Patents

Literature

48results about How to "Avoid muddying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

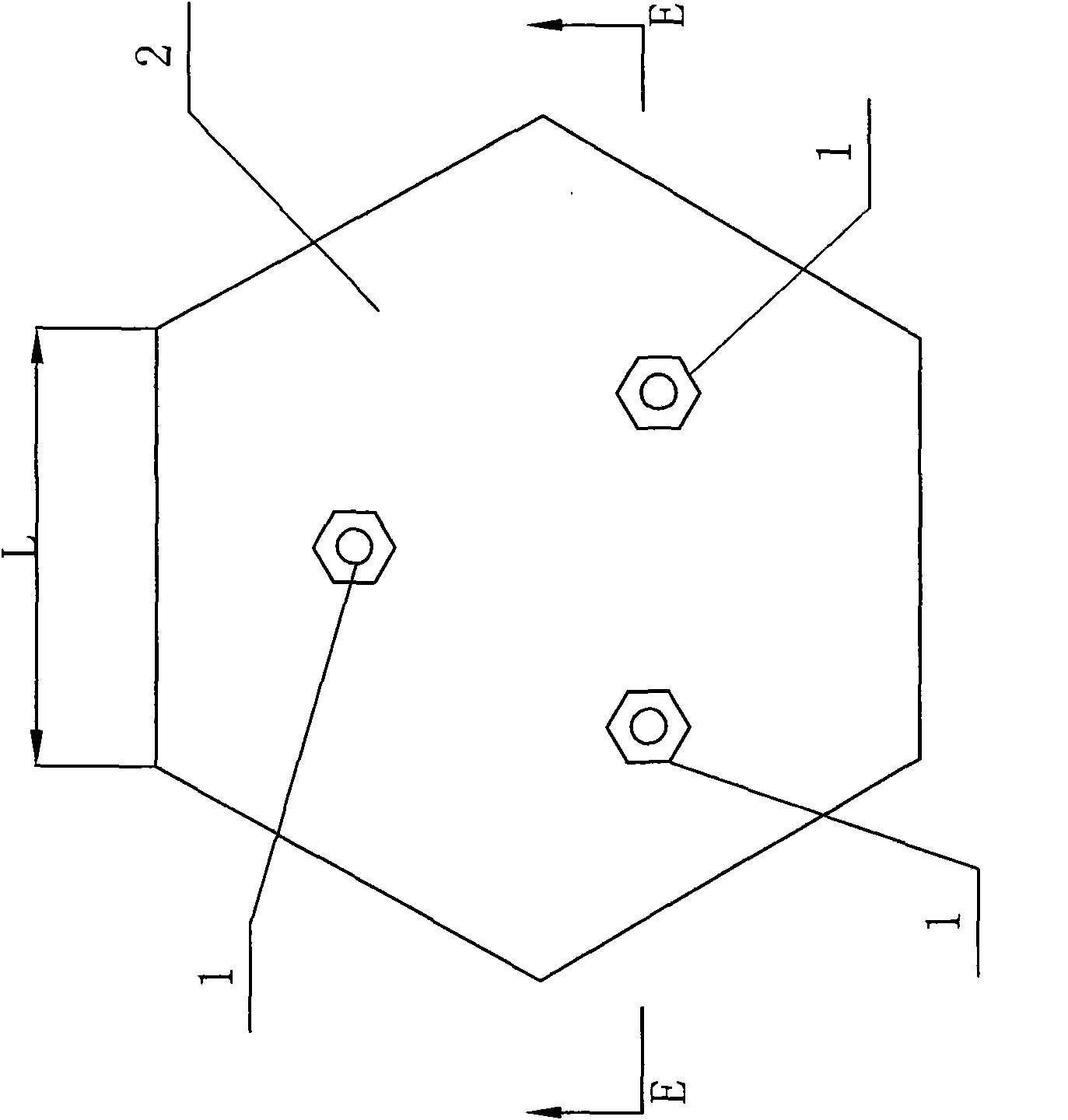

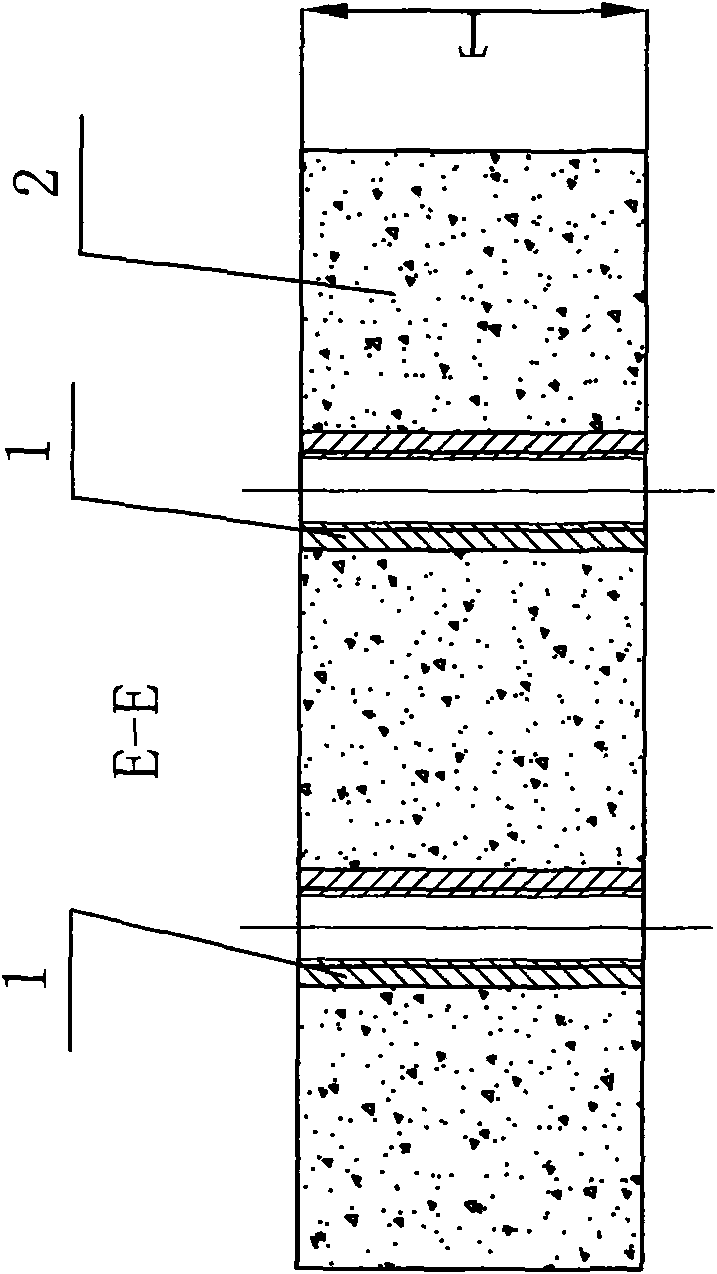

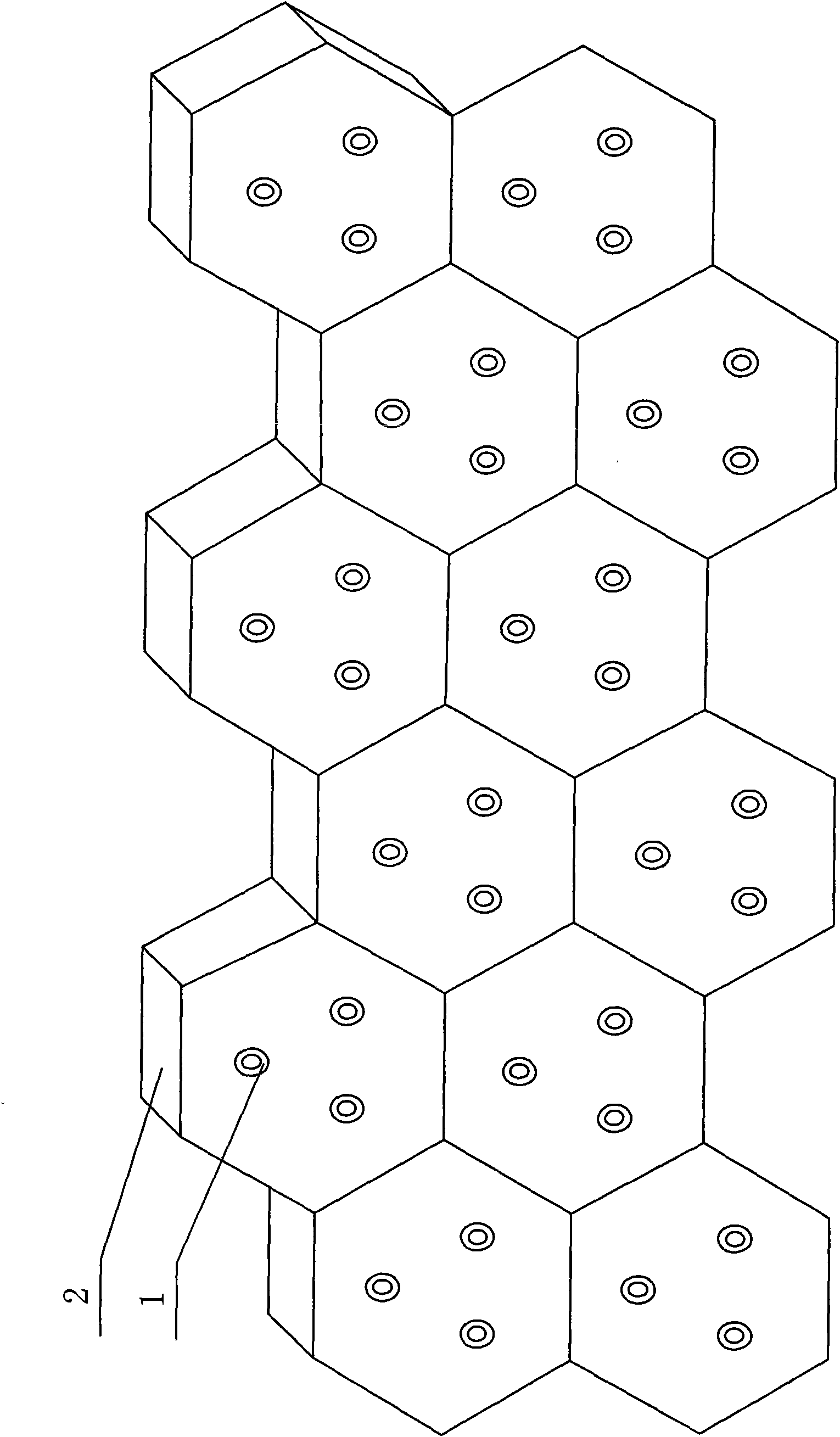

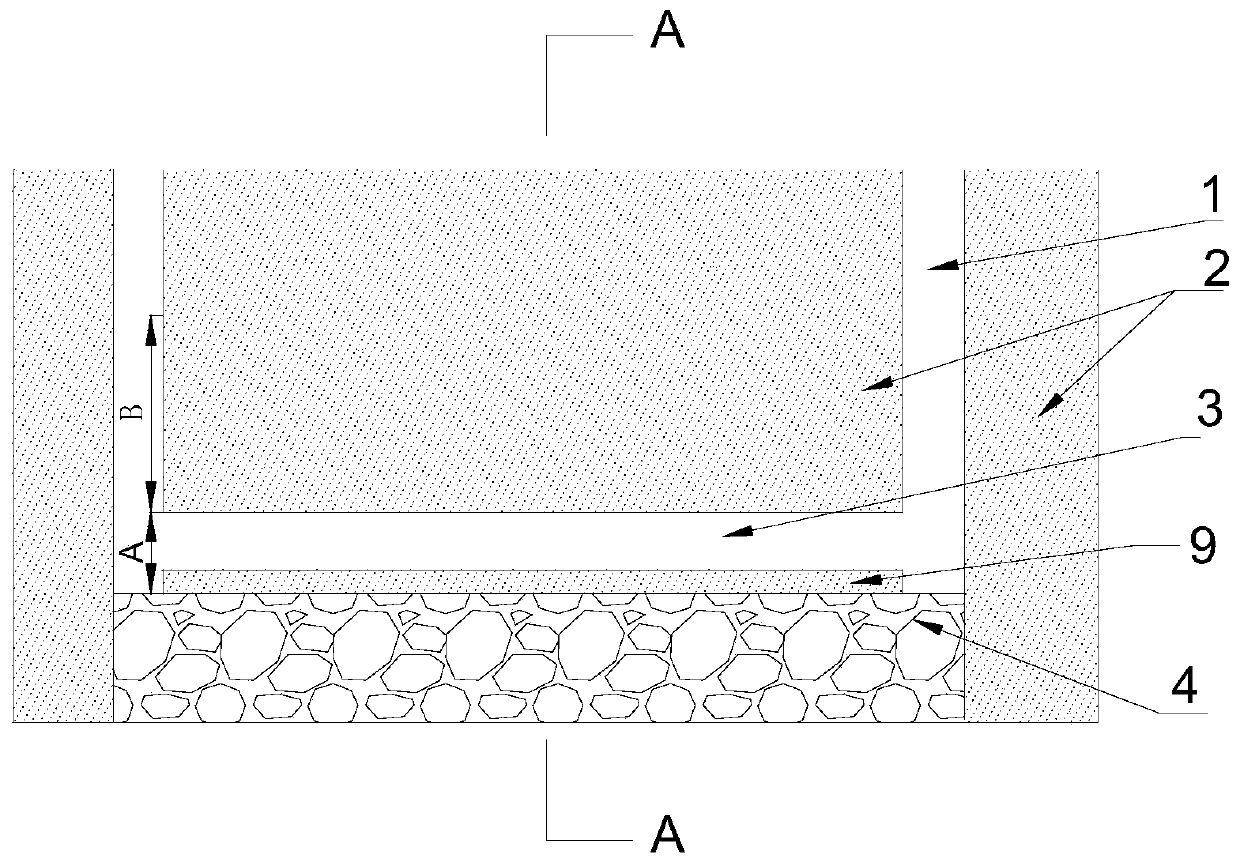

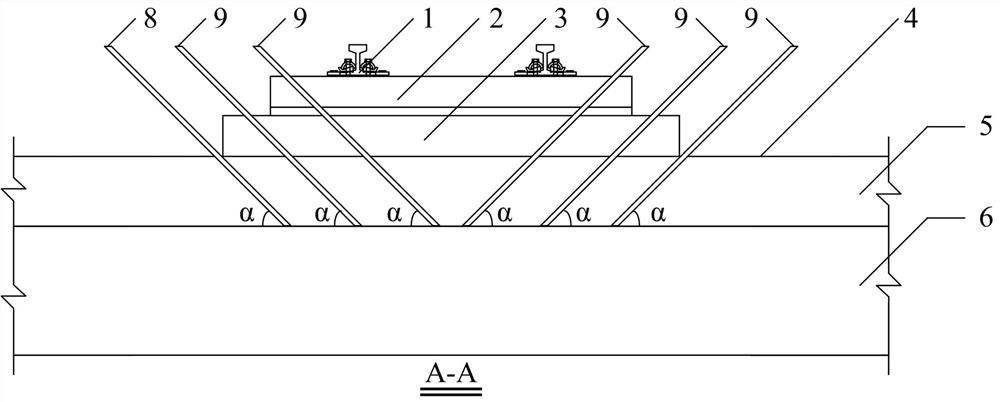

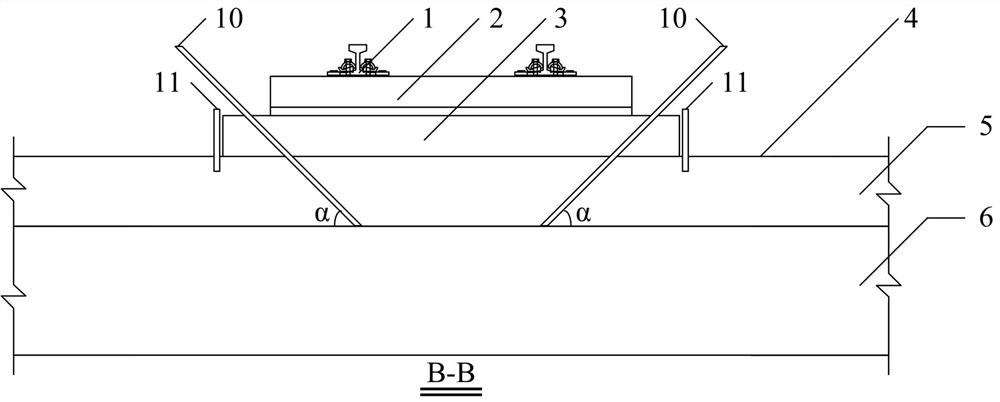

Method for fast paving urban road surfaces and special reinforced concrete block

The invention relates to a method for fast paving urban road surfaces and a special reinforced concrete block, relating to the method for paving the road surface and the reinforced concrete block specially used in the method. The method aims at solving the problems of uneven road surface, easy frost boiling of the road and long pavage period of the cement road surface caused by the easy deformation of the existing asphalt road surface. The method includes the steps as follows: preparing a great amount of reinforced concrete blocks according to requirements in advance; leveling a subgrade; and paving the reinforced concrete blocks one after another on the leveled subgrade by hoisting equipment, and forming the road surface by splicing the upper surfaces of a plurality of reinforced concrete blocks. A main body of each reinforced concrete block is provided with at least three nuts for hoisting rings in advance, the three nuts for the hoisting rings are welded together with bar reinforcements in the reinforced concrete blocks, and the two end faces of each nut for the hoisting rings are respectively exposed outside. The method of the invention has the advantages of fastness, convenience and short pavage period. As the nuts for the hoisting rings are arranged in the reinforced concrete blocks in advance, the reinforced concrete blocks can be easily transported by the hoisting rings.

Owner:李嘉树

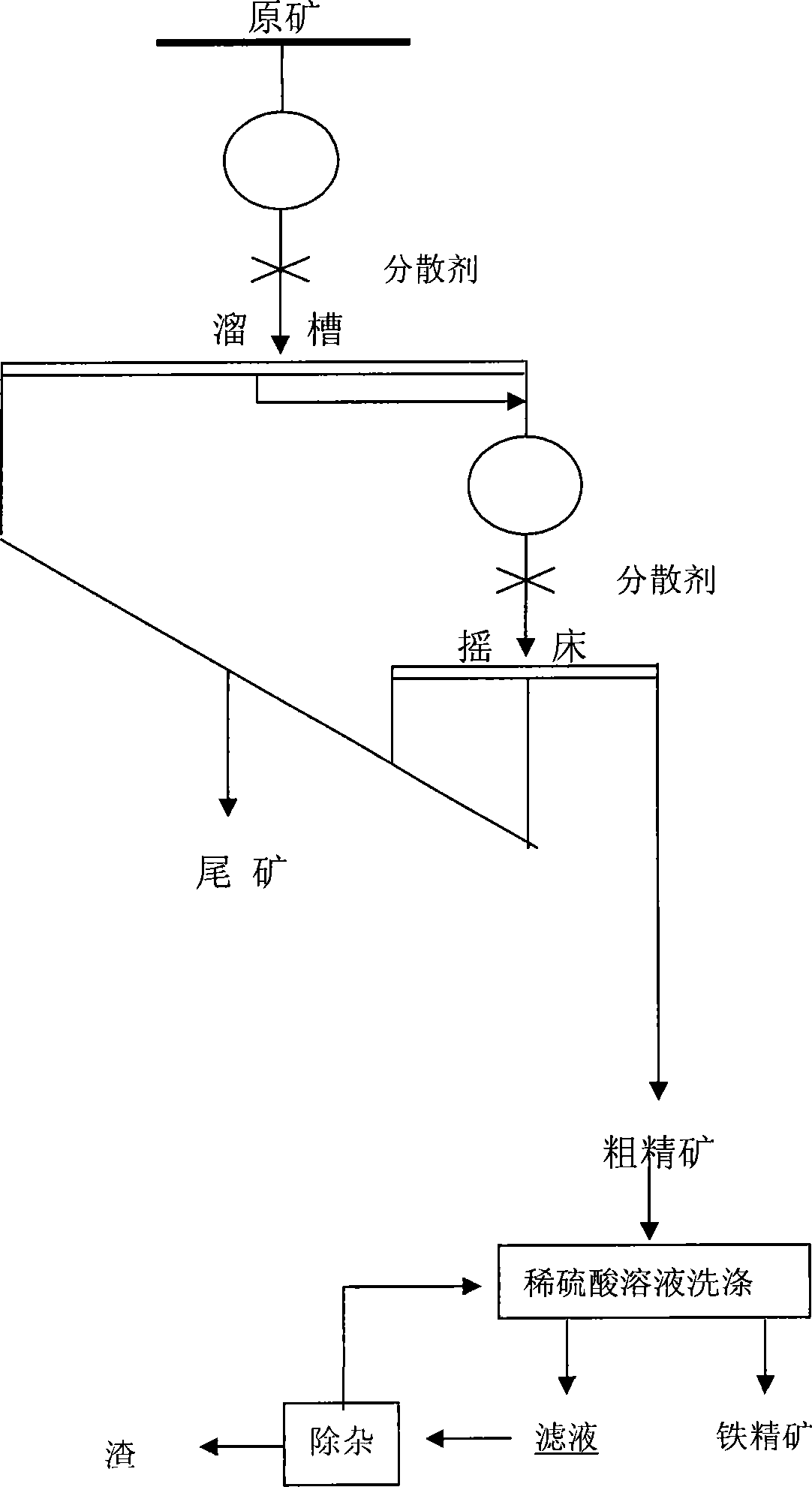

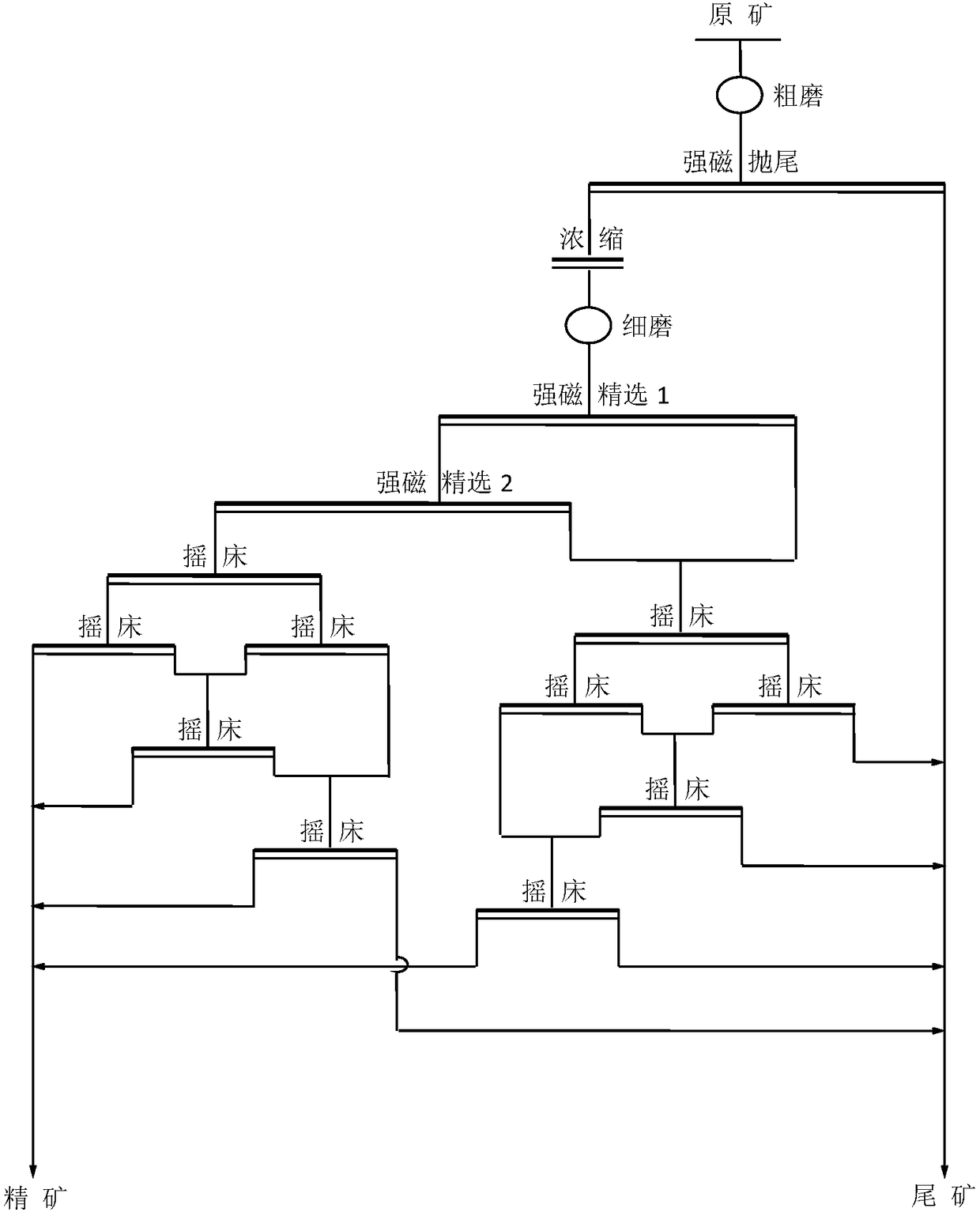

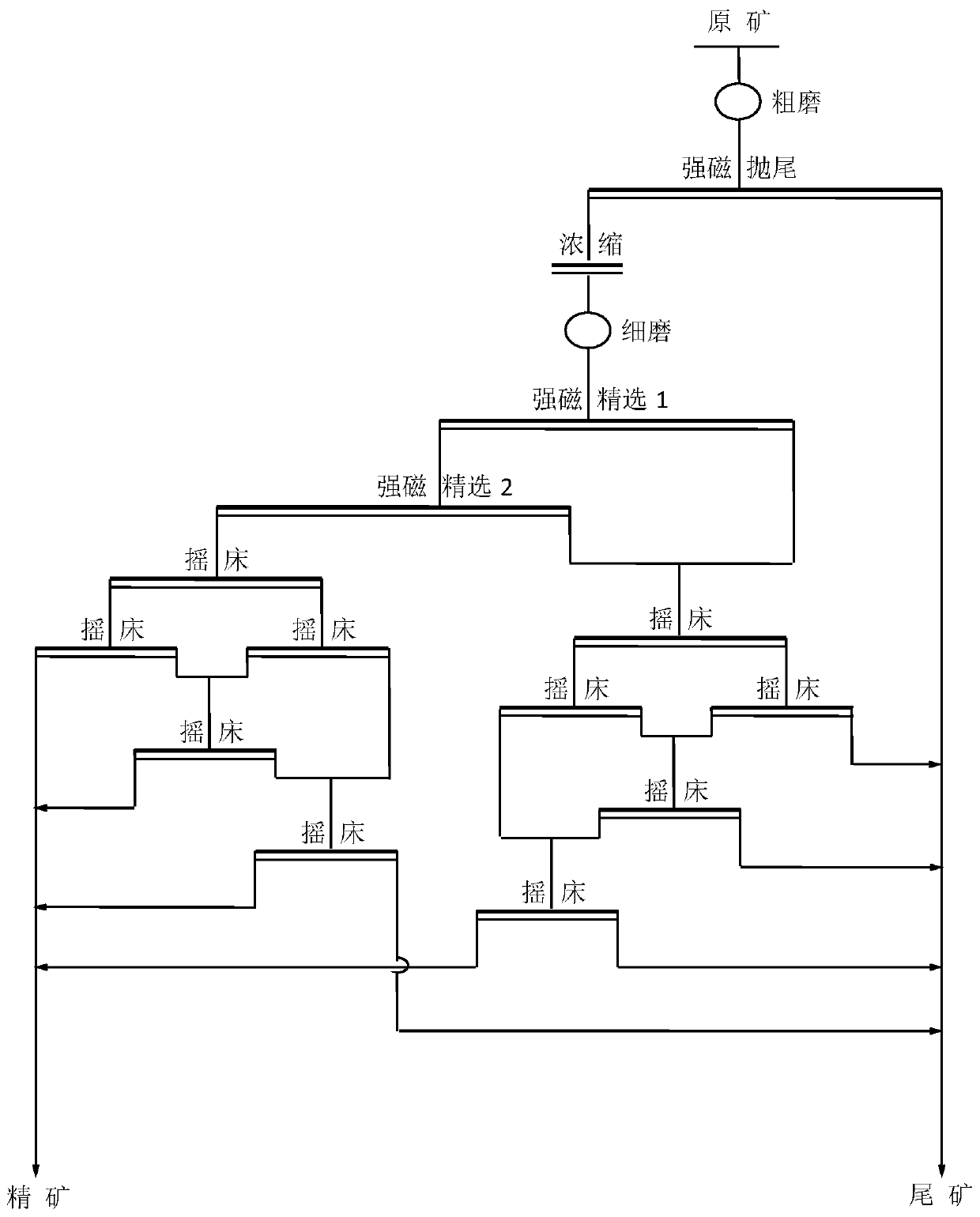

Method forpreparing iron concentrate for making iron from phosphorus-containing oolitic hematite

InactiveCN101054625AAvoid muddyingRaise the gradeProcess efficiency improvementGranularityRoom temperature

The invention discloses a method of producing iron ore concentrate containing roe - like phosphorus hematite for iron manufacture, comprising crashing the roe - like ore, wet grinding until the hematite of granularity < 0.074mm are 40-60 mass% of whole hematite, adjusting the pulp mass percent concentration to 20%-30%, adding the water glass as dispersant of 0.5-1.0kg / t, agitating adequately, selecting by helix shoot, grinding produced ore concentrate until the one with the granularity < 0.074mm are more than 80 mass%, having the water glass as dispersant of 0.2-0.5kg / t, agitating to disperse uniformly, then selecting by shaking table, washing produced iron ore concentrate in room temperature by 0.5%-1.5% dilute sulfuric acid solution for 5-15 minutes, centrifugal separation, in which the solid are iron ore concentrate. The invention treats the roe - like phosphorus hematite to obtain the iron ore concentrate with a tenor of 62%, P content less than 0.06%. The invention can fully and reasonably apply rich roe - like phosphorus hematite resource in our country, has a good effect of dephosphorization and a low cost. And produced iron ore concentrate have a high recovery ratio.

Owner:CENT SOUTH UNIV

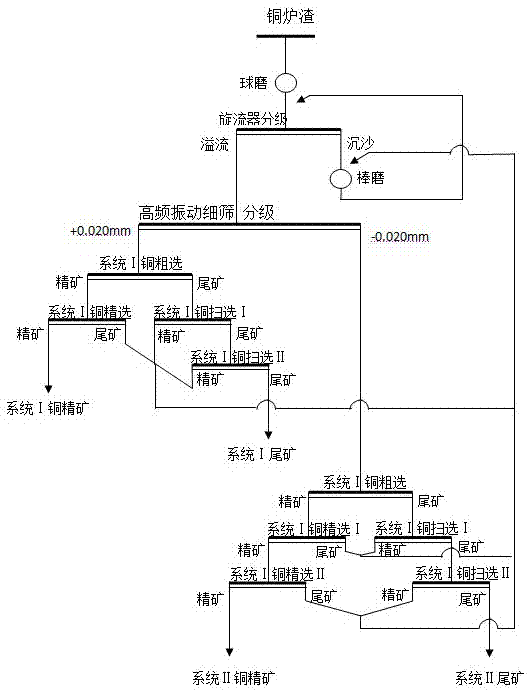

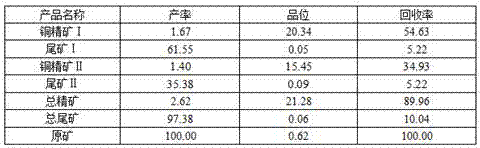

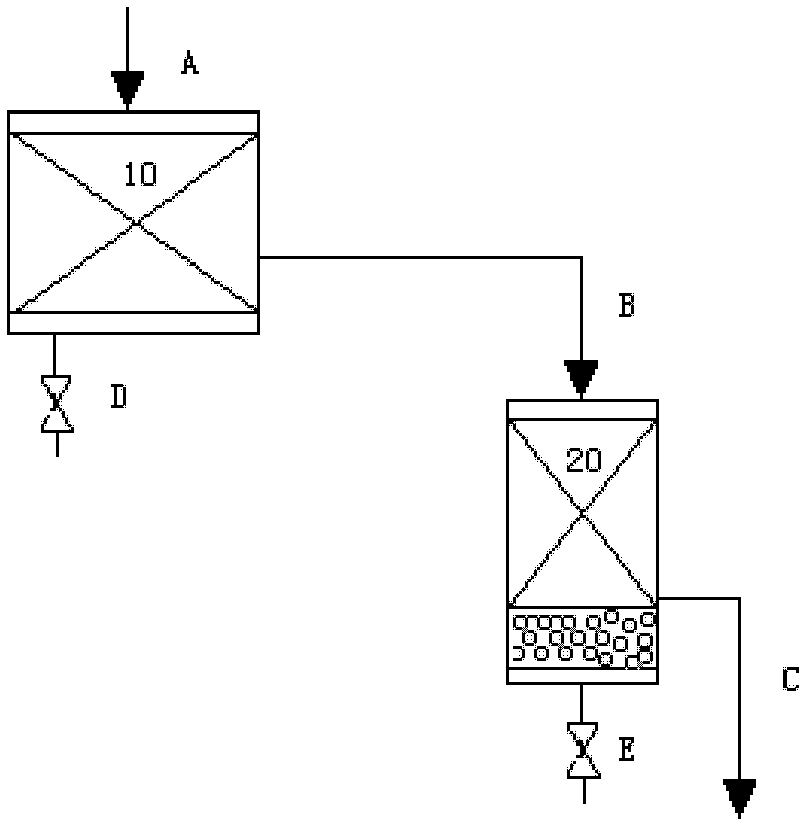

Mineral processing process for recovering copper from copper smelting slag through flotation

The invention discloses a mineral processing process for classifying recovery of copper from copper smelting slag. The mineral processing process adopts an ore grinding-grading-classifying separation process; a two-stage and one closed circuit grinding flow composed of a ball grinding mill, a rod mill and a hydrocyclone is used for the ore grinding of the copper smelting slag, and the occupancy of grinding products with granularity -0.044 mm is 80-90%; the grinding products are graded into +0.020 mm coarse products and -0.020 mm fine products by a high-frequency vibrating fine screen, the +0.020 mm coarse products are processed into copper concentrate I and gangue I through one-time roughing, one-time concentrating and twice scavenging flotation processes, and the -0.020 mm fine products are processed into copper concentrate II and gangue II through one-time roughing, twice concentrating and twice scavenging flotation processes. The flotation condition pertinence is improved, the reagent cost and energy consumption cost are lowered, and the purpose of effectively recovering the copper from the copper smelting slag is achieved.

Owner:KUNMING UNIV OF SCI & TECH

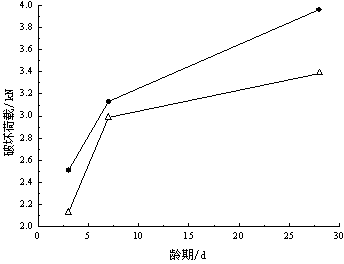

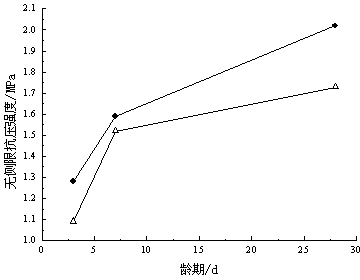

Compound stabilizing method for silty soil in Yellow River flooded areas

The invention discloses a compound stabilizing method for silty soil in Yellow River flooded areas and belongs to the technical field of road construction materials and road building. The method can be realized through reasonable mix proportion of a sodium methyl silicate aqueous solution, polyacrylamide, pulverized coal, lime and silty soil. According to the method, not only can the cost be lowered, but also the non-laterally confined compressive strength and anti-penetrability performance of the silty soil can be improved. In addition, the method also has the advantages that the functions of resisting capillary water and preventing rise of the capillary water can be achieved, and the stability property of the water can be enhanced so as to prevent the damage of roadbed and road surfaces; and the maintenance cost can be lowered, the road service life can be prolonged, and the like.

Owner:HENAN UNIVERSITY +2

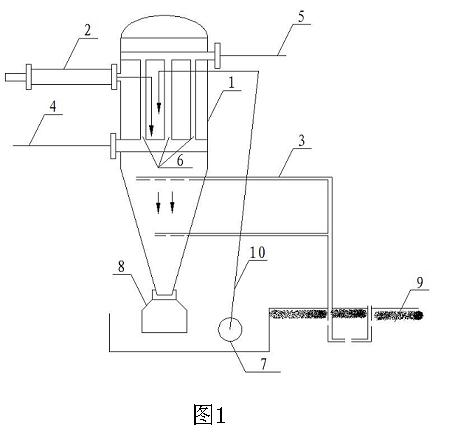

Pyrolysis furnace decoking gasification and purification as well as heat energy and material recovery device

InactiveCN102160936AHigh recovery rateReduce pollutionThermal non-catalytic crackingCombination devicesWater resourcesExhaust pipe

The invention relates to a pyrolysis furnace decoking gasification and purification as well as heat energy and material recovery device, comprising a tank body. The tank body is internally provided with a heat absorbing pipe, a water inlet pipe and a water outlet pipe, wherein, the water inlet pipe and the water outlet pipe are communicated with the heat absorbing pipe; the tank body is provided with an air inlet pipe and an exhaust pipe which are communicated with the inner chamber of the tank body; and the bottom of the tank body is provided with a solid / liquid material outlet. By adopting the device provided by the invention, the steam, coke powder, air and water in the waste gas from a pyrolysis furnace are separated, thus realizing 'four-phase separation'; the heat energy and the water resource in the waste gas are recovered; the emission is reduced; and the pollution on the environment is reduced. In the actual production, the device can directly replace a coke cleaning pot to operate.

Owner:李树生

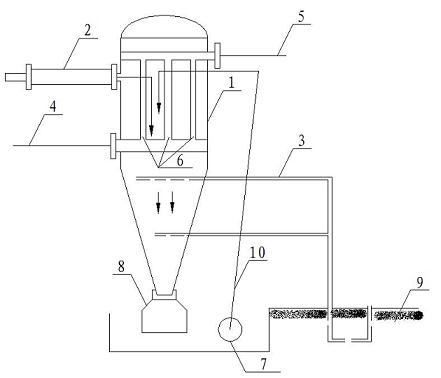

Process of naphtha desulphurization

InactiveCN103254930AAvoid erosionAvoid muddyingTreatment with plural serial refining stagesMolecular sieveNaphtha

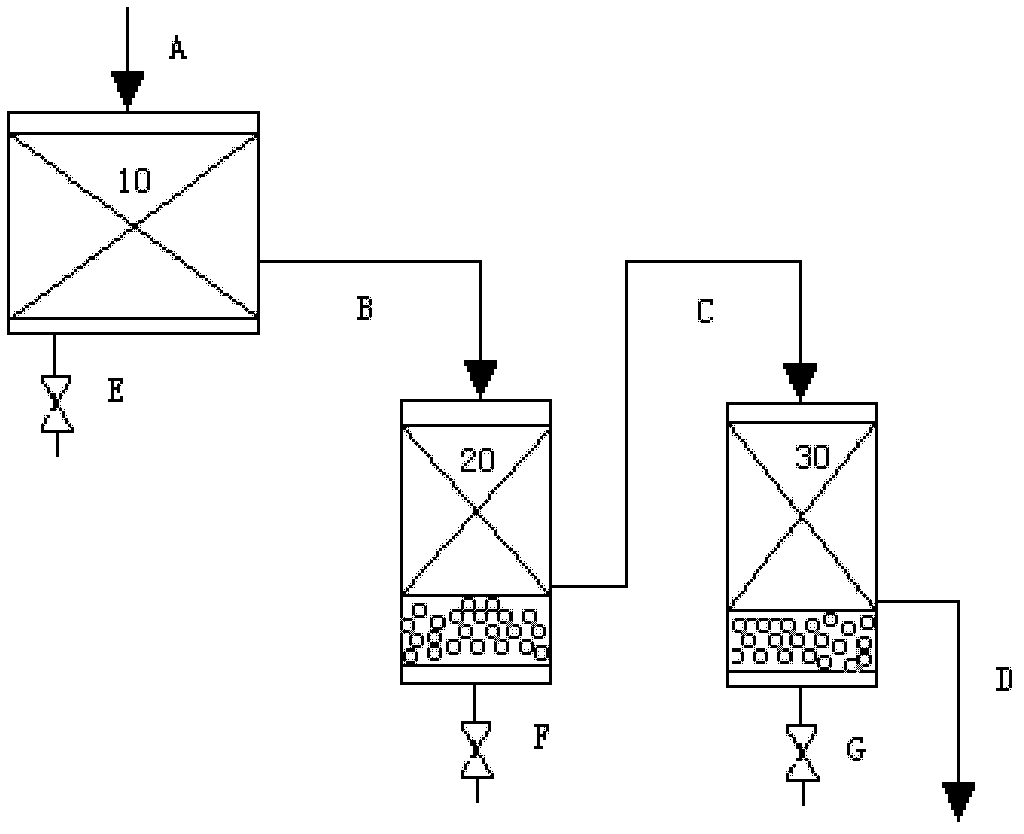

The invention relates to a process of naphtha desulphurization. The process comprises devices of a sedimentation tank and a desulphurization reactor, wherein size of the sedimentation tank is 2-3 times of that of the desulphurization reactor, a bottom of the sedimentation tank is provided with a draining valve; the desulphurization reactor is a fixed-bed desulphurization reactor, a bottom of the desulphurization reactor is filled with molecular sieves or ceramic ball inert substances, a desulfurizer is filled in the molecular sieves or the ceramic ball inert substances, a filled height of the molecular sieves or the ceramic ball inert substances is 1 / 10-1 / 3 of a filled height of the desulfurizer, and the bottom of the desulphurization reactor is provided with a draining valve. The naphtha is put into the sedimentation tank for sedimentation and dehydration, water generated in the sedimentation tank is discharged from the draining valve at the bottom, the dehydrated naphtha is put into the fixed-bed desulphurization reactor for desulphurization reaction, and water gathered at the bottom of the desulphurization reactor is discharged from the draining valve arranged at the bottom of the desulphurization reactor. The method can prevent damages of the water in the naphtha and the water generated during the reaction on desulfurizer strength, and thus the desulfurizer can be continuously used for more than one year.

Owner:PETROCHINA CO LTD

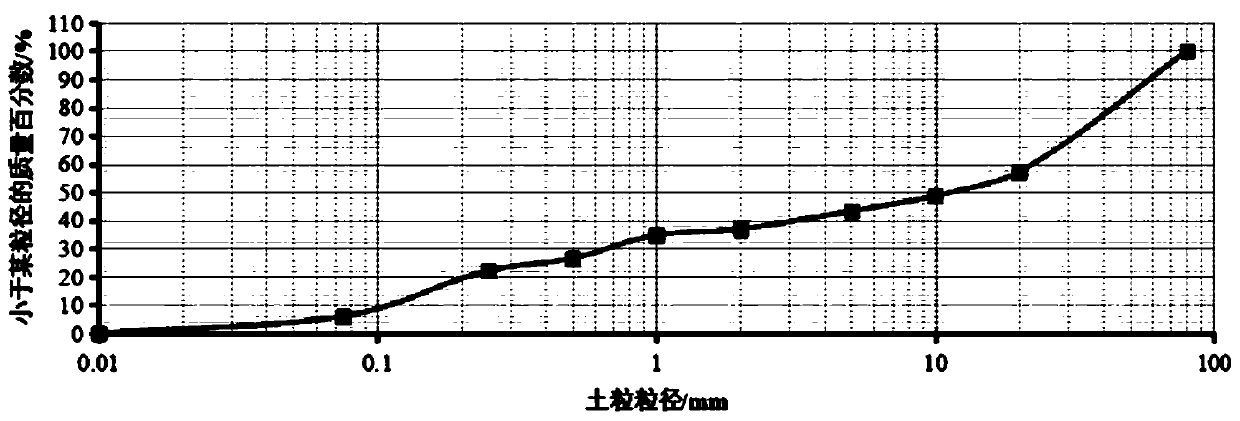

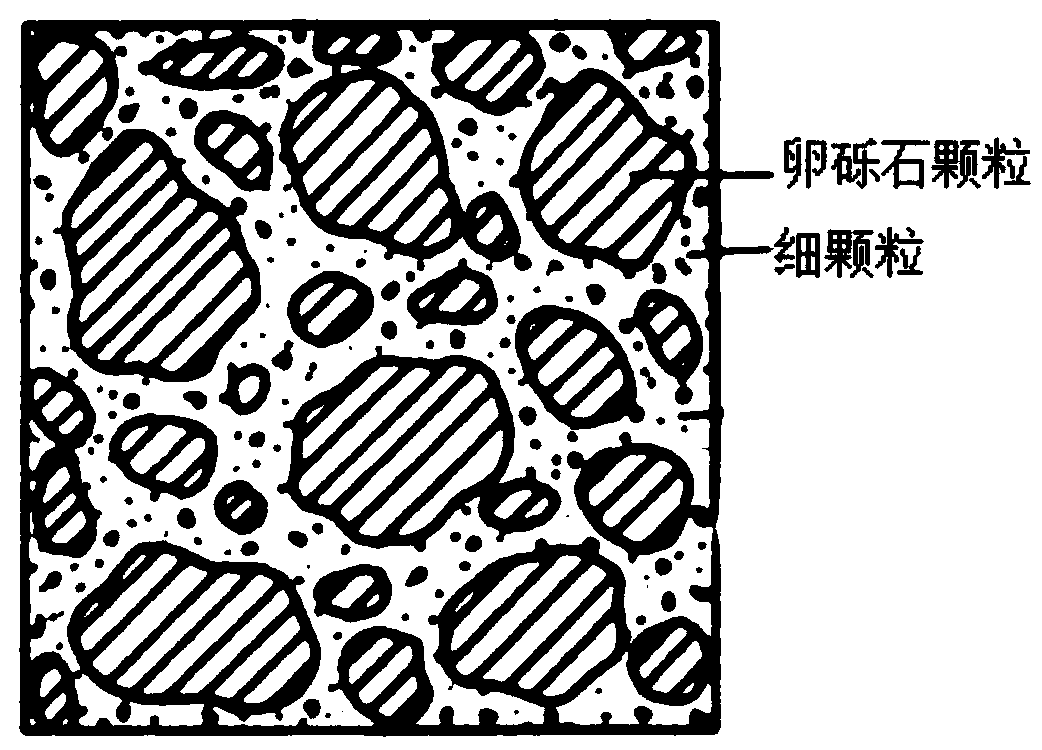

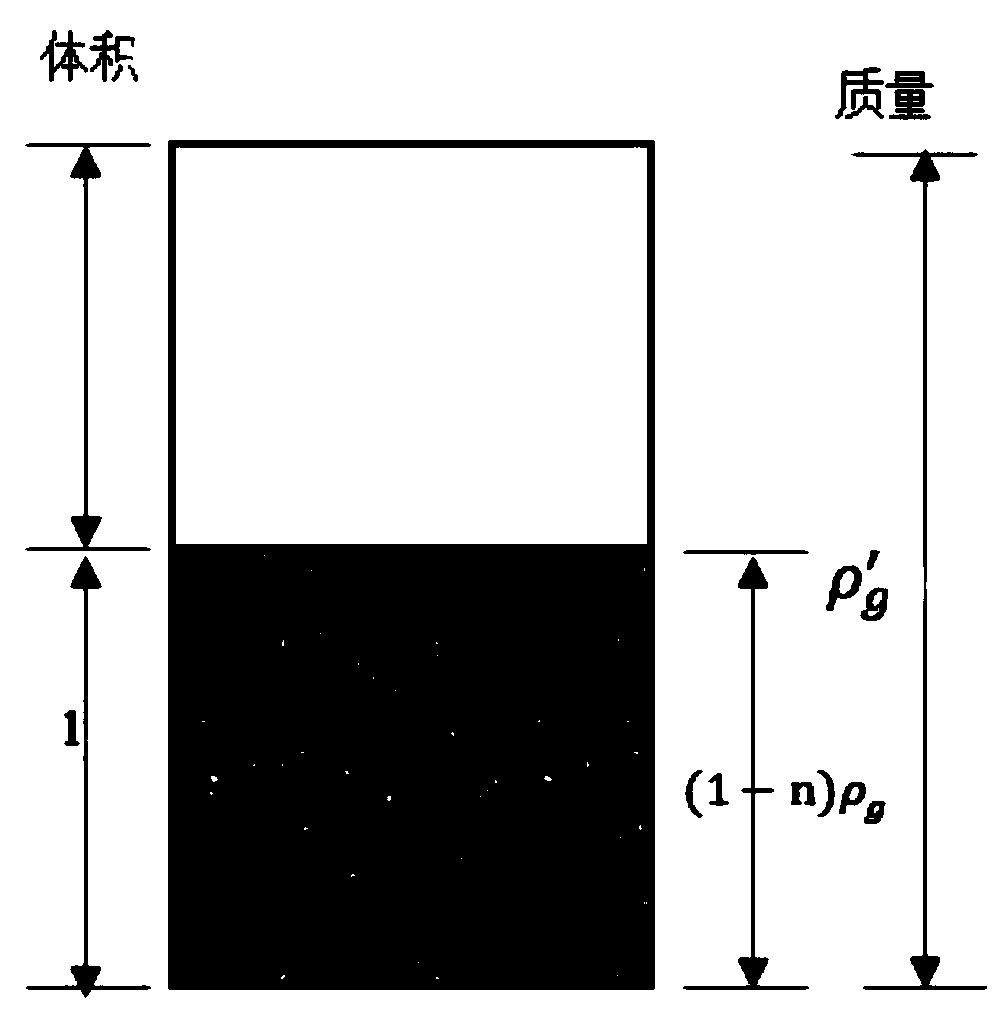

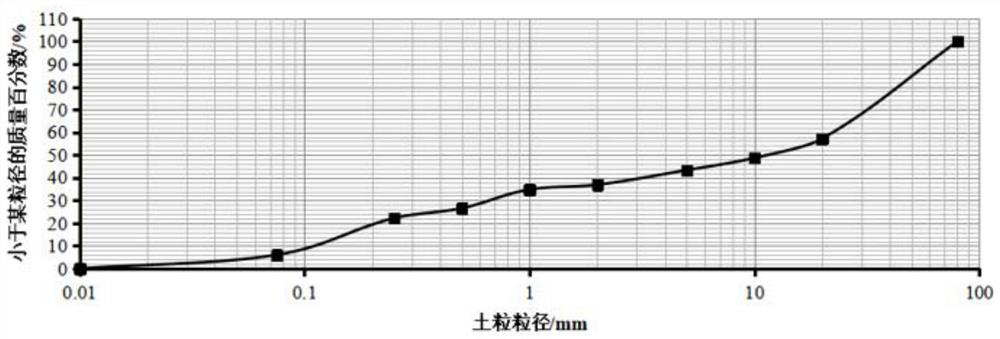

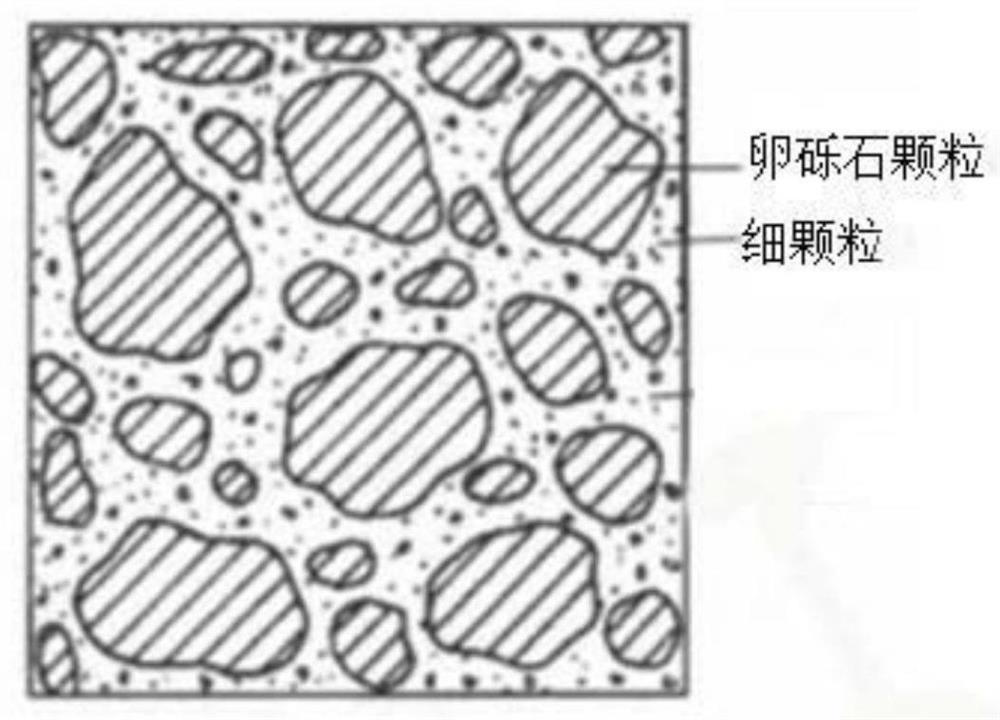

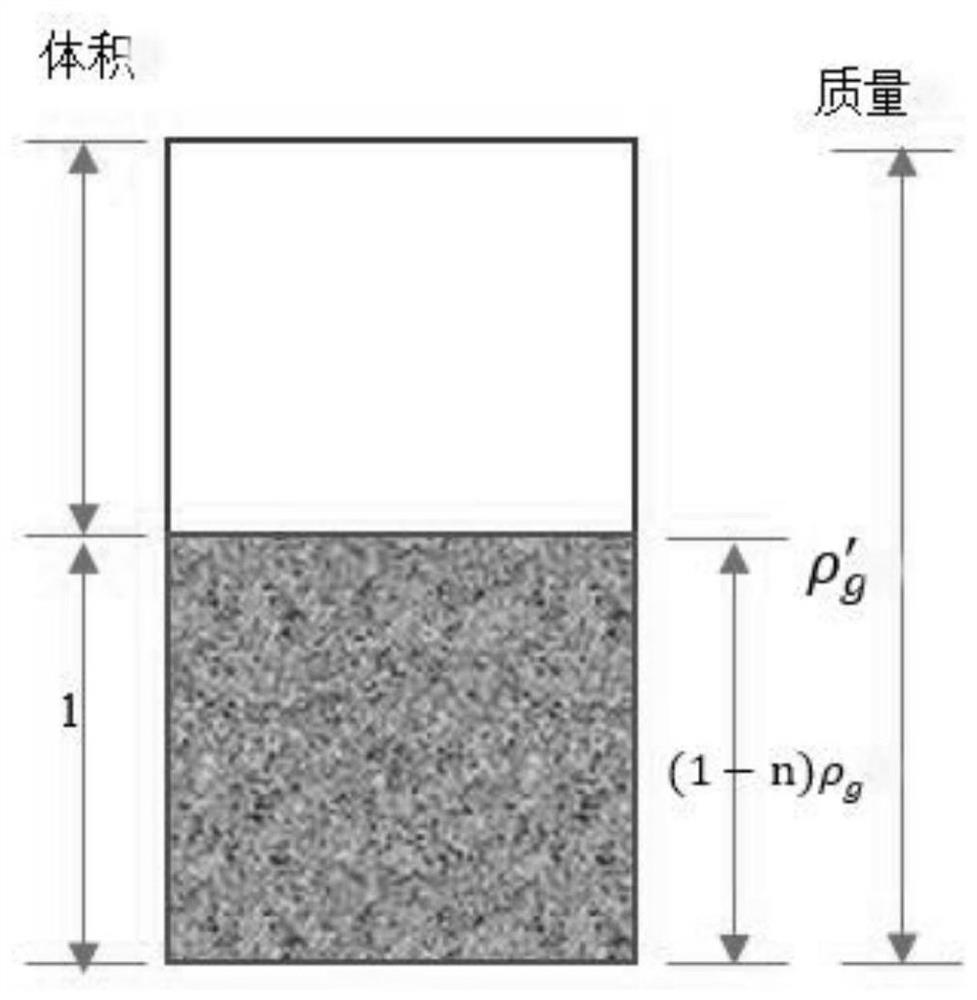

Soil pressure shield waste soil flow plasticity improvement method suitable for sandy cobble stratum

The invention discloses a soil pressure shield waste soil flow plasticity improvement method suitable for a sandy cobble stratum. The soil pressure shield waste soil flow plasticity improvement methodincludes the following steps that S1, according to a geological investigation report, the content of sandy cobble stratum fine particles in the total mass of the stratum is determined as the actual fine particle content; S2, the critical fine particle content is determined by a sandy cobble fluidity model; S3, according to the actual fine particle content and the critical fine particle content, the type of an improver is determined; and S4, the mixing amount of the improver is determined according to the actual fine particle content, wherein the fine particles in the S1, the S2 and the S3 refer to particles with the particle size less than 2 mm. According to the method, the sandy cobble stratum with the characteristic of 'three highs' has the good fluidity, cutter torque of a shield tunneling machine is lowered, cutter pasting is avoided, the viscosity of waste soil is lowered, the stability of the tunnel face is maintained, earthwork overexcavation is controlled, surface collapse andstagnant discharge or flowing are prevented, and the excavation efficiency is improved.

Owner:CHINA FIRST HIGHWAY ENG +1

Nutritional soil specially for planting potatoes

InactiveCN106588470AEnsure balancePrevent lodgingBioloigcal waste fertilisersUrea compound fertilisersNucleic acidPerlite

The invention relates to the field of agriculture, and particularly discloses nutritional soil specially for planting potatoes. The nutritional soil comprises the following components in parts by weight: 30 to 50 parts of peat, 20 to 30 parts of coconut chaff, 10 to 20 parts of perlite, 5 to 15 parts of gravels, 3 to 8 parts of a controlled release fertilizer, 5 to 8 parts of pine needle, 4 to 10 parts of sawdust, 5 to 13 parts of bone meal, 4 to 10 parts of rice chaff ash and 40 to 80 parts of barnyard manure. The prepared nutritional soil is suitable for planting potato seedlings, loose, aerated and high in moisture and fertilizer retention capability, and contains multiple mineral nutrients; the peat in the nutritional soil can enhance biological performance, is nutrient-rich and high in organic matter, humic acid and nutritional component content, and serves as a culture substrate as well as a good soil conditioner; by the barnyard manure, plant nutrients can be provided, comprising inorganic nutrients such as necessary macroelements including nitrogen, phosphorus, potassium, calcium, magnesium and sulfur and trace elements including iron, manganese, boron, zinc, molybdenum and copper; due to organic nutrients such as amino acid, amide and nucleic acid and active substances such as vitamins B1 and B6, the nutrients are kept relatively balanced.

Owner:昭平县科学技术指导站

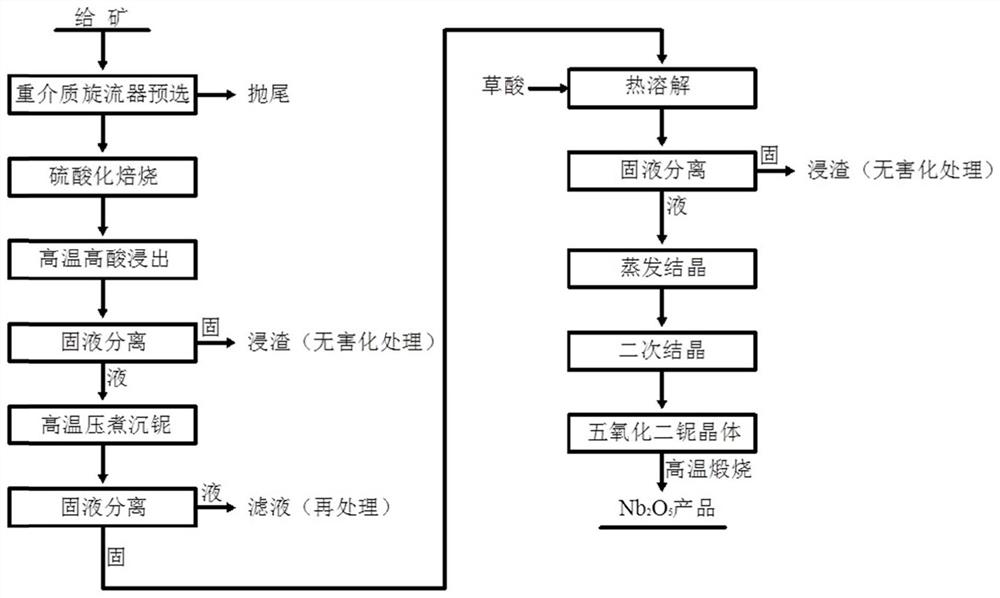

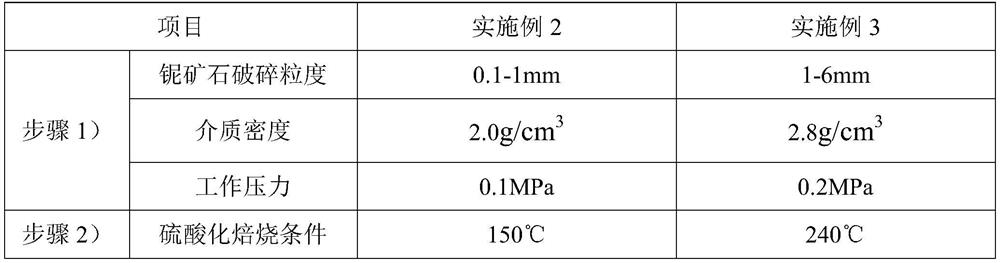

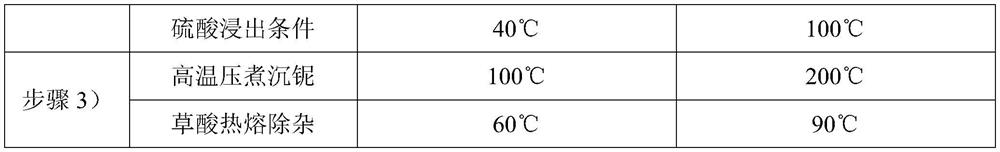

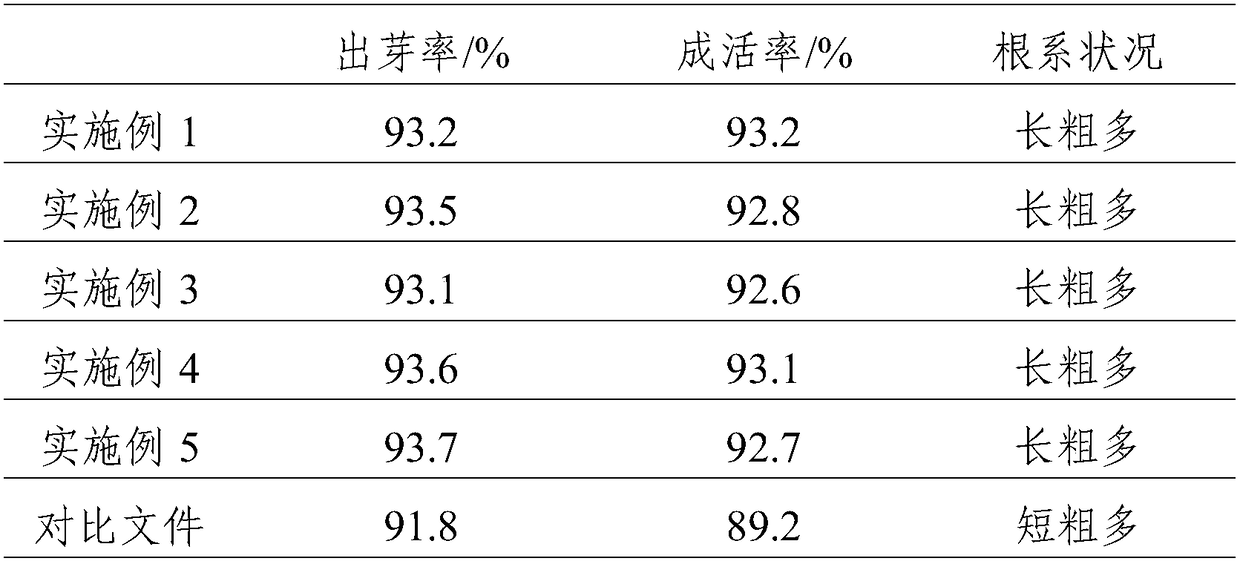

Method for preparing niobium pentoxide from low-grade niobium ore

PendingCN113149075AHigh Niobium Mineral RecoveryHigh recovery rateNiobium compoundsOXALIC ACID DIHYDRATEOre concentrate

The invention belongs to the field of preparation of niobium pentoxide, and particularly relates to a method for preparing niobium pentoxide from low-grade niobium ore. The method comprises the following steps: (1) crushing niobium ore, and then pre-selecting and discarding tailings through a dense medium cyclone to obtain pre-selected concentrate; (2) the pre-selected concentrate is subjected to sulfating roasting and sulfuric acid leaching, and a leaching solution is obtained; and (3) heating and autoclaving the leachate to precipitate niobium, performing hot melting impurity removal and crystallization on the obtained niobium precipitate by using oxalic acid to obtain niobium oxalate crystals, and calcining the niobium oxalate crystals to obtain niobium pentoxide. Compared with an early-stage combined mineral separation process, a high-temperature acid decomposition extraction process and other processes, the method for preparing niobium pentoxide from the low-grade niobium ore is simple in process, short in process, high in niobium ore recovery rate, relatively low in production cost and beneficial to development and utilization of mineral resources.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Strengthening technology for soft plastic collapse body karst tunnel

InactiveCN108331595AImprove reinforcementTargetedUnderground chambersTunnel liningKarst tunnelCoring

The invention discloses a strengthening technology for a soft plastic collapse body karst tunnel. The strengthening technology comprises the steps that S1, surveying is carried out, a jet grouting pile technology is adopted at a soft foundation, and a steel flower pipe pile technology is adopted at a rock layer; S2, drilling is carried out by using the jet grouting pile technology , and a hole isdrilled at a positioning position through a rotary vibration drilling machine; S3, a grouting pipe is lowered, and drilling and lowering the grouting pipe are completed at the same time; S4, jet grouting is carried out, after a jet pipe is inserted into a predetermined depth, jetting operation is carried out from bottom to top, and a columnar jetting pile solidified body is formed after jetting construction is finished; S5, drilling is carried out by using the steel flower pipe pile technology, the position of the rock layer is confirmed, and a deep hole drilling machine is used for drilling;S6, lowering a pipe and grouting are carried out, and a steel flower pipe is grouted through a horn grouting pump until completely dense grouting is achieved; and S7, testing process is carried out, and a geological drill drilling and coring method is used for testing. By adopting a composite foundation treatment method combining a jet grouting pile and a steel flower pipe pile, the strengtheningtechnology overcomes the defect of " paying attention to a vault and making light of a tunnel bottom" in the prior tunnel construction, and thus the operation safety is ensured.

Owner:三丈信息(深圳)有限公司

Vegetable seedling culture medium and preparation method thereof

InactiveCN108617466AStrong ability to degrade cellulosePromote seedling growthBio-organic fraction processingBioloigcal waste fertilisersDioxyethylene EtherSorbitan Monooleate

The invention relates to the technical field of agricultural production, in particular to a vegetable seedling culture medium and a preparation method thereof. The vegetable seedling culture medium comprises, by weight, 10-16 parts of vermiculite, 7-14 parts of perlite, 8-13 parts of coco coir powder, 20-28 parts of pine bark powder 1-5 parts of fermented vinegar residues, 4-9 parts of nonylphenolpolyoxyethylene ethers, 2-7 parts of polyoxyethylene dehydrated sorbitan monooleate and appropriate parts of water. The vegetable seedling culture medium has the advantages that vegetable root systems can absorb nutrients and moisture beneficially during growth, air permeability is high, corrosion of the vegetable root systems is avoided, vegetable growth is promoted, soil is protected, and sliming is avoided; initial water absorption capacity after trays are filled with the medium and the rewetting capability of the medium after drying in the seedling culture period are promoted, vegetable germination rate is increased, and vegetable growth is promoted.

Owner:和县中禾农业科技有限公司

Gold ore grinding classification system and grinding classification processing technology

PendingCN108927281AOptimize structure layoutEasy to handleGrain treatmentsWet separationReturn ratioEngineering

The invention discloses a gold ore grinding classification system and grinding classification processing technology. The grinding classification system includes a first section grinding classificationsystem and a second section grinding classification system. The first section grinding classification system comprises a semi-autogenous mill, a cylinder screen, a first classification pump pool andan inspection classification hydrocyclone group, and the second section grinding classification system comprises a ball grinding mill, a second classification pump pool and a control classification hydrocyclone group. Compared with original one-time screening processing, the gold ore grinding classification system reduces the sand-returning ratio of the semi-autogenous mill and improves the sand-returning ratio of the ball grinding mill, part of qualified materials in ore discharge of the semi-autogenous mill performs flotation operation in advance, the load of the two-stage ore grinding millsis optimized, the particle size composition of grinding products is optimized, the argillation problem caused by over-grinding is avoided, and the recovery rate of the ore dressing is improved.

Owner:DULAN JINHUI MINE CO LTD

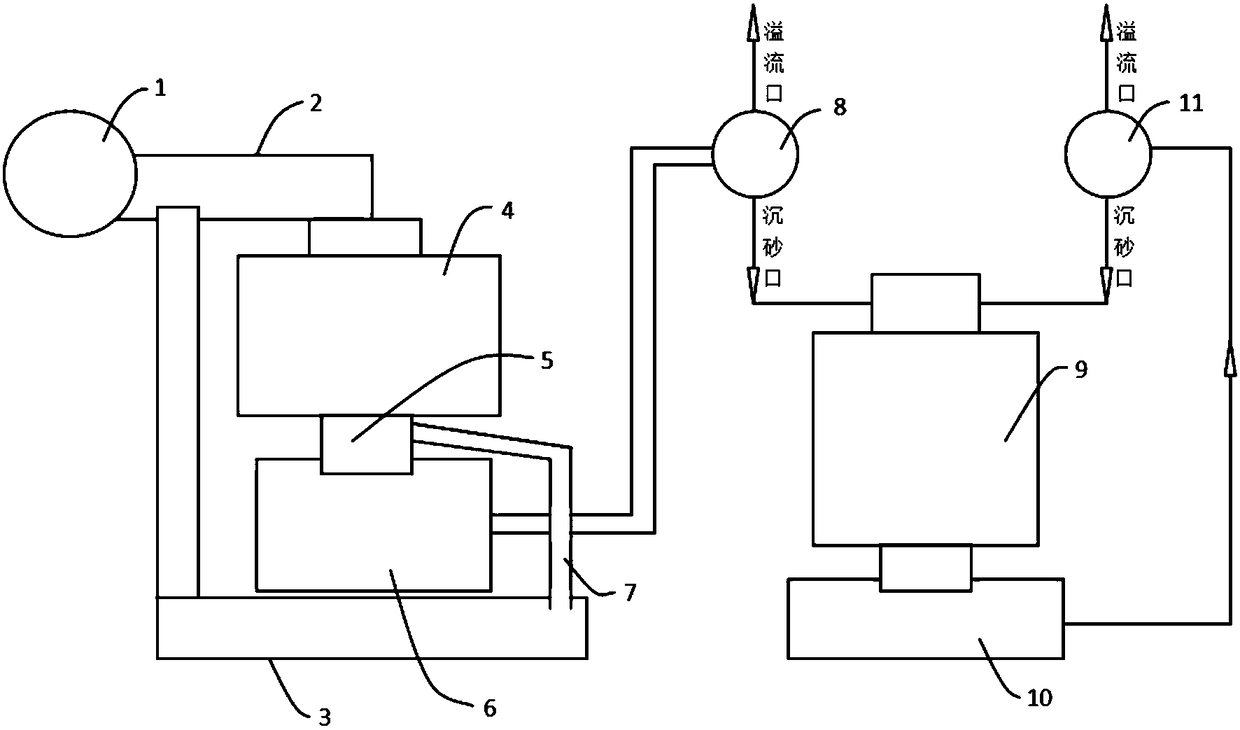

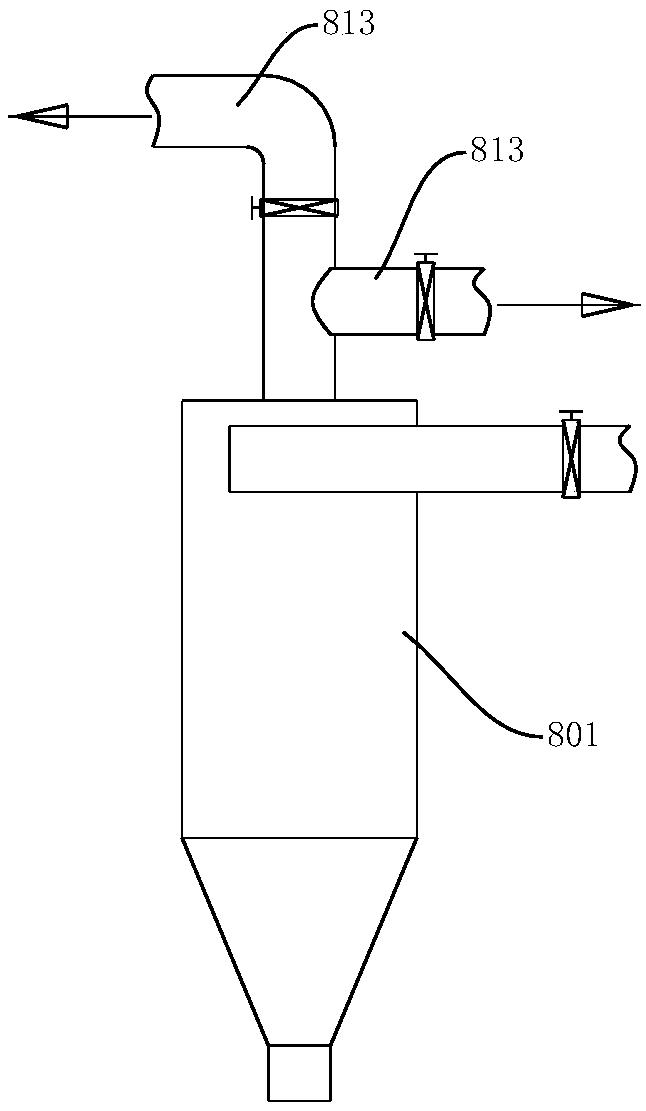

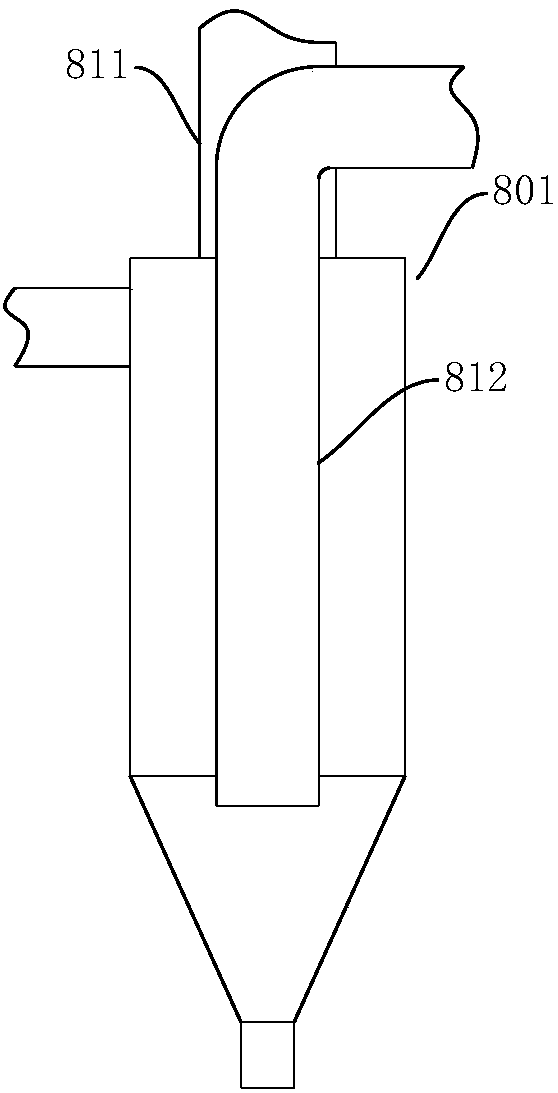

Mineral processing process capable of producing high-end chemical-stage chromite concentrates

InactiveCN108580022AControl particle concentrationHigh recovery rateWet separationChemical industryChromium Compounds

The invention discloses a mineral processing process capable of producing high-end chemical-stage chromite concentrates. The process uses a method of combining the magnetic reconnection process with the stage-grinding and stage-concentration to achieve sorting of the high-grade chromite, and the process comprises following steps that a, raw ore is subject to rough grinding through a rod mill, andstrong magnetic tailings discharging is carried out; b, the mass concentration of strong magnet rough concentrate ore pulp is concentrated to 50% to 60%; c, the concentrated ore pulp is subject to fine milling through an ISA mill, and two-time strong magnetic selection is carried out; d, high magnetic concentrates and middlings are subject to repeated grading through a yunnan tin table concentrator, and a final product is obtained. The high-quality chromite concentrates with the Cr2O3 content larger than or equal to 60% and the impurity SiO2 content smaller than or equal to 1.5% and capable ofmeeting the high-end chemical industrial chromium compound producing needs are obtained, the chromite recycling rate is ensured, the process flow is simple, the production cost is low, a chemical flotation agent does not need to be added, the pollution to the environment is small, the higher economic benefits and social benefits are achieved, and the process is worth of applying and popularizing.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

Baeckea frutescens organic cultivation medium

InactiveCN106508647ALow costEasy to makeBioloigcal waste fertilisersGrowth substratesAdditive ingredientDecomposition

The invention relates to an all organic cultivation medium used for soilless potted plants, namely a baeckea frutescens organic cultivation medium, and belongs to the technical scope of agricultural production. The baeckea frutescens organic cultivation medium is prepared from baeckea frutescens bran and soybean cake in a mass part ratio of 70:30 as raw materials, and the baeckea frutescens bran and the soybean cake are crushed, mixed and kneaded into balls. The baeckea frutescens organic cultivation medium is relatively low in cost of preparation raw materials and simple in preparation, contains natural ingredients, does not go mouldy after being used for a long time, has good water-retaining property and breathability, has the characteristic of slow natural decomposition rate, is beneficial to prolongation of the usage period of the medium and also can be recycled.

Owner:广西天源岗松油有限公司

Special areca-nut seedling breeding fertilizer as well as preparation method and application thereof

PendingCN110526769ASustained nutritionMeet nutritional contentAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersDiseaseAmylostereum areolatum

The invention relates to the field of areca-nut cultivation and in particular discloses a special areca-nut seedling breeding fertilizer as well as a preparation method and application thereof. The special areca-nut seedling breeding fertilizer disclosed by the invention comprises the following components in parts by weight: 40-50 parts of coco coir, 4-6 parts of an organic fertilizer, 15-25 partsof tea-oil tree bran cakes, 2-4 parts of rooting powder, 3-12 parts of an inorganic fertilizer and 0.1-1 part of complex microbial inoculants. The invention further provides the preparation method ofthe special areca-nut seedling breeding fertilizer. Within the period from germination of areca-nuts to delivery from nursery gardens and fixed planting, the special areca-nut seedling breeding fertilizer disclosed by the invention is used, then long-lasting nutrients can be provided for areca-nut seedlings, soil structures can be improved, the soil fertility can be improved, the areca-nut seedlings can grow rapidly and grow healthy and strongly, soil microorganisms are enriched, loosened and air-permeable soil is available, the stress resistance and the disease and insect resistance of the areca-nut seedlings can be remarkably improved, and a good basis can be made for good growth of areca-nuts.

Owner:COCONUT RES INST OF CHINESE ACAD OF TROPICAL AGRI SCI

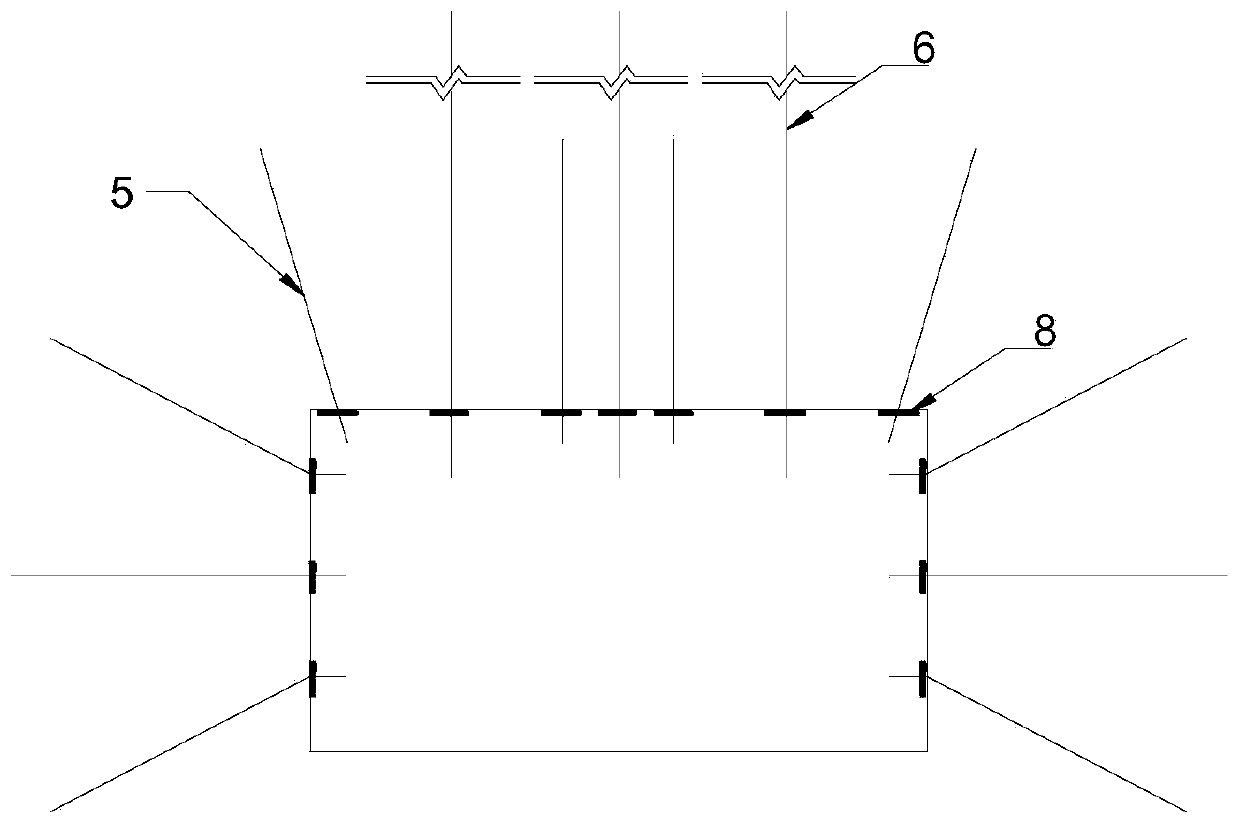

Caving coal mining roadway grouting anchor cable supporting structure and advanced supporting method thereof

InactiveCN110552731AImprove tensile propertiesImprove stress resistanceAnchoring boltsEngineeringRock bolt

The invention discloses a caving coal mining roadway grouting anchor cable supporting structure and an advanced supporting method thereof. The advanced supporting method of the caving coal mining roadway grouting anchor cable supporting structure includes following steps: step 1, confirming at least one mining roadway to be supported on a current mining face, wherein setting perpetual support on atop plate and two sides of each mining roadway, and using combined anchor-bolt and net support as the perpetual support due to the fact that each mining roadway is dug in advance and the perpetual support is performed in the digging process,; and step 2, performing advanced support on each mining roadway, wherein at the same moment of mining the mining face, constructing anchor cable holes everyother row of anchor bolts in the advancing direction and on the top plate of each mining roadway, mounting grouting anchor cables and anchor trays in the anchor cable holes while constructing the anchor cable holes, and using locksets for pre-tightening. The advanced supporting method of the caving coal mining roadway grouting anchor cable supporting structure and the advanced supporting method thereof have the beneficial technological achievements of 1) greatly improving supporting efficiency on the premise of guaranteeing safe mining; 2) greatly saving the space area of each mining roadway;and 3) being simple in structure, convenient to operate and low in cost.

Owner:CHINA UNIV OF MINING & TECH

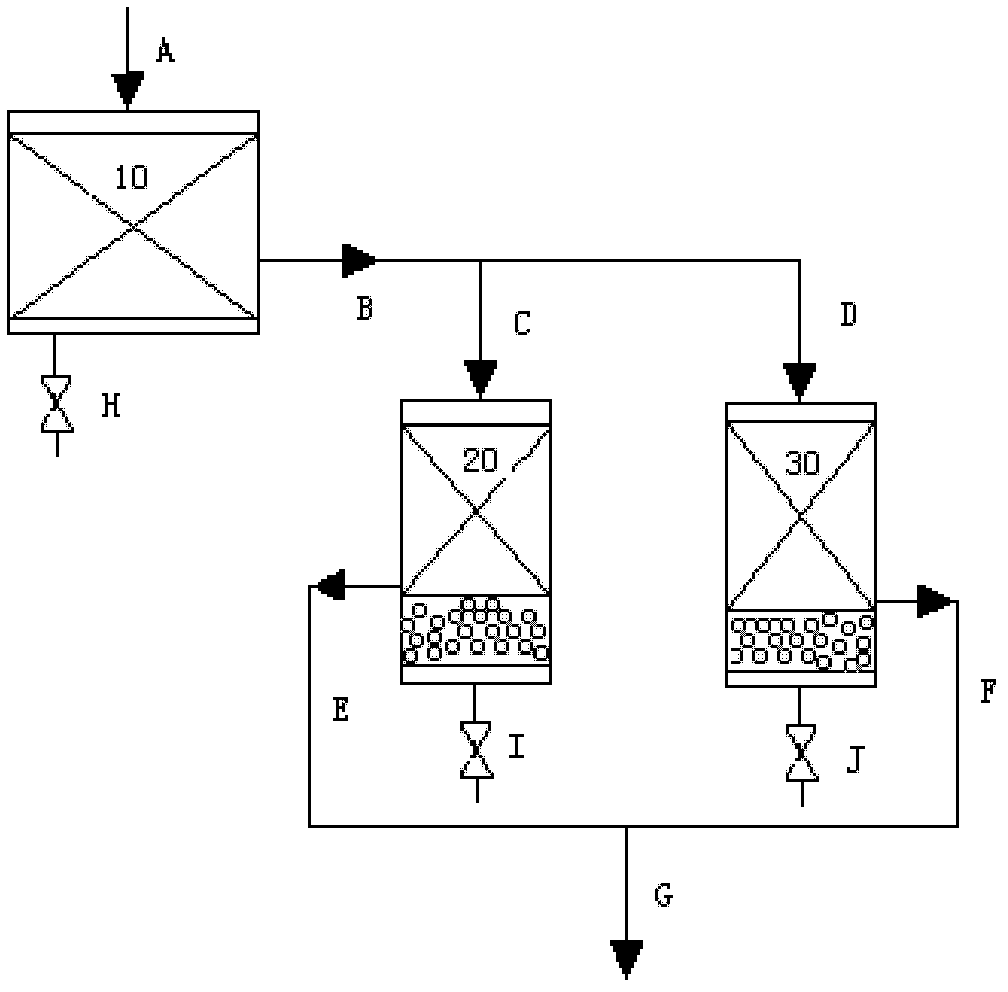

Method for increasing metal recycling rate of complex lead-zinc ore

The invention provides a lead-zinc ore flotation procedure and a chemical system. The lead-zinc ore flotation procedure and the chemical system aim at solving the problem that the recycling rate of lead-zinc ore is low. The lead-zinc ore with the recycling rate needing to be increased refers to the lead-zinc ore with the complex raw ore structure, uneven granularity and the high oxidation rate. Minerals are recycled through staged ore grinding, stepped quick flotation, oxygen-sulfur mixed flotation, combined chemical feeding and the like. Staged ore grinding and stepped quick flotation are conducted in the lead floatation process, fine-grain lead is recycled, and the circulation amount of coarse-grain lead is reduced; a product is directly output through a first zinc rough flotation groove, and remaining foam enters a second fine flotation machine; an original first fine flotation machine provides fine flotation and scavenging, so that the grade of concentrate is guaranteed, and the recycling rate is increased; and oxidized ore is recycled by adding an oxidation chemical in the scavenging process. By means of the whole set of lead-zinc ore flotation procedure and the chemical system, the metal recycling rate of the lead-zinc ore which is high in mud content and oxidation rate, uneven in granularity and fineness and the like can be effectively increased.

Owner:内蒙古森泰企业咨询有限公司

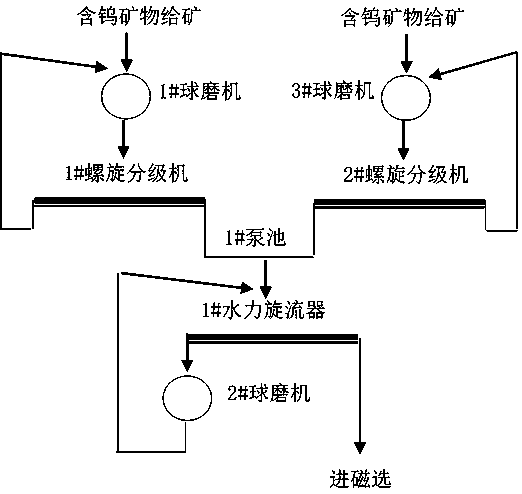

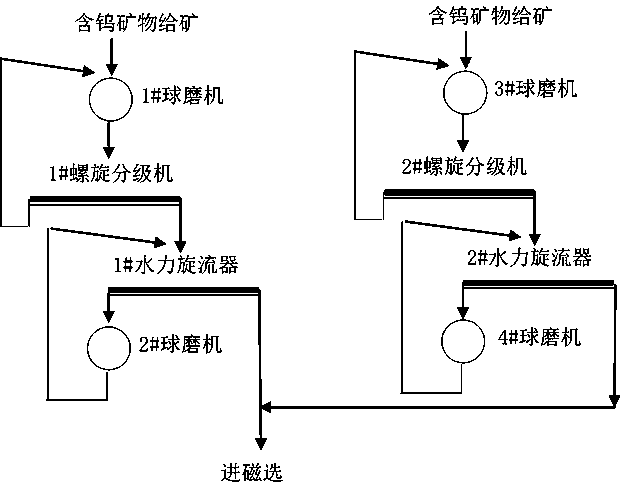

Non-standard-configured two-stage continuous ore grinding and grading process

InactiveCN110052321AUniform particle size distributionLow total grinding energy consumptionGrain treatmentsEngineeringBall mill

The invention discloses a non-standard-configured two-stage continuous ore grinding and grading process. Tungsten-containing raw ore is fed into two ball mills at the same time, ground products of each ball mill are fed into a corresponding spiral classifier for grading, graded returned sand returns to the corresponding ball mill for grinding again, each ball mill and the corresponding spiral classifier form closed-circuit grinding, graded overflow of the two spiral classifiers is fed into a same pump tank, ore pulp in the pump tank is fed into a hydrocyclone for grading, a graded overflow sample is obtained as a final product after grinding and grading, obtained grading grit is fed into a third ball mill for regrinding, and reground ore pulp is discharged into the pump tank to form closed-circuit grinding. The process has the advantages that for brittle and fragile tungsten-containing substances, not only total grinding energy consumption is low, the operation cost is low, process improvement is convenient, but also the graded overflow product has uniform particle size distribution, and the grade of tungsten-containing flotation tailings can be continuously reduced based on the prior art. The process is suitable for popularization and application of metallic mineral rich in tungsten.

Owner:HUNAN SHIZHUYUAN NON FERROUS METAL +1

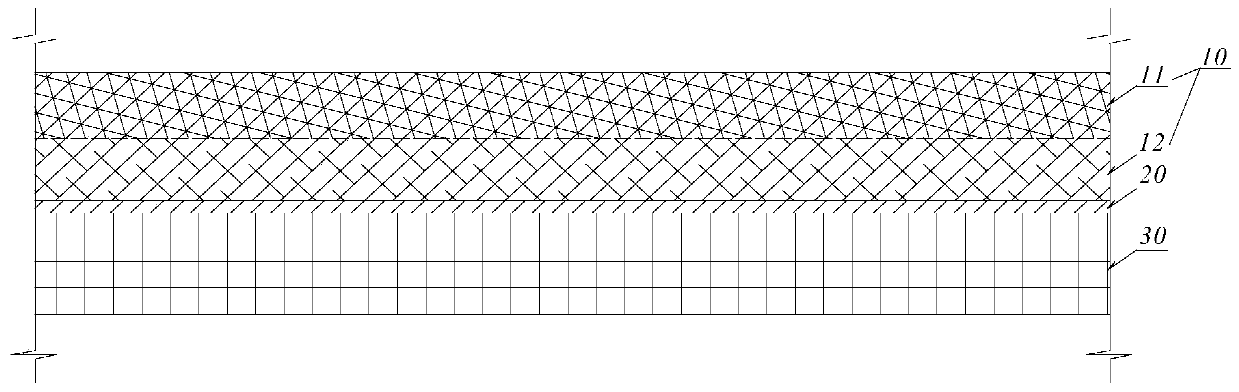

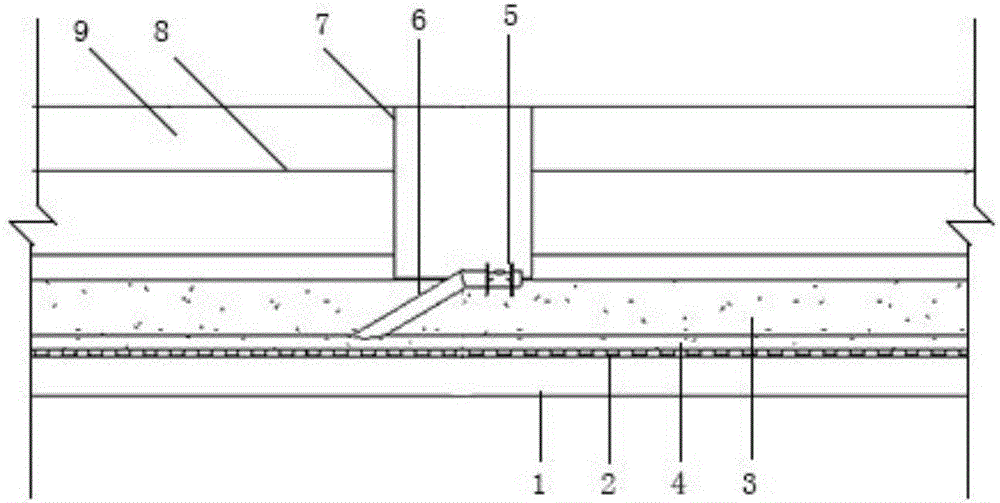

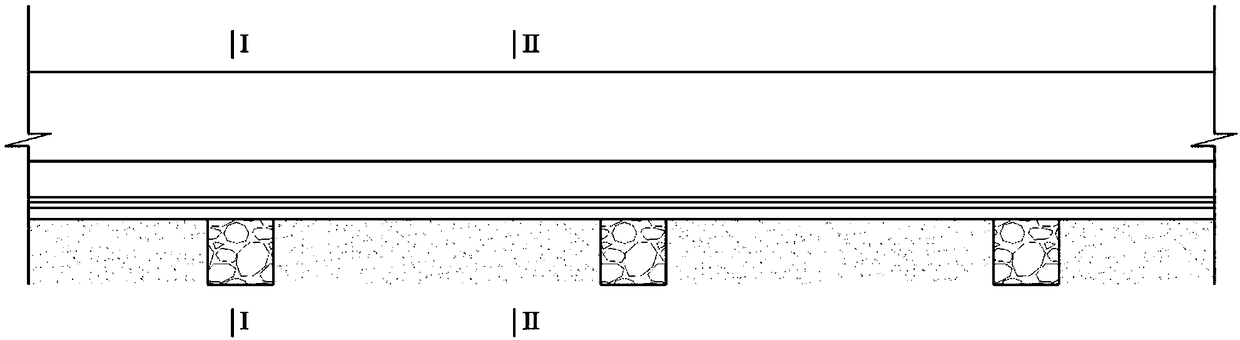

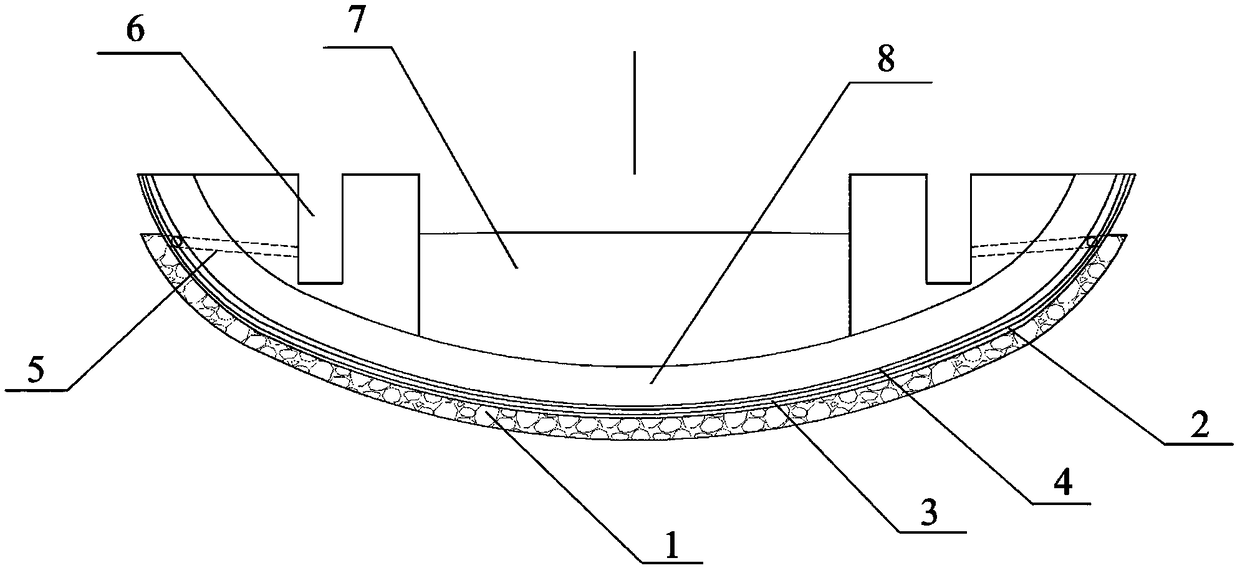

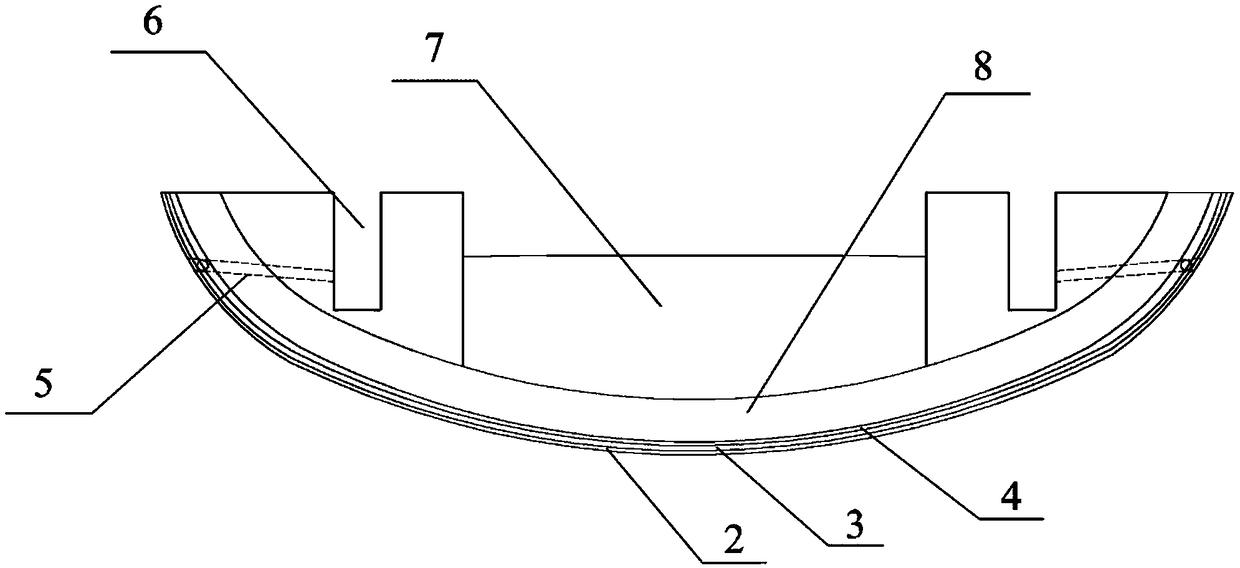

Composite geomembrane for high-speed railway roadbed

PendingCN109930428AImprove corrosion resistanceGood corrosion resistance, good cold resistanceRailway tracksFreeze thawingFiber

The invention provides a composite geomembrane for a high-speed railway roadbed. The corrosion resistance and freeze-thawing resistance of the composite geomembrane are effectively improved, so that the geomembrane has good drainage performance, and the use stability of the geomembrane is remarkably improved. The composite geomembrane is formed by compounding an upper polypropylene filament composite geotechnical cloth, a middle layer polyethylene or polyvinyl chloride composite geomembrane and a lower polypropylene filament needled geotechnical cloth which are sequentially stacked from top tobottom. The upper layer polypropylene filament composite geotechnical cloth is formed by compounding an upper layer fine polypropylene filament geotechnical cloth and a lower layer thick polypropylene filament geotechnical cloth, and the gram weight is 150-300 g / m<2>, wherein the gram weight of the upper layer fine polypropylene filament geotechnical cloth is 50-150 g / m<2>, the fiber fineness is5-7 D, the gram weight of the lower layer thick polypropylene filament geotechnical cloth is 75-250 g / m<2>, and the fiber fineness is 9-15 D.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD +2

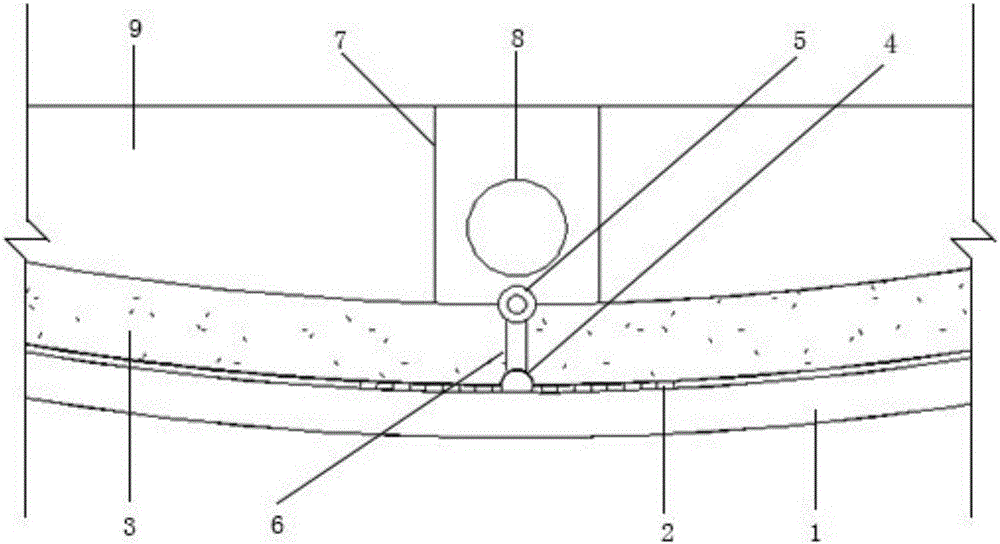

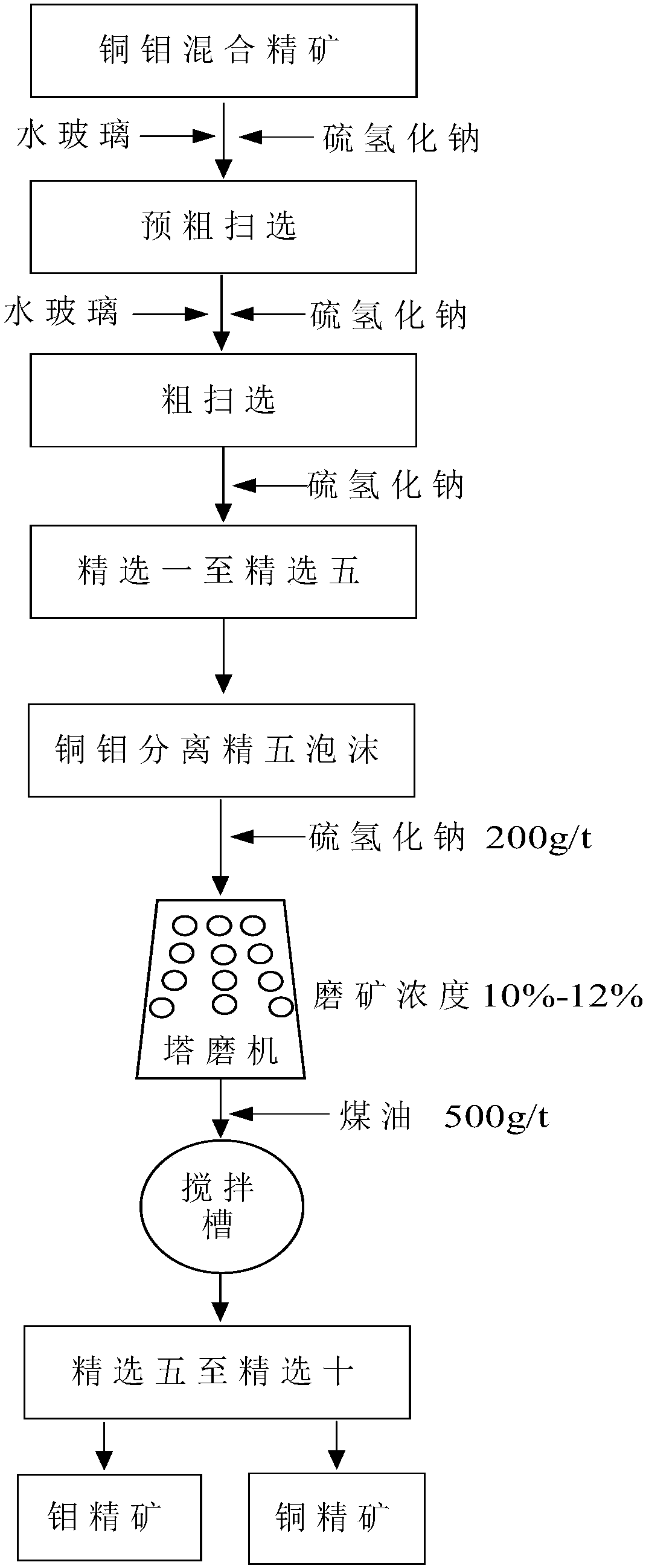

Reverse drainage system capable of reducing water pressure at bottom of tunnel

The invention discloses a reverse drainage system capable of reducing water pressure at the bottom of a tunnel. A transverse water collection system is arranged at the bottom position of a construction joint of an inverted arch, a longitudinal water guide system is arranged at the bottom of the inverted arch and is laid along the longitudinal direction, and an oblique water return system is arranged under an inspection well and is communicated with a longitudinal water collection pipe along the inclined direction; a transverse waterproof and drainage board is laid between a preliminary bracing and a lining of the inverted arch. The longitudinal water guide system consists of a longitudinal drain board and a circular tube, wherein the circular tube is arranged above a center line of the bottom of the preliminary bracing. The transverse water collection system is used for water prevention of a bottom structure of the tunnel and leading water into the longitudinal water guide system, and the water is discharged from the longitudinal water guide system; an oblique drainage system is used for reversely discharging the water at the bottom of the tunnel into a manholes and a central ditch of the inverted arch by reverse flow. After the reverse drainage system is adopted, the bottom structure of the tunnel is avoided being excavated again, so that the normal operation of the tunnel is not influenced; furthermore, the drainage system at the bottom of the tunnel can be maintained, so that the requirement of durability is met, and the water pressure at the back of the secondary lining of the tunnel is effectively reduced.

Owner:CHINA RAILWAY ECONOMIC & PLANNING RES INST +2

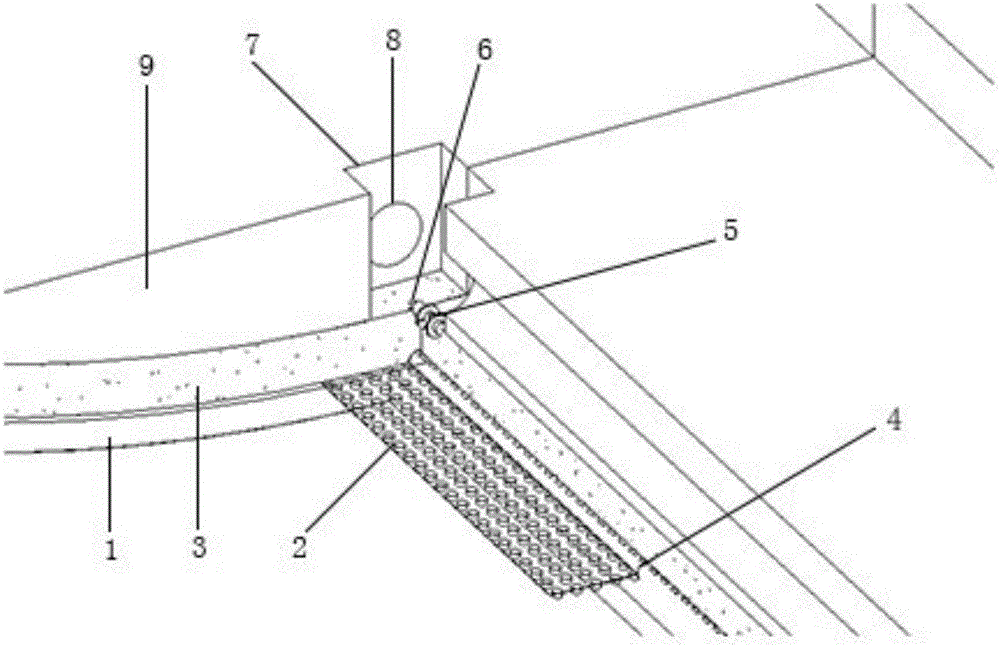

Method for reinforcing copper inhibition molybdenum extraction during copper-molybdenum separation

The invention relates to a method for reinforcing copper inhibition molybdenum extraction during copper-molybdenum separation, and belongs to the field of mineral separation. The method comprises thesteps of a, carrying out beforehand tailing discarding, one-time roughing, three-time scavenging and five-time concentration on copper-molybdenum mixed concentrate, so as to obtain concentrate foam; b, adding a copper inhibitor into the concentrate foam obtained in the step a; c, feeding pulp formed in the step b into a mill to be reground; d, adding a molybdenum collecting agent into an ore grinding product obtained in the step c; and e, carrying out six-time concentration to ten-time concentration flotation on a product obtained in the step d, so as to obtain final copper concentrate and molybdenum concentrate. According to the method, sodium hydrosulfide is added during the regrinding process of five-time concentration foam, the problem that copper minerals are hard to inhibit during the copper-molybdenum separation process is solved, and copper and molybdenum are effectively separated while the argillization phenomenon caused by mass crushing of gangue minerals is avoided through regrinding of five-time concentration foam; and besides, kerosene is added before the reground product enters the next process, so that recovery for molybdenum in follow-up operation is reinforced, andthe recovery rate of molybdenum is increased.

Owner:CHANGCHUN GOLD RES INST

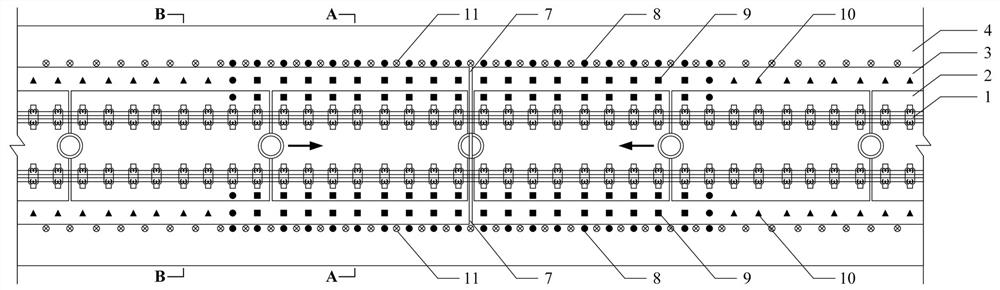

High polymer grouting repair method for treating ballastless track foundation bed mud pumping

The invention discloses a high polymer grouting repair method for treating ballastless track foundation bed mud pumping, which is characterized in that residual accumulated water and mud in a foundation bed surface layer in a mud pumping disease area are squeezed and discharged in a high-pressure grouting manner, and pores in the foundation bed surface layer and a void area at the bottom of a base plate are fully filled, so that the stress condition of the foundation bed surface layer is improved; the whip effect of the track structure under the train operation load effect is relieved; and meanwhile, grouting is conducted on the junction of the side edge of the base plate and the concrete sealing layer, and rainwater is prevented from intruding into the channel. And after high polymer grouting is completed, sealing glue is adopted for sealing expansion joints in the ends of the base plates and cracks in the side edges of the base plates correspondingly, and rainwater is further prevented from invading the channel. According to the method, the supporting rigidity of the surface layer of the foundation bed in the disease area is enhanced, the stress characteristic of the track structure is improved, a rainwater invasion channel is effectively blocked finally, the long-term service performance of the repaired foundation bed is guaranteed, and the frost boiling and mud emitting diseases of the ballastless track foundation bed of the high-speed railway can be well treated.

Owner:ZHEJIANG UNIV

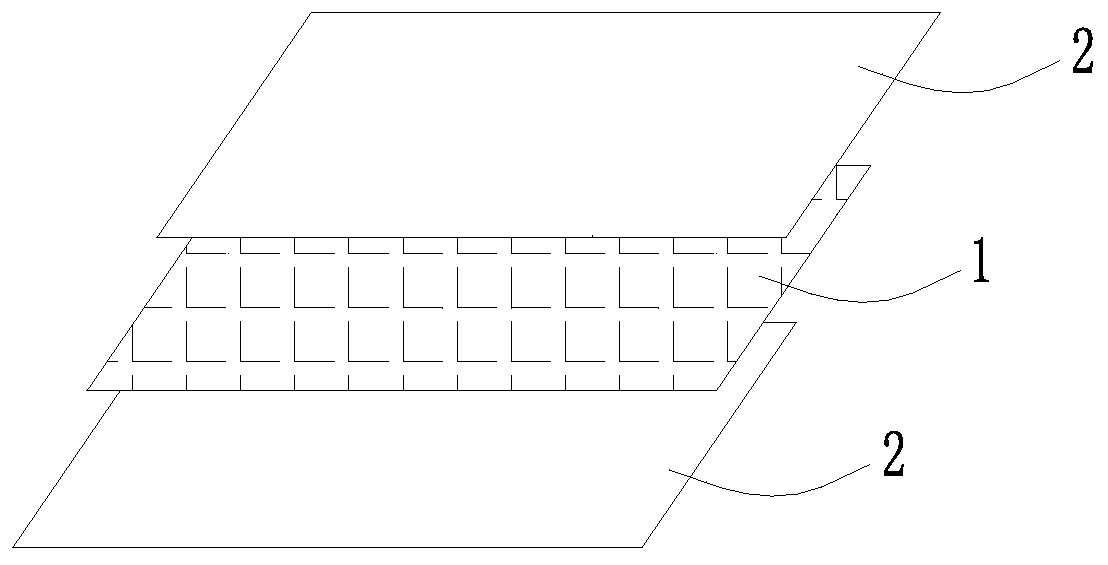

Anti-freezing water-resisting layer and roadbed

The application provides an anti-freezing water-resisting layer and a roadbed. The anti-freezing water-resisting layer is arranged at the bottom of the roadbed, and comprises at least one layer of anti-seepage film and non-woven geotextile, wherein the anti-seepage film is used for blocking the migration of water in frozen earth to the roadbed direction; and the non-woven geotextile is arranged ontwo side surfaces of the anti-seepage film and used for coating the anti-seepage film, so that the anti-seepage film can be isolated from a roadbed filler or the frozen earth and protected against relatively large deformation caused by load. The anti-freezing water-resisting layer provided by the invention is arranged at the bottom of the roadbed, and serves as a partition between the roadbed andthe frozen earth in a plateau seasonally-frozen zone; and due to the own anti-seepage function of the anti-freezing water-resisting layer, the migration of the water in the frozen earth to the roadbed can be blocked, the water content of the roadbed fill in the roadbed can be stabilized, and the roadbed frost-heaving or frost-boiling caused by the roadbed fill in a freezing and thawing environment can be avoided.

Owner:CHINA COMM NORTH ROAD & BRIDGE +1

Tunnel bottom structure of high water head water enriched tunnel and water draining method

The invention discloses a tunnel bottom structure of a high water head water enriched tunnel and a water draining method. The tunnel structure comprises water draining grooves annularly formed in tunnel bottom surrounding rock along the tunnel, and the water draining grooves are connected with water draining ditches; the water draining grooves are filled with seepy materials; the inner side of thewater draining groove in the surface of an inverted arch of the tunnel bottom is an initial branch composed of concrete; a non-woven fabric and a water-proof layer are successively arranged from thesurface of the initial branch to the inverted arch; the tunnel bottom structure can effectively reduce water pressure acted on the inverted arch to avoid fracturing of the tunnel bottom structure dueto the water pressure of the inverted arch, uplifting of a ballast bed and the frost boiling and mud coming phenomenon caused by the above problems.

Owner:中铁西南科学研究院有限公司

Method for planting calathea orbifolia

InactiveCN107455120ASlow use periodEasy to useBiocideCalcareous fertilisersCalathea orbifoliaScientific management

The invention discloses a method for planting calathea orbifolia. The method includes the steps of substrate preparation, pot transferring, watering, fertilizer applying, illumination, temperature, disease prevention and others. With the method, temperature and illumination control and scientific management are combined, cultivating management is simple, and the survival rate is high.

Owner:单泓睿

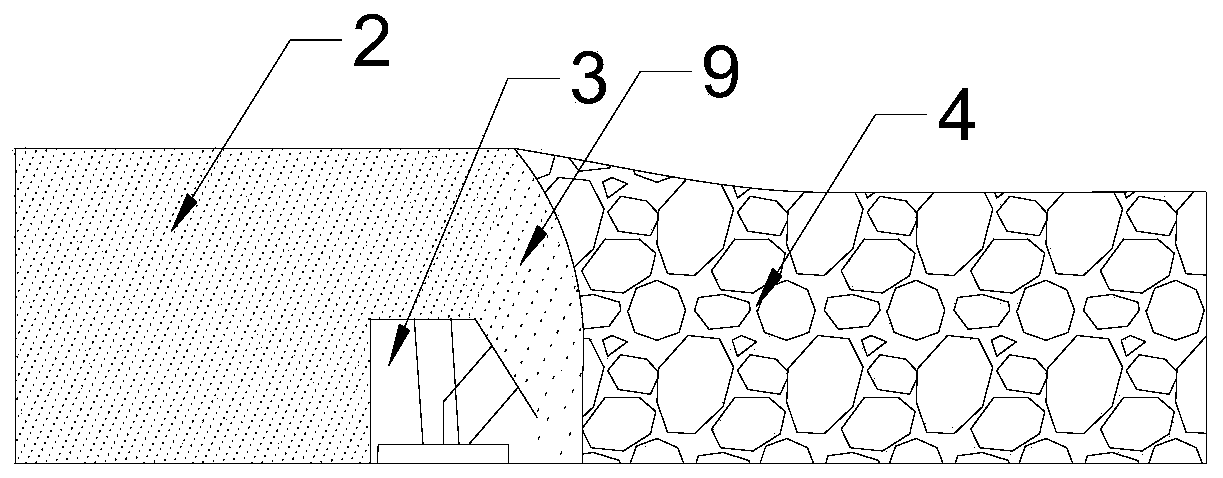

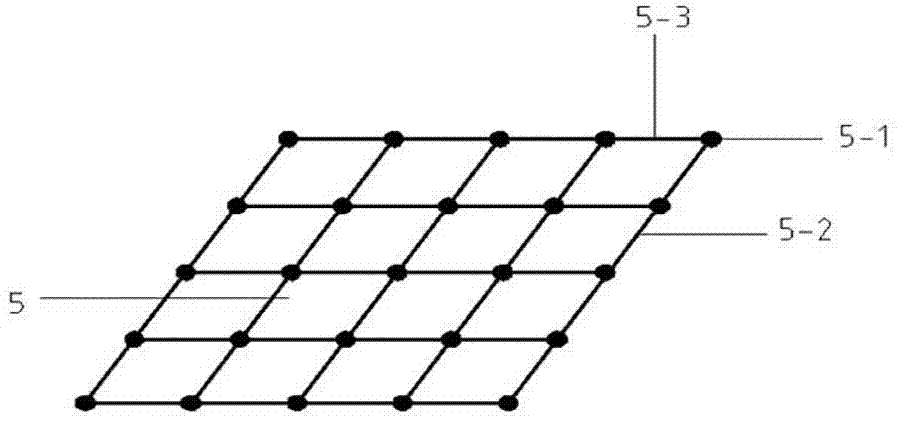

Method for splicing durable road structure by brickworks formed by organic mixture truss

ActiveCN103255695ARealize self-lockingRelieve stress concentrationIn situ pavingsTime segmentRoad construction

The invention relates to a method for splicing a durable road structure by brickworks formed by organic mixture trusses. The method is characterized by comprising the specific steps of: firstly, manufacturing truss structures; combining manufactured truss space bodies in a bidirectional break joint manner; putting the combined manufactured truss space bodies on a seat plate; respectively pouring an inorganic mixture into the manufactured truss space bodies to form an integral road base layer structure; and paving a conventional abrasion layer on the road base layer structure. The method disclosed by the invention adopts the truss formed by an organic mixture and the inorganic mixture is filled into the truss to form the brickworks; the brickworks are spliced into a durable road structure so that the aims of shortening a construction period and prolonging the usable time period of construction can be realized and the road construction working period can be effectively shortened; and the structure of a truss bridge sheet sufficiently utilizes the characteristic of the stability of a triangle so that the service life of a road can be prolonged in the use process.

Owner:CHANGCHUN MUNICIPAL ENG & RES INST CO LTD

A beneficiation process for producing chemical-grade chromite concentrate

InactiveCN108580022BControl particle concentrationHigh recovery rateWet separationChromium CompoundsChemical industry

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

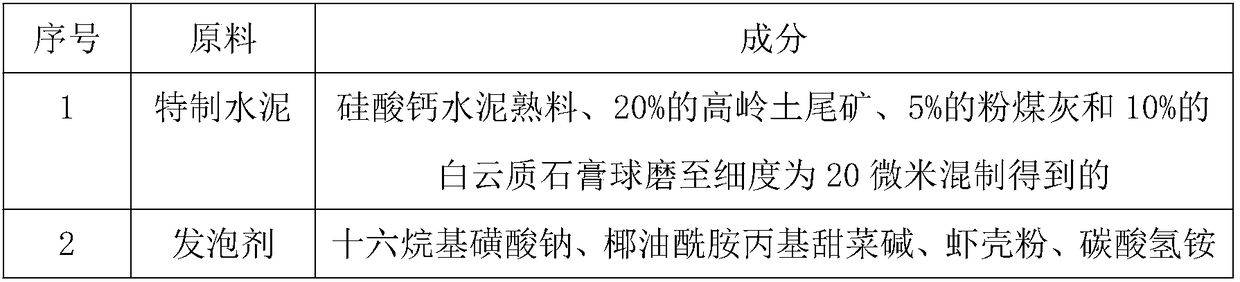

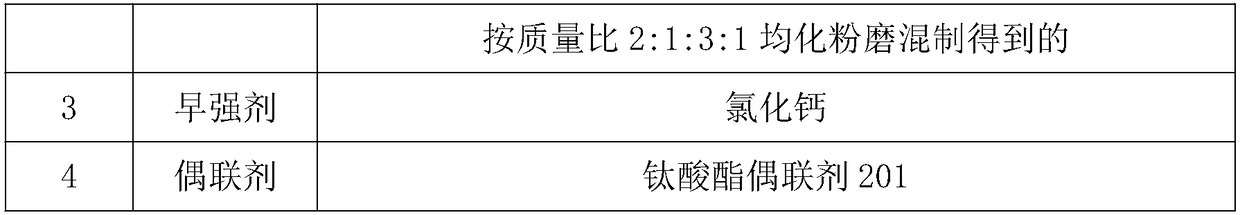

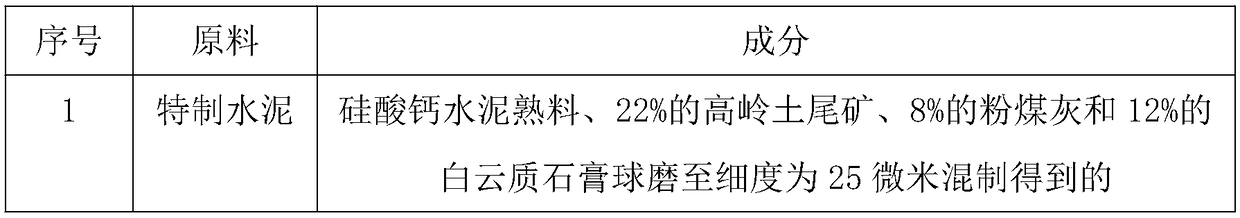

Foamed fireproof door core plate added with palygorskite and preparation method of core plate

The invention discloses a foamed fireproof door core plate added with palygorskite and a preparation method of the core plate, and relates to the technical field of door core plates. The fireproof door core plate comprises the following raw materials: special cement, palygorskite, sepiolite fibers, Qieganbulak vermiculite tailings from Xinjiang, musa basjoo juice, calcium lignosulfonate, carboxymethyl cellulose, polyacrylamide, a foaming agent, an early strength agent, a coupling agent and magnetized water. The preparation method comprises the following steps: mixing the raw materials, carrying out casting, carrying out autoclaved curing and the like. The fireproof door core plate provided by the invention is simple and convenient to prepare, is green and environmentally friendly, and hasexcellent characteristics of high mechanical strength, fire resistance, high-temperature resistance, heat preservation, noise resistance, electromagnetic shielding, water prevention, anti-seismic performance and the like; the functionality is strong; the service life is long; and the application occasions and fields of the fireproof door core plate are greatly broadened.

Owner:HEFEI OAKS NEW BUILDING MATERIAL CO LTD

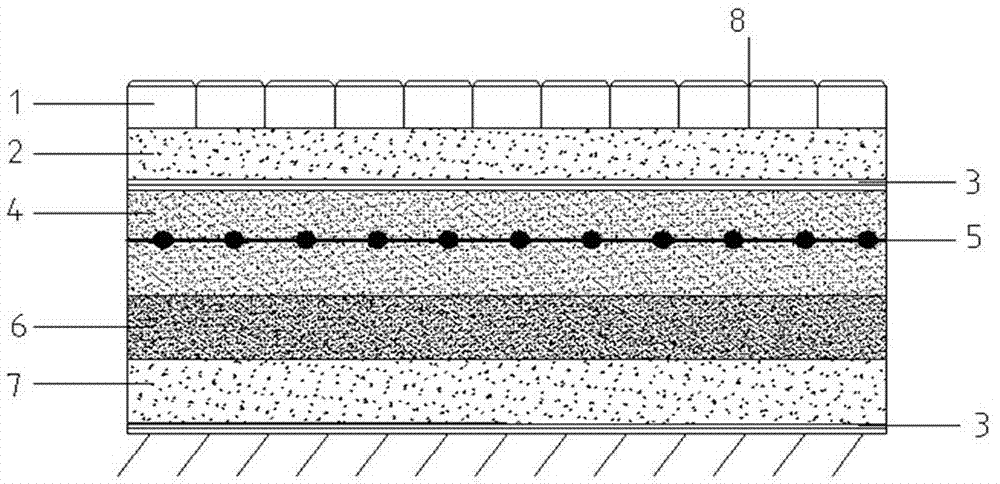

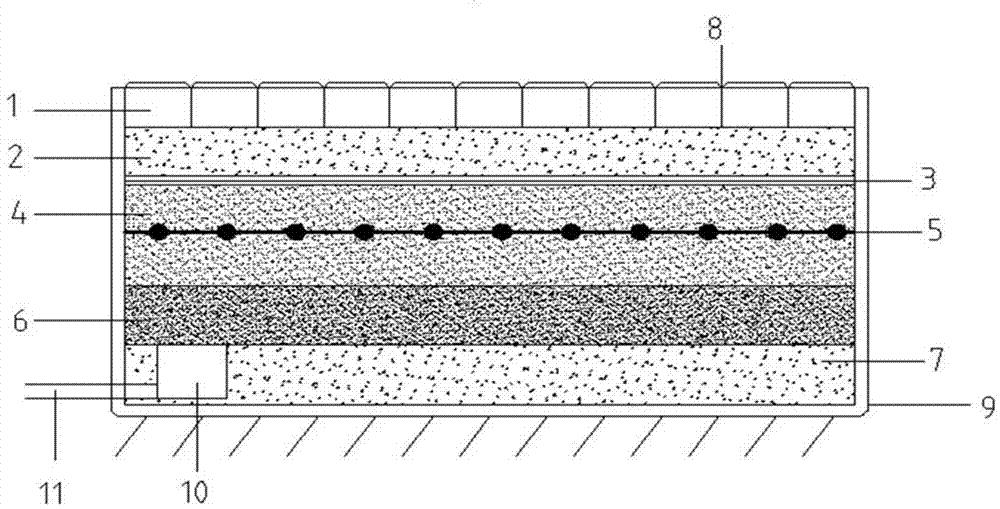

Water-permeable pavement and pavement method thereof

InactiveCN107354843AStop lossImprove stabilityPaving reinforcementsIn situ pavingsGlass fiberChipseal

The invention provides a permeable pavement and a laying method thereof. The permeable pavement comprises: a paving element, a filter layer, a first permeable concrete base, a second permeable concrete base and a crushed stone layer, and the crushed stone layer is laid on a consolidated foundation On the upper surface, a water collector is arranged in the gravel layer, and the water collector is connected to a drainage pipe. The first permeable concrete base is laid on the upper surface of the gravel layer, and the first permeable concrete base The upper surface of the second permeable concrete base is laid with a glass fiber geogrid, the upper surface of the second permeable concrete base is laid with the filter layer, and the upper surface of the filter layer is The paving elements are laid on the surface, and the paving elements are provided with gaps, wherein, the side and the bottom surface of the permeable pavement are both provided with impermeable membranes. The permeable pavement prepared by the invention has the advantages of strong bearing capacity, good durability and good water permeability.

Owner:SHENYANG JIANZHU UNIVERSITY

A Method for Improving Flow Plasticity of Earth Pressure Shield Slag Adapted to Sand and Pebble Stratum

The invention discloses a soil pressure shield waste soil flow plasticity improvement method suitable for a sandy cobble stratum. The soil pressure shield waste soil flow plasticity improvement methodincludes the following steps that S1, according to a geological investigation report, the content of sandy cobble stratum fine particles in the total mass of the stratum is determined as the actual fine particle content; S2, the critical fine particle content is determined by a sandy cobble fluidity model; S3, according to the actual fine particle content and the critical fine particle content, the type of an improver is determined; and S4, the mixing amount of the improver is determined according to the actual fine particle content, wherein the fine particles in the S1, the S2 and the S3 refer to particles with the particle size less than 2 mm. According to the method, the sandy cobble stratum with the characteristic of 'three highs' has the good fluidity, cutter torque of a shield tunneling machine is lowered, cutter pasting is avoided, the viscosity of waste soil is lowered, the stability of the tunnel face is maintained, earthwork overexcavation is controlled, surface collapse andstagnant discharge or flowing are prevented, and the excavation efficiency is improved.

Owner:CHINA FIRST HIGHWAY ENG CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com