Fluorocarbon nanometer solar heat-insulation reflective paint, preparation method and using method thereof

A technology of thermal insulation and reflection, fluorocarbon nanometer, applied in the direction of reflection/signal coatings, coatings, etc., can solve the problems of high cost, no large-scale promotion and application, and achieve high self-cleaning, good thermal insulation effect, and high reflectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In a 500ml beaker, add 35 grams of fluorocarbon resin ETERFLON4101 (Taiwan Changxing Company), nano-TiO 2 Concentrated slurry [Zhongke Nano Coating Technology (Suzhou) Co., Ltd.] 3 grams, dispersant (auxiliary) NUOSPERSE FX9086 [Hemings Special Chemicals (ELEMENTIS SPECIALTIES) Company] 1 g, mixed solvent 3 g, add infrared reflective pigment after stirring evenly Yellow 10C112 [Shepherd of American Shepherd Pigment Company] 20g, hollow microspheres [Shanghai Gerunya Nano Materials Co., Ltd.] 5g, pre-dispersed and ground, when the specified fineness is 30μm, add the remaining ETERFLON4101 fluorocarbon resin 25g and Leveling agent Levelol837 [ELEMENTIS SPECIALTIES] 0.2g, defoamer Dedom5400 [ELEMENTIS SPECIALTIES] 0.3g and mixed solvent 7.5g to adjust the viscosity to 300-400mPa·s , stirred evenly and filtered through a 200-mesh sieve to obtain component A; component A and component B [DESMODEYN75, German BAYER company] were evenly mixed according to the mass ratio of 100:...

Embodiment 2~5

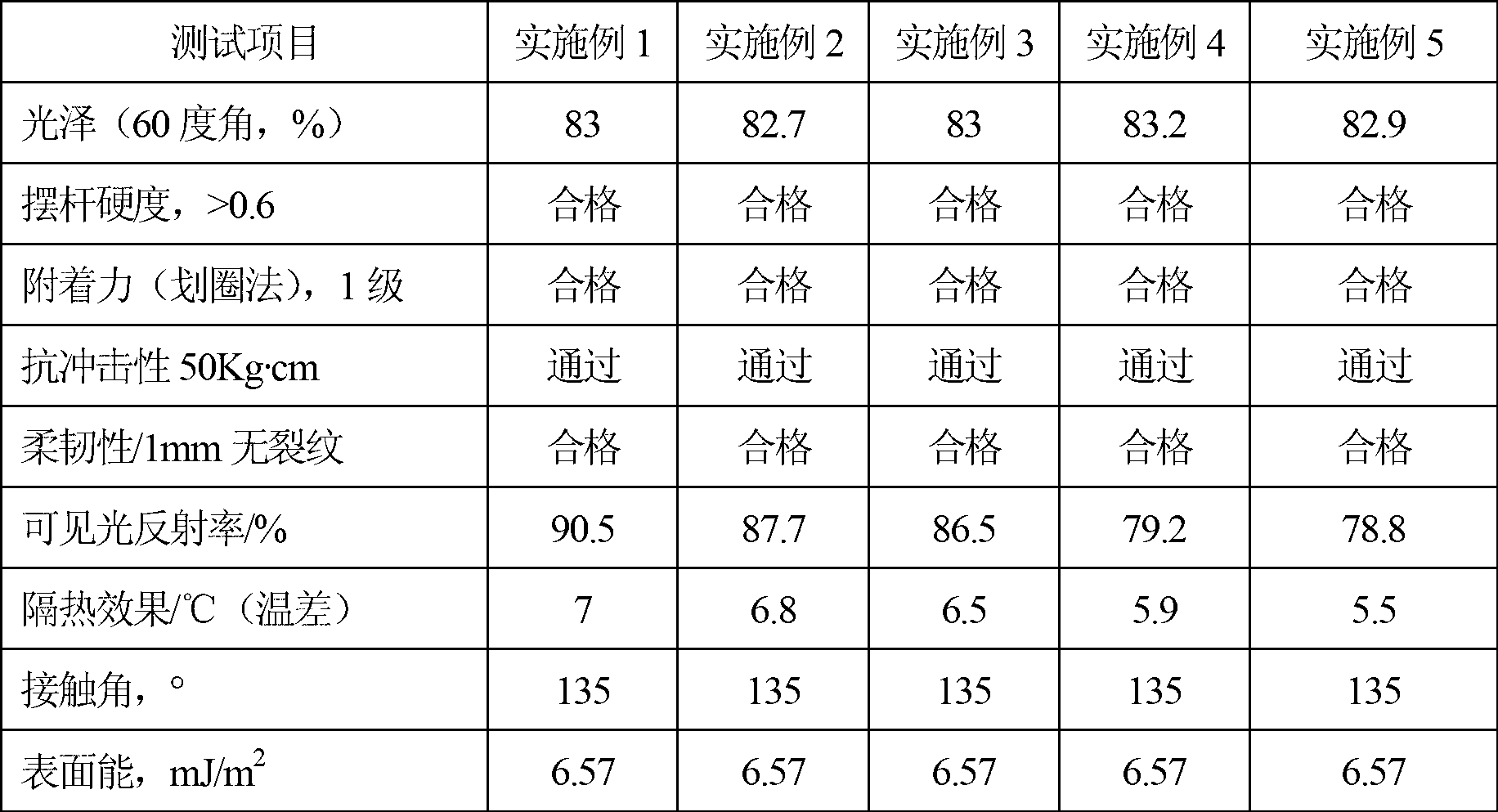

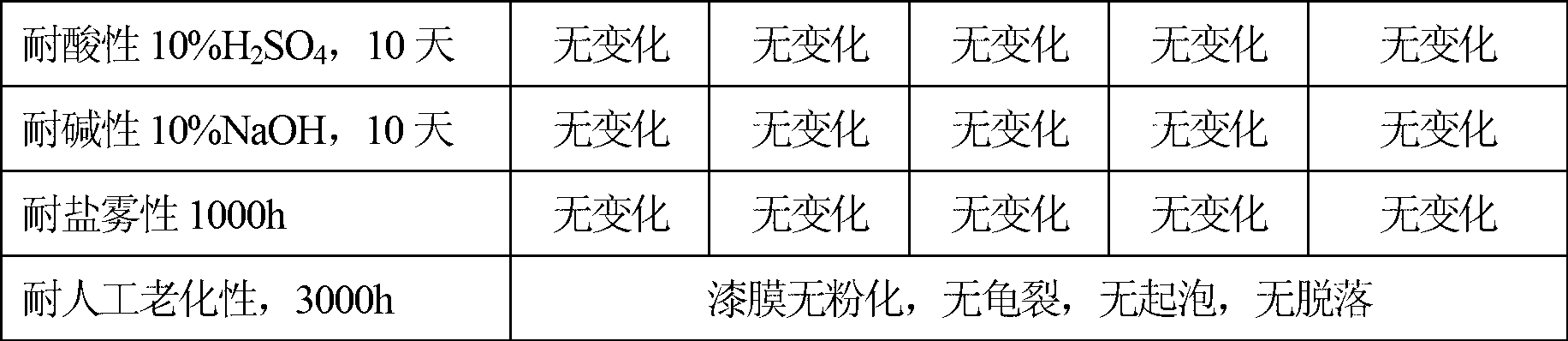

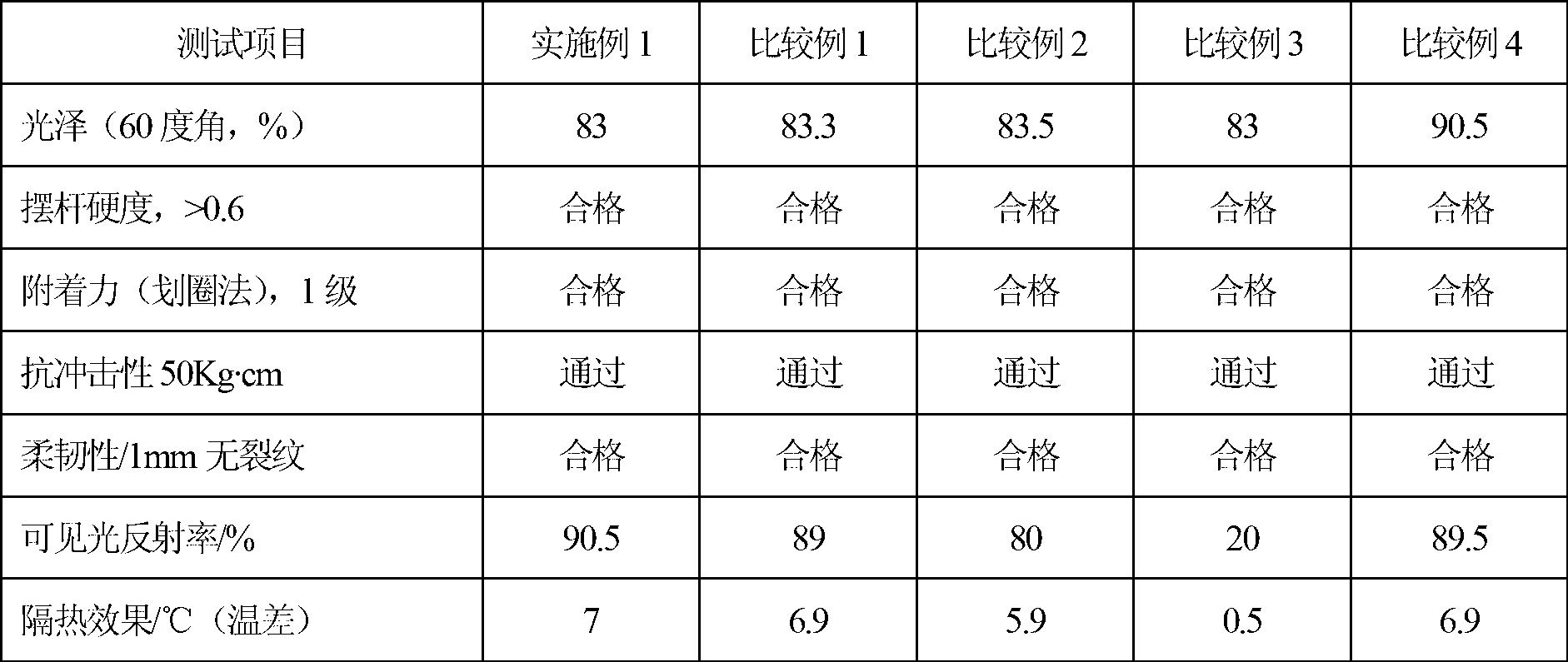

[0054] The operating steps and reaction conditions are the same as in Example 1, and the specific amounts of raw materials are shown in Table 1. The properties of the prepared fluorocarbon nano solar heat insulation reflective coating are shown in Table 2.

[0055] Table 1. Raw material ratio of Examples 1~5 (wt / wt)

[0056] raw material name

Example 1

Example 2

Example 3

Example 4

Example 5

ETERFLON4101 fluorocarbon resin, g

60

60

40

45

70

Nano-TiO 2 concentrate, g

3

3

10

8

5

Dispersant NUOSPERSE FX9086, g

1

1

1

1

1

Yellow Yellow10C112 pigment, g

20

-

-

-

-

Brown Brown157, g

-

20

-

-

-

Blue Blue424, g

-

-

30

-

-

Green Green187B, g

-

-

-

25

-

Black Black411A, g

-

-

-

-

10

Cenospheres, g

5

5

8

10

3

Lev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com