Convertor smelting technology method for producing low-phosphorous steel

A converter smelting and process method technology, applied in the manufacture of converters, etc., can solve the problem of in-depth dephosphorization without more detailed research reports, and achieve the effect of reducing raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

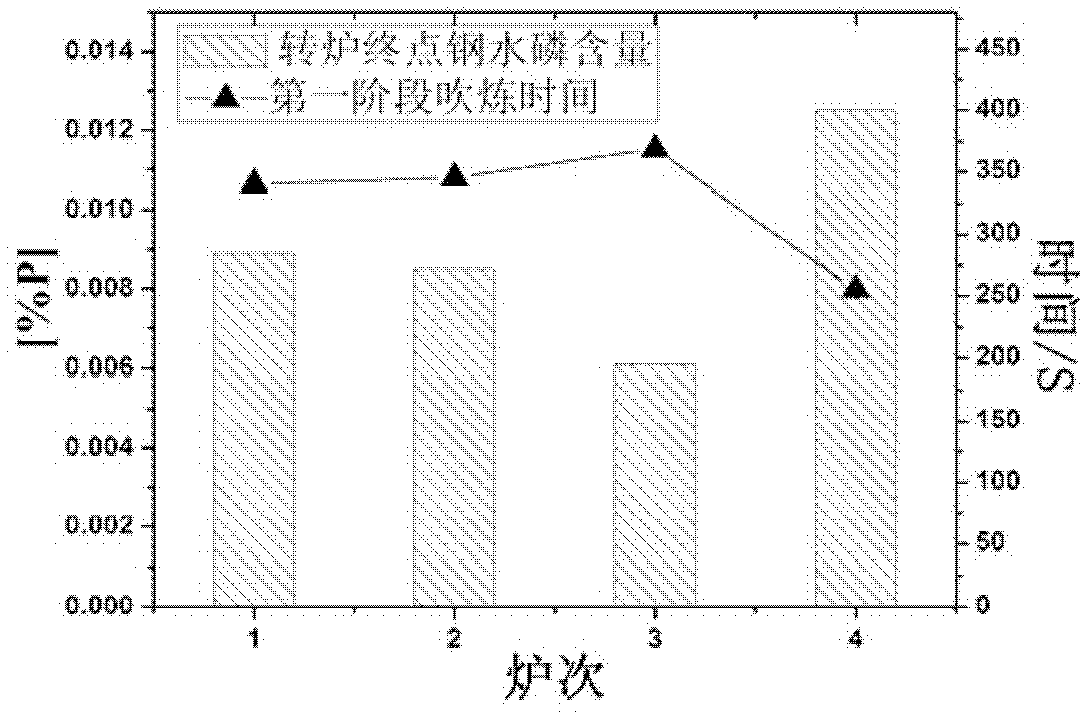

[0017] The initial phosphorus content of molten iron [%P]=0.0785, the temperature T=1305℃, and the oxygen supply in the early stage blowing is 3900Nm 3 , the amount of lime is 2.5t, the amount of iron ore is 2.0t, the amount of dolomite is 0.5t, the blowing time is 340 seconds, and the P 2 o 5 The percentage content is 3.71, 2.0t of lime and 1.5t of dolomite are added in the second stage of blowing, the molten steel at the end of the converter [%P]=0.0089, the temperature T=1689℃, and the final slag P 2 o 5 The percentage content is 1.66.

Embodiment 2

[0019] The initial phosphorus content of molten iron [%P]=0.0787, the temperature T=1255°C, and the oxygen supply in the early stage blowing is 3900Nm 3 , the amount of lime is 4.0t, the amount of iron ore is 1.5t, the blowing time is 345 seconds, and the P 2 o 5 The percentage content is 3.60, 2.5t of lime and 1.5t of dolomite are added in the second stage of blowing, the molten steel at the end of the converter [%P]=0.0085, the temperature T=1692℃, and the final slag P 2 o 5 The percentage content is 1.67.

Embodiment 3

[0021] The initial phosphorus content of molten iron [%P]=0.0804, the temperature T=1281℃, and the oxygen supply in the early stage of blowing is 4000Nm 3 , the amount of lime is 3.0t, the amount of iron ore is 1.0t, the amount of dolomite is 0.5t, the blowing time is 368 seconds, and the P 2 o 5 The percentage content is 3.26, 2.5t of lime and 2.0t of dolomite are added in the second stage of blowing, the molten steel at the end of the converter [%P]=0.0061, the temperature T=1658℃, and the final slag P 2 o 5 The percentage content is 1.79.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com