Patents

Literature

739 results about "Angle grinder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An angle grinder, also known as a side grinder or disc grinder, is a handheld power tool used for grinding (abrasive cutting) and polishing. Although developed originally as tools for rigid abrasive discs, the availability of an interchangeable power source has encouraged their use with a wide variety of cutters and attachments.

Sanding disks

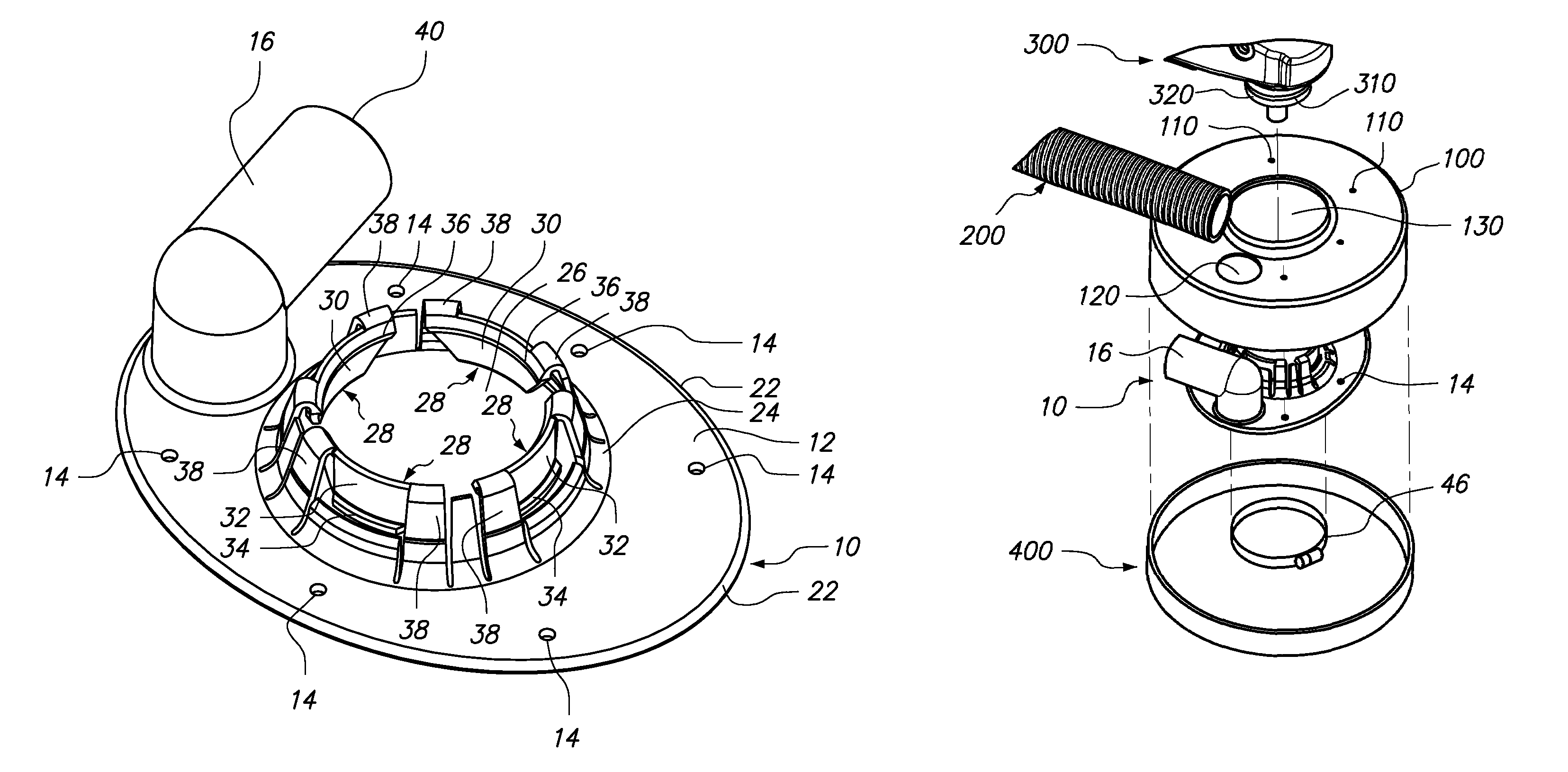

InactiveUS6312325B1Risk minimizationProtect from harmRevolution surface grinding machinesSupport wheelsAngle grinderEngineering

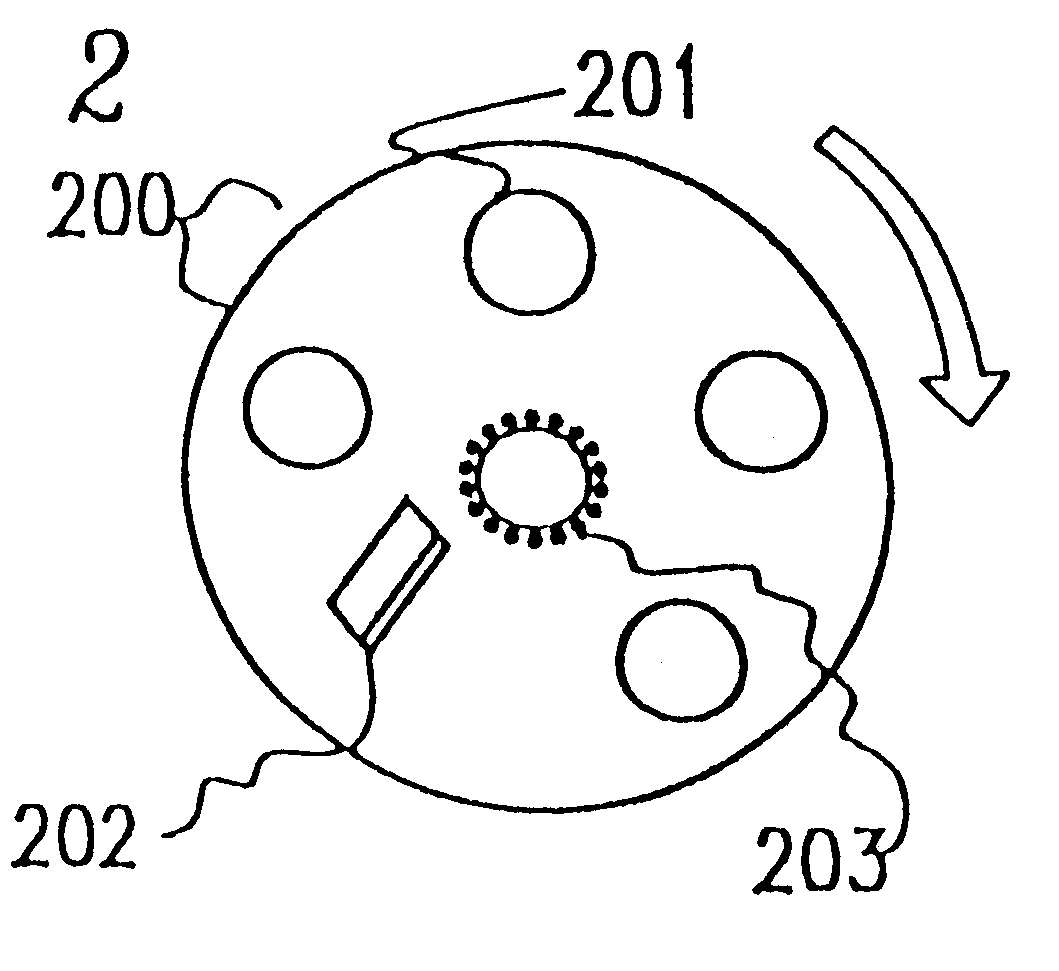

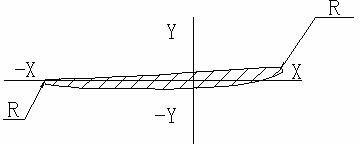

Accessories for an angle grinder include a disposable rotary sanding disk having quite large shaped ventilating / viewing apertures, for use with a resilient backing plate also having shaped ventilating apertures. The apertures of one or both parts are shaped so that snagging of the apertures on projections from the work surface is minimized and to facilitate air flow across the work surface during use. This air flow helps in cooling the work and ejecting detritus, so minimising clogging effects. The ventilating apertures also facilitate viewing the work to be sanded through the spinning disk during the abrasion process, so that operator feedback is immediate. The holes also give the sanding disk more resilience so that a greater area comes in contact with the work and the disk wears more evenly over its abrasive surface.

Owner:MORTON CO

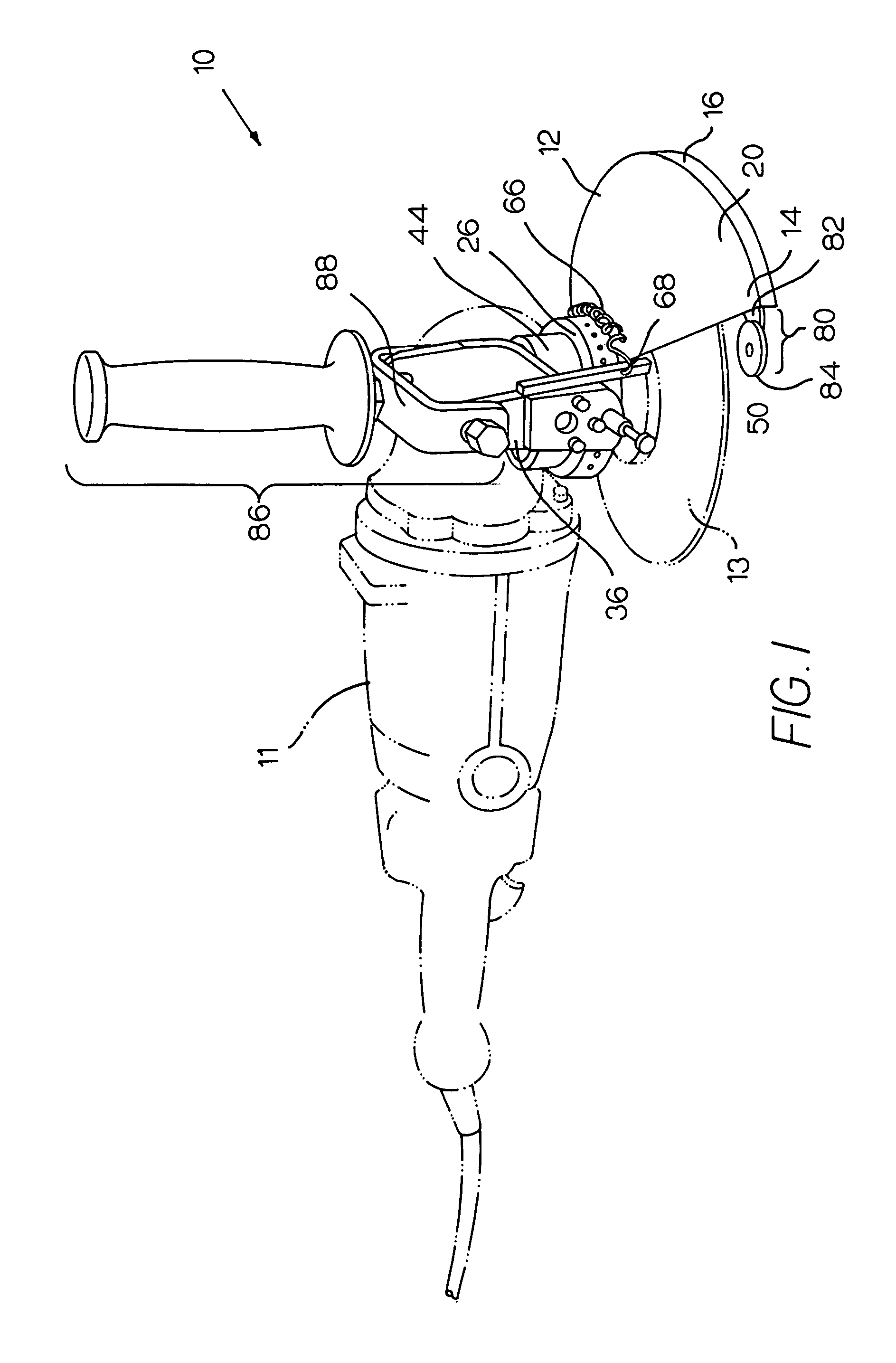

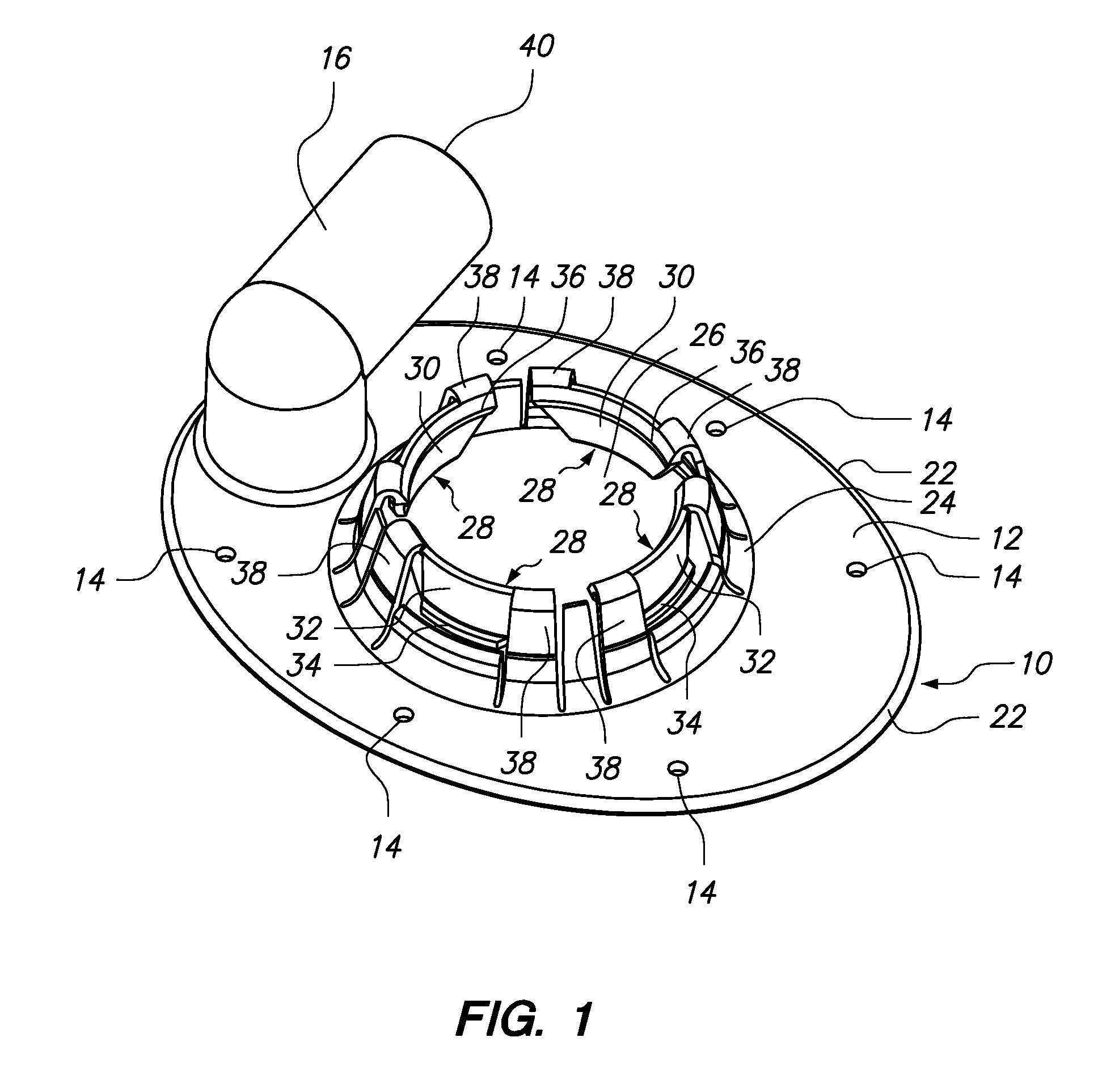

Rotating guard for angle grinder

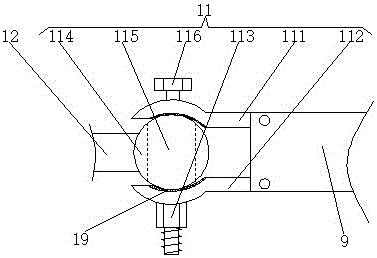

InactiveUS6893334B1Realize automatic adjustmentSimplified descriptionPortable grinding machinesGrinding/polishing safety devicesAngle grinderEngineering

A guard for a rotary cutting tool allows for automatic adjustment of the guard relative to the cutting disc and to a workpiece. Such an automatic adjustment allows a user to cut around substantially the entire circumference of a rounded workpiece, such as a pipe, without requiring alteration of the angle at which the tool is held, repositioning by the user, or repositioning or removal of the guard. The guard includes a bracket for mounting the guard to the rotary cutting tool, a hood mounted to the bracket and enclosing a portion of the cutting disc, and a spring for biasing one end of the hood into substantially continuous contact with the workpiece during operation of the rotary cutting tool.

Owner:STIVERS J DAVID

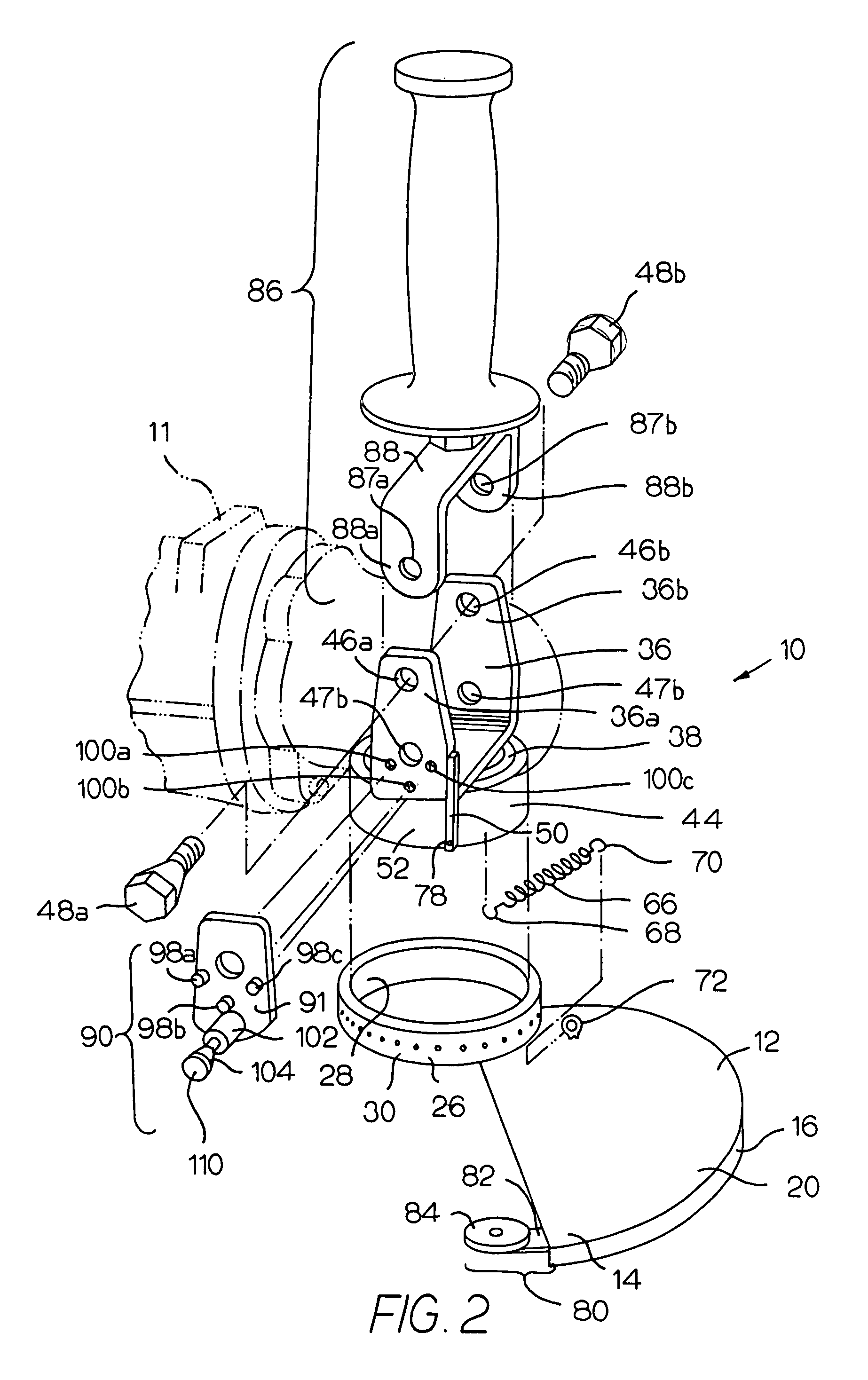

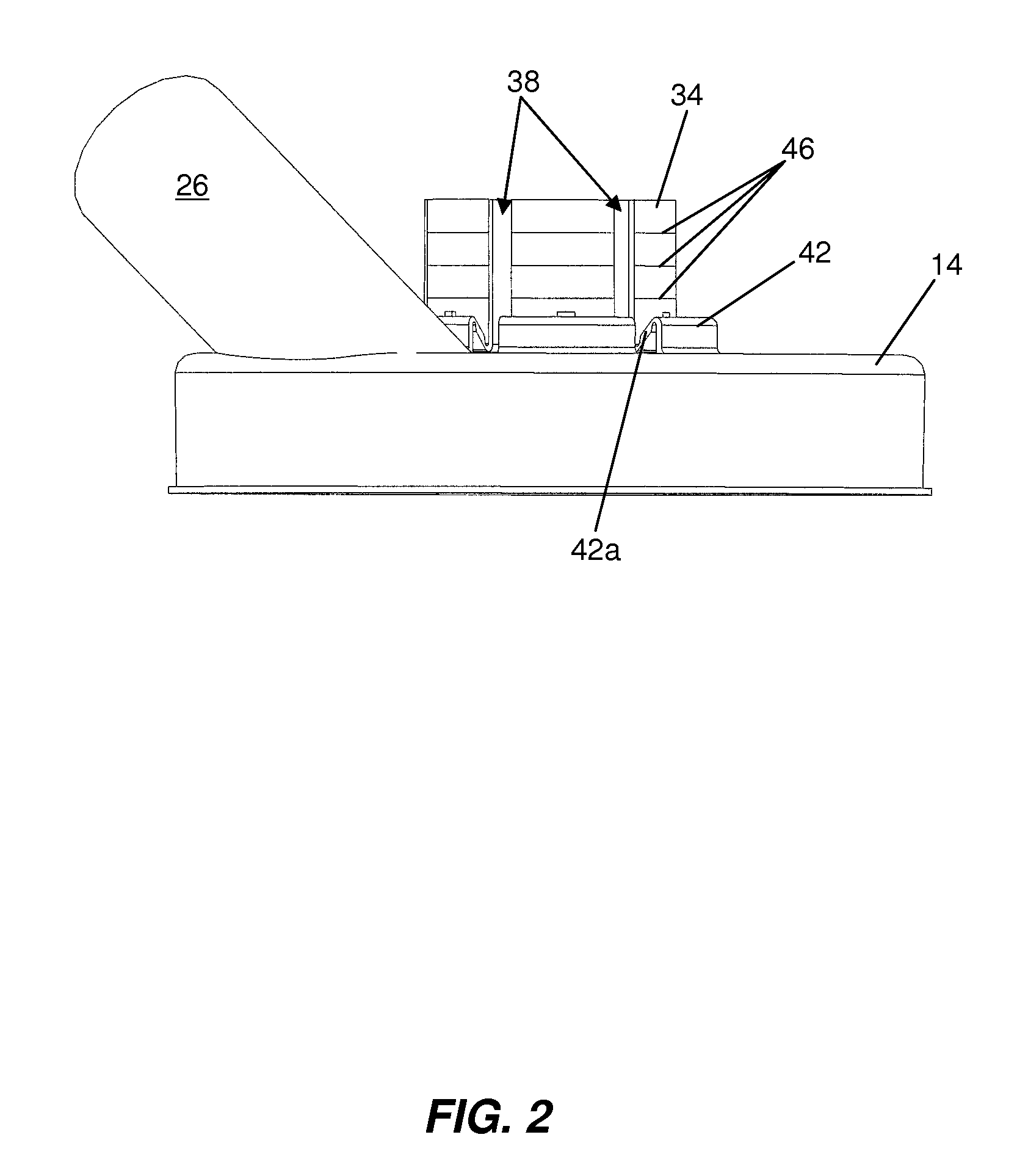

Method and apparatus for removing trip hazards in concrete sidewalks

InactiveUS7000606B2Smooth transitionMetal sawing devicesRevolution surface grinding machinesAngle grinderEngineering

An apparatus for cutting a chamfer on an upper edge of a concrete slab includes a hub designed for installation on the threaded output spindle of an angle grinder, and a specially-modified diamond-grit-edged rotary blade which mounts on the hub. For a preferred embodiment of the hub, an attachment collar is unitary and concentric with both a blade mounting flange having countersunk attachment screw holes and a blade centering shoulder on the flange. The attachment collar has at least one pair of flattened parallel sides for receiving a wrench used to tighten the hub on the output spindle. The blade, which is equipped with both countersunk attachment holes and a central positioning aperture sized to fit closely over the blade centering shoulder, is attachable with countersinking screws to the mounting flange so that the head of each screw is flush with the surface of the blade.

Owner:PRECISION CONCRETE CUTTING

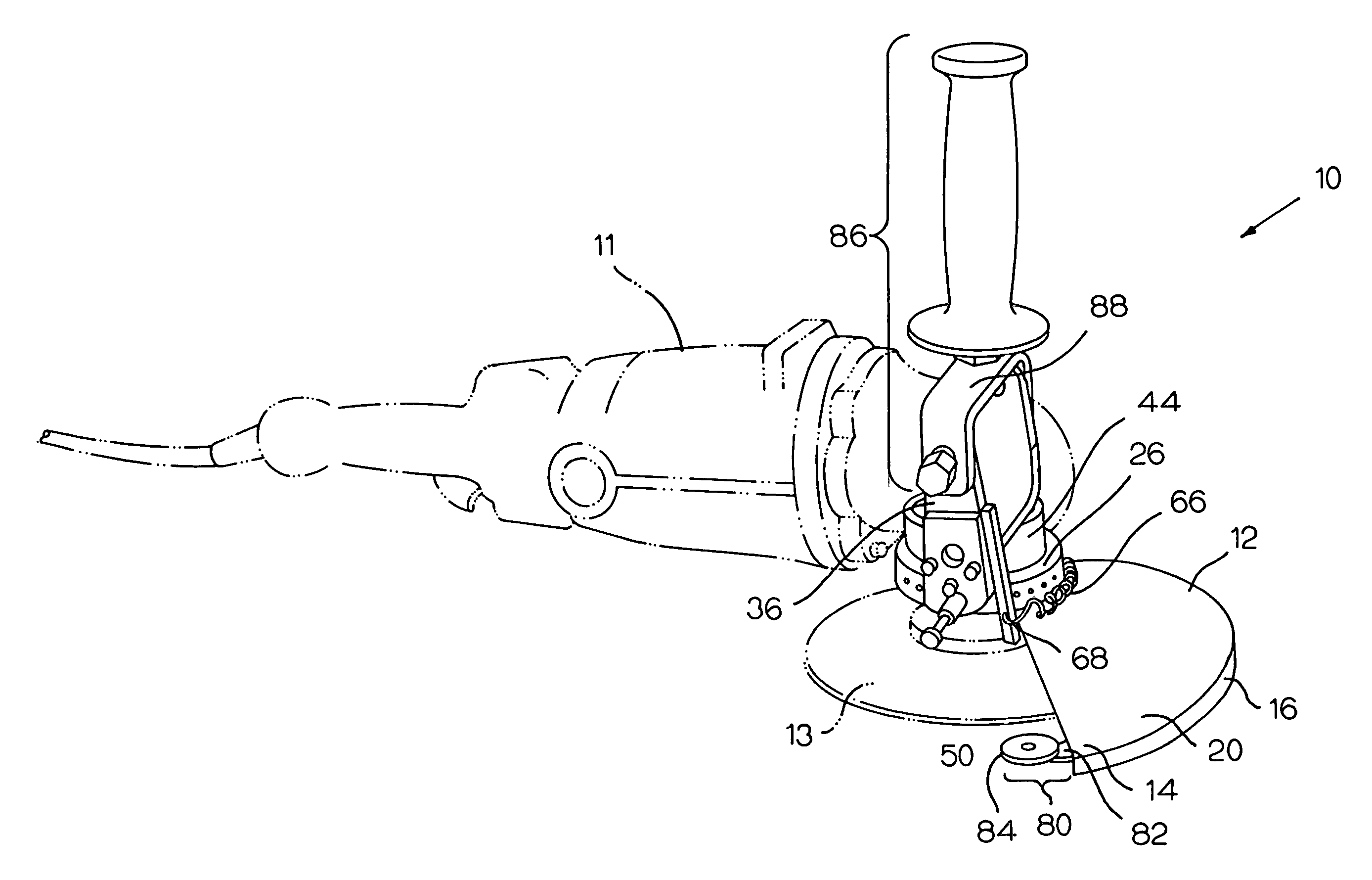

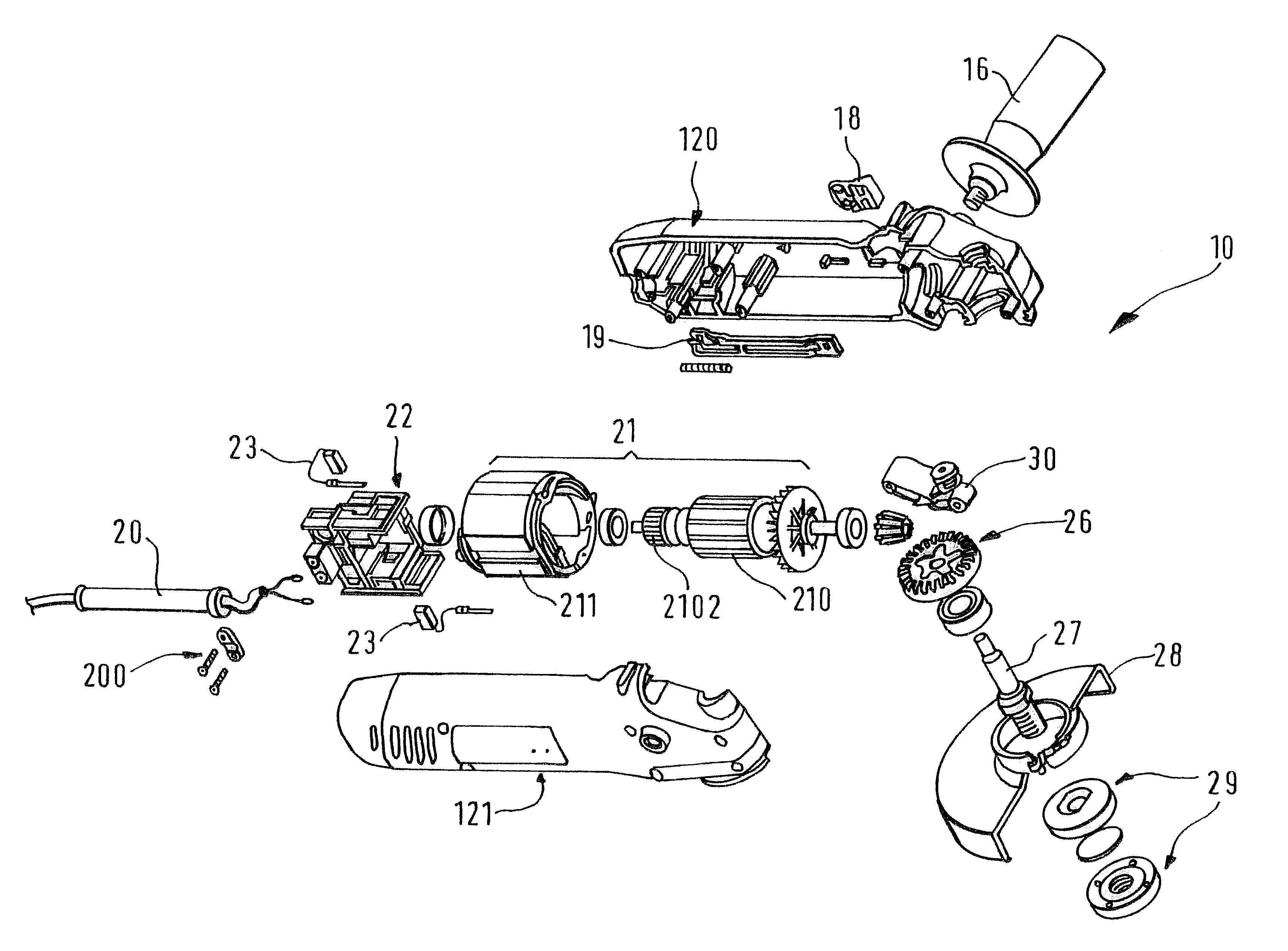

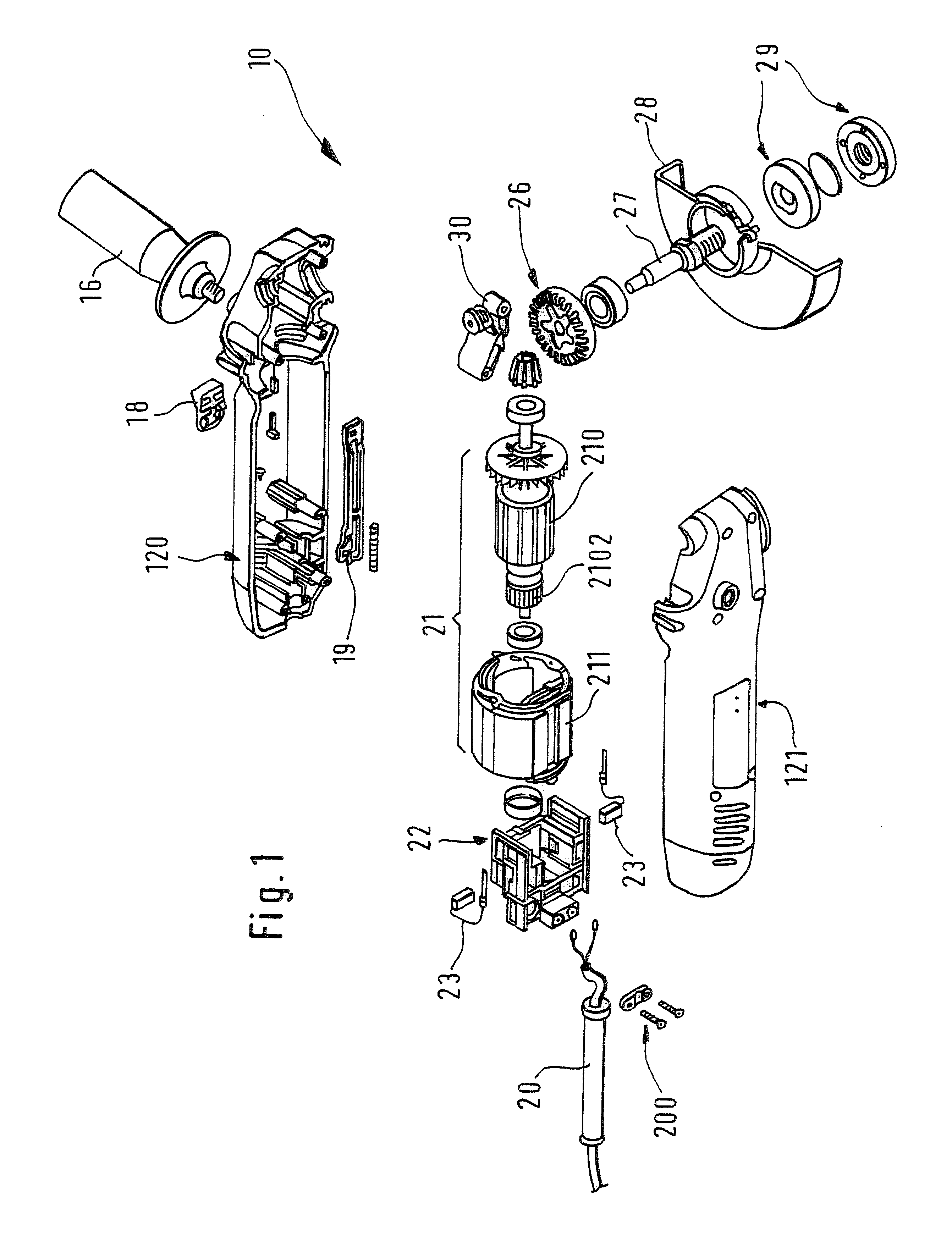

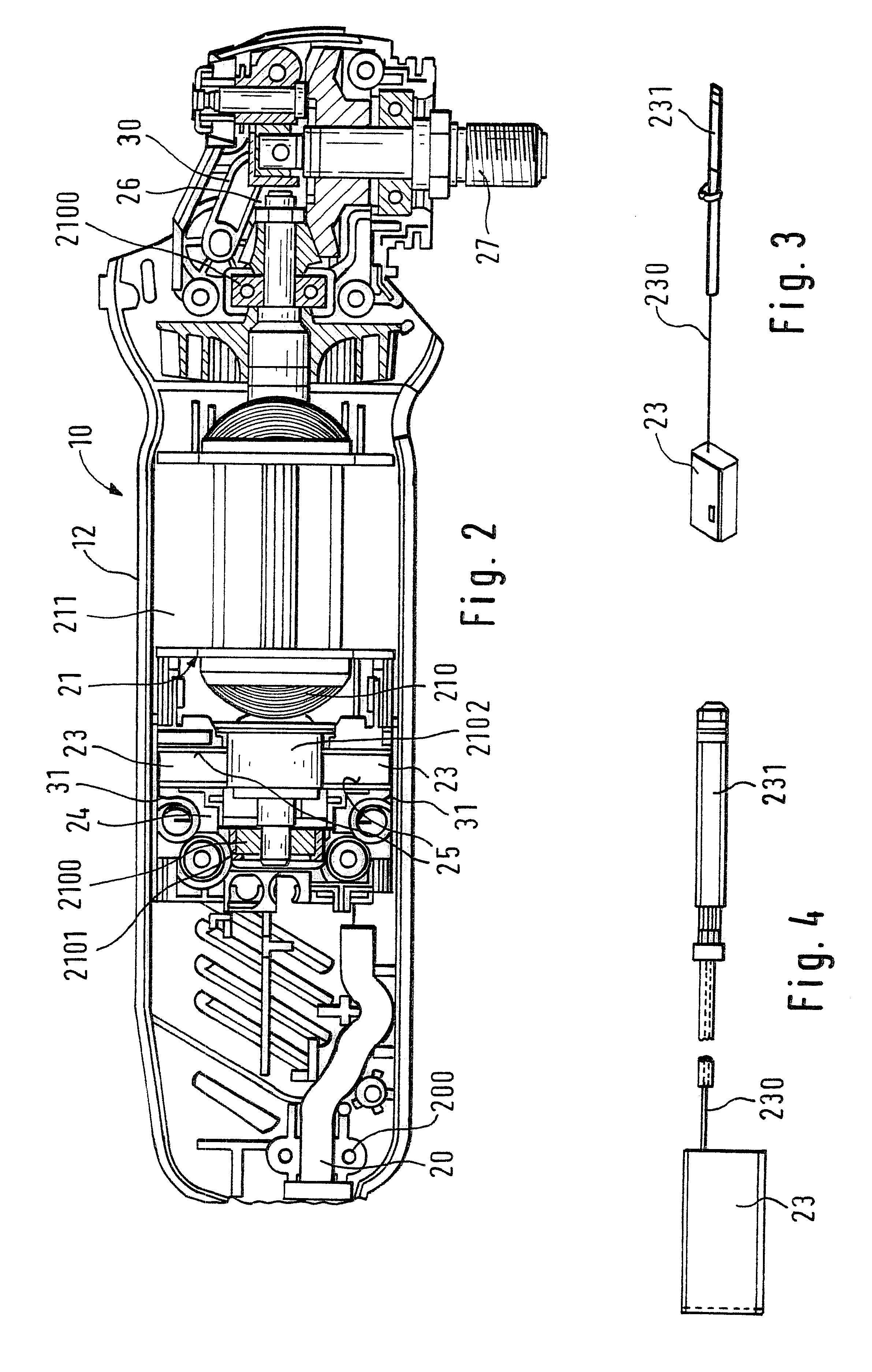

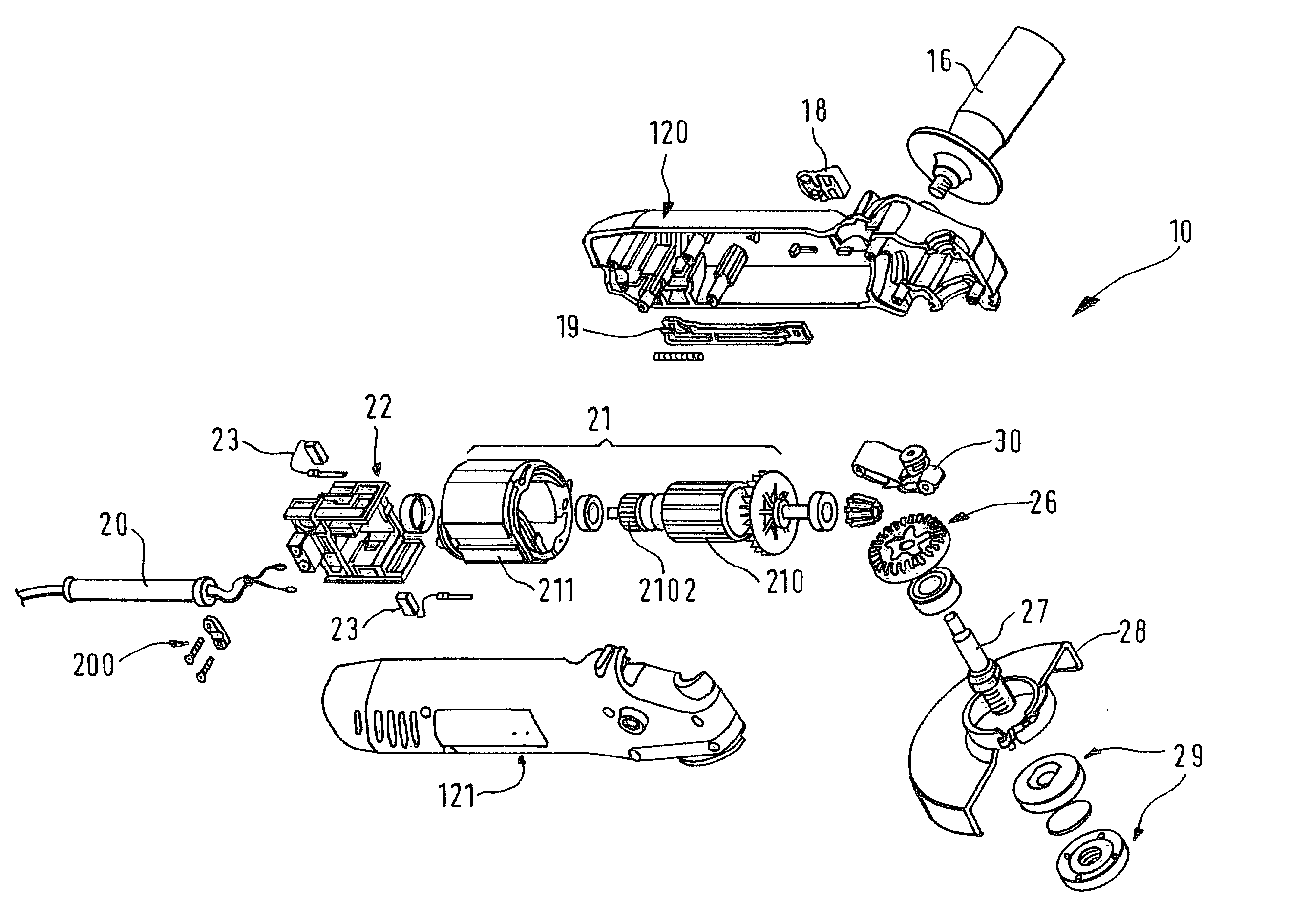

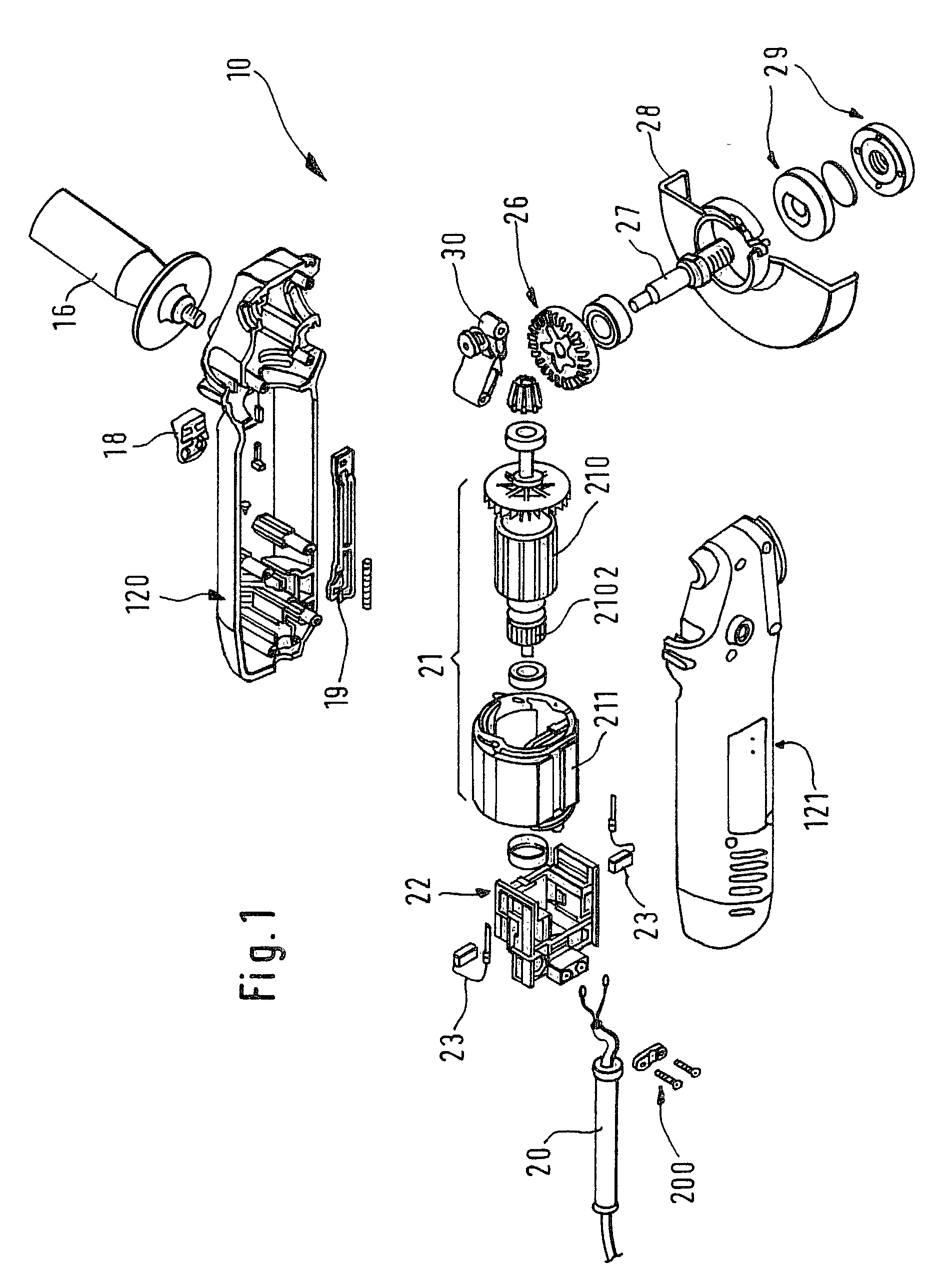

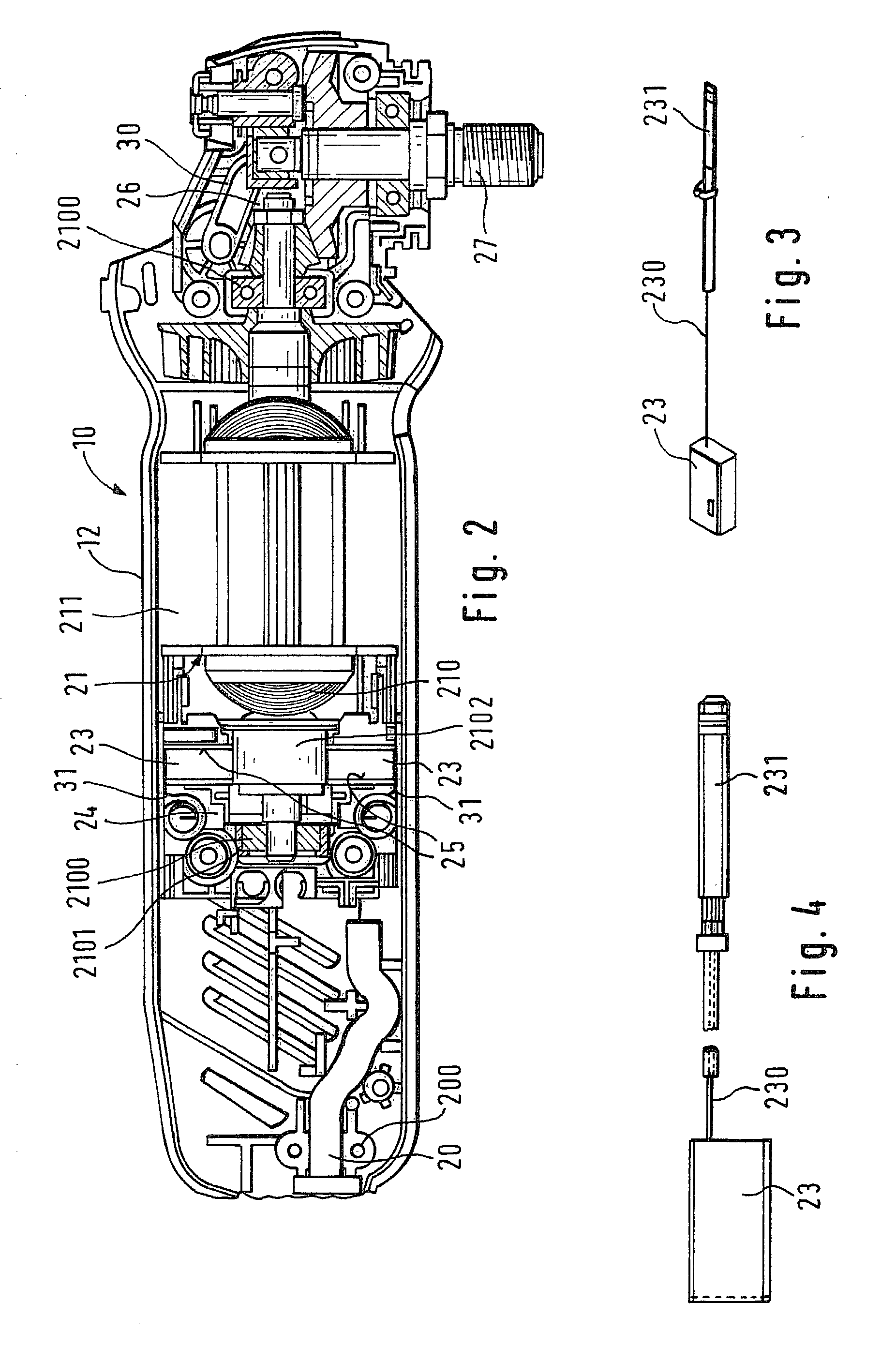

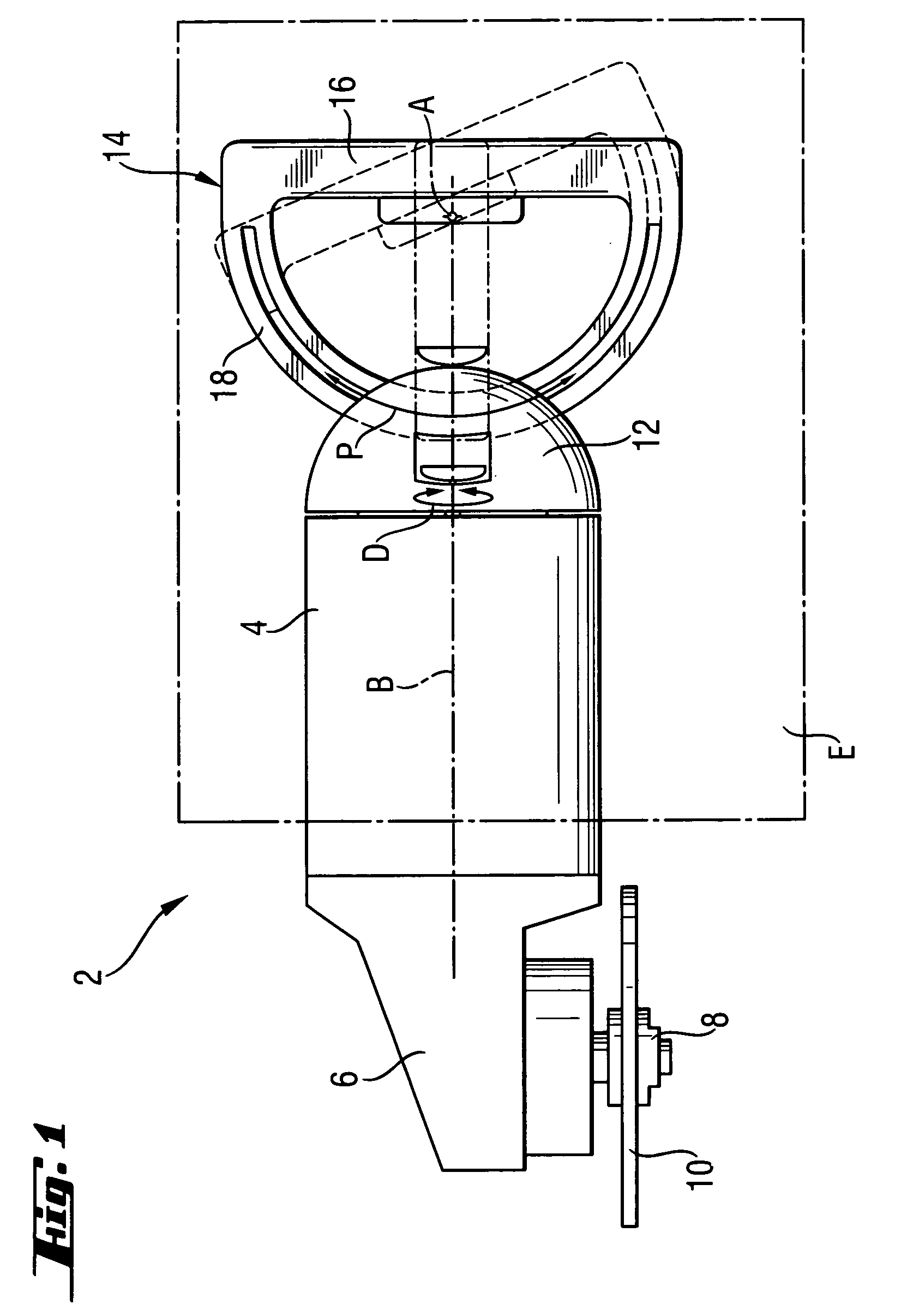

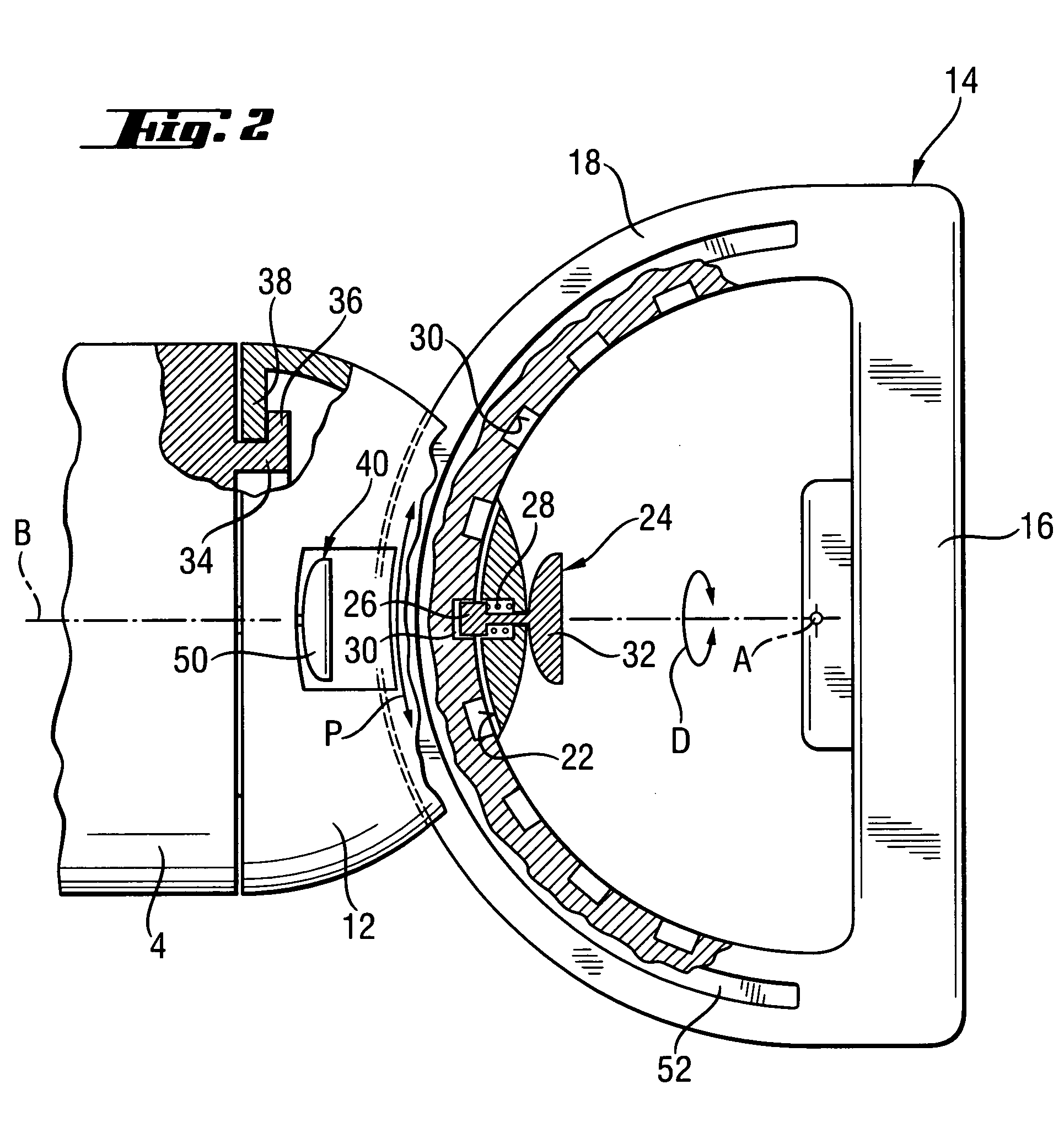

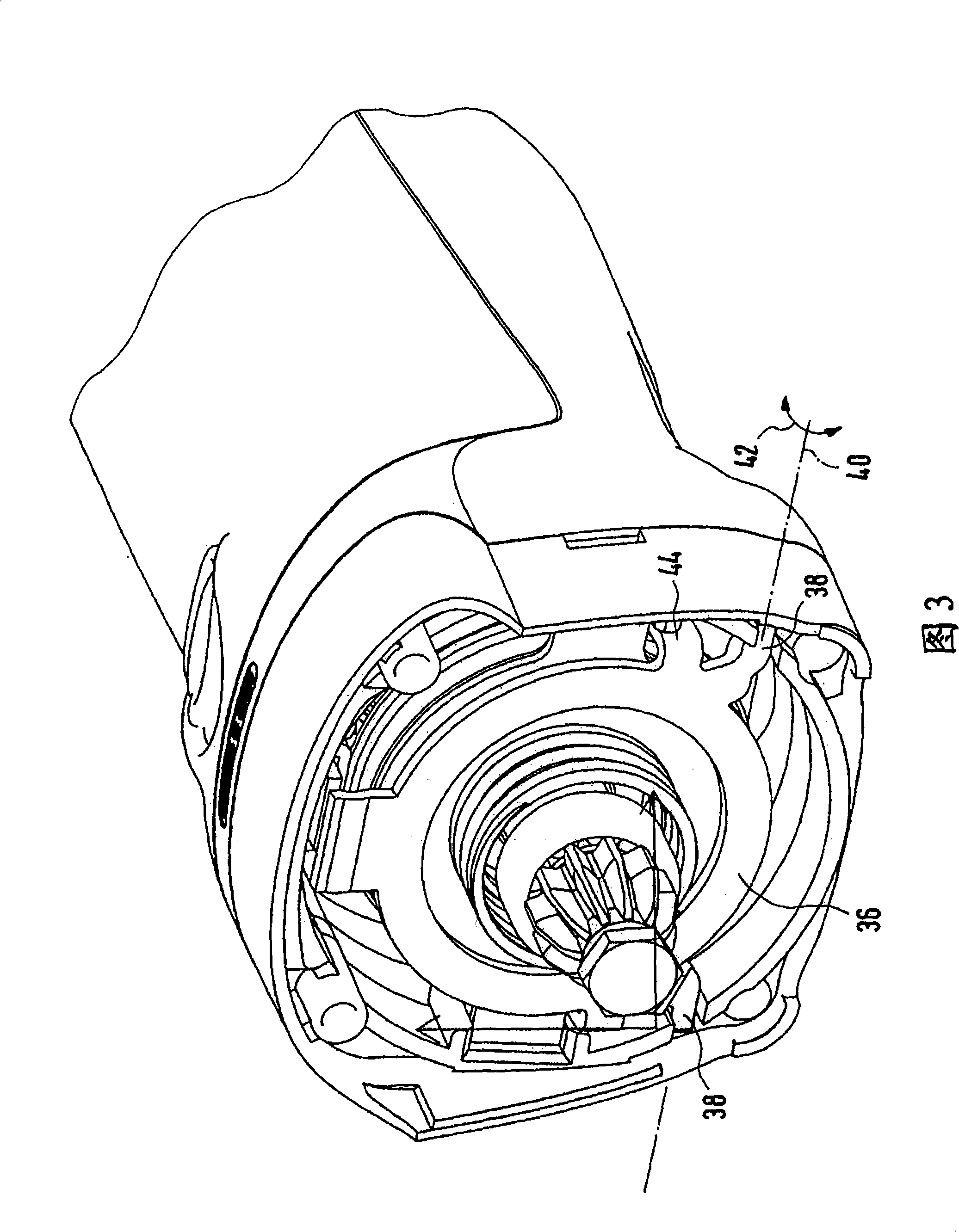

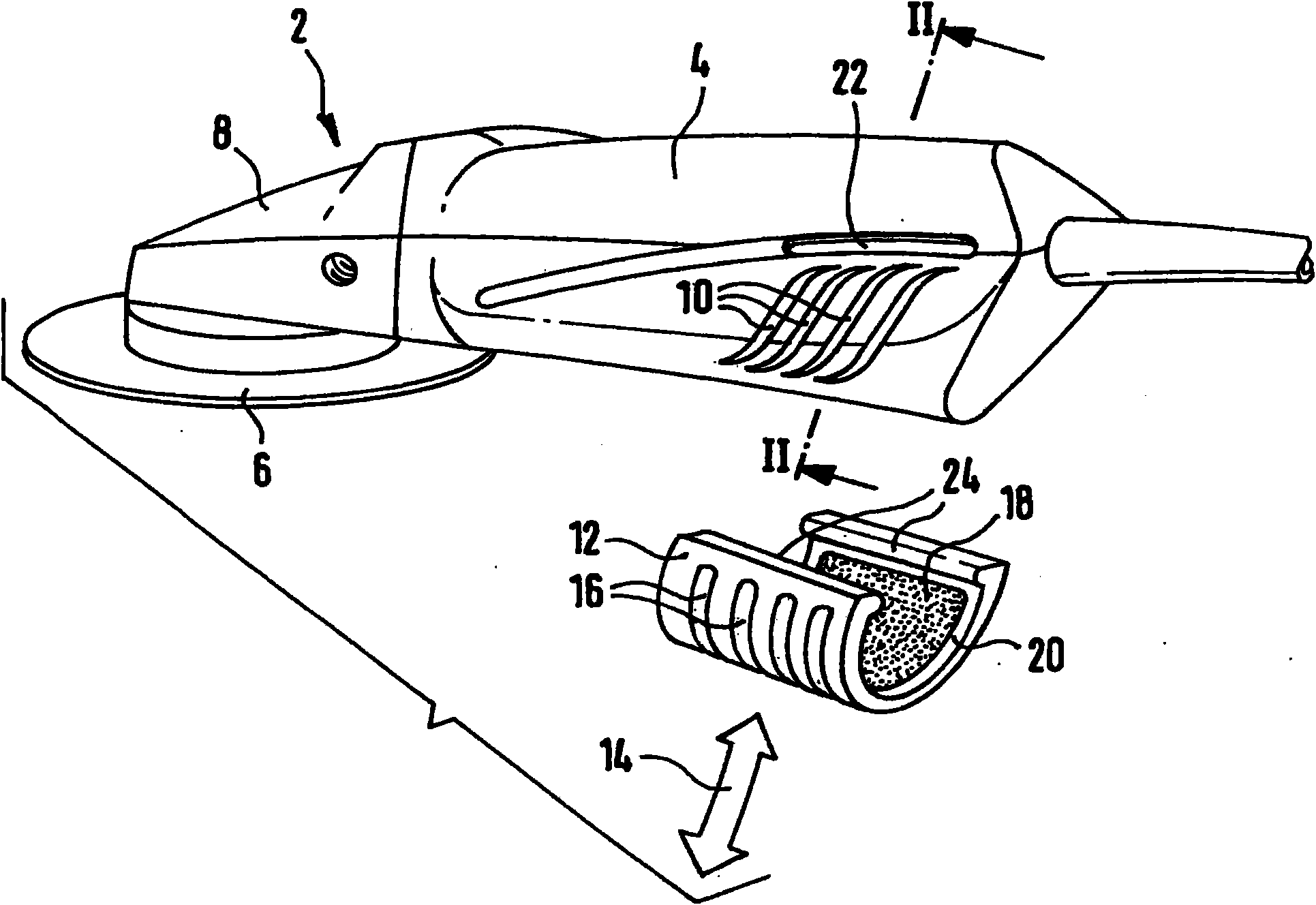

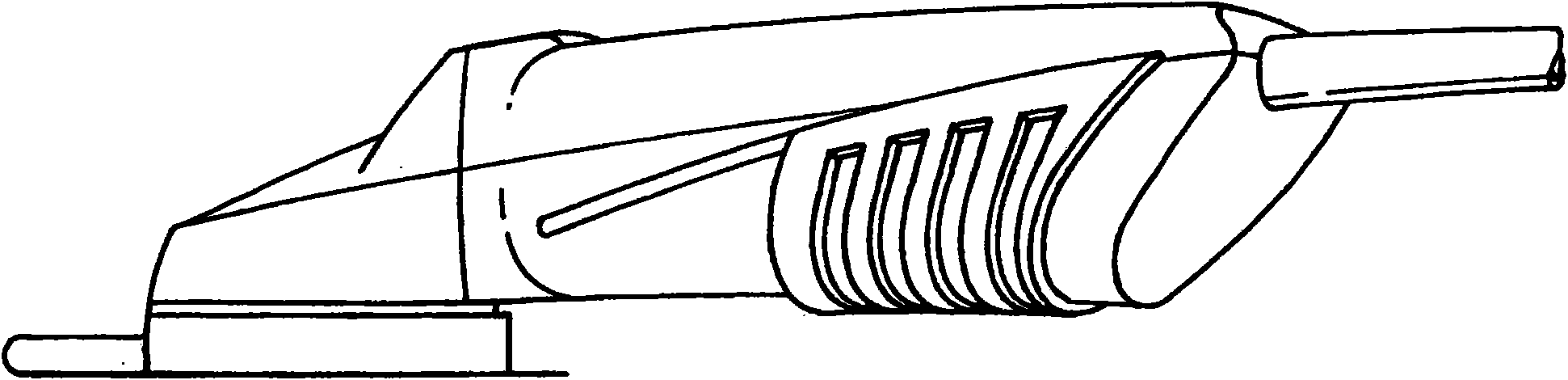

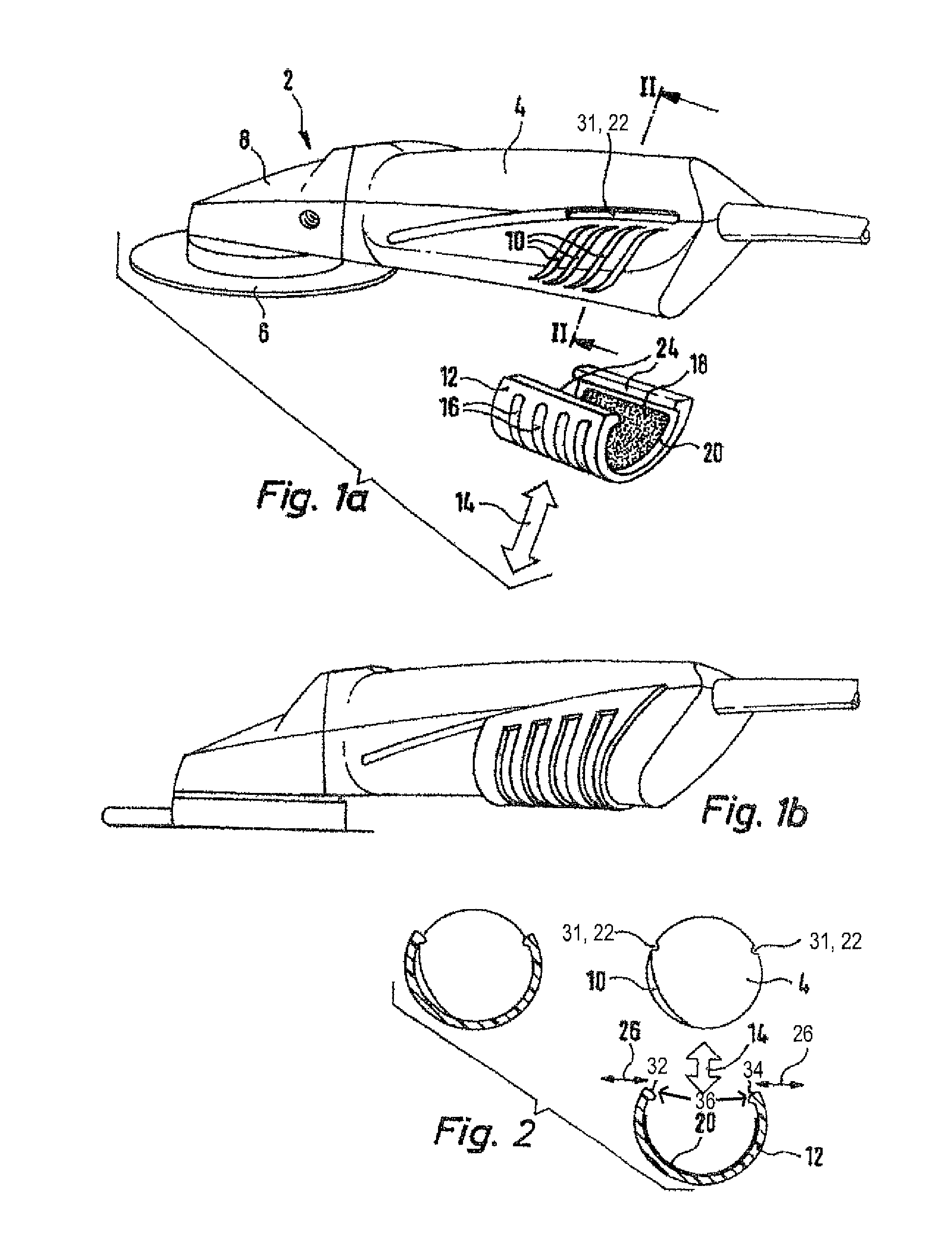

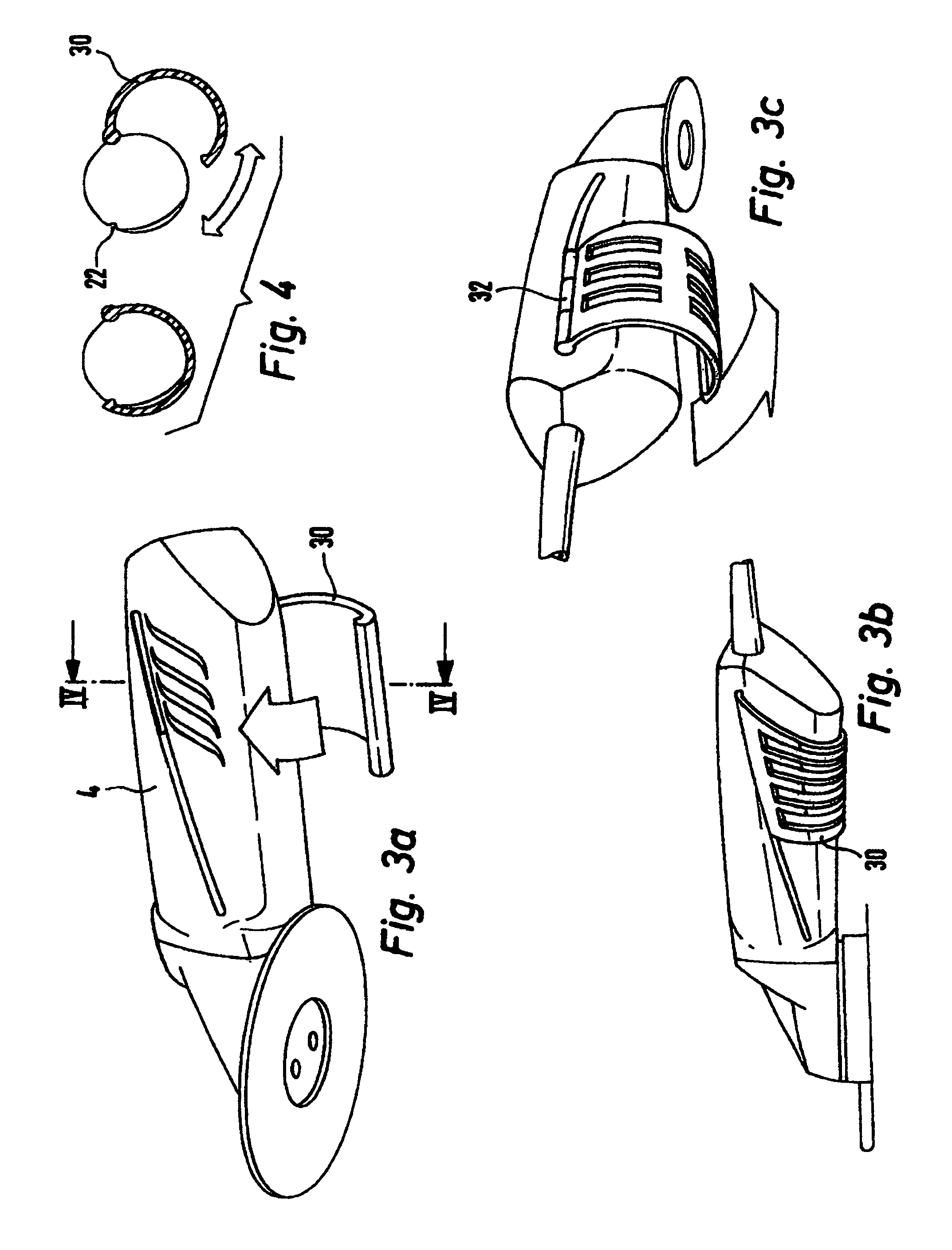

Angle grinder with electric drive

InactiveUS6632128B2Easy to replaceLow production costWindingsRotary current collectorAngle grinderGear wheel

A power tool (<HIL><PDAT>10< / BOLD><PDAT>), in particular an angle grinder, having a housing (<HIL><PDAT>12< / BOLD><PDAT>) that receives an electric motor (<HIL><PDAT>21< / BOLD><PDAT>) and a gear (<HIL><PDAT>26< / BOLD><PDAT>), the motor (<HIL><PDAT>21< / BOLD><PDAT>) having a rotor (<HIL><PDAT>210< / BOLD><PDAT>) which is guided in rotor bearings (<HIL><PDAT>2100< / BOLD><PDAT>) and on one hand carries a collector (<HIL><PDAT>2102< / BOLD><PDAT>), which collector can be put into contact with a voltage source via carbon brushes (<HIL><PDAT>23< / BOLD><PDAT>) supported in brush plates, is made sturdier and easier to install in that the housing (<HIL><PDAT>12< / BOLD><PDAT>) comprises two longitudinally split housing shells (<HIL><PDAT>120, 121< / BOLD><PDAT>), and that the brush plates are part of a bearing bridge (<HIL><PDAT>24< / BOLD><PDAT>) that carries both the rotor bearing (<HIL><PDAT>2100< / BOLD><PDAT>) and the carbon brushes (<HIL><PDAT>23< / BOLD><PDAT>), and the bearing bridge (<HIL><PDAT>24< / BOLD><PDAT>), in the guide region of the carbon brushes (<HIL><PDAT>23< / BOLD><PDAT>), comprises plastic.< / PTEXT>

Owner:ROBERT BOSCH GMBH

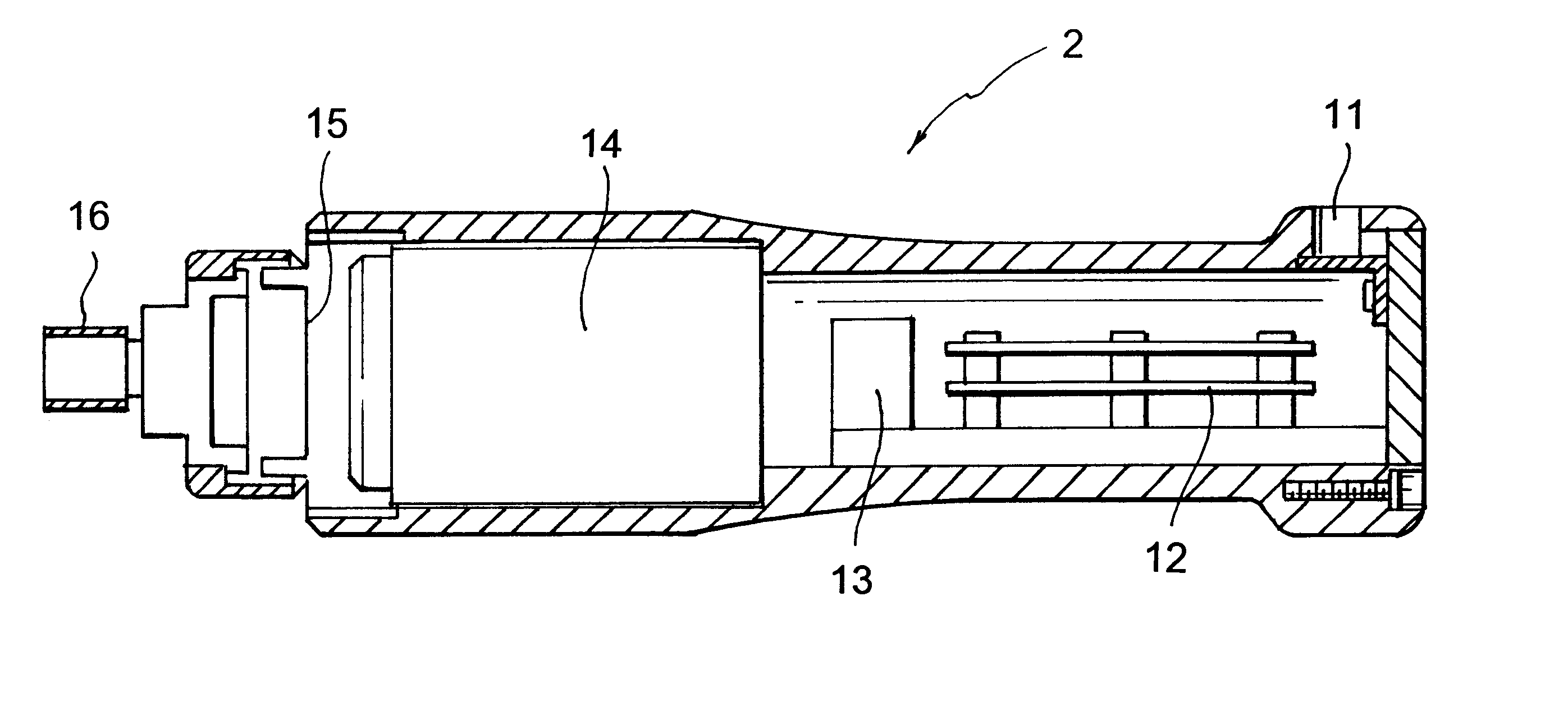

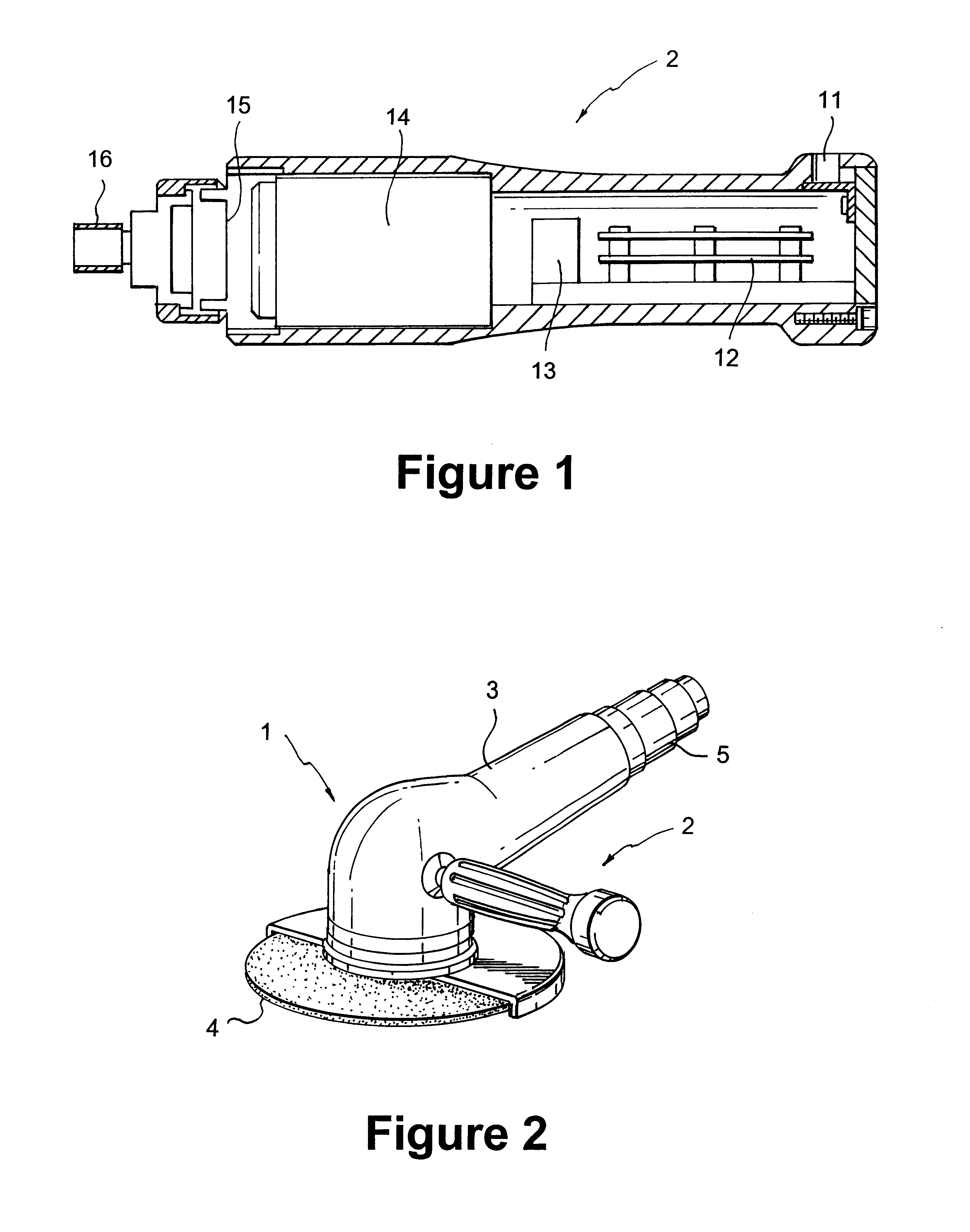

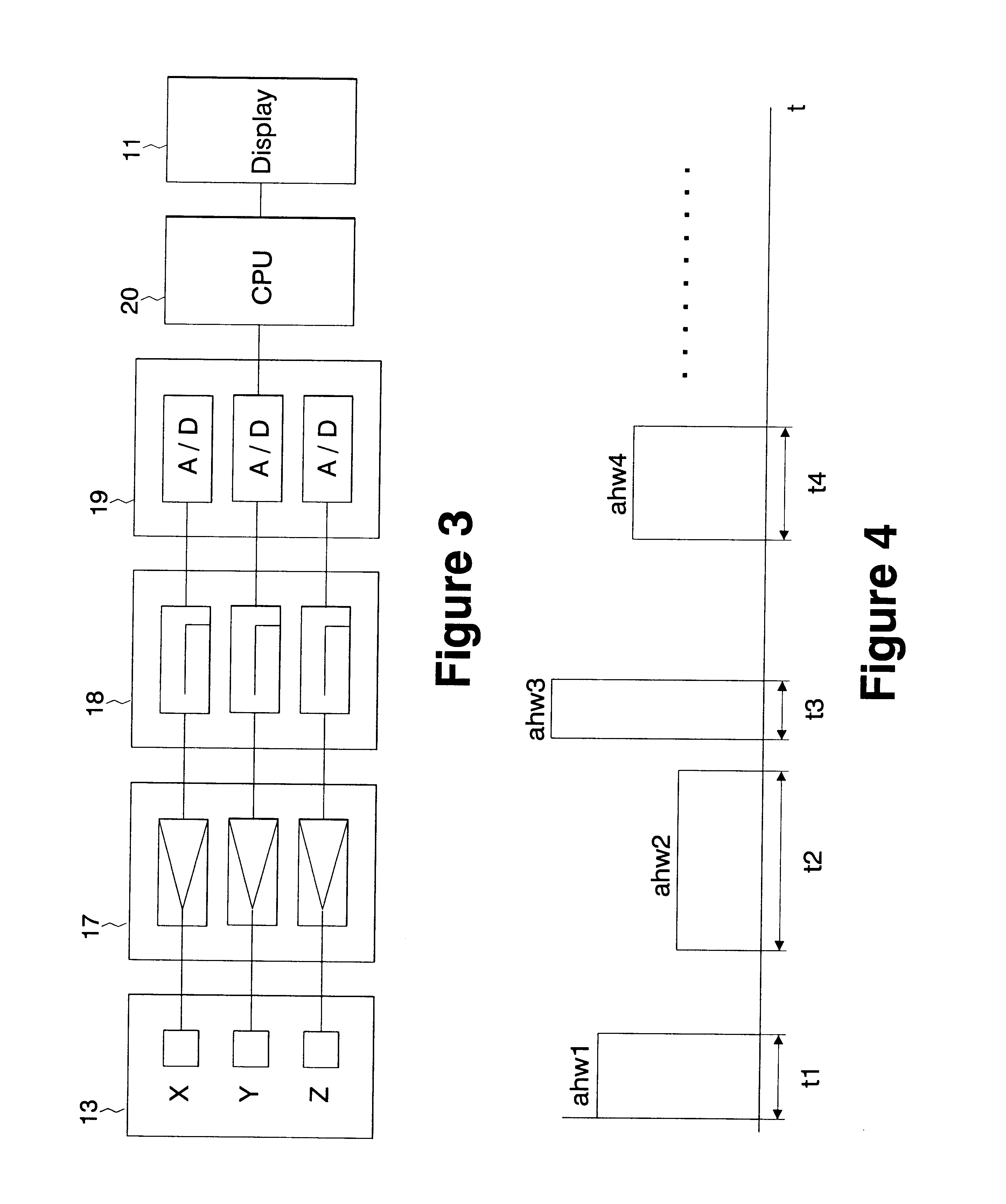

Human body vibration evaluation device and hand-held vibration tool

InactiveUS6490930B1Vibration measurement in solidsSubsonic/sonic/ultrasonic wave measurementMicrocomputerHuman body

A three-axis vibration acceleration pickup with the handle of a vibration-generating tool such as, an angle grinder or the like, feeds detected vibrations along the three axes to an A / D converter 19. A microcomputer processes the digitized data to feed a display portion. Each time continuous operation of the tool is interrupted, an 8-hour equivalent acceleration value is obtained based on the detected vibration acceleration signal. The result is added to previous acceleration values so as to accumulatively add up the total value in one day. Each time continuous operation is interrupted, a frequency load vibration acceleration value is obtained, and an 8-hour equivalent acceleration value is obtained based on this. A residual surplus time is obtained and displayed by using the 8-hour equivalent acceleration value.

Owner:FUJI AIR TOOL

Angle grinder with electric drive

InactiveUS20020151262A1Low production costEasy to replaceWindingsRotary current collectorAngle grinderGear wheel

A power tool (10), in particular an angle grinder, having a housing (12) that receives an electric motor (21) and a gear (26), the motor (21) having a rotor (210) which is guided in rotor bearings (2100) and on one hand carries a collector (2102), which collector can be put into contact with a voltage source via carbon brushes (23) supported in brush plates, is made sturdier and easier to install in that the housing (12) comprises two longitudinally split housing shells (120, 121), and that the brush plates are part of a bearing bridge (24) that carries both the rotor bearing (2100) and the carbon brushes (23), and the bearing bridge (24), in the guide region of the carbon brushes (23), comprises plastic.

Owner:ROBERT BOSCH GMBH

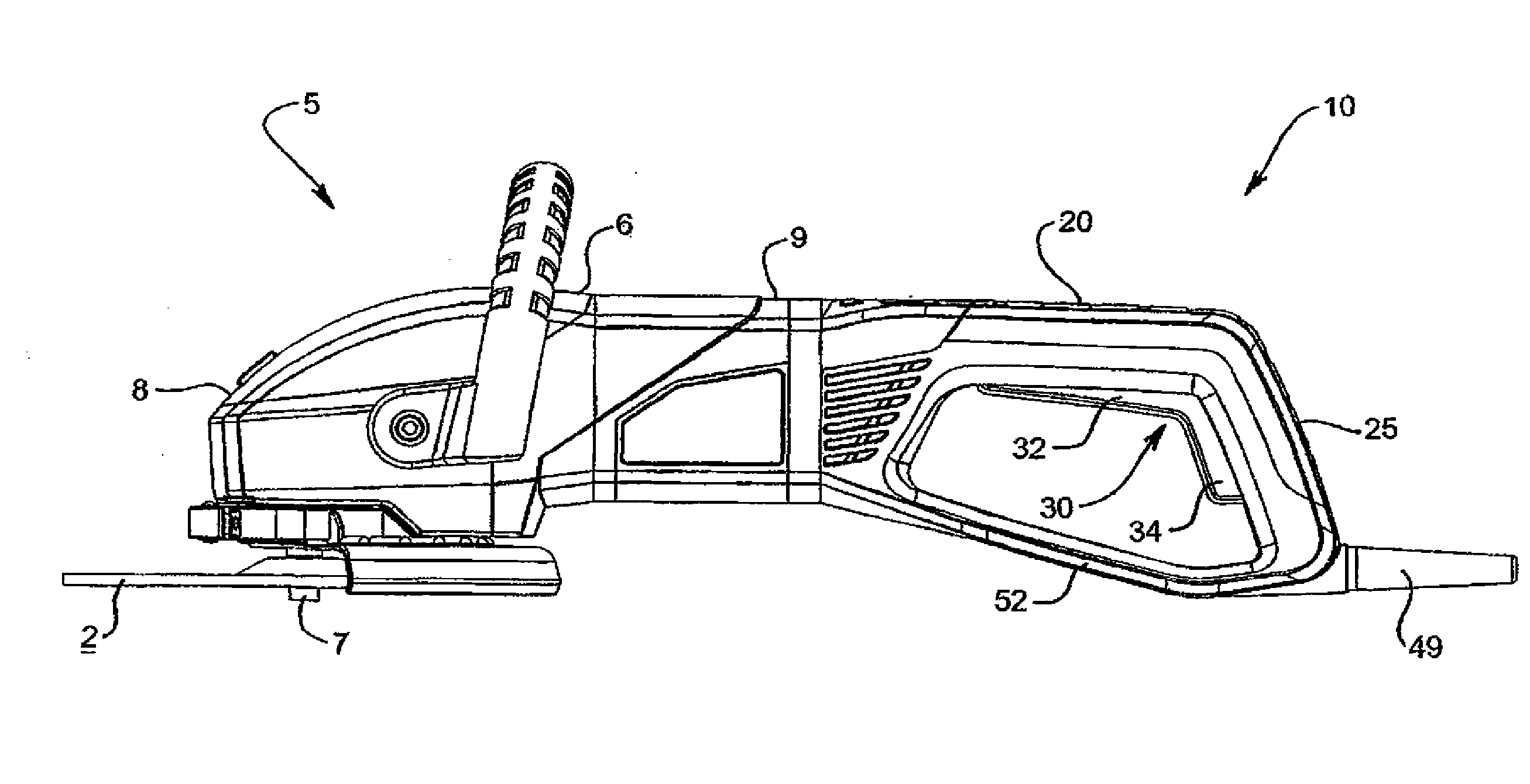

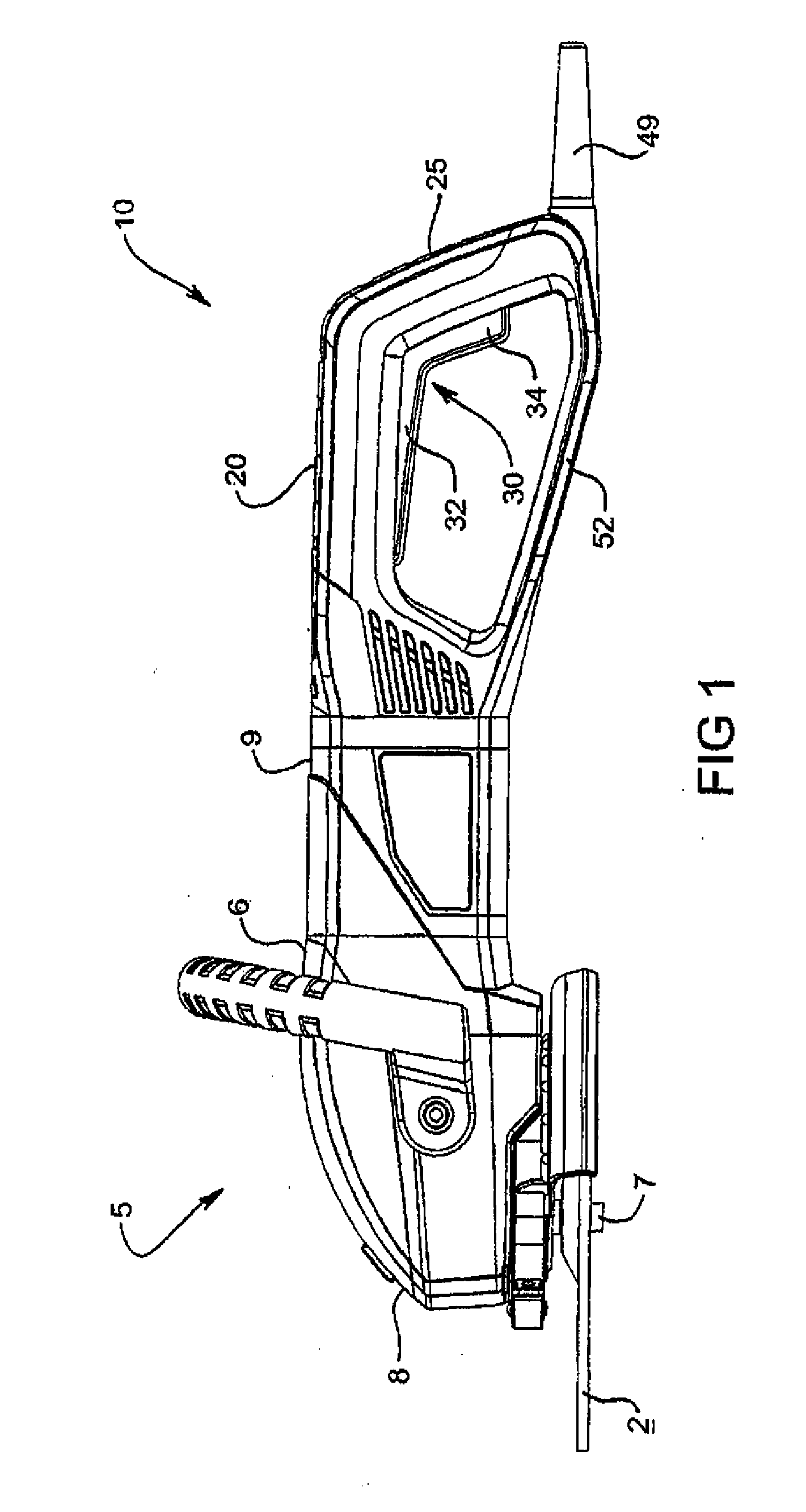

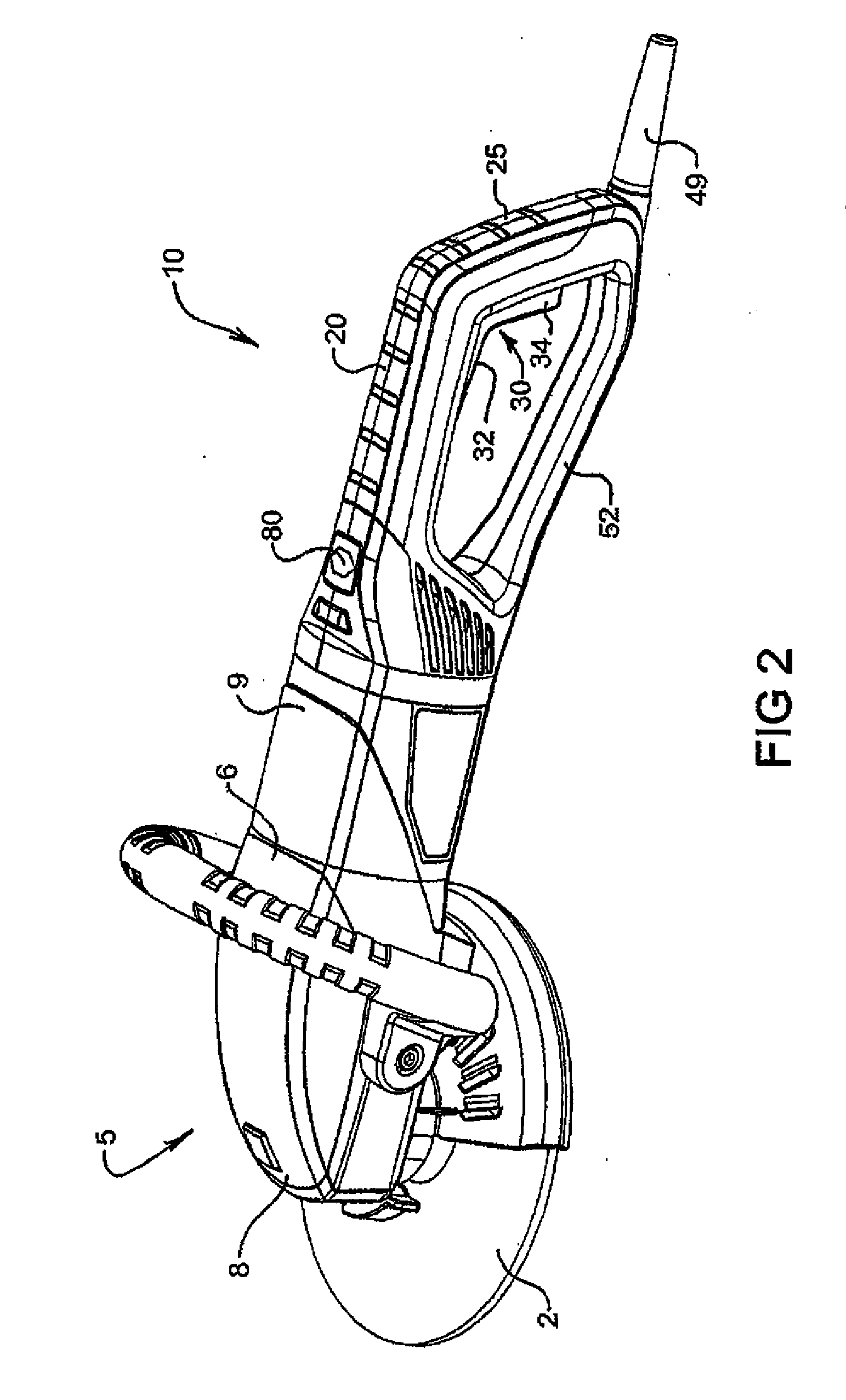

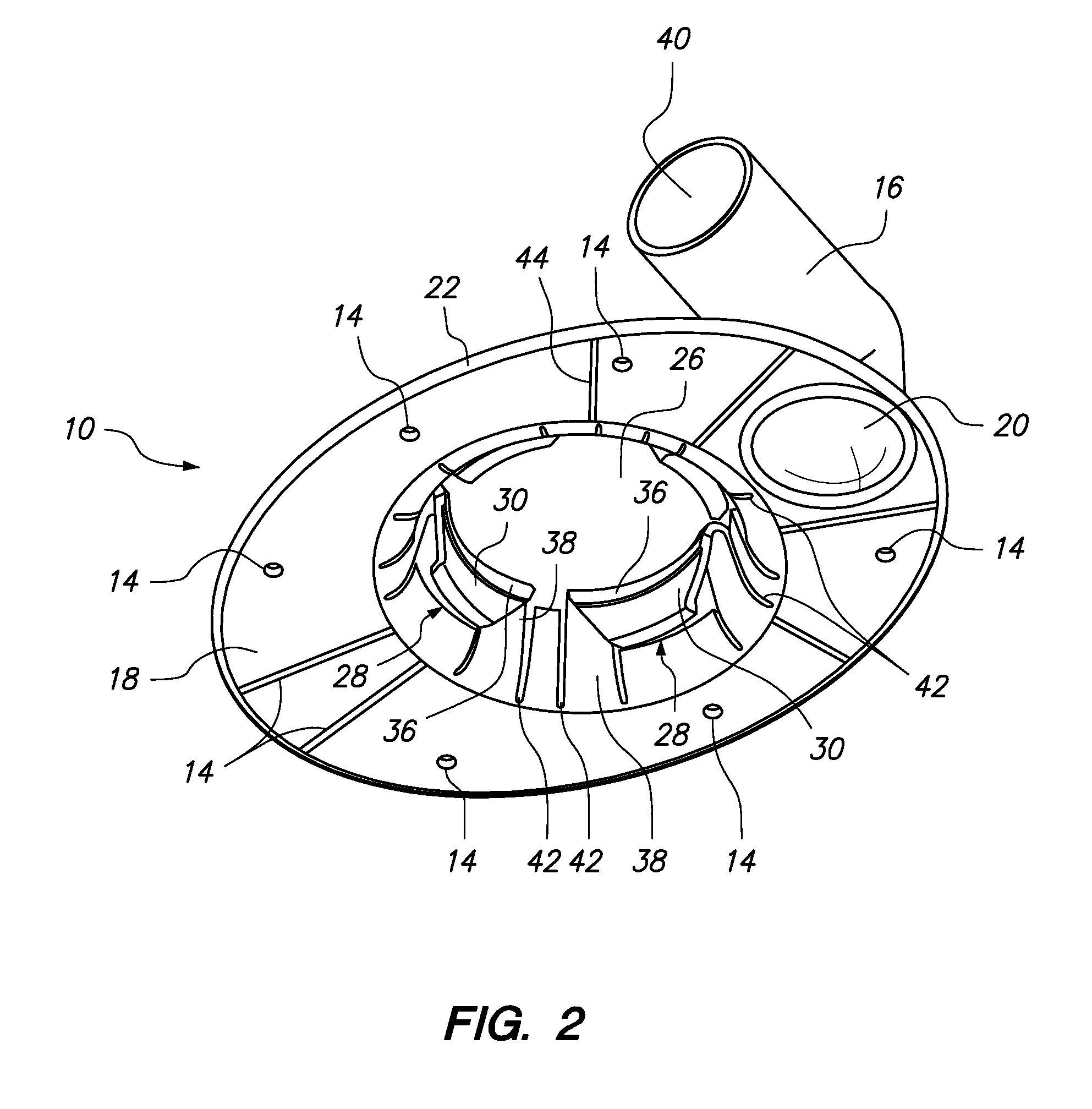

Handle assembly for a power tool

InactiveUS20090104861A1Process controlLess discomfortControlling membersOperator-supported drilling machinesAngle grinderEngineering

A handle assembly for a power tool, such as an angle grinder, including first and second handle portions for gripping the power tool, the first handle portion extending substantially transverse to the second handle portion. The handle assembly also having a trigger including an elongate portion associated with the first handle portion and a flange portion associated with the second handle portion and a switch for operating the power tool actuated by movement of either the elongate or flange portion of the trigger relative to the first or second handle portions respectively.

Owner:DEMAIN TECH

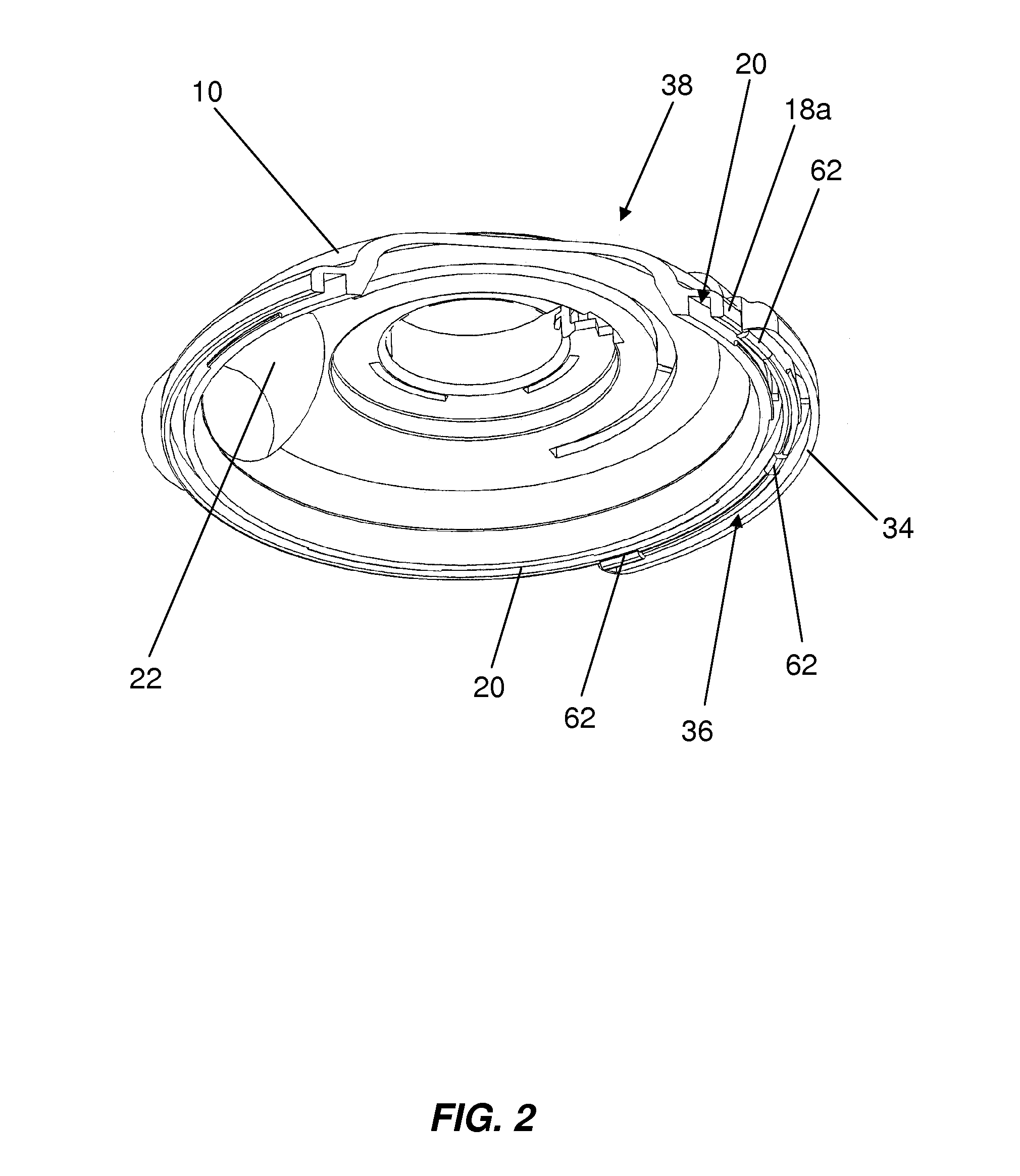

Angle grinder dust shroud with slideable access hatch

ActiveUS20110021121A1Improve complianceEasy to usePortable grinding machinesGrinding/polishing safety devicesAngle grinderEngineering

A dust shroud for an angle grinder includes an access hatch which slides along the shroud body to selectively expose an edge of a grinding disc to allow grinding into a corner. The hatch remains attached to the shroud body in both the open and closed position, making the hatch easier to use and less likely to become lost, resulting in increased worker compliance in properly using the hatch.

Owner:DUSTLESS DEPOT

Hood plates for handheld grinding tools

InactiveUS7625265B2Portable grinding machinesGrinding/polishing safety devicesAngle grinderHand held

Hood plates for use with hood covers designed for handheld power tools including angle grinders are disclosed herein. More specifically, the hood plates disclosed herein include means for easily attaching to a wide variety of available angle grinders and are easily configured to work with a soft hood cover to allow both horizontal and vertical movement of the grinding attachment within the hood cover.

Owner:IT INC

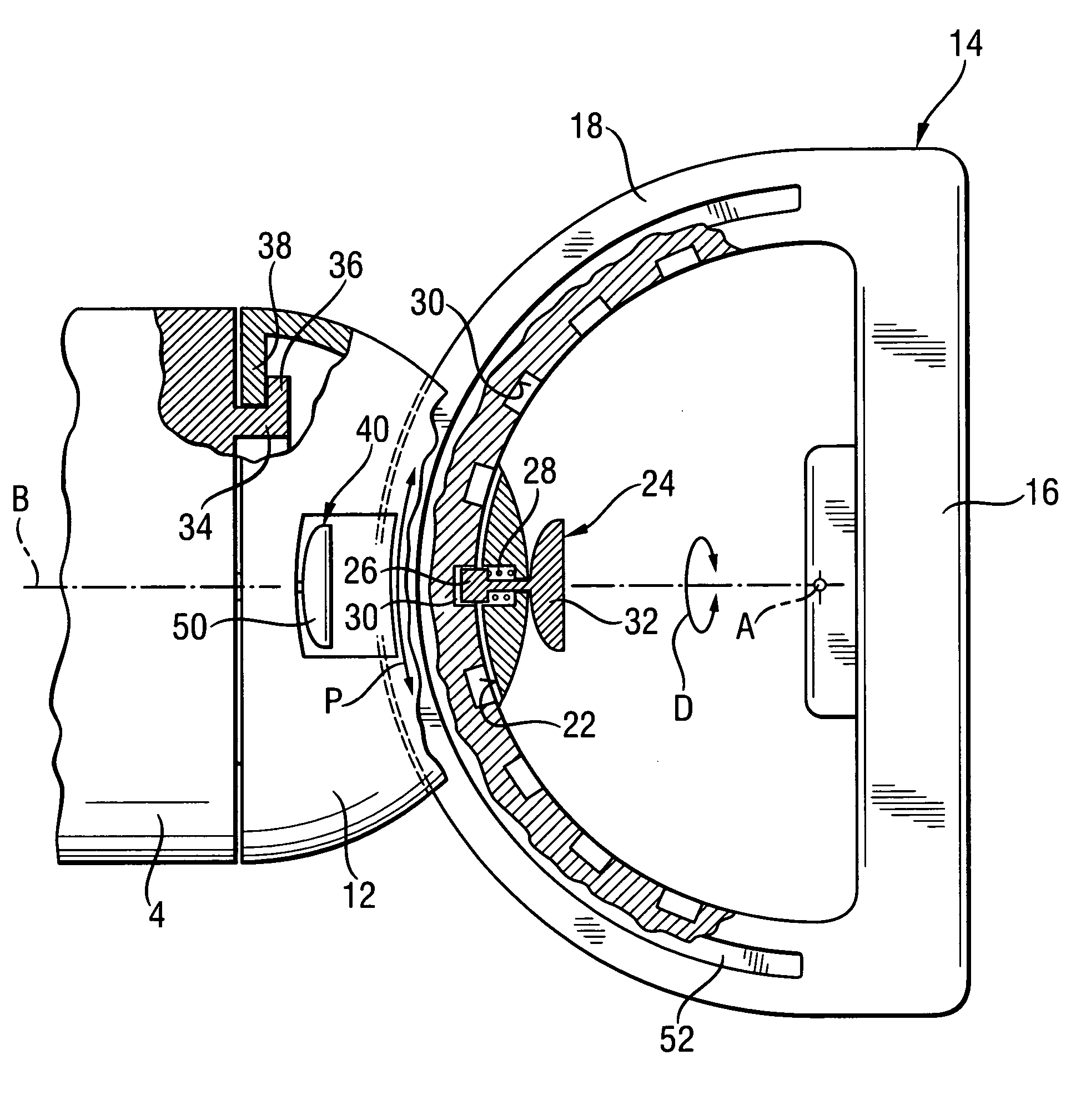

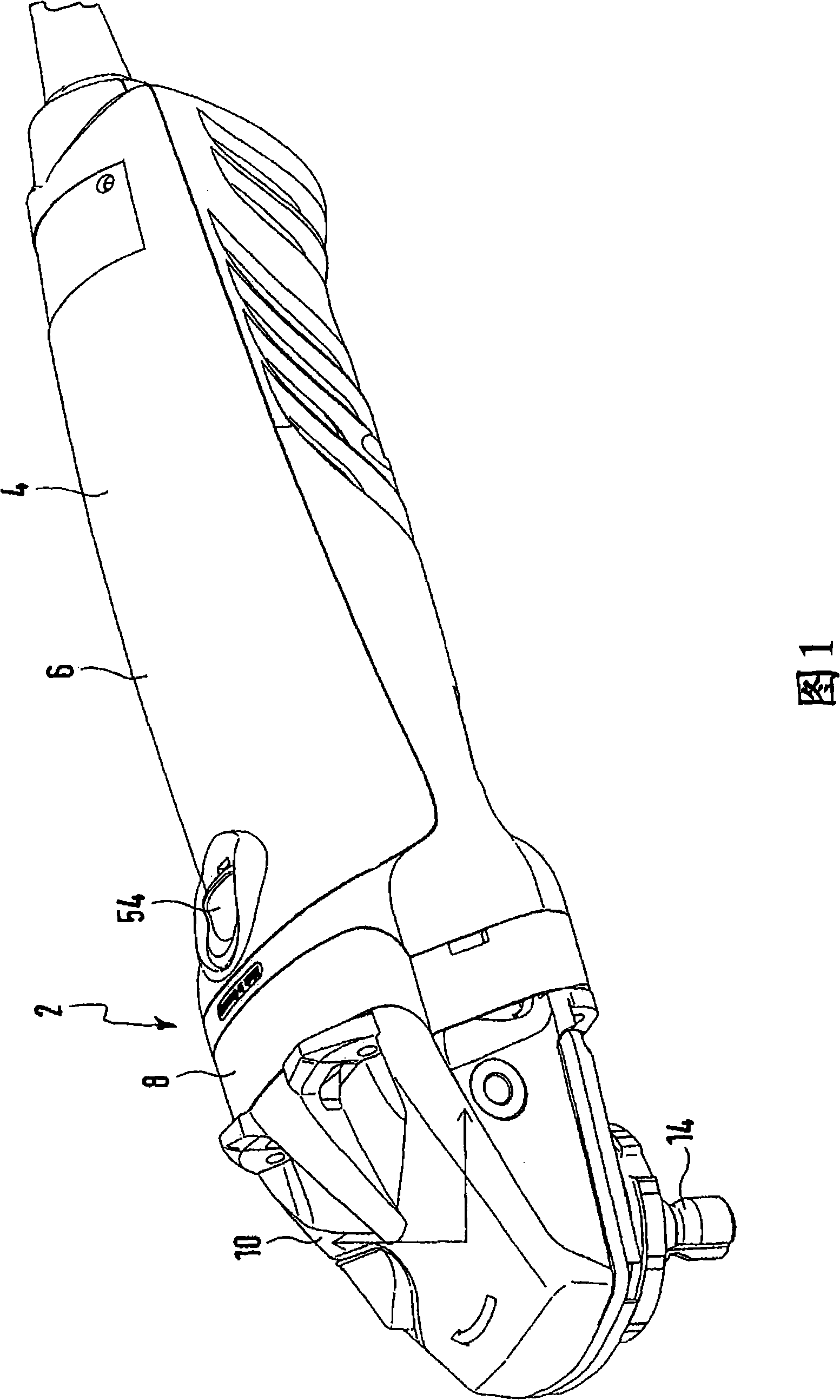

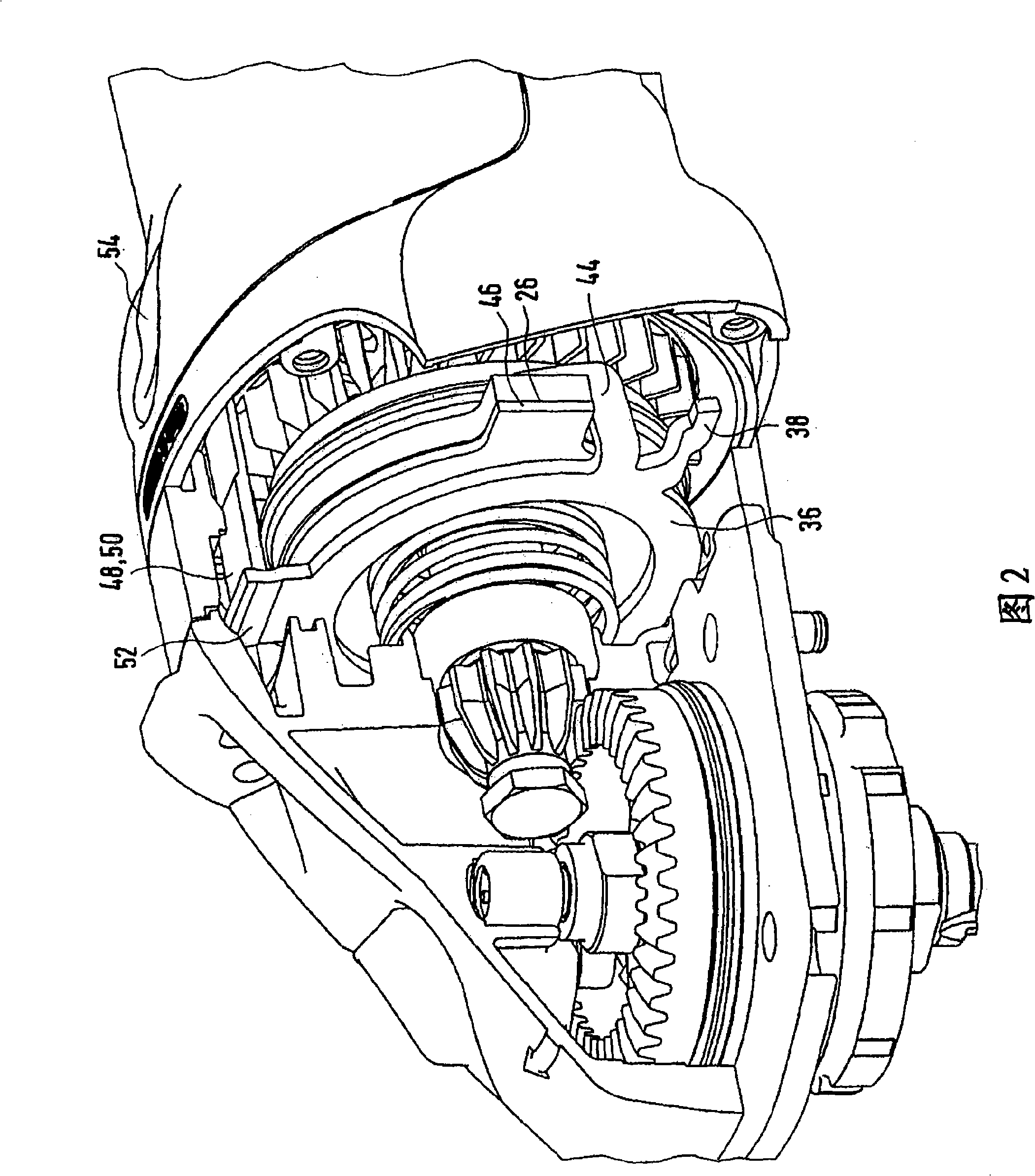

Handle for a power tool

InactiveUS20060025060A1Improve gripMany possibilityPortable grinding machinesPortable power-driven toolsRotational axisAngle grinder

A hand-held power tool, in particular an angle grinder, includes a housing (4) having, at its working tool side end, a tool head (6) to which a working tool (10) is secured; a main handle (14) connected to the housing (4) at its handle side end remote from the working tool side end of the housing (4), rotatable about a rotational axis (B), and having an adjustably inclined relative to the rotational axis (B).

Owner:HILTI AG

Portable electric tool with braking device

ActiveCN101254588AStable floating installationEasy to installSelf acting brakesPortable grinding machinesEngineeringAngle grinder

The electrical hand tool unit, particularly angle grinder or cut-off grinder, has a drive housing (10), a motor housing part (6) and handle part. A counter-brake disc (26) is moved in release direction from a laminar actuating mechanism (36) extending in a level parallel to the level of the counter-brake disc against the spring pre-tensioning and the laminar actuating mechanism is tilted relative to the earlier level around a certain level.

Owner:麦太保有限公司

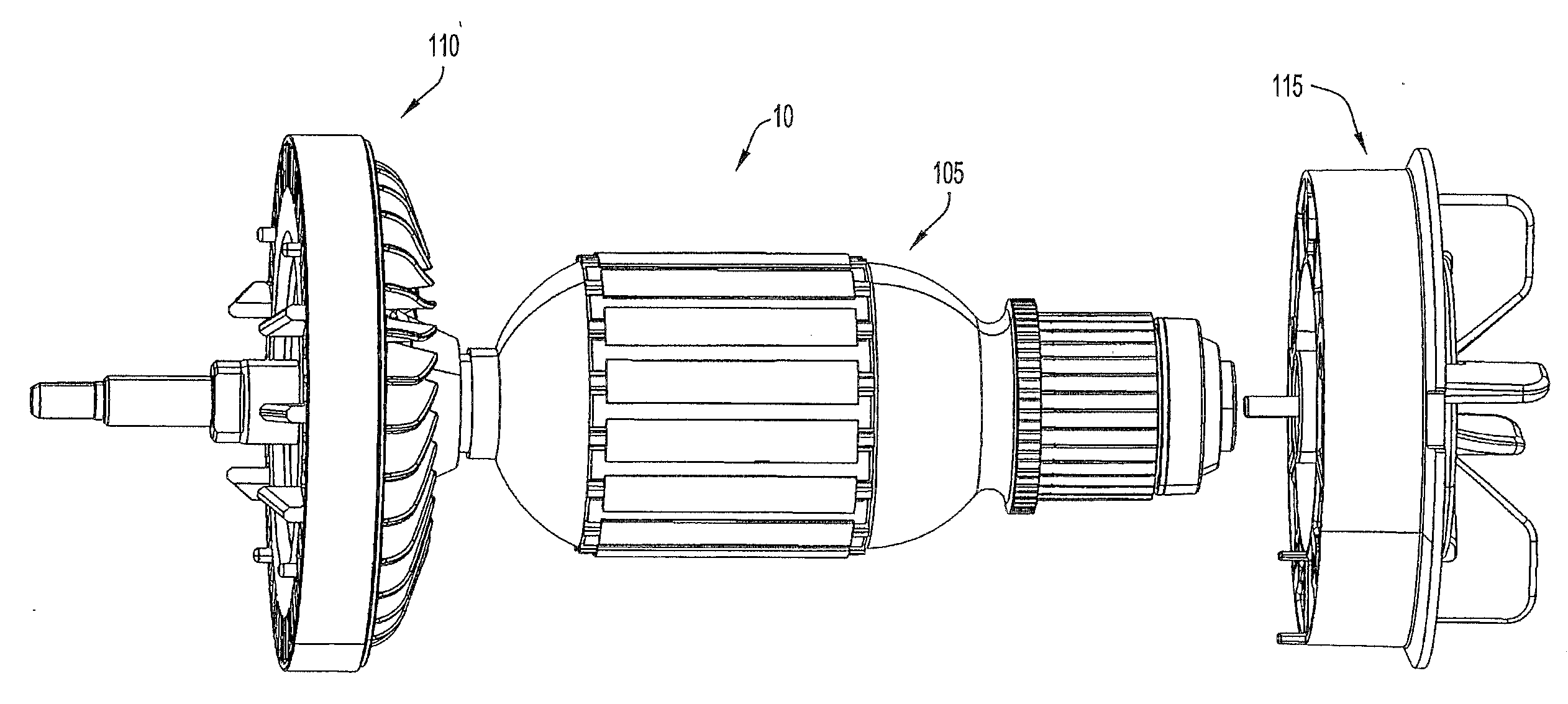

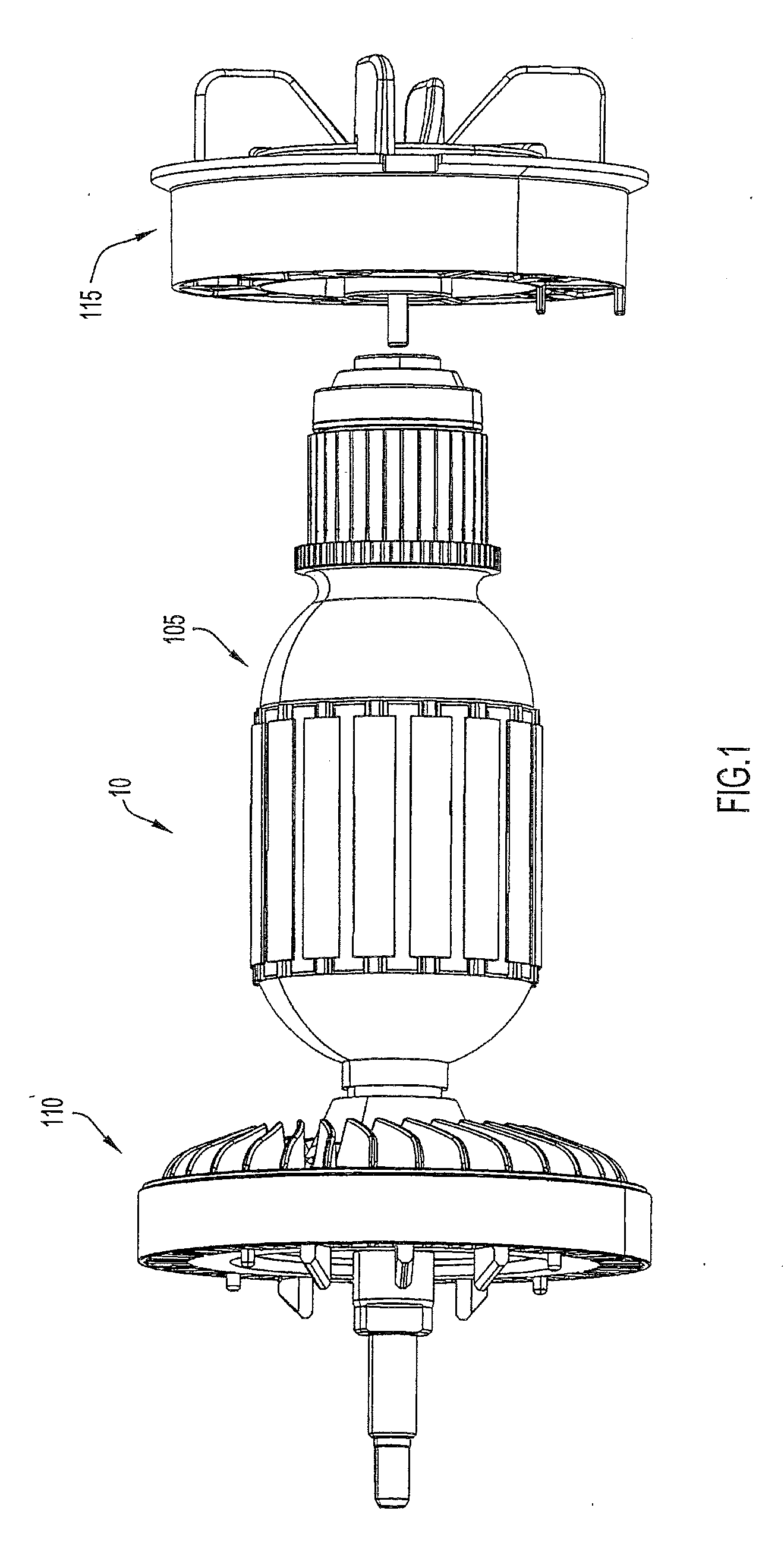

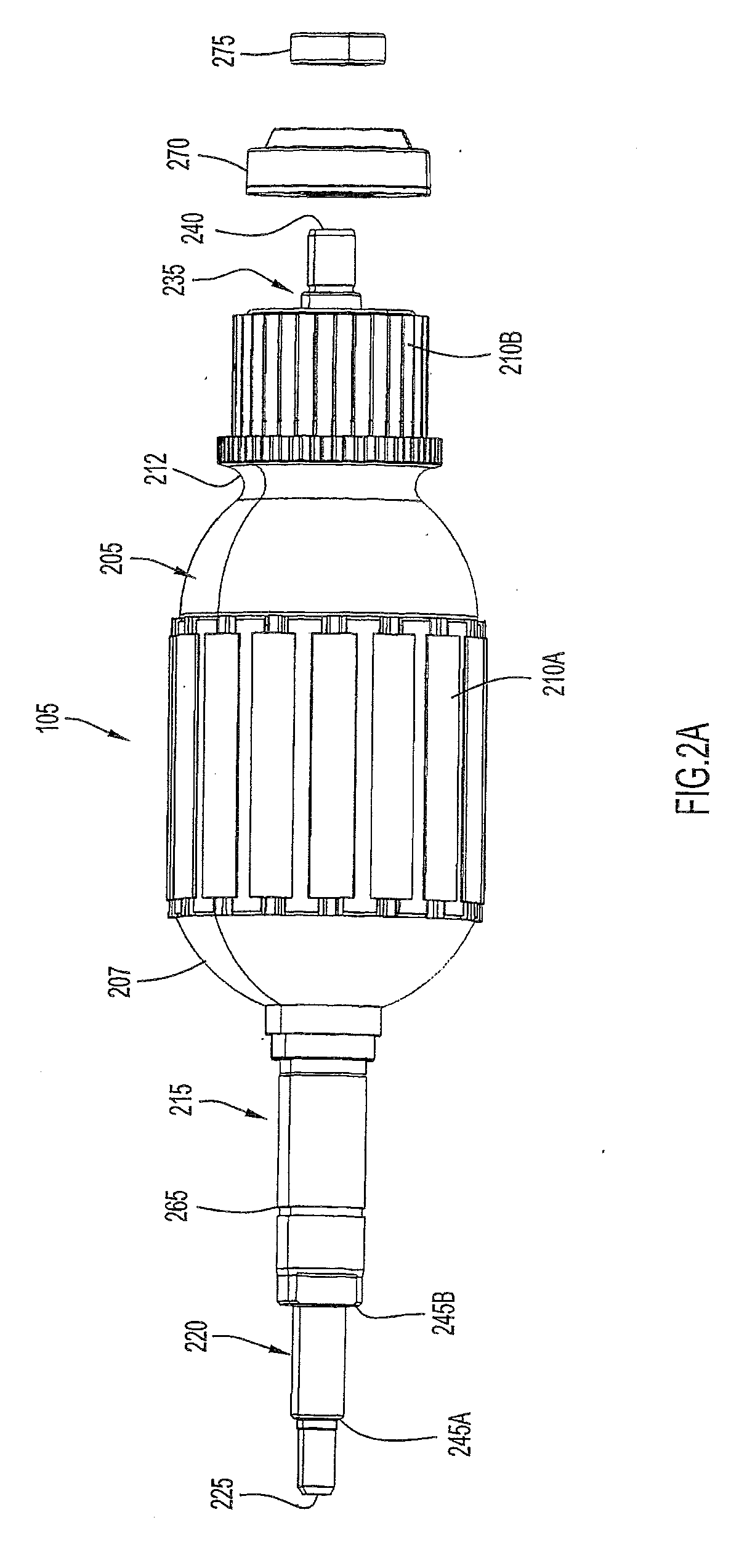

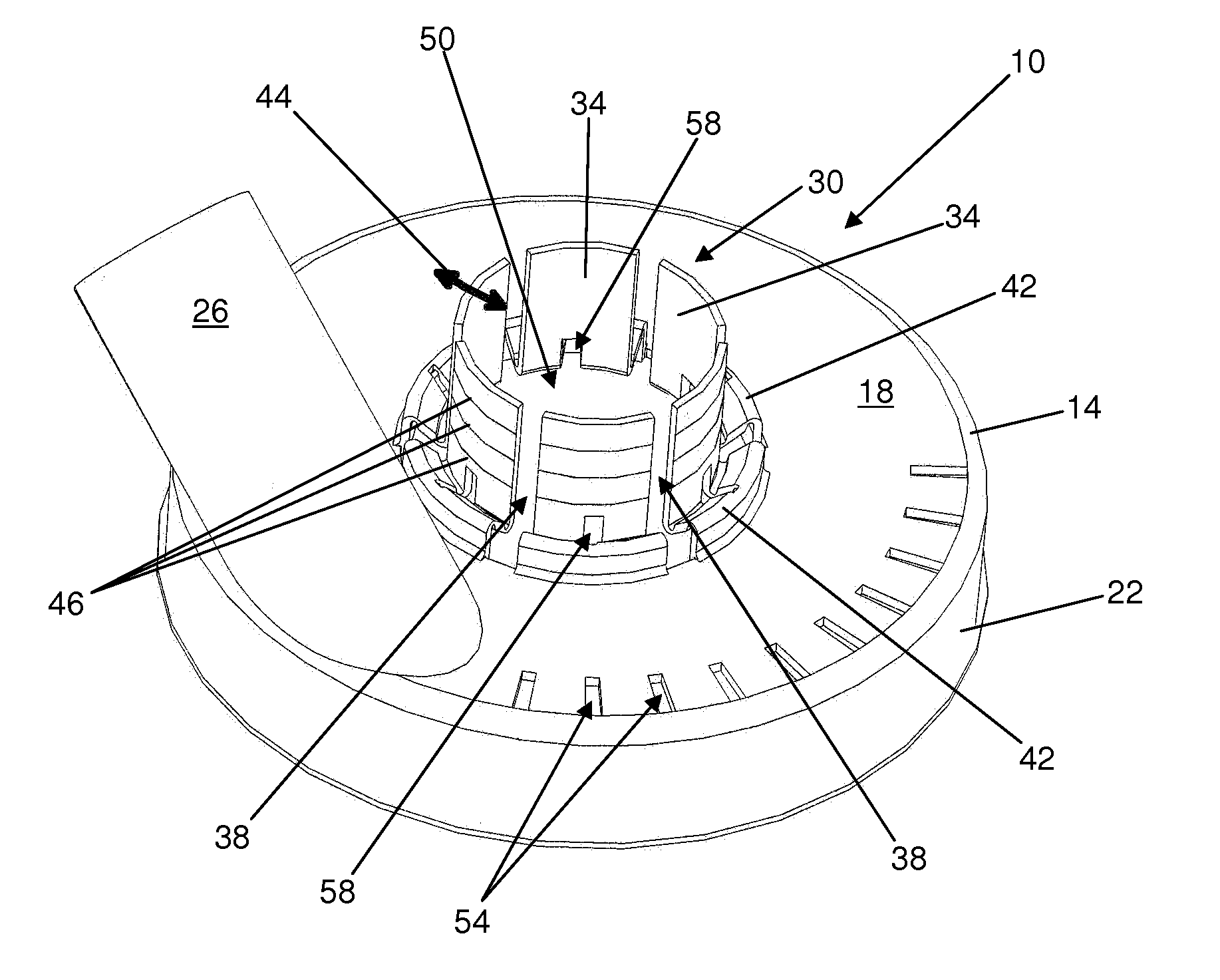

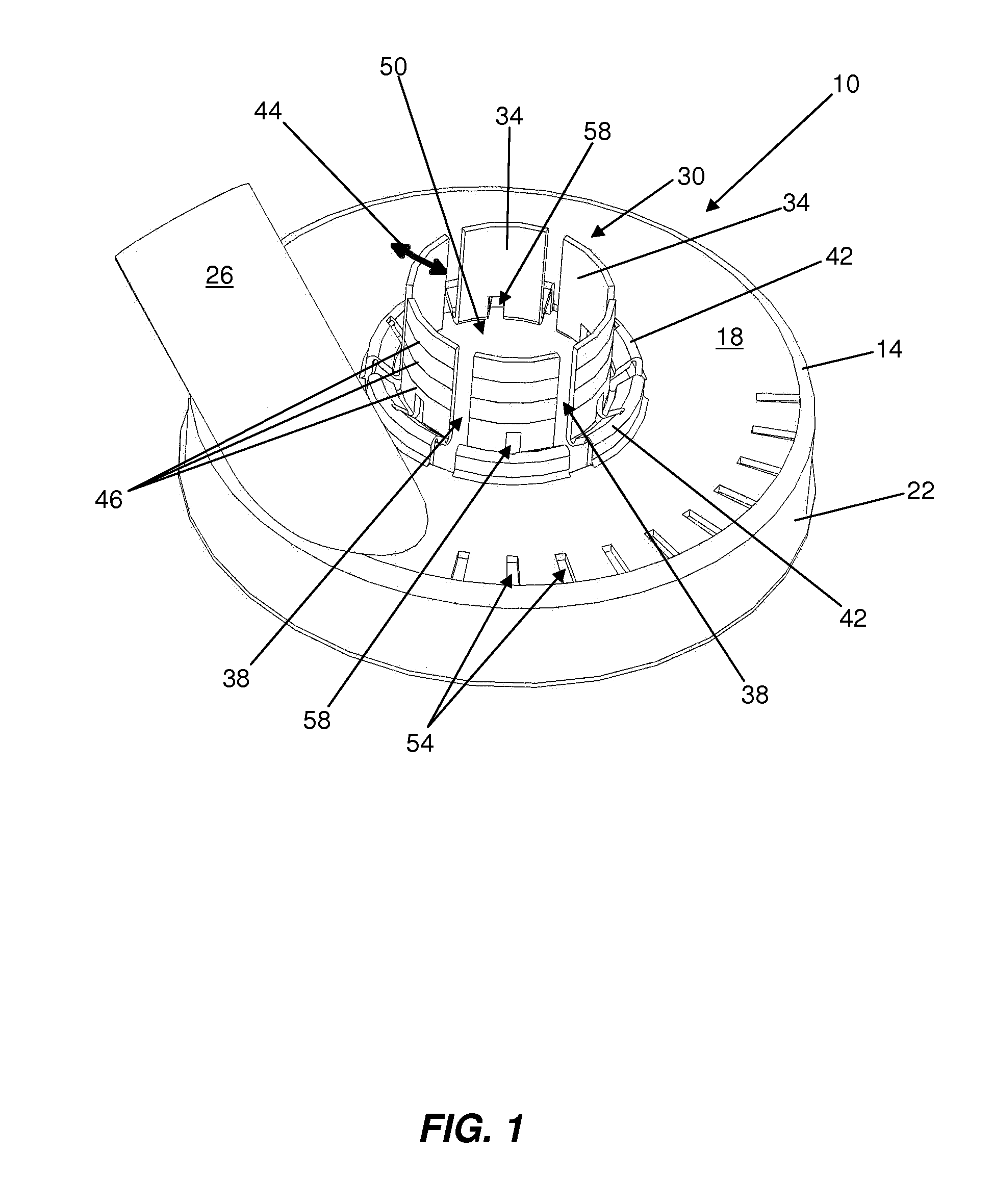

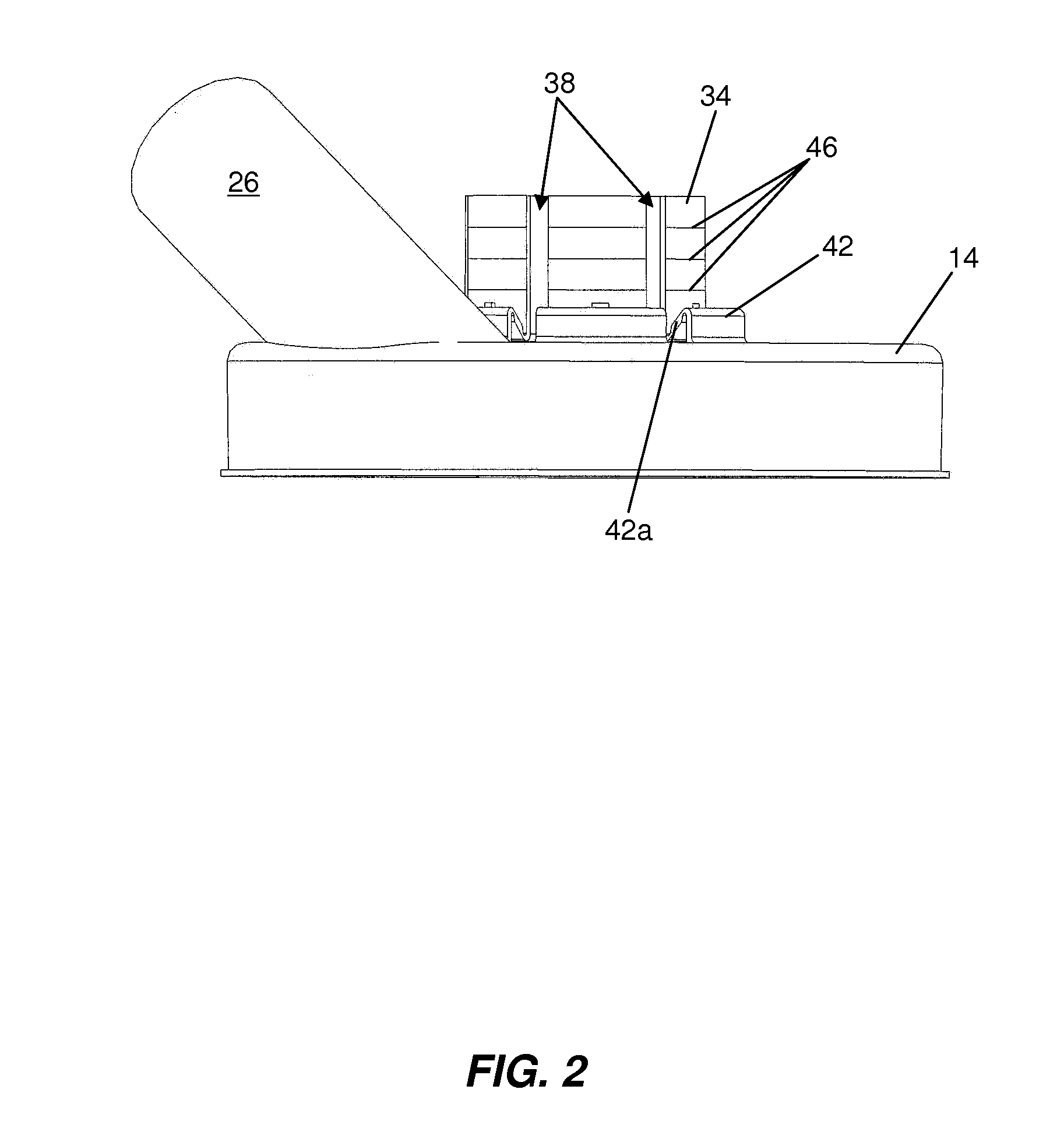

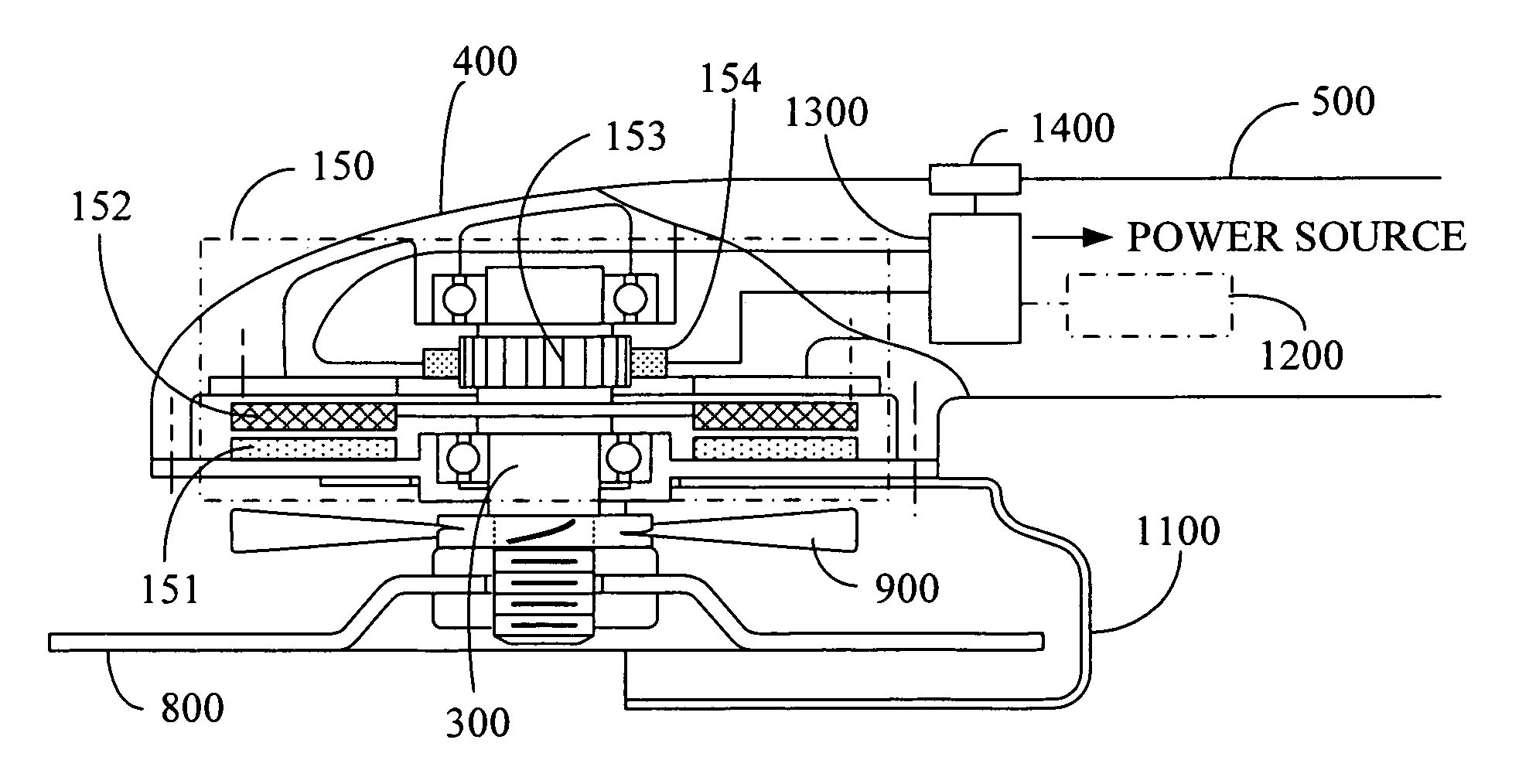

Airfolw arrangement for a power tool

The present invention is directed to an airflow generation and particle dispersion arrangement for a power tool (e.g., an angle grinder). The arrangement includes a motor, an airflow generation assembly, and a particle dispersion assembly. The airflow generation assembly includes a fan driven by the motor. When engaged, the driven fan generates an airstream that is drawn through the power tool. The particle dispersion assembly includes a passive fan that is not driven by the motor, but instead is driven by the airstream. In operation, the passive fan generates centrifugal and mechanical forces sufficient to remove particles from intake air passing through the particle dispersion assembly.

Owner:BLACK & DECKER INC

Angle grinder dust shroud with slideable access hatch

ActiveUS8523637B2Improve complianceEasy to usePortable grinding machinesGrinding/polishing safety devicesAngle grinderEngineering

A dust shroud for an angle grinder includes an access hatch which slides along the shroud body to selectively expose an edge of a grinding disc to allow grinding into a corner. The hatch remains attached to the shroud body in both the open and closed position, making the hatch easier to use and less likely to become lost, resulting in increased worker compliance in properly using the hatch.

Owner:DUSTLESS DEPOT

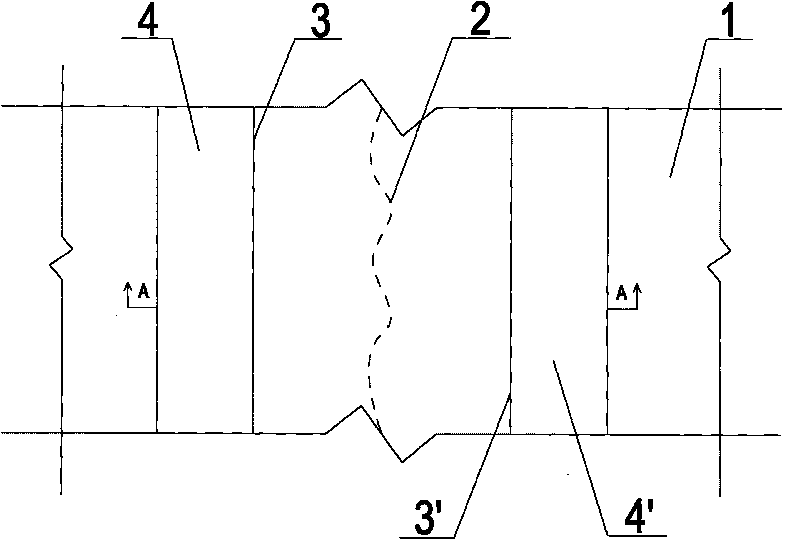

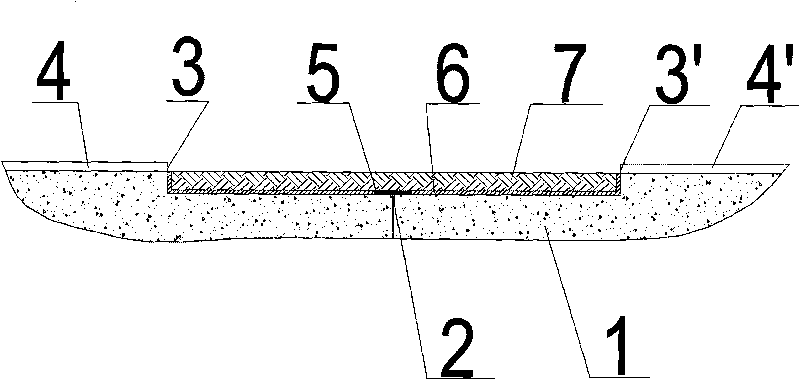

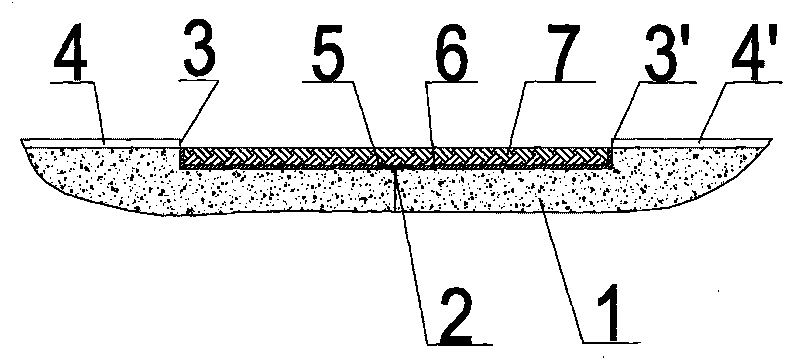

Seepage-proofing processing method of channel concrete panel crack

InactiveCN101701455AGood for seam deformationReduce peeling problemsMarine site engineeringAngle grinderWater flow

The invention belongs to the seepage-proofing technology field and in particular discloses a seepage-proofing processing method of a canal concrete panel crack; by taking the crack as a central line, a concrete panel crack is ground into a groove on site, an isolation layer is adhered or coated on the inseam surface of the groove, primer is coated on the inner surface of groove at two sides of the isolation layer, and then elastic seepage-proofing material is filled until the seepage-proofing material is leveled with the panel. The seepage-proofing processing method has the beneficial effects that: (1) the concrete for canal lining is C15-C30, an angle grinder is used to grind the groove easily; (2) the isolation layer is adhered or coated on the inseam surface of the groove, so as to be beneficial to leading material to be deformed with the seam; (3) high-intensity high-elongation elastic material is filled in the crack to meet water pressure function and to be adaptive to the deformation of the crack; (4)the primer is coated to improve the adhering and sealing effect of the elastic material and the concrete polished surface and current scouring and stripping resistant capacity; (5) the seepage-proofing material is leveled with the canal panel, so as to reduce the stripping function of the water current to the material, and the seepage-proofing material is leveled can not block water; (6) the construction speed is rapid and the manufacturing cost is low; (7) the method is suitable for impounding reservoir and sewage pool engineering and the like.

Owner:HENAN PROVINCIAL WATER CONSERVANCY RES INST

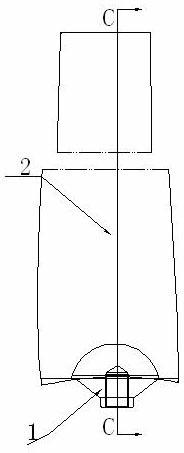

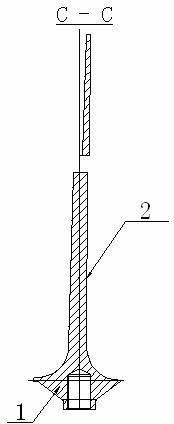

Motor parallel transmission portable angle grinder

InactiveUS20110081847A1Avoid making noiseImprove abilitiesRevolution surface grinding machinesGrinding drivesAngle grinderElectric machinery

The present invention relates to a motor parallel transmission portable angle grinder with a motor rotating part spindle parallel installed in a position adjacent to a grinding wheel spindle to form a parallel transmission device driving the grinding wheel. By means of the parallel transmission device, the present invention prevents the emission of noise made by angle type transmission devices; and / or an inertial body is installed on the motor rotating part to form a flywheel to improve the grinding, polishing and machining or cutting abilities of the grinding wheel; and / or a motor is established to be open or semi-hermetic for the space from the interior to a housing and / or a handle of the motor to improve the effect of heat dissipation outward.

Owner:YANG TAI HER

Processing method of titanium and titanium alloy wires

Owner:宝鸡市三鑫金属有限责任公司

Hood Plates for Handheld Grinding Tools

InactiveUS20080171501A1Portable grinding machinesGrinding/polishing safety devicesAngle grinderHand held

Hood plates for use with hood covers designed for handheld power tools including angle grinders are disclosed herein. More specifically, the hood plates disclosed herein include means for easily attaching to a wide variety of available angle grinders and are easily configured to work with a soft hood cover to allow both horizontal and vertical movement of the grinding attachment within the hood cover.

Owner:IT INC

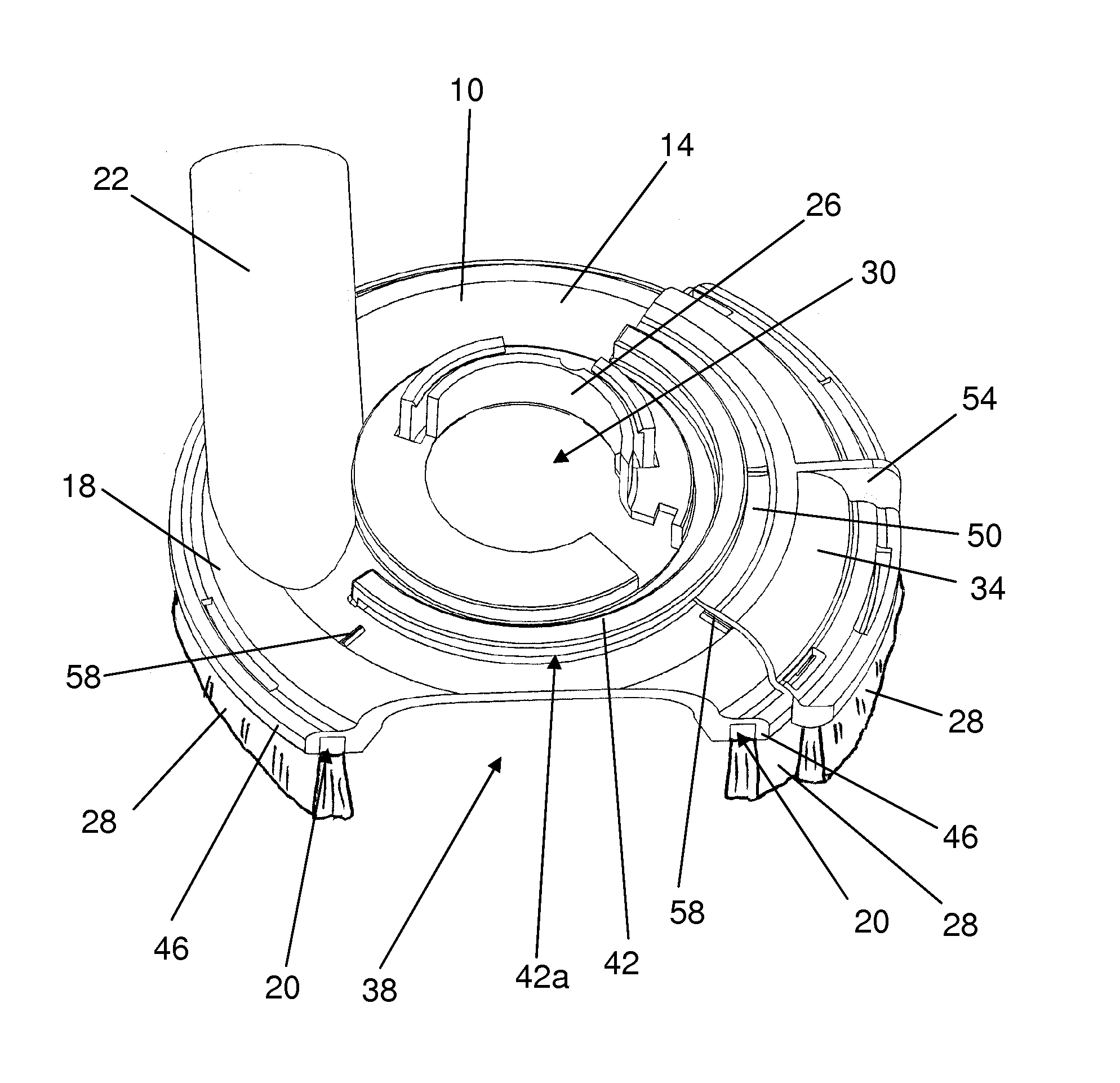

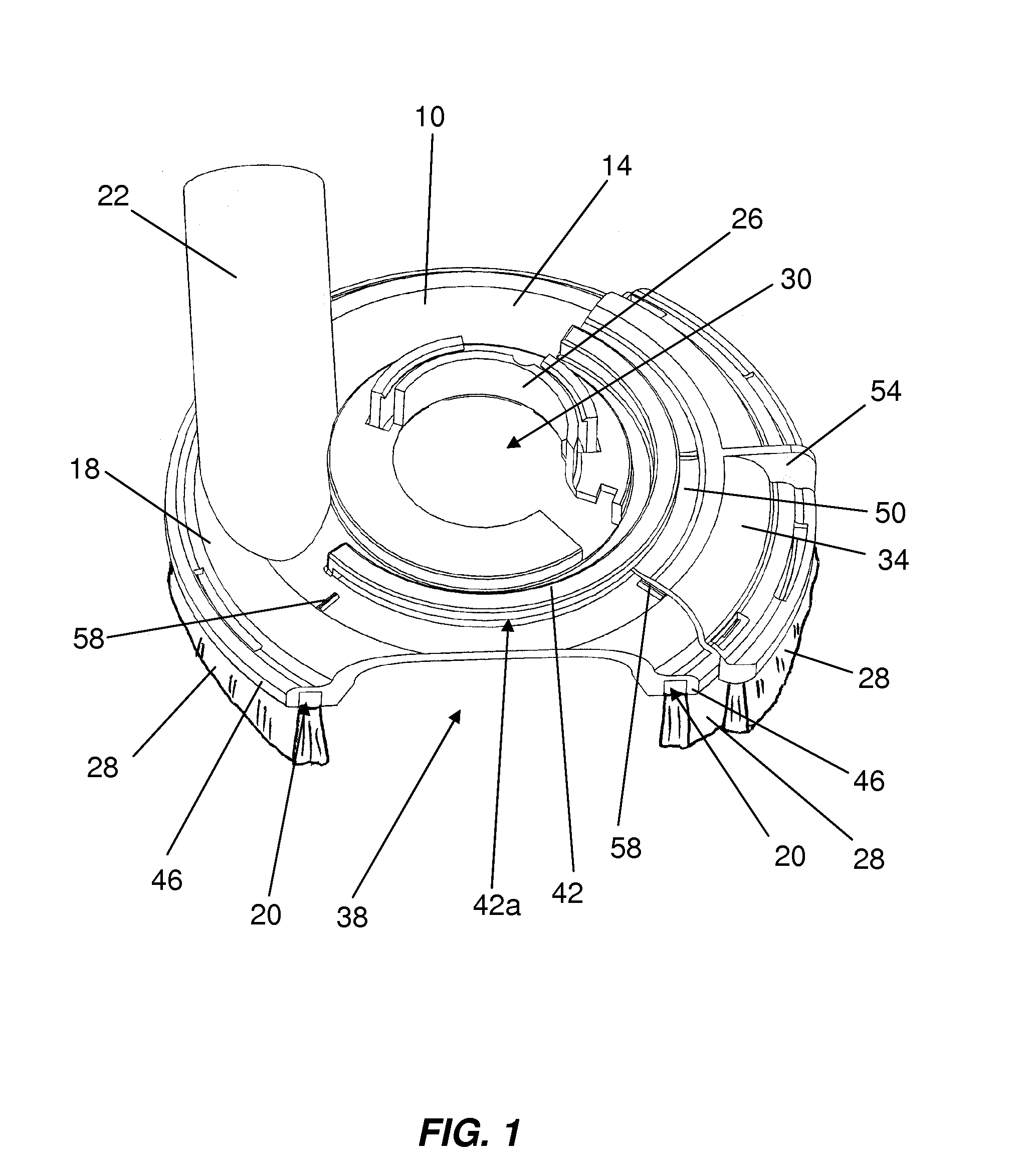

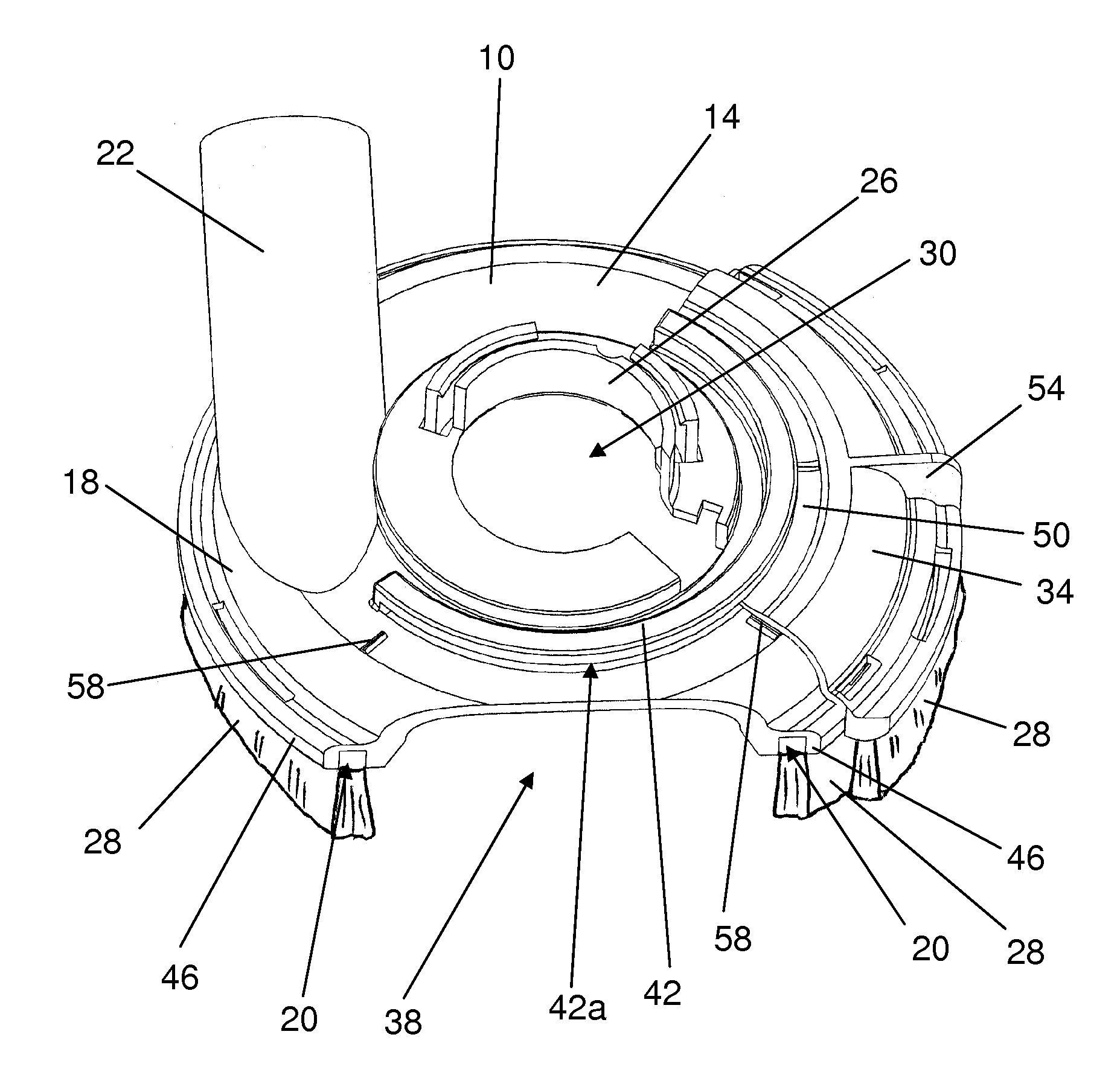

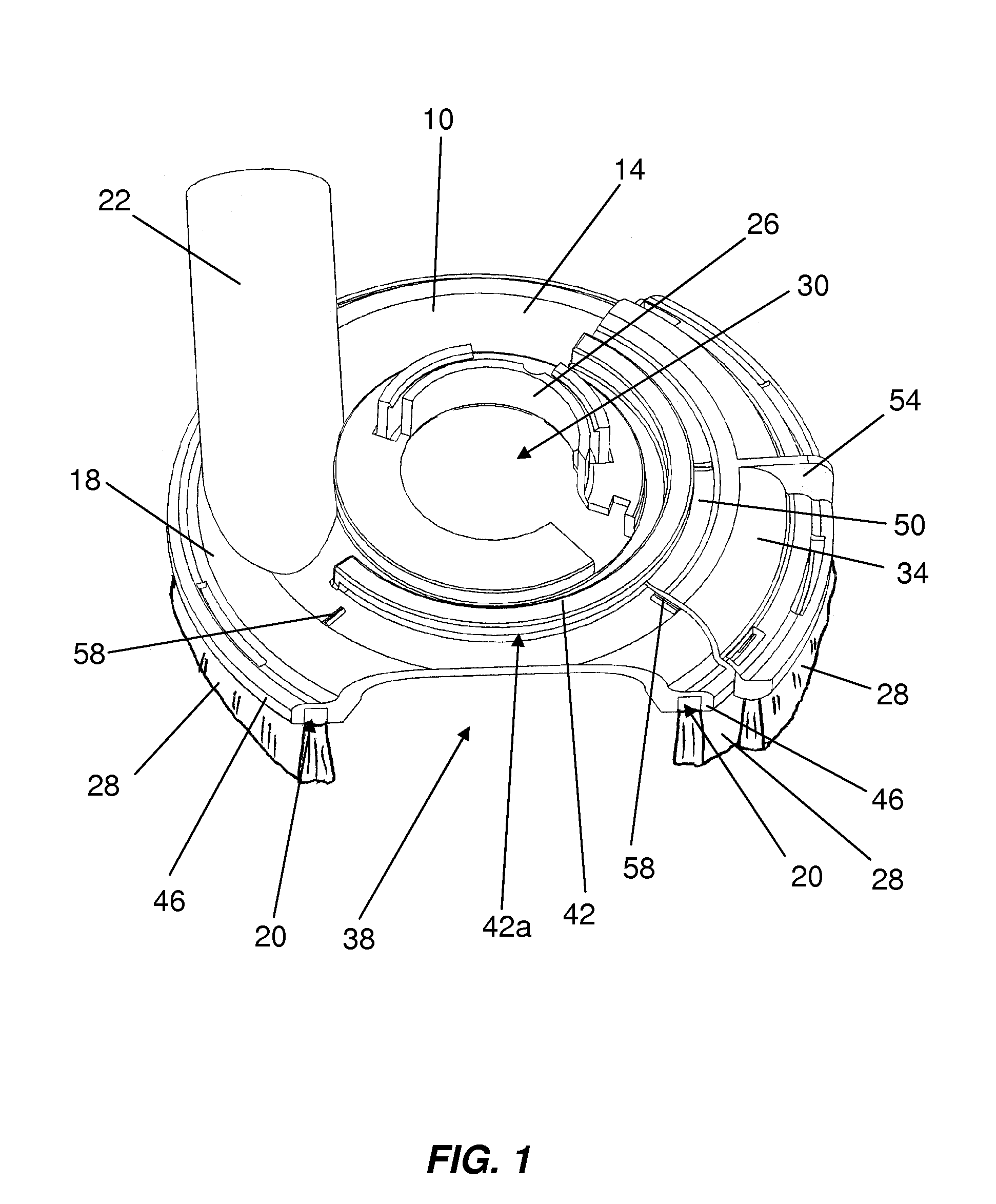

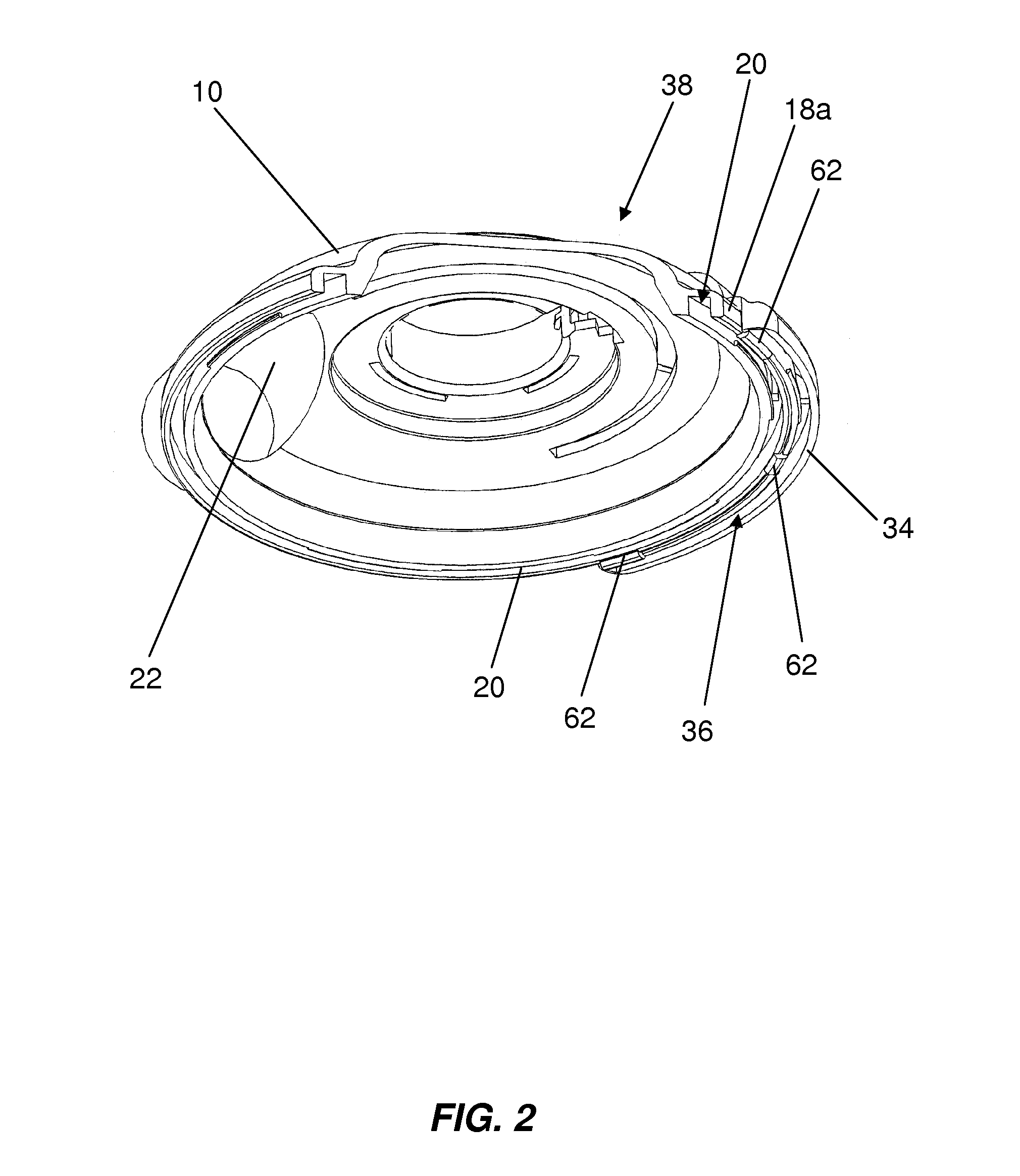

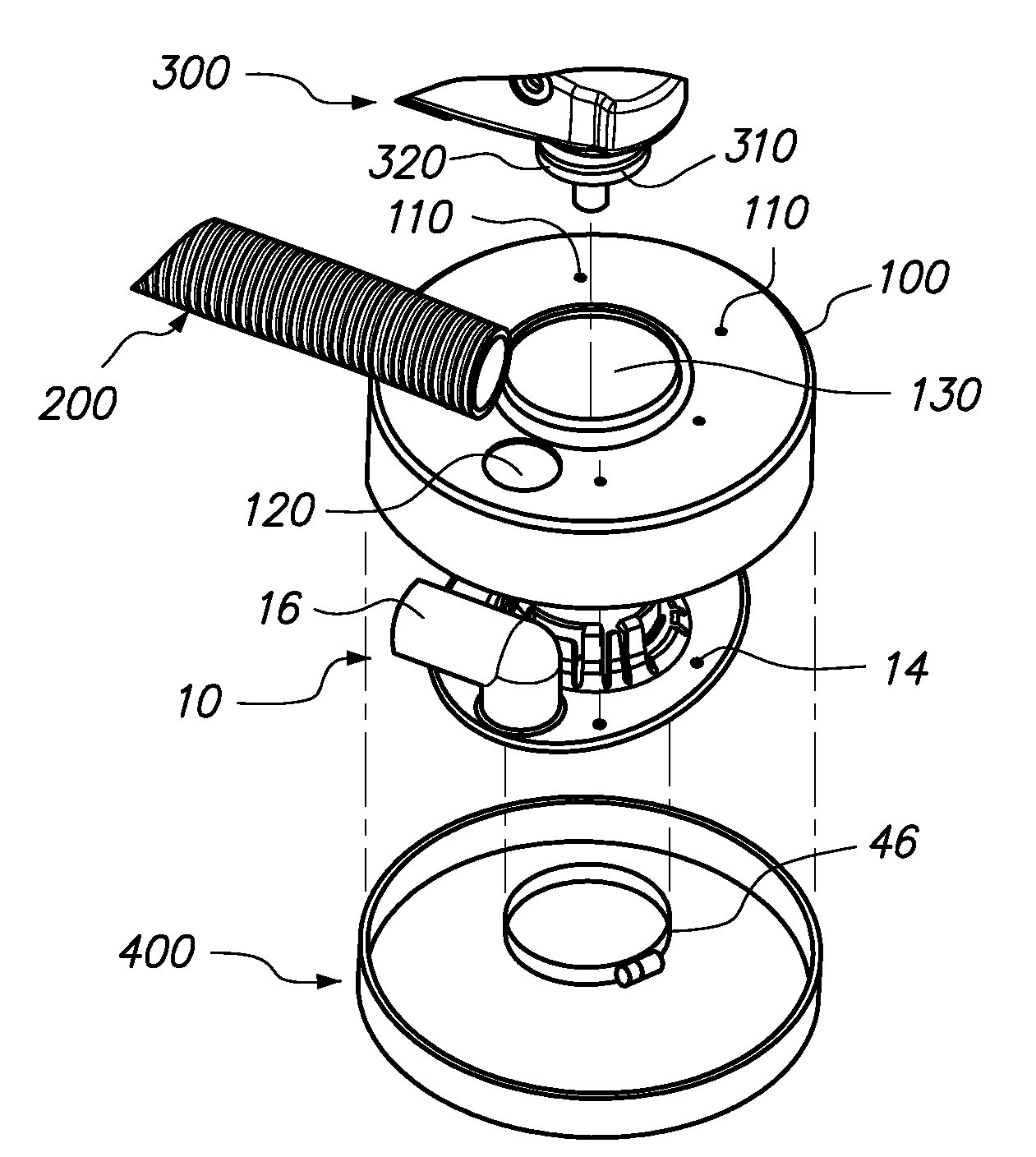

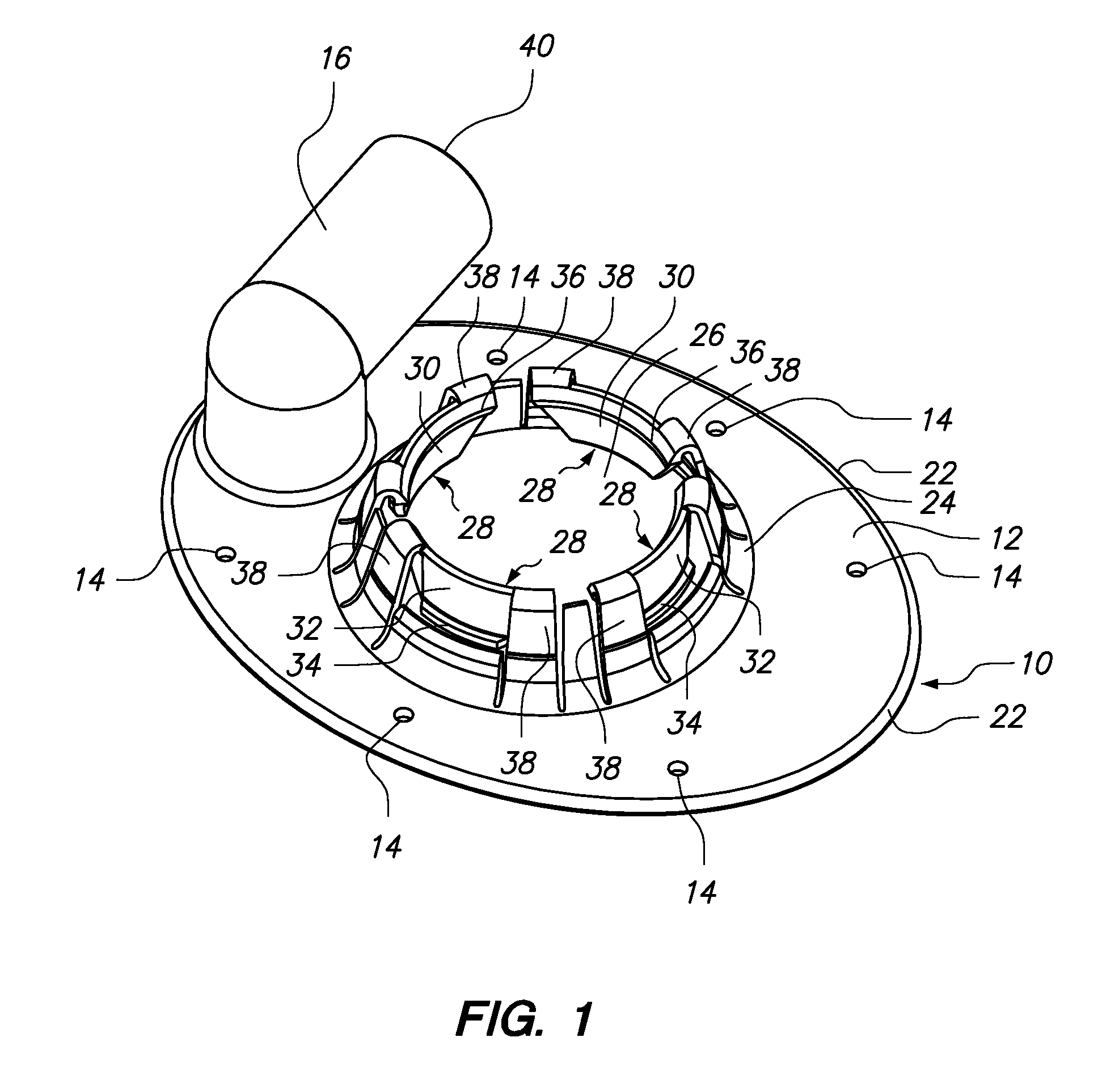

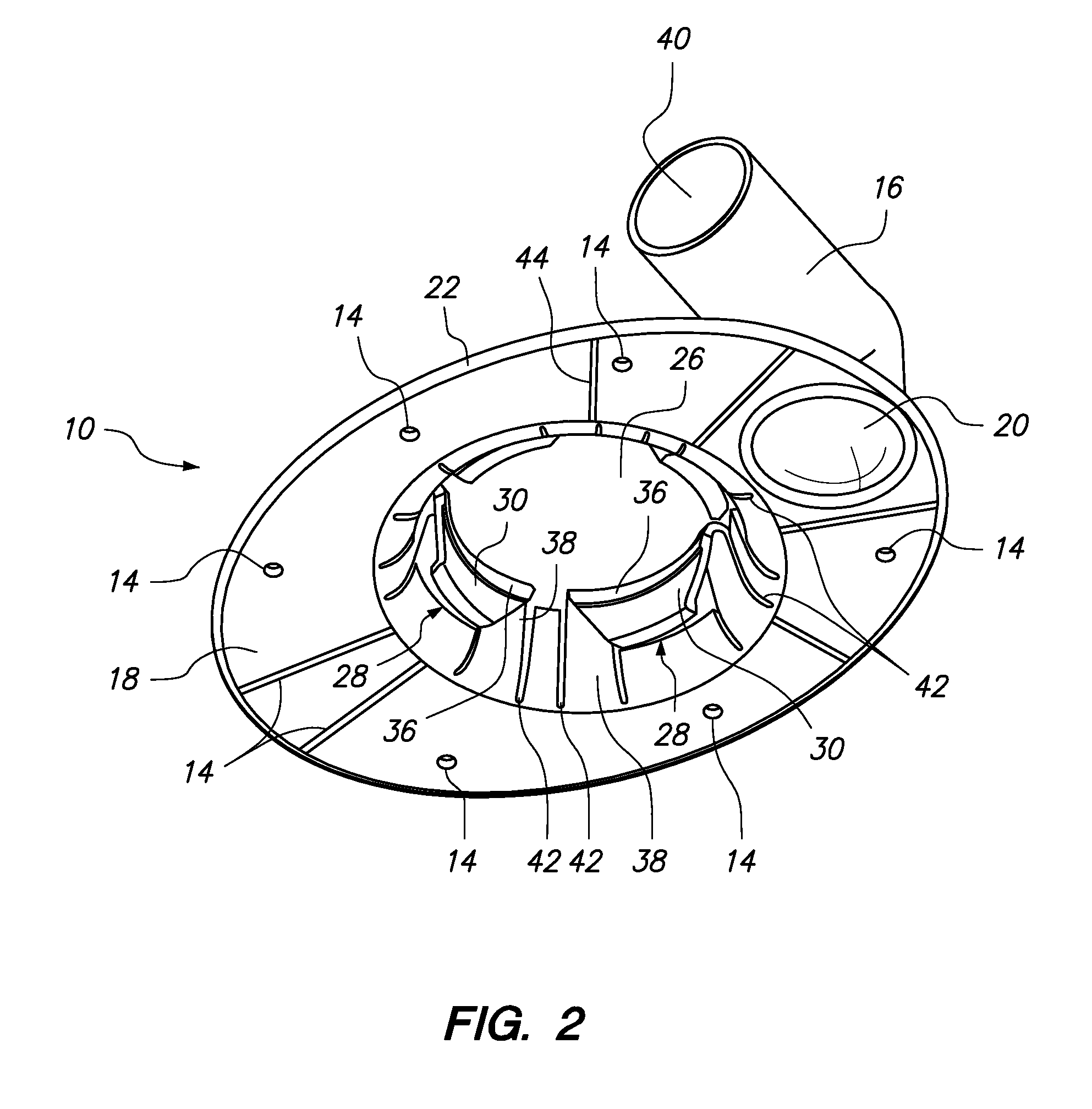

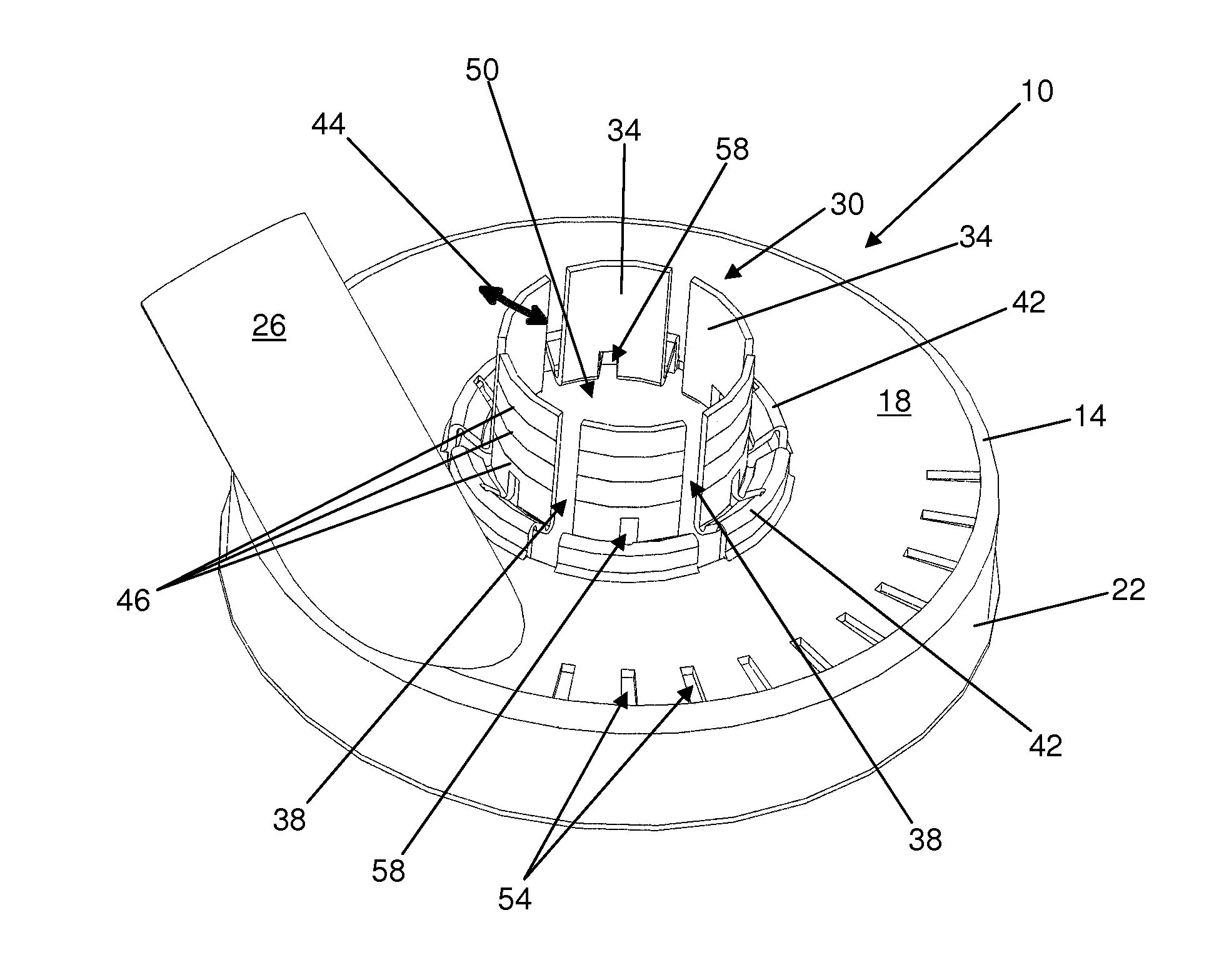

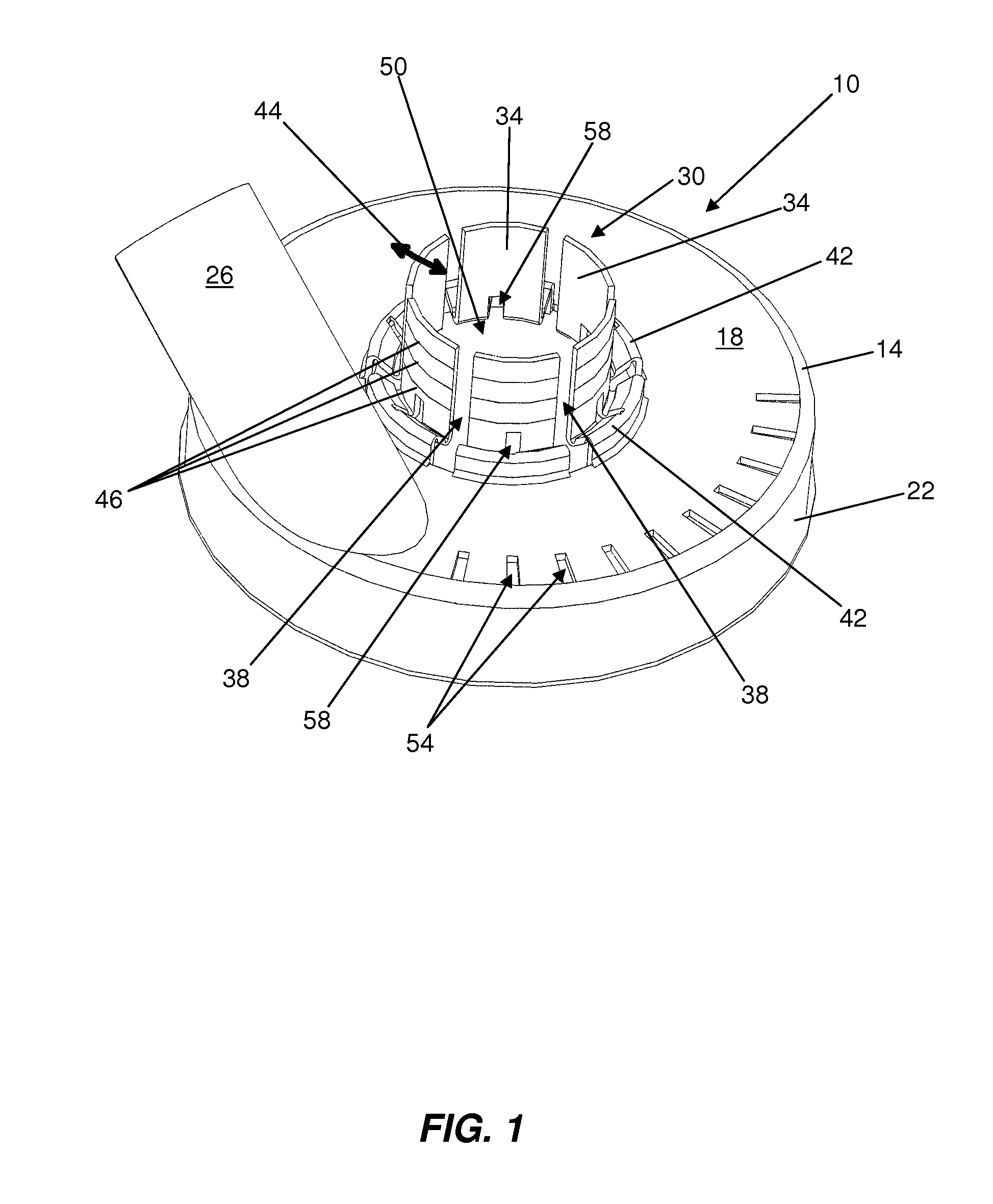

Angle grinder dust shroud with unitary adjustable mounting collar

ActiveUS20100285729A1Inexpensive and easy to useEasy to usePortable grinding machinesHaberdasheryAngle grinderEngineering

A universal dust shroud includes a unitary mounting bracket on top of the shroud body. The bracket includes a plurality of collar sections attached to the body via a ‘Z’ shaped joint which allows the collar sections to move radially inwardly and outwardly relative to each other to accommodate different angle grinders. The bracket may include slots formed at the base of the bracket. The slots allow air to flow in through the slots, out past the grinding disk, and to the vacuum port. As such, the slots can aid in cooling the grinder output and bearings, and helps keep dust and debris away from the bearings in order to extend the life of the grinder.

Owner:DUSTLESS DEPOT

Aluminum blade of fan and manufacturing technology thereof

ActiveCN102162469AHigh densityHigh strengthPump componentsEngine componentsAngle grinderManufacturing technology

The invention discloses an aluminum blade of a fan rotor for a mine and a highway tunnel, and the blade is made from an aluminum material and is manufactured by a precision forging technology. The manufacturing steps comprise: (1) manufacturing a set of forging mold according to the physical dimension and the profile shape of the blade, wherein the mold comprises a hammer forging die and a trimming die; (2) heating a forged aluminum bar stock, and forging a blank the shape of which is similar to that of the blade by adopting a free forging technology; (3) heating the blank, and placing the blank in the hammer forging die to perform hammer forging forming; (4) cutting burr by the trimming die; (5) polishing trimmed burr by an angle grinder; (6) checking the transmittance of a blade basin and a blade back of the blade body, taking the blade basin and the blade back with the transmittance less than or equal to 1.5mm into the next working procedure, or else returning for reforging; (7) carrying out heat treatment and quenching; (8) carrying out cold straightening; and (9) carrying out artificial treatment. The density and strength of the blade manufactured by the material and method is greater than that of the aluminum blade, by adopting the blade with the same specification, the rotation speed and the flow rate of the fan can be improved, the performance of the fan is strengthened, and the cost is reduced.

Owner:四川振强锻造有限责任公司

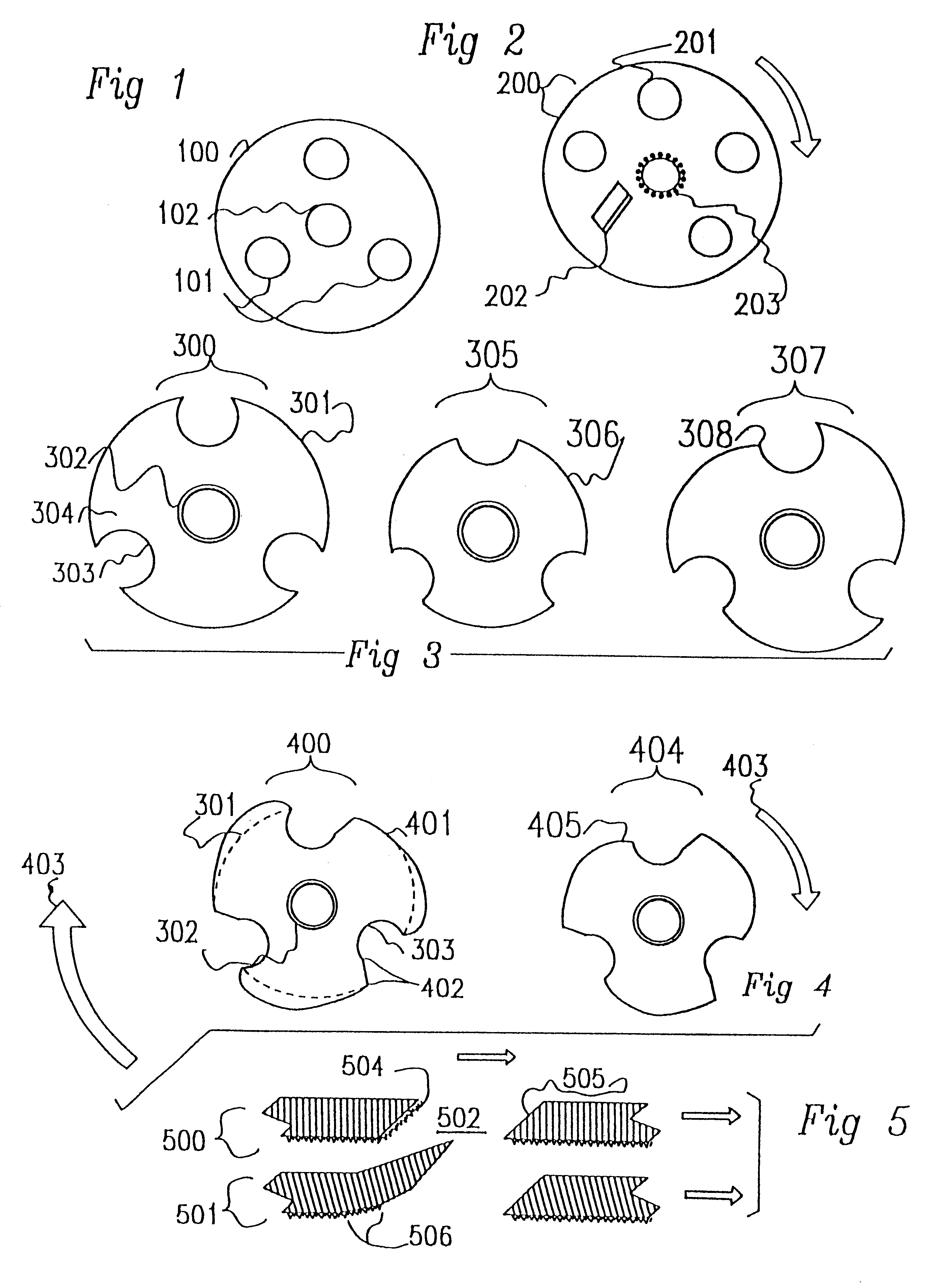

Surface finisher

ActiveUS7144194B2Sufficient flexibilityLess laborRoads maintainenceBuilding material handlingAngle grinderMachined surface

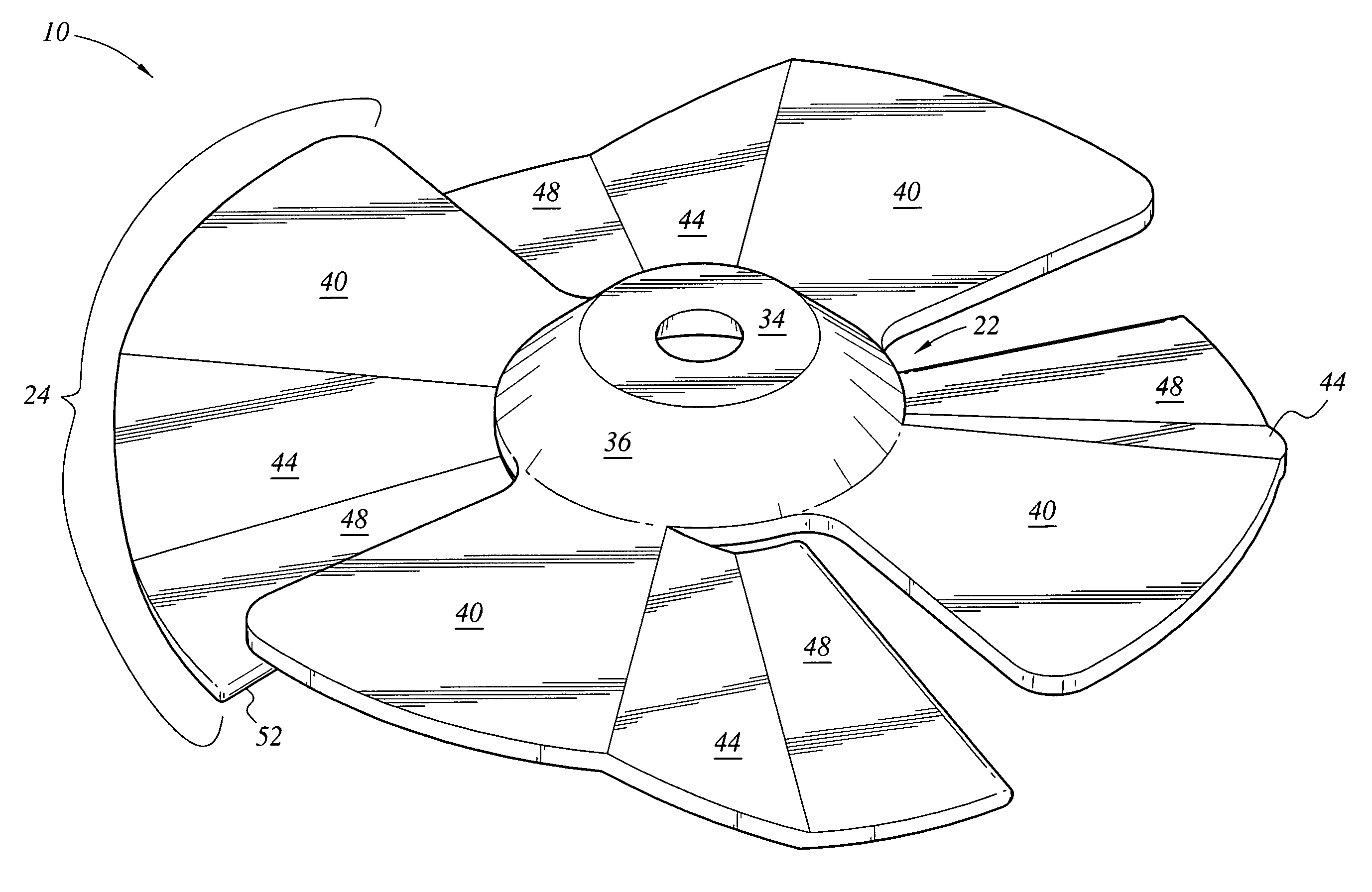

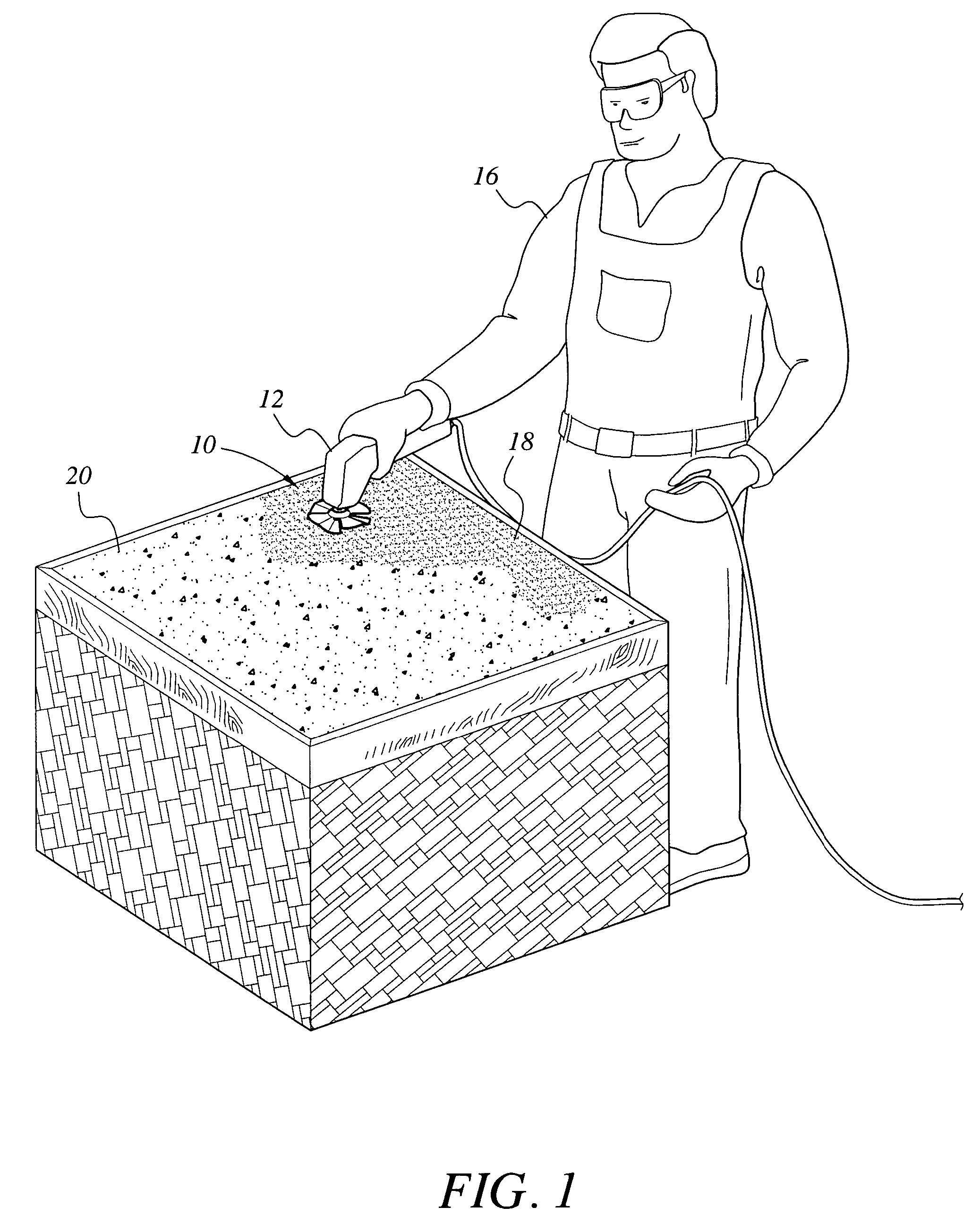

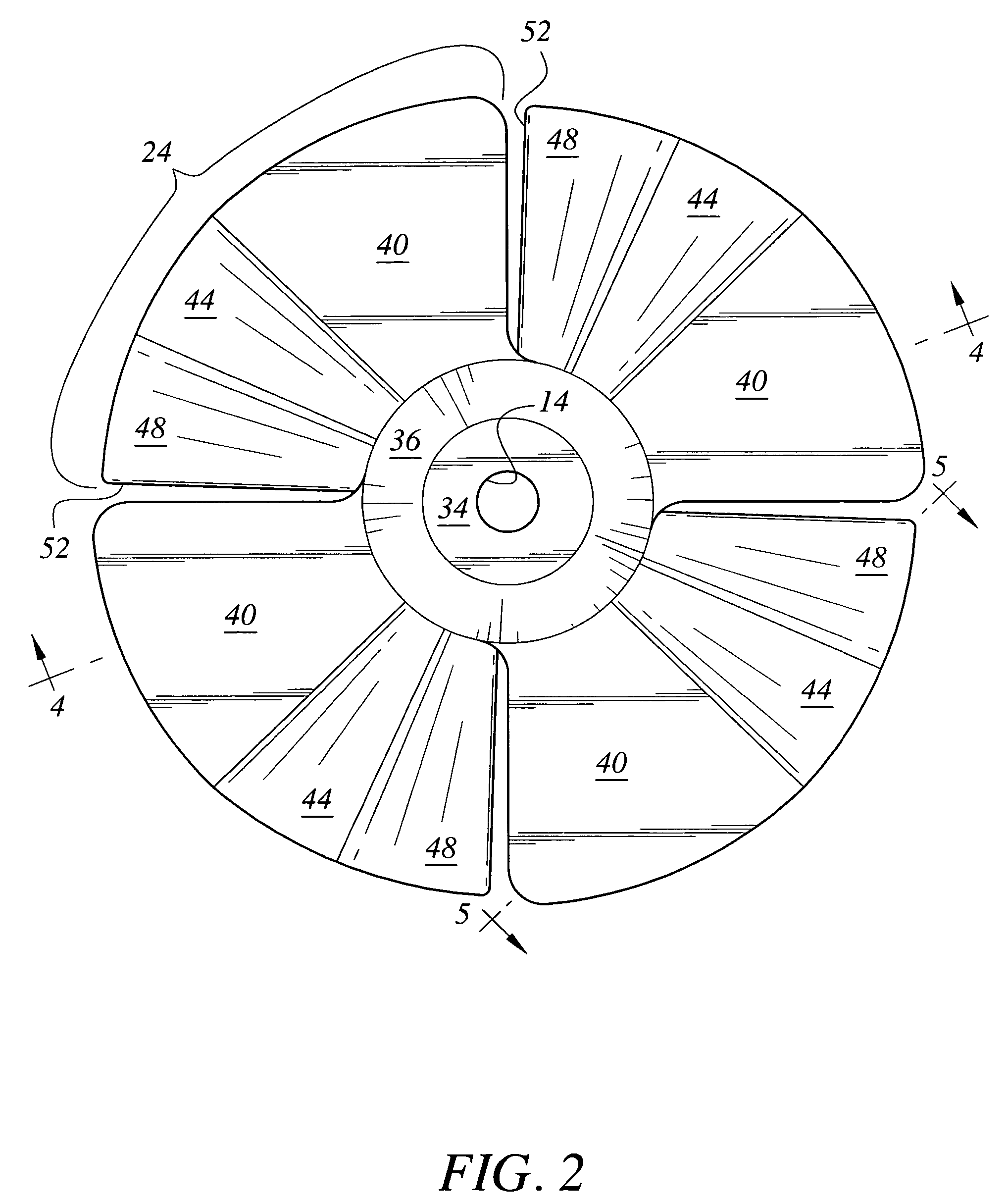

The surface finisher is an attachment for an angle grinder or other handheld prime mover that precludes the need to finish uncured concrete or other viscous, semi-fluid materials by hand. The surface finisher is a disk having a series of radially disposed blades extending from the plane of the disk, with the blades flexing over the surface to which they are applied to smooth the surface during operation. The disk and blades may be formed as a single, integral component, or may alternatively be formed as a flat, planar disk with a series of removable blades. Either embodiment may be formed of a variety of metal and / or plastic materials. The finishing blades bear against the surface and even out surface irregularities and put a slick, finished surface to the uncured surface, or may be used to form a pattern or texture in the uncured surface by using a contoured blade.

Owner:KIPP JR JOHN H

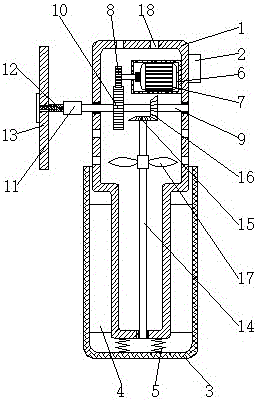

Internal rotation type direct motor-drive portable angle grinder

InactiveUS20110081846A1Avoid making noiseImprove abilitiesGrinding drivesGrinding feed controlAngle grinderMotor drive

The present invention relates to an internal rotation type direct motor-drive portable angle grinder. By means of the direct drive, the present invention prevents the emission of noise made by angle type transmission devices; and / or an inertial body is installed on the motor rotating part to form a flywheel to improve the grinding, polishing and machining or cutting abilities of the grinding wheel; and / or a motor is established to be open or semi-hermetic for the space from the interior to a housing and / or a handle of the motor to improve the effect of heat dissipation outward.

Owner:YANG TAI HER

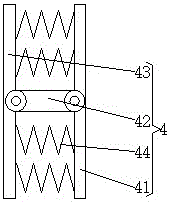

Angle grinder capable of adjusting angle of grinding disk

InactiveCN106378689AReduce vibrationSimplify the operating postureGrinding wheel securing apparatusPortable grinding machinesAngle grinderArchitectural engineering

The invention discloses an angle grinder capable of adjusting the angle of a grinding disk. The angle grinder comprises a casing; a controller is fixedly connected at the top of the right side of the casing; the bottom of the casing is sleeved with a casing pipe, penetrates through the top of the casing pipe and extends to an inner cavity of the casing pipe; damping devices are arranged between two sides of the inner cavity of the casing pipe and the casing; and each damping device comprises a first vertical plate, the right side of the first vertical plate is fixedly connected with the inner wall of the casing pipe, the center of the left side of the first vertical plate is movably connected with a connecting rod through a rotating shaft, and one end, far away from the first vertical plate, of the connecting rod is movably connected with a second vertical plate through a rotating shaft. With the angle grinder, the grinding disk is fixed, a ball is arranged, and the angle of the ball can be adjusted at will, so that the angle of the grinding disk can be adjusted, the operation posture of an operator is greatly simplified, the operator can operate the grinder in an easier posture, and the working efficiency is improved.

Owner:林志城

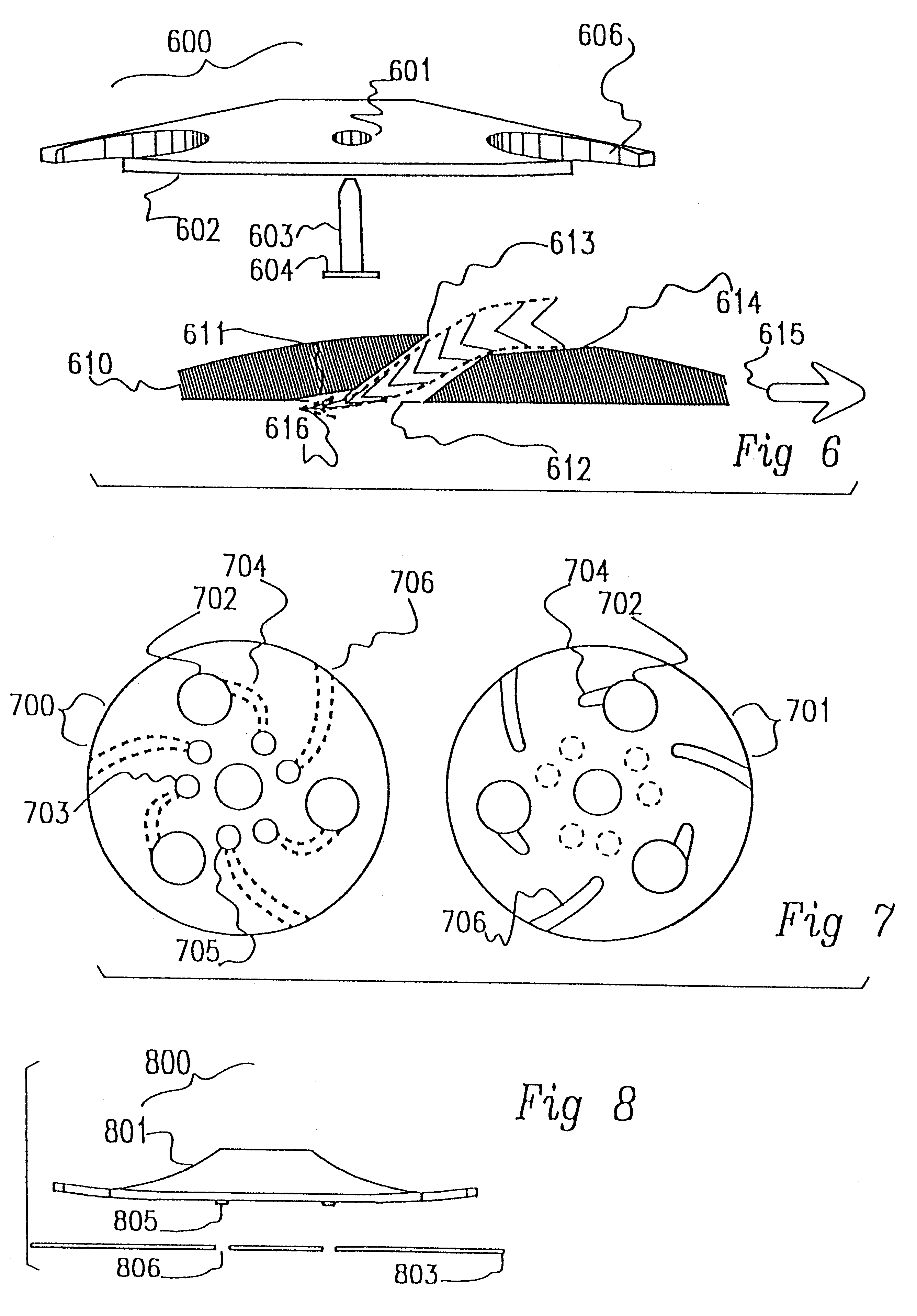

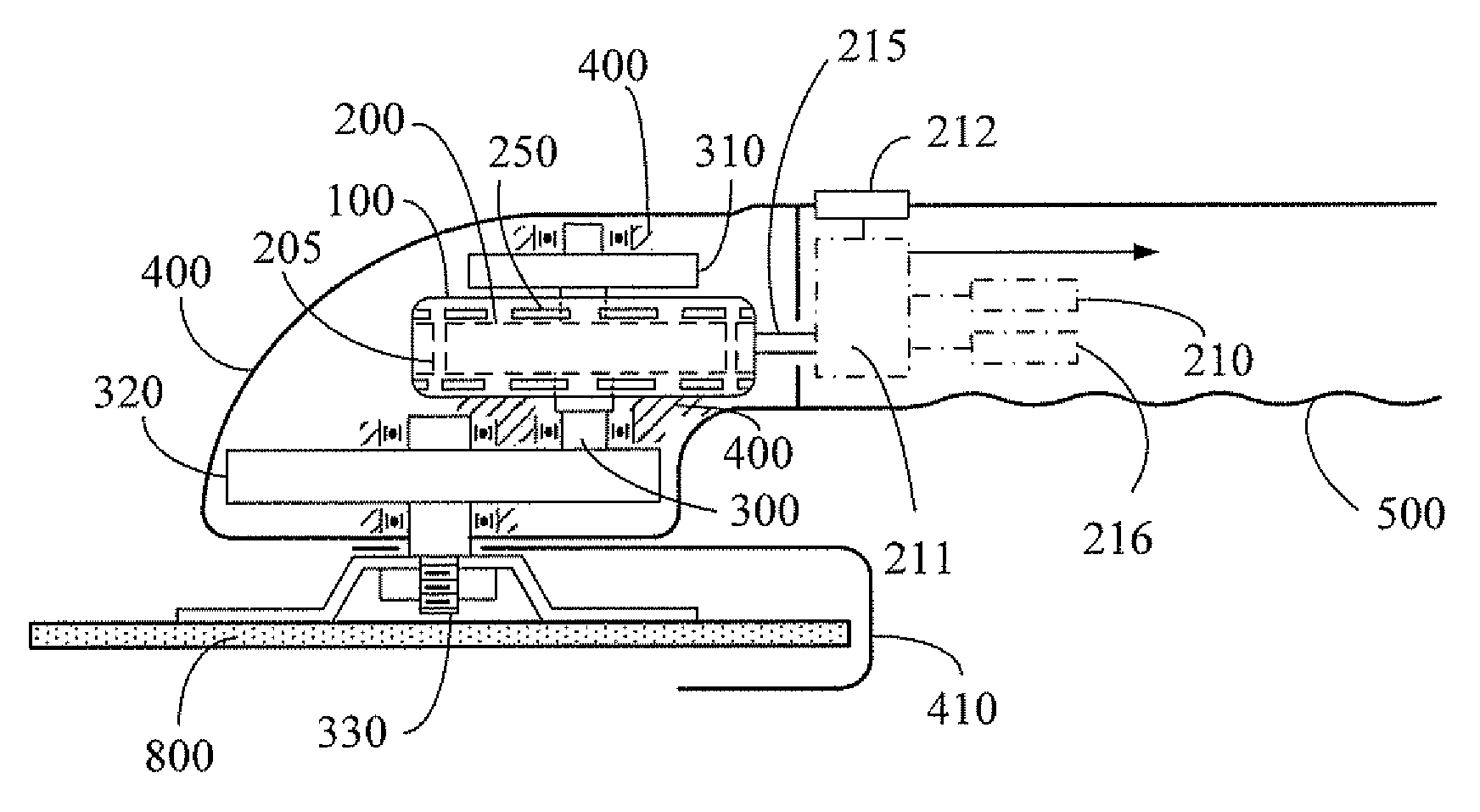

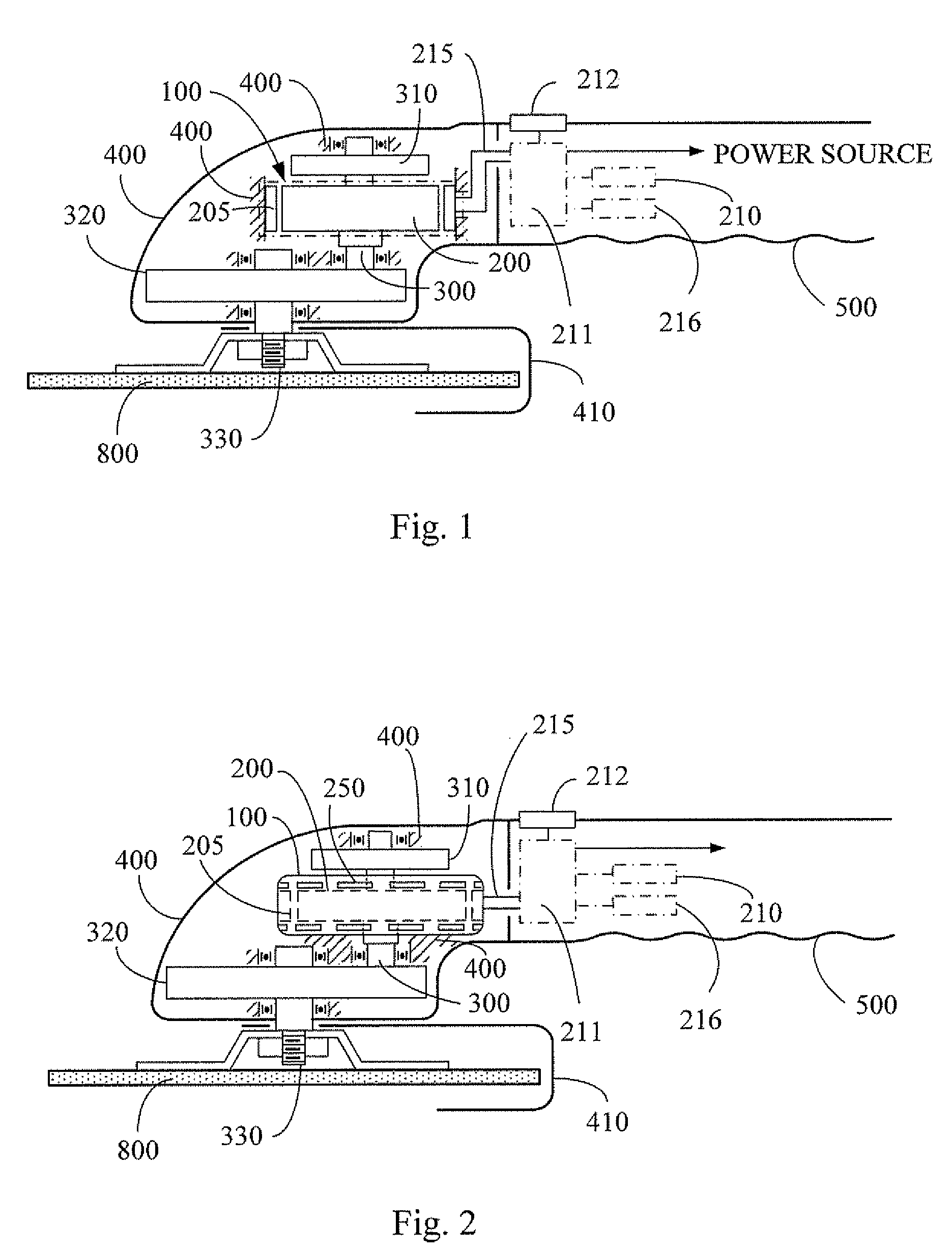

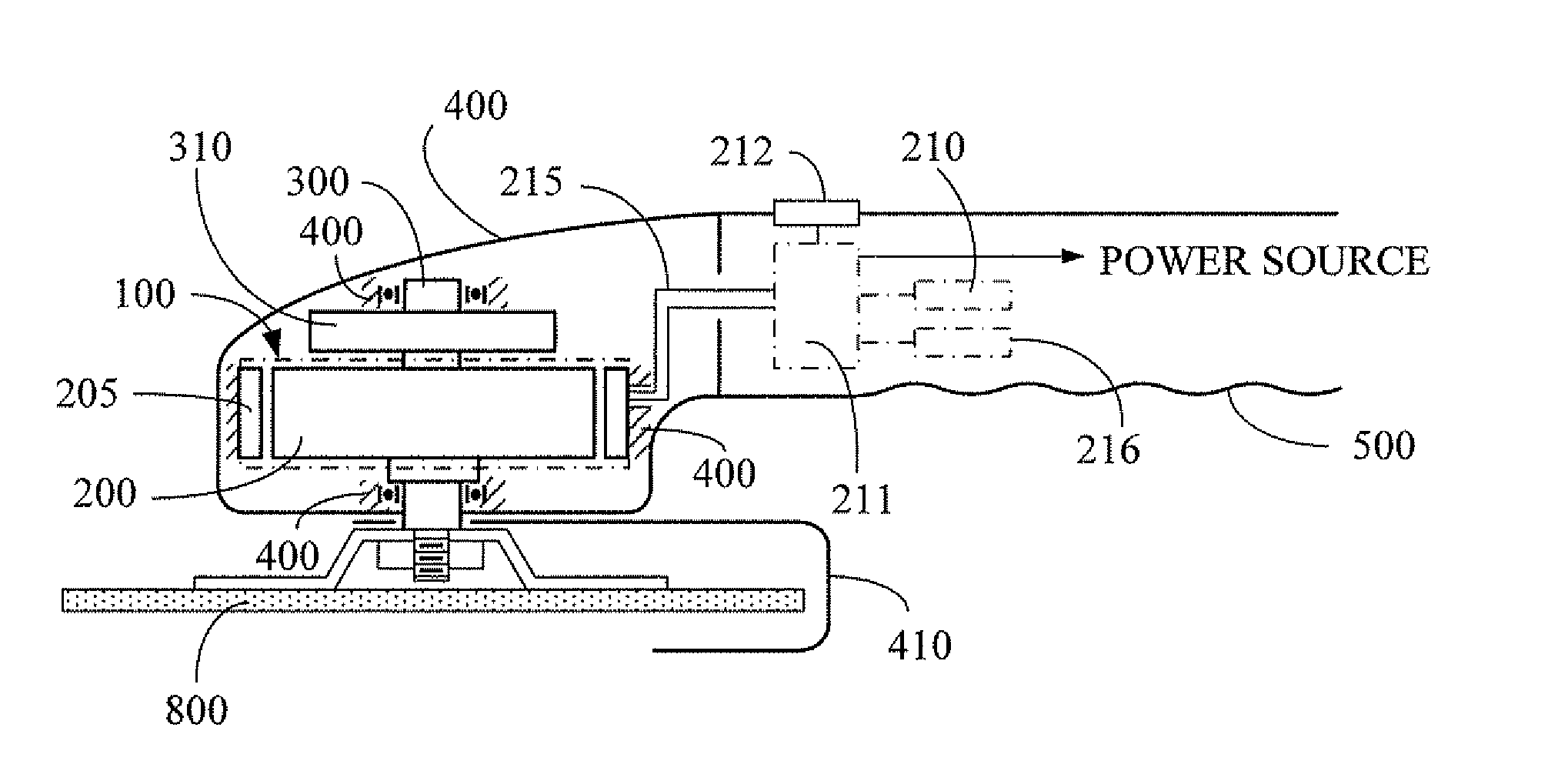

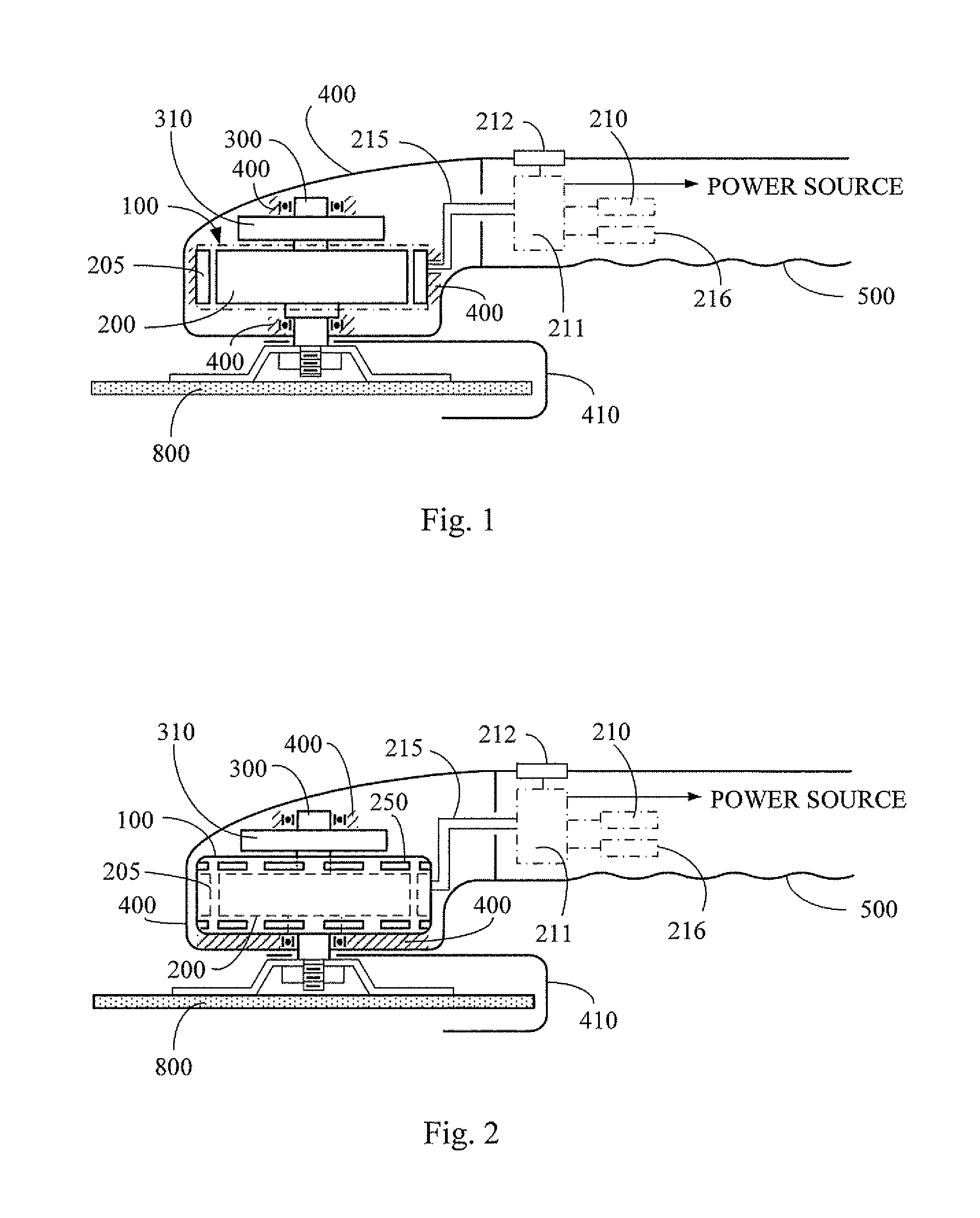

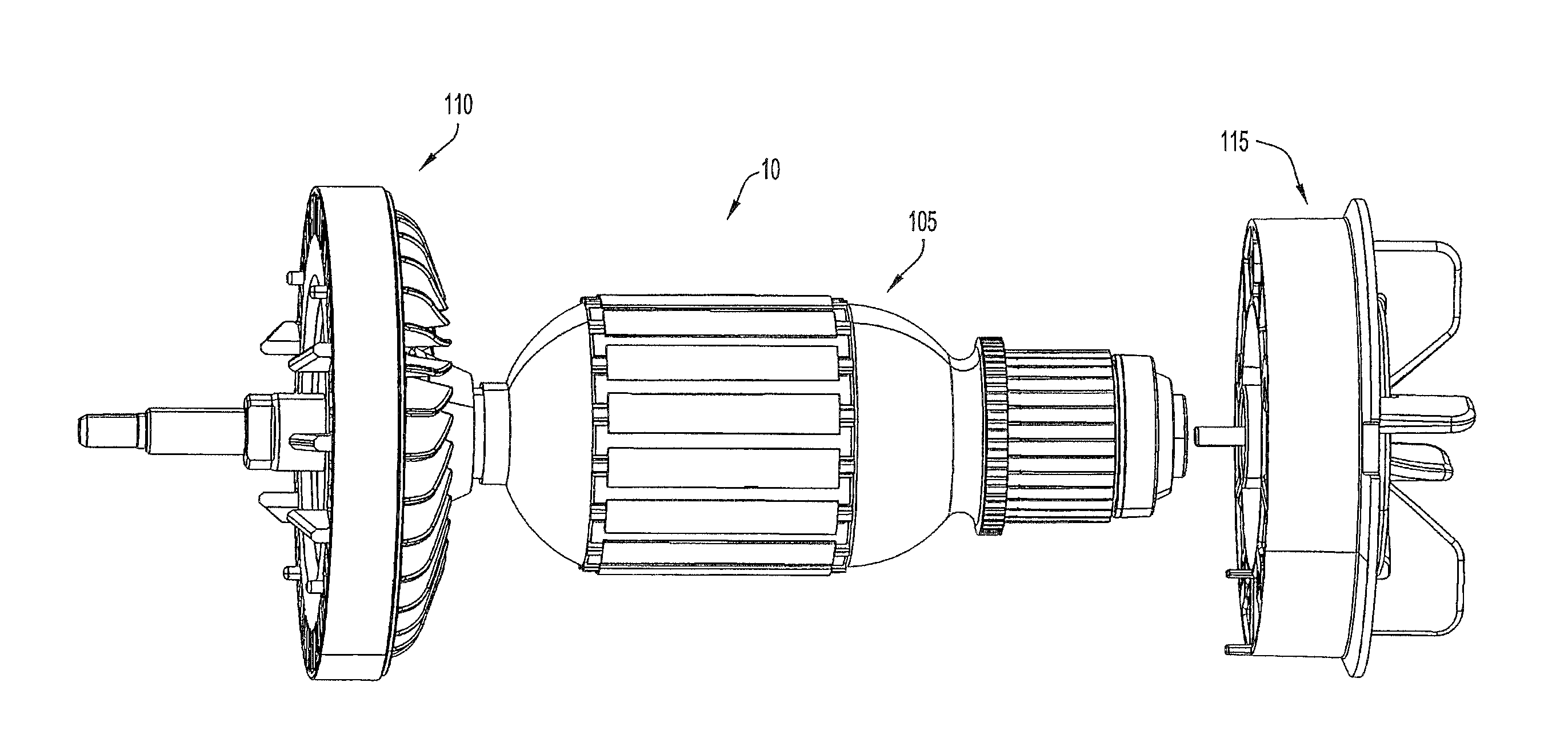

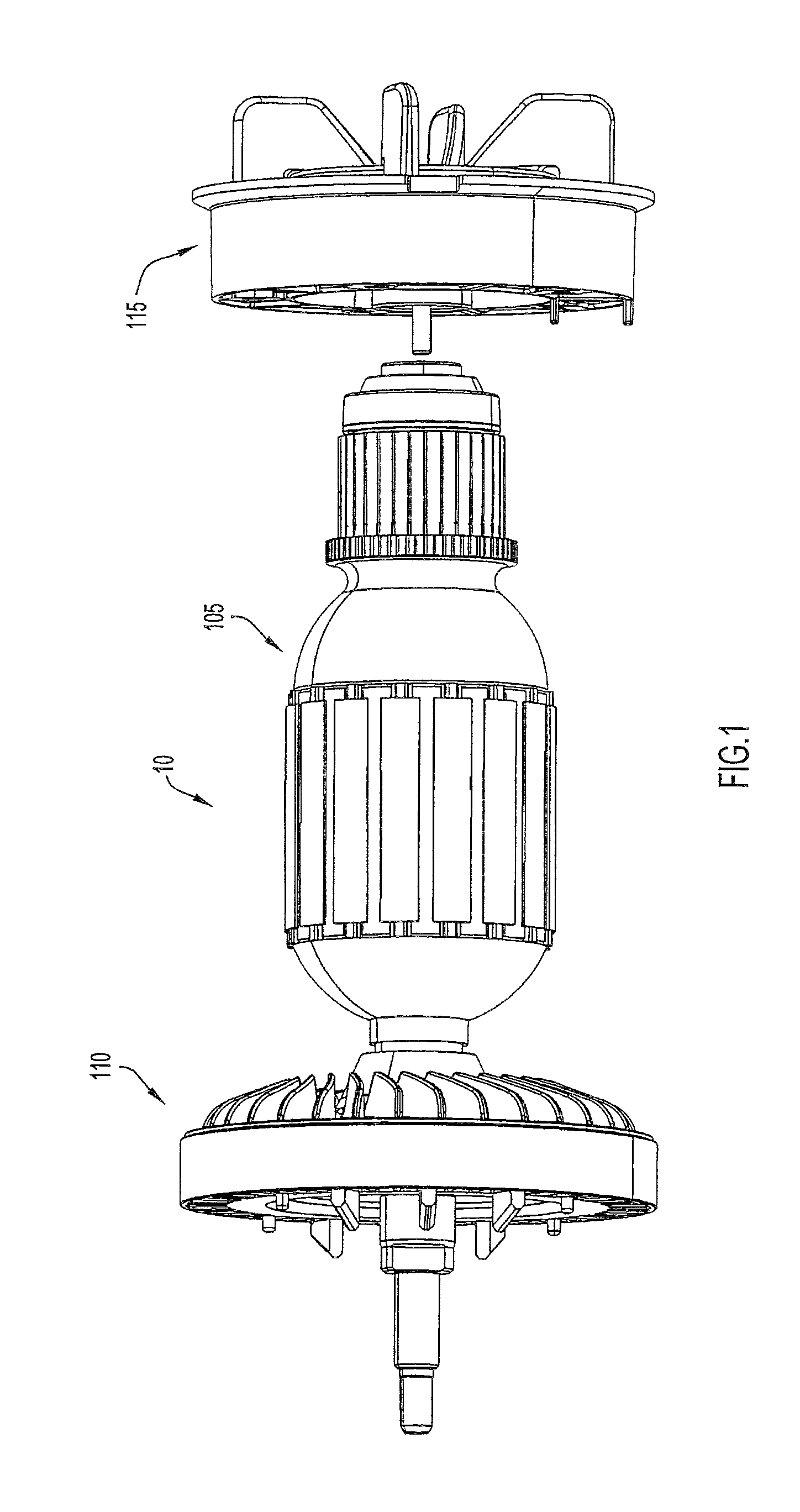

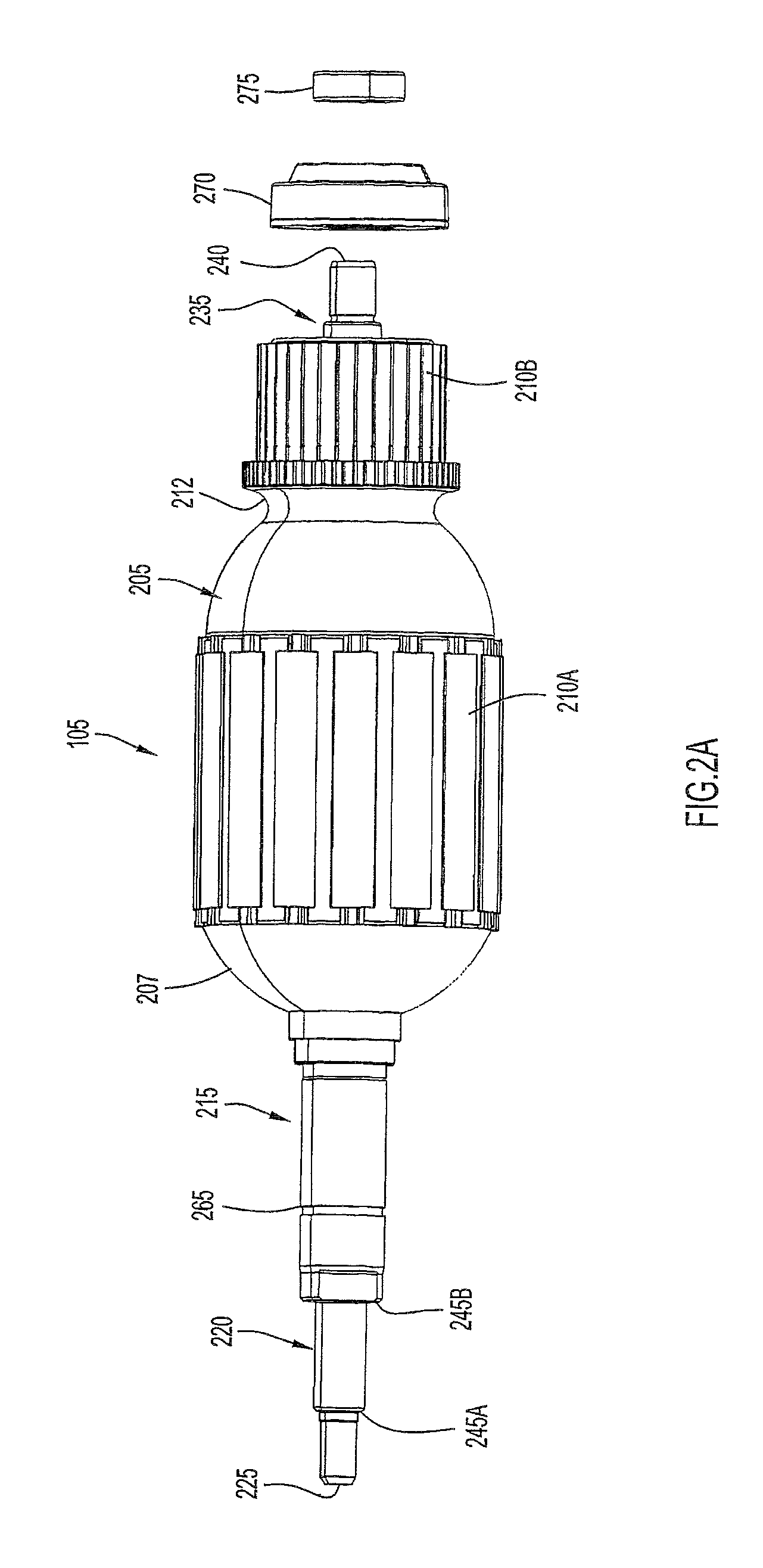

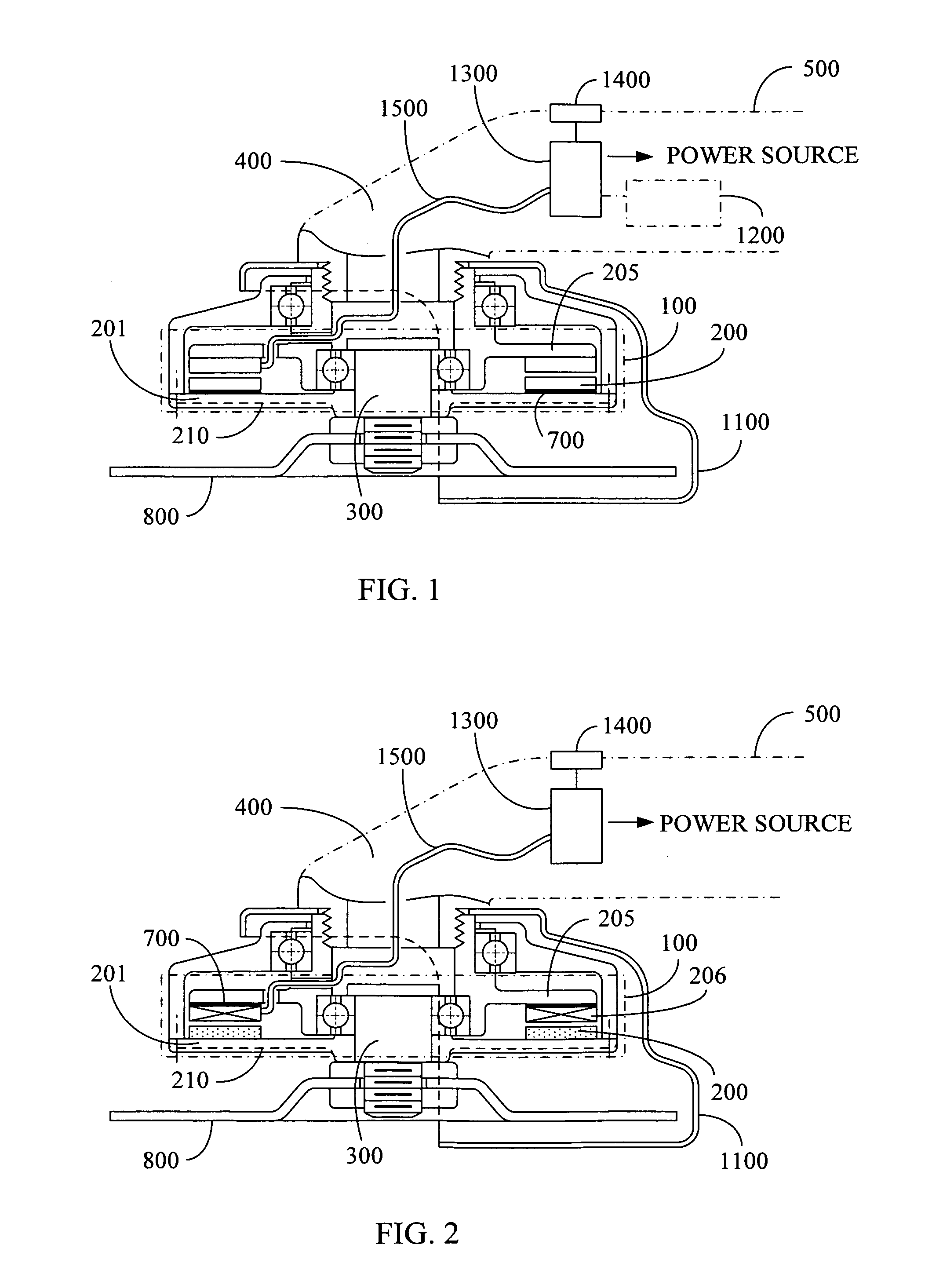

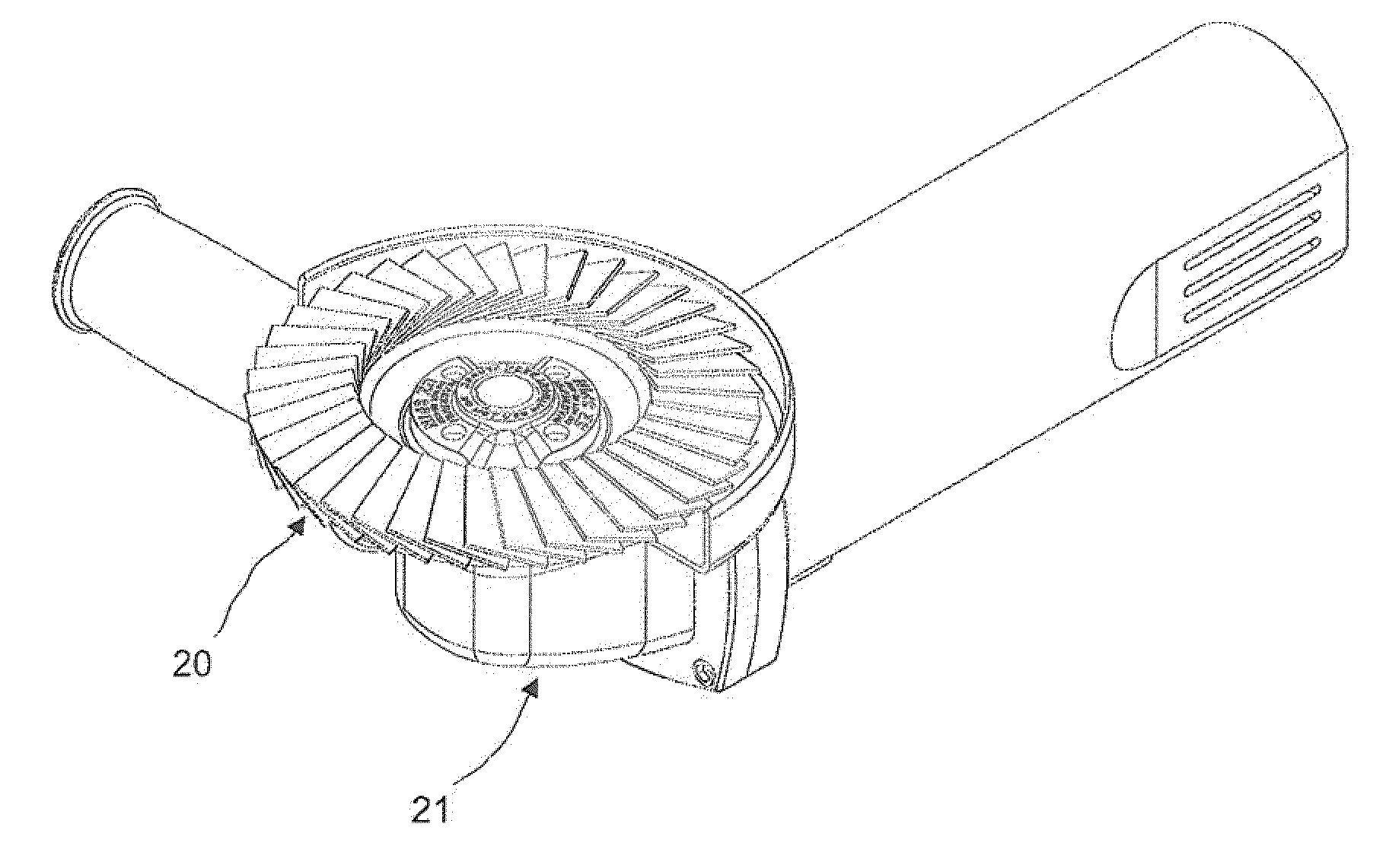

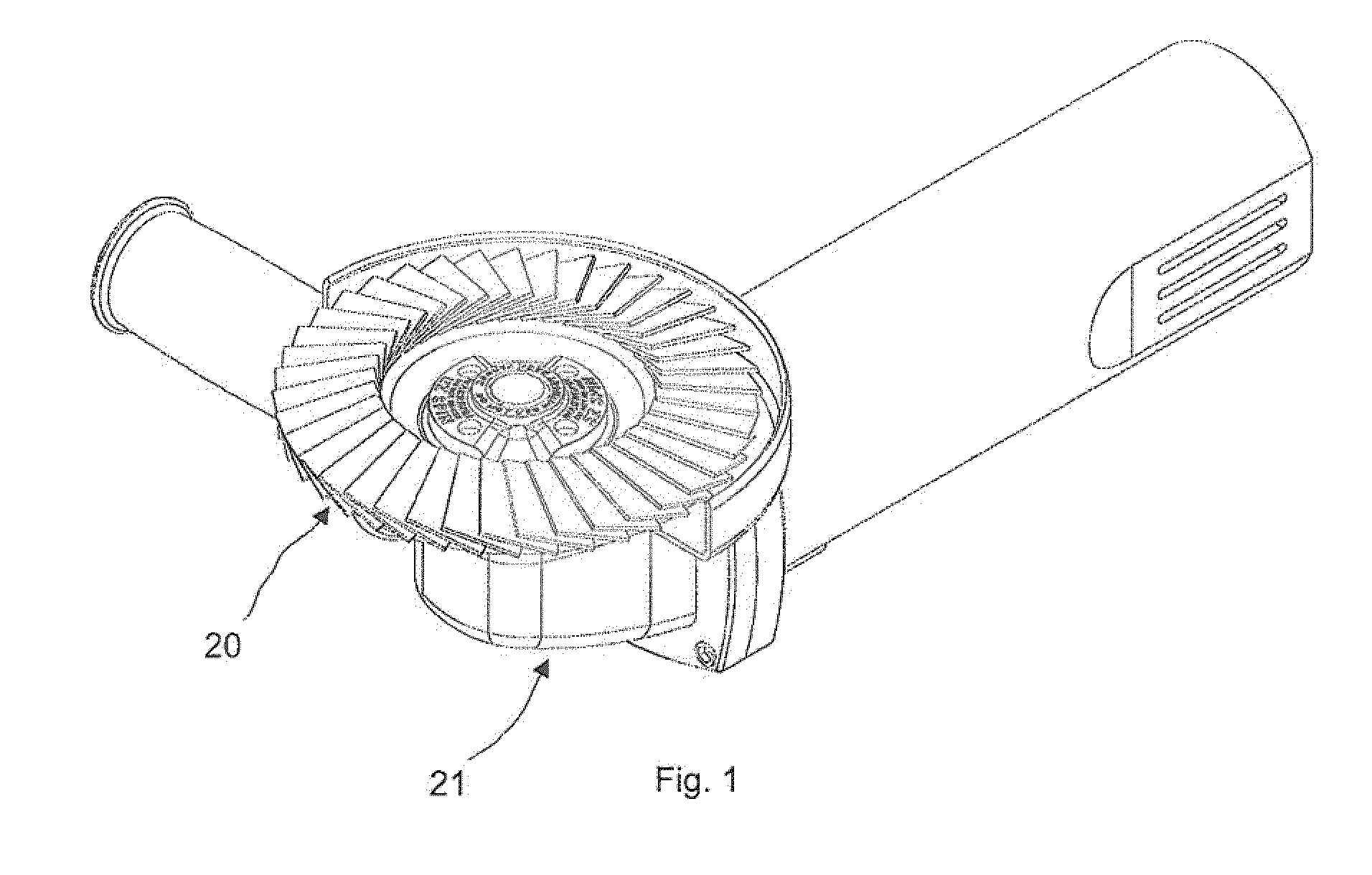

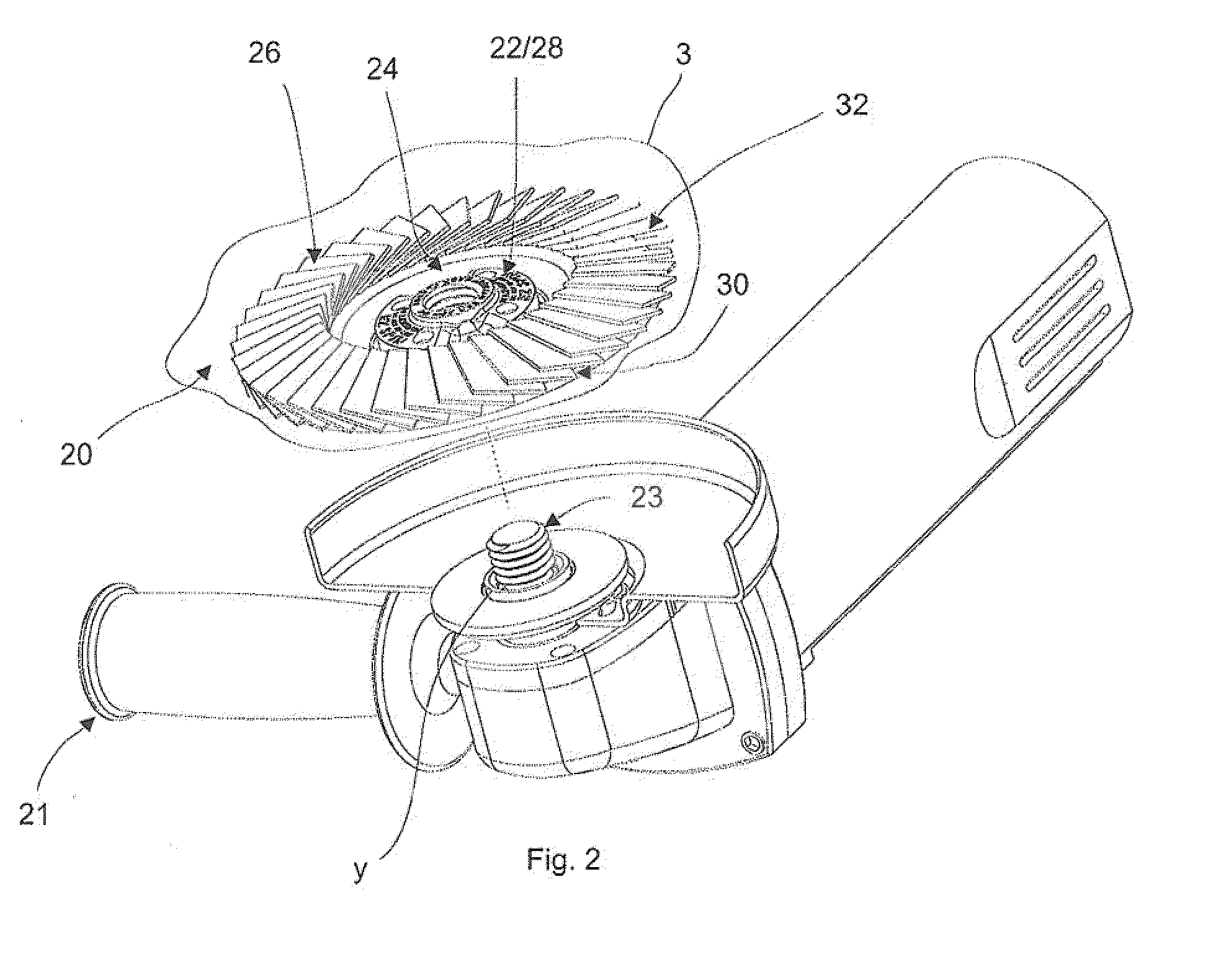

Airflow arrangement for a power tool

The present invention is directed to an airflow generation and particle dispersion arrangement for a power tool (e.g., an angle grinder). The arrangement includes a motor, an airflow generation assembly, and a particle dispersion assembly. The airflow generation assembly includes a fan driven by the motor. When engaged, the driven fan generates an airstream that is drawn through the power tool. The particle dispersion assembly includes a passive fan that is not driven by the motor, but instead is driven by the airstream. In operation, the passive fan generates centrifugal and mechanical forces sufficient to remove particles from intake air passing through the particle dispersion assembly.

Owner:BLACK & DECKER INC

Angle grinder dust shroud with unitary adjustable mounting collar

ActiveUS8702478B2Inexpensive and easy to useKeep dustSnap fastenersPortable grinding machinesAngle grinderEngineering

A universal dust shroud includes a unitary mounting bracket on top of the shroud body. The bracket includes a plurality of collar sections attached to the body via a ‘Z’ shaped joint which allows the collar sections to move radially inwardly and outwardly relative to each other to accommodate different angle grinders. The bracket may include slots formed at the base of the bracket. The slots allow air to flow in through the slots, out past the grinding disk, and to the vacuum port. As such, the slots can aid in cooling the grinder output and bearings, and helps keep dust and debris away from the bearings in order to extend the life of the grinder.

Owner:DUSTLESS DEPOT

Direct motor-drive portable angle grinder

ActiveUS20110014856A1Avoid making noiseImprove grinding and polishing and machining and cutting ability of grindingMetal sawing devicesGrinding drivesAngle grinderMotor drive

The present invention is an original direct motor-drive portable angle grinder with a disc type motor installed in a position adjacent to the grinding wheel and an outer motor rotating part coaxially and directly driving the grinding wheel. By means of the direct drive, the present invention prevents the emission of noise made by angle type transmission devices. Moreover, an inertial body is installed on the rotating housing that is integrated with the rotating part to form a flywheel or the rotating housing and the inertial body are integrated into a single reinforced structure to enable a flywheel function in order to improve the grinding, polishing and machining or cutting abilities of the grinding wheel.

Owner:YANG TAI HER

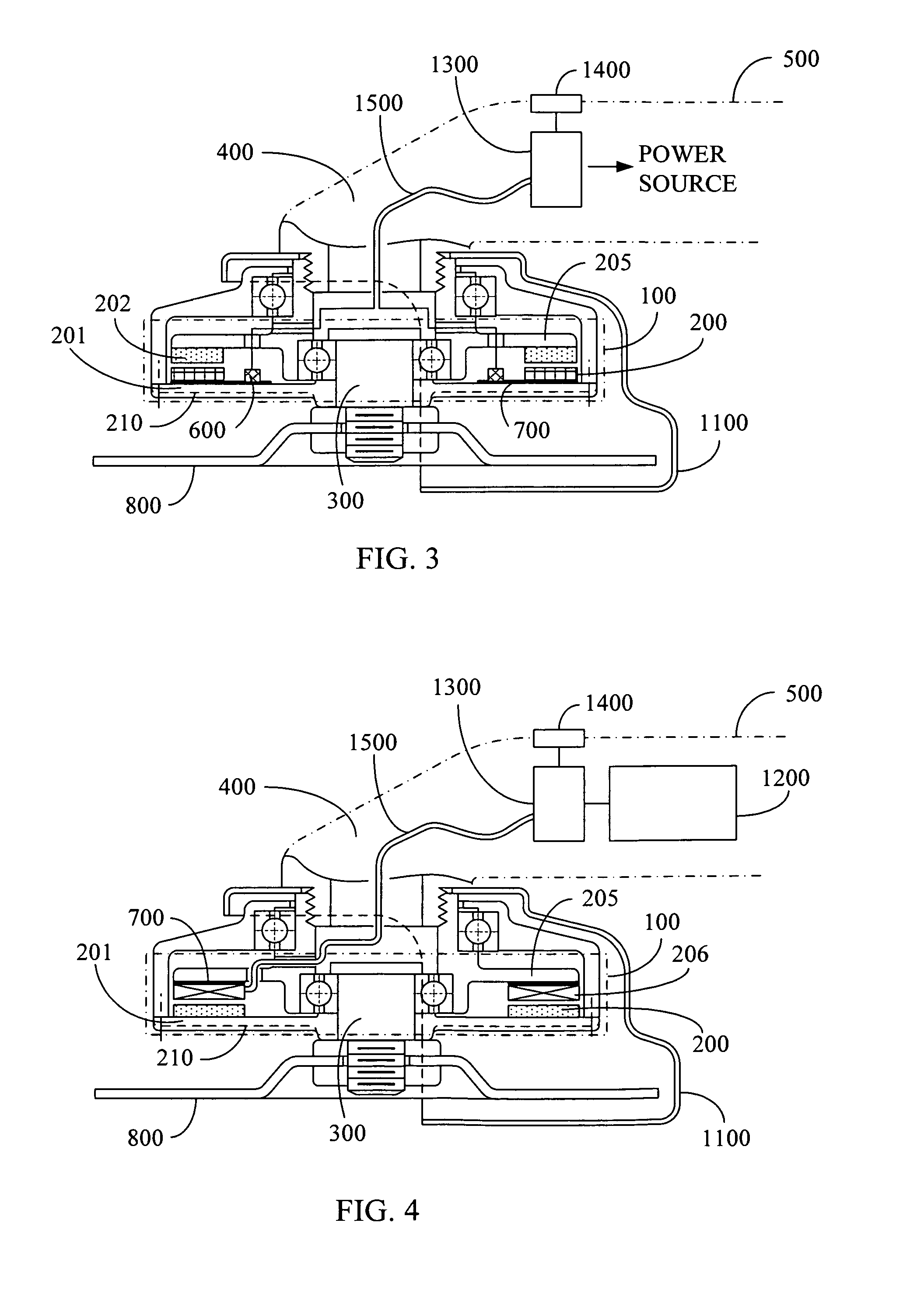

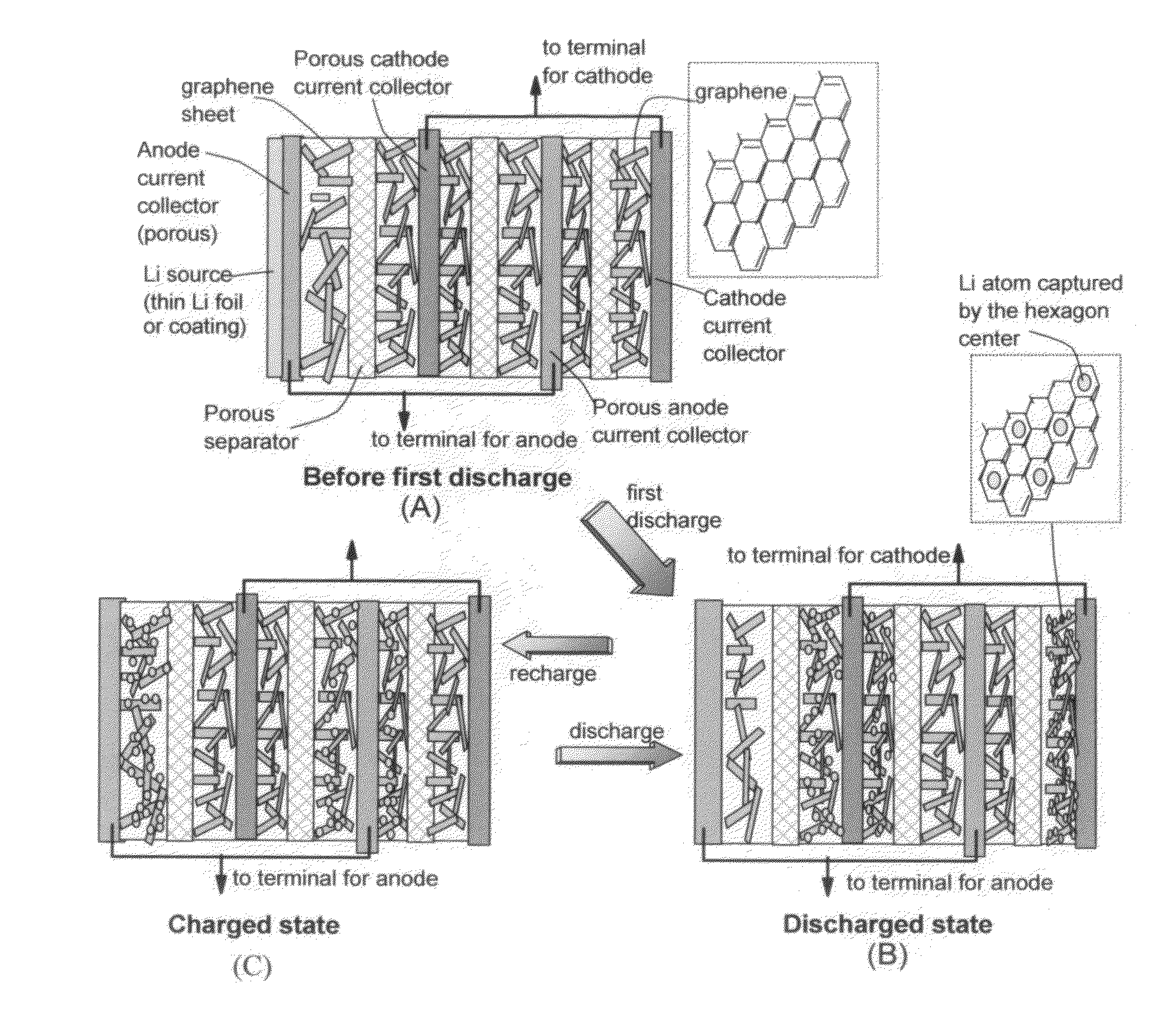

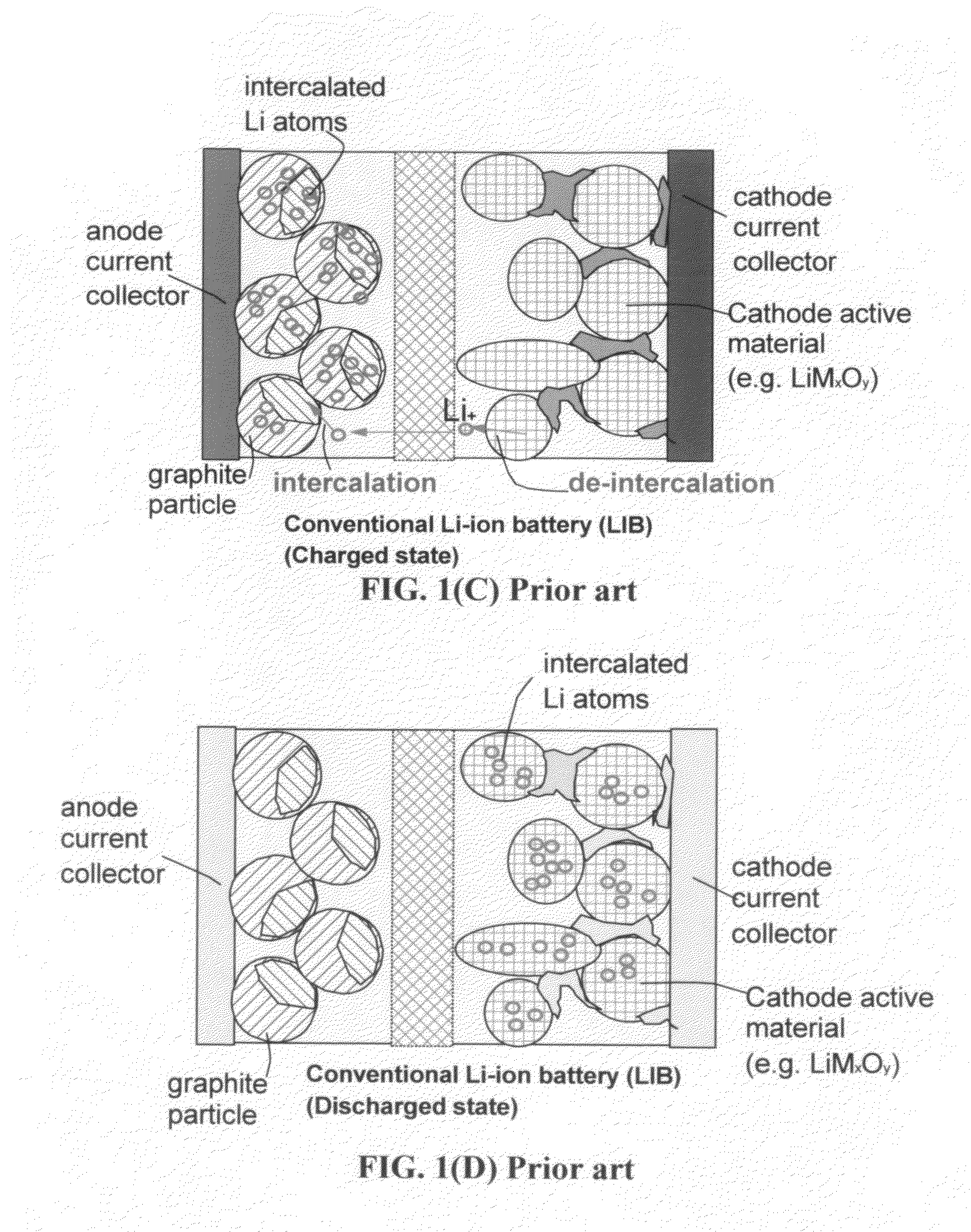

Surface-mediated cell-driven power tools and methods of operating same

ActiveUS20130213677A1Improve power densityEasy dischargeDrilling rodsCapacitor and primary/secondary cellsSanderAngle grinder

A portable power tool comprises an electric motor, actuator, or light-emitting hardware and a rechargeable power source connected to the electric motor, actuator, or light-emitting hardware, wherein the power source contains at least a surface-mediated cell (SMC). The power tools include, but are not limited to, impact driver, air compressor, alligator shear, angle grinder, band saw, belt sander, biscuit joiner, ceramic tile cutter tile saw, chainsaw, circular saw, concrete saw, cold saw, crusher, diamond blade, diamond tools, disc sander, drill, floor sander, grinding machine, heat gun, impact wrench, jackhammer, jointer, jigsaw, lathe, miter saw, nail gun, needle scaler, torque wrench, powder-actuated tools, power wrench, radial arm saw, random orbital sander, reciprocating saw, rotary reciprocating saw, rotary tool, sabre saw, sander, scroll saw, steel cut off saw, table saw, thickness planer, trimmer, wall chaser, wood router, or flashlight.

Owner:GLOBAL GRAPHENE GRP INC +1

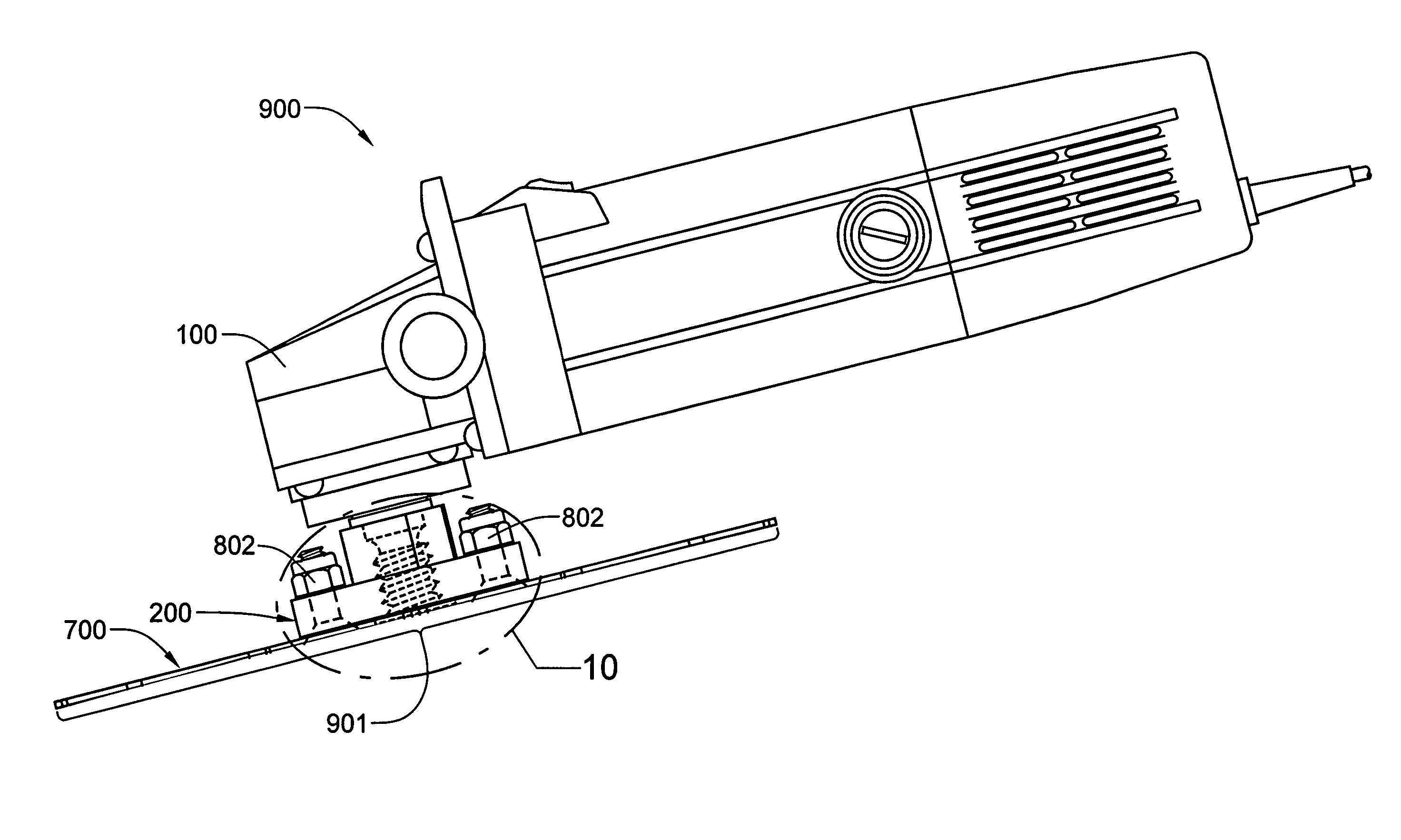

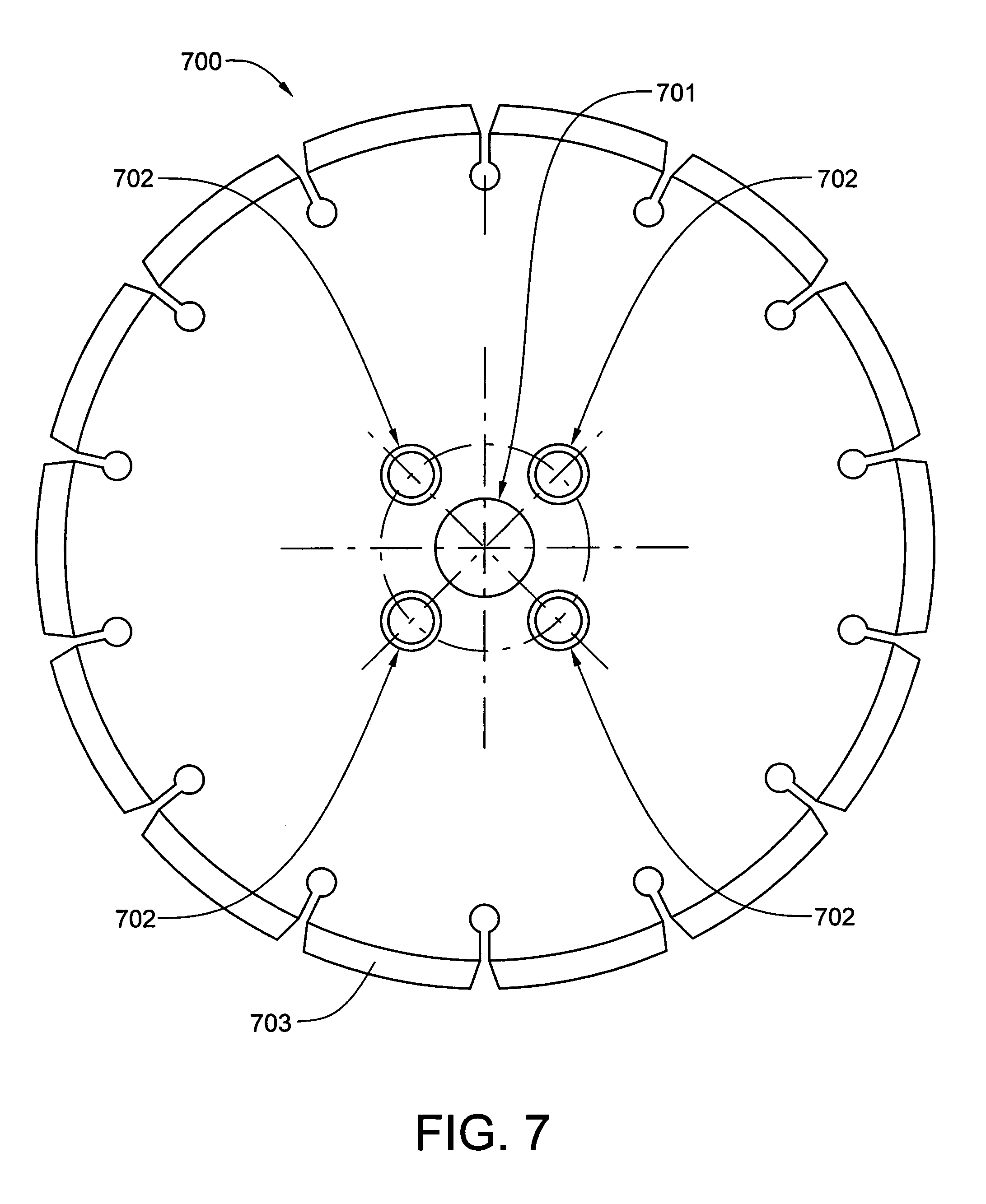

Abrasive Disc Construction

ActiveUS20100159813A1Grinding machine componentsRevolution surface grinding machinesAngle grinderEngineering

An improved abrasive disc for use with an angle grinder is disclosed. The grinder is of the type having a threaded spindle. The disc is of the type having: a central portion defining a threaded bore for receiving said spindle; and abrasive material surrounding the central portion. The improvement comprises: a hub defining the threaded bore; an annular element providing the abrasive material, the annular element having a central primary aperture aligned with the threaded bore in the hub to provide access to the bore by said spindle in use; and elements mechanically securing the hub to the annular element, for co-rotation. Apparatus and methods for producing discs are also disclosed.

Owner:VIRTUAL MASCH INC

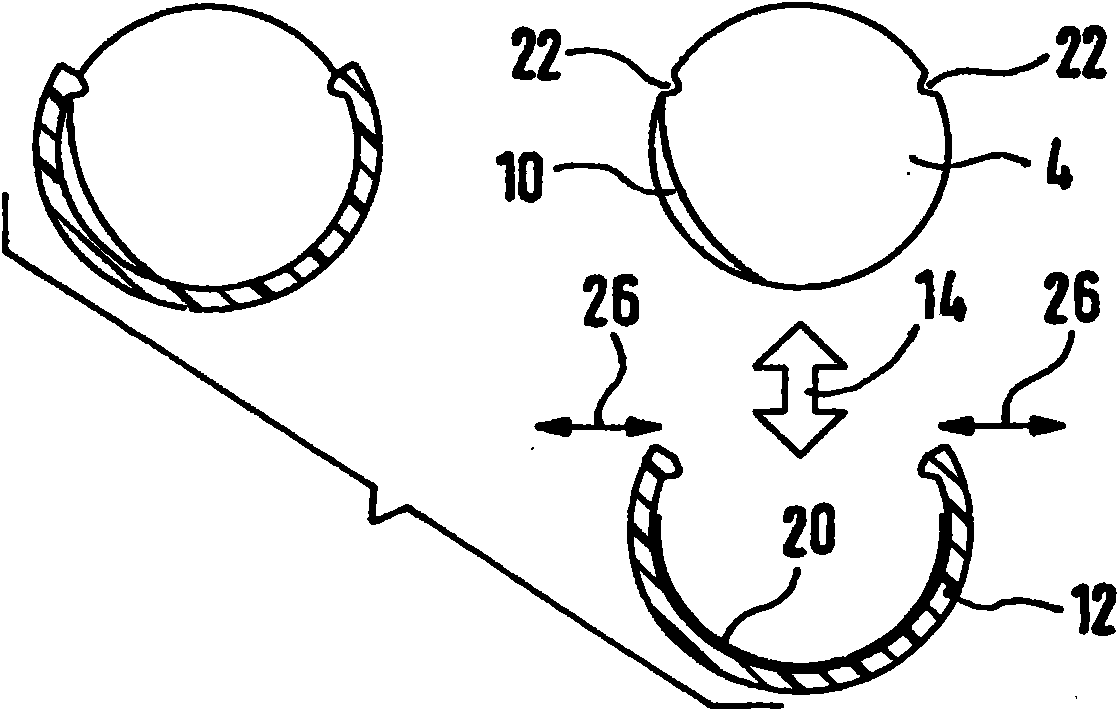

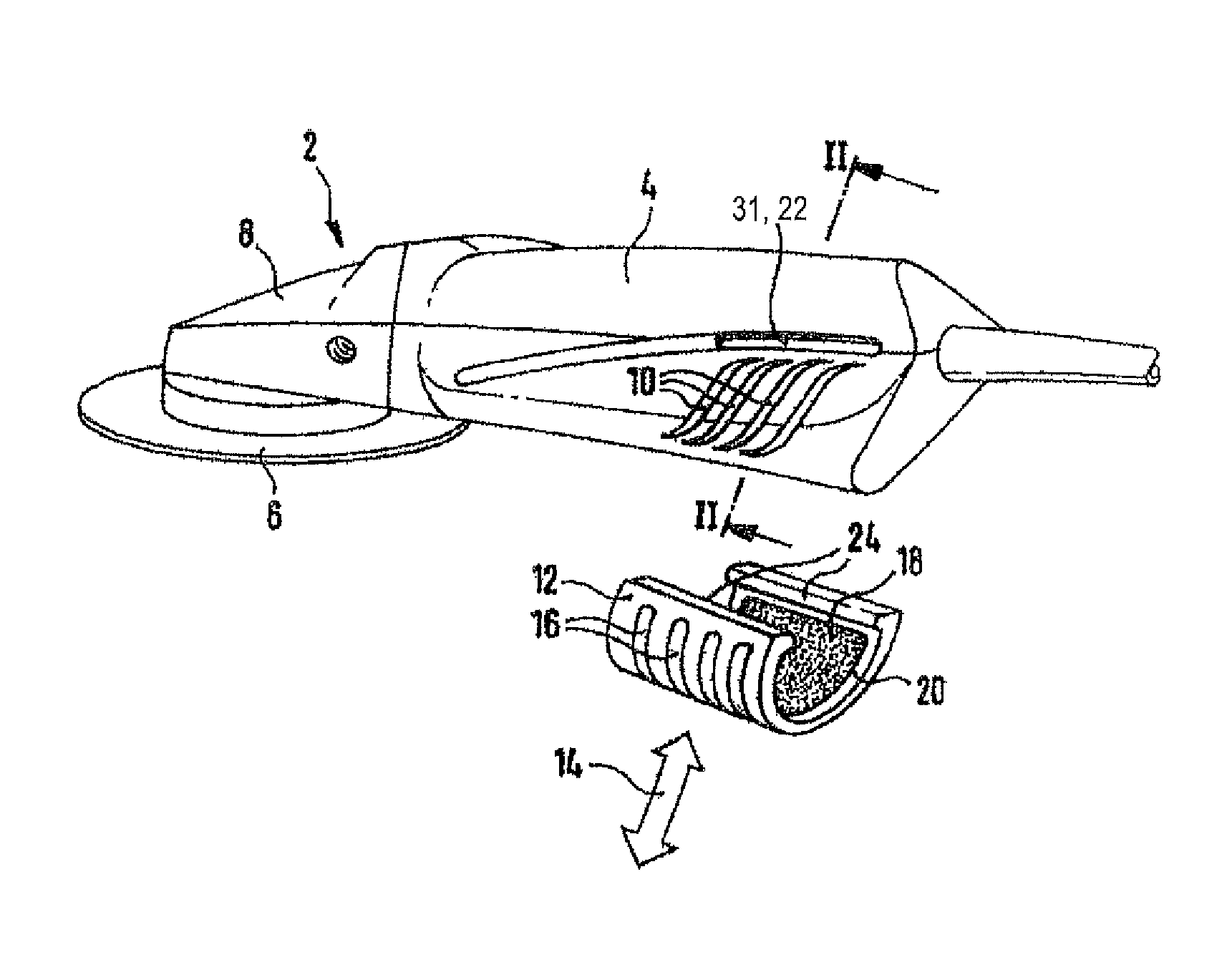

Dust-protected hand-held power tool

ActiveCN101925443AEasy to replaceImprove sealingPortable grinding machinesPortable power-driven toolsAngle grinderHand held

Owner:METABOWERKE

Repairing technology for fair-faced concrete defects

The invention discloses a repairing technology for fair-faced concrete defects. The repairing technology comprises the steps of surface pretreatment; surface filling; surface color treatment. The surface pretreatment step comprises the operation of cleaning a wall surface, wetting the wall surface through water and preparing for the next step. The surface filling step comprises the operation of a, bubble type hole treatment, wherein bubble type holes are remedied one by one through repairing material, then cured and dried after remedying is completed, polished through fine abrasive paper, washed cleanly through clean water after polishing is completed and finally air-dried; b, formwork joint treatment, wherein uneven parts of joints are ground by an angle grinder and then polished by a polishing machine, and the parts with serious defects need to be leveled through the repairing material. The surface color treatment step comprises the operation of carrying out color treatment on repaired parts of the surface of the wall body through concrete color matching agents; carrying out paint surface painting, wherein the repaired surface of the wall body is wholly painted with concrete protection paint. According to the technology, the treated surface of fair-faced concrete can be the same as the original surface, the appearance effect is good, and the concrete protection paint is additionally used so that protection to the surface of the concrete can be enhanced.

Owner:STATE GRID CORP OF CHINA +2

Dust-protected hand-held power tool

ActiveUS8398465B2Improve sealingEasy to replacePortable grinding machinesPortable power-driven toolsAngle grinderHand held

A battery-operated hand-held power tool (2), especially an angle grinder, comprises a housing base (4) accommodating the electromotive drive components and air inlet openings (10) supplying the electromotive drive components with a cooling air flow. In order to protect the electromotive components from dirt, the hand-held power tool is designed in such a manner that a filter element (20) is provided in the area of the air inlet openings (10) and keeps dust, especially magnetizable dust, away from the electromotive drive components. The filter element (20) is retained by a filter retaining part (12, 30) which can be attached to the exterior of the housing base (4). The filter retaining part (14, 30) can be elastically deformed to such an extent that it is slightly deformed, especially expanded, when attached to the housing base, and engages behind or snaps into an element on the housing base.

Owner:METABOWERKE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com