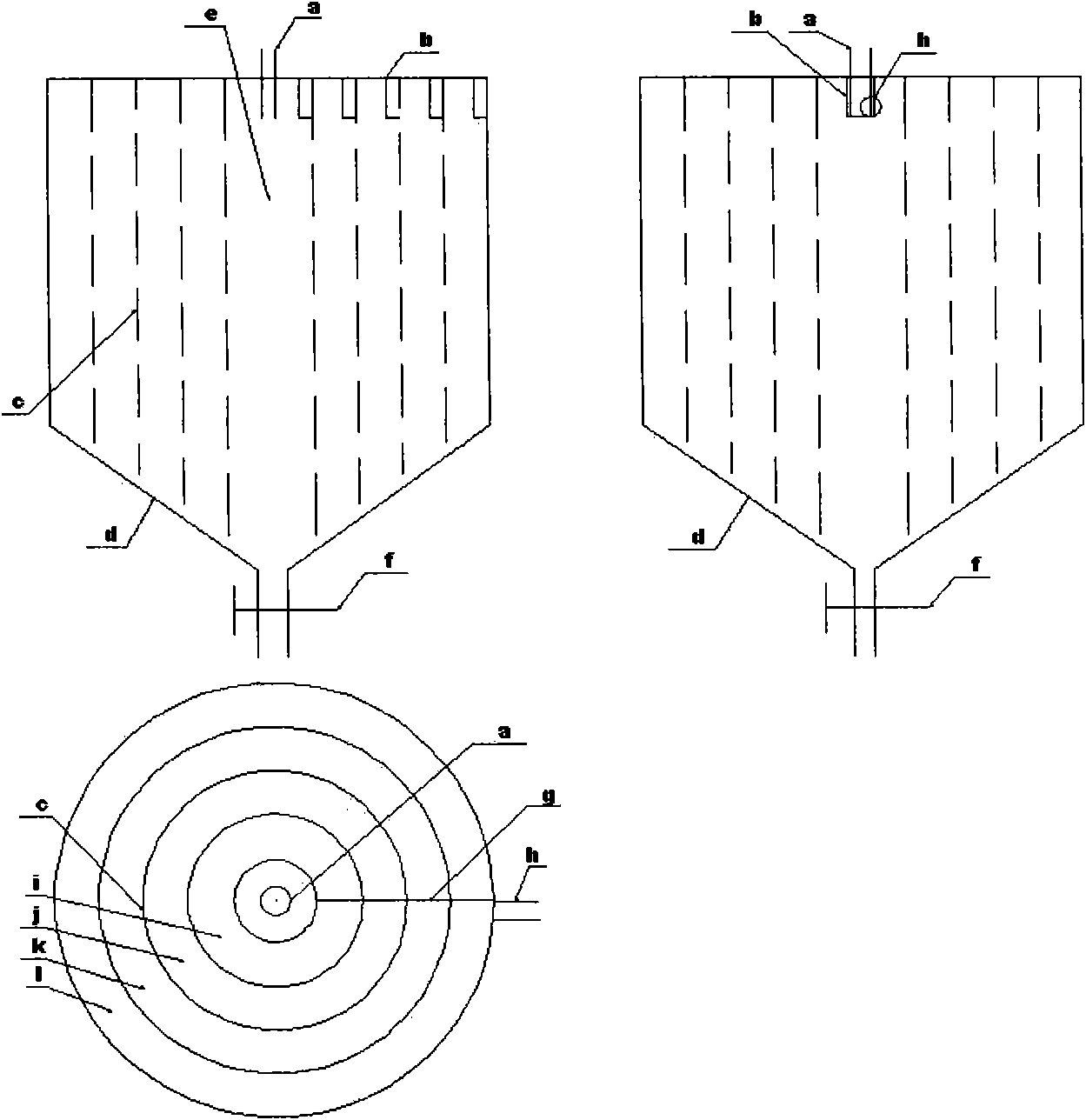

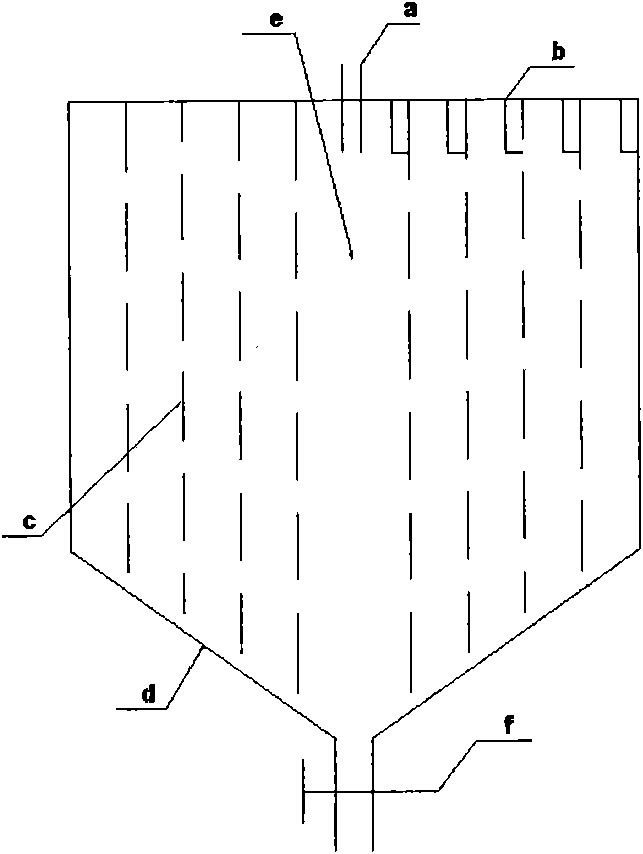

Freshwater shrimp culture tail water treatment system

InactiveCN108178447AAccelerated precipitationEfficient removalTreatment using aerobic processesTreatment involving filtrationConstructed wetlandWater discharge

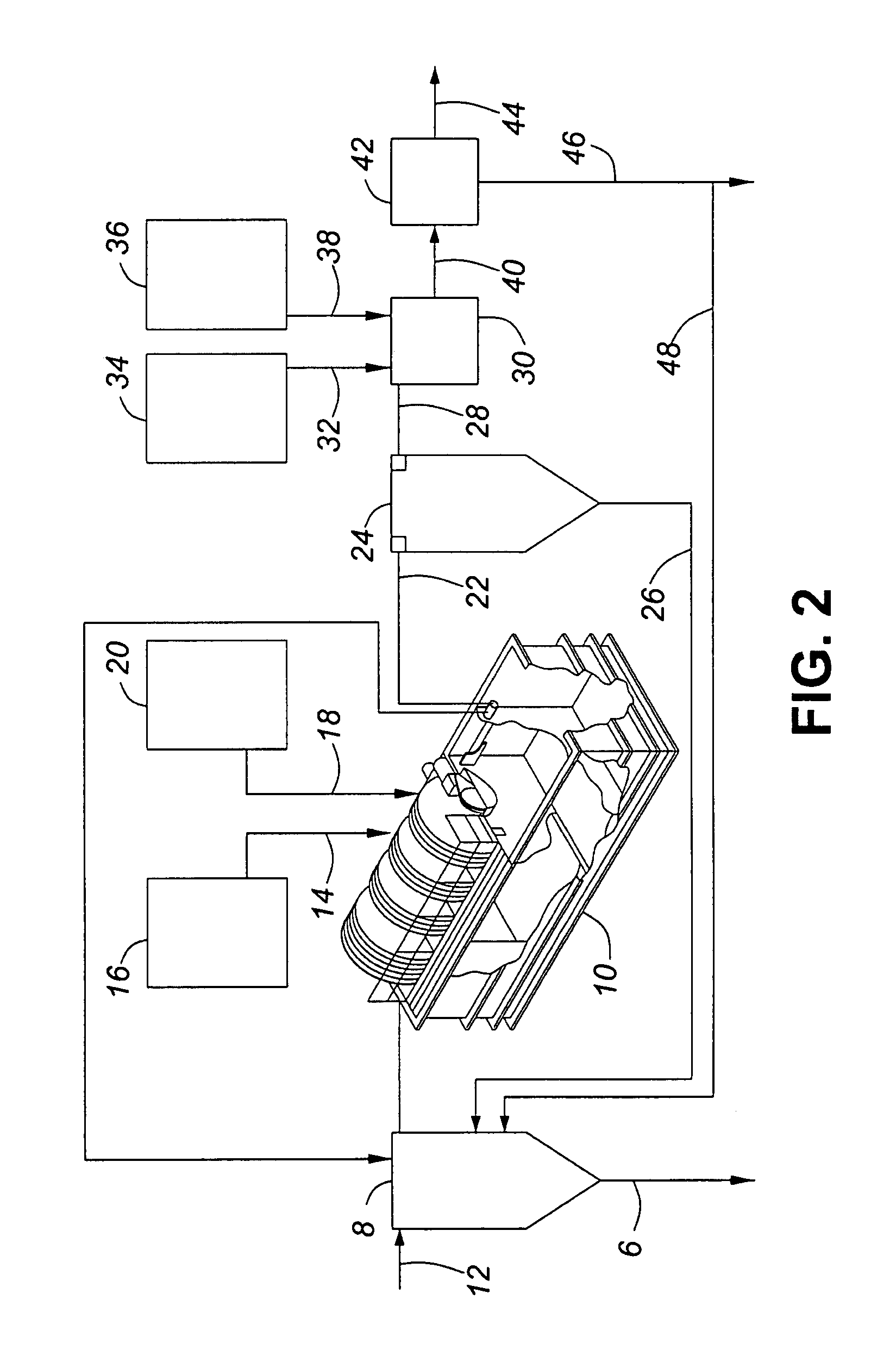

The invention discloses a freshwater shrimp culture tail water treatment system for treatment of the tail water of a culture pond. The freshwater shrimp culture tail water treatment system comprises:a pair of ecological ditches for preliminary purification of culture tail water, a sedimentation tank for sedimentation to remove granular solids in the culture tail water subjected to preliminary purification in the ecological ditches, a filtration dam for filtering solid particles in the culture tail water subjected to sedimentation treatment in the sedimentation tank, an aeration tank for aeration treatment of the culture tail water subjected to filtration treatment by the filtration dam, a biological purification tank utilizing fungi and animals to remove harmful substances, algae and thelike in the culture tail water subjected to aeration treatment in the aeration tank, and a constructed wetland for effective degradation of pollutants and harmful substances in the culture tail watersubjected to purification in the biological purification tank. The freshwater shrimp culture tail water treatment system provided by the invention can effectively remove solid particle impurities in culture tail water, lower the dissolved nitrogen and phosphorus content, and degrade pollutants and harmful substances. The treated culture tail water can reach the culture tail water discharge standard, and can finally be discharged into external rivers or recycle to culture ponds.

Owner:ZHEJIANG INST OF FRESH WATER FISHERIES

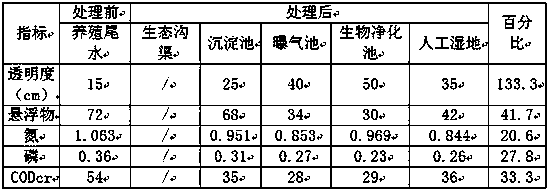

Flocculating agent for waste water treatment, and preparation method thereof

InactiveCN104071881AReduce CODReduce chromaWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationAluminum IonTurbidity

The invention discloses a flocculating agent for waste water treatment. The flocculating agent comprises components of calcium sulfate, aluminum ion salt, sodium carbonate, polyacrylamide, sodium thiosulfate, chitosan, chitosan quaternary ammonium salt, diatomite, cement and a pH adjusting agent, can be used for treating waste water discharged from food processing plants, metal manufacturing plants, chemical plants and the like, can also be used for treating waste water discharged from farms and slaughter plants, can also be used for purification of water quality in river channels and lakes, and can effectively reduce COD, color and turbidity of waste water.

Owner:廉勇

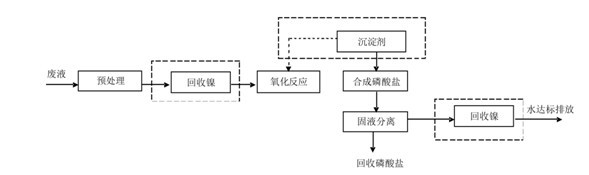

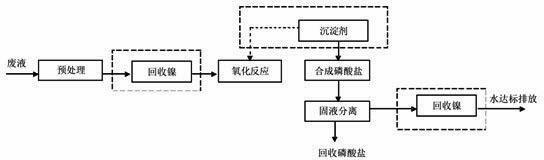

Method for degrading organic pollutant and recycling phosphate in chemical nickel-plating waste liquid

InactiveCN102616961AReduce phosphorus contentRemove completelyPhosphatesWaste water treatment from metallurgical processPhosphorous acidLiquid waste

The invention discloses a method for degrading organic pollutant and recycling phosphate in chemical nickel-plating waste liquid, which belongs to the technical field of environment-friendly waste water treatment and resource recycle. The method conducts oxidation degradation of organic pollutant in waste water through the oxidation technology, simultaneously oxidizes hypophosphorous acid radical and phosphorous acid radical in waste water into orthophosphate radical and recycles phosphate and nickel by enabling the orthophosphate radical and nonmetal or metal ions to be precipitated. The method achieves resource recycle while treating waste water and has good environment benefits and economical benefits and wide application prospect.

Owner:李朝林

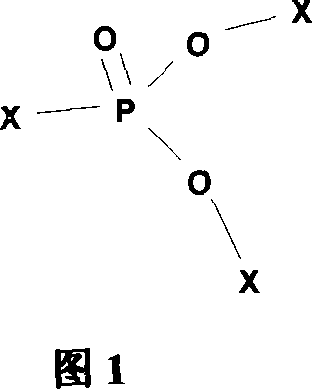

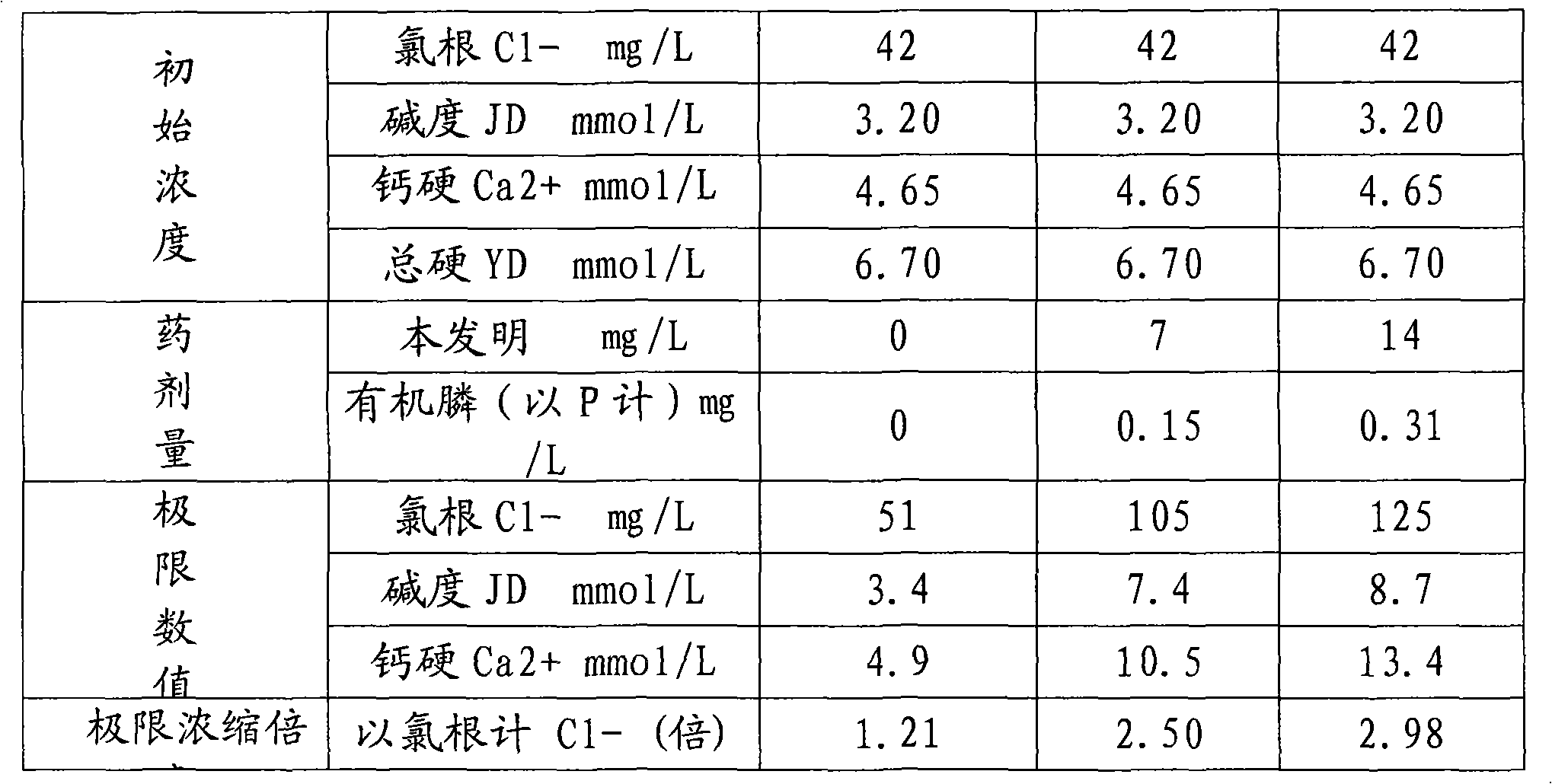

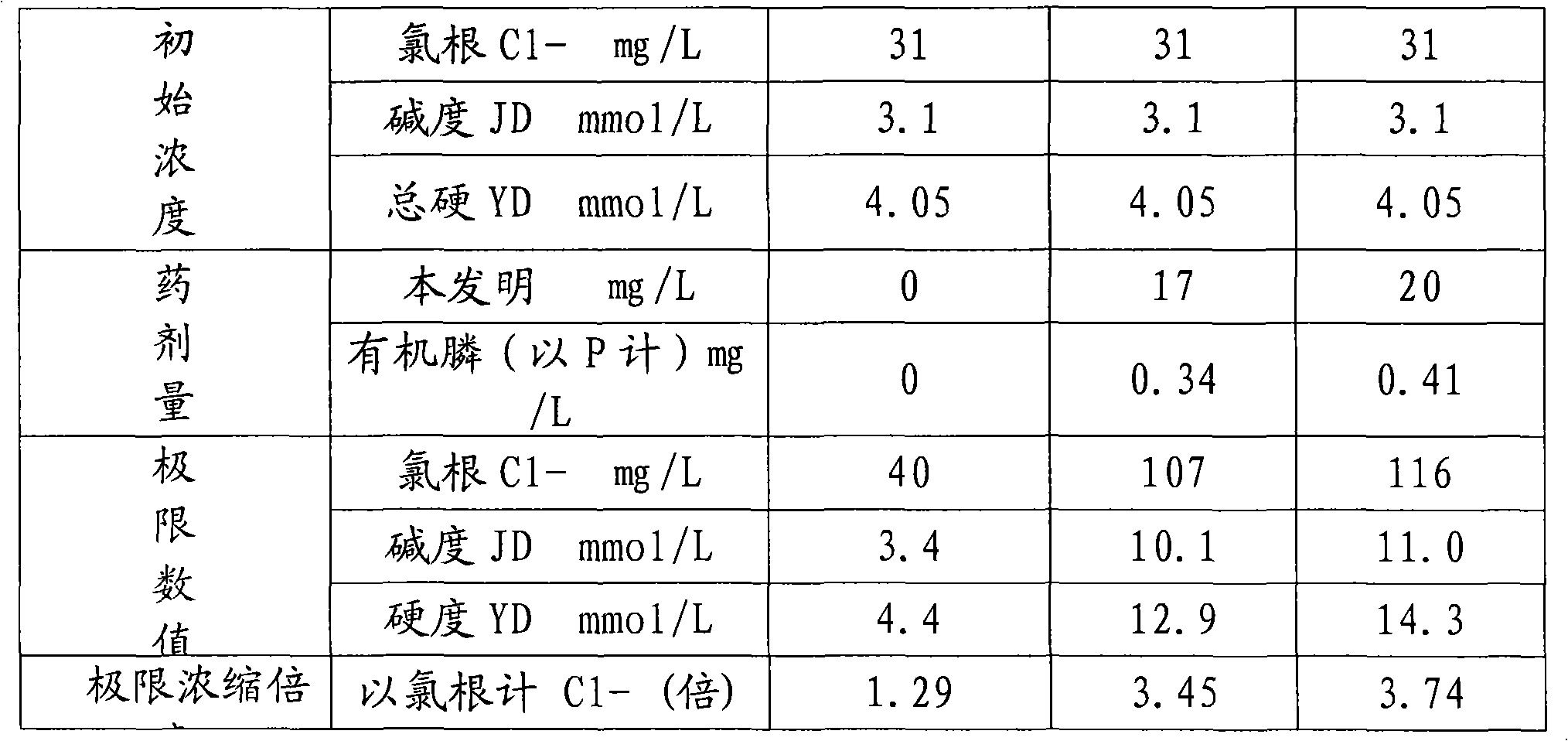

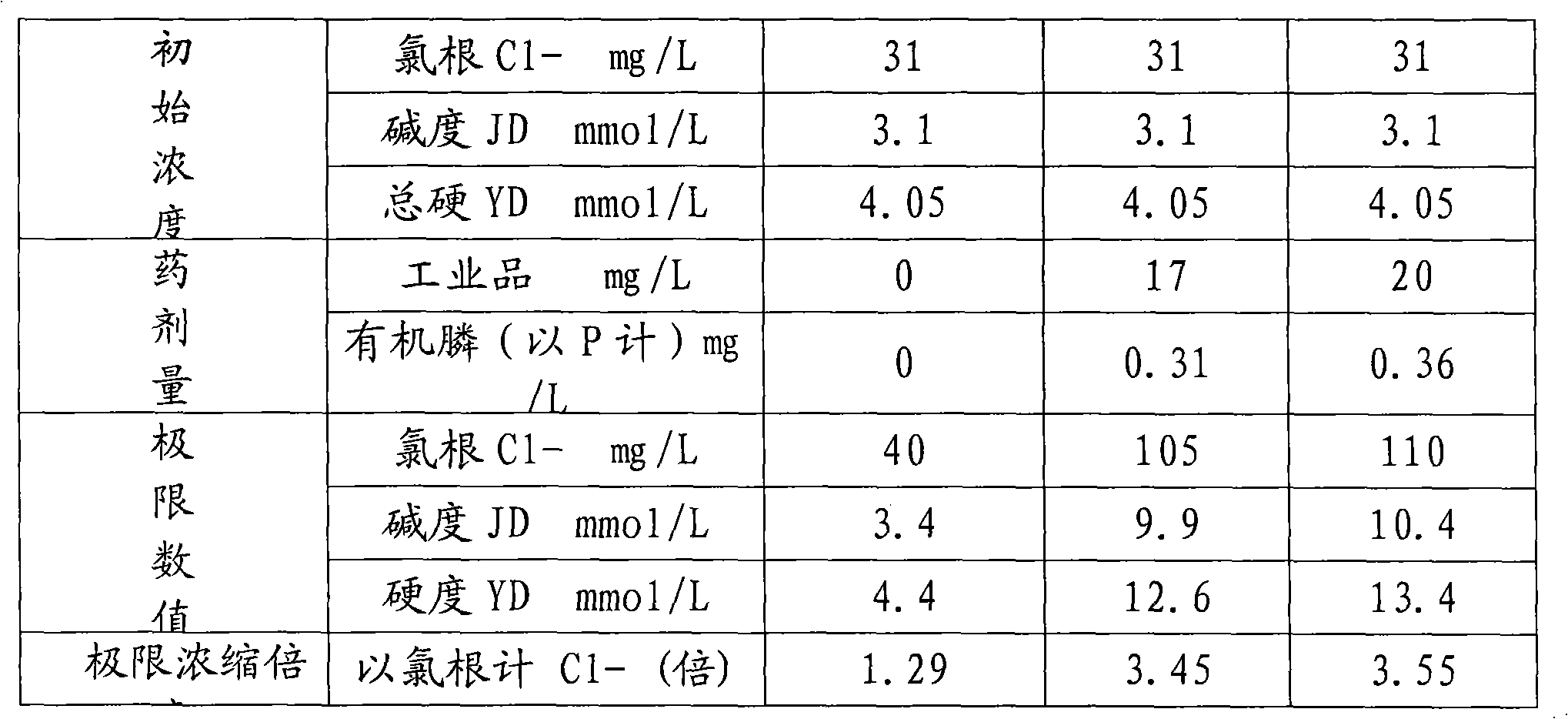

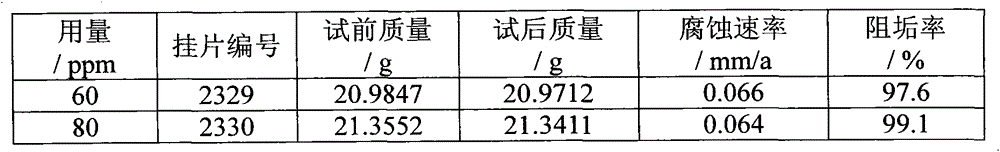

Low-phosphorus antiincrustation corrosion inhibitor and its use

ActiveCN1743281AImprove performanceExcellent resistance to CaCO

<sub>3</sub>

Dirt functionScale removal and water softeningAlkalinityPhosphor

This invention relates to a sort of low-phosphor scale-corrosion inhibitor which comprises 2-phospinobutane-1, 2, 4-tricarboylic acid (PBTCA) (or / and 2-hydroxyphonoacetic acid (HPAA)), zinc salts, molyadate or tungstate and carboxyl-containing copolymer, copper corrosion inhibitor (needed or not conditionally). This low-phosphor scale-corrosion inhibitor can be used to treat recirculated cooling-water in ways such as adjusting pH of high-hardness and high-alkalinity water or treating low-alkalinity and low-hardness water. Its phosphor concentration in recirculated water is no more than 1mg / L, reducing the hazard of phosphor discharge to environment.

Owner:BEIJING YANHUA PETRO CHEM +1

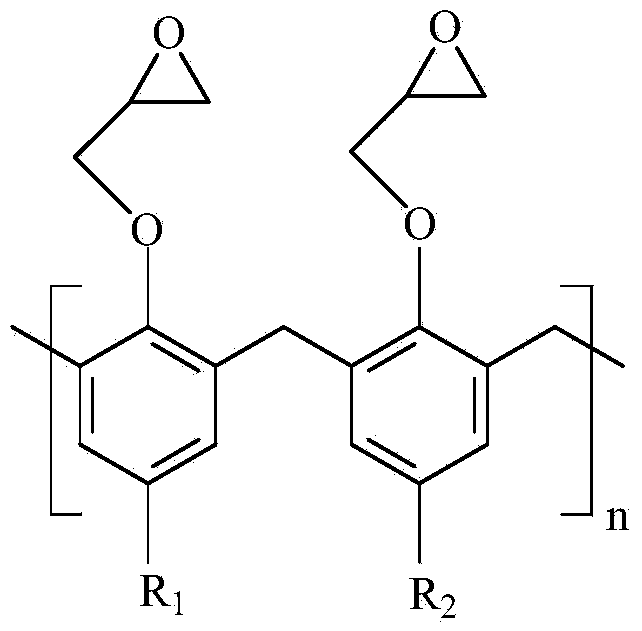

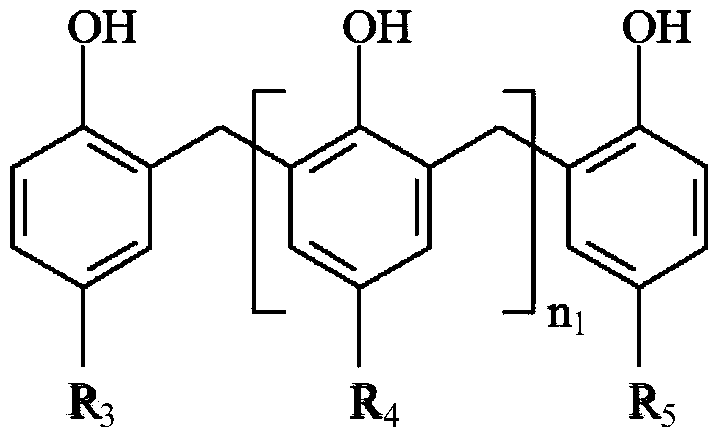

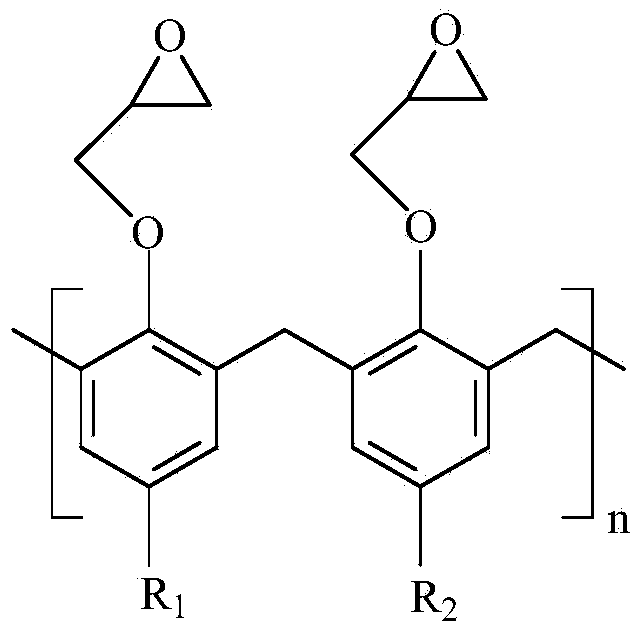

Halogen-free resin composition, prepreg prepared from halogen-free resin composition and laminated board prepared from halogen-free resin composition and used for printed circuit

ActiveCN103992622ALow dielectric constantReduce lossSynthetic resin layered productsCircuit susbtrate materialsAlkylphenolAbsorption rate

The invention discloses a halogen-free resin composition, a prepreg prepared from the halogen-free resin composition and a laminated board prepared from the halogen-free resin composition and used for a printed circuit. The halogen-free resin composition comprises alkylphenol epoxy resin, benzoxazine resin, an alkylphenol aldehyde curing agent and a phosphorus-contained flame retardant. The molecular structure of alkylphenol epoxy resin adopted in the halogen-free resin composition contains more branched alkyls, so that the halogen-free resin composition is relatively high in glass transition temperature, low in water absorption rate, favorable in heat resistance and excellent in dielectric performance; benzoxazine resin is mixed, so that the dielectric constant, dielectric loss value and water absorption rate of a solid can be further reduced; alkylphenol aldehyde is used as a curing agent, so that the advantages of excellent dielectric performance and low water absorption rate generated by more alkyls in the structure are sufficiently exerted. The prepreg prepared from the halogen-free resin composition and the laminated board prepared from the halogen-free resin composition and used for the printed circuit have the advantages of low dielectric constant, low dielectric loss factor, low water absorption rate, high size stability, high heat resistance, and favorable flame retardance, processability and chemical resistance.

Owner:江西生益科技有限公司

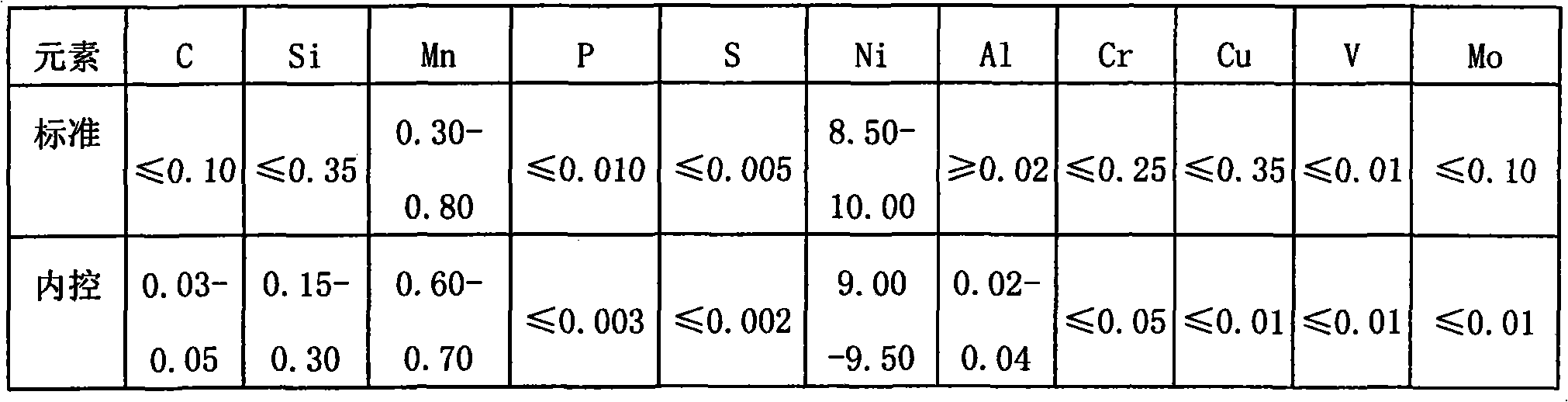

Smelting method of 9Ni steel

ActiveCN102747181AMeet the requirements of continuous castingReduce lossesManufacturing convertersCritical control pointSmelting process

A smelting method of 9Ni steel. The method has the following characteristics: 1.a smelting process comprises steps of pretreatment on molten iron (desulfuration), converter (double dephosphorization, melting nickel plate), LF furnace (desulfuration) and RH (degassing); 2. dephosphorization is conducted in the converter and comprises two steps: step one: blending molten iron desulphurized by KR and steel scrap into a dephosphorization converter for primary smelting, using ''dephosphorization converter smelting critical control point'' to desulphurize the molten iron to a phosphorus content below 0.020%, and carrying out semi-steel tapping; and step two: blending the molten semi-steel and nickel plate into a decarburization converter for converting, desulphurizing the molten steel after converting to a phosphorus content below 0.003%, and carrying out tapping; and 3. the nickel plate is melted in the decarburization furnace. According to the present invention, the two-step dephosphorization is carried out in the converter that molten steel after converting has low phosphorus content and is stably controlled, so as to benefit improvement on the yield of 9Ni steel. Decarburization converter slag has low phosphorus content, and ladle molten steel has a low rephosphorization amount, so as to clear out molten steel in the decarburization furnace and reduce molten steel loss in a steel leaving operation.

Owner:BAOSHAN IRON & STEEL CO LTD

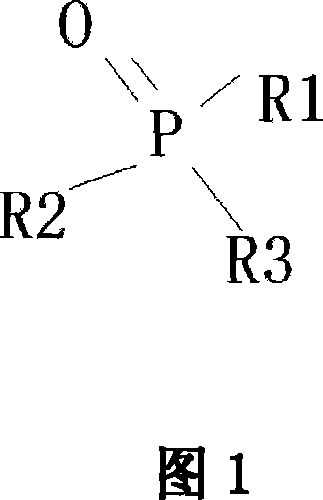

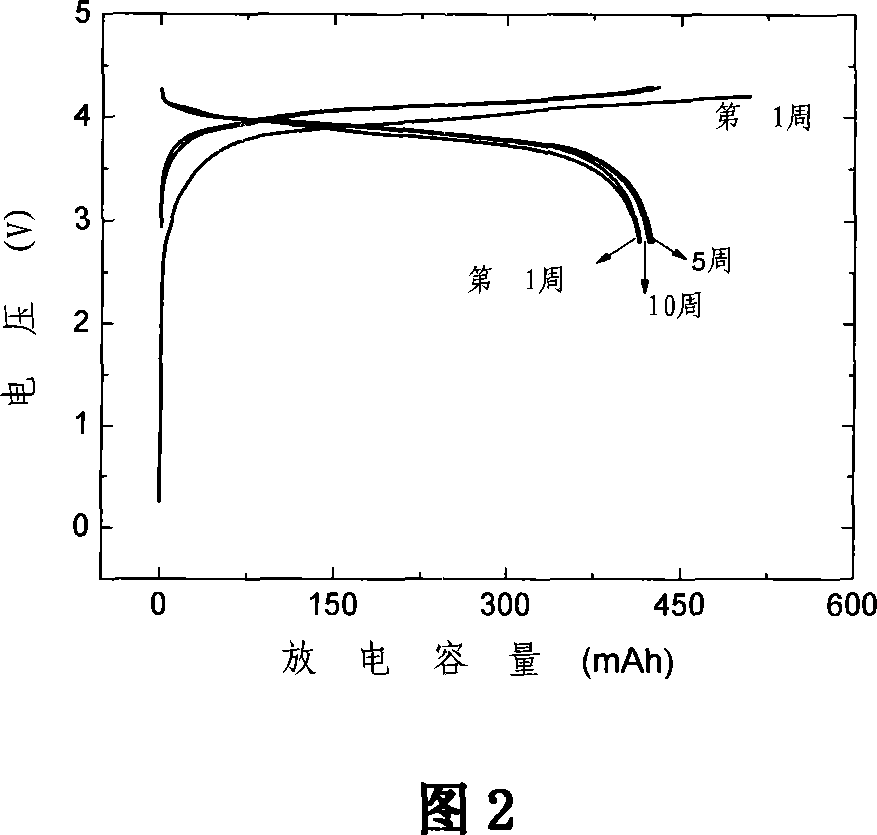

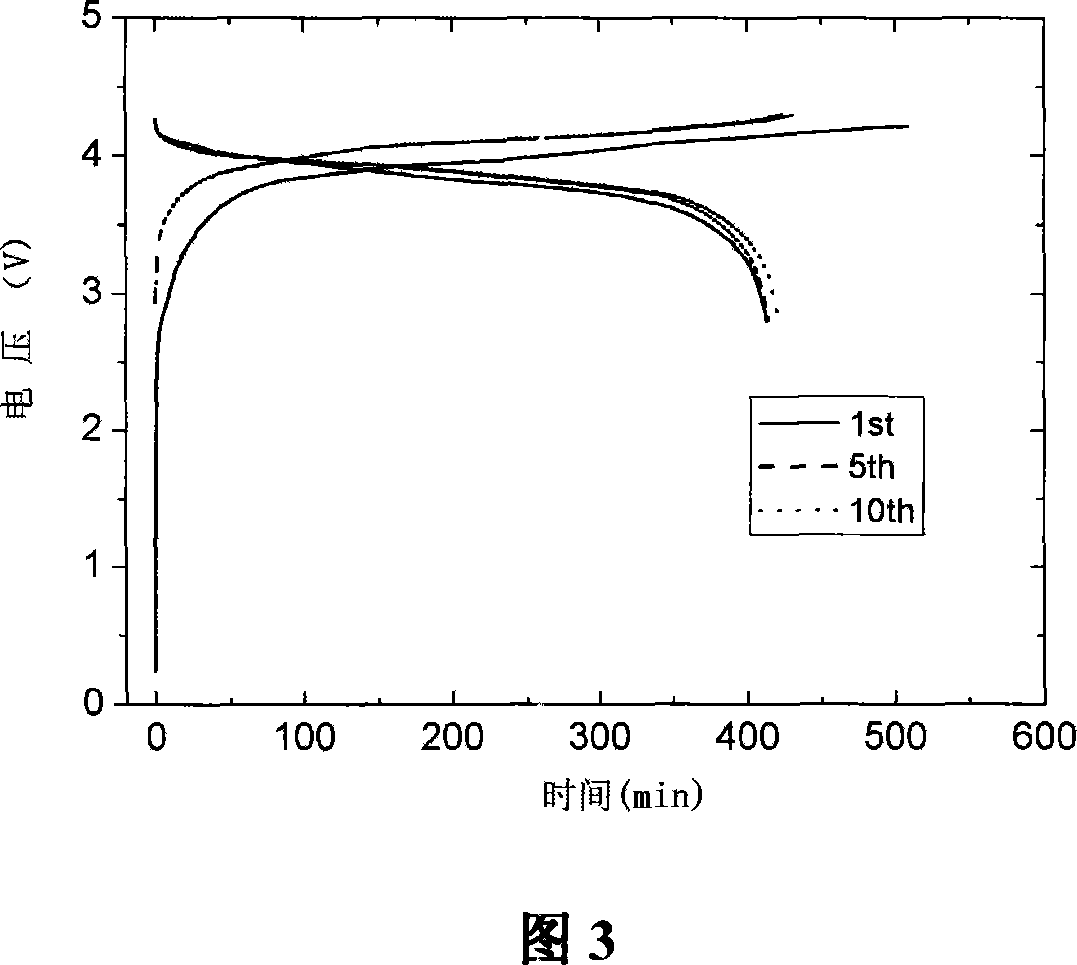

An electrolyte of efficient low-poison and combustion-resisting lithium cell and its lithium cell

InactiveCN101079504AReduce phosphorus contentHigh phosphorus contentOrganic electrolyte cellsSecondary cellsSolubilityCombustion

The invention discloses a high-effective low-toxic flameproof lithium battery electrolyte and lithium battery, which is characterized by the following: adopting one ore more phosphate (methyl phosphodimethylester, ethyl phosphodiethylester, ethyl phosphodimethylester) as pure solvent or solvent component; displaying incombustibility based on the electrolyte of phosphate; saving the cost; improving the conductivity and lithium salt solubility and safety with stable electrochemical property.

Owner:常熟紫金知识产权服务有限公司

Composite corrosion inhibition antisludging agent for ultralow rigidity circulation cooling water and preparation method thereof

InactiveCN102718329AGood anti-scaling effectGood dispersionTreatment using complexing/solubilising chemicalsPhosphateDiethylenetriamine

The invention provides a composite corrosion inhibition antisludging agent for ultralow rigidity circulation cooling water. The composite corrosion inhibition antisludging agent comprises the following raw materials in parts by weight: 5-15 parts of amino trimethylene phosphonic acid, 5-15 parts of hydroxyethylidene diphosphonic acid, 1-15 parts of diethylenetriamine pentamethylene phosphonic acid, 5-15 parts of hydrolytic polymaleic anhydride, 2-15 parts of terpolymer, 2-20 parts of heptahydrate, 0.1-2 parts of hydroxy benzotriazole and 3-79.9 parts of pure water. The hydroxy benzotriazole is added after the amino trimethylene phosphonic acid, the hydroxyethylidene diphosphonic acid, the diethylenetriamine pentamethylene phosphonic acid, the hydrolytic polymaleic anhydride and the terpolymer are stirred and mixed; and the composite corrosion inhibition antisludging agent is obtained by adding the water and the heptahydrate until the hydroxy benzotriazole is entirely dissolved. The hydrolytic polymaleic anhydride and the terpolymer used by the invention have a good diffusion effect, and can effectively prevent carbonates, phosphates and the like from being deposited and scaled. Meanwhile, the hydrolytic polymaleic anhydride and the terpolymer belong to a non-phosphate monomer, so that the agent phosphate content is reduced. Therefore, the composite corrosion inhibition antisludging agent is beneficial to environmental protection.

Owner:SHANDONG TAIHE WATER TREATMENT TECH CO LTD

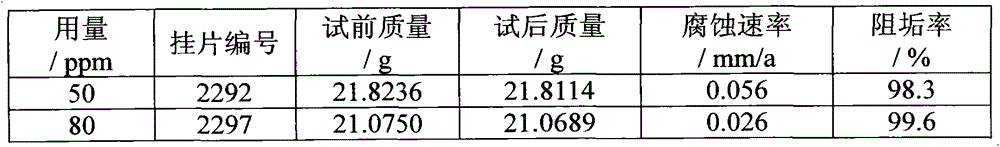

Low-phosphorous environment-friendly composite corrosion and scale inhibitor

InactiveCN101746901AImprove toleranceGood dispersionScale removal and water softeningHigh concentrationTricarboxylic acid

The invention discloses a low-phosphorous environment-friendly composite corrosion and scale inhibitor that is used in a circulating cooling water system. The low-phosphorous environment-friendly composite corrosion and scale inhibitor comprises 2-phosphonic butane- 1,2,4 -tricarboxylic acid, plyaspartic acid or polyepoxysuccinic acid, maleic anhydride-acrylic acid copolymer, acrylic acid-2-acrylamide-2-methyl propanesulfonic acid or acrylic acid-acrylate-sulfonate, acrylic acid-acrylate-phosphonic acid-sulfonate quaternary copolymer, zinc salts (zinc sulfate or zinc chloride) or hydroxy benzotriazole. The invention is particularly suitable for the circulating cooling water system with high concentration multiple, which needs to control the phosphorous content (the total phosphorous content is lower than 0.5mg / l) due to environmental pressure.

Owner:成都澳贝龙科技发展有限公司

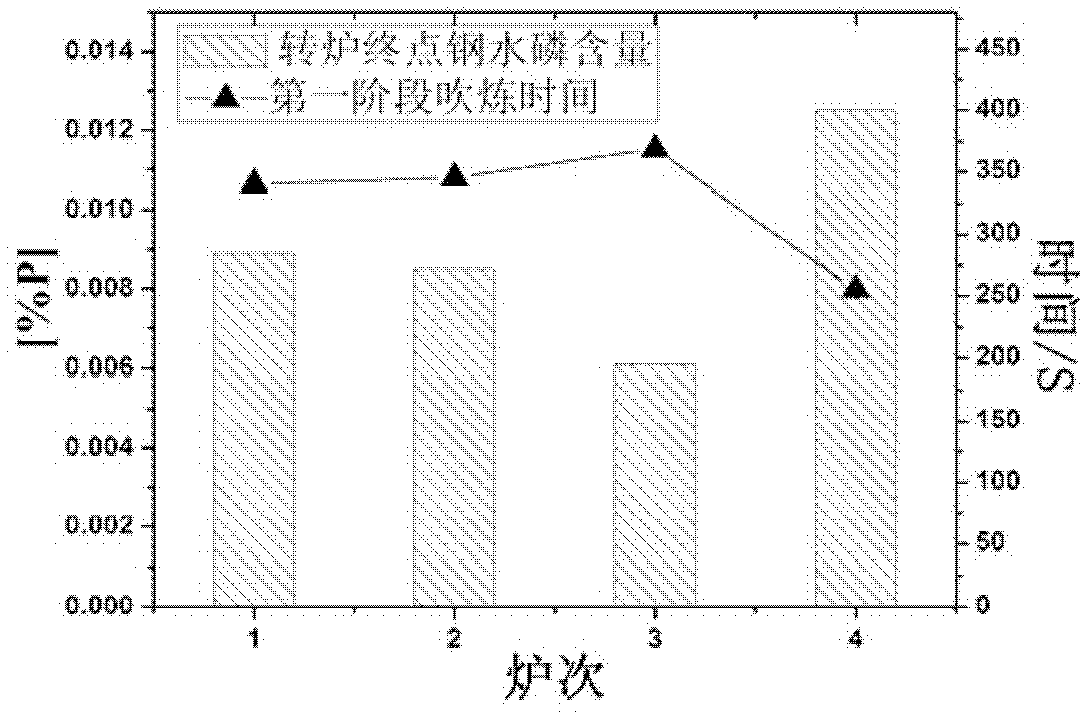

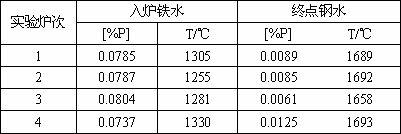

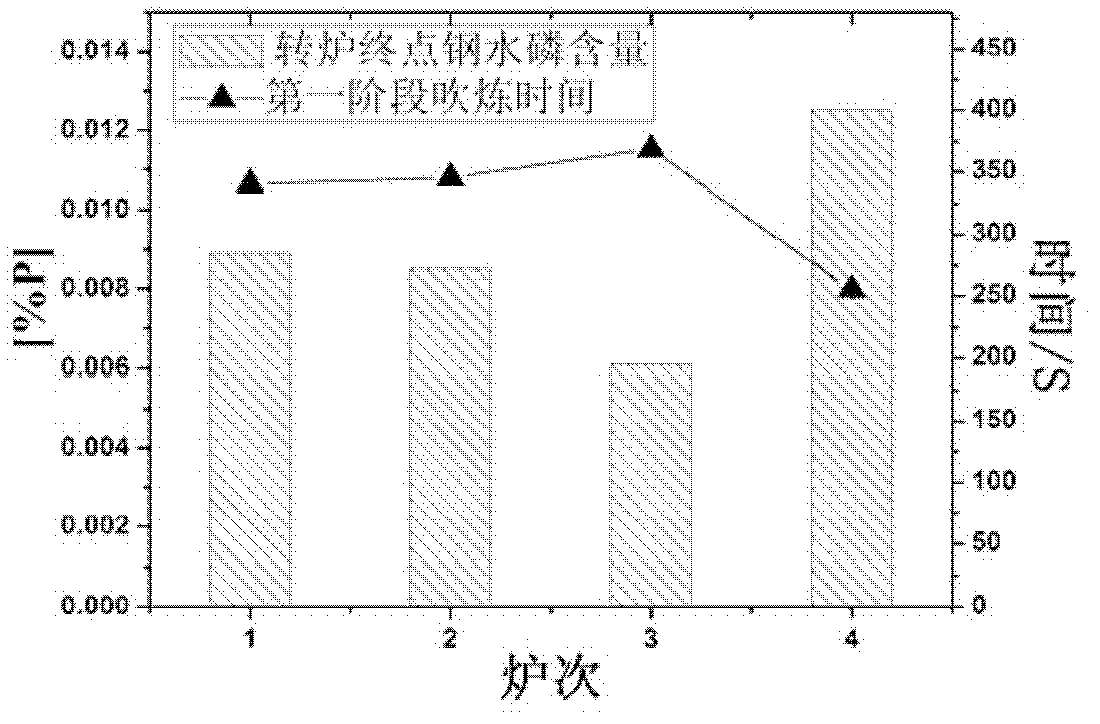

Convertor smelting technology method for producing low-phosphorous steel

InactiveCN102358912AReduce consumptionReduce water phosphorus contentManufacturing convertersSteelmakingMetallurgical industry

The invention relates to the technical field f convertor steel making in metallurgy industries, in particular to a method for smelting low-phosphorous steel through combined steel-tapping slag-left and double slag process technology, which aims at providing convertor technology for producing the low-phosphorous steel. The method prolongs previous dephosphorization blowing time, thereby prolonging reaction time of steel slag in a previous blowing stage, improving reaction temperature of dephosphorization steel slag in previous blowing, improving dynamics and thermodynamics conditions of steel slag reaction, improving dephosphorization effect in previous blowing and enabling phosphorus in steel liquid to be absorbed in slag as much as possible. Slag with high P2O5 content is poured out of a convertor so as to reduce phosphorus content of the whole convertor system, providing favorable conditions for dephosphorization in a later decarburization blowing stage and achieving the purpose of producing the low-phosphorous steel. Compared with other methods for producing the low-phosphorous steel, the method for producing the low-phosphorous steel has the advantages of being simple in operation methods, low in cost, easy to obtain and the like.

Owner:UNIV OF SCI & TECH BEIJING

Combustion-resisting electrolyte of lithium secondary cell and its lithium cell

InactiveCN101079505AImprove flame retardant performanceSafe storageSecondary cellsCombustionPhosphate

The invention discloses a flame-proof electrolyte and its lithium battery for secondary lithium battery, which is characterized by the following: adopting one or more phosphosubester (such as methyl acid phosphate dimethyl ester, ethyl phosphate diethyl ester and its derivant) as pure solvent or solvent component; reducing the price of electrolyte with incombustibility, low toxicity and high conductivity; improving the combusting safety effectively.

Owner:WUHAN UNIV

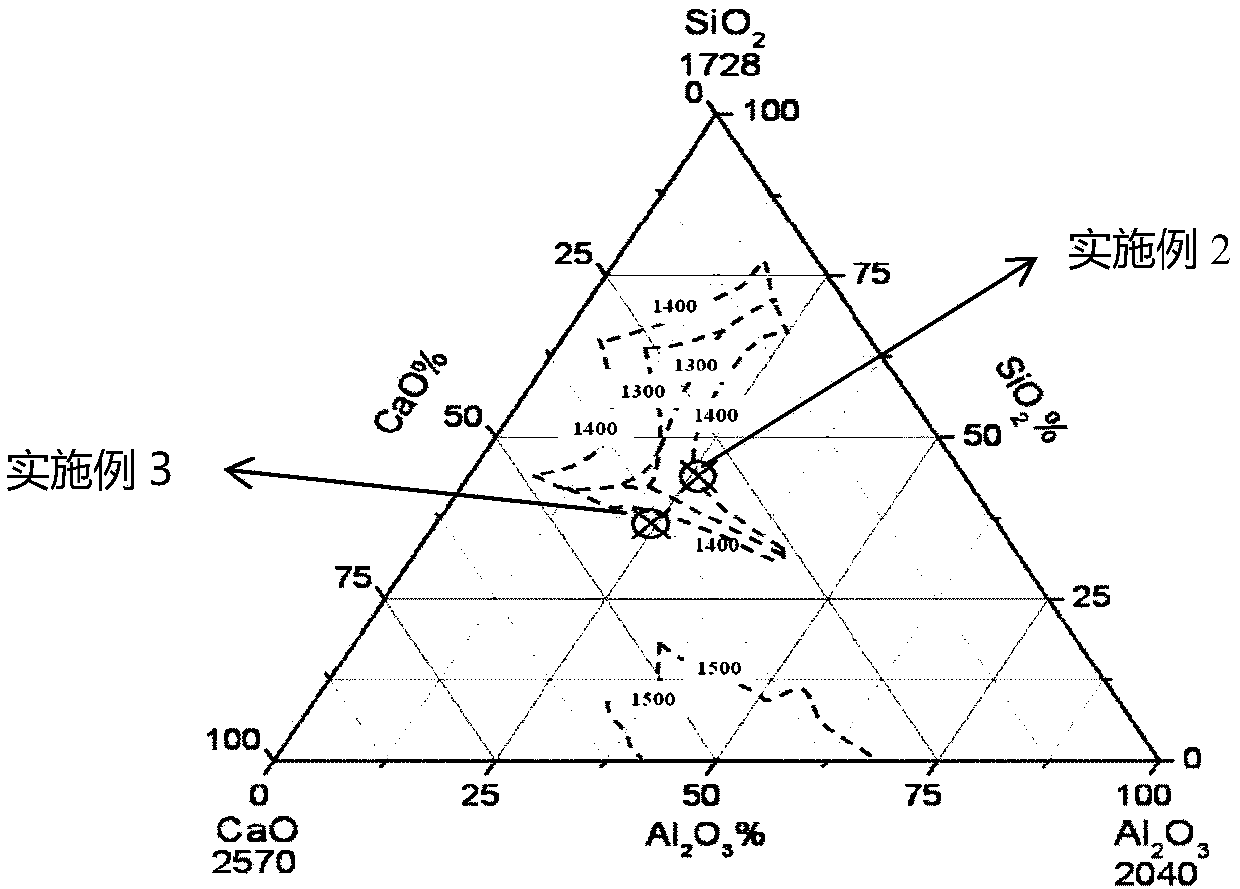

Aluminum industrial red mud-based dephosphorizing agent for converter steelmaking and preparation method thereof

InactiveCN103725825AMeet general requirementsReduce phosphorus contentManufacturing convertersSteelmakingRed mud

The invention discloses an aluminum industrial red mud-based dephosphorizing agent for converter steelmaking and a preparation method thereof, belonging to the field of converter steelmaking. The dephosphorizing agent is mainly prepared from the following raw materials by mass percent: 50-70% of dried red mud, 5-15% of lime, 15-30% of iron ore concentrate or iron sheet ball, 2-10% of light roasting dolomite, and 0.5% of binding agent. The dephosphorizing agent is prepared by the following steps of crushing the raw materials, mixing uniformly, pressing into chunks, roasting for 2-4 hours at 300-500 DEG C, cooling down, and then crushing into the dephosphorizing agent with grain size of 15-30mm. The dephosphorizing agent is added in dephosphorizing step in steelmaking by the converter, can be used for processing molten iron with middle or low content of phosphorus, and can remove more than 90% of phosphorus. By utilizing large amount of CaO and Fe2O3 in the red mud, the dephosphorizing agent not only has good dephosphorizing effect, but also solves the problem of red mud pollution, thus recycling the red mud and lowering the cost for steelmaking.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Scale and corrosion inhibitor

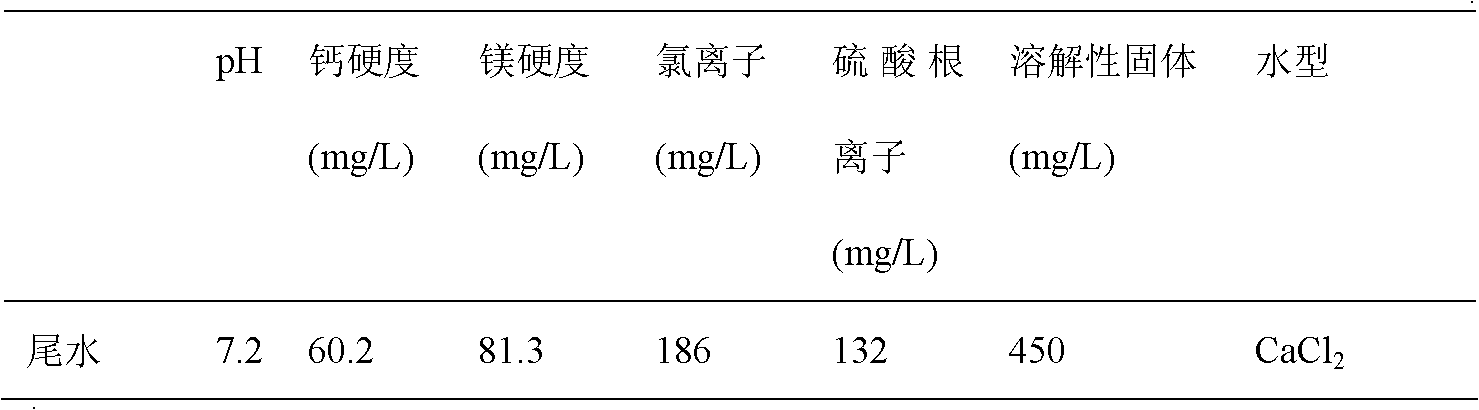

InactiveCN103319010AReduce eutrophication pollutionImprove protectionScale removal and water softeningEutrophicationFluorescence

The invention relates to a scale and corrosion inhibitor, comprising organic phosphonate, an inorganic scale and corrosion inhibition component, a carboxylic acid containing copolymer, zinc salt, a heterocyclic compound and a fluorescence tracing component. The scale and corrosion inhibitor is easy to compound, has good stability, and has good scale and corrosion inhibition performances for reusing tail water of a sewage plant into a circulating cooling system under a low addition amount; the scale and corrosion inhibitor can be directly added into a reclaimed water reusing pipeline, without needing to supplement calcium and alkali into the tail water in advance and regulating a pH value, and has a good treating effect; the scale and corrosion inhibitor does not contain a toxic compound and inorganic phosphatic, contains little phosphor, can reduce eutrophication pollution of a water body, and is in favor of environment protection.

Owner:常州市排水管理处 +1

Method for treating high-concentration acidic wastewater containing phosphorus and fluorine

InactiveCN102070267AReduce fluorine contentReduce phosphorus contentWater contaminantsMultistage water/sewage treatmentAluminium saltsChemistry

The invention discloses a method for treating acidic wastewater containing phosphorus and fluorine, which comprises the following steps: (1) firstly, adding calcium hydroxide into the acidic wastewater containing phosphorus and fluorine, and controlling the pH value of the system at 12-14 to obtain a precipitate-containing reaction system which is marked as a reaction system 1; (2) removing the precipitate in the reaction system 1, adding sulfuric acid into the residual liquid to regulate the pH value to 9-11, and then, adding aluminum sulfate to regulate the pH value to 6-7, thereby obtaining a precipitate-containing reaction system 2; and (3) settling down the precipitate in the reaction system 2, and removing the precipitate to obtain the treated wastewater. In the wastewater treated by the method disclosed by the invention, the content of fluorine is lower than 10 mg / L, the content of phosphorus is lower than 0.5 mg / L, and the pH value is 6-7, thus the treated wastewater achieves the Discharge Standard of Water Pollutants for Phosphate Fertilizer Industry (GB 15580-95). In the whole technological process, water overflows under the action of the gravity without an external energy supply, thereby saving the energy.

Owner:湖北大峪口化工有限责任公司

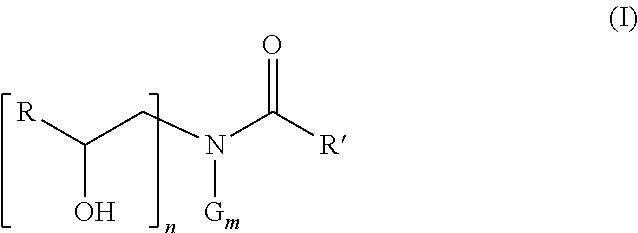

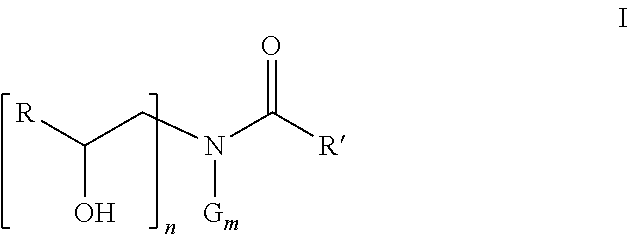

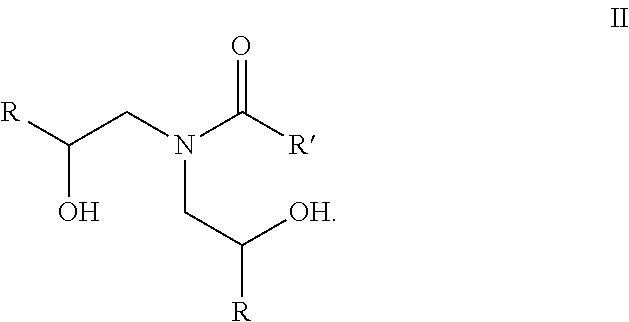

Method for reducing engine wear with lubricants comprising 2-hydroxyalkylamide friction modifying / Anti-wear compositions

ActiveUS20160251591A1Readily solubleStable and storable oil formulationAdditivesFriction reductionSolubility

Lubricant compositions comprising an improved ashless organic friction modifier additive have been found to be capable of reducing both friction and wear. It has been found that mixtures of fatty-alkanolamides containing secondary hydroxyls on the amino alkyl substituent, such as amide mixtures prepared from bis(2-hydroxyporopyl)amine and mixtures of at least two different C8-24 fatty acids, provide better oil solubility and friction reduction than alkanolamides with primary, hydroxyl functionality, such as amide mixtures prepared from di-ethanol)amine.

Owner:CHEMTURA CORP

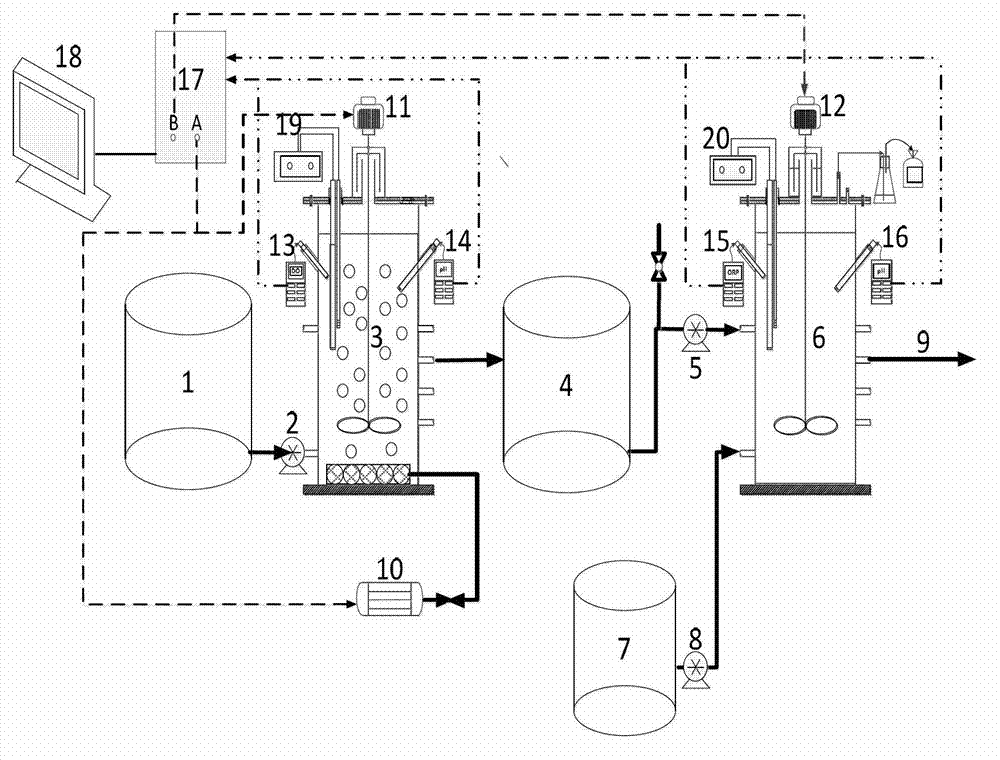

Method for enhancing nitrogen and phosphorus removal of urban sewage by sludge fermentation

ActiveCN103086511AReduce phosphorus contentGood removal effectTreatment with aerobic and anaerobic processesNitrogen removalSequencing batch reactor

The invention discloses a method for enhancing nitrogen and phosphorus removal of urban sewage by sludge fermentation, relates to the coupling control technology of sludge fermentation enhanced nitrogen and phosphorus removal technology and sludge fermentation technology, and belongs to the fields of urban sewage treatment and sludge biochemical treatment. The method employs a sequencing batch reactor to couple the sludge fermentation effect and the urban sewage nitrogen and phosphorus removal effect into a same system, so that easily degradable carbon source generated by sewage fermentation can be consumed timely by phosphorus-accumulating bacterium and denitrifying bacterium, the nitrogen removal effect of the urban sewage with a low C / N ratio is enhanced, the problem of lowered fermentation reacting rate caused by accumulation of products in the fermentation process is avoided, and the initial stabilization of primary sludge is achieved at the same time. The method for enhancing nitrogen and phosphorus removal of urban sewage by sludge fermentation is applicable to the enhanced nitrogen and phosphorus removal of the urban sewage with low C / N ratio and C / P ratio and the initial decrement and stabilization of the sludge. The method for enhancing nitrogen and phosphorus removal of urban sewage by sludge fermentation is saving in carbon source and improved in nitrogen removal efficiency, and has the advantages of simple equipment, flexible operation, high nitrogen removal efficiency and the like.

Owner:北控水务(中国)投资有限公司

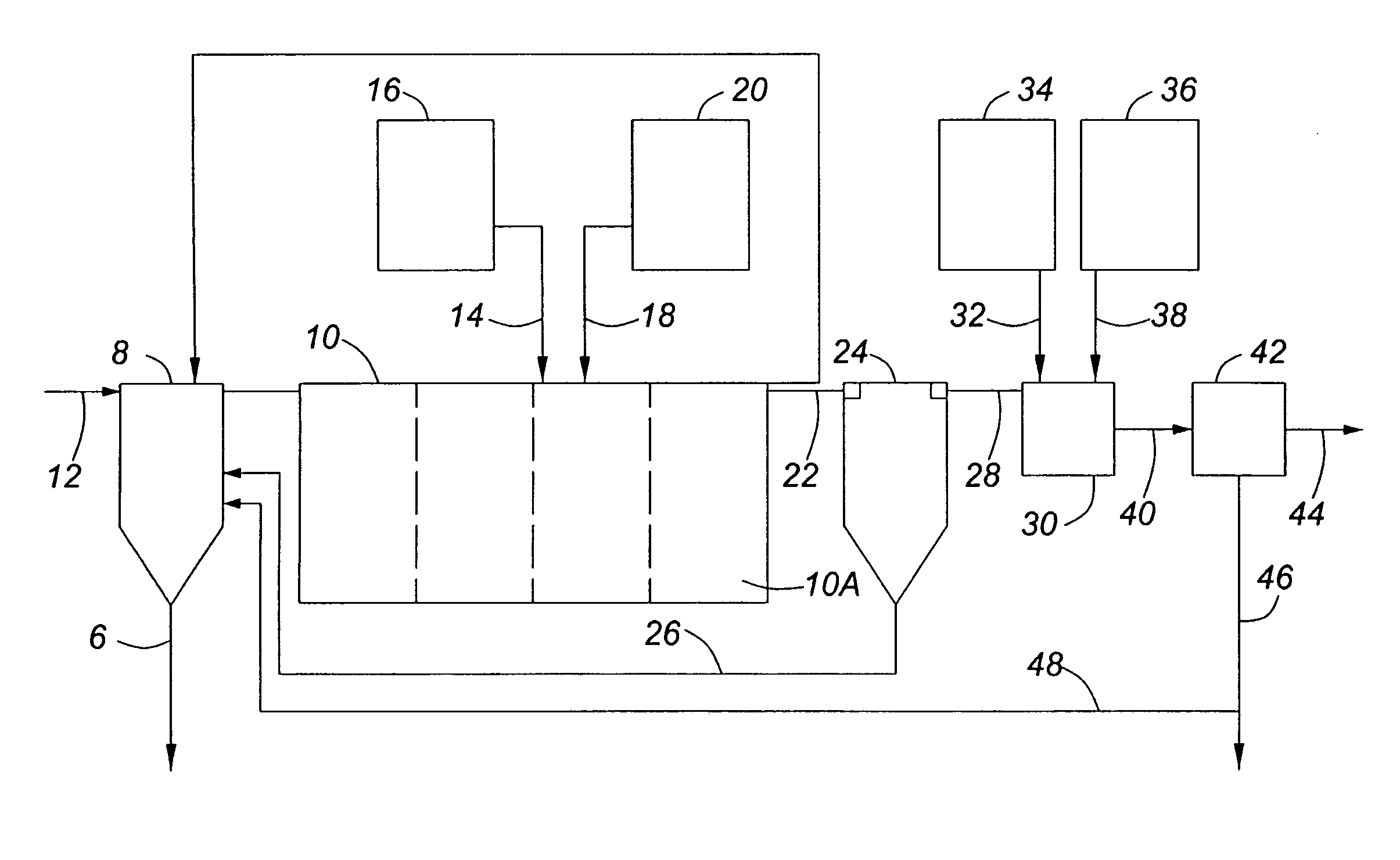

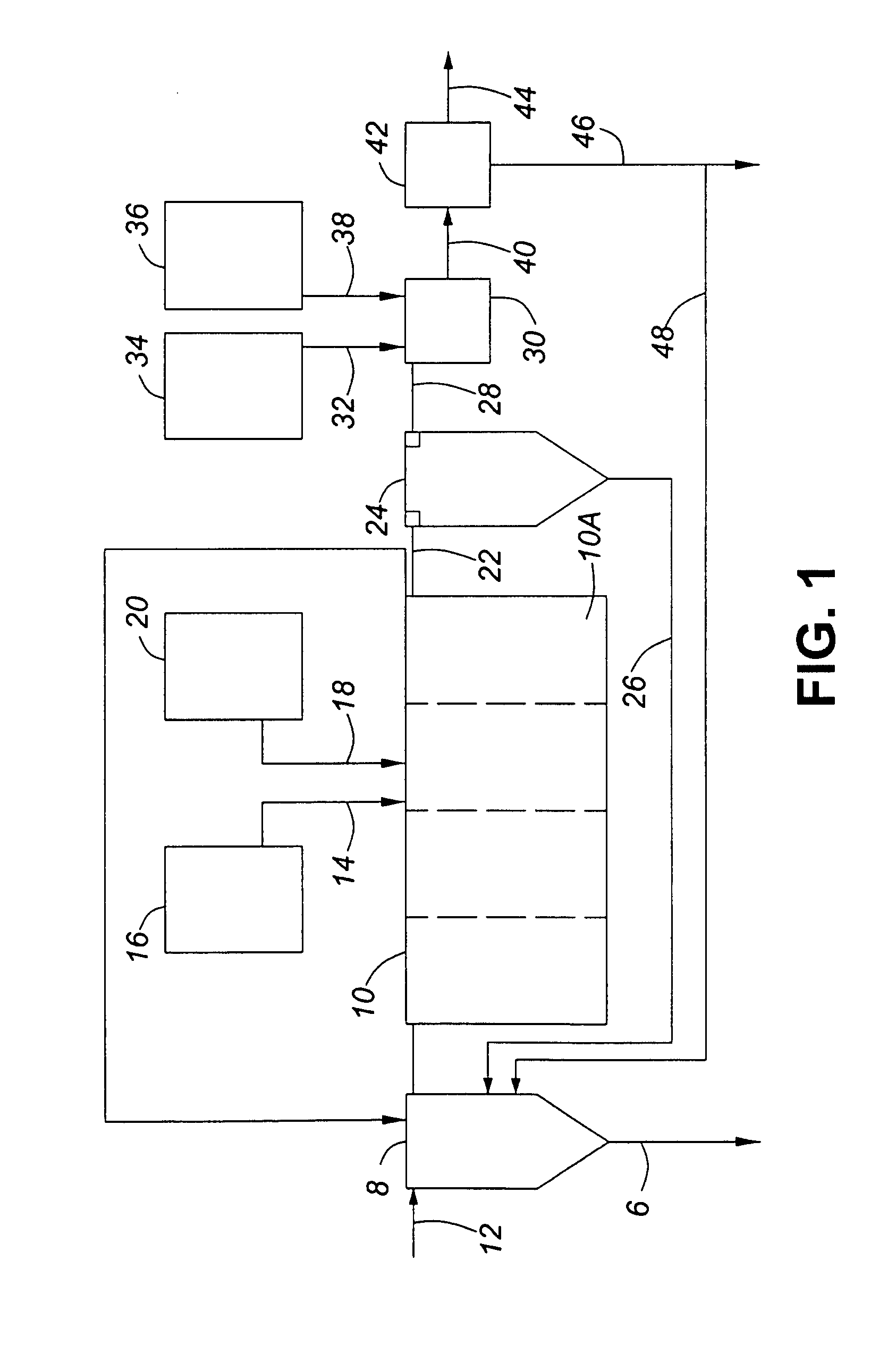

Removal of phosphorous from wastewater

InactiveUS7563373B2Reduce phosphorus contentTreatment using aerobic processesSolid sorbent liquid separationWastewaterAluminum silicate

Processes, methods and systems are provided herein for lowering the concentration of phosphorus in wastewater. The process includes adding a suitable amount of an aluminum-based coagulant / flocculent, for example, an aluminum-silicate coagulant / flocculent product to the wastewater while maintaining the pH of the wastewater at between about 4.5 and about 6.65. This step provides an eventual effluent stream of precipitated aluminum-based, phosphorus-containing flocs dispersed in the wastewater. The next step involves physically removing, as by filtering, the precipitated aluminum-based, phosphorus-containing flocs which is dispersed in the wastewater. These steps are able to provide a wastewater effluent containing less than about 0.03 mg total phosphorus per liter of wastewater. The disclosure also teaches novel methods and systems for carrying out the novel process.

Owner:BLUMETRIC ENVIRONMENTAL

Method for improving utilization efficiency of ozone and reducing COD of wastewater

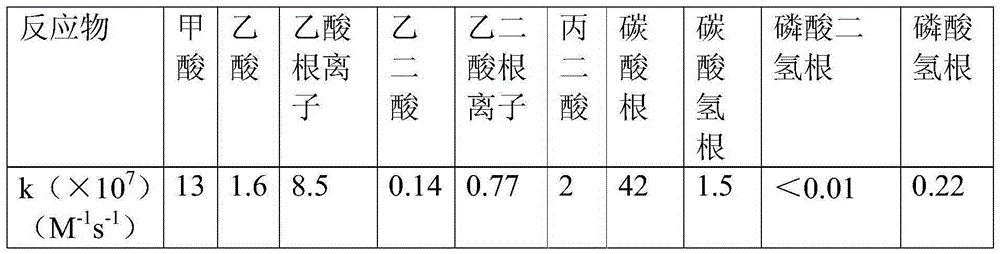

InactiveCN105366785AReduce CODReduce total phosphorusWater treatment parameter controlWater treatment compoundsOrganic matter mineralizationReaction rate

The invention provides a method for increasing the utilization efficiency of ozone and reducing the COD of wastewater. According to the method, a chemical agent for removing a hydroxyl radical capture agent generated in base catalysis ozone advanced oxidation is added into the wastewater so as to achieve the purposes. Calcium ions, barium ions and the like are added into a base catalysis ozone oxidation system, so that the hydroxyl radical capture agent becomes precipitate to be separated from the water and loses the capacity for capturing hydroxyl radicals, and accordingly the utilization efficiency of ozone is improved. In addition, part of organic acid generated by the calcium ions, the barium ions and the like and the ozone oxidation wastewater precipitates to be separated from the water, so that the consumption of ozone is reduced, and the utilization efficiency of the ozone treatment wastewater is indirectly improved. By means of the method, the reaction rate of ozone can be obviously increased, the utilization efficiency of ozone can be obviously improved, reaction time can be shortened, cost can be reduced, organic matter in the wastewater can be thoroughly mineralized, and the COD and the total phosphorus content of the wastewater can be significantly reduced.

Owner:BEIJING WEICHUANGLI TECH CO LTD

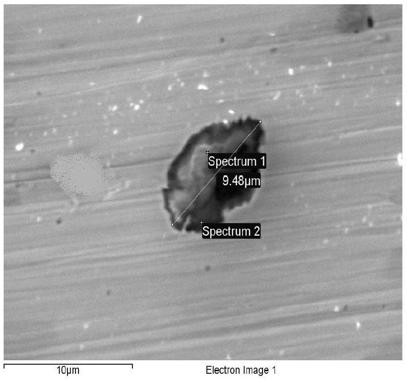

Smelting process for controlling spring steel inclusions

ActiveCN109097518ARelieve pressureFully integratedManufacturing convertersProcess efficiency improvementAlkalinitySmelting process

The invention discloses a smelting process for controlling spring steel inclusions. The smelting process comprises the following steps of (1) KR molten iron desulfurization pretreatment, (2) BOF top-bottom double combined flowing converter smelting, (3) LF furnace refining, (4) RH furnace refining and (5) continuous casting process, wherein the mass fraction of S is controlled to be below 0.005% after molten iron is processed by the step (1); the step (3) is carried out by high-purity silicon carbide for diffusion deoxidation, and the refining slag alkalinity is controlled to be 0.6-0.9; a lowalkalinity slag process is adopted in the step (4), and the final slag alkalinity is 0.5-0.7; and it is ensured that a molten steel contact part is free of aluminum in the step (5), a double electromagnetic stirring process is adopted in a secondary cooling zone and a casting blank solidification end zone, and a central carbon segregation index is controlled to be below 1.15. The smelting processadopts molten iron pretreatment, converter catching carbon, refining low alkali slag, continuous casting protective pouring and special refractory materials. Through the control over the oxygen potential of molten steel, the inclusion form and the central carbon segregation, the spring drawing performance is improved, and the spring fatigue limit is increased.

Owner:NANJING IRON & STEEL CO LTD

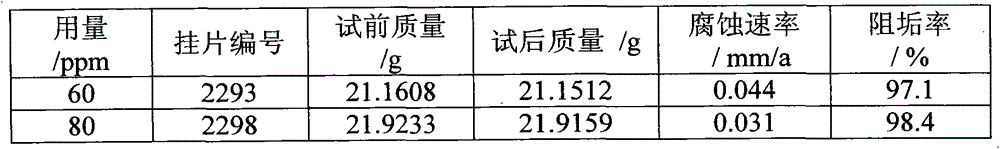

Efficient low-phosphorus corrosion and scale inhibitor

InactiveCN101560023AReduce phosphorus contentImprove performanceScale removal and water softeningAlkalinityTricarboxylic acid

The invention relates to a low-phosphorus compound corrosion and scale inhibitor and applications in the treatment of high-alkalinity and high-hardness circulating cooling water thereof. The efficient low-phosphorus corrosion and scale inhibitor is characterized by adding the following components according to the circulating water: 0.2-1.2mg / L of hydroxyethylidene diphosphonic acid, 0.125-1mg / L of 2-phosphonic acid-1,2,4-tricarboxylic acid, 0.14-1.2mg / L of sulphonate copolymer, 0.625-5mg / L of maleic acid-acrylic acid copolymer, 0-1.6mg / L of polyacrylic acid and 0-0.4mg / L of copper relief agent. The low-phosphorus compound corrosion and scale inhibitor can be used for the treatment of circulating cooling water, has the total phosphorus content less than or equal to 0.5mg / L in the circulating water, has the advantages of good comprehensive performance, excellent CaCO3 scale resistance function, corrosion inhibition performance and small dosage of less than or equal to 20mg / L under normal condition, is applicable to the treatment of circulating cooling water, and reduces the hazards of phosphorus emission on environment.

Owner:兰州华星高科技开发有限公司

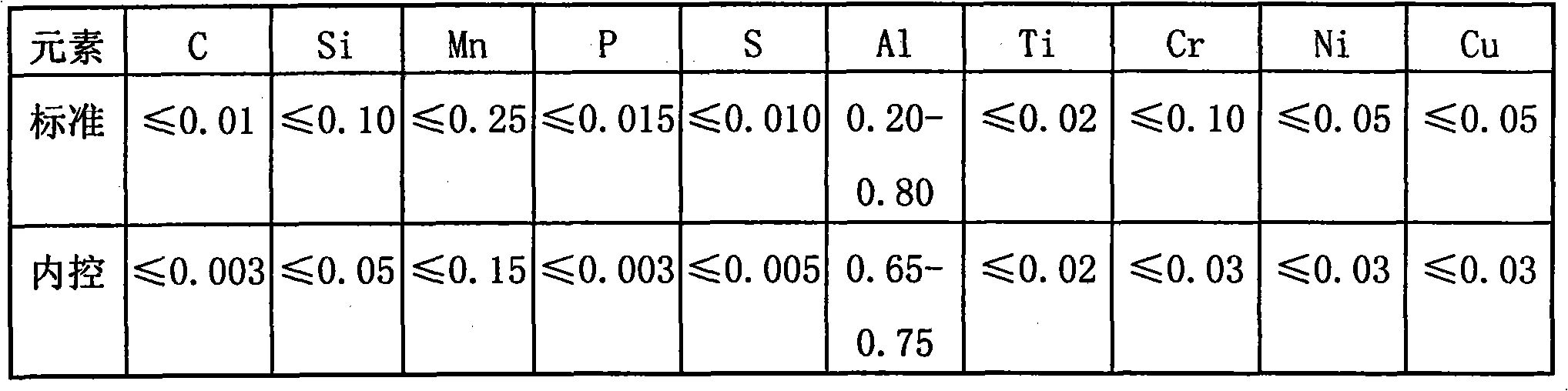

Tinning substrate for deep-punching food can and production method thereof

The invention relates to a steel metallurgical material, in particular to a tinning substrate for deep-punching food cans and a production method thereof. The tinning substrate comprises the following chemical element compositions in percentage by weight: less than or equal to 0.04% of C; less than or equal to 0.02% of Si, 0.20-0.25% of Mn, less than or equal to 0.02% of P, less than or equal to 0.018% of S, 0.005-0.040% of Als, and the balance iron and unavoidable inclusion. The production method comprises the following processes: smelting, continuous casting, heating, hot rolling, cooling and reeling, pickling and cold rolling, and annealing and leveling, wherein the heating temperature is 1210 DEG C, the primary rolling temperature is 1100-1150 DEG C, the final rolling temperature is 890+ / -10 DEG C, the reeling temperature is 560+ / -15 DEG C, the annealing temperature is 670-690 DEG C, and others are performed as conventional processes. The invention has small production control difficulty, low cost, stable performance and high can manufacturing percent of pass, and is suitable for manufacturing deep-punching food cans and can covers with more complex transformation.

Owner:TANGSHAN GUOFENG IRON & STEEL

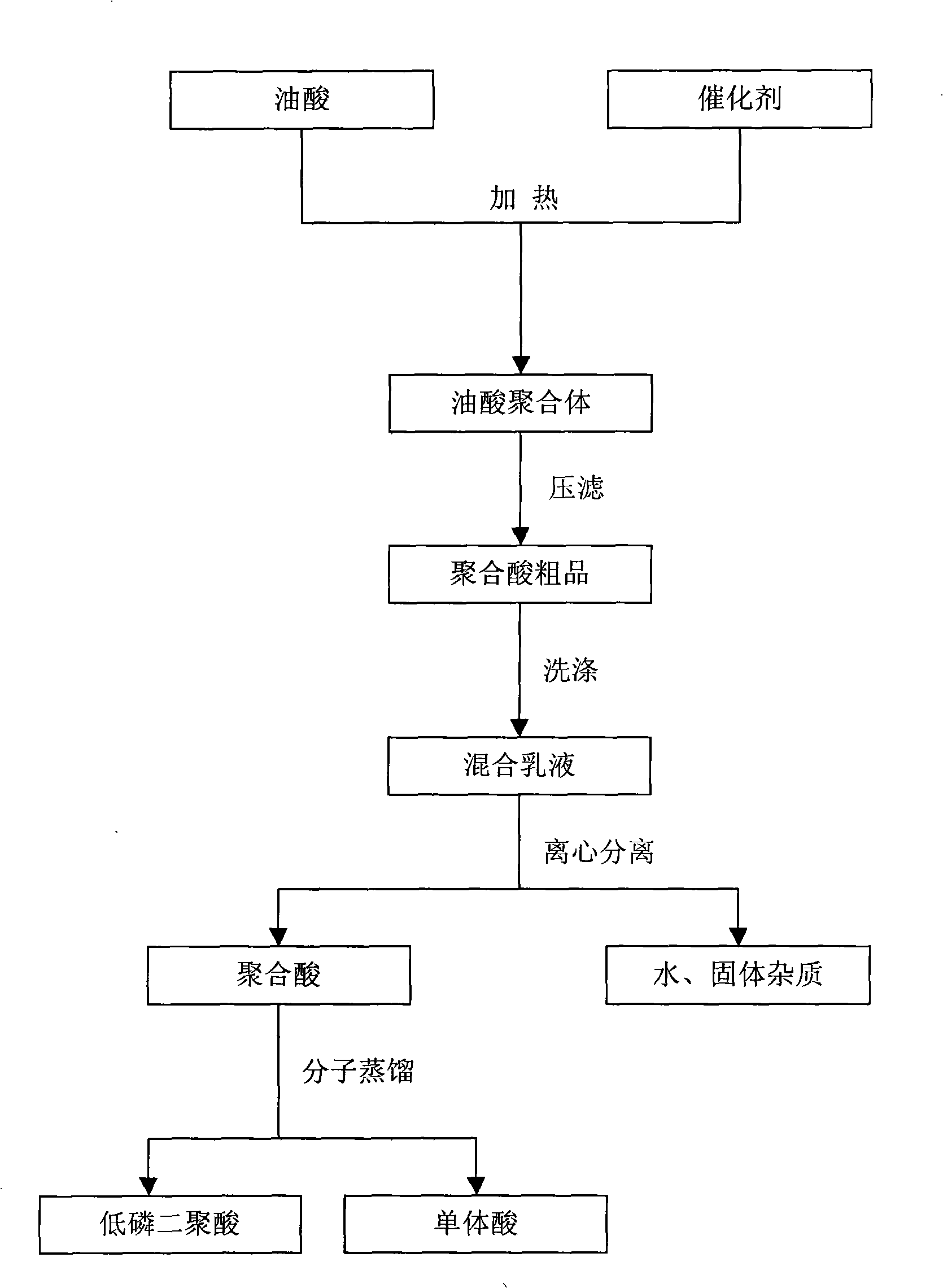

Method for producing low-phosphor dimer acid

ActiveCN101492358AImprove qualityContinuous separationOrganic compound preparationCarboxylic compound separation/purificationDistillationPhosphate

The invention relates to a method for producing low-phosphorous dimer acid and provides a method for producing dimer acid with low phosphor content. The method is characterized in that oleic acid is polymerized by catalysts of carclazyte, phosphoric acid and the like to obtain crude polymerized acid; the crude polymerized acid is washed by water; a centrifugal separation device is used for separating the polymerized acid from the water continuously to remove excessive phosphate and other filtered solid impurity to obtain low-phosphorous polymerized acid. The washing condition is as follows: the proportion of the polymerized acid and water (W / W) is 1: 0.1-10; the washing temperature is 10 DEG C to 100 DEG C; and the washing time is 0.1h to 3h. Molecular distillation is carried out on the low-phosphorous polymerized acid to obtain the low-phosphorous dimer acid and a side product of monomer acid. The invention increases the working procedures of washing and separating, thereby ensuring that the content of the phosphate of the dimer acid is reduced to be lower than 30mu g / g, reducing the content of the impurity in the dimer acid and improving the quality of the dimer acid and the downstream product.

Owner:YIHAI TIANCHENG LIANYUNGANG CHEM INDSCO

Adsorption material for treating phosphorus wastewater and use thereof

ActiveCN102151548AHigh removal rateLow costOther chemical processesWater/sewage treatment by sorptionContact timeWastewater

The invention relates to an adsorption material for treating phosphorus wastewater and use thereof. The adsorption material consists, by mass percent, of 50 to 70% of flyash zeolite and 30% to 50% of natural zeolite and is prepared by homogenously mixing the flyash zeolite with the natural zeolite based on the above proportion, the above resultant adsorption material is added, with the mass ratio of phosphorus to the adsorption material being 1: 100 to 200, to phosphorus wastewater with the pH from 3 to 10 and the phosphorus concentration from 0 to 150mg / l in order to treat the phosphorus wastewater, the contact time is 1 hour, the removal rate of phosphorus is larger than 90%, and the pH of zeolite subsequent to treatment is close to be neutral. The flyash zeolite resulting from modified synthesis in the invention not only has significant phosphorus adsorption effect, but can also realize the effective utilization of wastes to reduce the pollution of flyash to environment. Mutual combination of the flyash zeolite and the natural zeolite results in synergistic action for phosphorus adsorption, reducing the content of phosphorus in wastewater effectually. Therefore, the adsorption material of the invention for treating phosphorus wastewater has the advantages that the adsorption capacity is high, the utilization of wastes is favorable for environmental protection and the like.

Owner:HUBEI FORBON TECH

Method for ultra-deeply dephosphorizing in steel ladle

The invention discloses a method for ultra-deeply dephosphorizing in a steel ladle, which comprises the following steps in turn: (1) blowing in a converter in a normal mode, and before steel tapping of the converter, adding 7 to 9 kilograms of lime, 1.5 to 2.0 kilograms of fluorite and 3 to 5 kilograms of carbon steel dust-free briquette into each ton of molten steel in the steel ladle; (2) when steel is tapped from the converter, keeping the oxygen content of the molten steel less than 0.065 percent and the phosphorus content not more than 0.015 percent, preventing the molten steel from being deoxidized and alloyed, blowing argon at the bottom of the steel ladle and stirring in the whole steel tapping process, and keeping the blowing gas supply strength at the bottom of the steel ladle is 3.0 to 6.0L / min.t; and (3) blocking slag in steel tapping with the slag takeover being not more than 6kg / t and the temperature of the molten steel in the steel ladle not above 1,590 DEG C after the steel tapping, drossing with the slag content of the molten steel not more than 0.2 percent and after the drossing, heating the molten steel, deoxidizing, alloying and refining. When the method for ultra-deeply dephosphorizing in a steel ladle is used, the phosphorus content of the finished steel is as low as less than 0.003 percent.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Multi-component corrosion and scale inhibitor

ActiveCN104609579AReduce phosphorus contentReduce dosageScale removal and water softeningOrganic solventMolybdate

The invention relates to a corrosion and scale inhibitor, which comprises a component A and a component B, wherein the component A comprises an organic phosphine compound, a multipolymer dispersant and deionized water; the component B comprises polyphosphate, inorganic zinc salt and molybdate, wherein the mass ratio of the component A to component B is 2:1-1:2. The corrosion and scale inhibitor also comprises a component C, wherein the component C comprises an azole compound, a hydroxide, an organic solvent and deionized water. Compared with a traditional single liquid corrosion and scale inhibitor, the corrosion and scale inhibitor of the invention has strong composite formula adaptability, ratio and dilution times can be timely adjusted according to client on-site water quality; for the terminal clients, storage space is saved, transport cost is reduced, and usage cost of its agent is reduced simultaneously.

Owner:OCHEMATE MATERIAL TECH CO LTD

Process for water body repairing by microorganism film biologic chinampa for large type water body pollution treatment

InactiveCN1693236APlay a sustained and effectivePromote repairBiological water/sewage treatmentEutrophicationHazardous substance

Owner:杨发明

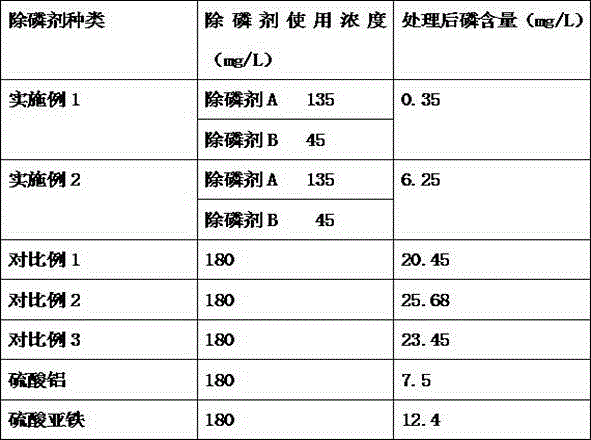

Domestic sewage phosphate removing agent

ActiveCN106430504AImprovement of Phosphorus RemovalReduce phosphorus contentWater contaminantsWater/sewage treatmentAluminium saltsPolyvinyl alcohol

The invention relates to a domestic sewage phosphate removing agent which includes a phosphate removing agent A and a phosphate removing agent B. The phosphate removing agent A is prepared from, by weight, 6.25 parts of polymeric aluminum, 5.42 parts of attapulgite, 2.15 parts of aluminum sulfate and 2.36 parts of ferrous sulfate. The phosphate removing agent B is prepared from, by weight, 1.85 parts of polymeric aluminum, 6.4 parts of polyvinyl alcohol and 2.15 parts of ferrous sulfate. According to the domestic sewage phosphate removing agent A and domestic sewage phosphate removing agent B, raw materials contain common water treatment agents, phosphate removing effect of the phosphate removing agent is greatly improved under PH (potential of hydrogen) conditions of the phosphate removing agent after the phosphate removing agent is compounded, high-phosphorus domestic sewage is treated by the method, and the content of phosphate in the treated sewage can be reduced to 0.25mg / L and reaches or is lower than national standards.

Owner:XINGAN ANHUI ELECTRIC LTD BY SHARE LTD

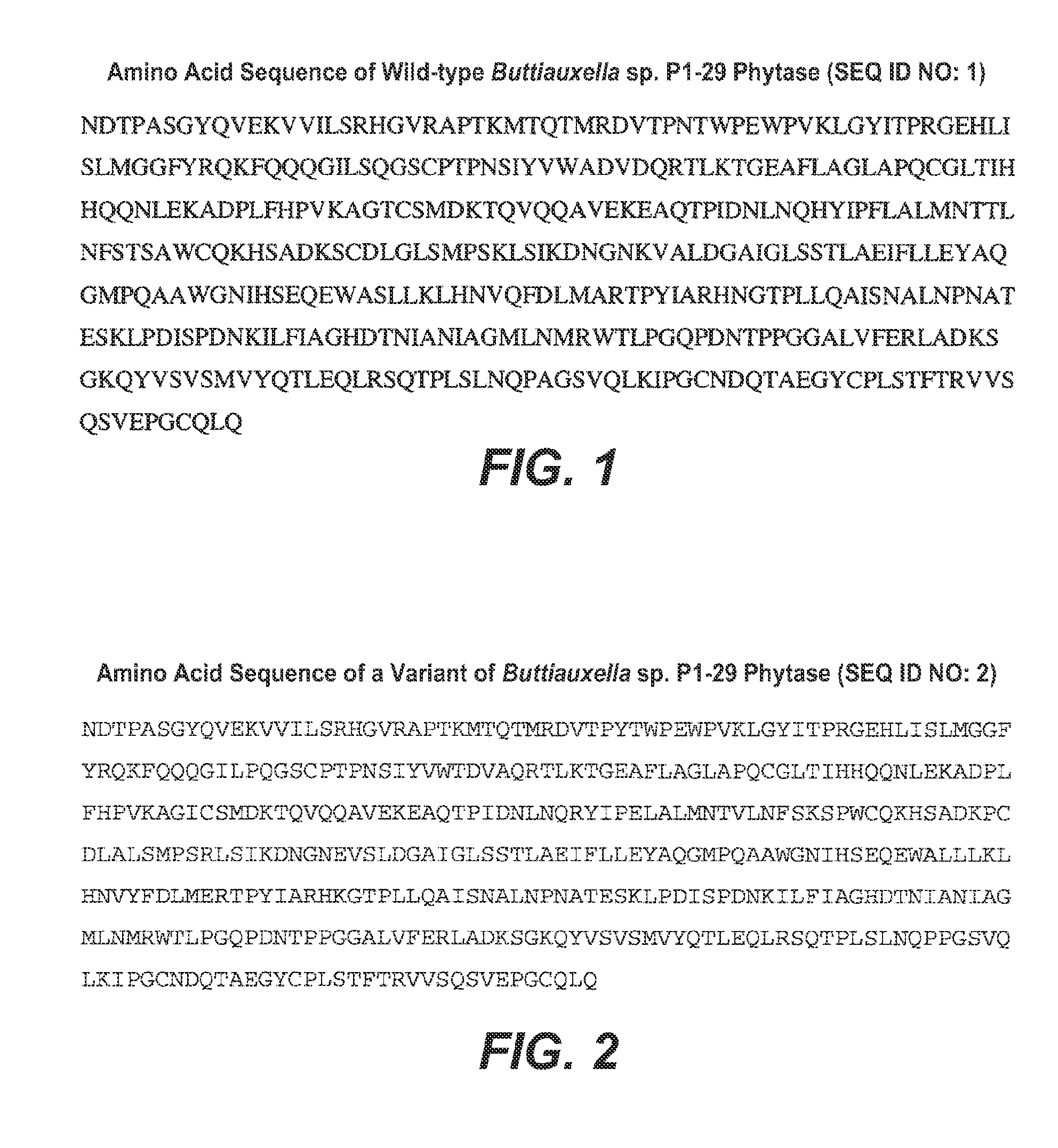

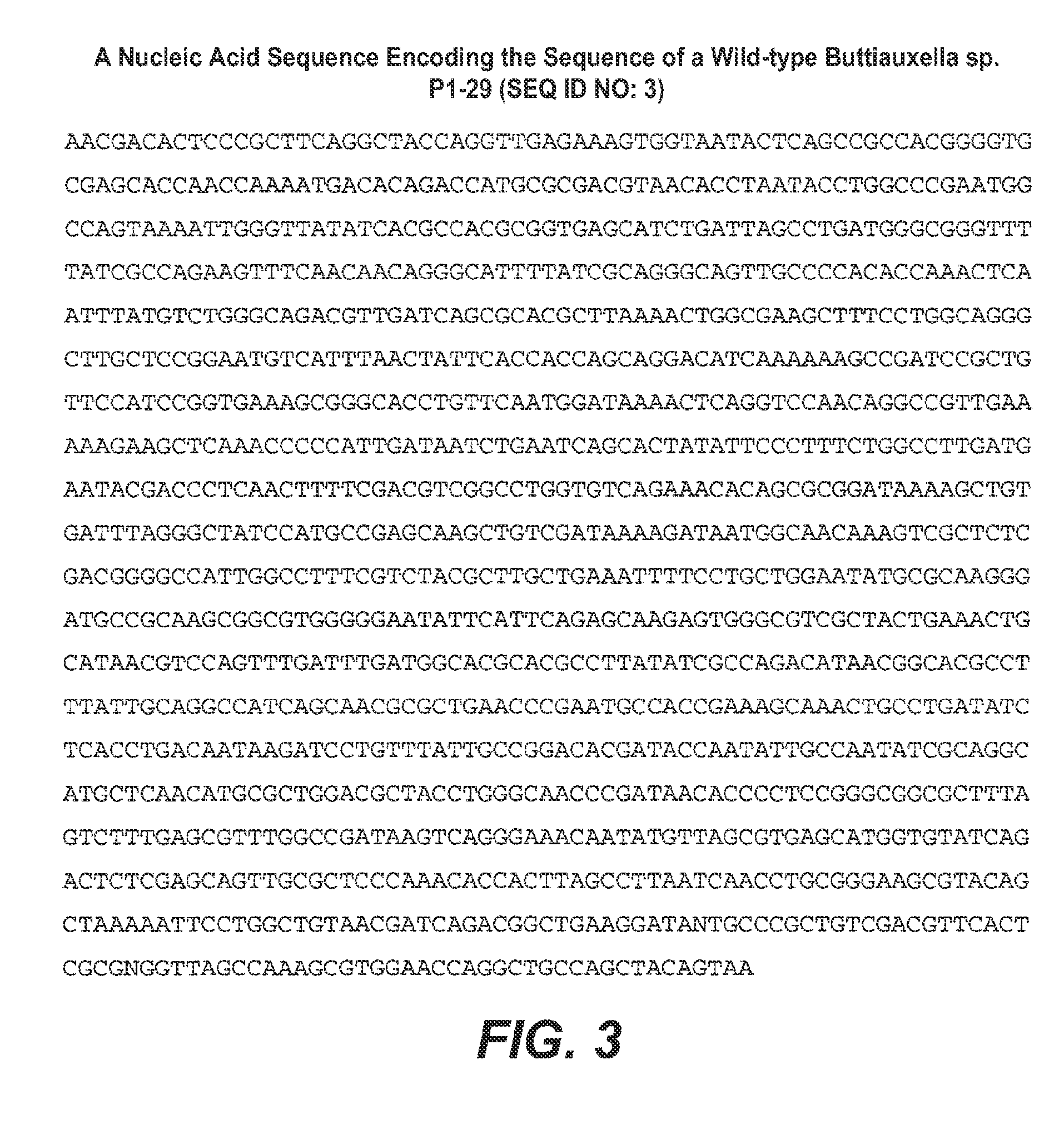

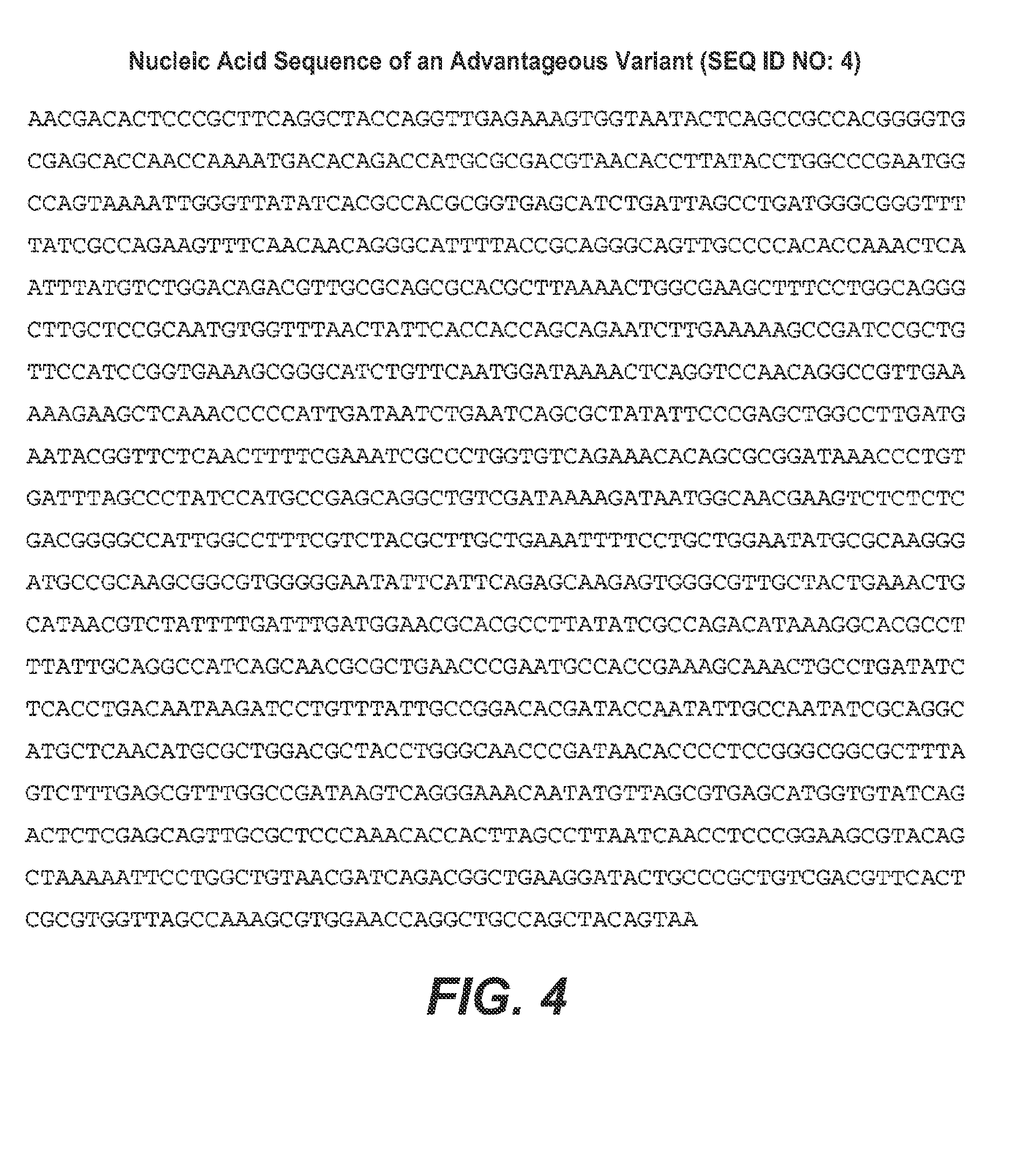

Buttiauxella sp. phytase variants

Owner:DANISCO US INC

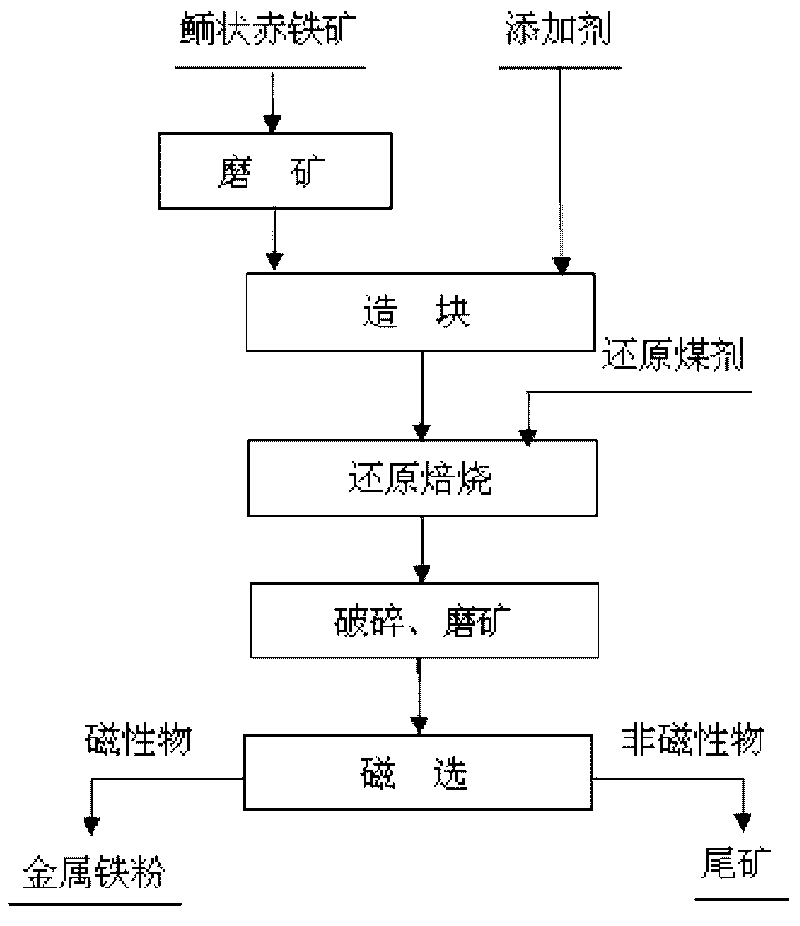

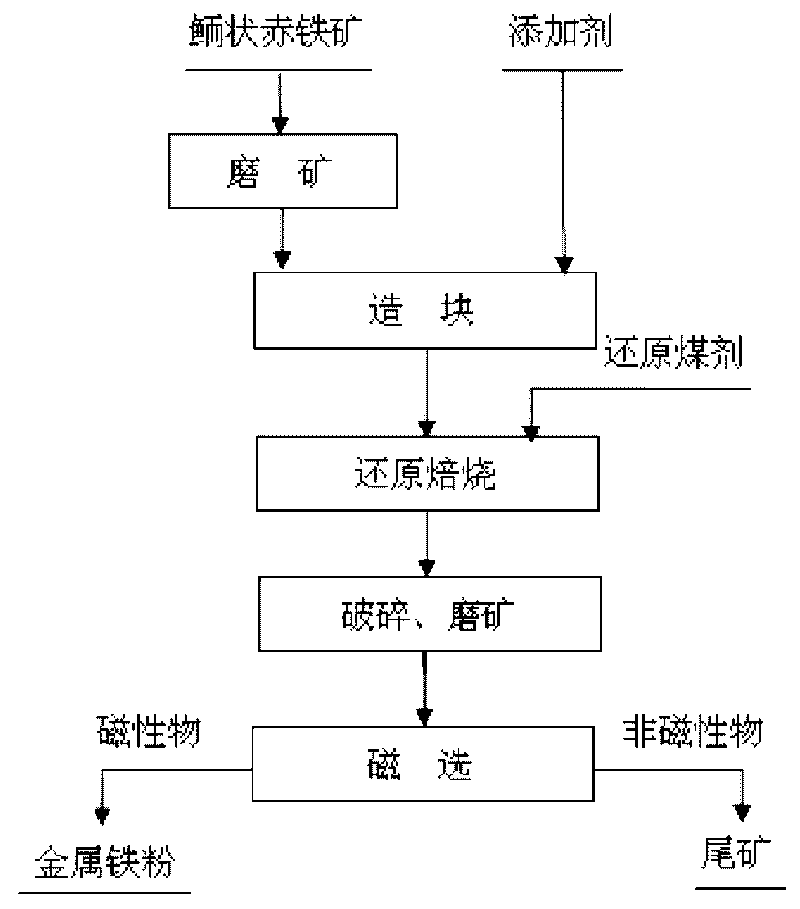

Method for preparing steel smelting furnace materials from phosphorus-containing globulitic hematite

The invention discloses a method for preparing steel smelting furnace materials from a phosphorus-containing globulitic hematite. The method comprises the following steps: adding adhesives with certain proportion into a globulitic hematite which is broken and grinded to the granularity smaller than 0.074mm and has the mass percentage of 50% to 60%, mixing evenly, then, agglomerating, reducing and sintering dried blocks with coal as reducing agent with the sintering temperature of 1000 to 1050DEGC and with the time of 2 to 1.5h, breaking and grinding cooled reduced blocks to smaller than 0.074mm with the mass percentage of 80% to 90%, magnetically selecting and separating the blocks with the magnetic field intensity of 0.1 to 0.12T, and obtaining the metal iron powder, wherein the adhesive is mixed by sodium sulfate powder, solubor, natrium humate and sodium xanthonate, the mass percentage of sodium sulfate powder in the hematite is 5% to 8%, the mass percentage of solubor in the globulitic hematite is 1% to 2%, the mass percentage of natrium humate in the globulitic hematite is 0.5 % to 1%, and the mass percentage of sodium xanthonate in the globulitic hematite is 0.5 % to 1%. The method has high utilization efficiency, excellent dephosphorization effect, excellent product quality, high iron recovery rate, low cost and low environment pollution.

Owner:CENT SOUTH UNIV

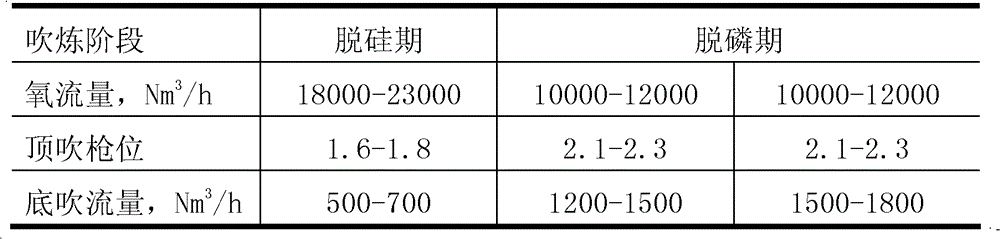

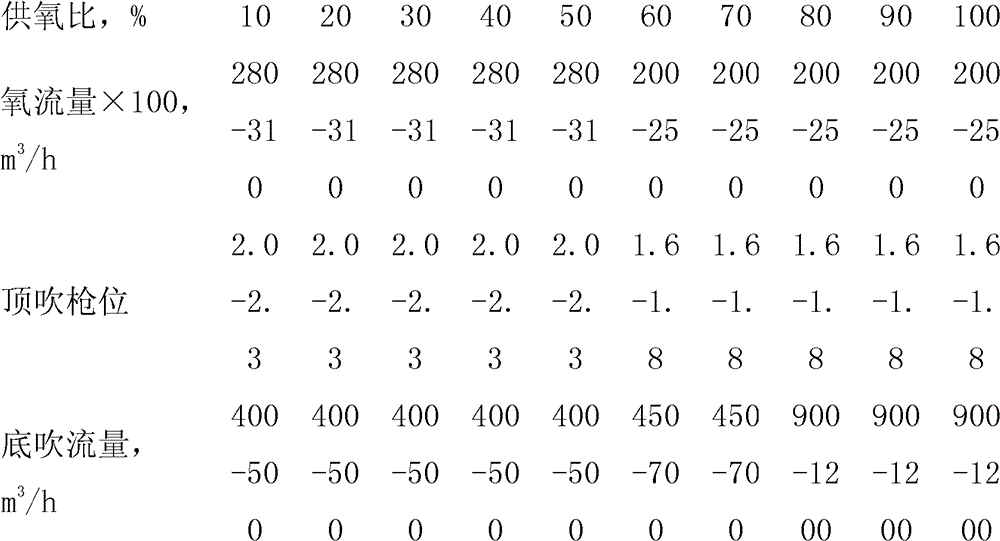

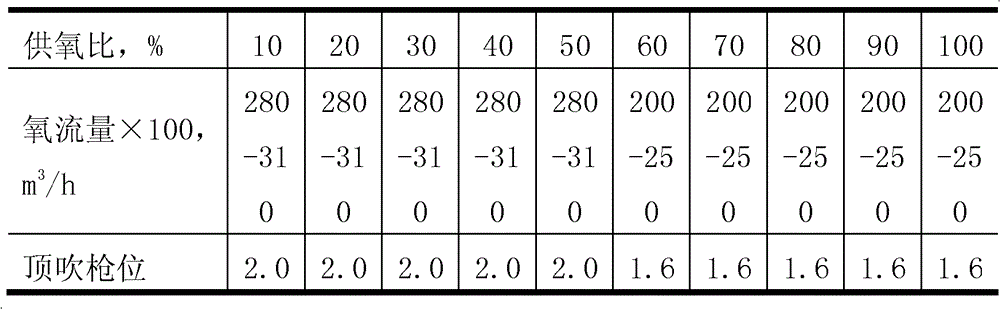

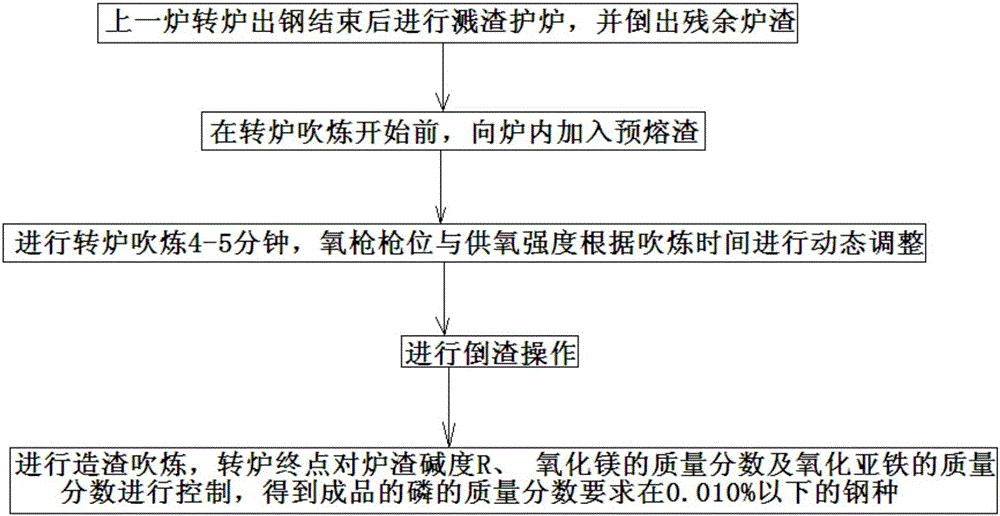

Smelting method of converter efficient dephosphorization

ActiveCN105671248AImprove dephosphorization efficiencyReduce phosphorus contentManufacturing convertersProcess efficiency improvementSlagFerrous metallurgy

The invention discloses a smelting method of converter efficient dephosphorization and belongs to the technical field of ferrous metallurgy. The smelting method of converter efficient dephosphorization comprises the following steps that after the last time of converter steel tapping, slag splashing furnace protection is conducted, and residual slag is poured out; before converter blowing is started, pre-melted slag is added into a converter; converter blowing is conducted for 4-5 minutes, the oxygen lance position and the oxygen supply intensity are adjusted dynamically according to blowing time; slag pouring operation is conducted; and slag-forming blowing is conducted, at the converter endpoint, the slag basicity R, the mass fraction of magnesium oxide and the mass fraction of ferrous oxide are controlled, and finished steel of which the phosphorus mass fraction is required to be 0.010% or below is obtained. Through the smelting method of converter efficient dephosphorization, the converter dephosphorization efficiency can be effectively improved, the phosphorus content at the converter endpoint is lowered, and the cost is low.

Owner:SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com