A kind of preparation method of the epoxy resin matrix composite material of toughening thermal conductivity and insulation

A technology of epoxy resin, heat conduction and insulation, which is applied in the field of modification and preparation of epoxy resin-based composite materials, which can solve problems such as performance degradation, and achieve the effects of increased quality, low peeling yield, and maintenance of bending properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

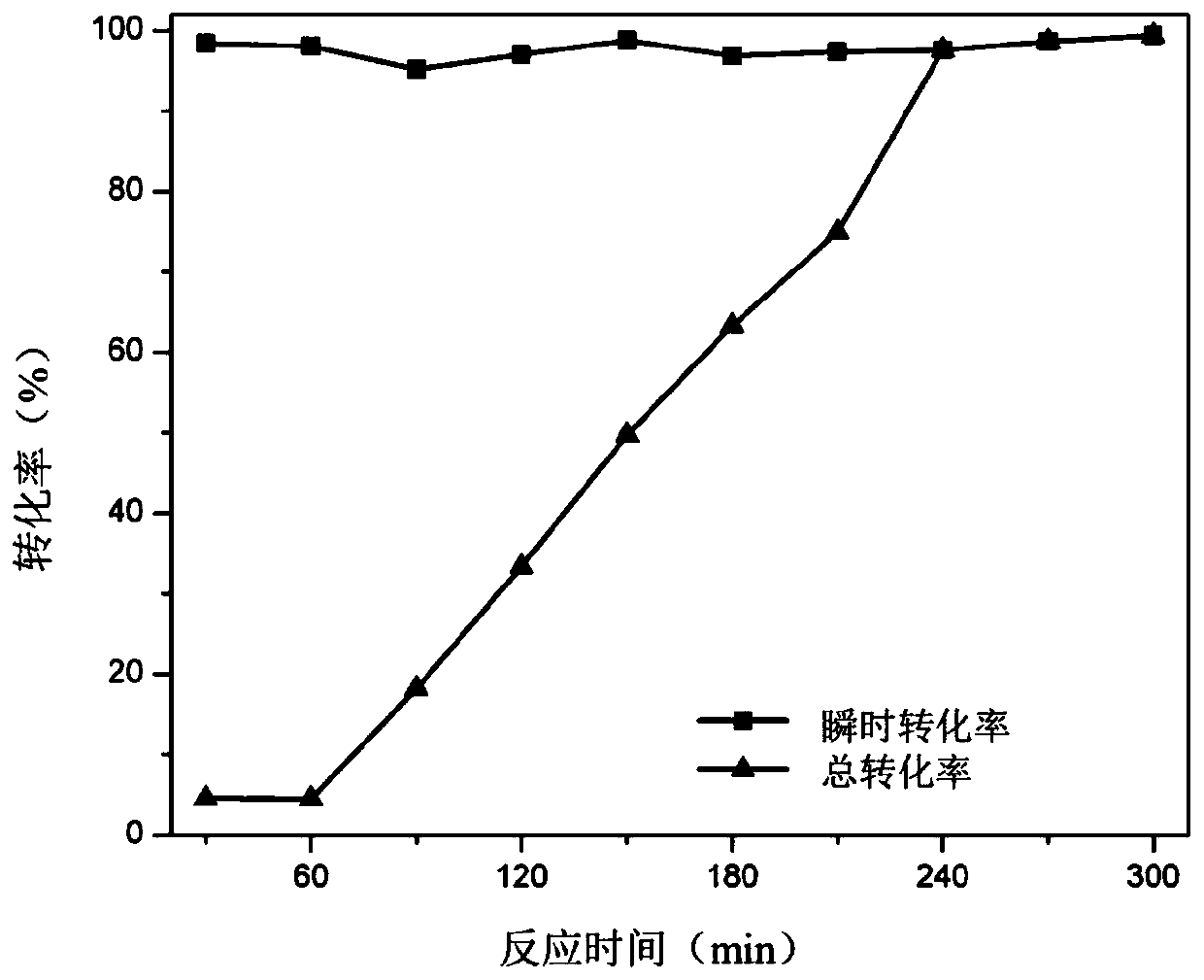

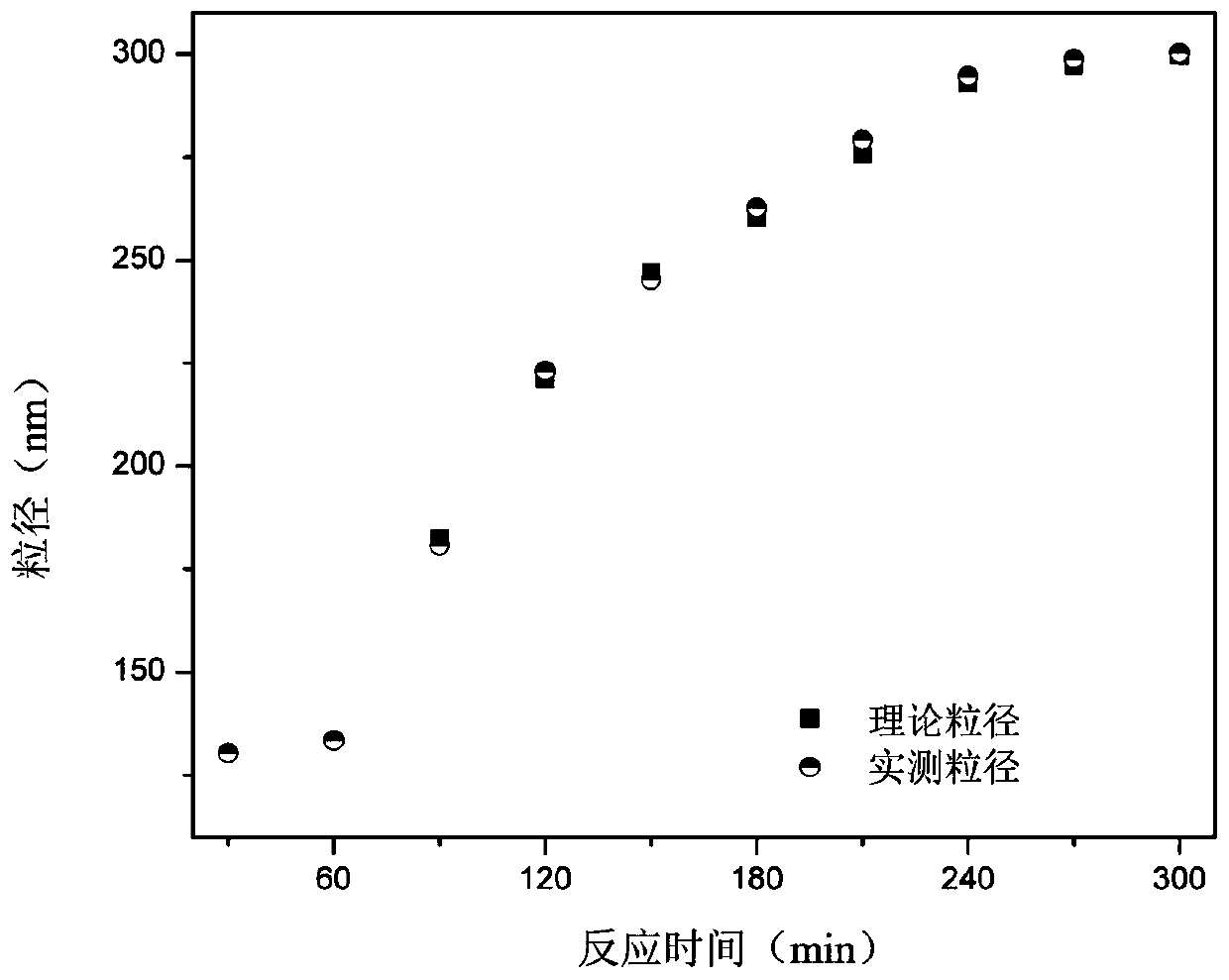

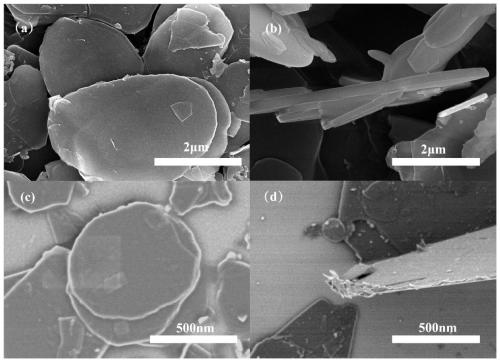

[0058] 1. Preparation of acrylate core-shell particles

[0059] a. Preparation of seed pre-emulsion

[0060] First, add 0.5g anionic emulsifier dipentyl sulfonate sodium dibutyrate and 140g deionized water to a 500ml four-necked flask, stirring and mixing for 15min; then add 0.05g crosslinking agent 1,3-propanediol diol into the four-necked flask Acrylate and 10 g of amyl acrylate were stirred and mixed for 10 minutes to obtain seed pre-emulsion, which was used for later use.

[0061] b. Preparation of core layer monomer pre-emulsion

[0062] Add 1.125g anionic emulsifier sodium diamyl sulfonate, 0.45g crosslinking agent allyl methacrylate and 80g amyl acrylate into the beaker, mix and stir for 15min to obtain the core layer monomer pre-emulsion, which is ready for use .

[0063] c. Preparation of the pre-emulsion of shell monomers

[0064] Into the beaker, add 2.2g anionic emulsifier dipentyl sodium sulfonate, 110g shell monomer ethyl methacrylate, 0.55g crosslinking agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com