Patents

Literature

613 results about "Dimethyl terephthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dimethyl terephthalate (DMT) is an organic compound with the formula C₆H₄(COOCH₃)₂. It is the diester formed from terephthalic acid and methanol. It is a white solid that melts to give a distillable colourless liquid.

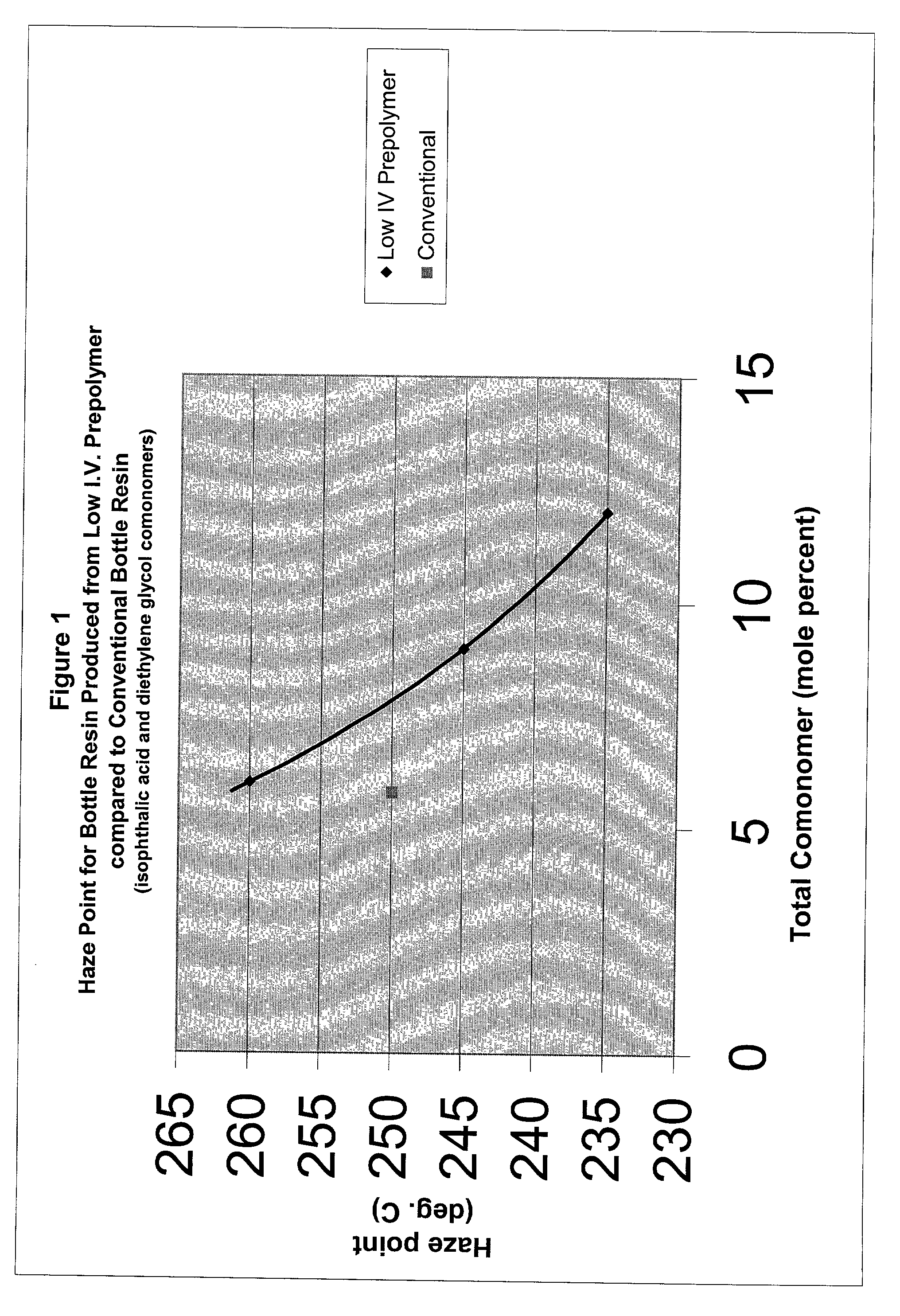

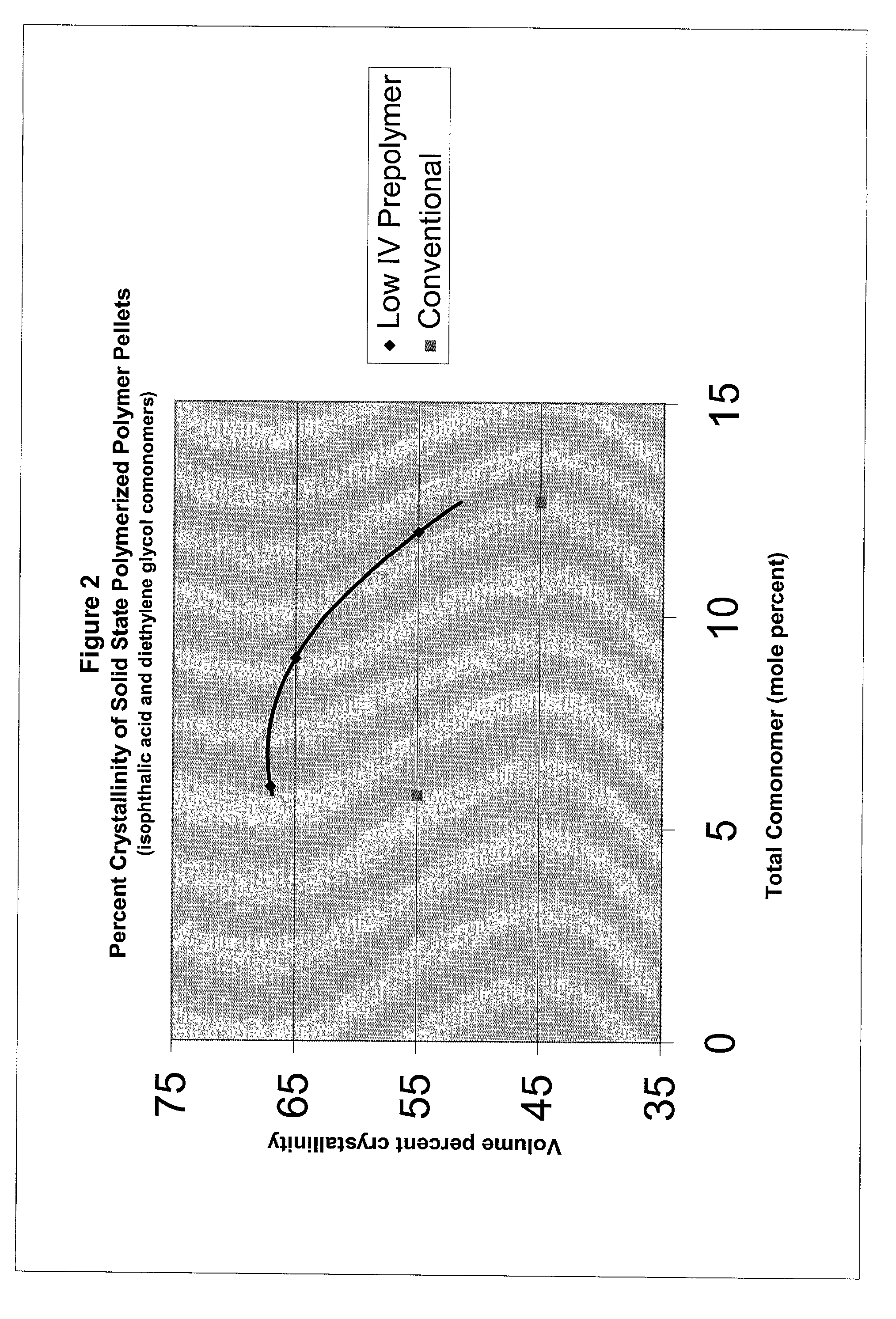

Method of preparing modified polyester bottle resins

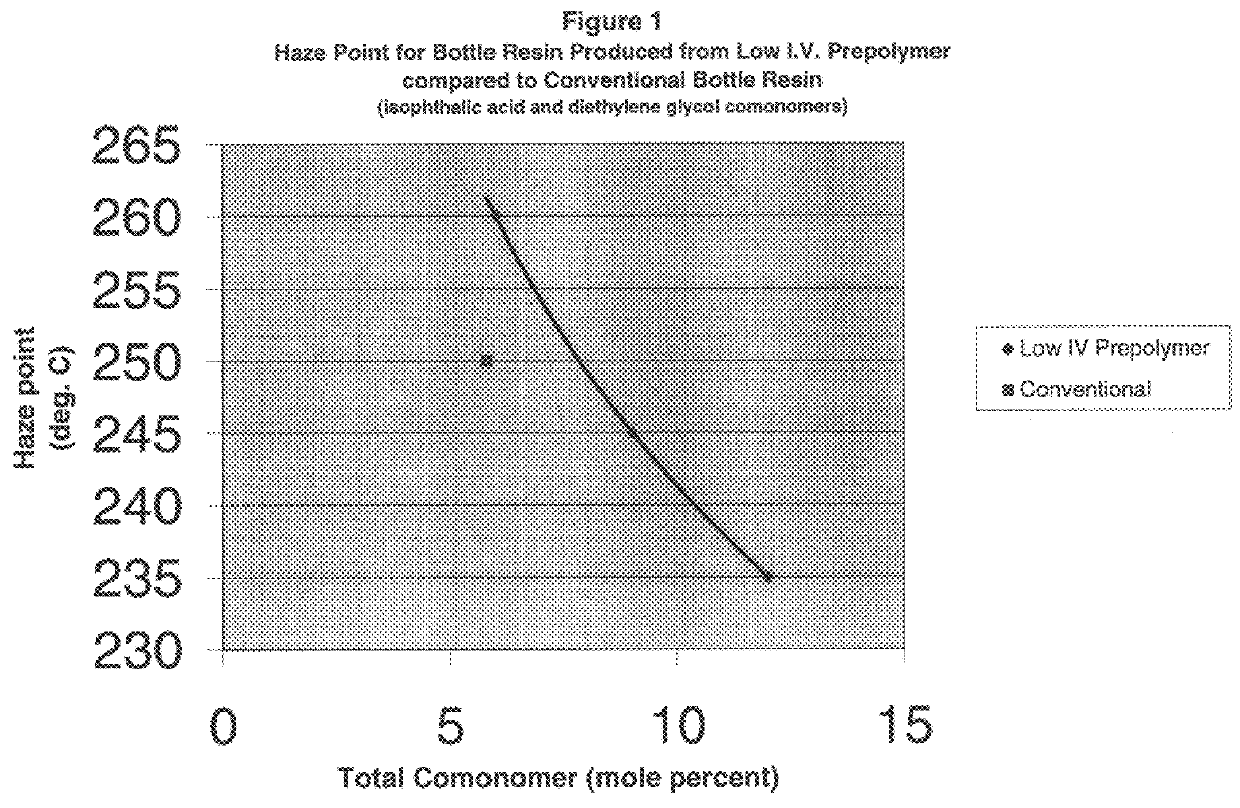

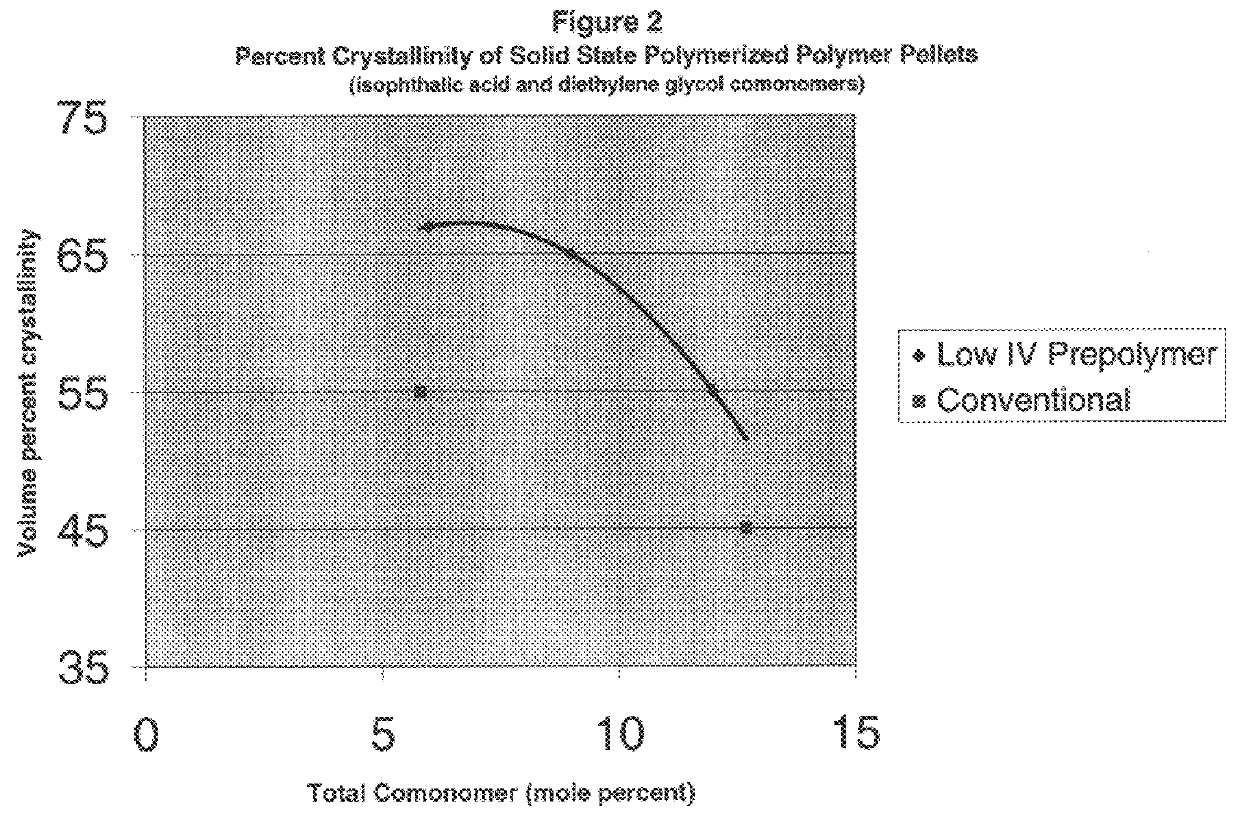

InactiveUS6284866B1Low haze pointLess heatBottlesSynthetic resin layered productsDimethyl terephthalatePolyethylene terephthalate

The present invention is a method of preparing a high molecular weight copolyester bottle resin that has excellent melt processing characteristics. The method includes the steps of reacting a diacid or diester component and a diol component to form modified polyethylene terephthalate, wherein diol component is present in excess of stoichiometric proportions. Together, the diacid or diester component and the diol component must include at least 7 percent comonomer. The remainder of the diacid component is terephthalic acid or dimethyl terephthalate and the remainder of the diol component is ethylene glycol. The modified polyethylene terephthalate is copolymerized in the melt phase to an intrinsic viscosity of between about 0.25 dl / g and 0.40 dl / g to thereby form a copolyester prepolymer. Thereafter the copolyester prepolymer is polymerized in the solid phase to form a high molecular weight bottle resin that has an intrinsic viscosity of at least about 0.70 dl / g, and a solid phase density of less than 1.413 g / cc.

Owner:WELLMAN INC

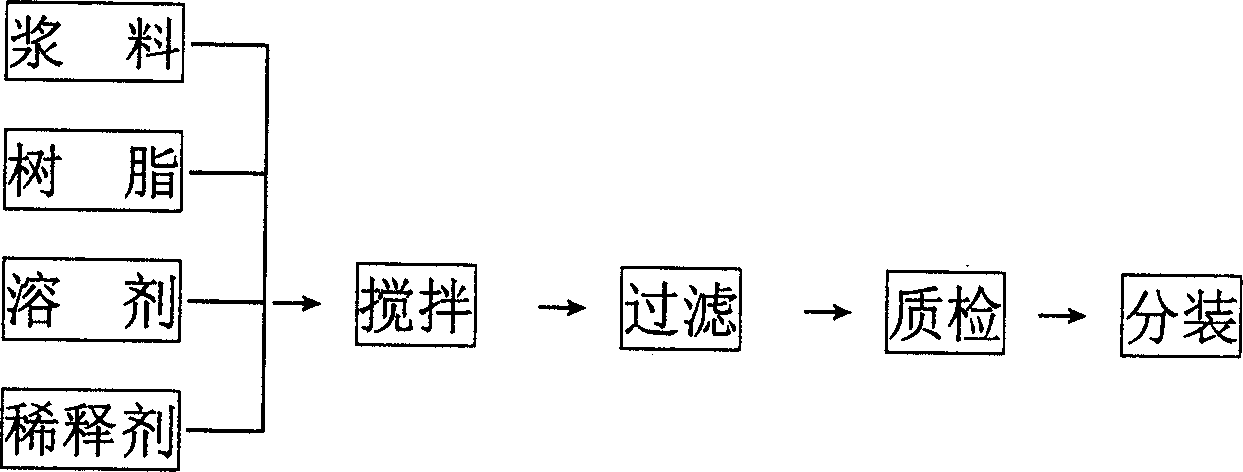

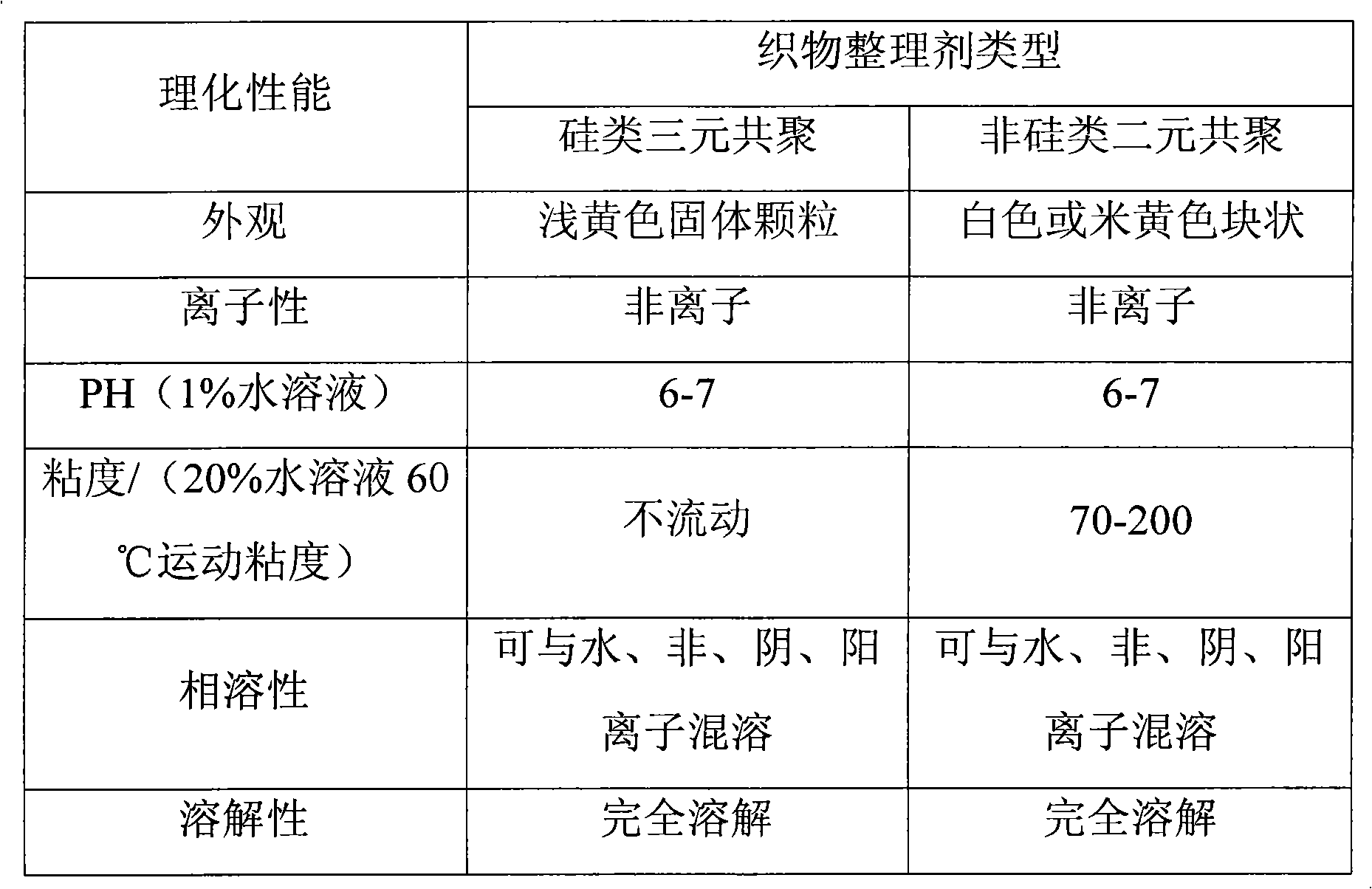

Moisture absorption perspiration-discharging dressing agent and its manufacturing technique and application

ActiveCN101265664AGood moisture absorption and perspirationGood modification effectFibre typesDyeing processFiberPolyester

The invention discloses the formula, the production process and the application of moisture absorbent and sweat conductive comfortable finishing agent which is used for modifying the polyester fiber to enable the polyester fiber to have moisture absorbent and sweat conductive capabilities. The formula of the moisture absorbent and sweat conductive comfortable finishing agent contains: polyethylene glycol, ethylene glycol, polyether and dimethyl terephthalate. The two-step continuous production process is adopted: in the first step of esterifying, polyethylene glycol, ethylene glycol, polyether and dimethyl terephthalate are put into a reaction vessel for esterification under the action of catalysts; and in the second step that the material produced after the esterification is transported to a polymerization kettle for polymerization under the actions of high temperature, vacuum, and catalysts, in order to generate polyester-polyether copolymer with high molecular weight to be 30000-50000, namely, the moisture absorbent and sweat conductive comfortable finishing agent. The moisture absorbent and sweat conductive comfortable finishing agent can be directly used or be used after being mixed with substances such as amino silicone oil and so on, and carry out chemical modification on the polyester fiber.

Owner:DUPLUS CHEM OF ZHANGJIAGANG CITY

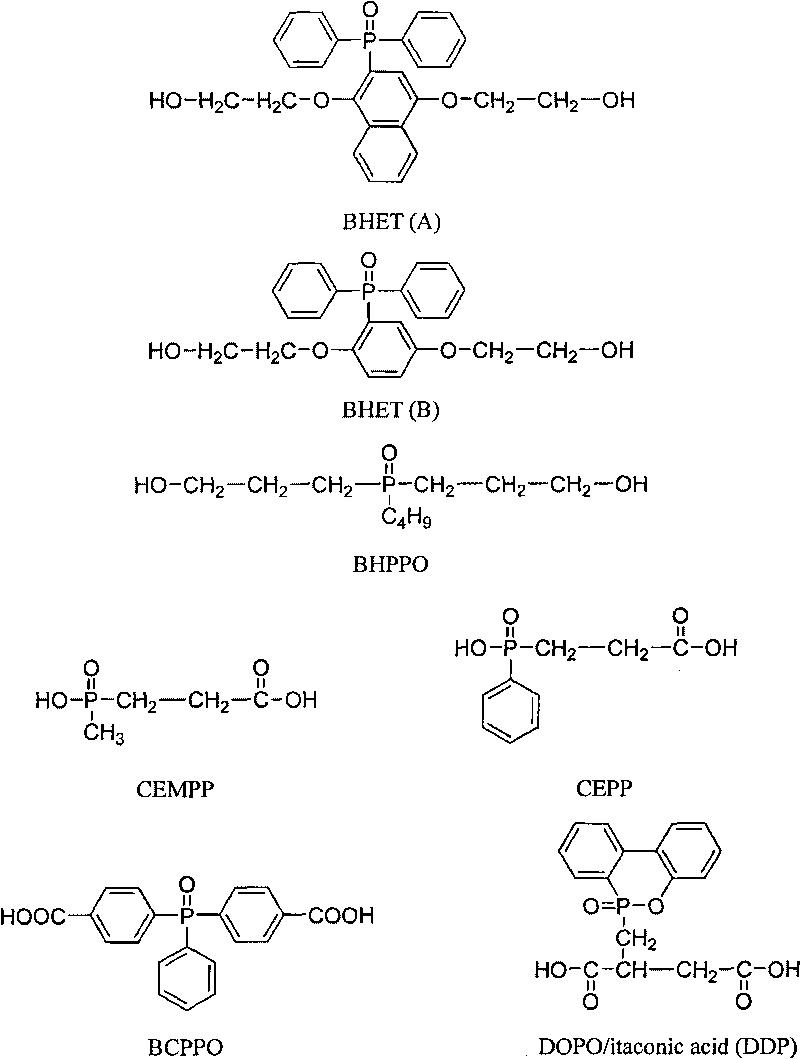

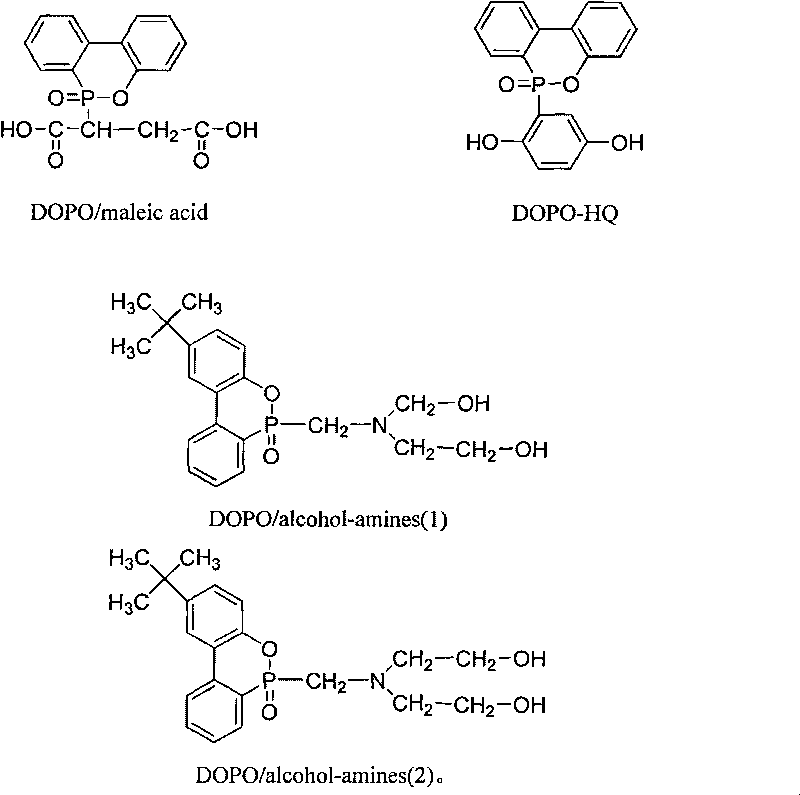

Phosphorus-contained flame-retarding nano-class ethanediol polyterephthalate/laminated silicate composition and its preparing process and application

InactiveCN1396206AImprove mechanical propertiesMeet practical requirementsFiberDimethyl terephthalate

A P-contained flame-retarding ethanediol polyterephthalate / laminar silicate composition is prepared from dimethyl terephthalate (or terephthalic acid), ethanediol, laminar silicate, P-contained flame retardant, intercalator, dispersing medium and catalyst. Its advantages are high mechanical properties and refractory nature, and simple preparing process.

Owner:SICHUAN UNIV

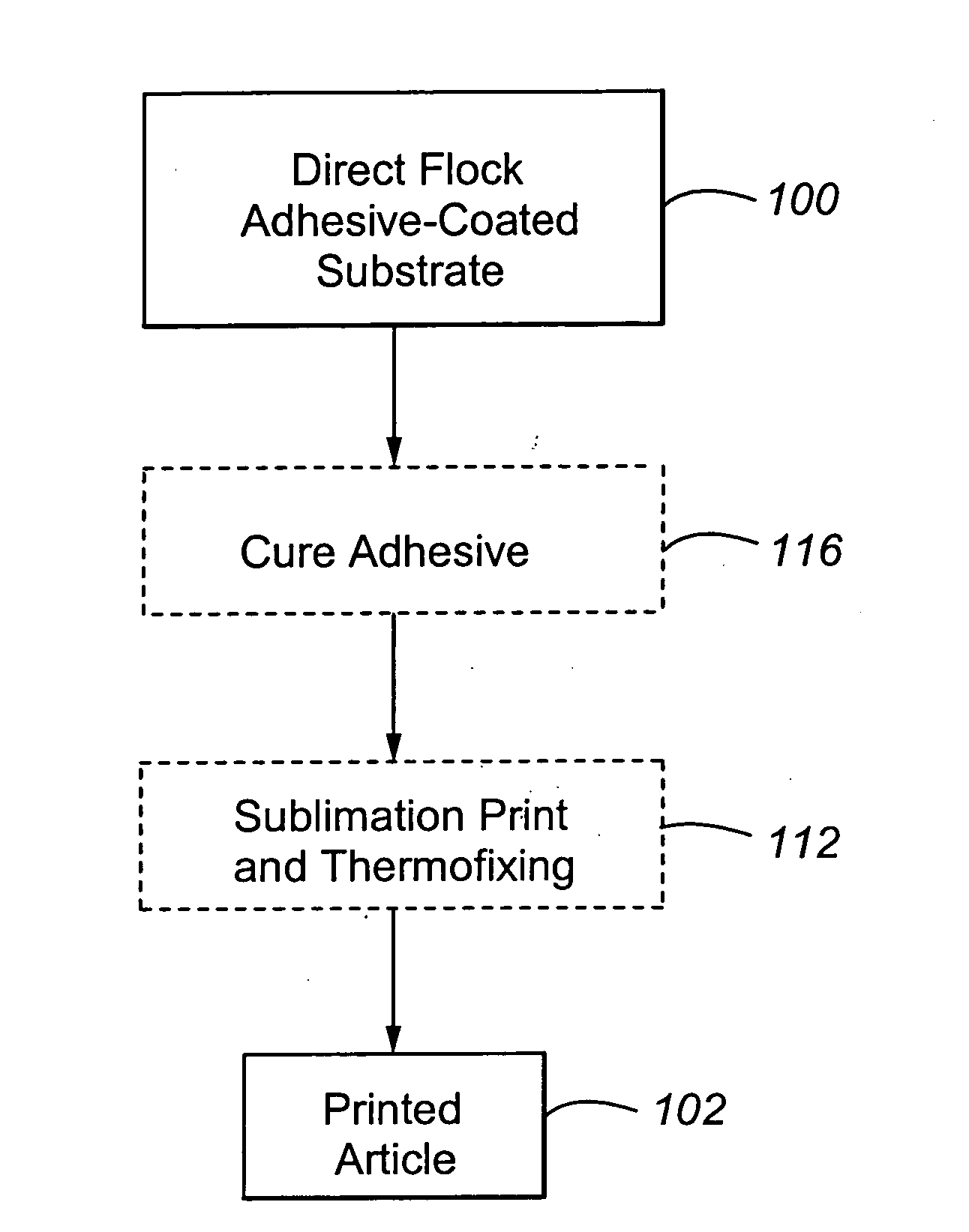

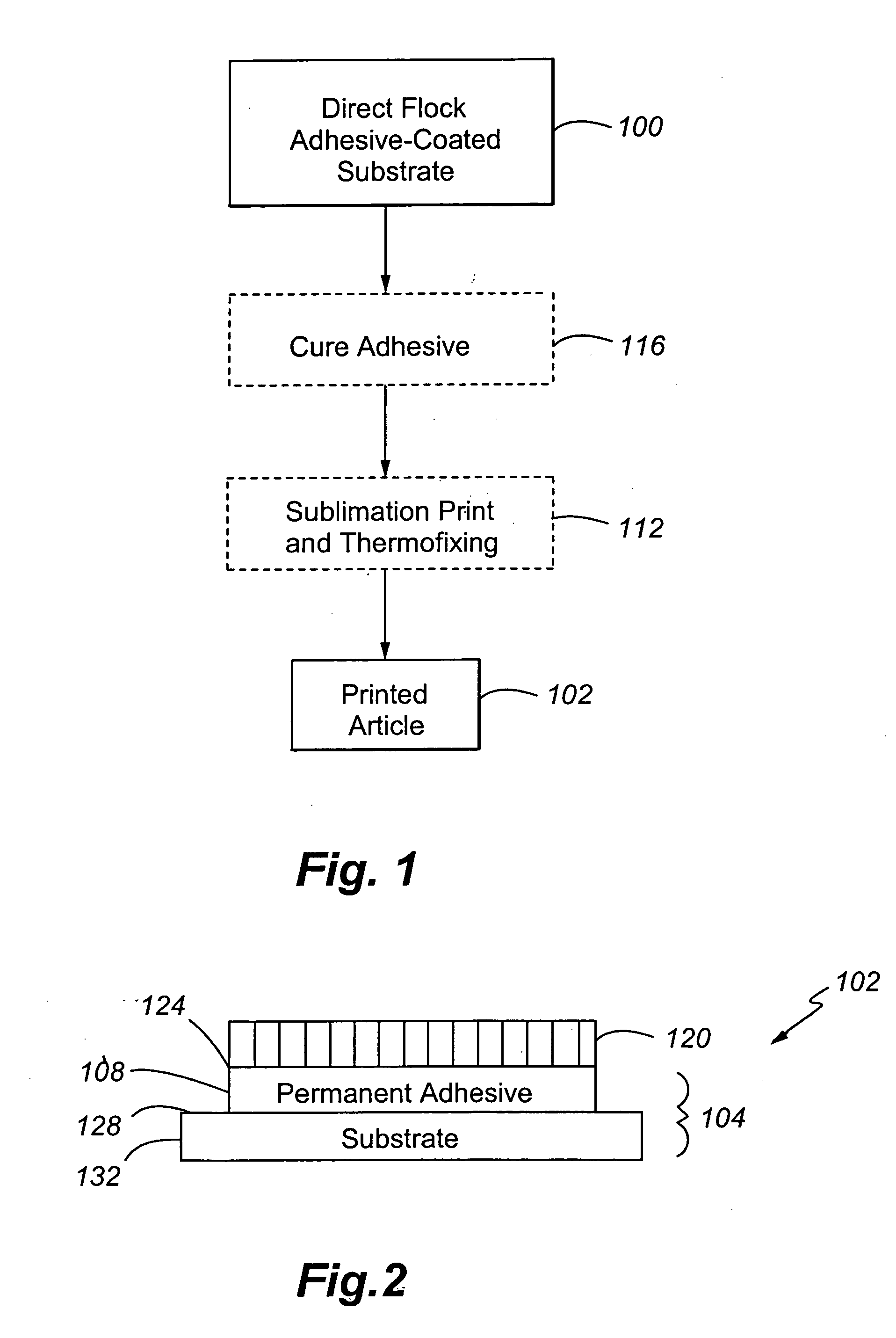

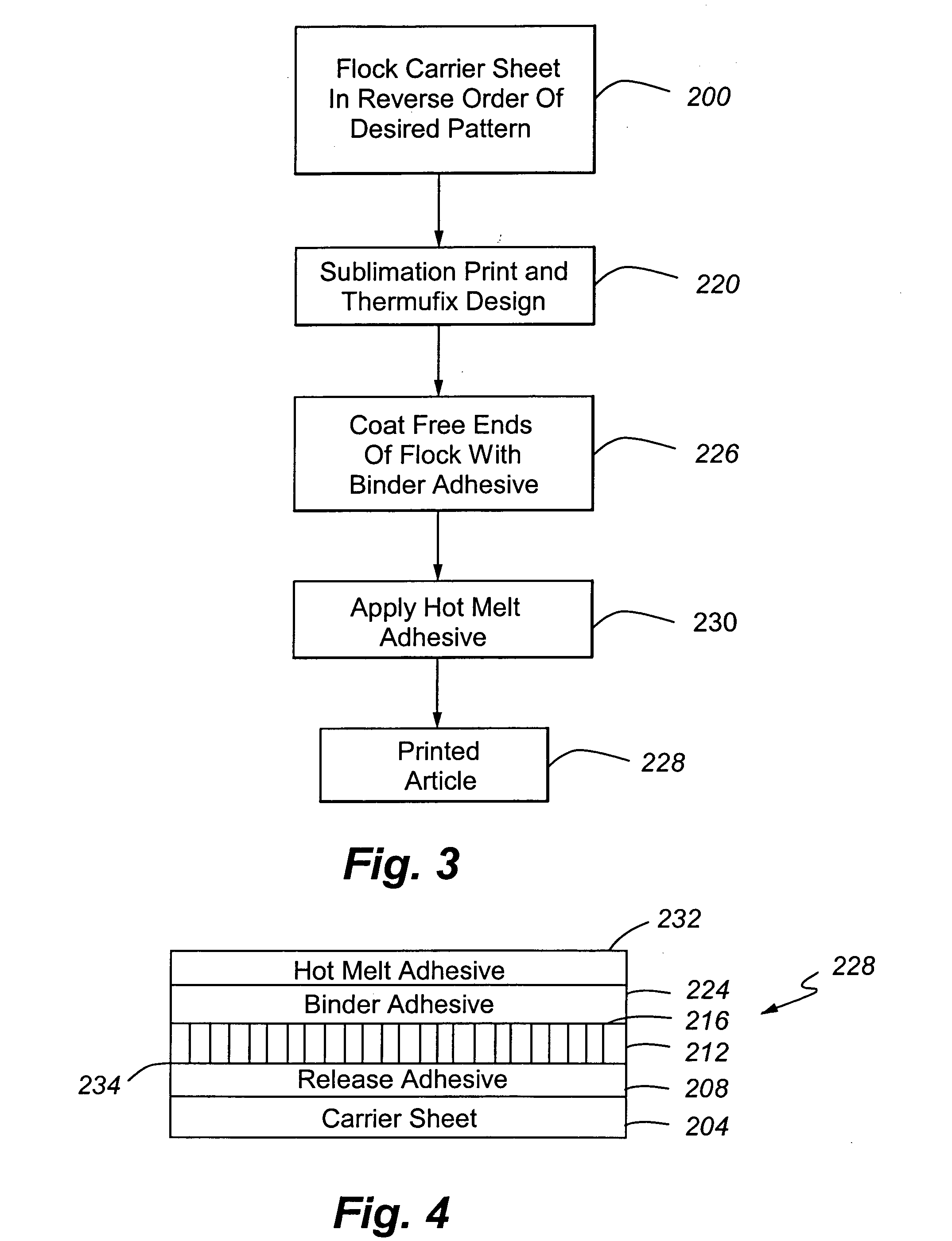

Process for high and medium energy dye printing a flocked article

InactiveUS20050268407A1Maintain loftStay flexibleTransfer printing processDyeing processDimethyl terephthalateFiber

The processes and articles of the present invention use thermally stable and loft retentive polymers in sublimation printed flock fibers, which are particularly attractive for forming molded and heat laminated articles. The process and articles use high, medium and low energy dyes on the fibers. A preferred polymer for use in the fibers is poly(cyclohexylene-dimethylene terephthalate).

Owner:ABRAMS LOUIS BROWN

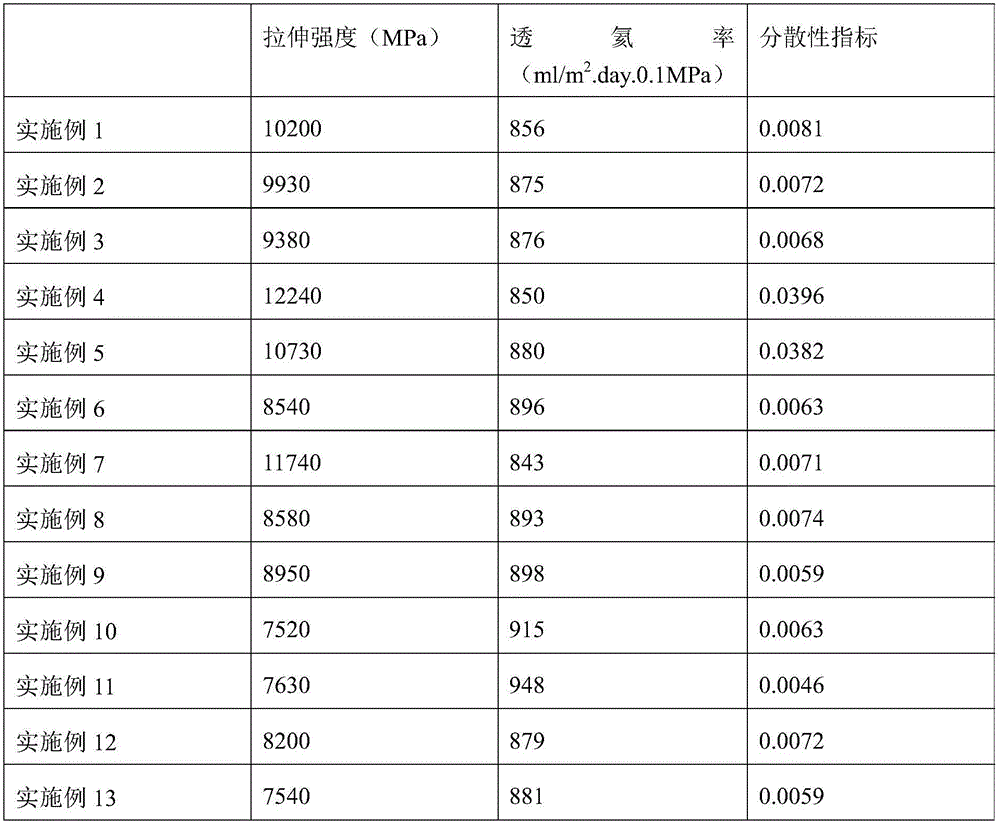

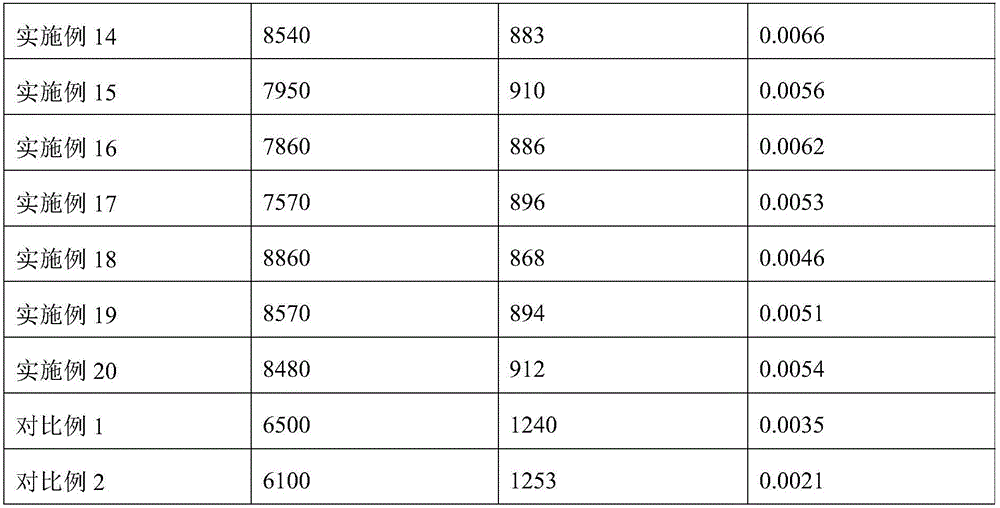

PET-based graphene composite material, preparation method thereof, and aerostat

ActiveCN105820519AGood dispersionImprove barrier propertiesRigid airshipsDimethyl terephthalateIn situ polymerization

Owner:LUOYANG INST OF CUTTING EDGE TECH +1

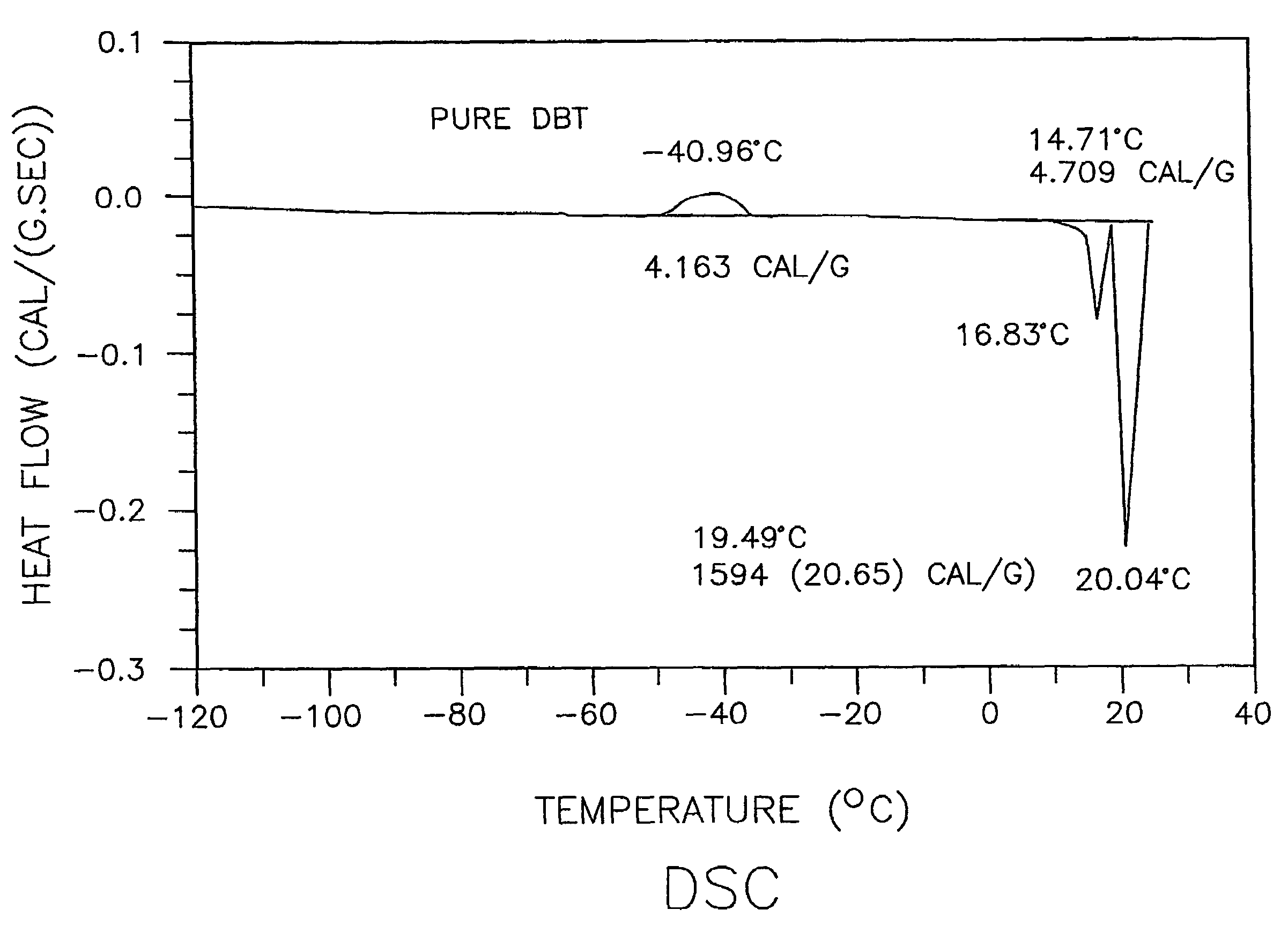

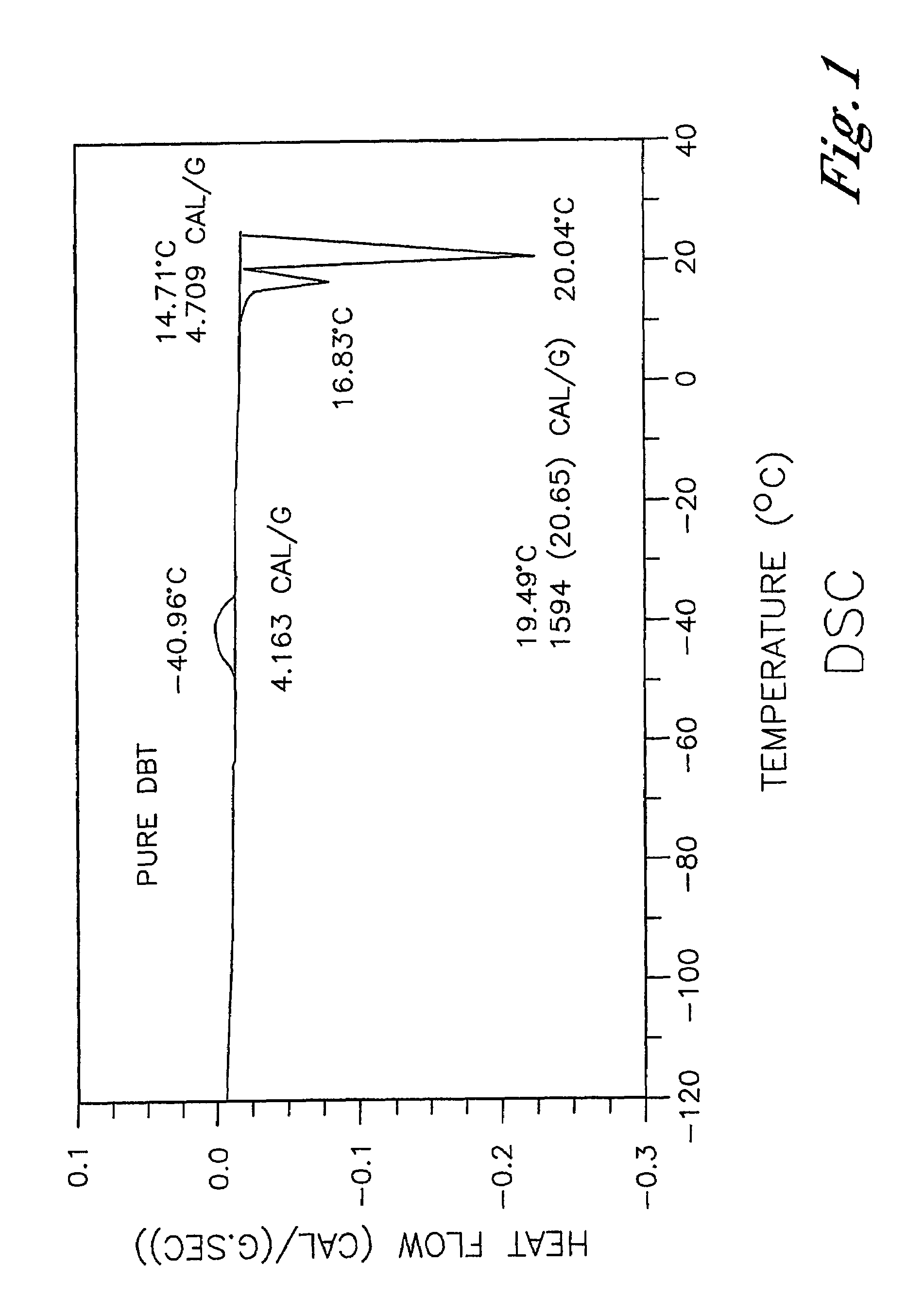

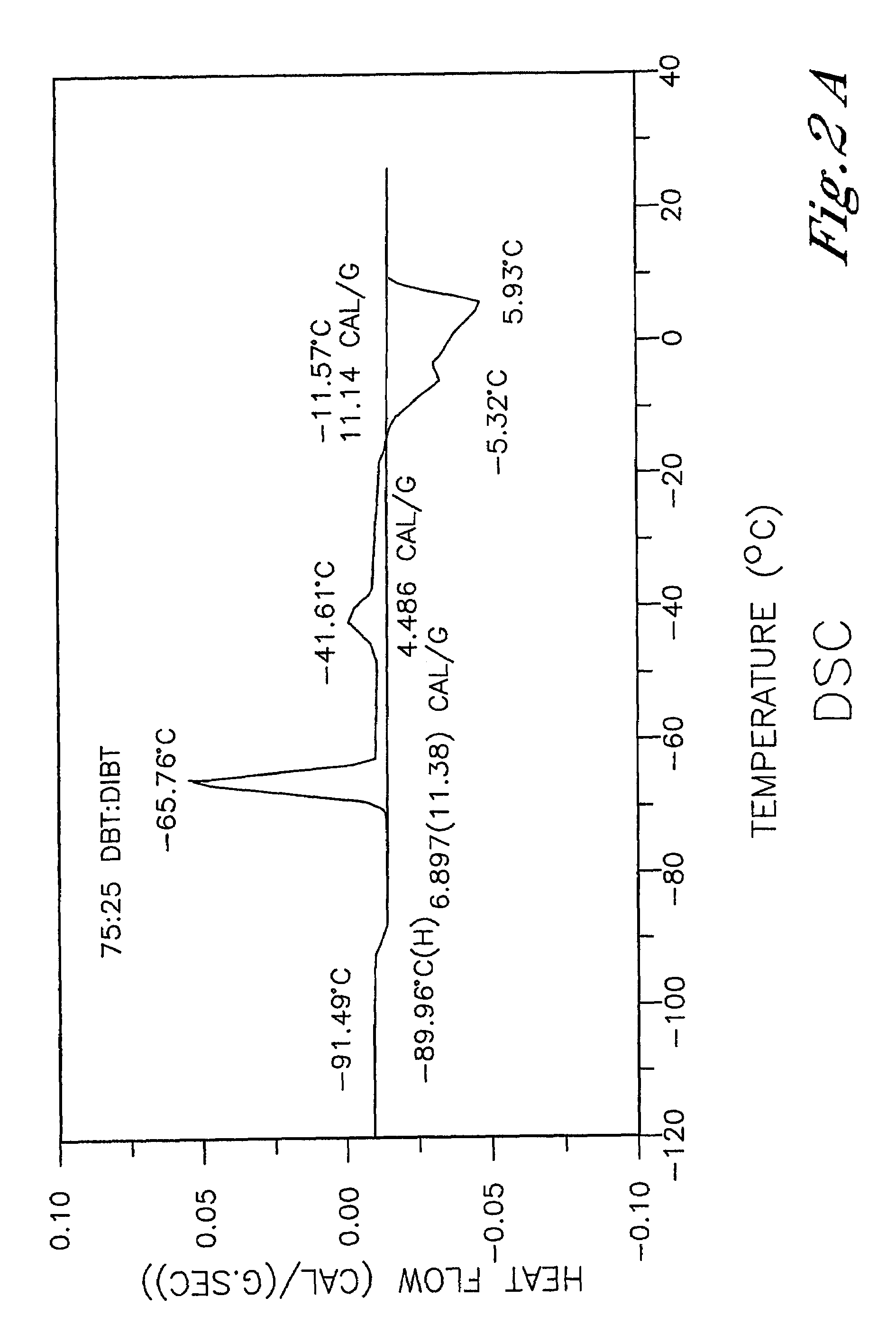

Low-melting mixtures of di-n-butyl and diisobutyl terephthalate

ActiveUS7361779B1Organic compound preparationCarboxylic acid esters preparationDimethyl terephthalateAlcohol

Mixtures of terephthalate diesters having lowered freezing points and methods of making the terephthalic acid diesters. The method includes contacting a first alcohol, a second different alcohol and dimethyl terephthalate in the presence of a catalyst to thereby form the terephthalate diesters.

Owner:EASTMAN CHEM CO

Phosphorus-containing PTT fire-resistant copolyesters/ nano composite material and preparation method thereof

ActiveCN101709137AAvoid the problemsImprove flame retardant performanceIn situ polymerizationIntrinsic viscosity

The invention discloses a phosphorus-containing PTT fire-resistant copolyesters / nano composite material which is formed after carrying out in-situ polymerization on terephthalic acid or dimethyl terephthalate, 1,3-propanediol, a phosphorus-containing fire-resistant monomer and inorganic nano-particles, wherein the phosphorus-containing fire-resistant monomer accounts for 1-20 percent of the fire-resistant copolyesters in weight, the inorganic nano-particles account for 0.1-15 percent of the fire-resistant copolyesters in weight, and the intrinsic viscosity of the composite material is 0.5-2.0dL / g. The invention also discloses a preparation method thereof. Because the phosphorus-containing fire-resistant monomer is a reactive flame retardant and the nano-particles are added in an in-situ composite way, the composite material has enhanced fire resistance and mechanical property and obtains higher molecular weight by further solid phase polymerization. The invention has simple technical operation, low cost and easy application.

Owner:SICHUAN UNIV

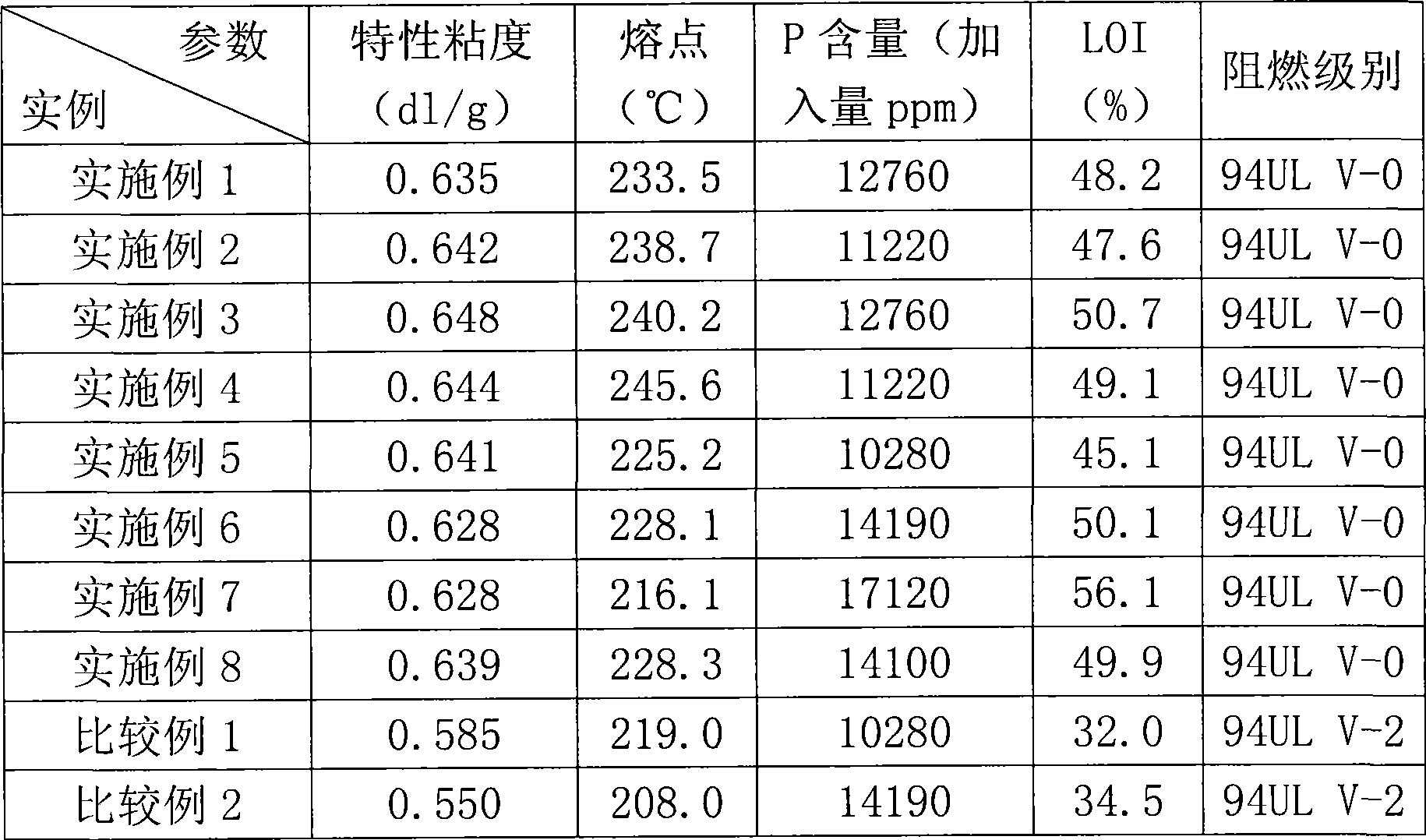

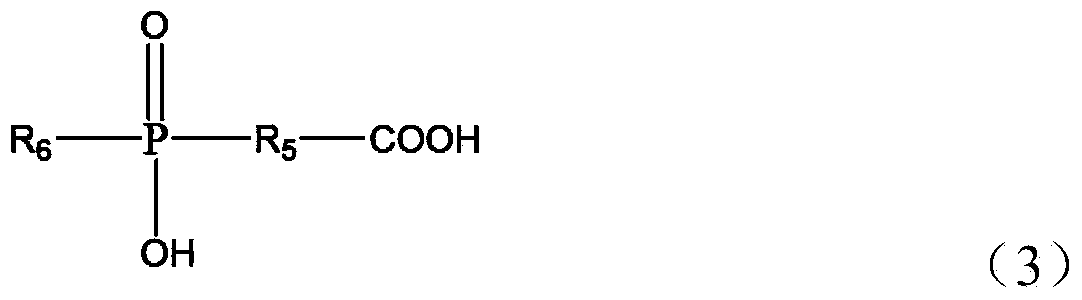

Method for preparing phosphor system halogen-free flame-proof copolymerization polyester

ActiveCN101508770AImprove responseIncrease the amount of effective additionFiberDimethyl terephthalate

The invention relates to a method for preparing phosphorus halogen-free flame retardant copolyester. The method is characterized in that halogen-free phosphoric copolymerized flame retardant and glycol are mixed to carry out esterification reaction for 4 to 6 hours under the temperature of 140-210 DEG C and the pressure of 40-70Kpa and then are filtered; flame-retardant esterified product solution is prepared from the filtrate; dimethyl terephthalate, the glycol and promoter are mixed to carry out ester exchange reaction for 2 to 4 hours under the temperature of 160-240 DEG C; after the reaction, the flame-retardant esterified product solution is added, and catalyst and stabilizing agent are added to carry out polyreaction for 2.5 to 4 hours under the temperature of 240-290 DEG C and the pressure of 100Pa; and the phosphorus halogen-free flame retardant copolyester is prepared after discharging the material. Polyester slice can be used as raw material for producing film with flame retardance of grade 94UL V-O or grade VTM-O (collectively called grade VO), flame retardant fibre with flame retardance of grade I or above and grade VO flame retardant plastic product, and the polyester slice has excellent flame retardance.

Owner:四川东方绝缘材料股份有限公司

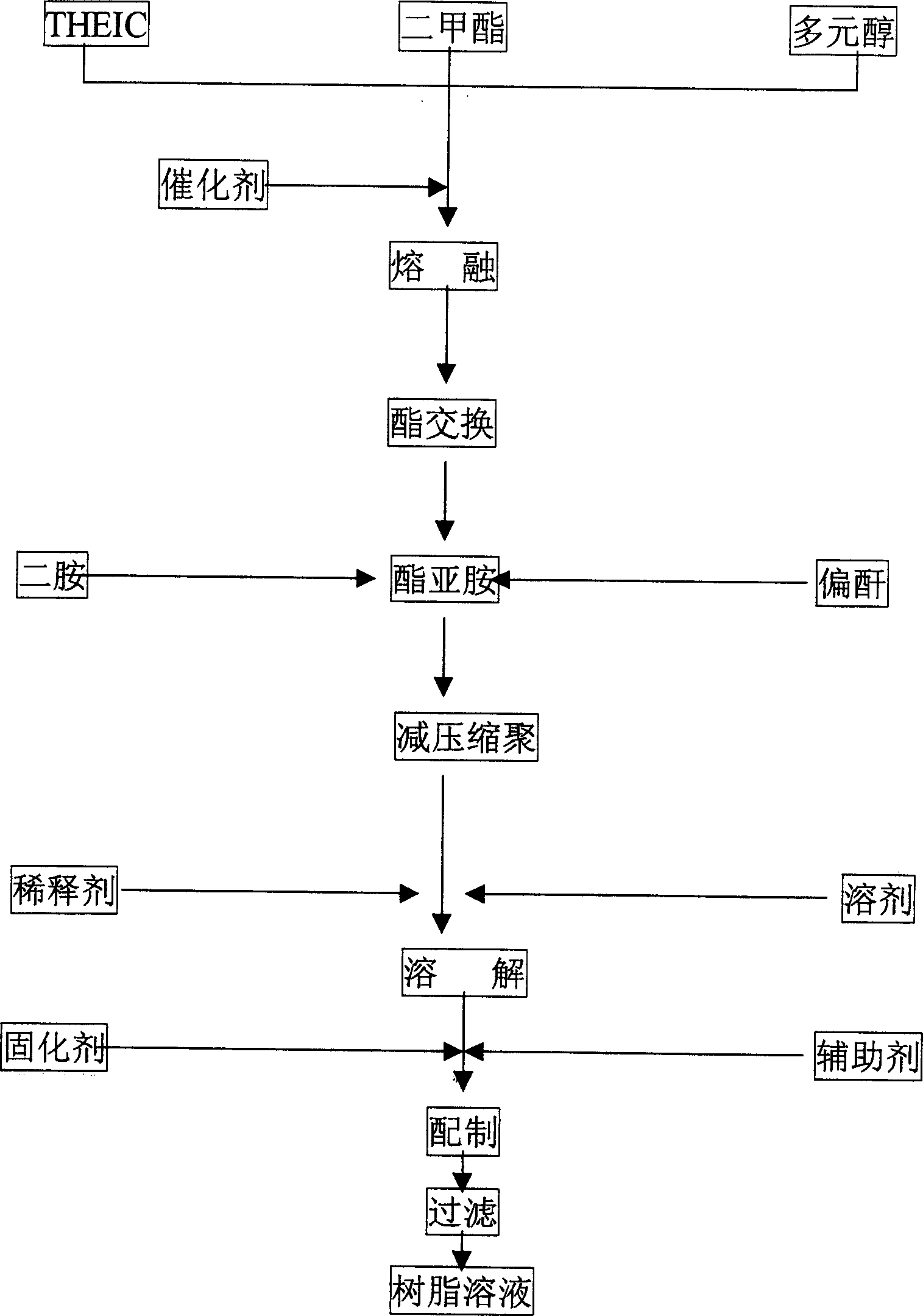

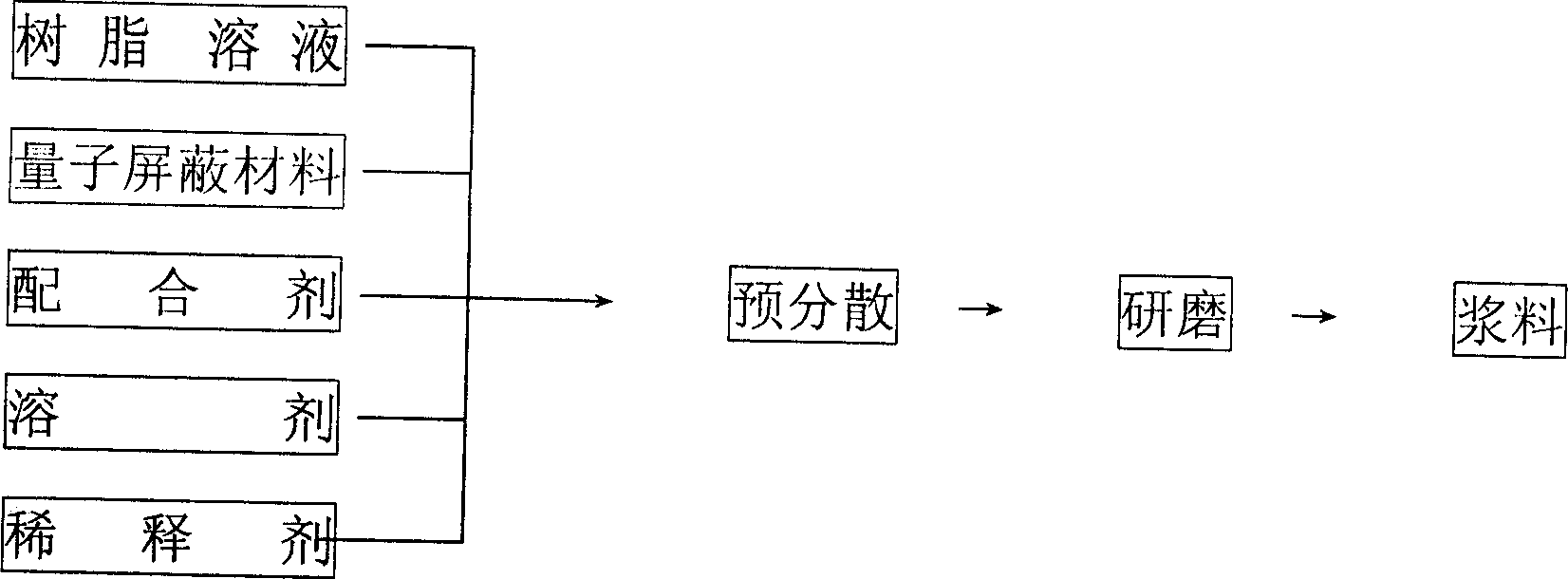

Method for preparing copolyether ester elastomer

The invention discloses a method for preparing copolyether ester elastomer. The method comprises the following steps of mixing aromatic binary acid, polyether glycol and micromolecule glycol to carry out an esterification reaction, removing by-products of tetrahydrofuran and water to obtain carboxylate after the reaction is finished; transferring the obtained carboxylate into a pre-polycondensation reactor, adding an antioxidant and a catalyst to react for 1-2 hours, so as to obtain a prepolymer; transferring the prepolymer to a polycondensation kettle, wherein the polymerization time is 1.5-3 hours and the pressure is 100-200Pa; and obtaining the copolyether ester elastomer after the reaction is finished. By adopting the method disclosed by the invention, the copolyether ester elastomer is prepared from terephthalic acid as a raw material; the cost is low; and the by-product tetrahydrofuran generated by reaction is rectified and purified to obtain the high-purity tetrahydrofuran. The method has no negative effect on the cost of synthetizing TPEE (thermoplastic polyeher ester elastomer); the performance of the synthetized copolyether ester elastomer is consistent with that of the product prepared from dimethyl terephthalate.

Owner:KINGFA SCI & TECH CO LTD +1

Corona resistant enamel-covered wire paint for variable frequency motor and preparing process thereof

InactiveCN1488697AImprove insulation performanceImprove performanceChemical industryInsulated cablesDimethyl terephthalatePolyester

Owner:上海汉邦化工有限公司

Preparation method of cationic dyeable flame-retardant polyester resin

The invention discloses a preparation method of cationic dyeable flame-retardant polyester resin. The manufacturing method is characterized by comprising the following steps: performing an esterification reaction on a halogen-free copolymerized phosphorus-based flame retardant, ethylene glycol and a composite catalyst to prepare an esterification solution of the halogen-free copolymerized flame retardant; performing ester exchange reaction on sulfoisophthalic acid dimethyl ester and the ethylene glycol to prepare a sulfonate-based bis(hydroxyethyl) isophthalate solution; performing an esterification reaction on terephthalic acid (or dimethyl terephthalate), the ethylene glycol and auxiliaries, then adding a catalyst, a stabilizer, the auxiliaries, the esterification solution of the phosphorus-based flame retardant (or a prepolymer solution of the phosphorus-based flame retardant) and the sulfonate-based bis(hydroxyethyl) isophthalate solution, performing condensation polymerization reaction, and cooling and dicing after the end of reaction to prepare the cationic dyeable flame-retardant polyester resin. The cationic dyeable flame-retardant polyester resin prepared by the method disclosed by the invention has the characteristics of good spinnability, polyester fiber cationic dye boiling dyeing under normal pressure conditions, complete chromatogram and strong dye adhesion.

Preparation of biodegradable block copolyester

The invention belongs to the technical field of macromolecular materials, and in particular relates to a preparation method for biodegradable blocked copolyester. The preparation method comprises the following steps: carrying out esterification reaction between adipate and 1,4 butanediol in the presence of catalyst, wherein the reaction time is 3 to 5h, nitrogen is adopted for protection, the reaction pressure is between 0.1 and 0.8MPa and the reaction temperature is between 130 and 180 DEG C during a first stage; and the reaction time is 1.5 to 5h, the reaction pressure is between 0.3 and 0.6MPa and the reaction temperature is between 150 and 200 DEG C during a second stage so as to generate polybutylene adipate; and carrying out ester exchange reaction of dimethyl terephthalate (DMT) and 1,4 butanediol in the presence of catalyst, wherein the nitrogen is adopted for protection, the reaction time is 2 to 5h, the reaction pressure is between 0.1 and 0.7MPa and the reaction temperature is between 150 and 170 DEG C so as to generate polybutylene terephthalate (pbt); and mixing both prepolymers and carrying out melt copolycondensation reaction under negative pressure, wherein the vacuum degree is controlled to be between 0 and 200Pa, the reaction temperature is between 210 and 260 DEG C and the reaction time is 3 to 8h. The preparation method carries out esterification reaction and ester exchange reaction, and the esterification reaction has two stages so as to effectively reduce secondary reaction of 1,4 butanediol. A prepared product has a characteristic viscosity number above 1.2dl / g, a melting point controlled between 100 and 140 DEG C, a tensile strength between 18 and 37MPa and a breaking elongation ratio from 800 to 1,500 percent.

Owner:TONGJI UNIV

Method for applying moisture control agent in fabric dyeing process

InactiveCN101798760AGood moisture wicking effectImprove antistatic performanceFibre typesDyeing processTO-18Fiber

The invention discloses a method for applying a moisture control agent together with dye in the same bath in a fabric dyeing process, which is characterized in that: the dye is added in the fabric dyeing process, and meanwhile the moisture control agent accounting for 0.1 to 5 percent of the weight of the fabric is also added, namely the moisture control agent and the dye are used in the same bath. The moisture control agent comprises the following components in part by weight: 80 to 100 parts of polyethylene glycol, 10 to 15 parts of ethylene glycol, 10 to 14 parts of polyether, 15 to 18 parts of dimethyl terephthalate and 0.2-1 part of metal acetate serving as a catalyst. The method can be widely applied to the dyeing process of the polyester fiber fabric.

Owner:DUPLUS CHEM OF ZHANGJIAGANG CITY

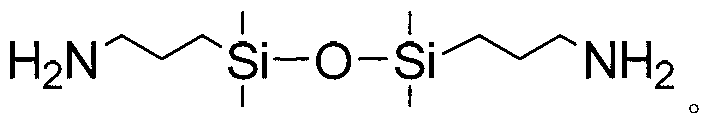

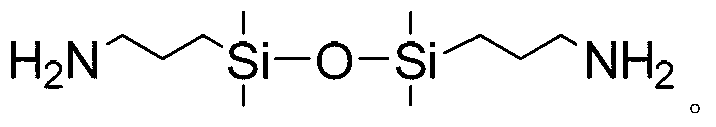

High-temperature leveling agent, and preparation method and application thereof

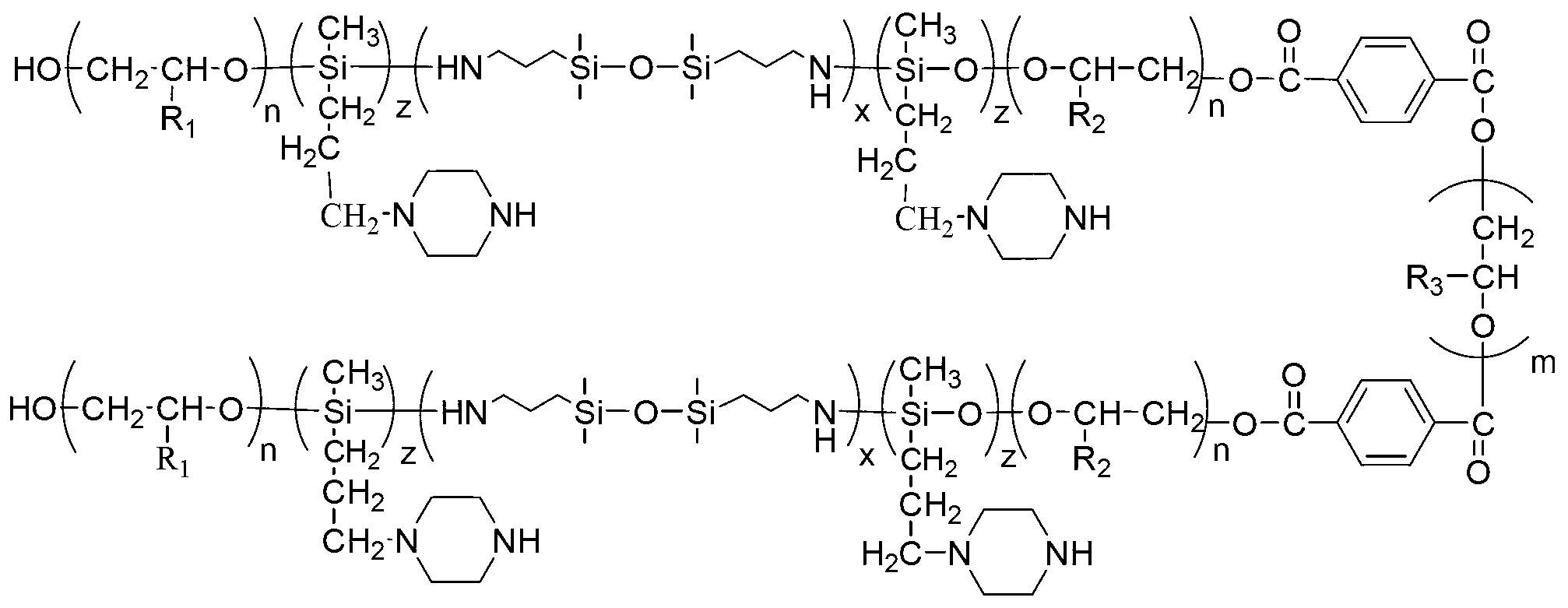

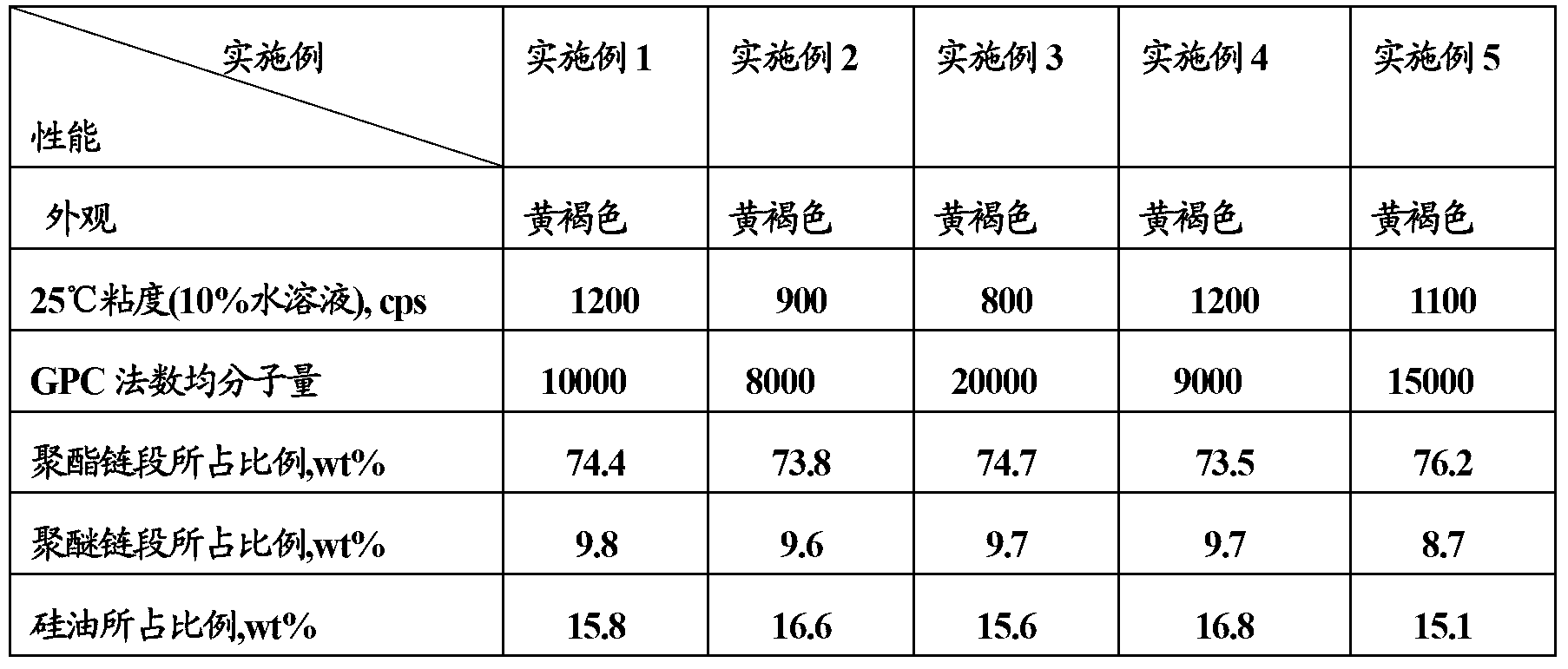

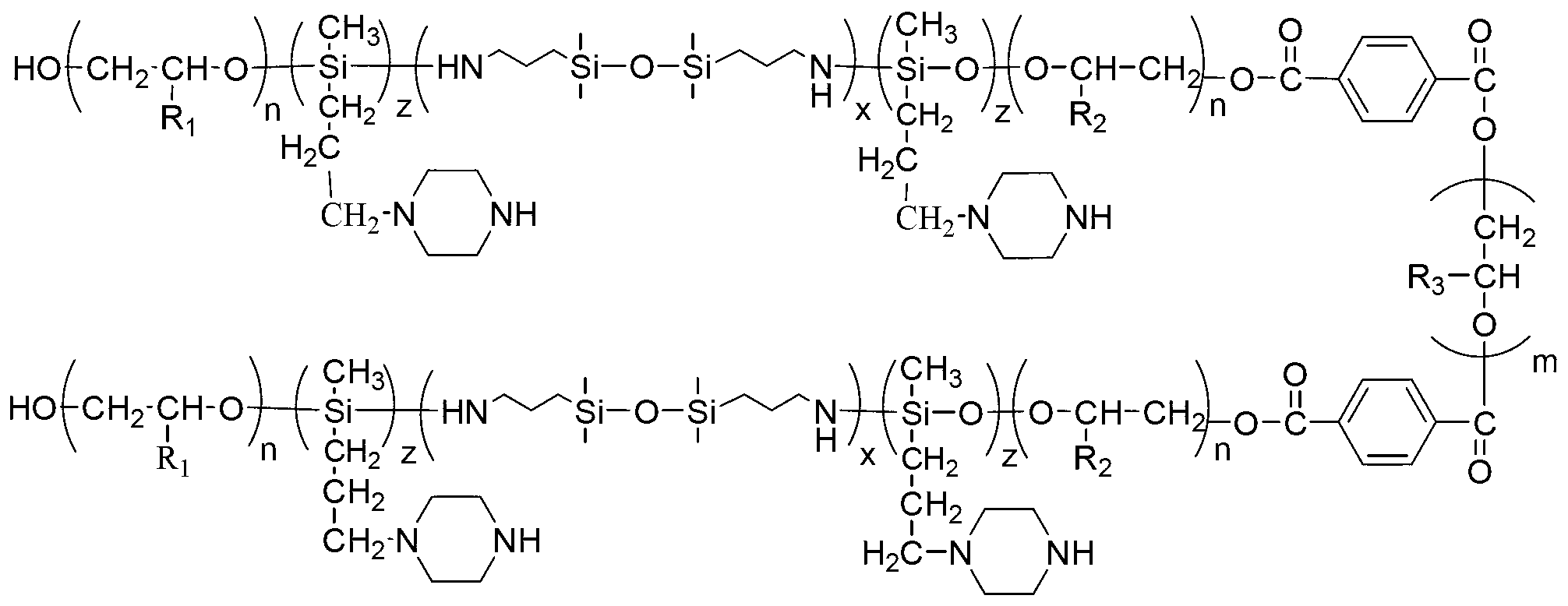

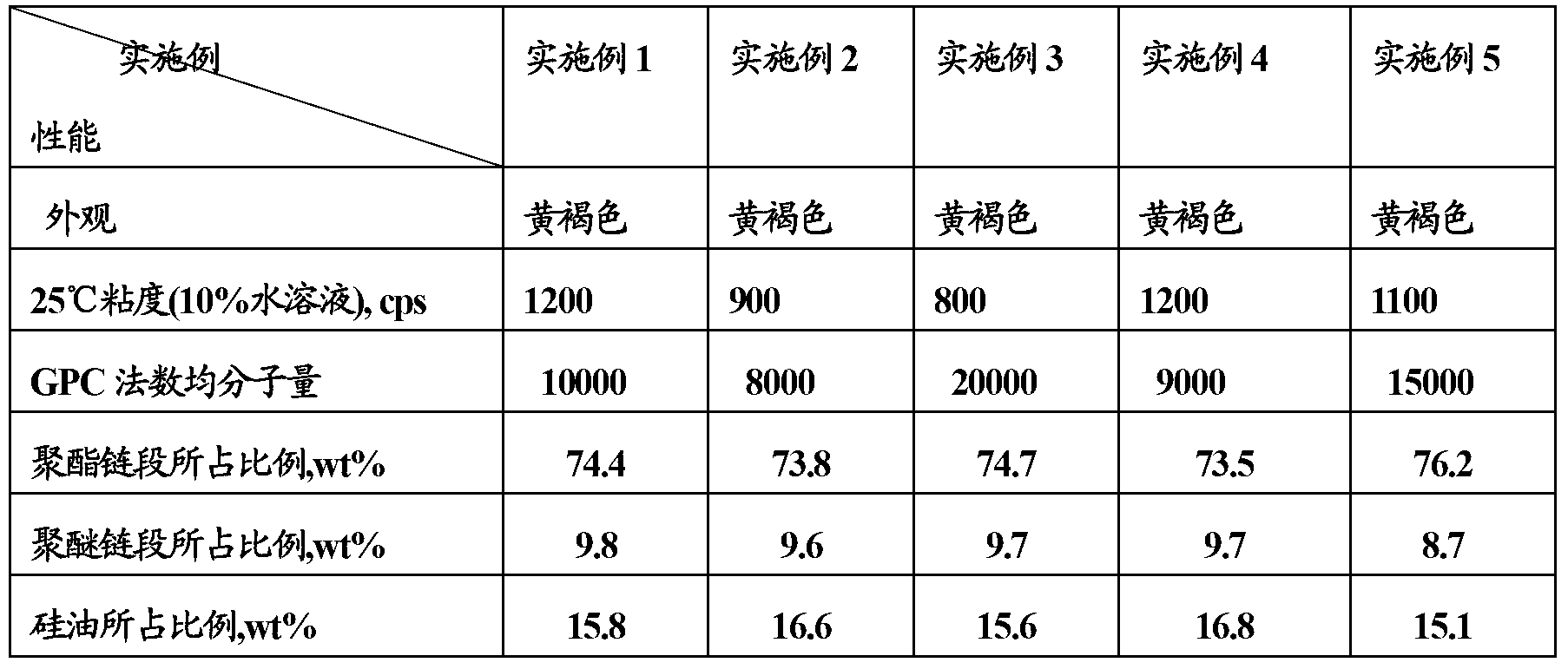

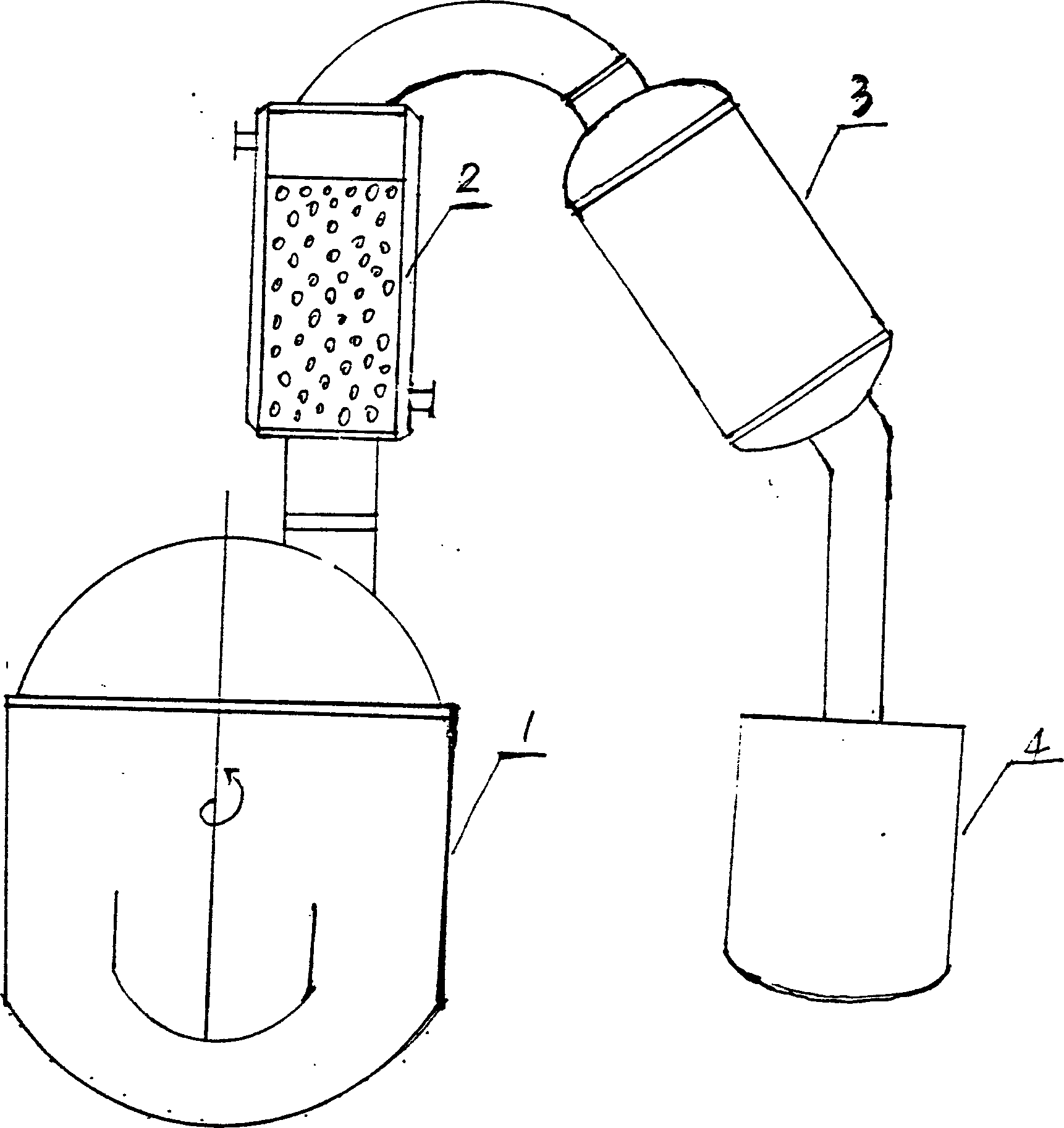

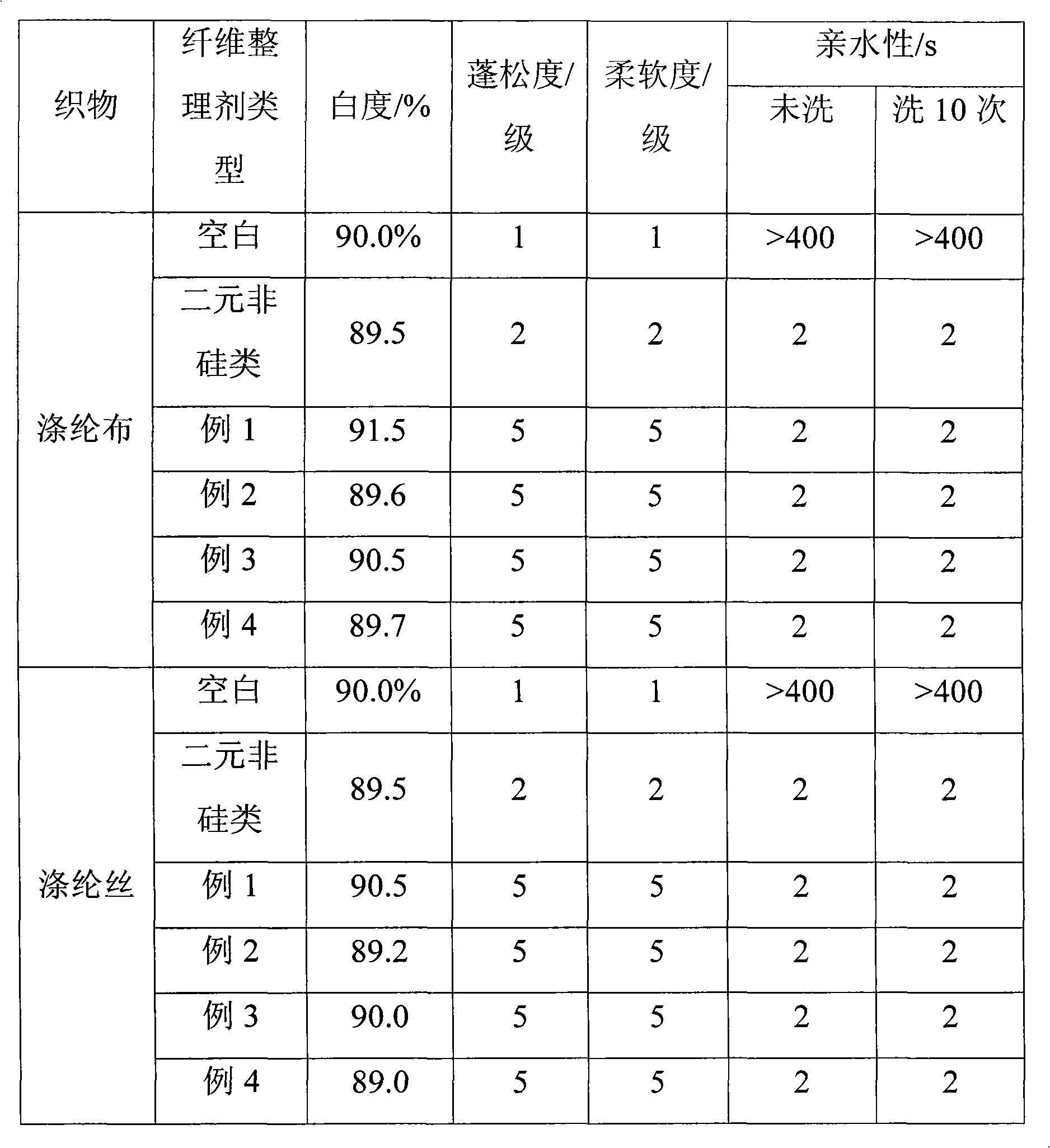

The invention relates to a high-temperature leveling agent, and a preparation method and an application thereof. The high-temperature leveling agent is prepared from 0.1-1% of a polyester-polyether-silicon oil block copolymer, 9-10% of polyethylene glycol monostearate, and balance of water. The polyester-polyether-silicon oil block copolymer is prepared from the raw materials of, by weight: 120-160 parts of polyethylene glycol, 18-30 parts of glycol, 15-25 parts of dihydroxy polyether, 20-28 parts of dimethyl terephthalate, 10-30 parts of an amino-terminated double-head sealant organosilicon, 5-10 parts of 3-piperazine propyl dimethoxysilane, and 0.2-2 parts of metal acetate. With the high-temperature leveling agent provided by the invention, dyeing quality of polyester fiber or fabric thereof can be improved, and the dyed polyester fiber or fabric thereof is provided with excellent fluffy and soft property, good antistatic performance, and good hydrophilic property. The dyed polyester or fiber thereof can be provided with excellent comfortableness with no other finishing.

Owner:DUPLUS CHEM OF ZHANGJIAGANG CITY

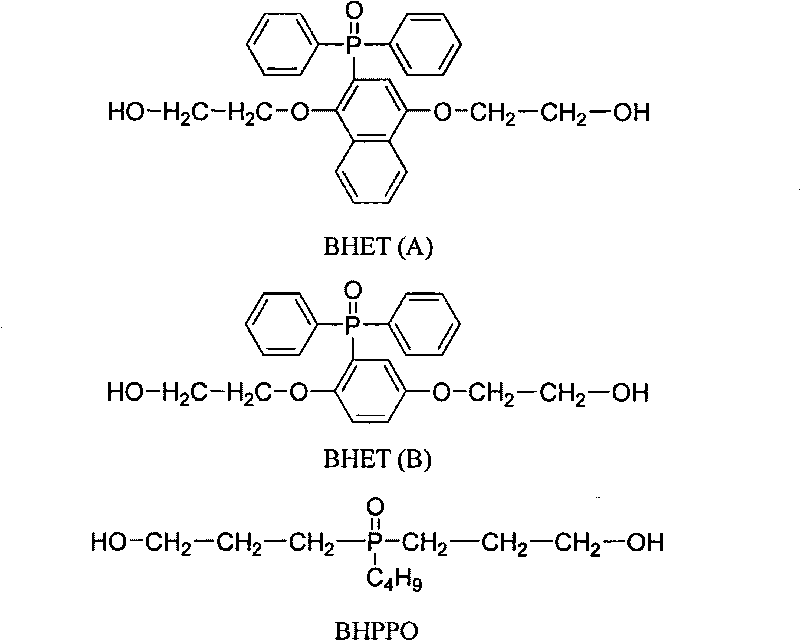

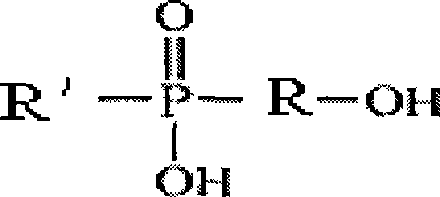

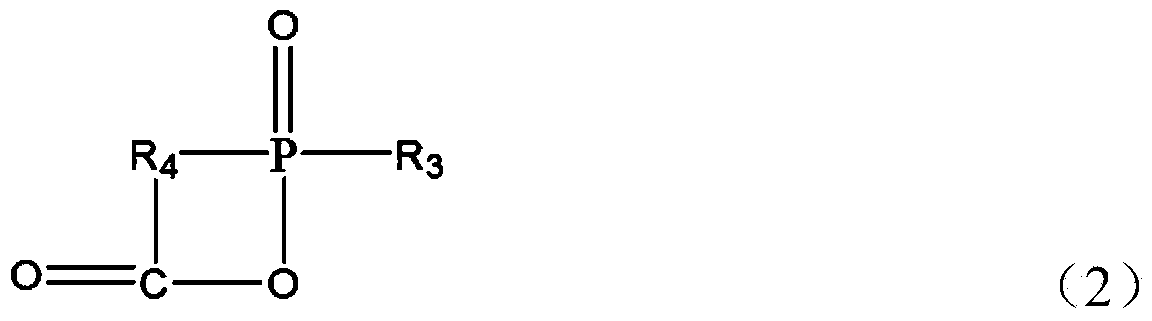

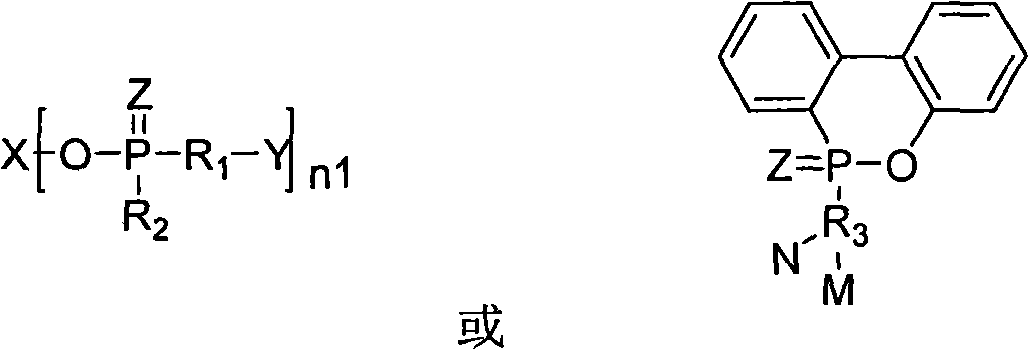

Droplet-resistant flame-retardant polyester, nanometer compound material thereof and method for preparing same

The invention discloses droplet-resistant flame-retardant polyester. The flame-retardant polyester is prepared by random copolymerization of a branched monomer, terephthalic acid or dimethyl terephthalate, ethylene glycol and flame-retardant monomer, wherein the branched monomer is an aliphatic compound or aromatic compound having three or more functional groups; and the flame-retardant monomers adopts any of the following structures. The invention also discloses a method for preparing the droplet-resistant flame-retardant polyester, a nanometer compound material containing the droplet-resistant flame-retardant polyester and a method for preparing the nanometer compound material. Because the droplet-resistant flame-retardant polyester provided by the invention simultaneously contains the branched monomer and the fire retardant having the droplet-resistant effect, the melt viscosity of the droplet-resistant flame-retardant polyester at the high temperature is greatly improved, the sensitivity of the droplet-resistant flame-retardant polyester to temperature is lowered, and the droplet-resistant effect is good; because of the nanometer effect and the blocking effect, the nanometer compound material shows better droplet-resistant effect; and the polyester and the nanometer compound material can be directly used as raw materials for preparing fibers, engineering plastics, films and the like.

Owner:SICHUAN UNIV

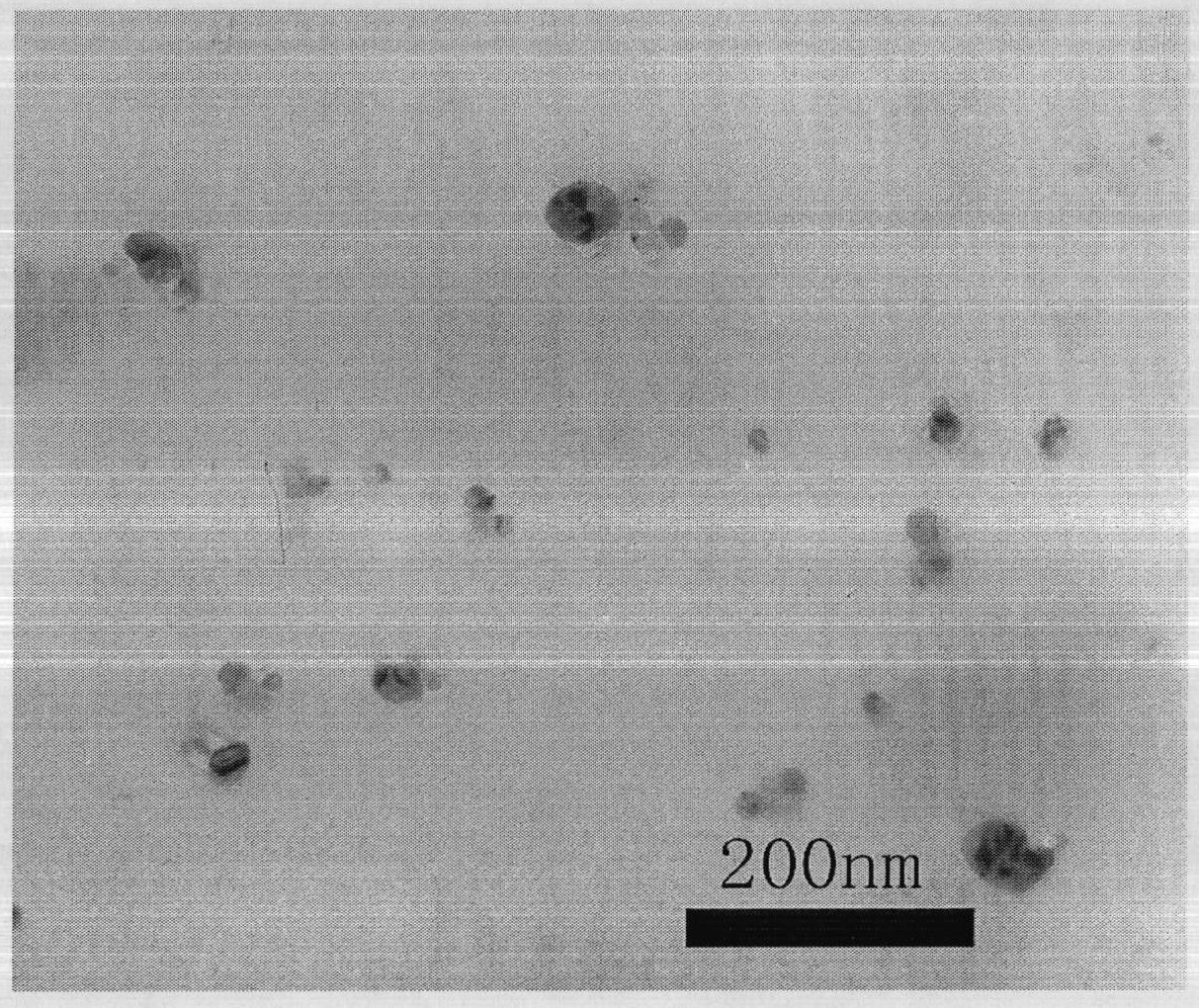

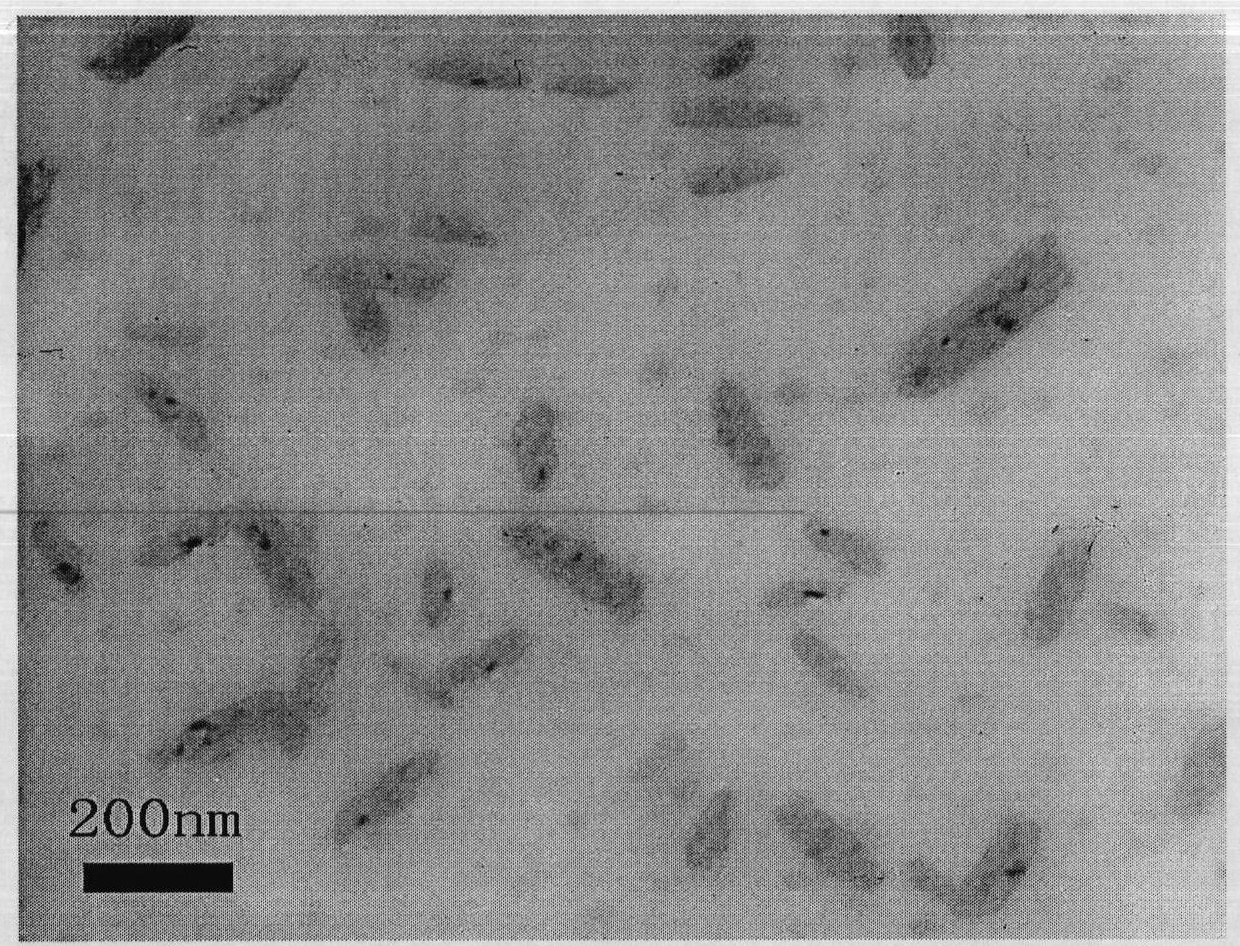

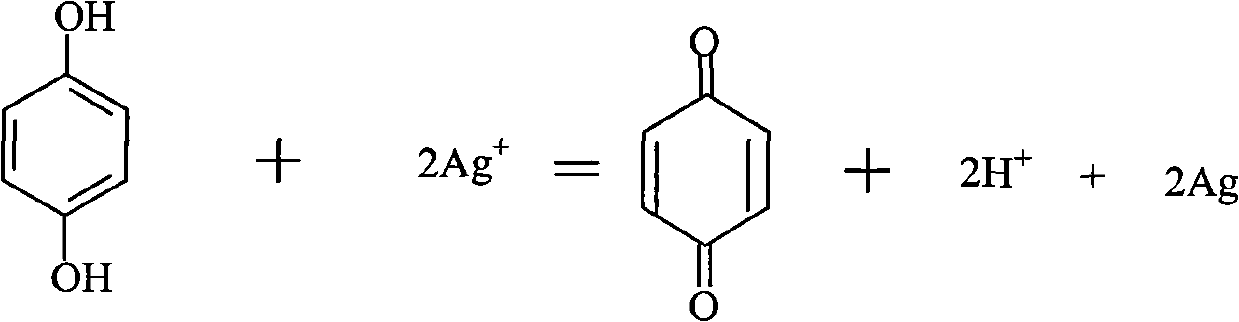

Preparation method and application of silver-containing PET based composite resin material

ActiveCN101993527AIngenious ideaSimple processMonocomponent polyesters artificial filamentArtifical filament manufactureDimethyl terephthalateColloidal Solution

The invention discloses a method for preparing a silver-containing PET based composite resin material. In the method, a monomer of terephthalic acid (PTA) or dimethyl terephthalate (DMT) for synthesizing PET and a precursor silver glycol colloid solution are polymerized in situ to prepare the material. The PET / Ag composite resin material prepared by the method has high spinnability and antibacterial property, and the preparation method has smart concept, simple process, short preparation period and low production cost without pollution, and is suitable for large-scale industrial production.

Owner:DONGHUA UNIV

Method for preparing polyester slices for optical film and optical film

The invention discloses a method for preparing polyester slices for an optical film. The method comprises the following steps of: (1) mixing glycol and dimethyl terephthalate in a pulping kettle to prepare a slurry solution, putting glycol and a catalyst in a catalyst preparation kettle to prepare a catalyst solution, and putting nanoscale additives and glycol into an additive preparation kettle to prepare an additive solution; (2) putting the slurry solution and the catalyst solution in an esterifying kettle and heating to carry out ester exchange reaction so as to obtain an esterified matter; (3) pressing the esterified matter and the additive solution in a pre-polycondensation kettle, vacuumizing during the process of pre-polycondensation reaction, discharging superfluous glycol; and (4) pressing the product of the pre-polycondensation into a final polycondensation kettle to increase the viscosity of a fusant, and cooling and pelleting the fusant to obtain the polyester slices for the optical film. According to the method for preparing the polyester slices for the optical film, disclosed by the invention, the difficult problem of dispersivity of the nanoscale additives is solved, meanwhile, the phenomenon of sand-granular fogging of an ordinary polyester film is overcome, the fogging degree of the film is lowered, and the high light transmittance of the polyester film is ensured.

Owner:南京兰埔成实业有限公司

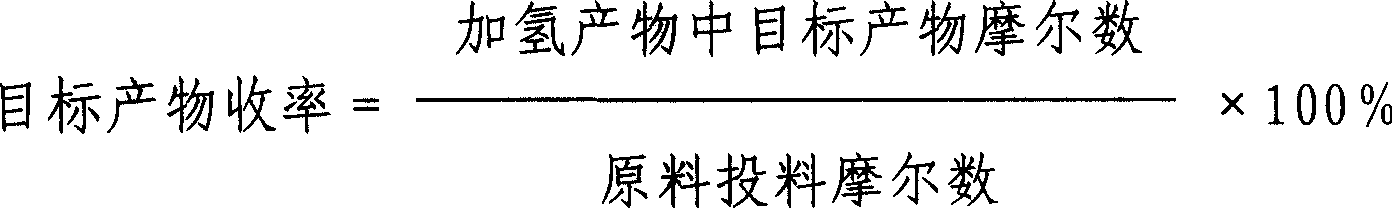

Method for preparing 1,4 ¿C cyclohexanedicarboxylate

InactiveCN1915962AHigh selectivityOrganic compound preparationCarboxylic acid esters preparationDimethyl terephthalateActive component

This invention discloses a method for preparing dimethyl 1,4-cyclohexane dicarboxylate by hydrogenation of dimethyl terephthalate in solvent in the presence of catalyst. The solvent is water or C1-4 fatty alcohol. The catalyst (80-200 mesh) is composed of Ru (0.5-10 wt. %) as the active component, and Al2O3 as the carrier. The weight ratio of dimethyl terephthalate to the solvent is 1: (0.5-10), while that of the catalyst to dimethyl terephthalate is 1: (5-20). The reaction is performed at 120-180 deg.C under 1.0-5.0 MPa for 0.5-8.0 h. Compared with present techniques, the method has such advantages as mild hydrogenation conditions, short hydrogenation time and long catalyst service time (recycleable for more than 9 times).

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Process for the Preparation of Polyesters with High Recycle Content

InactiveUS20130041053A1Reduce chain lengthReduce riskProductsReagentsDepolymerizationGlycol synthesis

Disclosed is a process for producing copolyesters with high levels of recycled content. Scrap or post-consumer poly(ethylene terephthalate) is depolymerized by methanolysis or glycolysis to produce a purified, recycled dimethyl terephthalate which can be repolymerized with 2 or more diols. The polyesters of this invention have physical properties and an appearance that is similar to polyesters prepared from virgin monomers. In addition to dimethyl terephthalate, the polyesters can be prepared from recycled ethylene glycol recovered from depolymerization of poly(ethylene terephthalate) and / or 1,4-cyclo-hexanedimethanol prepared by hydrogenation of recycled dimethyl terephthalate or recovered from depolymerized polyester mixtures.

Owner:EASTMAN CHEM CO

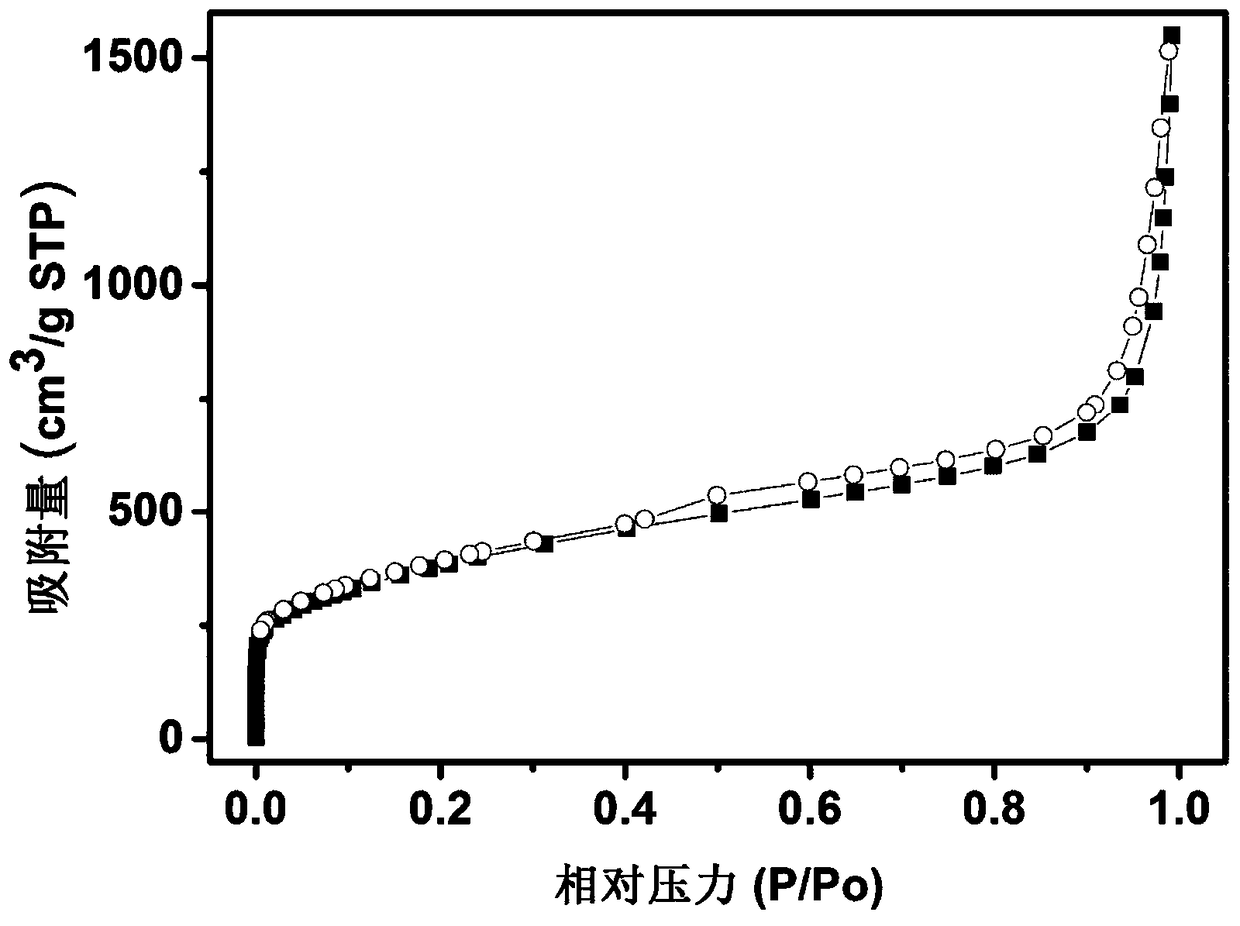

Preparation method for porous carbon material and porous carbon material

InactiveCN108622893AIncrease surface areaHigh pore volumeCarbon compoundsPolymer scienceCarbonization

The invention provides a preparation method for a porous carbon material. The preparation method comprises the following steps that a high polymer material and a foaming agent are uniformly mixed so as to obtain a mixture, the mixture is processed and formed so as to obtain a high polymer foam material, and the high polymer foam material is subjected to carbonization treatment so as to obtain theporous carbon material, wherein the high polymer material comprises one or more of ethylene, propylene, methyl methacrylate, styrene, butadiene, vinyl chloride, chloropropene, 1,3-butadiene, dimethylterephthalate, ethylene glycol, acrylonitrile, vinyl acetate, methyl acrylate, caprolactam and polymers synthesized by at least one of derivatives of caprolactam as monomers. The method has the advantages that the high polymer foam material is prepared by adopting a traditional processing and forming method and serves as a carbon source, carbonization heat treatment is carried out so as to obtainthe porous carbon material with the high specific surface area, the raw material source is wide, the cost is low, a preparation process is simple, and therefore the volume production of the porous carbon material is realized, and the cost is greatly lowered. The invention further provides the porous carbon material.

Owner:SHENZHEN UNIV

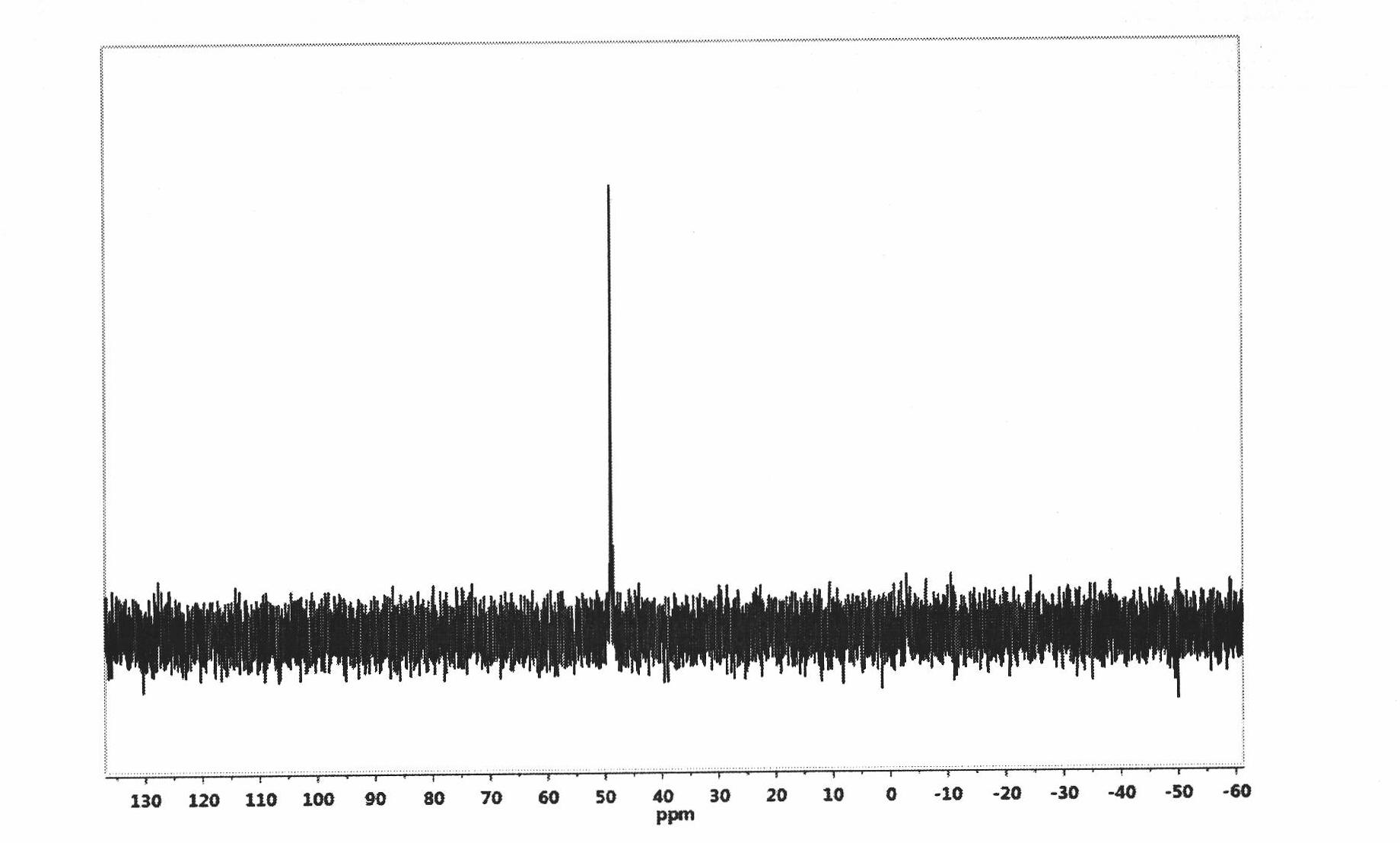

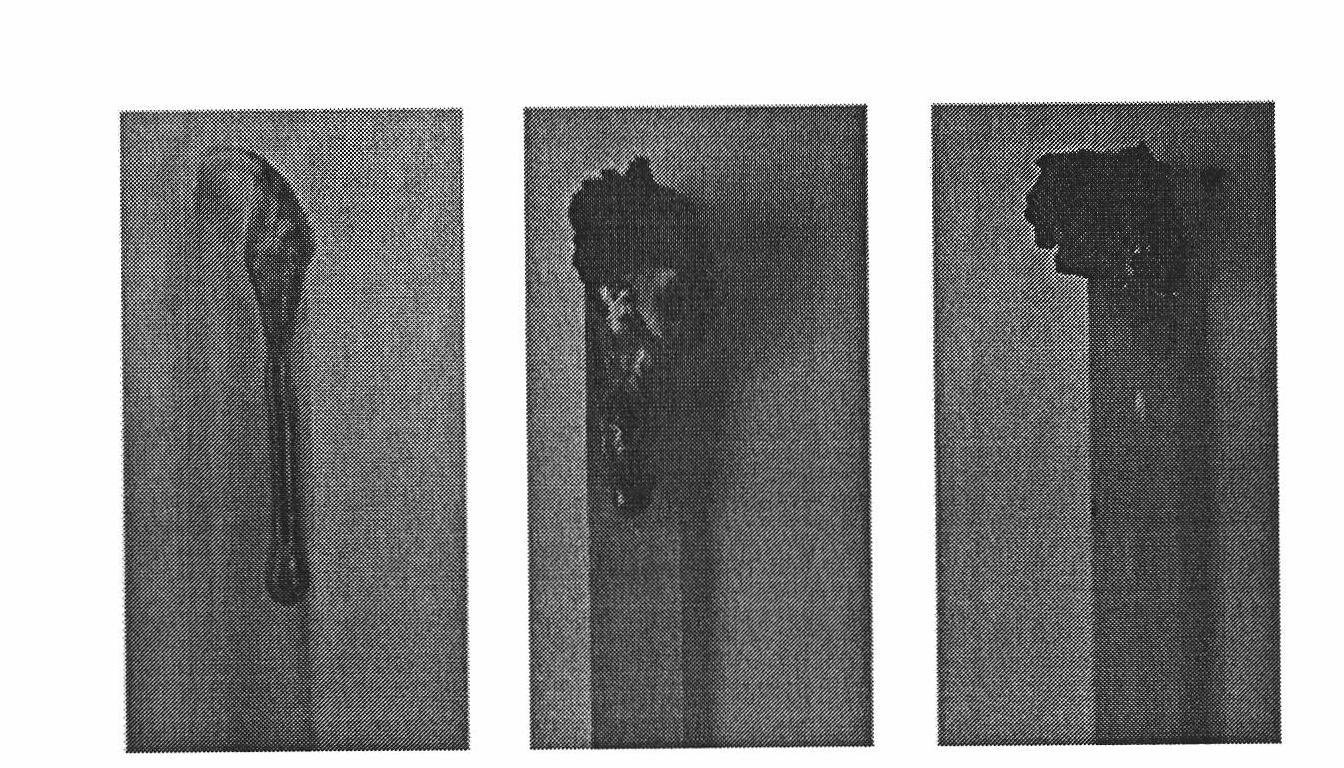

Fluffy and soft finishing agent used for polyester fiber, and preparation method thereof

The invention relates to a fluffy and soft finishing agent used in polyester fiber, and a preparation method thereof. The agent comprises the following components, by weight: 120-160 parts of polyethylene glycol, 18-30 parts of glycol, 15-25 parts of dihydroxy polyether, 20-28 parts of dimethyl terephthalate, 10-30 parts of an amino-terminated double-head sealant organosilicon, 5-10 parts of 3-piperazine propyl dimethoxysilane, and 0.2-2 parts of metal acetate as a catalyst. The polyester fiber fluffy and soft finishing agent is a polyester-polyether-silicone oil block copolymer produced through a reaction with the raw materials and with a number average molecular weight of 8000-20000. When the polyester fiber provided by the invention is used for finishing polyester, the polyester fiber is provided with extremely fluffy and soft texture. Also, polyester fiber antistatic property and hydrophilic property can be improved. Therefore, the comfortableness of the modified polyester fiber can be greatly improved. Also, the cost of the polyester fiber provided by the invention is low.

Owner:DUPLUS CHEM OF ZHANGJIAGANG CITY

Method for depolymerizing waste polyester

InactiveCN101565374ALow costReduce consumptionOrganic compound preparationCarboxylic acid esters preparationPolyesterPolyethylene glycol

The invention provides a method for depolymerizing waste polyester, which comprises the following steps of: adding methanol and cosolvent gas into a reaction system and utilizing the methanol and the cosolvent gas for depolymerizing waste polyester-polyethylene glycol terephthalate material so as to obtain dimethyl terephthalate and ethylene glycol on thesupercritical condition. According to the invention, as the cosolvent is added, the depolymerizing reaction temperature of the waste polyester is lowered and the reaction time is shortened, thereby reducing the energy consumption. As the cost of the cosolvent is relatively lower and easy for recycling, the recycling cost of the waste polyester is further lowered. In the method, the degradation rate of the olyethylene glycol terephthalate is more than 99.9 percent, the monosomic selectivity is high, and the content of oligomers in the product is low.

Owner:BEIJING UNIV OF CHEM TECH +1

Preparation of wire coated paint of polyester paint and polyester imine paint by using terephthalic acid

InactiveCN1670054AUniform molecular weightLow viscosityPolyester coatingsDimethyl terephthalatePolyester resin

The invention relates to a method for producing polyester, polyurethane glazed wire paint using terephthalic acid, which solves the problems of molecular weight disproportion, paint film continuity in the polyester fibre industrial process and clogging condensator easily, the environmental contamination by byproduct carbinol in the dimethyl terephthalate industrial process. The copper wires used in different standard as well as the polyester enamelled wire paint and polyurethane glazed wire paint allowable different needle speed are produced by controlling exit temperature of the dephlegmating column and other technological parameter strictly,

Owner:杨朝选

Method for preparing polyester and polyether modified silicone oil ternary copolymer textile finishing agent

The invention relates to a method for preparing a polyester and polyether modified silicone oil ternary copolymer textile finishing agent, and belongs to the field of the synthesis of ternary copolymer synthetic fiber finishing agents. The method comprises the following steps of: performing a hydrosilylation reaction of allyl polyether and hydrogen-containing silicone oil under the action of a chloroplatinic acid catalyst to form polyether modified silicone oil; and performing a polycondensation reaction of the polyether modified silicone oil and dimethyl terephthalate, glycol and polyethylene glycol under the action of antimonous oxide, manganese acetate, n-tetrabutyl titanate and triphenyl phosphate to obtain the polyester and polyether modified silicone oil ternary copolymer multifunctional textile finishing agent. The textile finishing agent can make textiles very absorbent, antistatic and washable and touch very soft.

Owner:LIAONING KELONG FINE CHEM

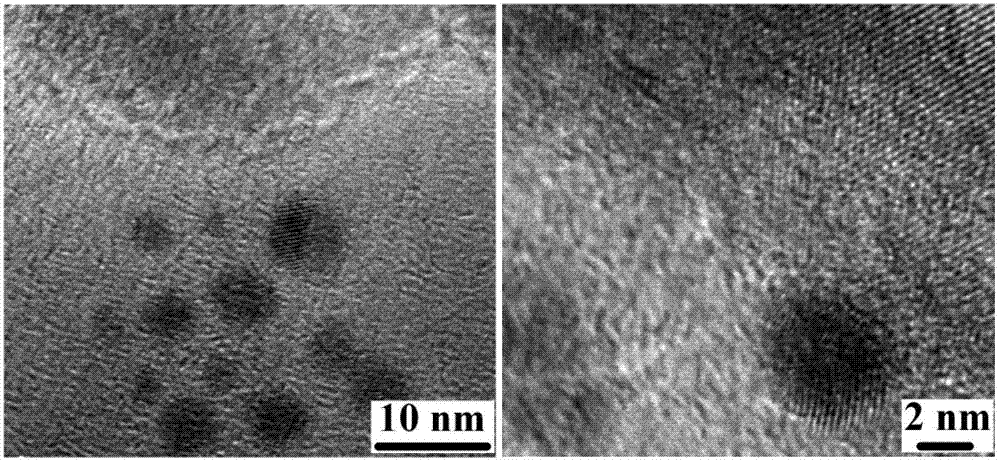

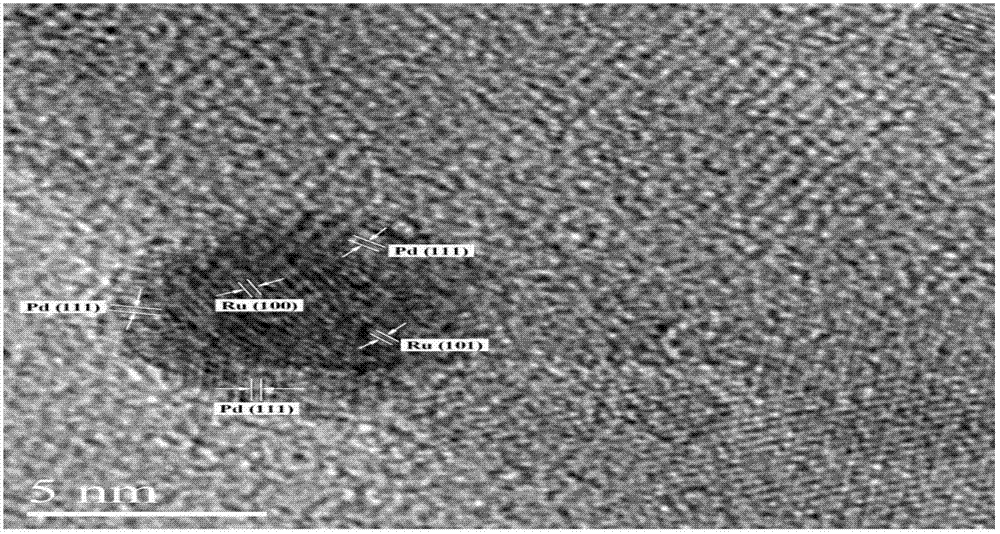

Low-content supported ruthenium-palladium bimetal hydrogenation catalyst and preparation method thereof

InactiveCN103157468ACatalytic selective hydrogenation performance improvement and enhancementLow costOrganic compound preparationCarboxylic acid esters preparationDimethyl terephthalateActive component

The invention belongs to the technical field of catalysts and particularly relates to a low-content supported ruthenium-palladium bimetal hydrogenation catalyst and a preparation method thereof. The preparation method of the catalyst comprises the following steps: preparing a ruthenium monometal solution and a palladium monometal solution; under ultrasonic conditions, supporting the two active components (ruthenium and palladium) of the metal catalyst on the surface of an aluminum oxide carrier by respectively adopting a co-impregnation method and a fractional impregnation method; and washing, drying, roasting, and performing other treatment processes to finally obtain the low-content supported ruthenium-palladium bimetal hydrogenation catalyst. According to the invention, the method is low in cost; and the prepared bimetal hydrogenation catalyst has high selective hydrogenation activity, and shows excellent catalytic activity, favorable catalytic stability and high 1,4-cyclohexanedicarboxylic acid dimethyl ester (CHDM) yield when being used in the reaction process of preparing CHDM through selective hydrogenation of dimethyl terephthalate.

Owner:BEIJING UNIV OF CHEM TECH

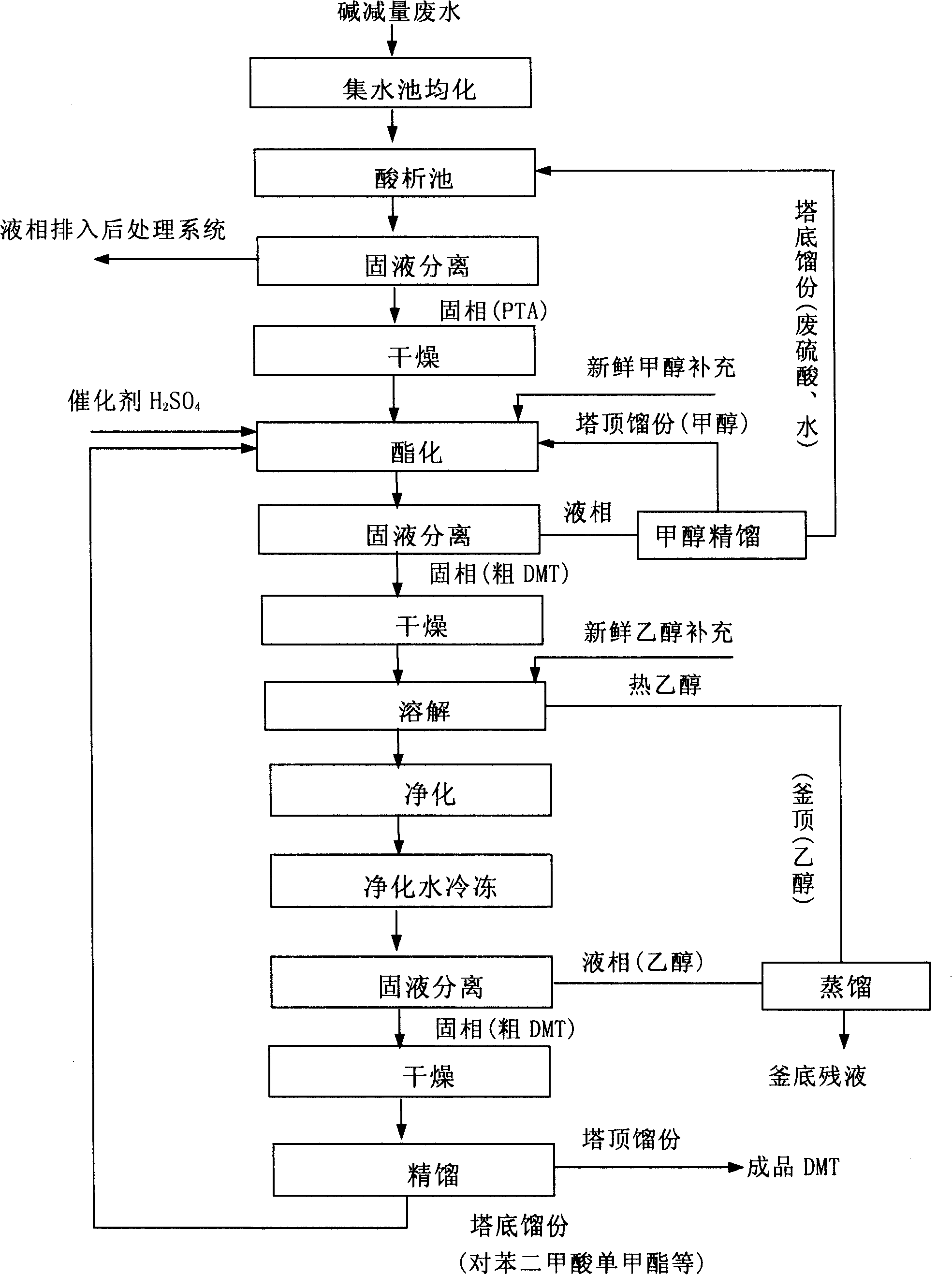

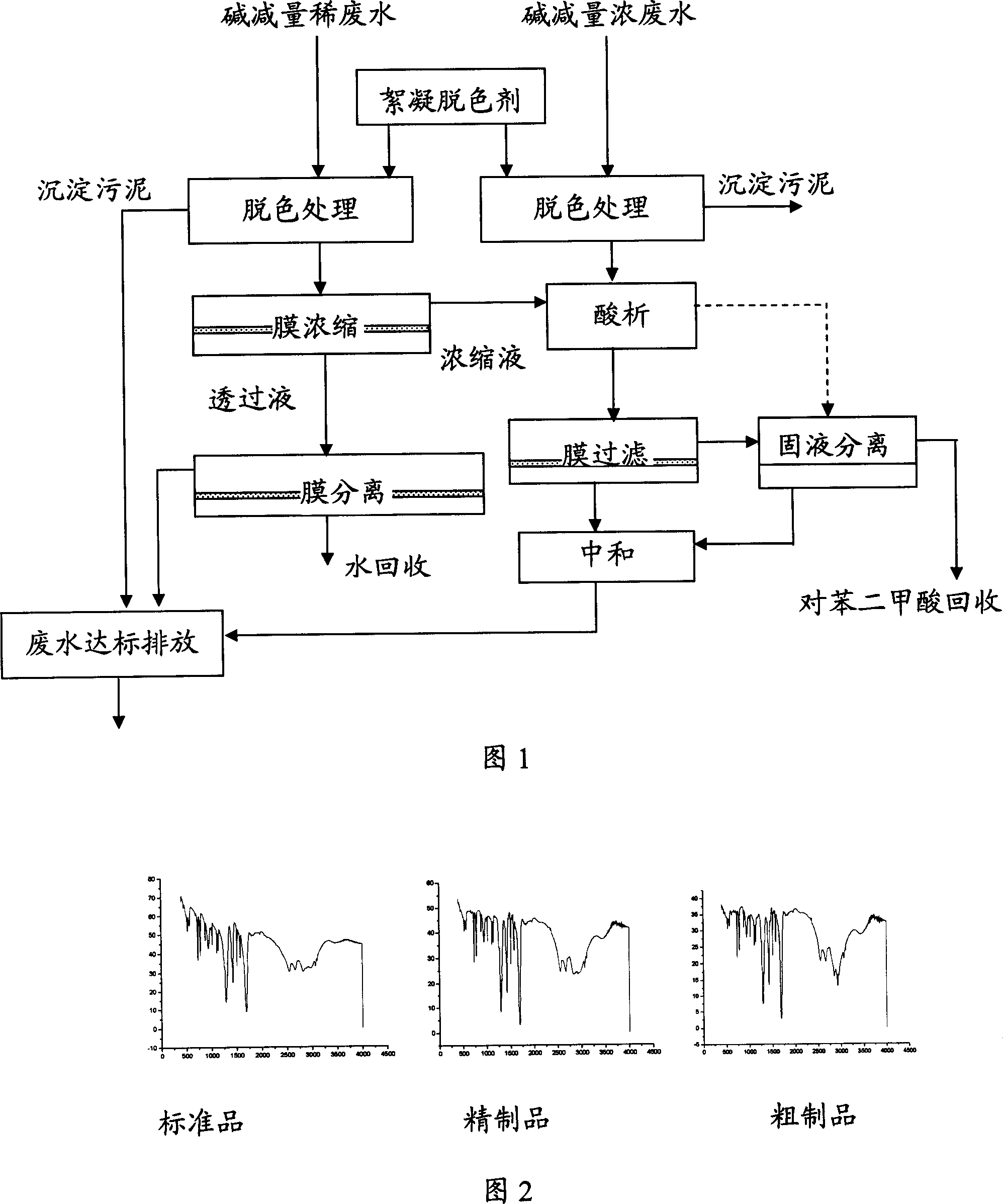

Alkali deweighting wastewater processing method and device

InactiveCN101244857AEliminate purification processEliminate polluting emissionsOrganic chemistryWater contaminantsDimethyl terephthalateIndustrial effluent

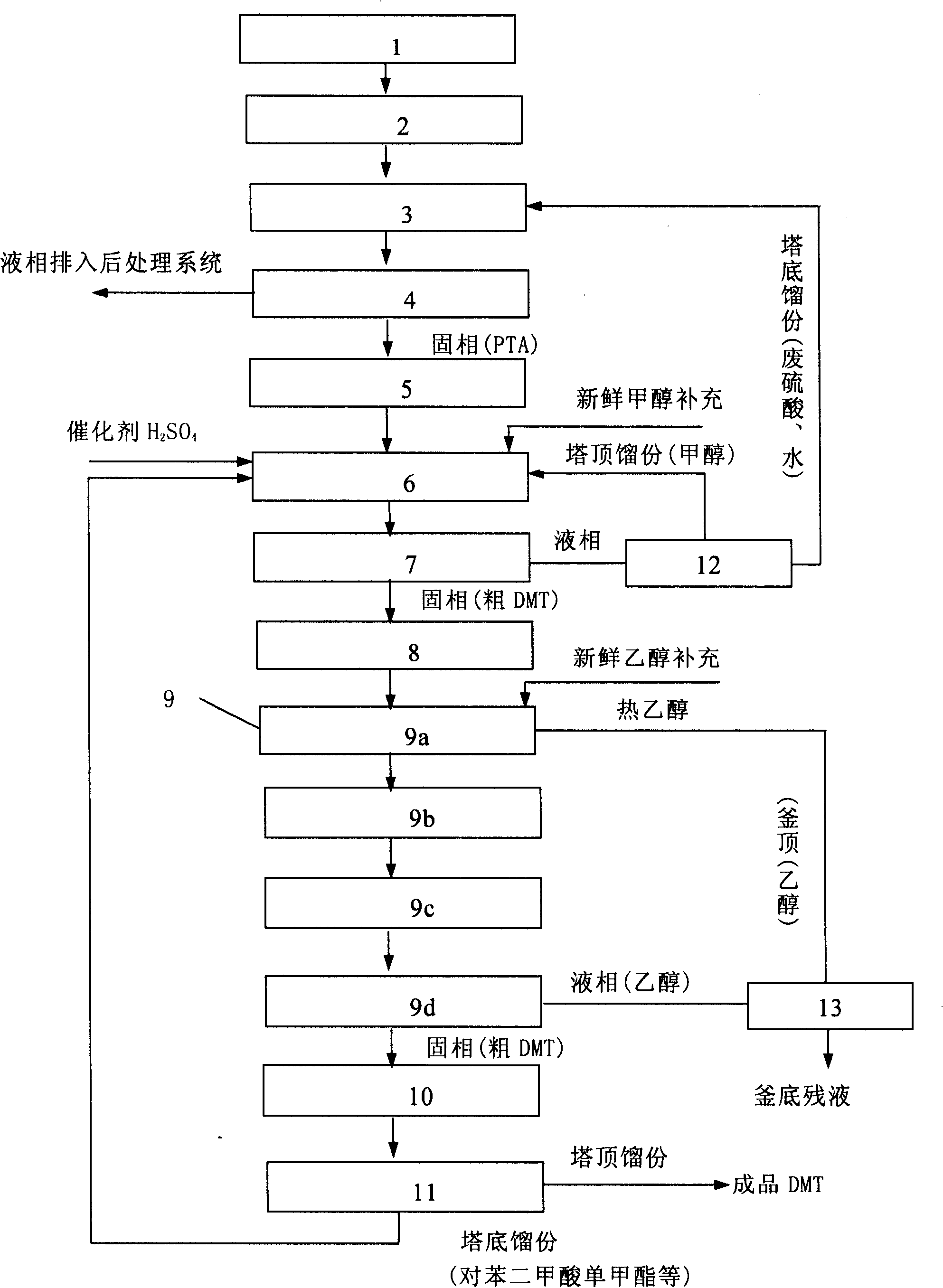

The invention provides a processing method for alkali-minimization wastewater, comprising a plurality of steps: (a) adjusting the PH value of alkali-minimization wastewater into 6.5 to 7, using the method of acid precipitation to obtain liquid phase and the solid phase with terephthalic acid; (b) carrying out esterification reaction for the solid phase from the procedure (a) in the presence of methanol to obtain a crude dimethyl terephthalate product. The method recovering terephthalic acid from alkali-minimization wastewater makes CODcr value of the wastewater removal of more than 75% and modifies the wastewater into Biodegradable industrial wastewater and at the same time changes the phthalic acid into dimethyl terephthalate.

Owner:SHAOXING COUNTY JINGSHENG RESIN TECH CO LTD

Method for synthesizing C-level polyurethane wire enamel

ActiveCN102618160ANo pollution in the processSimple processPolyurea/polyurethane coatingsPolyesterPhysical performance

The invention discloses a method for synthesizing C-level polyurethane wire enamel. The C-level polyurethane wire enamel prepared by the method has high heat-resistant performance and solderability and physical performance, and the heat-resistant level reaches a C level. The method for synthesizing the C-level polyurethane wire enamel mainly comprises the following steps of: synthesizing polyester polyol, synthesizing a diphenylmethane diisocyanate (MDI) tripolymer and preparing polyurethane paint, wherein the polyester polyol is prepared by reacting dimethyl terephthalate, tri-(2-ethoxy) isocyanurate and dihydric alcohol which serve as raw materials under the action of a catalyst; and the dihydric alcohol is N-methyldiethanolamine, and part of dimethyl terephthalate is replaced by addingtetracarboxylic dianhydride for reaction.

Owner:江苏四达特材科技有限公司 +1

Color fiber alkali decremental waste water treating and recovering process

InactiveCN1935703AReduce CODcr valueHigh purityOrganic chemistryWater/sewage treatment bu osmosis/dialysisFiberDimethyl terephthalate

The invention discloses a process of recovering terephatalic acid from colored alkali reduction waste water, processing two waste water streams thick and thin coming from alkali reduction process by qualities, firstly decolorizing by decolorizing agent, then integrating acid precipitation with diaphragm process to recover erephatalic acid from the waste water, thus making CODcr of waste water reduced by 50-70% for the convenience of follow-up biochemcial and physical chemcial treaments, where the purity of the recovered terephatalic acid is up to above 90%, able to act as chemcial raw material for preparing dimethyl terephthalate, and dioctyl terephthalate. And it can be applied to chemcial production, controlling pollution, improving environment, saving energy sources, reducing cost, and obtaining good economic and environmental benefits.

Owner:ZHEJIANG UNIV

Method of preparing modified polyester bottle resins

InactiveUS20010034431A1Maintain good propertiesCost-effectiveThin material handlingHollow articlesDimethyl terephthalatePolyethylene terephthalate

Owner:WELLMAN INC

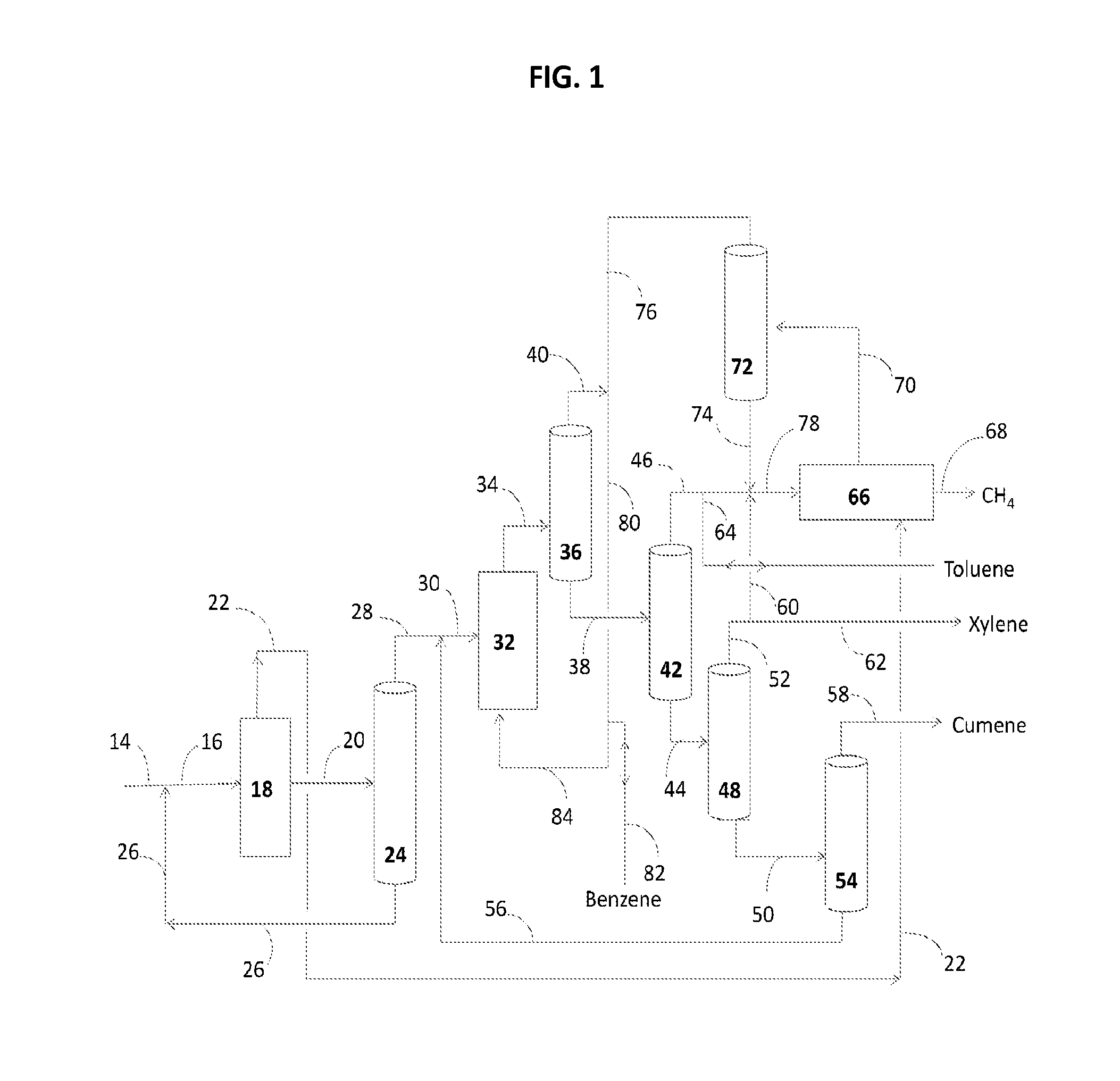

Production of renewable aromatic compounds

InactiveUS20130130345A1Hydrocarbon by isomerisationOrganic chemistry methodsBenzoic acidCyclohexanone

The invention provides a process for producing a variety renewable aromatic compounds such as benzene, toluene, xylenes, and cumene, as well as compounds derived from these including, for example, aniline, benzoic acid, cresol, cyclohexane, cyclohexanone, phenol and bisphenol A, toluene di-isocyanate, isophthalic acid, phthalic anhydride, terephthalic acid and dimethyl terephthalate. The invention also provides for renewable forms of these aromatic compounds.

Owner:JNF BIOCHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com