Magnetic latching relay capable of resisting short-circuit current

A technology of magnetic latching relays and short-circuit currents, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of unsatisfactory closing pressure and increased product cost, and achieve no sudden change in contact pressure, short circuit time, and contact pressure The effect of a steady rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

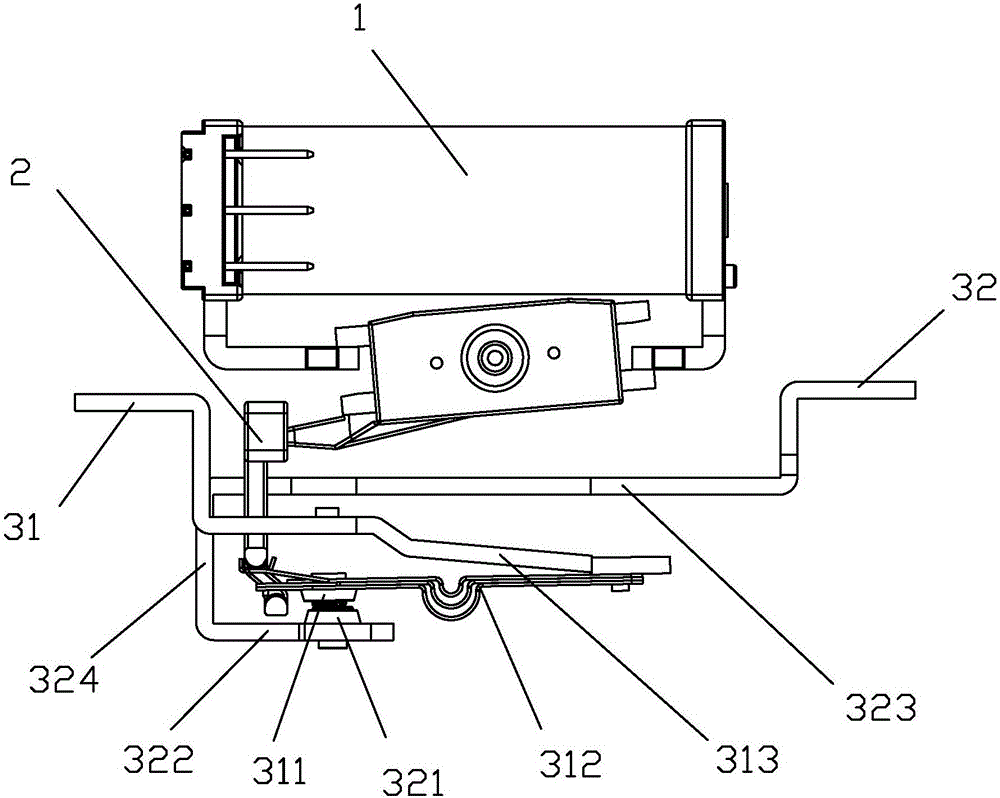

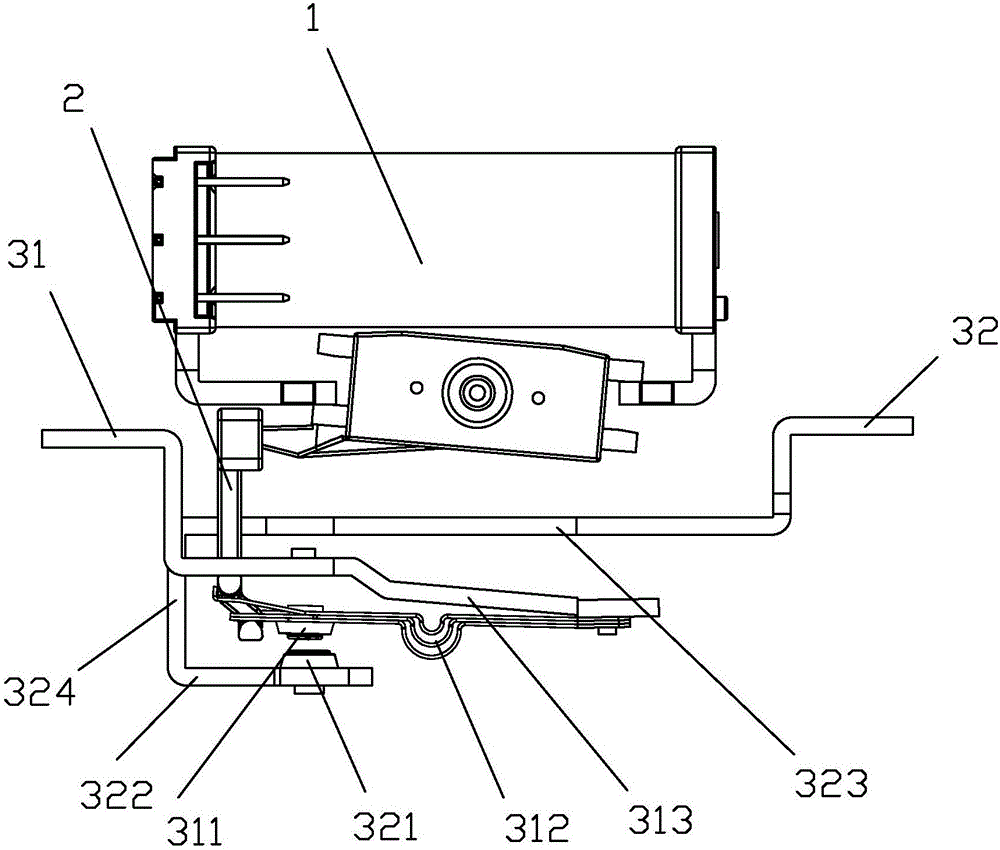

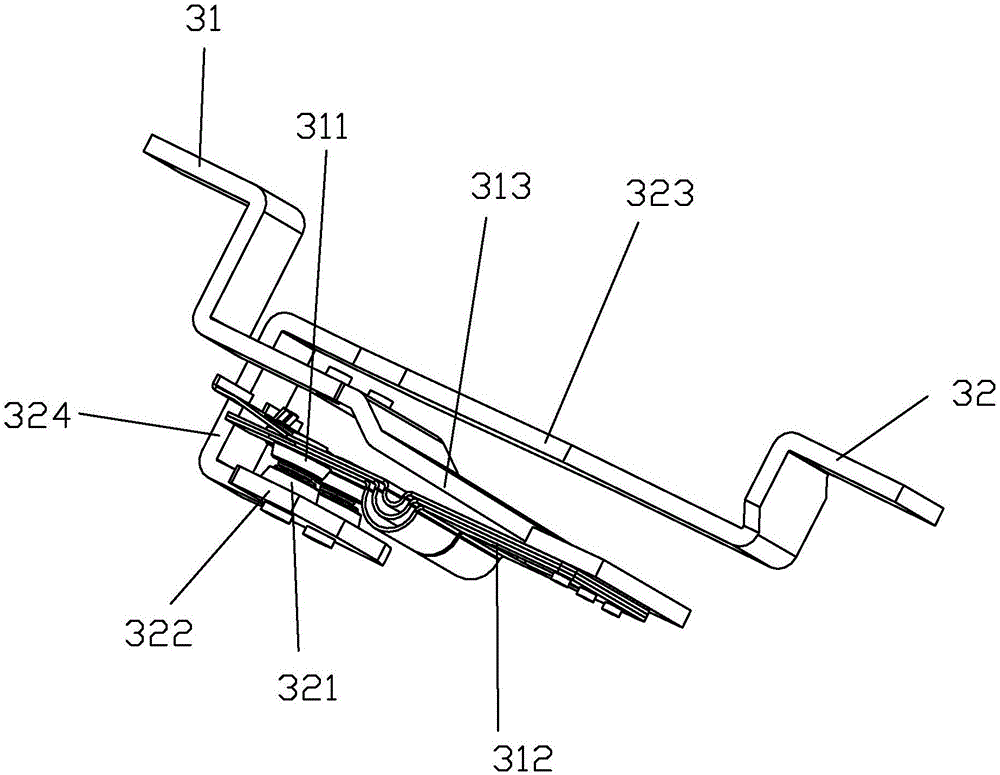

[0068] see Figure 1 to Figure 3 As shown, a magnetic latching relay capable of resisting short-circuit current of the present invention includes a magnetic circuit system 1, a contact system and a push mechanism 2, and the push mechanism 2 is connected between the magnetic circuit system 1 and the contact system; the contact The system includes a moving spring part and a static spring part; in this embodiment, the contact system is a group, including a set of moving spring parts and static spring parts that cooperate, that is, a moving spring part 31 and a static spring part 32, the The moving spring part 31 comprises a moving contact 311, a moving reed 312 and a moving spring lead-out piece 313, one end of the moving reed 312 is connected to the moving contact 311, and the other end of the moving reed 312 is connected to an end of the moving spring leading-out piece 313, The spring lead-out piece 313 is arranged on the thickness direction of the movable reed 312 and is away ...

Embodiment 2

[0092] see Figure 10 As shown, a magnetic latching relay capable of resisting short-circuit current of the present invention differs from Embodiment 1 in that the structure of the connecting piece 324 is different. In this embodiment, the connecting piece 324 is U-shaped, and the connecting piece 324 One side of the head of the driven reed 312 bypasses the head of the movable reed 312 and is connected between the static spring 322 and the lead-out piece 323 of the static spring.

Embodiment 3

[0094] see Figure 11 As shown, a magnetic latching relay capable of resisting short-circuit current of the present invention differs from Embodiment 1 in that the structure of the connecting piece 324 is different. In this embodiment, the connecting piece 324 is U-shaped, and the connecting piece 324 The other side of the head of the driven reed 312 bypasses the head of the movable reed 312 and is connected between the static spring 322 and the static spring lead-out piece 323 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com