Patents

Literature

1514results about How to "Improve self-cleaning ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

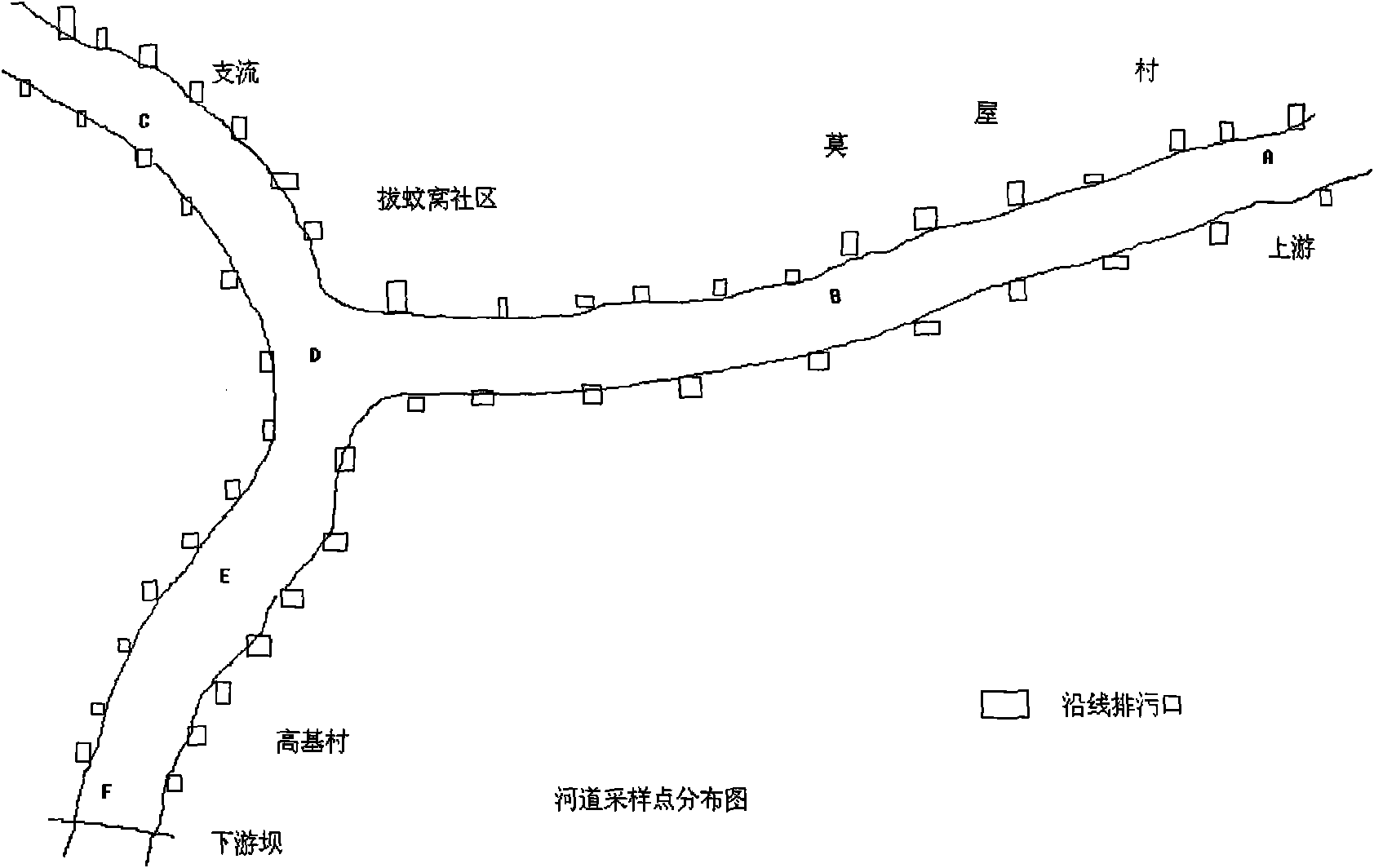

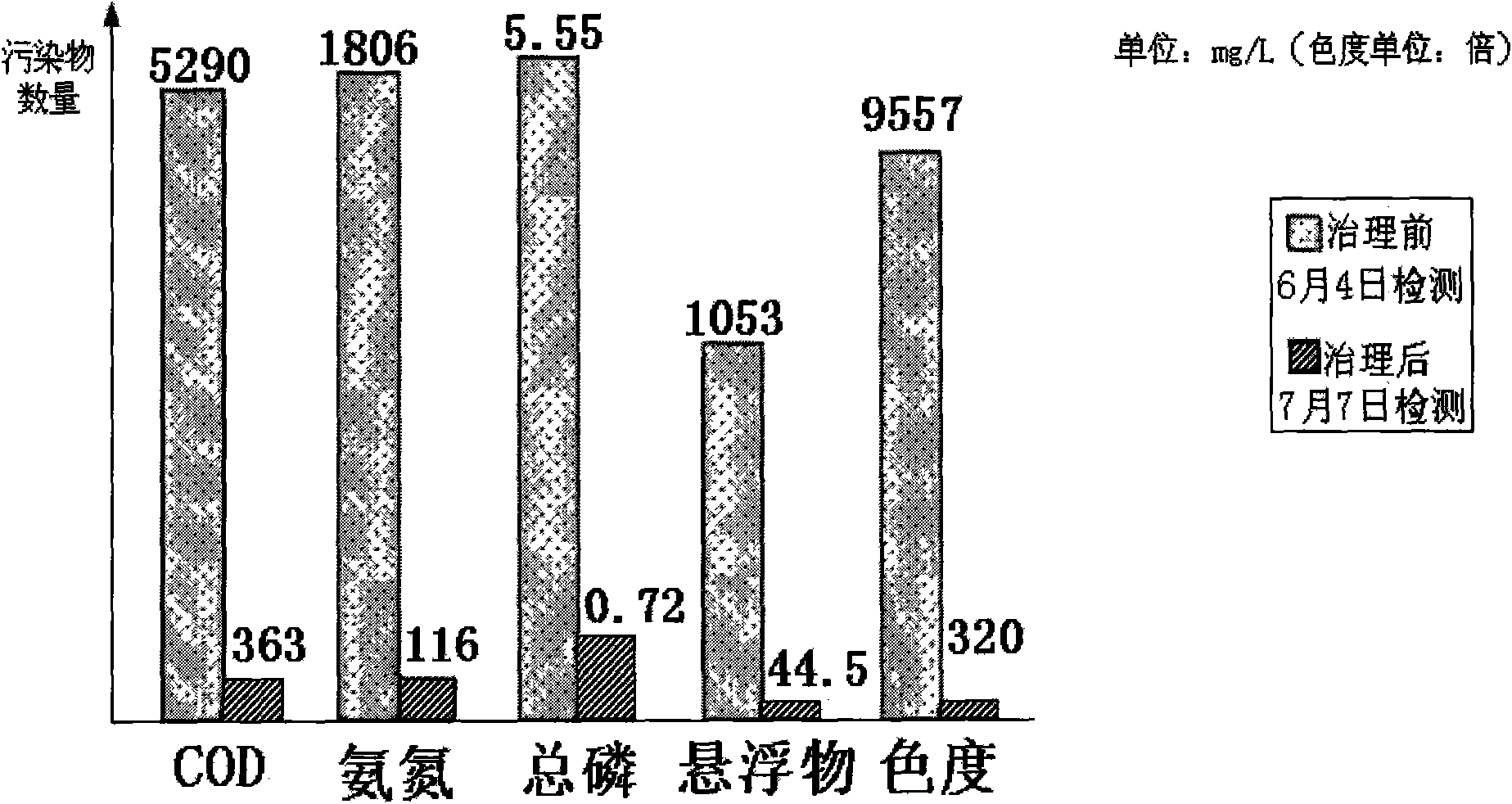

Black-odor river pollution treatment method

InactiveCN101417840AEfficient removalControl and reduce the total amount receivedTreatment using aerobic processesWater aerationMicrobial agentSelf purification

The invention discloses a method for managing town black and olid river pollution in situ by utilizing biological repair technology, which takes the steps and measures of aerating and oxygenizing in riverway, adding a complex microbial agent, biologically repairing bottom sediment, arranging a bio-nest system and the like, so as to control and eliminate the exogenous and endogenous pollution of the river, purify the water quality of the river, improve the self-purification ability of the water body and achieve the purpose of eliminating black and olid. The method does not need to build structures in the riverway or lead the river water out of the riverway to be treated, or dredge the bottom sediment in the river, therefore the method is generally applicable to incomplete sewage interception and dredging or the rivers which can not be intercepted sewage or dredged temporarily, and the in situ treatment to the riverway which is affected by tide and has complicated fluid variation. Therefore, the method which can lead the water body to recover normal ecological function provides the practical, economic and convenient treatment method for various town black and olid rivers.

Owner:黎赓桓 +1

Thermal-insulating external-wall coating of nano-composite water and its production

InactiveCN101029206AImprove insulation performanceGood weather resistanceFireproof paintsEmulsion paintsRefractive indexSlurry

A water nan-composite thermal-insulating coating for external wall and its production are disclosed. The coating consists of water, polymer emulsion, high-refractive index pigment, filler, nano-tin-antimony oxide slurry, nano-SiO2, wet dispersant, filming accessory, pH adjuster, thickener, de-foaming agent, anti-freezing agent and mildew-proof bactericide. It's cheap and simple, has excellent wash and weather resistances, better thermal-insulating performance, safe storage and no environmental pollution. It can be used for apparatus surface and architecture external wall.

Owner:SOUTH CHINA UNIV OF TECH +1

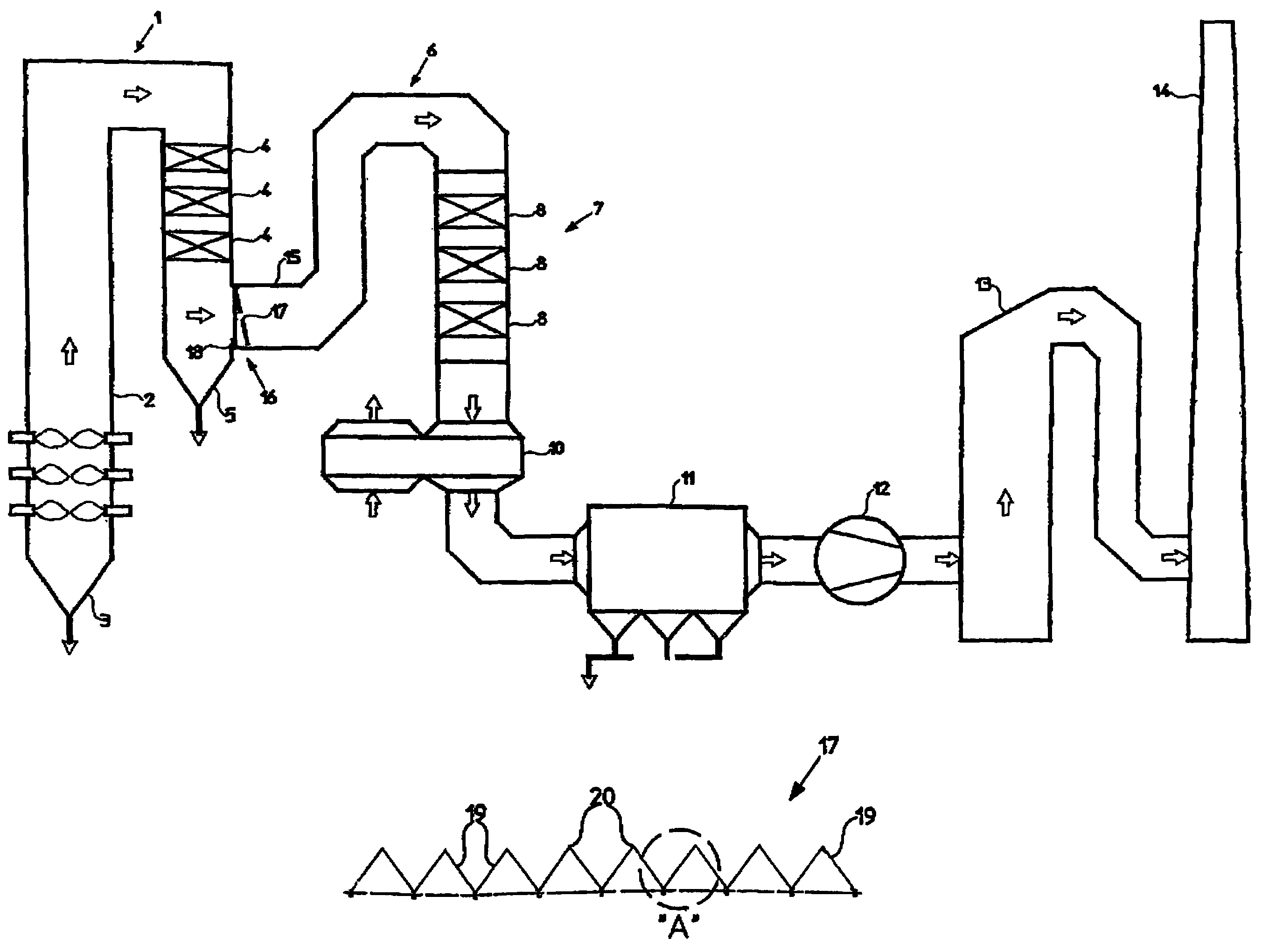

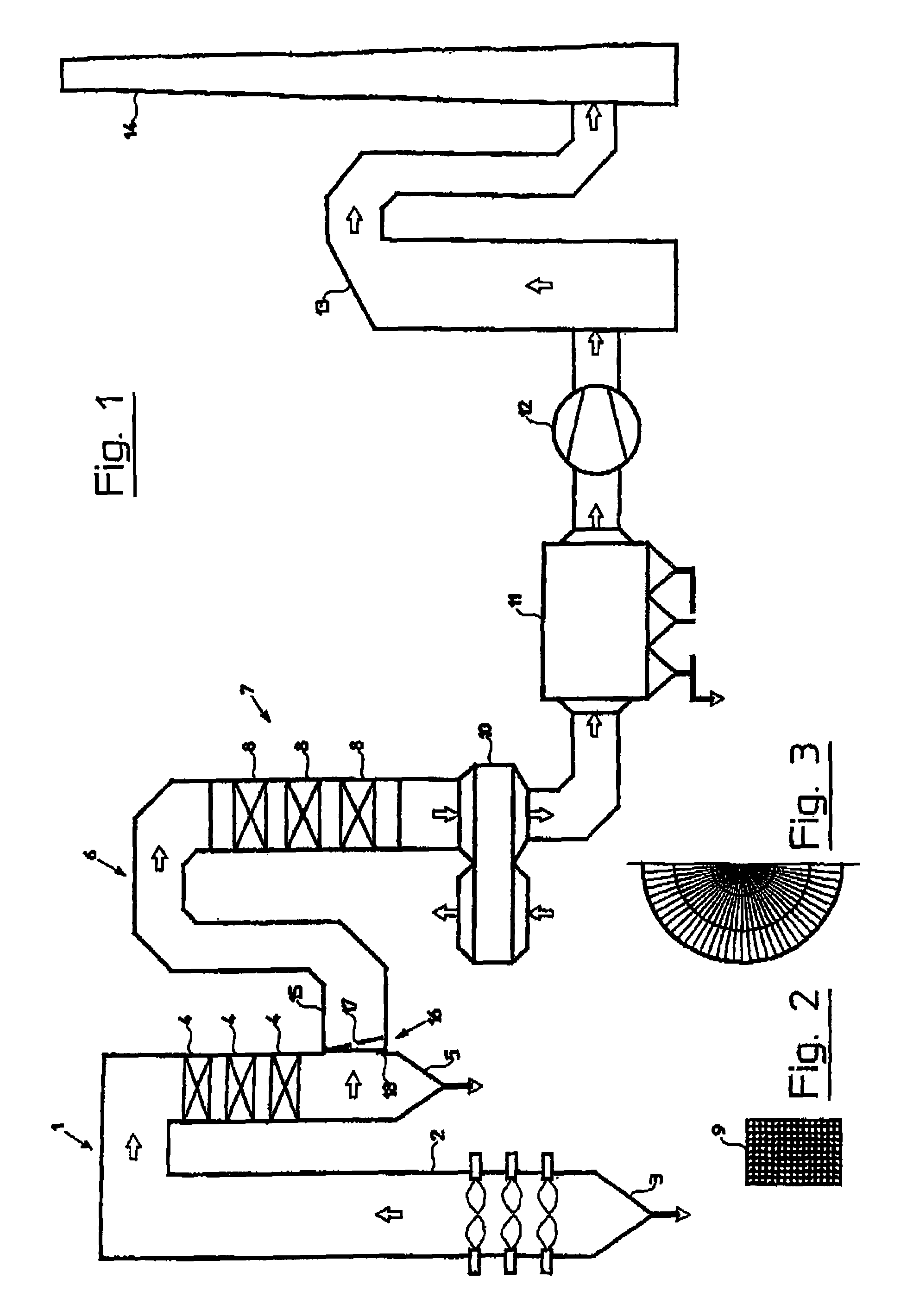

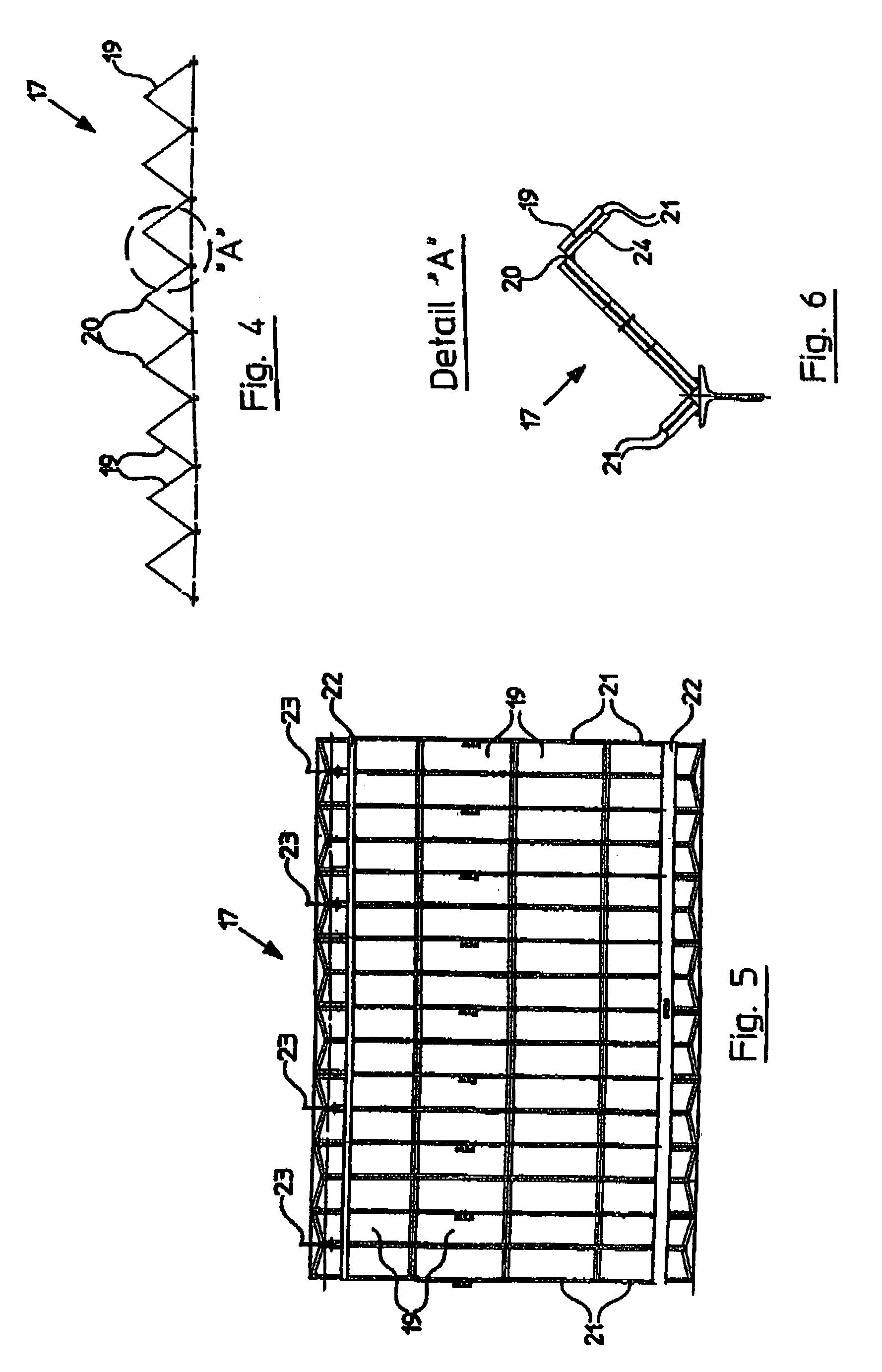

Coal-fired power station

InactiveUS6994036B2Easy constructionImprove self-cleaning abilityDispersed particle filtrationTransportation and packagingFlueProcess engineering

Owner:STEAG ENERGY SERVICES

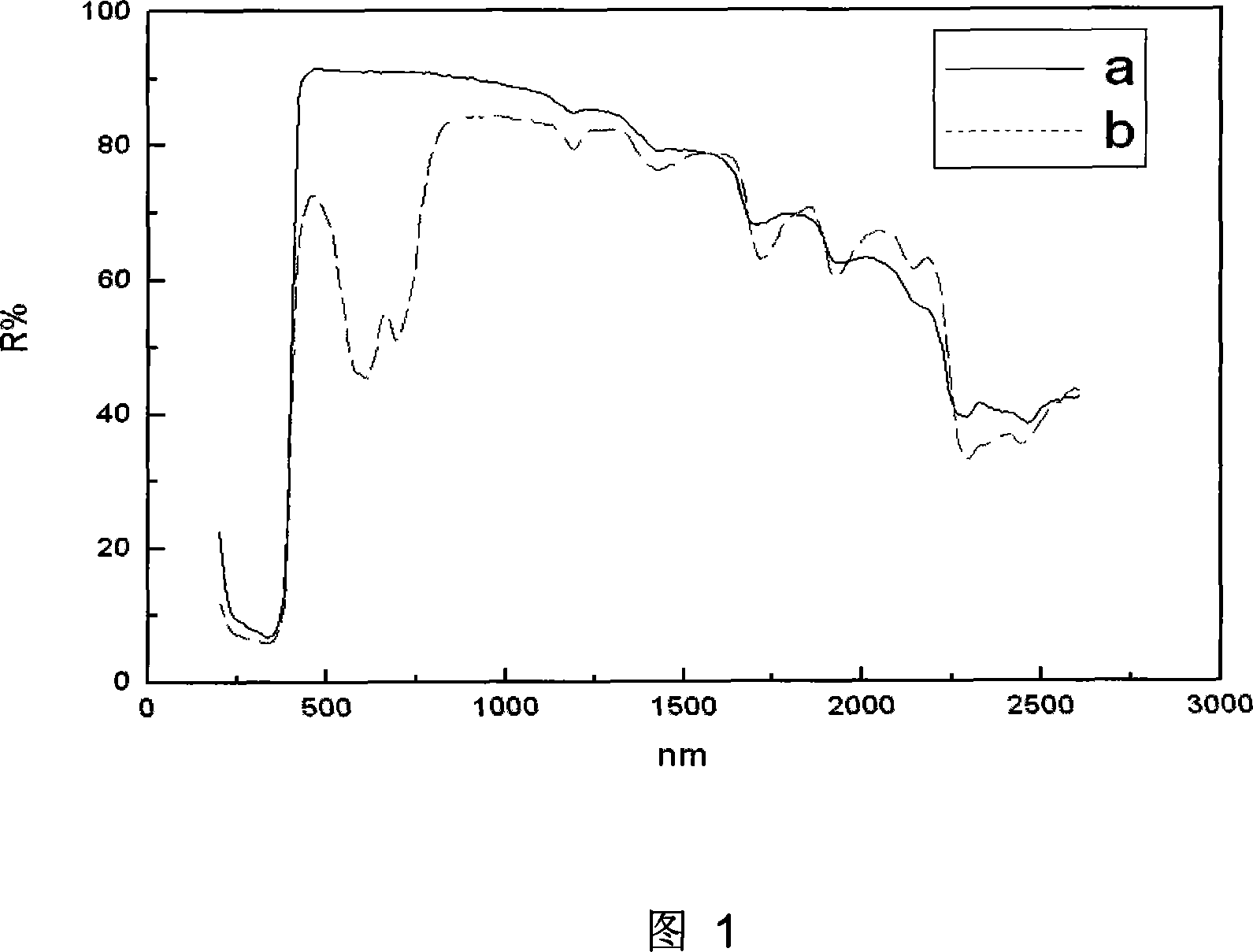

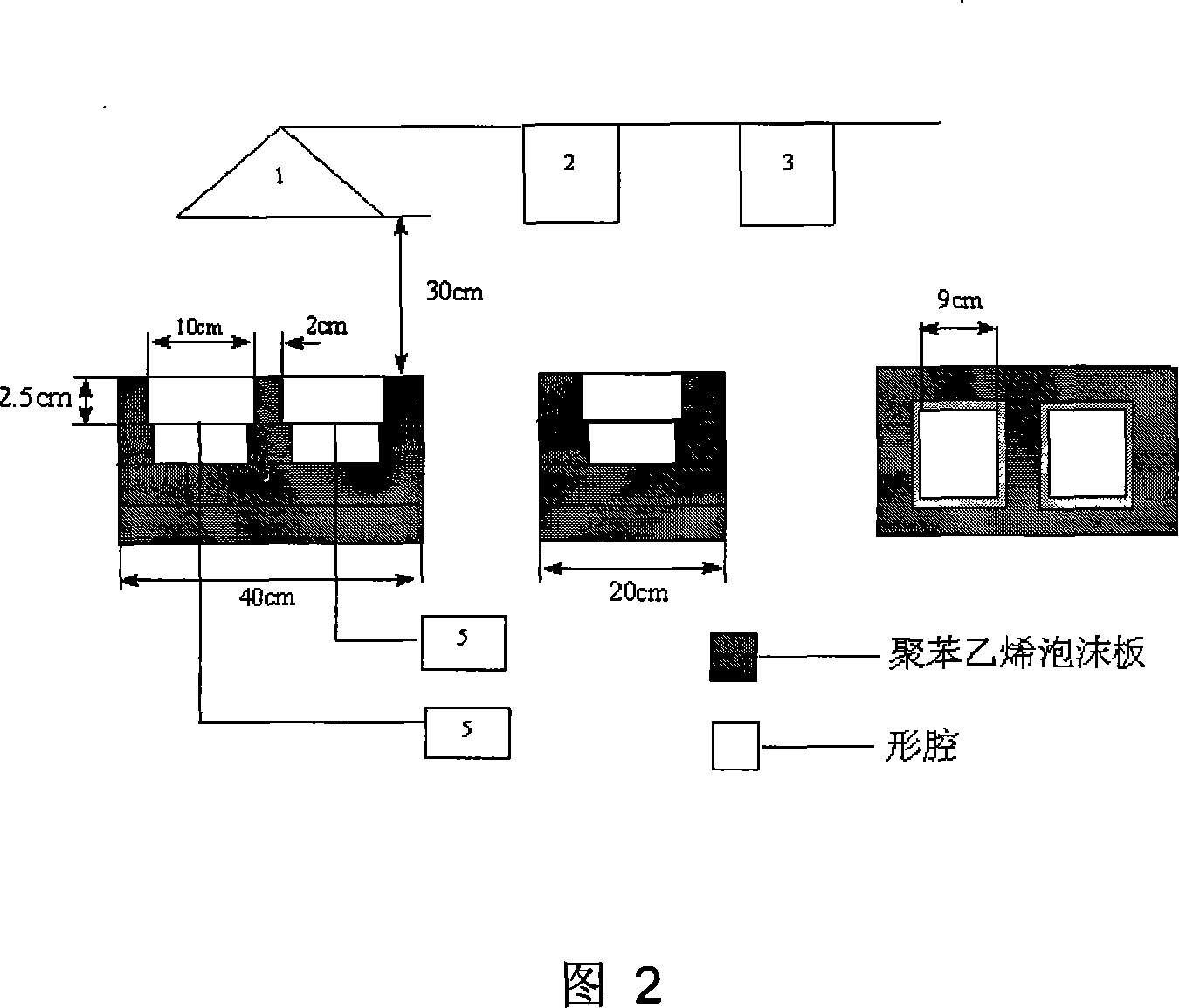

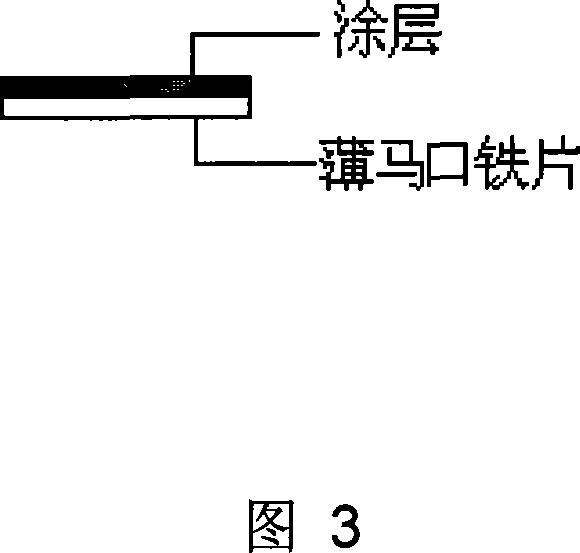

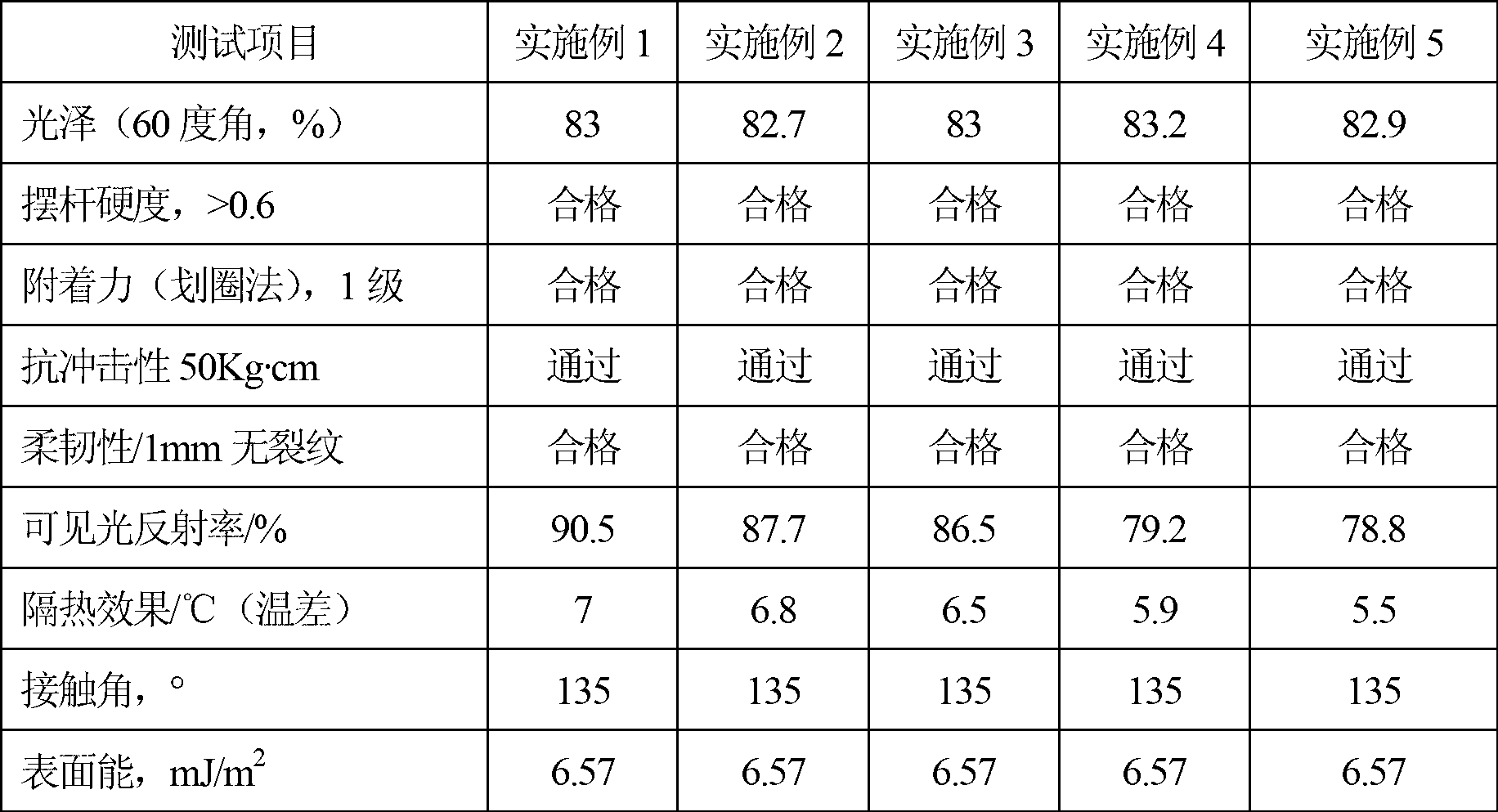

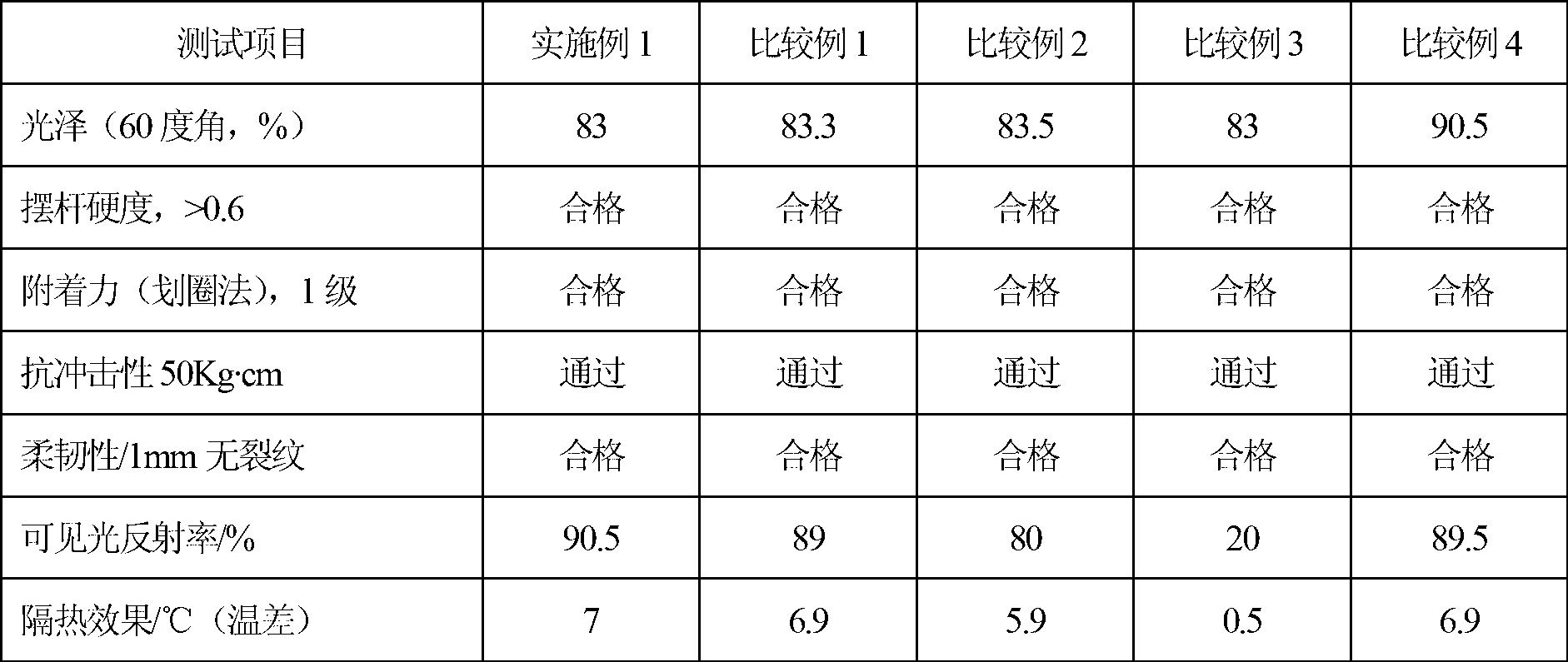

Fluorocarbon nanometer solar heat-insulation reflective paint, preparation method and using method thereof

ActiveCN103013241AImprove reflectivityImprove anti-corrosion performanceReflecting/signal paintsCross-linkInfrared

The invention relates to a fluorocarbon nanometer solar heat-insulation reflective paint, a preparation method thereof and a using method thereof. The paint can be used for roofs and glass curtain walls of the building industry, offshore drilling platforms, oil tanks and petroleum pipelines of the petroleum industry, the surfaces of cars and trains of the transportation industry, hulls and decks of the ship-building industry, and the tanks and warships of the weapon and aerospace industry. The fluorocarbon nanometer solar heat-insulation reflective paint comprises a component A and a component B, wherein the component A comprises the following materials in percentage by weight: 40%-70% of fluorocarbon resin, 1%-10% of nanometer TiO2 concentrated slurry, 10%-30% of infrared-ray reflective pigment, 3%-10% of hollow micro beads, 1%-5% of auxiliaries and 10%-20% of organic solvent; and the component B is cross-linking agent. The preparation method for the fluorocarbon nanometer solar heat-insulation reflective paint comprises the following steps: 1) preparing, dispersing and grinding the materials of the component A in proportion until the fineness is lower than 30 microns; and 2) mixing and curing the component A and the component B to prepare the fluorocarbon nanometer solar heat-insulation reflective paint. The fluorocarbon nanometer solar heat-insulation reflective paint provided by the invention is suitable for normal-temperature drying or low-temperature baking and drying; moreover, a coating film formed by the paint has the characteristics such as high reflectivity, a good heat-insulation effect, high corrosion prevention, high weather resistance, high self-cleanness, low friction and the like.

Owner:大连佳秀百隆新材料股份有限公司

Environment-friendly diatom ooze wall material powder and wall material and preparation method thereof

InactiveCN101700965AImprove adsorption capacityAdequate adsorptionMoisture absorptionAir purification

The invention discloses environment-friendly diatom ooze wall material powder and a wall material as well as a preparation method and application thereof. The diatom ooze wall material with macromolecule sieve structure is prepared by taking a plurality of natural environment-friendly non-metal material having strong adsorbability and good plasticity as main materials through a simple process. The environment-friendly diatom ooze wall material powder has the advantages of low cost, air purification, moisture absorption, deodorization, inflaming retarding, heat insulation, easy popularization,and the like.

Owner:QINGDAO CHUANSHAN NEW MATERIALS

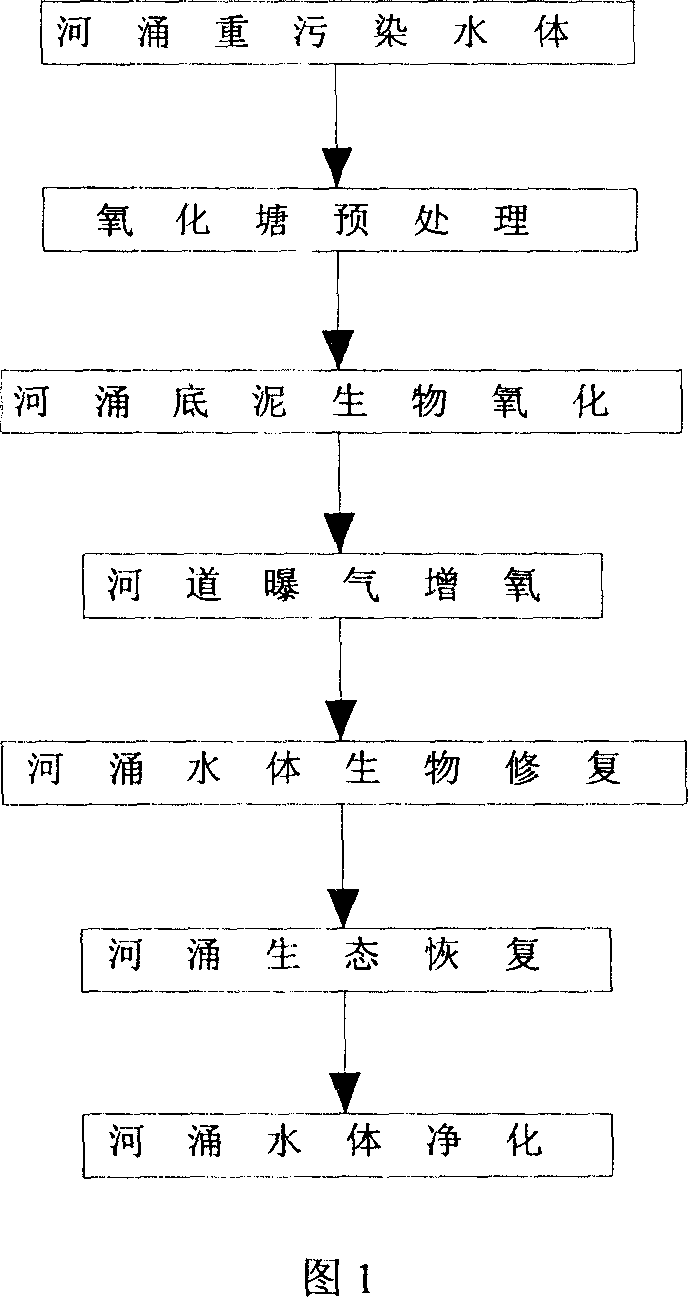

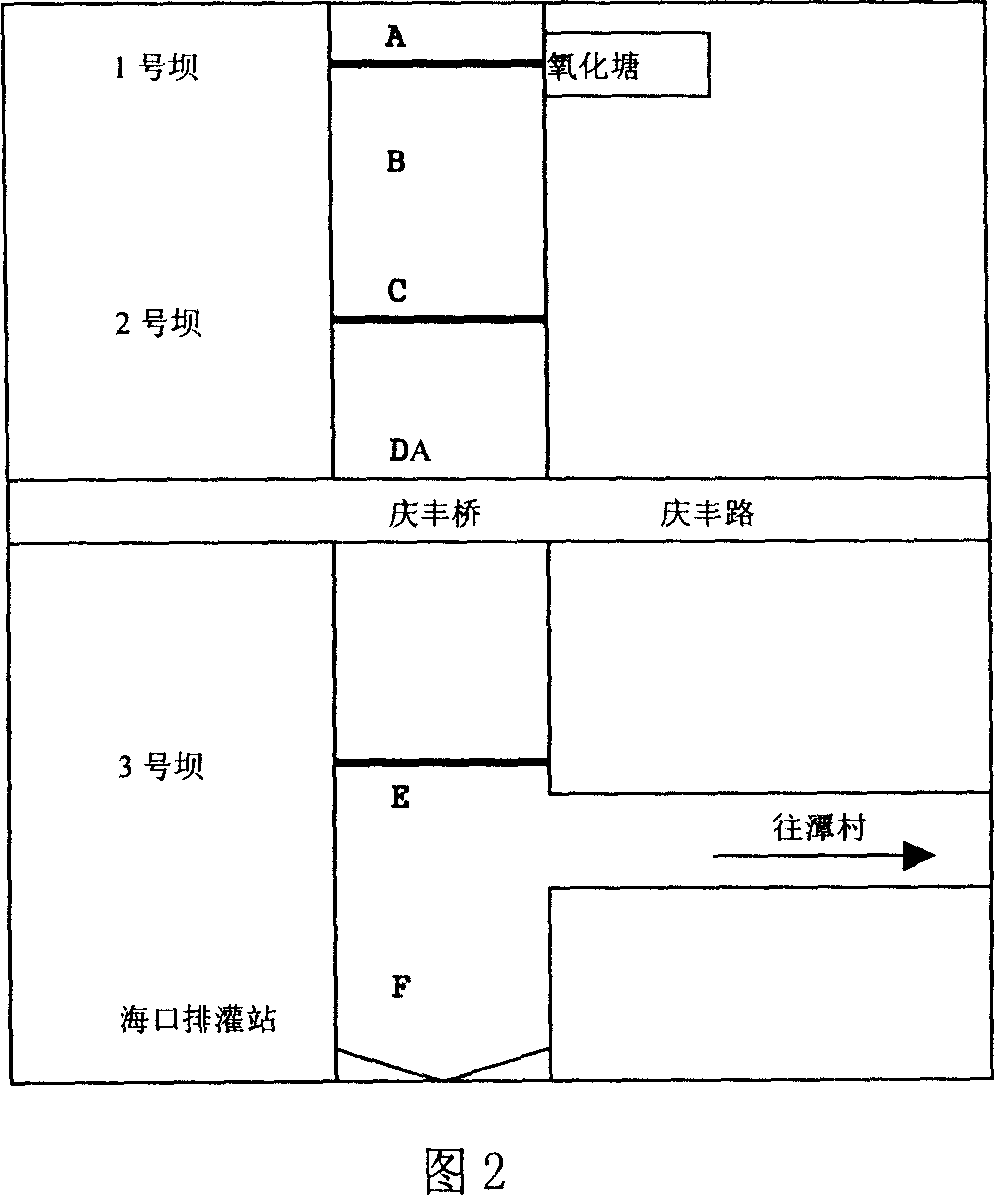

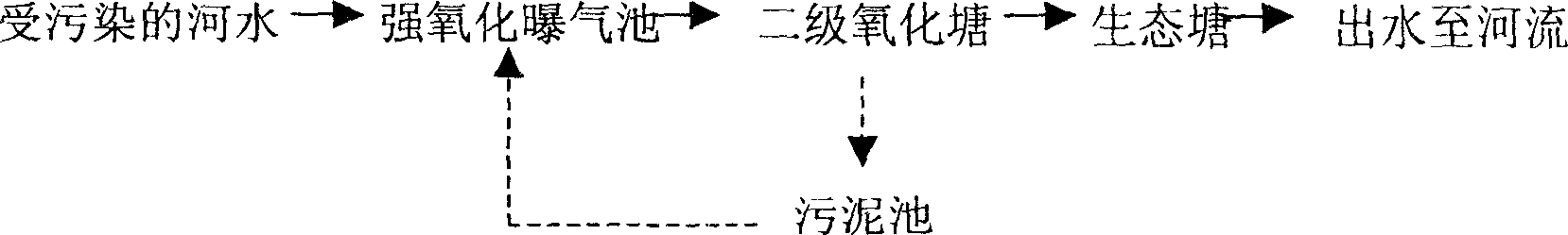

Method for governing pollution of river surge

InactiveCN101050041APurify waterEliminate black odorTreatment using aerobic processesSludge processingCombined methodWater quality

This invention provides a combined method for treating urban river surge with bioremediation as the major technique. The method comprises: pre-treating polluted water body of upstream urban river surge in an oxidation pool, performing biological oxidative remediation on bottom deposits in river, aerating river channel, performing bioremediation on middle reach water body, and performing ecological remediation on downstream water body. The method utilizes abandoned fishpond, vacant land or modified oxidation pool to perform pre-treatment on heavily polluted water body of urban river surge that cannot be treated by sewage interception. Then the method adopts biological oxidative remediation on bottom deposits to control internal pollution source of urban river surge, and artificial aeration, and biological-ecological remediation to effectively eliminate pollutants and odor of water body, improve water quality of urban river surge, and improve self-cleaning ability of urban river surge water body. The method is a feasible method in treating urban river surge.

Owner:国家环境保护总局华南环境科学研究所

Nano mirror spray coating

InactiveCN1944710AExtended use timeImprove adsorption capacityLiquid/solution decomposition chemical coatingPotassium borohydrideSpray coating

The nanometer mirror spraying process includes the following steps: 1. eliminating surface dust; 2. spraying primer; 3. sensitizing and activating treatment; 4. spraying solution A comprising silver nitrate solution, ammonia water solution and sodium hydroxide solution and solution B comprising sodium borohydride, potassium borohydride or p-methylaminophenol sulfate solution in the volume ratio of 1 to 1-1.7 to produce reduction; 5. shaping and developing; 6. blowing to dry; and 7. drying. The present invention has the advantages of diversified products, high corrosion resistance, suitability to mass production, high hardness, low cost, etc.

Owner:方宏亮

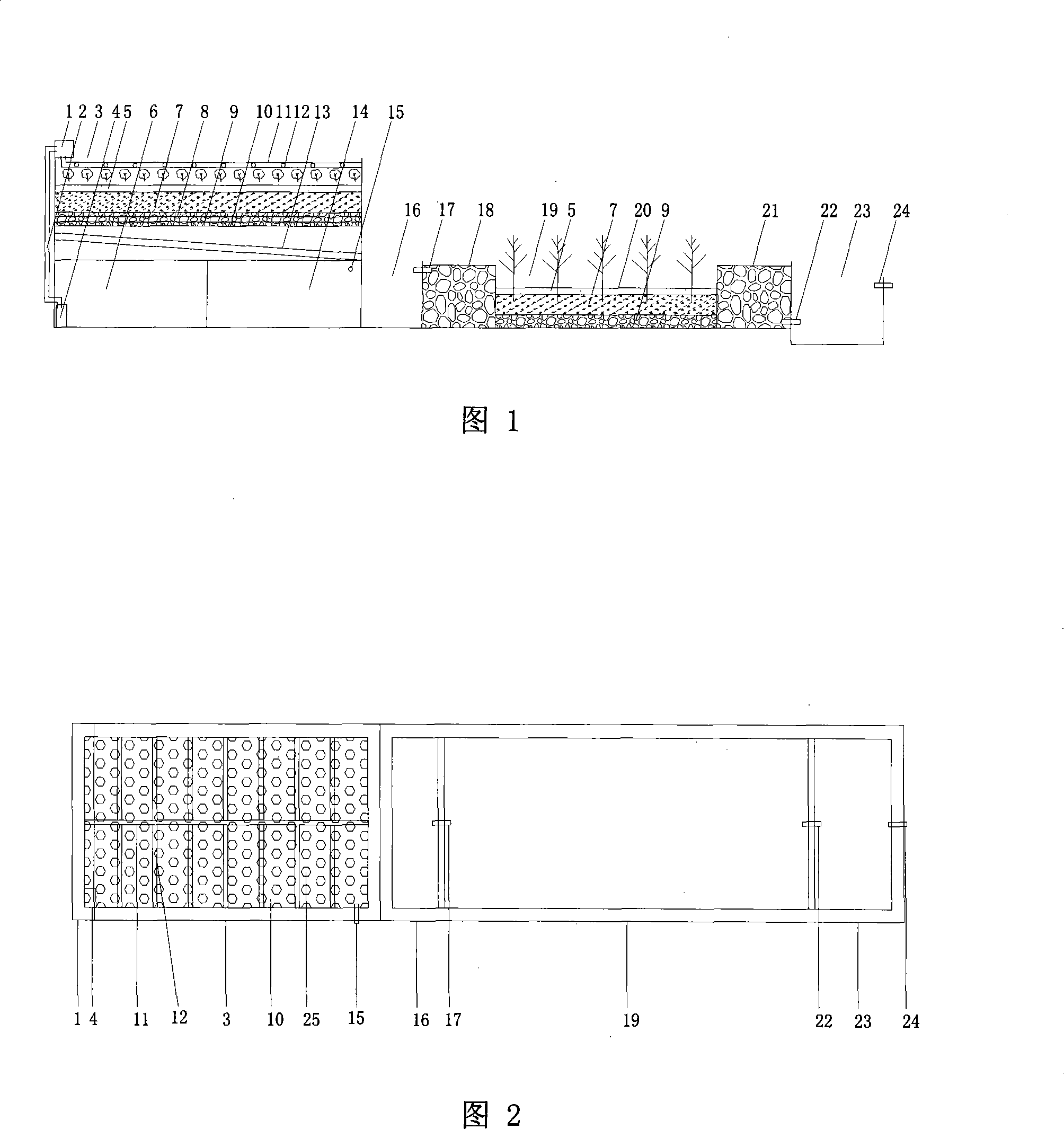

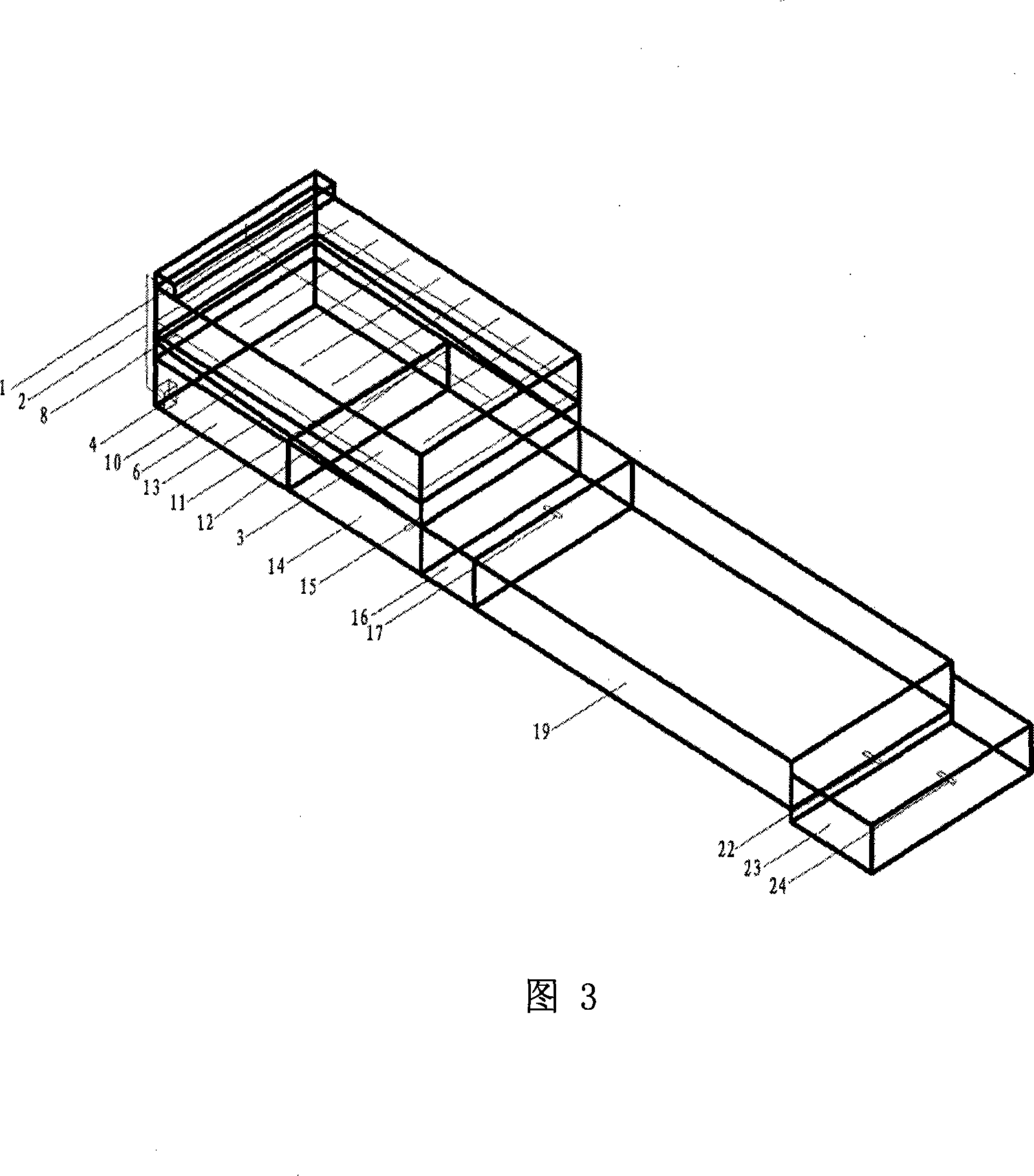

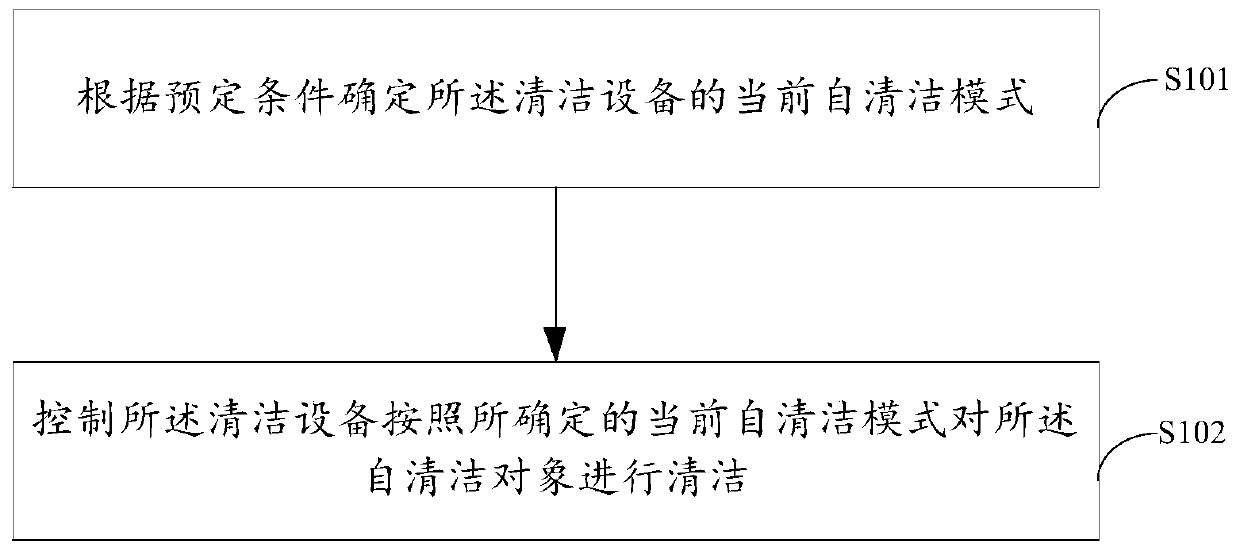

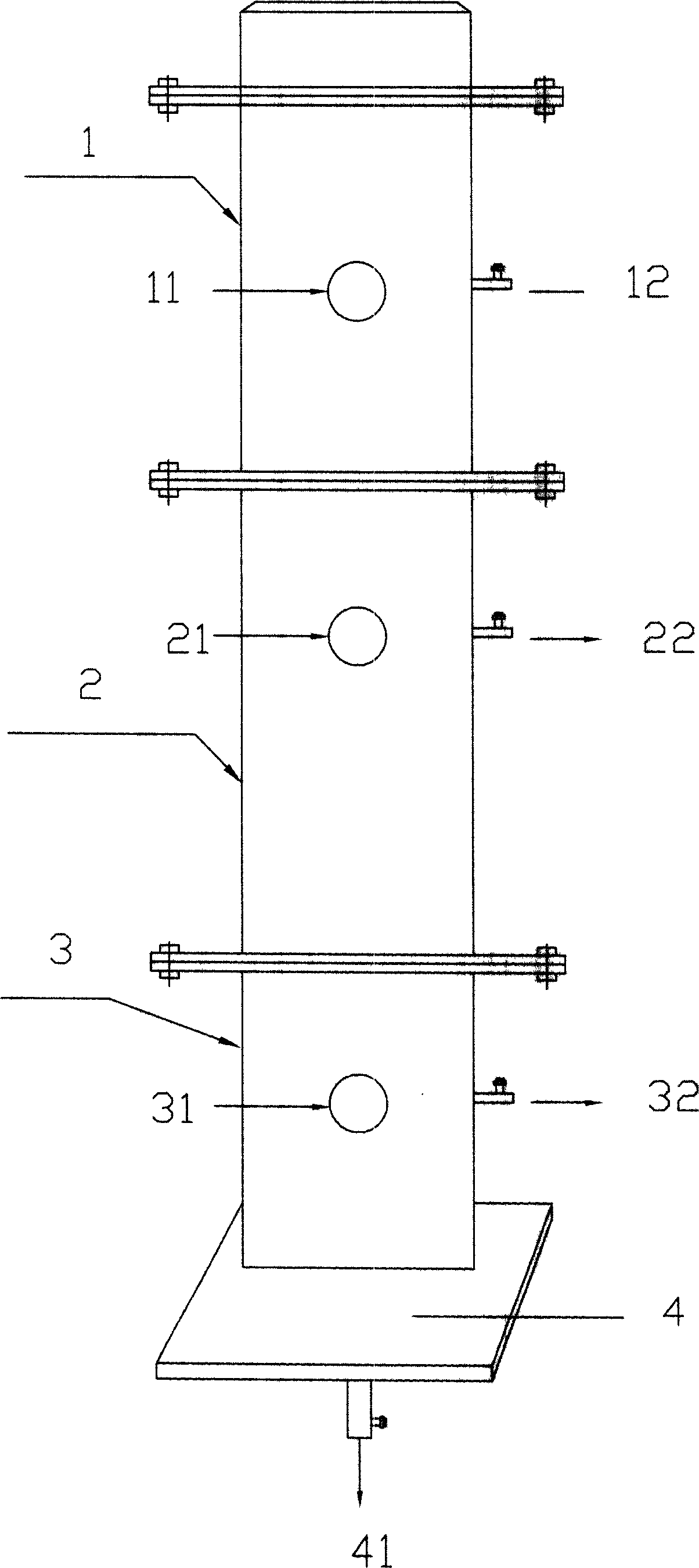

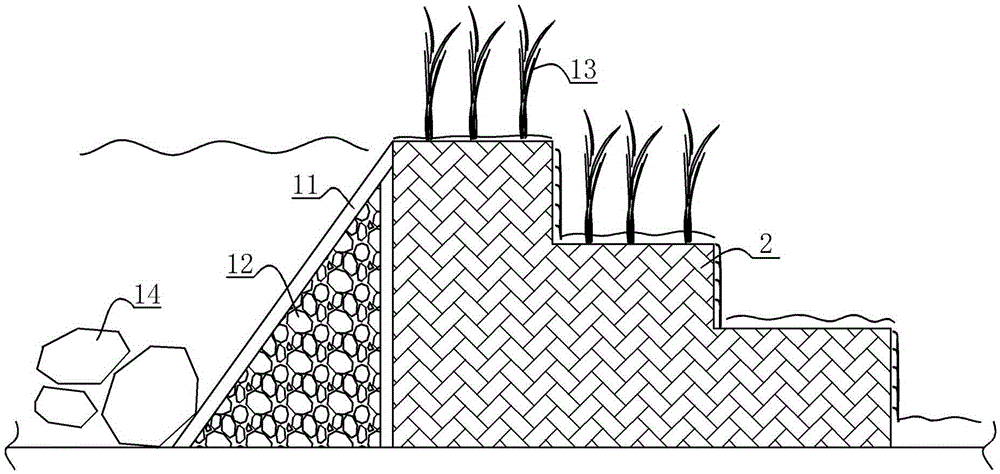

Stereo artificial wetland system for treating sewage

InactiveCN101186382AReduce closureHigh porositySustainable biological treatmentBiological water/sewage treatmentConstructed wetlandIndustrial waste water

The invention relates to the technical field of sewage treatment, in particular to a sewage treatment tridimensional artificial wetland system that is used for the industrial waste water treatment of small-scale isolated pollution sources. The invention aims at providing a tridimensional artificial wetland system that is used for sewage treatment and that has small floor occupancy, high hydraulic load, high pollution load and long service life so as to overcome the defects of the current sewage treatment of big artificial wetland floor occupancy, low hydraulic load, low pollution load and short system service life. The key points of the invention are that: the artificial wetland for sewage treatment adopts a tridimensional assembled structure of vertical current artificial wetland and horizontal subsurface flow artificial wetland, and base materials are filled in various directions to form the tridimensional artificial wetland system for sewage treatment; the tridimensional artificial wetland system for sewage treatment comprises a water collecting header, a porous water-filtering vertical current artificial wetland bed, a first-stage regulating tank, a water drop chute, a grid tank, a second-stage regulating tank, a horizontal subsurface flow artificial wetland bed and a water collecting tank.

Owner:ZHEJIANG NORMAL UNIVERSITY

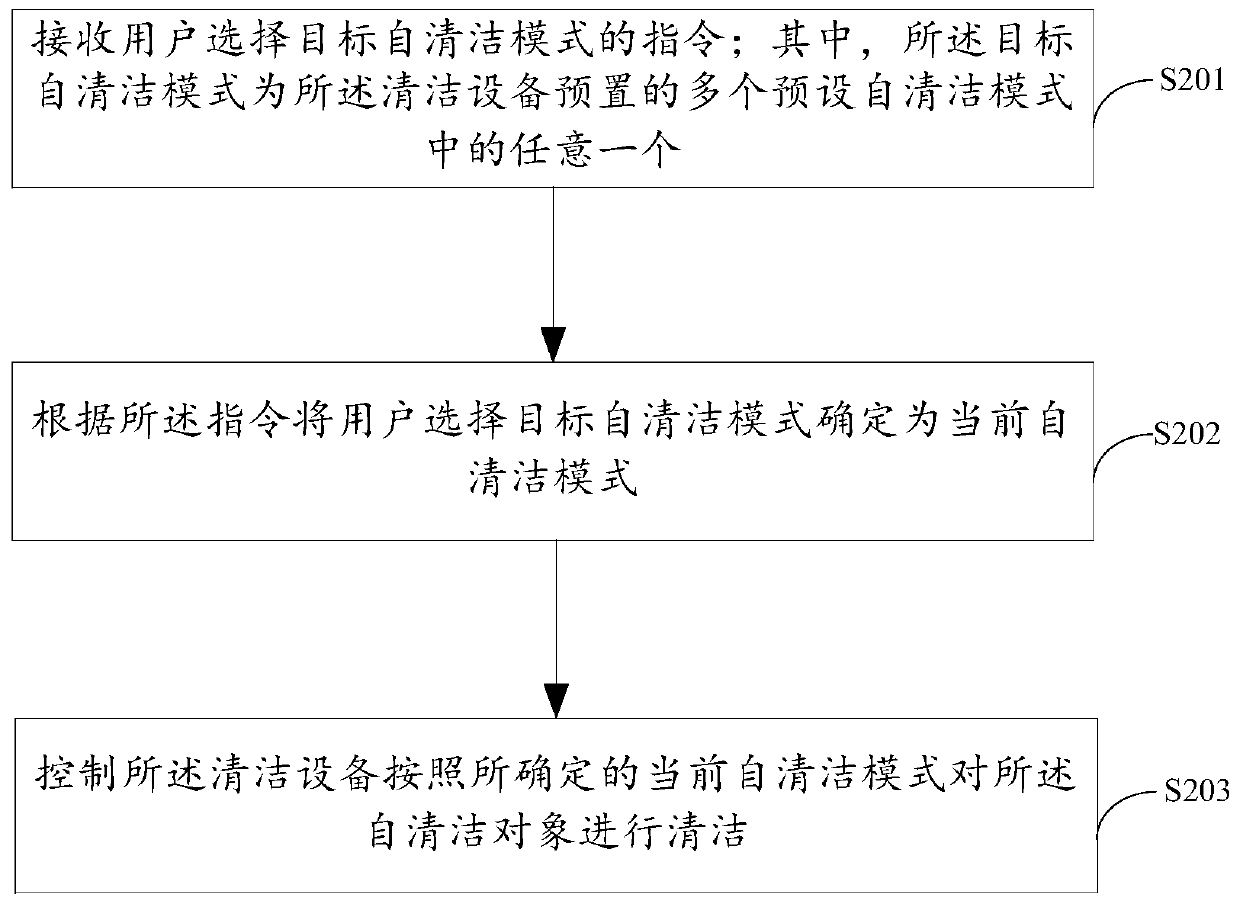

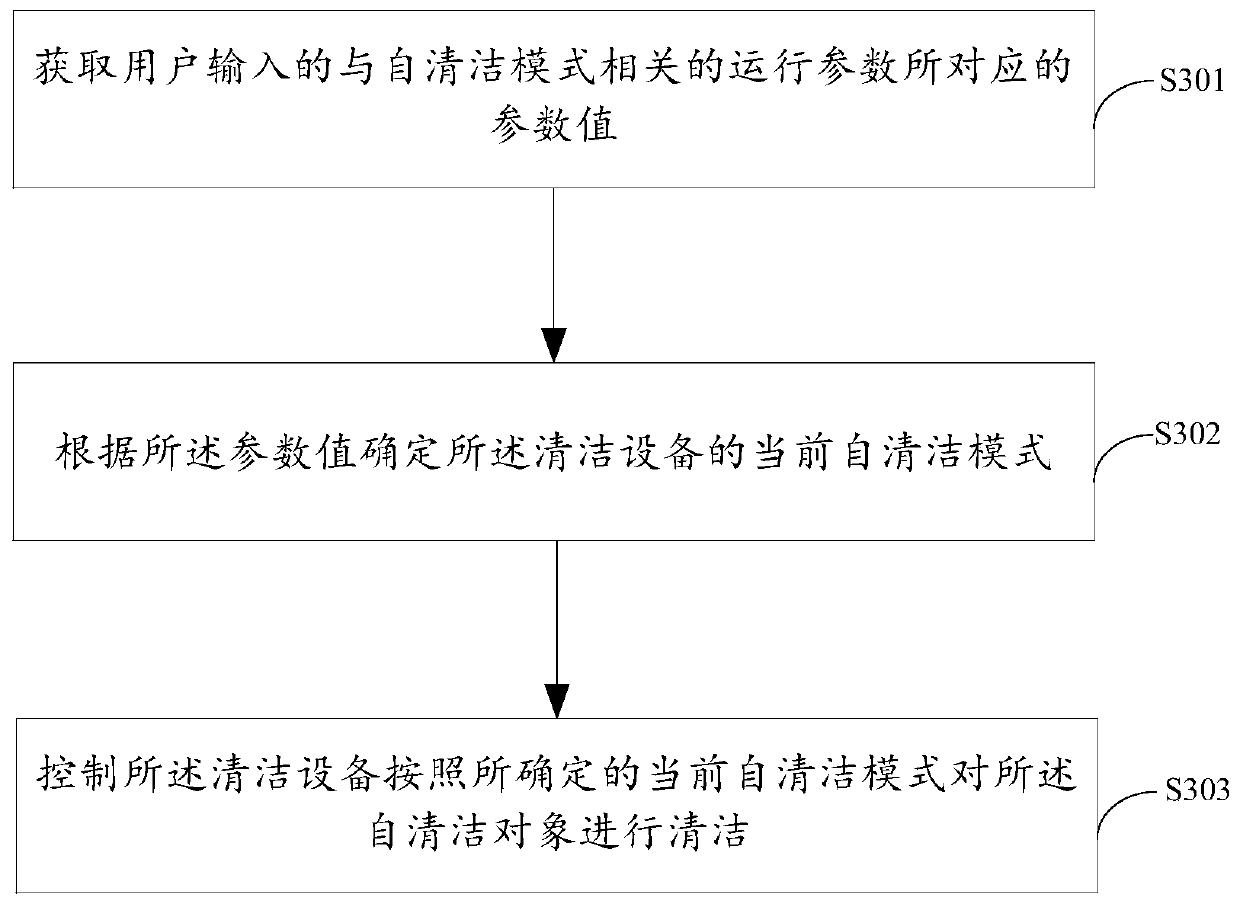

Self-cleaning control method of cleaning equipment, cleaning equipment and storage medium

InactiveCN111358342AIncrease flexibilityImprove self-cleaning effectCarpet cleanersFloor cleanersProcess engineeringManufacturing engineering

According to a self-cleaning control method of cleaning equipment, the cleaning equipment and a storage medium provided by the embodiment of the invention, the cleaning equipment is provided with at least one self-cleaning object, and the control method comprises the steps that: a current self-cleaning mode of the cleaning equipment is determined according to preset conditions; and the cleaning equipment is controlled to clean the self-cleaning object according to the determined current self-cleaning mode. According to the technical scheme of the embodiment of the invention, different self-cleaning modes can be selected according to different dirt conditions of the cleaning equipment, and the selection flexibility of the self-cleaning modes of the cleaning equipment is improved.

Owner:TIANKE INTELLIGENT TECH CO LTD

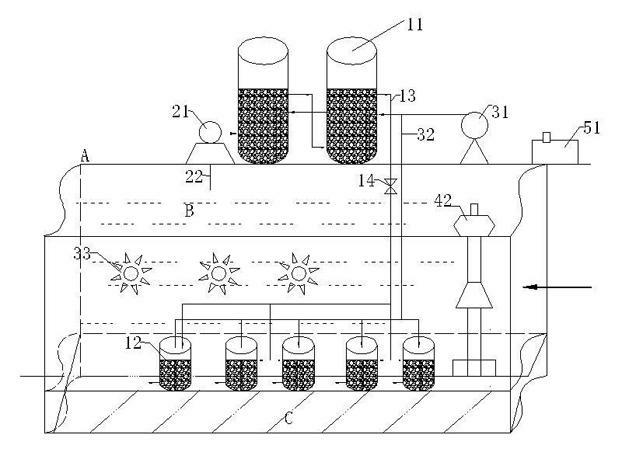

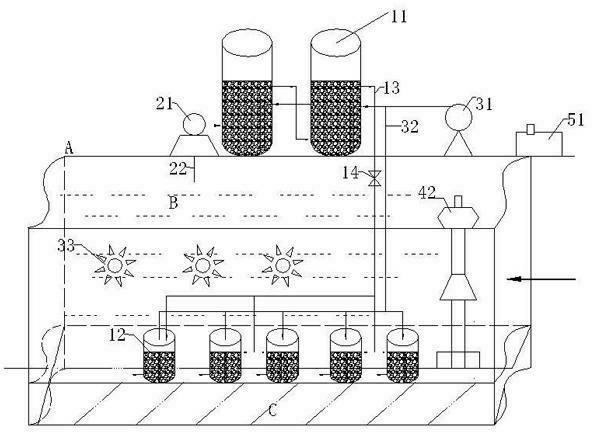

Method and device for utilizing microorganism in-situ circulation cultivation to treat water body pollution

InactiveCN102531201AIncrease environmental capacityImprove self-cleaning abilityBiological water/sewage treatmentMicroorganismDecomposition

The invention discloses a method for utilizing microorganism in-situ circulation cultivation to treat water body pollution, (1) riverway sewage is utilized to be in-situ cultured, circulated, acclimatized and separated microorganisms out in a culture tank and an biological generator for being put into a water body, and the water body pollution is removed through microorganism absorption, decomposition and transfer; (2) an aerating device is adopted to aerate and provide a good environment for the culture tank, the biological generator and the riverway water body; and (3) a mixer is adopted to stir water sediment, so the pollutant of the sediment enters the water to be utilized by the microorganisms, and the ecological dredging is realized. The invention further discloses a device which is adopted by the method. The method takes nutrients in the reverway sewage as a strain medium, the microorganism environment is improved through aeration and stirring, the added foreign bacterium is more applicable to the water body, is mass propagated and has strong decomposition capacity, so the excellent speed is improved, the source is stable, the purposes of high efficiency, continuity, thoroughness and low cost are realized, meanwhile, the device has strong movability, is convenient to install and dismantle, and has a wide application scope.

Owner:浙江天韵生态环境工程有限公司

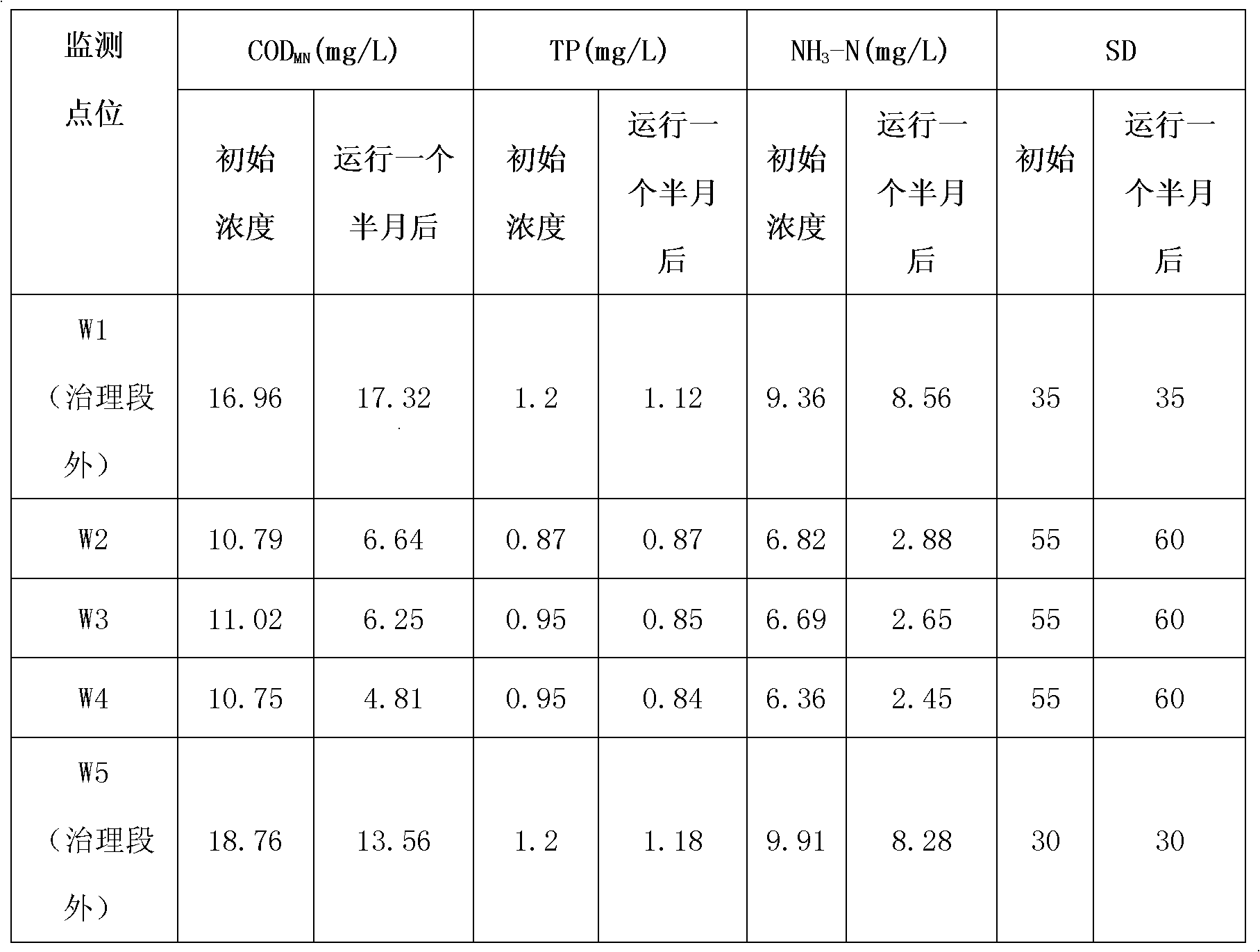

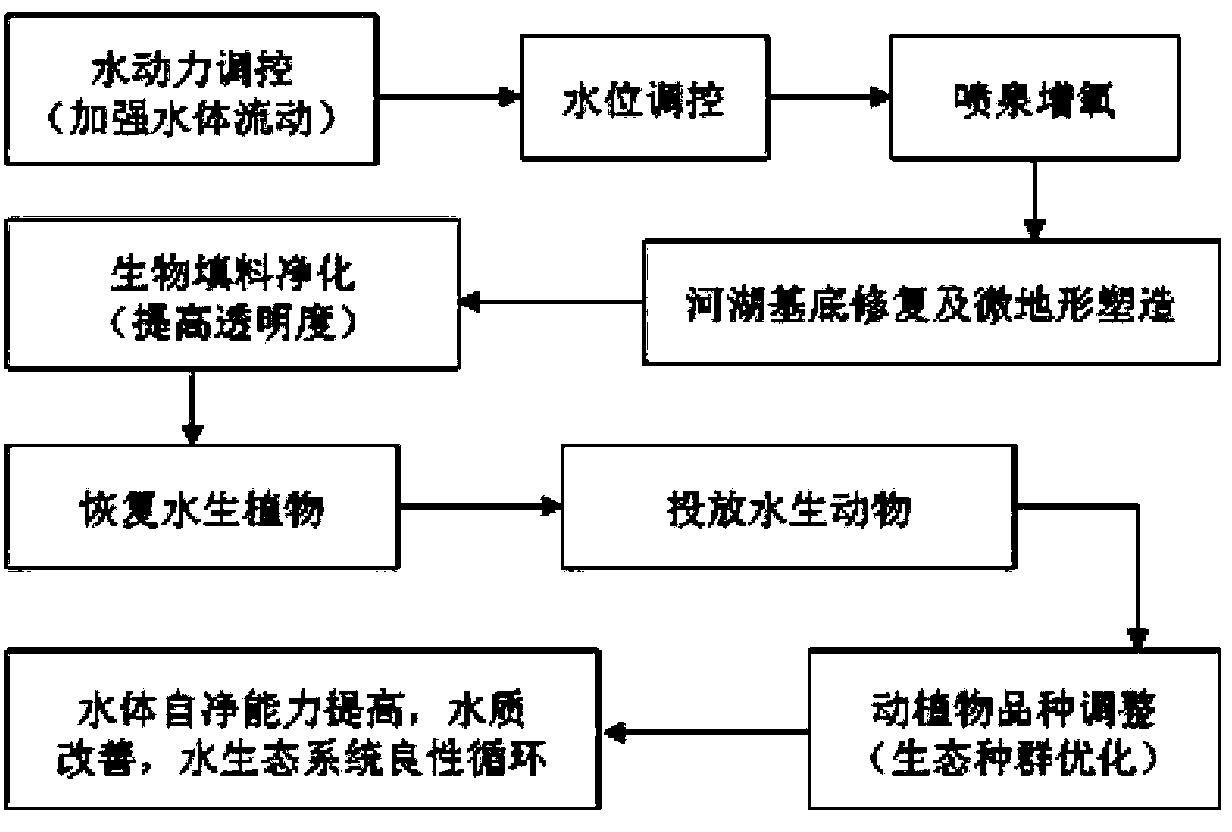

Rapid method for constructing river way water ecosystem

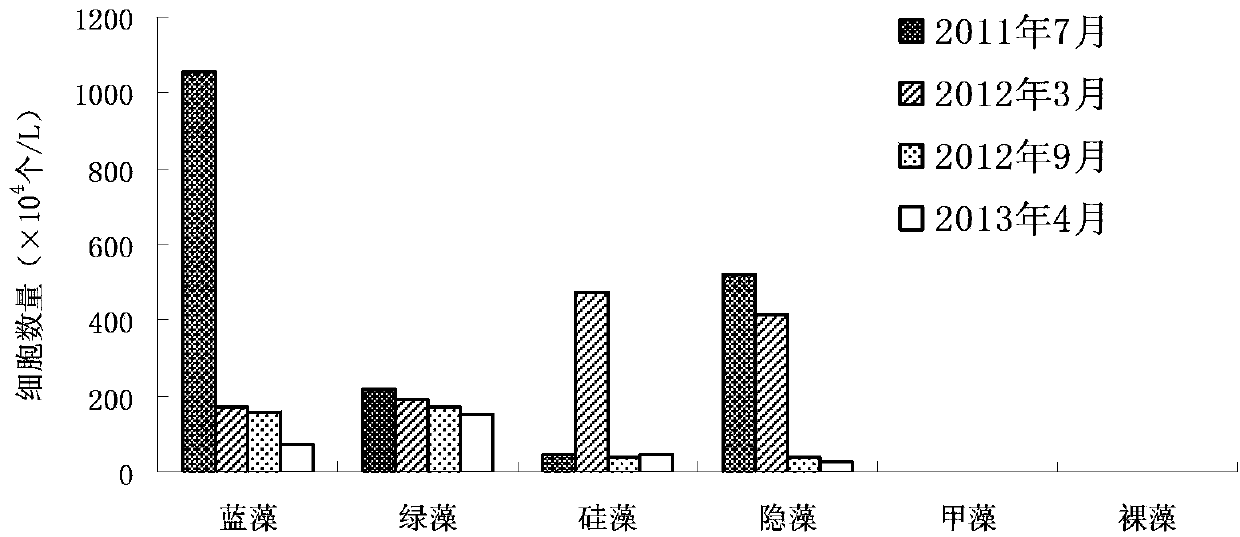

InactiveCN105565584ALow costHigh transparencyWater resource protectionEnergy based wastewater treatmentHydrometryEutrophication

The present invention belongs to the technical field of water ecological restoration, and specifically discloses a rapid method for constructing a river way water ecosystem, the method includes the following steps: 1, collecting of to-be-repaired river way water ecological information; 2, detailed analysis of pollution information, sewage interception reoxygenation and blackness and odor removal by microbial decomposition; 3, planting of emergent proper aquatic plants, submerged plants and the like according to water and hydrological information; 4, control of algae by aquatic animals; and 5, water ecosystem maintenance; wherein aquatic plants are usually harvested in November each year, and plant body residues are cleaned up in early spring. Through combination of an ECO-EGG plug-flow aerator and the constructed river way water ecosystem, physical, chemical and biological-ecological approaches are effectively combined for phased treatment, water quality is rapidly improved, water eutrophication is controlled, water self-purification capacity can be improved, the water ecological structure and function can be restored, water quality can be long term and effectively improved, meanwhile the effectiveness, long effectiveness, economical efficiency and ecological compatibility of polluted water treatment can be unified.

Owner:上海库克莱生态科技有限公司

Method for treating black-odor rivers and lakes with microbiological preparations

InactiveCN101555088AAchieve degradationImprove self-cleaning abilityMultistage water/sewage treatmentSustainable biological treatmentDecompositionSludge

The invention pertains to the technical field of environment protection, which provides a method for treating black-odor rivers and lakes with microbiological preparations and comprises the following steps of: (1) pre-treatment of the rivers or the lakes; (2) biofilm colonization treatment; (3) microorganism augmentation treatment by direct application; (4) water ecology recovery and oxidation reduction of reductive sludge at the bottom; and (5) protection and further improvement of water environment. The method for treating black-odor rivers and lakes with microbiological preparations employs a plurality of microbiological preparations to treat the black-odor rivers and lakes, realizes the decomposition of organic pollutants in the water body, improves water ecological balance, and oxidizes, and reduces the reductive sludge at the bottoms of the rivers and lakes.

Owner:李华林

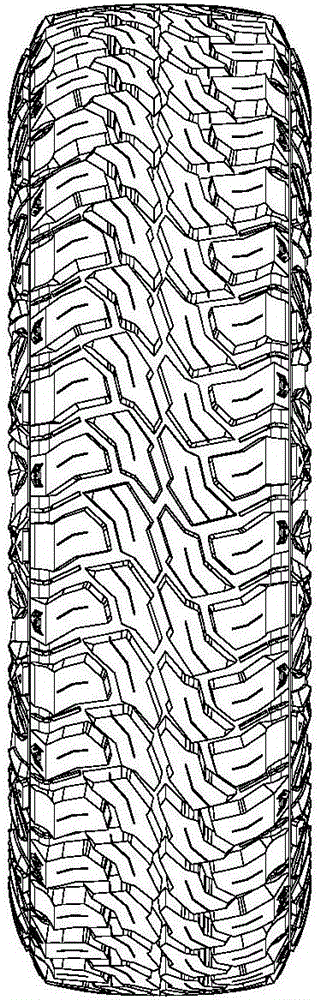

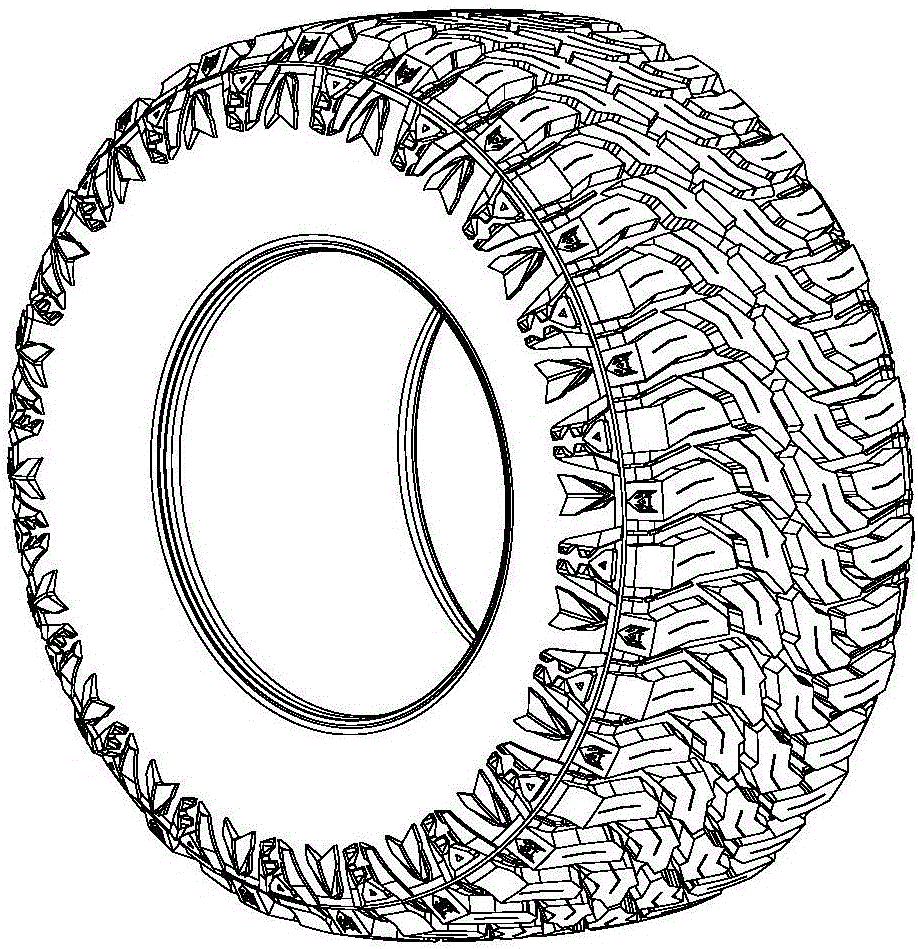

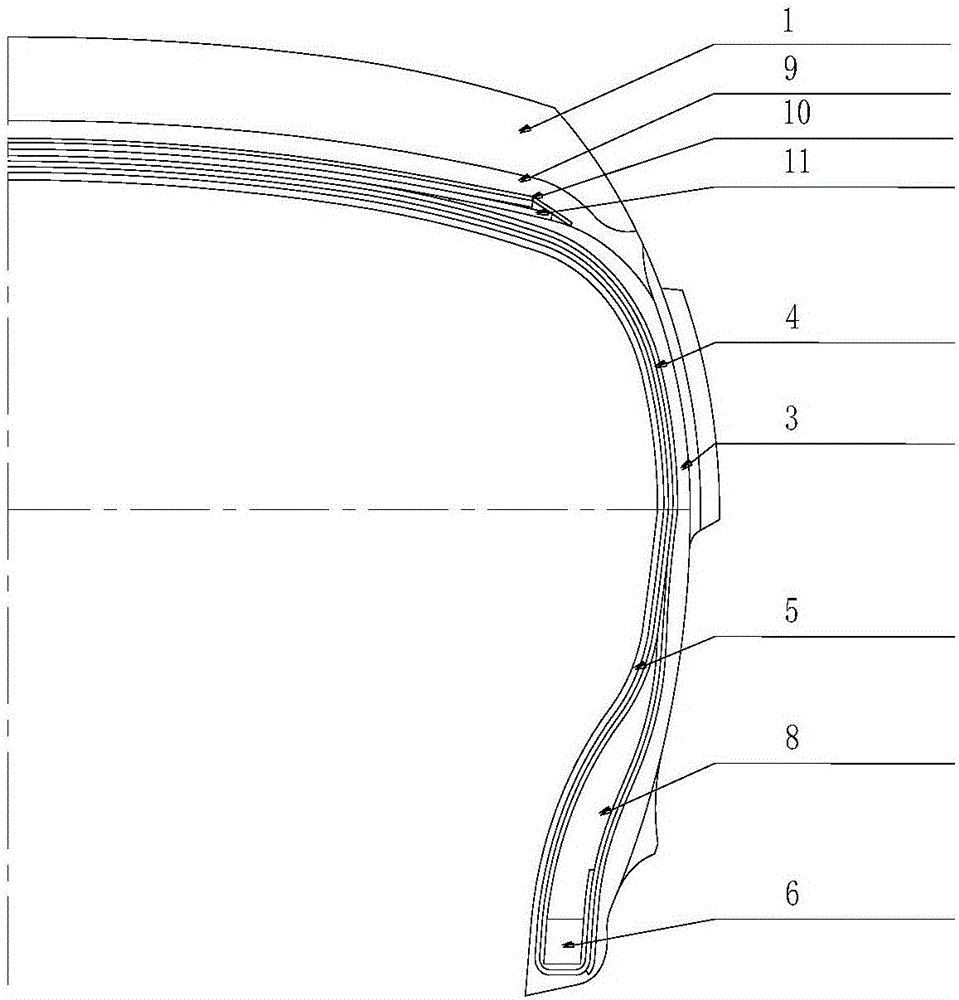

All-steel mud-field tire

InactiveCN106394128AHigh strengthImprove securityOff-road vehicle tyresPneumatic tyre reinforcementsUltimate tensile strengthTire iron

The invention provides a novel all-steel mud-field tire, and belongs to the field of tires. Through the adoption of the novel all-steel mud-field tire disclosed by the invention, improving tire strength is facilitated, impact resistance and durability of the tire are improved, and the service life of the tire is prolonged. A longitudinal section of the all-steel mud-field tire comprises a tire crown (1), a tire shoulder (2), a tire sidewall (3), a tire bead (6), and a tire body (4), wherein the tire crown (1) is located on the outer side of the upper part of the longitudinal section; the tire shoulder (2) is connected with the tire crown (1); the tire sidewall (3) is connected with the tire shoulder (2); the tire bead (6) connected with a wheel rim is arranged at the lower part of the tire sidewall (3); the tire body (4) is located on the inner side of the section of the tire; a tire shoulder pad (21) is arranged on the tire shoulder (2); a convex rib (31) is circumferentially and annularly arranged on the outer part of the tire sidewall (3); and the tire body (4) is a layer of all-steel tire body.

Owner:QINGDAO DOUBLESTAR TIRE IND CO LTD

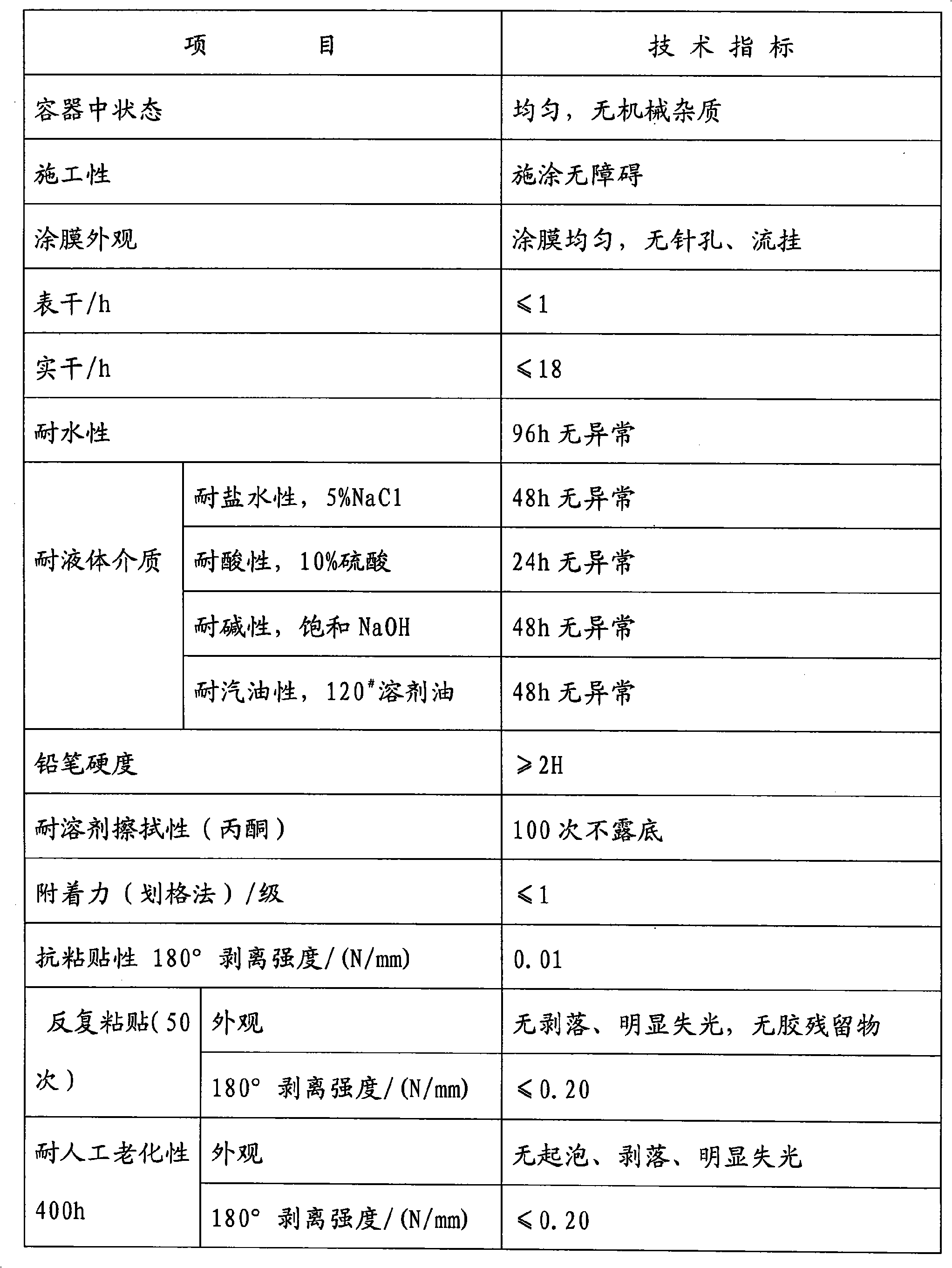

Oil-based anti-graffiti adhesion resistant paint and preparation method thereof

ActiveCN101585995AHigh hardnessImprove self-cleaningPolyurea/polyurethane coatingsAcrylic resinPolydimethyl siloxane

The invention discloses oil-based anti-graffiti adhesion resistant paint and a preparation method thereof, and belongs to paint and a preparation method thereof. Components A of the paint comprise hydroxy acrylic resin, fluorocarbon resin, modified polydimethyl siloxane resin, polyacrylate modified organic silicon resin, smooth flow agent, flatting agent, antifoaming agent, drier, dibutyl tin laurate, butyl acetate and dimethyl benzene; components B comprise hexamethylene diisocyanate, butyl acetate and ethylene glycol monoethyl ether acetate; and the mixture ratio of the components A to the components B is 3:1. The invention also discloses the preparation method thereof. The paint has the advantages of good anti-graffiti adhesion resistant function, super-strong scrubbing resistance, easy cleaning, and quick and convenient construction, has limited harmful substances, and achieves national requirement.

Owner:LANZHOU XUNMEI PAINT IND TECH

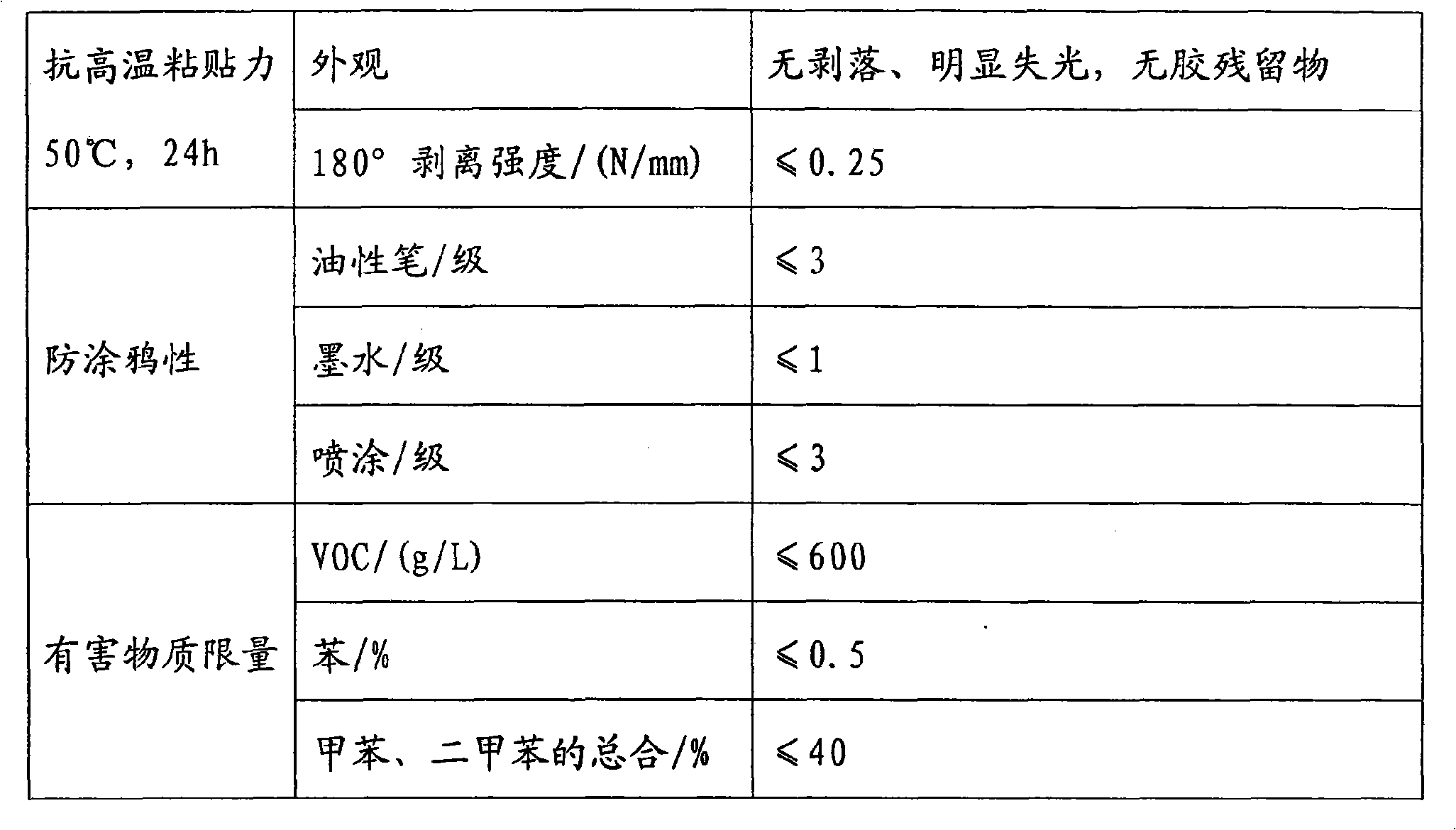

Comprehensive technology for ecological restoration of low-pollution river water

ActiveCN103359886AIncreased redox potentialPromote growthWater resource protectionWater aerationAquatic animalWater quality

The invention discloses a comprehensive technology for the ecological restoration of low-pollution river water. The technology constructs the low-pollution river water environment comprehensive control engineering treating flowing water as a base, treating ecological restoration as a core and giving consideration to the landscape improvement through the integration and optimization of ecologic restoration combination techniques comprising a water power control technique, a polluted basement restoration technique, an underwater microtopography shaping technique, an aquatic plant recovery technique, an aquatic animal restoration technique, an aquatic life reinforcement technique, a water landscape construction technique and the like. The comprehensive technology has a good pollutant removal performance, and the TN, NH3-N and TP reductions reach 75.5%, 84.5% and 92.0% respectively.

Owner:NANJING UNIV

Low-temperature dyeing and finishing technology of cottonette

InactiveCN105002730AProcess temperature changeLow processing temperatureBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsDiastase

The invention discloses a low-temperature dyeing and finishing technology of cottonette. The technology comprises the following steps: pretreatment; preshaping; modification treatment; dyeing; mordant removing; soaping; color fixing; post-treatment; drying; shaping; calendaring; rolling. According to the technology, pretreatment is carried out through the adoption of helicase and alpha-amylase, and modification treatment is carried out before dyeing, so that the property of the cottonette is fundamentally modified, and the dye-uptake of the fabric is increased; during the dyeing procedure, large quantities of alkaline substances and inorganic salt are not used, and a levelling agent, a low-temperature dyeing accelerant, a migration inhibitor and a dispersing agent are added, so that the dye uniformity is improved; during the whole dyeing process, the temperature is lower than 80 DEG C, and the dyeing process belongs to low-temperature dyeing, so that energy consumption is reduced; self-cleaning treatment is added in post-treatment, so that the self-cleaning capacity, wrinkle resistance and water washable firmness of the fabric are improved; post-treatment is carried out through the adoption of silk fibroin and sericin, so that the pilling resistance and antistatic property of the cottonette are improved; the whole technology is environment-friendly and free of pollution.

Owner:TAICANG TIANLONG CHEM FIBER

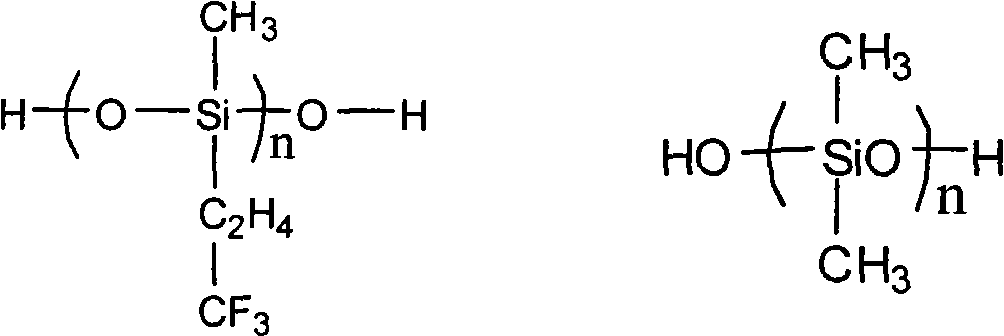

Fluorinated silicone rubber anti-pollution flashover coating for extra-high voltage and preparation method thereof

ActiveCN101597463ALower surface energyReduce adhesionCoatingsDecabromobiphenyl etherAluminium hydroxide

The invention provides a fluorinated silicone rubber anti-pollution flashover coating for extra-high voltage and a preparation method thereof; the fluorinated silicone rubber anti-pollution flashover coating (short for FRTV) has the following compositions by mass percent: 5-30 percent of fluorinated silicone rubber, 10-30 percent of silicon rubber, 4-8 percent of nanometer grade gas-phase white carbon black, 0.5-8 percent of compound fire retardants, 0.2-0.5 percent of firming agent, 0.01-0.05 percent of catalyst, 0.02-0.08 percent of antioxidant, 2-8 percent of flatting agents, 0.2-0.4 percent of de-foaming agent, 0.1-0.5 percent of paint and 30-60 percent of solvent. The compound fire retardant is composed of inorganic aluminium hydroxide and organic decabromodiphenyl oxide, wherein comprising 1-6 percent of the inorganic aluminium hydroxide and 0.5-3 percent of the organic decabromodiphenyl oxide. The preparing process of the coating is simple, and the coating has good weather ability, oil resistance and longer service life.

Owner:WUHAN NARI LIABILITY OF STATE GRID ELECTRIC POWER RES INST +1

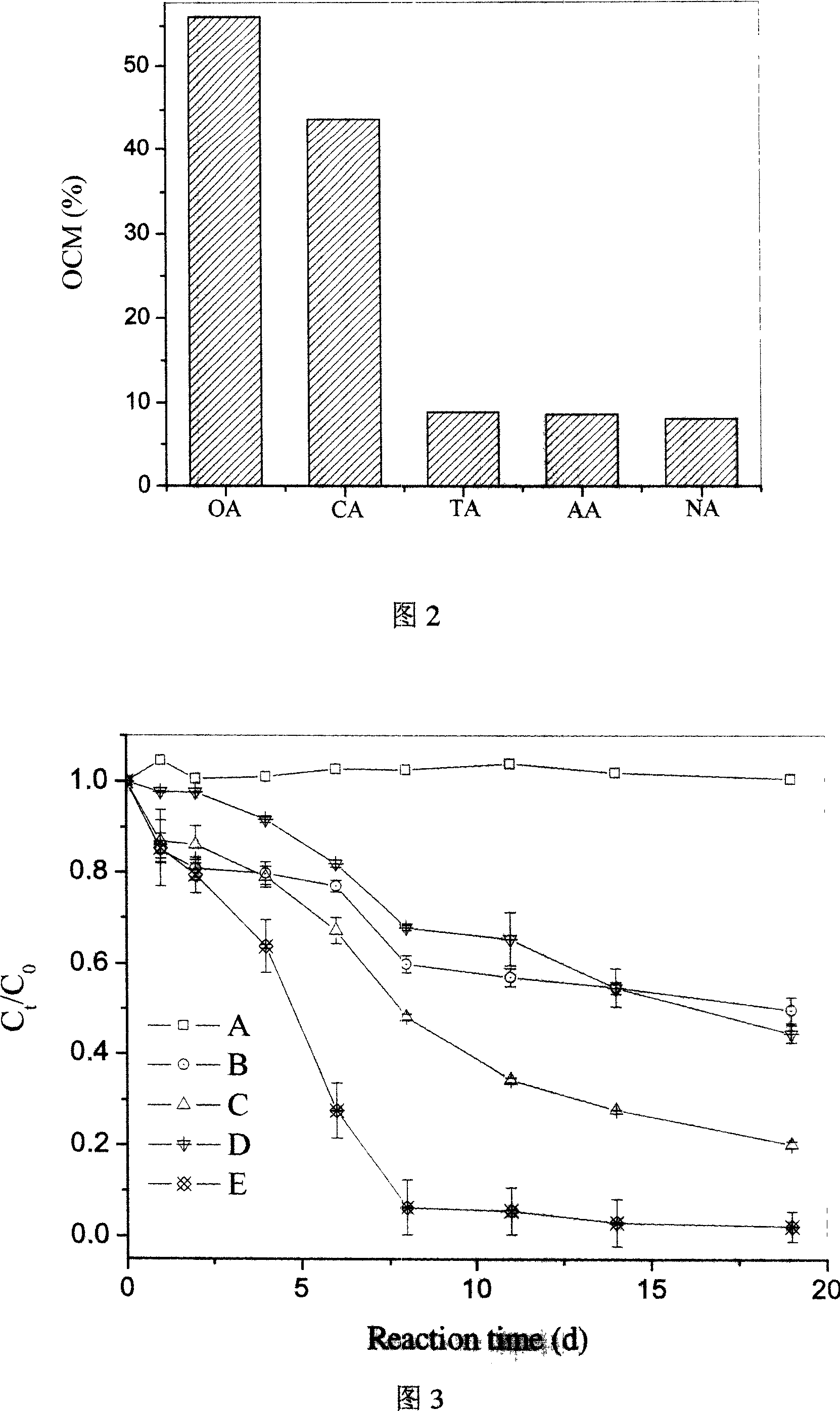

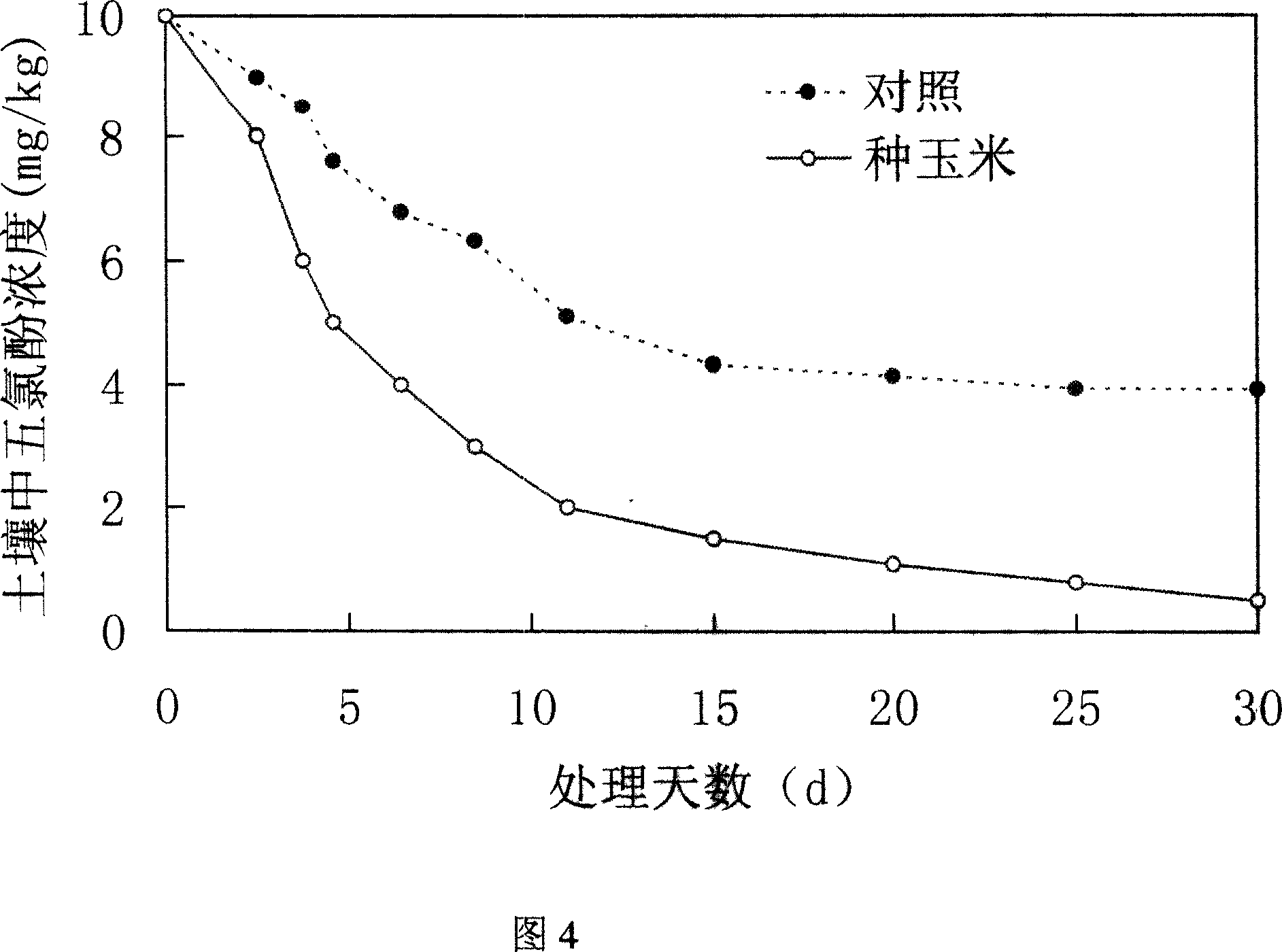

Method for accelerating deoxidization, degradation and transformation of organic contamination in soil

ActiveCN101011703APromote degradationEffective recoveryContaminated soil reclamationOrganic fertilisersContaminationEnvironmental chemistry

The invention relates to the speeding up degradation of organic pollutant in the soil, which uses strong reduction feature of metal nulvalent, synthetic metal oxidation and hydro oxidation, effectively reducing organochlorine insecticide and other contaminating pollutant, improving the biological degradation feature of organic pollutant. The above pollutant can be further degraded with the participation of organic acid. It can effectively realize the original position restoring of contaminated soil, particularly for the control and restoring of heavy polluted soil.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

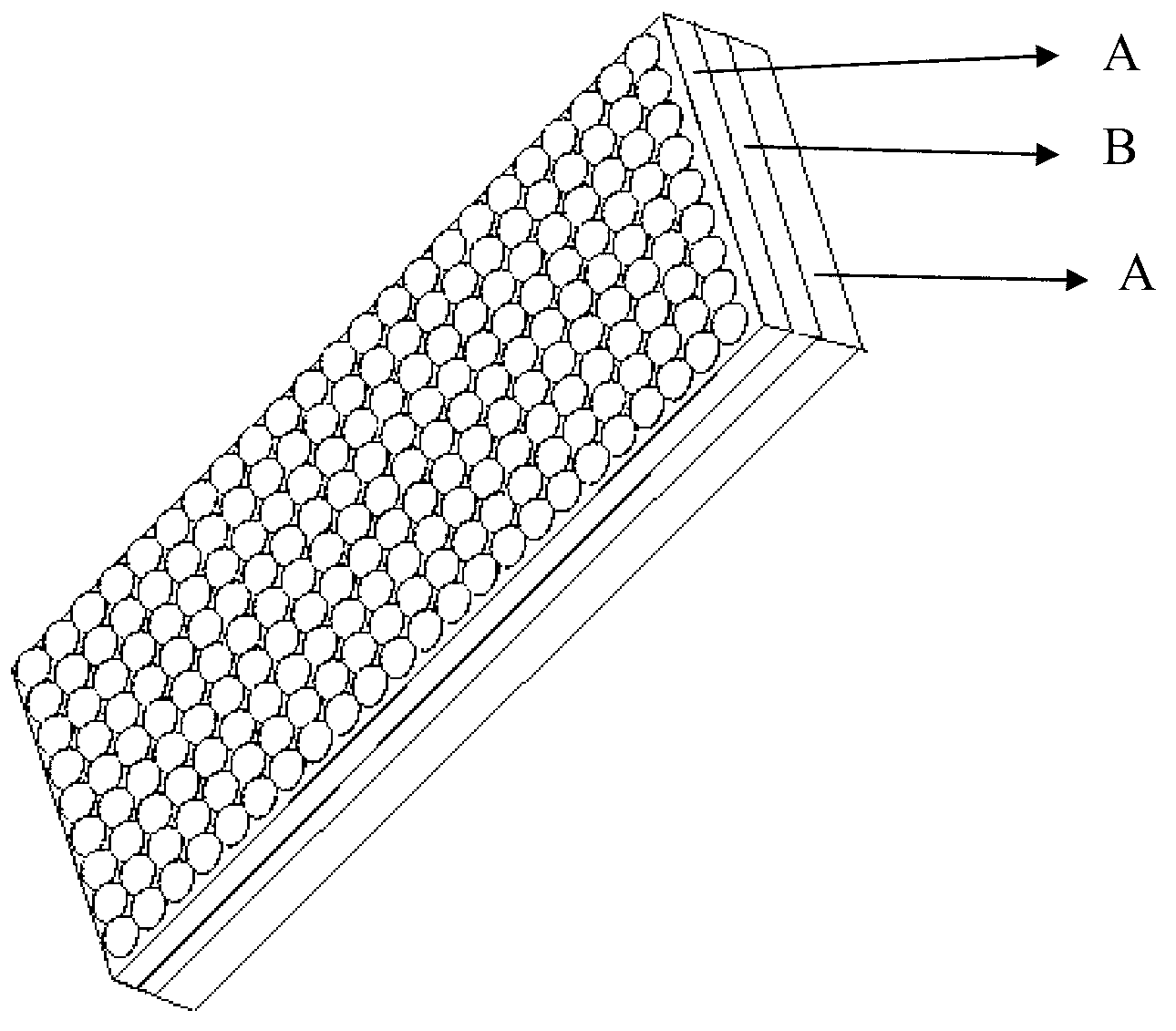

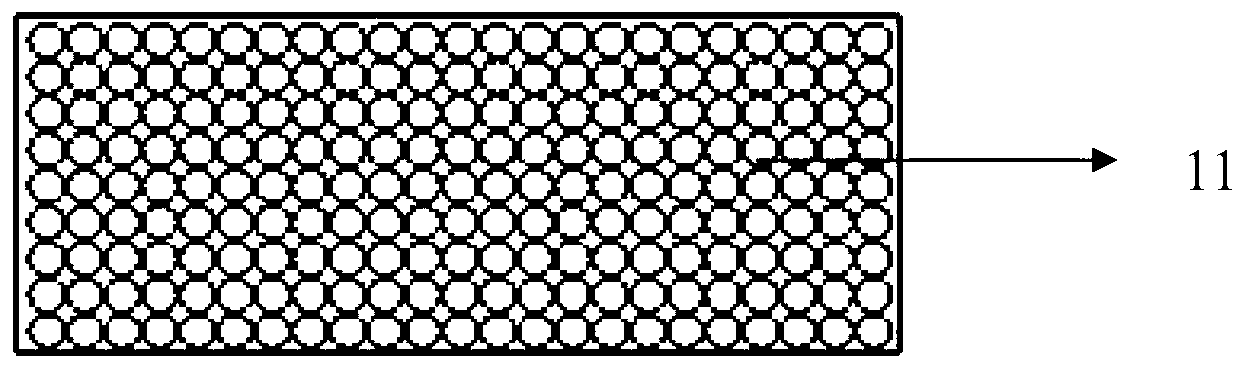

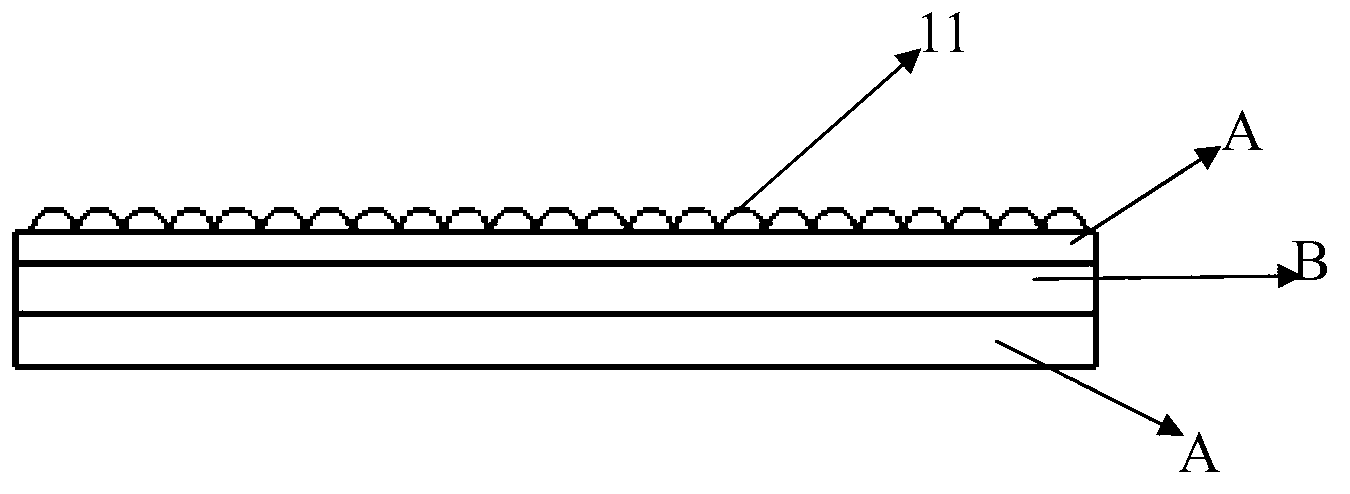

Antistatic material, self-cleaning light diffusion plate prepared therefrom, and preparation method of self-cleaning light diffusion plate

ActiveCN103242593ARaw materials are easy to getReduce manufacturing costOptical elementsAntioxidantAntistatic Materials

The invention relates to an antistatic material, a self-cleaning light diffusion plate prepared therefrom, and a preparation method of the self-cleaning light diffusion plate. The antistatic material comprises a matrix resin, a light diffusing agent, an antistatic agent, an antioxidant, a light stabilizer and a dispersing agent; the antistatic material has the resistivity up to 107 to 1011 and is remarkable in antistatic performance; the light diffusion plate prepared from such an antistatic material has high light transmission performance and high antistatic self-cleaning performance, effectively improves the light transmission performance and has long-term stability; in addition, raw materials are easy to obtain, the preparation cost is low, and the light diffusion plate is suitable for being applied to related fields of products requiring antistatic prevention and improvement of self-cleaning performance. The preparation method of the self-cleaning light diffusion plate, provided by the invention, is optimal in process, simple in operation, suitable for continuous production and manufacturing, low in economic cost, and suitable for popularization and application.

Owner:BEIJING UNIV OF CHEM TECH

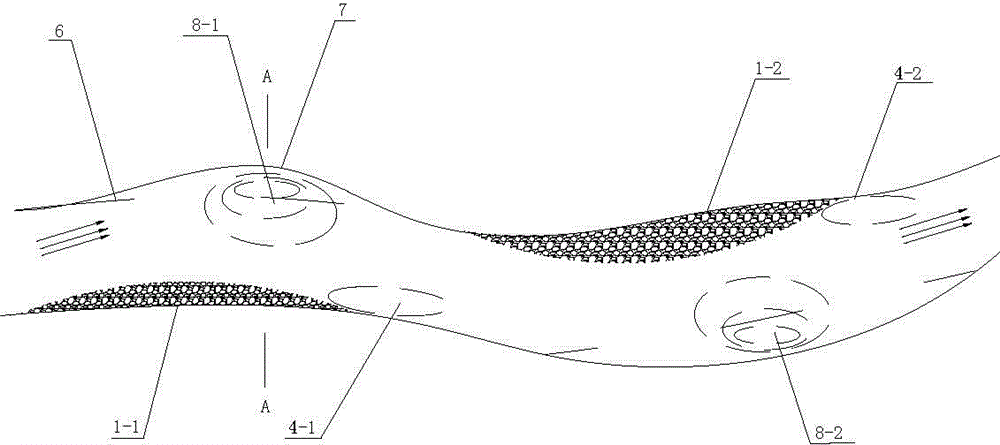

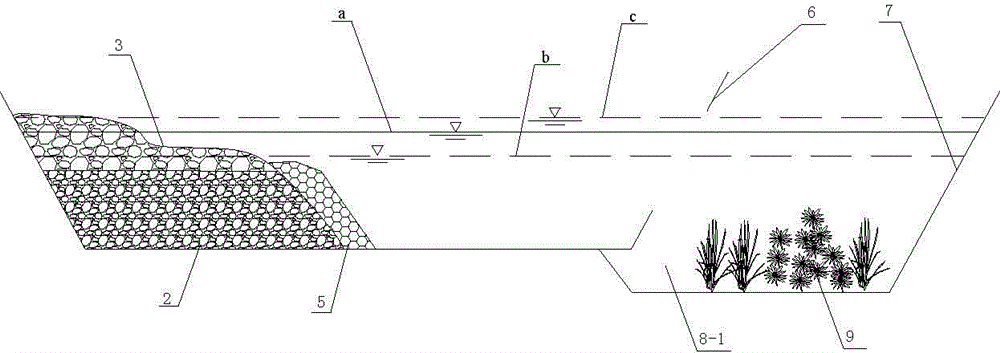

Winding form construction method for small-and-medium-sized linear riverways

ActiveCN104695377AImprove self-cleaning abilityWill not affect floodingClimate change adaptationStream regulationSocial benefitsEngineering

The invention relates to a winding form construction method for small-and-medium-sized linear riverways and aims to effectively solve the problem of winding form construction of the linear riverways. The method includes: throwing gravels to form gravel piles on one side of a main river channel from the bottom layer to the upper layer, wherein the distance between nearshore points and far off-shore points of the gravel piles is 1 / 5 of the width of the main river channel; arranging gabions on water sides and lateral sides of the gravel piles to fix the gravel piles; expanding a riverway opposite to the gravel piles to a width 1 / 5 of that of the main river channel; downwardly excavating one side, with the riverway modified, of a riverbed to form a deep pool, and piling up excavated earthworks to air faces of the gravel piles to form a shoal; positioning the two gravel piles on two sides of the riverway respectively to form a gravel pile group, enabling the air faces of the gravel piles to form a shoal structure, enabling the modified opposite bank to form a deep pool structure, and planting submerged plants in the deep pool; arranging three to five groups of gravel piles in the linear riverway to form an ecological gravel group to increase local winding degree of the riverway, so that winding form construction of the riverway is realized. The winding form construction method for the small-and-medium-sized linear riverways has the advantages that unification of purification and landscape functions is realized, and enormous economic and social benefits are achieved.

Owner:ZHENGZHOU UNIV

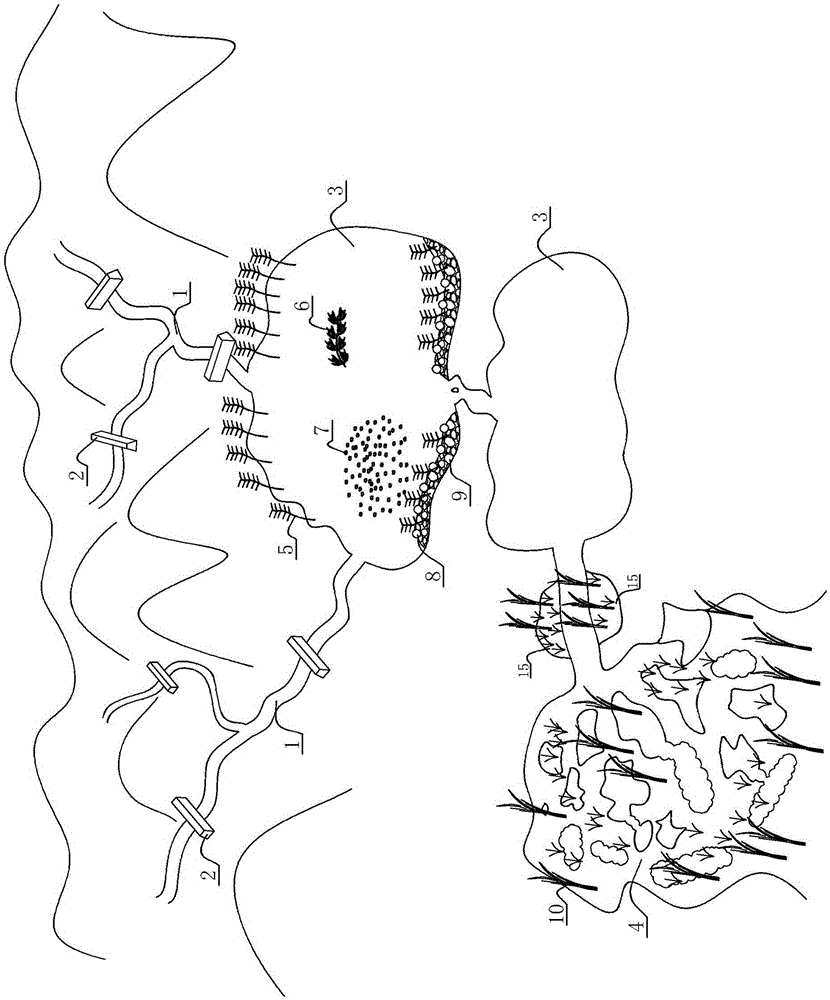

Ecological comprehensive treatment system of northern mountain river channel and construction method thereof

InactiveCN105297671AReduce pollutionImprove stabilityWater resource protectionStream regulationDry seasonFluvial

The invention discloses an ecological comprehensive treatment system of a northern mountain river channel. The system comprises three sub ecological systems of an ecological permeable dike built on the upstream of a main stream and a branch stream of a mountain river, a reservoir pond arranged at the middle and downstream area of the mountain river and a wet land communicated with the reservoir pond, and adopts an ecological treatment mode of closure-storage-preservation. The construction method comprises the steps of: a) building of the ecological permeable dike; b) setting of a triangular pyramidal wood pile stone cage; c) building of the reservoir pond; d) planting of plants of the reservoir pond; e) building of a wet land system; and f) recovery of a river bank band. The system and the construction method can effectively intercept the mountain debris flow and the river non-point source pollution, adjust the river runoff, improve the hydrologic conditions of the mountain river in non-flood season, decrease the dry season of the mountain river, and facilitate to recover the ecological system of the mountain river. Meanwhile, traditional depressions and empty ponds in the mountain river can be used in construction, so that the engineering building cost is reduced, and the self-cleaning capacity of river water is improved.

Owner:SHANDONG ANALYSIS & TEST CENT

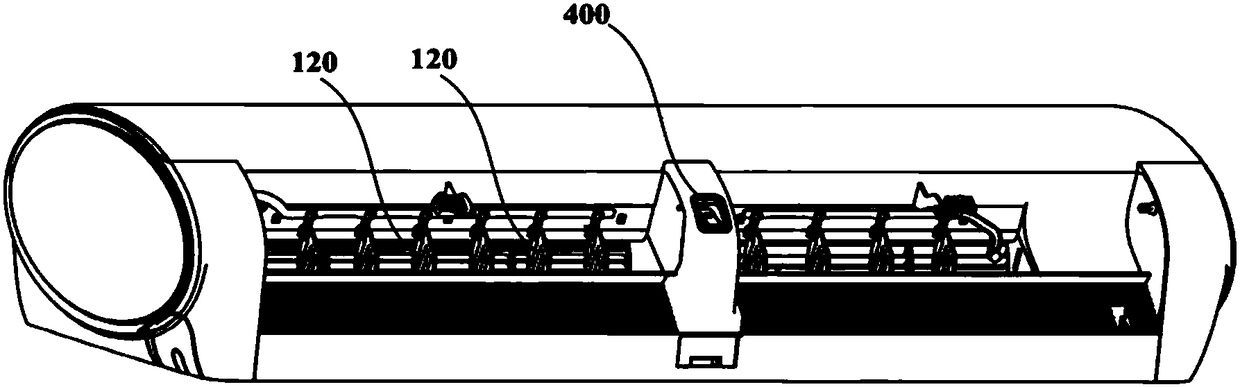

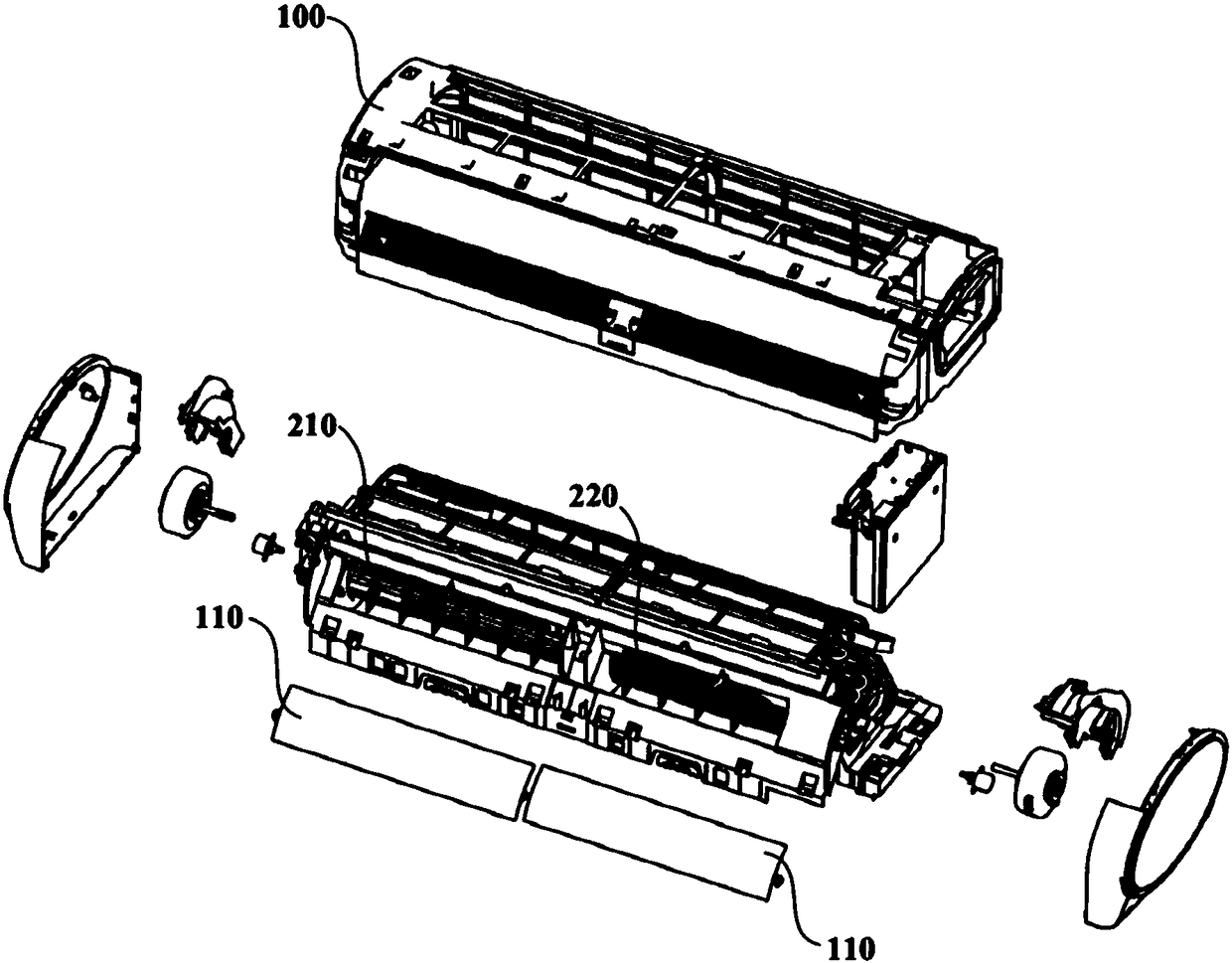

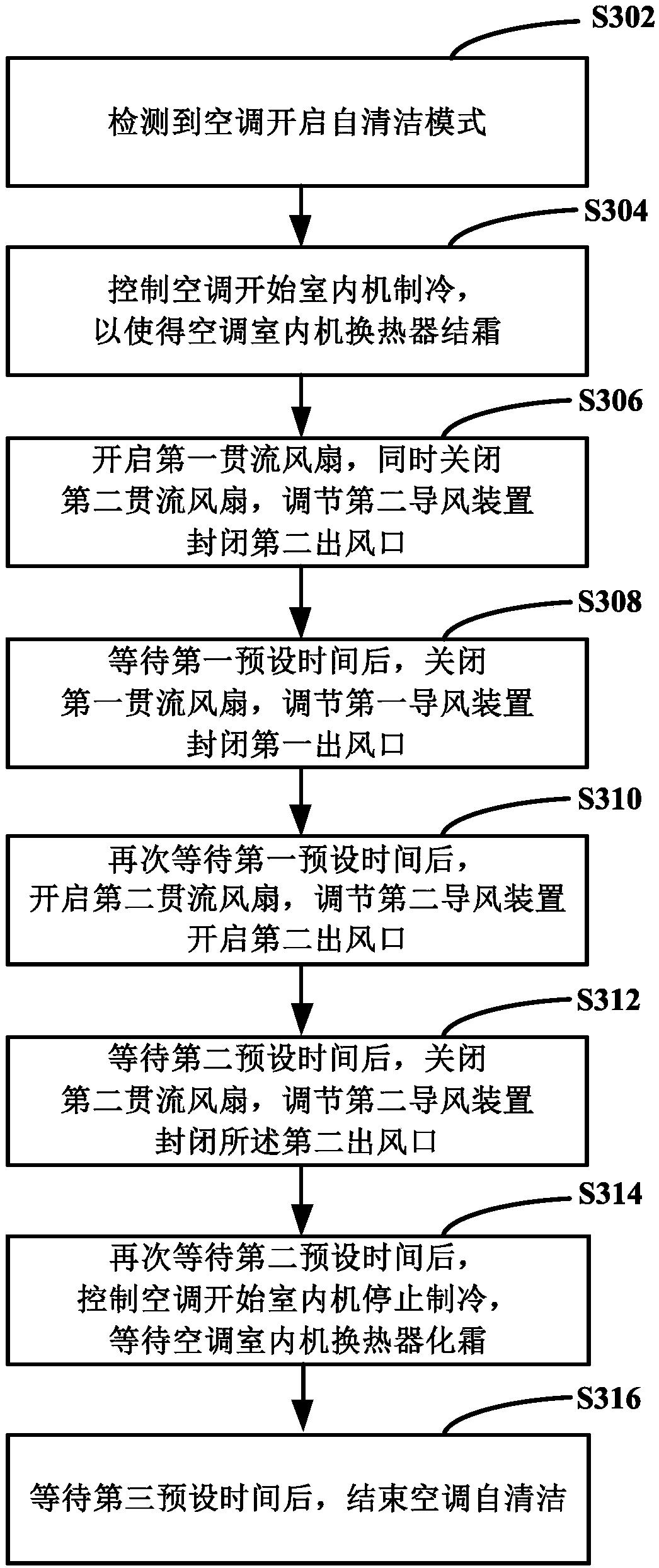

Wall-mounted air conditioner and self-cleaning control method thereof

ActiveCN108397818AFrosting evenlyImprove self-cleaning effectMechanical apparatusSpace heating and ventilation safety systemsEngineeringWall mount

The invention provides a wall-mounted air conditioner and a self-cleaning control method thereof. The self-cleaning control method is characterized in that according to the structure characteristic ofthe air conditioner with two cross-flow fans, in the self-cleaning refrigerating process, a left air area and a right air area are frosted separately, that is, the first cross-flow fan is started firstly, and a heat exchanger corresponding to the second cross-flow fan is frosted firstly; and then the first cross-flow fan is turned off, the second cross-flow fan is turned on, and at the moment, aheat exchanger corresponding to the first cross-flow fan is frosted then. In the self-cleaning process of the method, at most one air outlet discharges air, so that the cold amount output by an indoorunit in the refrigerating process is reduced, a user is prevented from feeling cold, and the use experience of the user is improved.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

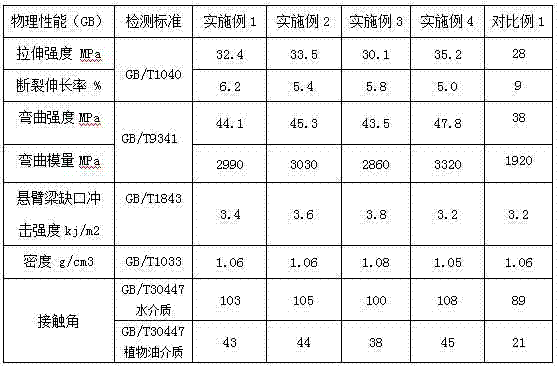

Reinforced greasy-dirt-resistant high-gloss polypropylene composite material and preparation method thereof

ActiveCN104744818ALower surface free energyGood oil resistancePolypropylene compositesPolymer science

The invention provides a reinforced greasy-dirt-resistant high-gloss polypropylene composite material and a preparation method thereof. The reinforced greasy-dirt-resistant high-gloss polypropylene composite material is prepared form the following components in parts by weight: 60-80 parts of PP resin, 10-15 parts of superfine precipitated barium sulfate, 6-10 parts of reinforced magnesium sulfate whiskers, 2-5 parts of fluoride, 0.2-0.4 part of an antioxidant, 0.1-0.3 part of a nucleating agent, 0.5-1 part of a lubricating agent and 0-3 parts of other auxiliaries. According to the reinforced greasy-dirt-resistant high-gloss polypropylene composite material prepared by the method disclosed by the invention, the surface polarity of the material is changed and the greasy dirt resistance of the material is improved; meanwhile, the composite material meets the European Union Regulation (EC) No.1935 / 2004 of related food contact materials, and has the characteristics of being high in gloss, low in after shrinkage, high in rigidity, and the like. The material is applied to a housing of a kitchen appliance, so that the surface of the kitchen appliance has capacity of resisting greasy dirt and self-cleaning capacity, and the self-cleaning anti-greasy-dirt environmental requirements of modern kitchen appliance are met.

Owner:ORINKO NEW MATERIAL CO LTD

Ecological restoring method of river water body

ActiveCN101607762AImprove self-cleaning abilityRestore diversityWater resource protectionFungiEutrophicationMicrobial agent

The invention provides an ecological restoring method of a river water body, comprising the following steps: (1) detecting pollution indexes of a river water body; (2) throwing composite microbial agents into a water body according to 5ppm to 9ppm; (3) transferring, translating and degrading matters in the river water body by the composite microbial agents; (4) throwing and / or planting water plants into a river; (5) detecting the pollution indexes of the river water body; and (6) repeating the steps from (2) to (5) from 15 days to 30 days until the river water body conforms to requirements. Each composite microbial agent comprises the components by weight percent: 5 to 10 photosynthetic bacteria, 10 to 15 bacillus subtilis, 5 to 10 nitrifying bacteria, 2 to 5 microzyme, 15 to 20 lactobacillus, 10 to 30 aspergillus, 10 to 30 acetobacter and 20 to 30 actinomyces. The ecological restoring method of a river water body aims at a river water body which carries out eutrophication treatment, leads the river water body to restore the bio-diversity of the river water body, radically restores ecology and has durable effect, low cost and simple use.

Owner:DONGGUAN SHENGYUAN ENVIRONMENTAL PROTECTION TECH

Pond poly-culture method for tilapia mossambica and litopenaeus vannamei

InactiveCN103621448AReduce sizeImprove yield per unit areaClimate change adaptationAnimal feeding stuffTilapiaPenaeus marginatus

The invention discloses a pond poly-culture method for tilapia mossambica and litopenaeus vannamei. The pond poly-culture method comprises the following steps of: adding quick lime into a dry pond in spring every year, injecting water to carry out water sterilization, adding 50 kg-100 kg of fermented chicken manure into each mu of the pond when the water temperature is stabilized to over 20 DEG C, injecting water until water depth is 40cm-60cm, waiting for 1-2 weeks, adding 8000-12000 litopenaeus vannamei shrimp seeds into each mu of the pond, and feeding special poly-culture feed; injecting water after 15-20 days until water depth is 100cm-120cm, adding 1500-2500 tilapia mossambica fries into each mu of the pond, feeding the poly-culture feed, injecting water after 15-20 days until water depth is 200cm-250cm, oxygenating for 3-7 hours every day, and mixing 20kg-30kg of the quick lime with water to spray for each mu of the pond once to twice every month; catching the tilapia mossambica and litopenaeus vannamei after 120-150 days. According to the pond poly-culture method disclosed by the invention, the special poly-culture feed is fed, prawn quality is high, water pollution is less, management is easy, cost is low and benefits are high.

Owner:GUANGXI UNIV

Conductive type polyaniline composite film, prepn. method and use thereof

InactiveCN1831033AImprove self-cleaning abilityNot affectedPlastic/resin/waxes insulatorsOther chemical processesFiberJet aeroplane

The invention relates to the current conducting ployaniline composite membrane having the framework of the lotus leaf genus. It is the cancellated film composed by the nm fibre with microsphere and has the tuber on the surface of the fibre and the microsphere. The producing process of the composite includes the below steps: the eigenstate polyaniline is dissolved into the solvent; the insoluble substance is rejected, the adulterating acid is added; then, the polystyrene is added; the current conducting polyaniline mixed liquor is gained; finally, the petrified urrent conducting ployaniline composite membrance is gained one the receiving system using the electrostatic spinning technique. The composite membrane is indicative of the contact angle of 160 degree and the roll angle of below 5 degree to the pure water, the acid and the alkaline solution in the range of the entirely PH value and express the sky high ability of self purging; at the same time, the conductivity of the conducting macromolecule composite membrane don't change with the acid and alkaline solution. The conducting composite membrane can be used for producing the resisting electromagnetic shielding material, the antistatic stuff, the anticorrosion stuff, the anti fouling stuff of the shipping and the airplane, the latent stuff, the liquid transmission without the loss and the micro-flow stuff.

Owner:INST OF CHEM CHINESE ACAD OF SCI

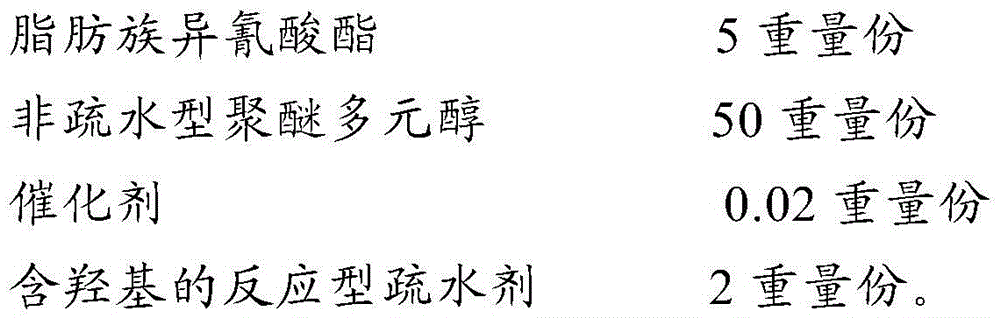

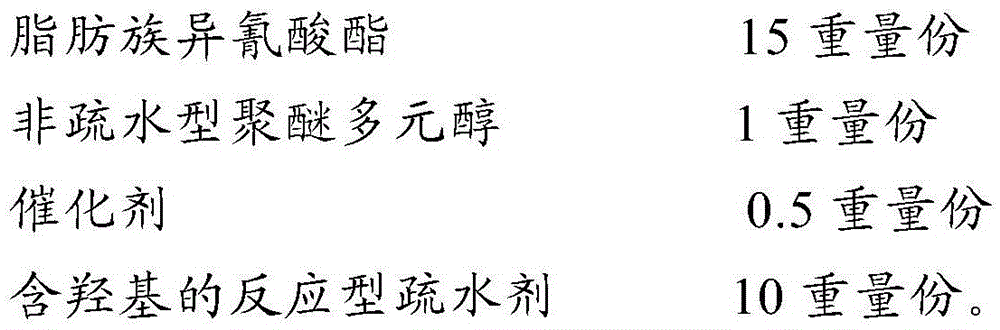

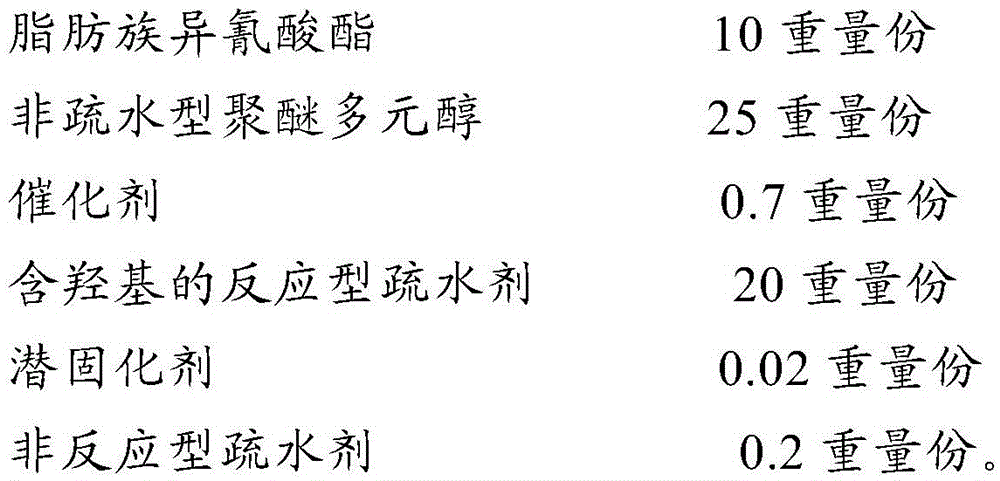

One-component polyurethane waterproof paint and preparation method thereof

ActiveCN105567072AGood weather resistanceColorfulPolyurea/polyurethane coatingsPolyolChemical reaction

The invention discloses one-component polyurethane waterproof paint and a preparation method thereof. The one-component polyurethane waterproof paint is prepared from aliphatic isocyanates, non-hydrophobic polyether polyol, catalysts, a hydroxyl containing reactive hydrophobic agent. The hydroxyl containing reactive hydrophobic agent in the one-component polyurethane waterproof paint is hydrophobic and highly compatible to other components, and accordingly compatibility of prepolymers generated by the hydroxyl containing reactive hydrophobic agent and the aliphatic isocyanates to other components of the one-component polyurethane waterproof paint is improved, and precipitation of the hydrophobic agent is avoided. Due to hydrophobility of the prepolymers, the one-component polyurethane waterproof paint is hydrophobic; since the hydroxyl containing reactive hydrophobic agent is combined into a molecular structure of polyurethane through chemical reactions, precipitation of the hydroxyl containing reactive hydrophobic agent is avoided permanently, hydrophobicity and hydrophobic stability of the one-component polyurethane waterproof paint are improved, and long-lasting hydrophobic effects are achieved.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

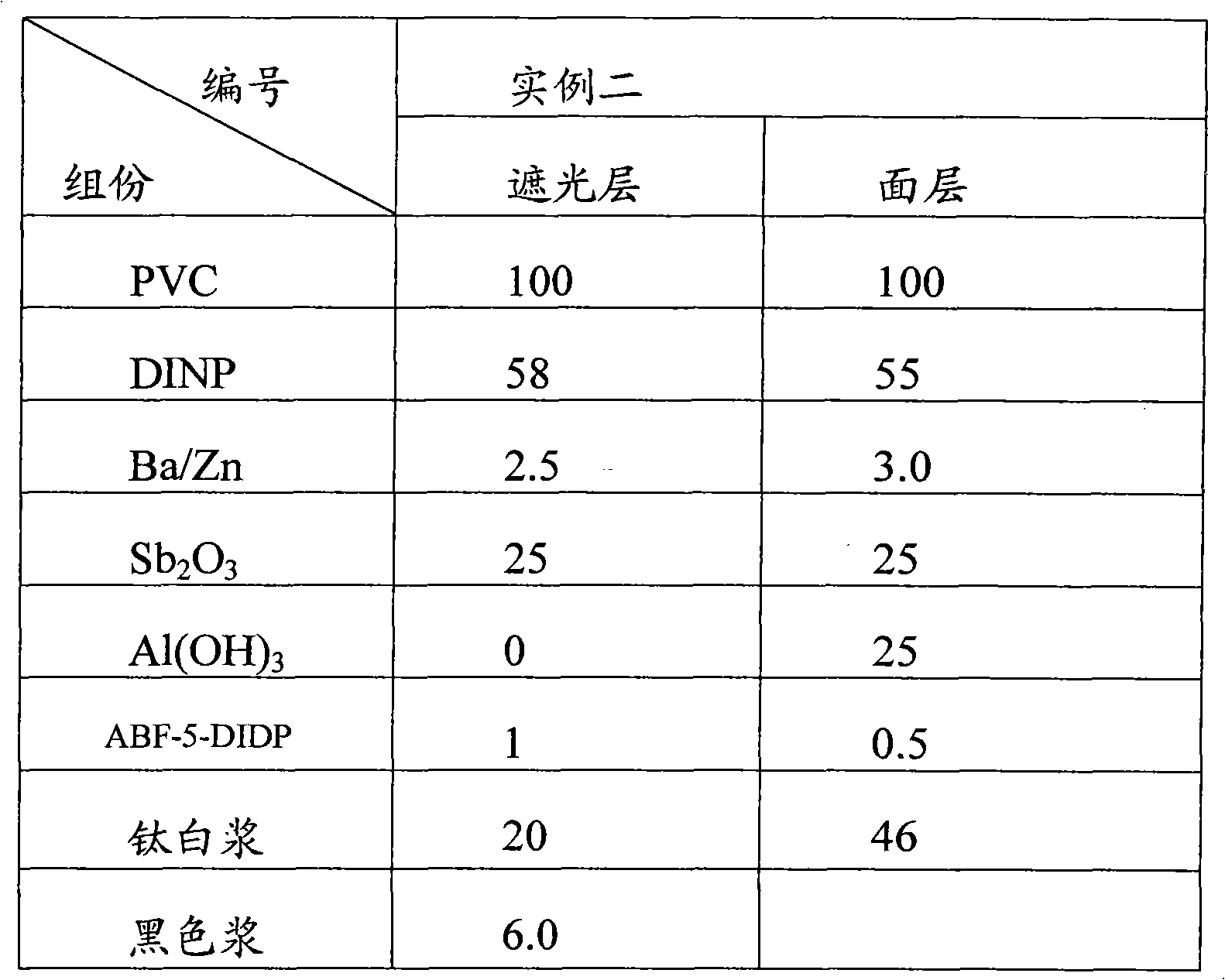

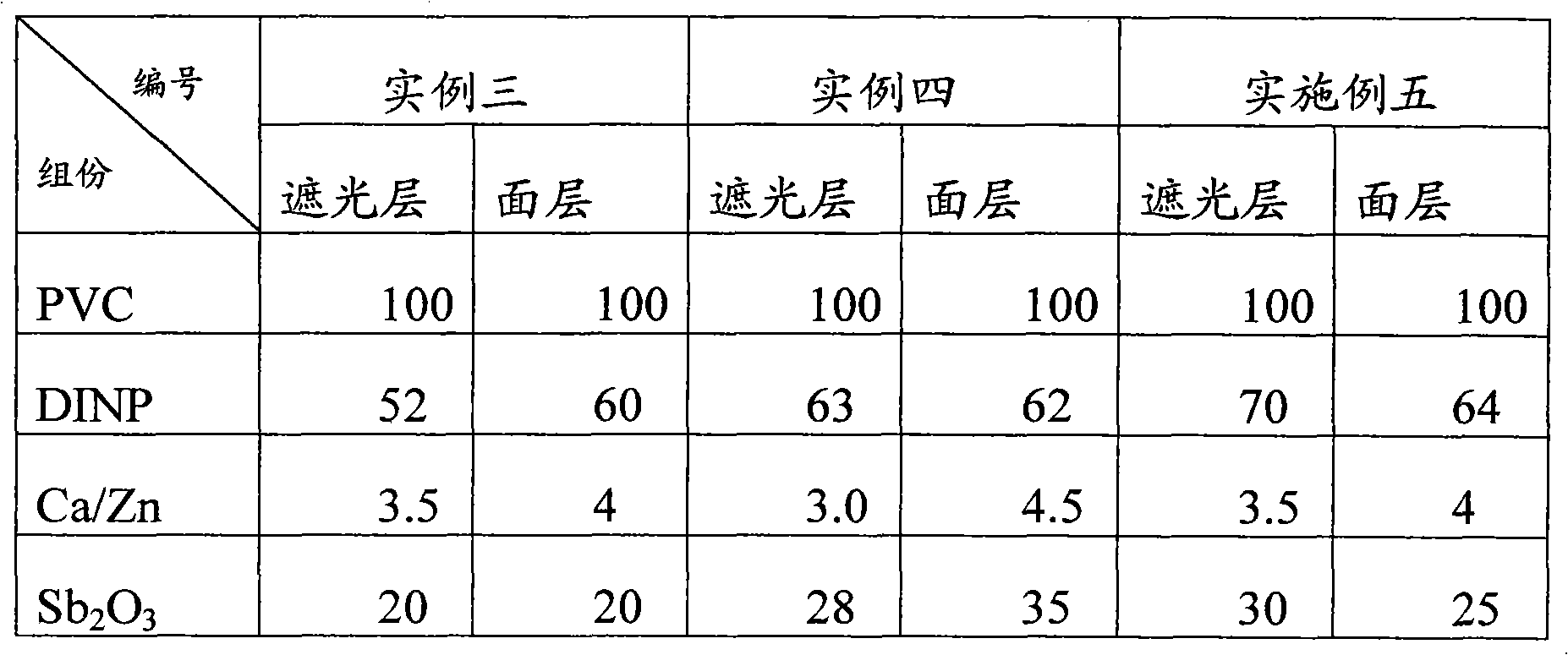

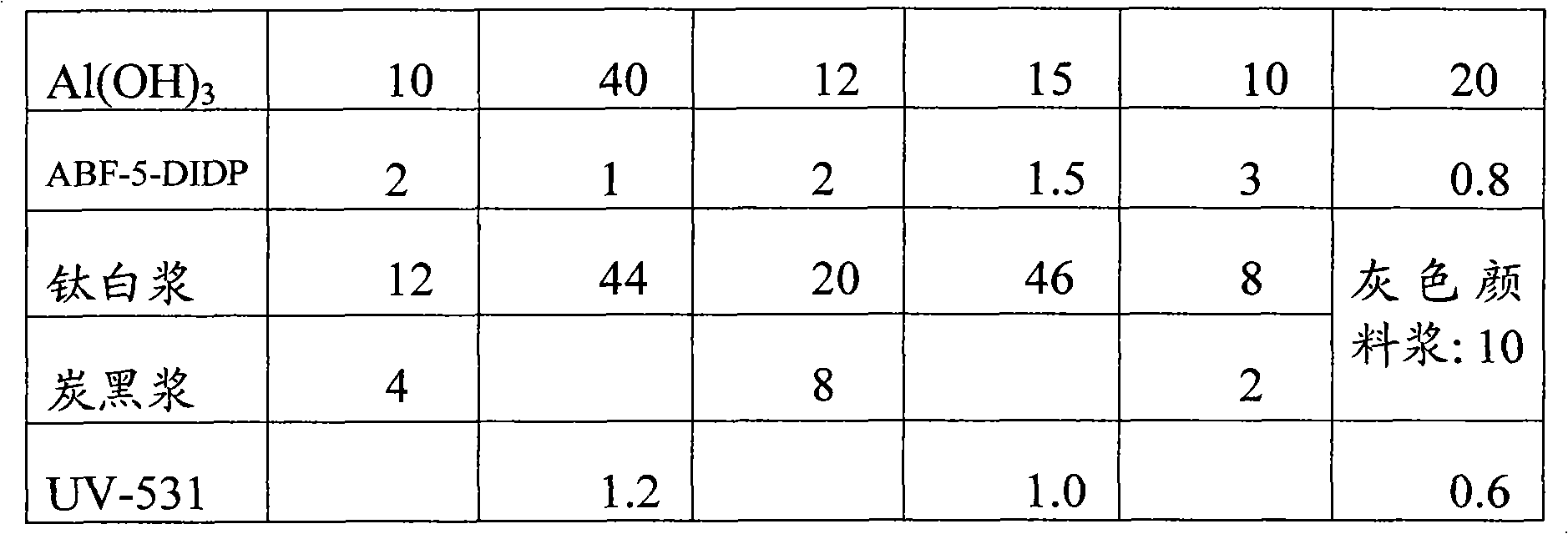

PVC coating tent material

InactiveCN101818589AGood shading effectImprove self-cleaningSynthetic resin layered productsTents/canopiesCoatingSelf cleaning

The invention relates to a PVC coating tent material. The invention is characterized in that the PVC coating tent material comprises substrate layers and PVC coatings coated on the surfaces of the substrate layers, and the tent material is provided with a front side and a back side, wherein the PVC coating on the front side comprises a front-side shading layer, a front-side main shading layer and a front-side facing layer which are orderly arranged from the substrate layer to the outside, the front-side shading layer and the front-side main shading layer are formed by coating opaque paint twice; the PVC coating on the back side comprises a back-side bottom layer and a back-side facing layer from the substrate to the outside; and the surface of the facing layer of the PVC coating is provided with a surface treatment layer. By coating the shading layer on the front side twice, a continuous shading layer can be formed, thereby achieving the excellent shading effect, and improving the yield. By coating both the front side and the back side twice with surface treatment paint, the quantity of the surface treatment paint can be ensured, thereby achieving the better self-cleaning effect. Besides, the invention realizes the free use of the tent material even without distinguishing the front side and the back side in use.

Owner:FOSHAN GAOMING YILONG PLASTICS & RUBBER IND

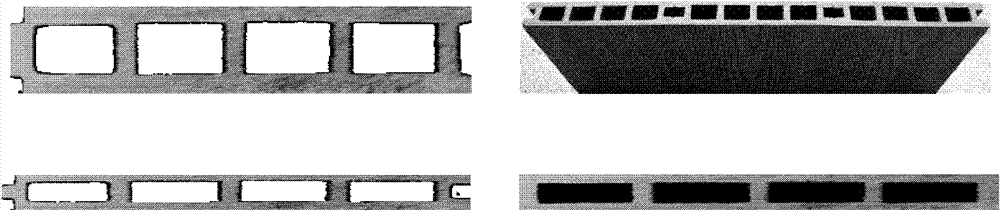

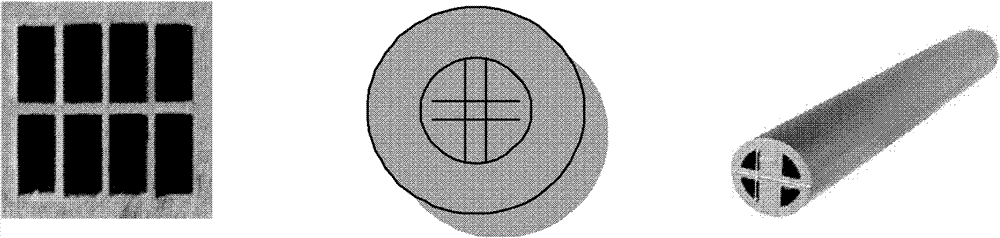

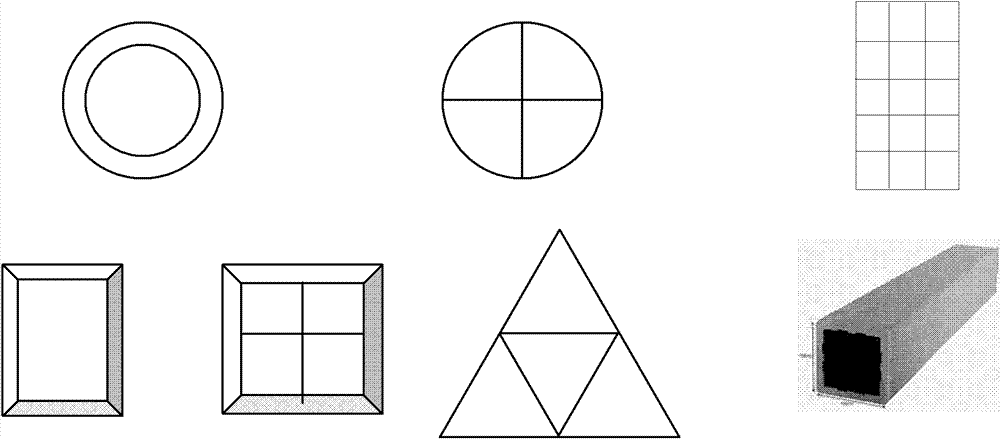

Composite material of imitated glass reinforced plastic, its manufacture method and its application

The invention discloses a composite material of an imitated glass reinforced plastic, which comprises a basic layer, the basic layer comprises the following ingredients by weight: 120-160 parts of active light calcium carbonate powder, 60-130 parts of recovered plastic, 30-60 parts of glass fiber and / or basalt fiber, 10-30 parts of coupling agent, 1-30 parts of foaming agent, 30-60 parts of processing auxiliary agent and 1-5 parts of stabilizing agent. The composite material also comprises a superficial layer and a filling layer. The composite material can replace a plurality of glass reinforced plastic products, steel products, stone products, ceramic products, wood products and plastic products. The composite material possesses the characteristics of wood, such as nailing, sawing, pasting and shaving, and enables secondary processing; and has the characteristics of B-1 grade fire protection, insect protection, no fumigation, water resistance, corrosion resistance, rust resistance, sound insulation, heat insulation, light weight, high intensity, impact resistance, strong plasticity, good physical properties, long service life, no formaldehyde containing, no radiation, acid and alkali resistance, hot and cold resistance, ultraviolet resistance, no paint requirement, easy construction, recoverable property, regeneration and utilization and the like.

Owner:黄云清

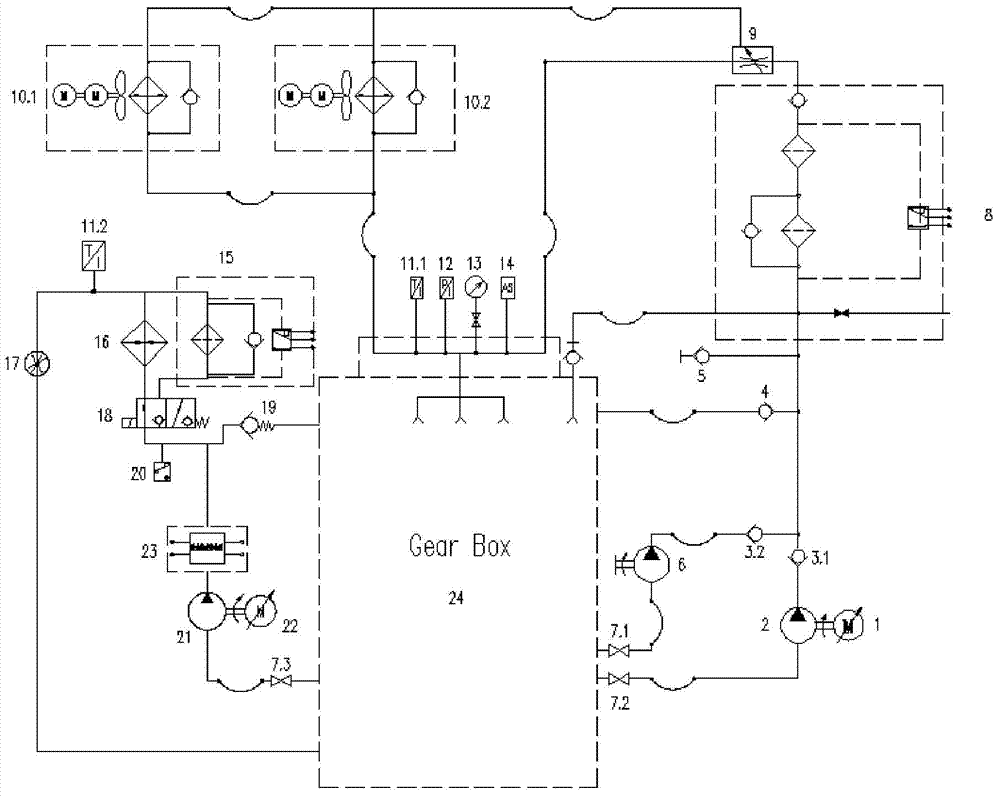

Wind power gear box lubricating system suitable for extreme condition

ActiveCN103498913AReduce momentary pressure shockLow failure rateGear lubrication/coolingDistribution equipmentElectric machineryAutomotive engineering

A wind power gear box lubricating system suitable for an extreme condition comprises a main lubricating oil circulating cooling unit and an external circulating filtration and heating unit, wherein the main lubricating oil circulating cooling unit comprises a main lubricating unit variable-frequency motor, a screw pump, a mechanical pump, a temperature control valve, a main lubricating unit filtration system, an air cooling machine and a sensor, and the external circulating filtration and heating unit comprises an external circulating variable-frequency motor, a screw pump, an on-line cleanliness detector, an electromagnetic directional valve, an external fine filter, an external heater and a flow switch. The wind power gear box lubricating system has the advantages that due to the fact that the variable-frequency motors and the screw pumps are arranged, stable starting at a dead slow speed and under the low-temperature condition can be achieved, shutting down at a gradually decreasing speed can be achieved, automatic following under different conditions can be achieved, instant pressure impact generated when an electric oil pump starts at the low temperature can be effectively reduced, and the failure rate of the lubricating system can be lowered, the application range is expanded, the system response is more rapid, the adaptability, the generality, the safety and the reliability of the system are enhanced, energy is saved, the self-cleaning capacity of the lubricating system is improved, and the service life of oil products is prolonged.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com