Patents

Literature

797 results about "Cyclohexanedimethanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

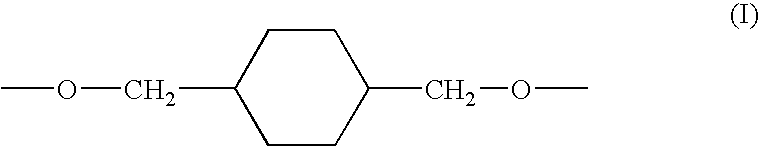

Cyclohexanedimethanol (CHDM) is a mixture of isomeric organic compounds with formula C₆H₁₀(CH₂OH)₂. It is a colorless low-melting solid used in the production of polyester resins. Commercial samples consist of a mixture of cis and trans isomers. It is a di-substituted derivative of cyclohexane and is classified as a diol, meaning that it has two OH functional groups. Commercial CHDM typically has a cis/trans ratio of 30:70.

Light-emitting diode assembly housing comprising poly(cyclohexanedimethanol terephthalate) compositions

InactiveUS20070213458A1Solid-state devicesGlass/slag layered productsCyclohexanedimethanolLight-emitting diode

Light-emitting diode assembly housing comprising high temperature poly(1,4-cyclohexanedimethanol terephthalate) compositions containing titanium dioxide.

Owner:TICONA LLC

Novel copolyester compositions with improved impact strength at low temperatures

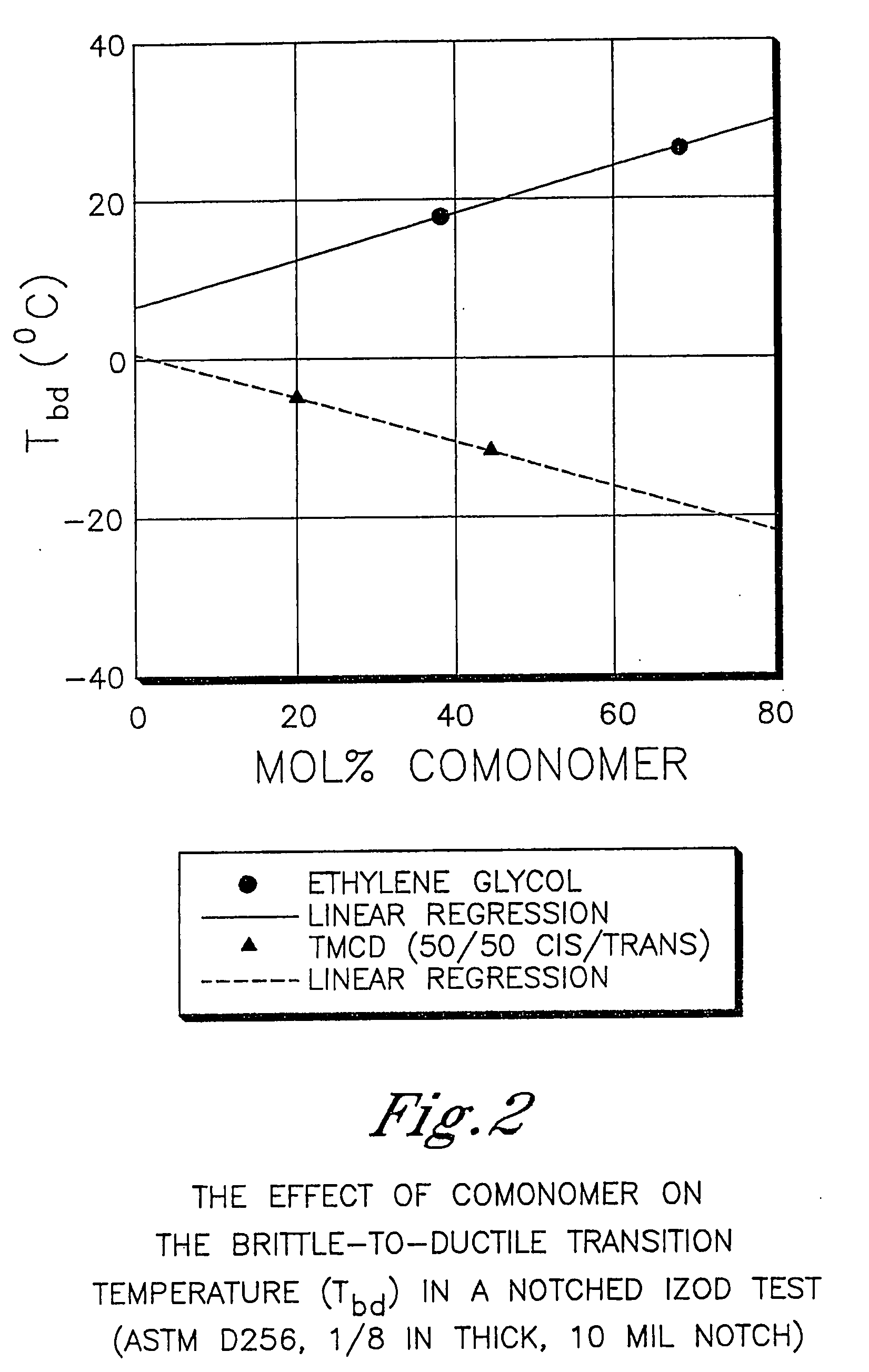

This invention relates to a polyester composition comprising: (i) diacid residues comprising at least 80 mole percent, based on the total moles of diacid residues, of one or more residues of: terephthalic acid, naphthalenedicarboxylic acid, 1,4-cyclohexanedicarboxylic acid, or isophthalic acid; and (ii) diol residues comprising from about 25 to about 70 mole percent, based on the total moles of diol residues, of the residues of 1,4-cyclohexanedimethanol, and from about 75 to about 30 mole percent, based on the total moles of diol residues, of the residues of 1,3-propanediol. This invention has surprising improved impact strength at low temperatures.

Owner:EASTMAN CHEM CO

Polyester resin and method for preparing the same

InactiveUS20120177854A1Superior heat-resistanceHigh impact strengthBio-packagingSynthetic resin layered productsCyclohexanedimethanolDiol

A polyester resin copolymerized with isosorbide and 1,4-cyclohexane dimethanol and having an improved impact strength, and a method for preparing the same are disclosed. The copolymerized polyester resin has an alternating structure of acid moieties which are derived from acid components and diol moieties which are derived from diol components, wherein the acid components comprise terephthalic acid, and the diol components comprise (i) 5˜99 mol % of 1,4-cyclohexanedimethanol and (ii) 1˜60 mol % of isosorbide with respect to the total diol components.

Owner:SK CHEM CO LTD

Polyester compositions containing cyclobutanediol having a certain combination of inherent viscosity and high glass transition temperature and articles made therefrom

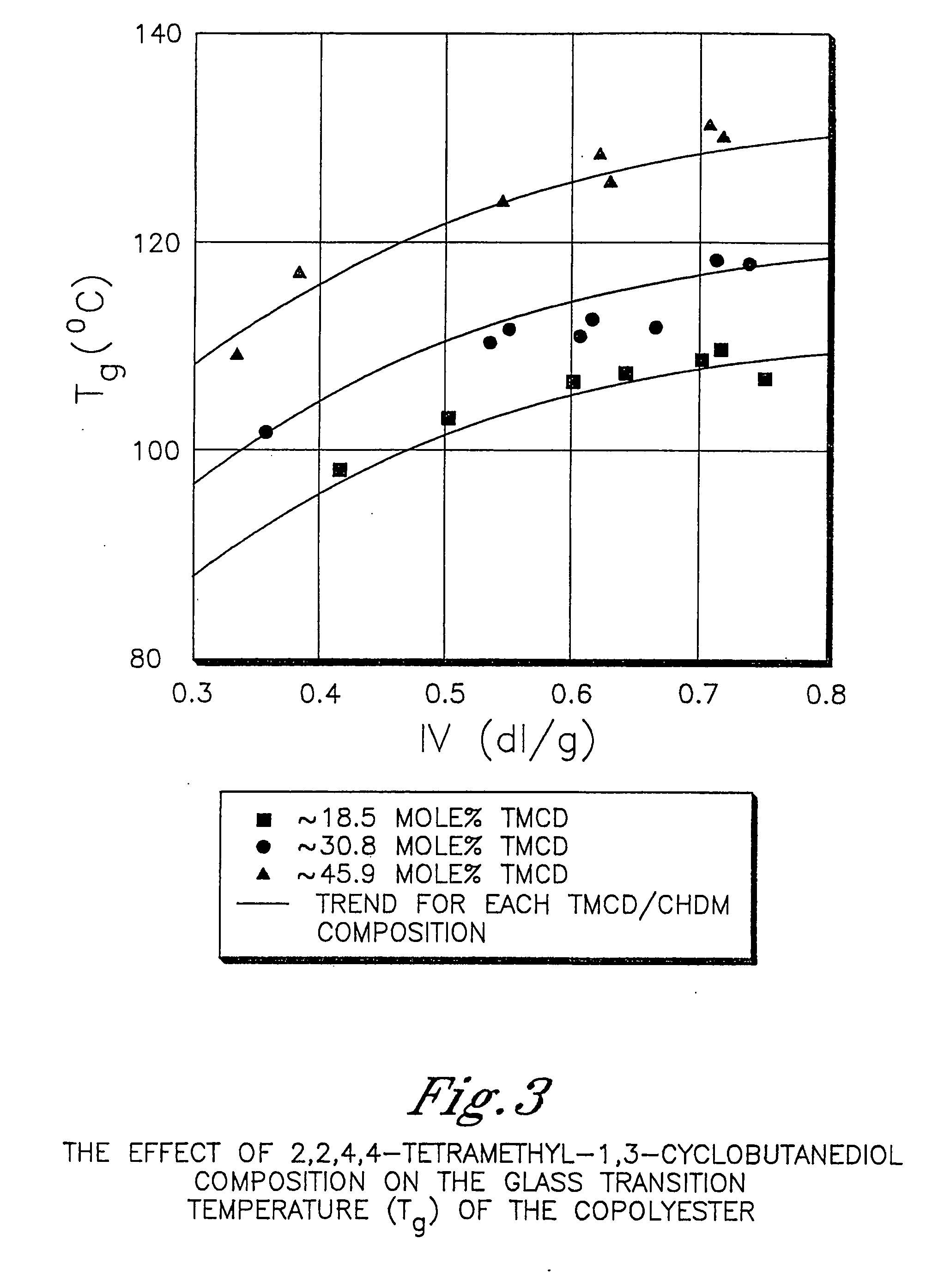

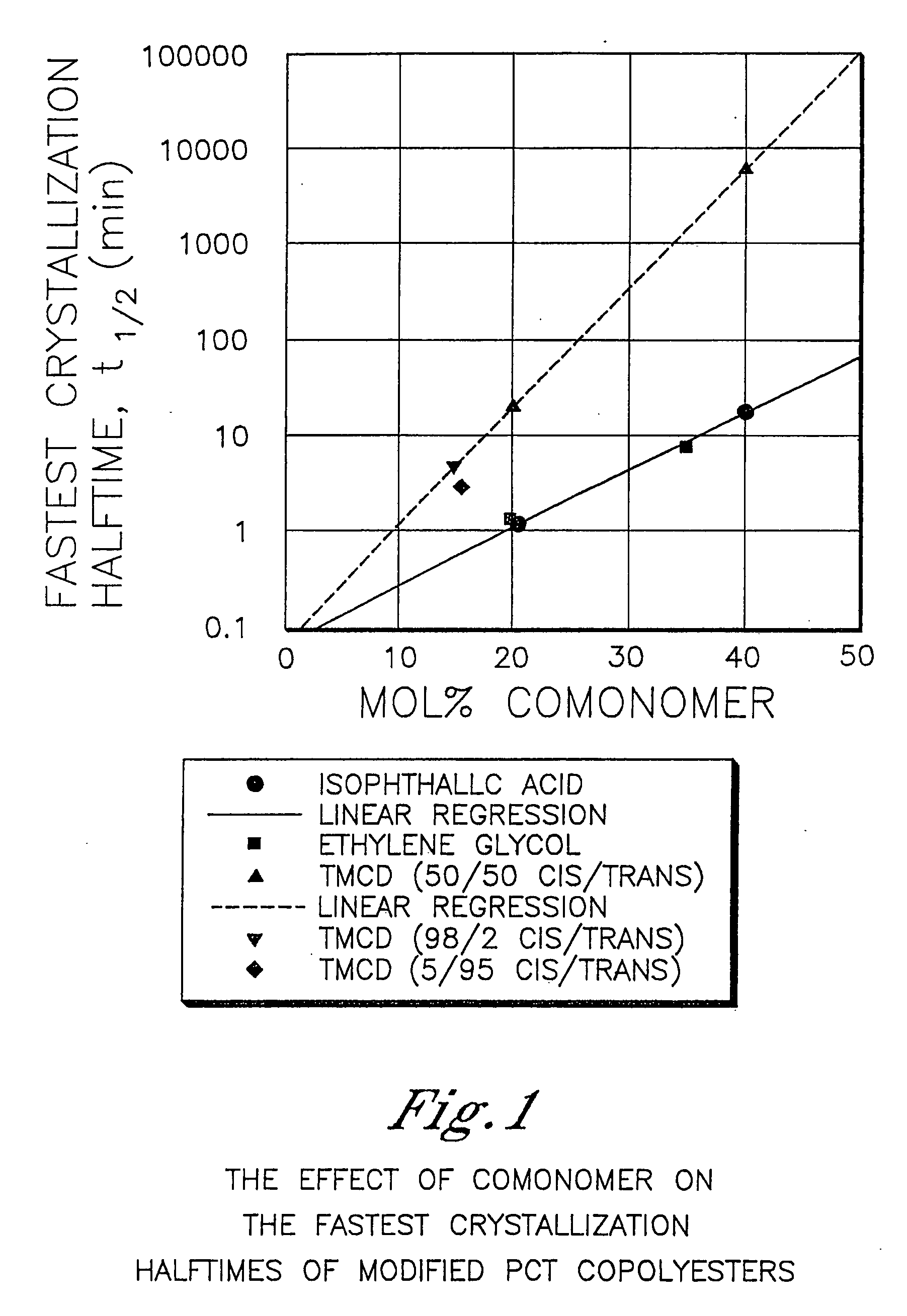

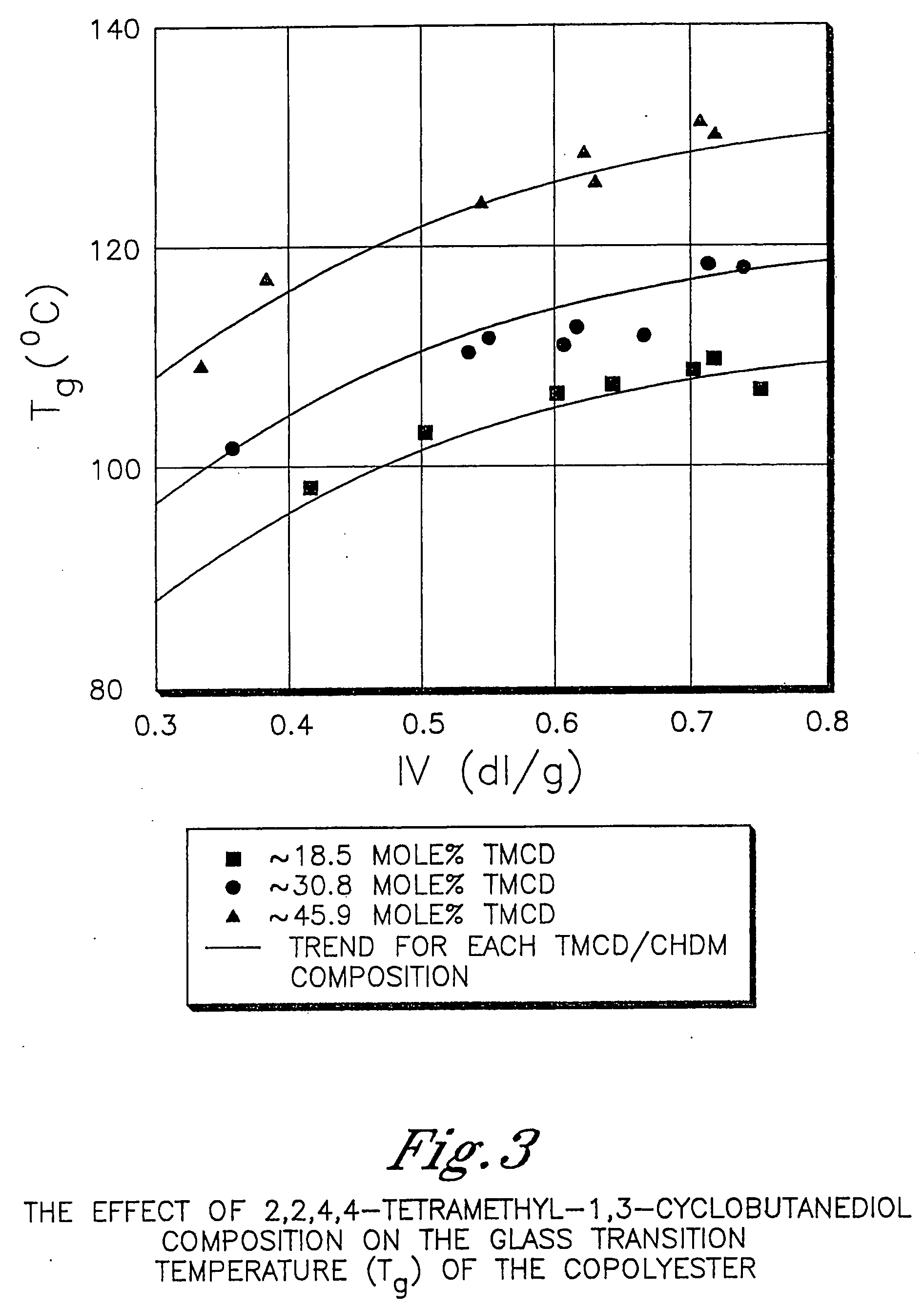

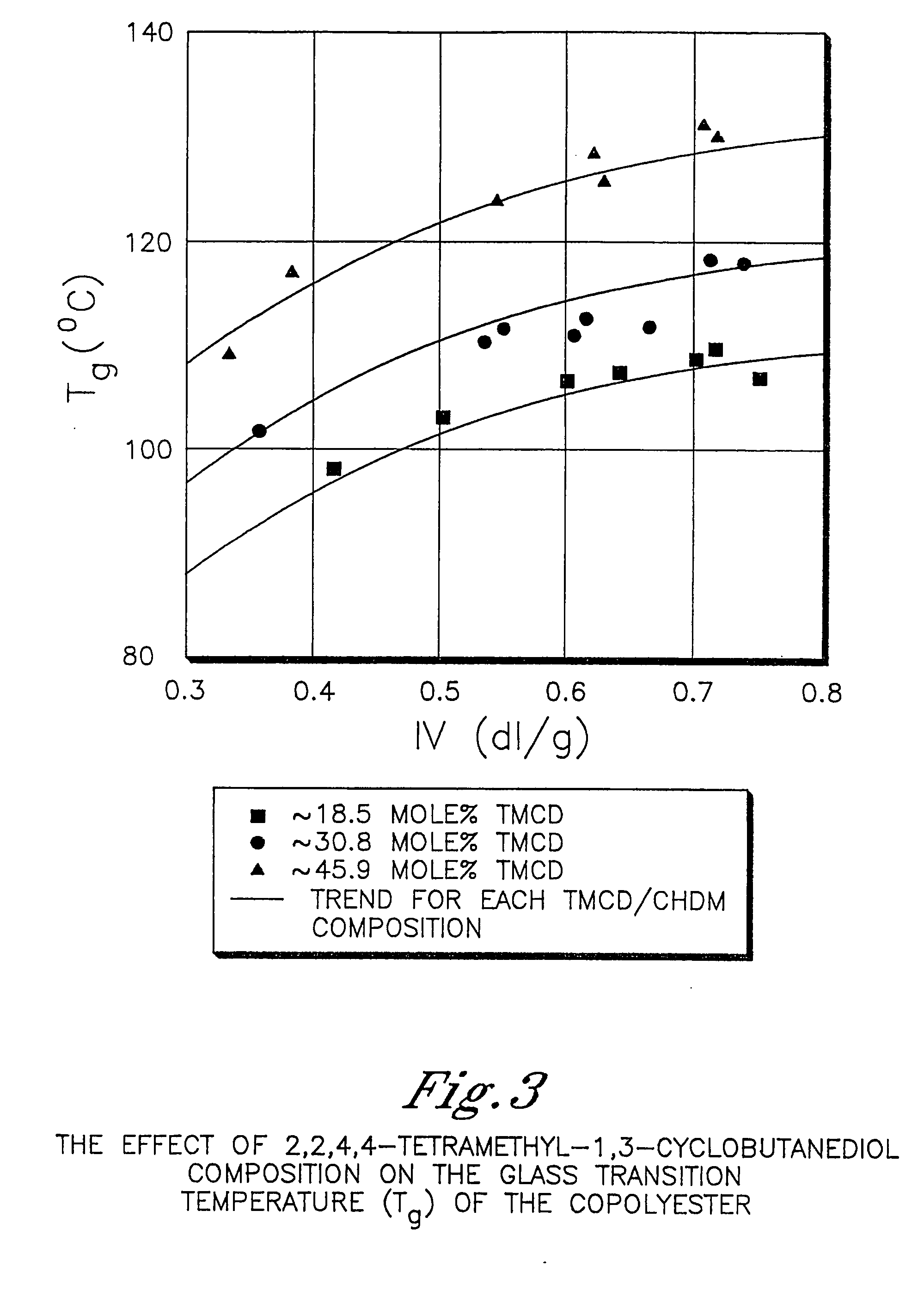

Described are polyester compositions comprising at least one polyester which comprises terephthalic acid residues, 2,2,4,4-tetramethyl-1,3-cyclobutanediol, and cyclohexanedimethanol, wherein the inherent viscosity and the Tg of the polyester provides for certain polyester properties. The polyesters may be manufactured into articles such as fibers, films, bottles or sheets.

Owner:EASTMAN CHEM CO

Polyester compositions containing cyclobutanediol having a certain combination of inherent viscosity and moderate glass transition temperature and articles made therefrom

ActiveUS20060293495A1Easy to optimizeHigh impact strengthDialysis systemsDialysisFiberCyclohexanedimethanol

Described are polyesters comprising (a) a dicarboxylic acid component comprising terephthalic acid residues; optionally, aromatic dicarboxylic acid residues or aliphatic dicarboxylic acid residues; 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and 1,4-cyclohexanedimethanol residues. The polyesters may be manufactured into articles such as fibers, films, bottles or sheets.

Owner:EASTMAN CHEM CO

Film(s) and/or sheet(s) comprising polyester compositions which comprise cyclobutanediol and have a certain combination of inherent viscosity and moderate glass transition temperature

ActiveUS20060293494A1Improve bindingIncrease temperatureDialysis systemsDialysisCyclohexanedimethanolCarboxylic acid

Described are film(s) and / or sheet(s) comprising polyesters comprising (a) a dicarboxylic acid component having terephthalic acid residues; optionally, aromatic dicarboxylic acid residues or aliphatic dicarboxylic residues; 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and 1,4-cyclohexanedimethanol residues.

Owner:EASTMAN CHEM CO

Certain polyester compositions which comprise cyclohexanedimethanol, moderate cyclobutanediol, cyclohexanedimethanol, and high trans cyclohexanedicarboxylic acid

InactiveUS20070232779A1Good chemical resistanceLess reactiveSynthetic resin layered productsOptical articlesPolyesterCyclohexanedimethanol

Described as one aspect of the invention are polyester compositions A polyester composition comprising at least one polyester which comprises:(A) a dicarboxylic acid component comprising:i) 70 to 100 mole % of cyclohexanedicarboxylic acid residues or an ester thereof comprising:(a) 80 to 99 mole % trans-cyclohexanedicarboxylic acid residues or an ester thereof; and(b) 1 to 20 mole % cis-cyclohexanedicarboxylic acid residues or an ester thereof;ii) 0 to 30 mole % of aliphatic dicarboxylic acid residues, other than cyclohexanedicarboxylic acid residues, having up to 16 carbon atoms or esters thereof, other than cyclohexanedicarboxylic acid residues; andiii) 0 to 10 mole % of aromatic dicarboxylic acid residues having up to 20 carbon atoms; and(B) a glycol component comprising:i) 5 to 35 mole % of 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; andii) 65 to 95 mole % of 1,4-cyclohexanedimethanol residues, 1,3-cyclohexanedimethanol residues, 1,2-cyclohexanedimethanol residues or esters thereof or mixtures thereof,wherein the total mole % of said dicarboxylic acid component is equal to 100 mole %;the total mole % of said glycol component is equal to 100 mole %;wherein the inherent viscosity of said polyester is from 0.35 to 1.2 dL / g as determined in 60 / 40 (wt / wt) phenol / tetrachloroethane at a concentration of 0.5 g / 100 ml at 25° C.; and wherein said polyester has a Tg of from 66 to 120° C. The polyesters may be manufactured into articles.

Owner:EASTMAN CHEM CO

Polyolefin Based Hot Melt Containing a Solid Plasticizer

A hot melt adhesive that is composed of a metallocene catalyzed polyethylene polymer, a hydrogenated styrenic block copolymer, a tackifying resin, and a solid plasticizer. The preferred polyethylene polymer is an ethylene-octene copolymer, and the preferred styrenic block copolymer is a styrene-ethylene-butylene-styrene having less than 30% styrene content. The preferred solid plasticizer is either glycerol tribenzoate or 1,4-cyclohexane dimethanol dibenzoate.

Owner:BOSTIK INC

Biaxially oriented polyester film and release film

InactiveUS20060210768A1Avoid painSynthetic resin layered productsRecord information storagePolyesterCyclohexanedimethanol

There is provided a biaxially oriented polyester film comprising a polyester which contains repeating units containing 1,4-cyclohexanedicarboxylic acid and 1,4-cyclohexanedimethanol as main components, and exhibits a melting point of not less than 200° C., wherein the biaxially oriented polyester film has a heat shrinkage percentage of not more than 5% as measured at 130° C. in each of longitudinal and width directions thereof, and a total light transmittance of not less than 90%. The biaxially oriented polyester film of the present invention exhibits an excellent heat resistance notwithstanding the film is composed of an aliphatic polyester, and a good transparency inherent to the aliphatic polyester, and can be suitably used in optical applications.

Owner:MITSUBISHI POLYESTER FILM +1

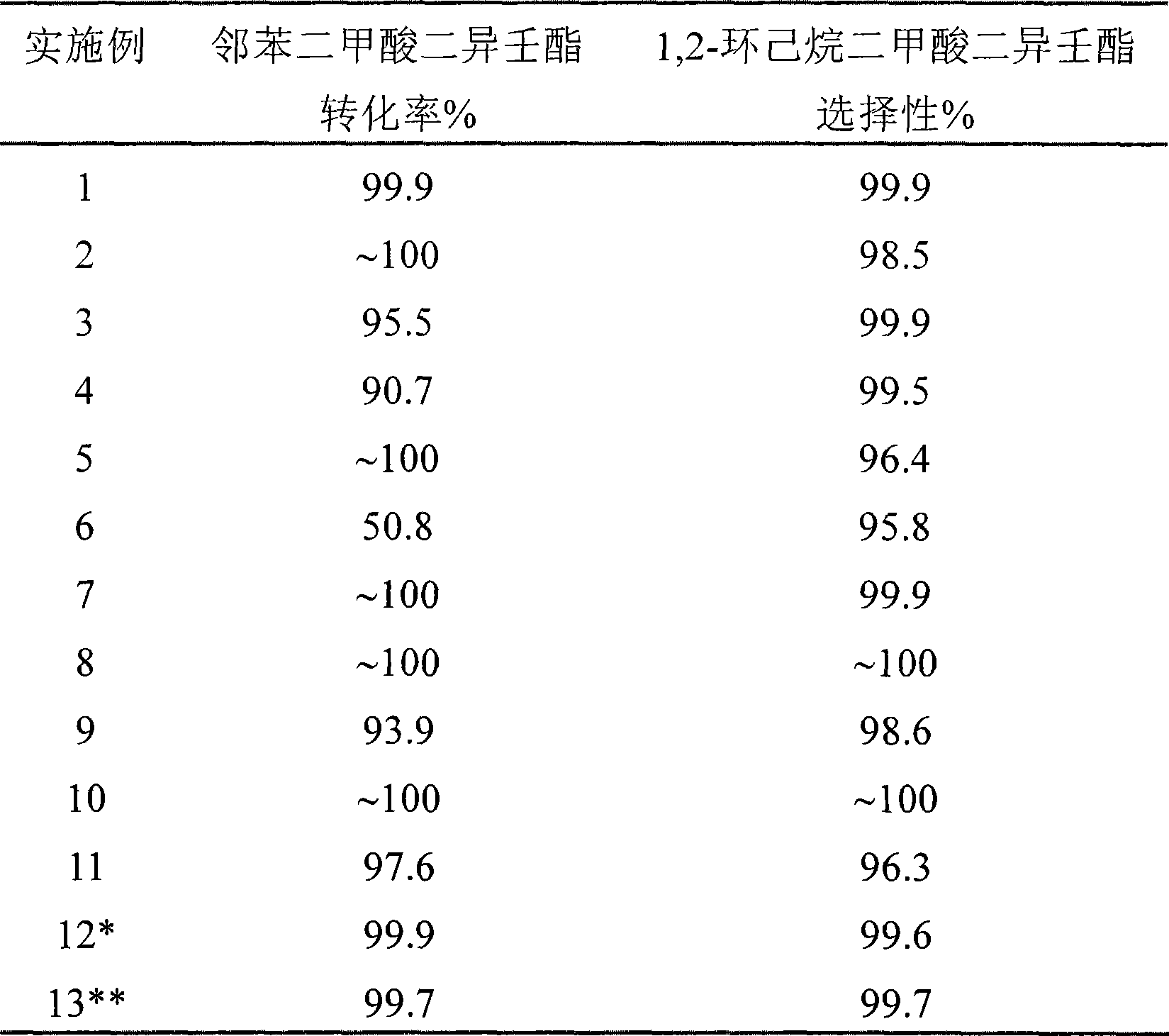

Method for preparing 1,2-cyclohexane cyclohexanedimethanol dibasic ester

ActiveCN101417950AHigh selectivityLow reaction pressureOrganic compound preparationCarboxylic acid esters preparationReaction temperatureDibasic ester

The invention relates to a method for preparing 1, 2-cyclohexanedicarboxylic acid ester of binary, comprising a reaction system composed by binary phthalate ester, hydrogen and a catalyst; the reaction temperature ranges from 100 to 250 DEG C; the reaction pressure ranges from 3.0 to 12.0 Mpa; the molar ratio of H2 and X ranges from 50 to 450; the liquid space velocity of binary phthalate ester ranges from 0.1 to 2.5 h<-1>; the catalyst uses Al2O3, ZrO2, TiO2 or SiO2-Al2O3 as vehicle, and load active component can be Ru, Pt, Pd, Rh, Fe, Co, Ni and Cu; the binary phthalate ester is diisonynol phthalate, diisooctyl phthalate or dibutyl phthalate; the product 1, 2-cyclohexanedicarboxylic acid ester of binary is 1, 2-cyclohexane diisononyl dimethyl ester, 1, 2-cyclohexane diisooctyl dimethyl ester or 1, 2-cyclohexane dibutyl dimethyl ester.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

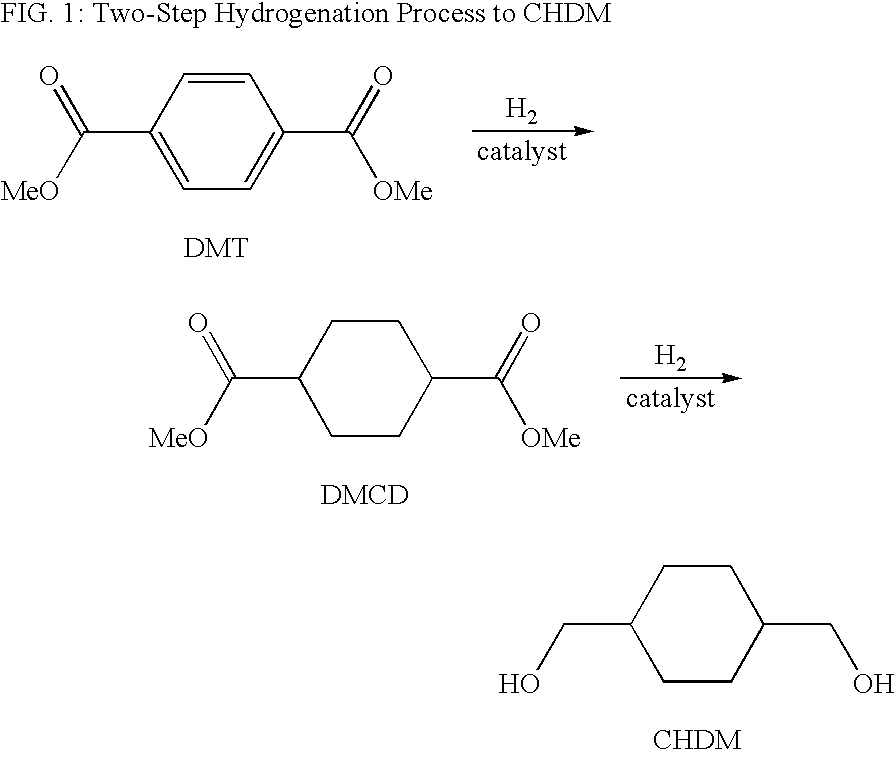

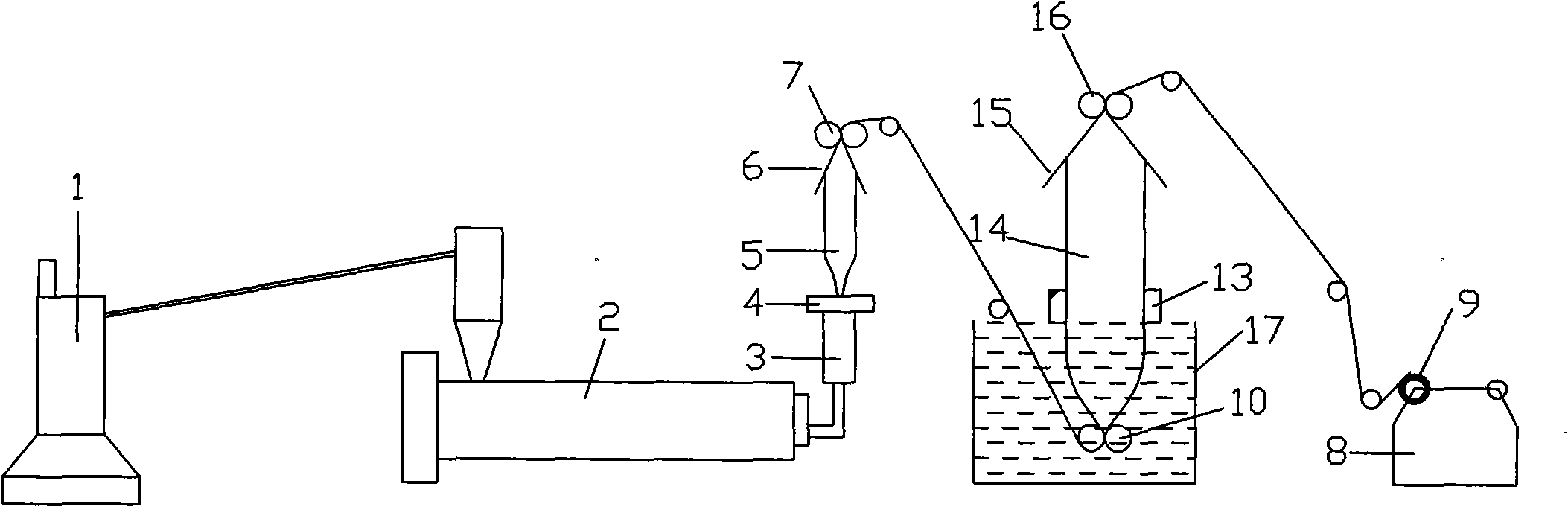

Process for a cyclohexanedimethanol using raney metal catalysts

InactiveUS6919489B1High trans contentOrganic compound preparationOxygen compounds preparation by reductionRheniumCyclohexanedimethanol

Disclosed is a process for a cyclohexanedimethanol by hydrogenation of a cyclohexane-dicarboxylate ester in the presence of a Raney metal catalyst doped with rhenium. The process is useful for the reparation of 1,4-cyclohexanedimethanol from dialkyl esters of 1,4-cyclohexanedicarboxylate or dialkyl terephthalates. When Raney nickel is used as the catalyst, the process produces CHDM having a high trans content.

Owner:EASTMAN CHEM CO

Low VOC additives for extending the wet edge and open time of aqueous coatings

ActiveUS20090326121A1Good coating effectPlastic/resin/waxes insulatorsOther chemical processesCyclohexanedimethanolWater dispersible

Disclosed is a low VOC coating additive employing a water-dispersible polymer, a water insoluble plasticizer, cyclohexanedimethanol, and optionally an amphiphilic component. The additive can be added to a coating to improve at least one performance characteristics of the coating, such as, wet-edge time, open time, scrub resistance, wet adhesion, and water resistance.

Owner:EASTMAN CHEM CO

Polyester compositions which comprise cyclobutanediol ethylene glycol, titanium, and phosphorus with improved color and manufacturing processes therefor

Described as one aspect of the invention are polyester compositions comprising at least one polyester which comprises: (a) a dicarboxylic acid component comprising: (i) about 90 to about 100 mole % of terephthalic acid residues; (ii) about 0 to about 10 mole % of aromatic and / or aliphatic dicarboxylic acid residues having up to 20 carbon atoms; and (b) a glycol component comprising: (i) about 1 to less than 90 mole % 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and (ii) about 0 to about 89 mole % cyclohexanedimethanol residues; (iii) greater than 10 mole % ethylene glycol residues, and (iv) less than about 2 mole % of a modifying glycol having from 3 to 16 carbon atoms; (c) titanium atoms and phosphorus atoms, wherein the total mole % of the dicarboxylic acid component is 100 mole %, and wherein the total mole % of the glycol component is 100 mole %; and wherein the inherent viscosity of the polyester is from 0.50 to 1.2 dL / g as determined in 60 / 40 (wt / wt) phenol / tetrachloroethane at a concentration of 0.25 g / 50 ml at 25° C. The polyesters may be manufactured into articles.

Owner:EASTMAN CHEM CO

Articles derived from compositions containing modified polybutylene terephthalate (PBT) random copolymers derived from polyethylene terephthalate (PET)

Compositions of matter including articles derived from (a) from 5 to 99.99 wt % of a modified polybutylene terephthalate random copolymer that (1) is derived from polyethylene terephthalate and (2) contains a at least one residue derived from polyethylene terephthalate selected from the group consisting of antimony, germanium, diethylene glycol groups, isophthalic acid groups, cis isomer of cyclohexane dimethanol, trans isomer of cyclohexane dimethanol, sodium benzoate, alkali salts, napthalane dicarboxylic acids, 1,3-propane diols, cobalt, cobalt-containing compounds, and combinations thereof, and (b) from 0.01 to 95 wt. % of a member selected from the group consisting of (1) fillers, (2) a carboxy reactive component, (3) polyethyelene terephthalate, (4) a component including a polycarbonate and an impact modifier. The articles may be derived from various conversion processes, e.g., injection molding processes, extrusion processes, thermoforming processes, melt-blown process.

Owner:SHPP GLOBAL TECH BV

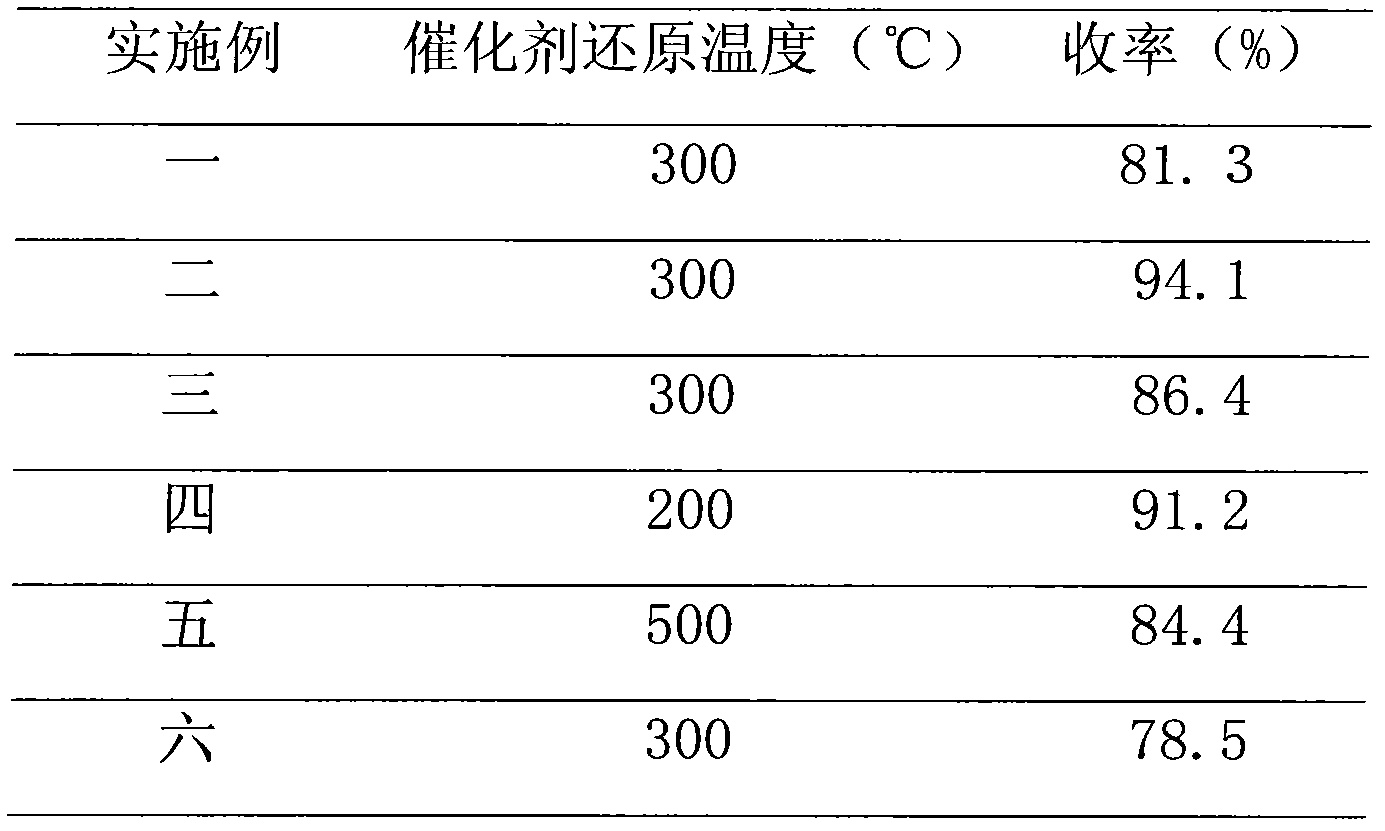

Hydrogenation catalyst and preparation method of 1,4-cyclohexanedimethanol

InactiveCN101982236ALow costEasy to prepareOrganic compound preparationHydroxy compound preparationCyclohexanedimethanolActive component

The invention discloses a hydrogenation catalyst and a preparation method of 1,4-cyclohexanedimethanol. The hydrogenation catalyst comprises a carrier and active components, wherein the carrier is mesoporous carbon, the active components are Ru and Sn, and the load capacity of the active components saccounts for 5%-15% of the hydrogenation catalyst in mass. The preparation method of the 1,4-cyclohexanedimethanol adopts the catalyst of the invention, and under the condition of a solvent and hydrogenation, the target product is produced with high selectivity. The catalyst and the method of the invention keep higher conversion rate and yield in reaction, simultaneously can maintain long service life of the catalyst, use the cheap mesoporous carbon as the carrier to reduce the cost of the catalyst, improve the reutilization rate of noble metal, and reduce consumption of the catalyst.

Owner:CHANGZHOU UNIV +1

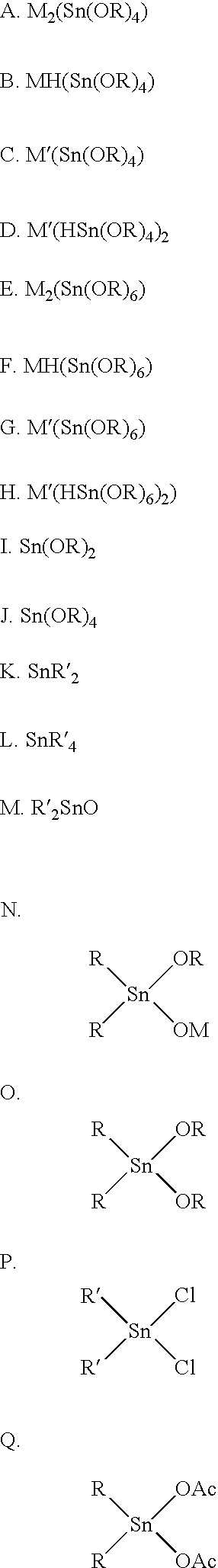

Process for the preparation of copolyesters based on 2,2,4,4-tetramethyl-1,3-cyclobutanediol and 1,4-cyclohexanedimethanol

ActiveUS20070276065A1Inherent viscosityEasy to useGroup 5/15 element organic compoundsCyclohexanedimethanolOligomer

Disclosed is a process for the preparation of high molecular weight, thermoplastic copolyesters by reacting a diester composition comprising a dialkyl ester of terephthalic acid with a diol composition comprising a first diol component comprising 2,2,4,4-tetramethyl-1,3-cyclobutanediol and a second diol component comprising 1,4-cyclohexanedimethanol. The diester composition can be reacted with the first diol component to produce a polyester oligomer that can be reacted further with the second diol component to produce a modified polyester oligomer. The modified polyester oligomer can then be heated to form a copolyester. The process reduces the precipitation of poly(1,4-cyclohexylene dimethylene) terephthalate in the reaction mixture.

Owner:EASTMAN CHEM CO

Polyester compositions comprising minimal amounts of cyclobutanediol

InactiveUS20060287496A1Reduce crystallinityDialysis systemsDialysisCyclohexanedimethanolCarboxylic acid

Described are polyester compositions comprising (a) a dicarboxylic acid component comprising terephthalic acid residues; optionally, aromatic dicarboxylic acid or aliphatic dicarboxylic acid residues; minimal amounts of 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; ethylene glycol, and optionally, 1,4-cyclohexanedimethanol residues.

Owner:CRAWFORD EMMETT DUDLEY +2

Certain polyester compositions which comprise cyclobutanediol, cyclohexanedimethanol, and high trans-cyclohexanedicarboxylic acid

InactiveUS20070232778A1Easily or more expensively stabilizedLess expensivePolyesterTetrachloroethane

Described as one aspect of the invention are polyester compositions comprising at least one polyester which comprises:(A) a dicarboxylic acid component comprising:i) 70 to 100 mole % of cyclohexanedicarboxylic acid residues or an ester thereof comprising:(a) 70 to 98 mole % trans-cyclohexanedicarboxylic acid residues or an ester thereof; and(b) 2 to 30 mole % cis-cyclohexanedicarboxylic acid residues or an ester thereof;ii) 0 to 30 mole % of aliphatic dicarboxylic acid residues, other than cyclohexanedicarboxylic acid residues, having up to 16 carbon atoms or esters thereof, other than cyclohexanedicarboxylic acid residues,; andiii) 0 to 10 mole % of aromatic dicarboxylic acid residues having up to 20 carbon atoms; and(B) a glycol component comprising:i) 1 to 99 mole % of 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; andii) 1 to 99 mole % of 1,4-cyclohexanedimethanol residues, 1,3-cyclohexanedimethanol residues, 1,2-cyclohexanedimethanol residues or esters thereof or mixtures thereof,wherein the total mole % of said dicarboxylic acid component is equal to 100 mole %;the total mole % of said glycol component is equal to 100 mole %;wherein the inherent viscosity of said polyester is from 0.35 to 1.2 dL / g as determined in 60 / 40 (wt / wt) phenol / tetrachloroethane at a concentration of 0.5 g / 100 ml at 25° C.; and wherein said polyester has a Tg of from 60 to 155° C. The polyesters may be manufactured into articles.

Owner:EASTMAN CHEM CO

PETG blow molding film and preparation method thereof

The invention relates to improvement of a PETG (polyethylene glycol terephthalate-1, 4-cyclohexanedimethanol ester) thin film and a preparation method. The PETG thin film is prepared by mixing 85-92 wt. % of PETG, 2.0-4.0 wt. % of opening agent, 0.5-1.5 wt. % of slipping agent, 0.2-1.0 wt. % of antistatic agent, 0.005-0.01 wt. % of chain extender and 5.0-10.0 wt. % of toughening agent blow molding, making film and shaping. Compared with casting and stretching, the invention has the advantages of short flow, convenient processing, no generation of scrap edge, high film-forming rate which can be increased by 8-10% than a stretching method, equipment investment saving, low operating cost, low production cost which can be reduced by about 20% or more and strong adaptability, adoption of various blowing measures for making the blown film, flexible and convenient product replacement and the like. Different blowing processes can be employed to obtain a non-shrinkage polyester film, and a unidirectional heat-shrinkable PETG film having approximate shrinkage rates lengthways and breadthways and giving priority to the lateral shrinkage rate. The resulting PETG thin film can be applied to a packaging film, a preservative film, a shed film, a label film and a tangle film.

Owner:YIXING GUANGHUI PACKAGE

Polyester compositions which comprise cyclobutanediol, cyclohexanedimethanol, and ethylene glycol and manufacturing processes therefor

Described as one aspect of the invention are polyester compositions comprising at least one polyester which comprises: (a) a dicarboxylic acid component comprising: (i) about 90 to about 100 mole % of terephthalic acid residues; (ii) about 0 to about 10 mole % of aromatic and / or aliphatic dicarboxylic acid residues having up to 20 carbon atoms; and (b) a glycol component comprising: (i) about 20 to about 40 mole % 2,2,4,4-tetramethyl-1,3-cyclobutanediol residues; and (ii) about 20 to about 40 mole % cyclohexanedimethanol residues; (iii) ethylene glycol residues, and (iv) less than about 2 mole % of a modifying glycol having from 3 to 16 carbon atoms; wherein the total mole % of the dicarboxylic acid component is 100 mole %, and wherein the total mole % of the glycol component is 100 mole %; and wherein the inherent viscosity of the polyester is from 0.50 to 1.2 dL / g as determined in 60 / 40 (wt / wt) phenol / tetrachloroethane at a concentration of 0.25 g / 50 ml at 25° C. The polyesters may be manufactured into articles.

Owner:EASTMAN CHEM CO

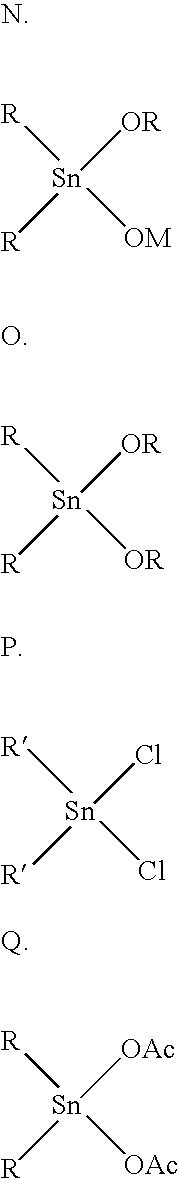

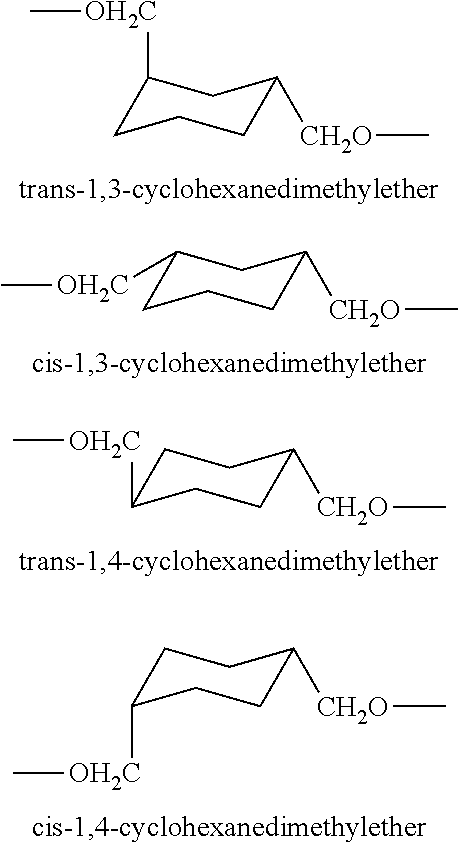

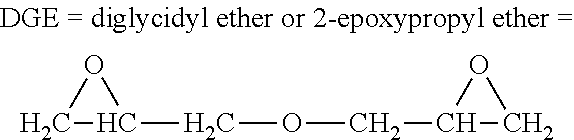

Epoxy resins and processes for preparing the same

InactiveUS20110039982A1Improve responseReduces potential corrosivityEpoxy resin coatingsEpoxyCyclohexanedimethanol

Epoxy resins comprising a cis, trans-1,3- and -1,4-cyclohexanedimethylether moiety and processes for preparing the epoxy resins. The process of preparation of the epoxy resins comprises reacting (a) a mixture of a cis-1,3-cyclohexanedimethanol, a trans-1,3-cyclohexanedimethanol, a cis-1,4-cyclohexanedimethanol, and a trans-1,4-cyclohexanedimethanol, (b) an epihalohydrin, (c) a basic acting substance, (d) optionally, a solvent, (e) optionally, a catalyst, and / or (f) optionally, a dehydrating agent. The process may be a slurry epoxidation process, an anhydrous epoxidation process, or a Lewis acid catalyzed coupling and epoxidation process.

Owner:BLUE CUBE IP

Hot melt adhesives for roll-applied labels

ActiveUS20100112250A1Plastic/resin/waxes insulatorsSynthetic resin layered productsPolyesterTriethylene glycol

Disclosed are hot-melt adhesives prepared from polyesters containing 1,4-cyclohexane-dicarboxylic acid as a diacid component and a diol component containing at least two diols chosen from 1,4-cyclohexanedimethanol, triethylene glycol, and diethylene glycol. These adhesives set up rapidly within a well-defined temperature window. The hot-melt adhesives can be used in a variety of applications, but are especially suited as seaming adhesives for roll-applied labels. These adhesives have melting temperatures and crystallization properties that allow their application at temperatures cool enough to prevent curling and premature shrinkage of the shrink label during seaming, and yet produce strong label seams that can withstand the elevated temperatures of a shrink tunnel without sacrificing line speed. Also disclosed are labeled containers and a process for applying a roll-on, shrink label to a container using the hot-melt adhesives of the invention.

Owner:EASTMAN CHEM CO

Blends of polyesters with modified polycarbonates

Disclosed are polymer blends comprising polycarbonate(s) and polyester(s) wherein the polycarbonate is a polycarbonate derived from dihydric phenols, aromatic dicarboxylic acid residues and carbonic acid residues and the polyester comprises residues of or is derived from one or more aromatic phthalic acid residues, 1,4-cyclohexanedimethanol, and alkylene glycols other than 1,4-cyclohexanedimethanol.

Owner:EASTMAN CHEM CO

Thermoplastic block copolyether ester elastomer and preparation method thereof

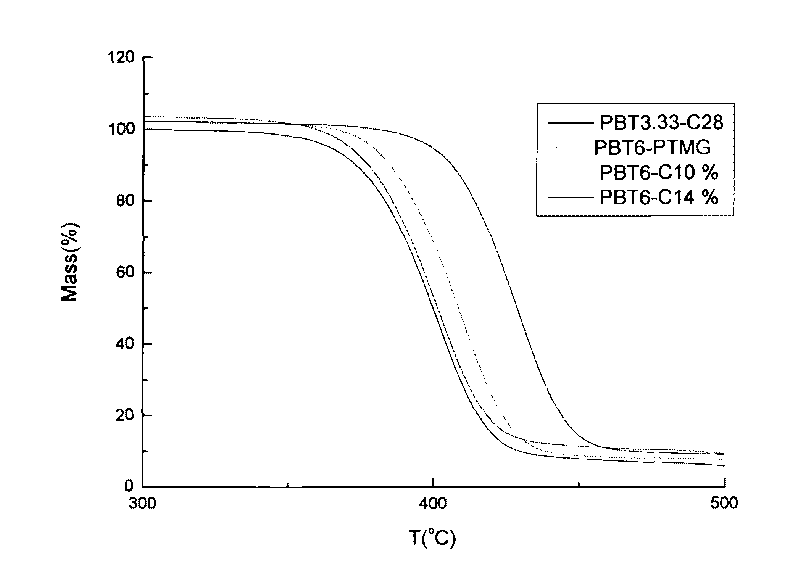

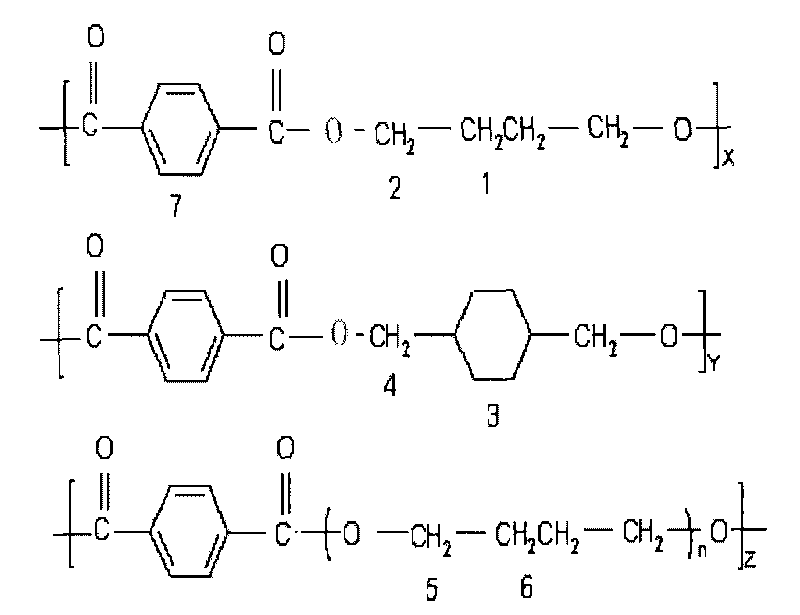

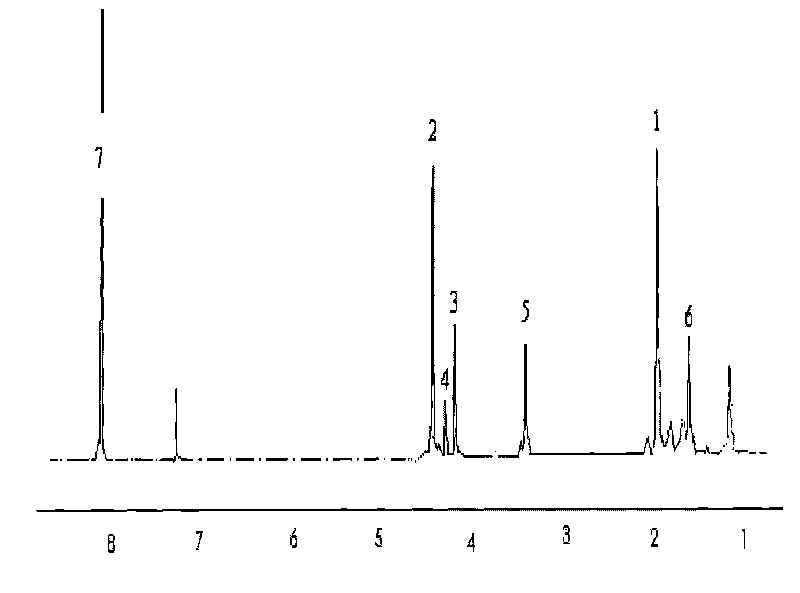

This invention relates to a thermoplastic block copolyether ester elastomer and a preparation method thereof, wherein the aromatic dicarboxylic acid and mixing divalent alcohol are reacted at 180-265 DEG C in the mol ratio of 1: 1.2-2.2; the titanium compound, the mixture of titanium compound and zinc compound or the mixture of titanium compound and magnesium compound is used as catalyst; the copolyether ester contains 15-90ppm of titanium element, 10-200ppm of zinc or magnesium, and 300-4000ppm of antioxidant; the obtained matter is reacted under pressure lower than 150Pa to distil out 1,4-butanediol and 1,4-cyclohexanedimethanol; the final temperature of the reaction is at 260-290 DEG C; in terms of total weight of the copolyether ester, the content of the hard segment is 50-92wt%; the inherent viscosity is 0.65-1.85dl / g; the melting point is at 160-220 degrees centigrade; the elongation at break is 500-1400% and the thermal decomposition temperature is 360 to 450 DEG C.

Owner:PETROCHINA CO LTD +1

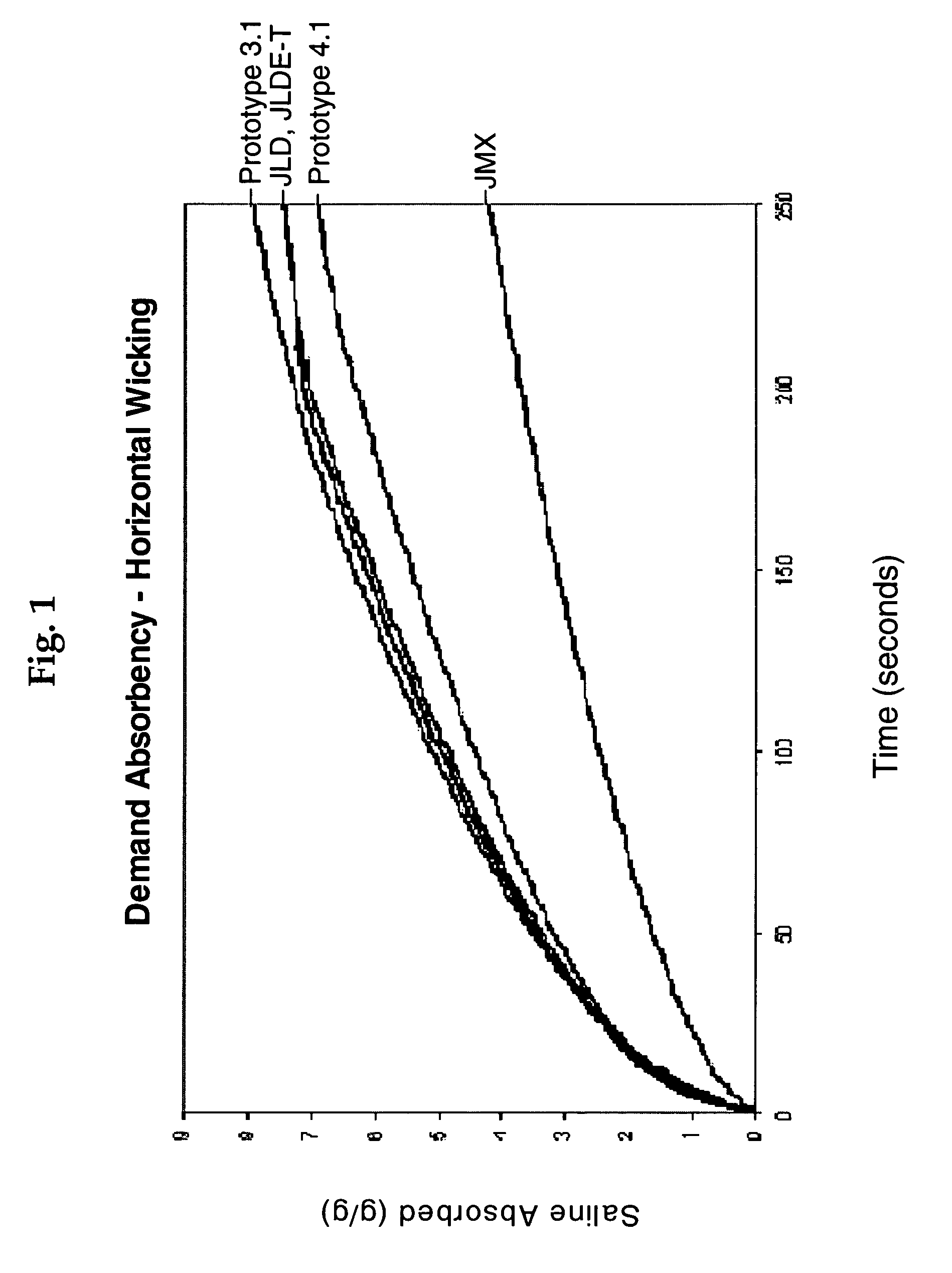

Plasticizing formulation for fluff pulp and plasticized fluff pulp products made therefrom

InactiveUS7854822B2Natural cellulose pulp/paperMechanical working/deformationCyclohexanedimethanolFluff pulp

Owner:RAYONIER PERFORMANCE FIBERS +1

Heat-shrinkable polyester film having excellent crystallinity

InactiveUS20050010018A1Low shrinkageAnimal housingThin material handlingCyclohexanedimethanolCrystallization temperature

Disclosed herein is a heat-shrinkable co-polyester film having terephthalic acid and ethylene glycol as main components and containing 1,4-cyclohexanedimethanol at the amount of 3-40 mol %. The heat-shrinkable co-polyester film has a crystallization temperature of 80-220° C., a heat shrinkage (%) higher than 30% in at least one direction of longitudinal and transverse directions in 90° C. hot water, and a maximum shrinkage stress lower than 3 kg / mm2. The film is suitable for use as various wrapping materials, such as covering, binding and casing materials. Particularly, the film is used to cover a cap, body and shoulder, etc. of various vessels and rod-shaped molded articles and thus to provide labeling, protection, binding or an improvement in product value. Also, the film can be used for multi-package.

Owner:TORAY SAEHAN

Biaxially oriented copolyester film and laminates thereof with copper

InactiveUS20060134409A1Liquid crystal compositionsSynthetic resin layered productsCyclohexanedimethanolCarboxylic acid

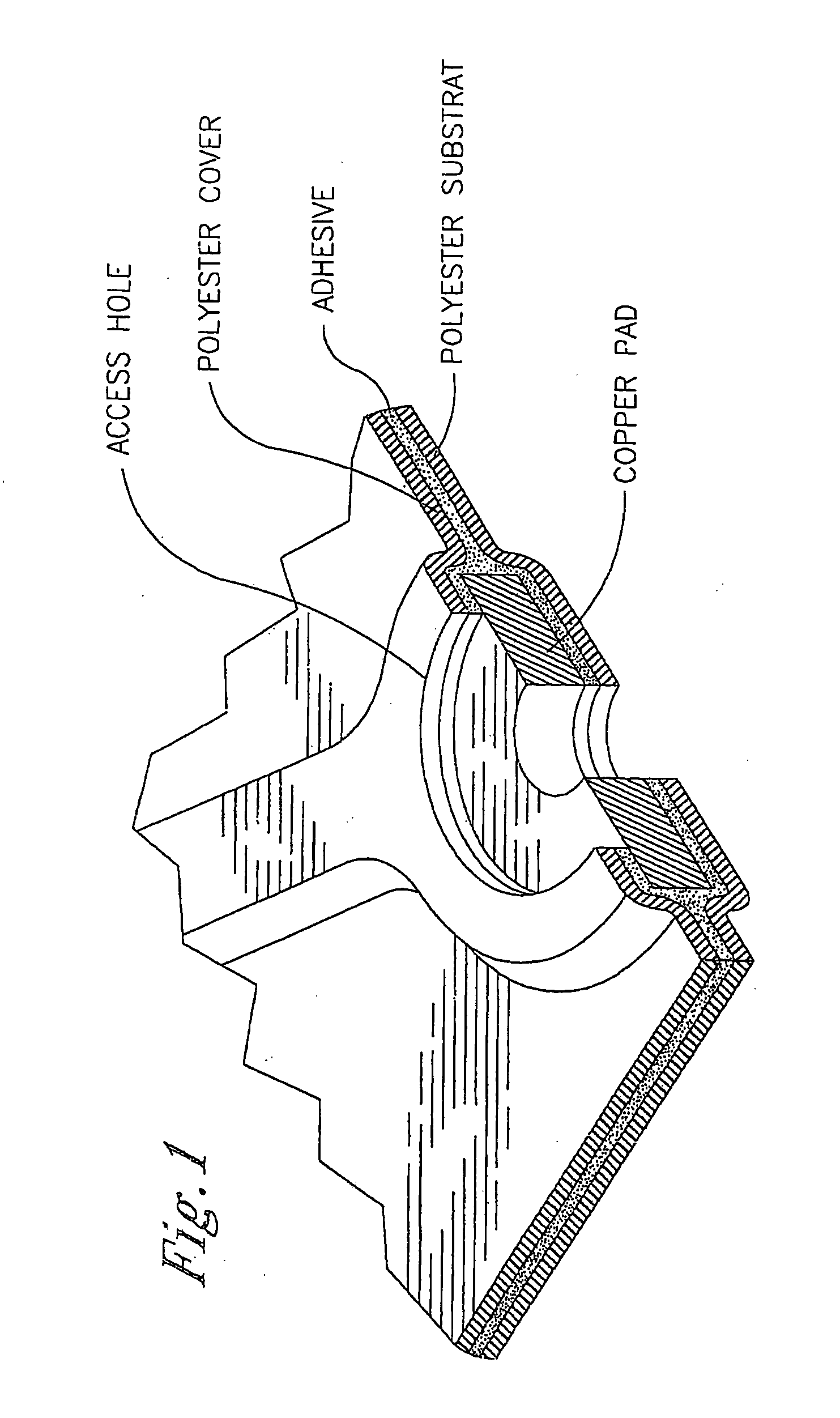

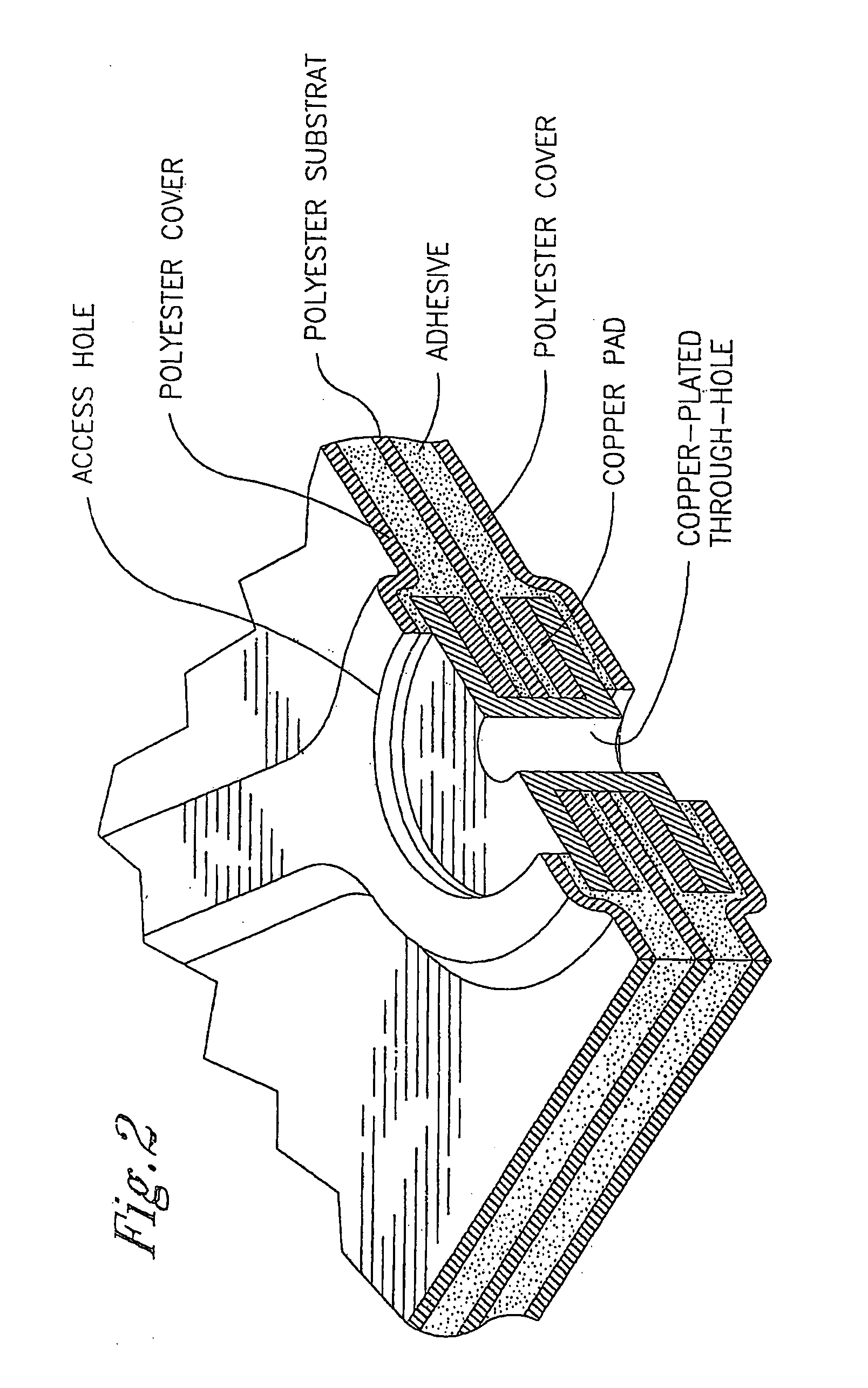

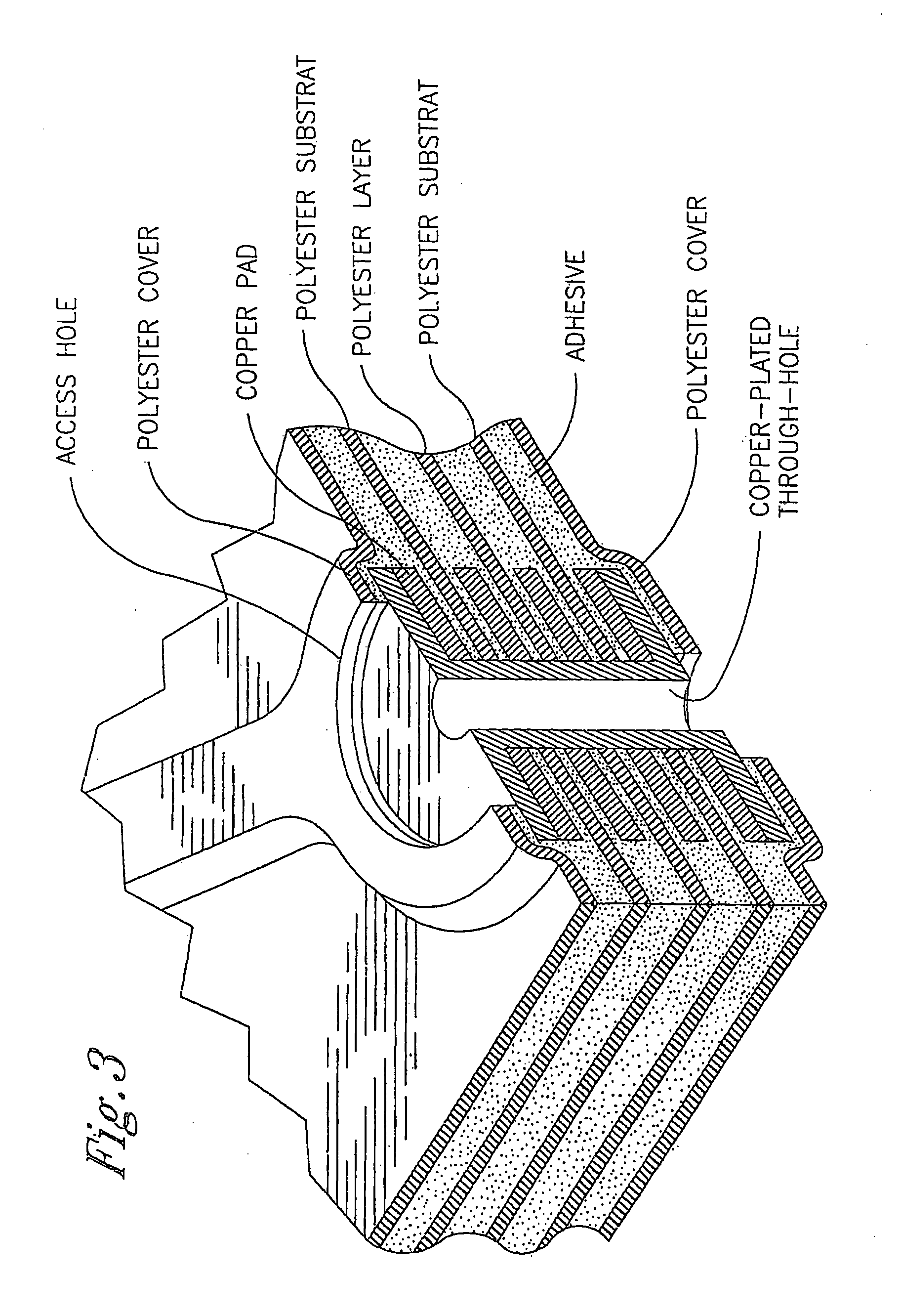

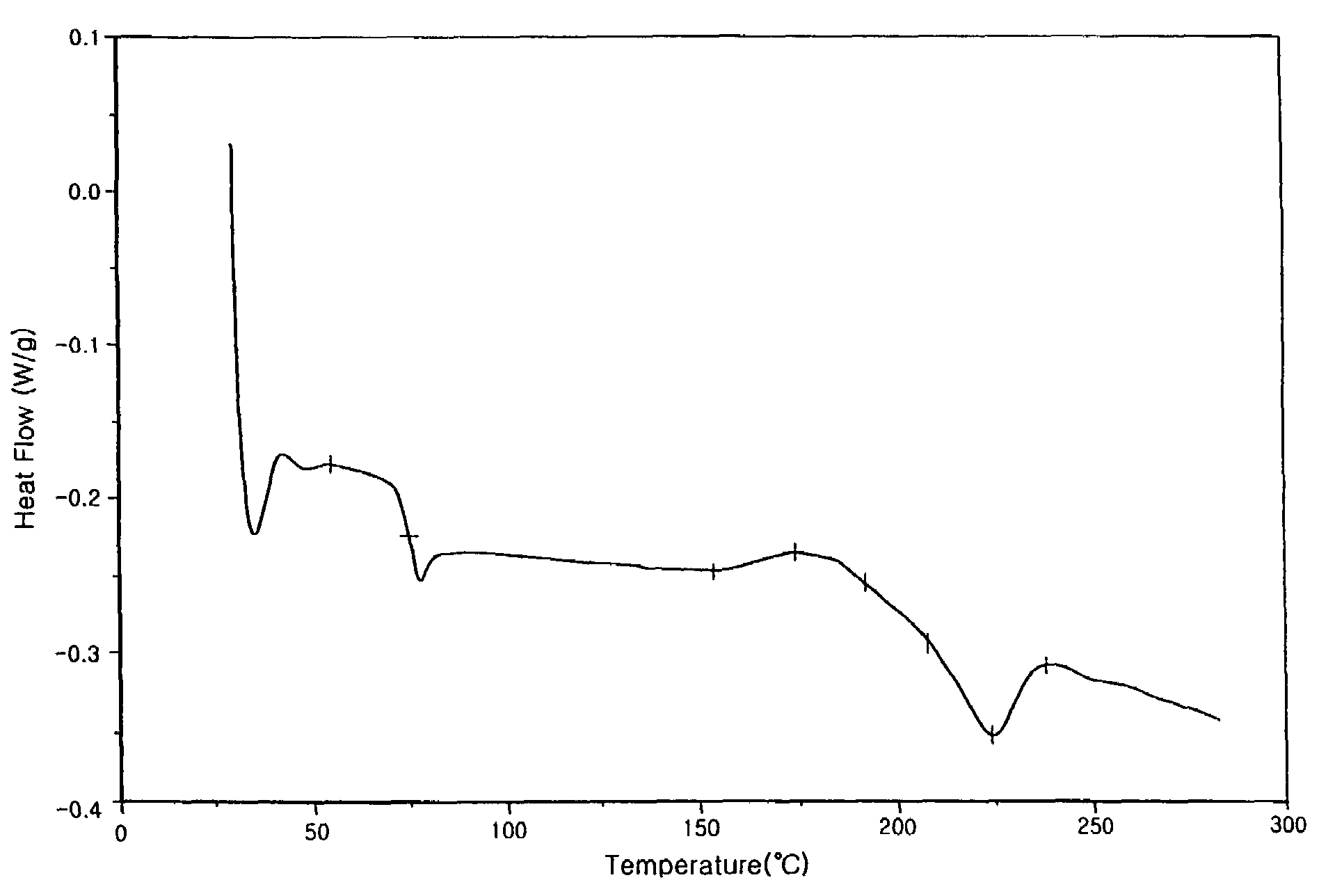

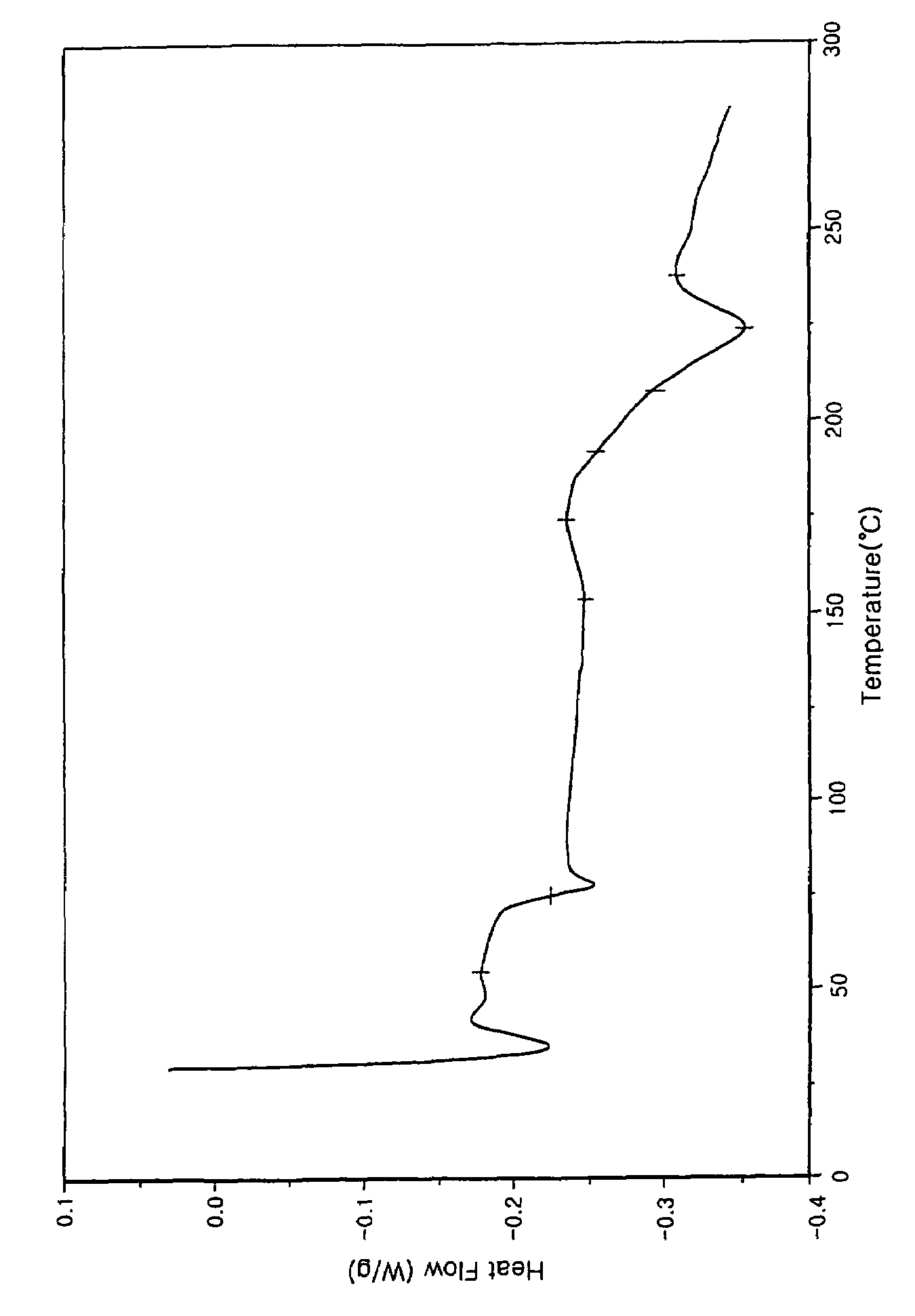

Disclosed is a biaxially-oriented polyester film produced from a polyester comprising: (1) diacid residues comprising between about 95 and about 100 mole percent of terephthalic acid residues; (2) diol residues comprising between about 95 and about 100 mole percent of 1,4-cyclohexanedimethanol residues; and (3) about 0.5 to about 5 mole percent of another dicarboxylic acid or diol residue, wherein the polyester comprises a total of 100 mole percent diacid residues and a total of 100 mole percent diol residues. In one embodiment, the biaxially-oriented film has a thickness of 70 to 150 microns (3-5 mils). In another embodiment, the biaxially-oriented film undergoes not more than 3% shrinkage when immersed for 10 seconds in a solder bath preheated to 260° C. The film can be made by stretching an essentially amorphous cast film of thickness between about 450-1800 micron (18-70 mil) at a ratio from about 2.5×2.5 to 3.5×3.5 while being held at a temperature between 90° C. and 130° C., and heat-setting the stretched film at an actual film temperature of from 260° C. to Tm, where Tm is the melting point of the polyester as measured by differential scanning calorimetry (DSC), while maintaining the dimensions of the stretched film.

Owner:EASTMAN CHEM CO

Heat-shrinkable polyester film having excellent crystallinity

InactiveUS7128863B2Low shrinkageAnimal housingThin material handlingCyclohexanedimethanolPolymer science

Disclosed herein is a heat-shrinkable co-polyester film having terephthalic acid and ethylene glycol as main components and containing 1,4-cyclohexanedimethanol at the amount of 3–40 mol %. The heat-shrinkable co-polyester film has a crystallization temperature of 80–220° C., a heat shrinkage (%) higher than 30% in at least one direction of longitudinal and transverse directions in 90° C. hot water, and a maximum shrinkage stress lower than 3 kg / mm2. The film is suitable for use as various wrapping materials, such as covering, binding and casing materials. Particularly, the film is used to cover a cap, body and shoulder, etc. of various vessels and rod-shaped molded articles and thus to provide labeling, protection, binding or an improvement in product value. Also, the film can be used for multi-package.

Owner:TORAY SAEHAN

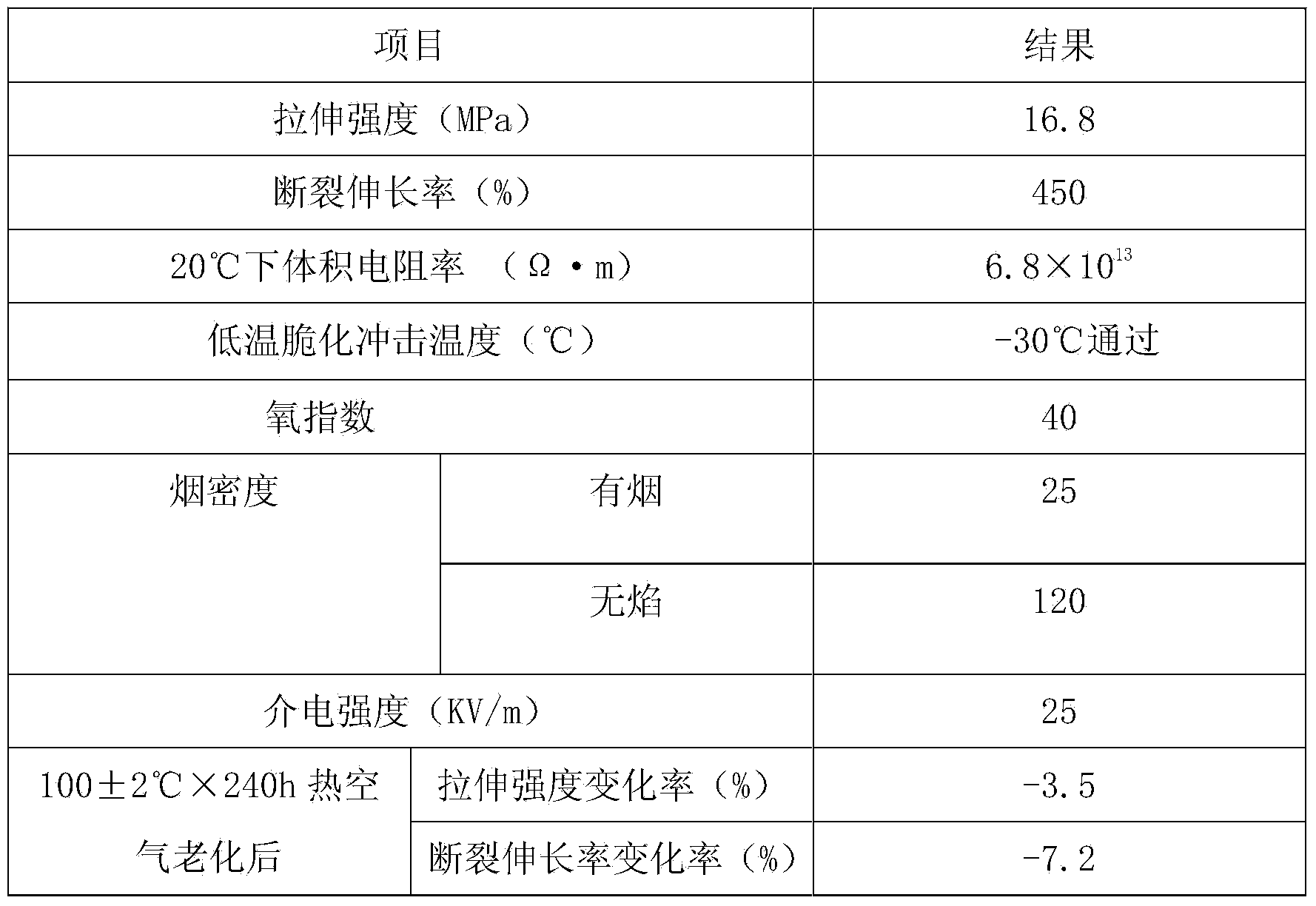

Flame-retardant oil-resistant aging-resistant thermoplastic elastomer cable material

ActiveCN103524913AFlame retardant hasFlame retardant and oil resistantPlastic/resin/waxes insulatorsInsulated cablesCalcium silicatePolyvinyl chloride

The invention provides a flame-retardant oil-resistant aging-resistant thermoplastic elastomer cable material prepared from the following raw materials in parts by weight: 100 parts of polyvinyl chloride SG-3, 10-20 parts of nitrile rubber N26, 10-15 parts of polycarbonate, 10-15 parts of poly(ethylene terephthalateco-1,4-cylclohexylenedimethylene terephthalate), 15-20 parts of a silane coupling agent, 30-40 parts of bisphenol-A bis(diphenyl phosphate), 20-30 parts of calcium carbonate, 1-2 parts of calcium silicate, 30-50 parts of barium stearate, 10-15 parts of cresyl diphenyl phosphate, 3-4 parts of glycerol trioleate, 2-3 parts of a crosslinking agent TAIC, 2-3 parts of stearic acid, 1-2 parts of N,N'-m-phenylenedimaleimide, 5-8 parts of alcohol ester-12, 0.5-1.0 part of PE wax, 1-2 parts of aluminum nitride powder, 1-2 parts of jade powder, and 8-10 parts of a modified filler. The flame-retardant oil-resistant aging-resistant thermoplastic elastomer cable material has the characteristics of flame retardancy, oil resistance, aging resistance, and acid and alkali resistance, and has lower specific density and low manufacture cost.

Owner:滁州君越高分子新材料有限公司

Impact-Resistant Polyurethane

ActiveUS20090171060A1Excellent thermo mechanical propertyGood chemical resistancePolyesterCyclohexanedimethanol

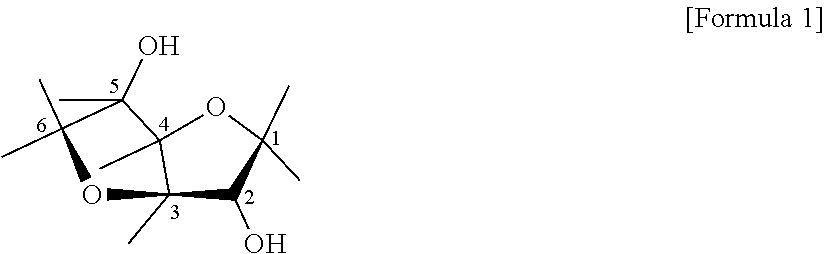

The present invention teaches a new process to produce novel, hard, optically clear, impact-resistant polyurethane polymers that are characterized by excellent thermo mechanical properties and chemical resistance, and the polymers made as a result of such a process.The polyurethanes are made by reactinga) a prepolymer made by reacting a polyisocyanate with a primary amine-terminated polyether with an amine functionality of about 2 and a molecular weight of >1000, and in which the free —NCO content of the resulting prepolymer is >18% by weight; withb) (i) a polyol having an average hydroxyl functionality greater than or equal to 2 and an average hydroxyl equivalent weight of from about 300 to about 1,000, and (ii) a curing agent that has isocyanate reactive groups, a functionality of 2 to 3 and a molecular weight of <400.More preferably the prepolymer is made by reacting a cycloaliphatic polyisocyanate with a primary amine-terminated polyether diamine of 2000 to about 2500 molecular weight, the polyol is either a polyester polyol triol with a molecular weight of between about 540 and 900, or a polyether glycol with a molecular weight of between about 650 and 2000, or a polyester polyol diol with a molecular weight of up to 2,000, and the curing agent is either dianhydrohexitol, an aromatic diamine, an aromatic ring containing diol or a cyclohexanedimethanol.

Owner:POLYPLEXX

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com