Patents

Literature

271 results about "Lifting gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A lifting gas or lighter than air gas is a gas that has a lower density than normal atmospheric gases and rises above them as a result. It is required for aerostats to create buoyancy, particularly in Lighter-than-air aircraft, which include free balloons, moored balloons, and airships. Only certain lighter than air gases are suitable as lifting gases. Dry air has a density of about 1.29 g/L (gram per liter) at standard conditions for temperature and pressure (STP) and an average molecular mass of 28.97 g/mol, and so lighter than air gases have a density lower than this.

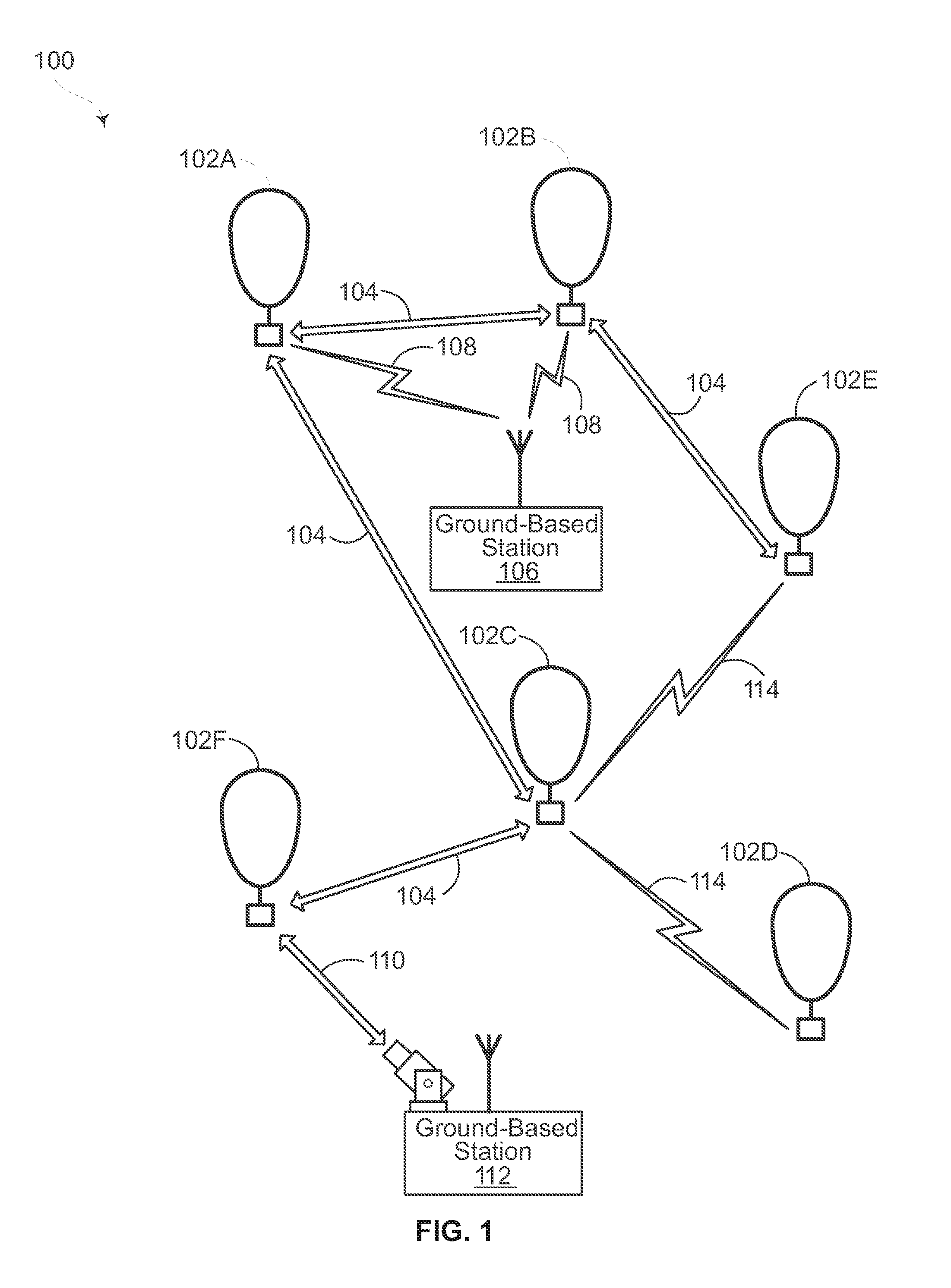

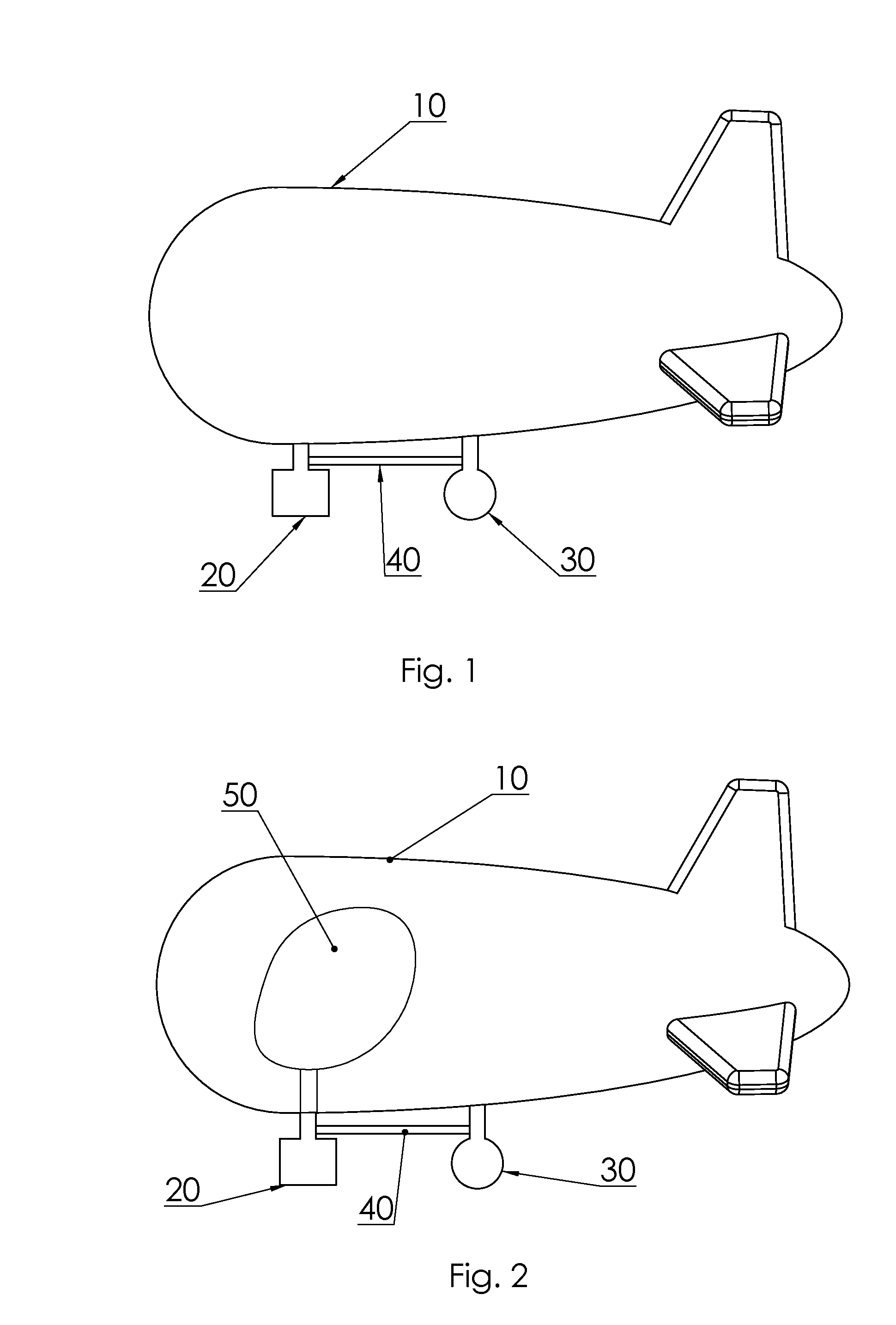

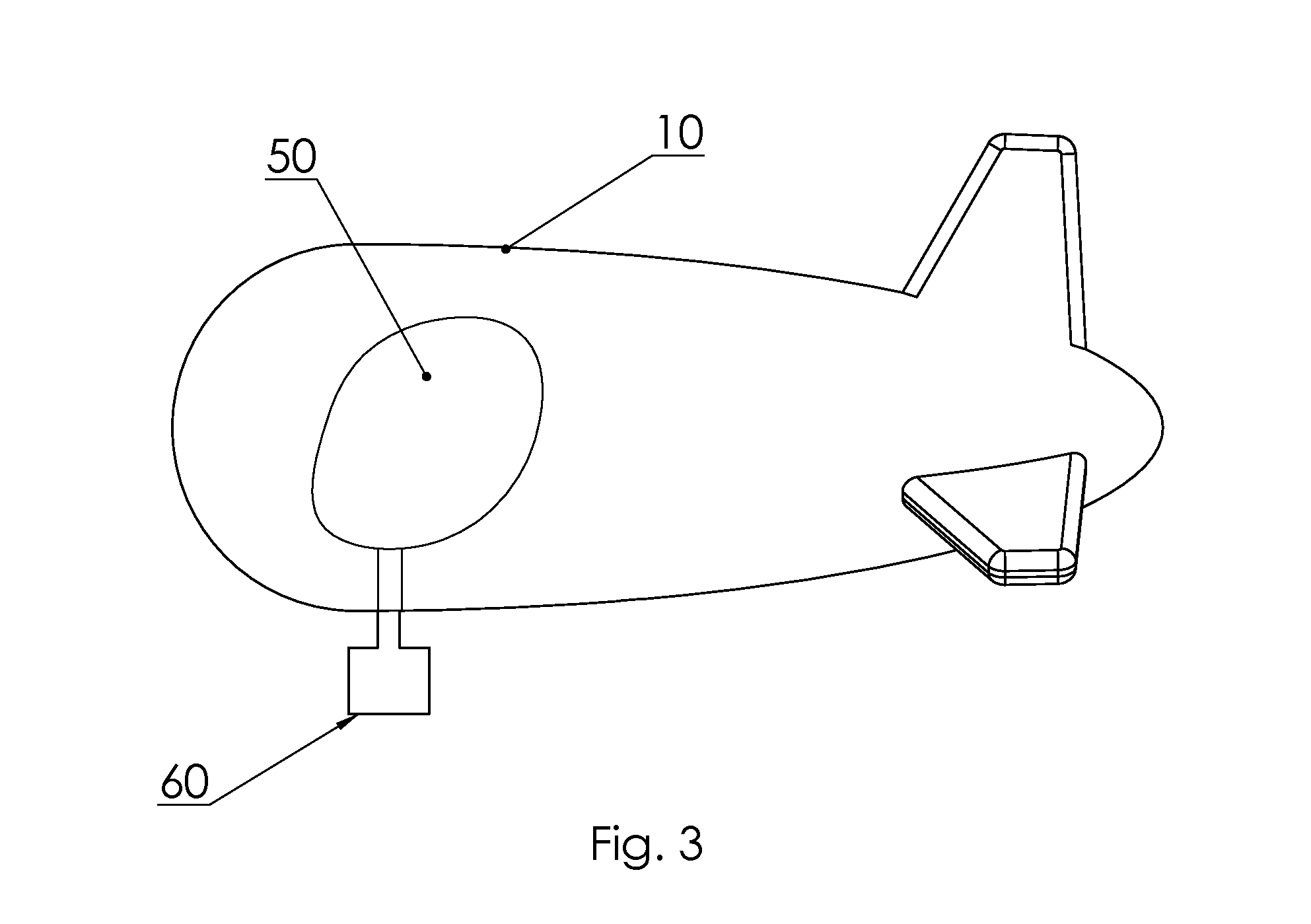

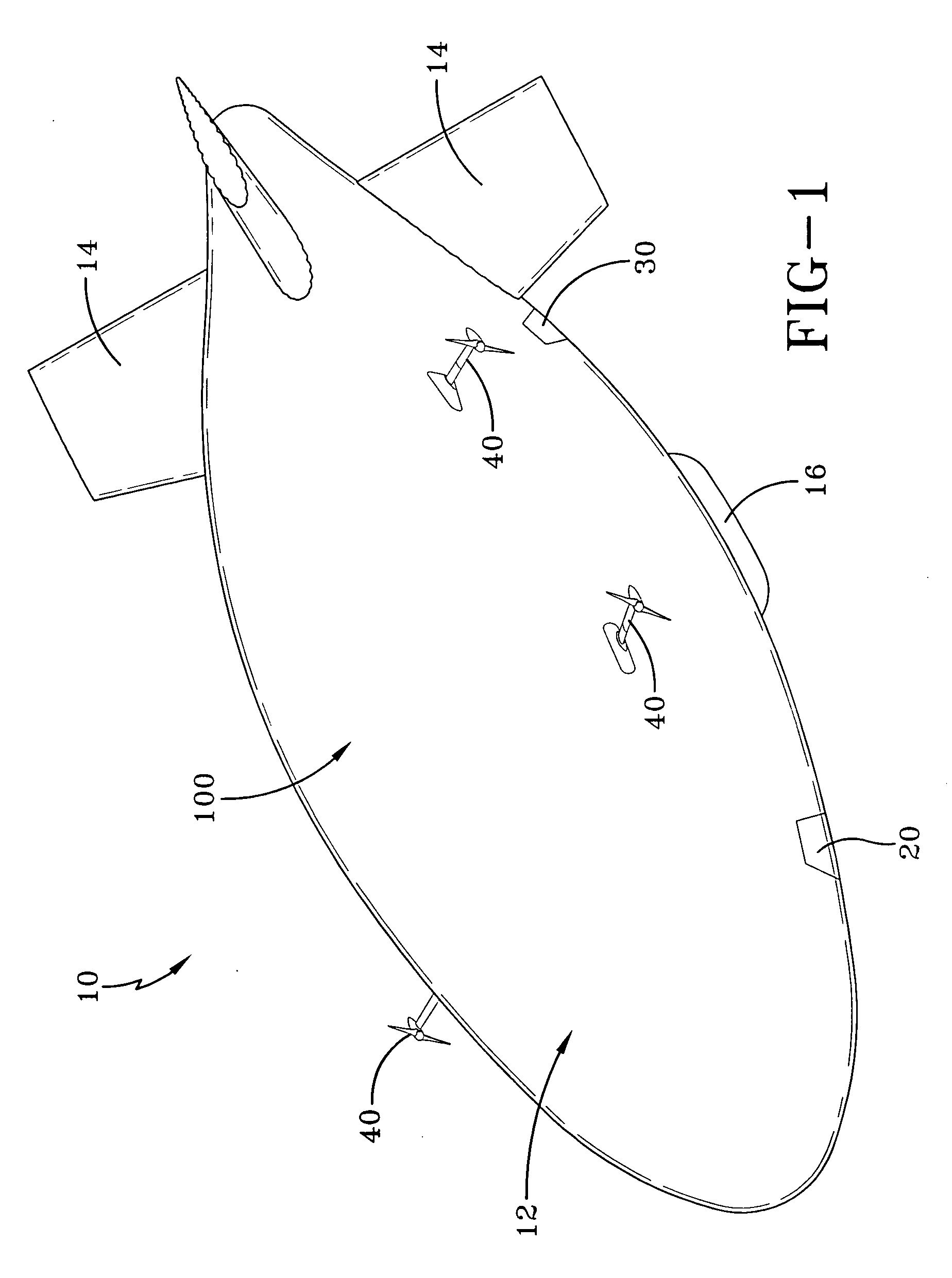

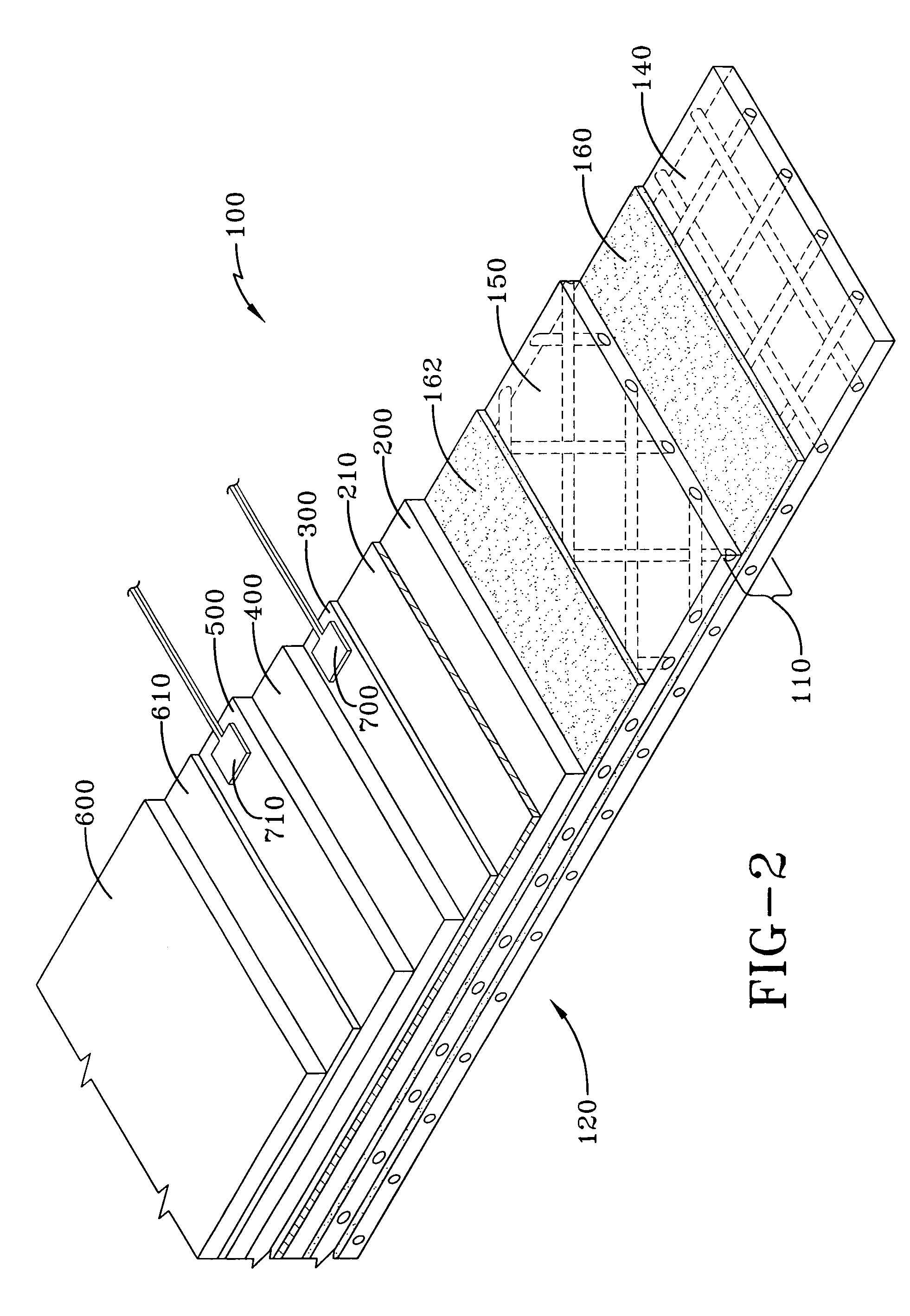

Systems for actively controlling the aerostatic lift of an airship

InactiveUS20060065777A1Statically heavyLess buoyantNon-rigid airshipsRigid airshipsInternal pressureAviation

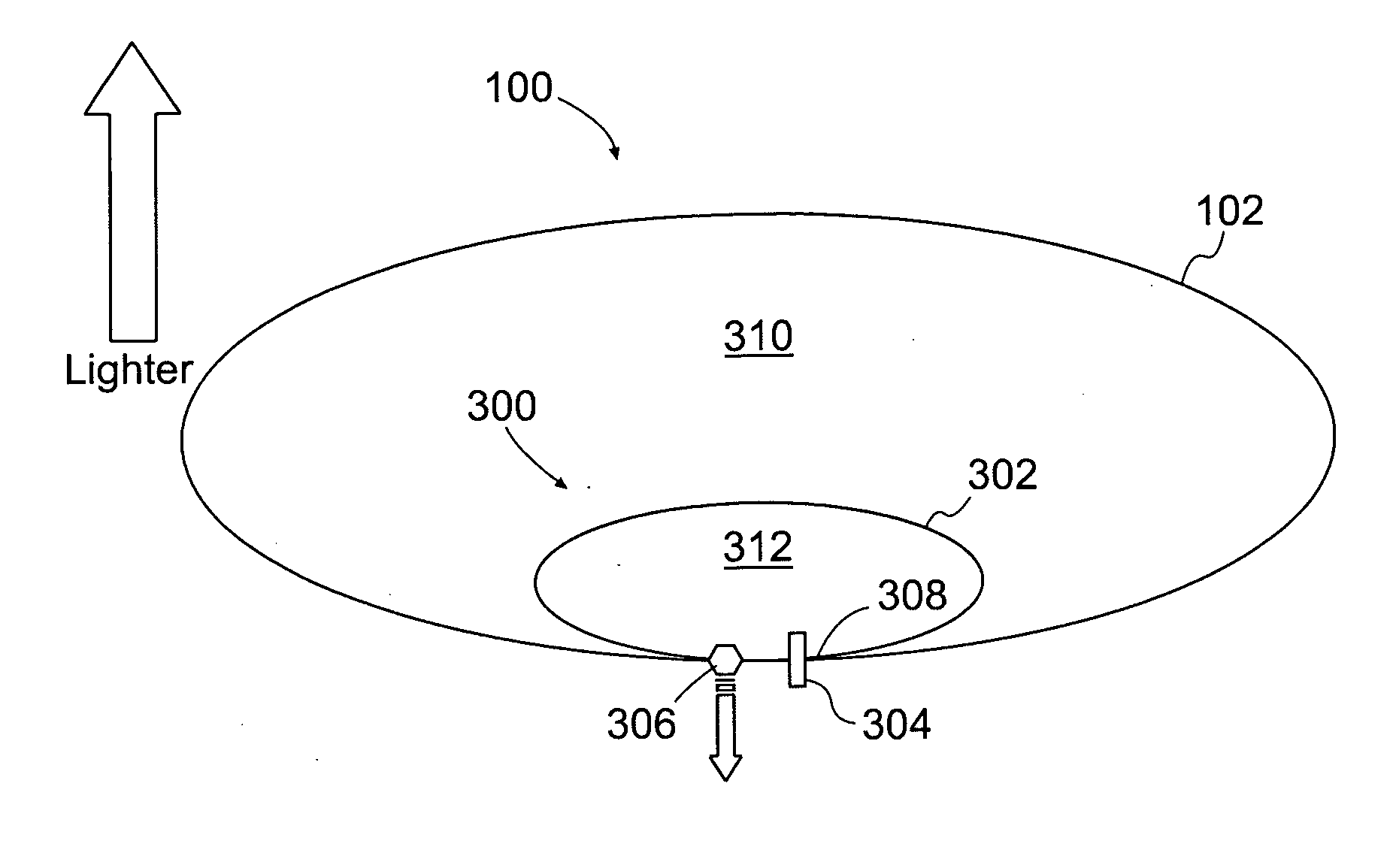

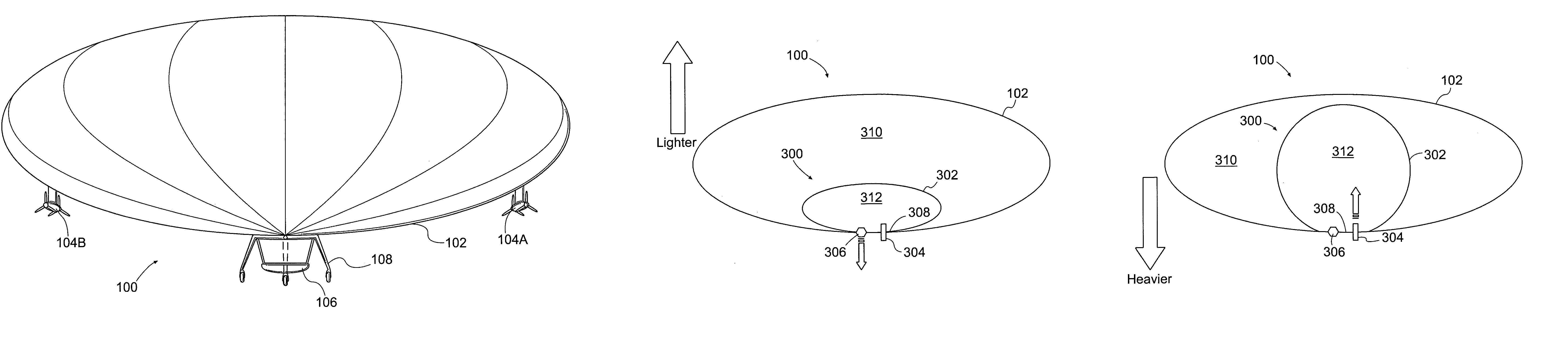

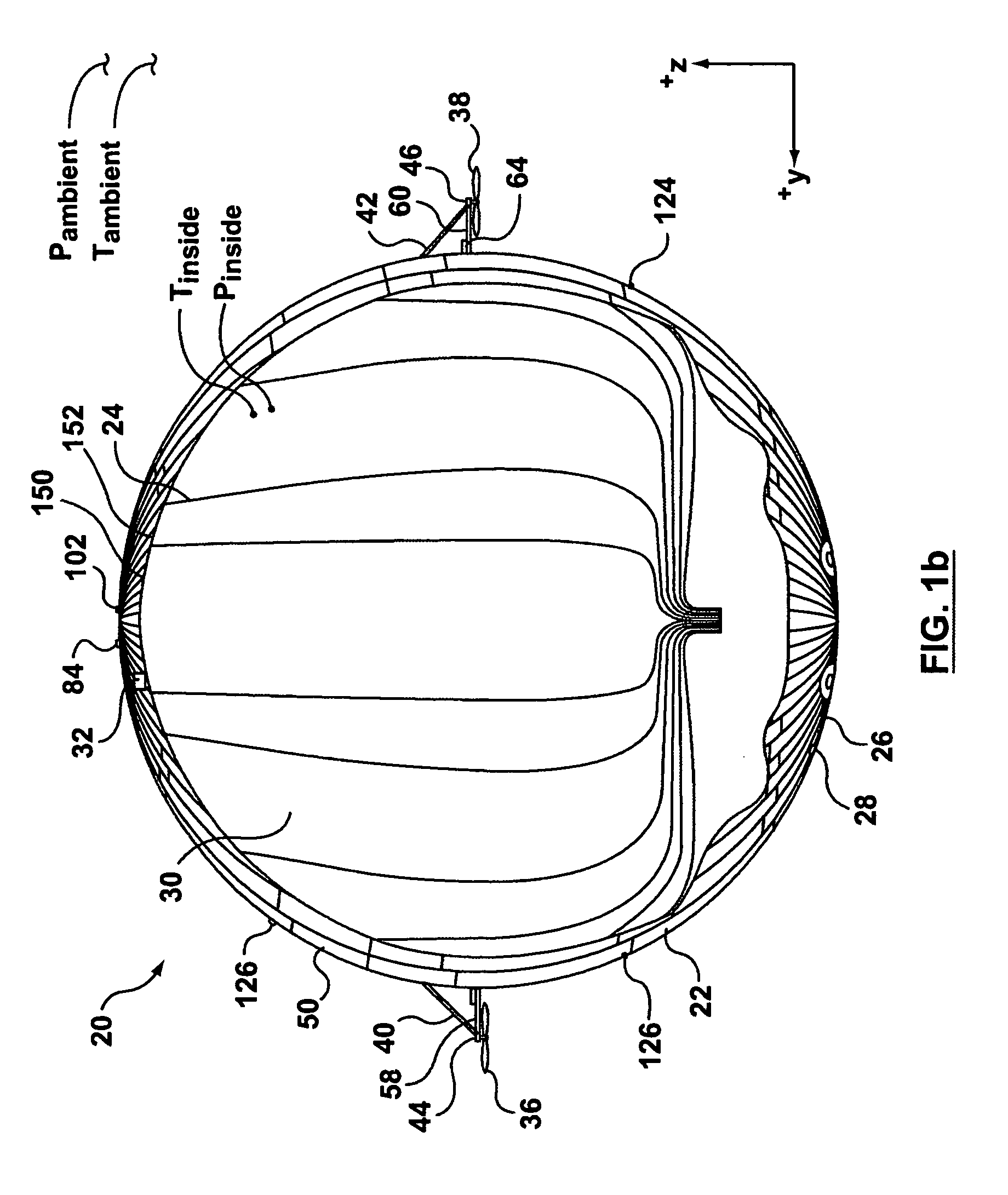

Various embodiments of the invention relate generally to systems for providing active vertical control of an airship. More particularly, at least one embodiment of the invention relates to a system for actively controlling the aerostatic lift of an airship by manipulating the ratio of air to lifting gas contained within the airship, and thus the overall mass of the airship. This manipulation is accomplished by actively compressing and / or decompressing the lifting gas or internal air, with the resulting pressure differential borne primarily by the hull and / or an internal pressure tank depending upon the configuration.

Owner:LTAS HLDG

Systems for actively controlling the aerostatic lift of an airship

InactiveUS7156342B2Statically heavyLess buoyantNon-rigid airshipsRigid airshipsInternal pressureLifting gas

Various embodiments of the invention relate generally to systems for providing active vertical control of an airship. More particularly, at least one embodiment of the invention relates to a system for actively controlling the aerostatic lift of an airship by manipulating the ratio of air to lifting gas contained within the airship, and thus the overall mass of the airship. This manipulation is accomplished by actively compressing and / or decompressing the lifting gas or internal air, with the resulting pressure differential borne primarily by the hull and / or an internal pressure tank depending upon the configuration.

Owner:LTAS HLDG

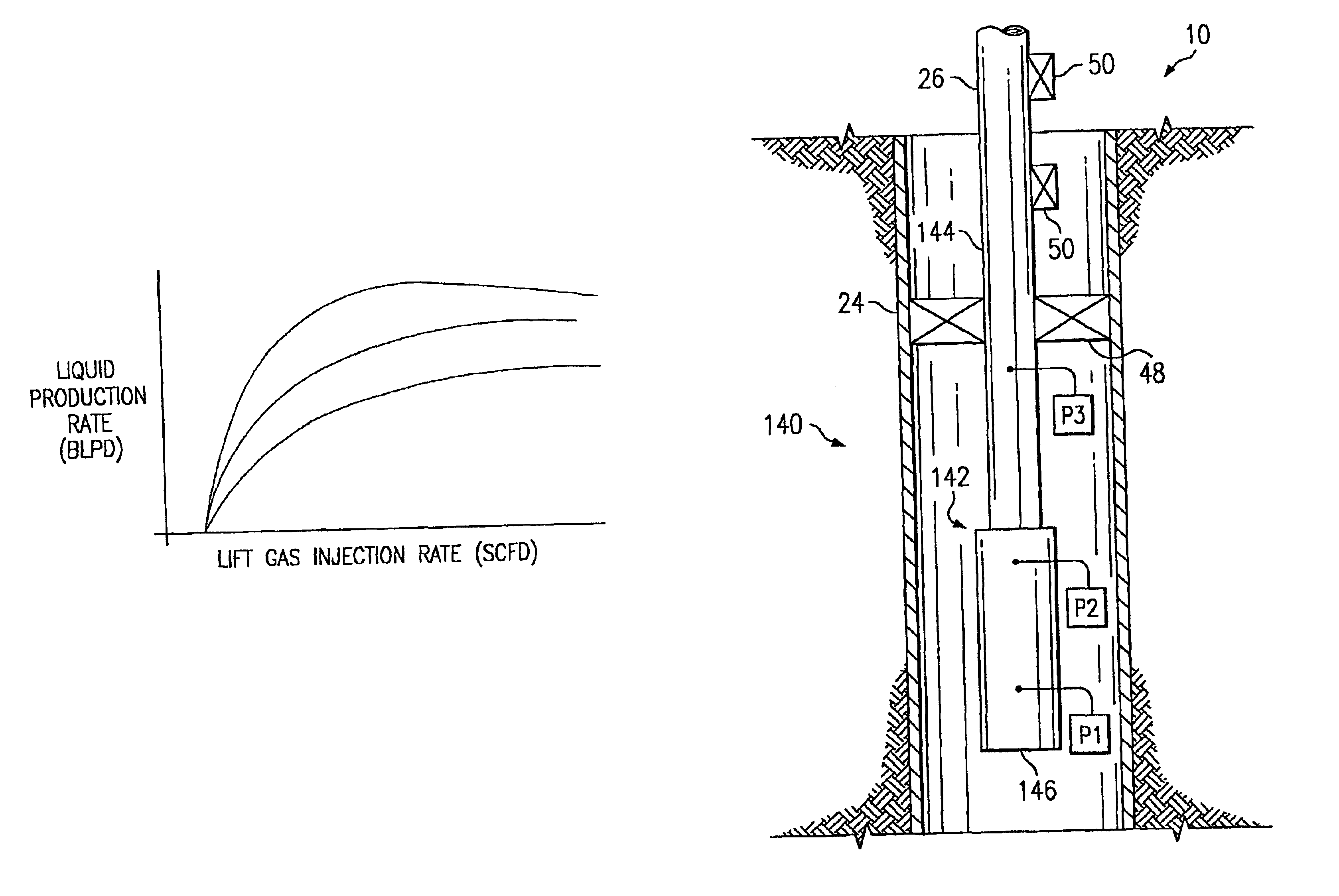

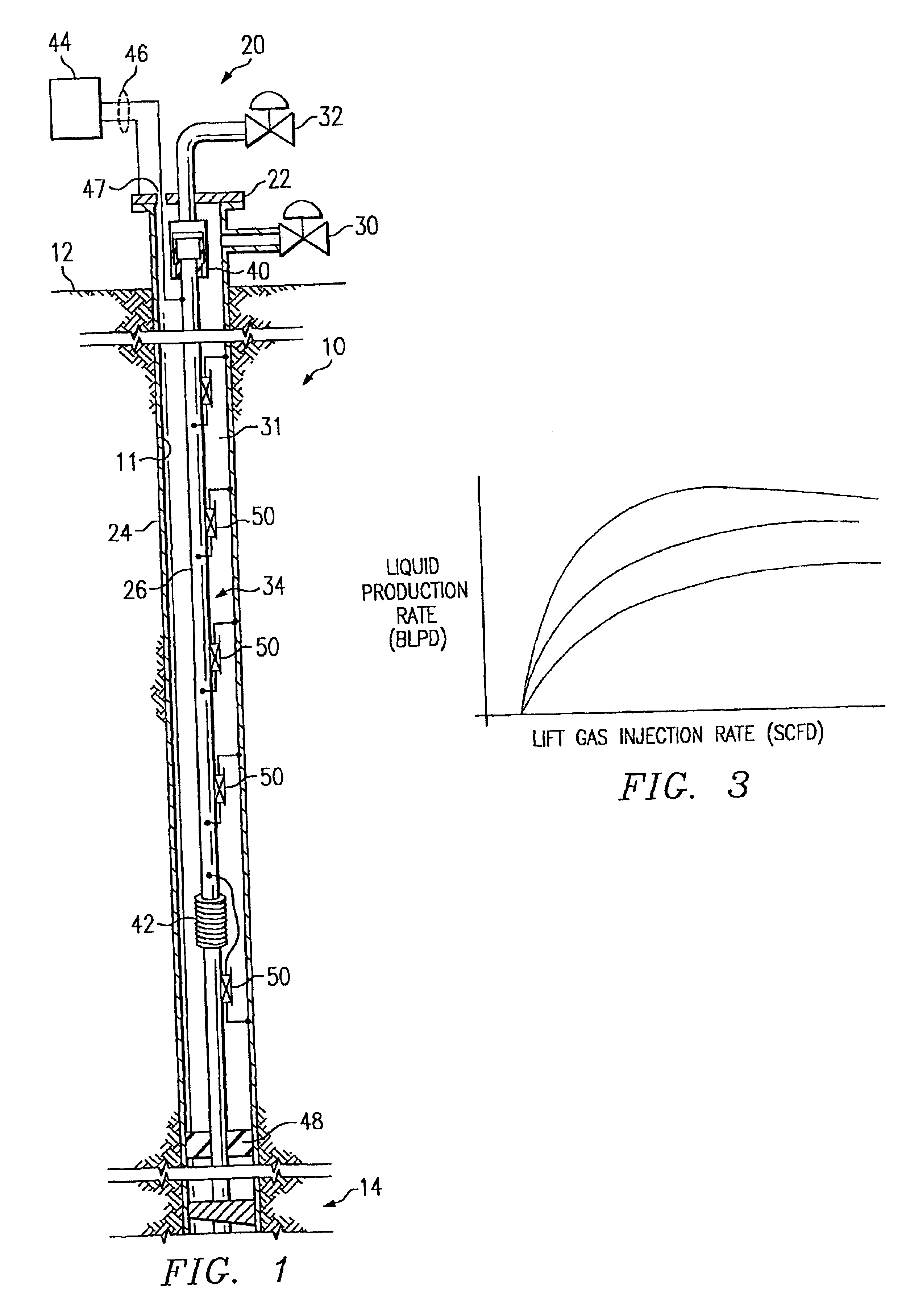

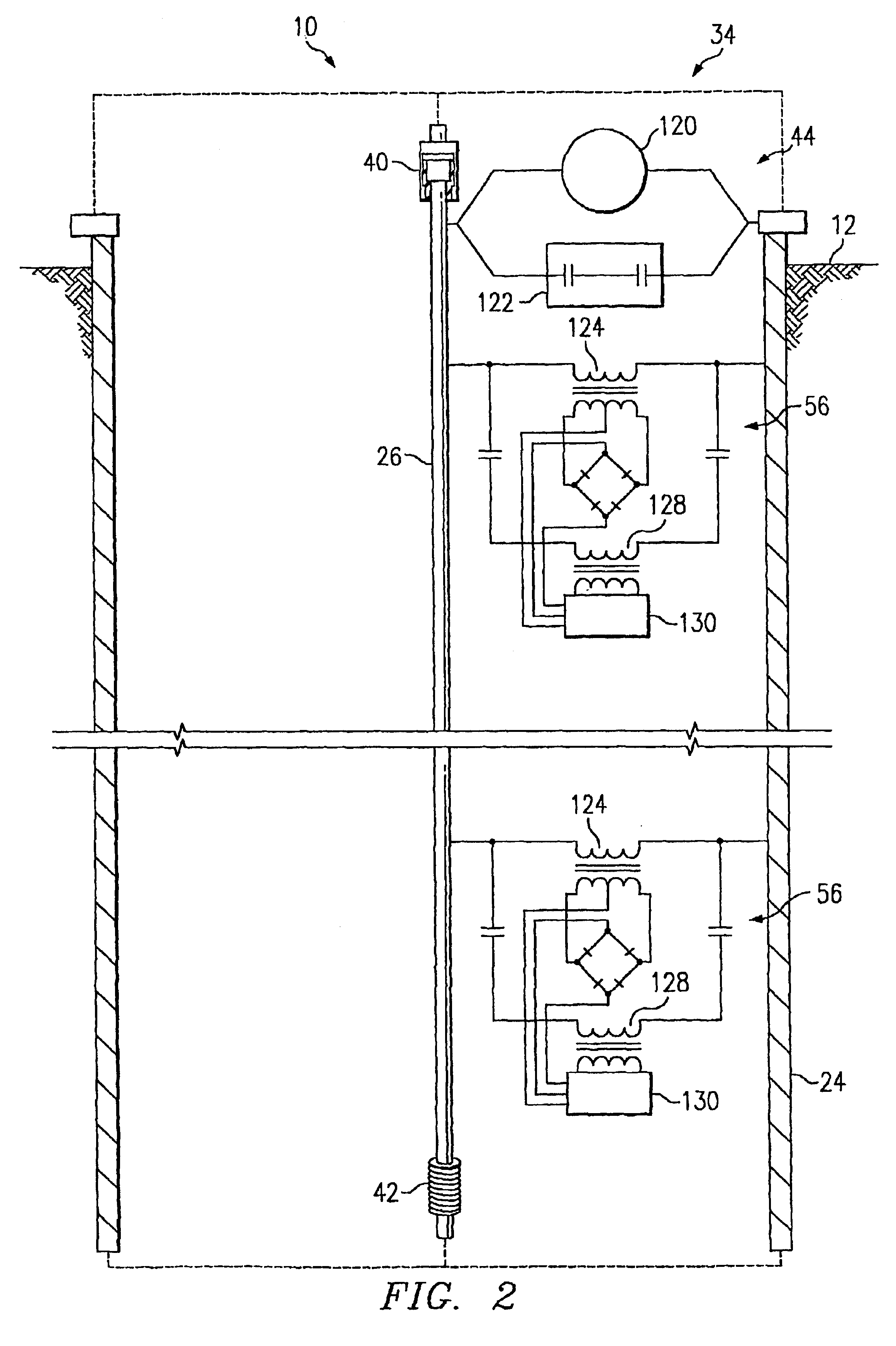

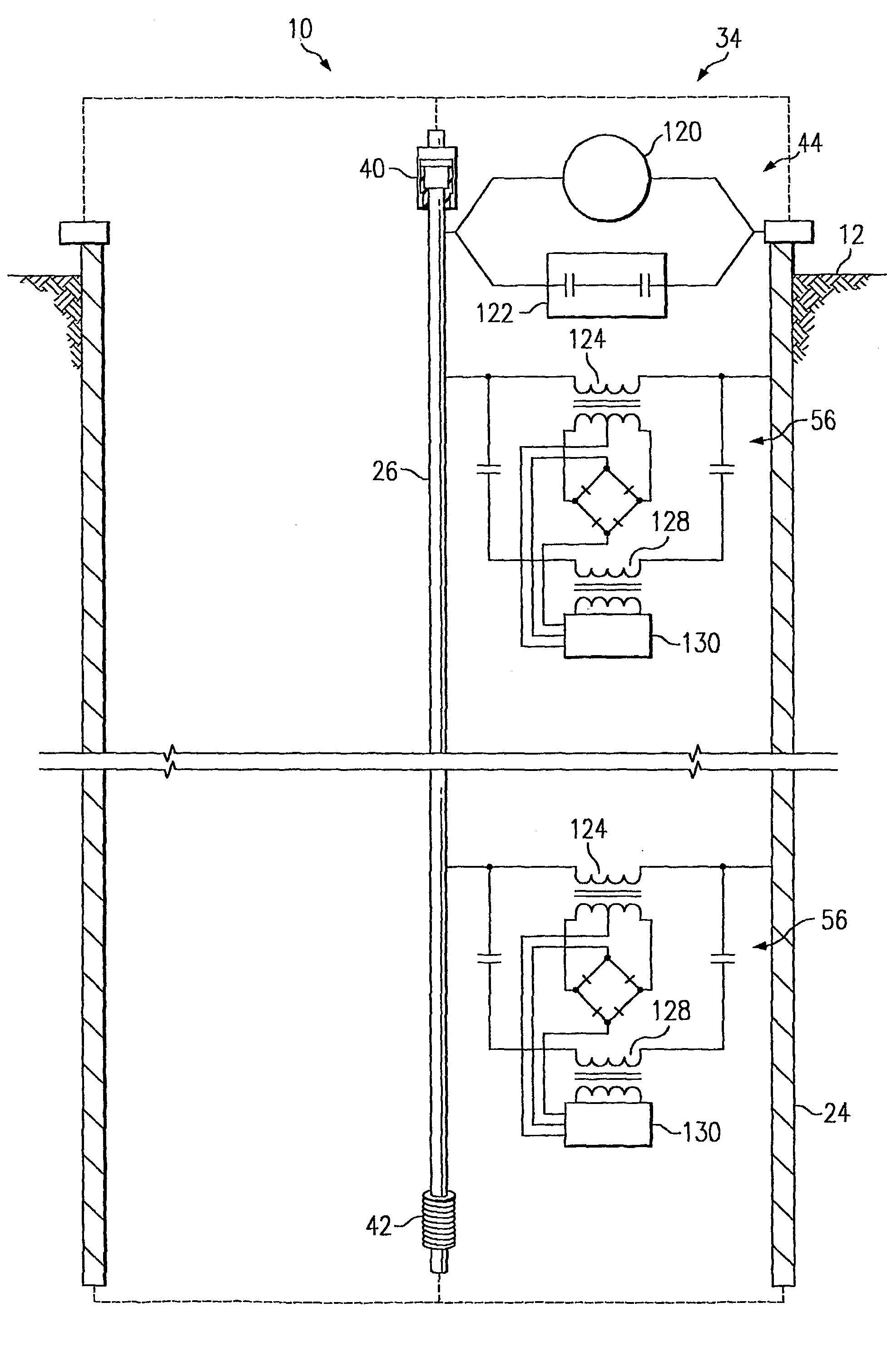

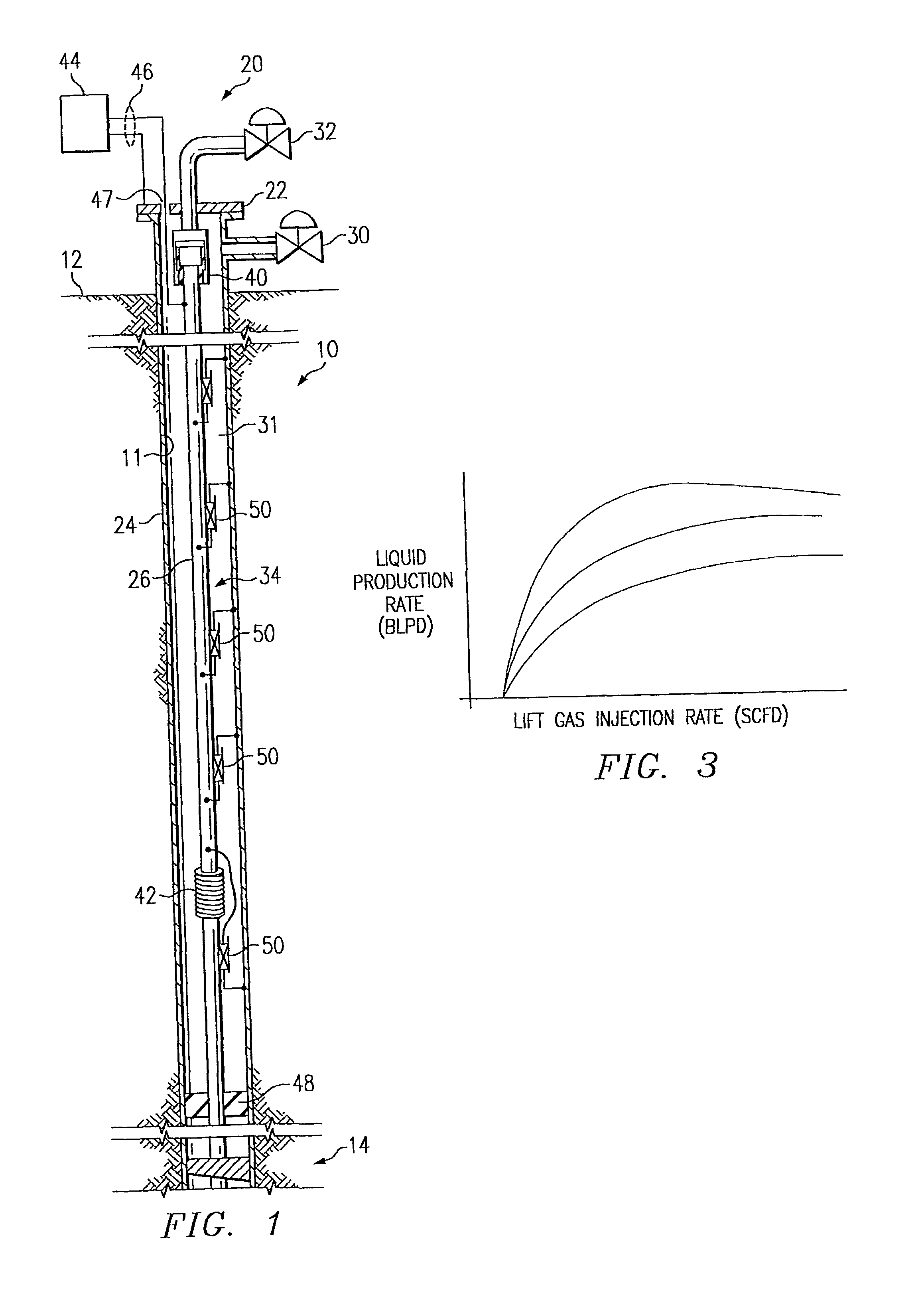

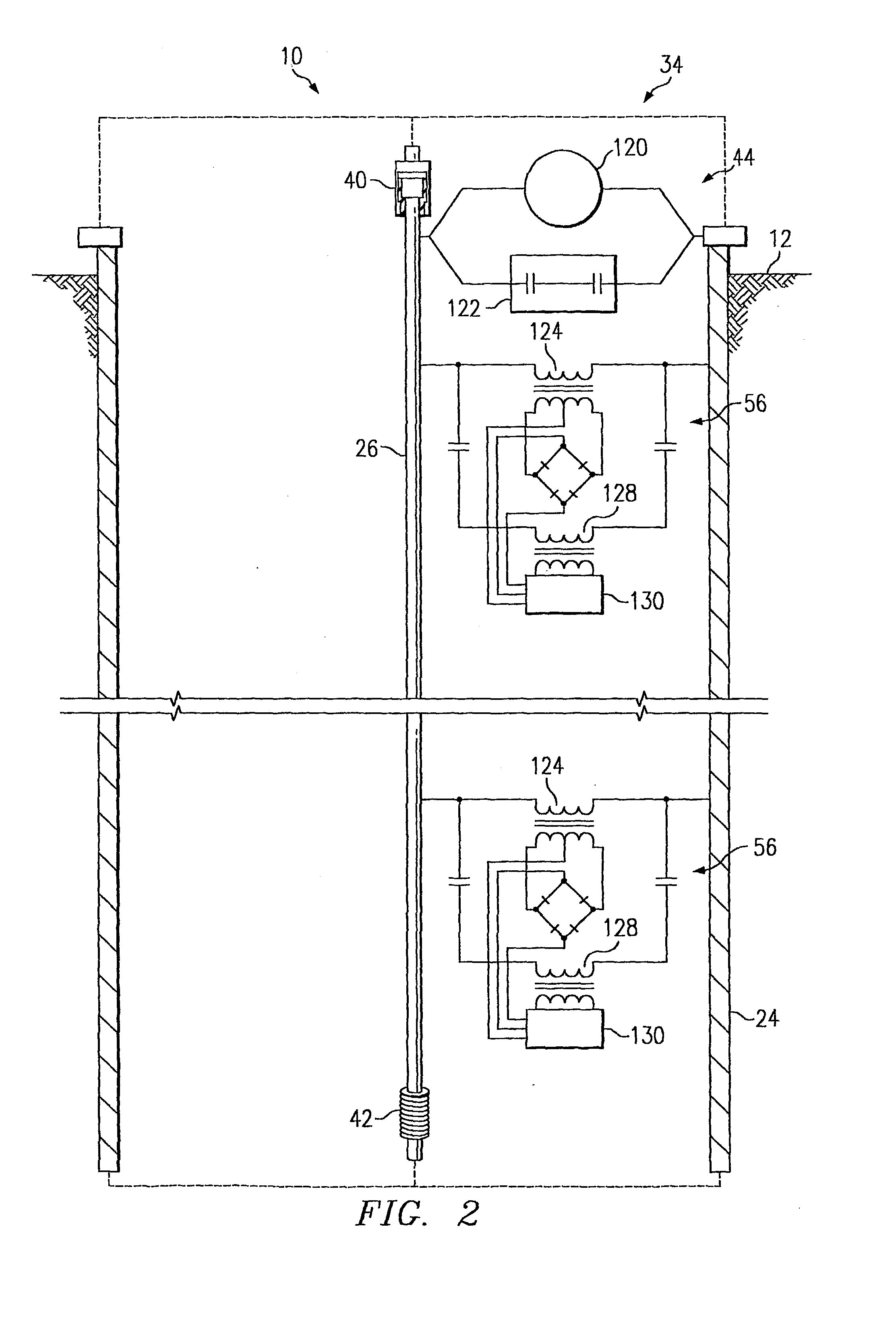

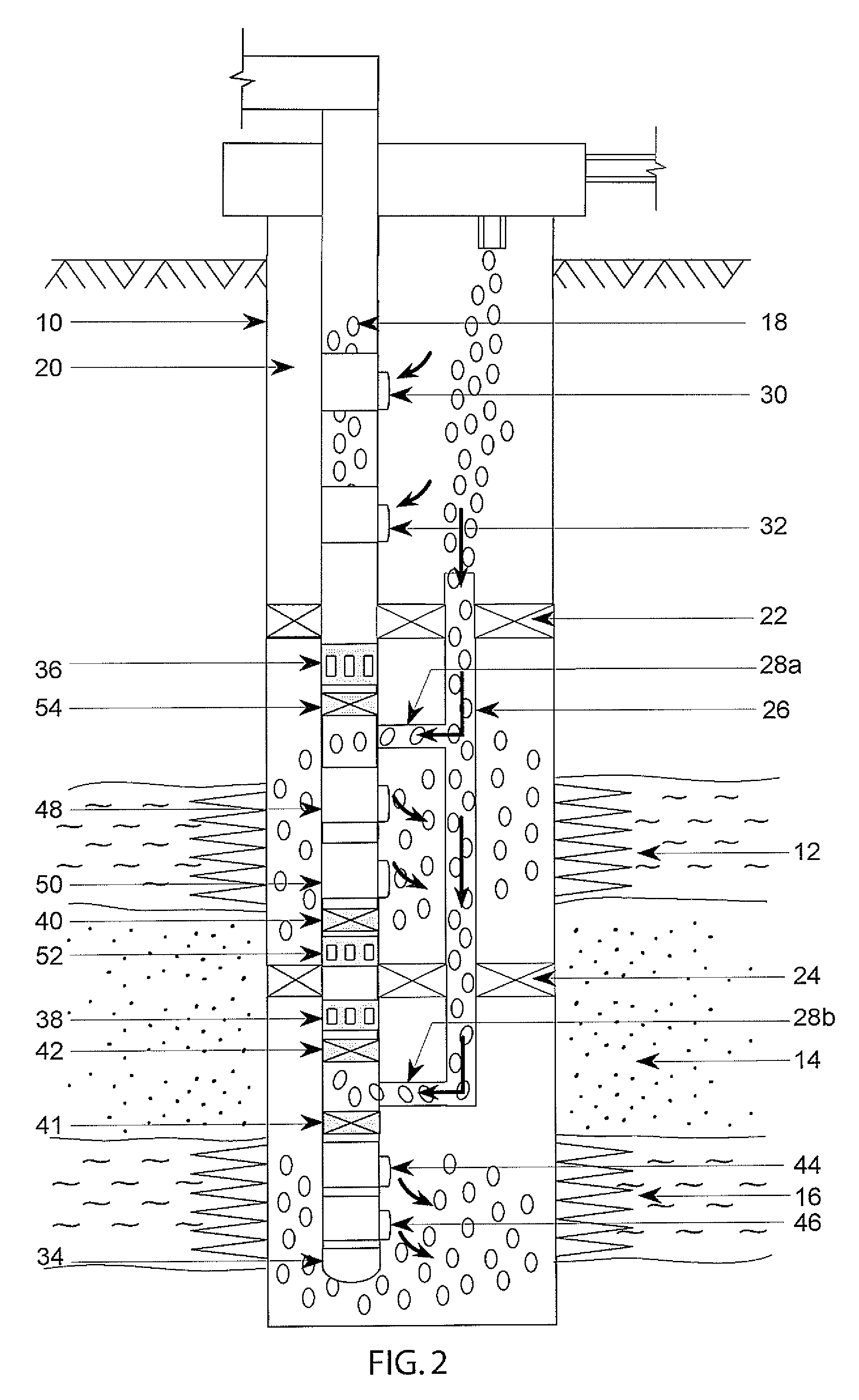

Wireless downwhole measurement and control for optimizing gas lift well and field performance

A method for optimizing the production of a petroleum well is provided. The petroleum well includes a borehole, a piping structure positioned within the borehole, and a tubing string positioned within the borehole for conveying a production fluid. Production of the well is optimized by determining a flow rate of the production fluid within the tubing string and determining a lift-gas injection rate for the gas being injected into the tubing string. The flow rate and injection rate data is communicated along the piping structure of the well to a selected location, where the data is collected and analyzed. After analysis of the data, an optimum operating point for the well can be determined.

Owner:SHELL OIL CO

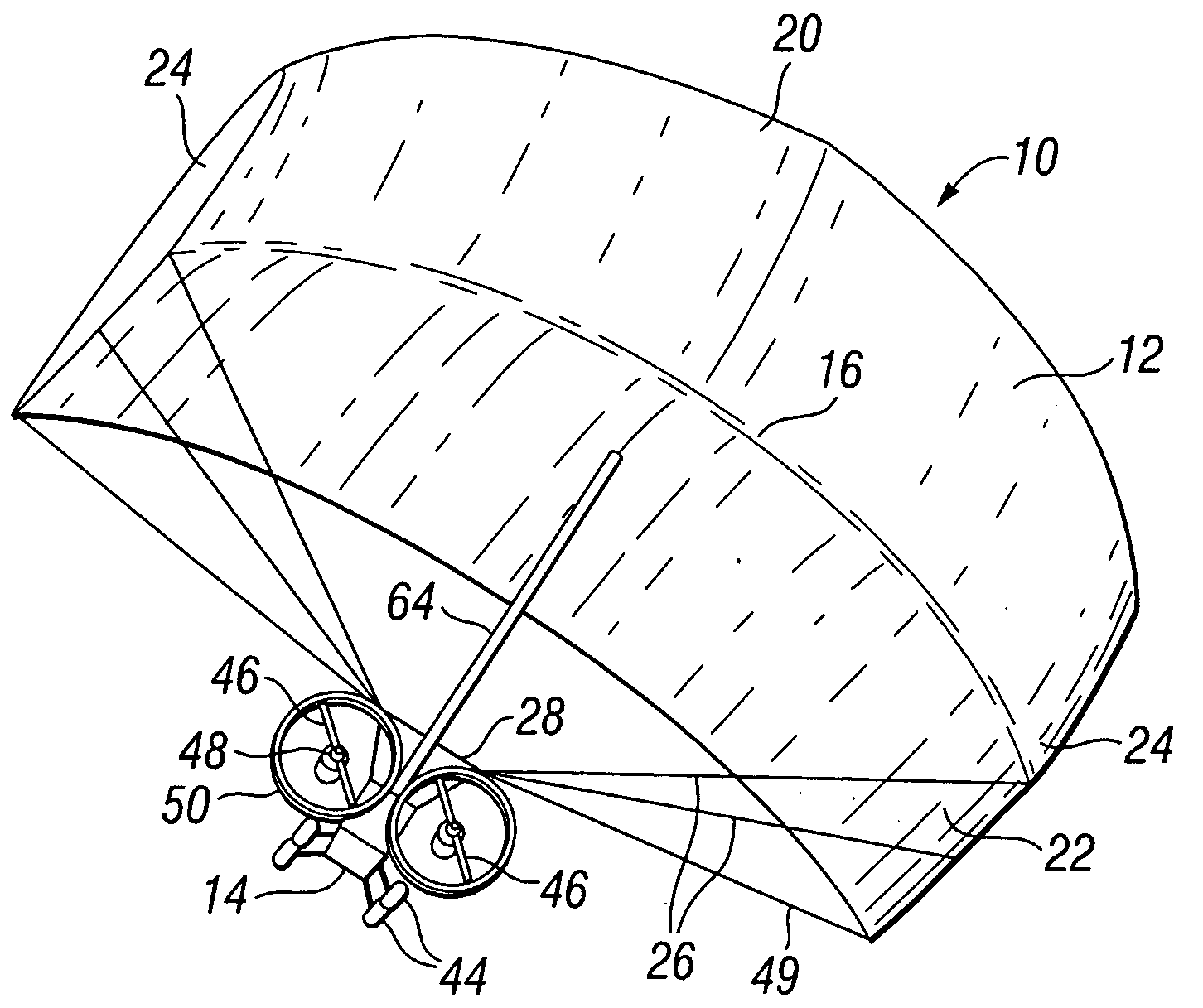

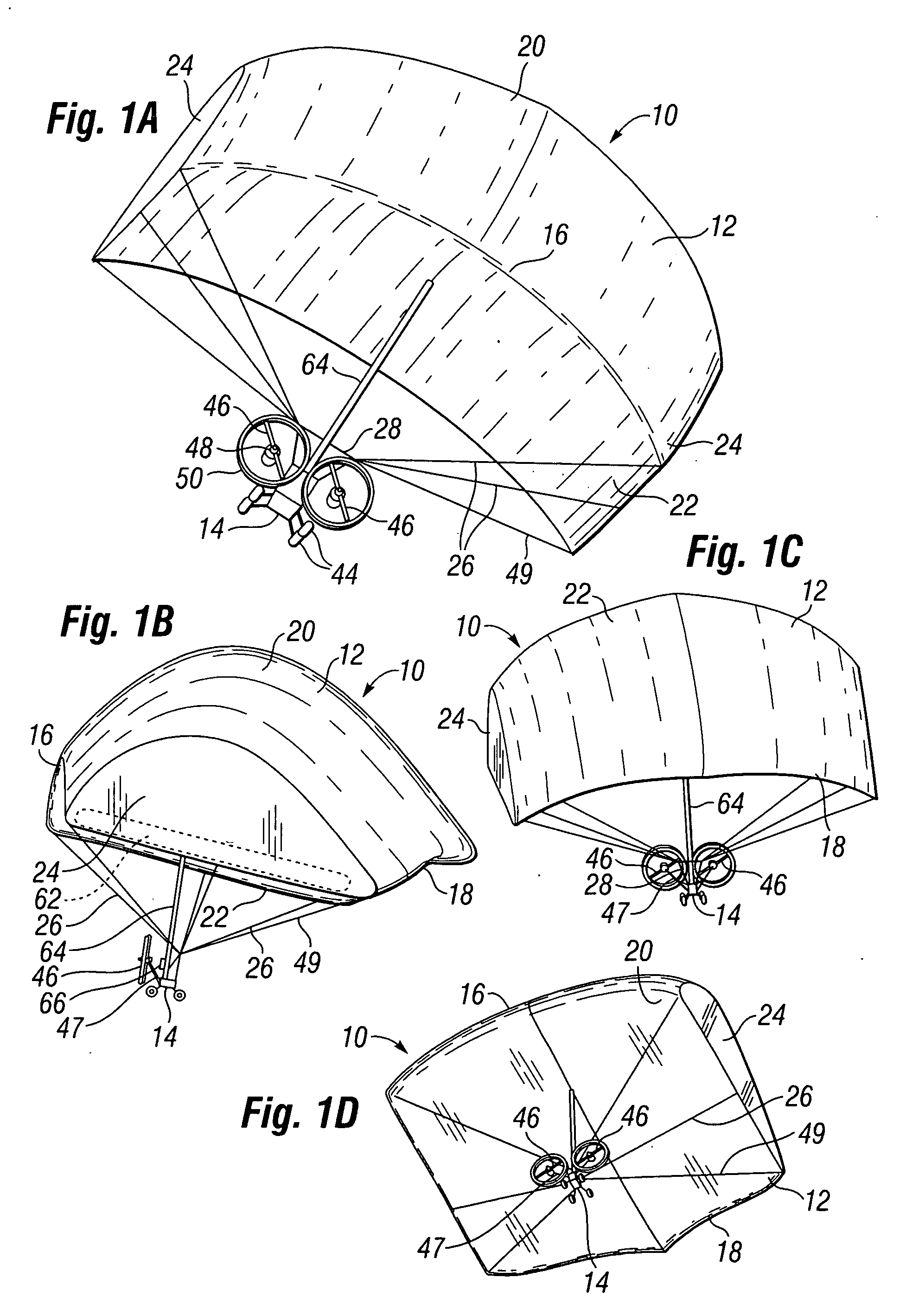

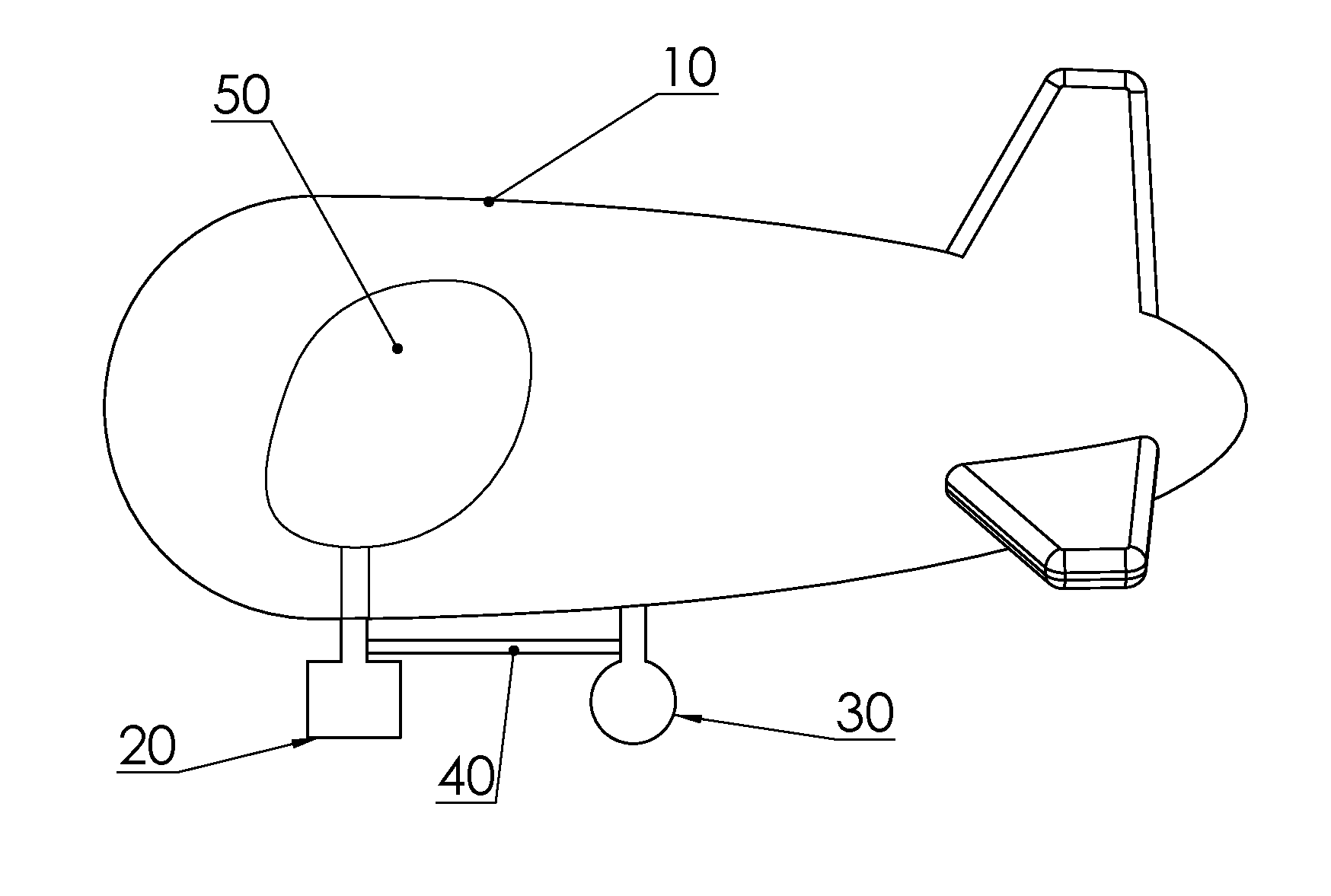

Inflatable wing flight vehicle

InactiveUS20090108135A1Improved lift characteristicThin atmosphereCosmonautic vehiclesCosmonautic partsNatural satelliteLow speed

The invention is an aircraft having an inflatable wing connected to a base unit, with the inflatable wing inflated with a lifting gas such as helium. The inflatable wing has a series of cell structures, and may be configured with ballonets to selectively introduce and expel outside air within the inflatable wing to vary the buoyancy and / or airfoil properties of the inflatable wing. The aircraft is particularly useful at low speeds and in thin atmospheres (such as at high Earth altitudes and on Mars), and can be used for interplanetary missions to explore planetary bodies, such as moons and planets, having atmospheres.

Owner:SHAW DONALD ORVAL

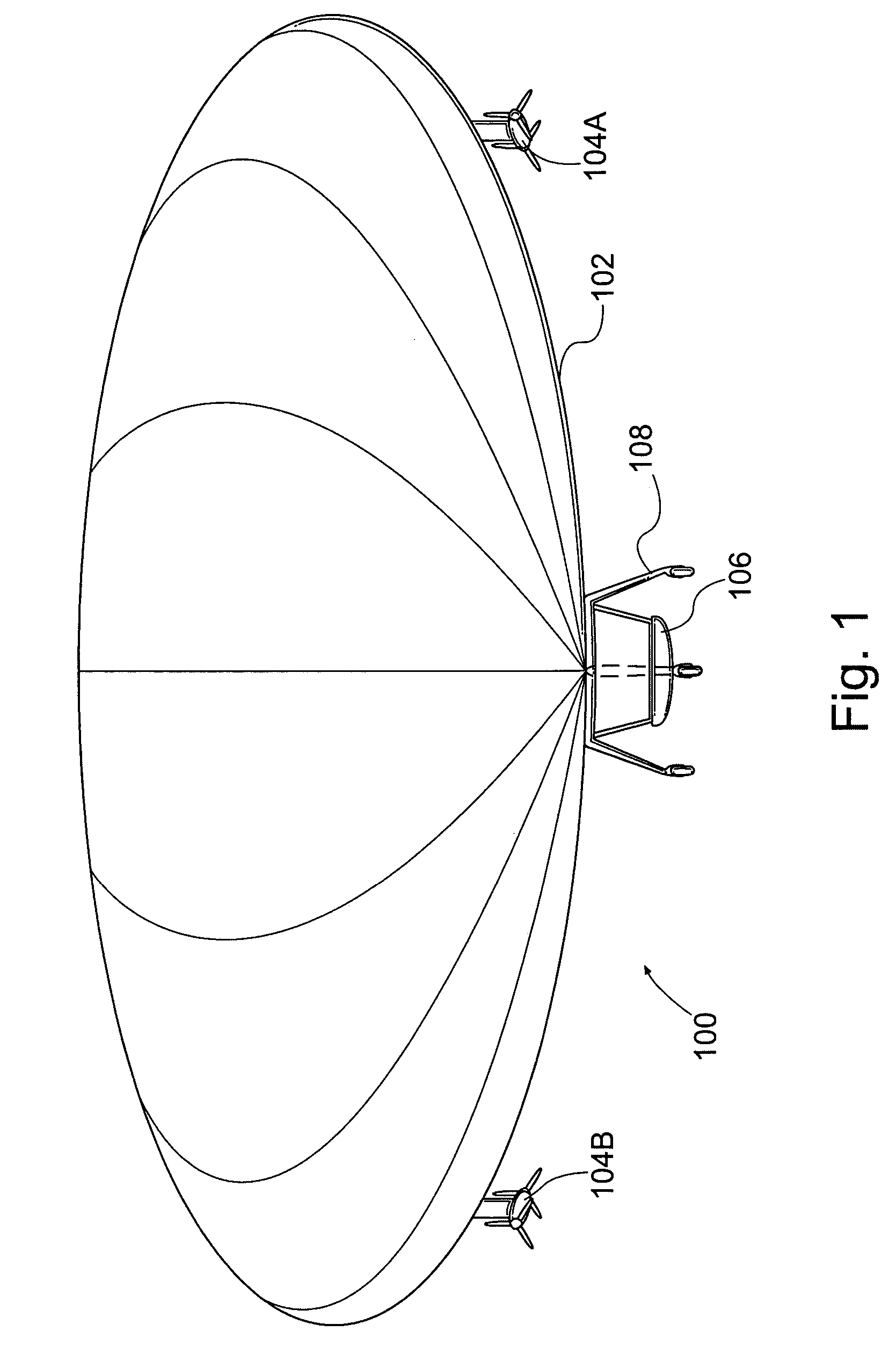

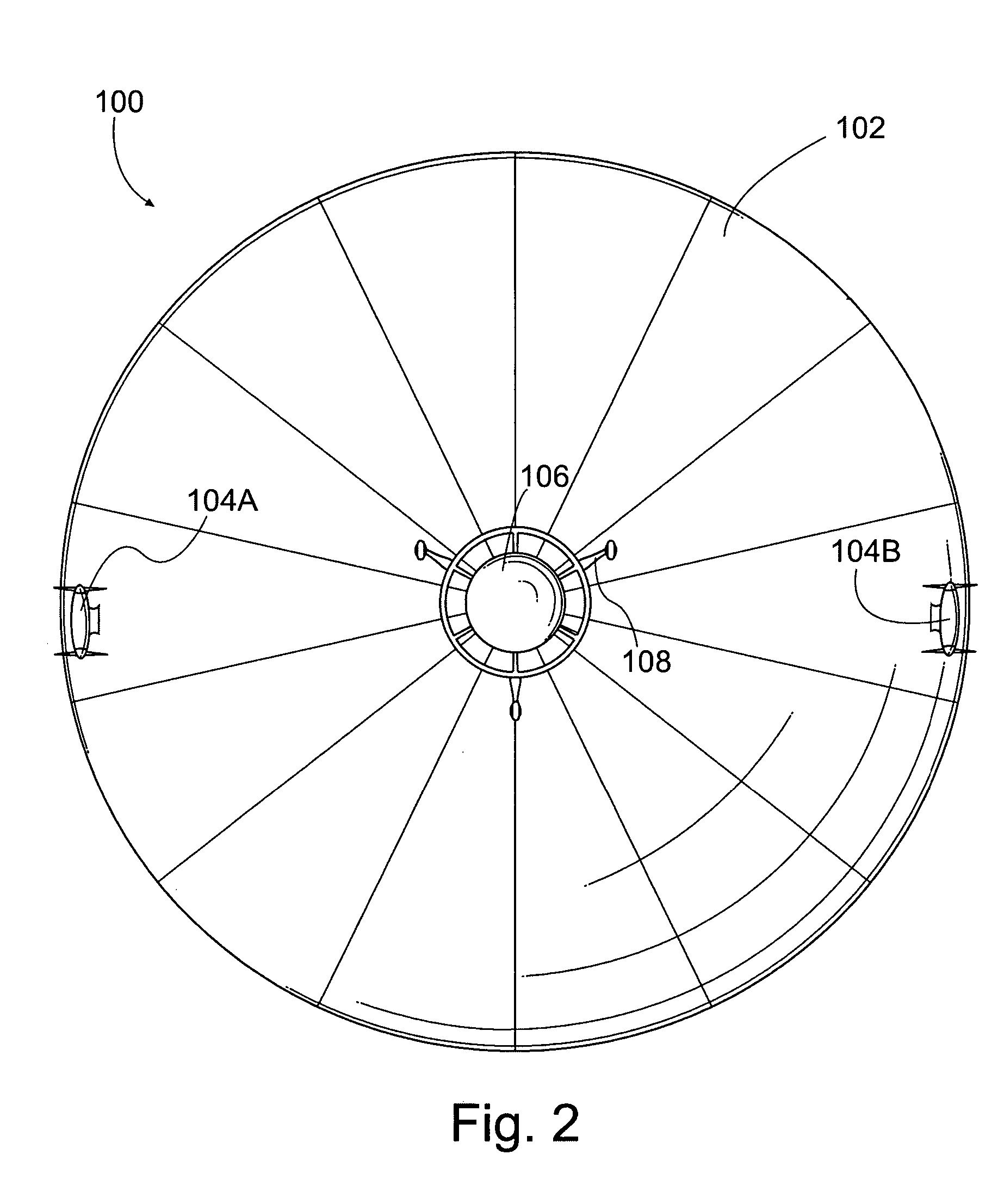

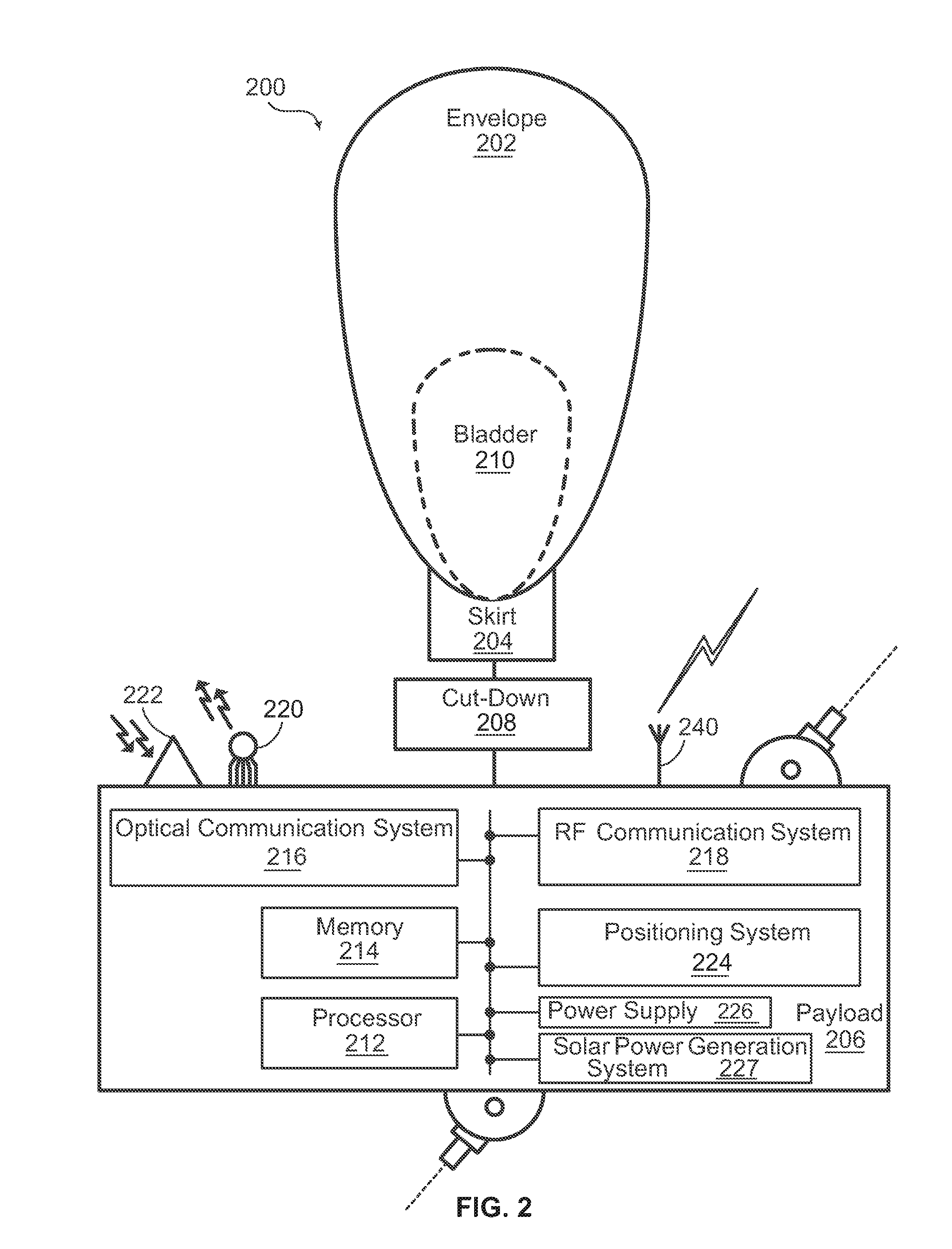

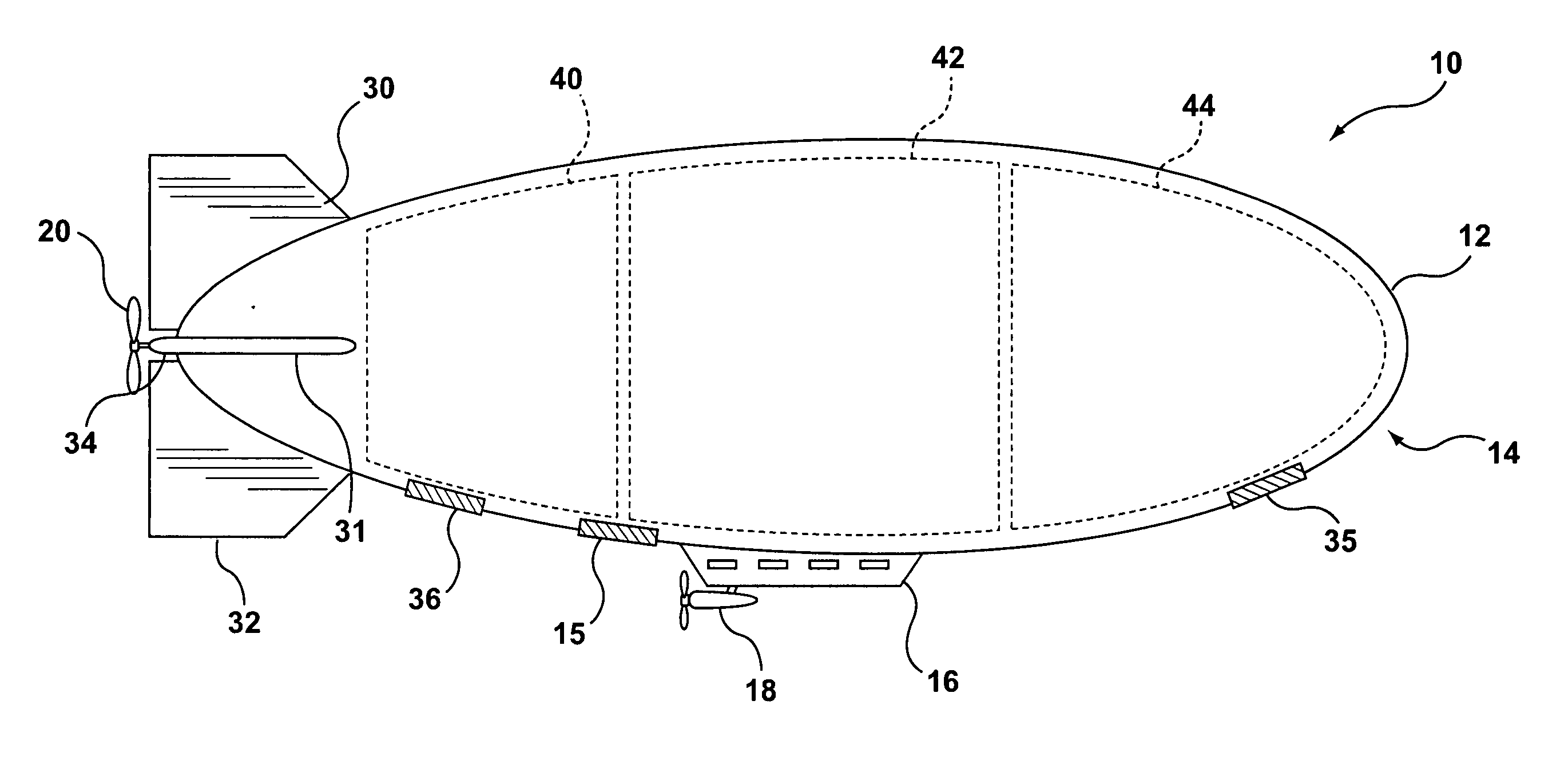

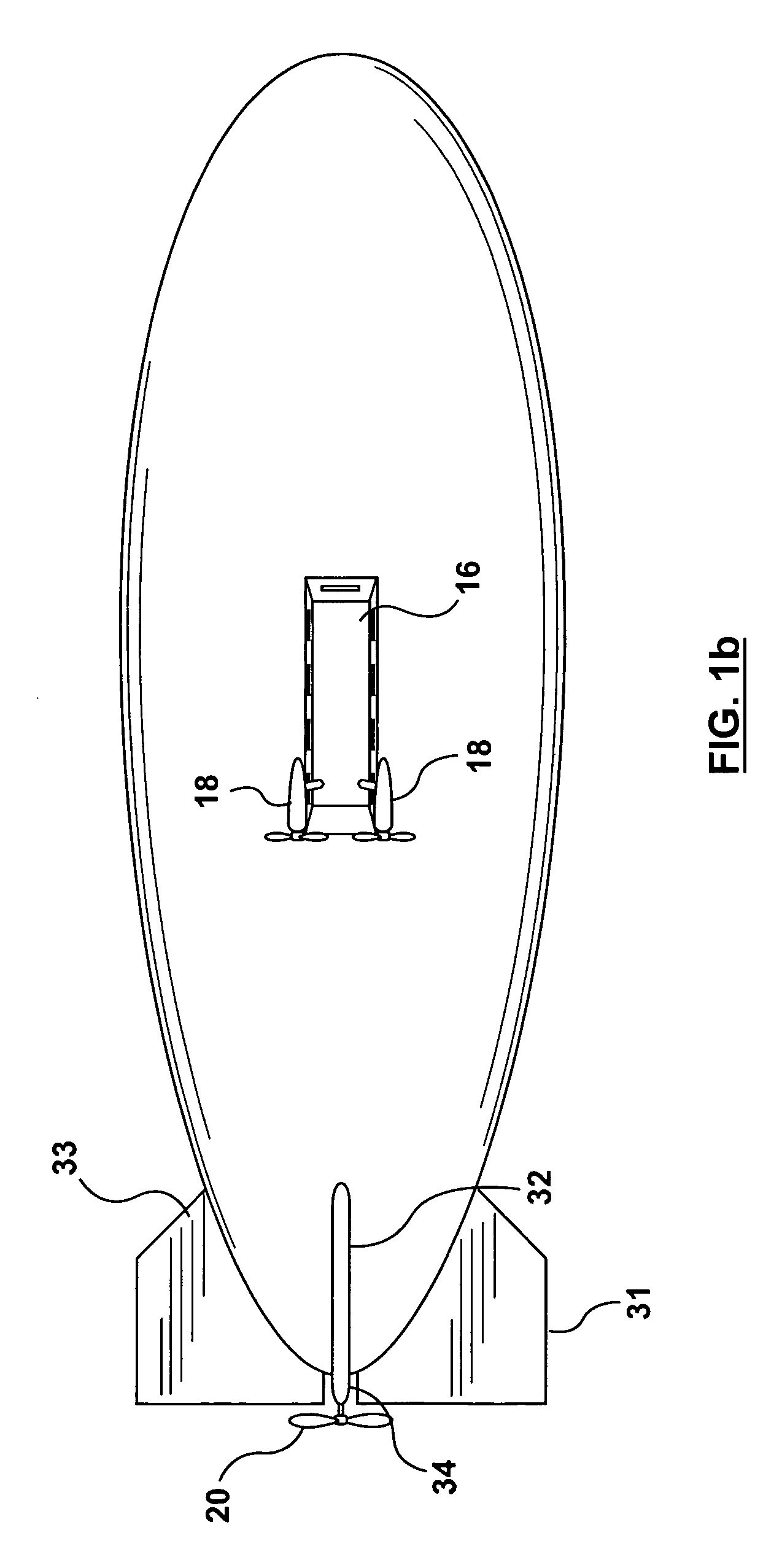

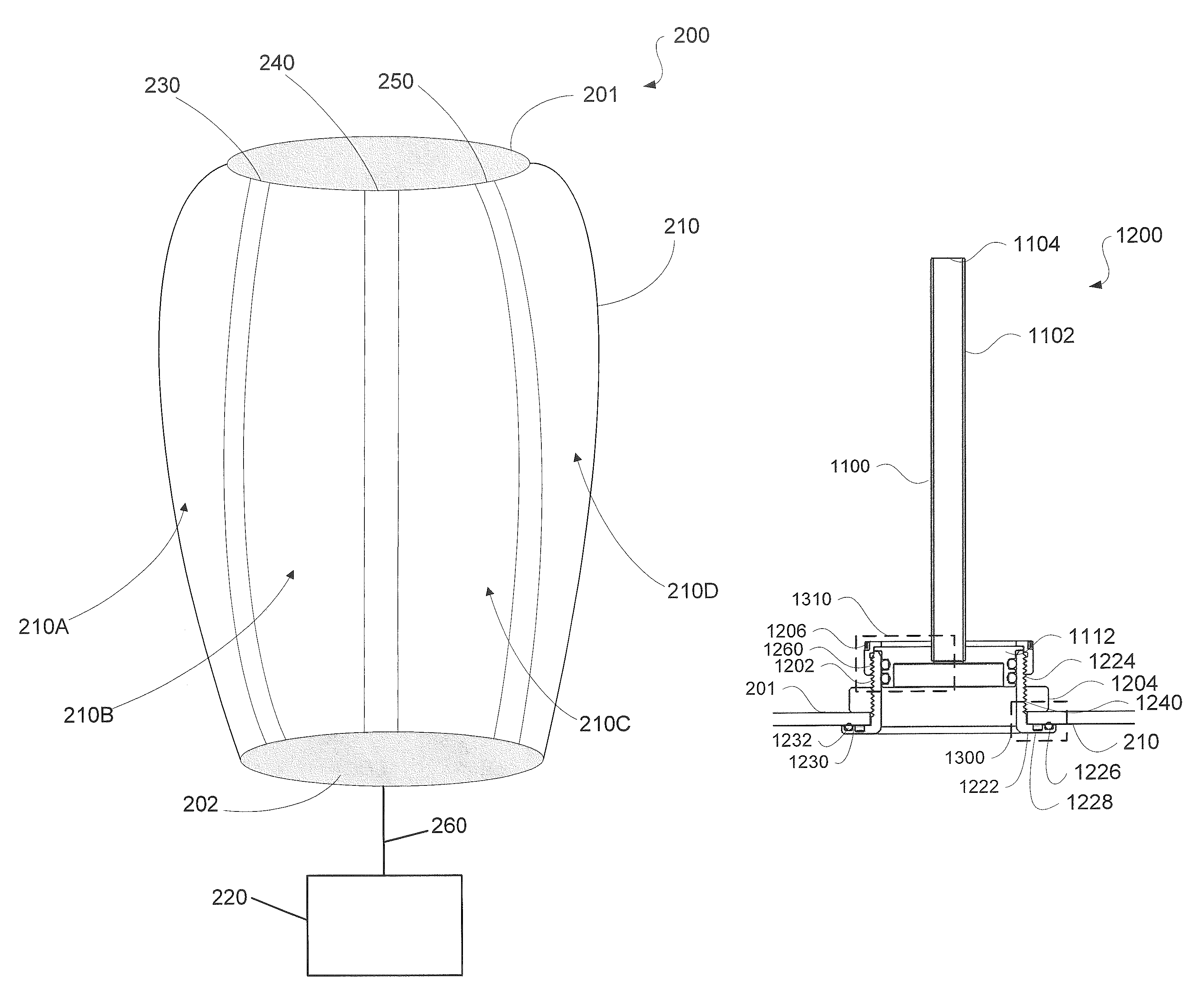

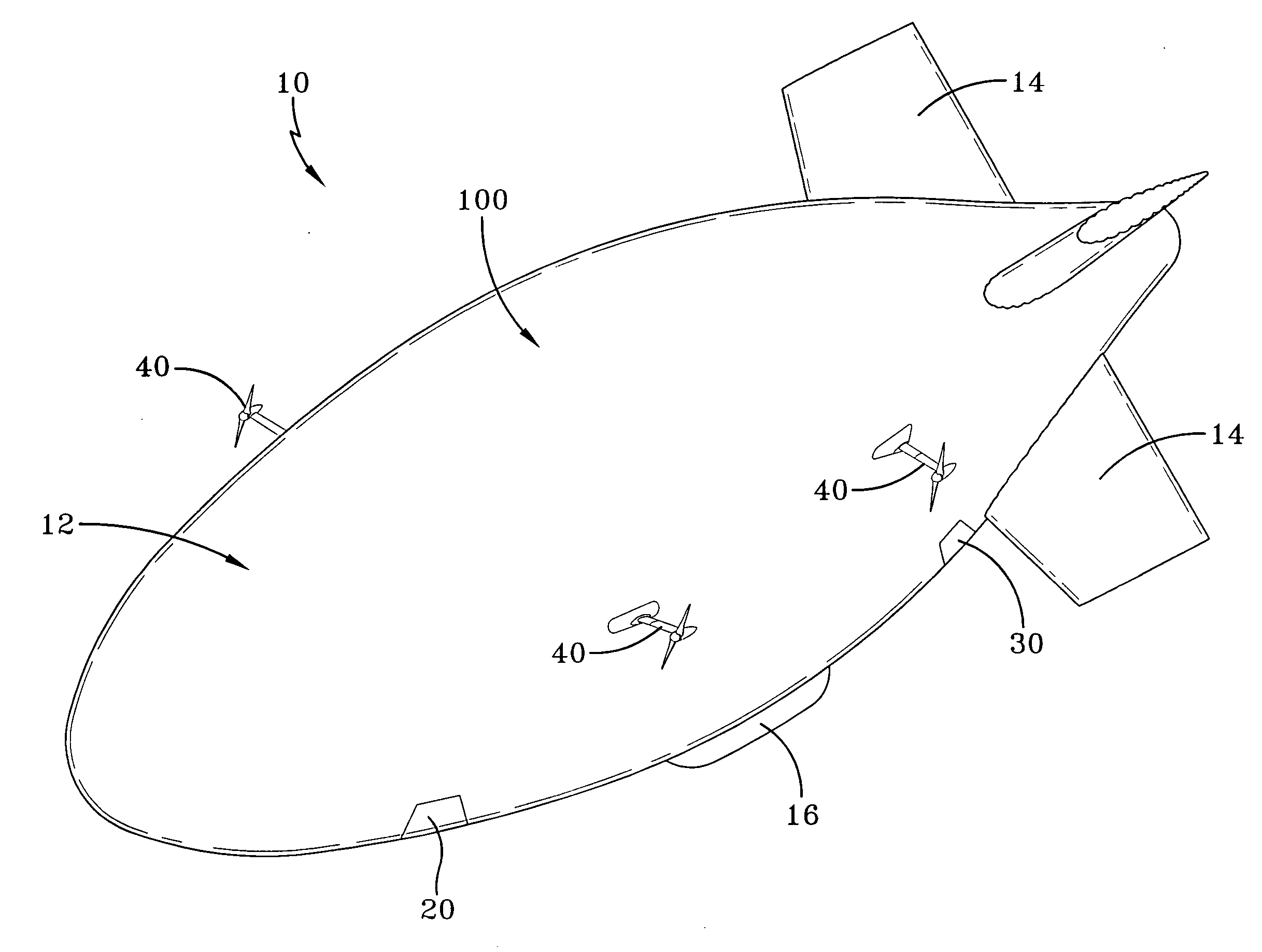

Airship and method of operation

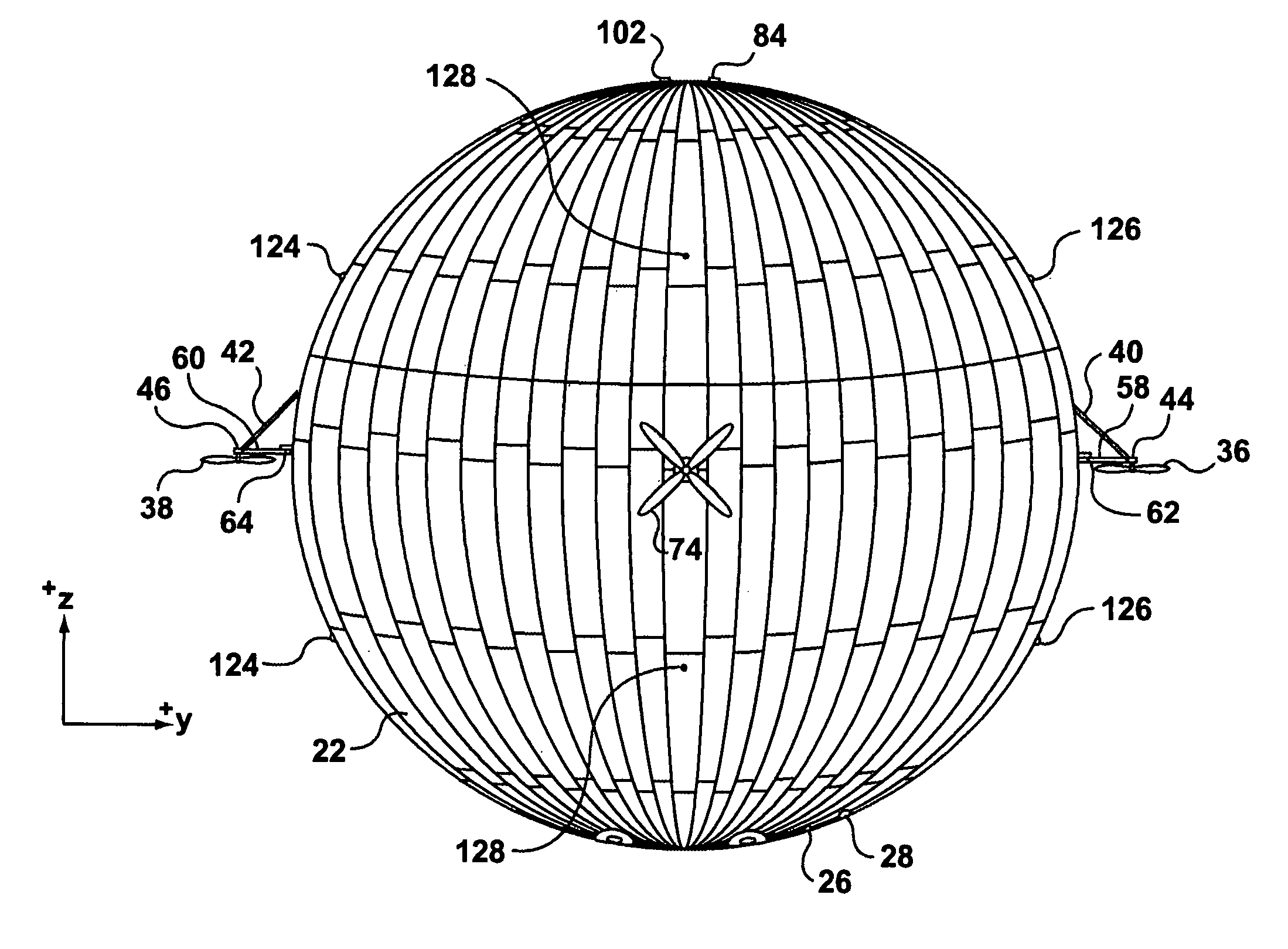

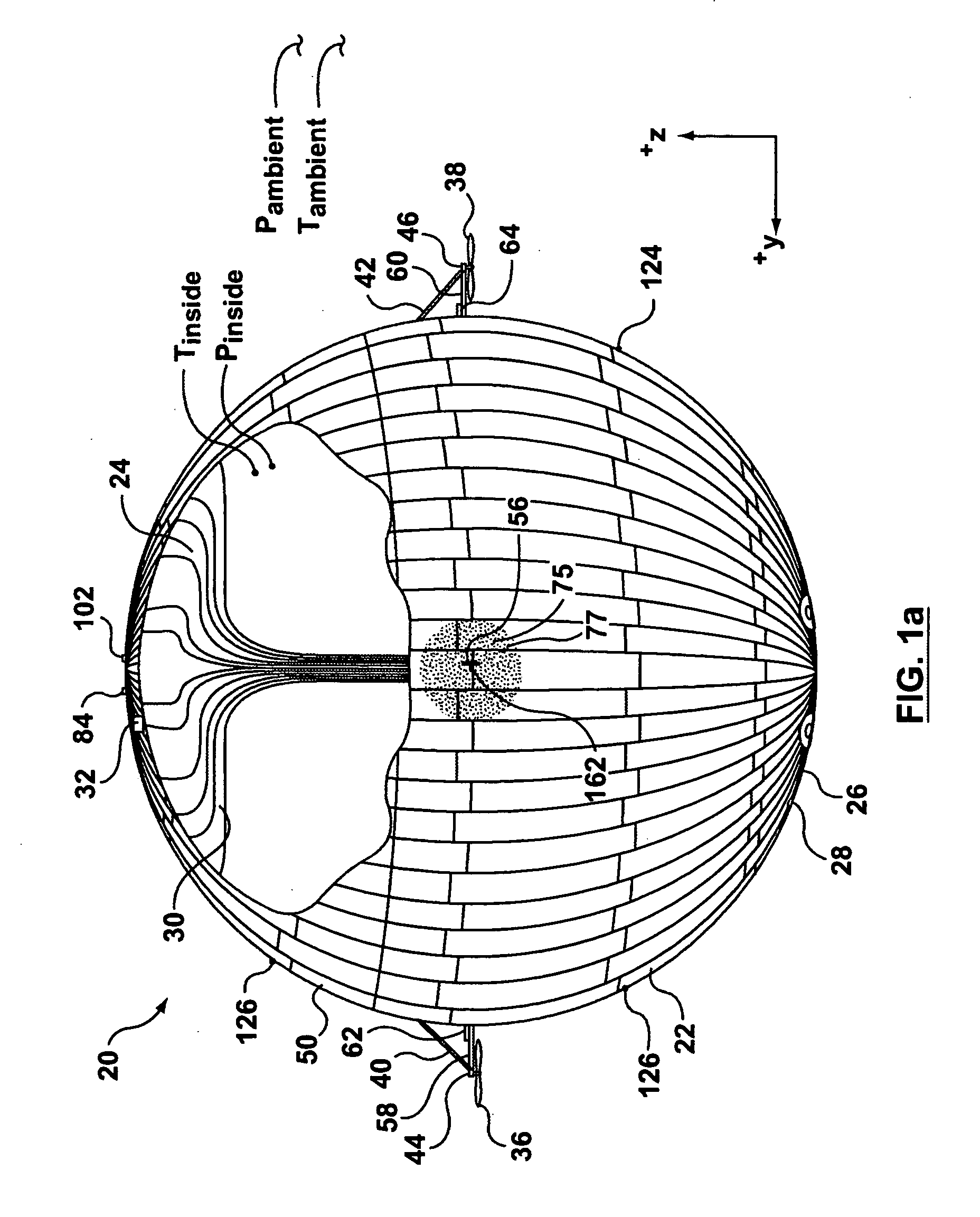

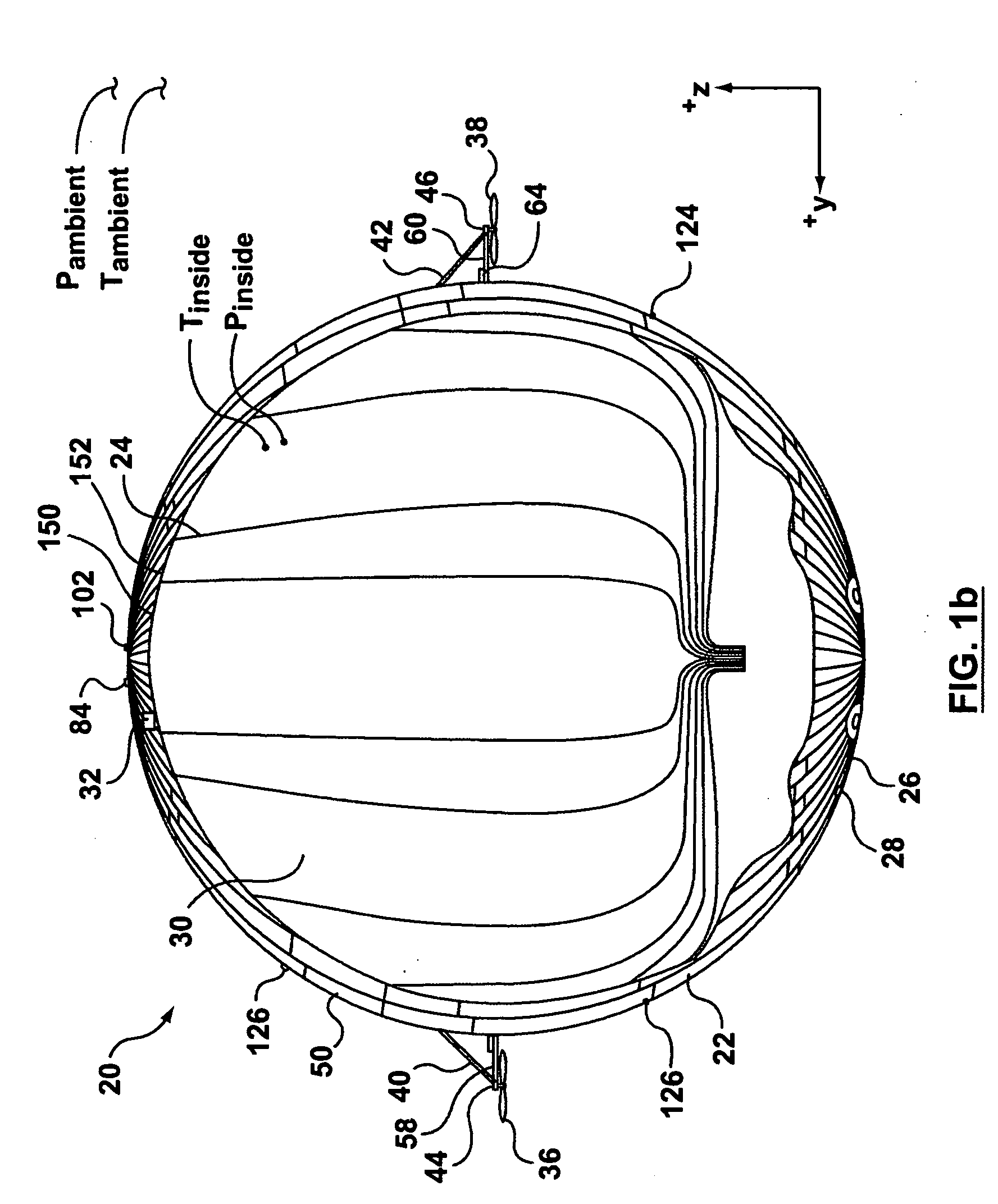

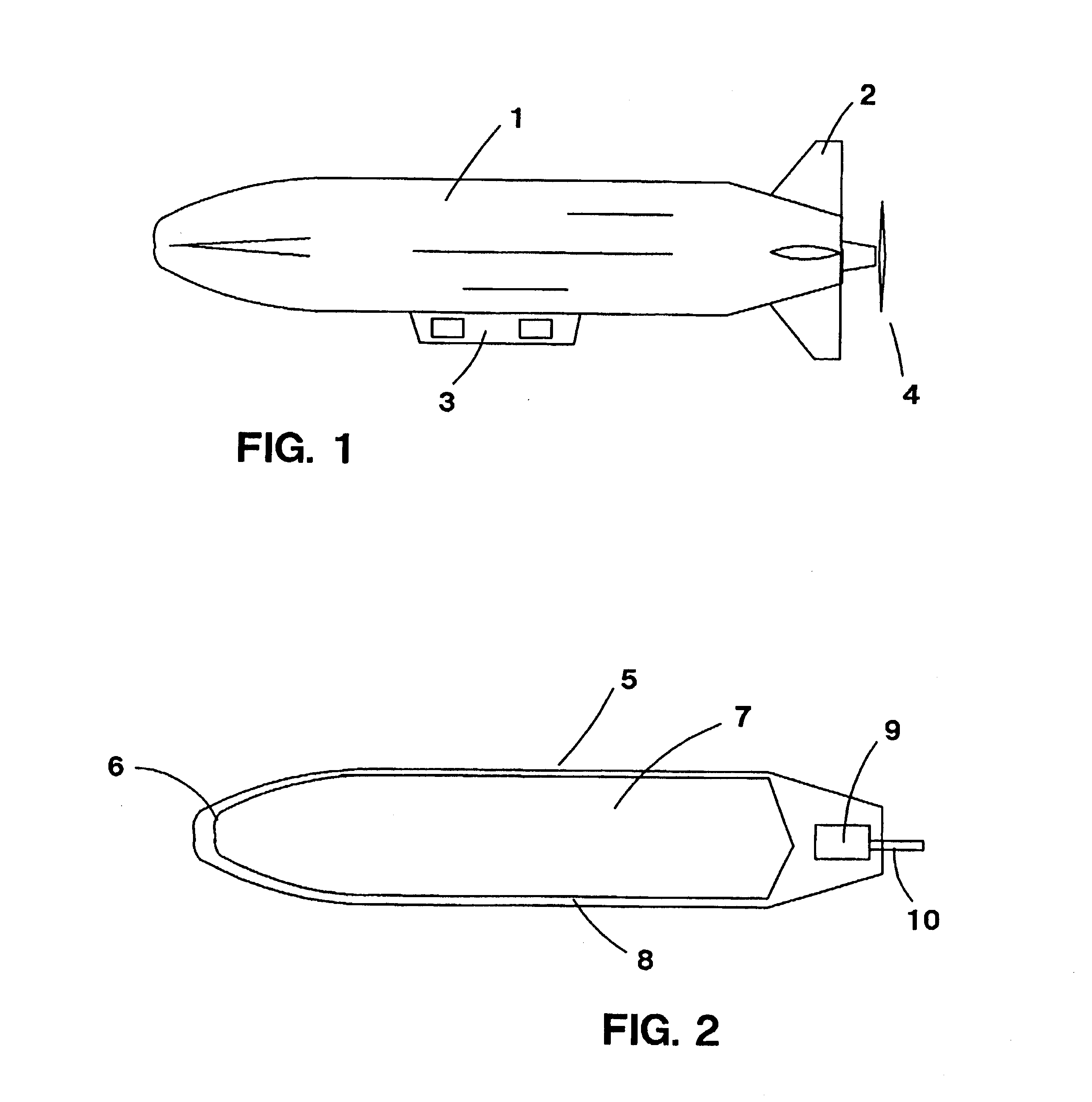

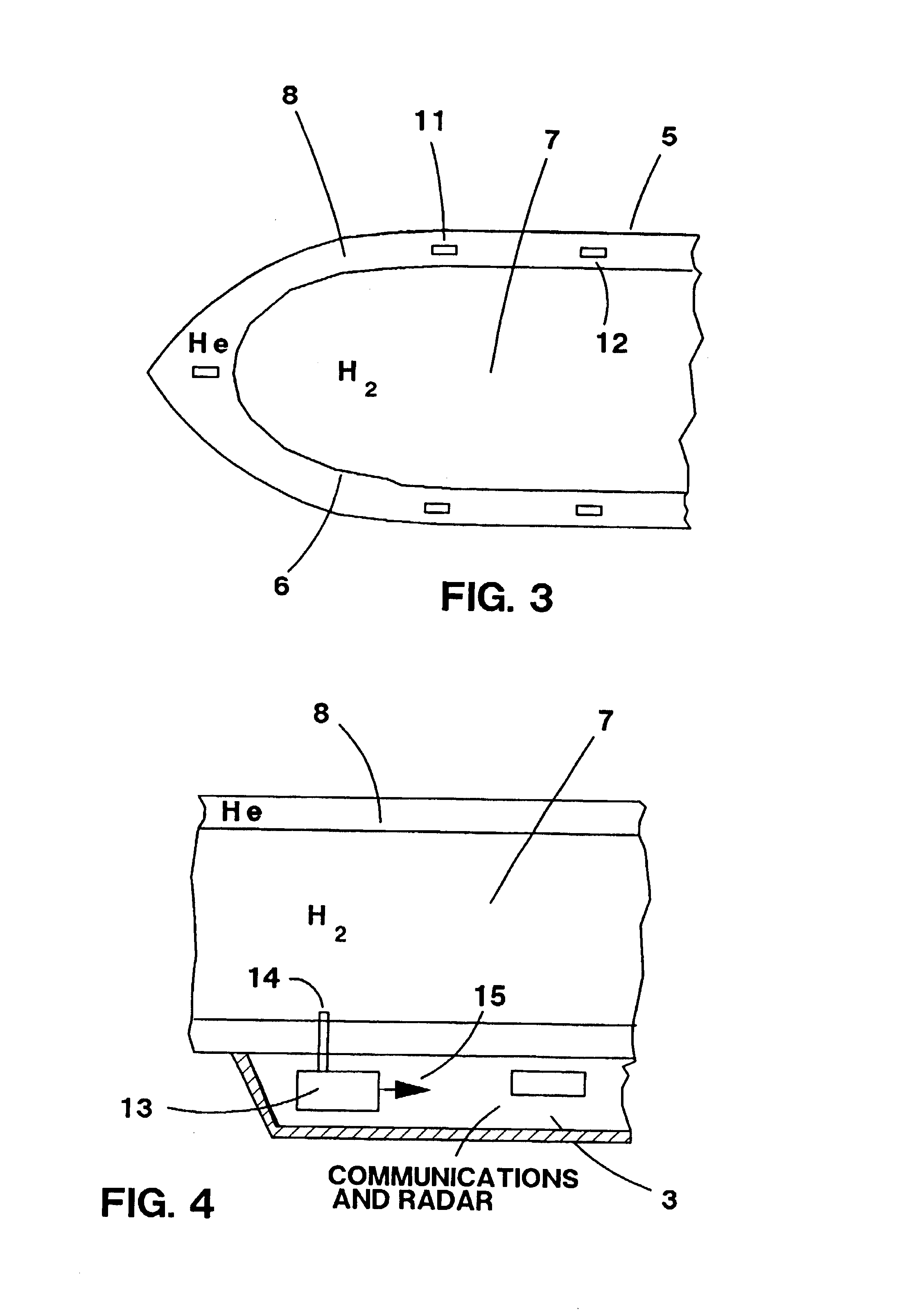

InactiveUS6966523B2Long endurance loiteringUnmanned aerial vehiclesRemote controlled aircraftSolar batteryPower apparatus

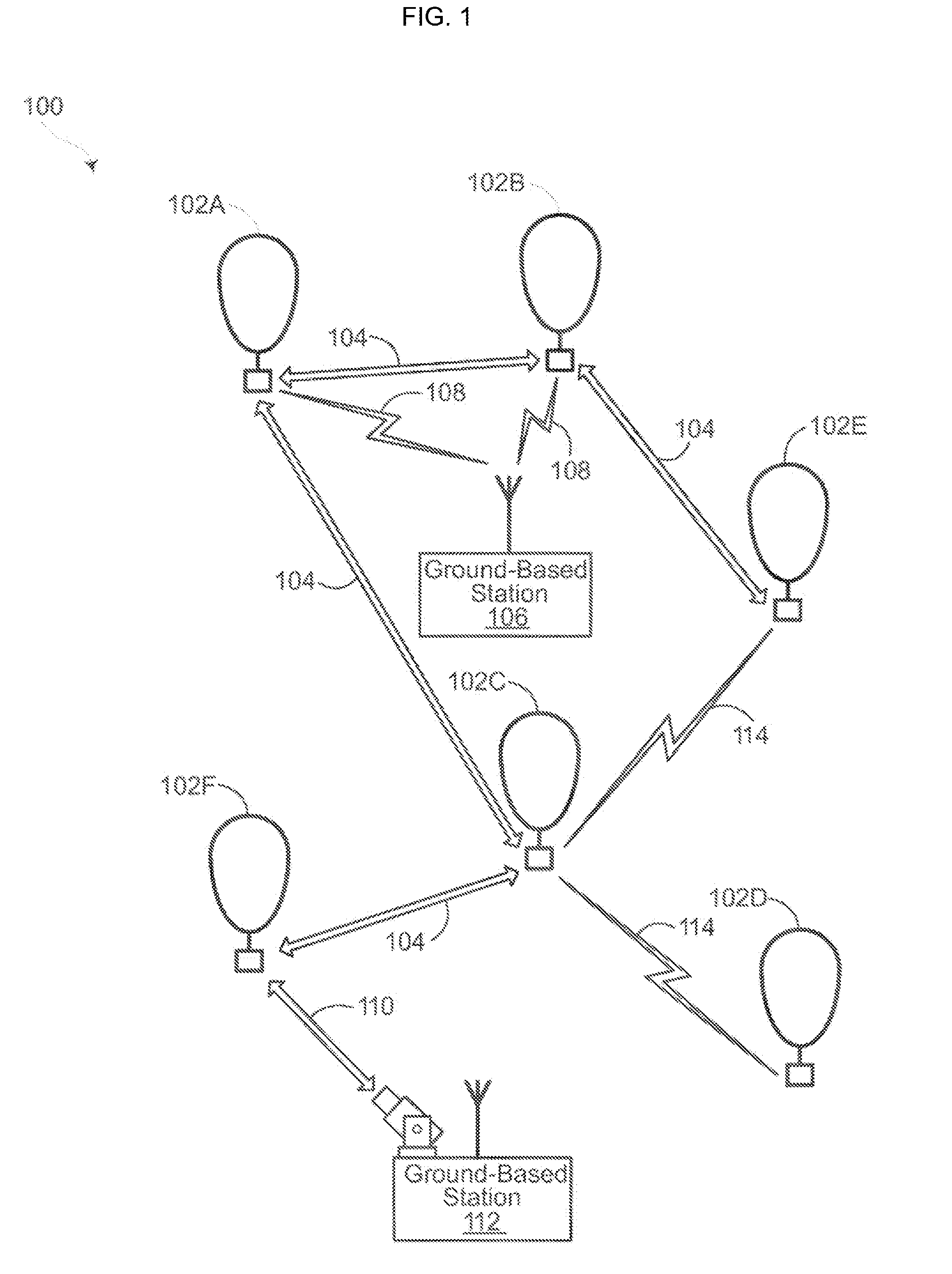

An airship has a generally spherical shape and has an internal envelope for containing a lifting gas such as Helium or Hydrogen. The airship has a propulsion and control system that permits it to be flown to a desired loitering location, and to be maintained in that location for a period of time. In one embodiment the airship may achieve neutral buoyancy when the internal envelope is as little as 7% full of lifting gas, and may have a service ceiling of about 60,000 ft. The airship has an equipment module that can include either communications equipment, or monitoring equipment, or both. The airship can be remotely controlled from a ground station. The airship has a solar cell array and electric motors of the propulsion and control system are driven by power obtained from the array. The airship also has an auxiliary power unit that can be used to drive the electric motors. The airship can have a pusher propeller that assists in driving the airship and also moves the point of flow separation of the spherical airship further aft. In one embodiment the airship can be refuelled at altitude to permit extended loitering.

Owner:21ST CENTURY AIRSHIP TECH

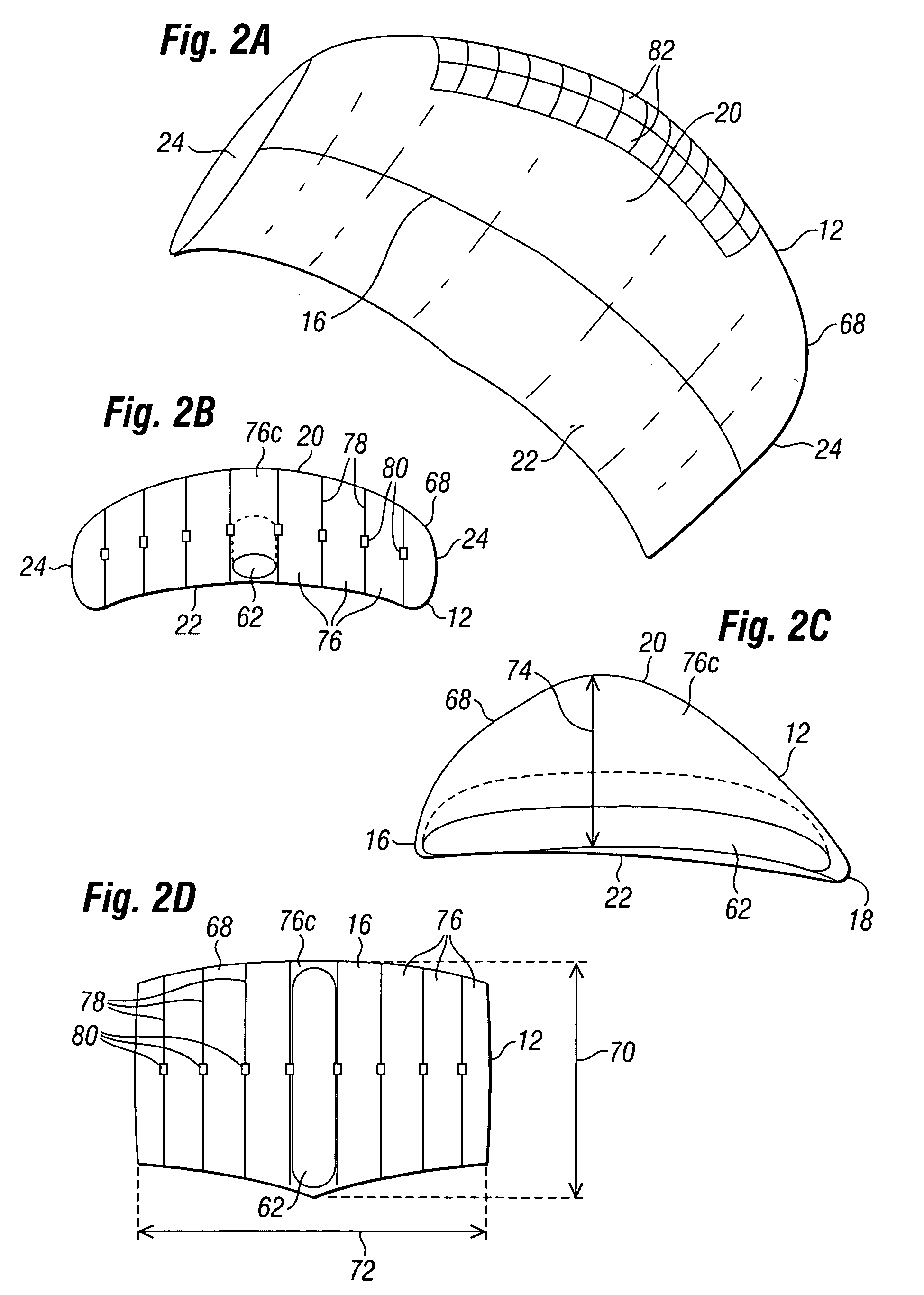

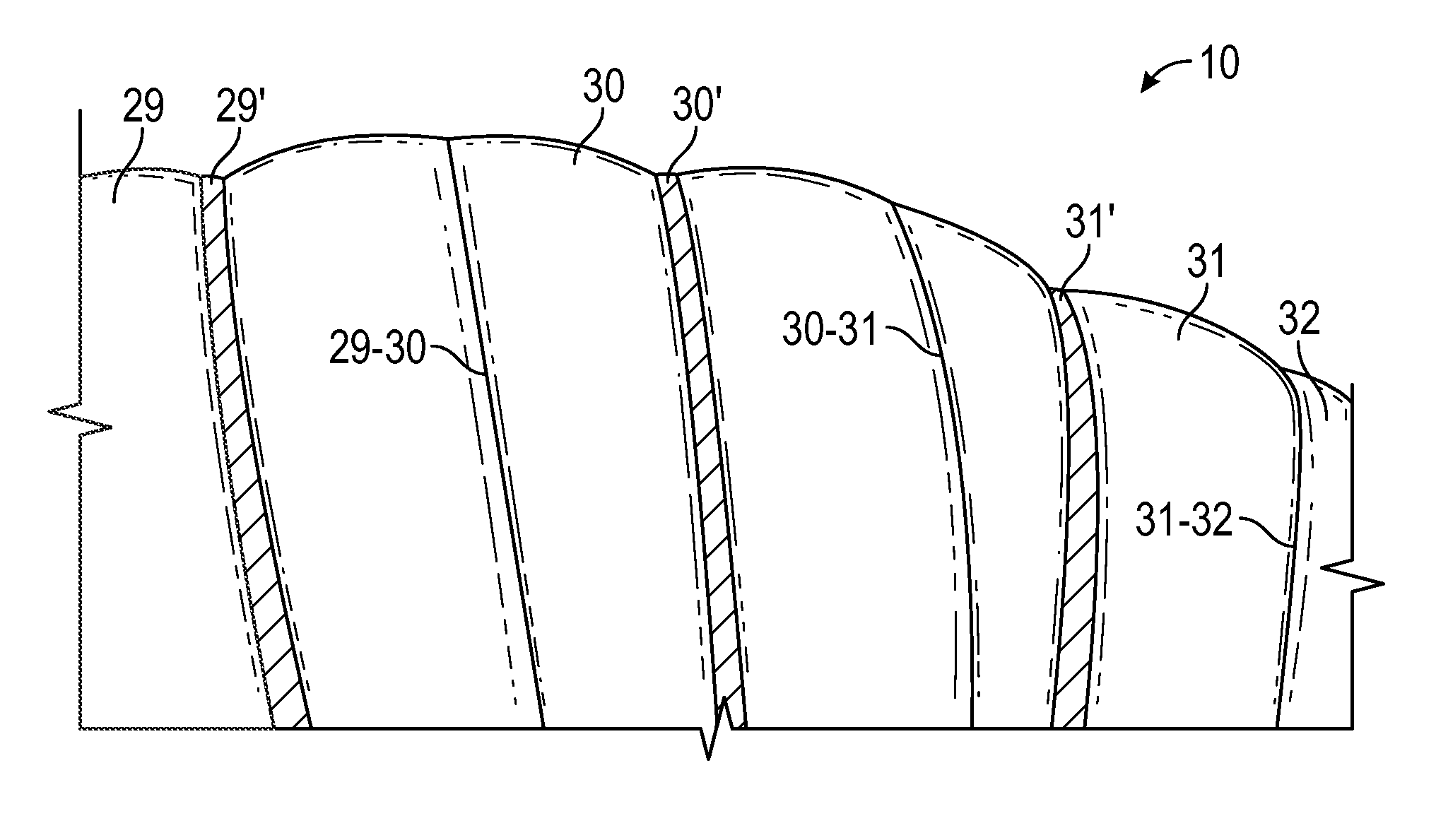

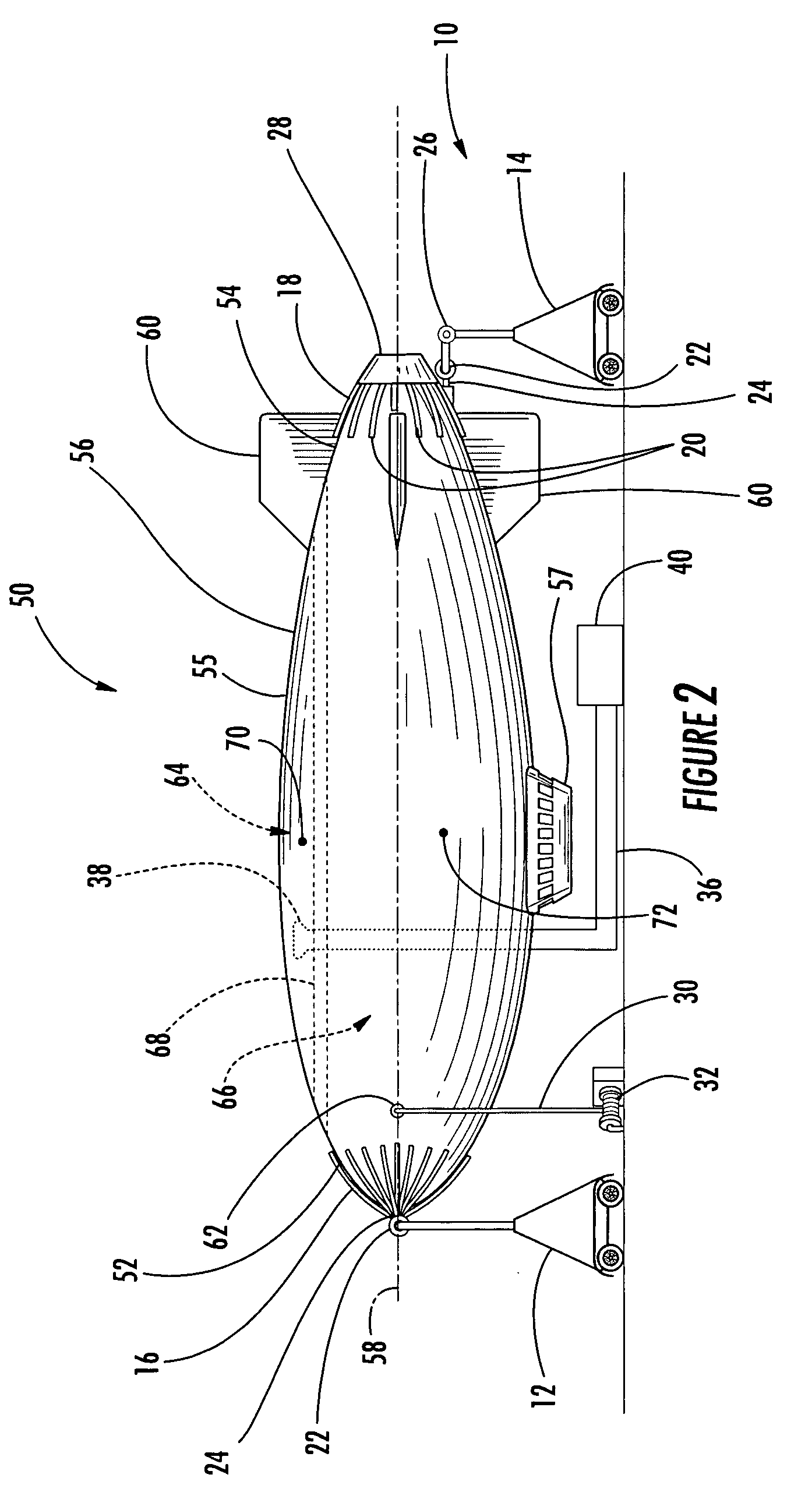

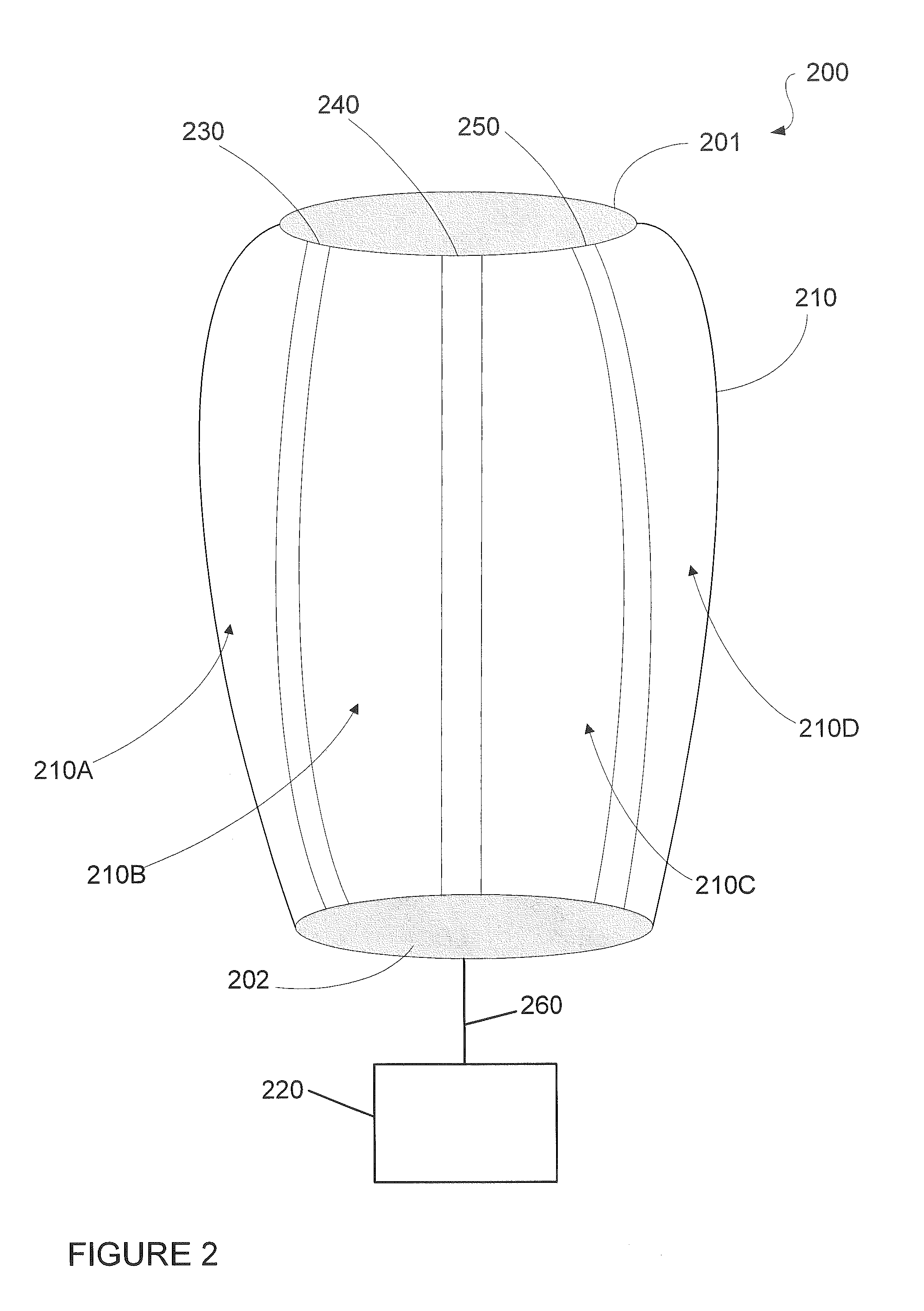

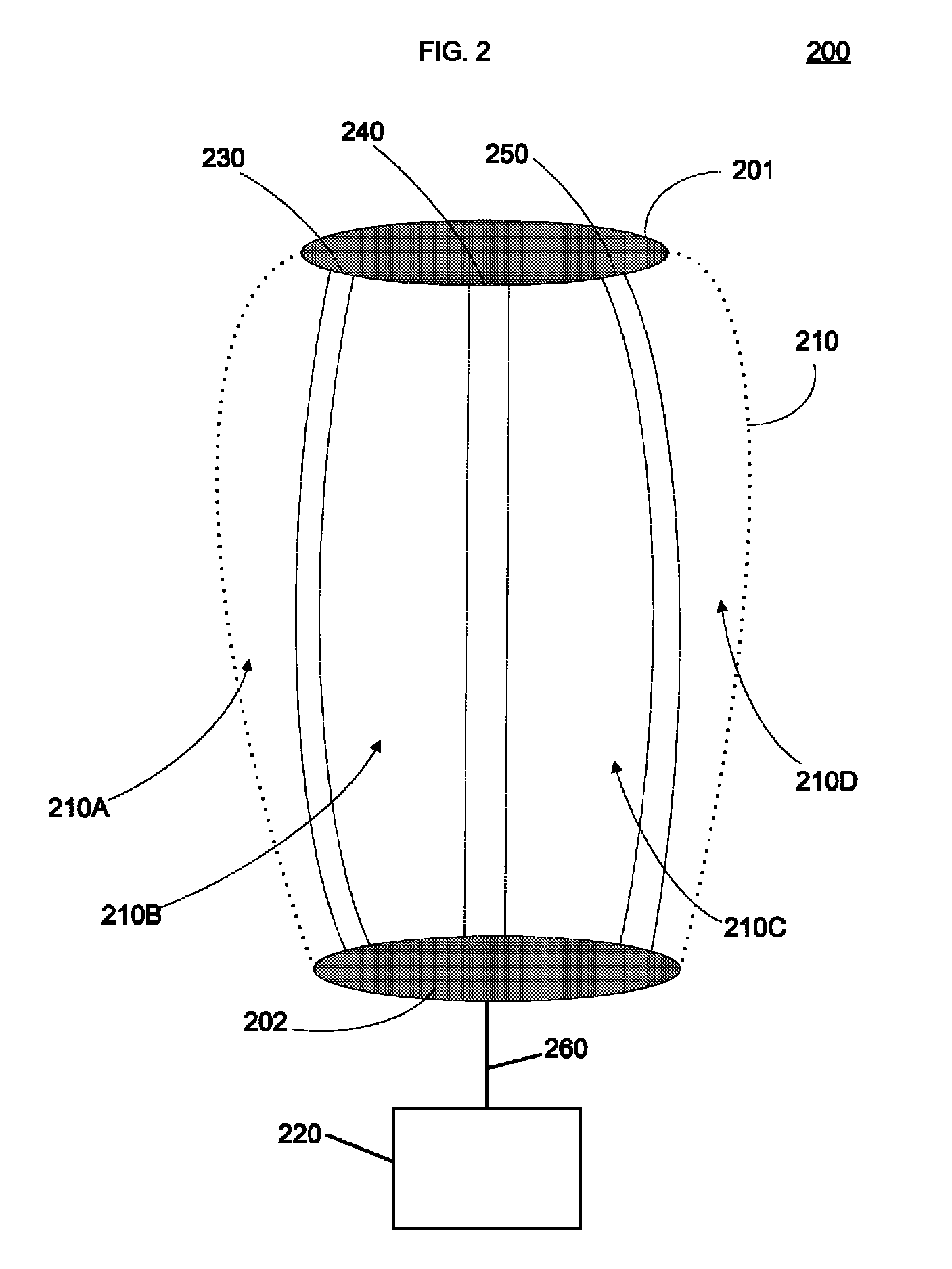

Superpressure polyethylene balloon with load tapes

A balloon having a balloon envelope formed with a plurality of adjacent envelope gores sealed together at their respective edges to form an edge seam between each of the adjacent envelope gores, a tape comprised of fibers applied to a centerline of each of the envelope gores, wherein the envelope gores are constructed such that the edge seam between each of the adjacent envelope gores is longer than the centerline of each of the envelope gores, and wherein a load caused by pressurized lifting gas within the balloon envelope is carried primarily by the fiber tapes on the centerlines of the envelope gores, rather than the edge seams between the adjacent envelope gores.

Owner:AEROSTAR INT LLC

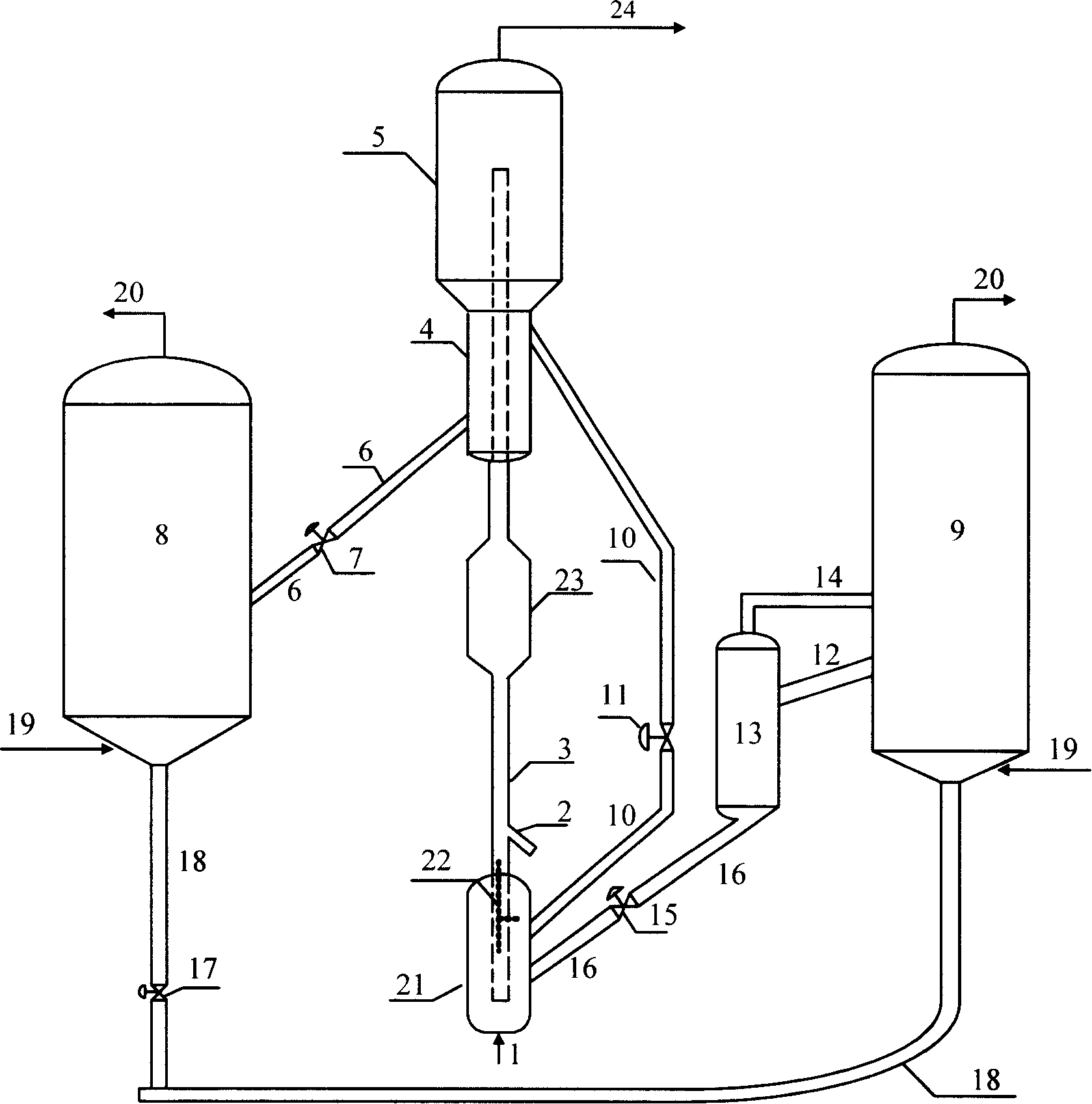

Conversion method for petroleum hydrocarbons

A transformation method for petroleum hydrocarbons includes the following steps: hot regenerated catalyst is returned to the bottom of a reactor after cooling down and is conveyed to the bottom of the first reaction zone of the reactor by pre-lifting gas so as to contact preheated base oil for cracking reaction; the mixture of reaction products, water vapor and catalyst enters into a diameter-expanded second reaction zone for further hydrocarbon transformation reaction with the reaction products, water vapor and spent catalyst undergoing gal-solid separation; gas phase products are separated to obtain various products; in addition, the spent catalyst is conveyed to a regenerator after steam stripping for recycling use after singeing regeneration or part of the spent catalyst directly enters into the mixer arranged at the bottom of the reactor. The method which adopts a reactor riser with two reaction zones improves the contact state of base oil and catalyst through lowering oil contact temperature so as to increase the yield and the selectivity of object reactant and to improve the properties of object product.

Owner:CHINA PETROLEUM & CHEM CORP +1

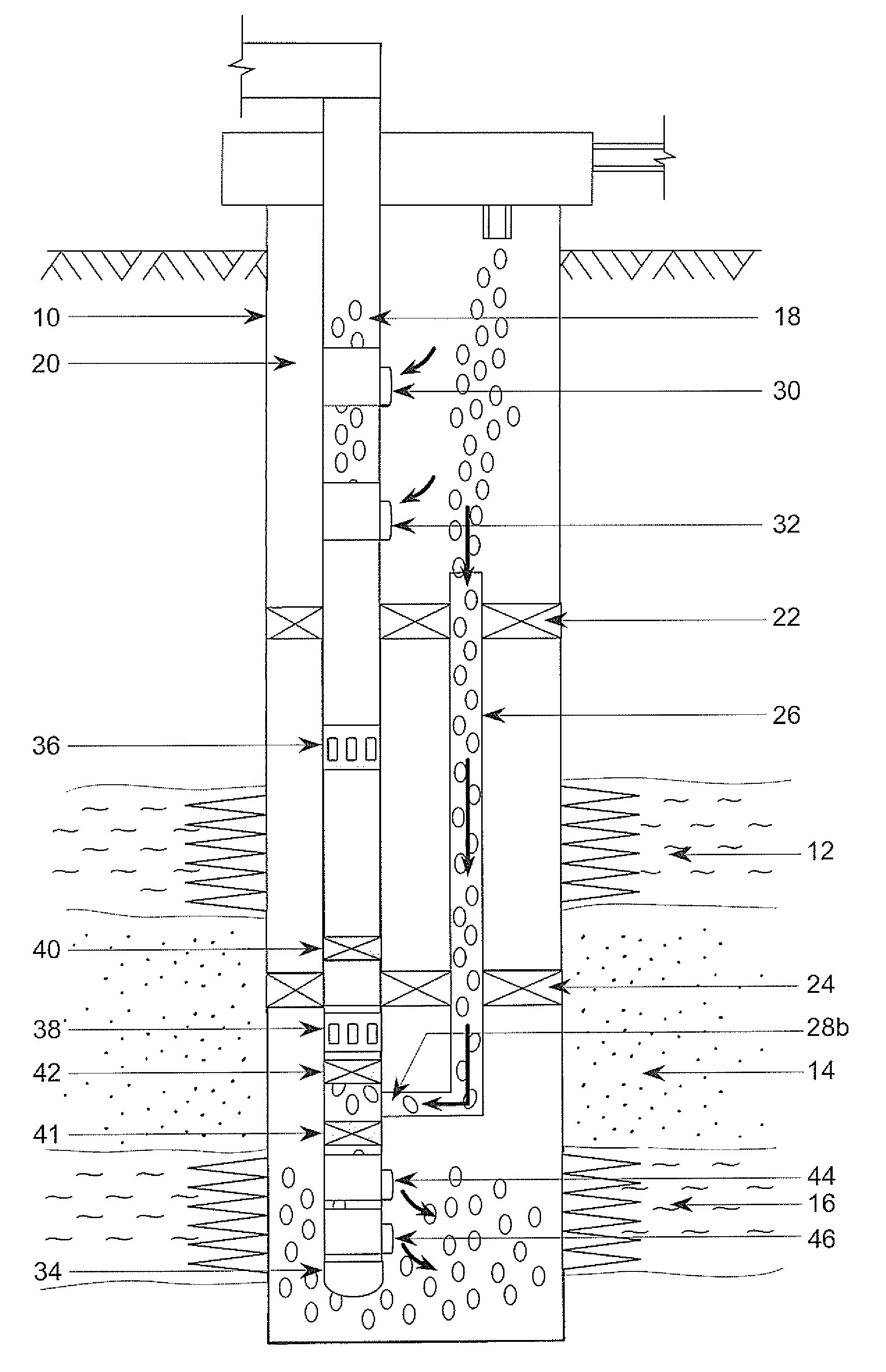

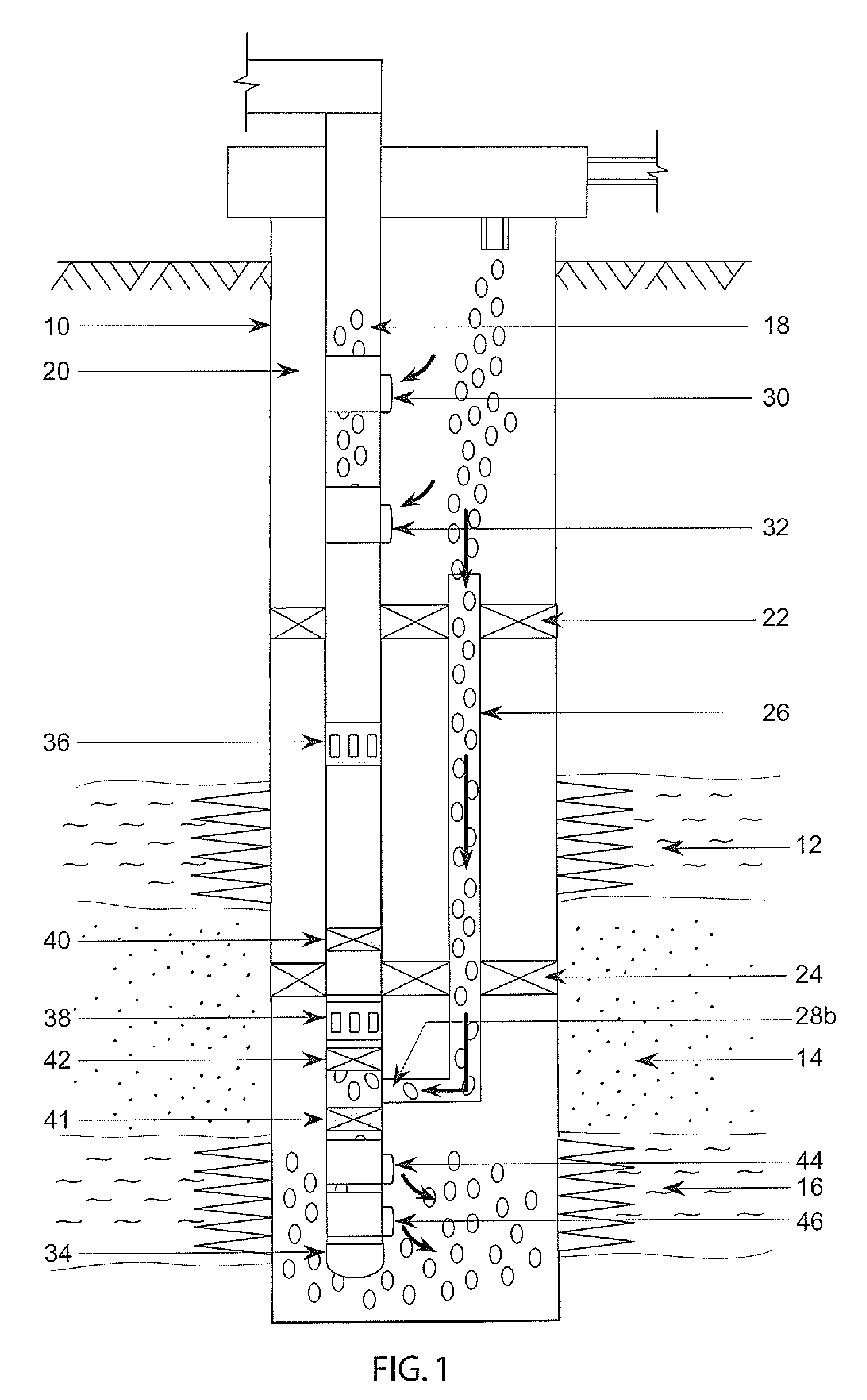

Wireless downwhole measurement and control for optimizing gas lift well and field performance

A method for optimizing the production of a petroleum well is provided. The petroleum well includes a borehole, a piping structure (24) positioned within the borehole, and a tubing string (26) positioned within the borehole for conveying a production fluid. Production of the well is optimized by determining a flow rate of the production fluid within the tubing string (26) and determining a lift-gas injection rate for the gas being injected into the tubing string. The flow rate and injection rate data is communicated along the piping structure of the well to a selected location (44), where the data is collected and analyzed. After analysis of the data, an optimum operating point (152) for the well can be determined

Owner:SHELL OIL CO

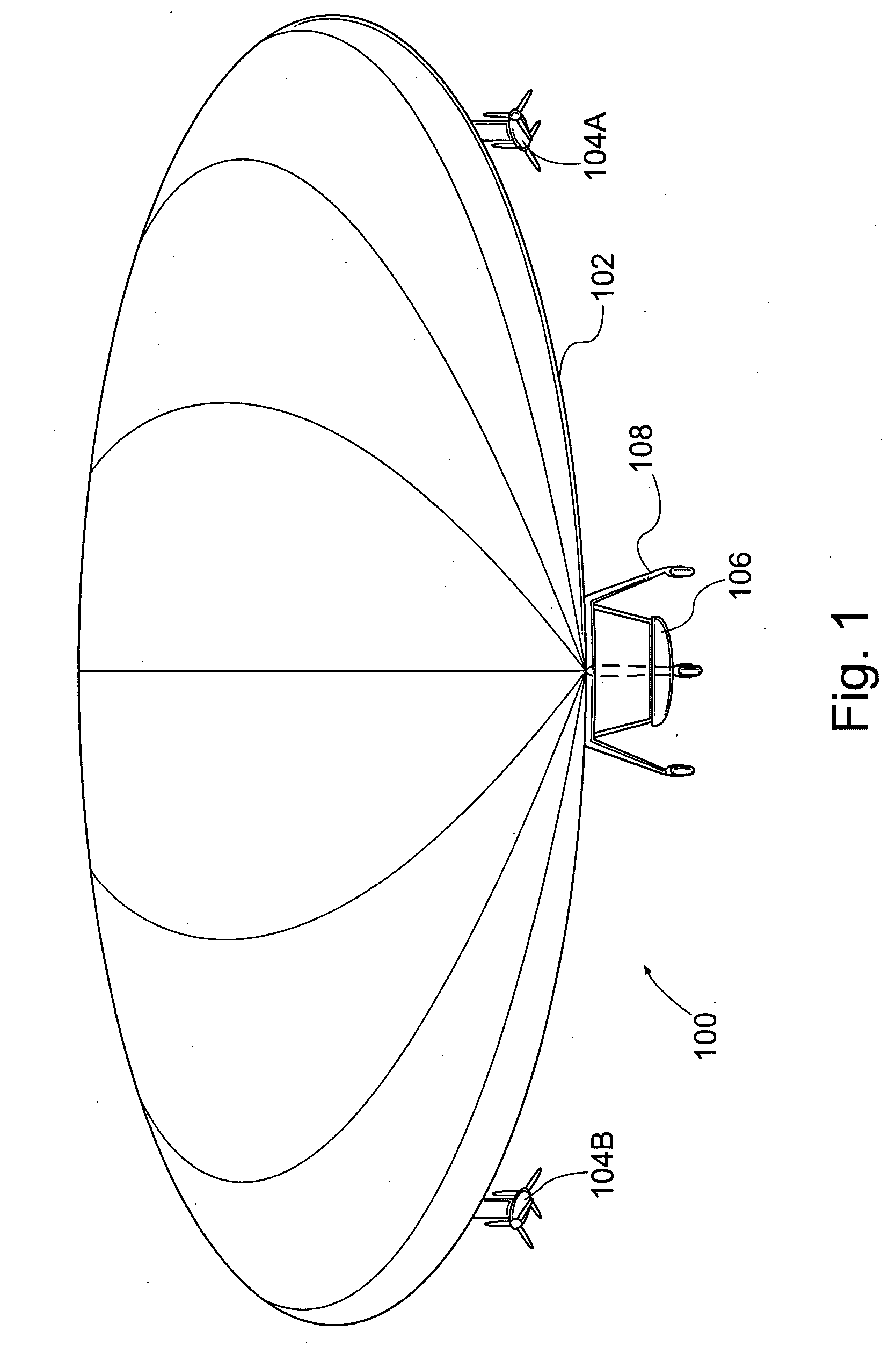

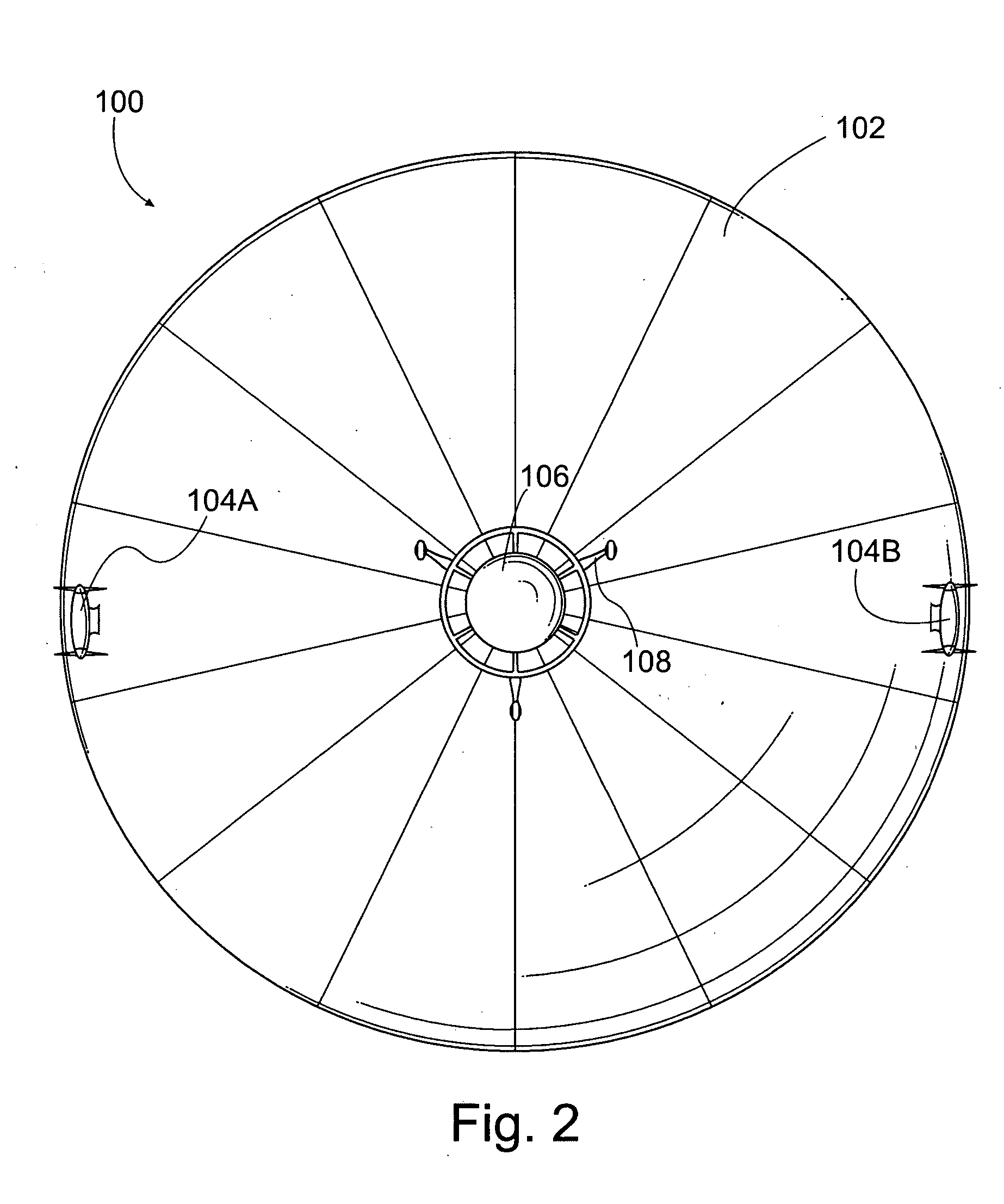

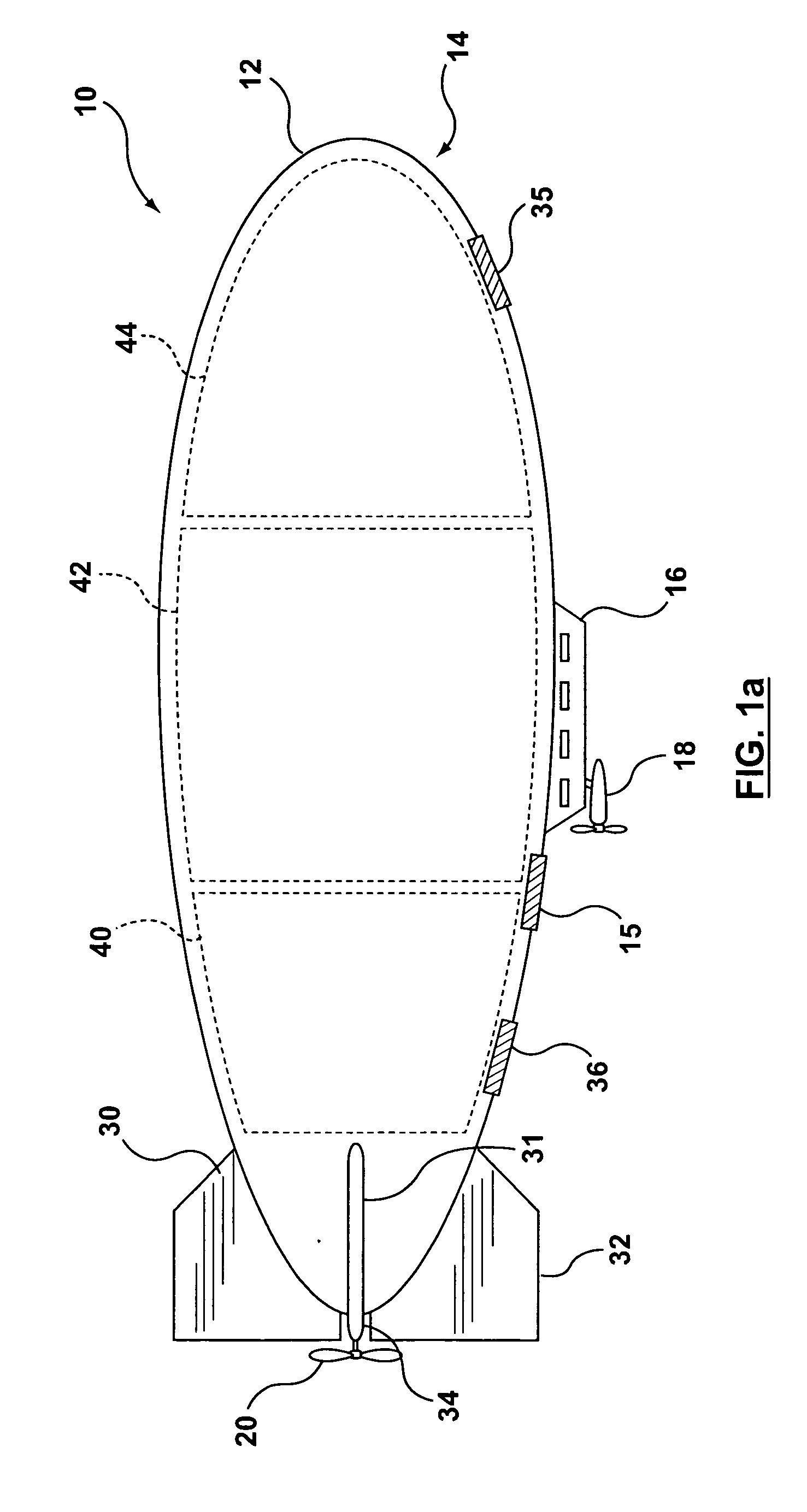

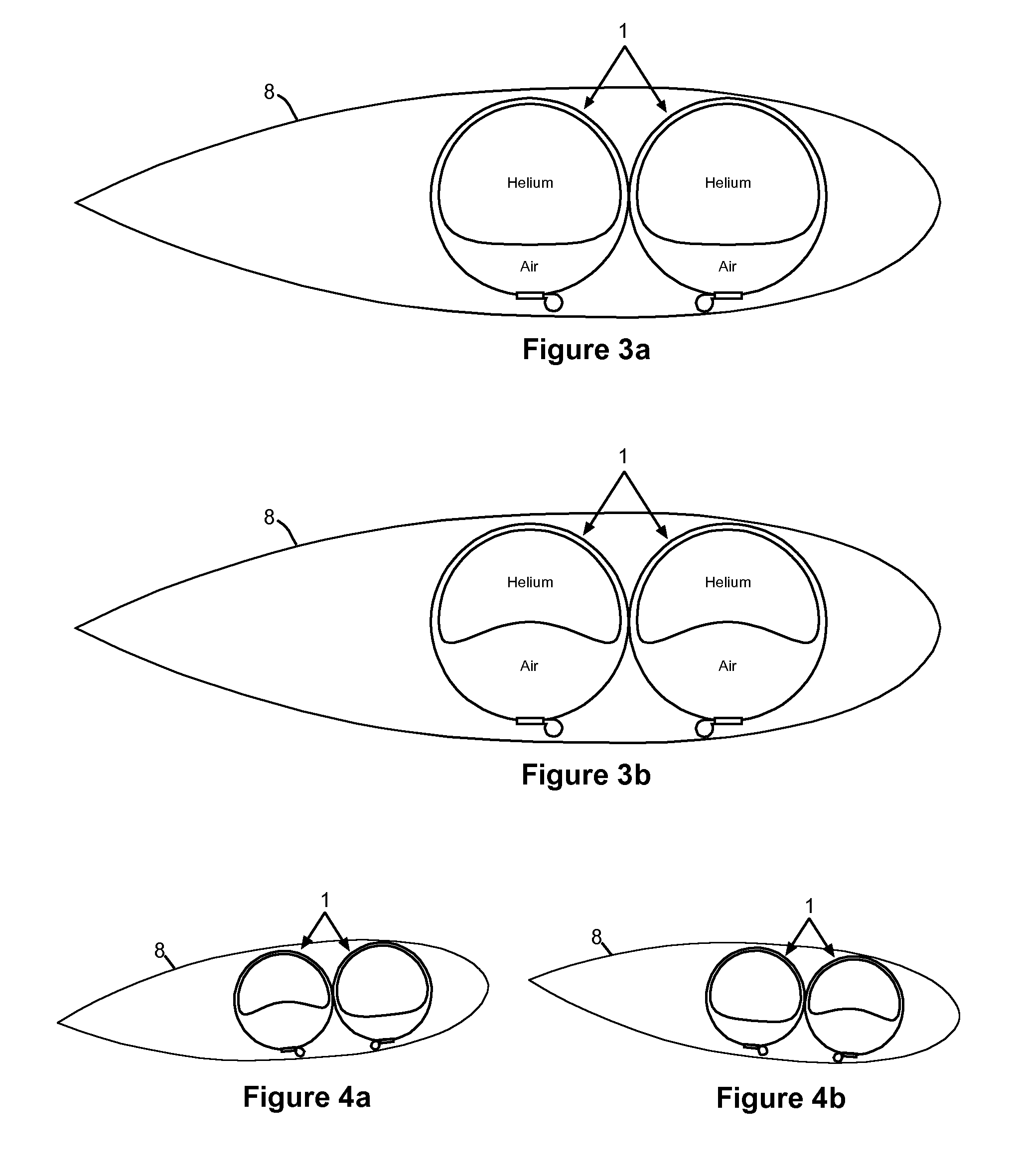

Airship & method of operation

InactiveUS20070069077A1Sufficient volumeCutting portionNon-rigid airshipsRigid airshipsFlight vehicleLifting gas

This invention relates to the field of buoyant aircraft and operation thereof, in particular, airships with improved stability. The present invention is directed to non-rigid, non-spherical airships having an envelop contained within the airship and at least one further envelop contained therein for holding a volume of lifting gas.

Owner:21ST CENTURY AIRSHIP TECH

Airship and method of operation

InactiveUS20050173591A1Long endurance loiteringUnmanned aerial vehiclesRemote controlled aircraftSpherical shapedAuxiliary power unit

An airship has a generally spherical shape and has an internal envelope for containing a lifting gas such as Helium or Hydrogen. The airship has a propulsion and control system that permits it to be flown to a desired loitering location, and to be maintained in that location for a period of time. In one embodiment the airship may achieve neutral buoyancy when the internal envelope is as little as 7% full of lifting gas, and may have a service ceiling of about 60,000 ft. The airship has an equipment module that can include either communications equipment, or monitoring equipment, or both. The airship can be remotely controlled from a ground station. The airship has a solar cell array and electric motors of the propulsion and control system are driven by power obtained from the array. The airship also has an auxiliary power unit that can be used to drive the electric motors. The airship can have a pusher propeller that assists in driving the airship and also moves the point of flow separation of the spherical airship further aft. In one embodiment the airship can be refuelled at altitude to permit extended loitering.

Owner:21ST CENTURY AIRSHIP TECH

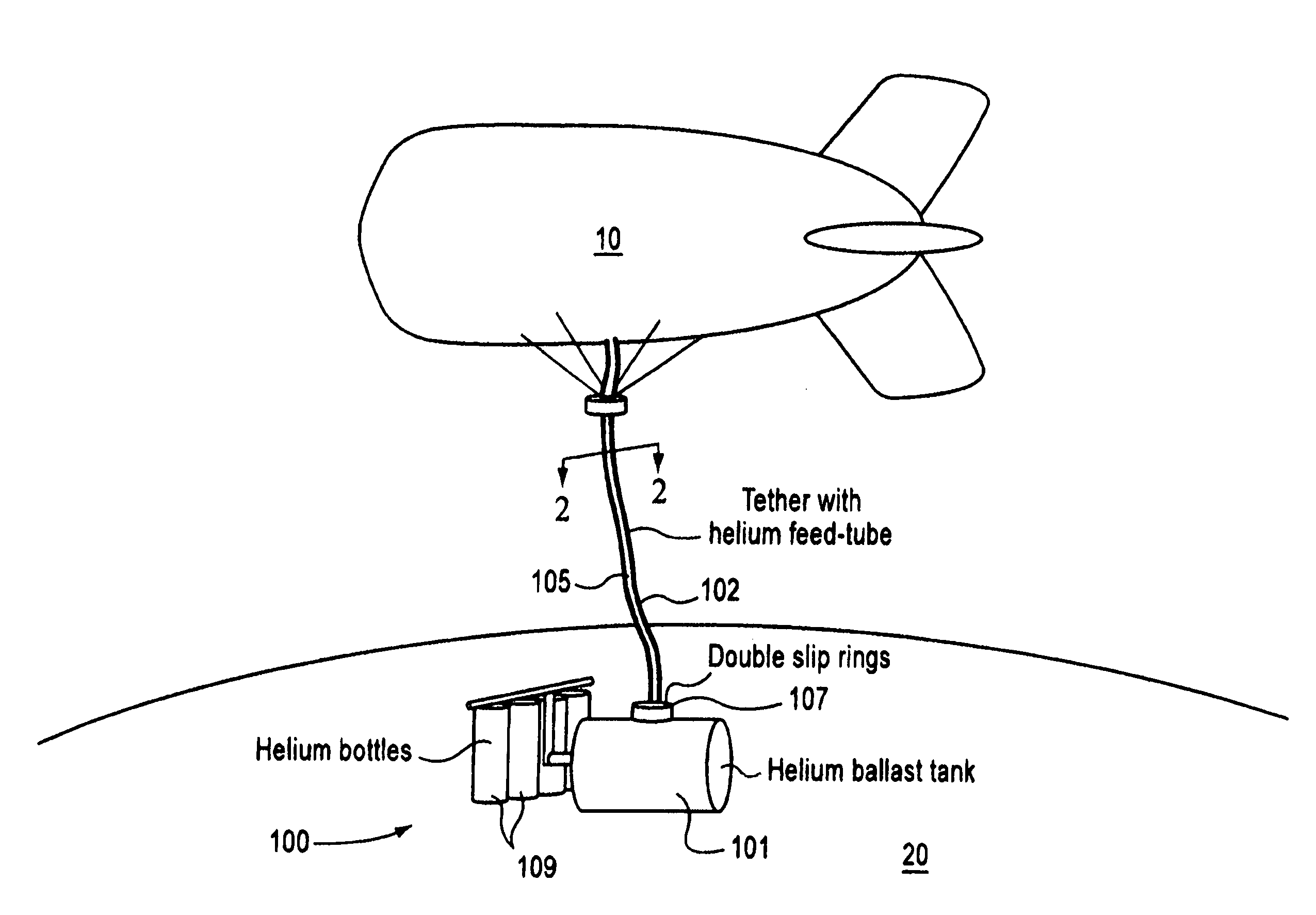

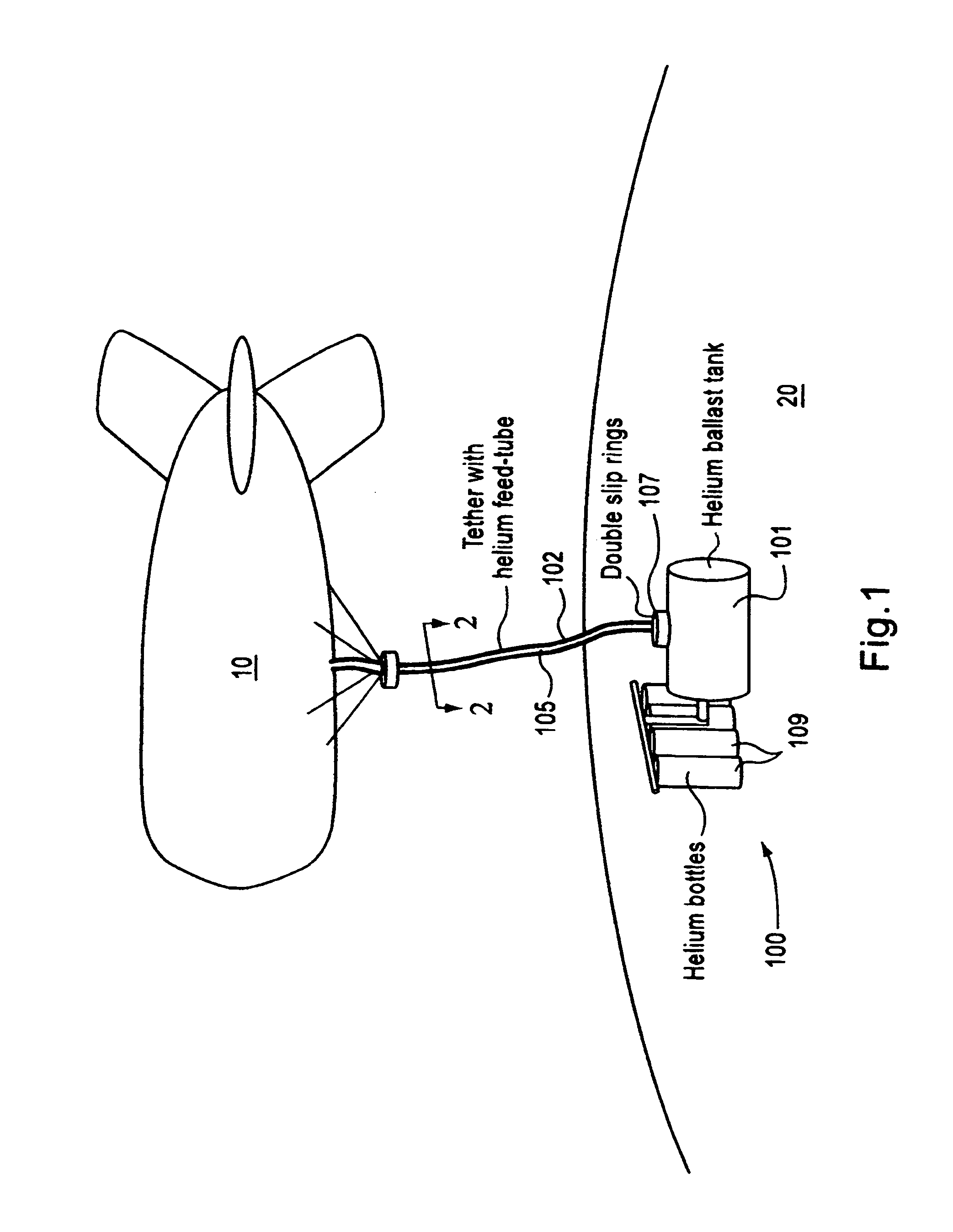

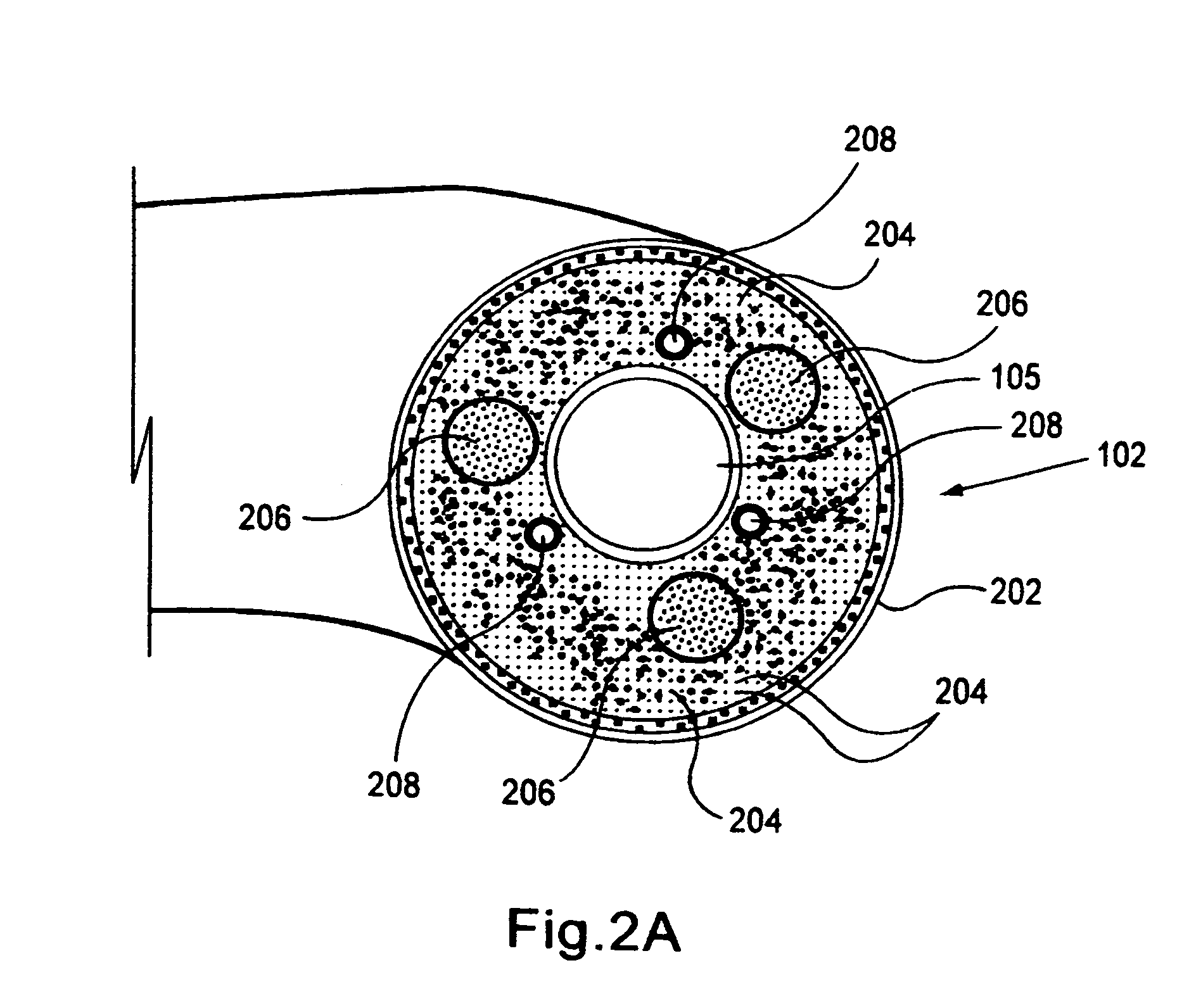

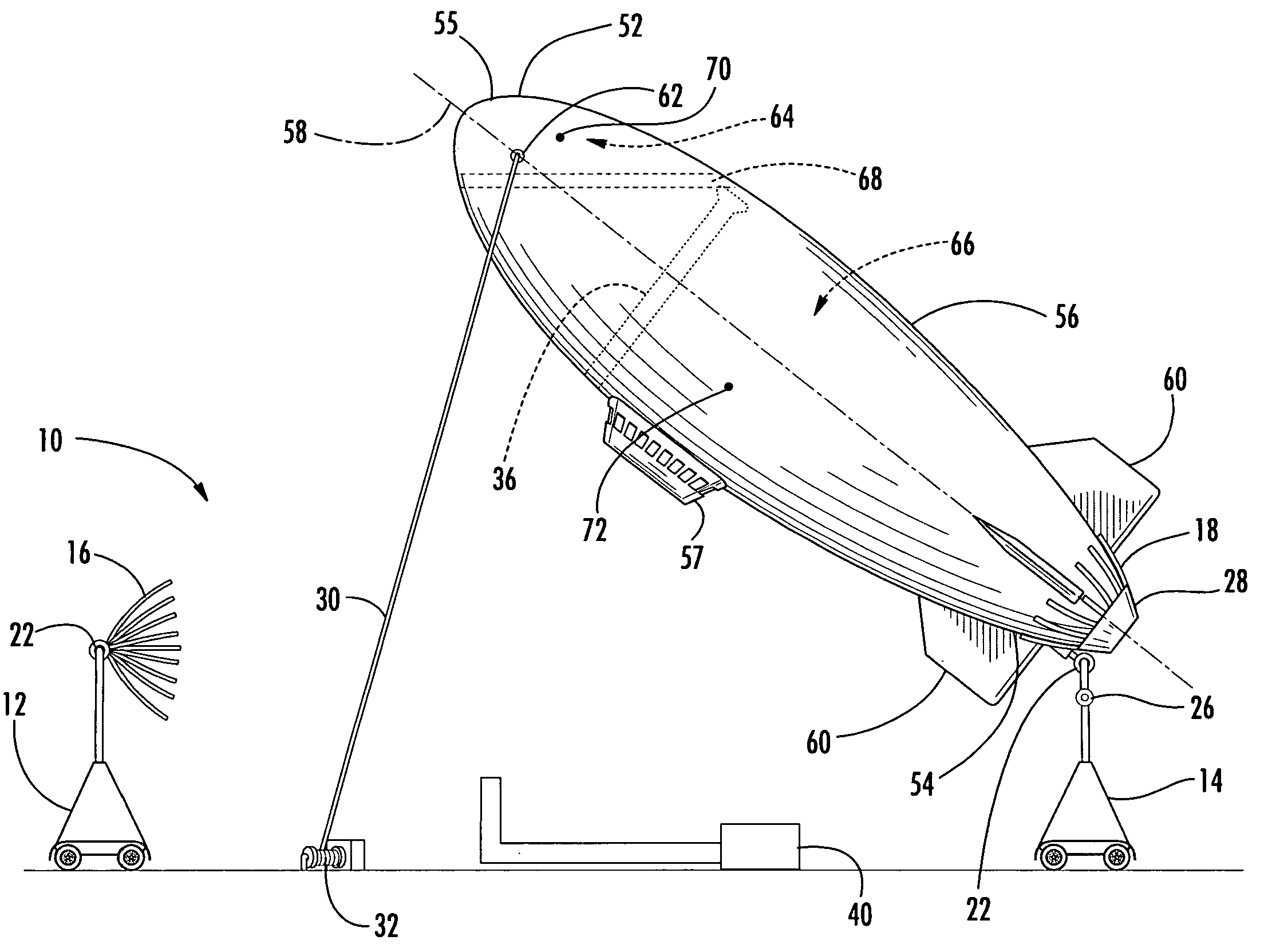

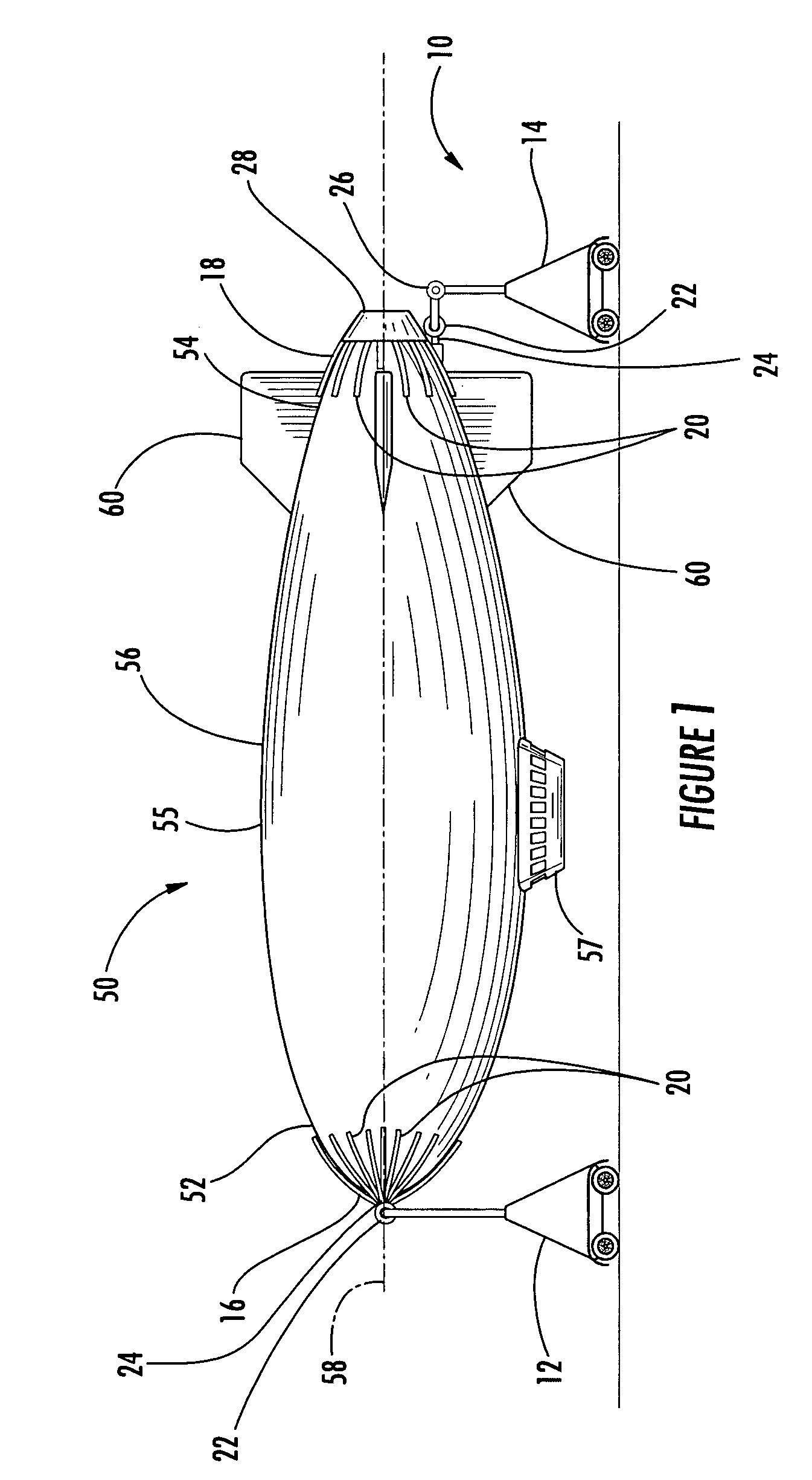

Long mission tethered aerostat and method of accomplishing

ActiveUS20120091261A1Stay rigidReducing reliance on ballonetsNon-rigid airshipsMovable targetsEngineeringGround station

Apparatus and method for a continuous replenishing of the lift gas and maintaining the proper pressure and lift of a tethered medium altitude aerostat utilizing a novel feed tube running the entire length of the tether. A first end of the feed tube is connected to the aerostat while a second end is connected through a novel slip ring means to a pressure controlled helium ballast chamber and scrubber on the ground to maintain pressure and lift by a reversible compressing pump. A plurality of pressure and temperature sensors and tension gauges strategically placed inside and around the airship continuously monitor the temperature and pressure changes in the aerostat. A data retrieval and communication unit mounted on the aerostat collects measurement data from the pressure, temperature and tension sensors which is relayed to the ground station and the data is used to regulate lifting gas pressure inside the aerostat.

Owner:STRATOCOMM CORP

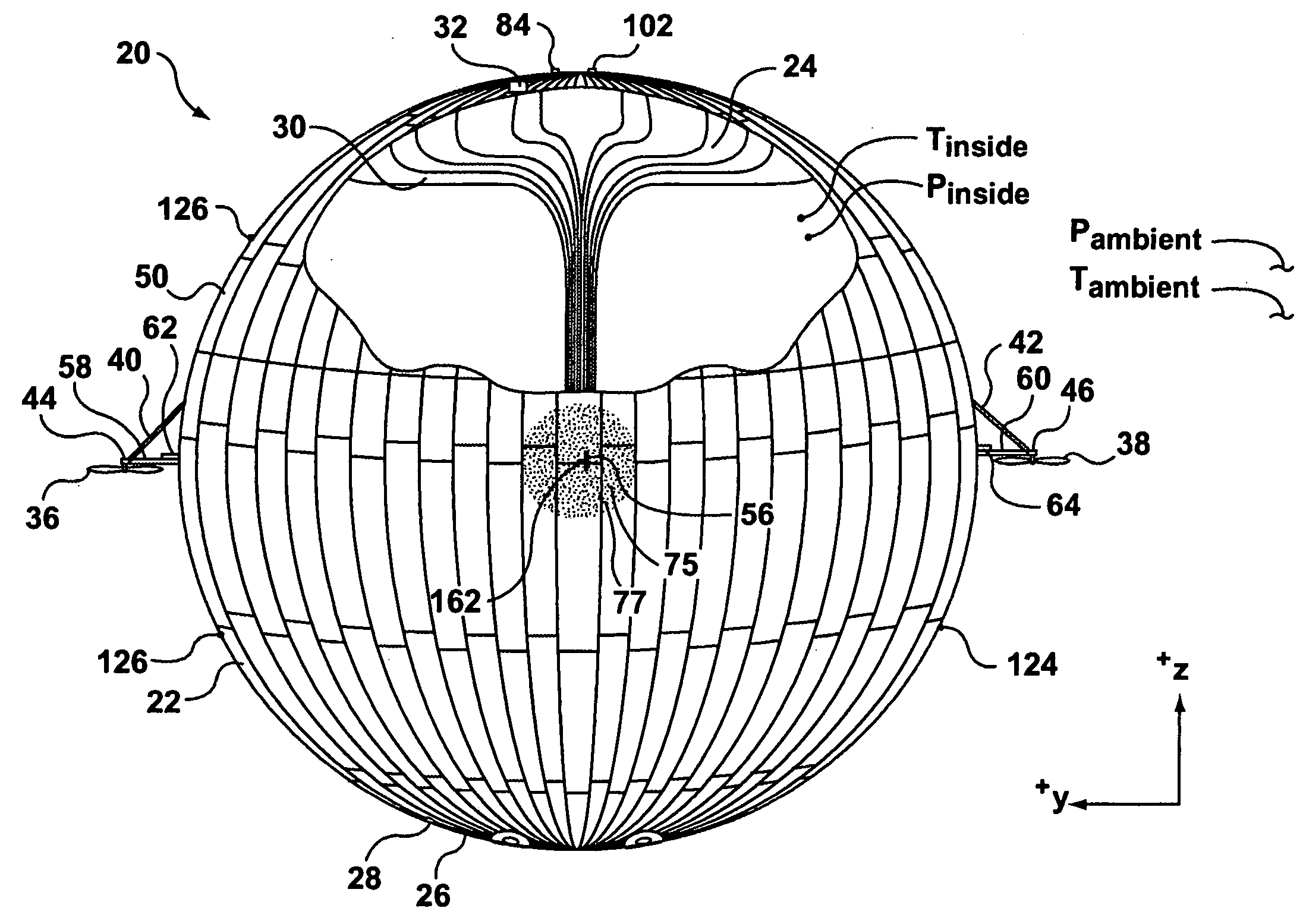

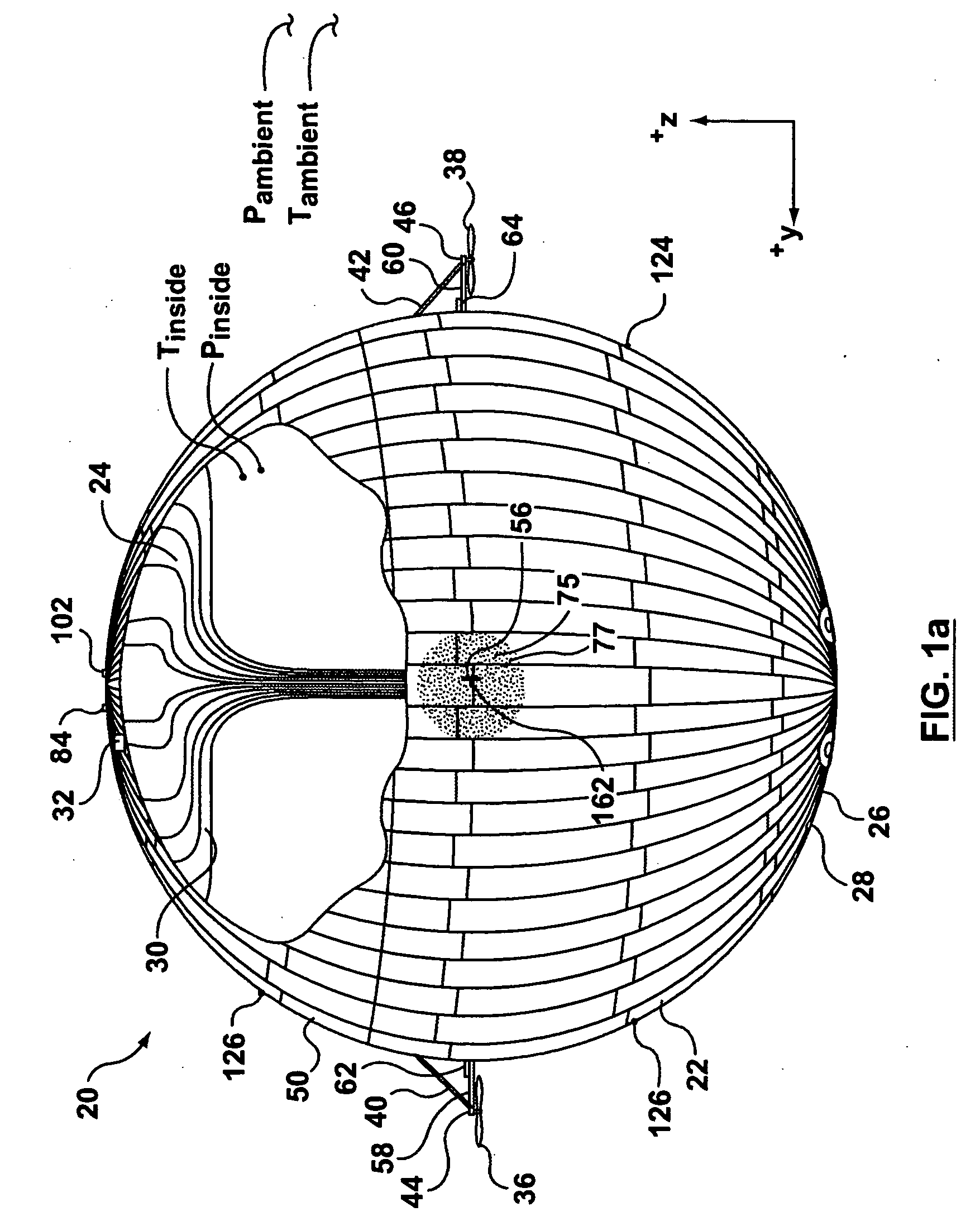

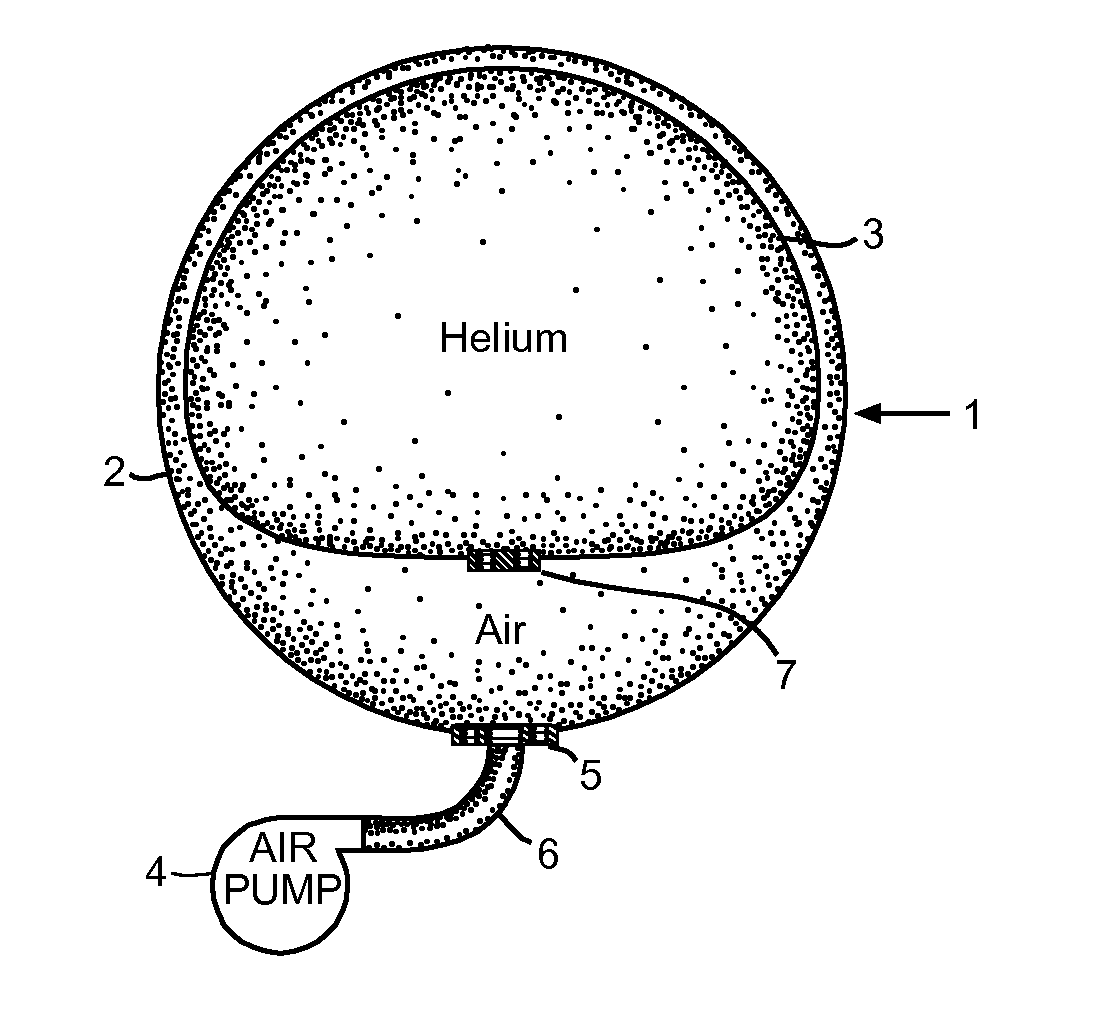

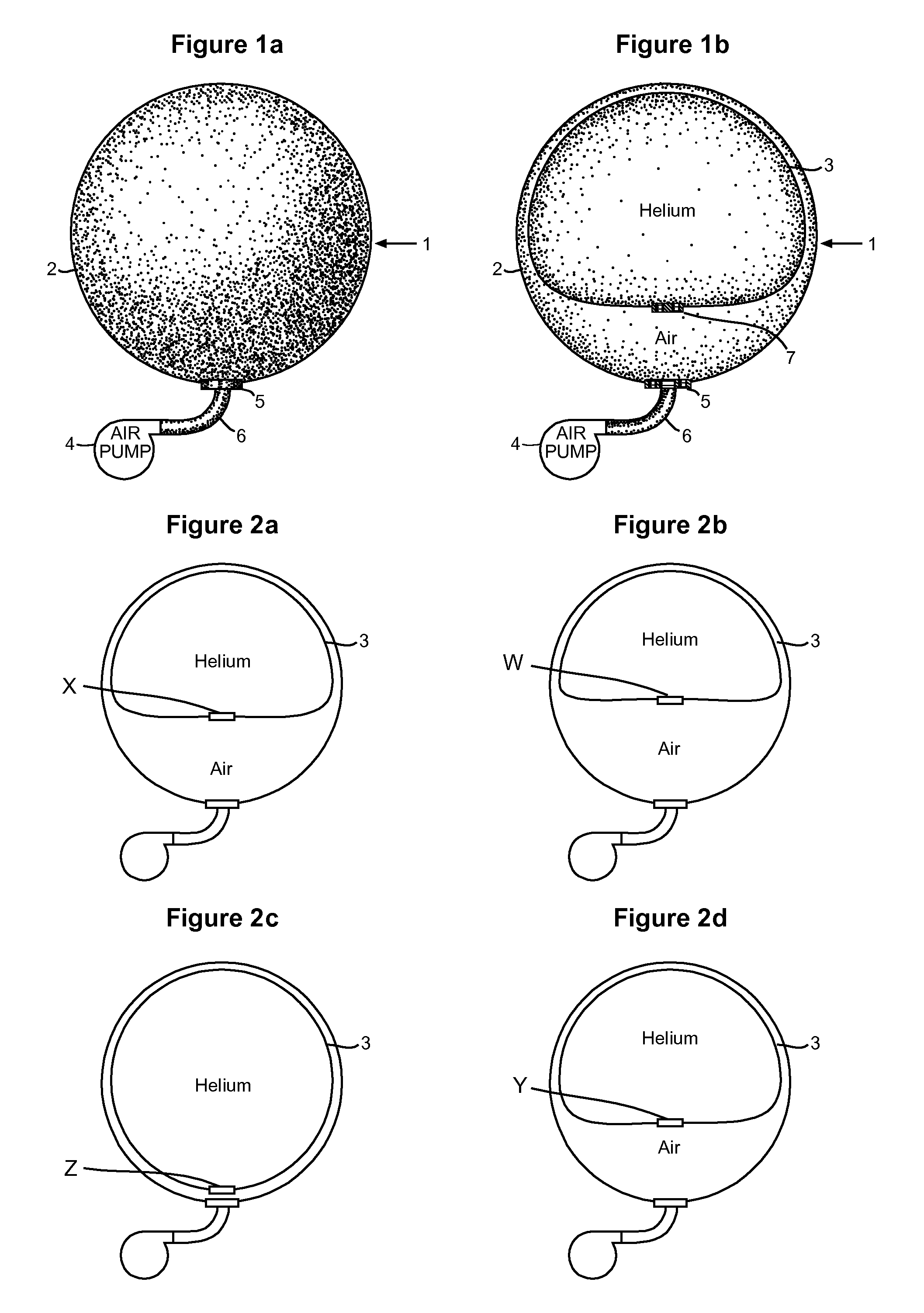

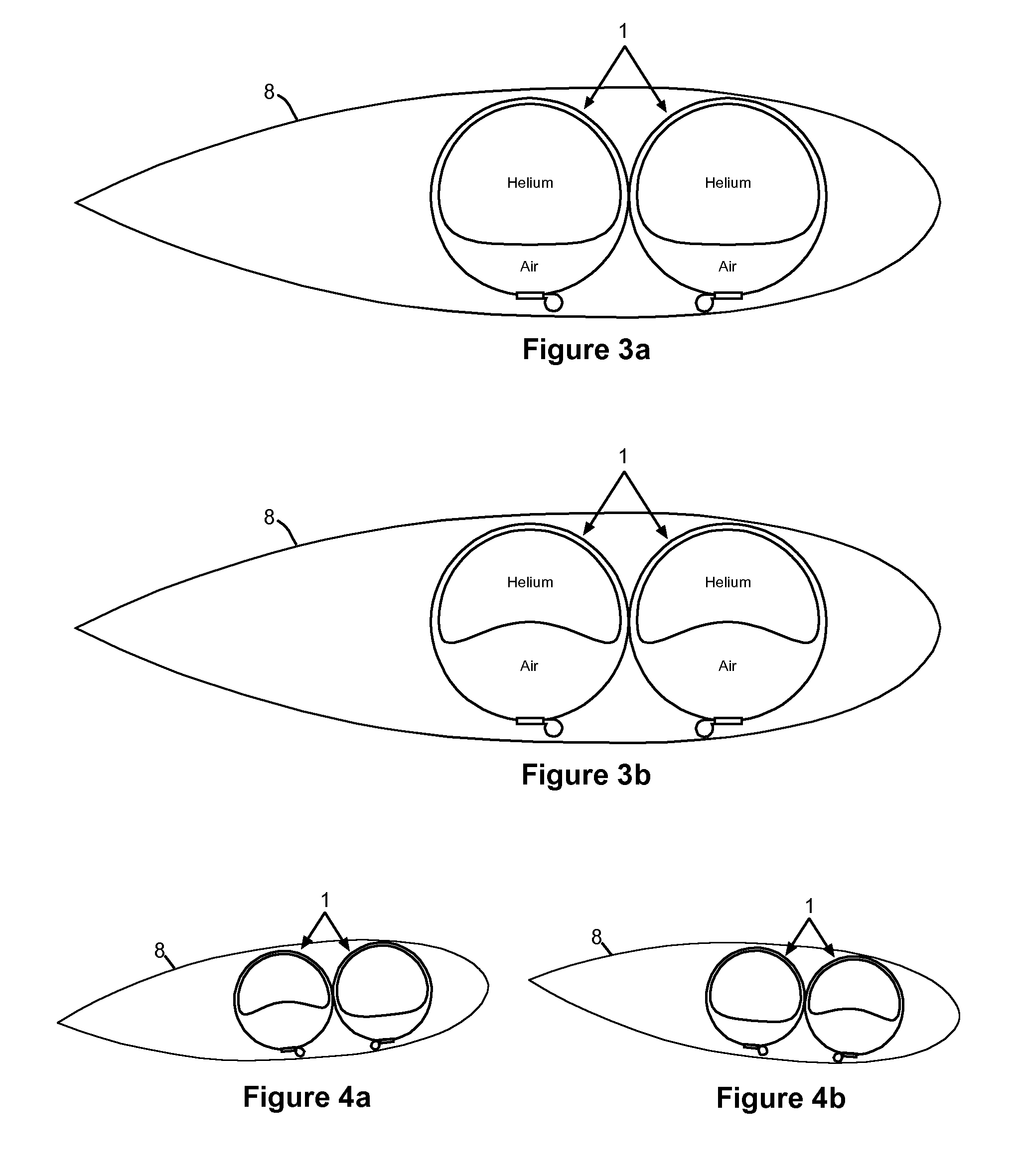

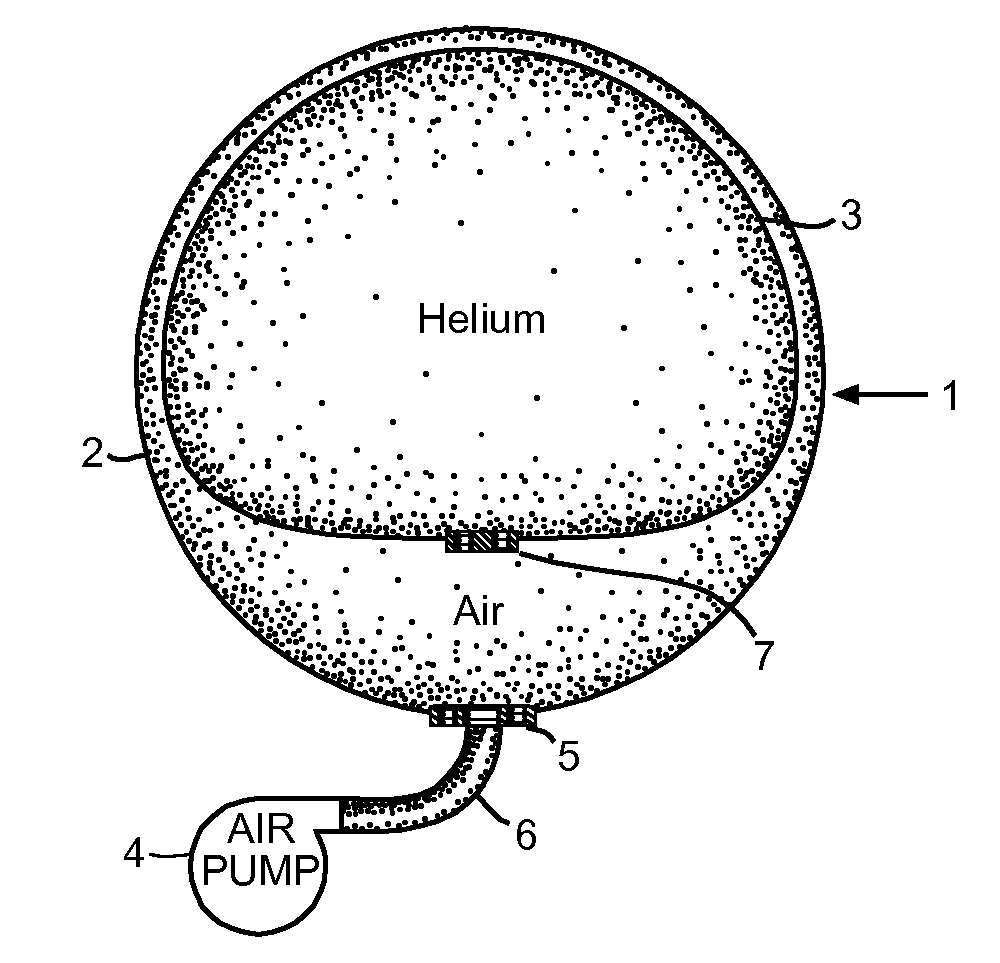

Aerostatic buoyancy control system

A system allowing for the active management of aerostatic lift in buoyant and semi-buoyant aerial vehicles comprised of a high tensile-strength outer pressure cell of a given volume and an inner compression cell of only slightly smaller dimensions. The inner compression cell is filled with a lifting gas, such as helium or hydrogen, to some fractional volume of its maximum, allowing for expansion of the lifting gas at different operational altitudes. When a reduction in aerostatic lift is desired, external air is compressed through the use of air handling means, and introduced into the outer pressure cell through a directional valve that prevents the pressurized air from leaving the pressure cell. When increased aerostatic lift is once again desired, the valve system may release all or a part of the pressurized air in the pressure cell, allowing the lifting gas to expand thereby displacing a greater volume of air and increasing lift.

Owner:VOORHEES MICHAEL TODD

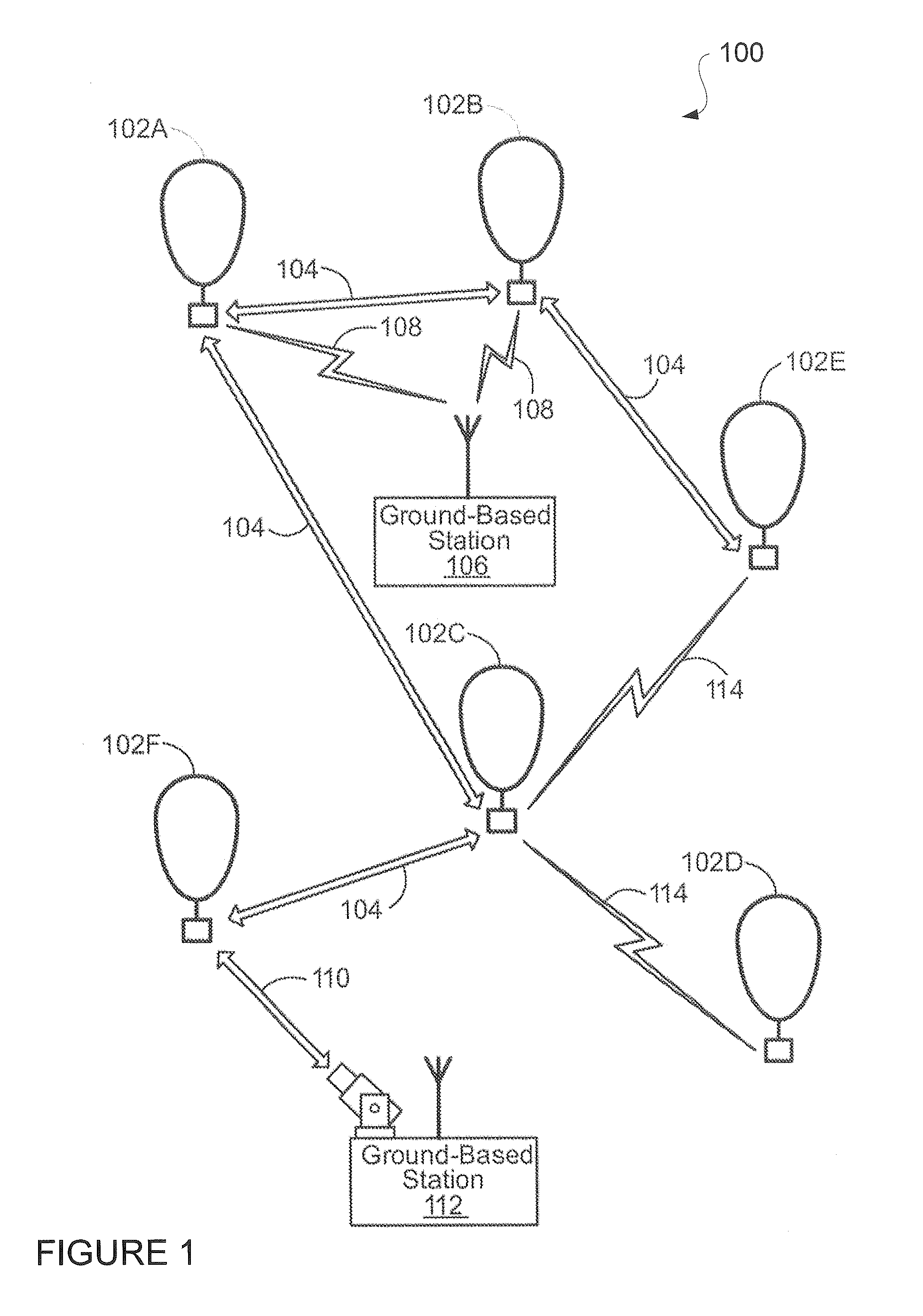

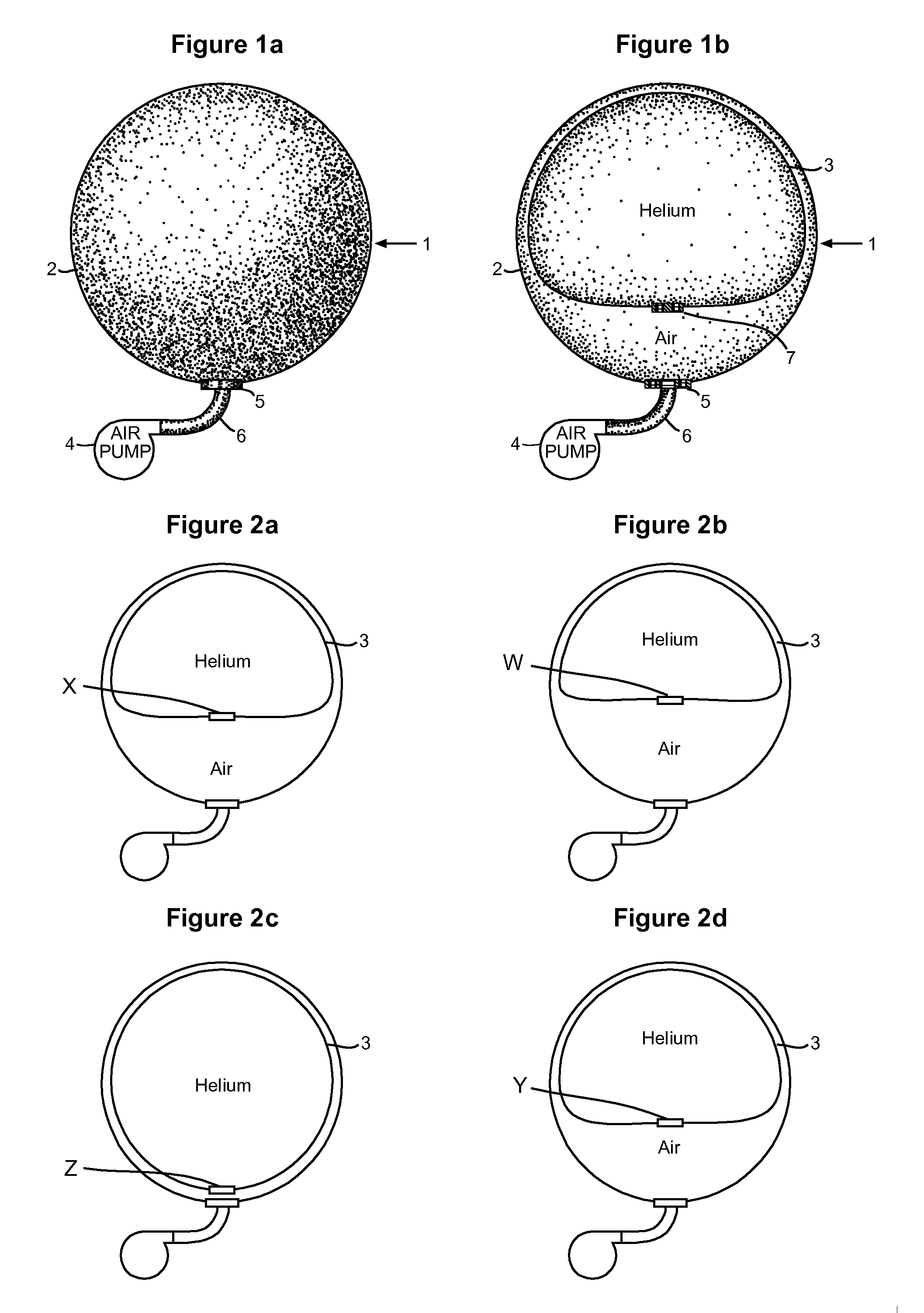

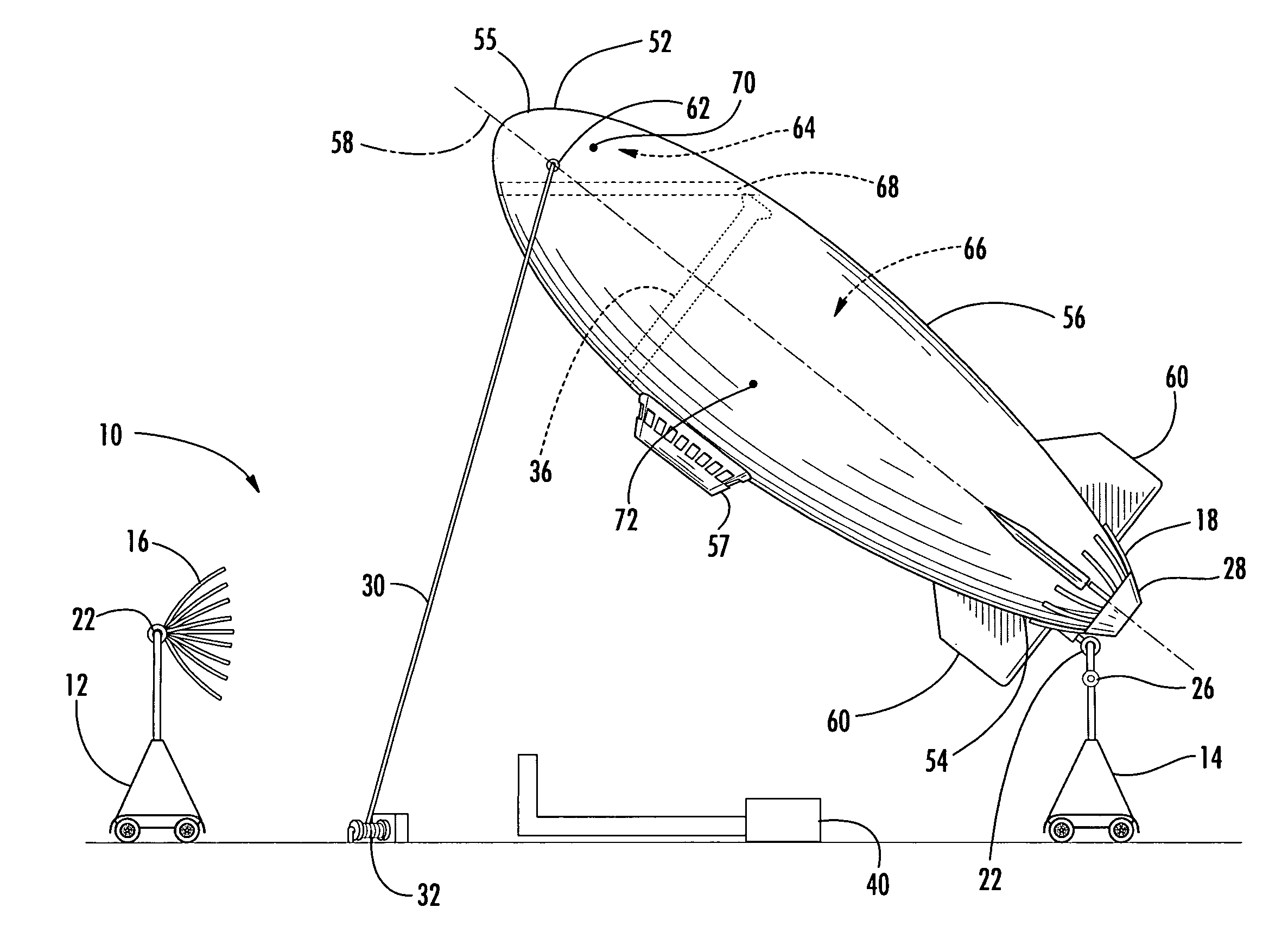

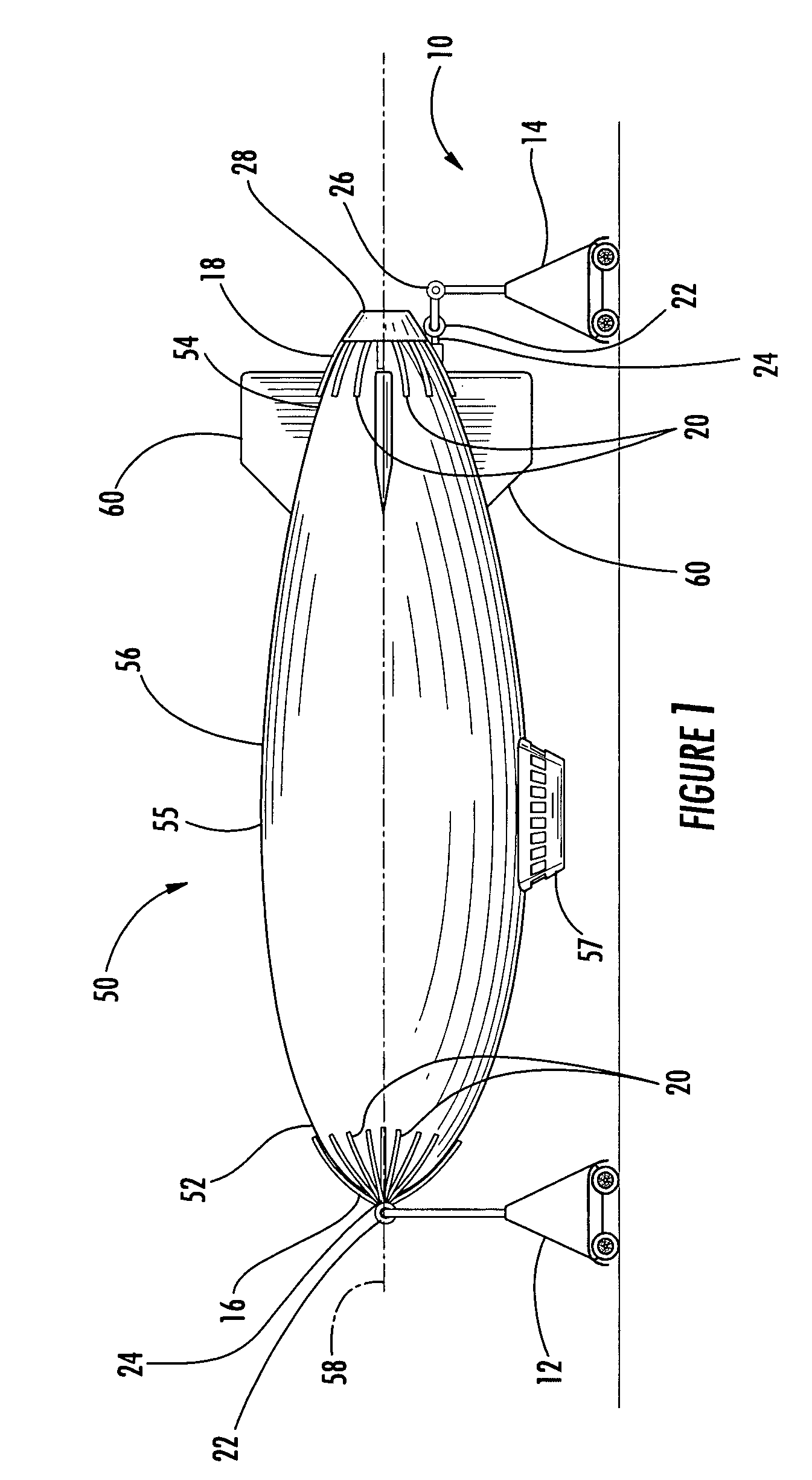

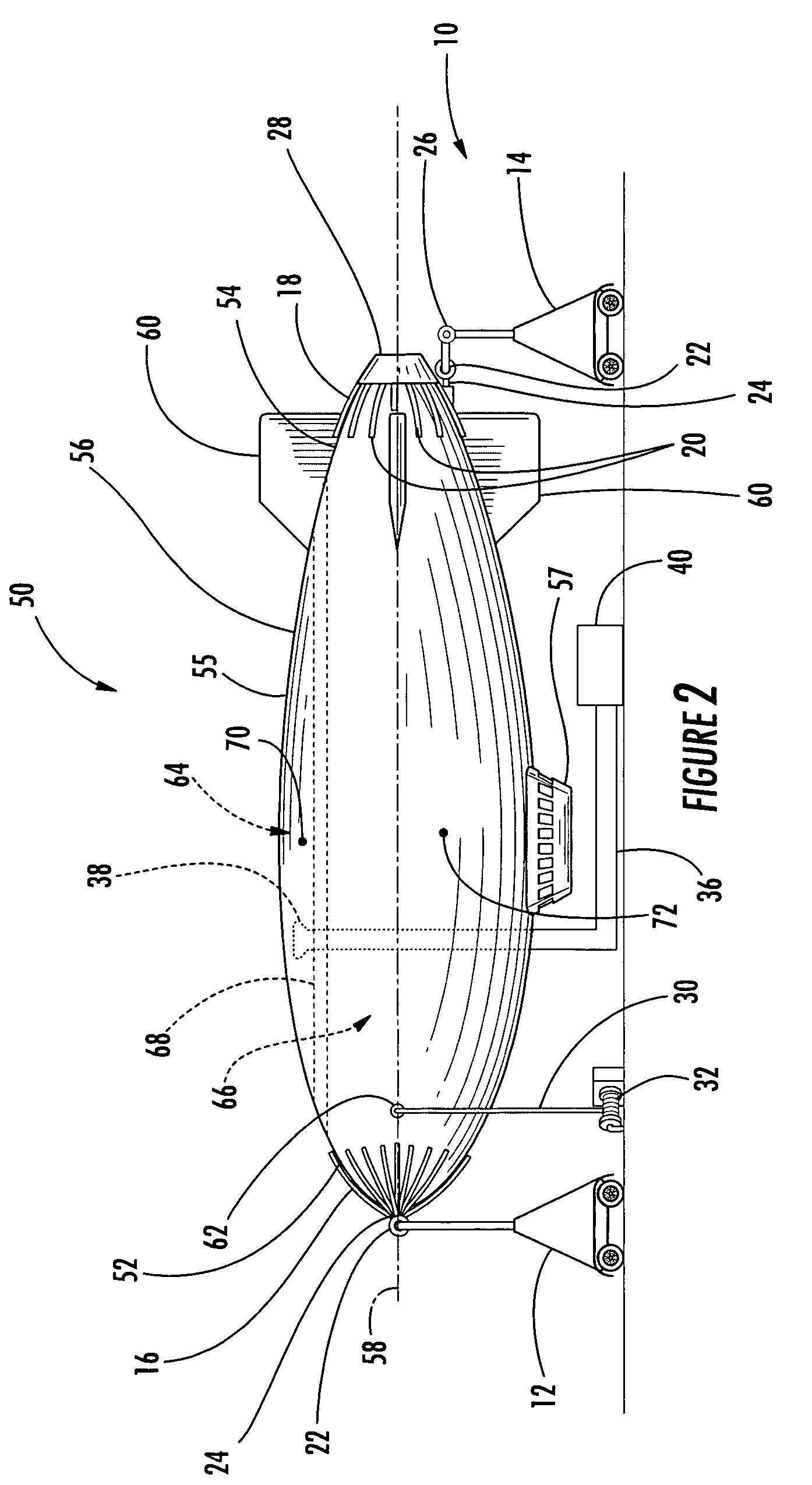

Apparatus and method for lighter-than-air aircraft

InactiveUS20050156082A1Minimize mixingAvoid shakingAnchoring installationsNon-rigid airshipsLifting gasLighter than air

An apparatus and associated method for launching and recovering a lighter-than-air aircraft are provided. The aircraft includes an envelope that is substantially filled before launch with a lift gas and a second gas. The lift gas and second gas are substantially separated in the envelope by a boundary layer of mixed gas, formed by the lift and second gases. The aircraft is supported by one or more masts as the lift gas is injected to achieve the required buoyancy for launch. The aircraft is then released and rises, for example, in an inclined orientation. As the aircraft climbs, the lift gas expands in the envelope, and the second gas is vented therefrom. During horizontal descent, air can be pumped into the envelope to maintain the envelope in a substantially filled configuration. The air and lift gas can be mixed to avoid sloshing and pooling.

Owner:THE BOEING CO

Filling apparatus for high-altitude balloons

ActiveUS9027877B1Simple and robust and economicalReduce the possibilityDollsCheck valvesHigh-altitude balloonLifting gas

High-altitude balloons and apparatuses for filling such high-altitude balloons are provided. As an example, an apparatus for filling a high-altitude balloon includes a tube extending through envelope material of the balloon is provided. The apparatus also includes a flange connected to a first end of the tube. The flange is connected to an interior surface of the balloon. A fitting is connected to a second end of the tube. The fitting is configured for attachment with an apparatus for filling the balloon with lift gas. In addition, methods of filing high-altitude balloons with lift gas and methods of manufacturing balloons are also provided.

Owner:AEROSTAR INT LLC

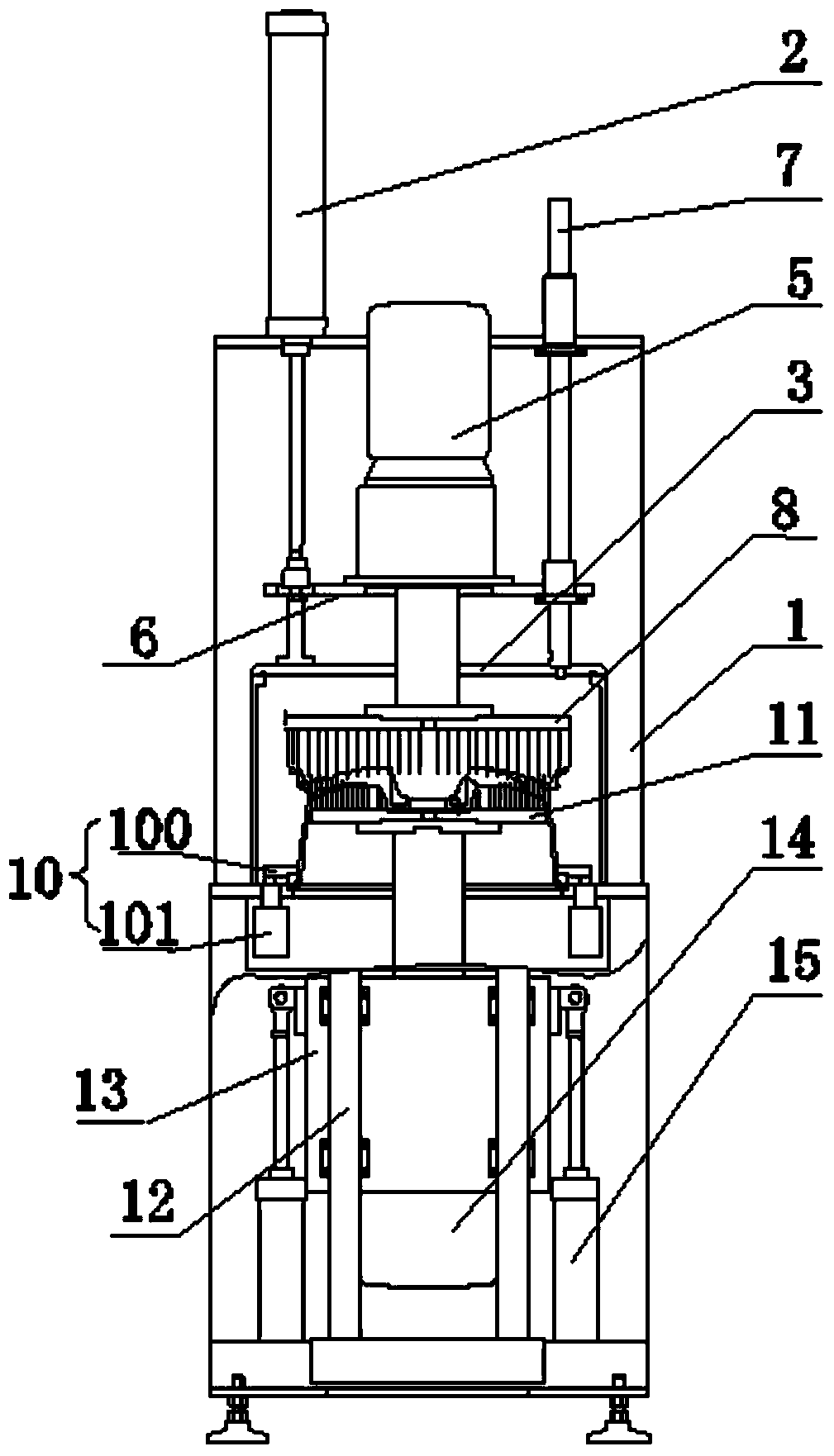

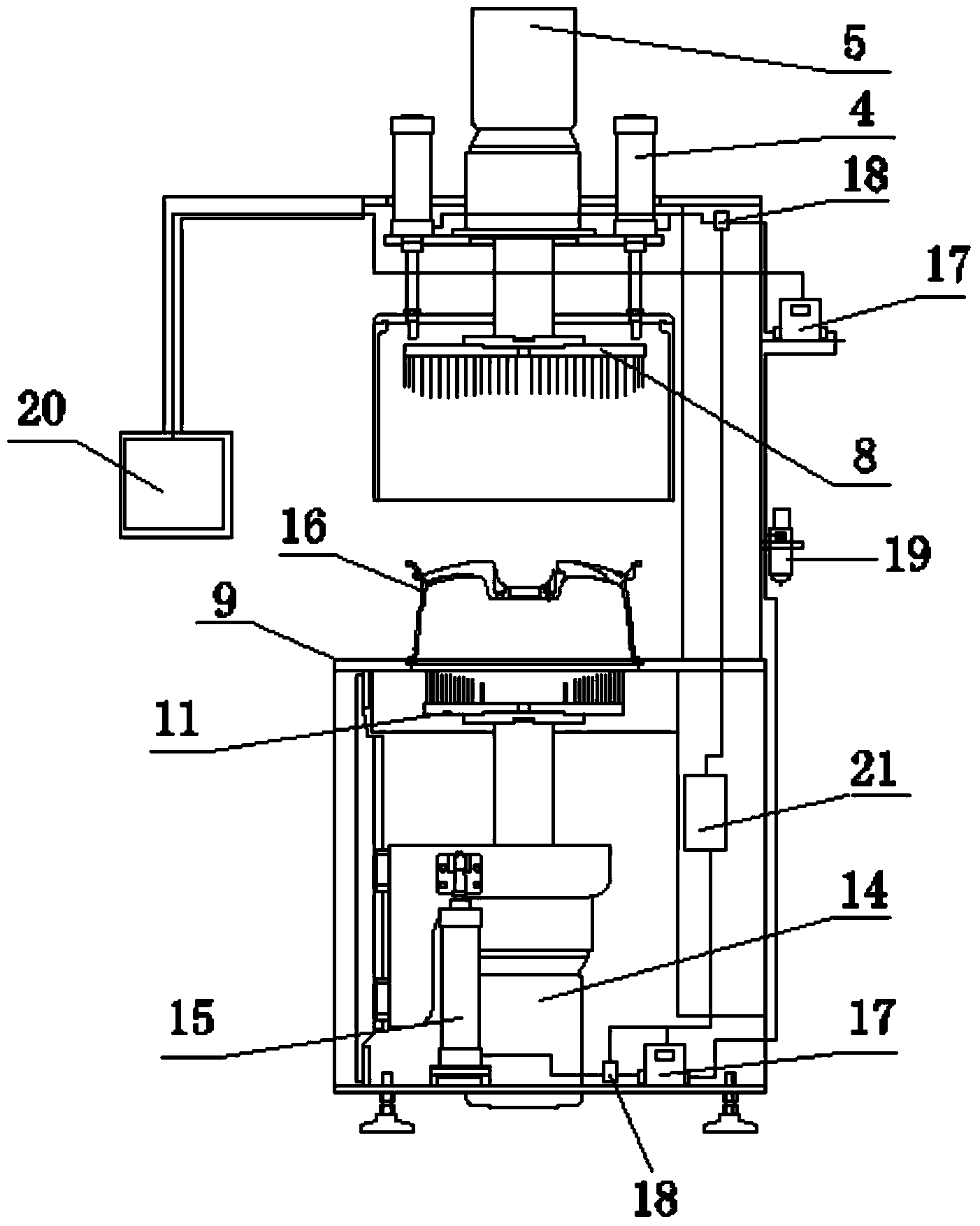

Constant-pressure automatic compensation system of aluminum alloy hub deburring machine

ActiveCN103447913AImprove pass rateAvoid dirtyEdge grinding machinesGrinding/polishing safety devicesProportional controlLifting gas

The invention discloses a constant-pressure automatic compensation system of an aluminum alloy hub deburring machine, wherein a processing platform, an upper hair brush plate, a lower hair brush plate, an upper lifting gas cylinder and a lower lifting gas cylinder are arranged on a machine frame in a positioning way; the upper lifting gas cylinder and the lower lifting gas cylinder are respectively used for driving the upper hair brush plate and the lower hair brush plate to act; proportional control valves are connected between the gas inlets of the upper lifting gas cylinder and the lower lifting gas cylinder and a gas source respectively; a pair of pressure sensors are also arranged between the gas inlets of the upper lifting gas cylinder and the lower lifting gas cylinder and the gas source; the pressure sensors are respectively used for sensing gas pressure signals at the gas inlets of the upper lifting gas cylinder and the lower lifting gas cylinder, and transmitting the gas pressure signals to a controller; the controller implements analysis and calculation on the gas pressure signals and controls the flow rate of gas flowing out from the two proportion control valves, so that the condition that the upper hair brush plate and the lower hair brush act by the constant-pressure push of the upper lifting gas cylinder and the lower lifting gas cylinder can be guaranteed; therefore, not only the problem that not all burs are removed due to insufficient pressure of the upper hair brush plate and the lower hair brush plate, but also the problems that due to overlarge pressure of the upper hair brush plate and the lower hair brush plate, a hub is scrapped, and the service lives of the upper hair brush plate and the lower hair brush plate are shortened can be prevented.

Owner:江苏天宏机械科技有限公司

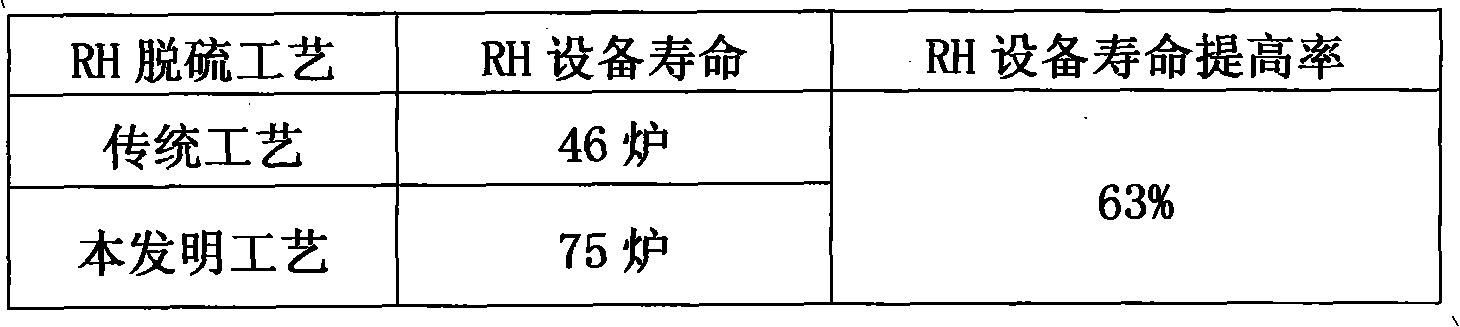

A low-cost process of increasing nitrogen and controlling nitrogen in rh molten steel

A low-cost RH molten steel nitrogen increasing process belongs to the technical field of steelmaking. The process route of "converter-ladle furnace refining-RH refining-continuous casting" is used for smelting; converter tapping adopts deoxidation alloying, and vanadium-iron alloy is added to match vanadium according to the target value of the steel type during the tapping process, and the molten steel temperature is raised according to the normal process in the ladle furnace , alloy fine-tuning and deep desulfurization treatment, after the molten steel is hoisted to the RH furnace, the lifting gas of the RH furnace is set to nitrogen, the flow rate is controlled according to 800-1200NL / min, and the vacuum treatment time is 8-10min. Blowing operation, to reach the level of nitrogen content in steel at 80-120ppm. The advantage is that it can partially replace the vanadium-nitrogen alloy and reduce the cost of the alloy; ensure the stability of the nitrogen content and reduce the performance fluctuation of the steel plate caused by the composition fluctuation; the RH refining stage uses nitrogen instead of argon to realize the dual functions of process and composition control, further reducing the steelmaking process cost.

Owner:QINHUANGDAO SHOUQIN METAL MATERIAL +1

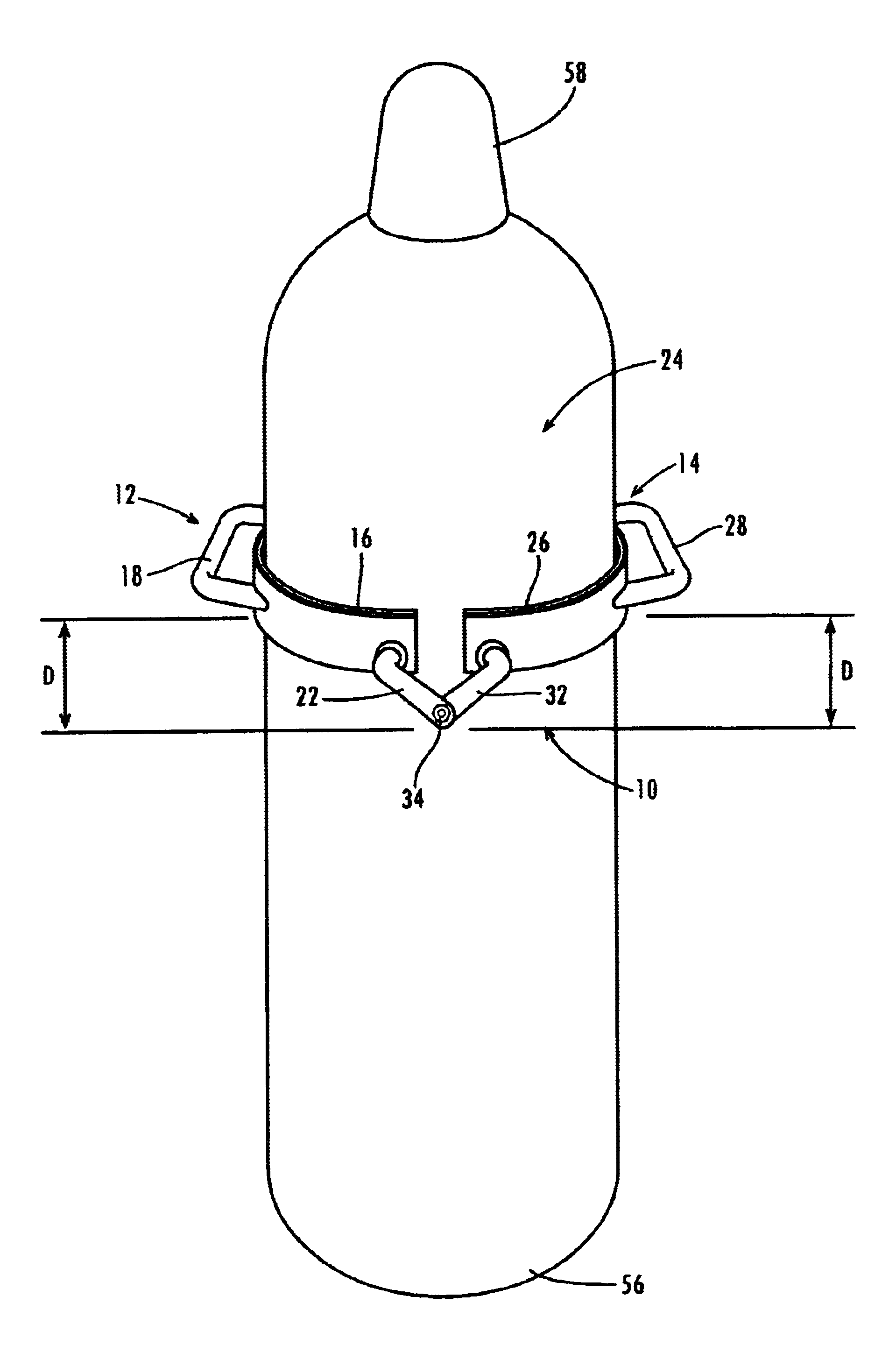

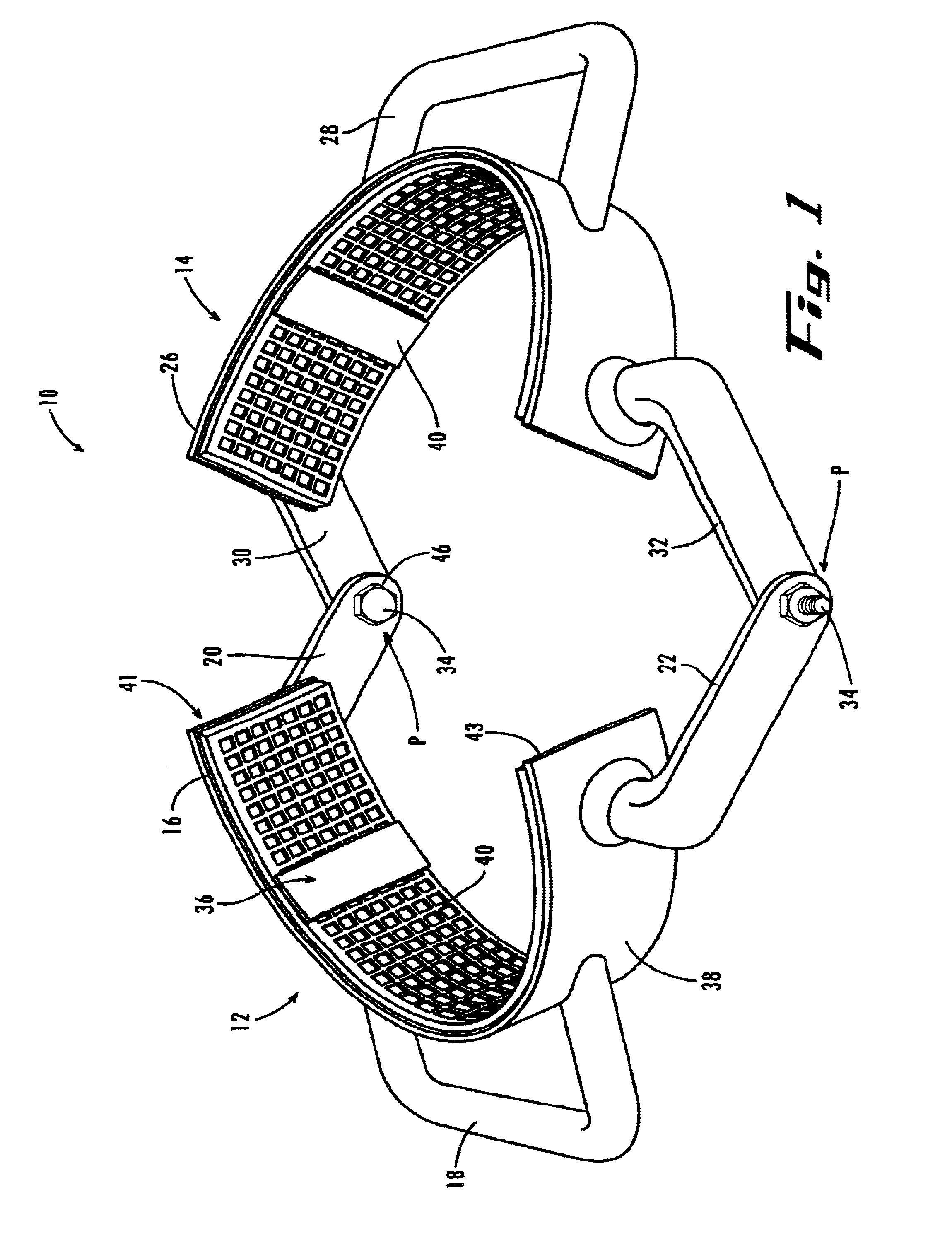

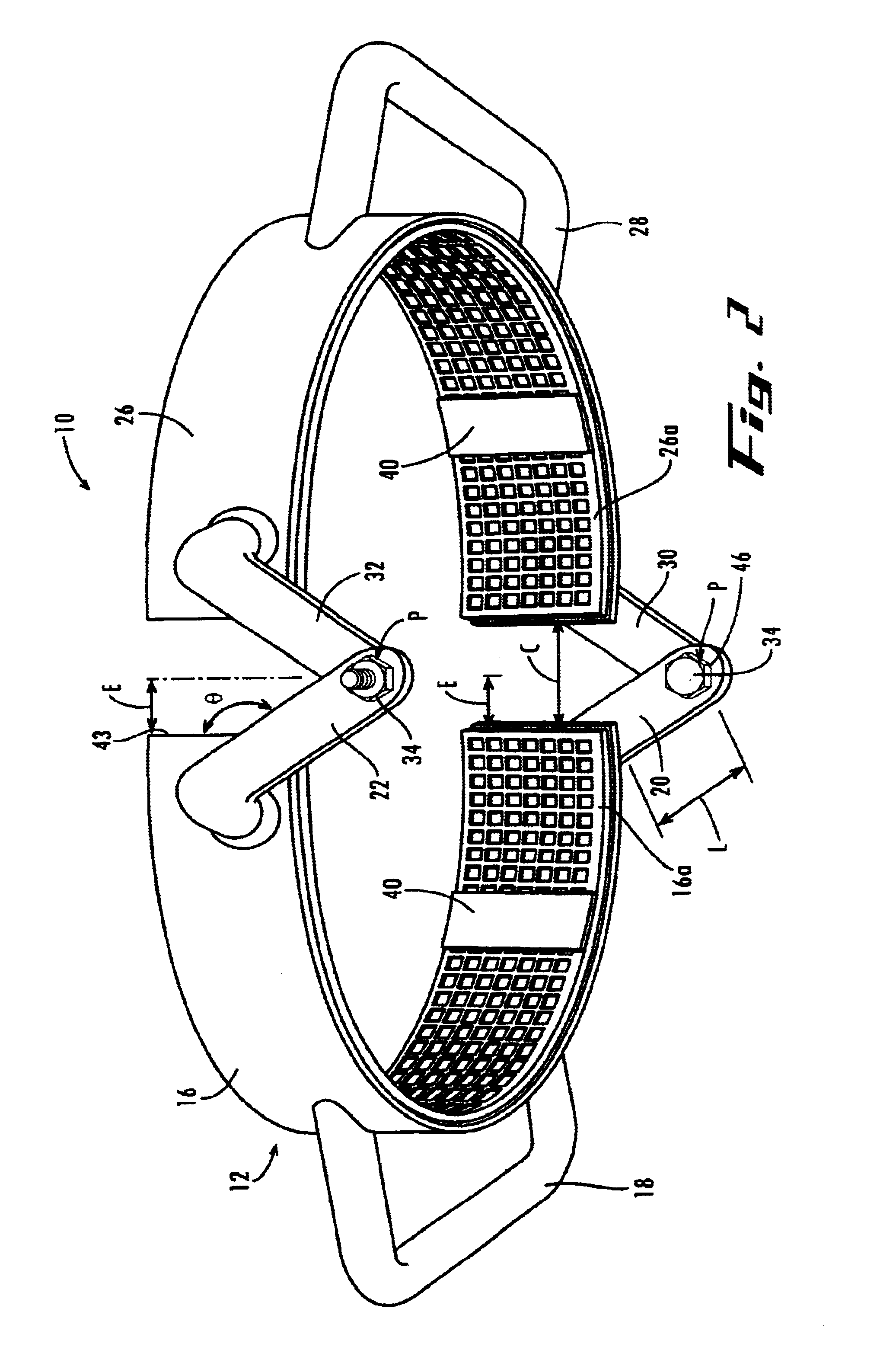

Device for lifting gas cylinders

InactiveUS6840556B1Difficult to liftNot easy to moveKitchen equipmentManual conveyance devicesGas cylinderLifting gas

A device for maneuvering cylinders having first and second semi-circular lifting members hingedly connected to one another by first and second hinge members. The lifting members are urged toward one another and the cylinder to frictionally secure the lifting members against the cylinder for maneuvering of the cylinder. First and second free ends of the first lifting member are maintained in a spaced apart relationship relative to first and second free ends of the second lifting member corresponding to a desired gap distance, and the first and second hinge members of each lifting member each define a hinge point located a desired hinge distance vertically spaced from free edges of each of the lifting members, such that the ratio of the gap distance to the hinge distance is at least about 1.25.

Owner:CATLETT LARRY K

System, apparatus, and method for producing a multiple zones well

ActiveUS20110132593A1Advantageously producedEasy constructionPressure pumpsFluid removalLifting gasEngineering

The present invention relates to a system, apparatus, and method provided to selectively produce petroleum fluid from multiple production zones well. The apparatus comprises a casing running downwardly into the well and a tubing string running in the casing. The upper and lower sealing mechanisms are provided for sealing the annular space between the casing and the tubing string, therefore, dividing the well into upper and lower production zones. Moreover, the invention comprises a bypass gaslift system provided with a tubular member, tubing string, connecting means and side pocket mandrels for injecting lifting gas into the multiple production zones well. The system and apparatus according to this invention can selectively operate to simultaneously or separately produce petroleum fluid from vertical apart multiple zones well.

Owner:PTT EXPLORATION & PROD PUBLIC CO LTD

Aerostatic Buoyancy Control System

InactiveUS20090114768A1Reduction in aerostatic liftLittle workRigid airshipsGas-bag arrangementsHydrogenControl system

A system allowing for the active management of aerostatic lift in buoyant and semi-buoyant aerial vehicles comprised of a high tensile-strength outer pressure cell of a given volume and an inner compression cell of only slightly smaller dimensions. The inner compression cell is filled with a lifting gas, such as helium or hydrogen, to some fractional volume of its maximum, allowing for expansion of the lifting gas at different operational altitudes. When a reduction in aerostatic lift is desired, external air is compressed through the use of air handling means, and introduced into the outer pressure cell through a directional valve that prevents the pressurized air from leaving the pressure cell. When increased aerostatic lift is once again desired, the valve system may release all or a part of the pressurized air in the pressure cell, allowing the lifting gas to expand thereby displacing a greater volume of air and increasing lift.

Owner:VOORHEES MICHAEL TODD

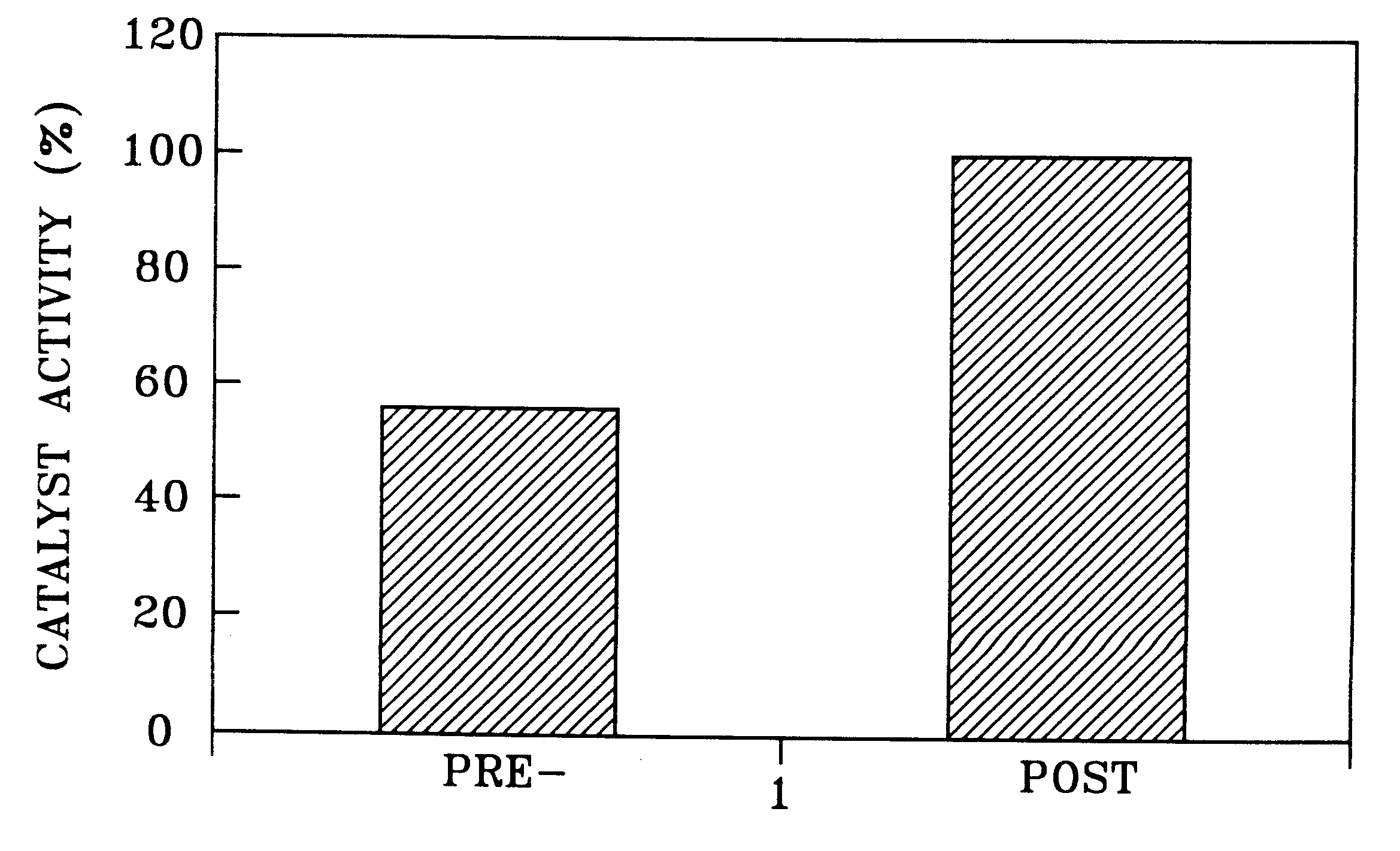

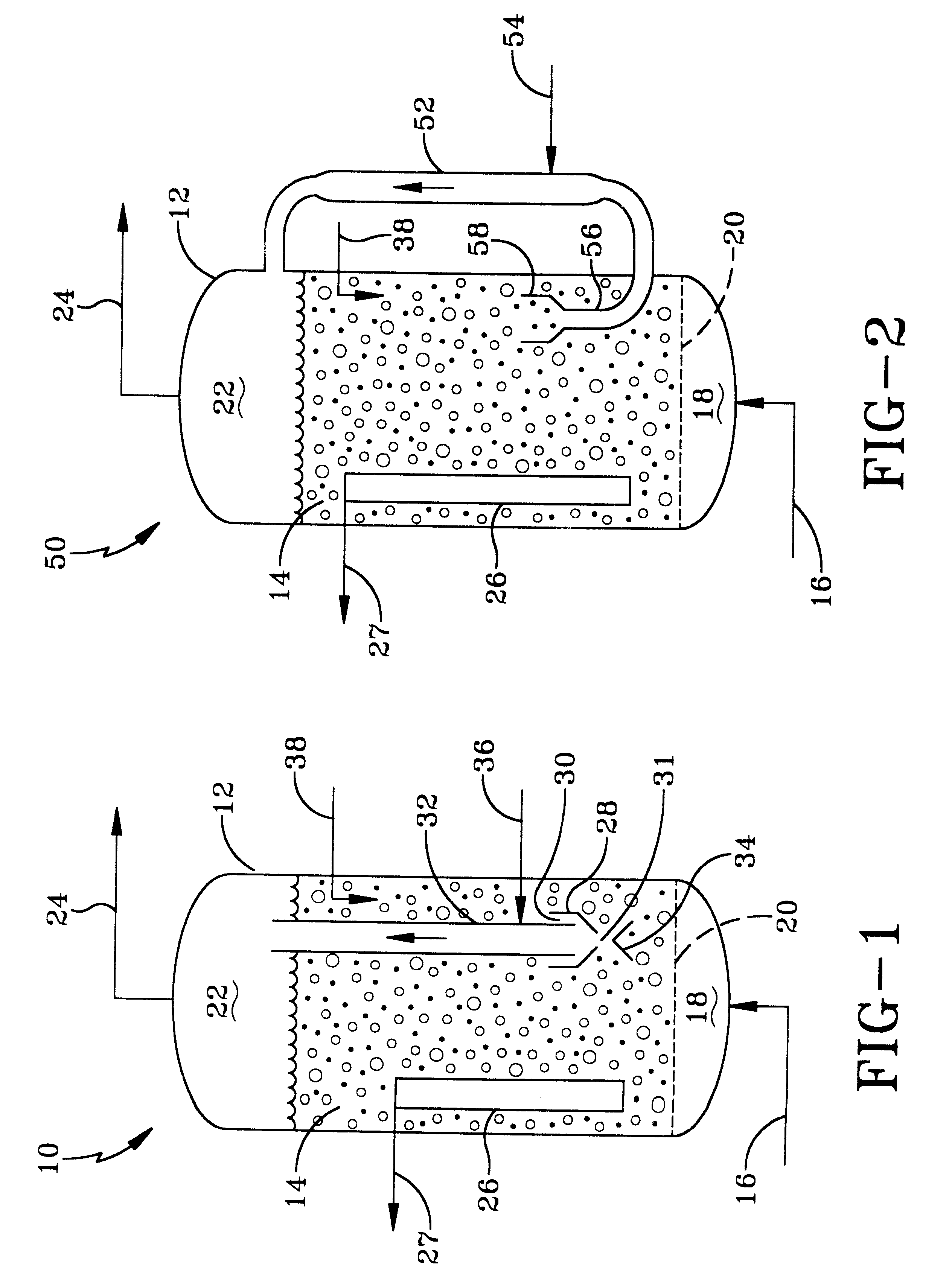

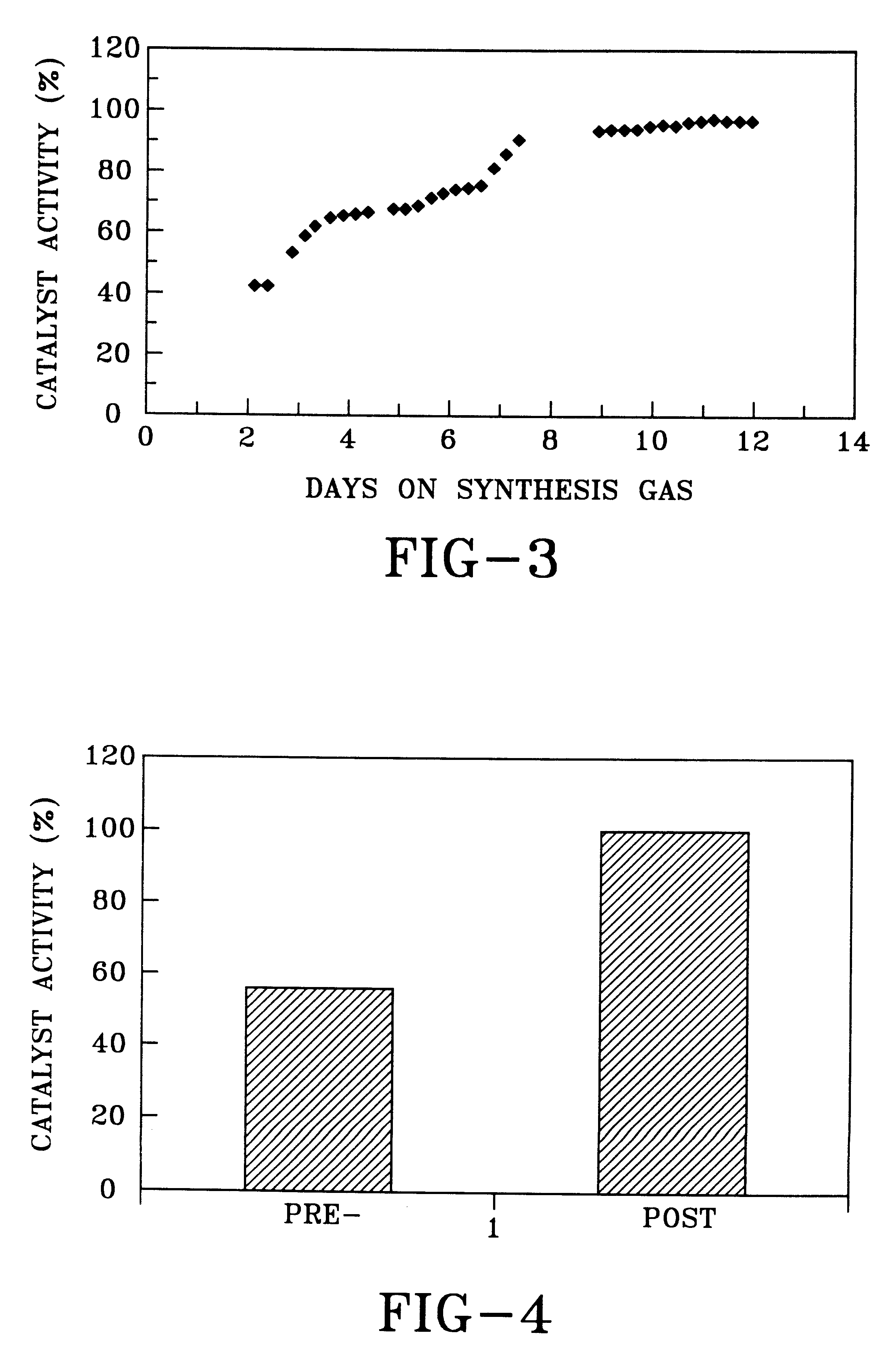

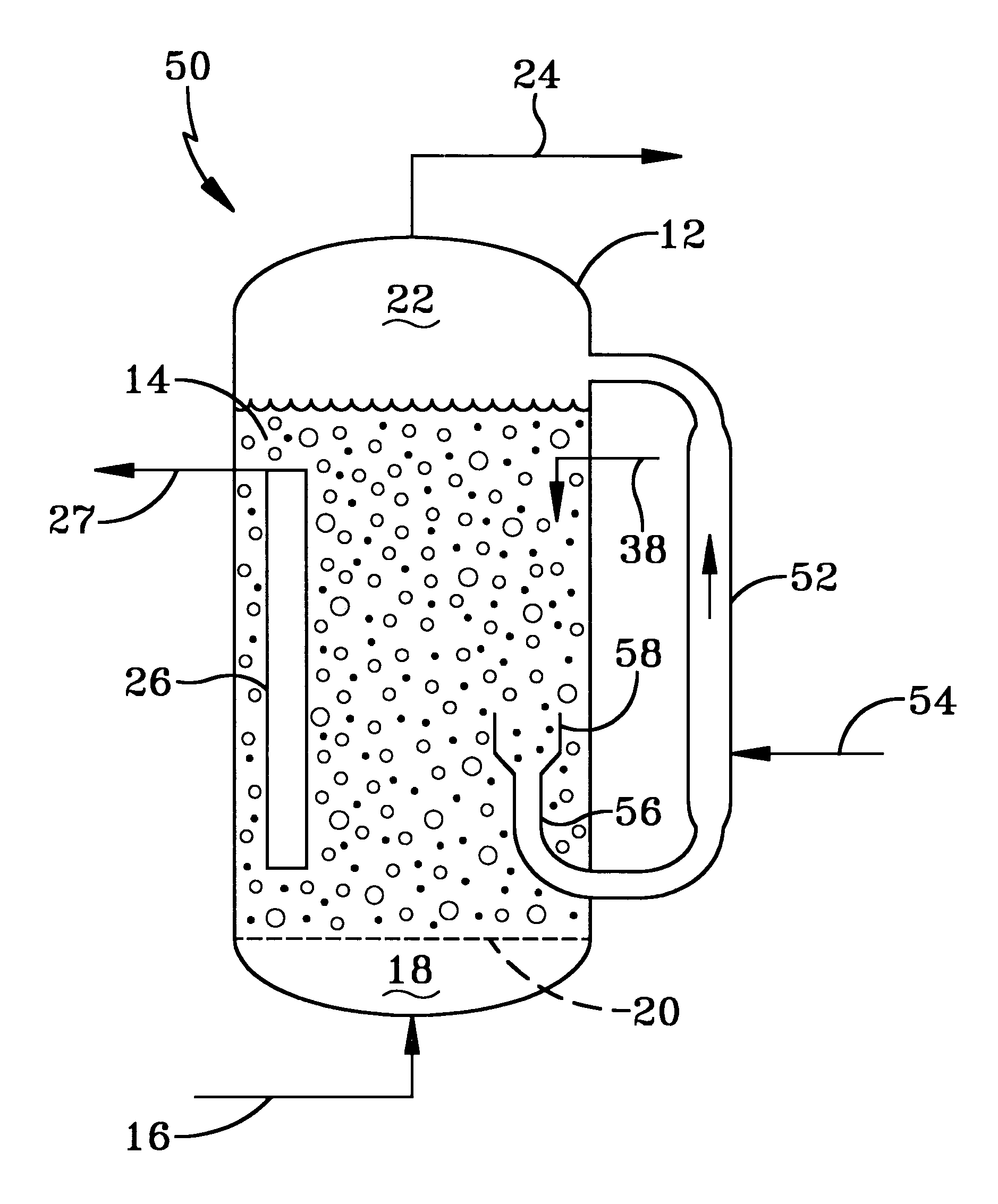

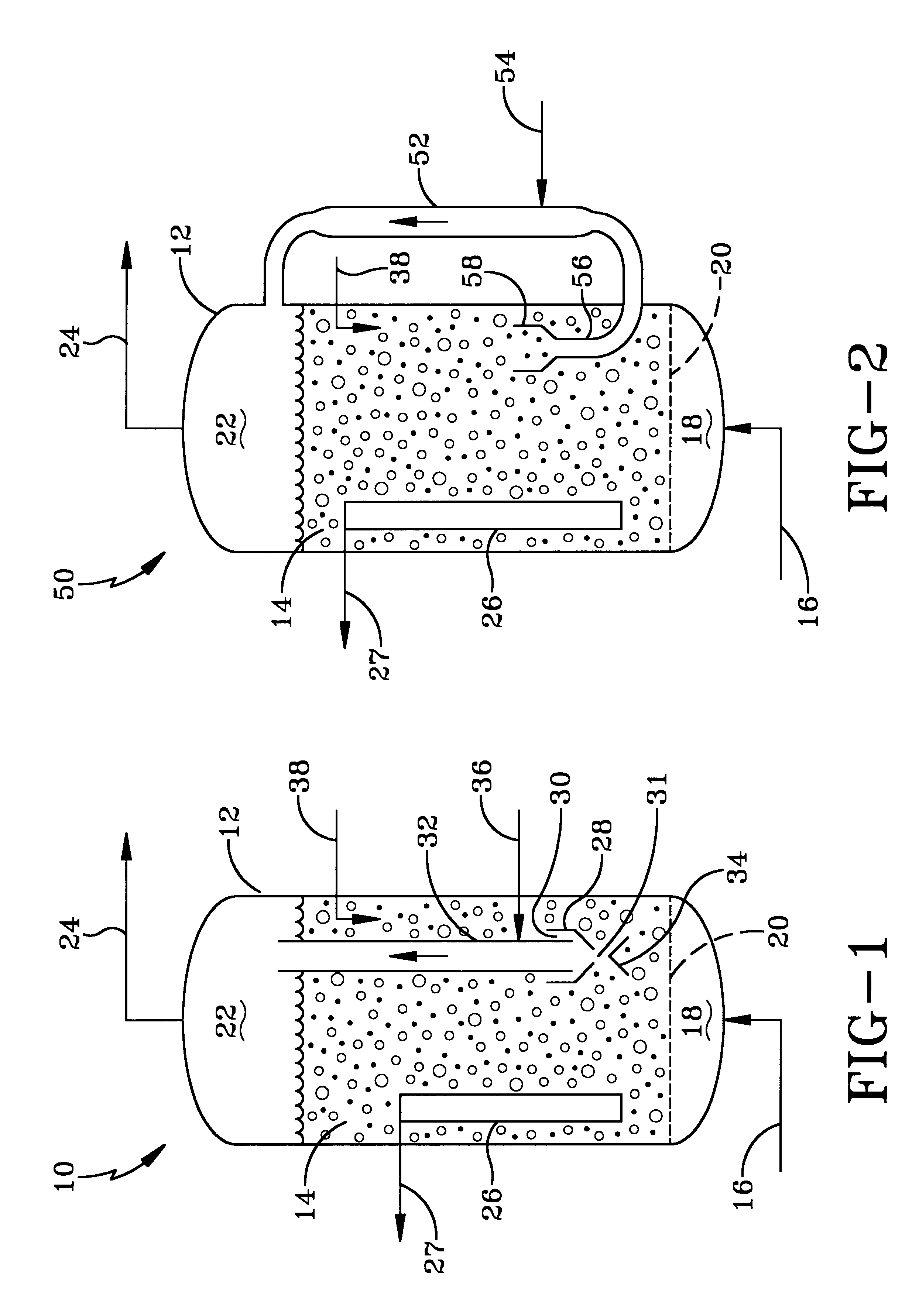

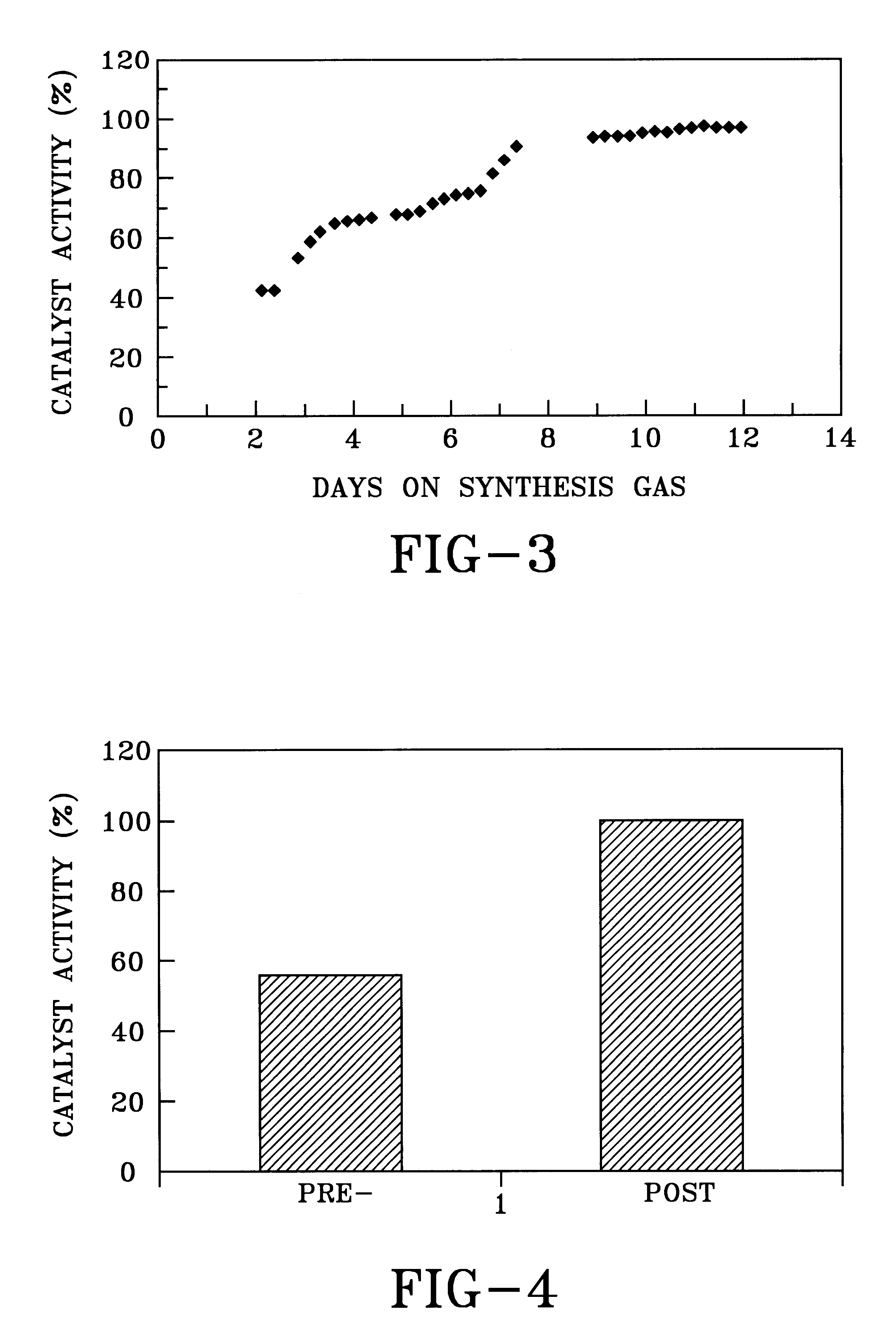

Slurry hydrocarbon synthesis with fresh catalyst activity increase during hydrocarbon production

InactiveUS6323248B1Organic chemistry methodsLiquid hydrocarbon mixture productionHydrogenLifting gas

Fresh catalyst particles are added to a slurry hydrocarbon synthesis reactor and their activity increased by contact with hydrogen in-situ in the slurry in a catalyst activity increasing means, while the reactor is producing hydrocarbons. The means may be a simple, vertically oriented and hollow tube, open at the top and bottom, into which slurry and a hydrogen treat gas are passed. The treat gas acts as a lift gas which provides slurry circulation into and out of the means and back into the slurry body, while increasing the activity of the catalyst particles. During the activity increase of the fresh catalyst, partially and reversibly activated catalyst particles are rejuvenated. The activity increasing means may be inside the reactor and at least partially immersed in the slurry or external of the reactor, or both.

Owner:EXXON RES & ENG CO

Hydrogen replenished lighter-than-air vehicle and method to replenish hydrogen

The present invention discloses a lighter-than-air vehicle and a method to replenish hydrogen into the vehicle while the vehicle is in the sky. The lighter-than-air vehicle can use helium or other gases that doesn't react with hydrogen as lifting gas. Hydrogen will be replenished into the lighter-than-air vehicle while it is still in mid-air. The lighter-than-air vehicles can comprise an aerostat, a hydrogen generator; a water tank and a duct. The present invention can also comprise an aerostat, a compartment, hydrogen generator, a water tank; and a duct. The present invention can also comprise an aerostat, a compartment, and a hydrogen storage alloy device. The present invention can also comprise an aerostat and a hydrogen storage alloy device.

Owner:PRINCETEL

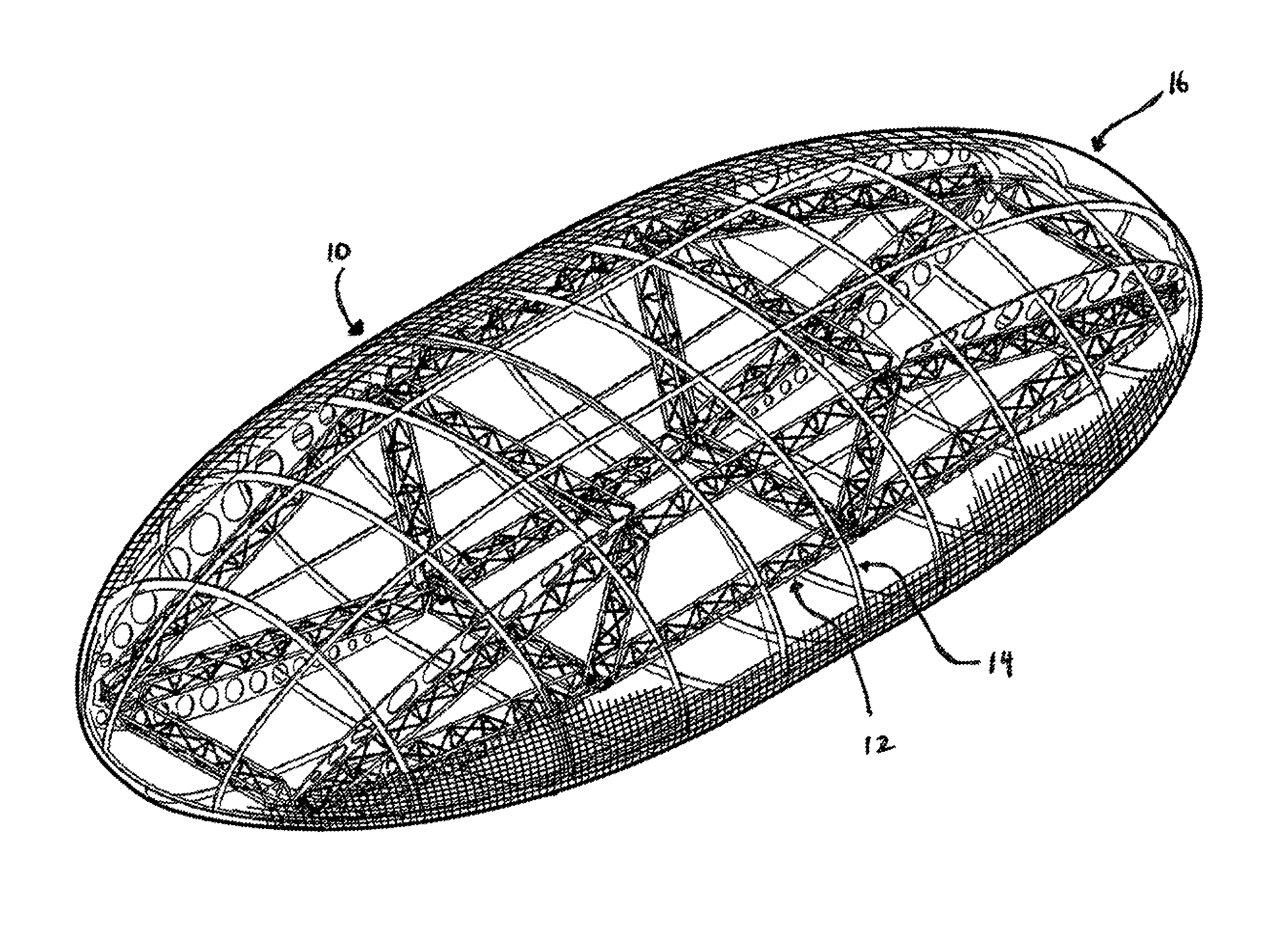

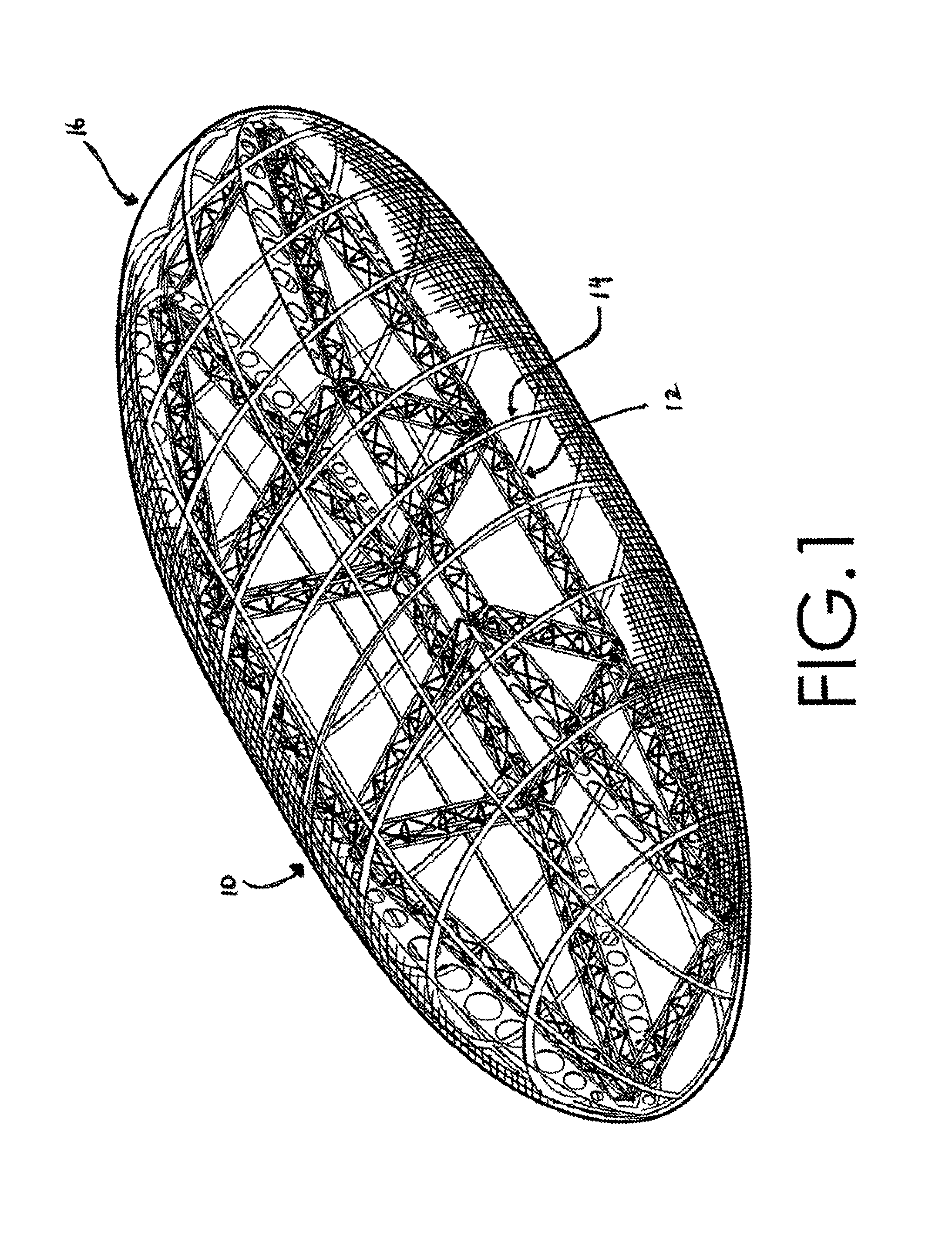

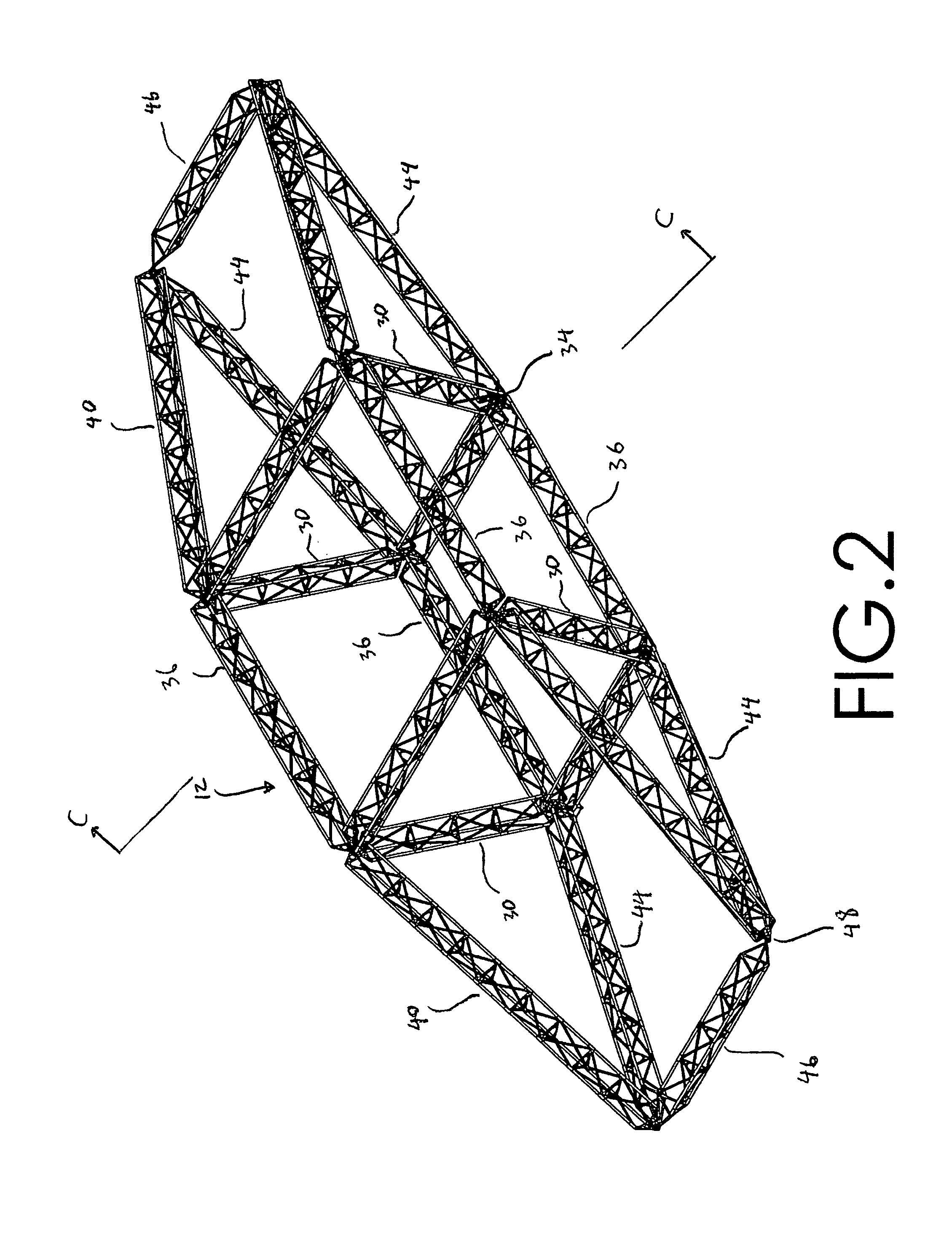

Aerostructure for rigid body airship

An airship hull is provided that is sufficiently light and cost effective so as to make lifting body type airships practical vehicles for carrying people and cargo. The present invention hull design includes three main structural features, i.e., a rigid internal main frame which carries all primary moment and shear loads induced in the vehicle, the vehicle's skin which forms a semi-rigid barrier membrane for the lighter-than-air lifting gas, and a rigid aeroshell frame interposed between the main frame and the skin. The aeroshell frame and skin, in combination, are referred to as the aeroshell. The aeroshell carries the aerodynamic pressure loads induced on the airship.

Owner:WORLDWIDE AEROS CORP

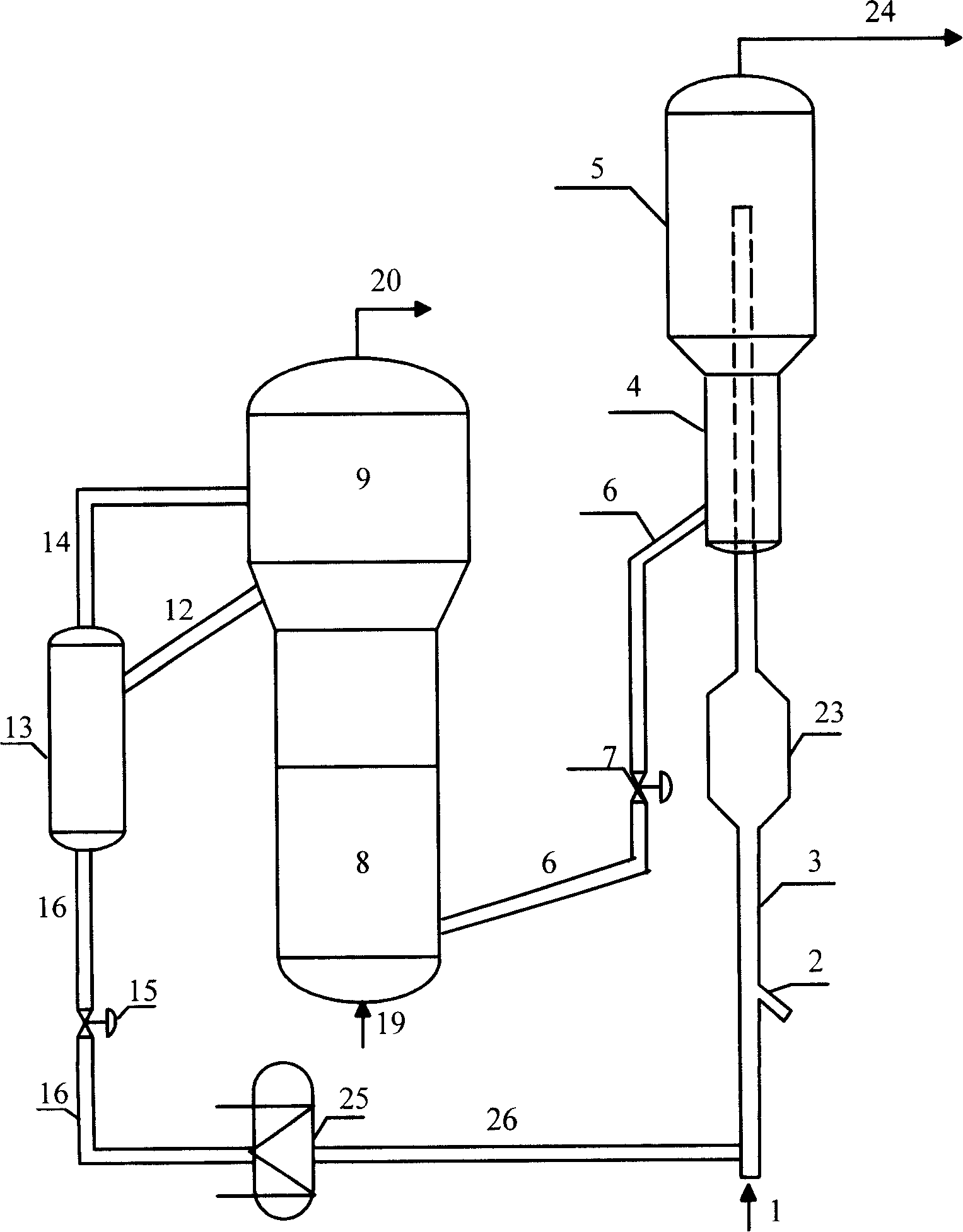

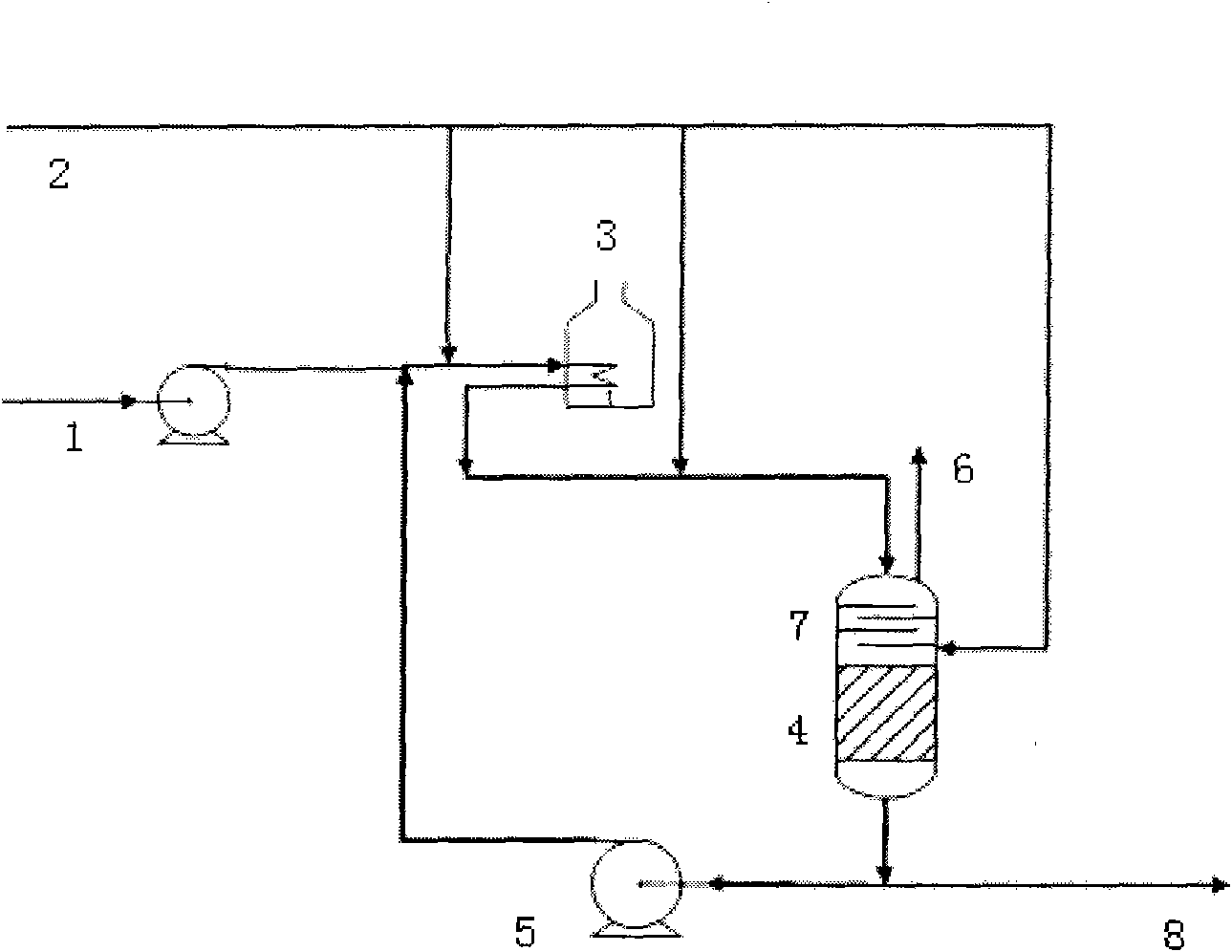

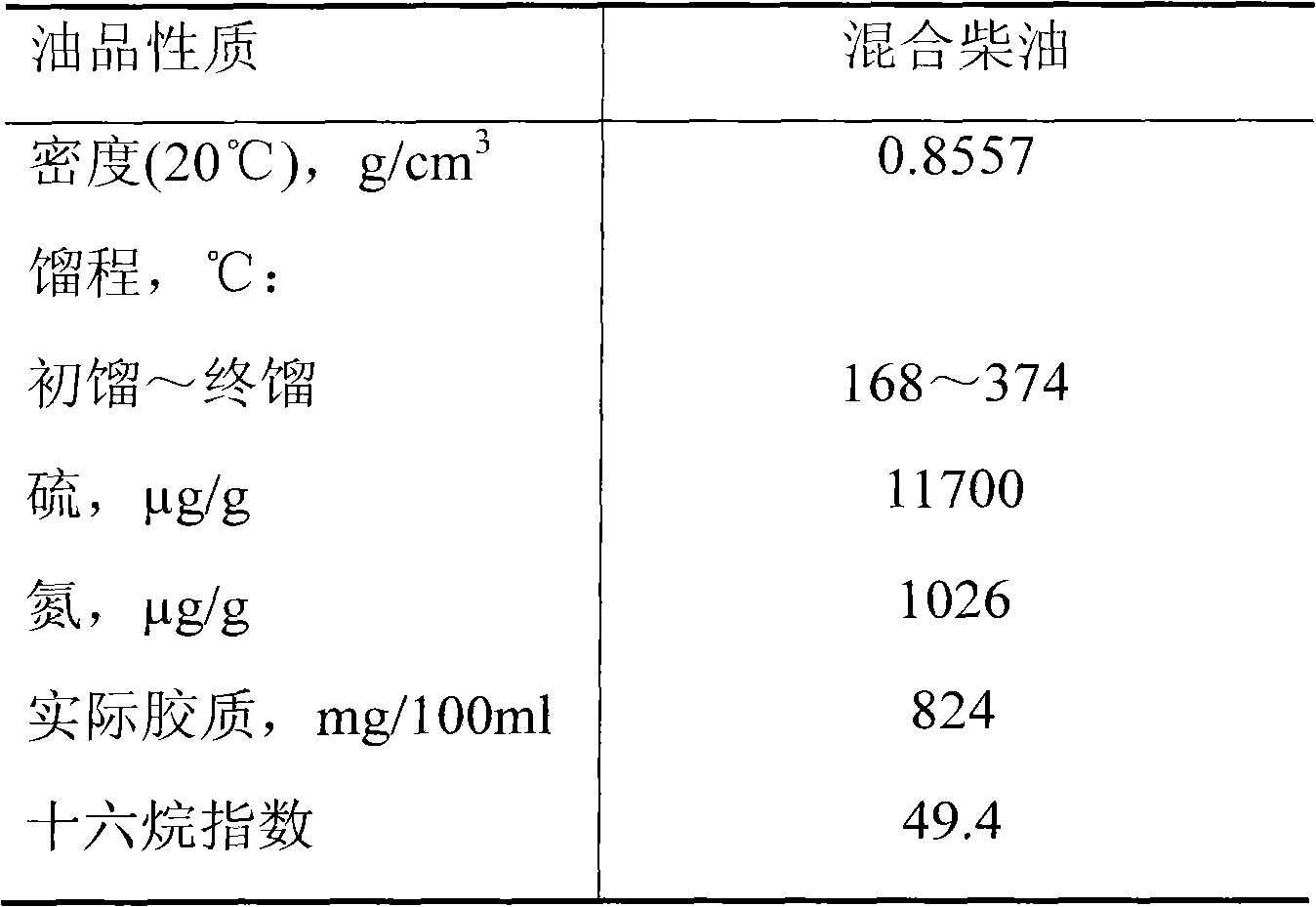

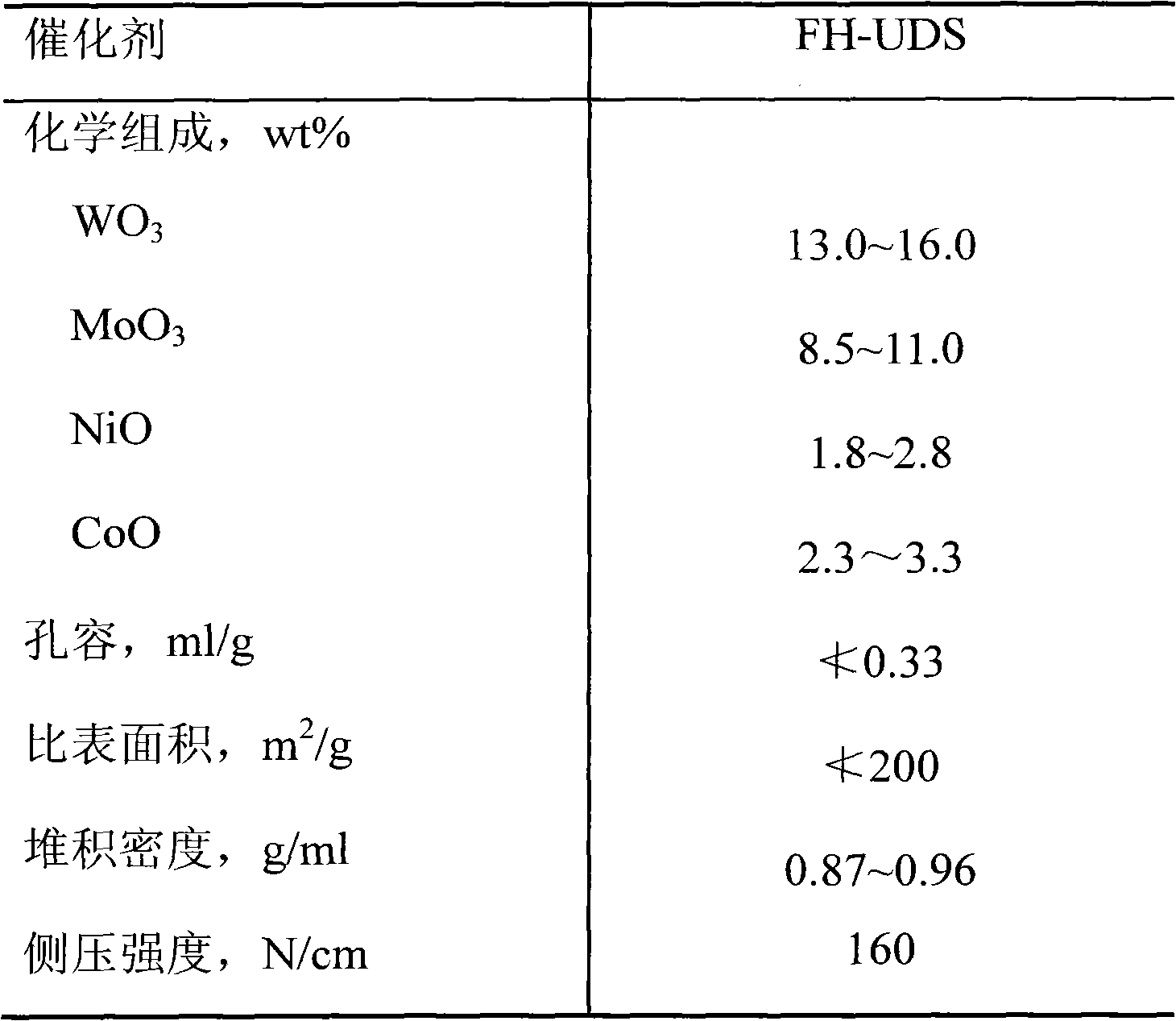

Hydrotreating method of product circulation

ActiveCN102029128AMaintain active stabilityImprove utilization efficiencyChemical/physical processesRefining to eliminate hetero atomsHydrogenation reactionLifting gas

The invention discloses a hydrotreating method of product circulation. One part of circulation of a hydrotreated liquid phase product is mixed with a raw material into a liquid phase material, and the liquid phase material enters the upper part of a reactor. The hydrotreating method of product circulation is characterized in that the upper part of the reactor is provided with at least one air-lift tray of which the lower part is introduced with hydrogen; the hydrogen and the liquid phase material contact on the air-lift tray for the air lift of hydrogen sulfide and ammonia in the liquid phase material; meanwhile, hydrogen is further dissolved in the liquid phase material; the air-lift liquid phase material enters a catalyst bed on the lower part of the reactor for hydrotreating reaction; and air-lift gas containing hydrogen sulfide and ammonia is discharged from the top of the reactor. The reactor adopted by the invention simultaneously has the action of catalytic hydrotreating reaction and the action on causing products H2S, NH3 and the like to be discharged out of a reaction system by air lift, thus greatly improving hydrotreating reaction efficiency and enhancing technology flexibility and raw material adaptability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogen lighter-than-air ship

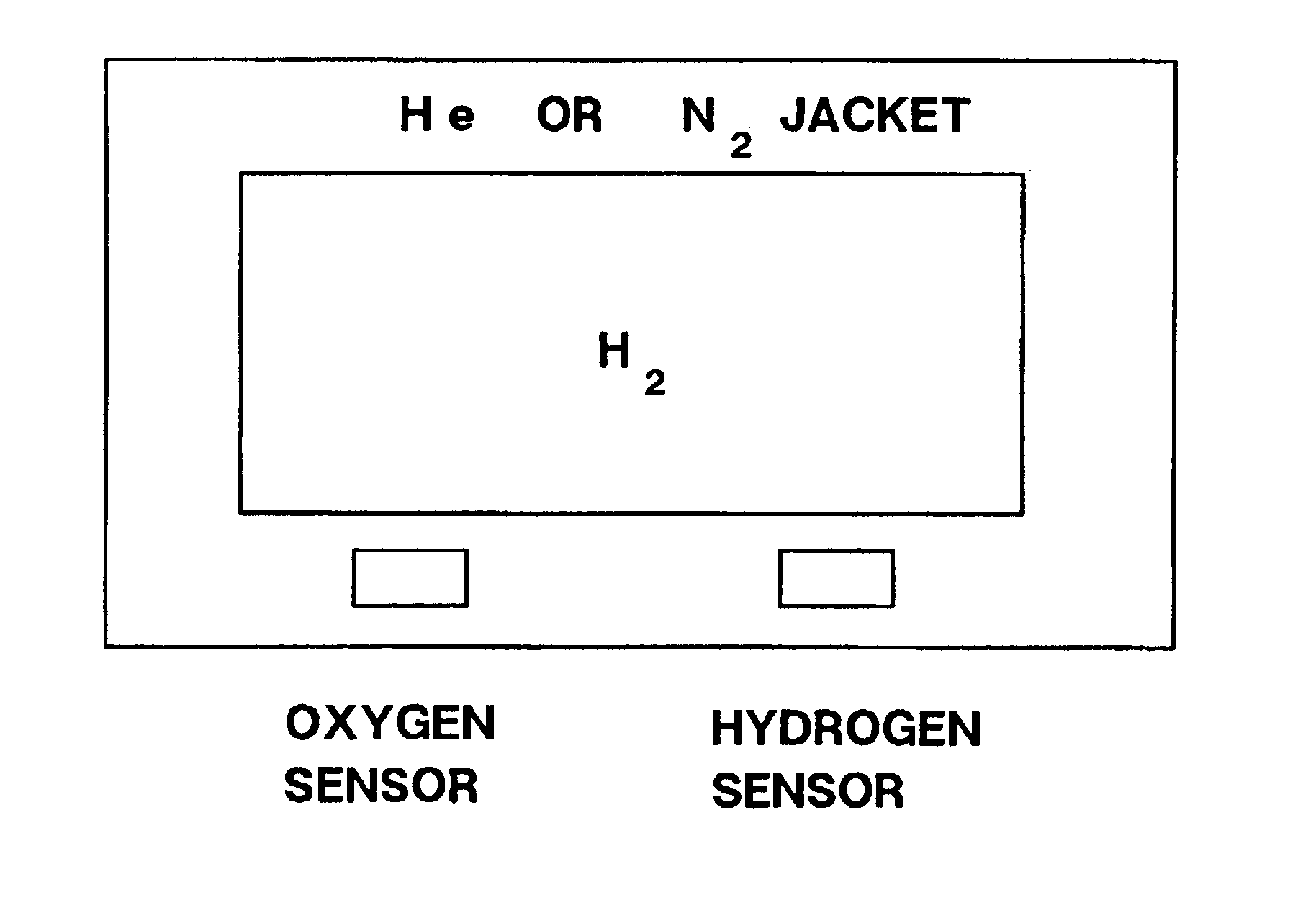

InactiveUS6896222B2Continuous monitoringSufficient oxygenPower installationsNon-rigid airshipsElectricityNuclear engineering

A lighter-than-air ship using hydrogen or other gas as a lift gas with at least one hydrogen fuel cell aboard. The fuel cell can draw hydrogen fuel from the lift gas reservoir to produce electricity both for the ship's use and optionally for propulsion. The waste product of the fuel cell is water which can be used for the needs of a crew on the ship. The hydrogen lift gas chamber, which can be compartmentalized for lift control, can be surrounded by a safety jacket filled with an inert gas and contain optional hydrogen and / or oxygen sensors.

Owner:ORO GRANDE TECH

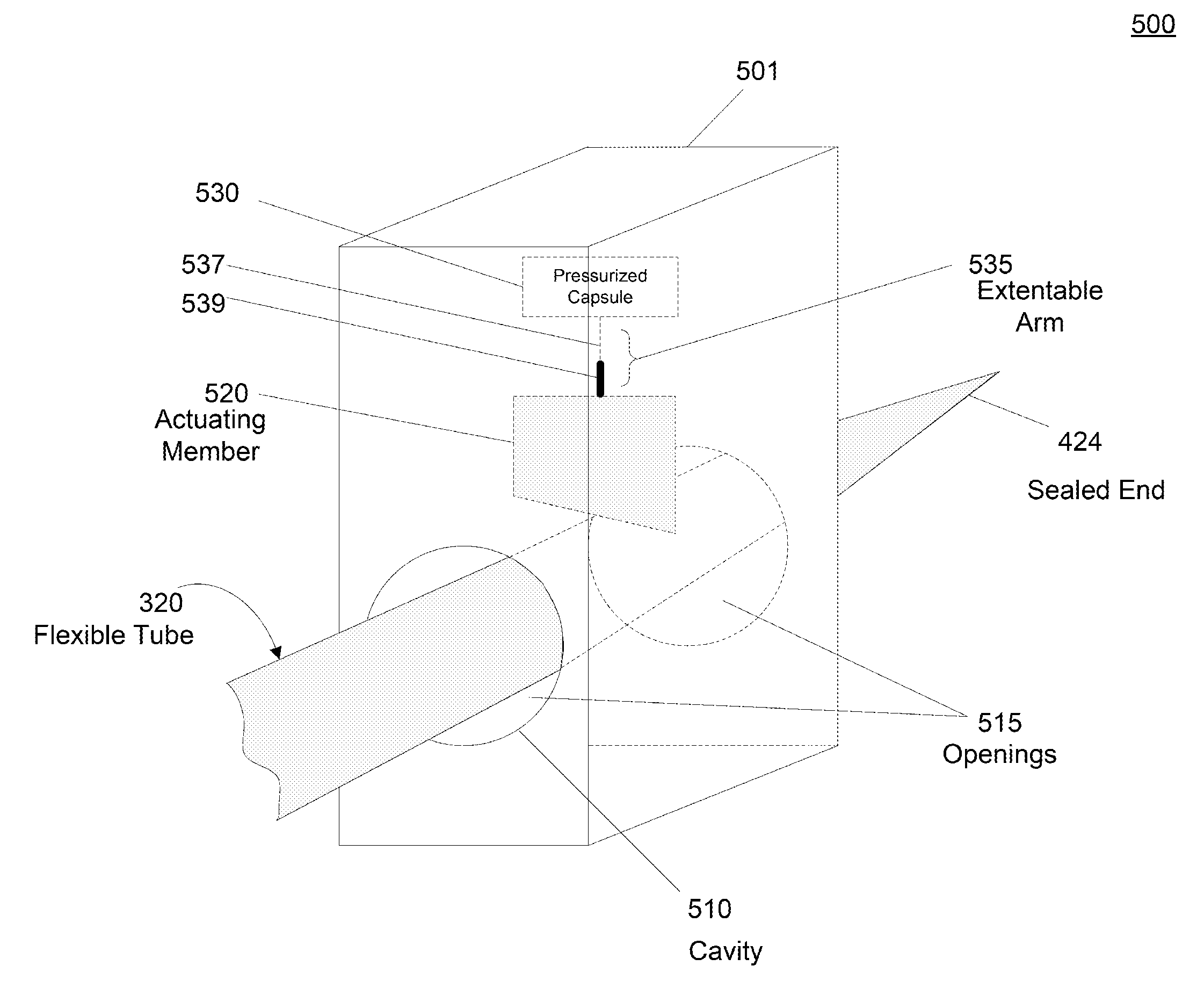

Flight termination system for a balloon

A system for terminating flight of a balloon having a balloon envelope is provided. The system includes an apparatus attached to the balloon. The apparatus includes a flexible tube that has first and second ends with a hollow tube portion disposed there between and a device attached to the flexible tube. The first end of the tube is sealed around a preconfigured opening in a balloon envelope and the second end is sealed shut. The device includes a main body that has an opening holding an actuating member that has a cavity and a cutting element. The cavity is arranged to hold at least a portion of the flexible tube. When activated, the device causes contact between the actuating member and the cutting element so as to cut open the partial portion of the flexible tube for allowing lift gas to escape the balloon envelope through the hollow tube portion.

Owner:AEROSTAR INT LLC

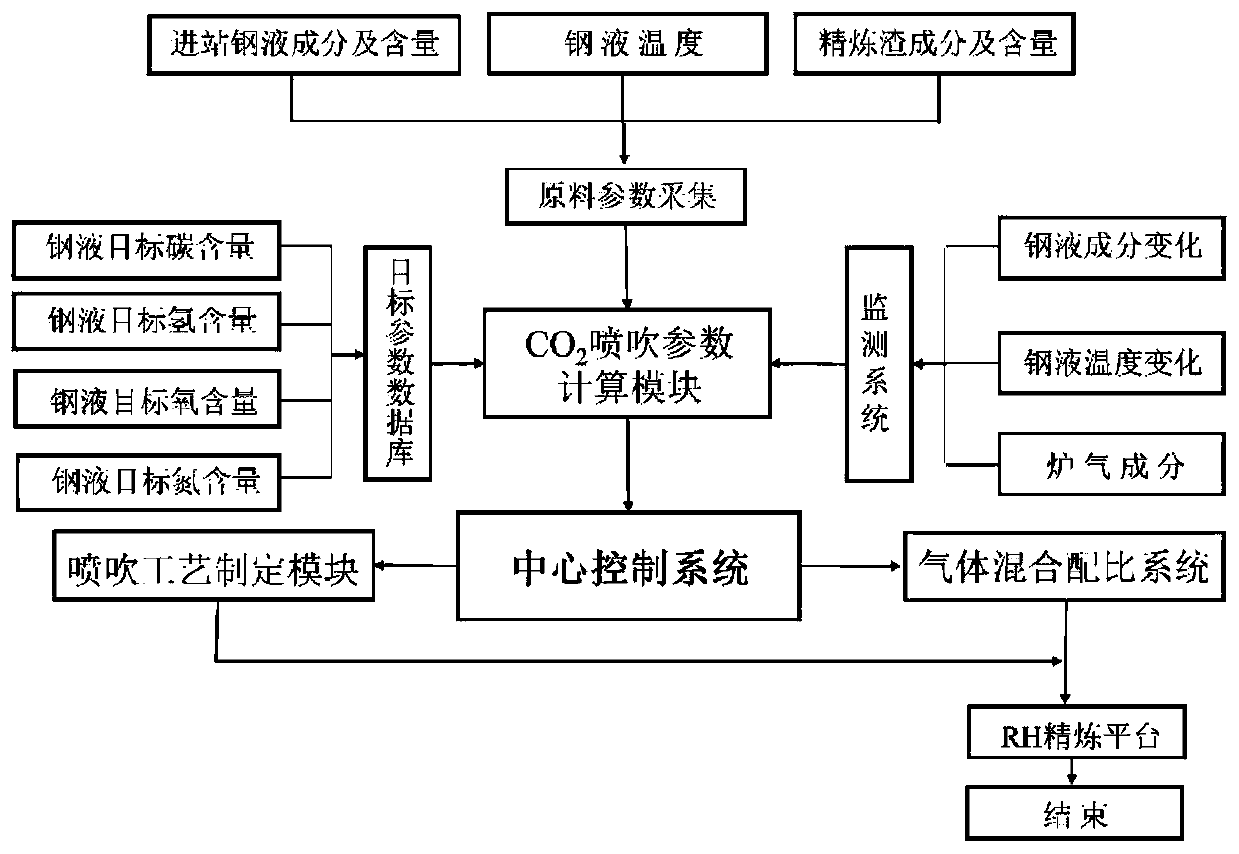

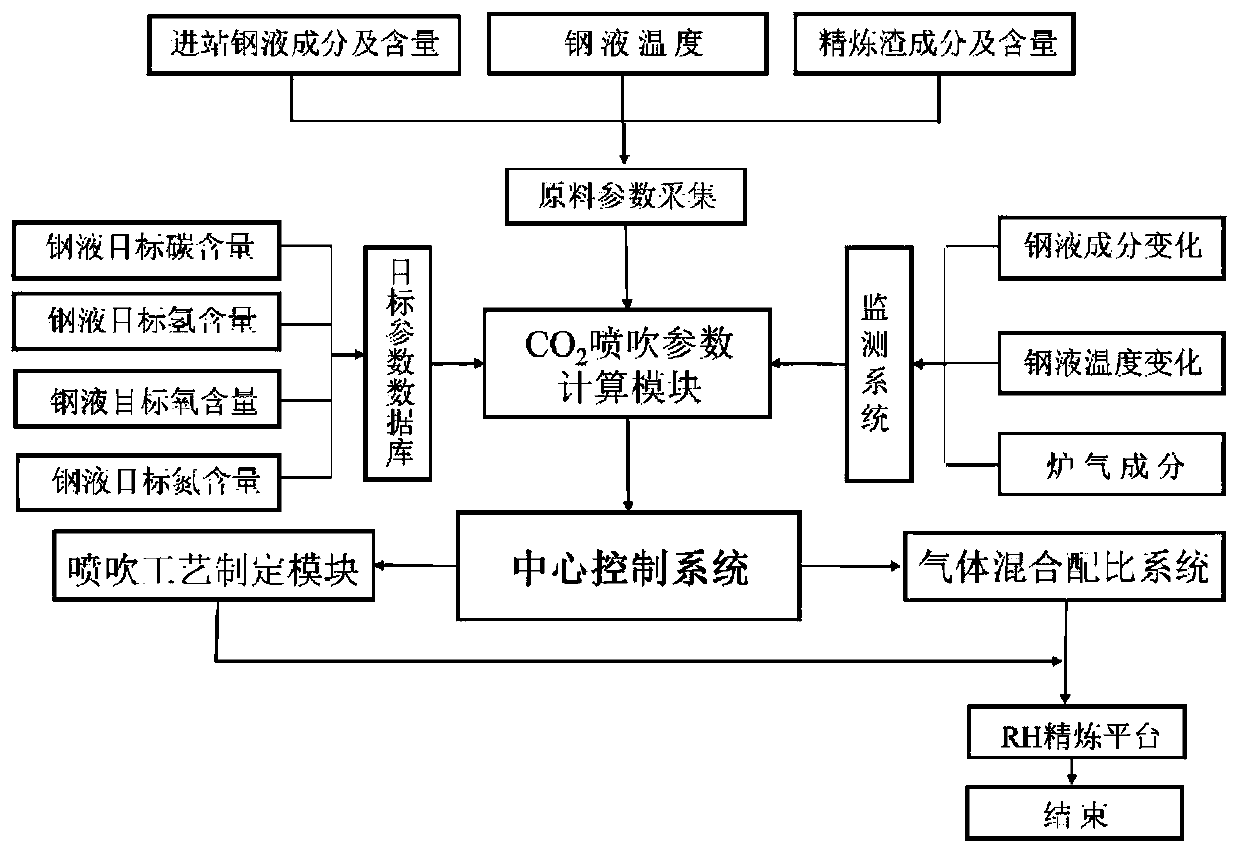

Dynamic control method for refining ultra-low carbon steel through RH CO2 spraying

The invention belongs to the technical field of steelmaking, and particularly relates to a dynamic control method for refining ultra-low carbon steel through RH CO2 spraying. The dynamic control method is suitable for a 30-300 t RH ladle refining process. In the RH refining process, O2 and CO2 are adopted as top-blowing gases, Ar and CO2 are used as lifting gases; molten steel components in the refining process are predicted based on material conservation according to RH refining in-station molten steel component data, refining process furnace gas component data and vacuum equipment working conditions; the top blowing and lifting gas flow is dynamically adjusted according to requirements of target components of refined molten steel stage by stage; on the basis of strengthening the stirringeffect of the RH refining process, the nitrogen content in the molten steel is further reduced, and the quality of molten steel is improved; and meanwhile, excessive oxidation of the molten steel inthe RH decarbonization process is avoided, the consumption of a deoxidized alloy is reduced, and on the basis of reducing the consumption of Ar, the production cost is further reduced, and the refining period is shortened. As a result, the alloy consumption is reduced by 3%-8%, the RH refining period is shortened by 1-2 minutes, the denitrification amount is increased by (3-10)*10<-6>, and the quality of the molten steel is improved.

Owner:UNIV OF SCI & TECH BEIJING

RH refining desulphurization process of non-oriented electrical steel

InactiveCN102010934AGood desulfurization effectMeet the requirements of deep desulfurizationAlkalinityElectrical steel

The invention discloses an RH refining desulphurization process of non-oriented electrical steel, belonging to the technical field of steel making. The process comprises the following steps: setting the lift gas flowrate to 1200 NL / min after the entering of the RH, and enhancing the lift gas flowrate to 1600 NL / min 3 minutes later; blowing oxygen to perform the forced decarburization when the vacuum degree is reduced to 2.0 mba, and when the oxygen blowing is finished and the vacuum degree is lower than 2.0 mba, performing the natural decarburization for 20 minutes; adding the aluminum for deoxidation when the vacuum decarburization is finished; and performing the silicon alloying by using the low carbon ferrosilicon, and adding the desulfurizing agent into the vacuum chamber in two timesthrough the RH alloy bin. The circulation time of the test furnace batch is from 10 minutes to 15 minutes. The process provided by the invention has the advantages that the RH device needs no reconstruction, and the operation is simple. The average RH desulphurization degree is 36.7%, and the desulphurization effect is better. The contents of the FeO and the MnO of the ladle slag have significantinfluence on the desulphurization effect, and the enhancing of the alkalinity of the ladle slag can increase the RH desulphurization efficiency as well as reduce the corrosion of the RH device.

Owner:KUNMING UNIV OF SCI & TECH

Apparatus and method for lighter-than-air aircraft

InactiveUS7055778B2Minimize mixingAvoid shakingAnchoring installationsNon-rigid airshipsLifting gasLighter than air

An apparatus and associated method for launching and recovering a lighter-than-air aircraft are provided. The aircraft includes an envelope that is substantially filled before launch with a lift gas and a second gas. The lift gas and second gas are substantially separated in the envelope by a boundary layer of mixed gas, formed by the lift and second gases. The aircraft is supported by one or more masts as the lift gas is injected to achieve the required buoyancy for launch. The aircraft is then released and rises, for example, in an inclined orientation. As the aircraft climbs, the lift gas expands in the envelope, and the second gas is vented therefrom. During horizontal descent, air can be pumped into the envelope to maintain the envelope in a substantially filled configuration. The air and lift gas can be mixed to avoid sloshing and pooling.

Owner:THE BOEING CO

Slurry hydrocarbon synthesis with fresh catalyst activity increase during hydrocarbon production

InactiveUS6696502B1Organic chemistry methodsLiquid hydrocarbon mixture productionHydrogenLifting gas

Fresh catalyst particles are added to a slurry hydrocarbon synthesis reactor and their activity increased by contact with hydrogen in-situ in the slurry in a catalyst activity increasing means, while the reactor is producing hydrocarbons. The means may be a simple, vertically oriented and hollow tube, open at the top and bottom, into which slurry and a hydrogen treat gas are passed. The treat gas acts as a lift gas which provides slurry circulation into and out of the means and back into the slurry body, while increasing the activity of the catalyst particles. During the activity increase of the fresh catalyst, partially and reversibly activated catalyst particles are rejuvenated. The activity increasing means may be inside the reactor and at least partially immersed in the slurry or external of the reactor, or both.

Owner:EXXON RES & ENG CO

Piezoelectric and pyroelectric power-generating laminate for an airship envelope

InactiveUS20090189012A1Piezoelectric/electrostrictive device manufacture/assemblyPower plant arrangements/mountingElectricityLifting gas

A power-generating laminate for an airship comprises a base fabric layer, a barrier layer disposed upon the fabric layer, an inner metal film layer disposed upon the barrier layer, a piezoelectric / pyroelectric layer disposed upon the inner metal layer, an outer metal layer disposed upon the piezoelectric / pyroelectric layer, and a cover layer disposed upon the outer metal layer. The power-generating laminate forms a gas-impervious envelope to maintain lifting gas and air therein, and is configured such that when the envelope is subjected to structural strain or experiences changes in temperature, power is generated, which is used to supply power to the various electrical systems aboard the airship.

Owner:LOCKHEED MARTIN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com