Patents

Literature

24173results about "Grinding/polishing safety devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Controlled electro-pneumatic power tools and interactive consumable

Owner:FORGUES SYLVAIN +1

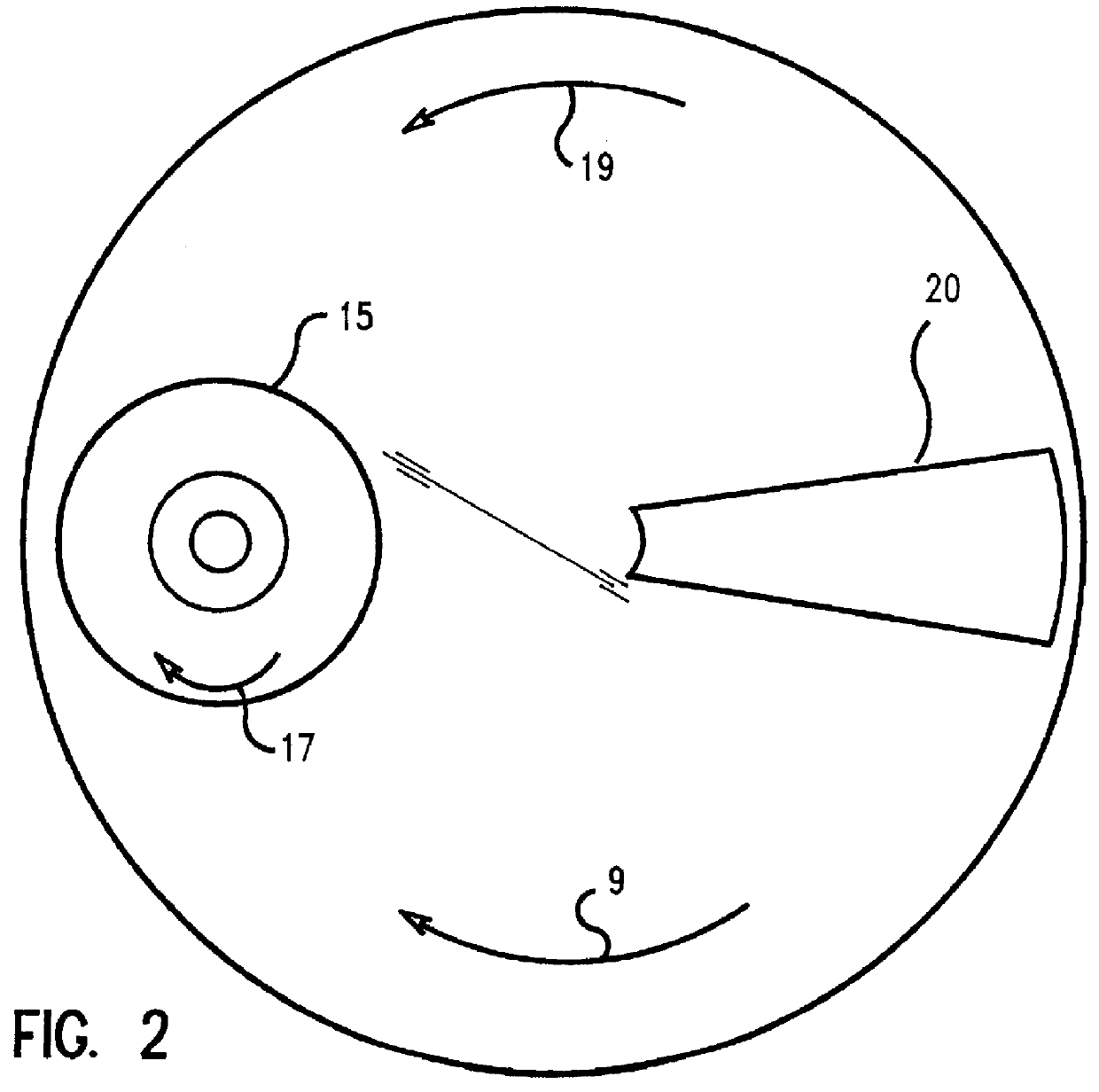

Wafer carrier checker and method of using same

ActiveUS20060252351A1Grinding drivesBelt grinding machinesSemiconductorElectrical and Electronics engineering

A tool and method for assessing whether a disk carrier, and especially a carrier for holding semiconductor disks, is properly dimensioned. The tool has a body that includes a socket in which a portion of the disk carrier will seat fully if the disk carrier is properly dimensioned. Alignment structures may be provided in the socket to align with features of the carrier to assist in determining whether the disk carrier is properly dimensioned. The socket may include two spaced apart cavities that correspond with end portions of walls of the disk carrier.

Owner:MICREL

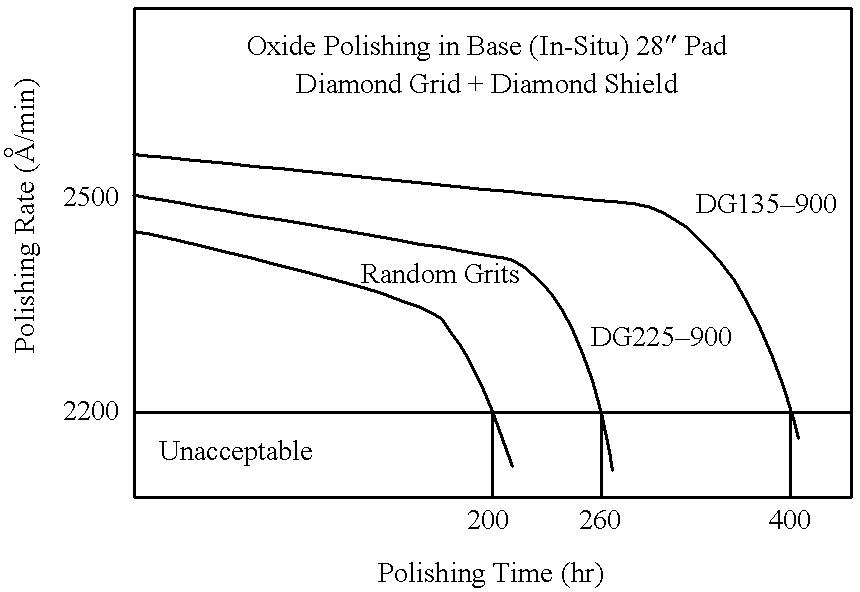

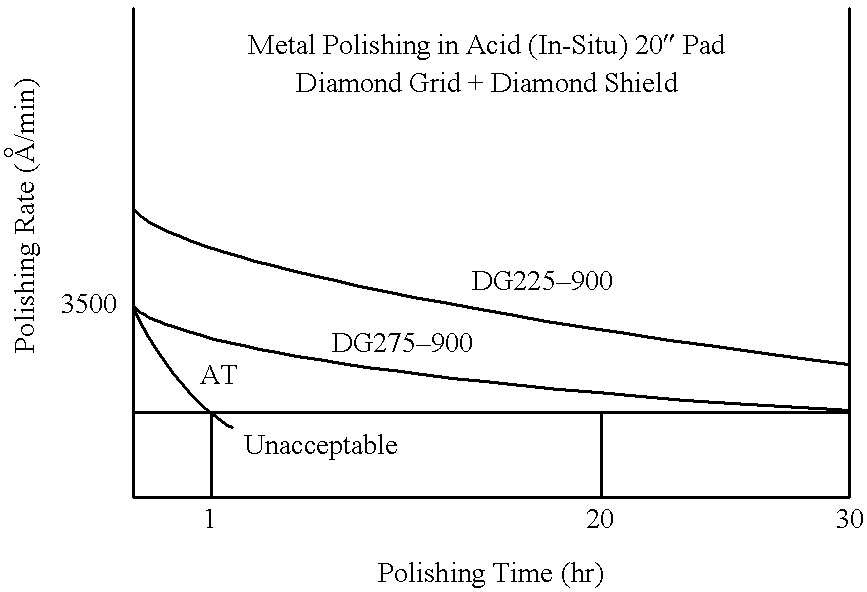

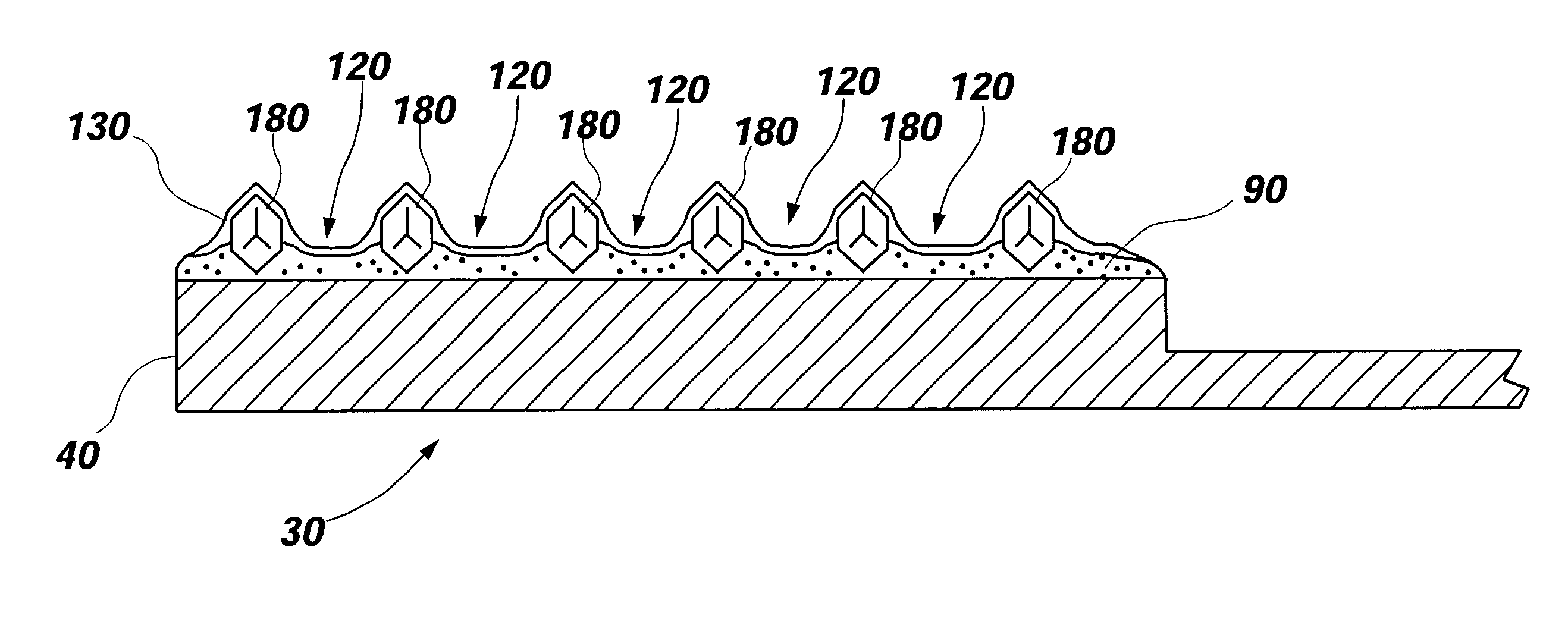

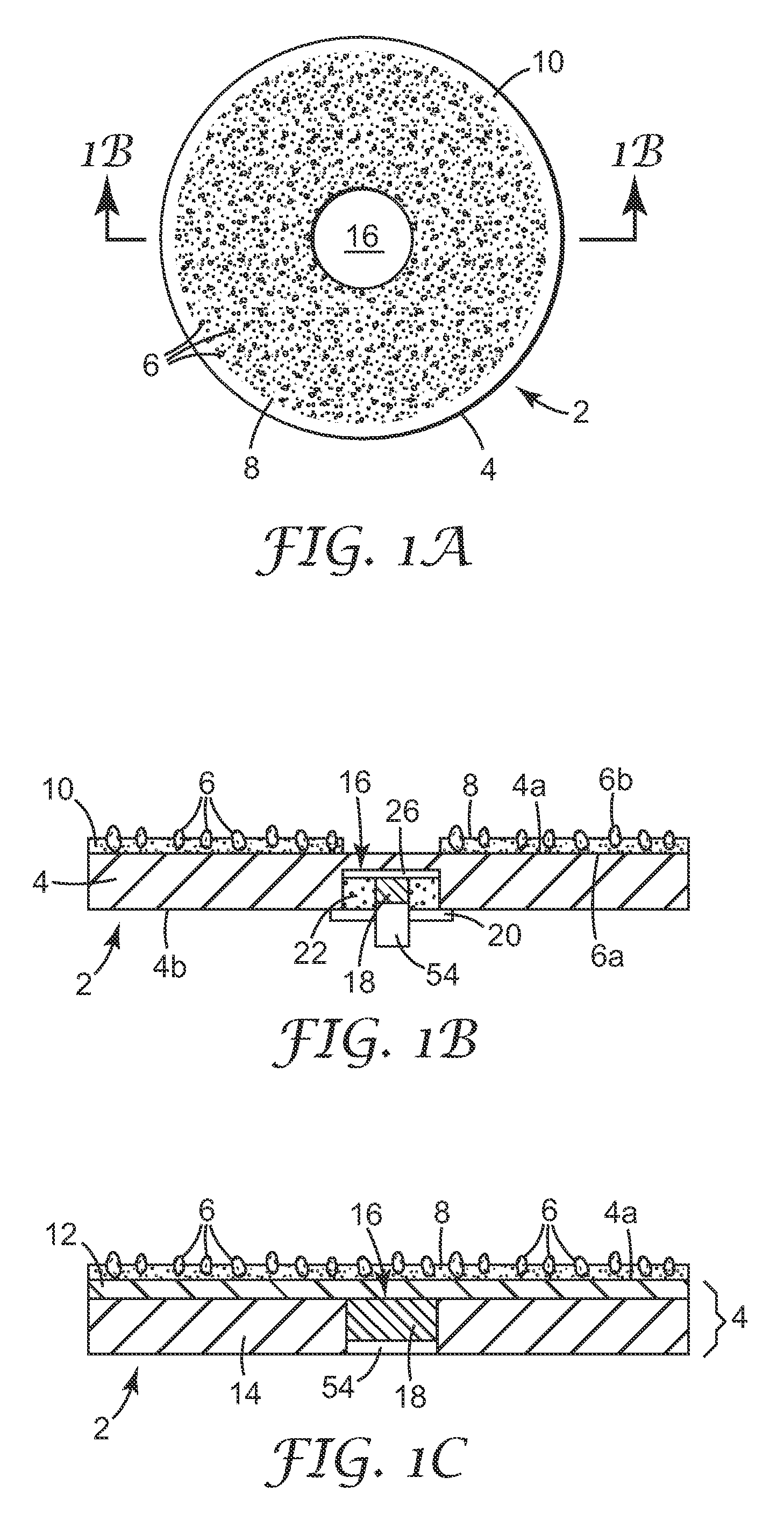

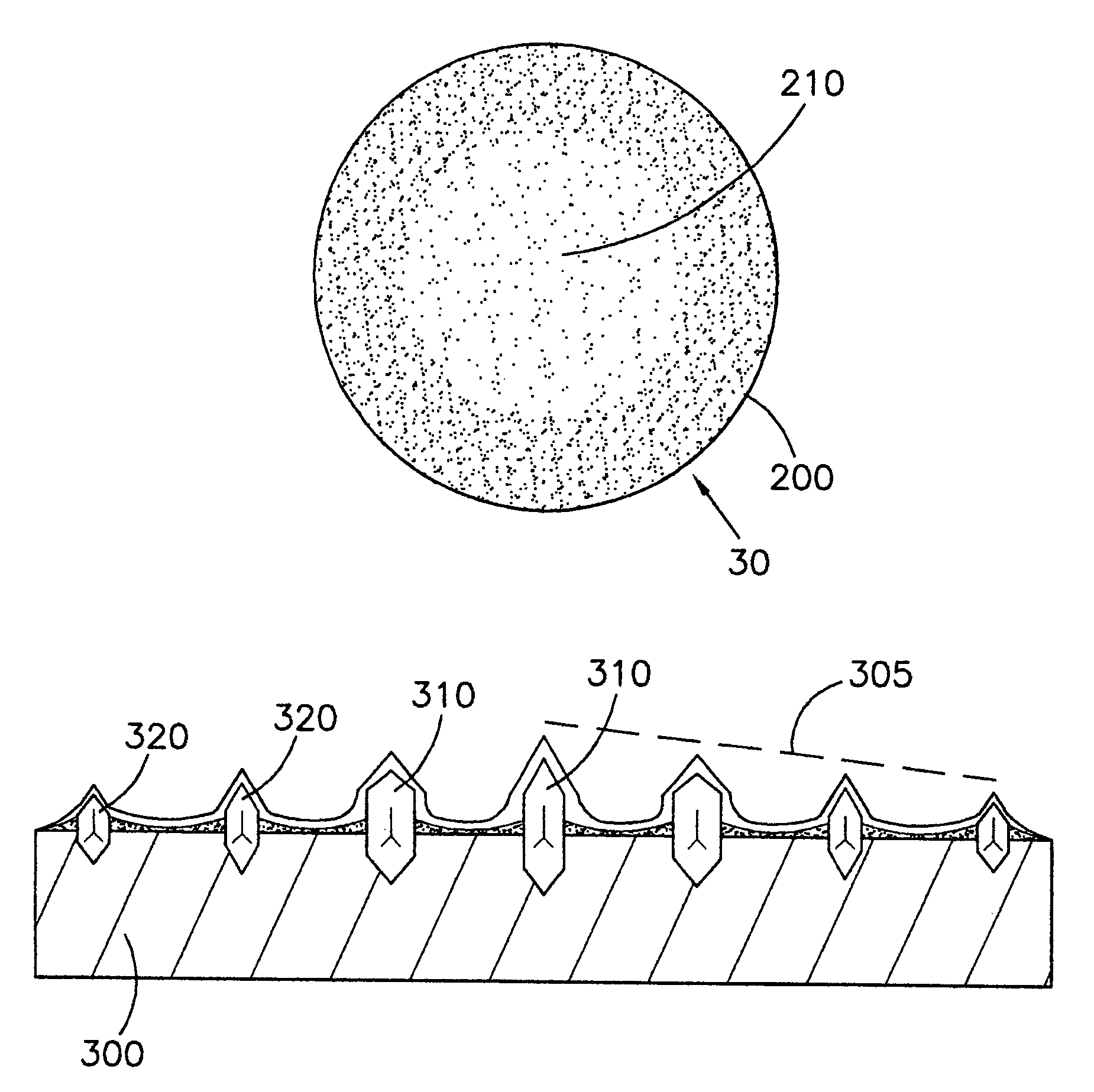

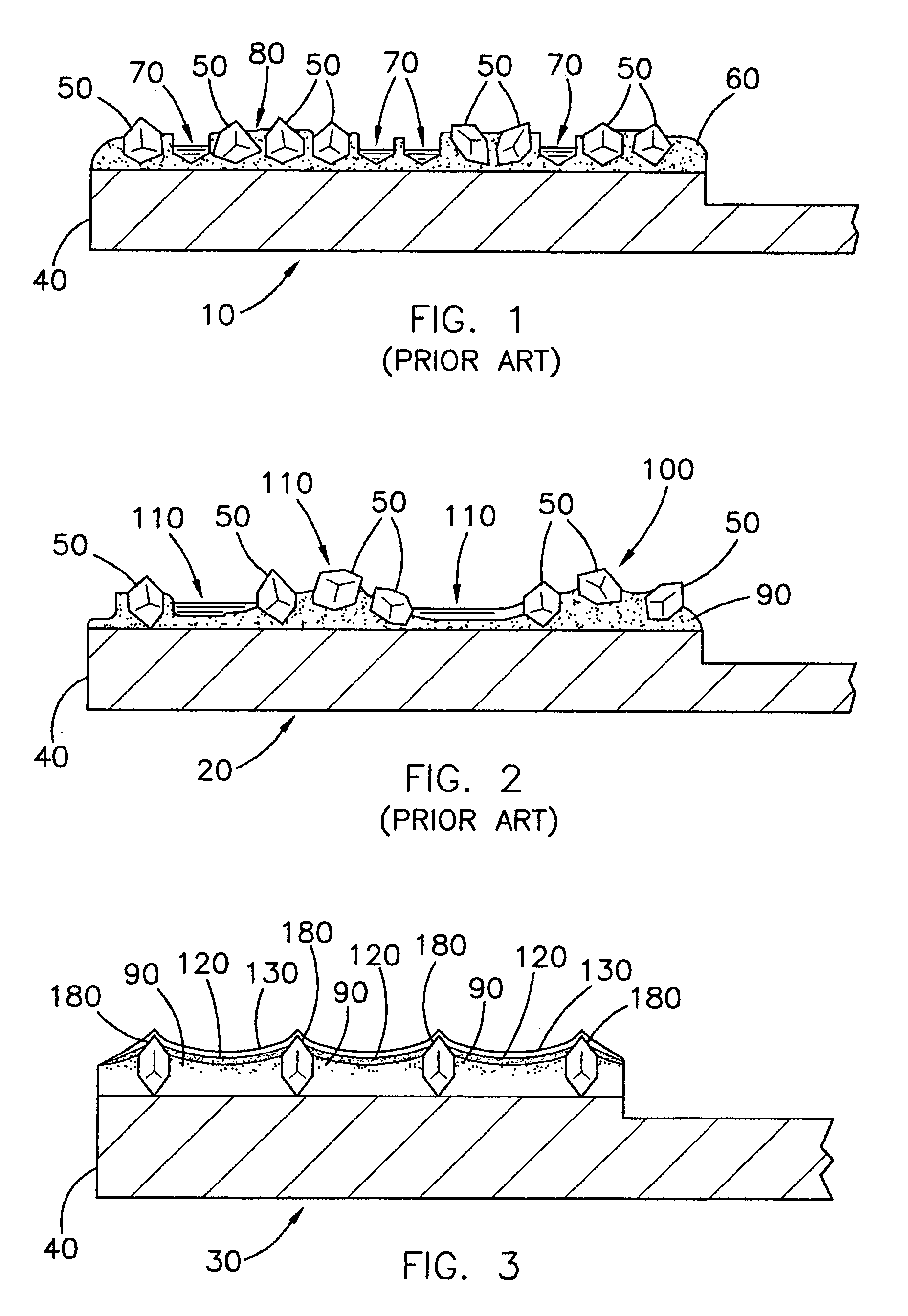

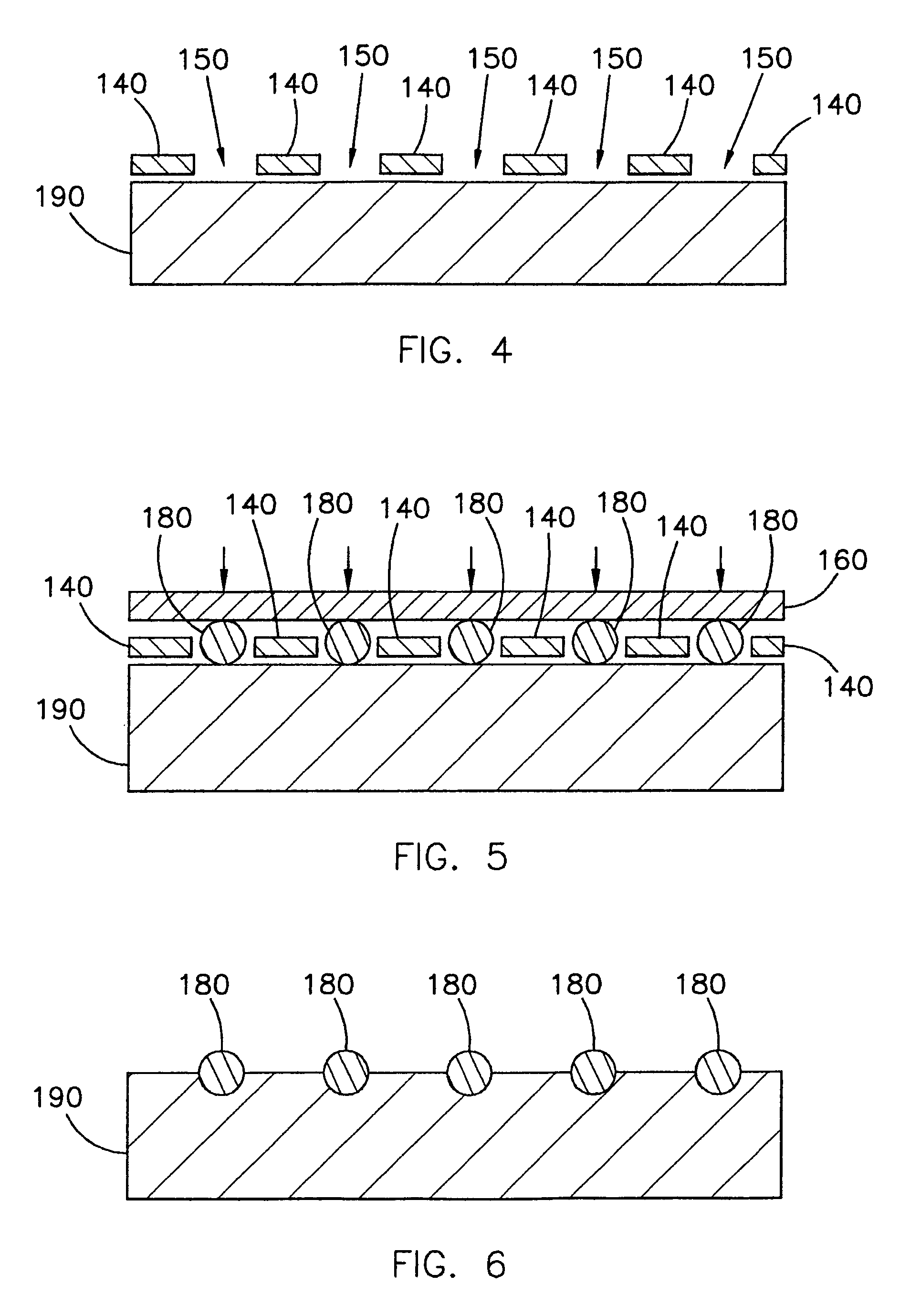

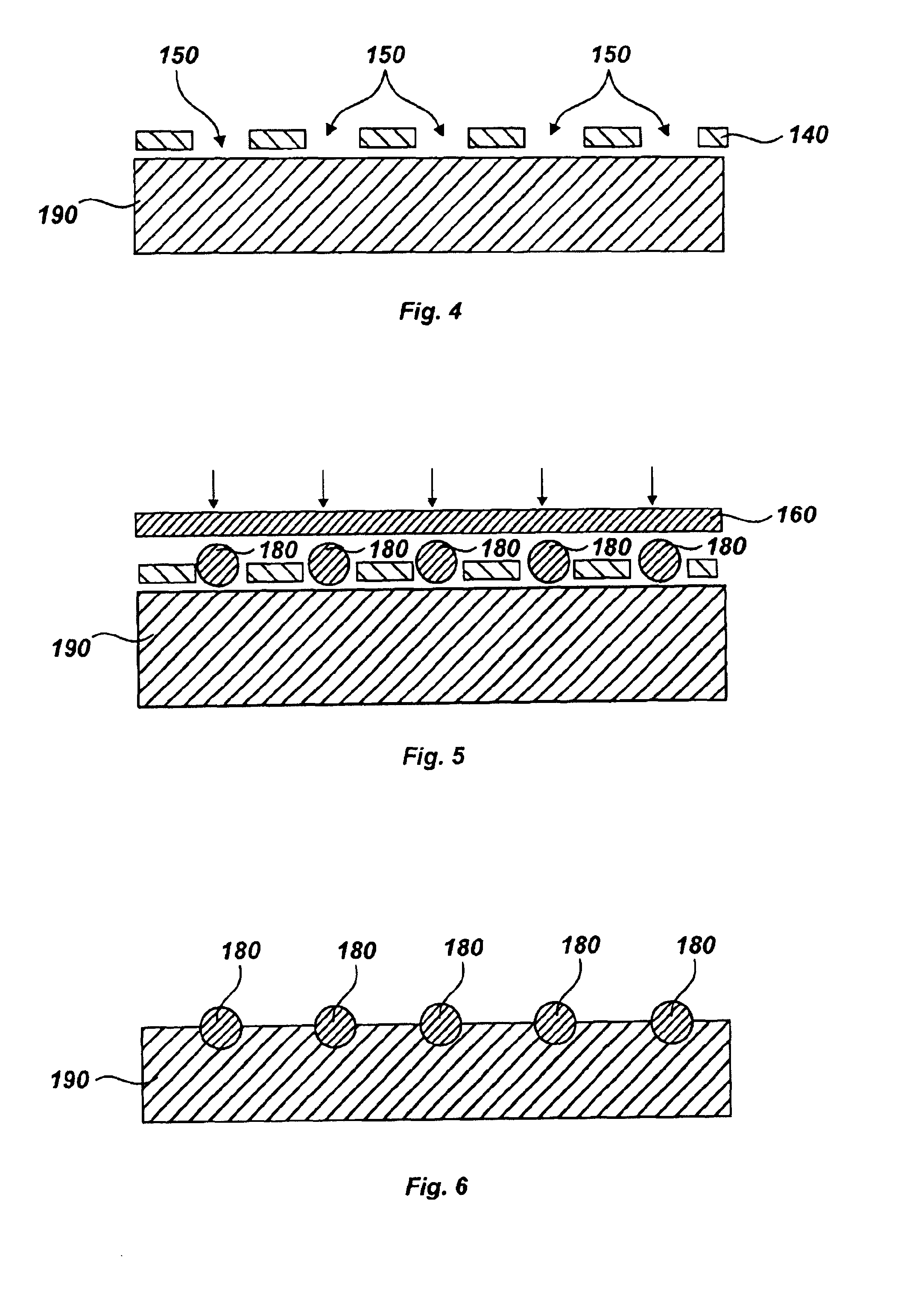

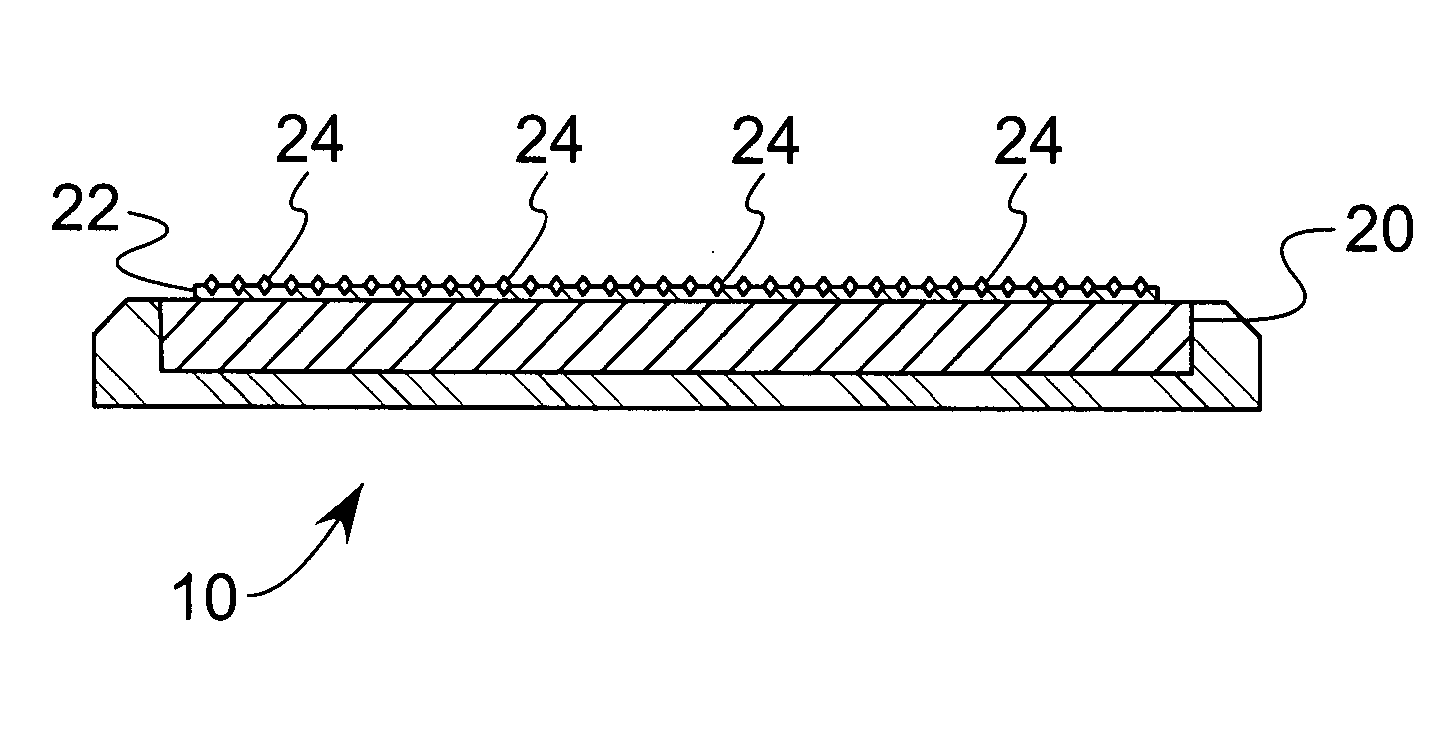

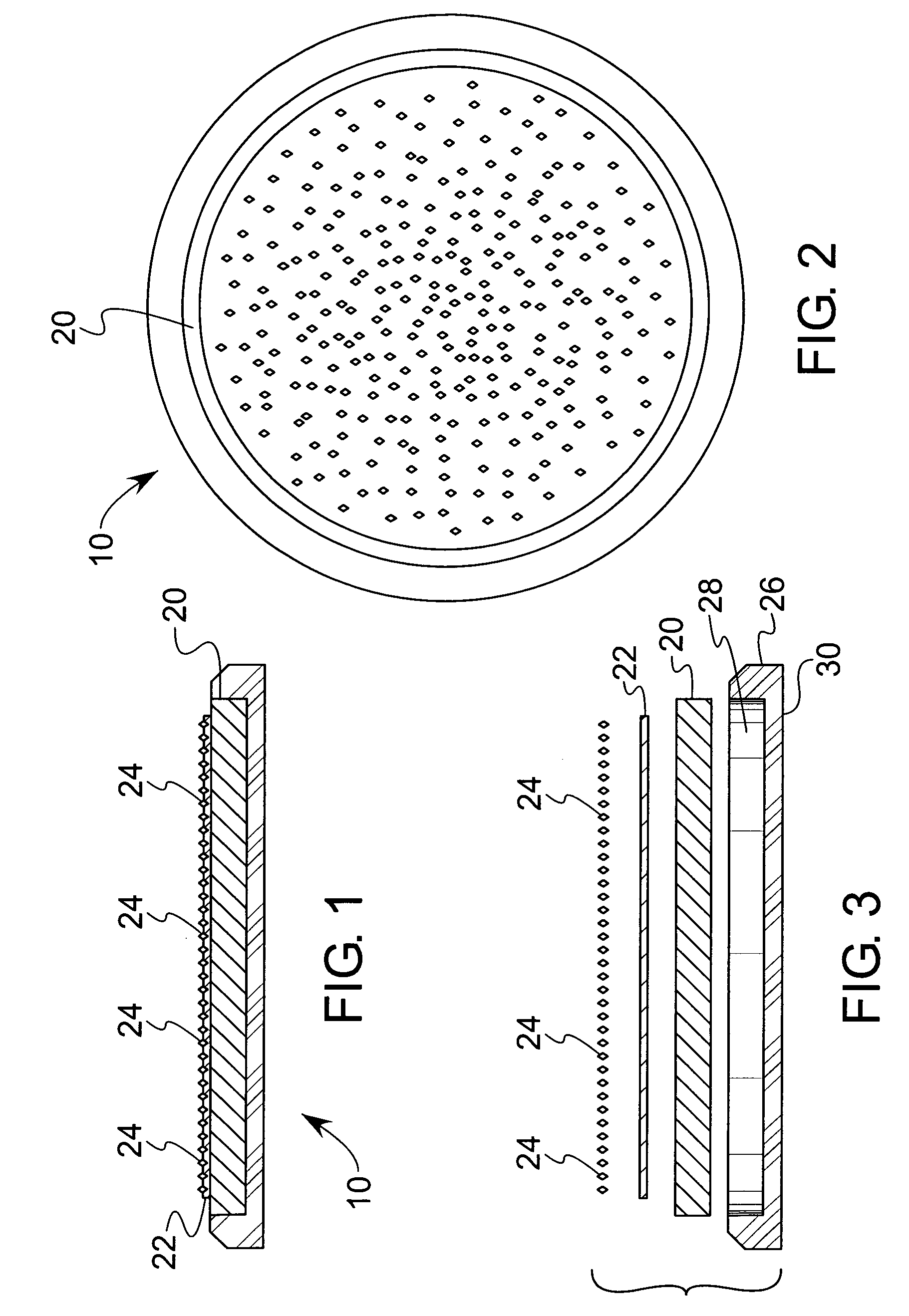

Diamond grid CMP pad dresser

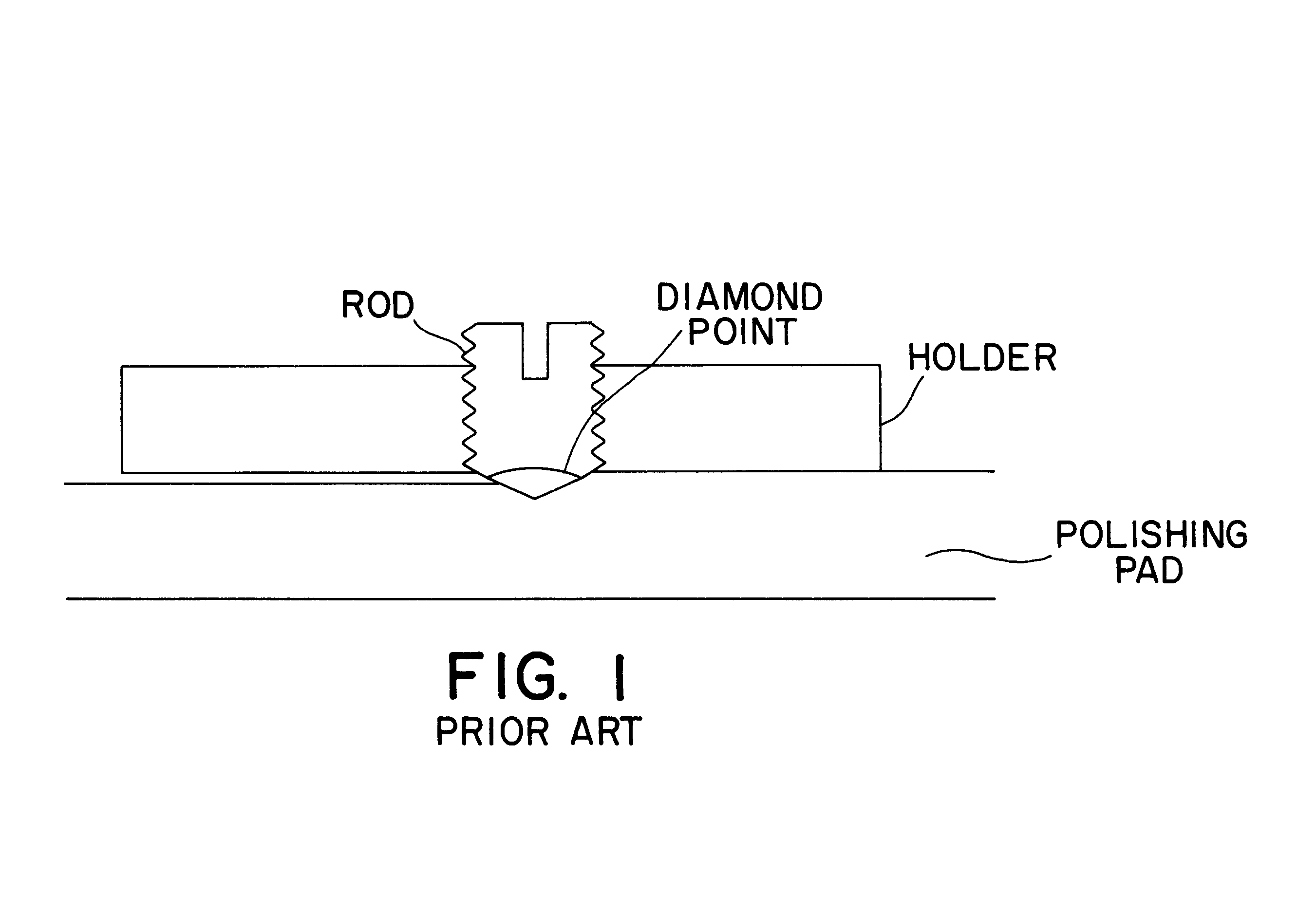

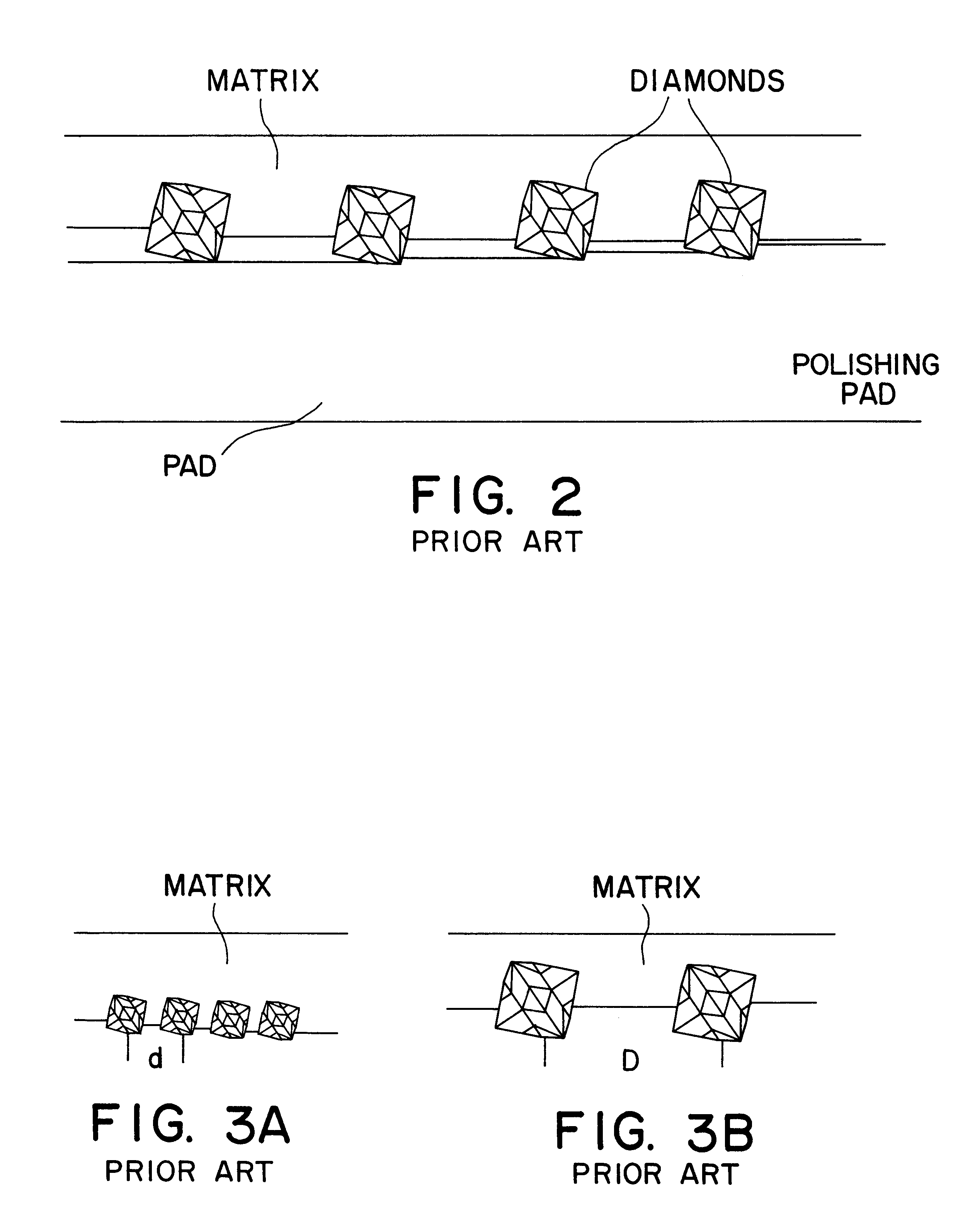

InactiveUS6368198B1Improve polishing efficiencyExtended service lifePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

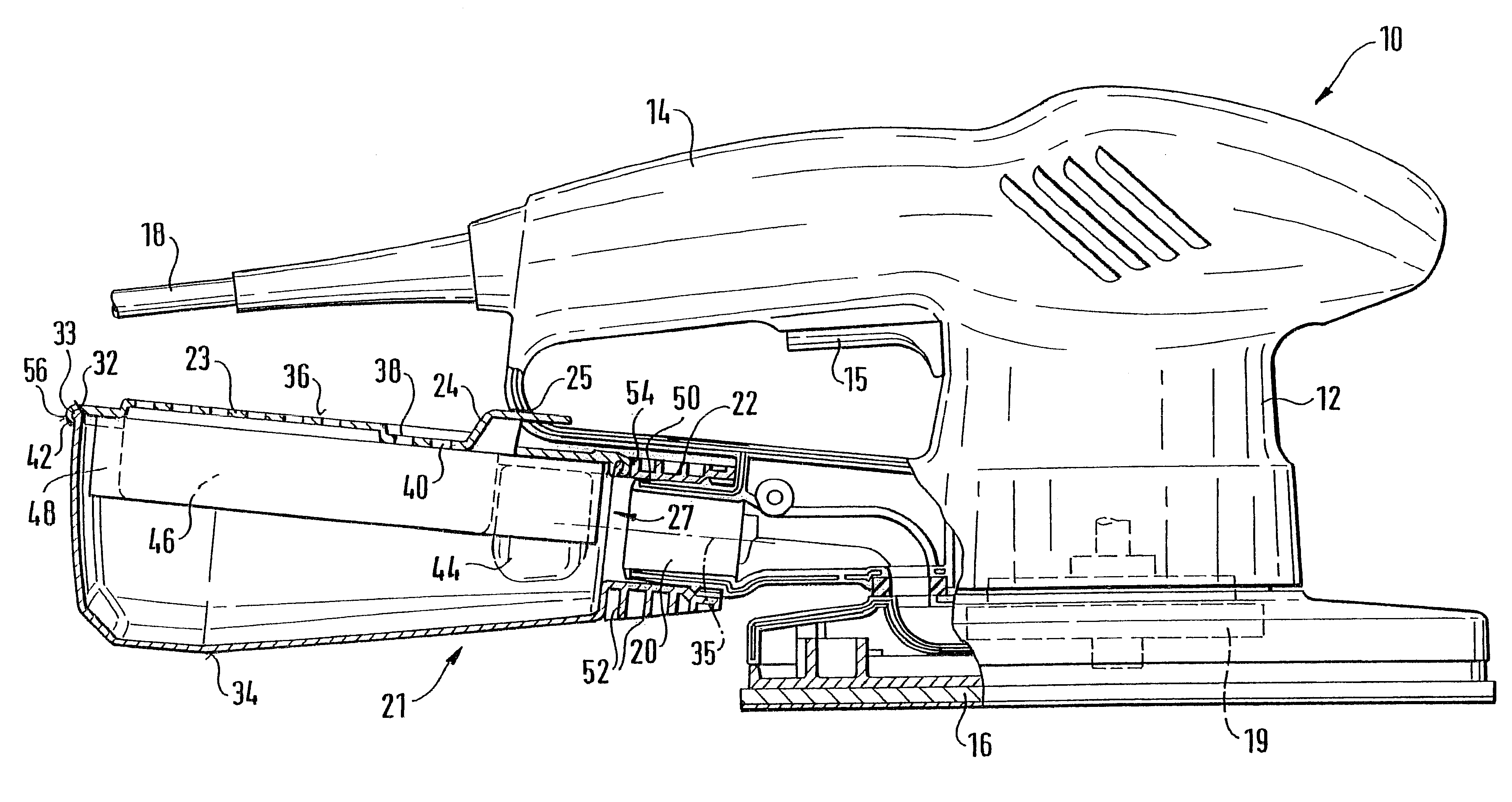

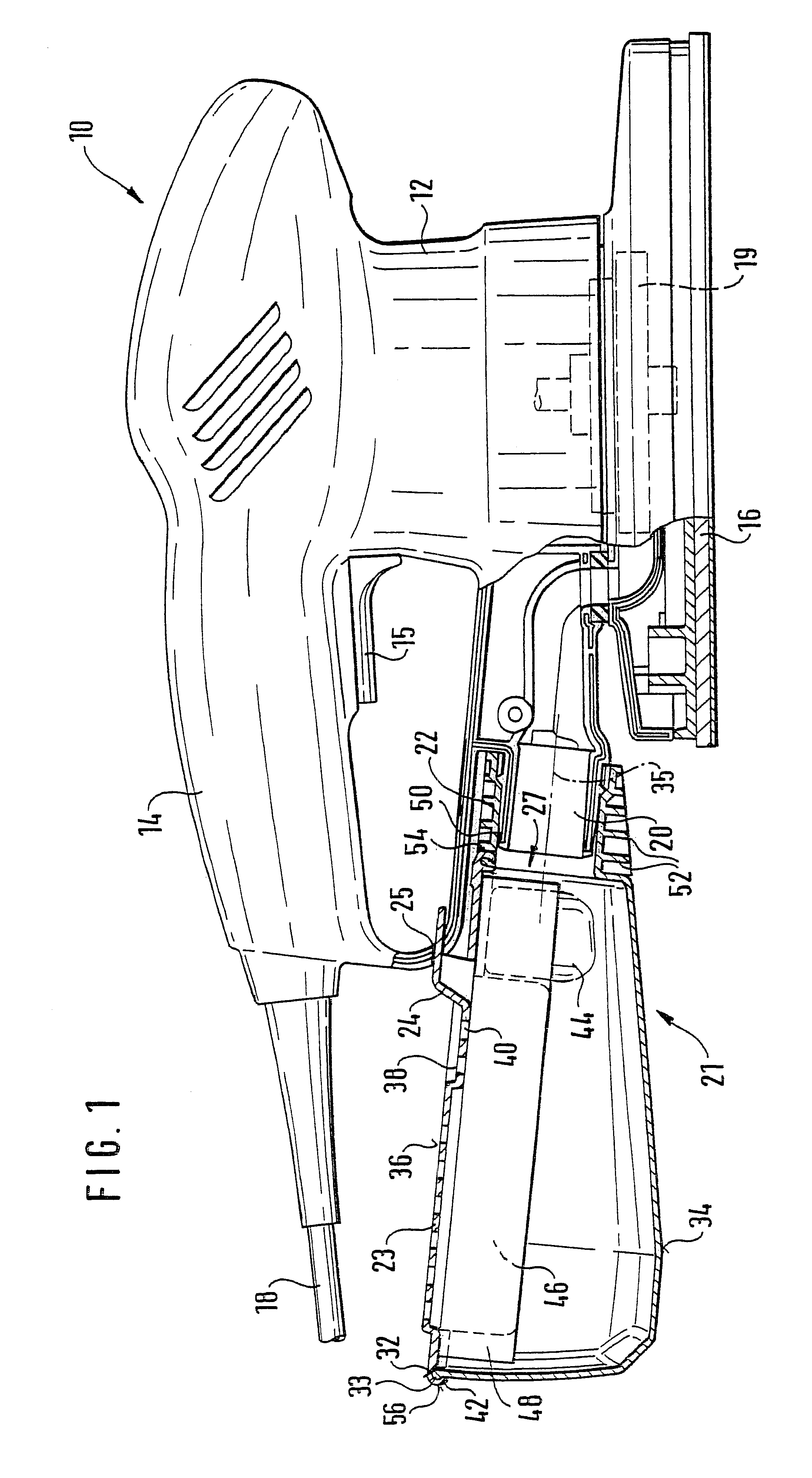

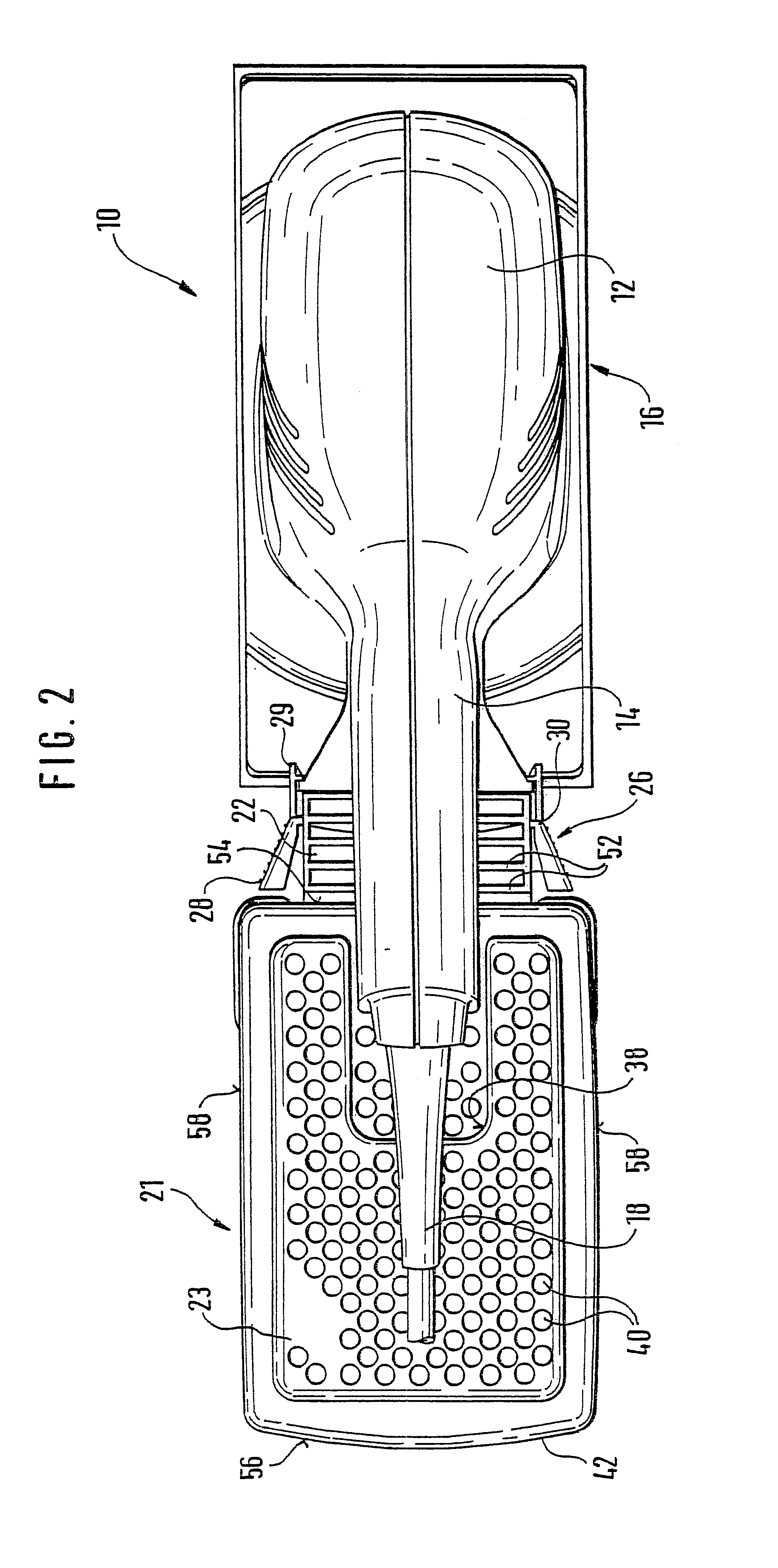

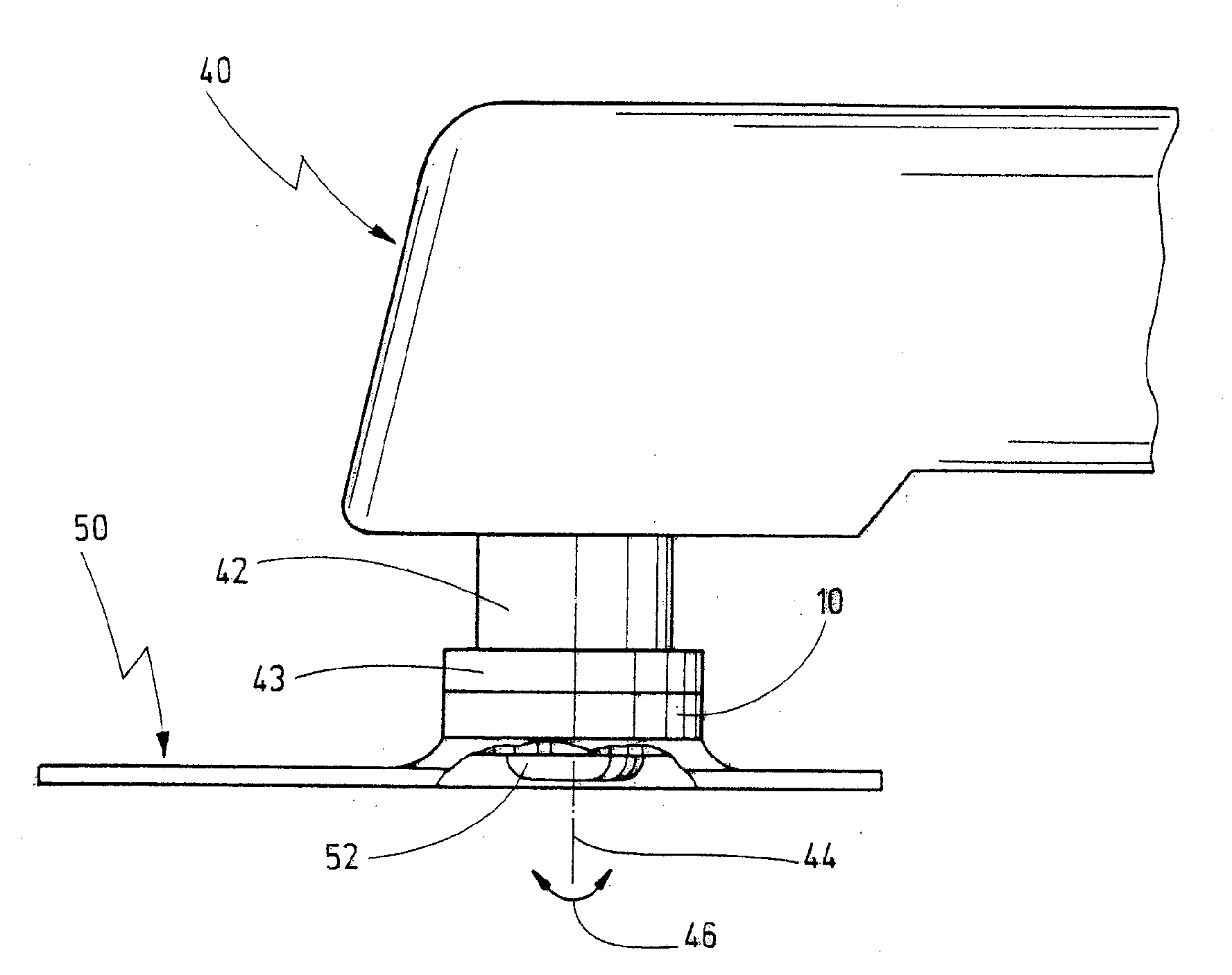

Hand-held machine tool with dust extraction

InactiveUS6514131B1Large filter areaHigh degreePortable grinding machinesMaintainance and safety accessoriesHand heldPower tool

A power tool (10) having a dust suction device (19) integrated into its housing (12) and having an ejection fitting (20) which is connected to the dust suction device (19) and can be detachably fastened with its injection fitting (22) to a dustproof dust box (21) is particularly suitable for containing sanding dust because of a number of side walls (34) of the dust box (21) have air openings (40) and on the inside, support at least one filter element (48), in particular a folded filter, which overlaps the air openings (40).

Owner:ROBERT BOSCH GMBH

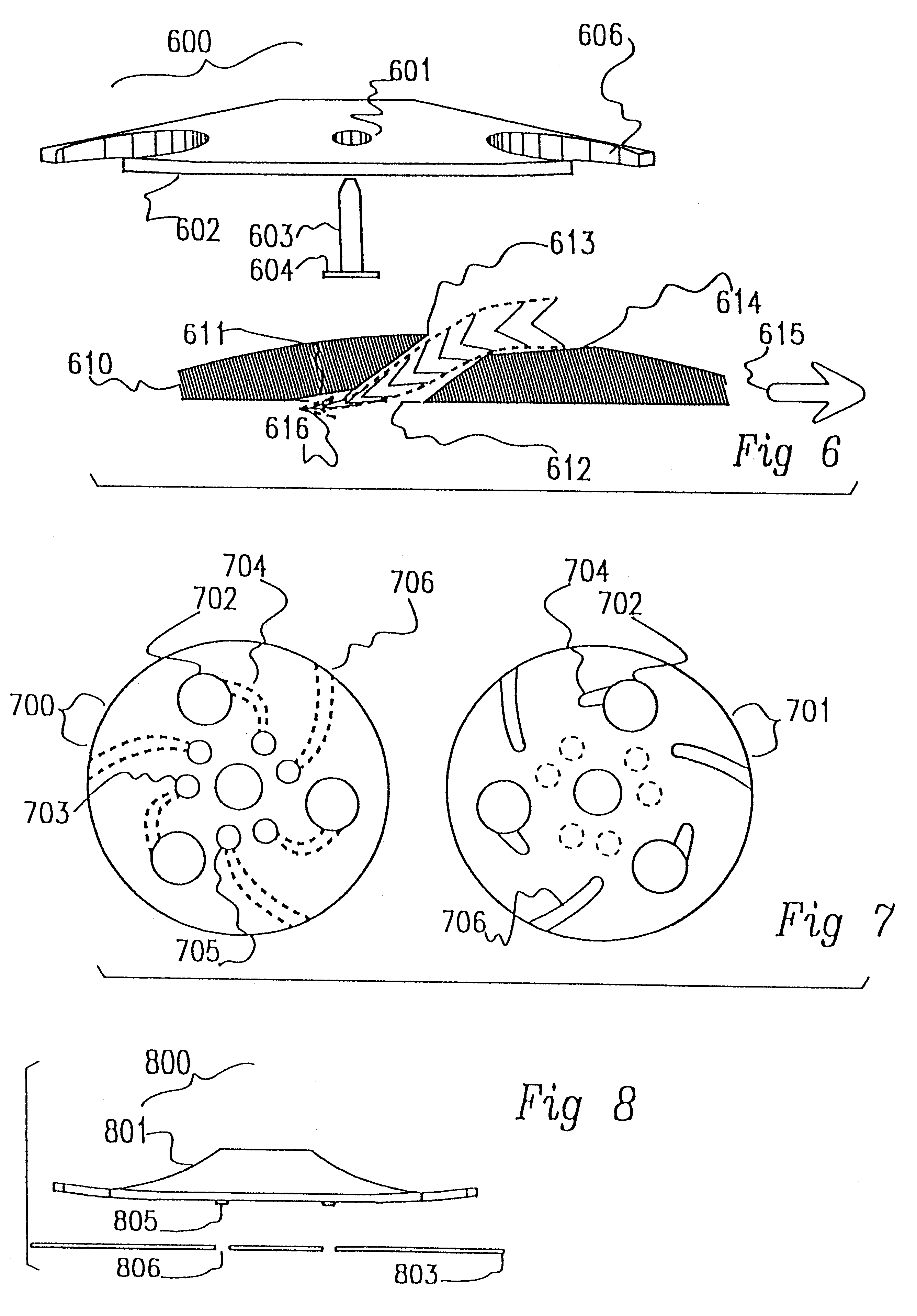

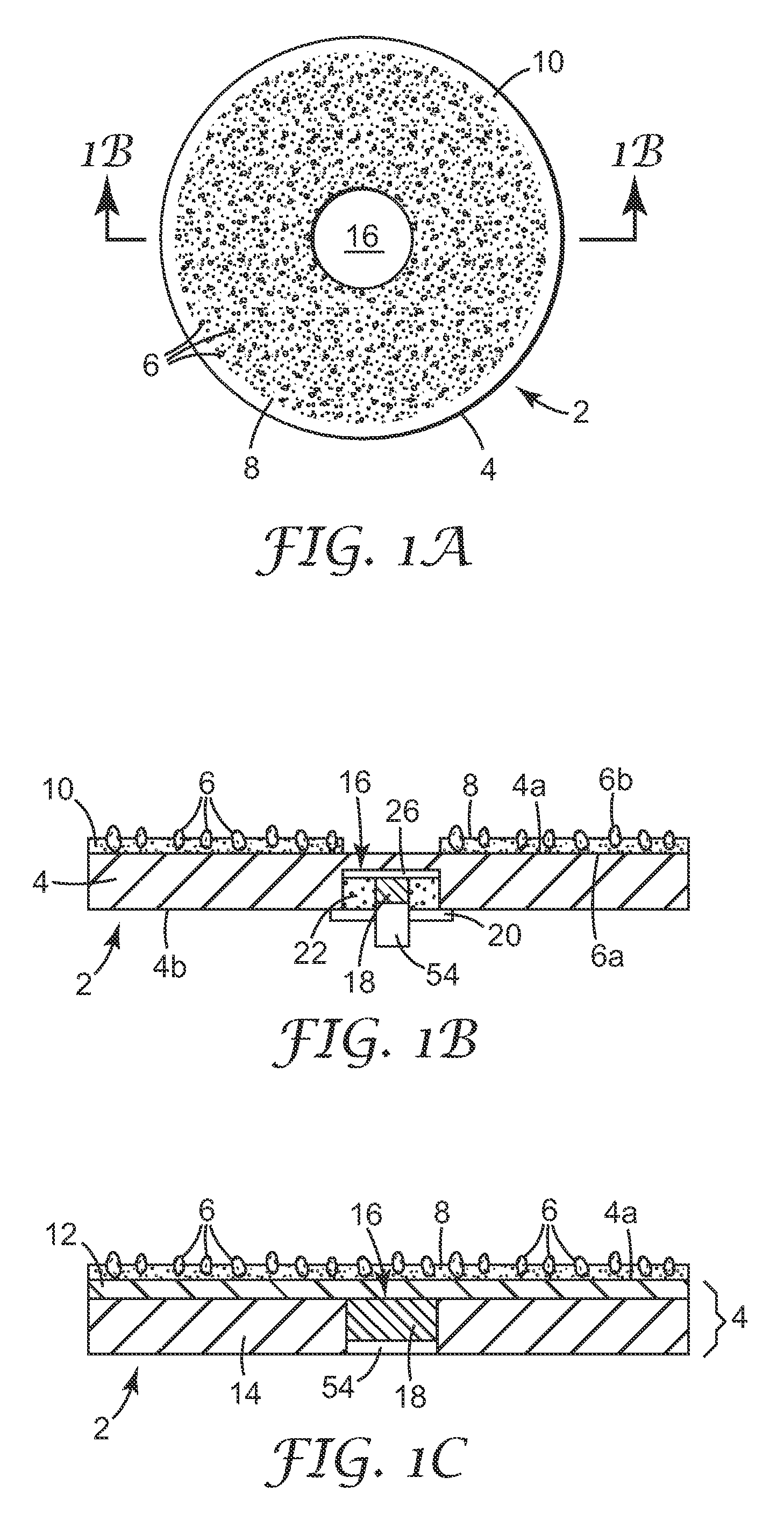

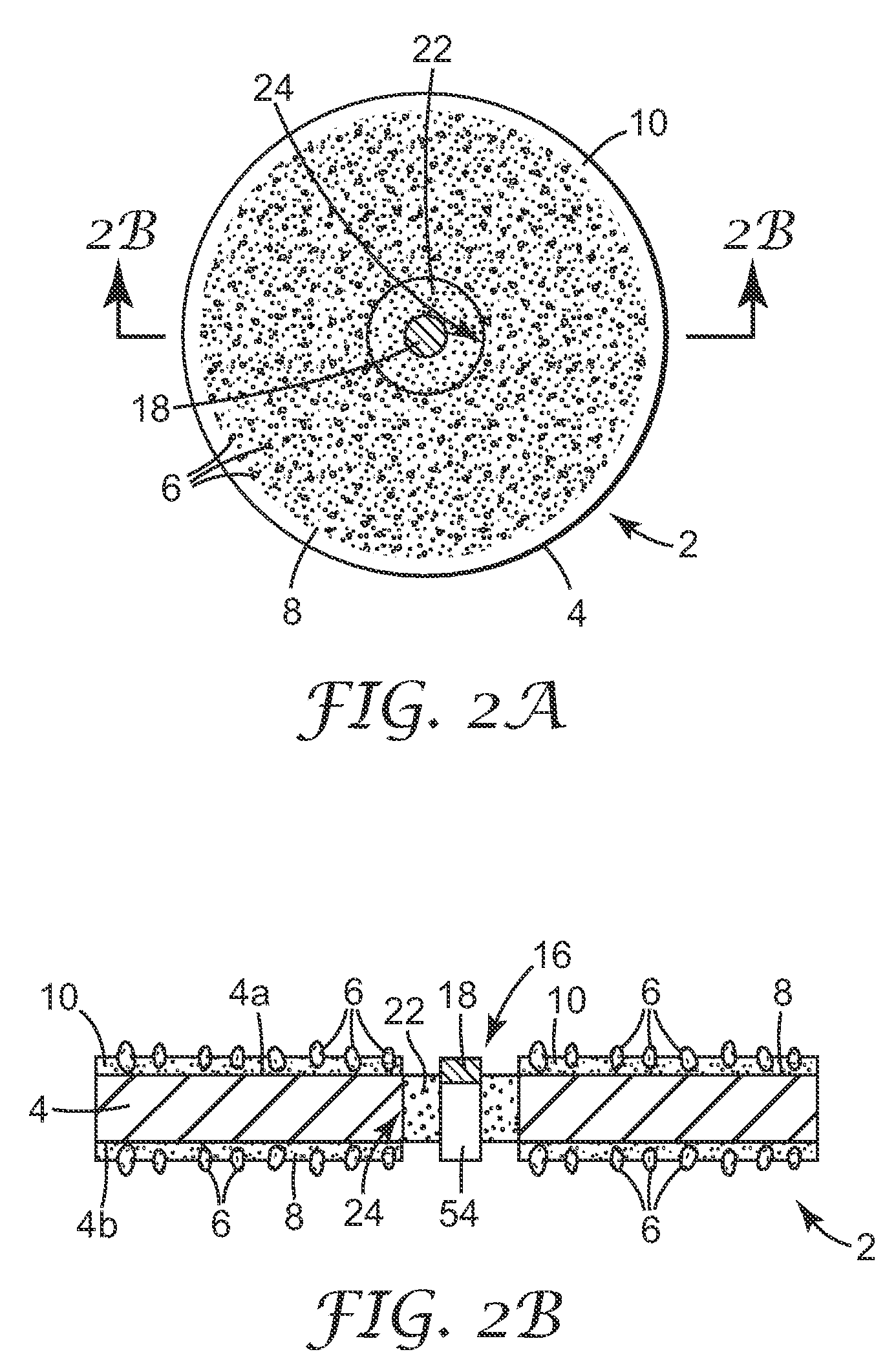

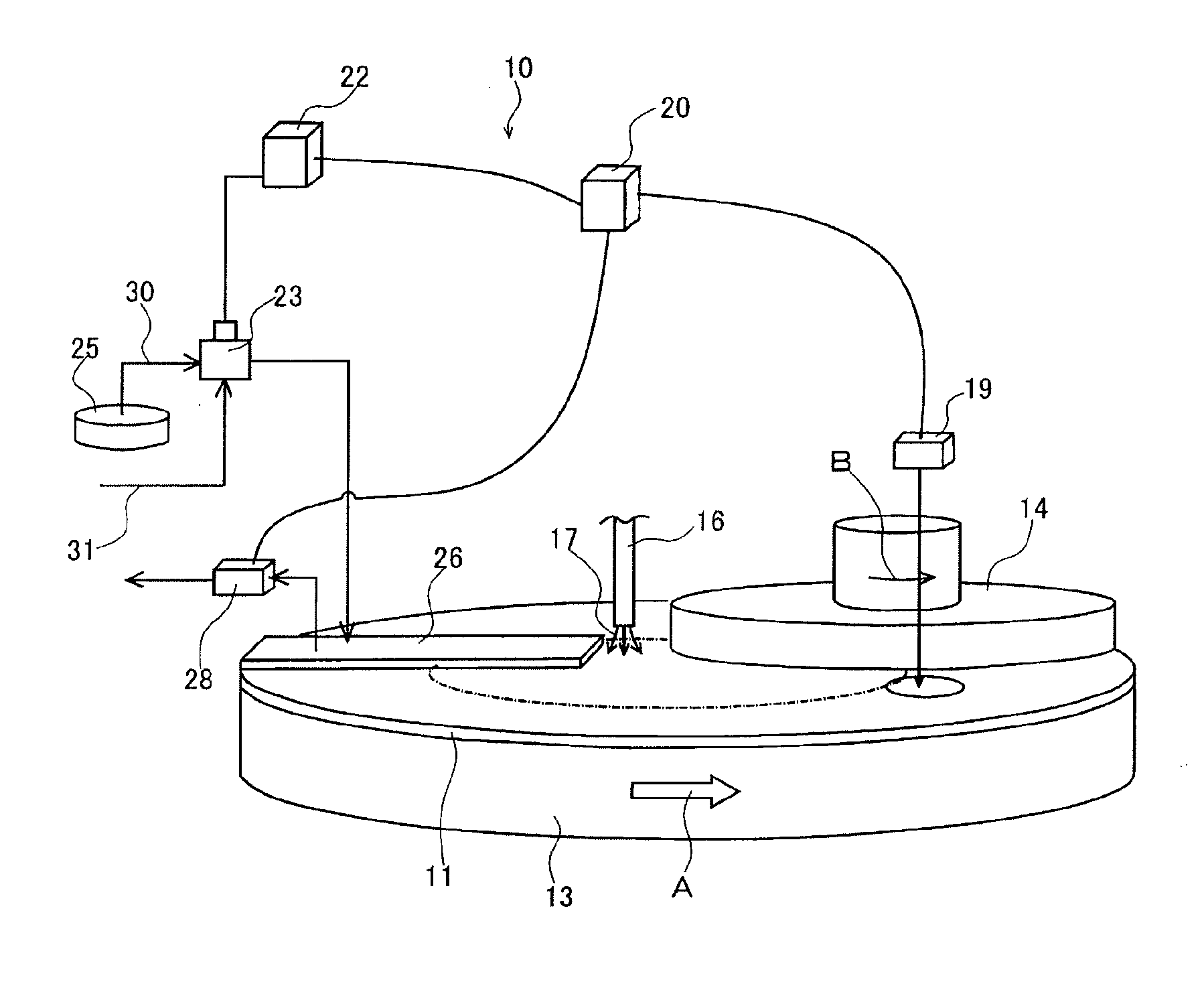

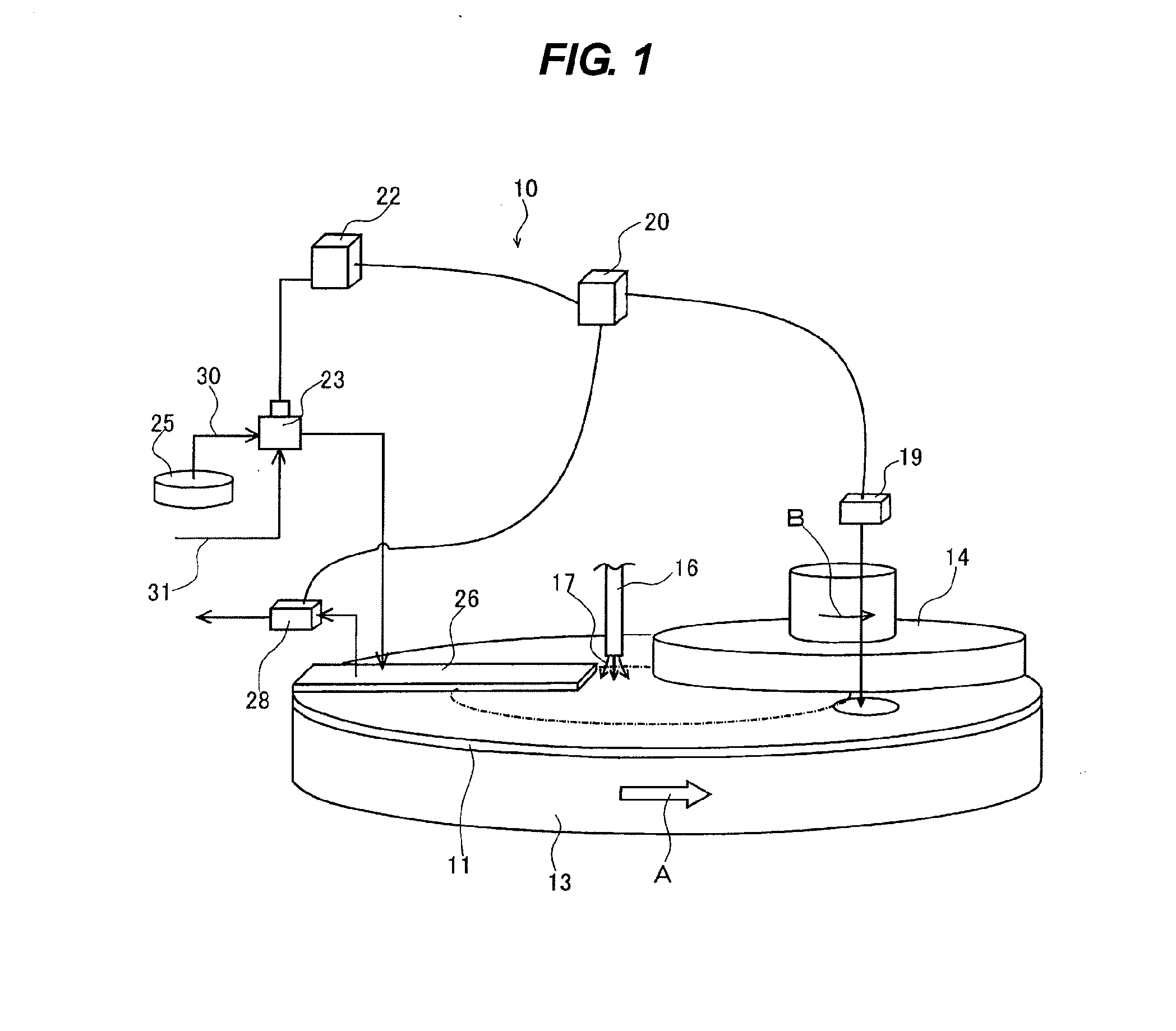

Abrasive Articles, CMP Monitoring System and Method

ActiveUS20080004743A1Easy to operate the machineAvoid damageGrinding drivesBelt grinding machinesMonitoring systemEngineering

The disclosure relates to abrasive articles useful in chemical-mechanical polishing (CMP), the articles including a substrate with opposite major surfaces, an abrasive material overlaying at least a portion of at least one of the major surfaces, a means for providing CMP information positioned near the substrate, and a transmitter positioned near the substrate and adapted to transmit the CMP information to a remote receiver. The disclosure also relates to a CMP pad conditioner having a means for communicating CMP information, a CMP process monitoring system, and a method for conditioning a CMP pad.

Owner:3M INNOVATIVE PROPERTIES CO

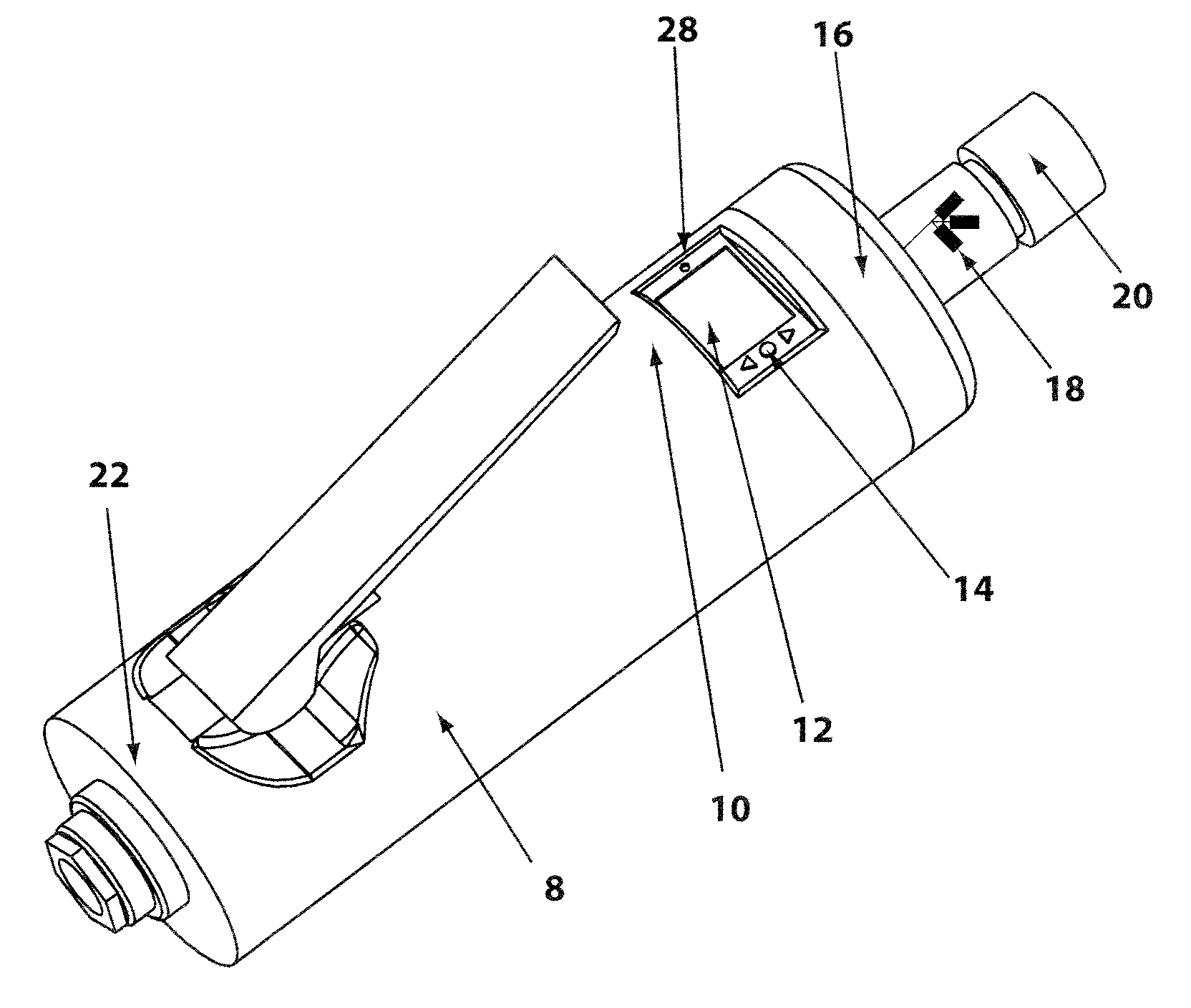

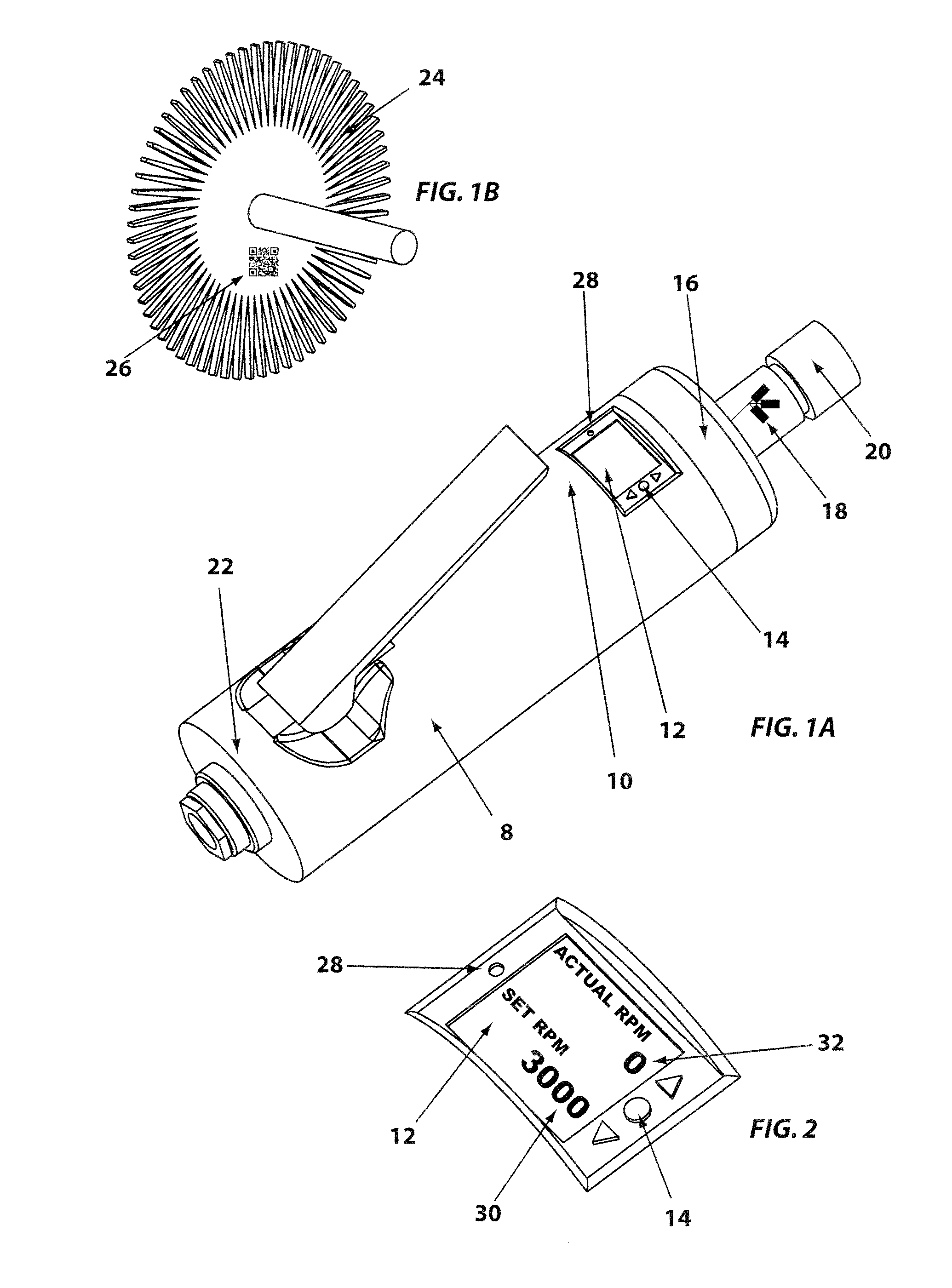

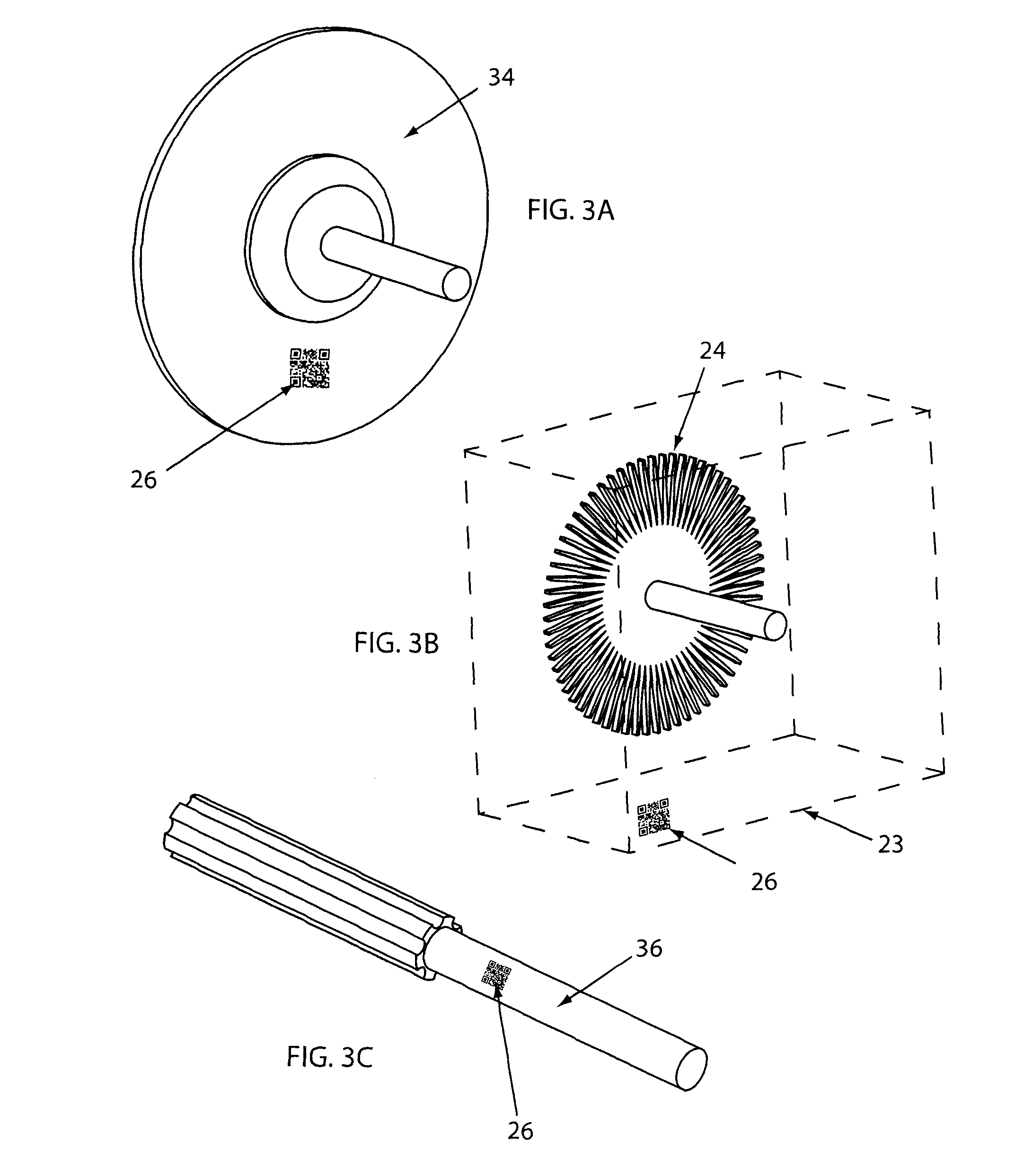

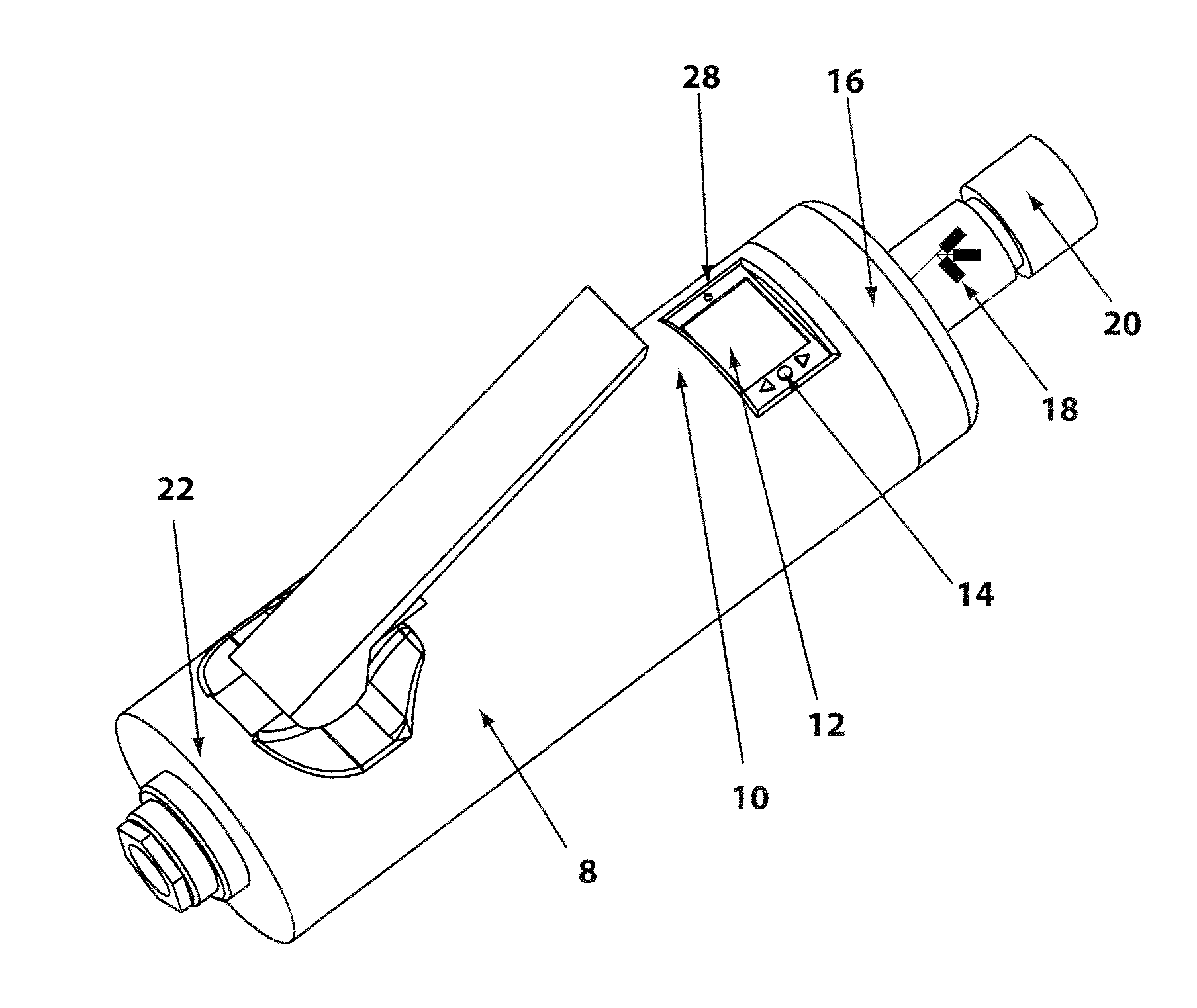

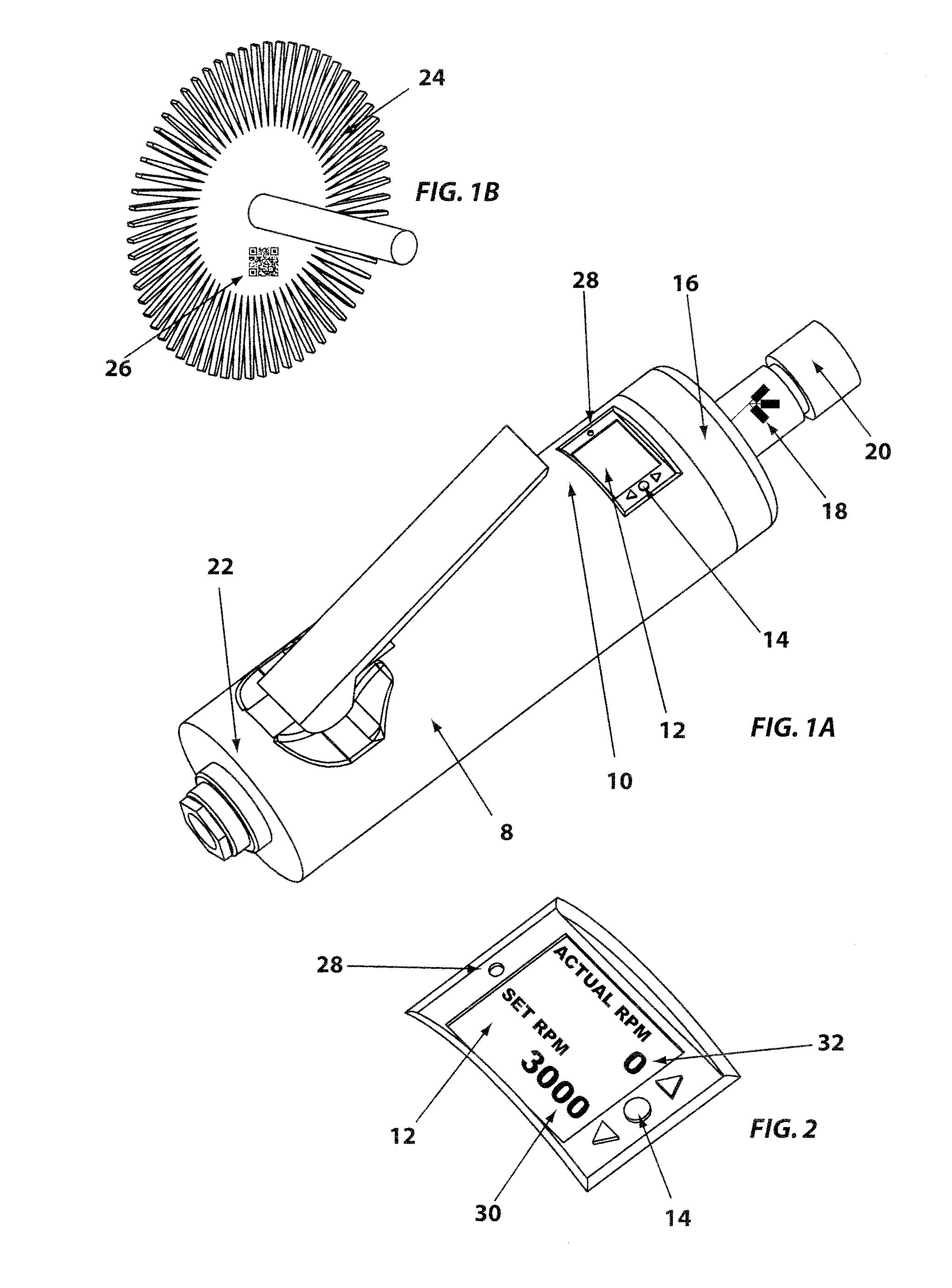

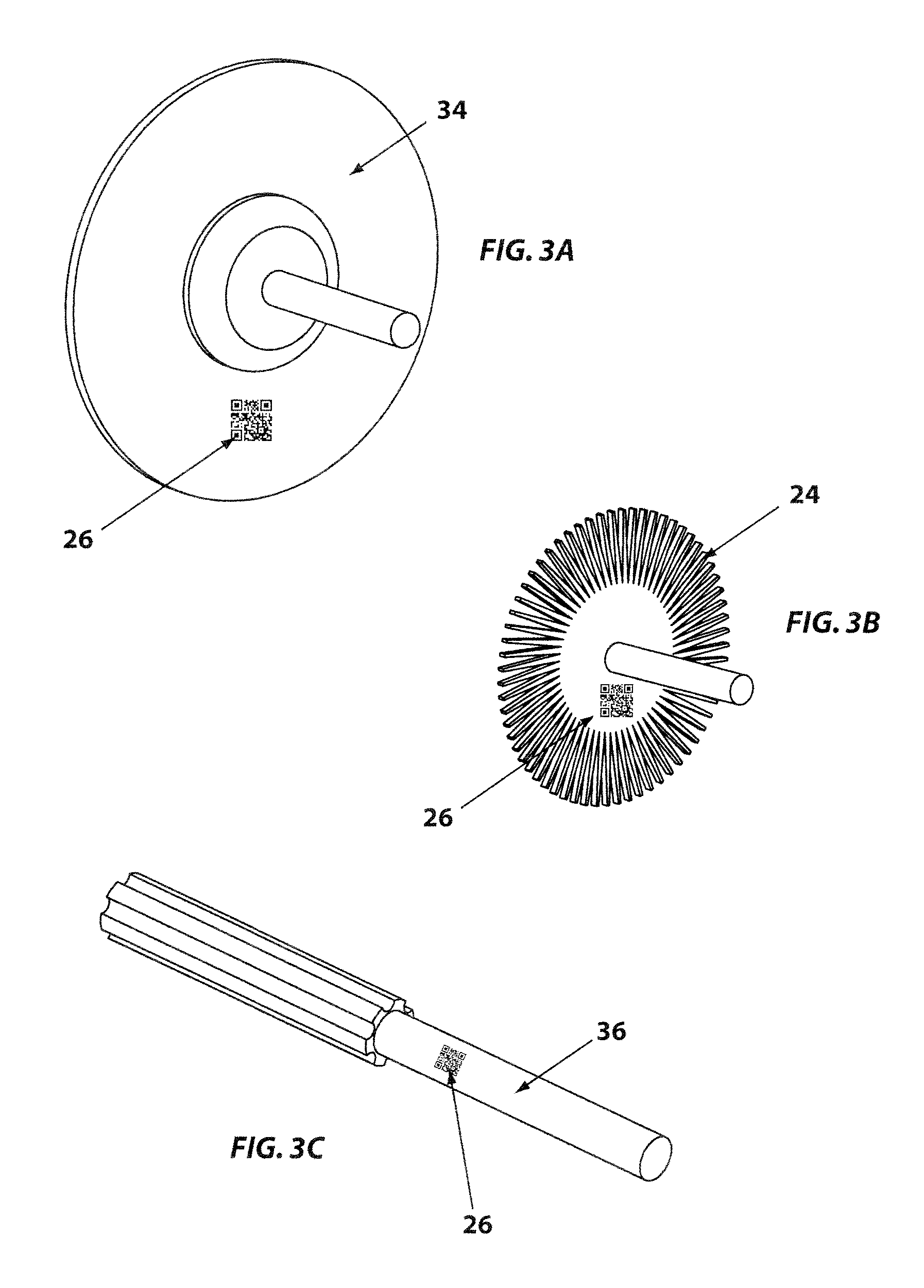

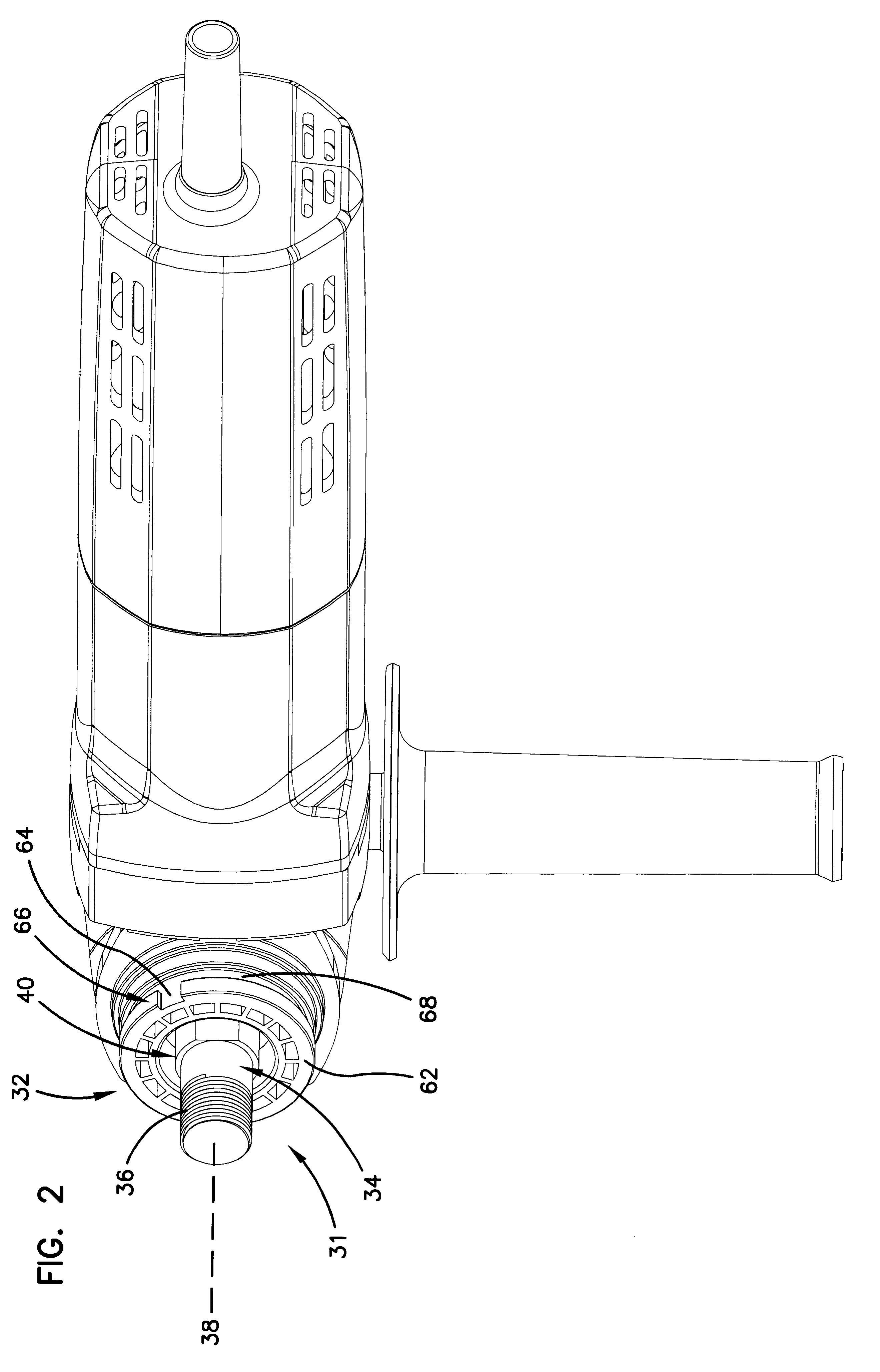

Controlled electro-pneumatic power tools and interactive consumable

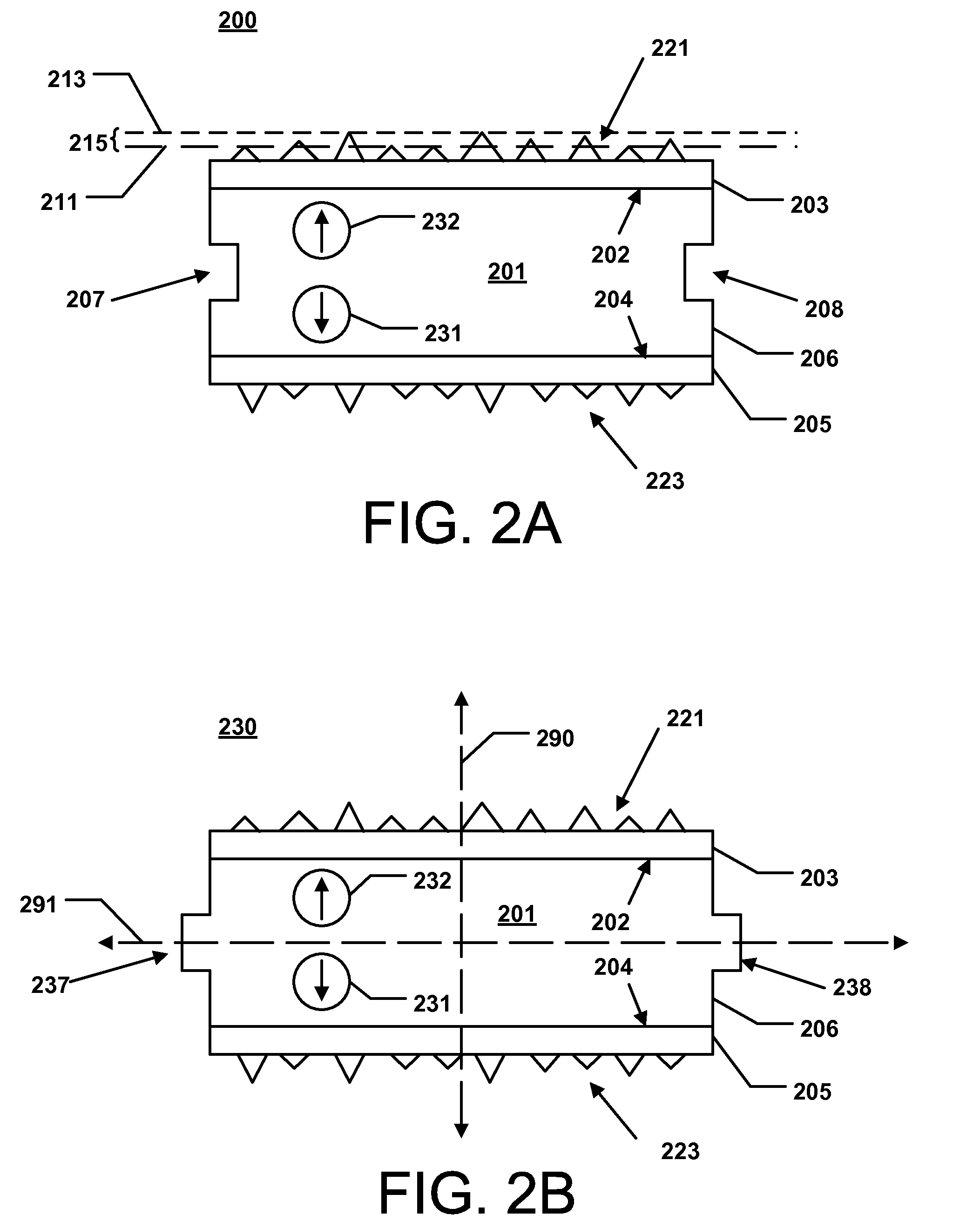

ActiveUS20120007748A1Electric signal transmission systemsTelemetry/telecontrol selection arrangementsMicrocontrollerElectrical battery

A controlled electro-pneumatic power tool includes an electro-mechanical adjustable valve, a pneumatic motor and a rotational speed sensor connected to a microcontroller for the selection, monitoring and adjustement of the rotational speed in real time. The electro-pneumatic power tool may include input buttons, data ports to save data and a communication port to read / write data from an interactive consumable. The electo-pneumatic power tool may also include a battery and a generator as well as a variable speed transmission with flexible shaft and lightweight handpiece. Using the communication port, important data for the consumable, such as optimum rotation speed, optimum applied pressure and average usage time, can be transmitted to the controlled electro-pneumatic power tool. The controlled electro-pneumatic power tool can read and utilise the transmitted data to select, adjust and maintain the optimum process parameters for the consumable without any input from the operator person. Furthermore, the communicated data can be used to warn the operator person that the tool used is inadequate for the selected consumable, to caution the operator person if he is using the consumable inadequately and to advise him when the consumable should be replaced for safe operation. This will increase the safety of the operator person, improve the quality of the work performed with pneumatic power tools and limit potential damages to the parts being treated.

Owner:FORGUES SYLVAIN +1

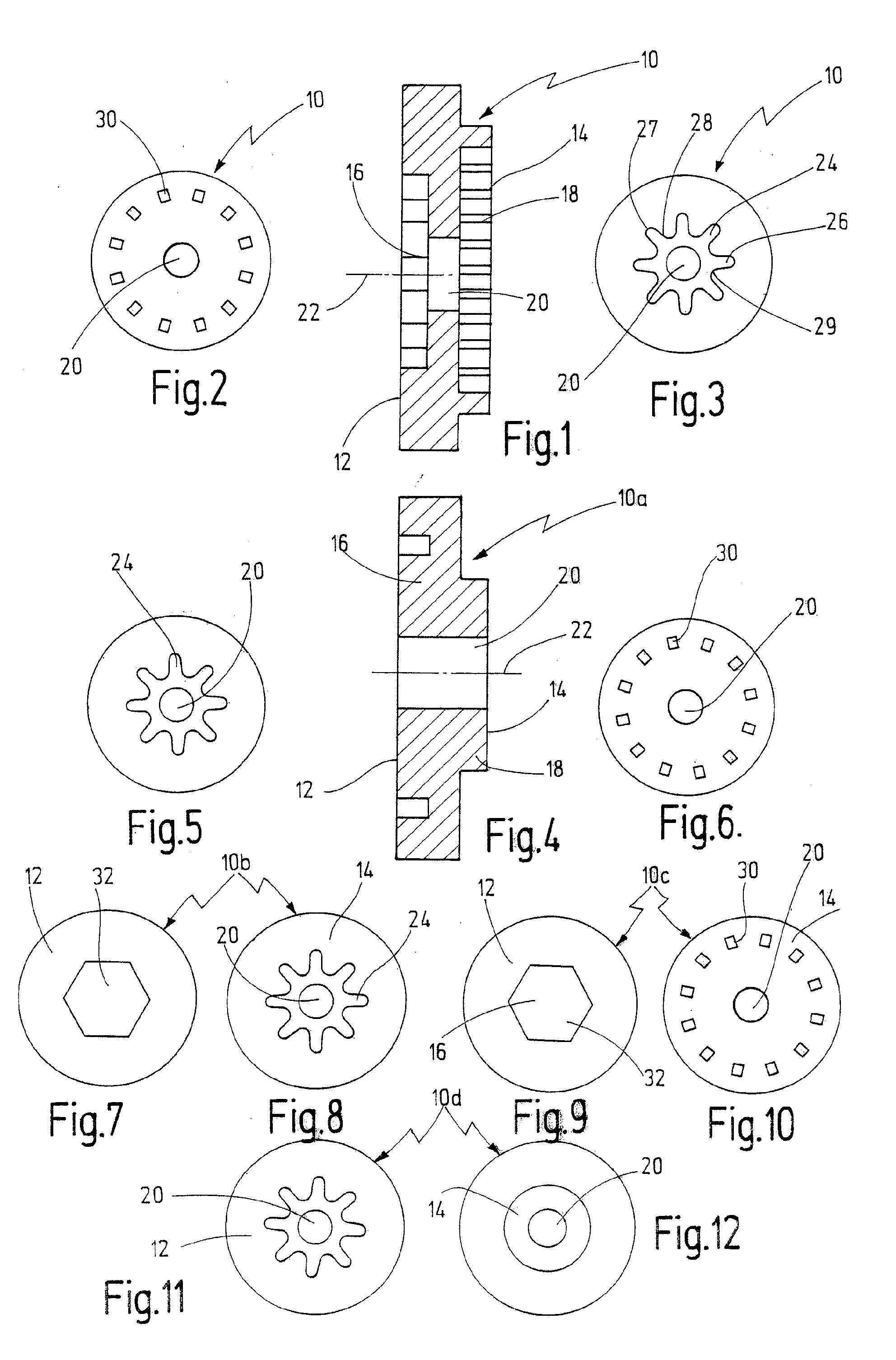

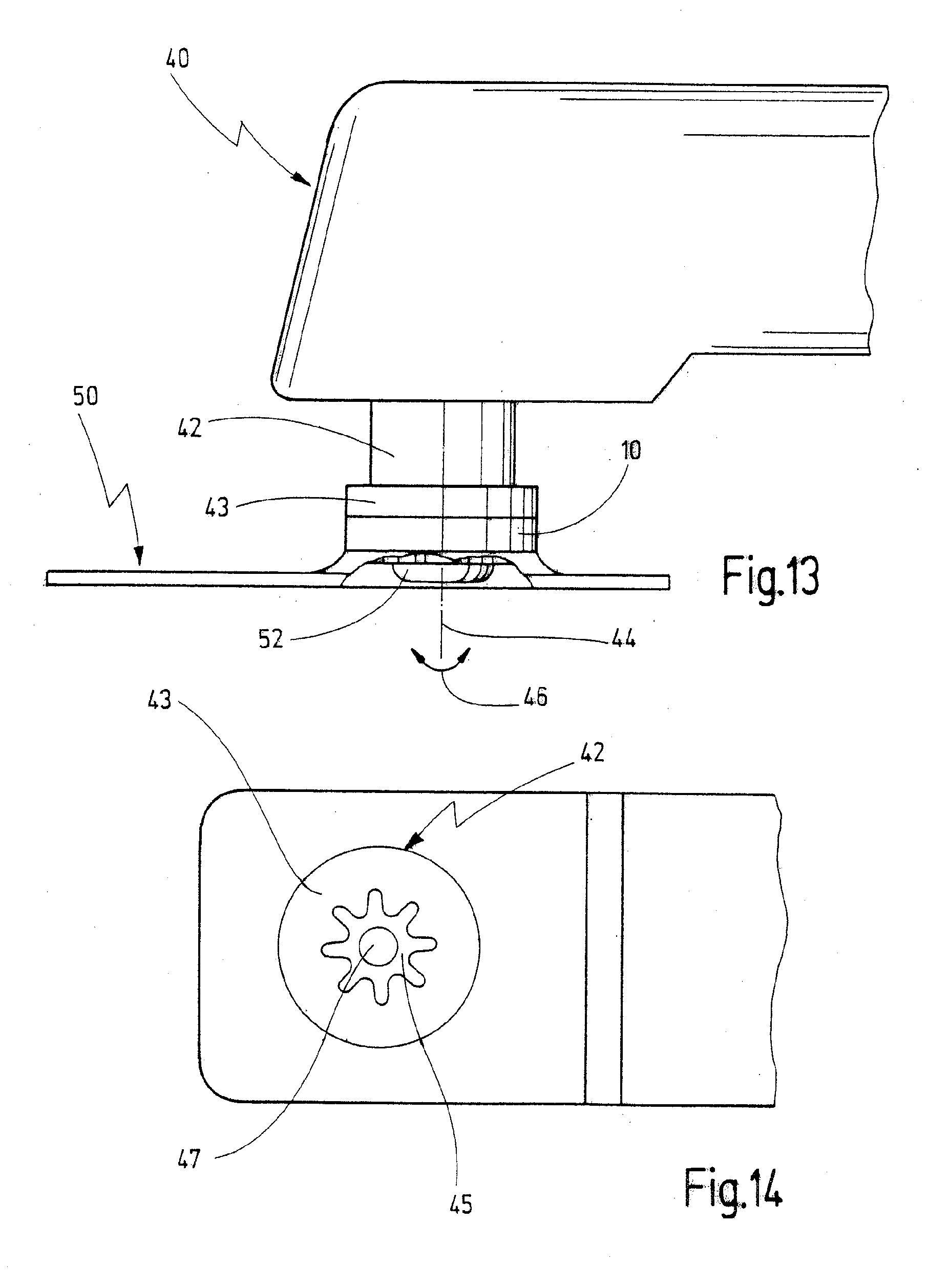

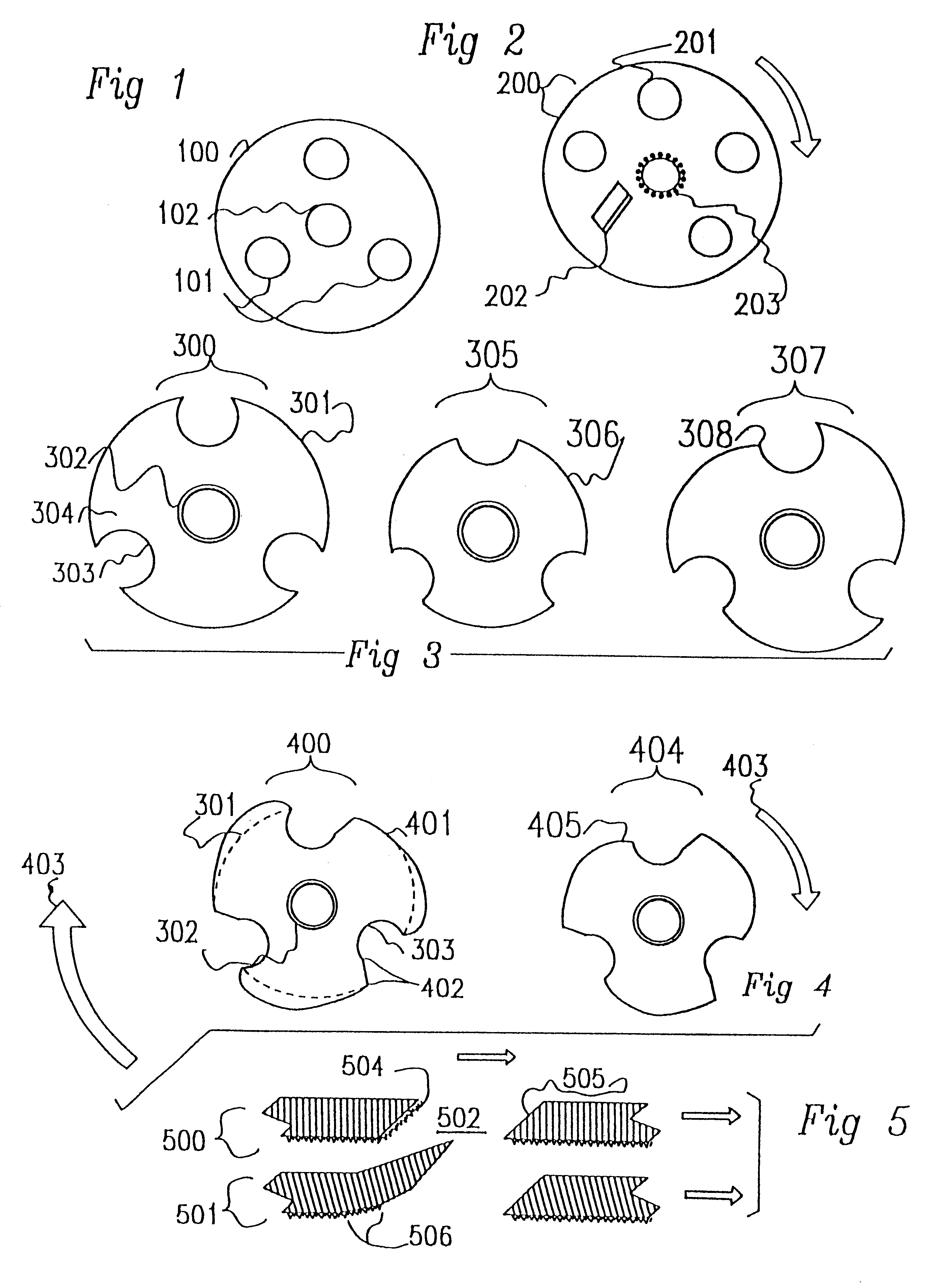

Adapter For Mounting A Tool On An Oscillating Drive

ActiveUS20100056029A1Reduce tool typesLow costGrinding wheel securing apparatusGrinding drivesMating connectionDrive shaft

An adapter is disclosed for mounting a tool on an oscillating drive having a drive shaft that can be driven to oscillate about its longitudinal axis, wherein the adapter is passed by a central opening, and has at its drive end at least one positive-locking element for positive connection with the tool, the positive-locking element having the shape of a regular polygon, or a plurality of positive-locking elements arranged on a circle concentric to the center axis, or a plurality of outwardly extending convex projections having rounded tips and being connected with neighboring projections via rounded concave lateral flanks, wherein the positive-locking elements on the drive end are configured for positive-locking connection with a matching positive-locking counter-element on the drive shaft, and wherein the adapter has a second receptacle on its tool end for effecting connection with a tool having a shape different from the first receptacle and being configured as a circle, or as a plurality of positive-locking elements arranged along a circle concentric to the center axis, or as plurality of outwardly extending convex projections with rounded tips and being connected with neighboring projections via rounded concave lateral flanks.

Owner:C & E FEIN GMBH & CO KG

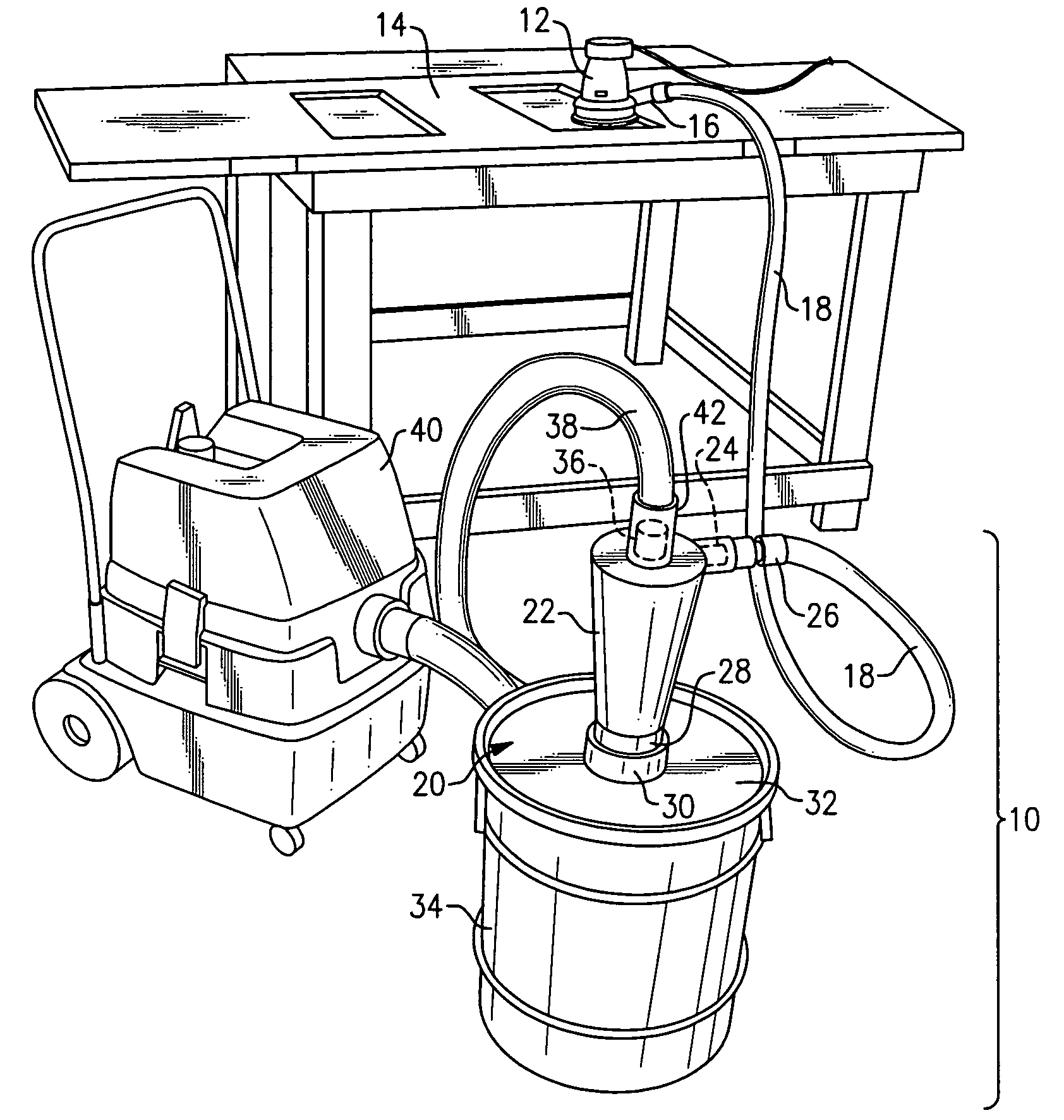

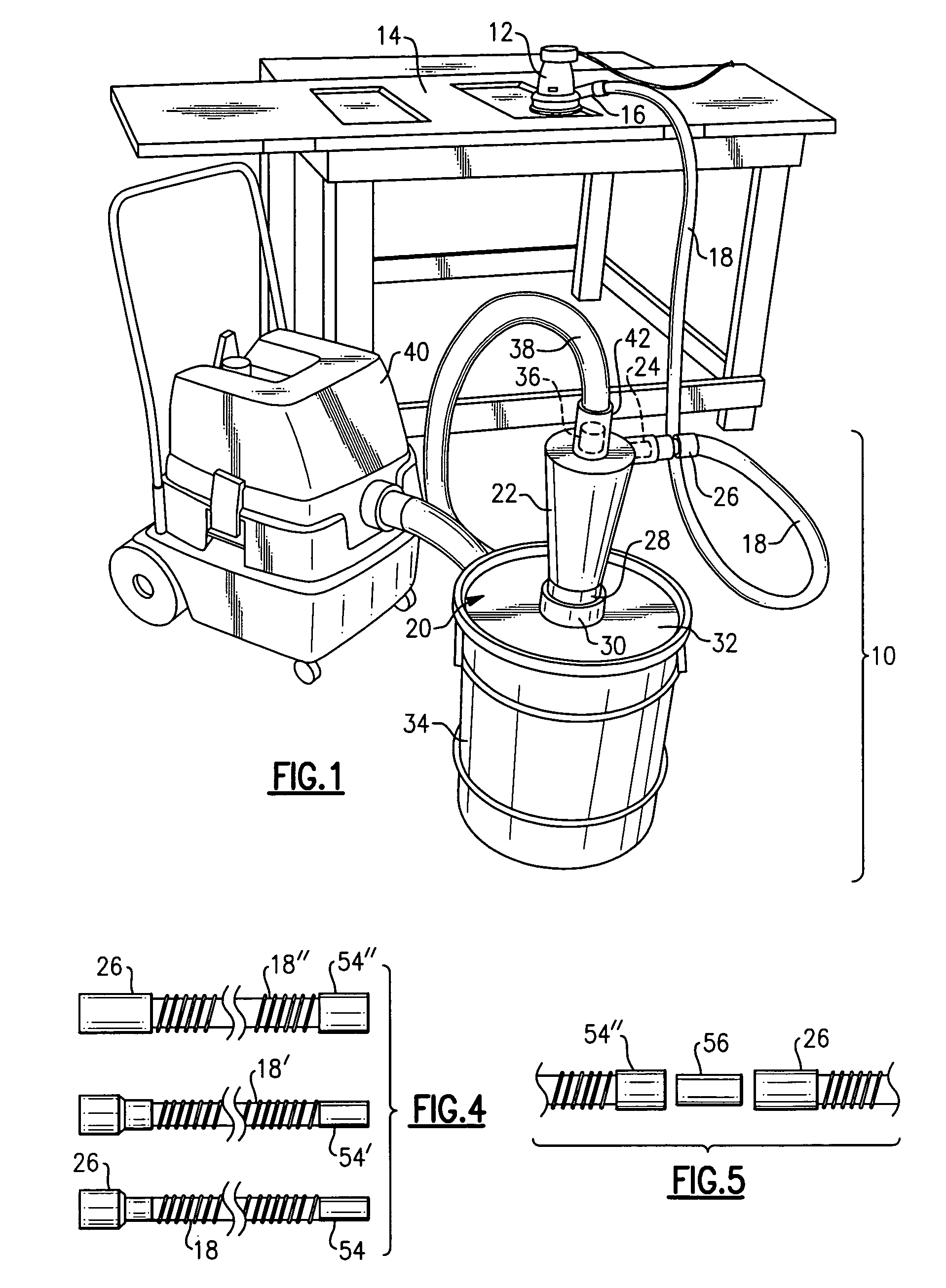

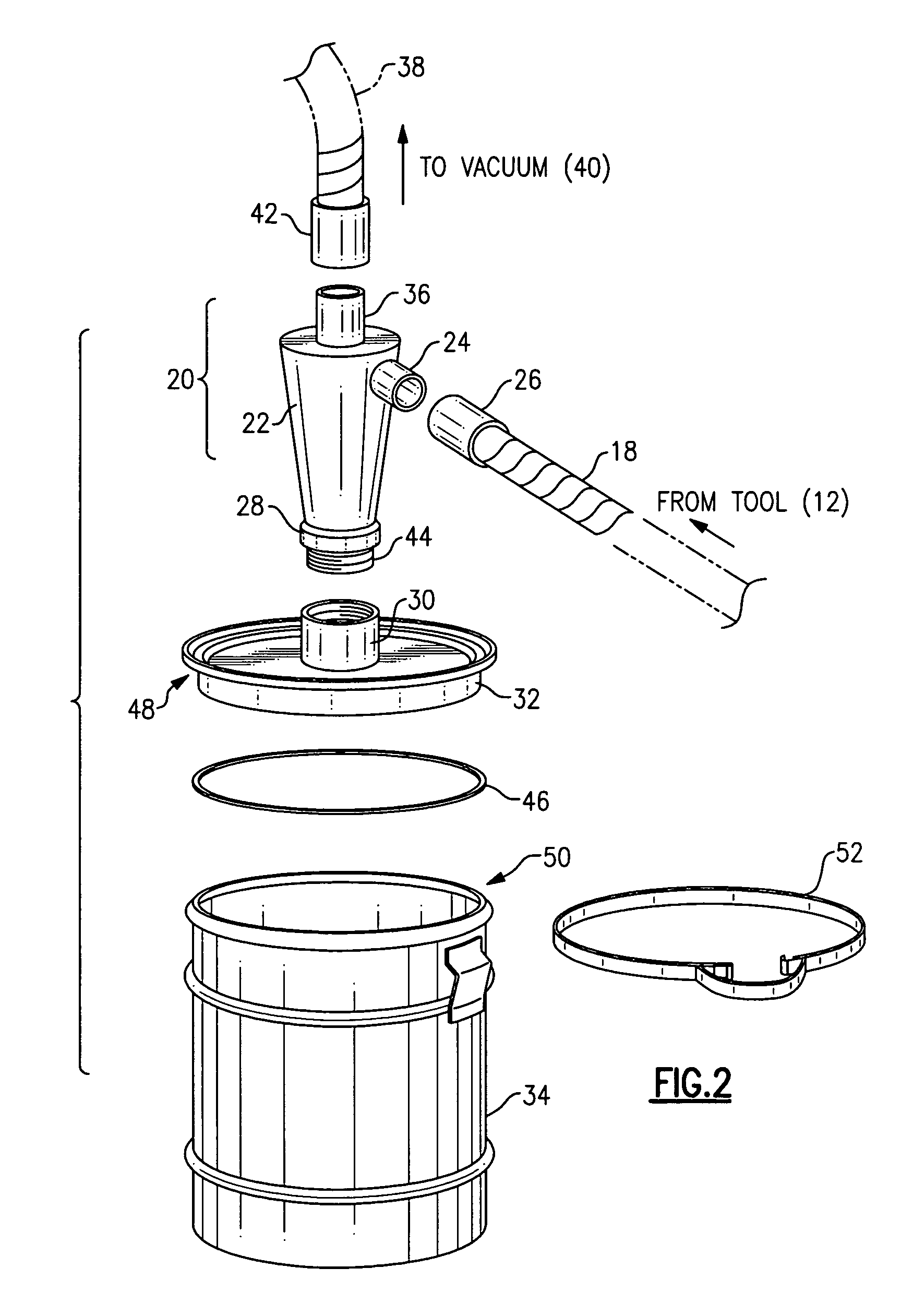

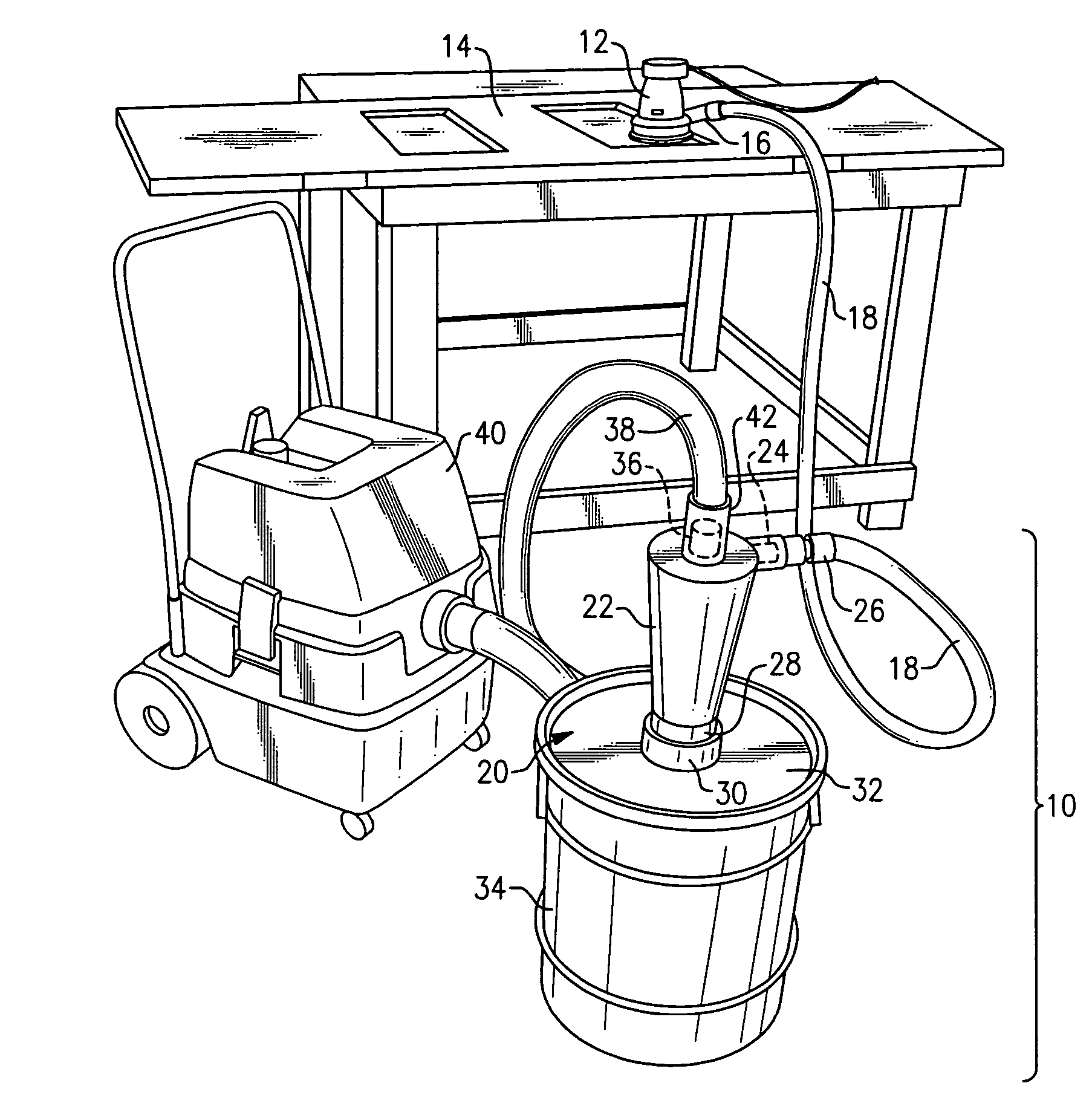

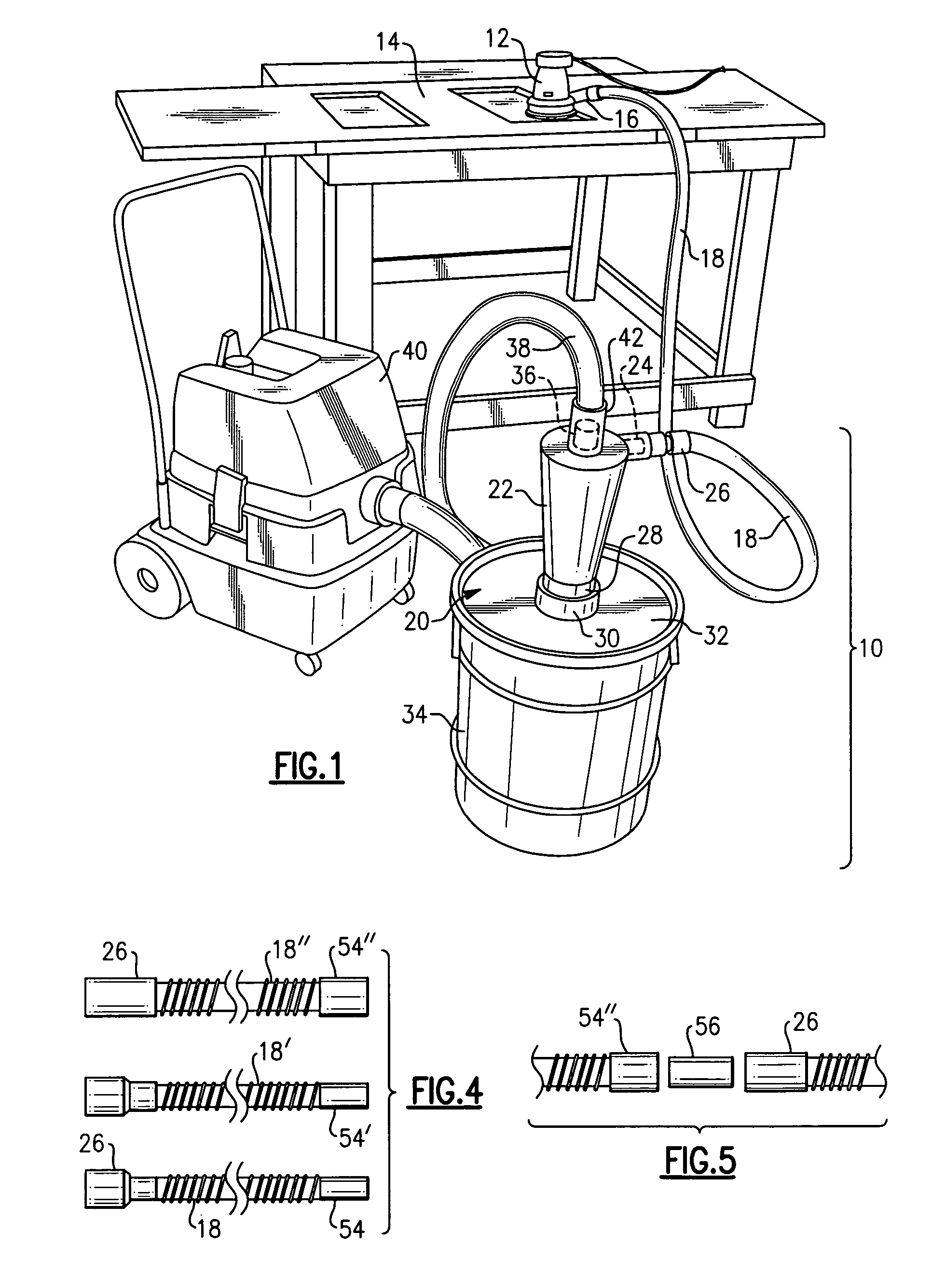

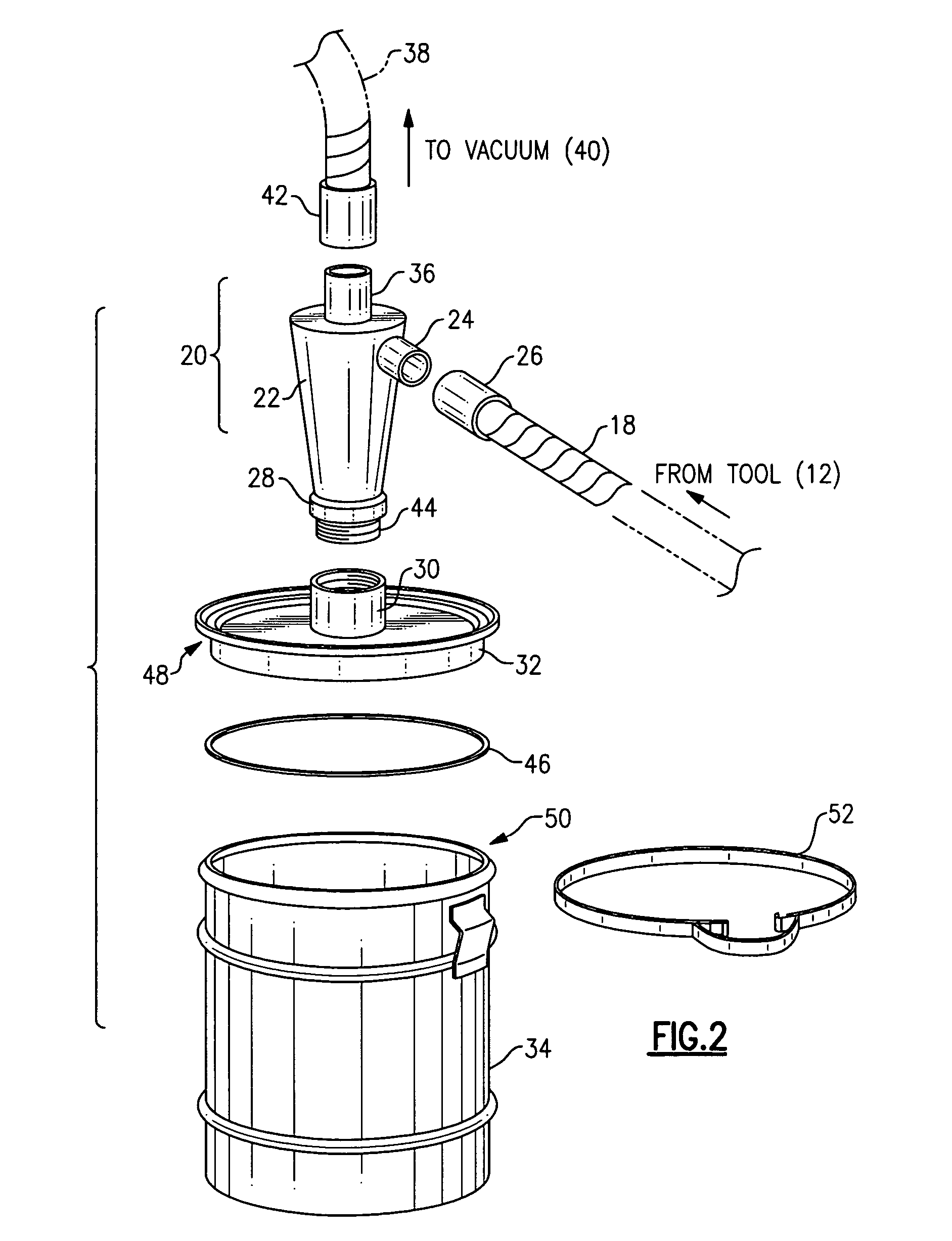

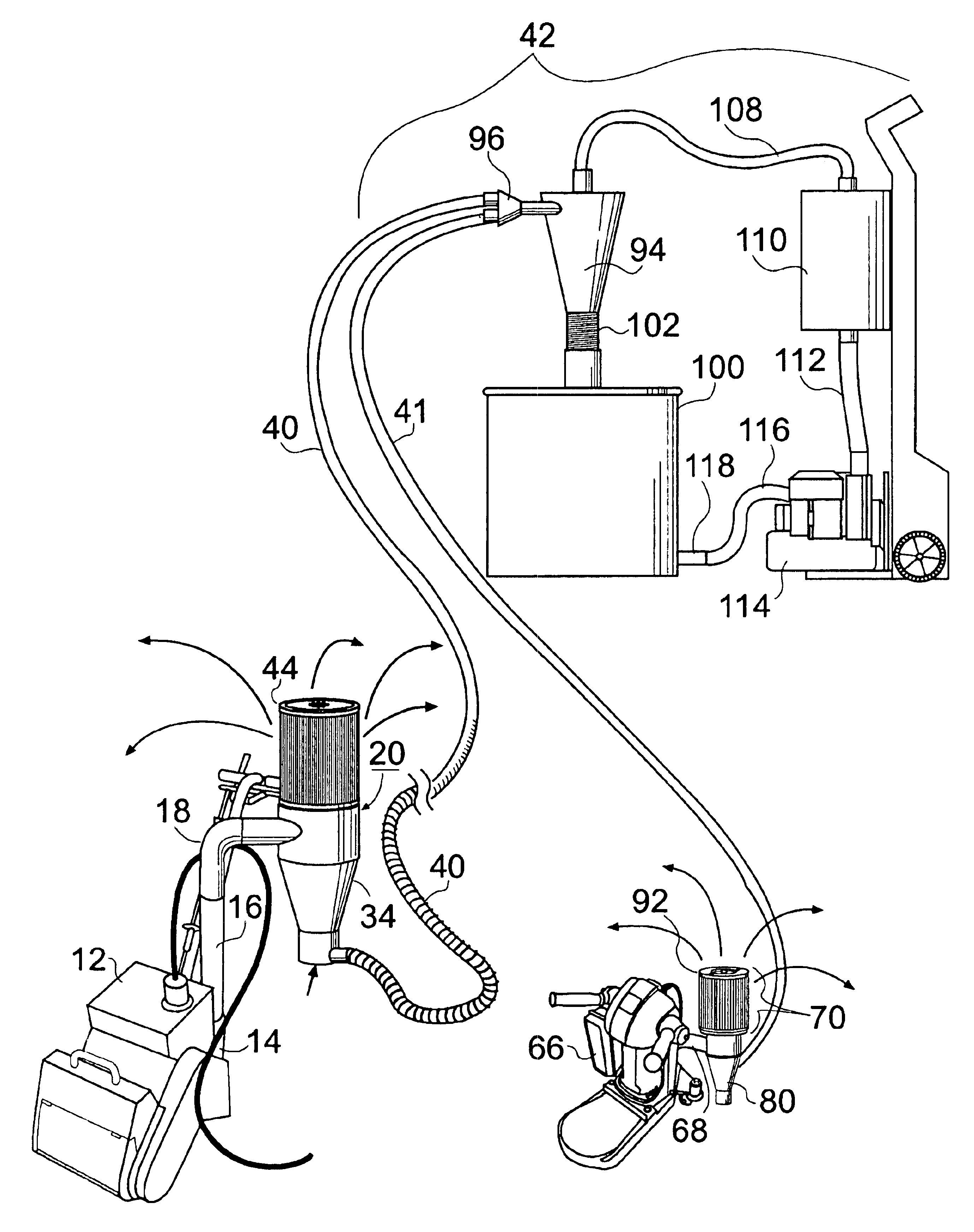

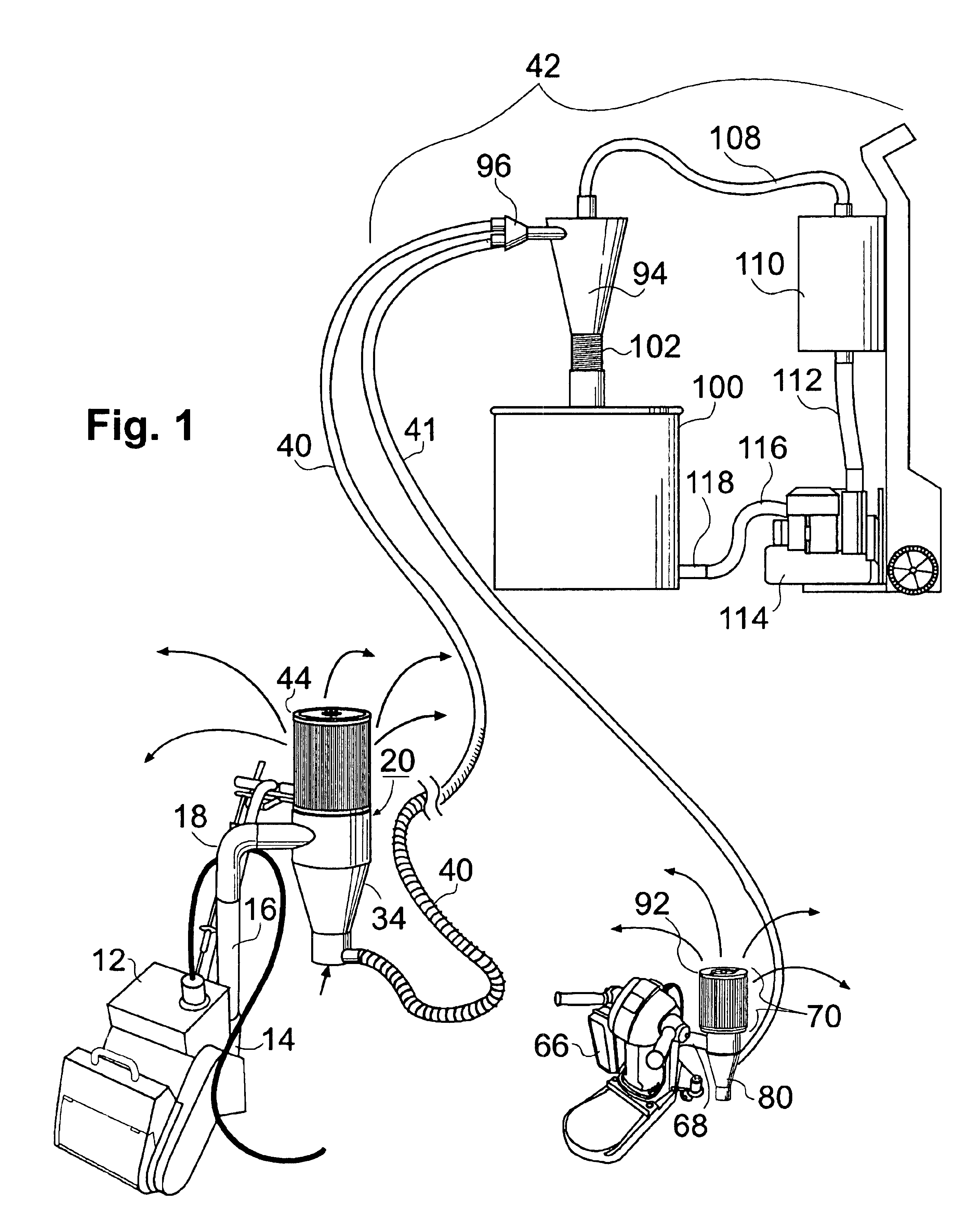

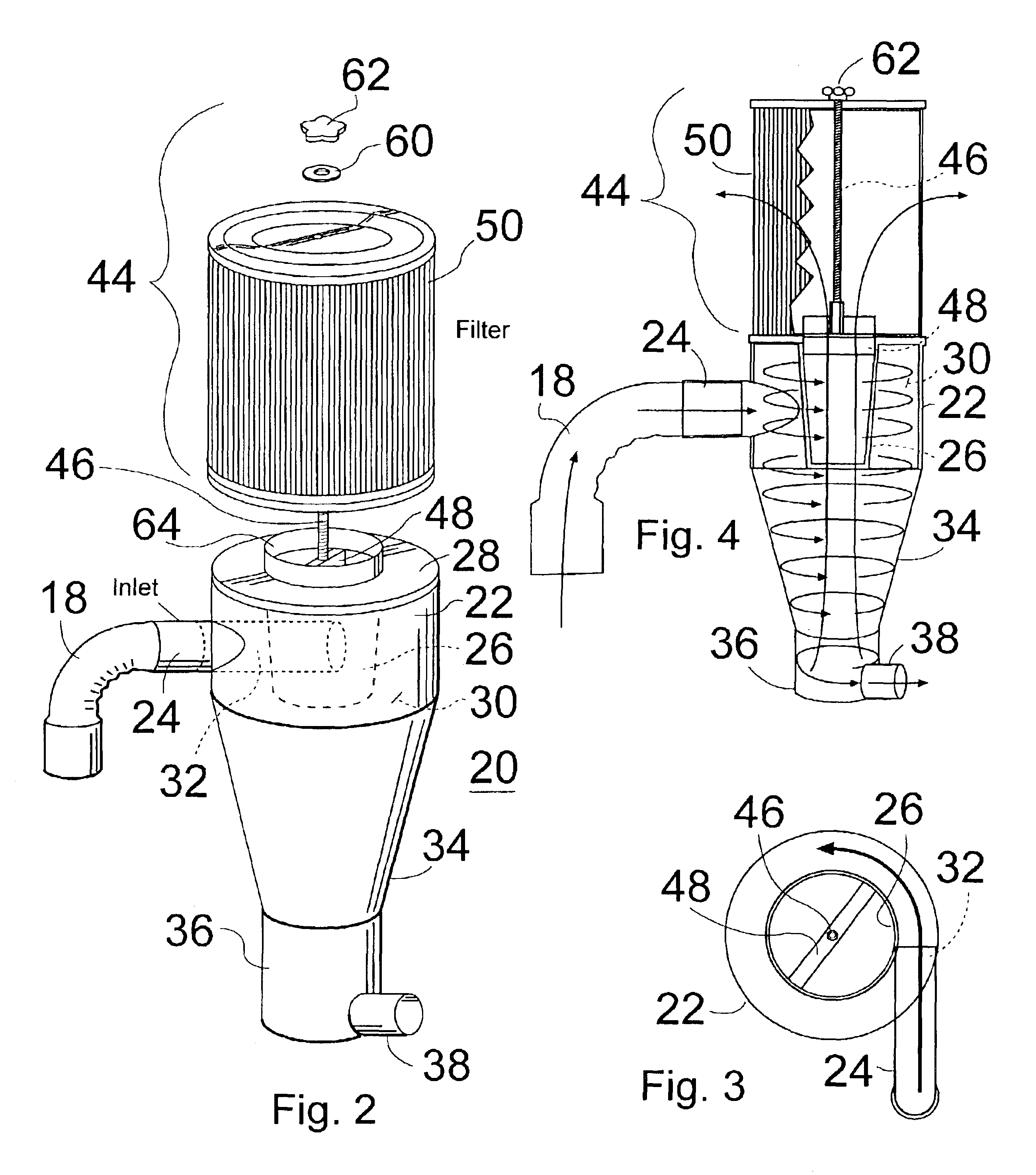

Auxiliary dust collection system

ActiveUS7282074B1Simple and straightforward in constructionImprove reliabilityCombination devicesReversed direction vortexSanderProcess noise

An auxiliary dust collection system can be interposed between a sander or other dust producing tool and a vacuum source, e.g., shop vacuum. This auxiliary system has a cyclonic separator connected by a flexible hose to the tool and by another hose to the vacuum source. The cone of the separator is mounted onto the lid of a drum into which the dust precipitates. For a tool that has its own blower, the vacuum source can be omitted, and the air leaving the outlet duct of the separator can be filtered and returned to the ambient. A drop in silencer formed of a sleeve or tube of acoustic foam can be positioned into the inlet side of a filter cartridge following a cyclonic separator. The silencer absorbs a significant fraction of the process noise.

Owner:WITTER ROBERT M

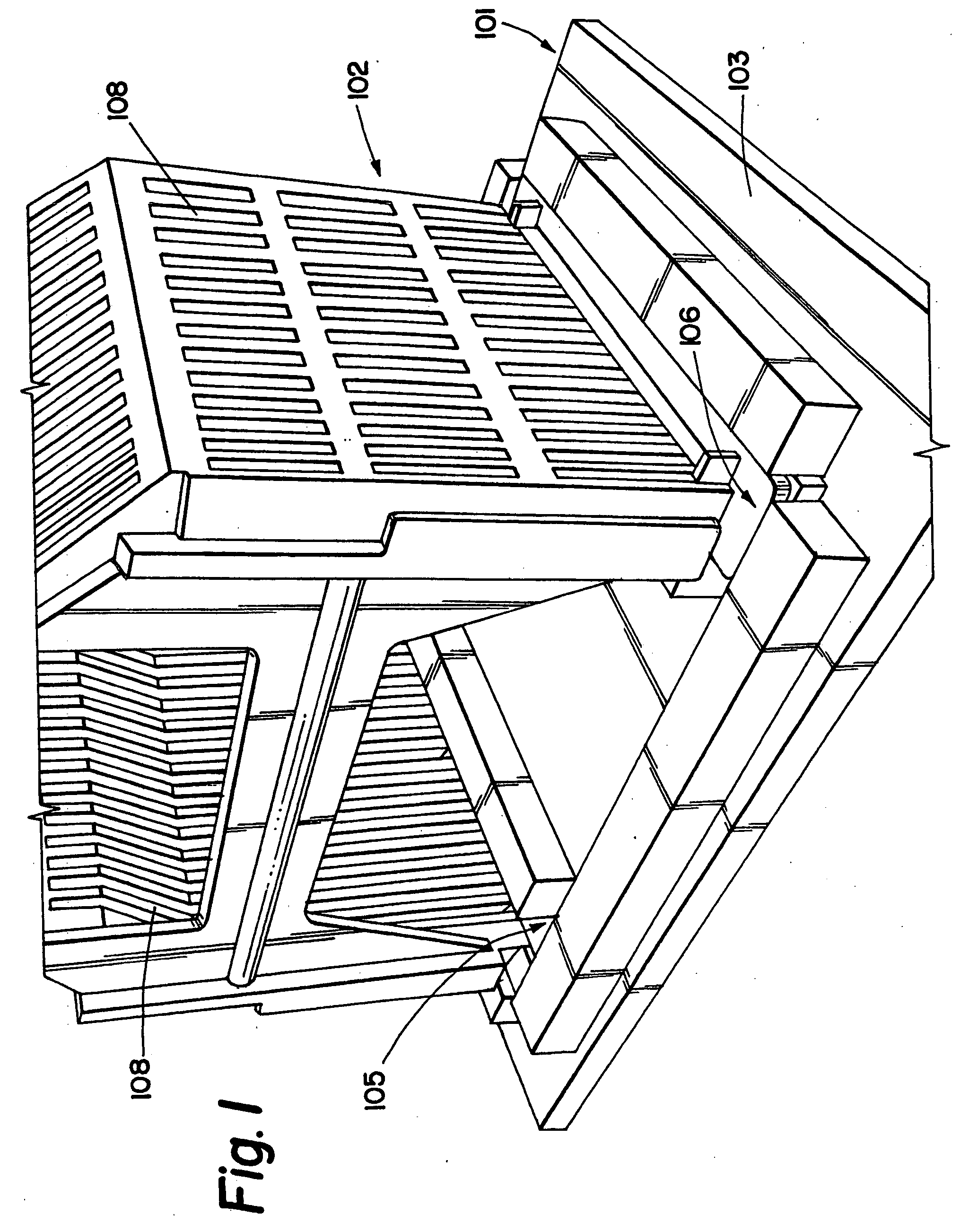

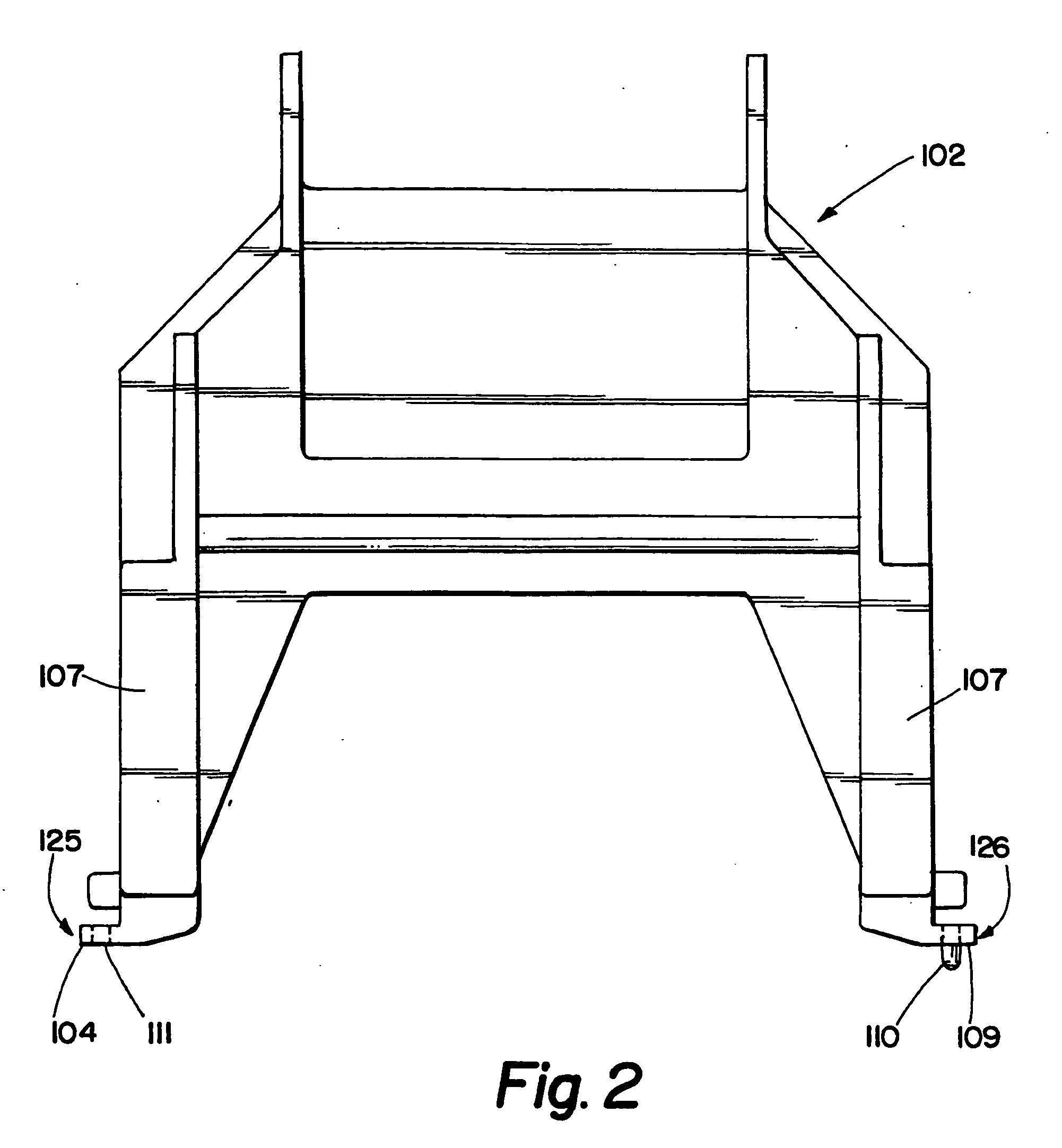

Polishing pad conditioning system

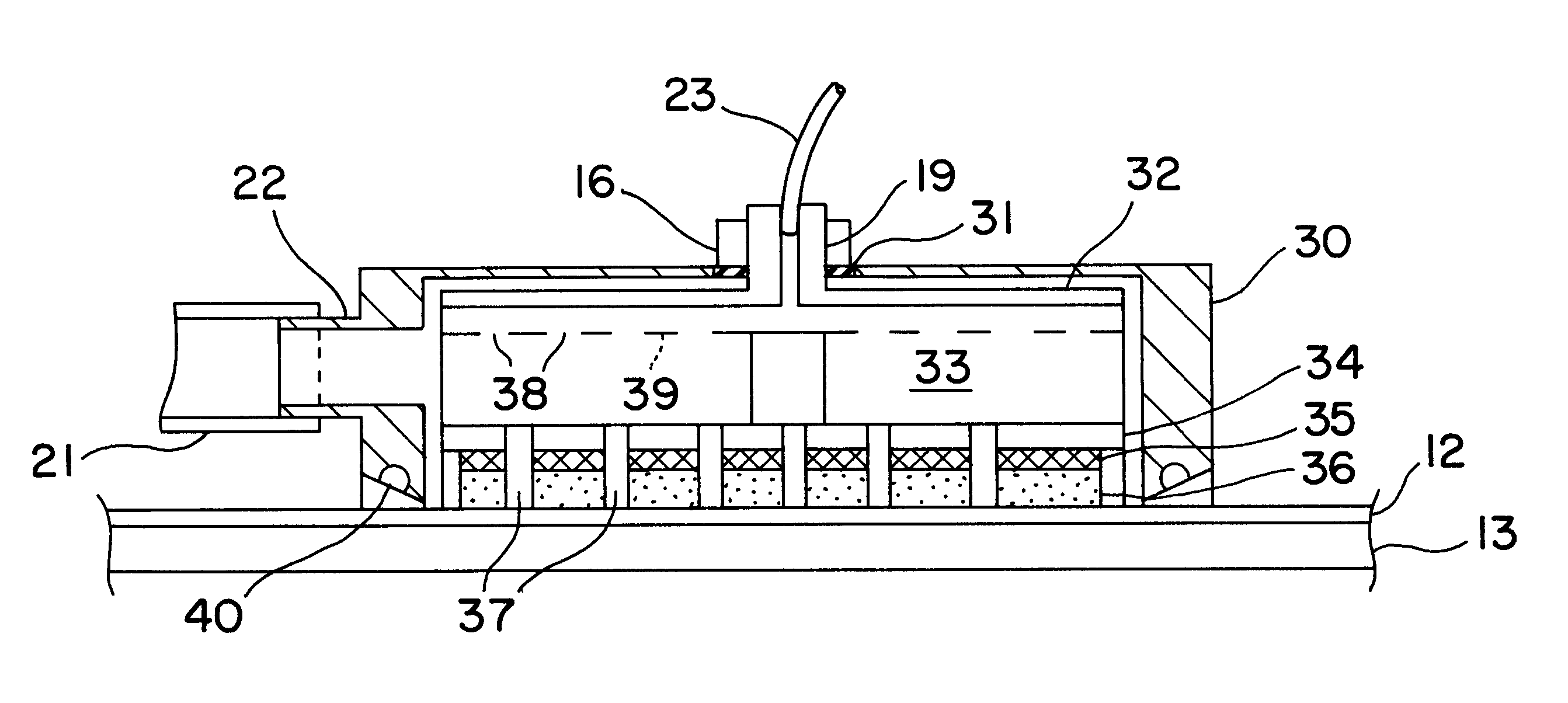

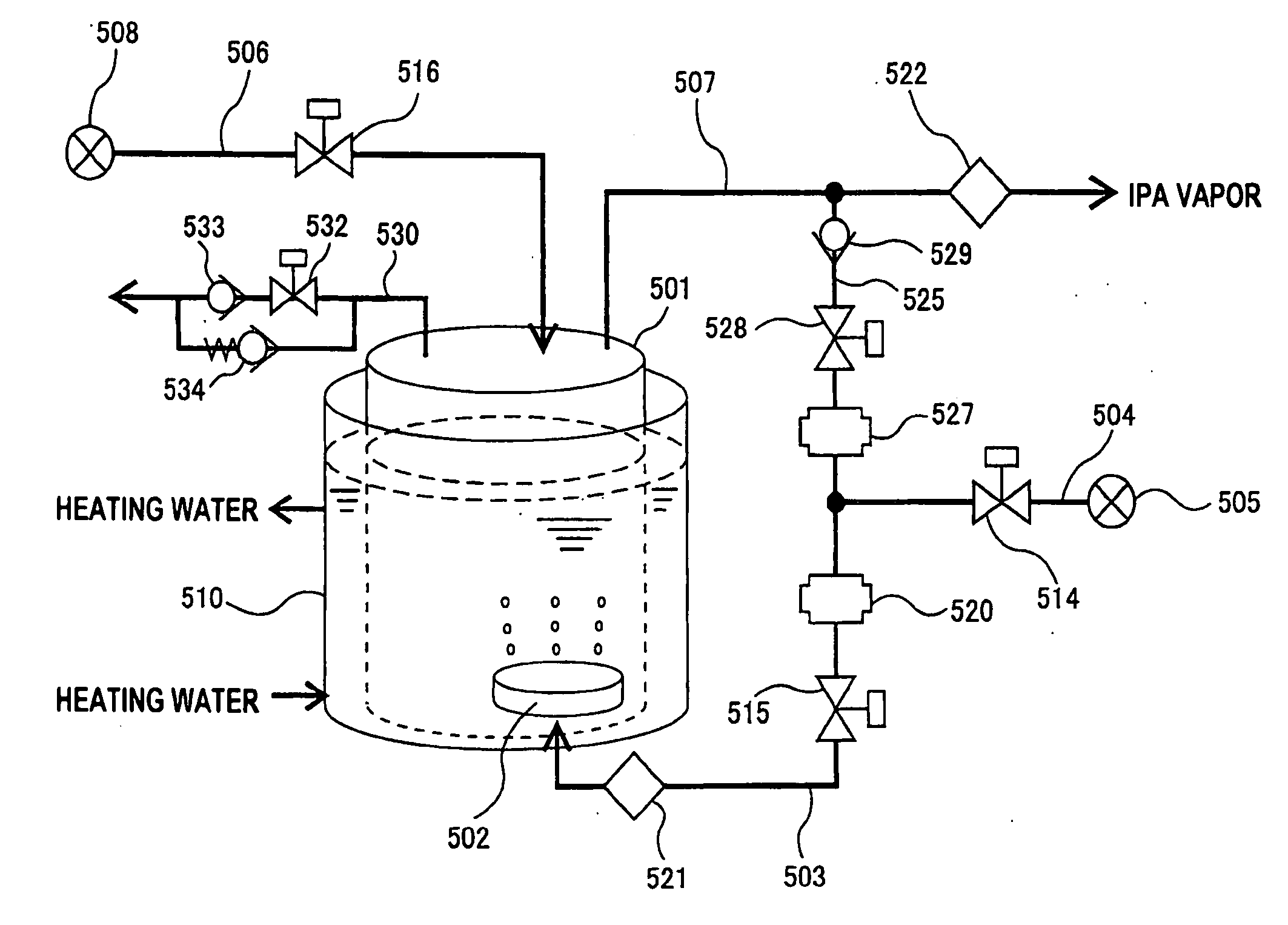

InactiveUS6508697B1Polishing machinesRevolution surface grinding machinesPiezo electricWaste material

A system for conditioning rotatable polishing pads used to planarize and polish surfaces of thin film integrated circuits deposited on semiconductor wafer substrates, microelectronic, and optical system. The system has a pad conditioning apparatus, process fluids, a vacuum capability to pull waste material out of the conditioning pad, self-contained flushing means, and a piezo-electric device for vibrating the pad conditioning apparatus.

Owner:BENNER ROBERT LYLE +2

Auxiliary dust collection system

ActiveUS20070251198A1Avoid disadvantagesSimple and straightforward in constructionCombination devicesReversed direction vortexSanderProcess noise

Owner:WITTER ROBERT M

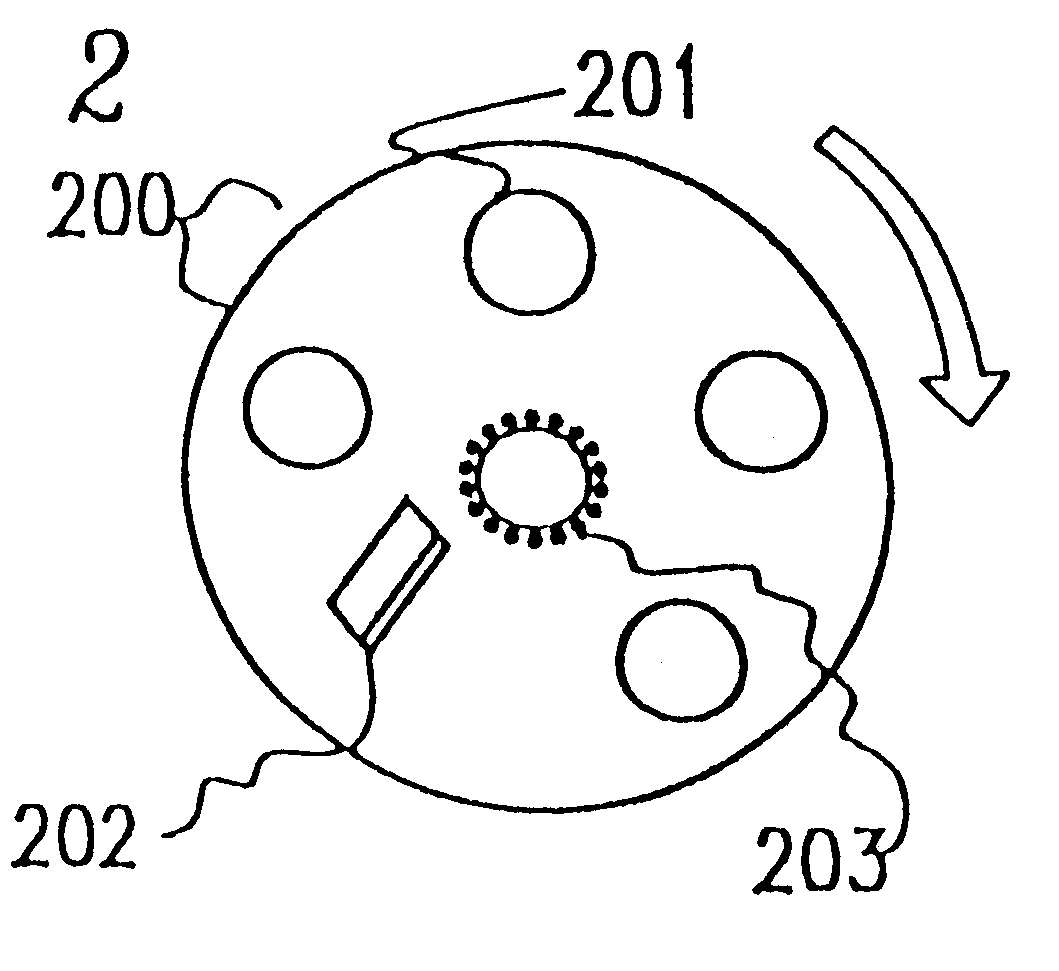

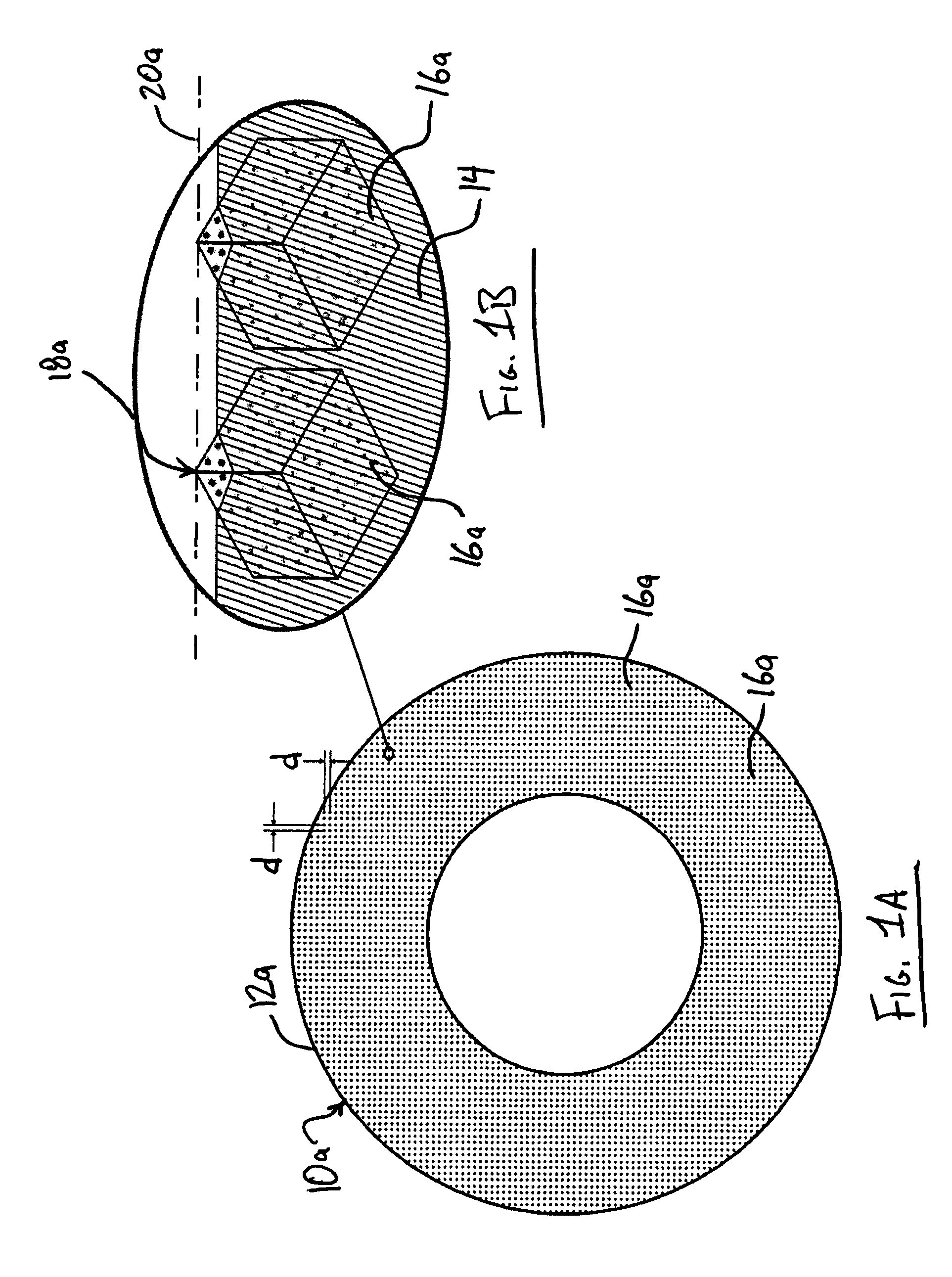

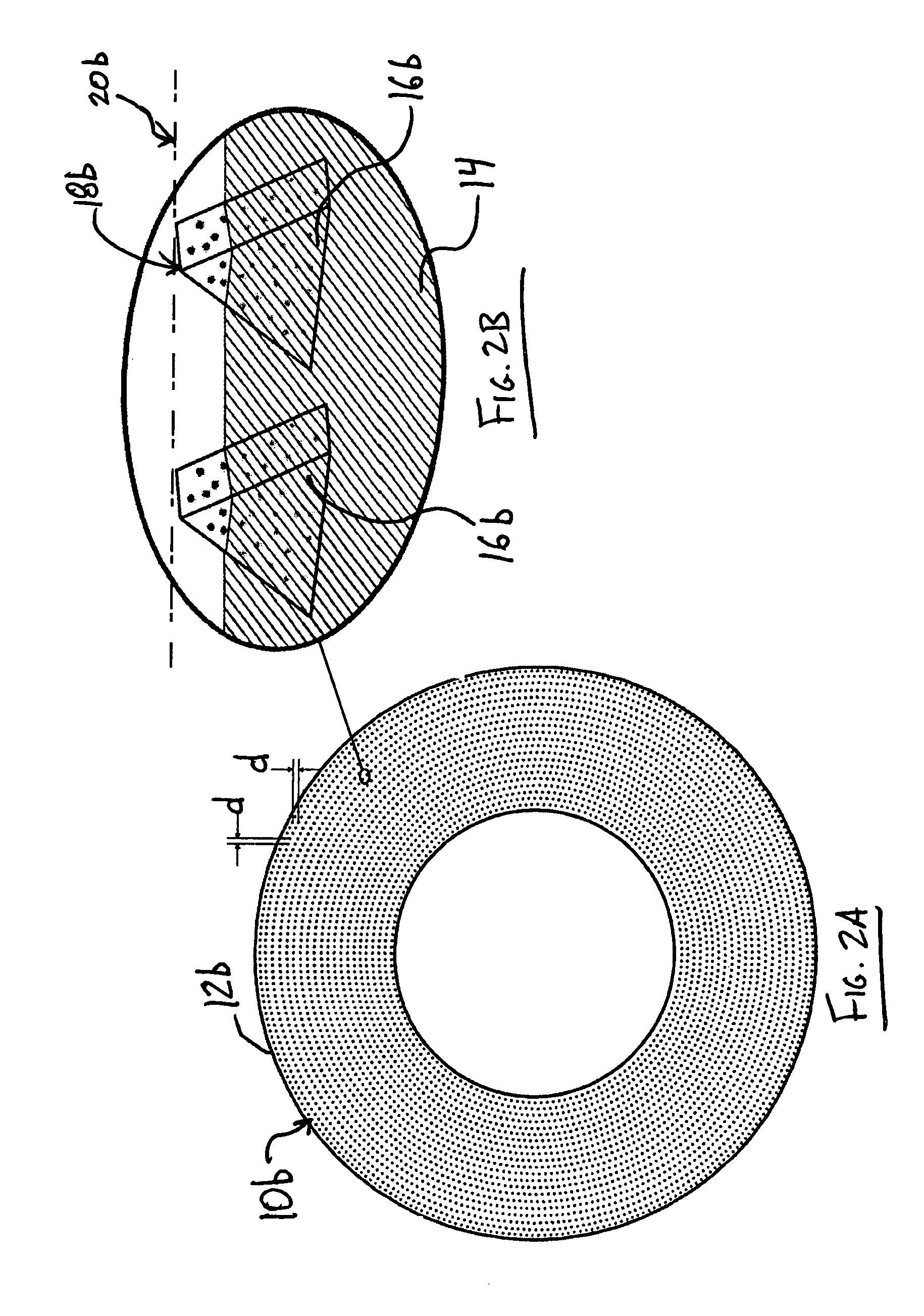

Sanding disks

InactiveUS6312325B1Risk minimizationProtect from harmRevolution surface grinding machinesSupport wheelsAngle grinderEngineering

Accessories for an angle grinder include a disposable rotary sanding disk having quite large shaped ventilating / viewing apertures, for use with a resilient backing plate also having shaped ventilating apertures. The apertures of one or both parts are shaped so that snagging of the apertures on projections from the work surface is minimized and to facilitate air flow across the work surface during use. This air flow helps in cooling the work and ejecting detritus, so minimising clogging effects. The ventilating apertures also facilitate viewing the work to be sanded through the spinning disk during the abrasion process, so that operator feedback is immediate. The holes also give the sanding disk more resilience so that a greater area comes in contact with the work and the disk wears more evenly over its abrasive surface.

Owner:MORTON CO

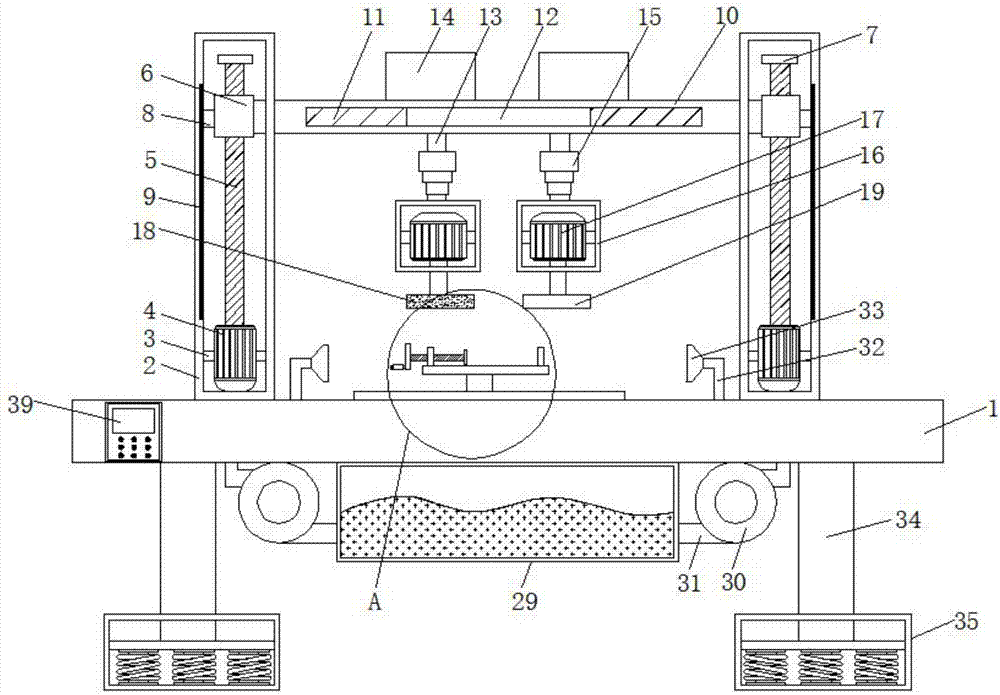

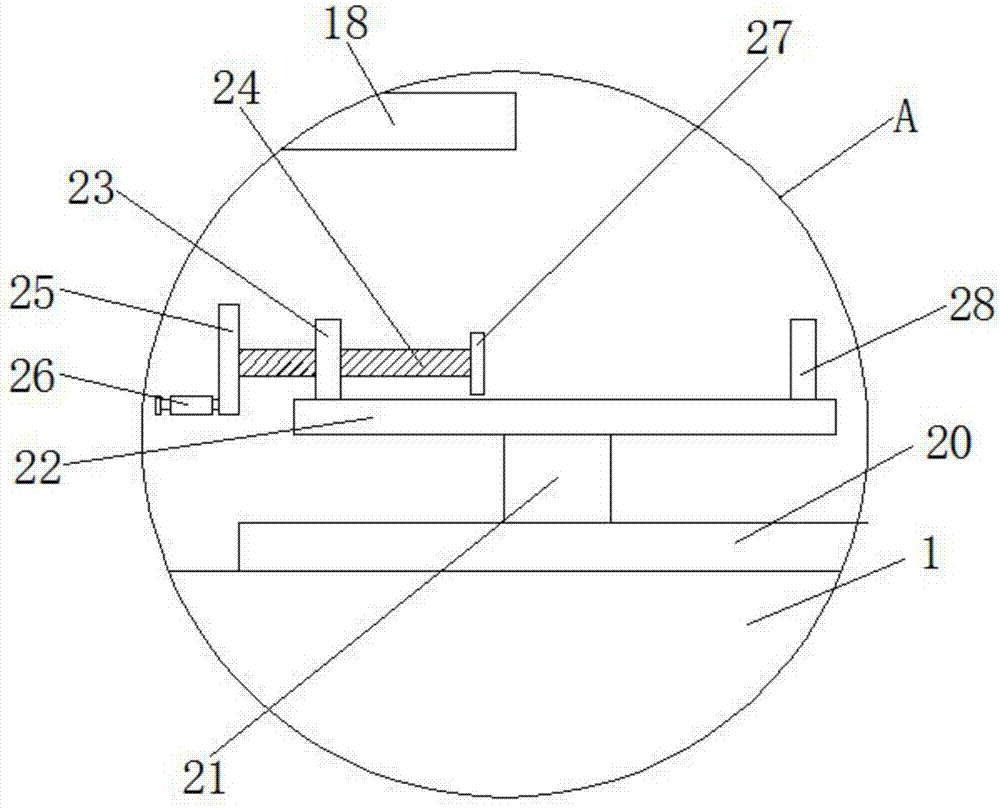

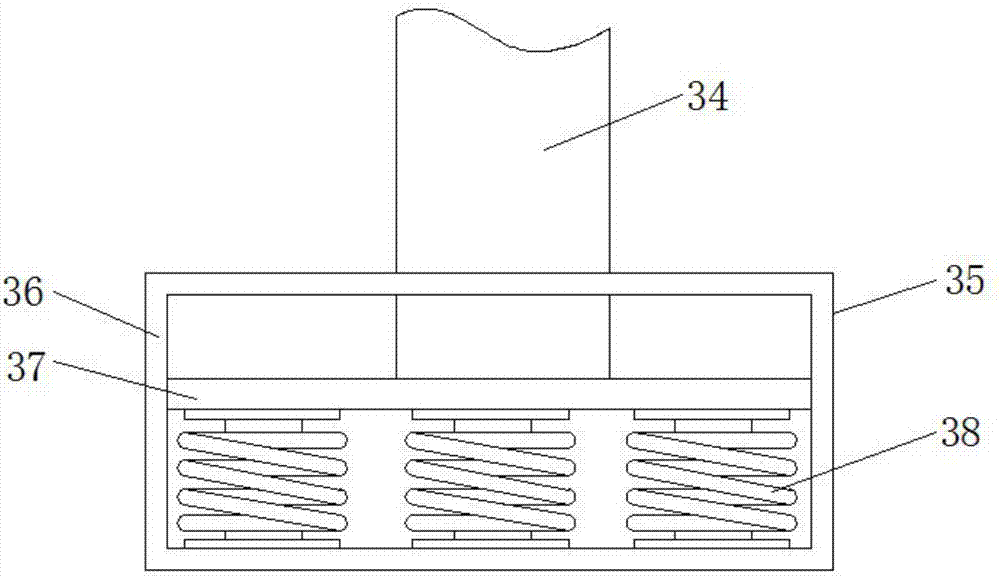

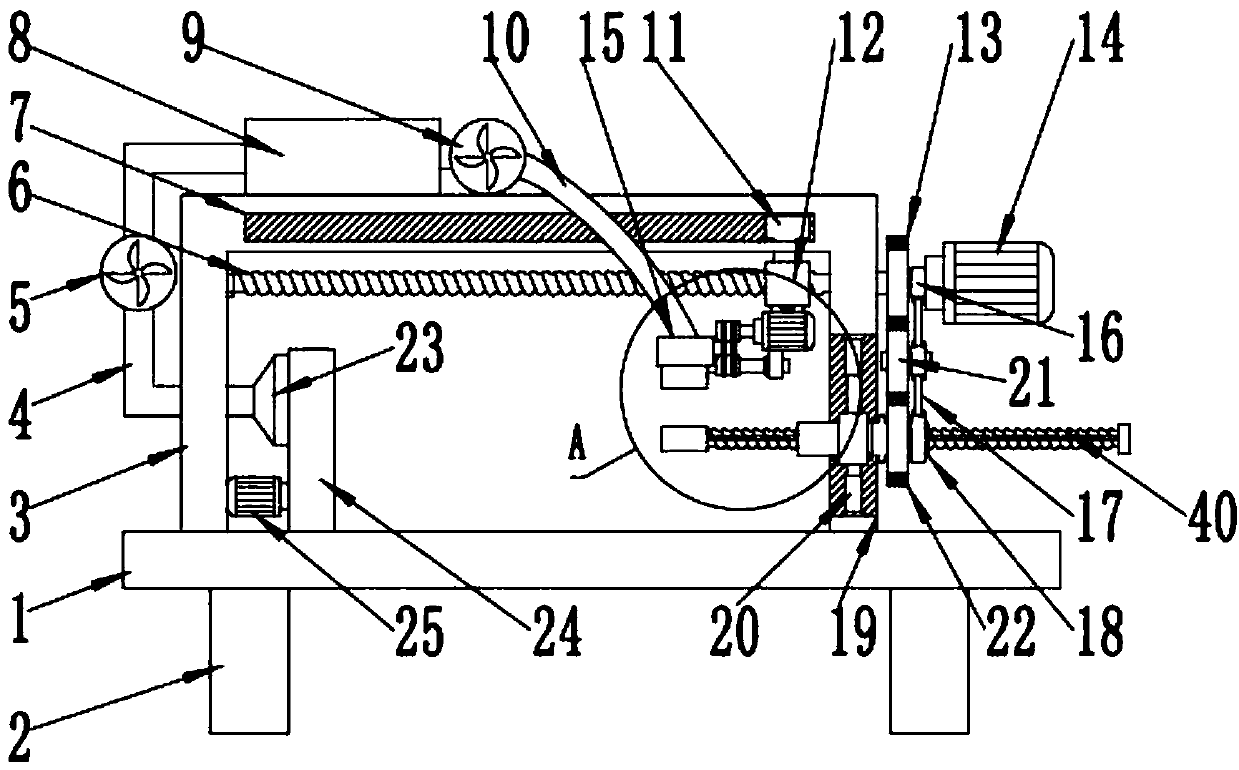

Automobile gear end surface polishing device

InactiveCN107336096AQuality improvementEasy to polishGrinding carriagesGrinding work supportsGear wheelEngineering

The invention provides an automobile gear end surface polishing device, and relates to the technical field of automobile gear polishing. The automobile gear end surface polishing device comprises a working table, standing columns are fixedly installed on both sides of the top of the working table, and motor mounting blocks are fixedly installed on both sides of the inner wall of each standing column. According to the automobile gear end surface polishing device, through arrangement of telescopic motors, threaded rods, telescopic blocks, sliding rods, a strip-shaped sliding groove and a cross plate, a polishing device body on the bottom of the cross plate can vertically move between the two standing columns under driving of the telescopic motors; through arrangement of the cross plate, the sliding groove and supports, the polishing device body on the bottom of the cross plate can transversely move on the bottom of the cross plate; through arrangement of a polishing table, a rotating rod and a clamping base, a gear to be polished which is fixed to the top of the clamping base in a clamped mode can conduct circular motion on the bottom of a polishing motor under driving of the rotating rod. In sum, by means of the automobile gear end surface polishing device, the effect that adjustment is convenient is achieved, it is convenient for people to polish the end surface of the gear from different angles, and the quality of the gear after polished is better.

Owner:姚飞

Dust collection system

InactiveUS6833016B2Reduced Power RequirementsReduce the risk of explosionCombination devicesReversed direction vortexCycloneCollection system

Owner:WITTER ROBERT M

Method for recycling silica powder and carborundum powder from cut waste mortar

The invention discloses an extracting method of high-purity silicon powder and carborundum powder from waste slurry of monocrystalline silicon cutting or grinding course, which comprises the following steps: separating solid from liquid for the waste slurry; using organic solvent to remove suspending agent and adhesive; doing gas float for solid sand; obtaining certain purity silicon powder; doing liquid float and gravity sorting for the silicon powder further; acidifying the silicon powder through acid; obtaining high-purity silicon powder; doing magnetic float for the composite powder of carborundum-metal through gravity; obtaining the pure carborundum powder. The invention can recycle high-purity silicon from waste slurry in the silicon bar cutting manufacturing course effectively, which changes waste into value with high receiving rate to solve the problem of resource shortage of high-purity silicon.

Owner:XI AN JIAOTONG UNIV

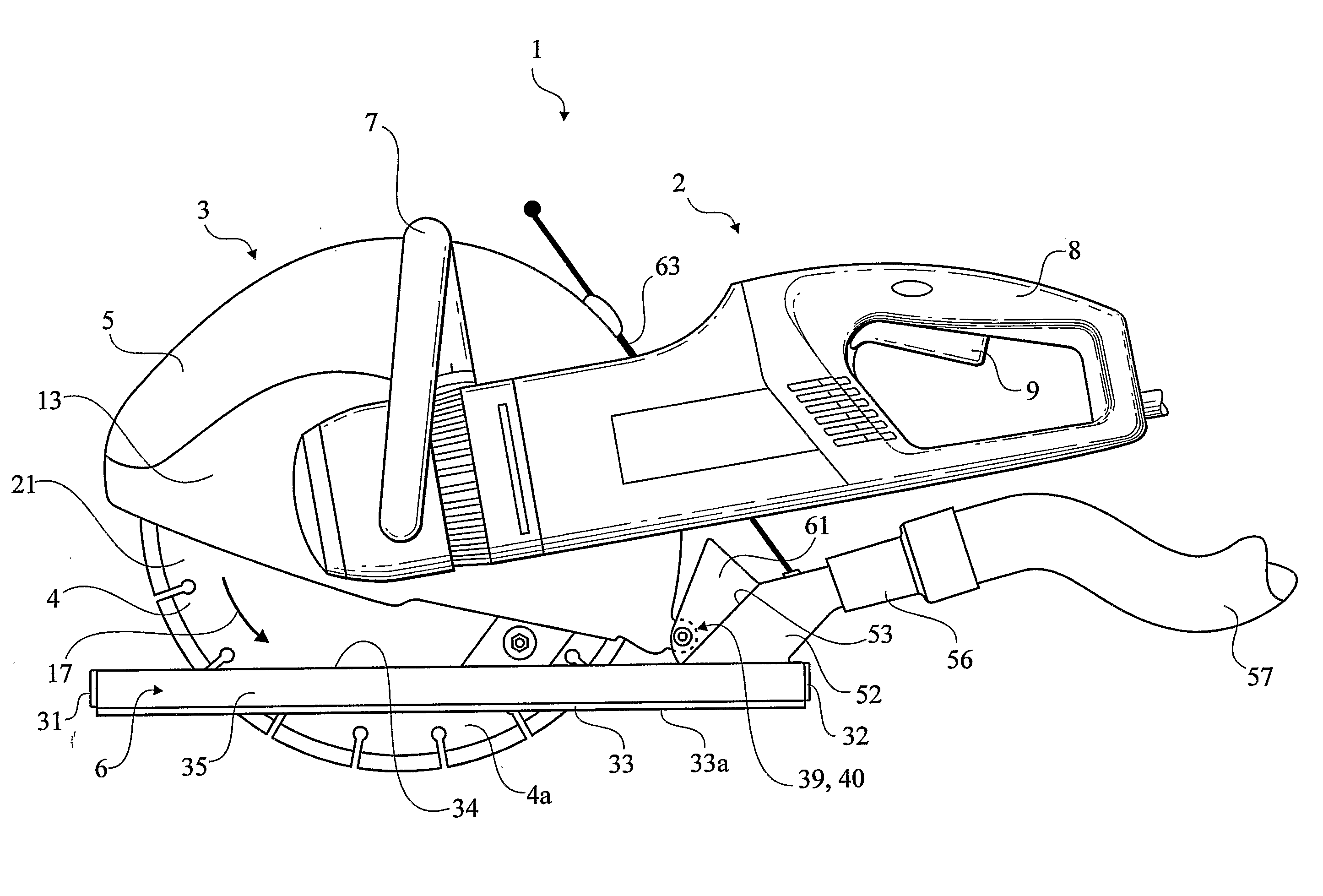

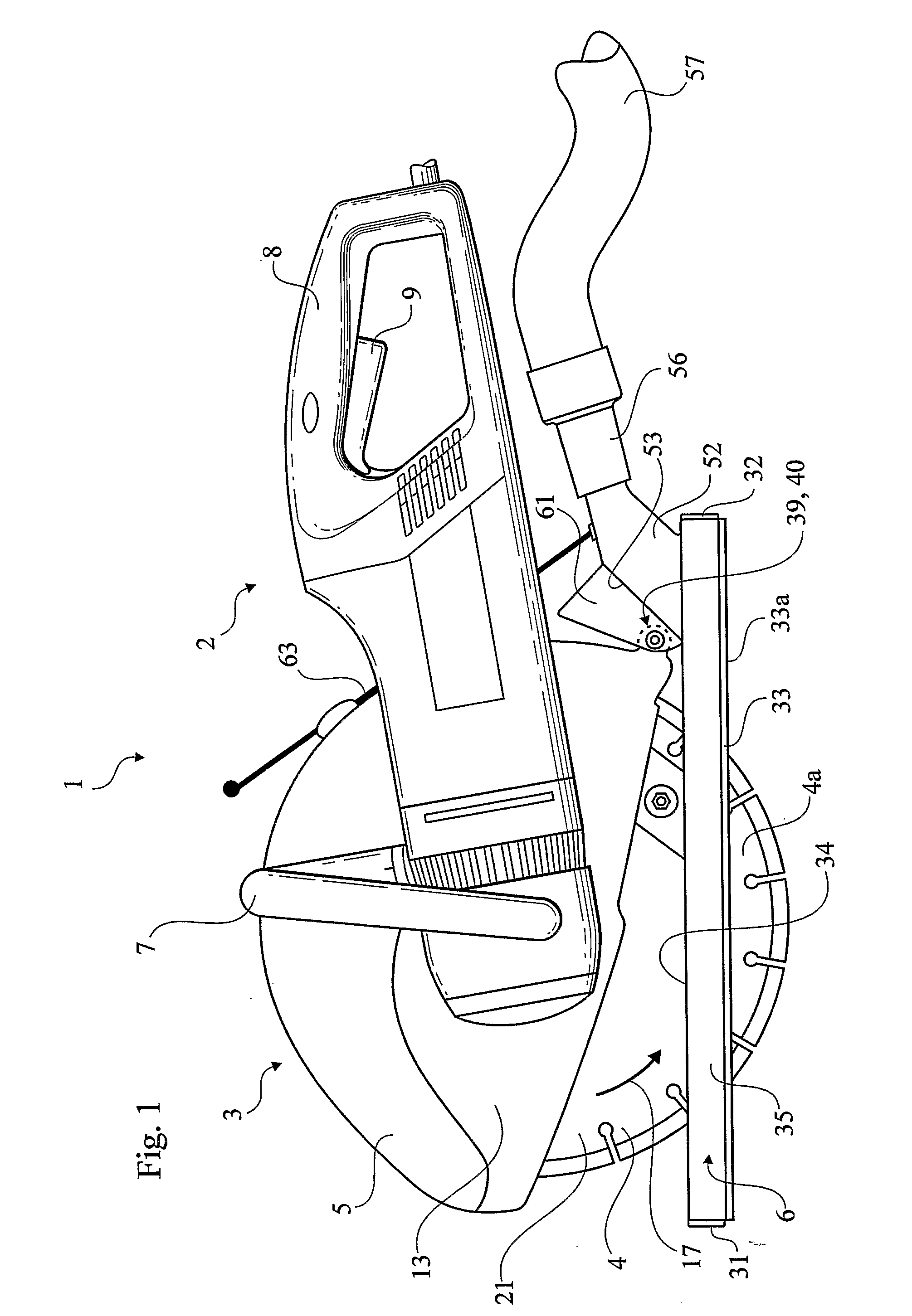

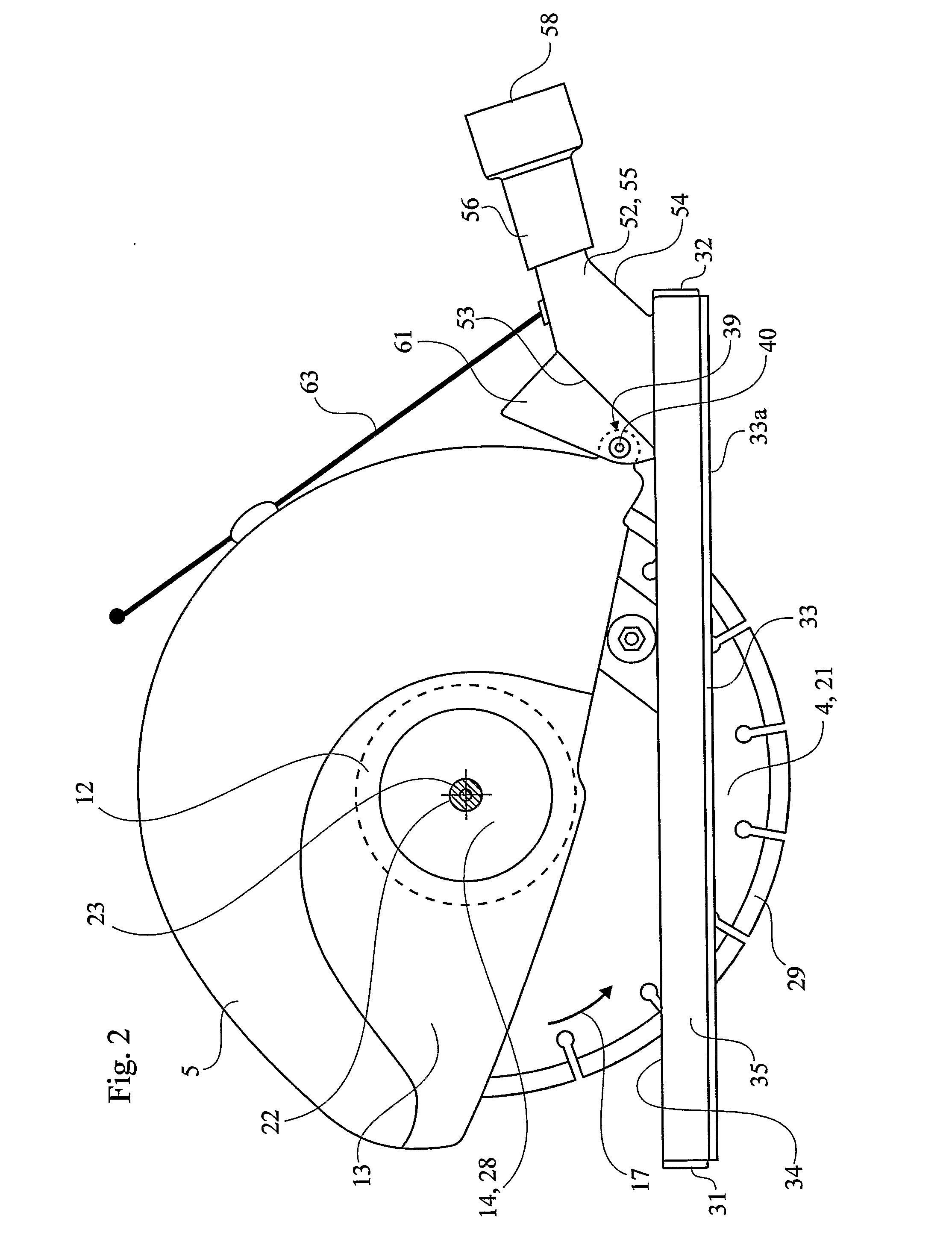

Cutting and Dust Collecting Assembly and Working Machine with Such Assembly

ActiveUS20080163492A1Avoid flyingEfficient collectionMetal sawing devicesMetal sawing accessoriesCircular sawDust control

A cutting and dust collecting assembly comprises a rotatable, circular saw blade (4) having a first side (20), a second side (21), and a cover device (6) with a terminal member (52). The bottom surface (36) of the cover device extends in a plane. A longitudinal passage (45, 46) for the saw blade extends through the cover device from its top surface to its bottom surface. The terminal member comprises a terminal chamber (60) having an inlet (45a), the mouth of which coincides with the plane of said bottom surface. An outlet (58) can be connected to a vacuum source. The direction of rotation of the operating blade is such that the rear part (4a) of the saw blade which has passed beyond the bottom surface of the cover device will move in a direction upwards-rearwards towards the bottom surface. The invention also concerns the cover device, a sealing body belonging to the cover device and a working machine which is provided with the cutting and dust collecting assembly.

Owner:HUSQVARNA AB

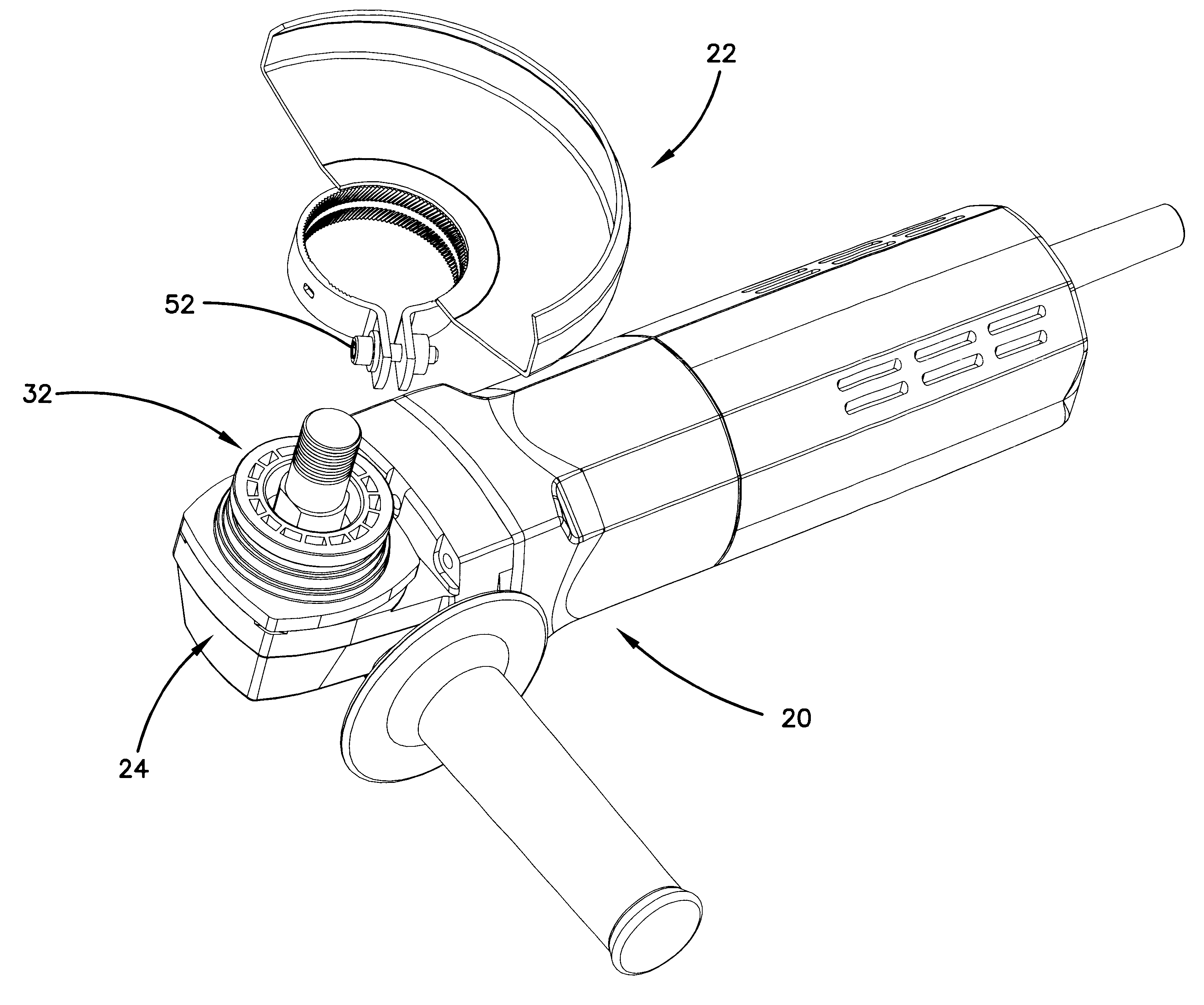

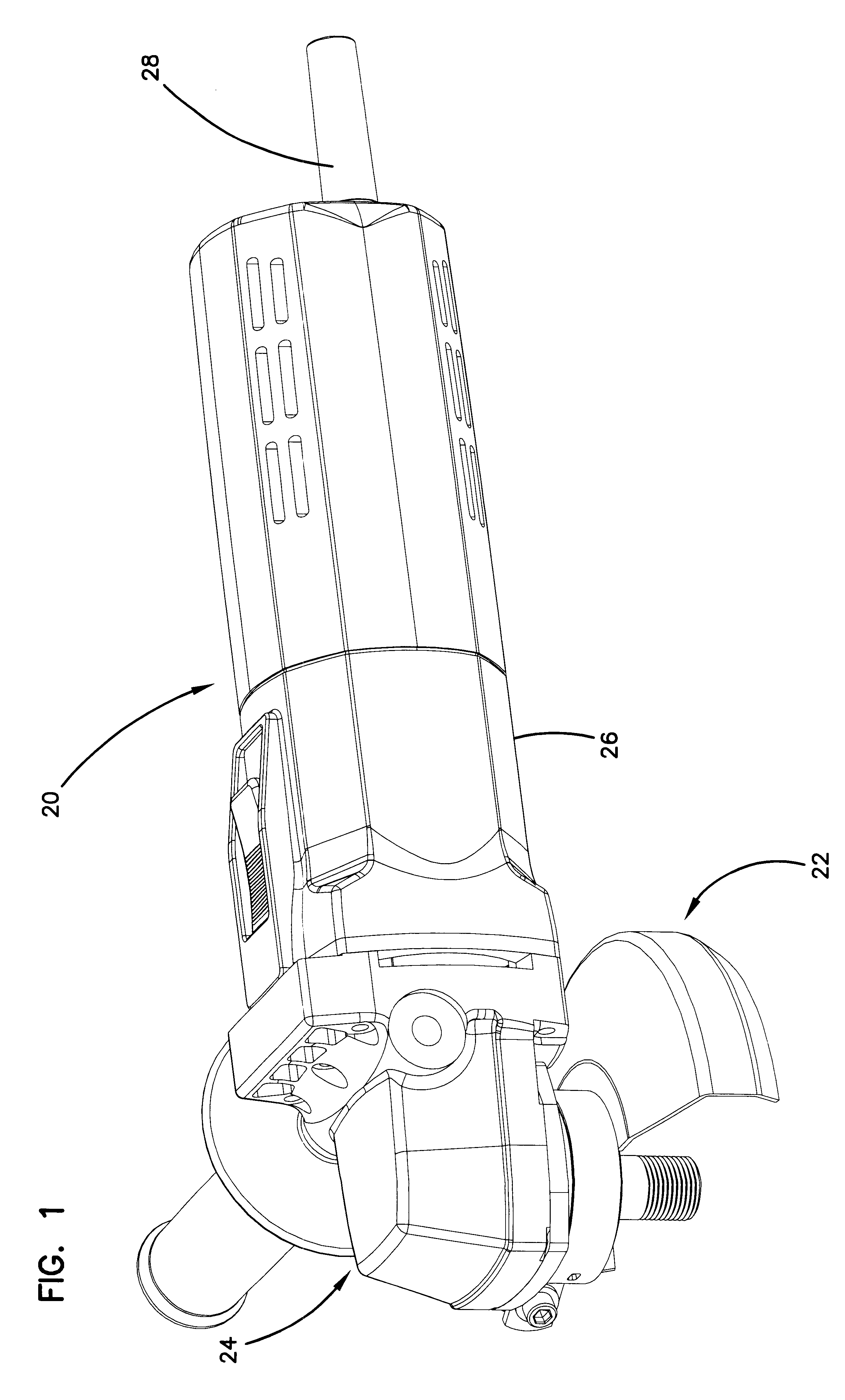

Guard attachment system with knurled clamp ring

InactiveUS6464573B1Portable grinding machinesMaintainance and safety accessoriesHand heldEngineering

A removable guard for a hand-held power tool. The guard is configured to cover an area proximate a spindle assembly of the tool between the spindle assembly and a user of the tool. The guard is further configured to be securely mounted to a semi-elastic lower bearing housing supporting the spindle assembly of the tool. The guard, when mounted to the semi-elastic lower bearing housing of the tool, and when in use during operation of the tool, must remain functional under conditions of flying debris, such as under conditions of an exploding, rotating abrasive grinding wheel mounted on the spindle assembly of the tool.The guard includes a clamp ring depending from a guard hood. The clamp ring's inner circumferential portion has at least a partially-knurled surface, whereby when securely tightened around the semi-elastic lower bearing housing, the at least partially-knurled surface of the clamp ring inner circumferential portion compresses into the semi-elastic lower bearing housing to securely mount the guard to the tool.

Owner:BLACK & DECKER INC

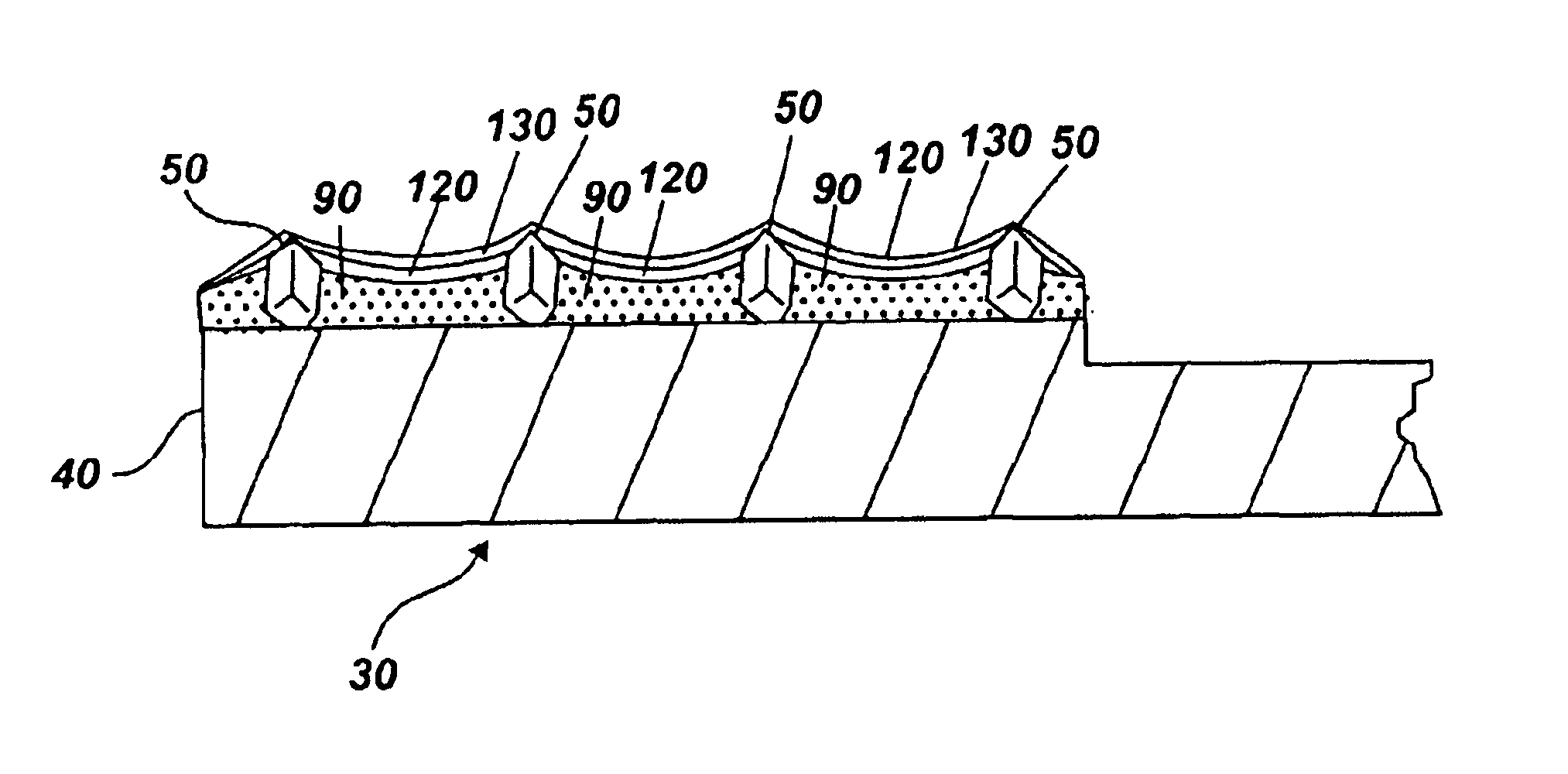

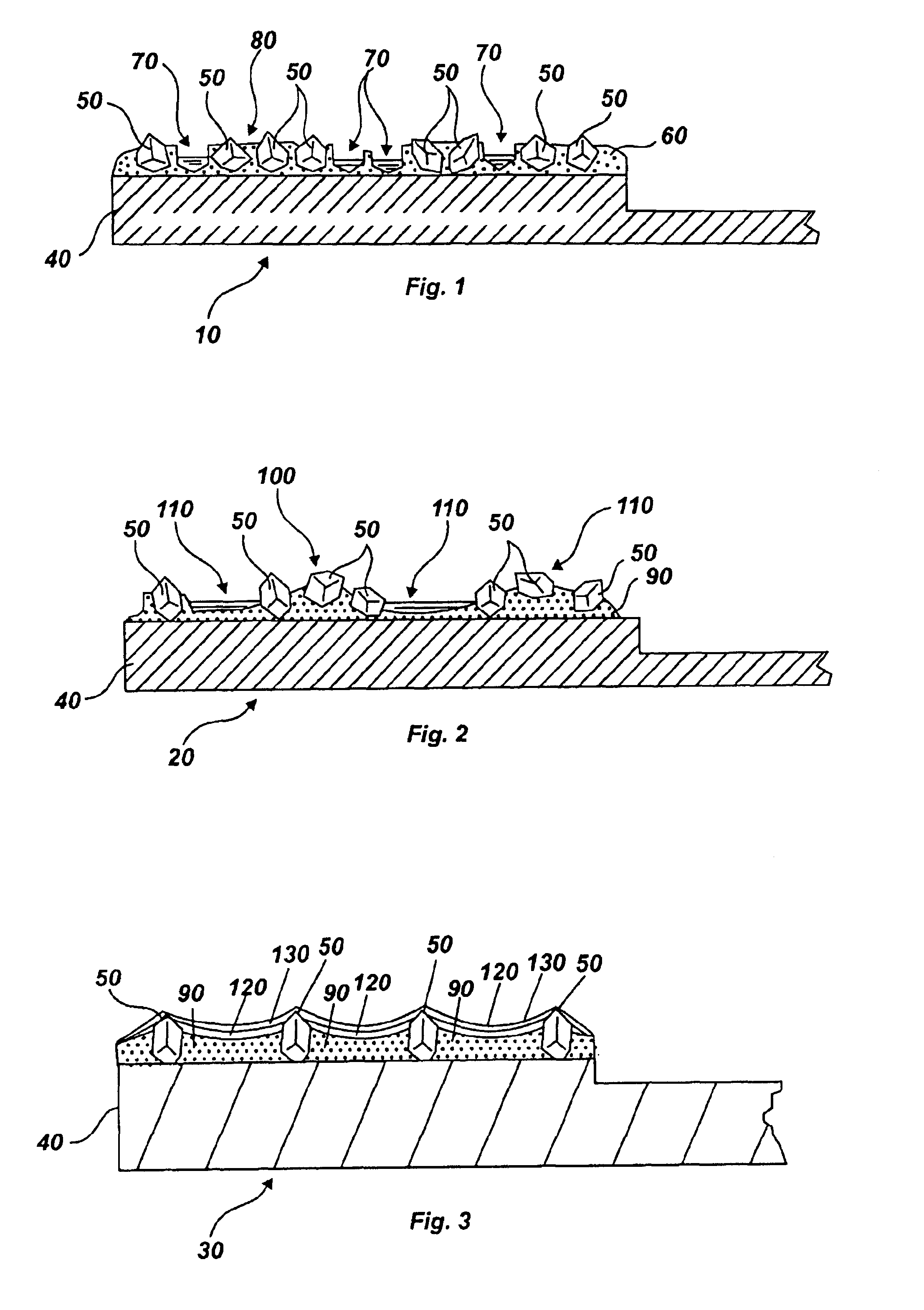

Contoured CMP pad dresser and associated methods

InactiveUS7201645B2Increase loadImprove permeabilityPolishing machinesRevolution surface grinding machinesEngineeringMechanical engineering

Owner:KINIK

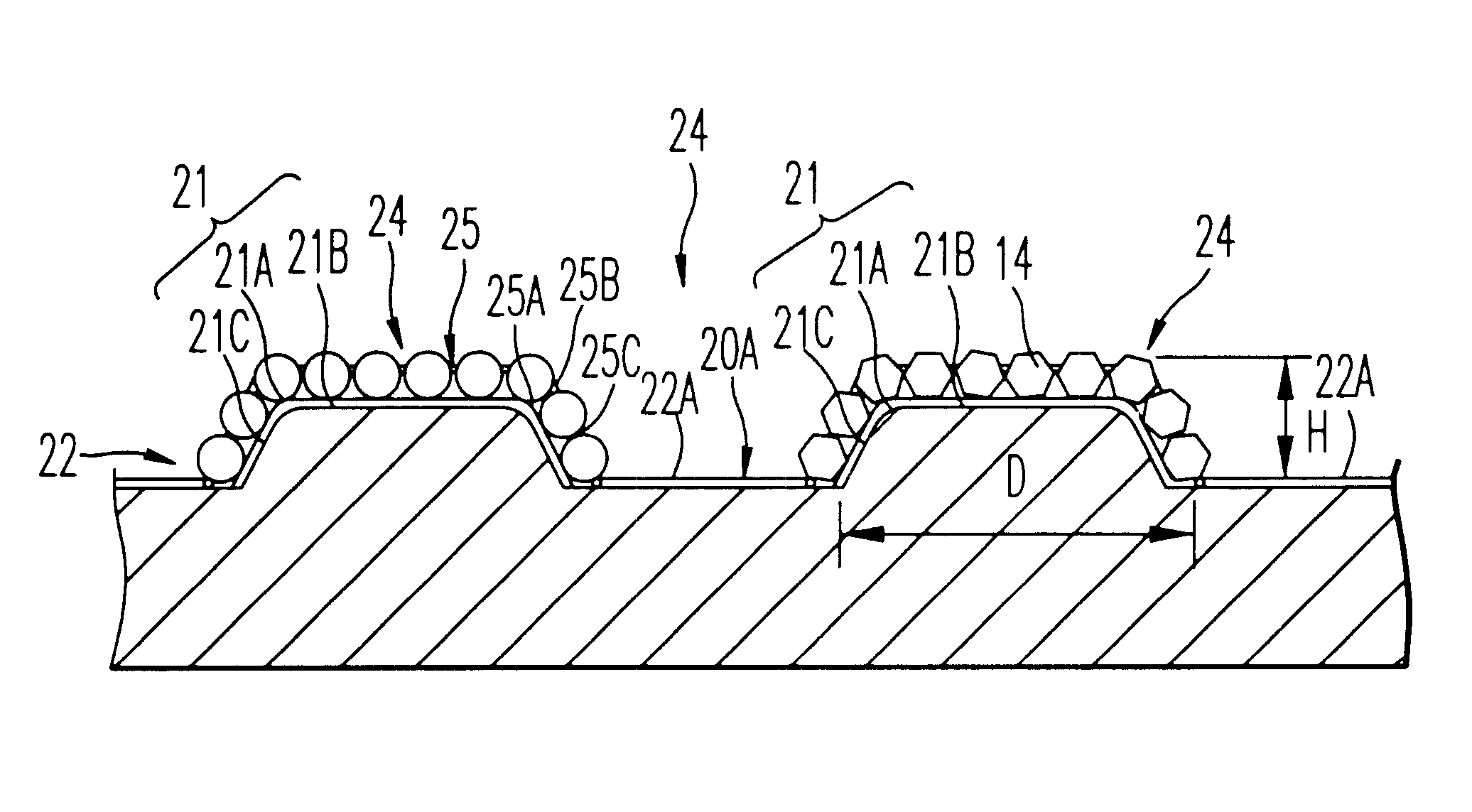

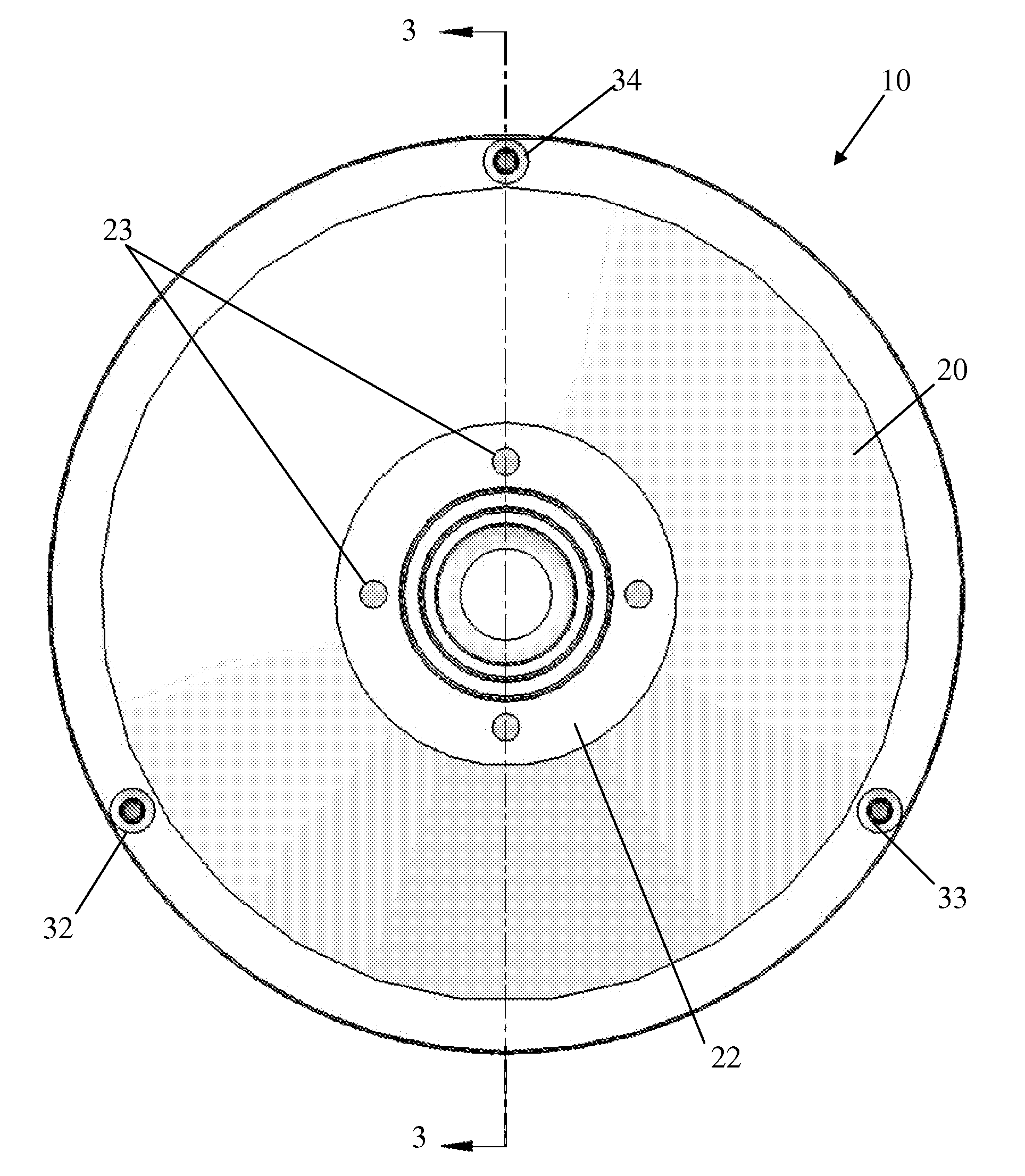

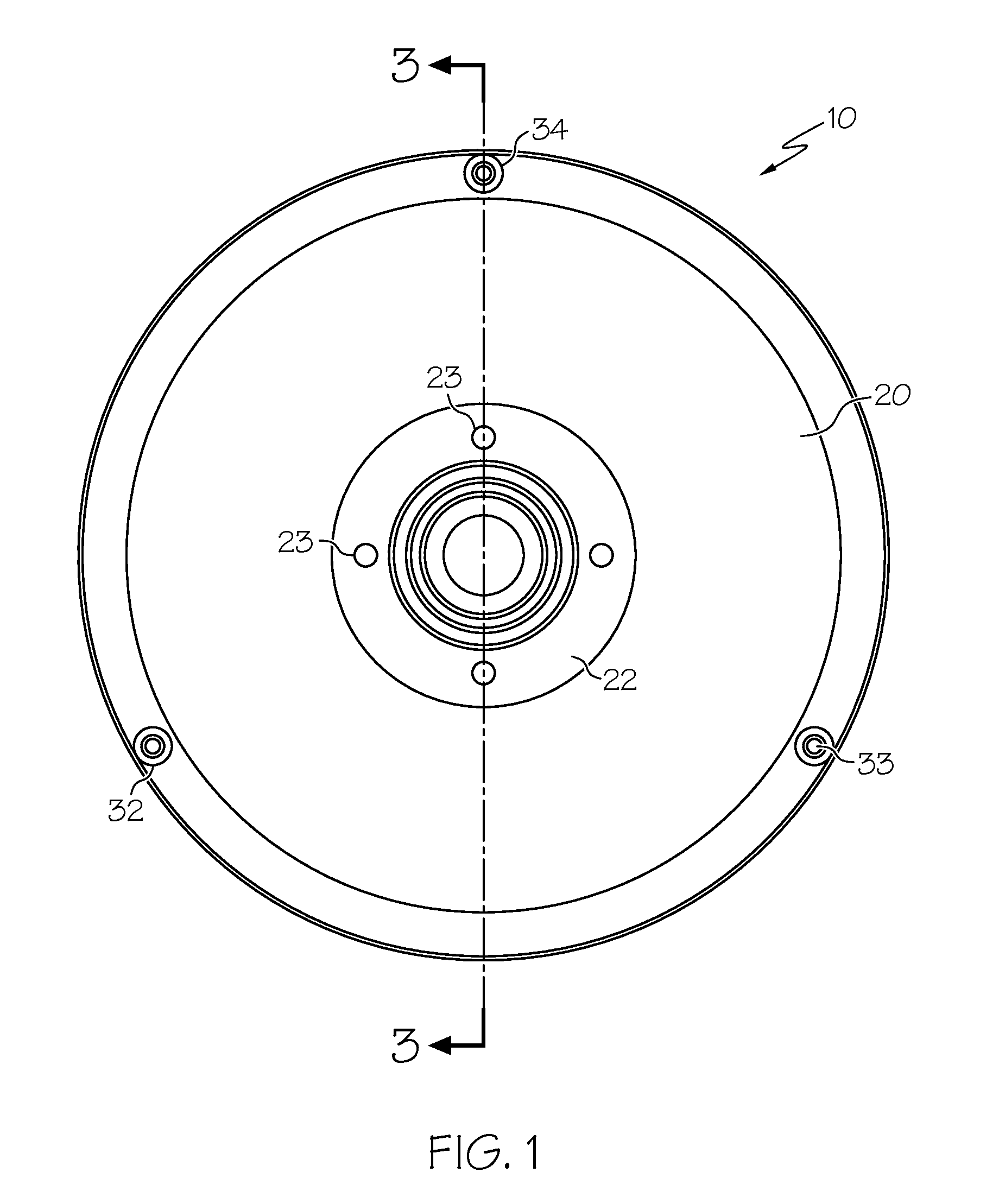

Diamond grid CMP pad dresser

InactiveUS6884155B2Easy to monitorUniform sizePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

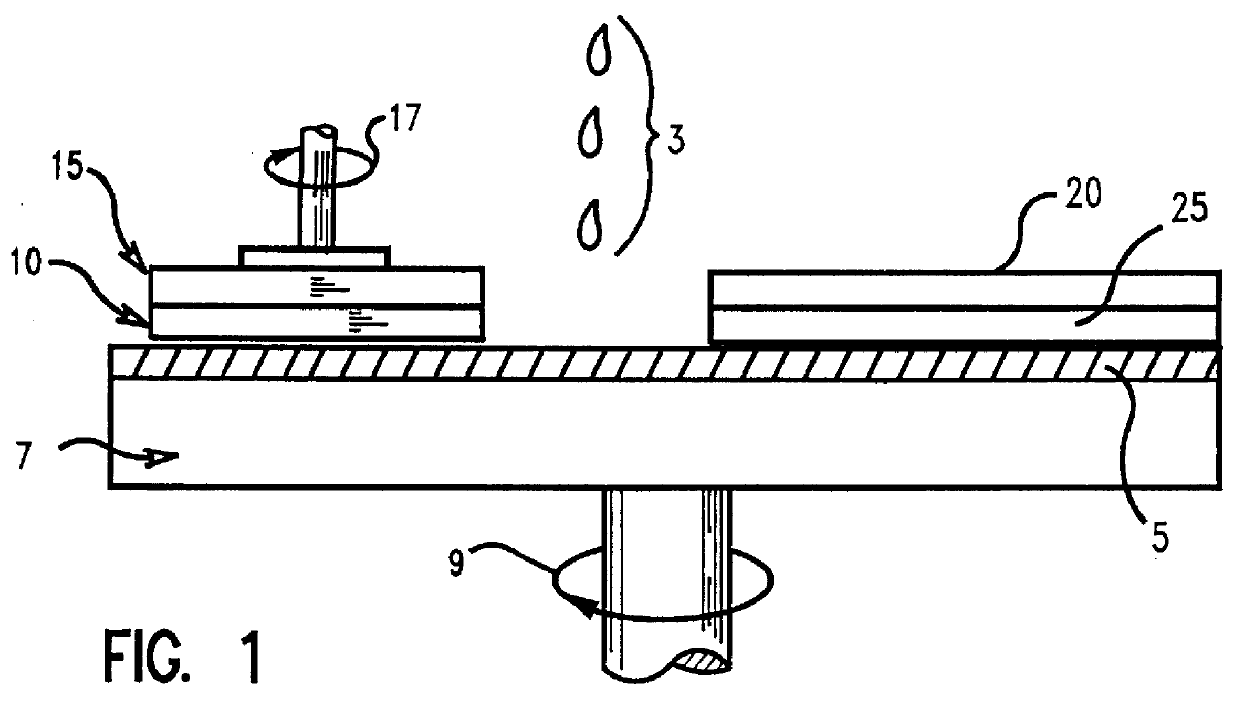

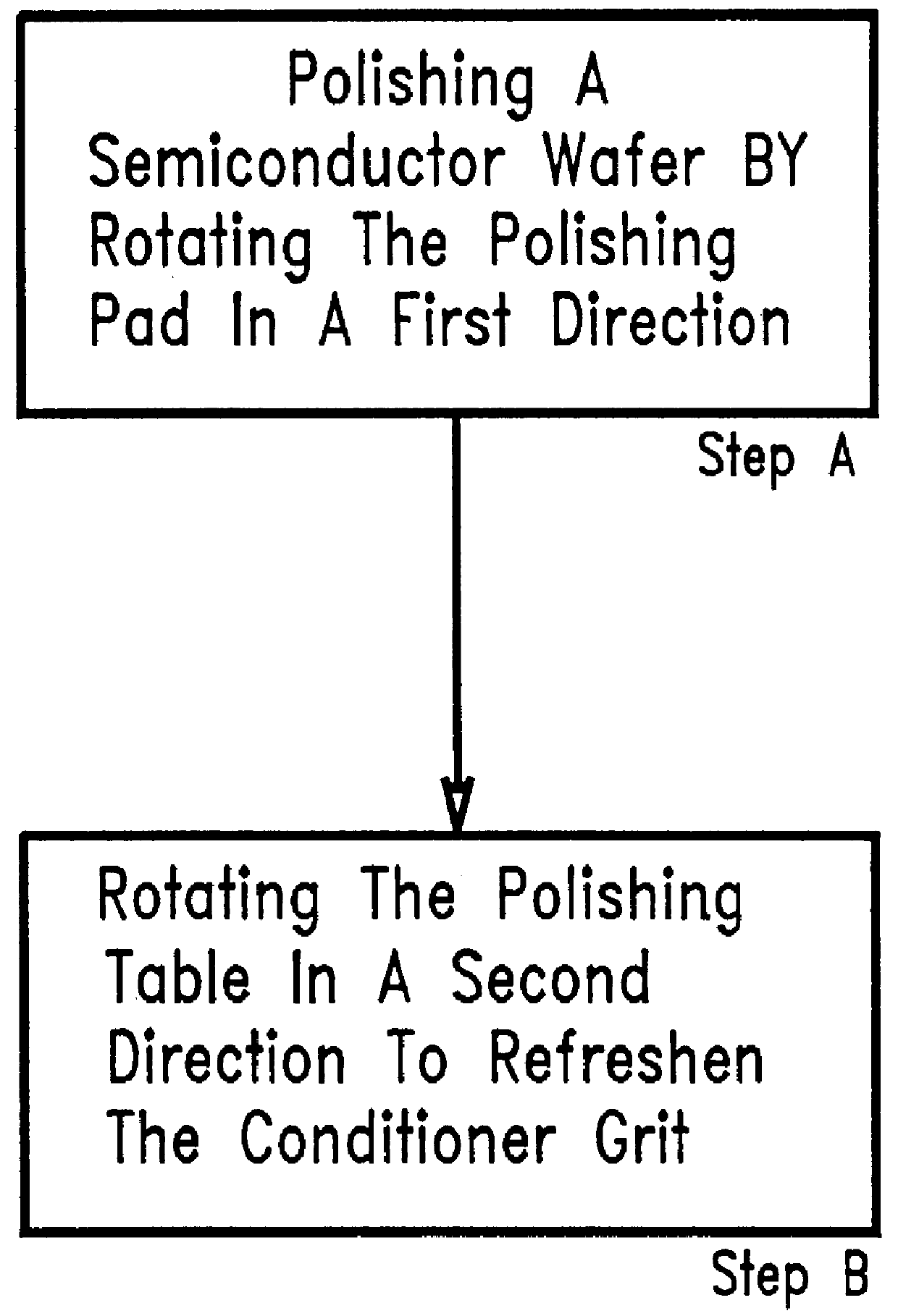

In-situ pad conditioning process for CMP

InactiveUS6022266AGood conditioning effectGrinding drivesBelt grinding machinesSlurryImproved method

Owner:GOOGLE LLC

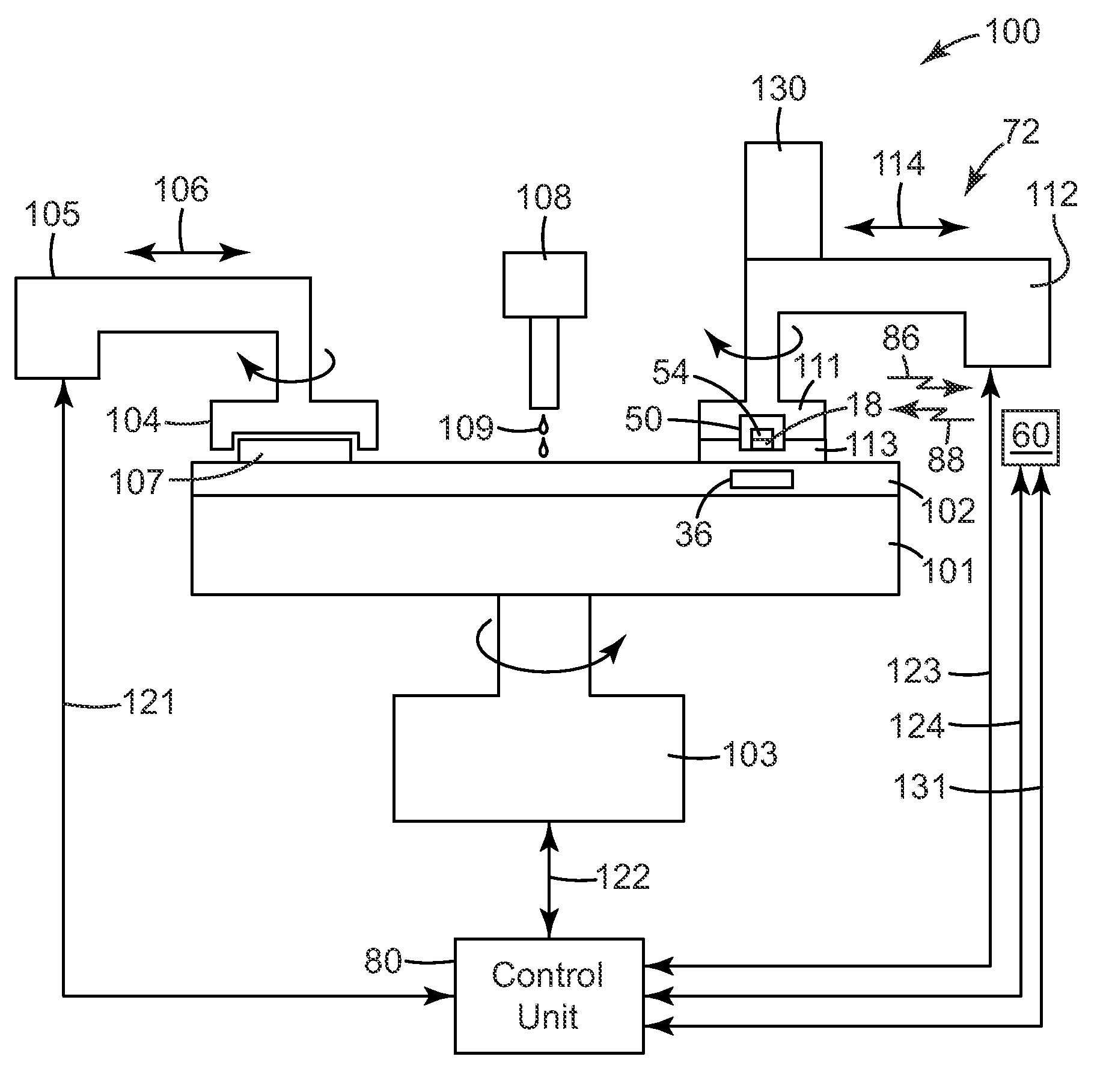

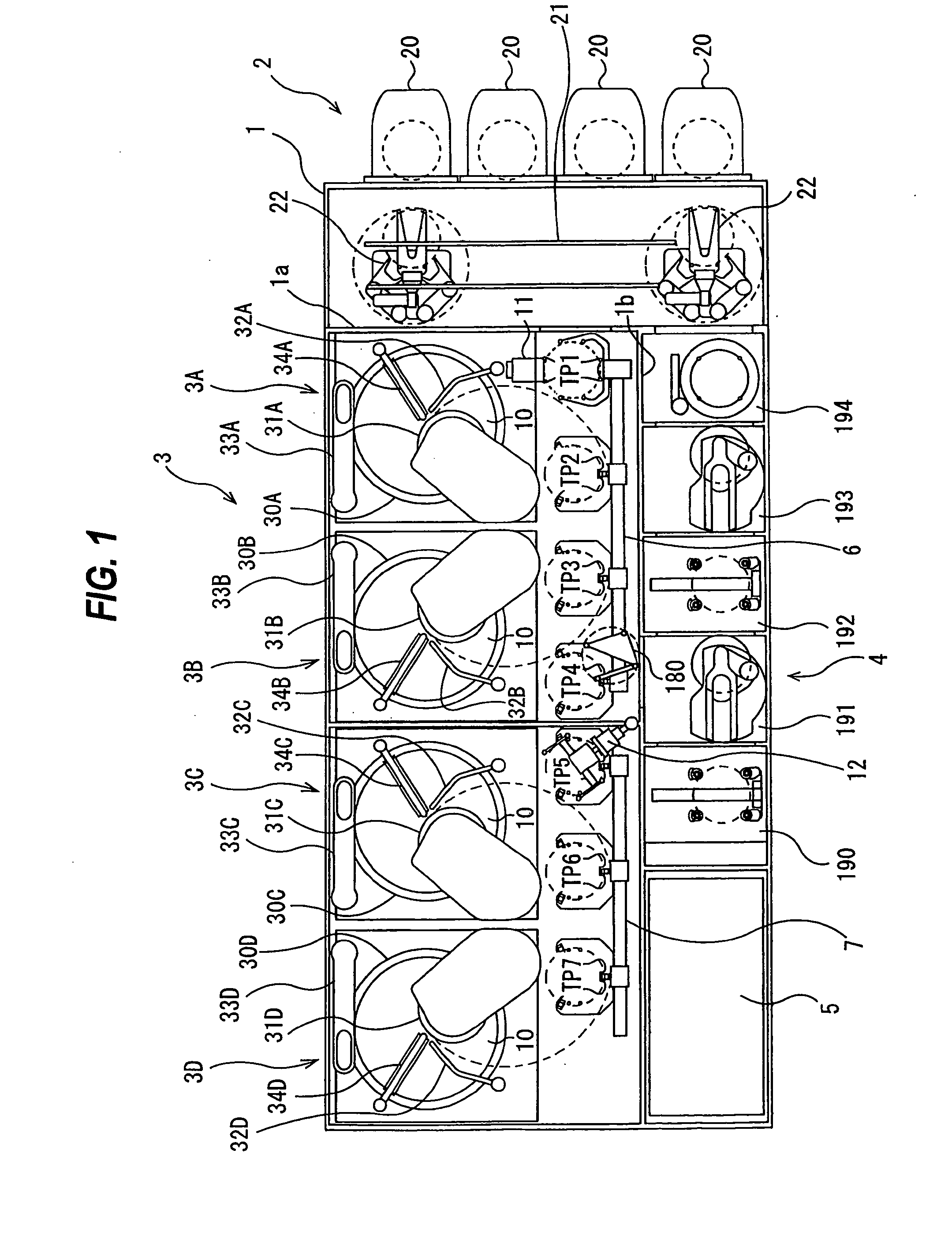

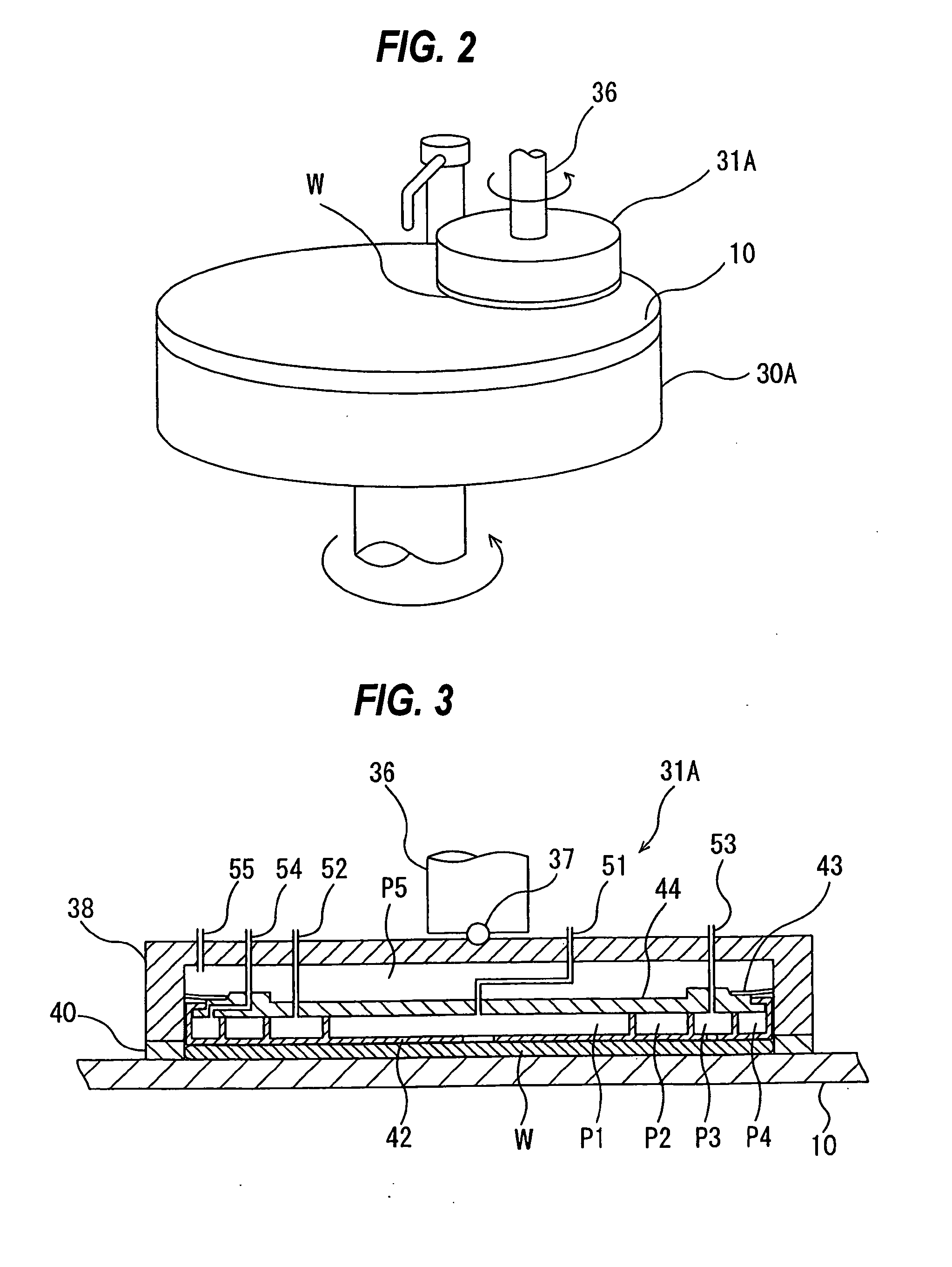

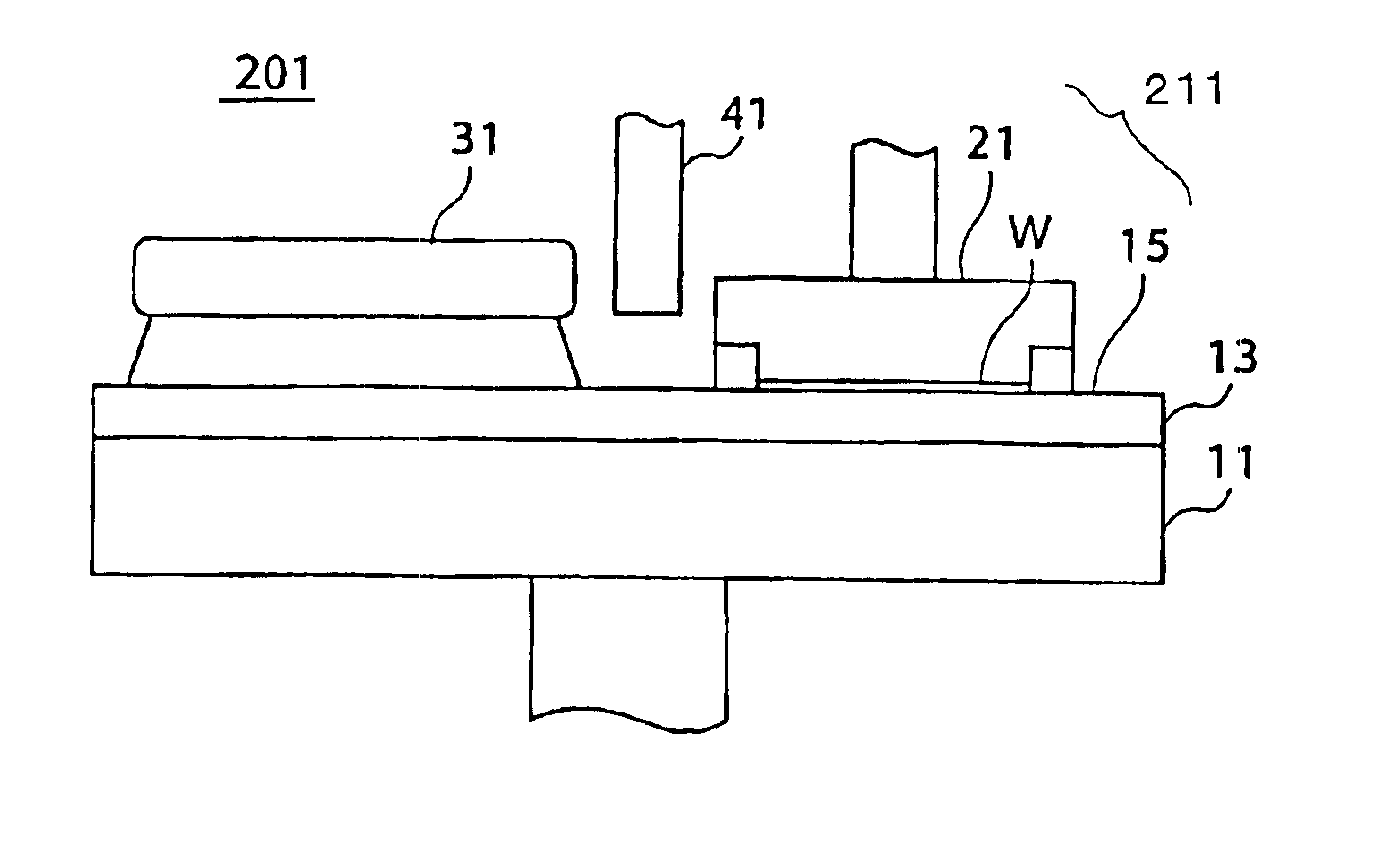

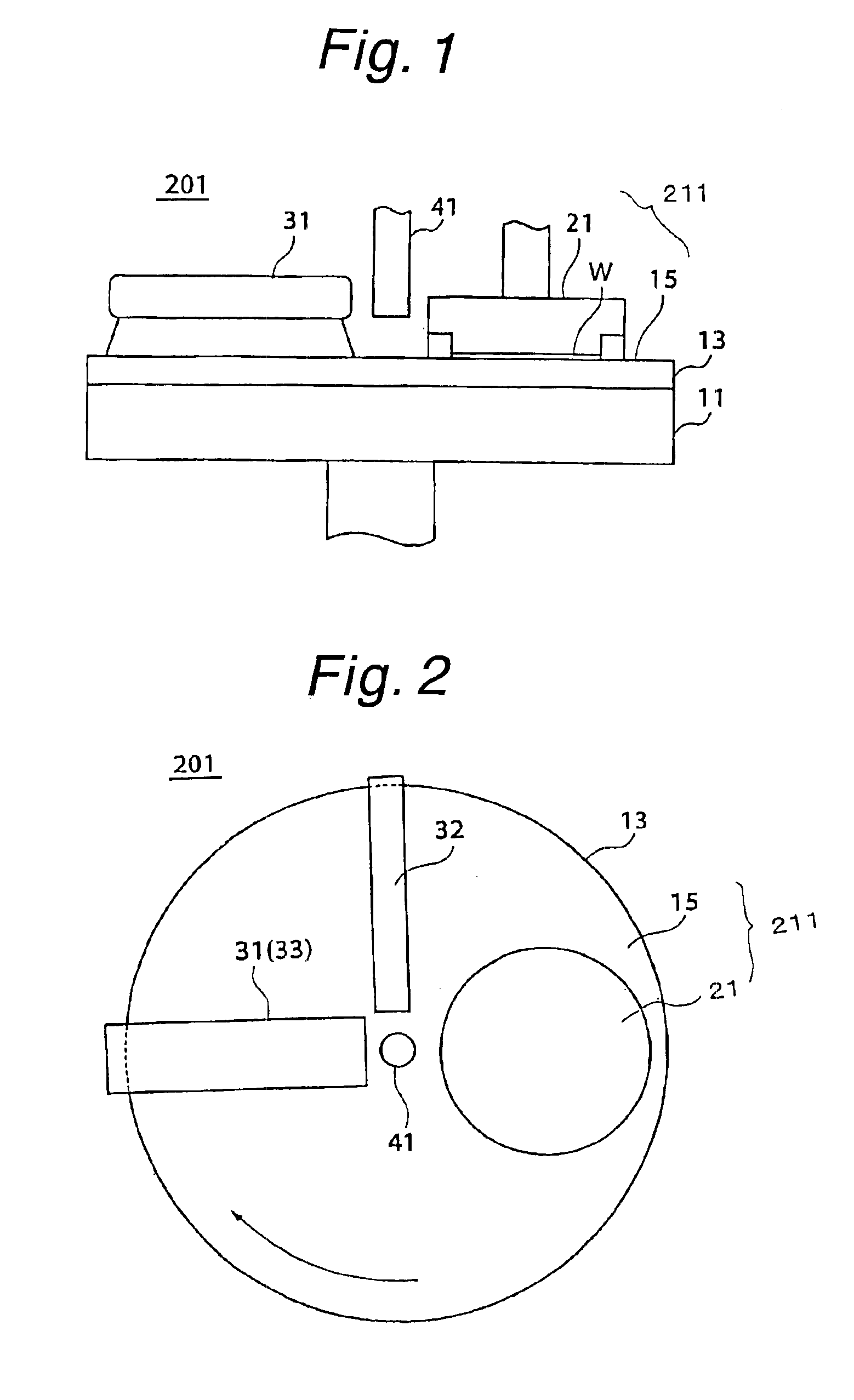

Substrate processing apparatus, substrate processing method, substrate holding mechanism, and substrate holding method

ActiveUS20090305612A1Easy maintenanceImprove throughputServomotor componentsDrying solid materials without heatTransfer mechanismElectrical and Electronics engineering

An apparatus for processing a substrate is disclosed. The apparatus includes a polishing section configured to polish a substrate, a transfer mechanism configured to transfer the substrate, and a cleaning section configured to clean and dry the polished substrate. The cleaning section has plural cleaning lines for cleaning plural substrates. The plural cleaning lines have plural cleaning modules and plural transfer robots for transferring the substrates.

Owner:EBARA CORP

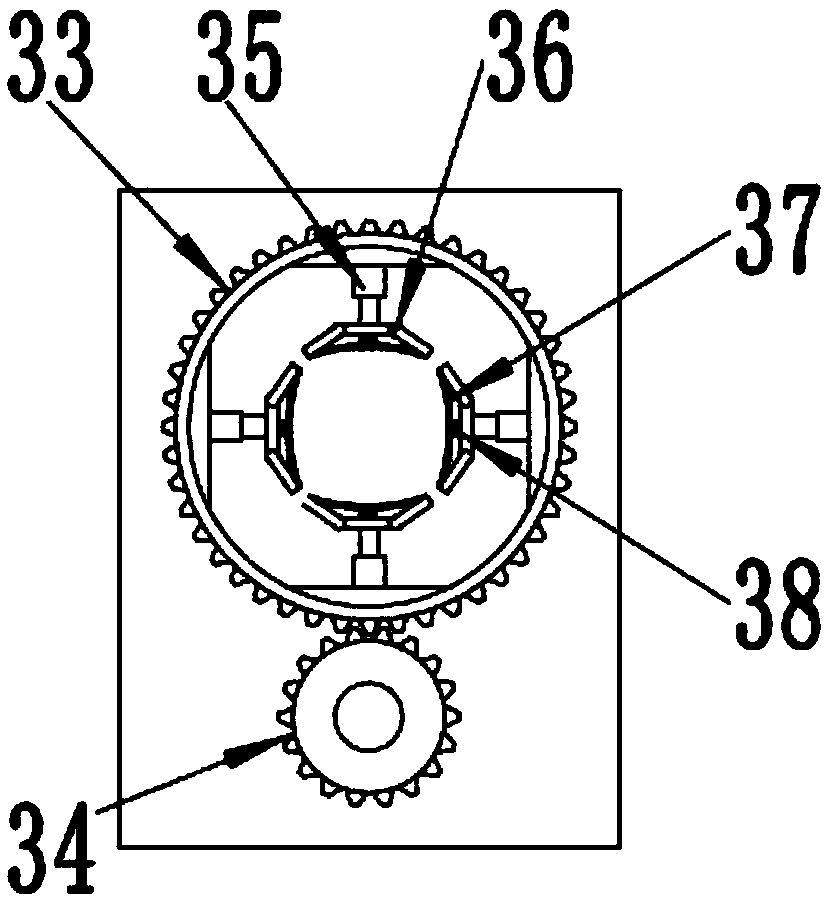

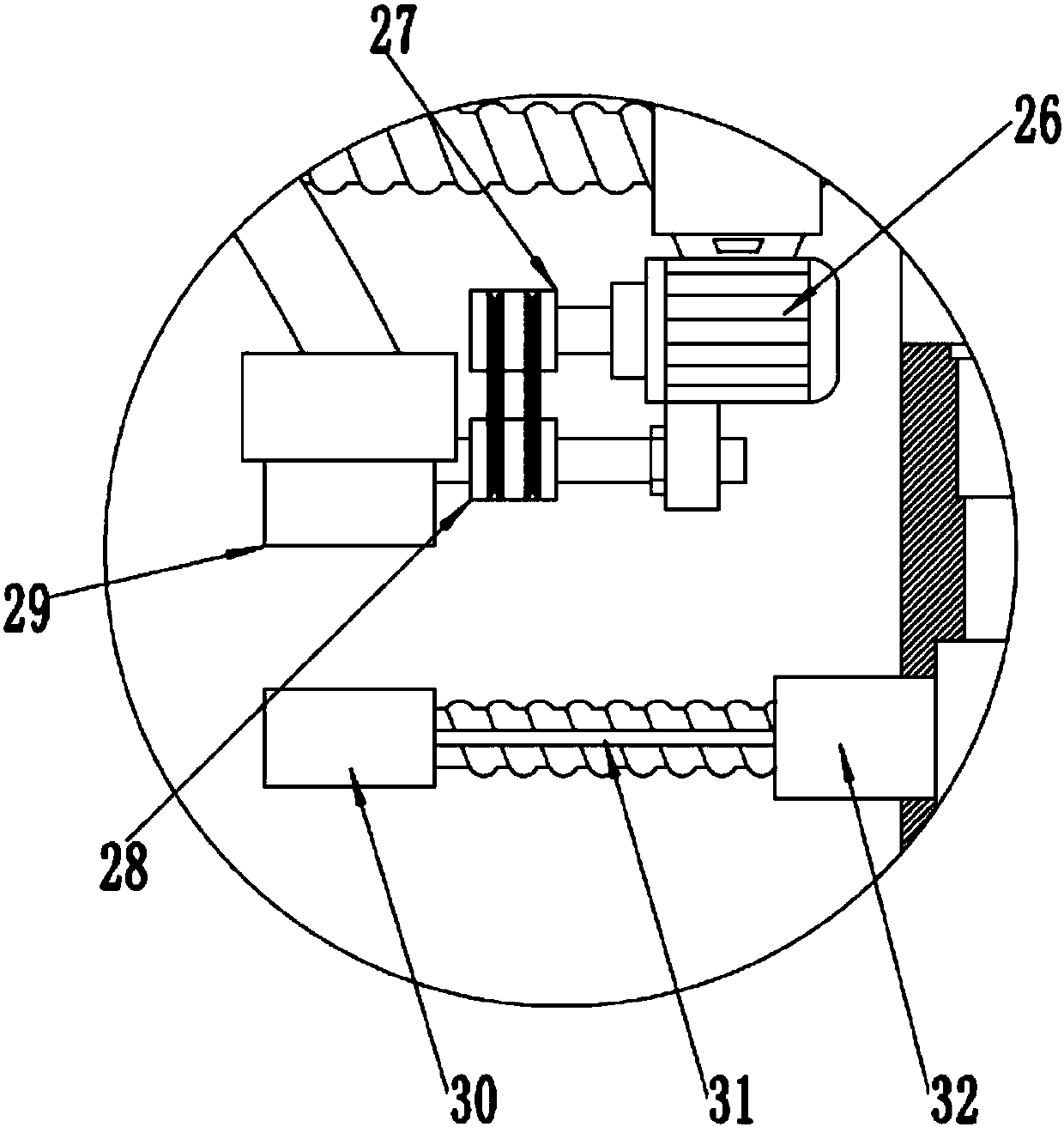

Device for simultaneously grinding inner walls and outer walls of steel pipes

InactiveCN107738167AAvoid pollutionShorten the timeGrinding carriagesRevolution surface grinding machinesHydraulic cylinderEngineering

The invention discloses a device for simultaneously grinding the inner walls and the outer walls of steel pipes. The device comprises a workbench, a support, a collecting tank, a clamping mechanism, an outer grinding mechanism and an inner grinding mechanism; the support is arranged at the upper end of the workbench, and the clamping mechanism is arranged at the left end of the inner side of the support and comprises a clamping plate, a rotating motor, an annular gear, a gear, electric telescopic rods, supporting plates, rubber pads and springs; the outer grinding mechanism is installed at thelower end of a moving block; and the inner grinding mechanism is arranged under the outer grinding mechanism and comprises an inner grinding wheel, a threaded rod B, a fixing sleeve, a threaded sleeve, a second sliding groove, an electric hydraulic cylinder, a drive gear, a driven gear A, a driven gear B, a rectangular block and a connecting rod. The device is novel in design, simple in structure, capable of simultaneously grinding the inner walls and the outer walls of steel pipes with different thicknesses, high in grinding efficiency, wide in application range, capable of effectively preventing impurities such as scrap iron from polluting the environment, high in practicality and worthy of popularization.

Owner:宁波高新区峰林化工科技有限公司

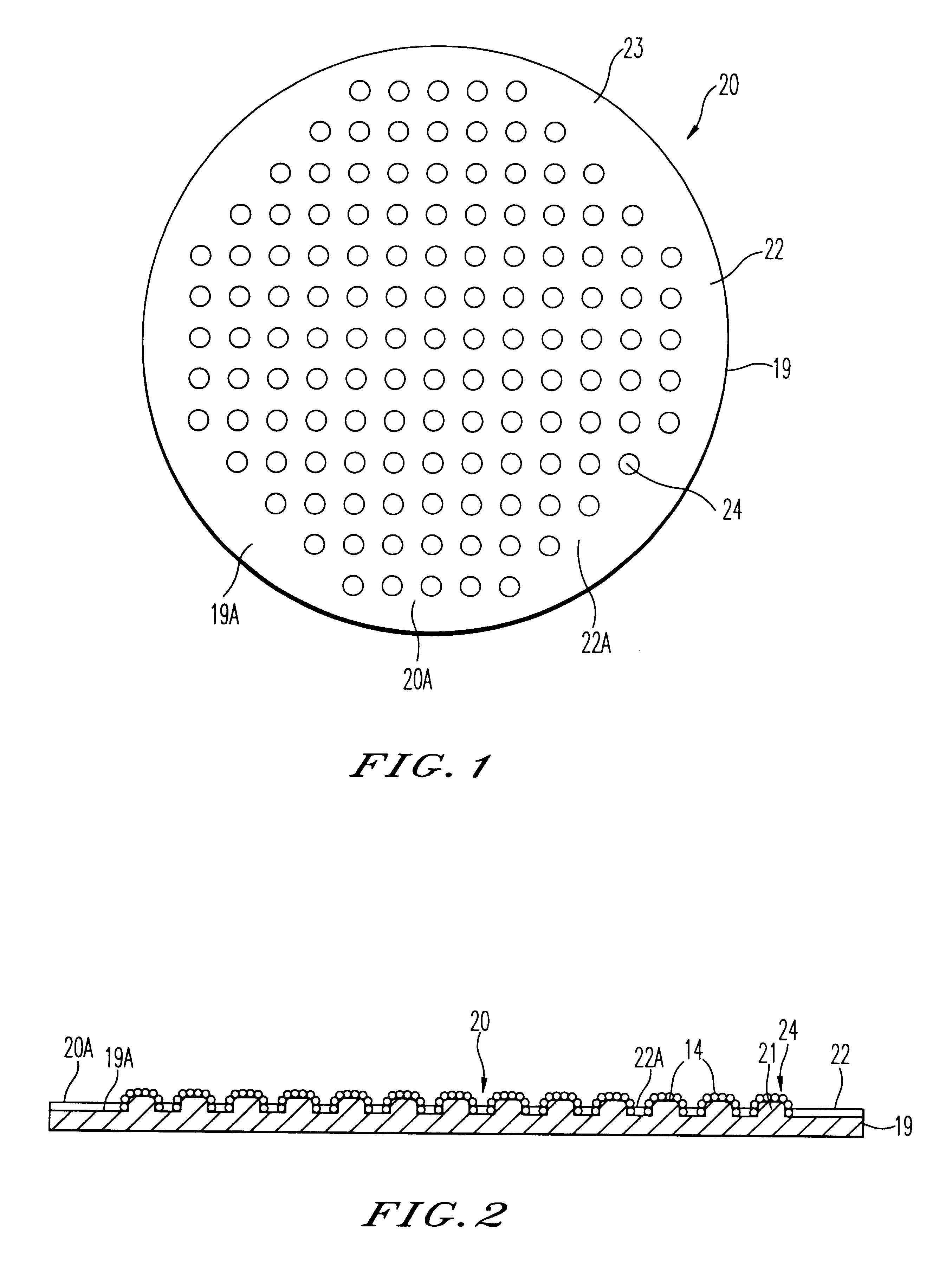

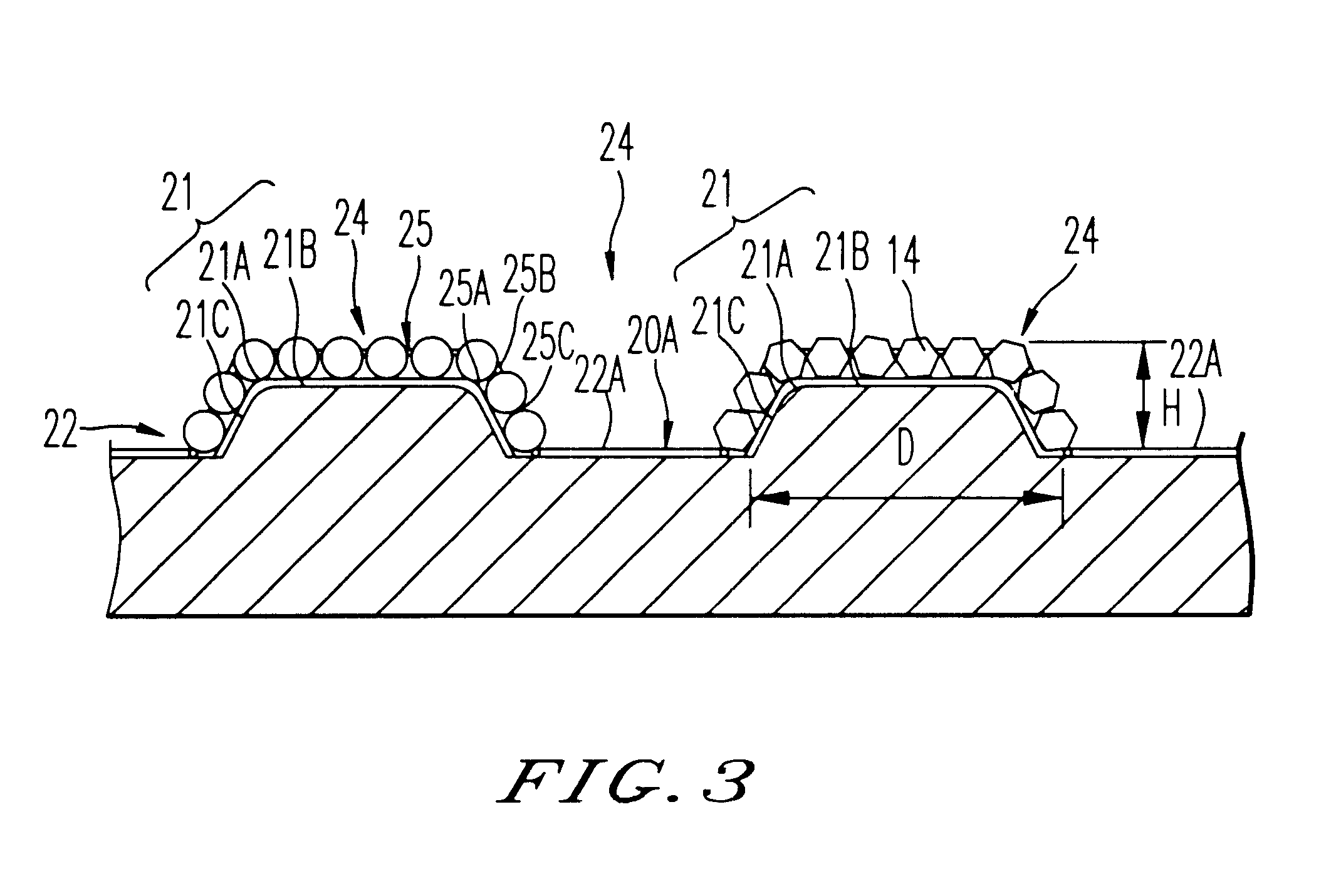

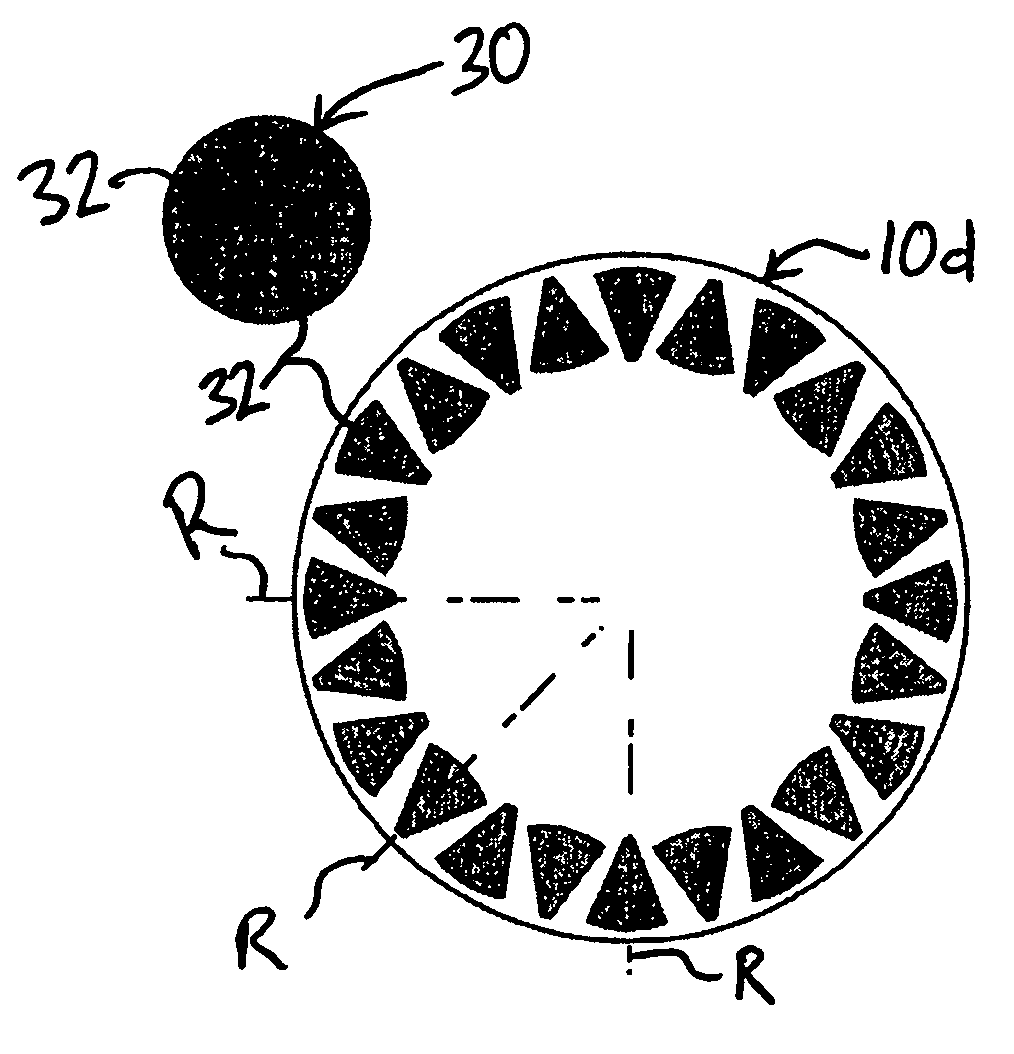

Abrasive tool with metal binder phase

InactiveUS6419574B1Sufficient sharpnessImprove discharge performanceRevolution surface grinding machinesGrinding drivesWear particleMetal

In the electrodeposited abrasive wheel 20 of the abrasive tool according to the present invention, plural mound parts 21, which are upheaved at the central domain of base metal 19 in almost columnar shape, are arranged mostly in the shape of lattice. An abrasive grain layer 22 is formed on a base metal 19, and plural ultra abrasive grains 14 are adhered only to each mound parts 21 by electrodeposited metal phase 25, and referred as the small abrasive-grain-layer parts 24, respectively. Ultra abrasive grains are laid out at corner R part 21a and top 21b of the mound parts 21 at the small abrasive-grain-layer parts 24. Ultra abrasive grains at each small abrasive-grain-layer parts are set as 11-500 pieces, and the rate which ultra abrasive grains occupy to the whole area of abrasive grain layer accounted by plane projection is set as 20%-80% of the range. At the time of grinding, only ultra abrasive grains contact to grinding work piece, then high abutment pressure is maintained, and sharpness and the discharge performance of ground wastes are good.

Owner:MITSUBISHI MATERIALS CORP

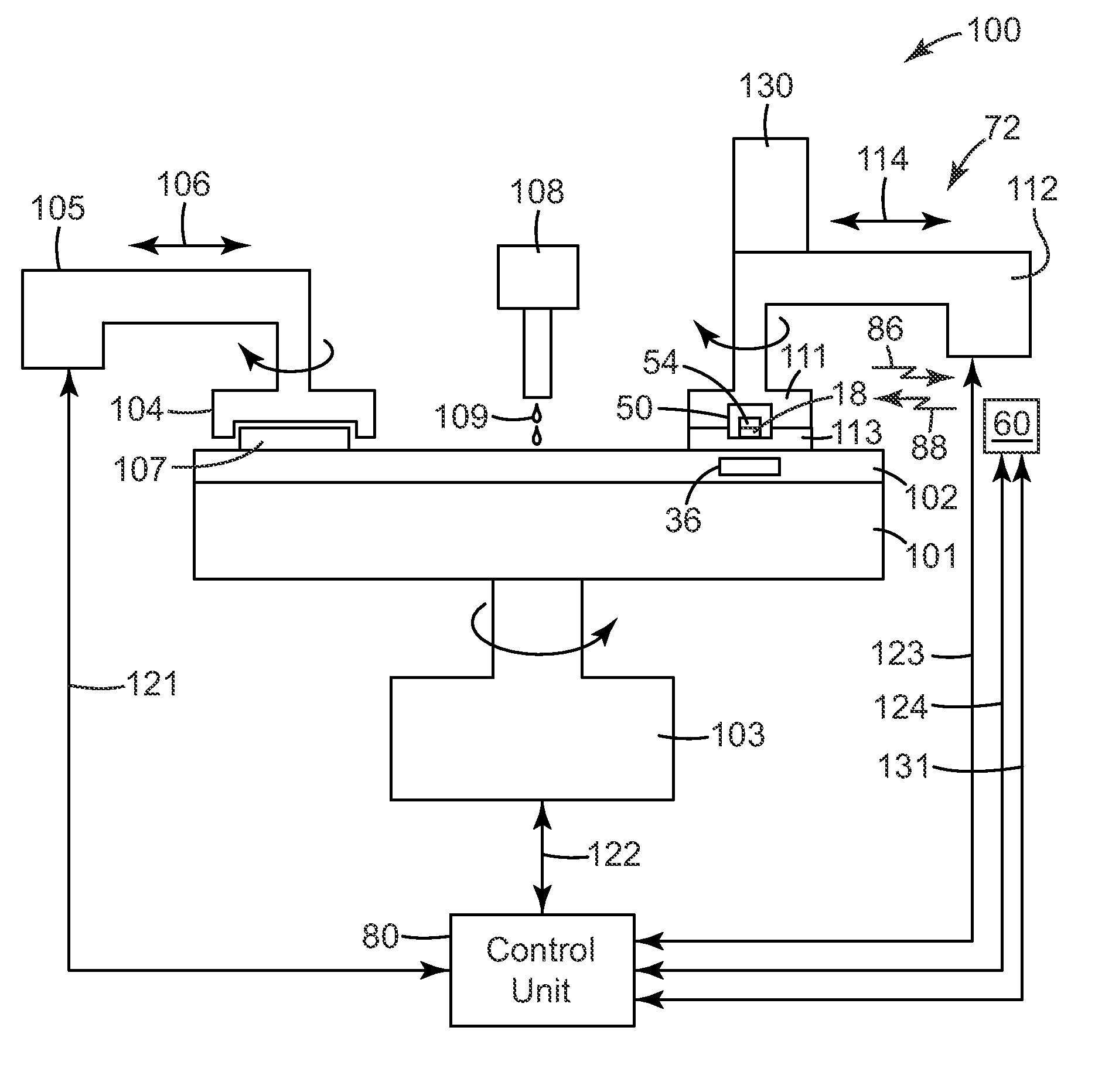

Abrasive articles, CMP monitoring system and method

ActiveUS7840305B2Easy to operate the machineAvoid damageGrinding drivesBelt grinding machinesMonitoring systemEngineering

The disclosure relates to abrasive articles useful in chemical-mechanical polishing (CMP), the articles including a substrate with opposite major surfaces, an abrasive material overlaying at least a portion of at least one of the major surfaces, and at least one of a radio frequency identification (RFID) tag, a RFID tag reader, or a sensor for providing CMP information to a transmitter positioned near the substrate, the transmitter positioned near the substrate and adapted to wirelessly receive CMP information and wirelessly transmit the CMP information to a remote receiver. The disclosure also relates to a CMP pad conditioner for wirelessly communicating CMP information to a remote receiver, a CMP process monitoring system for wirelessly communicating CMP information to a remote receiver, and a method for conditioning a CMP pad using a CMP process monitoring system for wireless communicating CMP information to a remote receiver.

Owner:3M INNOVATIVE PROPERTIES CO

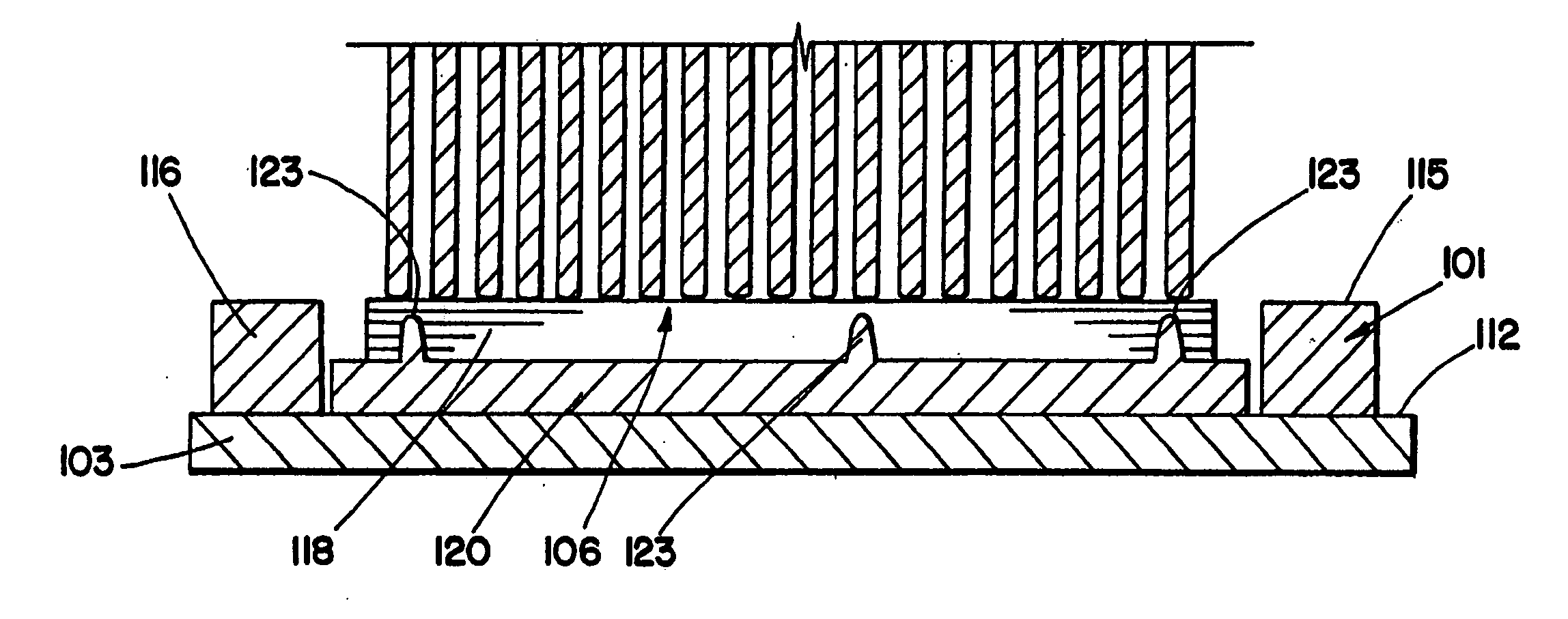

CMP diamond conditioning disk

A method of making and the resulting non-metallic CMP conditioning pad comprising a non-metallic substrate and a single layer of abrasive particles bonded to the substrate by a non-metallic bonding medium. Preferred substrates include aluminum oxide and graphite. A bonding system employing finely powdered aluminum oxide particles mixed with a suitable adhesive is employed to bond the abrasive layer to the aluminum oxide substrate. Silicon carbide particles mixed into a compatible adhesive carrier including a polymer composition is preferred for bonding the abrasive particle layer to a graphite or carbide substrate.

Owner:ABRASIVE TECH

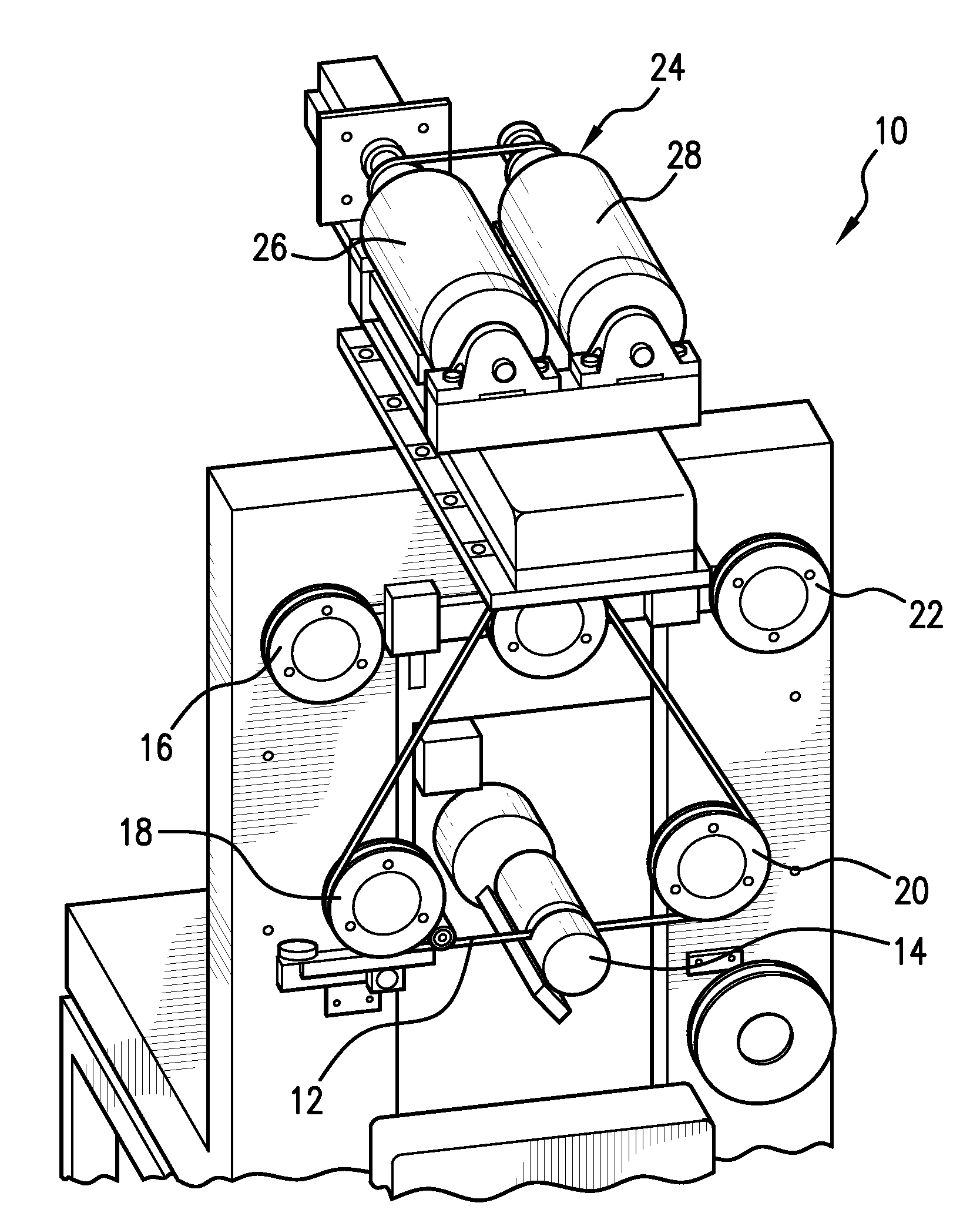

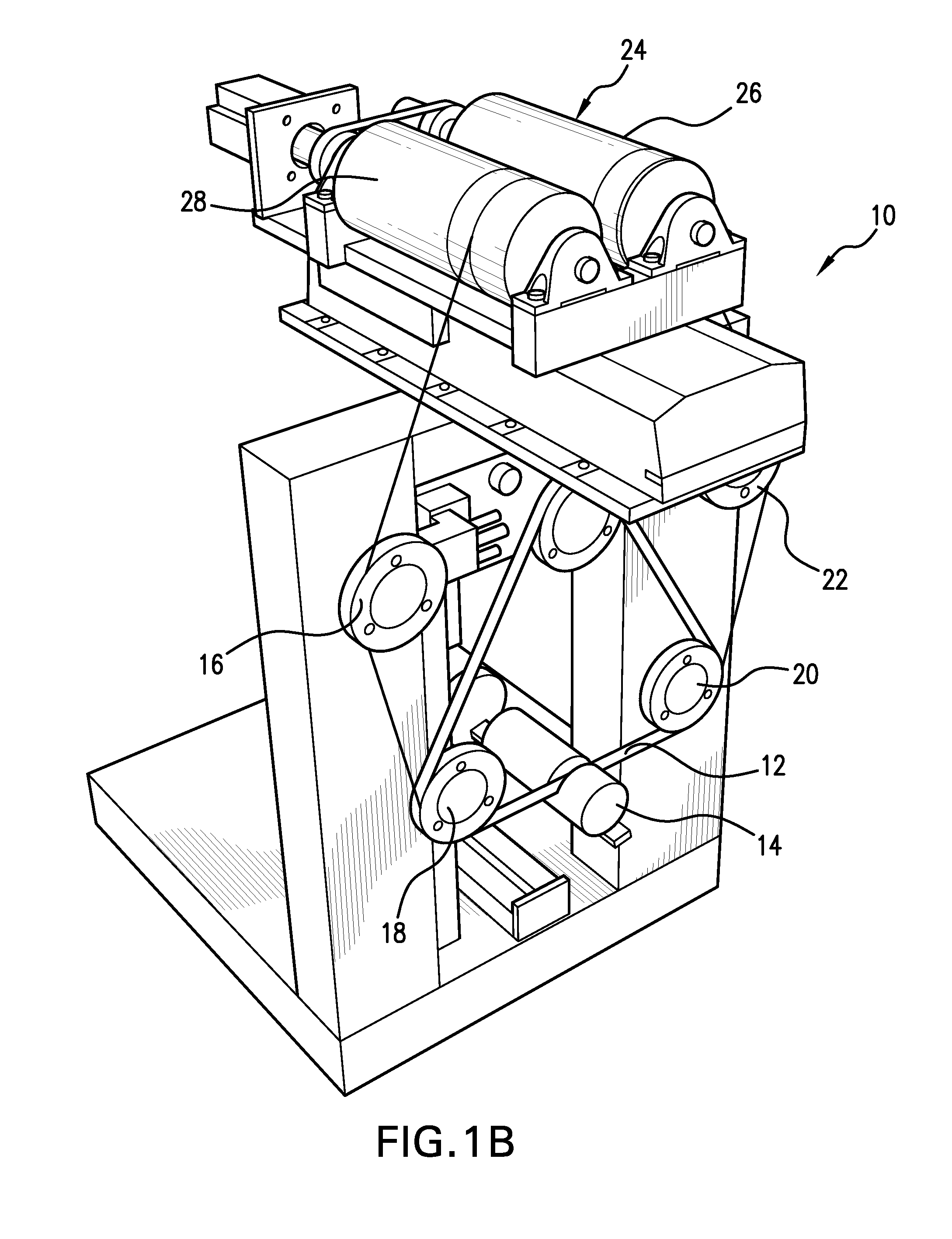

Wire slicing system

InactiveUS20100006082A1Fast cutting speedQuality improvementFine working devicesMetal working apparatusEngineeringAutomation

A wire slicing system and method for using it include one or more of the following features: arrangements and / or operations that relate to handling the wire; apparatus and methods that relate to wire tensioning; equipment and techniques for manipulating the workpiece; arrangements and / or operations designed for cooling and swarf (debris) removal; controls and / or automation that can be used in conjunction with these features.

Owner:SAINT GOBAIN ABRASIVES INC +1

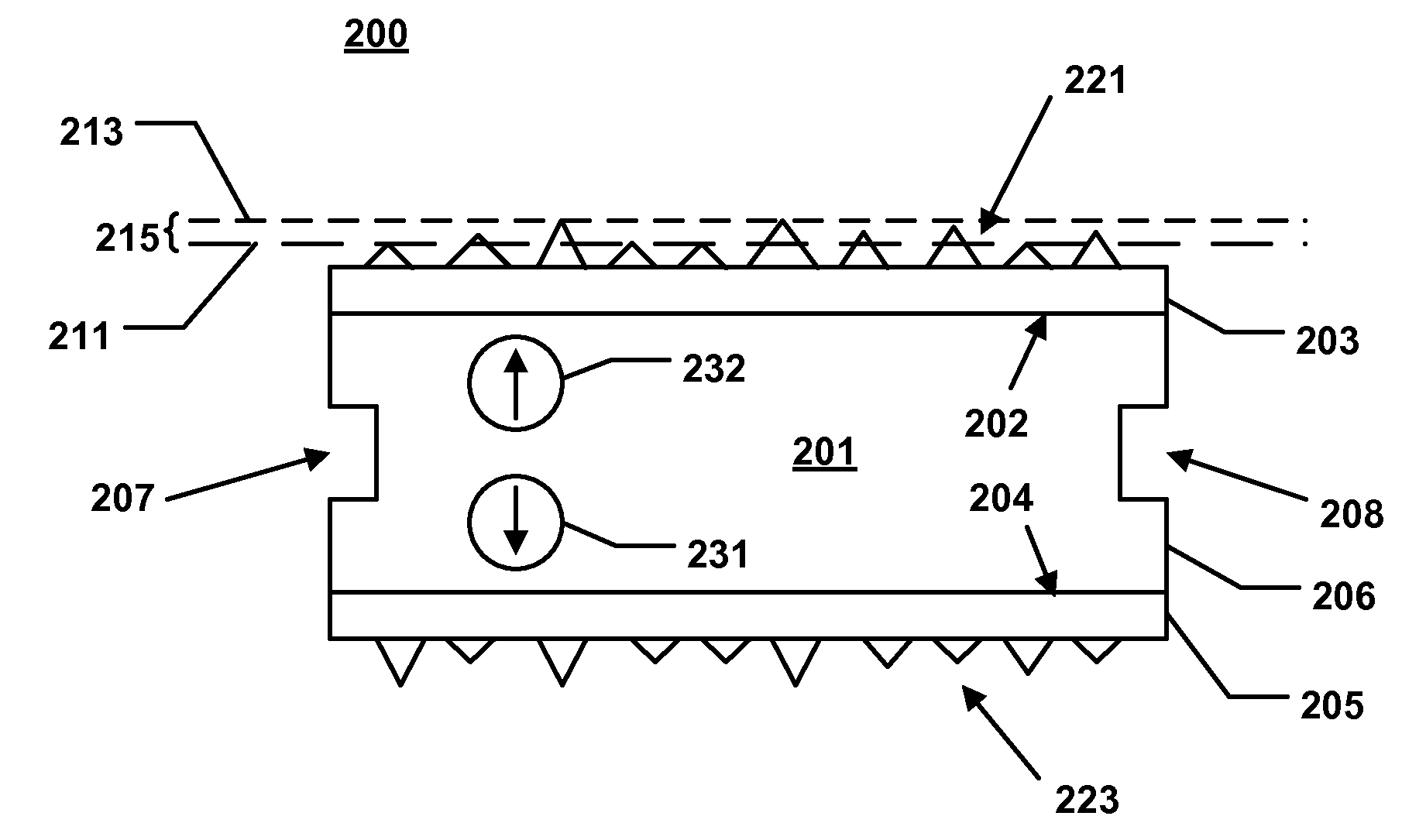

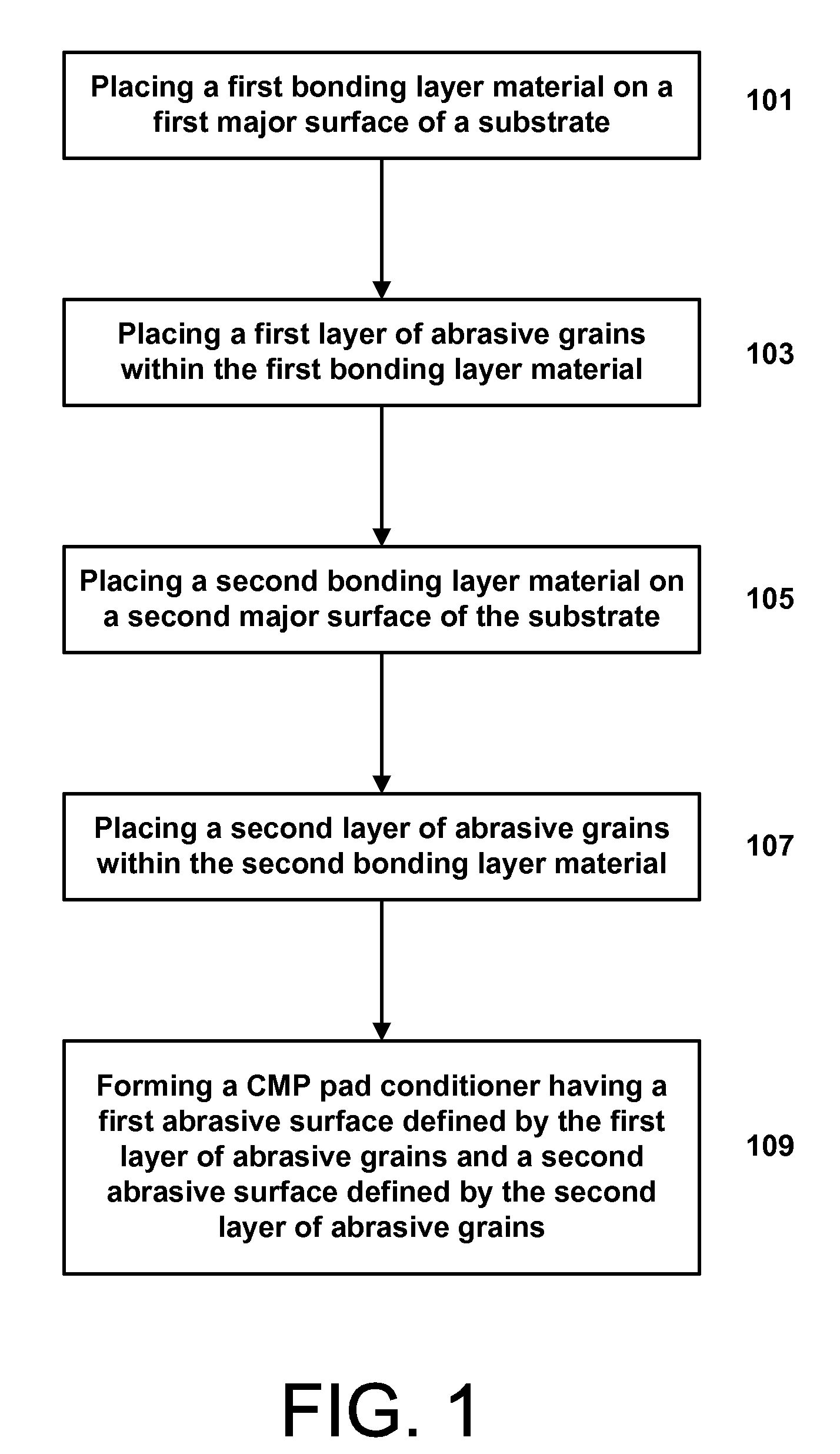

Abrasive tool for use as a chemical mechanical planarization pad conditioner

An abrasive tool including a CMP pad conditioner having a substrate including a first major surface, a second major surface opposite the first major surface, and a side surface extending between the first major surface and the second major, wherein a first layer of abrasive grains is attached to the first major surface and a second layer of abrasive grains is attached to the second major surface. The conditioner further includes a first sealing member extending in a peripheral direction along a portion of the side surface of the substrate.

Owner:SAINT GOBAIN ABRASIVES INC +1

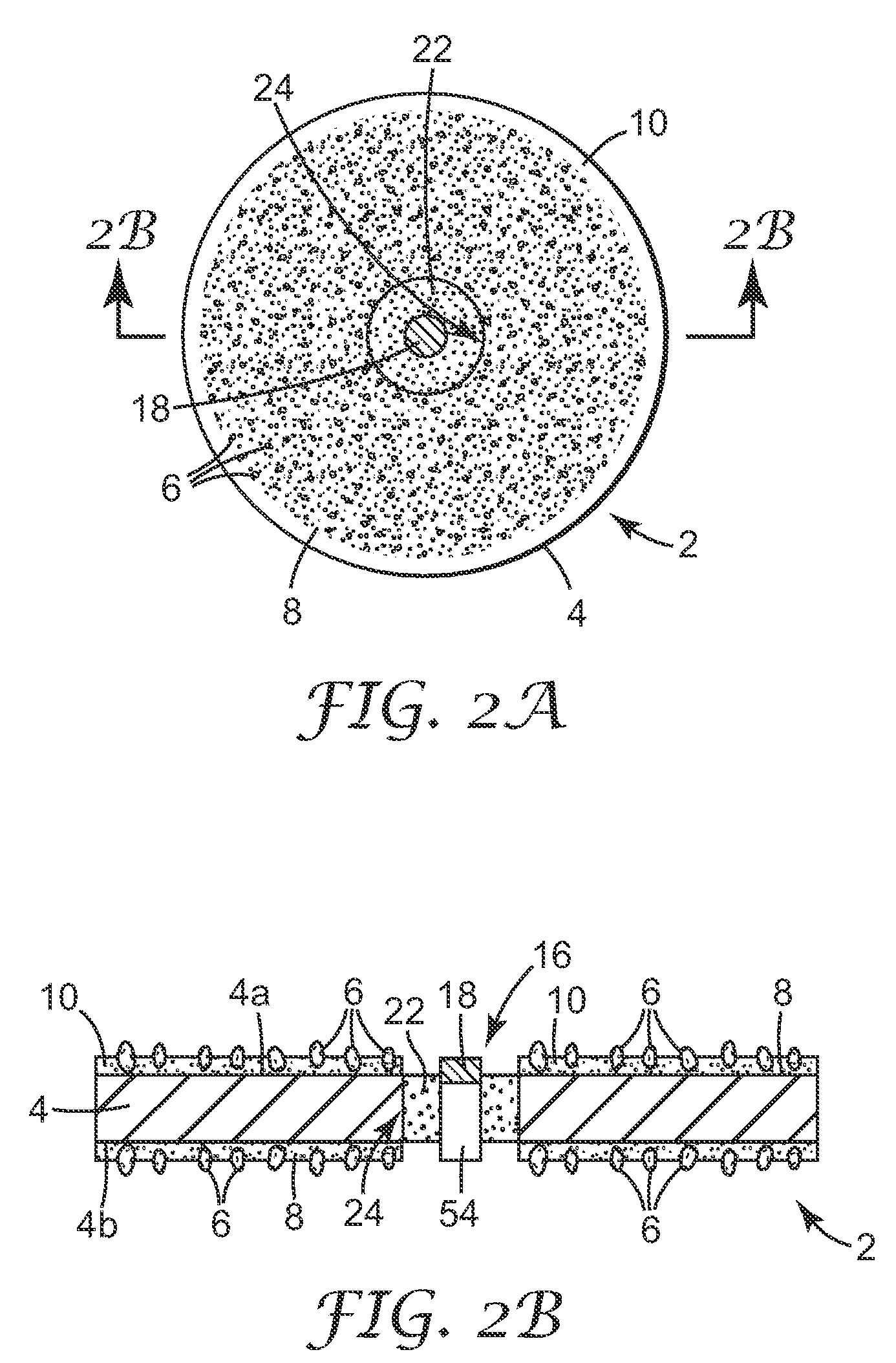

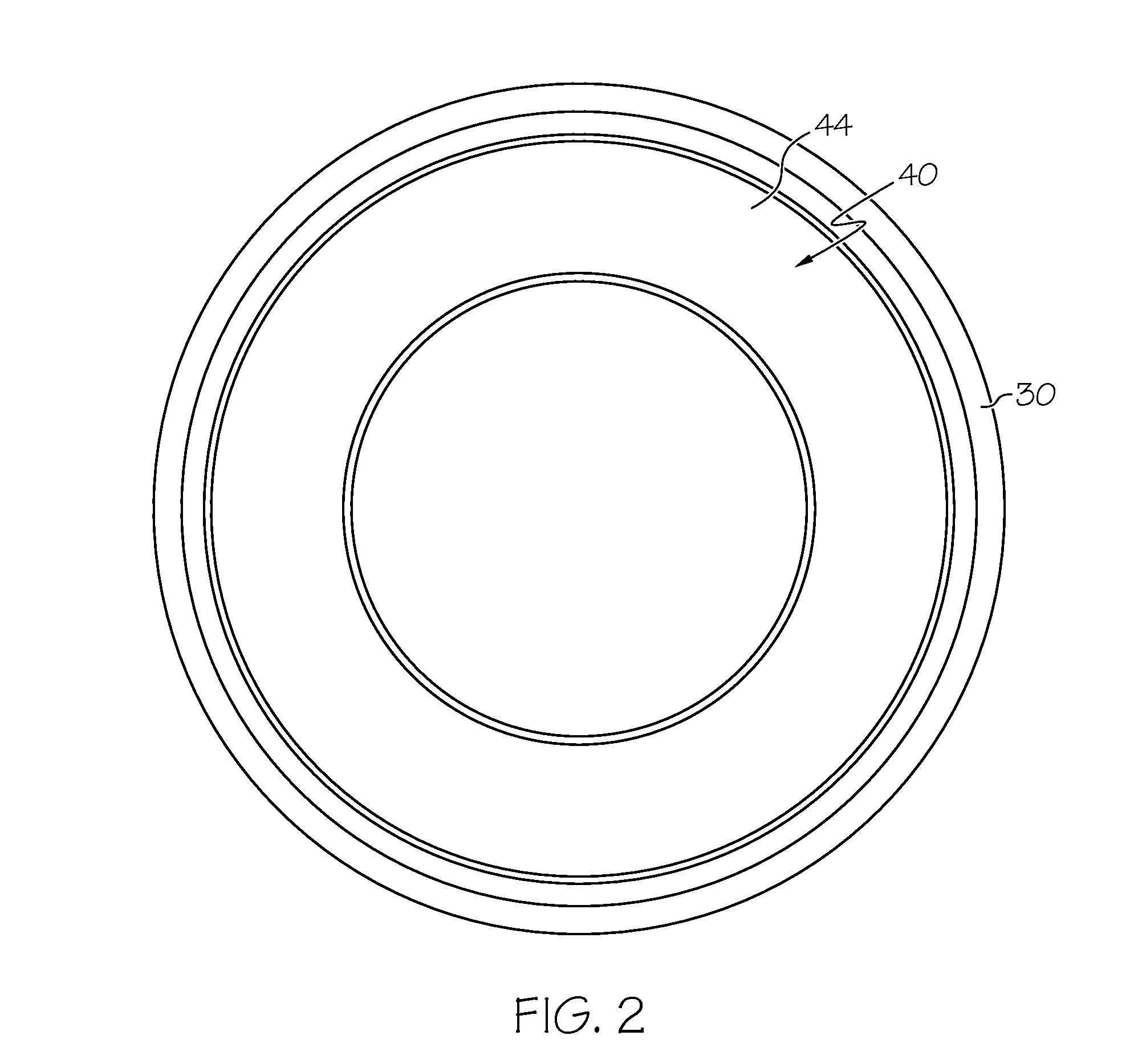

Multiple-sided cmp pad conditioning disk

InactiveUS20110097977A1Efficiently provideGrinding drivesBelt grinding machinesEngineeringMechanical engineering

A conditioning tool for restoring a used CMP polishing pad to an operable condition. The tool includes a base that attaches to a driven machine and has a surface from which a shoulder protrudes that receives a peripheral edge of a disk. The disk has two opposing surfaces, each of which is substantially planar and has abrasive mounted thereon. The disk's peripheral edge is held in place between the base shoulder and a ring that has a shoulder that is complementary to the disk's peripheral edge. The ring is fastened to the base with the abrasive of the first disk surface protruding through an aperture in the ring, and the opposing disk surface spaced from the base's surface. After the disk's first surface is worn, the disk can be turned around to expose the opposite surface's abrasive to a CMP pad.

Owner:ABRASIVE TECH

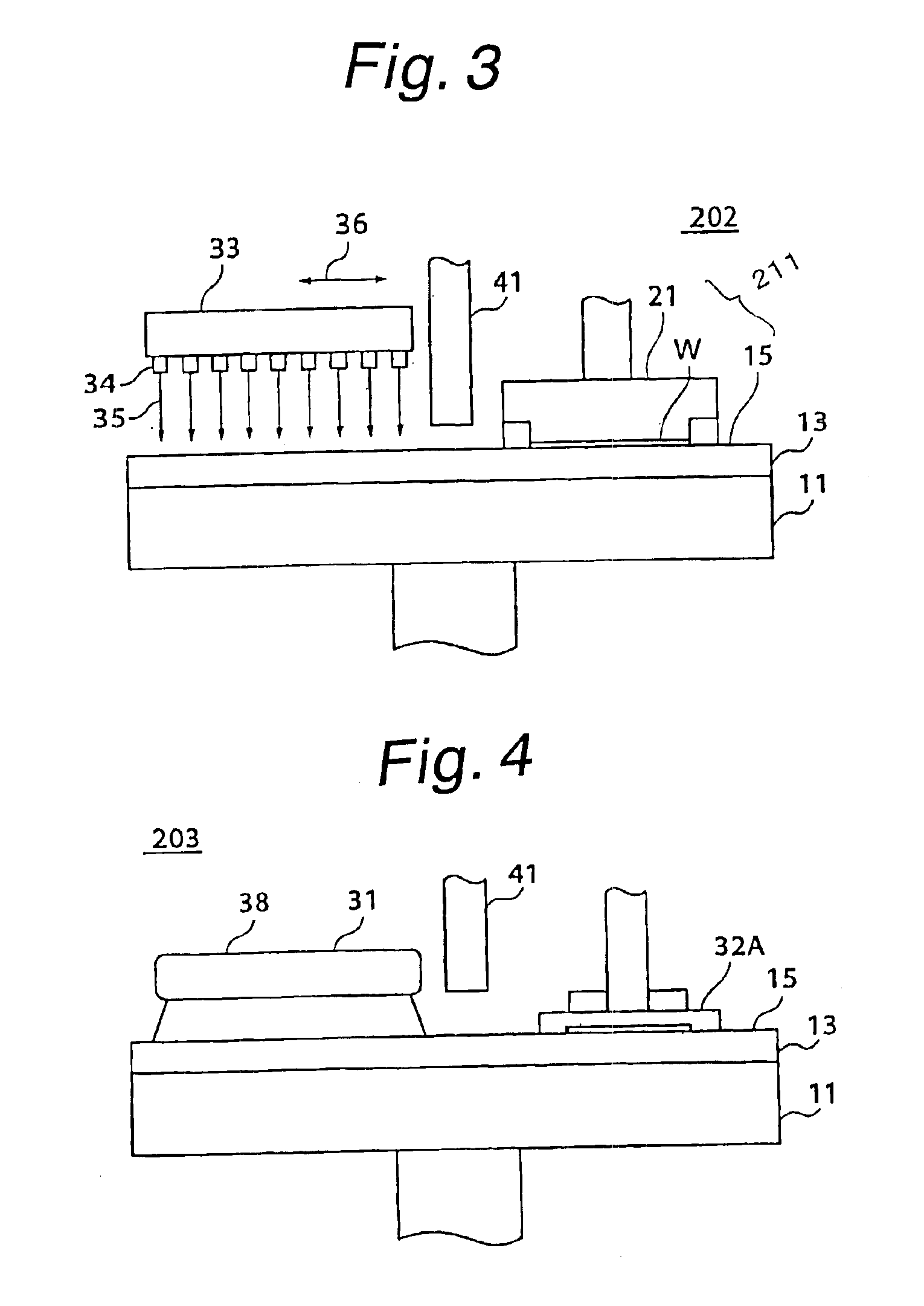

Polishing apparatus and dressing method for polishing tool

InactiveUS6899592B1Easy to dressReduce the binding forceGrinding drivesAbrasive surface conditioning devicesIrradiationBond Force

In a polishing apparatus, a polishing tool including abrasive particles and a binder for bonding together the abrasive particles is pressed against a substrate to polish the substrate. The polishing apparatus has a light source for irradiating a polishing surface with light rays for weakening a bond force of the binder for bonding together the abrasive particles, and a waste matter removing mechanism for forcefully removing waste matter produced by polishing or waste matter produced by irradiation. By irradiating the polishing surface with the light rays, dressing of the polishing surface is performed, and products resulting from dressing and the like are removed. The polishing apparatus supplies abrasive particles to the polishing surface stably by dressing and allows high-speed polishing of the substrate.

Owner:EBARA CORP

Superhard cutters and associated methods

A cutting device comprises a plurality of individual polycrystalline cutting elements secured in a solidified organic material layer. Each of the plurality of individual polycrystalline cutting elements has a substantially matching geometric configuration.

Owner:KINIK

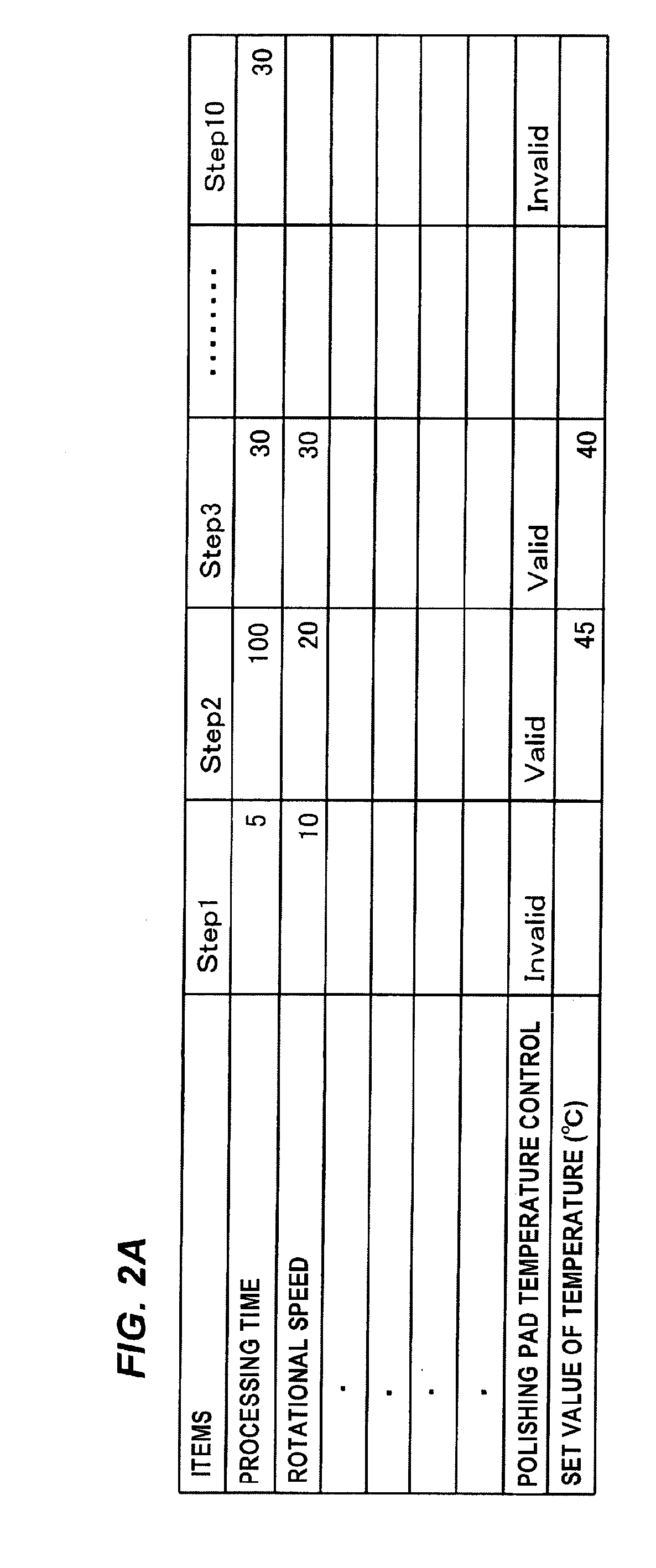

Substrate polishing apparatus, substrate polishing method, and apparatus for regulating temperature of polishing surface of polishing pad used in polishing apparatus

ActiveUS20110159782A1Polishing rate can be optimizedShorten polishing timeSemiconductor/solid-state device manufacturingLapping machinesTemperature controlEngineering

Owner:EBARA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com