Patents

Literature

83results about How to "Reduce the pumping volume" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

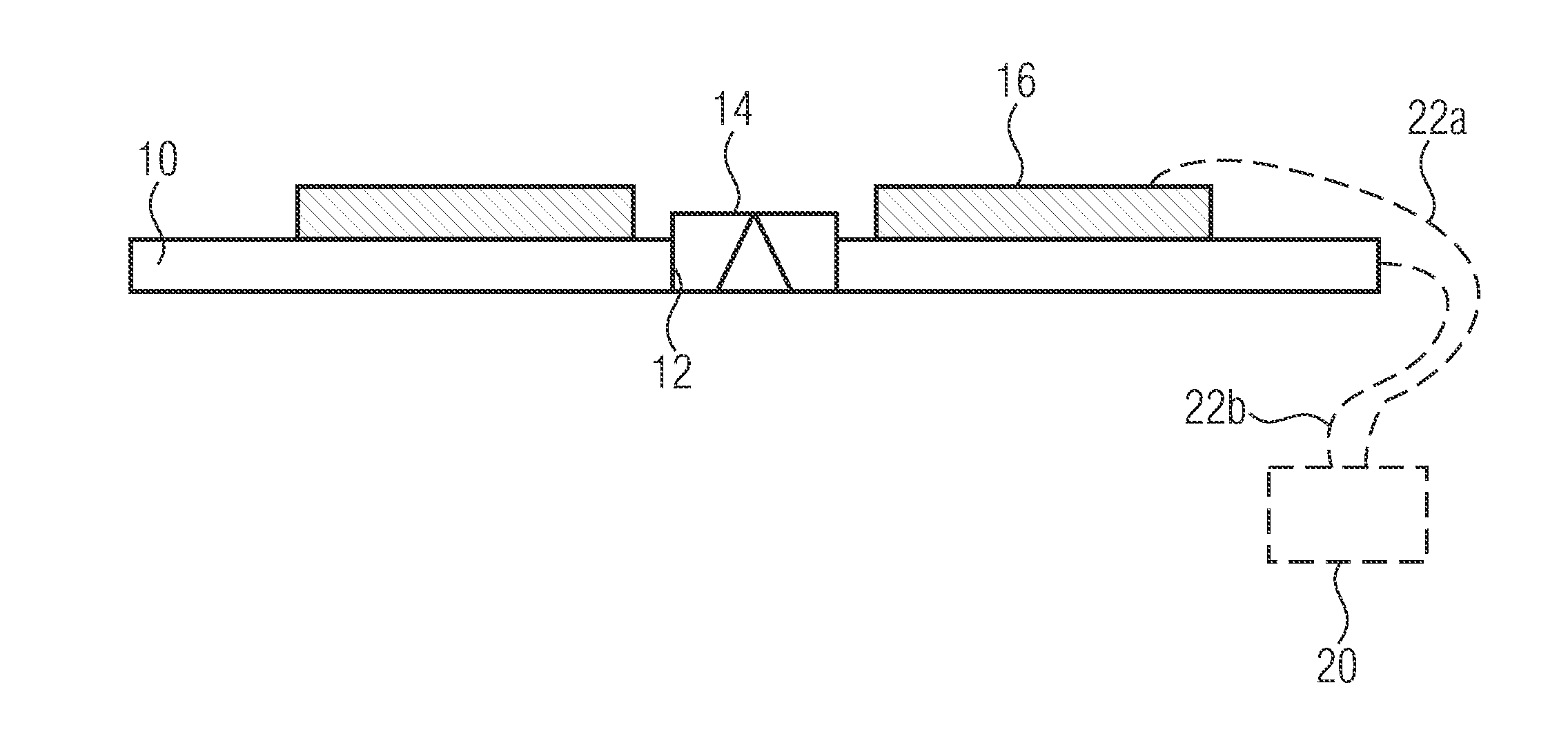

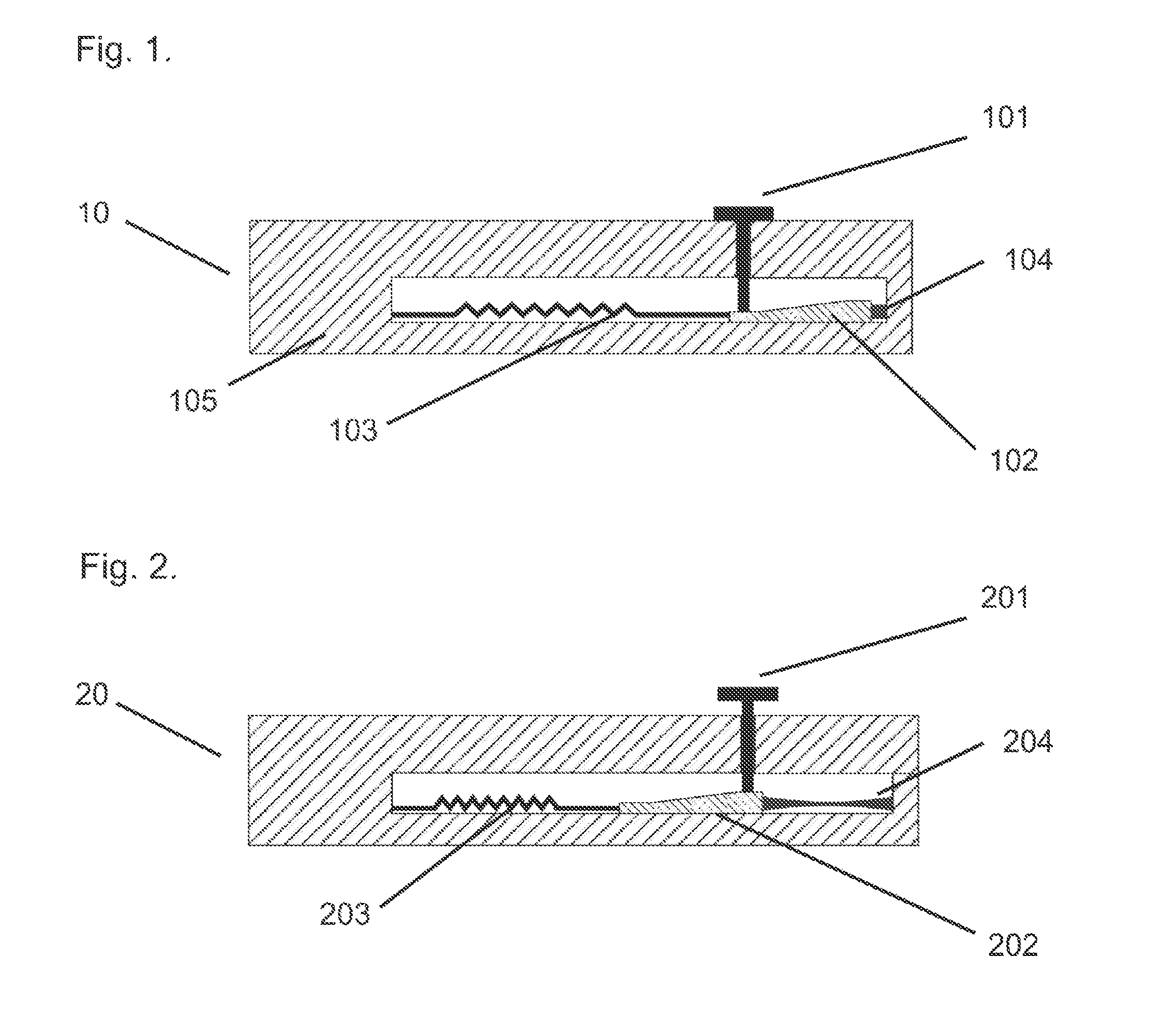

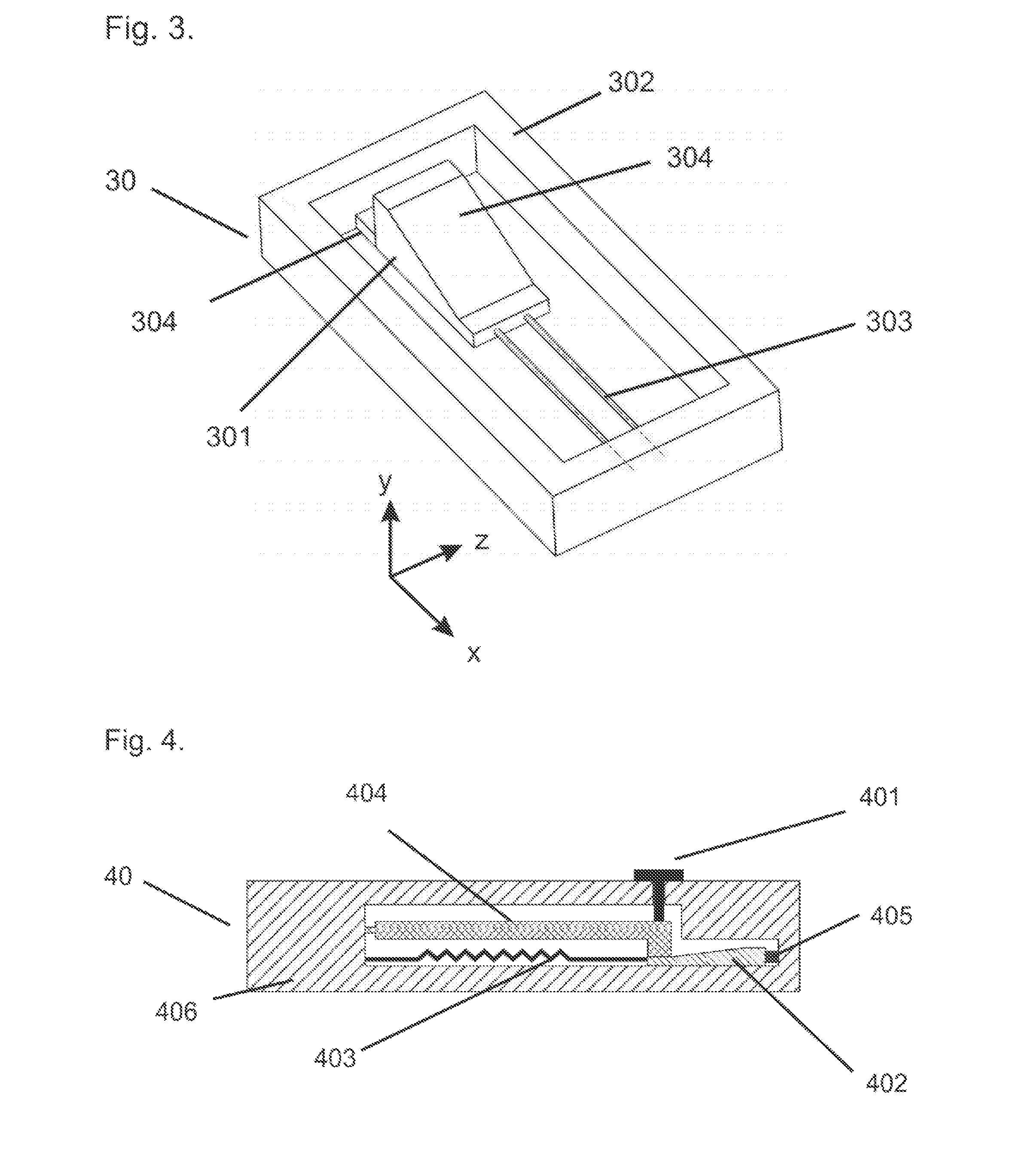

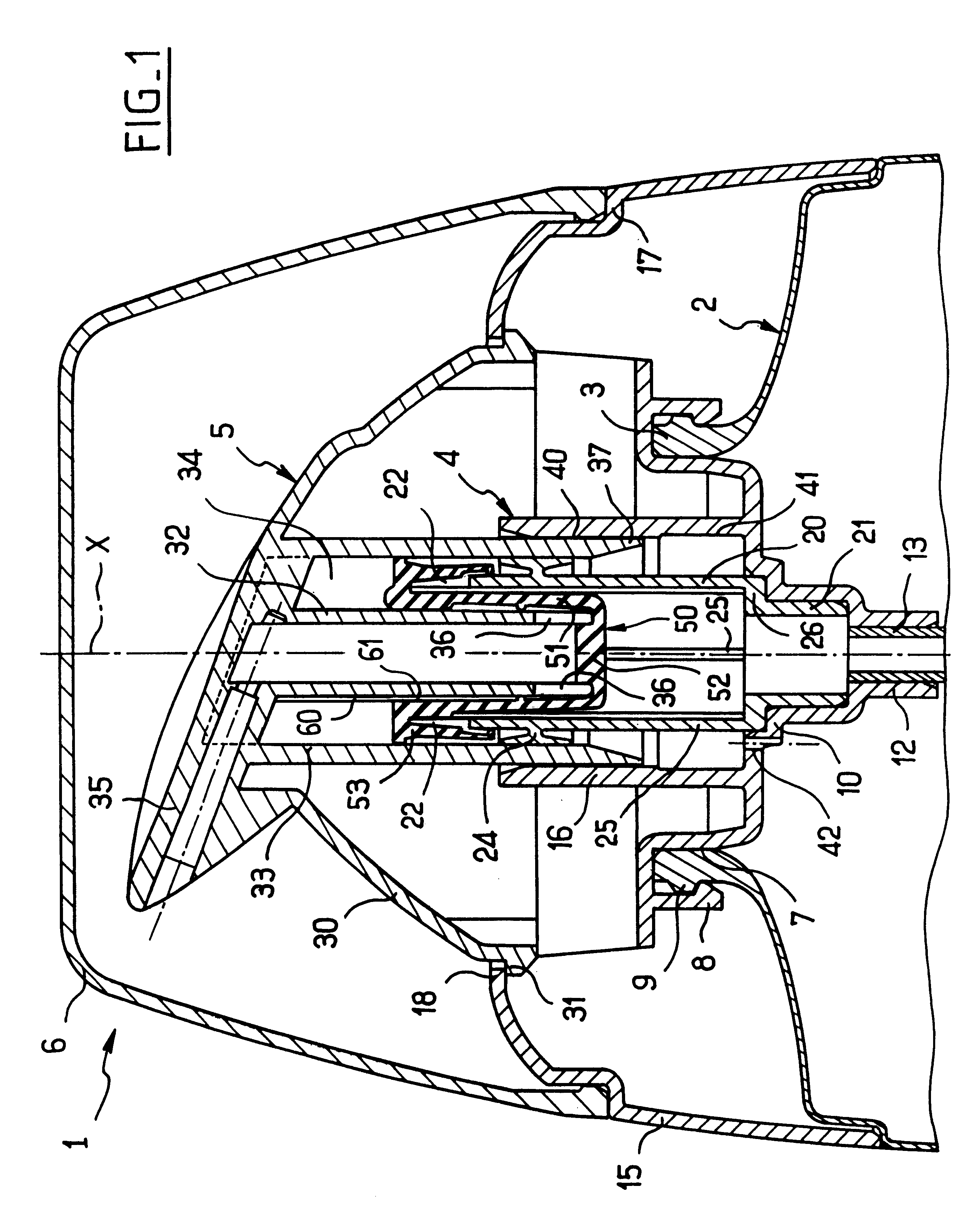

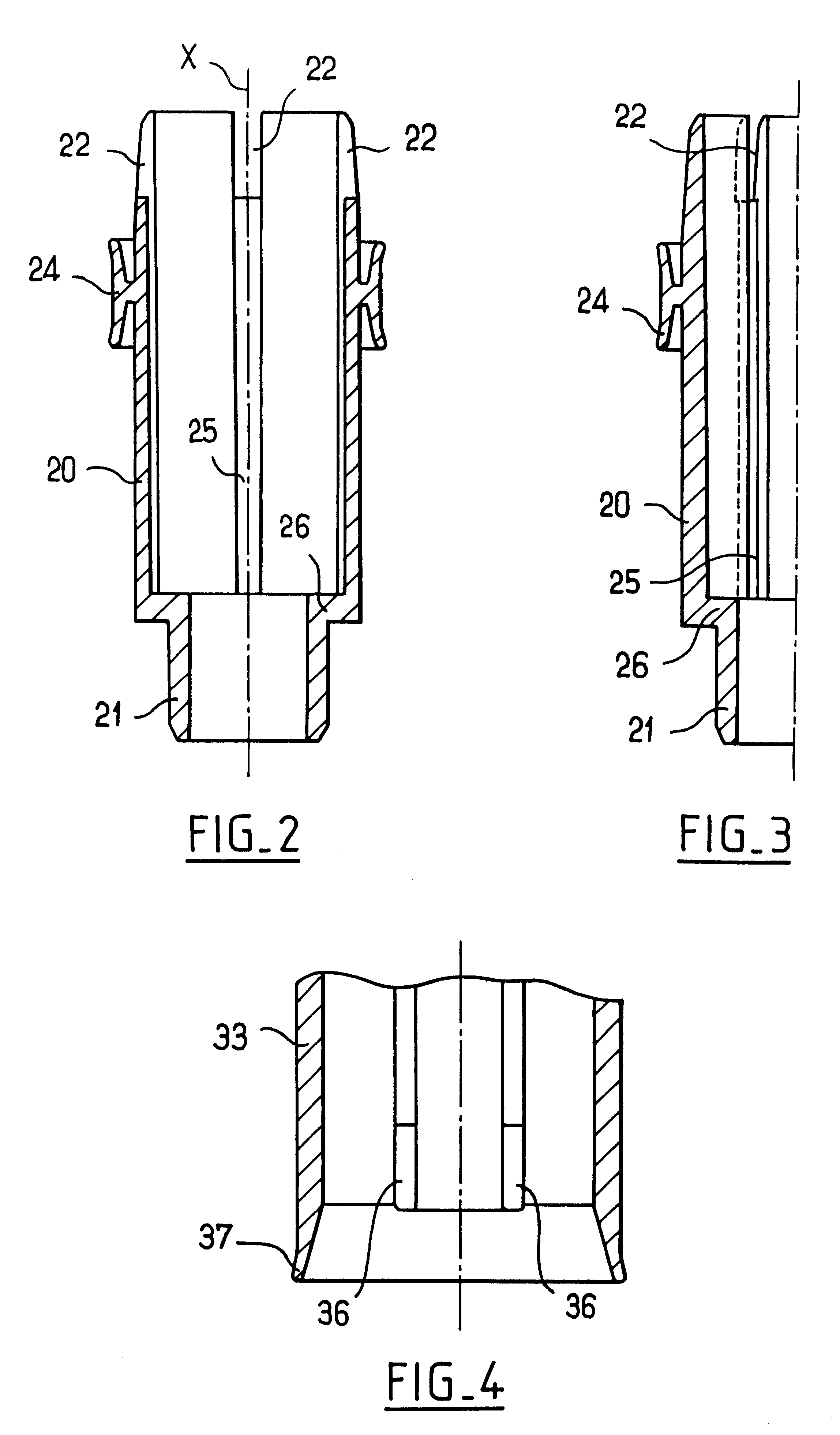

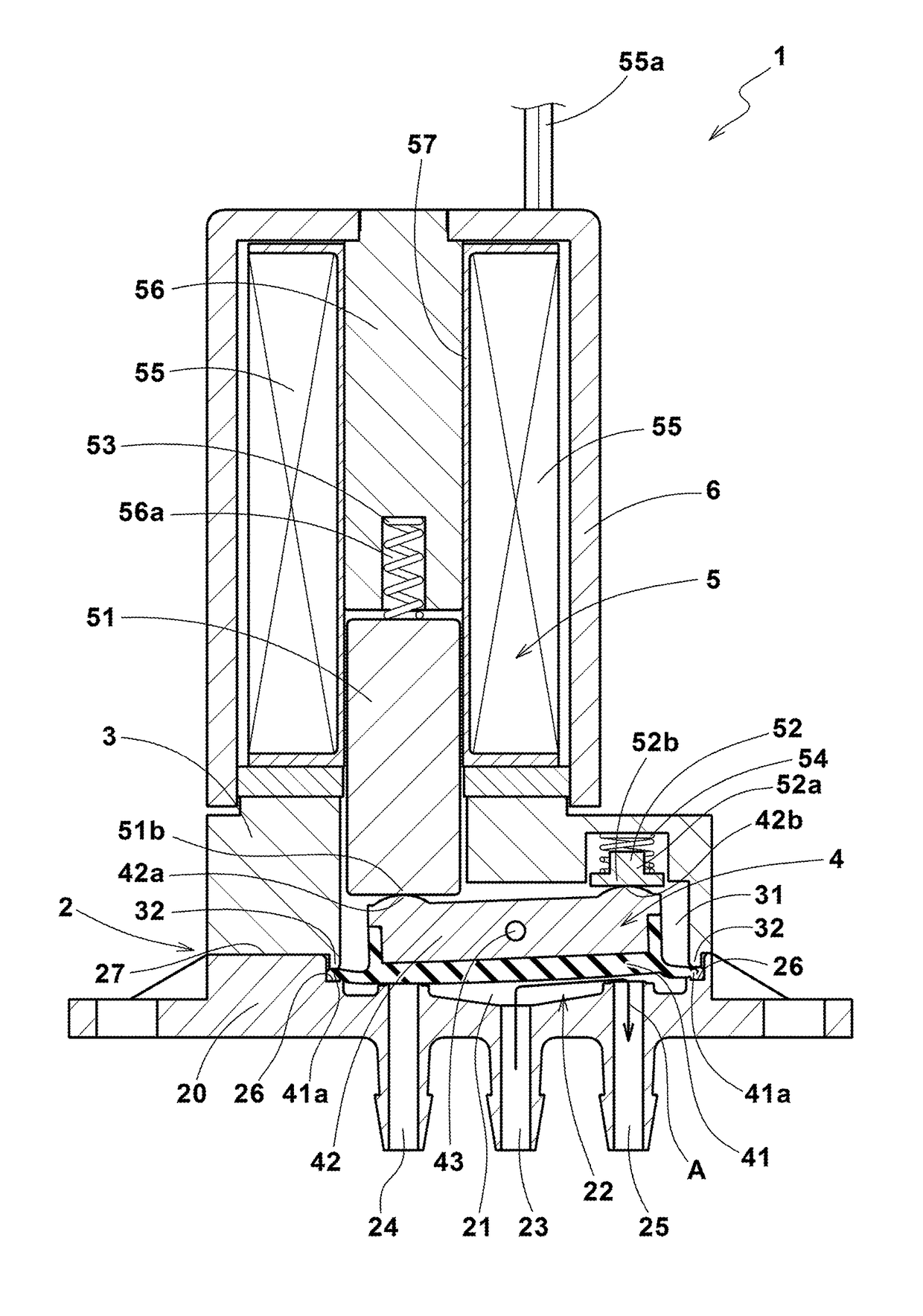

Peristaltic micropump

ActiveUS20050123420A1Easy constructionBubble-tolerant self-priming operationPositive displacement pump componentsFlexible member pumpsPump chamberMicropump

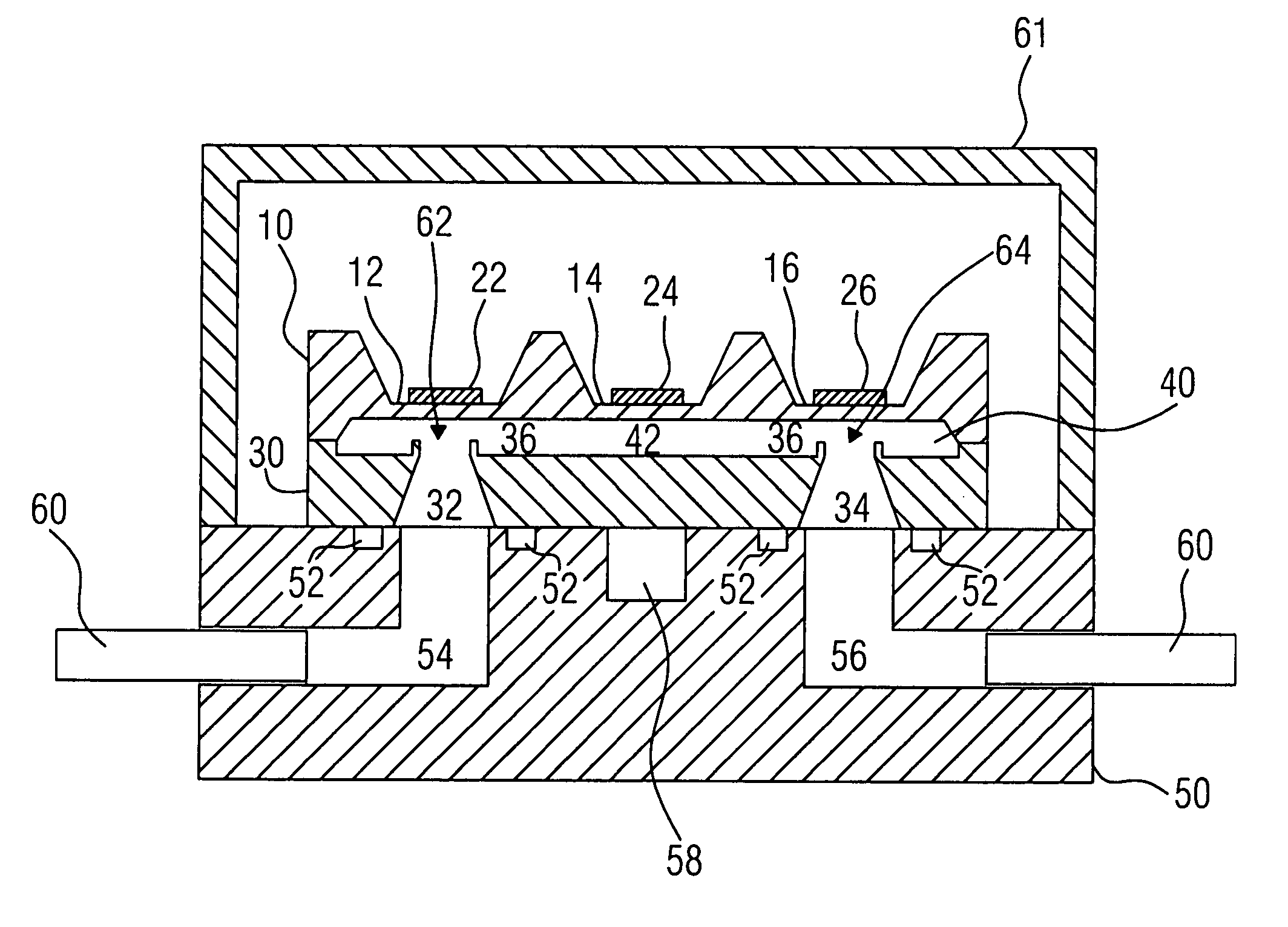

A Peristaltic micropump includes a first membrane region with a first piezo-actor for actuating the first membrane region, a second membrane region with a second piezo-actor for actuating a second membrane region, and a third membrane region with a third piezo-actor for actuating the third membrane region. A pump body forms, together with the first membrane region, a first valve whose passage opening is open in the non-actuated state of the first membrane region and whose passage opening may be closed by actuating the first membrane region. The pump body forms, together with the second membrane region, a pumping chamber whose volume may be decreased by actuating the second membrane region. The pump body forms, together with the third membrane region, a second valve whose passage opening is open in the non-actuated state of the third membrane region and whose passage opening may be closed by actuating the third membrane region. The first and the second valve are fluidically connected to the pumping chamber.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

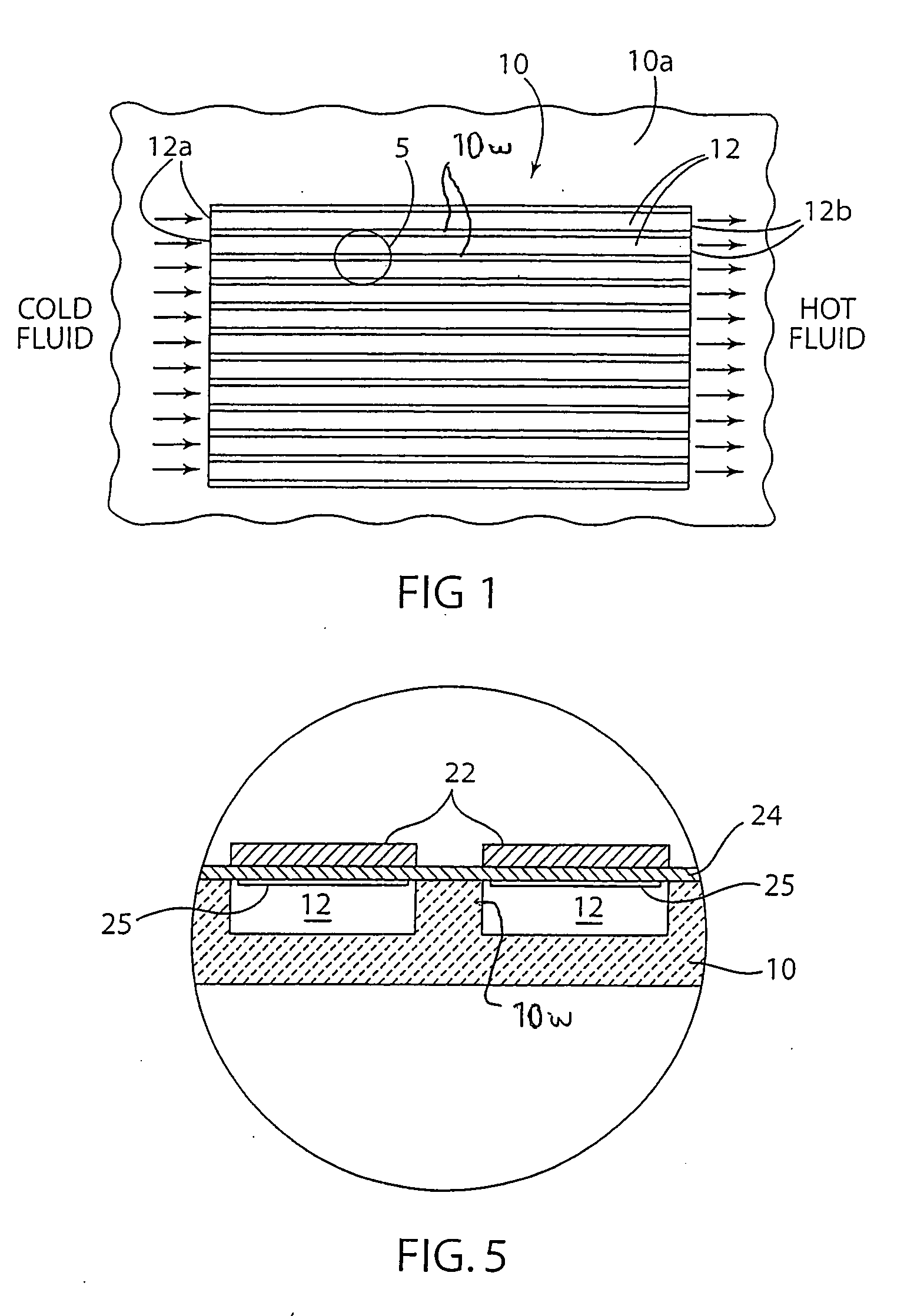

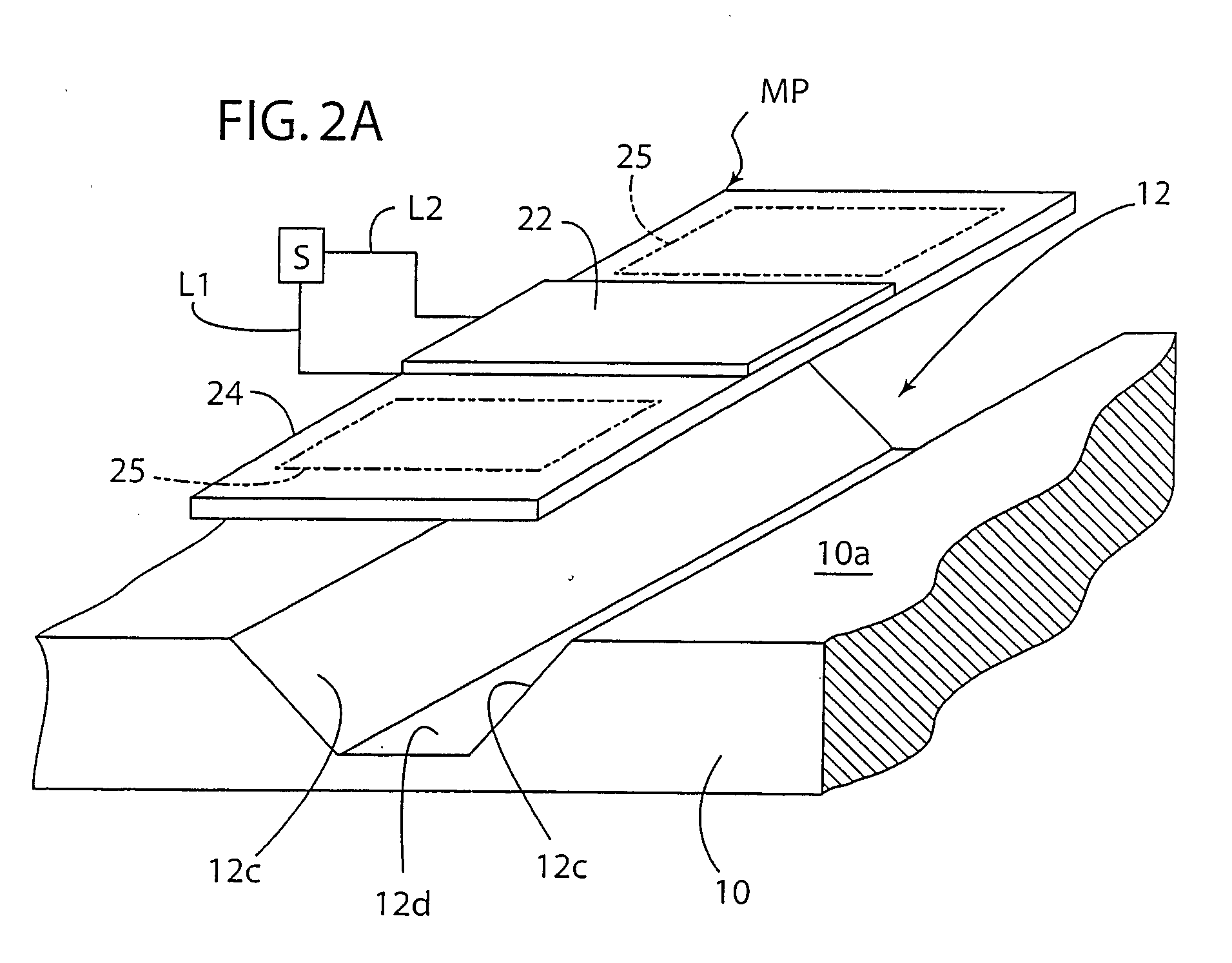

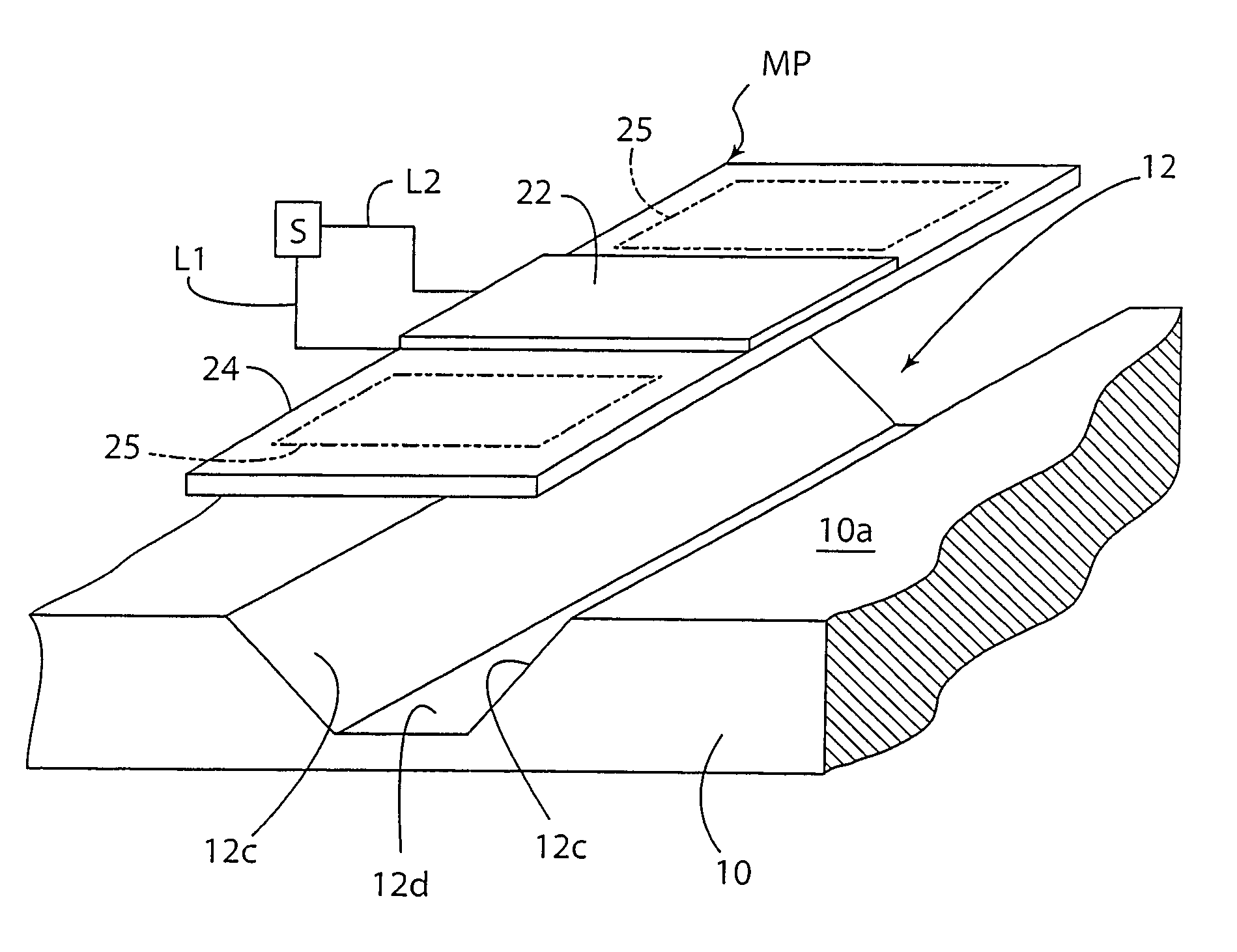

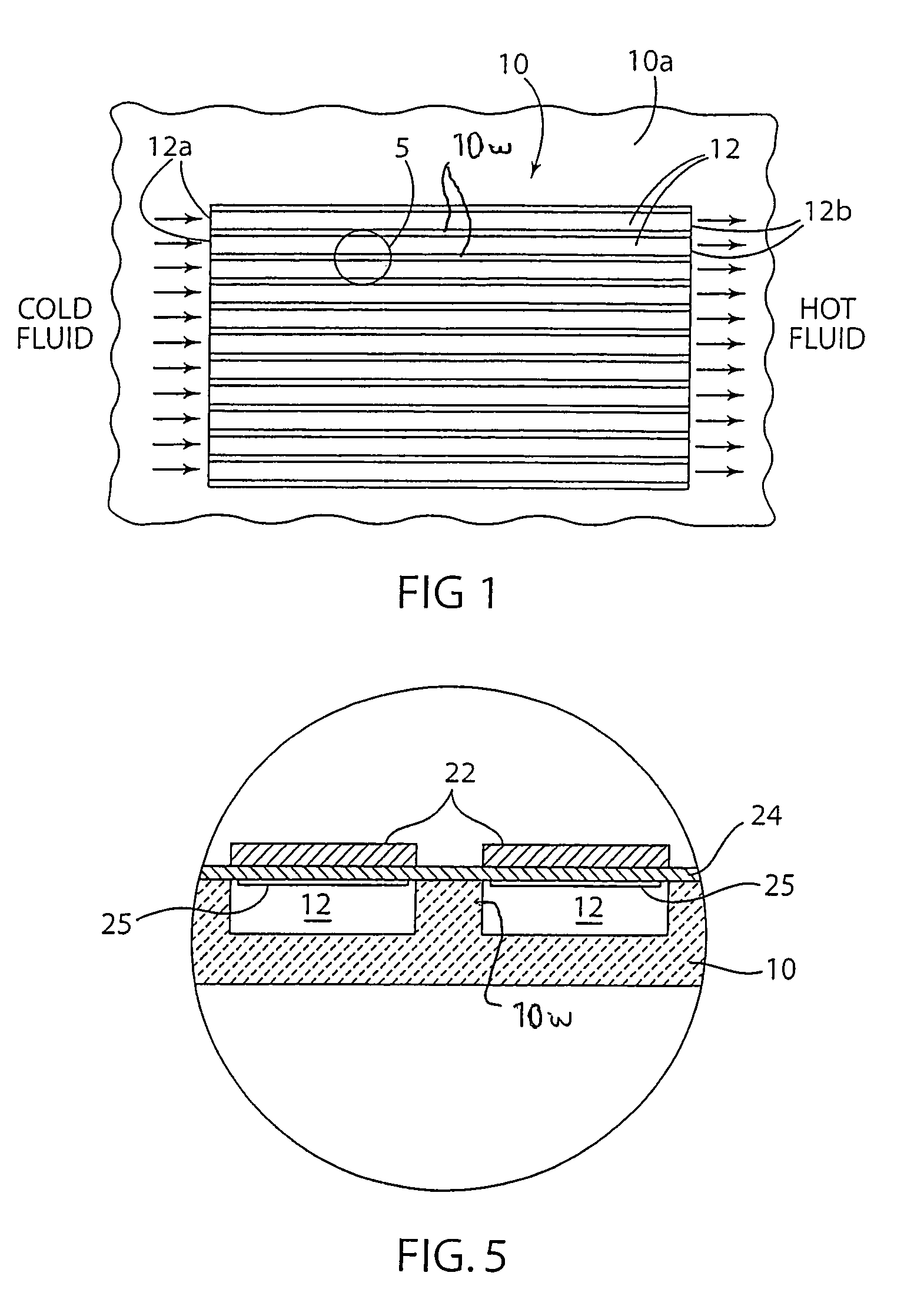

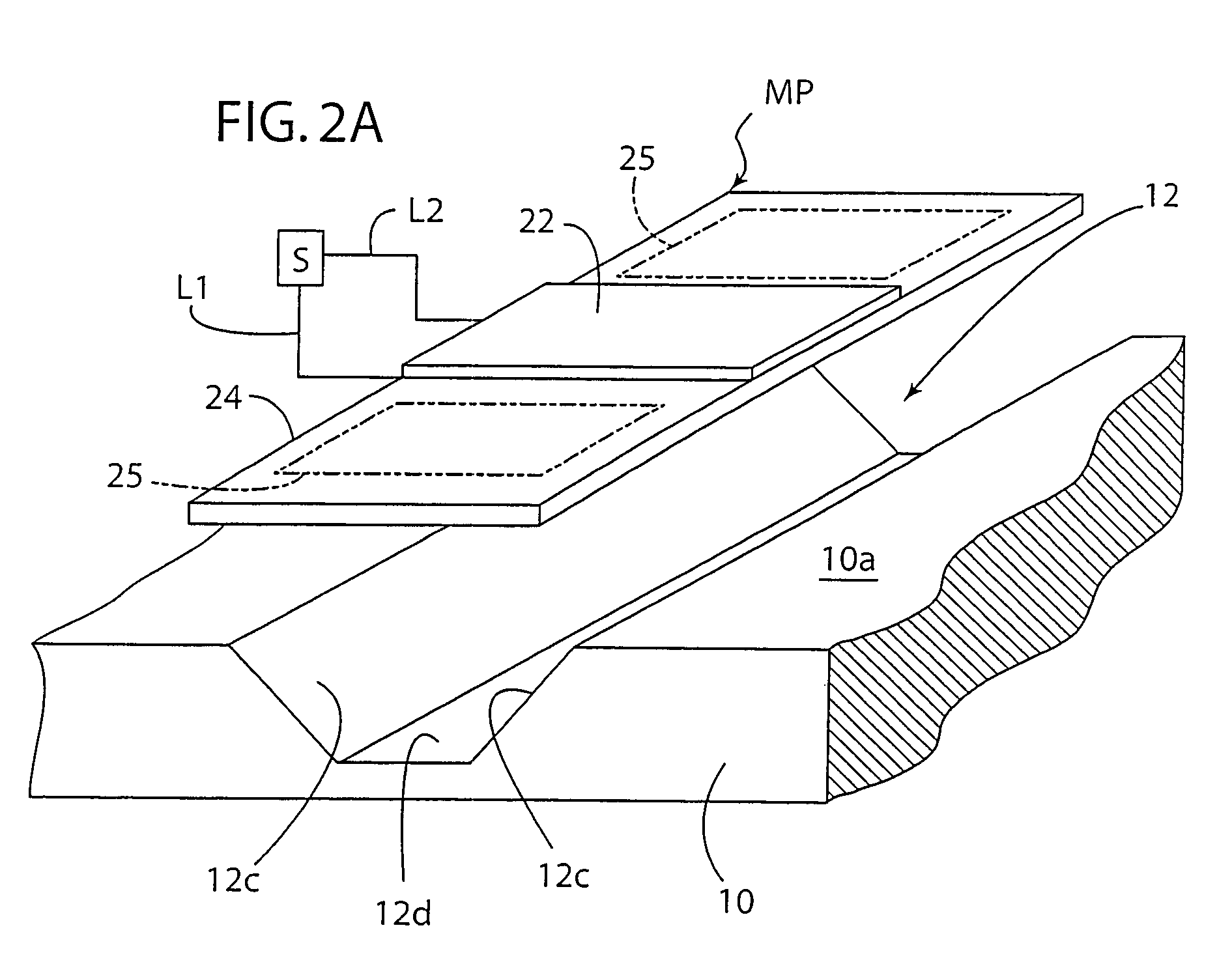

Micropump for electronics cooling

InactiveUS20070020124A1Improve fluid flowIncrease fluid velocityPositive displacement pump componentsFlexible member pumpsWorking fluidElectronics cooling

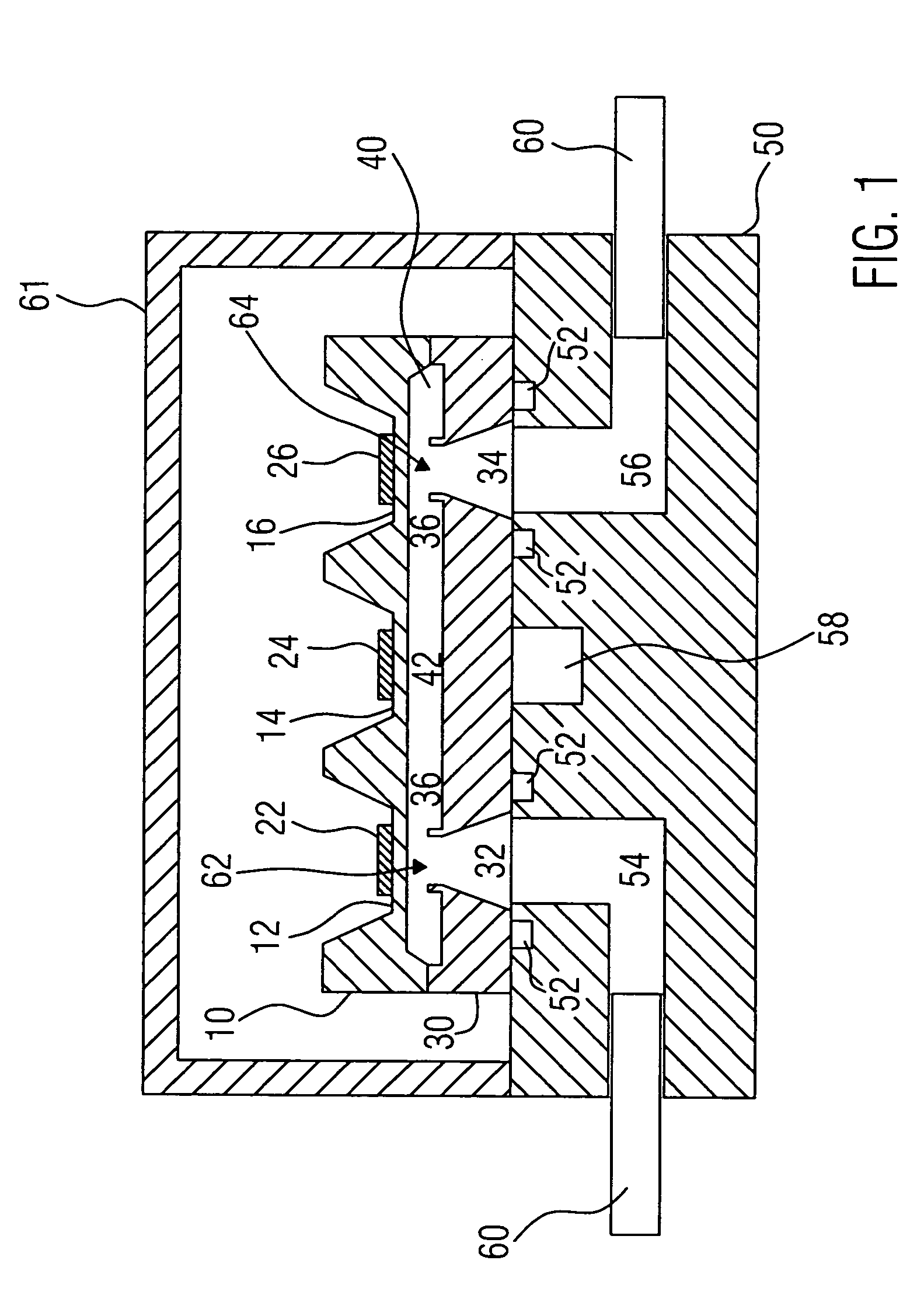

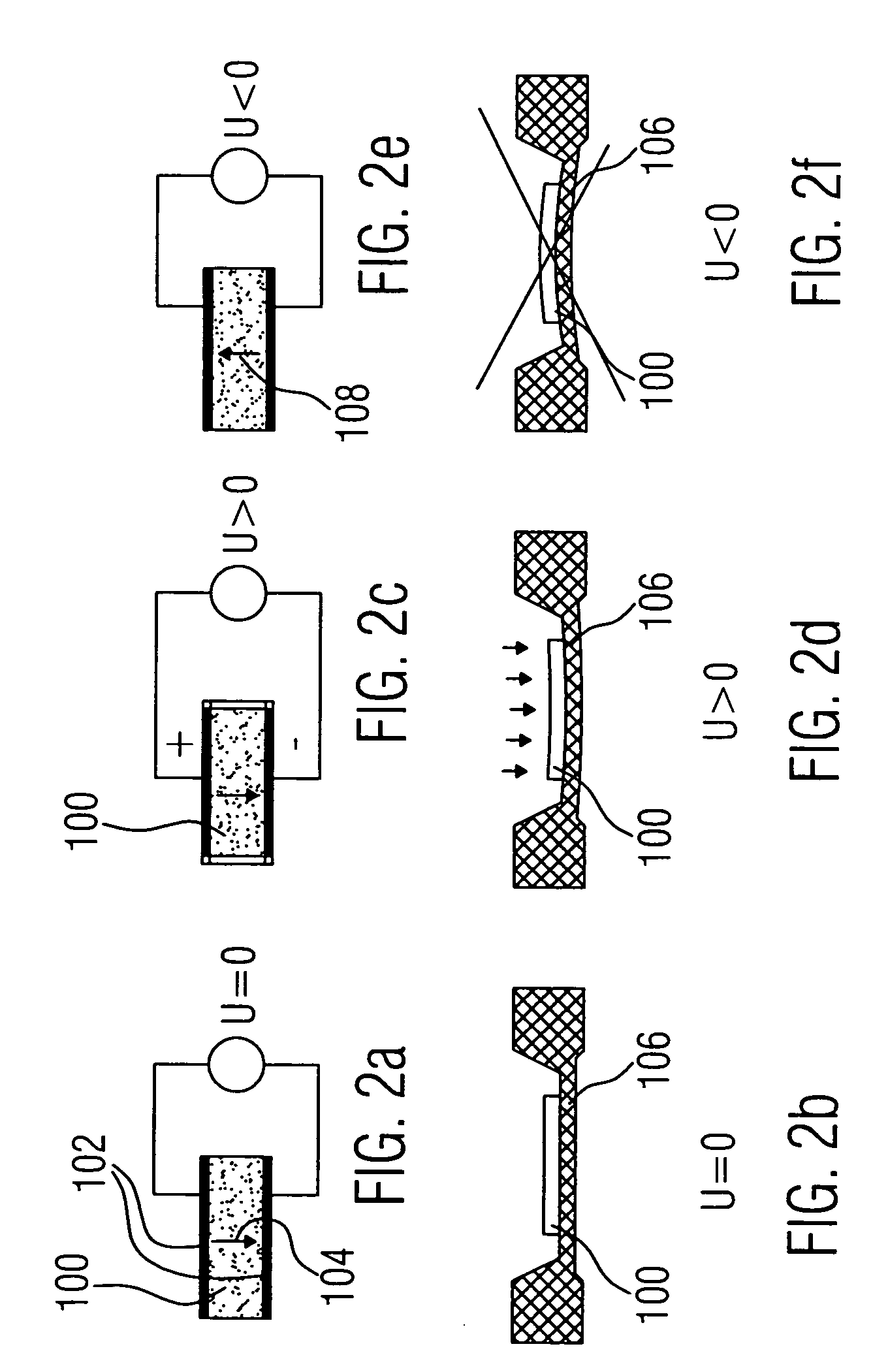

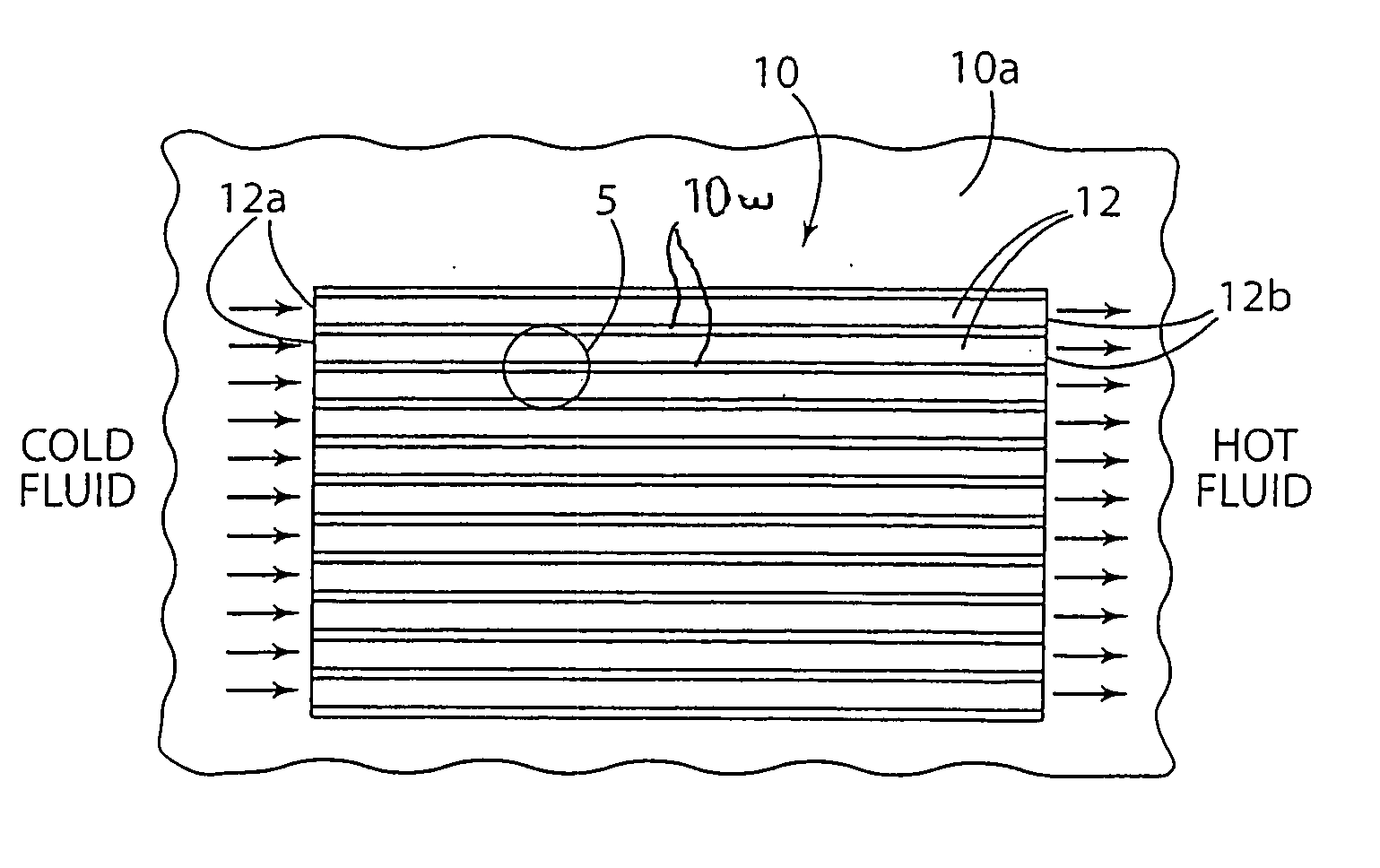

A micropump including one or more microchannels for receiving a fluid and a plurality of electrodes arranged on a diaphragm and energized in a manner to provide an enhanced electrohydrodynamic flow of fluid through the one or more microchannels. The micropump may be used for pumping a working fluid for removing heat from a heat-generating electronic component or for delivery of a drug, medicine, or other treatment agent as or in a fluid to a patient.

Owner:PURDUE RES FOUND INC

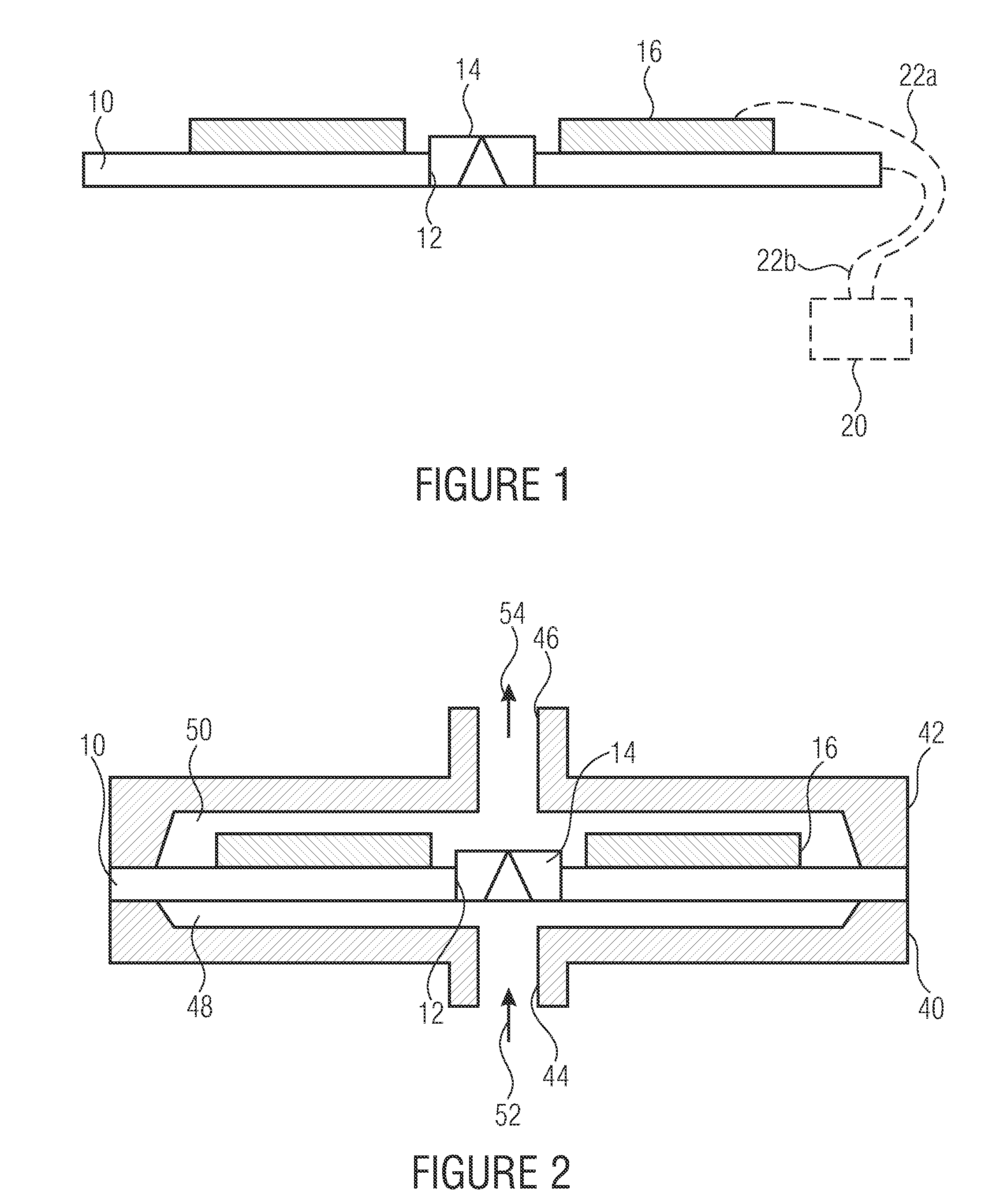

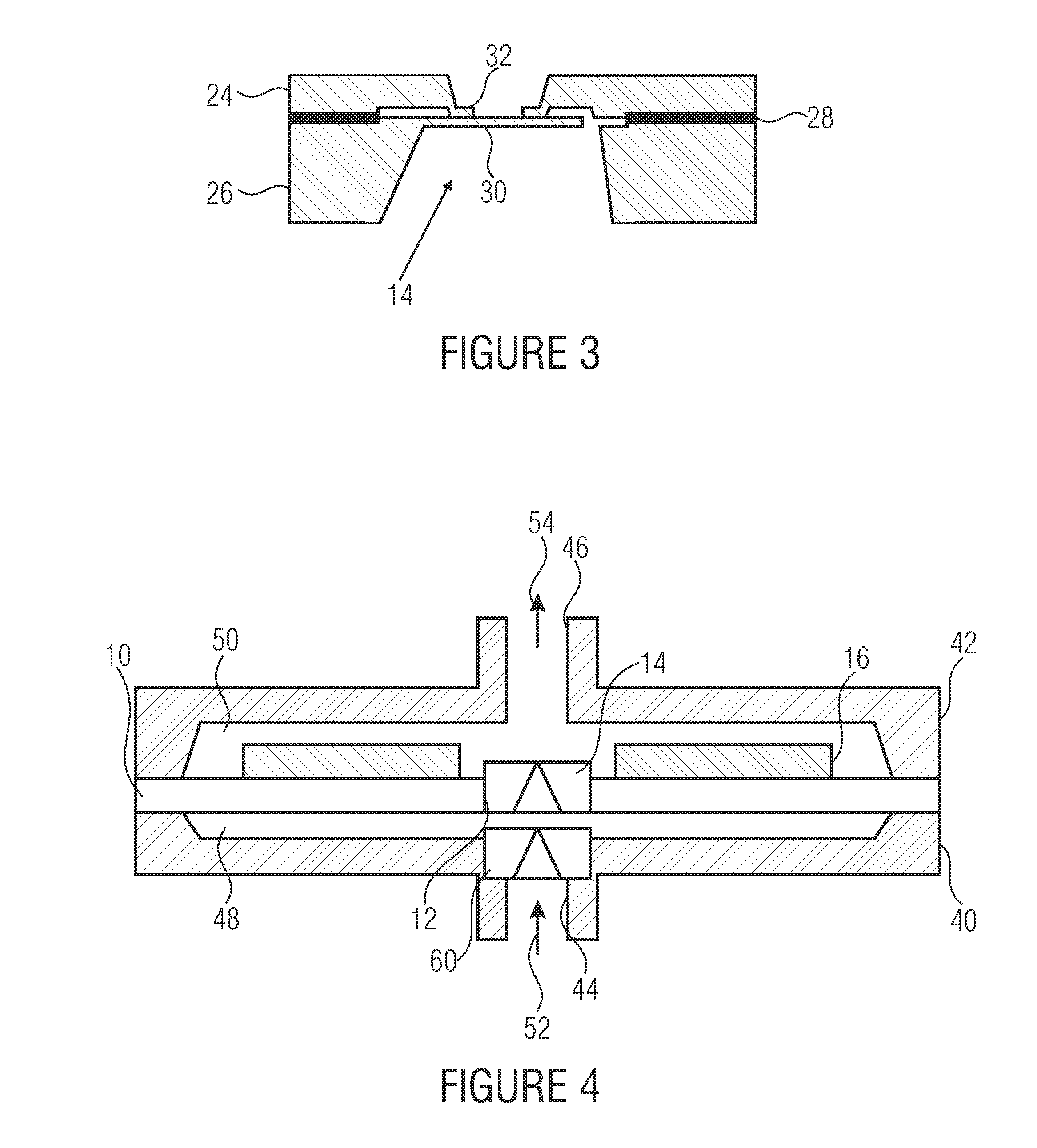

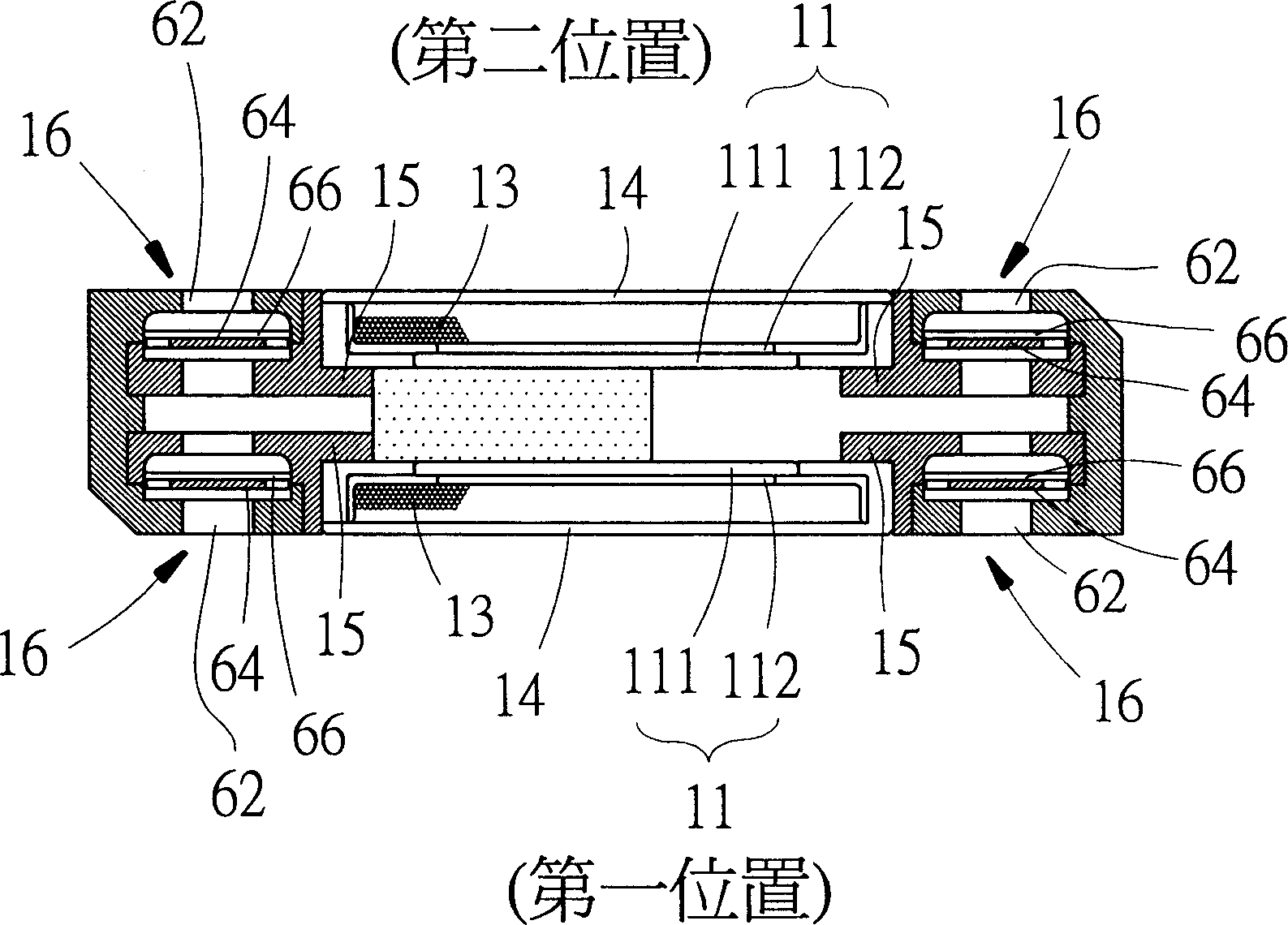

Pump, pump arrangement and pump module

ActiveUS20110280755A1Increase volumeLower the volumePositive displacement pump componentsFlexible member pumpsEngineeringActuator

A pump has an inlet opening, an outlet opening, a pump diaphragm comprising an opening, provided with a passive check valve, through the pump diaphragm, and an actuator configured to move the pump diaphragm between a first position and a second position. The passive check valve is configured such that a movement from the first position in the direction toward the second position has a closing effect, and that a movement from the second position in the direction toward the first position has an opening effect, so that a pumping cycle wherein the pump diaphragm is moved from the first to the second positions, and back, causes a net flow from the inlet opening to the outlet opening.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

Micropump for electronics cooling

InactiveUS7802970B2Improve fluid flowIncrease fluid velocityPositive displacement pump componentsFlexible member pumpsWorking fluidElectronics cooling

A micropump including one or more microchannels for receiving a fluid and a plurality of electrodes arranged on a diaphragm and energized in a manner to provide an enhanced electrohydrodynamic flow of fluid through the one or more microchannels. The micropump may be used for pumping a working fluid for removing heat from a heat-generating electronic component or for delivery of a drug, medicine, or other treatment agent as or in a fluid to a patient.

Owner:PURDUE RES FOUND INC

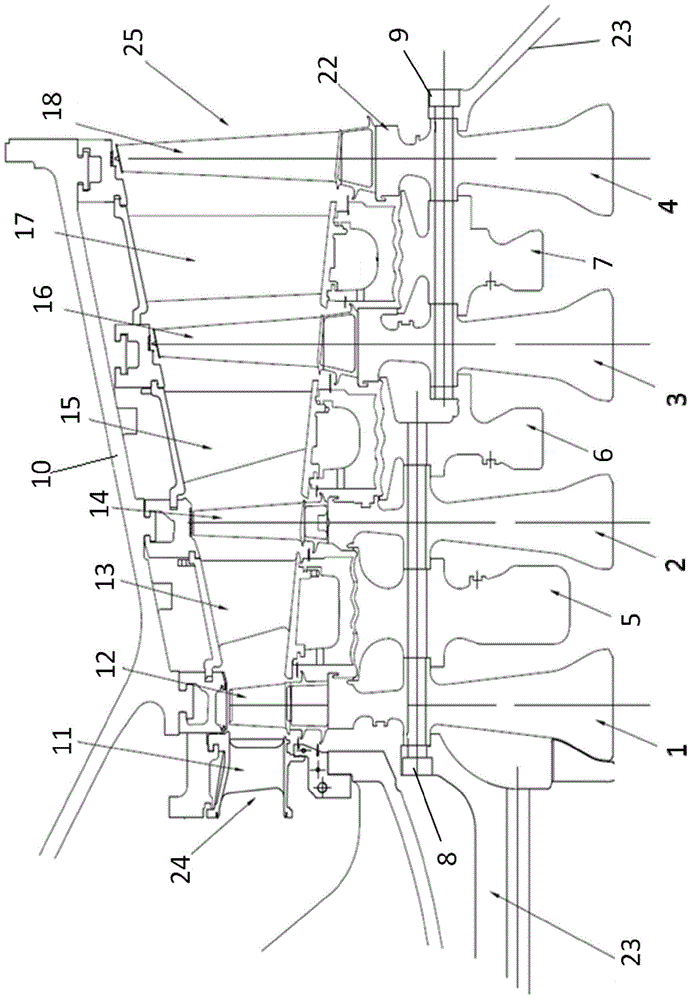

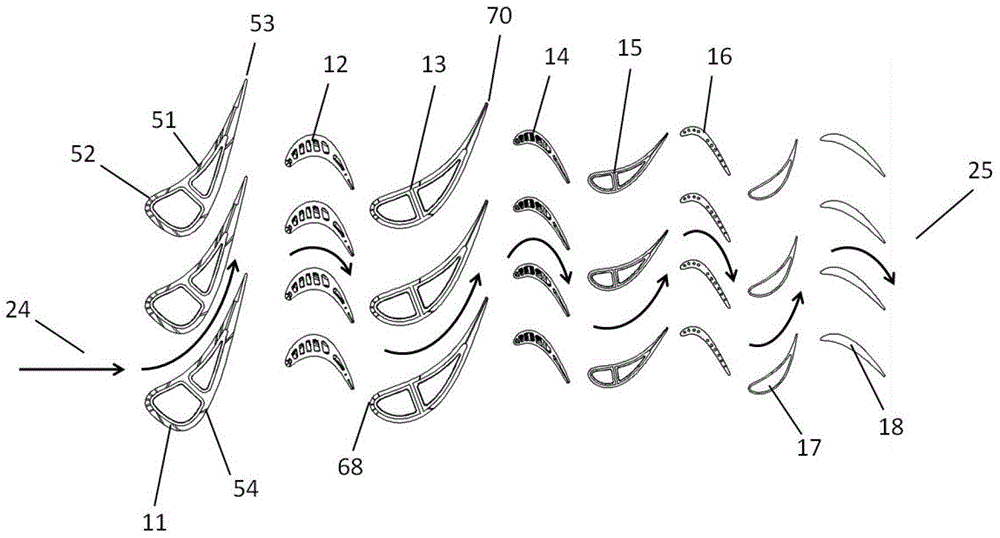

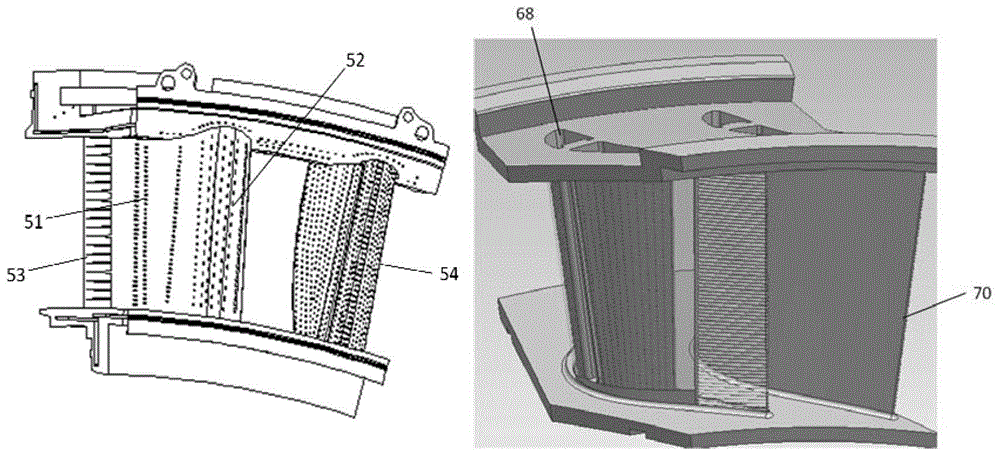

Turbine motor of gas turbine

ActiveCN104420887AReduce the pumping volumeLow efficiencyBlade accessoriesStatorsThree levelThermal energy

The invention discloses a turbine motor of gas turbine; the turbine motor comprises a casing, a turbine motor entrance, a turbine motor exit, a turbine rotor, four-level fixed blades, and four-level movable blades. The turbine rotor comprises four impeller disks and three intermediate disks; the four impeller disks and the three intermediate disks are alternately arranged along an axial direction, and are connected together via a group of pull rods. The fixed blades are mounted on the fixed casing, and an impingement cooling sleeve is arranged therein, film holes are arranged on the surface thereof, and a convection cooling channel is arranged on the trailing edge thereof. The movable blades are mounted on one side of the rotor and revolve together with the rotor, wherein three levels are hollow structures, a double-snakelike cooling channel and multiple groups of herringbone fins are arranged therein. The fixed blades and the movable blades are alternately arranged in the axial direction of the rotor, and form a gas combustion channel therein. When the gas turbine is running, the turbine motor is able to effectively change the thermal energy of the high-temperature gas into the mechanical energy for rotating the rotor, and ensure the safety of the mechanical movement by sufficient and reasonable cooling.

Owner:HARBIN TURBINE +1

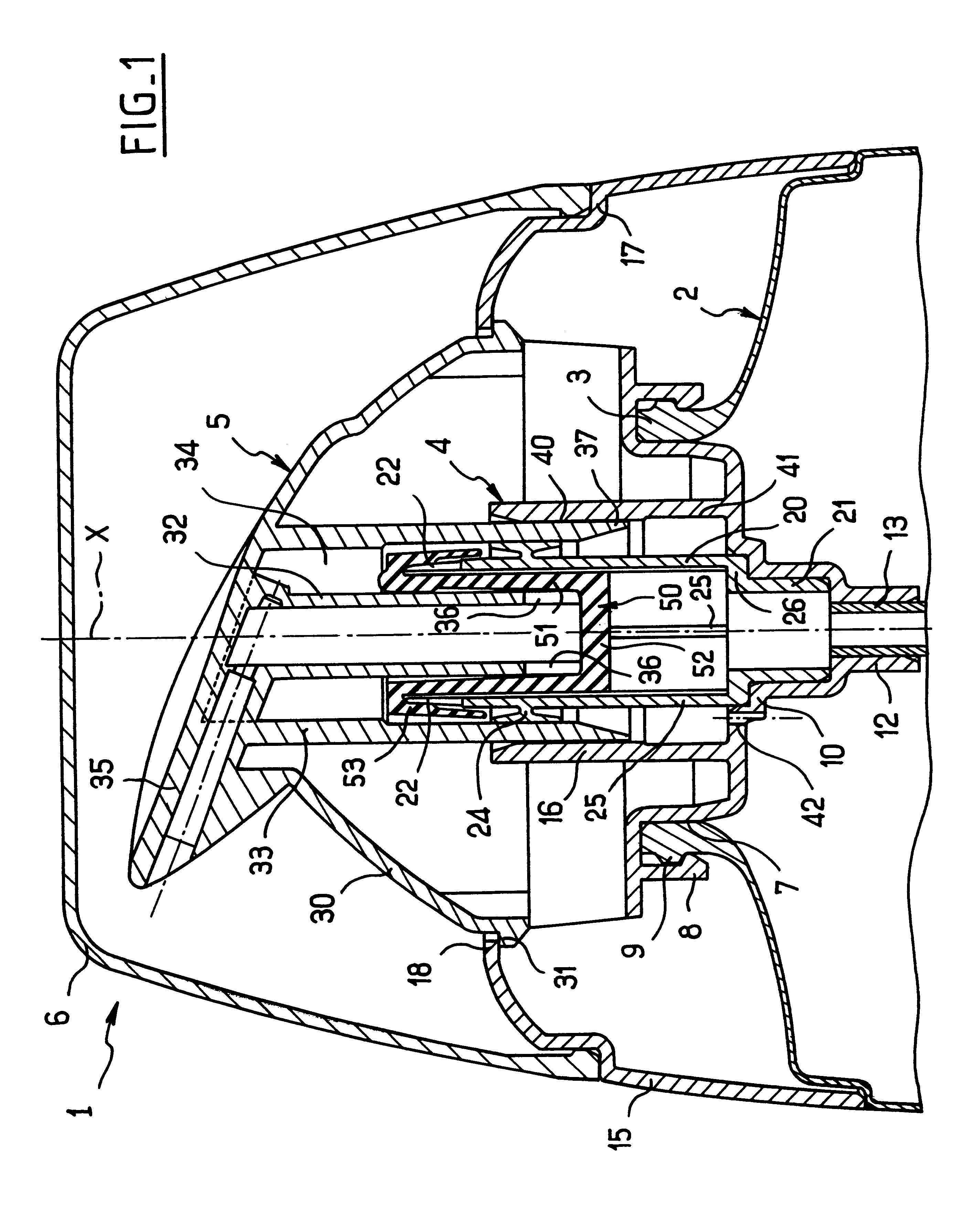

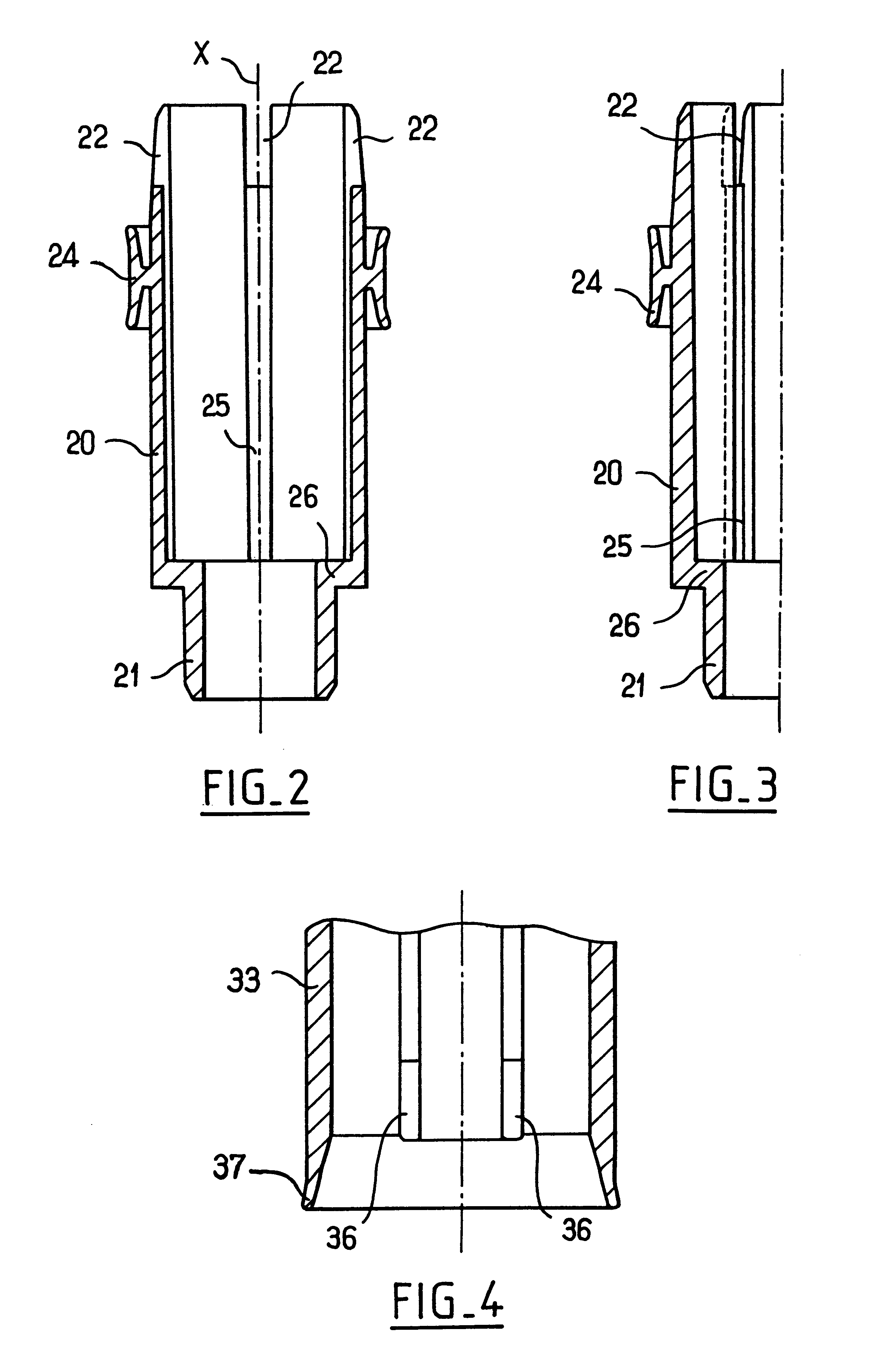

Pump and a receptacle fitted therewith

InactiveUS6202896B1Improve reliabilityImprove operational reliabilityClosuresLarge containersBiomedical engineeringPump chamber

The invention relates to a pump of the type including a moving member mounted to move relative to a support, the moving member having a central duct in which substance to be dispensed penetrates via at least one opening, the support co-operating with the moving member to define, around said central duct, a pump chamber of variable volume, said pump also having a membrane with a central portion in the form of a sleeve that is open at its top end and closed at its bottom end, said central duct being inserted in said central portion, the membrane being organized to isolate the pump chamber from the opening(s) of said central duct while the volume of the pump chamber is increasing and substance is being sucked into it. At least one of the membrane and the central duct is shaped to prevent a leakproof annular zone forming between the membrane and the central duct which would prevent the substance contained in the pump chamber from flowing via said central duct while the volume of the pump chamber is decreasing.

Owner:LOREAL SA

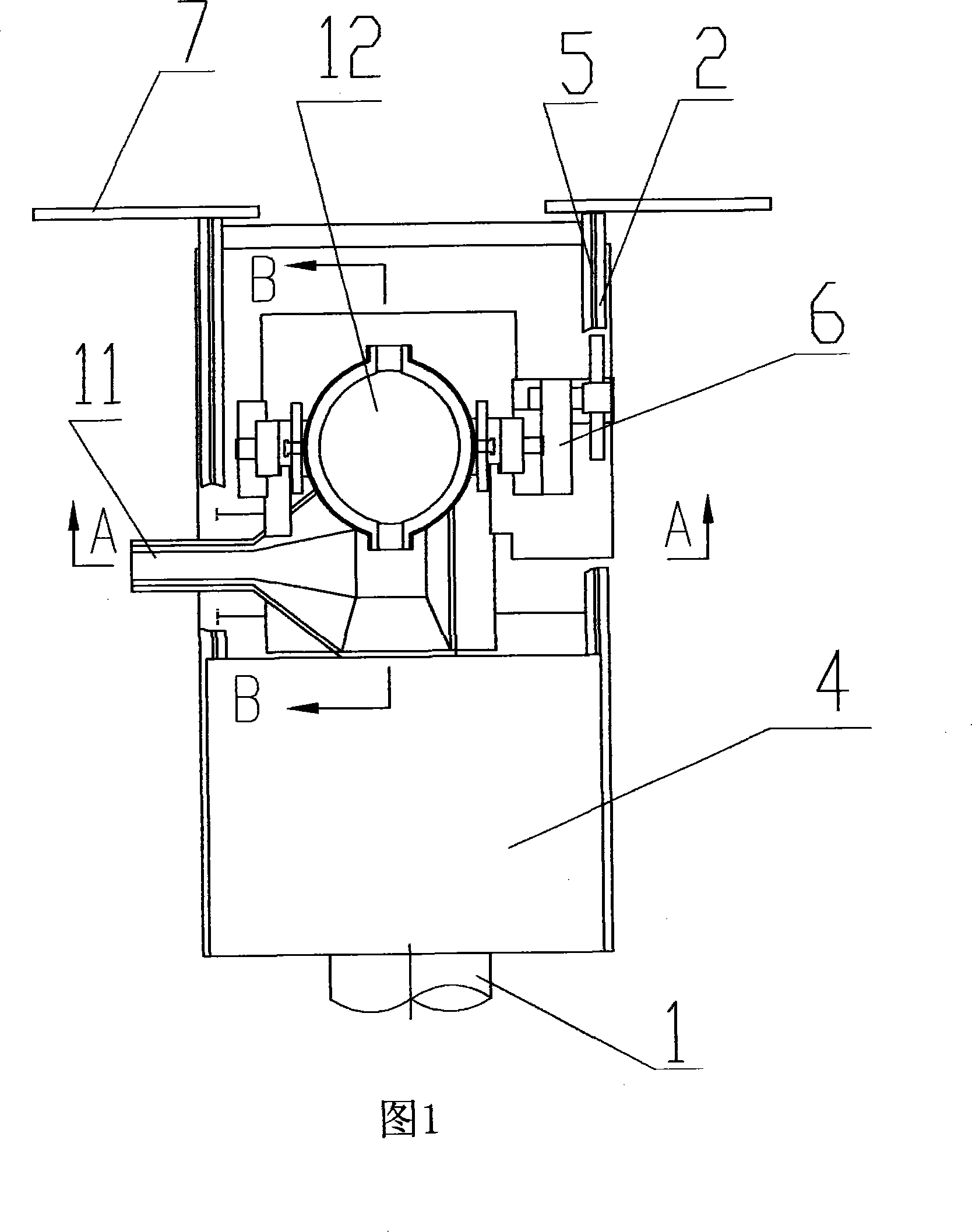

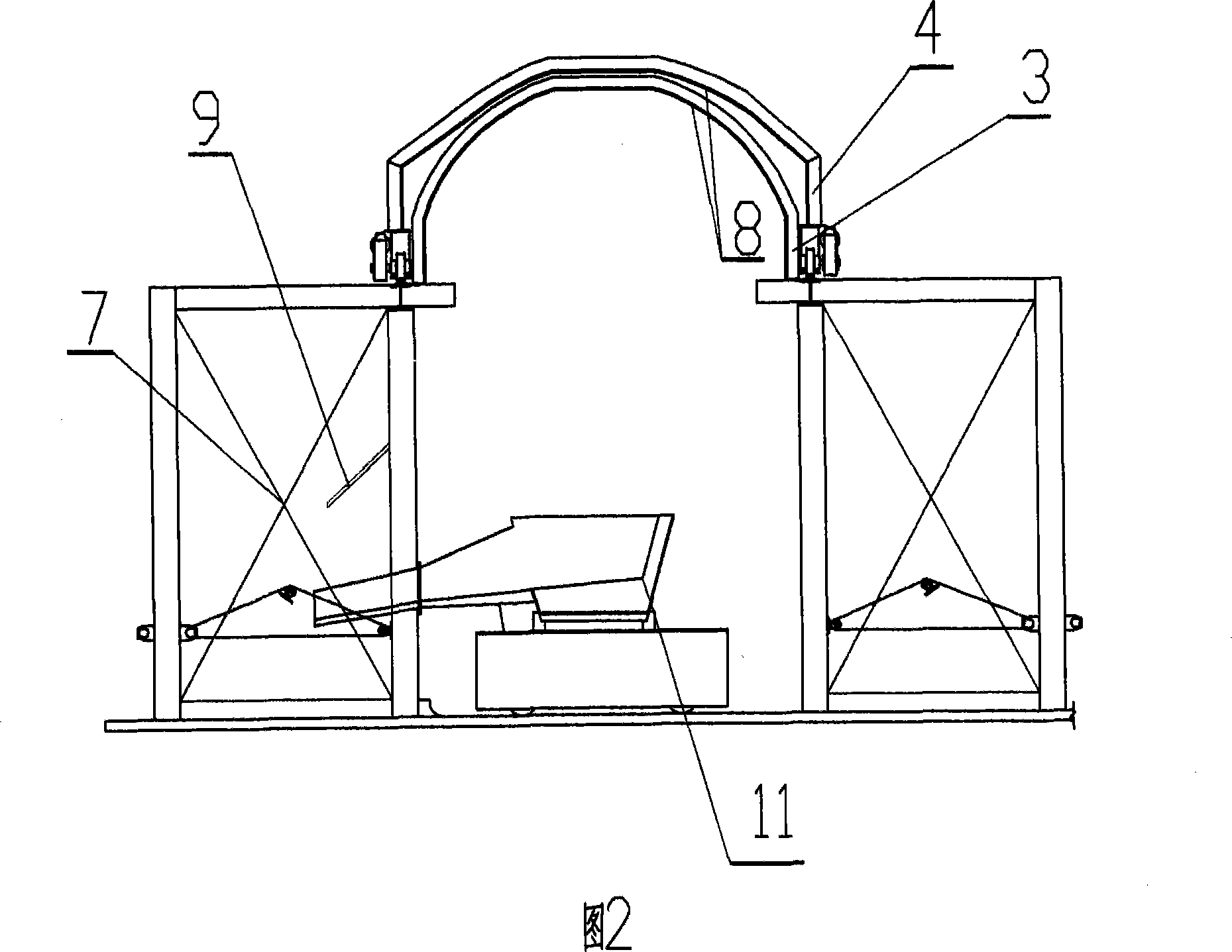

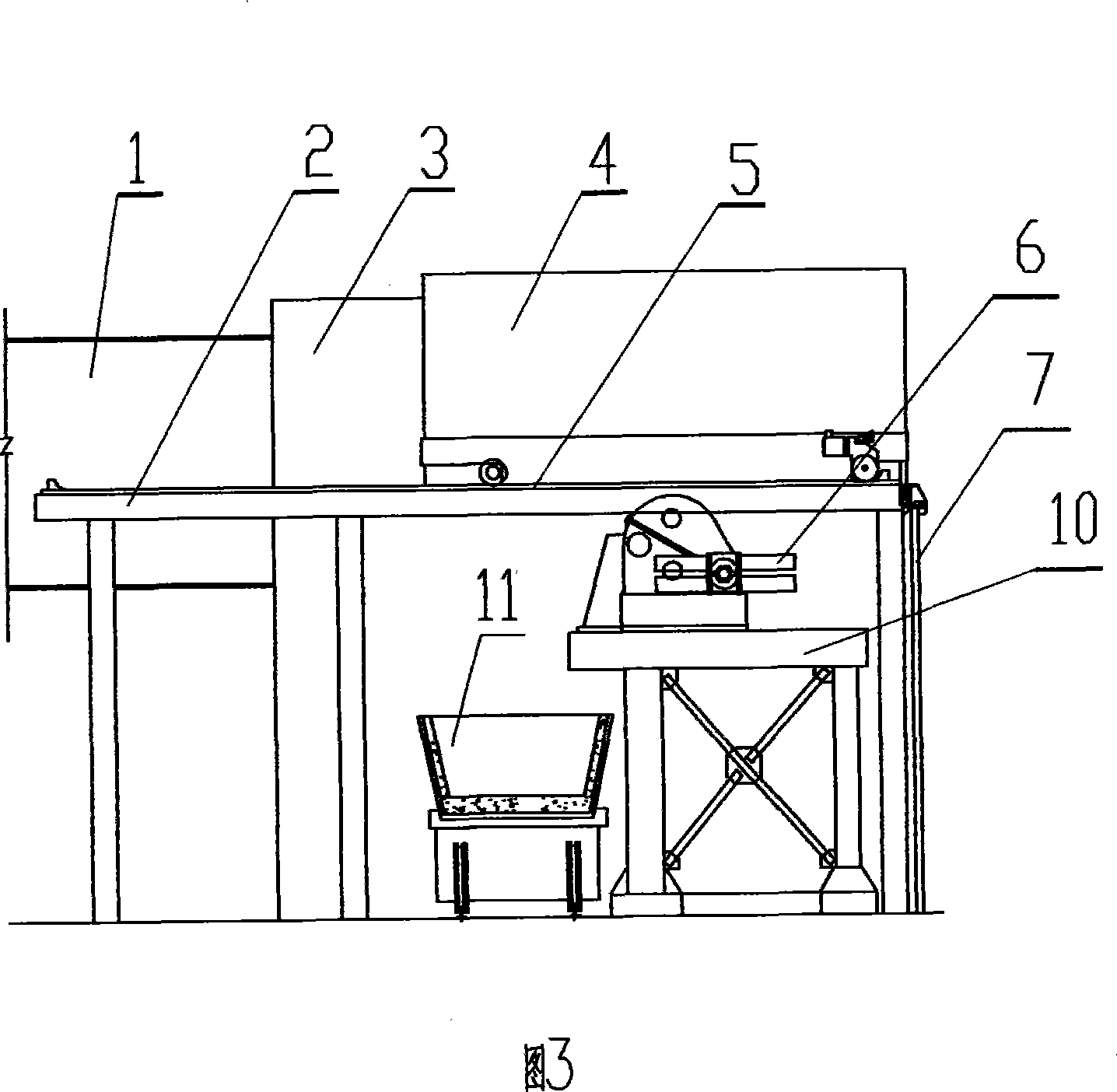

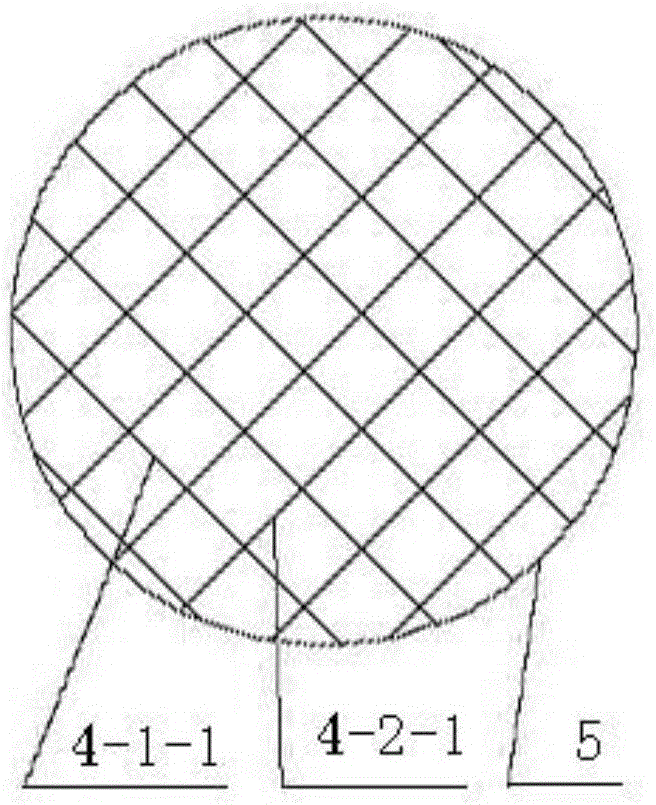

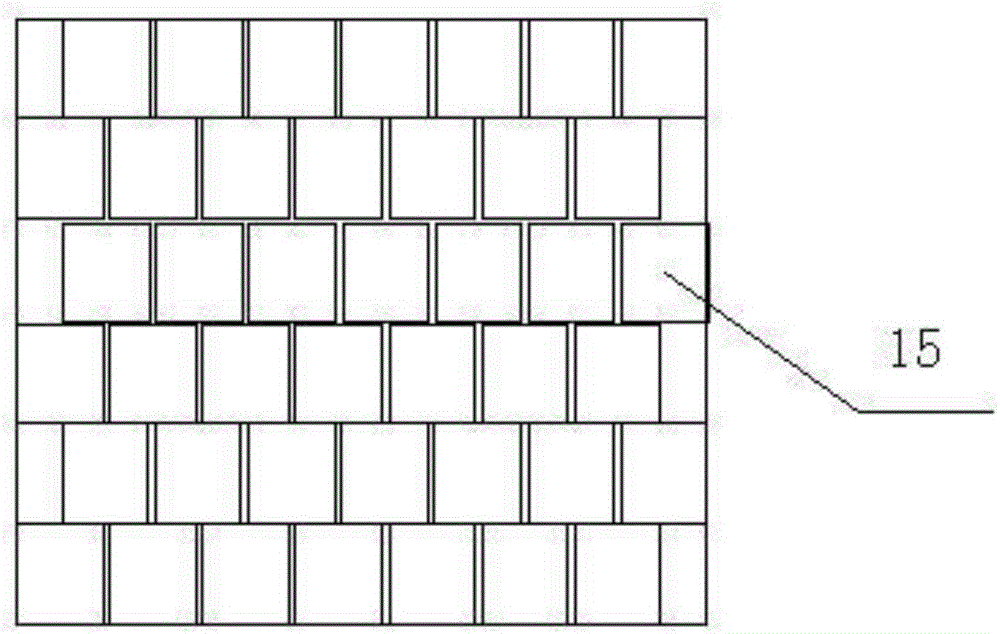

Mobile smoke blast trapping device for furnace mixer

The invention discloses a movable dust arrestment device used for a metal iron mixer, comprising a dedust pipe (1), a support (2), a fixed smoke cover (3) and a movable smoke cover (4). The movable dust arrestment device is characterized in that: the fixed smoke cover (3) and a guide way (5) are arranged on the support (2), and the movable smoke cover (4) can move along the guide way (5), and can be combined with the fixed smoke cover (3) to form a sealed dedust cover; a pig-iron ladle dumping device (6) is arranged on the support (2), and the dedust pipe (1) is arranged on one side of the fixed smoke cover (3). The movable dust arrestment device used for the metal iron mixer has the advantages of convenient usage, ensuring high dust arrestment rate and good dedust effect in the iron receiving process of metal mixer, being energy-saving, reducing running cost, improving the working environment of operating staffs and reducing the operating rate of cranes in workshop.

Owner:HUATIAN ENG & TECH CORP MCC

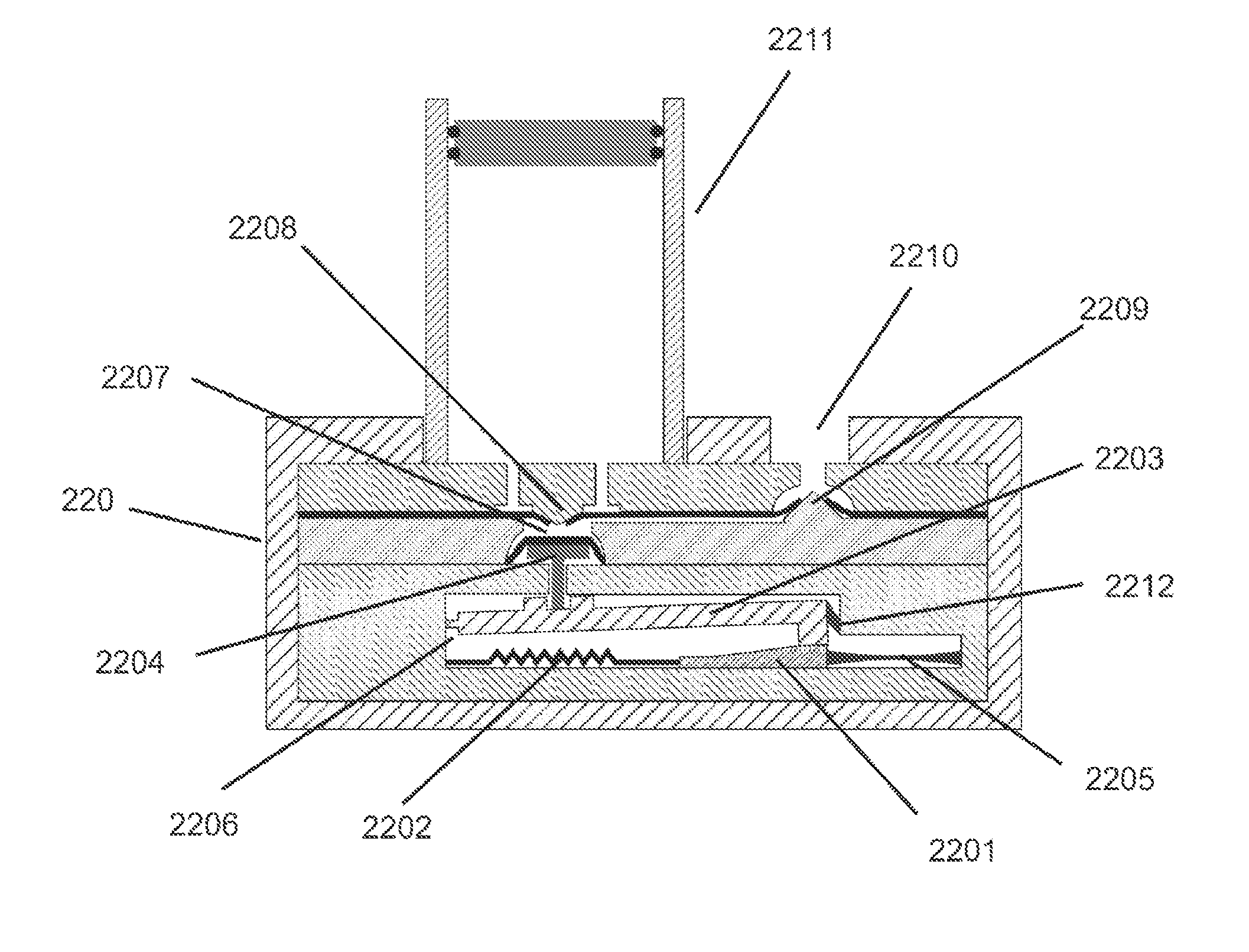

Mechanical driver

ActiveUS20150051547A1Reduce the pumping volumeAccuracyAutomatic syringesFlexible member pumpsShape-memory alloyBiological activation

A mechanical driver comprising a wedge shaped member operatively coupled to a shape memory alloy such that the shape memory alloy is able to displace the wedge shaped member in an essentially linear direction. The wedge shaped member is in constant contact with a lever arranged so that it can rotate about a fixed pivot point. A piston is arranged such that it is constant contact with the lever at a point between the pivot point of the lever and the contact point between the lever and the wedge shaped member. Return springs are provided to return the piston, lever and wedge shaped member to their respective start positions. Activation of the shape memory alloy displaces the wedge shaped member along its linear direction and this causes the lever to be deflected about its pivot point and the piston to be deflected in an essentially linear direction that is perpendicular to the linear direction of travel of the wedge shaped member.

Owner:VICENTRA

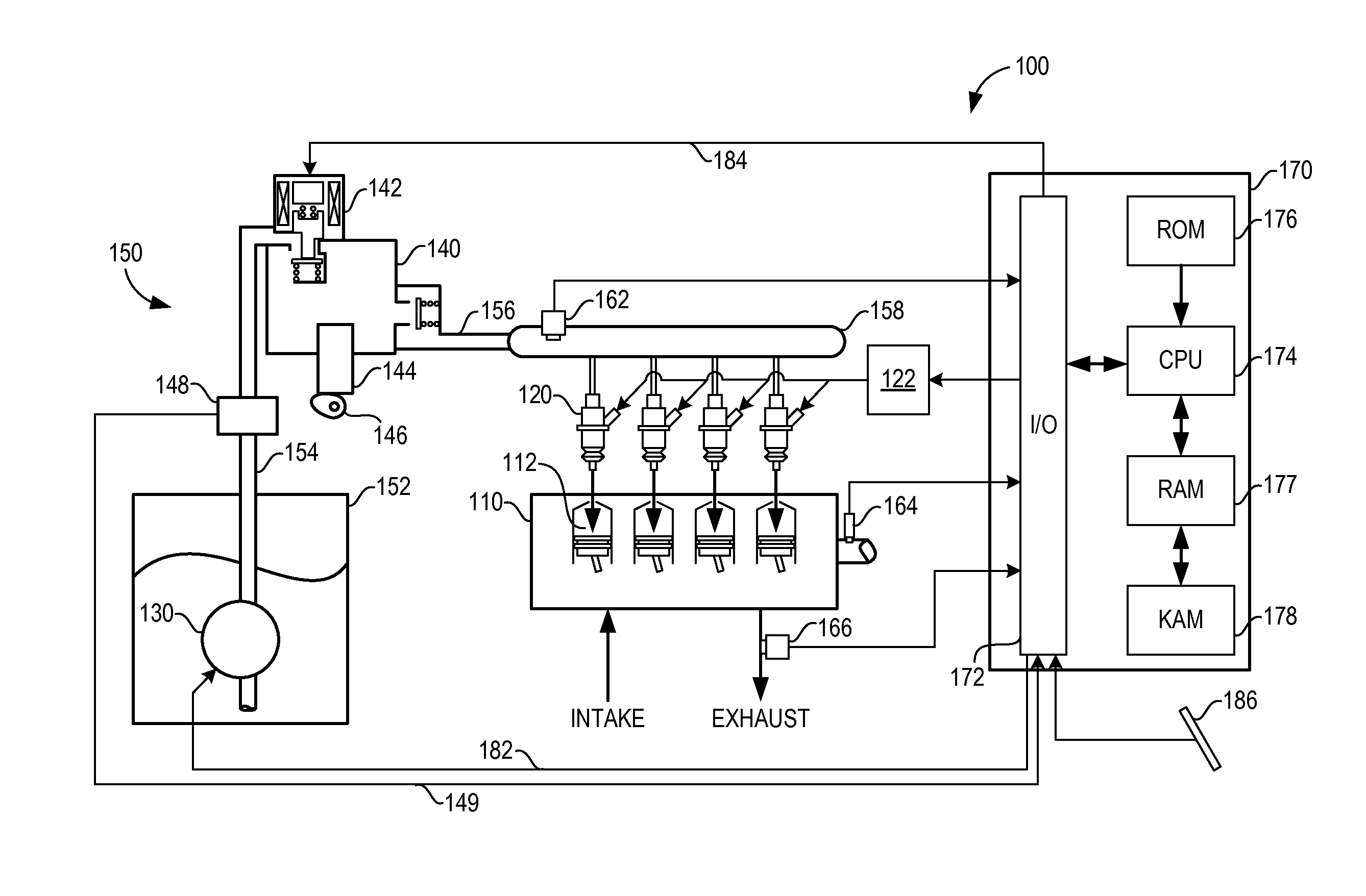

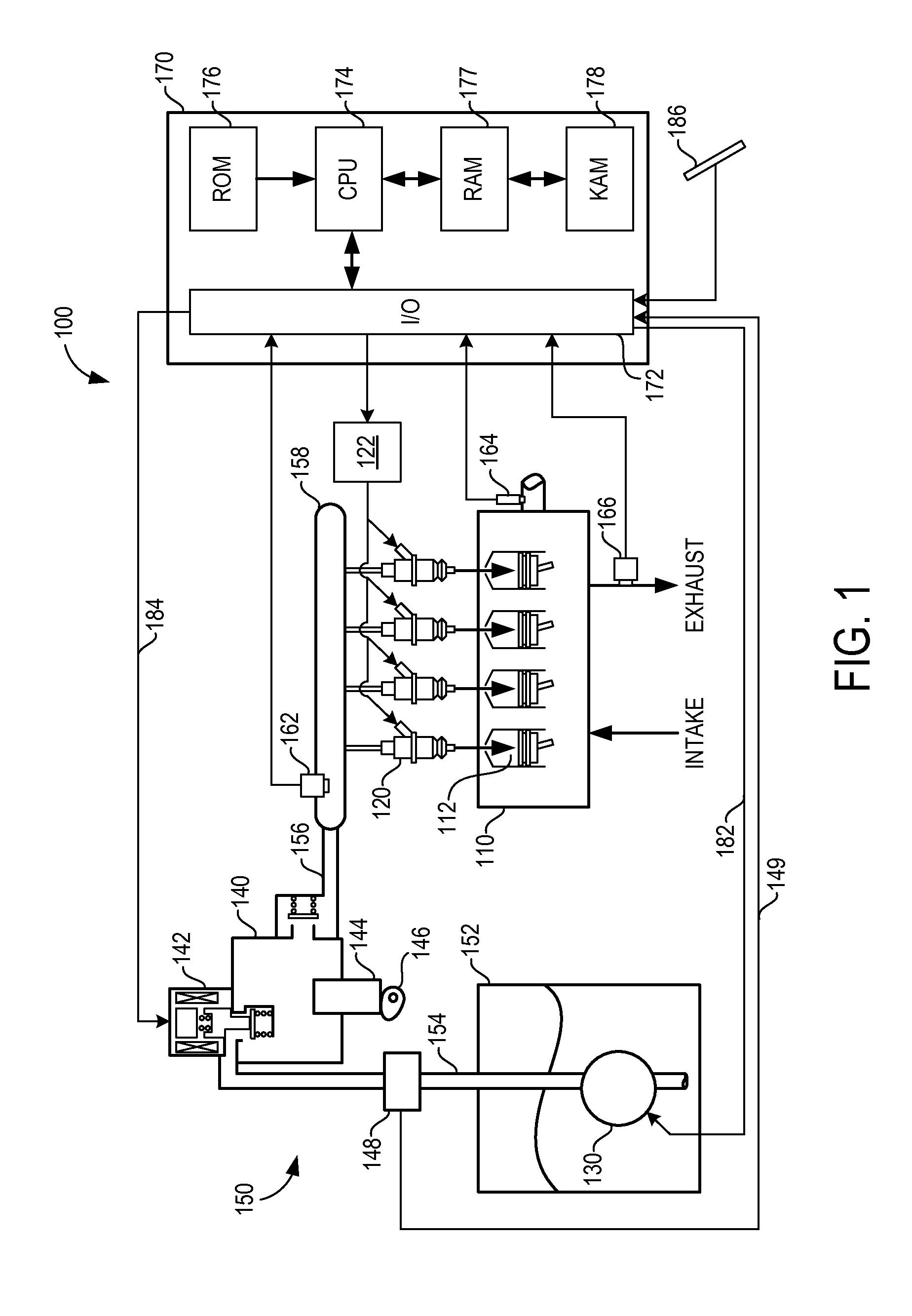

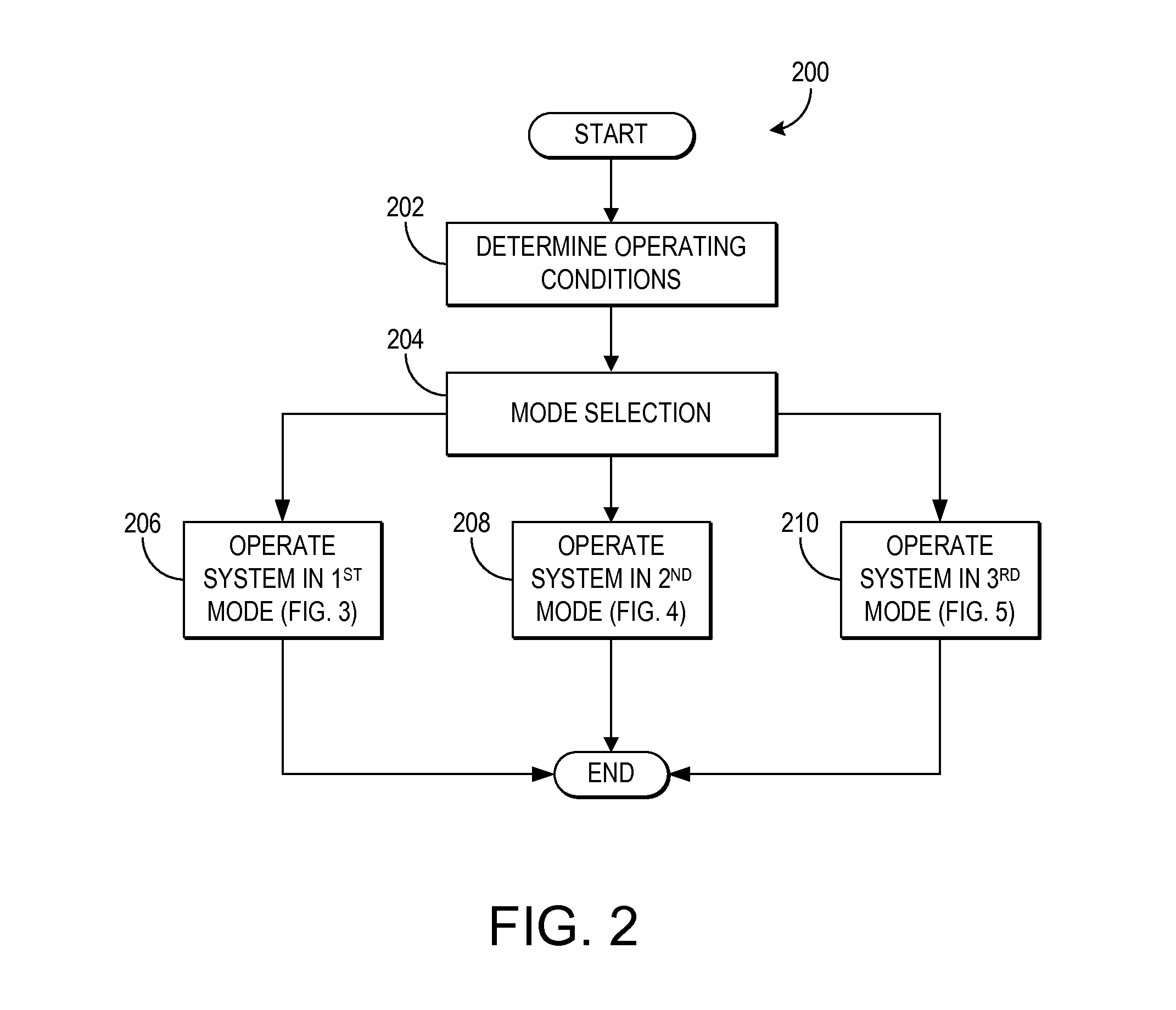

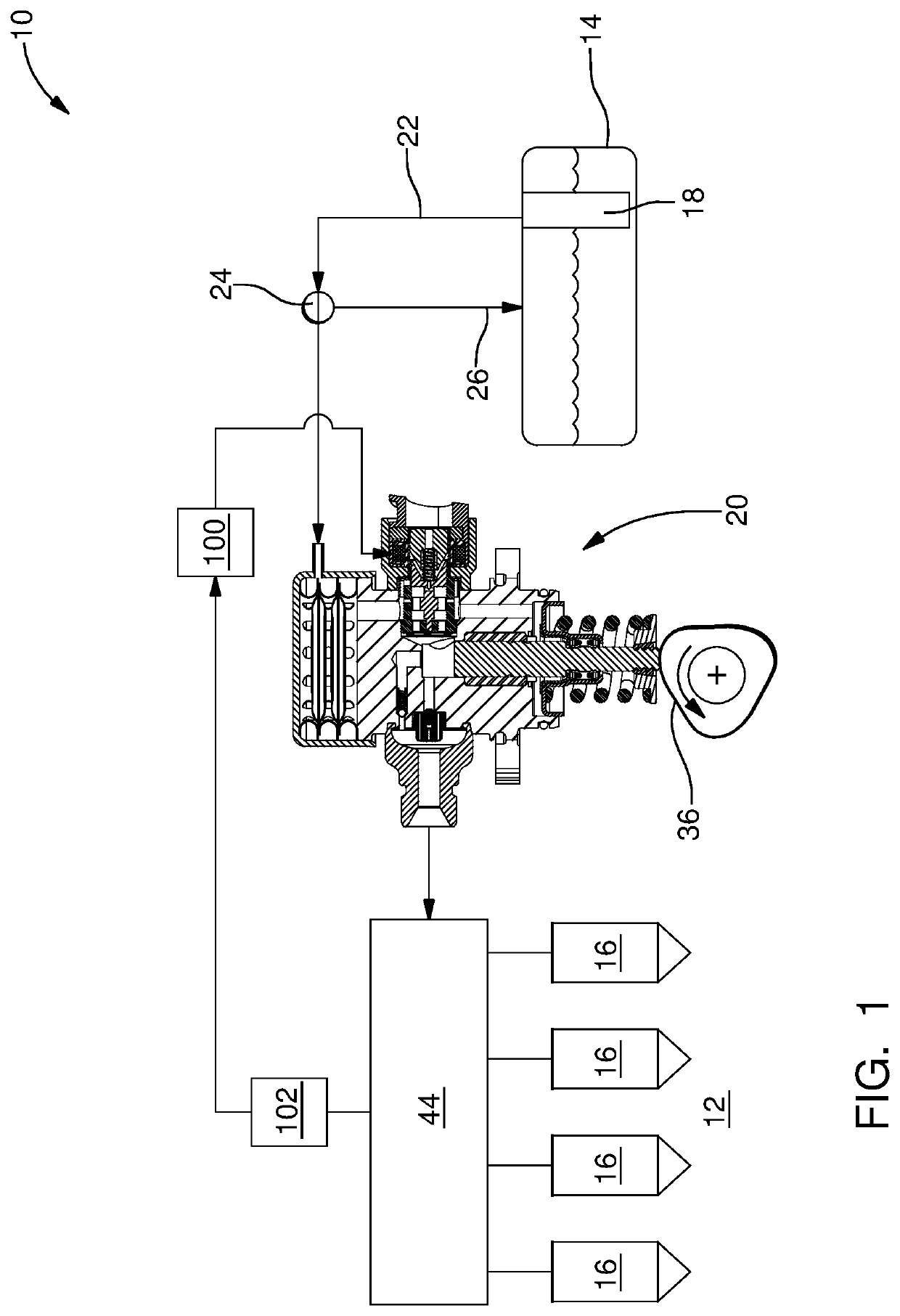

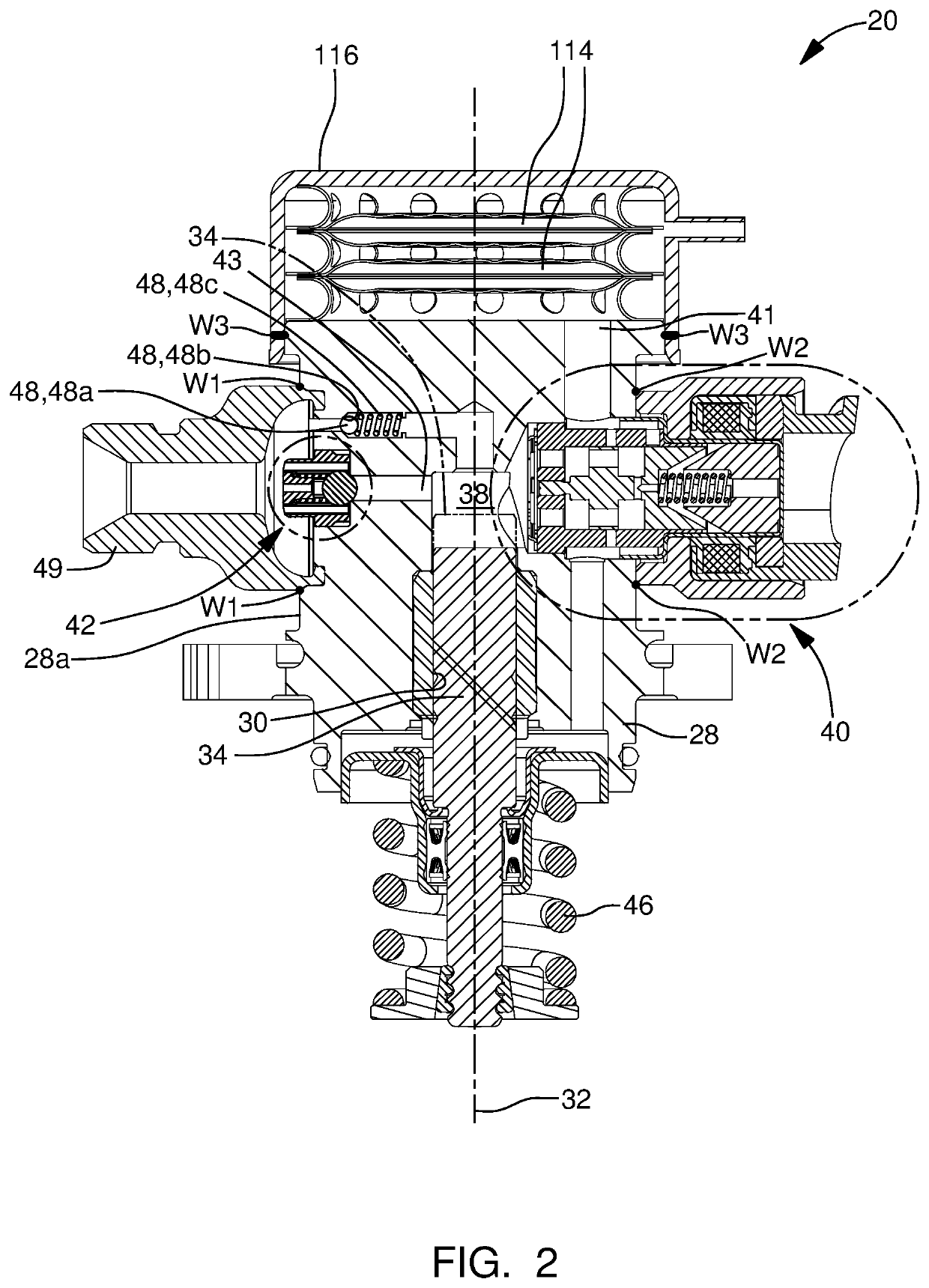

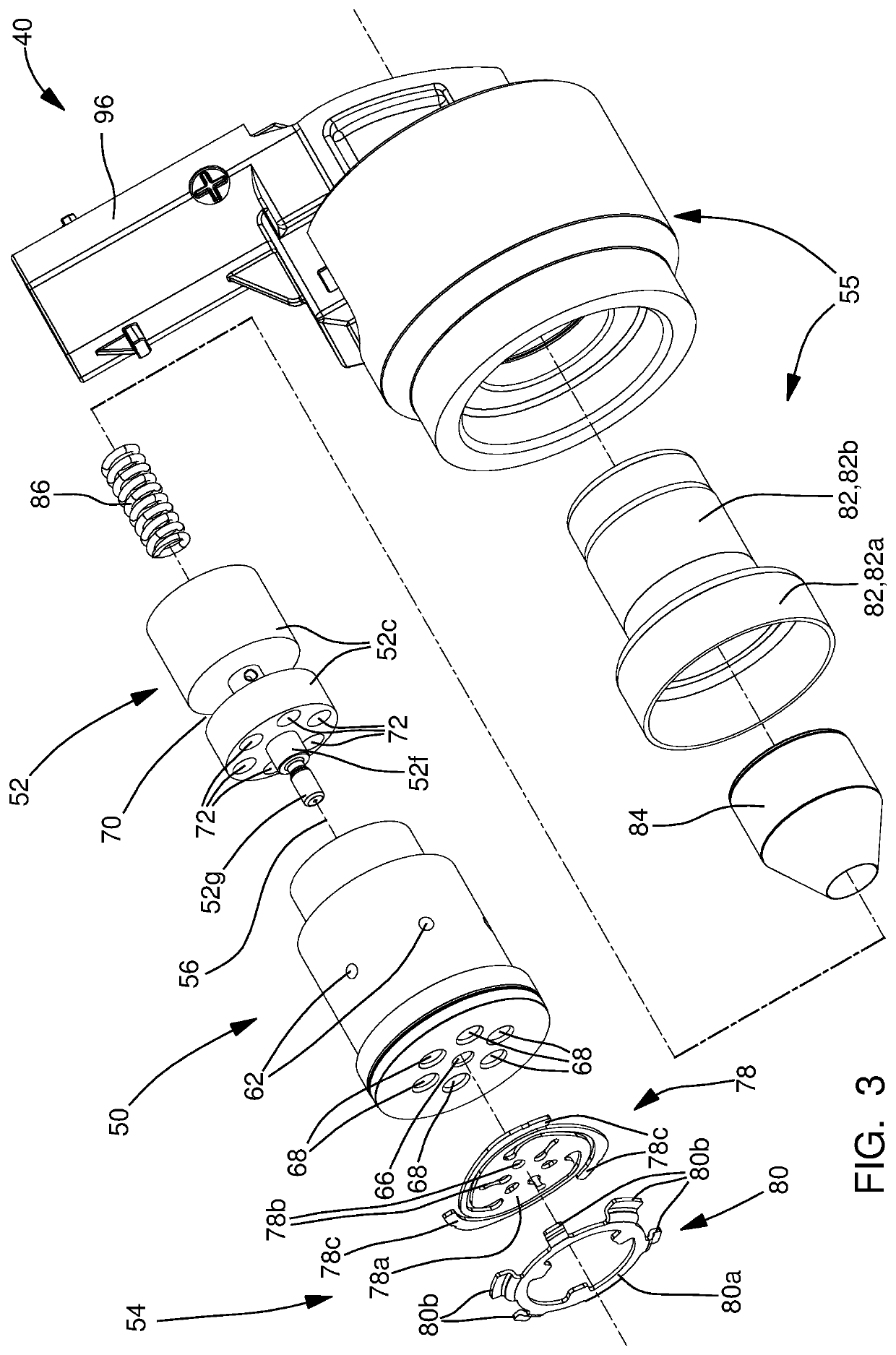

Methods and systems for a fuel system

InactiveUS20140230794A1Avoid vaporizationImprove system efficiencyElectrical controlMachines/enginesCapacitanceOperation mode

Various methods and system are described for a fuel system which includes a fuel composition sensor and a fuel lift pump disposed upstream of the sensor. The system may be operated in each of three different modes of operation. In each of the modes, a fuel lift pump voltage is adjusted responsive to a fuel capacitance output by the sensor, while a variable such as sensor temperature or fuel pump pressure is maintained depending on the mode of operation.

Owner:FORD GLOBAL TECH LLC

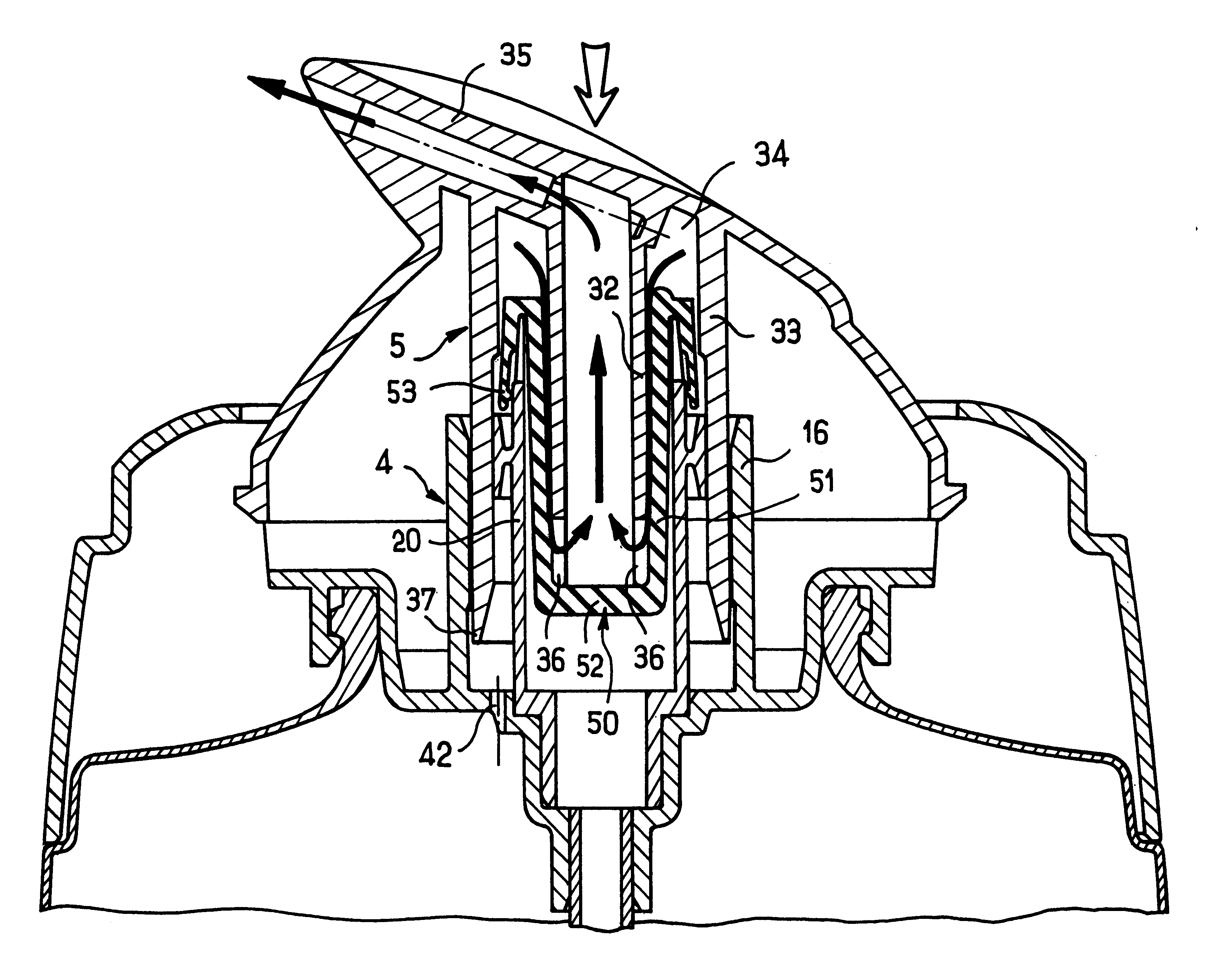

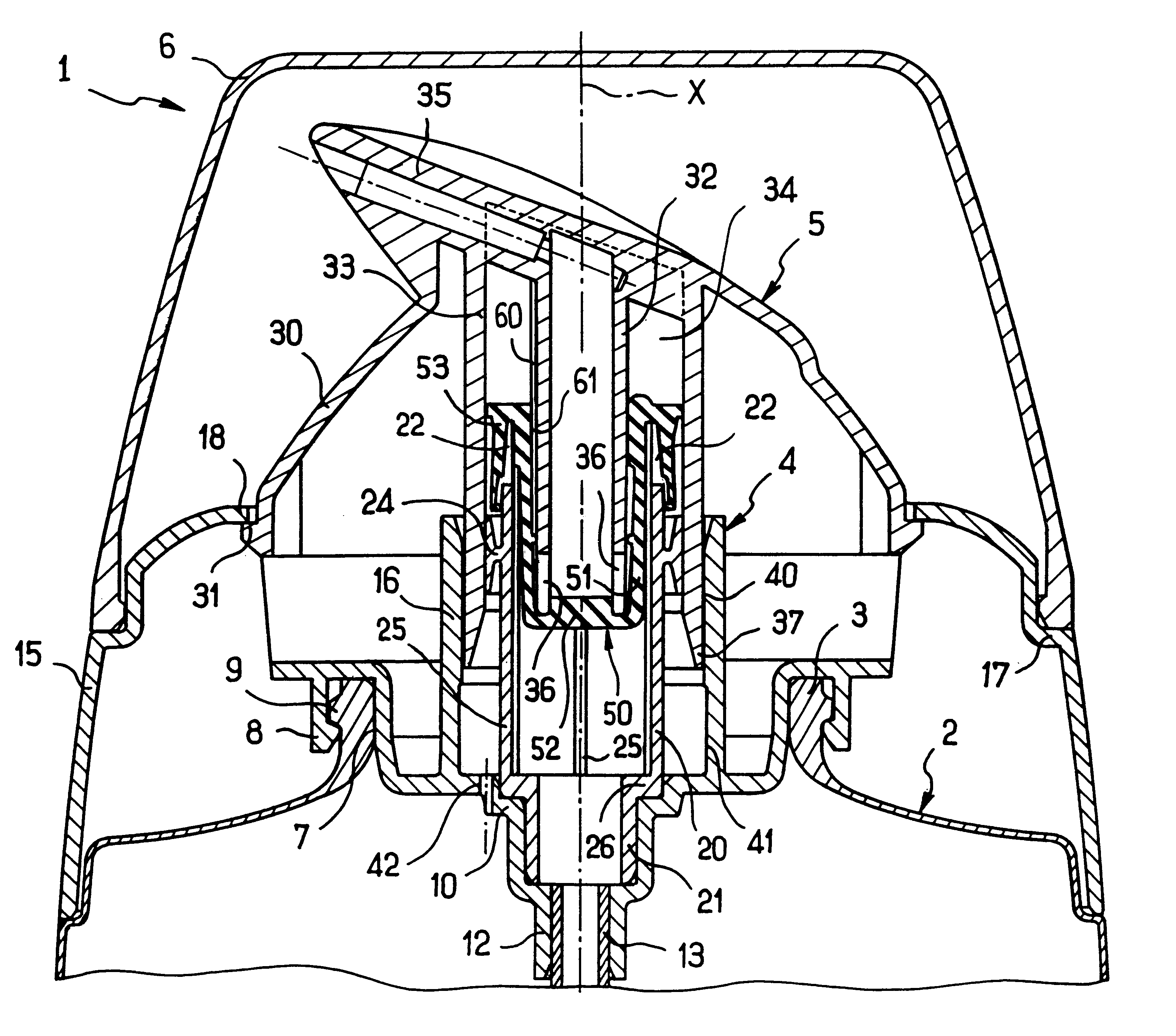

Diaphragm pump and a receptacle fitted therewith

InactiveUS6305581B1Improve reliabilityReduce the pumping volumeEngine diaphragmsClosuresDiaphragm pumpPump chamber

A pump of type comprising a moving member mounted to move relative to a support, the moving member having a central duct into which the substance to be dispensed penetrates via at least one opening, the support co-operating with the moving member to define a variable volume pump chamber around said central duct, the pump also having a diaphragm having a central portion in which said central duct is inserted, the diaphragm being organized in such a manner as to isolate the pump chamber from the opening(s) of the central duct when the volume of the pump chamber increases and the substance is sucked into it. At least one of the central duct and the central portion of the diaphragm includes an annular bulge that is suitable, when the volume of the pump chamber increases, for bearing in leakproof manner on the other of the central portion and the central duct of the diaphragm, so as to isolate the pump chamber from the opening(s) of the central duct.

Owner:LOREAL SA

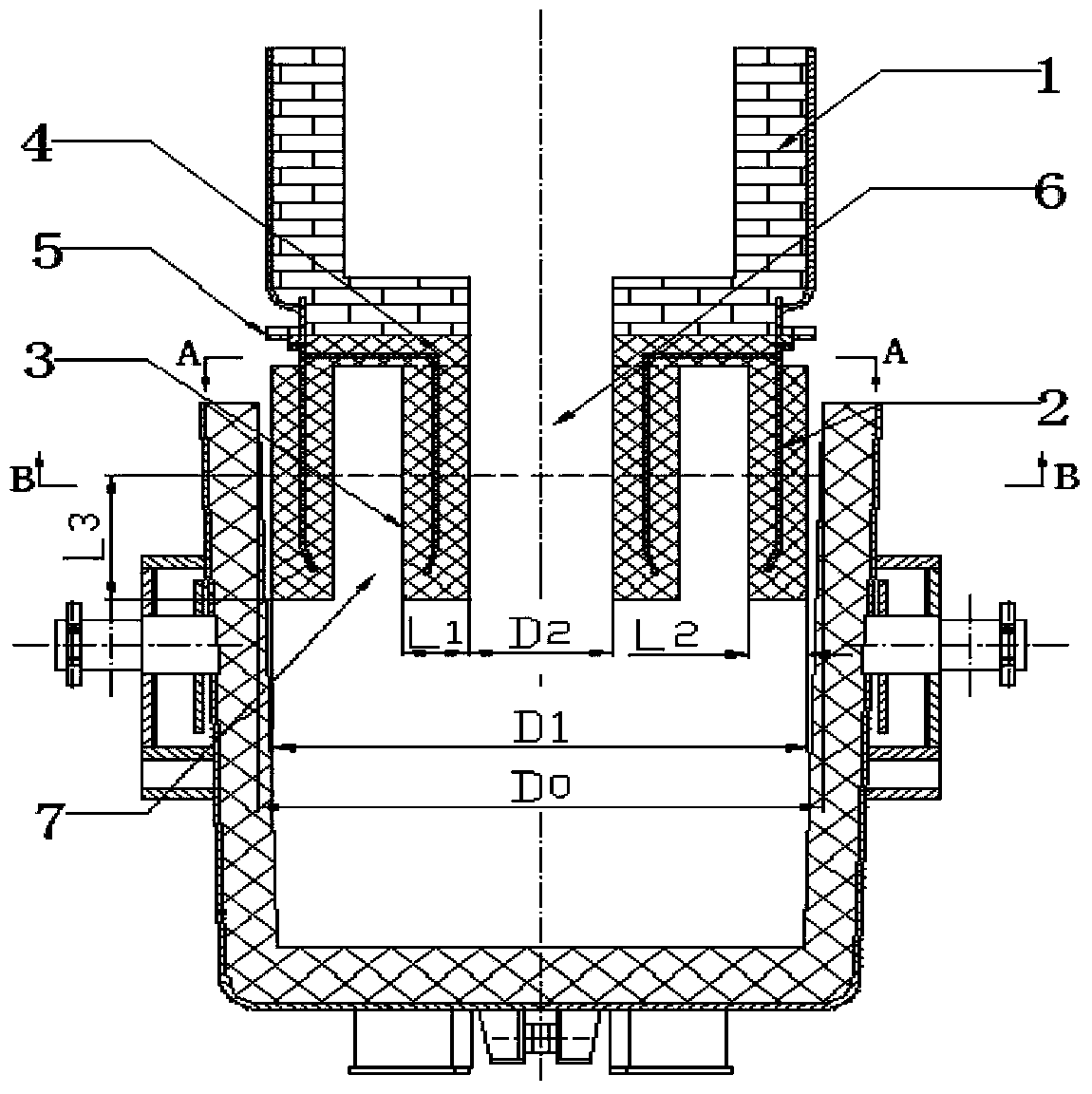

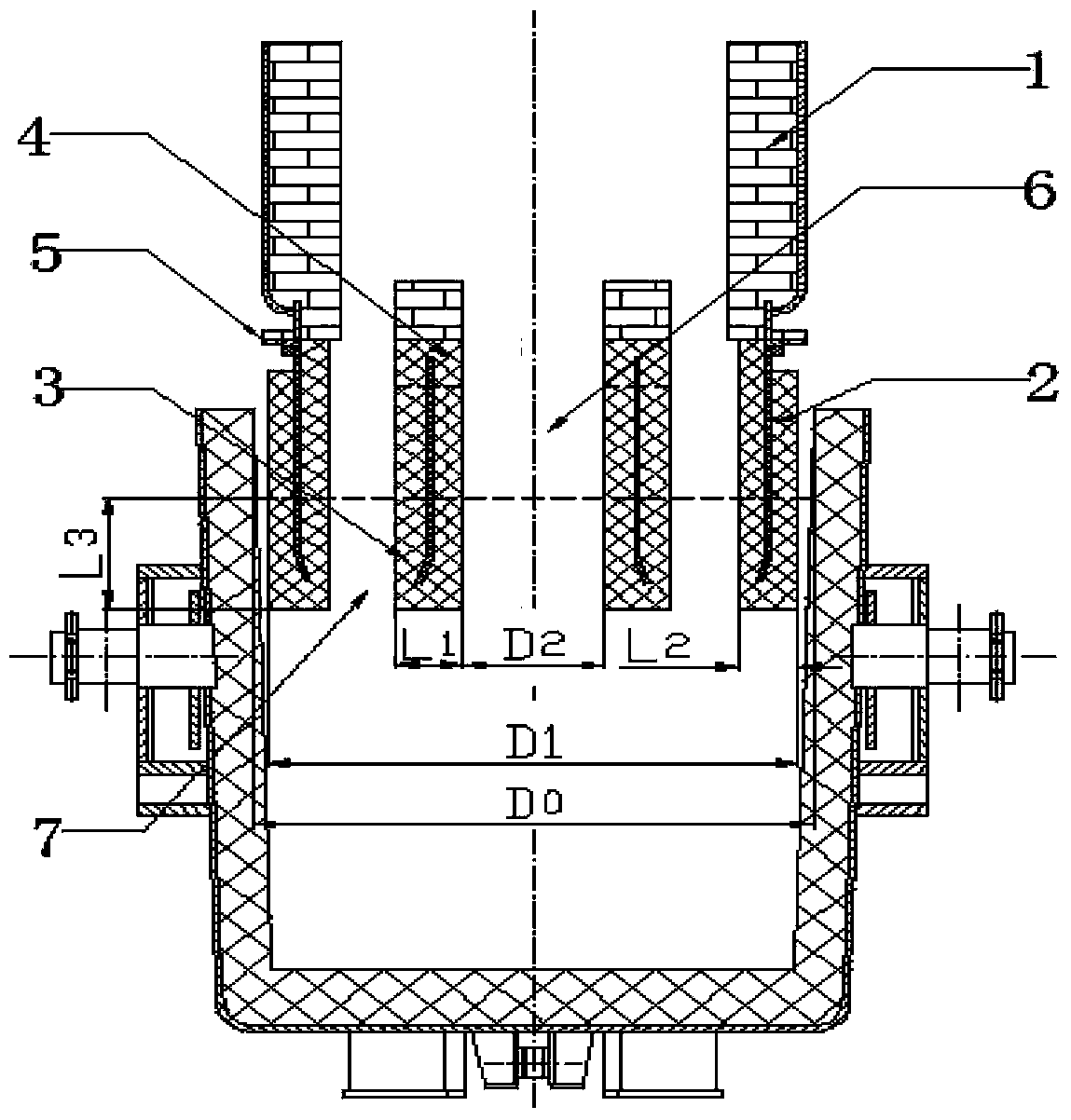

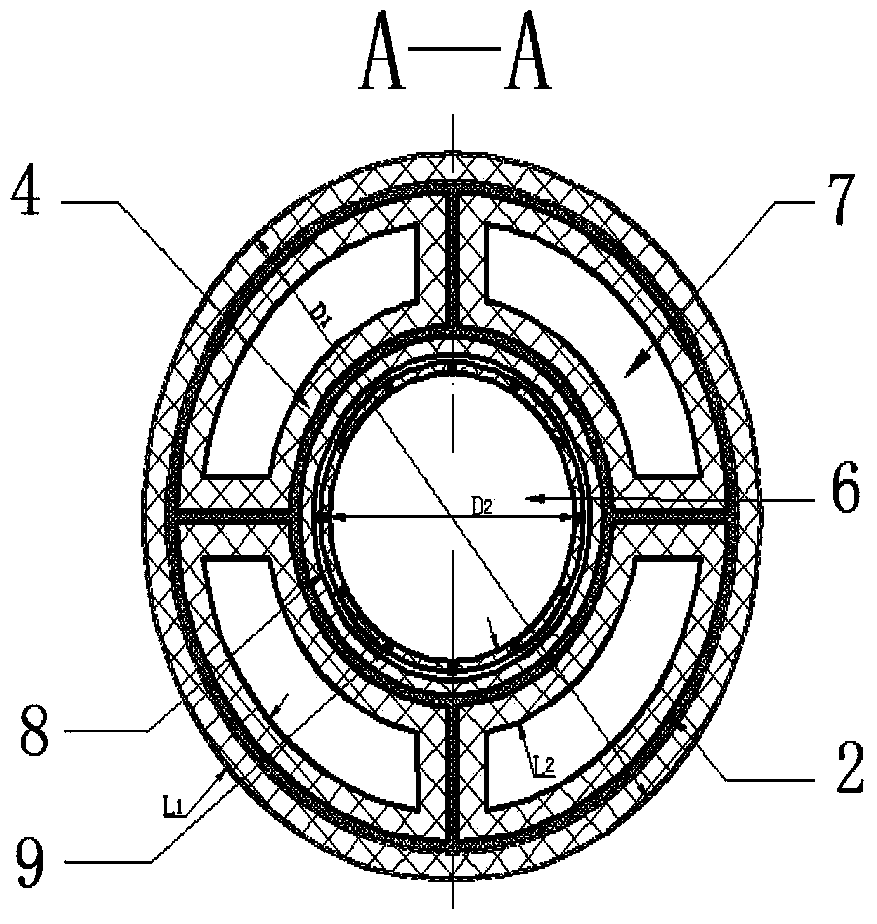

Sleeve type dip pipe for RH (Ruhrstahl Hereaeus) vacuum refining device

ActiveCN103866090AIncrease the circulation areaIncrease circulation flowArchitectural engineeringMolten steel

The invention discloses a sleeve type dip pipe for an RH (Ruhrstahl Hereaeus) vacuum refining device. The dip pipe mainly comprises an annular sleeve pipe, a circular-pipe-shaped partition wall, a cross beam and a flange plate, wherein the circular-pipe-shaped partition wall is coaxially arranged in the middle of the annular sleeve pipe; an inner circular pipe is formed on the inner side of the circular-pipe-shaped partition wall; an outer annular pipe is formed between the outer wall of the circular-pipe-shaped partition wall and the inner wall of the annular sleeve pipe on the outer side of the circular-pipe-shaped partition wall; the inner annular pipe and the outer annular pipe can be used as an ascending pipe and a descending pipe of the RH dip pipe respectively. As the space in the bottom of a vacuum chamber is fully utilized by the dip pipe with the structure to enlarge the circulation area of molten steel of the dip pipe, the circulation flow of an RH vacuum circulation degassing device can be remarkably increased.

Owner:NORTHEASTERN UNIV

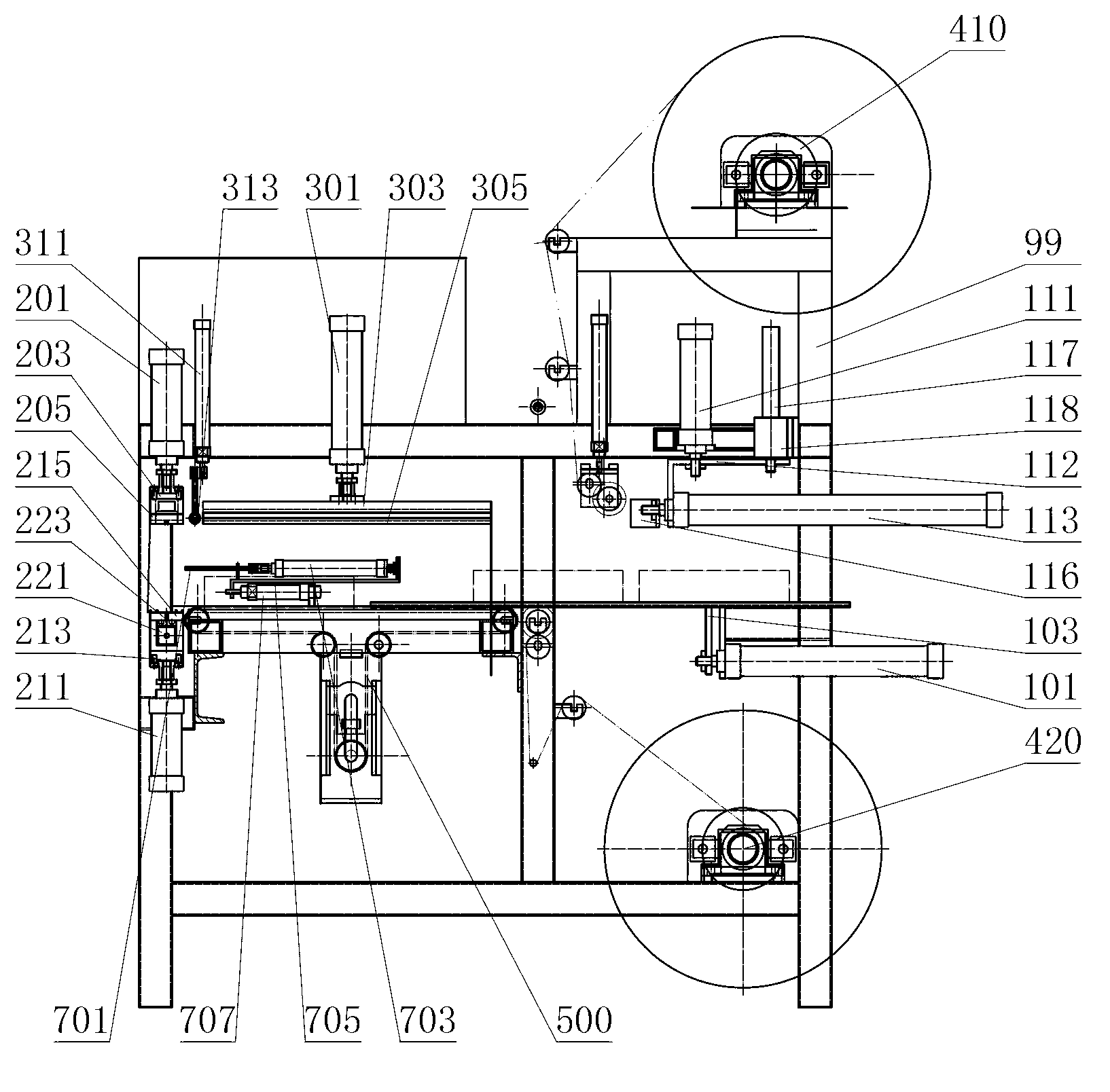

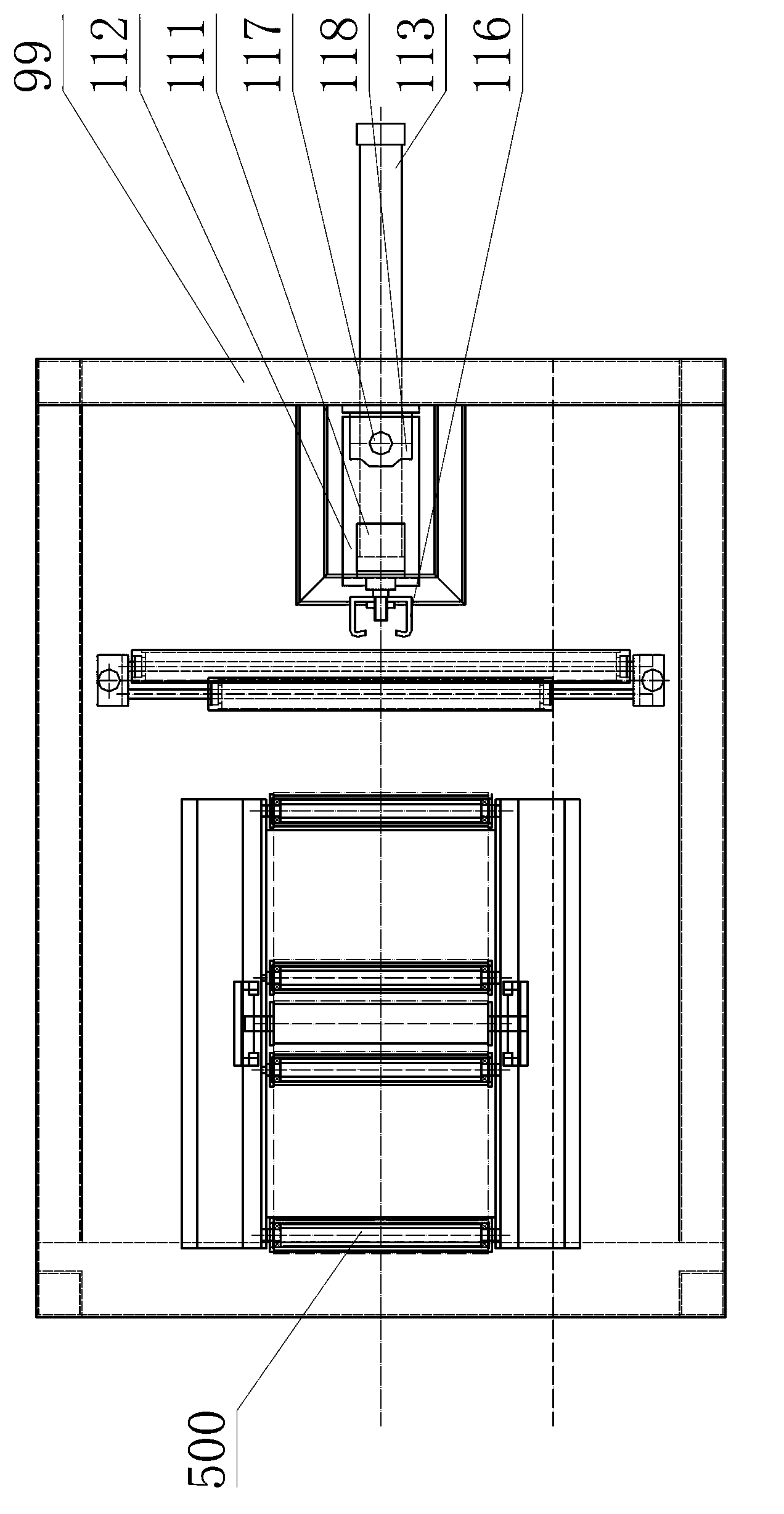

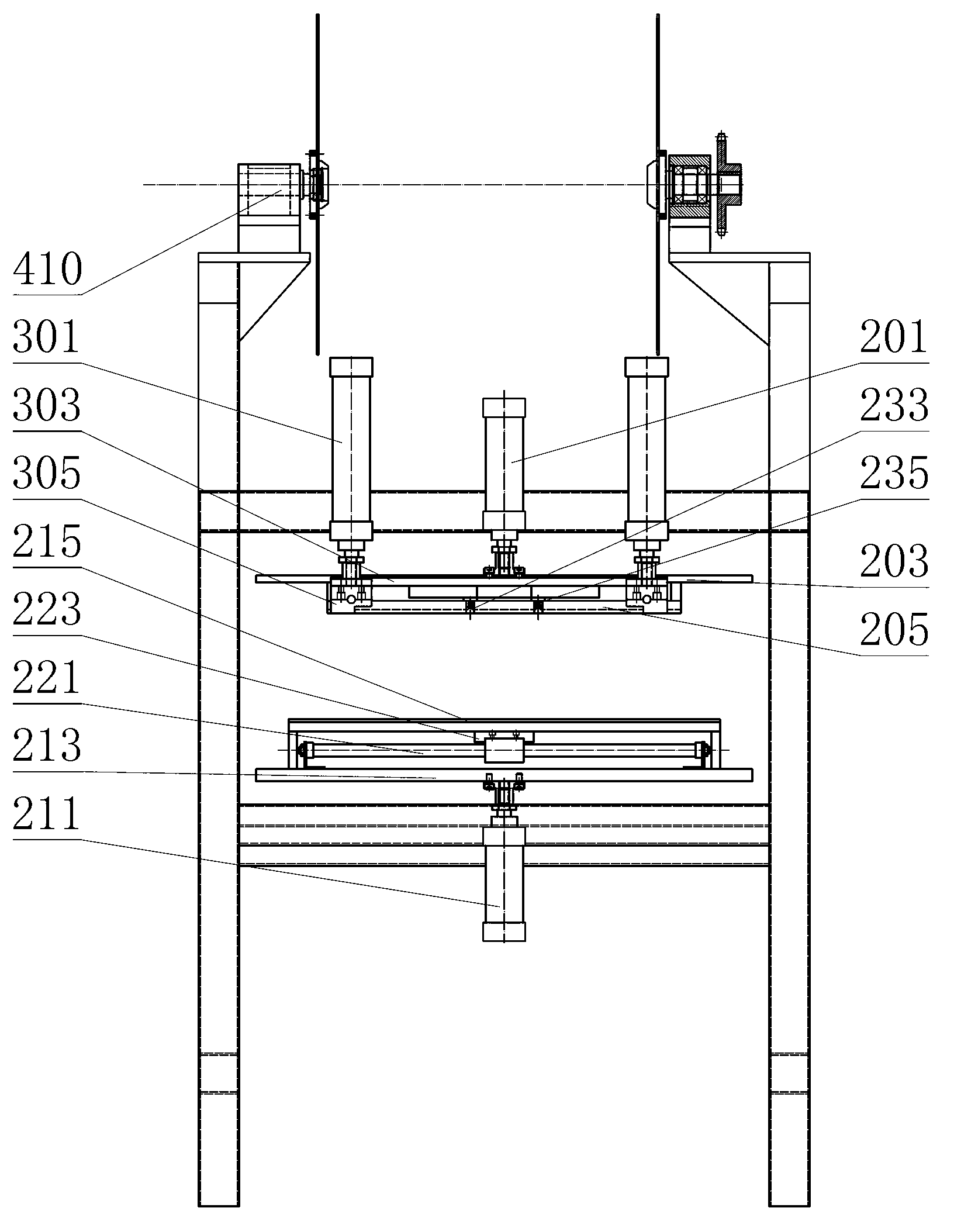

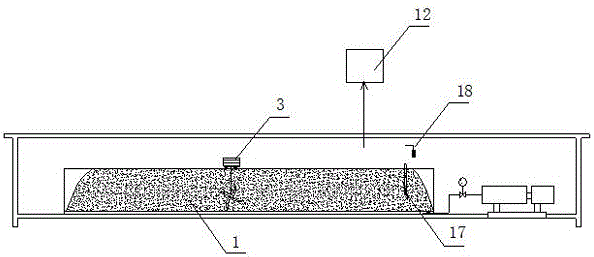

Vacuum package machine

ActiveCN103287614AImprove efficiencyReduce the pumping volumePackaging by pressurising/gasifyingWrappingVacuum pumpingEngineering

The invention relates to a vacuum package machine which comprises a welding wire disc feeding mechanism and a finished product delivery device and further comprises a film sealing device and a film supplying device. The film supplying device comprises an upper film supplying device and a lower film supplying device. The upper film supplying device is located on the upper portion of a machine frame and the lower film supplying device is located on the lower portion of the machine frame. The film sealing device comprises a front film sealing device and a side film sealing device. The front film sealing device is arranged on the outlet portion of the vacuum package machine. A film cutting device is further arranged on the front film sealing device. The side film sealing device is arranged on the upstream of the front film sealing device, a vacuum pumping device is further arranged on the upstream of the front film sealing device, and a semi-finished product delivery device is arranged on the upstream of the front film sealing device. The vacuum package machine has the advantages that the structure that a vacuum pumping tube is stretched into a bag is adopted so that a singe package bag can be vacuumized, the air pumping volume each time can be reduced to a great extent, and the operation efficiency of vacuum package can be improved; meanwhile, only one package bag is output backwards each time, so that the burden brought to following devices due to one-time input of a plurality of welding wire package bags is reduced.

Owner:TIANJIN SAINTEAGLE WELDING CO LTD

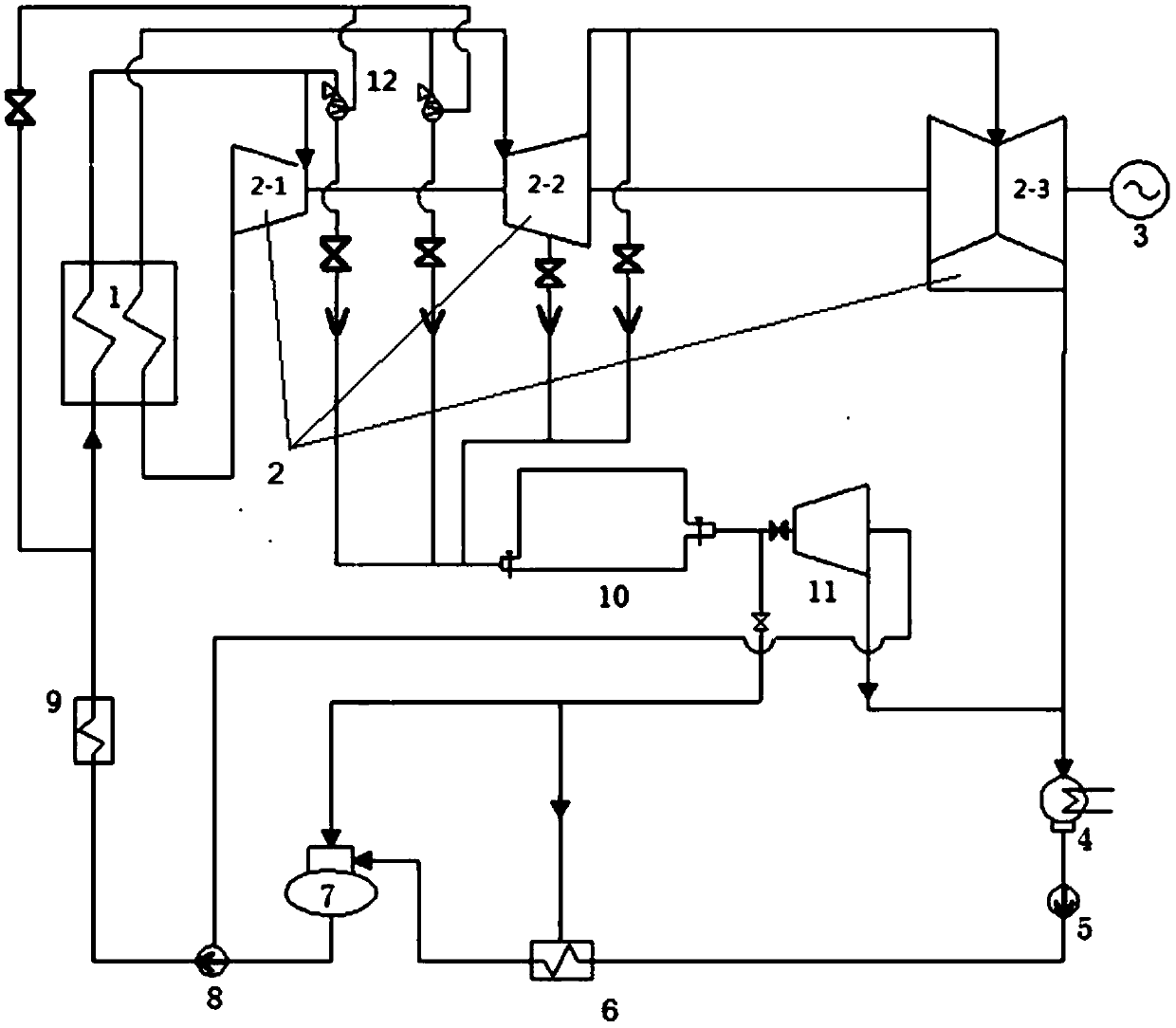

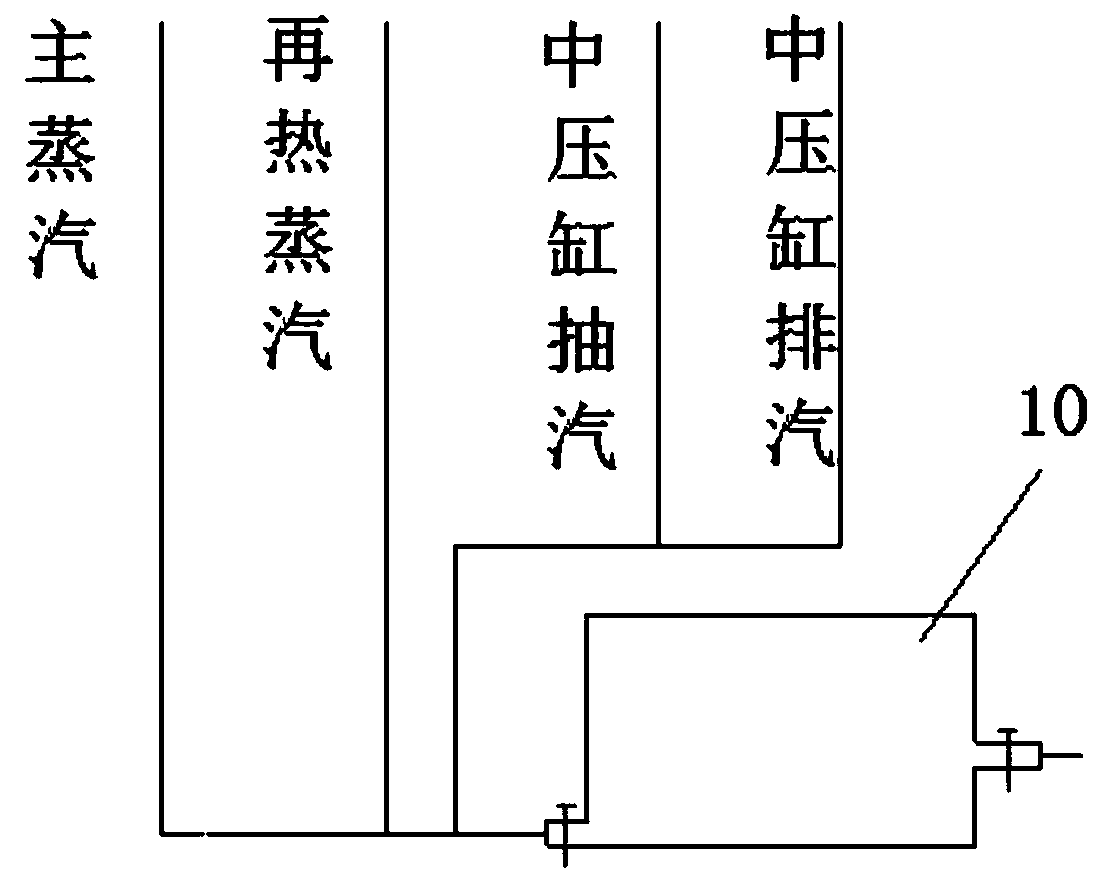

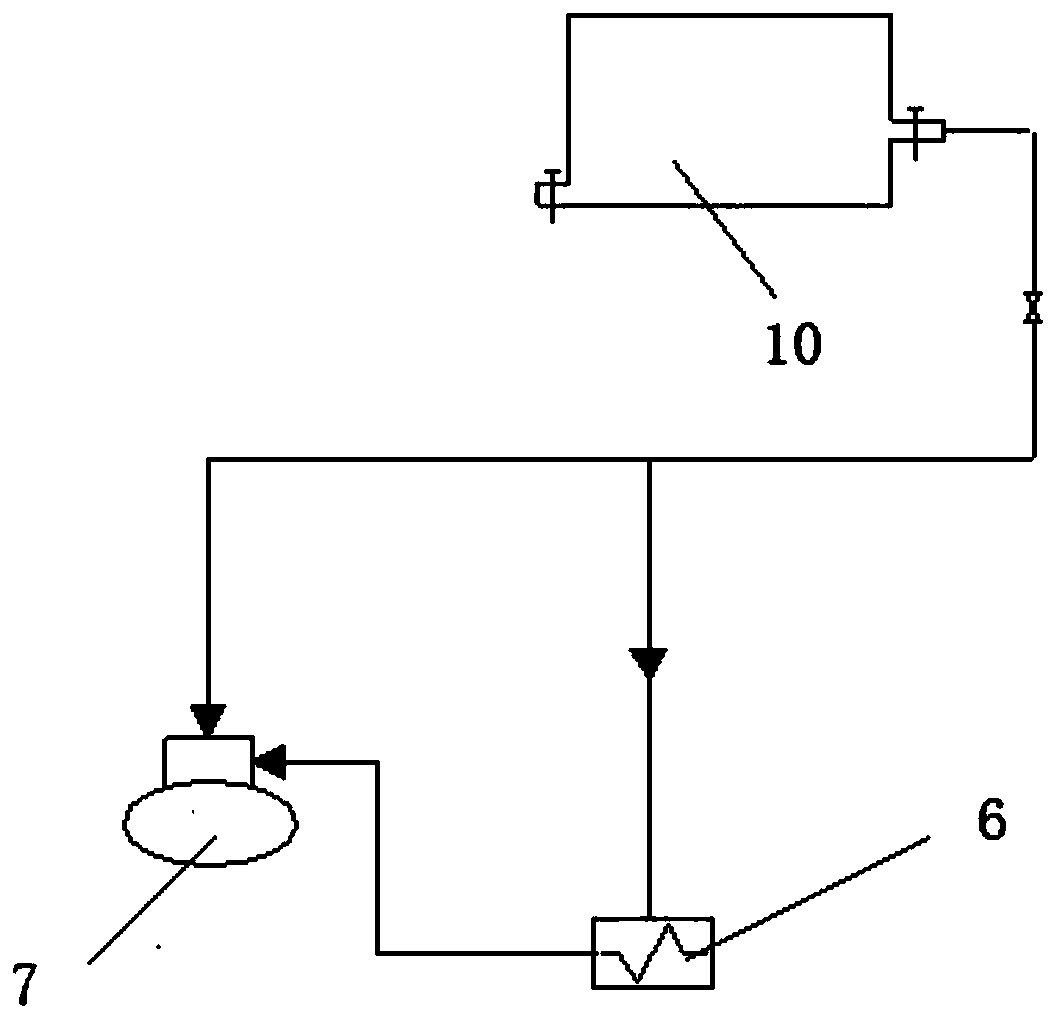

Heat regenerative system capable of improving unit peak load regulation capacity and dynamic calculation method of heat regenerative system heat storage tank steam temperature

InactiveCN109538317AImprove peak shaving performanceHigh outputLiquid degasificationDesign optimisation/simulationEngineeringDeaerator

The invention provides a heat regenerative system capable of improving the unit peak load regulation capacity. The heat regenerative system comprises a power station boiler, a steam turbine, an electric generator, a steam condenser, a condensate pump, a low pressure heater, a deaerator, a water feed pump, a high pressure heater, a small steam turbine and a temperature and pressure reducer. The heat regenerative system is characterized by further comprising a heat storage tank, and steam is supplied to the heat regenerative system and the small steam turbine through the heat storage tank. Whenthe unit electric generation load is reduced, the heat storage tank extracts rich high-temperature steam from the steam turbine, and heat is directly stored in the heat storage tank in a steam mode. When the unit load is high, boiler feed water is increased, steam consumption of the heat regenerative system and the small steam turbine is increased, at the movement, steam stored in the heat storagetank can be released to be provided for the heat regenerative system and the small turbine, steam extracted from the unit can be reduced, unit force discharge is increased, and the effect load leveling is achieved. The invention further provides a dynamic calculation method of heat storage tank temperature changes.

Owner:NORTHEAST DIANLI UNIVERSITY +2

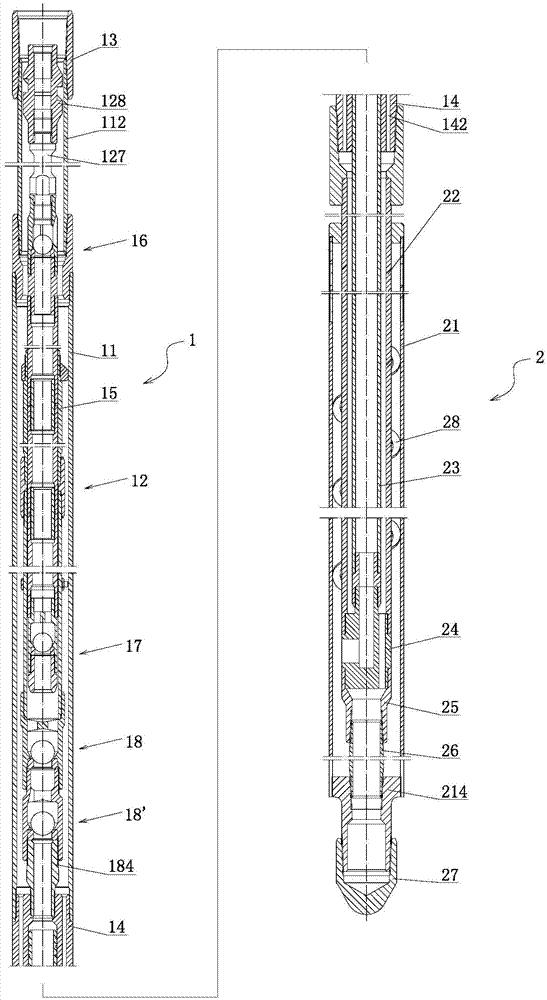

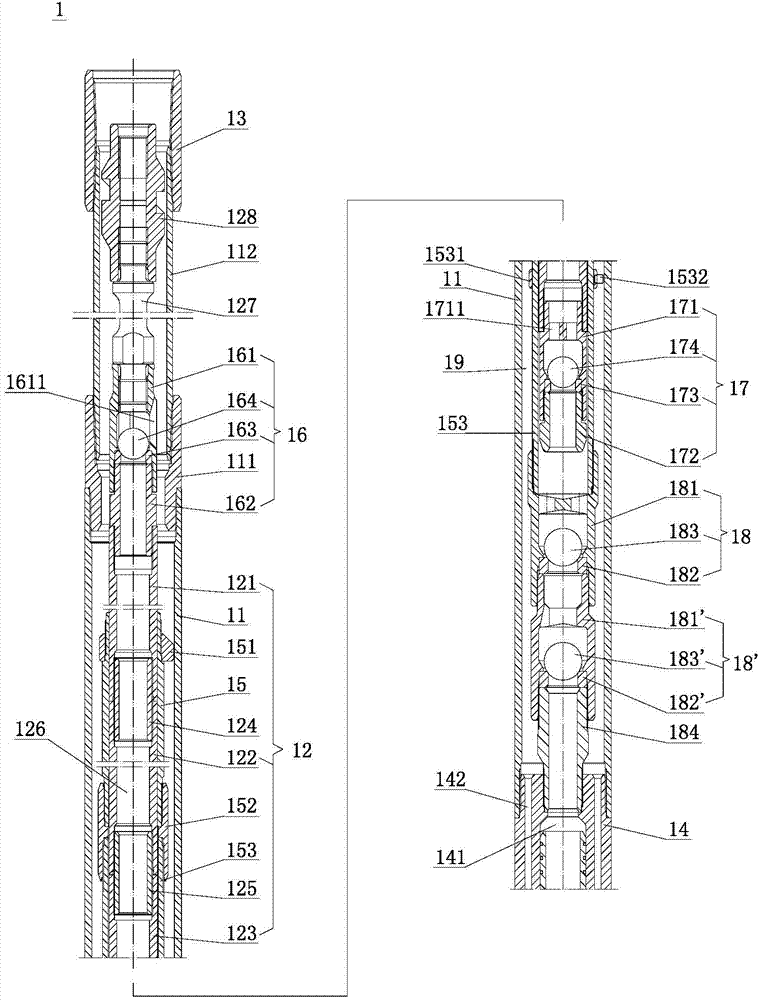

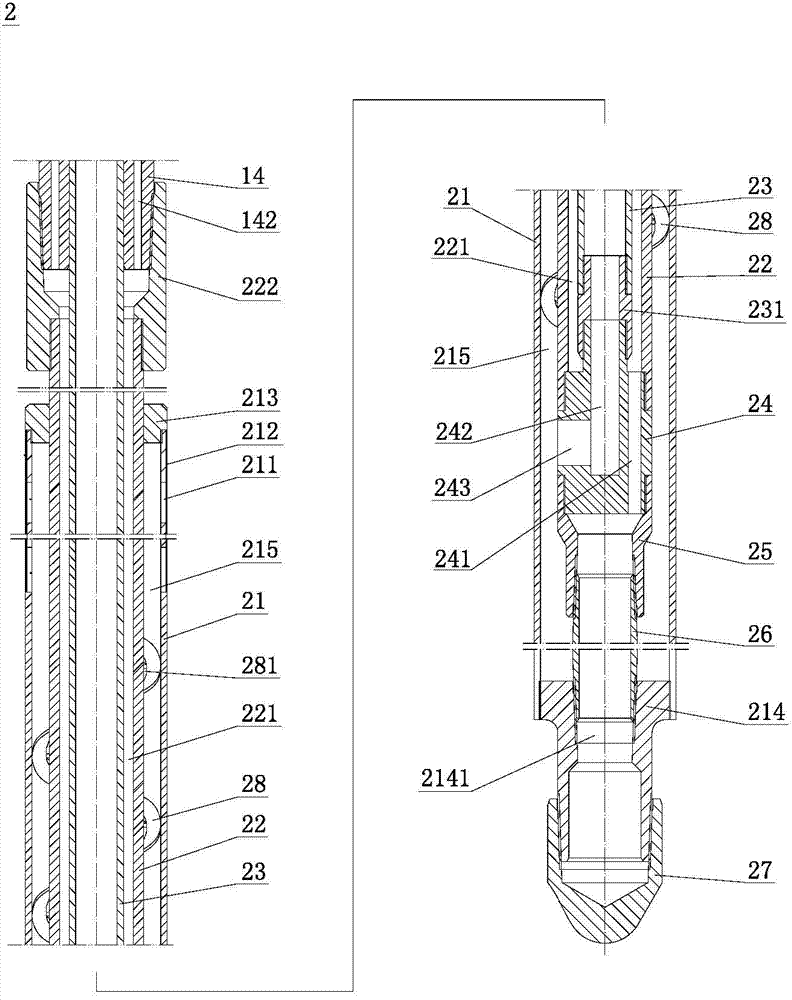

Sand-preventing gas-preventing integrated oil production device

ActiveCN103541887AReduce pump volumeImprove mining efficiencyPositive displacement pump componentsFlexible member pumpsInlet channelCoupling

A sand-preventing gas-preventing integrated oil production device comprises an oil pump and a gas anchor. The oil pump is provided with an outer tube and a plunger, the plunger is arranged in the outer tube in a penetrating mode, and the lower end of the outer tube is connected with a two-way coupling; the plunger is sleeved with a pump cylinder, the upper end of the plunger is connected with an upper traveling valve, the lower end of the plunger is connected with a lower traveling valve, the lower end of the pump cylinder is connected with a plurality of fixing valves, and the fixing valves are communicated with a center hole of the two-way coupling oppositely; the gas anchor is provided with an outer cylinder, an inner cylinder and a center tube, the upper end of the outer cylinder is provided with a liquid inlet hole, a screen is arranged outside the liquid inlet hole, the upper end of the outer cylinder is connected with a straightening ring, and the lower end of the outer cylinder is connected with a reducing coupling; the inner cylinder is located in the outer cylinder, the upper end of the inner cylinder is connected with the two-way coupling, and the lower end of the inner cylinder is connected with a two-way joint; the center tube is located in the inner cylinder, the upper end of the center tube is communicated with the center hole of the two-way coupling oppositely, and the lower end of the center tube is communicated with an oil inlet channel of the two-way joint oppositely. According to the sand-preventing gas-preventing integrated oil production device, in the oil production process, sand-preventing gas-preventing integration can be achieved, and oilfield exploitation benefits are improved.

Owner:PETROCHINA CO LTD

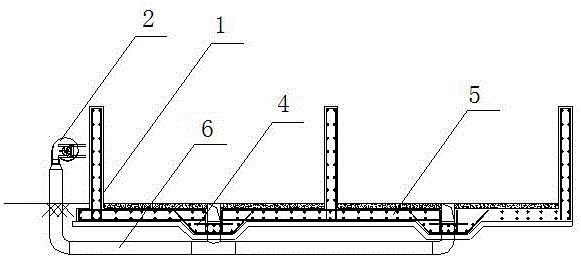

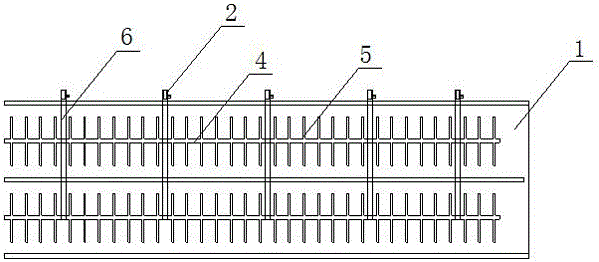

Aerating, collecting and exhausting combining system in solid-state-composting aerobic fermentation and application thereof

InactiveCN105859349AEffectively closedLower purchase costBio-organic fraction processingClimate change adaptationAir volumeElectric machinery

The invention discloses an aerating, collecting and exhausting combining system in solid-state-composting aerobic fermentation. The aerating, collecting and exhausting combining system comprises a fermentation trough, a medium-pressure draught fan set, a composting heap turner, main aeration ditches, fishbone-type branch aeration ditches, aeration ventilating pipes, aeration plates, a membrane sealing structure and an independent exhausting structure; the invention provides an application of the aerating, collecting and exhausting combining system. The combining system and the application thereof have the advantages that the medium-pressure draught fan set can be momentarily adjusted according to the oxygen requirement in the biological aerobic fermentation stage, the best suitable oxygen requirement is provided, the multiple kinds of air amount can be further provided without changed air pressure, broken openings and the dispersion state are reduced, the stability can be kept for a long time, and the cost, the maintenance cost and the requirement electric quantity are lower; the cost of a gas collecting system can be reduced through the membrane sealing fermentation trough, the stench concentration is further increased, the air sucking amount is decreased, and the defects that due to a single-trough or multiple-trough gas collecting cover and the gas collecting mode of a whole workshop, the air sucking amount is large, the air sucking difficulty is high, the motor power is large, and stench is spread in the whole workshop are overcome.

Owner:蔡永辉

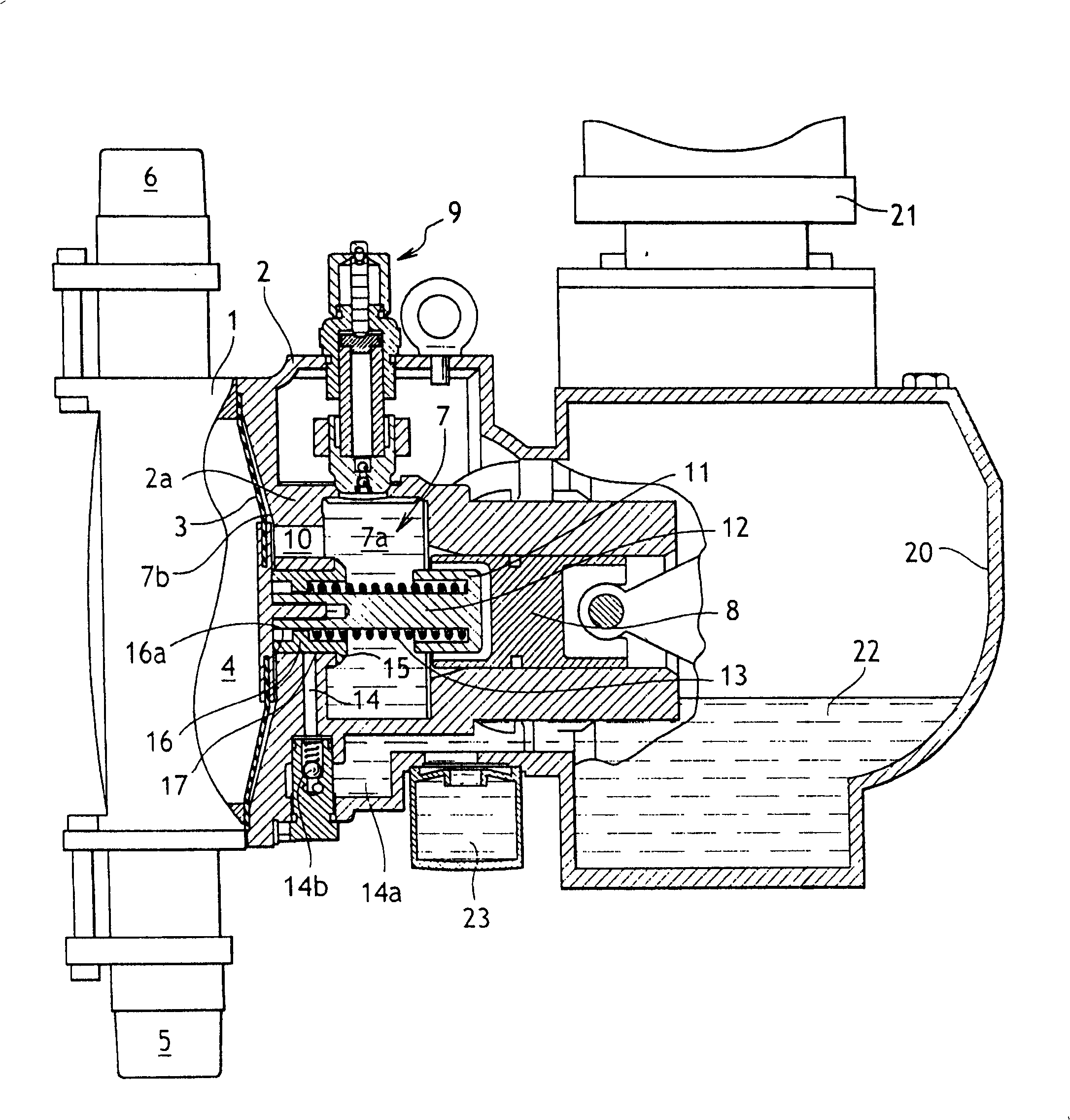

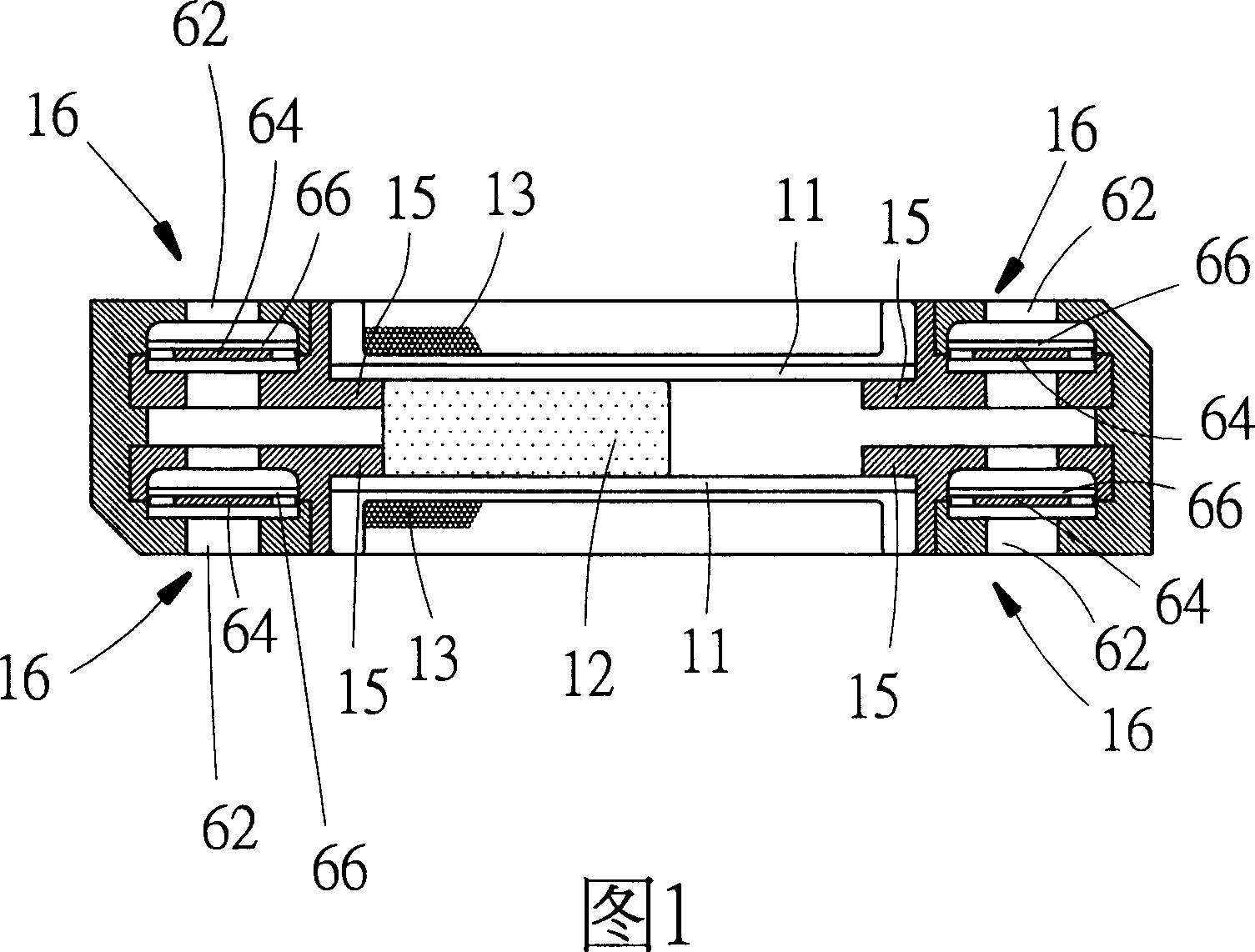

Hydraulic pressure driven membrane pump with leakage compensation equipment

InactiveCN101245777AReduce the pumping volumeFlexible member pumpsPiston pumpsDiaphragm pumpReciprocating motion

The invention provides a diaphragm pump (3) which comprises a hydraulic control chamber (7) which is arranged between a piston (8) which carries out a reciprocating movement and a diaphragm (3) in pump bodies (1, 2). The diaphragm pump comprises a device used for compensating the leakage of the hydraulic chamber (7); the device comprises a supplementary duct (14) which is provided with an opening which faces into the hydraulic chamber by a normal-close compensation valve (15) which can be driven to an opening position by the diaphragm (3). The diaphragm pump (3) is characterized in that the compensation valve (15) is driven by the diaphragm (3) of the free end (16a) of the rod (16) which pushes against and controls the valve; the diaphragm (3) is subject to the force of a pumping and suction booster spring (13); the spring (13) cooperates with the valve (15) and pushes back the free end (16a) of the control rod (16) to the diaphragm (3) and returns to a closed position; the spring (13) is matched with the valve (15) so as to form a movable component which can be moved without the deformation of the diaphragm (3) during the pumping and suction stroke.

Owner:MILTON ROY EURO

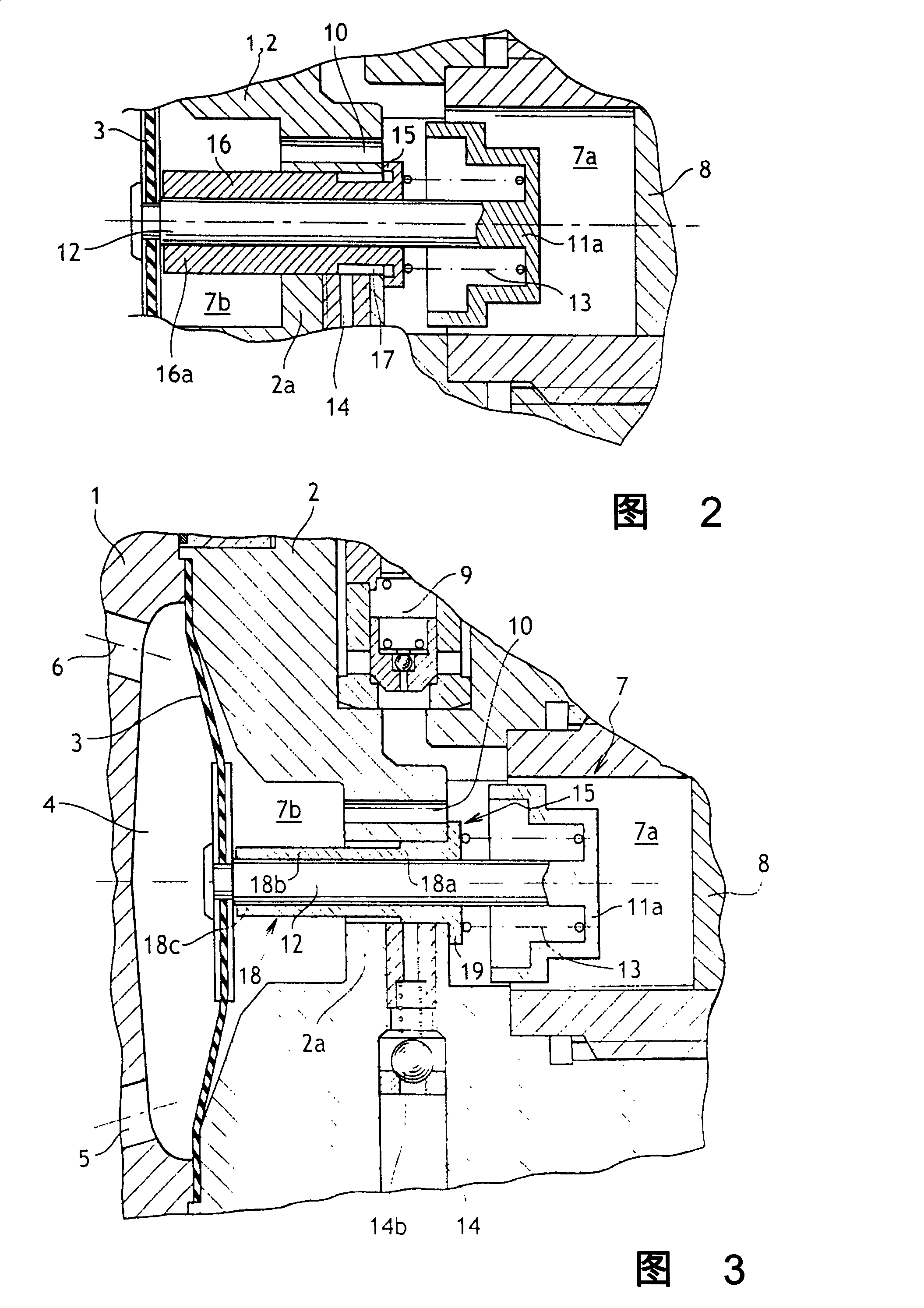

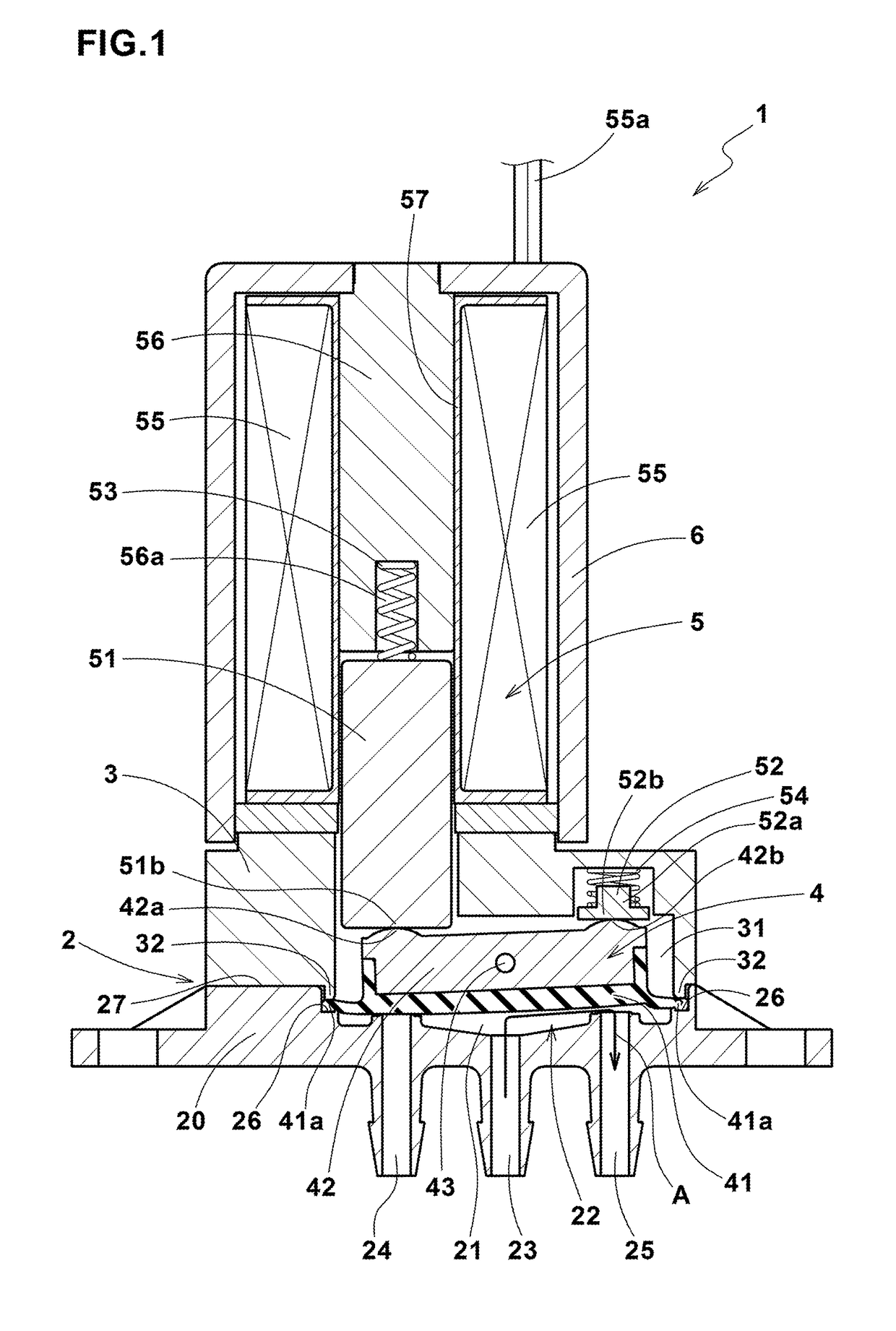

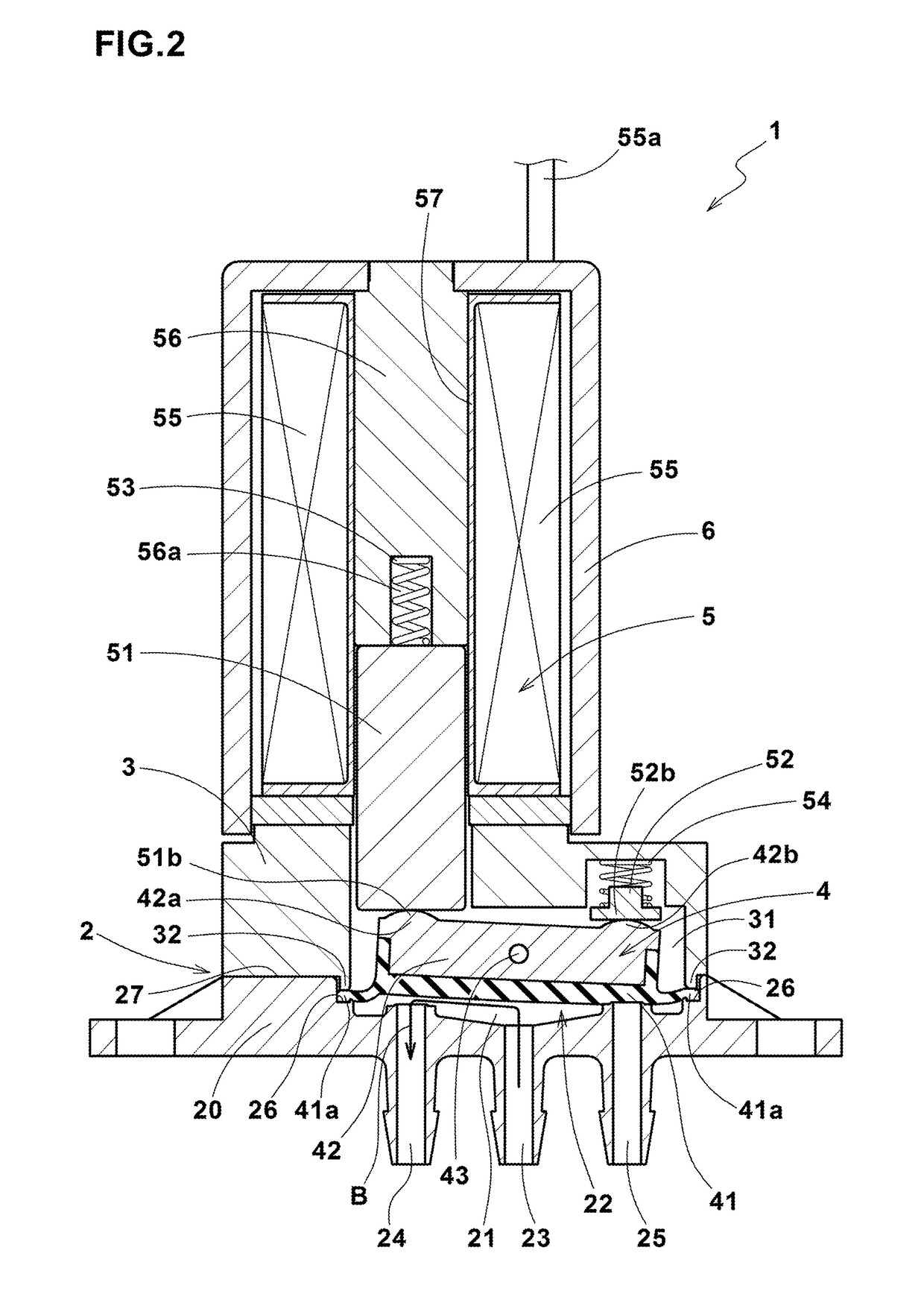

Valve device

ActiveUS9802198B2Increase volumeReduce the pumping volumeDiaphragm valvesOperating means/releasing devices for valvesVALVE PORTValve seat

A recess 22 provided in a passage block 20; a diaphragm covering the recess 22 to form a valve chest 21 in which a fluid flows; an inflow port 23 opened at the recess 22 and allowing the fluid to flow into the valve chest 21; an NC outflow port 24 and an NO outflow port 25 opened at the recess 22 and allowing the fluid to flow out from the valve chest 21; by oscillating the diaphragm, the diaphragm is closely fitted to any one of a first valve seat 24b formed by an opening 24a of the NC outflow port 24 and a second valve seat 25b formed by an opening 25a of the second outflow port 25, to allow the fluid in the valve chest 21 to flow out from the other outflow port. The recess 22 has a first inclined portion 81 and a second inclined portion 82 having a depth gradually increasing from the first valve seat 24b and the second valve seat 25b toward the inflow opening 23.

Owner:SUMITOMO RUBBER IND LTD

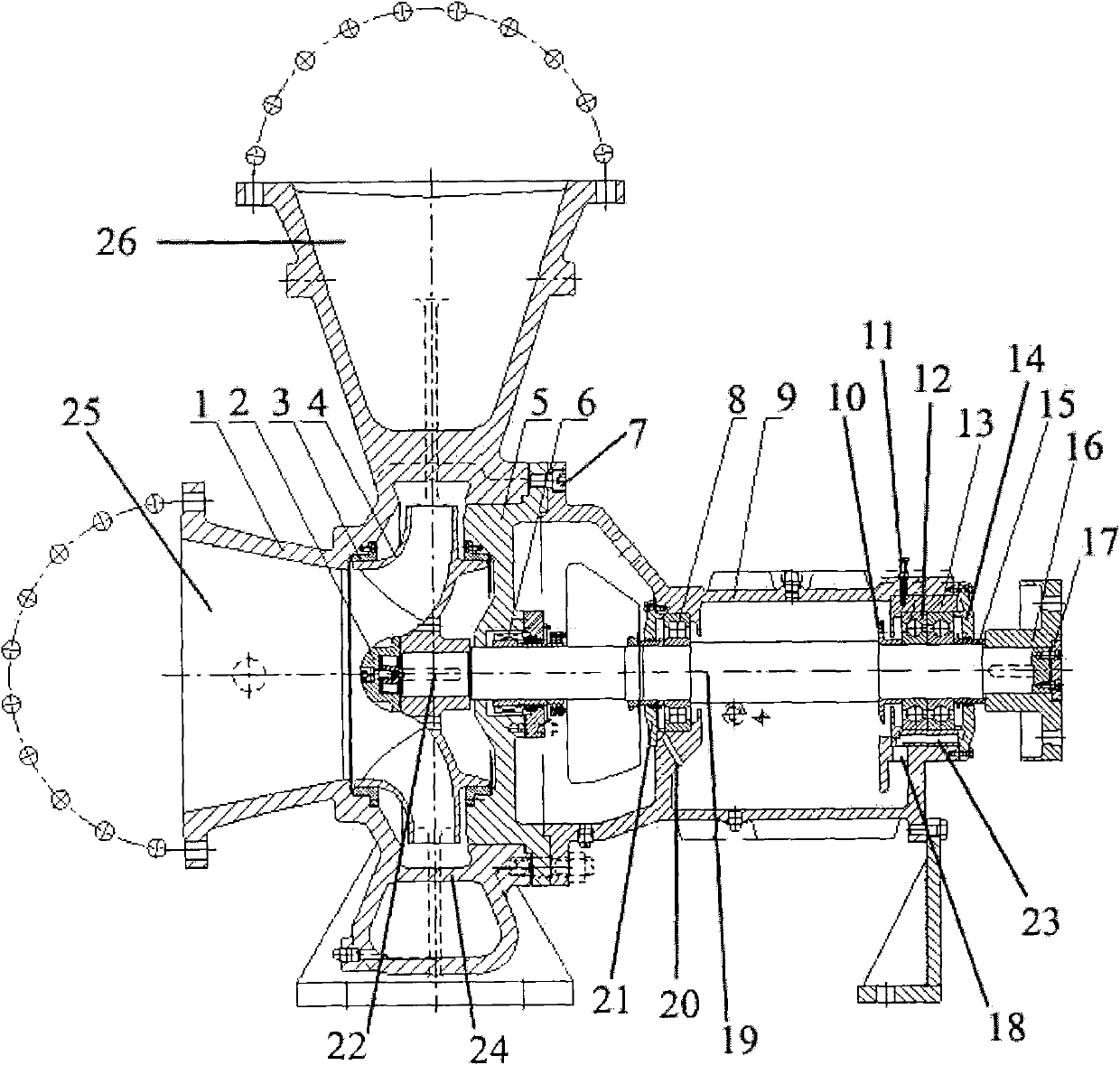

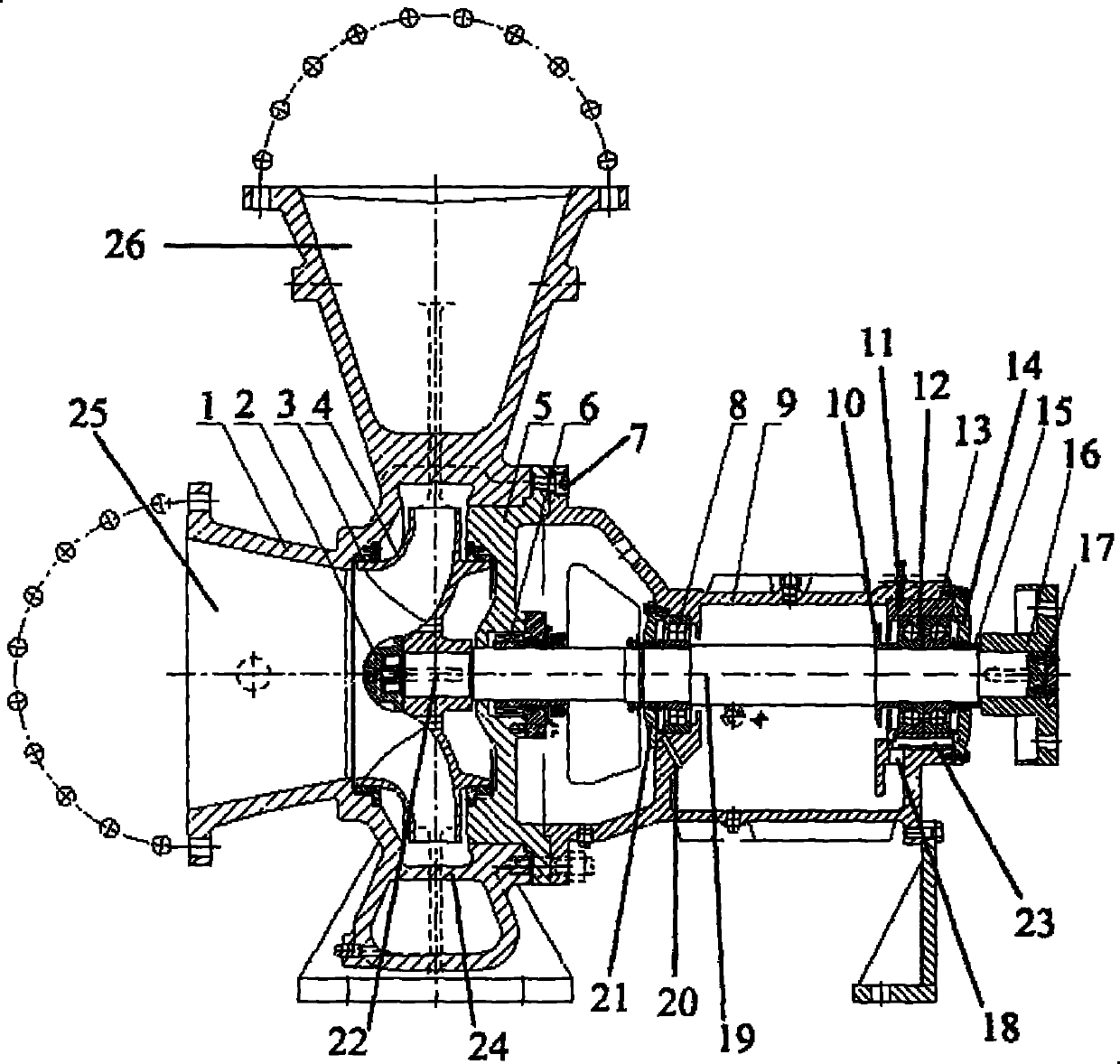

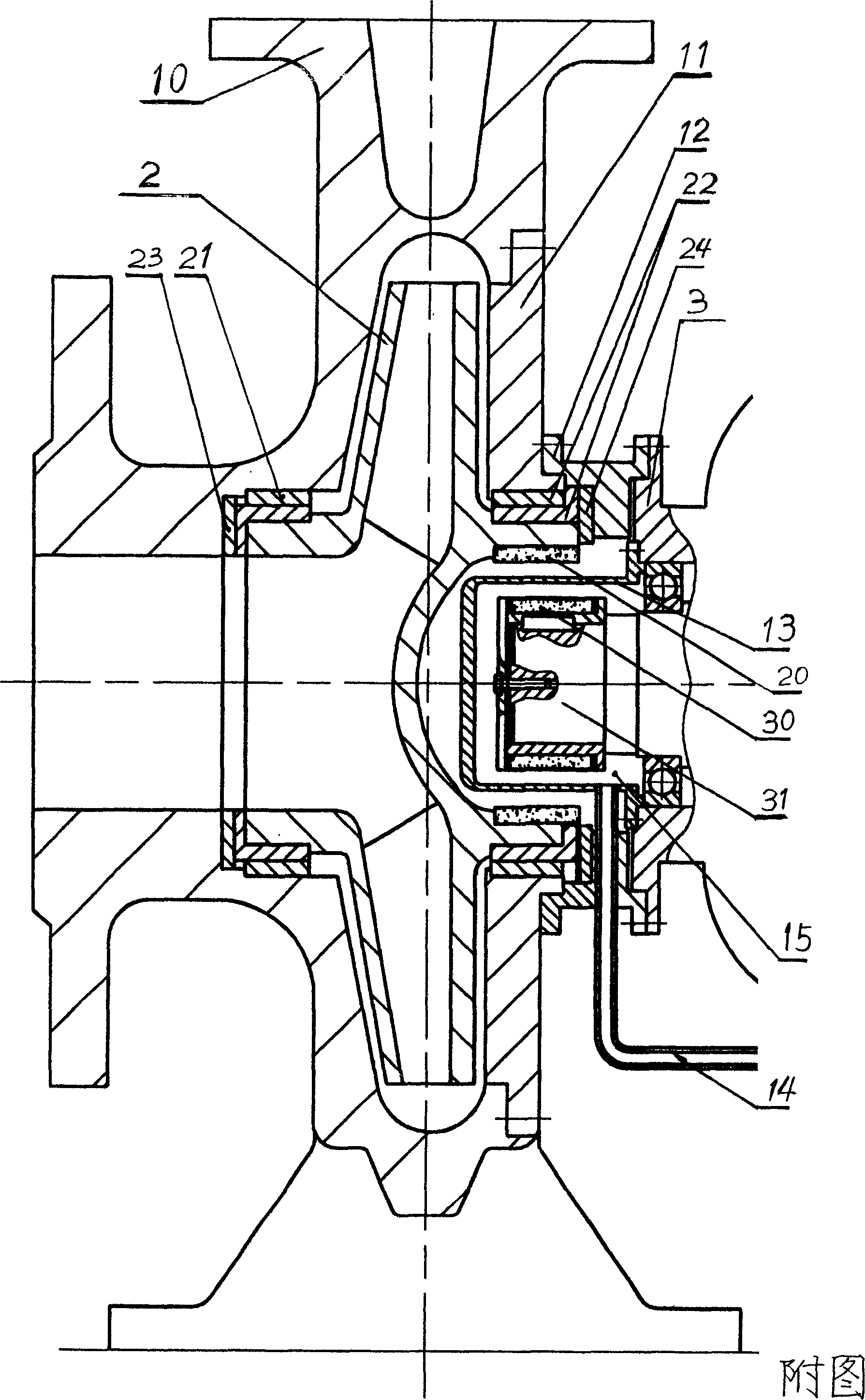

Component cooling water pump for nuclear power plant

InactiveCN102022339AReduce volumeImprove running stabilityPump componentsRadial flow pumpsCentrifugal pumpLubrication

The invention discloses a component cooling water pump for a nuclear power plant, which is a single-stage, single-suction, double-volute and horizontal arm-hanging type centrifugal pump. The pump is characterized in that a pump body is in a radial split-casing double-volute structure, one end of the pump body is provided with a suction inlet, and a pump cover is fixedly connected to the other end of the pump body; the upper side of the pump body is provided with a discharge outlet, and the suction inlet is perpendicular to the discharge outlet; a pump shaft passes through the pump cover and a bearing body; and a shaft seal assembly is composed of box-type mechanical seal components. The component cooling water pump disclosed by the invention has the advantages that the pump body is in a radial split-casing double-volute structure, and the centre line of an impeller is coincide with the centre line of the pump body, therefore, the radial force of the pump in the process of operating can be reduced, the shock resistance is enhanced, the service life is prolonged, and the volume of the pump is reduced; and because a thin-oil self-lubricating system is adopted, the pump can directly start without pre-lubrication, thereby enhancing the operating stability of the pump.

Owner:SHANGHAI APOLLO MACHINERY

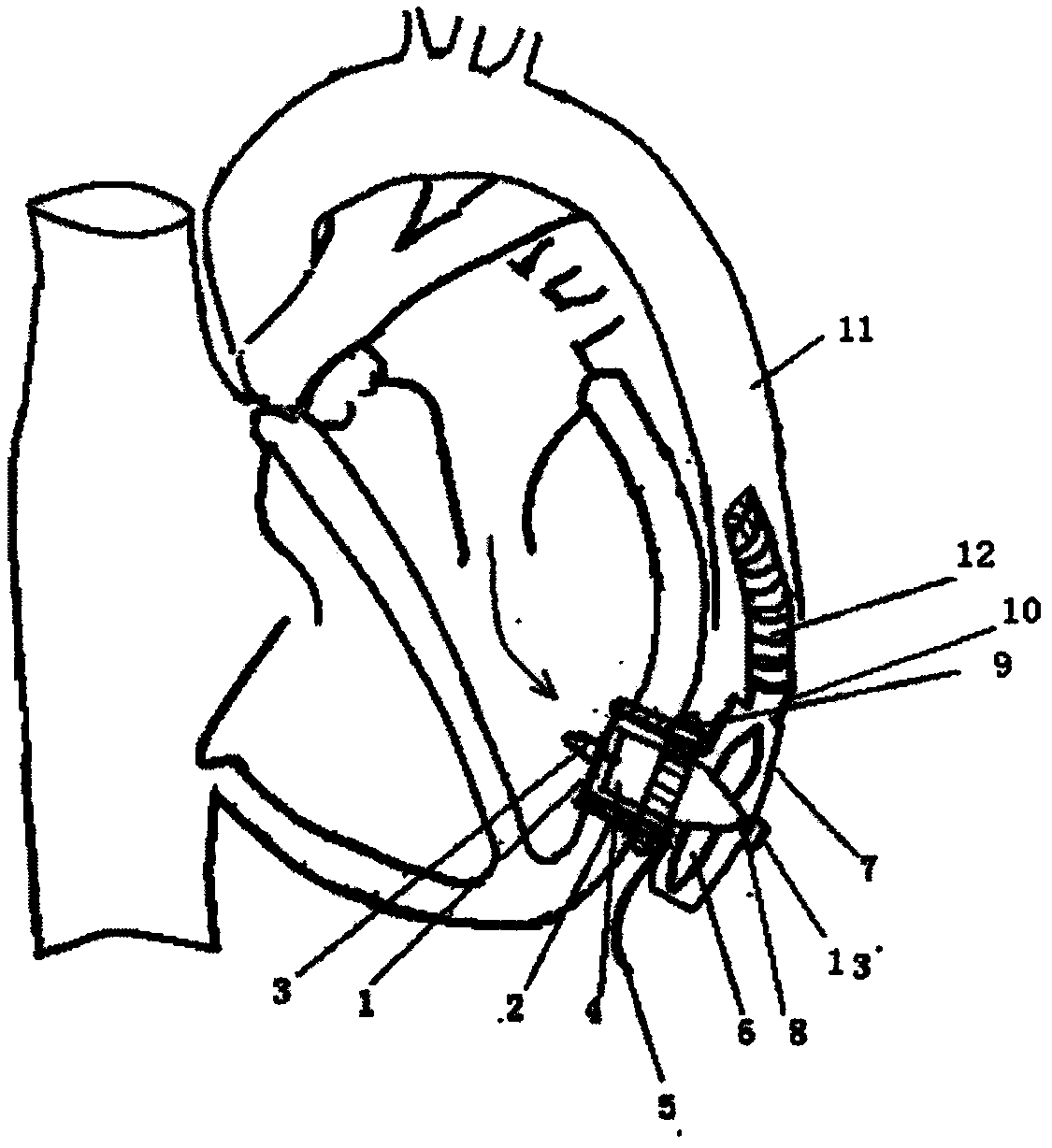

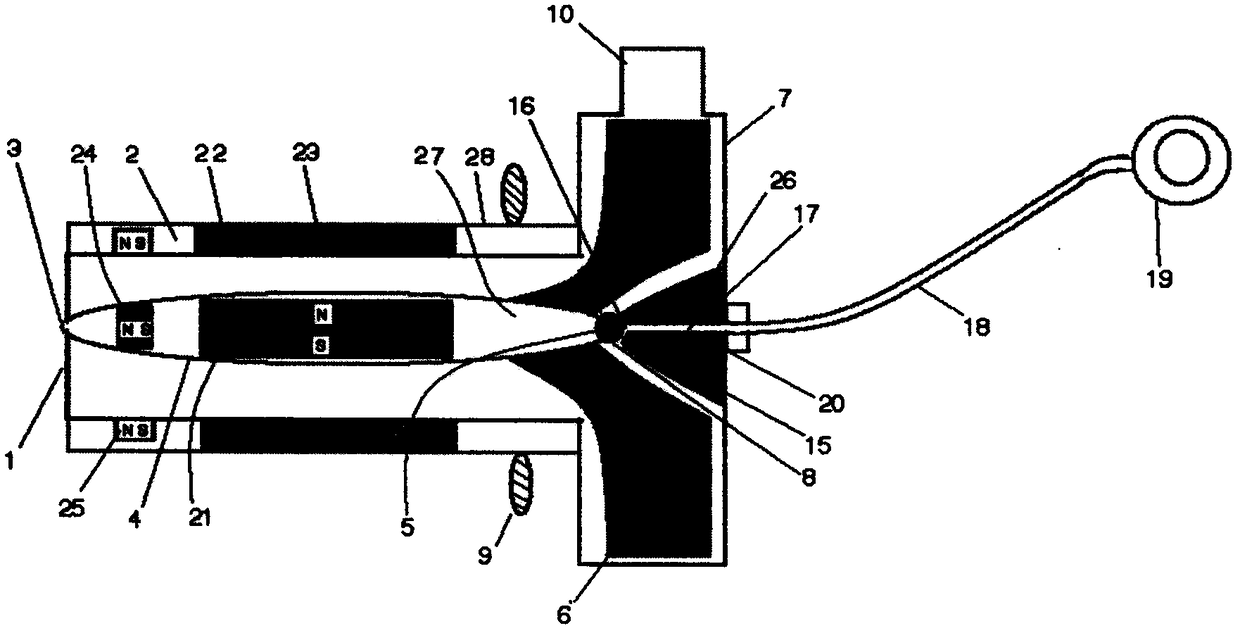

Ultrasonic anti-thrombus magnetic suspension cardiac apex centrifugal pump

InactiveCN108498888AAvoid formingReduce the pumping volumeBlood pumpsMedical devicesThrombusEngineering

The invention discloses an ultrasonic anti-thrombus magnetic suspension cardiac apex centrifugal pump. A stator iron core (22) and a stator winding (23) are arranged in the wall of a pump cylinder (2), and a rotor permanent magnet (21), a rotor radial suspension magnet (24) and a stator radial suspension magnetic ring (25) are arranged in a rotor cylinder (4). A flow guiding cone (26) is arrangedin the center of the rear wall of a blade shell (7), a mechanical fulcrum ball socket (15) is arranged at the top end of the flow guiding cone (26), a mechanical fulcrum ball (5) is arranged at the rear end of the rotor cylinder (4), and the mechanical fulcrum ball (5) and the mechanical fulcrum ball socket (15) form a mechanical fulcrum (8). A fulcrum clearance (16) communicates with a drug catheter (18) and a drug injection plunger (19) through a center hole (17). The drug injection plunger (19) is implanted below the abdominal wall skin to accept anticoagulant liquid medicine to enter the fulcrum clearance (16). The flow guiding cone (26) is internally provided with an ultrasonic transducer (20) which can generate ultrasonic vibration to be transmitted to a centrifugal impeller (27) through the mechanical fulcrum (8), and thrombosis is prevented from being formed on the surface of the centrifugal impeller (27) through the ultrasonic cleaning effect.

Owner:李国荣 +1

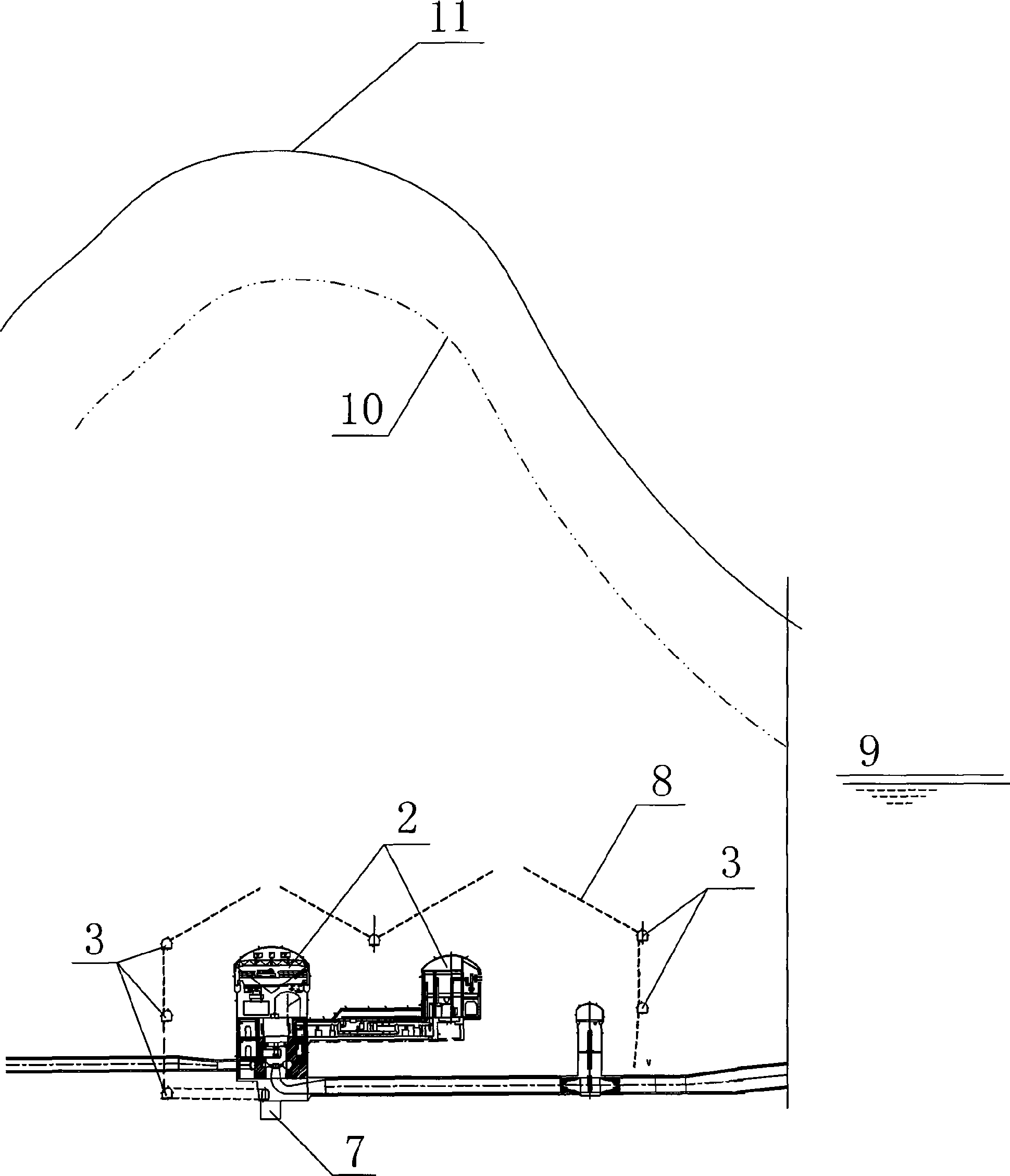

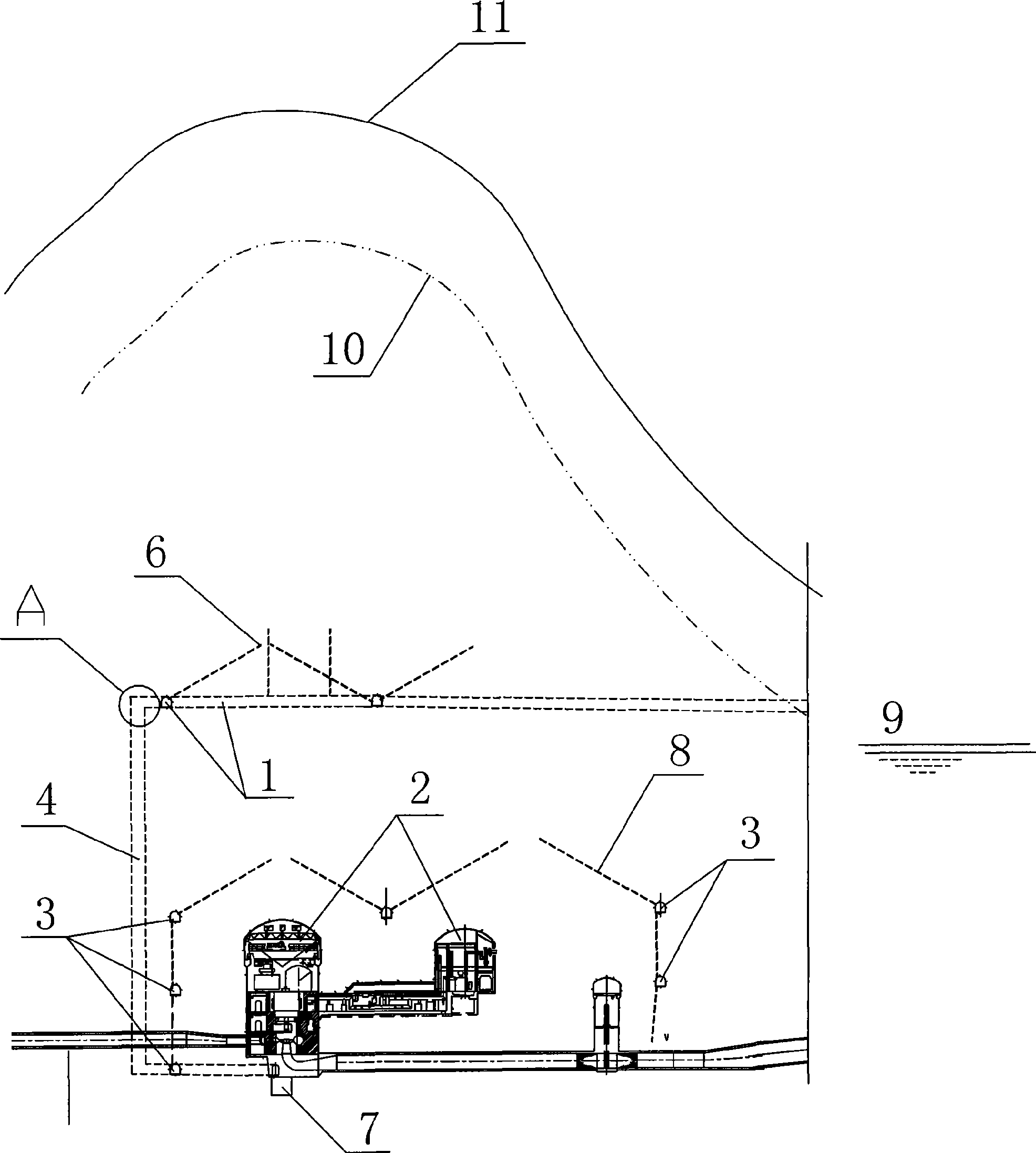

Layered drainage structure of underground powerhouse chamber of hydropower station in water-rich region and construction method thereof

ActiveCN101446107AReduce water seepageSmall volumeFoundation engineeringSewage drainingRiver routingPower station

The invention relates to a layered drainage structure of an underground powerhouse chamber of a hydropower station in a water-rich region and a construction method thereof. The technical problem to be solved by the invention is to provide the layered drainage structure of the underground powerhouse chamber of the hydropower station in the water-rich region and the construction method thereof, and the invention aims at effectively reducing the drainage and discharge capacity of the underground powerhouse, reducing the operation cost by power-driven drainage and discharge, and ensuring the safe construction of the underground powerhouse and a safe running period. The technical proposal for solving the problem is as follows: the layered drainage structure of the underground powerhouse chamber of the hydropower station in a water-rich region with great buried depth is provided with the underground powerhouse chamber, the bottom part thereof is provided with a water-collecting well and a power-driven drainage and discharge device, a plurality of layers of drainage galleries are arranged around the underground powerhouse chamber, the various layers of the drainage galleries are all communicated with the water-collecting well, and the layered drainage structure is characterized in that a layer of intercepting gallery is arranged in a mountain body above the underground powerhouse chamber which is higher than the water level of a river course, and the intercepting gallery is communicated with the water-collecting well through a vertical or inclined connecting gallery. The invention can be used for water conservancy and hydropower underground powerhouse chamber projects.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

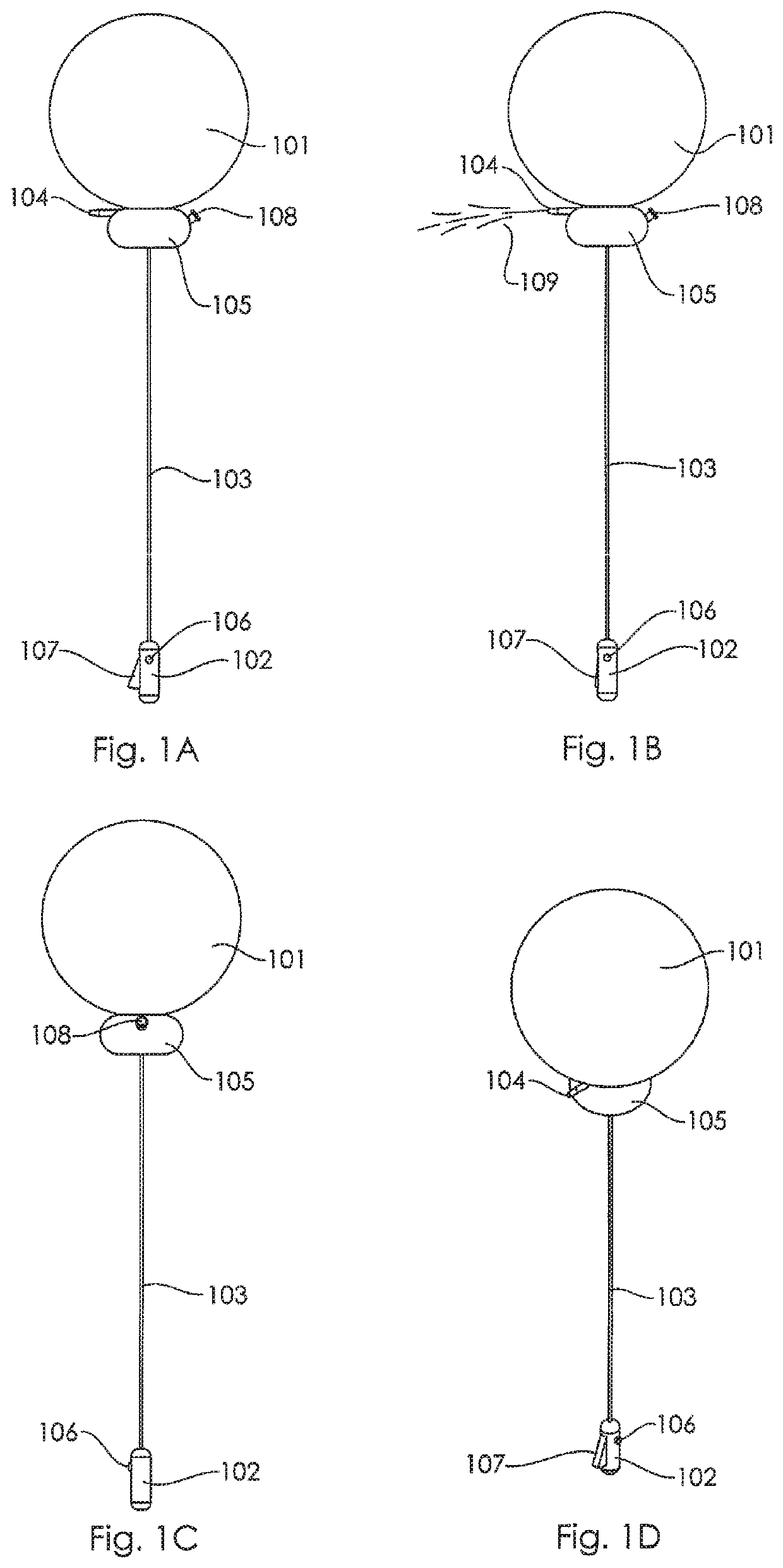

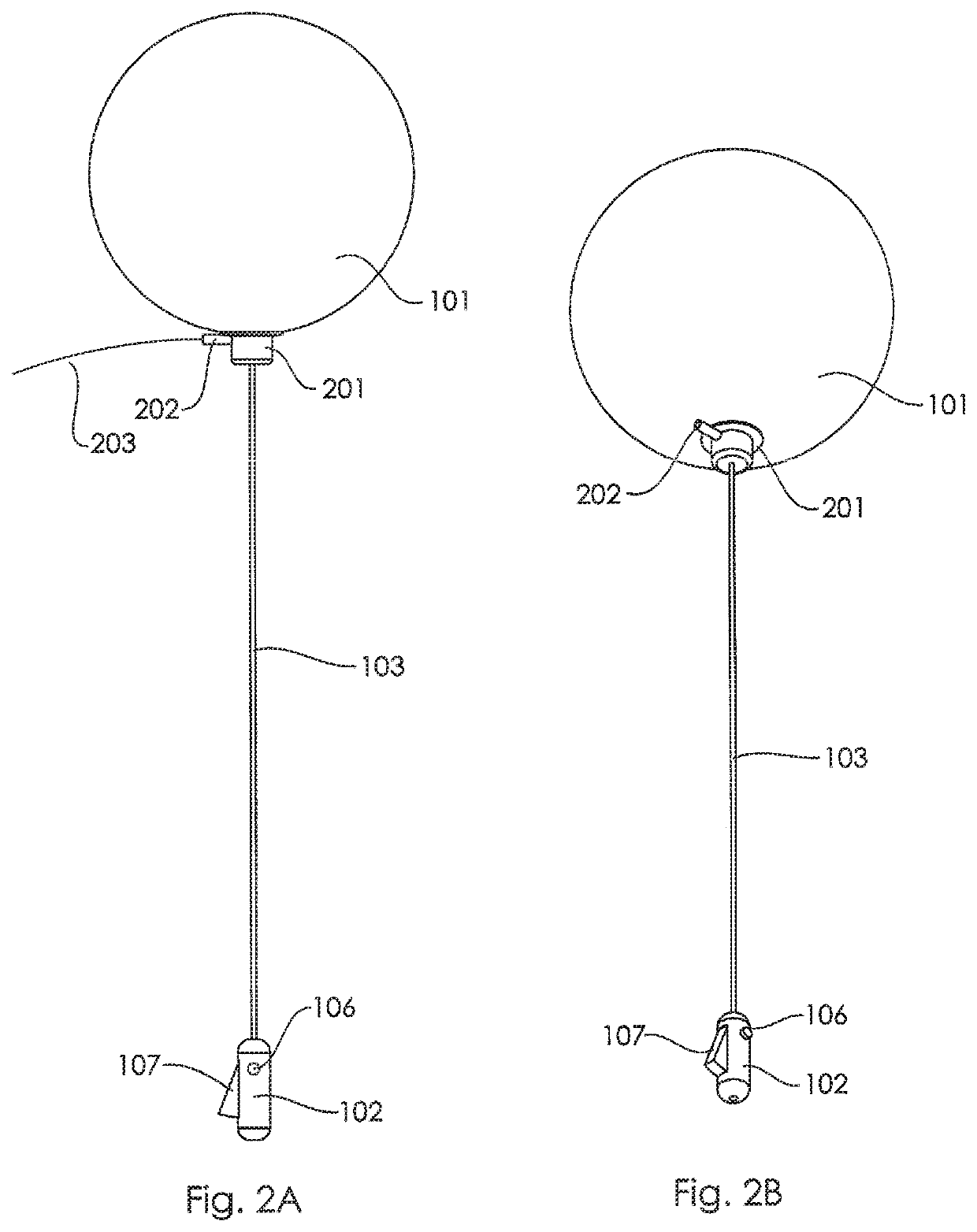

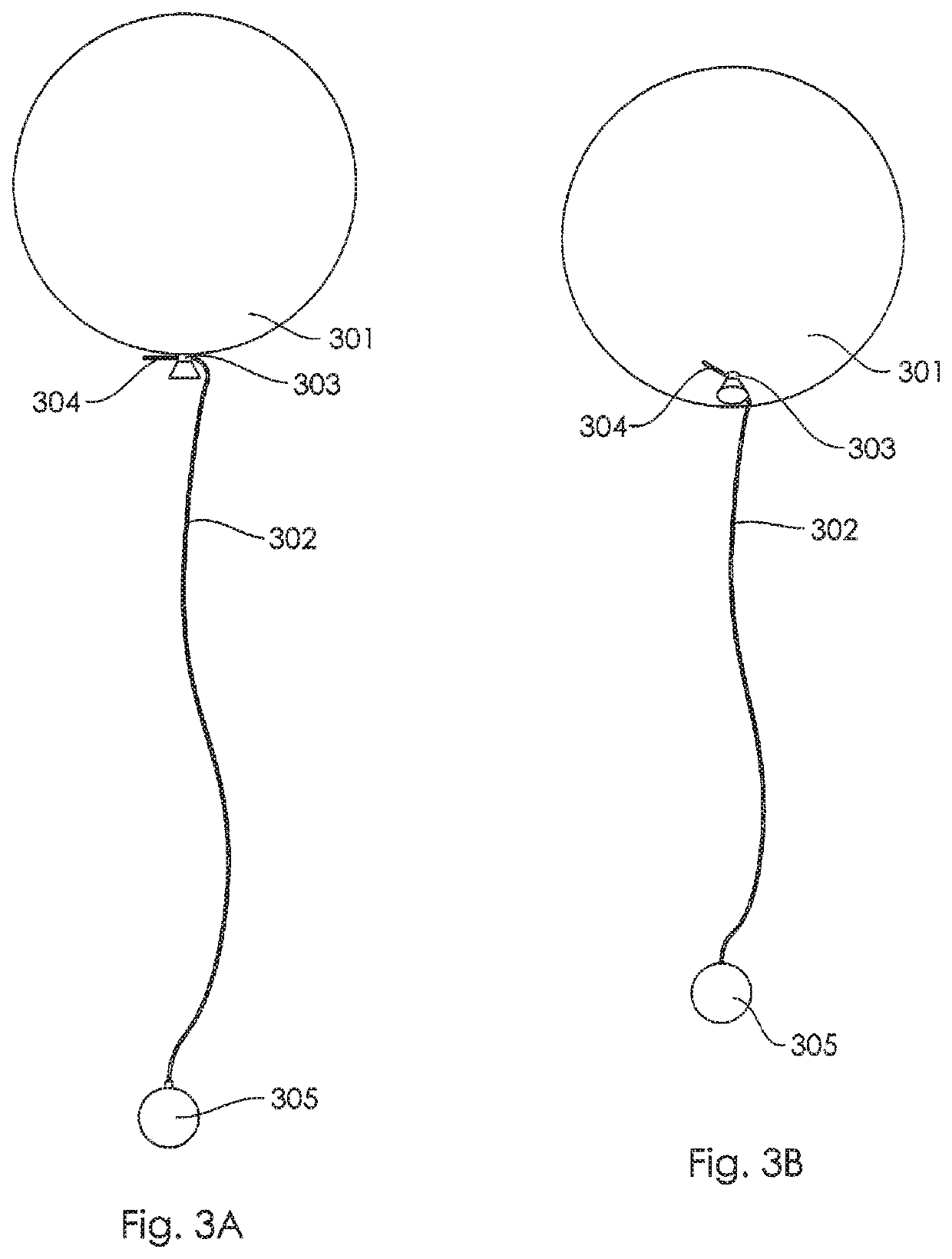

Balloon play apparatus or the like

ActiveUS10717017B2Less impededReduce the pumping volumeToy aircraftsLiquid spraying apparatusMedicineEngineering

A play apparatus has a gas filled balloon and an opening through which fluid is squirted or otherwise released. Fluid is delivered to the opening from an adjacent or nearby reservoir which is connected to at least one hollow tube whereby liquid is transferred from the reservoir to the release point on or adjacent to the balloon, such that the buoyancy of the balloon is unimpeded, for the purposes of play and amusement.

Owner:PUBLICOVER MARK +1

Boiler feed water heating system of paralleling operation steam turbine units

ActiveCN105089724ASave energyReduce the pumping volumeLiquid degasificationFeed water supplyEngineeringDeaerator

The invention provides a boiler feed water heating system of paralleling operation steam turbine units. The boiler feed water heating system comprises boilers, high-back-pressure steam turbines, low-back-pressure steam turbines, condensers, condensation water pools, circulating cooling water pumps, circulating water cooling towers, high-pressure heaters, low-pressure heaters and deaerators. Through the paralleling operation steam turbine units different in steam exhaust back pressure, exhaust steam and circulating water waste heat of the high-back-pressure steam turbines are used for replacing exhaust steam of the low-back-pressure steam turbines for heating of boiler feed water of the low-back-pressure steam turbines, and the energy saving aim of reducing the coal consumption rate in power generation of the turbines is achieved.

Owner:李俊峰

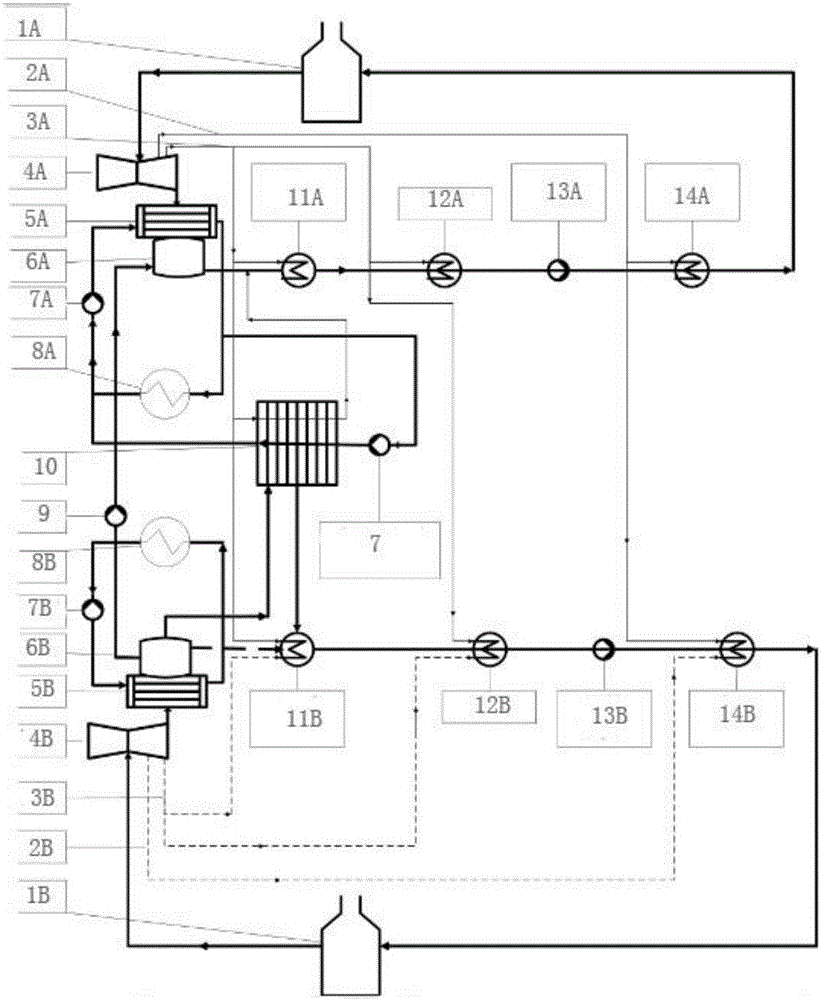

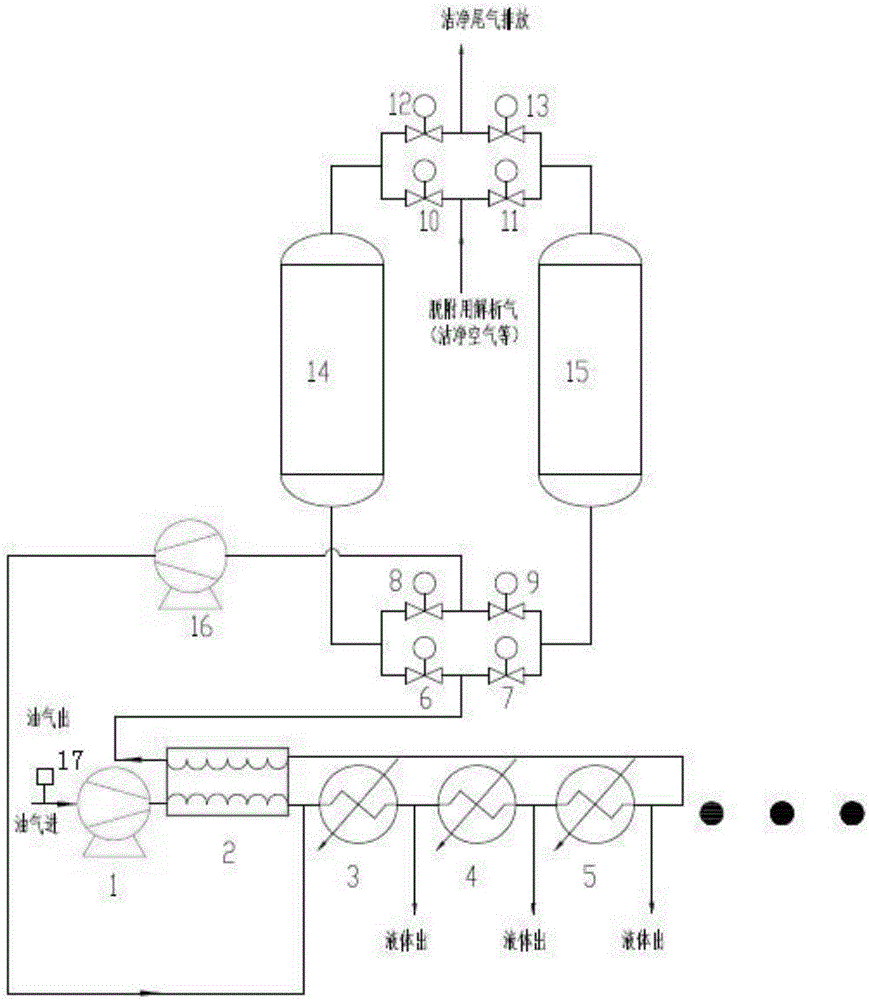

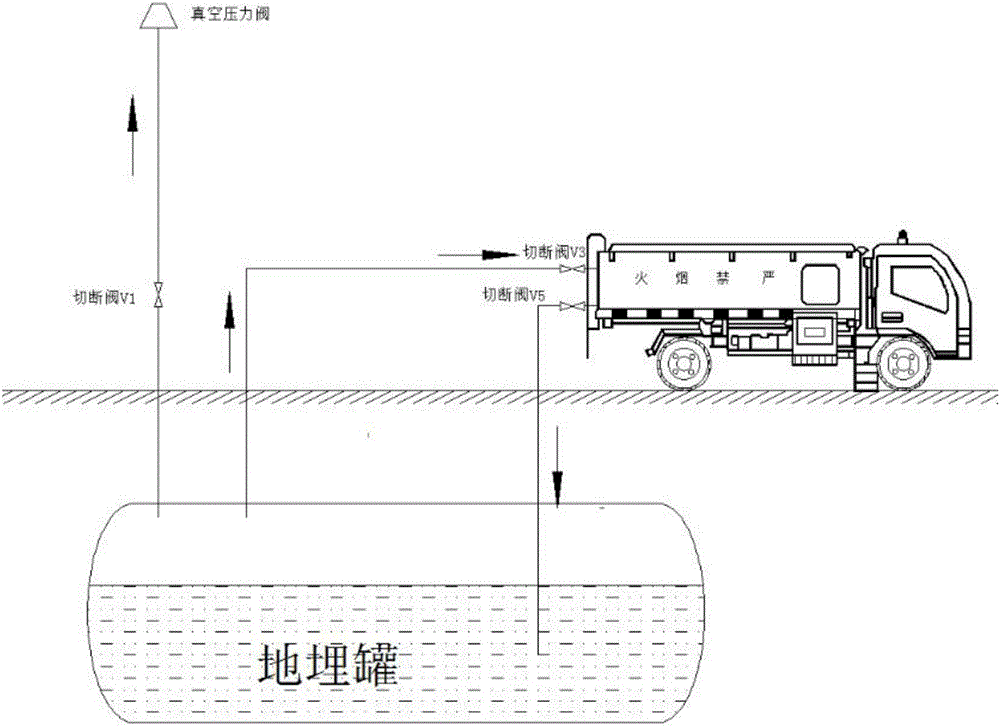

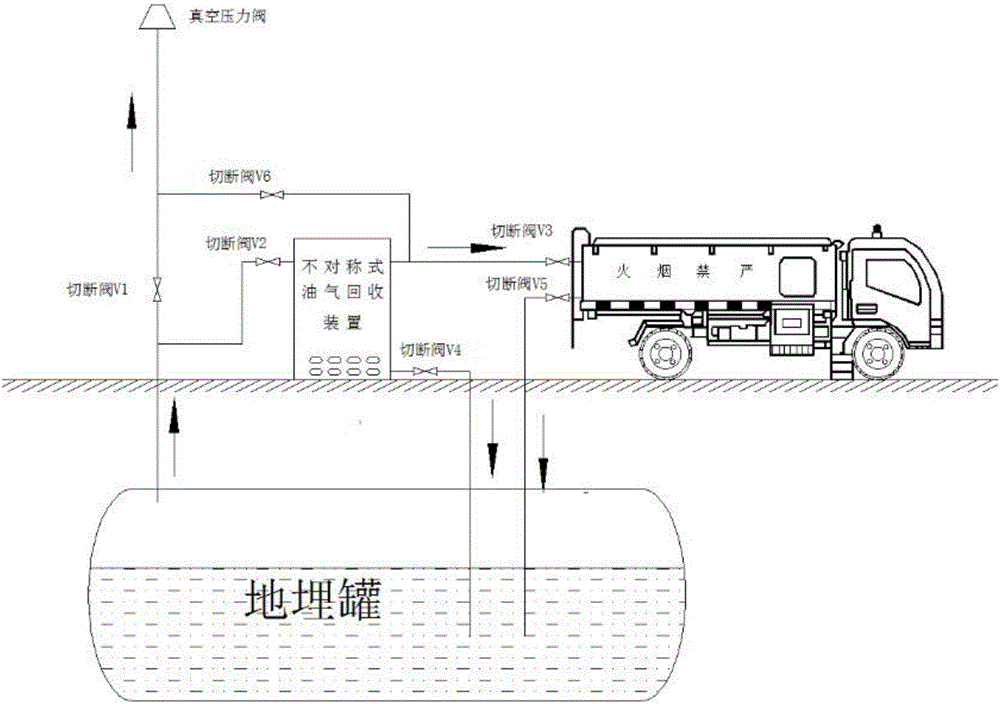

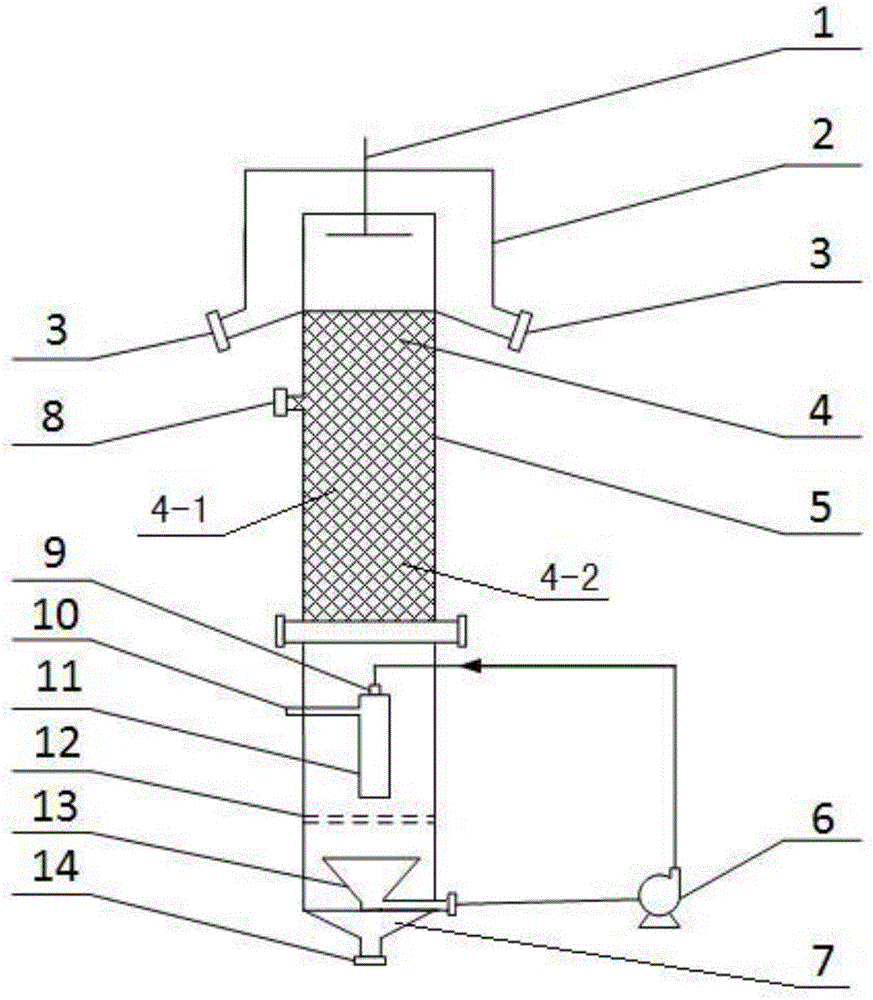

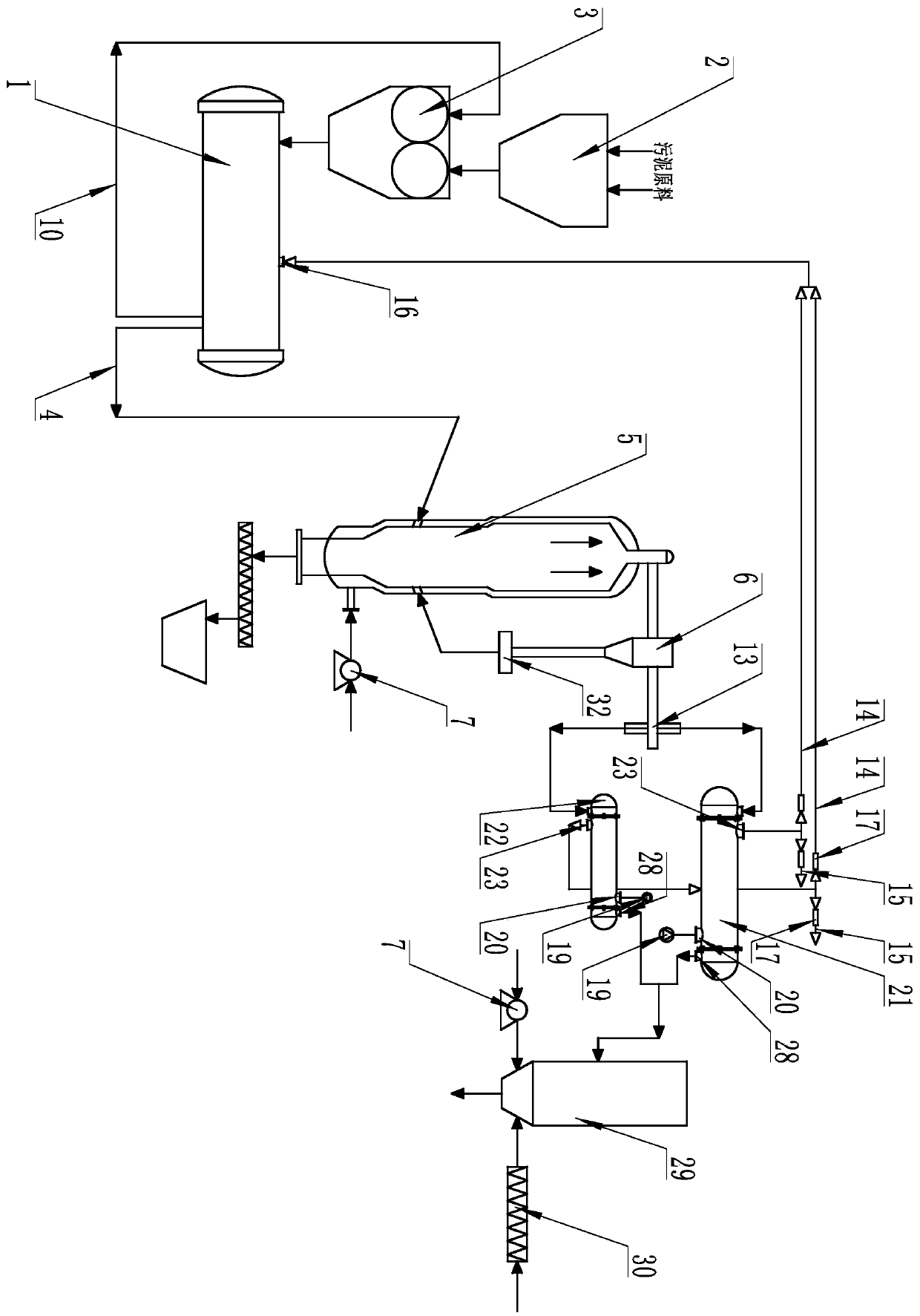

Recovery system and recovery method for oil gas absorbed and desorbed by asymmetric double pots

ActiveCN106310699AReduce the pumping volumeExtend regeneration timeGas treatmentDispersed particle separationActivated carbonRecovery method

The invention discloses a recovery system and a recovery method for an oil gas absorbed and desorbed by asymmetric double pots. The recovery system comprises a first stop valve, a first-level oil gas condenser, a second-level oil gas condenser, a second stop valve, a first-level big activated carbon canister and a third stop valve, wherein an oil gas inlet is connected with one end of the first stop valve; a positive input end of the first-level oil gas condenser is connected with the other end of the first stop valve; a positive output end of the first-level oil gas condenser is connected with an input end of the second-level oil gas condenser; an output end of the second-level oil gas condenser is connected with a negative input end of the first-level oil gas condenser; a negative output end of the first-level oil gas condenser is connected with one end of the second stop valve; the other end of the second stop valve is connected with one end of the first-level big activated carbon canister; one end of the third stop valve is connected with the other end of the first-level big activated carbon canister; the other end of the third stop valve is connected with a first oil gas outlet; the first stop valve, the first-level oil gas condenser, the second-level oil gas condenser, the first-level oil gas condenser, the second stop valve, the first-level big activated carbon canister and the third stop valve are successively connected and form an oil gas recycling subsystem.

Owner:上海聚宸新能源科技有限公司

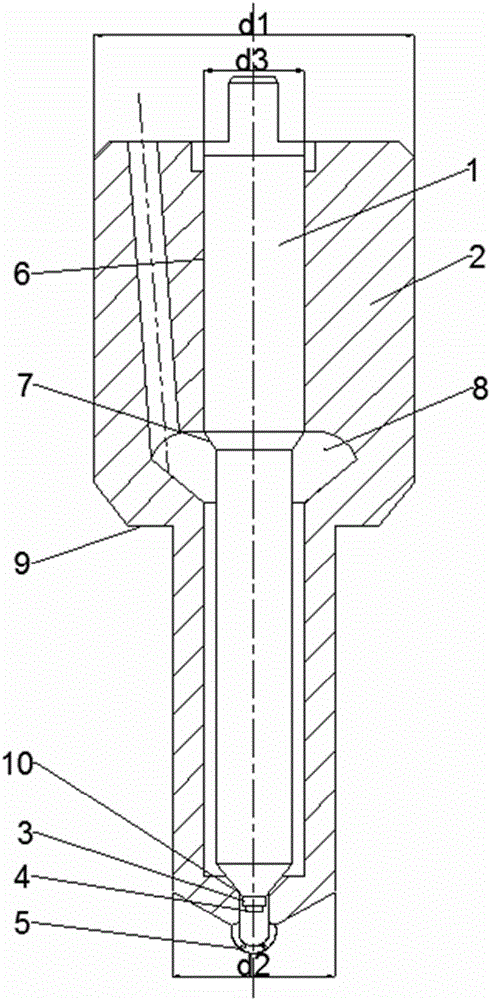

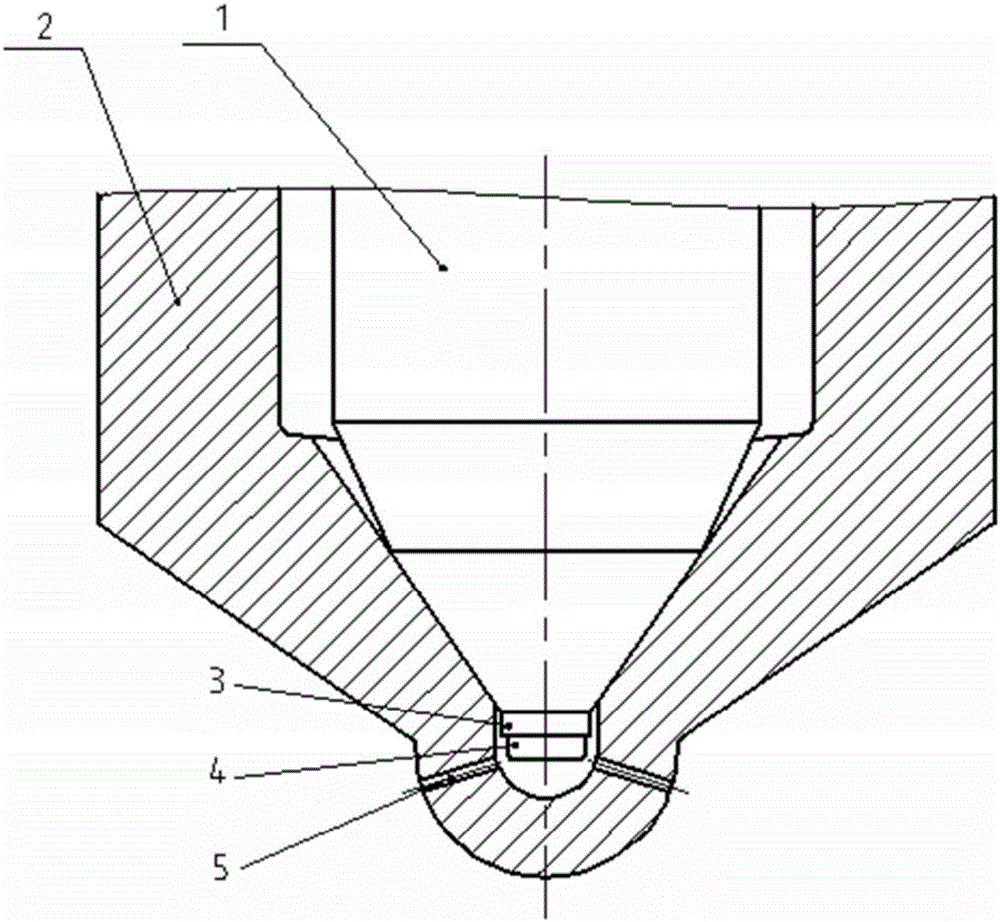

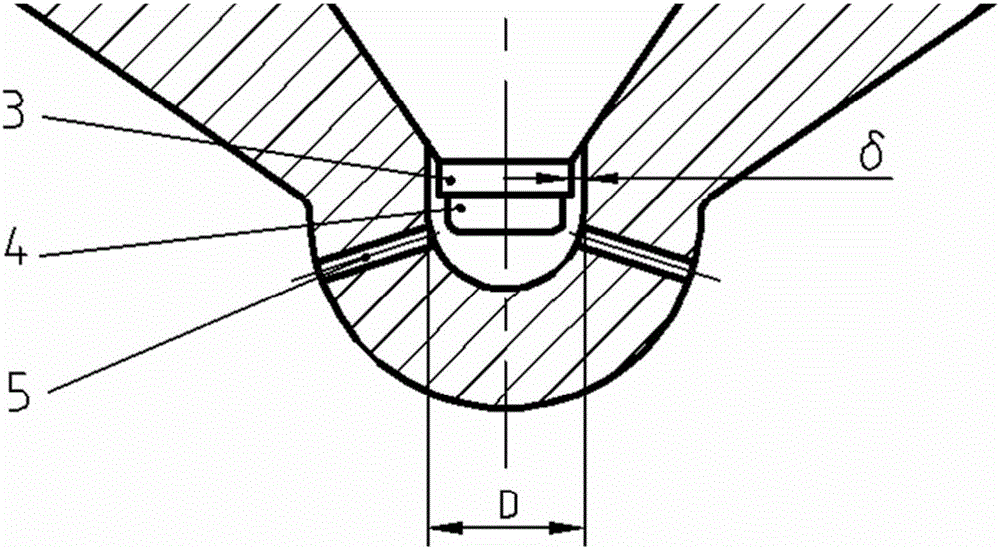

Hole type oil nozzle for controlling low-oil-amount spraying stability of commercial vehicle diesel engine

InactiveCN106762303AHigh working reliabilityExtended service lifeFuel injection apparatusMachines/enginesEngineeringFuel oil

The invention discloses a hole type oil nozzle for controlling low-oil-amount spraying stability of a commercial vehicle diesel engine. The hole type oil nozzle comprises a needle valve and a needle valve body, the head of the needle valve is composed of two stairs, the height of the first stair is 0.2-0.8 time the maximum lift range of the needle valve, and the diameter of the first stair is slightly larger than that of the second stair; in the small needle valve lift range, the annular circulating sectional area of fuel oil between the head of the needle valve and the needle valve body in a pressure chamber is decreased to be smaller than the spraying hole area, and then precise control over small-flow fuel oil spraying is achieved; the inner diameter of the upper portion of the needle valve body is the same as the outer diameter of the needle valve and is in clearance fit with the outer diameter of the needle valve, and then an axial sealing surface for high-pressure fuel oil is formed; an oil nozzle sealing conical surface used for controlling high-pressure fuel oil spraying is formed by a conical body arranged on the lower portion of the needle valve body and a boss arranged on the head of the needle valve; the outer diameter d2 of the lower portion of the needle valve body of the oil nozzle ranges from 11 mm to 13 mm. According to the hole type oil nozzle, the low-oil-amount fuel oil flowing performance of the oil nozzle and the low-oil-amount spraying stability are improved while the spraying reliability and power performance under the condition of the high circulating oil supply amount are guaranteed.

Owner:JIANGSU UNIV

Floatation column intensified separation device with filler structure and separation method

InactiveCN105834011ASolve the problem of unstable concentrate qualityReduce backmixingFlotationMineral particlesEngineering

The invention discloses a floatation column intensified separation device with a filler structure. The floatation column intensified separation device with the filler structure comprises a hollow column body, wherein a foam collection device is arranged at the top of the column body; a filler, a middling mineralization pipe, a screen plate and a middling collection hopper are sequentially arranged inside the column body from top to bottom; a discharge hole connected with a tailing pipe is formed in the bottom of the column body; the middling collection hopper is connected with a middling nozzle through a middling circulating pulp pump; the middling nozzle is arranged at the top of the middling mineralization pipe; an air inlet pipe is arranged at the middle upper part of the middling mineralization pipe; and a crude ore feeding pipe is arranged at the upper part of the column body. The invention further provides an ore separation method. According to the separation device and the separation method, static separation is achieved on the mineralized mineral particles, the backmixing and inclusion of mineral impurities and fine silt which are not floatable are reduced, and the quality of a concentrate product is improved.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

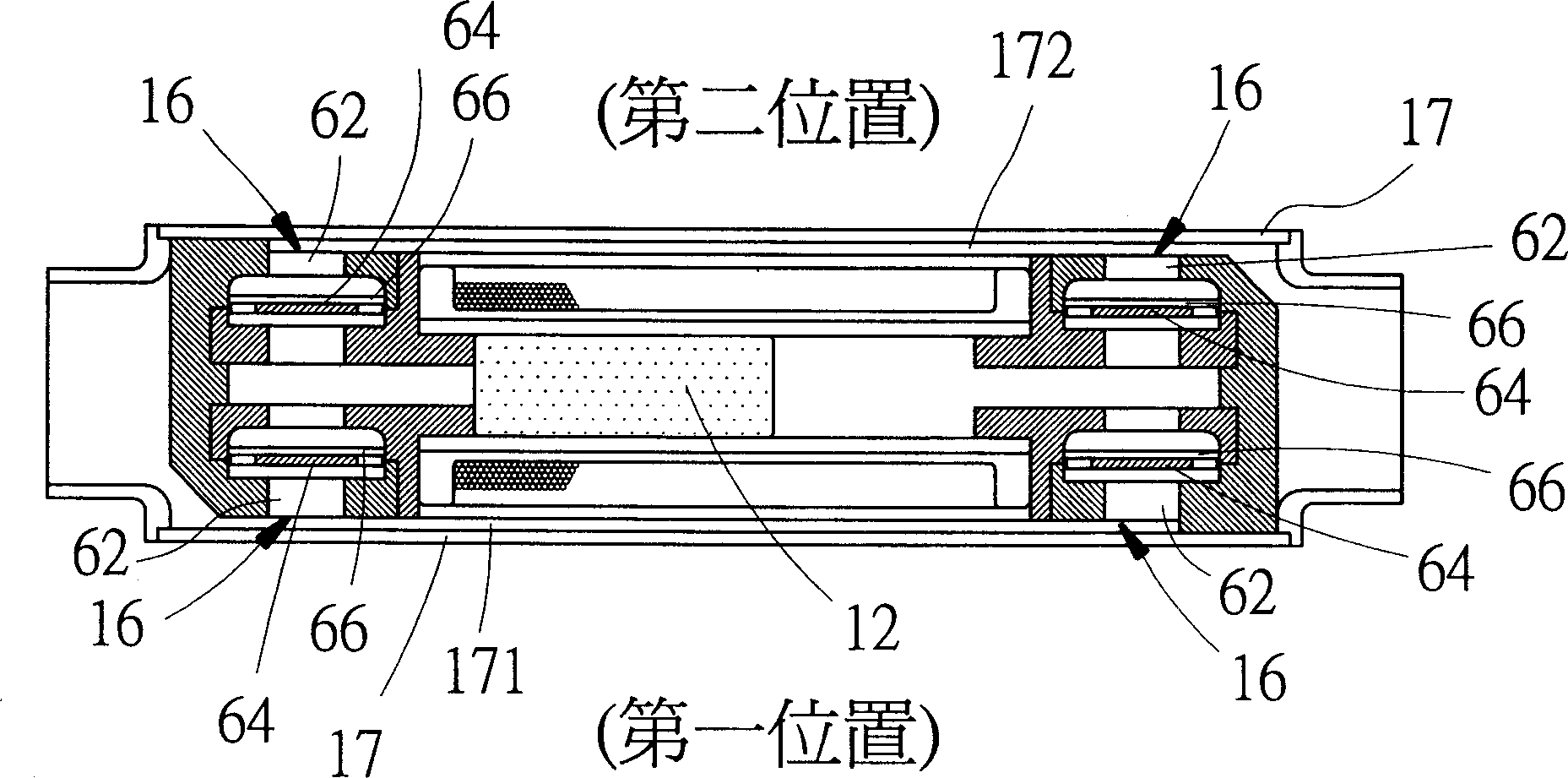

Pump unit using magnetic driving core body

InactiveCN1869442AReduce the pumping volumeEasy to assemblePositive displacement pump componentsPumpsElectrical and Electronics engineering

The invention relates a pump unit that driving a core identity by magnetic force. It includes an identity, a core identity, and a coil. A container is contained in the identity, and the outside is magnetic guiding material. The core identity has a certain length. And the inner margin shape could be set in the container. The coil is twisting outside the identity, and connecting to a circuit that supply current to coil to drive the core identity taking back and forth movement. The container connecting the hatch of the identity, and two single direction valve sections set the two ends of the identity to allow the liquid flow from the first location to the second location direction to achieve the function of driving the liquid.

Owner:刘 明华 +2

No-shaft magnetic pump

ActiveCN1811192AReduce dissolution lossSimple structurePump componentsPump installationsImpellerControl theory

The present invention is one technological scheme of no-shaft magnetic pump with the pump vane wheel and the motor output shaft as the magnetically driven rotors and isolating sleeve to close the motor and the pumping space. The technological scheme has greatly simplified pump structure, greatly reduced volume loss and obviously raised pumping efficiency, and the closed isolating sleeve creates condition for reinforcing the cooling design.

Owner:丹东克隆先锋泵业有限公司

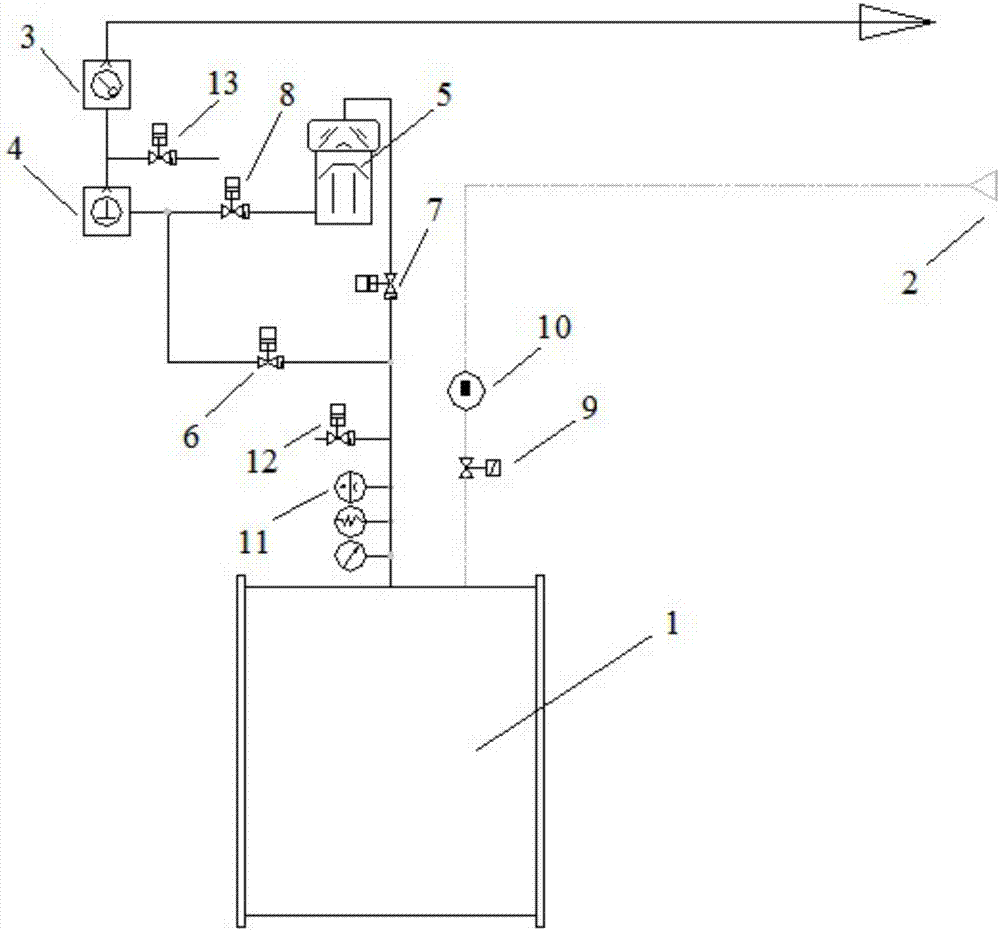

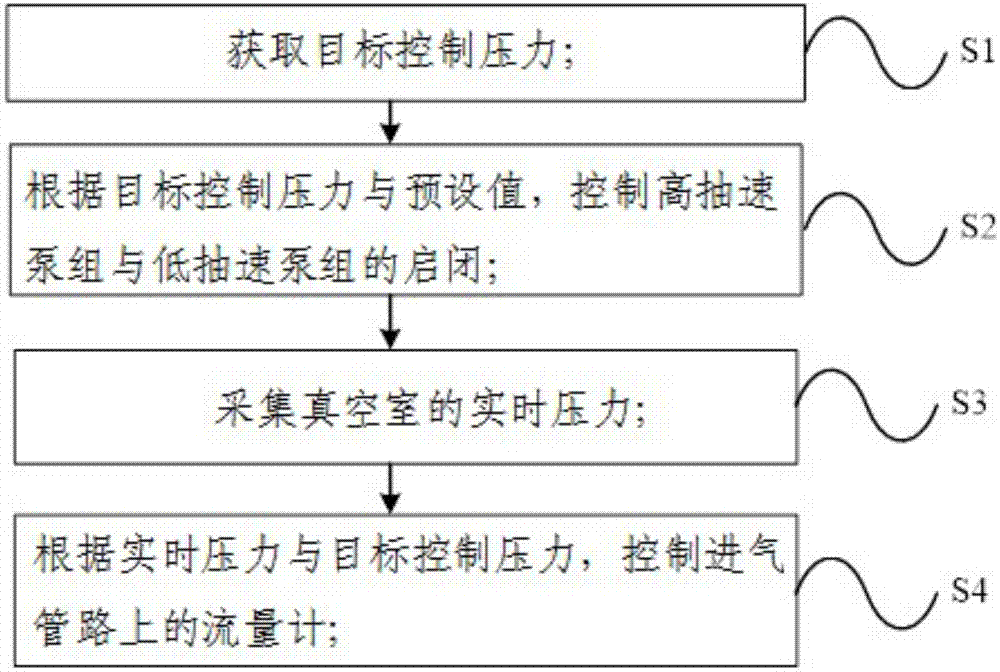

Pressure control system and pressure control method

InactiveCN107881306ARegulating pressureIncrease pressureHeat treatment process controlTarget controlControl system

The invention provides a pressure control system comprising a vacuum chamber, an air source, multiple grades of vacuum pump groups and a control unit. The vacuum chamber communicates with the air source through an intake pipeline. The intake pipeline is provided with an intake valve. The vacuum chamber communicates with the multiple grades of vacuum pump groups through an exhausting pipeline. A high vacuum valve is arranged on the exhaust pipeline. The intake valve, the high vacuum valve and the multiple grades of vacuum pump groups are connected with the control unit. The control unit controls the pumping speeds of the multiple grades of vacuum pump groups according to the target control pressure, so that pressure adjustment in a vacuum furnace is achieved. The invention provides a pressure control method. The pressure control method comprises the steps that the target control pressure is obtained; according to the target control pressure and a preset value, a high-pumping-speed pumpgroup and a low-pumping-speed pump group are controlled to started or stopped, if the target control pressure is higher than the preset value, the high-pumping-speed pump group is stopped, and the low-pumping-speed pump group is started, and if the target control pressure is lower than a preset value, the high-pumping-speed pump group and the low-pumping-speed pump group are both started. By the adoption of the pressure control system and the pressure control method, the change of the intake amount does not need to be changed, the cost is low, and the pressure control range is large.

Owner:北京北方华创磁电科技有限公司

Fuel pump for gasoline direct injection

ActiveUS20200309076A1Reduce in quantityReduce manufacturing costOperating means/releasing devices for valvesPositive displacement pump componentsGasoline direct injectionReciprocating motion

A fuel pump includes a fuel pump housing made of stainless steel and having a pumping chamber therewithin, a plunger bore extending thereinto, an inlet passage extending thereinto, and an outlet passage extending thereinto. A pumping plunger reciprocates within the plunger bore such that an intake stroke of the pumping plunger increases volume of the pumping chamber and a compression stroke of the pumping plunger decreases volume of the pumping chamber. An outlet valve controls fuel flow from the pumping chamber out of the fuel pump housing. The outlet valve includes an outlet valve seating surface formed by the fuel pump housing within the outlet passage such that a nitrided layer extends from the outlet valve seating surface into the fuel pump housing. The outlet valve also includes an outlet valve member within the outlet passage which is moveable between a seated position and an unseated position.

Owner:DELPHI TECH IP LTD

Sludge grading drying gasification coupled coal-fired power generation system and process method thereof

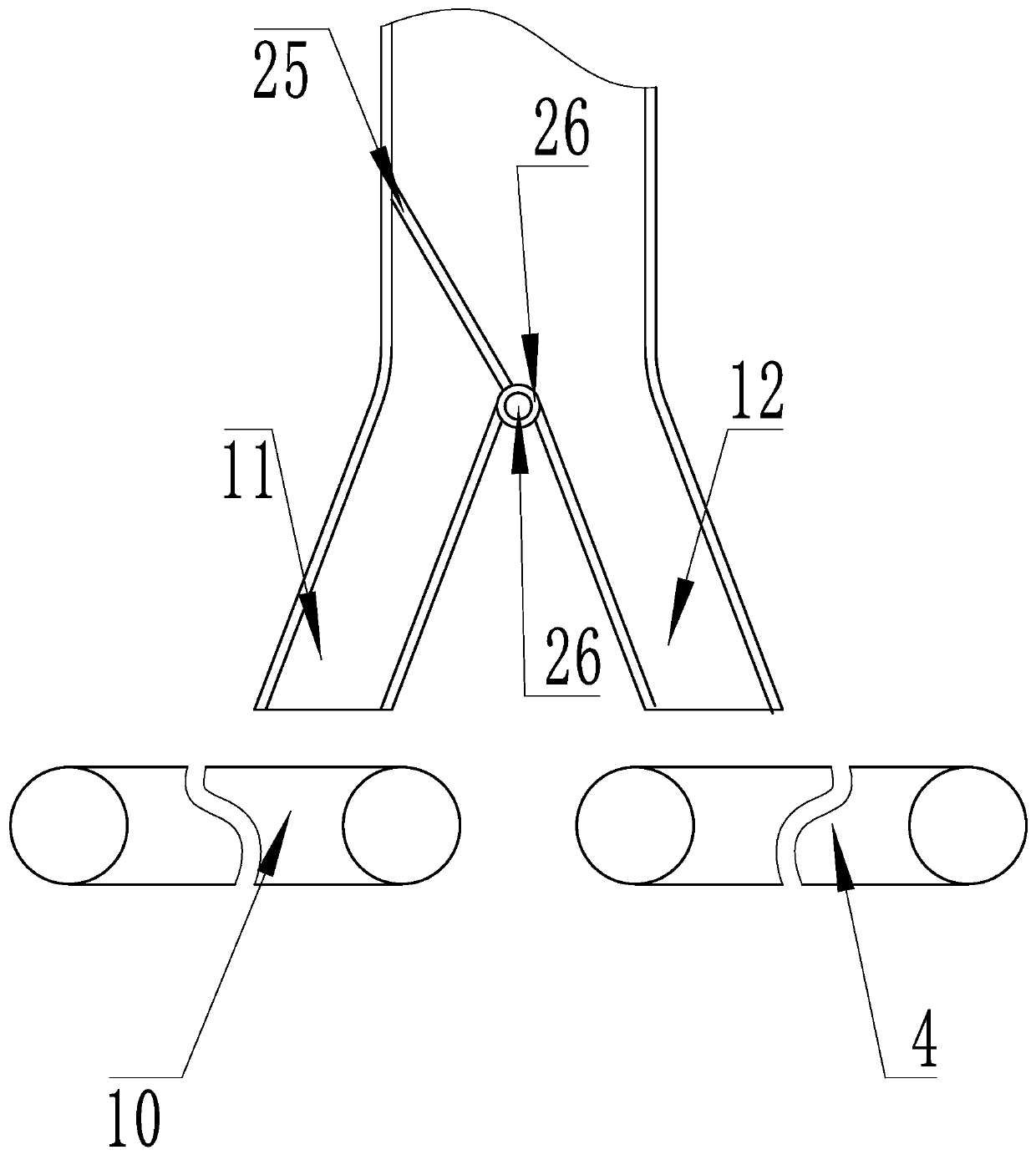

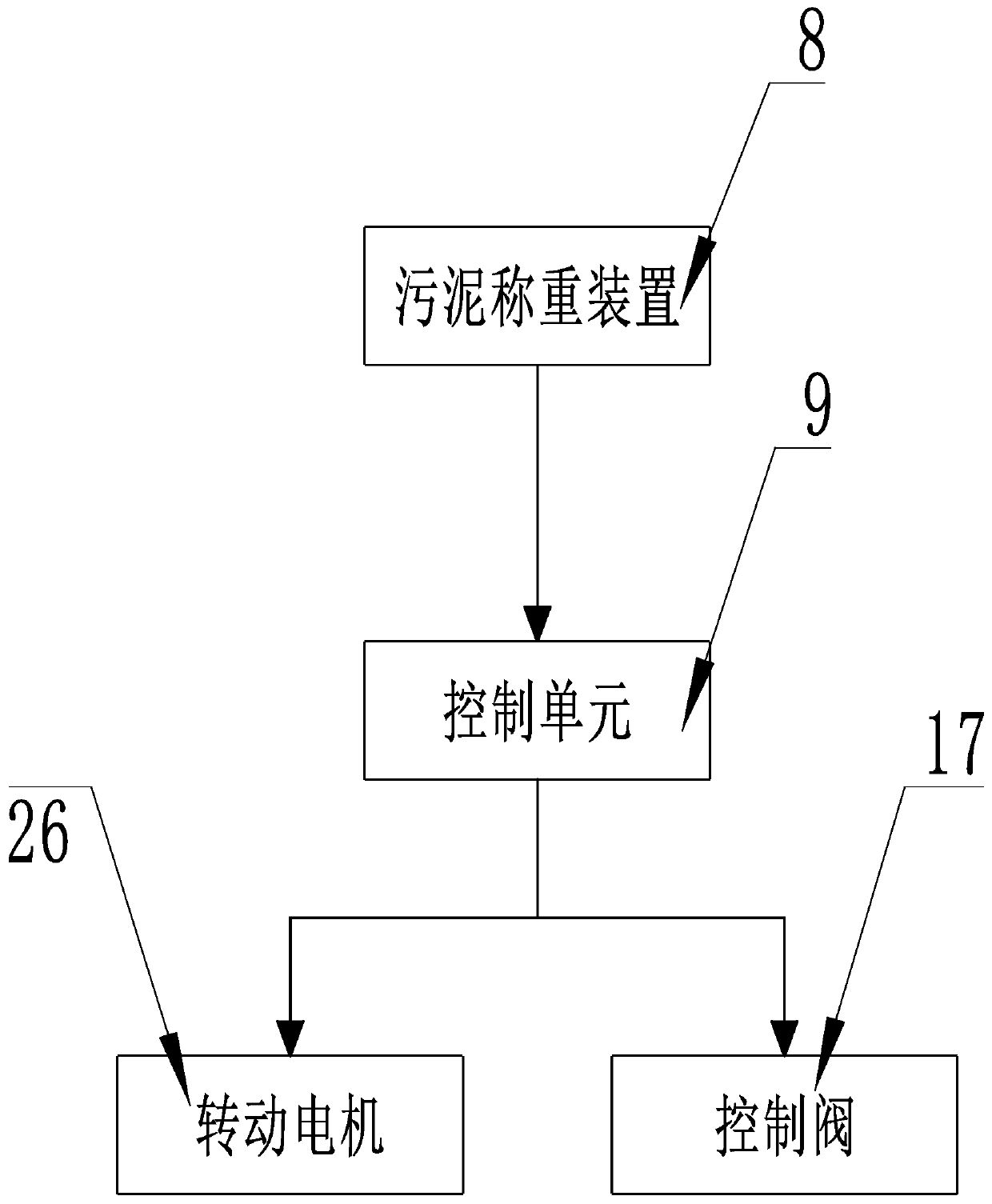

PendingCN110436740AIncrease burnoutIncrease profitSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeWater content

The invention relates to a sludge grading drying gasification coupled coal-fired power generation system, which is characterized in that a sludge weighing device is arranged in a drum type sludge drying box, and is connected to a control unit set with a sludge water content threshold, a dry sludge conveying device comprises a gasification conveying branch line connected to a circulation fluidizedbed sludge gasification furnace and a sludge circulation drying branch line connected to a sludge conveyor, the material outlet of the drum type sludge drying box comprises a gasification material outlet and a circulation sludge outlet closed or opened by the control unit, the gasification material outlet is connected to the gasification conveying branch line, and the circulation sludge outlet isconnected to the sludge circulation drying branch line. According to the present invention, the sludge grading drying gasification coupled coal-fired power generation system for reducing the sludge water content through circulation grading drying, and the process method thereof are provided.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com