Patents

Literature

838 results about "Repulsion force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Repulsion is a force that pushes two things apart, such as the force that there is in magnets. ...the electric repulsion between charged electrons.

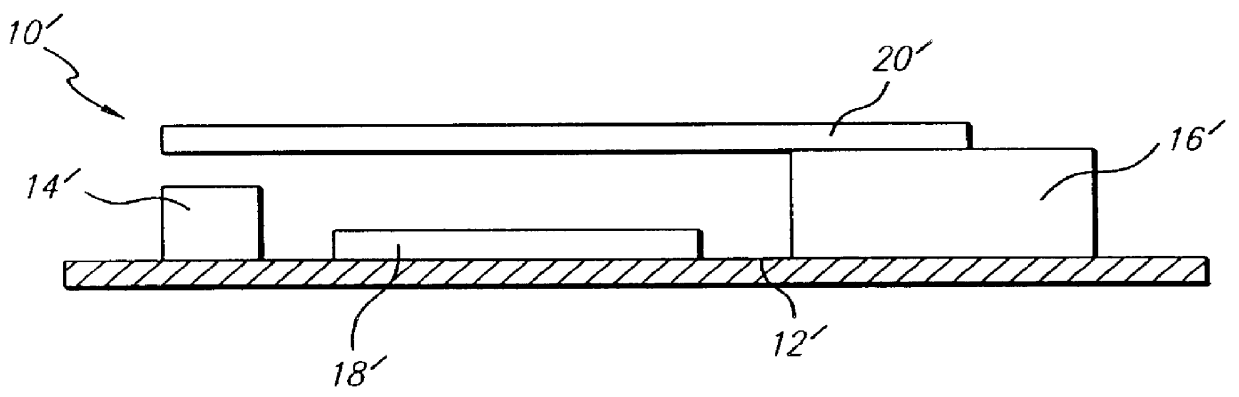

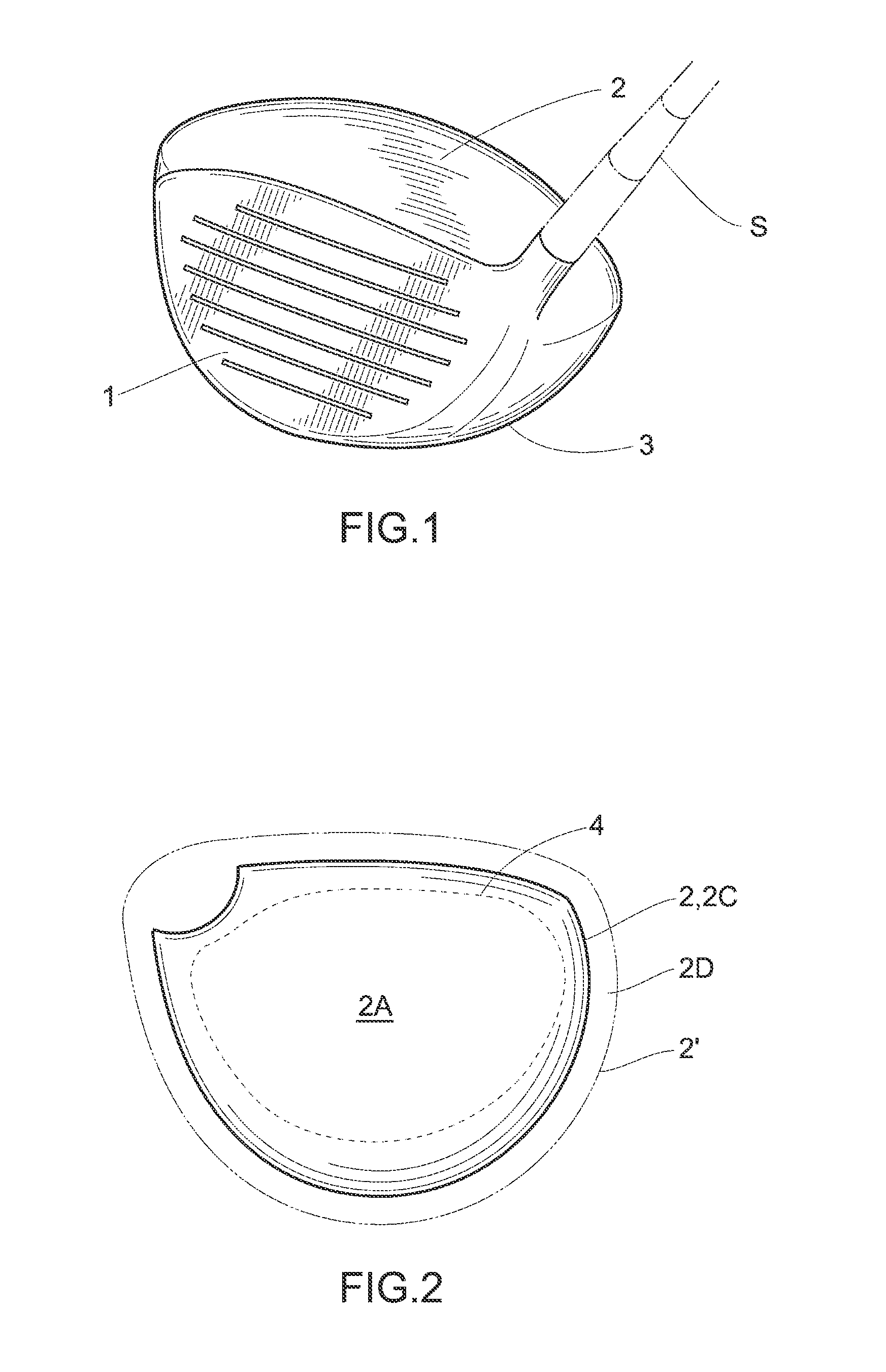

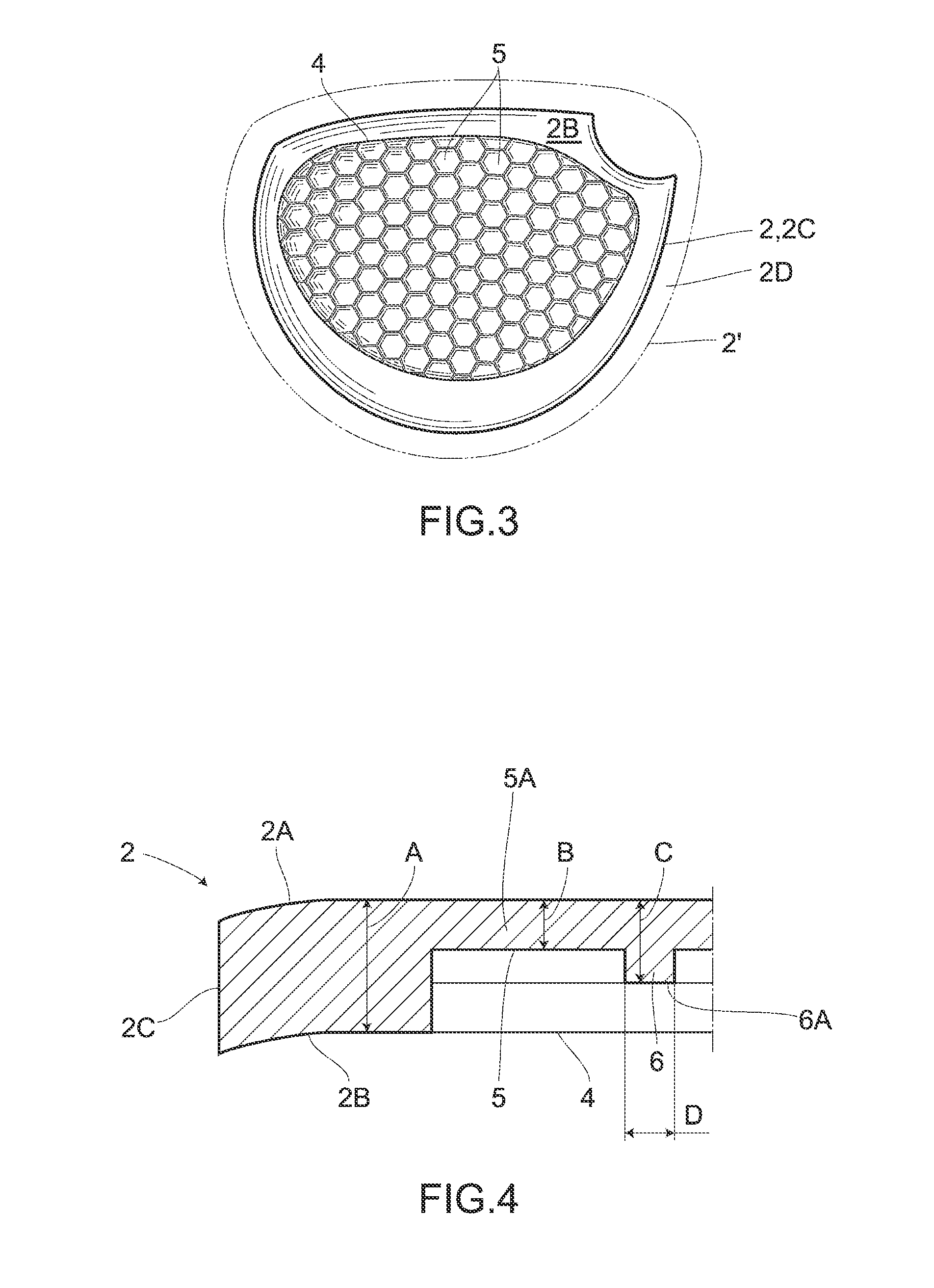

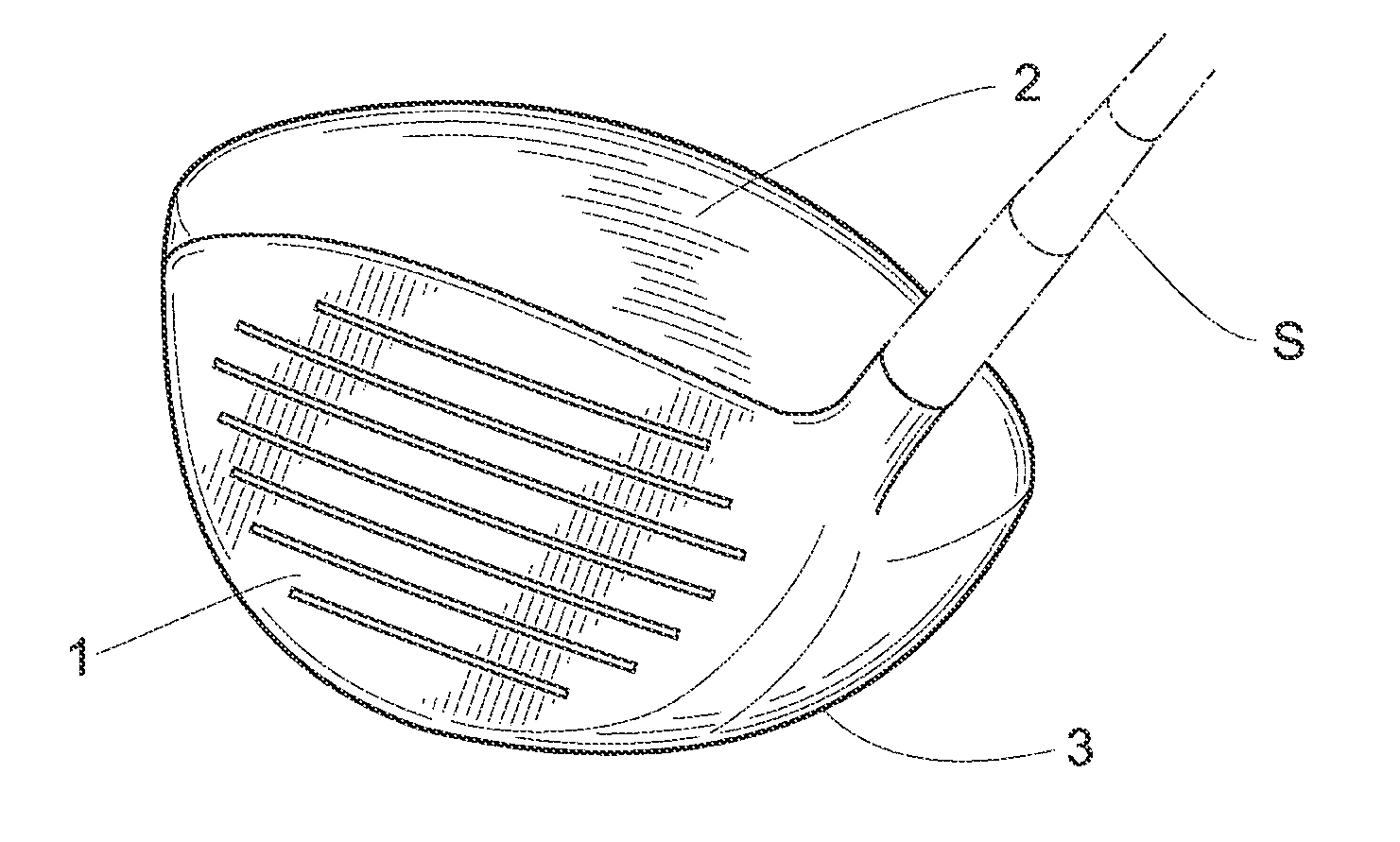

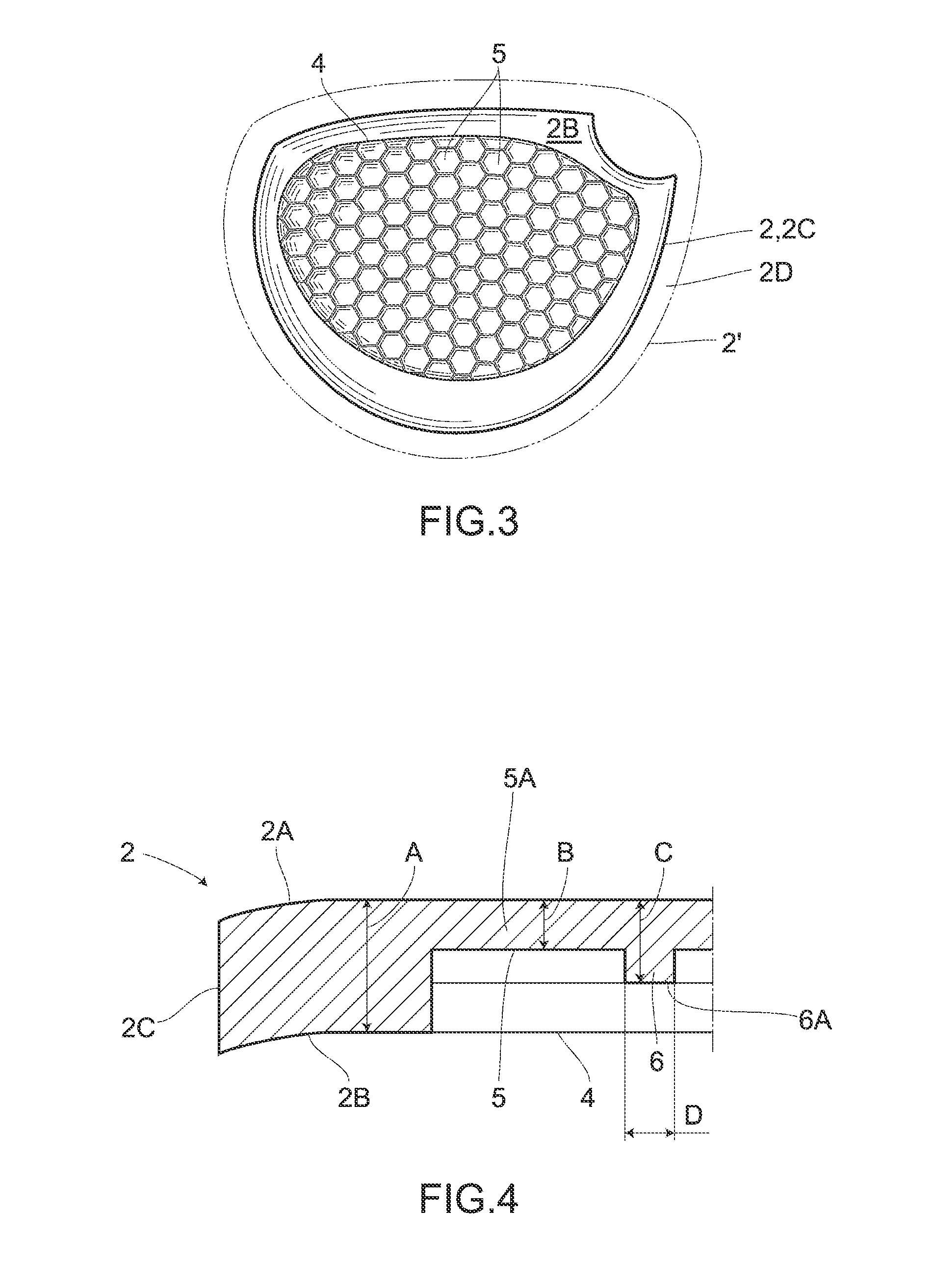

Golf club

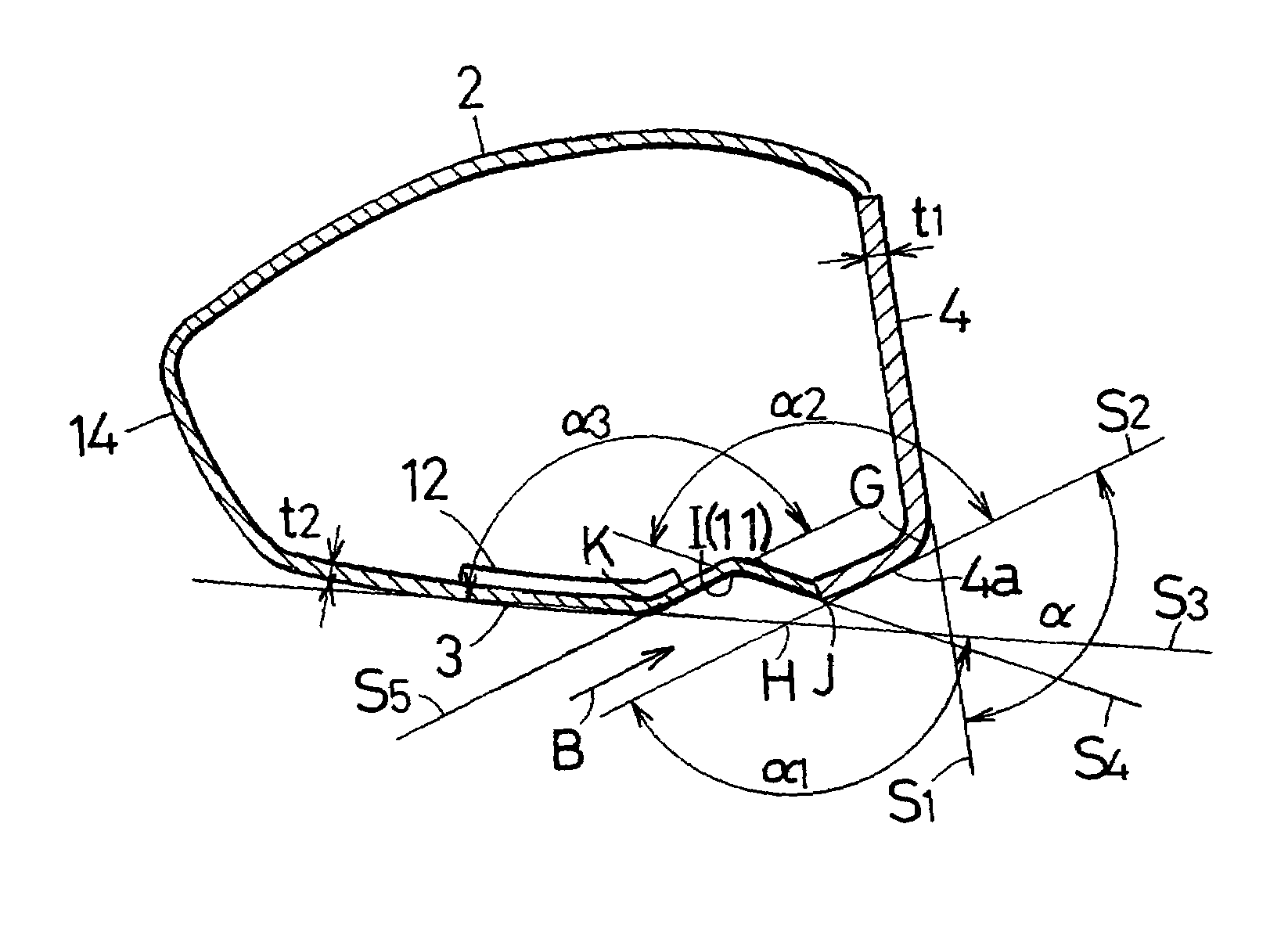

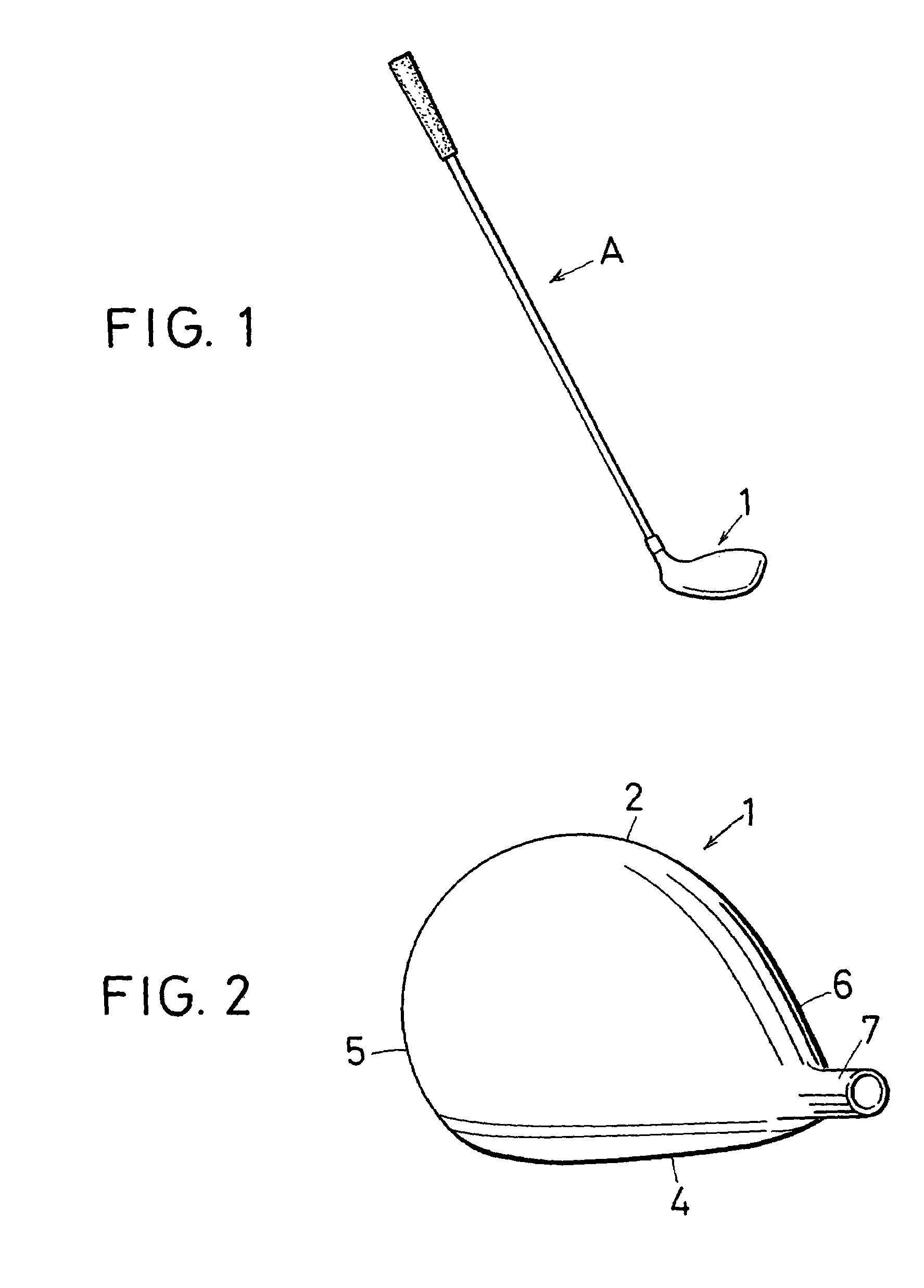

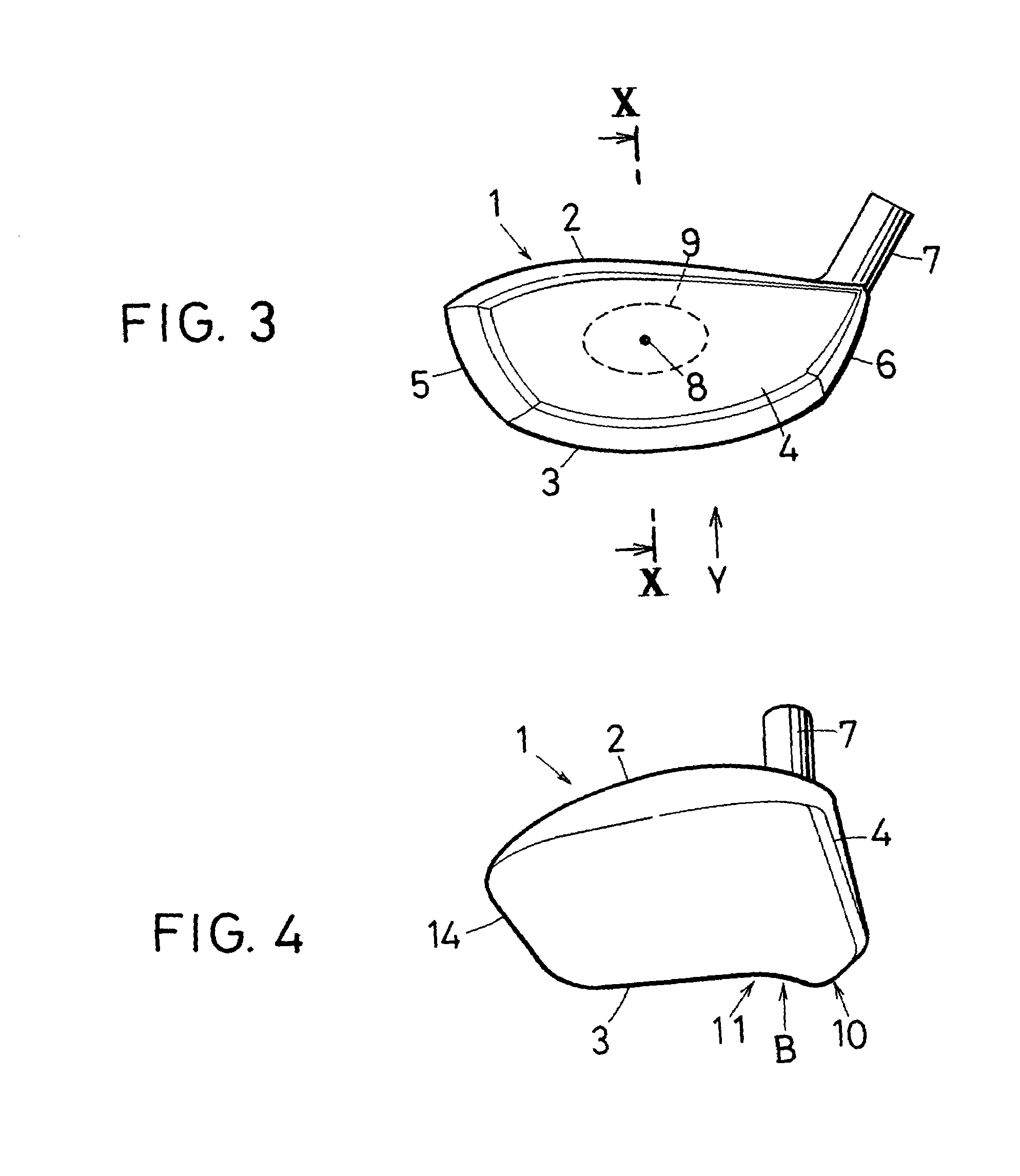

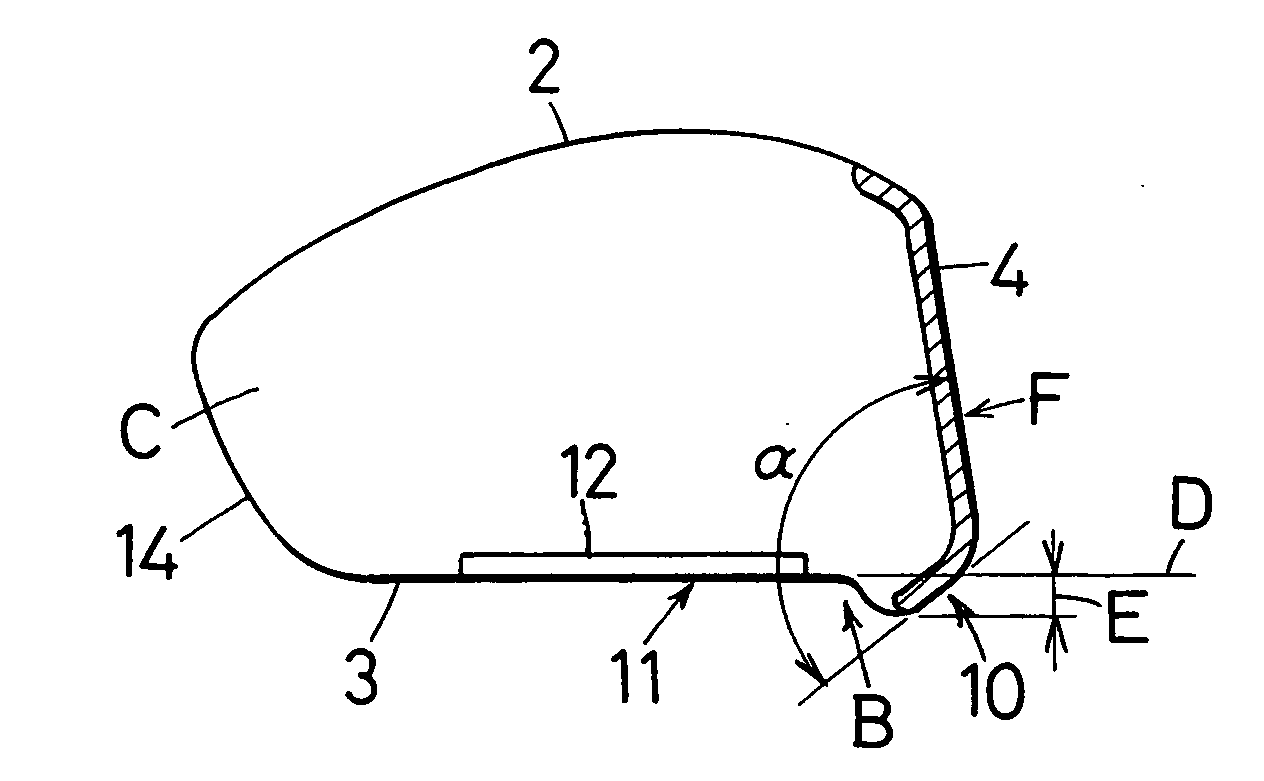

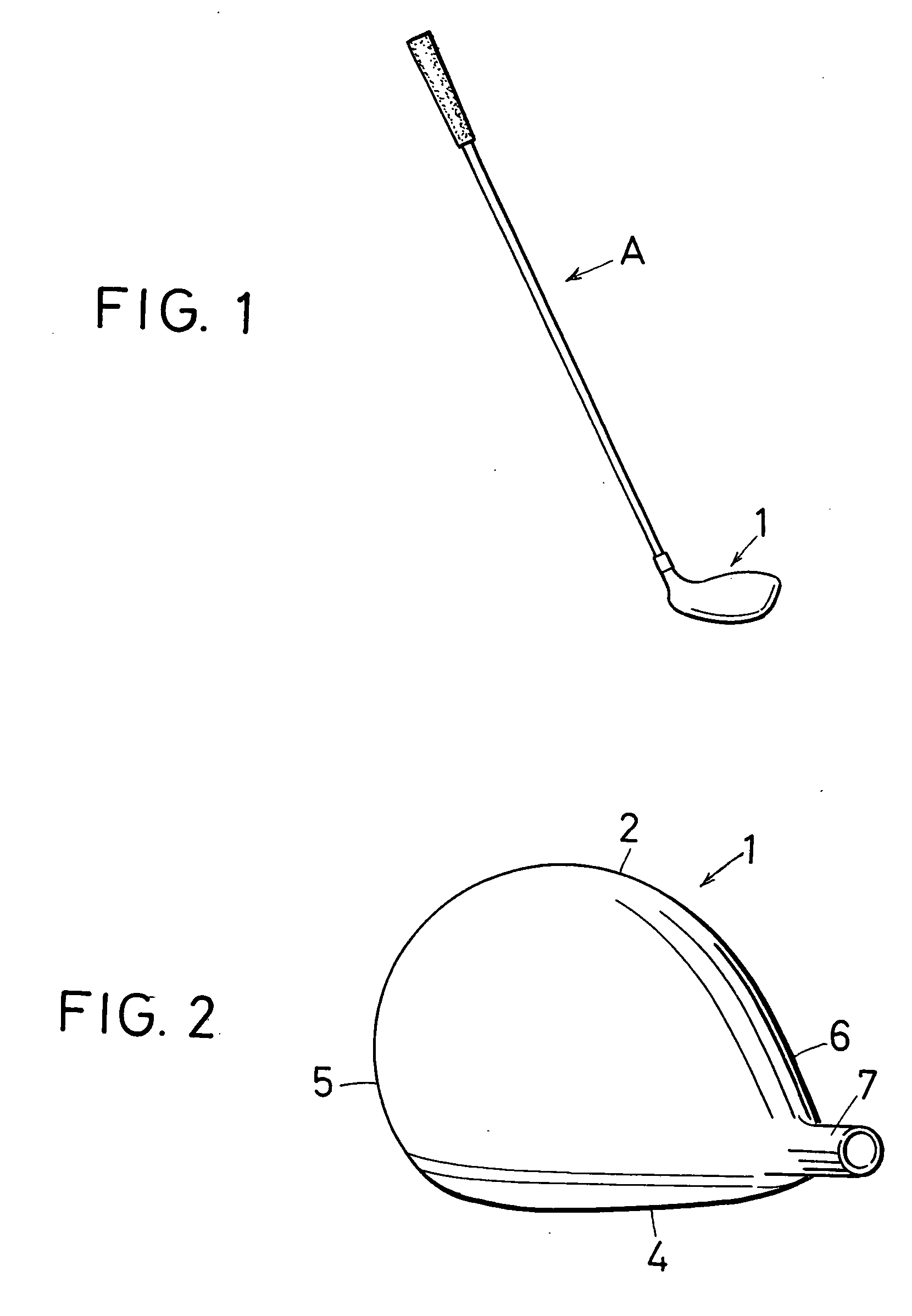

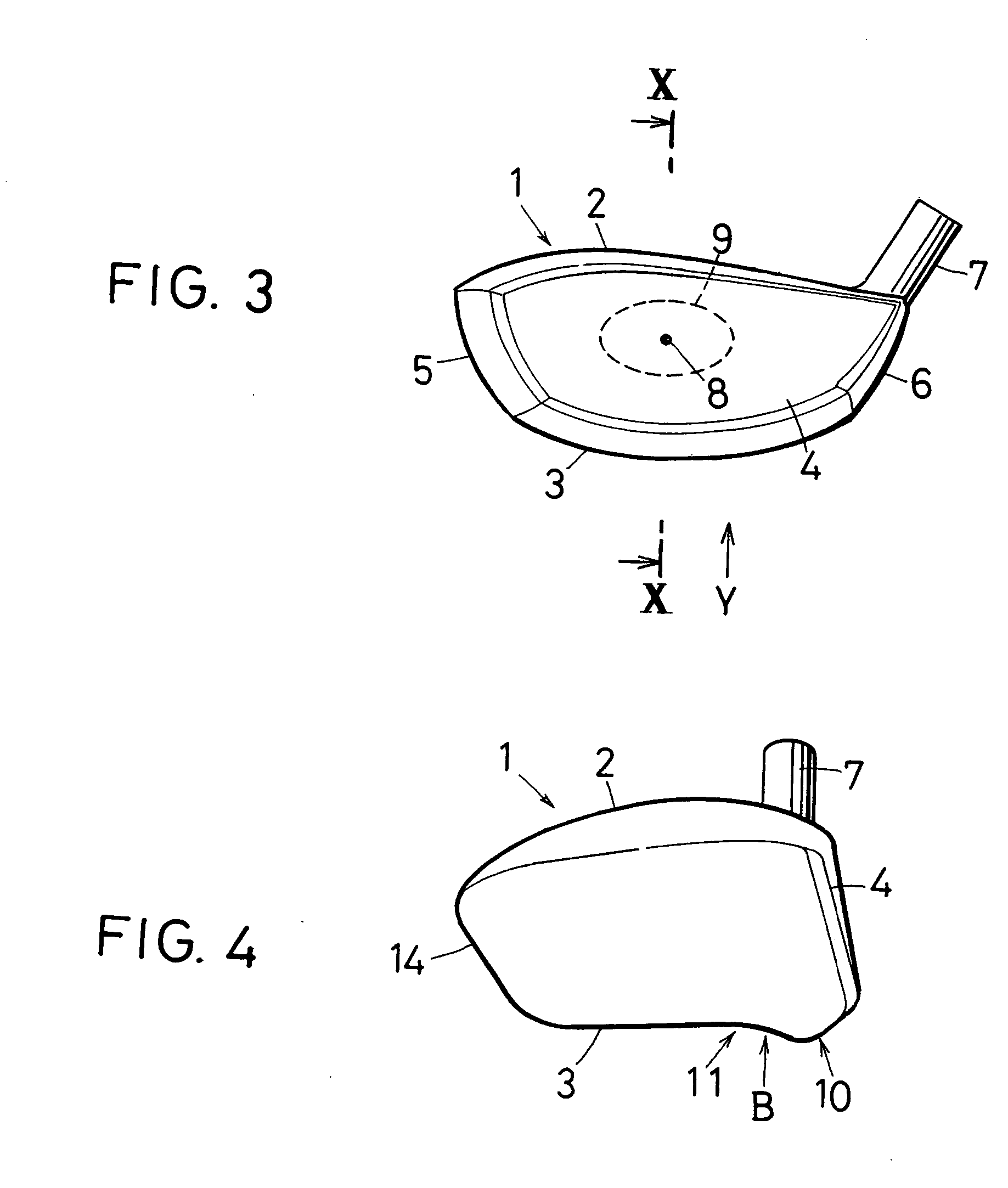

In a driver golf head (1) comprising a face (4) having a hitting surface, a sole (3) forming a lower portion, and a crown (5) forming an upper portion, the sole (3) is improved. The sole (3) in the position close to the face (4) was formed into an elastically deformable recess-projection shape, and part of the face (4) was formed into a projecting shape and integrated with the sole (3) to increase rigidity. Using a configuration with increased rigidity and decreased rigidity between the face (4) and sole to obtain an elastically deformable portion and providing a high-rigidity body (12) increased the repulsion force in the lower portion of the face and extended the traveling distance of the golf ball.

Owner:ENDO MFG COMPANY

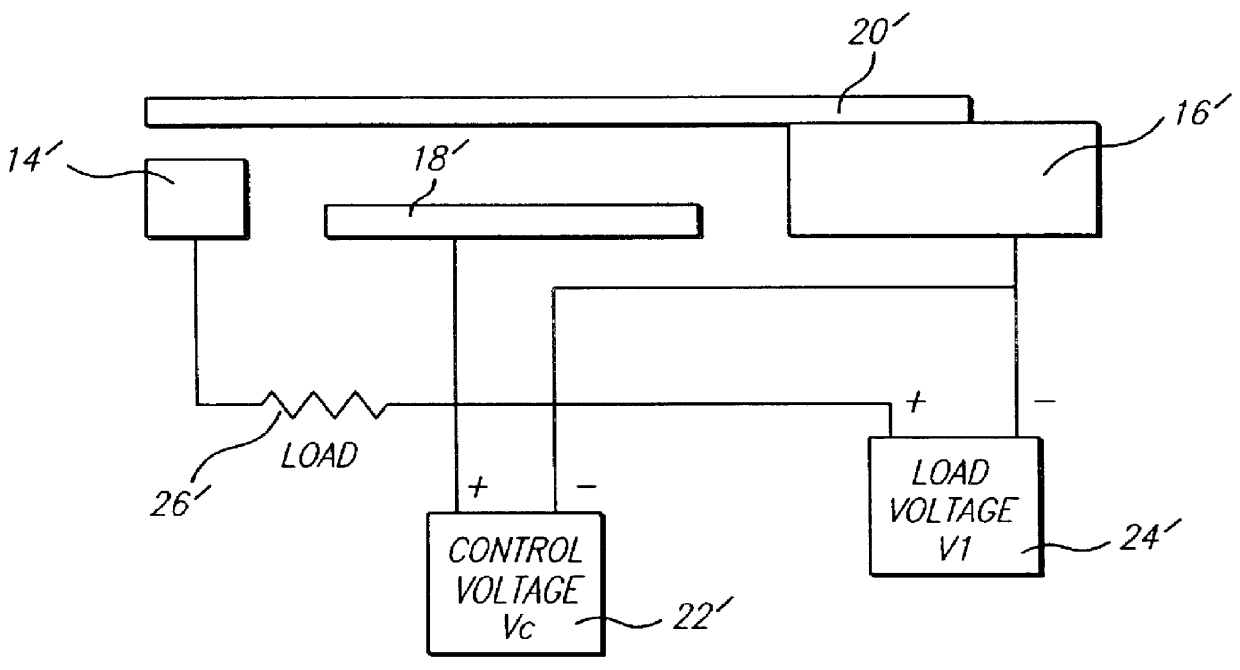

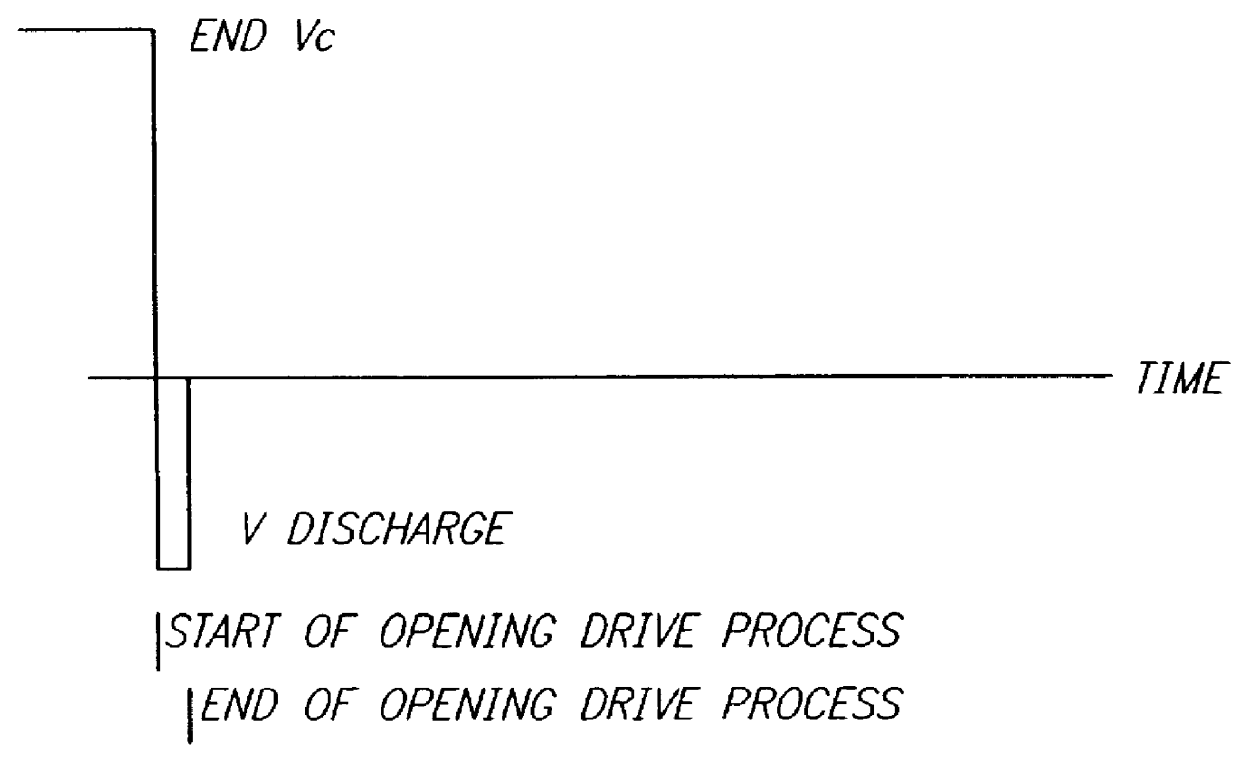

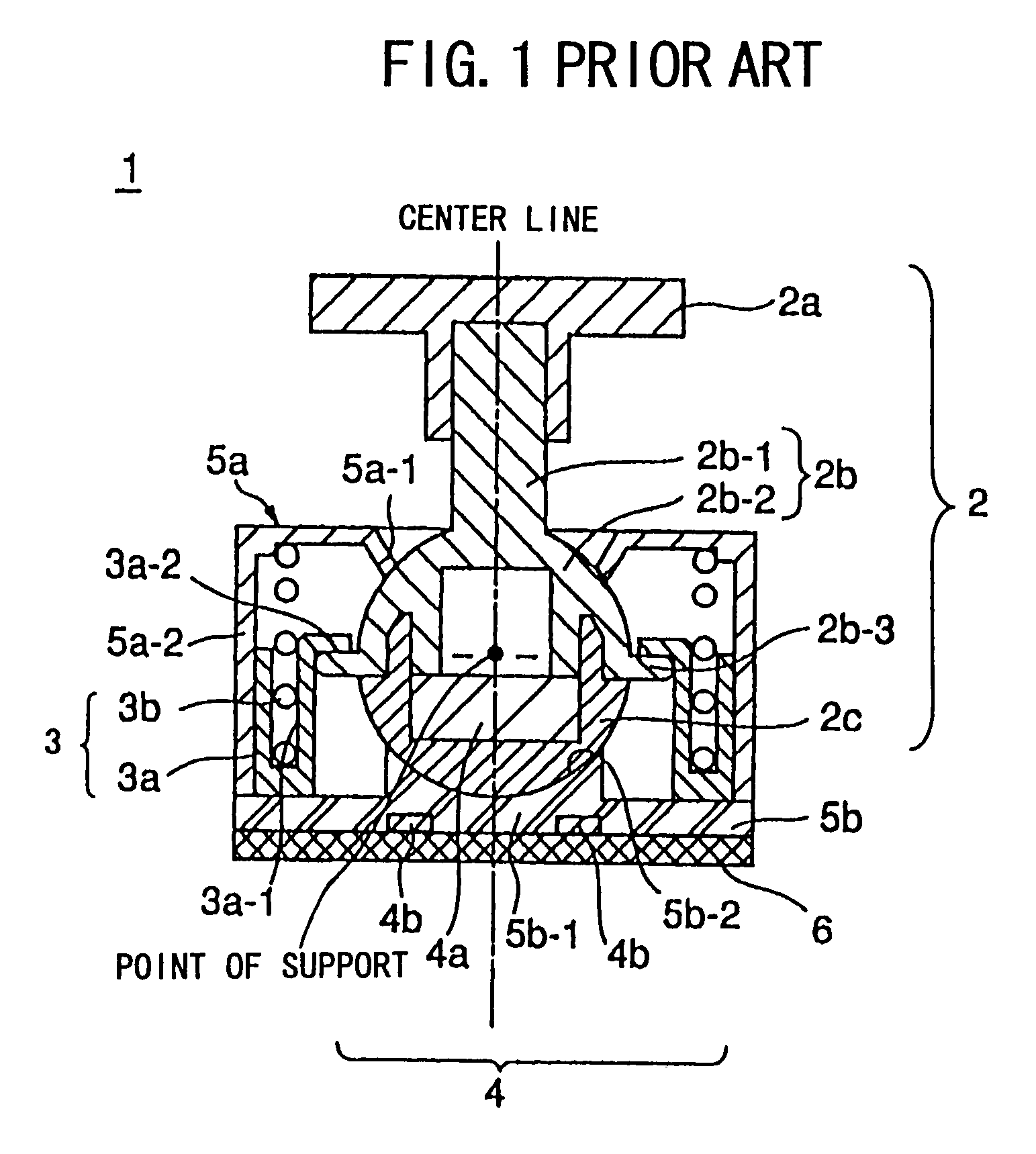

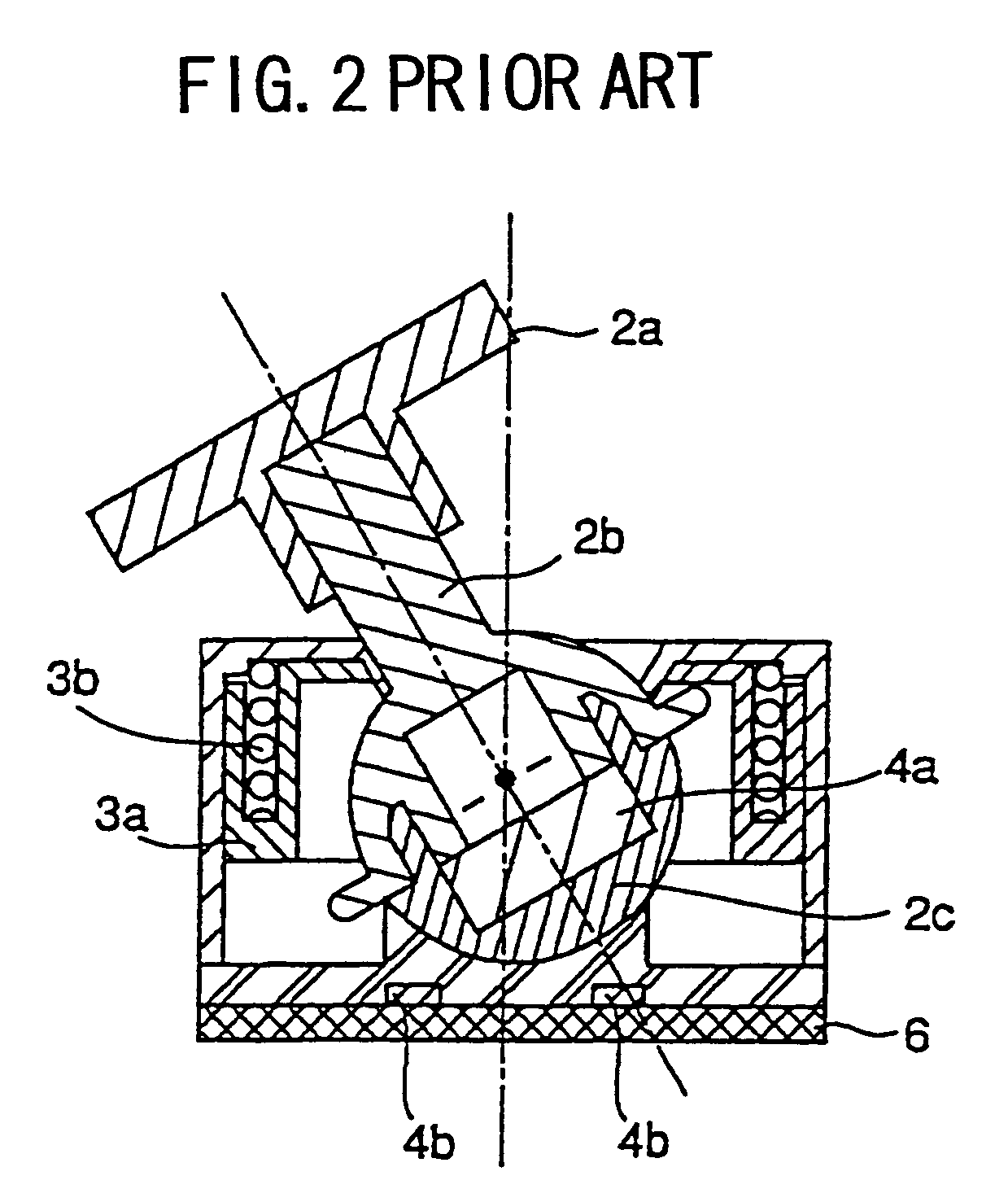

Method and apparatus for an improved single pole double throw micro-electrical mechanical switch

InactiveUS6160230AElectrostatic/electro-adhesion relaysCapacitor with electrode distance variationRepulsion forceCantilever

A single pole, double throw micro-electromechanical (MEM) switch. The inventive switch includes a first contact providing a first terminal of the switch. A second contact provides a second terminal of said switch. A cantilever beam provides a third terminal of the switch. The inventive switch includes a system for electrostatically pushing or pulling the beam to disengage the first contact and engage the second contact. In an illustrative implementation, the system for electrostatically operating the switch includes a first charge storage structure on the beam, a second charge storage structure on the switch, and an electrical supply for creating an electrical charge on the first and the second charge storage structures. The first and second charge storage structures are effective to create a force of repulsion therebetween on the application of an electrical charge thereto. The "pull" electrostatic force closes the MEM switch. The "push" force aids in opening the switch. The "push" capability is the result of the use of like (same polarity) electrostatic charges on the control surfaces. The like charges provide an electrostatic repulsion force during the switch opening process.

Owner:RAYTHEON CO

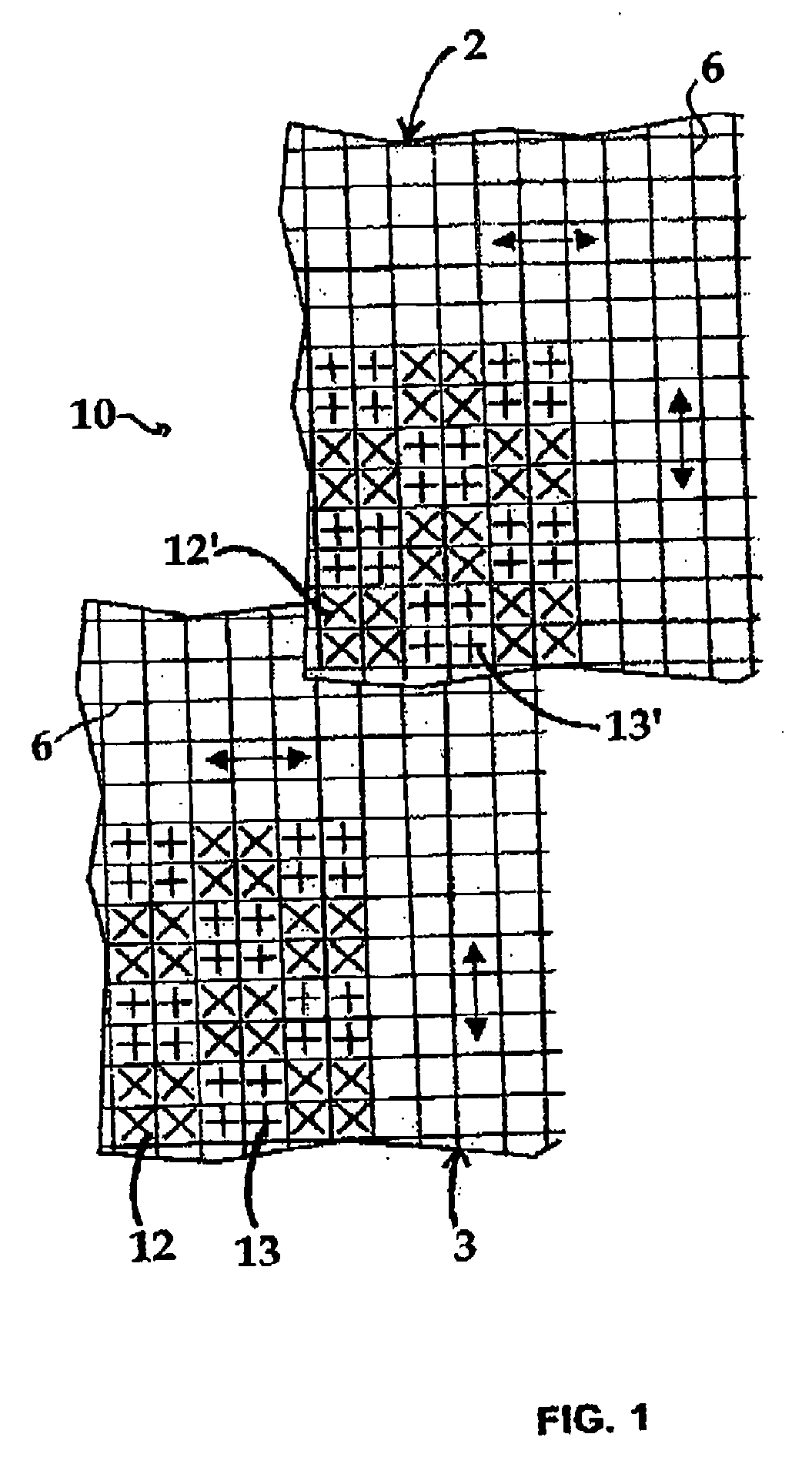

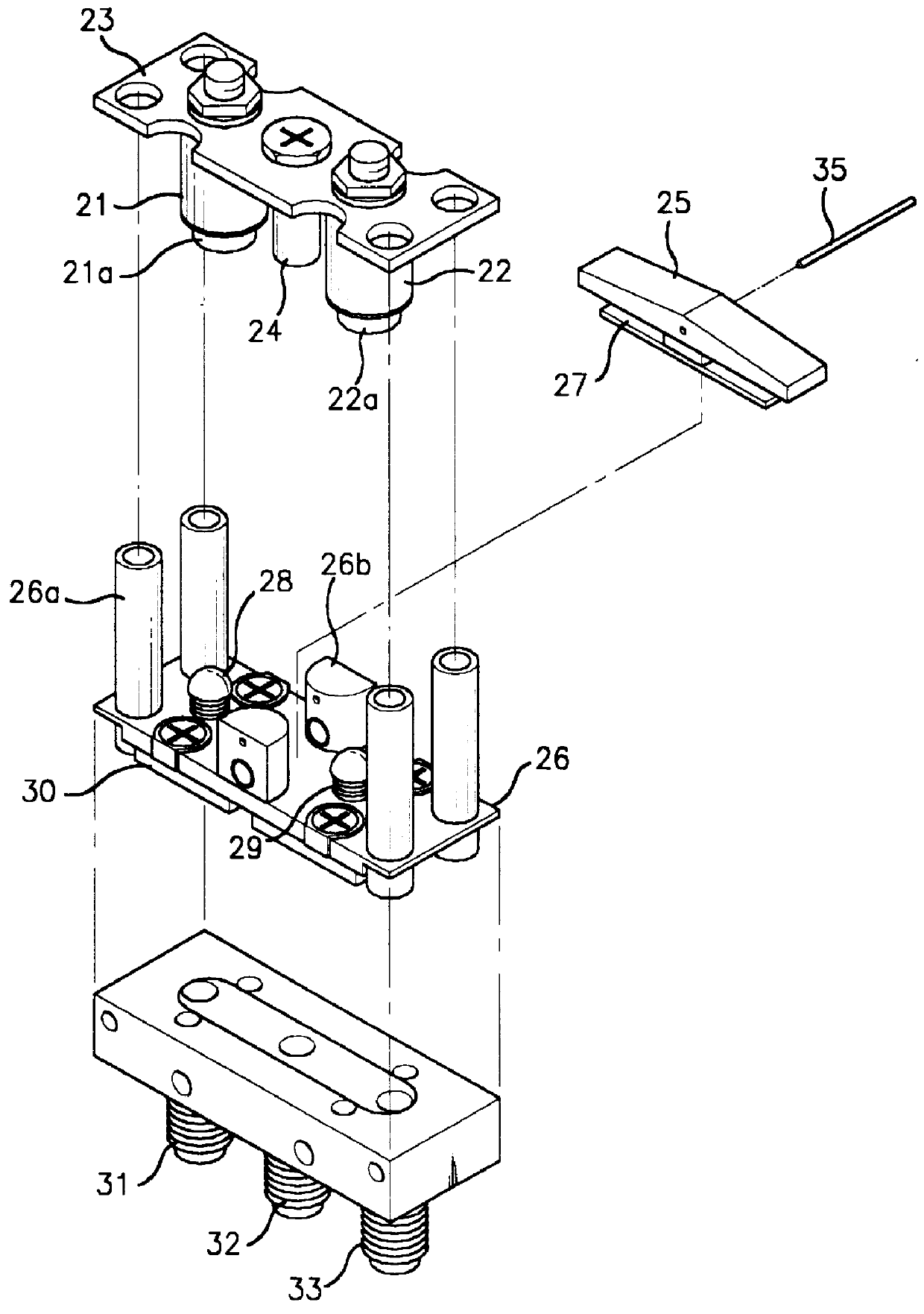

Magnetic device for slidable adjustment

ActiveUS20080282517A1Cheap manufacturingInexpensive to maintainSnap fastenersMagnetsPull forceRepulsion force

A magnetic fastening device with discrete slidable adjustments, comprising first and second sheets, each having a plurality of magnetic section elements with first and second poles disposed in alternating groups defining predetermined abutting patterns. The magnetic section elements are abuttingly disposed in two groups. In one group, the elements' magnetic field is disposed in one direction perpendicular to the sheets. In the other group, the elements' field is disposed in the opposite direction. The groups repeat themselves in an alternating pattern. The movement of the first and second sheets is constrained to keep them in an abutting relationship with respect to each other over a predetermined path over the first and second sheets, thereby permitting the sheets to be slidably movable along a predetermined distance relative to each other in discrete steps that overcome the attraction and repulsion forces of the magnetic section elements upon the application of a pulling force of a predetermined magnitude.

Owner:CLARO FELIPE

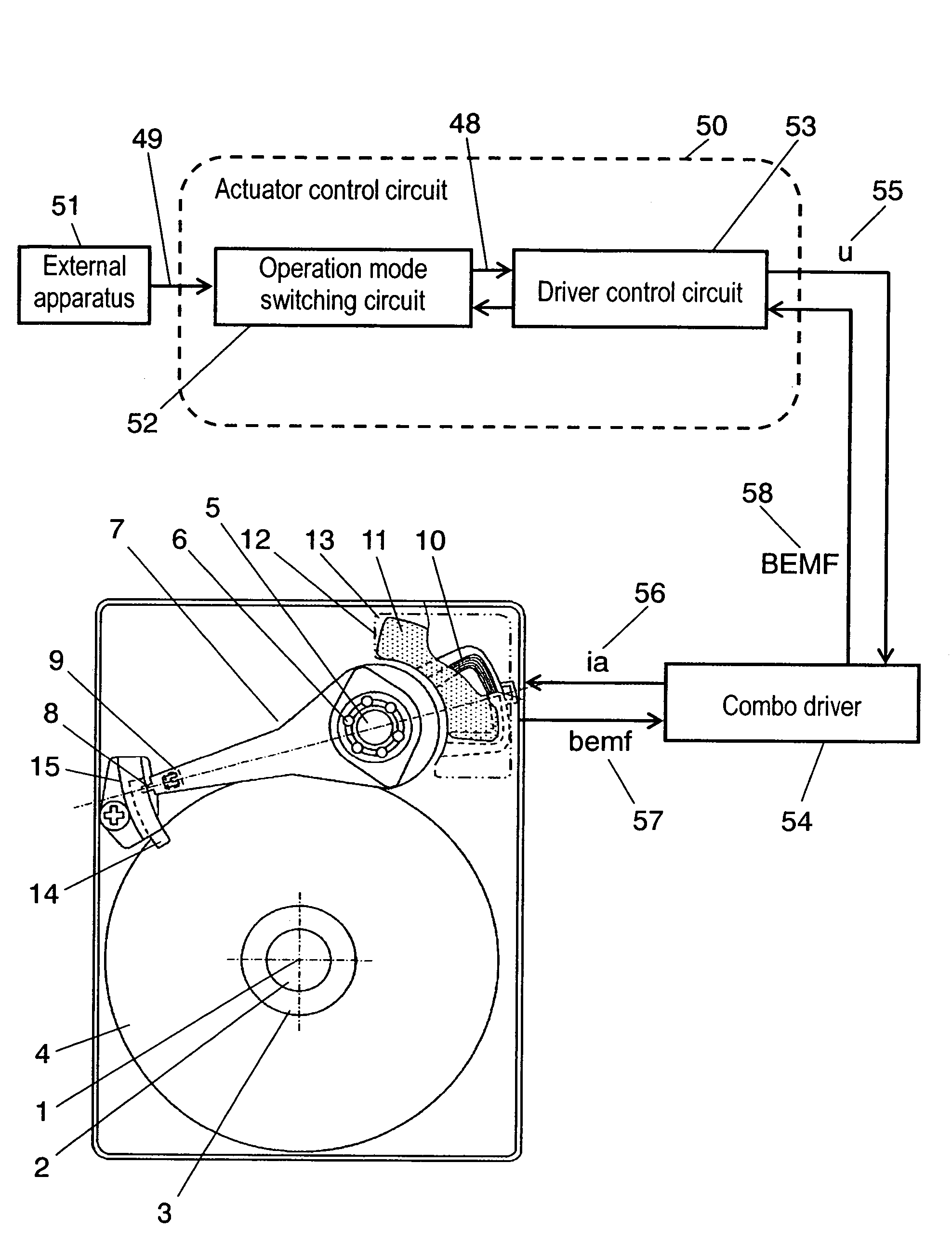

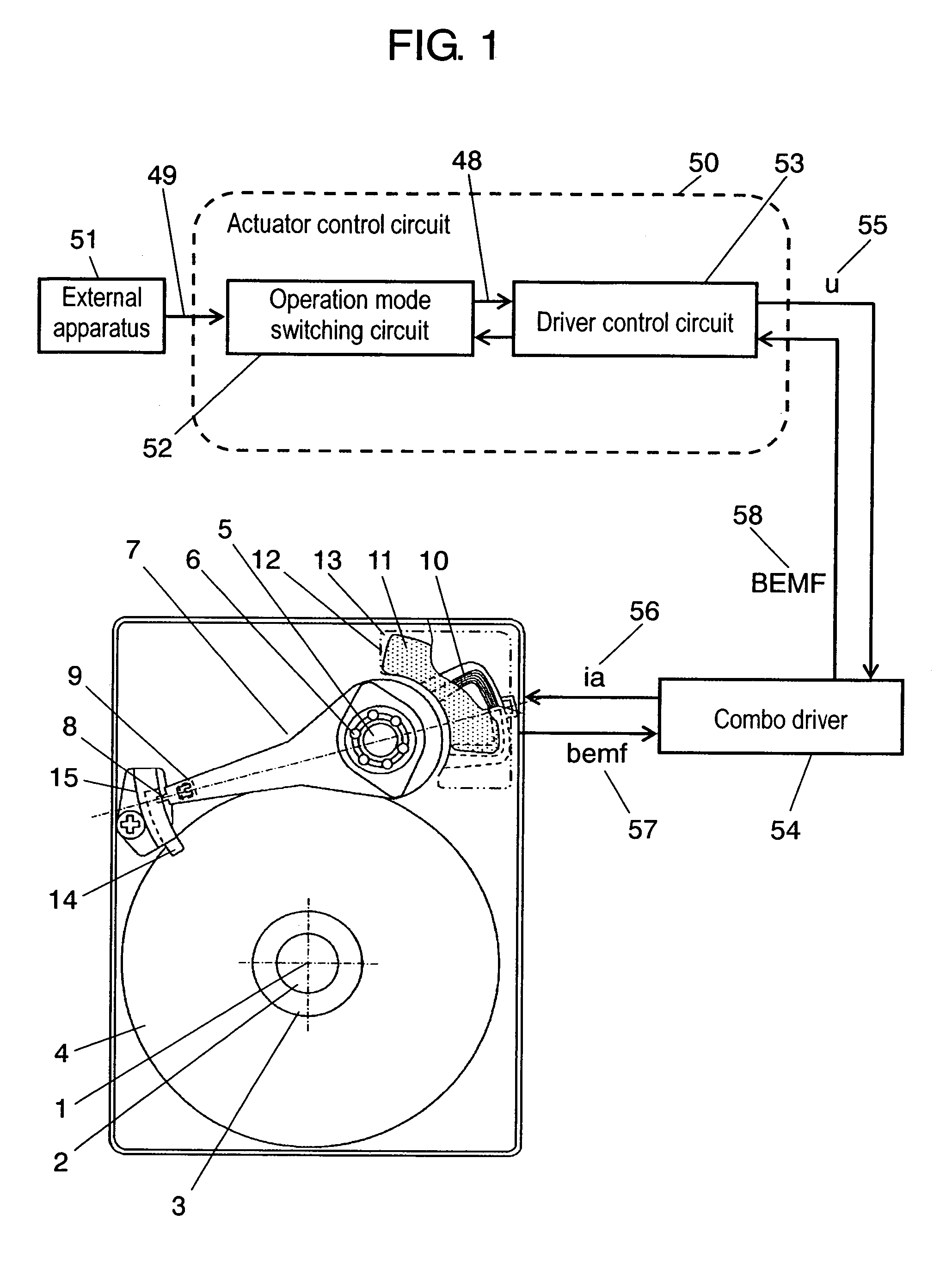

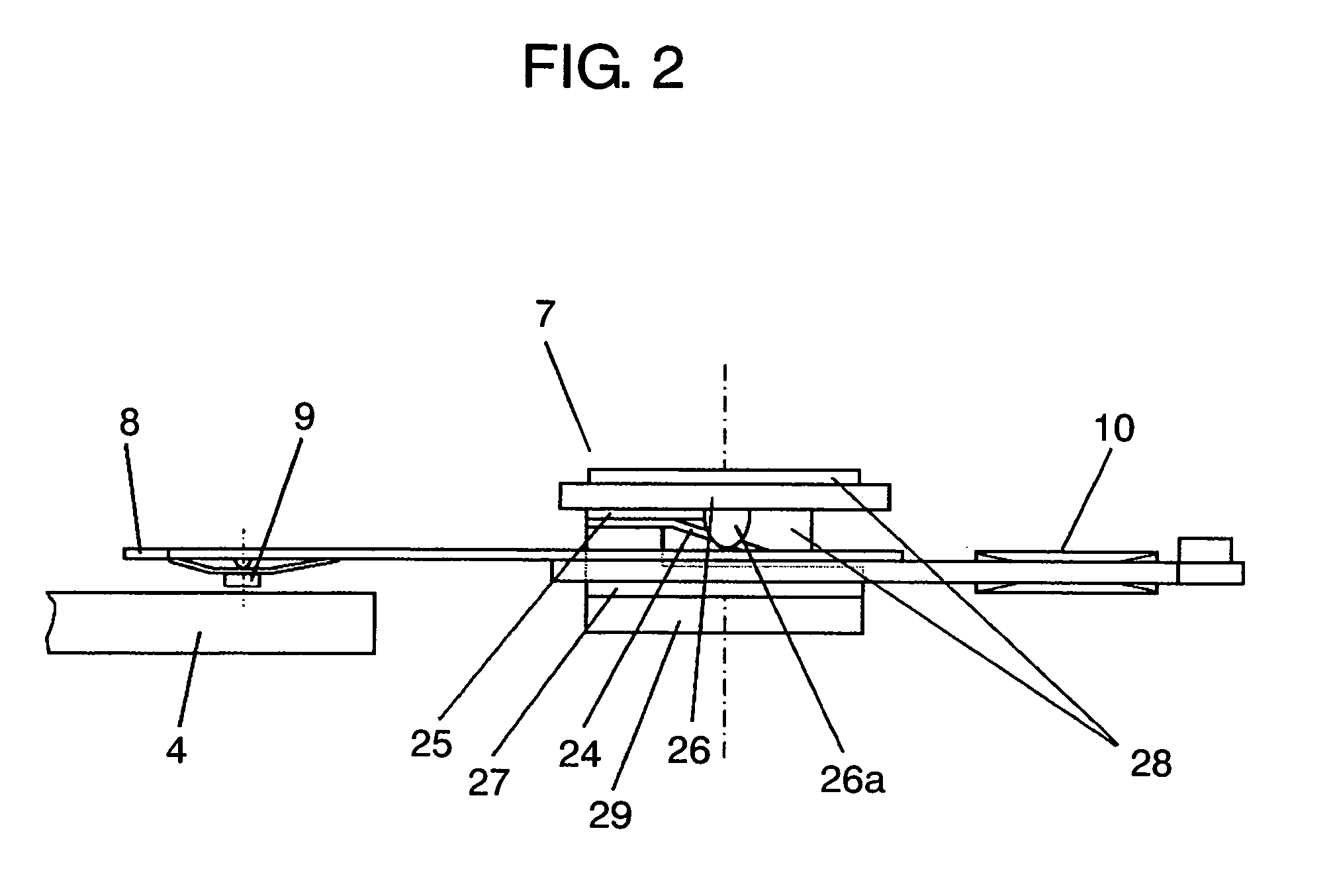

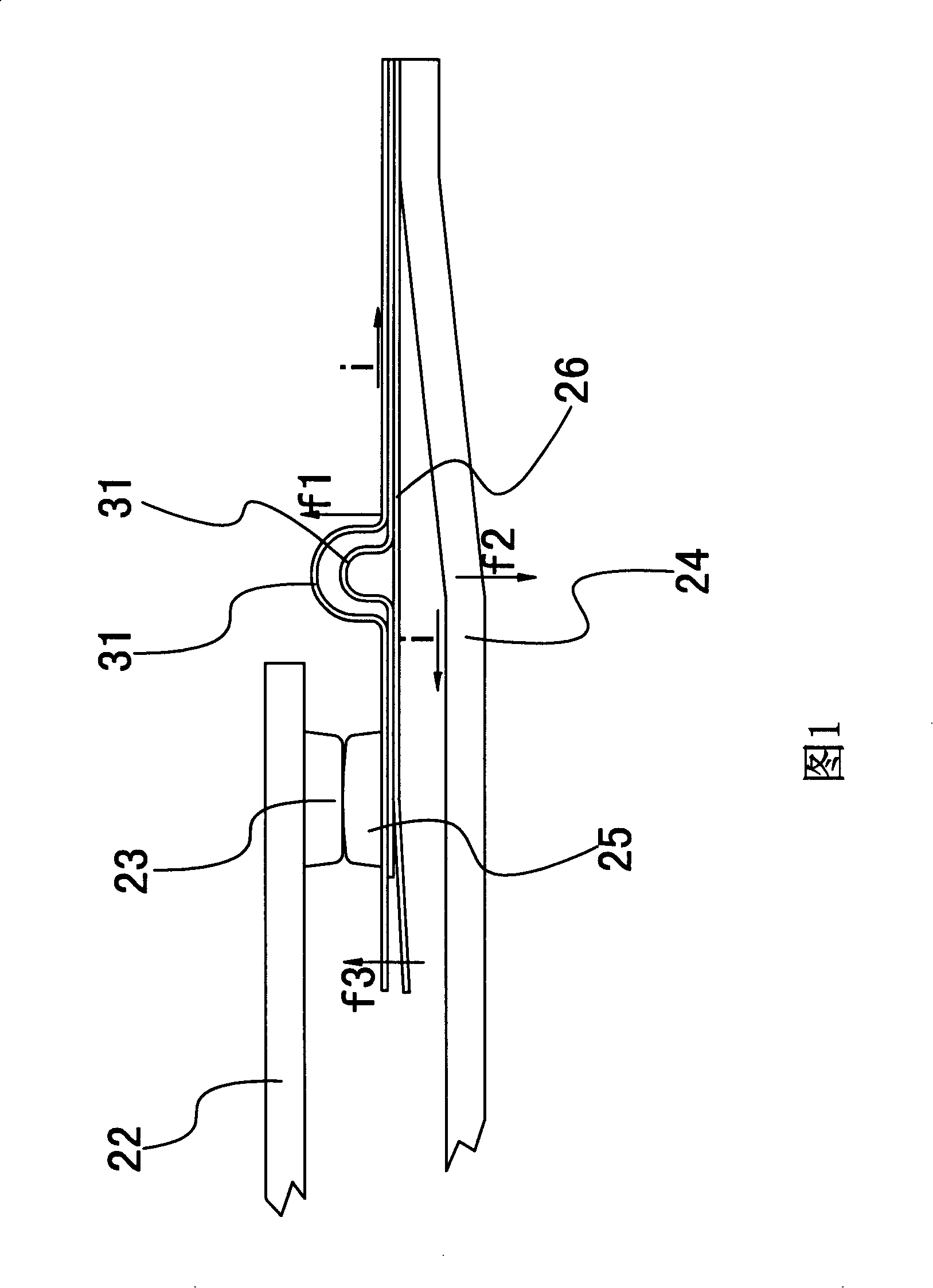

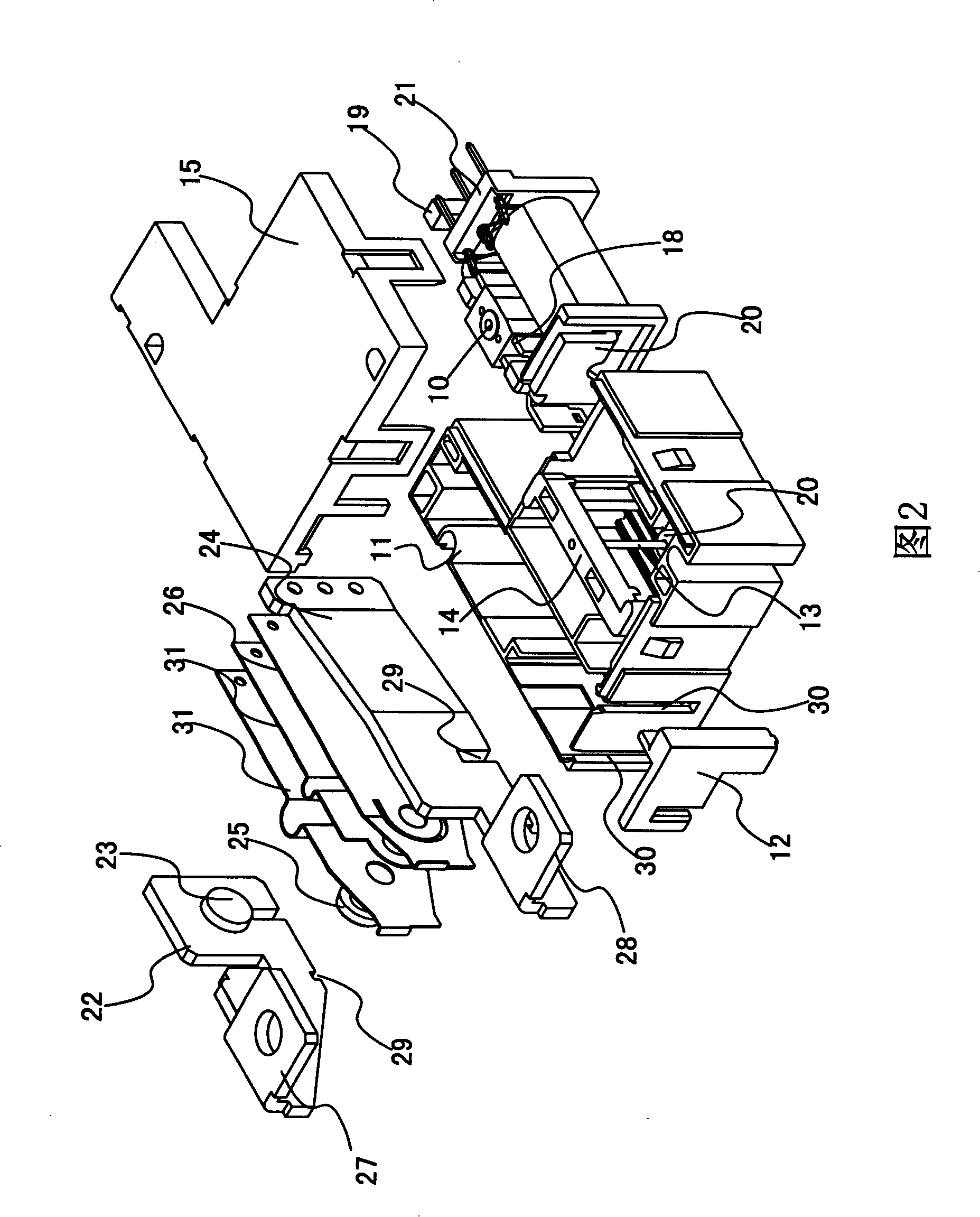

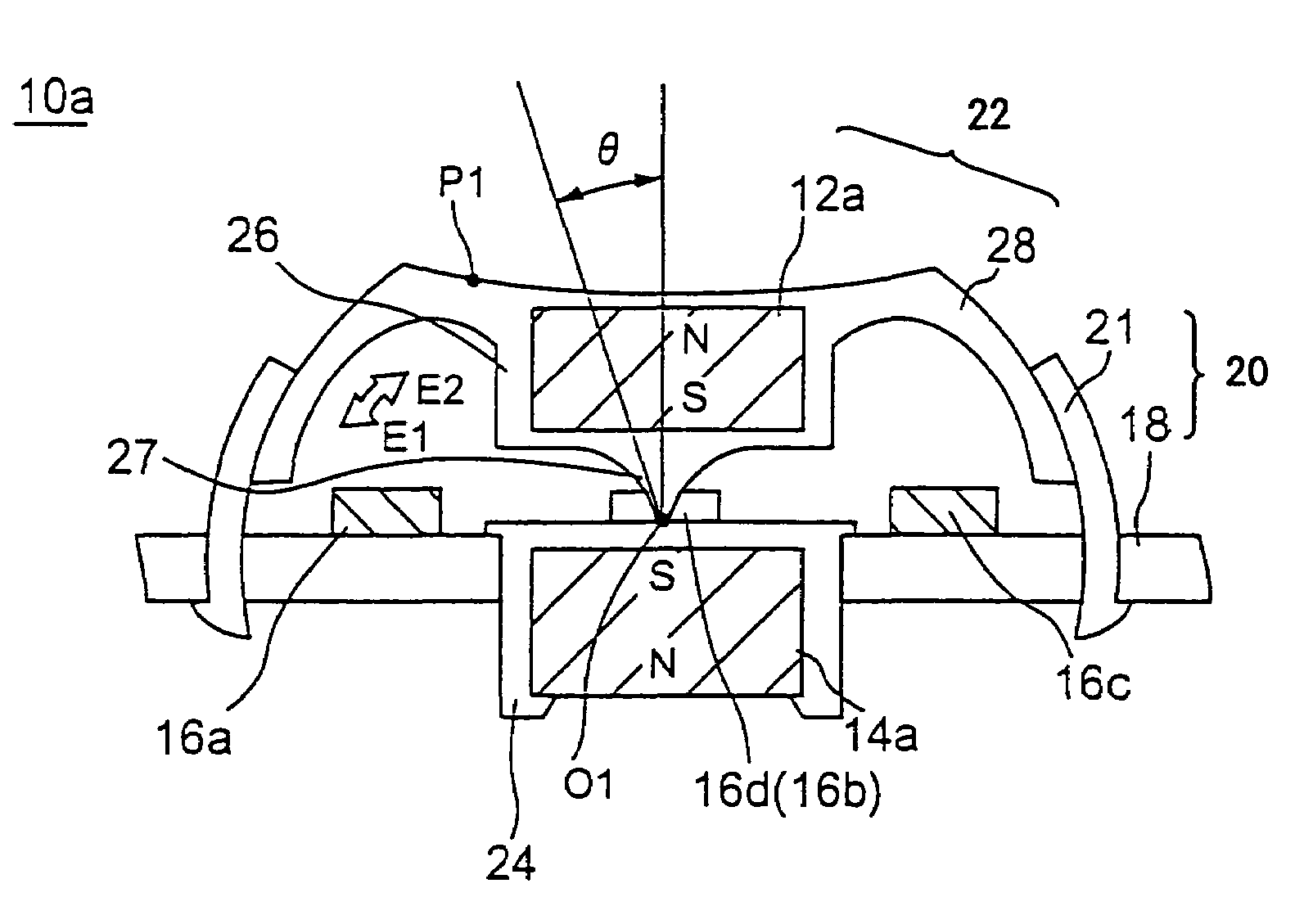

Method of controlling an actuator, and disk apparatus using the same method

InactiveUS7265929B2Power saving and downsizingReduce placementDisposition/mounting of recording headsDriving/moving recording headsDriving currentRepulsion force

Owner:PANASONIC CORP

Golf club

ActiveUS20070021234A1Increase travel distanceImprove hitting effectGolf clubsRepulsion forceEngineering

In a driver golf head (1) comprising a face (4) having a hitting surface, a sole (3) forming a lower portion, and a crown (5) forming an upper portion, the sole (3) is improved. The sole (3) in the position close to the face (4) was formed into an elastically deformable recess-projection shape, and part of the face (4) was formed into a projecting shape and integrated with the sole (3) to increase rigidity. Using a configuration with increased rigidity and decreased rigidity between the face (4) and sole to obtain an elastically deformable portion and providing a high-rigidity body (12) increased the repulsion force in the lower portion of the face and extended the traveling distance of the golf ball.

Owner:ENDO MFG COMPANY

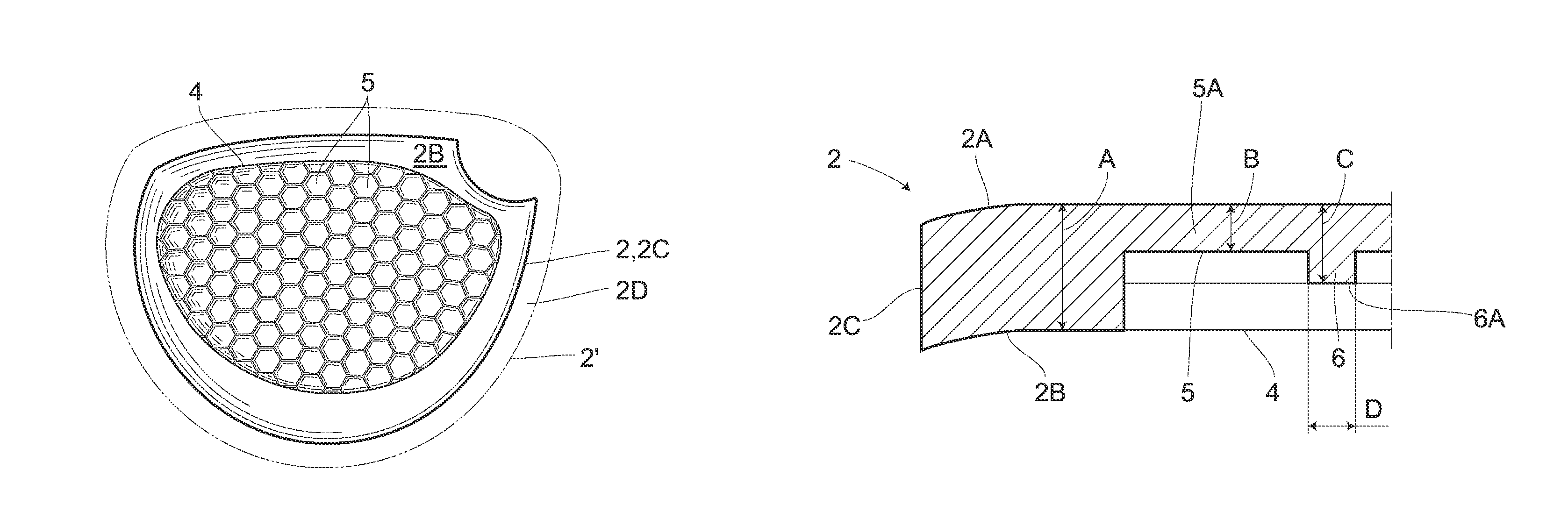

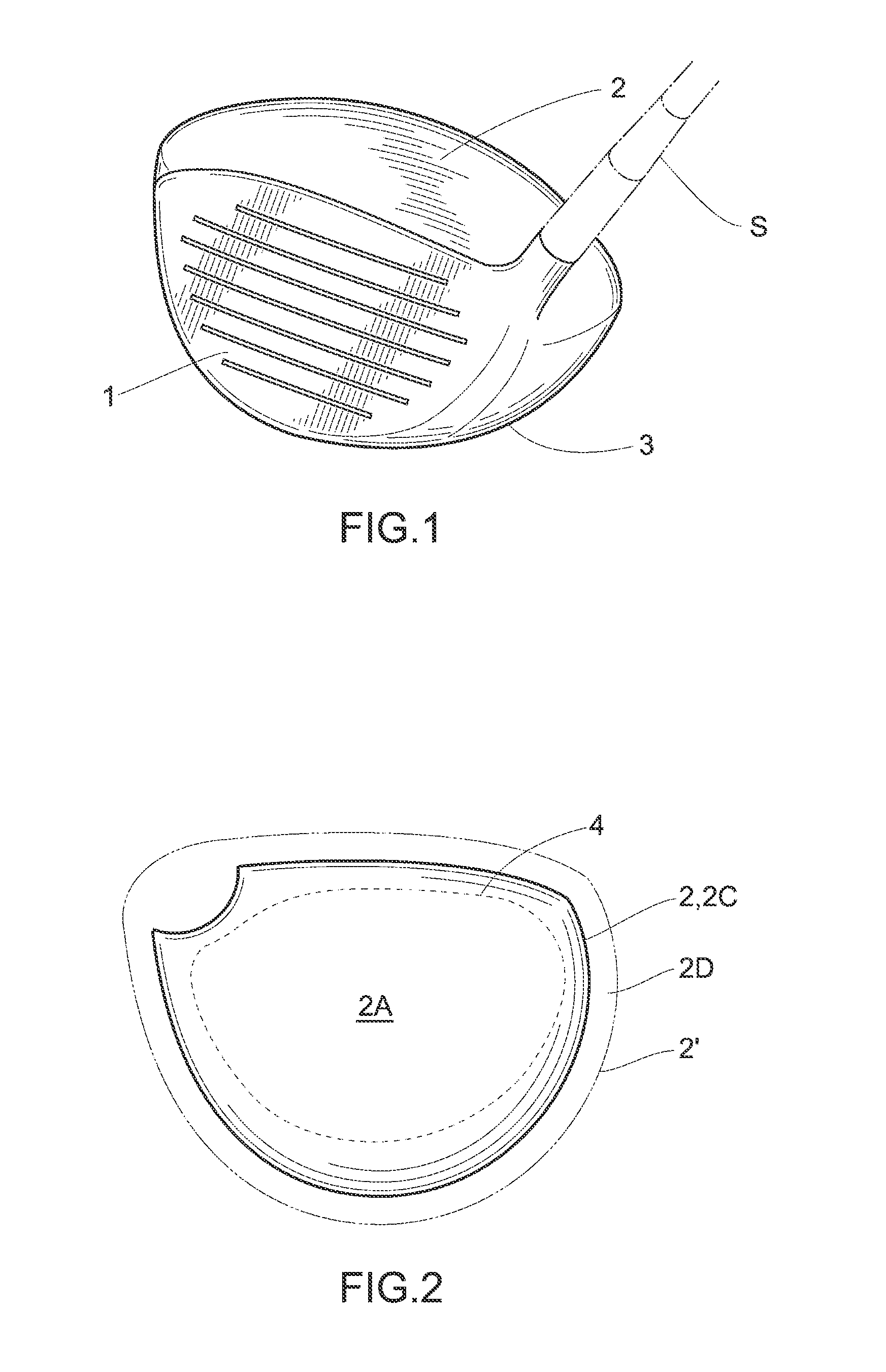

Hollow golf club head

InactiveUS8540590B2Improve performanceIncrease freedomGolf clubsStringed racketsRepulsion forceAlloy

There is provided a Ti alloy hollow club head which is more lightweight yet capable of realizing a better repulsion force by adjusting weight and thickness of a club head plate, with its strength ensured. Ribs are formed by chemically polishing the inner surface of a material of a crown plate to a 0.3 to 0.9 mm thickness, and a 0.3 to 4 mm width, and then first concave portions are formed to a 0.2 to 0.5 mm thickness. Thus, strength of the crown plate can be ensured by the ribs, while making the thickness thereof as thin as possible.

Owner:ENDO MFG COMPANY

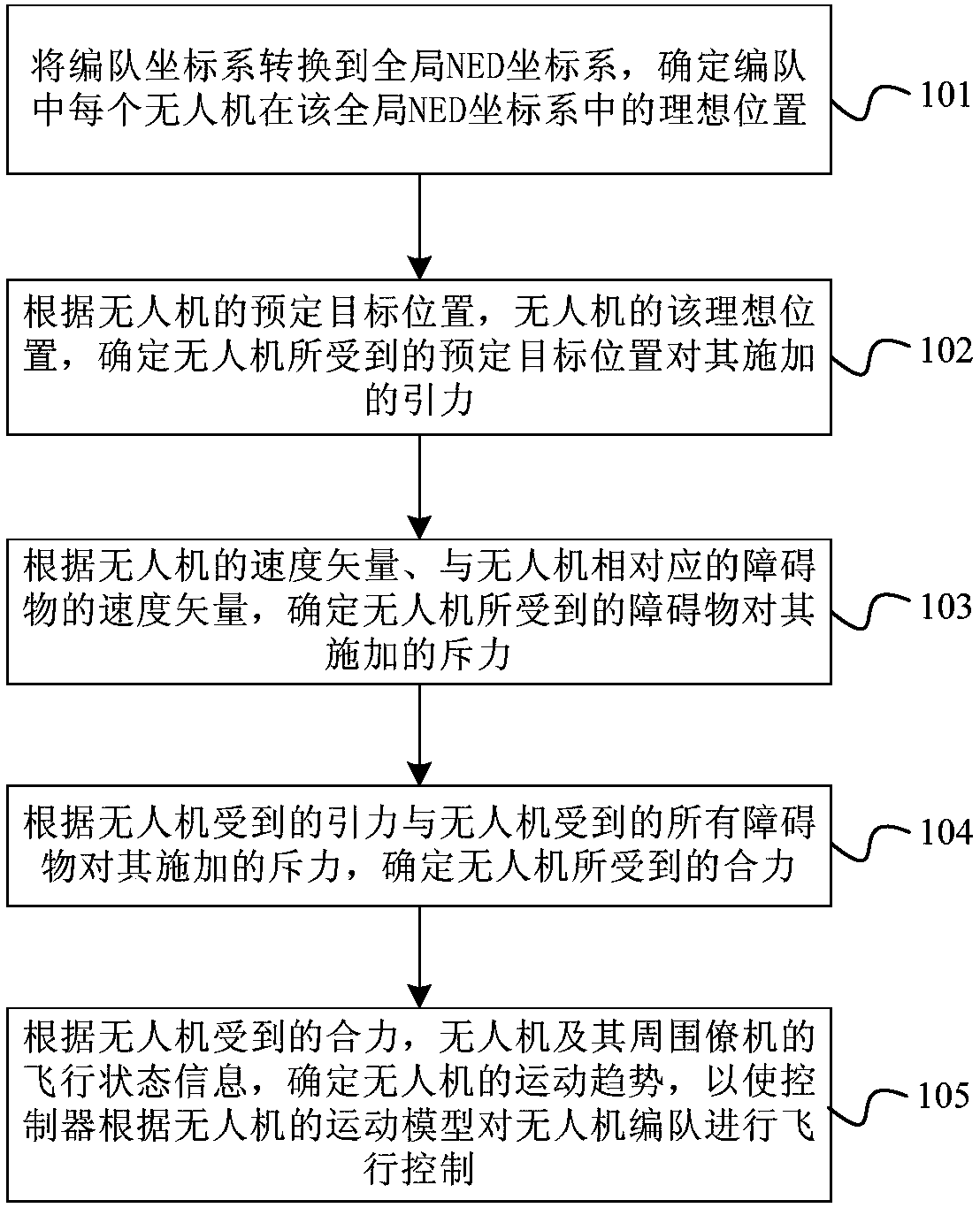

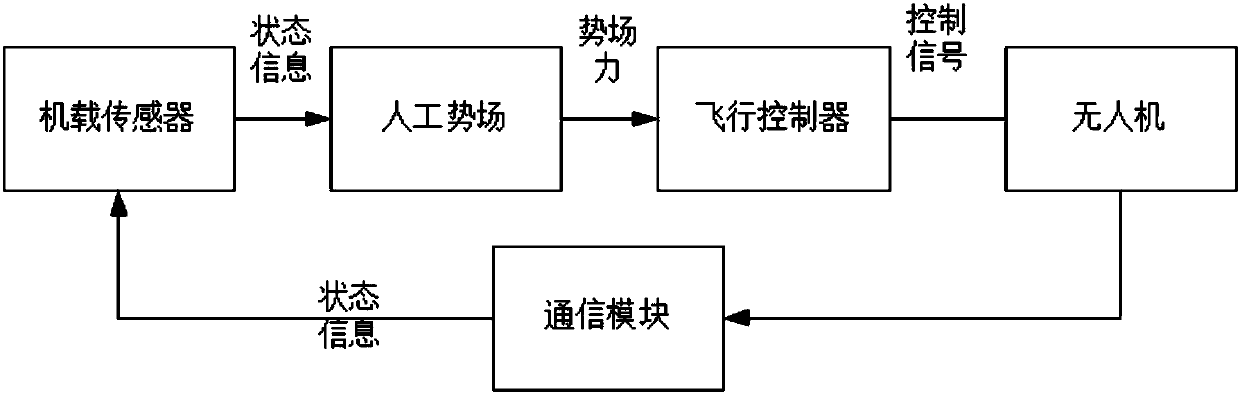

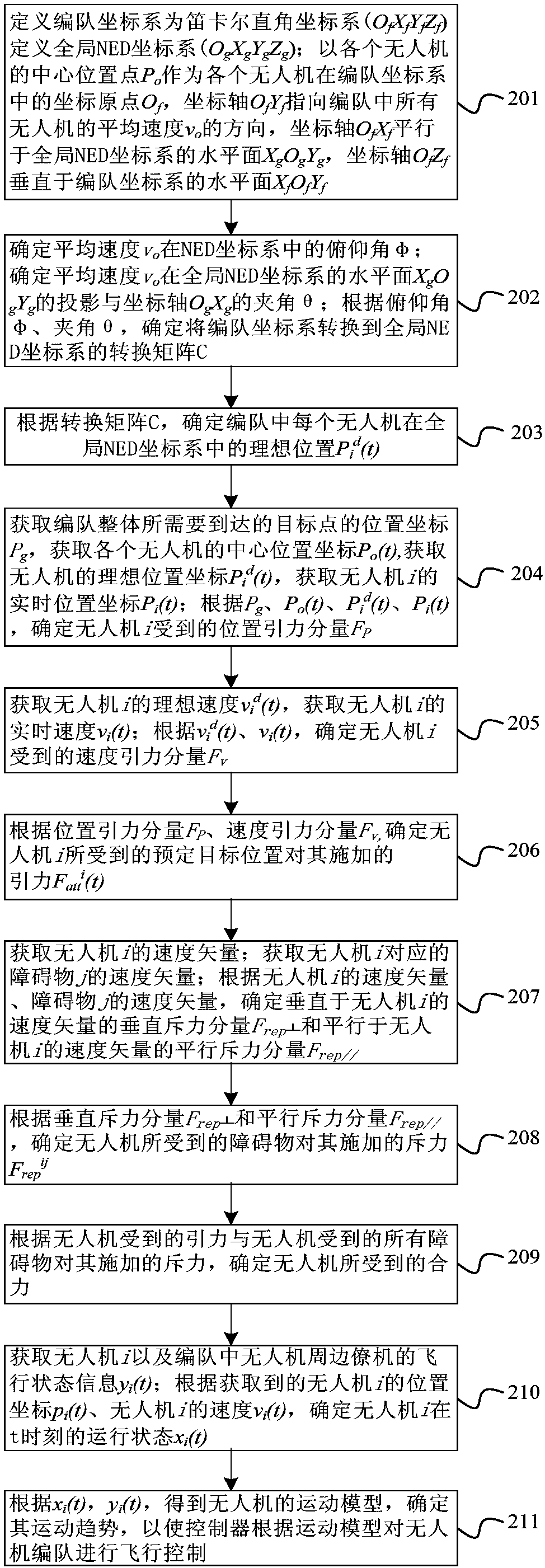

UAV (unmanned aerial vehicle) formation control method and device based on artificial potential field

ActiveCN108459612AMeet real-time dynamic requirementsImprove consistencyPosition/course control in three dimensionsPotential fieldRepulsion force

The invention relates to a UAV (unmanned aerial vehicle) formation control method and device based on an artificial potential field. The method is characterized by converting a formation coordinate system to a global NED coordinate system, and determining an ideal position of each UAV in the formation in the global NED coordinate system; according to a preset target position of the UAV and the ideal position of the UAV, determining gravity applied to the UAV by the preset target position; according to velocity vector of the UAV and velocity vector of a barrier corresponding to the UAV, determining repulsion force applied to the UAV by the barrier; according to the gravity applied to the UAV and the repulsion force applied to the UAV by all barriers, determining resultant force applied to the UAV; and according to the resultant force applied to the UAV and flight status information of the UAV and wing planes around, determining movement trend of the UAV to enable a controller to carry out flight control on the UAV formation according to a motion model of the UAV.

Owner:BEIHANG UNIV

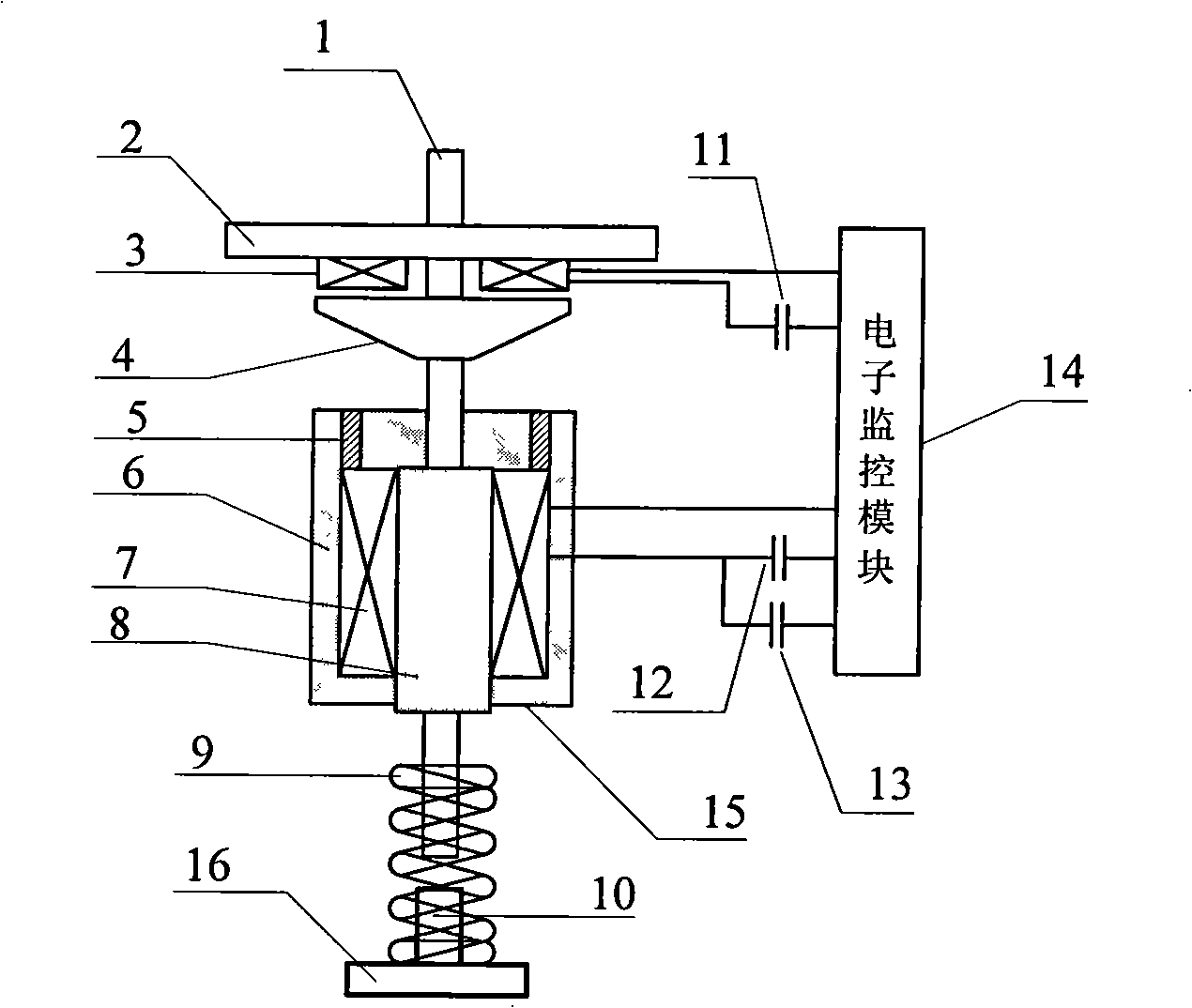

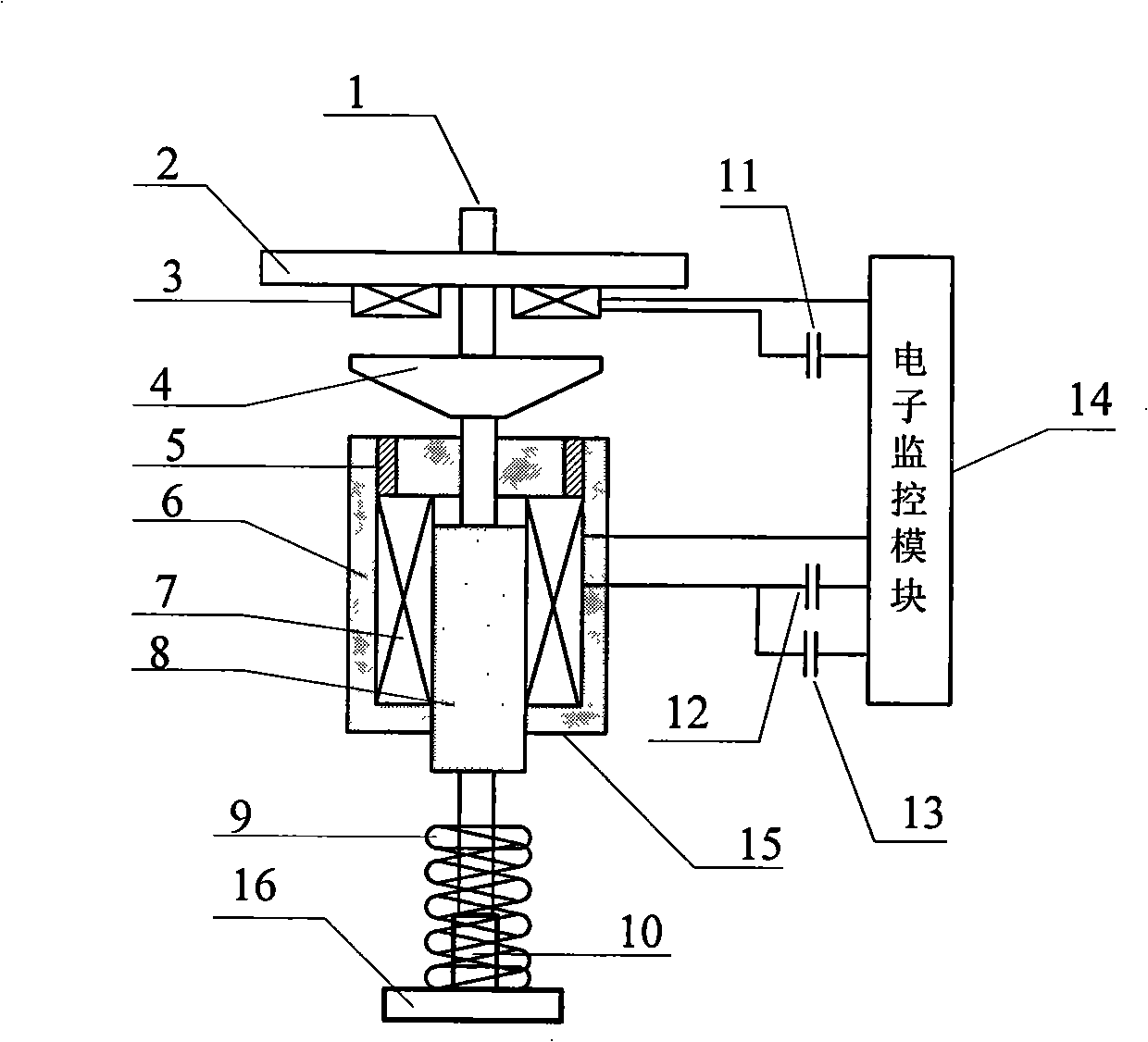

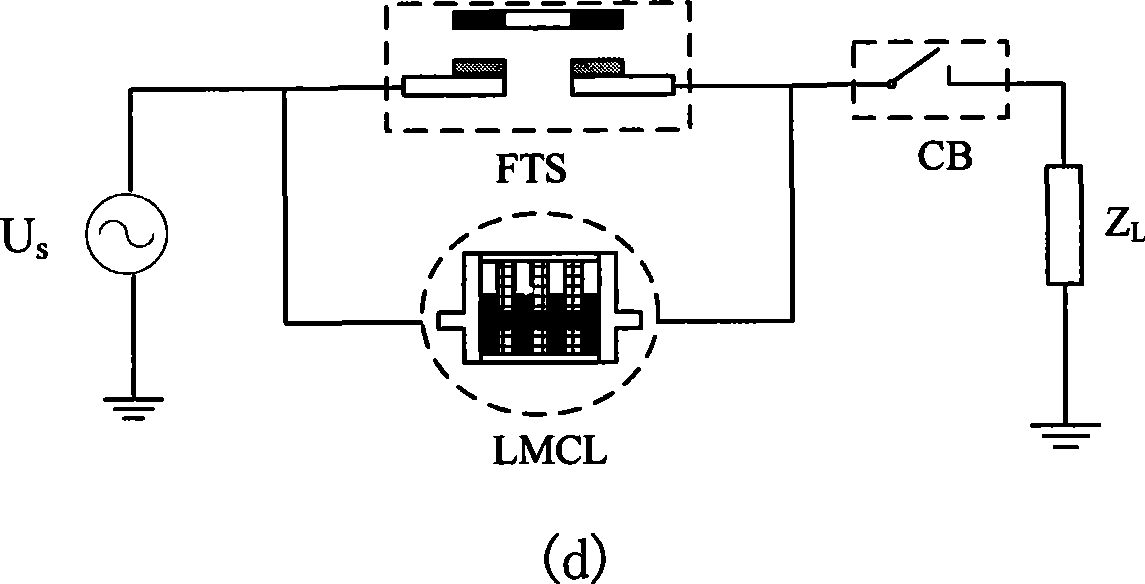

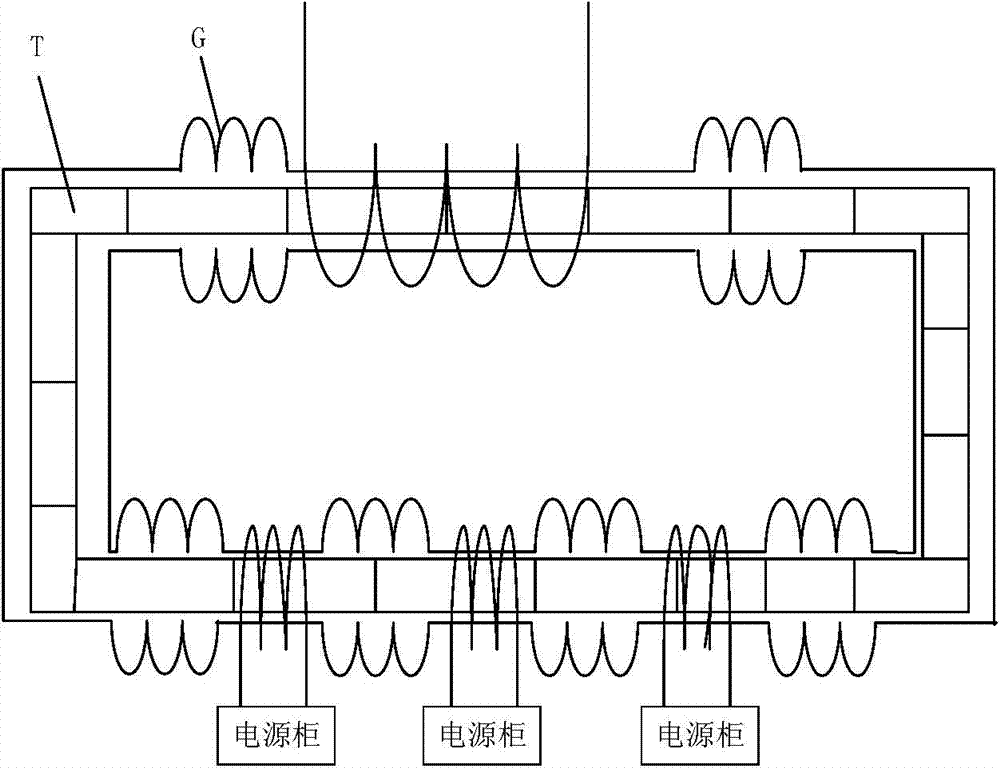

Electromagnetic repulsion force system and permanent magnetic system coupled self-adapting control mechanism

InactiveCN101315836AMaintain mechanical strengthMaintain output capacitySwitch power arrangementsHigh-tension/heavy-dress switchesKinematicsRepulsion force

The invention discloses a self-adaptive control mechanism which couples an electromagnetic repulsion system with a permanent magnetism system. The invention adopts an electromagnetic repulsion device spinning disk of circular table structure, relatively to the circular disk spinning disk, which maintains the mechanical strength and output capacity of the spinning disk, simultaneously greatly reduces the increase of kinematic scheme mass of the control mechanism, and greatly enhances the driving load capacity of the control mechanism. The control mechanism of the invention adopts the self-adaptive motion proposal, which avoids the frequent high speed motion of a breaker, reduces the mechanical strength request for the breaker, and prolongs the motion life of the breaker effectively.

Owner:XI AN JIAOTONG UNIV

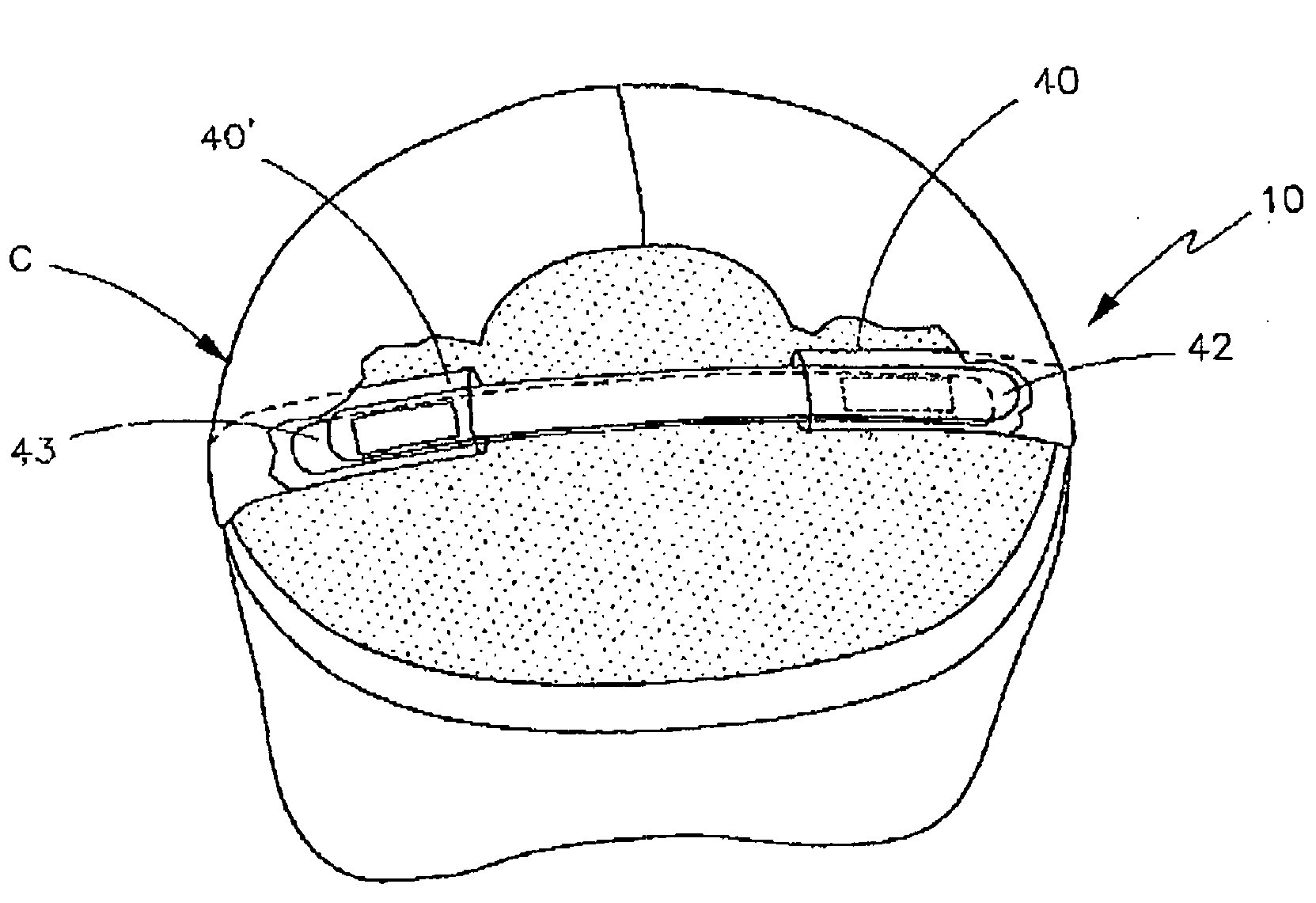

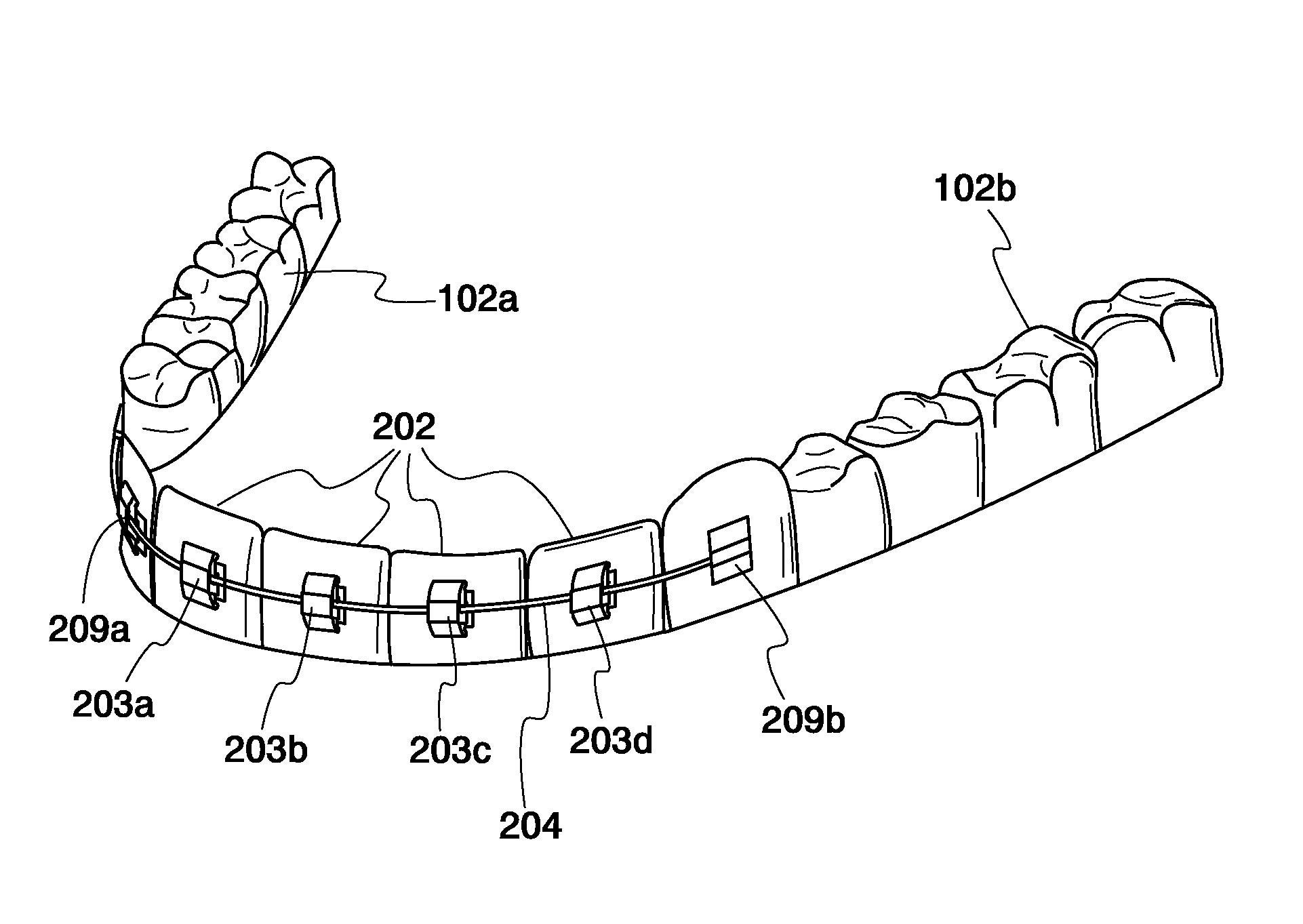

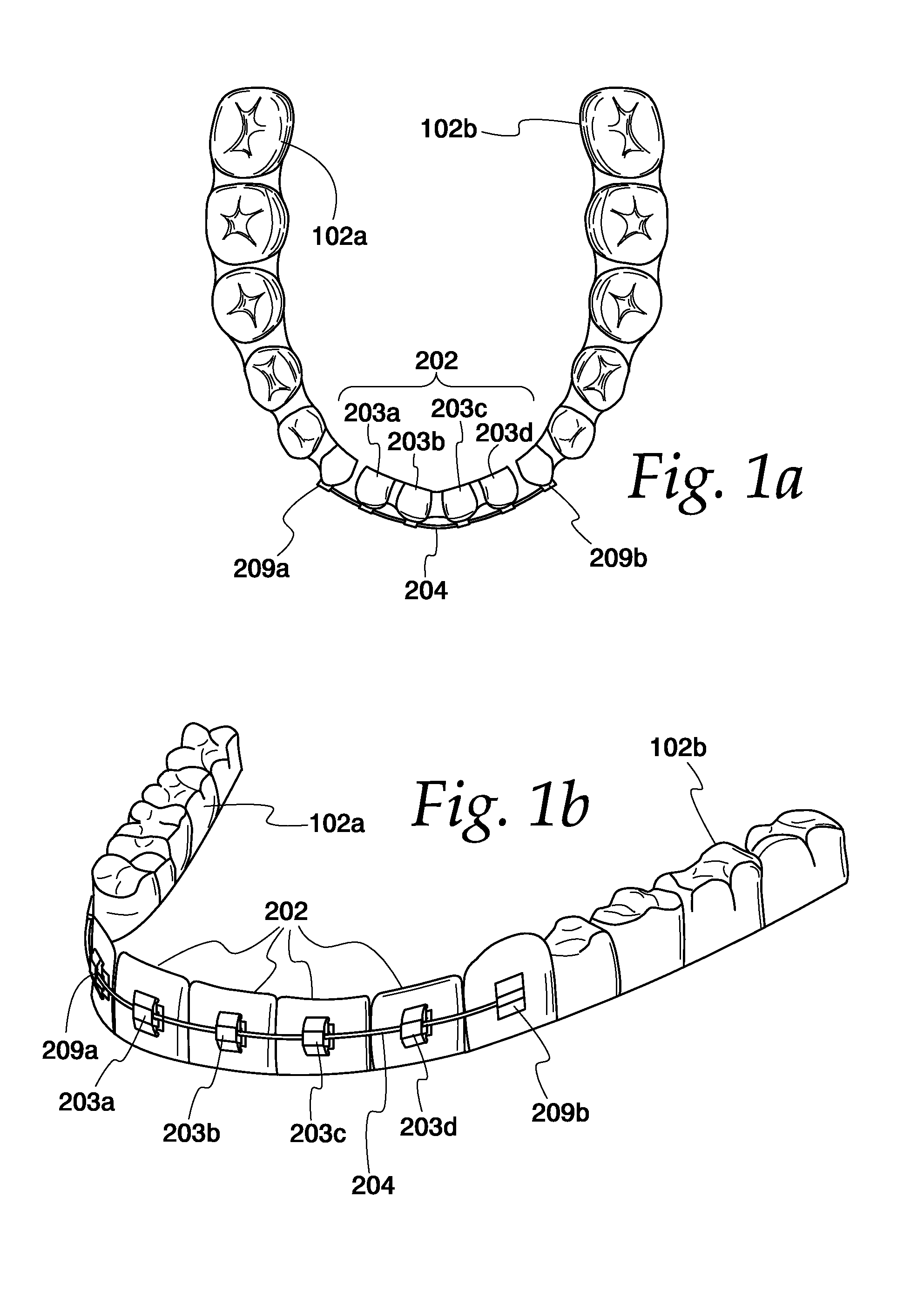

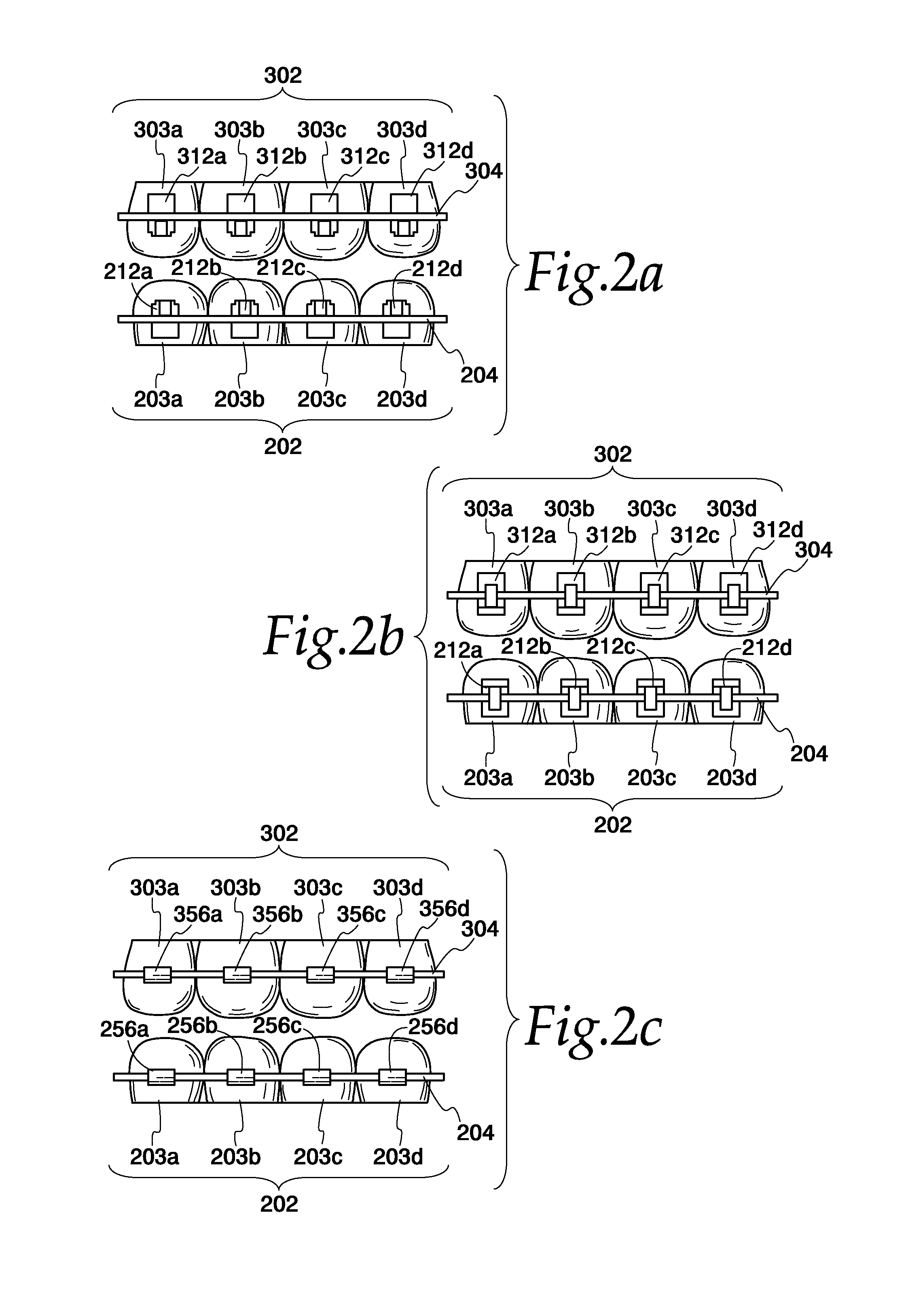

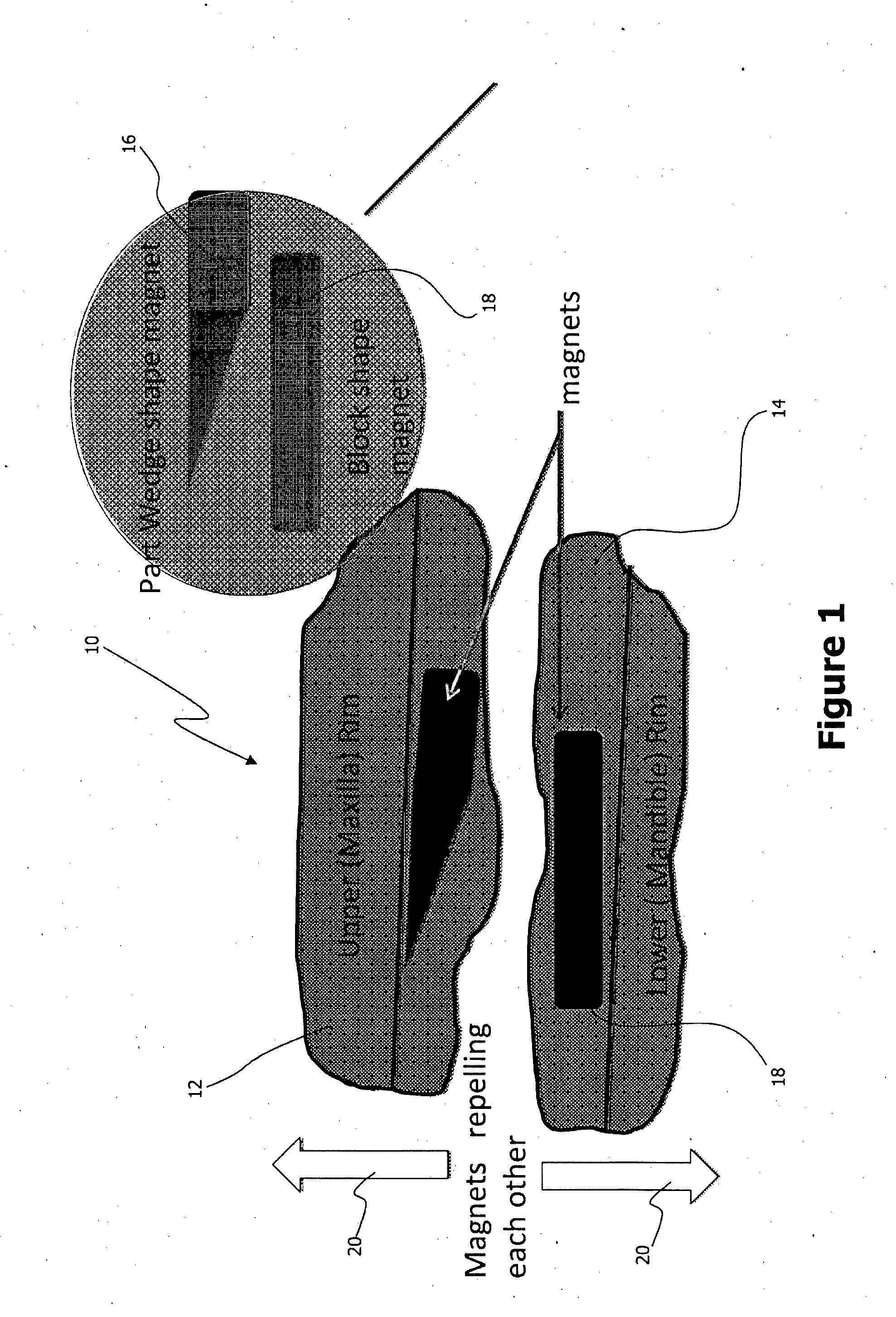

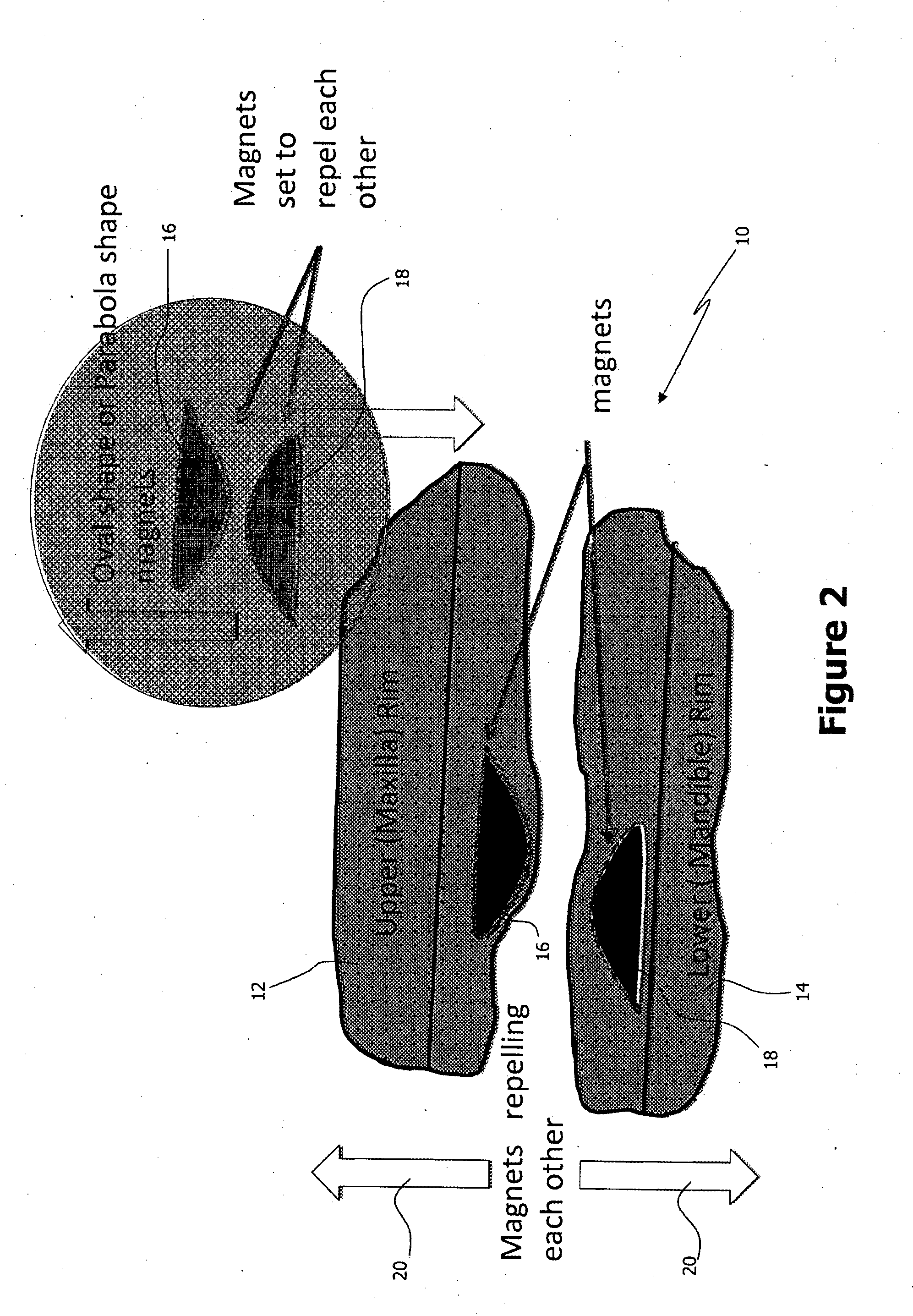

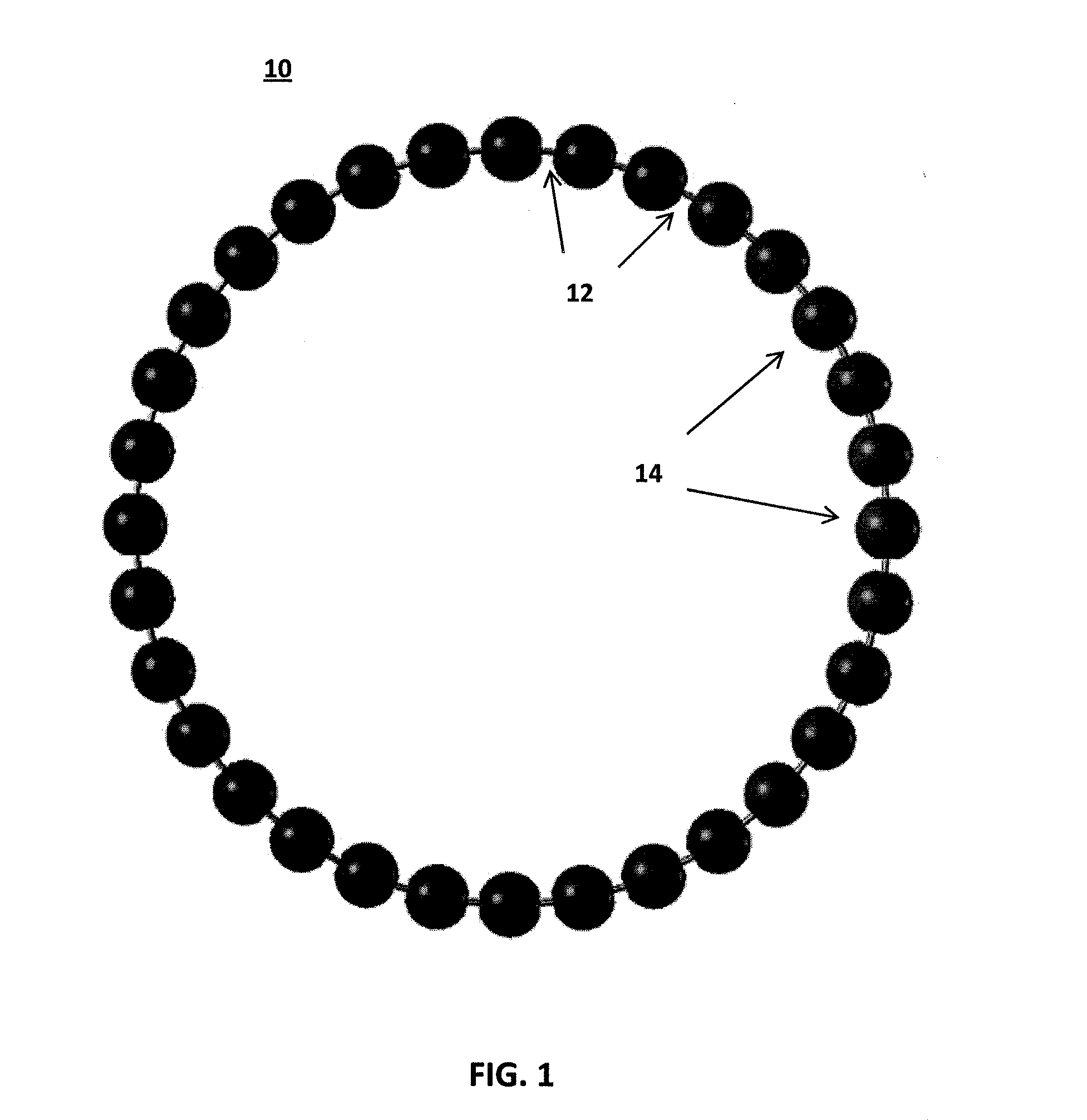

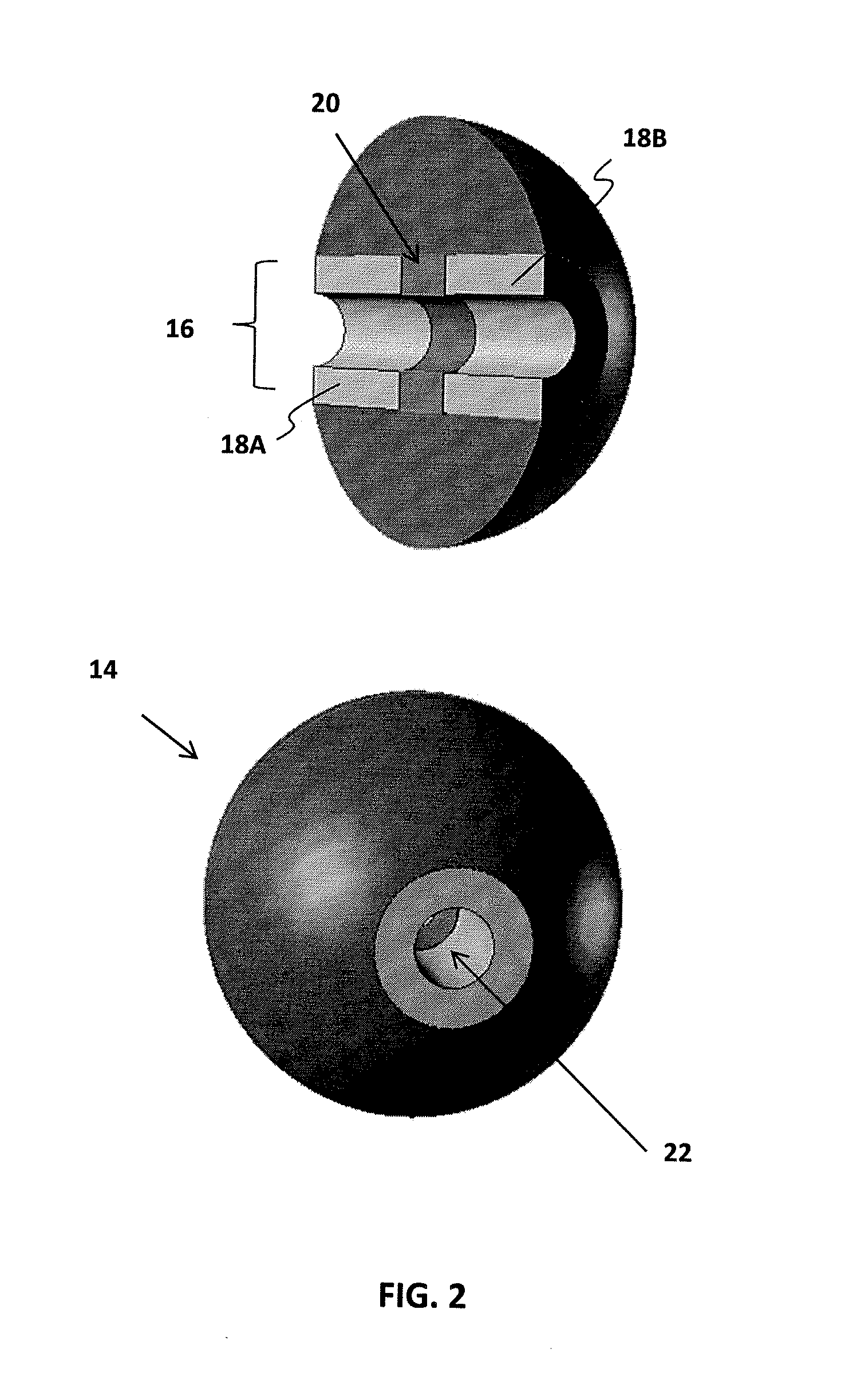

Magnetic orthodontic assembly

An orthodontic assembly for moving selected teeth of a patient includes a hollow aligner shell that fits over a set of selected teeth. The aligner shell supports a series of tooth moving elements, such as magnets or metal engagement plates that are fixed in place in alignment with the selected teeth. Metal plates or magnets are affixed to the selected teeth and when the aligner shell is fitted over the teeth, the magnets in the shell exert attraction or repulsion forces on the metal plates to move the selected teeth in accordance with a treatment protocol.

Owner:PATEL RUCHIR RAMESH

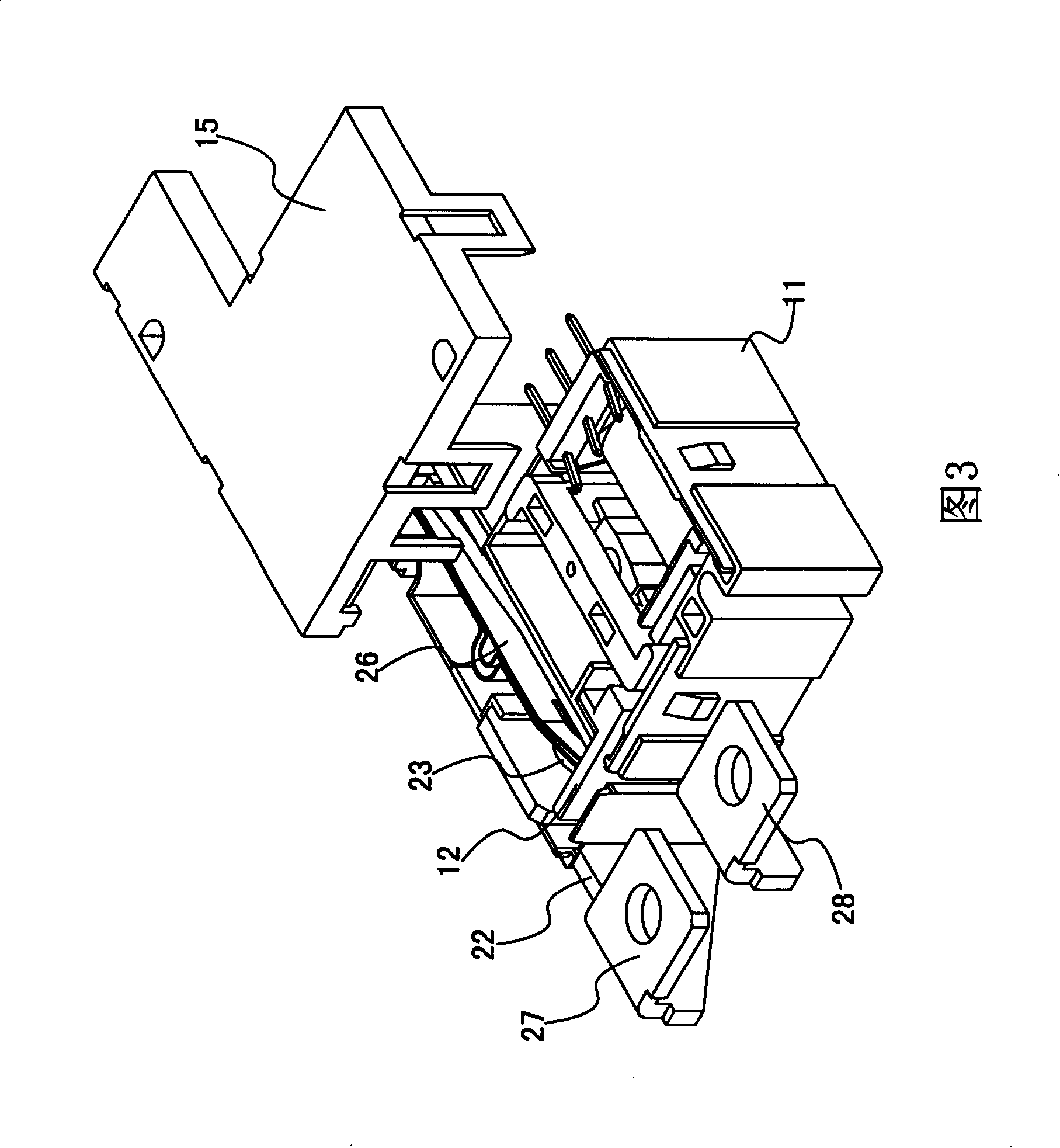

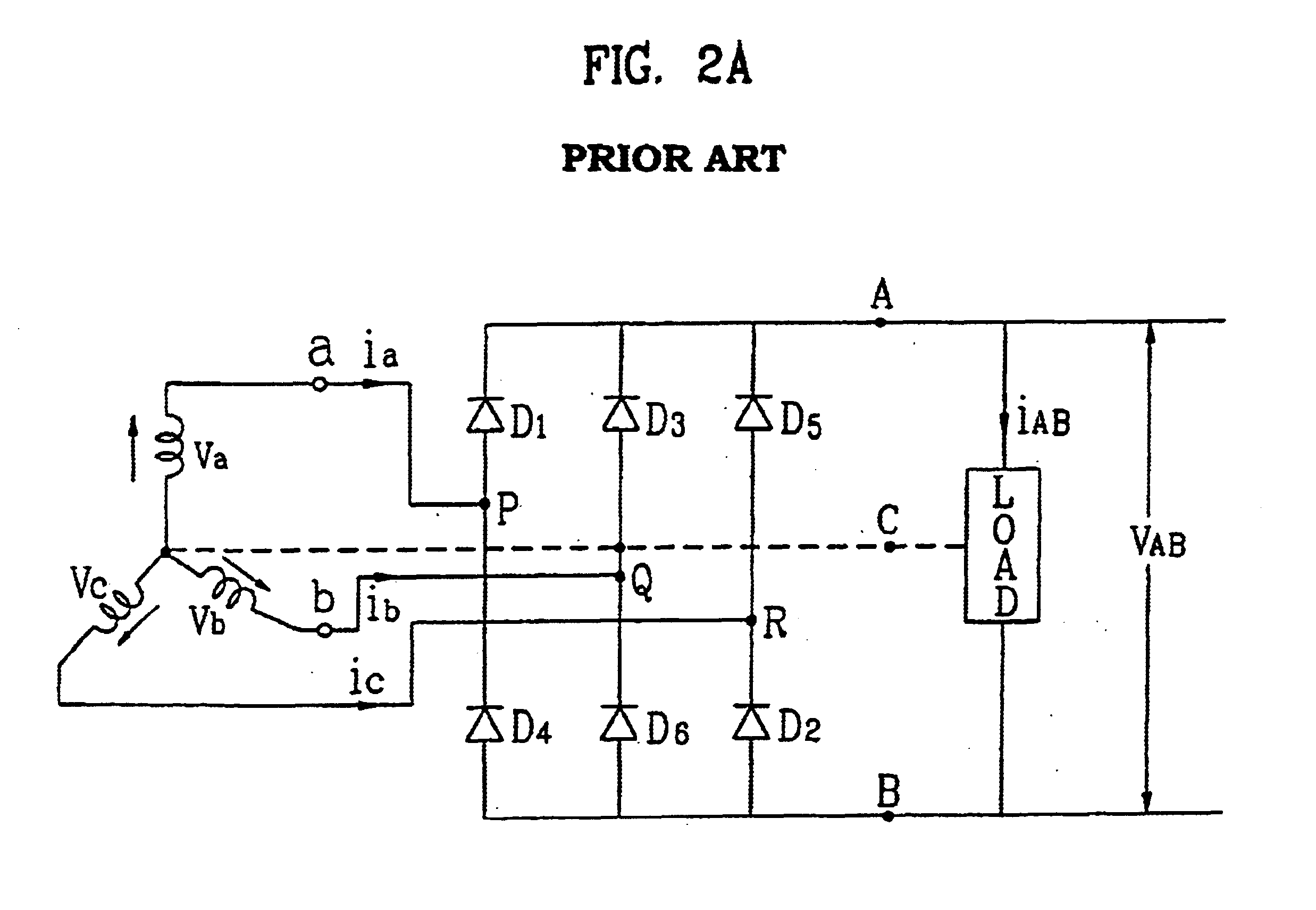

Electromagnetic relay resistant to electric repulsive force

InactiveCN101231923ASolve the technical problem of easy bounceReliable contactElectromagnetic relay detailsNon-polarised relaysMagnetic tension forceContact pressure

The invention discloses an electromagnetic relay which resists electric repulsion force. When a relay contact is closed and the electromagnetic relay works, the relay is loaded, and a coil is provided with a setting signal. The current direction of a second leading-out sheet is opposite to the current direction of a movable spring, thus producing a magnetic field through the interaction. The magnetic field enables the movable spring to produce electromagnetic force. The produced electromagnetic force is in the same direction as the pushing force produced by a pushing card, thus increasing the contact pressure of a contact which is enough to resist the destruction of the electric repulsion force. The invention completely eliminates the technical problem that the electric repulsion force causes the contact to return easily in prior art. The invention further has the advantages of large resultant force of the electromagnetic force and the pushing force, small contact pressure of the contact, small contact resistance, reliable and stable electrical contact of the contact, capability of resisting short-circuit current, preventing the functional relay from being damaged, large switching power of the contact, capability of working under large load for long term, compact conformation, shock resistance, high impact capability, high capability of carrying load, low price, high manufacturability. In addition, the switching frequency of the invention shall not be too high, and the invention is applicable for streamlined production in large quantity.

Owner:XIAMEN HONGFA ELECTRIC POWER CONTROLS

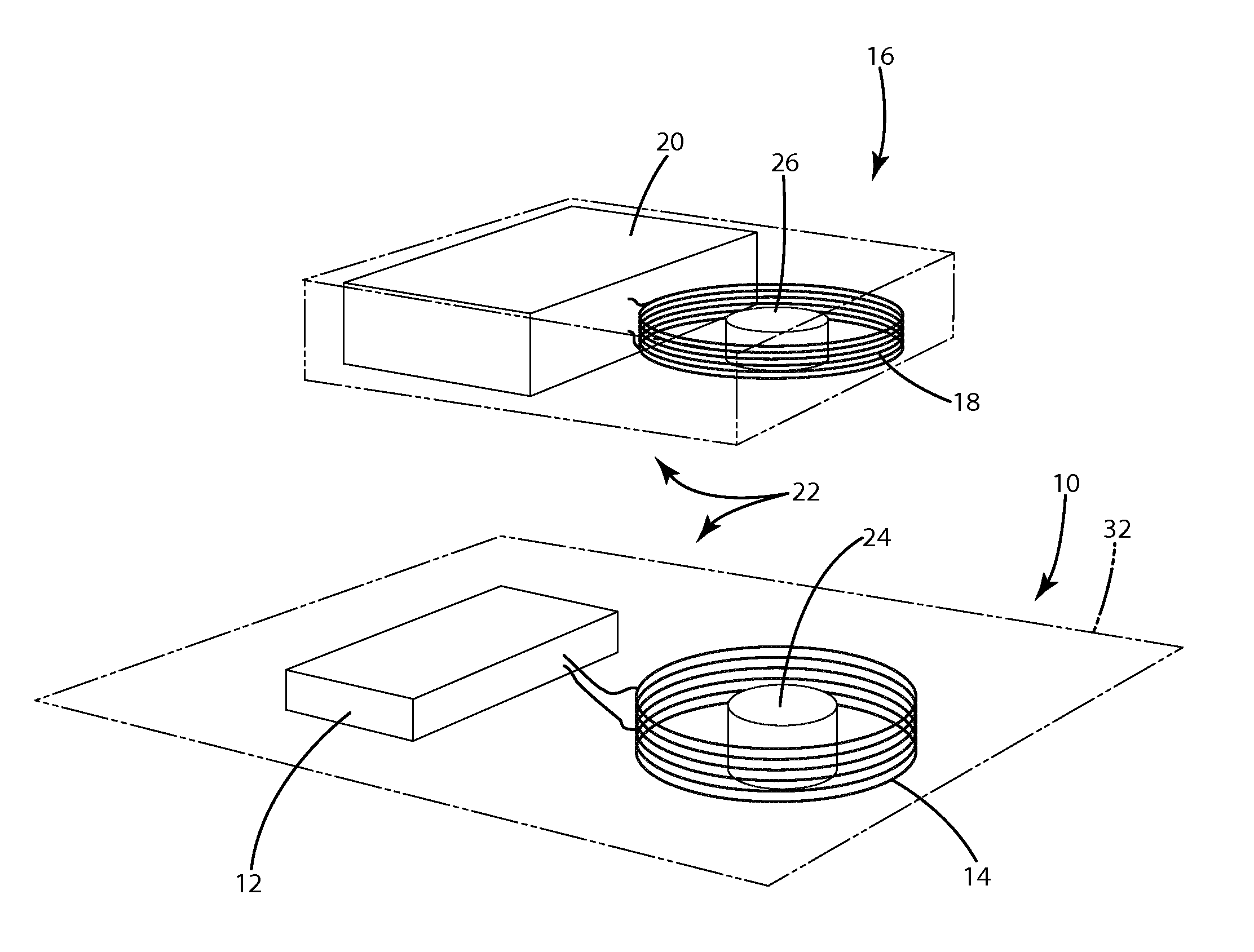

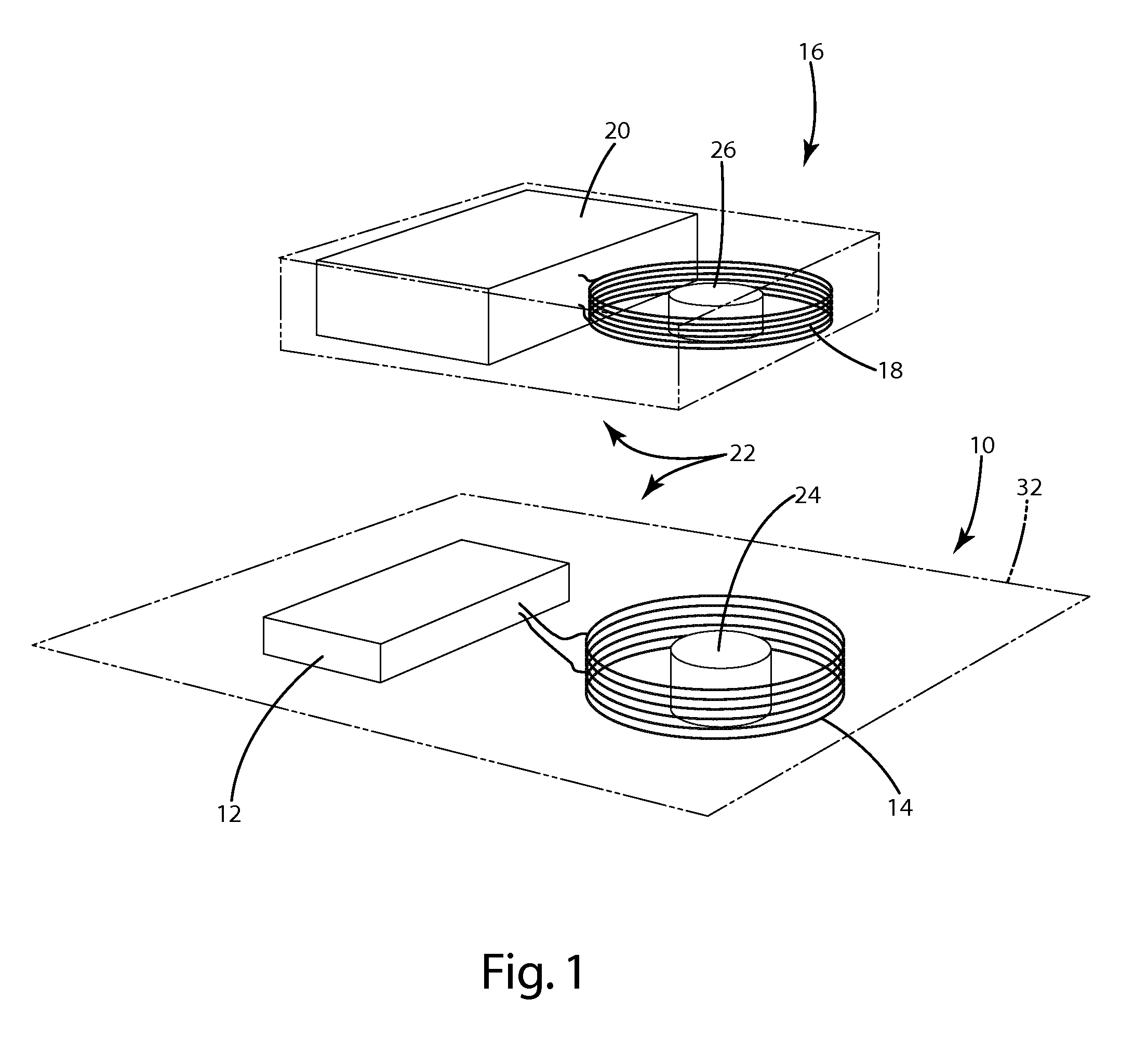

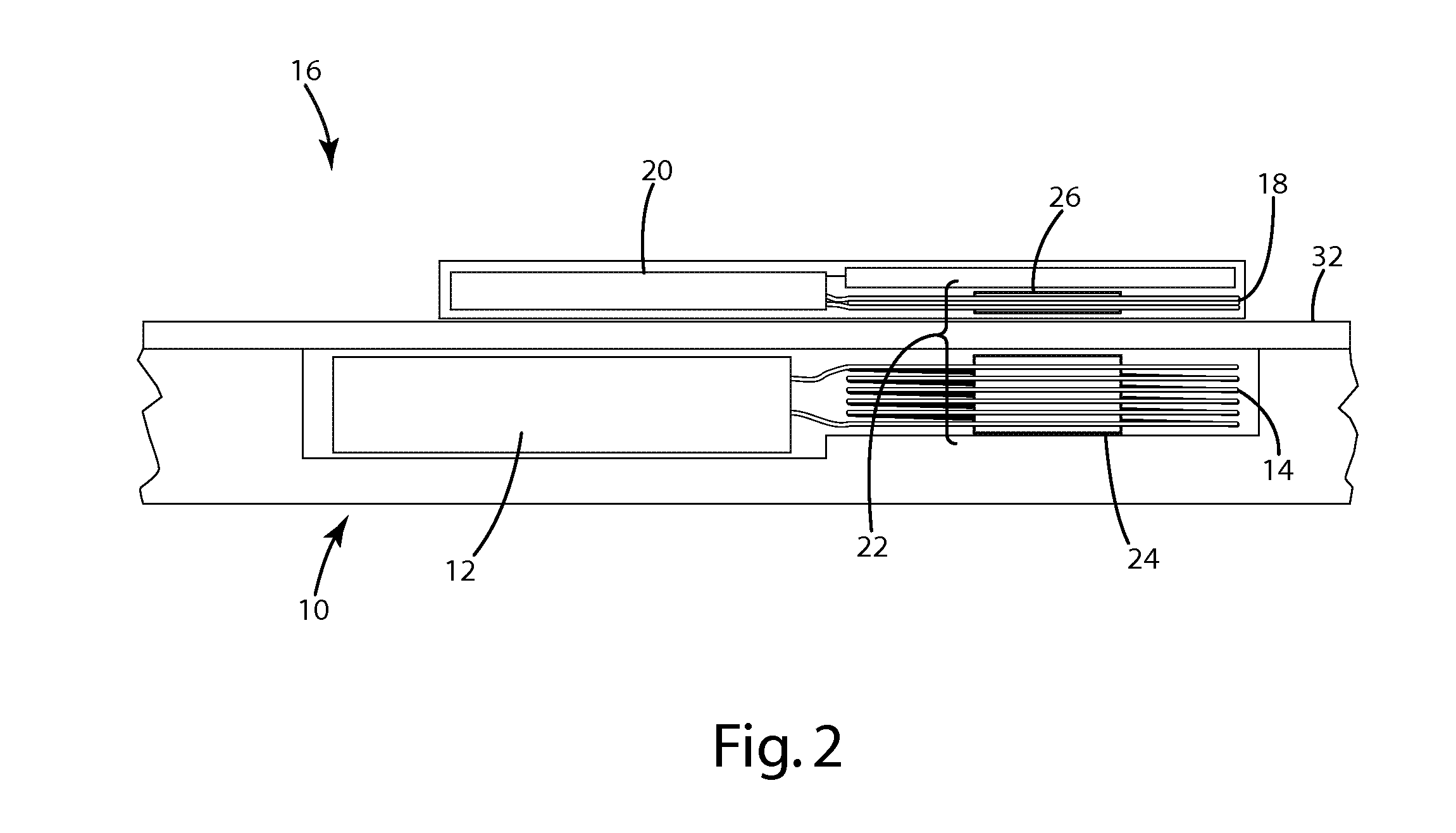

Magnetic positioning for inductive coupling

ActiveUS20120181876A1Enhanced magnetic forceReduce the amount requiredNear-field transmissionBatteries circuit arrangementsMagnetic tension forceRepulsion force

A magnetic positioning system for use in inductive couplings. The magnetic positioning system having a magnet that provides sufficient magnetic force, but does not have enough electrical conductivity to overheat in the presence of the anticipated electromagnetic field. The magnet may be a bonded magnet or a shielded magnet. In another aspect a plurality of magnets are used to provide magnetic attraction forces and said magnetic repulsion forces that cooperate to align the inductive power supply and the remote device. In another aspect, a sensor allows differentiation between different positions of the remote device or inductive power supply. In another aspect, multiple magnets in the inductive power supply interact with multiple magnets in the remote device to position the remote device in different positions.

Owner:PHILIPS IP VENTURES BV

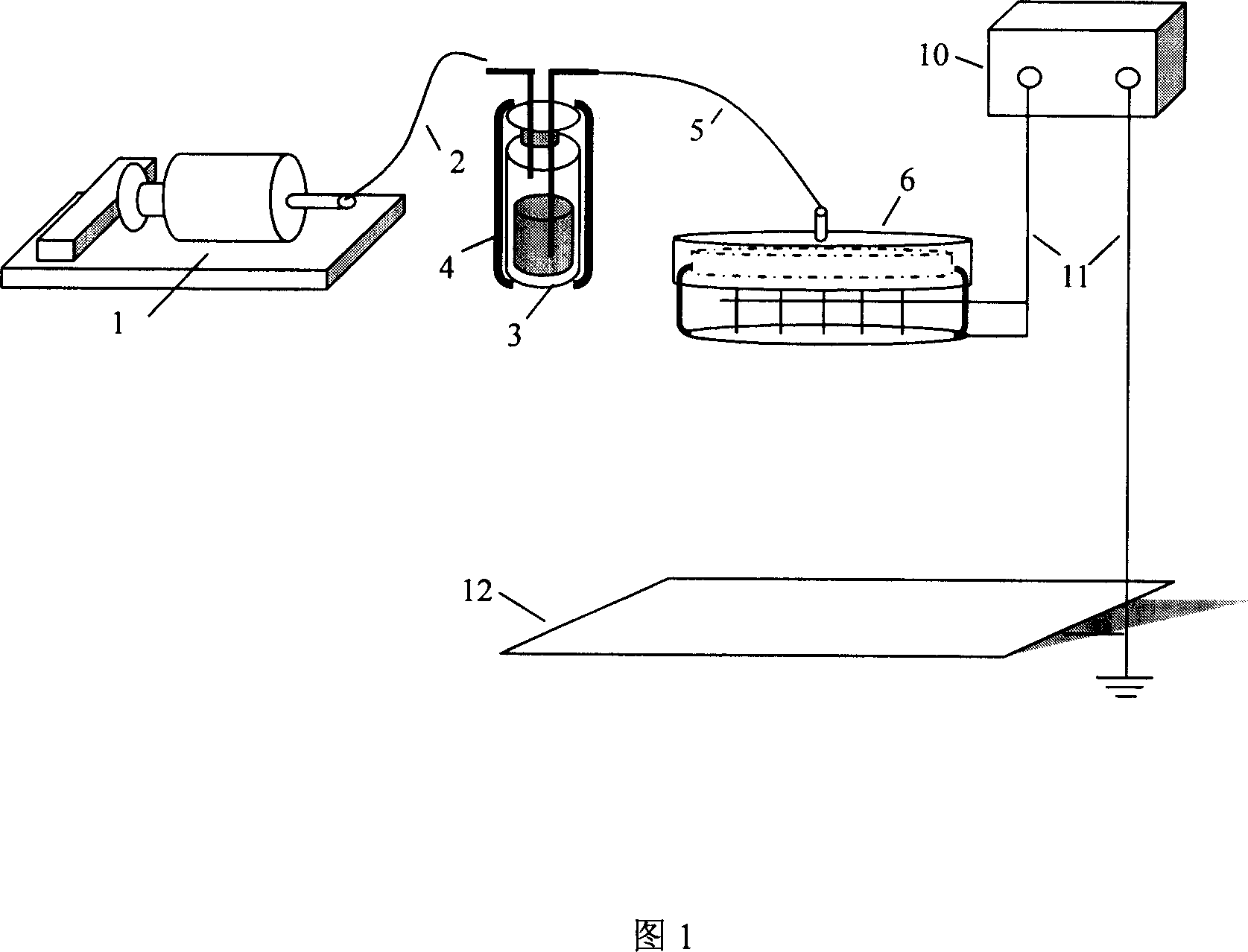

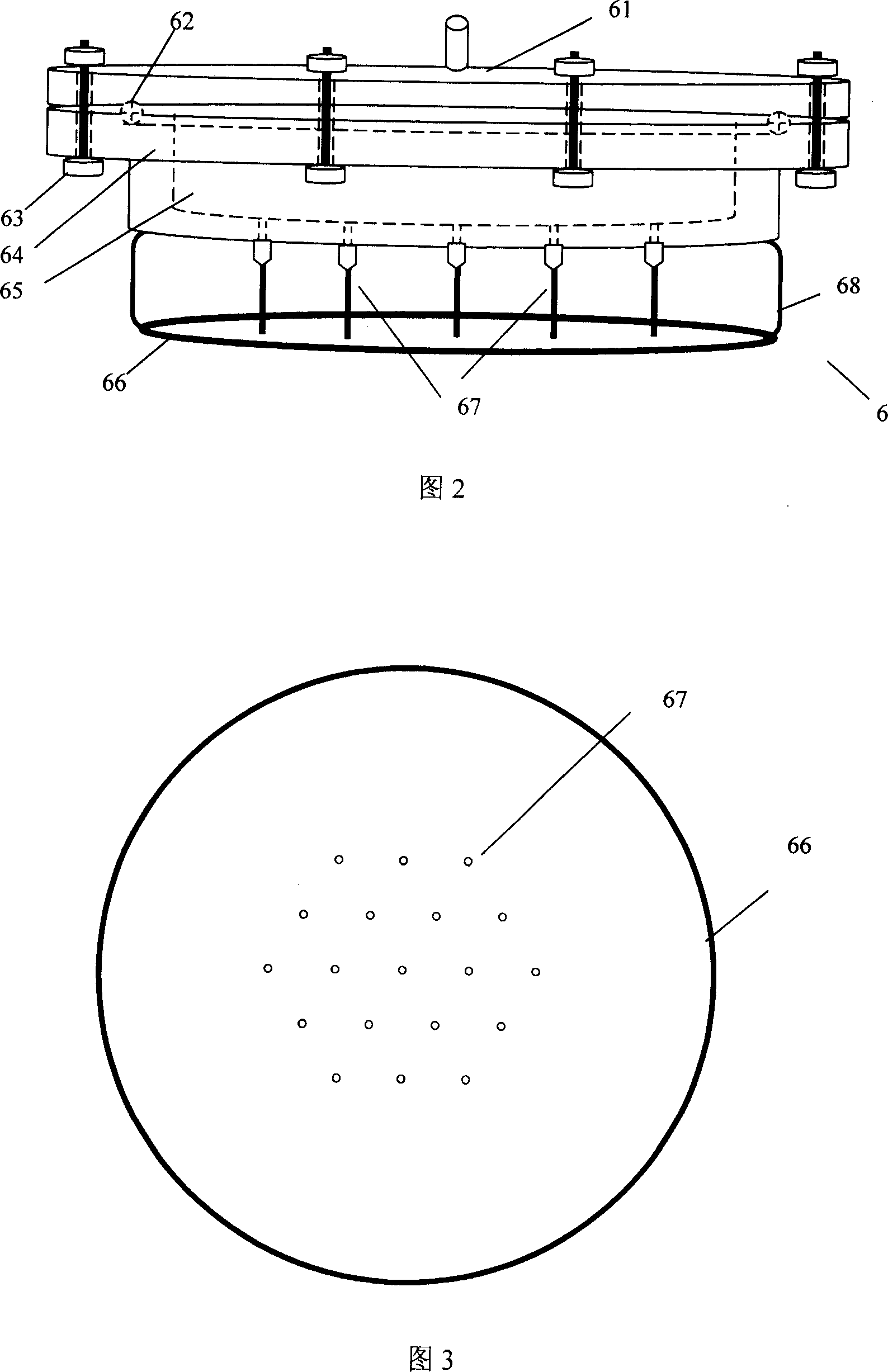

High-performance multineedle electrostatic spinning jet device

InactiveCN1962966AUniform thicknessReduce jet electrostatic repulsionSpinnerette packsFilament/thread formingFiberElectrospinning

The efficient multineedle electrostatic spinning sprinkling device includes constant pressure supplying system, spinnerette connected with the constant pressure supplying system, receiver electrode plate and electrostatic generator; said spinnerette is multineedle combined spinnerette, it includes spinnerette main body, cover and seal ring the two, the main body is provided with fluid cavity,the bottom of the main body is equipped with several metal nozzles, three adjacent metal nozzles are set up in regular triangle and the abduction of each circle of metal nozzles is in regular hexagon; insulated supporting parts are installed on the bottom of the main body, metal rings encompassing all metal nozzles are installed on the lower of said supporting parts, said metal rings and metal nozzles are connected with electrostatic generator directly. The invention achieves the goal of multi-needle injection simultaneously by improving the intensity of field of spinnerette, reduces the fluid jet electrostatic repulsion forces greatly caused by the small distance between the needles and makes the receiver can receive fiber in small range, so increases the efficiency in unit area and obtains carpet fiber with more uniform thickness.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

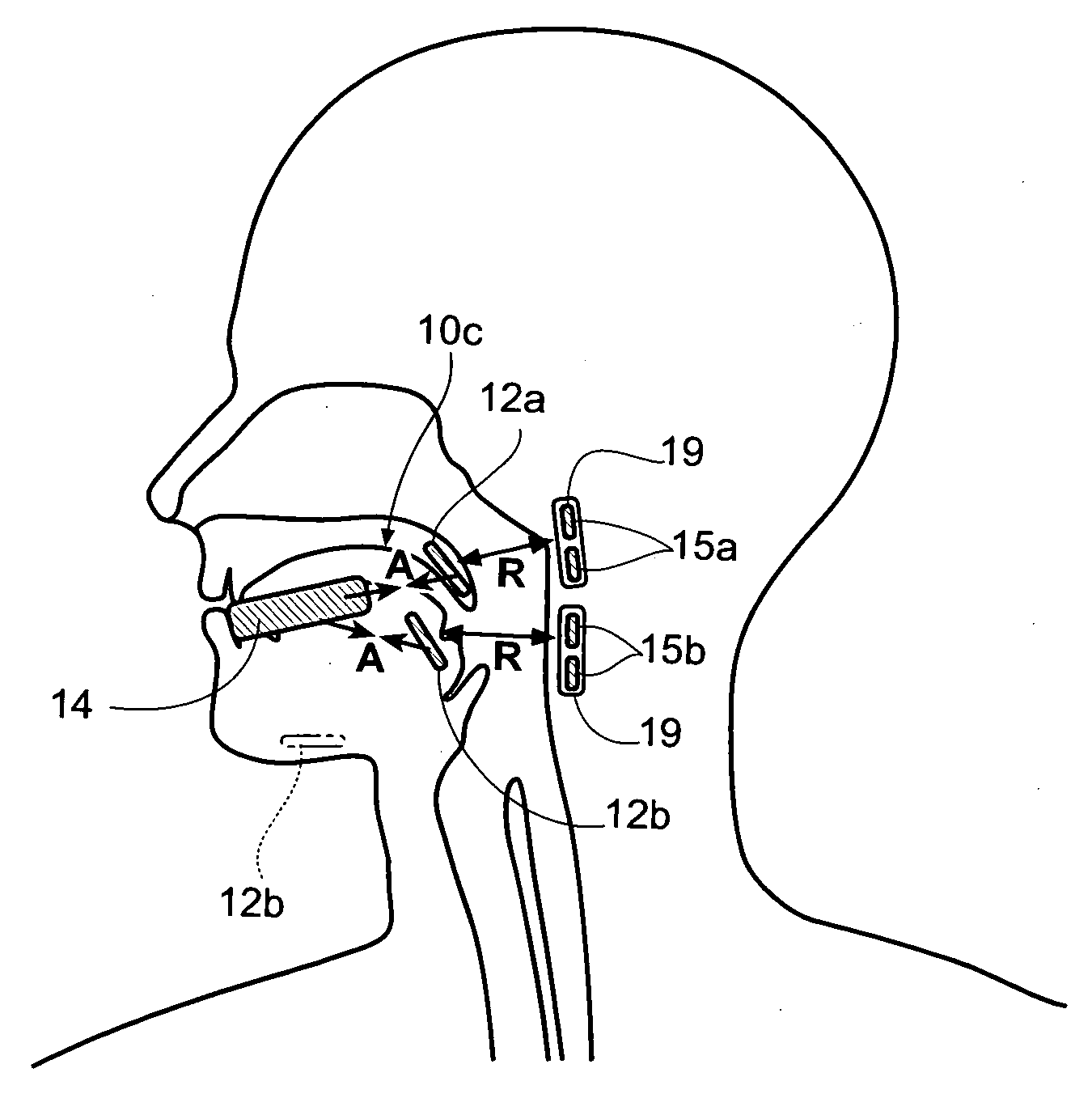

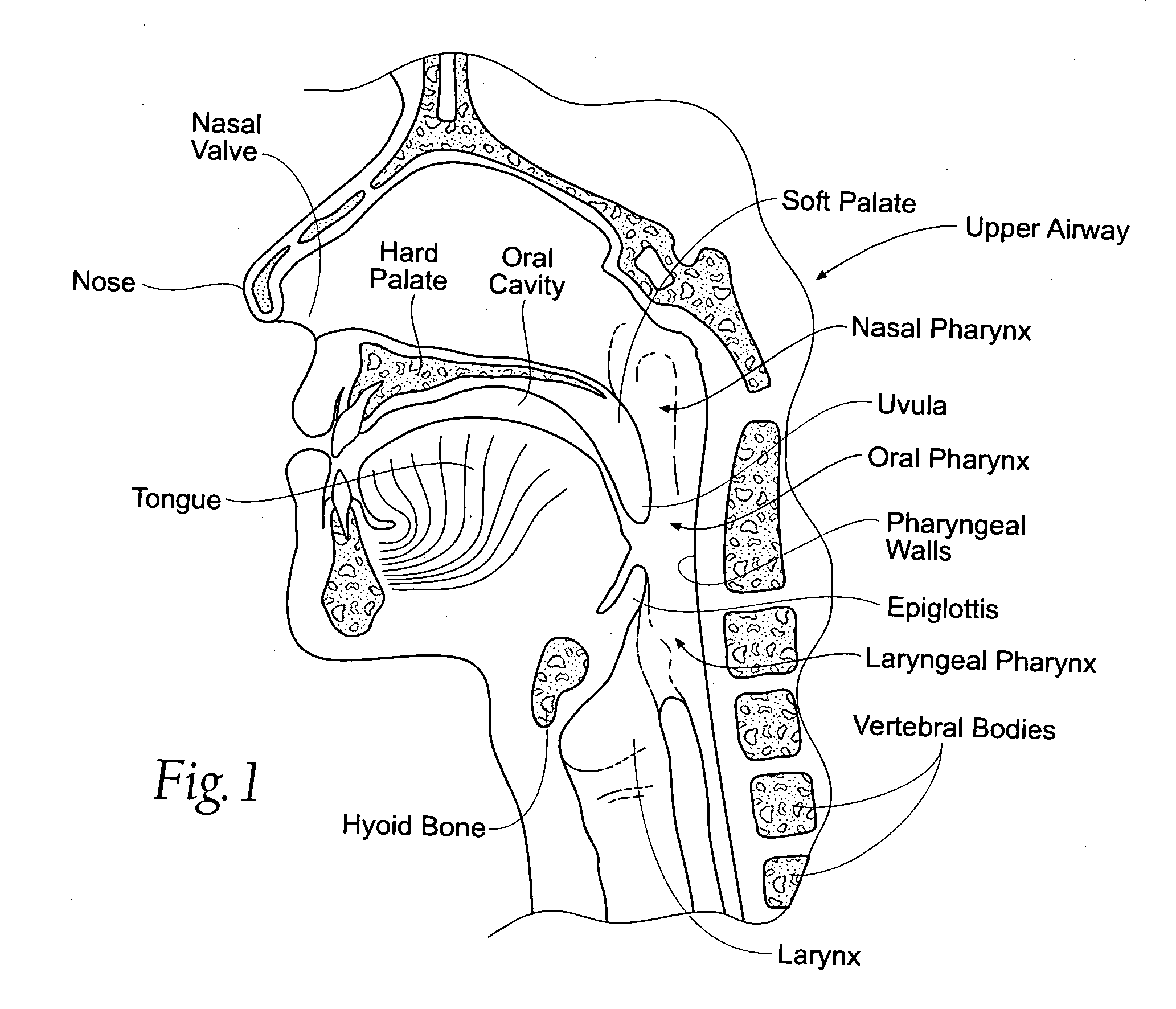

Device, systems and methods having mobile ferromagnetic structures

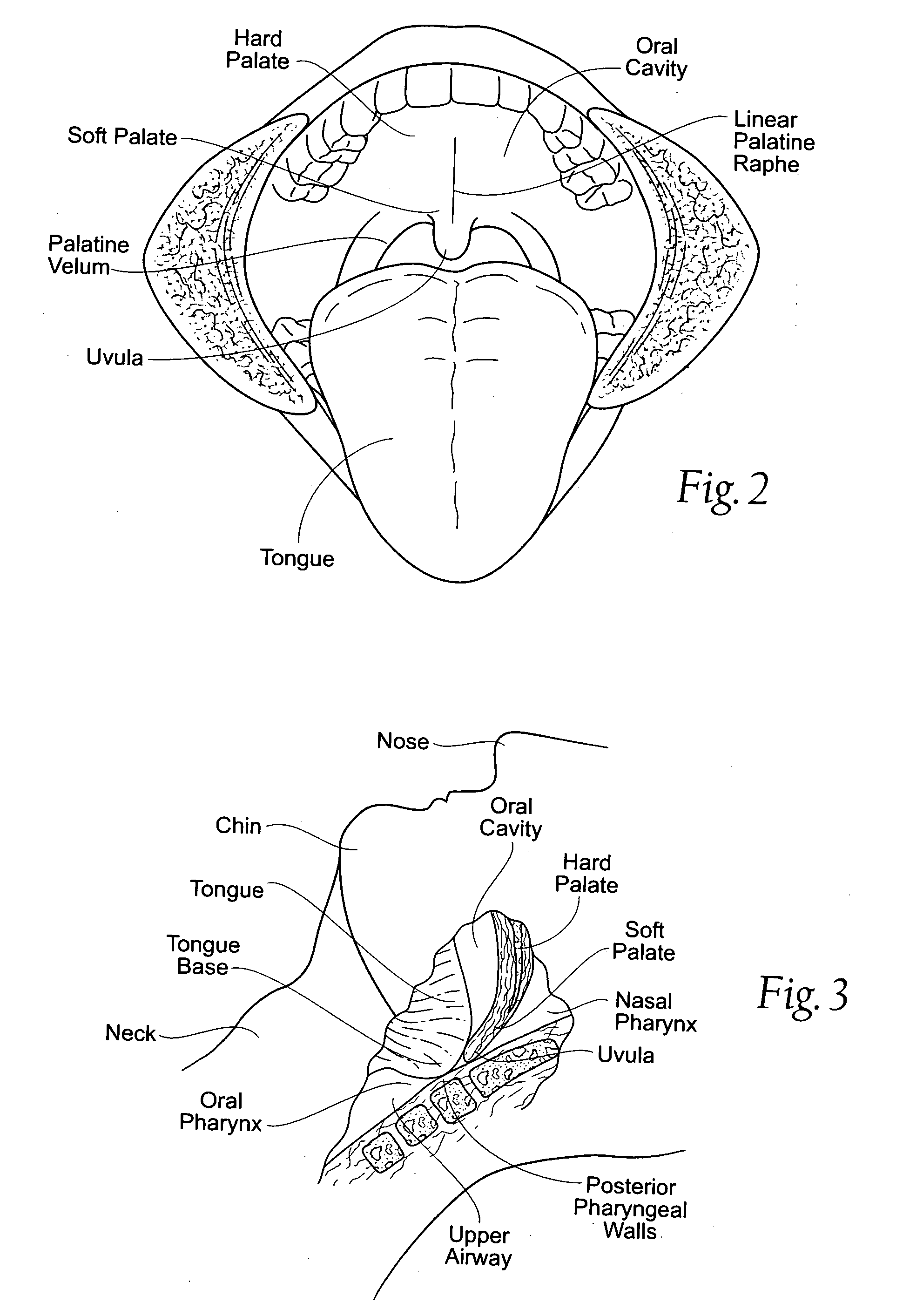

InactiveUS20070144531A1Prevent tissue collapseSnoring preventionNon-surgical orthopedic devicesCombined useEngineering

A carrier is sized and configured for placement in or on a tissue region. The carrier includes at least one interior compartment. At least one ferromagnetic material is carried within the compartment. The compartment and the ferromagnetic material are mutually sized and configured to allow movement of the ferromagnetic material within the compartment in response to magnetic interaction with a magnetic material located outside the carrier. The magnetic interaction can include either a magnetic attracting force or a magnetic repelling force. The carrier can be used in association with a source of magnetism sized and configured for placement in or on a tissue region outside the carrier for magnetic interaction with the ferromagnetic material carried within the compartment, e.g., to stabilize the orientation of a tissue region within an airway.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Suspension maglev rail transit system

ActiveCN109131370AReduce frictionReduced forward resistanceSliding/levitation railway systemsElevated railway with suspended vehicleGuidance systemRepulsion force

A suspension maglev rail transit system includes an orbital system, a suspension system, a control system and a car system, wherein the control system comprises a drive system, a guidance system and asuspension control system, wherein the track system is suspended in the air through upright posts, the car system is suspended vertically below the track system through the suspension system, and thedrive system and the guidance system cooperate to drive the car system to operate in the track system. The invention utilizes the levitation force with the permanent magnet repulsion force as the main force and the electromagnetic regulation as the auxiliary force to suspend the car on the air track, and realizes the stable operation through the non-contact traction of the linear motor. The invention has the advantages of low energy consumption, high safety, no land occupation, low cost, strong climbing ability, small turning radius and wide adaptability.

Owner:JIANGXI UNIV OF SCI & TECH +1

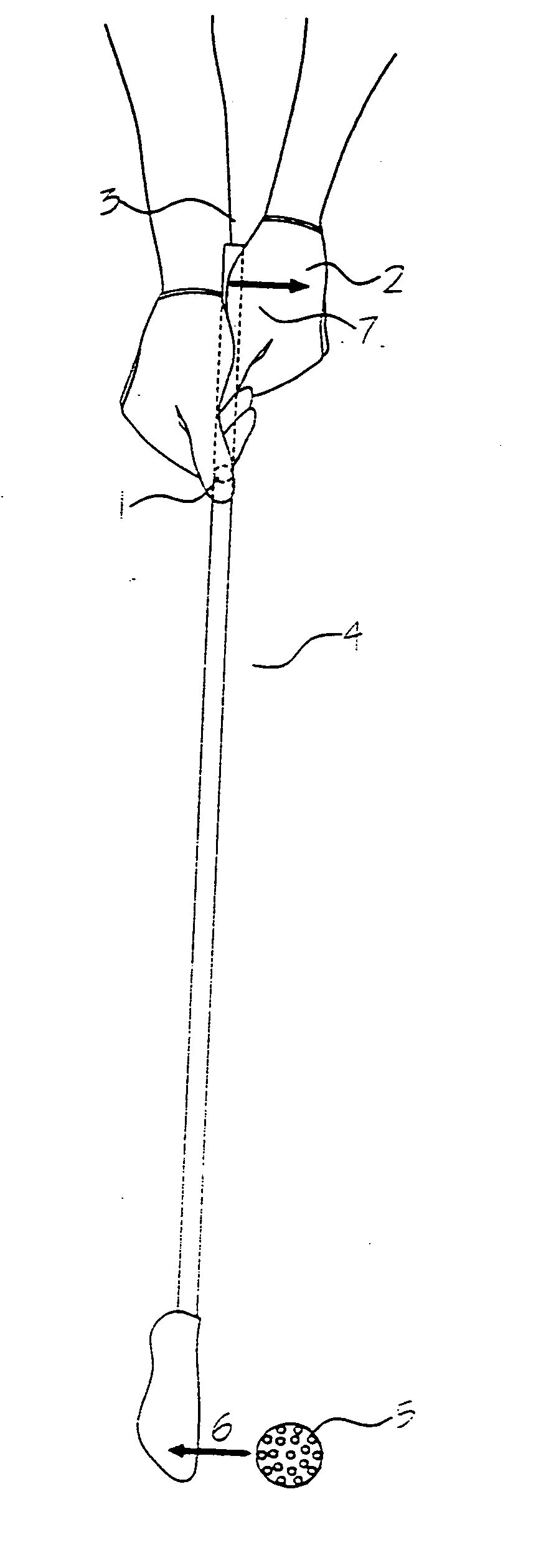

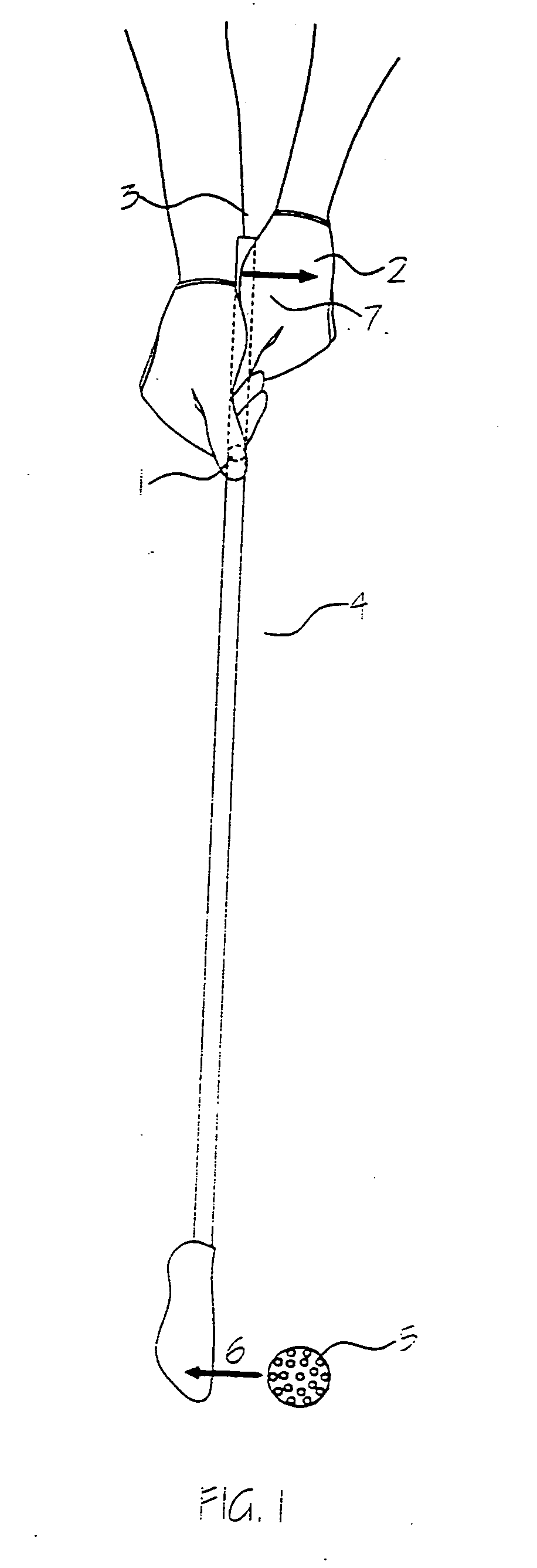

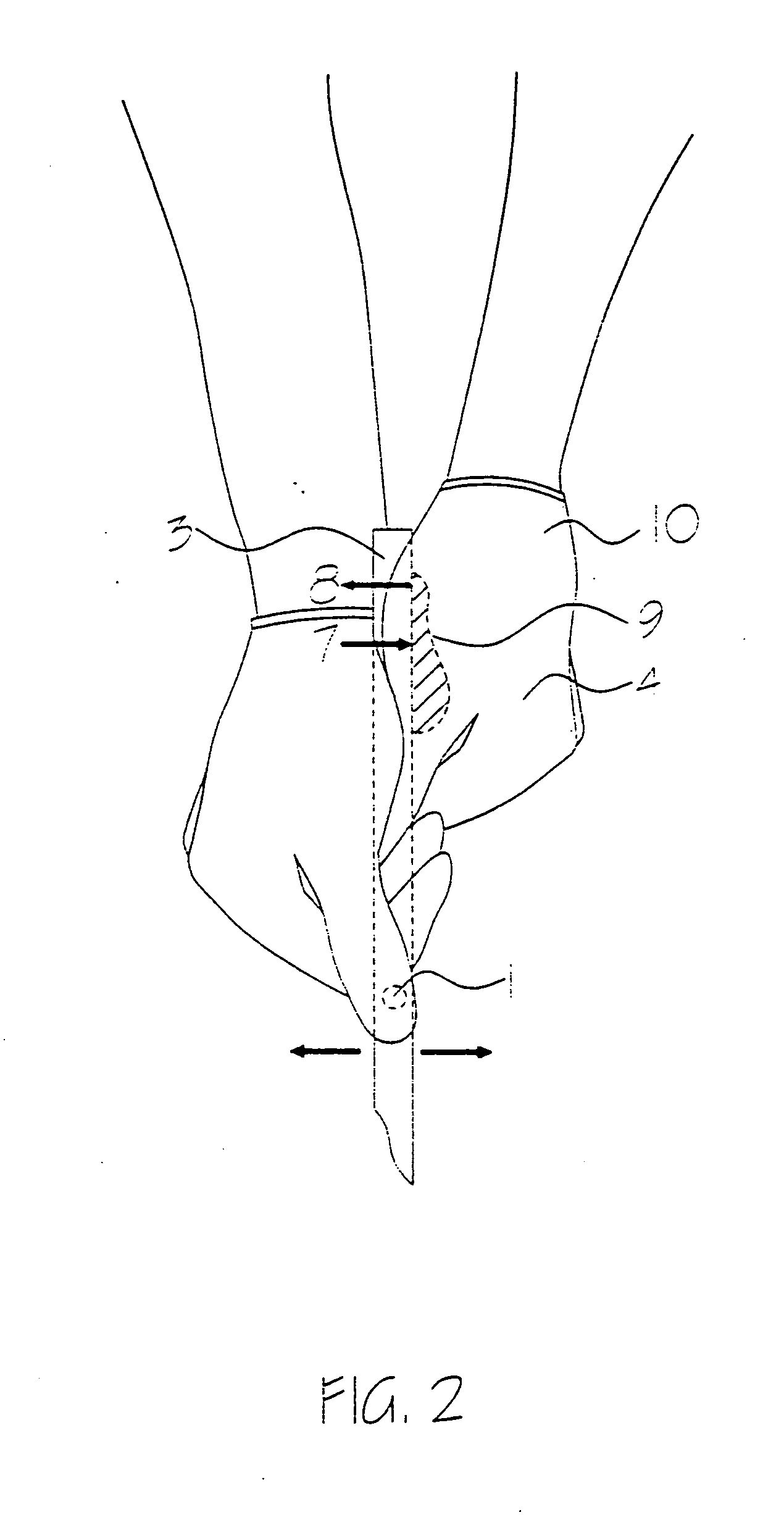

Golf glove with action/anti-action device

InactiveUS20050229285A1Flying distance can be improvedIncrease distanceGlovesSport apparatusElastomerRepulsion force

A golf glove for increasing the flying distance of golf ball has an insert that provide a repulsion forces to the grip of a golf club when the head of the club impacts a golf ball. The insert is made of synthetic elastomer such as polyurethane, silicon rubber, EVA (Ethylene Vinyl Acetate copolymer, EMA (Ethylene Methyl Acetate copolymer), or EAA (Ethylene Acrylic Acetate copolymer). The insert has a planar shape that fits to the concave inner surface of human palm. The insert is firmly attached to the inner surface of the palm side of a golf glove.

Owner:CHUNG PAUL HOON

Box cover locking device

InactiveCN102582950AImprove use reliabilityImprove self-sustaining timeLocking devicesRepulsion forceHolding time

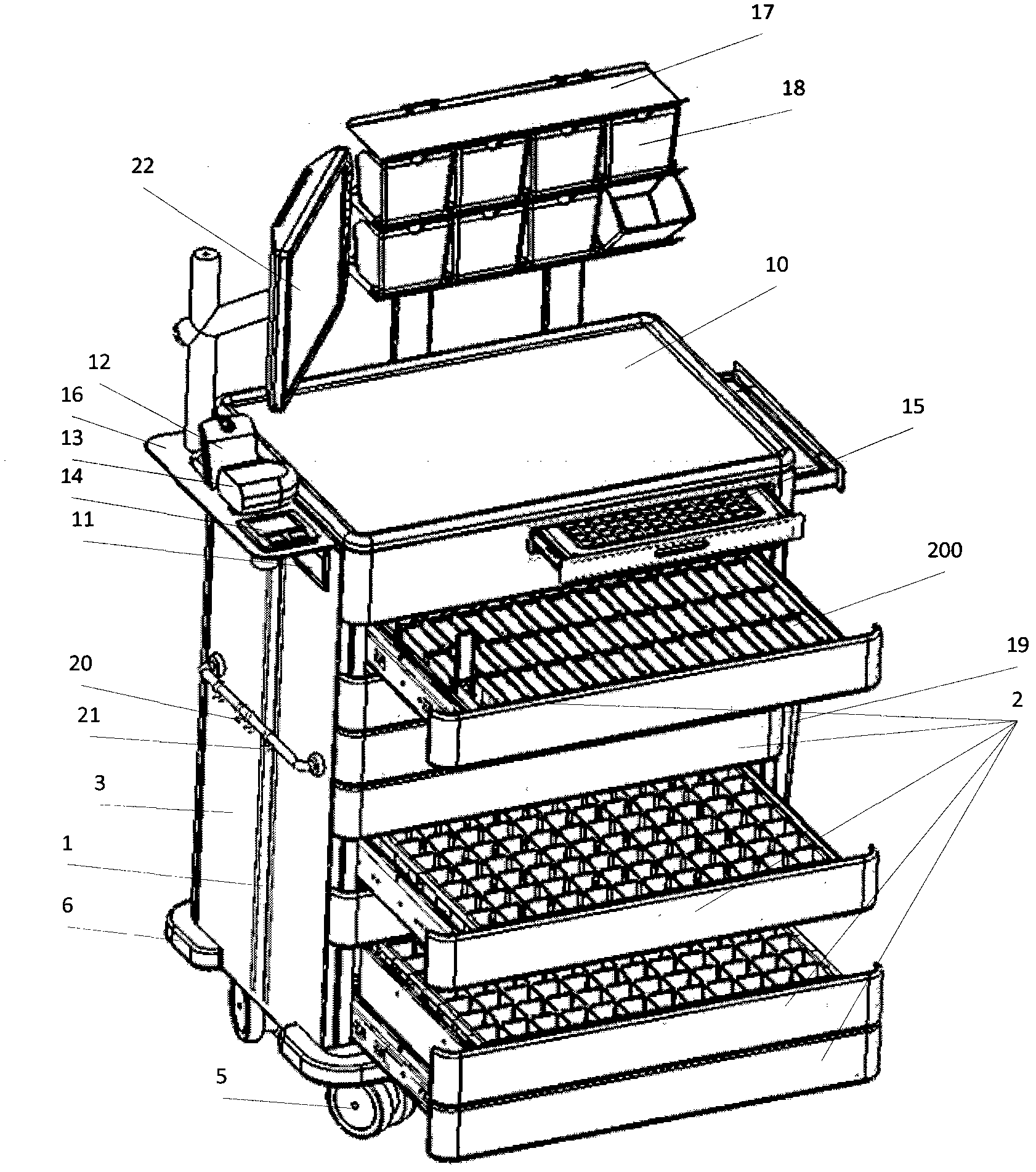

The invention provides a box cover locking device, which comprises an electromagnet. A permanent magnet is arranged on a box cover. The magnetic pole of the electromagnet is opposite to the magnetic pole of the permanent magnet, so that the box cover can be opened by the repulsion force generated between the electromagnet and the permanent magnet on the box cover when the electromagnet is powered on. When the electromagnet is powered off, the electromagnetic force of the electromagnet disappears, and an iron core of the electromagnet is attracted by the permanent magnet so that the box cover is closed. The box cover locking device has the advantages that the reliability in use of the locking device is improved since motion components, extra holes and plug-in and plug-out mechanisms are omitted; power consumption is reduced and the self-holding time of an automatic storage management system is prolonged by the aid of the design that the box cover is opened when the electromagnet is powered on and is closed when the electromagnet is powered off. The invention further provides a controllable storage box comprising the box cover locking device and a drug consumable storage system comprising the controllable storage box.

Owner:北京华兴长泰物联网技术研究院有限责任公司

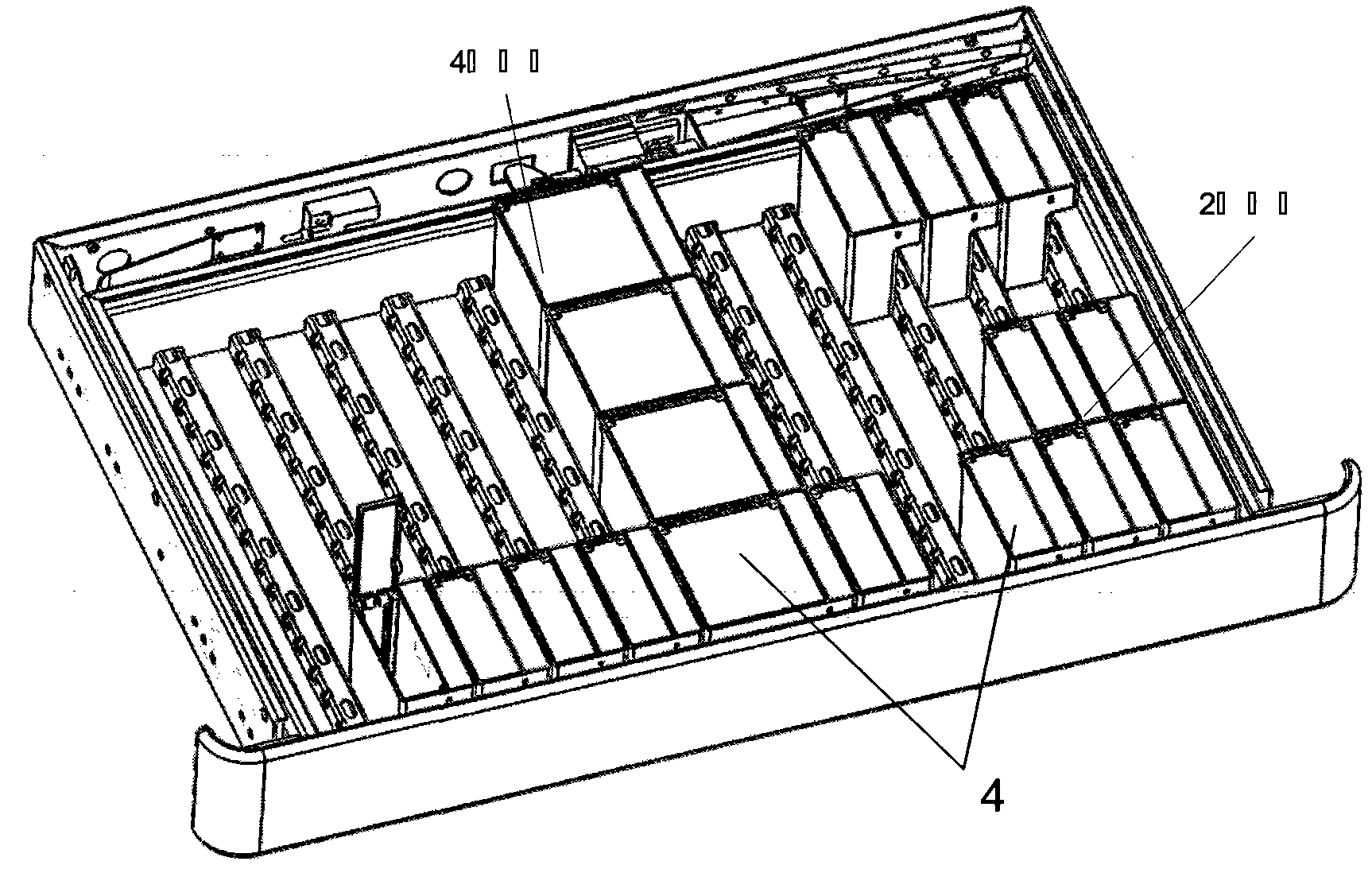

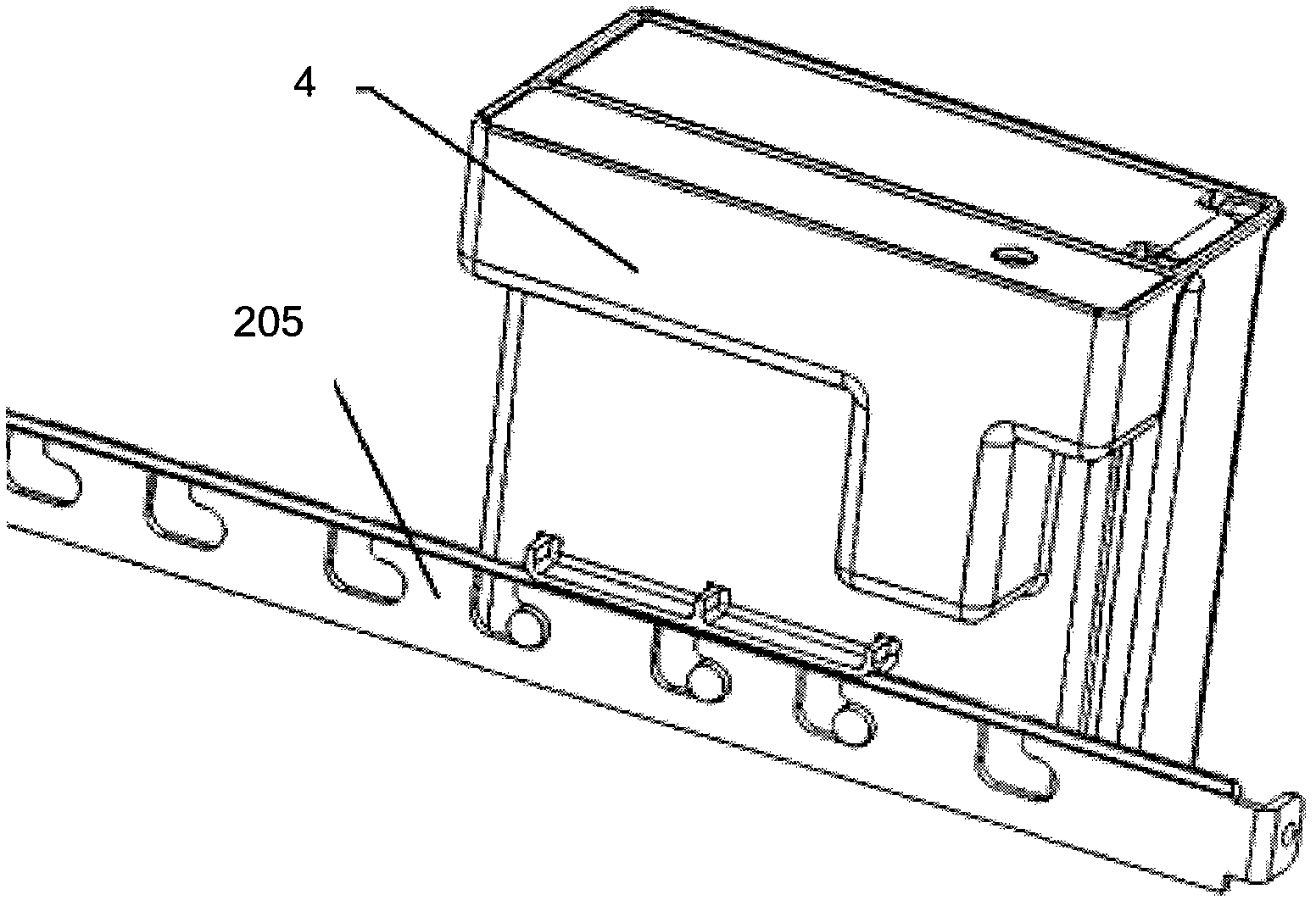

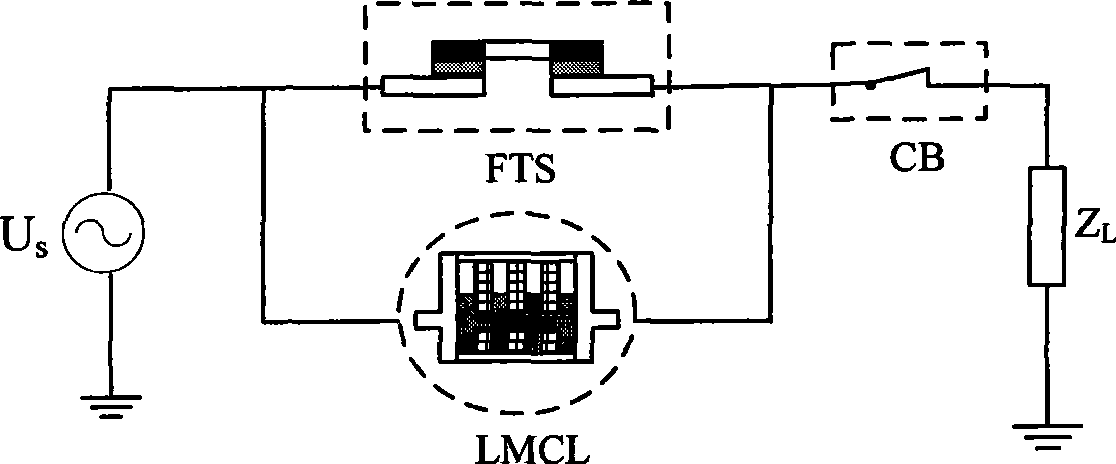

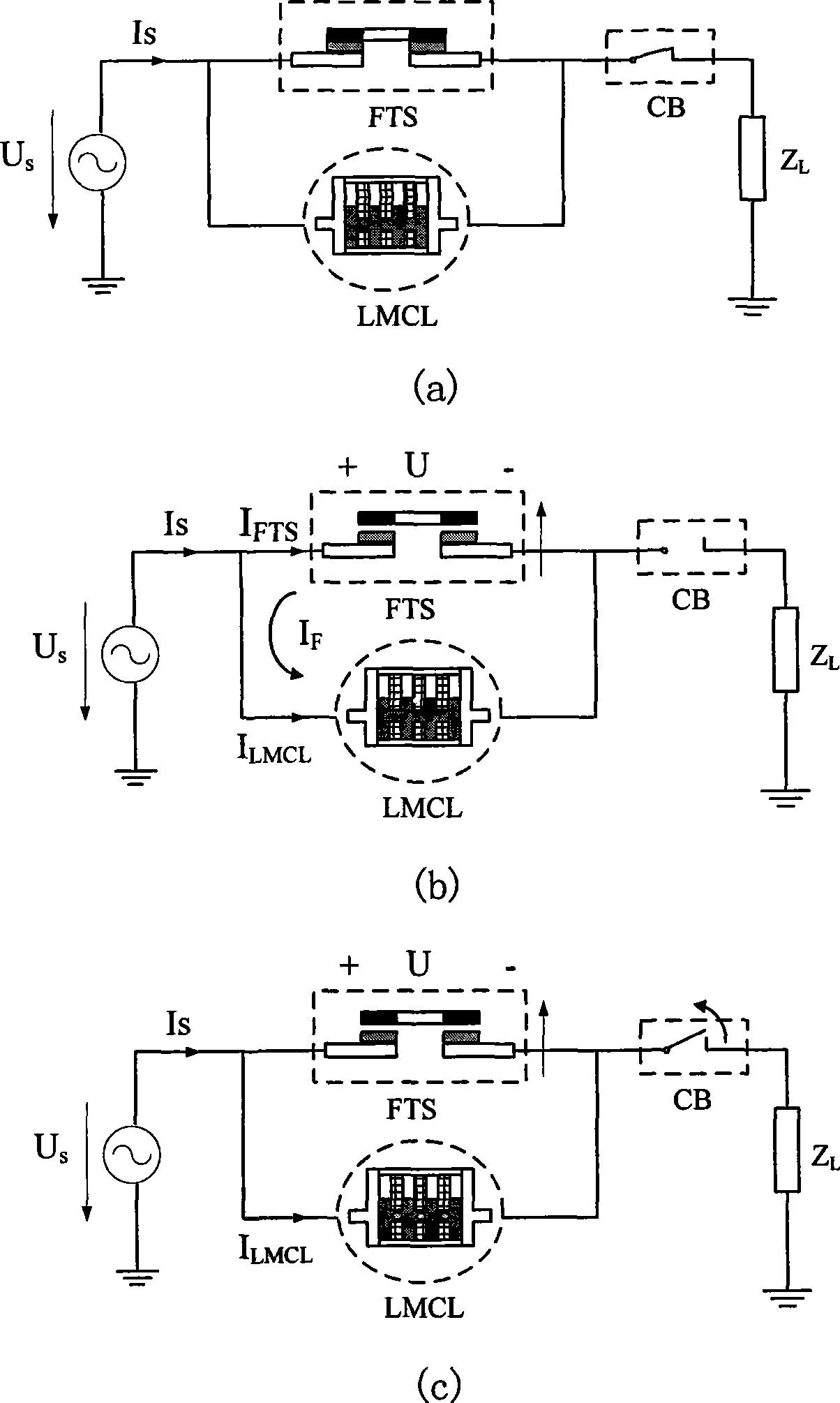

Current limiting device based on quick converting switch and liquid metal current limiting device, current limiting method therefor

InactiveCN101394085AReliable contactReduce temperature riseEmergency protective arrangements for limiting excess voltage/currentProtective switch operating/release mechanismsCurrent limitingLiquid state

Based on a quick switcher and a liquid metal flow restricting device and a flow restricting method, the quick switcher is connected with the liquid metal flow restricting device in parallel and then connected with a circuit breaker in series. Under normal working circumstances, most of the currents can flow through the branch circuit in which the quick switcher is arranged nearly without loss; and once the short circuit current error occurs, a repulsion force mechanism quickly drives a connecting rod to cause a bridge contact to realize quick disjunction, and the currents are gradually transferred to the branch circuit in which the liquid metal flow restricting device is arranged. When the liquid metal flow restricting device restrains the short circuit currents to a range which the circuit breaker can open and close, the circuit breaker can open and close the short circuit currents. The invention has a simple structure, is particularly suitable for restraining the error currents in middle-lower pressure field AC / DC system, and can reduce the burden of various electrical devices such as circuit breaker.

Owner:XI AN JIAOTONG UNIV

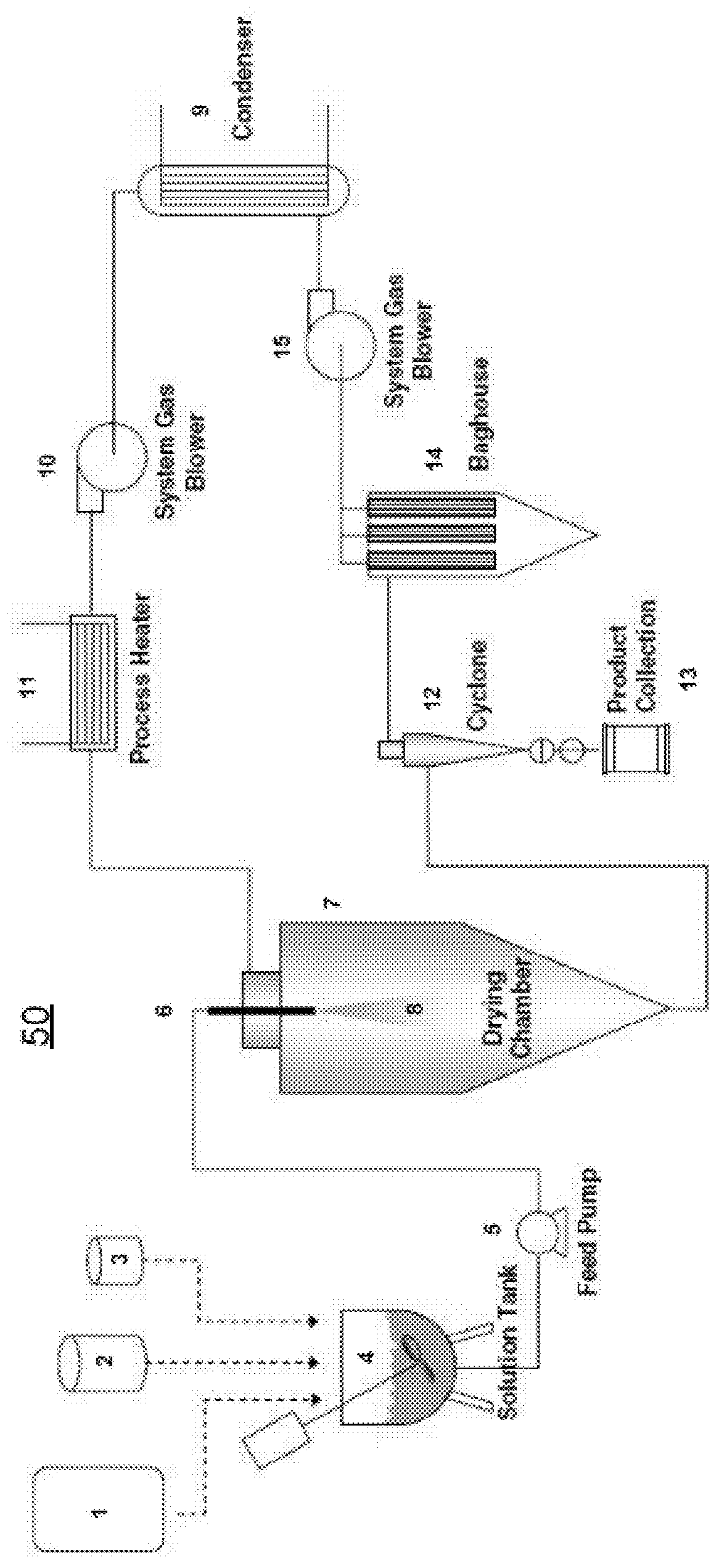

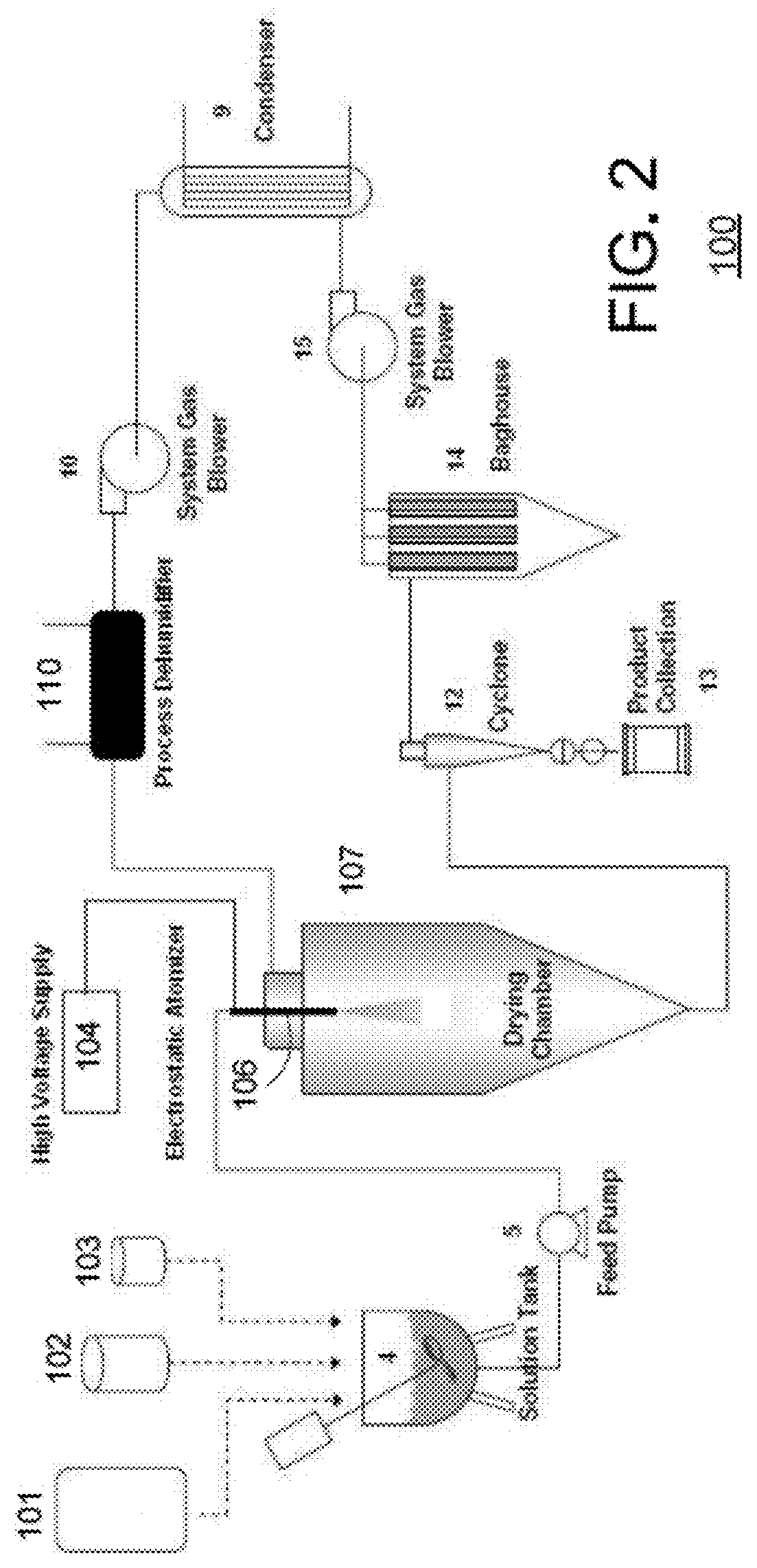

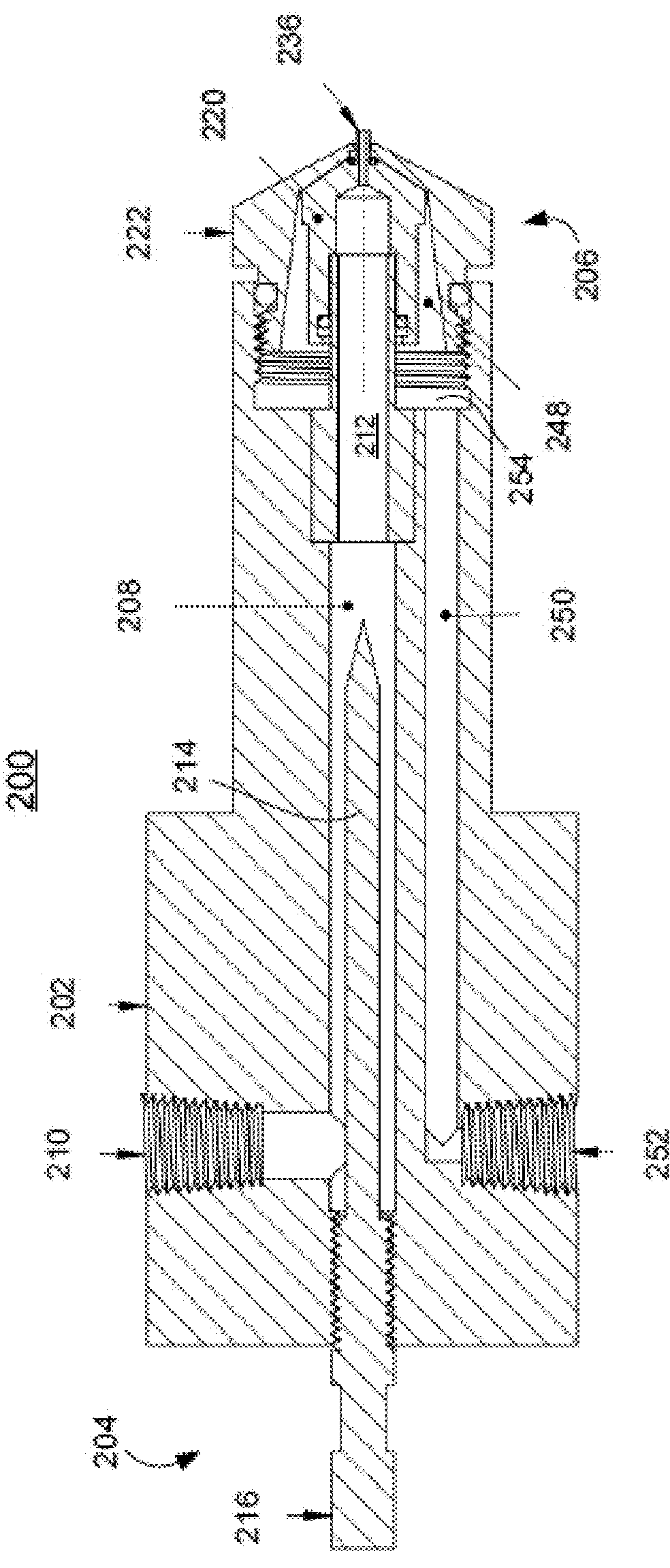

Methods and apparatus for low heat spray drying

ActiveUS9332776B1Liquid surface applicatorsDrying solid materials with heatLiquid productSufficient time

Methods and apparatus provide for spray drying a liquid product into a dried powder without applying heat, including: forming a slurry including a liquid solvent, a carrier, and an active ingredient; applying an electrostatic charge to the slurry; atomizing the charged slurry to produce a plurality of electrostatically charged, wet particles; suspending the electrostatically charged, wet particles for a sufficient time to permit repulsive forces induced by the electrostatic charge on at least some wet particles to cause at least some of such particles to divide into wet sub-particles; and continuing the suspending step, without the presence of any heated drying fluids, for a sufficient time to drive off a sufficient amount of the liquid solvent within most of the wet particles to leave a plurality of dried particles (the powder), each dried particle containing the active ingredient encapsulated within the carrier.

Owner:ZOOMESSENCE INC

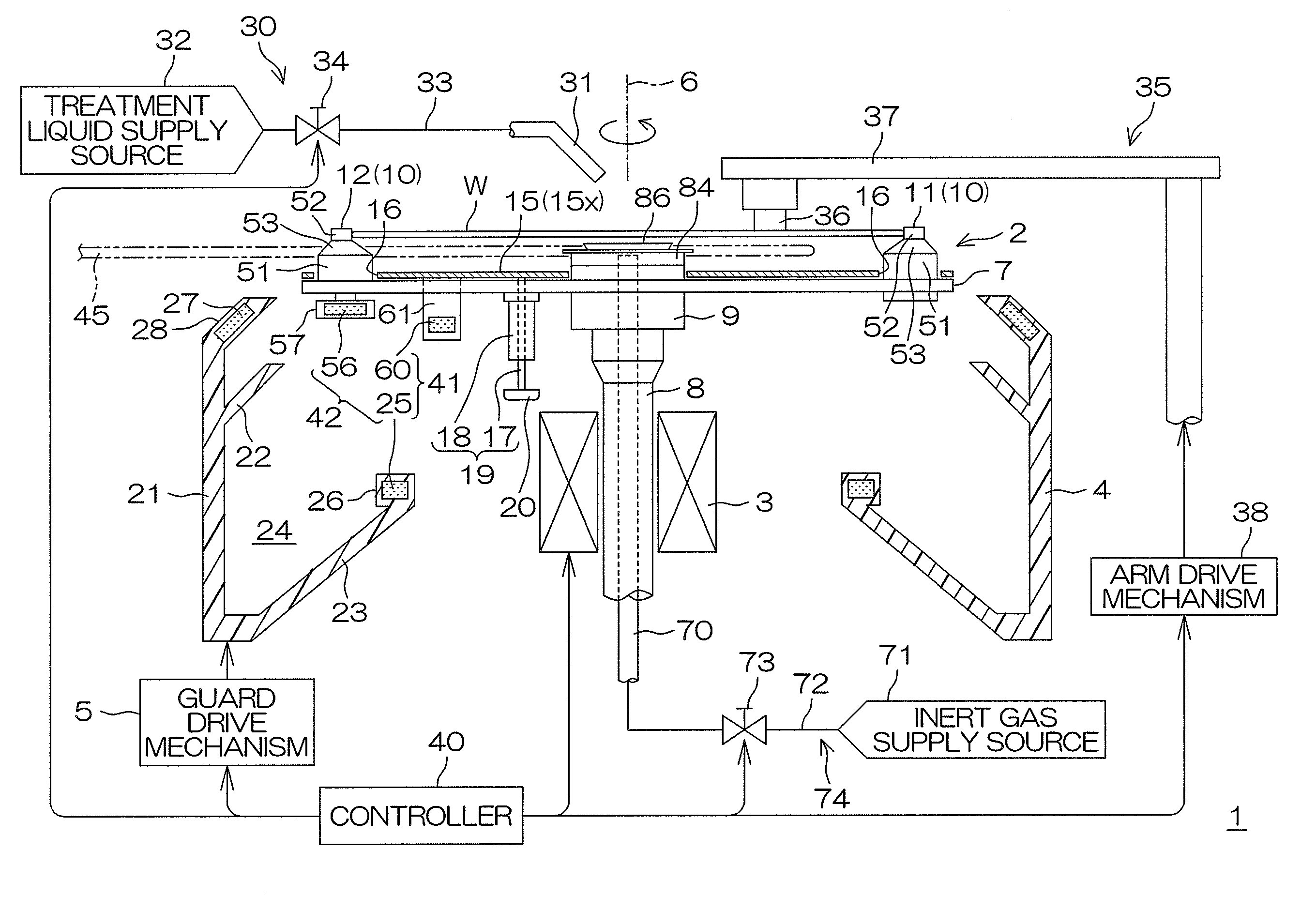

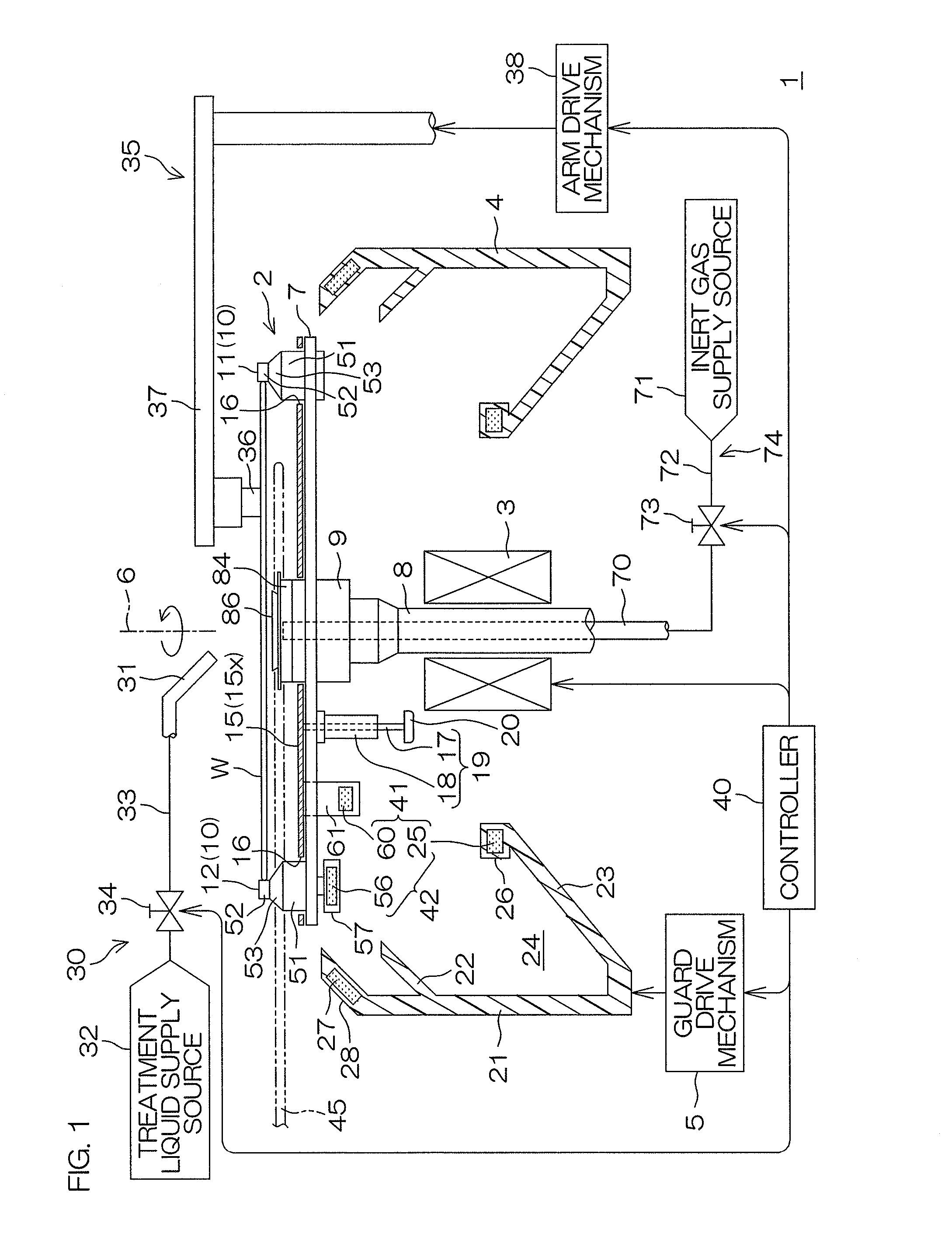

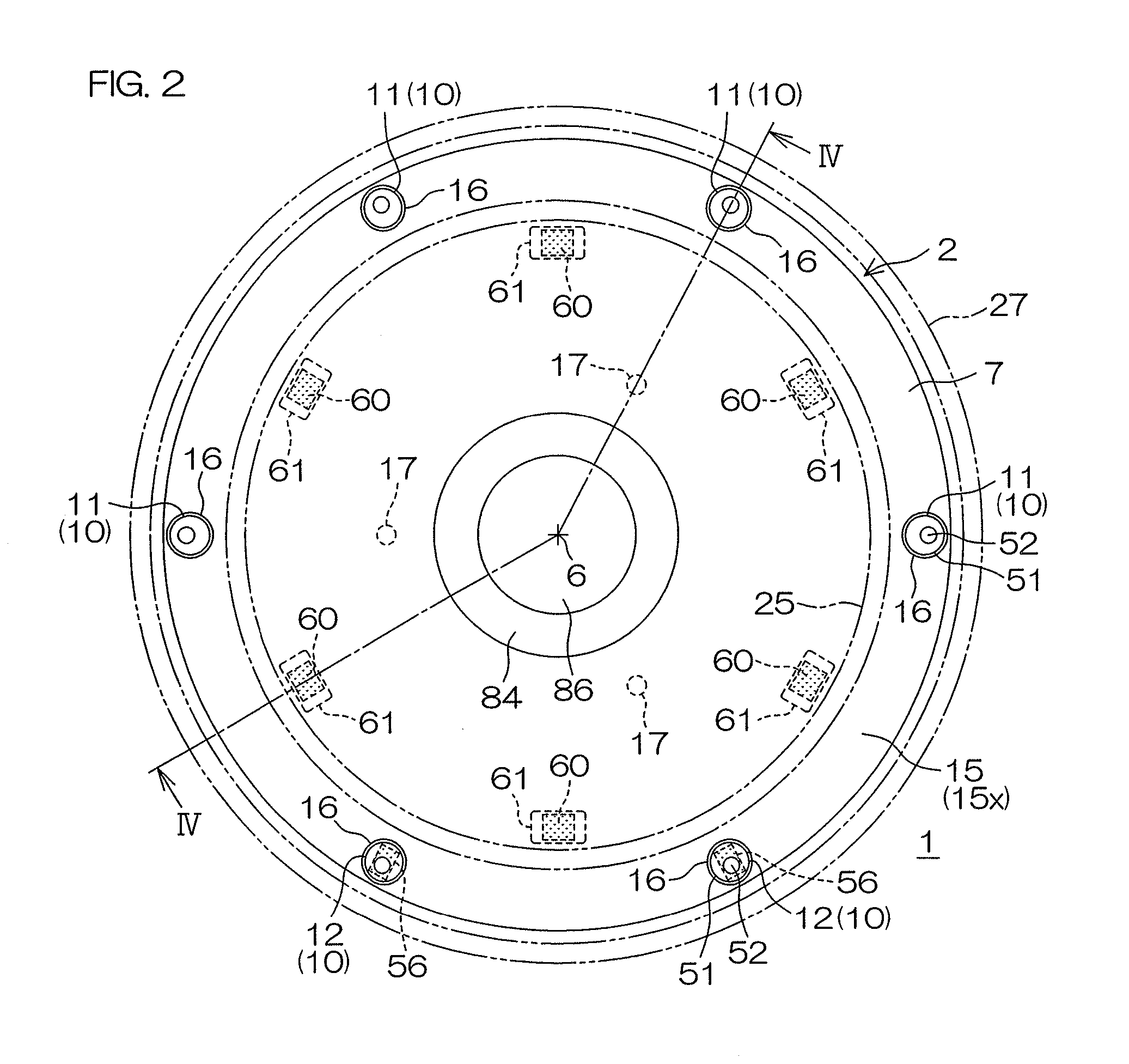

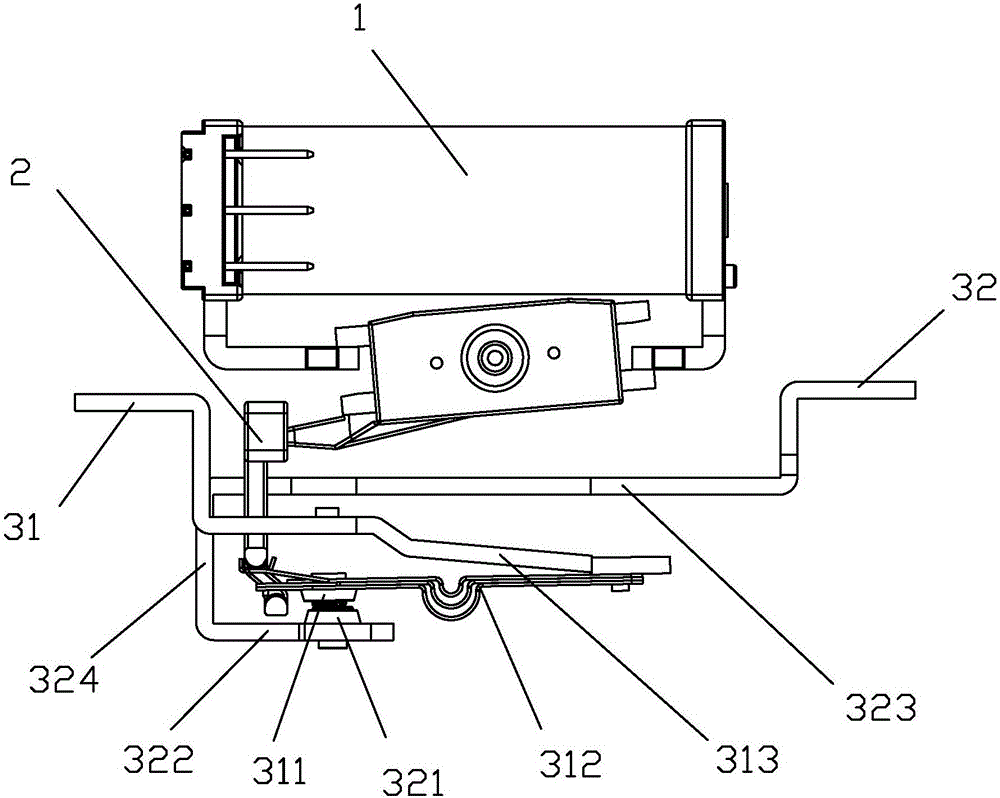

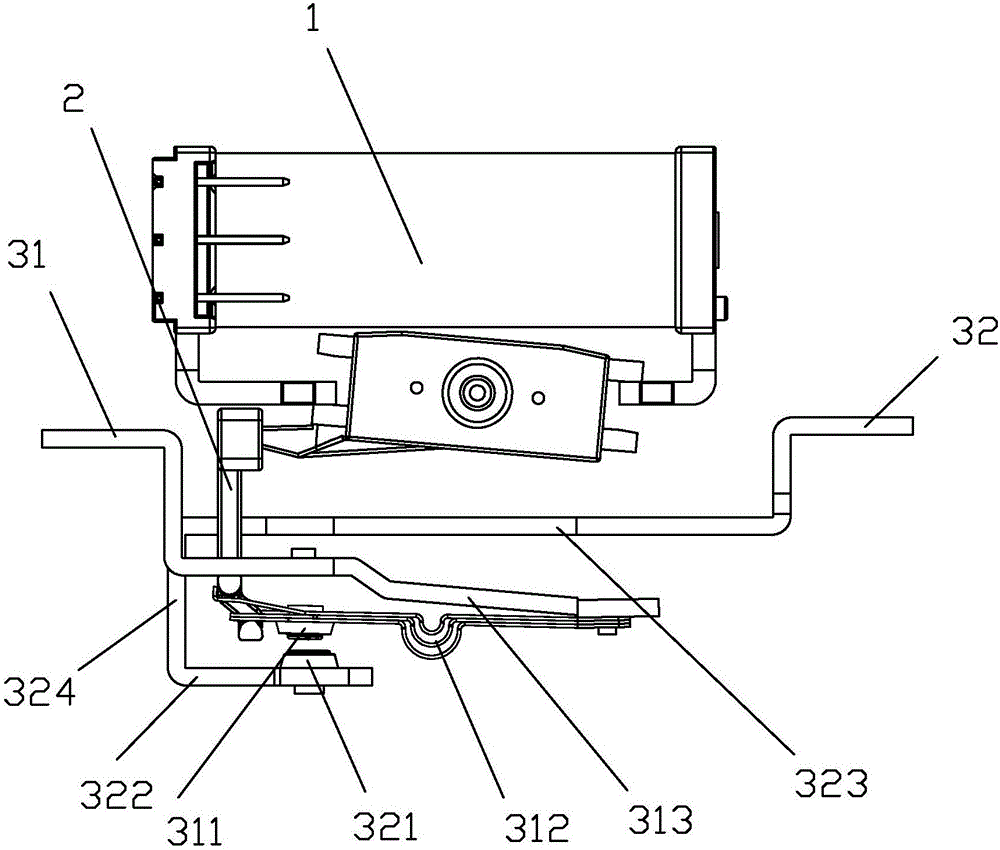

Substrate holding and rotating device, substrate processing device equipped with same, and substrate processing method

ActiveUS20160096205A1Avoid stickingInhibitionSemiconductor/solid-state device manufacturingCleaning using gasesEngineeringMagnetic levitation

A substrate treatment apparatus includes a turntable, a rotative drive unit, a holding pin provided on the turntable, a protection disk for covering a lower surface of a substrate, and a magnetic levitation mechanism that levitates the protection disk from the turntable. The protection disk is vertically movable relative to the turntable between a lower position and an adjacent position above the lower position and close to a lower surface of the substrate. The magnetic levitation mechanism includes a protection disk permanent magnet and an annual guard permanent magnet held by a splash guard. When a guard drive mechanism moves up the splash guard, the protection disk is levitated from the turntable and held at the adjacent position by a magnetic repulsive force generated between the permanent magnets.

Owner:DAINIPPON SCREEN MTG CO LTD

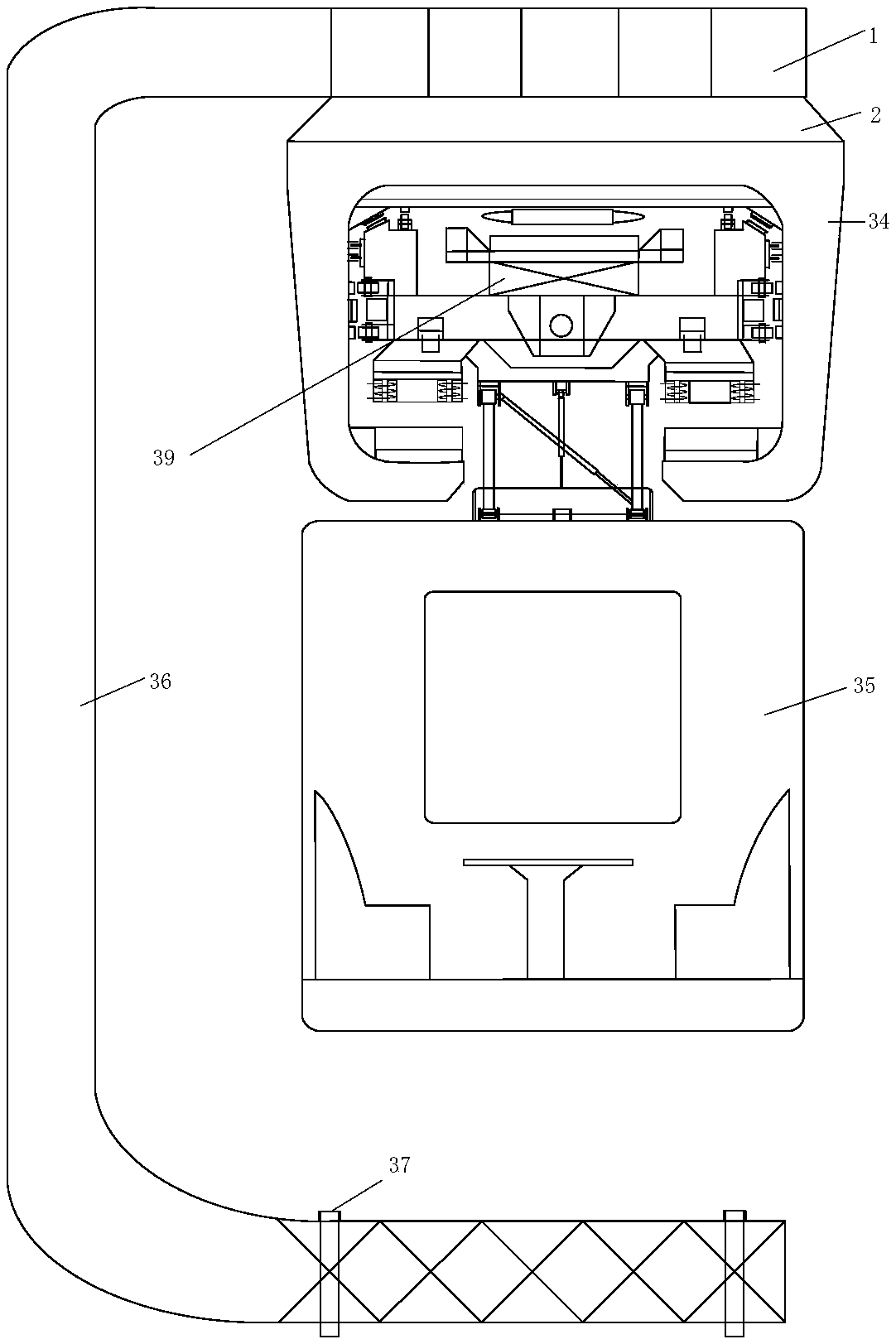

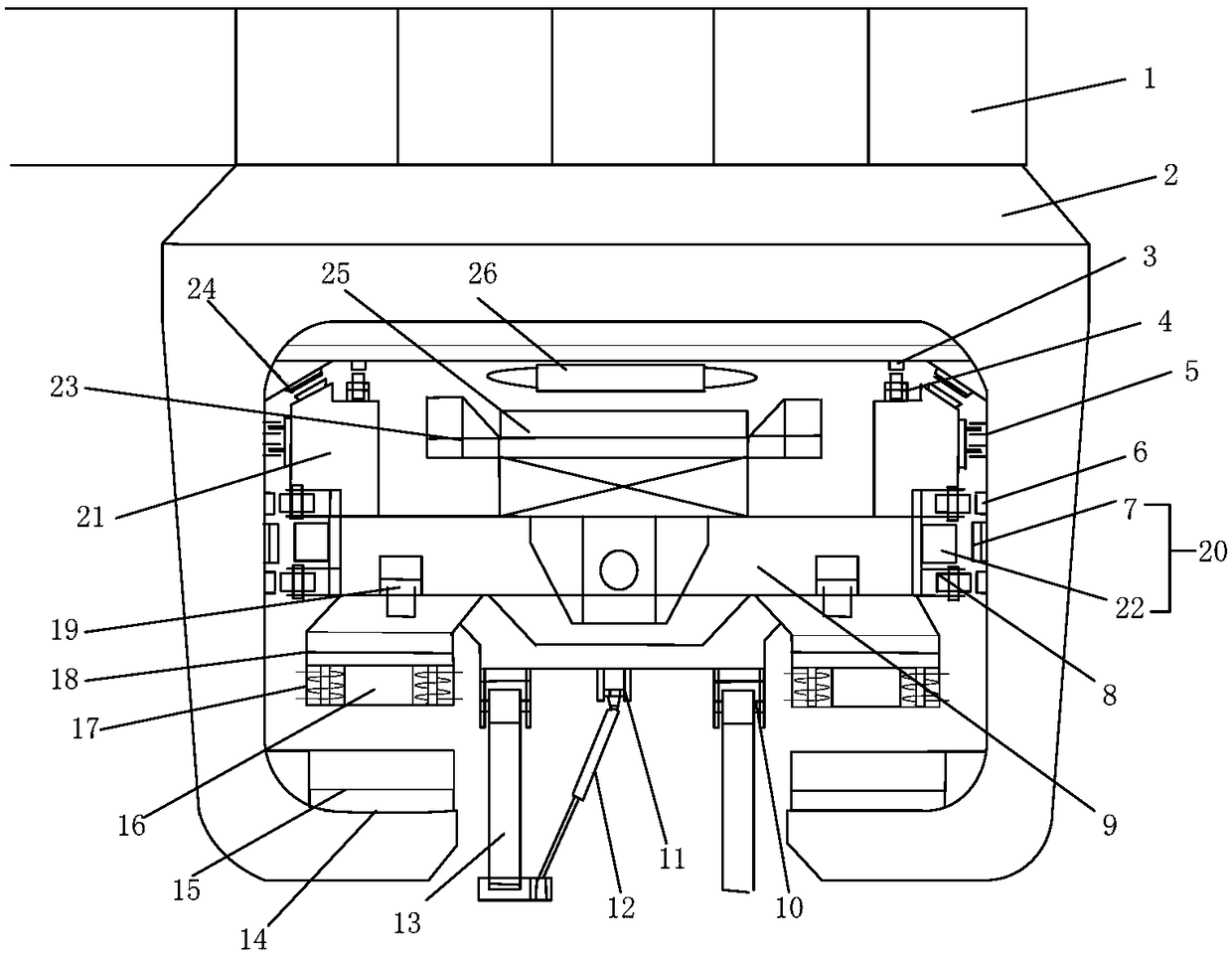

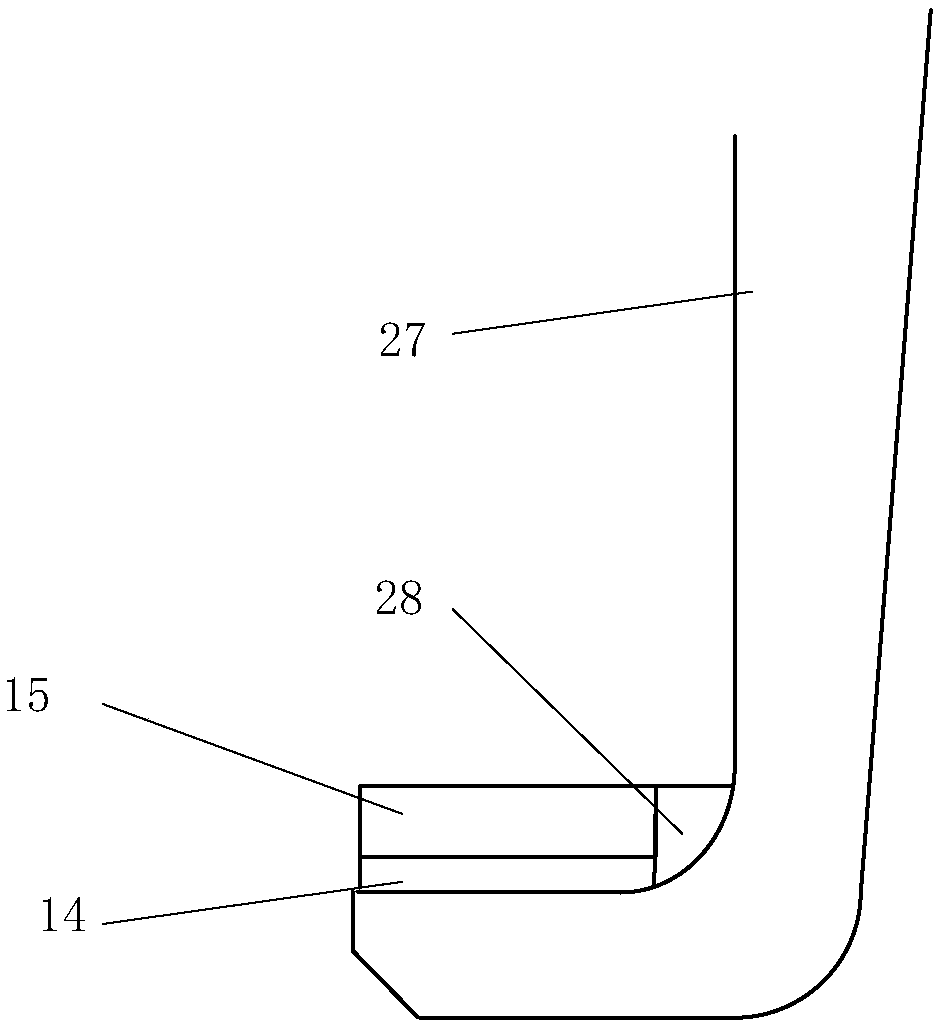

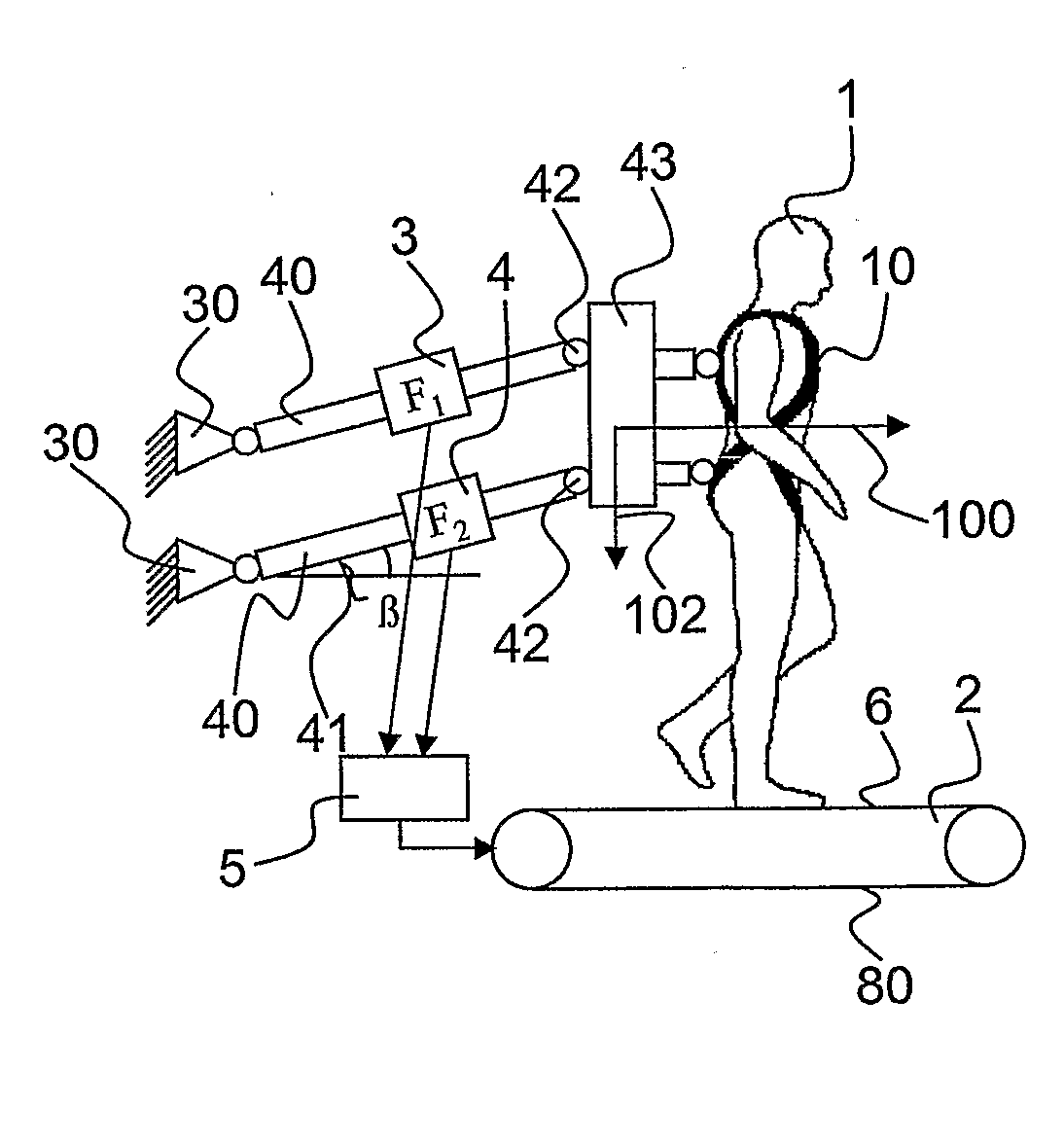

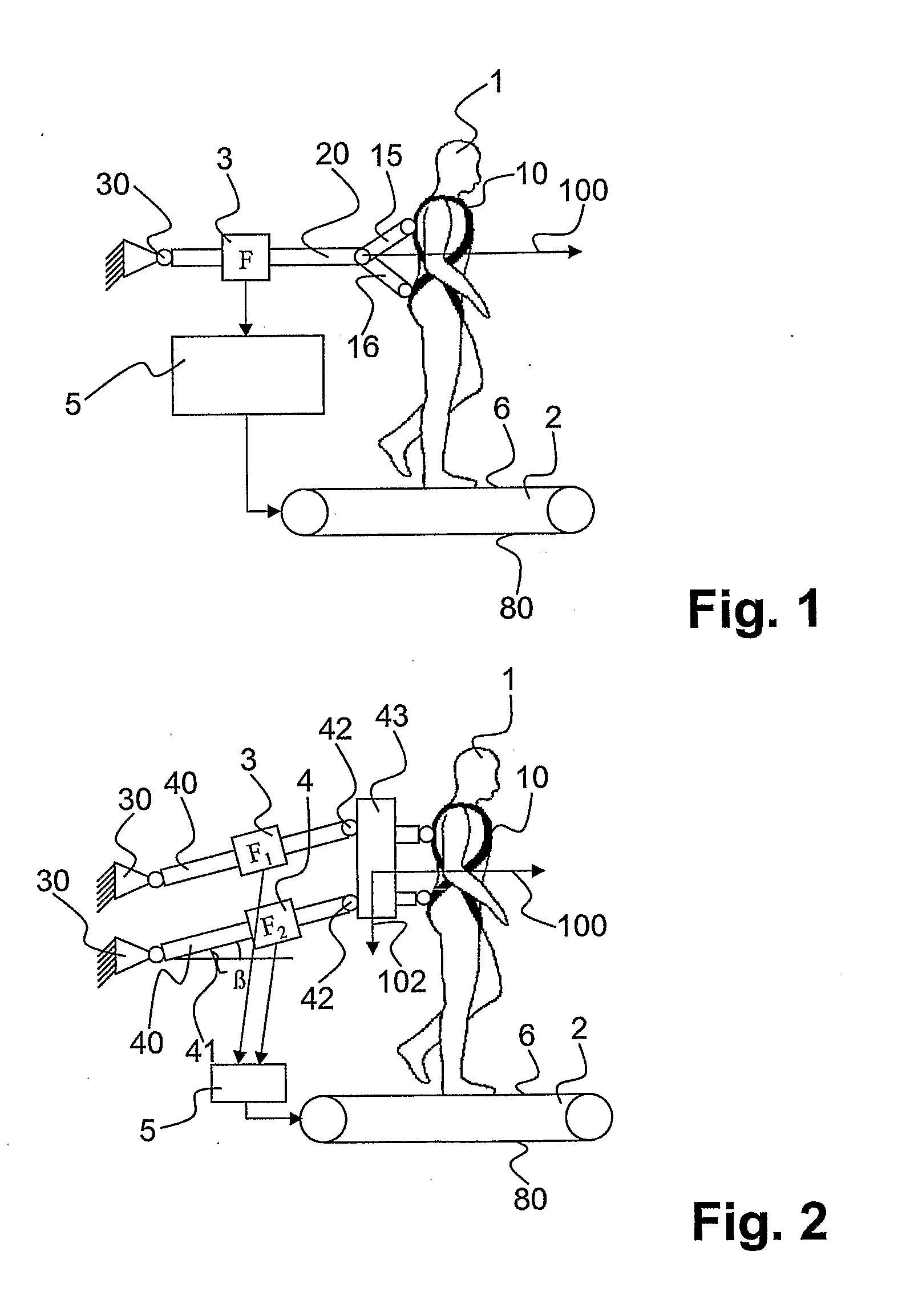

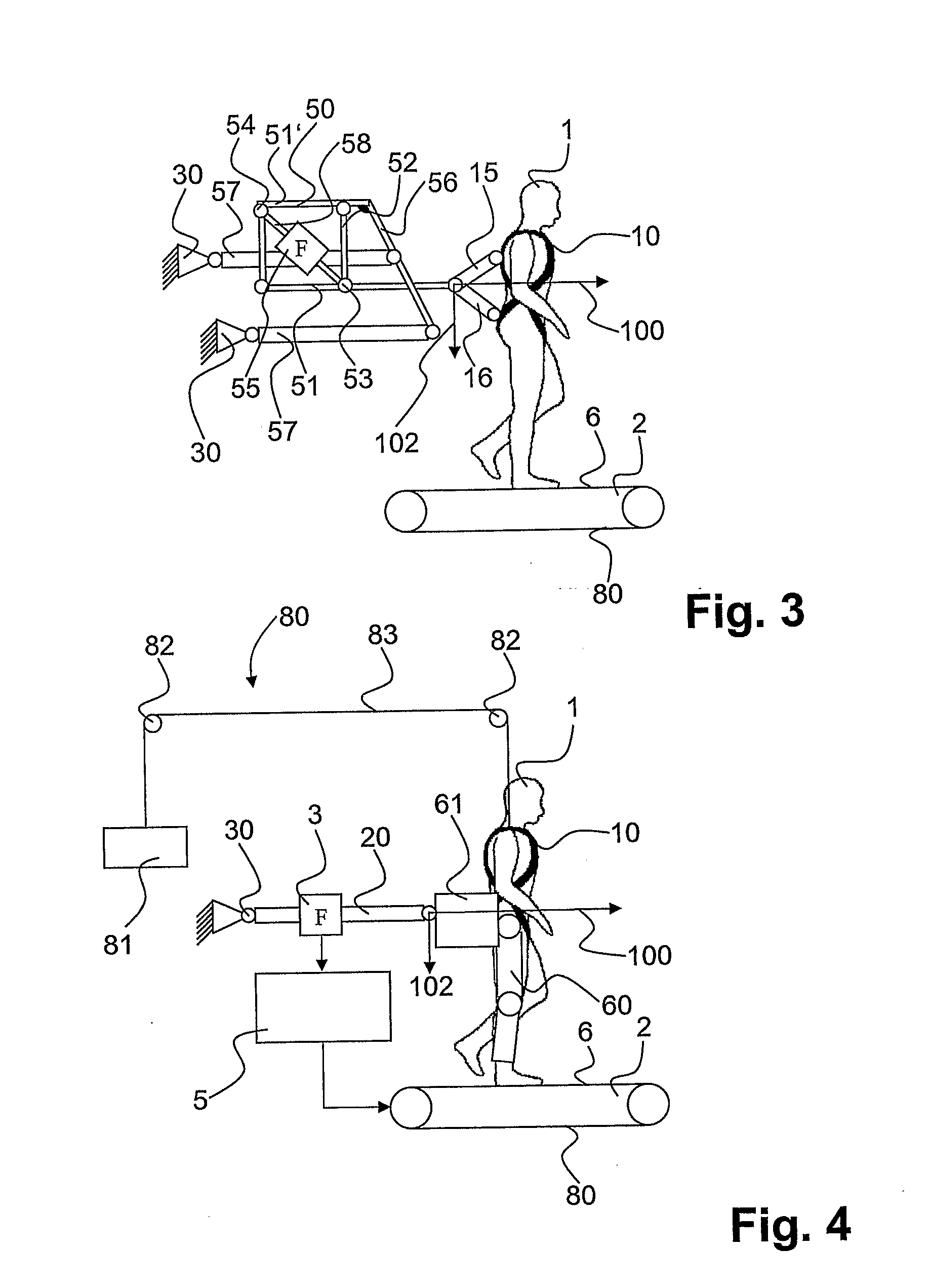

Device and Method for an Automatic Treadmill Therapy

A method to control the velocity of a treadmill according to the walking velocity of the person that is using the treadmill. A reaction force is measured, which occurs when a longitudinal repulsion force is created between the treadmill (2) and the person (1). A signal representation for said reaction force is transmitted to a control unit. The control unit is used to control the velocity of the treadmill.

Owner:ETH ZZURICH

Hollow golf club head

InactiveUS20110306441A1Increase freedomImprove performanceGolf clubsStringed racketsRepulsion forceAlloy

There is provided a Ti alloy hollow club head which is more lightweight yet capable of realizing a better repulsion force by adjusting weight and thickness of a club head plate, with its strength ensured. Ribs are formed by chemically polishing the inner surface of a material of a crown plate to a 0.3 to 0.9 mm thickness, and a 0.3 to 4 mm width, and then first concave portions are formed to a 0.2 to 0.5 mm thickness. Thus, strength of the crown plate can be ensured by the ribs, while making the thickness thereof as thin as possible.

Owner:ENDO MFG COMPANY

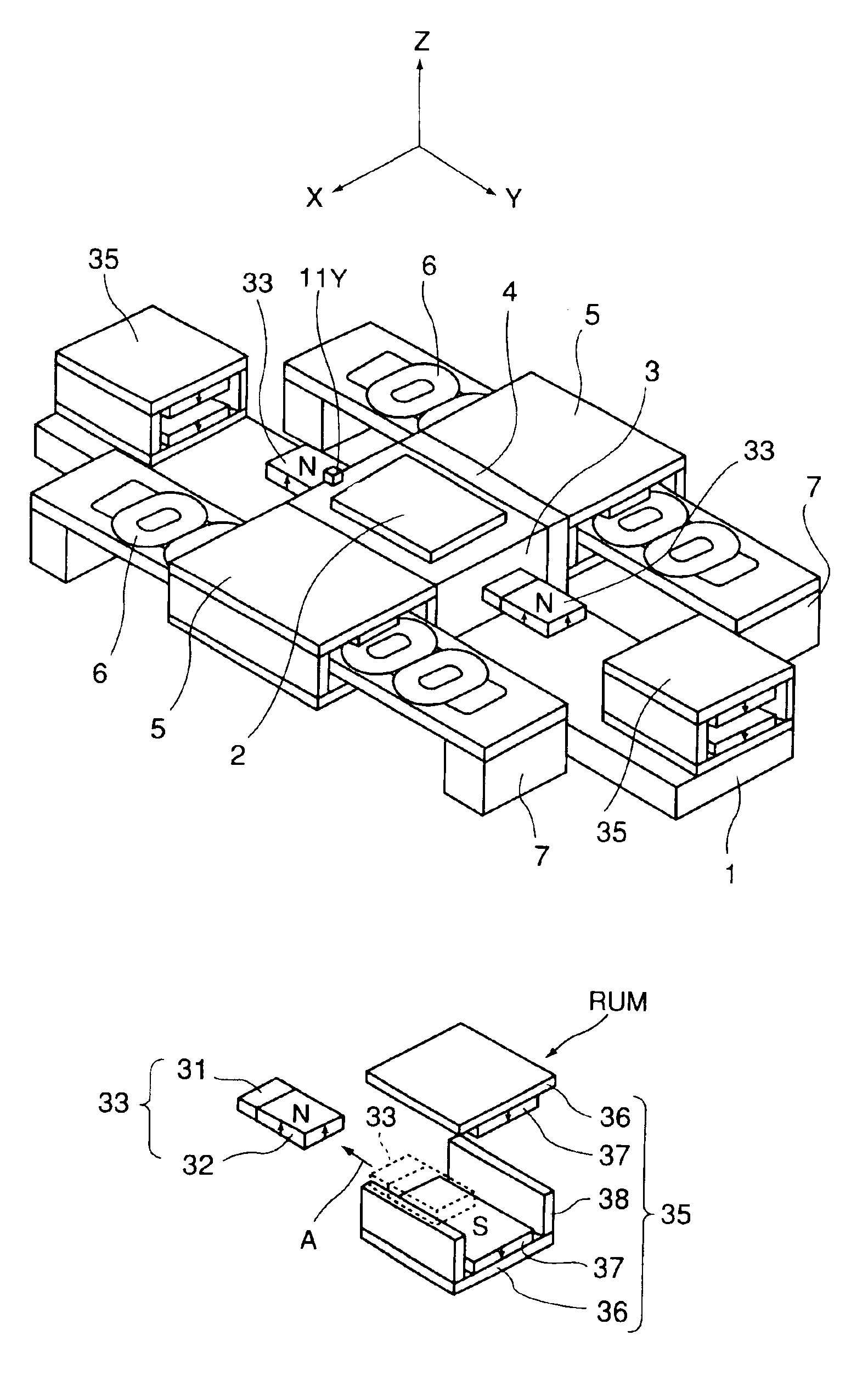

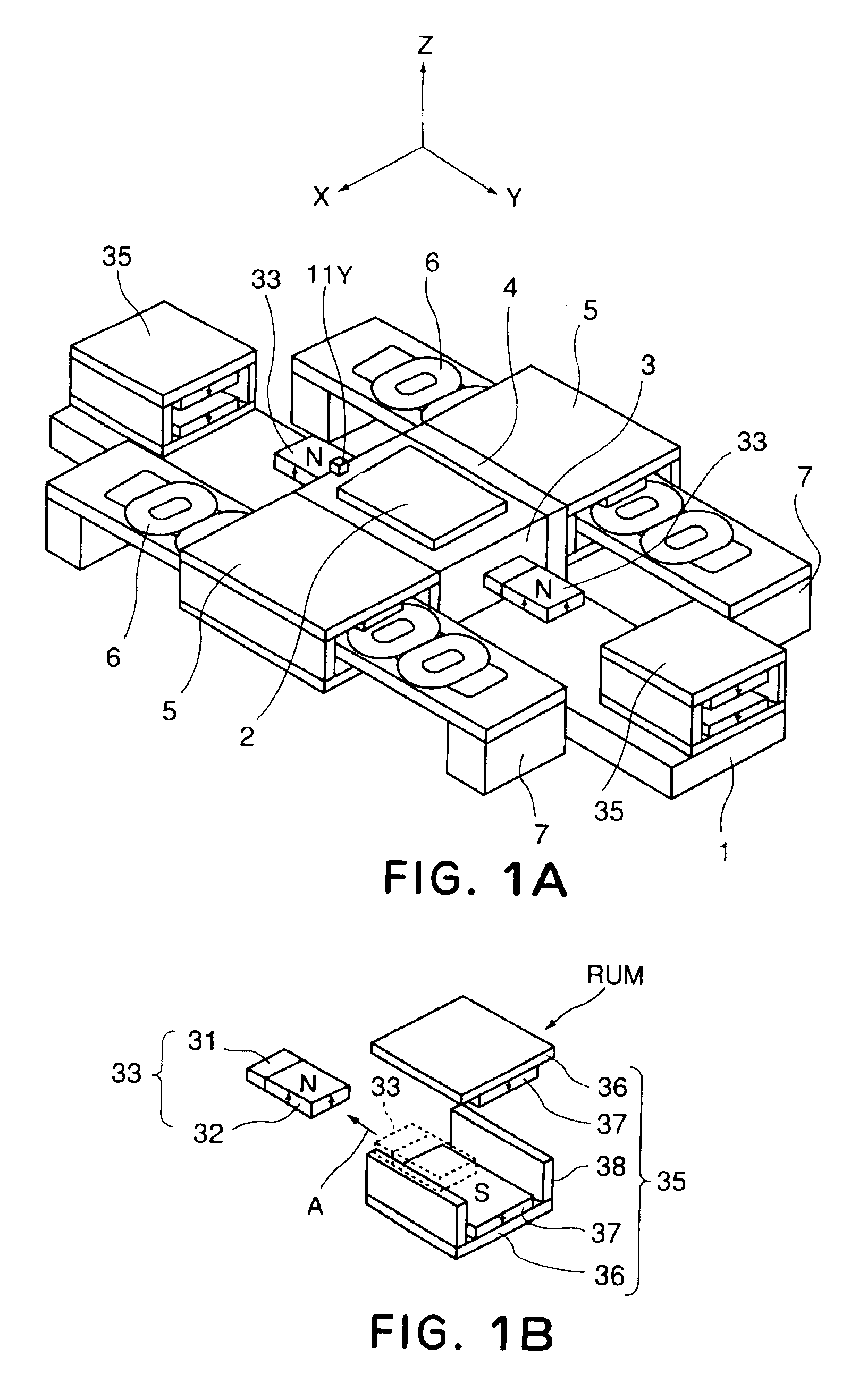

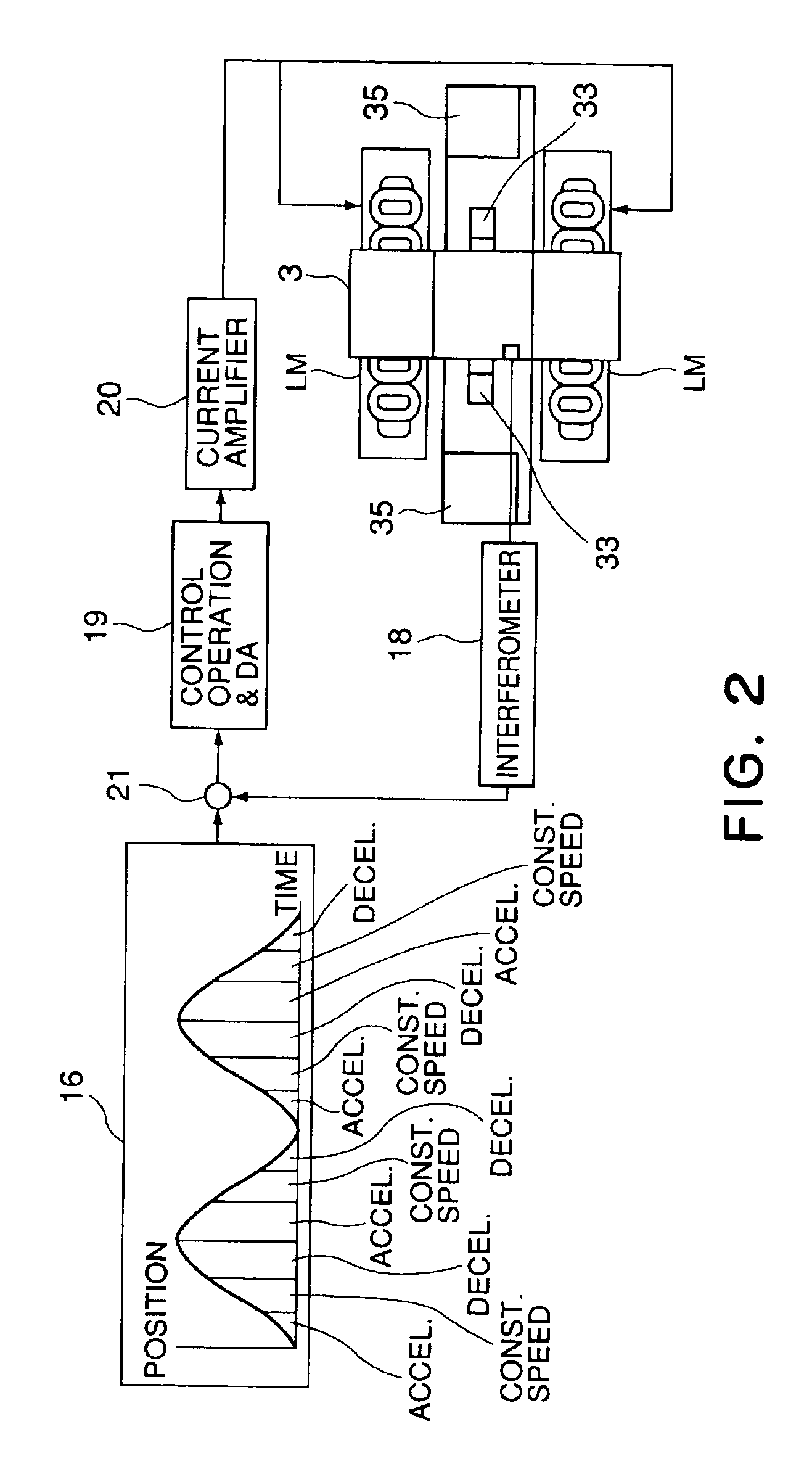

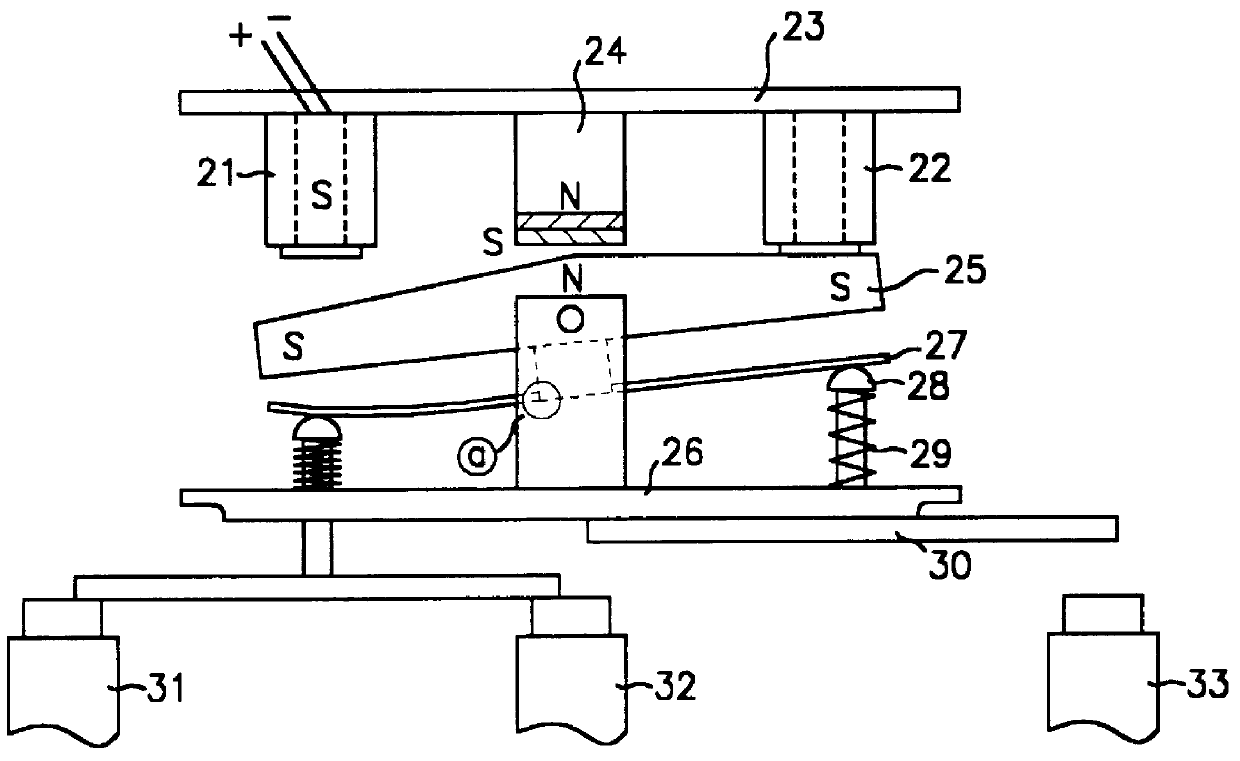

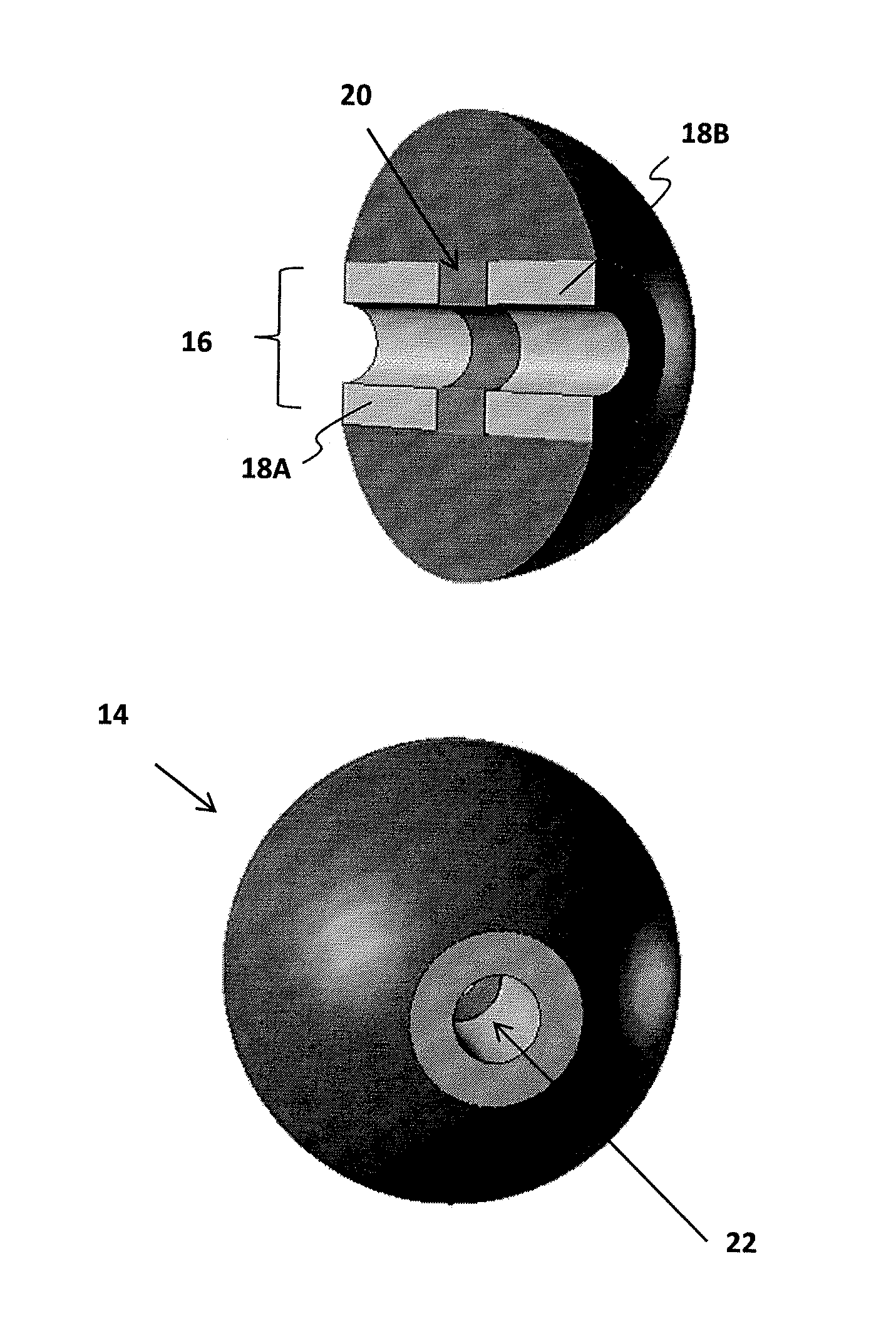

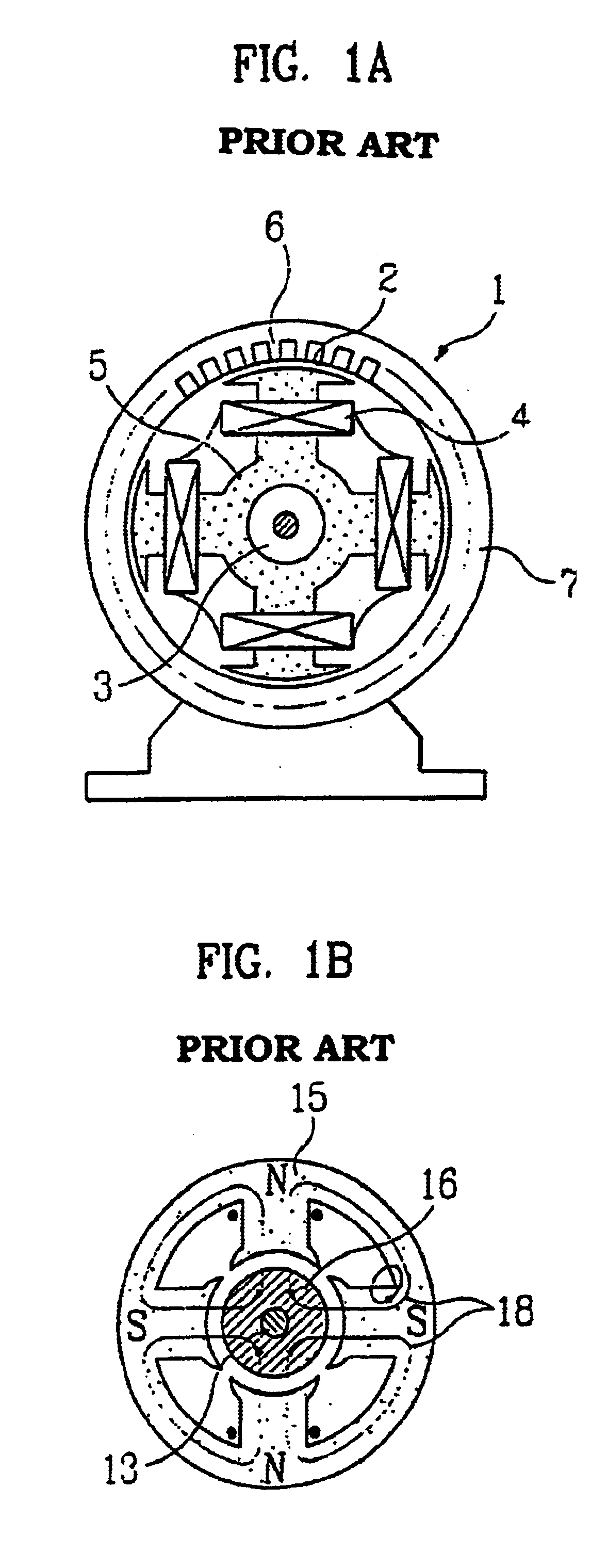

Moving stage device in exposure apparatus

InactiveUS6903468B2Low heat generationExtended control timePhotomechanical apparatusSemiconductor/solid-state device manufacturingMagnetStator

Disclosed is a stage device by which high precision motion and high speed motion can be accomplished simultaneously. The stage device includes a stage, a repulsive magnet unit for accelerating and / or decelerating the stage with respect to a movement direction, and a magnetic driving system for controlling the position of the stage. The repulsive force generator has (i) a repulsive stator, as a set magnet, including a plurality of magnets disposed along a direction orthogonal or substantially orthogonal to the movement direction, with a spacing therebetween while different poles of them are opposed to each other, and (ii) a repulsive movable element, as an insert magnet, to be mountably and demountably inserted into the spacing and being disposed in relation to the repulsive stator so that the same poles are opposed to each other.

Owner:CANON KK

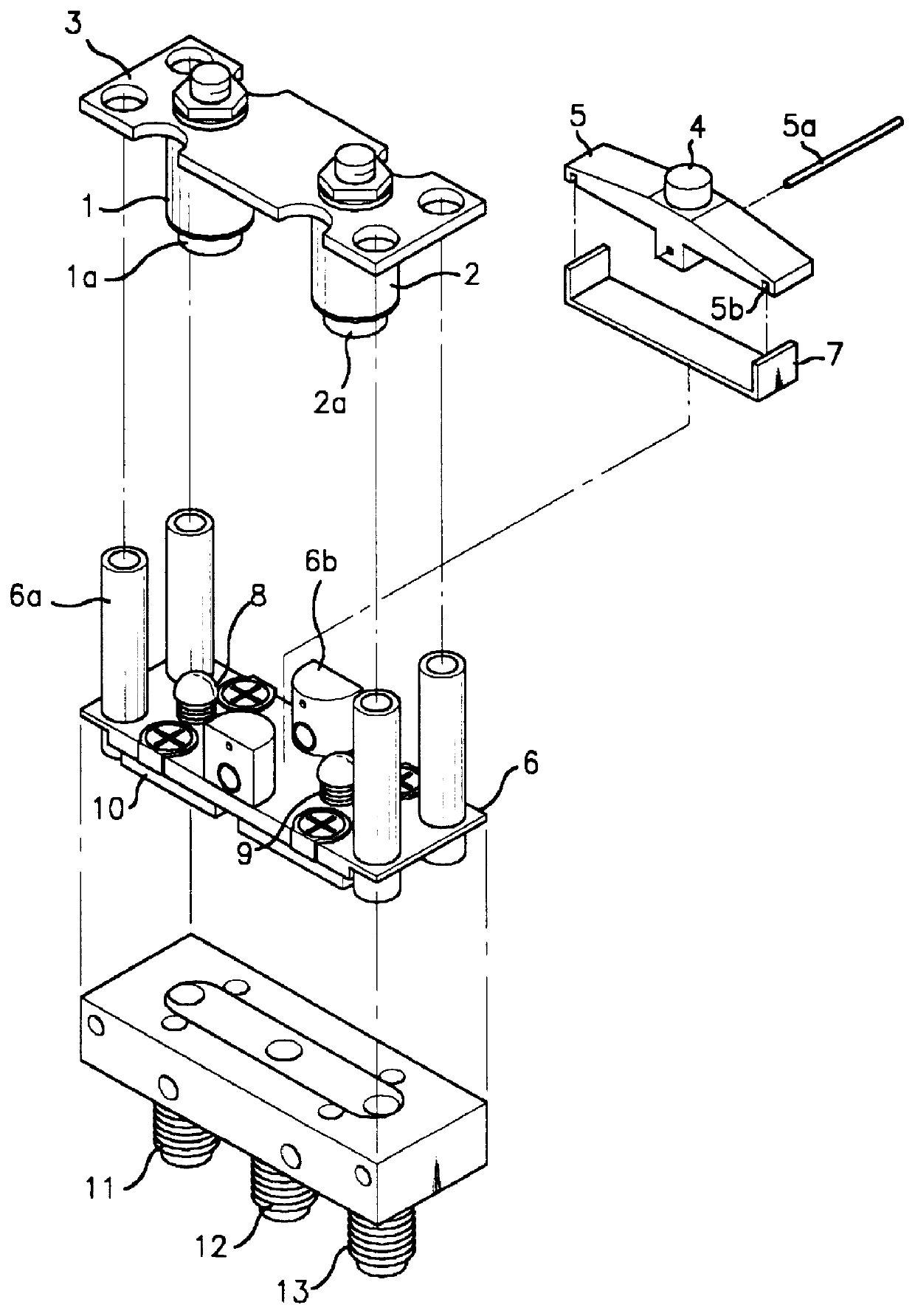

Switch with a rocker, which has an affixed magnet

InactiveUS6124771AMagnetic/electric field switchesElectromagnetic relay detailsEngineeringElectromagnet

The present invention relates to a switch with a rocker, which has an affixed magnet, capable of being reliably opened or closed by a mechanical operation of a magnetized rocker. The present invention comprises of a supporting plate and a plurality of electromagnets occurring a magnetic force when a power is supplied thereto and being disposed in a bottom surface of the supporting plate. Further, the present invention has a rocker made of a magnetic substance, magnetized in order to occur repulsion with the electromagnet and then rotated by a predetermined angle. Furthermore, the present invention at least one magnet for magnetizing the rocker and retaining an inclined state of the rocker by the if occurred attraction with the electromagnet, and being disposed on the rocker. Also, the present invention has a plate spring, to provide a pressure along with the rotation of the rocker, having erect portions on both end portions thereof, in which the erect portions are fixed to the rocker, and a contact means to contact with connectors by the pressure of the plate spring.

Owner:K M W CO LTD

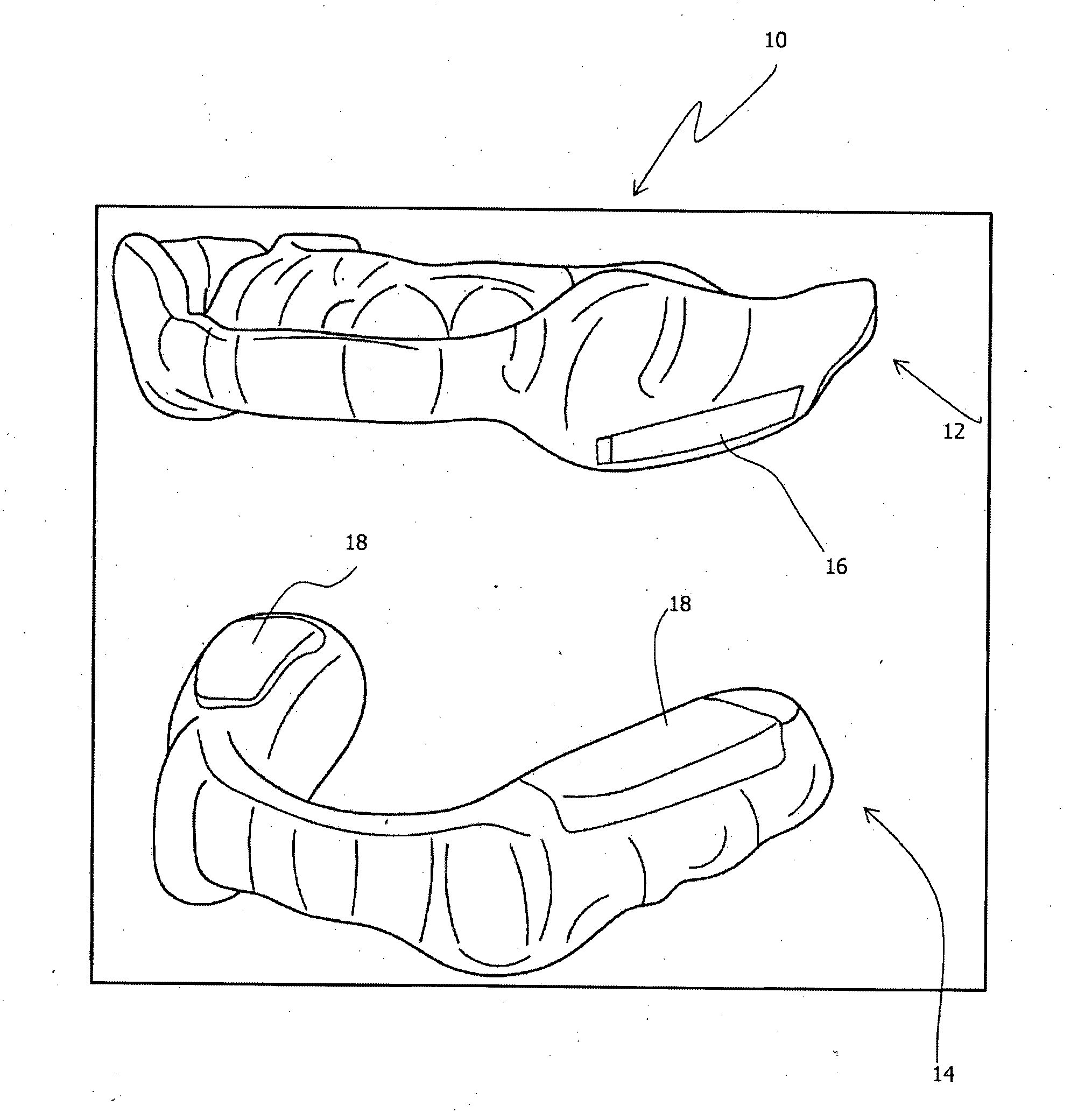

Dental device

A dental device which comprises both an upper part fitted to the upper jaw of a wearer and a lower part fitted to the lower jaw of the wearer, wherein the upper part includes an upper magnet, the lower part includes a lower magnet, and the magnets are arranged so as to establish a magnetic repulsion between the magnets which opposes the closing of the jaw, thereby opposing direct contact between the upper part and the lower part.

Owner:AIROSPACE ENTERPRISES

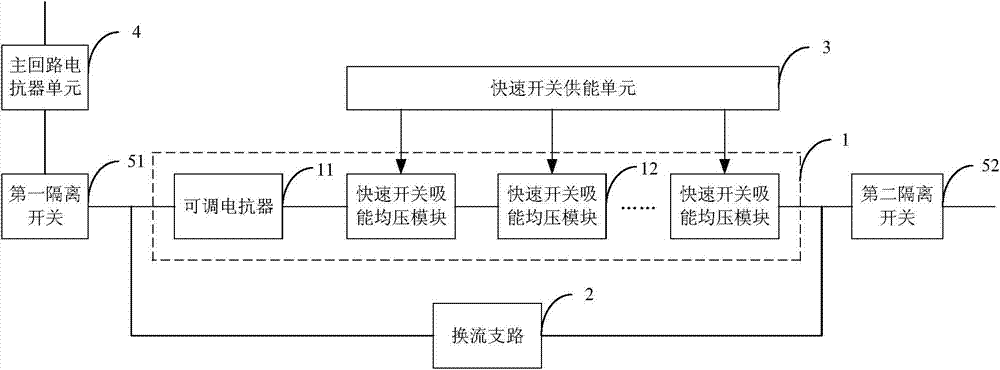

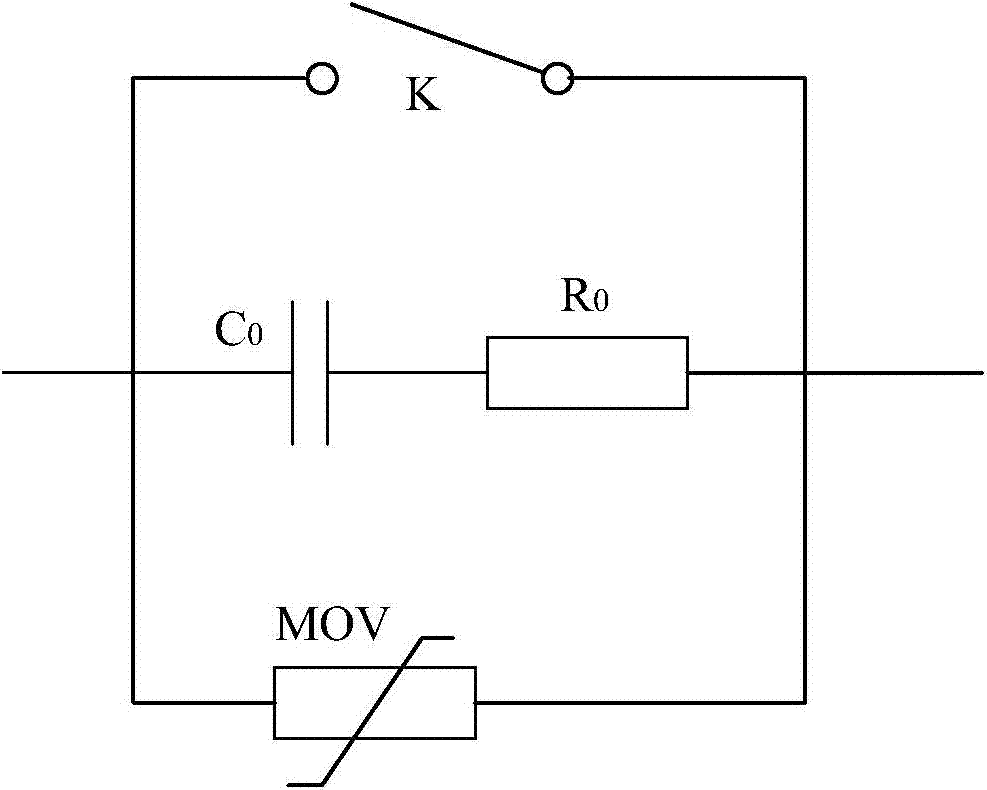

High-voltage direct-current circuit breaker based on rapid repulsion force mechanism and insulating transformer

InactiveCN103928913AReduced insulation requirementsEasy to solveEmergency protective circuit arrangementsEnergy absorptionTransformer

The invention discloses a high-voltage direct-current circuit breaker based on a rapid repulsion force mechanism and an insulating transformer. The circuit breaker topologically comprises a current conversion branch circuit, a main circuit breaker branch circuit, a rapid switching energy supply unit, a main loop electric reactor unit and a main loop isolation switching unit. The current conversion branch circuit is an LC oscillation branch circuit. The main circuit breaker branch circuit is formed by connecting an adjustable electric reactor and a plurality of rapid switching energy absorption voltage-sharing modules in series. Each rapid switching energy absorption voltage-sharing module is formed by connecting a rapid switch, a lightning arrester and an RC voltage-sharing branch circuit in parallel. The rapid switching energy supply unit ensures rapidity and cooperativity of actions of the rapid switches. The main loop electric reactor unit is used for reducing a fault current ascending rate. The main loop isolation switching unit is used for protecting internal components after the circuit breaker conducts breaking successfully. According to the high-voltage direct-current circuit breaker, on the basis of the rapid repulsion force mechanism and the insulating transformer, the breaking speed is high, the fault current is prevented from ascending to the larger amplitude, the voltage level borne by the circuit breaker is high, breaking reliability is high, the structure is simple, and the manufacturing cost is low.

Owner:HUAZHONG UNIV OF SCI & TECH

Coordinates input apparatus

InactiveUS7151526B2Eliminate needSimple structureInput/output for user-computer interactionManual control with multiple controlled membersThree-dimensional spaceSoftware engineering

An improved coordinates input apparatus for designating a particular set of coordinates in three-dimensional space has a substantially box-like frame, a first magnet, a second magnet, and a plurality of magnetoelectric transducers. The first magnet and second magnet are mounted on the frame and disposed so that sides thereof having identical magnetic poles are disposed opposite each other. The second magnet is disposed so as to be tiltable in response to a disposition of forces acting thereupon. The forces include a repulsive force arising between the first magnet and the second magnet and a pressing force exerted on the second magnet. The plurality of magnetoelectric transducers mounted on the frame opposite the second magnet and output voltage values that vary according to a change in a gap between the magnetoelectric transducers and the second magnet, such that the voltage values indicate a set of X,Y coordinates in two-dimensional space.

Owner:FUJITSU TAKAMIZAWA COMPONENT LTD

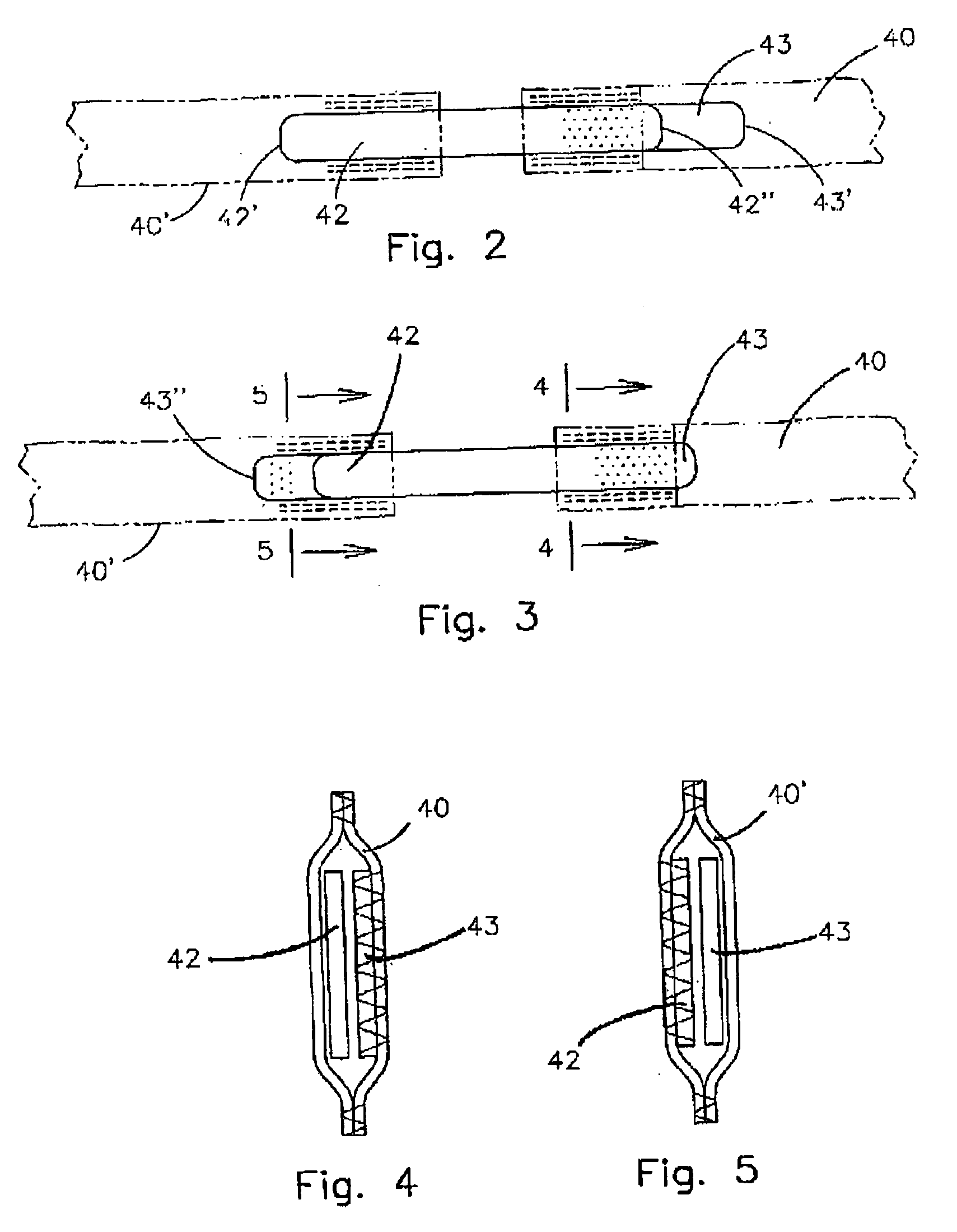

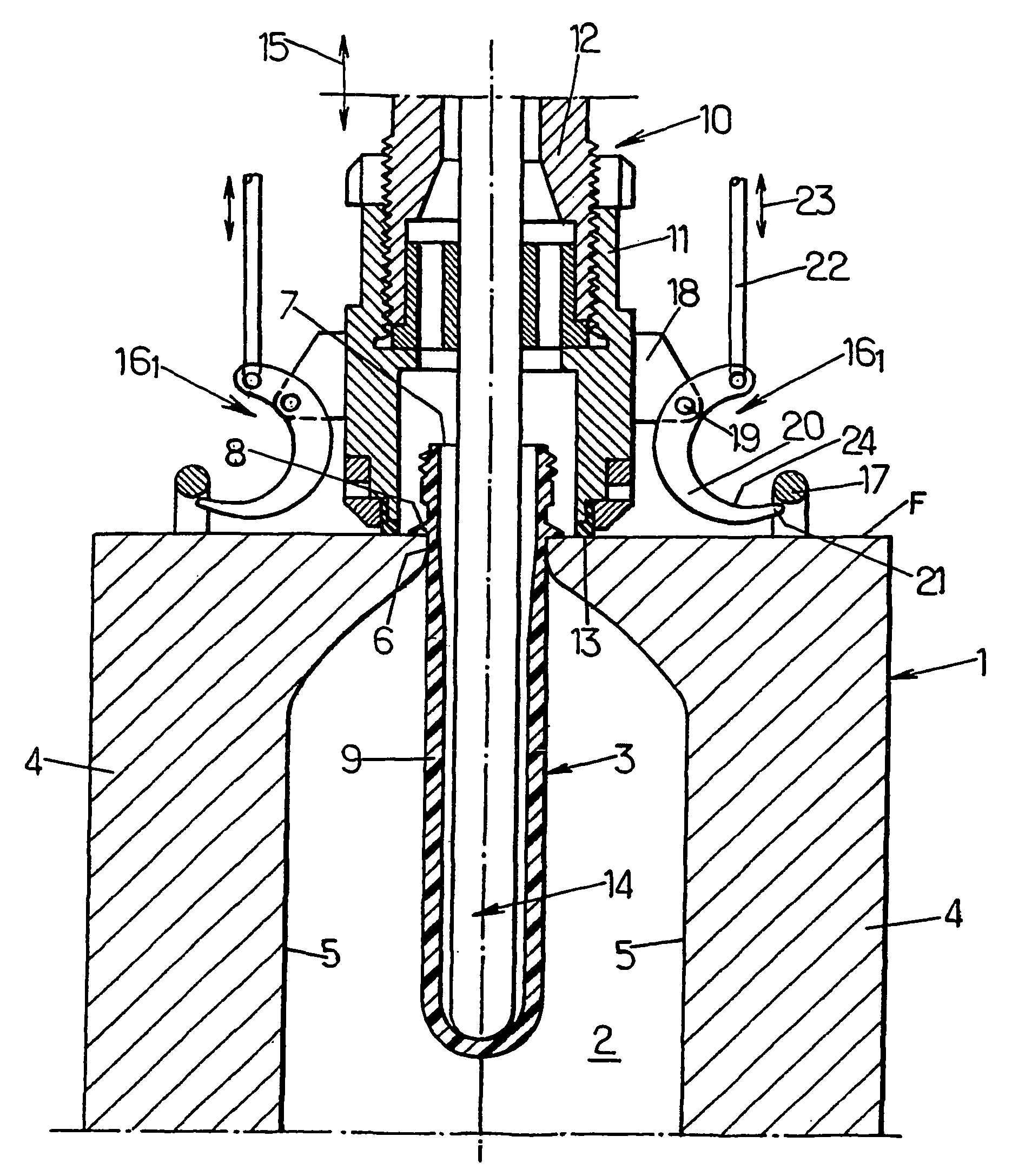

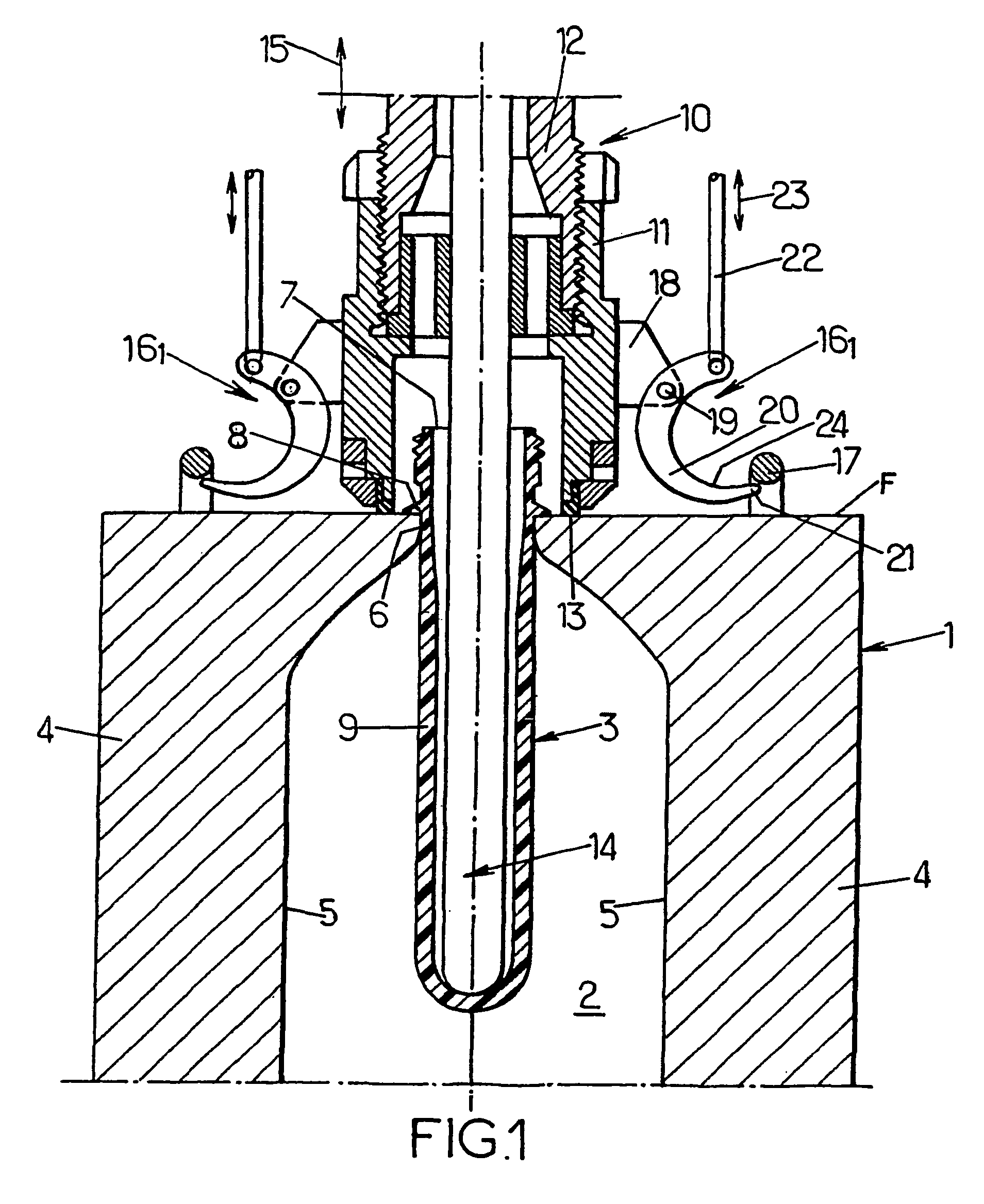

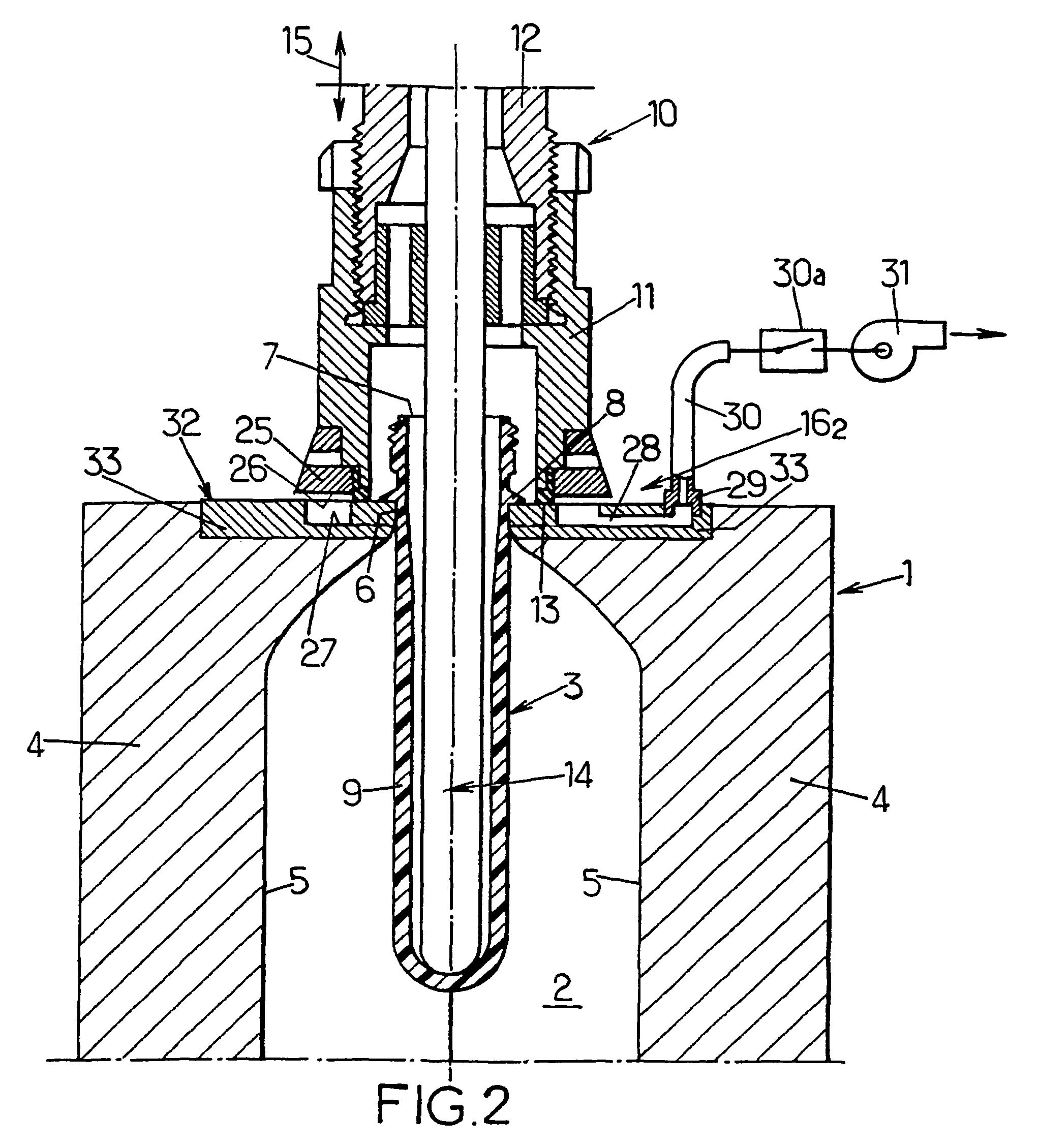

Bell-type nozzle blow-molding installation

InactiveUS7165956B2Light weightReduce weightAuxillary shaping apparatusDomestic articlesBlow moldingRepulsion force

A blow-molding installation for manufacturing receptacles from blanks of thermoplastic polymer, said installation comprising a bell-nozzle for blowing a fluid under pressure into a blank (3) disposed in a cavity (2) of a mold (1), the end of the nozzle being in the shape of a bell (11) which is suitable, during blow-molding, for being pressed into leaktight end-to-end abutment against a wall (F) of the mold while capping the neck (7) of the blank that emerges from said wall; said installation further comprises means (161) for securing the nozzle to the wall of the mold by mutual attraction, which means can be activated, after the nozzle has been brought into end-to-end contact with the wall (F) of the mold without flattening a sealing gasket (13), so as to attract the nozzle (10) and the wall (F) towards each other with an attraction force greater than the repulsion force due to the pressure of the blow-molding fluid.

Owner:SIDEL PARTICIPATIONS SAS

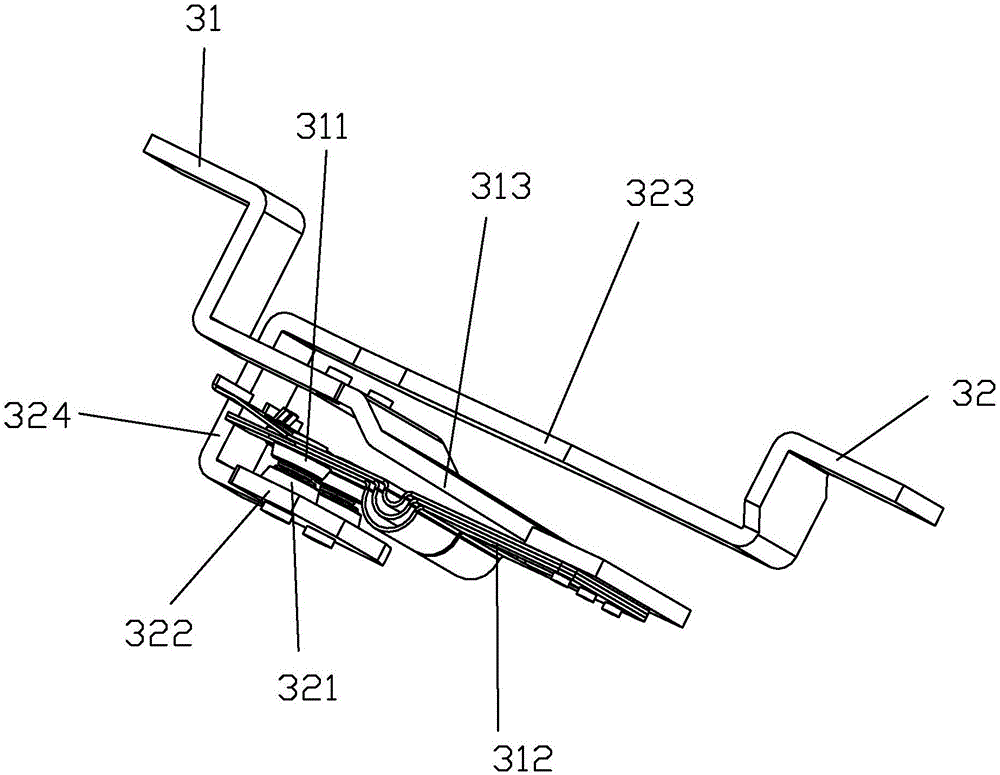

Magnetic latching relay capable of resisting short-circuit current

InactiveCN106504949AIncrease closing pressureIncreased form factorElectromagnetic relay detailsNon-polarised relaysPower flowRepulsion force

The invention discloses a magnetic latching relay capable of resisting a short-circuit current. The magnetic latching relay comprises a magnetic circuit system, a contact system and a push mechanism, wherein a movable spring part comprises a movable contact, a movable spring plate and a movable spring lead-out plate; the movable spring lead-out plate is arranged at one side, departing from the moving contact, in the thickness direction of the movable spring plate; a fixed spring part comprises a fixed contact, a fixed spring plate and a fixed spring lead-out plate; the fixed spring lead-out plate also is arranged at one side, departing from the moving contact, in the thickness direction of the movable spring plate, so that the direction of current flowing through the movable spring lead-out plate is opposite to that of the current flowing through the movable spring plate. According to the magnetic latching relay, the electro-dynamic repulsion force generated by single short-circuit current between the movable contact and the fixed contact can be resisted by electromagnetic repulsion force generated by formed double short-circuit current on the movable spring plate on the basis of not increasing the overall dimension of a product or not increasing the power consumption of a coil control part, so that the closing pressure of the movable contact and the fixed contact is greatly improved, the short-circuit current is resisted and the requirements of the product on simple, compact and small structures are met.

Owner:XIAMEN HONGFA ELECTRIC POWER CONTROLS

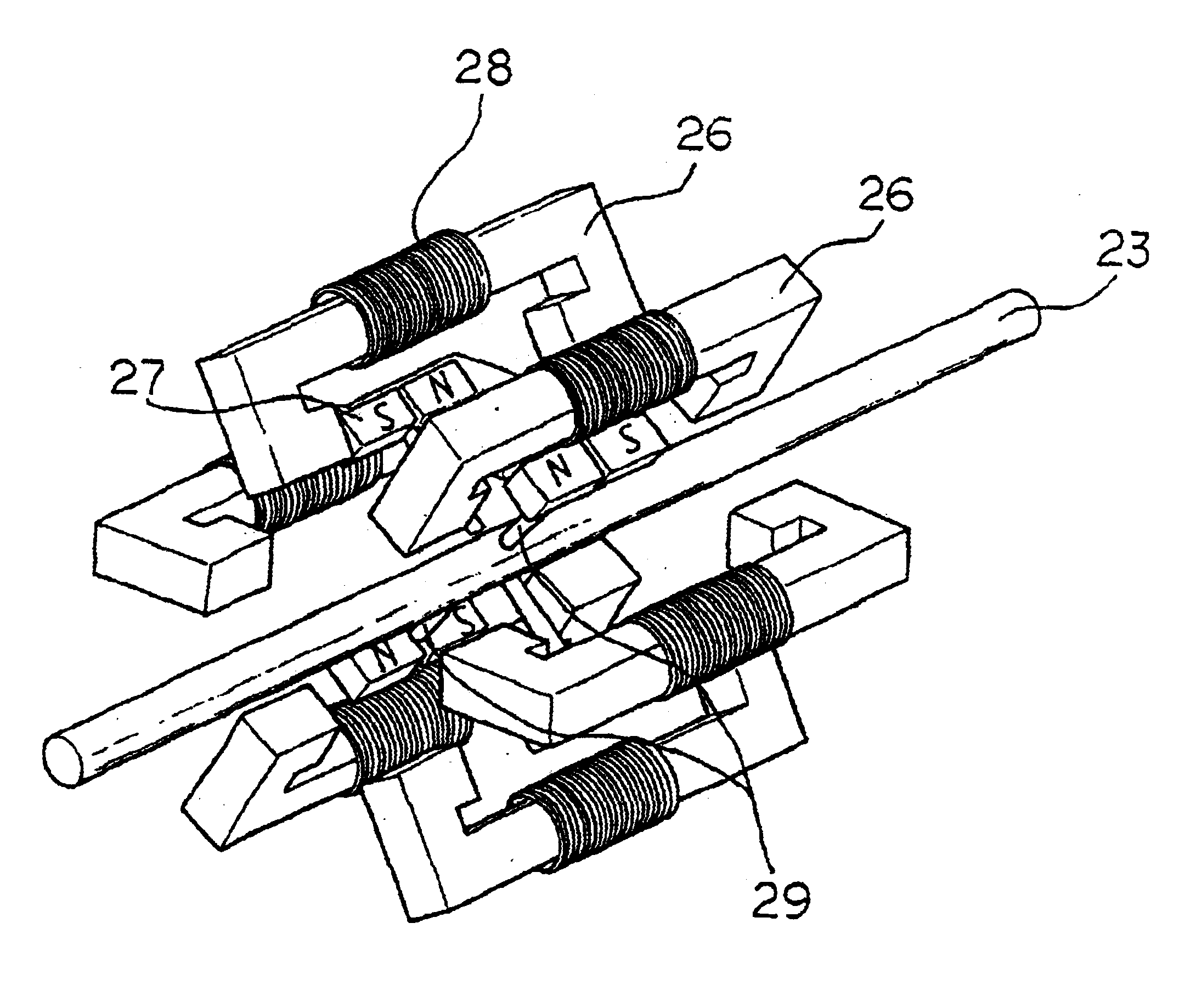

Magnetic circuit for rotating apparatus

InactiveUS6717313B1Magnetic circuit stationary partsSynchronous machines with stationary armatures and rotating magnetsRepulsion forceEngineering

An energy conversion magnetic circuit is constituted with magnet pole pieces of magnets or armatures which are in parallel with respect to the shaft to obtain a dynamic force or an electromotive force. The magnetic circuit for a generator or an electric motor has a rotating shaft, a plurality of supporters fixedly mounted in a perpendicular direction to the circumference of the rotating shaft, a plurality of rotors arranged in parallel with respect to the shaft on each end of the plurality of supporters to be rotated by attraction force and repulsion force of a magnetic field, and a plurality of armatures having a coil wound on the body thereof. The coil is mounted at an interval outside the rotors and receives induced alternate magnetic flux of the rotors to generate a rectangular wave electromotive force or to obtain a high torque with input of electrical energy. The alternate magnetic flux generated when rotated, and magnet pole piece are arranged in parallel with the rotating shaft

Owner:ENERTEC KOREA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com