Corona resistant enamel-covered wire paint for variable frequency motor and preparing process thereof

An enameled wire varnish, variable frequency motor technology, applied in the field of wire and cable, can solve the problems of poor corona resistance, intolerable, not satisfactory, etc., to achieve high product performance, improve corona resistance, and increase insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below with the embodiment of preparing 100KG corona resistant paint: the proportioning of its component is: dimethyl terephthalate 10 kilograms, glycerin 5 kilograms, ethylene glycol 10 kilograms, THEIC 6 kilograms, catalyst 0.1 kg, 10 kg of terephthalic anhydride, 5 kg of 4.4-diaminodiphenyl ether, 0.2 kg of curing agent, 5 kg of shielding agent, 1.2 kg of compounding agent, 27 kg of solvent, 20 kg of diluent, and 0.5 kg of auxiliary agent.

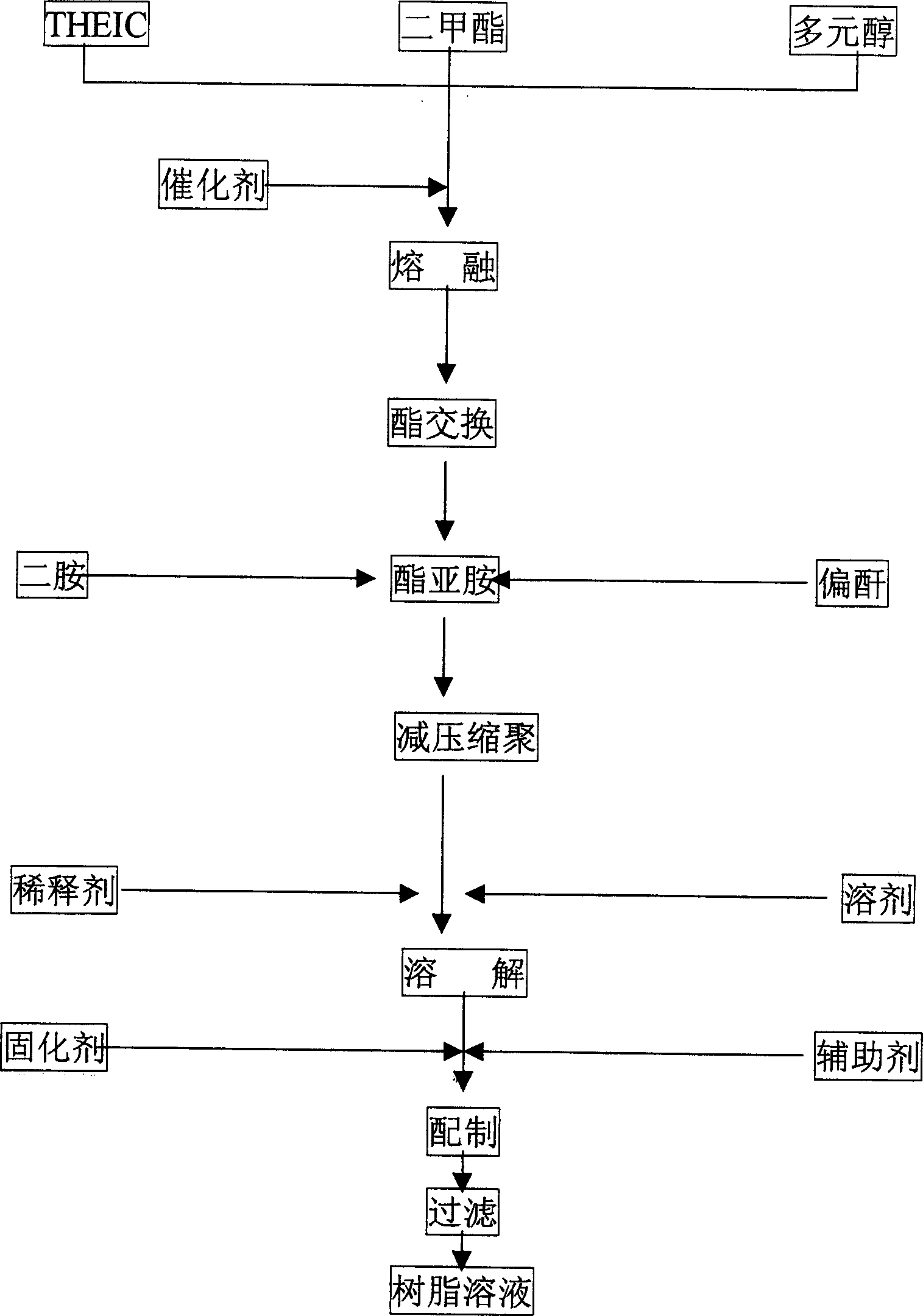

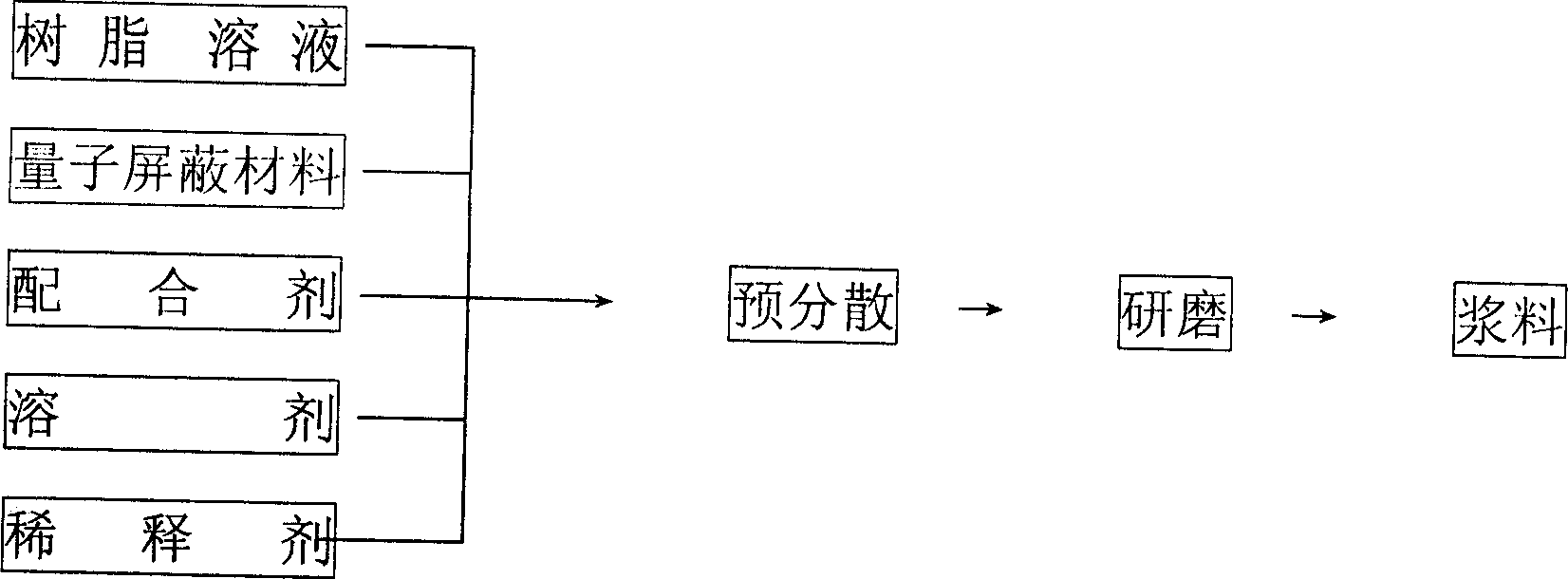

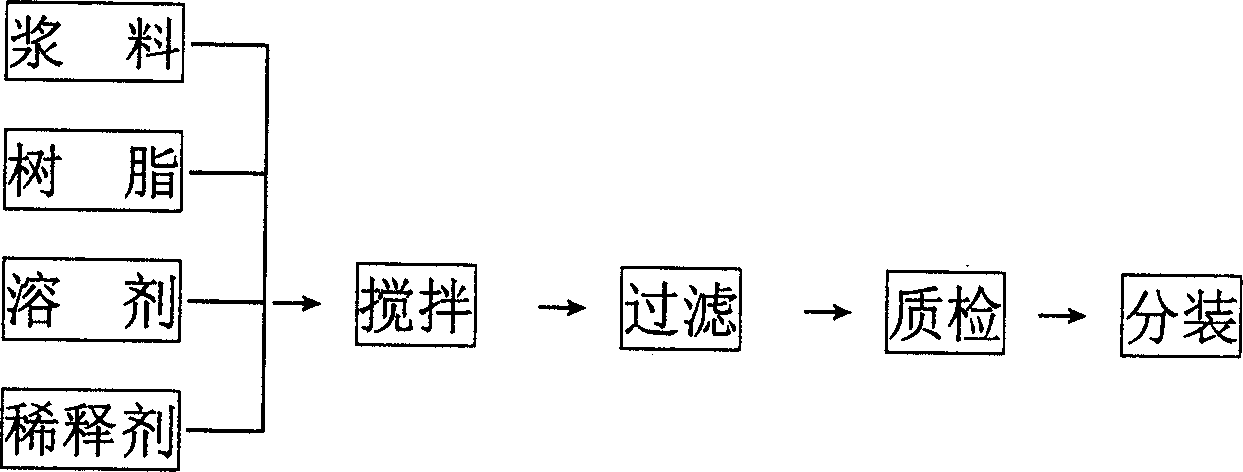

[0029] Production process of polyesterimide resin containing THEIC: add catalyst to THEIC, dimethyl ester and polyol mixture, obtain ester imine through melting and transesterification, add diamine and partial anhydride to ester imine for decompression compression polymerization, And add diluent and solvent to dissolve, then add curing agent and auxiliary agent to prepare and filter to obtain polyesterimide resin solution. The temperature of the transesterification reaction and polyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com