Cold cutting bag-making machine without stretching heat sealing line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

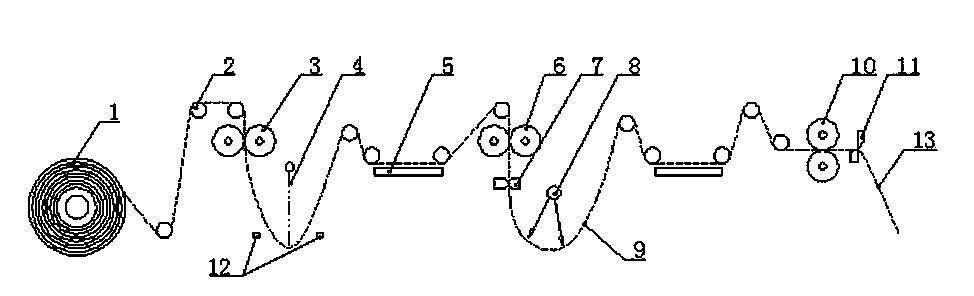

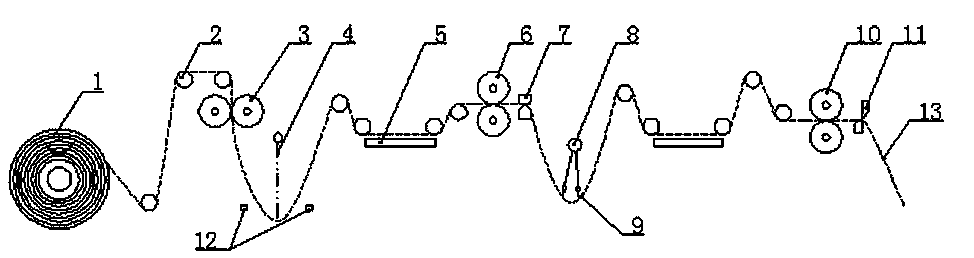

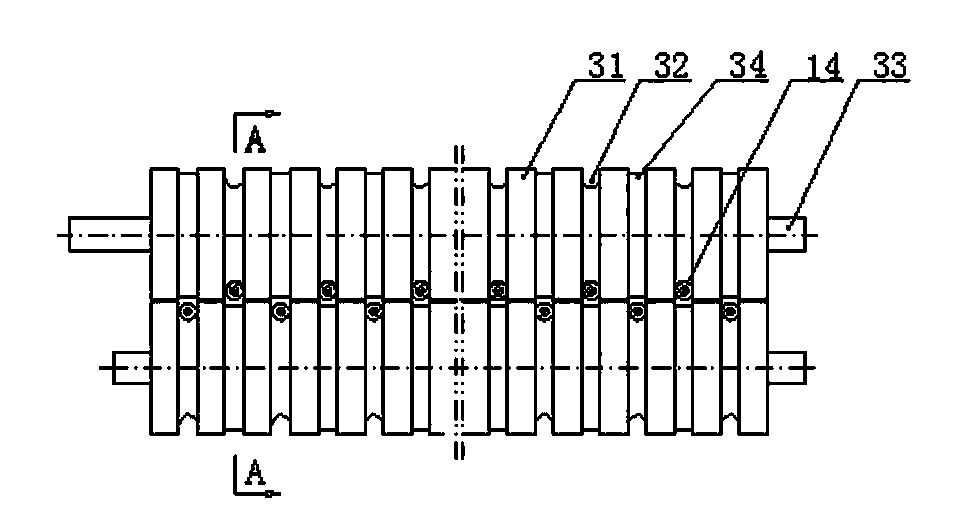

[0019] see Figure 1 to Figure 6 , the present invention is a cold-cut bag-making machine with heat-sealing line without stretching, including in the prior art, a material shaft 1, a first feeding roller 3, a feeding control device (curtain, Keep the stretched state of the raw material) 4, the heat sealing knife 7, the second feeding roller 10 and the cold cutting knife 11. Necessary roller shafts 2 are also installed between the above-mentioned devices, which are used to stretch and position the bag-making raw materials 13; Tracking and positioning of printed patterns), a second feed roller 10 and a cold cutter 11 are provided behind the stretch platform 5 at the back. The composition shown in the accompanying drawings is just an embodiment, and the present invention is applicable to any existing cold-cut bag-making machine of any configuration. It is characterized in that a group of heat-sealing feed rollers 6 are arranged in front of the heat-sealing knife 7, and a blowin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com