Patents

Literature

206results about How to "Good dephosphorization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Converter oxide and nitrogen top-blown dephosphorizing method

InactiveCN1552919AHigh carbon contentInhibition of decarburization reactionsManufacturing convertersSputteringSlag

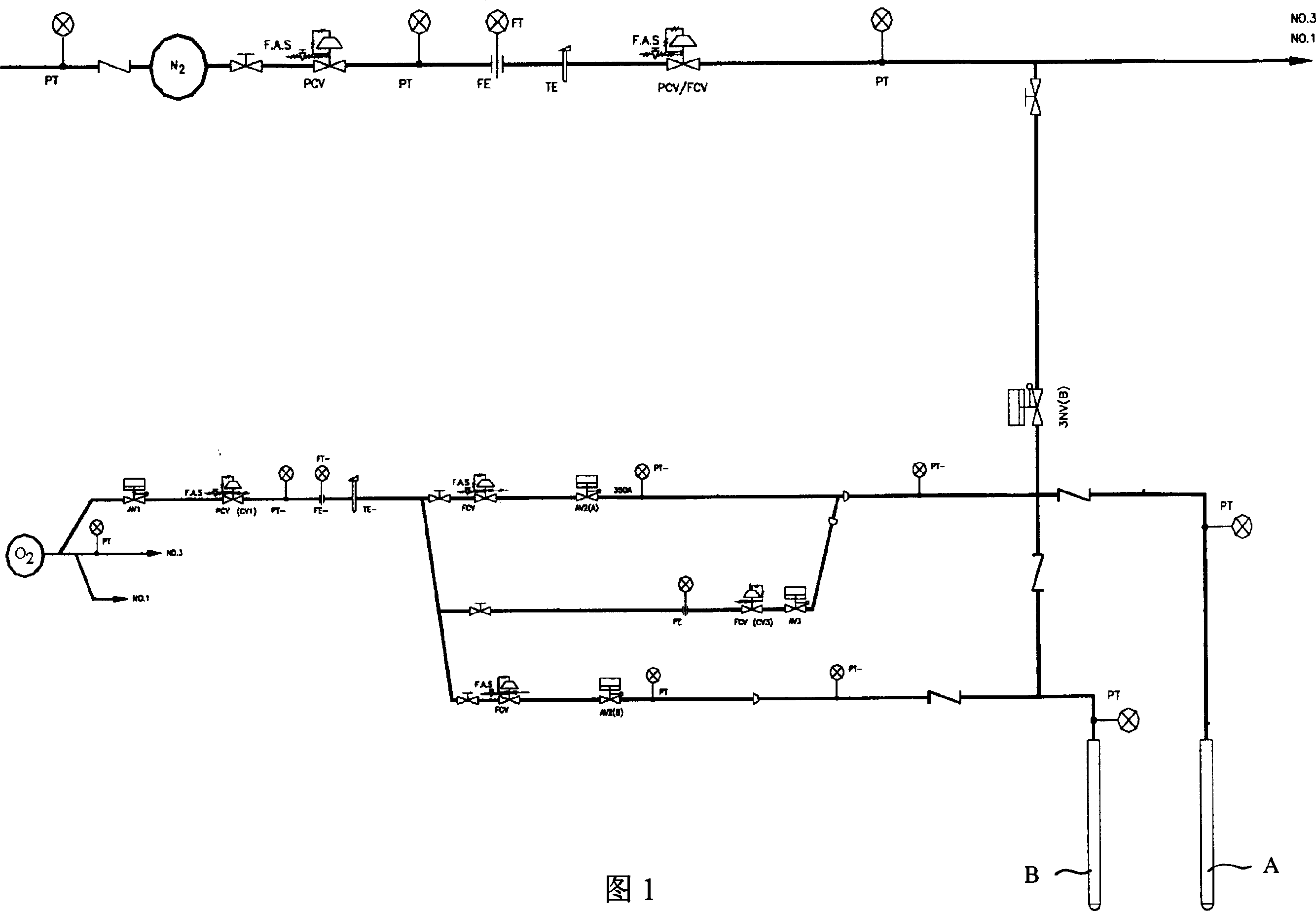

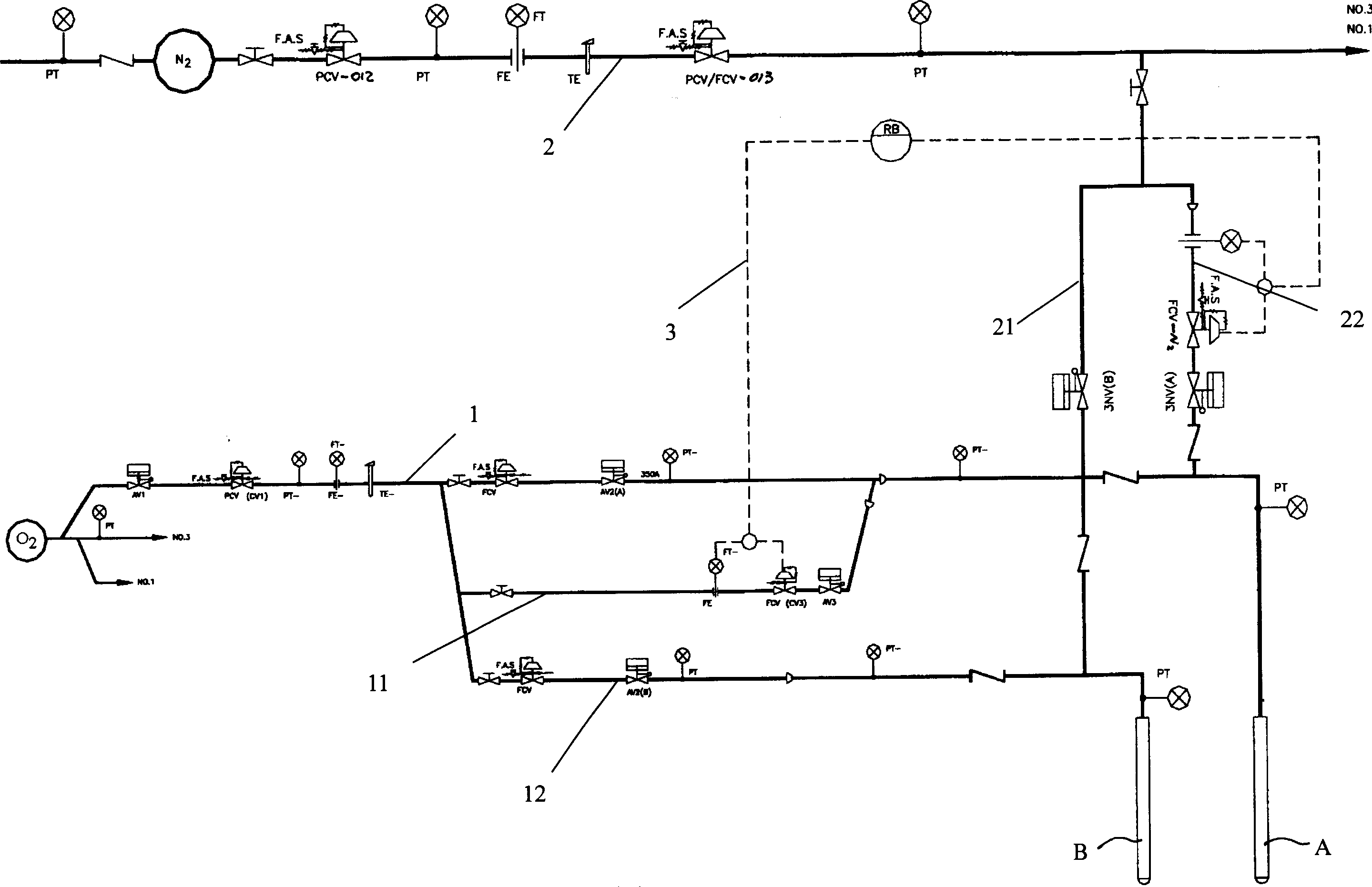

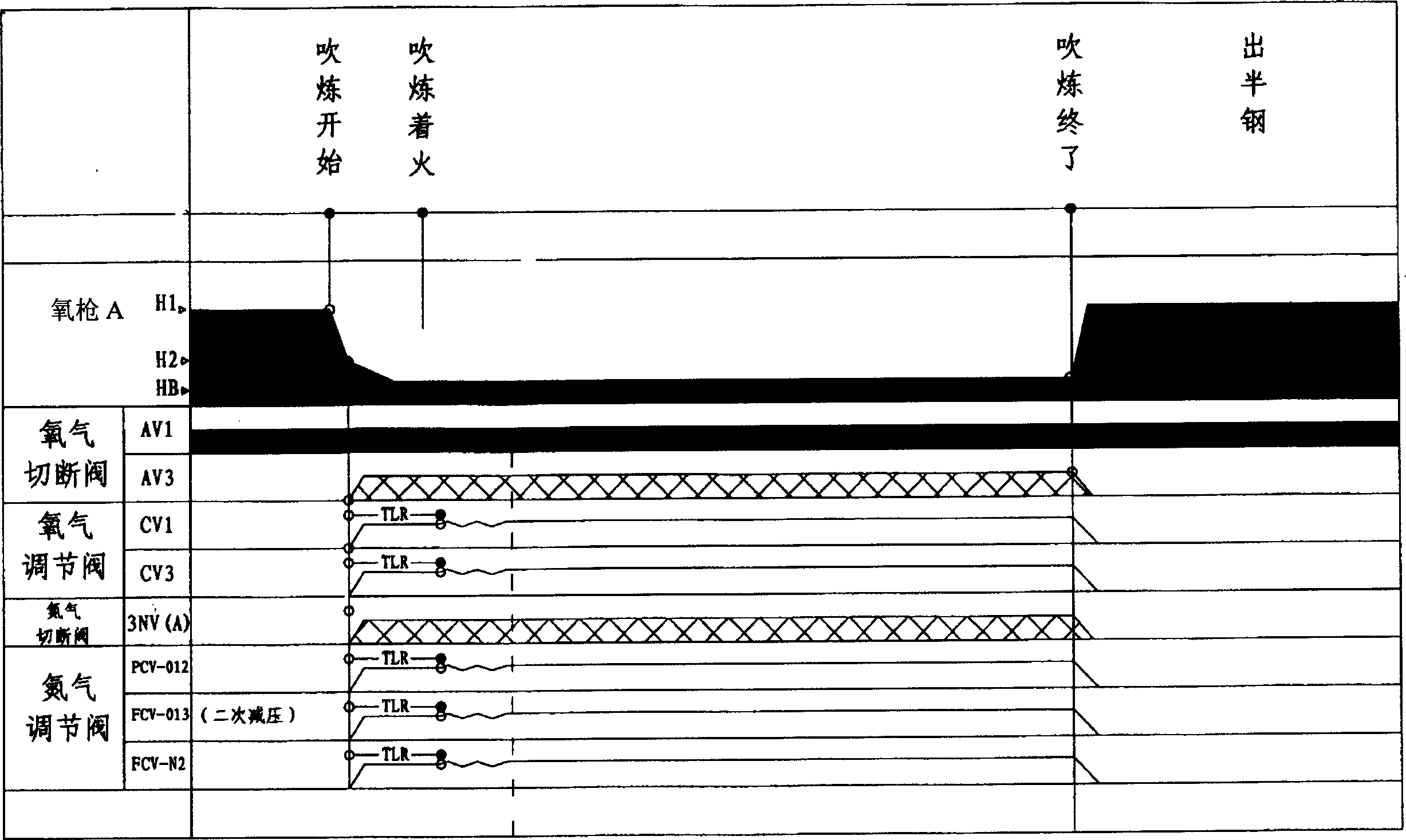

An oxygen-nitrogen top blowing converter process for desulfurization is carried out by blowing oxygen-nitrogen at its top while blowing nitrogen or inertial gases at its bottom to desulfurise. Its top blowpipe controls oxygen blowing to desulfurise in two modes, with mixed gases at some ratio or with pure oxygen switched with pure nitrogen, in order to inhibit sputtering and to enhance stirring in smelting pool when sputter occurs by excessive oxidation, so that balance of (P) / [P] in dynamics is improved. It desulfurises better when bottom blowing is weak, can inhibit decarbonise reaction effectively with >70% recovery of Mn in molten iron, also, strengthen blowing at top to stir strongly and shorten pre-treat time, increase rate of desulfurization, control slag elimination in procedure effectively to prevent sputtering, and increase stability and security.

Owner:BAOSHAN IRON & STEEL CO LTD

Convertor steelmaking method capable of reducing slag quantity

ActiveCN102212640AProtective liningReduce metal splashManufacturing convertersProcess efficiency improvementDolomiteScrap

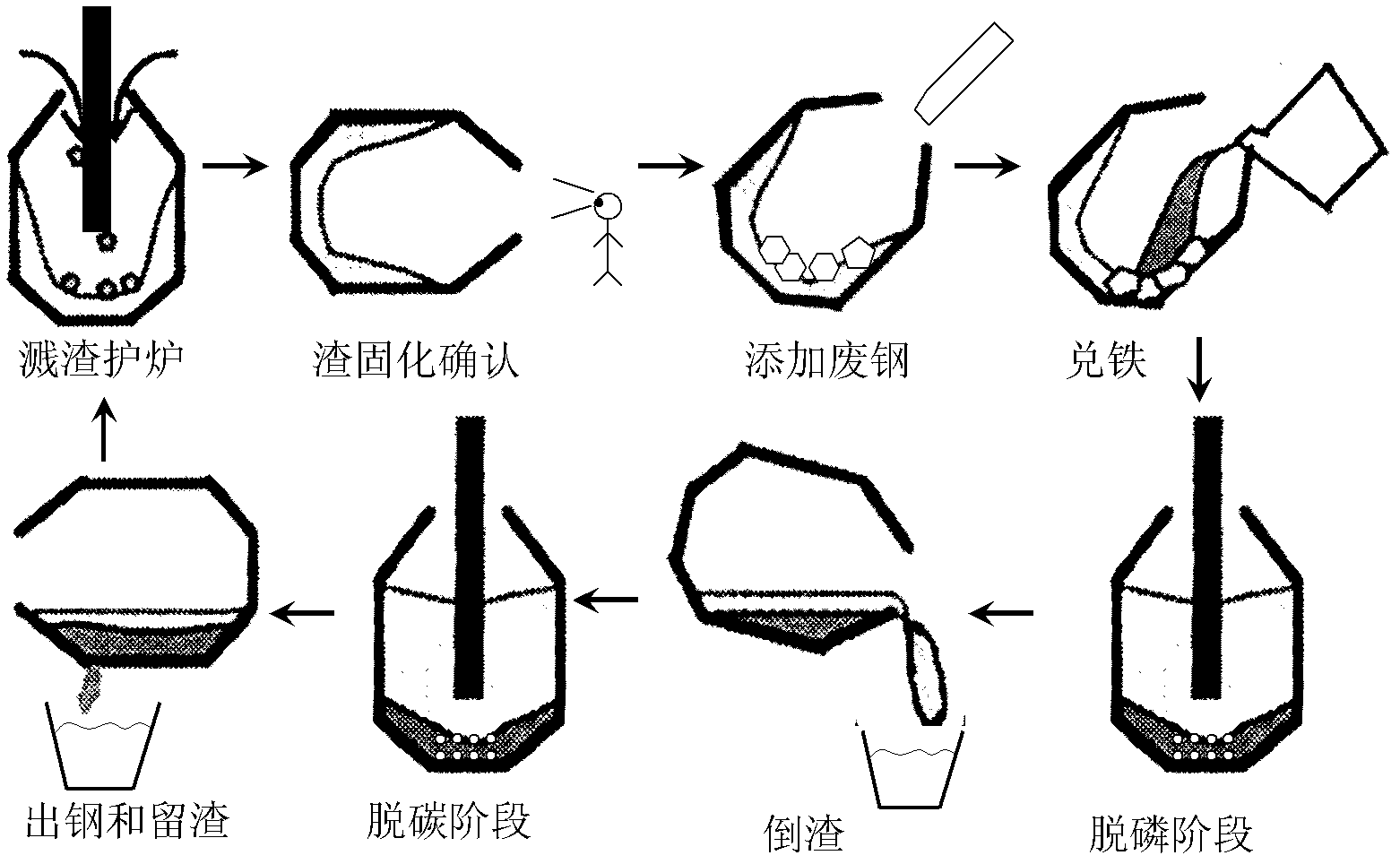

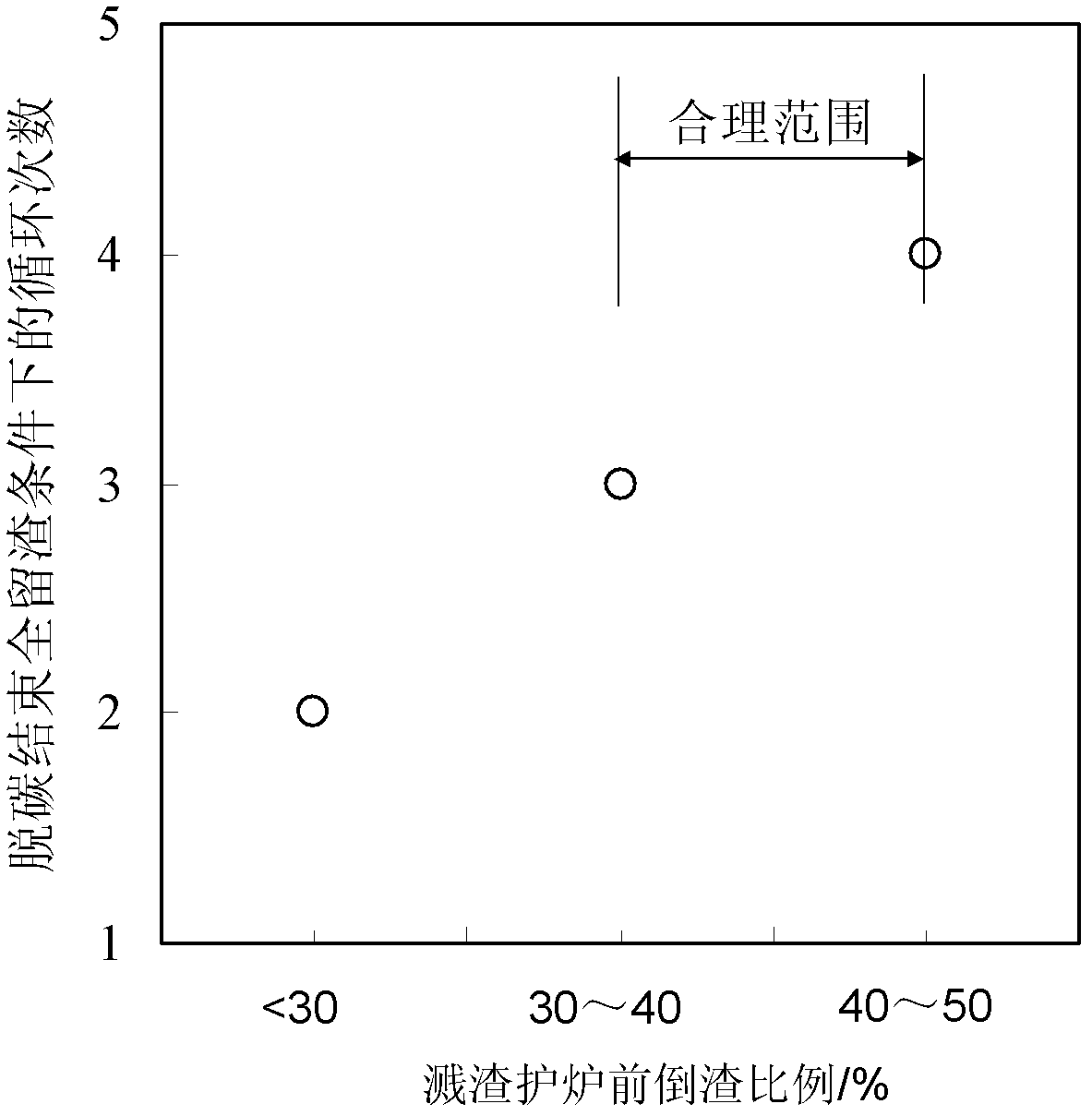

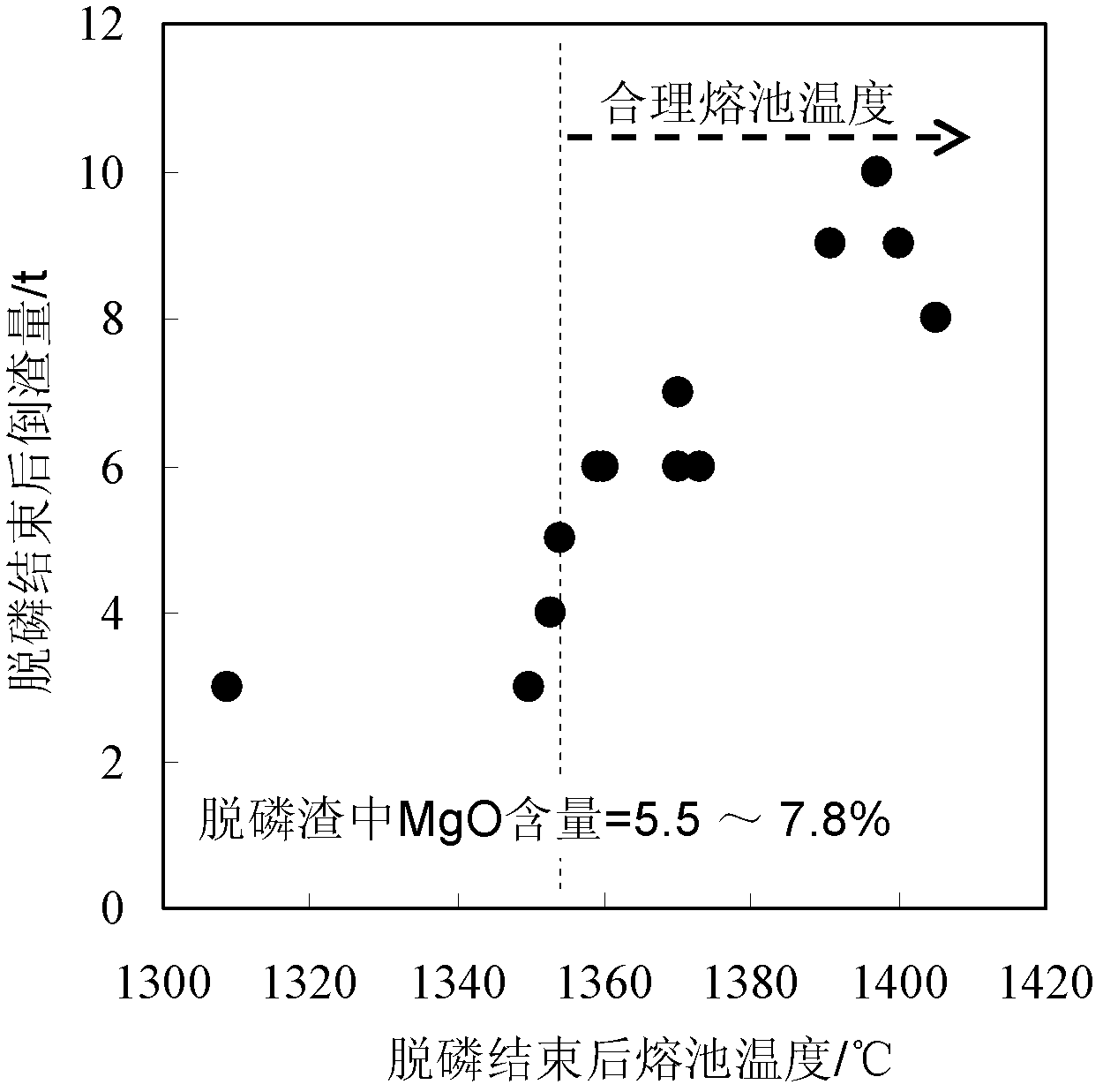

The invention belongs to the technical field of convertor steelmaking, and provides a convertor steelmaking method capable of reducing slag quantity. The process flow disclosed by the invention is circular process flow starting with step of protecting a furnace by slag splashing and ending with the step of remaining slag in the furnace. The process flow specifically comprises the following eight stages: protecting a furnace by slag splashing; curing liquid slag in the furnace; adding scrap steel; adding molten iron; blowing-dephosphorizing at a first stage; deslagging in the middle; blowing-decarbonizing at a second stage; tapping; and remaining slag in the furnace. Compared with the conventional convertor steelmaking process, the convertor steelmaking provided by the invention has the beneficial effects that lime consumption is lowered by 40.5%, light-roasting dolomite consumption is lowered by 76.8%, and the total consumption of the lime and light-roasting dolomite is lowered by 55.5% on the premise that phosphorus content at the end point is not more than 0.015%.

Owner:SHOUGANG CORPORATION

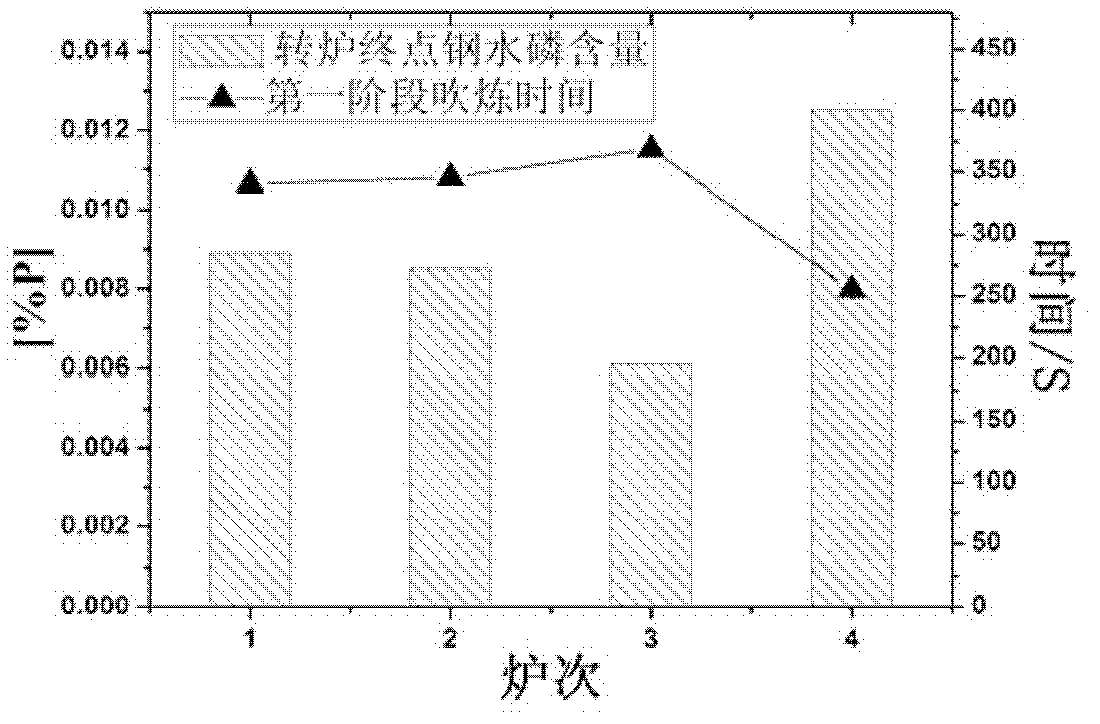

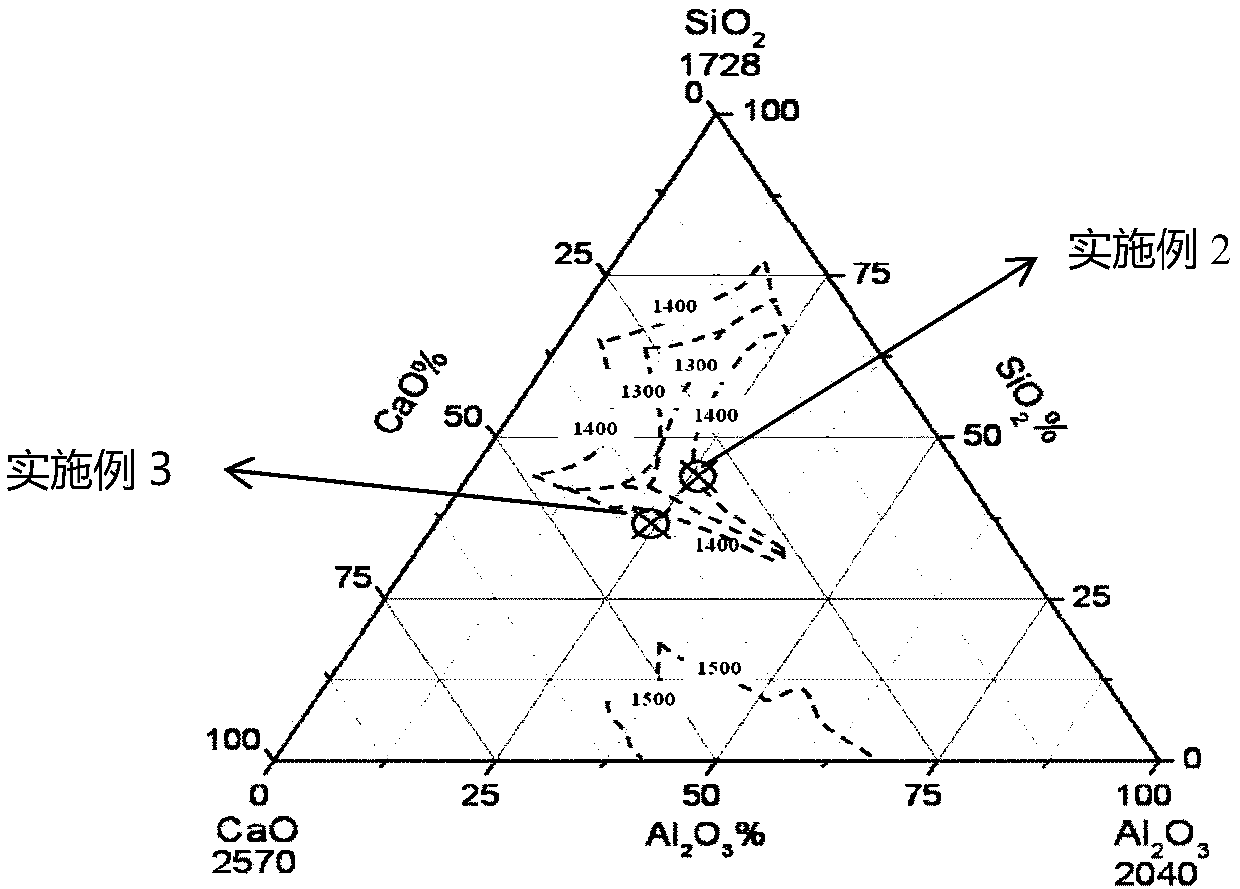

Convertor smelting technology method for producing low-phosphorous steel

InactiveCN102358912AReduce consumptionReduce water phosphorus contentManufacturing convertersSteelmakingMetallurgical industry

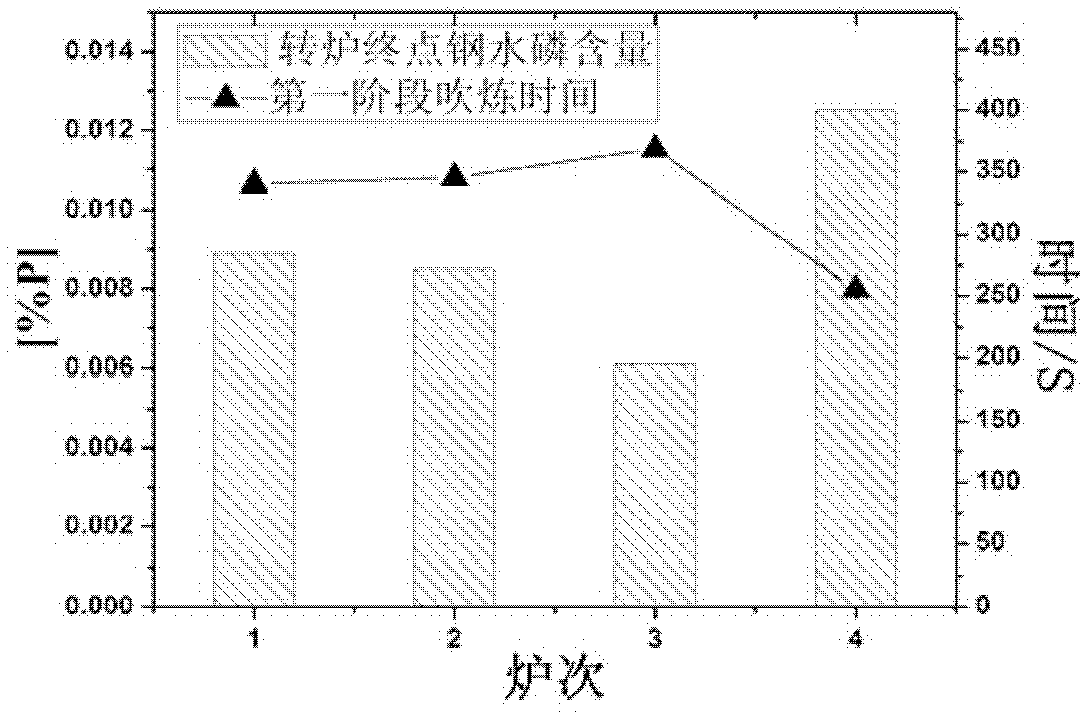

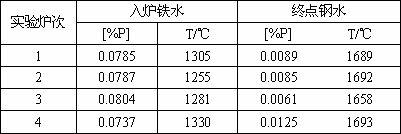

The invention relates to the technical field f convertor steel making in metallurgy industries, in particular to a method for smelting low-phosphorous steel through combined steel-tapping slag-left and double slag process technology, which aims at providing convertor technology for producing the low-phosphorous steel. The method prolongs previous dephosphorization blowing time, thereby prolonging reaction time of steel slag in a previous blowing stage, improving reaction temperature of dephosphorization steel slag in previous blowing, improving dynamics and thermodynamics conditions of steel slag reaction, improving dephosphorization effect in previous blowing and enabling phosphorus in steel liquid to be absorbed in slag as much as possible. Slag with high P2O5 content is poured out of a convertor so as to reduce phosphorus content of the whole convertor system, providing favorable conditions for dephosphorization in a later decarburization blowing stage and achieving the purpose of producing the low-phosphorous steel. Compared with other methods for producing the low-phosphorous steel, the method for producing the low-phosphorous steel has the advantages of being simple in operation methods, low in cost, easy to obtain and the like.

Owner:UNIV OF SCI & TECH BEIJING

Aluminum industrial red mud-based dephosphorizing agent for converter steelmaking and preparation method thereof

InactiveCN103725825AMeet general requirementsReduce phosphorus contentManufacturing convertersSteelmakingRed mud

The invention discloses an aluminum industrial red mud-based dephosphorizing agent for converter steelmaking and a preparation method thereof, belonging to the field of converter steelmaking. The dephosphorizing agent is mainly prepared from the following raw materials by mass percent: 50-70% of dried red mud, 5-15% of lime, 15-30% of iron ore concentrate or iron sheet ball, 2-10% of light roasting dolomite, and 0.5% of binding agent. The dephosphorizing agent is prepared by the following steps of crushing the raw materials, mixing uniformly, pressing into chunks, roasting for 2-4 hours at 300-500 DEG C, cooling down, and then crushing into the dephosphorizing agent with grain size of 15-30mm. The dephosphorizing agent is added in dephosphorizing step in steelmaking by the converter, can be used for processing molten iron with middle or low content of phosphorus, and can remove more than 90% of phosphorus. By utilizing large amount of CaO and Fe2O3 in the red mud, the dephosphorizing agent not only has good dephosphorizing effect, but also solves the problem of red mud pollution, thus recycling the red mud and lowering the cost for steelmaking.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

RH injection refining device and application thereof

The invention provides an RH injection refining device and application thereof. The device comprises an RH ascending pipe and an RH descending pipe; pipe walls of the RH ascending pipe and the RH descending pipe are provided with through holes which are connected with an external air supply or a feeding device by spraying pipes. A method of removing small inclusions by using the device comprises:after deoxidation alloying, blowing inert gas into the descending pipe by using the spraying pipes, wherein the gas flow is 10-500L / min and air pressure is 1.0-15atm; or blowing carbonate power into steel liquid, wherein the particle size of the powder is less than 3mm, the feeding rate is 1-100kg / ton steel, the carrier is Ar, N2 or CO2 inert gas, the gas flow is 10-800L / min, and air pressure is 1.0-20atm. The invention has the characteristics of simple equipment, convenient operation, reasonable process, low cost, and good effect. The invention has the advantages of effectively removing small inclusions from steel, regulating alloying elements, manufacturing dispersion steel of small oxide, and achieving the aims of decarburization, desulfurization, dephosphorization, steel slag modification and the like.

Owner:ANGANG STEEL CO LTD

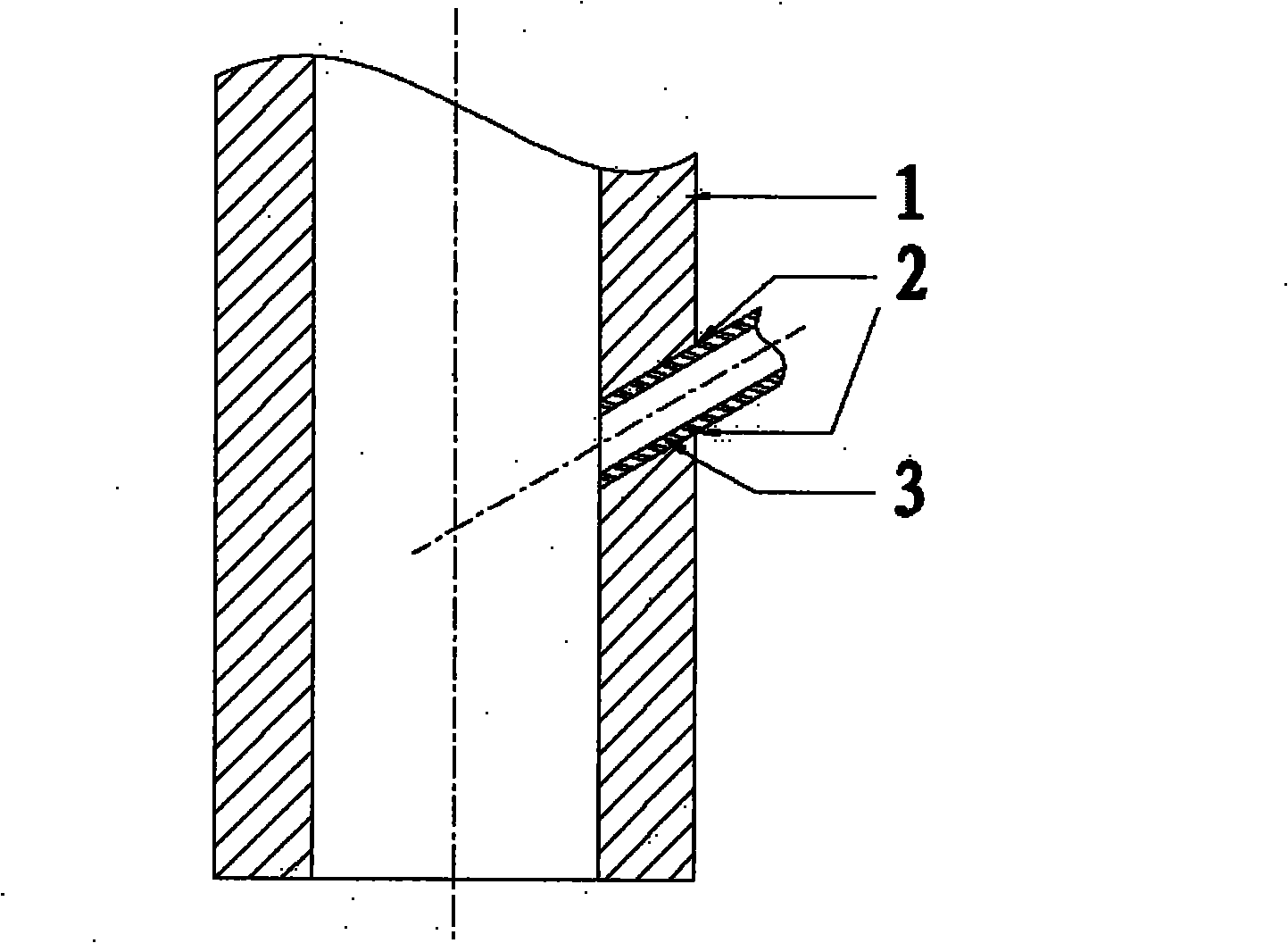

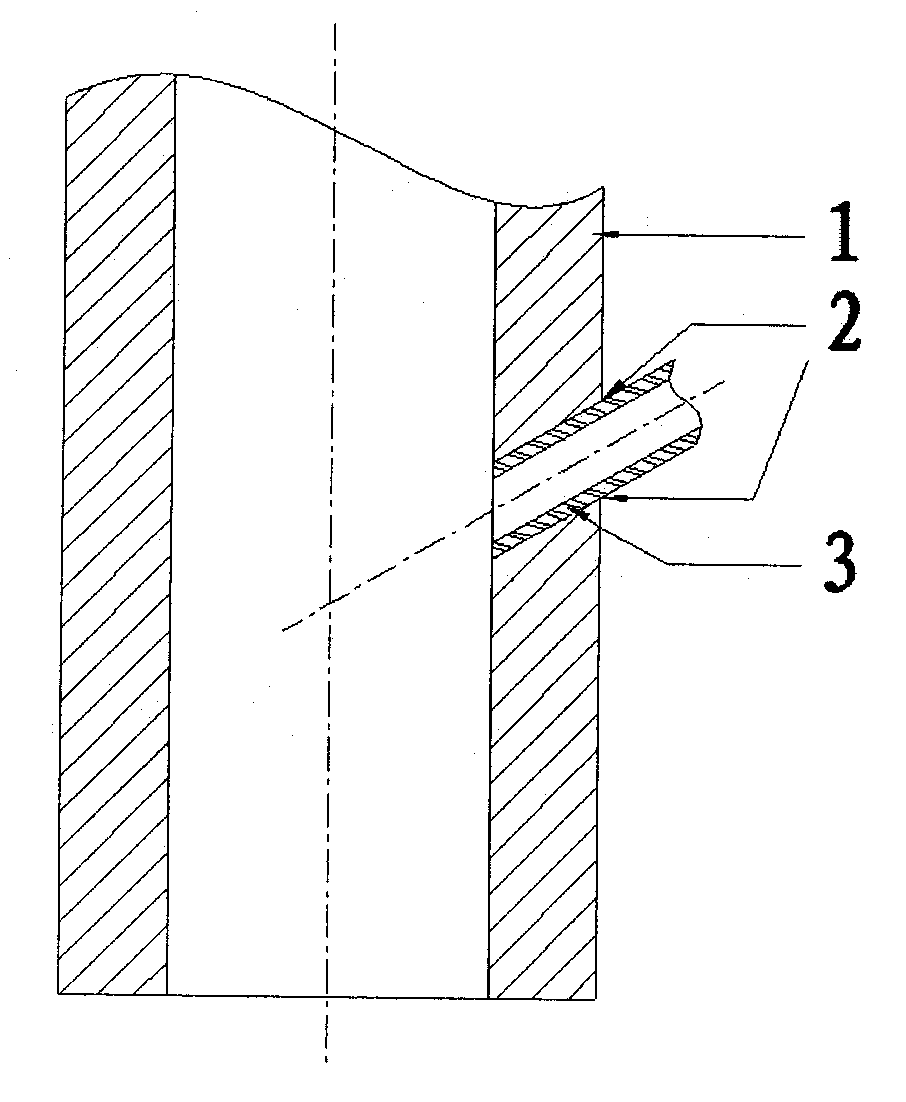

Efficient dephosphorization method of combined blown converter

ActiveCN104250672AProlong the reaction time at low temperatureGood dephosphorization effectManufacturing convertersProcess efficiency improvementSpray nozzleMaterials science

The invention relates to an efficient dephosphorization method of a combined blown converter. The method comprises the steps of: subjecting molten iron to desulphurization, and adding determined scrap steel cold material to the desulfurized molten iron; adjusting the position of an oxygen lance and open blowing parameters; adding a first batch of material, thoroughly melting, lowering the position of the oxygen lance by lowering the position of the spray nozzle of oxygen lance by 40-50 mm every 20-30 s, and adding 2.14-4.44 kg / t of active lime every time before lowering the position of the spray nozzle of the oxygen lance; lowering the position of the oxygen lance to 1500-1600 mm, fixing, adding all the residual active lime and controlling the open blowing oxygen pressure of the spray nozzle of the oxygen lance at 0.83-0.85 Mpa; converting 6-8 min, adding the remaining sinter and grain steel in molten iron by batches under addition amount of the sinter and grain steel of 3.0-6.22 kg / t respectively each batch and feeding interval of 35-60 s, adding all the sinter and grain steel; continuing converting for 3-5min, using a sublance TSC probe to measure temperature of the hot metal and sampling, after measurement of carbon temperature by the sublance TSC probe, adjusting the oxygen pressure of the oxygen lance to 0.83-0.85 Mpa, continuing lowering the position of the oxygen lance to 1200mm until the end of the blowing, and hoisting the oxygen lance; and tapping.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

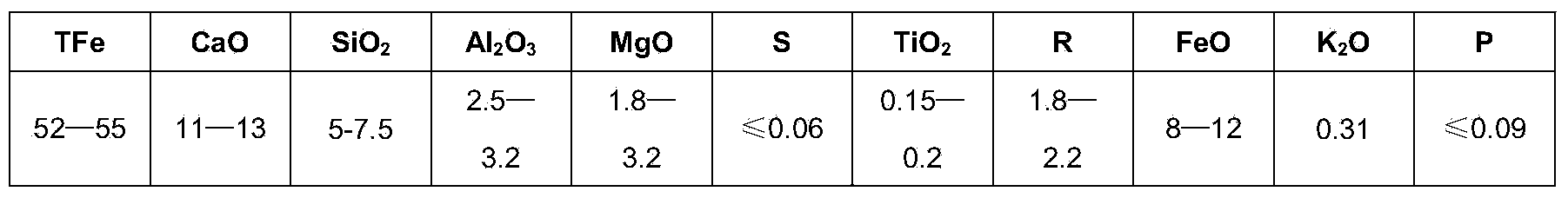

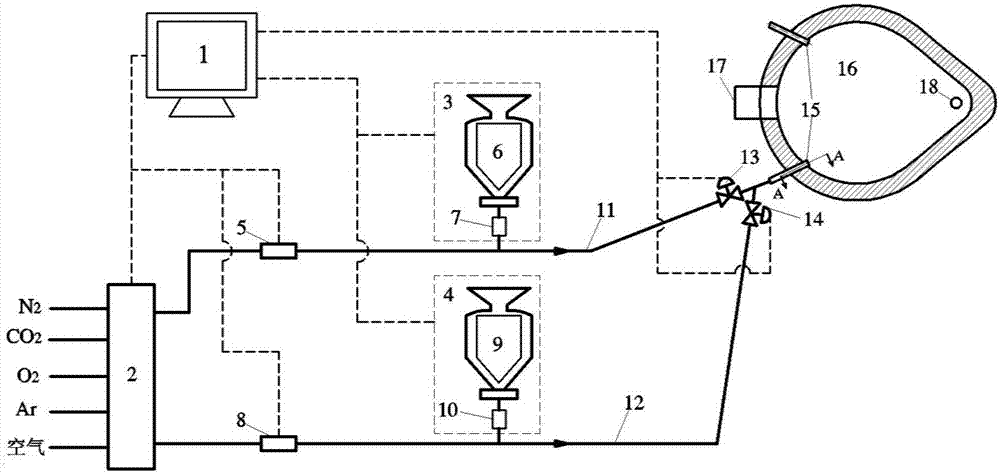

Full-steel-scrap electric arc furnace cleanness rapid smelting method

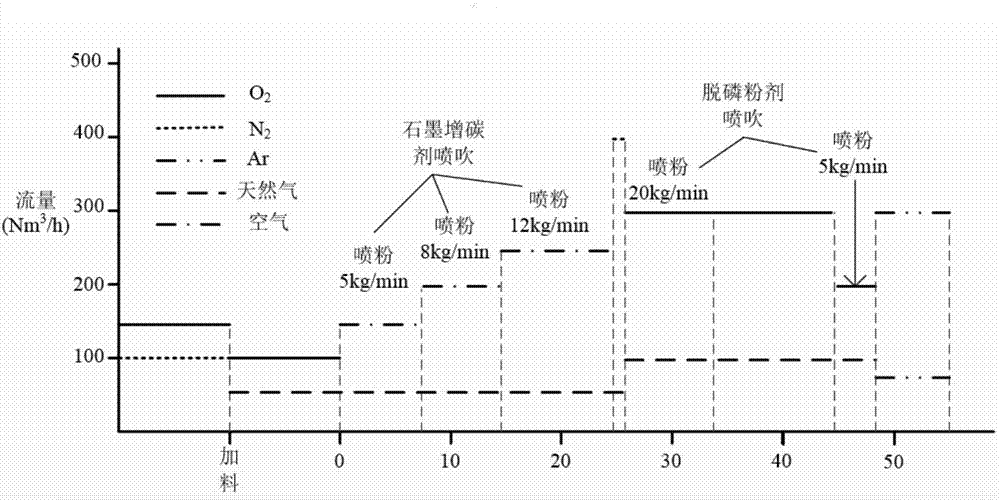

ActiveCN107502702AImprove cleanlinessShorten the smelting cycleProcess efficiency improvementElectric furnaceSteelmakingElectric arc furnace

The invention belongs to the technical field of electric arc furnace steelmaking and particularly relates to a full-steel-scrap electric arc furnace cleanness rapid smelting method which is applicable to the 30-300t full-steel-scrap electric arc furnace smelting process. According to the full-steel-scrap electric arc furnace smelting process, spray guns buried in refractory materials on the side faces of the furnace bottom of an electric arc furnace are used for blowing different types of media at different smelting stages; at the stage of recarburization and melting acceleration, melting-down of a molten pool is accelerated through carburization, and the carbon content of the molten pool is increased. At the stage of high-efficiency dephosphorization and deep denitrification, molten pool reaction is intensified to conduct high-efficiency dephosphorization and deep denitrification. Accordingly, the smelting rhythm of the full-steel-scrap electric arc furnace is accelerated, the dephosphorization and denitrification effects are improved, the cleanness of molten steel is improved, and full-steel-scrap electric arc furnace cleanness rapid smelting is realized.

Owner:UNIV OF SCI & TECH BEIJING

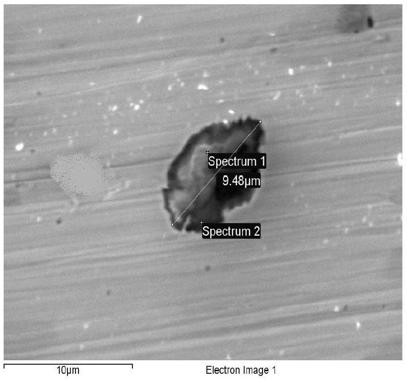

Smelting process for controlling spring steel inclusions

ActiveCN109097518ARelieve pressureFully integratedManufacturing convertersProcess efficiency improvementAlkalinitySmelting process

The invention discloses a smelting process for controlling spring steel inclusions. The smelting process comprises the following steps of (1) KR molten iron desulfurization pretreatment, (2) BOF top-bottom double combined flowing converter smelting, (3) LF furnace refining, (4) RH furnace refining and (5) continuous casting process, wherein the mass fraction of S is controlled to be below 0.005% after molten iron is processed by the step (1); the step (3) is carried out by high-purity silicon carbide for diffusion deoxidation, and the refining slag alkalinity is controlled to be 0.6-0.9; a lowalkalinity slag process is adopted in the step (4), and the final slag alkalinity is 0.5-0.7; and it is ensured that a molten steel contact part is free of aluminum in the step (5), a double electromagnetic stirring process is adopted in a secondary cooling zone and a casting blank solidification end zone, and a central carbon segregation index is controlled to be below 1.15. The smelting processadopts molten iron pretreatment, converter catching carbon, refining low alkali slag, continuous casting protective pouring and special refractory materials. Through the control over the oxygen potential of molten steel, the inclusion form and the central carbon segregation, the spring drawing performance is improved, and the spring fatigue limit is increased.

Owner:NANJING IRON & STEEL CO LTD

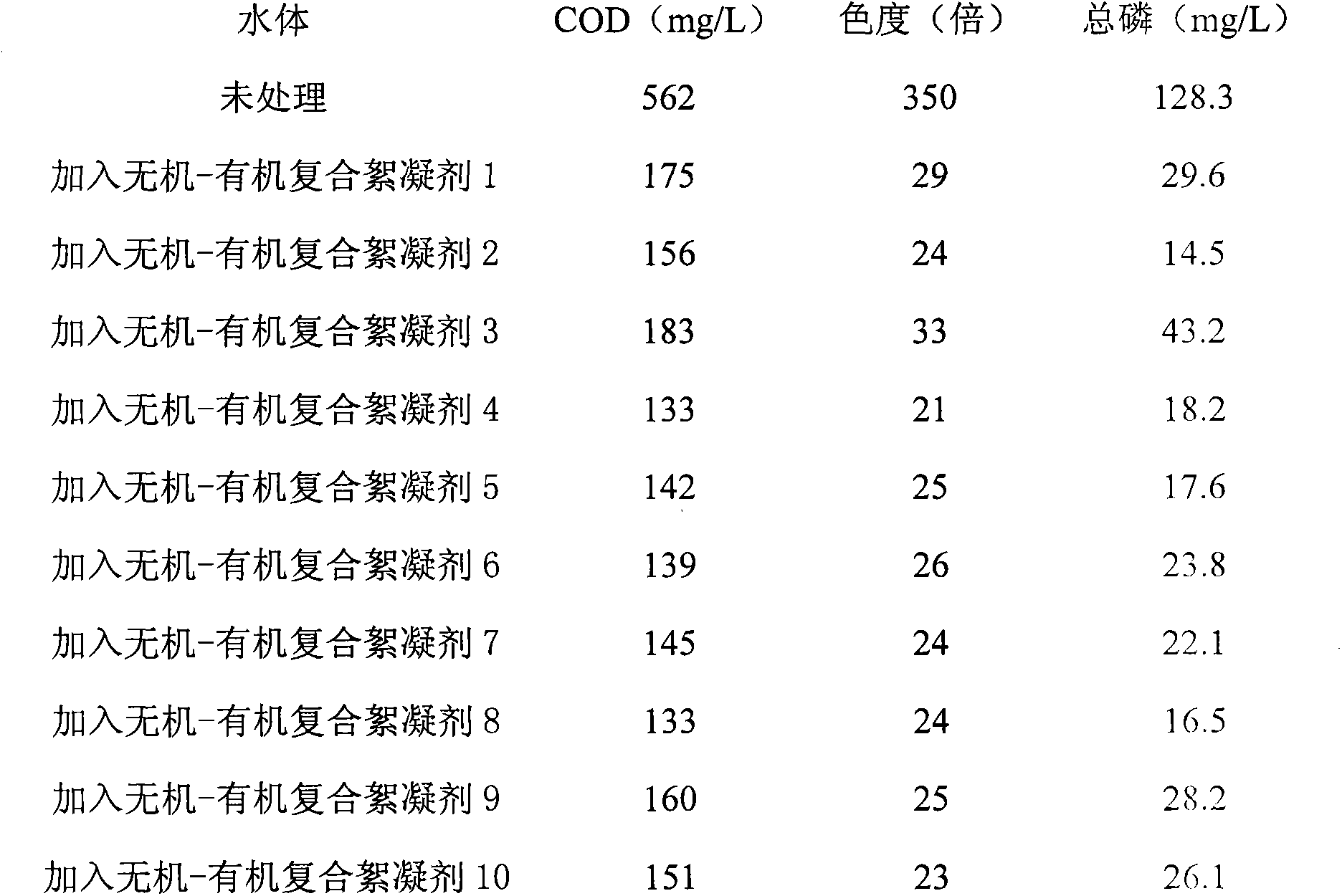

Dephosphorization flocculating agent and preparation method thereof

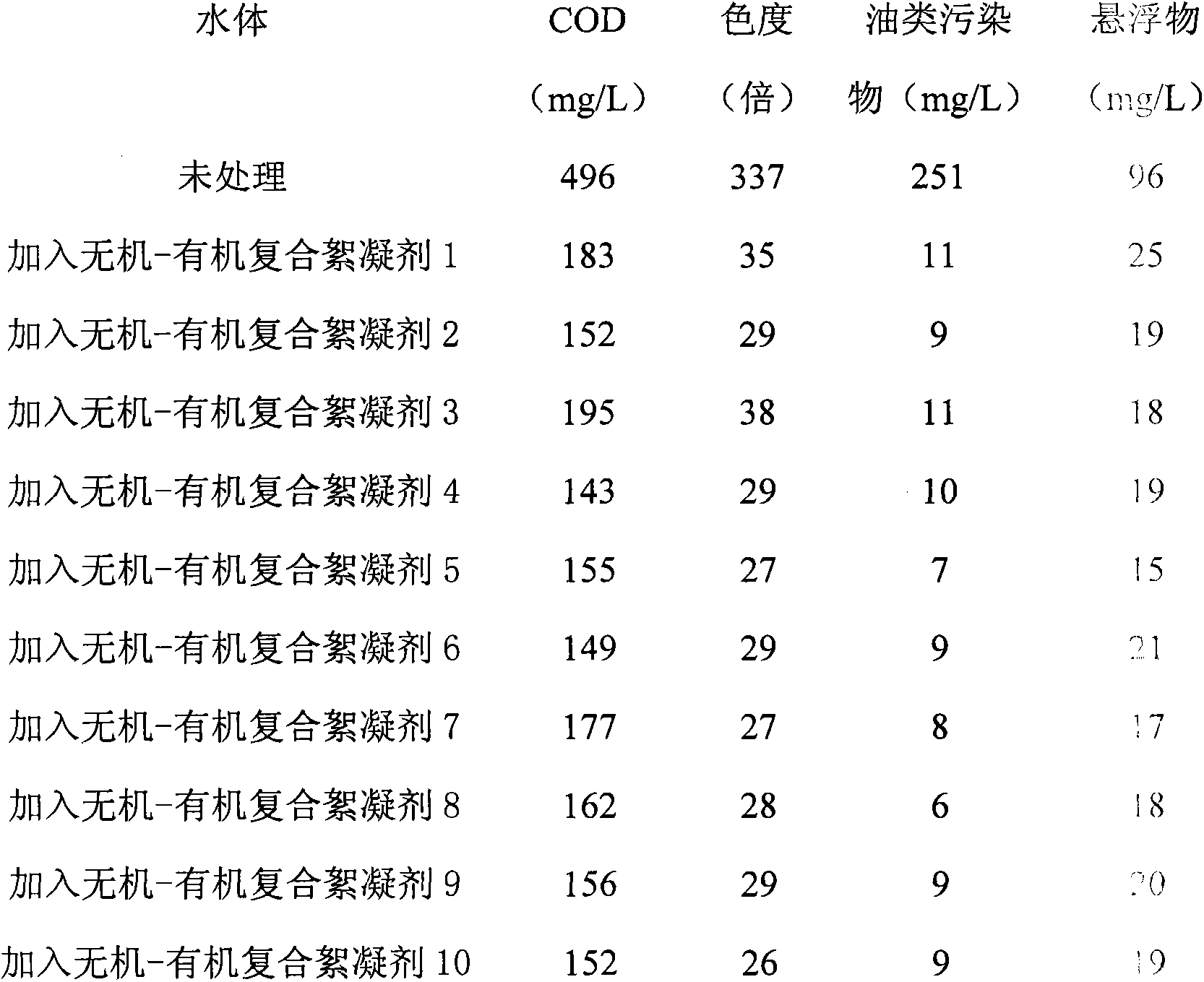

ActiveCN104261530AGood flocculation effectGood dephosphorization effectWater/sewage treatment by flocculation/precipitationAluminateWater quality

The invention discloses a dephosphorization flocculating agent and a preparation method thereof. The dephosphorization flocculating agent is formed by compounding an inorganic flocculating agent and an organic flocculating agent. The raw materials of the inorganic flocculating agent comprise sodium ferrate, borax, ferrous sulfate, silicate or aluminate; the raw materials of the organic flocculating agent comprise modified chitosan or modified polyacrylamide. The preparation process comprises the following steps: firstly adding a non-oxidizing acid into the silicate or aluminate to obtain a polysilicate colloid or an aluminum hydroxide colloid, then adding a borax solution and a sodium ferrate solution sequentially while stirring, further dropping a ferrous sulfate solution, mixing to form the inorganic flocculating agent, standing, then adding the modified polyacrylamide or modified chitosan into the inorganic flocculating agent, curing and adding the acid till the pH value is less than 7 to obtain the finished dephosphorization flocculating agent. The flocculating agent is suitable for a wide range of water quality, is little affected by co-existing salts, the pH value of sewage and temperature and is particularly effective for dye wastewater, oilfield sewage and the like.

Owner:内蒙古昕晟科贸有限责任公司

Double-slag and full-slag-remaining semi-steel steelmaking method

InactiveCN107151723ARapid dephosphorizationGood for dephosphorizationManufacturing convertersProcess efficiency improvementHigh magnesiumSteelmaking

The invention belongs to the technical field of metallurgy, particularly relates to a double-slag and full-slag-remaining semi-steel steelmaking method and provides the double-slag and full-slag-remaining semi-steel steelmaking method so as to solve the problems of late initial smelting slag forming time, poor dephosphorization effect, high auxiliary material consumption and the like for existing semi-steel steelmaking. The method comprises the steps as follows: a, the first furnace: after semi-steel is mixed, active lime, high-magnesium lime and an acidic compound slag former are added to the furnace while top blowing of oxygen is performed, then silicon iron is added, the oxygen is blown continuously, and molten steel and slag are obtained; b, the second furnace: the slag obtained in the previous furnace is completely left in the furnace, and the acidic compound slag former is added; the oxygen is blown continuously after the semi-steel is mixed, and when the temperature of the semi-steel ranges from 1,350 DEG C to 1,400 DEG C, part of the slag is discarded; and then secondary slag forming is performed, and molten steel and slag are obtained. According to the method, 4-5 furnaces form a cycle, the auxiliary material consumption is low, early-stage dephosphorization is fast, and the dephosphorization effect is good. The method is simple to operate, low in production cost and suitable for popularization and use.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Dephosphorization and iron-increasing method of high phosphorus hematite by direct reduction

InactiveCN101984079ATo achieve the purpose of dephosphorization and ironSimple processProcess efficiency improvementIron increasedPotassium carbonate

The invention particularly relates to a dephosphorization and iron-increasing method of high phosphorus hematite by direct reduction, and the technical scheme comprises the following steps: mixing 60-83wt% of high phosphorus hematite powder, 10-15wt% of carbonaceous reducing agent, 6-15wt% of quicklime and 1-10wt% of additive uniformly, pressing the mixture into blocks, drying, reducing in a high temperature furnace under 1250-1350 DEG C, and keeping the temperature for 15-30 minutes; carrying out furnace cooling until the temperature is 600-800 DEG C, taking the reduction product out, naturally cooling, grinding and performing the magnetic separation to obtain pig iron particles. The additive is sodium carbonate, or potassium carbonate, or the mixture of the sodium carbonate and the potassium carbonate; drying is carried out under the condition of 110-120 DEG C until the weight of the mixture of raw materials is constant; and the high temperature furnace is a resistance furnace, or a rotary kiln, or a rotary hearth furnace, and the atmosphere in the high temperature furnace is neutral or weak-reductive. The invention has the advantages of short reduction time, simple process, high dephosphorization rate, high iron yield, less environmental pollution, recyclable residue and the like.

Owner:WUHAN UNIV OF SCI & TECH

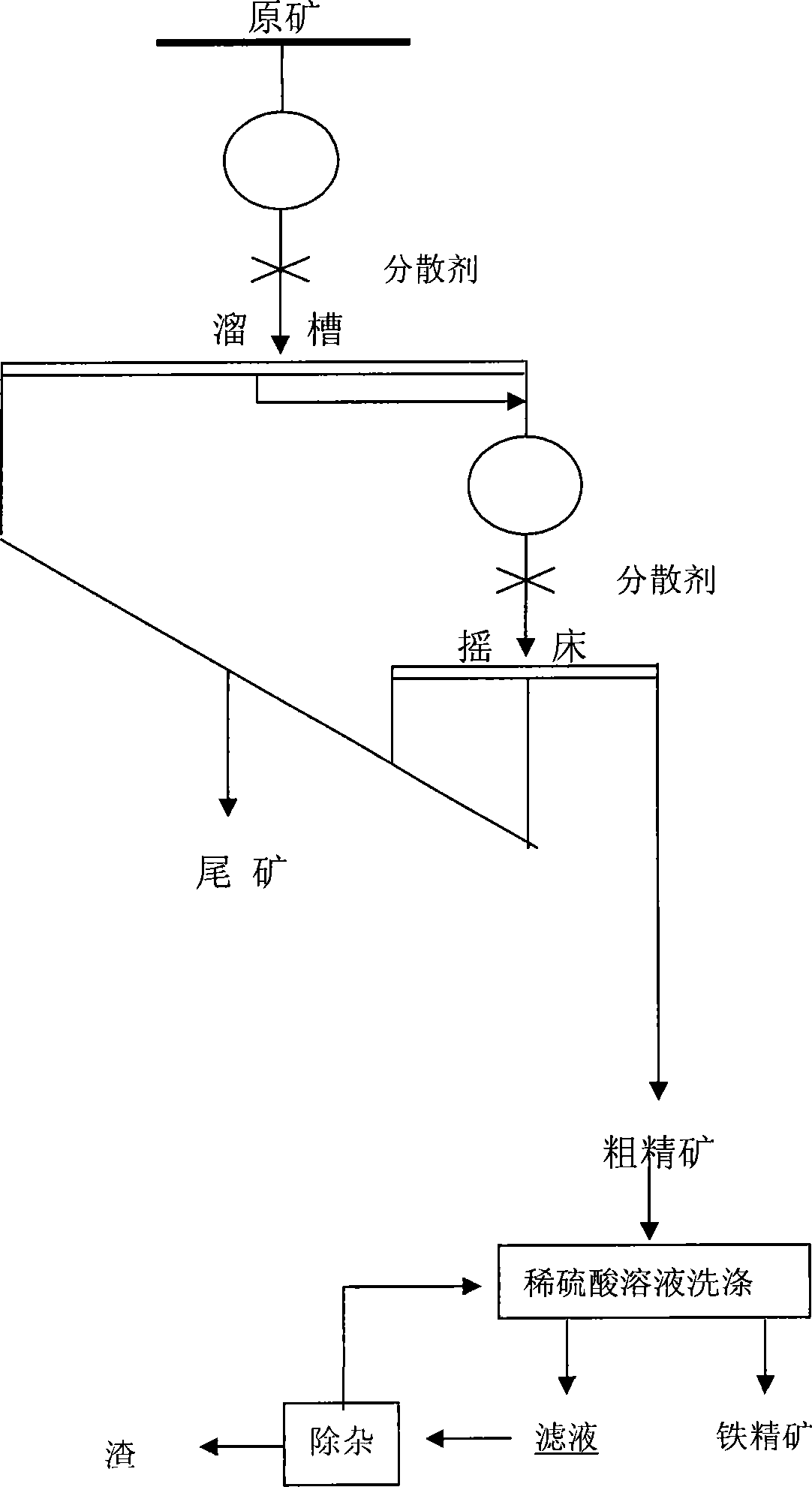

Method forpreparing iron concentrate for making iron from phosphorus-containing oolitic hematite

InactiveCN101054625AAvoid muddyingRaise the gradeProcess efficiency improvementGranularityRoom temperature

The invention discloses a method of producing iron ore concentrate containing roe - like phosphorus hematite for iron manufacture, comprising crashing the roe - like ore, wet grinding until the hematite of granularity < 0.074mm are 40-60 mass% of whole hematite, adjusting the pulp mass percent concentration to 20%-30%, adding the water glass as dispersant of 0.5-1.0kg / t, agitating adequately, selecting by helix shoot, grinding produced ore concentrate until the one with the granularity < 0.074mm are more than 80 mass%, having the water glass as dispersant of 0.2-0.5kg / t, agitating to disperse uniformly, then selecting by shaking table, washing produced iron ore concentrate in room temperature by 0.5%-1.5% dilute sulfuric acid solution for 5-15 minutes, centrifugal separation, in which the solid are iron ore concentrate. The invention treats the roe - like phosphorus hematite to obtain the iron ore concentrate with a tenor of 62%, P content less than 0.06%. The invention can fully and reasonably apply rich roe - like phosphorus hematite resource in our country, has a good effect of dephosphorization and a low cost. And produced iron ore concentrate have a high recovery ratio.

Owner:CENT SOUTH UNIV

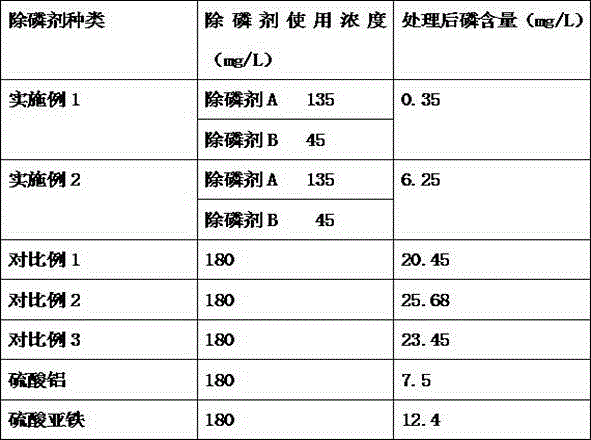

Domestic sewage phosphate removing agent

ActiveCN106430504AImprovement of Phosphorus RemovalReduce phosphorus contentWater contaminantsWater/sewage treatmentAluminium saltsPolyvinyl alcohol

The invention relates to a domestic sewage phosphate removing agent which includes a phosphate removing agent A and a phosphate removing agent B. The phosphate removing agent A is prepared from, by weight, 6.25 parts of polymeric aluminum, 5.42 parts of attapulgite, 2.15 parts of aluminum sulfate and 2.36 parts of ferrous sulfate. The phosphate removing agent B is prepared from, by weight, 1.85 parts of polymeric aluminum, 6.4 parts of polyvinyl alcohol and 2.15 parts of ferrous sulfate. According to the domestic sewage phosphate removing agent A and domestic sewage phosphate removing agent B, raw materials contain common water treatment agents, phosphate removing effect of the phosphate removing agent is greatly improved under PH (potential of hydrogen) conditions of the phosphate removing agent after the phosphate removing agent is compounded, high-phosphorus domestic sewage is treated by the method, and the content of phosphate in the treated sewage can be reduced to 0.25mg / L and reaches or is lower than national standards.

Owner:XINGAN ANHUI ELECTRIC LTD BY SHARE LTD

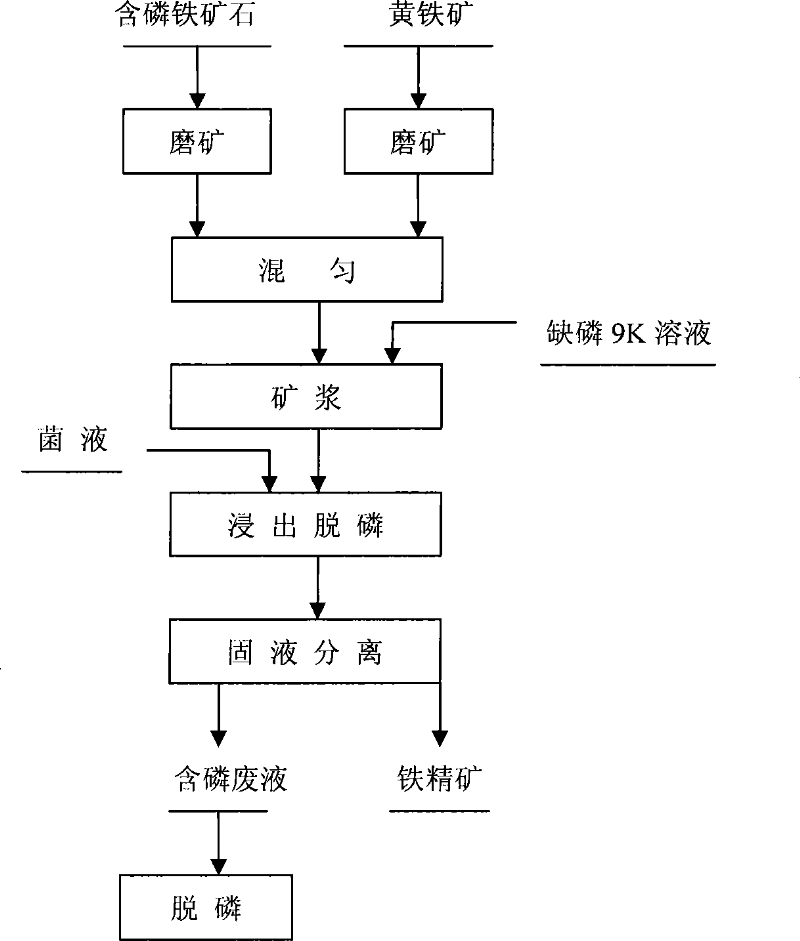

Dephosphorization method of phosphorus-containing iron ore

InactiveCN101037724AReduce dephosphorization costsGood dephosphorization effectProcess efficiency improvementPhosphorPyrite

A method for dephosphorizing from phosphor-containing iron ore is disclosed, wherein phosphor-containing iron ore is broken to the granularity of less than 0.074mm and mixed with iron pyrite prebroken to the granularity of less than 0.074mm based on mass percent of 5%-20%, the mass concentration of ore slurry is adjusted to 10%-20% by the aphosphorosis 9K culture and pH of original ore slurry is in the range of 1.5 to 3.5, then noculating ferrous and sulfur oxide bacilli lysate of 2% -10% mass percent in which bacteria is cultrued by 9K culture beforehand ro reach exponential phase of growth in ore slurry, extracting dephosphorization, solid-liquid separation after 30 -45 days, and the solid is iron ore concentrate. The invention is suitable for direct-extracting dephosphorizing from each phosphor-containing iron ore microbe, the ore dephosphorizing yield can be exceeded 80%, The content of phosphorus satisfies the requirement of blast furnace ironmaking materials, and having comprehensive utilization of iron pyrite. The process provides a reliable technical support for developing rich high phosphorus iron ore in our country with low cost and good dephosphorization.

Owner:CENT SOUTH UNIV

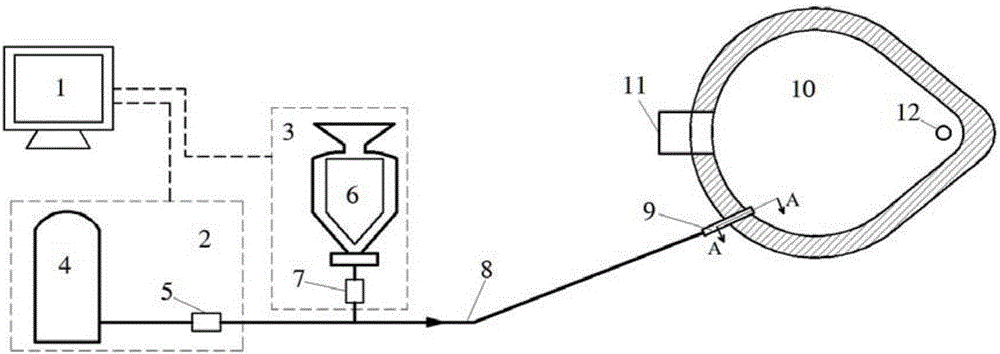

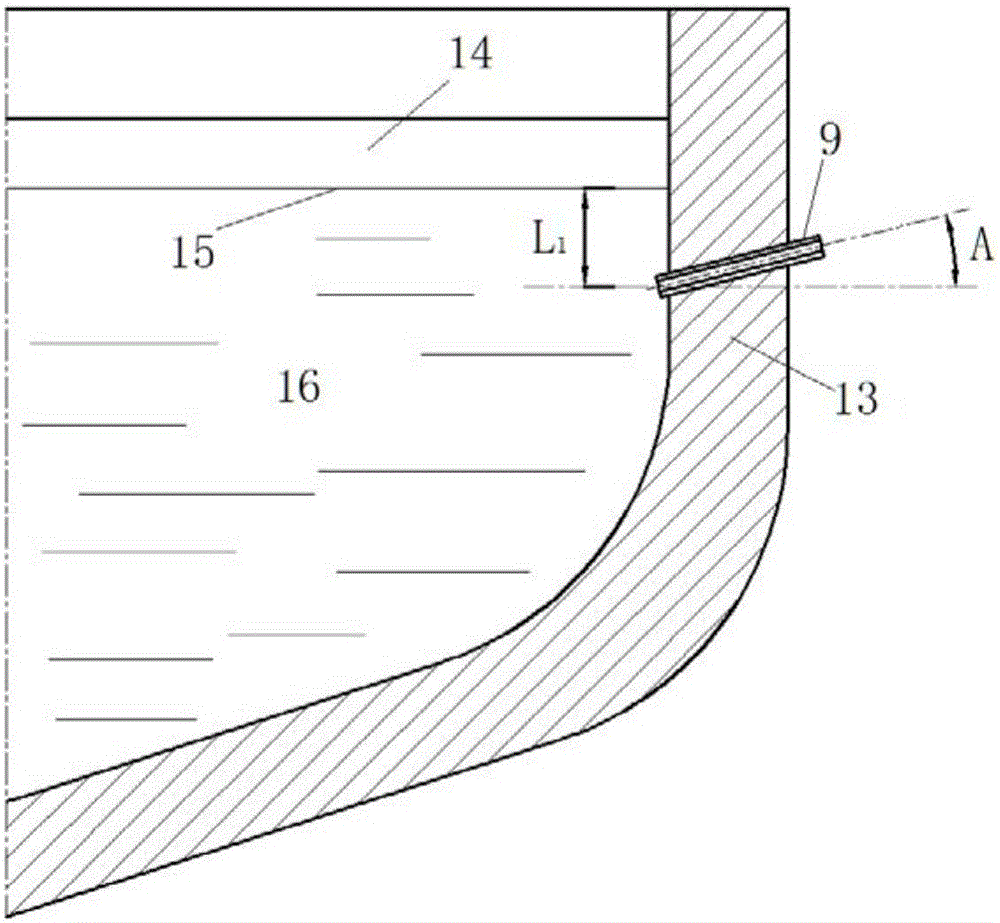

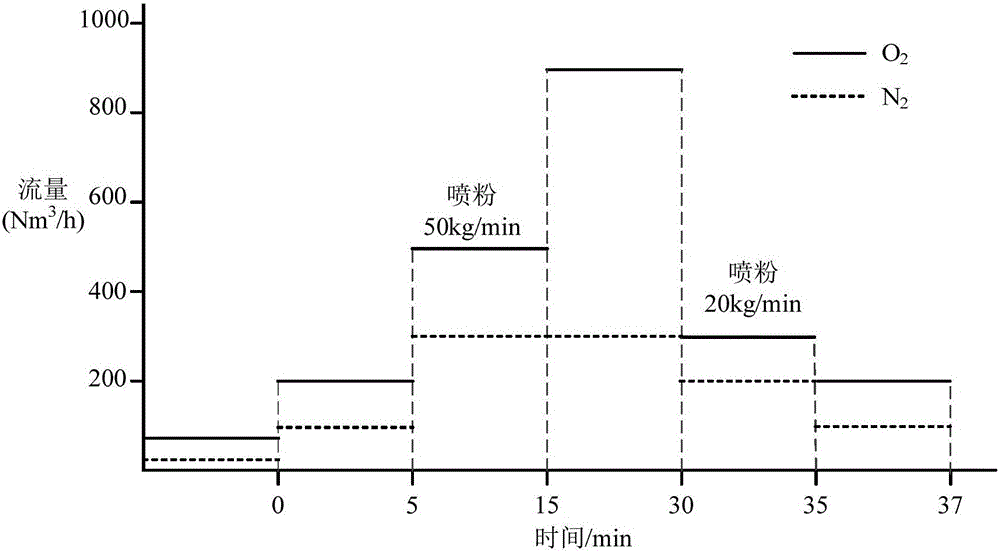

Dephosphorization method for electric-arc furnace steelmaking

ActiveCN105803155AImprove product qualityFully functional abilityProcess efficiency improvementElectric furnaceSteelmakingElectric arc furnace

The invention provides a dephosphorization method for electric-arc furnace steelmaking, and belongs to the field of electric-arc furnace steelmaking. The dephosphorization method is characterized in that the same spray gun is utilized for delivering oxygen gas, protective gas and carrier gas-dephosphorization powder into an electric-arc furnace molten pool directly, wherein the carrier gas-dephosphorization powder is dephosphorization powder carried in the carrier gas; gas flow violently impacts and stirs a steelmaking molten pool, so that the dephosphorization powder is in sufficient contact with molten steel directly, and good thermodynamic and dynamic conditions are provided for molten pool dephosphorization reaction, and dephosphorization efficiency of an electric-arc furnace steelmaking process is improved, consumption of slag charge such as a dephosphorization agent is reduced, a dephosphorization rate of a smelting process is increased, the quality of end-point molten steel is improved, and the production cost is reduced.

Owner:UNIV OF SCI & TECH BEIJING

Method for producing high carbon steel through double-slag high drawing carbon tapping

ActiveCN102559984AGood dephosphorization effectLess slagManufacturing convertersSteelmakingHigh carbon

A method for producing high carbon steel through double-slag high drawing carbon tapping belongs to the technical field of smelting high carbon steel through a converter. The method comprises processing steps as follows: molten iron and steel scraps are loaded in the converter according to a certain molten iron ratio; in a first stage of converter steelmaking, the converting is performed at the oxygen supplying intensity of 2.8 Nm<3> / min / t, active lime and ore fluxing mediums are added in the converter, and a larger bottom blown flow rate is adopted to stir; the converting is performed at a standard lance height in the prior period for the converting of the converter, and then the lance height rises gradually; part of furnace slag is dumped through a rocking furnace; in the second stage for the converting of the converter, the converting is performed at the oxygen supplying intensity of 3.3 Nm<3> / min / t, and active lime and the ore fluxing mediums are added in the converter; the lance height rule that the converting is performed at a higher lance height in the later period and the lance height descends stage by stage is adopted; a small quantity of ores and fluorites are added frequently within 80 to 90 percent of total converting oxygen consumption; after the converting of the converter is finished, deslagging is performed through the rocking furnace of the converter, and temperature measurement and sampling are carried out; and converter tapping is carried out. The method has the advantage of overcoming the shortages of serious rephosphoration caused during the tapping process, low production efficiency, and so on.

Owner:SHOUGANG CORPORATION

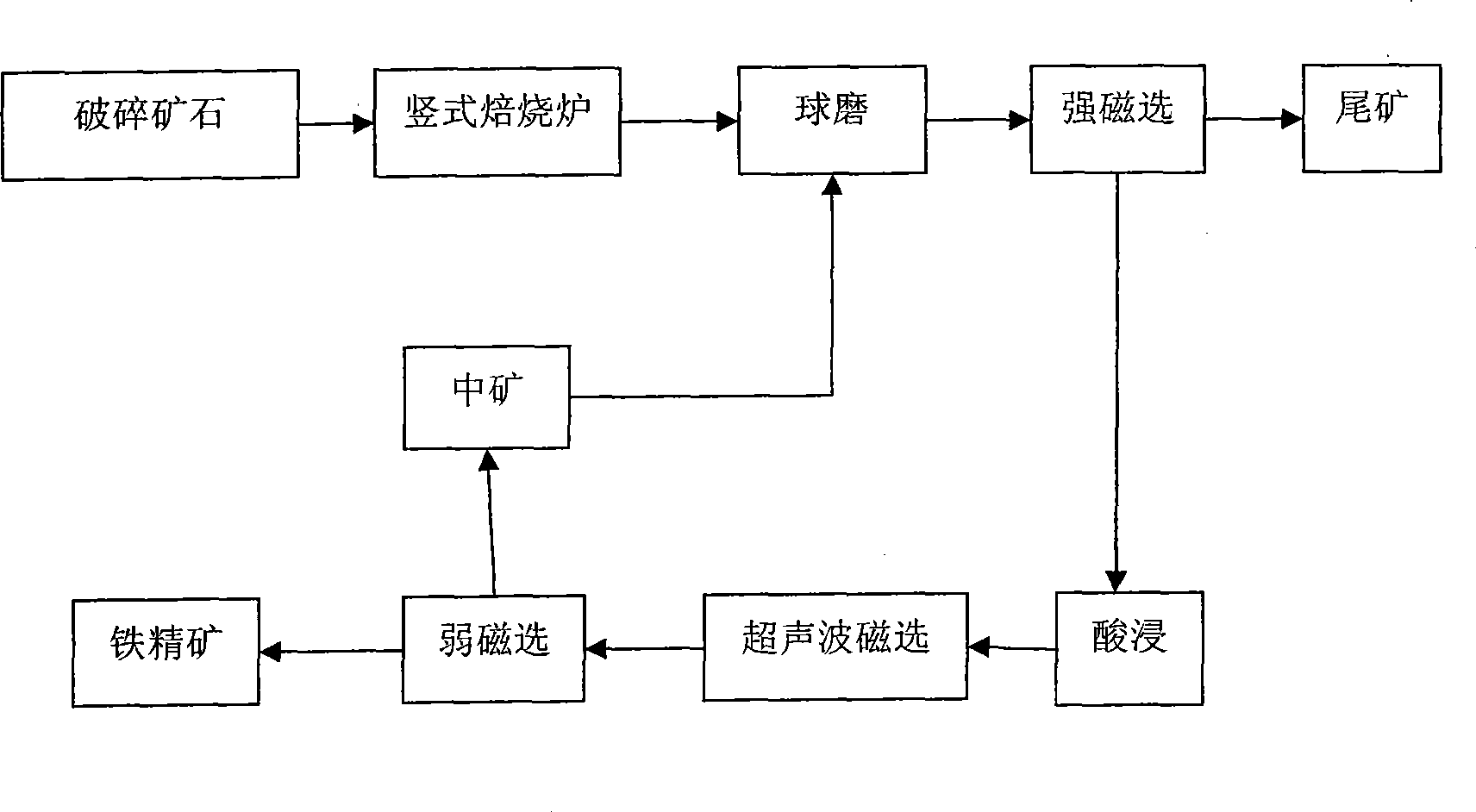

Dephosphorization method for oolitic high phosphorus iron ore

InactiveCN101487081ASimple processEasy to operateProcess efficiency improvementShaft furnaceHigh phosphateHigh intensity

The invention relates to a high-phosphate oolitic iron ore dephosphorization method. The raw ore is roasted at the temperature of between 400 DEG C and 800 DEG C after crushing, high intensity magnetic separation is carried out after ore grinding, and acid leaching is carried out to ore powder by using industrial sulfuric acid or industrial nitric acid or industrial hydrochloric acid with the proportion being: 4 percent to 10 percent of acid:90 percent to 96 percent of water; the soaking time is 1.5 to 5 hours; phosphorus is obtained by vibration cleaning ore powder by using ultrasonic waves with the frequency being 4000 hertz to 20 000 hertz and vibration time is 15 to 20 minutes, and then concentrates and middlings are picked out by using low intensity magnetic separation. The dephosphorization method has the advantages of low dephosphorization cost, simple dephosphorization technology and equipment and good dephosphorization effects.

Owner:解能 +1

Exothermic agent for converter molten iron with low heating value

InactiveCN101988137AAdjust alkalinityPlay the role of supplementing molten iron [Si]Manufacturing convertersSlagSilicon

The invention discloses an exothermic agent for converter molten iron with a low heating value, which comprises the following components in percentage by weight: 31-44 percent of carbonaceous material, 35-48 percent of siliceous material, 6-14 percent of bauxite, 4-10 percent of iron granules or scrap iron and 4-8 percent of binder, and the bulk specific weight of the exothermic agent is 2.2-3.5ton / m<3>. The exothermic agent for the converter molten iron with the low heating value has the characteristic of raising the temperature obviously and promoting slagging for low-silicon and low-temperature molten iron, and can improve the dephosphorizing capability of converter slag.

Owner:BAOSHAN IRON & STEEL CO LTD

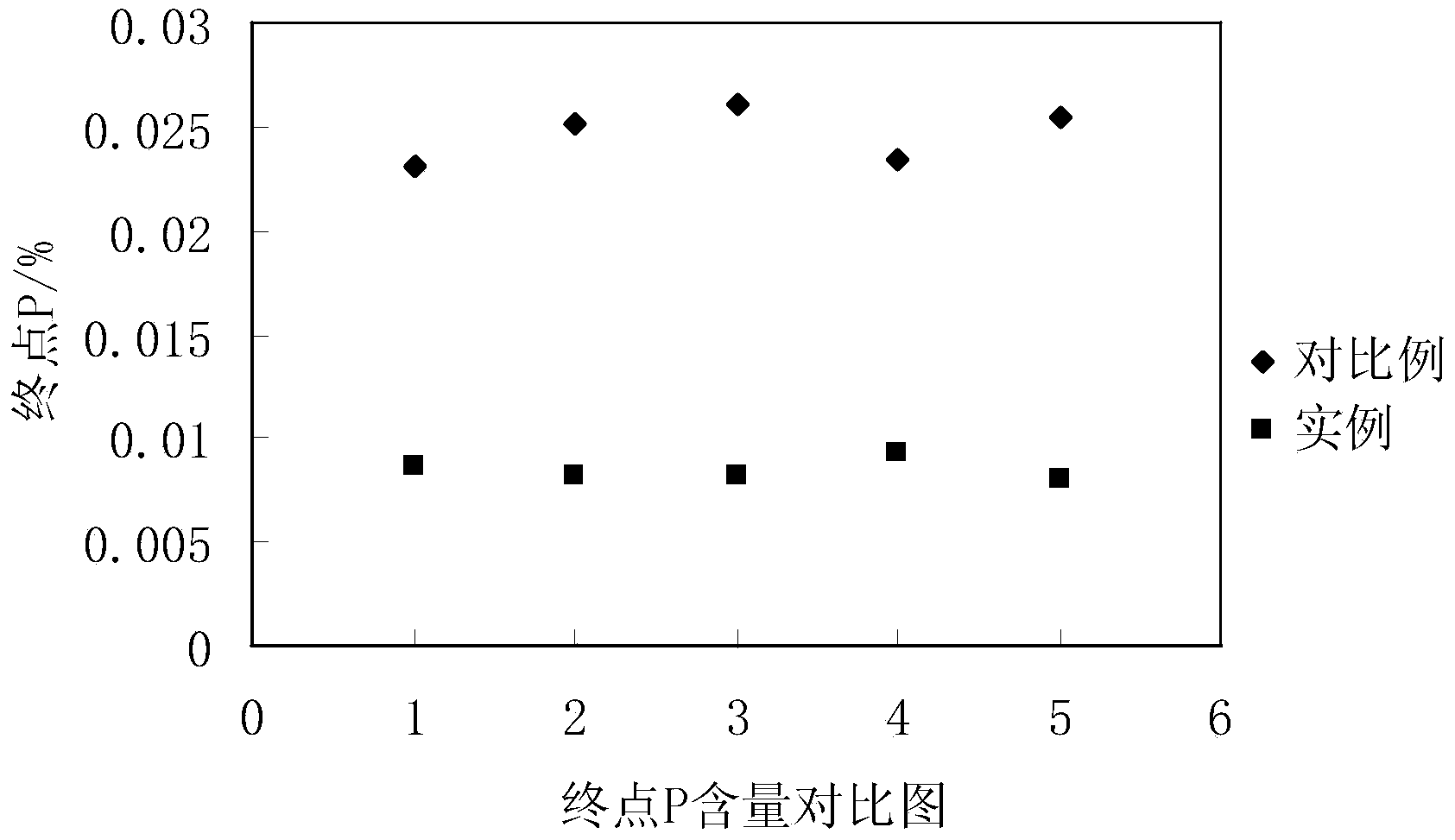

Method for smelting high-phosphorus molten iron to produce steel with converter end point P less than or equal to 0.01% by adopting slagless material

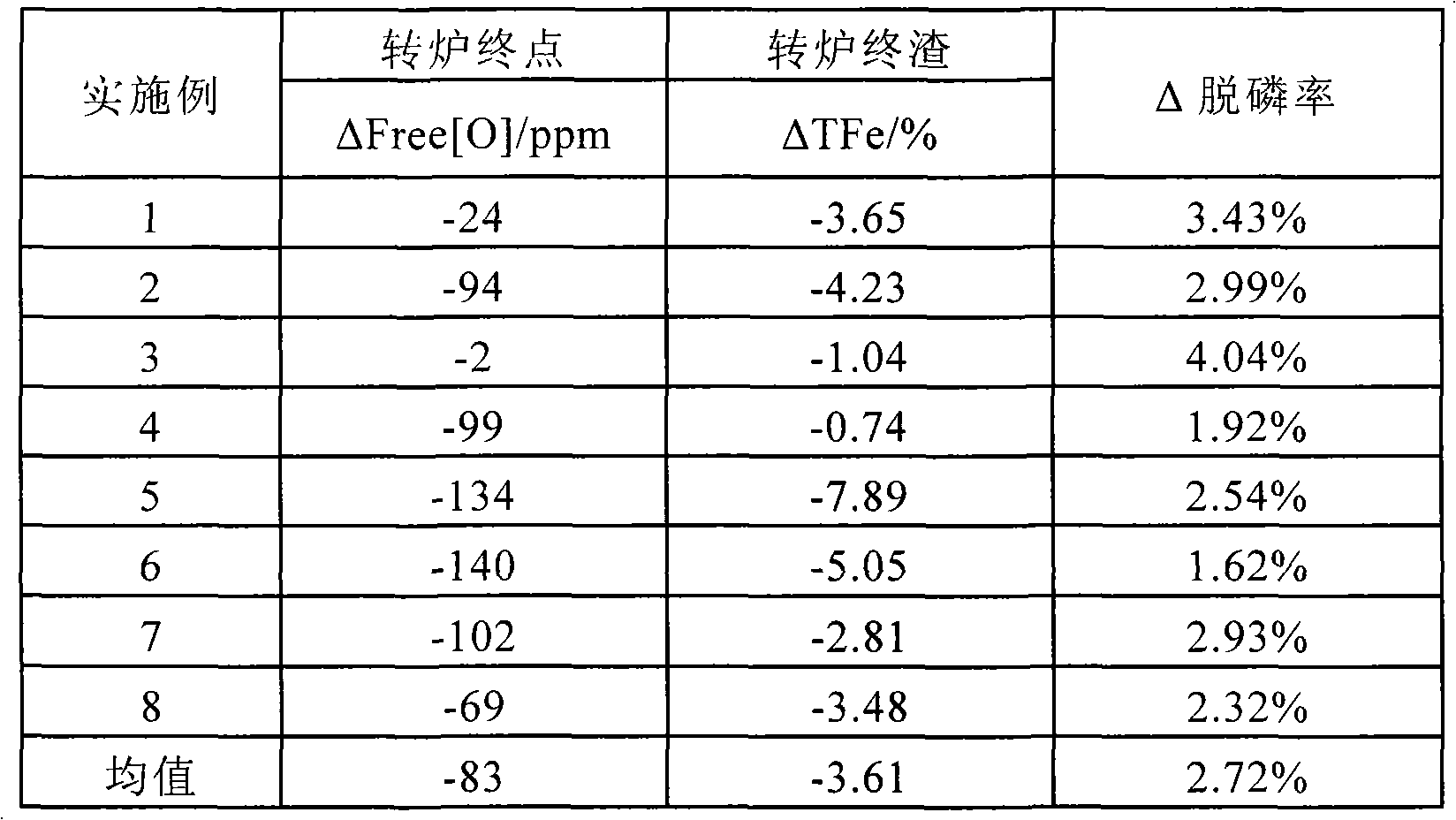

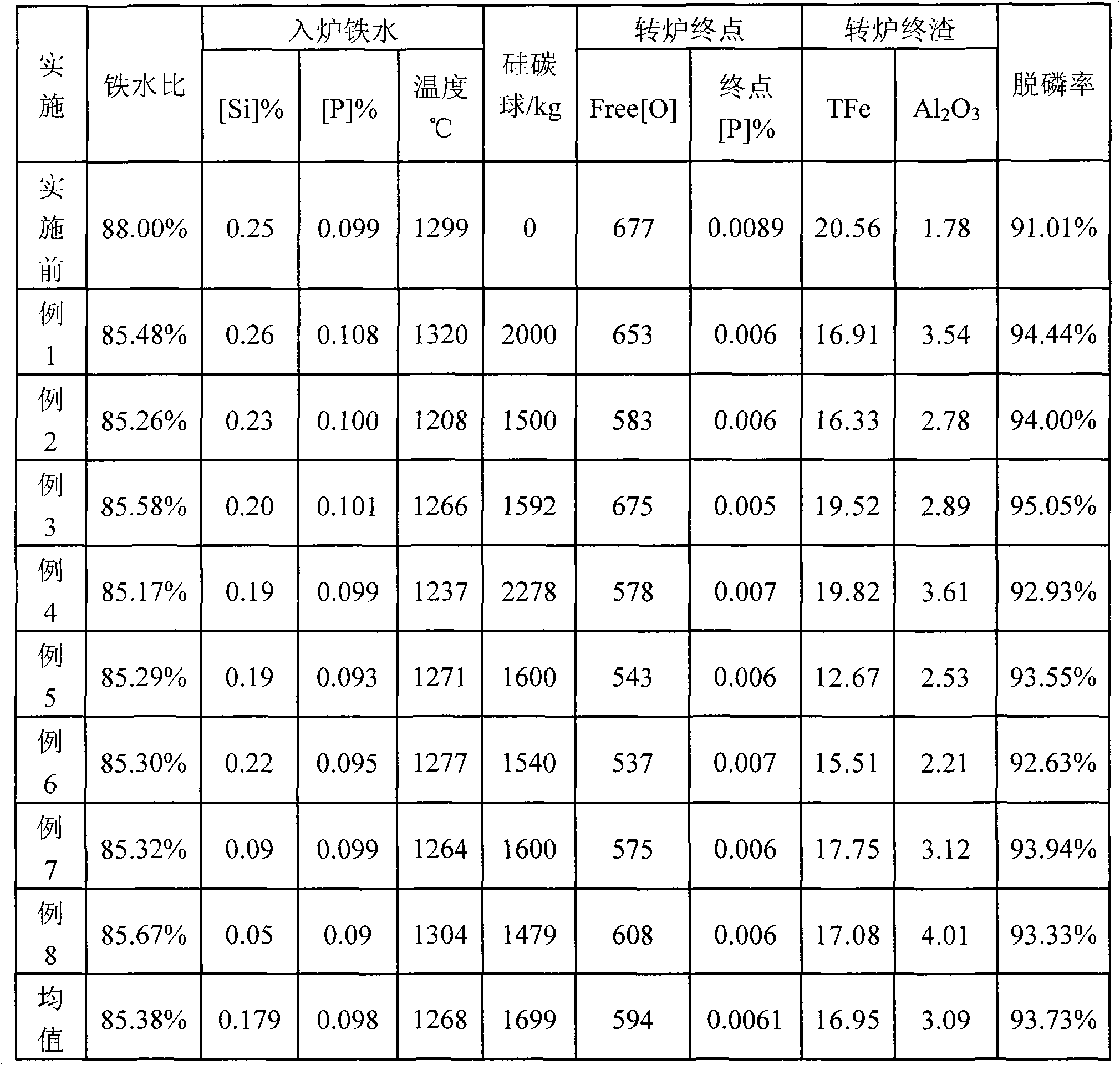

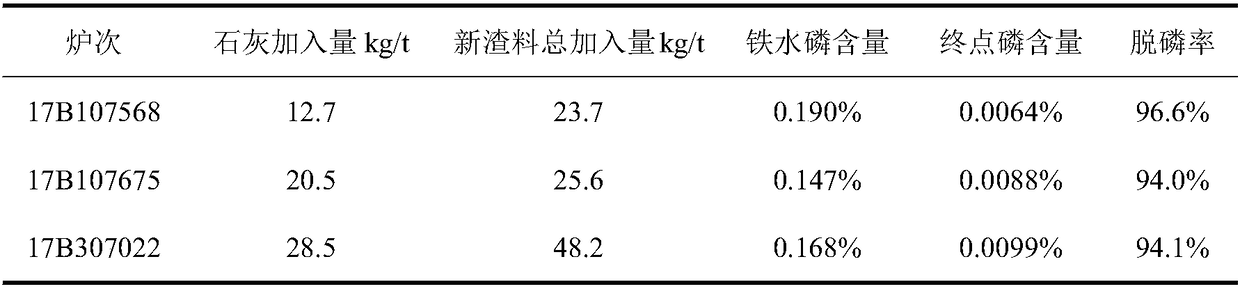

ActiveCN109280731AAvoid going backReduce the temperatureManufacturing convertersProcess efficiency improvementSteelmakingNitrogen

The invention belongs to the technical field of converter steelmaking processes, and particularly relates to a method for smelting high-phosphorus molten iron to produce steel with converter end pointP less than or equal to 0.01% by adopting slagless material. The method comprises the following steps that loading low-silicon high-phosphorus molten iron and steel scrap which are not subjected to triple-removal pretreatment into a converter, a single-slag method is adopted to carry out blowing, a slagging material is added twice in a blowing process and a gun position control mode of high, low, high and low is adopted in the blowing process, and oxygen supply and nitrogen supply are carried out in the blowing process; after the blowing is completed, the steel is discharged, slag splashingis carried out after the steel is discharged, slag is reserved after the slag splashing, and is used for smelting in the next furnace. According to the method, on the premise that lime consumption ofa steel liquid is less than or equal to 30 kg / t, and the consumption of the new slag material is less than or equal to 50 kg / t, dephosphorizing of the molten iron with the following components, by weight, 0.14-0.26% and Si, 0.15-0.20% of P is carried out until P is less than or equal to 0.01%, and a dephosphorization rate is larger than or equal to 94%, so that the problem that low-phosphorus steel is smelted by a low-silicon high-phosphorus molten iron with the few slag material in the single-slag method is solved.

Owner:UNIV OF SCI & TECH BEIJING

Arc furnace deep dephosphorization technology and deep dephosphorization agent thereof

InactiveCN101892352AImprove dephosphorization effectImprove dephosphorization efficiencyProcess efficiency improvementElectric furnaceSlagIron oxide

The invention relates to arc furnace deep dephosphorization technology and a deep dephosphorization agent thereof. The arc furnace deep dephosphorization technology comprises the following steps of: melting steel by using slag, performing deep dephosphorization and preparing foamed slag, and is characterized in that lime and the deep dephosphorization agent are added after the addition of scrap steel and before complete melting of the scrap steel in parts so as to enhance the deep dephosphorization effect. The deep dephosphorization agent consists of the following components in percentage by weight: 25 to 40 percent of lime, and 60 to 75 percent of ferric oxide powder. The method for preparing the dephosphorization agent comprises the following steps of: smashing the raw materials into 100 to 150 meshes and uniformly mixing; and premelting the materials at the high temperature of between 1,200 and 1,550 DEG C, cooling and processing into granules with the diameter of 3 to 50 mm. Compared with the prior art, the invention has the advantages that: the deep dephosphorization technology and the deep dephosphorization agent are adopted for deep dephosphorization, the lime is not added before charging, and the lime and the deep dephosphorization agent are added after charging and before complete melting of the materials in parts to enhance the deep dephosphorization effect, so that the tapping phosphorus is reduced to 0.0030 percent or even lower.

Owner:辽宁中汇环保科技有限公司

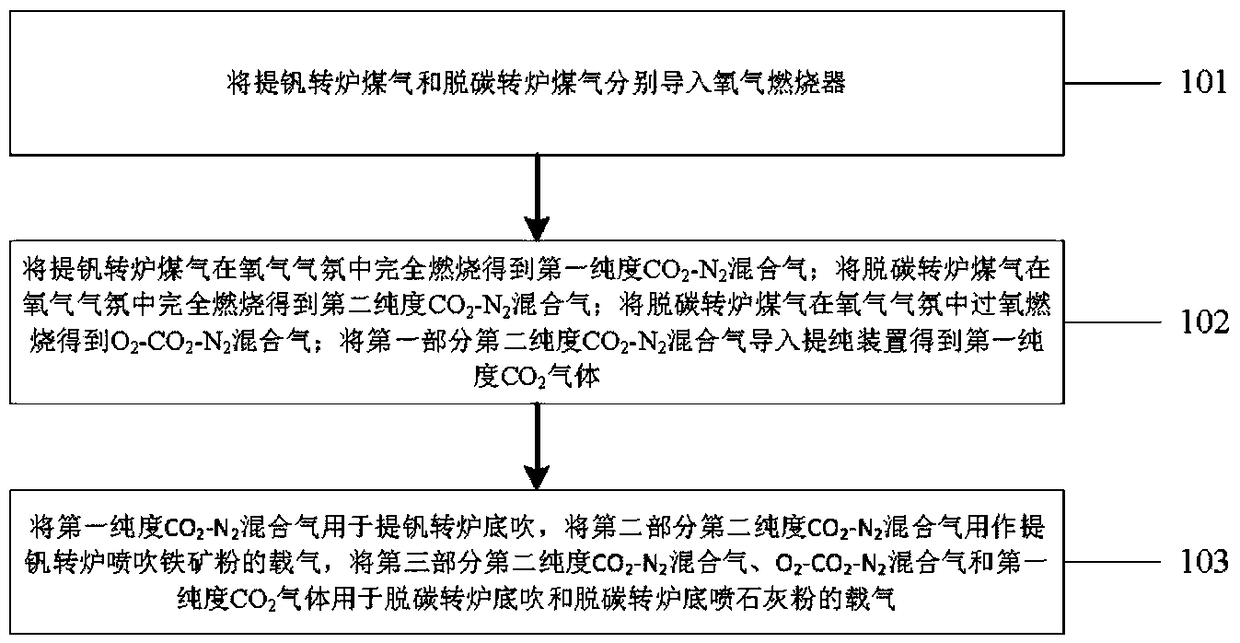

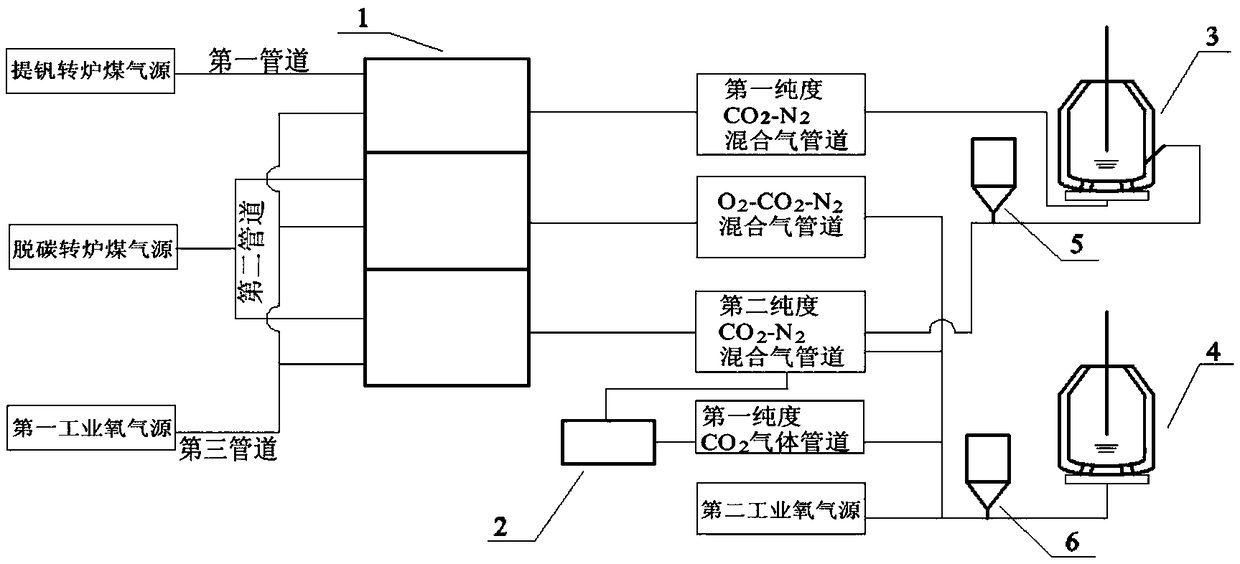

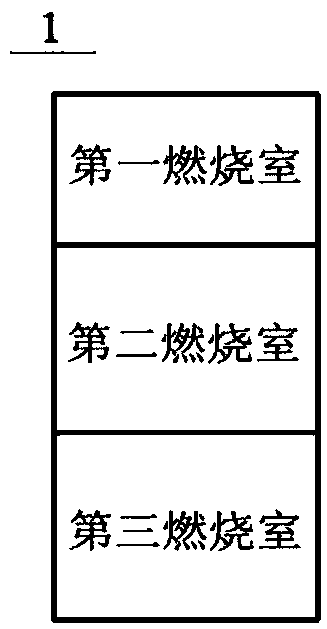

Efficient and long-service-life blowing method and system of vanadium extraction-decarburization dual converter

ActiveCN109234490ALower acquisition costsImprove efficiencyGas treatmentOxide/hydroxide preparationSteelmakingCombustor

The invention discloses an efficient and long-service-life blowing method and system of a vanadium extraction-decarburization dual converter and belongs to the technical field of vanadium-containing liquid iron steelmaking. The efficient and long-service-life blowing method comprises the following steps: conducting vanadium extraction converter coal gas and decarburization converter coal gas intoan oxygen combustor; obtaining CO2-N2 mixed gas with first purity through the vanadium extraction converter coal gas; obtaining CO2-N2 mixed gas with second purity through the decarburization converter coal gas; btaining O2-CO2-N2 mixed gas through decarburization converter coal gas; obtaining CO2 gas with first purity through CO2-N2 with the second purity; carrying out vanadium extraction converter bottom blowing by utilizing the CO2-N2 mixed gas with the first purity; taking the CO2-N2 mixed gas with the second purity as iron ore powder carrier gas of vanadium extraction converter blowing; O2-CO2-N2 mixed gas and the CO2-N2 mixed gas with the first purity are used as lime powder carrier gas of the vanadium extraction converter bottom blowing and decarburization converter bottom spraying.By adopting the efficient and long-service-life blowing method, the vanadium oxidization rate of a vanadium extraction converter is improved and the dephosphorization effect of a decarburization converter is improved; the service life of the vanadium extraction converter and the decarburization converter is prolonged.

Owner:UNIV OF SCI & TECH BEIJING

Multifunctional slagging material findings and method for producing the same

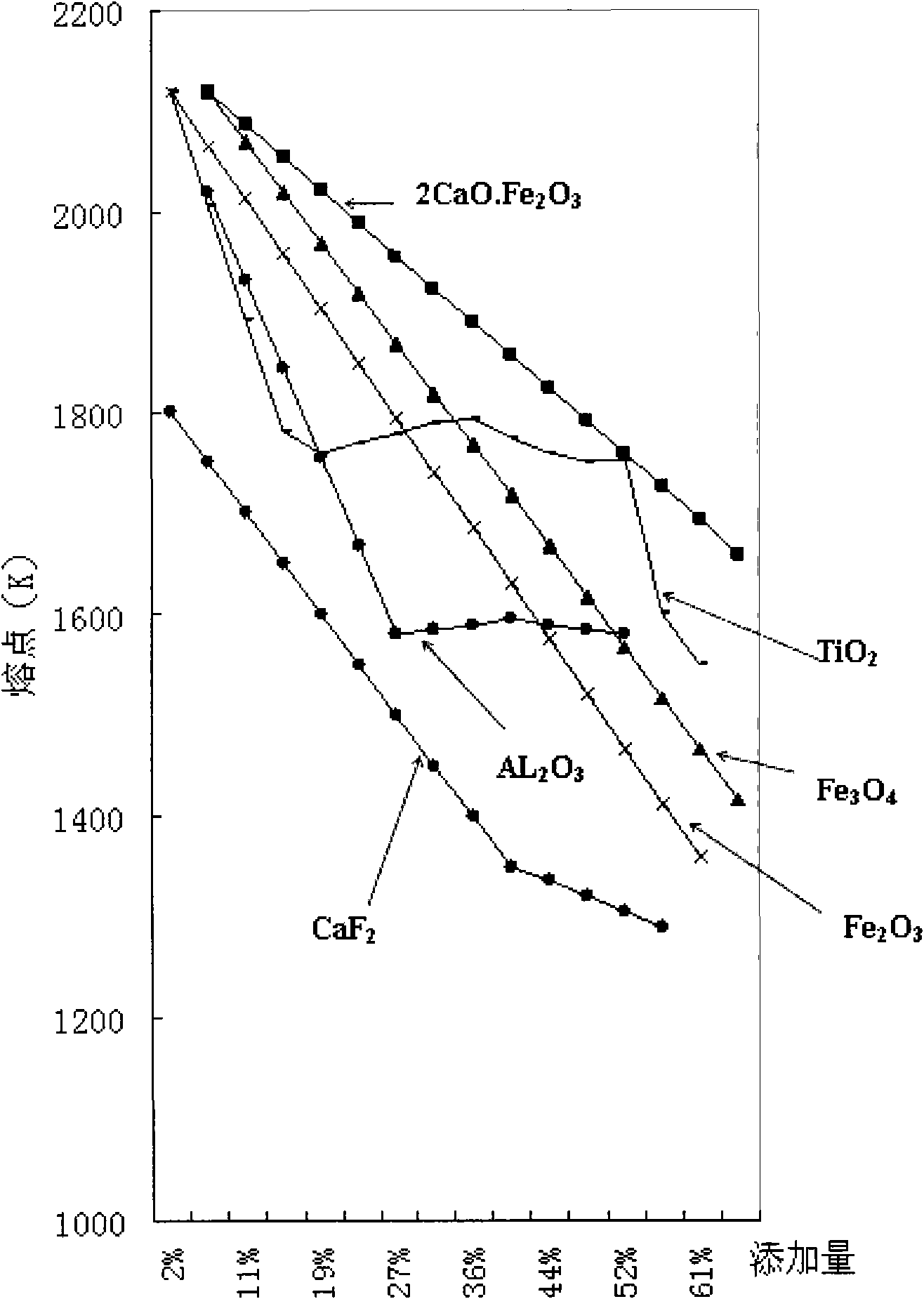

InactiveCN101173323ALow melting pointFacilitate chemical reactionsManufacturing convertersProcess efficiency improvementSteelmakingDolomite

The invention relates to a plurality of assistant materials of slagging materials and a preparation method, belonging to metallurgy field, which is characterized in comprising the components in the following weight matching: steel slag of converter 8.0 to 9.5 shares and addition agent 0.5 to 2 shares; wherein, the addition agent comprises the components in the following weight percentage: Na2CO3 is 5.00 to 10.00 percent, FeO is 70.00 to 80.00 percent and BaCO3 is 10.00 to 20.00 percent. The assistant materials of slagging materials can be used in slagging and also used as slugging agent and dephosphorizing agent. The invention achieves the recycle utilization of the steel slag of converter, therefore has the advantages of lowering the amount of waste slag during steel-making, saving the dosages of current slagging material: lime and dolomite and improving the slagging performance, and also has the advantages of slagging rapid, sludging rapid and dephosphorizing effectively. The invention provides a new method to recycle the steel slag of converter for people.

Owner:攀钢集团成都钢铁有限责任公司

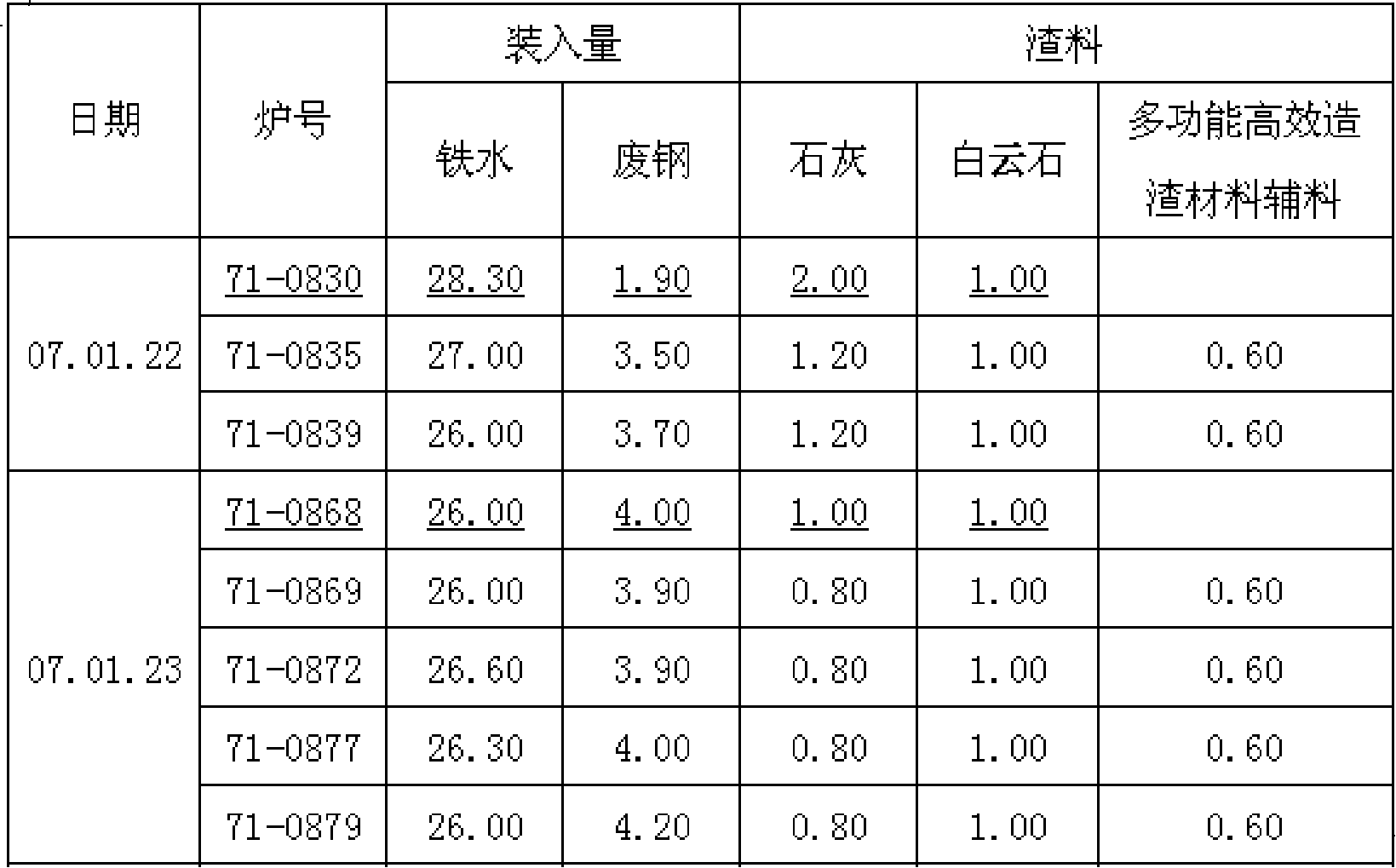

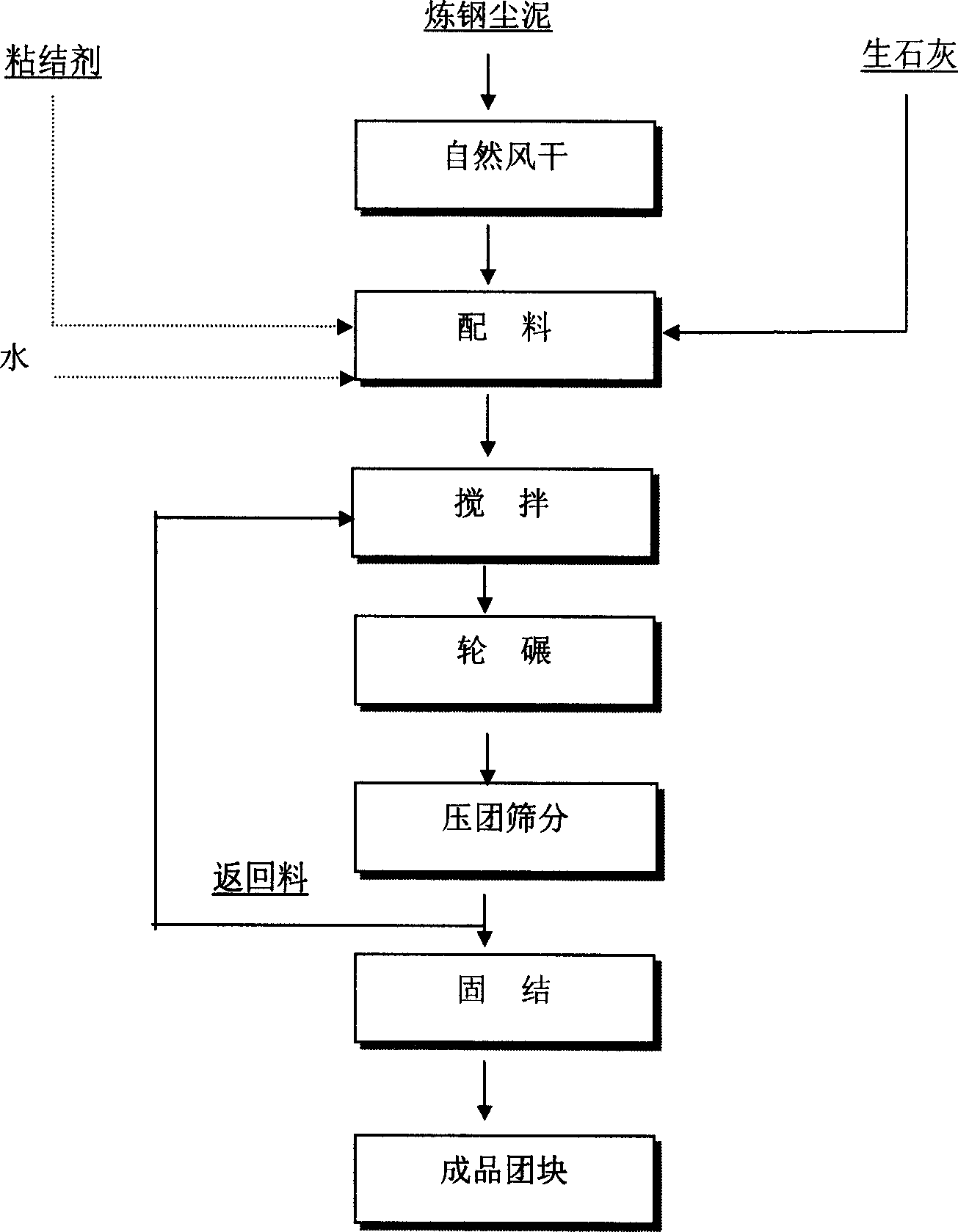

Process for preparing slag by pelletization of steel-making dust slime

InactiveCN1664120AHigh strengthIncreased degree of plastic deformationManufacturing convertersProcess efficiency improvementSteelmaking

The invention relates to a comprehensive utilization method of dust and mud in steelmaking process, which is specifically a spheroiditic slagging agent production process. The invention comprises the following steps: drying dust and mud in the open, adding 2-6% burnt lime and 0.5-1% adhensive to the mud to produce mixture, sending the mixture to agitator to intimate mixing, sending the mixture to roller to be pulverized fully, sending it to pelletizer to produce green-ball of phi20-phi30mm size by roll-type briquetting process in presure of 40-60KN, processing green-ball in jigging screen to get green-ball end product on sifter and sliver as return material under sifter and sending green-ball to tower furnace via charging system to be adglutinate and get end product.

Owner:张清学

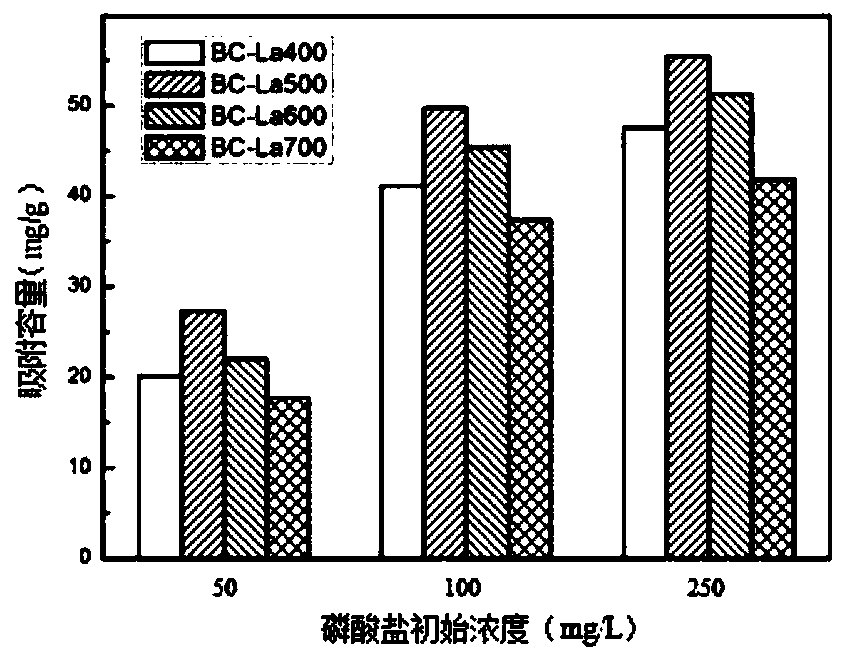

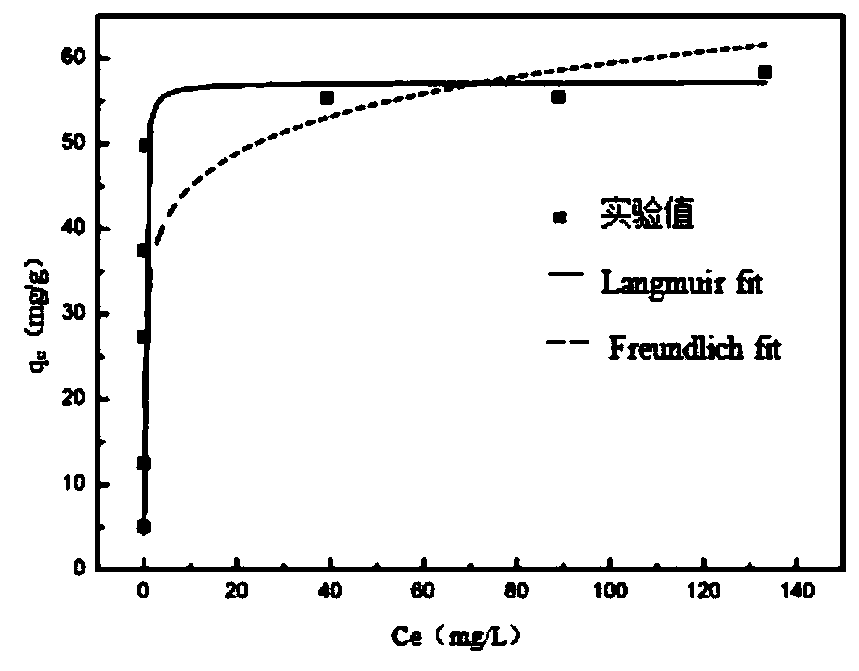

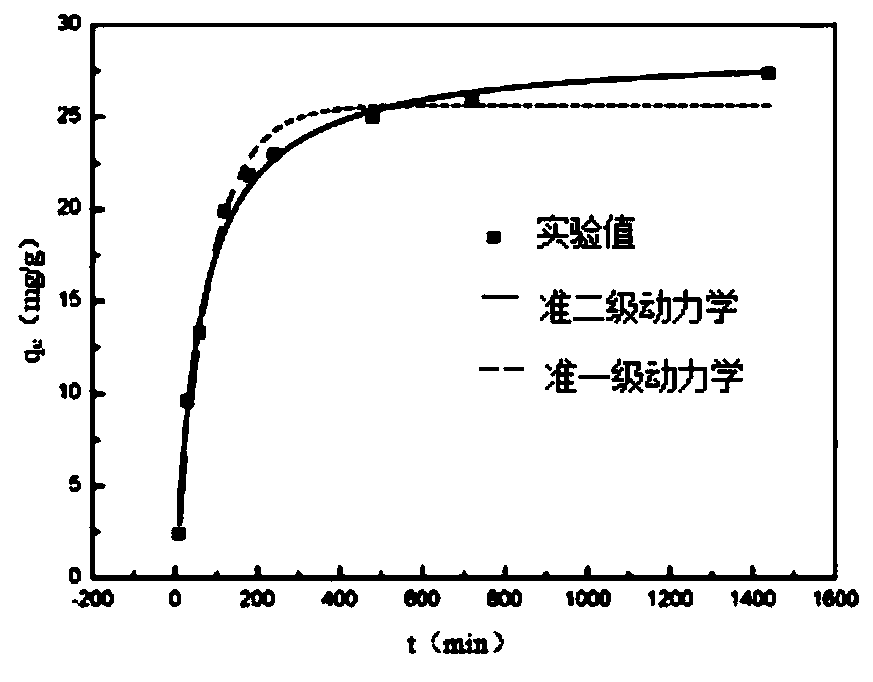

Lanthanum-modified biochar, and preparation method and application thereof

InactiveCN111589416AWell-developed pore structureLarge specific surface areaOther chemical processesWater contaminantsPhosphateLanthanum(III) chloride

The invention relates to the technical field of biochar, and especially relates to a lanthanum modified biochar, and a preparation method and application thereof. The preparation method provided by the invention comprises the following steps: pyrolyzing sheep manure to obtain sheep manure biochar; and washing the sheep manure biochar, dipping the washed sheep manure biochar in a lanthanum chloridesolution, and adjusting the pH value to 8-11 to obtain the lanthanum modified biochar. According to the record of the embodiment, the adsorption capacity of the lanthanum-modified biochar prepared bythe preparation method in the technical scheme on phosphate can reach 58.33 mg / g at most.

Owner:AGRO ENVIRONMENTAL PROTECTION INST OF MIN OF AGRI

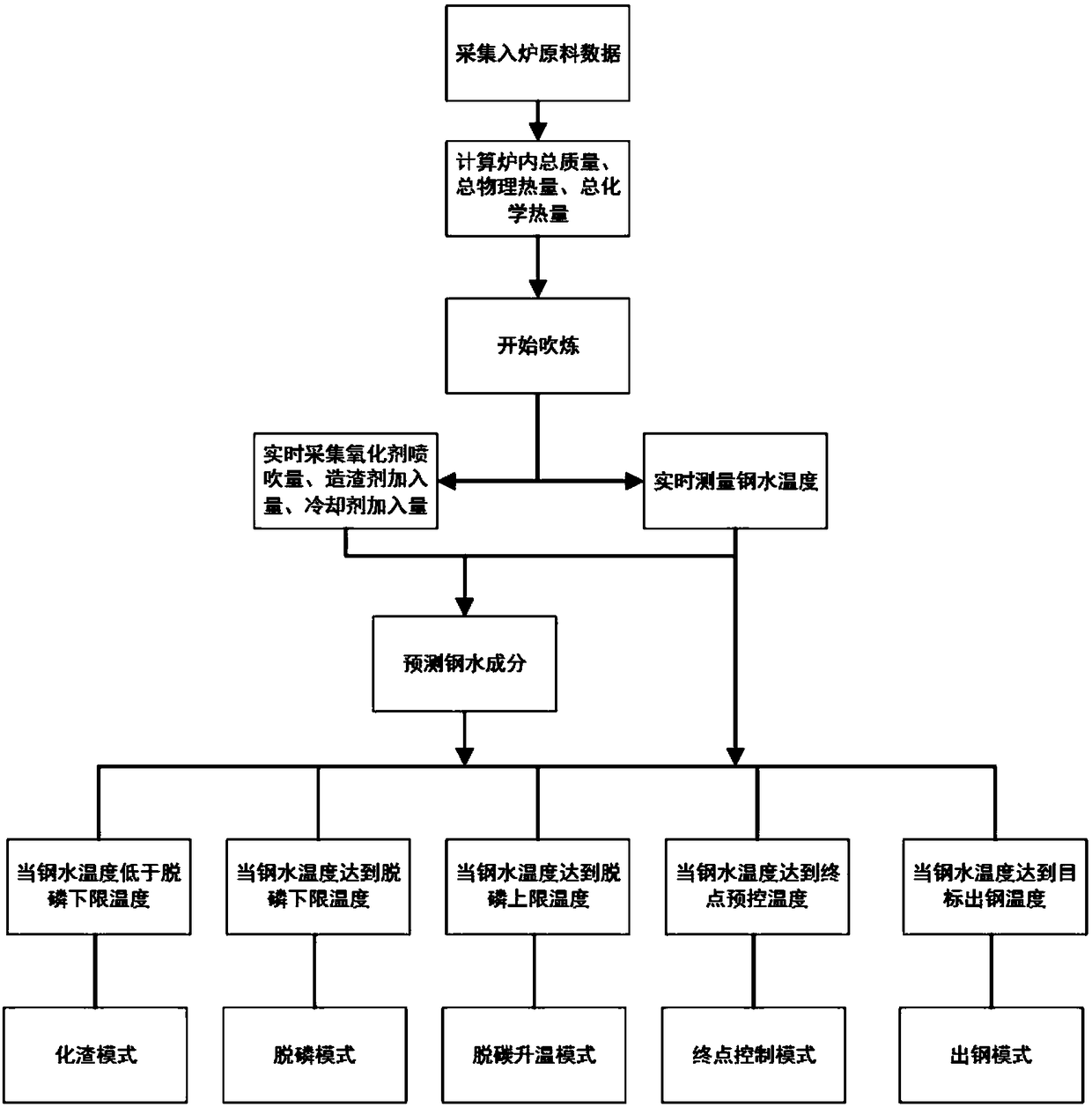

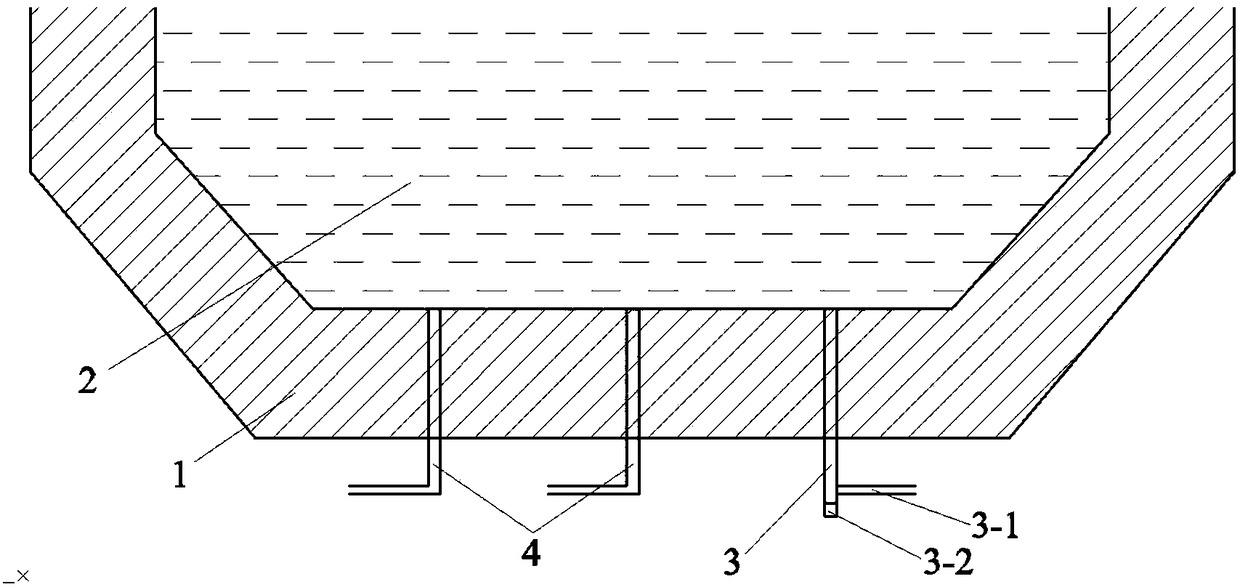

Bottom blowing oxygen converter smelting process control method based on molten steel continuous temperature measurement

ActiveCN108359766AImprove dephosphorization effectIncreased double hit rateManufacturing convertersOxygen converterBottom-blown oxygen converter

The invention relates to the field of bottom blowing oxygen converter steelmaking, and provides a bottom blowing oxygen converter smelting process control method based on molten steel continuous temperature measurement. A temperature measurement spraying gun is installed at the furnace bottom of a bottom blowing oxygen converter to measure the temperature of molten steel in the converter, molten steel ingredients are forecasted in real time according to the molten steel temperature and the converter blowing and feeding conditions, staged control over the smelting process of the bottom blowingoxygen converter is carried out based on the molten steel temperature, the spraying parameters of the bottom blowing spraying gun are dynamically adjusted, and optimum control and double hitting of the final molten steel temperature and the carbon content in the smelting process are achieved. A new method is provided for the process and the terminal control of the bottom blowing oxygen converter,the double hitting rate of the final molten steel temperature and the carbon content is improved by 10%, the final molten steel phosphorus content can be stably controlled within 80 ppm, and consumedsteel is reduced by 10 kg / t.

Owner:UNIV OF SCI & TECH BEIJING

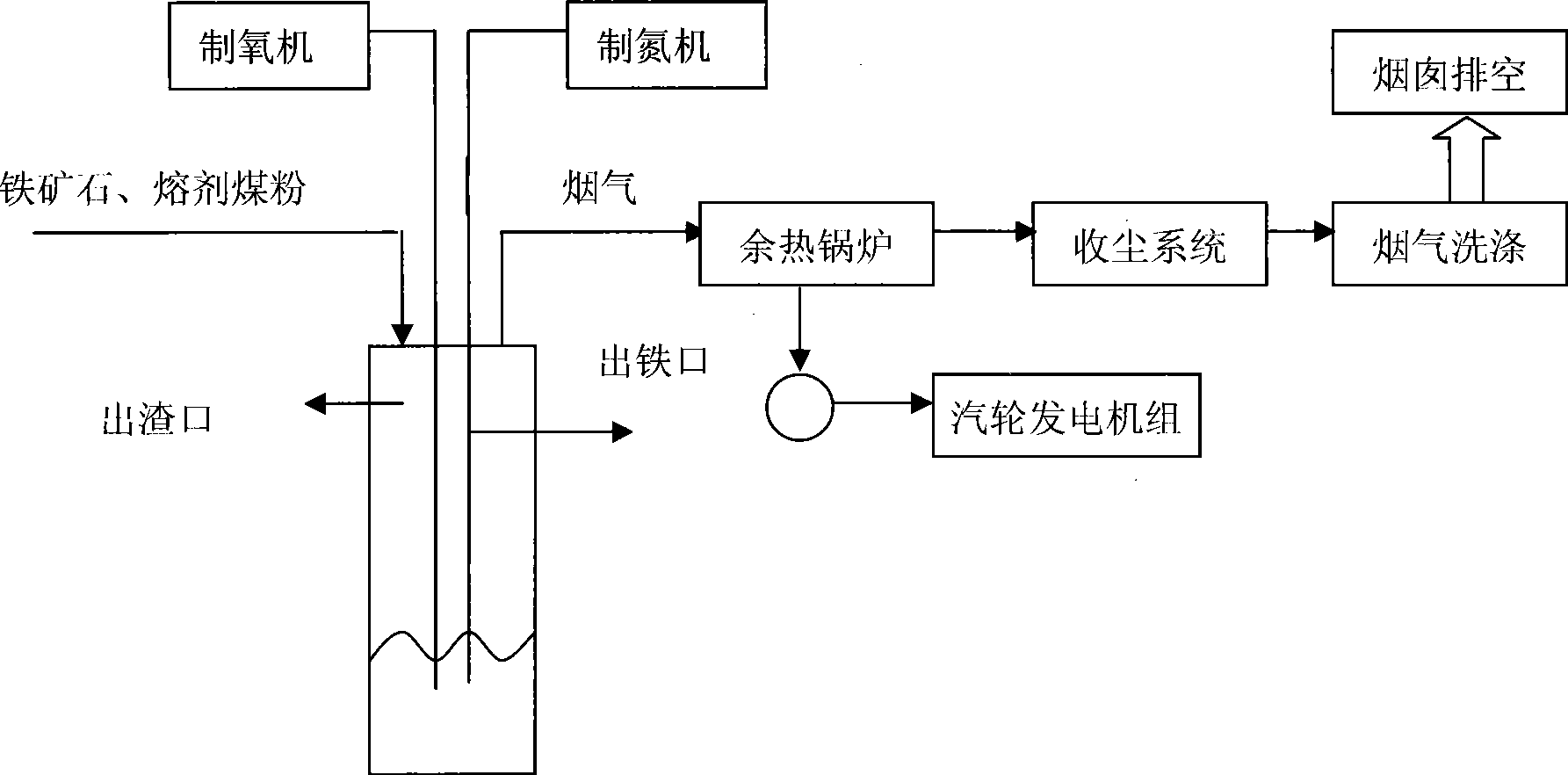

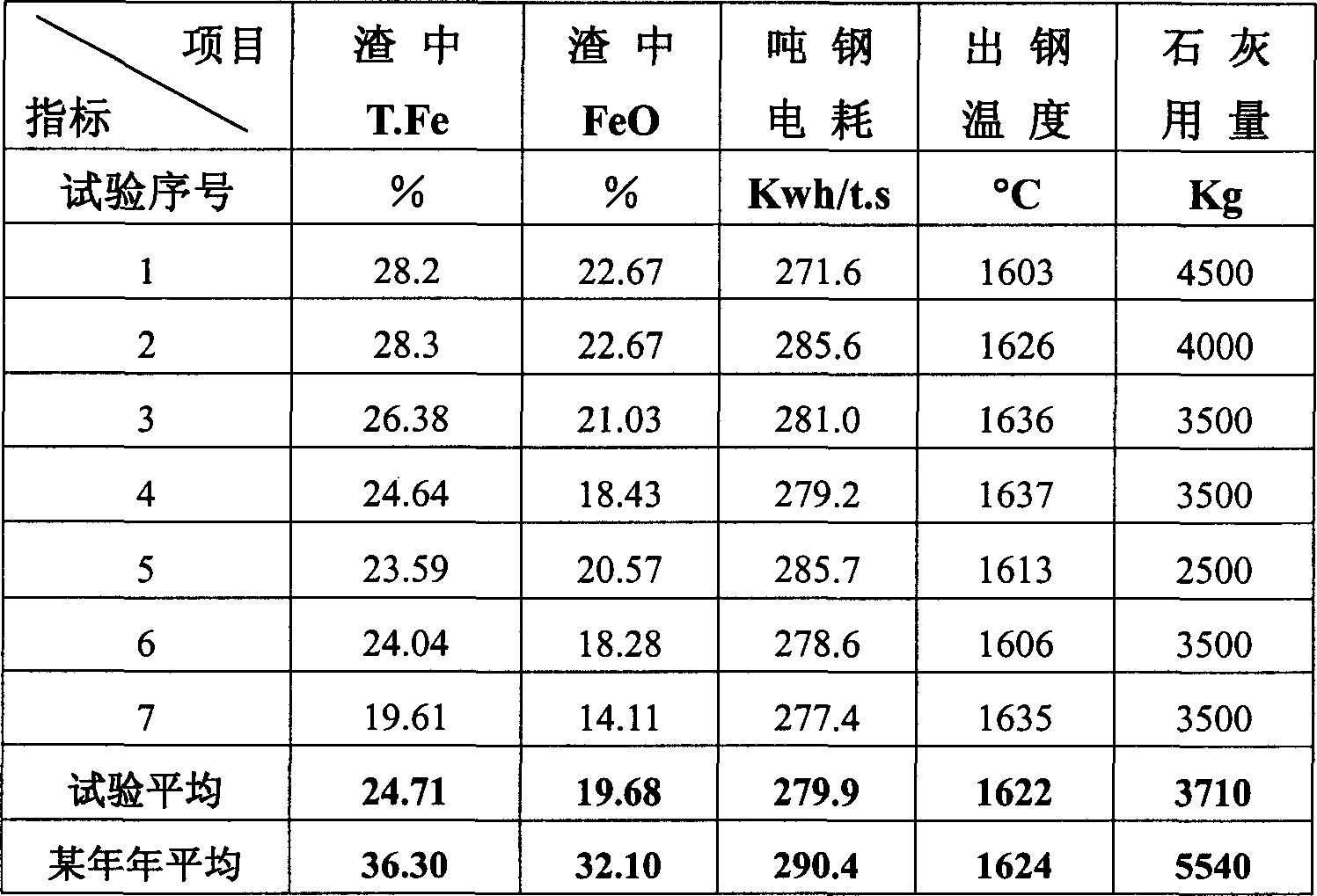

Method for preparing molten iron by utilizing oxygen top blown smelting reduction ironmaking

The invention relates to a method for producing molten iron by directly utilizing coal to deoxidize iron ore under smelting state, belonging to the technical field of energy source and metallurgy. The method comprises the following steps: charging iron ore, dolomite, lime and deoxidized coal are crushed, the crushed for materials are evenly mixed according to a certain proportion and added to a smelting reducing furnace from a material inlet at the top of the smelting reducing furnace; a central nitrogen pipe of a spray gun is inserted into a slag layer of a smelting pool to spray nitrogen to stir the slag layer, and one period of reaction, smelted high-temperature molten iron and slag are respectively discharged from an iron outlet and a slag outlet, wherein the oxygen jacket of the spray gun is higher than the smelting slag. In the method, raw materials do not need to be treated in advance so that a coking procedure is omitted and the environment pollution is reduced; coal of various levels can be used as fuel; the oxidizing atmosphere in the furnace is very strong so as to be very beneficial to dephophorization; and investment for the construction is low and can be recovered in a short time.

Owner:KUNMING UNIV OF SCI & TECH

Vanadium-titanium nodular cast iron smelting method

The invention discloses a vanadium-titanium nodular cast iron smelting method which comprises the steps of weighing furnace burden, smelting, spheroidizing and inoculating, wherein the smelting step comprises the sub-steps: adding oxide scale of which the addition amount is 0.5-1.5 percent of the weight of the furnace burden, and adding the oxide scale at the bottom of the furnace burden during smelting and charging; in the smelting step, after the furnace burden is molten down, adding silicon iron into molten iron for regulating the components, so as to achieve the deoxidation effect. The method has the beneficial effects that the low-price oxide scale is added into the bottom of the furnace burden during charging, and the element Ti is oxidized preferentially, so that the titanium content is reduced, the inverse spheroidizing effect of titanium is weakened, nodularizing in vanadium-titanium ductile iron is guaranteed, and a good dephosphorization effect is achieved when the oxide scale is added during smelting; the oxide scale is wide in source and low in price, the oxide scale is reasonably utilized, the production cost can be reduced, and the environment-friendly energy-saving effects are achieved. According to the method, the process is simple, the operation is convenient and the cost is low, and the comprehensive performance of the vanadium-titanium nodular cast iron is guaranteed.

Owner:XIHUA UNIV

Composite water purifying agent and preparation method and application thereof

ActiveCN104445553ATightly boundGood flocculation effectWater contaminantsWater/sewage treatment by flocculation/precipitationSludgeSilanes

The invention relates to the field of water treatment, in particular to a composite water purifying agent and a preparation method and application thereof. The composite water purifying agent is mainly prepared from polymeric ferric sulfate, dimethyl diallyl ammonium chloride, vinyl trimethoxy silane and polysilicic acid. The total amount of iron and the pH value of the composite water purifying agent are limited, the combination of organic components and inorganic components is closer, the flocculation capability of obtained flocculating constituents is greatly improved, and the composite water purifying agent has a good effect of removing phosphorus in water. According to the special preparation method, the combination of the organic components and the inorganic components forming the composite water purifying agent is closer, and the flocculation capability of the flocculating constituents is improved. The method is simple and easy to operate, does not produce harmful gas in the production process, and is safe and reliable. The composite water purifying agent is applied to treatment for phosphorus wastewater, has the advantages of being less in feeding amount, compact in flocculating constituents, high in sedimentation velocity, good in water-out effect, less in sludge quantity and low in treatment cost, and has significant social and economic benefits.

Owner:神美科技有限公司

Slag regulating agent for super high power large electric furnace smelting

ActiveCN1782101AReduce iron contentTotal iron content dropped toProcess efficiency improvementElectric furnaceElectricityElectric arc furnace

The present invention relates to super high power arc furnace smelting technology, and is especially slag regulating agent for super high power large electric furnace. The present invention features that the slag regulating agent consists of C 30-35 wt%, Al 5-7 wt%, MgO 8-10 wt%, Al2O3 10-12 wt%, CaO 20-25 wt%, SiC 9-10 wt% and impurity the rest, and has bulk density of 1.8-2.0 g / cu cm. The slag regulating agent of the present invention can form homogeneous foamed slag continuously in the furnace to reduce FeO, Fe2O3, etc. in the slag layer, raise smelting yield, raise steel alloy yield, raise the heat efficiency of the furnace, lower power consumption, raise the dephosphorization capacity of the furnace and prolong the service life of the furnace.

Owner:BAOSHAN IRON & STEEL CO LTD

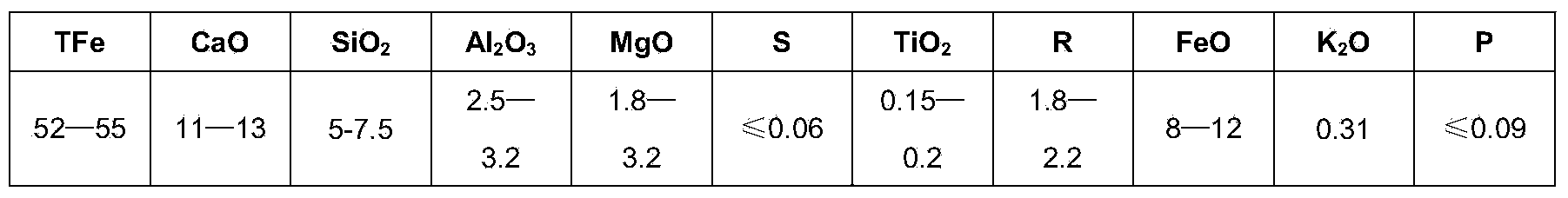

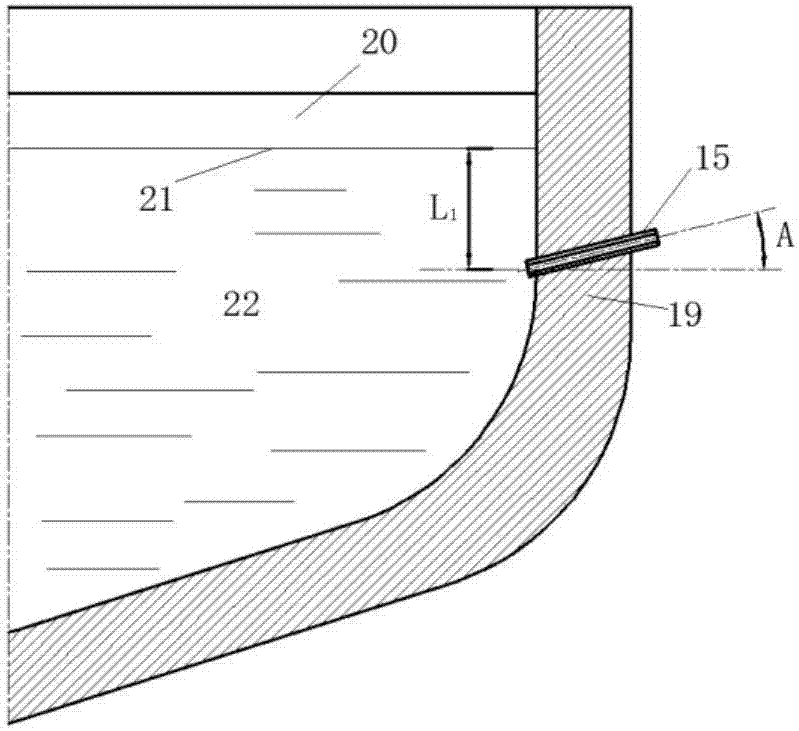

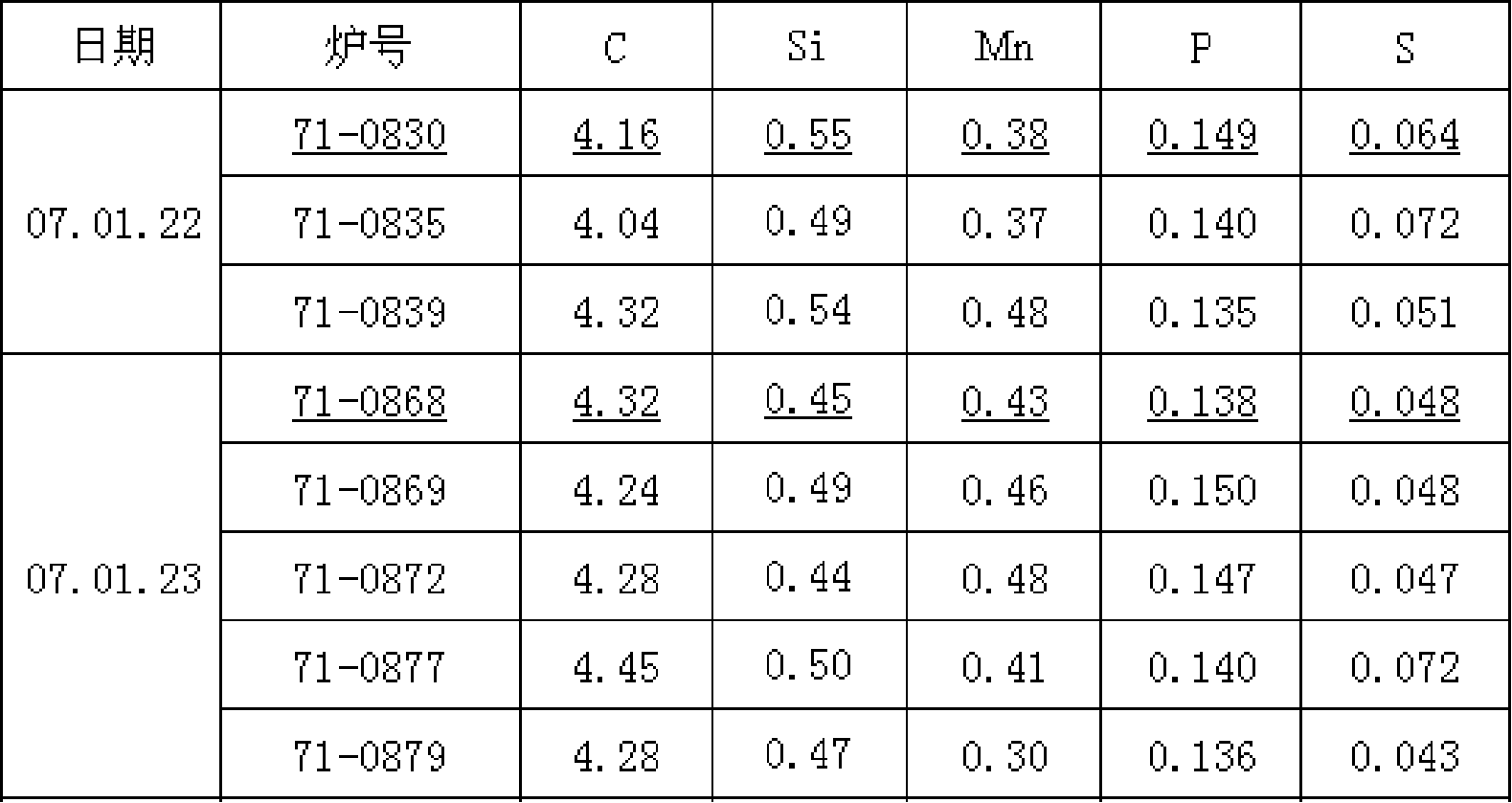

Converter smelting method for improving end molten steel remainder Mn with medium-high-Mn, high-P and low-Si molten iron

ActiveCN109097522AIncrease the residual Mn contentReduce back phosphorusManufacturing convertersProcess efficiency improvementSteelmakingAlkalinity

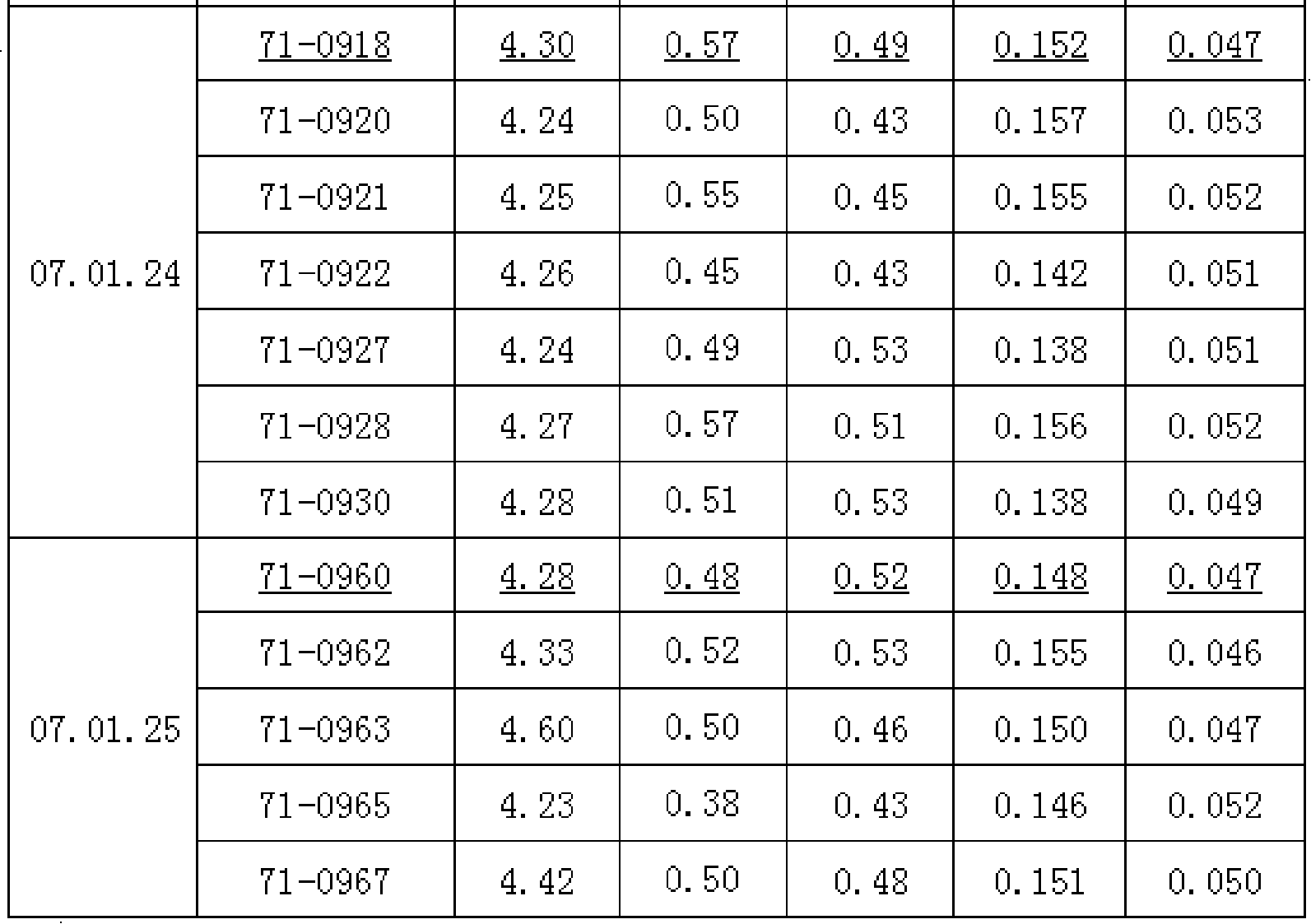

The invention discloses a converter smelting method for improving end molten steel remainder Mn with medium-high-Mn, high-P and low-Si molten iron (C4.20-4.60wt, Mn 0.90wt%-1.15wt%, Si 0.05-0.15wt%, P0.100-0.130wt% and S smaller than or equal to 0.040wt%). Integrated innovation is conducted on processes such as slag retention operation, continuous casting residual slag application, low-alkalinityslagging process, constant-pressure low lance position operation in the smelting process and tapping slag washing in the whole process, smelting reaction dynamics and thermodynamic conditions are optimized, the distribution concentration of MnO in slag in the smelting process is increased, better smelting slagging and dephosphorization effects are obtained under the conditions of little slag andlow-alkalinity slag systems, rephosphorization of molten steel in the later period of smelting and the tapping process is reduced to the greatest extent, the content (0.43wt%-0.55wt%) of end point molten steel residual Mn is significantly increased, the addition amount of Mn alloys in the deoxidation alloying process is reduced, the steelmaking alloy consumption and alloying cost are significantlyreduced, the economic indexes of the smelting technology is improved, and the market competitiveness of products is improved.

Owner:WUKUN STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com