High-flow and temperature-resisting PPO/PA composition for LEDs and preparation method thereof

A composition and high-flow technology, applied in the field of PPO/PA composition for high-flow and temperature-resistant LED and its preparation, can solve the problems of poor fluidity, poor temperature resistance, and lack of light-shielding properties of pure PPO, and achieve good flame retardancy. properties and dimensional stability, improving dispersion effect, and meeting shading requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

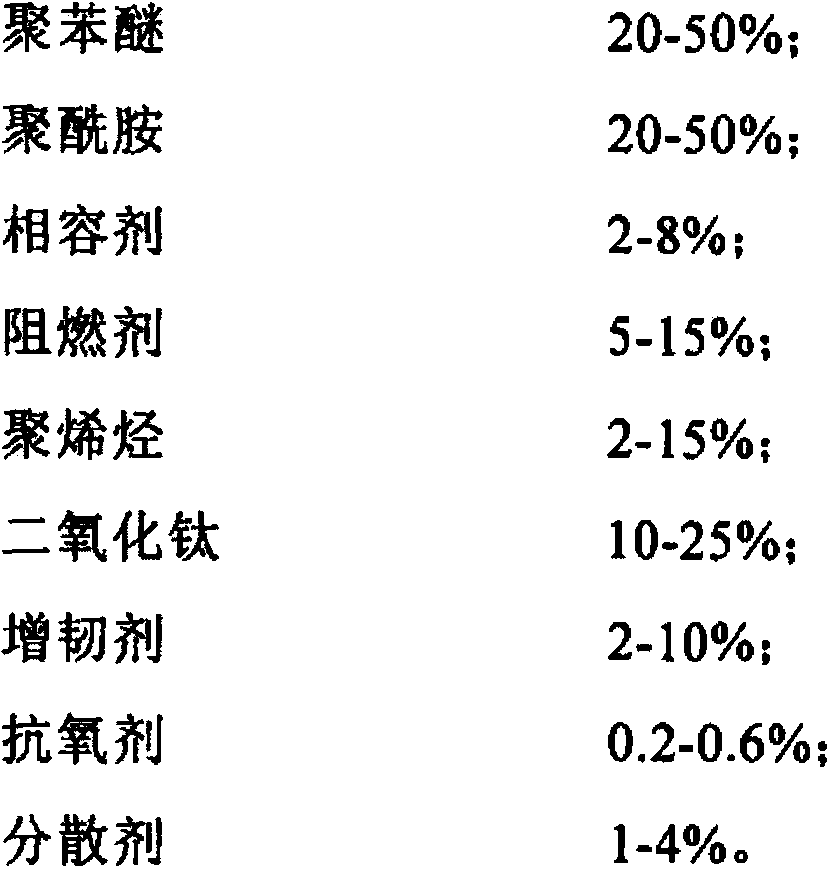

[0040] The raw materials are weighed according to the following percentage by weight:

[0041]

[0042]

[0043] (1) Weigh 25% of R-105 according to the weight ratio and put it into the stirring dryer. The temperature of the stirring dryer is set at 80°C. After stirring and drying for 2 minutes, add 4% polyzincamide, and then mix 5 minutes; then add 20% PPO LXR045, 25% PA66 EPR2.7, 4% FG1901, 5% G1651, 0.6% 1098 and mix for 3 minutes, discharge the material, add it from the main feeding port of the twin-screw extruder after cooling;

[0044] (2) Weigh 8% RDP and 8.4% PB680 according to the weight ratio and mix them in proportion, then add them from the fourth section of the twin-screw extruder through the feeding pump.

[0045] (3) After extruding and granulating through a twin-screw extruder, the rotating speed of the screw machine is 180 rpm, and the temperature is 235°C.

Embodiment 2

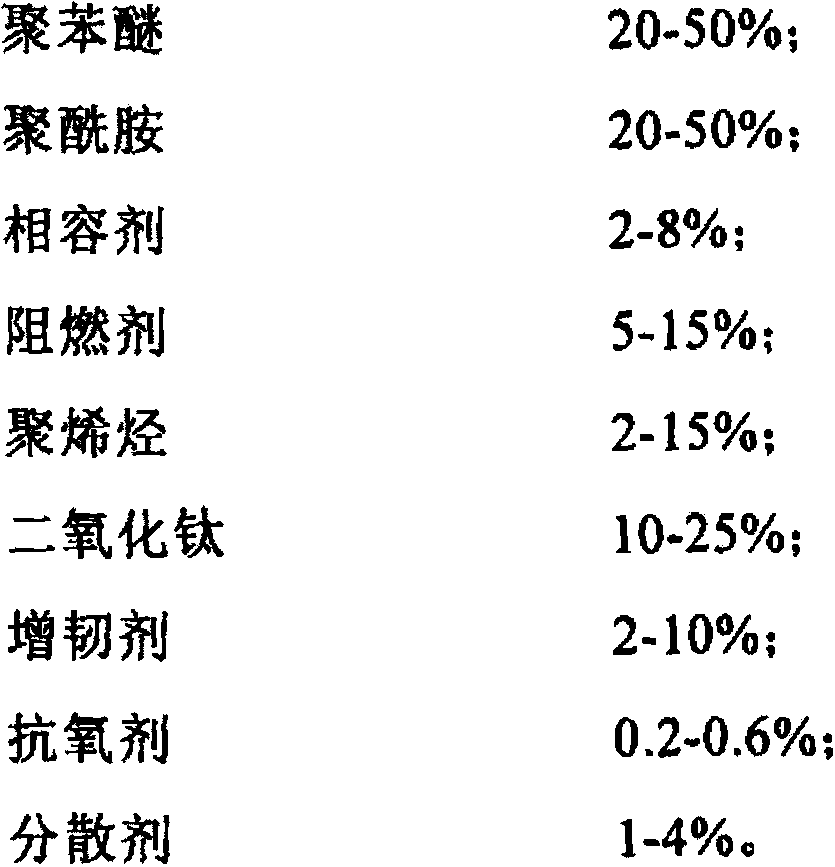

[0047] The raw materials are weighed according to the following percentage by weight:

[0048]

[0049](1) Weigh 12.5% R-105 according to the weight ratio and put it into the stirring dryer. The temperature of the stirring dryer is set at 80°C. After stirring and drying for 5 minutes, add 1% polyzincamide, and then mix 2 Minutes; then add 50% PPO LXR045, 20% PA6 1013B, 4% FG1901, 2% G1701, 0.5% 1098 and mix for 5 minutes, discharge the material, add it from the main feeding port of the twin-screw extruder after cooling;

[0050] (2) Weigh 5% RDP and 5% PB680 according to the weight ratio and mix them in proportion, then add them from the fourth barrel of the twin-screw extruder through the feeding pump.

[0051] (3) After extruding and granulating through a twin-screw extruder, the rotating speed of the screw machine is 600 rpm, and the temperature is 275°C.

Embodiment 3

[0053] The raw materials are weighed according to the following percentage by weight:

[0054]

[0055] (1) Weigh 10% R-105 according to the weight ratio and put it into the stirring dryer. The temperature of the stirring dryer is set at 100°C. After stirring and drying for 5 minutes, add 2% polyzincamide, and then mix 3 Minutes; then add 20% PPO LXR045, 50% PA6 1013B, 2% FG1901, 3.8% G1651, 0.2% 1098 and mix for 4 minutes, discharge the material, add it from the main feeding port of the twin-screw extruder after cooling;

[0056] (2) Weigh 10% RDP and 2% PB680 according to the weight ratio and mix them in proportion, then add them from the fourth section of the twin-screw extruder through the feeding pump.

[0057] (3) After extruding and granulating through a twin-screw extruder, the rotating speed of the screw machine is 400 rpm, and the temperature is 245°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com