Patents

Literature

257results about How to "Improve electrical life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

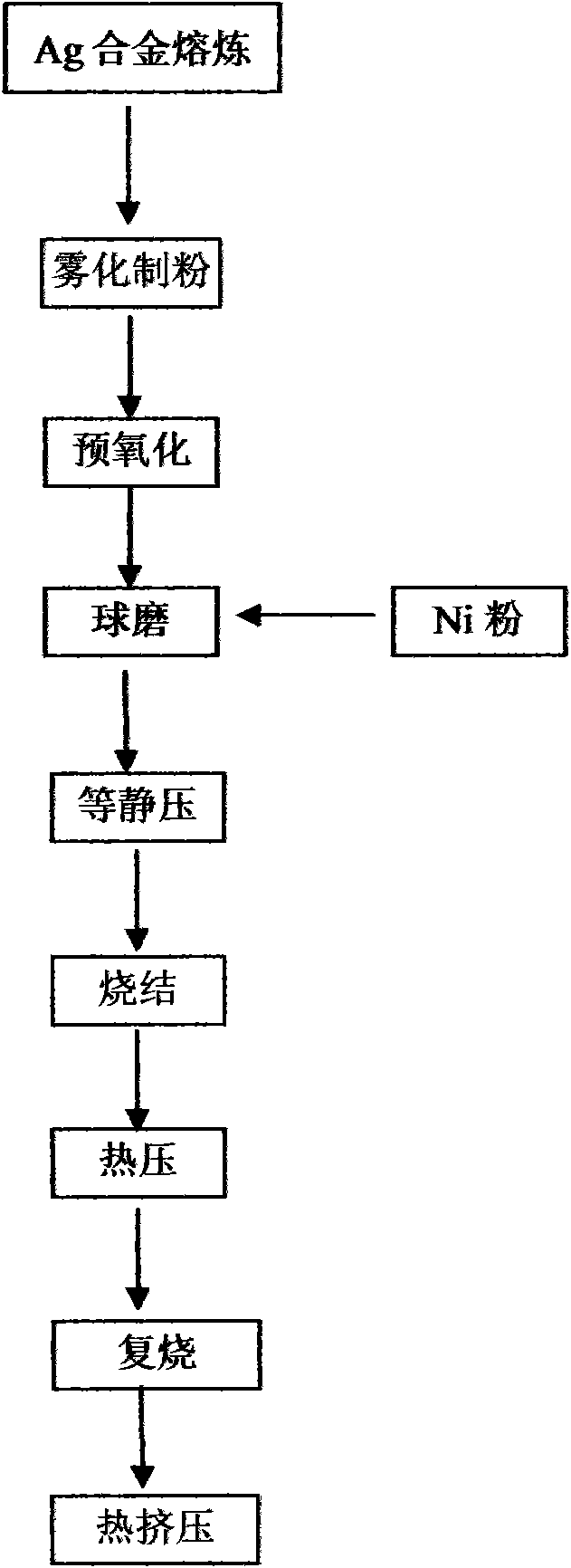

Ag-Ni-oxide electrical contact material and preparation method thereof

The invention discloses an Ag-Ni-oxide electrical contact material and a preparation method thereof. The preparation method comprises the following steps: re-oxidizing Ag alloy powder to obtain oxideparticle reinforced Ag base powder, and then mixing with Ni powder to prepare the new Ni particle and oxide particle reinforced Ag-Ni-oxide base electrical contact material. The material comprises thefollowing components by weight percent: 5%<=Ni<=10%, 0.1%<=oxide particle<=5% and the balance Adding. The oxide particle is one or more of CuO, NiO, SnO2, ZnO, CdO, In2O3 and Bi2O3 and the average grain size of oxide and Ni particle is 0.1-10mu m. The reinforced phase particles of the material of the invention are dispersed evenly and have good bonding strength with Adding, and the Ag-Ni-oxide electrical contact material has good fusion welding resistance and electric arc burning loss resistance and higher electrical life.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

Silver-copper-based metal oxide electrical contact material containing additive elements and preparation method thereof

The invention discloses a silver copper based metal oxide electrical contact material containing adding elements and a preparation method thereof. The electrical contact material is characterized by comprising the following components in percentage by weight: (20-50)% of silver metal oxide alloy, (0.3-9)% of electric conductive ceramics, (0.7-1.8)% of lanthanum nickel alloy, (0.7-4.9)% of adding elements, and the balance of silver copper alloy; and the contact material provided by the invention comprises the following simple substance elements in percentage by weight: (15-63)% of silver, (4-25)% of metal oxide, (0.3-9)% of electric conductive ceramics, (0.01-5)% of rear earth, (0.7-4.9)% of adding elements, and the balance of copper. The preparation method is characterized by comprising the following steps: smelting, pulverizing and milling (silver metal alloy power, and silver copper alloy powder) in proportion for optimization performances of the material, cladding electric conductive ceramic micro powder by silver, mixing powder of the adding elements in a certain mass ratio, pressing an ingot blank, sintering and extruding, rolling or drawing, thus obtaining the contact material. The electrical contact material provided by the invention has the advantages of low cost and excellent overall performance.

Owner:张树堂

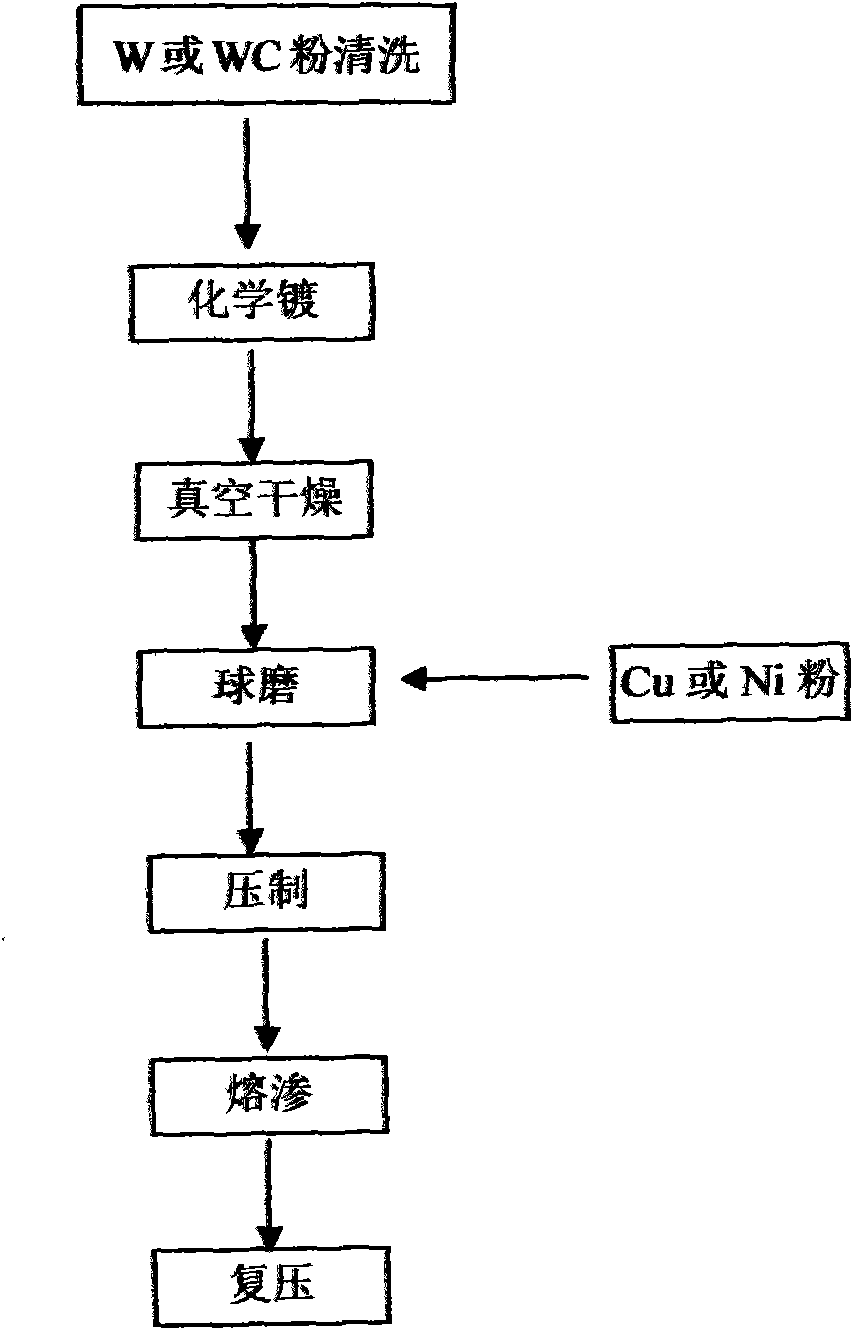

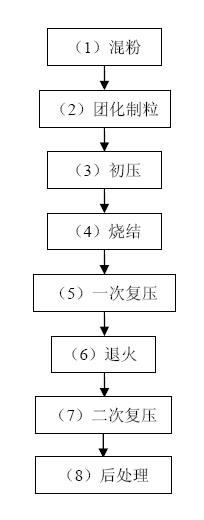

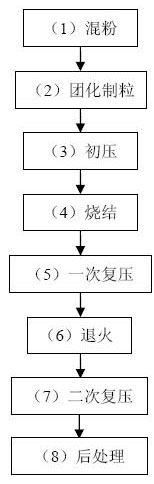

Submicron particle reinforced Ag-based electrical contact material and preparation method thereof

ActiveCN101651050AImprove welding resistanceImprove arc ablation resistanceContactsCopperFusion welding

The invention discloses a submicron particle reinforced Ag-based electrical contact material and a preparation method thereof. The method comprises the following steps: adopting chemical plating method to coat silver on the surface of submicron W particles or WC particles, and then adopting pressing infiltration method to prepare dense micron particle reinforced Ag-based composite material. The material comprises the following components by weight percent: 0.1%<=Ni<=2%, 0.1%<=Cu<=2%, 30%<=W(or WC)<=80% and the balance Ag, wherein the grain size of W or WC powder is 0.01-1mu m. The material ofthe invention has good mechanical and physical properties and the reinforced phase particles are dispersed evenly. Compared with the traditional Ag-W material or Ag-WC material, the material has better fusion welding resistance, lower electric arc burning loss resistance and longer electrical life as the tiny high melting point reinforced phase is distributed evenly in the material substrate in dispersion manner.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

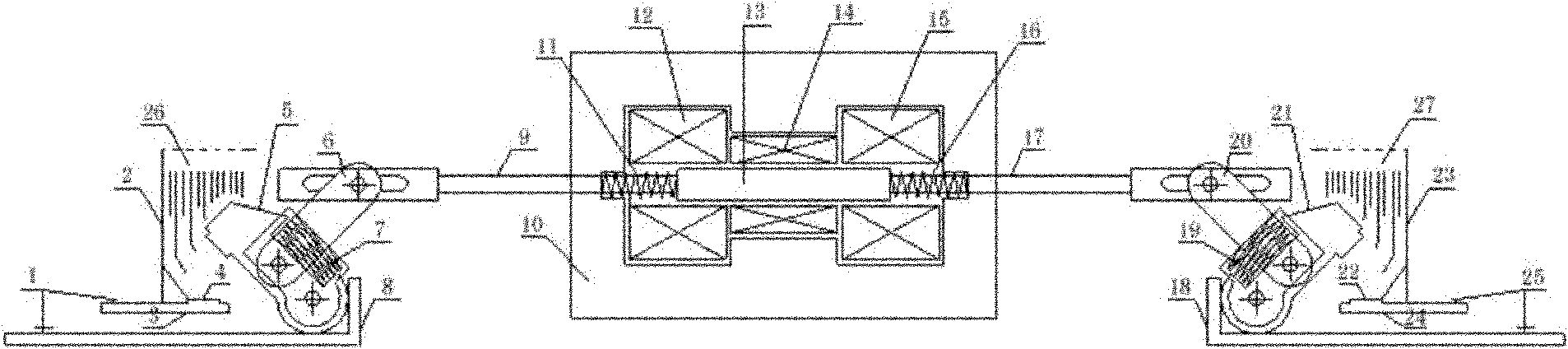

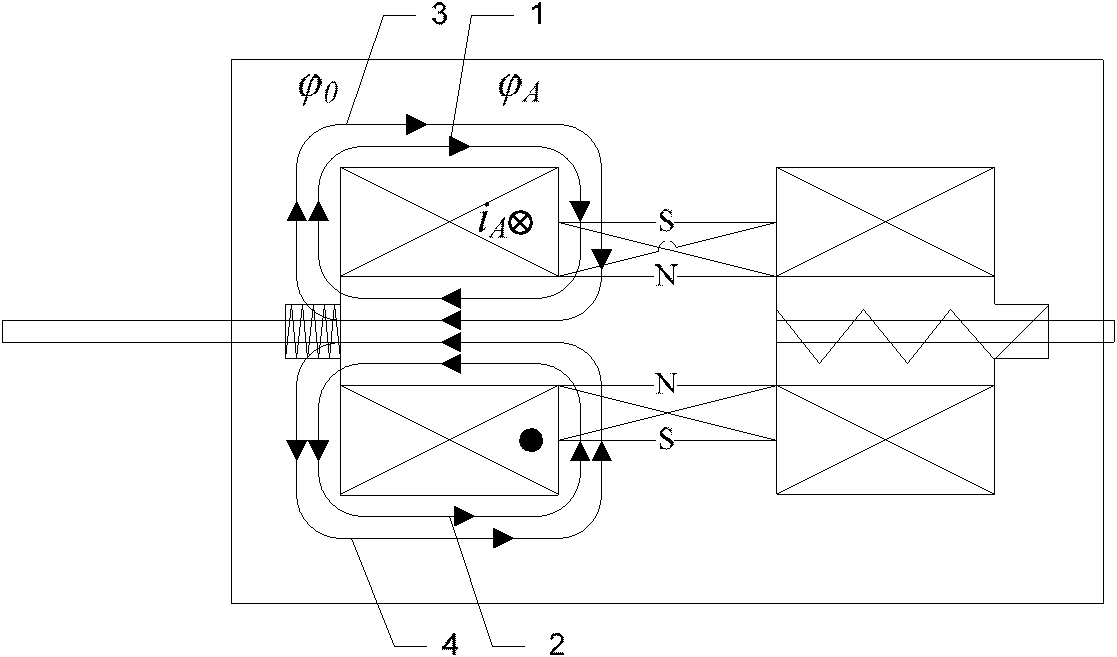

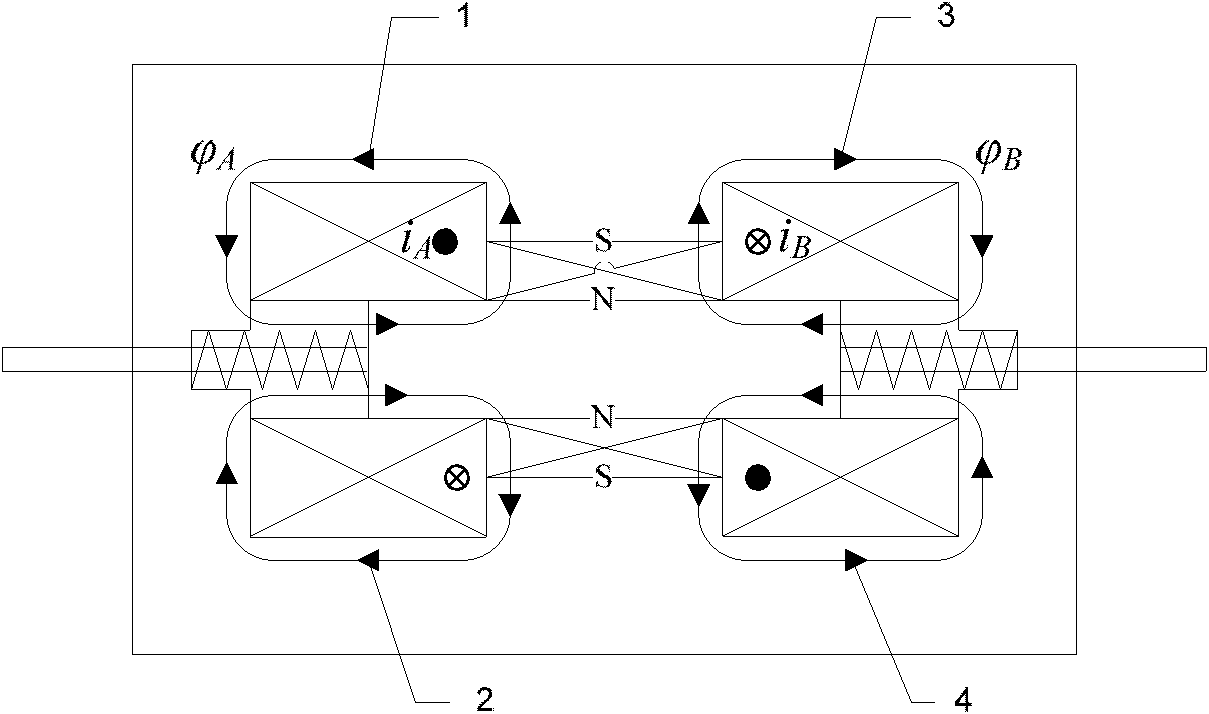

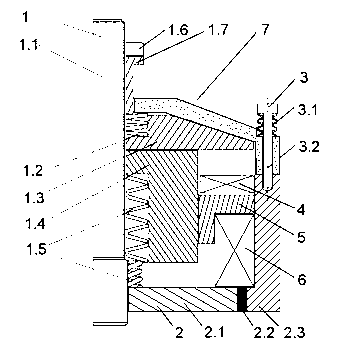

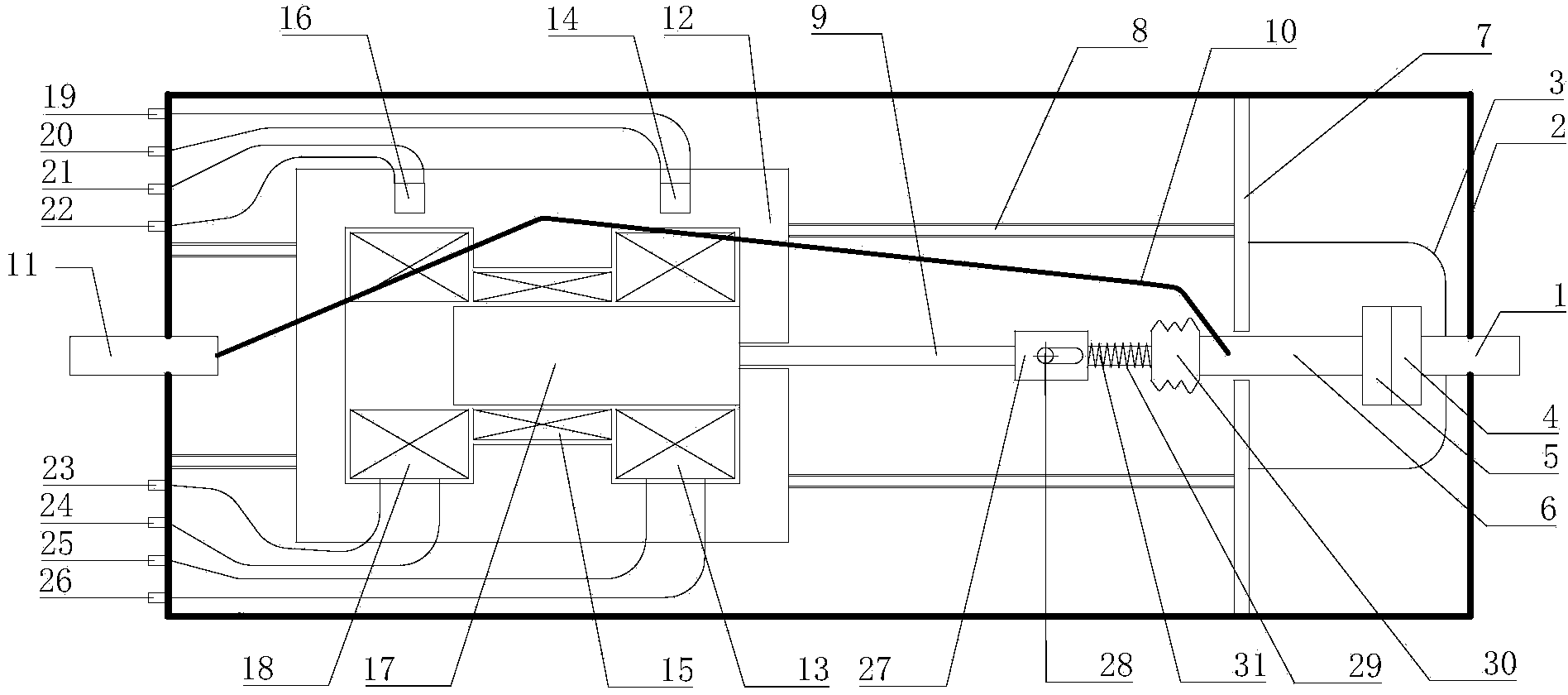

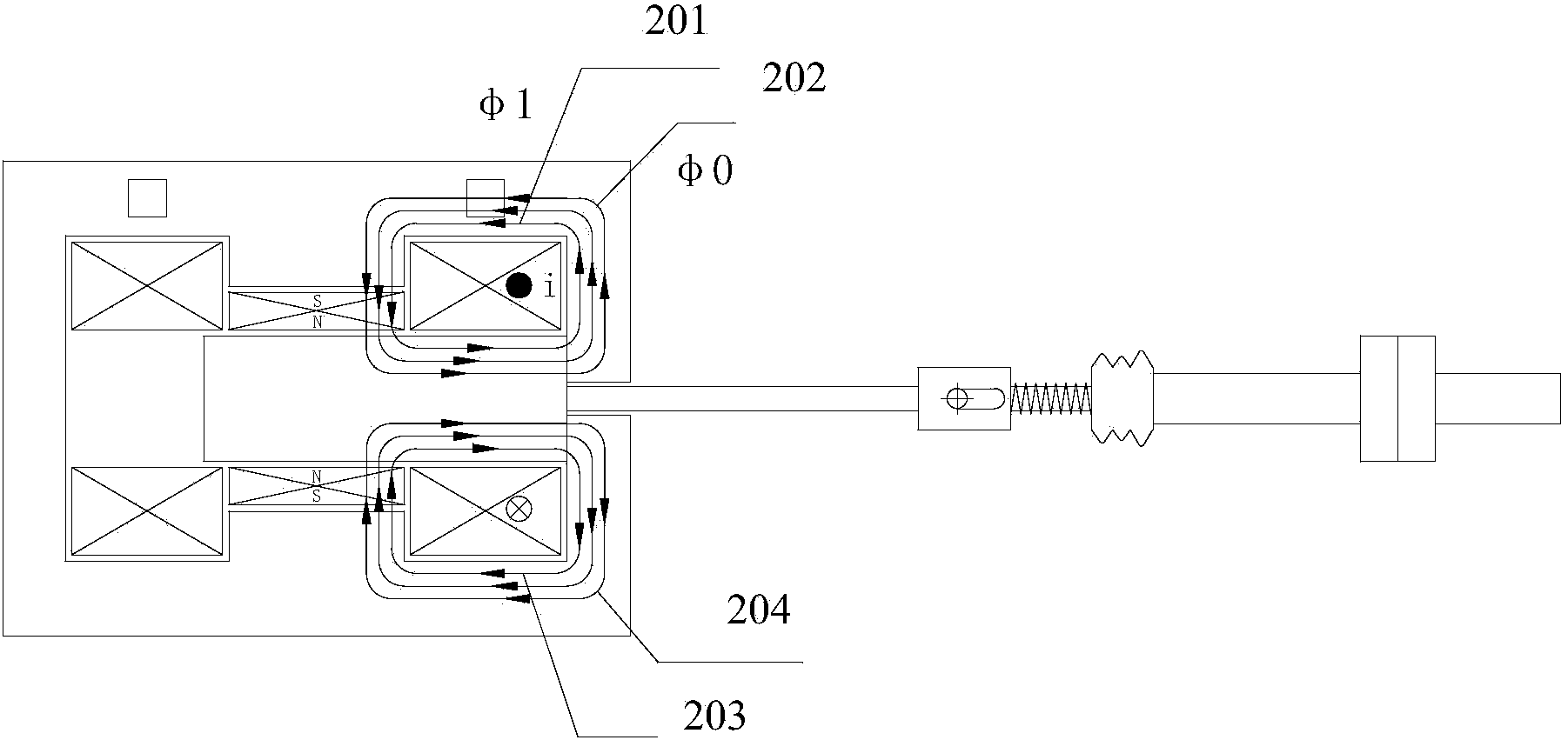

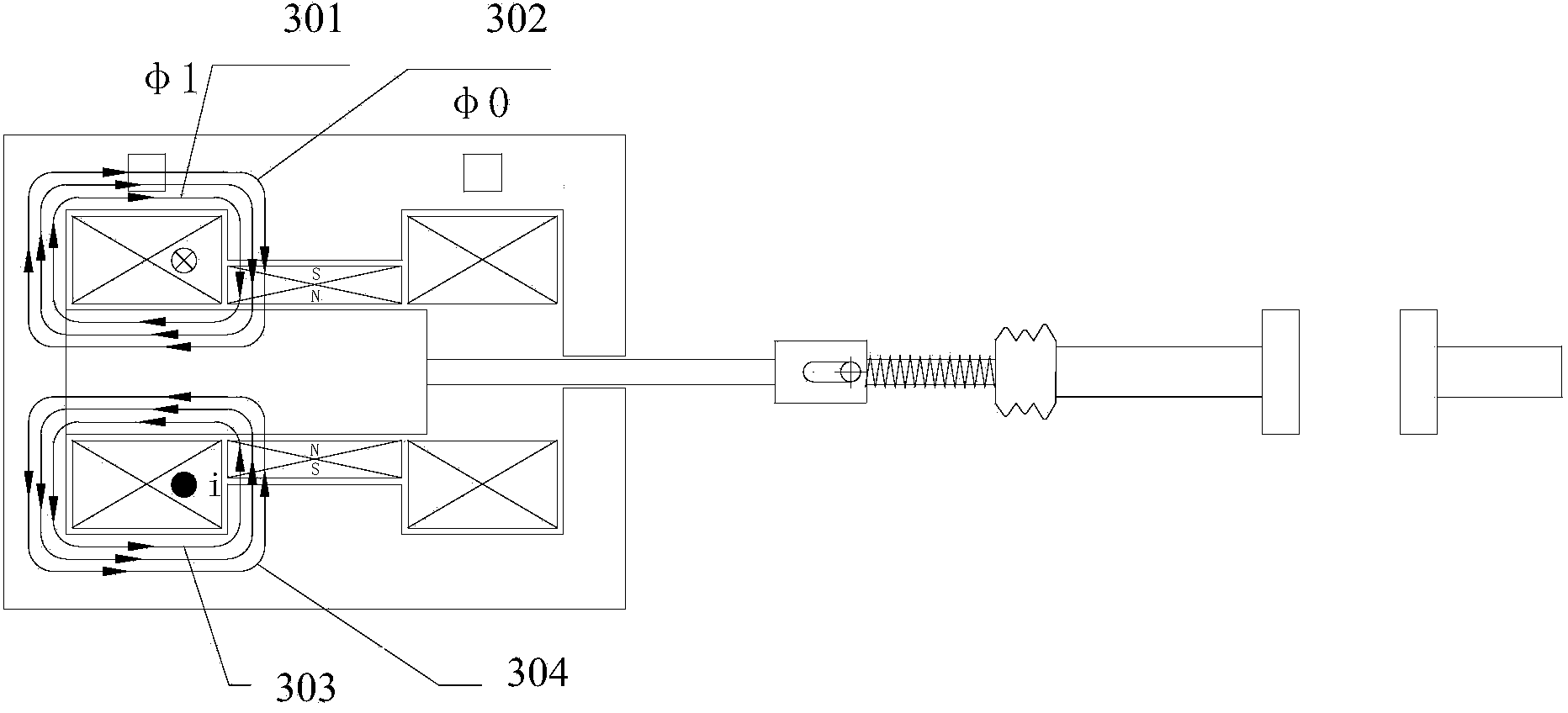

Permanent magnet mechanism automatic changeover switch

ActiveCN102034619AImprove electrical lifeReduce ablationSwitch power arrangementsEmergency protective devicesLow voltageEngineering

The invention belongs to low voltage electrical equipment, and relates to an operation mechanism and an arc extinguish chamber structure of an automatic changeover switch, in particular to a permanent magnet mechanism automatic changeover switch. The permanent magnet mechanism automatic changeover switch comprises two groups of dynamic and static contacts and arc extinguish chambers, a set of permanent magnet mechanism, and corresponding driving connecting rods and conducting rods, and is characterized in that: the permanent magnet mechanism is provided with three stable working positions andcan realize changeover control over the three working states of the automatic changeover switch; when the two groups of contacts are closed respectively, a permanent magnet provides holding force; when the two groups of contacts are opened at the same time, two opening springs provide the holding force; and an electromagnetic coil is electrified to work only during state changeover, so that the electric energy consumption of an electromagnetic mechanism is greatly reduced. When a three-phase system is formed, every phase adopts independent mechanism control so as to realize phase-separated operation, and arc-free break can be realized by phase-selected control; and the operation mechanism has a few parts, a simple structure and high reliability.

Owner:XI AN JIAOTONG UNIV

An intelligent high-voltage dual power conversion switch

InactiveCN101266894ANo simultaneous power feeding accidentsImprove electrical lifePower network operation systems integrationSwitches with unconnected briding contactsElectricityStandby power

The invention discloses an intelligent high-pressure dual power supply shift switch, comprising a gas seal box, three primary power supply terminals disposed on the gas seal box, three standby power supply terminals and three load terminals, and a power supply shift mechanism set in the gas seal box; characterized that: the switch also comprises a three-phase vacuum breaker device, the three-phase vacuum breaker device comprises three vacuum interrupters, three moving contacts, three static contact and a operation mechanism; each of the moving contact / static contact is connected with the corresponding primary power supply terminal / standby power supply terminal via the power supply shift mechanism, each of the static contact / moving contact is connected with a corresponding load terminal. The invention has the advantages of simple structure, low costs, suitable for eliminating potential security hazard effectively.

Owner:黄勤飞

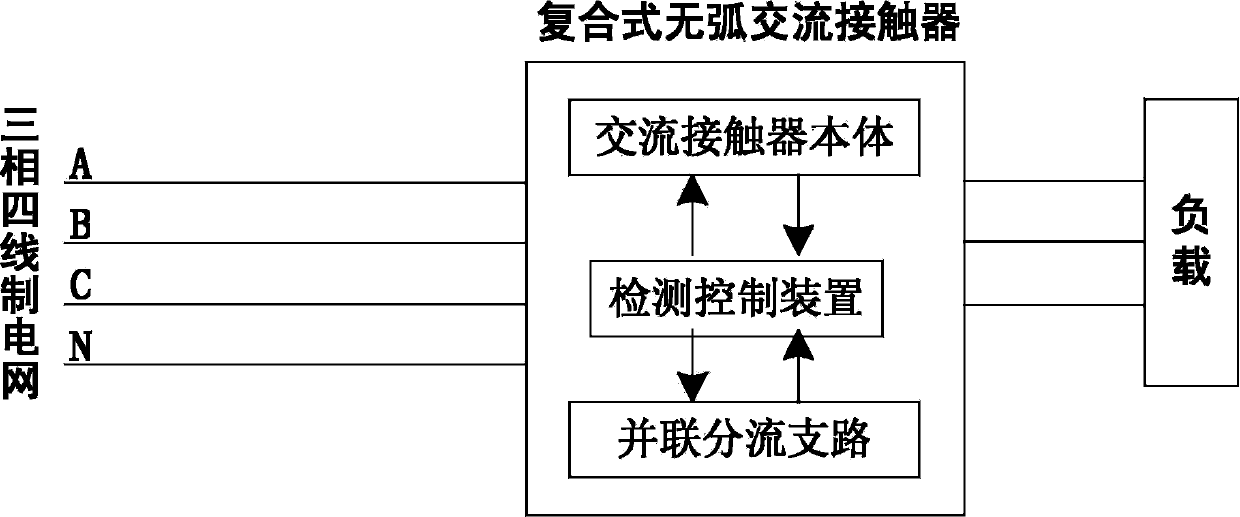

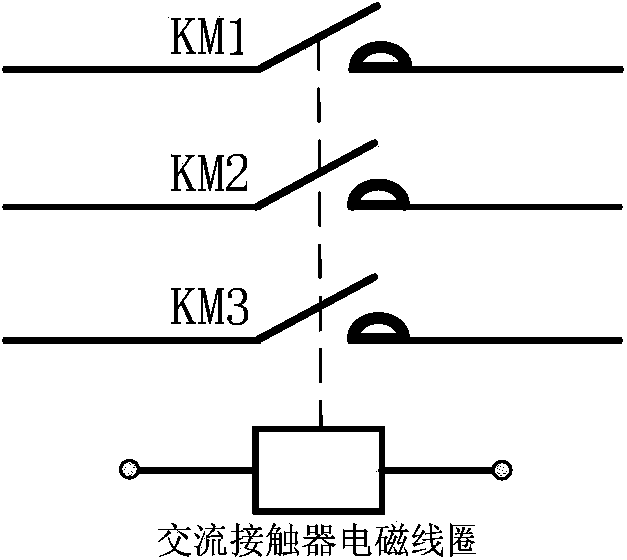

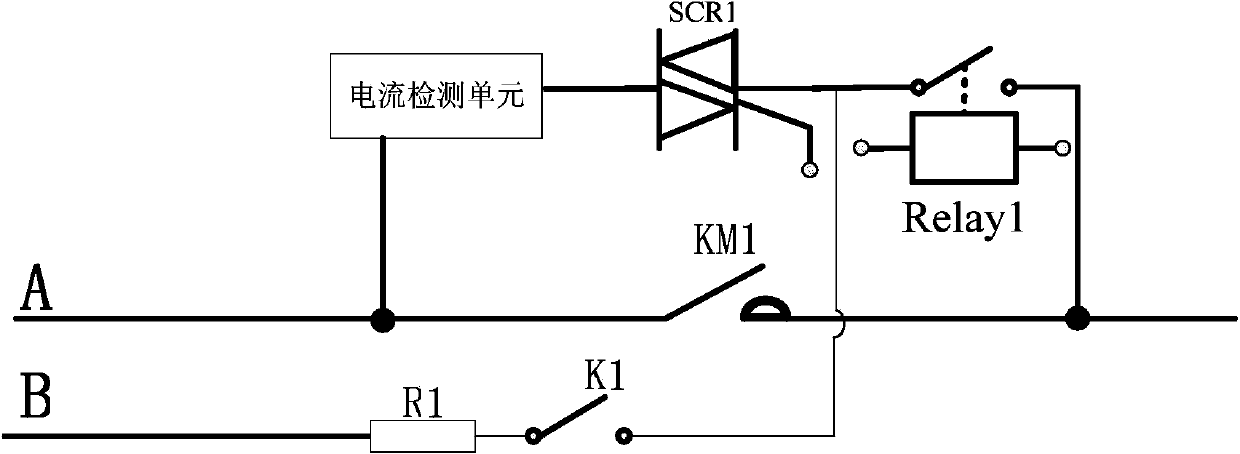

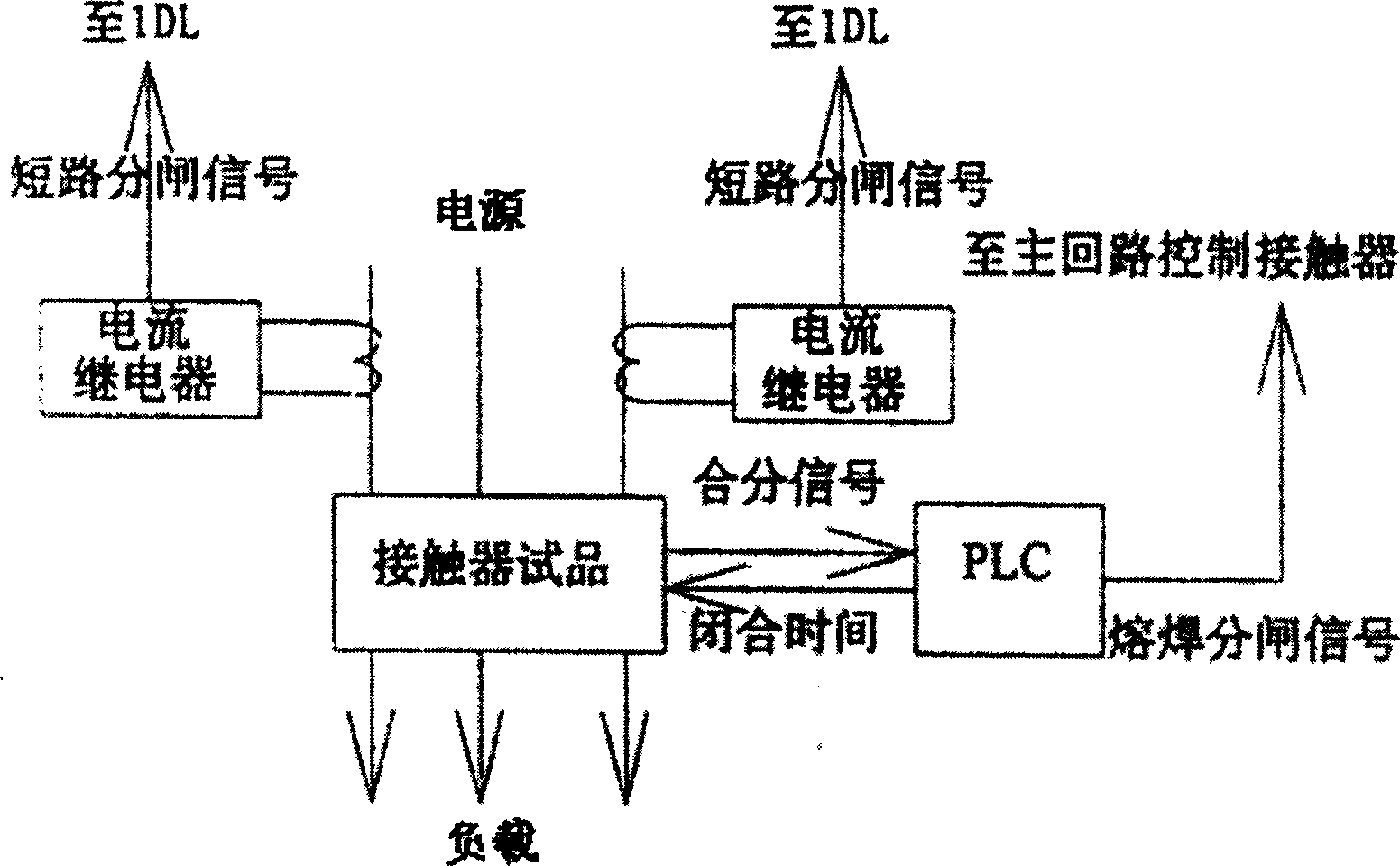

Combined type arc-free alternating-current (AC) contactor with function of thyristor fault diagnosis

InactiveCN103745883AReduce power consumptionReduce erosionElectromagnetic relay detailsMicrocontrollerPhase currents

The invention provides a combined type arc-free alternating-current (AC) contactor with the function of thyristor fault diagnosis. The combined type arc-free AC contactor comprises an AC contactor body, parallel shunt branch circuits and a detection control device, wherein the parallel shunt branch circuits are respectively connected to the two ends of each three-phase main contact of the AC contactor body in parallel; the parallel shunt branch circuit of each phase comprises a current detection unit, a bidirectional thyristor, a thyristor self-check relay, a thyristor self-check resistor and an electromagnetic relay; the detection control device comprises a three-phase voltage detection unit, an A-phase voltage zero-crossing detection unit, a three-phase current detection unit, an A-phase current zero-crossing detection unit, a solenoid excitation unit, a thyristor drive unit, an electromagnetic relay drive unit, a current detection unit, a resistance-capacitance buck power supply and a microcontroller. The combined type arc-free AC contactor is used for frequently connecting or disconnecting an AC main circuit, and the generation of electric arcs during each action of the contactor is inhibited through the instant current shunting of power electronic devices, so that the erosion to the main contacts of the contactor caused by the electric arcs is reduced greatly.

Owner:LIAONING TECHNICAL UNIVERSITY

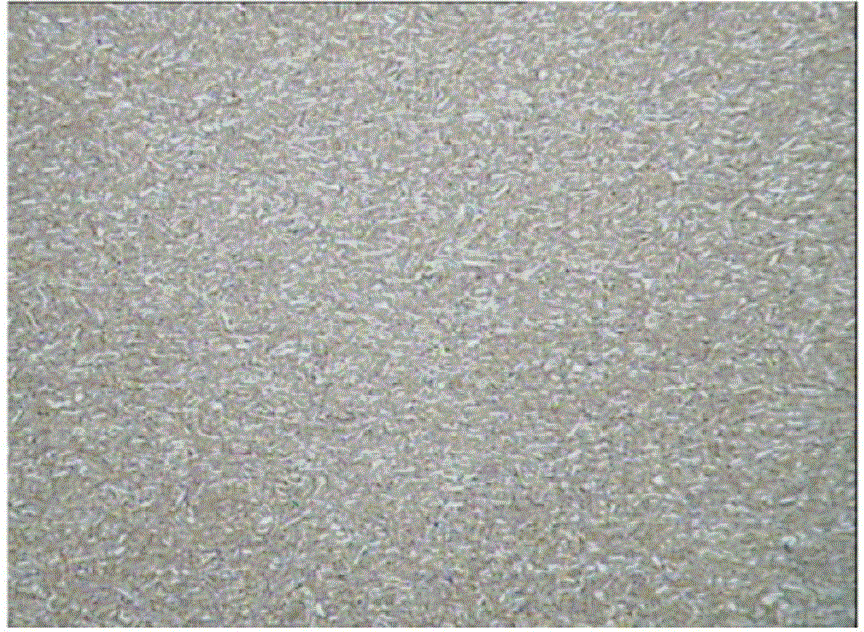

Method for preparing silver-based electrical contact material with fibrous structure

ActiveCN102002651AImproved arc erosion resistanceImprove conductivityContactsFusion weldingElectrical resistivity and conductivity

The invention discloses a method for preparing a silver-based electrical contact material with a fibrous structure, which comprises the following steps: 1, uniformly mixing reinforcing-phase material powder with substrate silver powder uniformly, and ball milling; 2, feeding the obtained mixed powder and substrate silver powder into a powder mixer for mixing powder; 3, performing isostatic cool pressing; 4, sintering; 5, performing hot pressing; and 6, performing hot extrusion and obtaining the silver-based electrical contact material. The method of the invention can prepare the sliver-based electrical contact material with an obvious fibrous structure regardless the processing deformation amount and the levels of the plasticity and ductility of a reinforcing phase; and in the method, theprocess is simple, it is convenient to operate, the cost is low, and special requirements on equipment are avoided. The fusion welding resistance, arc erosion resistance and conductivity of the material prepared by the method are all improved greatly, and the processing performance of the material is high.

Owner:WENZHOU HONGFENG ELECTRICAL ALLOY

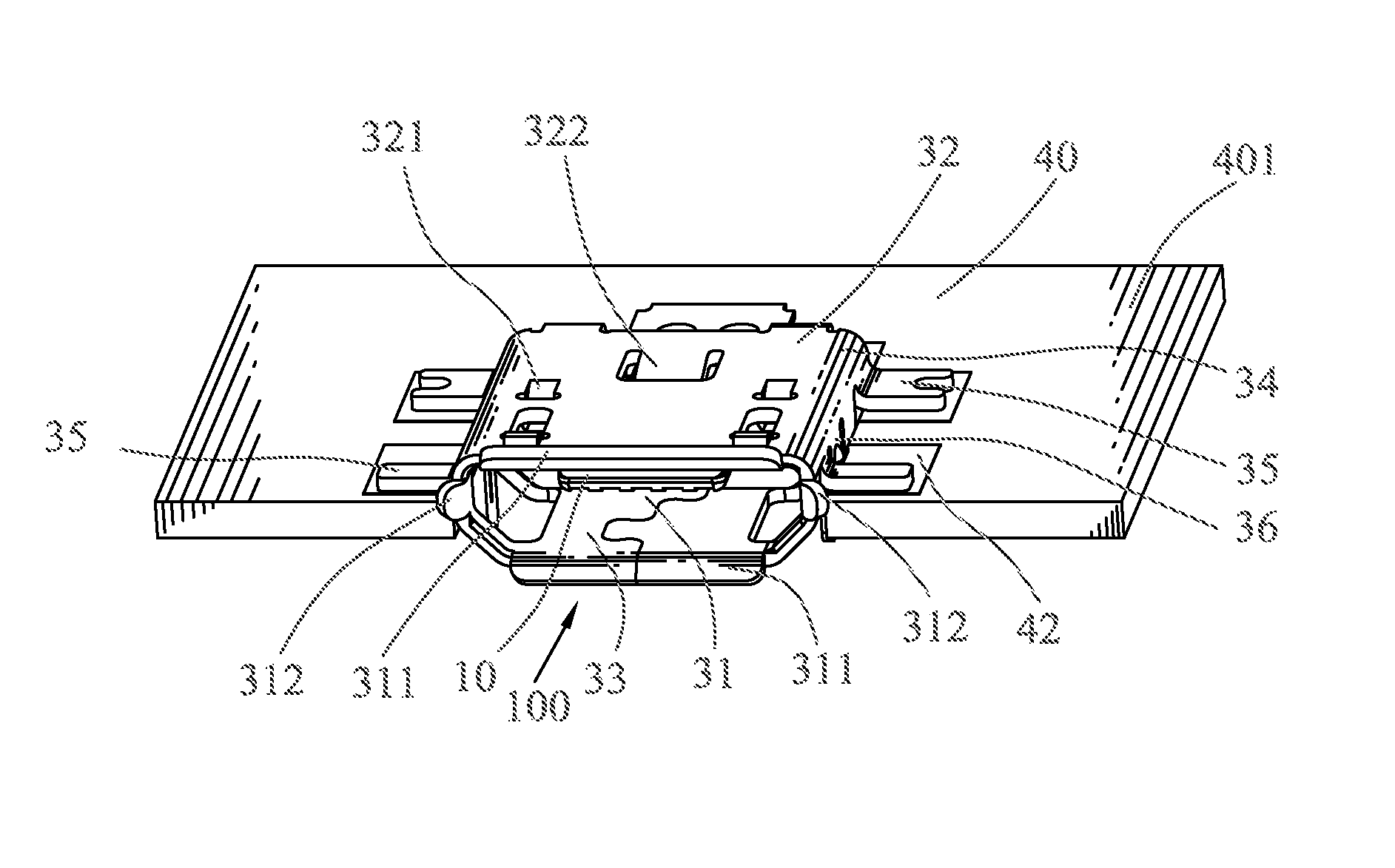

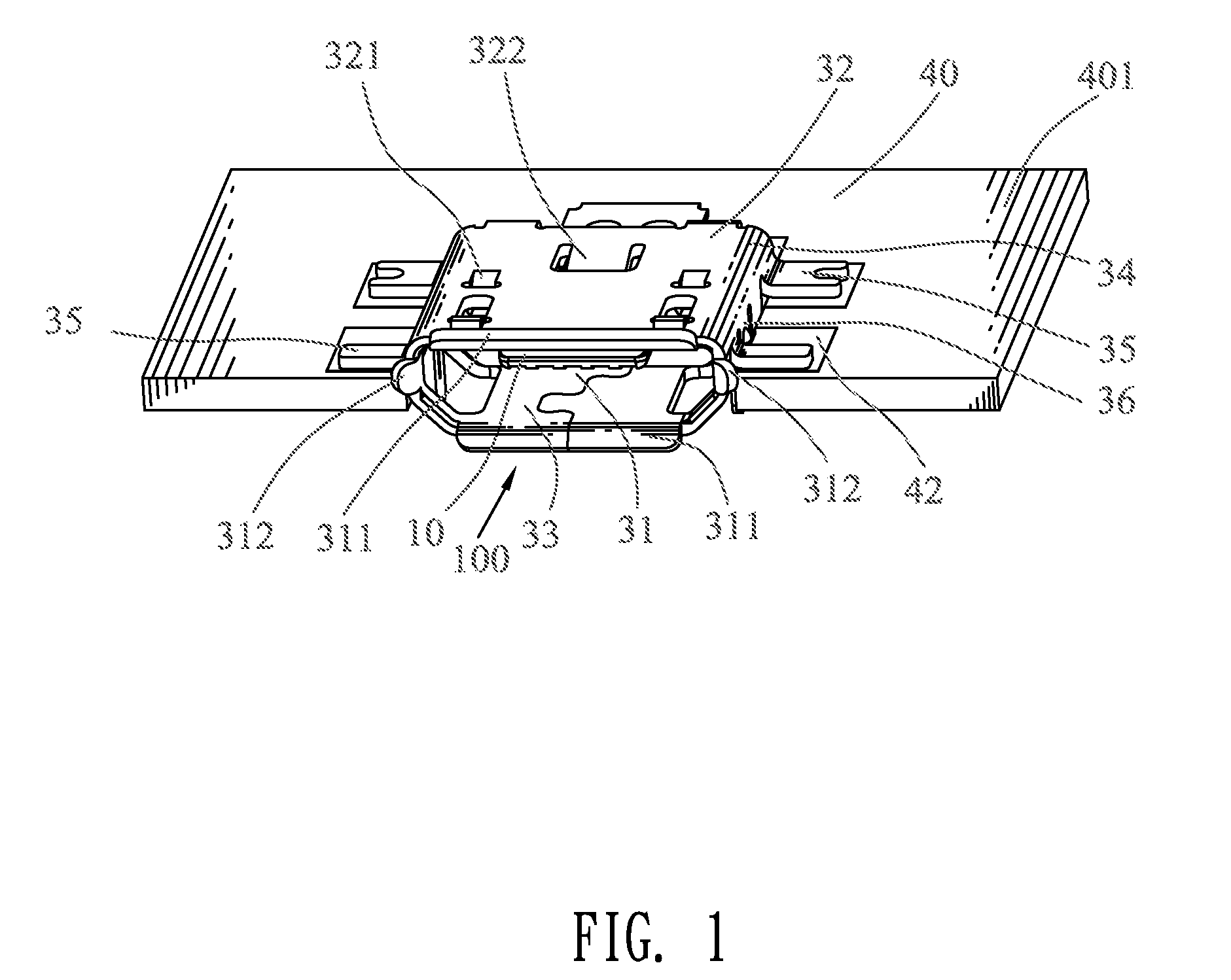

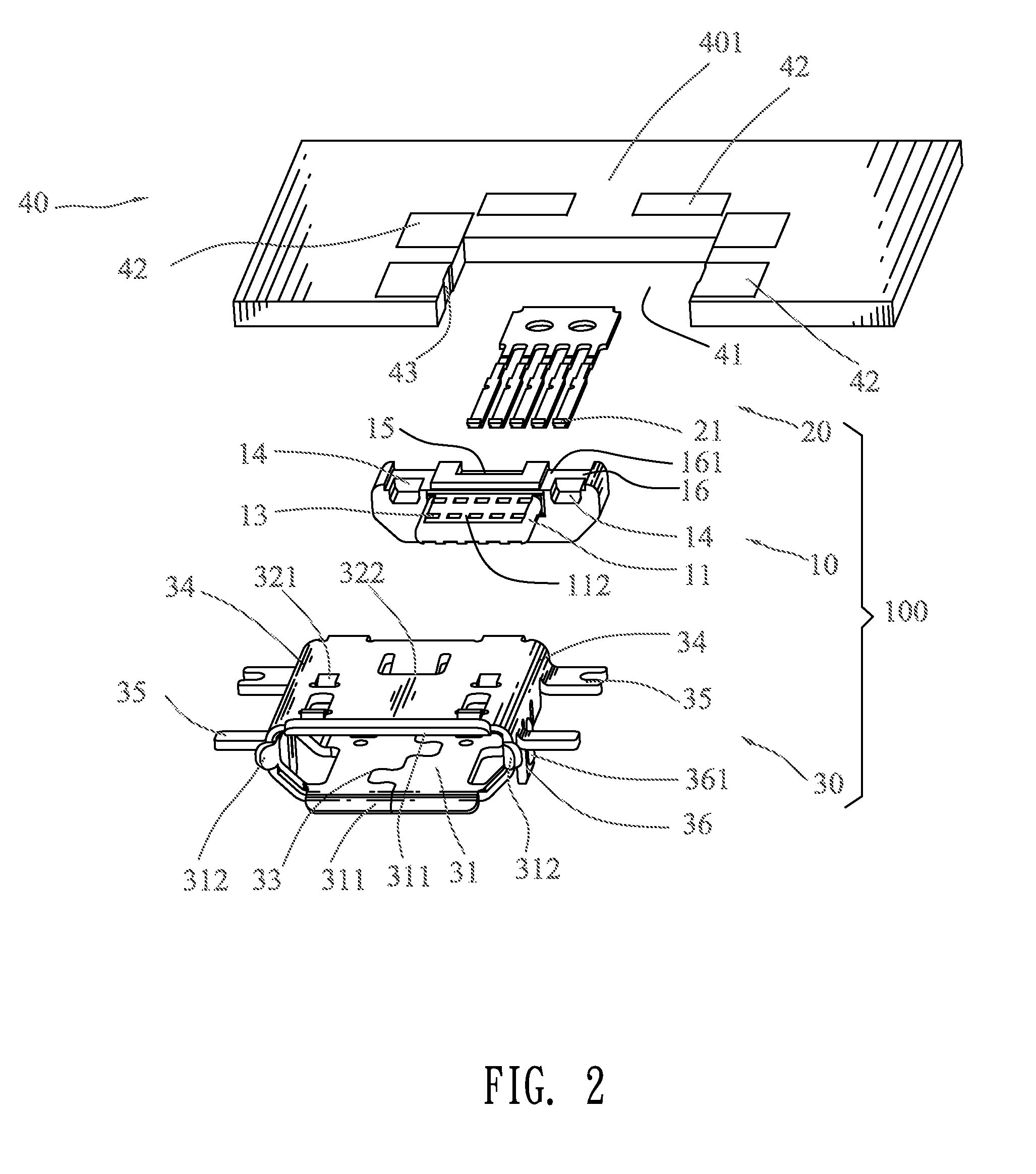

Electrical connector soldered on a printed circuit board

InactiveUS8142225B2Reduce the possibilityImprove electrical lifeFixed connectionsPrinted circuitsElectrical connectorSoldering

Owner:CHENG UEI PRECISION IND CO LTD

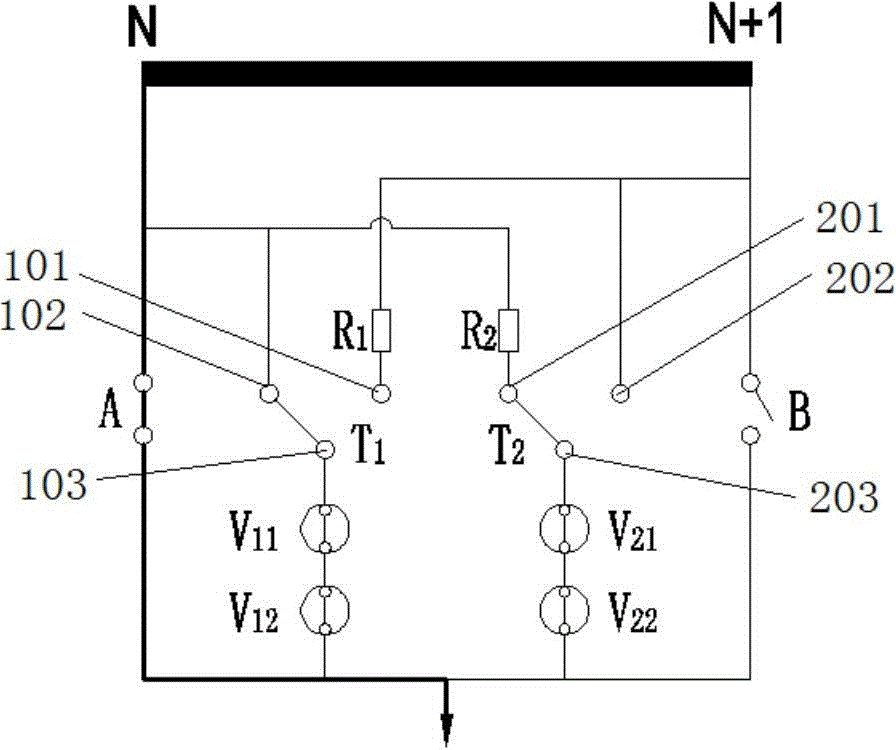

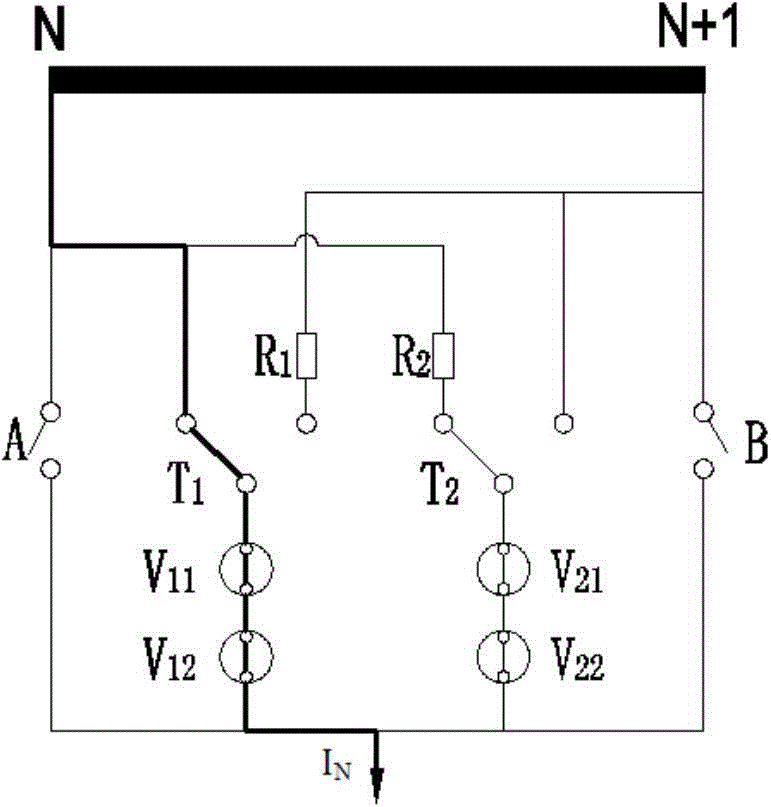

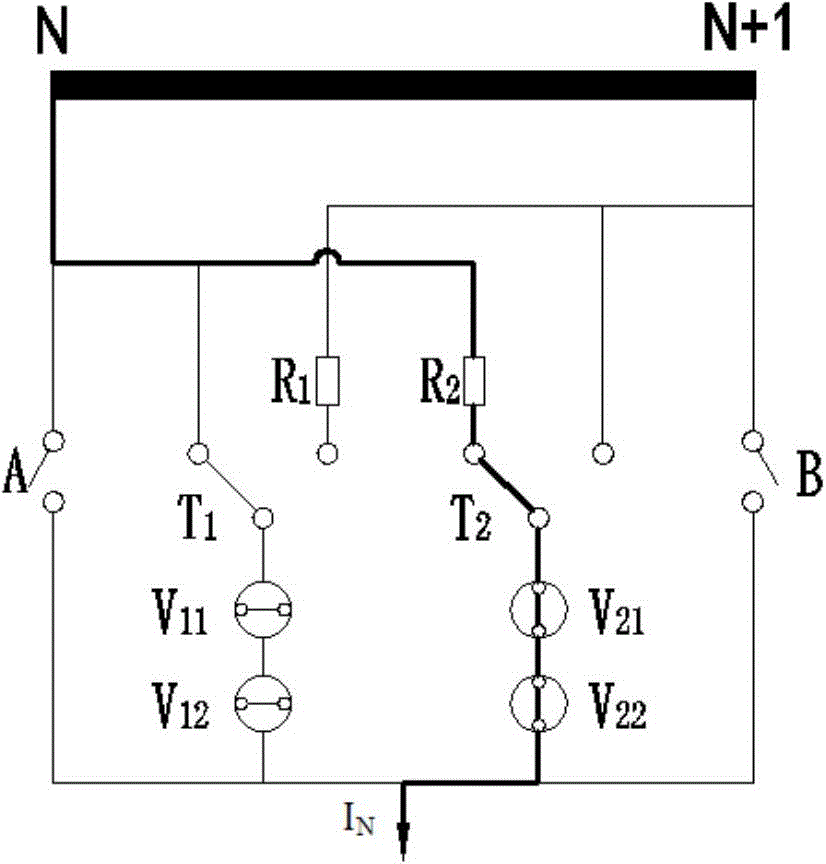

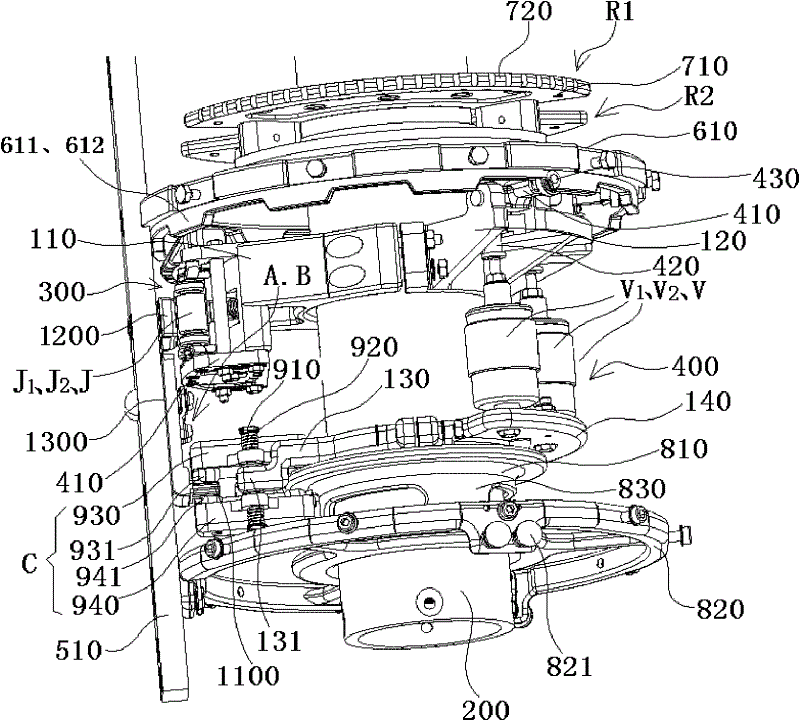

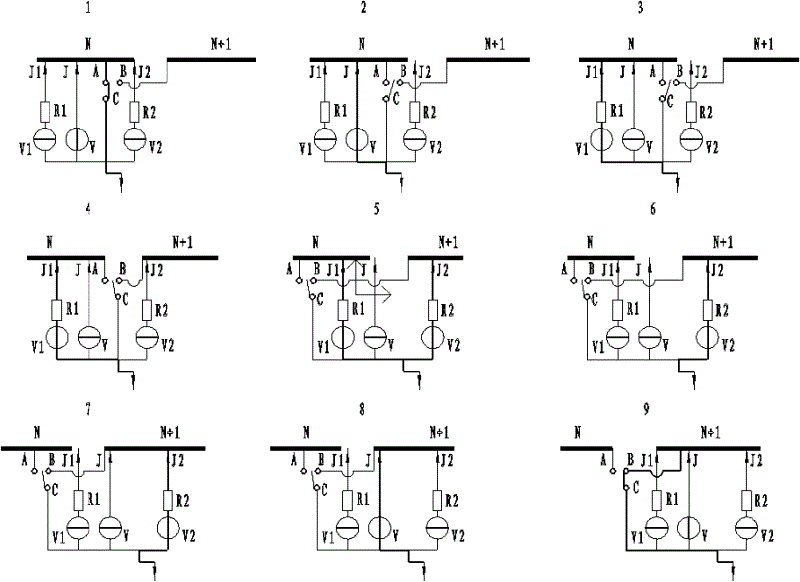

Transition circuit of vacuum type on-load tap-changer and operation method

InactiveCN104465168ARecovery voltage dropSame burning lossVariable inductancesElectric switchesElectrical resistance and conductanceState of art

The invention provides a transition circuit of a vacuum type on-load top-changer and an operation method. The transition circuit of the vacuum type on-load top-changer comprises a main contact A, a main contact B, a vacuum contact A, a vacuum contact B, a change-over switch T1, a change-over switch T2, a transition resistor R1 and a transition resistor R2, wherein the vacuum contact A and the vacuum contact B are used as a main switching contact and a transition contact in turn. The main contact A is connected with taps, with the odd numbers, of a regulating winding of a transformer, and the main contact B is connected with taps, with the even numbers, of the regulating winding of the transformer. Each change-over switch comprises a first static contact, a second static contact and a movable contact, wherein the first static contact is connected with the corresponding taps of the regulating winding of the transformer, the second static contact is connected with the corresponding taps of the regulating winding of the transformer through the transition resistor, and one end of the movable contact is connected with the corresponding vacuum contact. Compared with the prior art, the transition circuit of the vacuum type on-load top-changer and the operation method have the advantages that the switching tasks of the main switching contact and the transition contact are in the charge of two vacuum pipes in turn, the switching procedure is symmetrical, so that the burning losses of the two vacuum contacts are completely identical, and the electrical service life of the whole on-load tap-changer is greatly prolonged.

Owner:STATE GRID CORP OF CHINA +2

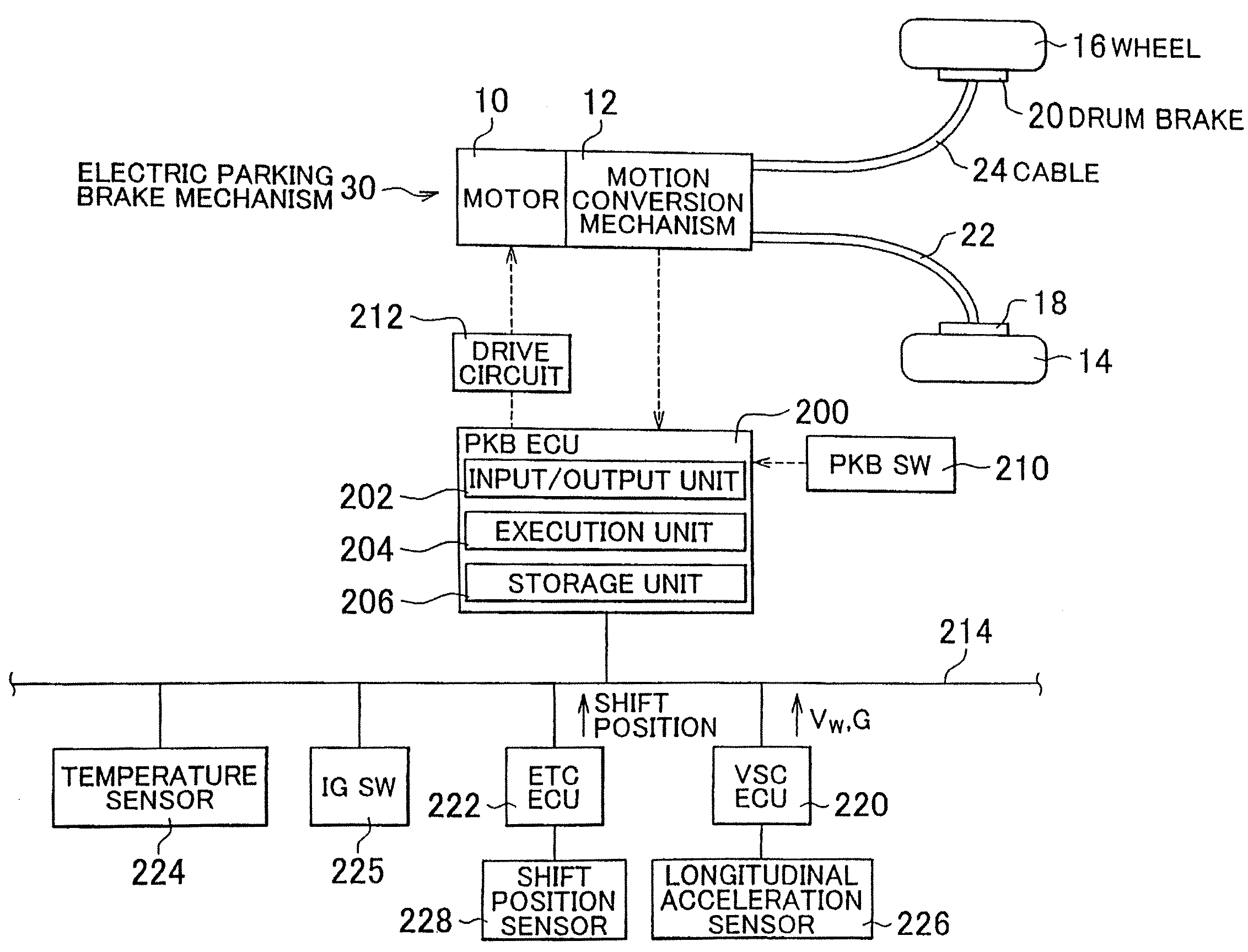

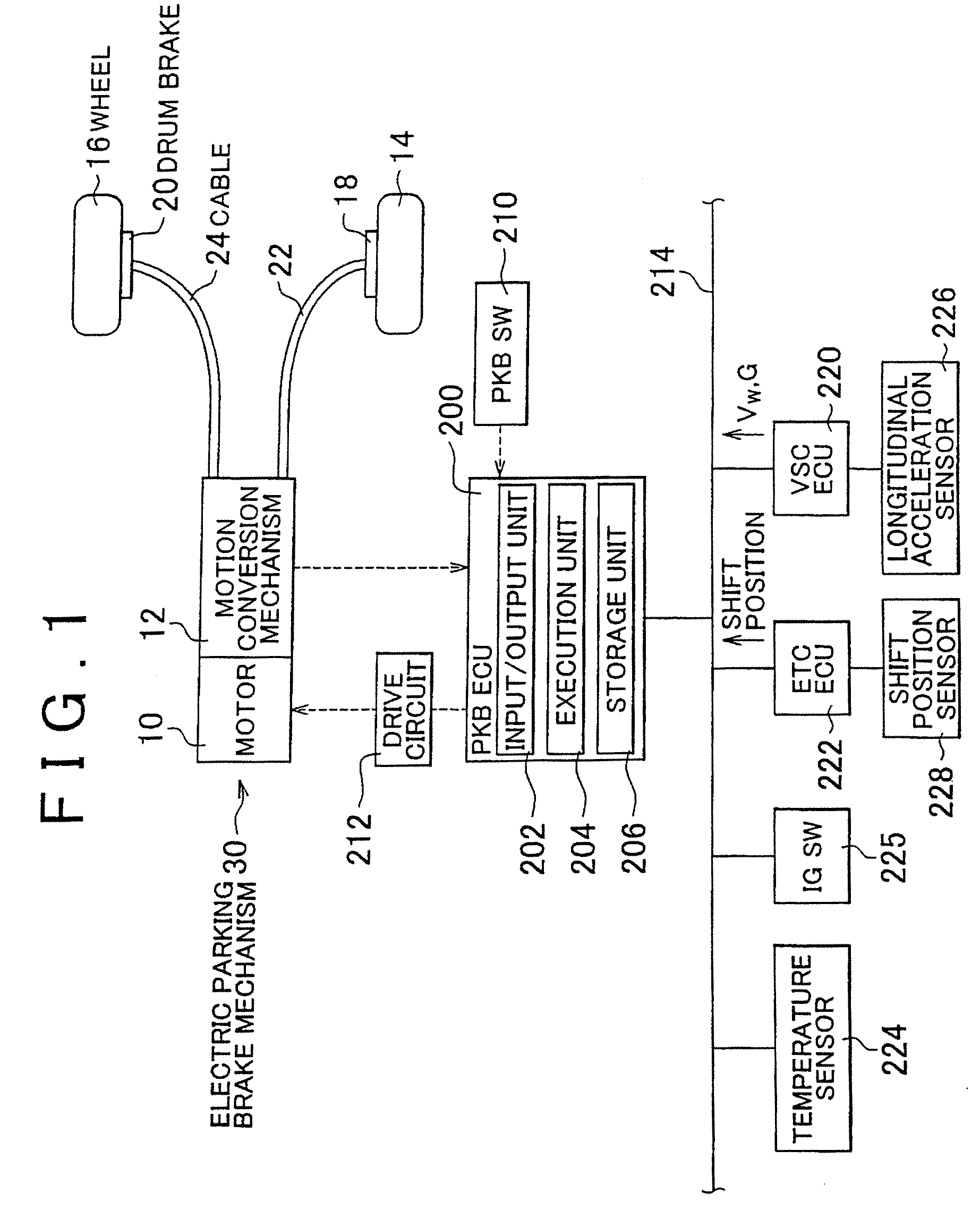

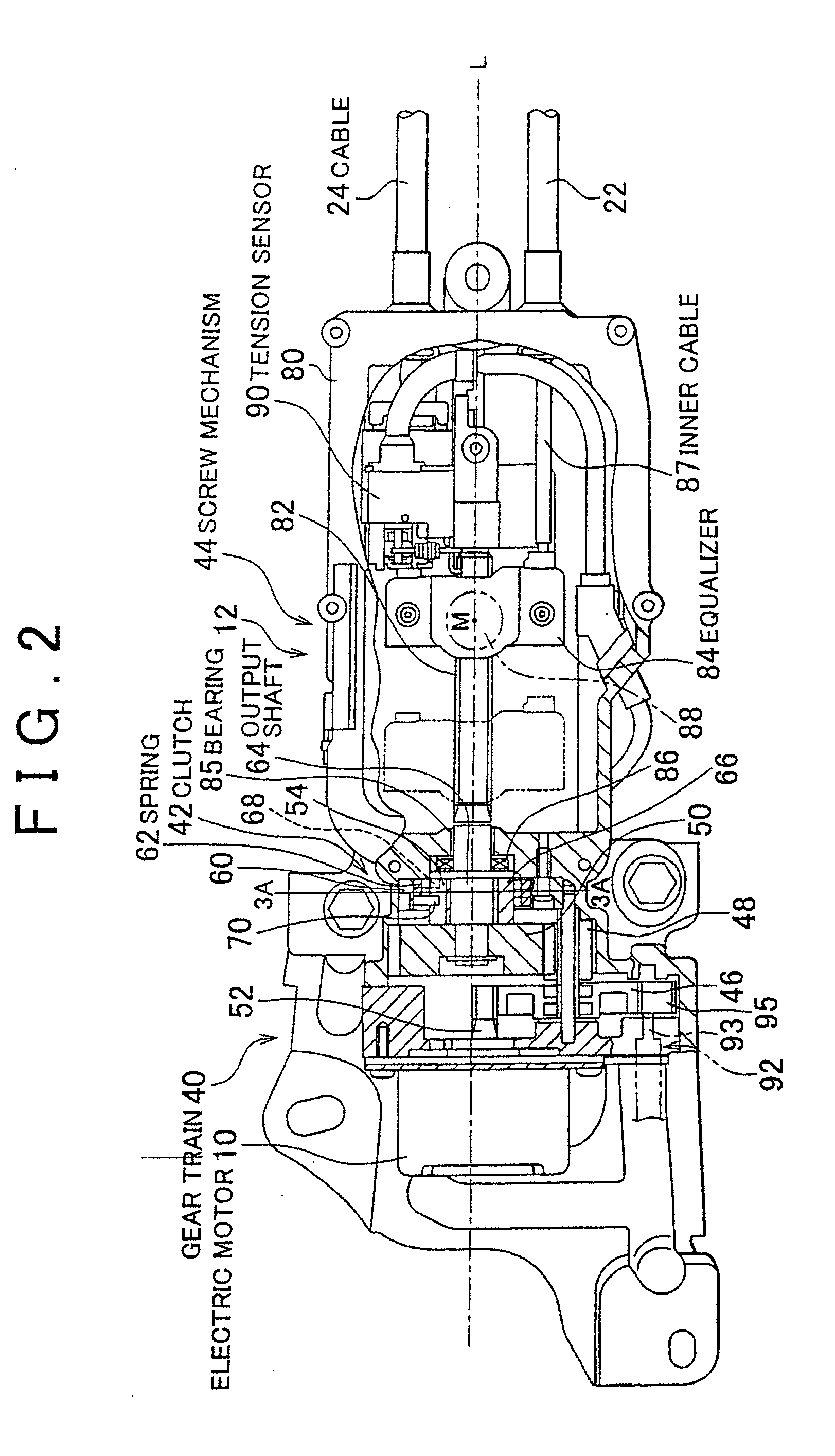

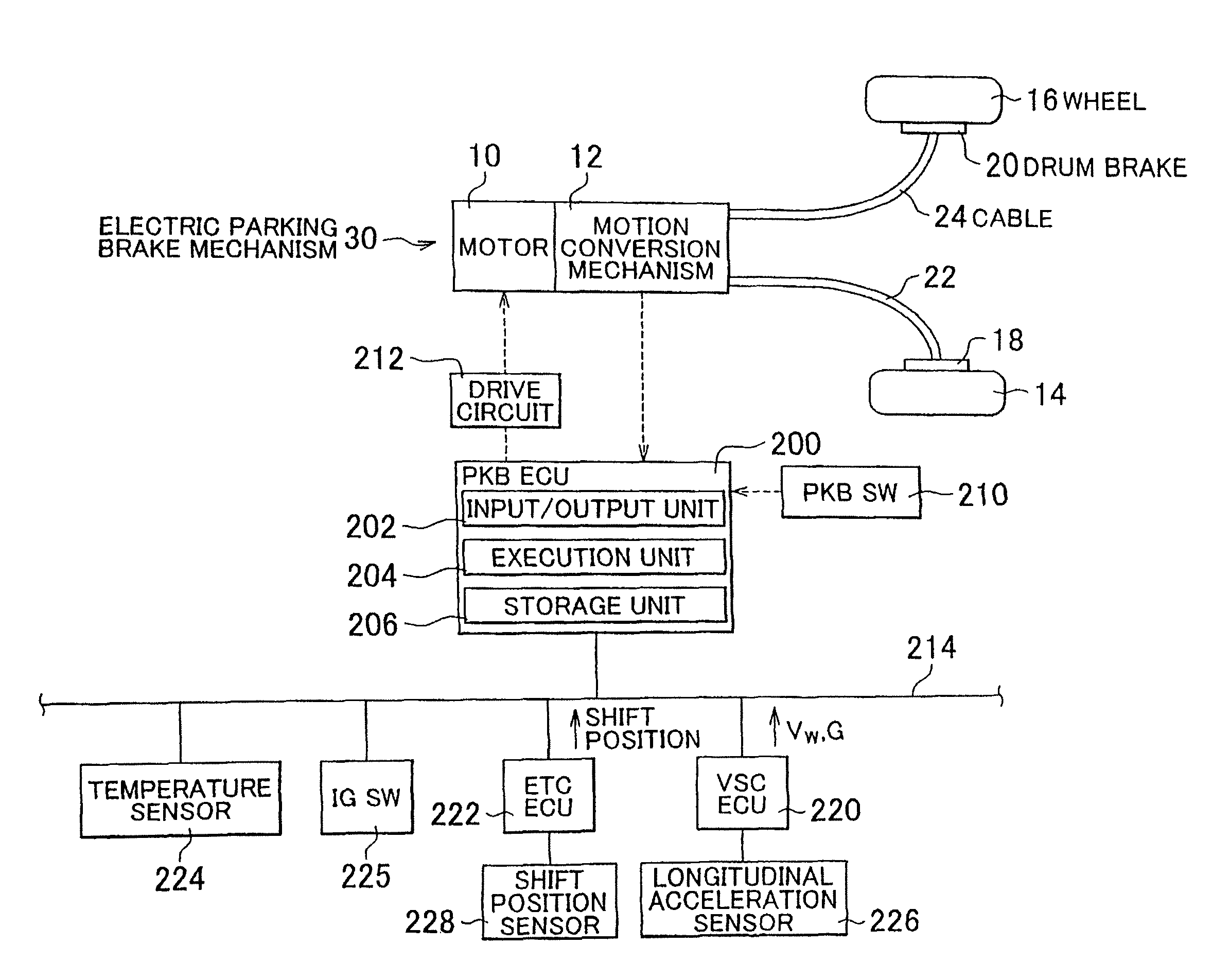

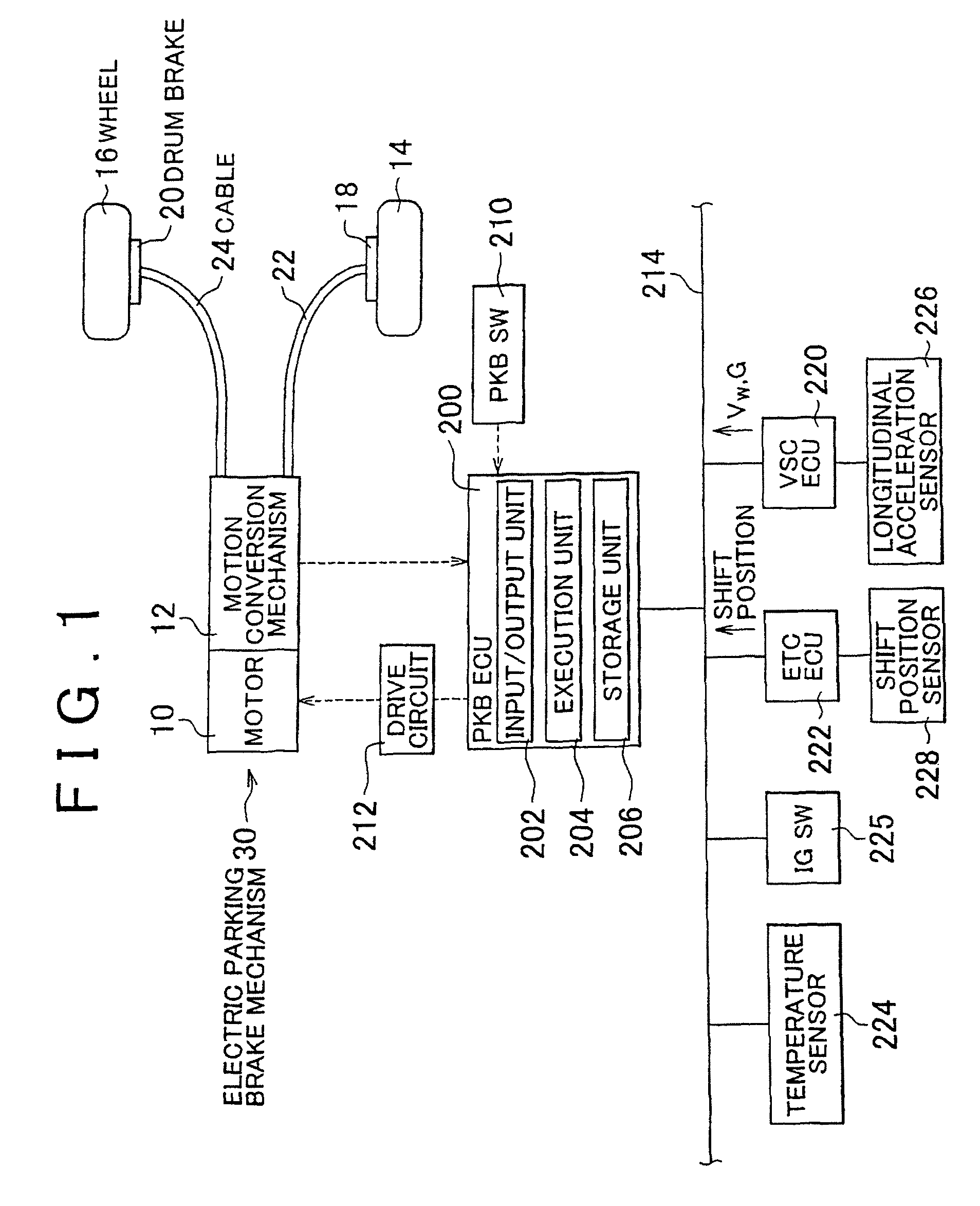

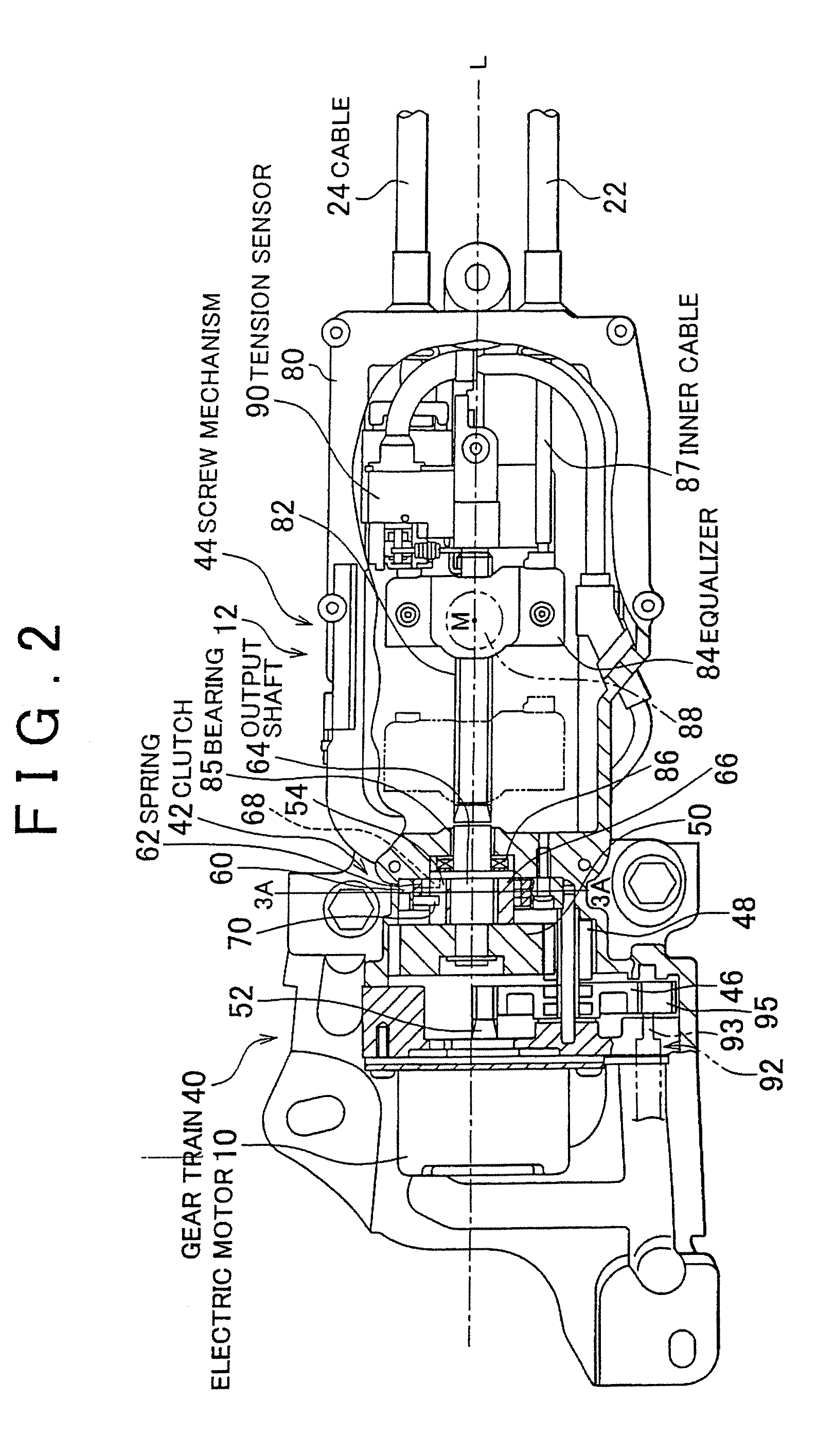

Electric parking brake system and method for controlling the electric parking brake system

ActiveUS20080071456A1Reduce in quantityShorten the timeAnalogue computers for trafficBraking action transmissionElectric parking brakeAutomotive engineering

During the standstill state maintenance control executed by an electric parking brake system, the moving force-based target tension Frefb is determined based on the inclination angle of a vehicle and the shift position each time the predetermined program is executed, and the tentative target tension Fref(n) in the current routine is set to a smaller value from among the moving force-based target tension Frefb and the maximum value Fmax. The control target tension Fref(n)* is set to a larger value from among the control target tension (the final target tension) Fref(n−1)* in the immediately preceding routine and the tentative target value Fref(n). Even if the tentative target tension Fref(n) is smaller than the control target tension Fref(n−1)*, the control target value Fref(n)* is not set to a value smaller than the control target tension Fref(n−1)*.

Owner:TOYOTA JIDOSHA KK

High antifusion weding performance silver nickel base electric contact material and its preparation method

InactiveCN1478913AImprove electrical lifeNo other performance degradationContact materialsFiberFusion welding

An AgNi-base electric contact resisting fusion welding contains Ni (0-10%), W (0-5%), GeO2 (0-1%), Li2Co3 (0-100 ppm) and Ag (rest), and is made up through die pressing, sinter and squeezing. Its advantage is long service life elongated by 5 times or more and low cost.

Owner:XI AN JIAOTONG UNIV

Composite vacuum on-load tap-changer switching assembly

ActiveCN102623202AImprove electrical lifeReduce maintenance workloadVariable inductancesHigh-tension/heavy-dress switchesQuenchingTap changer

A composite vacuum on-load tap-changer switching assembly comprises a transition resistor assembly fixedly installed on an insulation spindle, an upper support and a lower support. A contact assembly, which is installed on the upper support, comprises two transition contacts and one main on-off contact. A vacuum tube assembly, which is installed between the upper support and the lower support, comprises three vacuum tubes and three groups of vacuum tube opening and closing mechanisms. Two vacuum tubes are connected in series with the transition contacts and the transition resistor. One vacuum tube is connected in series with the main on-off contact. A cam, which is installed on a batten of a switch cage body, drives the motion of the three groups of vacuum tube opening and closing mechanisms so that the three vacuum tubes close and disconnect according to a certain opening and closing time sequence. An inner end of a moving contact assembly installed on the lower support clamps a moving contact eduction disc assembly installed on the batten of the switch cage body and an outer end clamps a main contact in a static contact assembly. According to the invention, during switching, electric arc only generates in the vacuum tube. Using the vacuum tube to perform quenching of the arc can not pollute transformer oil in a switch oil chamber so that the switch can be maintenance-free.

Owner:SHANGHAI HUAMING POWER EQUIP CO LTD +1

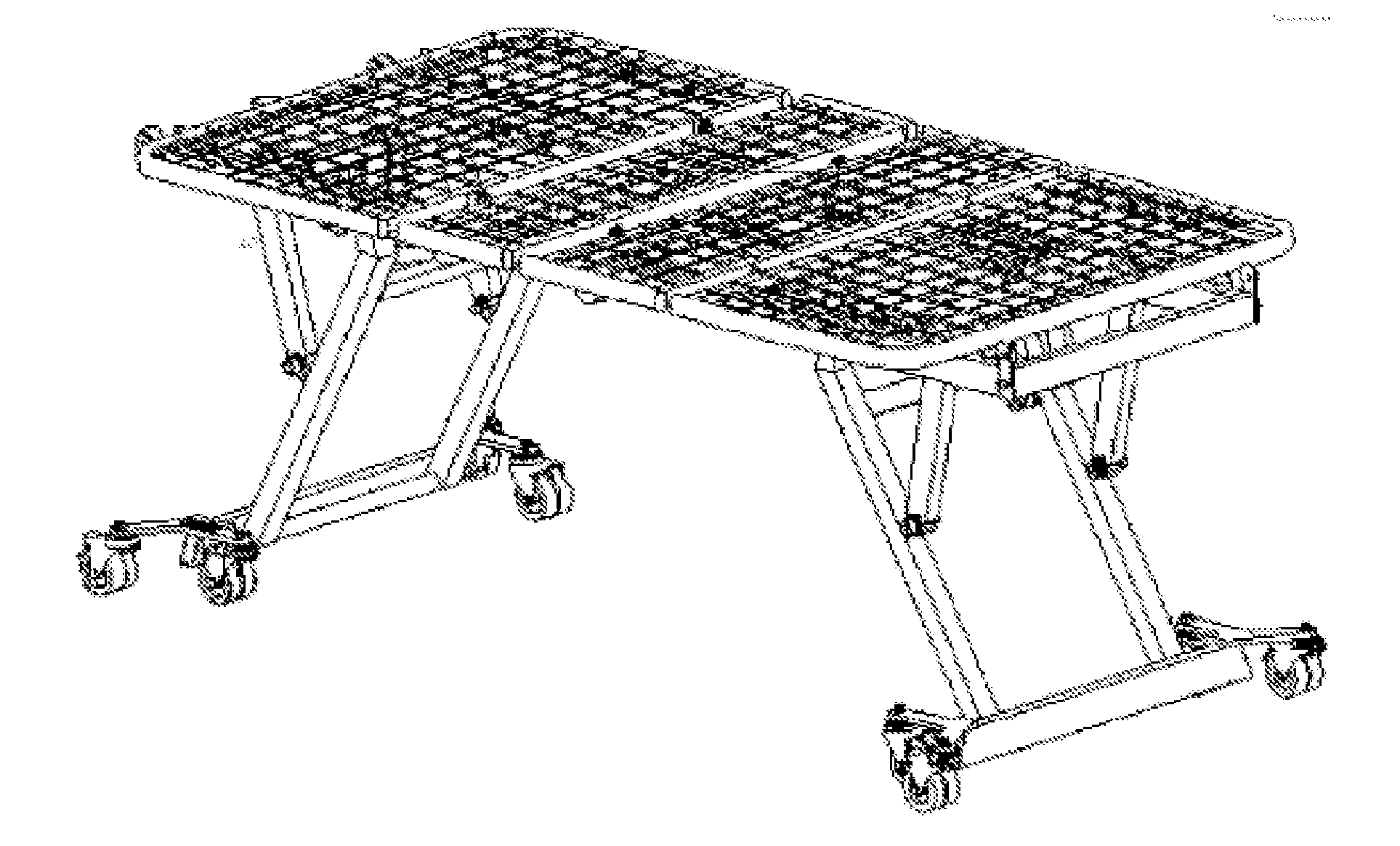

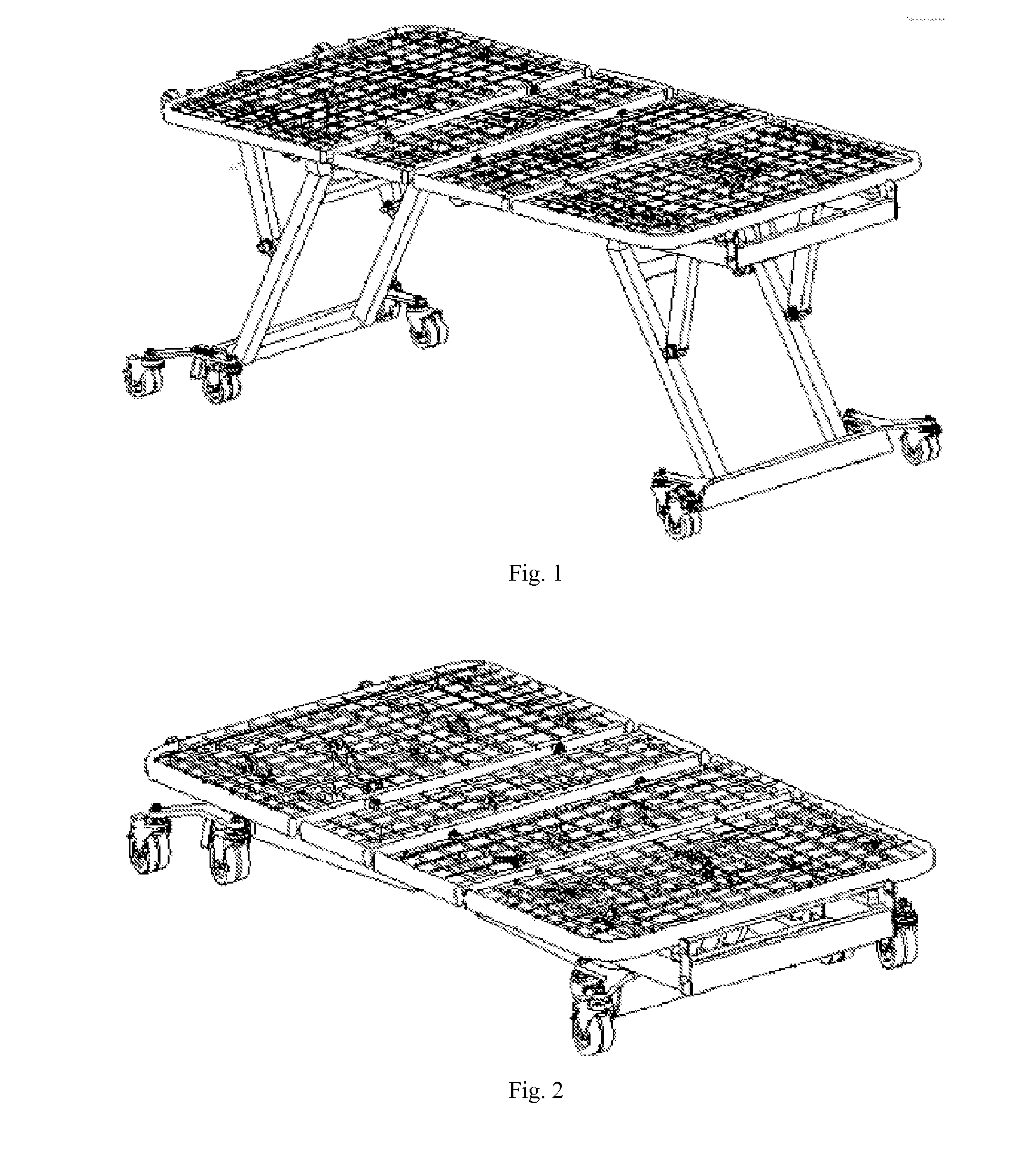

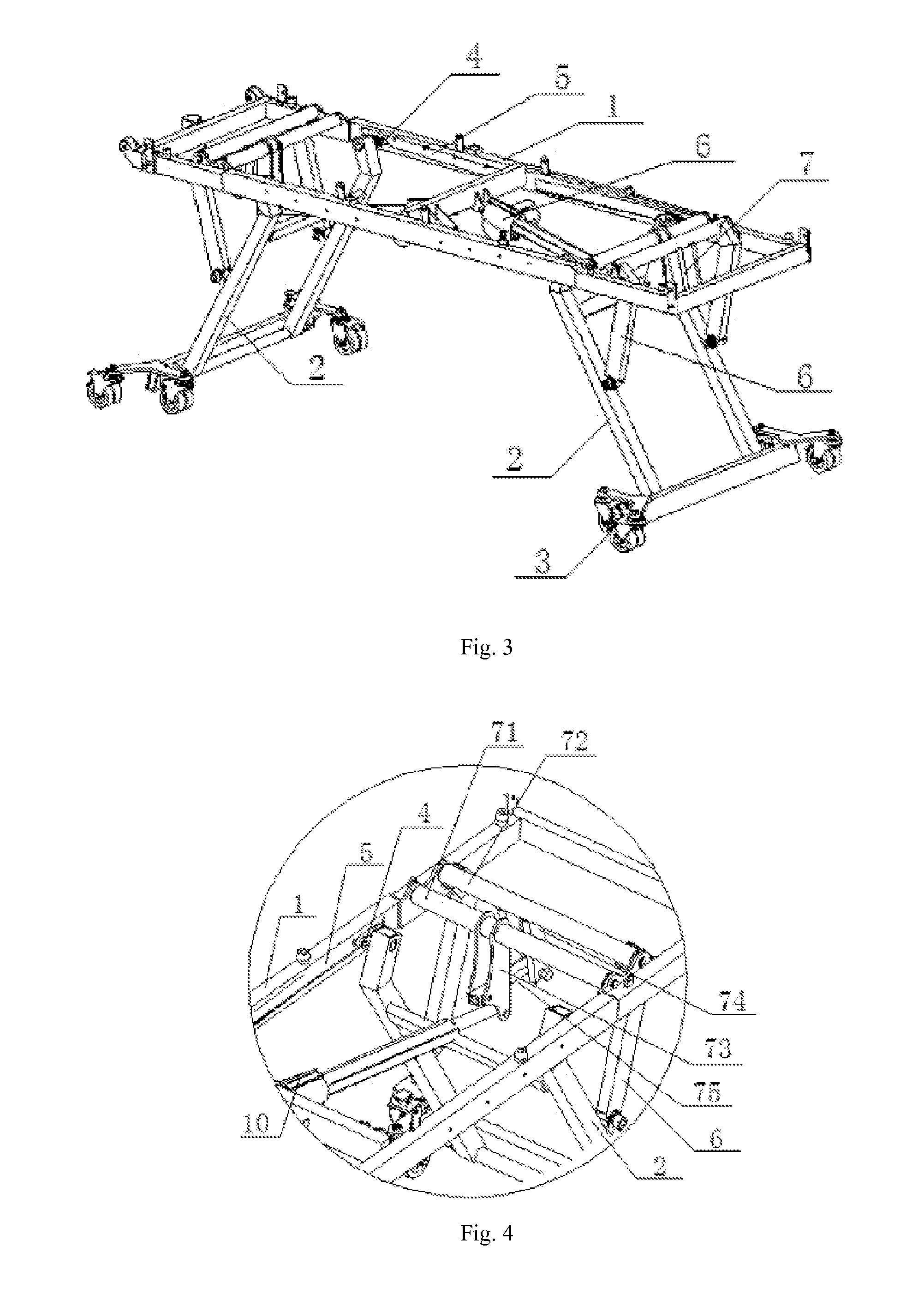

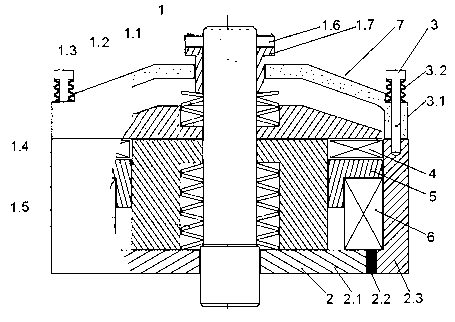

Liftable Hospital Bed

ActiveUS20150033472A1Little powerLow production costOperating tablesStretcherEngineeringHospital bed

Disclosed is a liftable hospital bed, comprising a bedplate base frame (1) symmetrical about a transverse central plane and a longitudinal central plane, wherein two ends of the bedplate base frame (1) are provided with bed leg rods (2), the lower end of the bed leg rods (2) being hinged to a first roller device (3) in contact with the ground and the upper end of the bed leg rods (2) being connected to a second roller device (4), the second roller device (4) being slidable in tracks (5) on the bedplate base frame (1) and the tracks (5) being parallel to a longitudinal axis of the bedplate base frame (1); connecting rods (6) are hinged to the bed leg rods (2); and a turnover mechanism is further provided for changing included angles between the bed leg rods (2) and the bedplate base frame (1) to lift the bedplate base frame (1), the turnover mechanism comprises the connecting rods (6) and a thrust mechanism, end portions of the thrust mechanism drive the connecting rods (6) to rotate via a hinged four-rod mechanism (7), and the connecting rods (6) drive the bed leg rods (2) to turn over relative to the bedplate base frame (1), so that the lifting of the hospital bed is realized.

Owner:NINGBO KANGMAILONG MEDICAL APP

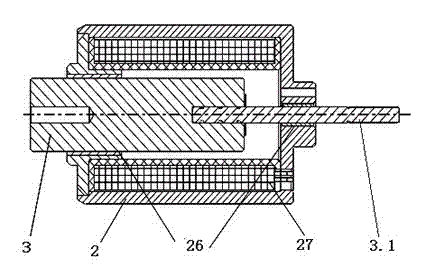

Permanent-magnet rapid operation mechanism

ActiveCN102800506ASimple structureEasy to install and debugSwitch power arrangementsMagnetEngineering

The invention relates to a permanent-magnet rapid operation mechanism, which comprises a movable iron-core component, a static iron-core component, an opening coil, a flange, a closing coil, a cover plate and a buffering component, wherein the movable iron-core component comprises a guide rod and a plurality of members sleeving the guide rod; the static iron-core component comprises a bottom plate sleeving the guide rod and contacted with the movable iron-core spring; the bottom plate is sleeved with a permanent magnet; the permanent magnet is sleeved with a sleeve; on the side of the flange facing the permanent body is sleeved with the closing coil; the opening coil sleeving the movable iron core is positioned on the side of the flange facing a repulsion plate; and the cover plate sleeving an adjusting nut is connected with an end surface of a sleeve through the buffering component. The permanent-magnet rapid operation mechanism has the following advantages: 1, the opening operation can be carried out in a common speed opening mode and a failure rapid opening mode as required; 2, the permanent-magnet rapid operation mechanism has the characteristics of closing maintenance of a permanent magnet mechanism and rapid opening of a repulsion plate mechanism; and 3, the structure is simple, and the installation and the debugging are convenient.

Owner:中国船舶重工集团公司第七一二研究所

Electric contact material made of silver-tungsten carbide graphite and preparation method thereof

The invention relates to an electric contact material made of silver-tungsten carbide graphite and a preparation method thereof. The electric contact material comprises the following main components in percentage by weight: 11%-14% of tungsten carbide-zirconium carbide solid solution, 2%-6% of graphite, 0.3%-0.6% of additive and the balance of silver, wherein the added element is one or the combination of Ti, Co and Cr. The tungsten carbide and the zirconium carbide are added in form of solid solution with the ratio of (6:4)-(9:1). Compared with the traditional electric contact made of silver-tungsten carbide graphite, the electric contact material has higher welding resistance, electric arc burning resistance and high-temperature oxidation resistance. A low-voltage electric appliance adopting the electric contact material has lower contact resistance, longer electric service life and high reliability. Therefore, the novel electric contact material with high reliability is more suitable for being applied in various different plastic-shell circuit breakers, small high-interruption circuit breakers and alternating-current contactors.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

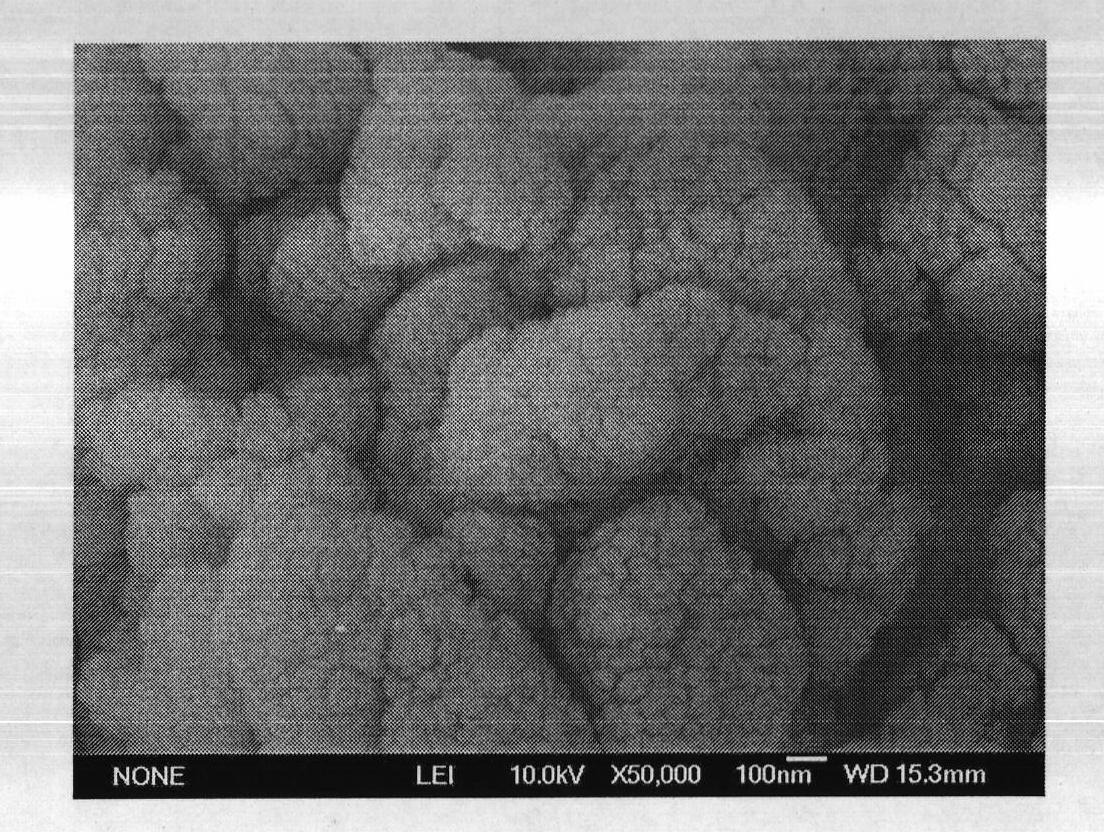

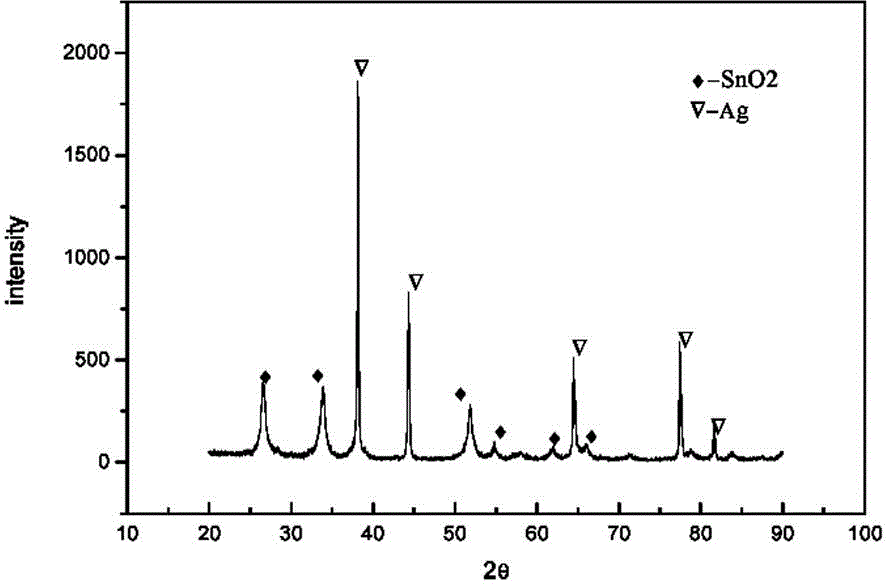

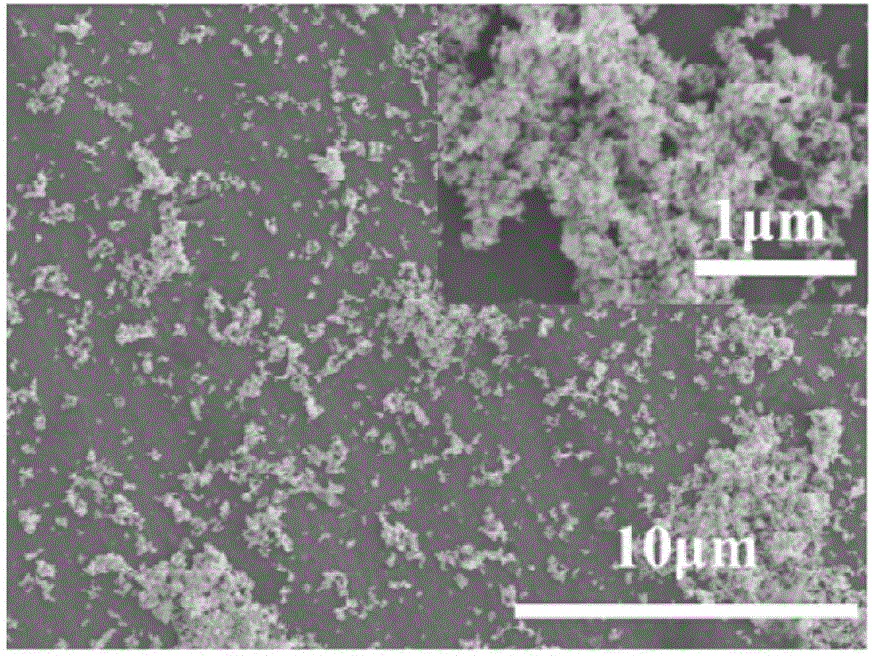

SnO2/Ag nanometer composite powder and preparation method thereof

InactiveCN104402041APure ingredientsHigh crystallinityMaterial nanotechnologyTransportation and packagingInorganic saltsFluid phase

The present invention relates to good-dispersity SnO2 / Ag nanometer composite powder and a preparation method thereof. The preparation method comprises: adopting soluble inorganic salts SnCl2.2H2O and AgNO3 as raw materials, respectively preparing solutions with a certain concentration, mixing according to a certain ratio to obtain milky white precipitate, adding ammonia water to the precipitate to adjust the pH value so as to obtain brown precipitate, and finally carrying out washing, drying and sintering on the obtained precipitate to obtain the SnO2 / Ag nanometer composite powder. According to the present invention, the diffused distribution of the nano-SnO2 in the composite powder is achieved through the liquid phase precipitation method, such that the problem of easy agglomeration of the nanoparticle in the conventional powder metallurgy method is avoided; and the method of the present invention has characteristics of simple process, energy saving, time saving, and broad application prospects, and is suitable for industrial production and promotion.

Owner:CHINA THREE GORGES UNIV

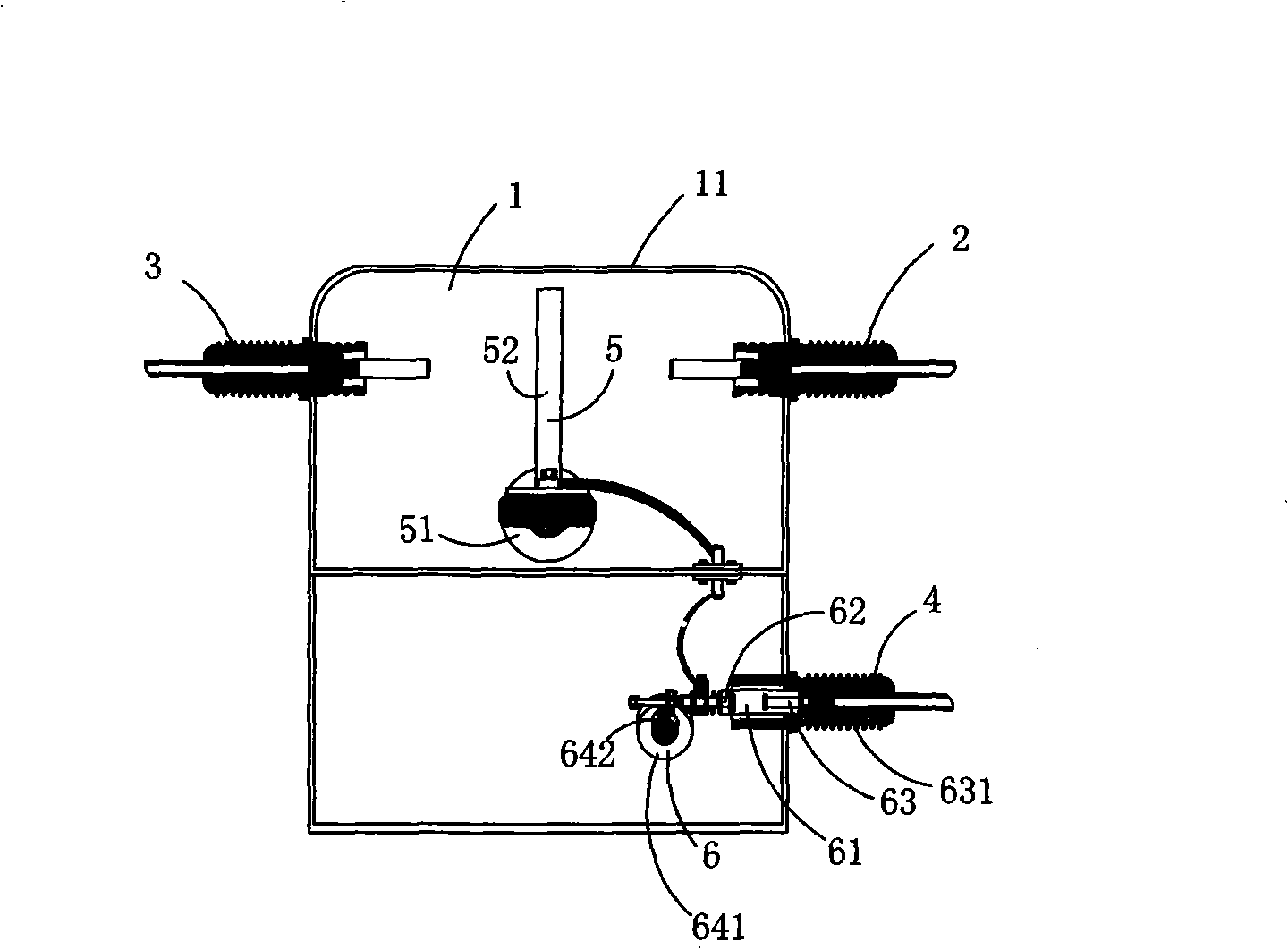

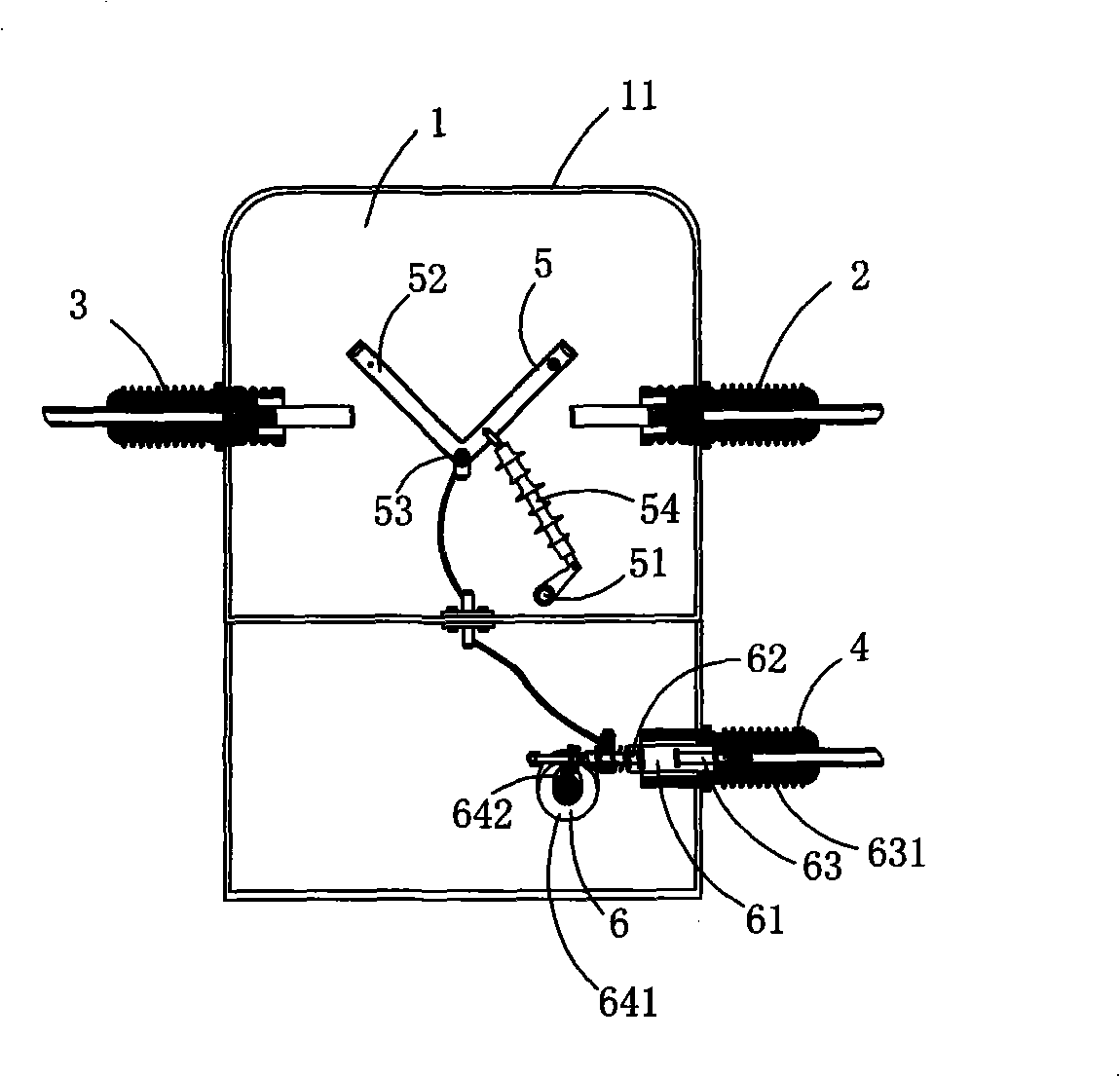

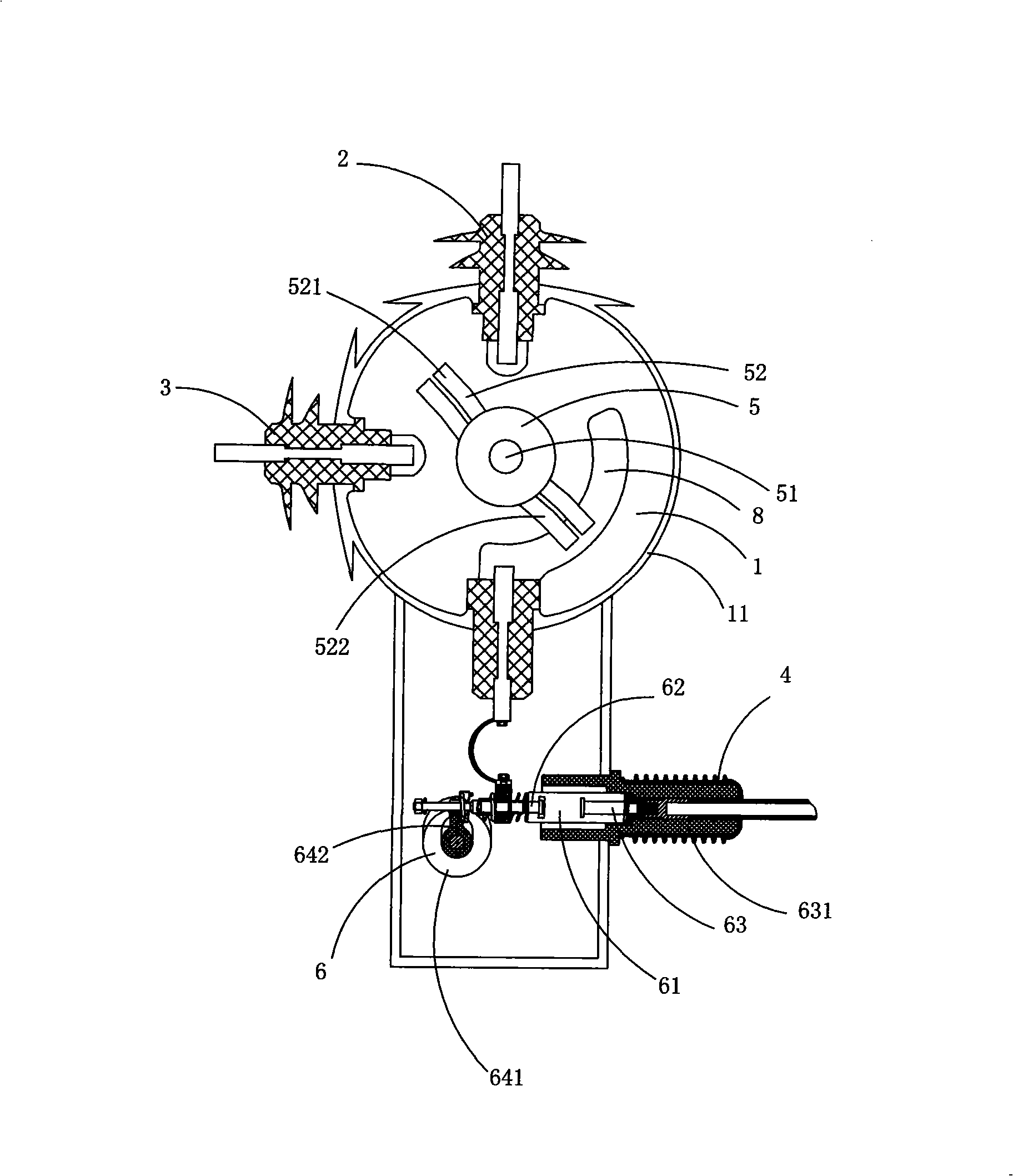

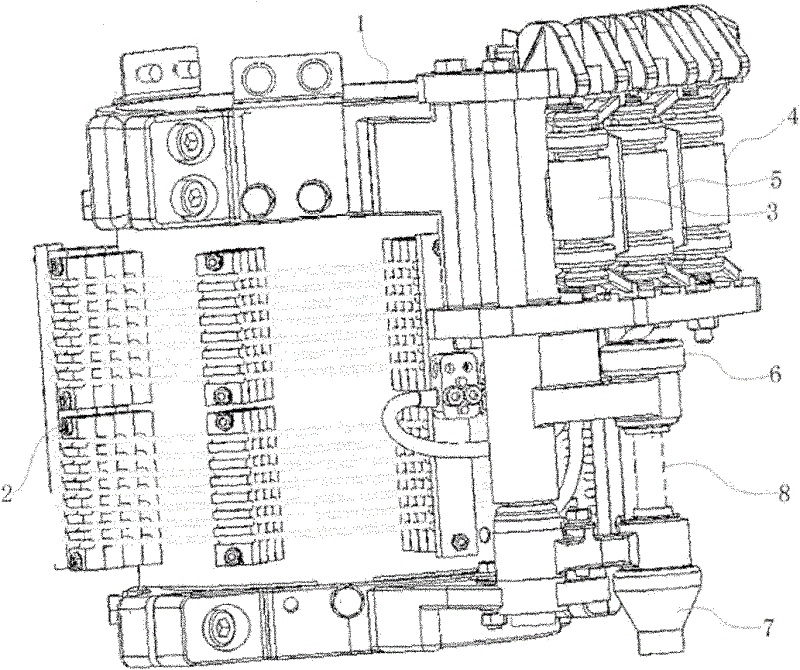

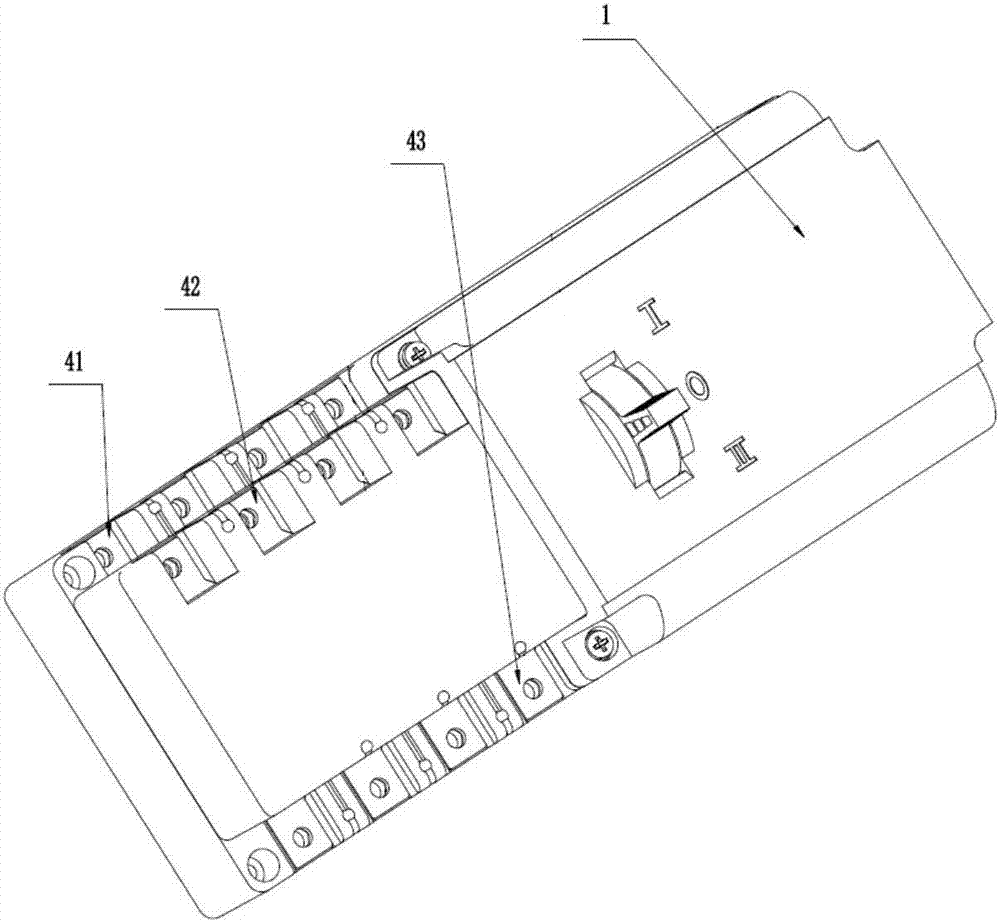

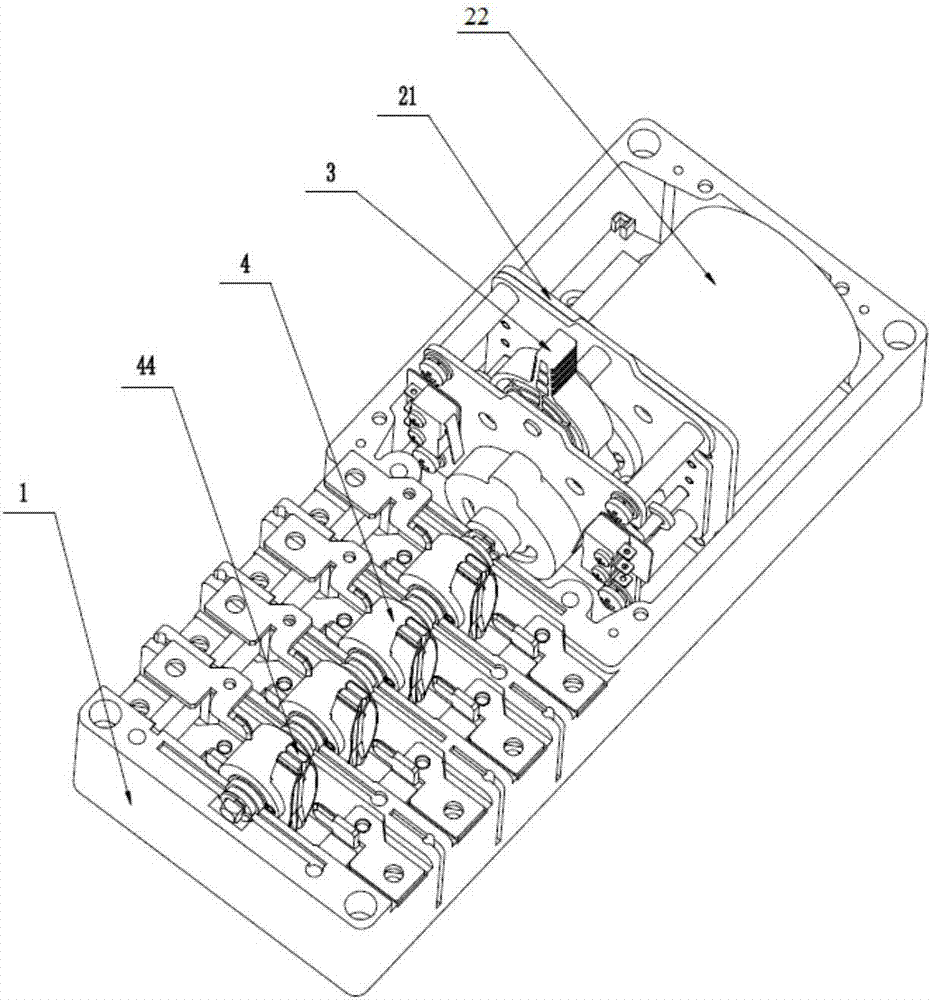

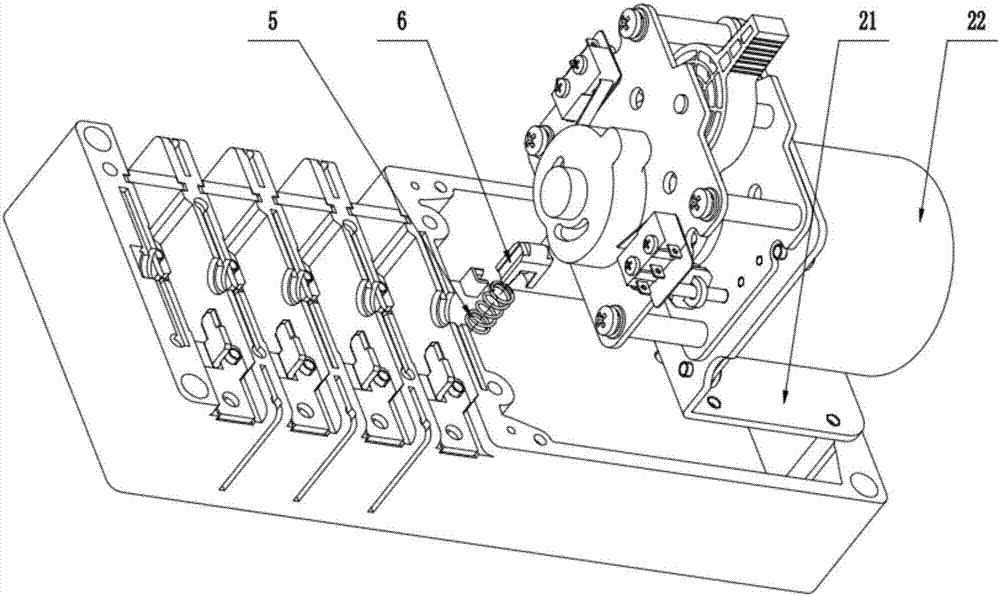

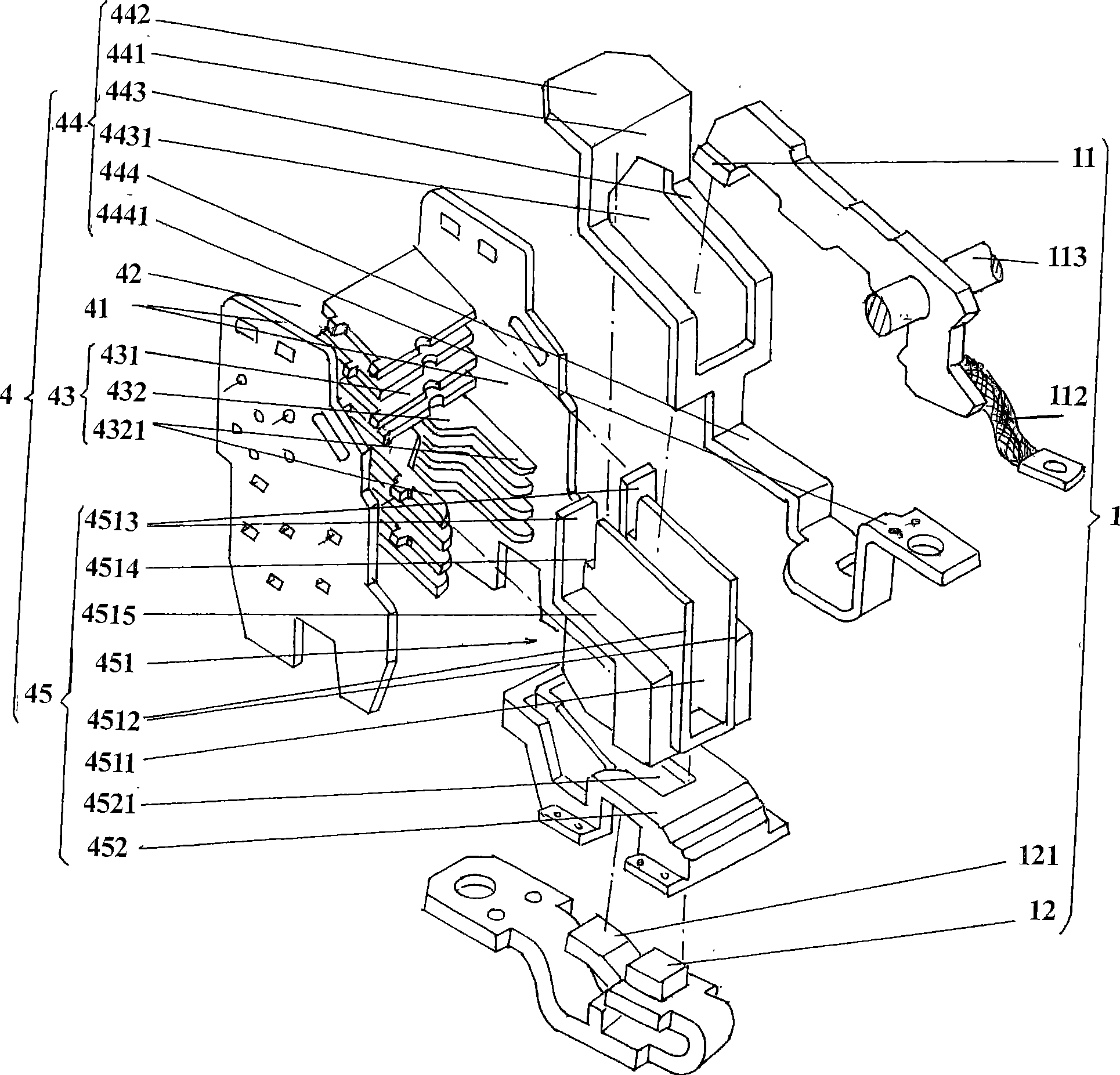

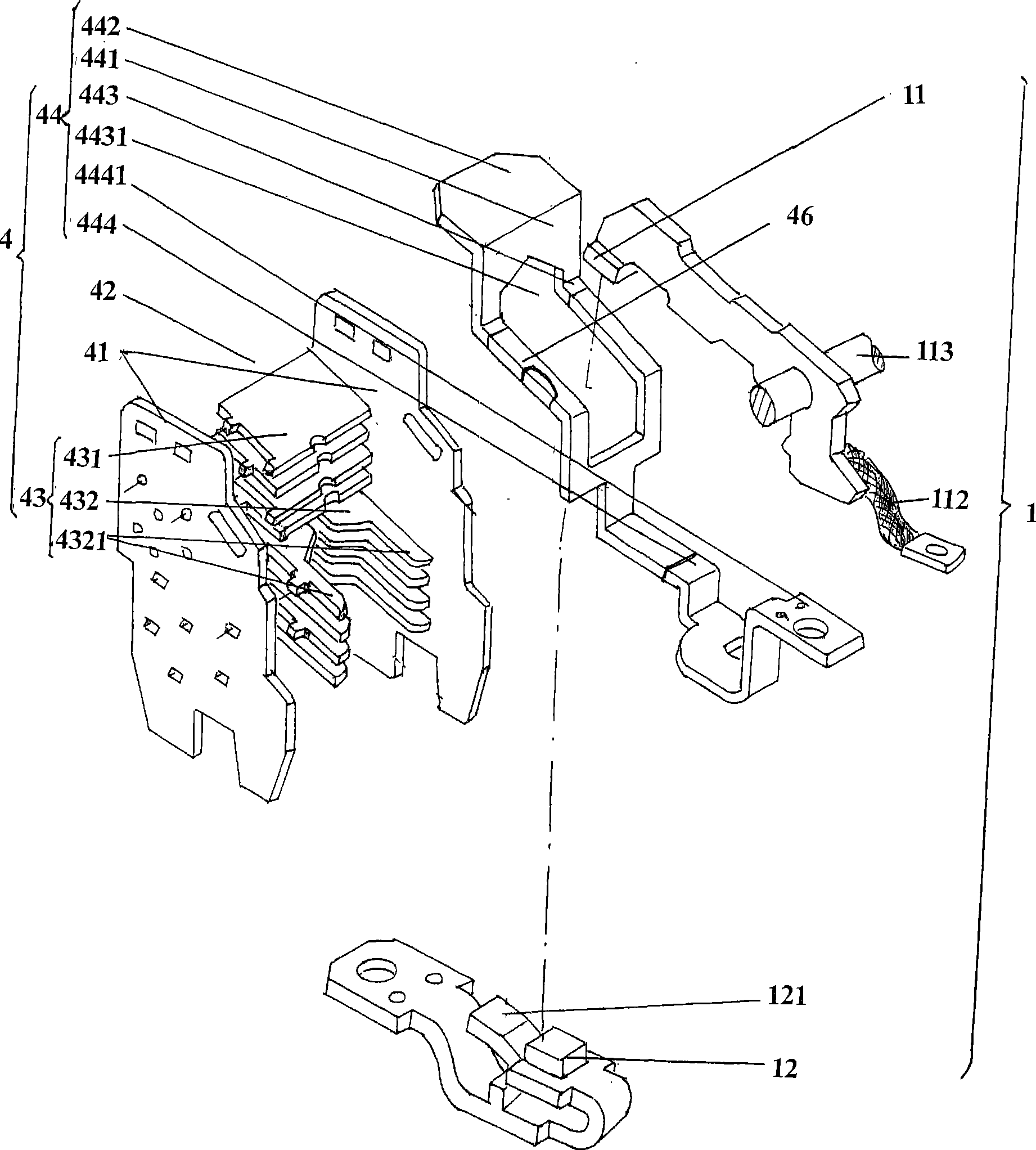

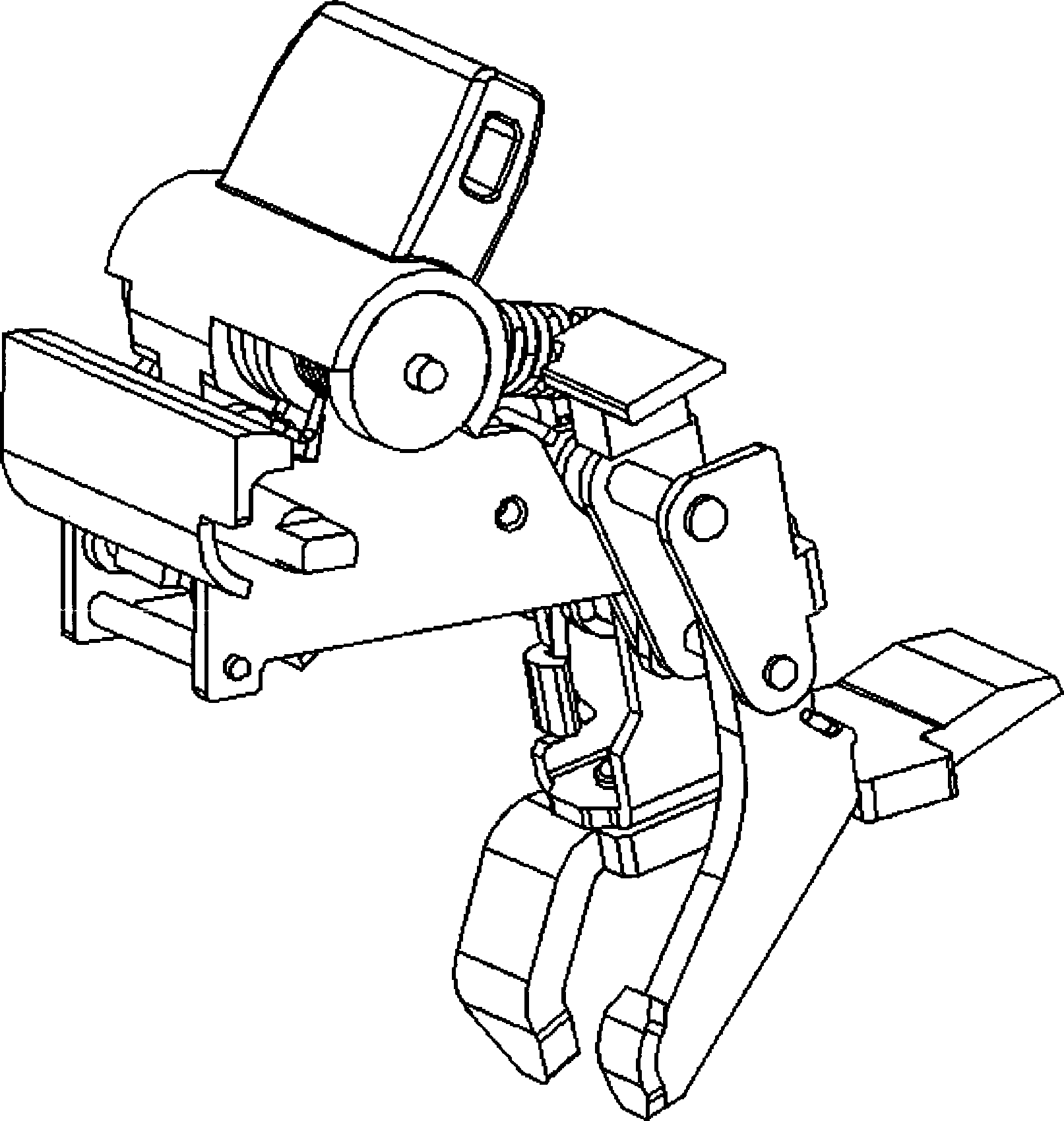

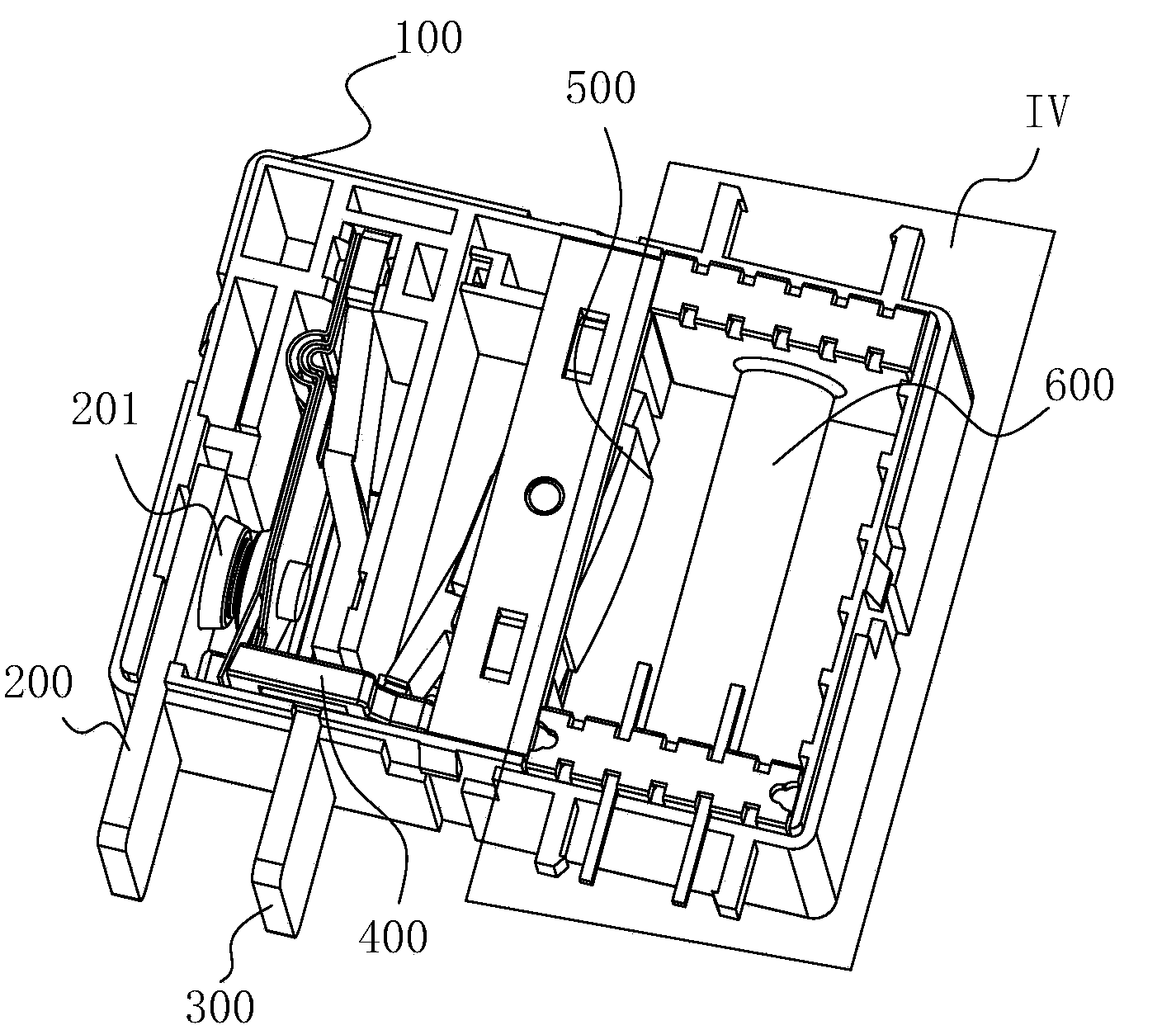

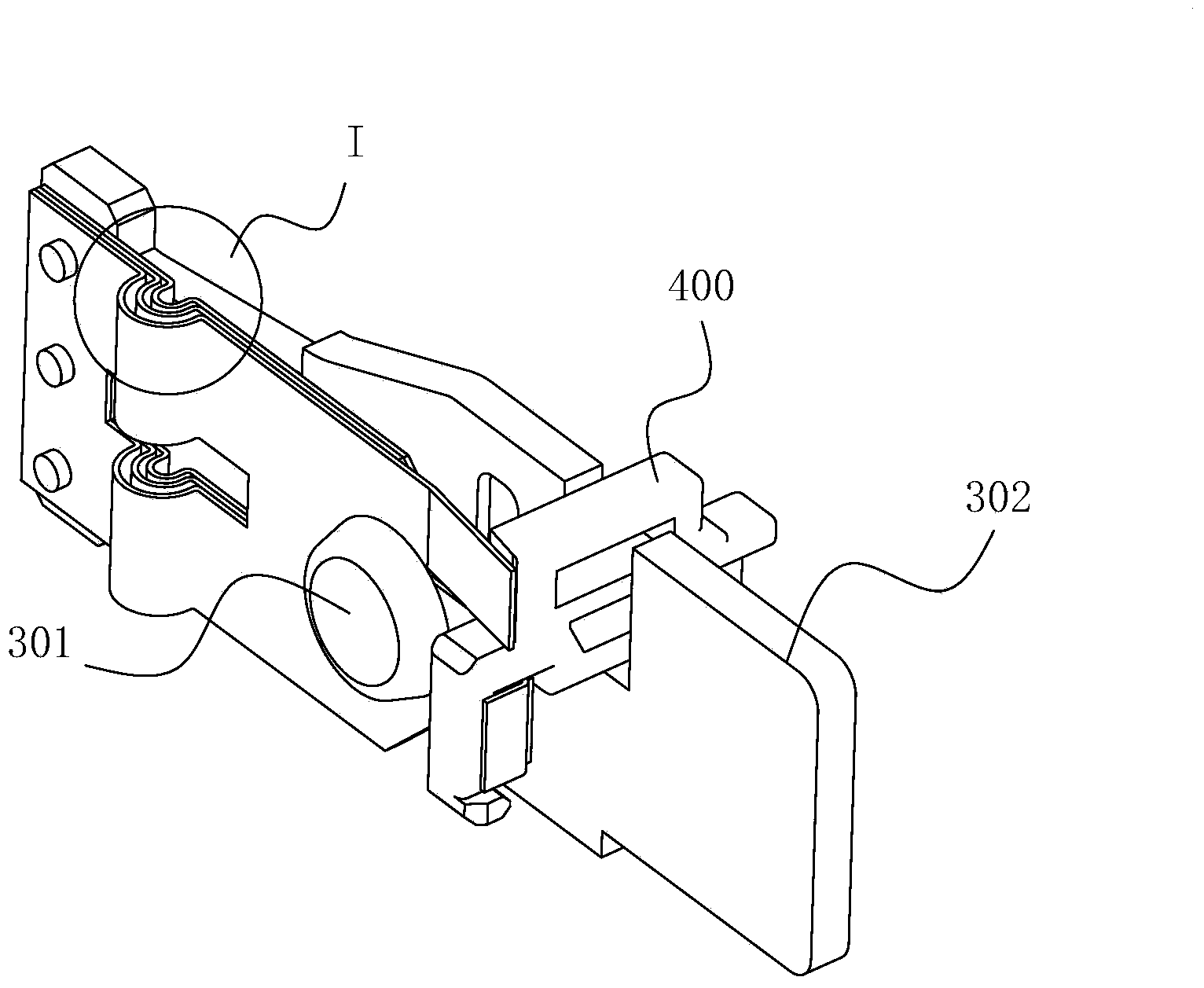

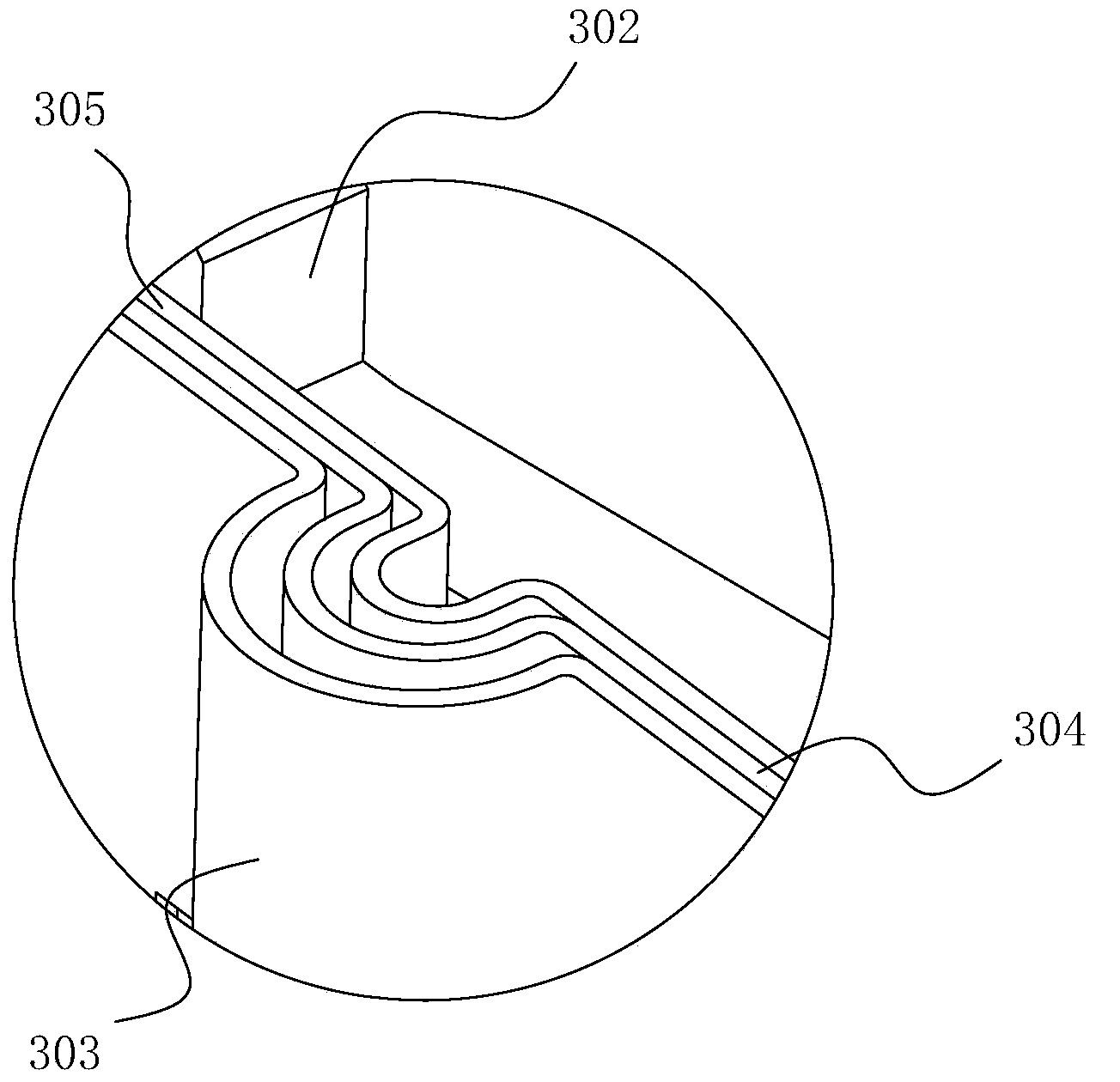

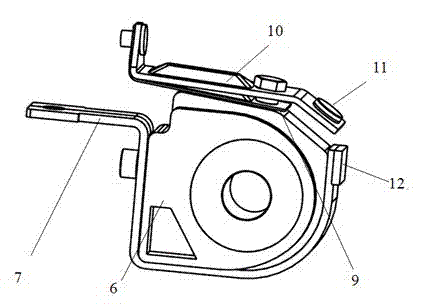

PC-class automatic changeover switch device with energy storage mechanism

The invention relates to a PC-class automatic changeover switch device with an energy storage mechanism. The device comprises a base, a contact system which is arranged on the base, the energy storage mechanism which is in transmission connection with the contact system and a drive motor which is in transmission connection with the energy storage mechanism, wherein the drive motor is fixed on the base through a motor support; the energy storage mechanism comprises an energy storage support unit, an energy storage gear, an energy storage handle, an energy storage spring assembly and an energy storage cam, wherein the energy storage support unit is fixedly connected to the motor support; the energy storage gear is arranged in the energy storage support unit and is in transmission connection with the drive motor; the energy storage handle which is arranged above the energy storage gear and the bottom of the energy storage handle which is engaged with the energy storage gear; the energy storage spring assembly cooperates with the energy storage gear; and the energy storage cam is coaxial to the energy storage gear, is arranged at the outer side of the energy storage support unit and is in transmission connection with the contact system. Compared with the prior art, the device has simple and compact overall structure and convenient processing and manufacturing, and the energy storage mechanism is provided, so that when the automatic changeover switch rotates, the phenomenon of clamping stagnation or failed linkage cannot occur, and the device is safe and reliable.

Owner:DELIXI ELECTRIC

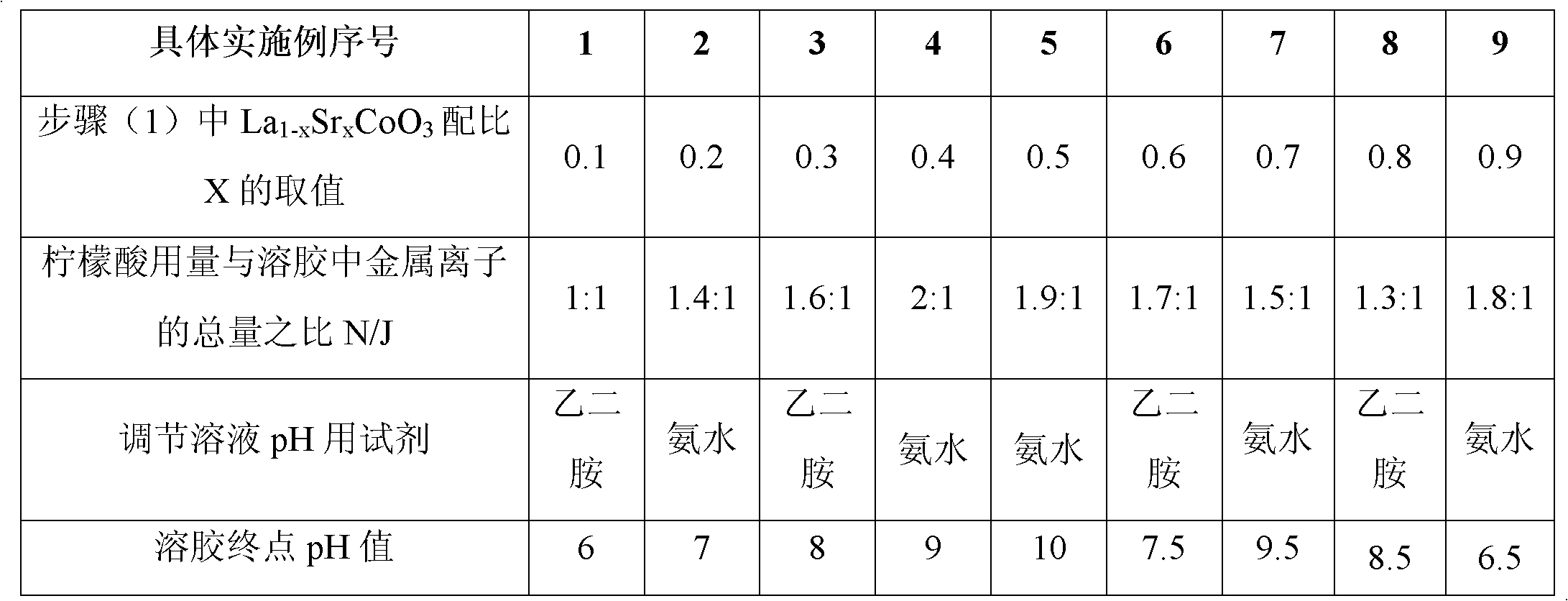

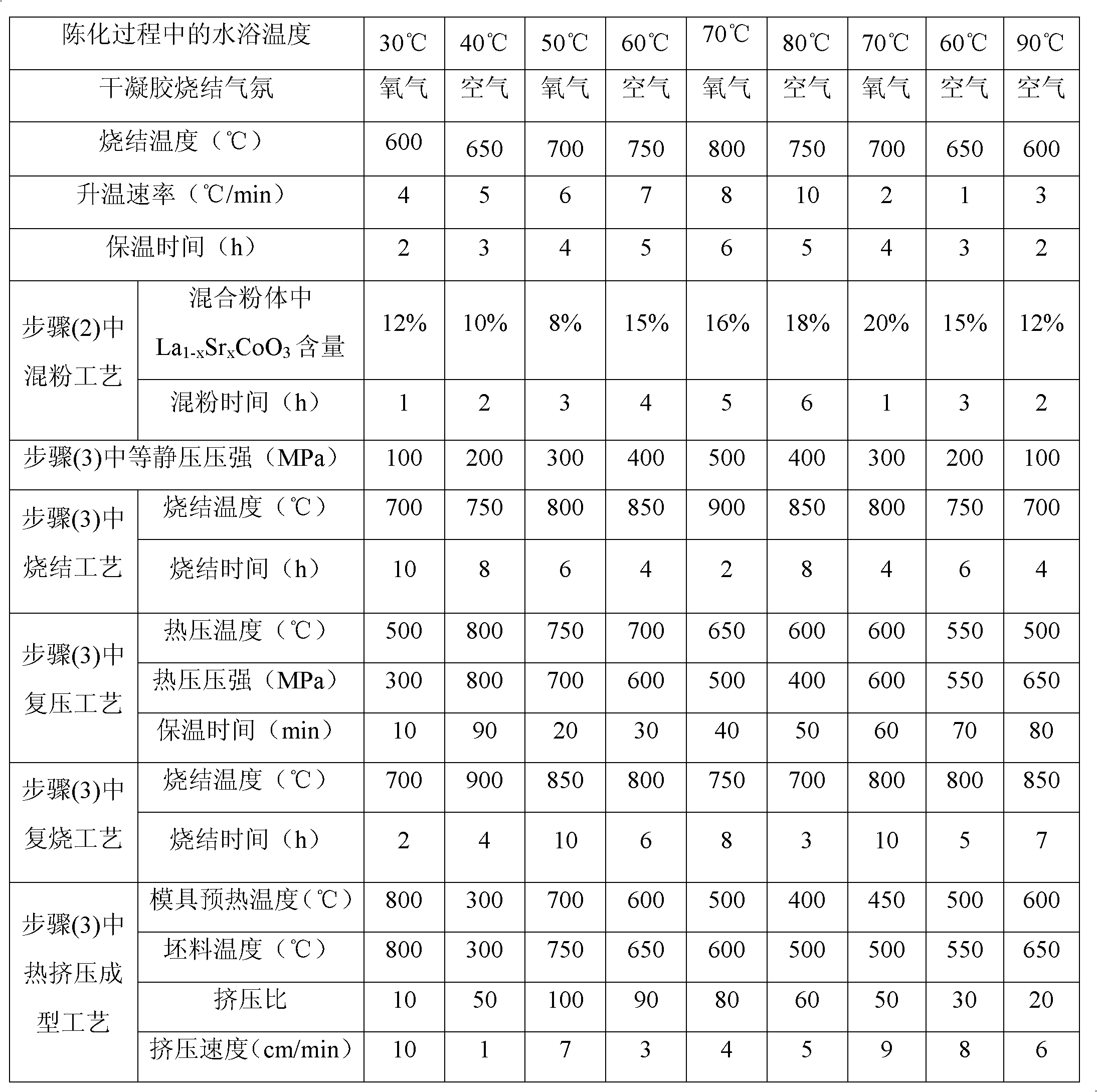

Method for preparing Ag/La1-xSrxCoO3 electric contact composite material

The invention relates to preparation of an electric contact composite material, and aims to provide a method for preparing an Ag / La1-xSrxCoO3 electric contact material. The method includes preparing conductive ceramic micro-nano-powder of an La1-xSrxCoO3 system by a sol-gel method; uniformly mixing the La1-xSrxCoO3 micro-nano-powder and silver powder in a V-shaped powder mixer, and leading the La1-xSrxCoO3 powder to account for 8-20% of the total mass of mixed powder; and isostatically pressing the uniformly mixed powder into a blank, sequentially realizing sintering, re-pressing and re-sintering processes and finally obtaining the Ag / La1-xSrxCoO3 electric contact composite material by means of thermal extrusion forming. The Ag / La1-xSrxCoO3 electric contact composite material is prepared by the sol-gel method, a wild phase La1-xSrxCoO3 in the composite material is nano-level powder, the melt viscosity in micro-molten pools on the surface of the electric contact material under effects of electric arcs can be improved by the high specific surface area of the wild phase, performances including the electric conductivity, the mechanical strength, the abrasion resistance, the electric arc ablation and the like of the electric contact material are comprehensively enhanced, and the problem of difficulty in processing and forming is avoided.

Owner:ZHEJIANG UNIV

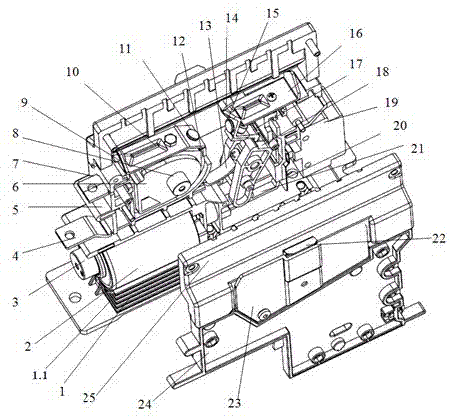

Low-voltage circuit breaker

ActiveCN101546681AImprove electrical lifeImprove breaking capacityElectric switchesCircuit-breaking switch detailsElectricityElectric arc

The invention relates to a low-voltage circuit breaker belonging to the technical field of low-voltage apparatus and comprising a shell and a contact system, a release system and an arc extinguishing mechanism, wherein the arc extinguishing mechanism comprises a pair of arc extinguishing grating sheet brackets and a stack grating sheet; and the contact system comprises an upper contact and a lower contact. The low-voltage circuit breaker is characterized in that the arc extinguishing mechanism also comprises an arc striking plate and an insulation device, one end of the arc striking plate extends above an explosion chamber and corresponds to the outer side of the movement locus of the upper contact, and the other end is electrically connected with the release system; and the insulation device is directly combined on the arc striking plate or is arranged on the lower contact. The invention has the advantages that the upper contact can be protected, thereby the electrical endurance of the breaker is improved obviously; the arc striking plate extends above the explosion chamber, thereby being convenient for voltaic arc to enter the explosion chamber and enabling the breaking capacity of the breaker to be improved.

Owner:CHANGSHU SWITCHGEAR MFG CO LTD (FORMER CHANGSHU SWITCHGEAR PLANT)

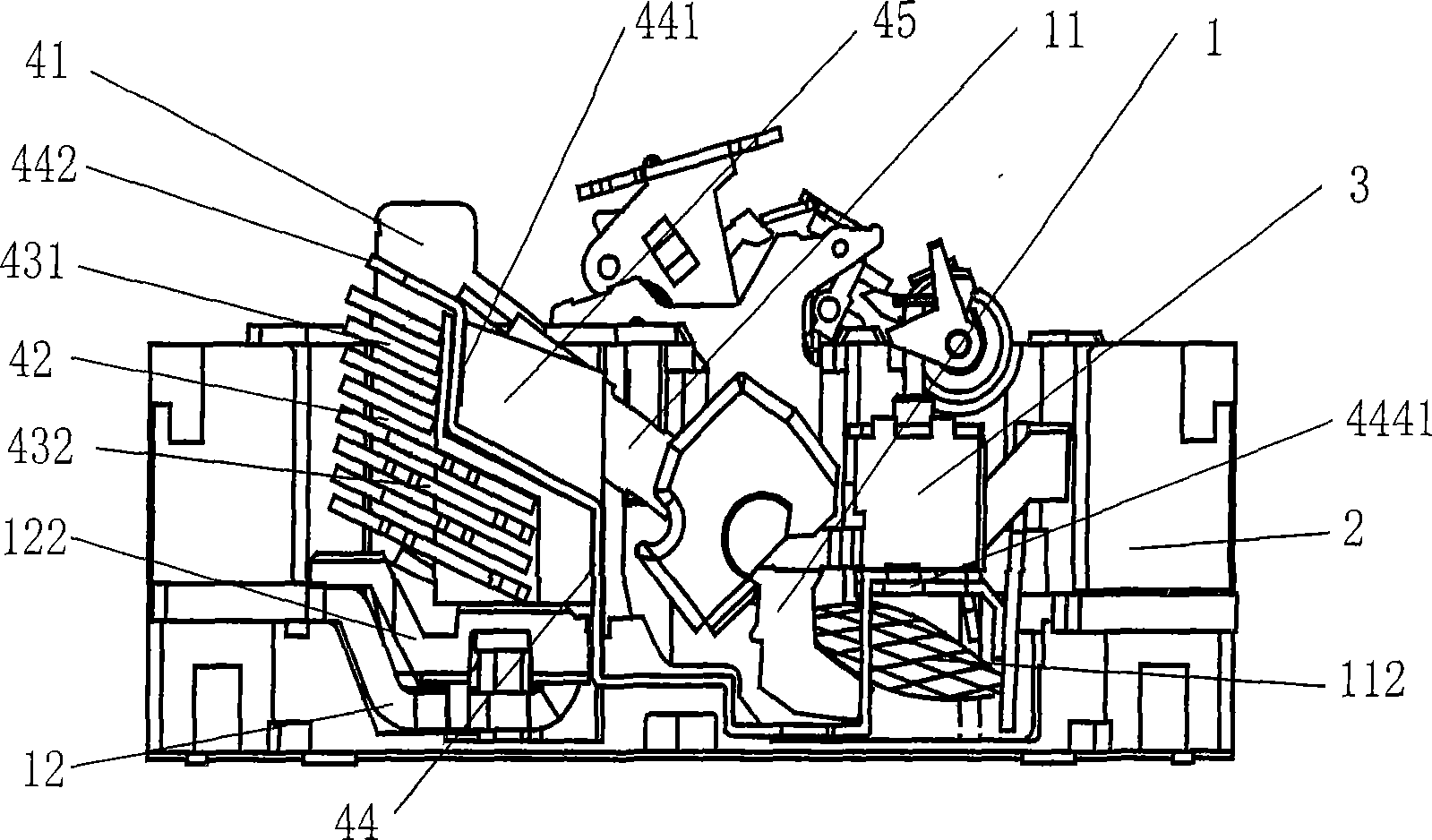

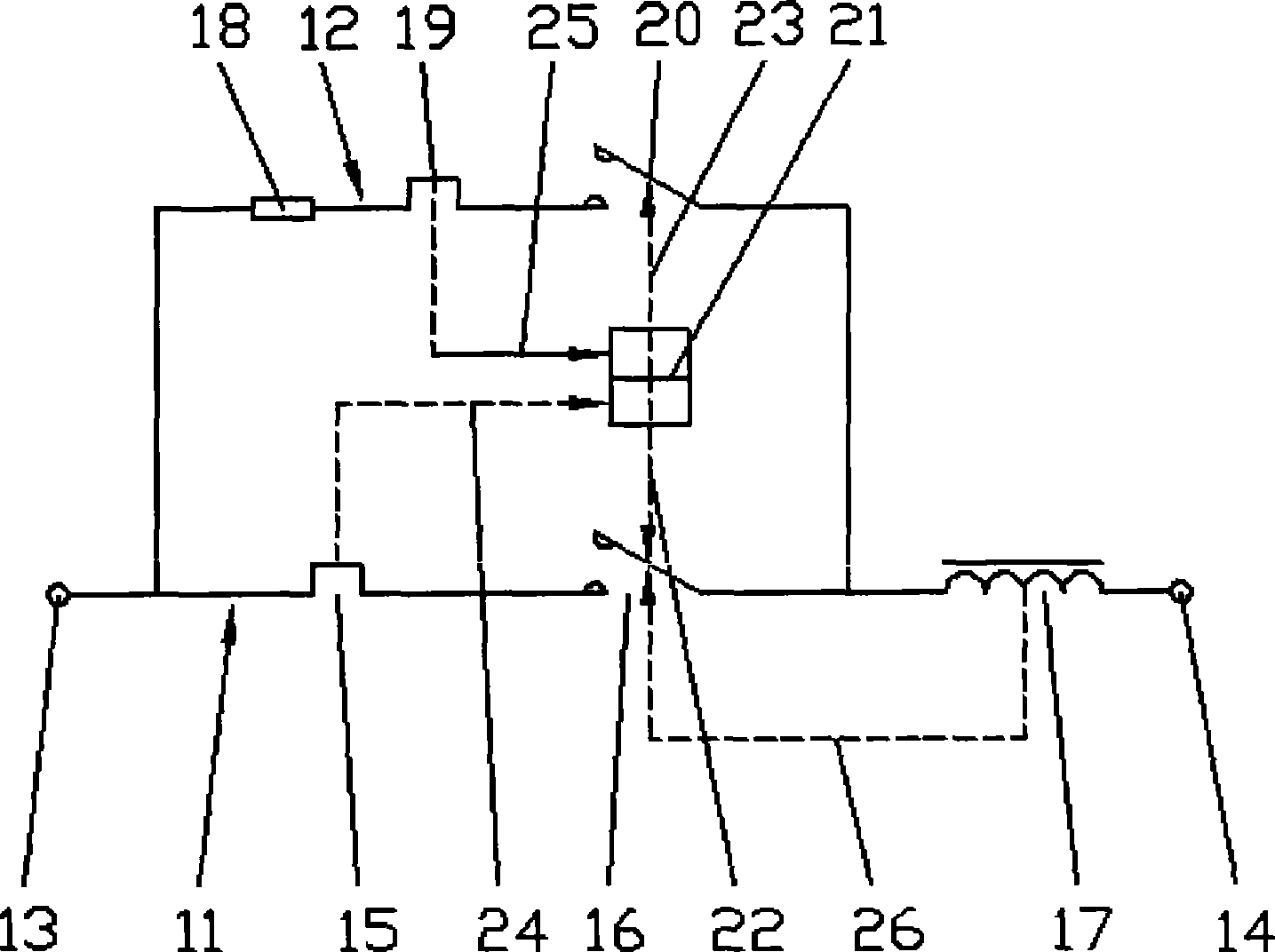

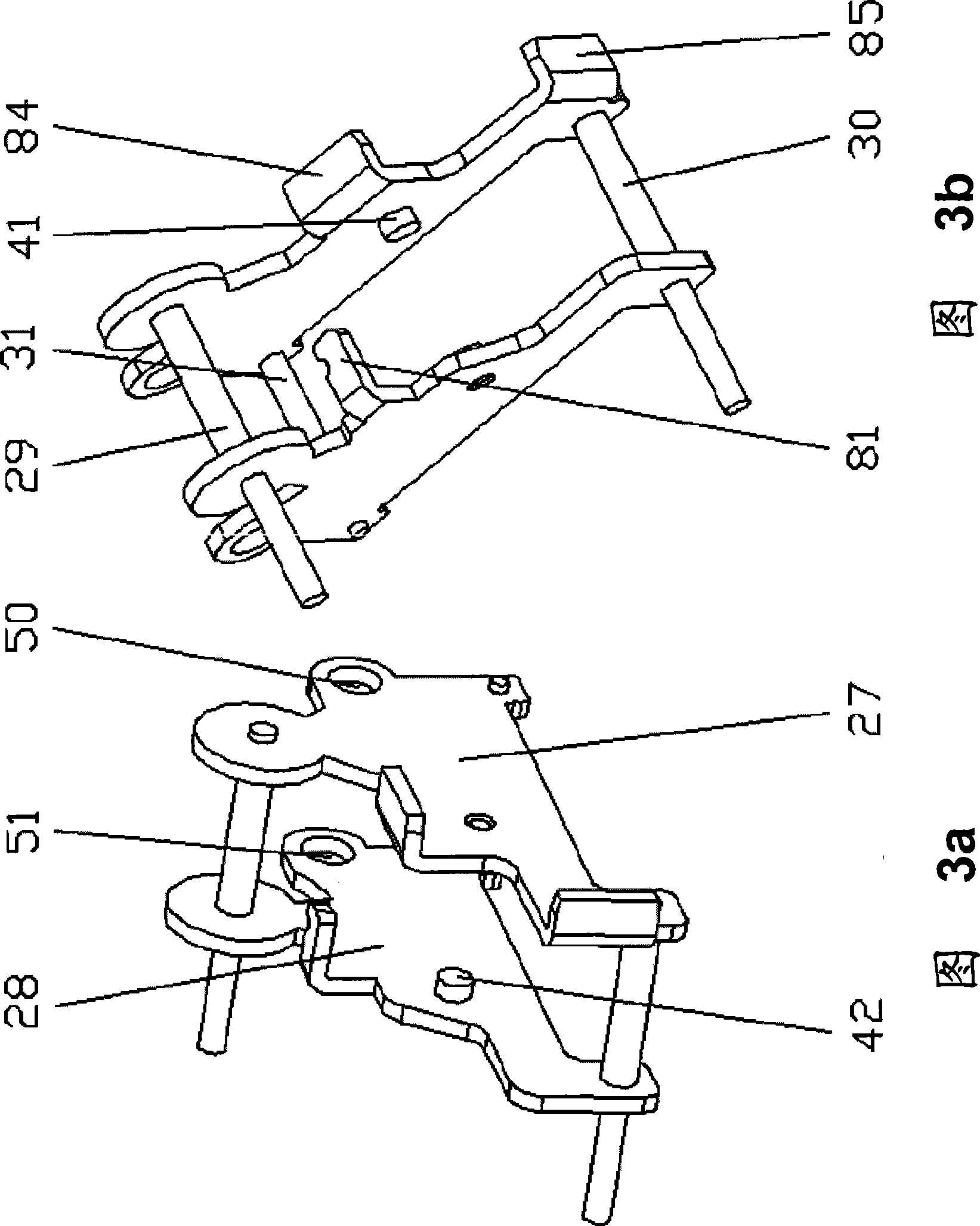

Selective protection switch and operation mechanism thereof

ActiveCN101488423AImprove electrical lifeRespond to closing and opening status in timeEmergency protective arrangements for automatic disconnectionCircuit-breaking switch detailsCurrent limitingEngineering

The invention discloses a selective protection switch, comprising a main loop, an auxiliary loop and an operation mechanism, wherein the main loop is arranged between an inlet terminal and an outlet terminal, and comprises an overcurrent release, a main contact and an electromagnetic mechanism which are connected in series, wherein the electromagnetic mechanism leads the main contact to be disconnected and maintain the disconnected position through a third working line; the auxiliary loop is connected with the overcurrent release and the main contact on the main loop in parallel, and comprises a current-limiting resistor, a selective protection release and an auxiliary contact which are connected in series; the operation mechanism is provided with an operation handle, and respectively acts on the main contact and the auxiliary contact by a first working line and a second working line through rotating the operation handle, so that the main contact and the auxiliary contact are disconnected or closed; the overcurrent release acts on the operation mechanism through a forth working line, so that the operation mechanism is released; the selective protection release acts on the operation mechanism through a fifth working line, so that the operation mechanism is released; and after the operation mechanism is released, the main contact and the auxiliary contact are disconnected simultaneously.

Owner:SEARI ELECTRIC TECH +2

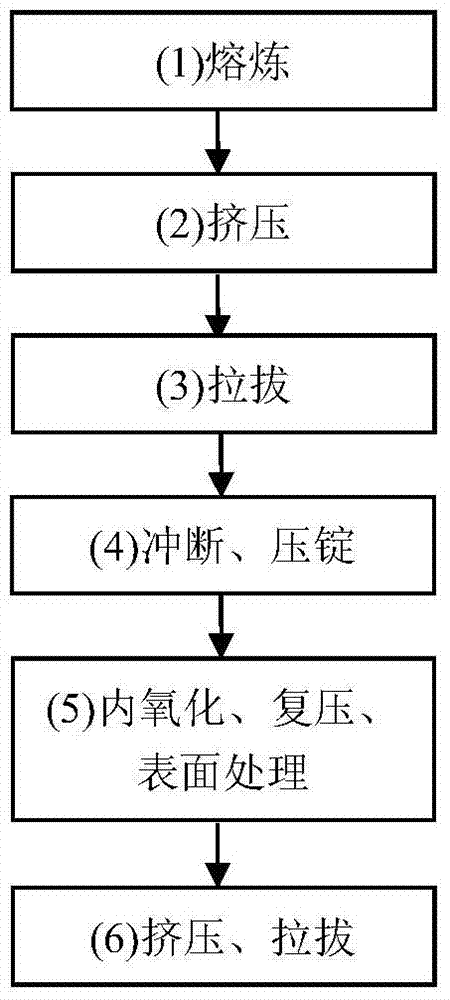

Preparing method of AgSnO electric contact materials with uniform tissues

ActiveCN103700544AImprove transfer abilityUniform tissueSolid state diffusion coatingRelaysIngotMaterial transfer

The invention relates to a preparing method of AgSnO electric contact materials with uniform tissues. The method comprises the steps of smelting, surface treatment, extrusion, drawing, pushing and cutting, ingot pressing, inner oxidation, re-pressing, surface treatment, extrusion and drawing, wherein additives are any two kinds of materials or more than two kinds of materials from Cu, Ga, Ce, Zr and CO. The materials comprise the following ingredients in percentage by weight: 86 to 92 percent of Ag, 5 to 8 percent of Sn, 2 to 3 percent of In, 0 to 2 percent of Cu, 0 to 1 percent of Ga, 0 to 0.2 percent of Ce, 0 to 0.3 percent of Zr and 0 to 0.5 percent of Co. The key steps of the process include the ingot pressing after the wire material pushing and cutting,the inner oxidization, the re-pressing and the surface treatment. The wire materials prepared by the method have the advantages that the metallographic structure is uniform, and the oxide aggregation and silver aggregation phenomena do not occur. Meanwhile, the hardness of the wire materials is low, the elongation percentage is high, after the materials are made into rivets, electric performance tests are carried out, the material transfer resistance performance is good, and the AgSnO electric contact materials prepared by the method are suitable for being applied to various different vehicle-mounted relays.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

Integrated permanent magnet mechanism vacuum switch

ActiveCN103779137AMake electrical connectionsRealize detectionHigh-tension/heavy-dress switchesAir-break switchesElectrical connectionRelative motion

The invention discloses an integrated permanent magnet mechanism vacuum switch. The structure of a traditional permanent magnet mechanism vacuum switch is redegined, the bellows is removed, components, such as the permanent magnet mechanism, moving and fixed contacts, a drive rod, an arc extinguishing system, etc., are all placed in the vacuum environment surrounded by a ceramic housing (all moving components are integrated in the ceramic vacuum housing), and wire connection terminals on two ends are fixedly connection with the ceramic vacuum housing (no relative movement exists), wherein one wire connection terminal is connected with the fixed contact, and the other wire connection terminal is in electrical connection with a conductive rod of the moving contact end through soft connection.

Owner:XI AN JIAOTONG UNIV

Platinum alloy electrical contact material

InactiveCN1546697AImprove electrical contact performanceExtended service lifeContact materialsPlatinumUltimate tensile strength

The invention discloses a platinum based alloy and its preparing process, wherein the platinum based alloy comprises the constituents by wt% of Ir 5.0-25.0, Ru 1.0-10.0, 0.1-2.0% of La, Sm, or Y, and balancing Pt. The preparation process includes, disposing each element of Pt, Ir, Ru, La (Sm, Y) according to the alloy composition requirement, alloying in vacuum smelting furnace, fabricating into sheet material or shredded material through forging, thermal treatment, rolling or drawing.

Owner:KUNMING INST OF PRECIOUS METALS

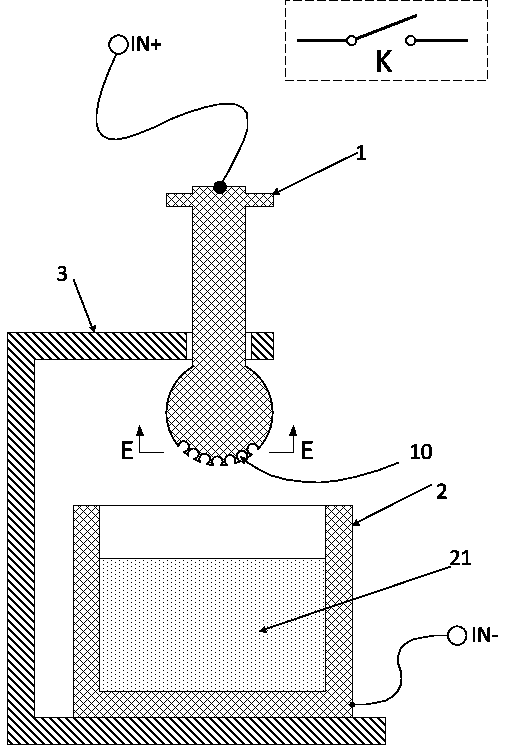

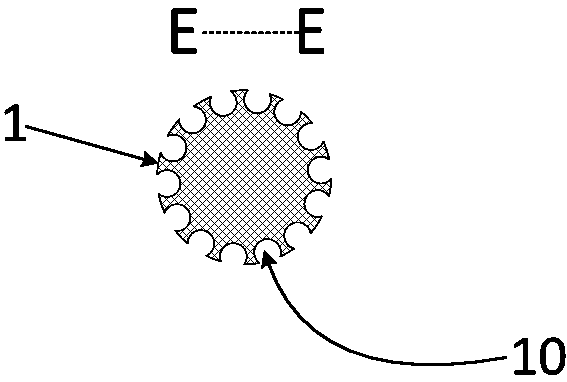

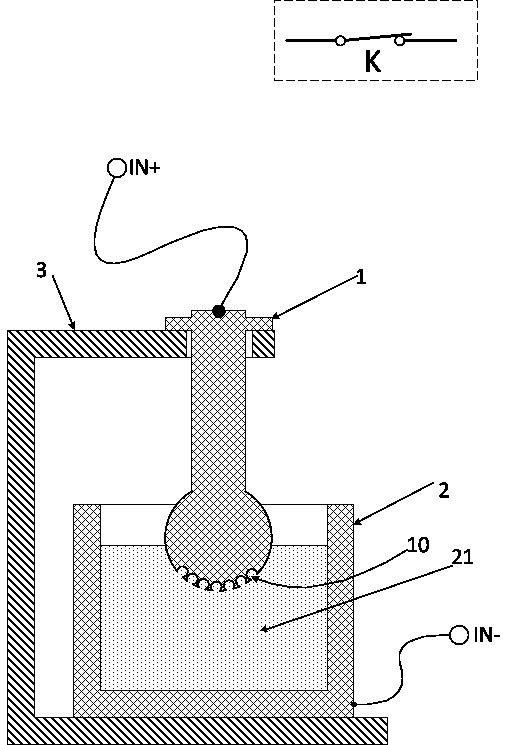

Power switch, power circuit and power system

A power switch comprises a gate (1), a container (2), a support body (3), liquid metal (21), a first electrical node (IN+) and a second electrical node (IN-). The gate (1) is provided with a spherical contact; the spherical contact is provided with spherical cavities (10); the spherical centers of the spherical cavities (10) are within the surface of the spherical contact; and each spherical cavity (10) is provided with a circular opening (101) making the spherical cavity (10) and the outside communicated on the surface of the spherical contact; and the diameter of the circular openings (101) is smaller than that of the spherical cavities (10). A power circuit comprises the power switch. A power system comprises the power switch. The power switch of the invention is low in cost, flexible in application, long in service life, and stable and reliable.

Owner:ZAOZHUANG POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER +1

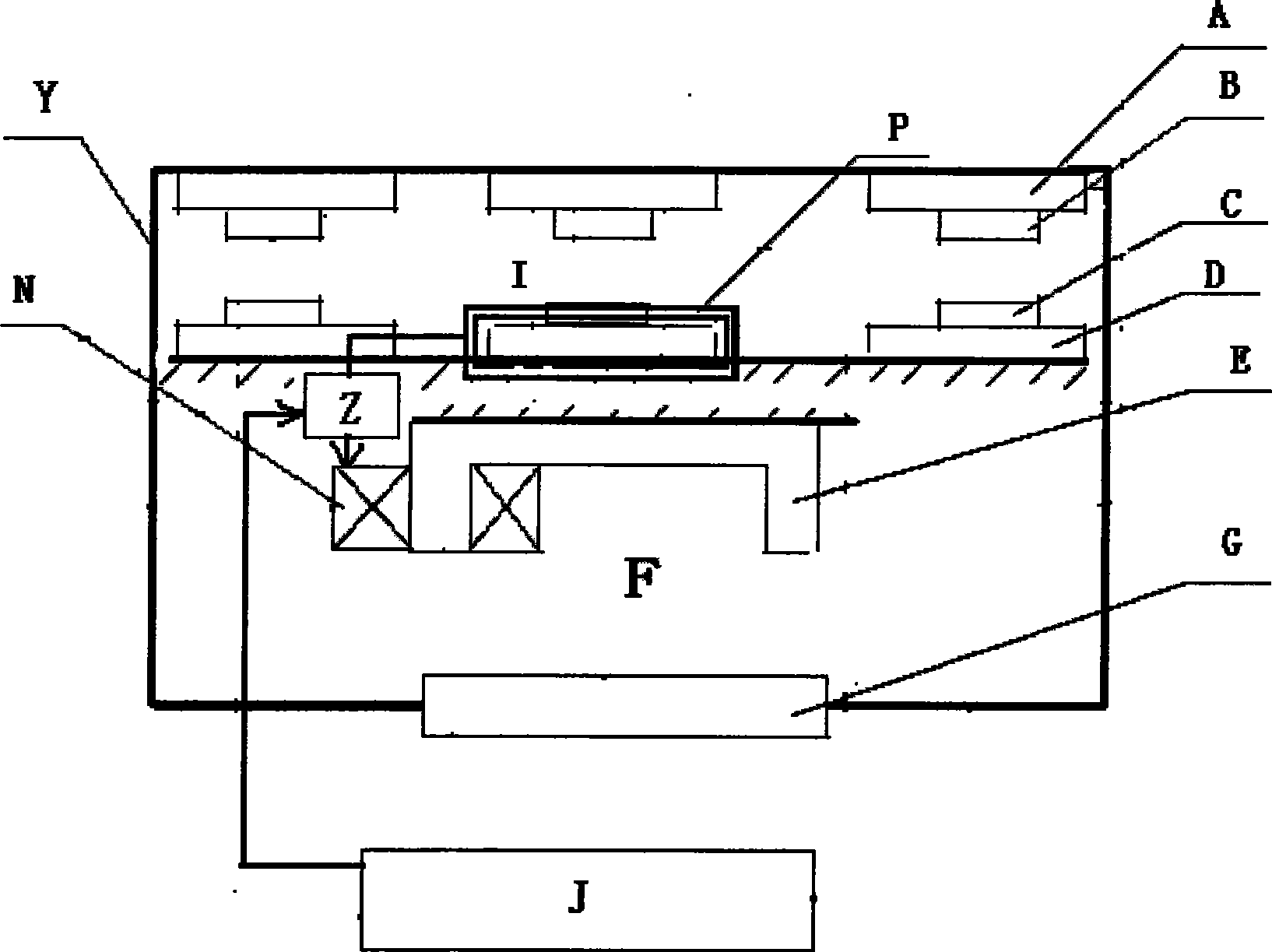

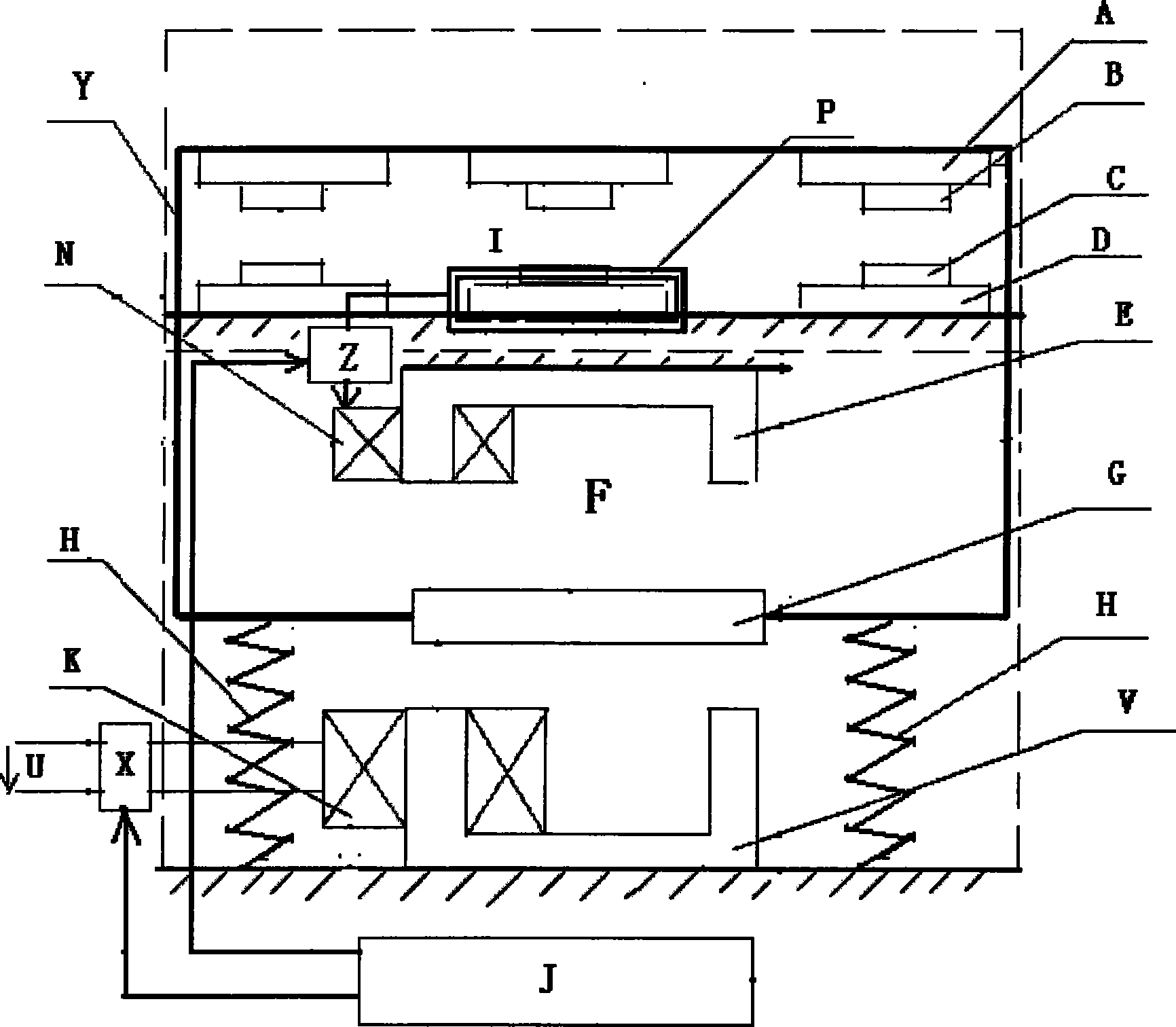

Electric appliance rapid disjunction motion mechanism based on main circuit current excitation

InactiveCN101414530AQuick breakImprove breaking capacityProtective switch operating/release mechanismsComputer control systemElectricity

The invention relates to an electrical appliance rapid breaking action mechanism which is based on current excitation of a main circuit, the electrical appliance rapid breaking action mechanism comprises a moving contact bridge, a moving contact, a static contact, a static contact bridge, a moving iron core, a current excitation static iron core, a current excitation coil of the main circuit, a current transformer, a current excitation control circuit, a computer control system and a support; when the rapid breaking action of an electrical appliance is required, the computer control system is used for control, the current of the main circuit is introduced into the current excitation coil of the main circuit via the current transformer and the current excitation control circuit, and the moving iron core drives the moving contact to rapid open and break the circuit under the action of the electromagnetic attraction, thereby ensuring the high breaking capacity of the electrical appliance, high electrical service life and reliable operation.

Owner:FUZHOU UNIV

Magnetic latching relay

ActiveCN104037026AEnsure consistencyGuaranteed stabilityElectromagnetic relay detailsNon-polarised relaysEngineeringContact position

The invention discloses a magnetic latching relay. The magnetic latching relay includes a relay shell. A static piece assembly and a dynamic reed assembly are arranged in the relay shell. The dynamic reed assembly comprises a dynamic piece and an elastic piece. One end of the elastic piece is fixed on the dynamic piece, and the other end of the elastic piece is driven by a push card and can move in the direction towards or away from the static piece assembly. The end, connected with the push card, of the elastic piece is provided with a card slot. The elastic piece is connected with the push card through the card slot. The end, making contact with the push card, of the elastic piece is of a straight piece type structure. The push card is fixed through the arranged card slot, so that the position, making contact with the elastic piece, of the push card is fixed relatively, no gap between the elastic piece and the push card exists in the process of pressing the elastic piece through the push card, the pressed position is determined and unique, it is guaranteed that the pressure is constant, and the consistency and stability of relay products are guaranteed.

Owner:EVE ENERGY CO LTD

High-voltage direct-current contactor

ActiveCN102436976ACompact spaceImprove cooling effectElectric switchesElectromagnetic relay detailsCapacitanceHigh-voltage direct current

The invention relates to a high-voltage direct-current contactor which is suitable for medium load systems in electrical power, metallurgy, mines, petroleum, traffic transportation and the like, and is especially suitable for a capacitor charging loop on an electric locomotive converter. The high-voltage direct-current contactor comprises an engine part, an electromagnetic drive part, a transmission part, a magnetic blow-out part, an auxiliary contact and an arc extinguish chamber, wherein the engine part is provided with a base, a main frame and a main frame cover plate; the transmission part is provide with a push rod, a reset spring, a rotary rack, a moving main contact and a moving arc contact; the electromagnetic drive part is provided with a cylindrical yoke, a movable iron core and a coil, and a lining is arranged between the cylindrical yoke and the movable iron core; and the magnetic blow-out part is provided with an iron core, a magnetic conducting iron plate, a magnetic blow-out coil, a static arc contact, an upper connecting copper bar and a static main contact. The high-voltage direct-current contactor has the advantages of long electric service life, high breaking speed, strong shock resistance capacity, compact structure, small volume, good tightness and the like, and is convenient in assembly and maintenance.

Owner:武汉长海电气科技开发有限公司

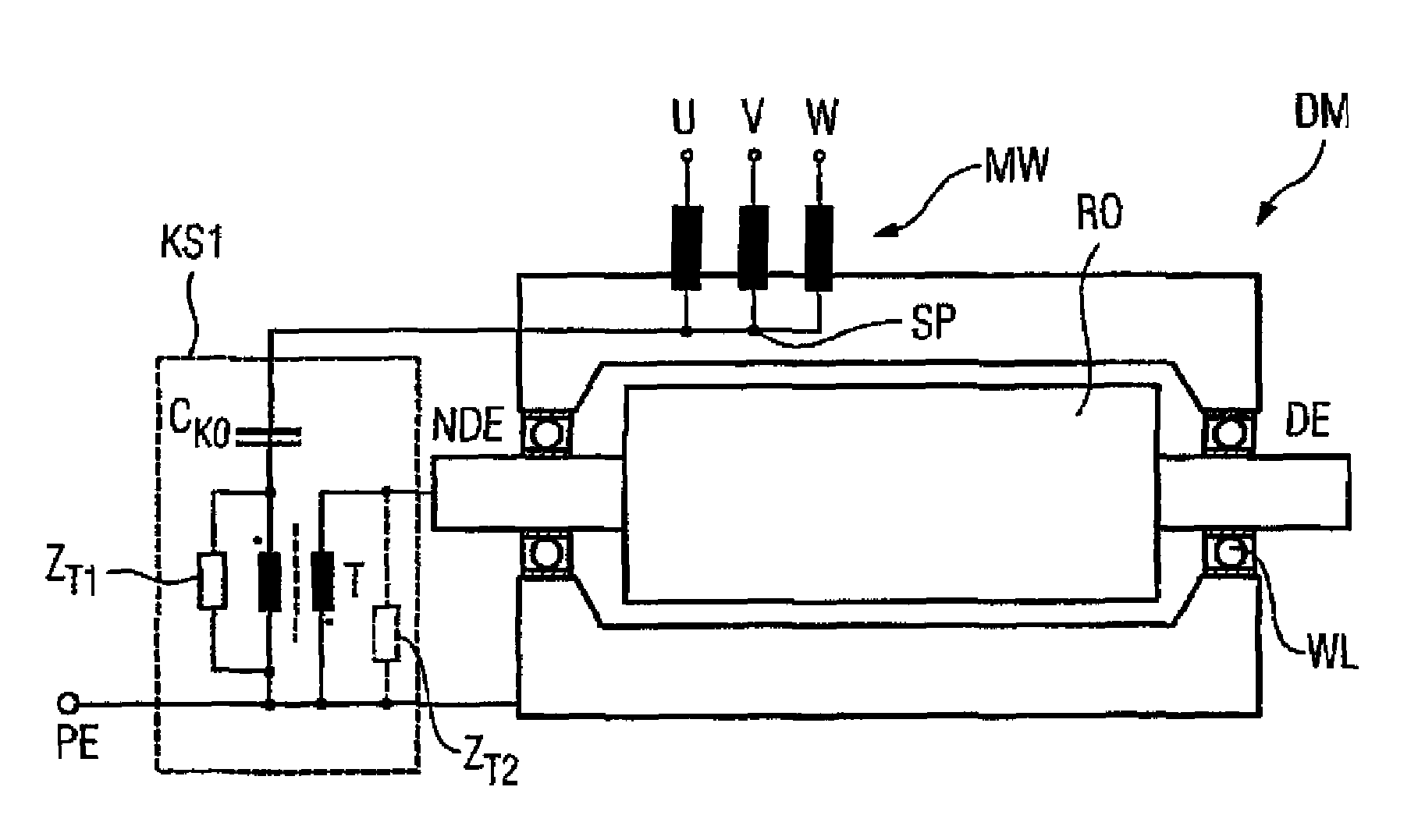

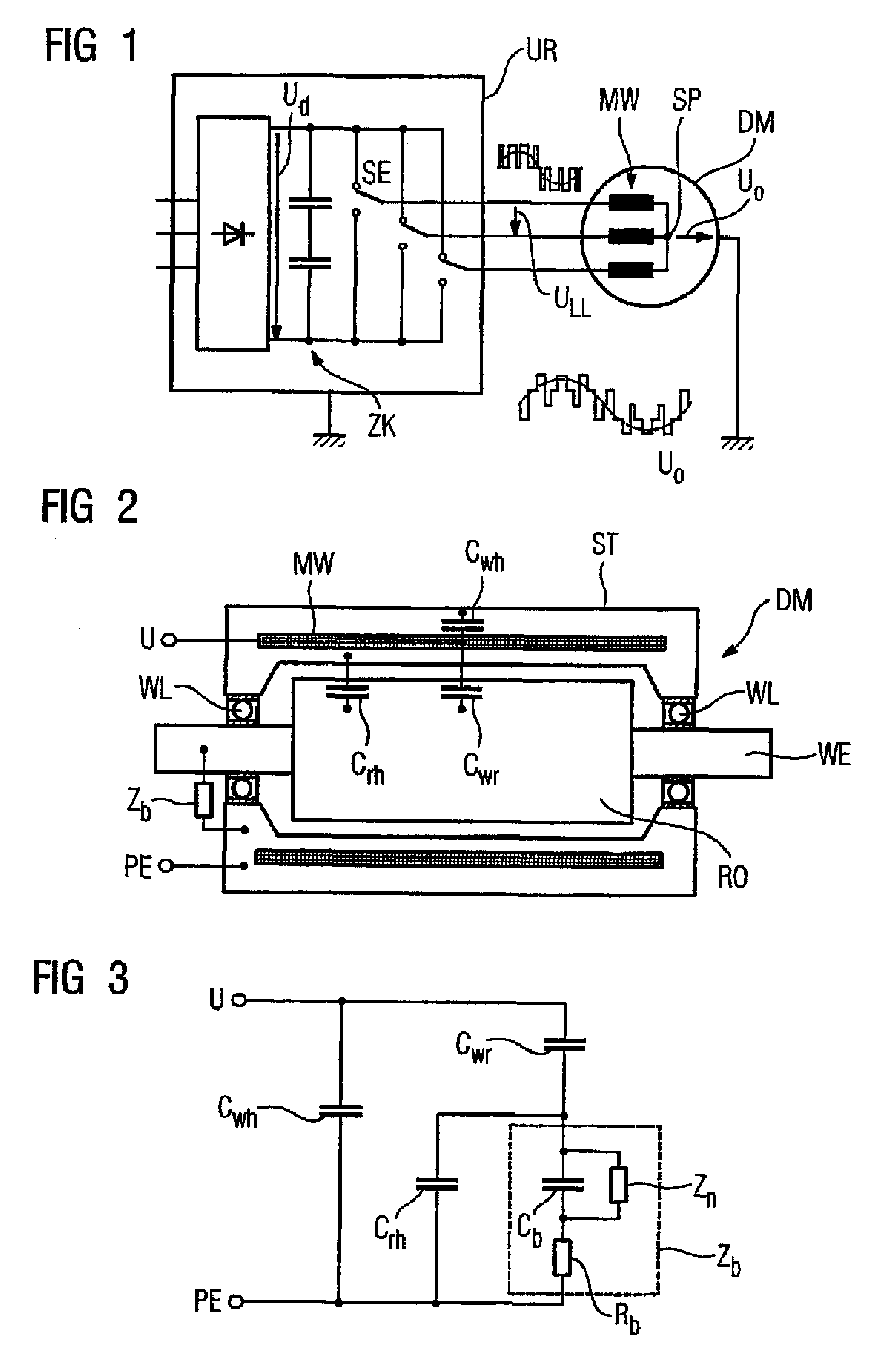

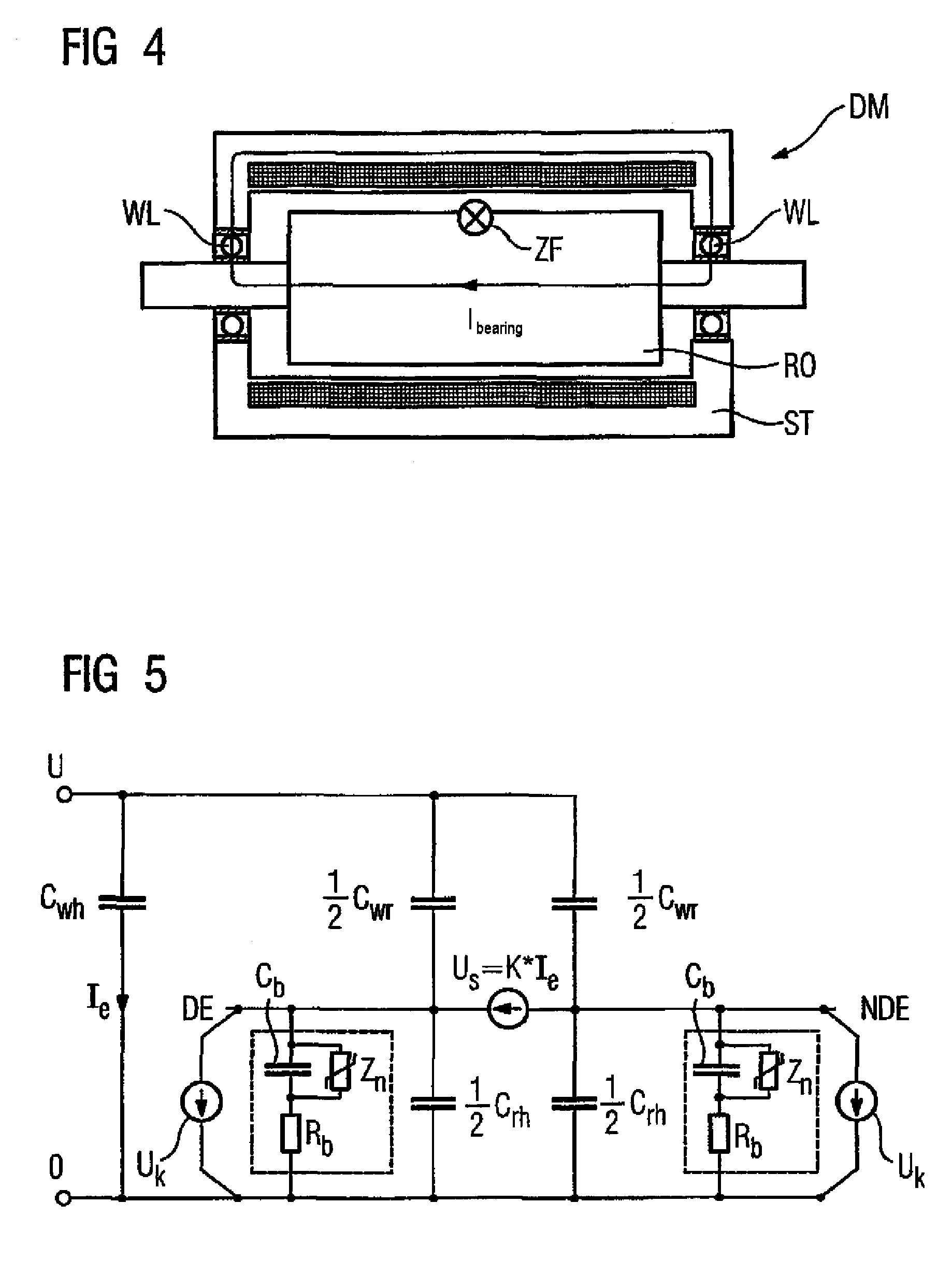

Compensation method and apparatus for preventing damaging bearing currents in an electrical machine

InactiveUS7501784B2Simple designImprove electrical lifeAssociation with grounding devicesTemperatue controlElectric machineLubricant

In an apparatus to increase the service life of bearings in an electric machine, the bearing currents that act on the bearings of the rotor are reduced by the application of a corresponding negative field voltage to the rotor, obtained with the aid of a compensation unit. The reduction of the bearing currents prevents ripple formation in the bearing and increased ageing of the lubricant.

Owner:SIEMENS AG

Electric parking brake system and method for controlling the electric parking brake system

ActiveUS7925408B2Shorten the timeTarget valueAnalogue computers for trafficBraking action transmissionElectric parking brakeAutomotive engineering

During the standstill state maintenance control executed by an electric parking brake system, the moving force-based target tension Frefb is determined based on the inclination angle of a vehicle and the shift position each time the predetermined program is executed, and the tentative target tension Fref(n) in the current routine is set to a smaller value from among the moving force-based target tension Frefb and the maximum value Fmax. The control target tension Fref(n)* is set to a larger value from among the control target tension (the final target tension) Fref(n−1)* in the immediately preceding routine and the tentative target value Fref(n). Even if the tentative target tension Fref(n) is smaller than the control target tension Fref(n−1)*, the control target value Fref(n)* is not set to a value smaller than the control target tension Fref(n−1)*.

Owner:TOYOTA JIDOSHA KK

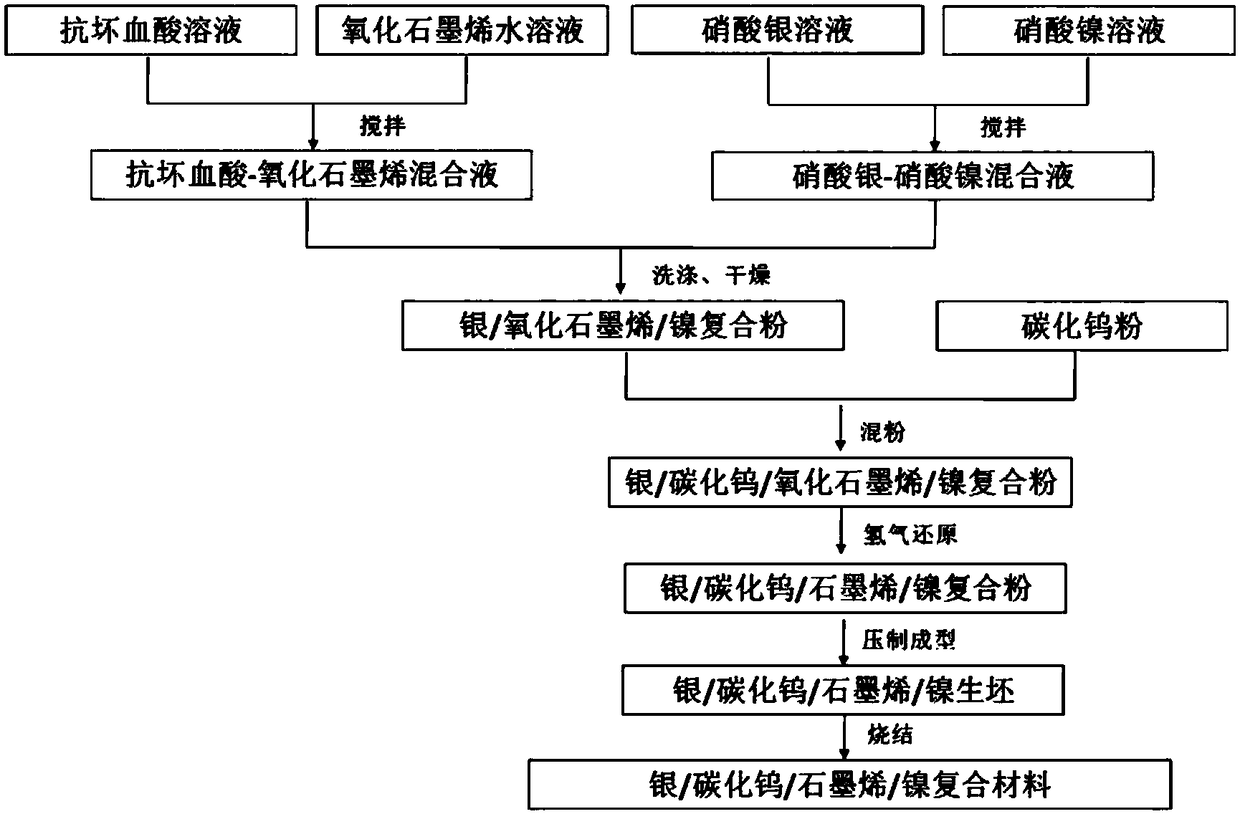

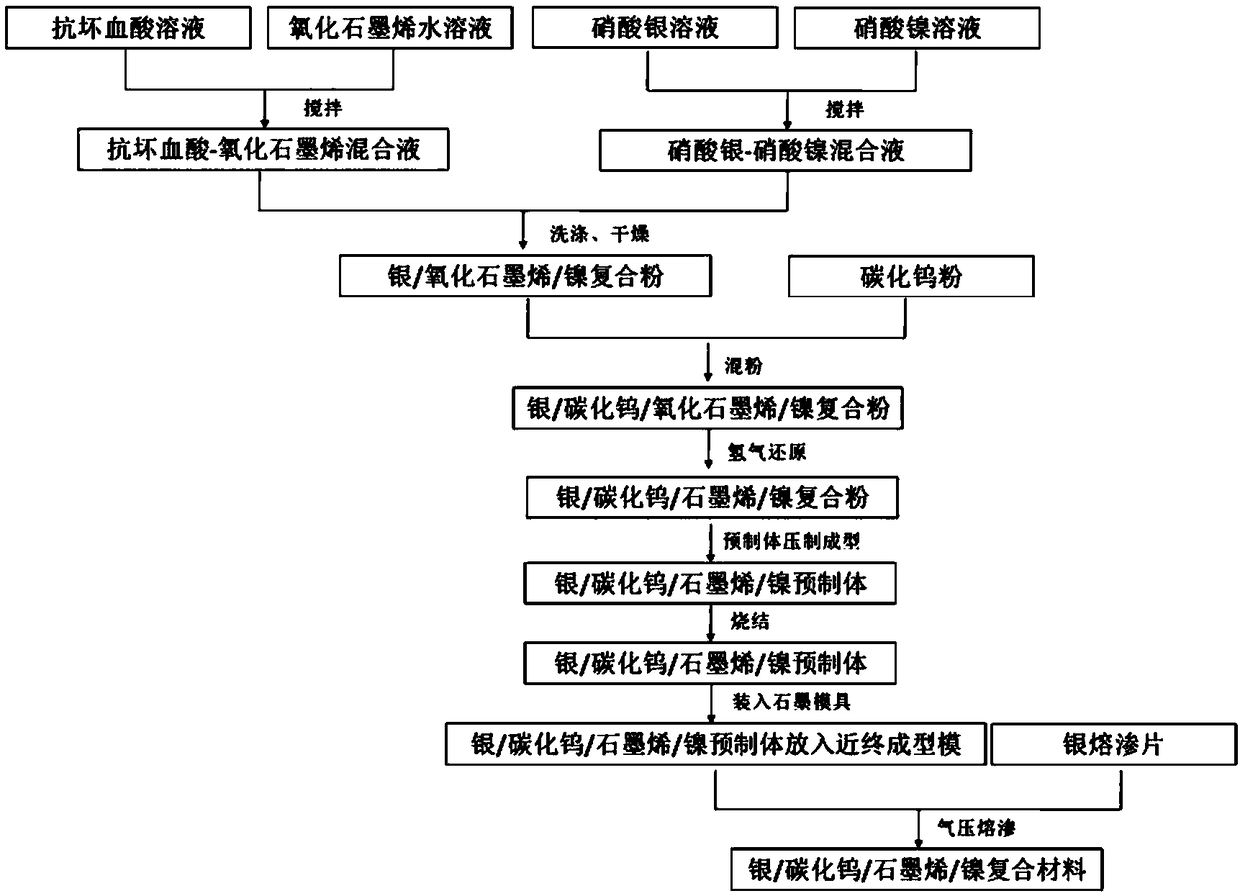

Silver tungsten carbide graphene electrical contact material and preparation method thereof

ActiveCN108531764AInterface is well integratedReduce contact resistanceCvd graphenePowder metallurgy

The invention discloses a silver tungsten carbide graphene electrical contact material and a preparation method of the silver tungsten carbide graphene electrical contact material. Silver is adopted as a base material, tungsten carbide serves as a first reinforcement phase, graphene serves as a second reinforcement phase, and nickel serves as a third reinforcement phase. The invention further discloses the preparation method of the material. Silver / graphene oxide / nickel compound powder is prepared through a chemical method; tungsten carbide powder is subjected to ball milling compounding withthe silver / graphene oxide / nickel compound powder, a silver / tungsten carbide / graphene oxide / nickel compound powder body is obtained, then the compound powder body is subjected to reduction treatment, and a silver / tungsten carbide / graphene / nickel compound powder body is obtained; and the material is prepared through a powder metallurgy technology or prefabricated body pressing and forming or an airpressure infiltration technology. The nickel element is introduced through a chemical coprecipitation method, then through ball milling and powder mixing, the silver, nickel and tungsten carbide forma mechanical alloying structure, good combination between the tungsten carbide and a base body is guaranteed, operation is simple, the process is easy to control, and scaled production is realized easily.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com