Clamping and lifting type car carrier

A car carrier and clip-lift type technology is applied in the field of clip-lift car carriers to achieve the effects of reducing costs, preventing vehicles from tipping over, and improving bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

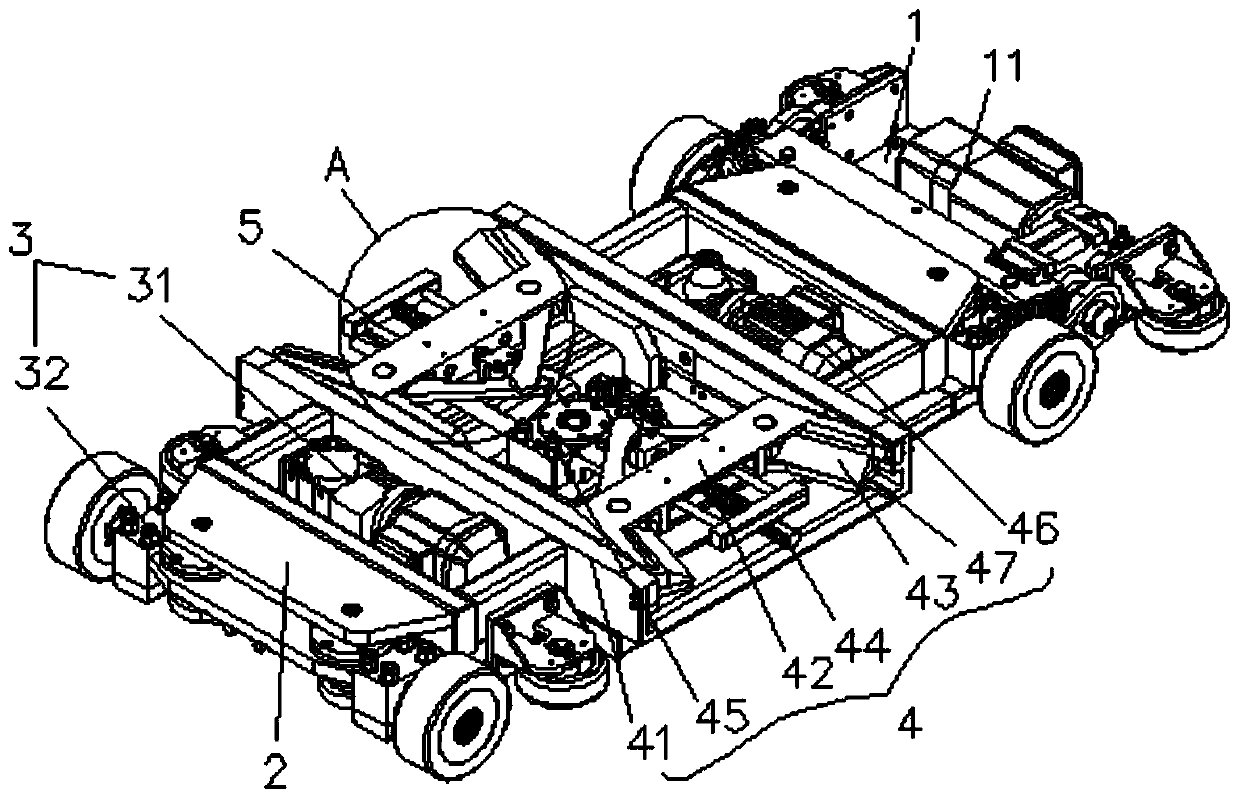

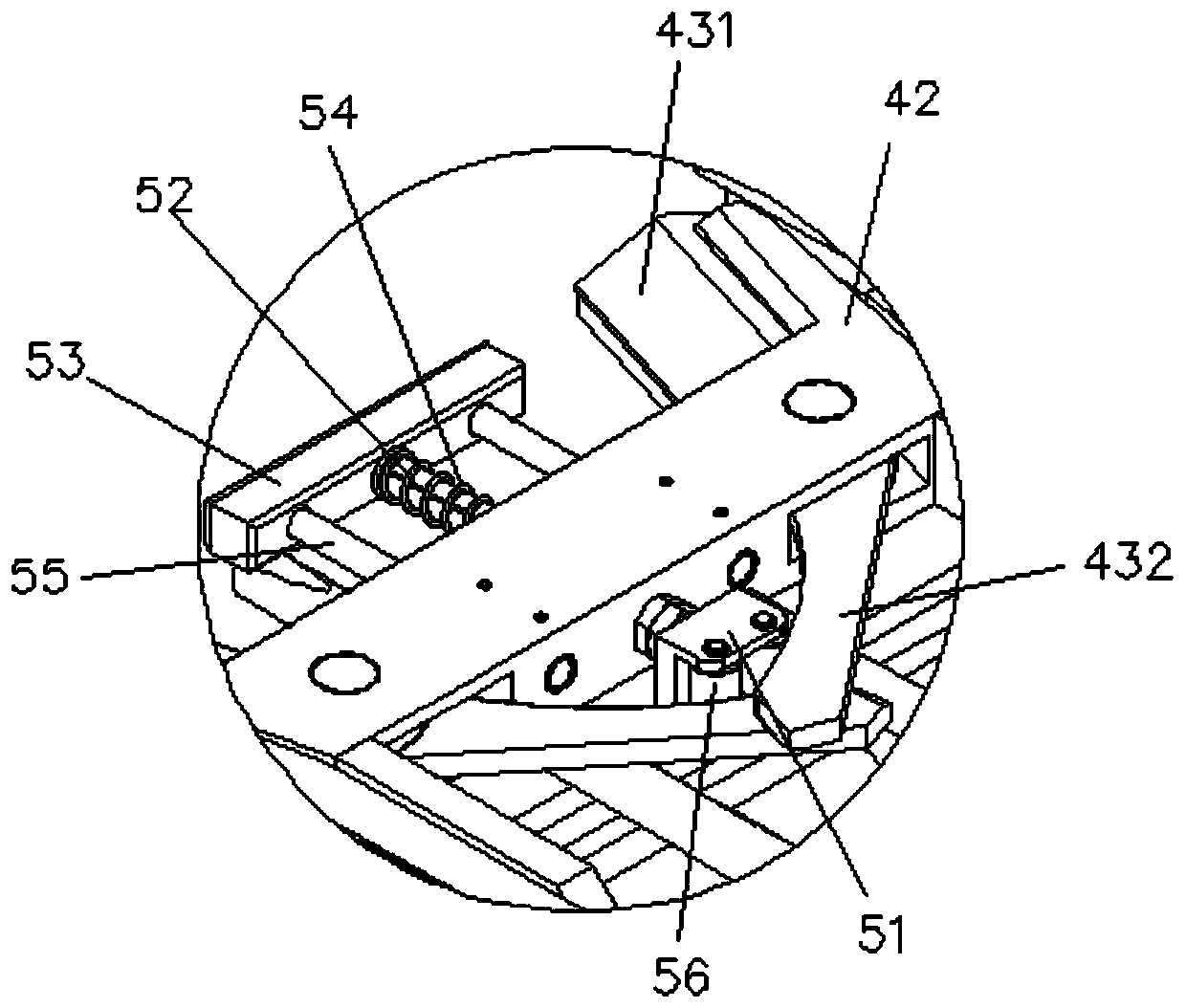

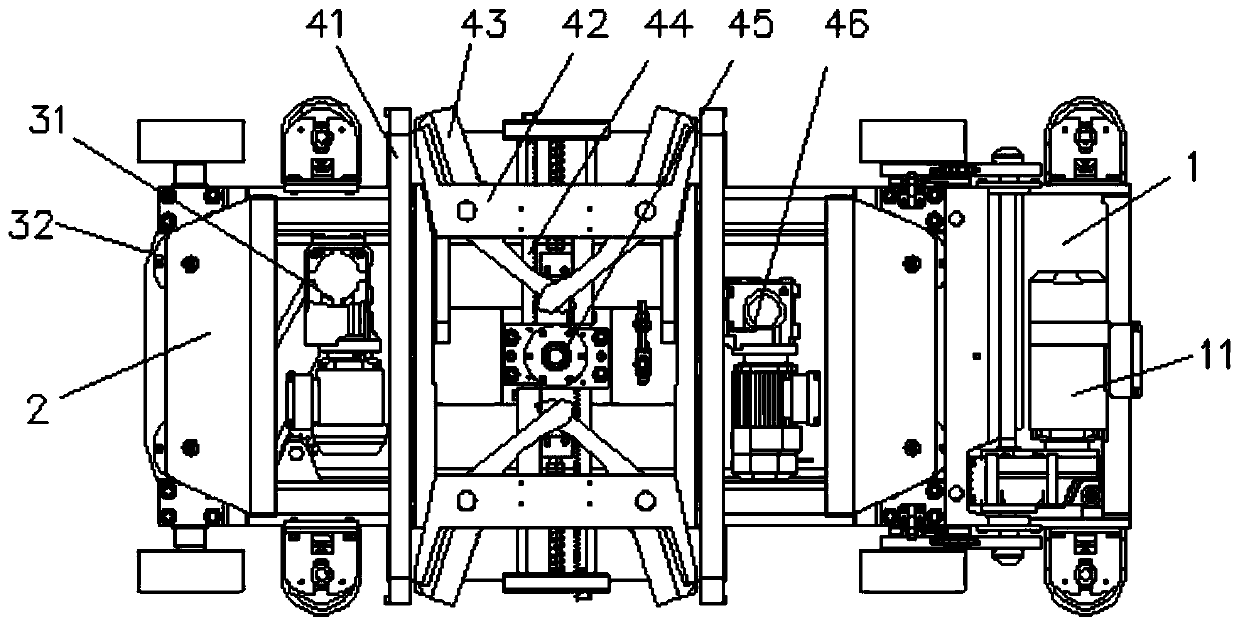

[0045] see Figure 1-5, a clamp-lifting type vehicle carrier, including two carriers with the same structure, the carrier includes a traveling vehicle body 1 for walking, a lifting frame 2 arranged above the traveling vehicle body 1, and a lifting frame for jacking up and down The lifting mechanism 3 of the frame 2 and the clamping mechanism 4 arranged on the lifting frame 2, the clamping mechanism 4 includes a guide rail 41, two groups of clamping arm lifting frames 42 that roll and cooperate with the guide rail 41, and hinged on the clamping arm bracket. The clamp arm 43 on the lifting frame 42; the lifting frame 2 between the guide rails 41 is provided with a synchronous gear box 45, and the output end of the synchronous gear box 45 synchronously drives two groups of clamp arm brackets through two sets of synchronous racks 44 The expansion and contraction of the lifting frame 42, the input end of the synchronous gear box 44 is connected to the centering motor 46 on the side...

Embodiment 2

[0050] Same as the first embodiment, the difference is that the stopper 51 is provided with a roller 56 that rolls and fits with the two self-locking ends 432, so as to avoid scratching of the clamp arm 43 by the stopper 51 and reduce damage.

Embodiment 3

[0052] Same as the first embodiment, the difference is that the clamp arm lifting frame 42 is provided with an outwardly extending auxiliary bracket 47, the position of the auxiliary bracket 47 matches the clamp arm 43 and is arranged lower than the clamp arm 43 . In this way, an auxiliary support force can be provided for the clamp arm 43 during clamping, and the stress on the clamp arm 43 can be reduced, so as to achieve better bearing capacity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com