High antifusion weding performance silver nickel base electric contact material and its preparation method

An electrical contact material, silver-nickel-based technology, applied in the direction of contact materials, etc., can solve the problems of low production efficiency and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

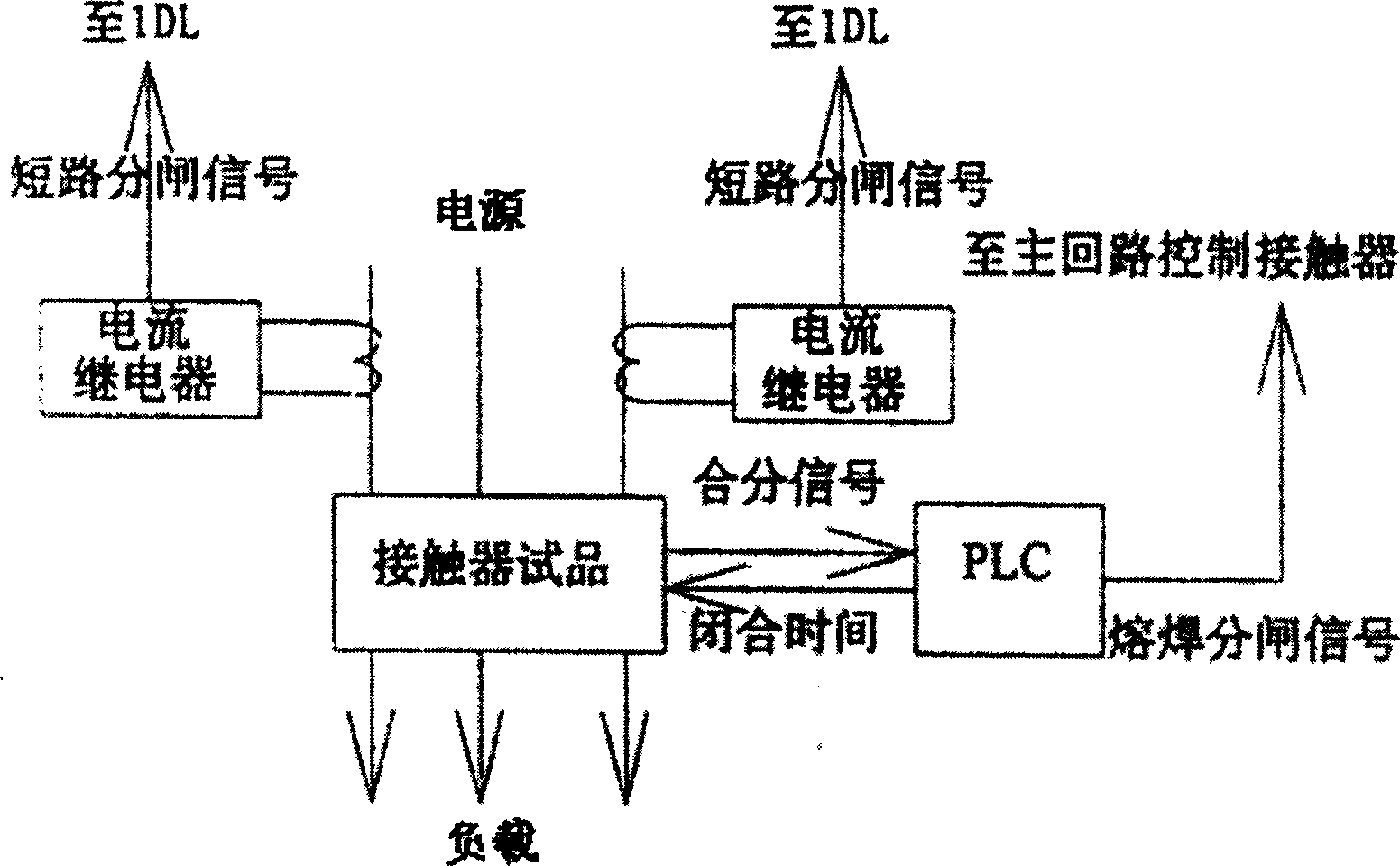

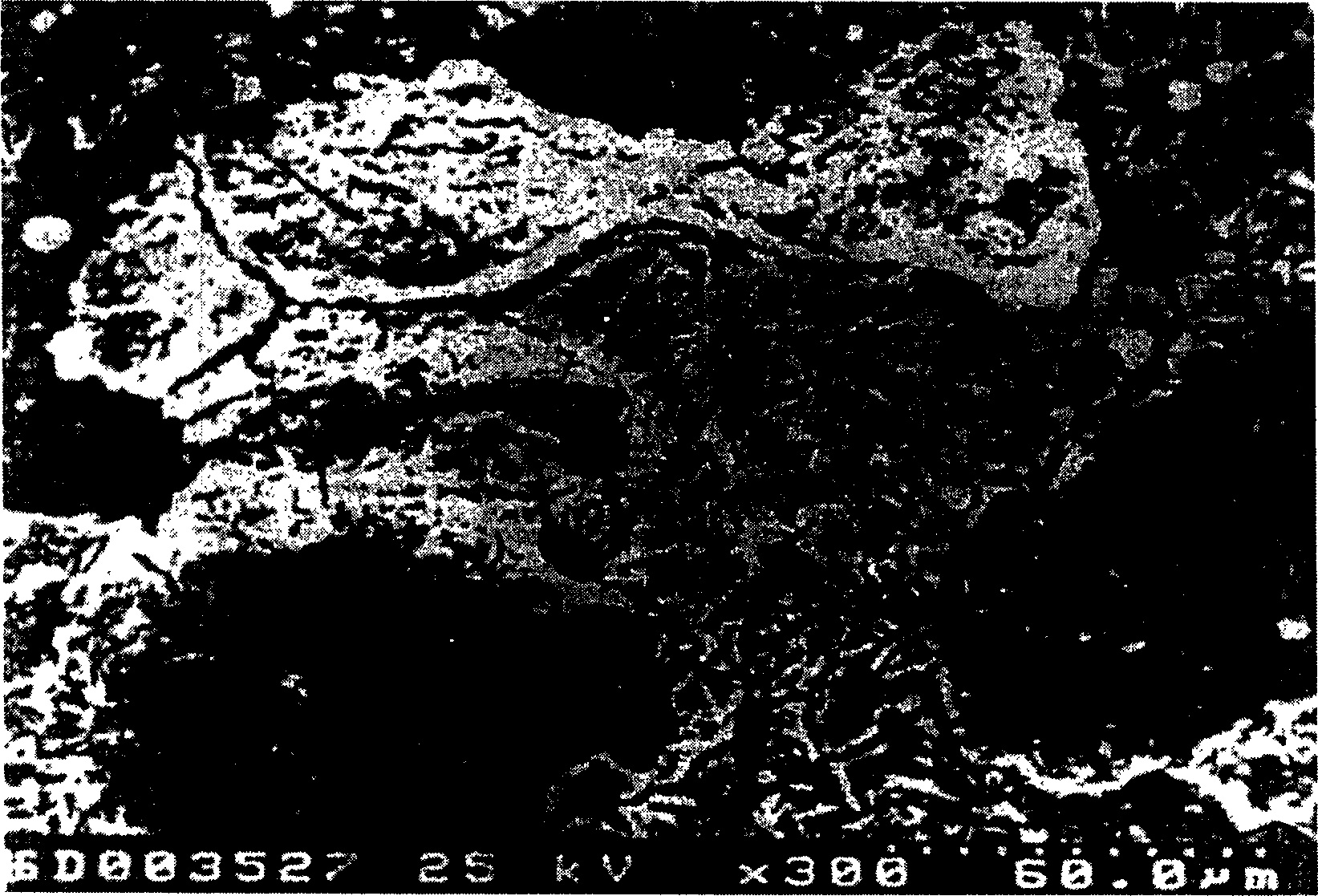

[0054] Contact samples were prepared according to the AgNi-based contact material formulation and preparation method of the present invention, respectively assembled in 3TB-42 contactors produced by Suzhou Siemens, and tested at the National Low-Voltage Electrical Appliance Quality Supervision, Inspection and Testing Center for 660V, 16A, AC -4 condition electrical life test. The test results show that: 1. The electrical life of the new AgNi-based electrical contact material reaches 41814 times without failure, which is 5 times higher than that of the original contact material; 2. The trace additive used for the diffusion arc root - alkali metal ( Lithium carbonate powder), its content must be strictly controlled; 3. The addition of wetting agent (germanium dioxide) delays the deterioration process of the contact matrix, Figure 5 The surface morphology of the new AgNi-based contact after arcing is shown; Image 6 shows the surface morphology of the new AgNi-based contact aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com