Non-viscous granite imitation paint, waterborne fluororesin granite non-viscous coating prepared from non-viscous granite imitation paint and coating method of non-viscous granite imitation paint

A technology of imitating granite coating and non-stick coating, which can be applied in the direction of coating, the device for coating liquid on the surface, etc., which can solve the problems of small scattered patterns and differences.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

[0072] A non-stick imitation granite paint, the paint is a water-in-water colorful paint, and its preparation method is:

[0073] a. Two or more kinds of color paints and protective glue are mixed, dispersed and granulated, and liquid color particles are formed in the protective glue to obtain mixture A. The mass ratio of single color paint to protective glue is 1:1 to 2:1 ;

[0074] b. Add a non-stick coating to the mixture A, stir evenly to obtain a granite-like coating, and the amount of the non-stick coating is 30%-70% of the total mass of the granite-like coating. The proportioning ratio of each component in this method is specifically shown in Table 5. The formula of the protective glue is shown in Table 2, the formula of the colored paint is shown in Table 3 (including black and white colored paint), and the formula of the non-stick coating is shown in Table 4.

[0075] Table 2 The composition ratio of the protective glue (unit: kg)

[0076] formula

1

...

Embodiment 6-14

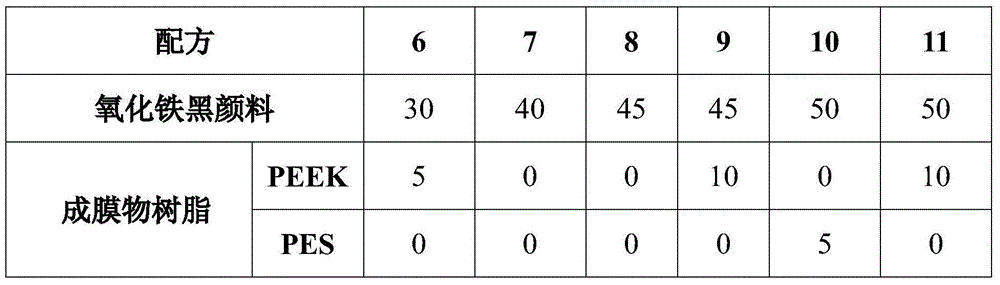

[0104] Example 6-14: Water-based fluororesin granite non-stick coating

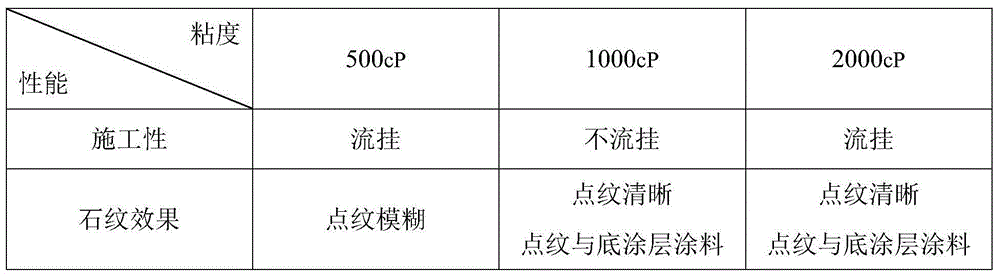

[0105] The coating method of the water-based fluororesin granite non-stick coating is as follows: first spray the primer on the substrate, the primer can be sprayed with an ordinary spray gun, and before the primer film is dry, use The spray gun specially used for spraying multi-color paints sprays the middle coat paint. After the point-like color particles are evenly distributed on the surface of the primer paint, it is sent to the oven to bake and dry. The temperature range of the bake is controlled between 100-400°C. , because the film thickness of the base coat paint and the middle coat paint is relatively thick, according to the drying method of the base coat paint of the ordinary three-layer paint (between 80-180°C), the time required is too long, which affects the efficiency, and 300 Baking at a temperature above ℃, the heating rate should not be too fast, otherwise bubbles will be generated. At t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com