Hydrogenation catalyst and preparation method of 1,4-cyclohexanedimethanol

A technology of cyclohexanedimethanol and hydrogenation catalyst, which is applied in the preparation of organic compounds, preparation of hydroxyl compounds, chemical instruments and methods, etc., can solve the problems of difficult recovery of precious metals, and achieve low cost, simple preparation method, and easy recovery Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

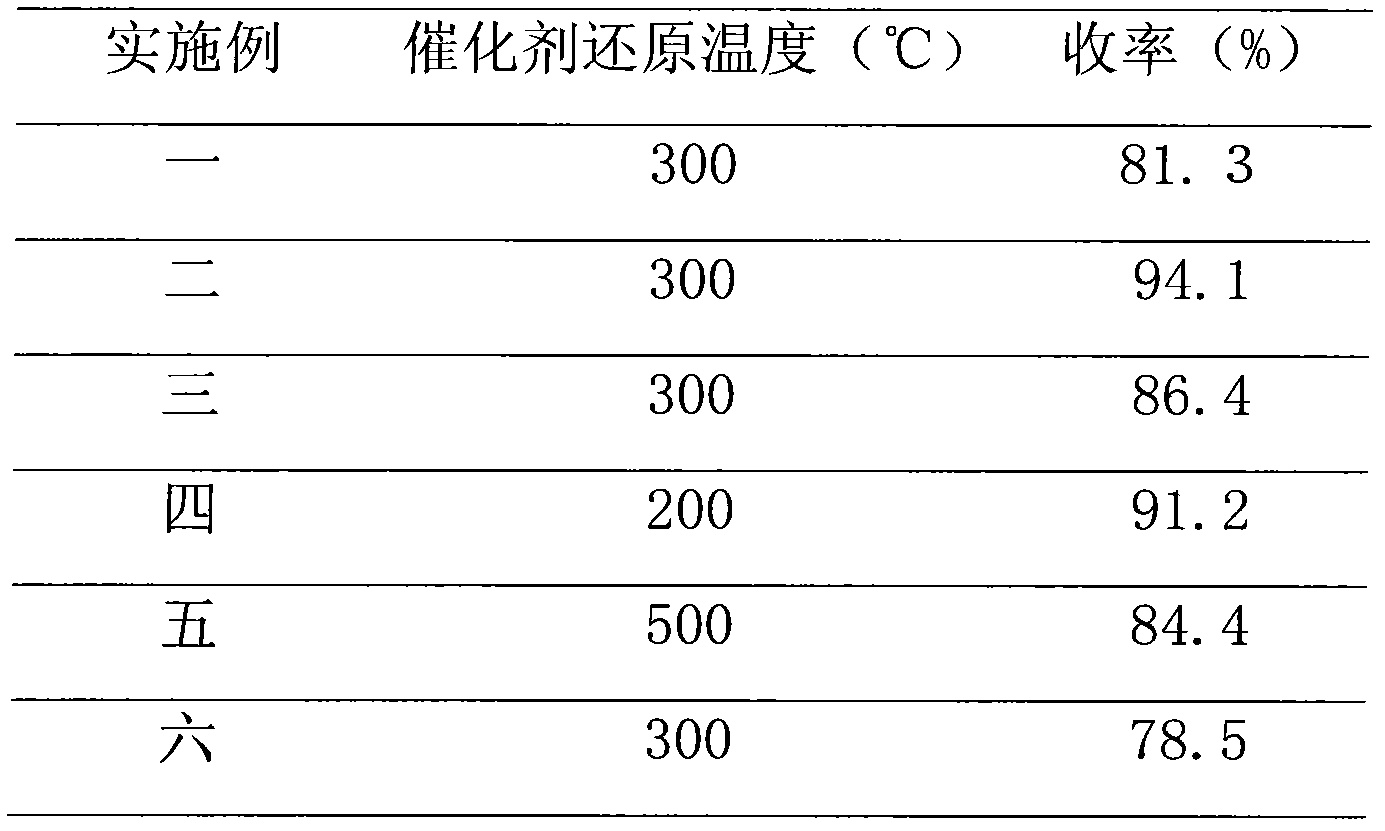

Embodiment 1

[0017] Embodiment one: in the autoclave with stirring, add 0.5g of 5%Ru-6%Sn / mesoporous carbon catalyst (the pore volume of carrier mesoporous carbon is 2.0mL / g, specific surface area is 1500m 2 / g, pore diameter is 5nm, carrier mesoporous carbon without pretreatment), 1.5g of 1,4-cyclohexanedicarboxylic acid, 25ml of distilled water, close the reactor, replace the air in the reactor with nitrogen for three times, and then use hydrogen Replace the nitrogen in the reactor for three times, then fill the reactor with hydrogen to make the reaction pressure of the reactor reach 8.0MPa, heat the reactor to make the reaction temperature reach 230°C, start stirring, keep the temperature until the pressure no longer drops, take out the reaction product, and filter The catalyst was removed and analyzed by gas chromatography.

Embodiment 2

[0018] Embodiment two: in the autoclave with agitation, add 5%Ru-6%Sn / mesoporous carbon catalyst 0.5g (carrier mesoporous carbon is through 1M hydrochloric acid pretreatment 24 hours, and the pore volume of carrier mesoporous carbon is 1.7 mL / g, the specific surface area is 1800m 2 / g, pore diameter is 4nm), 1,4-cyclohexanedicarboxylic acid 1.5g, distilled water 25ml, close reactor, replace the air in the reactor with nitrogen three times, then replace the nitrogen in the reactor with hydrogen three times, Then recharge hydrogen to make the reaction pressure of the reactor reach 8.0MPa, heat the reactor to make the reaction temperature reach 230°C, start stirring, keep the temperature until the pressure no longer drops, take out the reaction product, remove the catalyst by filtration, and analyze by gas chromatography.

Embodiment 3

[0019] Embodiment three: in the autoclave with agitation, add 5%Ru-9%Sn / mesoporous carbon catalyst 0.5g (carrier mesoporous carbon is pretreated 2 hours with 6M hydrochloric acid, the pore volume of carrier mesoporous carbon is 2.4 mL / g, specific surface area is 1400m 2 / g, pore diameter is 7nm,), 1,4-cyclohexanedicarboxylic acid 1.5g, distilled water 25ml, close reactor, replace the air in the reactor with nitrogen three times, then replace the nitrogen in the reactor with hydrogen three times, Then recharge hydrogen to make the reaction pressure of the reactor reach 8.0MPa, heat the reactor to make the reaction temperature reach 250°C, start stirring, keep the temperature until the pressure no longer drops, take out the reaction product, remove the catalyst by filtration, and analyze by gas chromatography.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com