Magnetic latching relay

A magnetic latching relay, relay technology, applied in the direction of electromagnetic relays, relays, electromagnetic relay details, etc., can solve the problem of reducing the electrical life of the relay contacts and the ability to withstand short-term current impact, the relay contact bounce time is large, affecting the relay. Reliability and other issues, to achieve the effect of improving the resistance to short-term current impact, ensuring consistency and stability, and uniform and soft elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

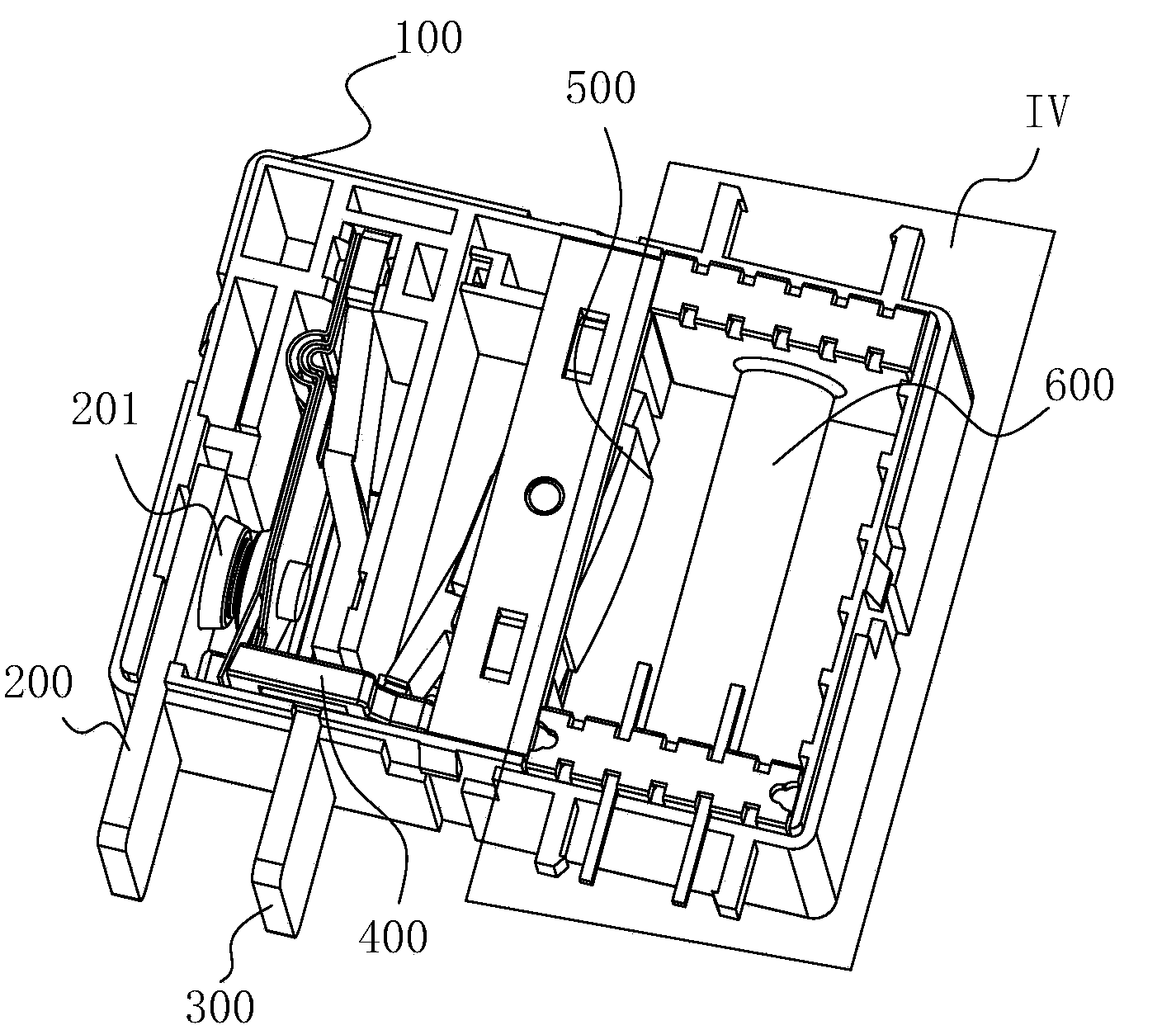

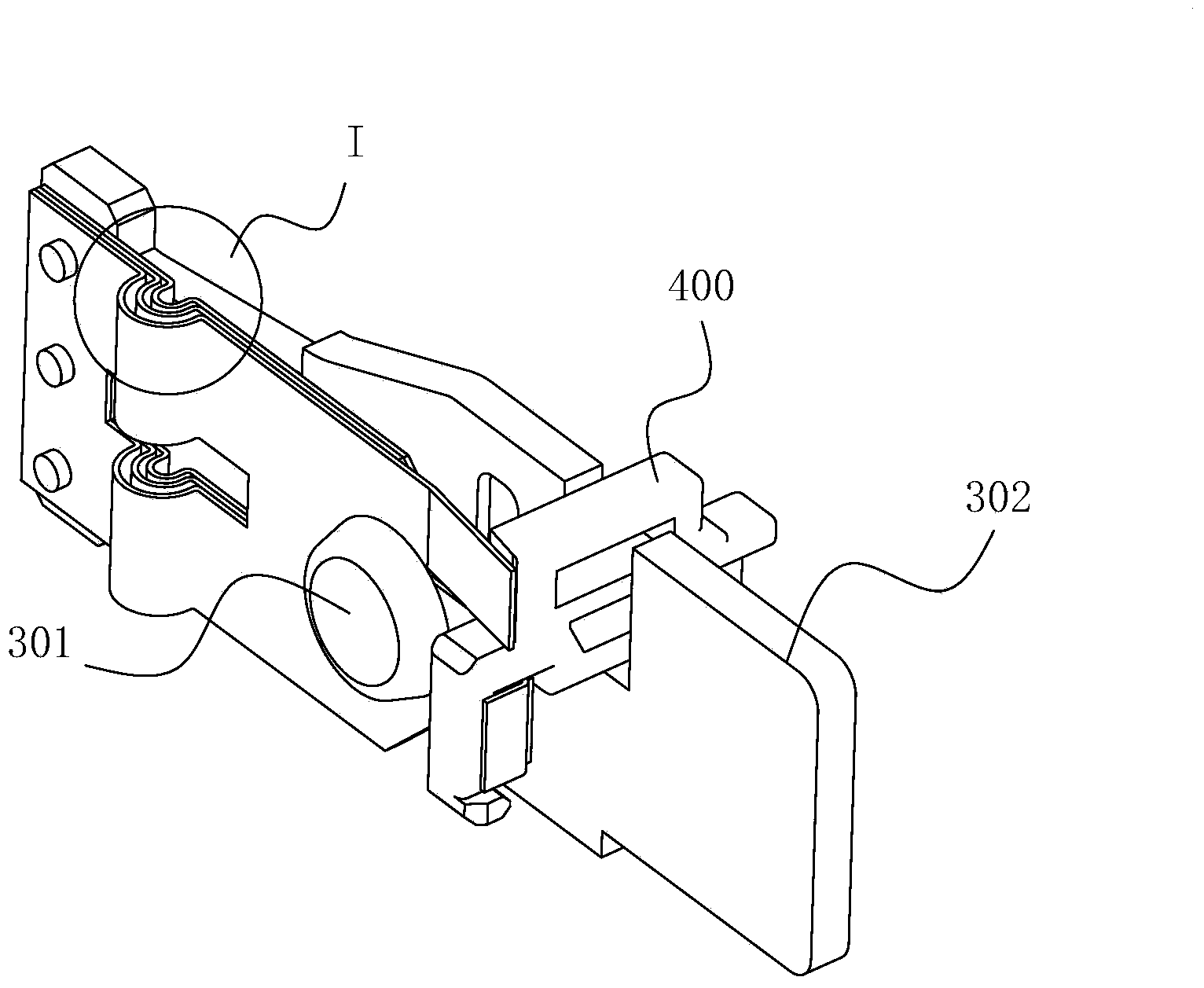

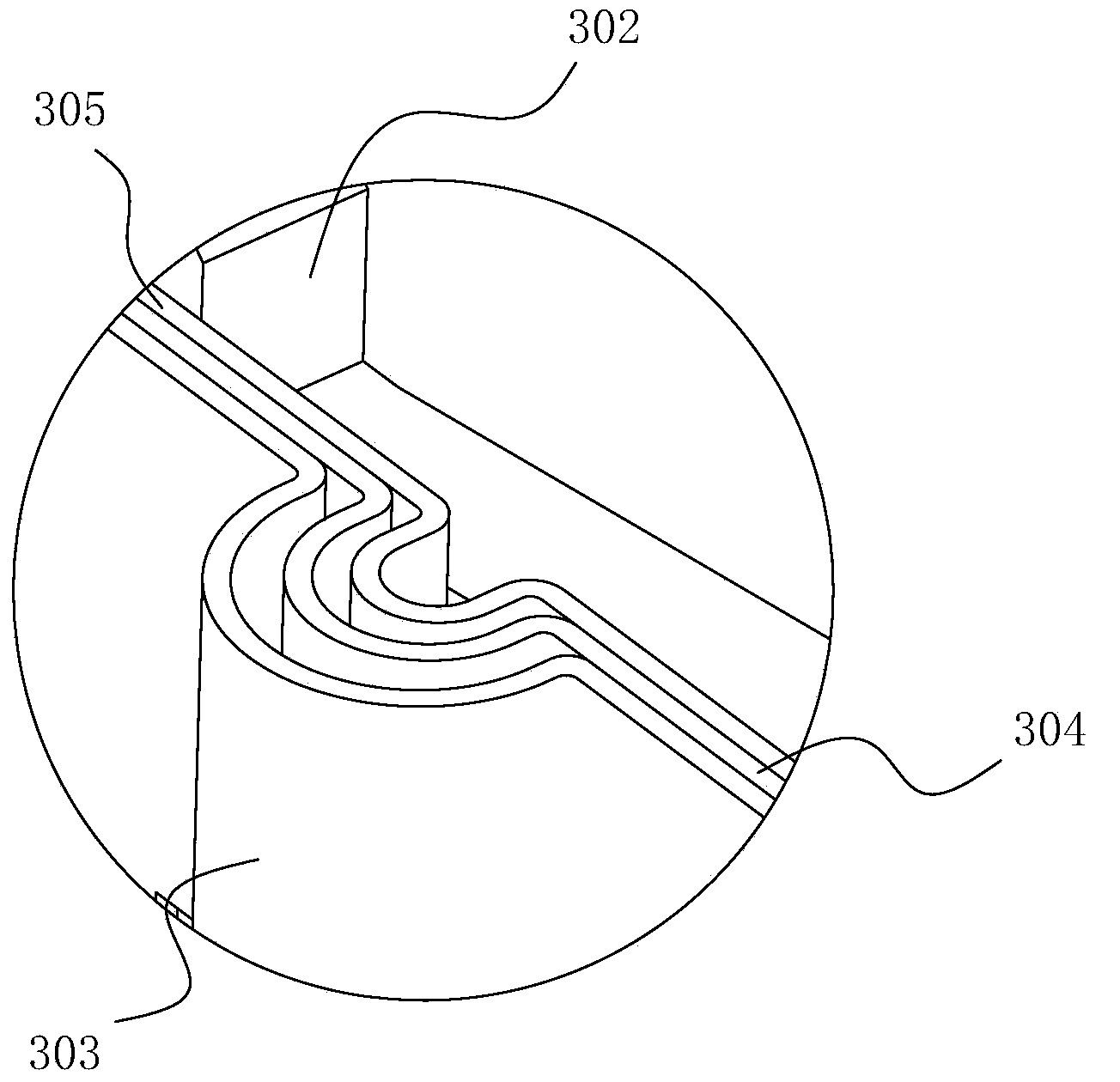

[0049] Such as Figure 1-8 As shown, in this embodiment, a magnetic latching relay according to the present invention includes a relay housing 100, and inside the relay housing 100, a static plate assembly 200 and a moving reed assembly corresponding to the static plate assembly 200 are arranged. 300, the static contact 201 is set on the static piece assembly 200, and the moving contact 301 is set on the moving reed assembly 300. The electrical equipment supplies power, and when the movable contact 301 is separated from the static contact 201, the relay forms an open circuit and the electrical equipment is powered off. The moving reed assembly 300 is connected with the push card 400 and is driven to move by the push card 400 , the push card 400 is driven by the armature assembly 500 , and the movem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com