Patents

Literature

1822 results about "Feeding pumps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

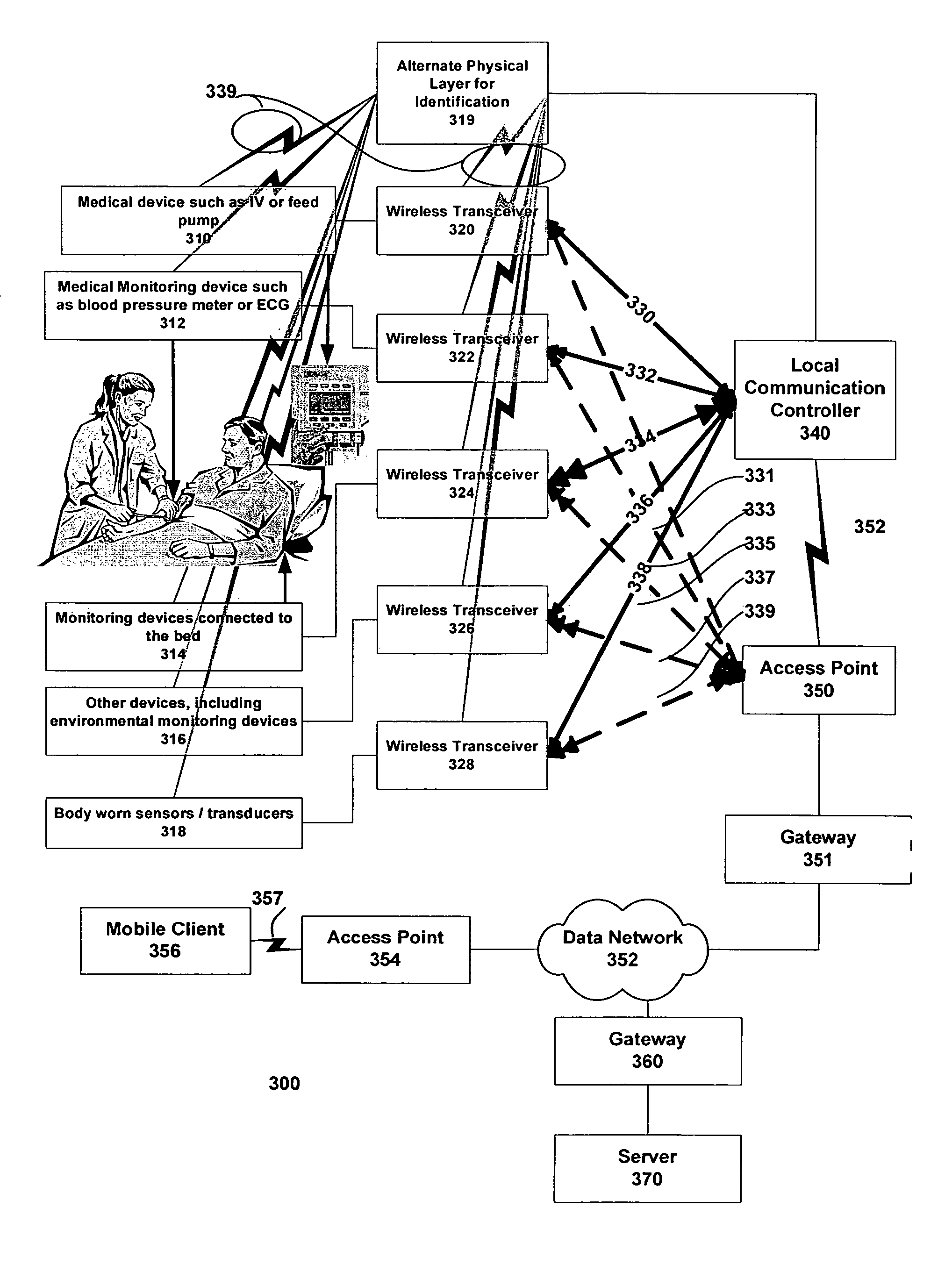

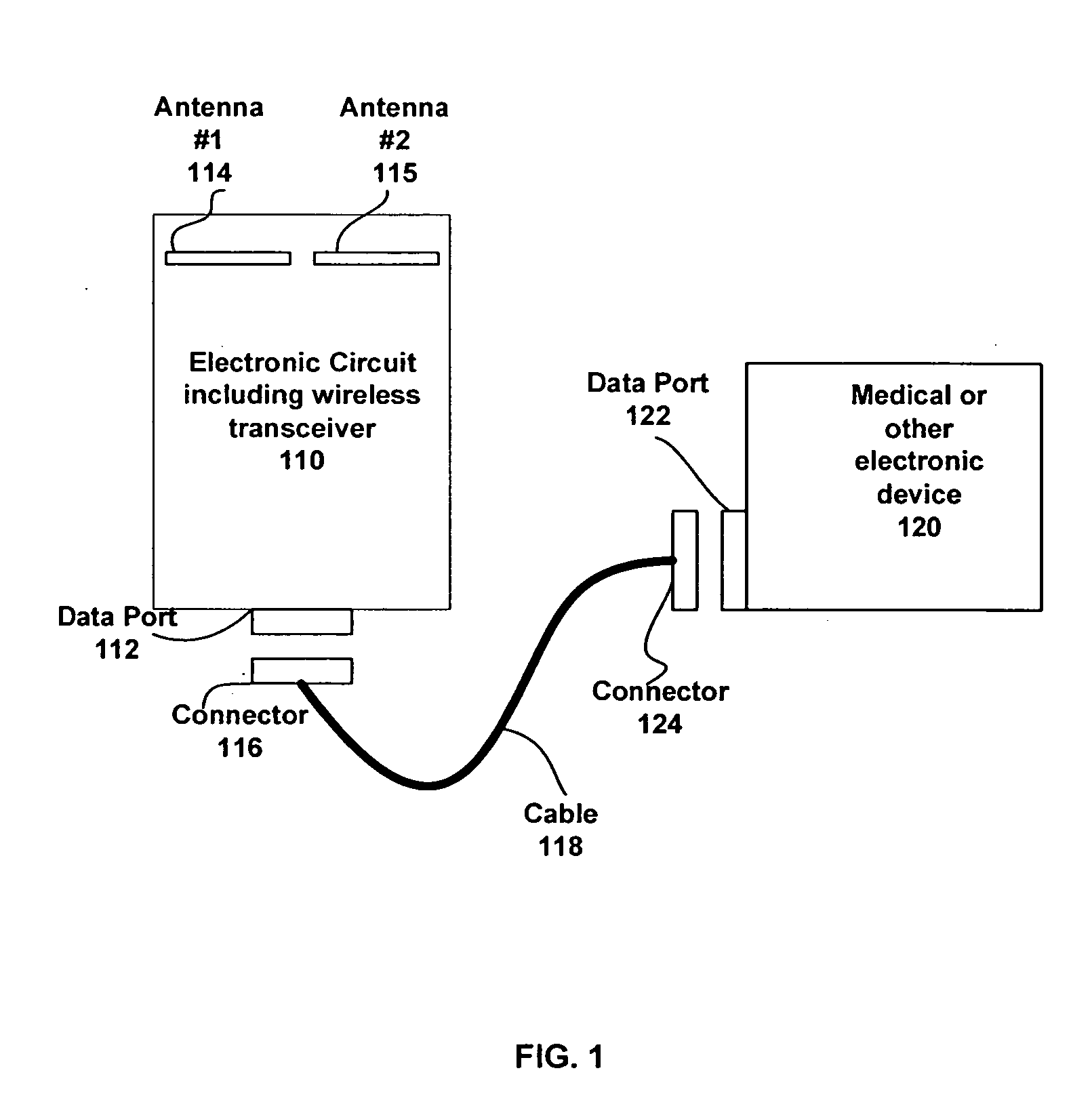

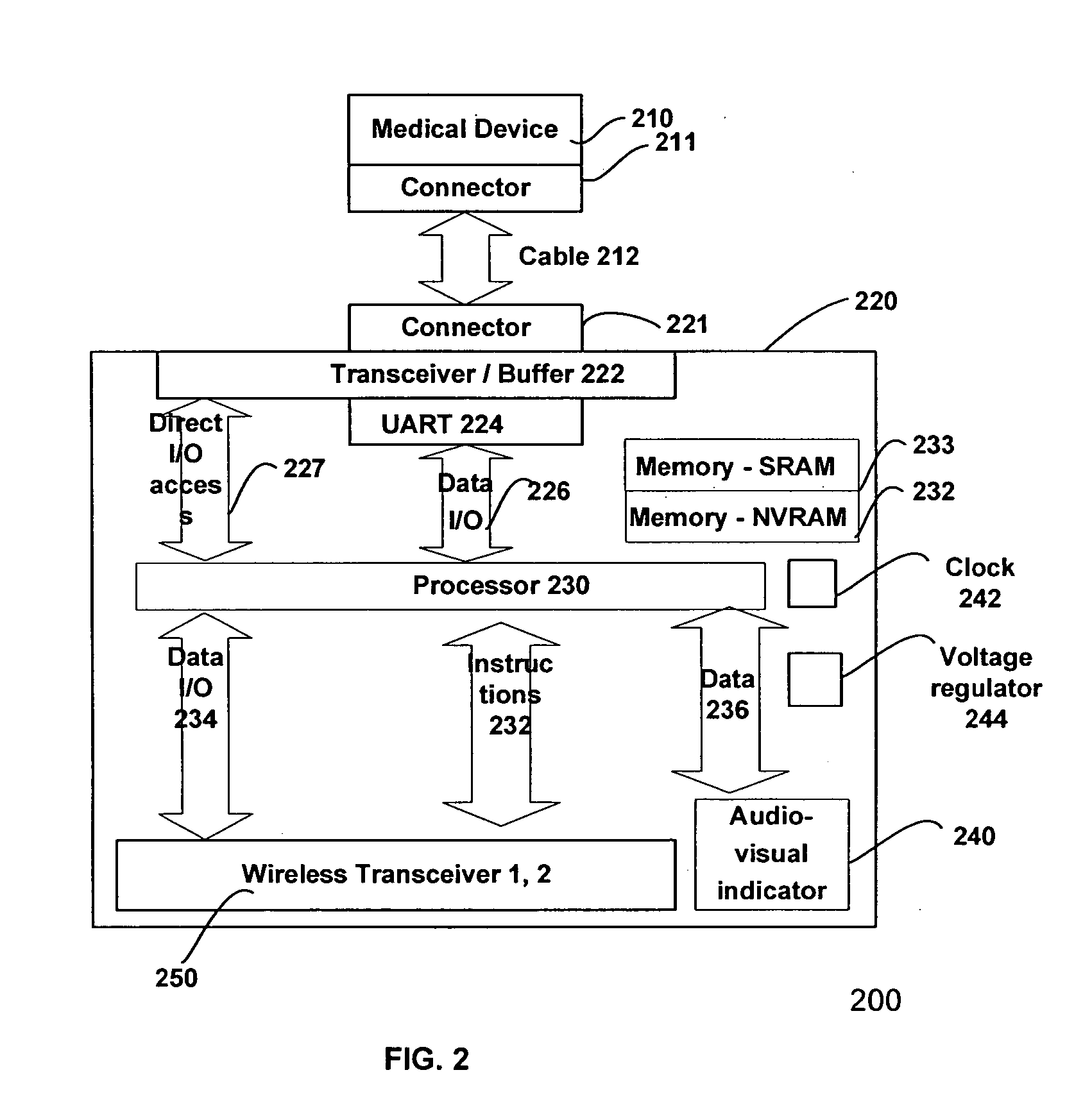

Provisioning and controlling medical instruments using wireless data communication

This invention teaches a method of automating some of the tasks requiring continuous data collection at the patient bedside in a hospital in a manner which significantly reduces the chances of error in providing treatment. These tasks include provisioning of the IV pumps or other fluid infusion pumps, feed pumps, oxygen delivery systems, gathering, recording, storing, and analyzing signals from ECG machine or pulse oxymeter or any other medical device. This invention teaches the use of wireless transceiver modules which are connected to the data ports on the medical instrument to gather the data and transmit the data to a wireless access point. Protocols to identify the patient, care provider, medicine, equipment, and treatment are described. Use of an external means for verifying the identity of the medical device and the medicine is also described.

Owner:CARETRENDS

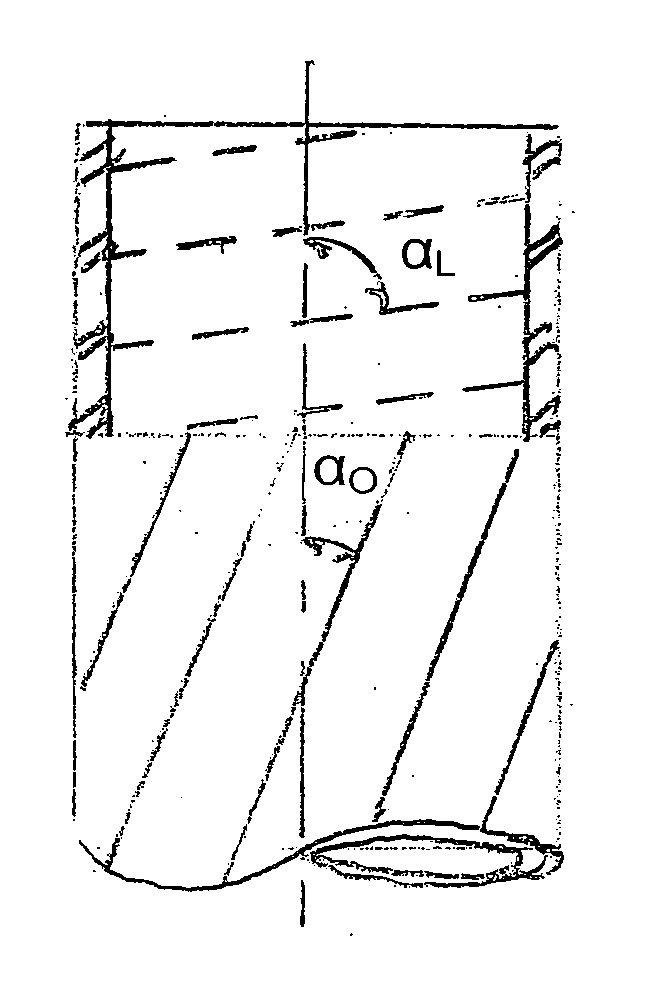

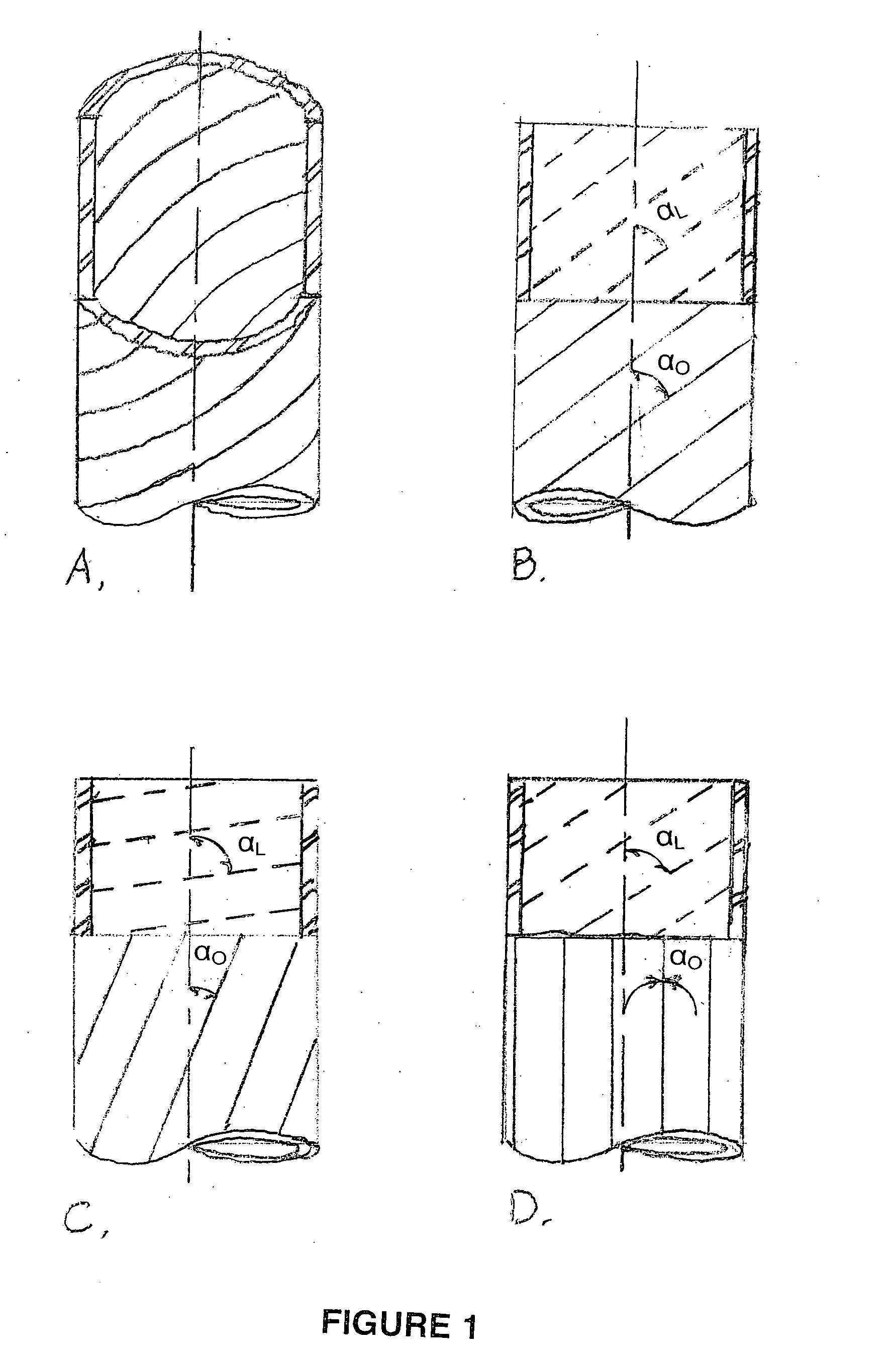

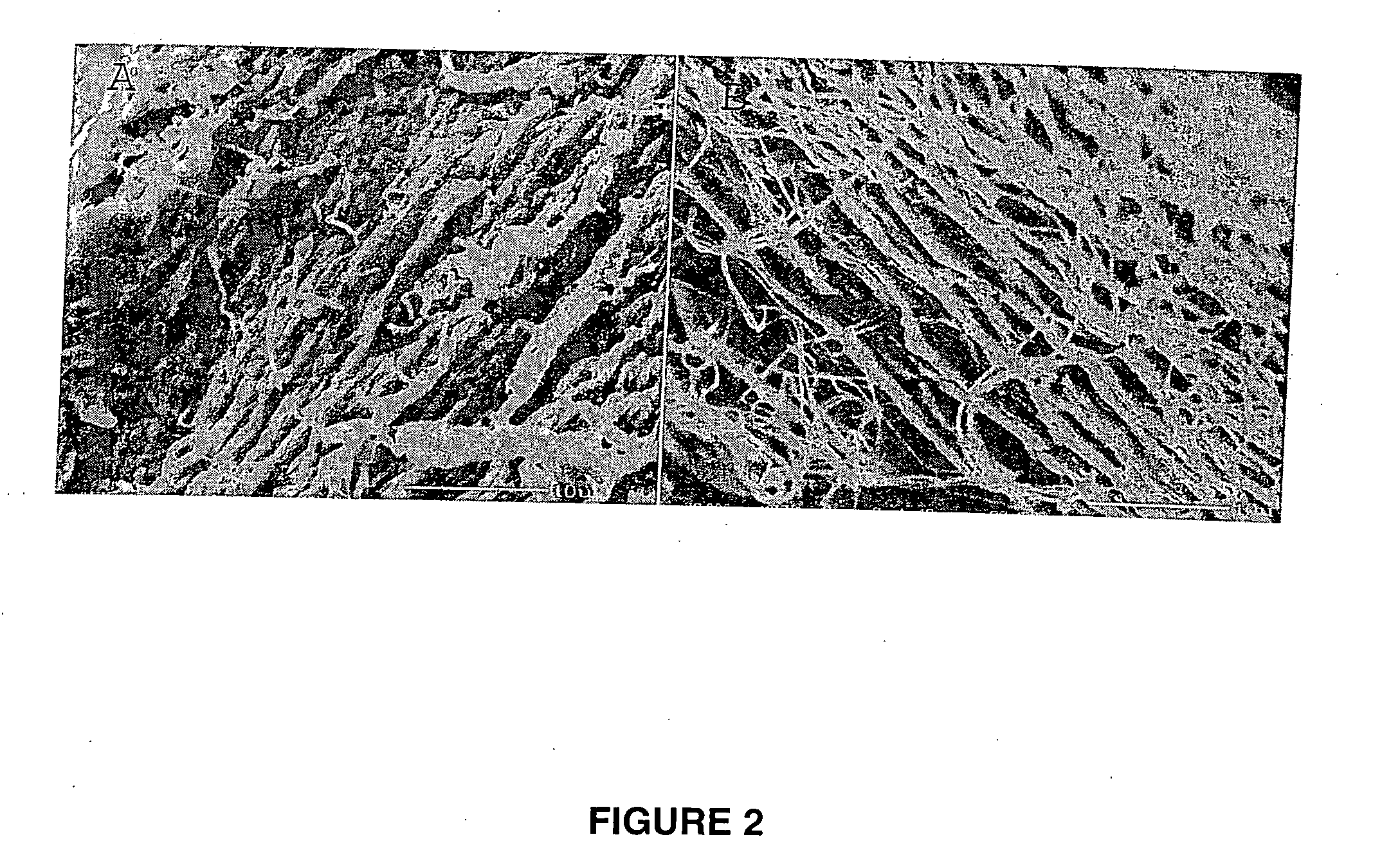

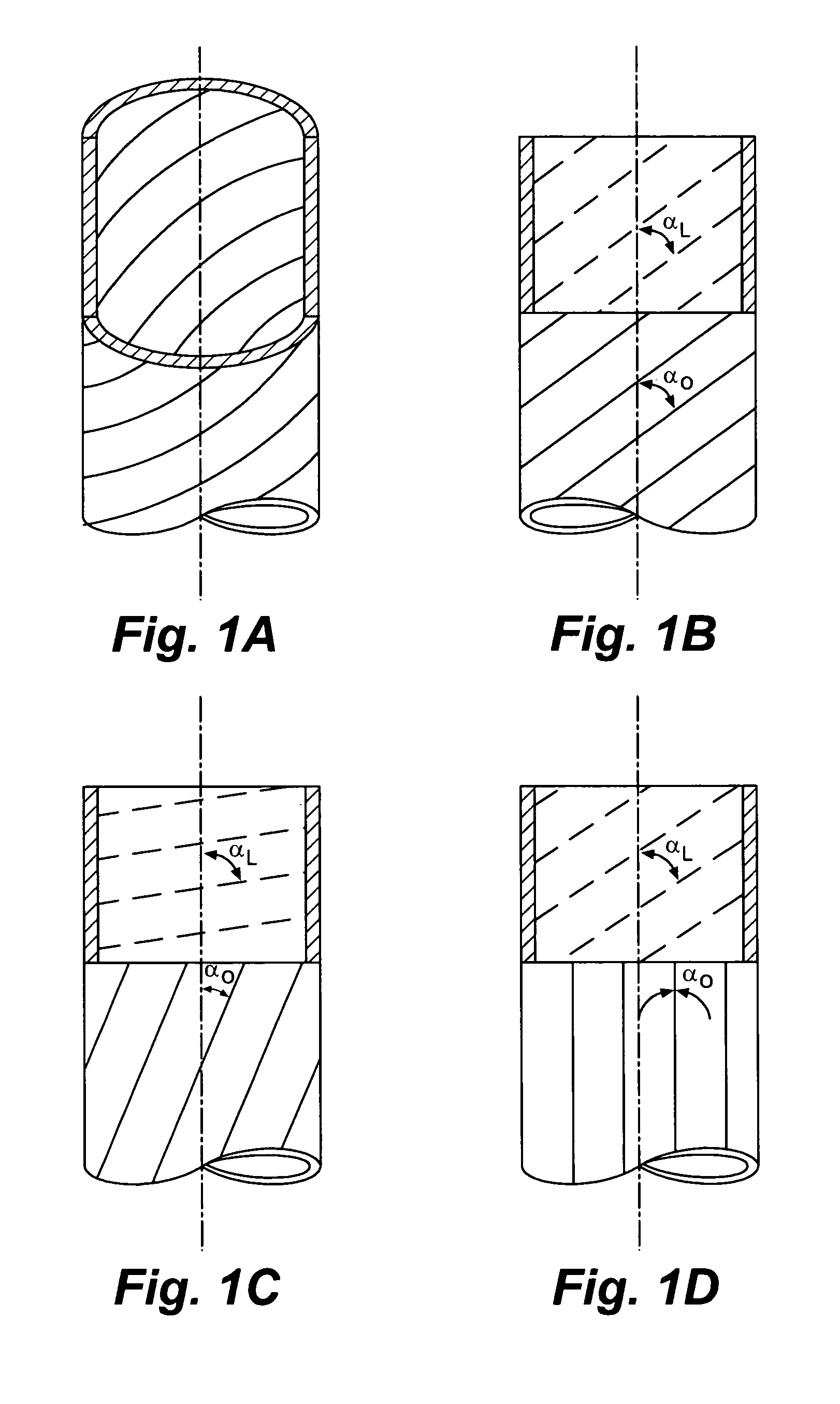

Tissue scaffold having aligned fibrils, apparatus and method for producing the same, and artificial tissue and methods of use thereof

ActiveUS20050009178A1Improve structural strengthMinimal immunological responsePeptide/protein ingredientsHollow filament manufactureFiberRadial position

A tubular tissue scaffold is described which comprises a tube having a wall, wherein the wall includes biopolymer fibrils that are aligned in a helical pattern around the longitudinal axis of the tube where the pitch of the helical pattern changes with the radial position in the tube wall. The scaffold is capable of directing the morphological pattern of attached and growing cells to form a helical pattern around the tube walls. Additionally, an apparatus for producing such a tubular tissue scaffold is disclosed, the apparatus comprising a biopolymer gel dispersion feed pump that is operably connected to a tube-forming device having an exit port, where the tube-forming device is capable of producing a tube from the gel dispersion while providing an angular shear force across the wall of the tube, and a liquid bath located to receive the tubular tissue scaffold from the tube-forming device. A method for producing the tubular tissue scaffolds is also disclosed. Also, artificial tissue comprising living cells attached to a tubular tissue scaffold as described herein is disclosed. Methods for using the artificial tissue are also disclosed.

Owner:UNIVERSITY OF SOUTH CAROLINA

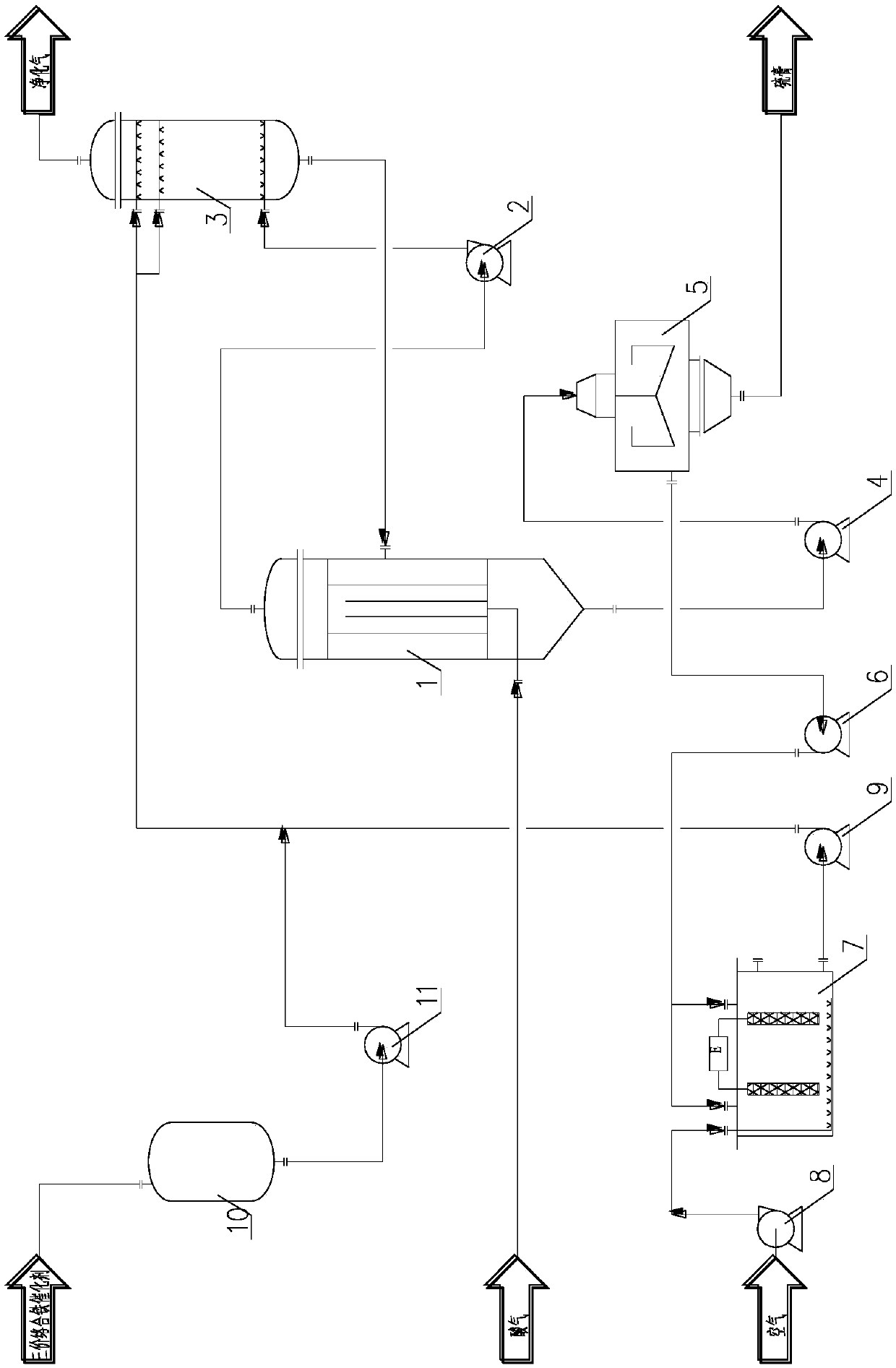

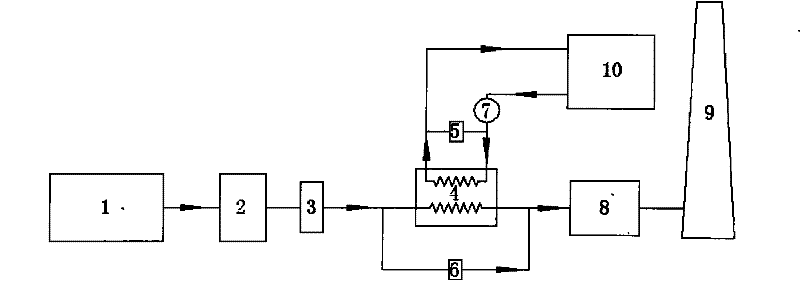

Natural gas desulfurization process suitable for offshore floating platform

InactiveCN108034466AFast regenerationImprove oxidation regeneration efficiencyGaseous fuelsChemical industryChemical reaction

The invention relates to the field of natural gas chemical industry, in particular to a natural gas desulfurization process suitable for an offshore floating platform. The natural gas desulfurizationprocess comprises a reactor, a re-reactor and a centrifugal machine; acid gas coming from a boundary region is directly introduced into the reactor, a trivalent complex iron catalyst enters the re-reactor, the trivalent complex iron catalyst at the bottom of the re-reactor enters the reactor under the control of a valve and a pipeline, a chemical reaction is then carried out, divalent complex ironobtained by means of the reaction is centrifuged, the divalent complex iron is conveyed to an electrochemical regeneration device by means of a regenerative feed pump so as to complete the regeneration, and the regenerated trivalent complex iron catalyst is returned to the re-reactor by means of a circulation pump. The natural gas desulfurization process is simple in technological process, smallin equipment size and compact in structure, and adapts to the condition limit of limited production space of offshore floating liquefied natural gas (FLNG).

Owner:SICHUAN HENGRI GAS ENG CO LTD

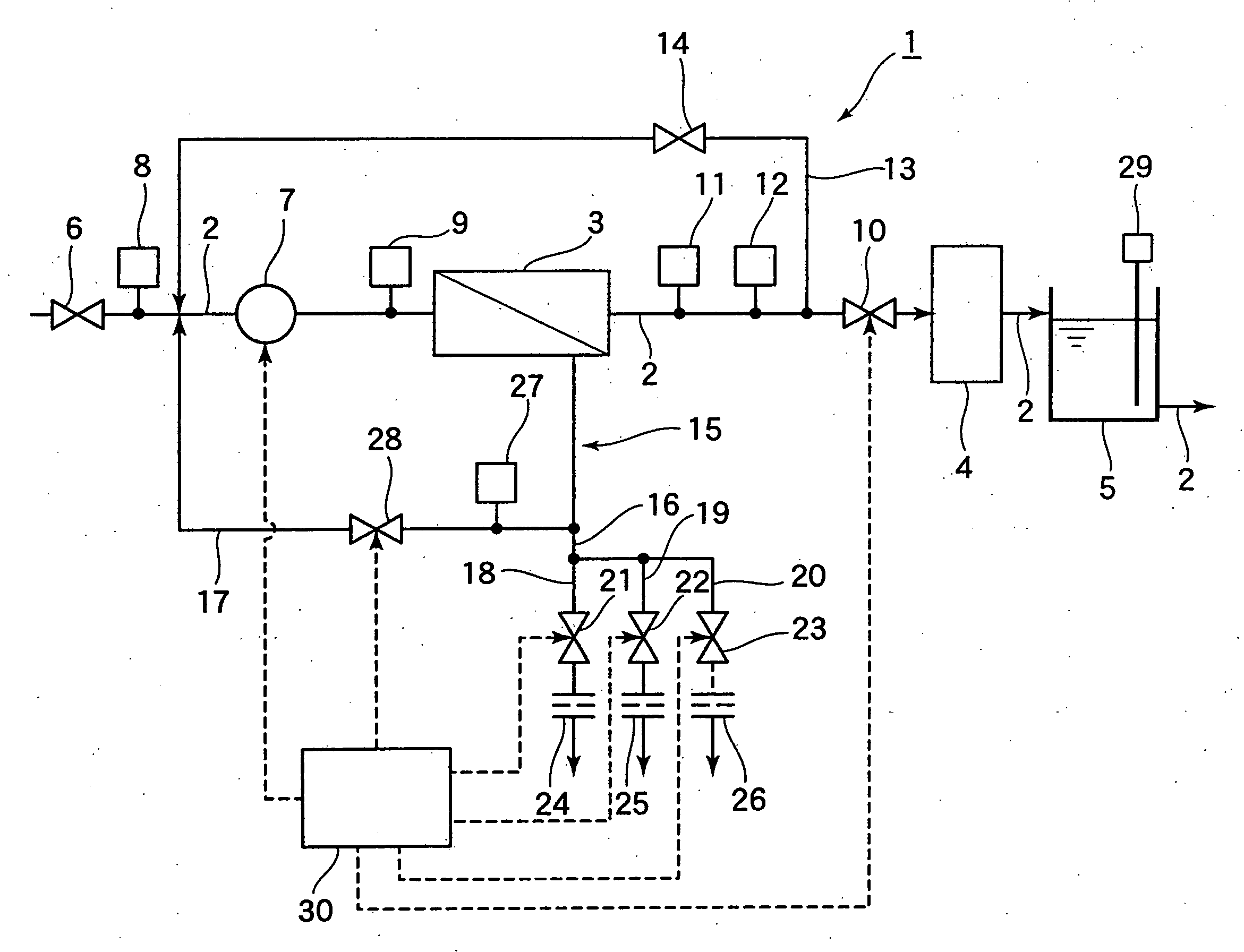

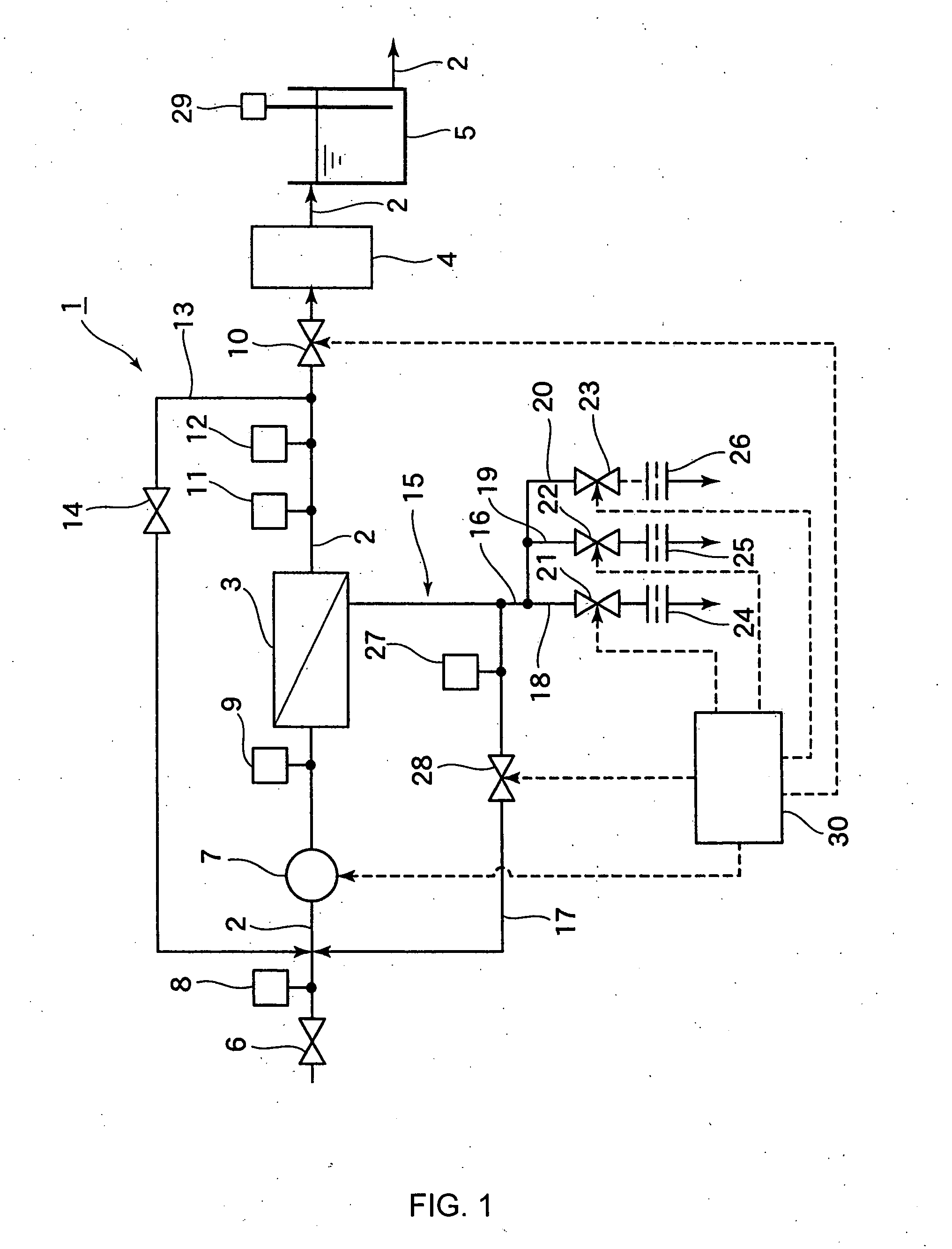

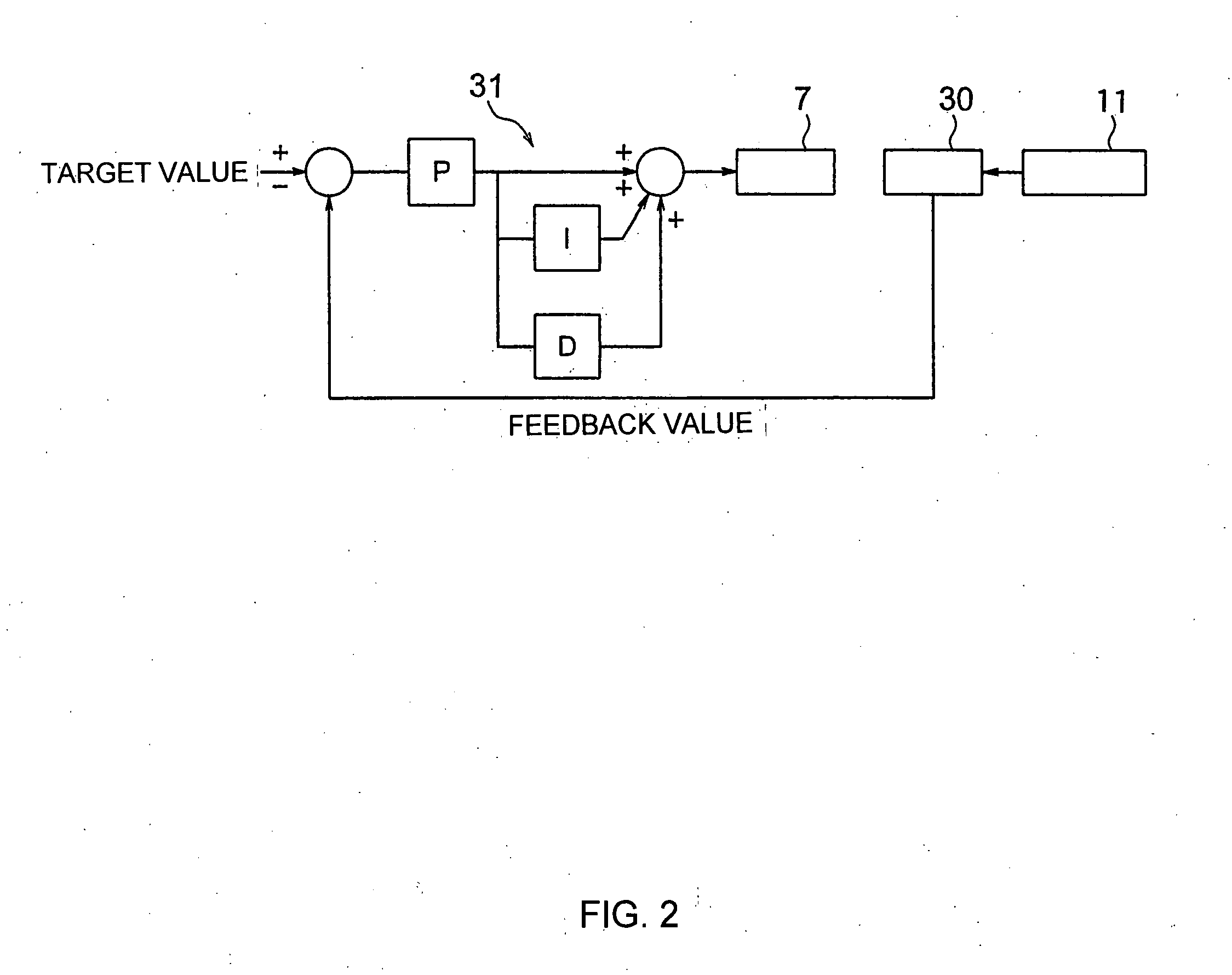

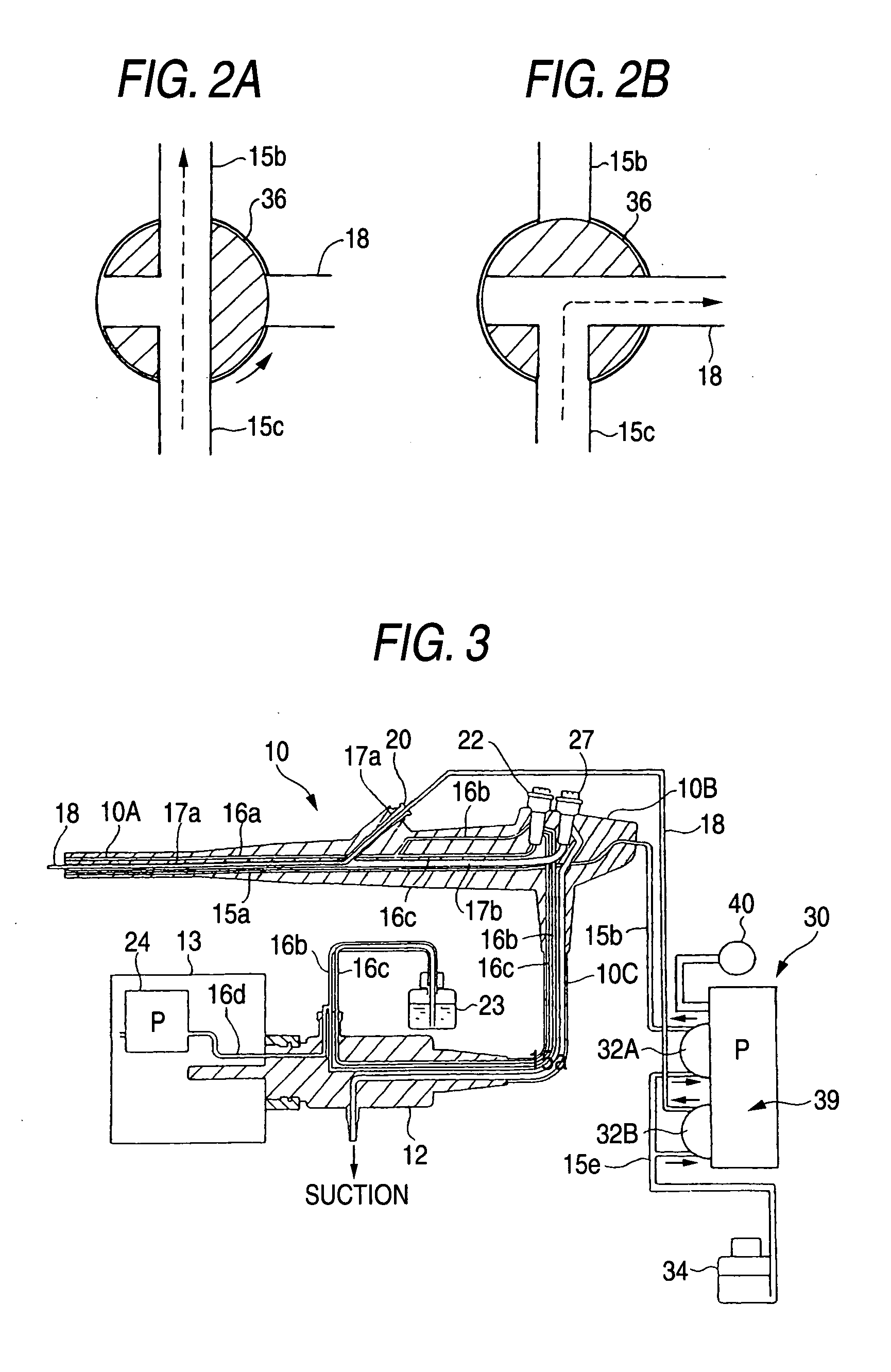

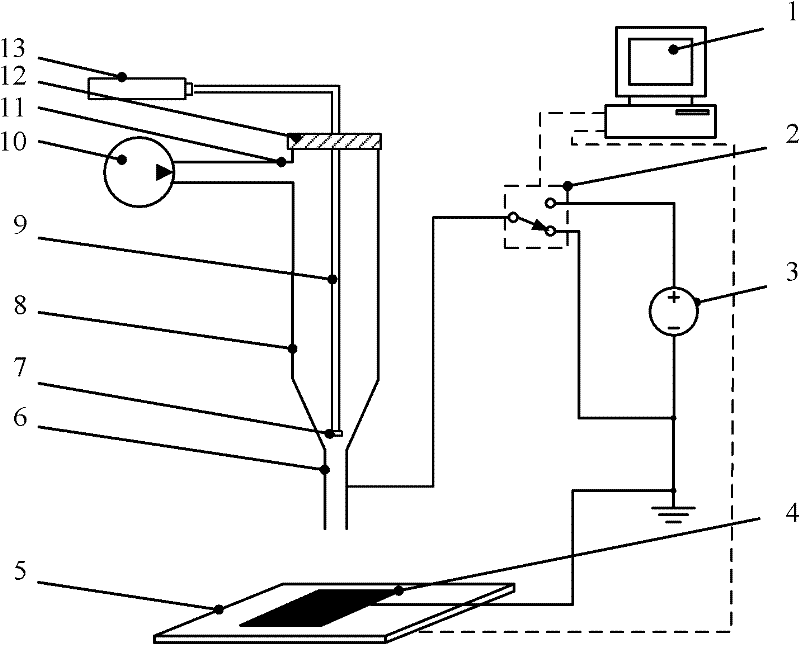

Membrane filtration system

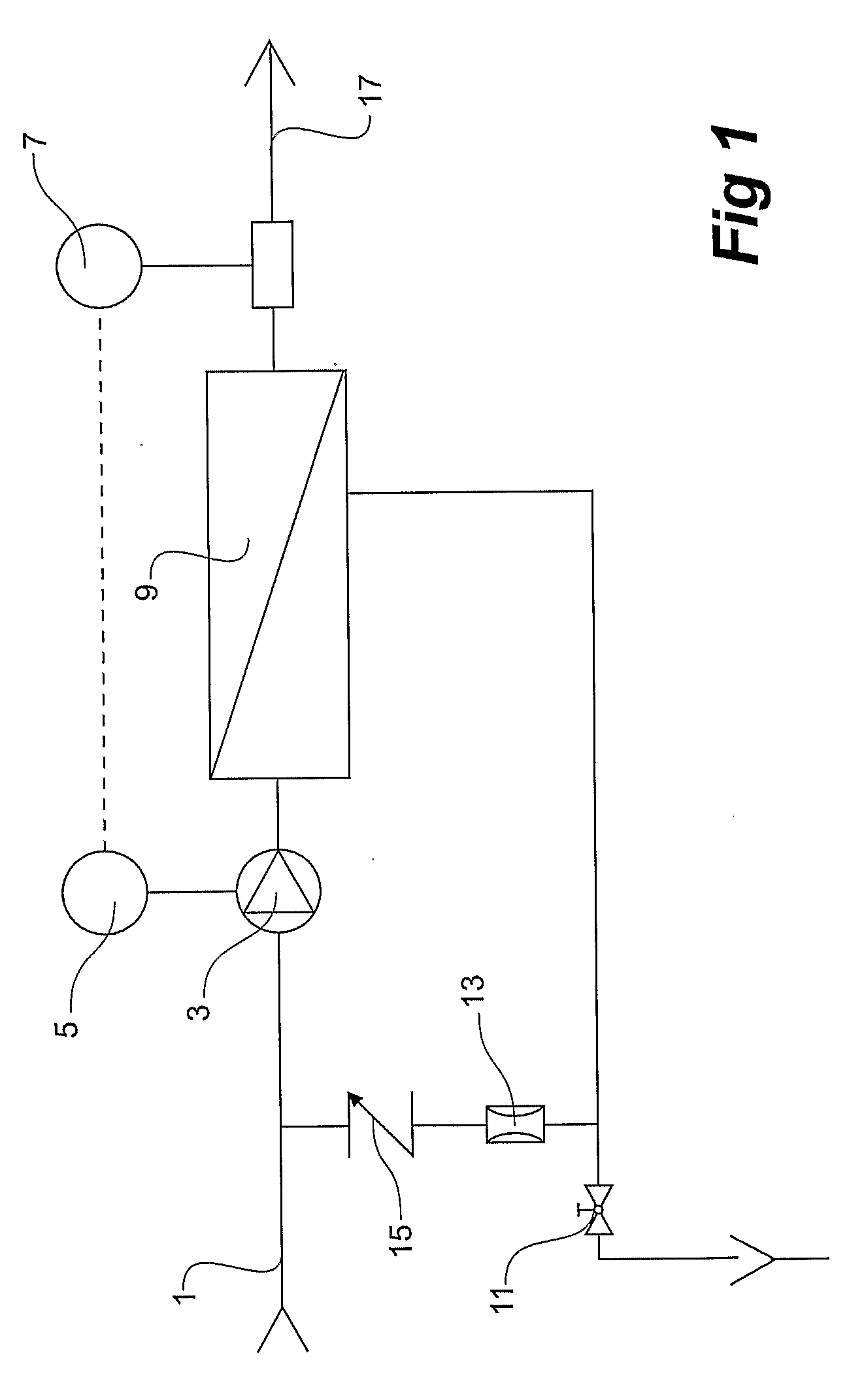

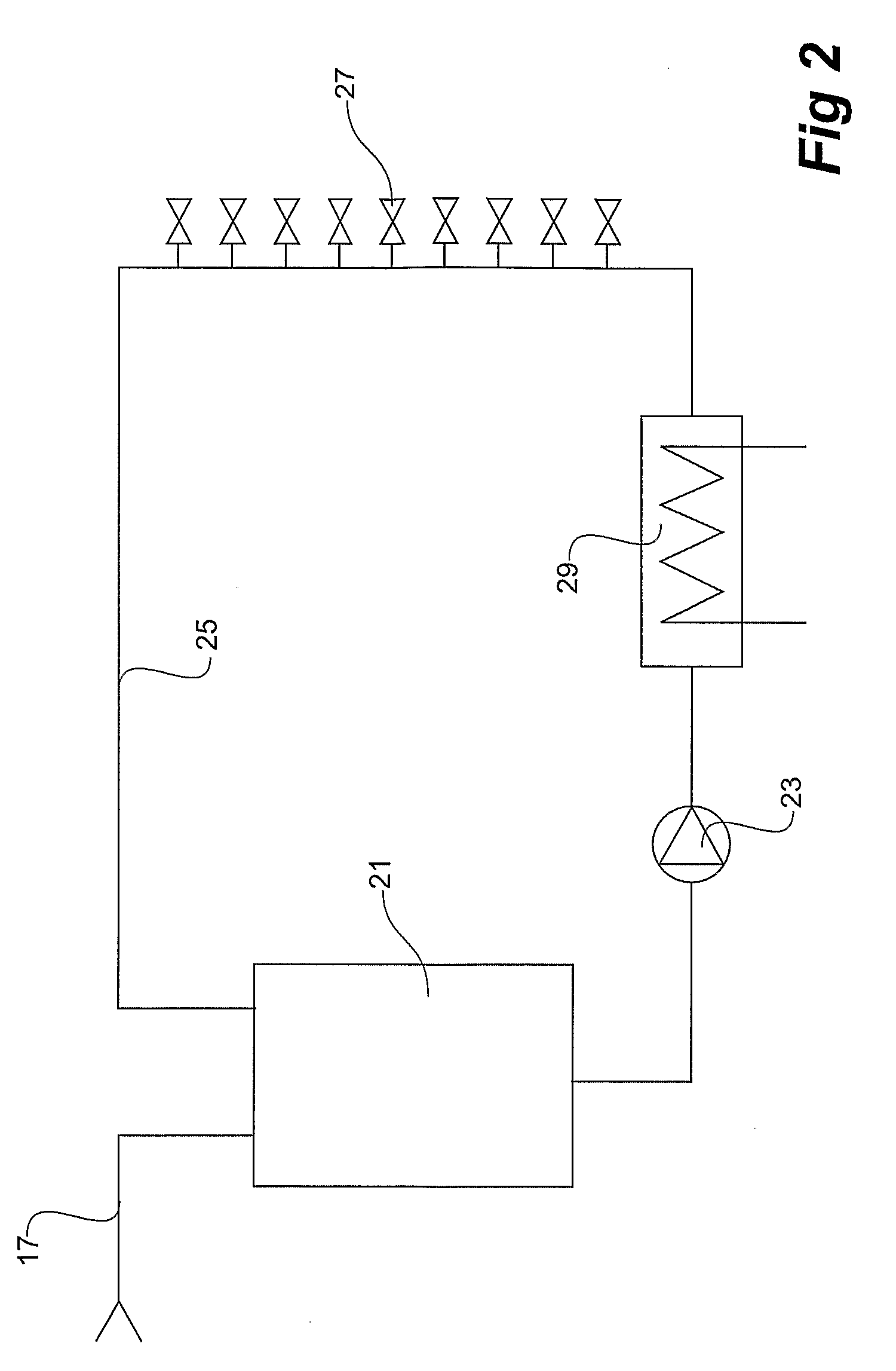

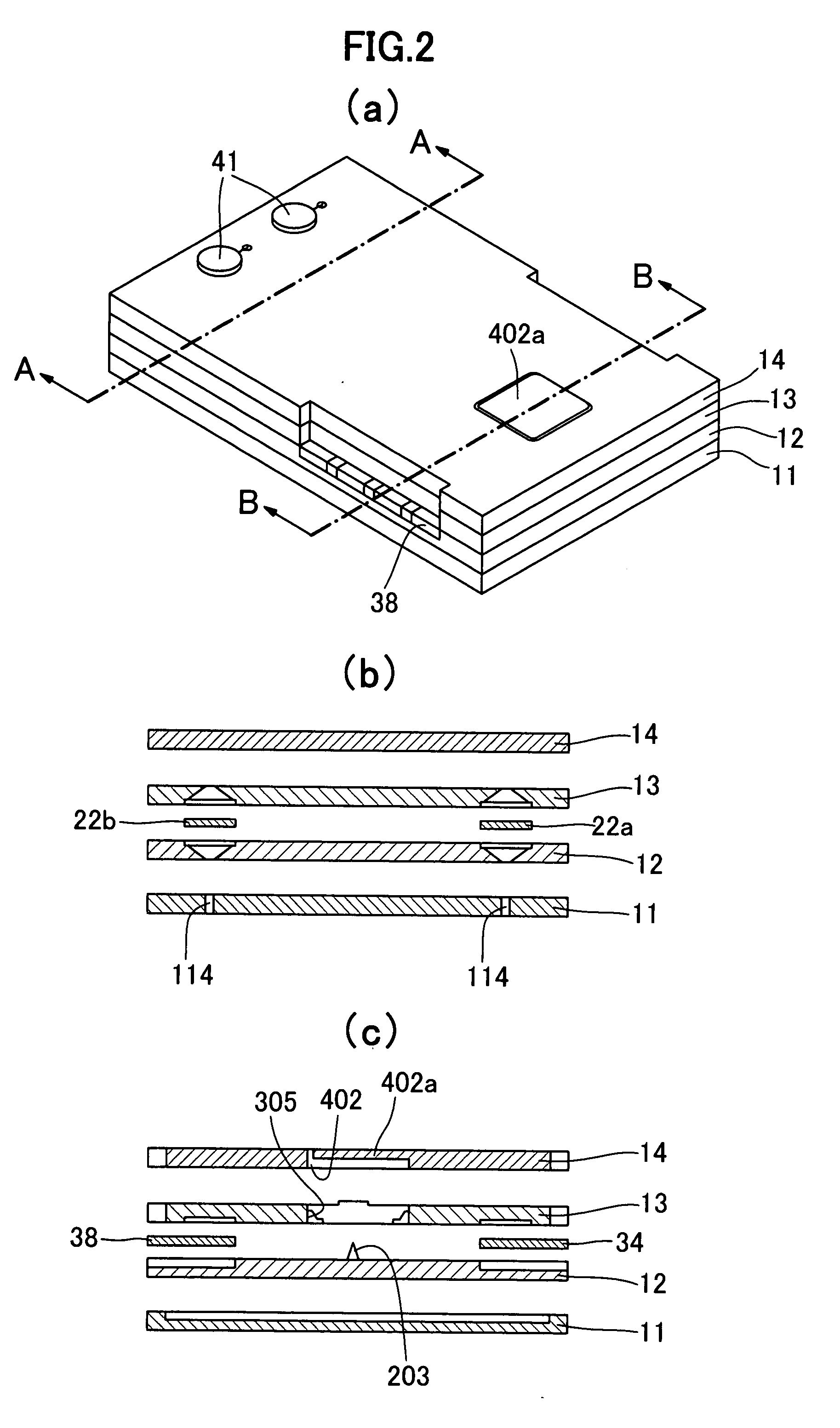

ActiveUS20070295650A1Prevent wasteful power consumptionAvoid cloggingWater treatment parameter controlMembranesFiltrationImpurity

The present invention provides a membrane filtration system (1) including: a filtering membrane portion (3) for removing impurities in feed water; a drain line (16) for draining a part of concentrate from the filtering membrane portion (3) to an exterior of a system; a concentrate return line (17) for returning a remainder of the concentrate from the filtering membrane portion (3) to an upstream side of the filtering membrane portion (3); a return flow rate adjusting portion (28) for concentrate provided in the concentrate return line (17); and a control portion (30) controlling the return flow rate adjusting portion (28) based on a drain flow rate of the concentrate or a flow rate of product water from the filtering membrane portion (3). With this construction, it is possible to suppress wasteful power consumption in a feed pump (7) for feeding water to the filtering membrane portion (3) and to prevent clogging in the filtering membrane in the filtering membrane portion (3).

Owner:MIURA COMPANY LIMITED

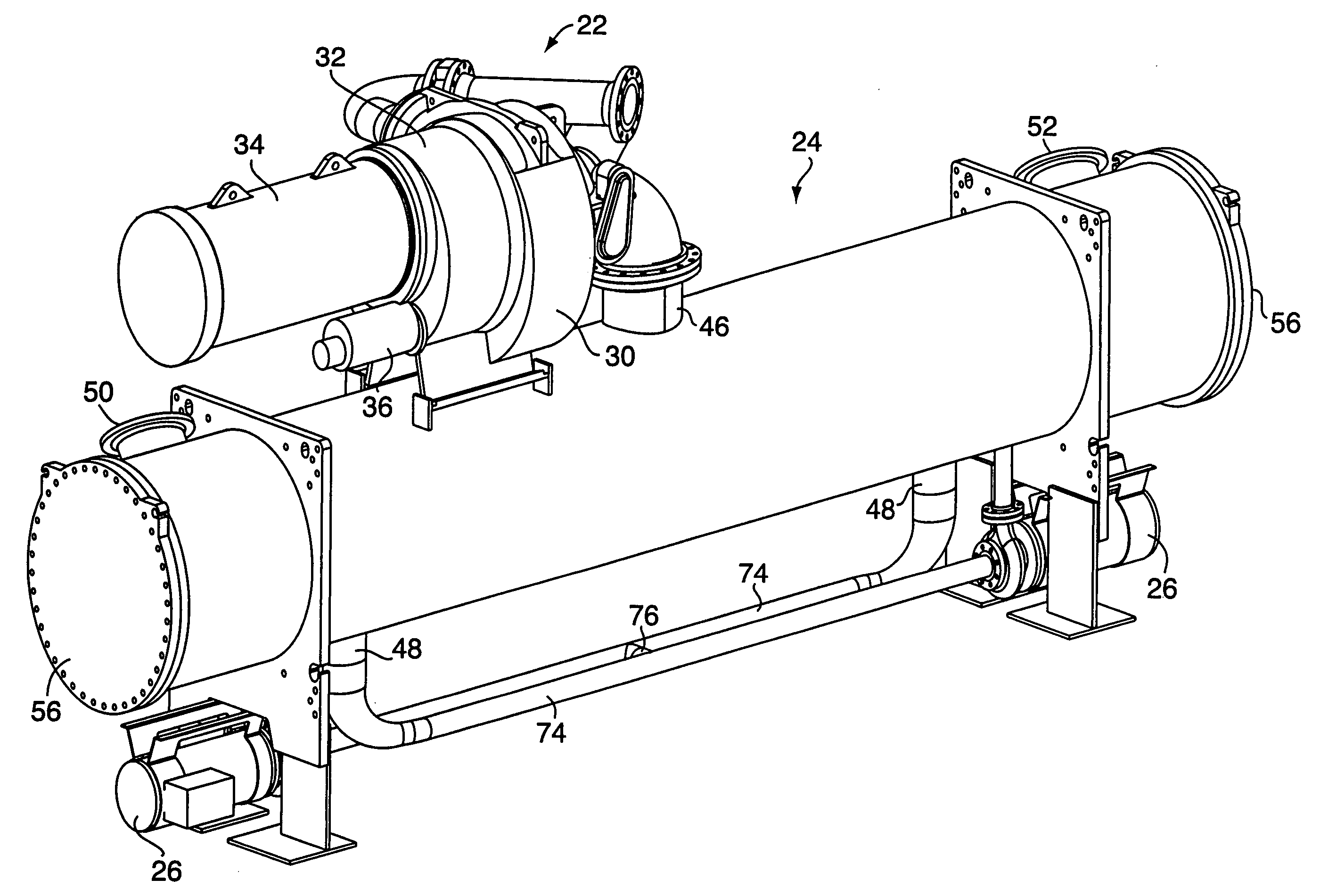

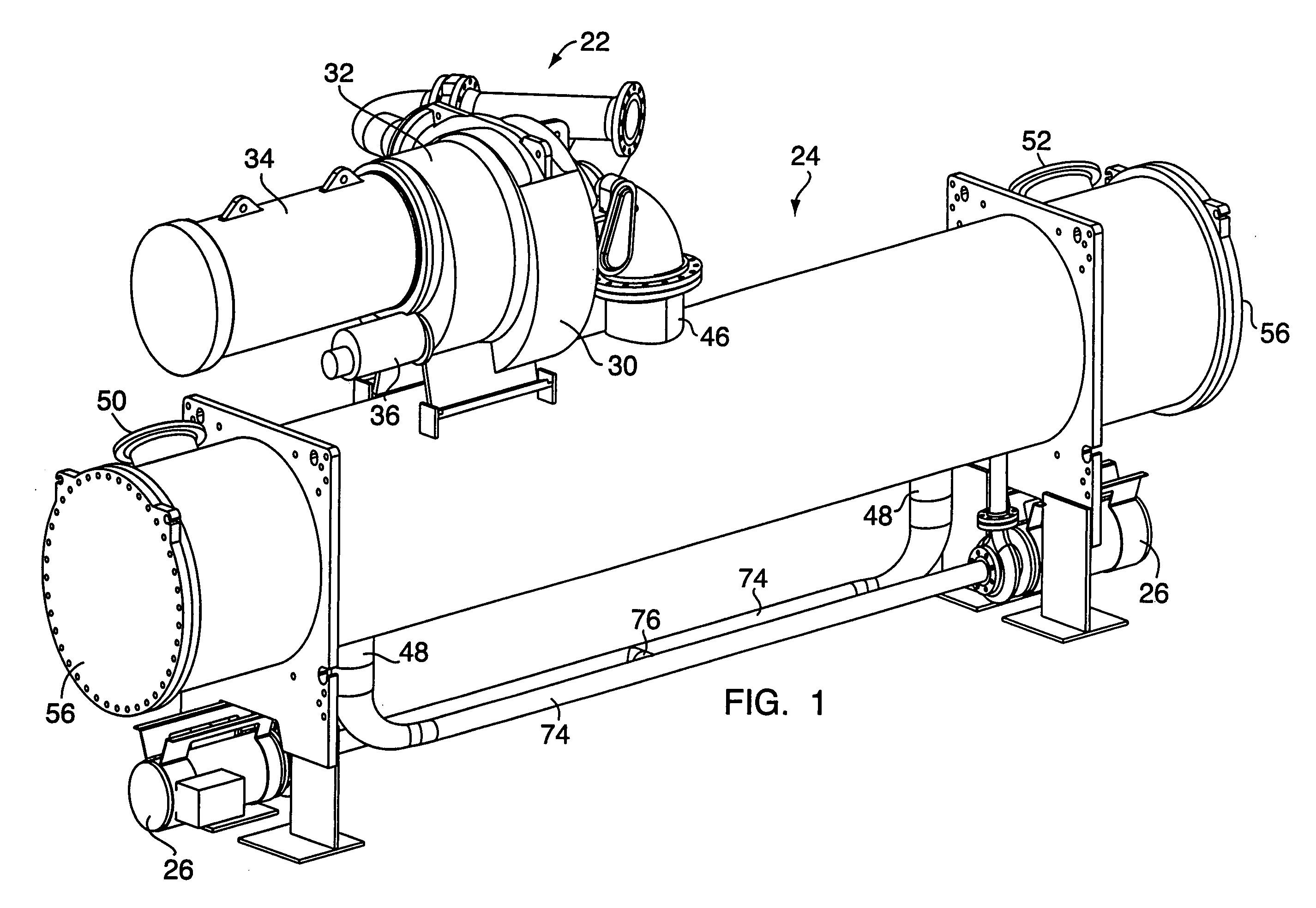

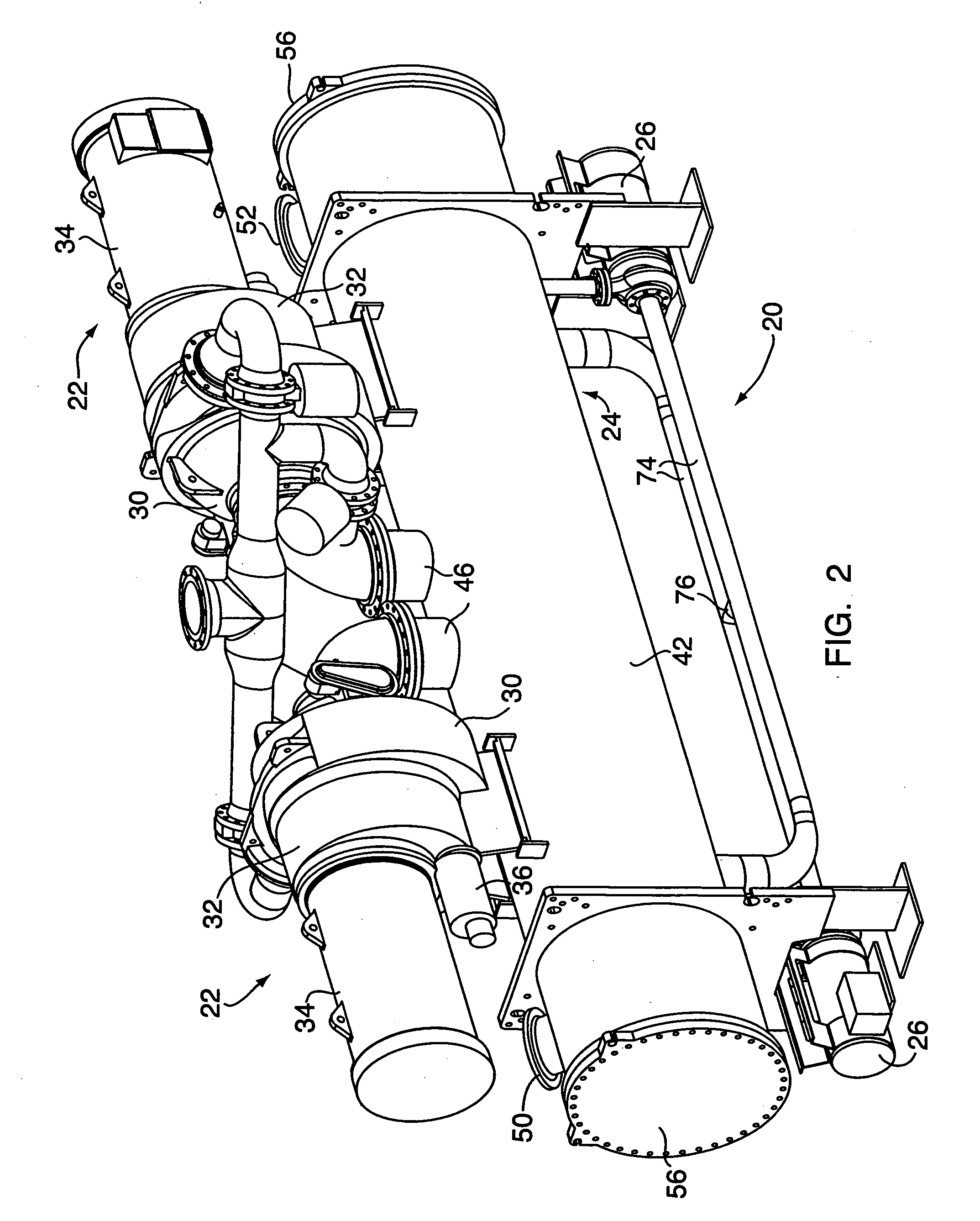

Method and apparatus for power generation using waste heat

InactiveUS20060112693A1High densityReduce flowSteam generation heating methodsSteam usePower stationEngineering

According to the present invention, a method and apparatus for generating power aboard a marine vessel is provided. The method comprises the steps of: (a) providing a Rankine Cycle device that includes at least one of each of an evaporator, a turbo-generator that includes a turbine coupled with an electrical generator, a condenser, and a refrigerant feed pump; (b) disposing the one or more evaporators within an exhaust duct of a power plant of the marine vessel; (c) operating the power plant; and (d) selectively pumping refrigerant through the Rankine Cycle device, wherein refrigerant exiting the evaporator powers the turbine, which in turn powers the generator to produce power.

Owner:CARRIER CORP

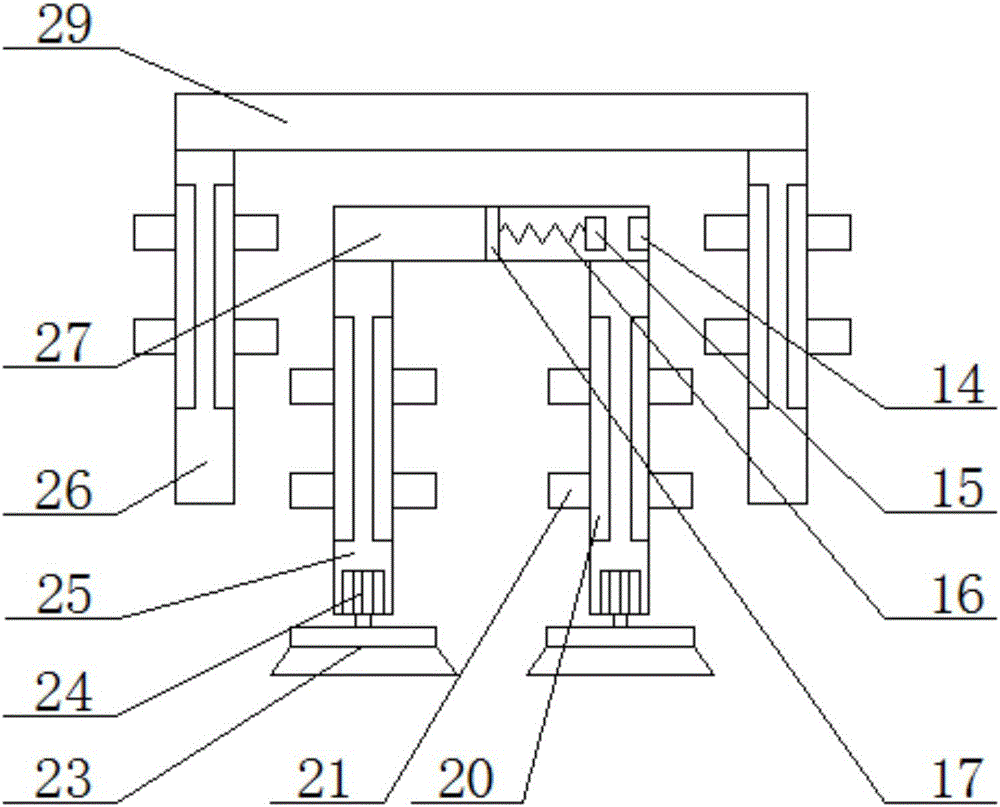

Multi-material multi-scale 3D (3-dimensional) printing device provided with single spray nozzle as well as working method of 3D printing device

ActiveCN105196550ARealize printingReasonable control of macro geometryManufacturing platforms/substratesTransportation and packagingMulti materialSpray nozzle

The invention discloses a multi-material multi-scale 3D (3-dimensional) printing device provided with a single spray nozzle as well as a working method of the 3D printing device. The 3D printing device comprises a base, a work table, a bearing table, a substrate, a power supply, the spray nozzle and a bracket, wherein the base is mounted at the bottommost part, the bracket and the work table are mounted above the base, the spray nozzle is mounted on the bracket, the bearing table is fixed on the work table, and the substrate is fixed above the bearing table; an anode and a cathode of the power supply are connected with a nozzle body of the spray nozzle and the bearing table respectively; relative motion between the spray nozzle and the substrate in x, y and z directions is realized by the aid of relative motion between the work table and the bracket. The spray nozzle is provided with a plurality of feed openings connected with different trace feeding pumps, multiple materials are thoroughly mixed under the action of a stirrer after entering the spray nozzle, and multi-material printing is realized. The macroscopic geometrical shape as well as microstructures in an object and on the surface of the object is controlled reasonably, and multi-scale structural integrated manufacture is realized.

Owner:兰红波

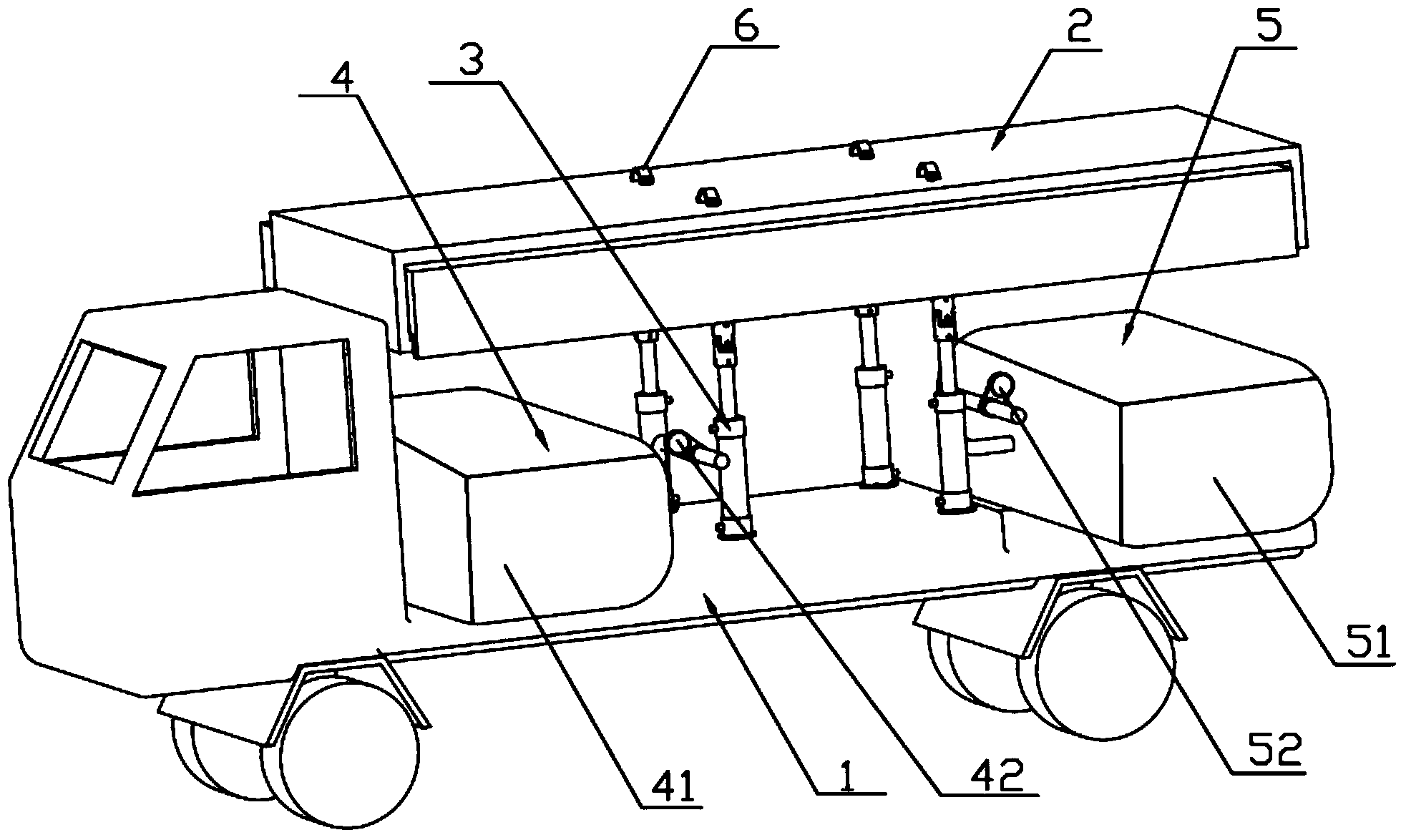

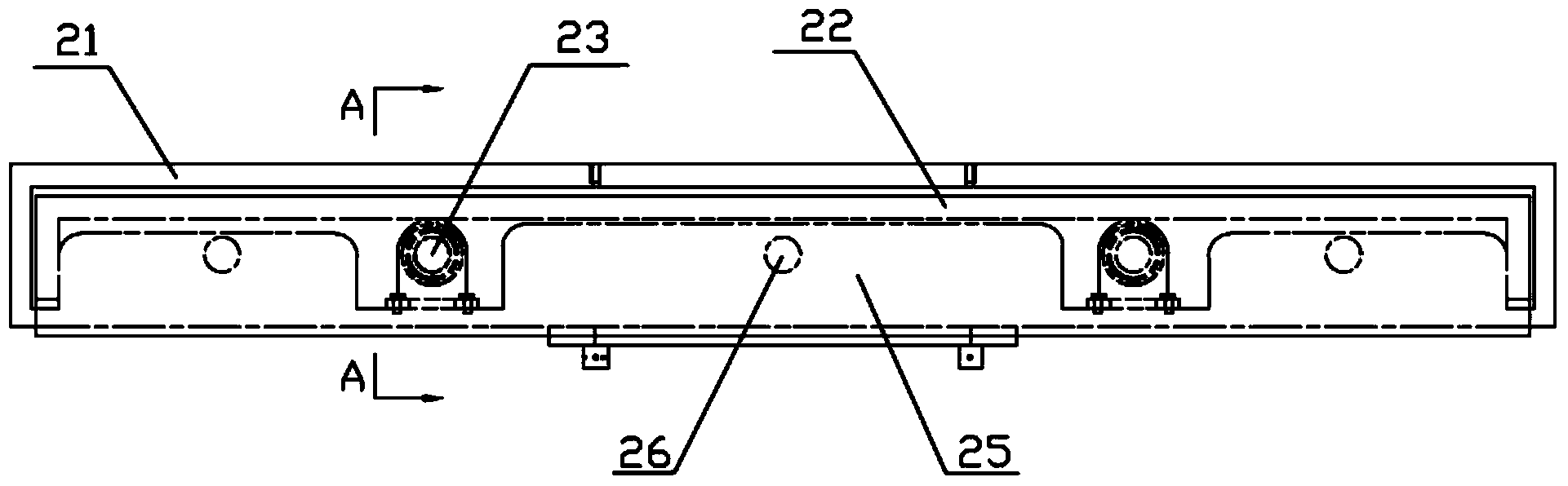

Feeding platform and feeding method suitable for field operation feeding for agricultural unmanned aerial vehicle

InactiveCN104386258AReduce personal safety concernsContinuously workingItem transportation vehiclesGround installationsUncrewed vehicleEngineering

The invention discloses a feeding platform and a feeding method suitable for field operation feeding for an agricultural unmanned aerial vehicle. The feeding platform comprises a mobile rack, and a take-off and landing platform unit, a pesticide supplementing unit and an energy supplementing unit arranged on the rack; the take-off and landing platform unit comprises a landing plate and a lifting mechanism, and the lifting mechanism is arranged between the bottom of the landing plate and the rack; the pesticide supplementing unit comprises a pesticide storage box and a pesticide feed pump. According to the invention, the mobile rack is adopted to carry the feeding platform, and thus the unmanned aerial vehicle can be carried to move flexibly and conveying is facilitated; when the unmanned aerial vehicle performs operation, the take-off and landing positions of the unmanned aerial vehicle can be changed continually midway for supplementing energy and spraying materials, and the take-off and landing positions adjacent to the operation positions can be selected, so that effective operation duration of the unmanned aerial vehicle is increased, and the operation efficiency of the unmanned aerial vehicle is improved. The lower part of the landing plate is provided with the lifting mechanism, so that the landing plate not only can be maintained in a horizontal state in the uneven farmland ground, but also can be adjusted to an appropriate height.

Owner:SOUTH CHINA AGRI UNIV

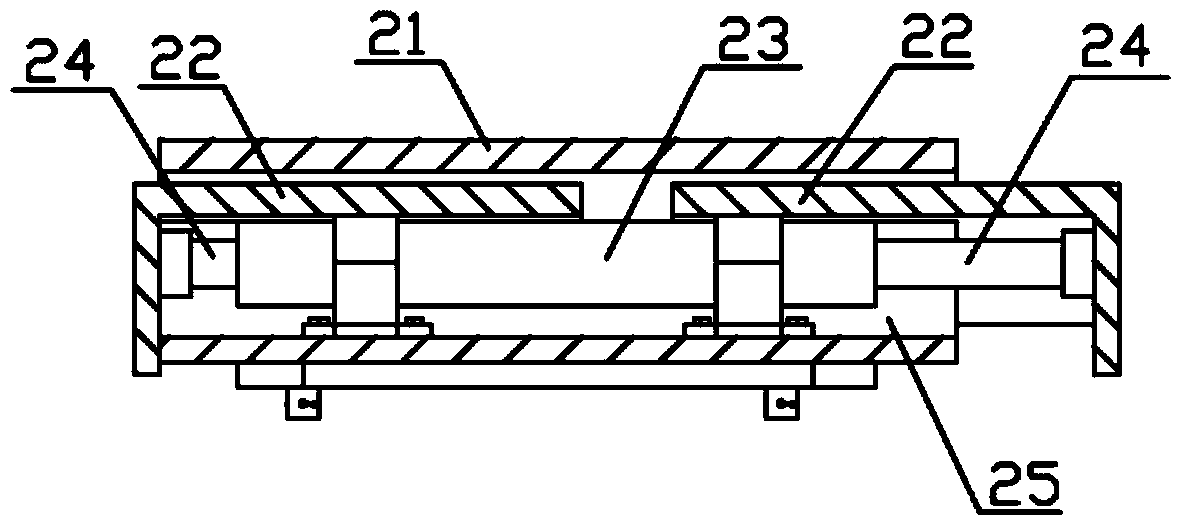

Purified Water Production and Distribution System

InactiveUS20090134080A1Maintain microbiological cleanlinessReduce water wasteWater treatment parameter controlMembranesWater productionClosed loop

A closed loop water purification system comprising a feed water line (42) to supply feed water, a high pressure feed pump (62), a filter assembly (66) having an inlet supplied by the high pressure feed pump, a distribution line (68) and a reject water line (70), the reject line returning reject water from the filter assembly to the feed water line, the distribution line supplying at least one purified water take off point (86) and returning to a junction (50) in the feed water line upstream of the high pressure feed pump. The reject water line is connected to the junction in the feed water line upstream of the high pressure feed pump. A first backflow prevention device (48) is on the feed water line upstream of the junction. A second backflow prevention device (100) is on the distribution line upstream of the junction and a third backflow prevention device (80) is on the reject water line upstream of the junction. A heater system (56) is in one of the distribution line, the reject line or the feed water line.

Owner:OSMOFLO

Method for improving solidifying point of Fischer-Tropsch wax

InactiveCN103980940AImprove stabilityHigh melting pointPetroleum wax recoveryChemical industryTwo step

The invention relates to a method for preparing high-melting-point refined wax capable of being applied to plastics, rubber processing, wood processing, food processing and other industries and particularly relates to a method for improving the solidifying point of Fischer-Tropsch wax. According to the method for preparing high-melting-point refined wax with excellent performances, distillation refining is carried out on light-weight oil serving as a raw material by means of continuous high-vacuum distillation, wherein the light-weight oil is produced by indirect coal liquefaction; According to the technical scheme, the method comprises two steps, namely, firstly, feeding the raw material in an evaporator by a feed pump so as to heat and evaporate the oil components and other low-boiling-point substances under the conditions of high temperature and high vacuum degree; secondly, feeding the coal-based synthetic oil without oil components and other low-boiling-point substances into a distiller, heating and evaporating the coal-based synthetic oil products by using heat-conduction oil under extremely high vacuum condition, condensing and capturing in a condenser to obtain the target product. The method disclosed by the invention can be widely used in the field of chemical industry.

Owner:SHANXI LUAN MINING GRP

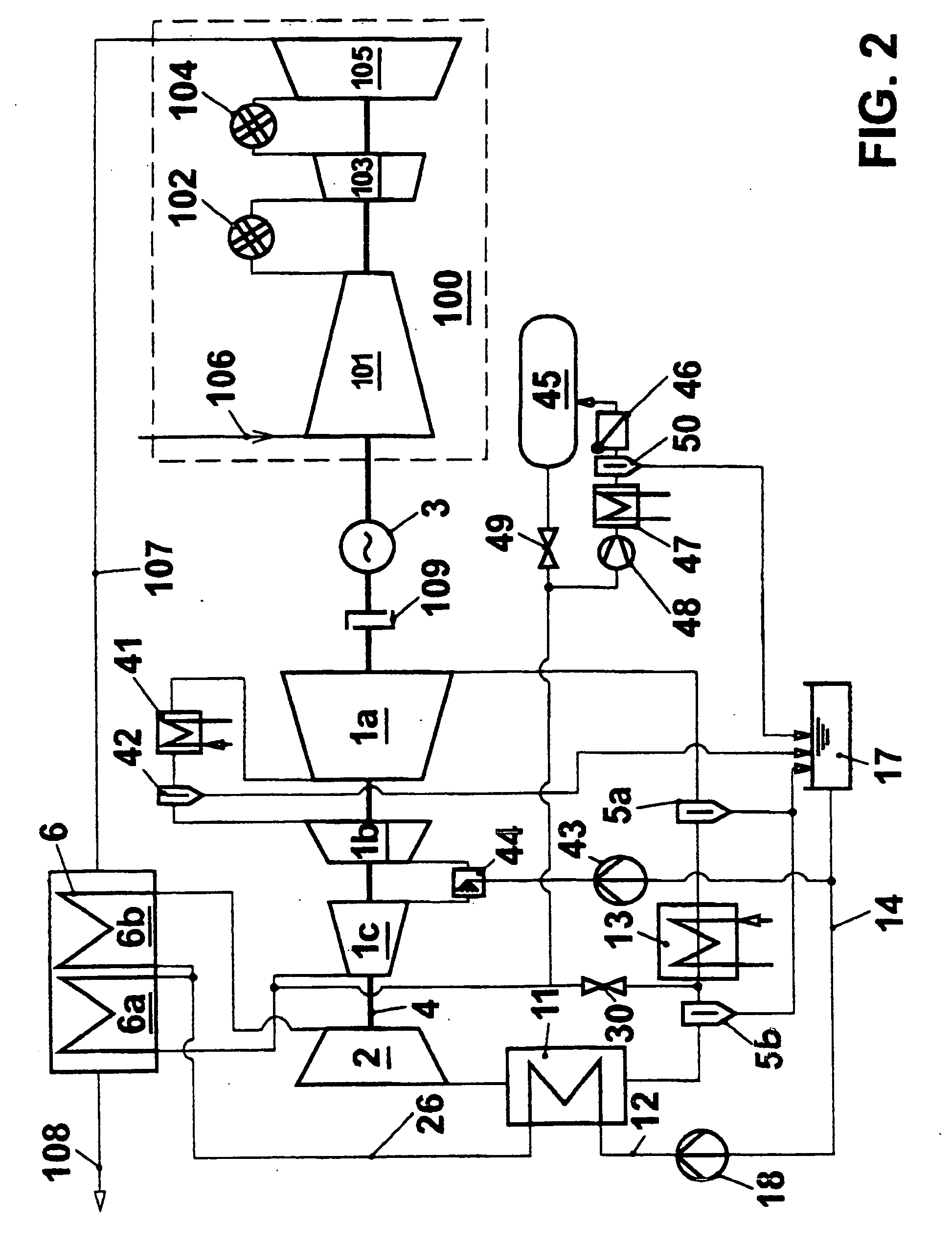

Thermal power process

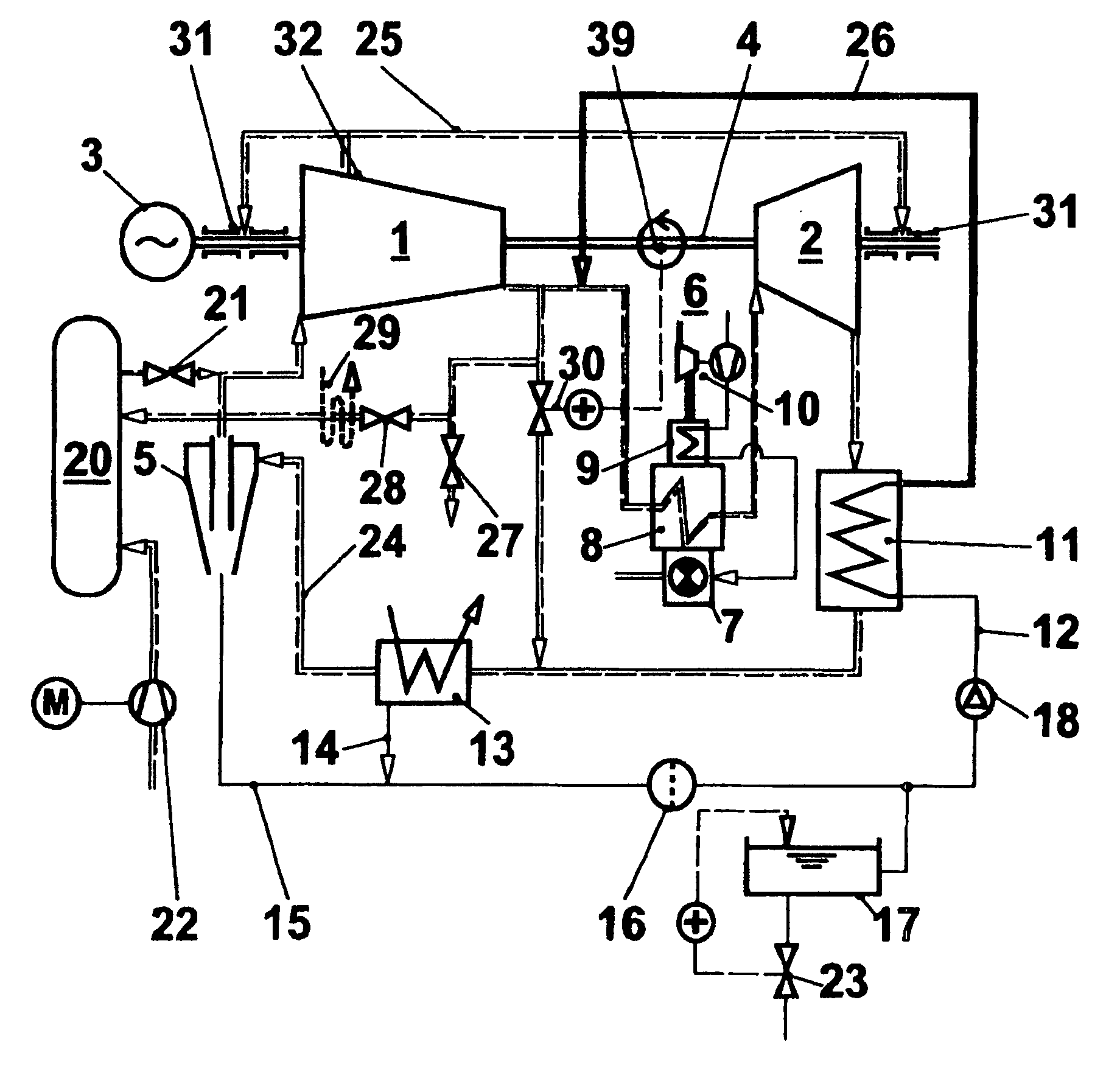

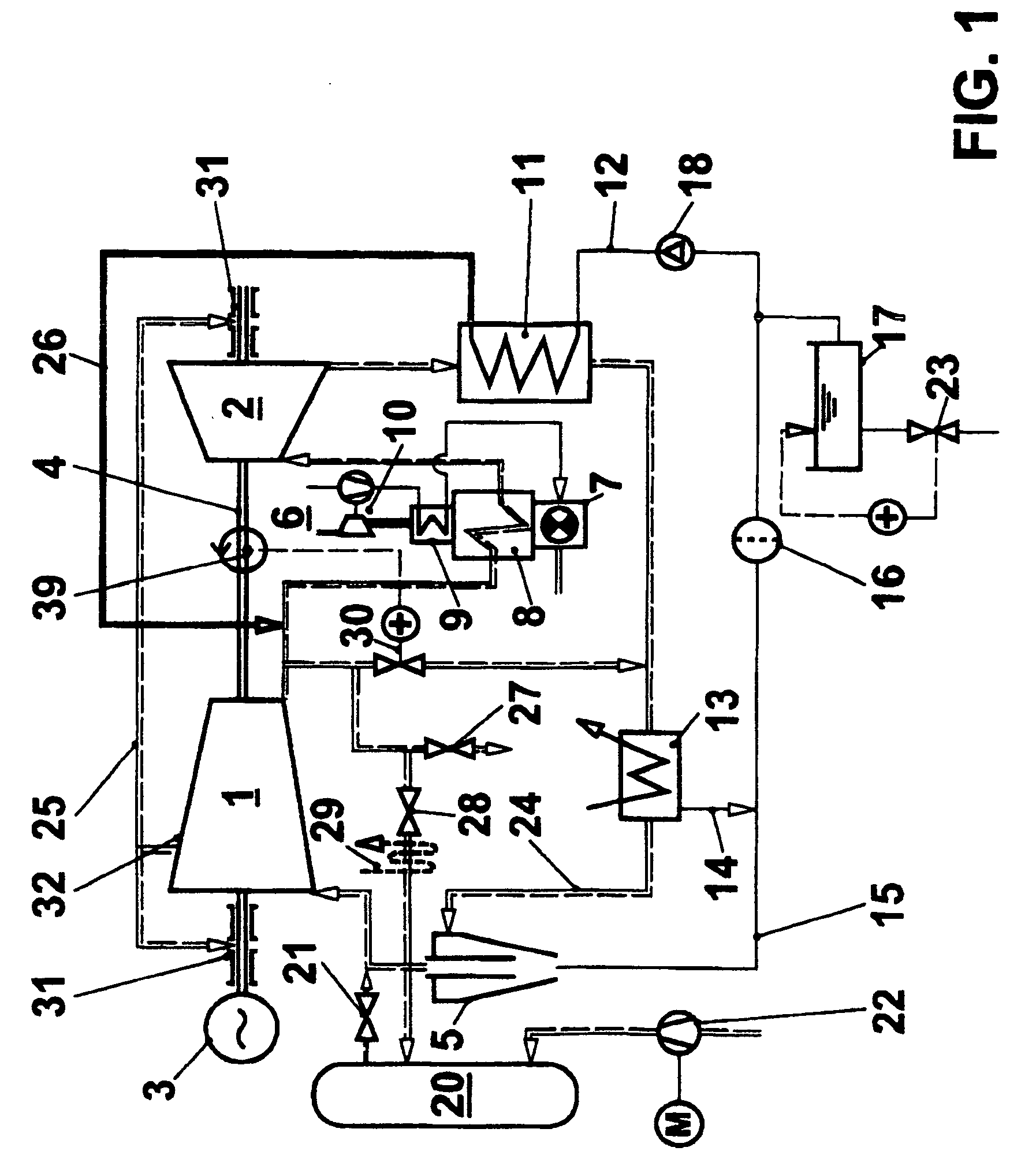

InactiveUS20050072154A1Increased processing pressureStrong dimensionSteam accumulatorsGas turbine plantsCompression deviceEngineering

In a power generation unit, especially in a gasturbo group, a gaseous process fluid is guided in a closed cycle. The gaseous process fluid flows through a compression device (1), a heater (6) and an expansion device (2), especially a turbine. Downstream from the expansion device at least one heat sink (11, 13) is arranged in which the gaseous process fluid is cooled before it is returned to the compressor device (1). At least one heat sink includes a waste heat steam generator in which an overheated amount of steam (26) is generated that is added to the compressed gaseous process fluid. Together with the gaseous process fluid the steam flows through the heater (6) if necessary and is expanded together with it. The expanded steam condenses in the waste heat steam generator (11) and another heat sink (13); the condensate is processed in a filter (16) and is returned to the waste heat steam generator (11) under pressure via a feed pump (18). Due to the closed process any kind of process fluid and process filling for controlling performance can be used.

Owner:ALSTOM TECH LTD

Tissue scaffold having aligned fibrils and artificial tissue comprising the same

ActiveUS7338517B2Sufficient structural strength to withstand pressureMinimal immunological responsePeptide/protein ingredientsDough-sheeters/rolling-machines/rolling-pinsFiberFibril

Owner:UNIVERSITY OF SOUTH CAROLINA

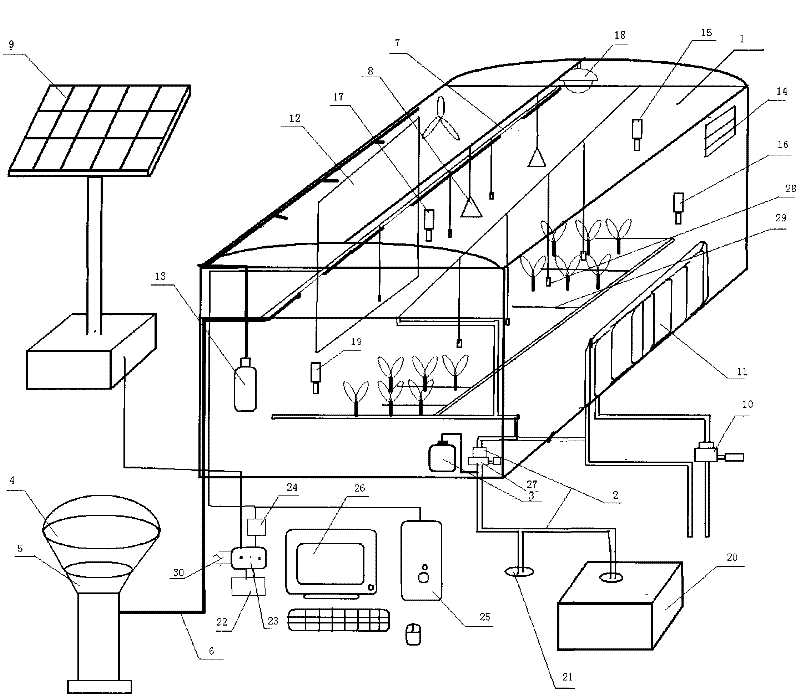

Intelligent ecological greenhouse system based on solar light supplement and geothermal insulation

InactiveCN102487754AImprove growing conditionsImprove efficiencyClimate change adaptationRenewable energy machinesSolar lightRainwater harvesting

The invention provides an intelligent ecological greenhouse system based on solar light supplement and geothermal insulation. The system comprises a greenhouse, a water accumulation and feed device, a fertilization device, a solar light condensation device, an optical fiber receiver, an optical fiber light splitter, a light supplement lamp, a solar photovoltaic generation device, a geothermal pump, hot water heat-radiating fins, a water curtain cooler, a CO2 generation device, a constant-flow ventilating window, a temperature sensing device, a humidity sensing device, a photosensitive sensor, a video monitor device, a CO2 sensing device, a rainwater collection pool, a storage battery, a power supply controller, an inverter, a control host, a monitor, a mains supply and the like, wherein electric power of a solar photovoltaic module and electric power of the mains supply are respectively supplied to the geothermal pump and the control host as well as a water feed pump and the light supplement lamp; and the control host respectively receives different signals of the temperature sensing device, the humidity sensing device, the photosensitive sensor and the CO2 sensing device to control respective terminal devices, respectively performs light supplement, temperature insulation, watering, fertilization and CO2 adjustment, and carries out remote monitoring at the same time.

Owner:王干

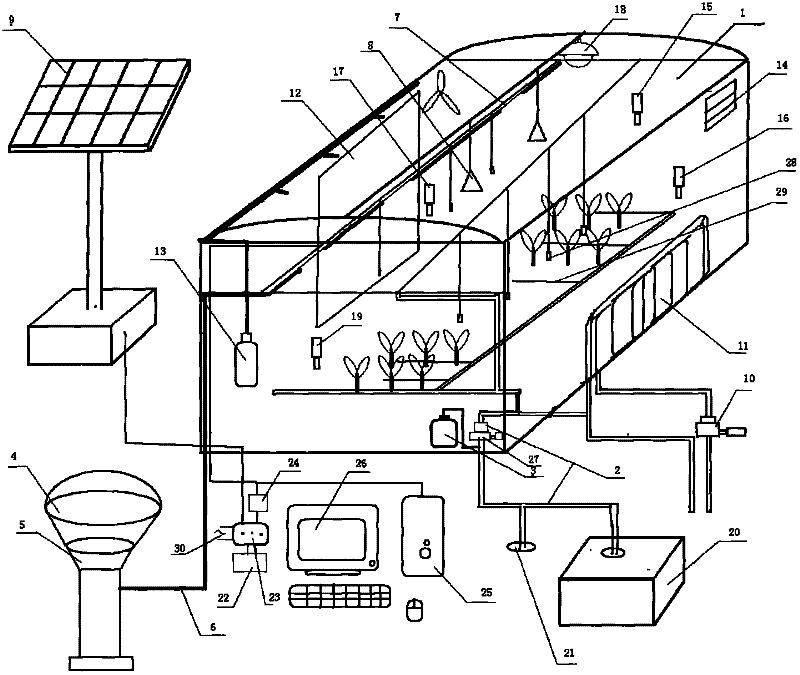

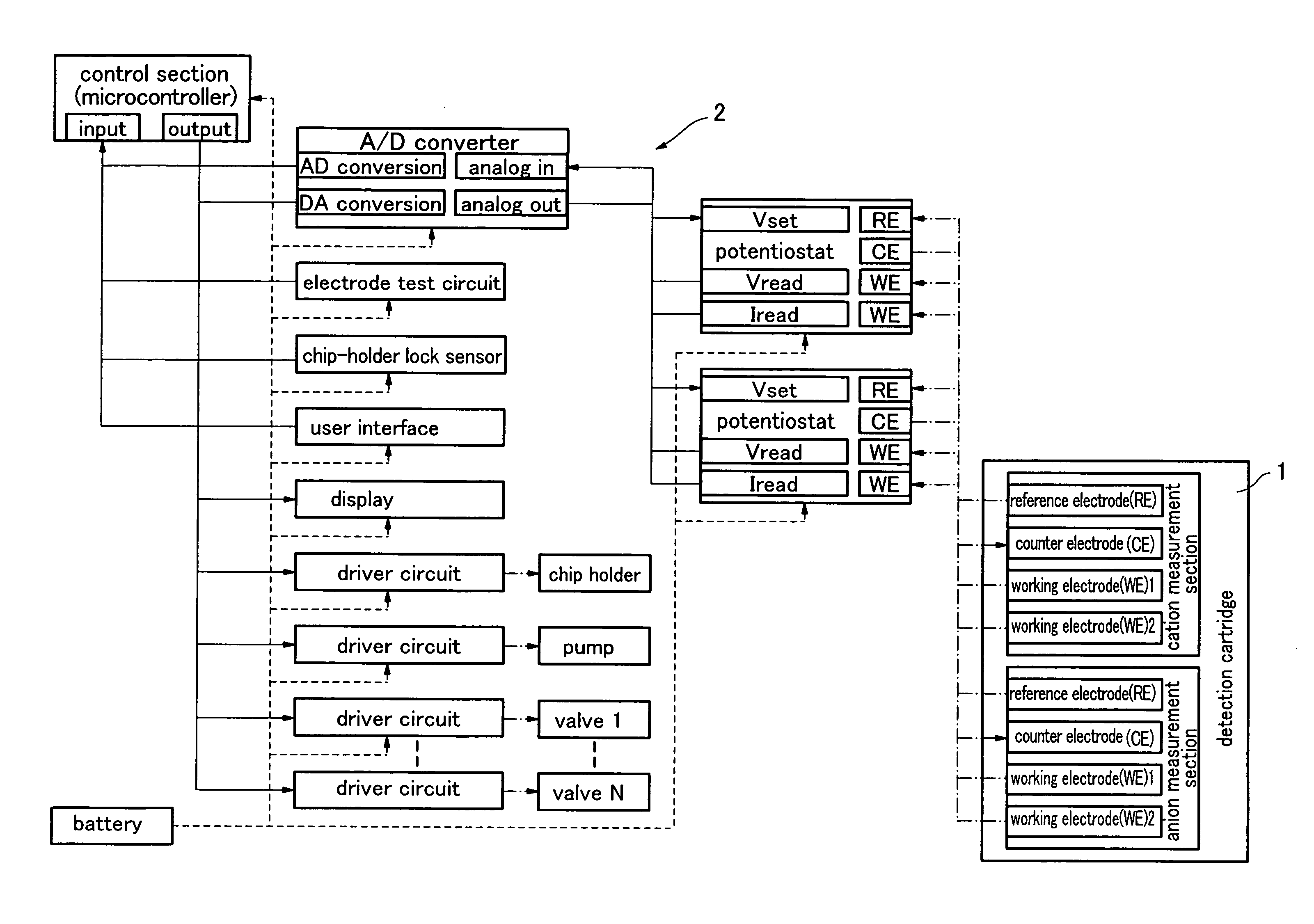

Detection apparatus using cartridge

InactiveUS20070263046A1Reduce loadEasy to cleanComponent separationEarth material testingEngineeringLine switching

Discloses is a cartridge-type detection apparatus which comprises a detection cartridge having a passage for passing a sample liquid containing an target substance, and a processing unit adapted to be loaded with the detection cartridge so as to produce information about the target substance contained in the sample liquid passed through the detection cartridge. The detection cartridge includes an storing section for temporarily storing the target substance, a liquid passage routed through the storing section, and a plurality of ports in liquid communicate with the liquid passage. The detection cartridge is provided with a part or entirety of a detection mechanism on a downstream side relative to the storing section. The processing unit includes a liquid feed pump and a line switching valve mechanism adapted to switchingly provide liquid communication between the liquid feed pump and a selected one of the plurality of ports of the detection cartridge. The valve mechanism is operable to switch between a first passage connection mode for allowing the sample liquid supplied into the detection cartridge to be passed through the storing section and then discharged out of the detection cartridge, and a second passage connection mode for allowing a reagent to be supplied from one of the plurality of ports to the storing section of the detection cartridge by an action of the liquid feed pump, and allowing the reagent passed across the storing section to be discharged out of the detection cartridge from one of the remaining ports.

Owner:SEKISUI CHEM CO LTD

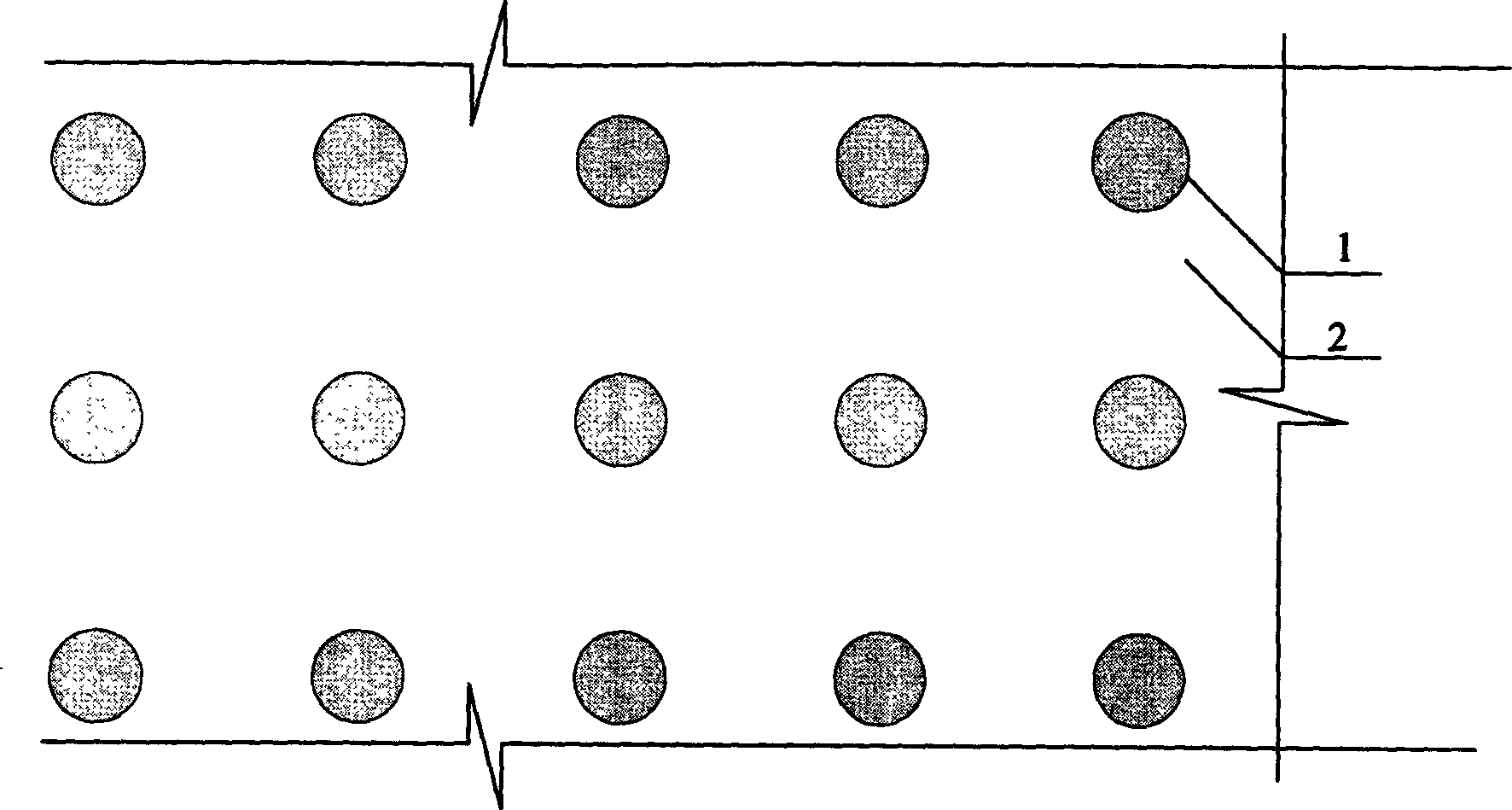

Pile forming operation method for bi-directional stirring piles

The piling operation method of two-way mixing pile is a foundation treatment method, which is suitable for soft soil foundation treatment. The operation method is: a: leveling the site; Centering; c: Stirring and sinking: start the two-way stirring pile driver, make the drill pipe of the two-way stirring pile driver cut the soil downward along the guide frame, turn on the slurry pump, spray cement slurry to the soil, and the drill pipe of the two-way stirring pile driver is respectively positive , The counter-rotating blades rotate at the same time to stir the cement and soil; d: The drill pipe of the two-way stirring pile machine continues to sink and stir the cement and soil until the design depth; e: While stirring and lifting, the drill pipe of the two-way stirring pile machine rotates forward and reverse f: lift and stir to the ground surface or 50cm above the design elevation, and complete the construction of the two-way mixing cement-soil mixing pile (1). The cement-soil mixing pile (1) is arranged in a plum blossom shape or square to ensure quality and pile quality.

Owner:南京路鼎搅拌桩特种技术有限公司

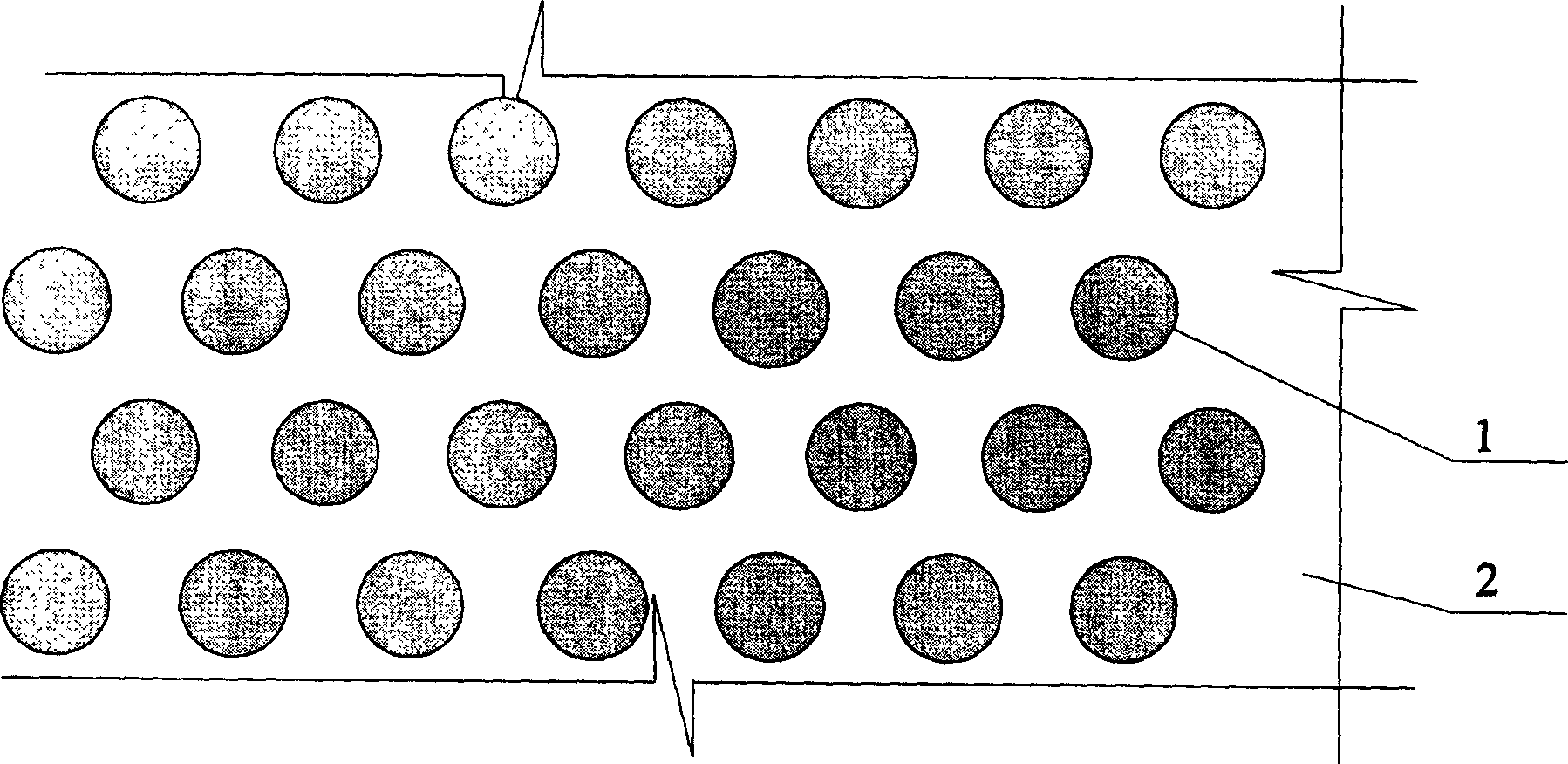

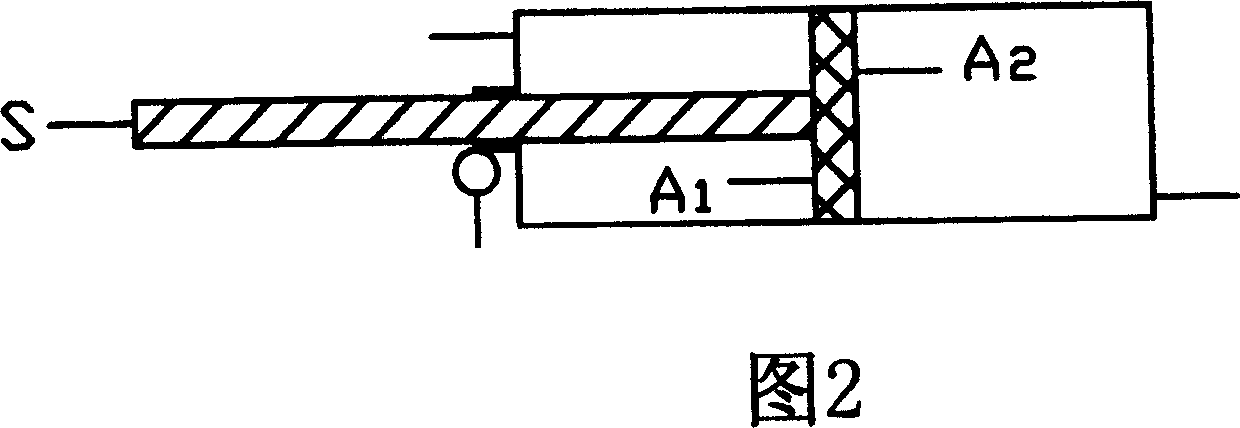

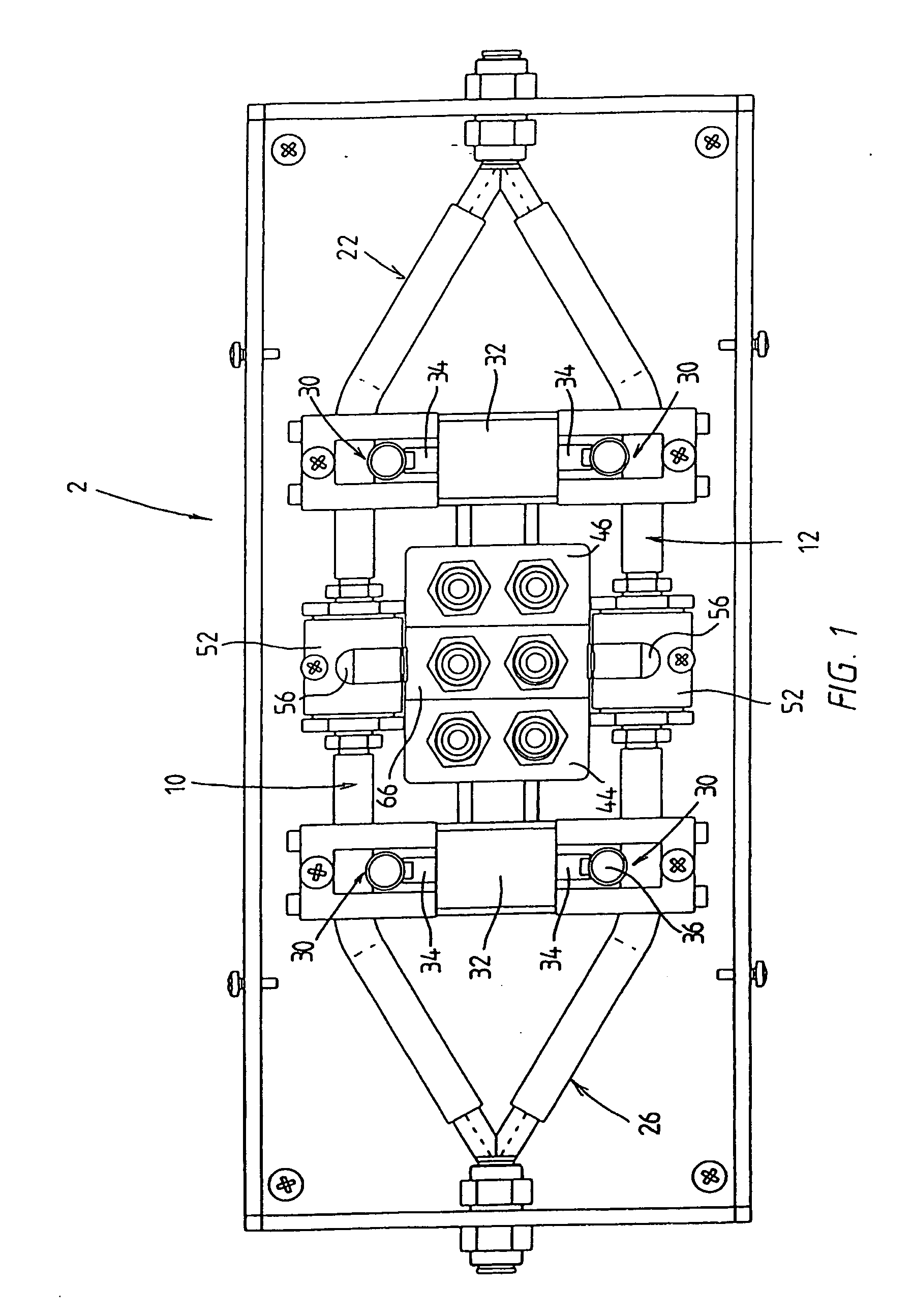

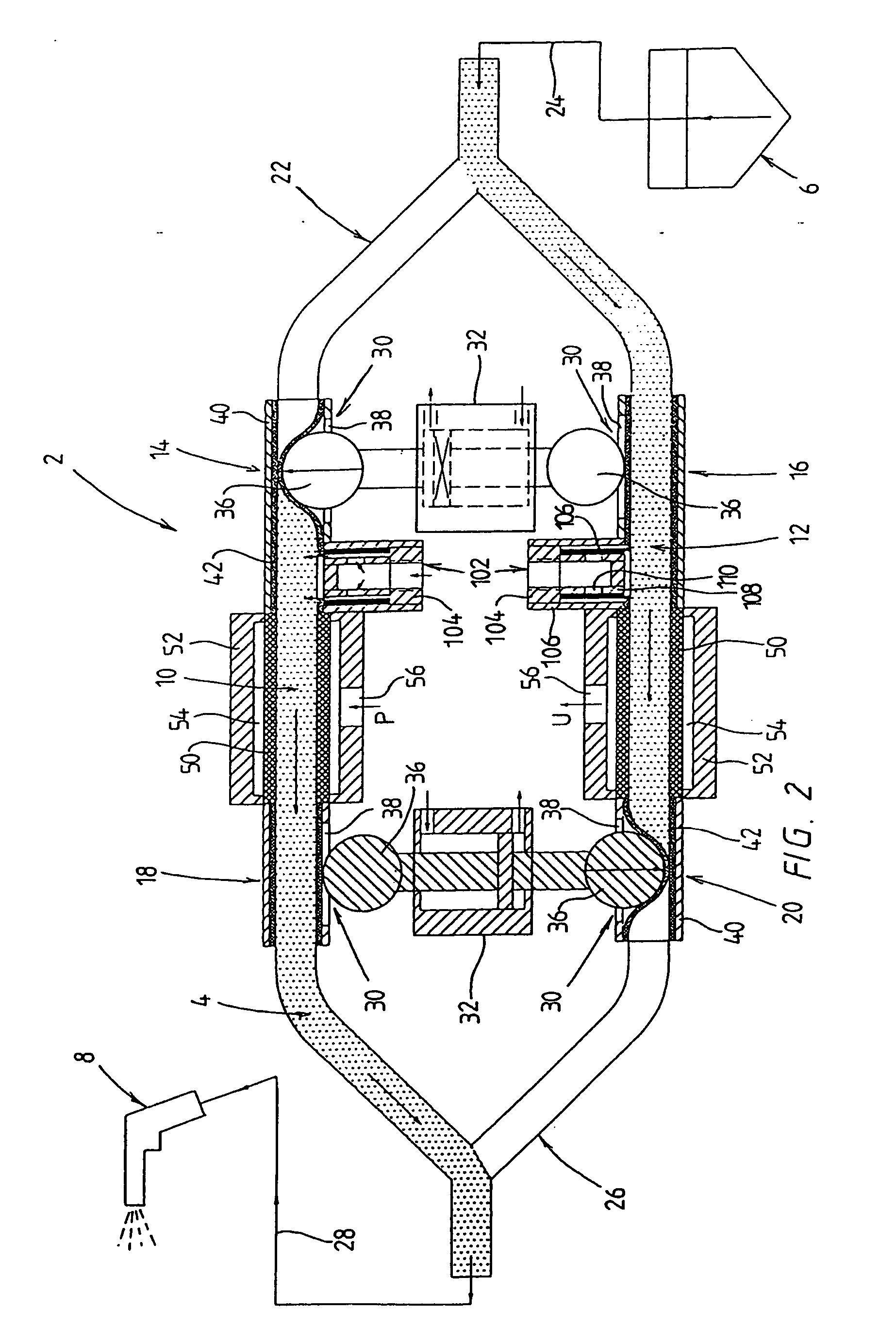

Powder feed pump and appropriate operating system

ActiveUS20050178325A1High measurement accuracyLiquid surface applicatorsBulk conveyorsOperational systemEngineering

An operating system for a power feed pump and a power feed pump having a transfer chamber with an inlet and an outlet. The outlet of the transfer chamber is closed, the inlet of the transfer chamber is opened, and a negative pressure is generated in the transfer chamber to suck a powder in through the inlet to the transfer chamber. The inlet of the transfer chamber is closed, the outlet of the transfer chamber is opened, and the powder in the transfer chamber is delivered through the outlet. The negative pressure in the transfer chamber is built up at least partially before the inlet of the transfer chamber is opened.

Owner:DURR SYST INC

Strong brine energy recovery device based on reverse osmosis desalination technology

InactiveCN100341609CGuaranteed uptimeReduce consumptionGeneral water supply conservationReverse osmosisHydraulic cylinderSaline water

This invention discloses energy-recovery device for strong brine based on desalination technique by reverse osmosis, which comprises hydraulic cylinder with guide bar connected to piston; water inlet three-way solenoid valve with one end connected to end of guide bar, and other two ends connected separately to water outlets of low and high pressure water-feed pumps; drainage three-way solenoid valve with one end connected to the hydraulic cylinder end far away guide bar, and other two ends connected to strong brine discharge pipes of reverse osmosis membrane; sensor, to obtain the position signal of piston; controller, to control the synchronized open and shut of two aforementioned three-way solenoid valves. It has high efficiency, runs stably, switches quickly and fit to spread in industry.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

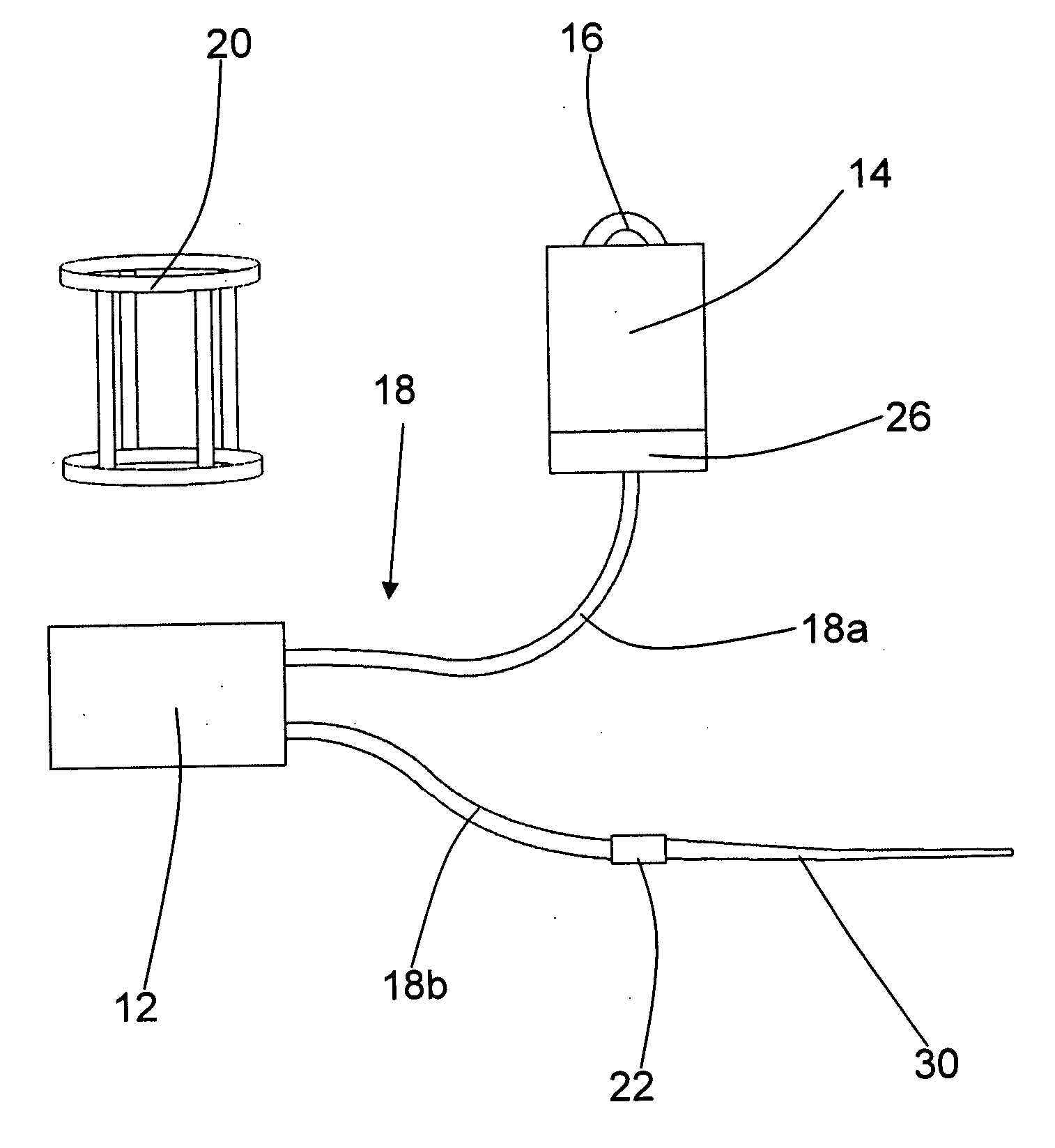

Method and apparatus for controlled feeding of an infant

InactiveUS20070118078A1Easy to useReliable nutritionMilking pumpMedical devicesEnteral feedingsPeristaltic pump

A method and apparatus for controlled feeding of an infant provides a safer and less expensive apparatus for the enteral feeding of a neonatal infant, as well as a mechanism for minimizing separation of fluid for any enteral feeding patient. The apparatus allows for dispensing the feeding solution from conventional baby bottles or breast pump reservoirs, or other convenient reservoirs in combination with a peristaltic pump. The feeding system helps reduce the risk for contaminating the feeding solution by minimizing the handling of the feeding solution. By utilizing a pump which is less expensive than current neonatal feeding pumps, the feeding system is more cost effective in all environments and more suitable for home use.

Owner:ZEVEX

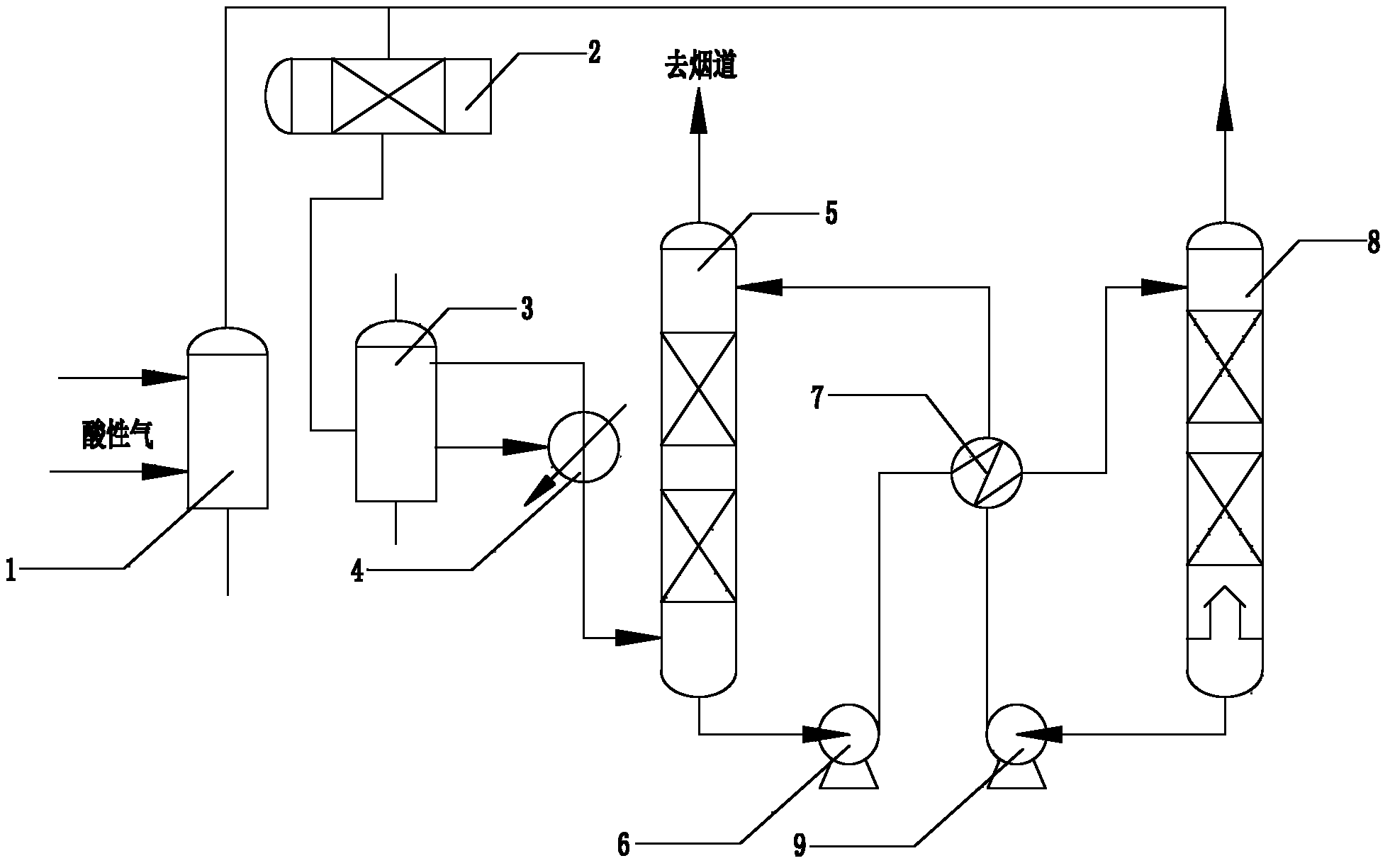

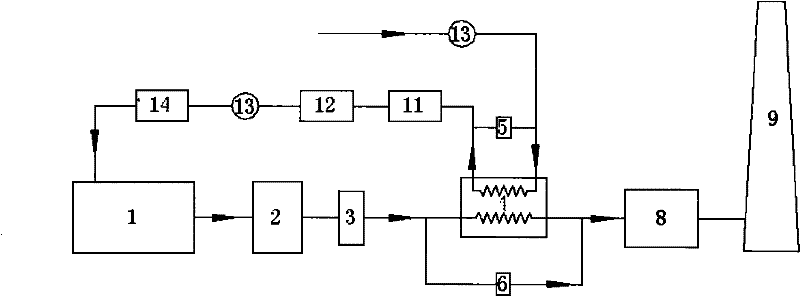

SWSR (SunWay Sulfur recovery)-1 device and technique

ActiveCN103482583AReduce sulfur dioxide contentThe effect achieved is excellentDispersed particle separationSulfur preparation/purificationAntioxidantIonic liquid

The invention relates to an SWSR (SunWay Sulfur recovery)-1 device and technique. The invention relates to a tail gas treatment combination device and technique by adopting Claus sulfur recovery and ionic liquid cycle absorption process. The device comprises a sulfur production burning furnace, a Claus reaction system, a sulfur production tail gas incinerator, a rich SO2 process gas heat exchanger, an SO2 absorption tower, a rich liquid pump, a lean and rich liquid heat exchanger, an SO2 regeneration tower and a lean liquid feed pump. The technique comprises the steps: (1) enabling hydrogen sulfide-containing acid gas to generate a Claus reaction, and recovering sulfur and heat energy in the reaction process; (2) burning sulfur production tail gas to generate SO2; (3) removing SO2 from rich SO2 process gas through an ionic liquid absorption tower; and (4) feeding rich SO2 ionic liquid into a regeneration tower for separating and regenerating sulfur. The ionic liquid is an aqueous solution which takes organic positive ions and inorganic anions as main components and a little amount of activating agent and antioxidant as additives. The SWSR-1 device and technique are low in equipment investment, high in material safety, short in technique flow, safe and reliable in technique processes, high in SO2 recovery rate, and the content of SO2 in effluent gas can be reduced by 50ppm below which can meet the national regulation requirement.

Owner:SHANDONG SUNWAY PETROCHEMICAL ENGINEERING CO LTD +1

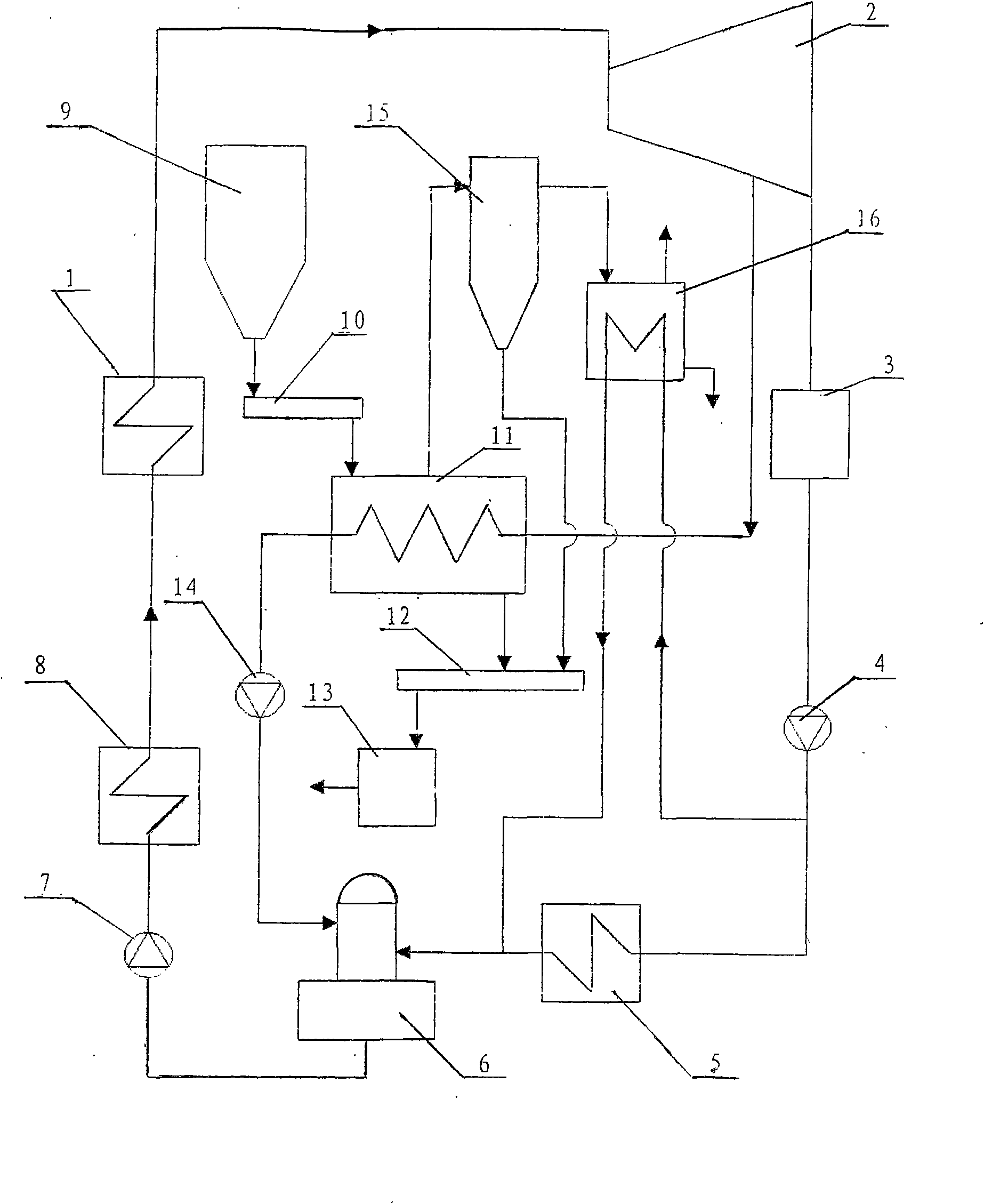

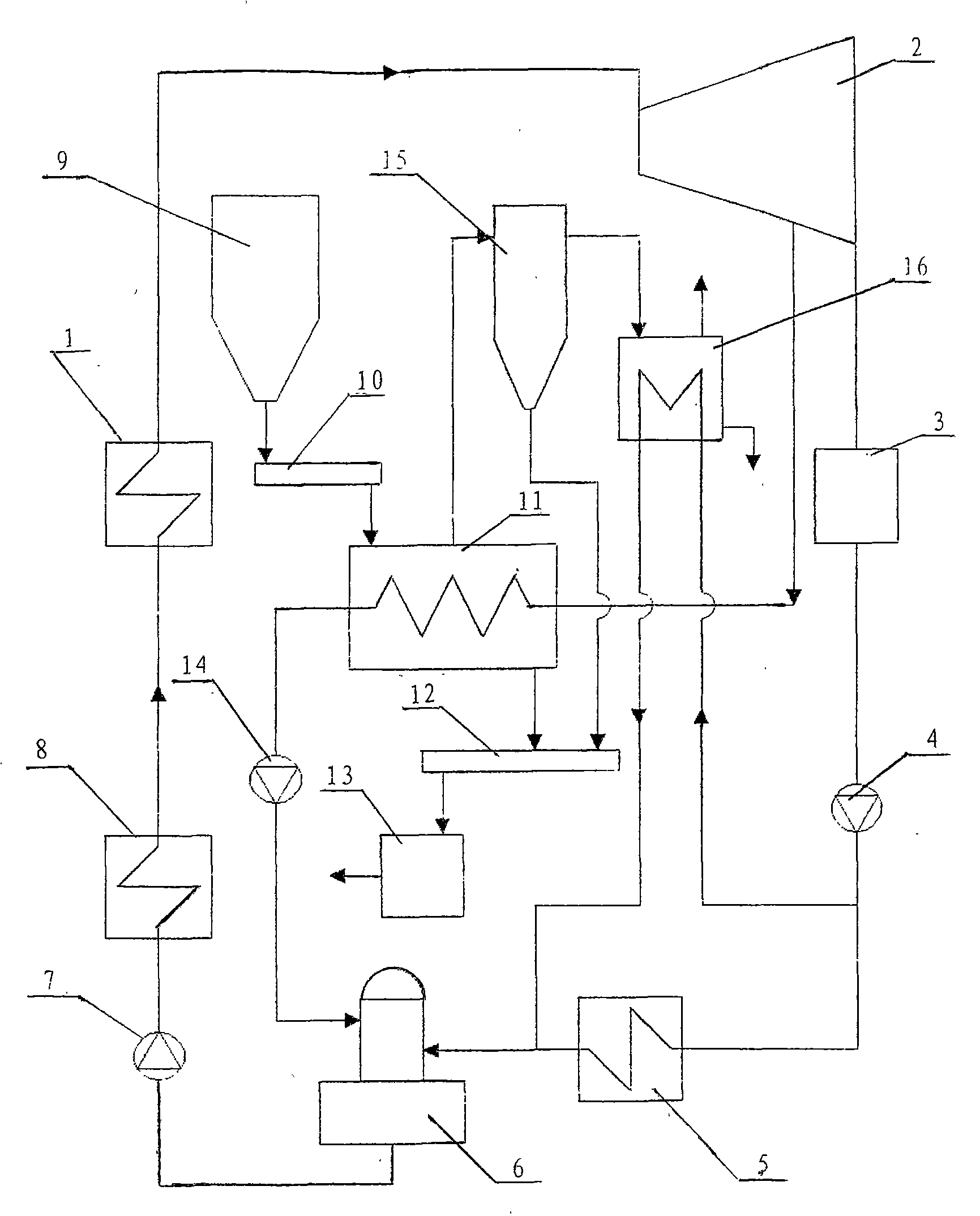

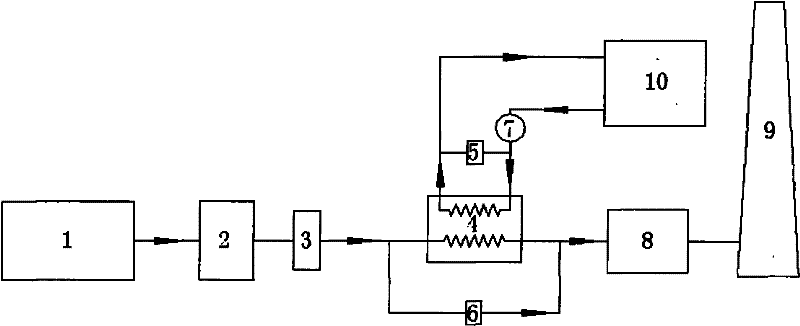

Thermal power generation system based on high-moisture lignite pre-drying upgrading and recovering technology

ActiveCN101881191AIncrease energy densityReduce smoke lossDrying solid materials with heatSteam regenerationDeaeratorHigh pressure

The invention relates to a thermal power generation system based on a high-moisture lignite pre-drying upgrading and recovering technology. The thermal power generation system comprises a boiler, a turbine, a condenser, a condensation pump, a low pressure heater, a deaerator, a water feed pump, a high pressure heater, a wet coal bin, a wet coal feeder and a coal mill and is characterized in that a lignite pre-drying device, a drain pump, a dry coal feeder, a dust remover and a heat energy and waste water recovering device are additionally arranged in the power generation system. The invention improves the energy density of fire coal and accordingly increases the efficiency of the boiler, and is capable of reducing the investment of the boiler and a milling system by a larger extent, simultaneously reducing the plant power utilization ratio, further improving the energy source comprehensive utilization efficiency of a thermal power generation plant, recovering a great deal water by using coal to produce water and saving precious water resources. The invention achieves the effects of high efficiency, energy saving, water saving and emission reduction and accords with the industrial policy of developing the low-carbon economy in China.

Owner:CHINA POWER ENG CONSULTING GRP +1

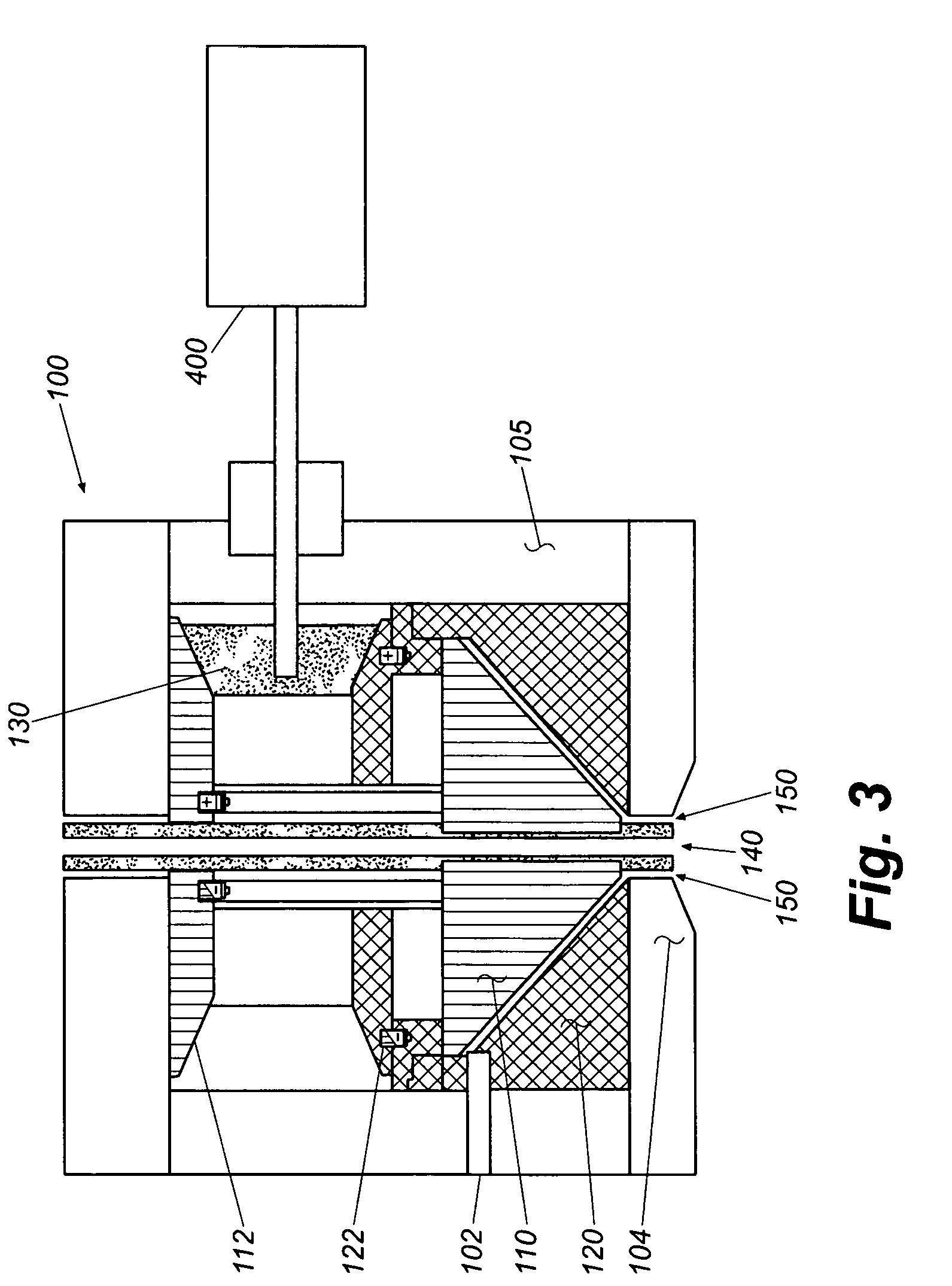

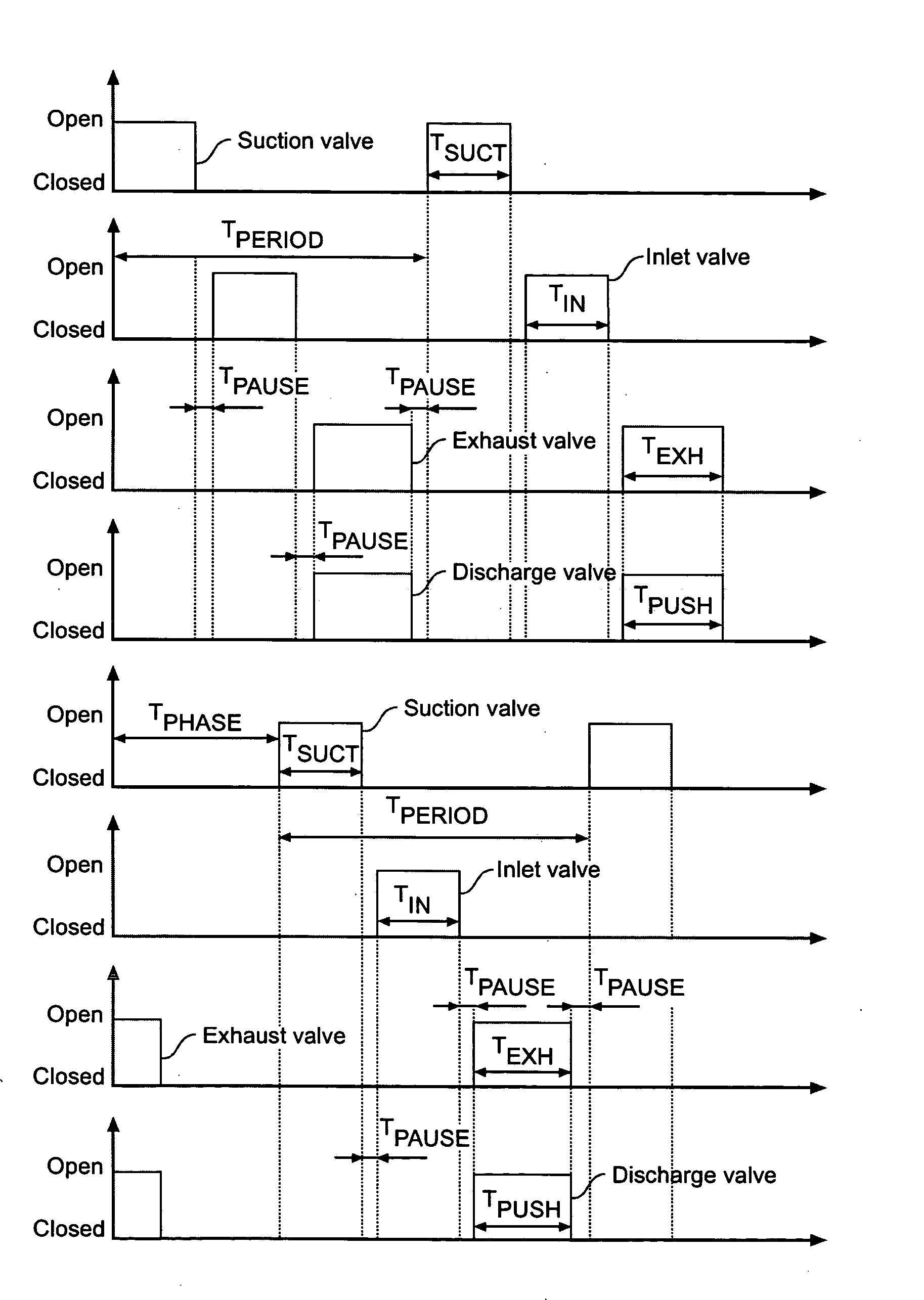

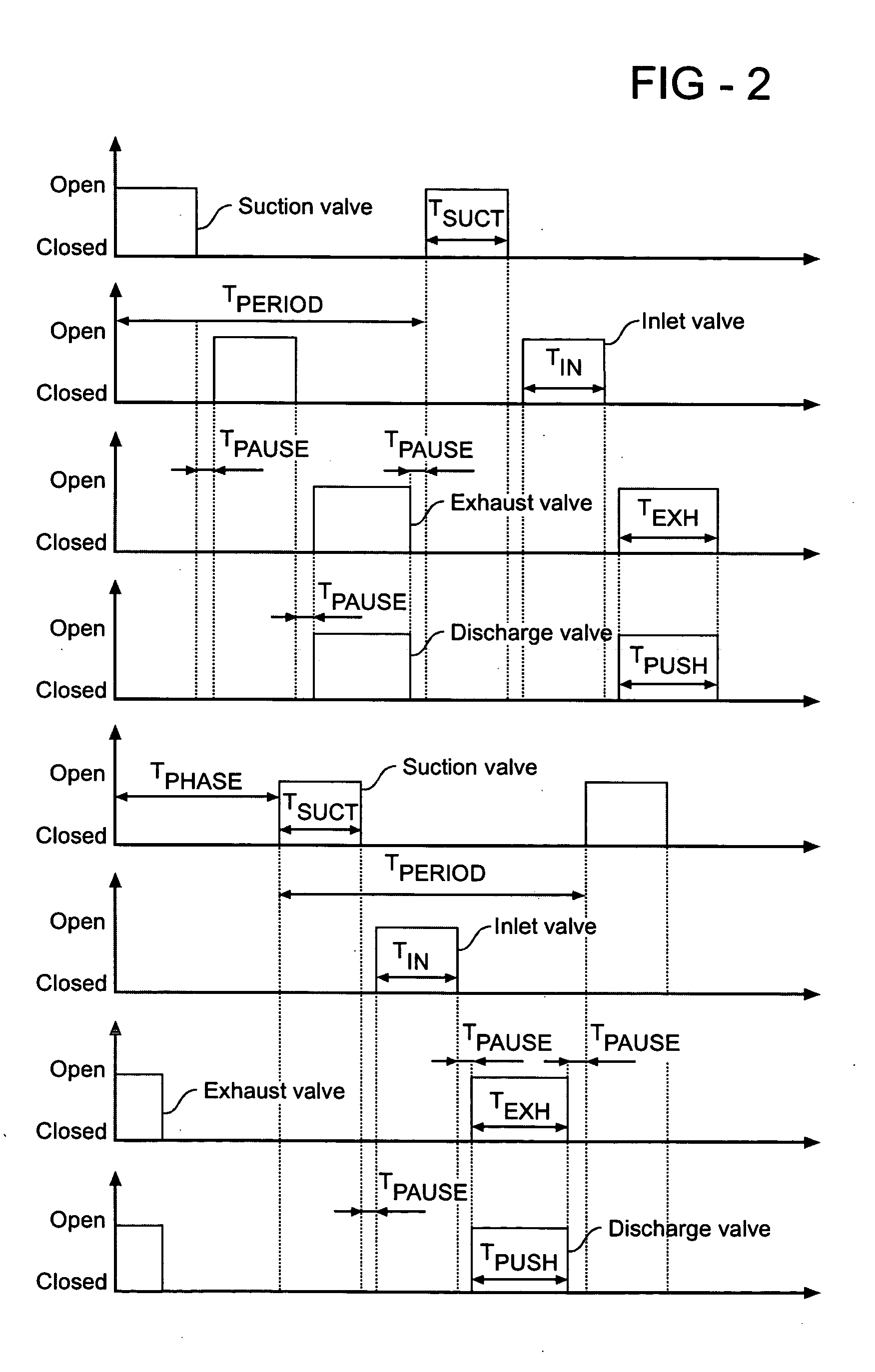

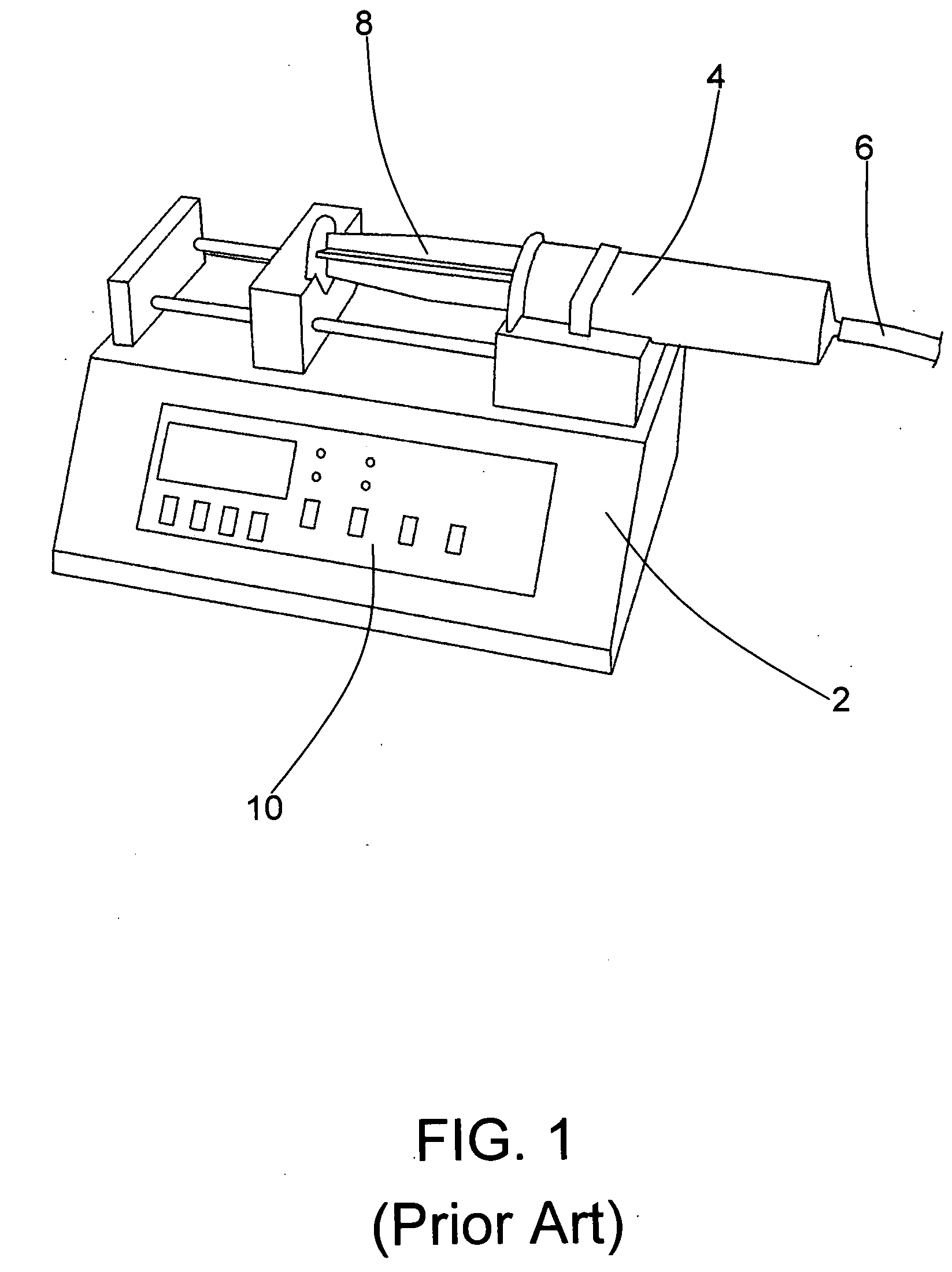

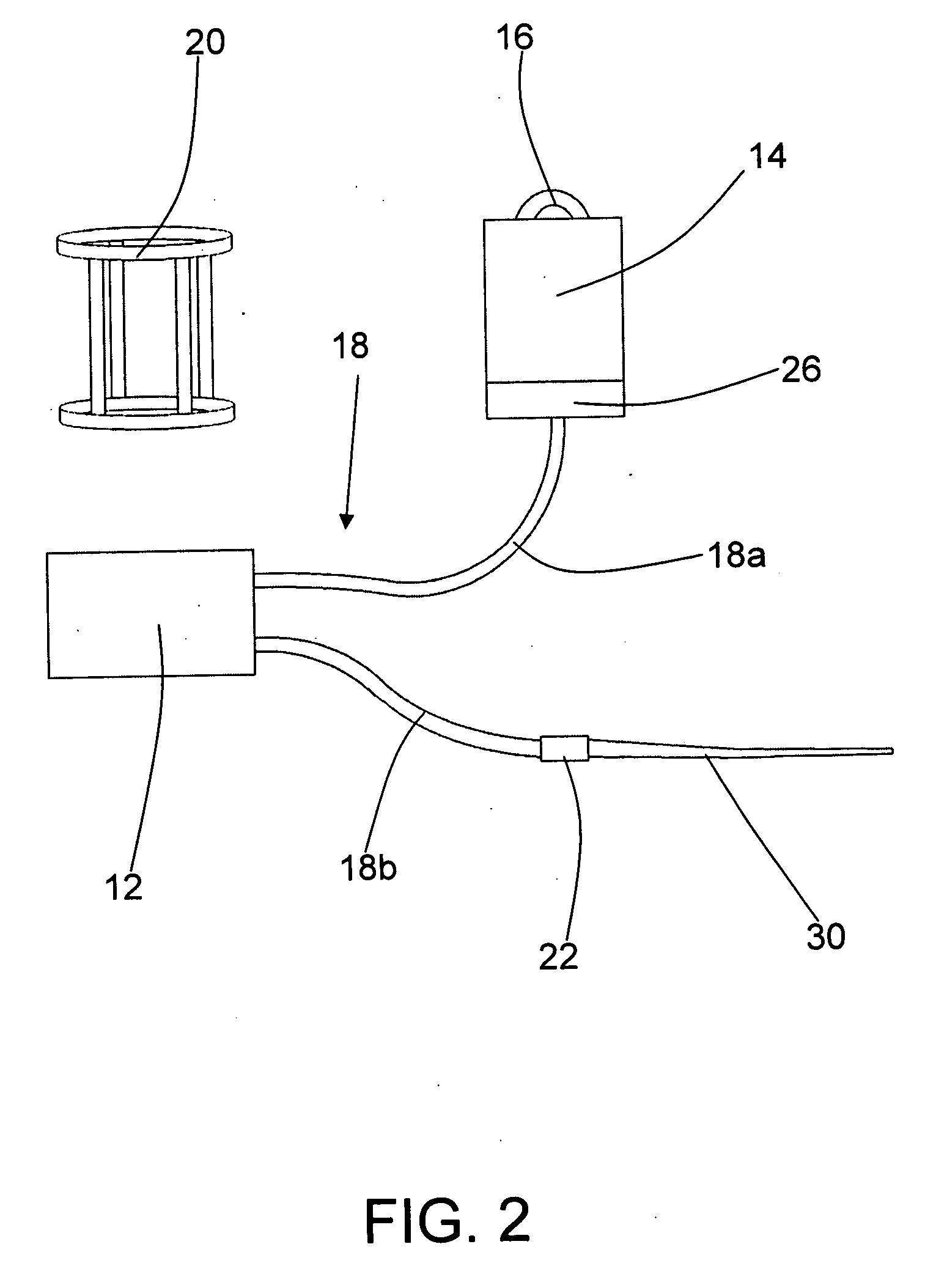

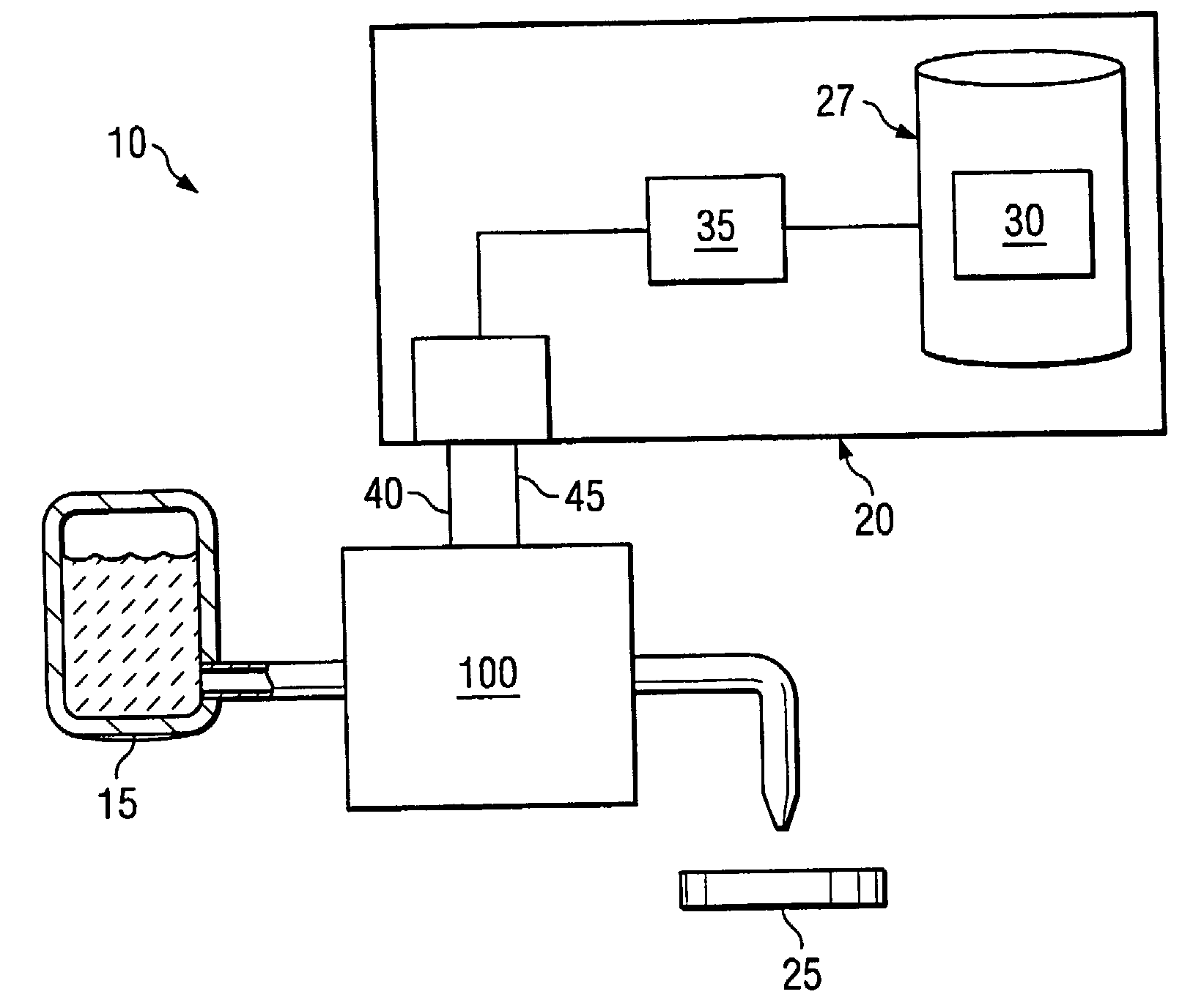

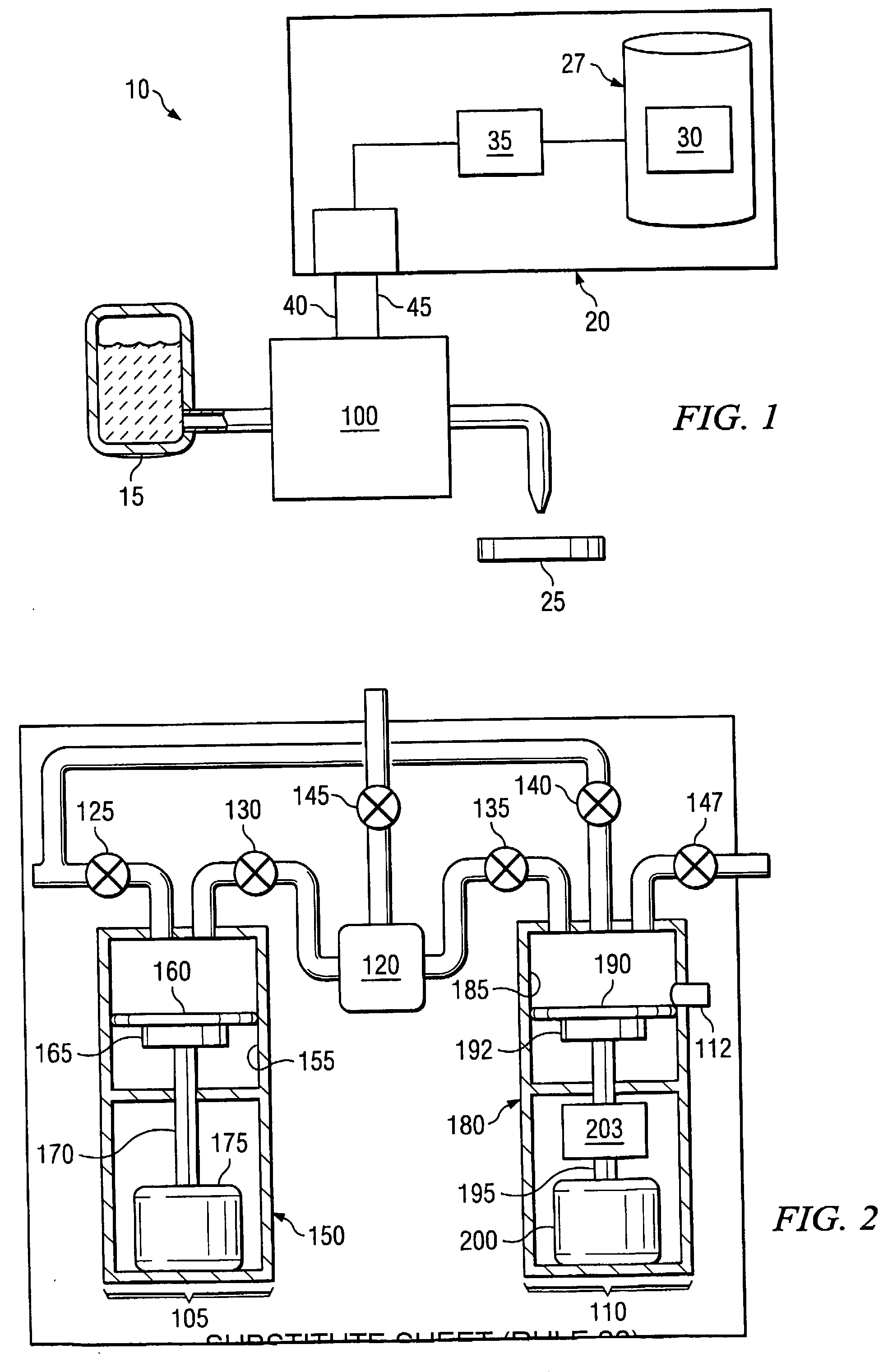

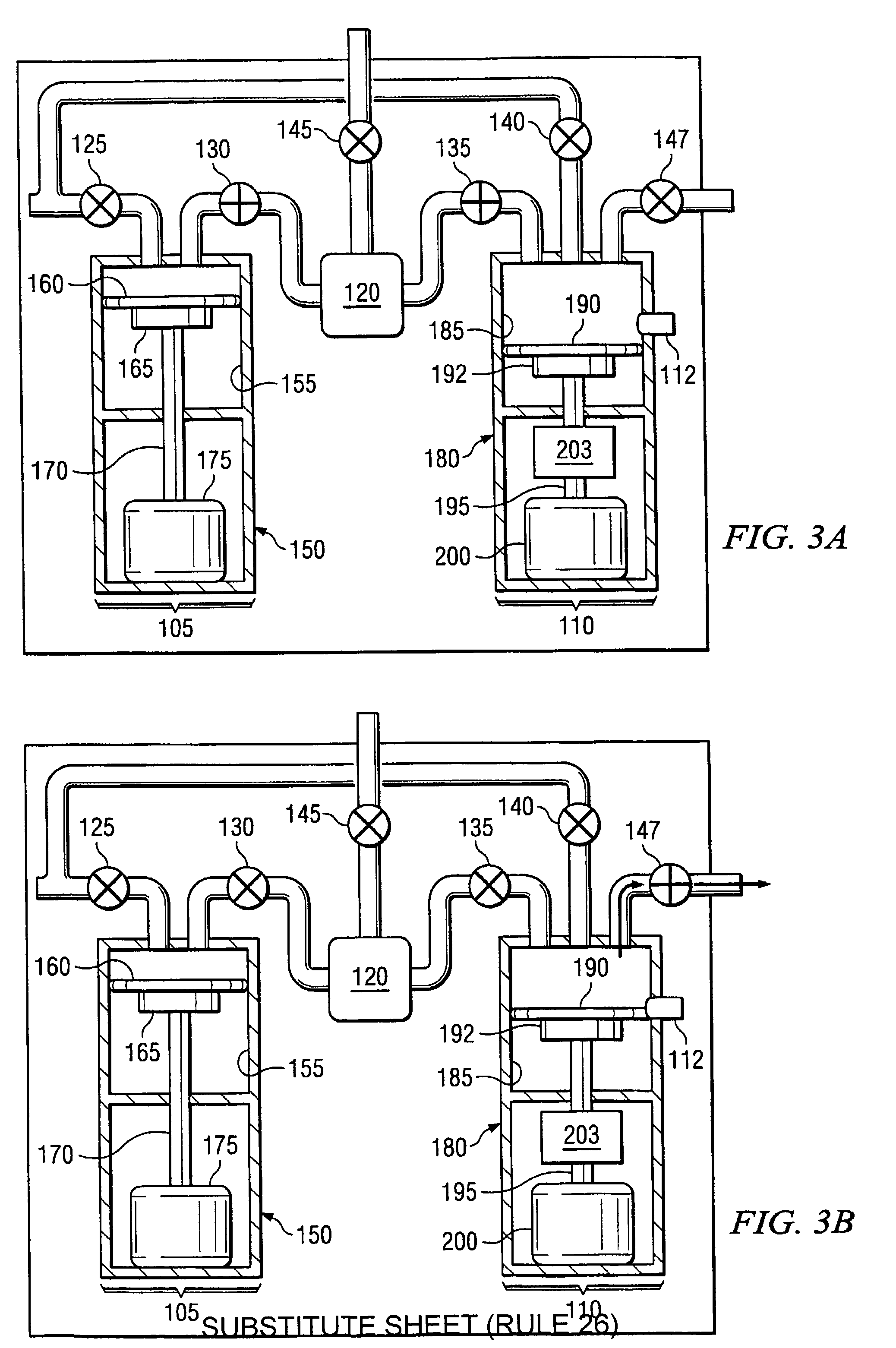

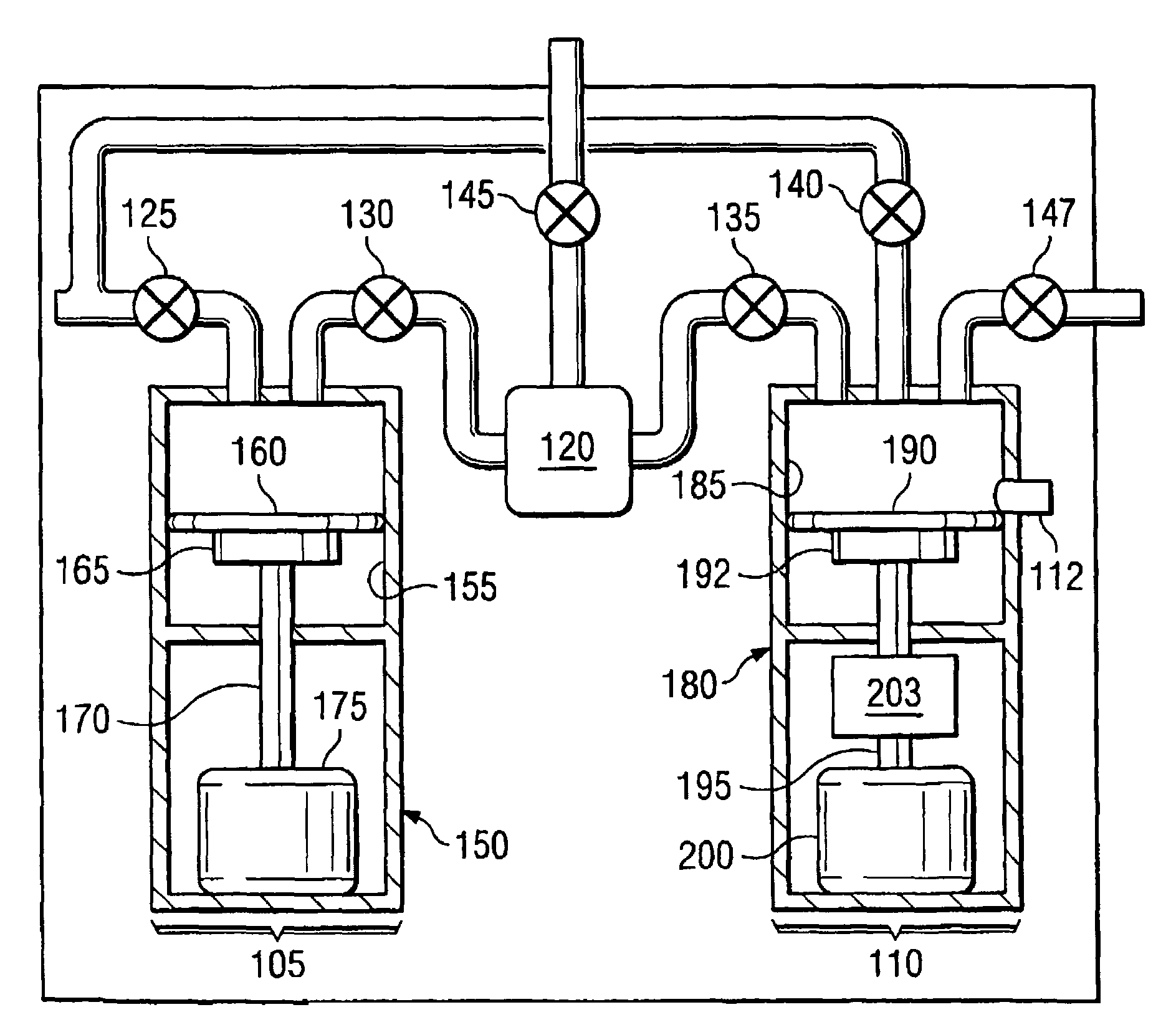

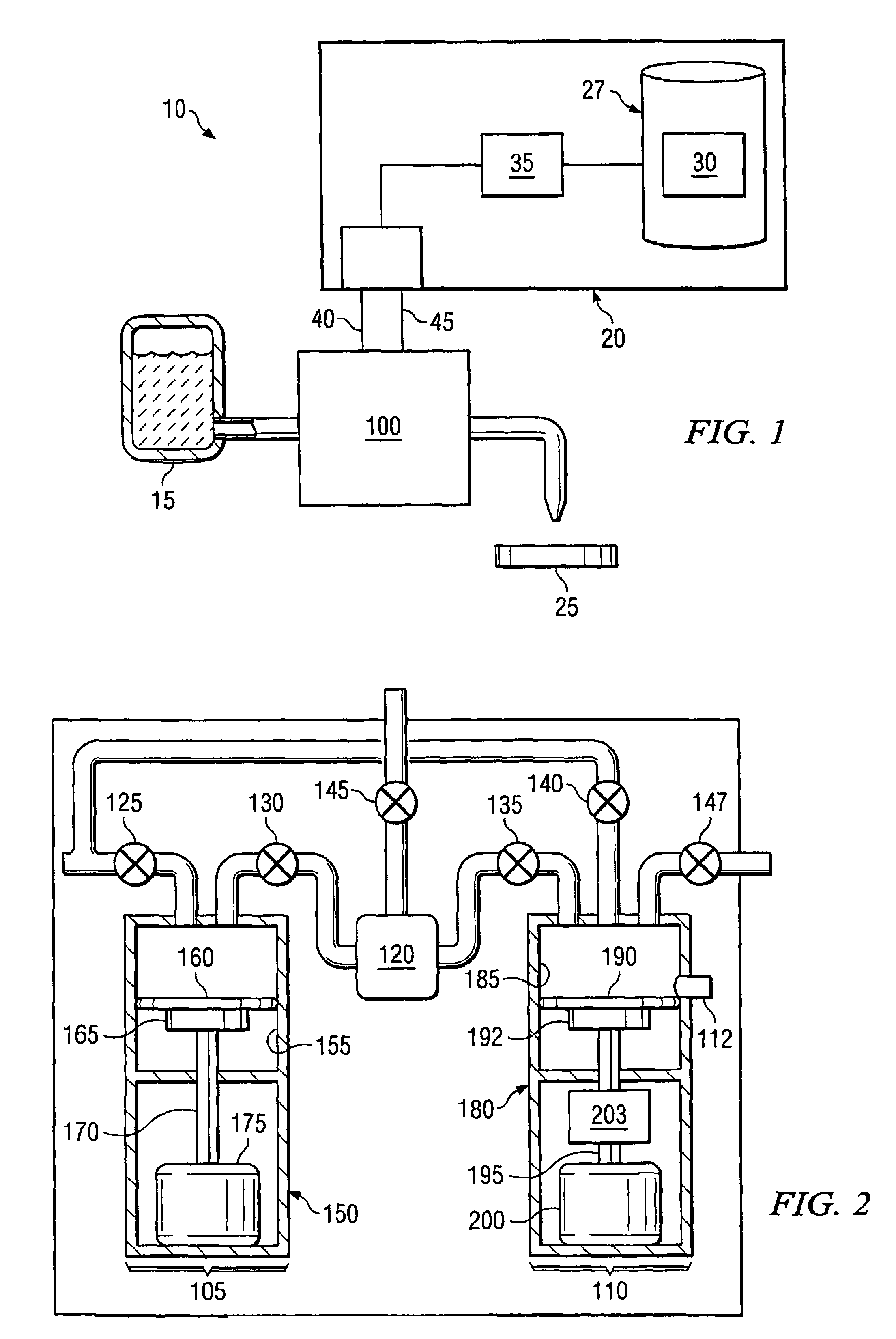

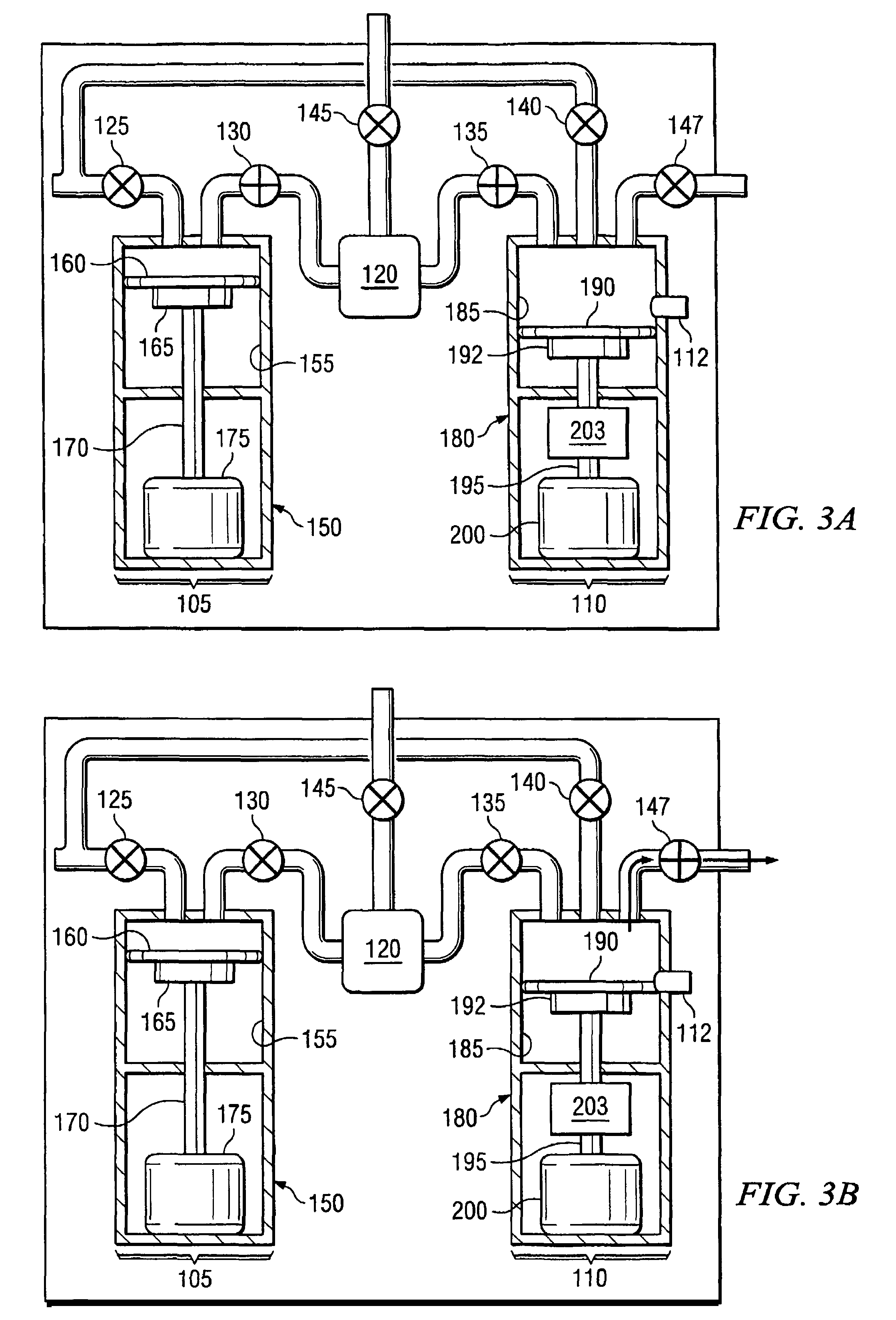

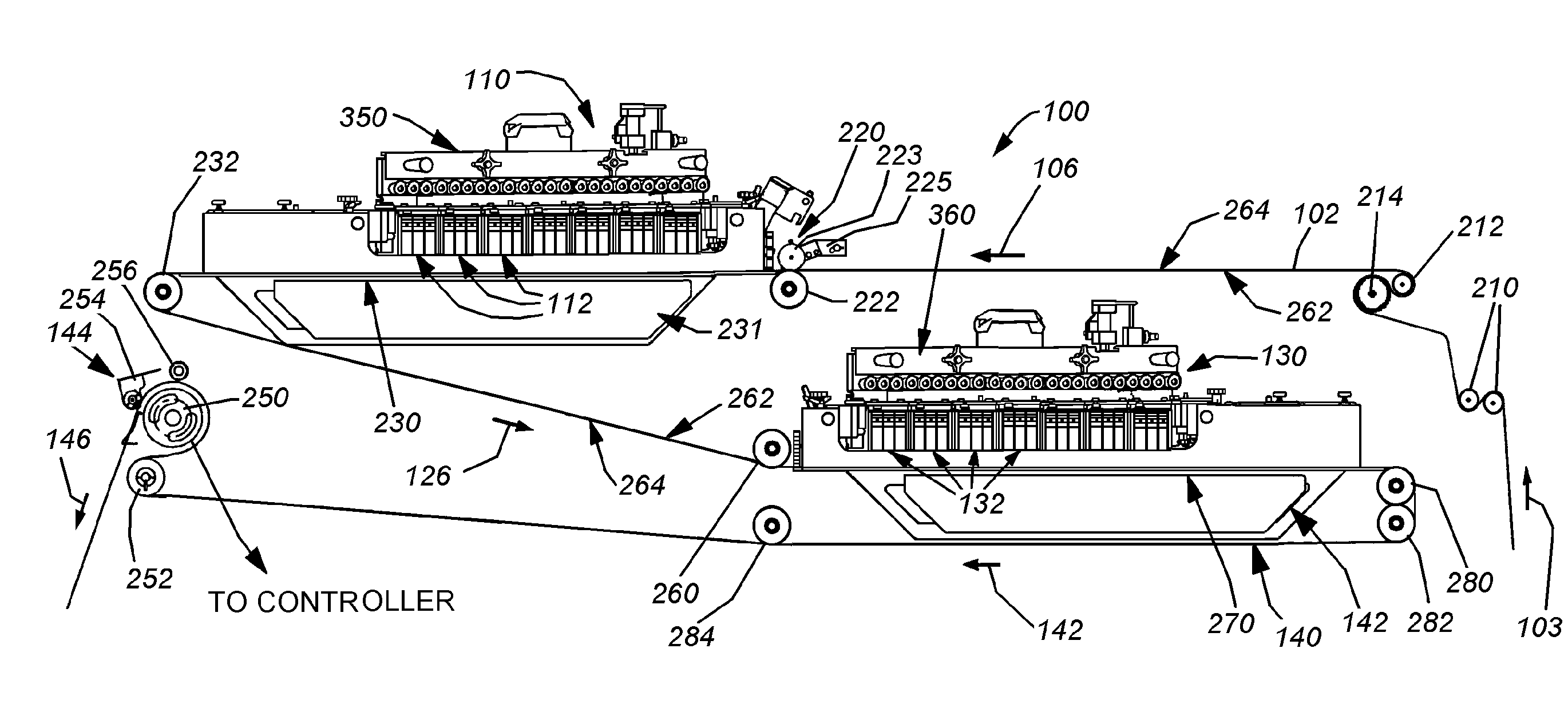

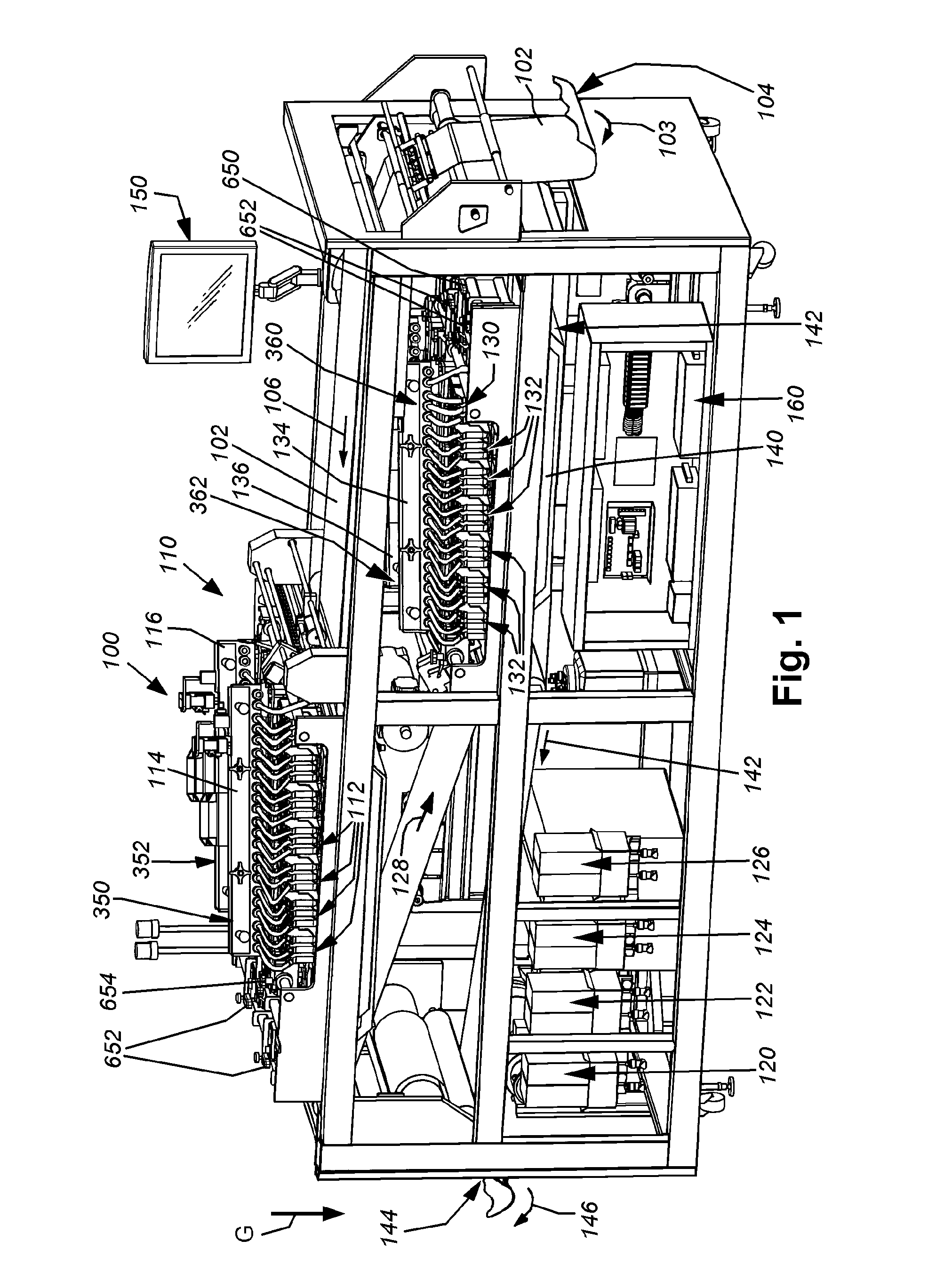

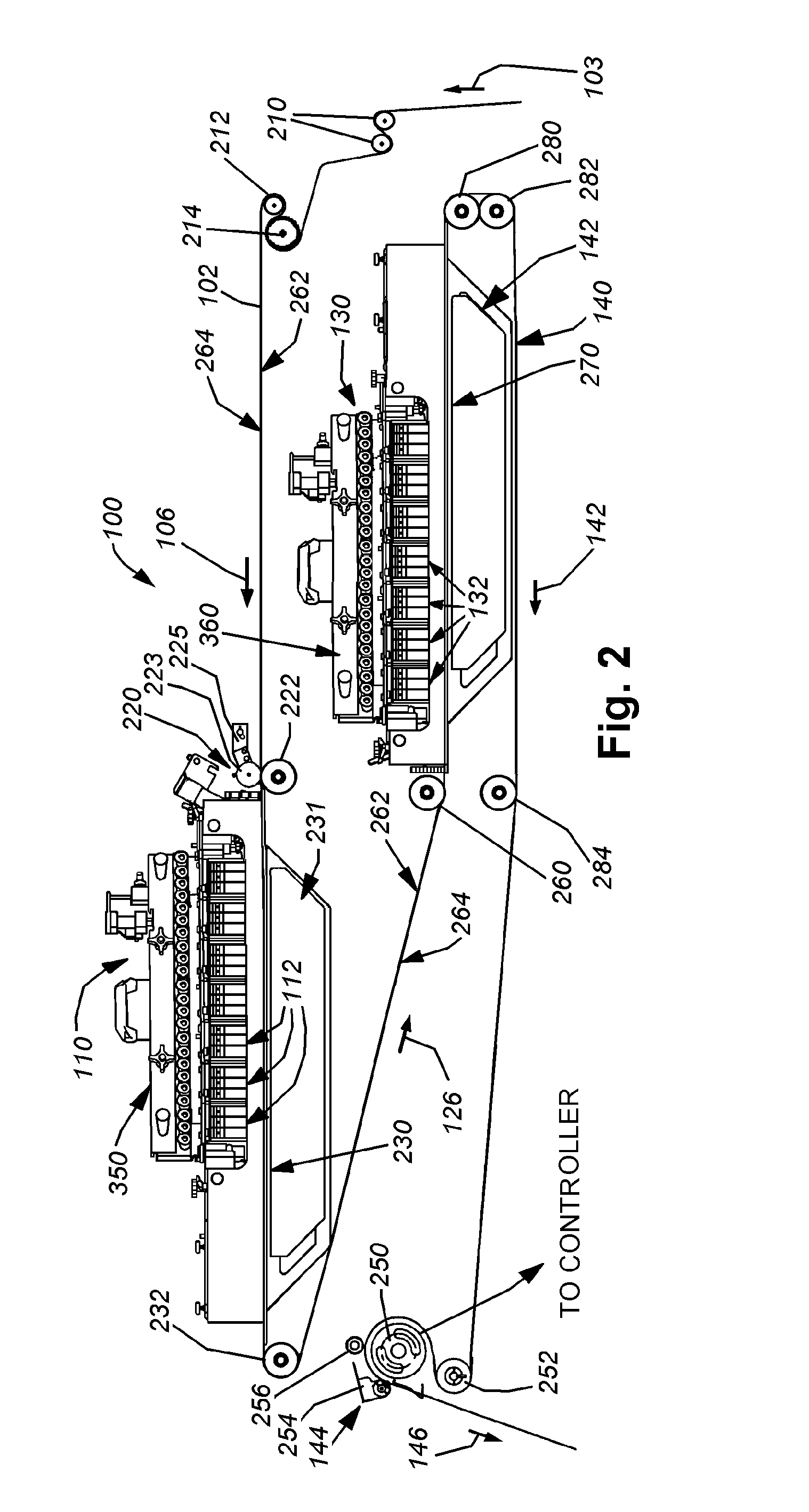

System and Method for a Variable Home Position Dispense System

ActiveUS20090132094A1Reduce the pumping volumeReduce processPower operated devicesFlexible member pumpsEngineeringFeeding pumps

Embodiments of the present, invention provide a system and method for reducing the hold-up volume of a pump. More particularly, embodiments of the present invention provide a system and method for determining a home position to reduce hold-up volume at a dispense pump and / or a feed pump. The home position for the diaphragm can be selected such that the volume of the chamber at the dispense pump and / or feed pump contains sufficient fluid to perform the various steps of a dispense cycle while minimizing the hold-up volume. Additionally, the home position of the diaphragm can be selected to optimize the effective range of positive displacement.

Owner:ENTEGRIS INC

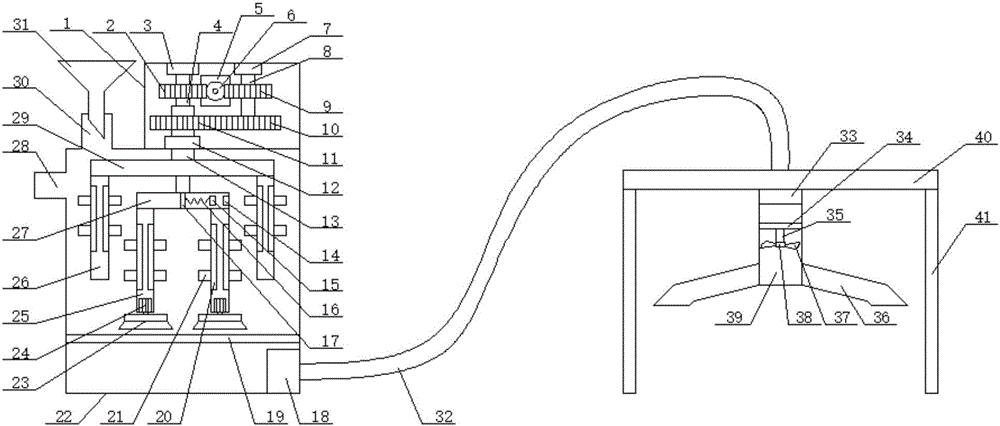

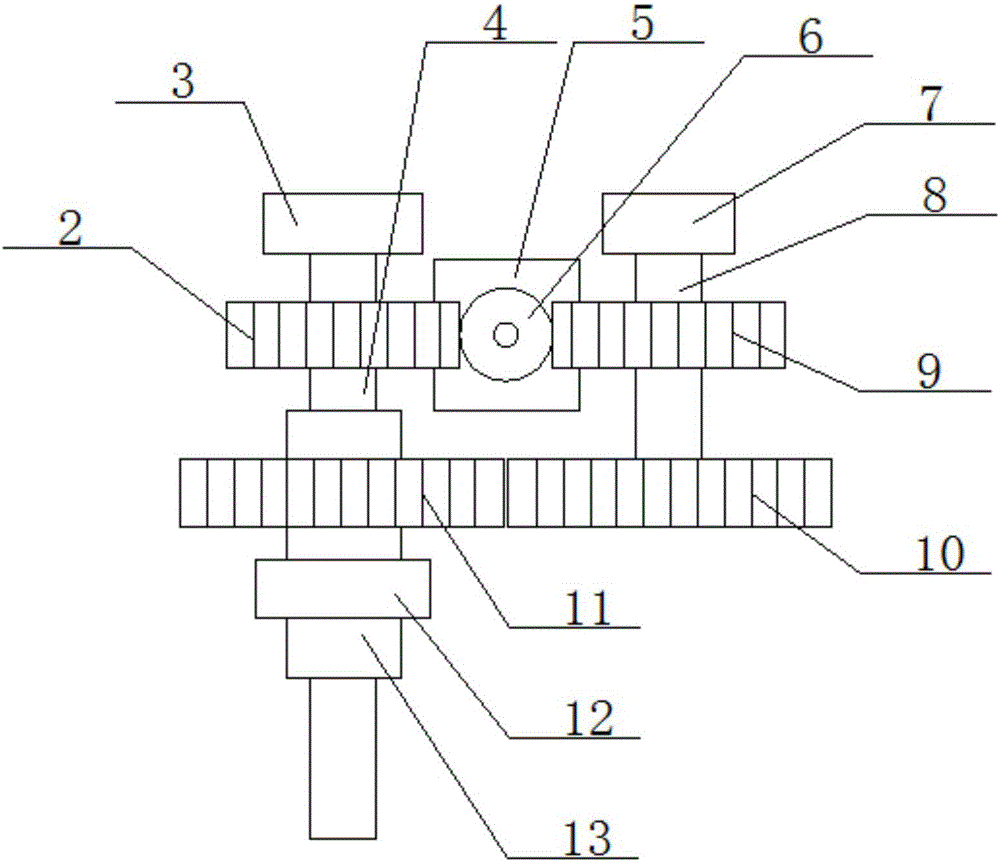

Automatic fish feed feeding device

ActiveCN106614214APromote digestion and absorptionStir wellRotary stirring mixersTransportation and packagingSlurryMechanical engineering

The invention relates to an automatic fish feed feeding device which comprises a water pump, a feed pumping pipe, a stirring mechanism and a putting mechanism. The stirring mechanism comprises a driving chamber, a stirring chamber, a feed hopper, a feed inlet, a water inlet, a filter screen, a driving unit and a stirring unit, and the putting mechanism comprises a support plate, third support rods, a fourth bearing, a rotating unit and a putting unit. According to the automatic fish feed feeding device, feed and water are fully stirred by the stirring mechanism, heating can be conducted when much feed needs to be stirred, and therefore the stirring efficiency is improved; the feed which is not fully stirred can be filtered out through the filter screen, the fully-stirred feed is pumped out through the feed pumping pipe, not only can the feed pumping pipe not be likely to be blocked, but also the feed stirred more fully can be put, coarse feed slurry filtered out by the filter screen can be finer and flows out through the filter screen, therefore, the filter screen is not likely to be blocked, and the filter efficiency is improved; the feed is put by a feed putting branch pipe while the feed putting branch pipe rotates, uniform putting is achieved, the putting efficiency is improved, and the automatic fish feed feeding device can be applied to a large-scale aquaculture mode.

Owner:MAANSHAN HETIAN ELECTRONICS INTELLIGENCE CONTROL SYST CO LTD

Method for recovery and utilization of waste heat from low temperature flue gas

InactiveCN102269401AReduce heatIncreasing energy efficiencyHot-water central heatingThermal energyBoiler feedwater pump

The invention discloses a method for recovering and utilizing waste heat from low-temperature flue gas. An air-water heat exchanger (4) is connected in series or in parallel in the flue at the rear of the induced draft fan or booster fan (3) of the existing boiler or kiln (1). The inlet port of the hot side of the air-water heat exchanger is connected with the induced draft fan or booster fan (3), the outlet port of the hot side is connected with the desulfurization absorption tower (8) or the chimney (9), and the inlet port of the cold side is circulated with the heat user The outlet pipe or condensate pipe of the water or boiler softened water system is connected, the cold side outlet is connected with the hot user circulating water supply or the boiler feed water pump, and a waterway is connected between the hot side outlet pipe and the cold side inlet pipe of the air-water heat exchanger A bypass pipe, and a waterway bypass regulating valve (5) is arranged on the pipe; a flue gas bypass pipe between the induced draft fan or booster fan and the desulfurization absorption tower (8), and a flue gas bypass pipe A flue bypass regulating valve (6) is arranged on it. By connecting a gas-water heat exchanger in series or in parallel in the flue behind the induced draft fan of the boiler or kiln, the purpose of saving heat energy can be achieved.

Owner:LUOYANG BLUE SEA INDAL

System and method for a variable home position dispense system

Embodiments of the present, invention provide a system and method for reducing the hold-up volume of a pump. More particularly, embodiments of the present invention provide a system and method for determining a home position to reduce hold-up volume at a dispense pump and / or a feed pump. The home position for the diaphragm can be selected such that the volume of the chamber at the dispense pump and / or feed pump contains sufficient fluid to perform the various steps of a dispense cycle while minimizing the hold-up volume. Additionally, the home position of the diaphragm can be selected to optimize the effective range of positive displacement.

Owner:ENTEGRIS INC

Powder pump flow monitoring method and system

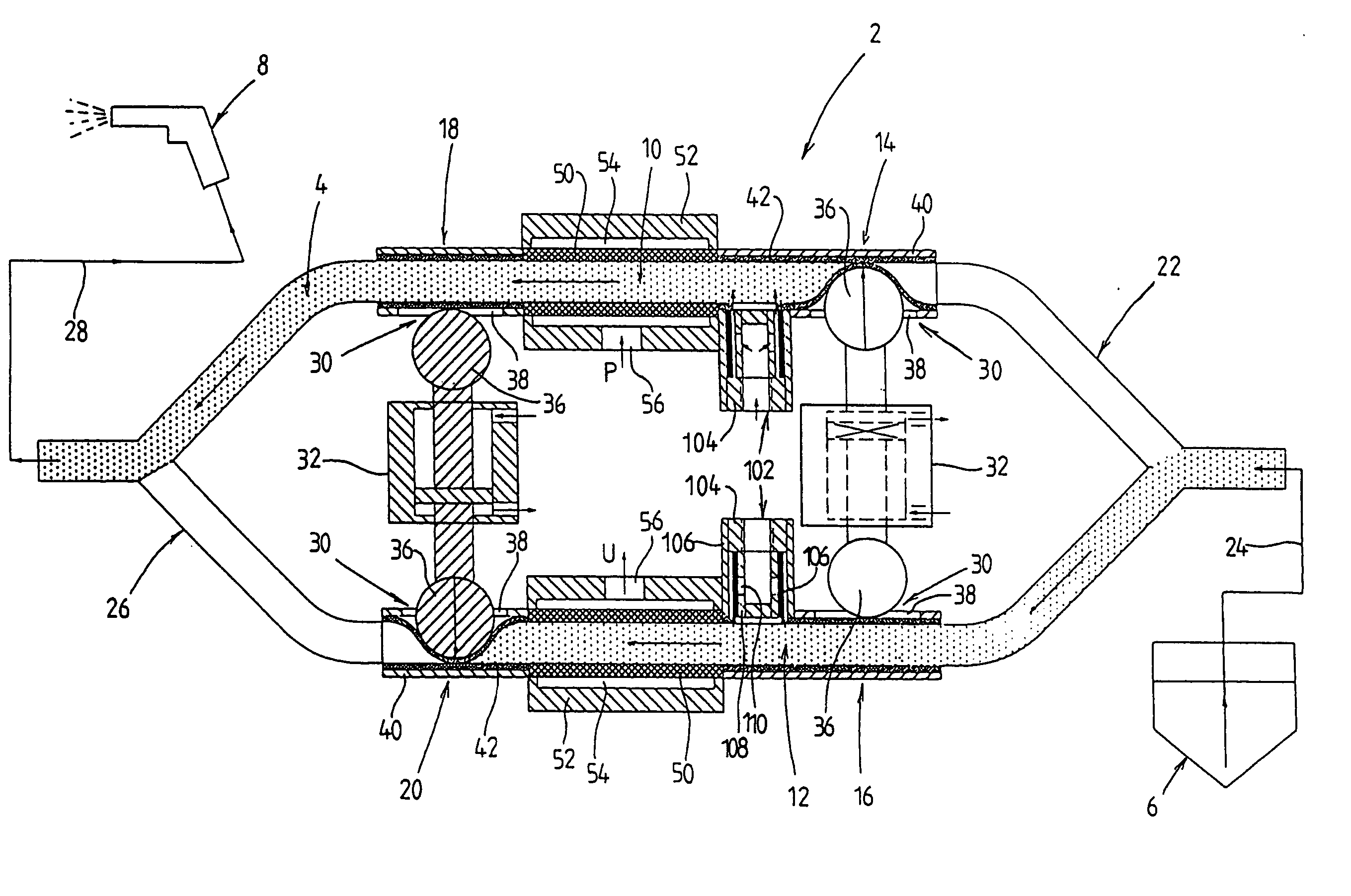

InactiveUS20060093442A1Drop in flow rate flowDrop in flow flow volumeBulk conveyorsLiquid spraying apparatusEngineeringFeeding pumps

The invention concerns a method and a device for monitoring flow conditions in a pipe system (28), into which a mixture of pulverulent material and compressed conveying air is admitted from a feed pump (2) by alternately filling at least two chambers (10, 12) of the feed pump (2) with pulverulent material and then alternately emptying the chambers into the pipe system (28) by feeding compressed conveying air from a compressed air source (48) into one of the previously filled chambers (10, 12). To detect fluctuations in the flow conditions and especially to detect obstructions within the pipe system (28) and in this way to allow continuous process monitoring, the invention proposes that the flow rate of the compressed conveying air be measured and analyzed in a common compressed air feed line (70) leading from the compressed air source (48) to the two chambers (10, 12).

Owner:NORDSON CORP

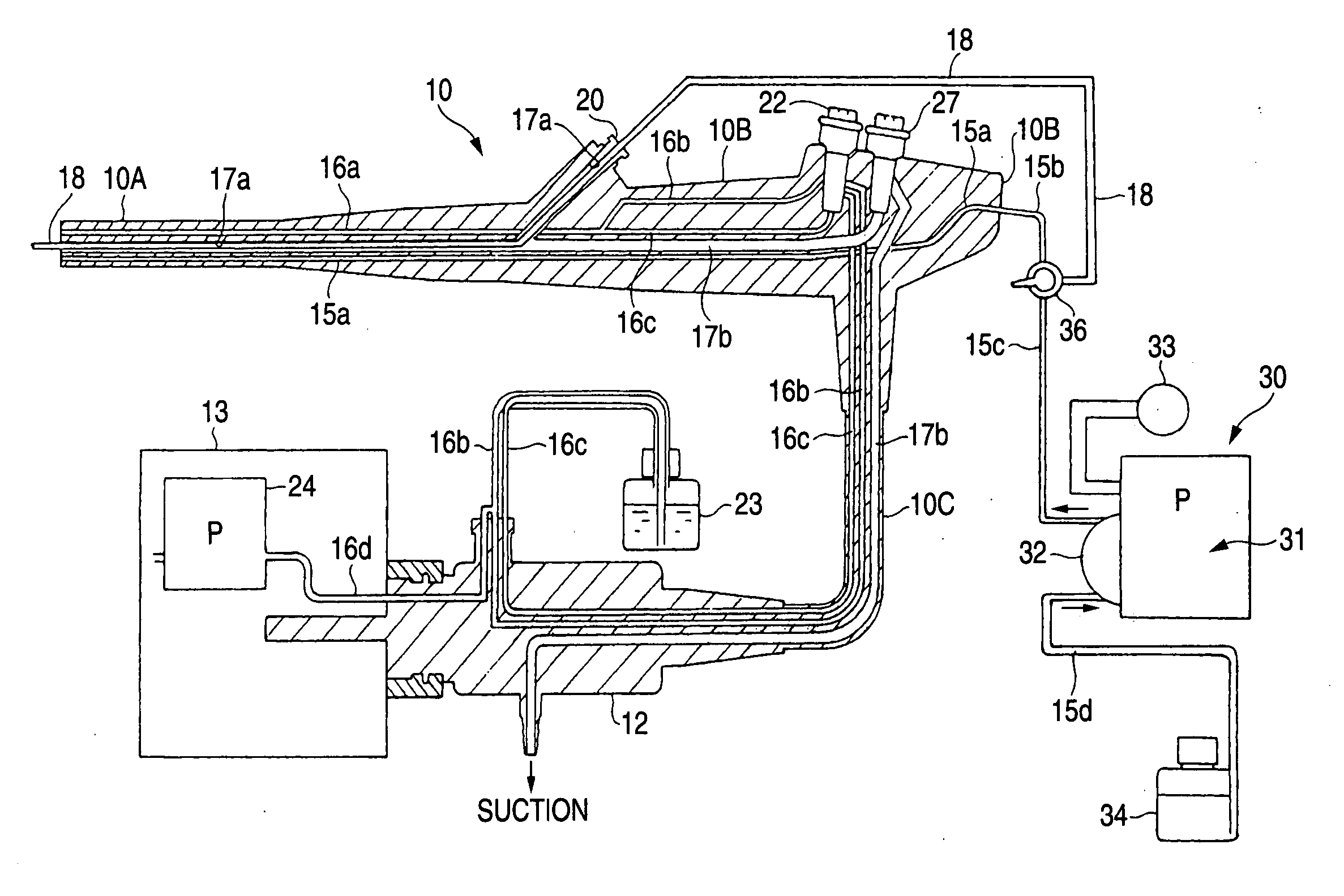

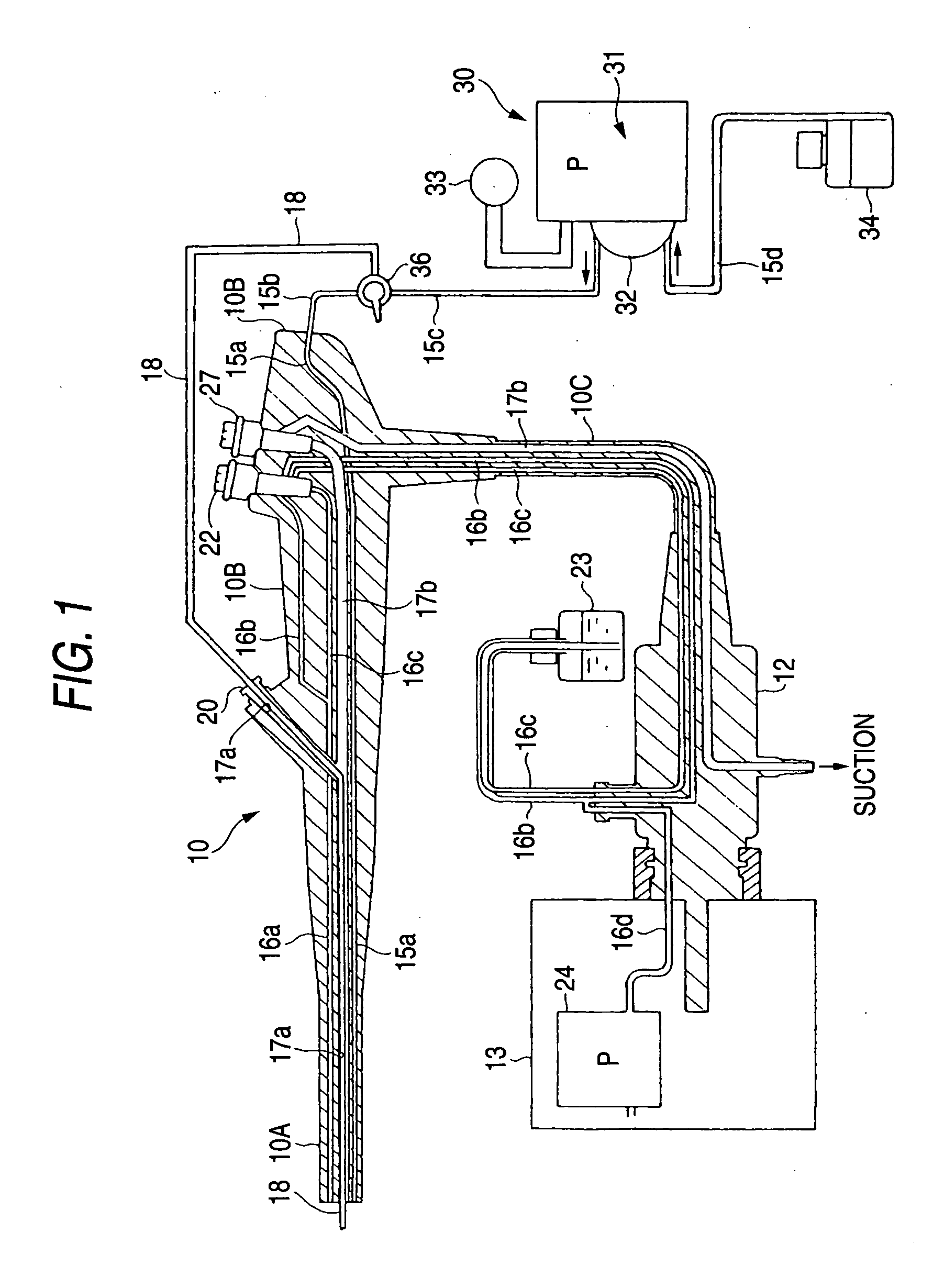

Water feeding device for endoscope

InactiveUS20060266423A1Easily properly injectedImprove hygieneEndoscopesDomestic plumbingLine tubingEngineering

A water feeding device for an endoscope, comprises: a first water feeding pipe line connected to an in-endoscope water feeding pipe line that feeds liquid into an object under observation; a second water feeding pipe line that is introduced into the object under observation through a treatment instrument insertion channel of the endoscope and supplies liquid; a water feeding pump portion that supplies liquid stored in a storage portion by a pump; and a pipe line switching section that selectively supplies the liquid stocked in the storage portion to the first and second water feeding pipe lines.

Owner:FUJI PHOTO OPTICAL CO LTD

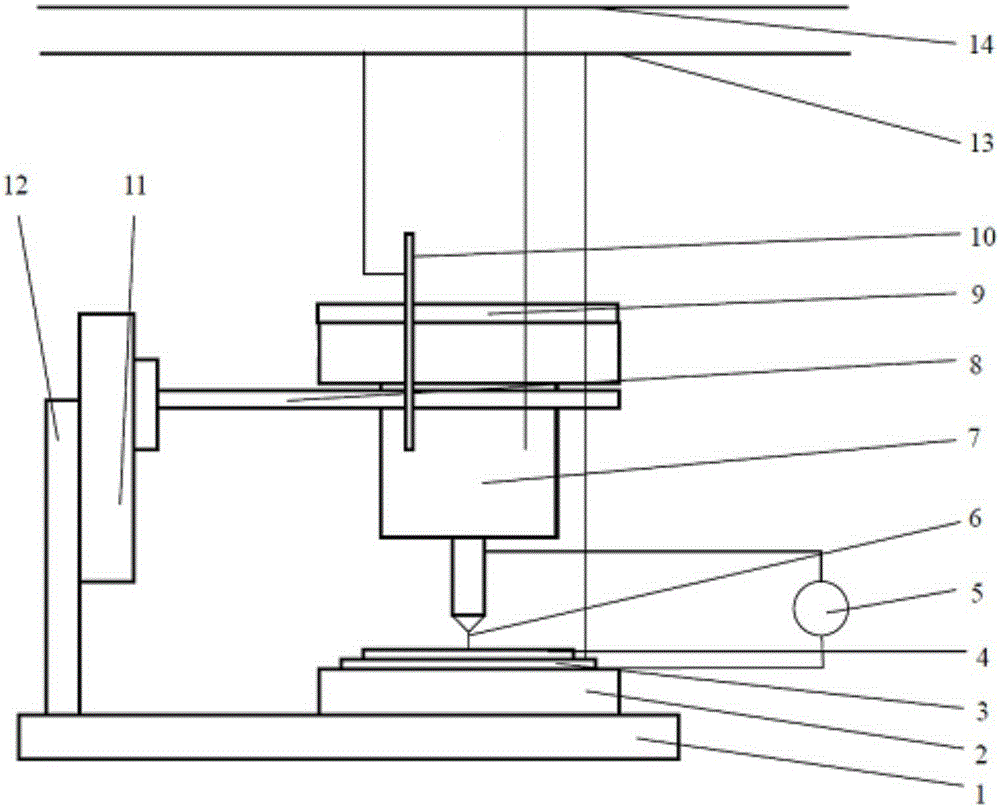

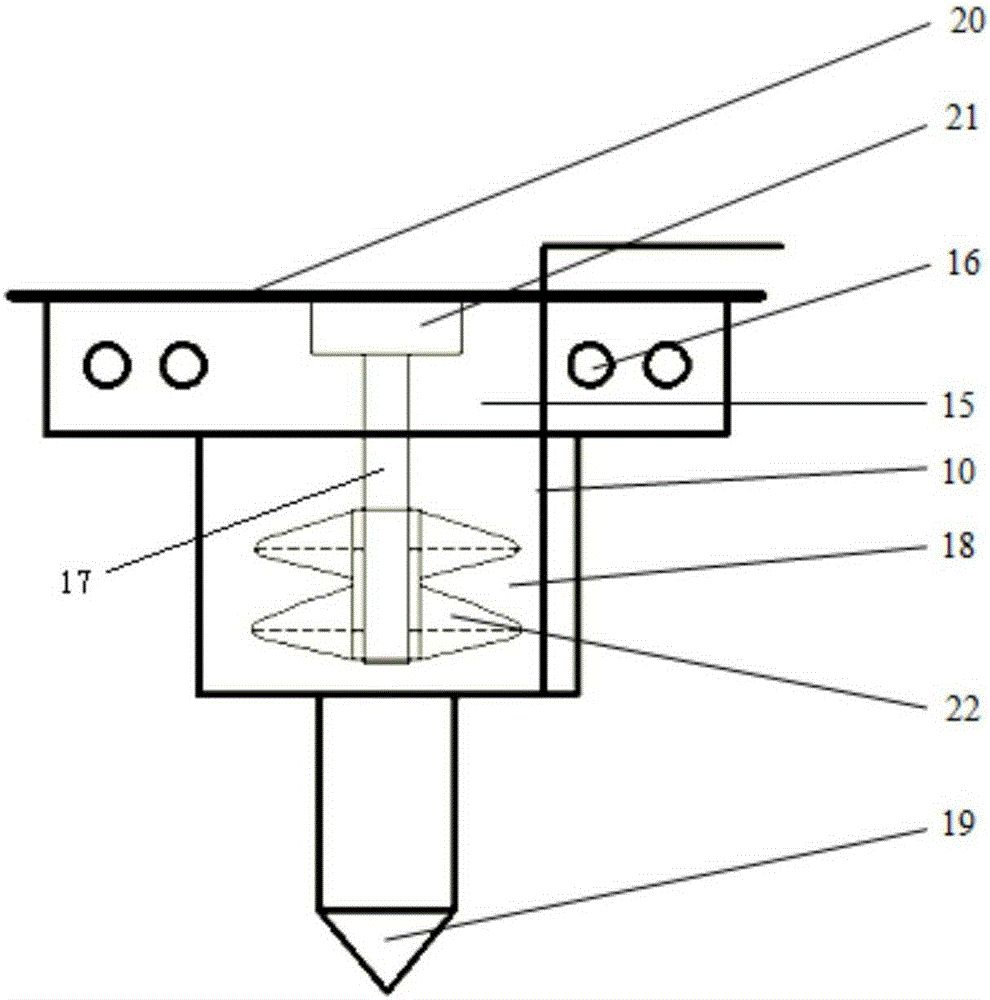

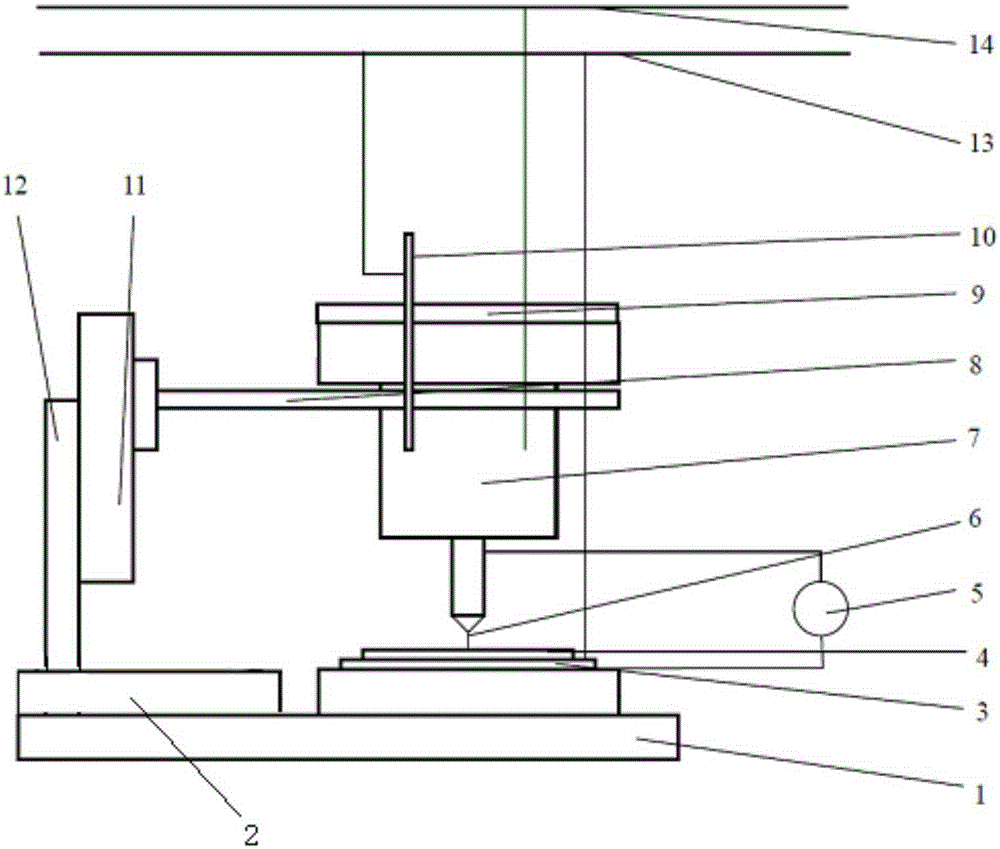

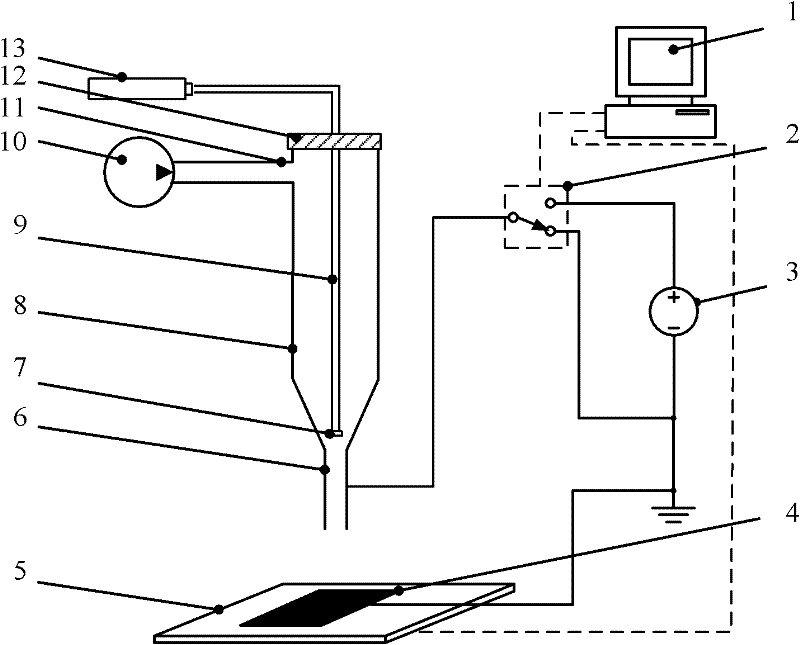

Laser-guided electrospinning direct writing device

InactiveCN102162175AImprove stabilityExtend exercise timeSpinnerette packsSpinning head liquid feederComing outElectrical conductor

The present invention provides a laser-guided electrospinning direct writing device capable of realizing long-time controllable preparation and precise positioning of single uniform micro / nanostructure. The device is provided with a controller, a high-voltage relay, an electrostatic high-voltage [power] source, a hollow nozzle, a collimating focusing lens set, optical fibers, a sealing adjusting part, a laser, a solution feed pump, a solution feed pipe, a collecting board and a motion platform, wherein the controller is connected with the high-voltage relay; ends of the high-voltage relay are respectively connected with the electrostatic high-voltage [power] source, the collecting board and a conductor nozzle arranged at the front end of the hollow nozzle; the sealing adjusting part is in a sealing connection with the rear end of the hollow nozzle; the optical fibers pass through the center of the sealing adjusting part and are fixedly connected with the sealing adjusting part; the collimating focusing lens set is arranged at the front end of the optical fibers; the rear end of the optical fibers comes out of the hollow nozzle and is connected with the laser; the solution feed pump is communicated with the hollow nozzle through the solution feed pipe; and the collecting board is fixed on the motion platform and faces the hollow nozzle. The laser constraints the disordered motion of spinning jet flow and guides the spinning jet flow to deposit at the laser spot of the collecting board.

Owner:XIAMEN UNIV

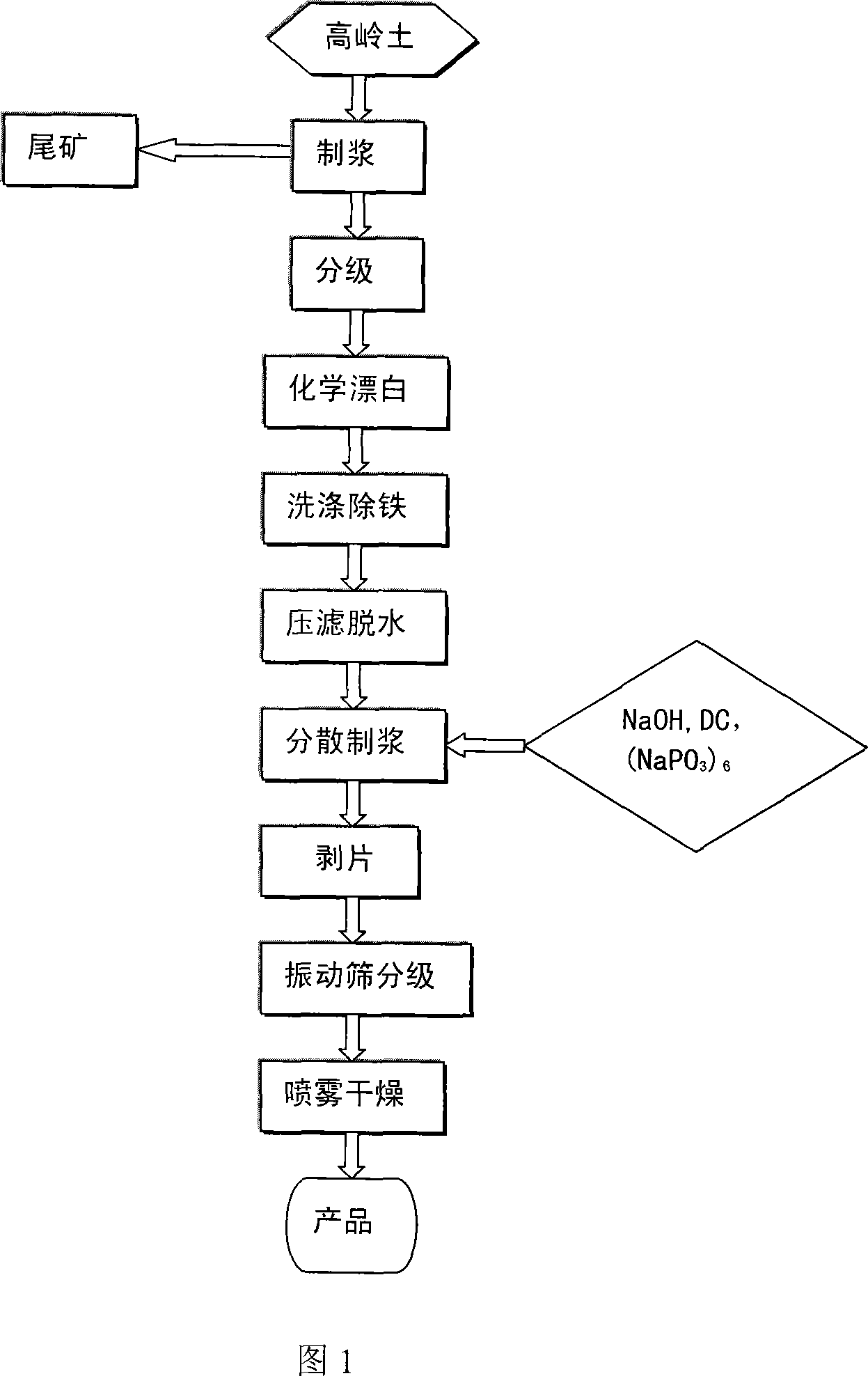

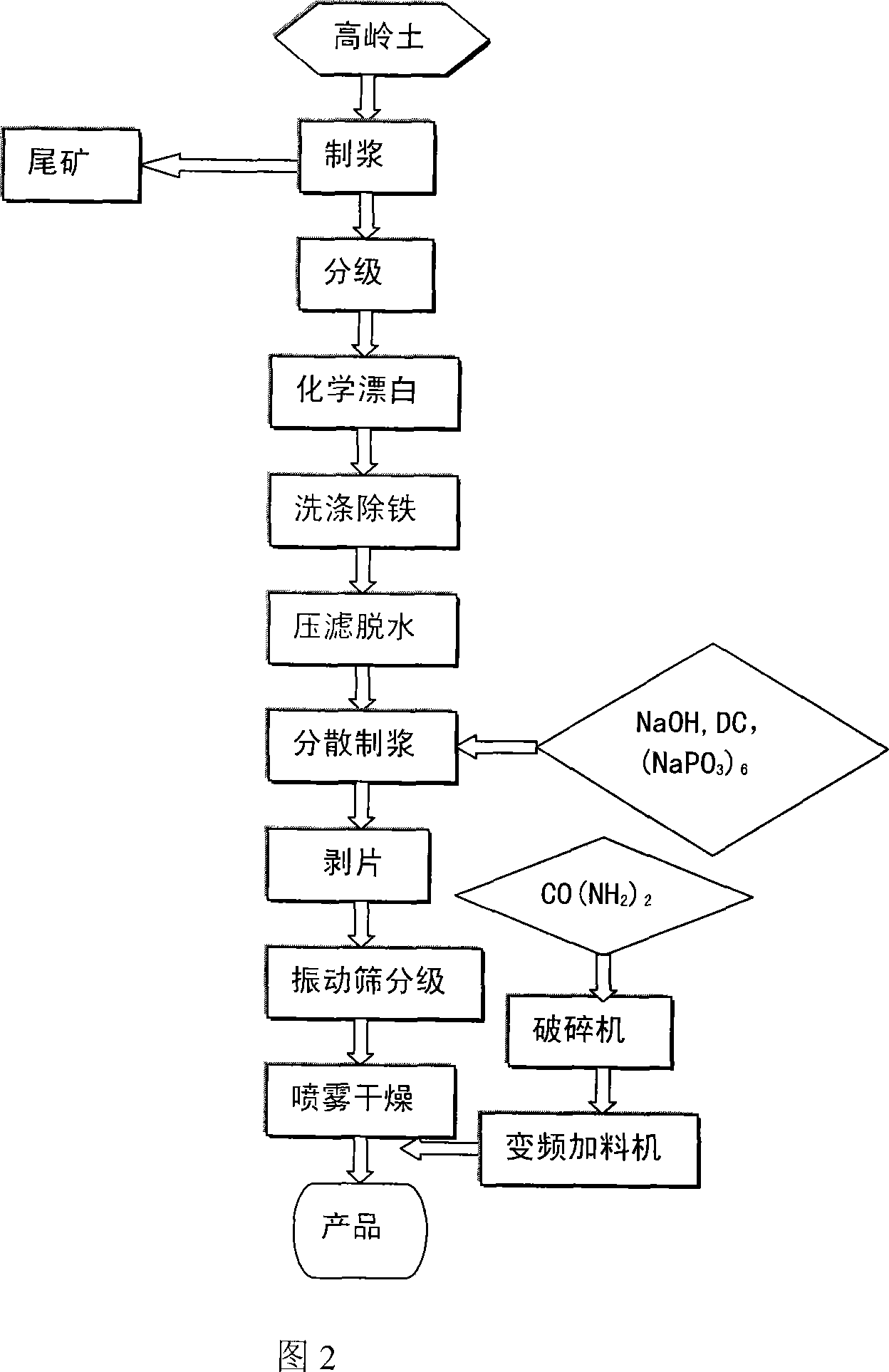

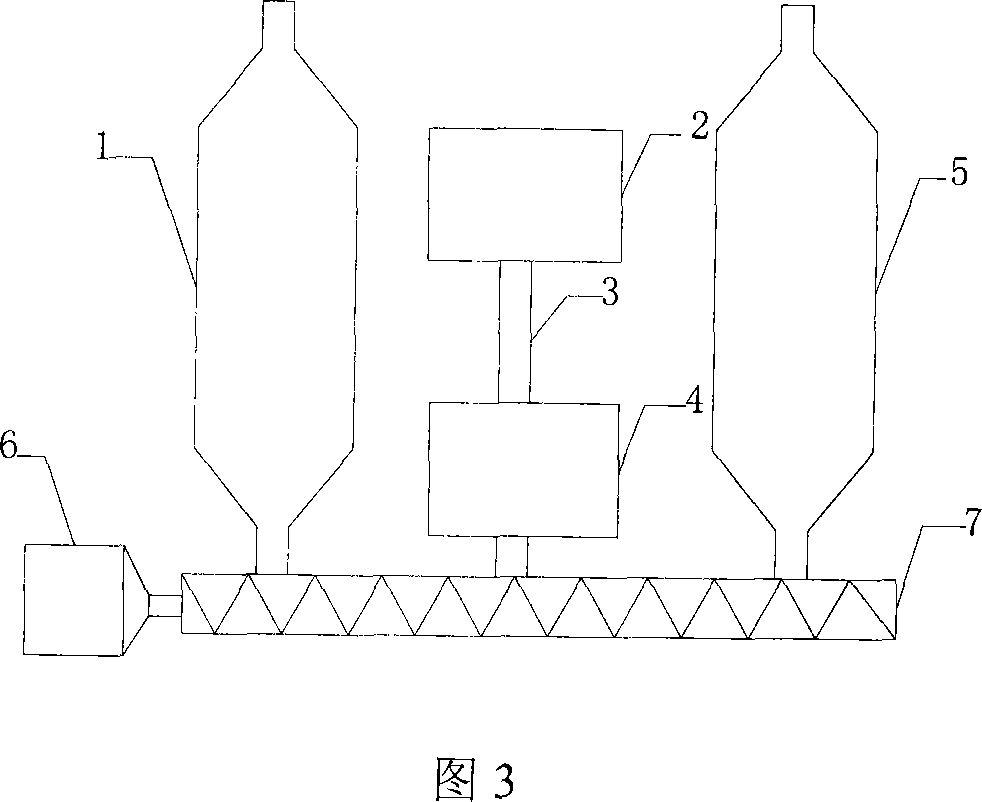

Production technology of high

InactiveCN101117004AImprove performancePerformance impactClay processing apparatusThermal insulationKaolin clay

The present invention relates to a manufacturing technique of kaolin with high viscosity and concentration. A manufacturing technique of kaolin with high viscosity and concentration is characterized by comprising following procedures: 1) manufacturing kaolin slurry J with kaolin extracted by hydraulic machinery method undergoing pulping, classification, chemical bleaching, iron removal by washing, dehydrating through pressure filters, dispersed pulping, exfoliation, vibration screen classification ; 2) spray drying and intercalation which is accomplished by a) firstly, improving product lines of a spray drying equipment, that is, adding a thermal insulation layer to a packing auger, a lift pot and a storage hopper of the spray drying equipment, and then arranging a variable frequency feeding machine communicated with a urea crusher through pipelines on the packing auger of the bottom of a spray drying mouth of the spray drying equipment; b) spray drying to achieve kaolin powder; c) intercalating intercalation agent urea with the kaolin powder through the variable frequency feeding machine with parameter of a fresh feed pump between 2 HZ and 8 HZ and with additional of mass of the intercalation agent urea between 2 percent and 10 percent of the mass of the kaolin powder; thereby getting final kaolin products with viscosity and concentration between 72 percent and 73.7 percent. The manufacturing technique can produce kaolin with high viscosity and concentration.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

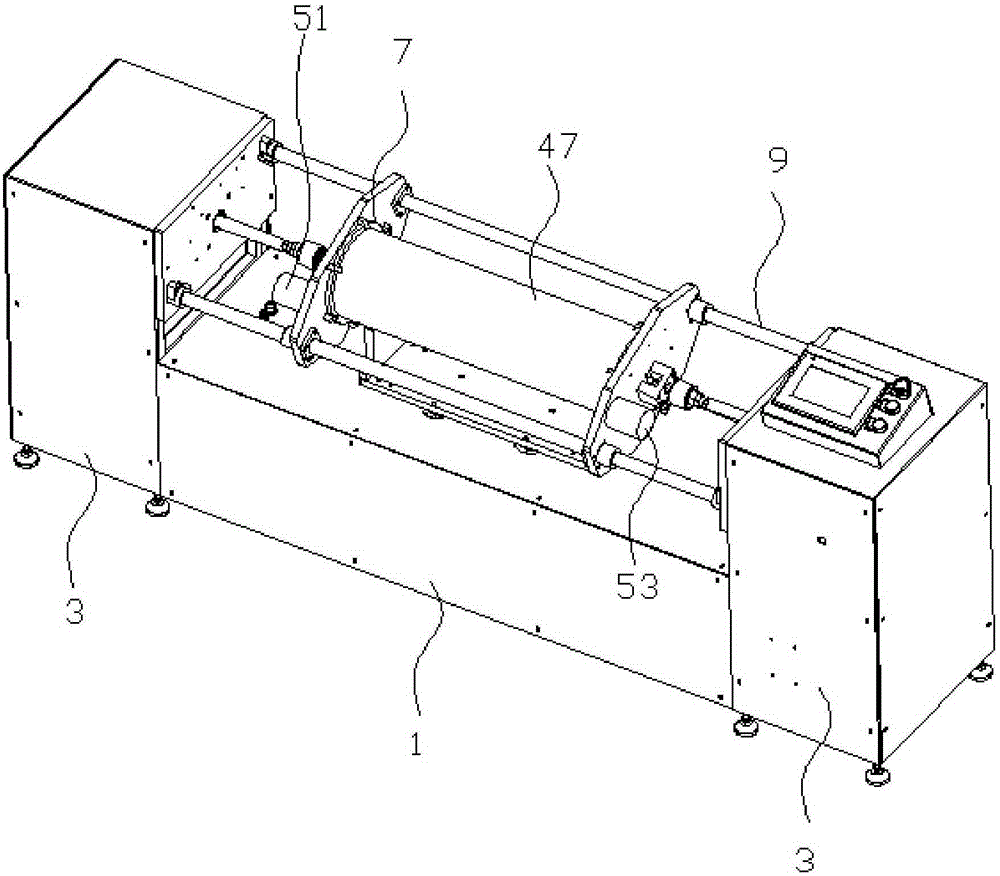

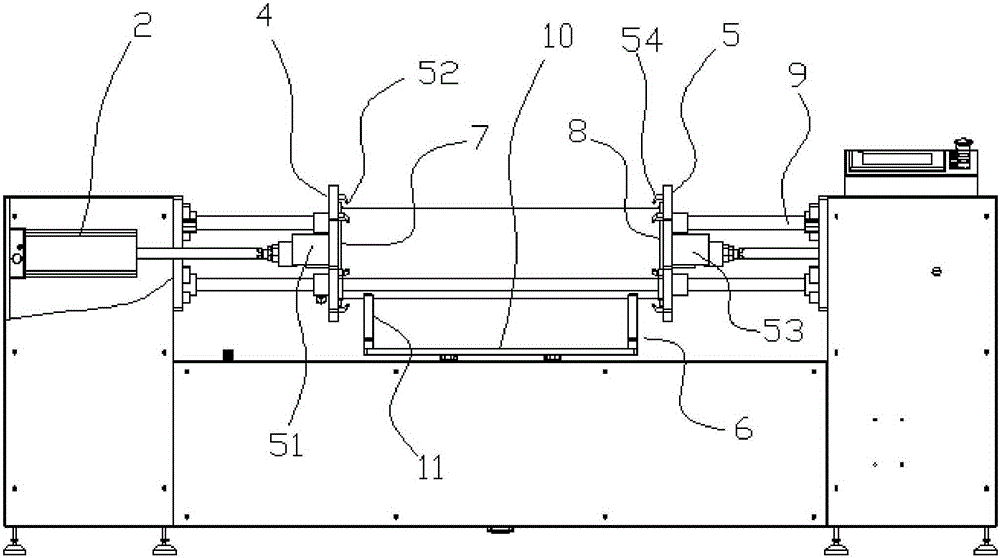

Pipe fitting sealing property testing device

InactiveCN105203274ANo pinchingPrevent fallbackMeasurement of fluid loss/gain ratePipe fittingEngineering

The invention discloses a pipe fitting sealing property testing device and aims at achieving the effects that the pipe fitting sealing property testing device is convenient to operate, high in testing result accuracy and capable of guaranteeing that the two pipe ends of a pipe fitting are not prone to being damaged due to clamping. The device comprises an air feed pump, a baroceptor, a main rack, two push plate air cylinders, two side racks, a main end cover and a subsidiary end cover, the two push plate air cylinders are arranged on the two side racks respectively, a piston rod of one of the push plate air cylinders is connected with the main end cover, a piston rod of the other push plate air cylinder is connected with the subsidiary end cover, a main elastic sealing ring pad is arranged on the main end cover, a subsidiary elastic sealing ring plate is arranged on the subsidiary end cover, and a main cover air hole is formed in the main end cover. The pipe fitting sealing property testing device has the advantages that the pipe fitting can be positioned to the right position, the sealing property can be guaranteed, and the pipe fitting is not damaged due to clamping; the device is provided with a sealing structure which can be adjusted in a self-adaptation mode, and the sealing effect in the high pressure testing process can be intensified; the device is provided with an assistant positioning structure, the end covers can be prevented from moving backward, the push plate air cylinders can be protected, the sealing effect can be improved, and stability in the testing process can be maintained.

Owner:宁波新合博园林机械有限公司

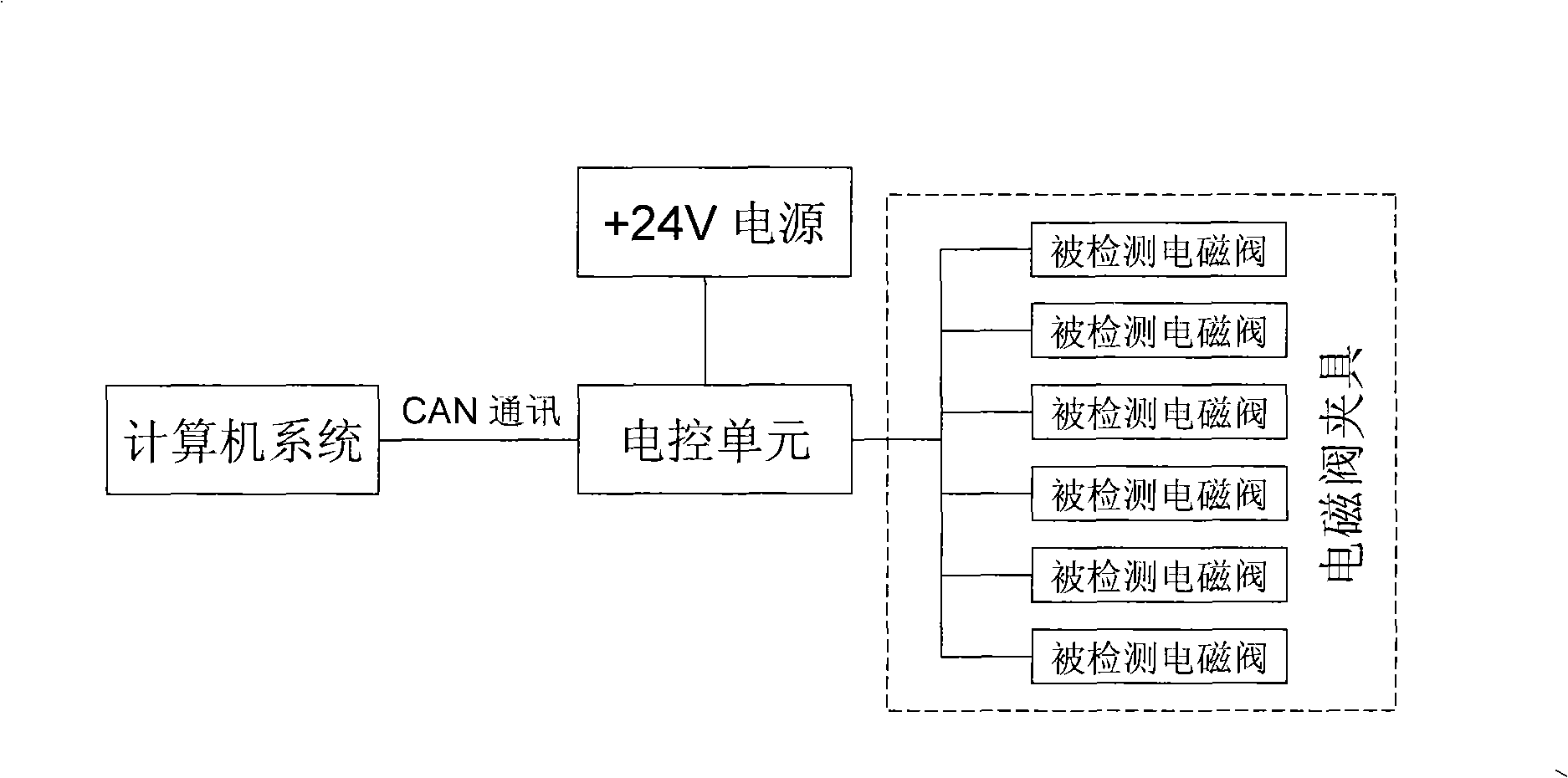

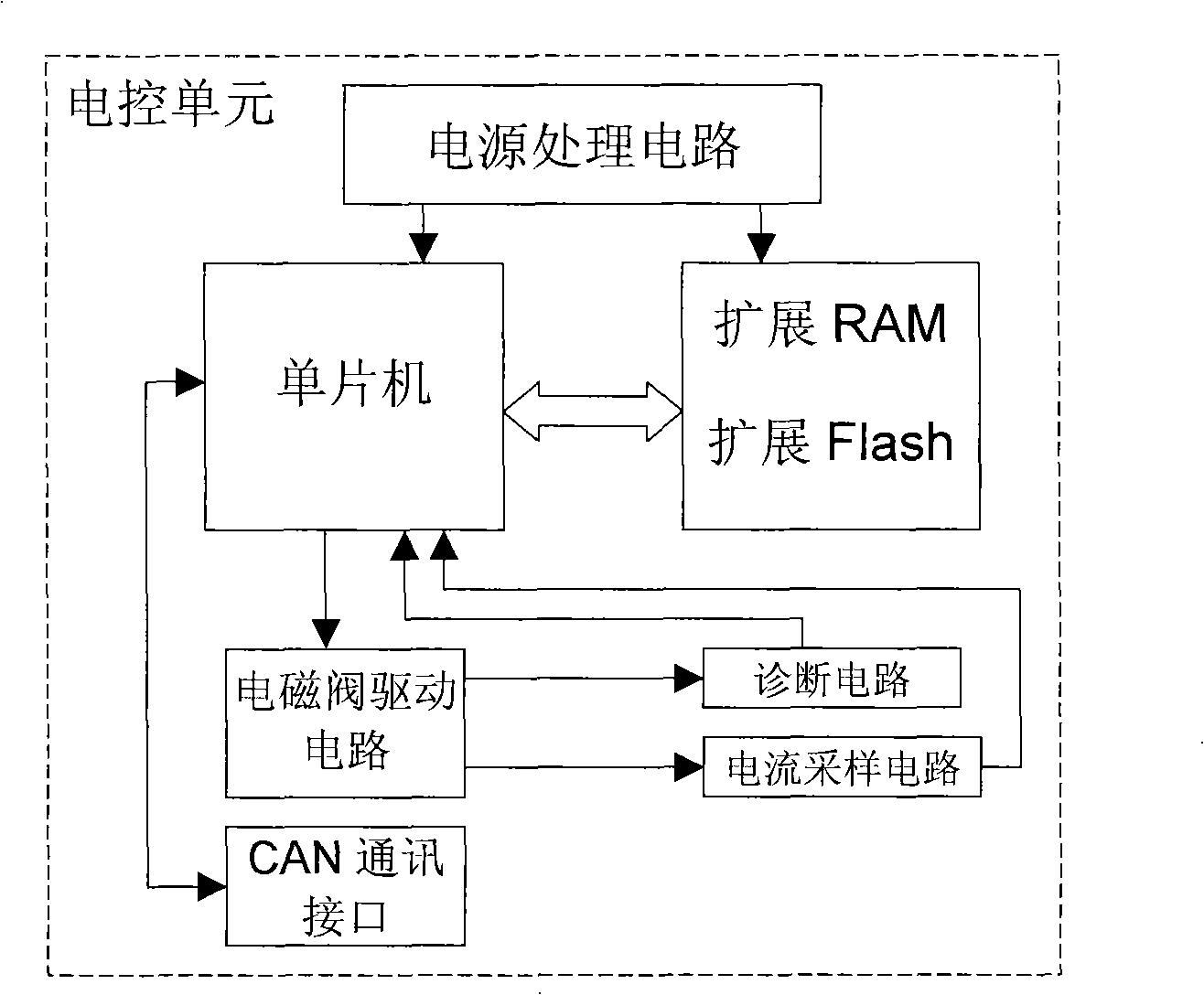

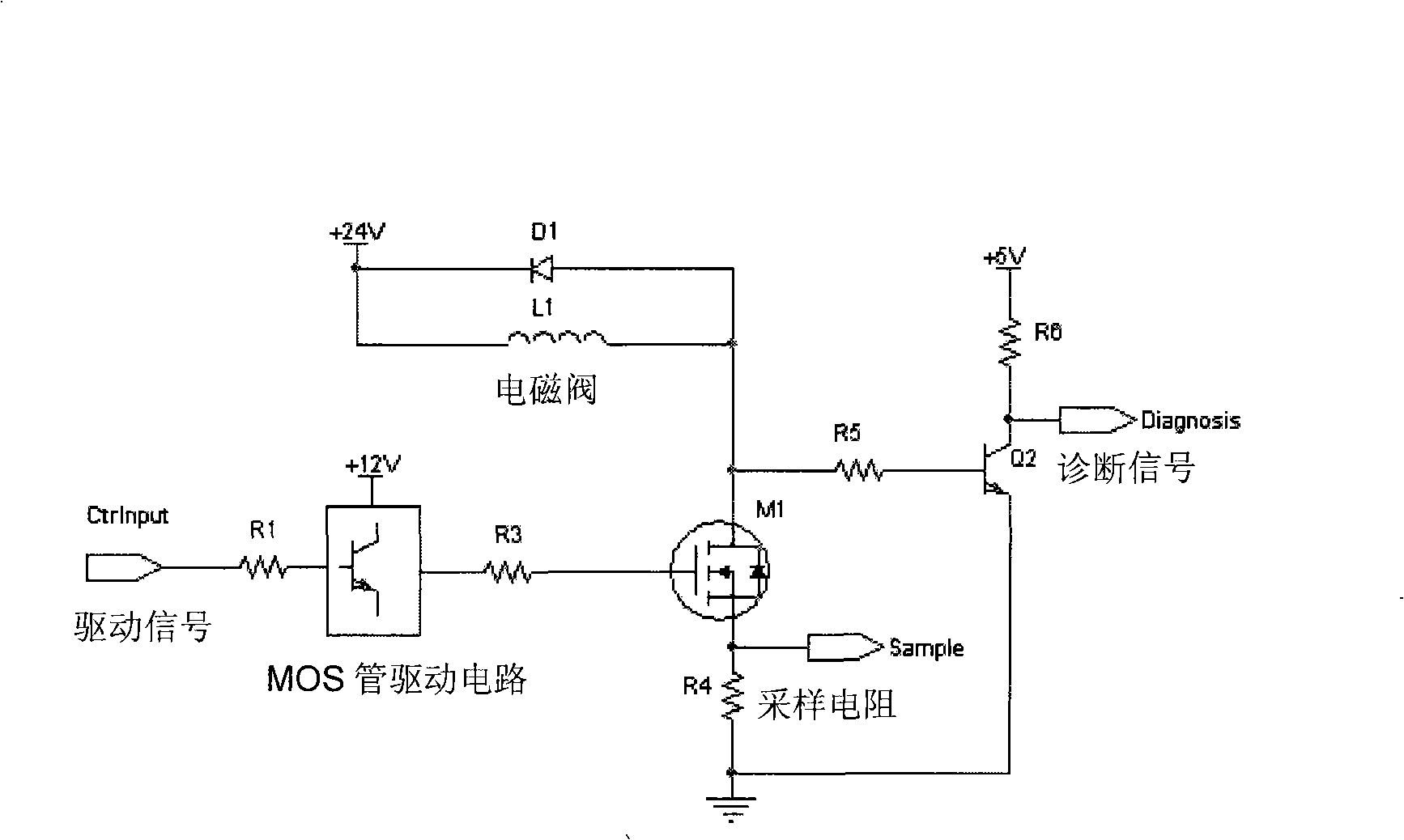

Solenoid valve diagnosis detecting method and device for electric-controlled co-rail fuel feed pump

InactiveCN101294534AImprove consistencyImprove performanceEngine testingFuel injection apparatusSolenoid valveCommon rail

The invention relates to a diagnosis and detection method and a device for an electromagnetic valve used for an electrically controlled common rail fuel feed pump. The method is characterized in that control parameters predetermined by test is input by a monitor program, current waveform during the drive of the electromagnetic valve is detected in real time and curve fitting is conducted; accordingly, the characteristics of the electromagnetic valve are judged, the movement circumstances when turning-on and shutting-down of the electromagnetic valve delays are measured and then whether the electromagnetic valve has the fault of deadlocking or open circuit can be analyzed. When the electromagnetic valve diagnosis and detection device is in use, no fuel injection pump test stand is needed; the use of the device can improve the consistence of the performance of the fuel feed pump electromagnetic valve, thereby greatly improving the performance and reliability of a common rail fuel injection system. The electromagnetic valve detection device has the advantages of low manufacture cost, convenient use, good self-diagnostic function and easy implementation in mass production.

Owner:CHINA FIRST AUTOMOBILE

System and method for printing a continuous web employing a plurality of interleaved ink-jet pens fed by a bulk ink source

InactiveUS20090027449A1Improve flatnessEnough timeInking apparatusSpacing mechanismsSufficient timeCoupling

This invention provides a system and method for printing continuous web and feeding ink to printing pens (or cartridges) that employs an array of interleaved ink-jet pens that are arranged to receive bulk ink through a manifold. The manifold and pens are mounted on a fixed array suspended over the web feed path. The manifold includes a plurality of self-sealing quick-disconnect couplings that each serve a discrete ink-jet pen. The pens lay down ink in a registered manner across the full width of the web. The pens are organized into two parallel, multi-pen arrays that are each diagonally oriented with respect to the feed direction. The feed path allows for duplex printing with a second web-side's array located on a lower level of the device, generally beneath the first-side's array. Duplex printing is facilitated due to its inherent length of the feed path. The printed part of the web is free of contact over predetermined lengths that ensure sufficient time for the drying of ink. Each pen is interconnected with a connection to a respective manifold that maintains a vacuum so as to prevent seepage of ink from the pen nozzles. The vacuum is maintained by a draw pump, while ink is continuously provided to the manifold via a float switch in a pressure regulator. The regulator is fed by a bulk ink supply using a feed pump. A check-valve standpipe on each manifold assists in removing any trapped air from the system, thus assisting in maintaining the vacuum.

Owner:ROLL SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com