Patents

Literature

215 results about "Spinning disk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

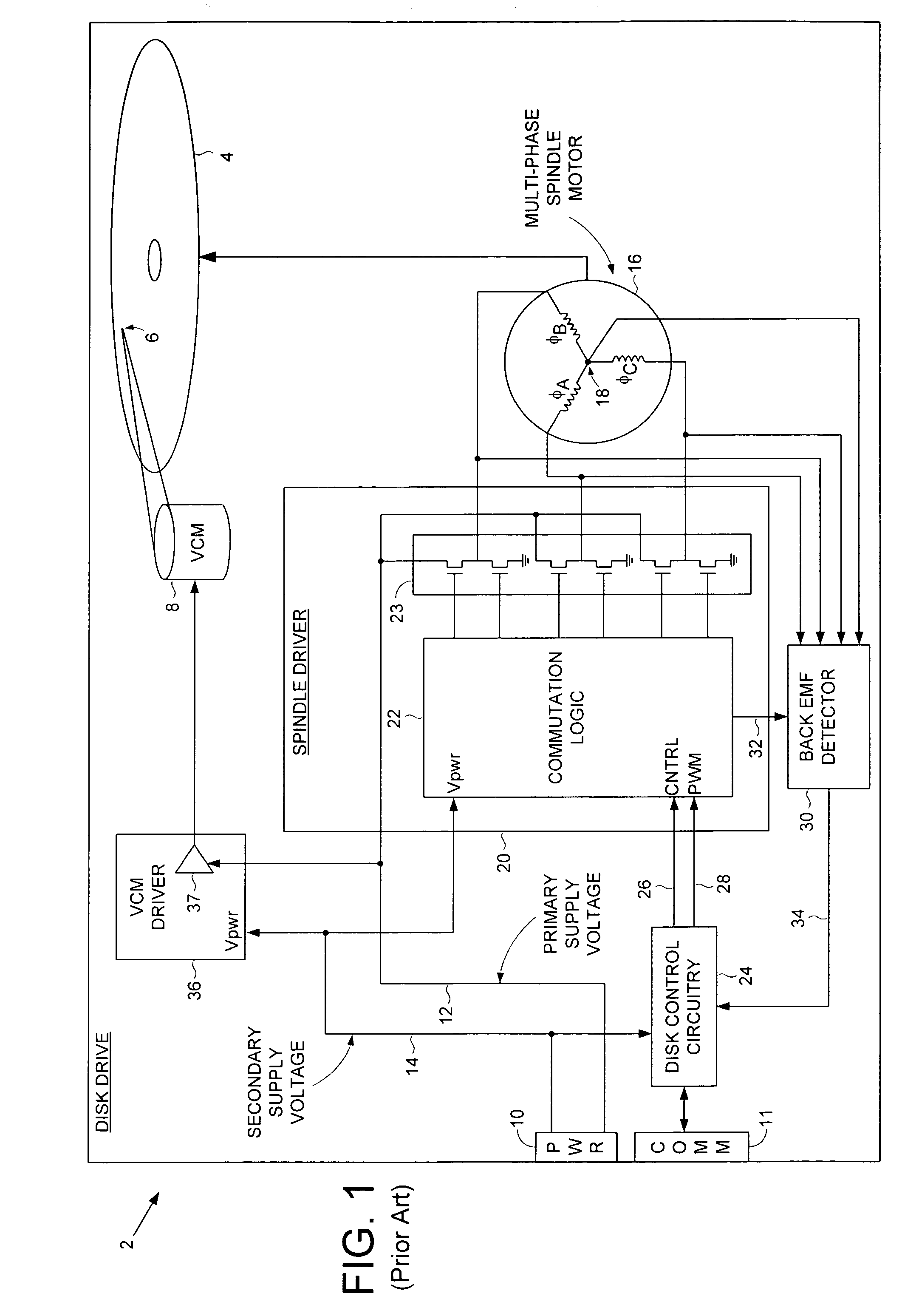

A spinning disk is the mechanism within a hard disk drive to which memory is written. With rotating plates attached to an arm that writes the data, the spinning disk mechanism physically resembles a record player (although it is sealed within an enclosure).

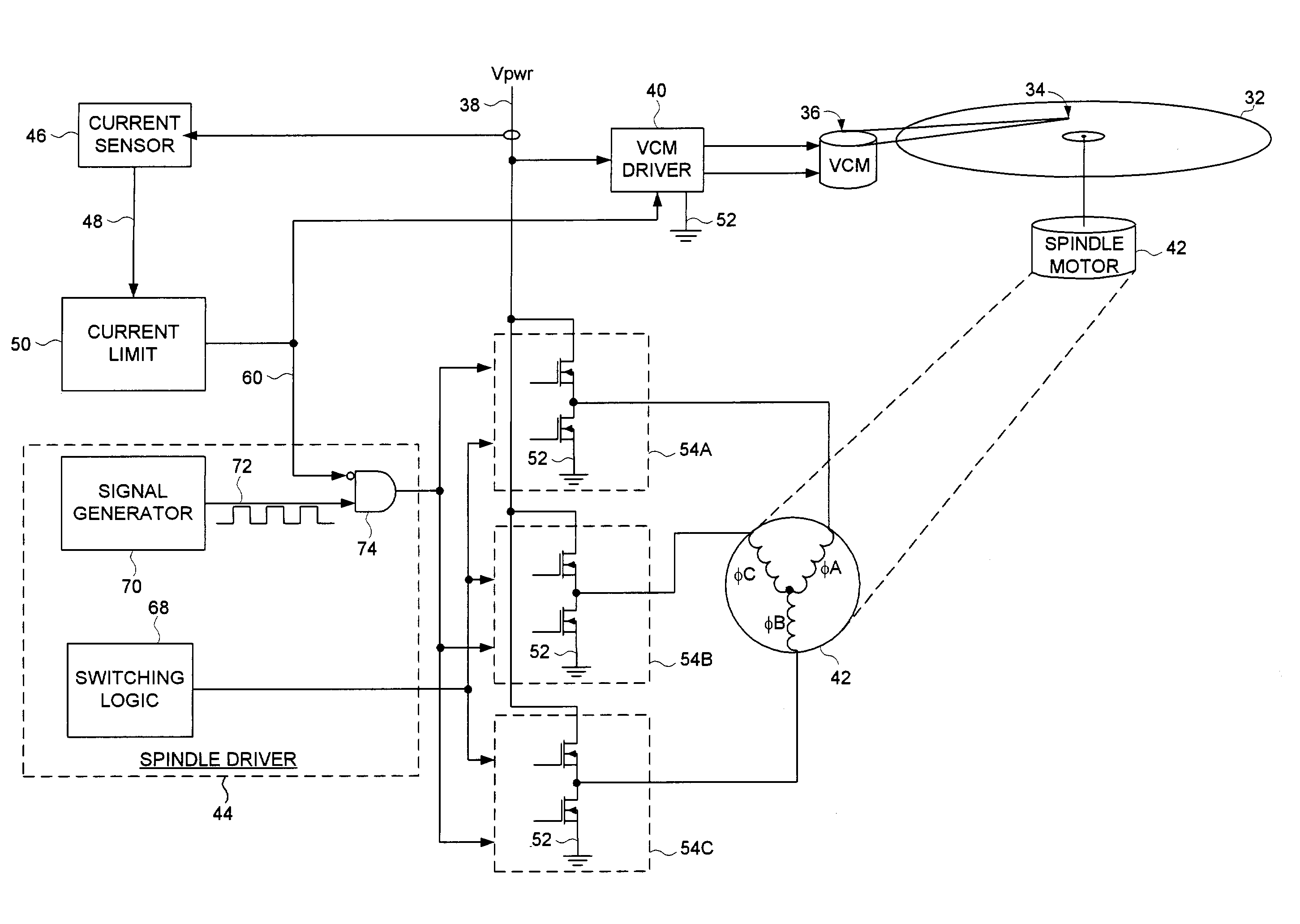

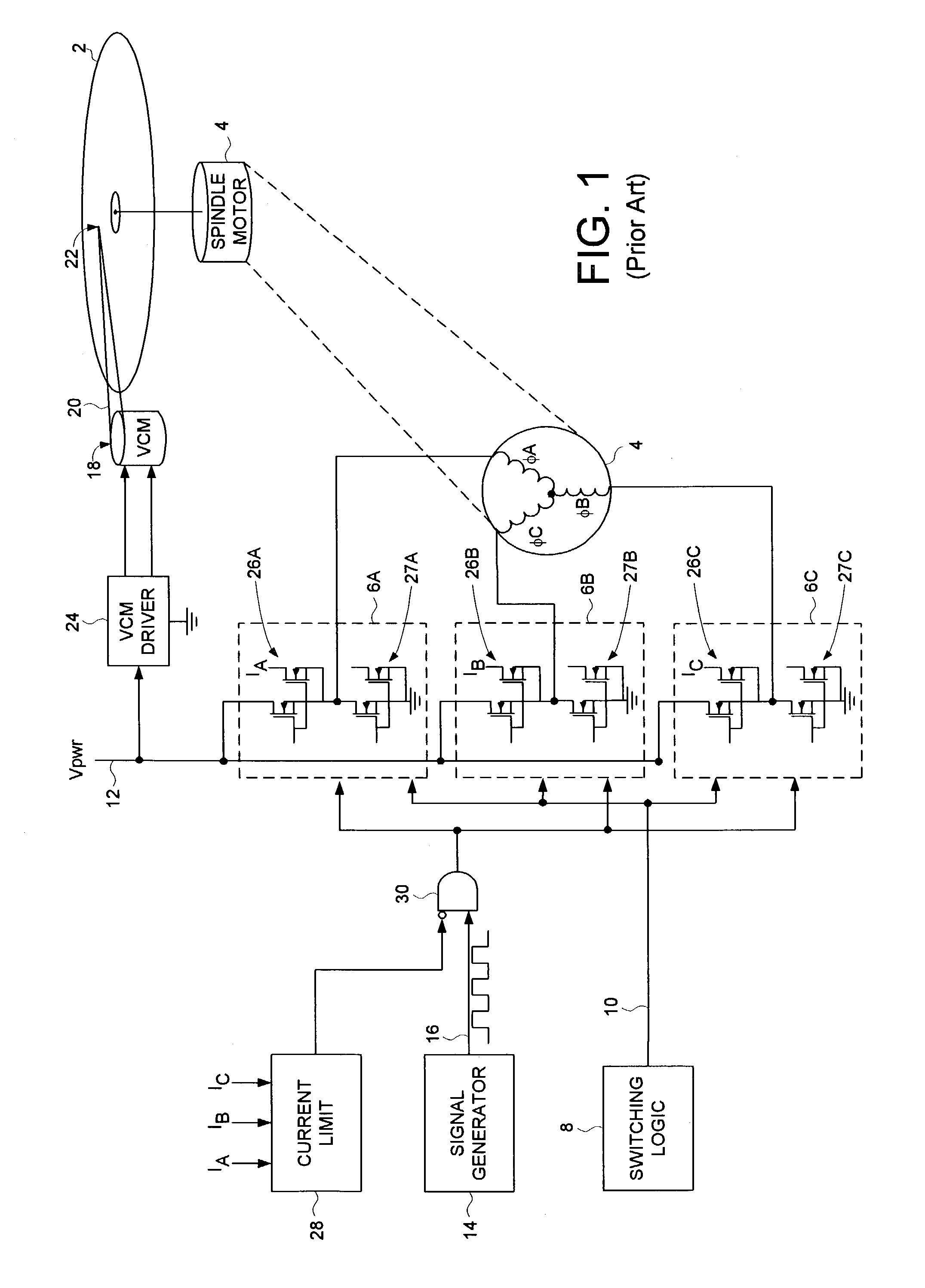

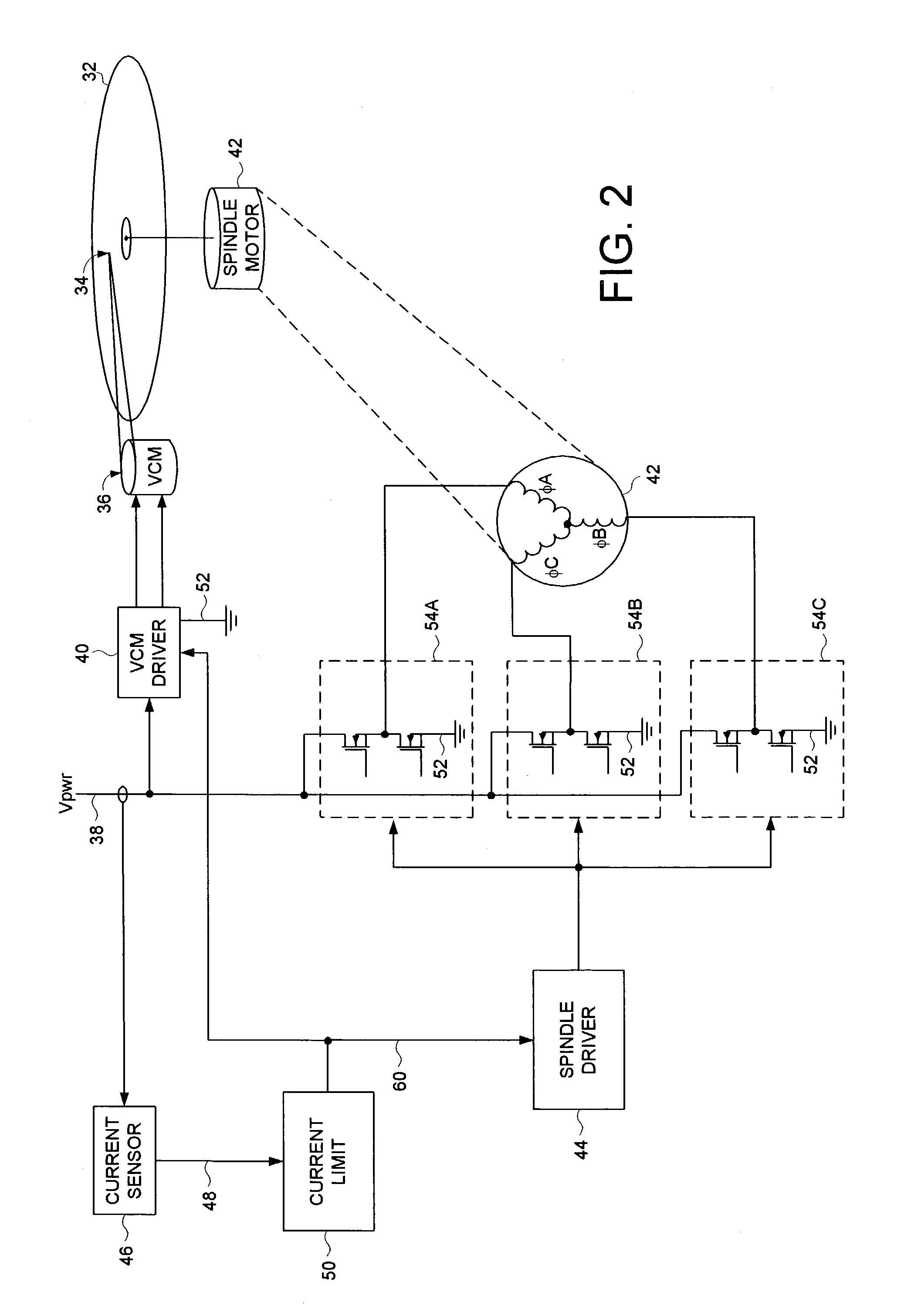

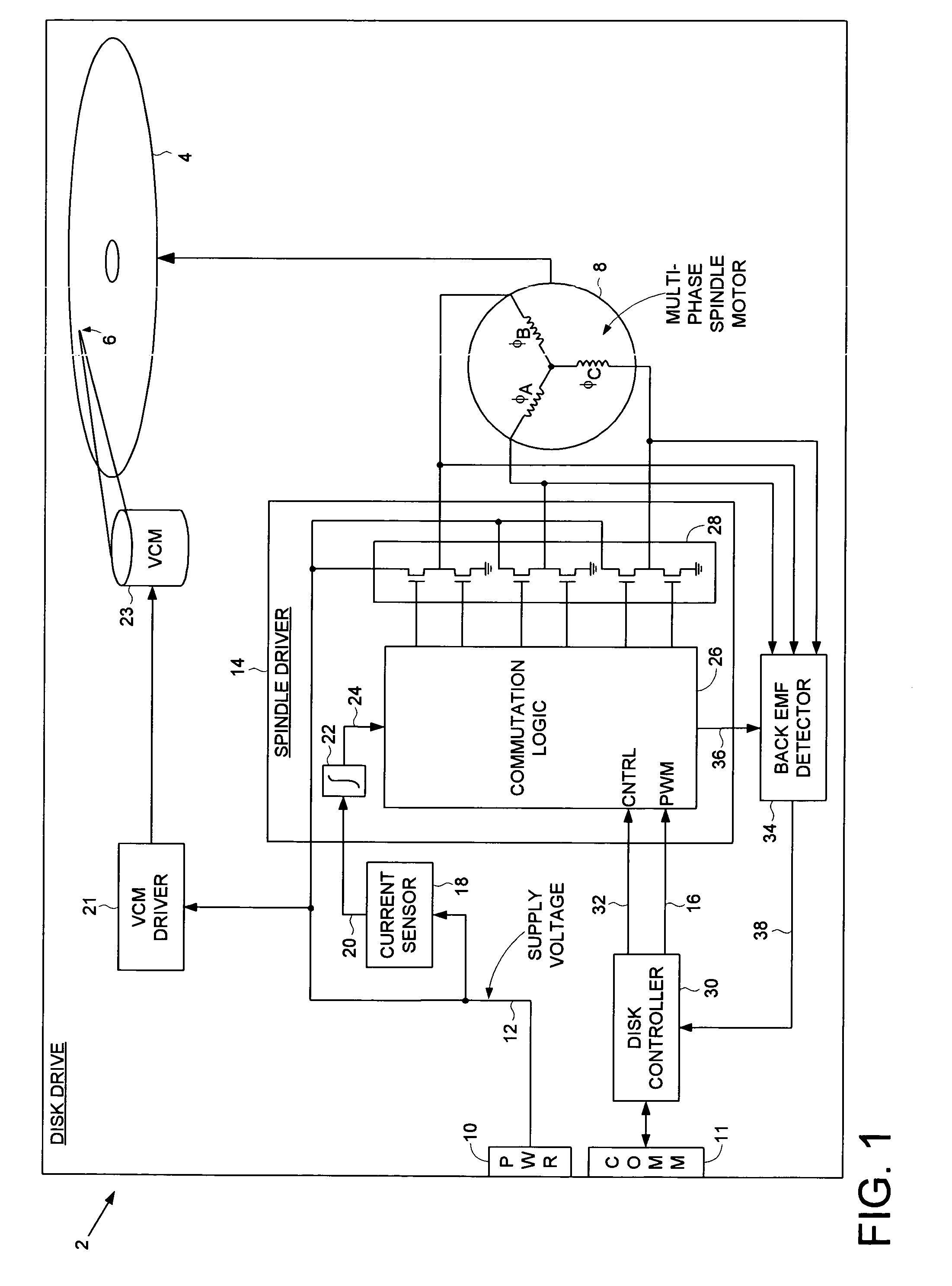

Disk drive monitoring a supply current to protect motor driver circuits

ActiveUS6934135B1Record information storageEmergency protective arrangements for automatic disconnectionDriver circuitEngineering

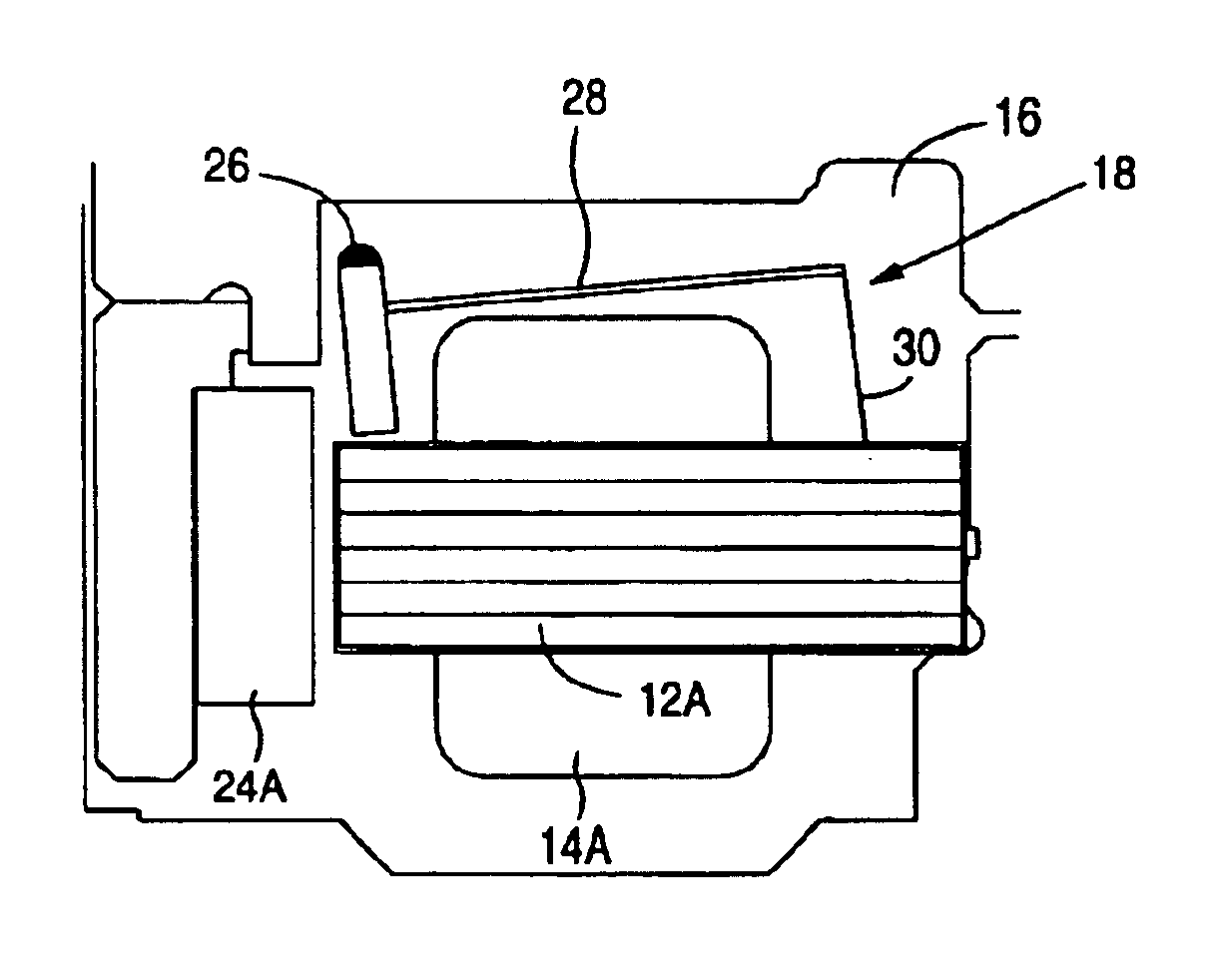

A disk drive is disclosed comprising a spindle motor for rotating a disk and a voice coil motor (VCM) for actuating a head over the disk. The spindle motor comprises a plurality of windings, and the VCM comprises a voice coil. If the current flowing from a supply voltage exceeds a threshold, the windings are disconnected from the supply voltage, the voice coil is disconnected from the supply voltage, and the first and second ends of the voice coil are connected to ground.

Owner:WESTERN DIGITAL TECH INC

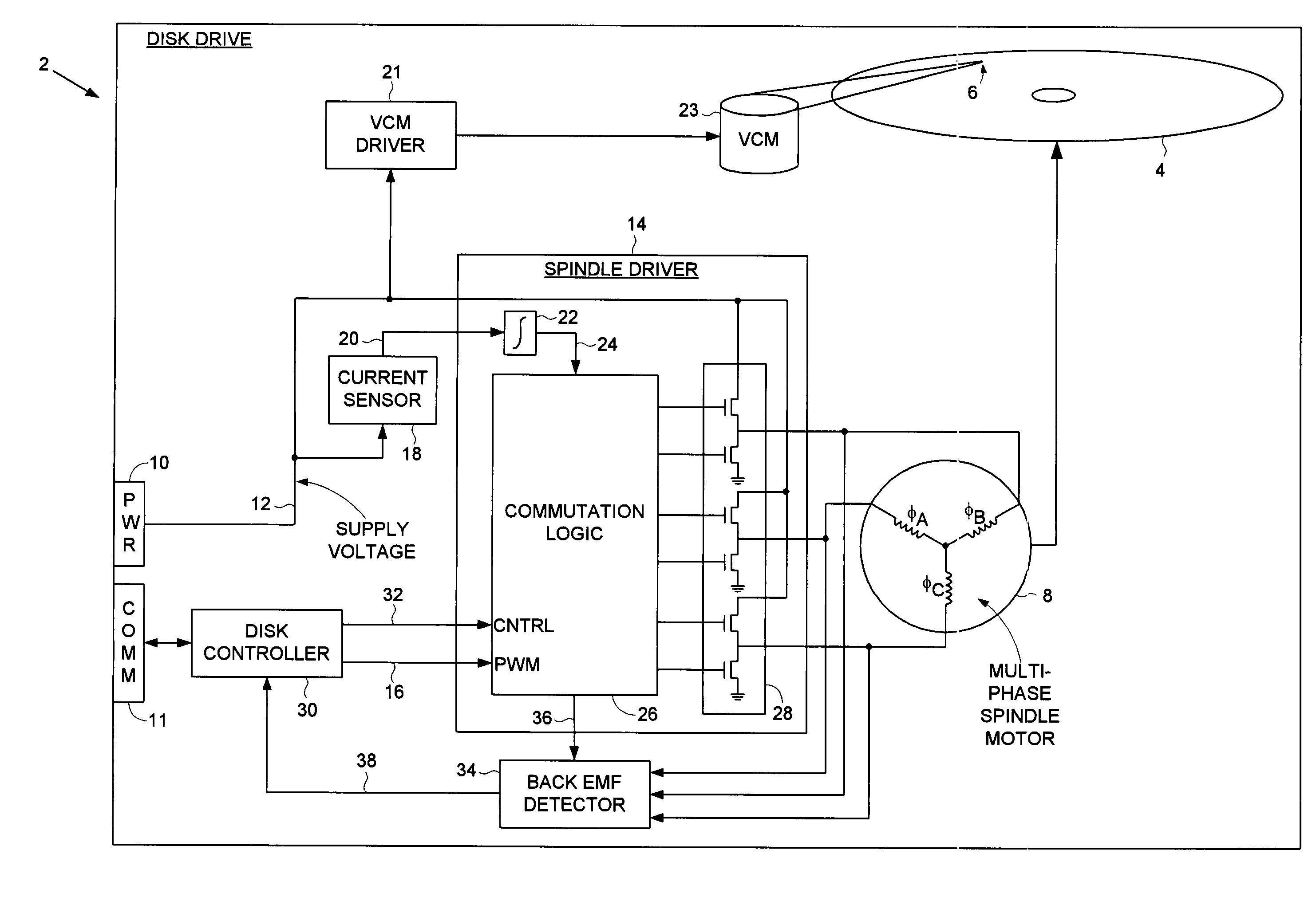

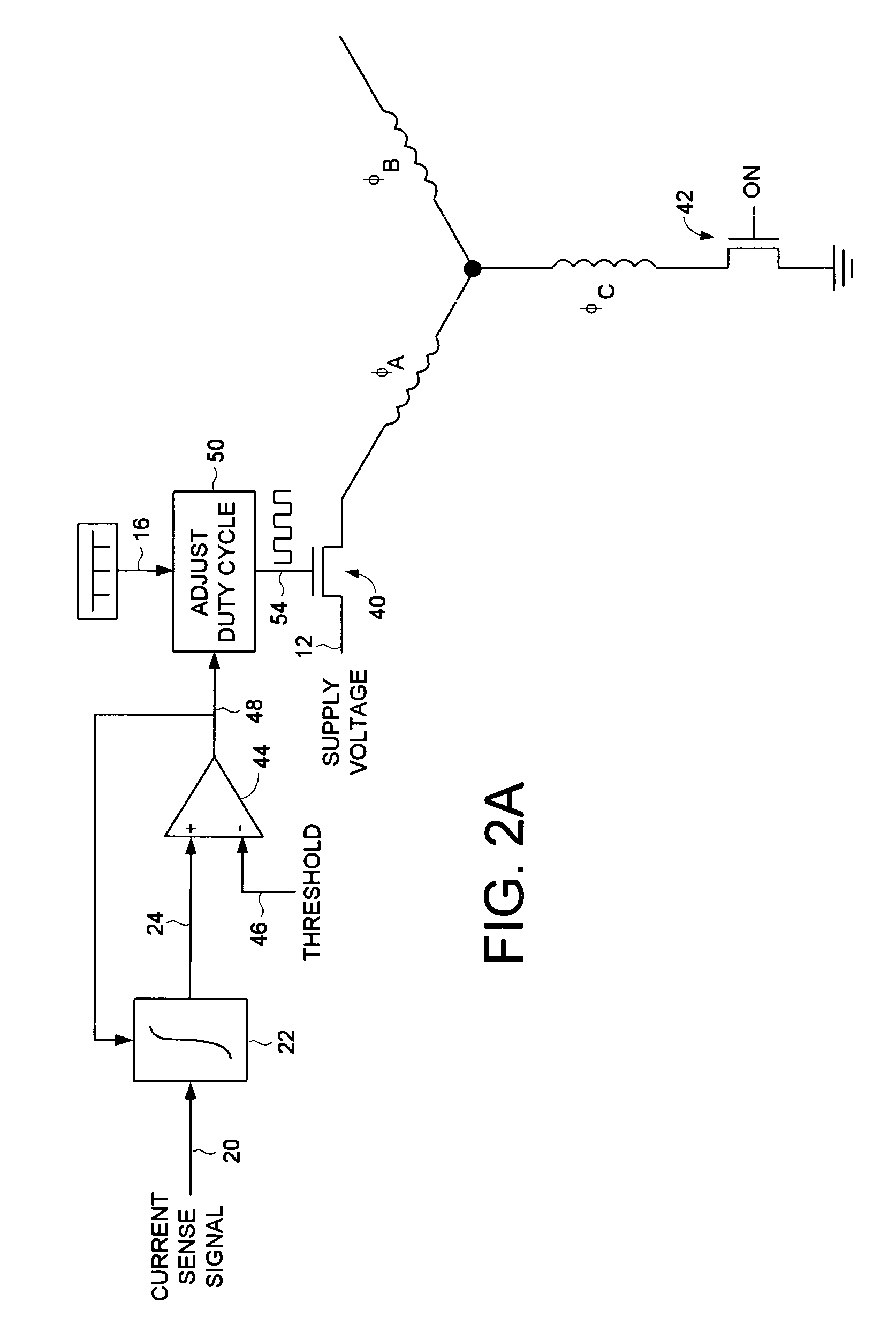

Decreasing spin up time in a disk drive by adjusting a duty cycle of a spindle motor PWM signal to maintain constant average input current

A disk drive is disclosed comprising a spindle motor for rotating a disk, wherein the current applied to the spindle motor is controlled by adjusting a duty cycle of a pulse width modulated (PWM) signal. A current sensor generates a current sense signal representing a current flowing from a supply voltage. The current sense signal is integrated to generate an integration signal. The integration signal is compared to a threshold, and the result of the comparison is used to adjust the duty cycle of the PWM signal. In this manner the disk drive draws essentially constant average input current from the supply voltage which decreases the spin up time of the disk.

Owner:WESTERN DIGITAL TECH INC

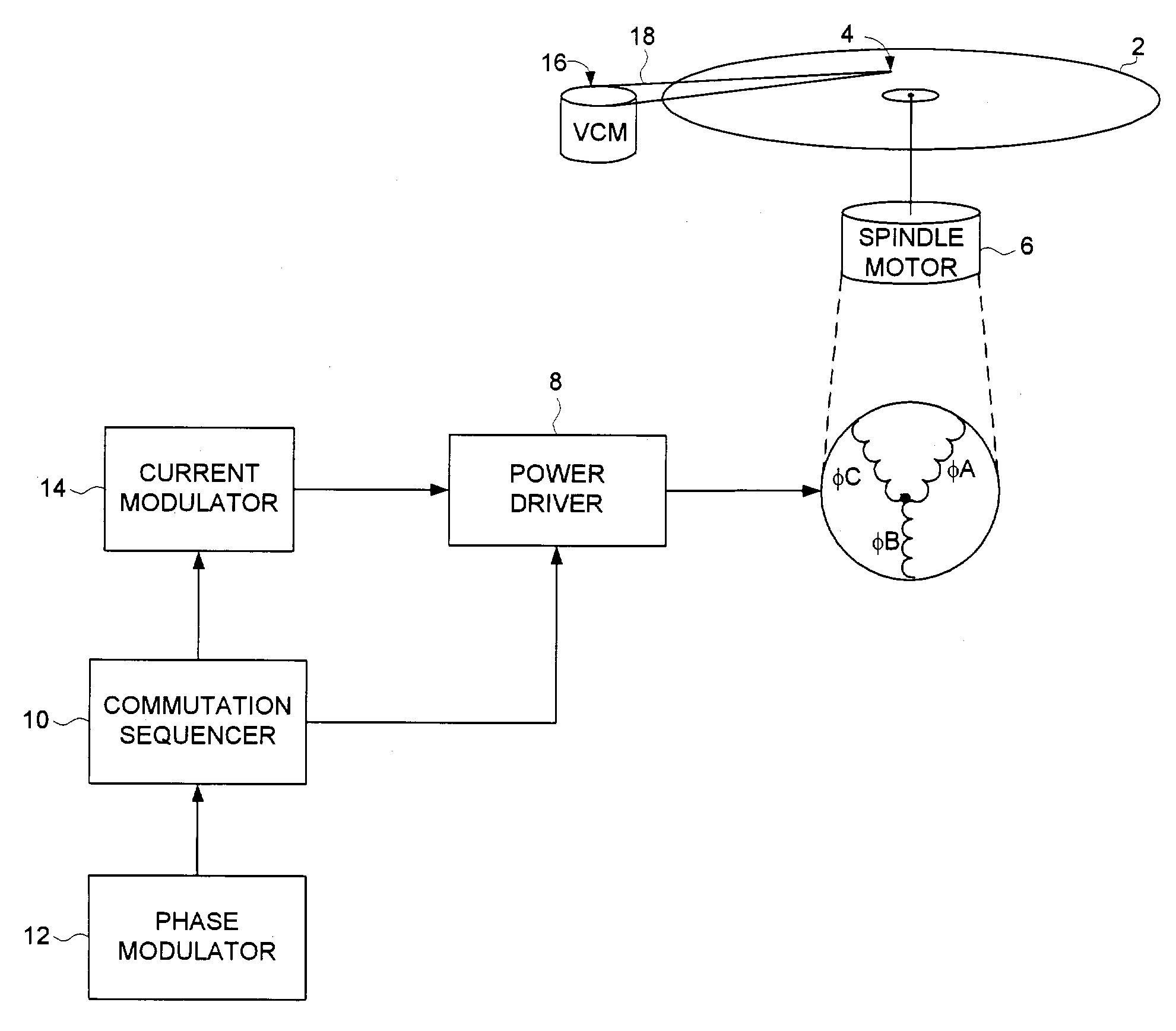

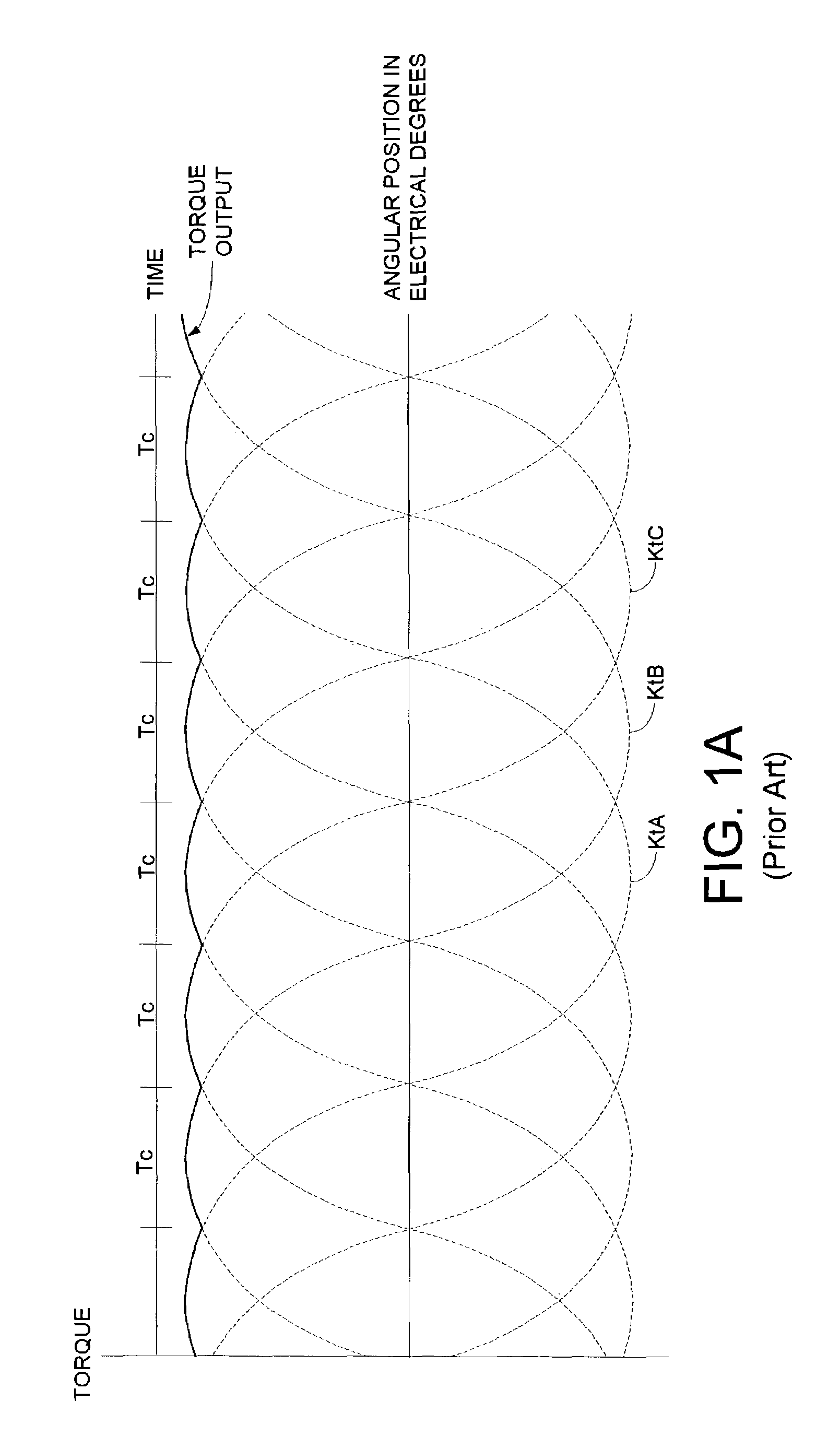

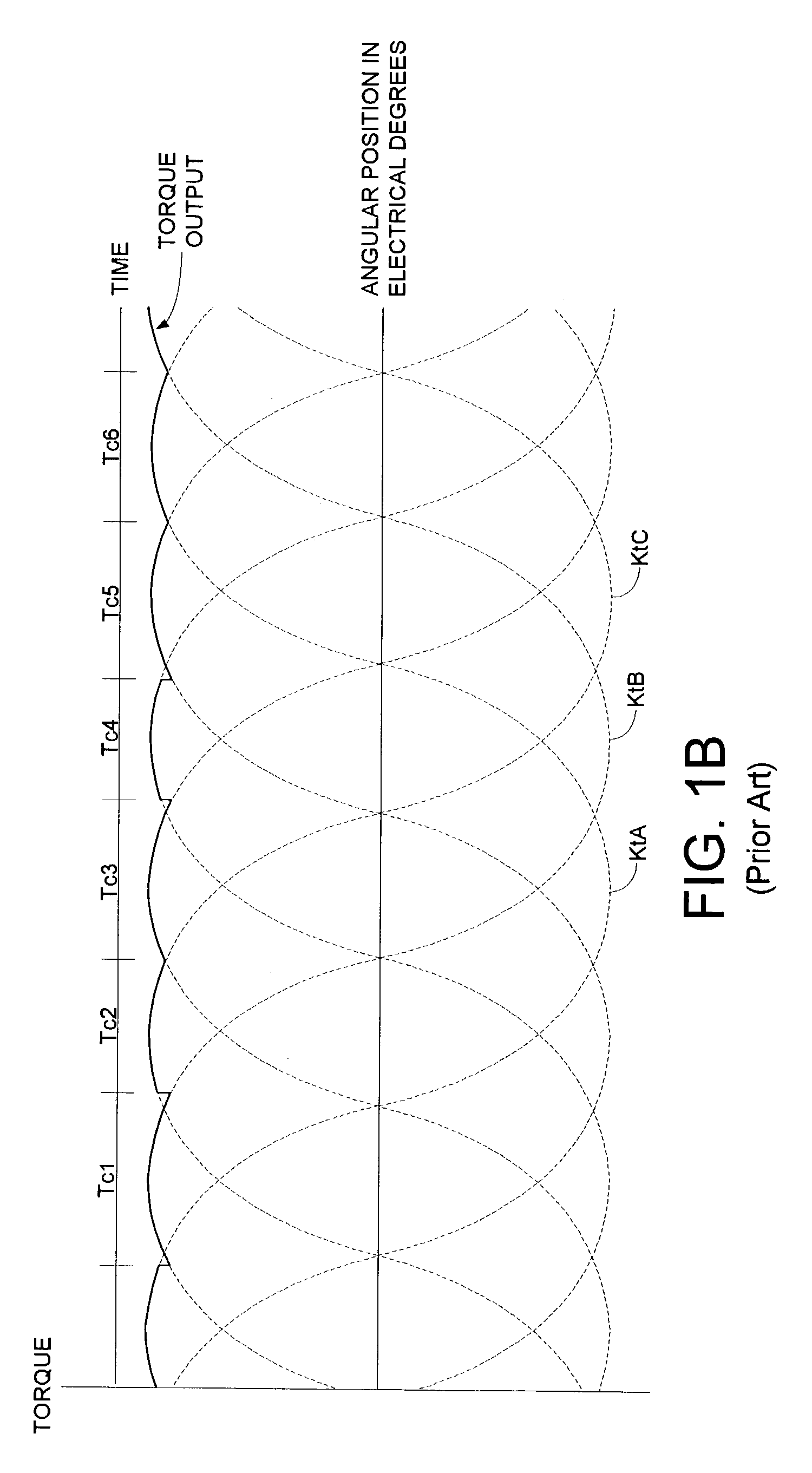

Disk drive employing commutation phase modulation and current modulation of a spindle motor

InactiveUS6972539B1Reduce discontinuityReduce vibrationAC motor controlDC motor speed/torque controlElectric machineNoise reduction

A disk drive is disclosed comprising a spindle motor comprising a plurality of windings for rotating a disk. The spindle motor is rotated by commutating the windings over a plurality of commutation states, wherein audible noise generated by the disk drive is reduced by phase modulating the commutation interval. Further audible noise reduction is achieved by modulating a current applied to the windings which substantially reduces discontinuities in the torque output of the spindle motor caused by phase modulation of the commutation intervals.

Owner:WESTERN DIGITAL TECH INC

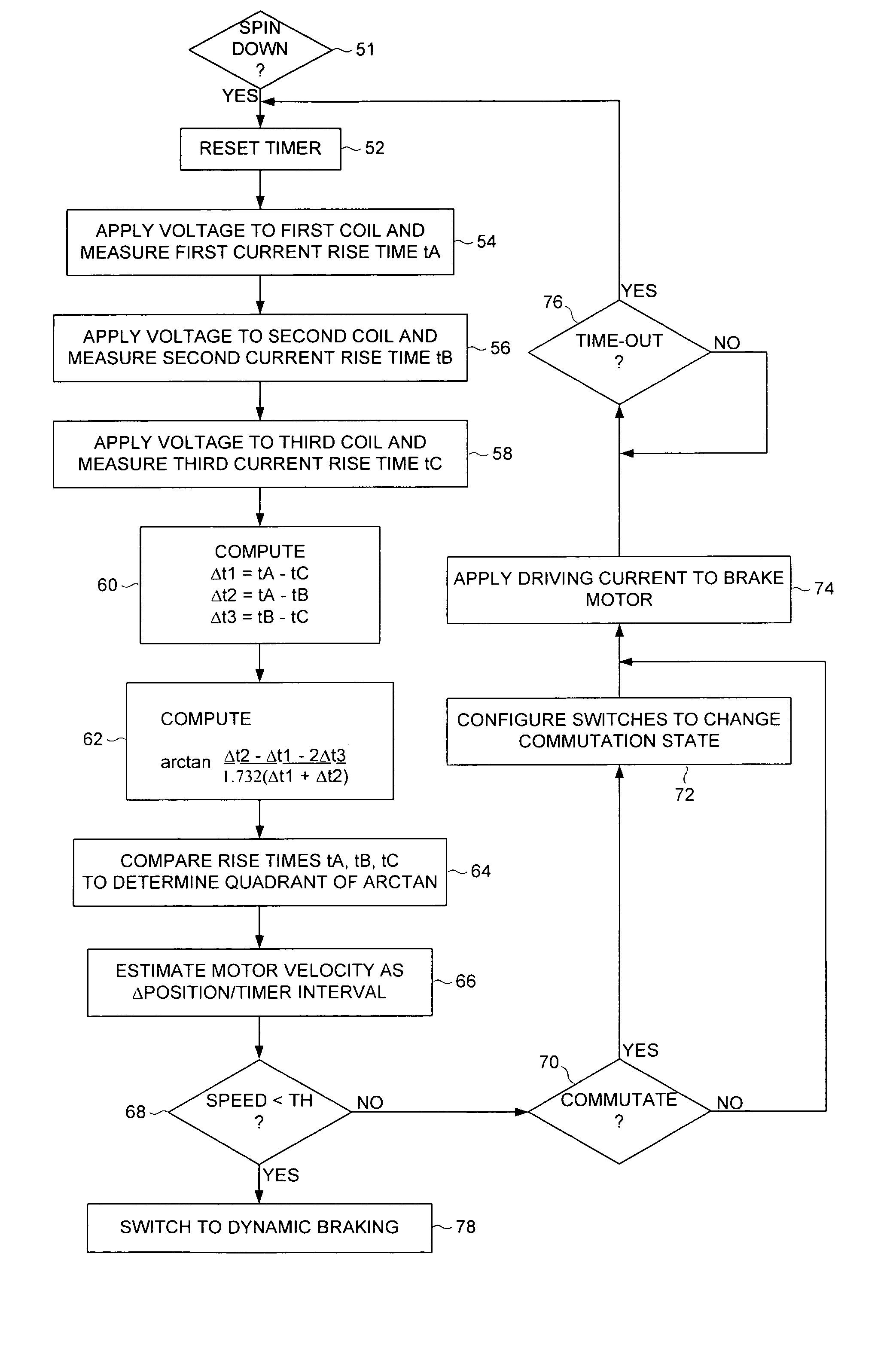

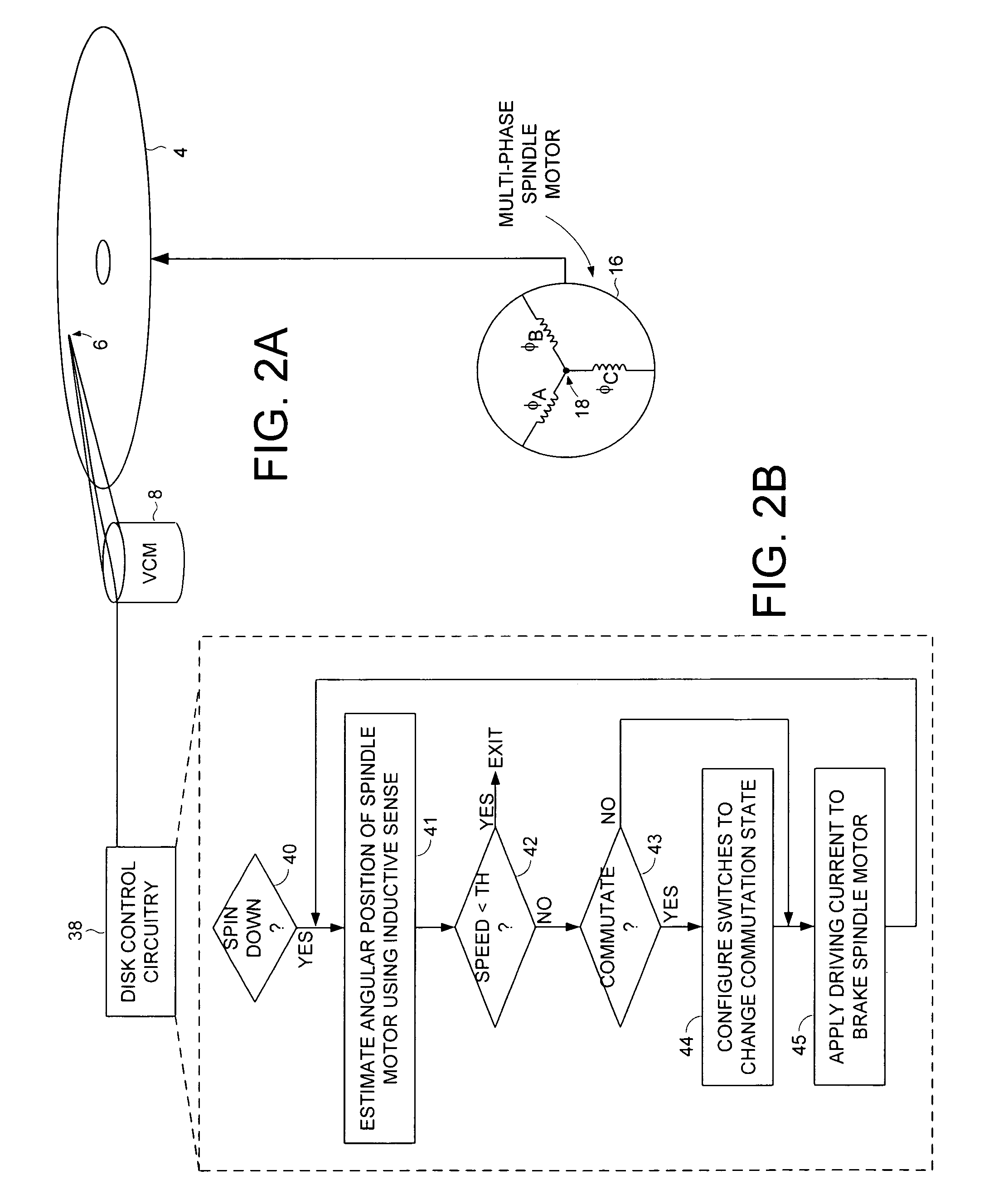

Disk drive employing active braking using inductive sense

InactiveUS7158329B1Synchronous motors startersDC motor speed/torque controlDriving currentControl circuit

A disk drive is disclosed comprising a disk, a head actuated over the disk, and a spindle motor for rotating the disk, the spindle motor comprising a plurality of windings. Disk control circuitry executes a spin-down operation of the spindle motor by estimating an angular position of the spindle motor by applying a voltage to at least one of the windings and evaluating a rise time of current flowing through the winding. The windings are commutated in response to the estimated angular position, and a driving current is applied to the windings to brake the spindle motor.

Owner:WESTERN DIGITAL TECH INC

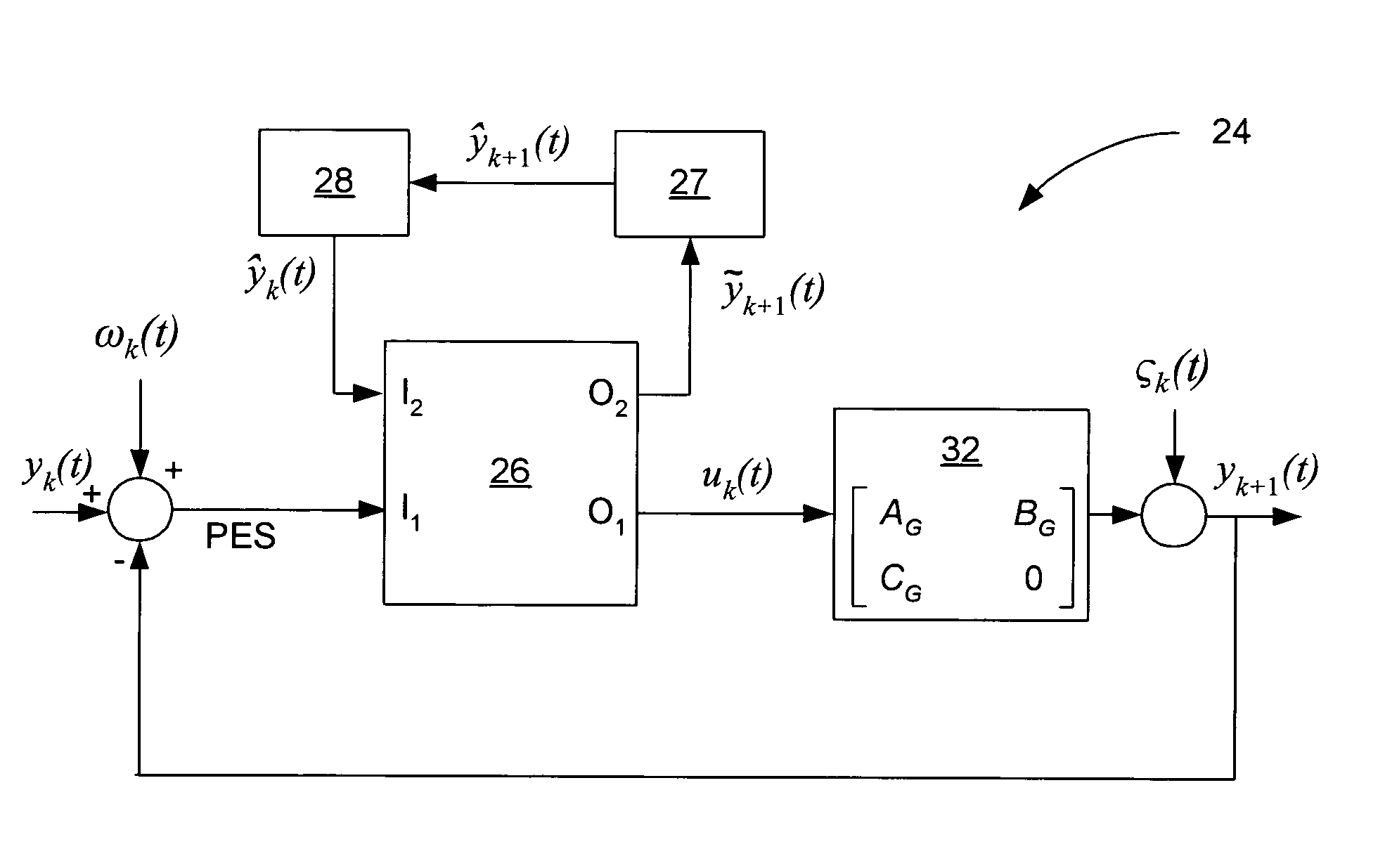

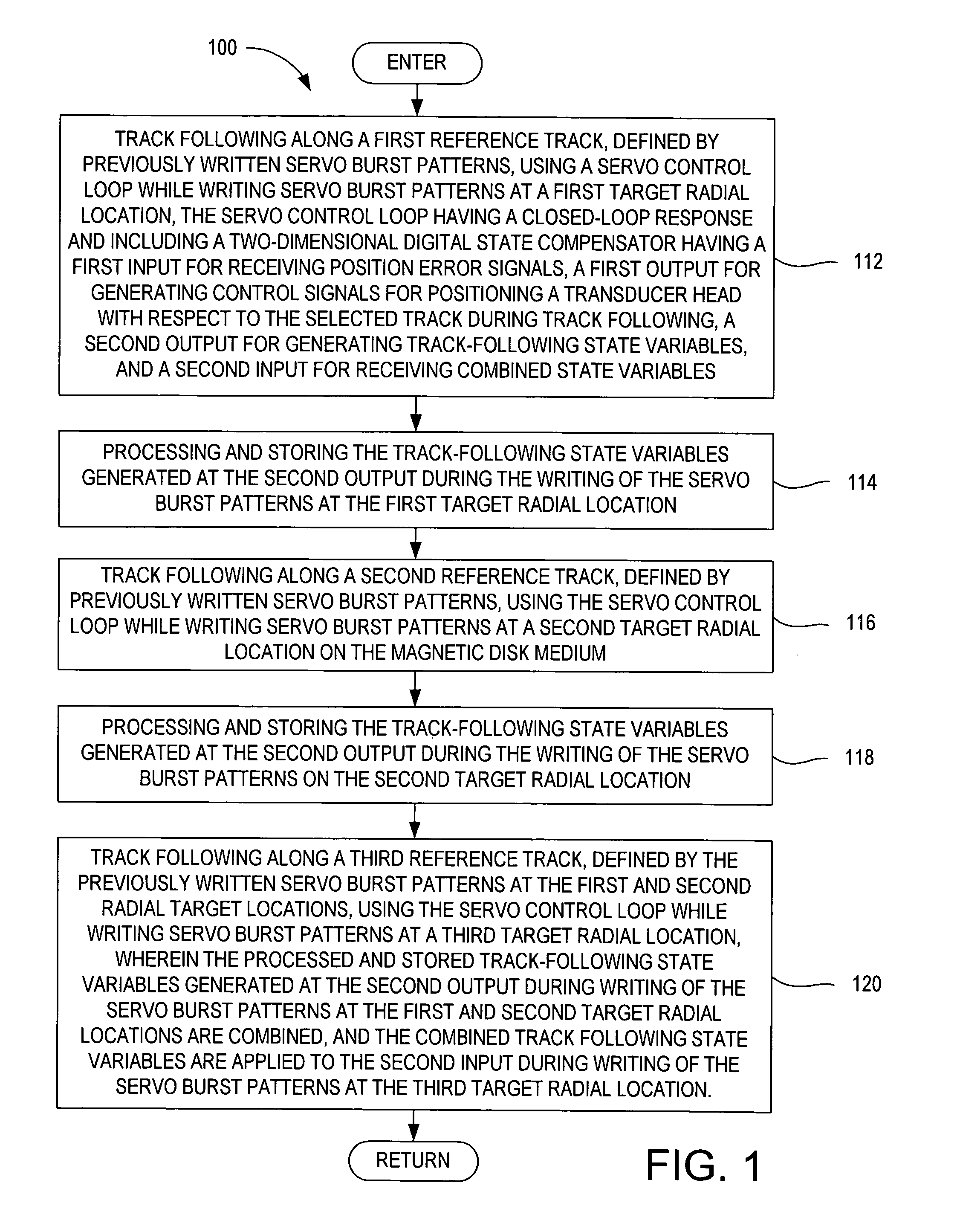

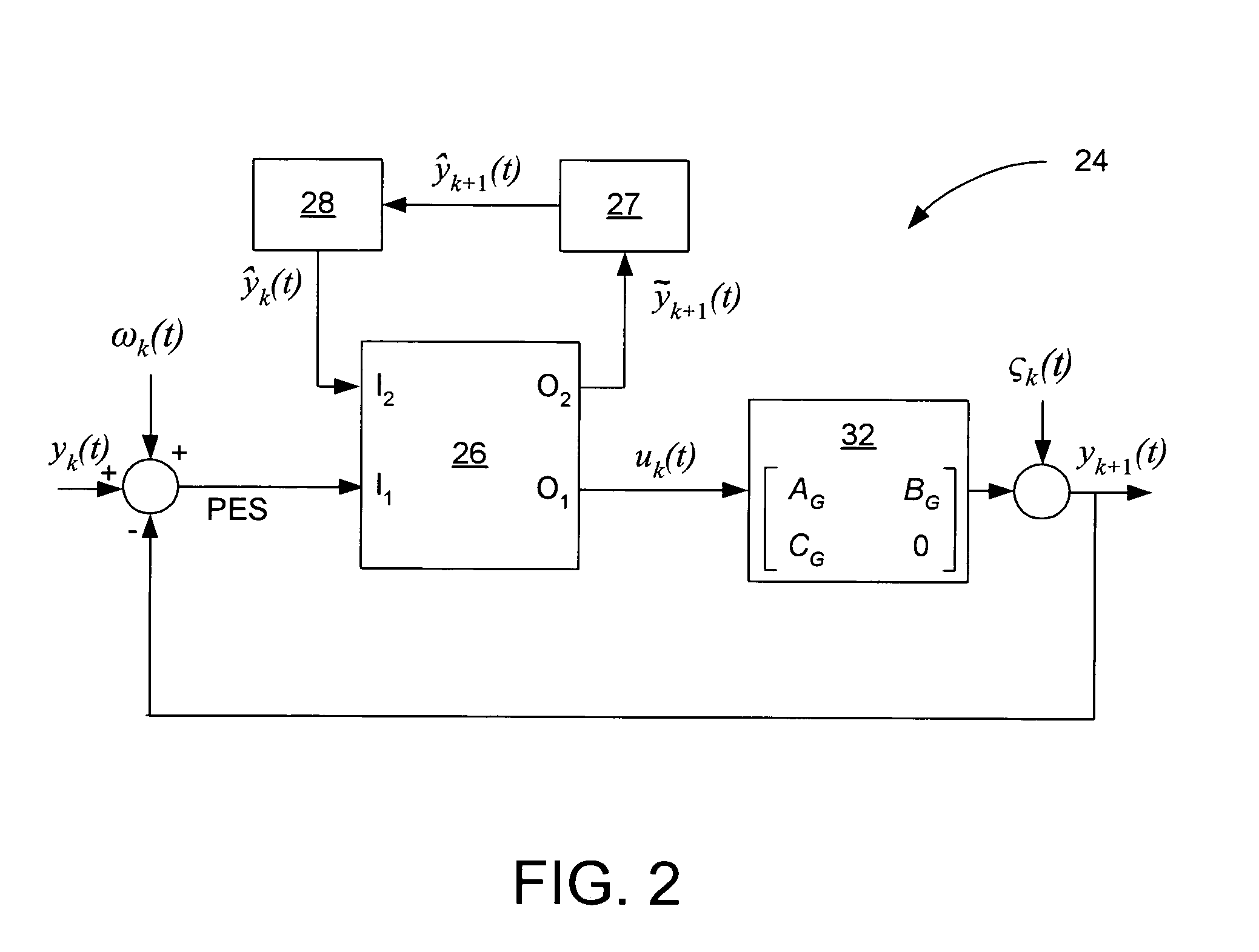

Method and apparatus for self servowriting of tracks of a disk drive using a servo control loop having a two-dimensional weighted digital state compensator

InactiveUS6999263B1Driving/moving recording headsRecord information storageState variableControl signal

A method is disclosed for defining tracks on a rotating magnetic disk medium of a disk drive. Reference tracks are followed using a servo control loop while writing servo burst patterns defining a first target servo track. The servo control loop includes a two-dimensional digital state compensator having a first input that receives position error signals, a first output that generates control signals for positioning a transducer head, a second output that generates track-following state variables, and a second input that receives processed and stored track-following state variables. The first target track is followed using the servo control loop while servo burst patterns are written, and while the processed and stored track-following state variables corresponding to the servo burst patterns defining the first target track are applied to the second input.

Owner:WESTERN DIGITAL TECH INC

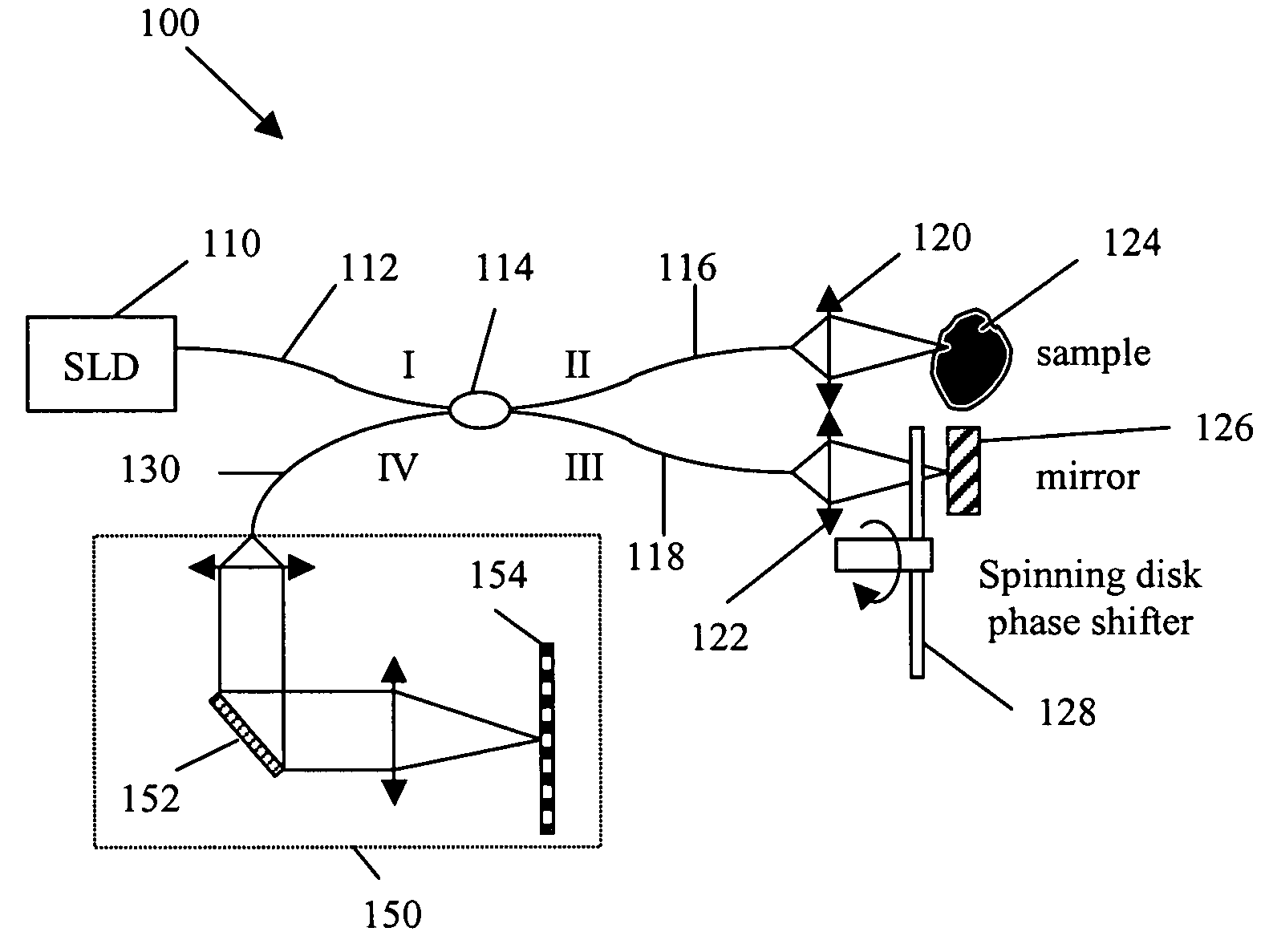

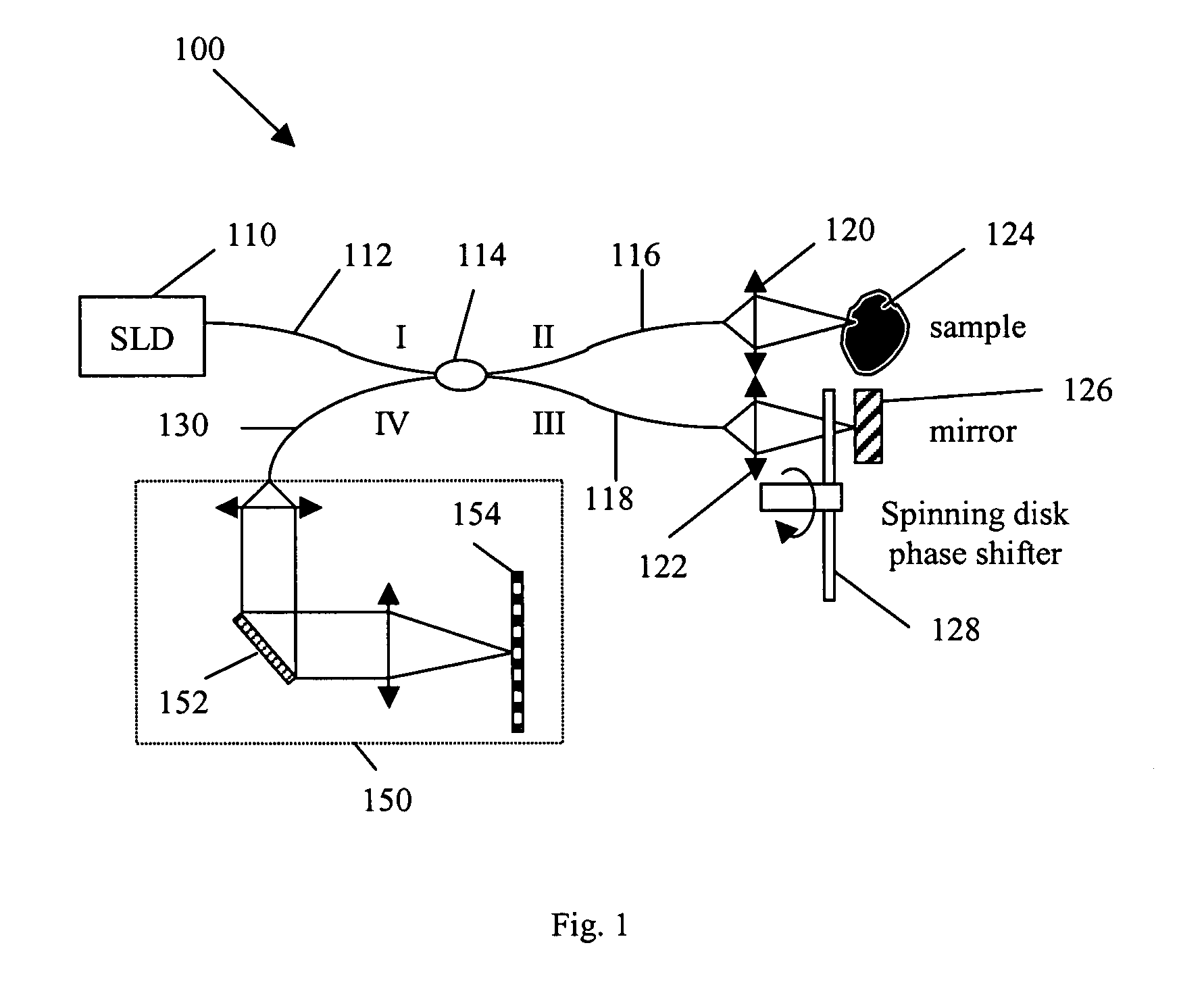

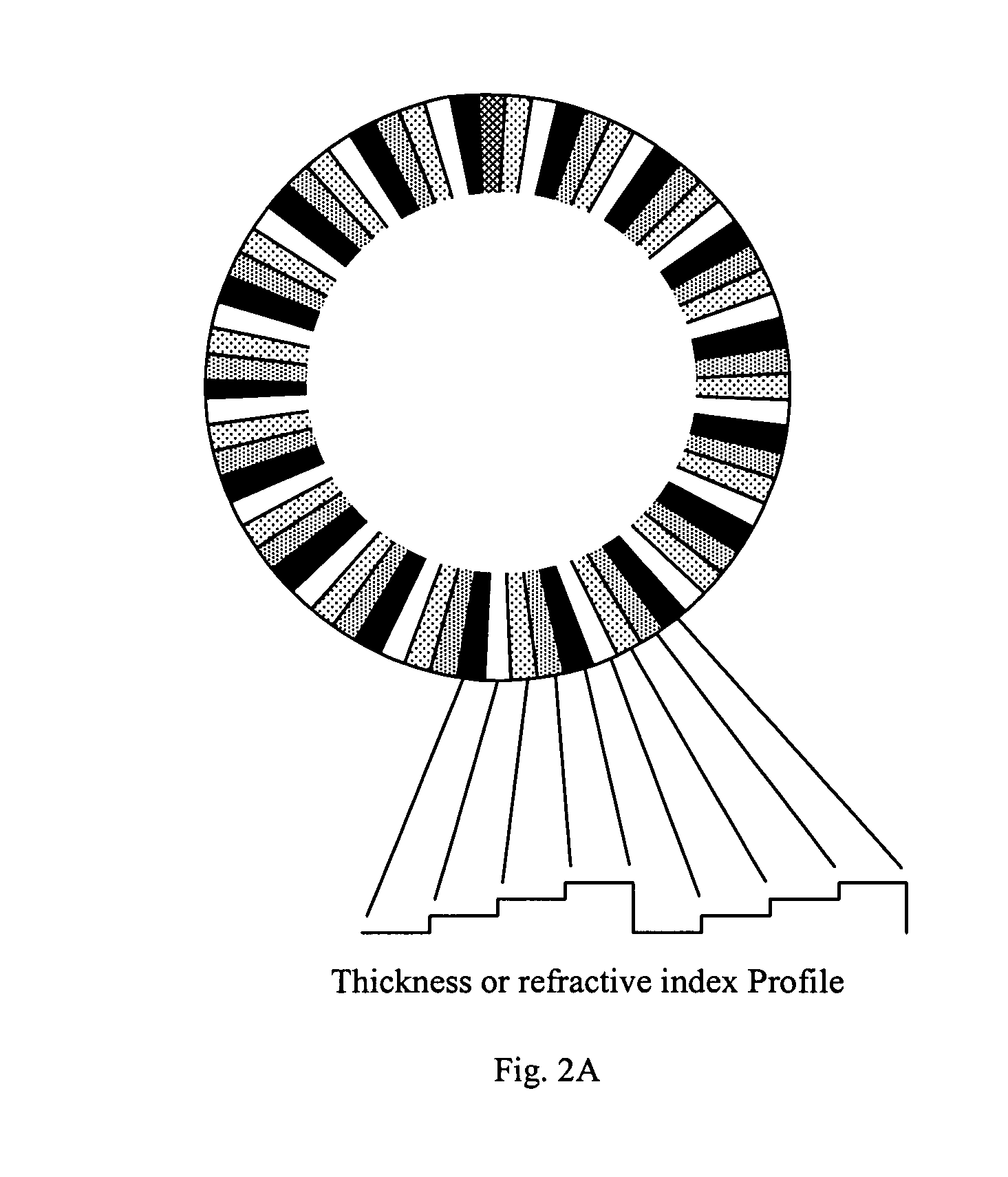

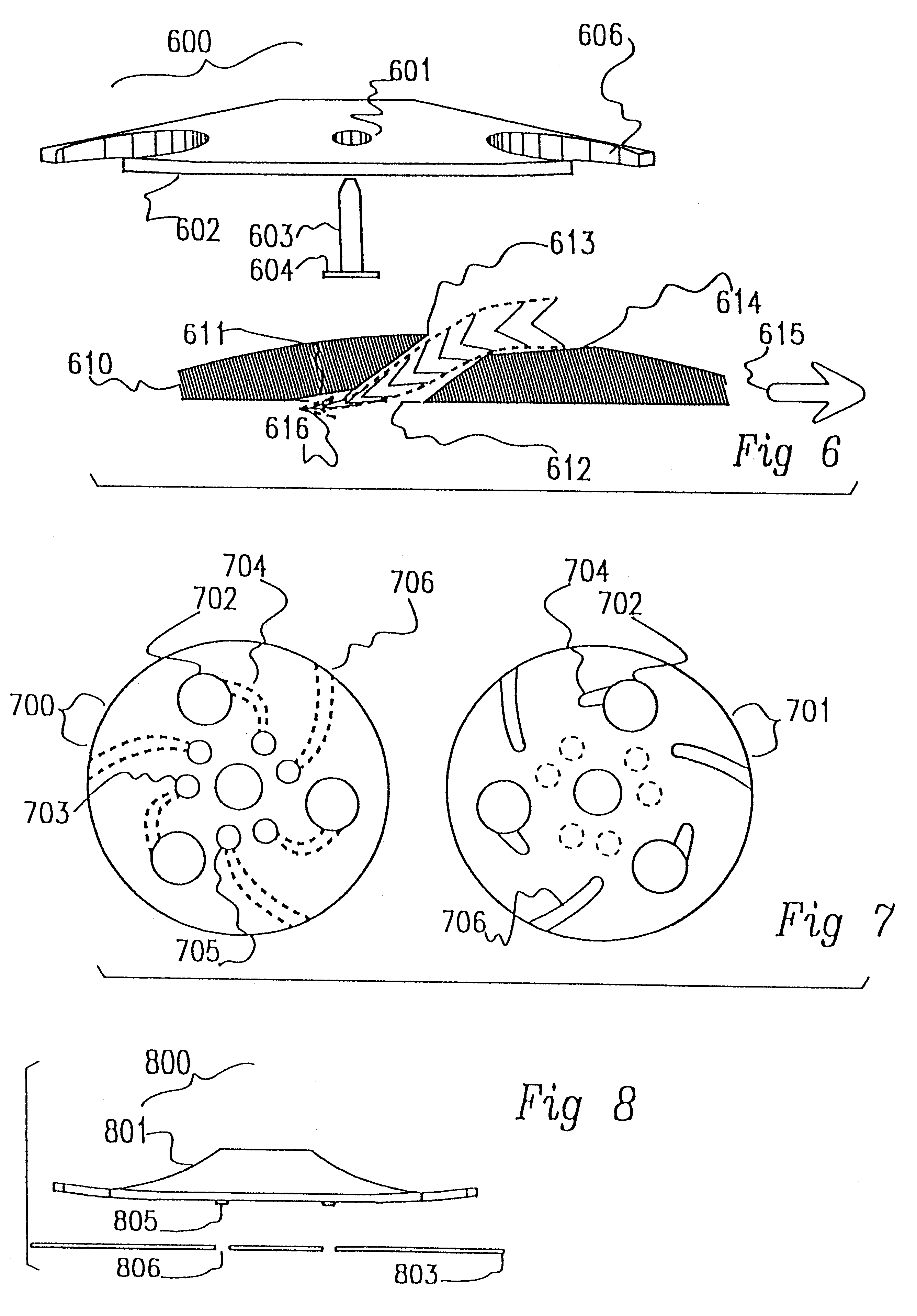

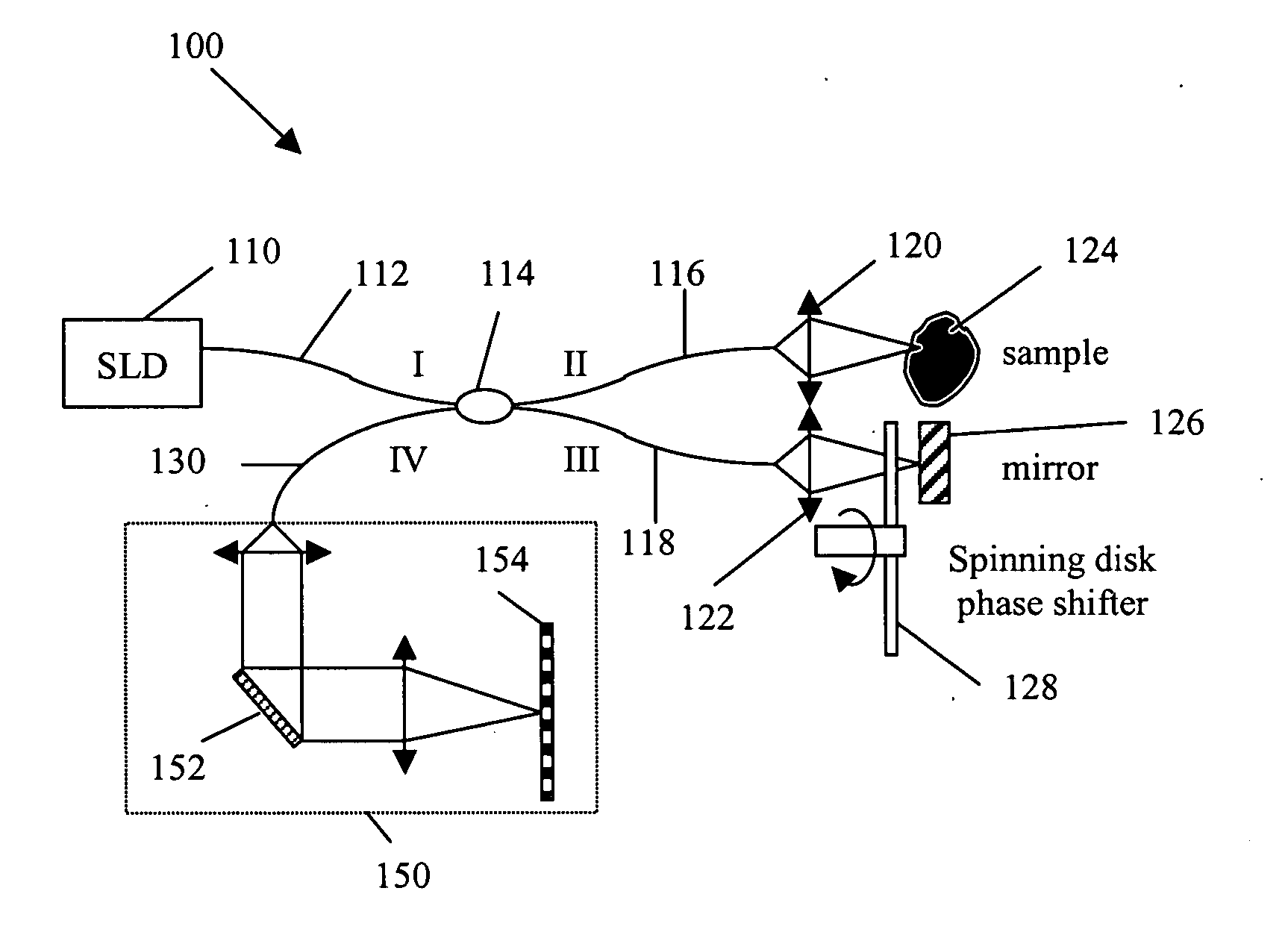

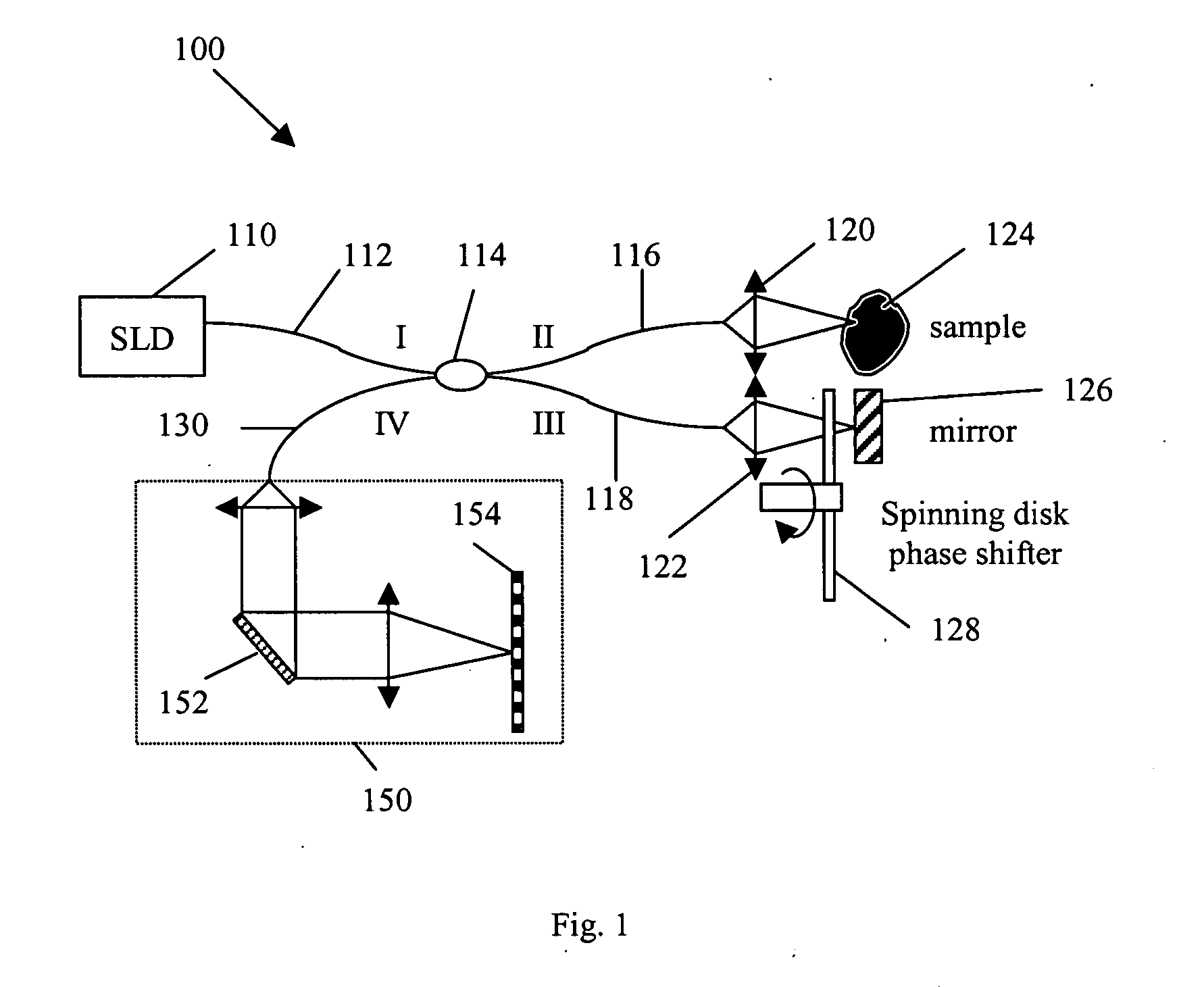

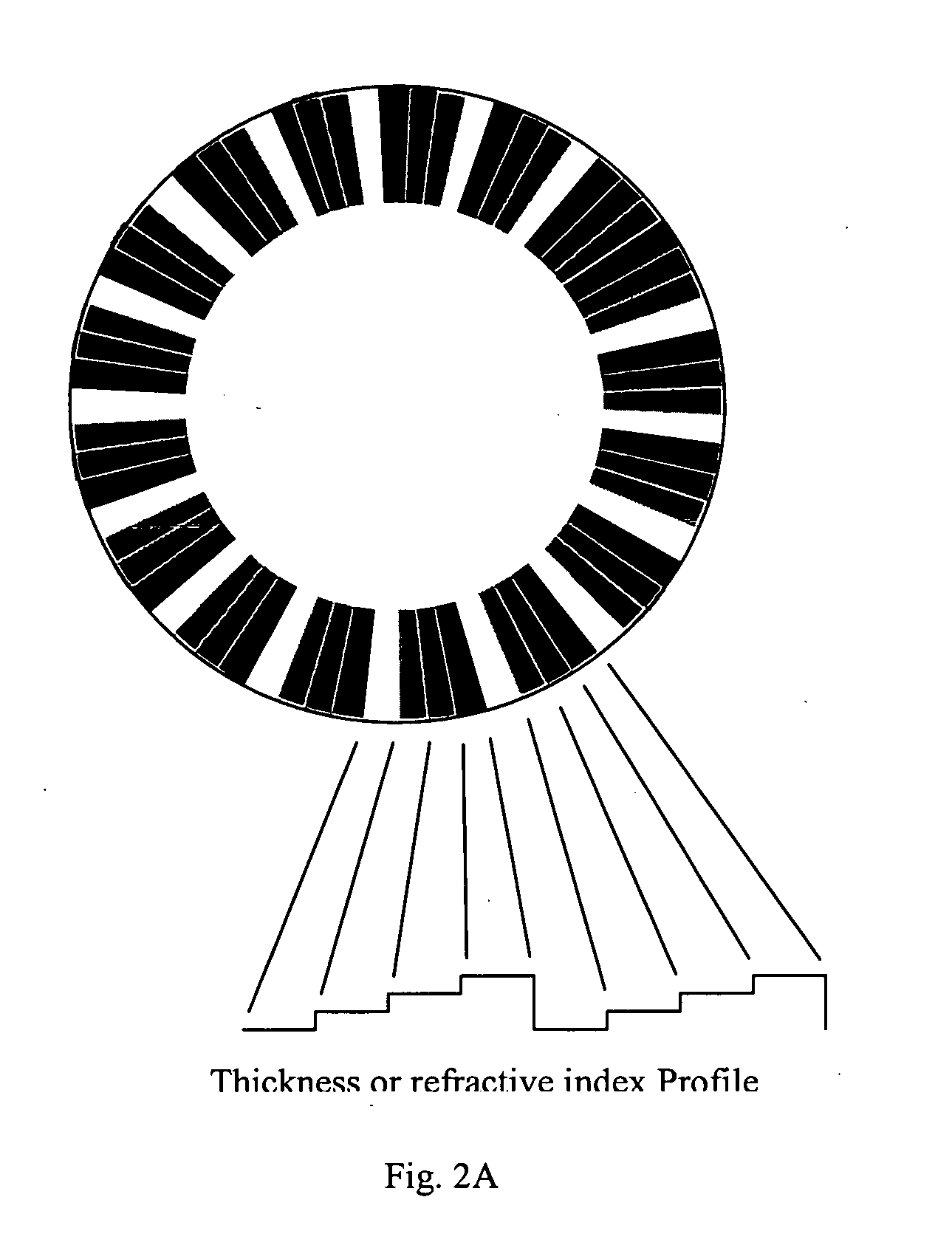

Patterned spinning disk based optical phase shifter for spectral domain optical coherence tomography

InactiveUS7433046B2Low costSolve the slow scanning speedInterferometersEye diagnosticsPhase shiftedPhase retardation

A low cost patterned spinning disk is disclosed for achieving relatively rapid discrete optical phase shifts for an optical beam. The invention is particularly useful in a spectral domain optical coherence tomography system. The disk contains stepped patterns of different heights and / or refractive index distribution such that as it spins, an optical beam passing through or being reflected by the disk will experience different discrete optical phase delays. The disk can be operated as a phase shifter or it can be operated in synchronization with an intensity modulating chopper disk or a direct intensity modulation of the light source. The disk can also contain intensity modulating patterns such that both phase shifting and intensity modulation can be achieved at the same time. Various possible methods are also disclosed for the fabrication of the disk.

Owner:CARL ZEISS MEDITEC INC

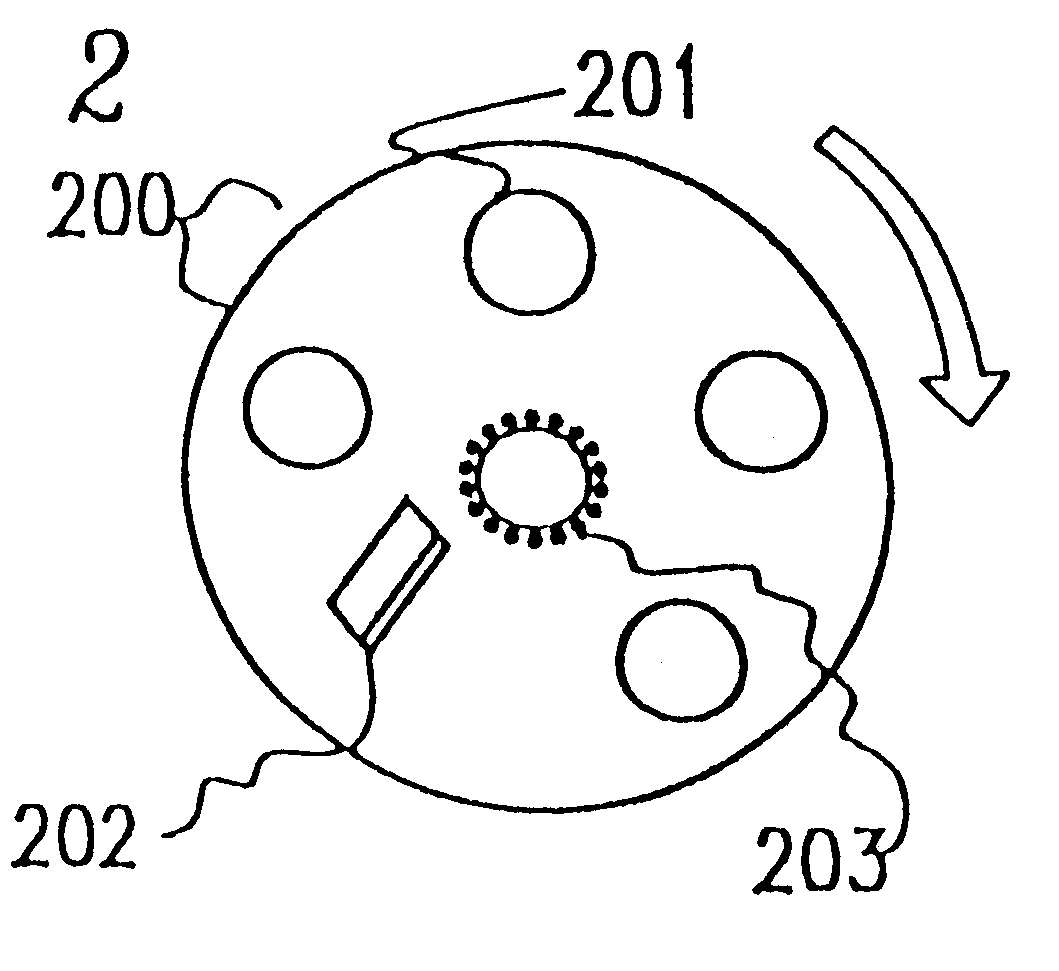

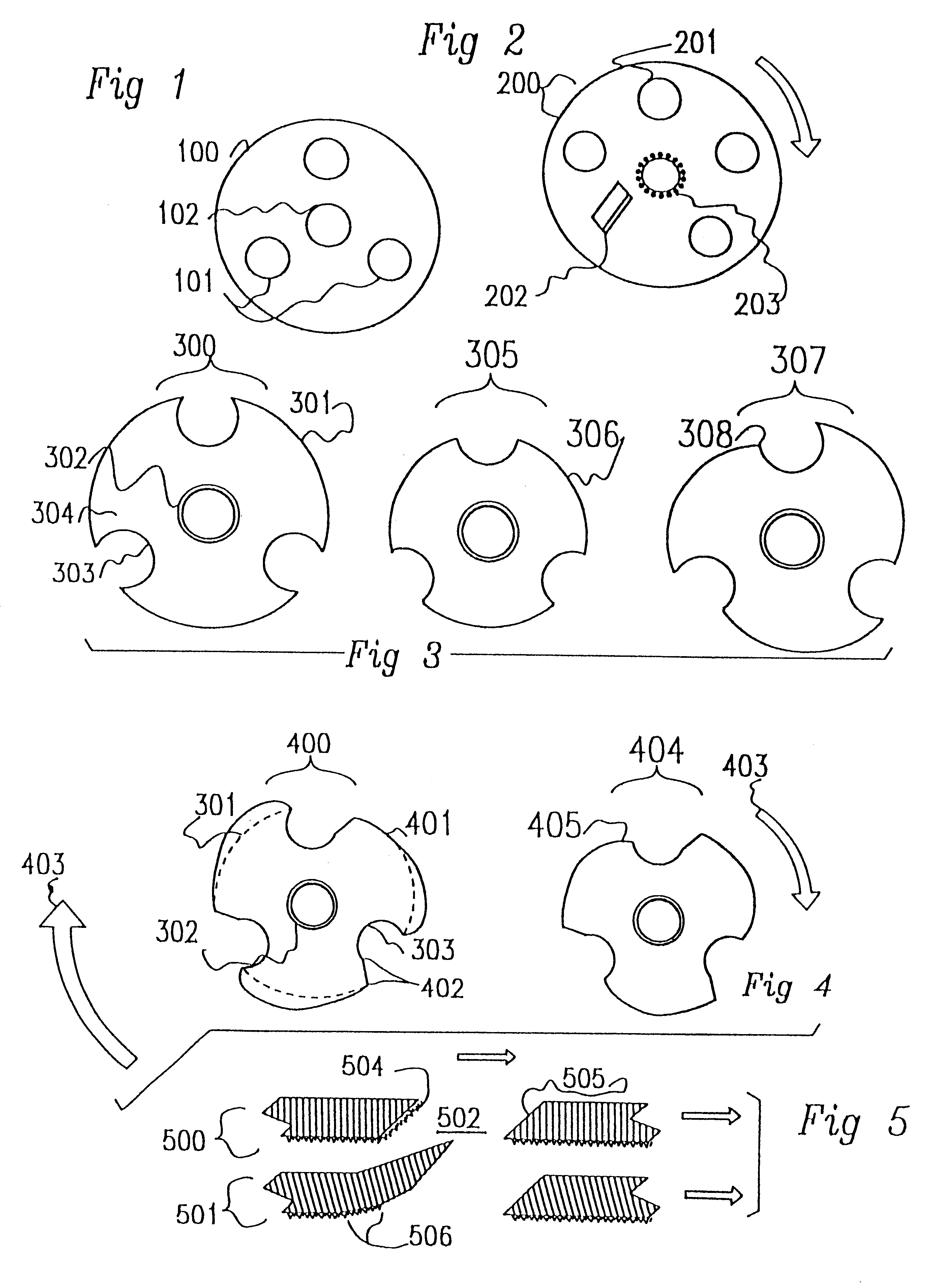

Sanding disks

InactiveUS6312325B1Risk minimizationProtect from harmRevolution surface grinding machinesSupport wheelsAngle grinderEngineering

Accessories for an angle grinder include a disposable rotary sanding disk having quite large shaped ventilating / viewing apertures, for use with a resilient backing plate also having shaped ventilating apertures. The apertures of one or both parts are shaped so that snagging of the apertures on projections from the work surface is minimized and to facilitate air flow across the work surface during use. This air flow helps in cooling the work and ejecting detritus, so minimising clogging effects. The ventilating apertures also facilitate viewing the work to be sanded through the spinning disk during the abrasion process, so that operator feedback is immediate. The holes also give the sanding disk more resilience so that a greater area comes in contact with the work and the disk wears more evenly over its abrasive surface.

Owner:MORTON CO

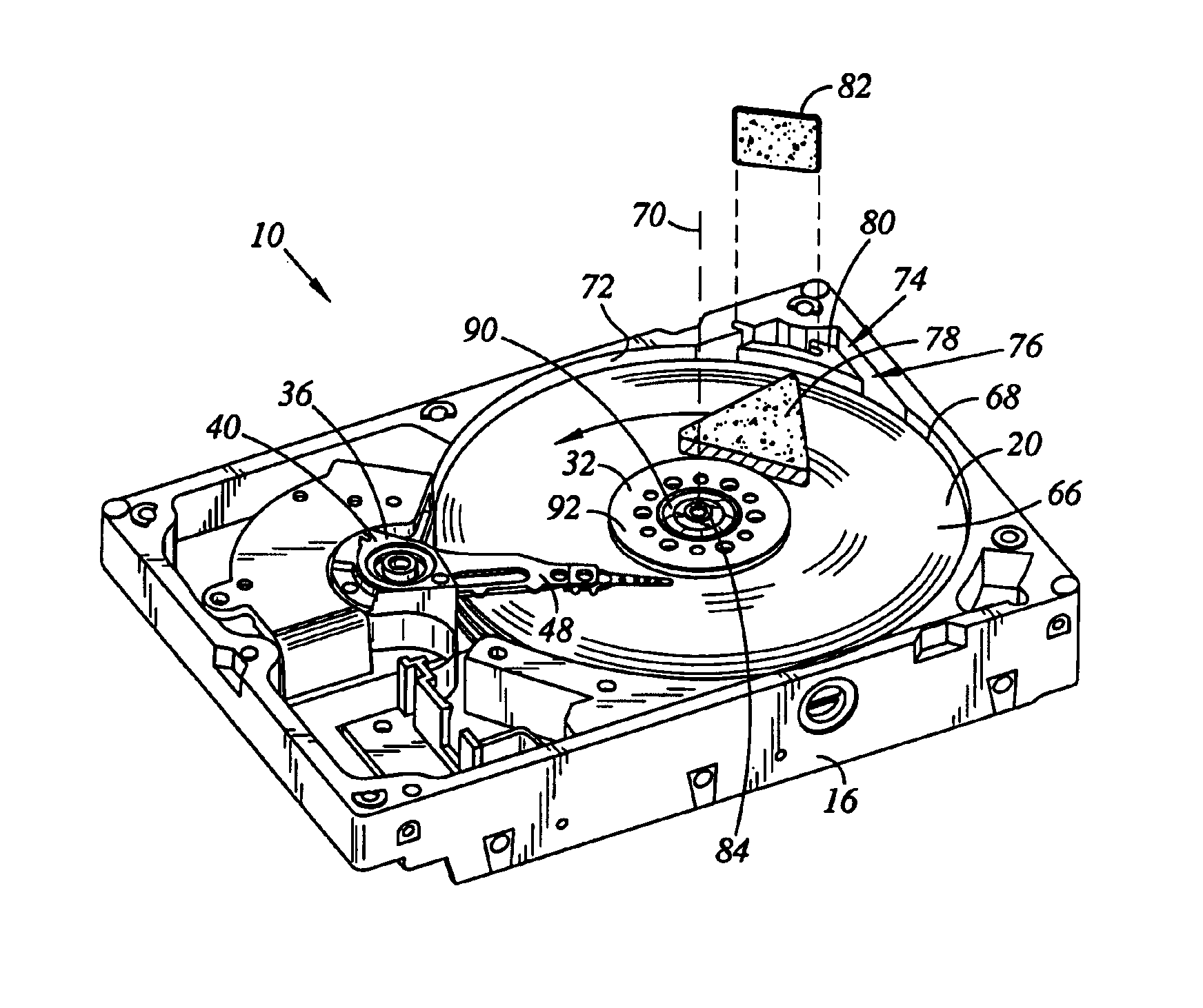

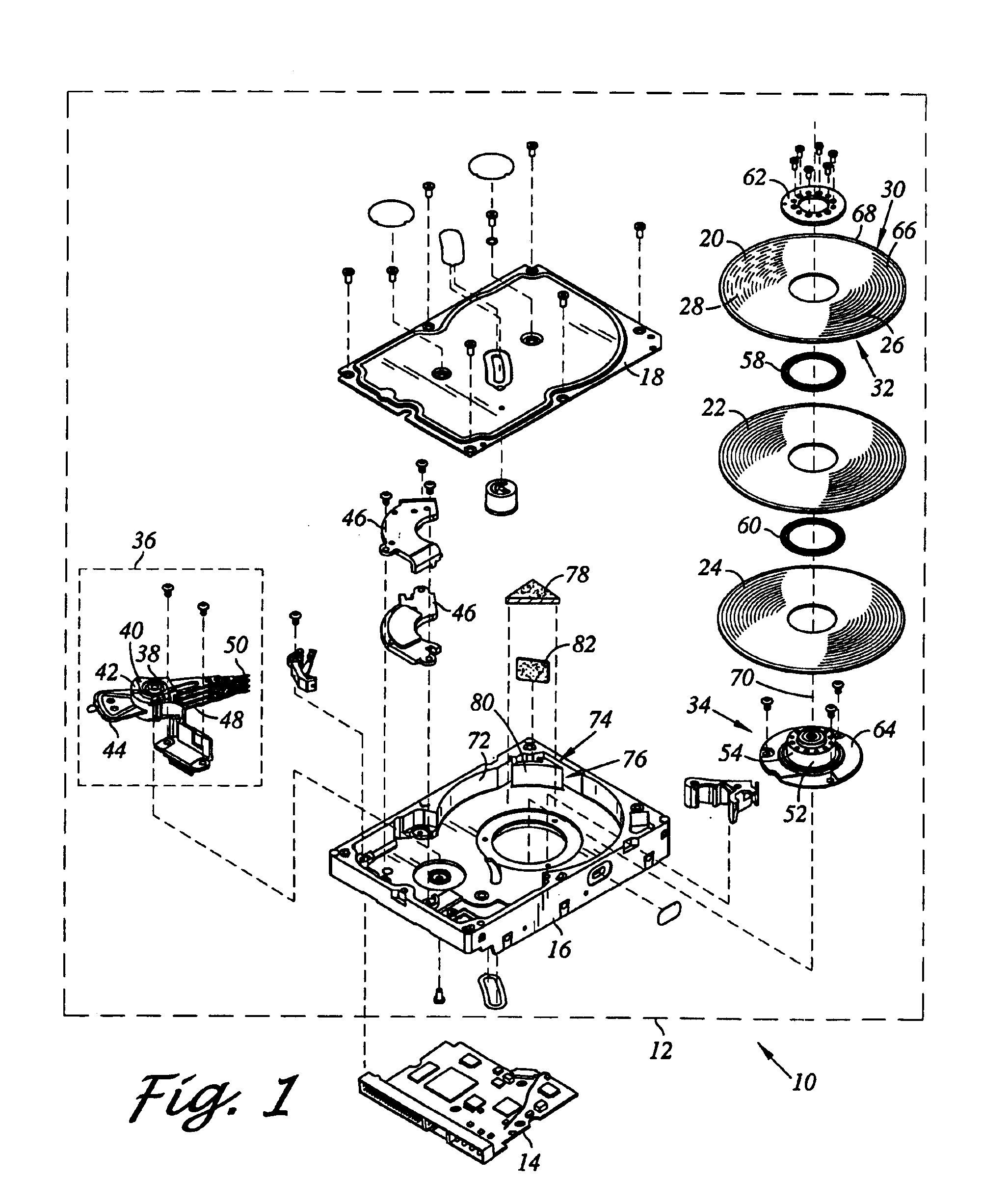

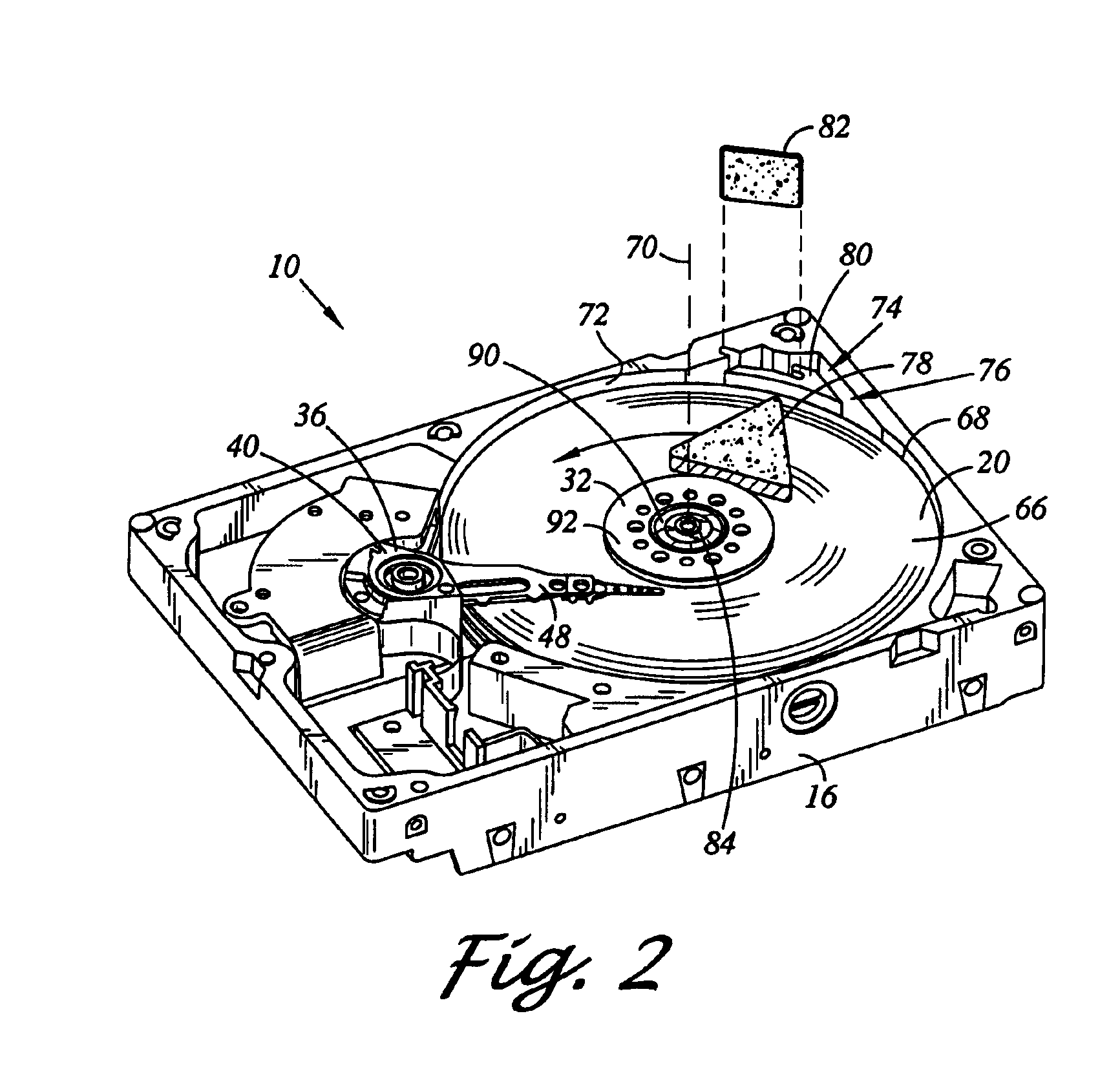

Disk drive including an airflow diverter element radially between spindle motor axis of rotation and cavity in shroud surface

InactiveUS6876514B1Reducing temperature influence on carrierApparatus for flat record carriersRotational axisDisk pack

A disk drive including a disk drive base and a cover attached to the disk drive base. The disk drive further includes a rotatable disk including a disk surface extending to an outer periphery. The disk drive further includes a spindle motor including an axis of rotation. The spindle motor is rotatably coupled to the disk drive base for rotating the disk about the axis of rotation. The disk drive further includes a shroud surface concentrically formed about and adjacent the outer periphery. The disk drive further includes a cavity formed in the shroud surface. The cavity extends to a cavity opening adjacent the outer periphery. The disk drive further includes an airflow diverter element extending from the cover towards the disk surface radially between the cavity opening and the axis of rotation for diverting disk rotation induced airflow adjacent the disk surface.

Owner:WESTERN DIGITAL TECH INC

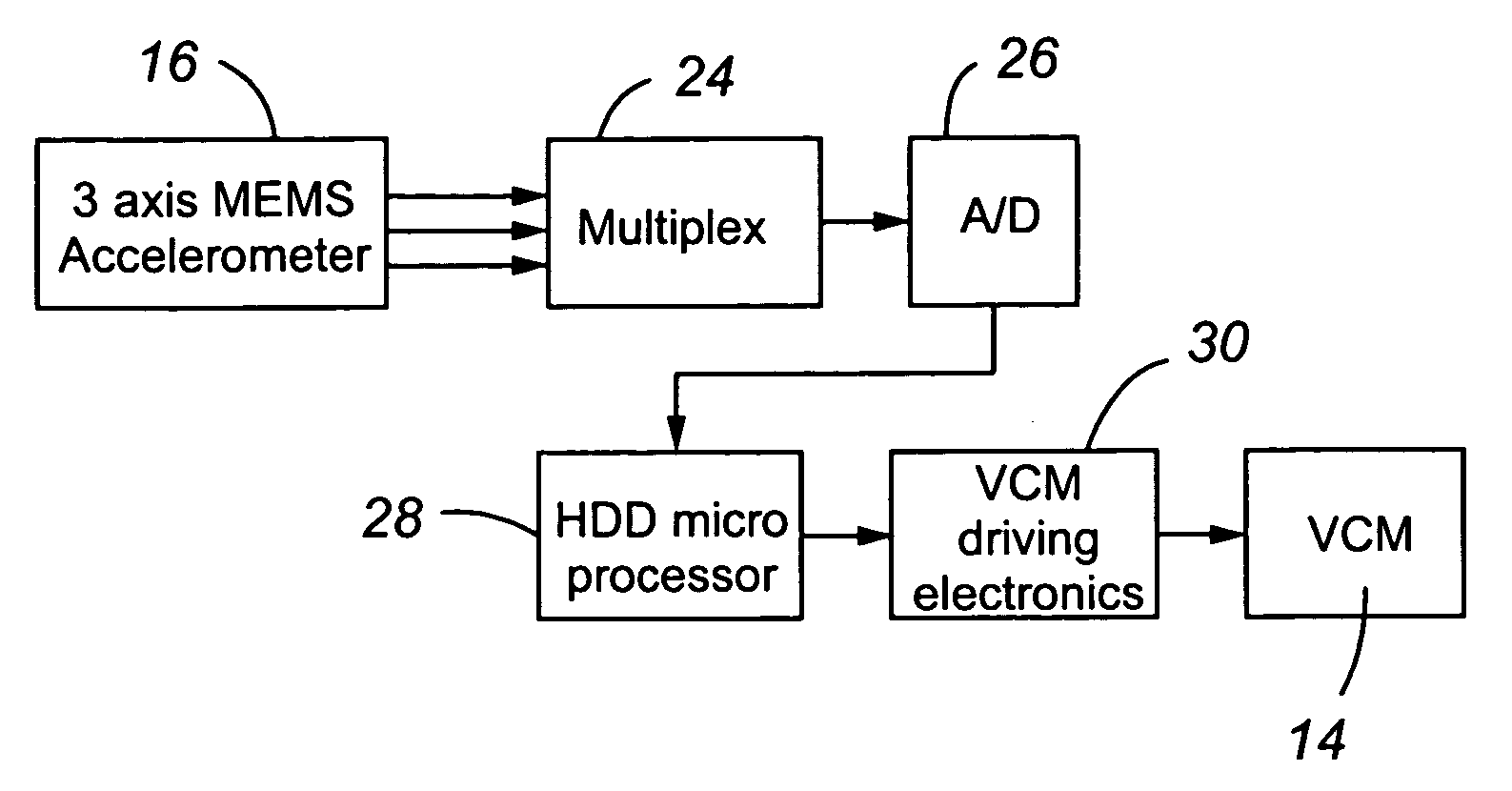

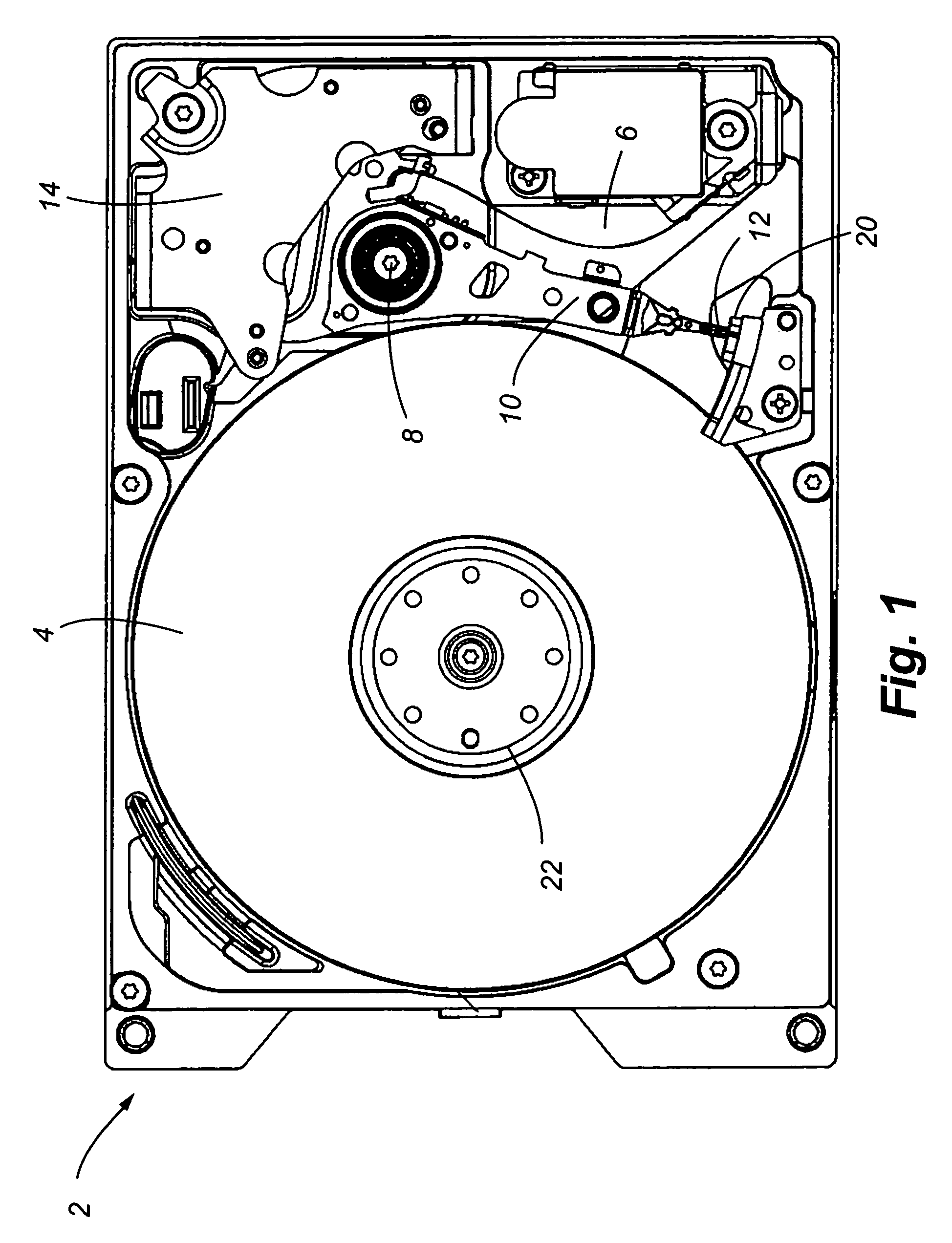

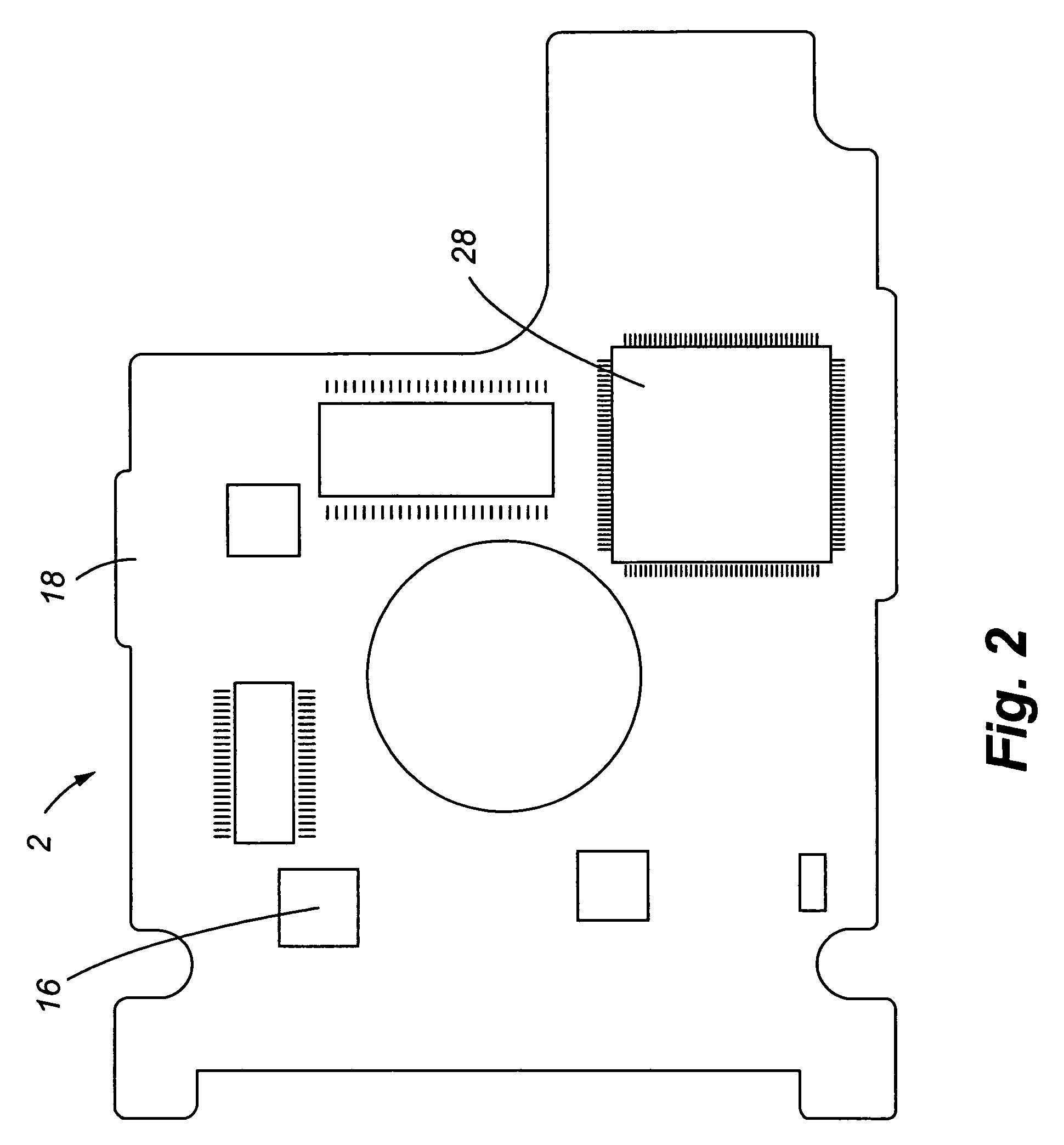

Mobile hard disk drive free fall detection and protection

ActiveUS7369345B1Reliable and quicker and precise to measureReliable, quicker and more precise way to measure free fallDisposition/mounting of recording headsDriving/moving recording headsFree fallingHard disc drive

A system provided for protecting a disk drive from impact damages. More specifically, a disk drive is provided that includes an accelerometer interconnected to a printed circuit board that detects free fall of the disk drive. In addition, the velocity of spinning disks of the disk drive is also monitored to assess changes in velocity thereof that may indicate the presence of a tumbling condition. Furthermore, the change in acceleration measured by the accelerometer is monitored to prevent false indications of free fall due to common vibrations. Thus an enhanced system is provided that protects disk drives from the effect of free falls under a wide variety of conditions and allowing for drops from shorter distances to be identified.

Owner:SEAGATE TECH LLC +1

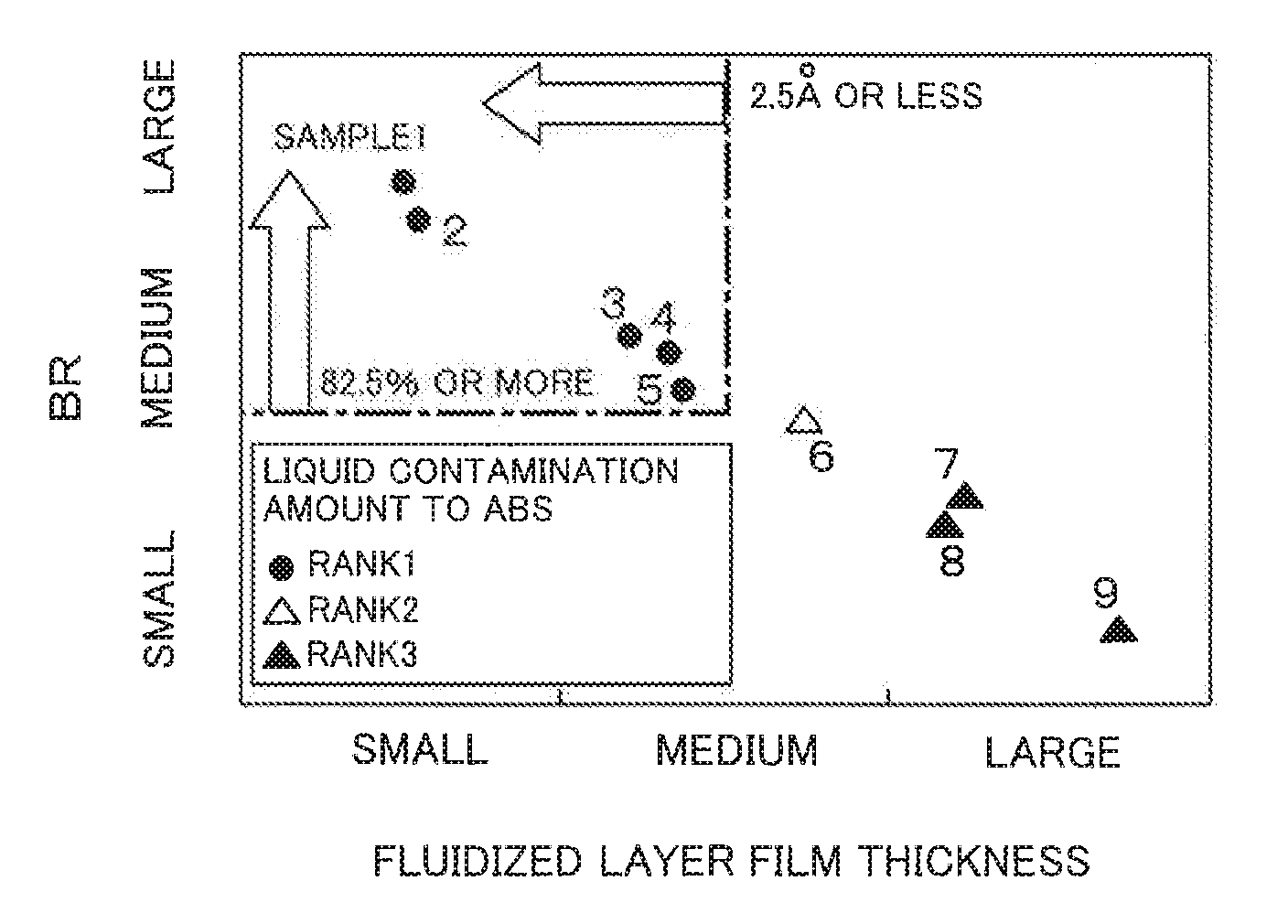

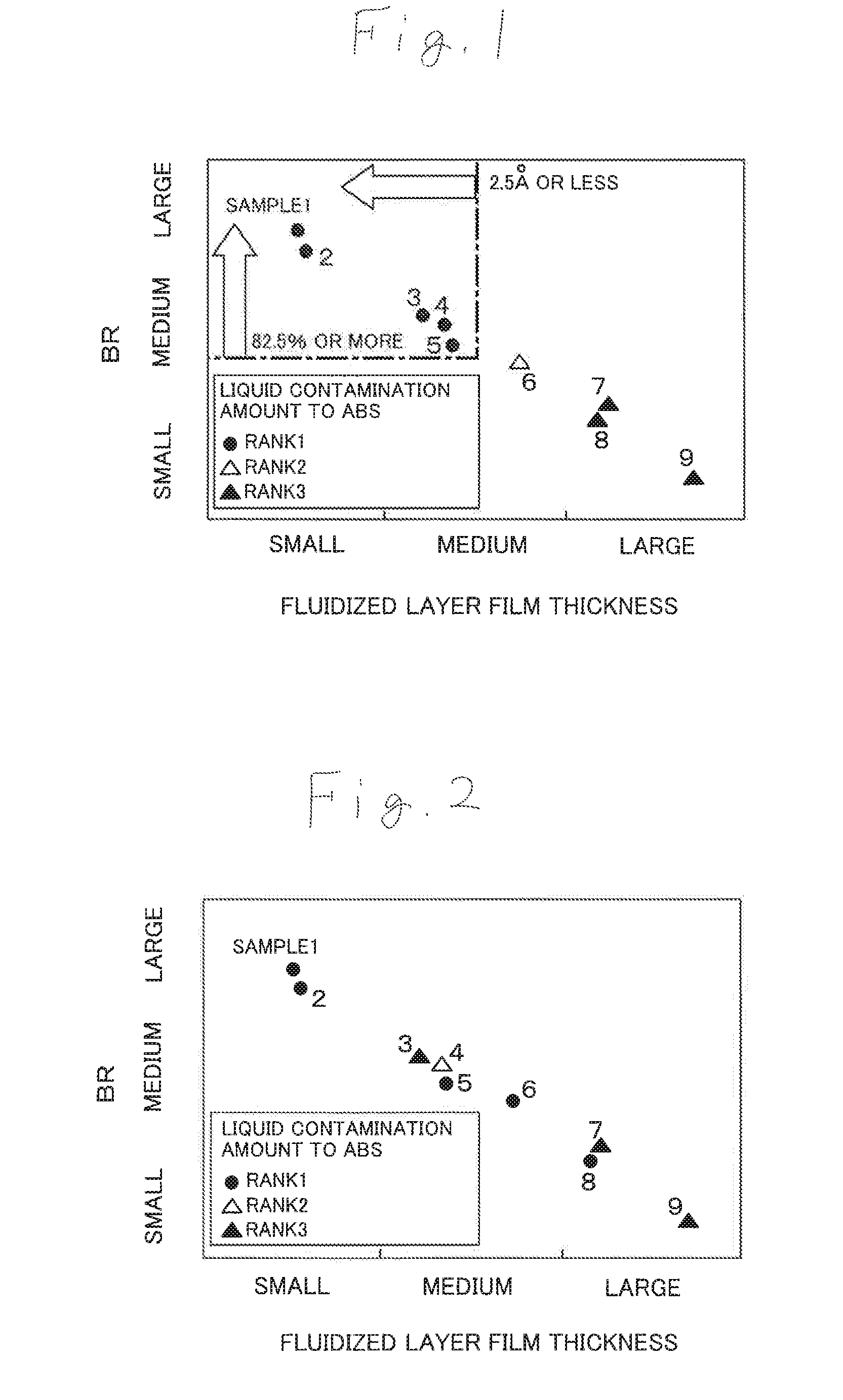

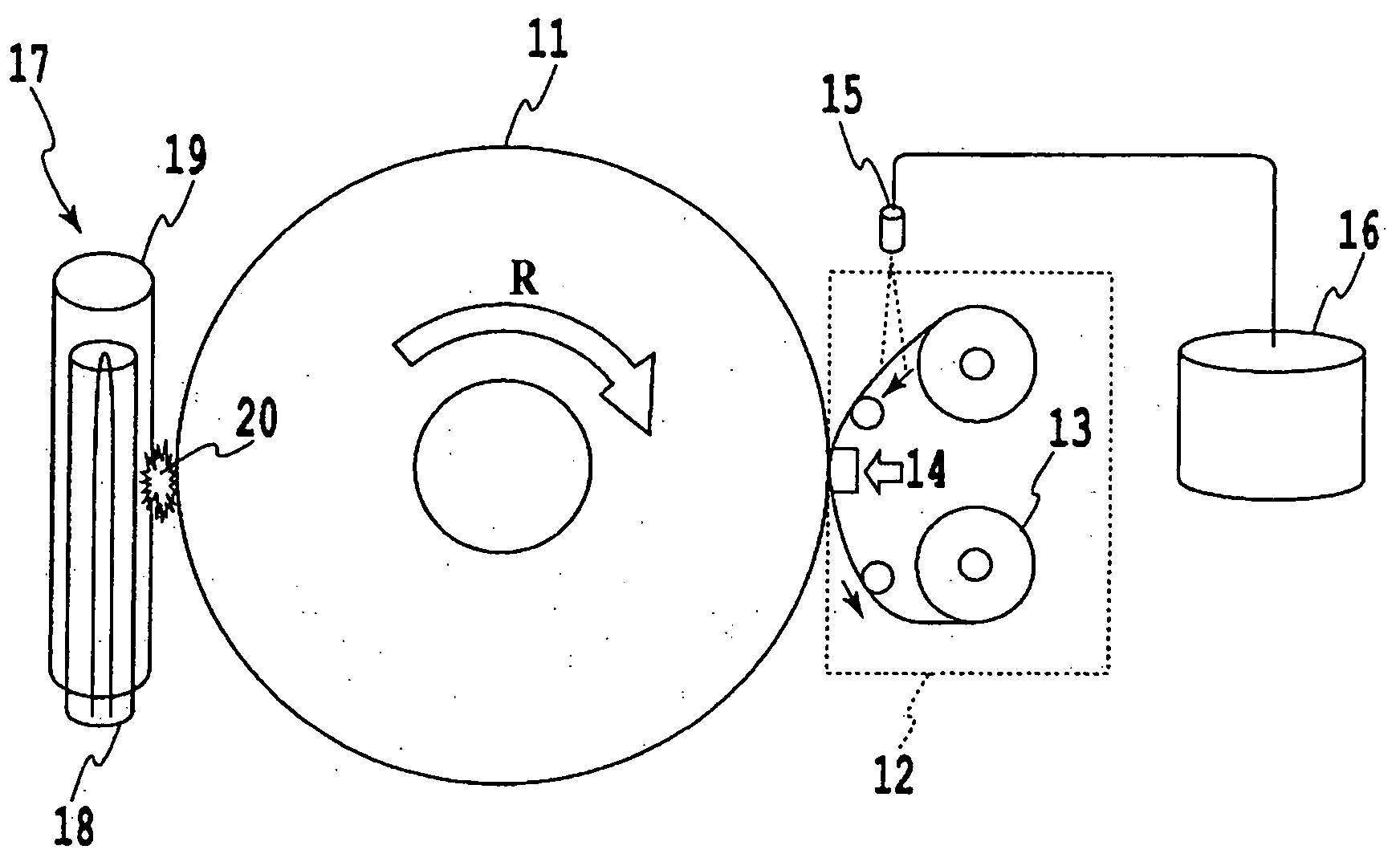

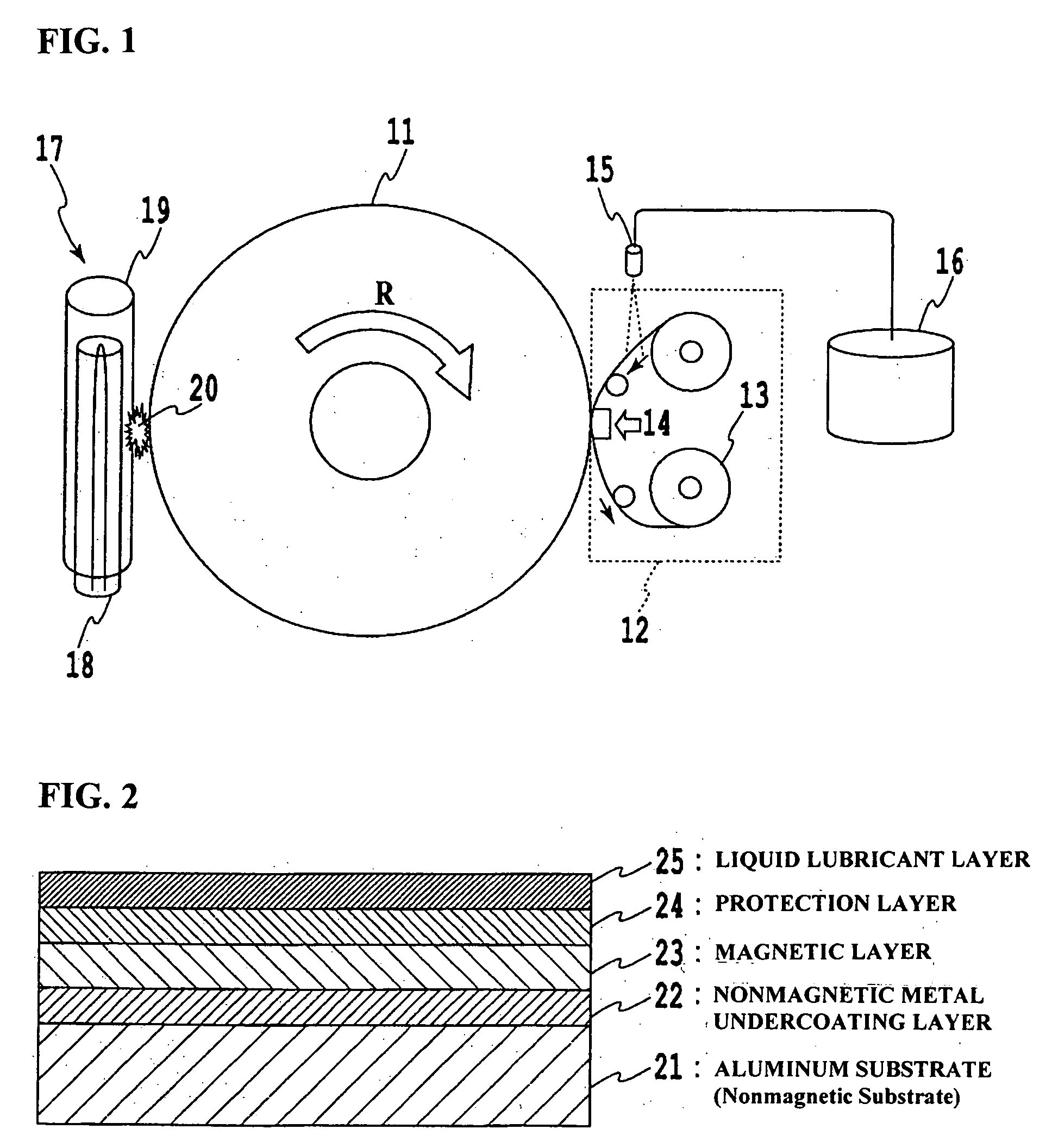

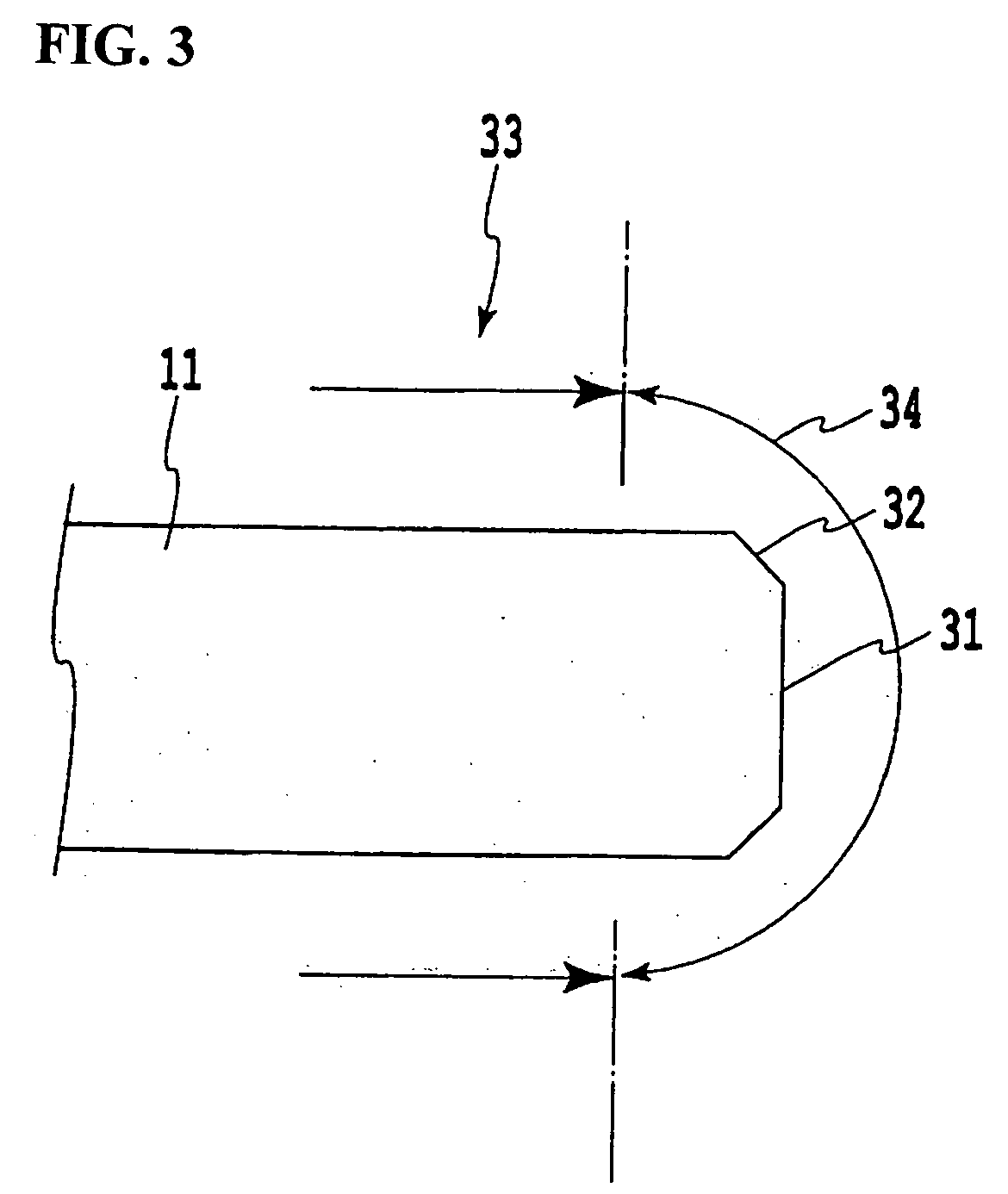

Evaluation method of magnetic disk, manufacturing method of magnetic disk, and magnetic disk

InactiveUS20120077060A1Easily evaluate propertyAccurately evaluate propertyMagnetic materials for record carriersRecord information storageCarbon filmRadial position

An evaluation method that can easily evaluate properties of a carbon protective film and a lubricant on a magnetic-disk surface or particularly, an evaluation method of a magnetic disk in which the properties of the magnetic-disk surface can be evaluated accurately so that a strict demand for interactions between the magnetic-disk surface and a head can be met is provided. In a state in which an element portion of the magnetic head provided with the head element portion that projects by thermal expansion is projected, after being brought into contact with a predetermined radial position on the surface of the rotating magnetic disk, the head is further made to perform seeking in a state in which the element portion is projected by a specified amount, whereby the properties of the carbon film or the lubricant formed on the magnetic-disk surface is evaluated.

Owner:WD MEDIA SINGAPORE PTE

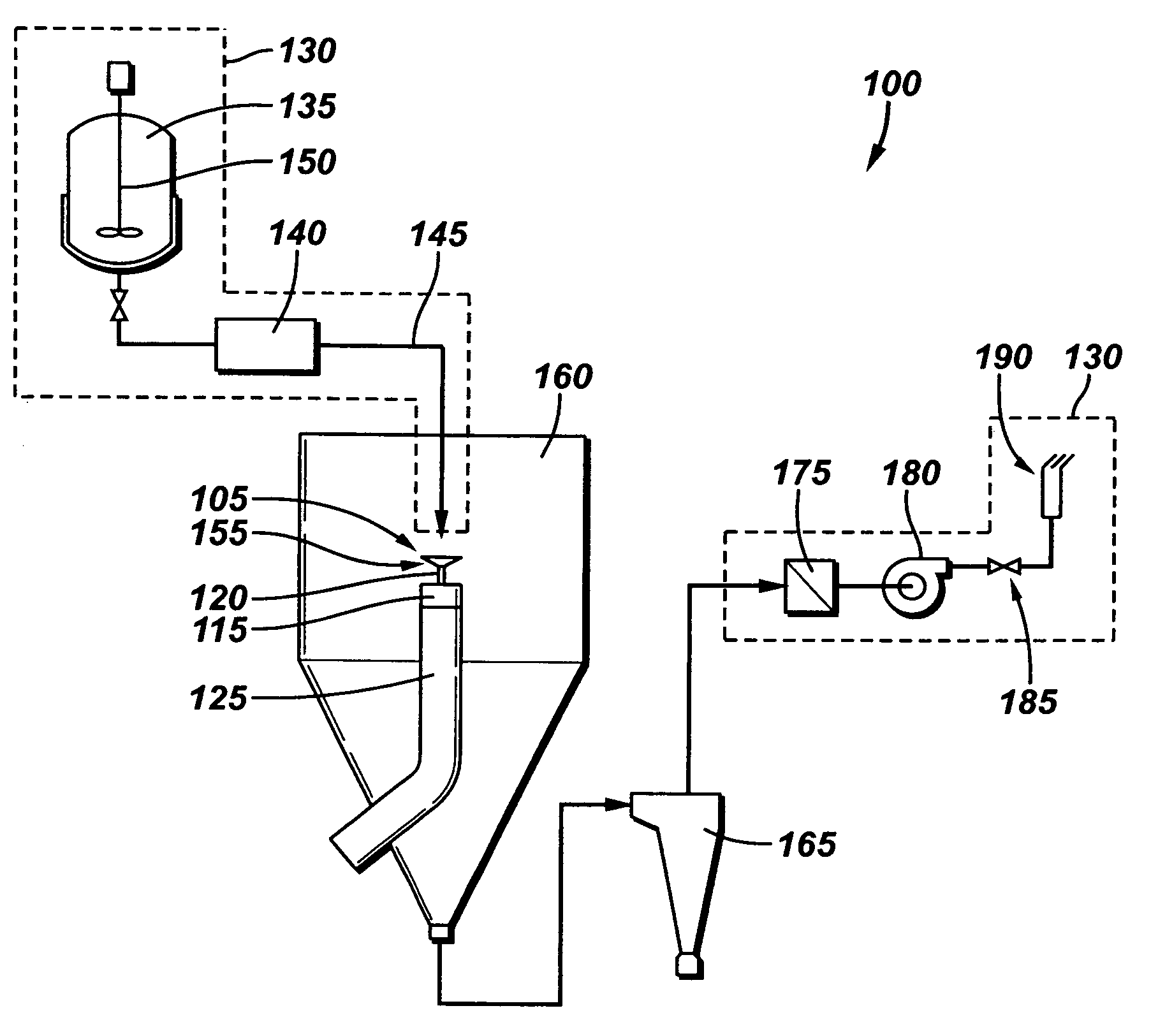

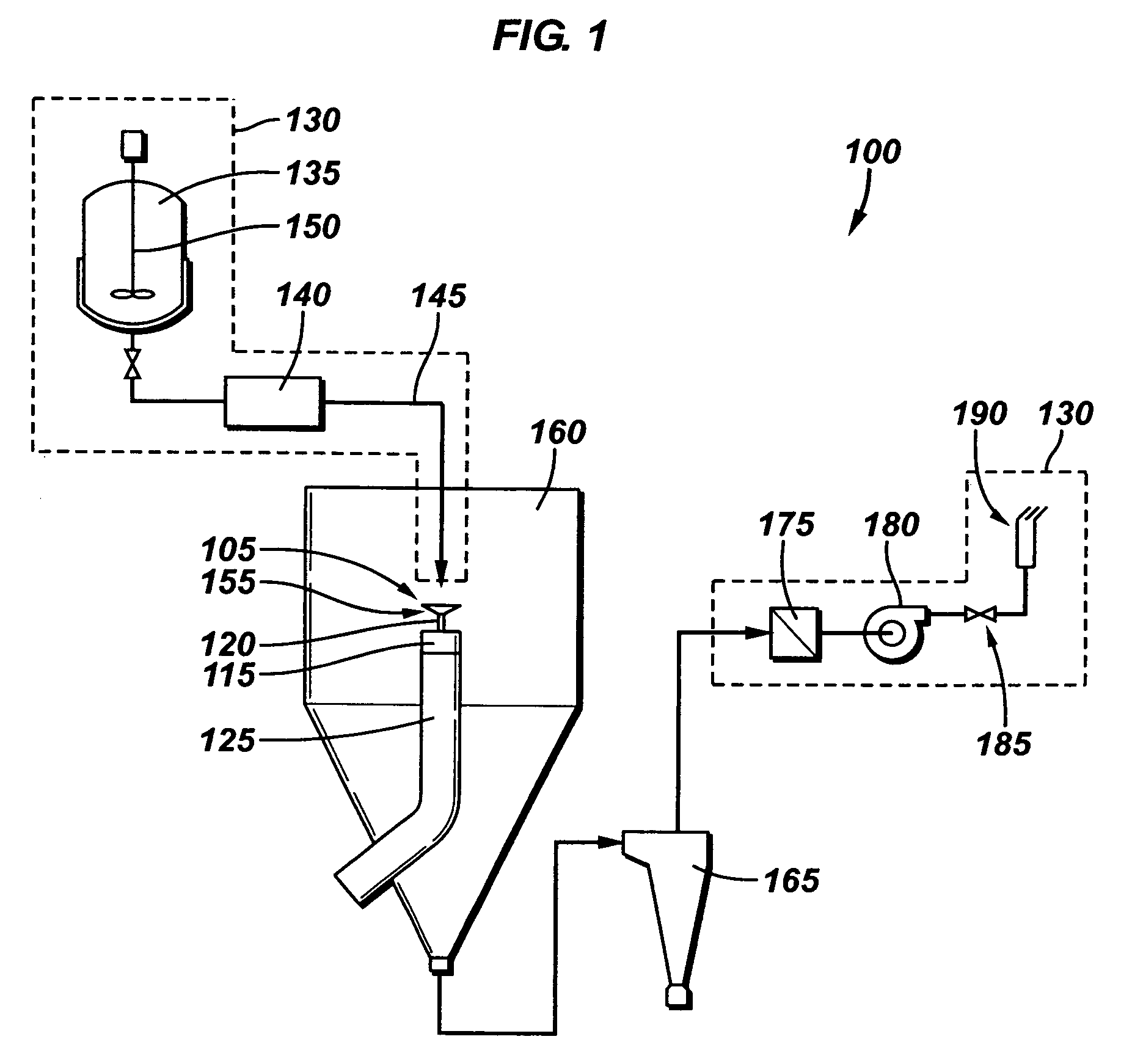

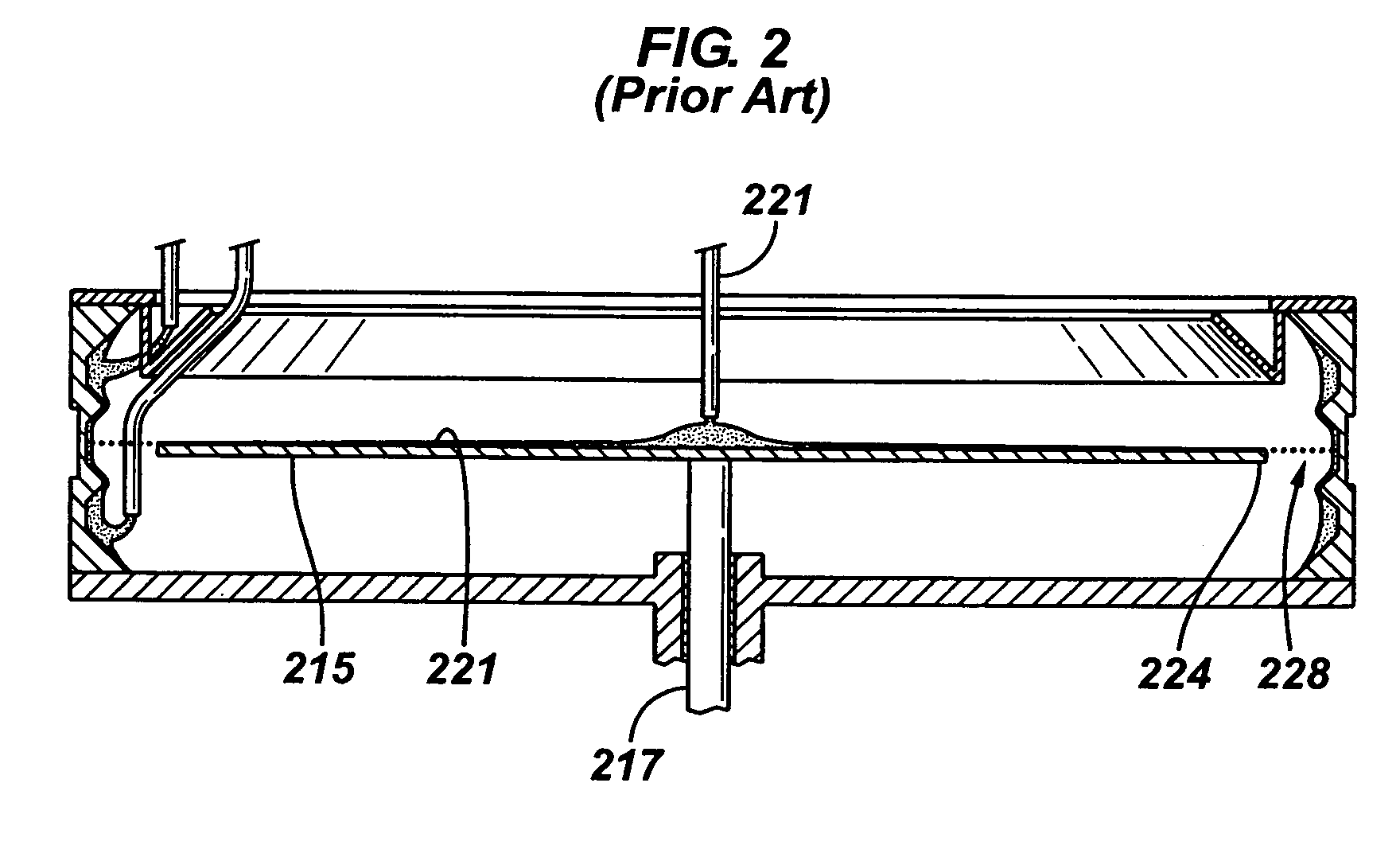

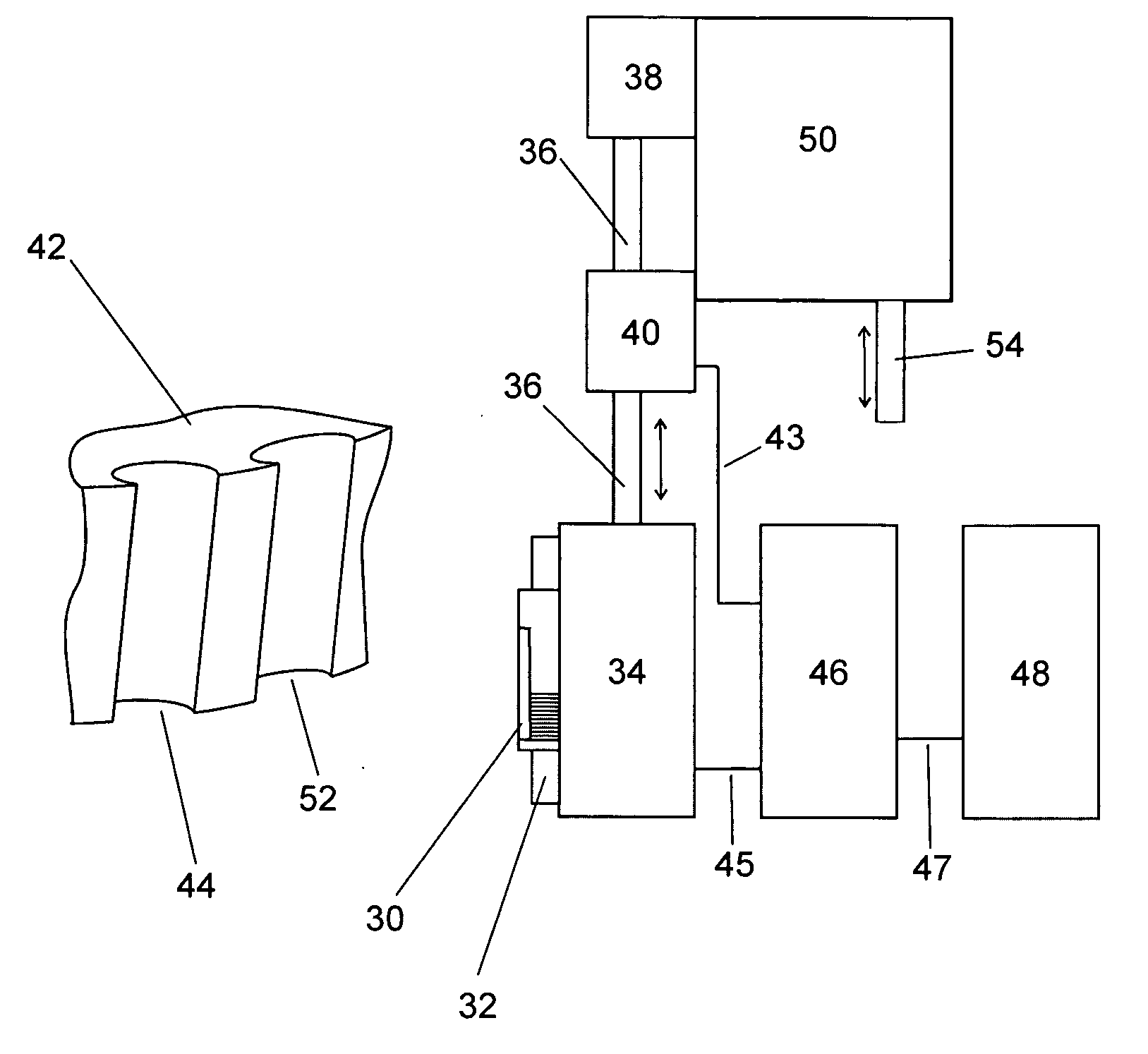

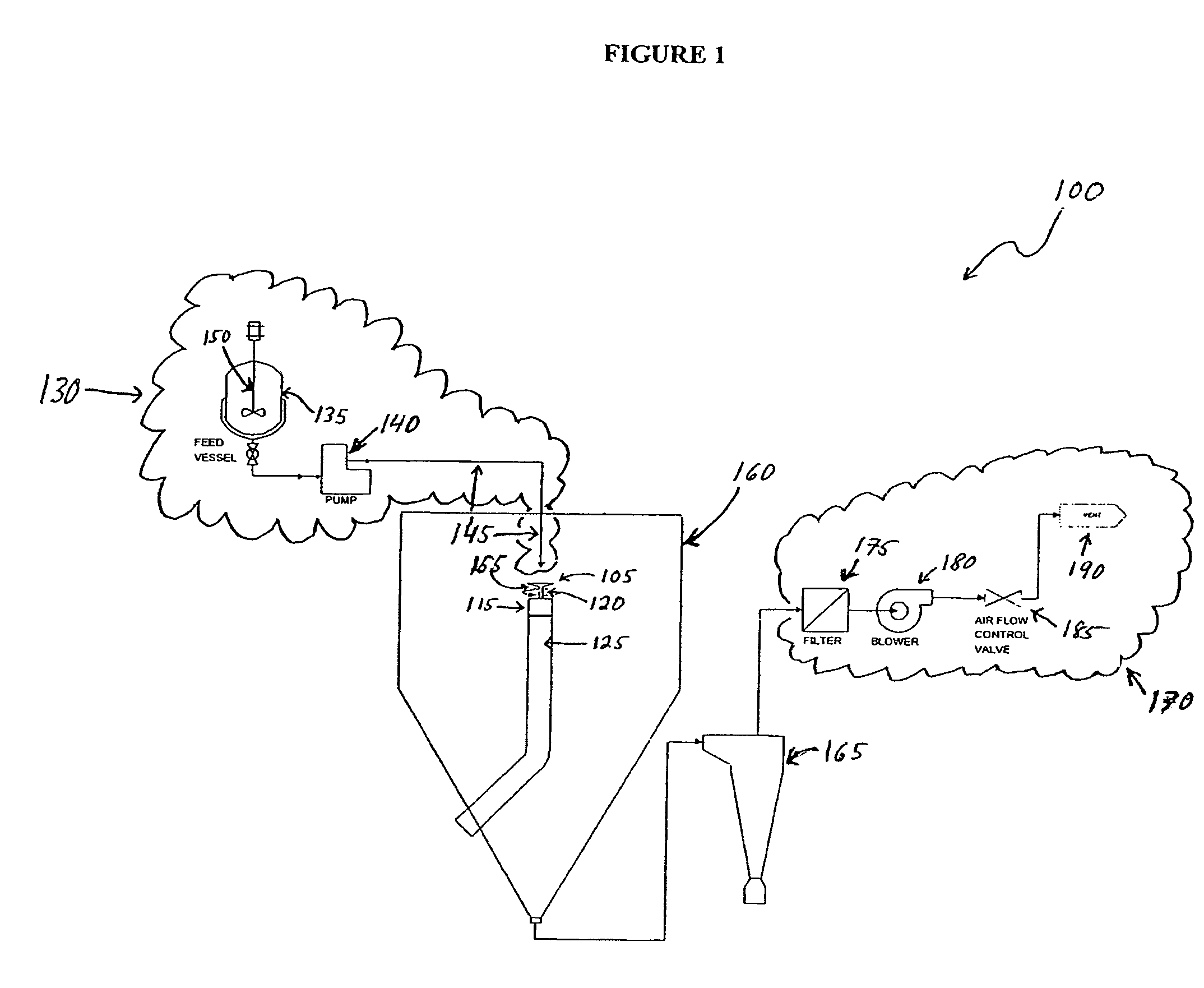

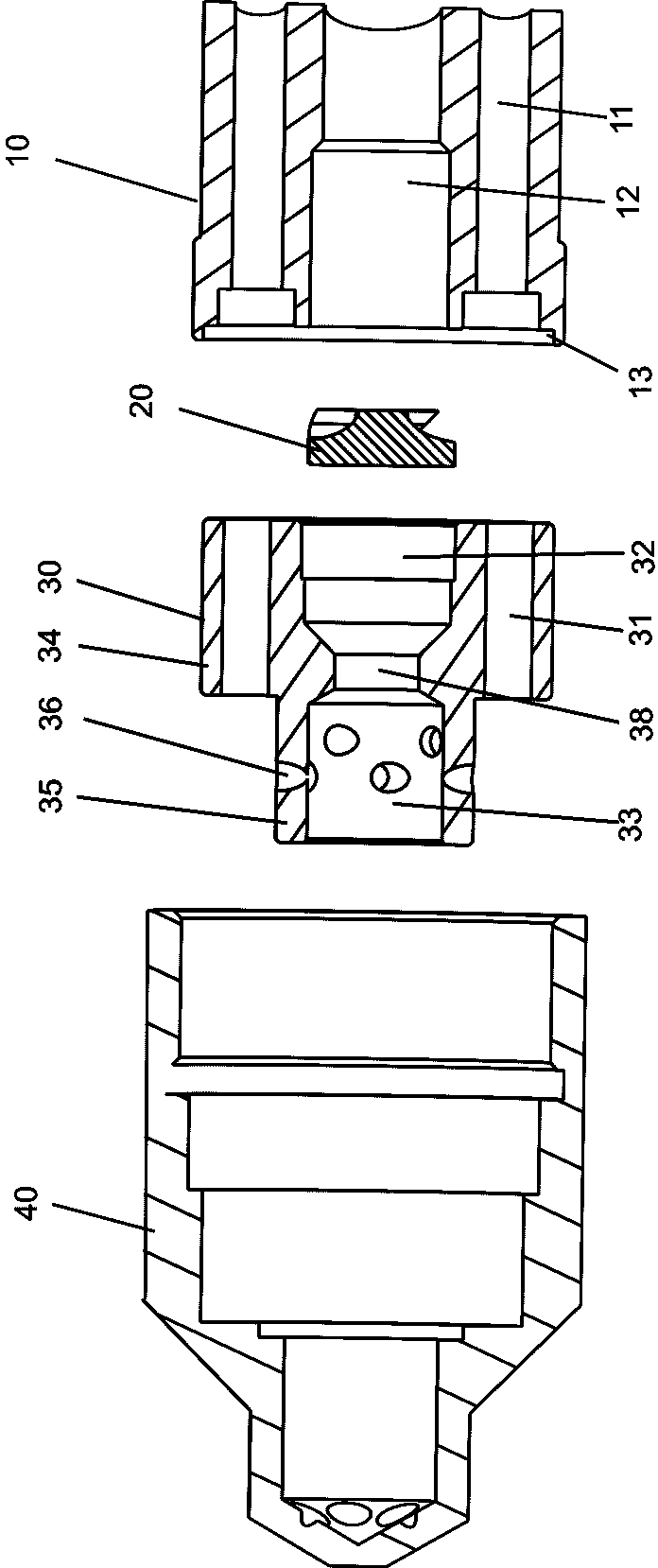

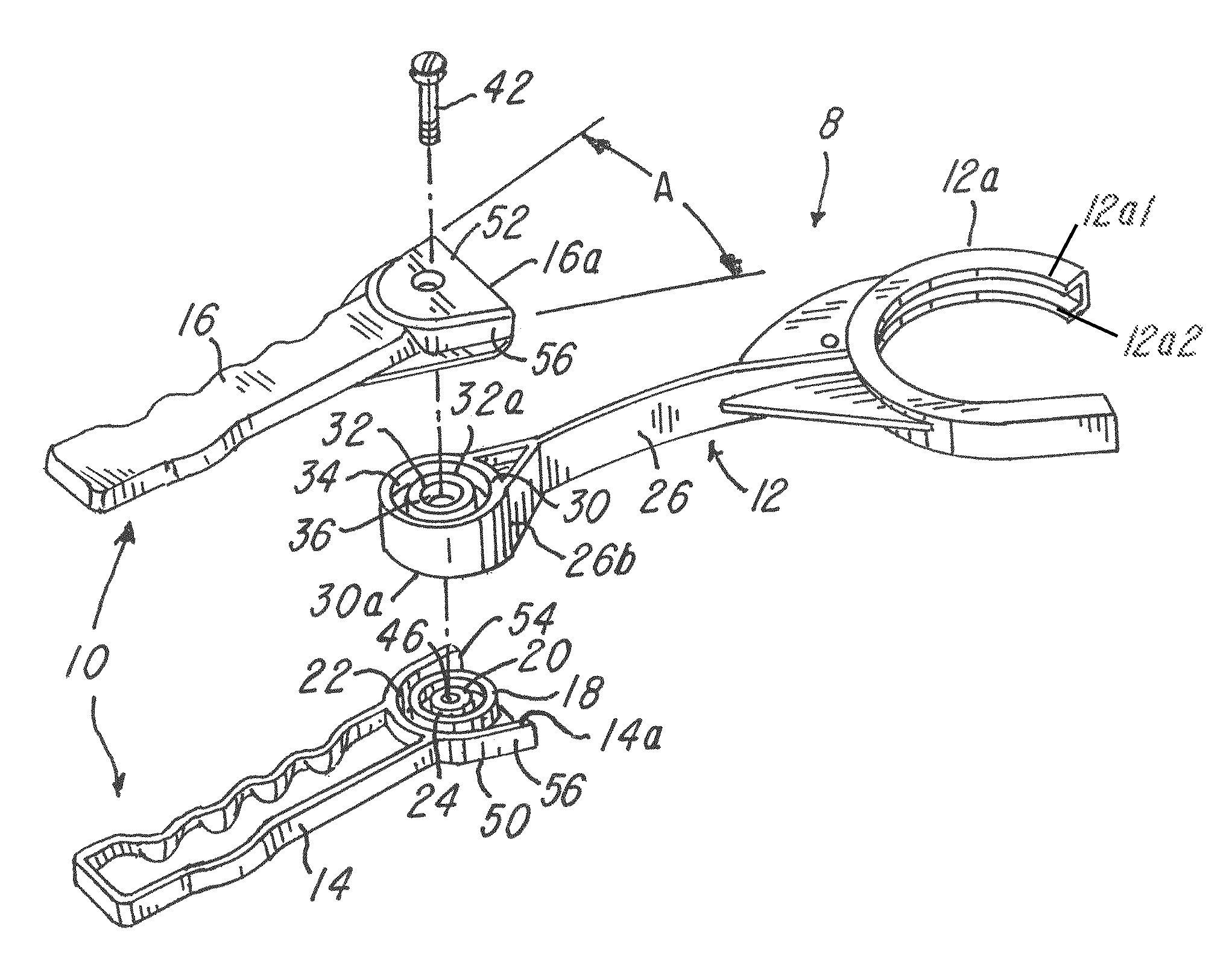

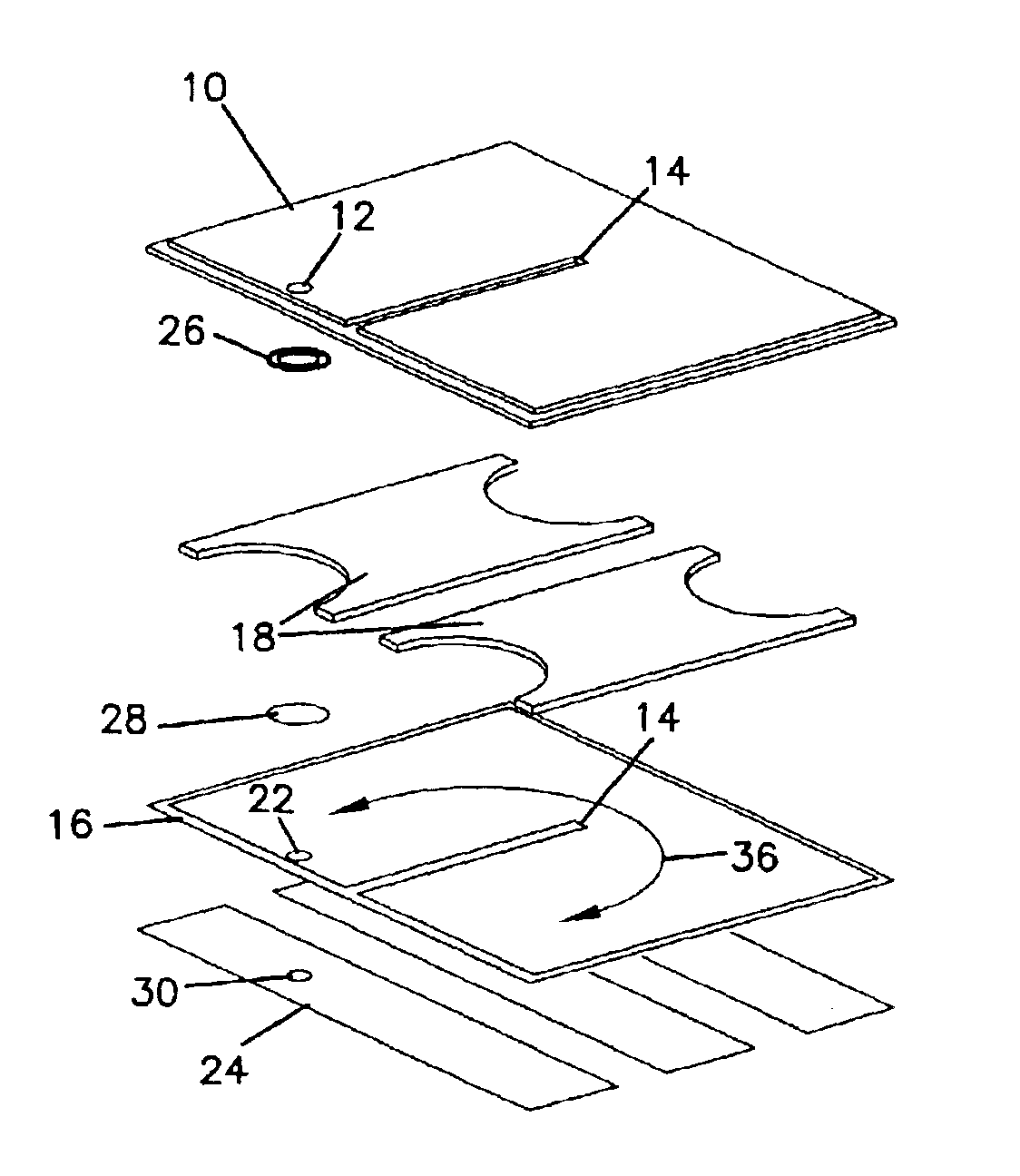

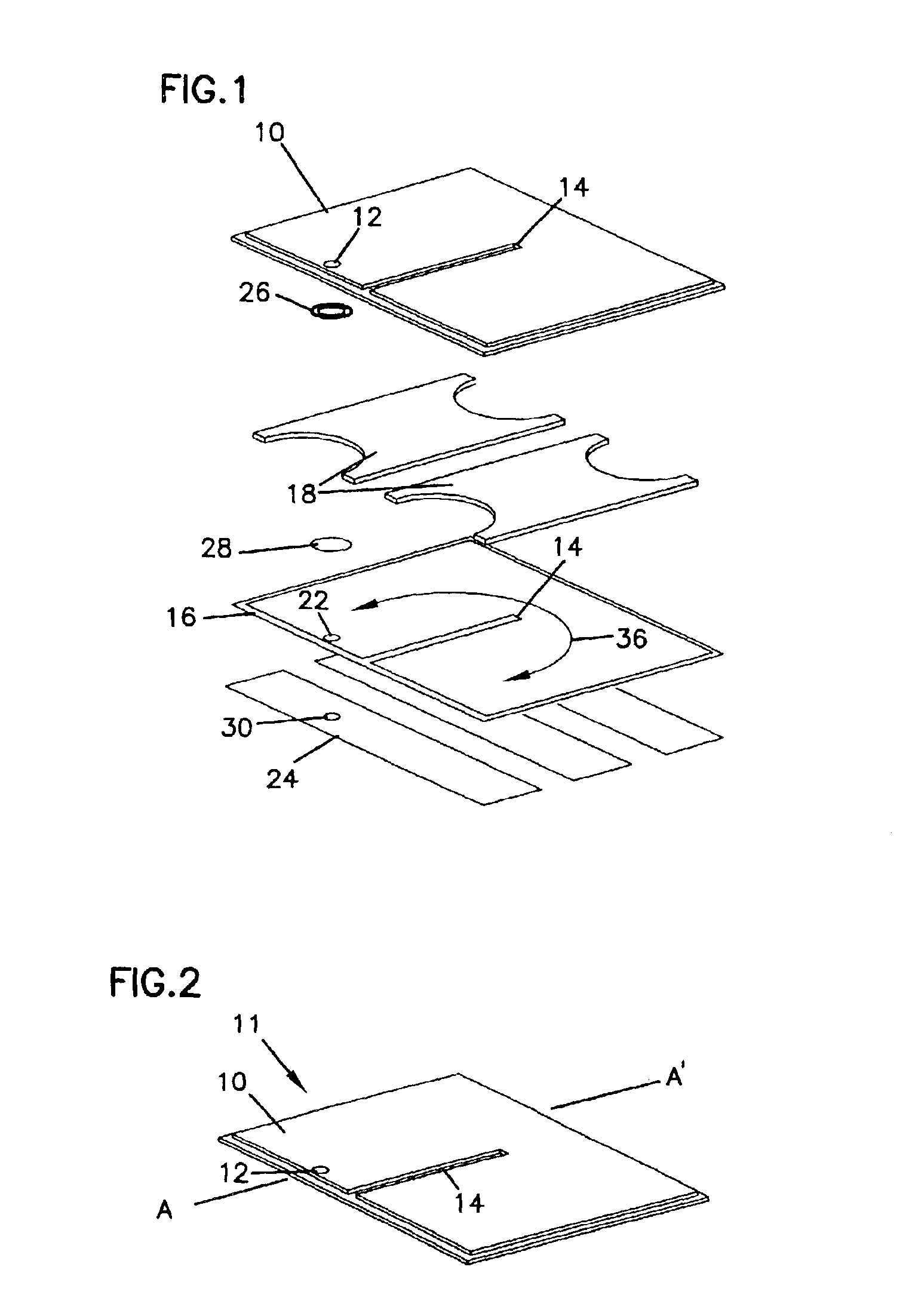

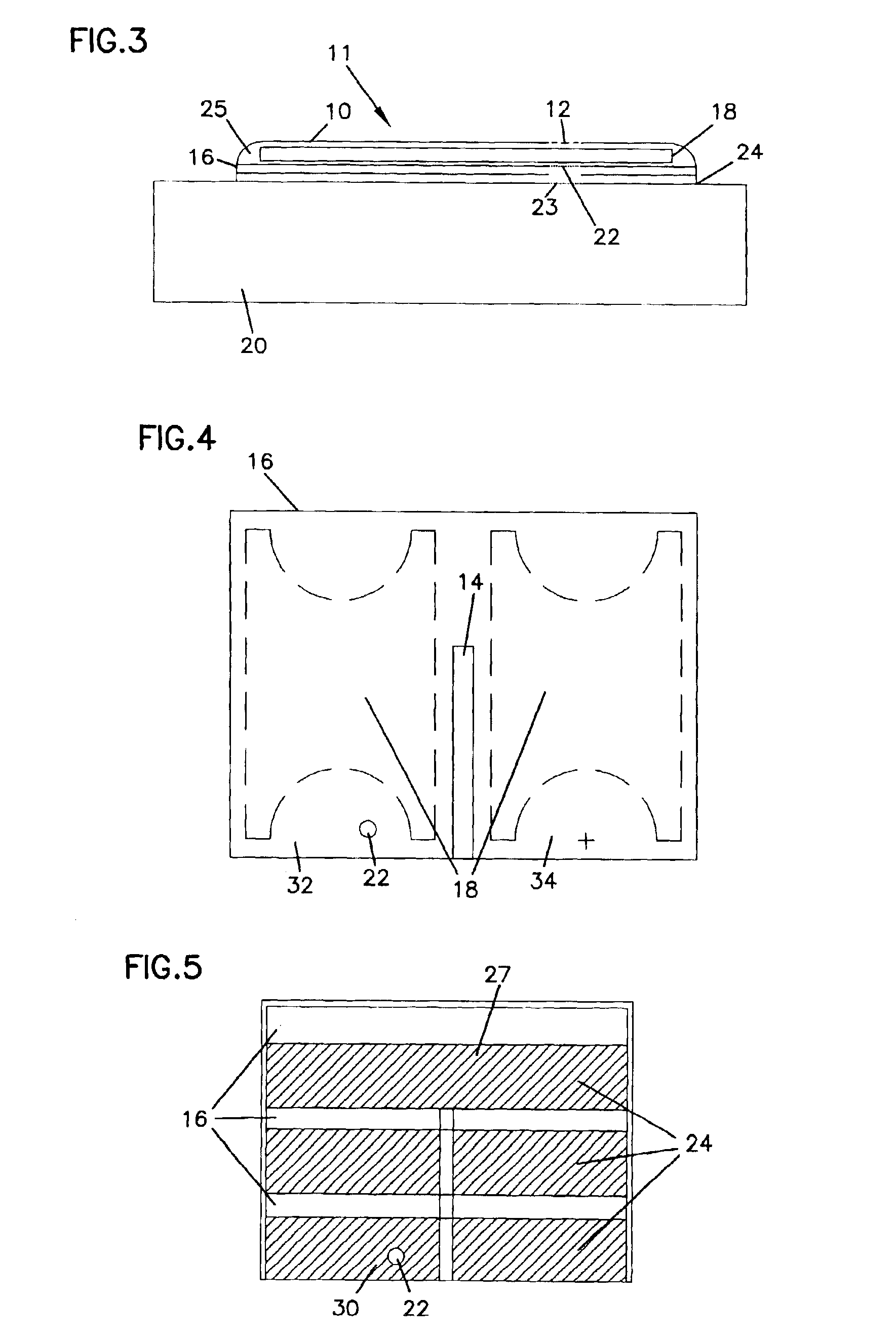

Apparatus for preparing biodegradable microparticle formulations containing pharmaceutically active agents

ActiveUS7261529B2Auxillary shaping apparatusGranulation in stationary drums/troughsRotational axisActive agent

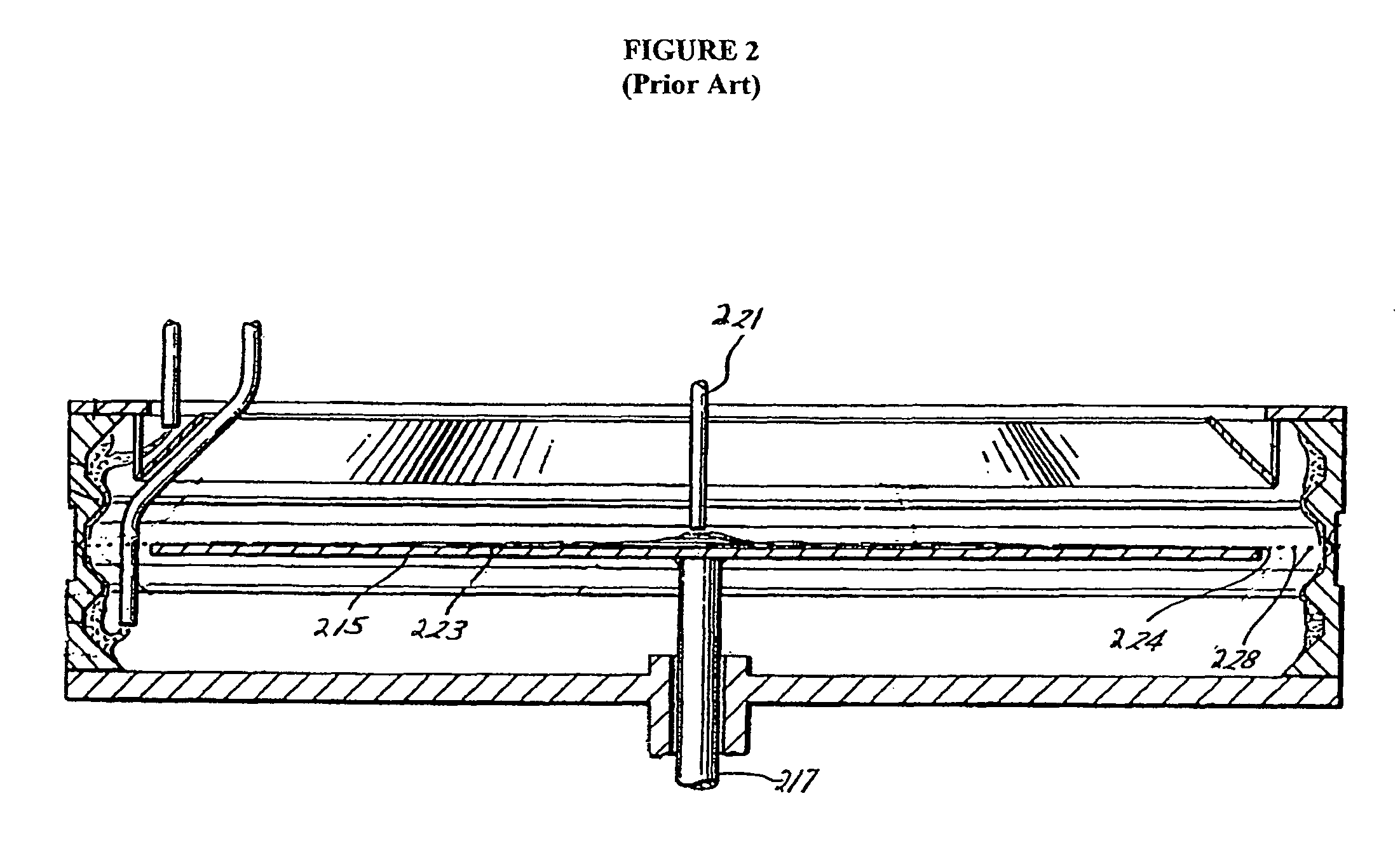

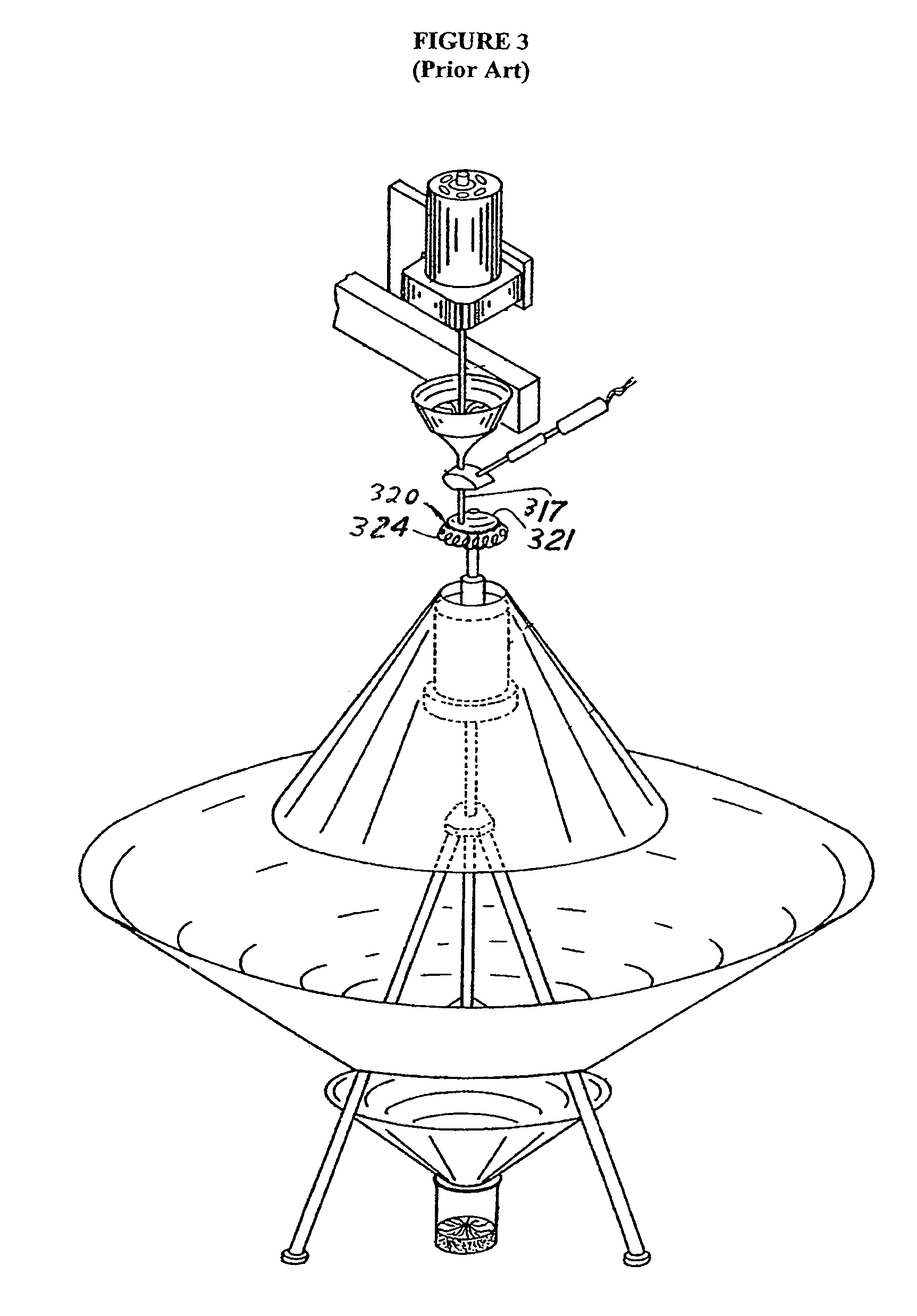

This invention is directed to an apparatus and method for producing microparticles comprising pharmacologically active agents and biodegradable polymers. The apparatus includes a spinning disk containing a reservoir in the center thereof and a flat inclined surface. The apparatus optionally includes serrations and / or a flat surface beneath the periphery of the disk that is parallel to the rotational axis of the disk. The invention is also directed to a method for producing microparticles containing pharmacologically active agents, using the spinning disk apparatus. Formulations containing ophthalmically active agents are provided. Formulations exhibiting zero order release rates are also described.

Owner:ALCON INC +1

Centrifugal solution spun nanofiber process

The invention relates to a process for forming nanofibers from a spinning solution utilizing a high speed rotating spin disk having a flat surface. The nanofibers can be collected into a uniform web for selective barrier end uses.

Owner:DUPONT SAFETY & CONSTR INC

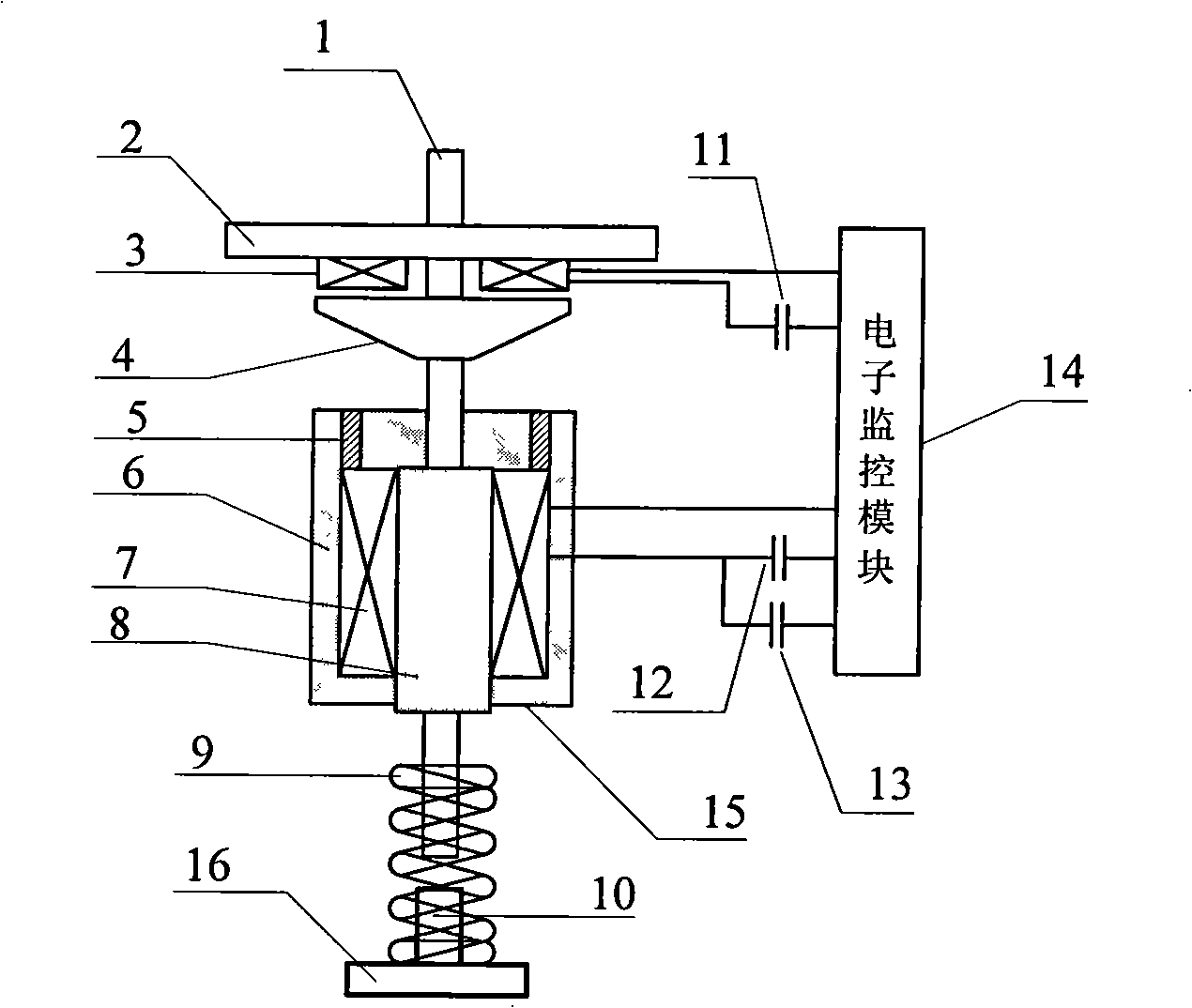

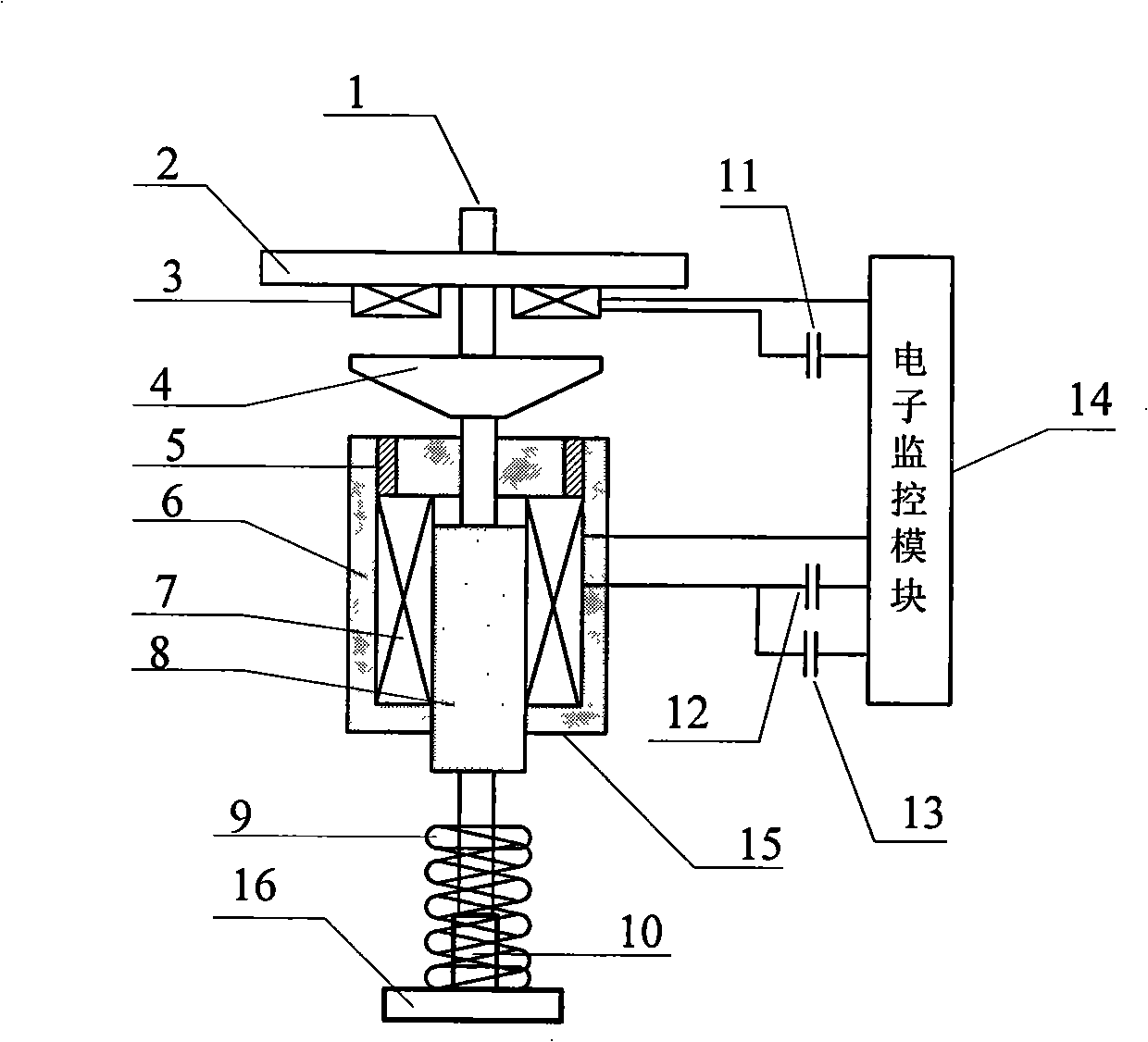

Electromagnetic repulsion force system and permanent magnetic system coupled self-adapting control mechanism

InactiveCN101315836AMaintain mechanical strengthMaintain output capacitySwitch power arrangementsHigh-tension/heavy-dress switchesKinematicsRepulsion force

The invention discloses a self-adaptive control mechanism which couples an electromagnetic repulsion system with a permanent magnetism system. The invention adopts an electromagnetic repulsion device spinning disk of circular table structure, relatively to the circular disk spinning disk, which maintains the mechanical strength and output capacity of the spinning disk, simultaneously greatly reduces the increase of kinematic scheme mass of the control mechanism, and greatly enhances the driving load capacity of the control mechanism. The control mechanism of the invention adopts the self-adaptive motion proposal, which avoids the frequent high speed motion of a breaker, reduces the mechanical strength request for the breaker, and prolongs the motion life of the breaker effectively.

Owner:XI AN JIAOTONG UNIV

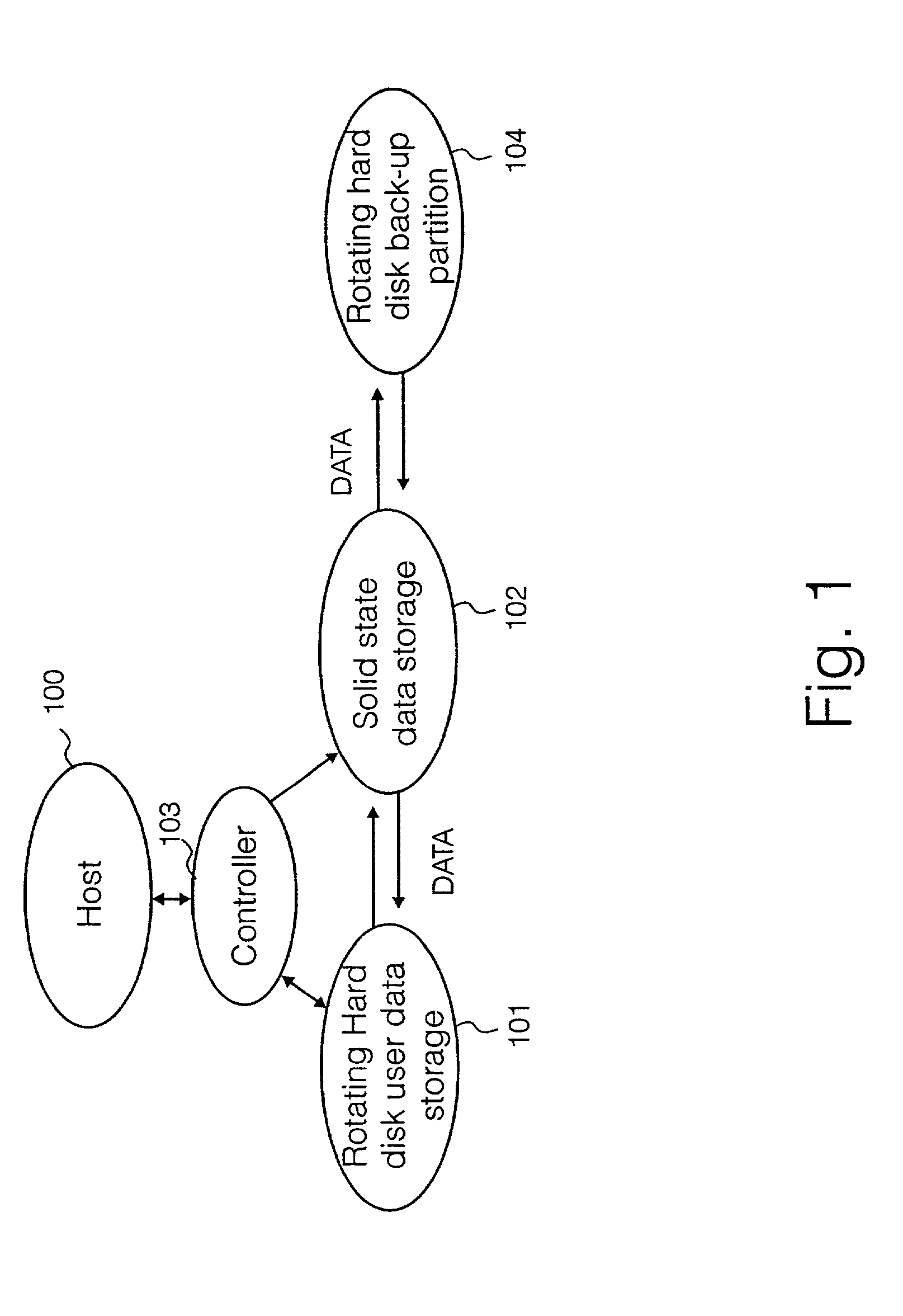

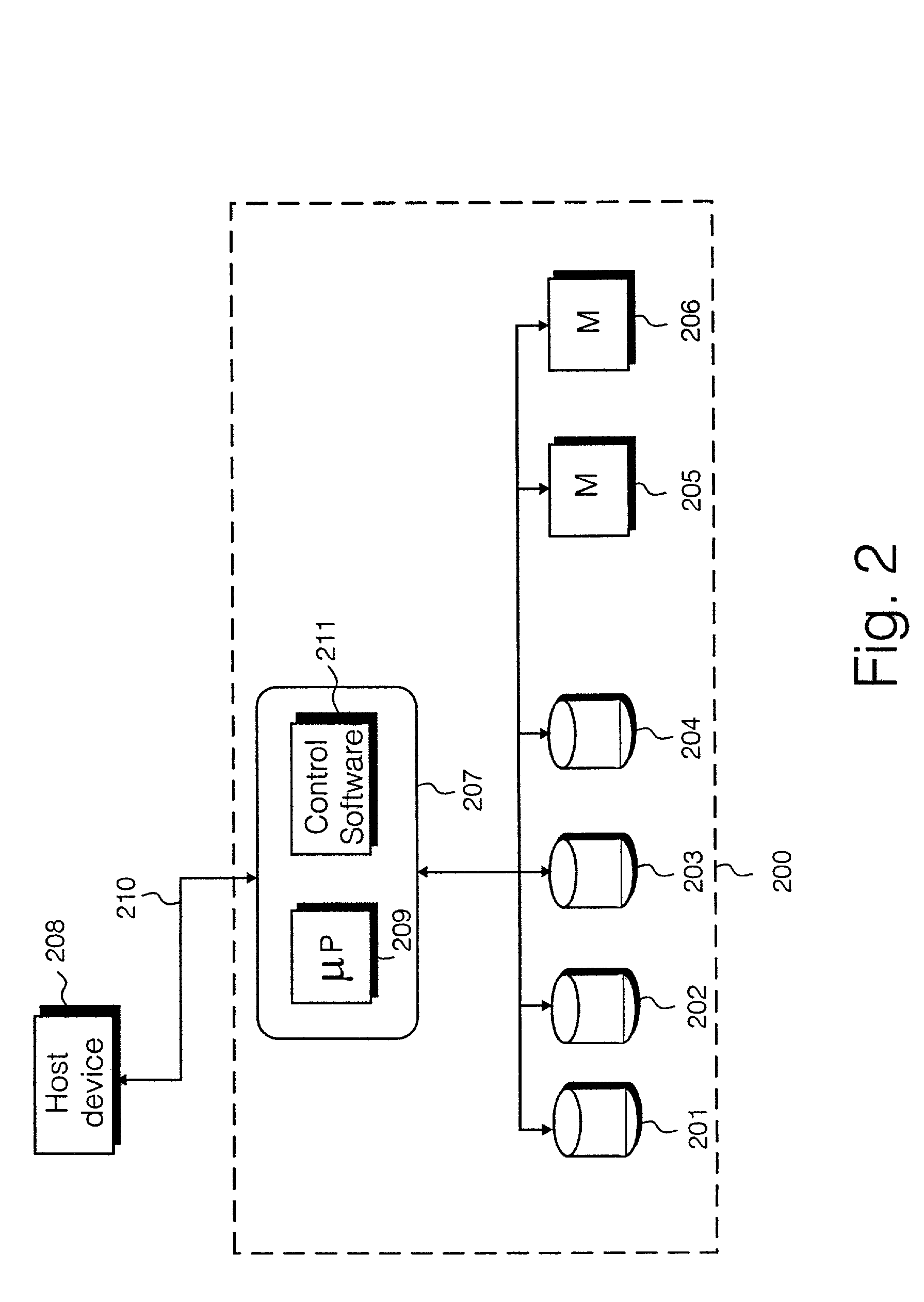

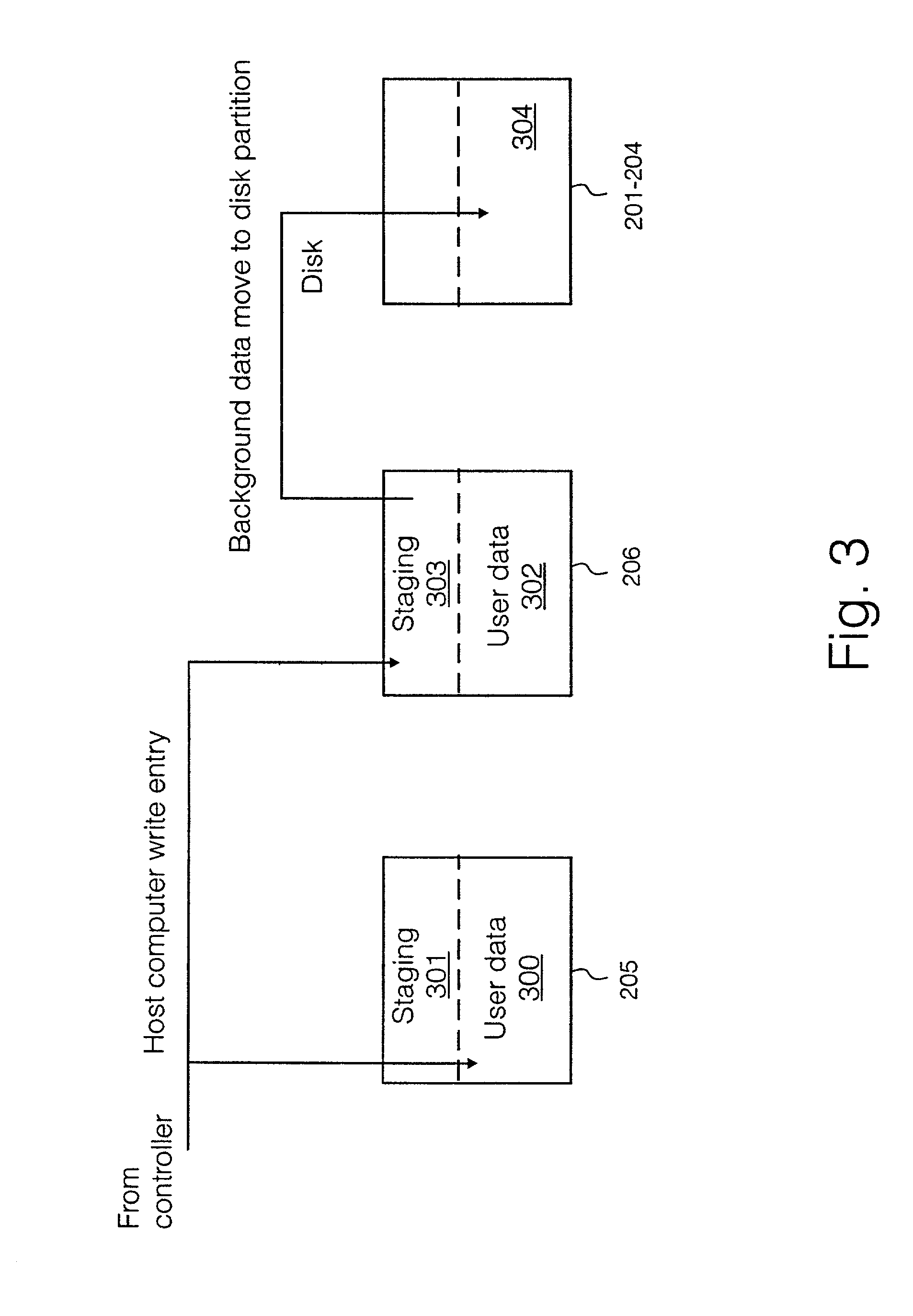

Data storage system having redundant solid state data storage device

InactiveUS20010018728A1Input/output to record carriersMemory adressing/allocation/relocationRAIDAccess time

A RAID device is provided with a pair of non-volatile solid state data storage devices and one or more rotating disk drives, giving improved access time performance to the array. Data is staged on the pair of solid state data storage devices, and periodically backed up to the rotating disk drive(s).

Owner:HEWLETT PACKARD CO

Disk drive employing a spindle motor comprising a locking spring arm disengaged through stator coil flux

InactiveUS6867946B1Dynamo-electric brakes/clutchesRecord information storageEngineeringMagnetic flux

A disk drive is disclosed comprising a disk, a head actuated radially over the disk, and a spindle motor for rotating the disk. The spindle motor comprises a stator having at least one stator coil wrapped around a stator tooth. The spindle motor further comprises a hub rotated by the stator when current is applied to the stator coil, and a locking spring arm having a fixed base. The locking spring arm engages the hub when no current is applied to the stator coil, and the locking spring arm disengages from the hub when current applied to the stator coil generates a magnetic flux which pulls the locking spring arm away from the hub.

Owner:WESTERN DIGITAL TECH INC

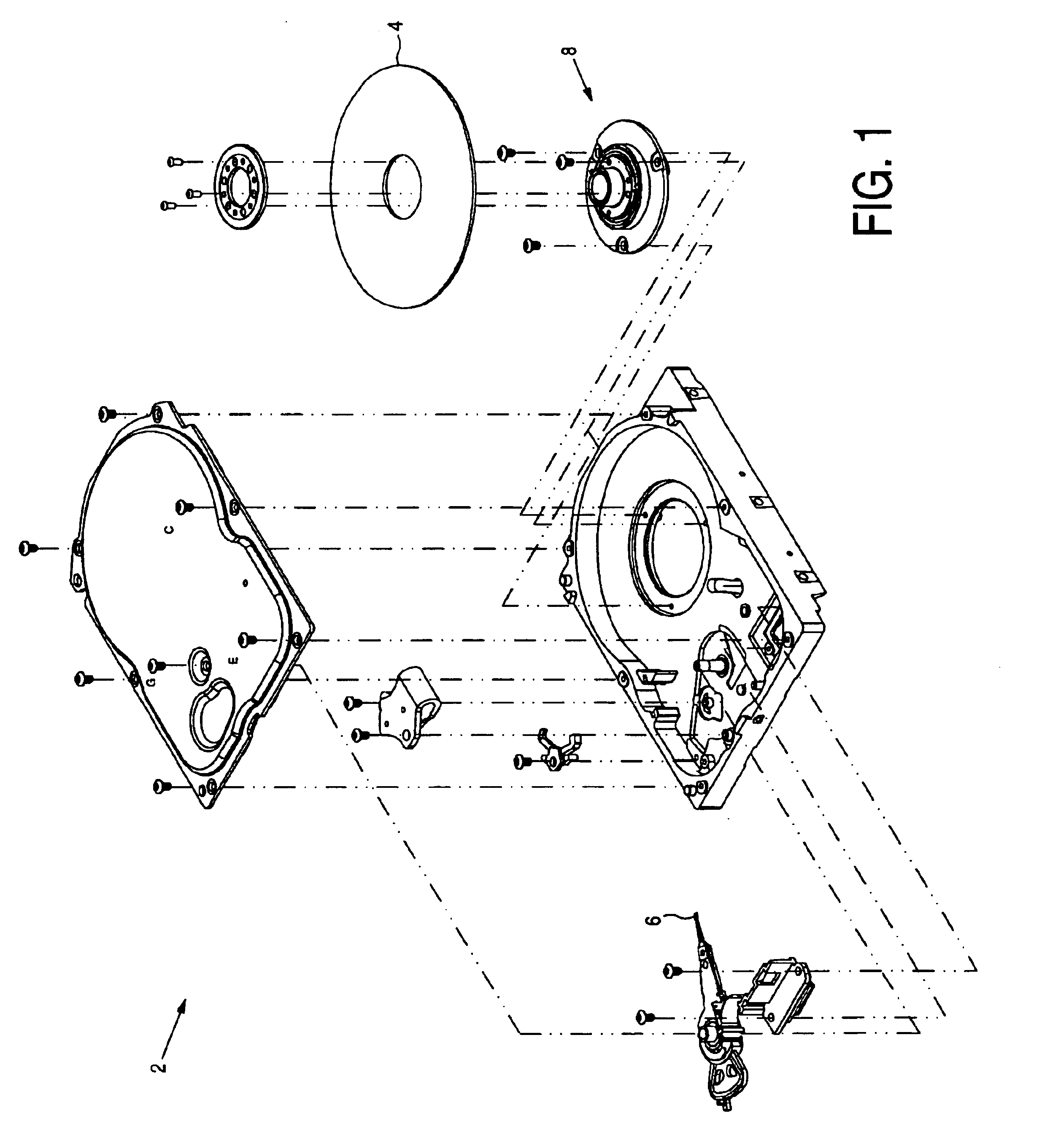

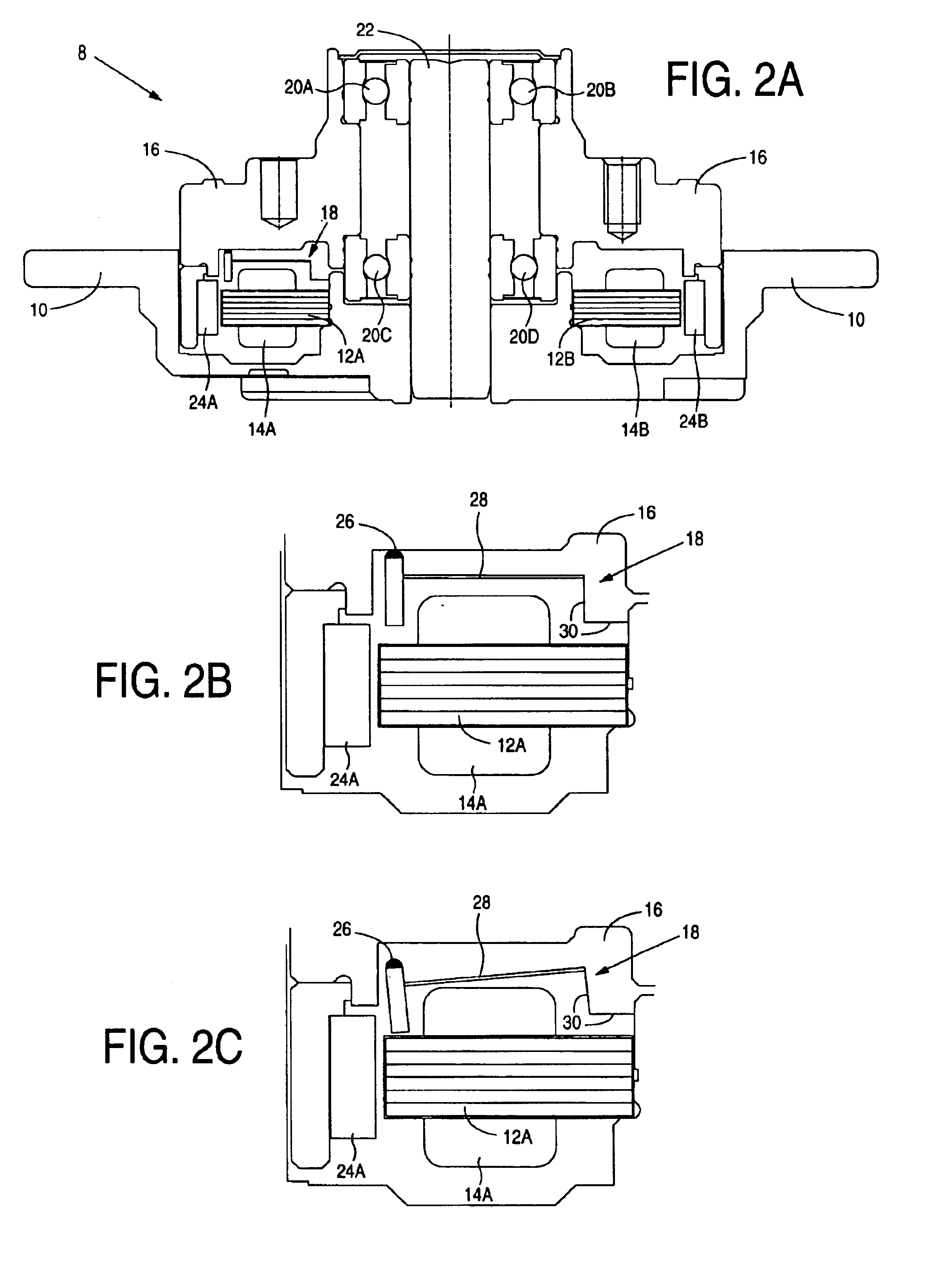

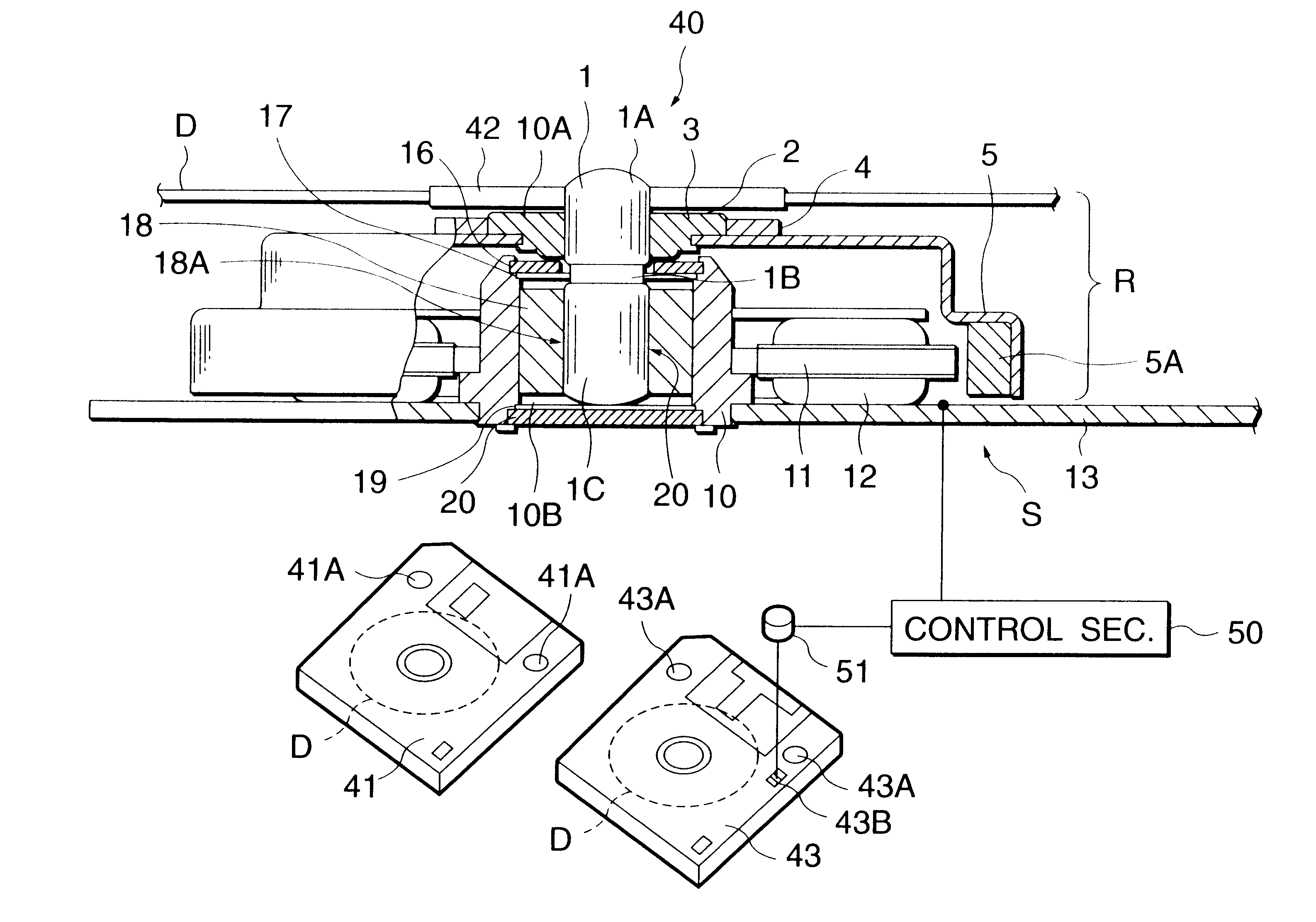

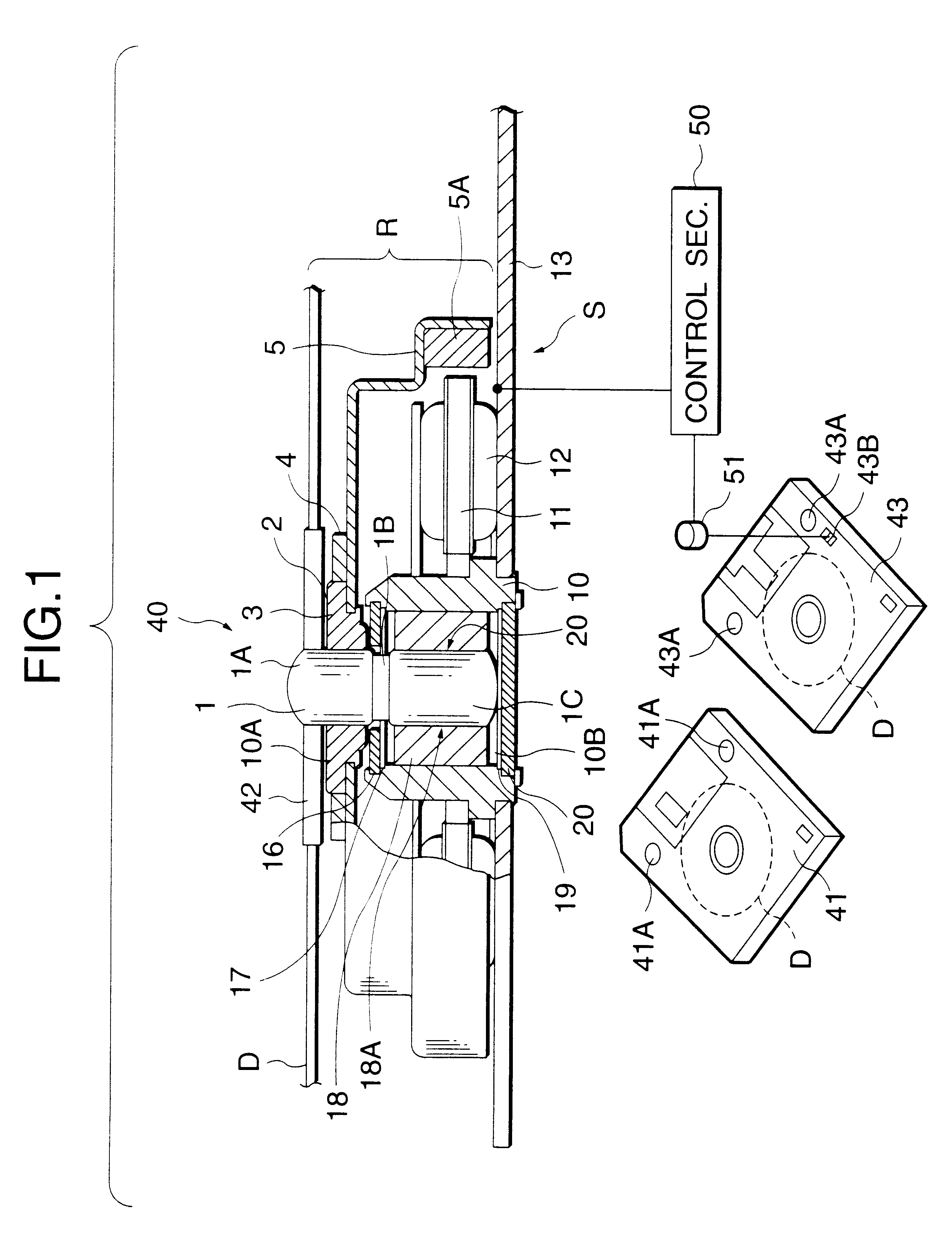

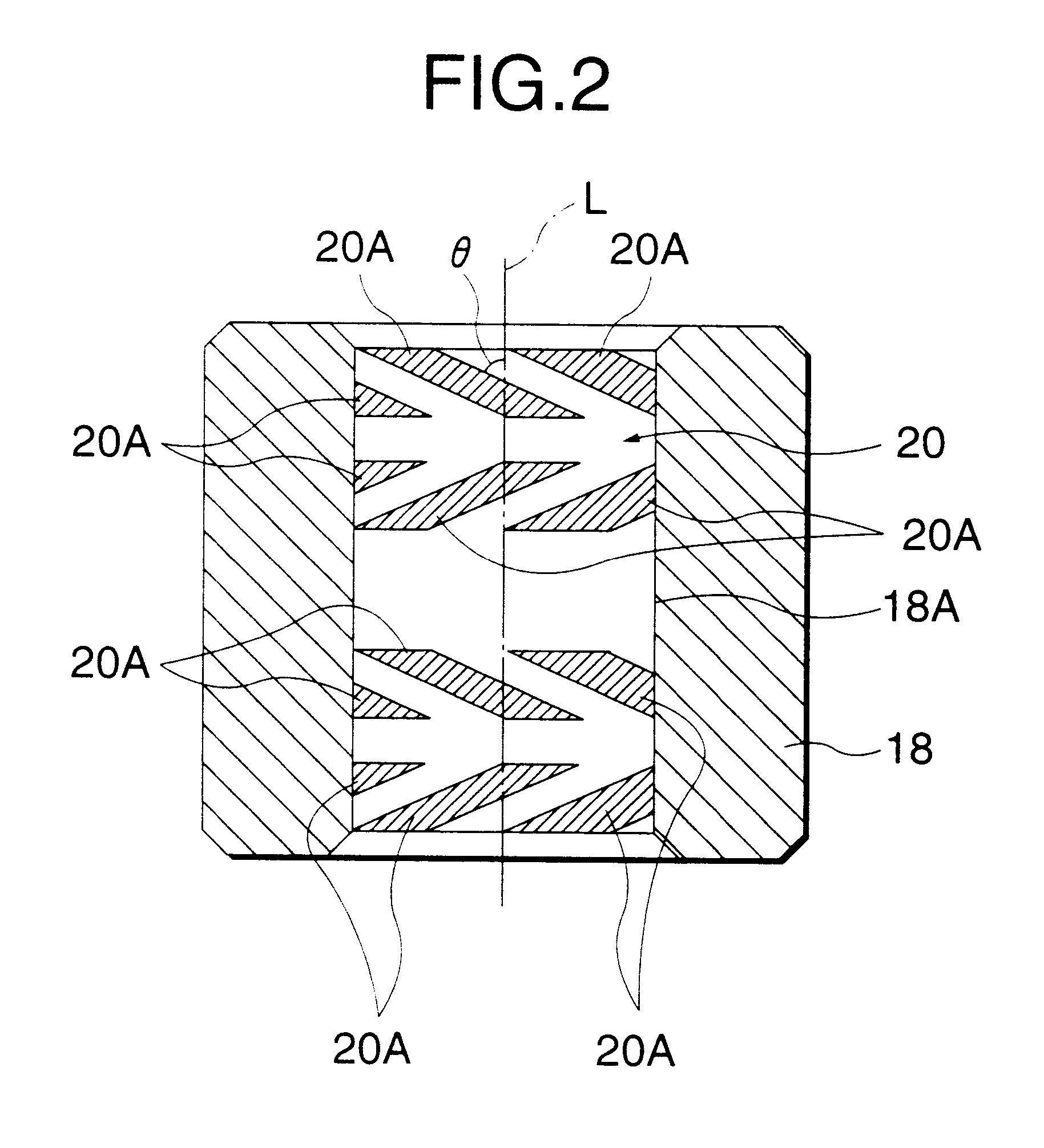

Motor for rotating a disk-shaped information recording medium in a disk drive apparatus

A motor for rotating a disk-shaped information recording medium for a disk drive apparatus which is capable of rotating a higher-capacity information recording medium and a relatively lower-capacity recording medium at different speeds. This motor includes a stator; a rotor that rotates with respect to the stator with a shaft as the center of rotation when a drive winding is energized; a bearing that is provided on the side of the stator and rotatably supports the shaft of the rotor; a dynamic pressure generation section for generating dynamic pressure by filling a fluid between the bearing and the shaft when the shaft is rotated above a predetermined speed; a judging member for judging whether the disk-shaped information recording medium that is attached to the rotor is a relatively lower-capacity medium or a higher-capacity medium; and a control section for supplying the drive winding of the stator with a drive signal for a first rotation speed when a judgment signal produced by the judging member indicates the relatively lower-capacity medium, and with a drive signal for a second rotation speed that is higher than the first rotation speed when the judgment signal indicates the higher-capacity medium.

Owner:SONY CORP

Patterned spinning disk based optical phase shifter for spectral domain optical coherence tomography

InactiveUS20060072424A1Low costSolve the slow scanning speedInterferometersRecord information storageCircular discIntensity modulation

A low cost patterned spinning disk is disclosed for achieving relatively rapid discrete optical phase shifts for an optical beam. The invention is particularly useful in a spectral domain optical coherence tomography system. The disk contains stepped patterns of different heights and / or refractive index distribution such that as it spins, an optical beam passing through or being reflected by the disk will experience different discrete optical phase delays. The disk can be operated as a phase shifter or it can be operated in synchronization with an intensity modulating chopper disk or a direct intensity modulation of the light source. The disk can also contain intensity modulating patterns such that both phase shifting and intensity modulation can be achieved at the same time. Various possible methods are also disclosed for the fabrication of the disk.

Owner:CARL ZEISS MEDITEC INC

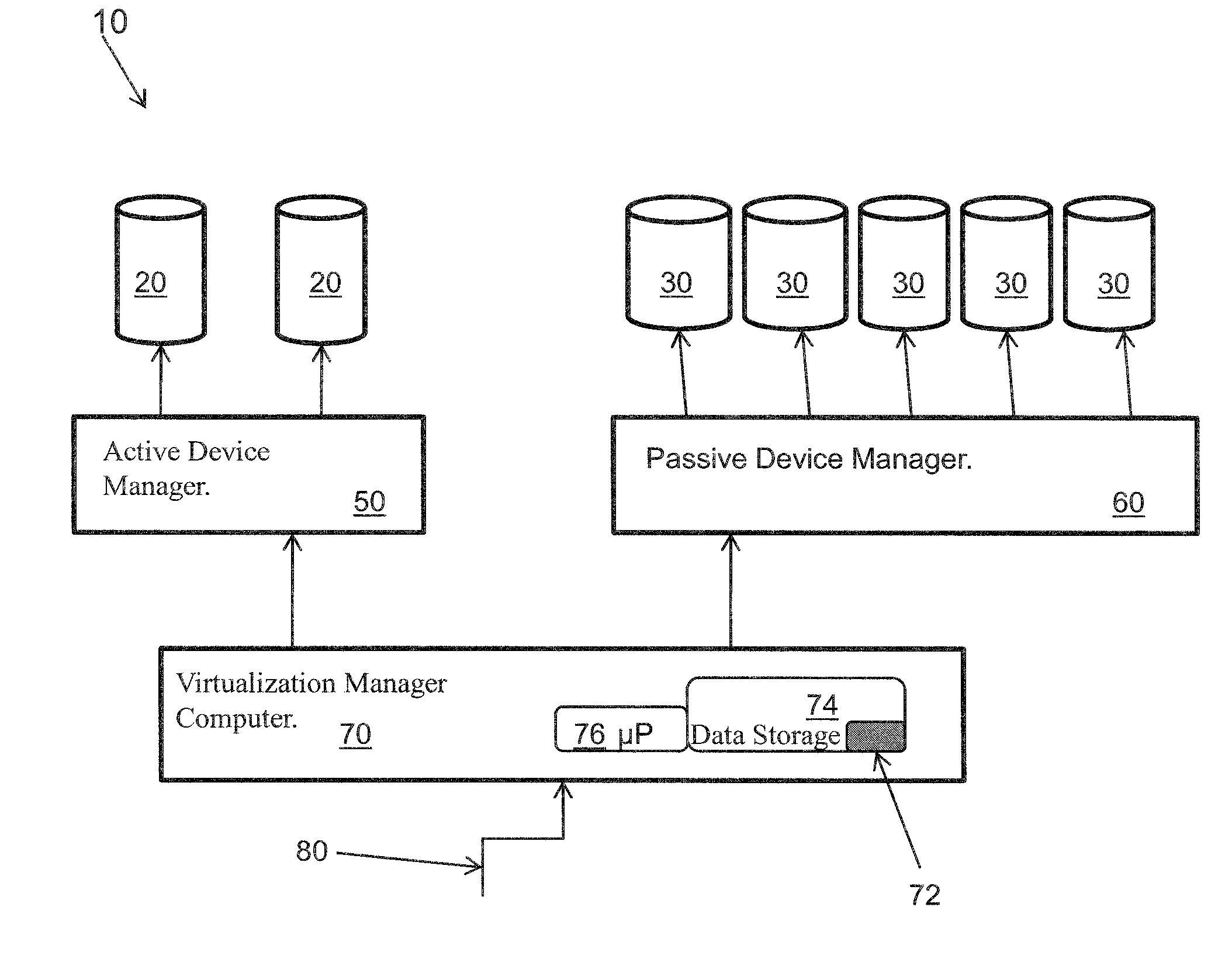

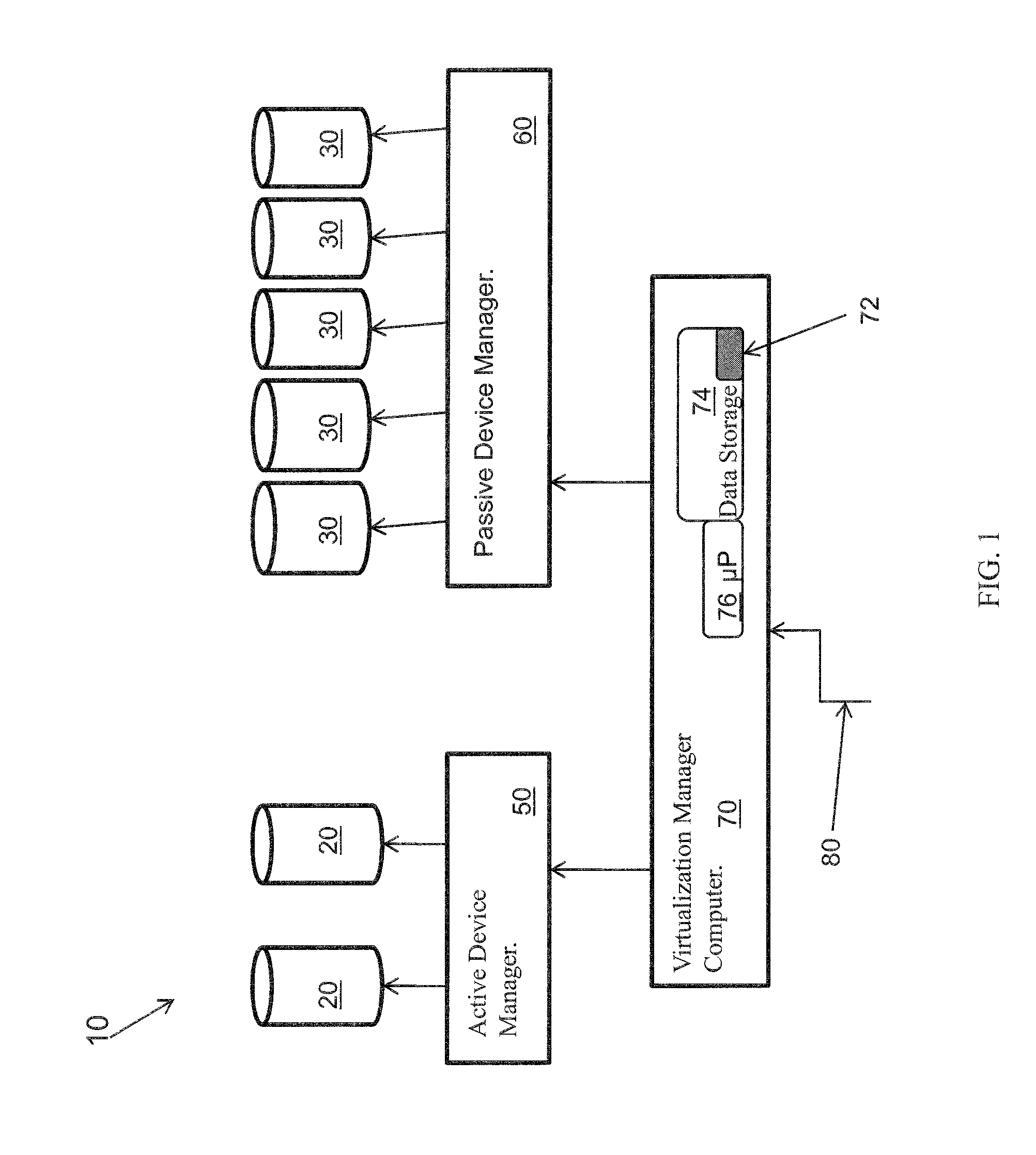

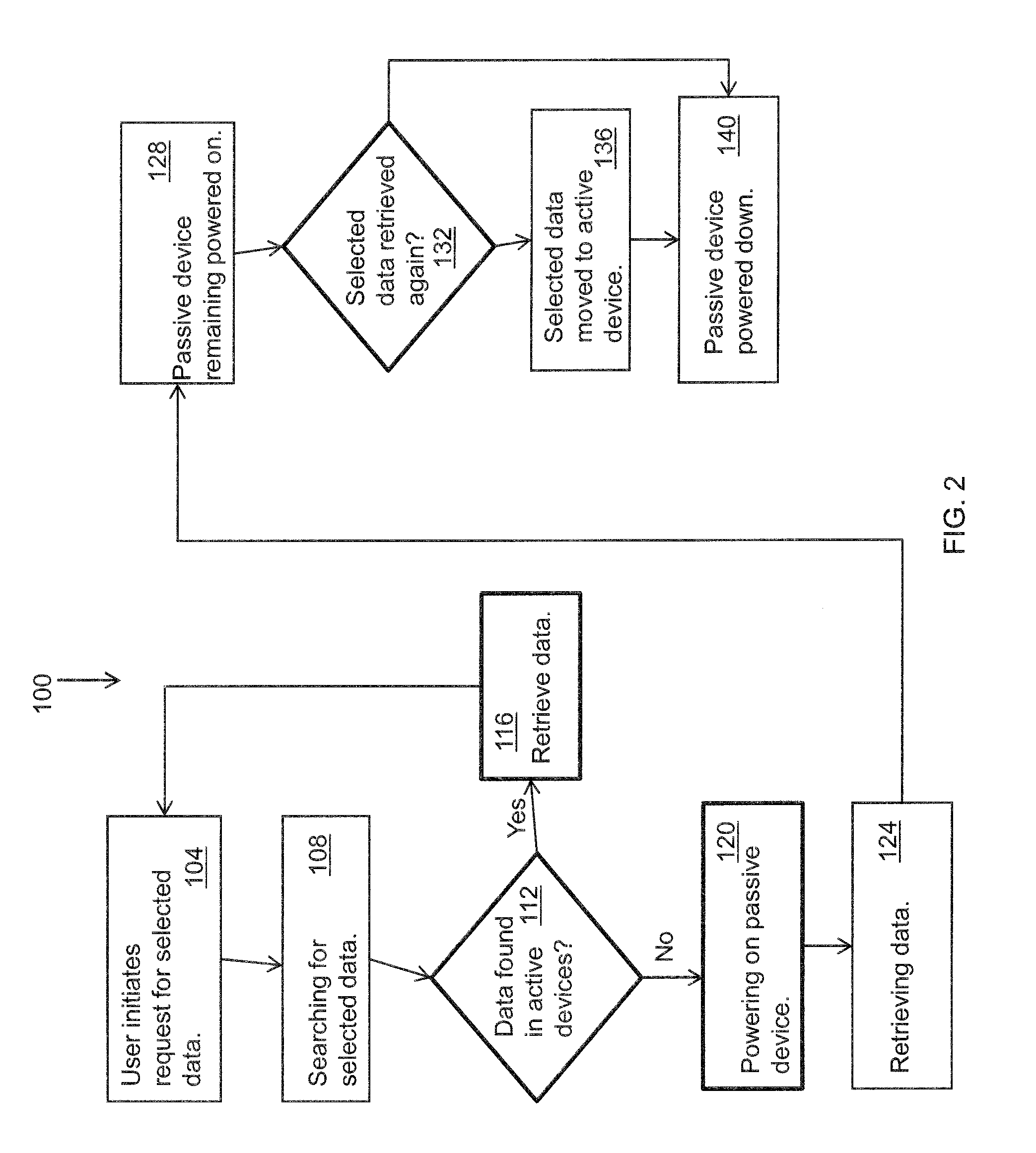

Virtual storage migration technique to minimize spinning disks

A method, and system for employing the method, for virtual data storage migration providing a plurality of data storage devices communicating with at least one computer system. A plurality of data being managed by the computer system and an archive data storage device is selected from the plurality of data storage devices. Specified data is selected for archiving in the archive data storage device when the archive data meets a specified archive criteria. After the archived specified data is accessed in the archive data storage device at a predetermined frequency, the archive data is migrated to an active data storage device in a powered up state. The archive data storage device is then powering down.

Owner:IBM CORP

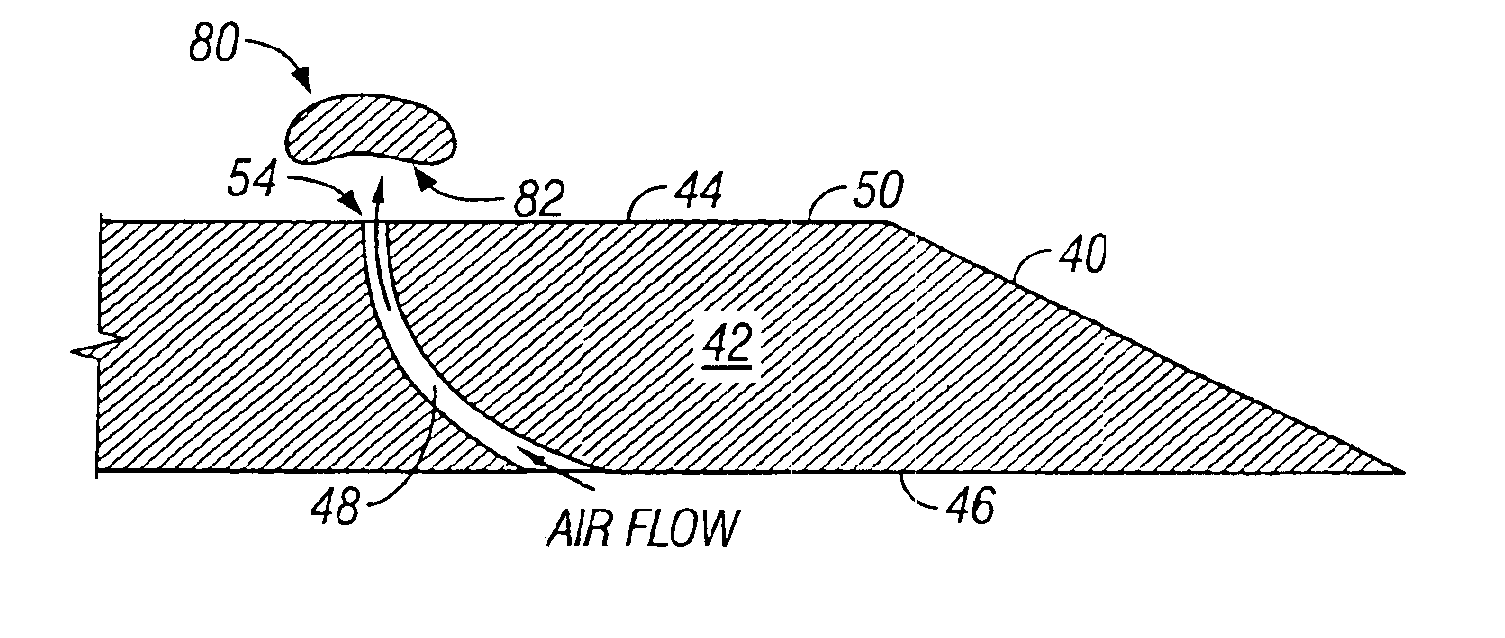

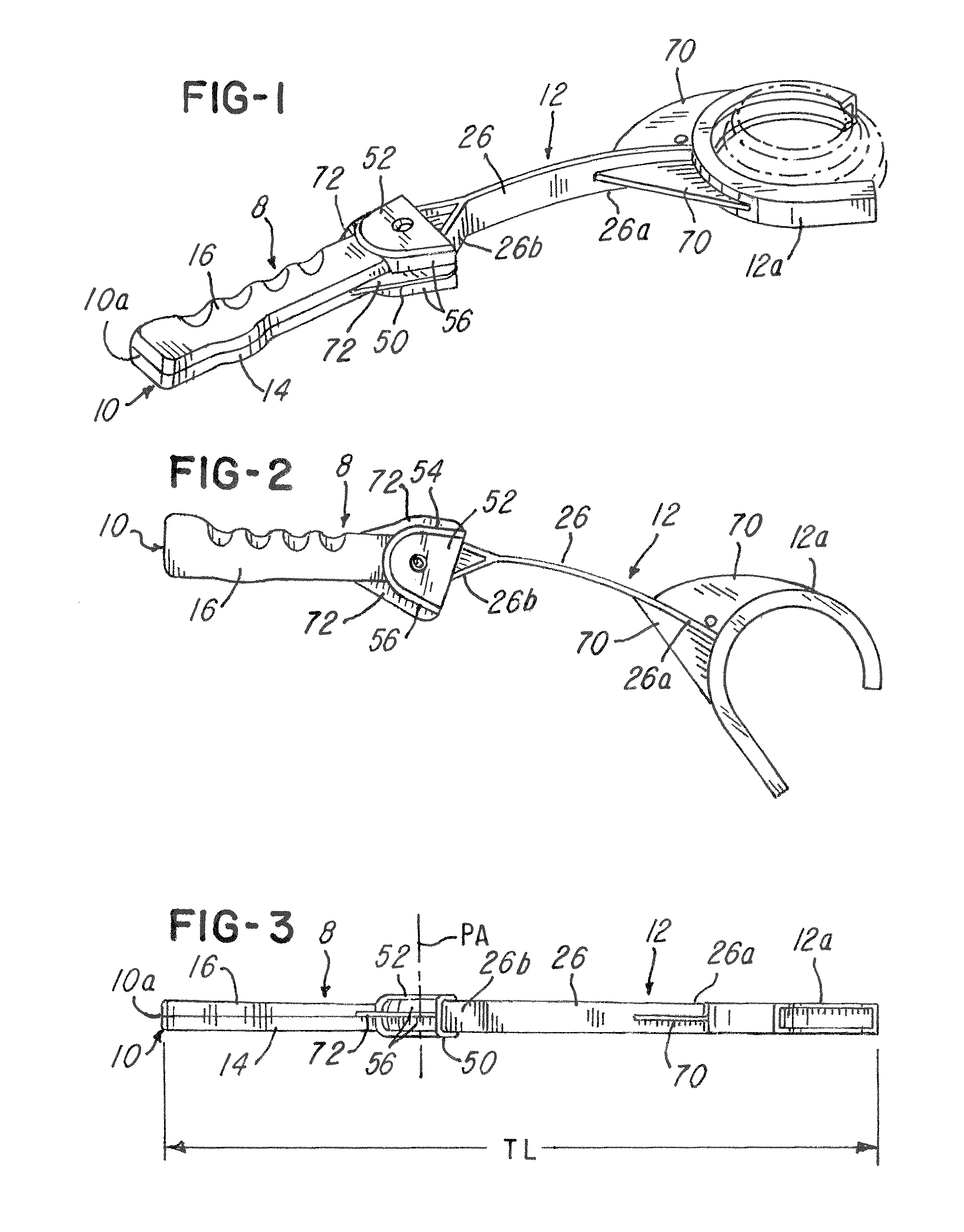

Airflow assisted ramp loading and unloading of sliders in hard disk drives

InactiveUS6856489B2Assist in loadReduce rotationDriving/moving recording headsRecord information storageHard disc driveEngineering

Windage proximate to a spinning disk within a disk drive is directed through a plurality of apertures in a ramp situated near the outside diameter of the disk. A tab extending from a load beam that supports a slider rests on the ramp when the drive is not in use. When the drive is started the disk begins to spin and an actuator moves the load beam to bring the slider over the surface of the disk. As the load beam moves, the tab is guided along the ramp and cushioned by the air flow emerging from apertures in the ramp beneath it. When the drive is stopped the actuator brings the load beam back so that the tab engages the ramp. A cushion of air is again provided as the tab is moved along the ramp as the tab is returned to a parked position.

Owner:WESTERN DIGITAL TECH INC

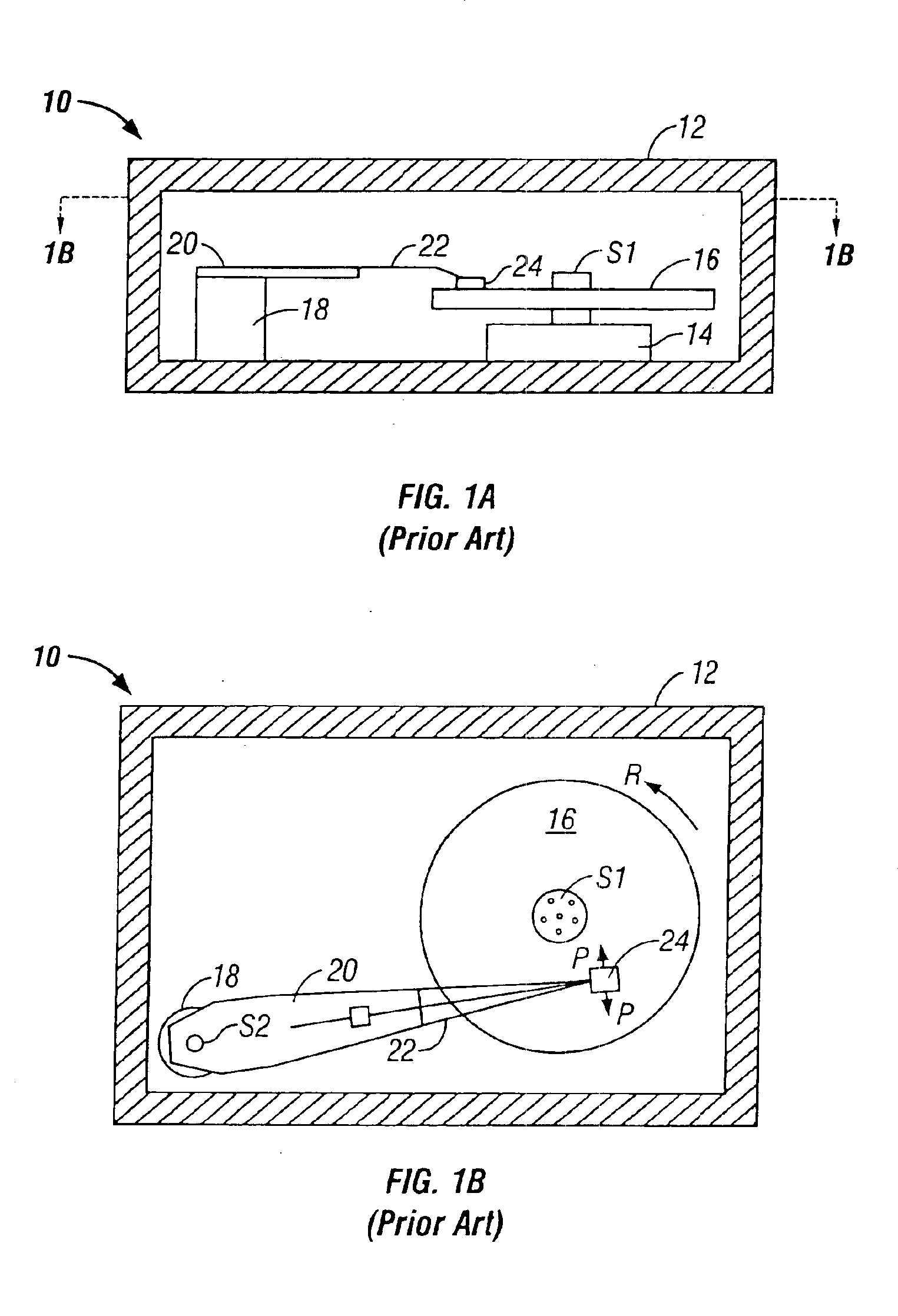

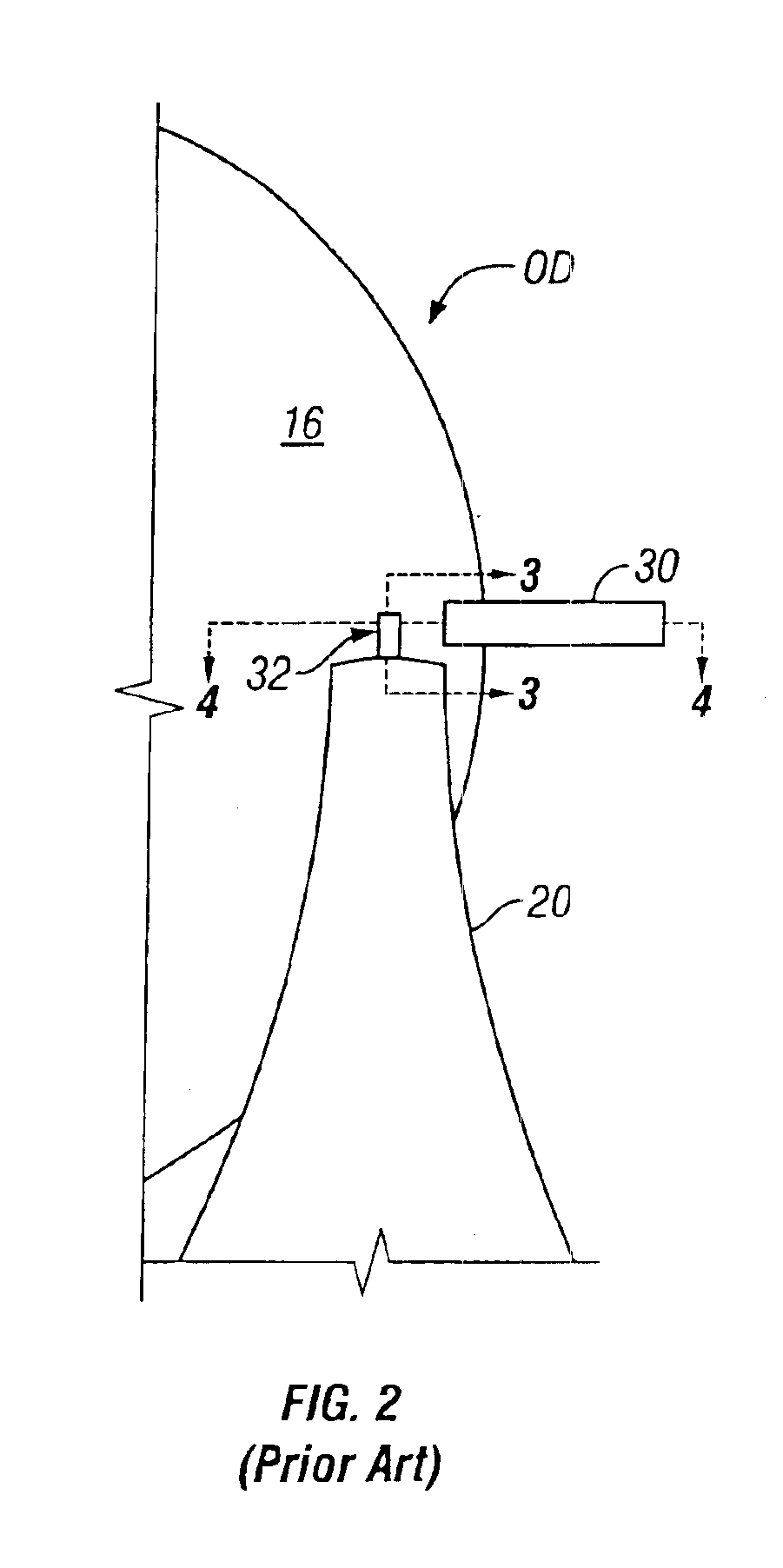

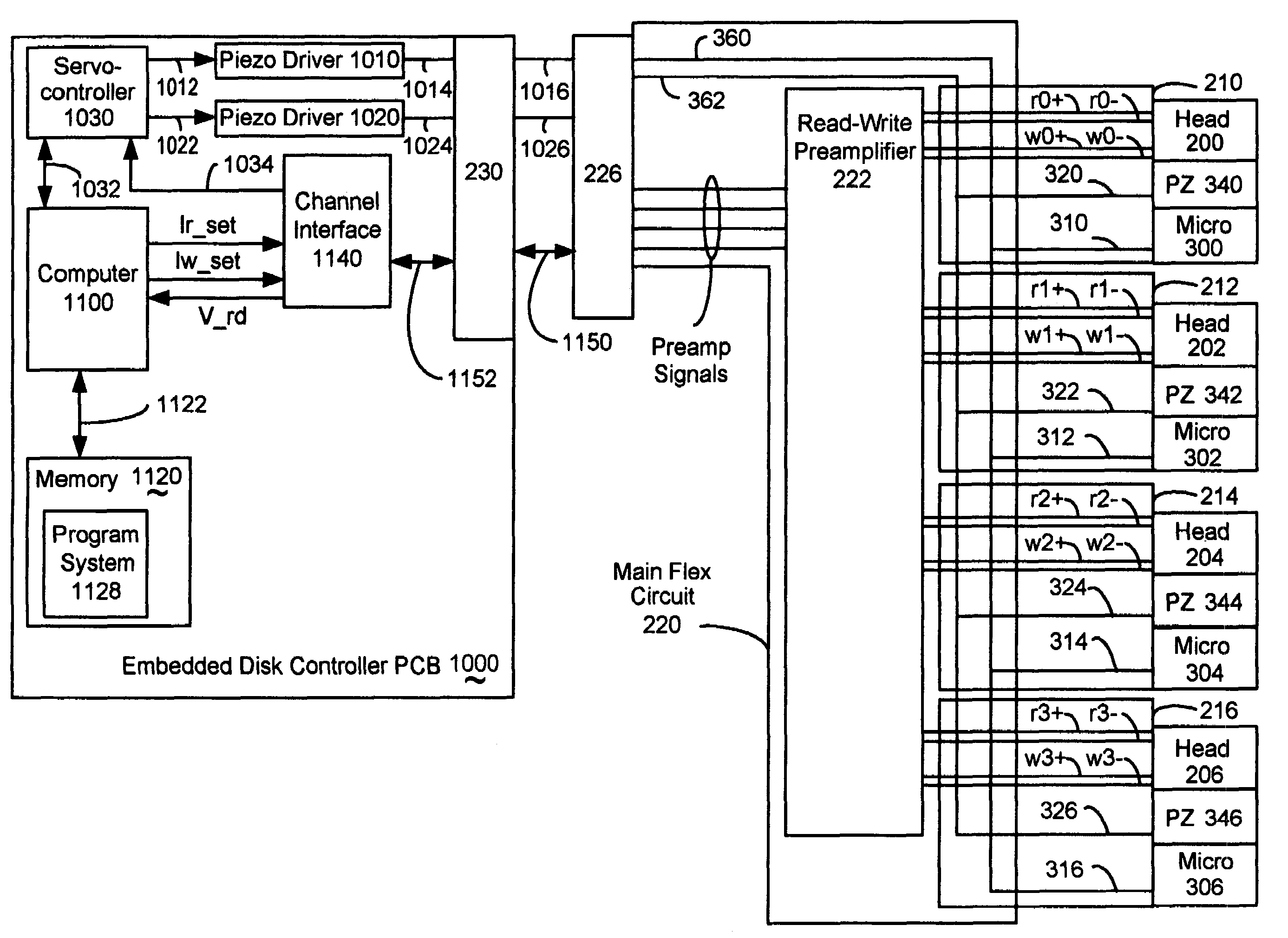

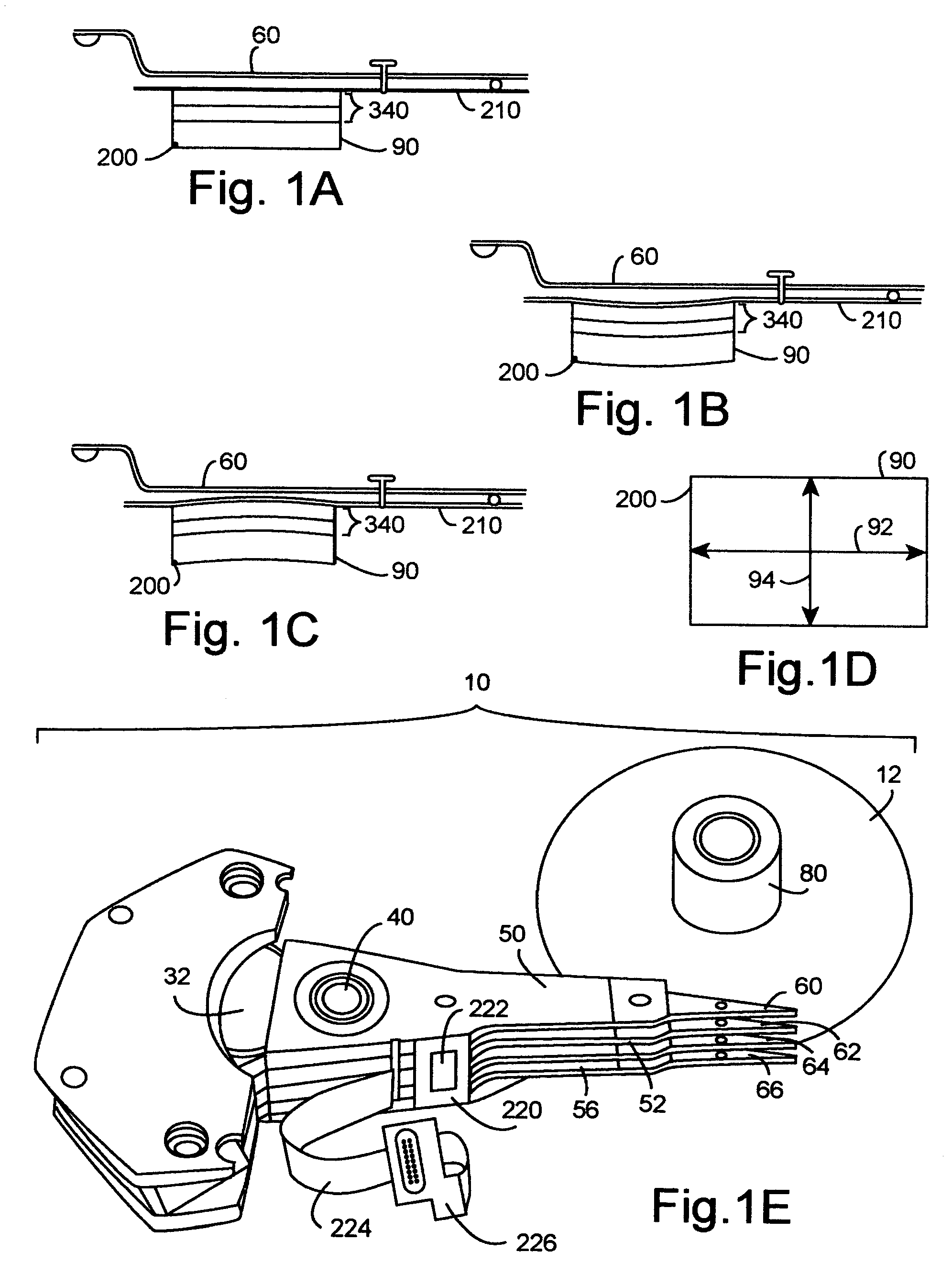

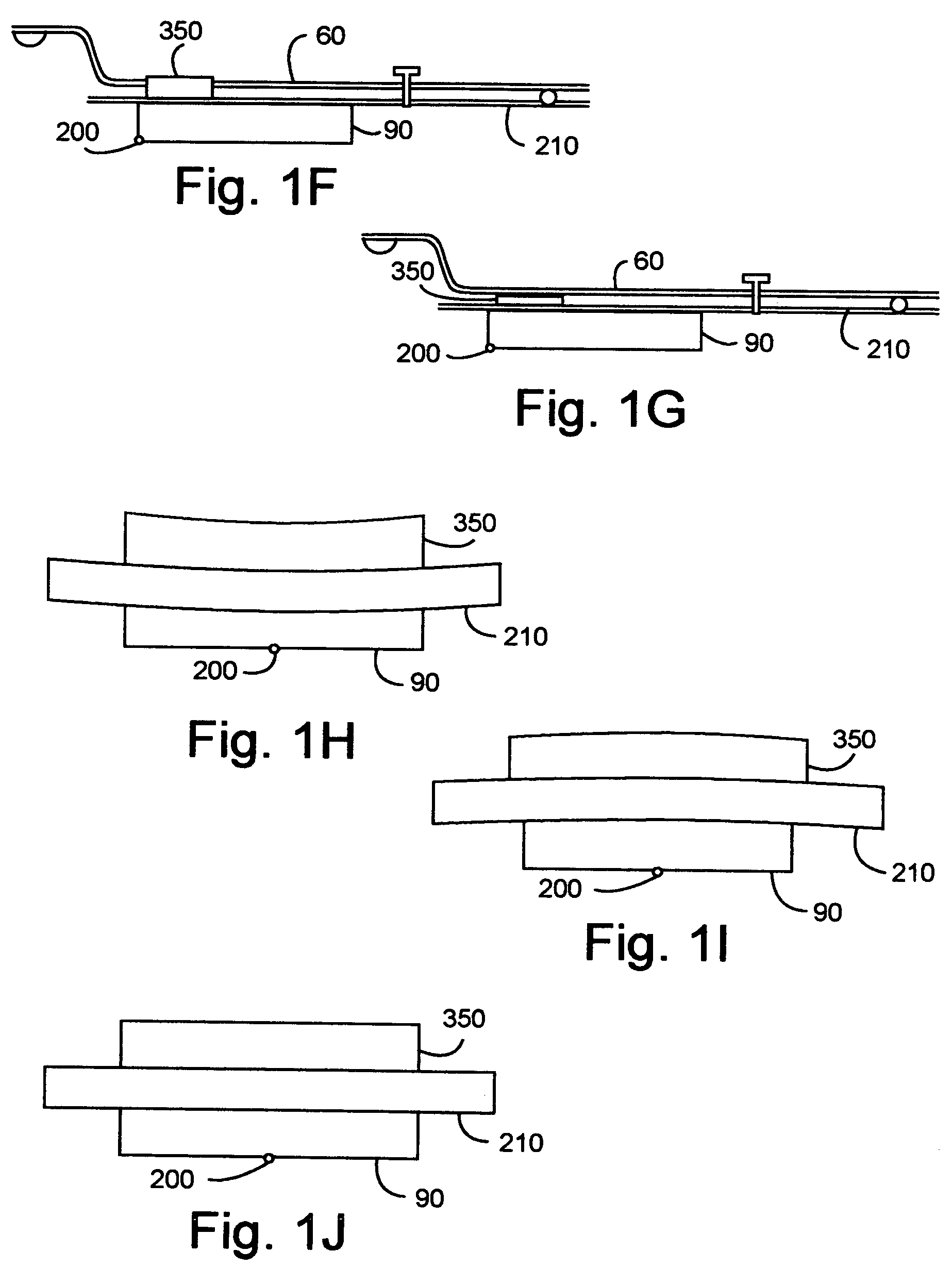

Head gimbal assemblies for very low flying height heads with optional micro-actuators in a hard disk drive

InactiveUS7336436B2Change shapeContactElectrical connection between head and armDriving/moving recording headsHard disc driveFlexible circuits

Owner:SAMSUNG ELECTRONICS CO LTD

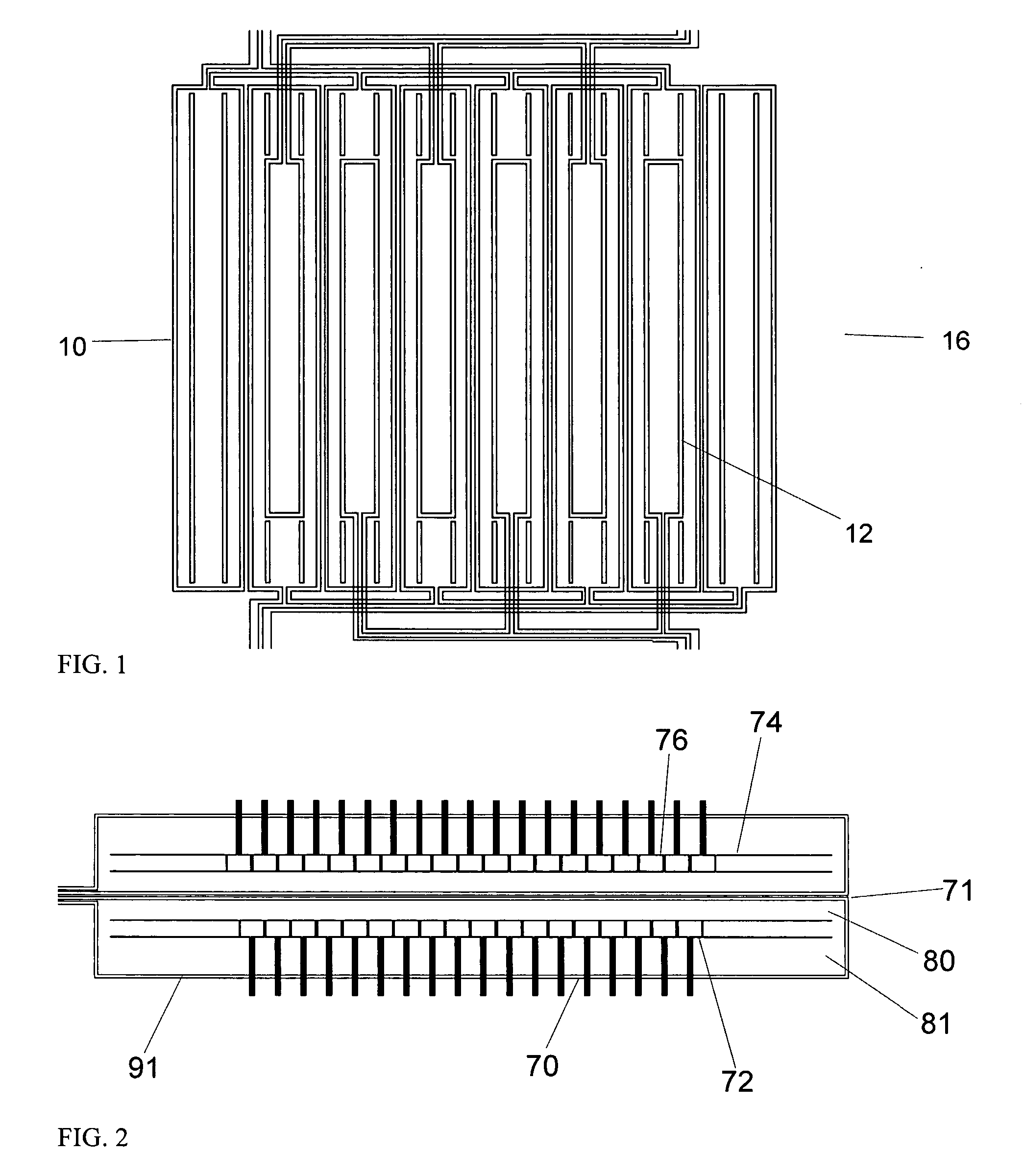

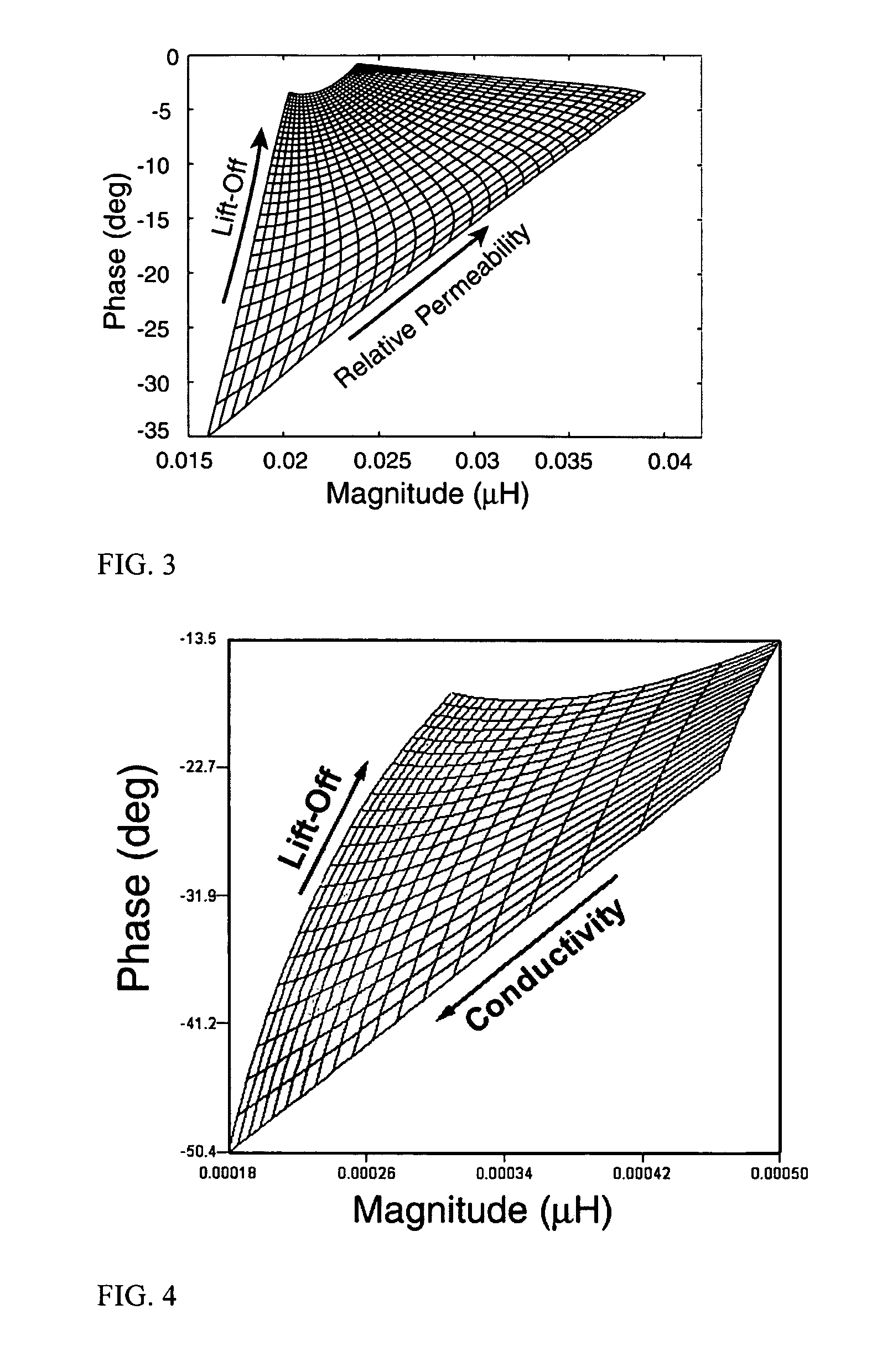

Material characterization with model based sensors

InactiveUS20070069720A1Improve crack detection reliabilityImprove reliabilityMaterial magnetic variablesSensor arrayElectric field sensor

Nondestructive material condition monitoring and assessment is accomplished by placing, mounting, or scanning magnetic and electric field sensors and sensor arrays over material surfaces. The material condition can be inferred directly from material property estimates, such as the magnetic permeability, dielectric permittivity, electrical property, or thickness, or from a correlation with these properties. Hidden cracks in multiple layer structures in the presence of fasteners are detected by combining multiple frequency magnetic field measurements and comparing the result to characteristic signature responses. The threshold value for indicating a crack is adjusted based on a high frequency measurement that accounts for fastener type. The condition of engine disk slot is determined without removal of the disk from the engine by placing near the disk a fixture that contains a sensor for scanning through the slot and means for recording position within the slot. Inflatable support structures can be placed behind the sensor to improve and a guide can be used to align sensor with the slot and for rotating the disk. The condition of an interface between a conducting substrate and a coating is assessed by placing a magnetic field sensor on the opposite side of the substrate from the coating and monitoring at least one model parameter for the material system, with the model parameter correlated to the interfacial condition. The model parameter is typically a magnetic permeability that reflects the residual stress at the interface. Sensors embedded between material layers are protected from damage by placing shims on the faying surface. After determining the areas to be monitored and the areas likely to cause sensor damage, a shim thickness is determined and is then placed in at least one area not being monitored by a sensor. The condition of a test fluid is assessed through a dielectric sensor containing a contaminant-sensitive material layer. The properties of the layer are monitored with the dielectric sensor and correlated to contaminant level.

Owner:JENTEK SENSORS

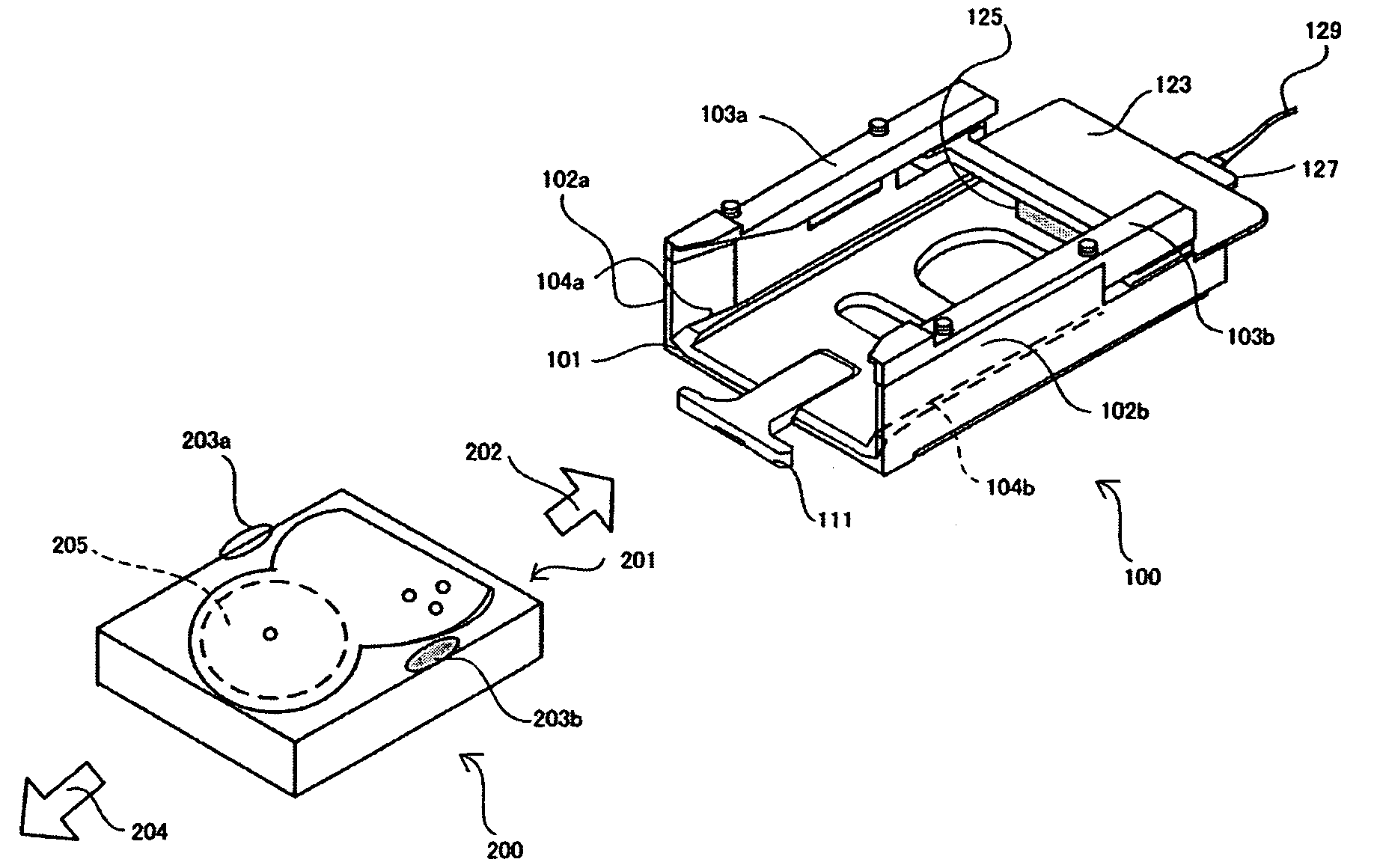

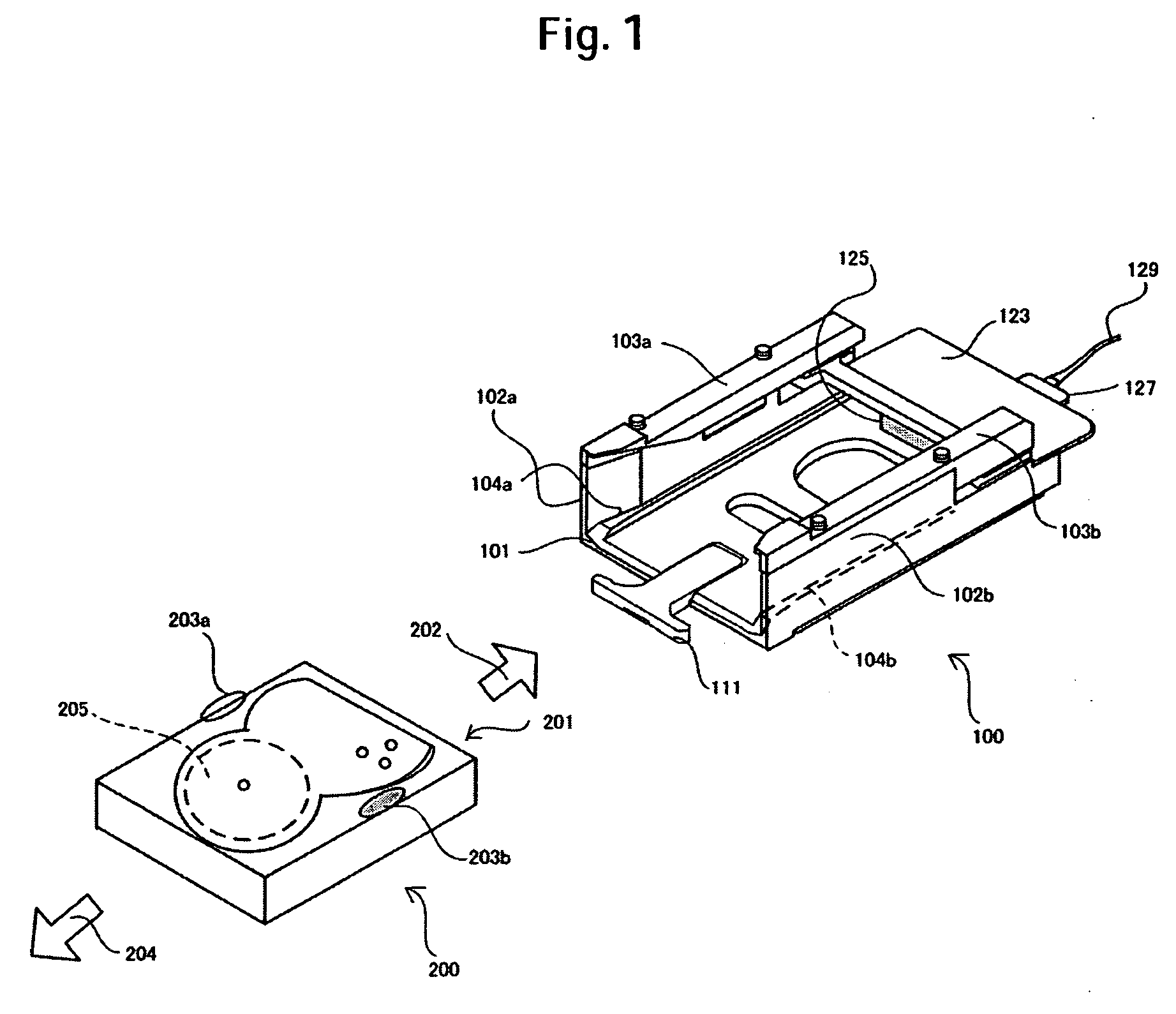

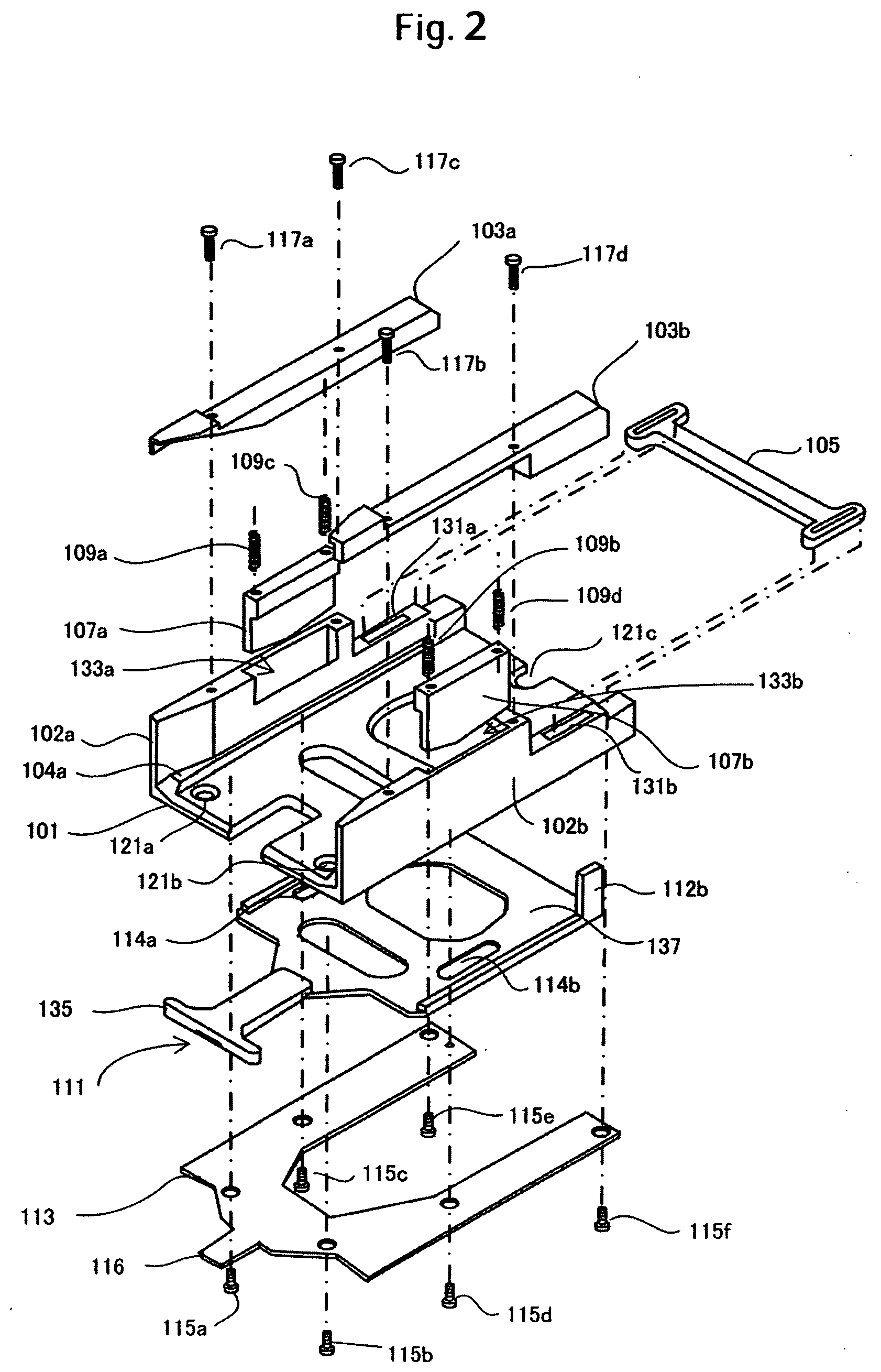

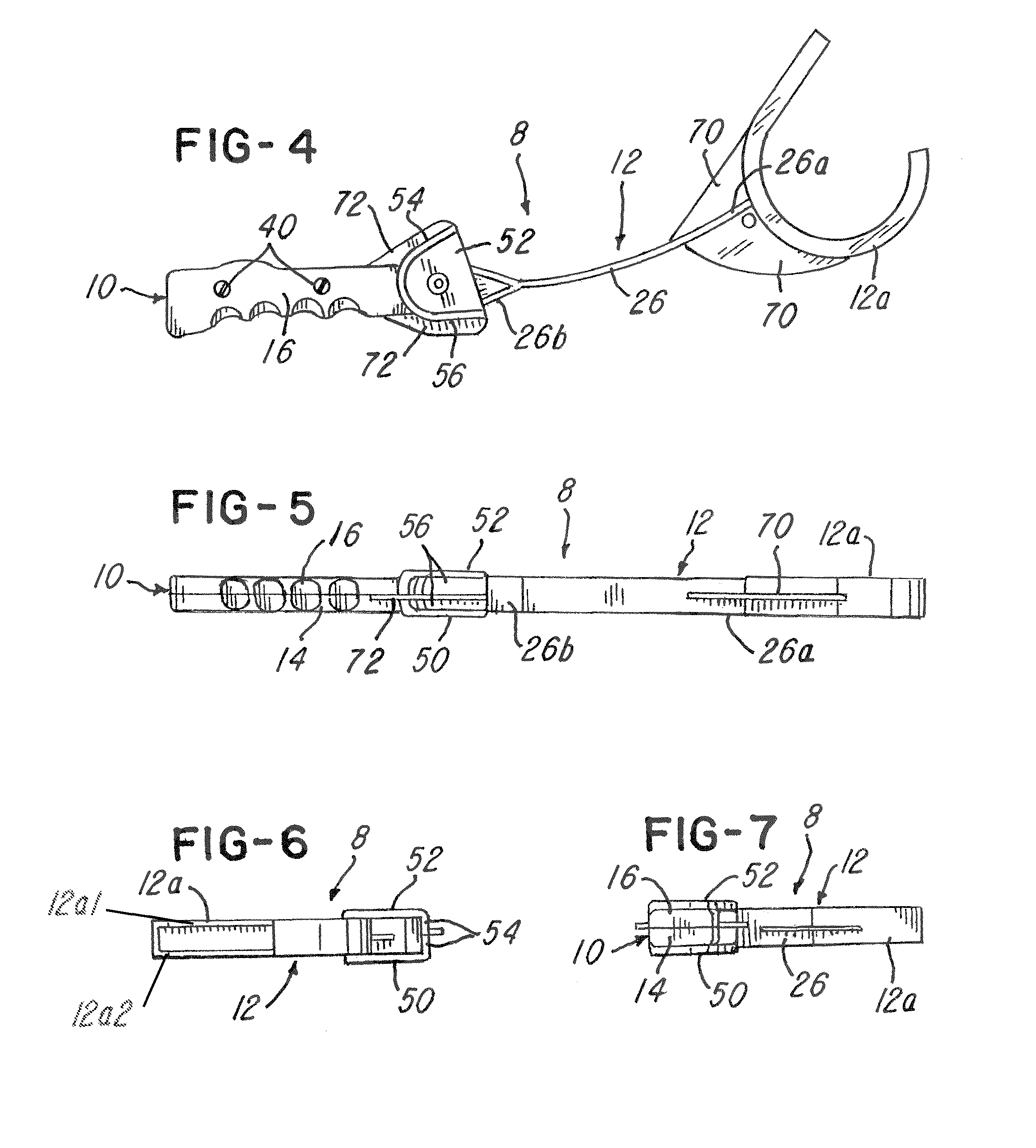

Mounting structure and mounting method for rotating disk storage device

InactiveUS20060133030A1Simply operating the leverPrevent removalDigital data processing detailsCarrier casesEngineeringFixed position

Embodiments of the invention provide a mounting structure adapted to easily attach and remove a magnetic disk drive thereto and therefrom. In one embodiment, the mounting structure includes a device connector connectable to an interface connector. A clamper moves between a fixing position and a releasing position to secure or release an end portion of a housing. A lever keeps the clamper at the releasing position until the interface connector is connected to the device connector when a magnetic disk drive is pushed into a mounting structure. The clamper positions the clamper at the fixing position after the interface connector has been connected to the device connector.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Magnetic recording medium and the method of manufacturing the same

ActiveUS20050003106A1Eliminate the problemProtective coatings for layersFibre treatmentEngineeringLubricant

A magnetic recording medium and a manufacturing method for making it are disclosed. The method facilitates preventing the lubricant deposited on the end face of the magnetic recording medium from migrating onto the major surfaces thereof. The lubricant deposited on an end face of a magnetic disk, which may migrate onto the major surfaces of the magnetic disk, is wiped off by the rotating magnetic disk with the lubricant deposited thereon, by spraying a solvent onto a wiping tape while feeding the wiping tape, and by pressing the wet wiping tape containing the solvent to the end face of the magnetic disk with a pad while the feeding of the wiping tape is discontinued. Alternatively, the lubricant deposited on the end face of a magnetic disk is solidified to deprive the lubricant of its fluidity by rotating the magnetic disk with the lubricant deposited thereon while irradiating it with ultraviolet radiation from a UV lamp through a slit opened in a shield on the lamp to the end face of the magnetic disk.

Owner:FUJI ELECTRIC CO LTD

Methods for preparing biodegradable microparticle formulations containing pharmaceutically active agents

This invention is directed to an apparatus and method for producing microparticles comprising pharmacologically active agents and biodegradable polymers. The apparatus includes a spinning disk containing a reservoir in the center thereof and a flat inclined surface. The apparatus optionally includes serrations and / or a flat surface beneath the periphery of the disk that is parallel to the rotational axis of the disk. The invention is also directed to a method for producing microparticles containing pharmacologically active agents, using the spinning disk apparatus. Formulations containing ophthalmically active agents are provided. Formulations exhibiting zero order release rates are also described.

Owner:SOUTHWEST RES INST +1

Two-fluid atomization nozzle

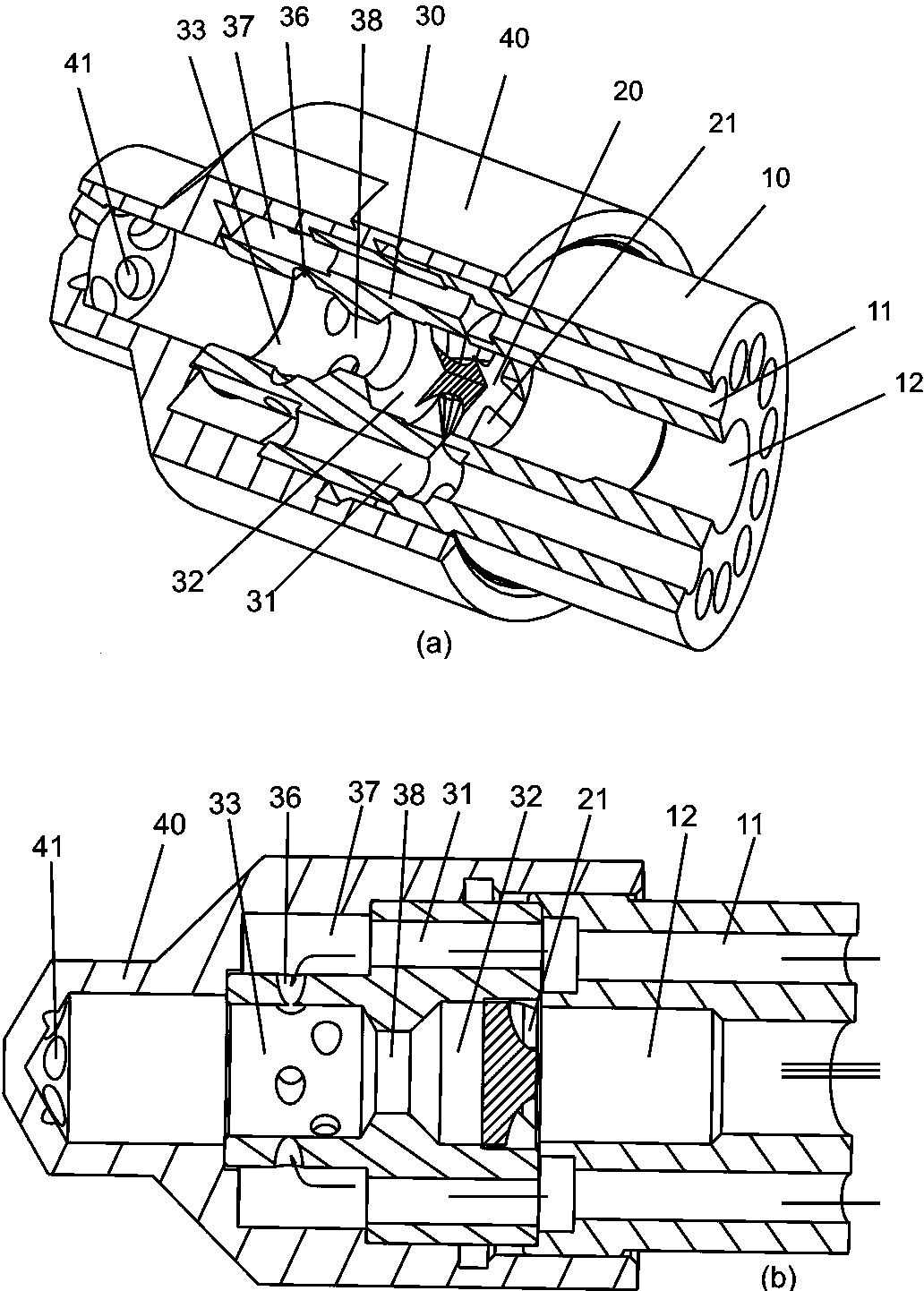

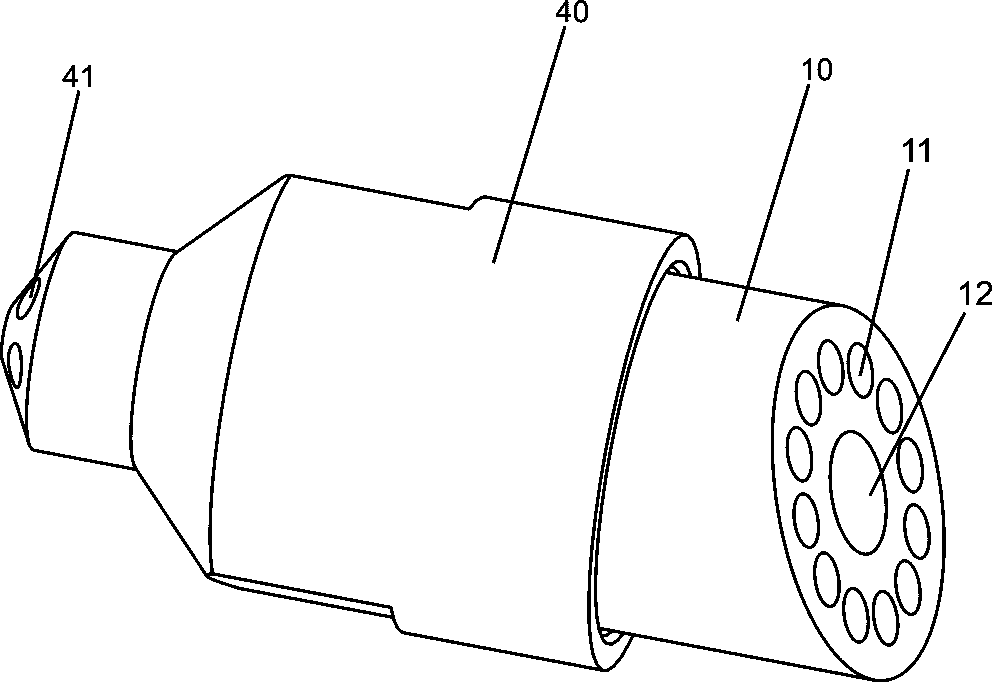

ActiveCN104384037AEnsure atomization rateFlexible disassemblyLiquid spraying apparatusSpray nozzleEngineering

The invention discloses a two-fluid atomization nozzle which comprises a fluid joint, a liquid spinning disk, a two-fluid atomization cavity and a sprayer, wherein the sprayer is internally provided with a hollow cavity; one end of the hollow cavity is provided with an opening and the other end of the hollow cavity is provided with spray holes; the two-fluid atomization cavity, the liquid spinning disk and the fluid joint are sequentially assembled towards the opening in the hollow cavity; the two-fluid atomization cavity is internally provided with a first gas runner and a first liquid runner; an atomization cavity is formed at the junction of the first gas runner and the first liquid runner and is communicated with the spray holes; the liquid spinning disk is arranged at the liquid inlet end of the first liquid runner; the liquid joint is internally provided with a second gas runner and a second liquid runner. Therefore, the two-fluid atomization nozzle is formed by detachably assembling multiple split components, so that the replaceability of local atomization components is realized and the maintenance and replacement costs are lowered; furthermore, the two-fluid atomization nozzle can well ensure the high atomization rate and atomization degree of liquids.

Owner:YICHUAN TECH CHENGDU CO LTD

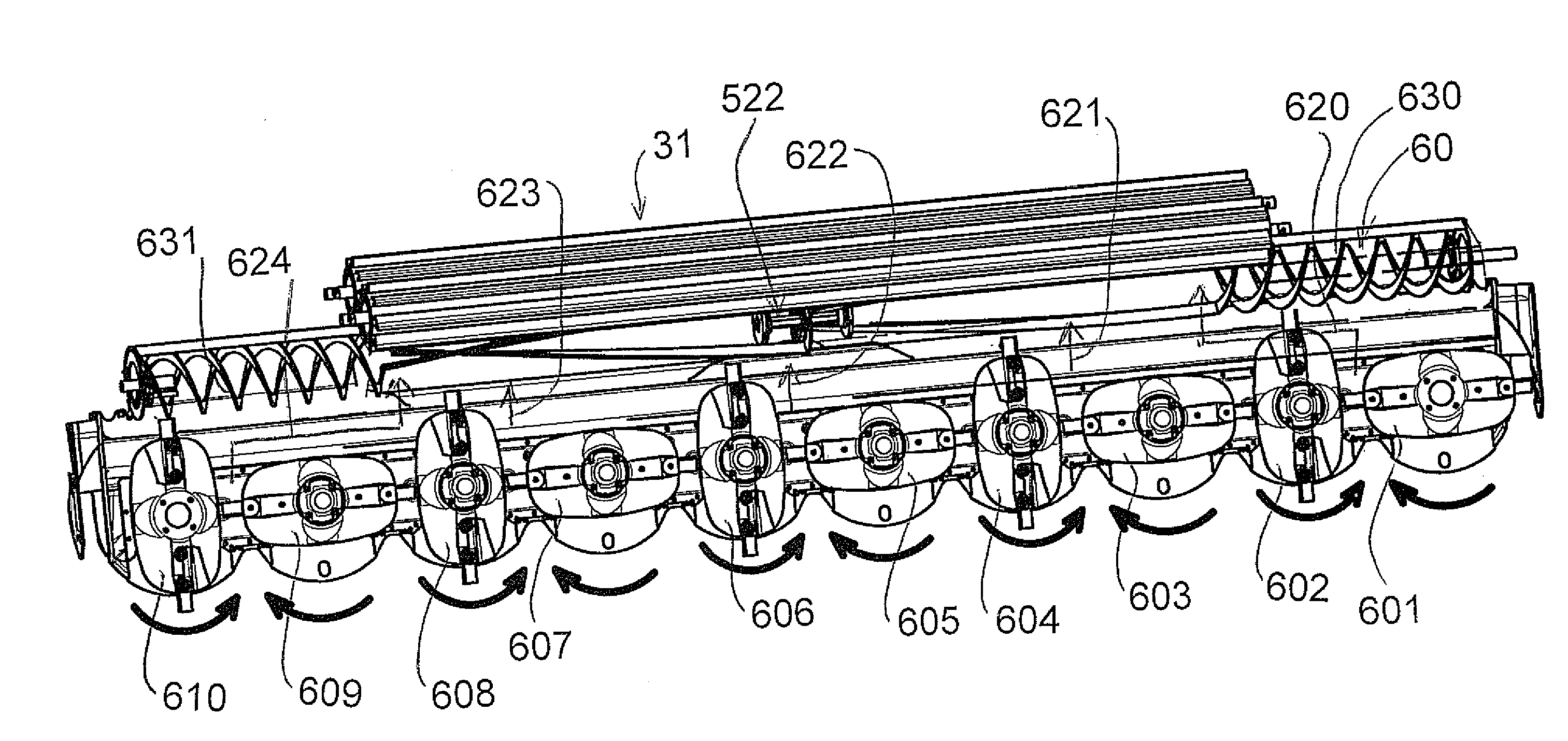

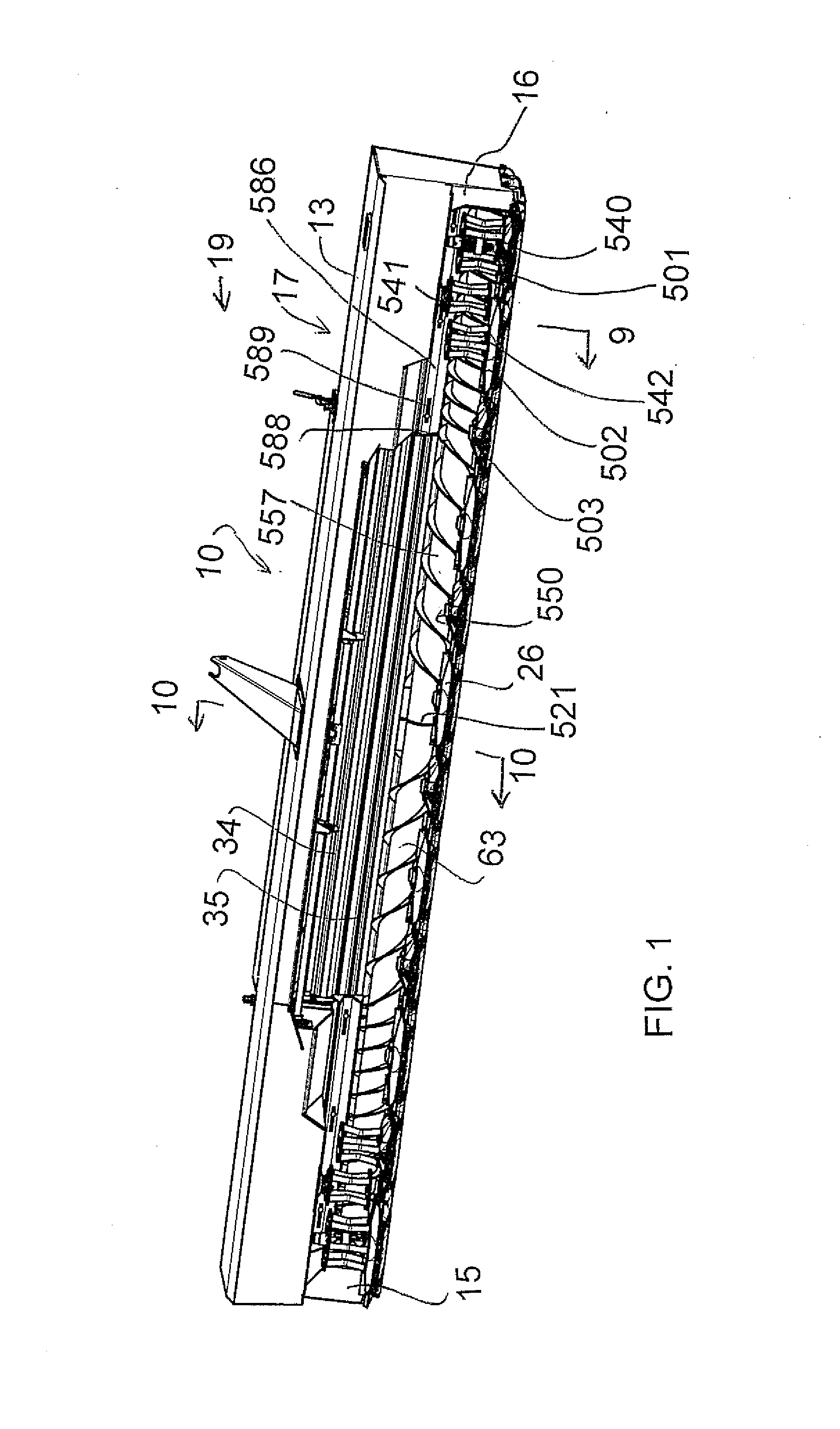

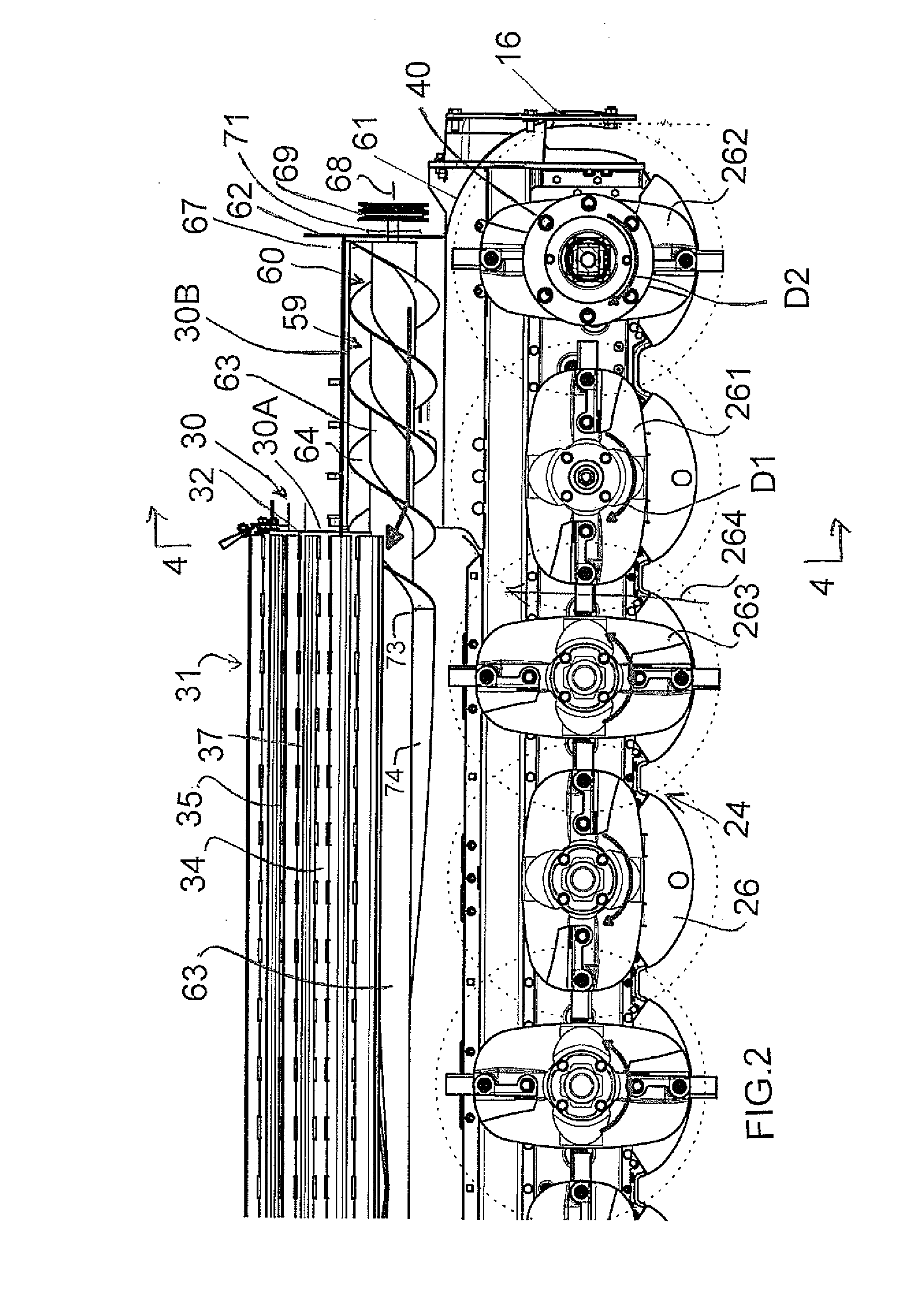

Rotary disk crop harvesting header with an auger for transferring the crop

A crop header has generally horizontal flail disks mounted for driven rotation about generally upright axes. A pair of conditioner rolls is mounted in a discharge opening. A crop converging system includes two over-shot auger elements defined by a common auger shaft with an auger flight carried thereon arranged generally longitudinal of the cutter bar so as to carry the cut crop longitudinally of the cutter bar to the entrance opening. Each auger element is arranged with a forwardmost tangent to the auger flight located behind the axes of the rotary disks and with an outer end thereof spaced outwardly of the respective end of the entrance mouth. The common auger shaft is driven by a common rotary drive with the bottom roll of the conditioner rolls. The augers terminate inwardly of the outer end of the cutter bar to locate the drive inboard of the end plates.

Owner:MACDON INDS

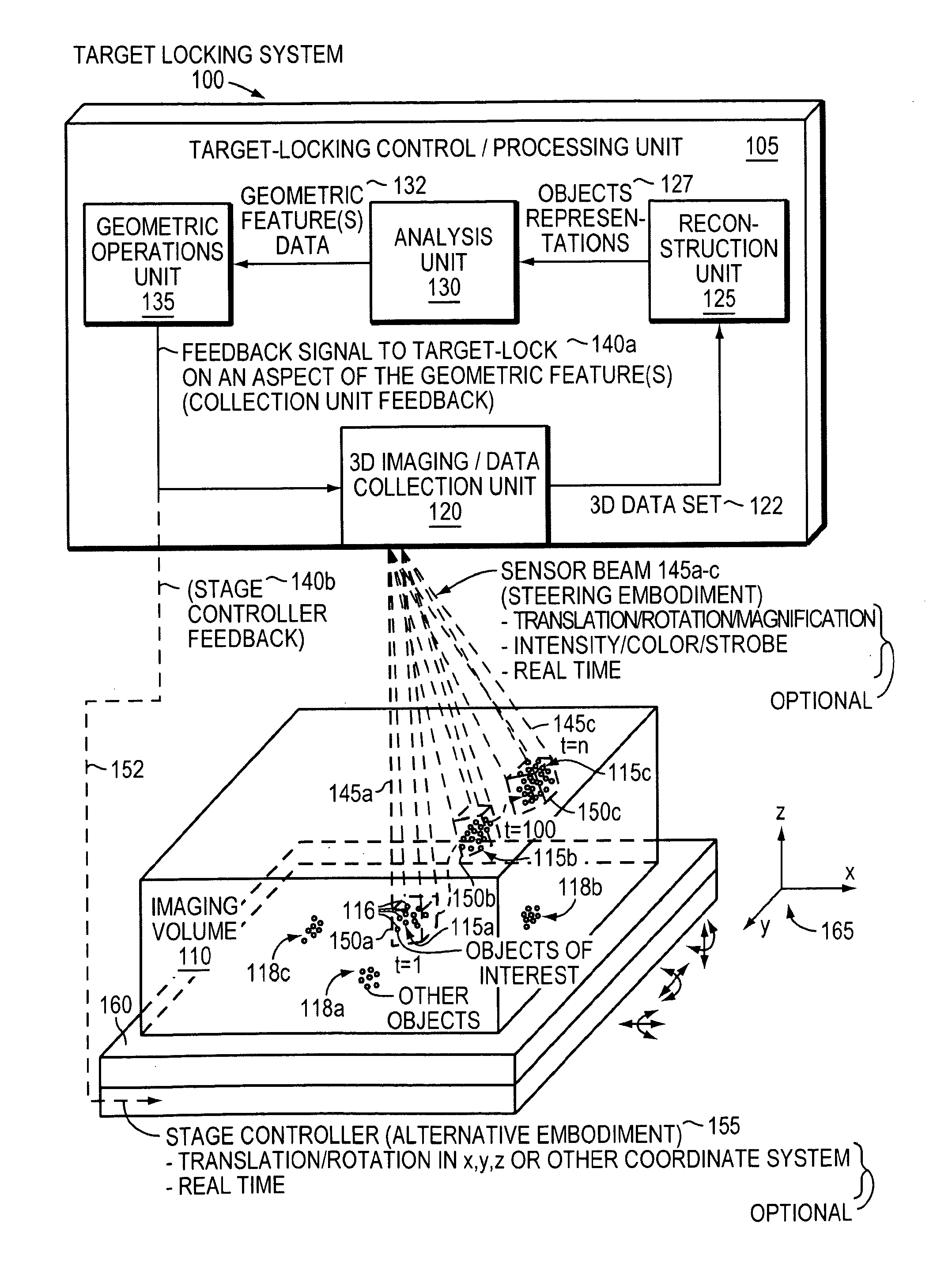

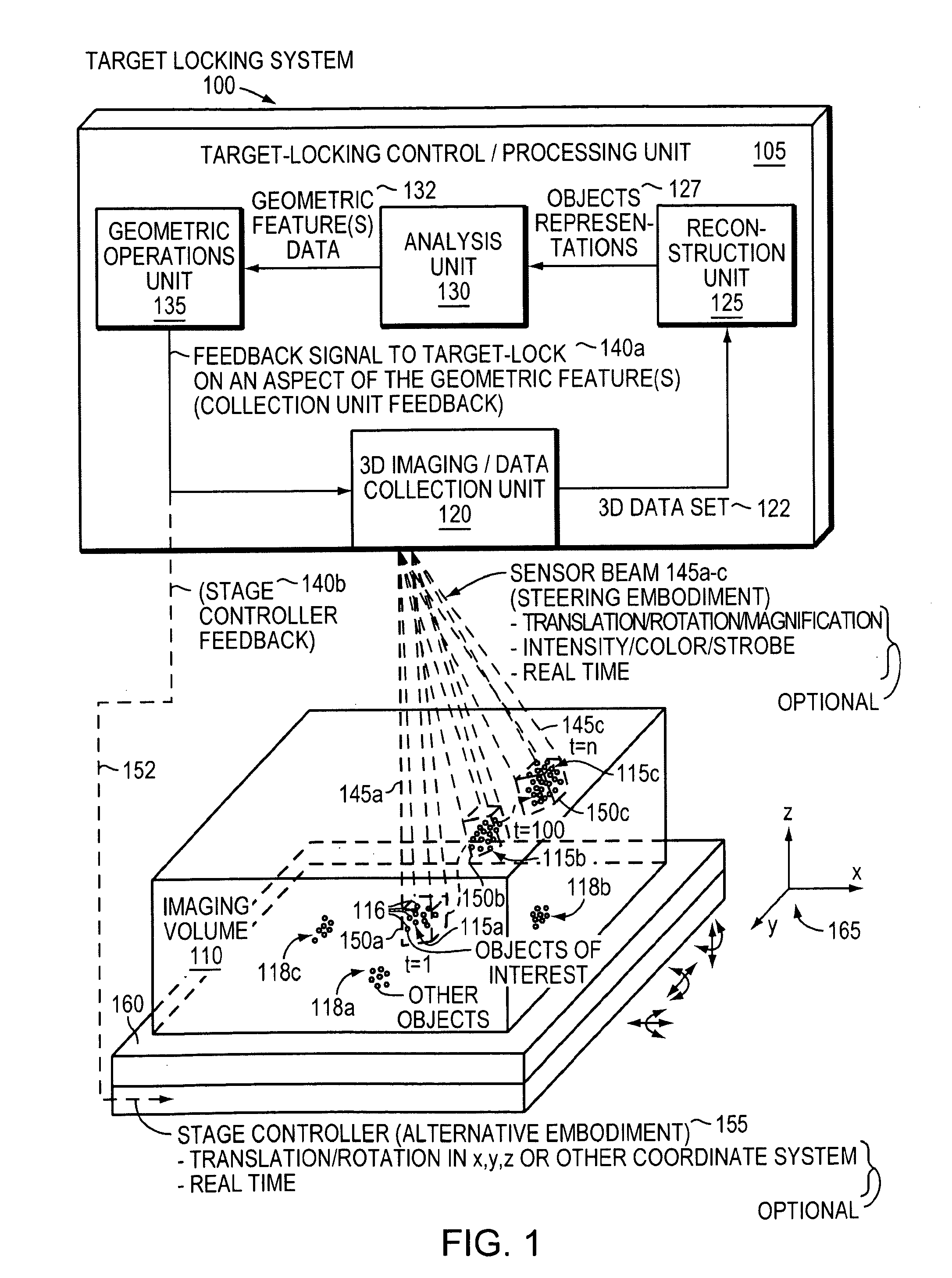

Target-locking acquisition with real-time confocal (TARC) microscopy

Presented herein is a real-time target-locking confocal microscope that follows an object moving along an arbitrary path, even as it simultaneously changes its shape, size and orientation. This Target-locking Acquisition with Realtime Confocal (TARC) microscopy system integrates fast image processing and rapid image acquisition using, for example, a Nipkow spinning-disk confocal microscope. The system acquires a 3D stack of images, performs a full structural analysis to locate a feature of interest, moves the sample in response, and then collects the next 3D image stack. In this way, data collection is dynamically adjusted to keep a moving object centered in the field of view. The system's capabilities are demonstrated by target-locking freely-diffusing clusters of attractive colloidal particles, and actively-transported quantum dots (QDs) endocytosed into live cells free to move in three dimensions for several hours. During this time, both the colloidal clusters and live cells move distances several times the length of the imaging volume. Embodiments may be applied to other applications, such as manufacturing, open water observation of marine life, aerial observation of flying animals, or medical devices, such as tumor removal.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Clay bird thrower

Owner:MTM MOLDED PRODS

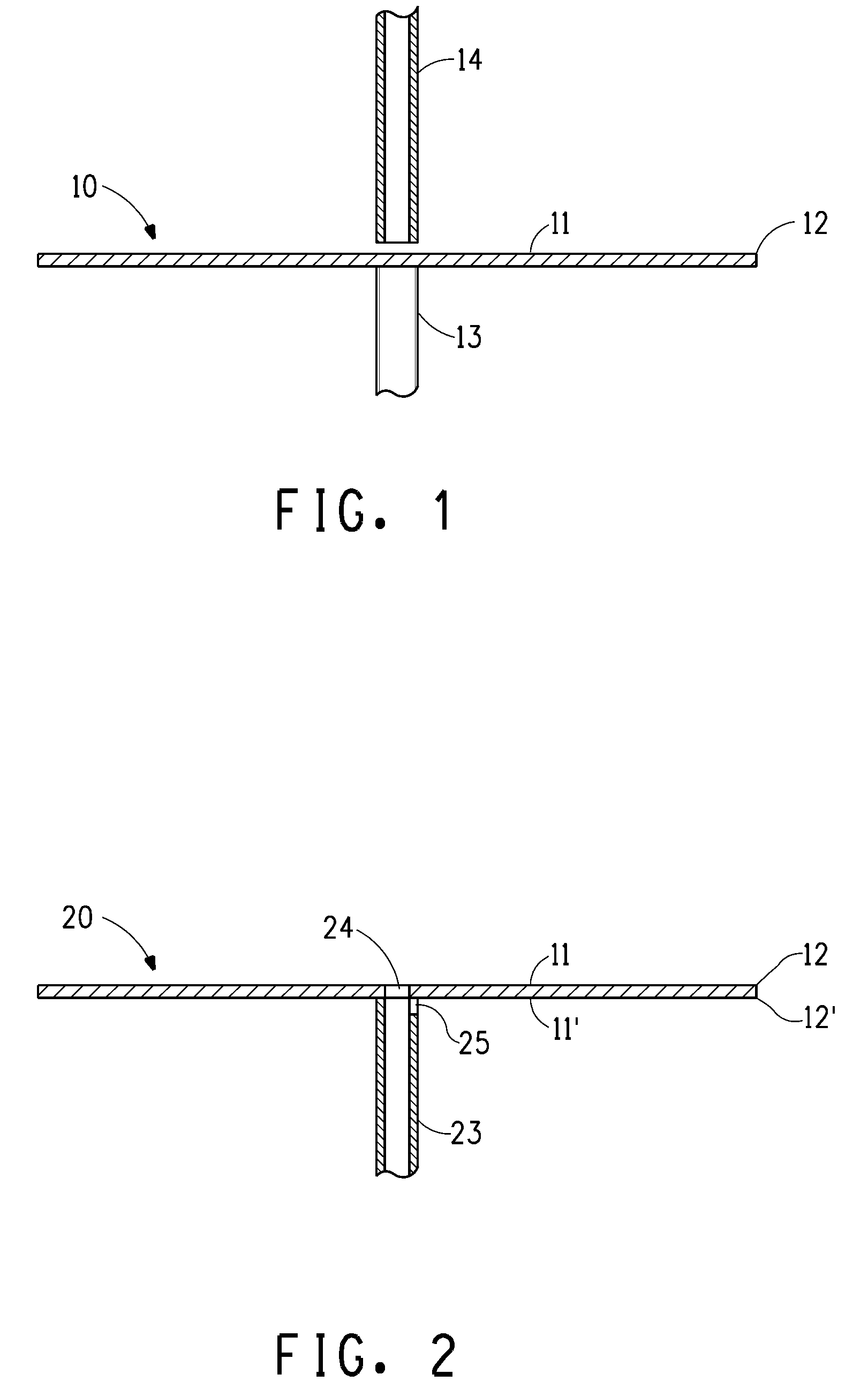

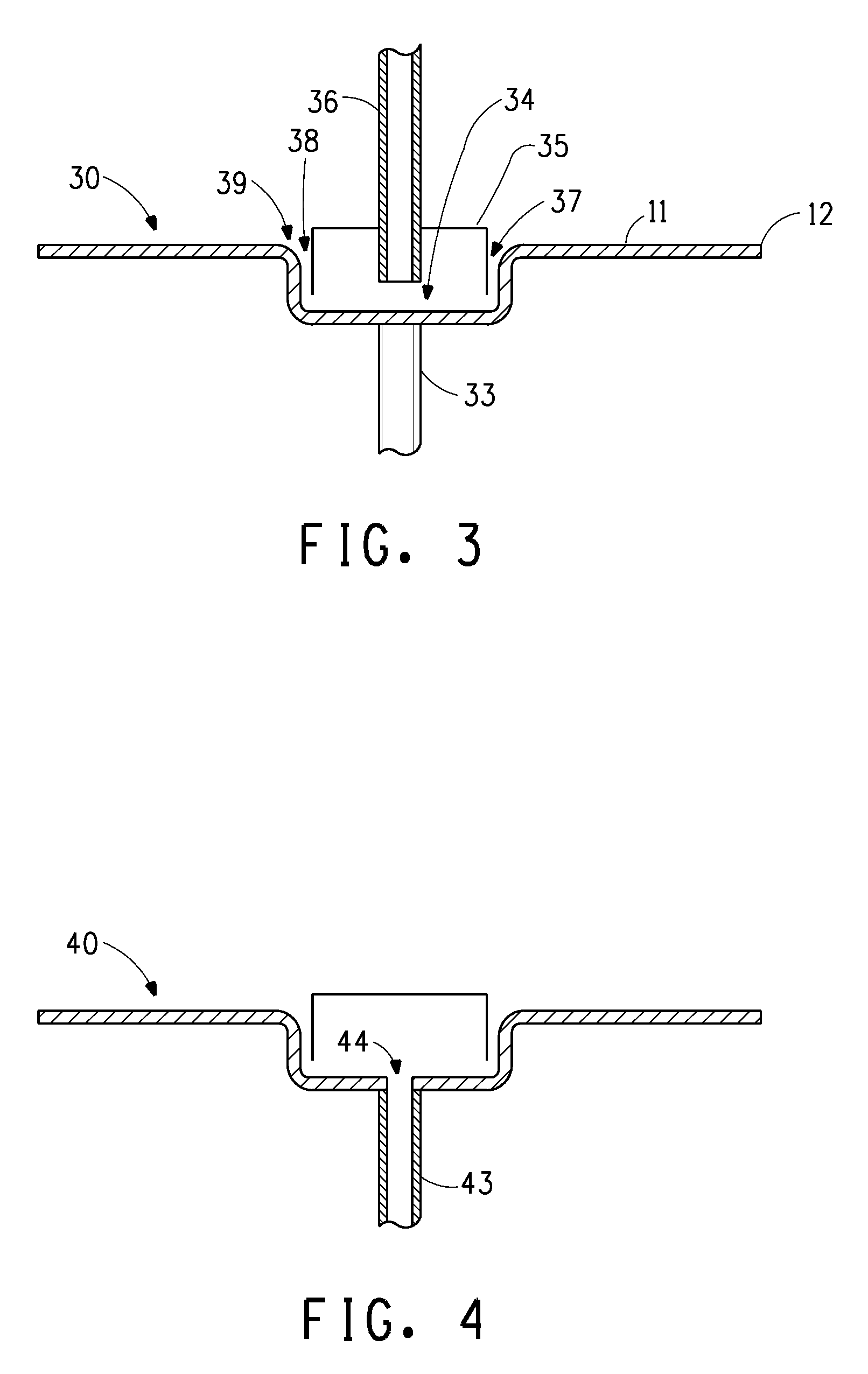

Electronic breather bag filter

A breather bag filter assembly for use with an electronic enclosure, such as a hard disk drive enclosure containing a rotating disk, is disclosed. The filter assembly provides filtration of air entering and exiting an electronic enclosure through a breather hole. The filter assembly is a deformable sealed cavity that exchanges air with the drive enclosure as the air pressure inside the drive enclosure fluctuates. In one implementation of the invention the filter assembly contains three layers of material. Two layers of material form the exterior of the filter assembly surrounding a third layer that is composed of an adsorbent material.

Owner:DONALDSON CO INC

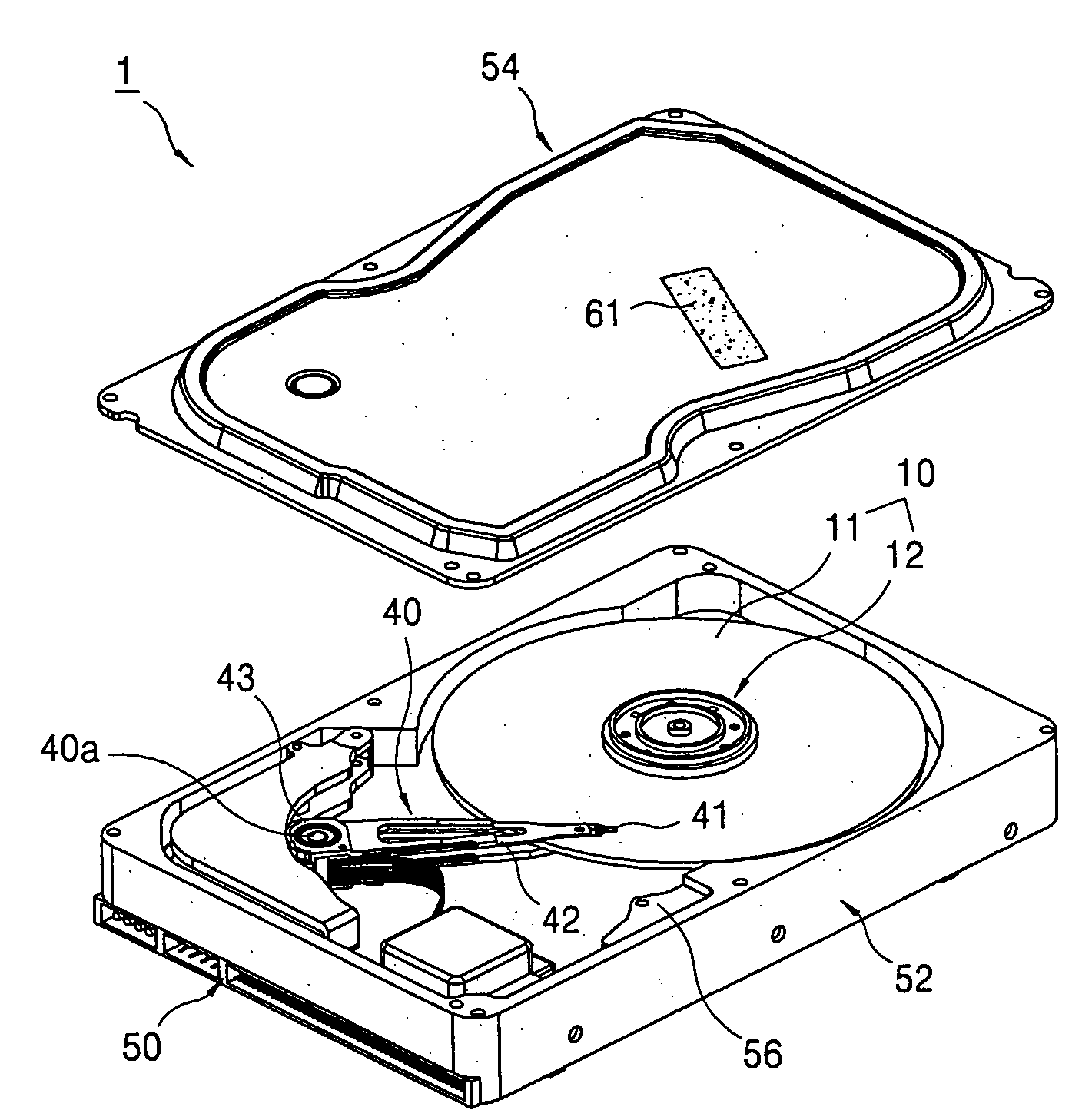

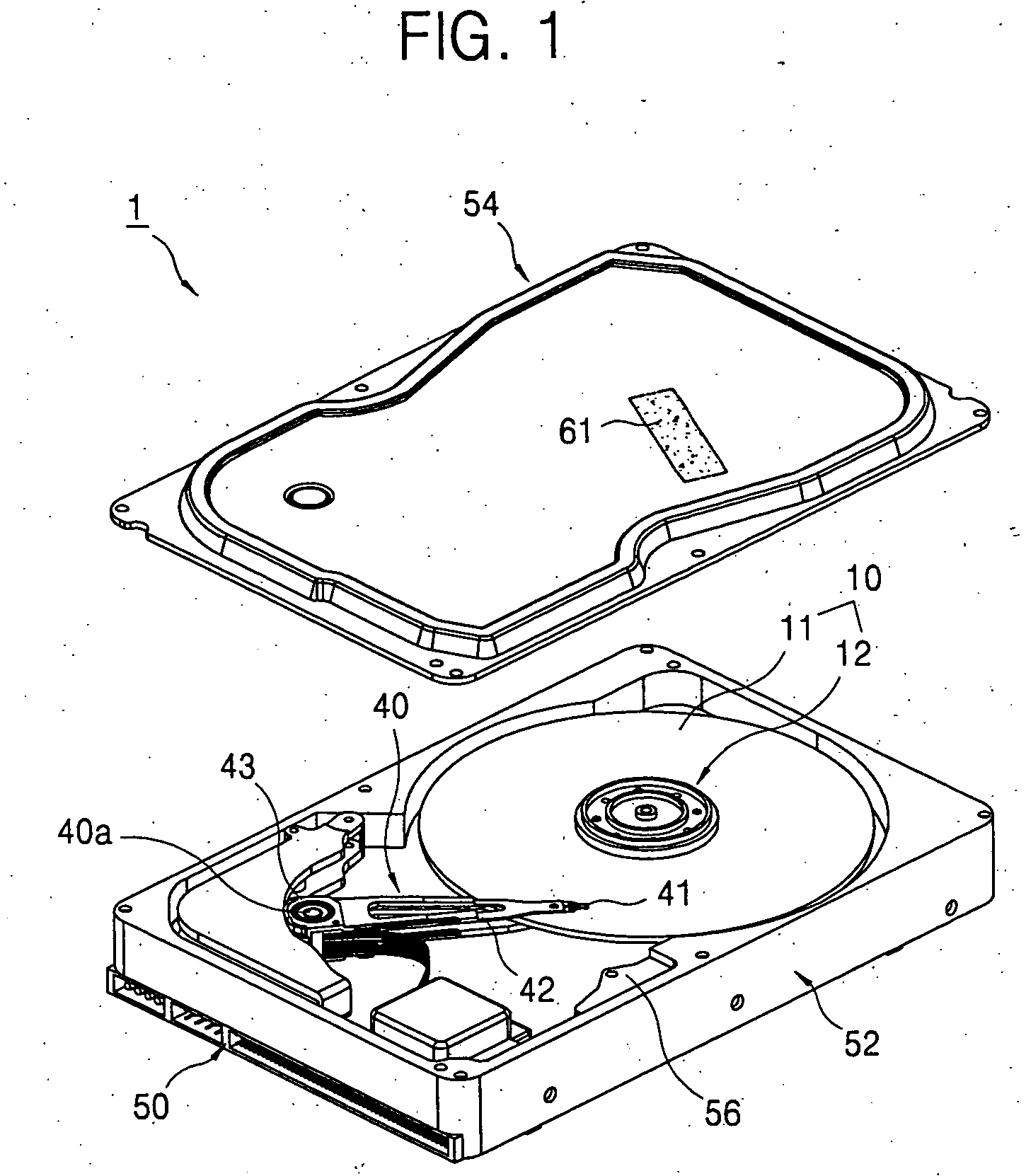

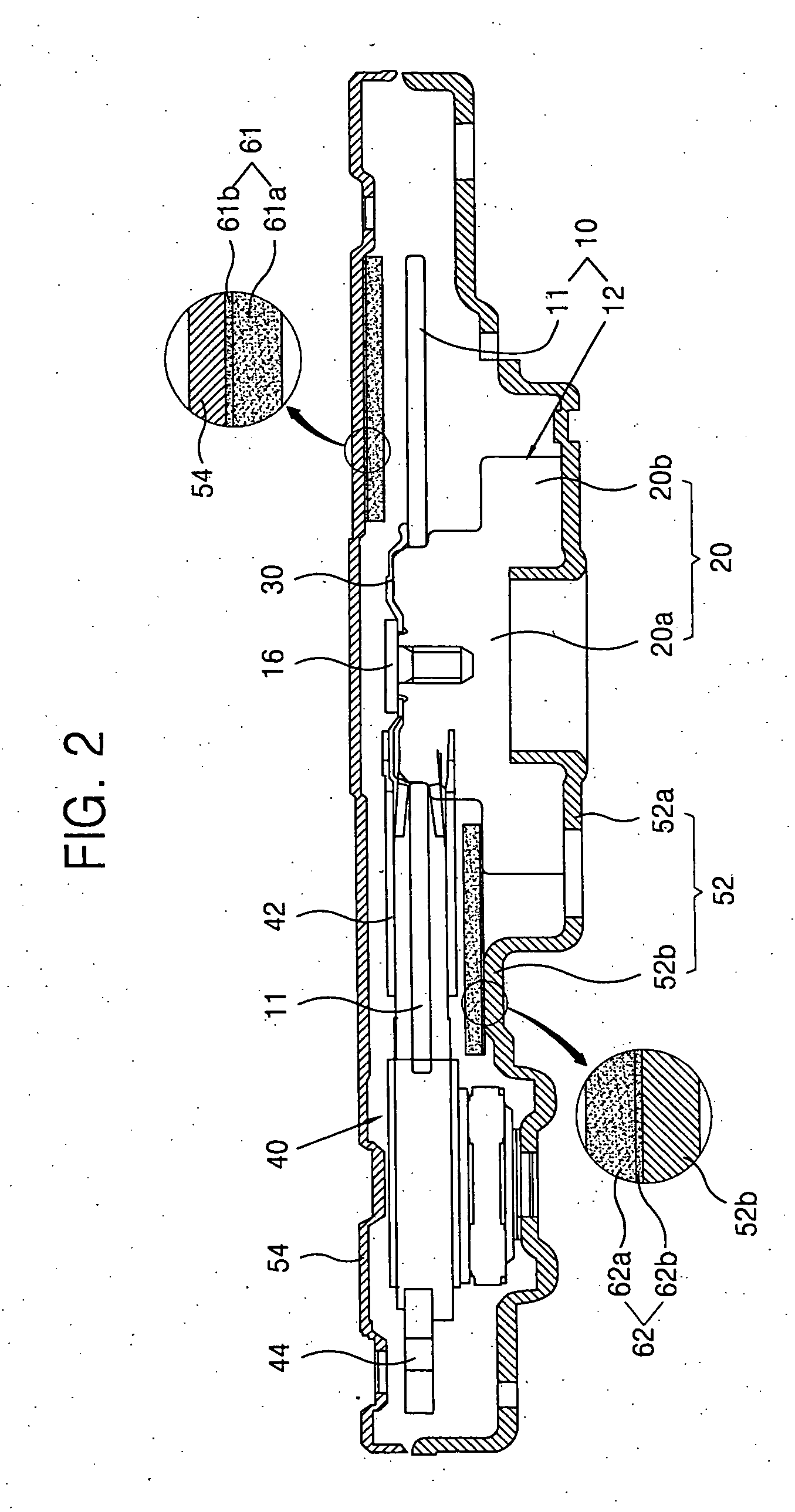

Hard disk drive

InactiveUS20070171567A1Efficient removalUndesired vibrations/sounds insulation/absorptionReducing carrier contaminationHard disc driveElectric machine

A hard disk drive includes a disk pack having at least one disk for recording and / or storing data and a spindle motor that support and rotates the disk, a base to which the disk pack is mounted, a cover that covers an upper surface of the base, and a respective filter disposed close to each of at least one of the major surfaces of the disk and extending in the radial direction of the disk including over at least an inner peripheral region of the disk. The filter has an absorbent layer capable of absorbing particles that come in contact with it. Particles on the surface of the disk, from the inner to the outer peripheral regions of the disk, are removed by the filter when the disk is rotated and the particles are flung off of the disk. Thus, particles will not damage the magnetic head(s) of the hard disk drive nor will the particles cause errors to occur in the recording and / or reproducing of data.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com