Method for splicing durable road structure by brickworks formed by organic mixture truss

An organic mixture and road structure technology, applied in the direction of roads, roads, coagulation pavement paved on site, etc., can solve the problems of shortening the service life of the road, restriction of the road construction plan, and short service life of the road structure, etc., and prolong the service life. , Reduce the number of rebuilds, and prevent the effect of reflection cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1) Firstly, the truss structure is made. Two transverse diaphragms and two longitudinal diaphragms are poured with epoxy resin mixed mortar to form a truss space body and sit on the bottom plate. The inclination angle between the two transverse diaphragms and the bottom plate is an acute angle. The inclination angle between the two longitudinal septum plates and the bottom plate is an obtuse angle;

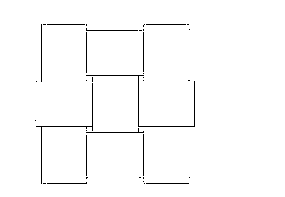

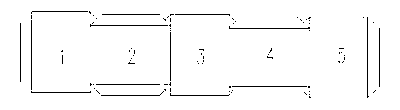

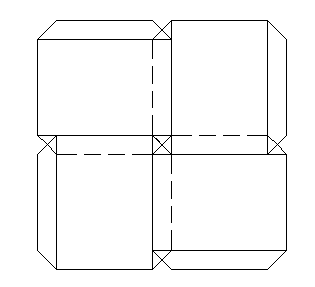

[0036] 2) Combine the prepared quadrilateral truss space body in the form of two-way staggered joints, such as figure 1 , 3 As shown, every four adjacent space bodies can form an hourglass-shaped cavity, and epoxy resin mixed mortar is poured into the cavity to form a truss column 4; the column shape is as follows Figure 5 , 6 shown.

[0037] 3) After the truss space body 1 is combined, it sits on the bottom plate 3, where the bottom plate 3 is composed of a geogrid embedded in crushed stones and filled with epoxy resin mixed mortar to form a composite bottom plate loca...

Embodiment 2

[0045] 1) First of all, the truss structure is made, which is formed by pouring epoxy resin mixed mortar to form three transverse diaphragms and three longitudinal diaphragms to form a truss space body and sit on the bottom plate. The inclination angle between the three transverse diaphragms and the bottom plate is an acute angle. The inclination angle between the three longitudinal septum plates and the bottom plate is an obtuse angle;

[0046] 2) Combine the prepared hexagonal truss space body 1 in a honeycomb shape, and every three adjacent space bodies can form an hourglass-shaped cavity, and pour epoxy resin mixed mortar into the cavity to form the truss column 4;

[0047] 3) After the truss space body 1 is combined, it sits on the bottom plate 3, where the bottom plate 3 is a composite bottom plate composed of geogrid 5 embedded in crushed stones and filled with epoxy resin mixed mortar;

[0048] 4) Pour the inorganic mixture into the truss space to form a complete road...

Embodiment 3

[0051] 1) if Figure 7 As shown, firstly, the truss structure is made. Two transverse diaphragms and two longitudinal diaphragms are poured with epoxy resin mixed mortar to form a truss space body 1 and sit on the bottom plate 3. The inclination angle between the two transverse diaphragms and the bottom plate is an acute angle, and the inclination angle between the two longitudinal septums and the bottom plate is an obtuse angle; Image 6 As shown, the upper end faces of the diaphragm and the longitudinal diaphragm are Y-shaped, which can relieve stress concentration and block reflection cracks.

[0052] 2) Combine the prepared quadrilateral truss space bodies in the form of two-way staggered joints, in which every four adjacent space bodies can form an hourglass-shaped cavity such as Figure 5 As shown, the epoxy resin mixed mortar is poured into the cavity to form the truss column 4;

[0053] 3) After the truss space body 1 is combined, it sits on the bottom plate 3, where...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com