Sleeve type dip pipe for RH (Ruhrstahl Hereaeus) vacuum refining device

A technology of vacuum refining and dipping tube, applied in the field of refining outside the molten steel furnace, can solve the problems of increasing the structural size of the dipping tube, and achieve the effects of prolonging the period of maintenance and final scrapping, reducing the maximum speed and reducing the amount of cold steel attached

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

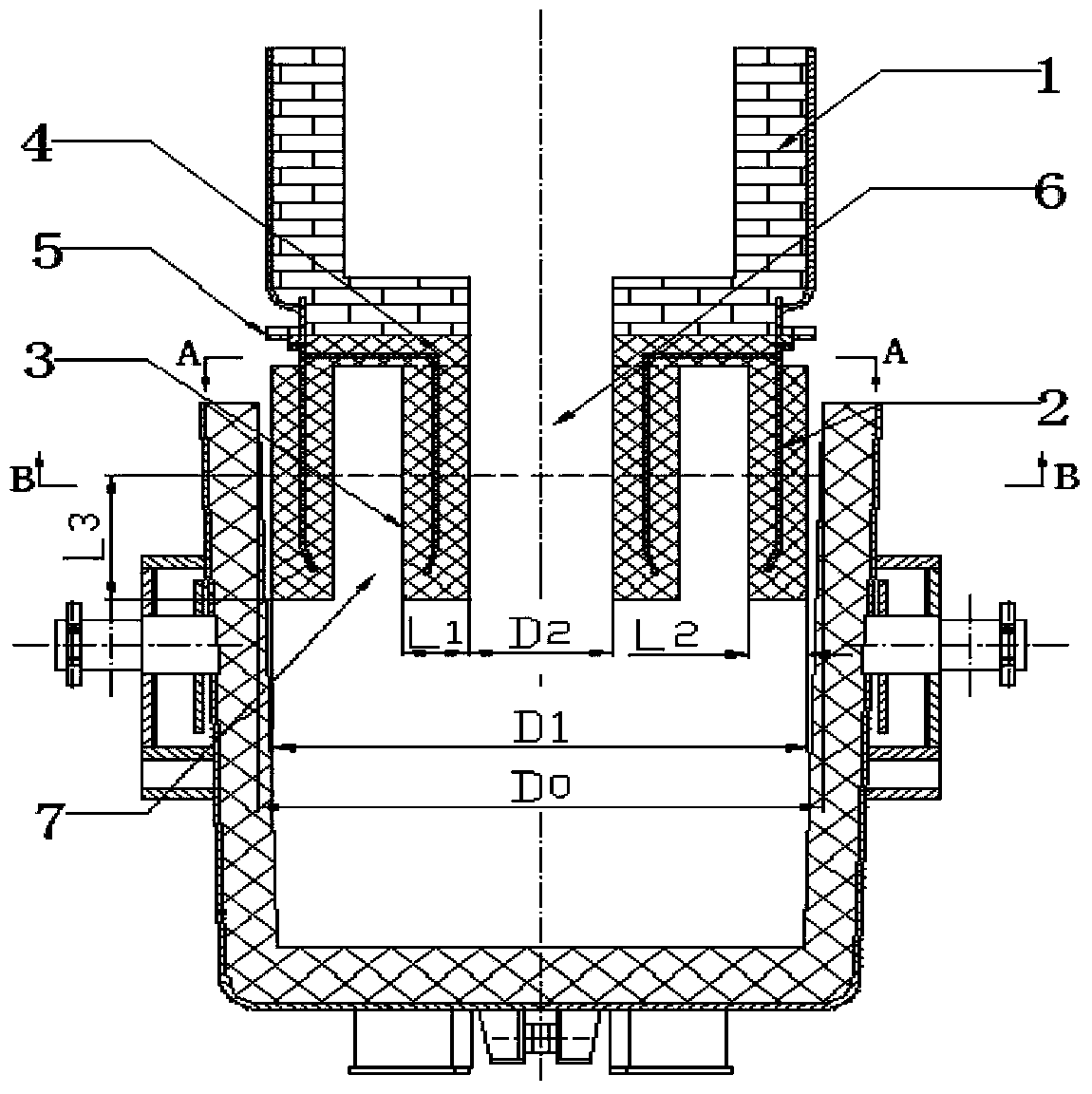

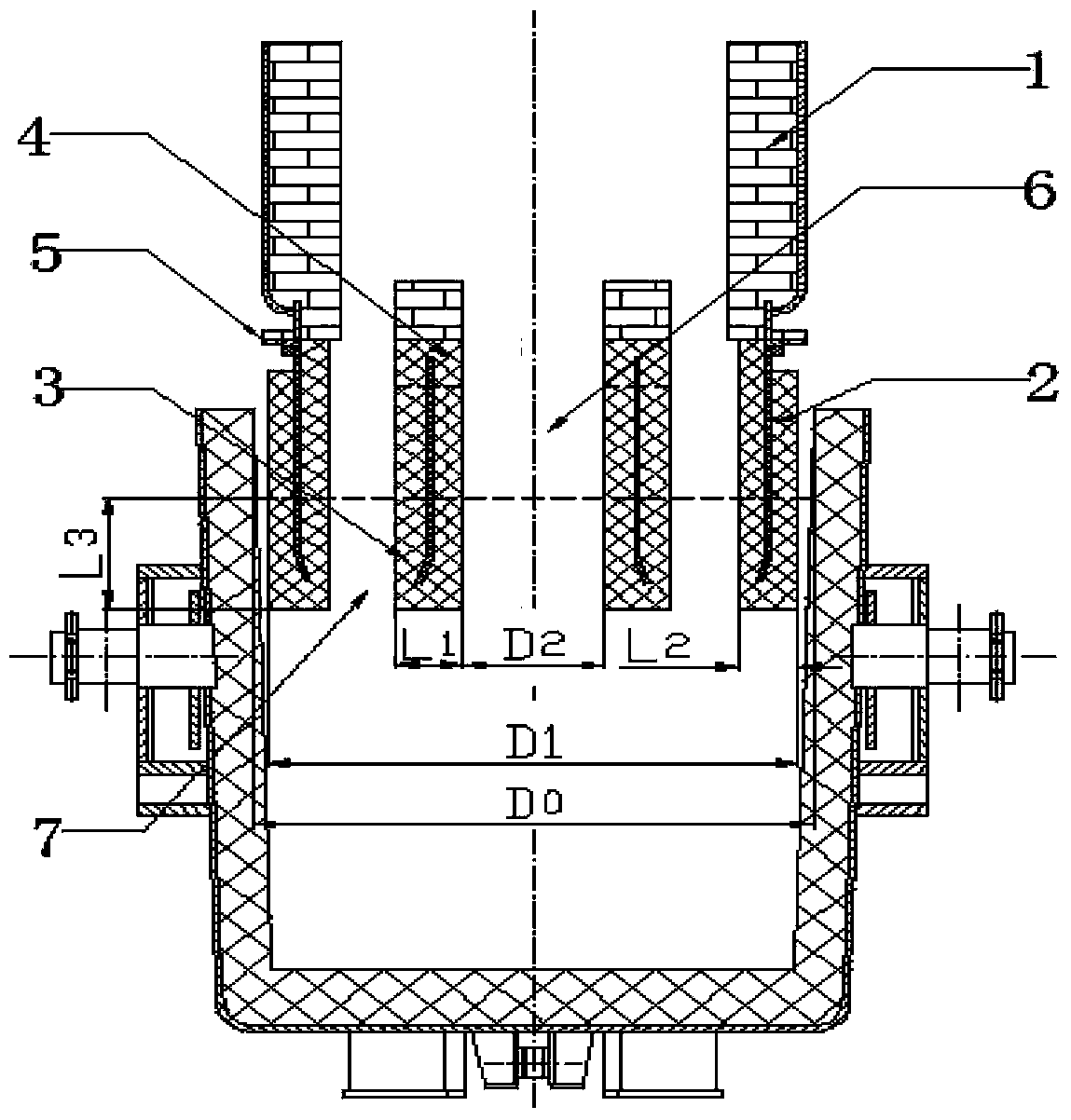

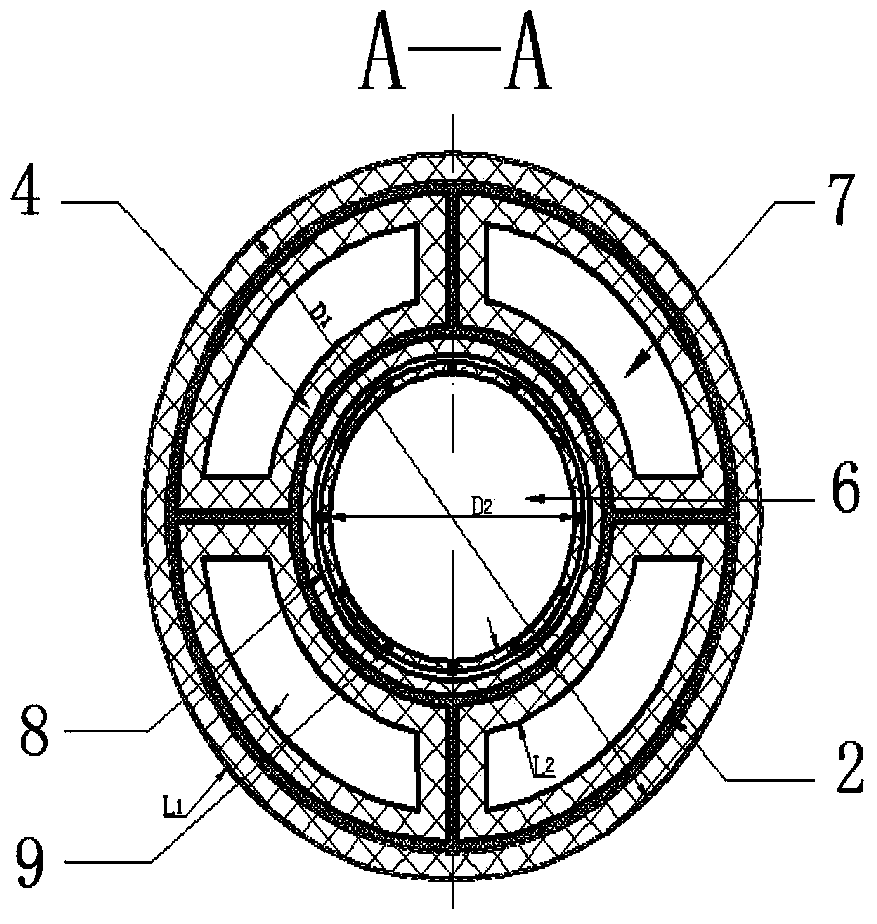

[0041] The present invention will be further described by taking the inner circular tube as the rising tube and the outer circular tube as the downcomer as an example. Such as figure 1 , figure 2 , image 3 and Figure 4As shown, the sleeve-type dipping tube used in the RH vacuum refining device of the present invention is mainly composed of an annular sleeve 2, a circular tube-shaped partition wall 3, a beam 4 and a flange 5, wherein: the annular sleeve 2 is the dipping tube The outer tube of the circular tube-shaped partition wall 3 is set up in the middle of the annular casing 2 and is coaxial with the annular casing 2. The girder 4 has an inner hole, and the diameter of the girder inner hole is consistent with the inner diameter of the tubular partition wall 3, and the steel structure inside the refractory lining is welded and fixed with the steel structure at the top of the tubular partition wall. The outer end of the girder is provided with 4 fin plates at an angle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com