Nanometer compound water-based heat insulation anticorrosion paint used for metal and preparation method thereof

A nano-composite, anti-corrosion coating technology, applied in anti-corrosion coatings, reflective/signal coatings, coatings, etc., can solve problems such as loss, and achieve excellent heat insulation performance and anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

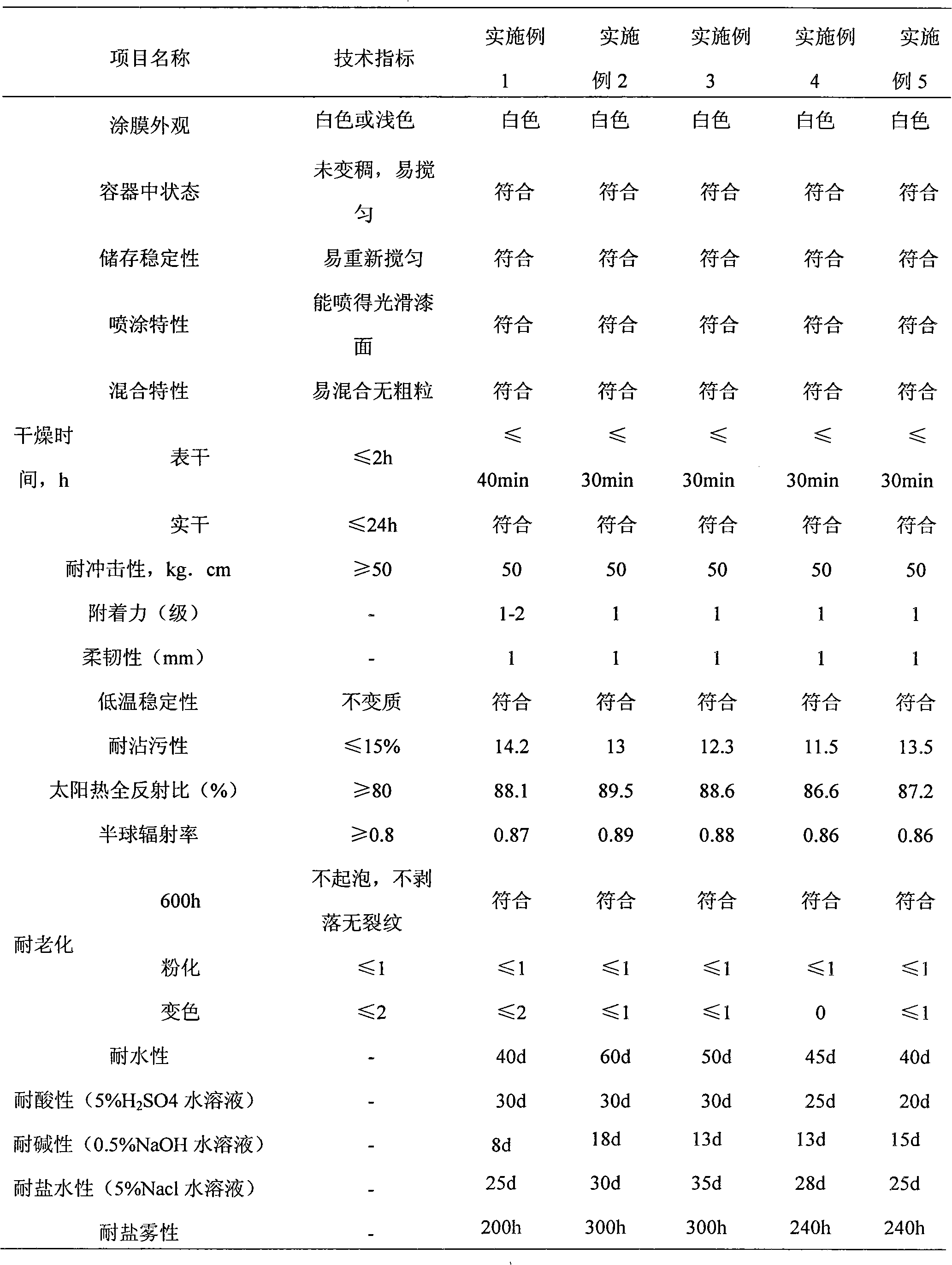

Examples

Embodiment 1

[0031] The raw material formula of a kind of metal nanocomposite water-based heat-insulating anticorrosion coating is: tap water 14Kg (14%), water-based acrylic emulsion (RS-998A, Guangdong Shunde Bade Fu Industrial Co., Ltd.) 55Kg (55%), composite iron-titanium powder (WD-S-400, Wuxi Wanda Technology Co., Ltd.) 5Kg (5%), rutile titanium dioxide (SR-237, Shandong Dongjia Group Co., Ltd.) 8Kg (8%), sericite (1250 mesh sericite, Chuzhou City Wenlong Sericite Co., Ltd.) 5Kg (5%), hollow glass microspheres (K1, U.S. 3M Company) 5Kg (5%), water-based nano-zirconia slurry (Shandong Yitong New Material Co., Ltd.) 2Kg (2%) ), anti-settling agent (BYK-420, BYK Chemical Company of Germany) 0.1Kg (0.1%), antifungal agent (EPW, Canadian Nord Company) 0.1Kg (0.1%), wetting and dispersing agent A (SN-5040, Shenzhen Haichuan Chemical Co., Ltd.) 0.3Kg (0.3%), wetting and dispersing agent B (X-405, Rohm and Haas Company of the United States) 0.1Kg (0.1%), antifreeze (propylene glycol, Guangzho...

Embodiment 2

[0036] The raw material formula of a kind of metal nanocomposite water-based heat-insulating anticorrosion coating is: tap water 10Kg (10%), water-based acrylic emulsion (RS-2709, Guangdong Shunde Bade Fu Industrial Co., Ltd.) 56Kg (56%), composite iron-titanium powder (WD-S-400, Wuxi Wanda Science and Technology Co., Ltd.) 5Kg (5%), rutile titanium dioxide (R-KB-6, American Kemeiqi Company) 9.5Kg (9.5%), sericite (1250 mesh sericite, Chuzhou City Wenlong Sericite Co., Ltd.) 5.5Kg (5.5%), hollow glass microspheres (S60, U.S. 3M Company) 7Kg (7%), water-based nano-zirconia slurry (Shandong Yitong New Material Co., Ltd.) 2Kg (2 %), anti-settling agent (BYK-420, BYK Chemical Company of Germany) 0.2Kg (0.2%), antifungal agent (EPW, Canadian Nord Company) 0.1Kg (0.1%), wetting and dispersing agent A (SN-5040 , Shenzhen Haichuan Chemical Co., Ltd.) 0.3Kg (0.3%), wetting and dispersing agent B (X-405, Rohm and Haas Company of the United States) 0.1Kg (0.1%), antifreeze (propylene gly...

Embodiment 3

[0041] A kind of raw material formula of nanocomposite water-based heat-insulating anticorrosion coating for metal is: tap water 10Kg (10%), water-based acrylic emulsion (BLJ-818, Shanghai Baolijia Chemical Co., Ltd.) 55Kg (55%), composite iron-titanium powder (WD -S-400, Wuxi Wanda Technology Co., Ltd.) 6Kg (6%), rutile titanium dioxide (CR-826, American Kemeiqi Company) 11Kg (9%), sericite (1250 mesh sericite, Chuzhou Wenlong sericite Co., Ltd.) 5Kg (5%), hollow glass microspheres (S38, 3M Company of the United States) 6Kg (6%), water-based nano-zirconia slurry (Shandong Yitong New Material Co., Ltd.) 2Kg (2%), anti-settling agent (BYK-420, German BYK Chemical Company) 0.1Kg (0.1%), antifungal agent (EPW, Canadian Nord Company) 0.1Kg (0.1%), wetting and dispersing agent A (731A, U.S. Rohm and Haas Company) 0.5Kg (0.5%), wetting and dispersing agent B (X-405, American Rohm and Haas Company) 0.1Kg (0.1%), antifreeze (propylene glycol, Guangzhou Xiangfeng Chemical Technology Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com