Patents

Literature

444 results about "Granolithic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Granolithic screed, also known as granolithic paving and granolithic concrete, is a type of construction material composed of cement and fine aggregate such as granite or other hard-wearing rock. It is generally used as flooring, or as paving (such as for sidewalks). It has a similar appearance to concrete, and is used to provide a durable surface where texture and appearance are usually not important (such as outdoor pathways or factory floors). It is commonly laid as a screed. Screeds are a type of flooring laid on top of the structural element (like reinforced concrete) to provide a level surface on which the "wearing flooring" (the flooring which people see and walk on) is laid. A screed can also be laid bare, as it provides a long-lasting surface.

Extruded fiber reinforced cementitious products having stone-like properties and methods of making the same

InactiveUS20110120349A1Improve flexural strengthHigh tensile strengthConstruction materialSolid waste managementBuilding productCement composites

A cementitious composite product that can function as a substitute for stone and solid surface materials, such as granite, marble, and engineered stone is provided. Furthermore methods for manufacturing the cementitious composite product using an extrudable cementitious composition that can be extruded or otherwise shaped into stone-like building products that can be used as a substitute for many known stone products is disclosed. In one embodiment, the cementitious composite products can be manufactured more cheaply to be as tough or tougher and more durable than stone and solid surface materials.

Owner:E KHASHOGGI INDS

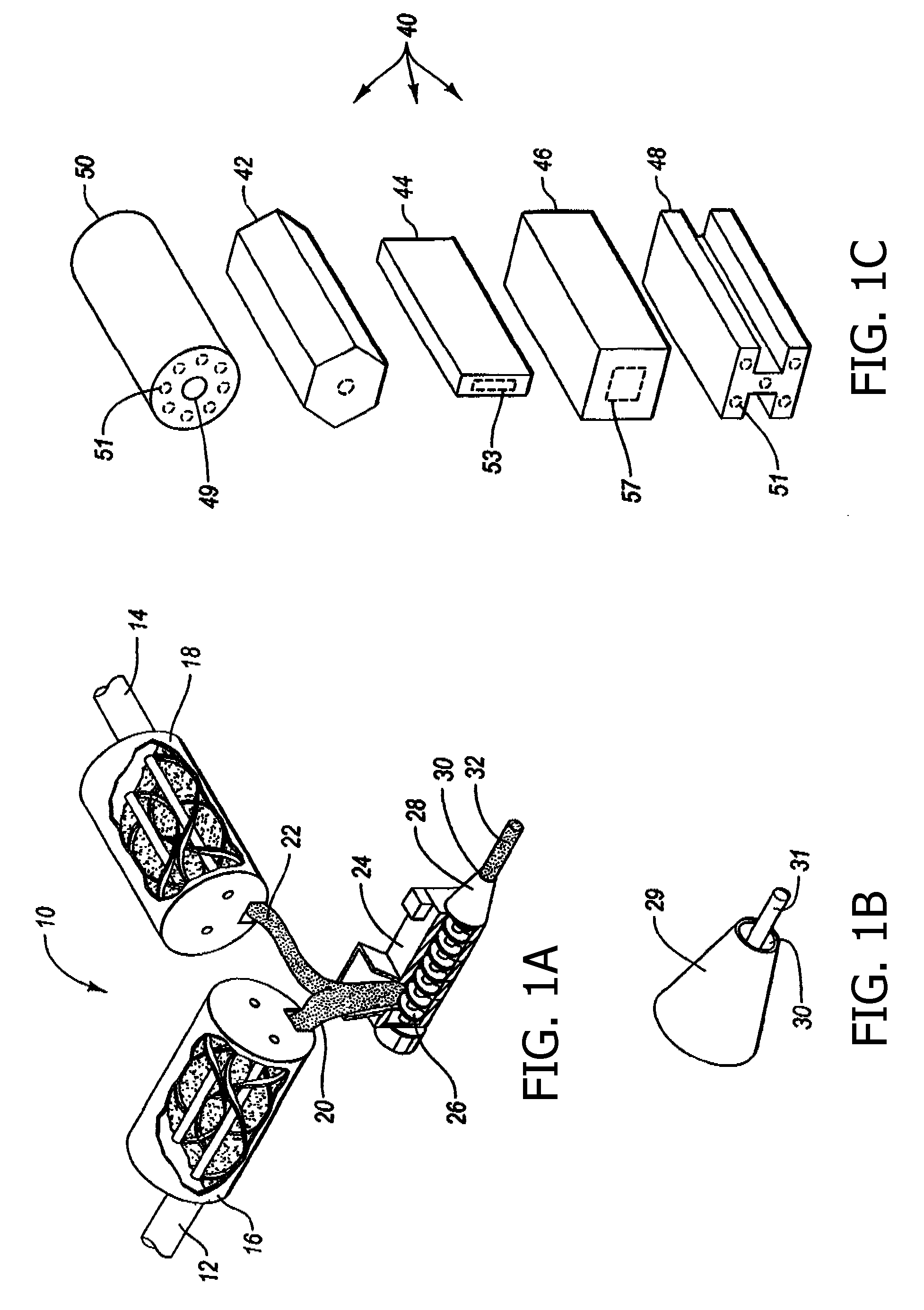

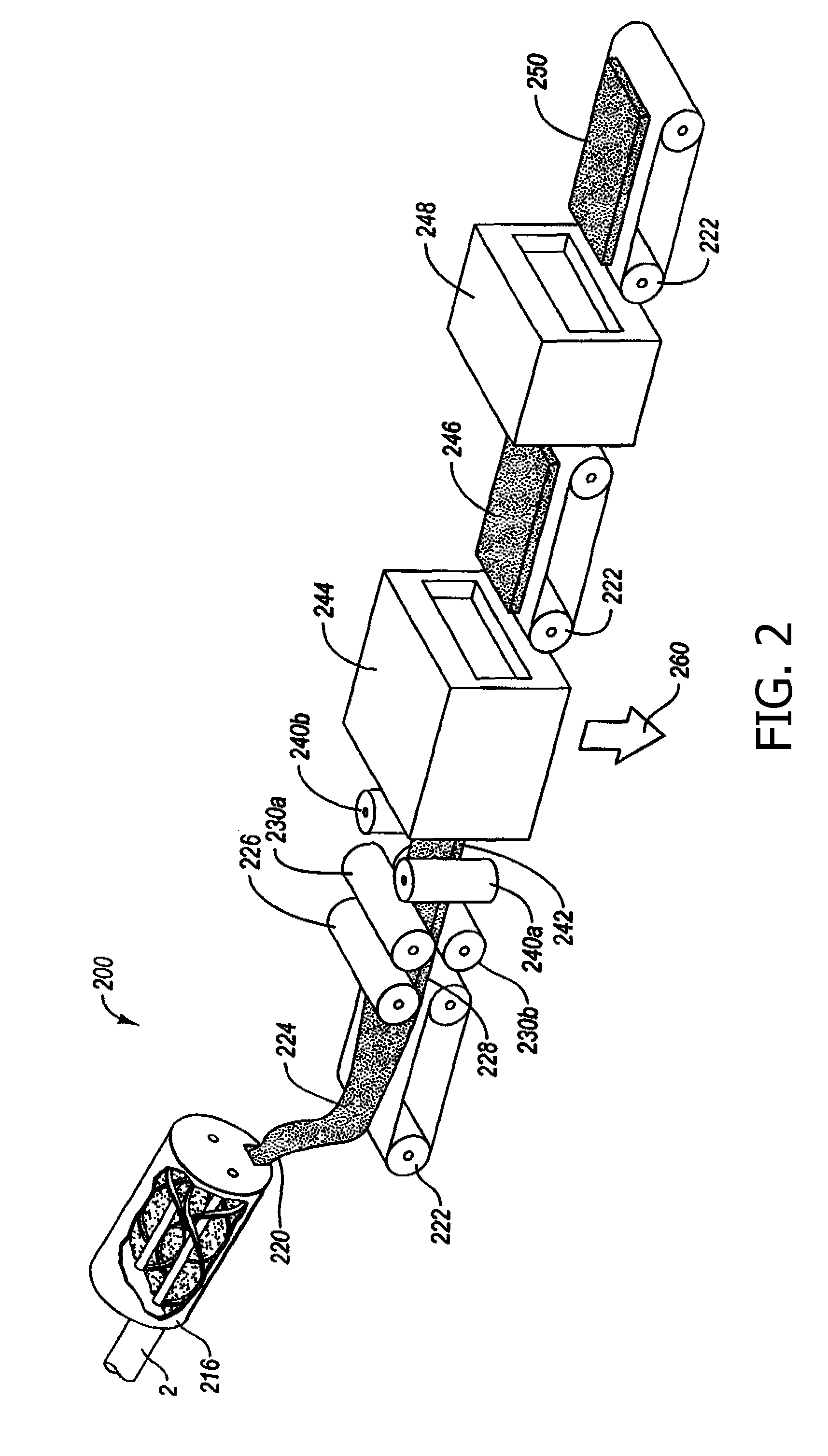

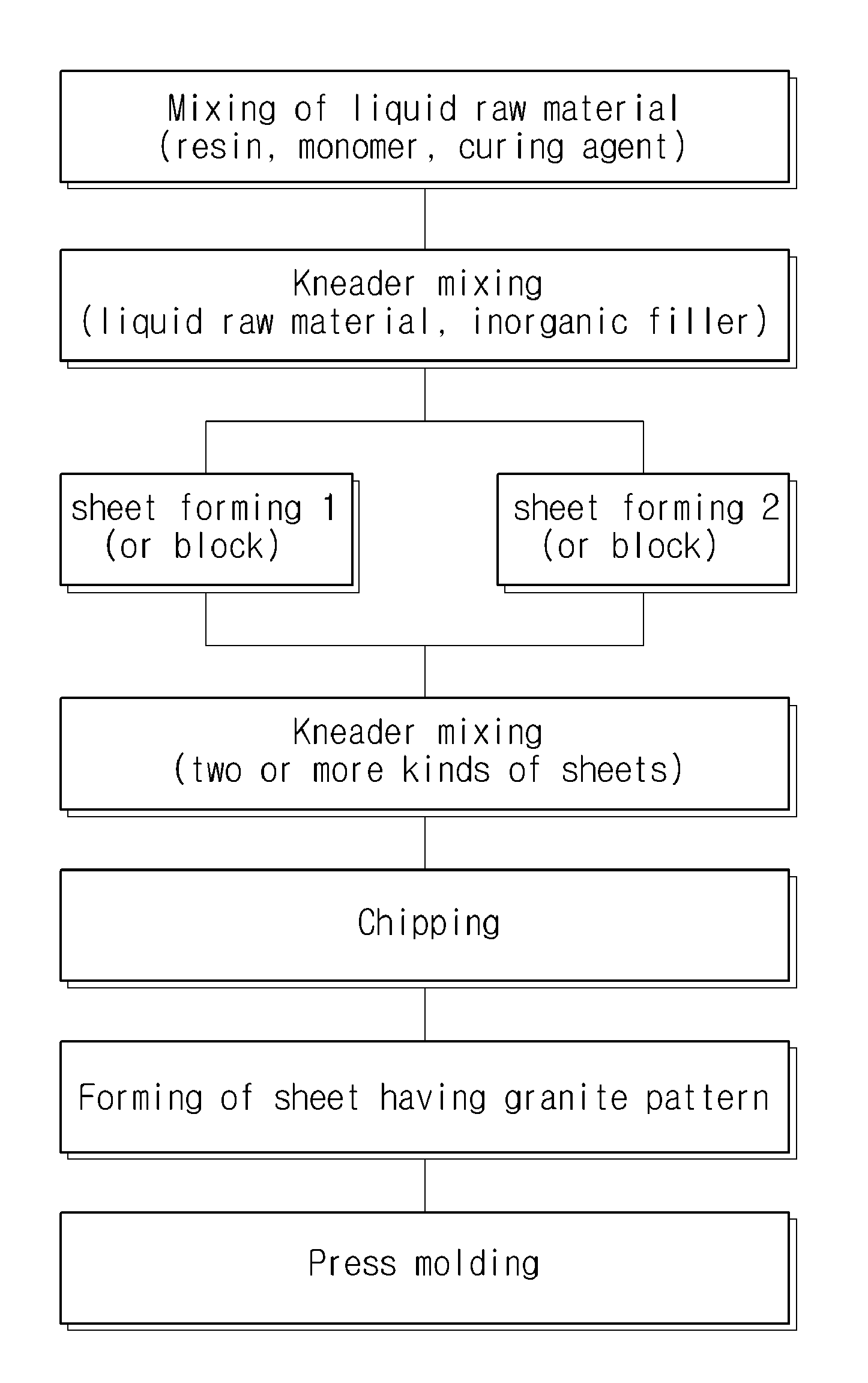

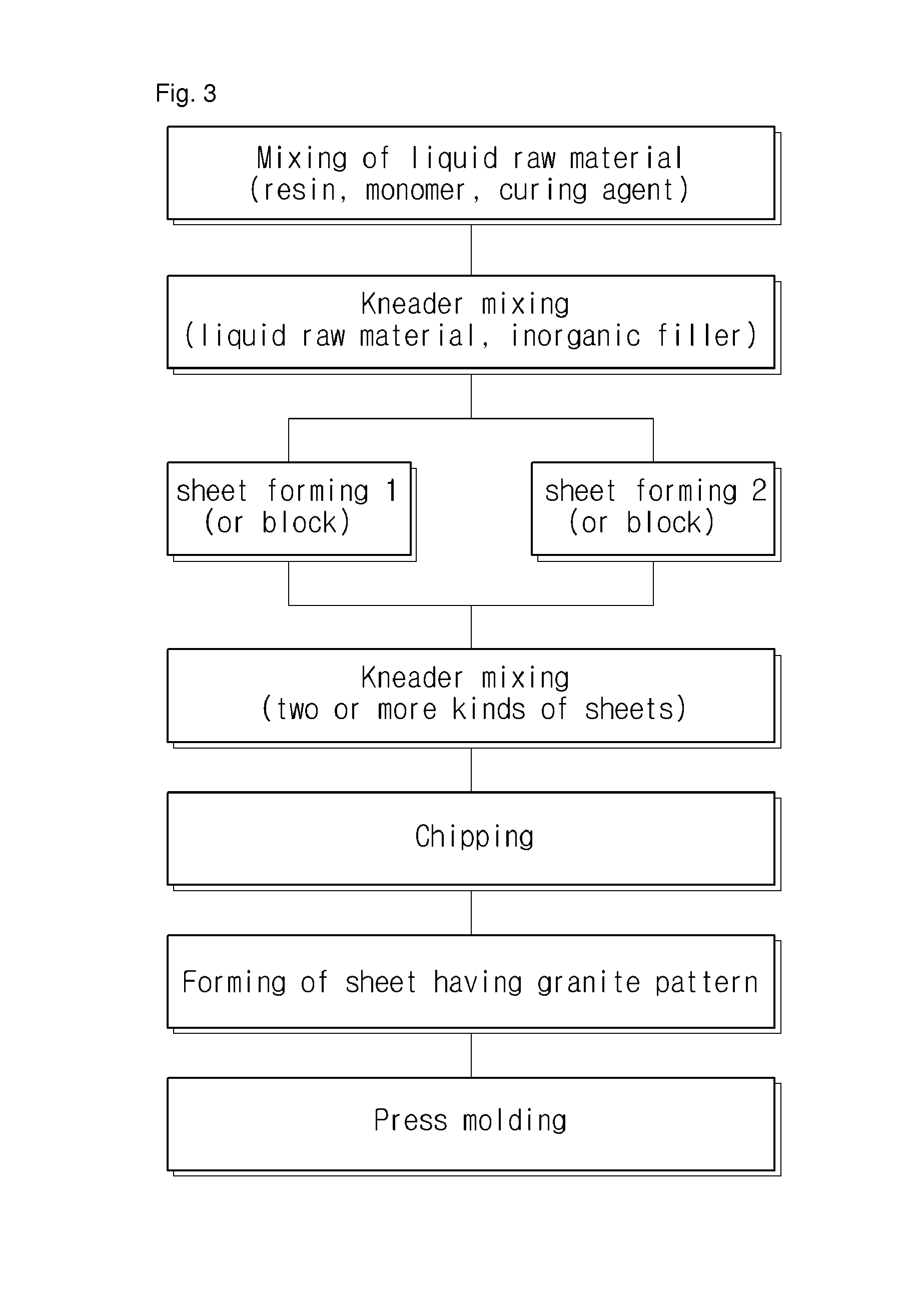

Acrylic artificial marble having granite pattern and method of manufacturing the same

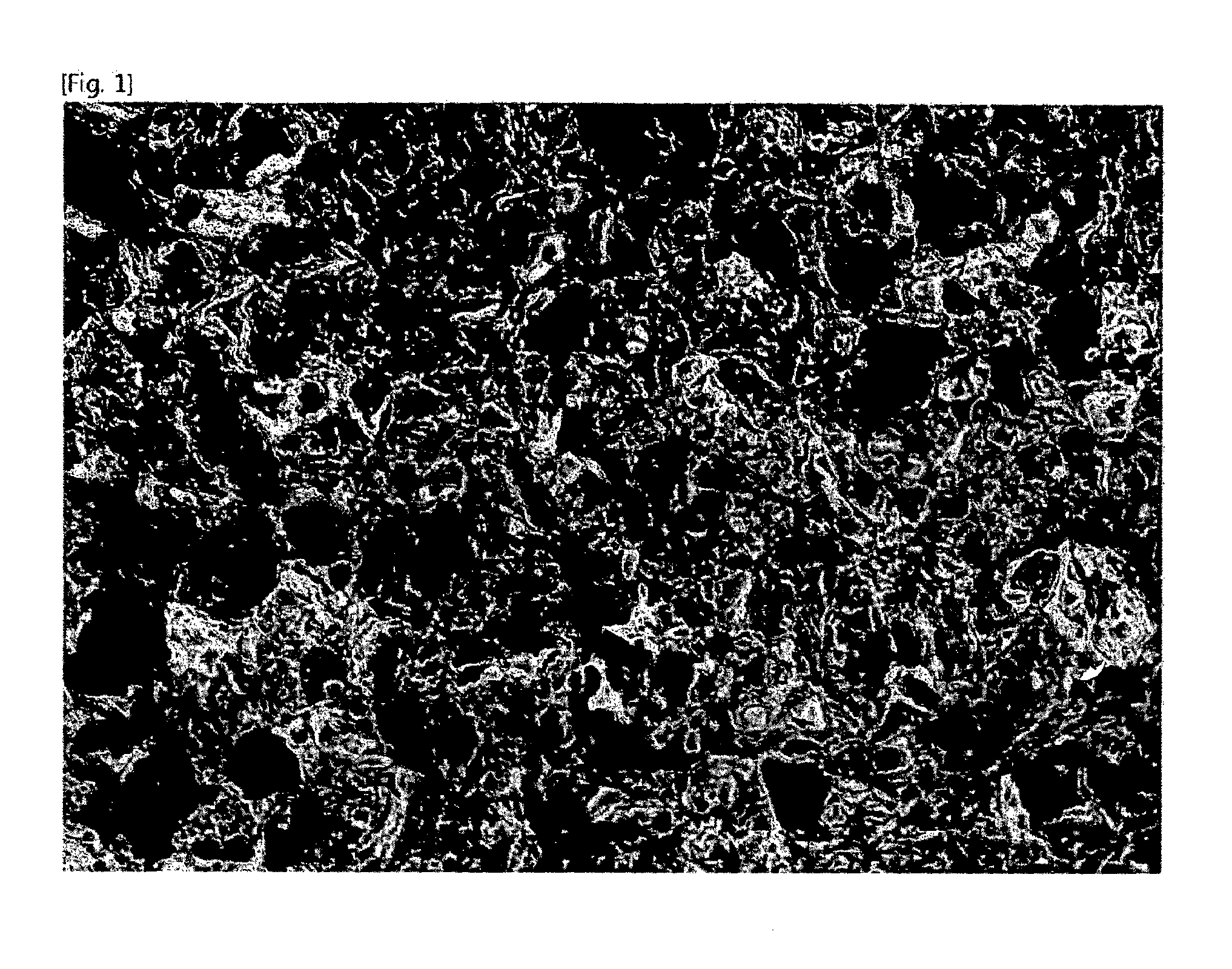

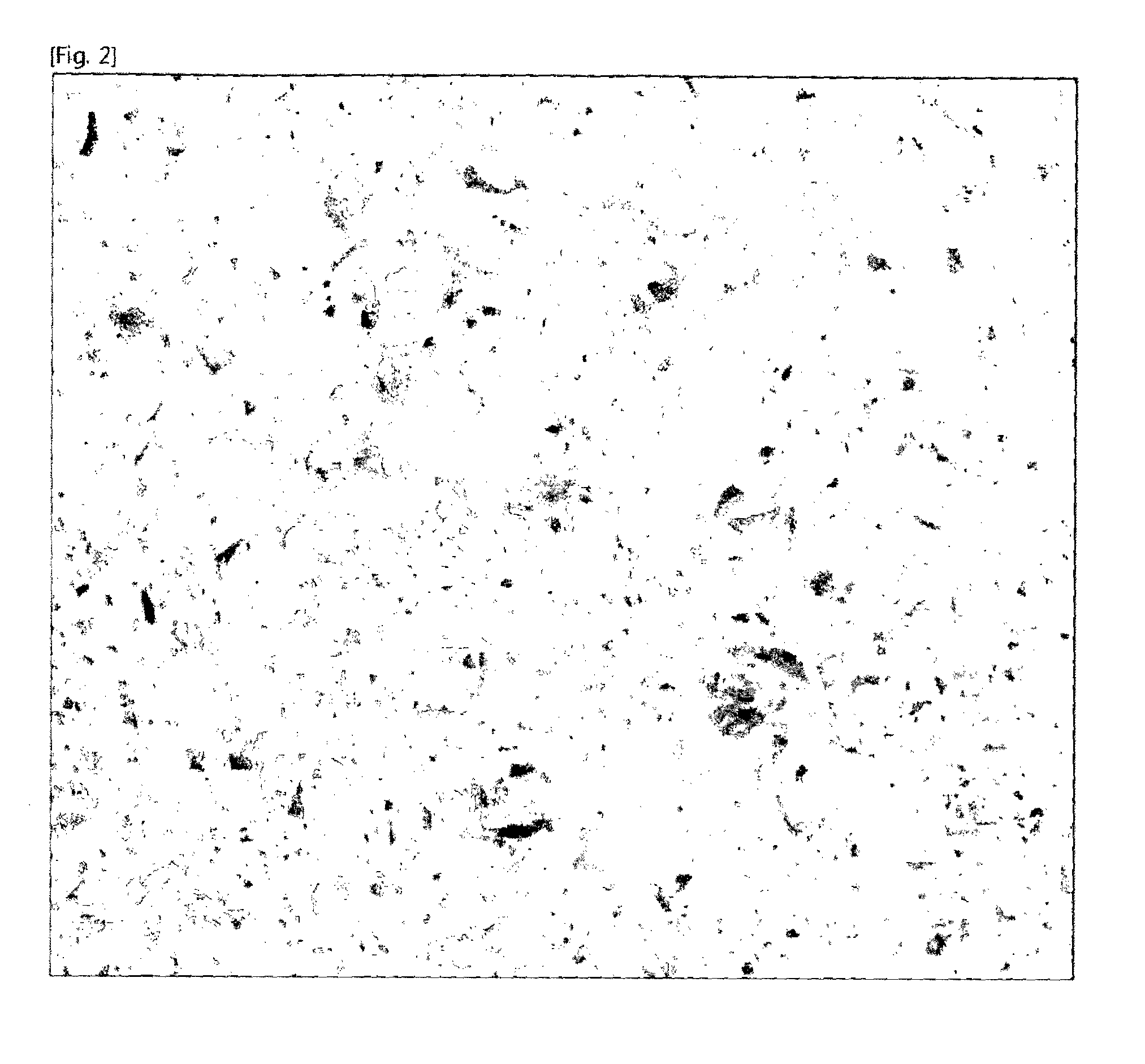

InactiveUS20130137810A1Well mixedDesired patternNatural patternsNon-woven fabricsShell moldingGranolithic

The present invention relates to an acrylic artificial marble having a granite pattern and a method of manufacturing the same, which can provide a natural marble effect by mixing and molding two or more compounds having different colors and thus can obtain a granite pattern in which patterns of the two or more compounds are smoothly mixed, and which can obtain a desired pattern remarkably similar to a pattern of natural stone by using a multicolor chip sheet.

Owner:LG HAUSYS LTD

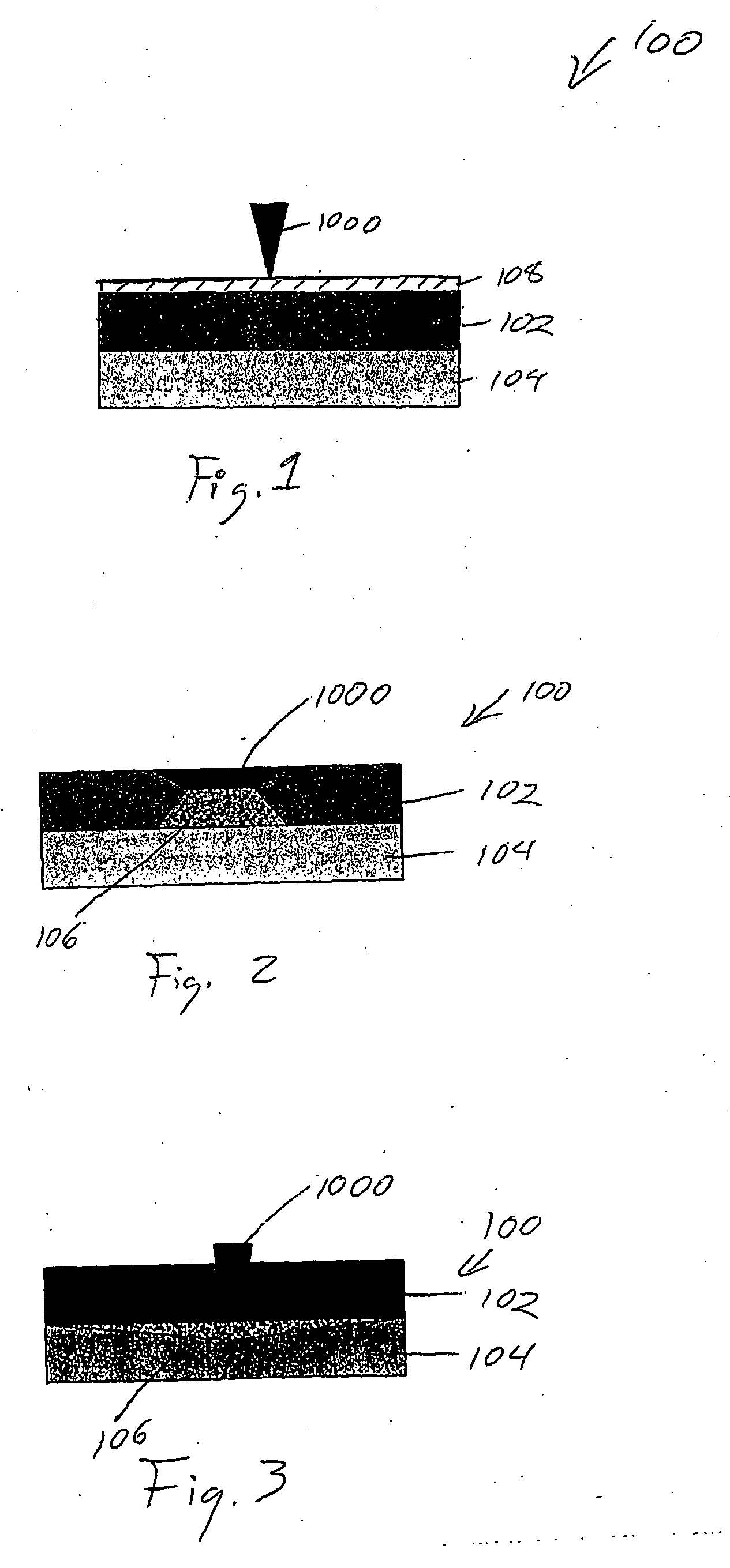

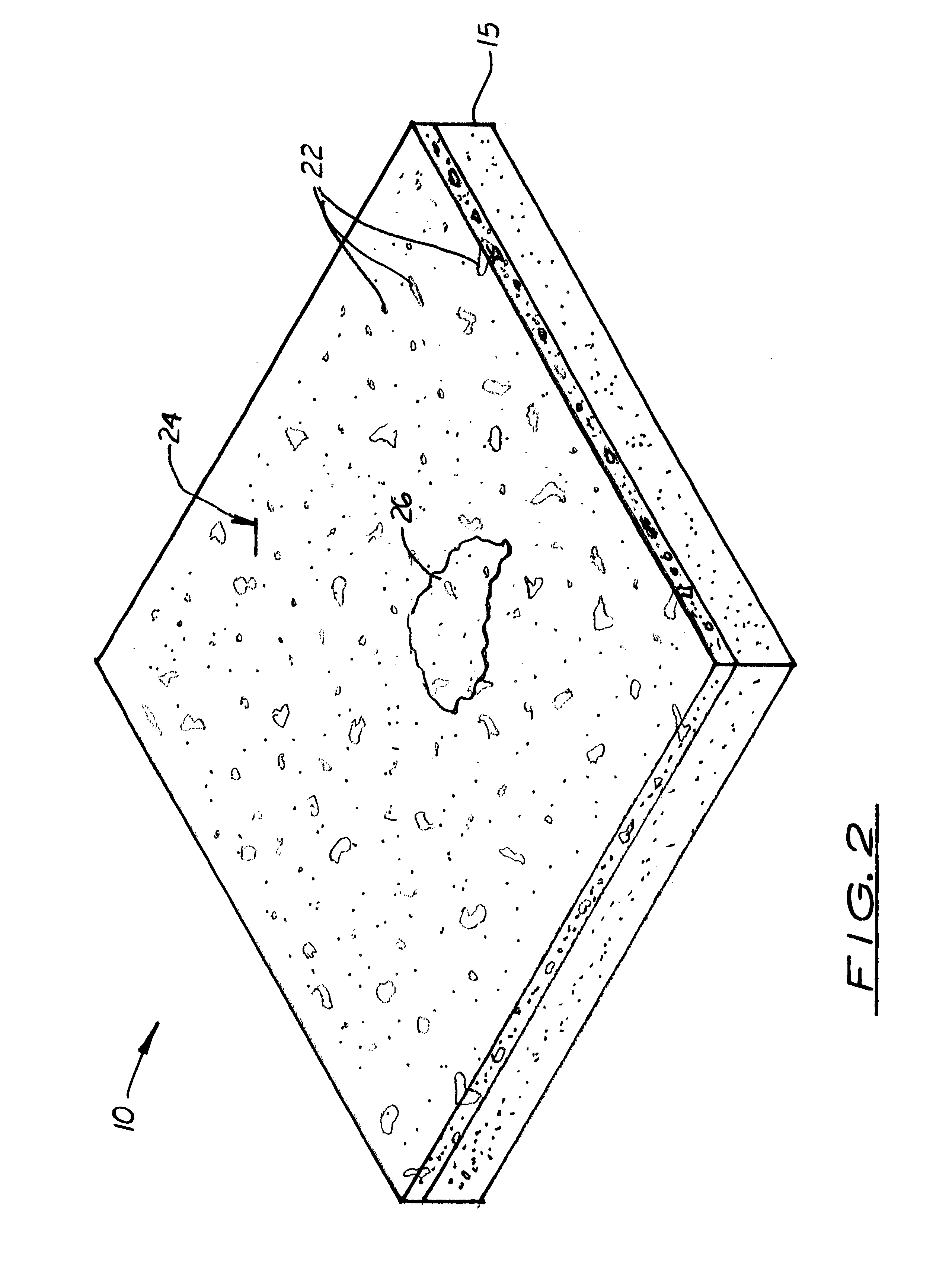

Armor Panel System

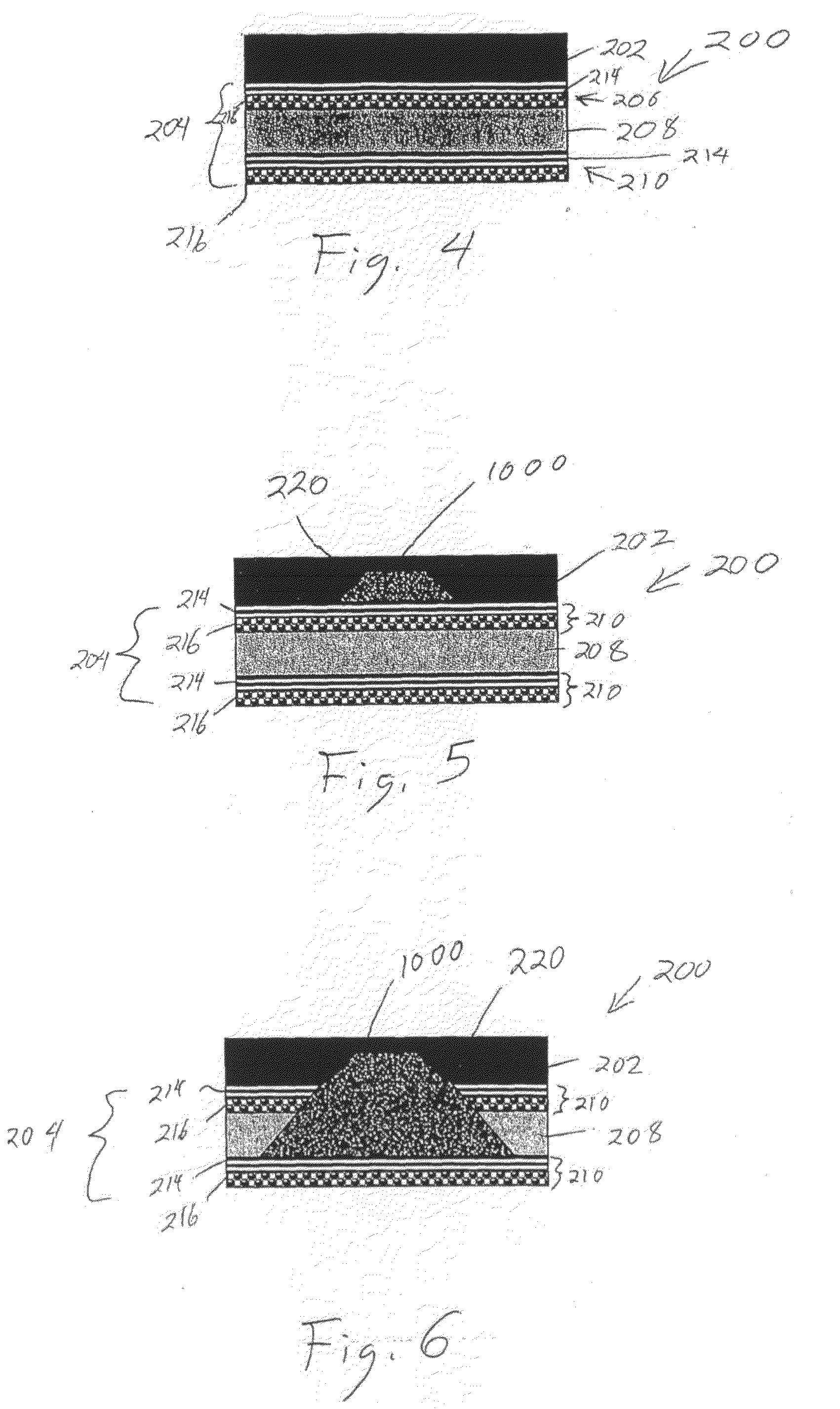

InactiveUS20090169855A1Improved multi-hit performanceHigh stiffnessSynthetic resin layered productsDoor/window applicationsGranolithicHigh intensity

An armor system has a hardened strike panel and a backing panel. The strike panel utilizes common hard materials such as granite, hardened concrete or ceramic tile. The backing panel utilizes reinforcement materials having high strength and stiffness to provide support to the strike panel upon impact of a projectile. A reinforcement product marketed under the trade name Hardwire™ is used in some embodiments. This reinforcement material has wire strand cords extending through a support layer that may be molded and provides superior strength to weight ratios. The backing panel also may utilize a core material with a reinforcement layer or layers attached to each face in a preferred embodiment. Staples may extend through the layers to provide additional resistance against delamination.

Owner:TUNIS GEORGE

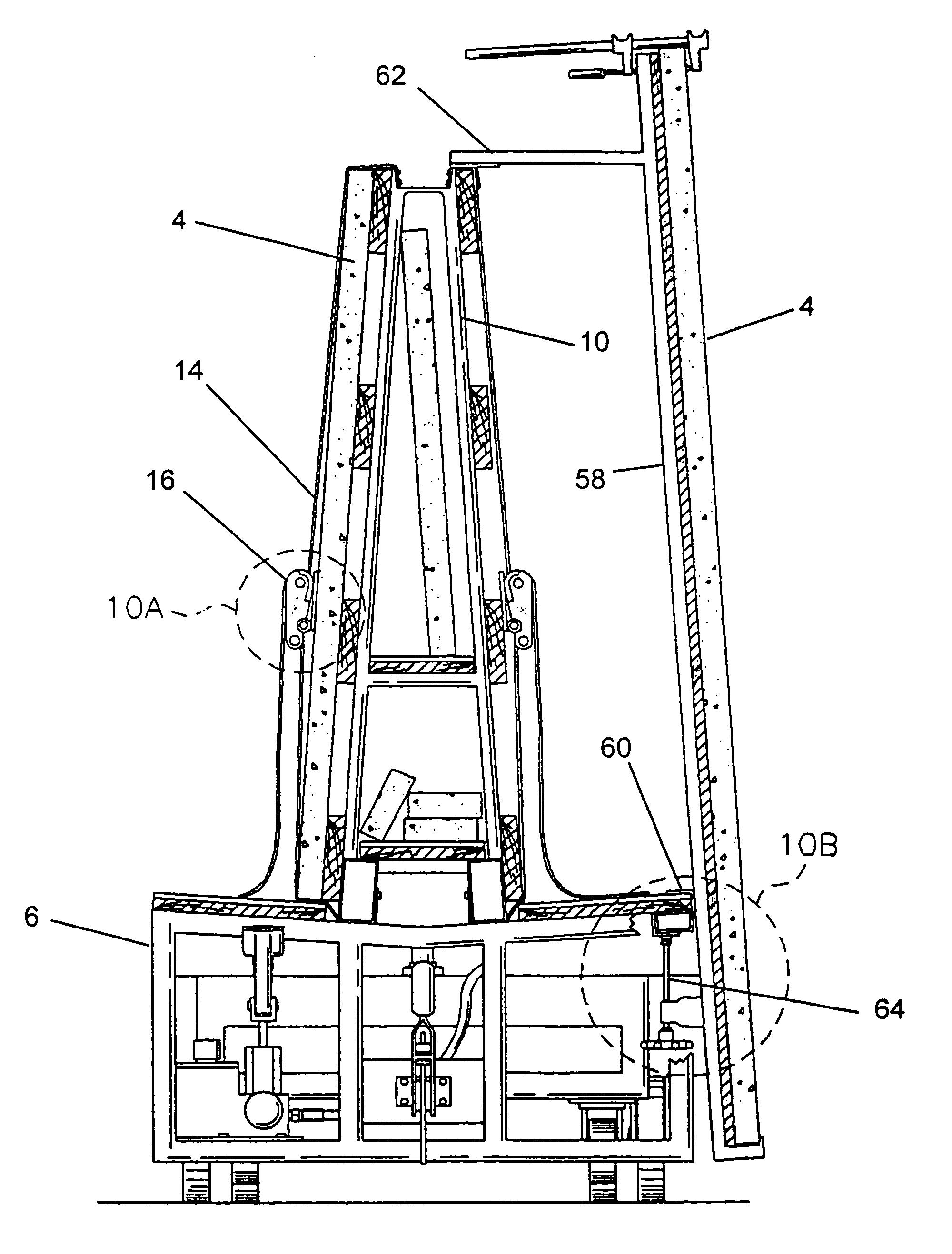

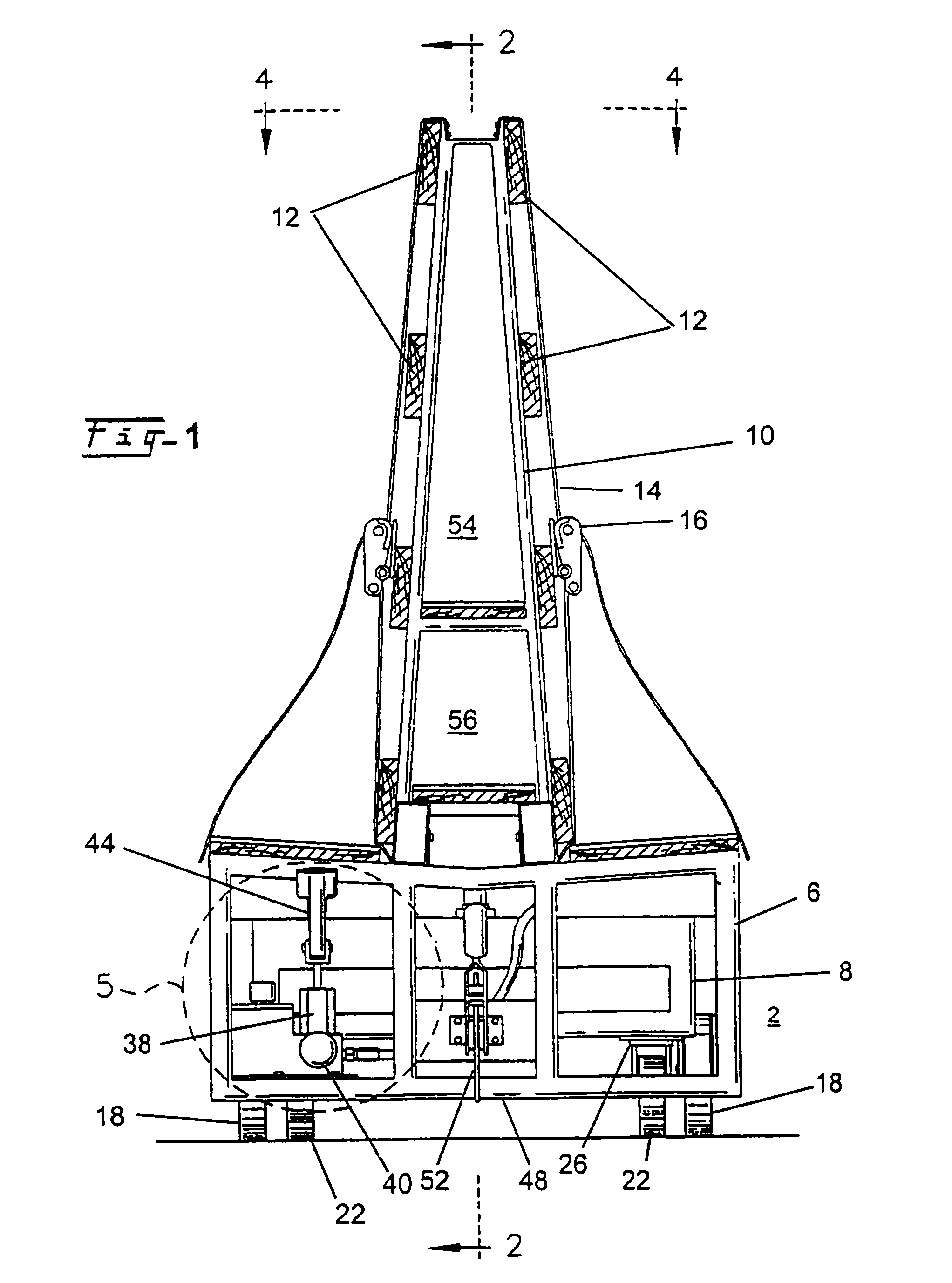

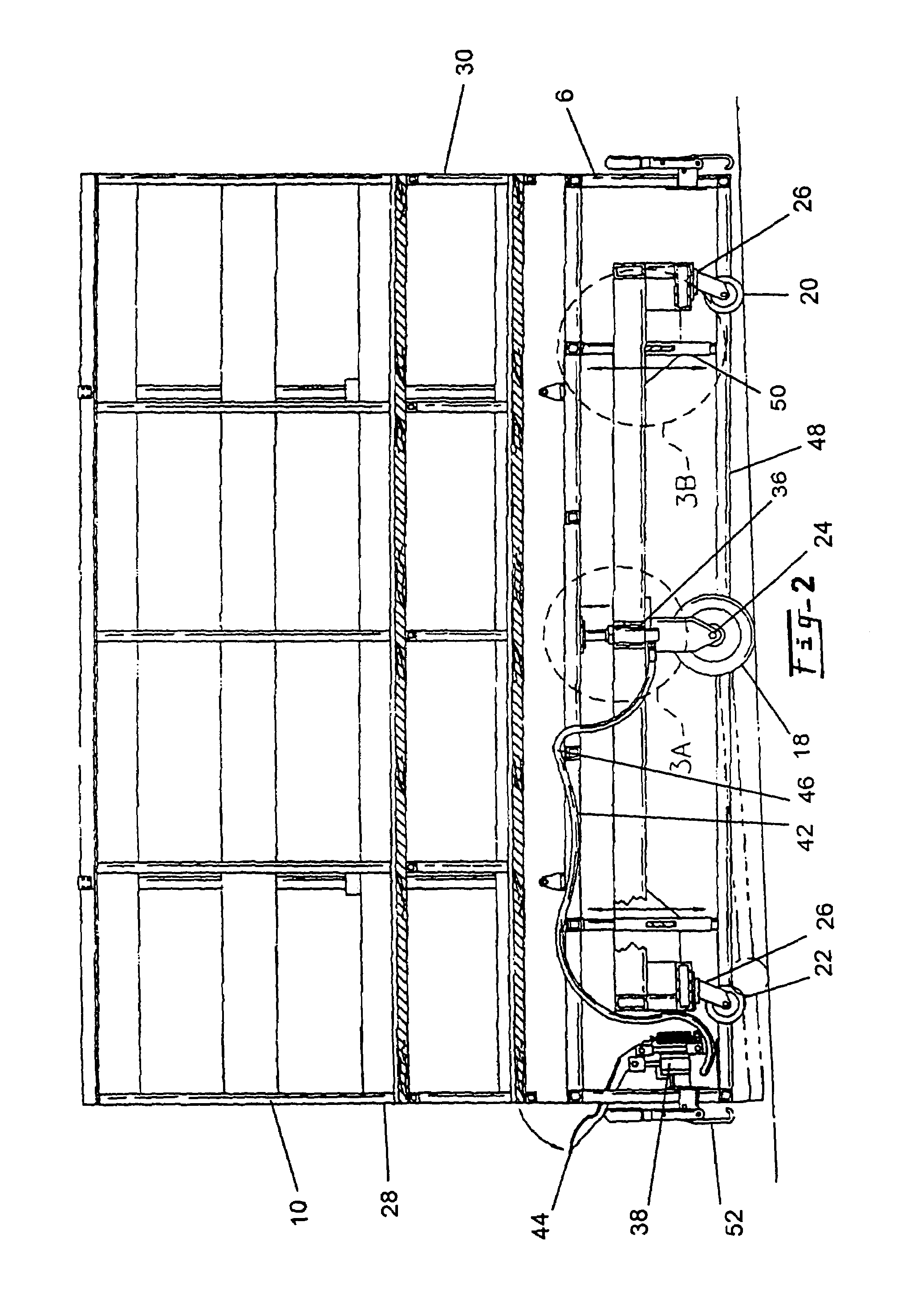

Cart for large slabs

InactiveUS7004483B1Easy to maneuverSmooth rotationGlass plate transportationUnderstructuresGranolithicEngineering

The Invention is a cart for moving slabs of stone, such as marble and granite. In a first embodiment, main wheel support the weight of the slabs while front and rear end wheel prevent tipping of the cart. A hydraulic system withdraws the wheels, rendering the cart stationary. In a second embodiment, a main wheel carriage is clamped directly to a slab and bears its weight while smaller front and rear end wheel carriages clamped to the slab prevent tipping of the slab. The wheel arrangement of both embodiments allows the heavy slabs of stone to be readily maneuvered and rotated.

Owner:MARBLE CRAFTERS

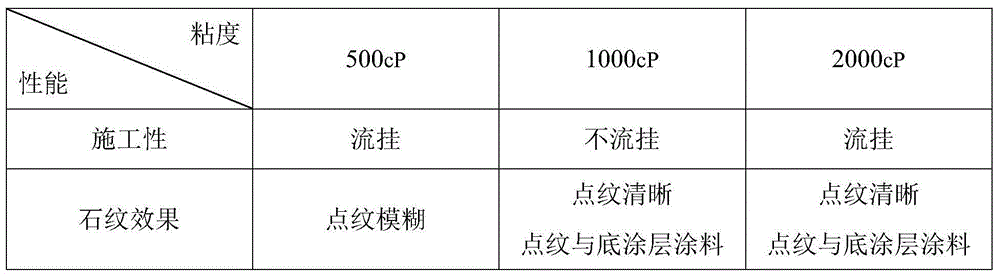

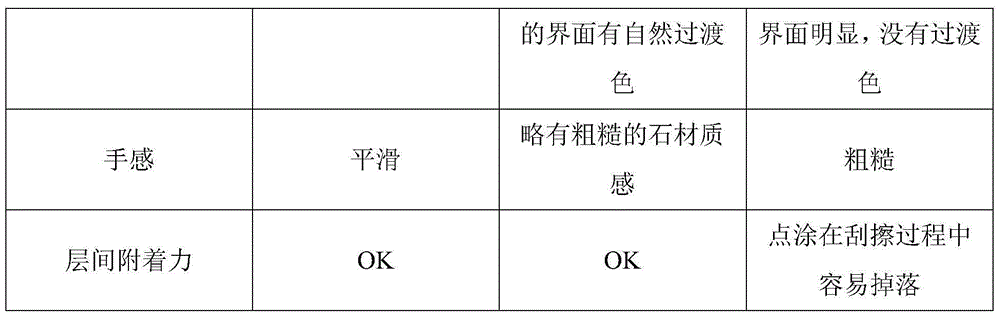

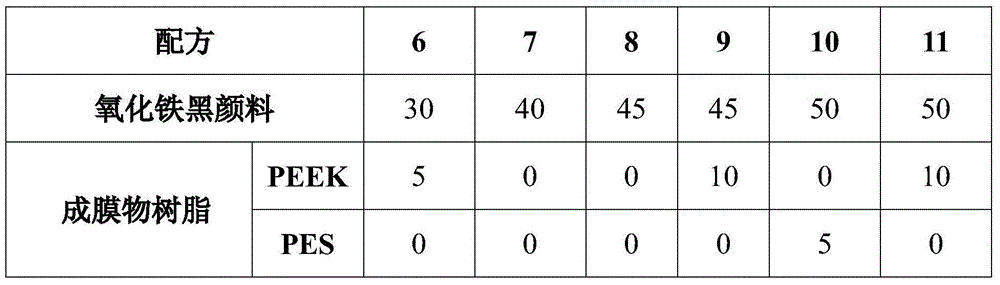

Full water-borne granite multicolor painting and preparation method thereof

The invention provides a full water-borne granite multicolor painting comprising base paint, colloid and synthesized emulsion, wherein the weight ratio of the three components is 30-40:30-40:20-40. The full water-borne granite multicolor painting is a full water-borne product, has low Voc, is environmental-friendly and solvent-free and is an ideal substitute for marble, granite and the like; the properties of the full water-borne granite multicolor painting can satisfy the GB / T9755-2001 synthetic resin exterior wall painting material standard; and the full water-borne granite multicolor painting has good elasticity and can cover small cracks of a wall body.

Owner:ASIA PAINT SHANGHAI

Cement based adhesive, and preparation method

This invention provides a method for preparing cement-based adhesive, which is composed of: cement, sand, calcium carbonate powder, water-retaining agent, organic adhesive, thickener and anti-sliding agent. When used, the cement-based adhesive is added into an appropriate amount of water, and stirred at normal temperature and pressure. The cement-based adhesive has such advantages as simple construction, low cost, high construction performance, long drying time, high anti-sliding ability, and high adhesiveness. The cement-based adhesive can be used to adhere various walls and floor tiles, especially marble and granite bricks, and does not slide even when the surface density is up to 80 kg / m2.

Owner:张焰峰

External thermal insulation system of water-based simulated natural granite paint finish

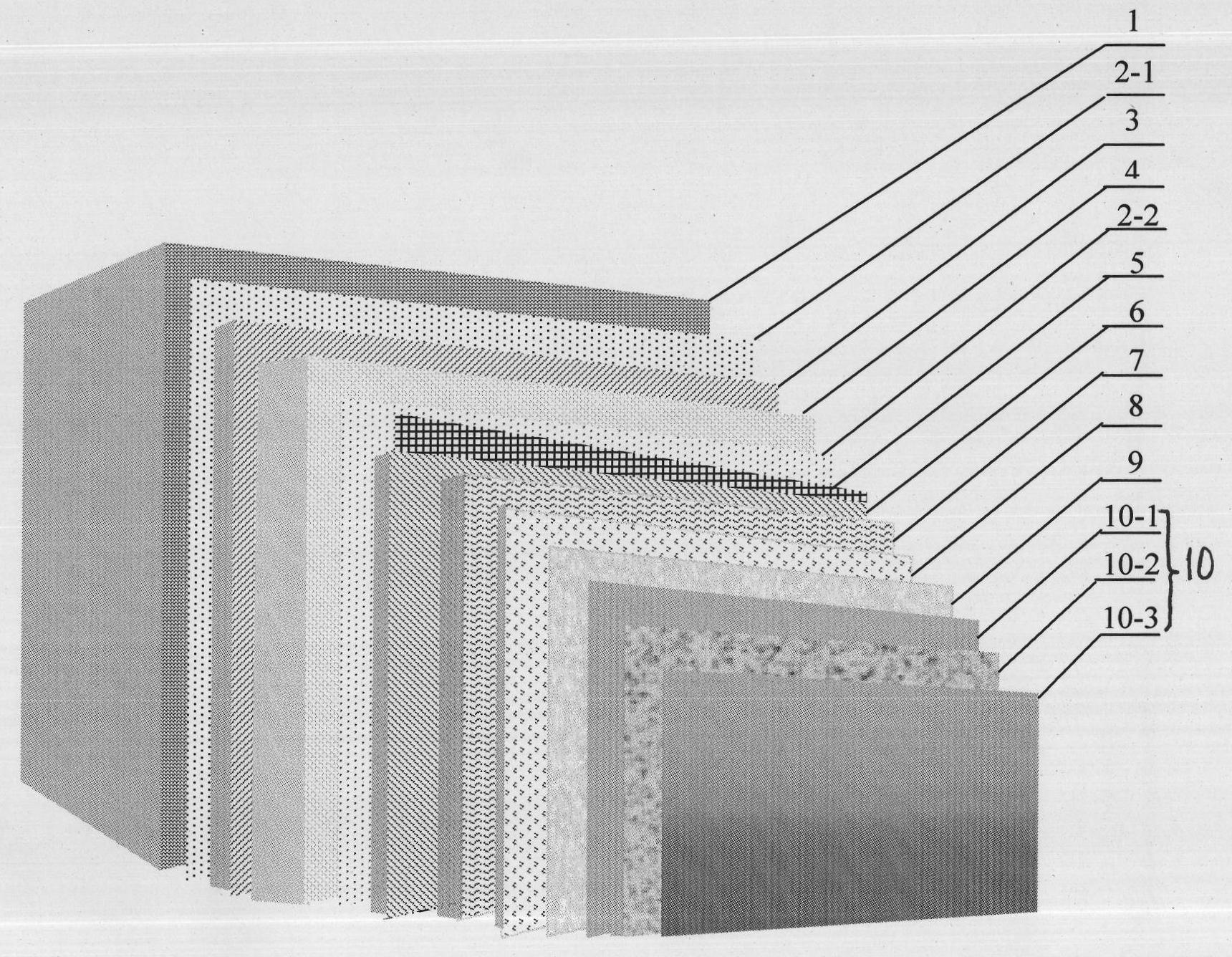

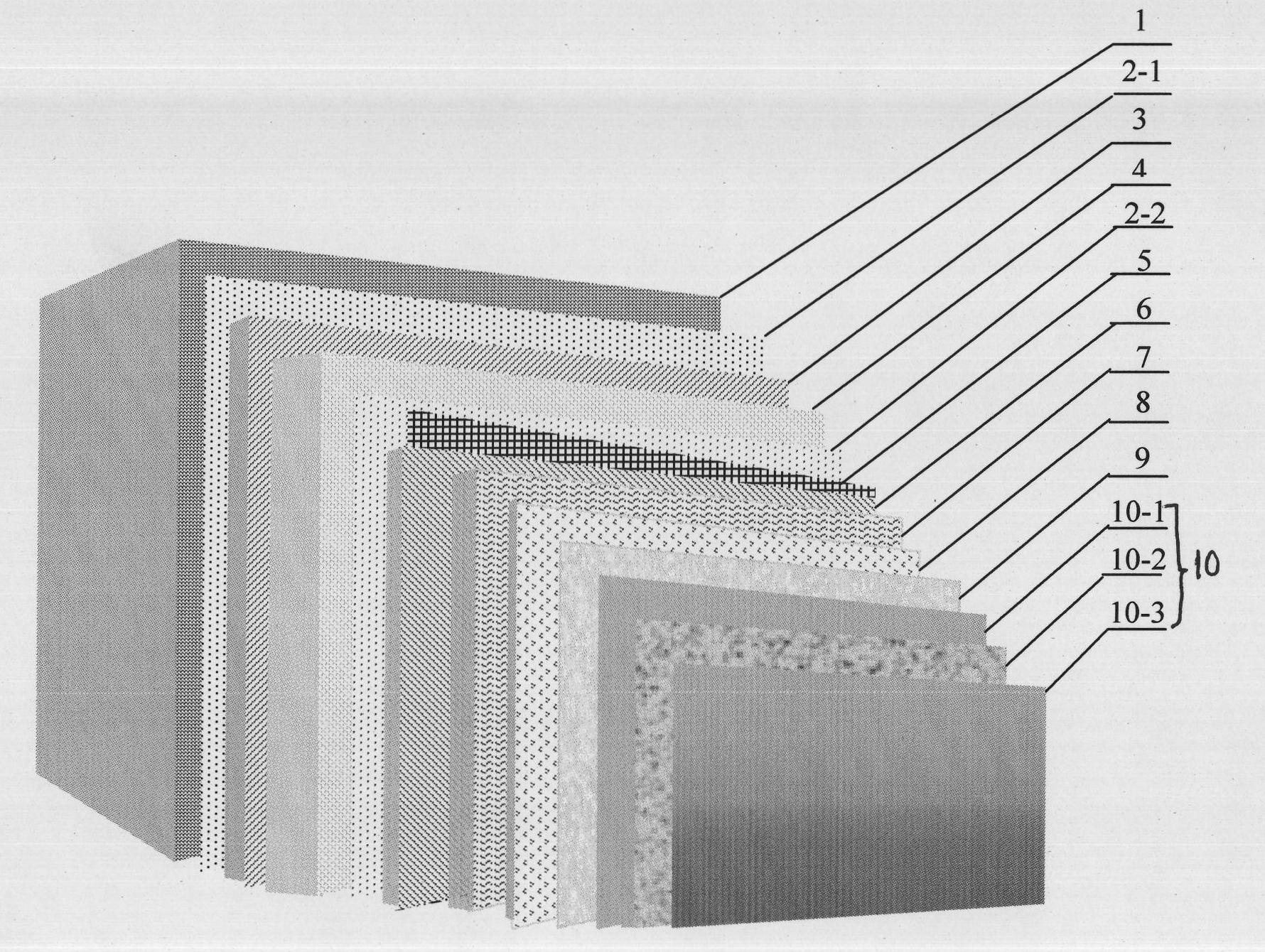

ActiveCN101798860AElastic enoughGood value for moneyCovering/liningsMulticolor effect coatingsWater basedFiberglass mesh

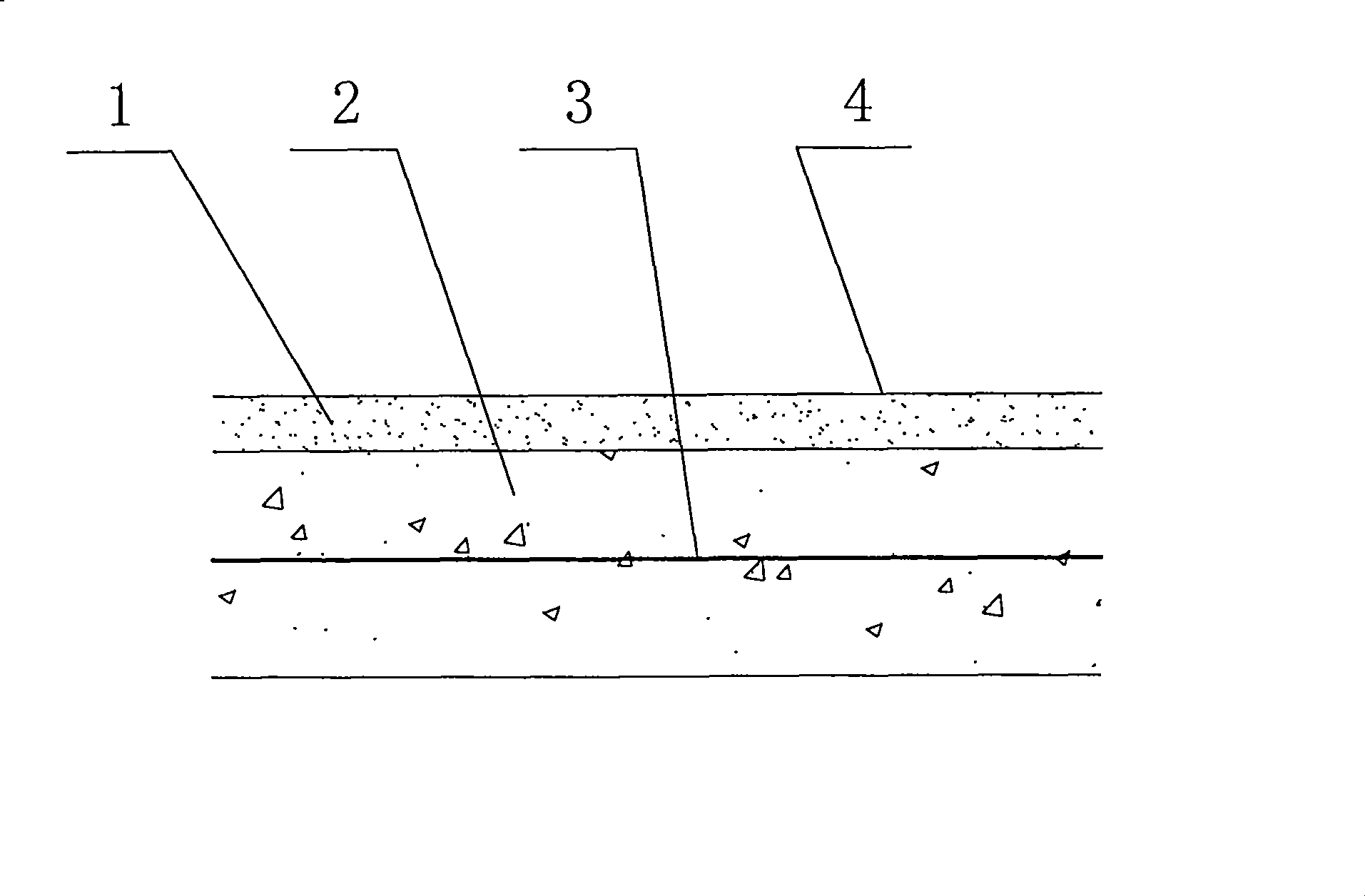

The invention relates to an external thermal insulation system of a water-based simulated natural granite paint finish. The specific structure is as follows: sequentially arranging a first interface binder layer (2-1), an adhesive mortar layer (3), a polystyrene board thermal insulation layer (4), a second interface binder layer (2-2), a polymer anti-crack mortar rendering layer (6) of a liner fiberglass mesh (5), a polymer flexible putty leveling layer (7), a smooth putty layer (8), a seal primer layer (9) and a finishing layer (10) which are arranged on the external surface of a basal layer wall body (1) from inside to outside, and the invention is characterized in that the finishing layer (10) consists of a flexible ground color layer (10-1), a water-based flexible colorful pattern layer (10-2) and a mat coat protection layer (10-3) sequentially arranged from inside to outside, and the various layers are integrated with the basal layer wall body (1) after drying and curing. With an appropriate price and simple process, the invention makes the building get the effect of granite building material and improves the external thermal insulation and the safety of the external wall.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Granite stone paint and preparation method thereof

The invention relates to a granite mineral varnish, which is prepared by raw material according to the following percentage by weight, water-based resin 10-25 parts, film forming additive 1-3 parts, propylene glycol 0.5-2 parts, mildew preventive 0.1-0.5 parts, defoaming agent 0.1-0.3 parts, color quartz sand 60-80 parts, color compound rock slices 8-30 parts and thickening agent 0.5-2 parts. The process for preparing the granite mineral varnish of the invention comprises the following steps: adding water-based resin, film forming additive, propylene glycol, mildew preventive, defoaming agent and thickening agent into a dispensing tank according to proposition, adding color quartz sand after evenly stirring, and then evenly stirring, adding color compound rock slices, and obtaining granite mineral varnish end products after evenly stirring. The granite mineral varnish has the advantages that first, excellent simulation effect, no matter near viewing or remote viewing, textures are lively, which has no difference with natural granite mineral varnish, second, excellent anti-fouling performance, third, big binding strength, fourth, excellent artificial aging (more than 800h), fifth, simple construction, only single-gun single-hole is needed, and the single gun is colorful.

Owner:HANGZHOU SENLESHI COATING

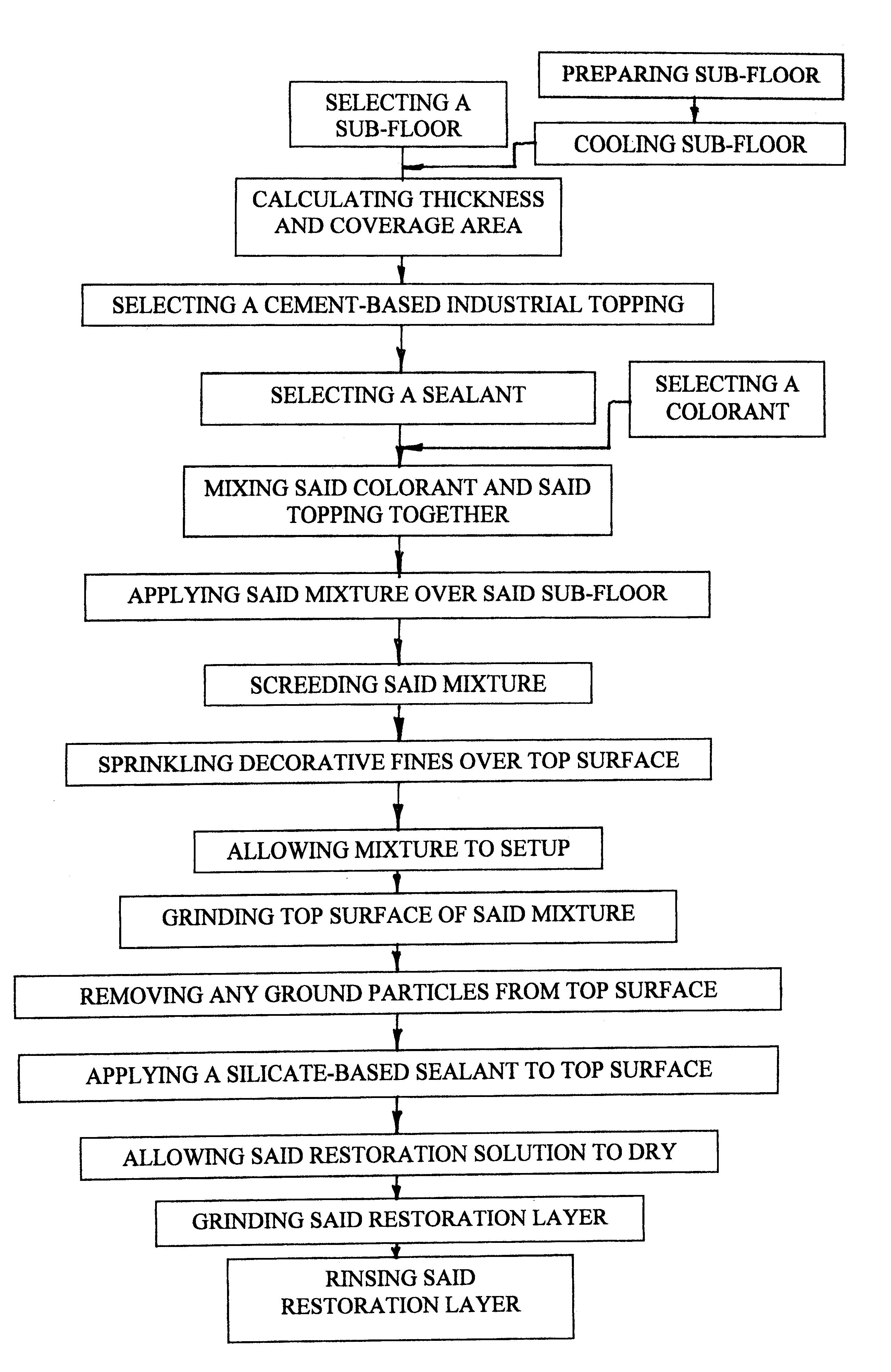

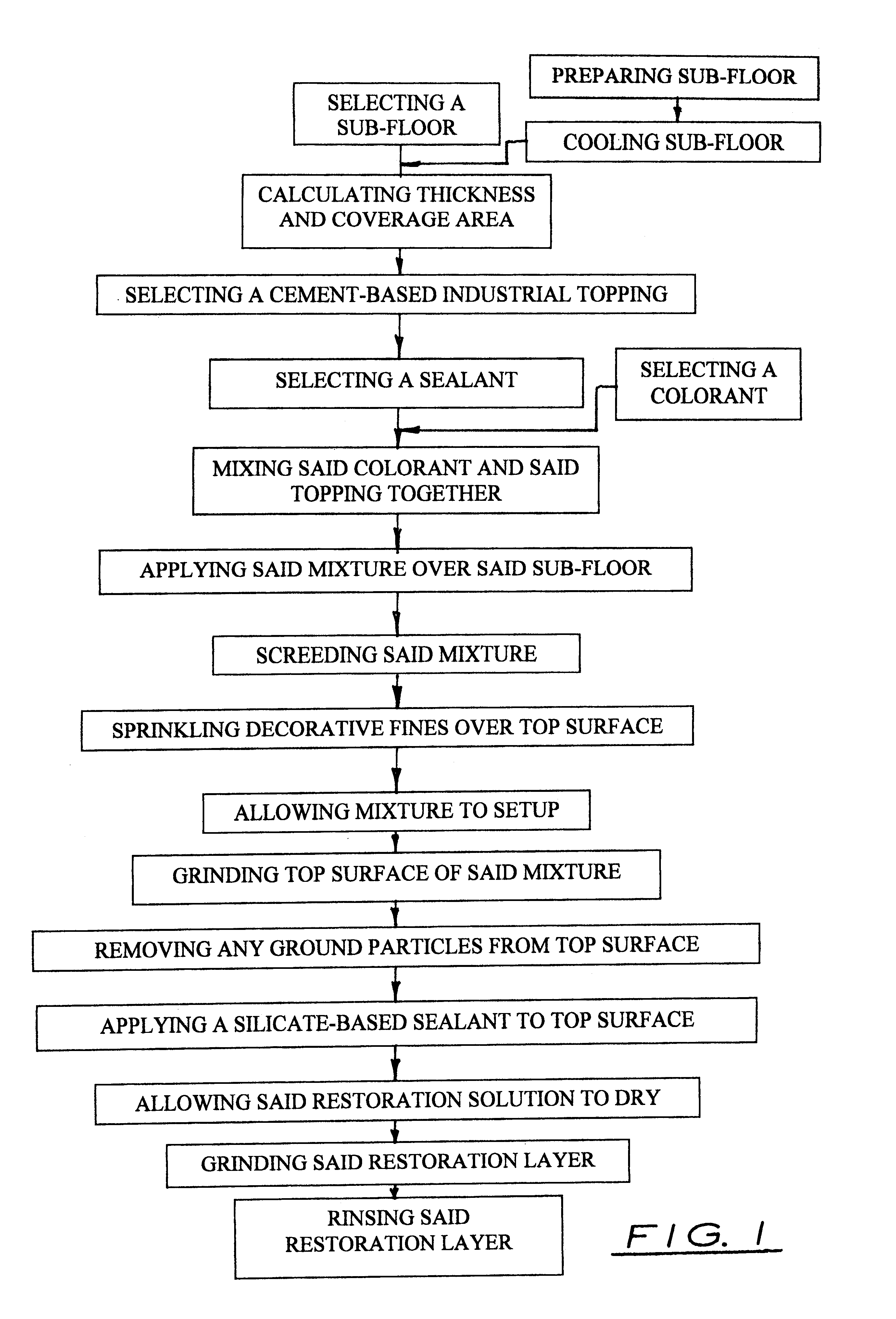

Method of manufacturing decorative cementuous floor surface

InactiveUS6568146B2Easy to installEmission reductionBuilding repairsBuilding material handlingWood veneerGranolithic

A method of manufacturing a low-moisture penetrating decorative floor surface. The completed floor surface has an appearance of a solid granite slab floor with greater durability. The floor surface has a smooth, flat appearance and can be manufactured in different shapes. The floor surface may be formed over a wood or concrete sub-floor and includes a self-leveling, cementous, low moisture penetrating material to which suitable colorants may be added. The cementous material comprises a topping and silicate-based sealant mixture that is mixed together and poured and leveled over the sub-floor to a desired height. Flakes of contrasting material is then sprinkled over the top surface of the mixture to create a decorative appearance. After drying, the surface is finely ground to a smooth finish. A coat of silicate-based sealant is then applied to the surface that penetrates the porous surface to create a low moisture emitting surface The surface is then ground to a fine surface and rinsed.

Owner:HARVEY JAMES

Manufacturing method of recycled foam material using granite powder as raw material

InactiveCN102786316ANo chemical pollutionFully digestedSolid waste disposalCeramicwareThermal insulationGranolithic

The invention discloses a manufacturing method of a recycled foam material using granite powder as a raw material. The recycled foam material comprises the following formula and components: 70%-90% of granite powder, 6%-25% of flux filler, 1%-5% of pore-forming material, and 1%-5% of polymerization martial. The manufacturing method sequentially comprises the following steps of: controlling the fineness of the particles of the powder to be over 100 meshes; uniformly stirring and mixing; pressing mixture into a required granular material; stacking and forming the granular material; feeding into a high temperature furnace to heat; and finally cooling and taking out to obtain the recycled foam material finished product. A product produced by the manufacturing method has the advantages of fully consuming granite powder waste material, solving the problem of serious environmental pollution existing at a granite processing base for a long time and meeting environmental protection requirements, along with stable physical performance, light weight, thermal insulation, compression resistance, bending resistance, capabilities of being used for building wall or external wall decoration and fulfilling the aims of weight reduction and energy conservation of a building, fire prevention, water prevention and sound isolation performance and capability of being used as a fire-proof material and a wall isolating material.

Owner:宁波振强科技有限公司

Heat-insulation and decorative integral plate and manufacturing method thereof

InactiveCN102535787AImprove thermal insulationOvercome fire resistanceCovering/liningsSpecial surfacesInsulation layerGranolithic

The invention discloses a heat-insulation and decorative integral plate and a manufacturing method thereof. The heat-insulation and decorative integral plate comprises a heat-insulation layer, a middle protecting layer and a decorating layer; the heat-insulation layer is made of a nano aerogel felt material with treated surfaces or a nano aerogel plate material with treated surfaces; the middle protecting layer is made of anti-crack plastering mortar; and the decorating layer is made of coatings or finish or vetrified tiles for curtain walls or granite materials for curtain walls or non-granite materials. The manufacturing method is simple, the heat-insulation and decorative integral plate is mounted on a wall surface in an adhesion or anchoring combination mode, and a total system meets A-level incombustible standards, is safe and reliable, is convenient and fast in construction, and realizes integration of decoration and heat insulation.

Owner:上海英硕聚合材料股份有限公司

Finishing compound foam ceramic based on granite tailings and preparation method of same

InactiveCN106187087AReduce construction proceduresReduce construction costsCeramic materials productionCeramicwareFritGranolithic

The invention discloses a finishing compound foam ceramic based on granite tailings and a preparation method of same. The finishing compound foam ceramic includes a finishing layer and foam ceramic, wherein the finishing layer includes: 55-85% of high-permeability frits, 5-20% of clay, and 0-10% of an inorganic pigment; the foam ceramic includes 60-90% of the granite tailings, 10-25% of clay, 1-10% of a fluxing agent, 1-10% of a foamer, 0.5-2% of a stabilizer and 0-2% of a peptizer. The preparation method includes the steps of: respectively preparing the finishing layer and the foam ceramic, and preparing the finishing compound foam ceramic through a reverse pavement method. The finishing layer and the foam ceramic are integrated, so that an extra decorative process after a heat insulation material is pasted onto external walls is avoided. The material not only reduces construction processes but also saves a large amount of cost, and greatly reduces construction cost and difficulty.

Owner:深圳超超科技控股有限公司

Foaming ceramic light sheet material prepared from granite scraps and preparation method thereof

InactiveCN108752035AImprove uniformityOrdinary firing fastCeramic materials productionCeramicwareSpray GranulationTunnel kiln

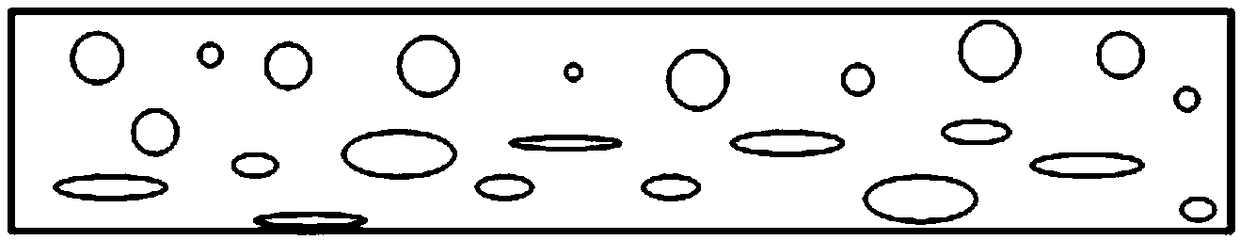

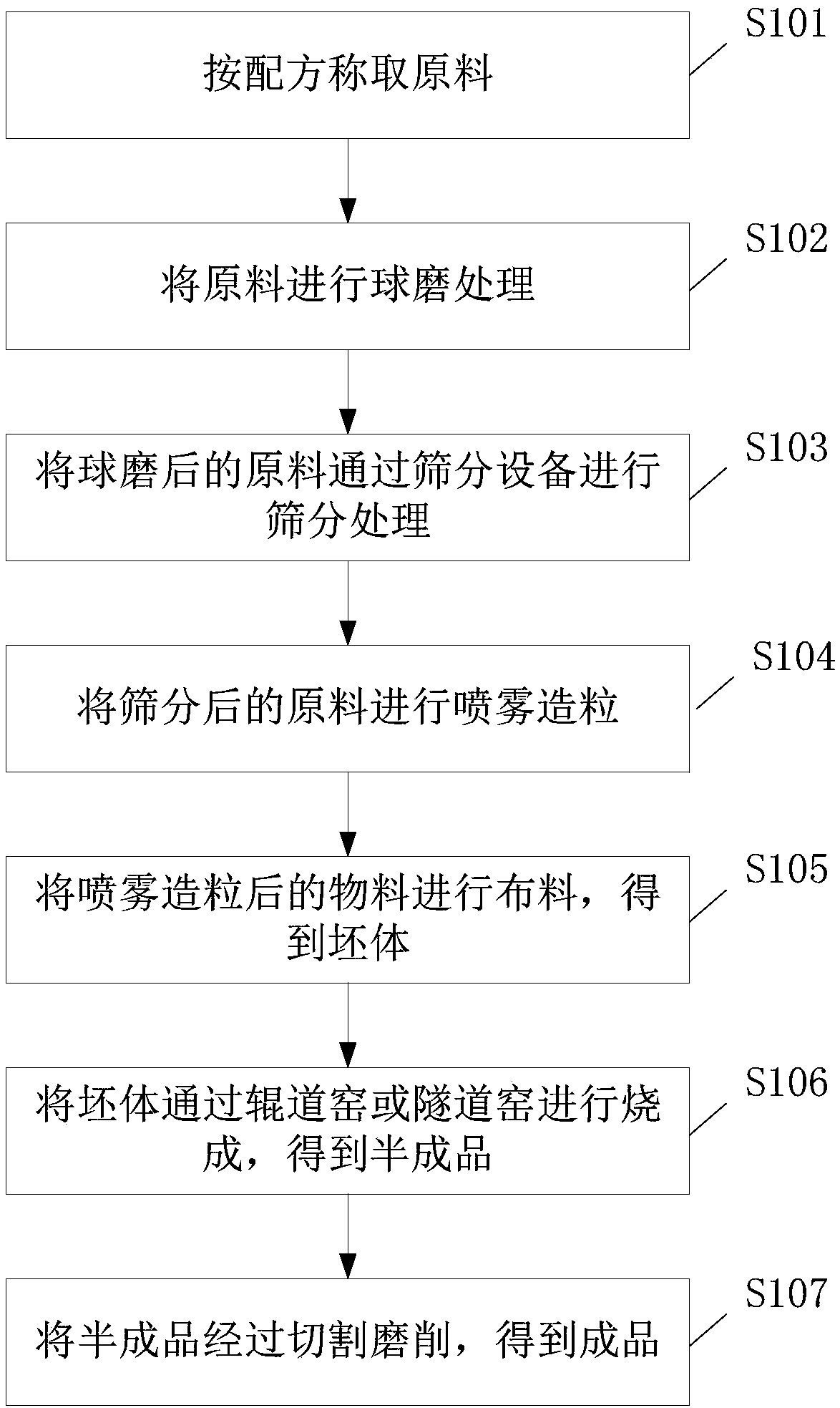

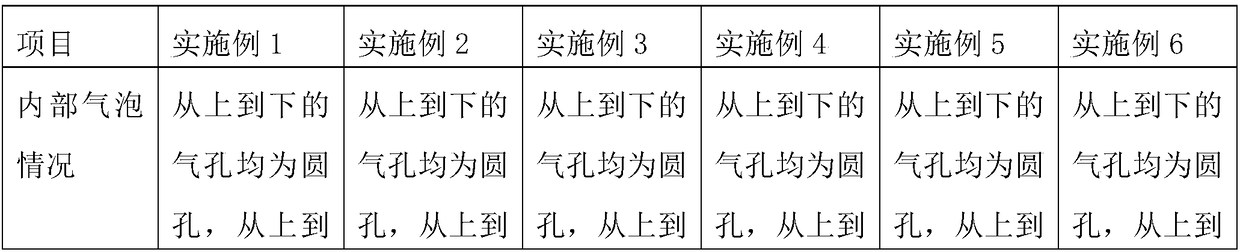

The invention discloses a method of using granite scraps to prepare a foaming ceramic light sheet material. The method comprises following steps: (1) weighing following raw materials in percentage byweight: 70 to 90% of granite scraps, 5 to 20% of clay, 0.01 to 5% of foaming agent, and 0.1 to 5% of manganese dioxide; (2) ball-milling raw materials; (3) after ball milling, sieving raw materials bya sieving facility; (4) after sieving, spray-granulating sieved raw materials; (5) after spray granulation, distributing the raw materials to obtain a green body; and (6) burning the green body in aroller kiln or a tunnel kiln to obtain a finished product. Correspondingly, the invention also discloses a foaming ceramic light sheet material prepared by the method mentioned above. The air holes ina cross section of the foaming ceramic light sheet material are uniform from top to bottom; the air hole uniformity is high, and the sheet material can be prepared by a tunnel kiln or a roller kiln.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Simulation stone facing concrete element and method for producing the same

InactiveCN101418538ANice appearanceStrong three-dimensional senseArtificial islandsCovering/liningsFiberSurface layer

The invention relates to a concrete member for an artificial stone surface layer and a production method thereof. The member consists of the artificial stone surface layer and a fibrous concrete layer. The artificial stone surface layer is prepared from cement, carpolite, quartz sand and water and is manufactured through adopting a thrashing process. The appearance of the member has attractiveness and strong third dimension; the whole pattern is harmonious; color is abundant, natural and bright and does not fade; and the member has consistent texture effect with a marble or granite veneer, reduces cost by 30 percent and reduces weight by 25 to 35 percent. The method has a simple production process and does not need a special machine. The artificial stone surface layer and the fibrous concrete layer are tightly combined into a whole, are skidproof and wearable, have high strength (compressive strength is more than or equal to 60 MPa, and bending strength is more than or equal to 11 MPa) and are uneasy to rupture. The method has convenient construction, low expense and wide application range, can be used for manufacturing a tree protective plate, a road plate brick, an inspection well cover and other planar members and can be also used for manufacturing an upright post, a decorative metope and other three-dimensional members.

Owner:句容市科达技术开发有限公司

Artificial compound board prepared by granite stone powder waste material

The invention relates to a novel artificial composite board which is prepared by granite waste materials. The formula comprises a resin, a curing agent, a promoter, granite stone powder and broken stone particles, etc. The artificial composite board has more styles, and the length can be made to be large enough, thereby being applied on various possible occasions. At the same time, the technology utilizes the broken stone waste materials and stone powder as raw materials, thereby benefiting for the protection and the conservation of natural resources.

Owner:FUJIAN QIDALI GROUP

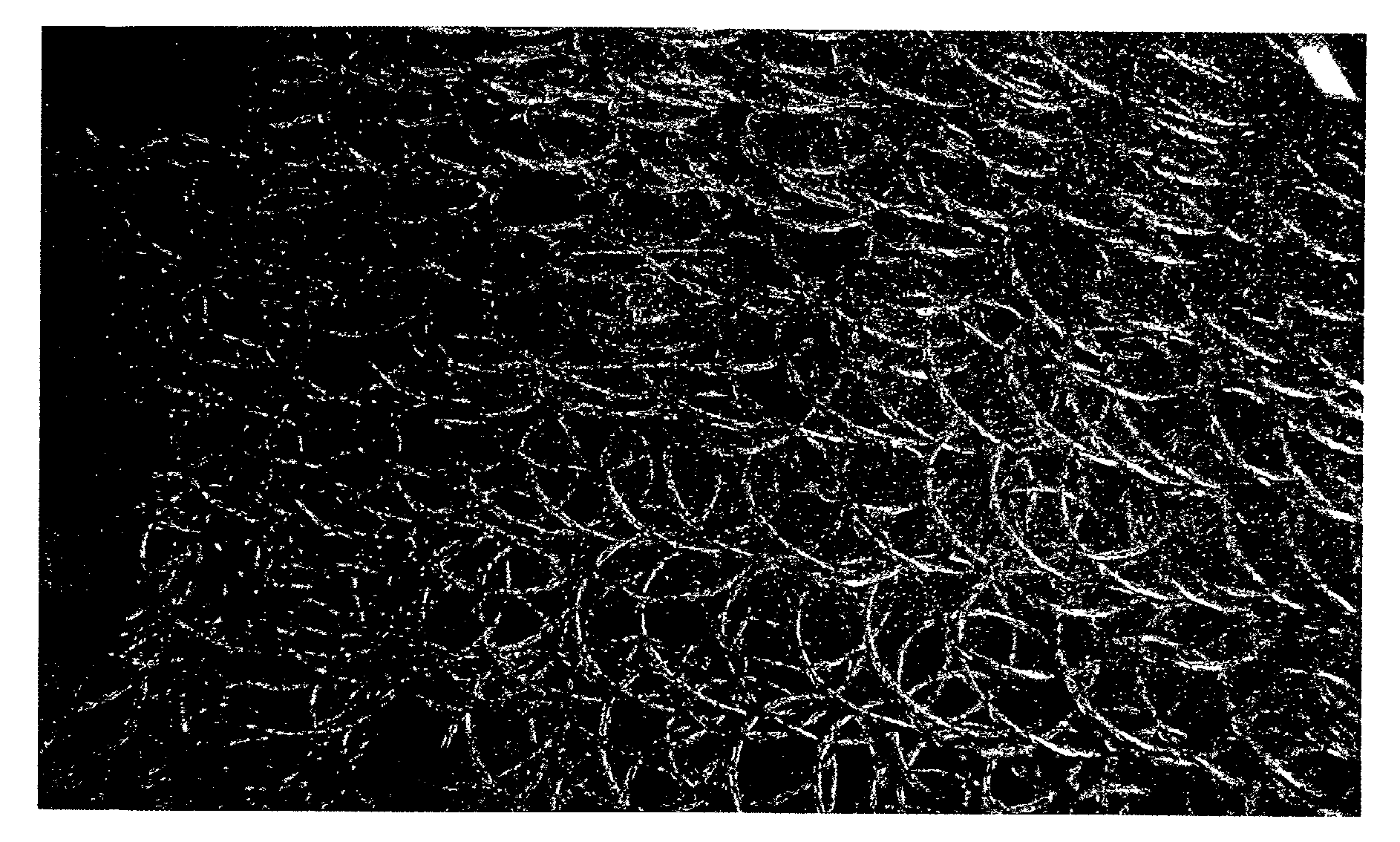

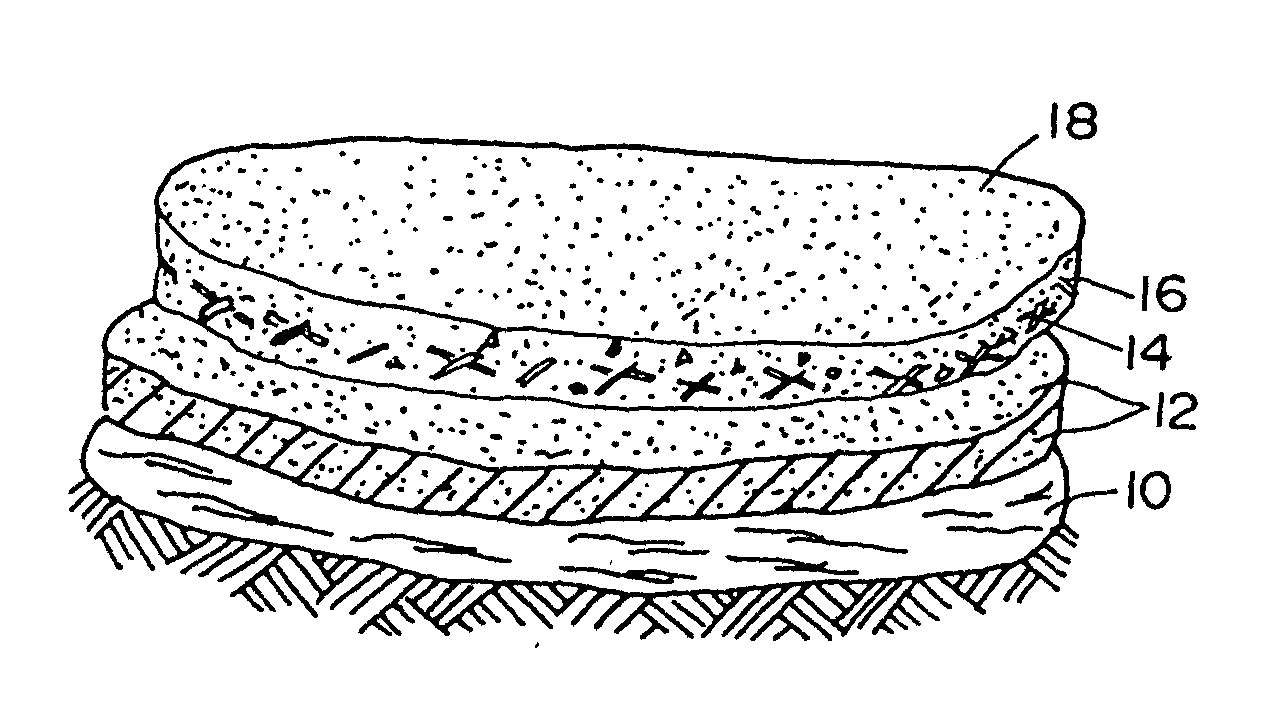

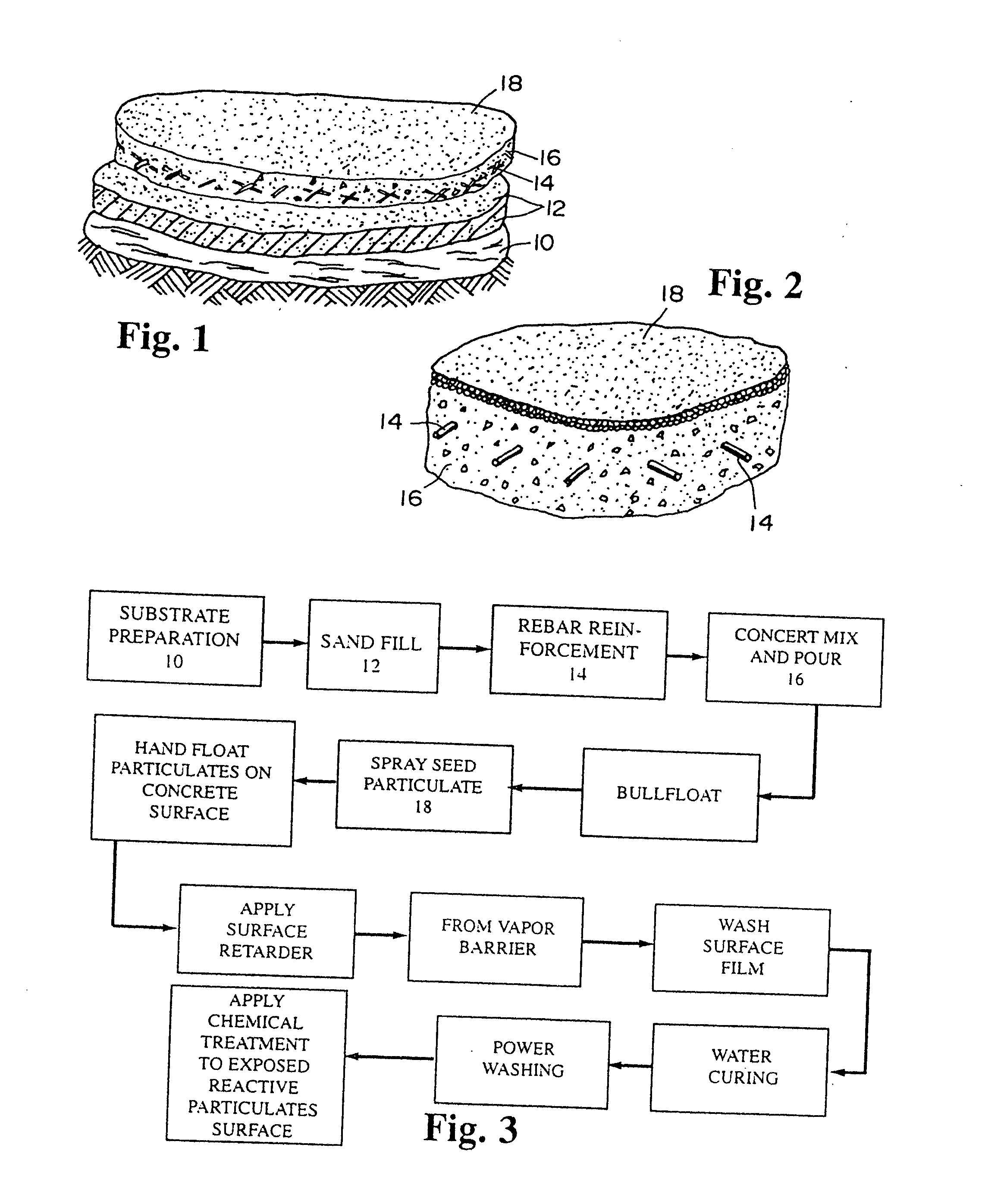

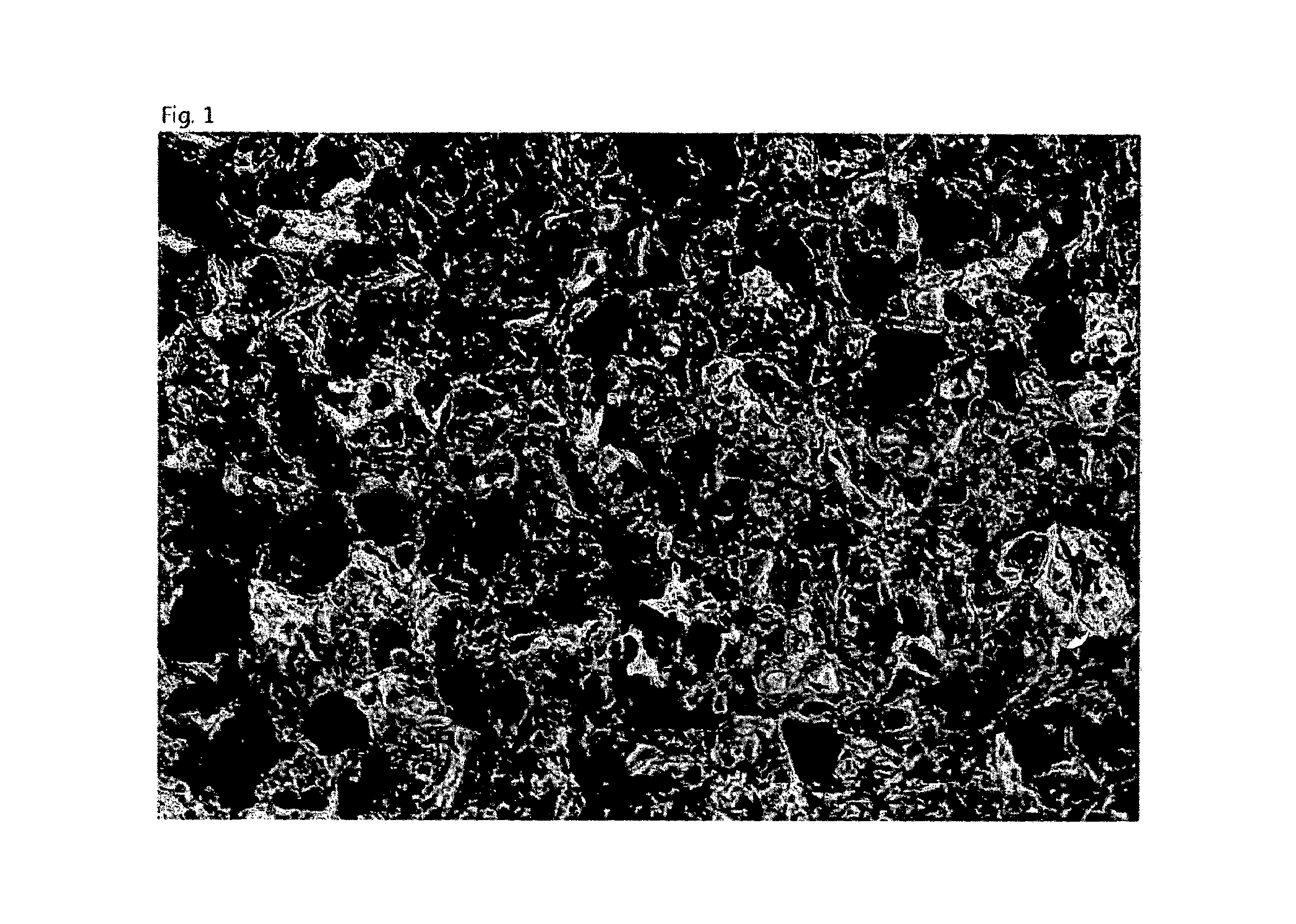

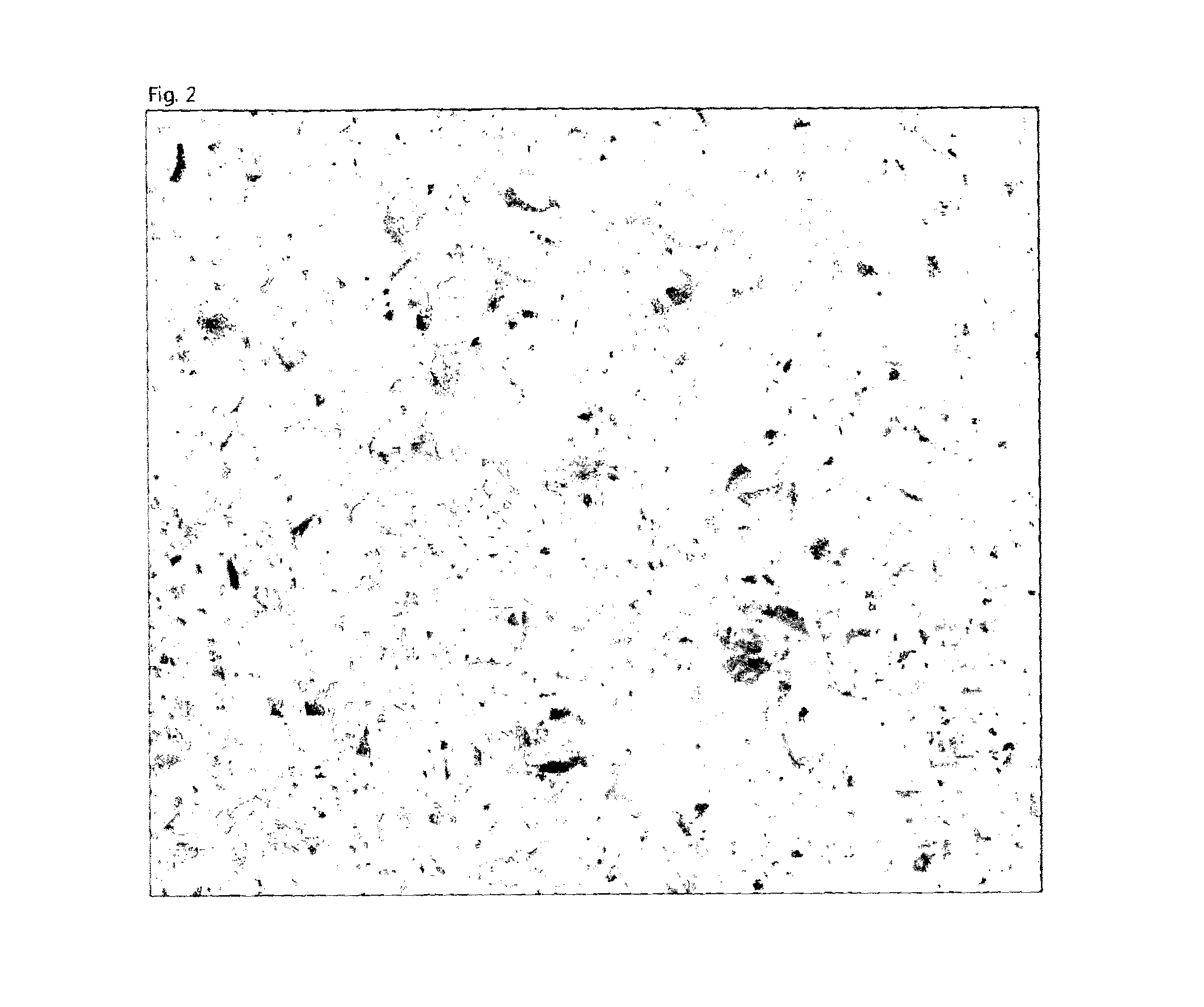

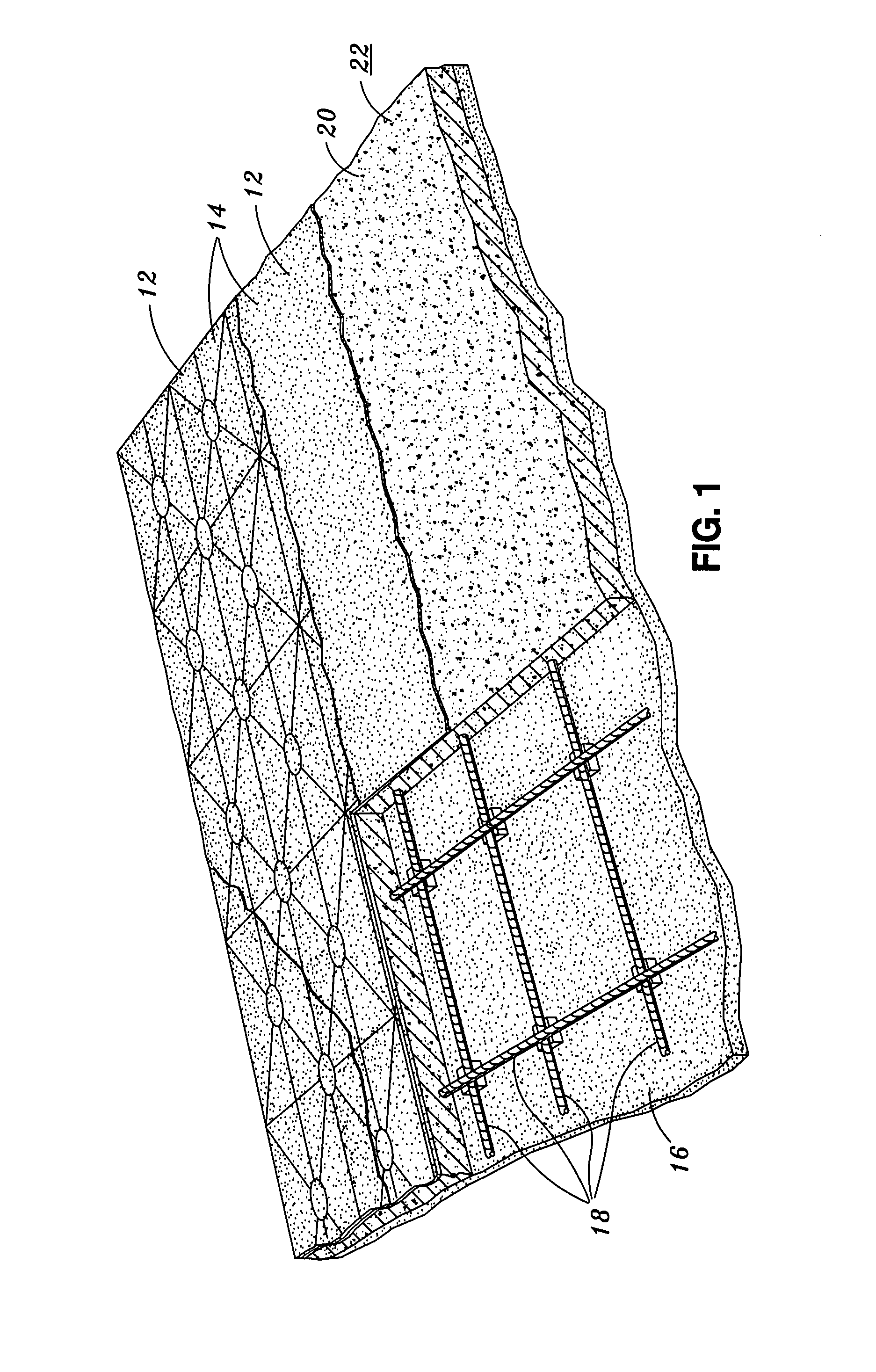

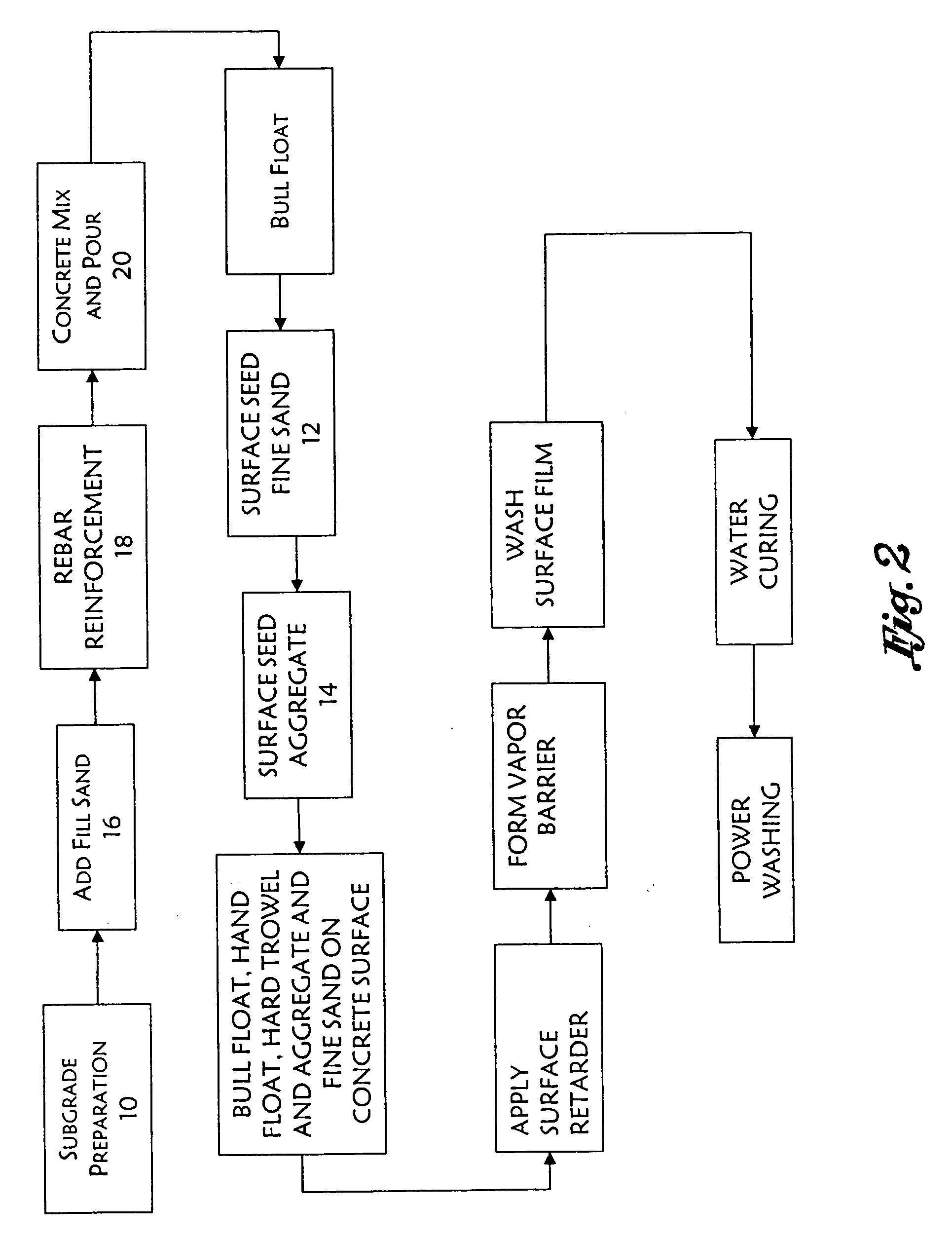

Method of forming surface seeded particulate

An improved surface seeded exposed particulate concrete and method of making the improved surface seeded exposed particulate concrete is disclosed. Small particulate is sprayed over the upper surface of the concrete. The particulate may be sprayed using a material sprayer. The particulate may be uniformly sprayed to distances exceeding twenty feet. The particulate is mixed into a cement paste derived from the concrete mixture using floats. A surface retarder is then applied to cover the concrete surface. Subsequently, any surface film is washed from the surface of the concrete and the concrete is cured. The result is a surface seeded particulate with an exposed surface that is flat and is suitable for high traffic areas. The resultant surface may resemble stone, granite or marble.

Owner:SHAW LEE A +1

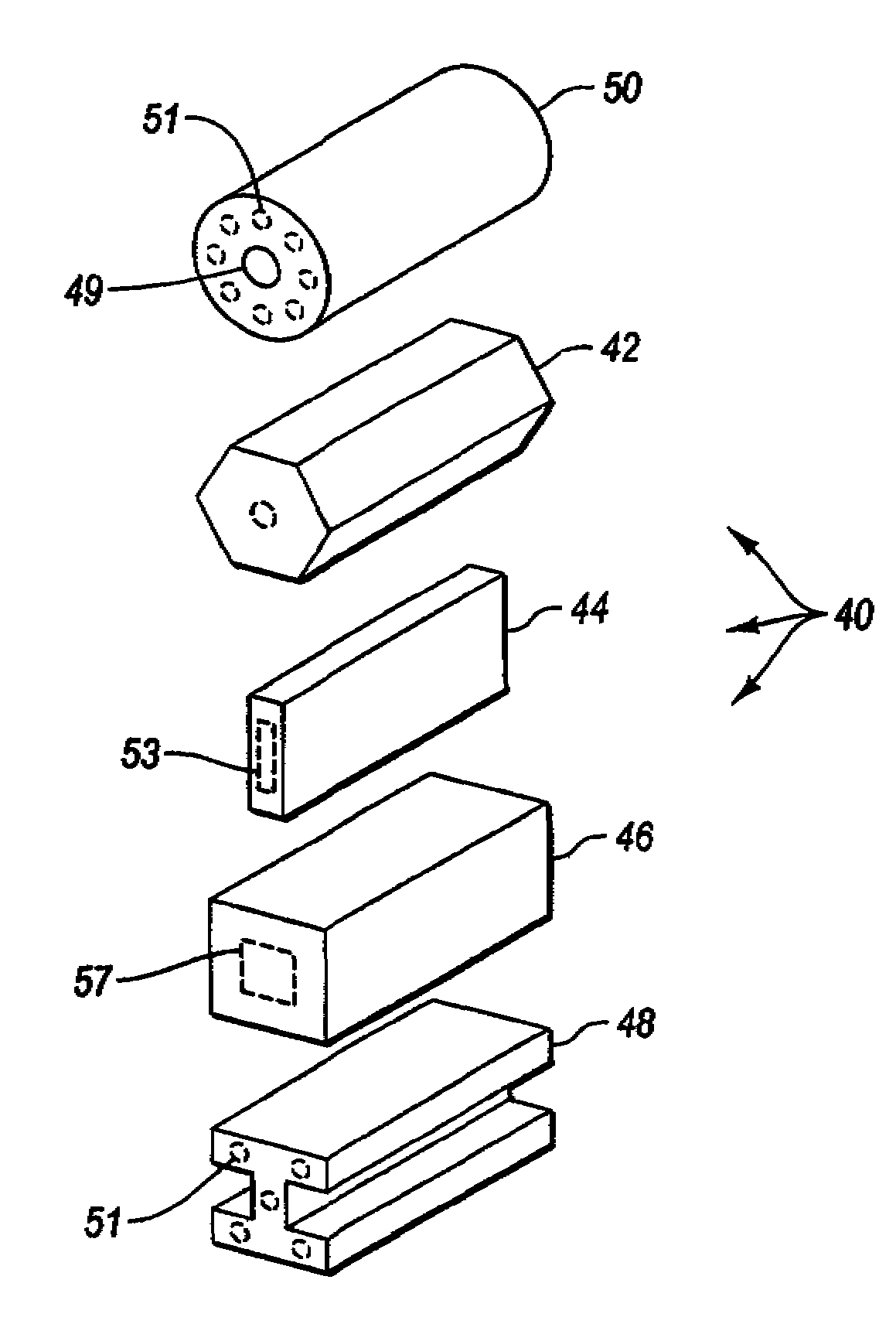

Acrylic artificial marble having granite pattern and method of manufacturing the same

InactiveUS9012532B2Well mixedEvenly mixedNatural patternsCeramic shaping apparatusShell moldingGranolithic

The present invention relates to an acrylic artificial marble having a granite pattern and a method of manufacturing the same, which can provide a natural marble effect by mixing and molding two or more compounds having different colors and thus can obtain a granite pattern in which patterns of the two or more compounds are smoothly mixed, and which can obtain a desired pattern remarkably similar to a pattern of natural stone by using a multicolor chip sheet.

Owner:LG HAUSYS LTD

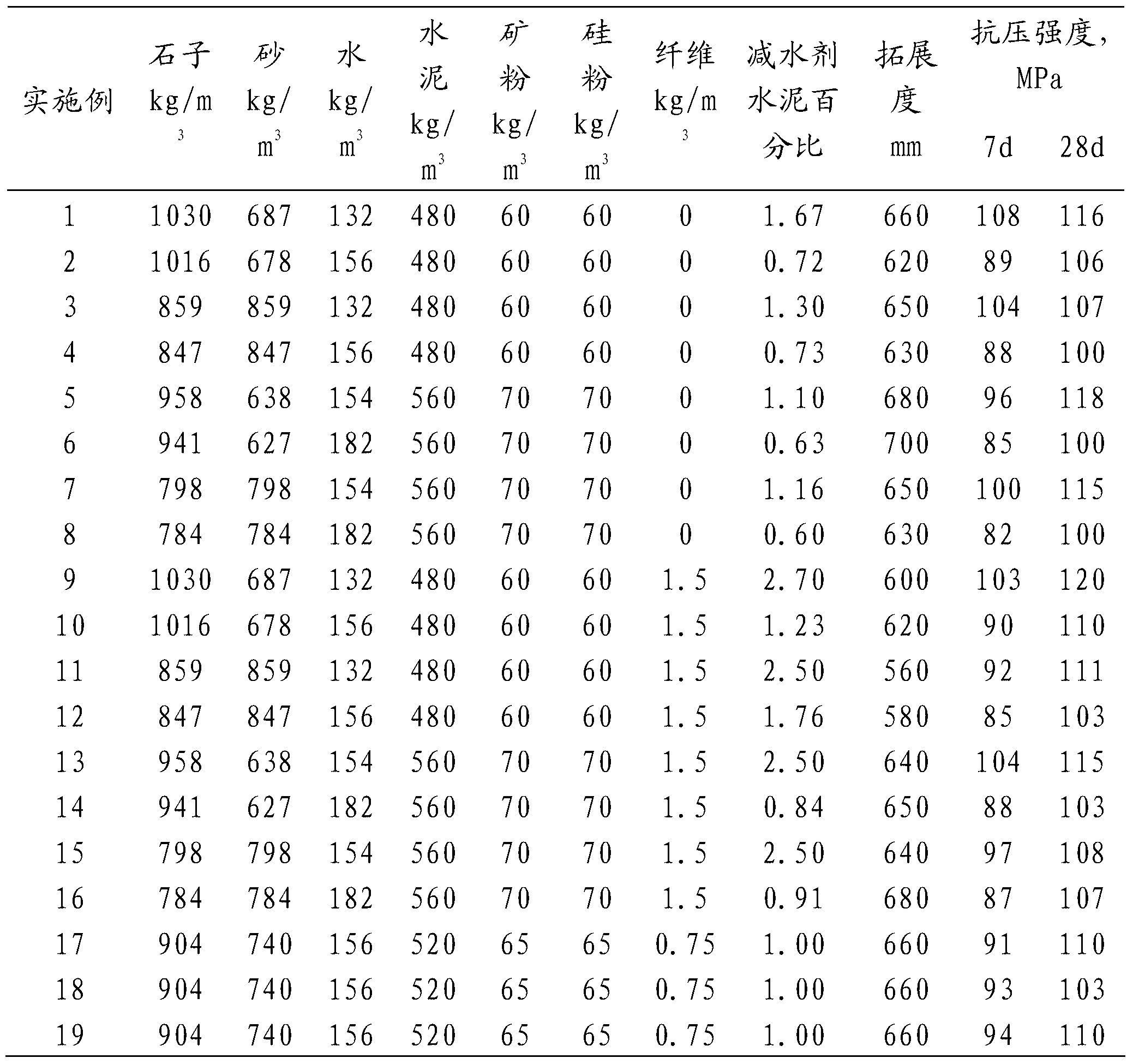

Ultrahigh-strength self-compacting concrete and preparation method thereof

InactiveCN103304206AImprove microscopic propertiesImprove the interface transition areaFiberPolyvinyl alcohol

The invention discloses an ultrahigh-strength self-compacting concrete and a preparation method thereof. The ultrahigh strength self-compacting concrete is mainly composed of a cementing material, an efficient water reducer, a fine aggregate, a coarse aggregate, water and PVA (Polyvinyl Alcohol) fibers, wherein the cementing material is composed of 70%-80% of common silicate cement, 10%-20% of mineral slag and 5%-10% of silicon powder by weight percentage; the fine aggregate is medium sand; the coarse aggregate is granite macadam. The ultrahigh-strength self-compacting concrete has the beneficial effects that the advanced techniques of the ultrahigh-strength concrete and the self-compacting concrete in the field of the concrete materials at present are studied, the advantages of the two concrete techniques are combined so that the dosage of the cement is reduced while ultrahigh performance of the concrete is realized, and furthermore, the purposes of emission reduction of CO2, materials saving and environmental protection as well as green construction are achieved.

Owner:SHENZHEN UNIV

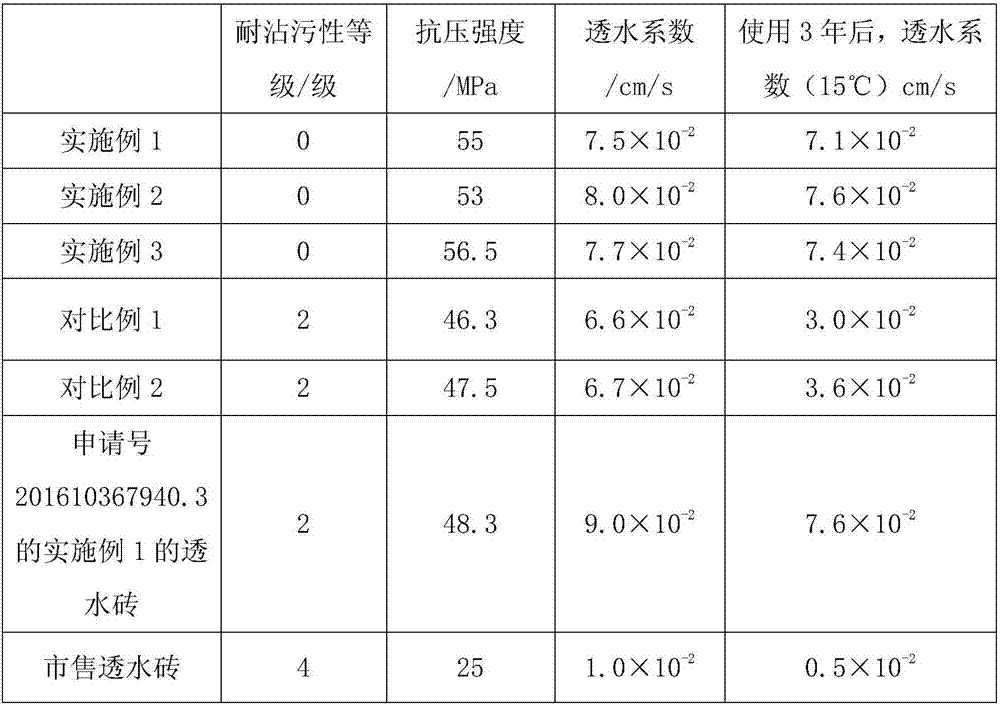

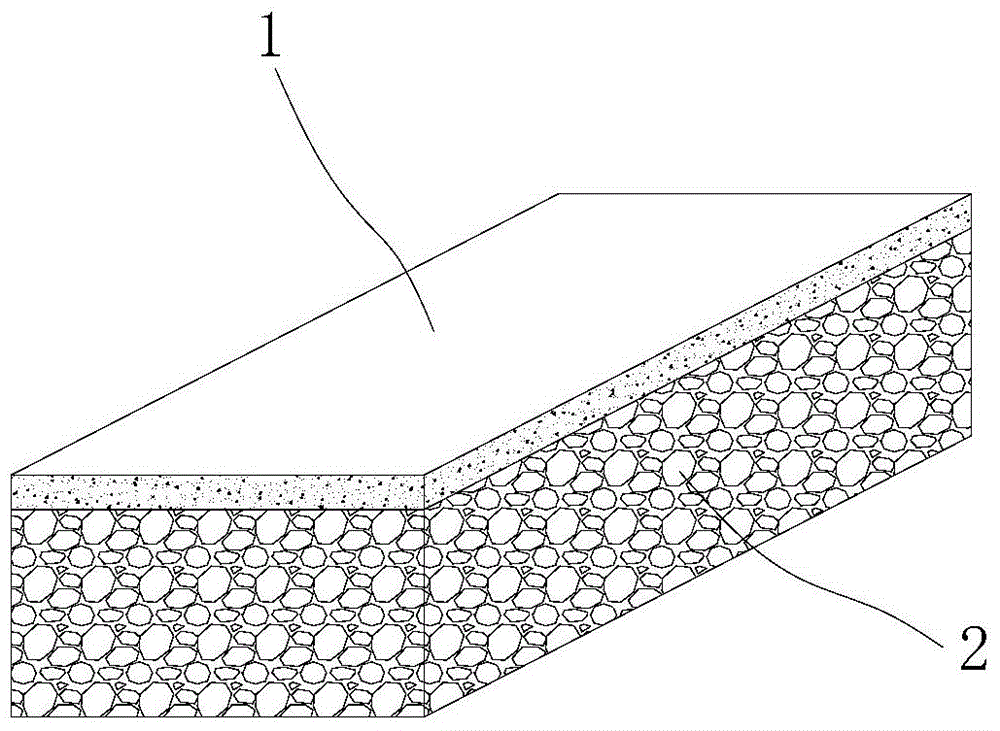

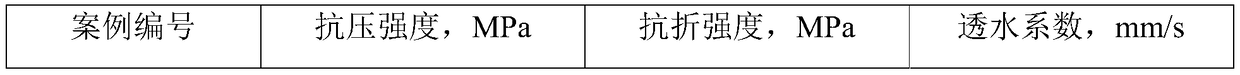

Anti-fouling and water-permeable brick with natural stone imitating effect and preparation method of anti-fouling and water-permeable brick

The invention provides an anti-fouling and water-permeable brick with a natural stone imitating effect and a preparation method of the anti-fouling and water-permeable brick. The anti-fouling and water-permeable brick comprises an anti-fouling and water-permeable surface layer and a water-permeable base layer, wherein the anti-fouling and water-permeable surface layer is prepared from raw materials in parts by mass as follows: 10-15 parts of cement, 0.5-2 parts of an aqueous adhesive, 65-75 parts of modified fine aggregate, 2-4.5 parts of water, 1.5-2 parts of a water-permeable agent and 3-8 parts of pigment; the water-permeable base layer is prepared from raw materials in parts by mass as follows: 15-25 parts of fly ash, 5-10 parts of cement, 10-20 parts of carbide slag, 5-15 parts of slag, 15-20 parts of construction waste, 2-4 parts of the water-permeable agent and 3-8 parts of water. A mass ratio of the anti-fouling and water-permeable surface layer to the water-permeable base layer is 1:(7.5-8.5), and the modified fine aggregate is prepared from one or more fine aggregate of granite debris, marble flakes, quartz sand and silica sand through modification. The anti-fouling and water-permeable brick has the advantages of being high in anti-fouling level, resistant to wear, good in water permeability, high in strength, low in cost and smooth in surface, achieving the attractive natural stone imitating effect and the like.

Owner:山东鑫旺节能建材有限公司

Imitated stone environment-friendly concrete road brick and making method thereof

ActiveCN104891888ACan express its own textureGood flexibilitySingle unit pavingsEnvironmental resistanceEpoxy

The invention relates to an imitated stone environment-friendly concrete road brick which comprises a surface layer and a base layer. The surface layer comprises, by weight, 5-30% of cement, 70-95% of at least one of quartz sand, granite broken sand and tailing sand and 5-30% of one of ethylene vinyl acetate, acrylic resin and waterborne epoxy resin, and the base layer comprises 3-10% of cement, 0-20% of mineral powder, 0-10% of coal ash, 10-50% of coal ash slag, 10-40% of iron ore dressing bits of 1.0-3.0% in fineness modulus and 35-50% of iron ore dressing bits of 2-10mm in grain diameter. The invention further relates to a making method of the road brick. The making method includes that an original producing, stirring and feeding sequence is adjusted, a binder is completely used to replace water for the surface layer, and a stirring process is improved specially. After a new material is used, feasibility of production links like stirring, material distributing, mould press-forming and demoulding is realized by technical means like changing feeding sequence and increasing stirring time. Compared with conventional surface layer mortar, the new surface layer is higher in flexibility and better in waterproofness, alkali efflorescence of cement products is inhibited, sand is protruding in texture, and the road brick has imitated stone effect integrally.

Owner:爱尔建材(天津)有限公司

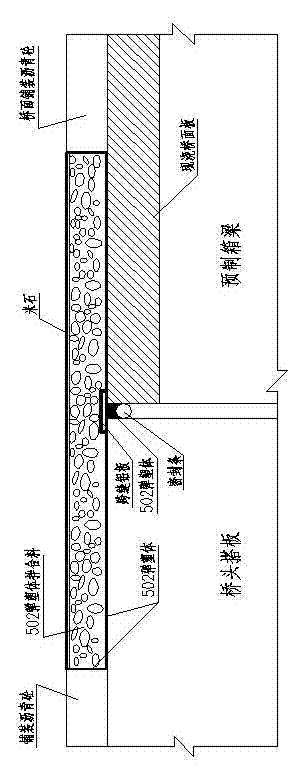

Construction method of bridge seamless type expansion joint

InactiveCN103088752APrevent fallingImprove adhesionBridge structural detailsExtensibilityGranolithic

The invention discloses a construction method of bridge seamless type expansion joint. The construction method of the bridge seamless type expansion joint includes the steps of embedding a sealing strip in the seam portion of the expansion joint, pouring melted 502 elastic-plastic bodies, placing a cross-seam aluminum sheet well, paving various high molecular polymers which fit in with the American society for testing material (ASTM) standard layer by layer, wherein the various high molecular polymers are mixed materials of the 502 elastic-plastic bodies and granite of a corresponding grade, finally using granitic plaster as a surface wearing layer, and the bridge seamless type expansion joint is achieved. The construction method of the bridge seamless type expansion joint has the advantages of satisfying stretch and displacement of an upper portion structure of the bridge, guaranteeing that cars run stably, improving riding comfort, and being strong in elastic restoring force, capable of resisting the high and low temperature, good in plasticity, extensibility, durability, waterproof performance and adhesion performance, long in service life, convenient to install, flexible in installation, rapid in traffic openness and the like. In addition, the construction method of the bridge seamless type expansion joint further has the advantage that the extensible displacement is from 20mm to 50 mm.

Owner:江西省城乡规划设计研究总院

Multifunction imitated natural granite coating

InactiveCN101338100AImprove the protective effectAvoid defectsEmulsion paintsCelluloseColloidal particle

The invention relates to a multi-functional imitating natural granite coating which is designed to solve the defects that in spite of stylish and dignified decoration effect and excellent protection performance, natural granite has quite high cost and the resources on the earth are limited, human beings keep consuming the resources, so that the resources are more in short and the use of the resources is limited, etc.; the coating is building emulsion paint with styrene-acrylic emulsion polymer as the main film-forming substance and cellulose sheet-shaped colloidal particles as the main filler; the prescription is prepared by the following percent: 25.0 percent to 30.0 percent of styrene-acrylic emulsion, 1.5 percent to 2.0 percent of 2,2,4-collidine-1,3 pentanediol single-hetero butyric ester film-forming assistant and 68.0 percent to 73.0 percent of cellulose sheet-shaped colloidal particles in all colors. The coating is characterized by and has the advantages of energy saving, environment protection, no harm and toxin, simple and safe operation, low product and construction cost, can achieve plenty of decoration effect of the granite, has strong protection performance to the walls of buildings, super-strong stain resistant and self-cleaning functions, and prevents a plurality of defects of natural stone in exterior wall decoration.

Owner:LIAONING BUILDING SCI RES INST

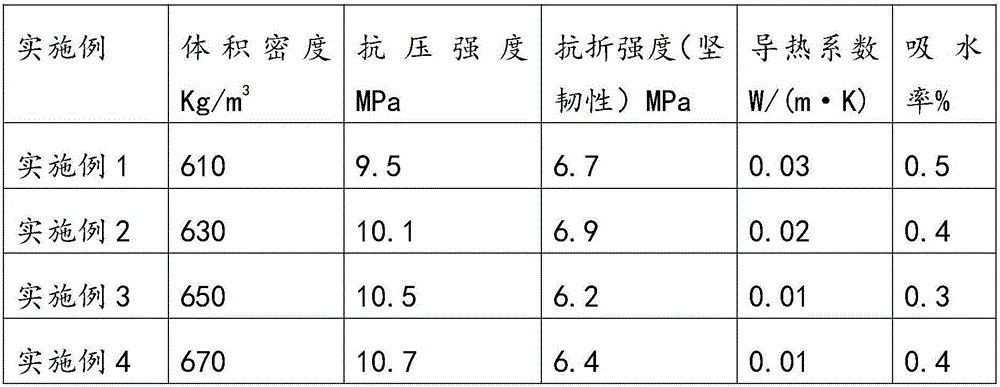

Granite-stone-flour-based autoclaved aerated concrete block and manufacture method thereof

InactiveCN106542844ARealize resource utilizationSimple production processCeramicwareResource utilizationHigh pressure

The invention discloses a granite-stone-flour-based autoclaved aerated concrete block and a manufacture method thereof. The autoclaved aerated concrete block comprises, by mass percentage, 60-65% of granite stone flour, 18-21% of cement, 8-11% of quicklime, 3-6% of desulfurized gypsum, 0.1-0.15% of aerated aluminium powder paste, and 0.1-0.3% of an air-entrainer, with the water-to-material ratio being 0.4-0.5%. The manufacture method comprises: taking finely-ground granite stone flour as a main raw material, adding cement, gypsum, quicklime, aluminium powder paste and the air-entrainer, performing stirring with water, carrying out casting moulding, gas generation and expansion, precuring and cutting, and performing high-pressure steam curing to obtain the block. Waste granite stone flour produced in a processing process of stone is used, so that resource utilization of waste is realized, and the problems of coal ash resource shortage and environmental pollution are overcome. The block belongs to a novel wall material, and the production technology is simple, and is low in cost and suitable for popularization.

Owner:UNIV OF JINAN +1

Curb produced by using waste ceramic slag and waste road concrete and manufacturing method

InactiveCN103058613AImprove performanceEnhance and improve performanceSolid waste managementBrickCalcium formate

The invention relates to a curb produced by using waste ceramic slag and waste road concrete and a manufacturing method. The curb is characterized in that the waste ceramic slag, the waste road concrete, waste incineration residue, waste granite slag, silicate cement, calcium oxide powder, calcium sulfate powder, polycarboxylate efficient water reducing agent, calcium formate, sodium sulfate and water are used as raw materials; and the raw materials are stirred to be moist through a stirrer, extruded by using a hydraulic machine and manufactured into the waste ceramic slag and waste road concrete curb under the pressure of 25 to 30MPa, and the curb is naturally dried and cured for 28 days at normal temperature by using a water spraying method. The raw materials can be manufactured into top wall bricks, plaza bricks and sidewalk bricks with different sizes; and the curb has the advantages of light weight, high strength, pollution prevention, low cost and high benefits. The invention meets the requirements for national energy conservation and emission reduction development and low-carbon economy.

Owner:清远绿由环保科技有限公司 +1

Water-permeable bricks prepared from granite stone waste materials and preparation method thereof

The invention belongs to the technical field of building materials and in particular relates to water-permeable bricks prepared from granite stone waste materials and a preparation method thereof. Thewater-permeable bricks prepared from the granite stone waste materials are prepared from granite stone grains, high-bauxite aggregate grains, granite stone mud, plastic clay, high-bauxite fine powderand an auxiliary binding agent according to the weight ratio of (55 to 65) to (8 to 12) to (10 to 15) to (5 to 8) to (5 to 8) to (5 to 8). The water-permeable bricks prepared by the invention have the following two remarkable advantages that firstly, the water-permeable bricks have good water permeability and relatively high strength; secondly, a lot of the waste materials in a granite stone production region can be consumed and wastes are changed into valuable things; a raw material supply range of the water-permeable bricks is expanded; meanwhile, the local environment protection problem issolved.

Owner:SHANDONG UNIV OF TECH +1

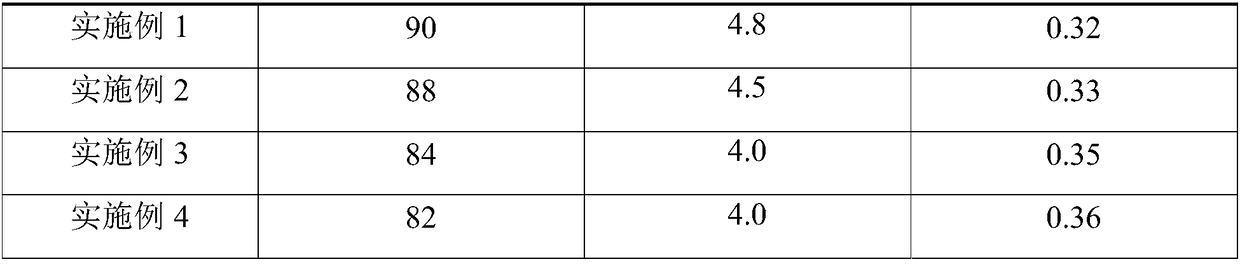

Surface seeded fine aggregate concrete simulating quarried stone

A method and a surface seeded exposed aggregate concrete product are provided that precisely simulate the appearance and qualities of various types of natural quarried stone, such as granite, marble, rhinestone, bluestone, and brownstone, to name a few. Implementations of the present invention are characterized by the use of fine sand and aggregate broadcast over the exposed surface of poured concrete, which surface has been prepared to receive the same. Subsequently, a surface retarder and finishing steps are performed to produce the concrete product which assimilates the characteristics and colors of natural quarried stone, such as speckles, inclusions, flecks, graining, fractures, joints, knots, crystallization patterns, streaks, weathering, etc.

Owner:SHAW CRAFTSMEN CONCRETE LLC

Liquid rock particles of artificial granite sand textured coating

ActiveCN103627272AWater resistantGood weather resistanceAnti-corrosive paintsCelluloseCrack resistance

The invention discloses liquid rock particles of an artificial granite sand textured coating. The artificial granite coating is excellent in texture performance, crack resistance, weather fastness and dirt resistance, and also has excellent simulation on natural stone. The liquid rock particles of the artificial granite sand textured coating are prepared from an elastic acrylic emulsion, titanium dioxide, natural painted sand, inorganic powder, inorganic gel, a setting agent, an antifreeze agent, a defoaming agent, a bactericide, a dispersant, an alkali swelling and thickening agent, a cellulose thickening agent, a wetting agent, a coalescing agent and water. The liquid rock particles are capable of causing the decoration effect of the artificial granite coating to be vivider and also causing the artificial granite coating to have excellent weather fastness, acid-base resistance and hardness and natural color and gloss just as the natural stone; the liquid rock particles are used in the artificial granite sand textured coating to achieve the imitation stone effect of single-gun multiple colors.

Owner:HUBEI QILI NEW MATERIAL CO LTD

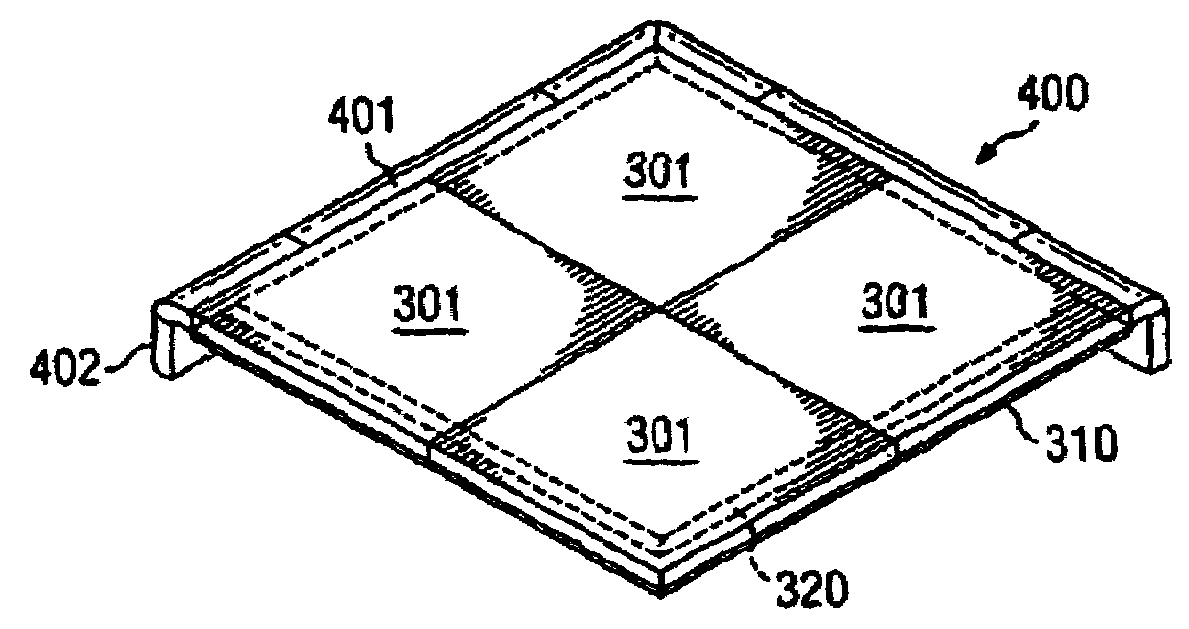

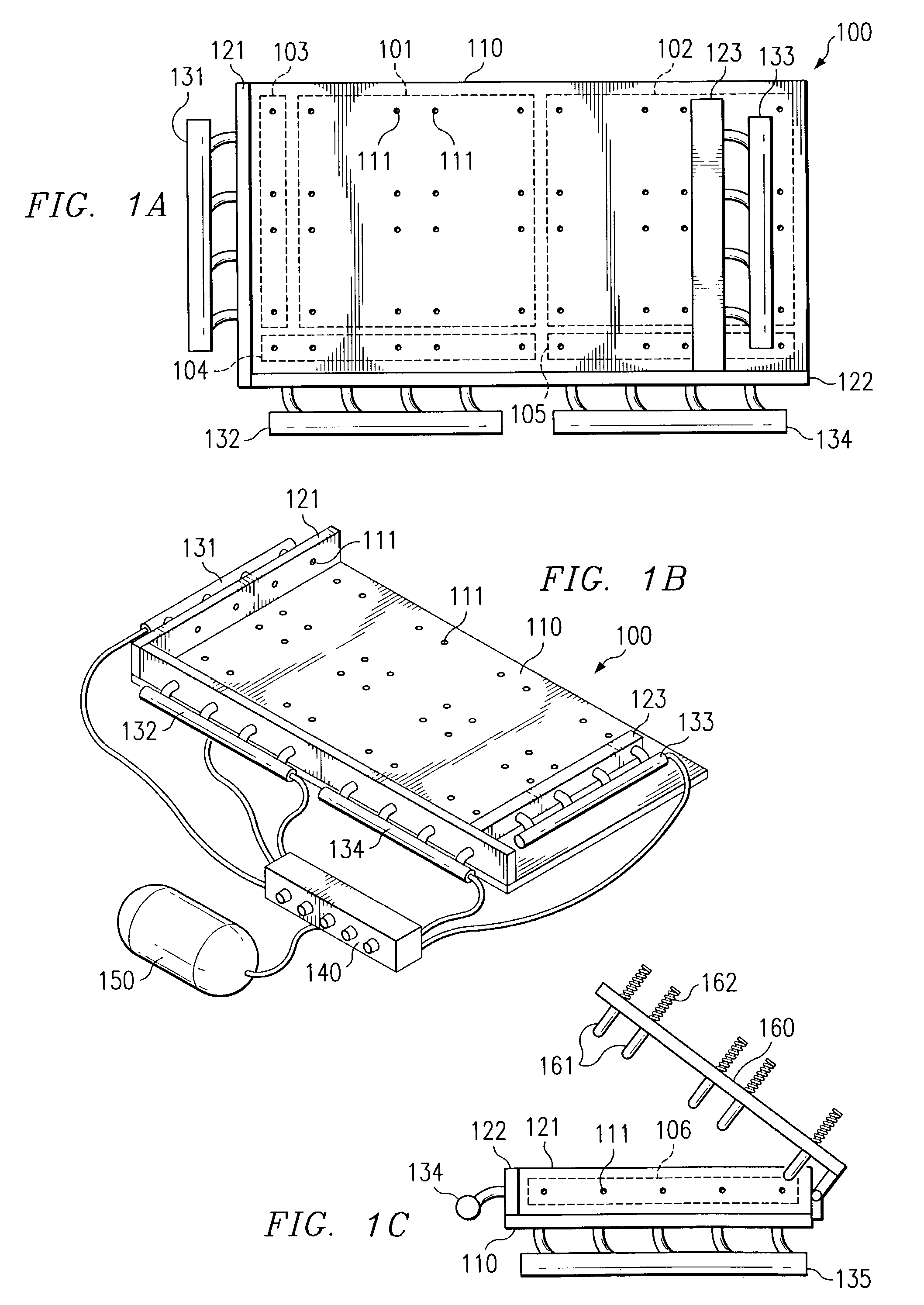

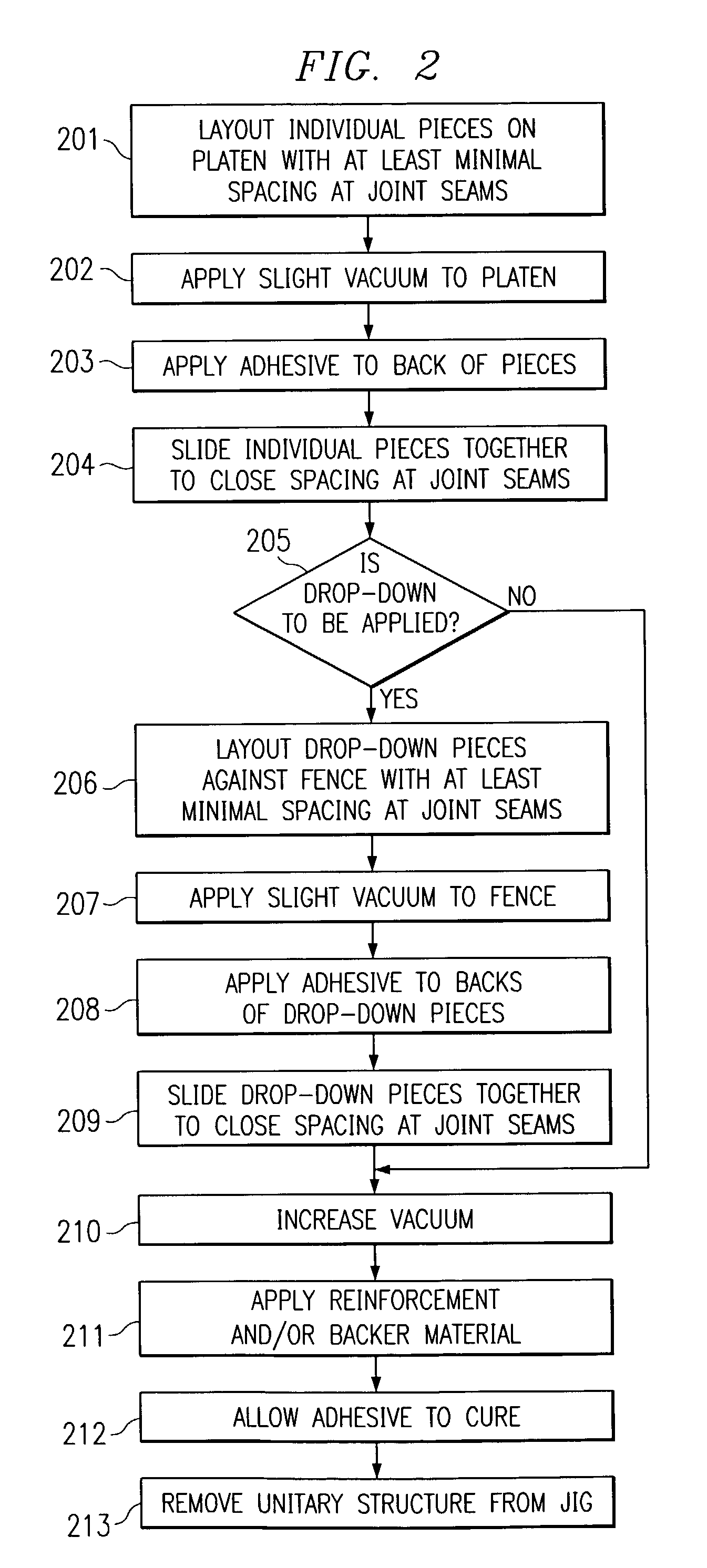

System and method for forming surfaces using tiled components and product resulting therefrom

InactiveUS7216461B1Minimize their visual impactEasy to installTreadsCovering/liningsBrickGranolithic

Disclosed are systems and methods which provide durable and substantially smooth surfaces comprised of a number of smaller pieces of surfacing material. For example, tiles of natural materials, such as marble or granite, are formed into larger unitary structures, wherein the surfaces of the tiles are substantially dead flat and the seams therebetween are diminished in size so as to minimize their visual impact. These unitary structures are preferably adapted to interconnection to thereby allow formation of substantially larger surfaces. Jig apparatus and methods for there use are disclosed for casting unitary structures of various shapes and configurations in such a manner that a dead flat surface with very little to zero lippage is provided.

Owner:CLEMMER CLAY E

Non-viscous granite imitation paint, waterborne fluororesin granite non-viscous coating prepared from non-viscous granite imitation paint and coating method of non-viscous granite imitation paint

ActiveCN105001780AStay non-stickImprove wear resistance and non-stick performanceLiquid surface applicatorsCoatingsOrganic solventGranolithic

The invention relates to non-viscous paint, in particular to non-viscous granite imitation paint, a waterborne fluororesin granite non-viscous coating prepared from the non-viscous granite imitation paint and a coating method of the non-viscous granite imitation paint. The non-viscous granite imitation paint is colorful water-in-water paint. The non-viscous granite imitation paint comprises, by solid content, 0.1%-3% of protecting glue, 10%-50% of pigment, 30%-60% of organic adhesive resin, 10%-30% of fluorine-containing polymer and a proper amount of water, organic solvent, dispersing auxiliary and thickening agent. The non-viscous granite imitation paint can achieve the effects of colorful granite paint under the condition that the film thickness (40-60 microns) is small.

Owner:ZHEJIANG PFLUON TECH CO LTD +1

Super strengthen adhesives for adhering ceramic tile of wall and floor

The invention relates to a wall and floor tile paving ultrastrong adhesive, composed of cement, yellow sand, limestone powder, sulphoaluminate sweller, fibrin and polyvinyl acetate emulsion powder, and it can completely efficiently paving the wall surfaces and top surfaces of buildings, improving the binding strength of ceramic wall tiles and natural and man-made stone materials to the bases by a large margin, and it has high press-cut-binding strength, water resistance, high temperature resistance and good freeze-thaw resistance, and can be cold-placed and has long regulating time, and low shrinkage. It is applied to pasting the decorative materials, such as ceramic wall and floor tiles or marble, granite, man-made stone materials, etc on the surfaces of clay brick, cement mortar, cement and concrete and concrete bricks.

Owner:TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com