PVC coating tent material

A tent and coating technology, applied in the field of tent materials, can solve the problems that tent membrane materials cannot be localized, affect the popularization and use of tent membrane materials, and high prices of imported tent membrane materials, achieve good self-cleaning effect, improve yield, and improve The effect of the shading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Embodiment one, weight is 830g / m , the light-shielding tent material of the white acrylic surface treatment of B1 fireproof

[0012] 1. Preparation of PVC coating slurry:

[0013] 1. Light-shielding PVC coating (parts by weight), prepare polyvinyl chloride (paste resin with a K value of 60-80): 100 parts, plasticizer DINP: 58 parts, Ba-Zn stabilizer: 2.5 parts, flame retardant Sb 2 o 3 : 25 parts, anti-mildew additive ABF-5-DIDP: 1 part, carbon black pulp: 6.8 parts, titanium white pulp: 20 parts.

[0014] 2. Surface PVC coating: prepare polyvinyl chloride (paste resin with K value of 60-80): 100 parts, plasticizer DINP: 55 parts, Ba-Zn stabilizer: 3 parts, flame retardant Sb 2 o 3 : 25 parts, Al(OH) 3 : 25 parts, anti-mildew additive ABF-5-DIDP: 1 part, titanium white paste: 50 parts, ultraviolet absorber UV-531: 1.2 parts.

[0015] When configuring: add plasticizer and stabilizer to the container; then add polyvinyl chloride, functional additives, and anti-mold a...

Embodiment 2

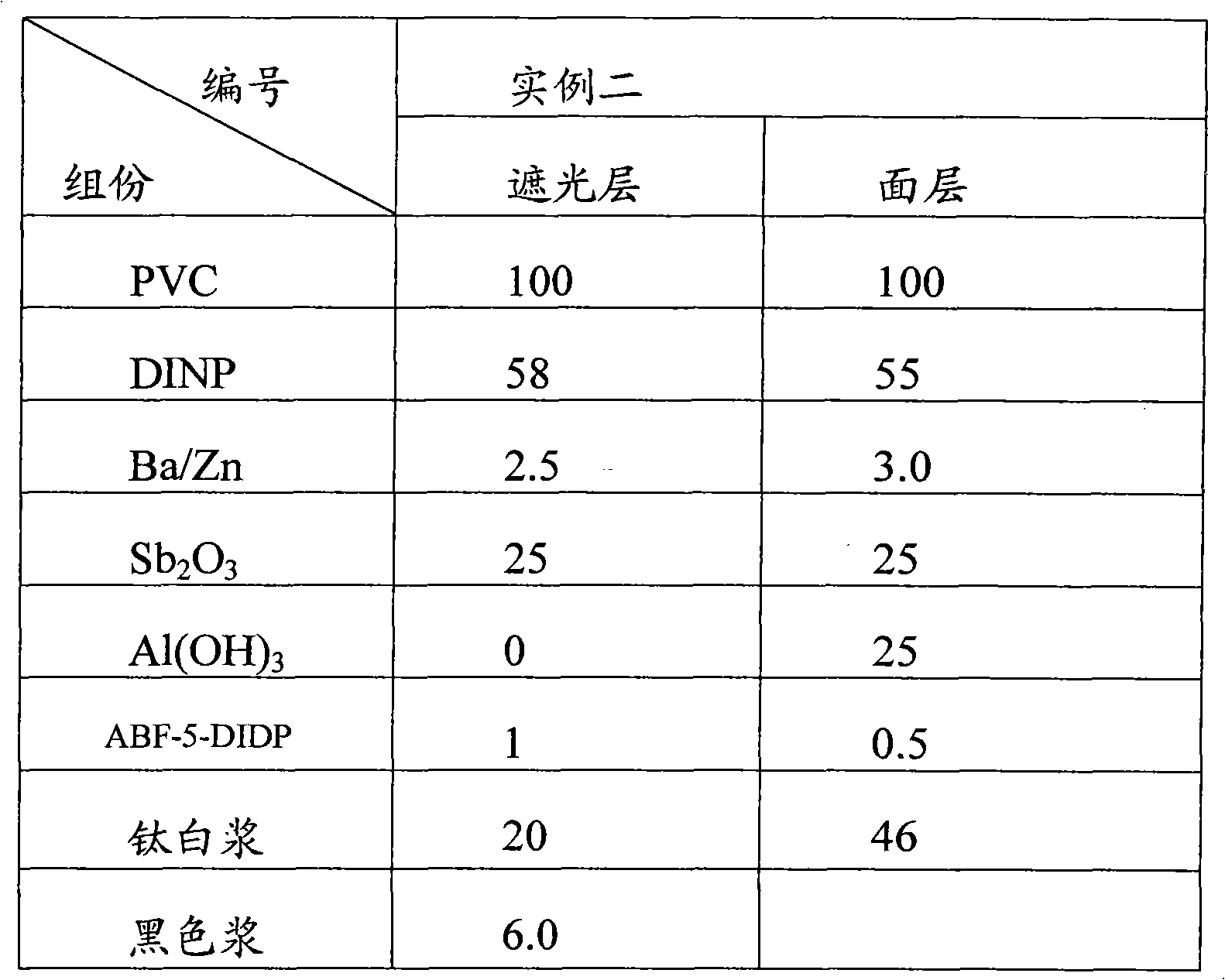

[0020] Embodiment two, weight is 830g / m 2 , B1 fireproof white PVDF surface blackout tent.

[0021] For its preparation process, please refer to Example 1, which will not be repeated here. In the present embodiment, the formula (parts by weight) of the PVC coating is as shown in Table 1 below:

[0022] Table 1, the formula of the PVC coating of embodiment two

[0023]

[0024] In this embodiment, the formulation of the surface treatment paint is (parts by weight): PVDF: 100 parts, butanone 20 parts.

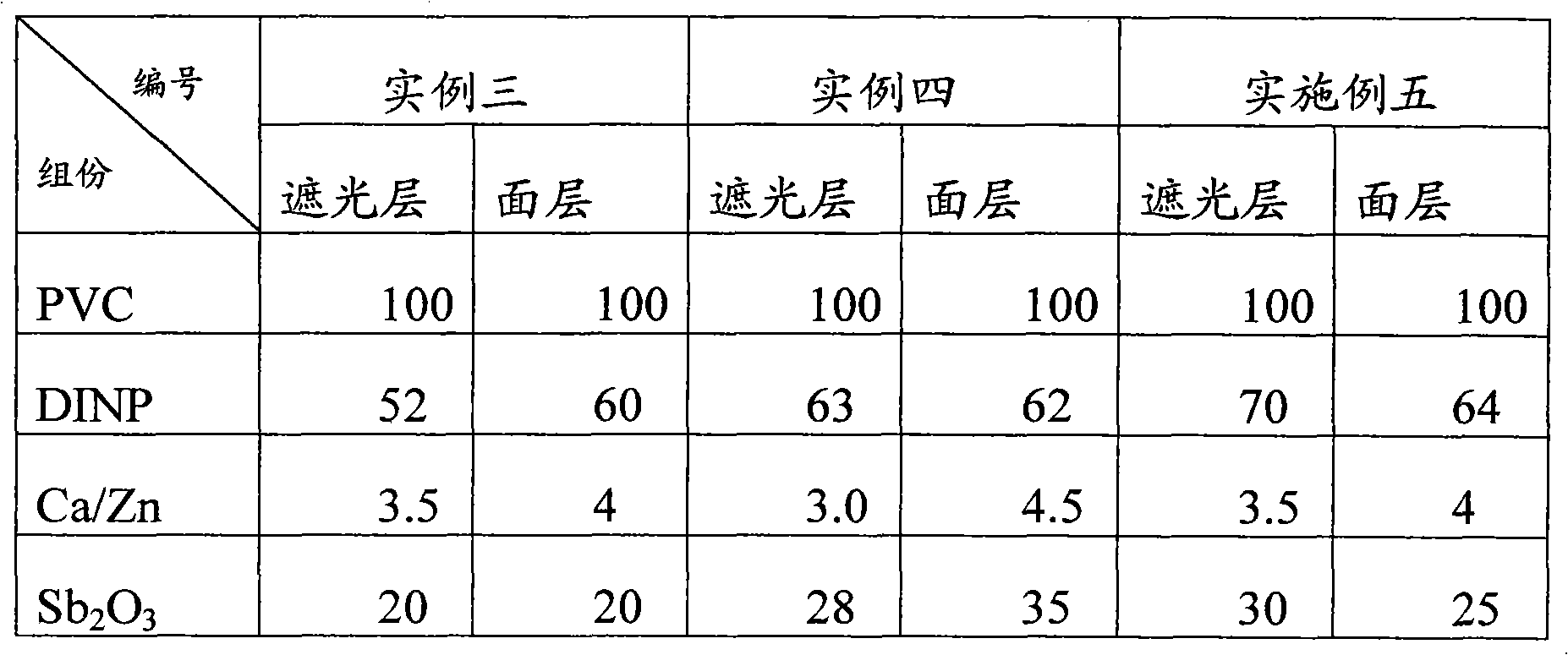

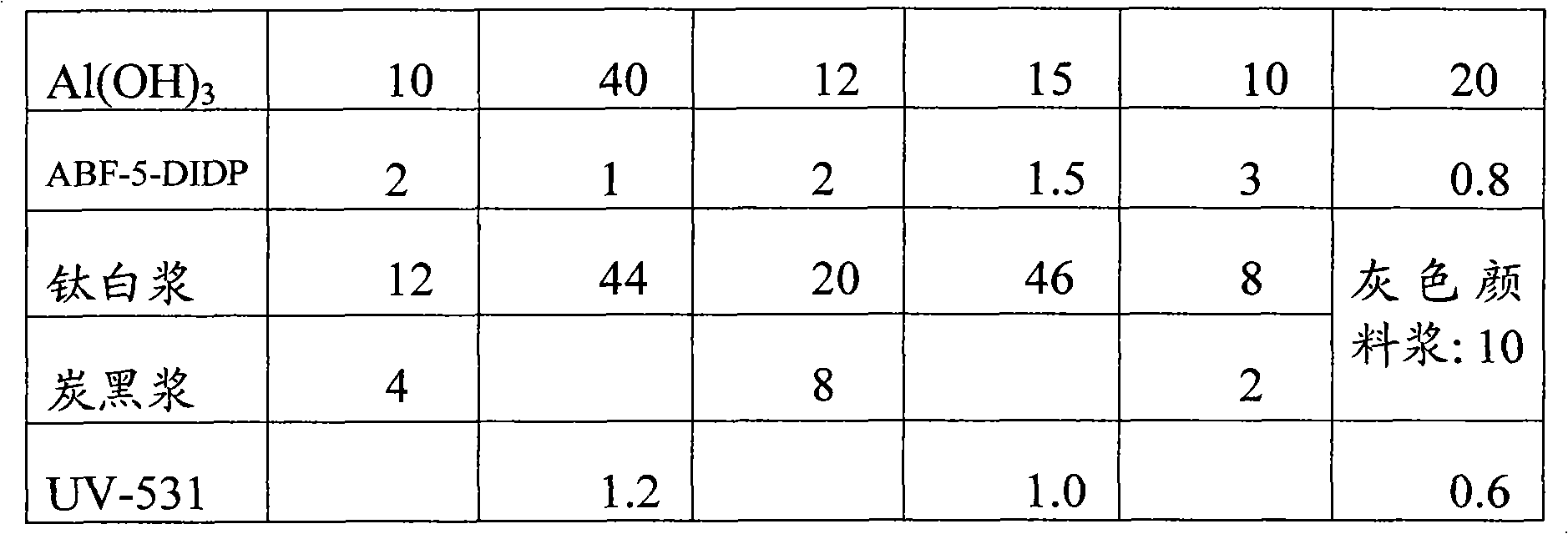

[0025] In several other embodiments of the present invention, the formula (parts by weight) of the PVC coating is as follows:

[0026]

[0027]

[0028] In the above-mentioned embodiment three, four, and five, the surface treatment coating formula is respectively (parts by weight): embodiment three, PVDF: 100 parts, 20 parts of toluene; Embodiment four: PVDF: 100 parts, butanone 30 parts; Implementation Example 5: PVDF: 100 parts, toluene 50 parts. Please refer to E...

experiment example

[0029] Experimental example: the performance comparison of the PVC sunshade tent material of the present invention and existing products is shown in the following table:

[0030] Table 2 Performance comparison between high-performance self-cleaning products and existing products

[0031] Features

[0032] From the performance comparison table above, it can be seen that the high-grade tent material of the present invention has high self-cleaning performance, high light-shielding performance and high weather resistance performance in addition to the waterproof, mildew-proof and flame-retardant functions of general tent materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com