Constant-pressure automatic compensation system of aluminum alloy hub deburring machine

A technology for aluminum alloy wheels and deburring machines, which is applied to metal processing equipment, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve problems such as reduced work efficiency, over-brushing, and uncontrollable up and down pressure, and achieves improved qualification efficiency, reduce production costs, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

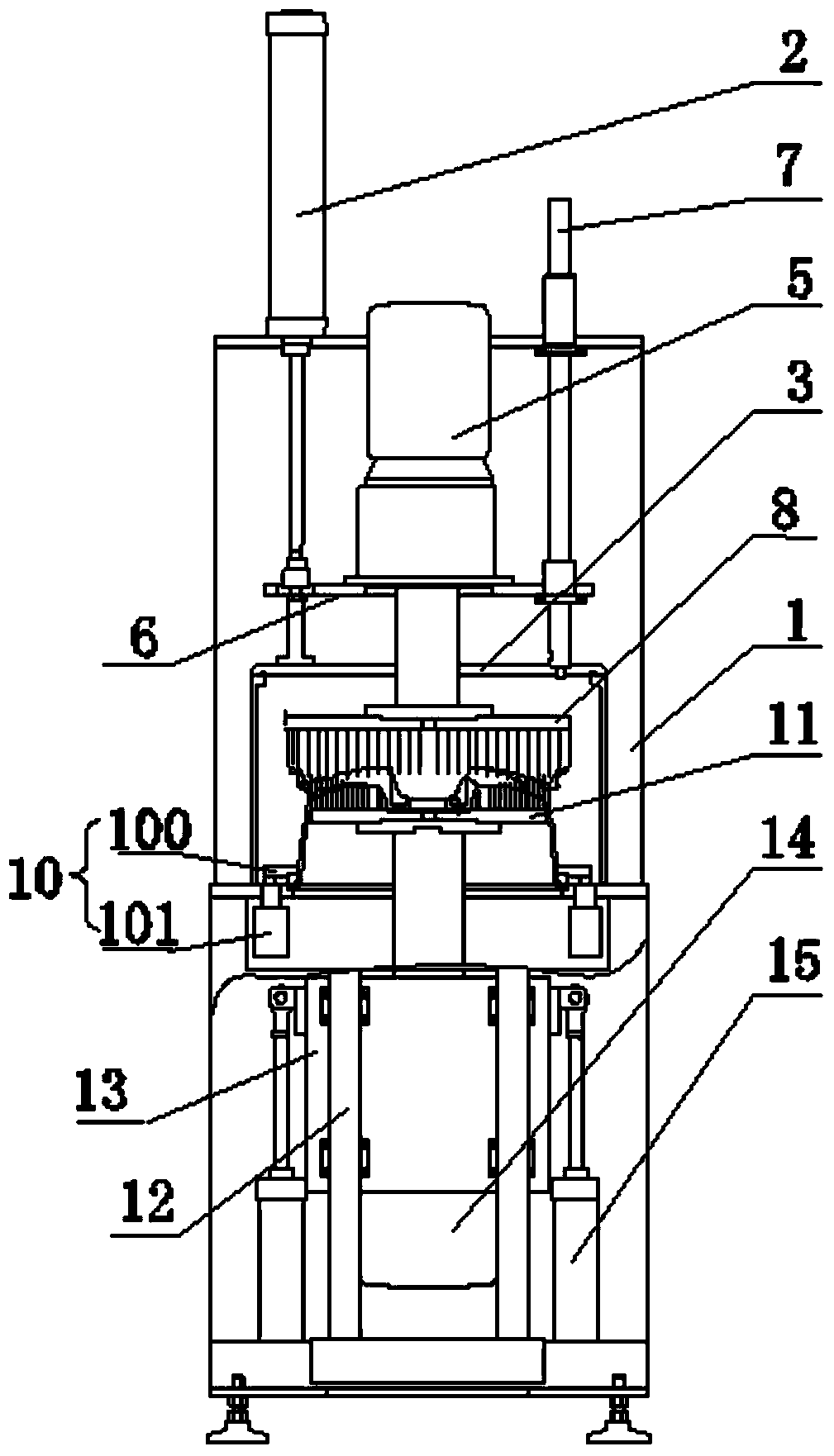

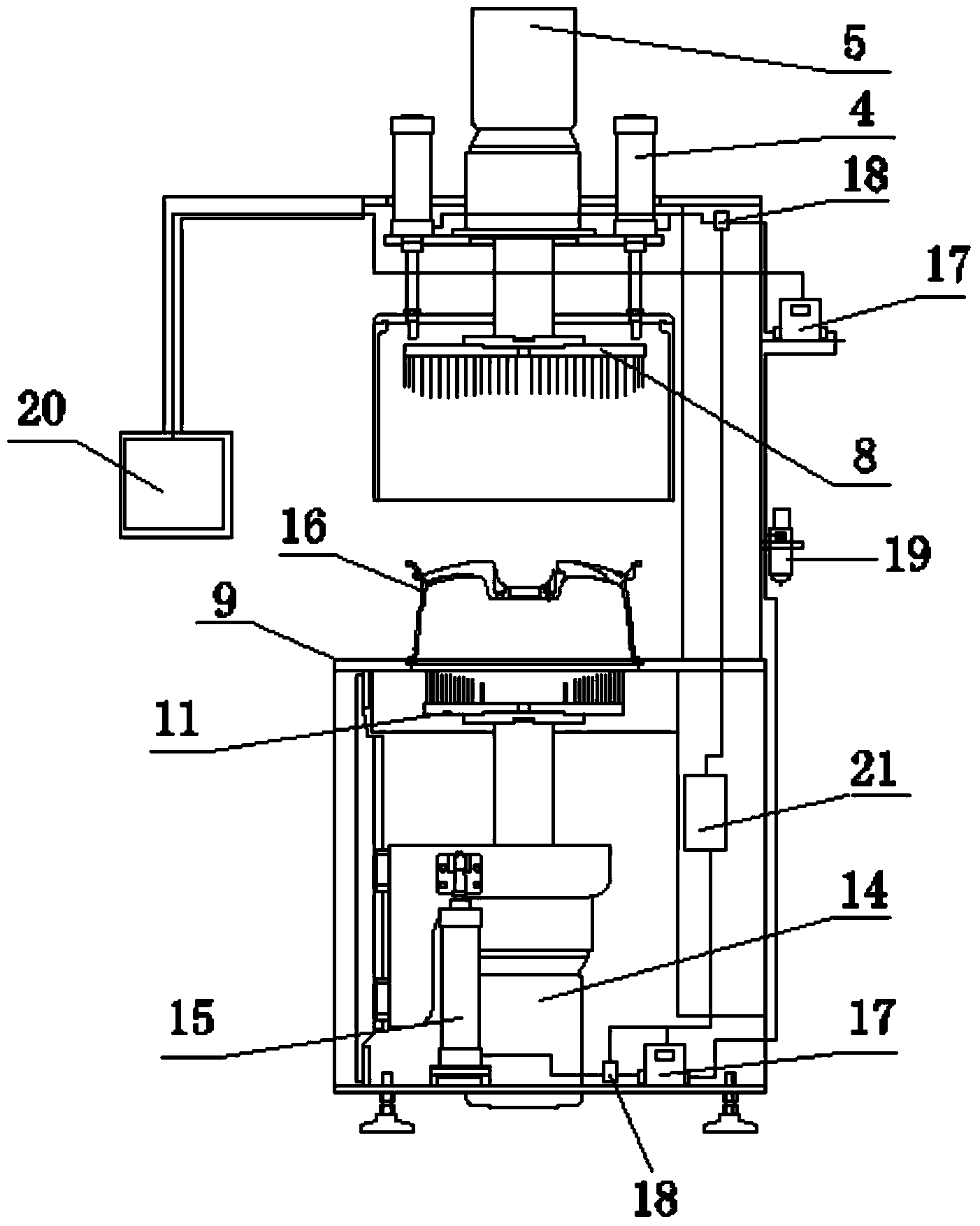

[0031] Preferred embodiments of the present invention will be described in detail below with reference to the drawings.

[0032] A constant pressure automatic compensation system for an aluminum alloy wheel hub deburring machine according to the present invention, the deburring machine includes a frame 1, and a processing platform 9 for carrying the wheel hub is positioned on the frame 1. The brush disc 8, the next brush disc 11, and the upper lifting cylinder 4 and the lower lifting cylinder 15 respectively used to drive the action of the upper brush disc and the lower brush disc, the upper brush disc 8 and the lower brush disc The discs 11 are respectively located on the upper and lower sides of the processing platform 9, and the upper lifting cylinder 4 and the lower lifting cylinder 15 can correspondingly drive the upper brush disc 8 and the lower brush disc 11 to move up and down relative to the processing platform 9. reciprocating positioning, and simultaneously said upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com