Patents

Literature

65results about How to "Interface is well integrated" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pre-processing reinforced type impregnating agent for basalt fiber chopped spun yarn and preparation method of pre-processing reinforced type impregnating agent

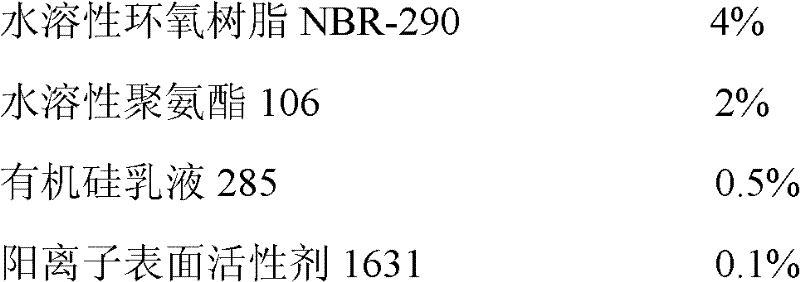

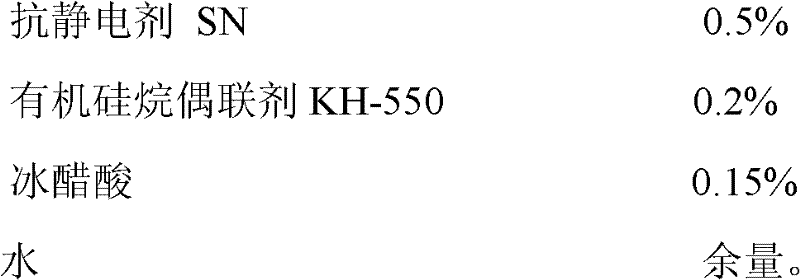

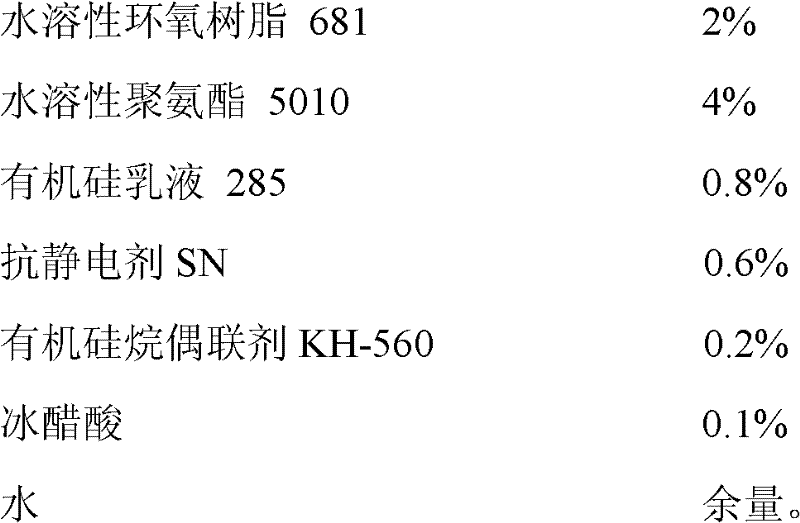

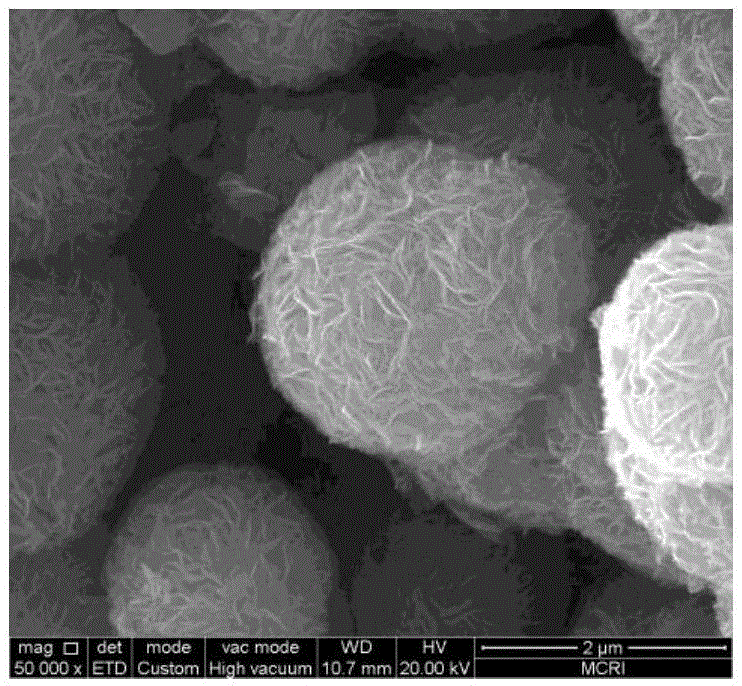

The invention relates to a pre-processing reinforced type impregnating agent for a basalt fiber chopped spun yarn and a preparation method of the pre-processing reinforced type impregnating agent and belongs to the technical field of the impregnating agent. The pre-processing reinforced type impregnating agent comprises the following components by weight percent: 2-4% of water-soluble epoxy resins, 2-4% of water-soluble polyurethanes, 0.5-1% of organic silicon latexes, 0-0.1% of cation surface active agents, 0.5-1% of antistatic agents, 0.2-0.5% of organic silane coupling agents, 0.1-0.2% of pH adjusting agents and the balance water. The pre-processing reinforced type impregnating agent and the preparation method provided by the invention are simple in technology and are suitable for the production of the basalt fiber chopped spun yarn with a single fiber diameter of 3.5-7.5 microns. The basalt fiber chopped spun yarn produced by utilizing the pre-processing reinforced type impregnating agent is high in strength and excellent in flexibility; a produced high-temperature acupuncture filter felt is free from being subjected to heat treatment; silicon oil and tetrafluoro coatings can be directly coated; energy source is saved; environmental pollution is reduced; and the pre-processing reinforced type impregnating agent is excellently combined with an interface of a produced product substrate and is high in strength.

Owner:山东兴国大成特种纤维科技有限公司

Method for in-situ preparation of TiBO2 reinforced magnesium-based composite material

The invention relates to a method of in-situ preparing TiB2 granule strengthening Mg-based composite material in the composite material technical field. The steps are that: powder of K2TiF6, KBF4 and Na3AlF6 are mixed uniformly and then put into a kiln for drying, thus obtaining waterless powder. Aluminum ingot is melted in a resistance furnace with heat preservation and uniformity; the waterless powder after dried is added to the melting Al melt liquid by batch and then is stirred with a graphite disc, and scum on the surface of the melt liquid is removed after stirred and stewed, thus obtaining TiB2-Al intermediate alloy; magnesium alloy is smelted with the protection of SF6 and CO2 mixing gas, and flame retardant element beryllium is added; the TiB2-Al intermediate alloy is added into the magnesium alloy melting solution slowly, stirred, stewed and cast. The technology of the invention is comparatively simple, has low cost, and the density of TiB2 / Mg composite material is between 1.8-2.0g / cm<3> and tensile strength thereof is increased by more than 60 percent than base alloy.

Owner:SHANGHAI JIAO TONG UNIV

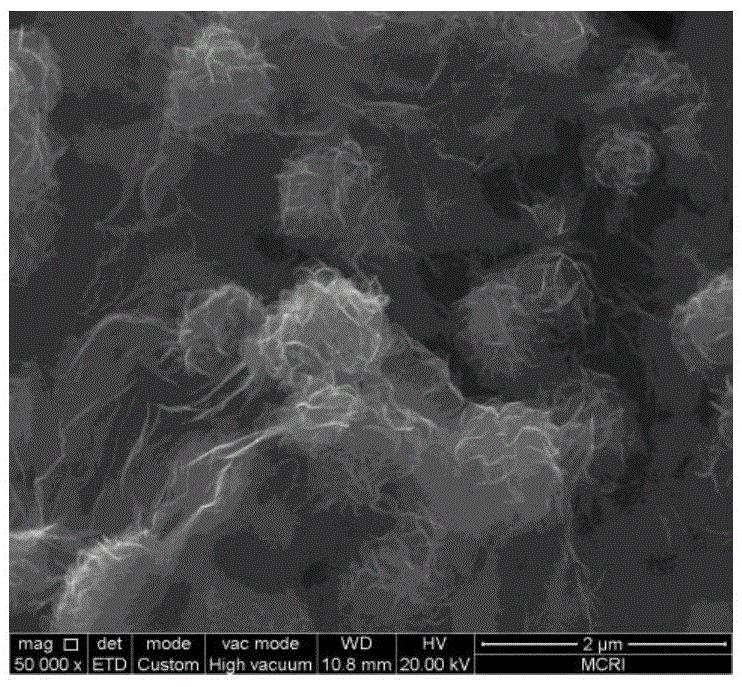

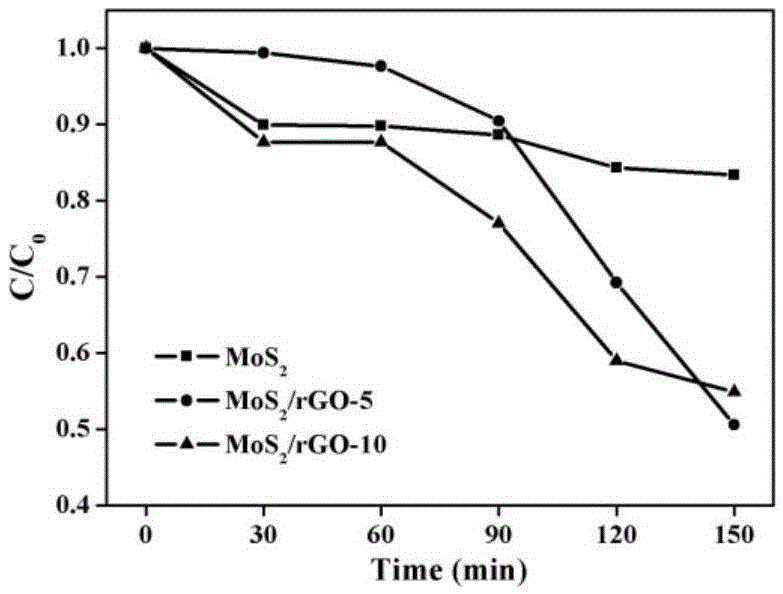

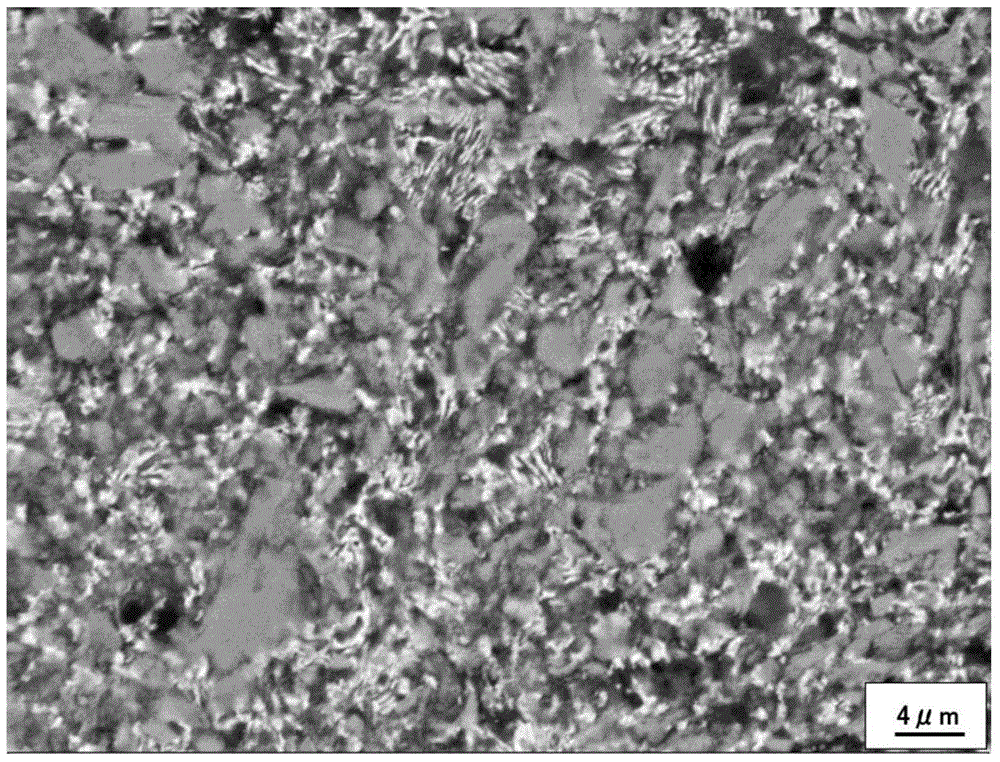

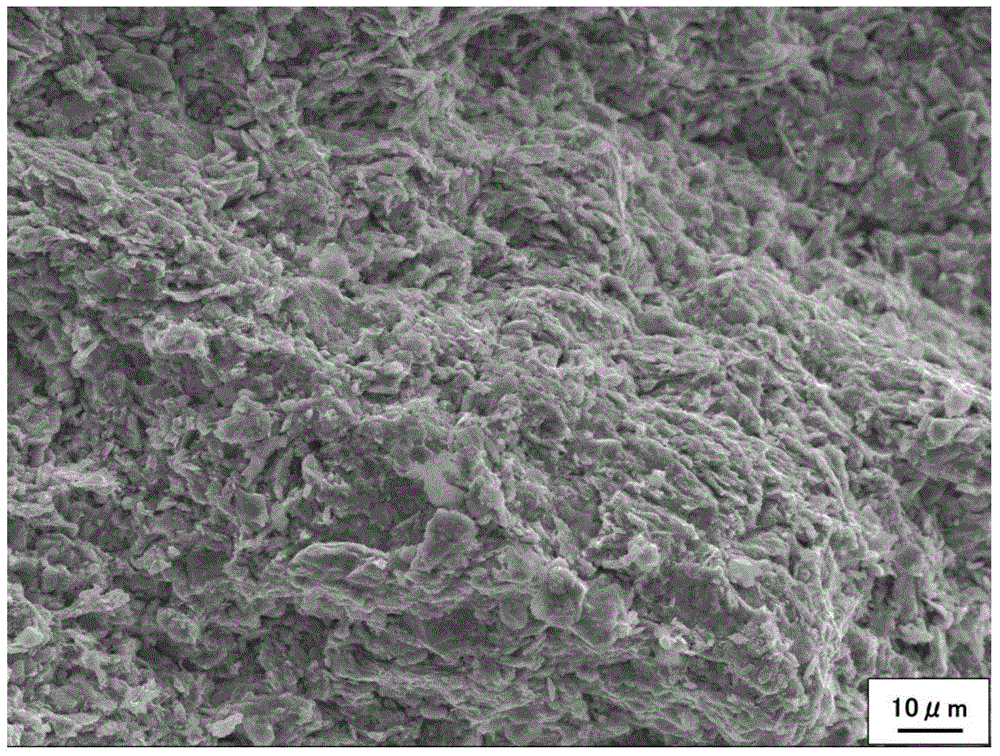

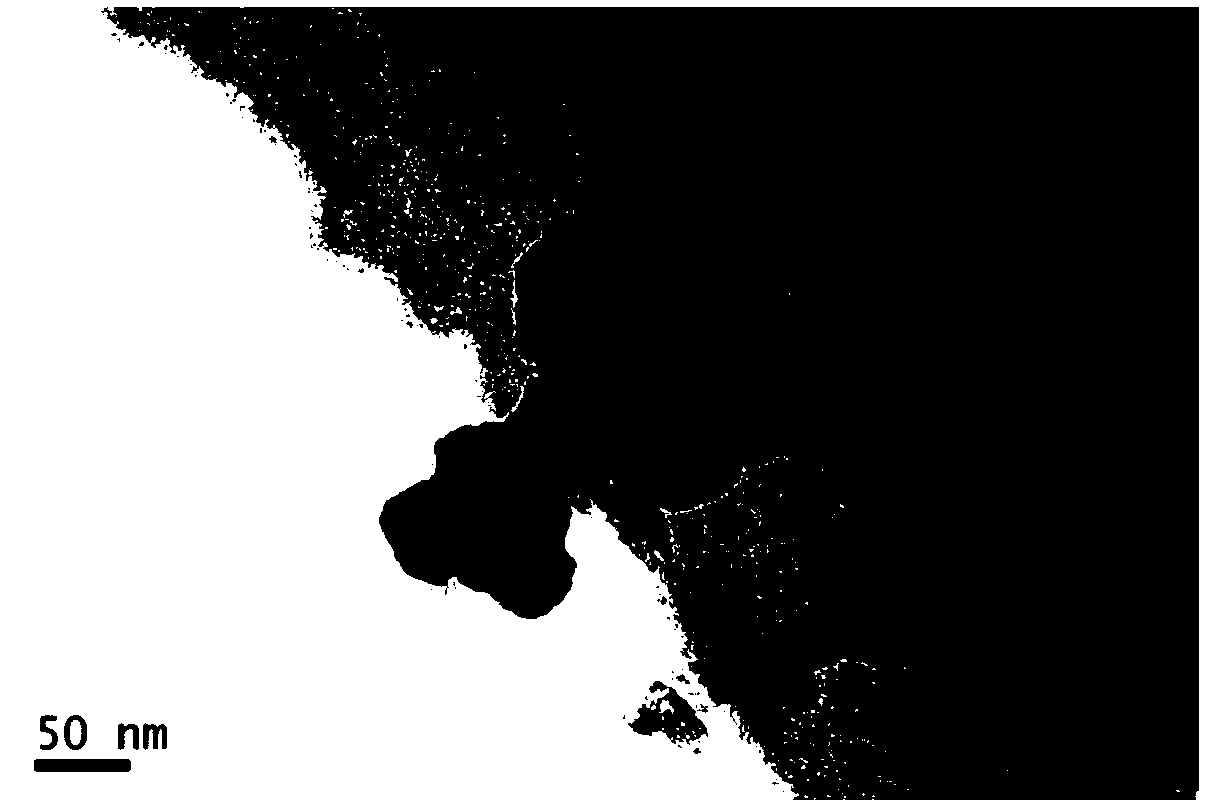

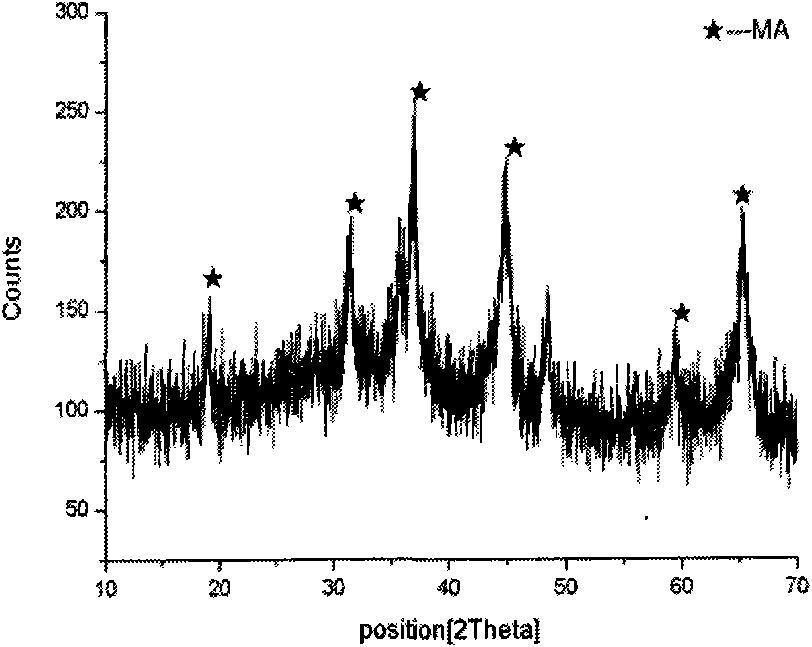

Method for preparing rGO-loaded petal-shaped MoS2 heterostructure

InactiveCN105618085AInterface is well integratedIncreased catalytic sitesPhysical/chemical process catalystsPhotocatalytic degradationCvd graphene

The invention discloses a method for preparing rGO-loaded petal-shaped MoS2 heterostructure, and aims to improve the efficiency of photocatalytic degradation of organic dye. The method is a treatment method for increasing the crystallization degree through one-step hydrothermal reaction synthesis and annealing treatment, a heterogeneous composite structure that petal-shaped MoS2 clusters and rGO clusters are twined mutually can be formed, adsorption of organic pollutants can be remarkably improved due to the large specific surface area of a two-dimensional material, photo-induced electrons can be prompted to be rapidly transferred to a graphene lamella due to a heterogeneous interface of the two-dimensional material, photo-induced holes with oxidability in an MoS2 valence band is engaged in organic pollutant degradation, and thus the photocatalysis property of the material can be greatly improved. Moreover, the MoS2 / rGO heterostructure plays a prompting role in improving the response of the material within a visible light range. The method is simple and clear in technical idea, and the degradation efficiency of the composite material to the organic dye is remarkably improved. The invention further discloses the technical idea for preparing semiconductor heterostructure by using a hydrothermal method and improving the efficiency of photocatalytic degradation of the organic dye.

Owner:XI AN JIAOTONG UNIV

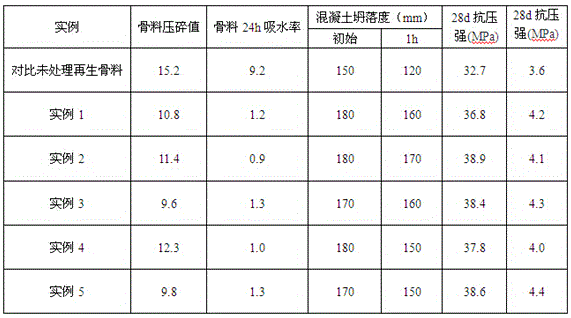

Recycled aggregate surface treating agent and use method thereof

The invention discloses a recycled aggregate surface treating agent and a use method thereof. The recycled aggregate surface treating agent is characterized by comprising the following components in percentage by weight: 4%-6% of acrylate, 0.2%-0.9% of peroxysulphate, 0.1%-0.5% of triethanolamine, 3%-5% of a cross-linking agent, 1%-3% of a silane coupling agent, 0.5%-1% of lignosulphonate calcium and 83.6%-91.2% of water. According to the recycled aggregate surface treating agent, the water absorption rate of recycled aggregates can be obviously decreased, and the property of an interfacial transition zone between the recycled aggregates and cement stone is improved, so that the concrete strength is improved.

Owner:HUAIAN TESTING CENT FOR CONSTR ENG

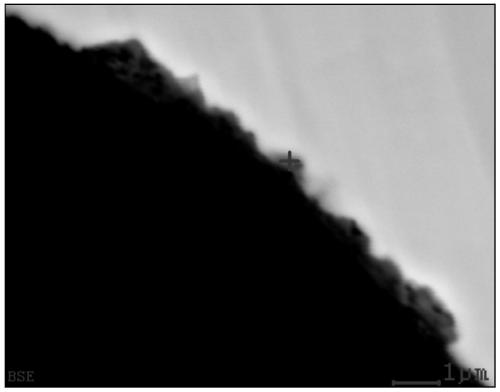

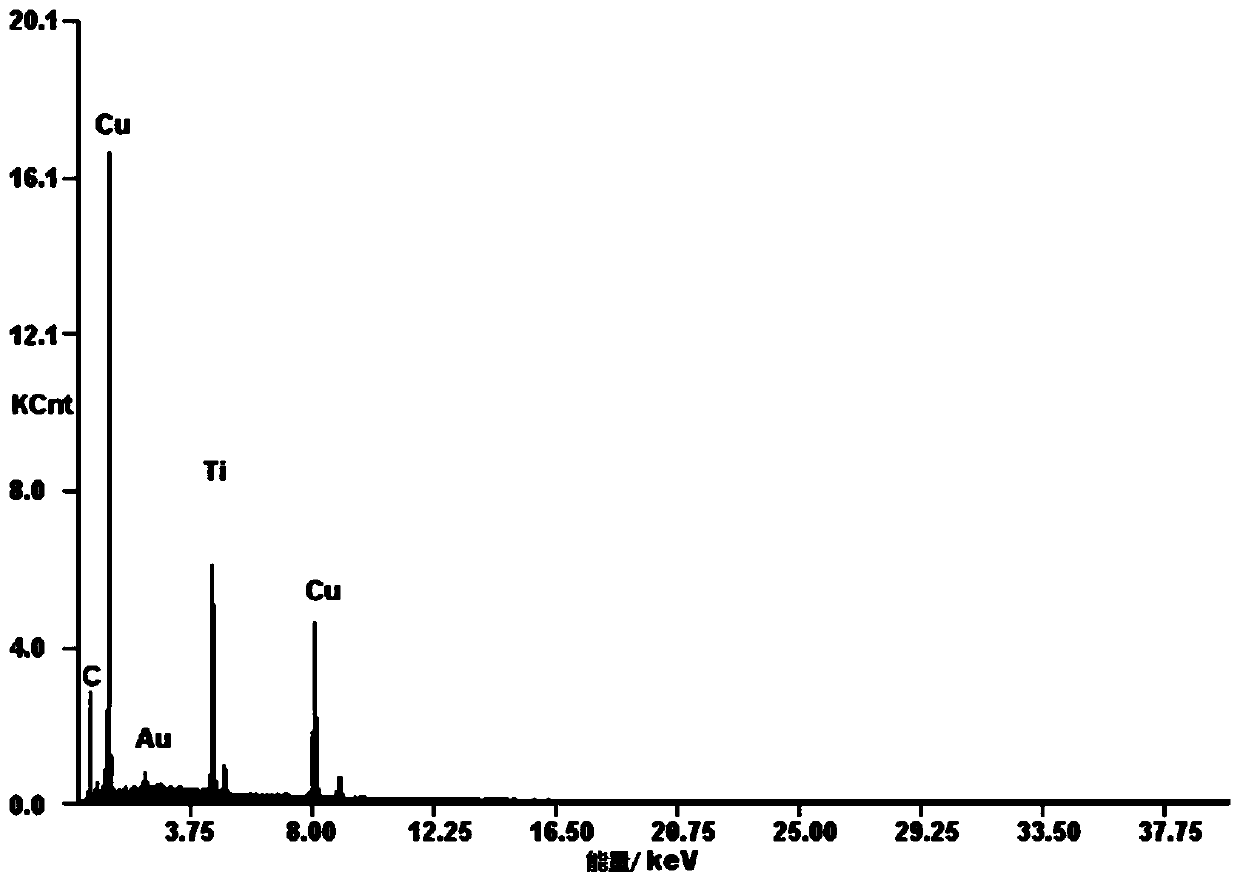

Carbon fiber reinforced titanium alloy compound material and preparation method thereof

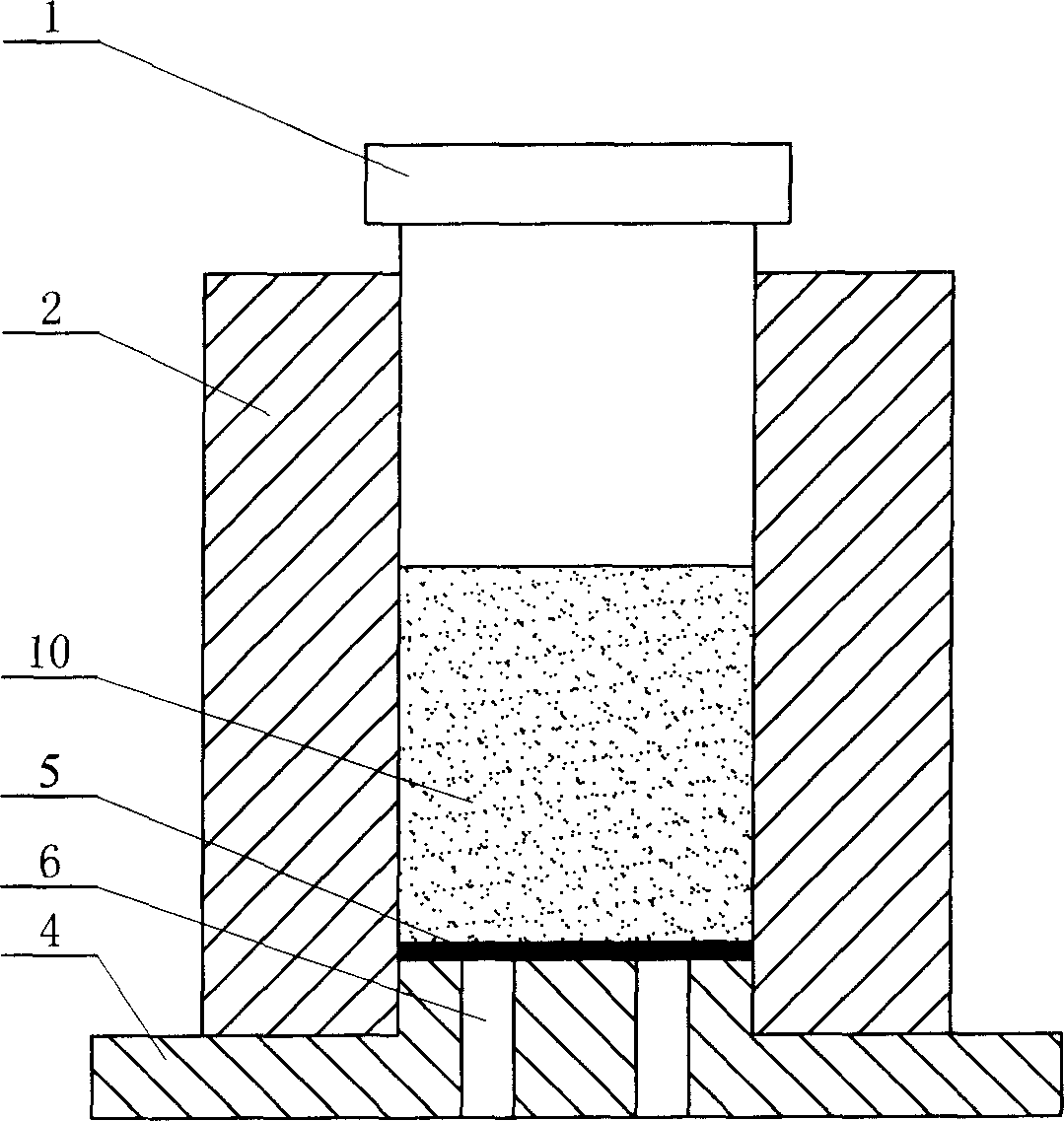

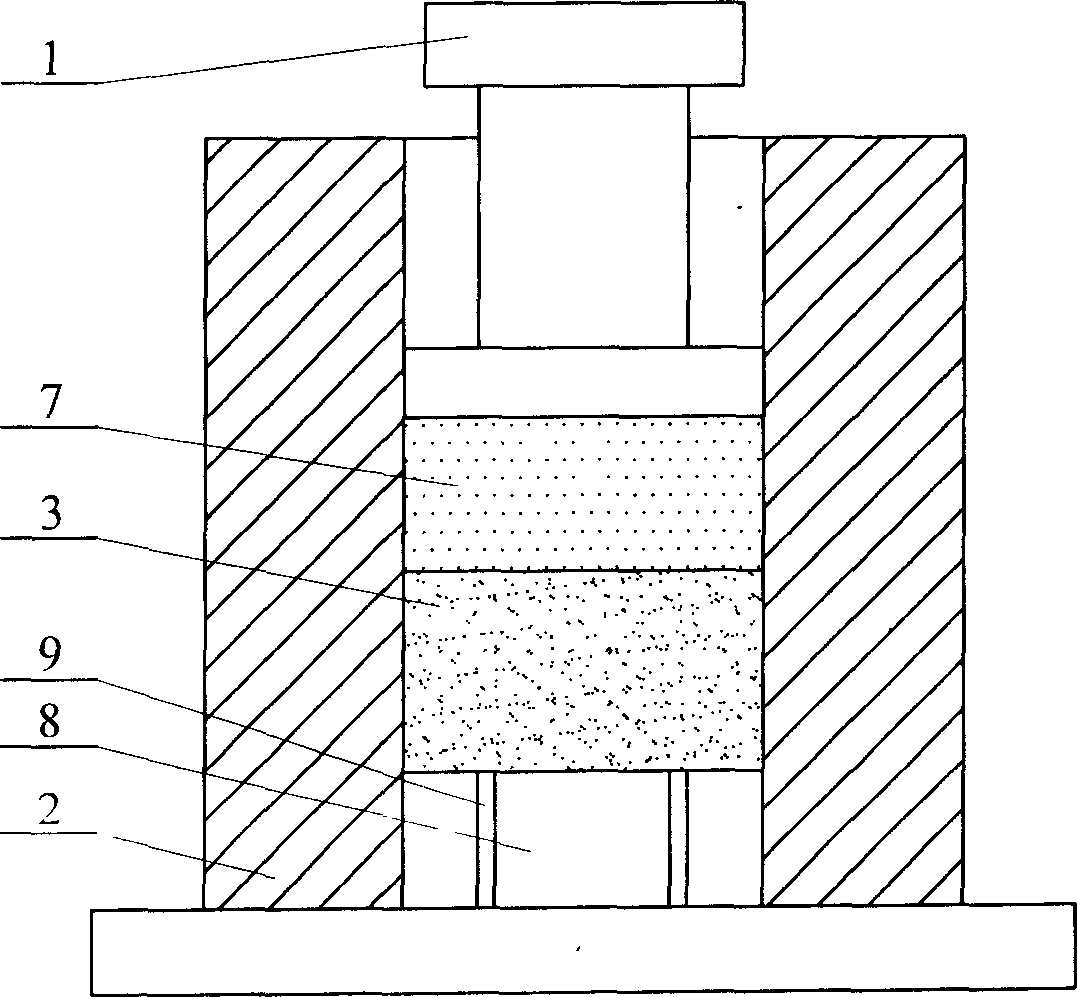

The invention discloses a carbon fiber reinforced titanium alloy compound material and a preparation method thereof. The preparation method comprises the steps as follows: 1, preprocessing a carbon fiber; 2, conducting chemical copper plating on the surface of the carbon fiber, namely coating copper onto the surface of the carbon fiber by utilizing a chemical plating method; 3, conducting chemical vapor phase deposition on pure tungsten, namely conducting chemical vapor phase deposition on the surface of the copper-coated carbon fiber to obtain a tungsten deposition layer; 4, cutting according to the design requirement to obtain the carbon fiber with the proper length; and 5, mixing powder according to the design requirement of titanium alloy content, placing a mixture and the carbon fiber into a pressing mould for hot-press forming, and sintering to obtain the carbon fiber reinforced titanium alloy compound material in the required shape at last. According to the carbon fiber reinforced titanium alloy compound material prepared by the method, the compositionality is good, the titanium alloy content is adjustable, the carbon fiber distribution is controllable, and the carbon fiber is not decarburized. The carbon fiber reinforced titanium alloy compound material is high in specific modulus, low in density, high in specific strength and impact toughness and good in adiabatic shear failure resistance, and is a high-performance structural material.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method of modified high-manganese steel base TiC steel bonded carbide

The invention relates to a preparation method of modified high-manganese steel base TiC steel bonded carbide. The preparation method is characterized by preparing in-situ synthesized TiC powder in a required proportion from titanium powder and graphite powder according to the atomic ratio of C to Ti, namely 0.8-1.0; preparing the raw materials including ferromolybdenum powder, ferrovanadium powder, ferrochrome powder, ferromanganese powder, ferrosilicon powder, ferrum powder, nickel powder, colloidal graphite and rare earth according to a required proportion of mass ratios of chemical components of bonding phase metals, filling steel balls, performing ball milling, adding absolute ethyl alcohol used as a medium and PVA (polyvinyl alcohol) to the steel balls, drying the slurry after ball milling, and then forming the slurry by pressing and sintering the product, thus obtaining steel bonded carbide. The preparation method has the advantages that the modified high-manganese steel base TiC steel bonded carbide is prepared by combining an in-situ reactive synthesis technology and a liquid phase sintering technology; as TiC is synthesized in situ inside a matrix through reaction in the sintering process, the reinforced particles have small sizes and do not have sharp corners on the surfaces, and the matrix is better in interface bonding and has a clean interface; the preparation method of steel bonded carbide is conductive to improving the comprehensive mechanical properties of carbide, is low in price and is simple and convenient in process.

Owner:JIANGSU HUICHENG MACHINERY MFG

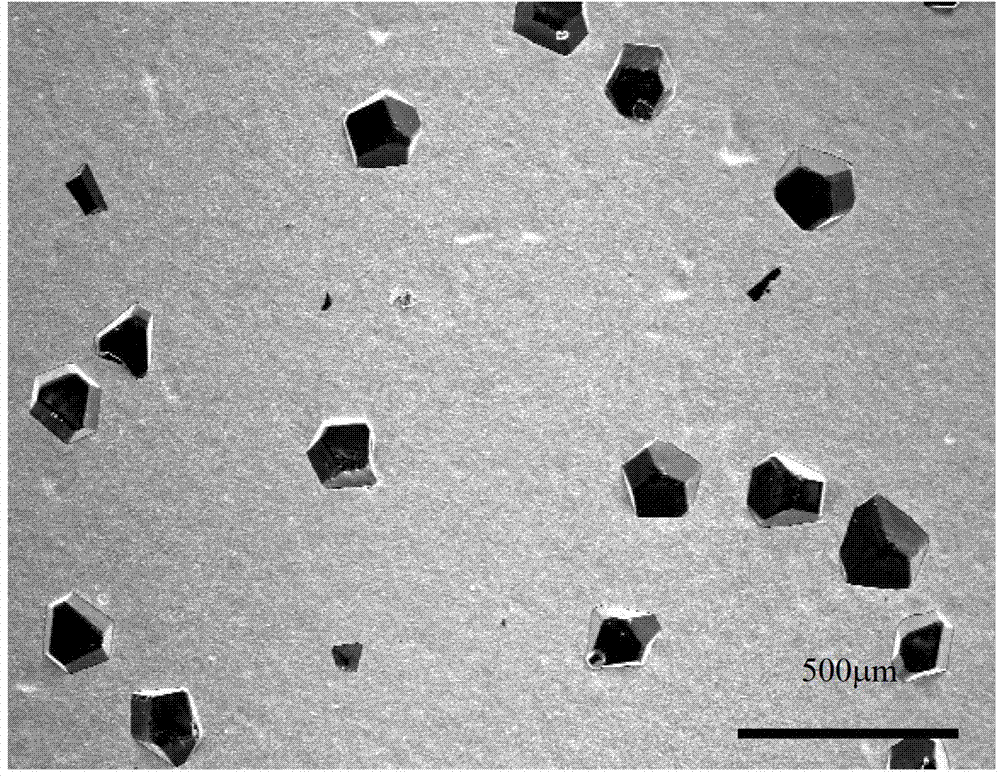

Preparation method for diamond/copper composite material with high heat conductivity and low thermal expansion coefficient

The invention discloses a preparation method for a diamond / copper composite material with high heat conductivity and low heat expansion coefficient, which relates to a preparation method for a diamond / copper composite material, to solve the technical problem of low heat conductivity of the traditional composite material prepared by directly compositing the diamond and pure copper by adopting a powder metallurgy or infiltration method. The preparation method comprises the following steps of: (1) plating copper on the surface of diamond powder by adopting a chemical copper plating method to prepare copper plated diamond powder; (2) mixing the copper plated diamond powder in the step (1) with copper powder by adopting a mechanical powder mixing mode to form mixed powder; and (3) performing cold pressing and molding on the mixed powder prepared in the step (2), and compounding the mixed powder with copper through vacuum hot pressing and sintering to obtain the diamond / copper composite material with high heat conductivity and low heat expansion coefficient. After sintering, the interface bonding of the composite material is better, and the density is higher; and the heat conductivity of the composite material reaches 500W / m.K, and the heat expansion coefficient is reduced to 7.8*10<-6> / K. The preparation method is applied to the field of preparation of diamond / copper composite materials.

Owner:HARBIN INST OF TECH

Carbon nanotube metal based composite materials and process for preparing the same

The preparation method for composite material with 5-20v% carbon nano tube and 20-95v% metal-base comprises: 1. dispersing with supersonic wave, cleaning, and filtering for tube treatment; 2. plating Ni on the tube; 3. grinding the polyimide; 4. preparing mixed solution with supersonic wave; 5. pouring the mixed solution into mold for preblocking; 6. putting the block on mold, casting metal-base liquid for heating and extruding. This invention overcomes detect in prior art, and obtains the material with compact tissue and well interface bond.

Owner:HARBIN INST OF TECH

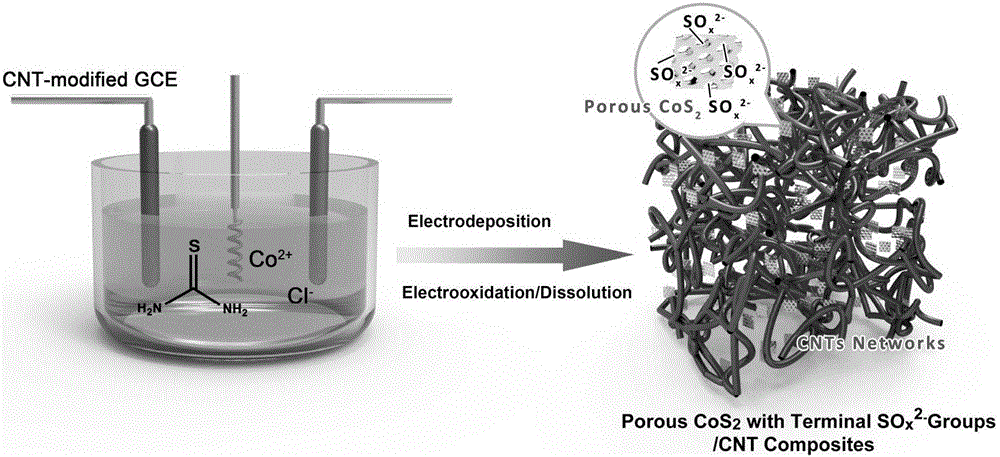

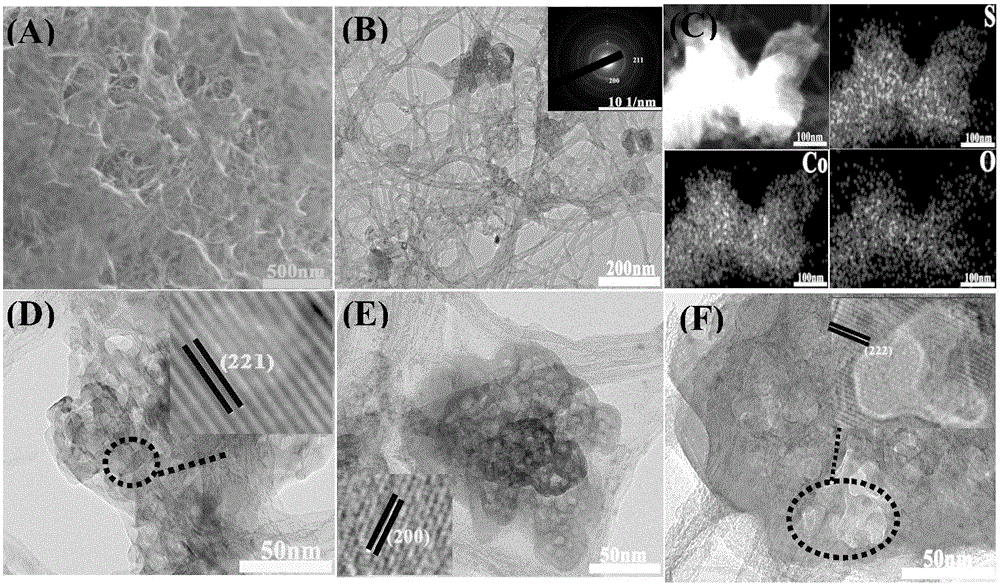

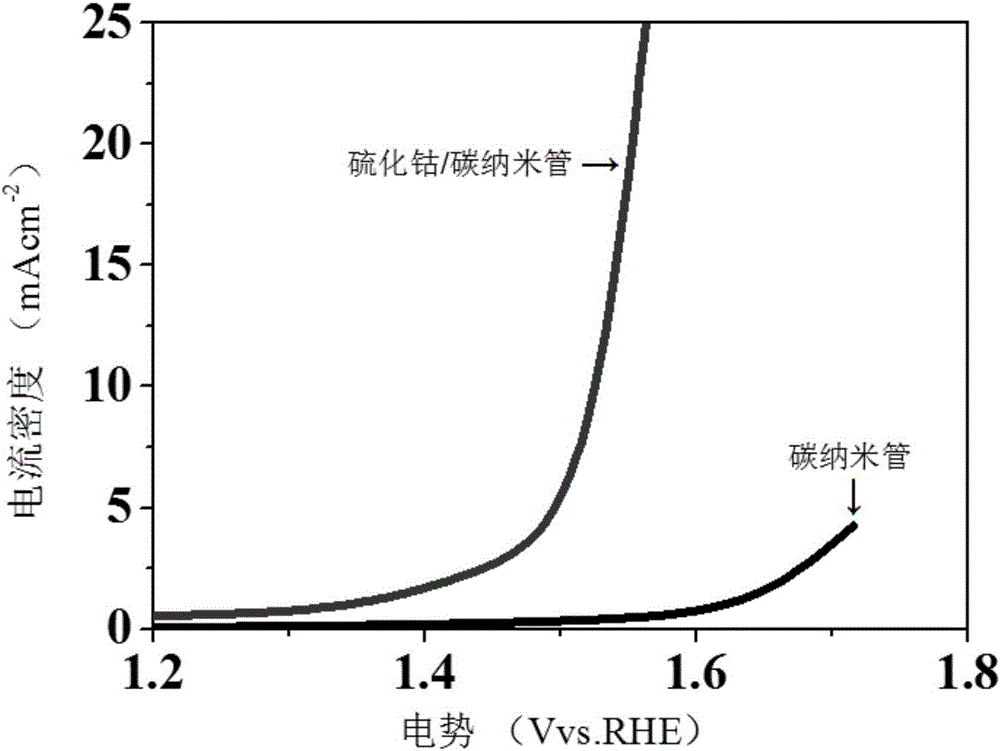

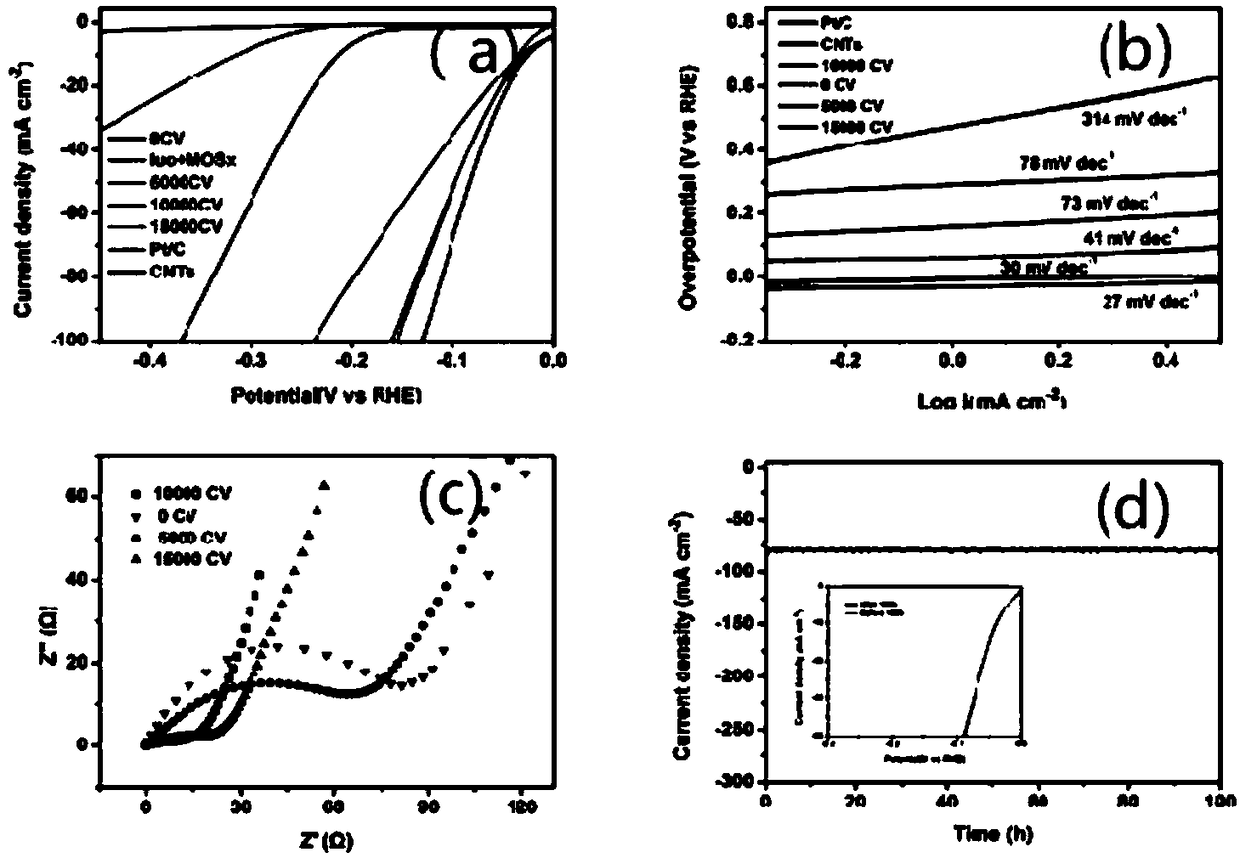

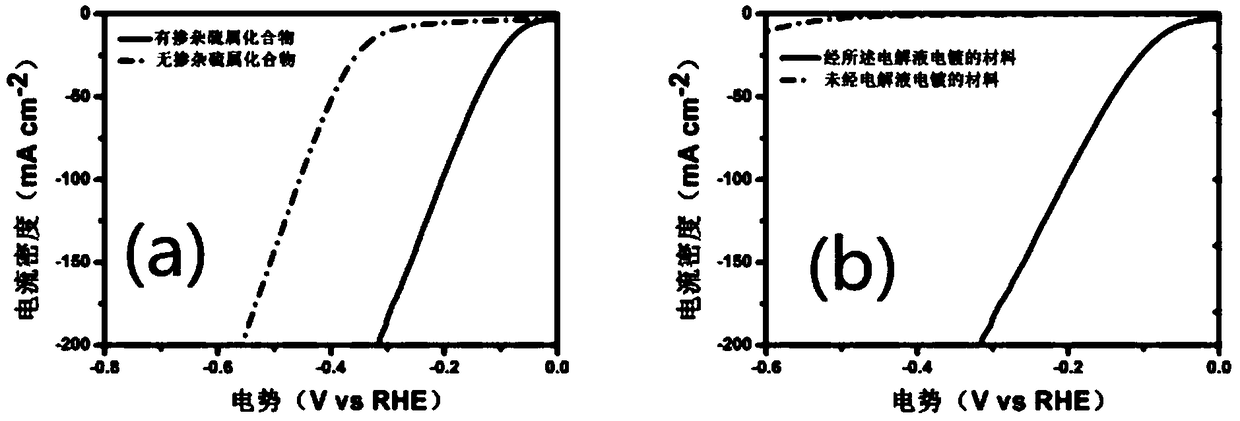

Transition metal sulfide/carbon nanotube composite material as well as preparation method and application thereof

InactiveCN106669739AAperture size controllableMore edge active sitesElectrolytic inorganic material coatingCatalyst activation/preparationThioureaCarbon nanotube

The invention provides a transition metal sulfide / carbon nanotube composite material. A preparation method of the transition metal sulfide / carbon nanotube composite material comprises the following steps: adding carbon nanotubes to a solvent, forming a suspension by ultrasonic treatment; dropping the suspension on the surface of a pretreated glassy carbon electrode; naturally airing to form a uniform thin layer of carbon nanotubes, to obtain a carbon nanotube-modified glassy carbon electrode; adding thiourea and transition metal salt to deionized water; adjusting pH to 0-13 to obtain an electroplating solution; placing the carbon nanotube-modified glassy carbon electrode in the electroplating solution for electroplating to obtain the glassy carbon electrode covered with a transition metal sulfide / carbon nanotube composite material; washing with water and drying naturally; scraping the transition metal sulfide / carbon nanotube composite material from the surface of the glassy carbon electrode. The preparation method provided by the invention is simple in operation and easy in mass production; the prepared composite material has great advantages in catalytic oxygen evolution and energy conversion, and can be used as a catalyst for photo and electro-catalytic oxygen evolution reaction.

Owner:WENZHOU UNIVERSITY

High-strength and high-tenacity polypropylene composite materials and preparation method thereof

The invention discloses high-strength and high-tenacity polypropylene composite materials. The high-strength and high-tenacity polypropylene composite materials solve the problems that existing polypropylene is poor in tenacity and poor in strength. The high-strength and high-tenacity polypropylene composite materials are formed by the following components, by weight, 35-75% of polypropylene, 10-40% of calcium carbonate, 8-25% of calcium sulfate whisker masterbatch, 0.1-2% of coupling agents, 2-8% of compatilizer, 0.3-4% of lubricating agents and 0.2-0.8% of antioxygen. The invention further provides a preparation method of the high-strength and high-tenacity polypropylene composite materials. According to the preparation method of the high-strength and high-tenacity polypropylene composite materials, through the mode that calcium sulfate whiskers are made into masterbatch, the calcium sulfate whisker masterbatch is added to plastics to carry out co-extrusion mixing with the plastics and the like, thus, compared with powdery whiskers, material preparation can be evener and controllable, the problem that material preparation of the calcium sulfate whiskers is difficult is solved, meanwhile, the calcium sulfate whiskers are made to have better dispersity in plastic substrate, and the surfaces of products are smoother.

Owner:四川万润非金属矿物材料有限公司

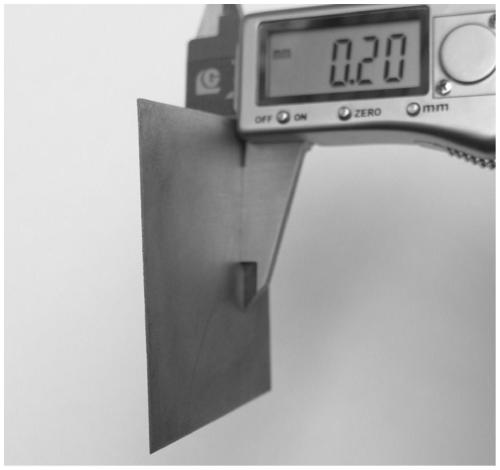

Preparation method for large-size slice-shaped and ultrahigh-heat-conductivity diamond/copper composite material

The invention provides a preparation method for a large-size slice-shaped and ultrahigh-heat-conductivity diamond / copper composite material and relates to the preparation method for the diamond / coppercomposite material. The purpose of the preparation method for the large-size slice-shaped and ultrahigh-heat-conductivity diamond / copper composite material is to solve the problems of the low heat conductivity and the poor interfacial bonding strength of the diamond / copper composite material. The preparation method comprises the steps that diamond particles coated with metal films are filled intoa mold cavity of a graphite mold to obtain a prefabricated body; and the prefabricated body is placed into a crucible, block-shaped pure copper and copper alloy are placed at the upper portion of theprefabricated body inside the crucible to be placed into an air pressure leaching furnace, interfacial layer material tissue form adjusting and control are performed under an argon protective atmosphere, warming copper melting, heat preservation and pressure maintaining leaching are performed, and finally, pressure maintaining stepped cooling is performed. In an obtained composite material component, the diamond volume fraction is 60-85%, the heat conductivity reaches 1500 W / mK, the edge length reaches 60-130 mm, and the thickness reaches 0.2-4 mm. The preparation method for the large-size slice-shaped and ultrahigh-heat-conductivity diamond / copper composite material is suitable for preparing the high-heat-conductivity diamond / copper composite material.

Owner:哈尔滨锦威科技有限公司

Pressureless sintering-pressurized densifying preparation method for titanium-aluminum-carbon particle enhanced zinc-aluminum matrix composite

The invention discloses a pressureless sintering-pressurized densifying preparation method for a titanium-aluminum-carbon (Ti3AlC2) particle enhanced zinc-aluminum matrix composite. The method comprises two steps of sintering and densifying. The method comprises the following steps: sintering mixed powders of titanium aluminum carbon and zinc-aluminum alloy at a relatively high temperature; conducting pressurized densifying at a relatively low temperature. Sintering at the relatively high temperature can obviously improve the interface bonding force between the titanium aluminum carbon enhanced phase and the zinc-aluminum alloy matrix, and pressurized densifying at the relatively low temperature can prevent zinc-aluminum alloy liquids from being extruded out because of pressurization; the titanium-aluminum-carbon particle enhanced zinc-aluminum matrix composite is uniform and compact in organization, less in defects and close in combination between the matrix and the enhanced phase, and has good physical properties and mechanical properties.

Owner:BEIJING JIAOTONG UNIV

Carbon nanotube/copper-zinc alloy composite material as well as preparation method and application thereof

ActiveCN109261155ALarge specific surface areaStrong chemical adsorptionCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsCarbon nanotubeChemical adsorption

The invention discloses a carbon nanotube / copper-zinc alloy composite material as well as a preparation method and application thereof and belongs to the technical field of preparation of materials. The carbon nanotube / copper-zinc alloy composite material is prepared from a matrix carbon nanotube (CNT) and copper-zinc alloy nanoparticles loaded on the surface of the matrix carbon nanotube; a preparation process comprises the following steps: firstly, carrying out purification, sensitization and activation treatment on the CNT; then loading Cu nanoparticles on the CNT; plating Zn by utilizing zinc chloride; finally, carrying out alloying to obtain the carbon nanotube / copper-zinc alloy composite material. According to the carbon nanotube / copper-zinc alloy composite material, the CNTs are used for loading a nano copper-zinc alloy; on one hand, the advantages that the CNTs subjected to strong acid treatment have a relatively large specific surface area, relatively strong chemical adsorption, uniform distribution of metal elements on pipes and high thermal stability can be expressed; on the other hand, the CNTs are used as carriers of the copper-zinc nanoparticles and the property of isolating and dispersing the copper-zinc nanoparticles is realized; the distance between the copper-zinc nanoparticles is increased, the anti-sintering performance of the copper-zinc nanoparticles is improved and the agglomeration problem of nano copper-zinc alloys is solved.

Owner:CENT SOUTH UNIV

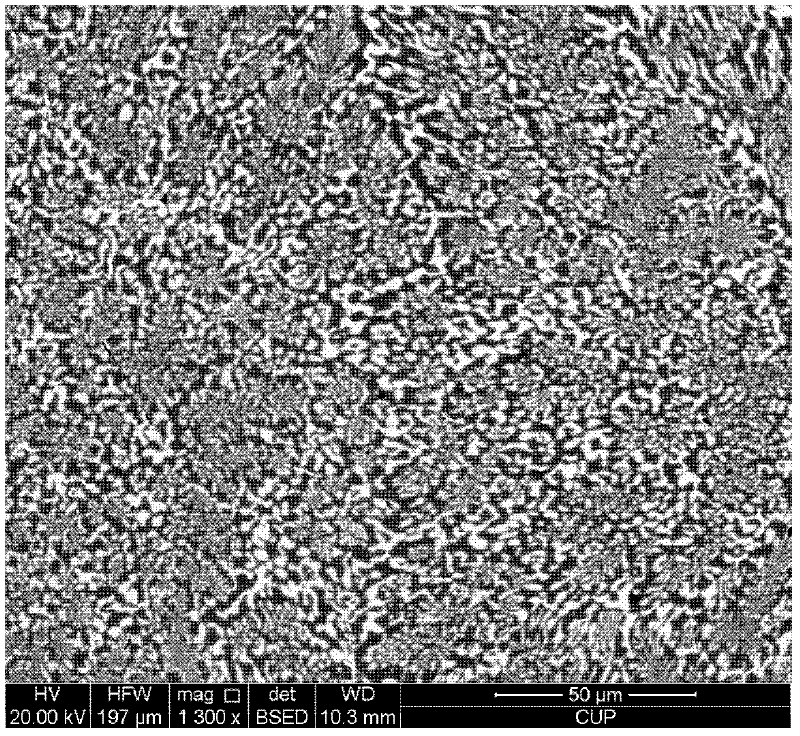

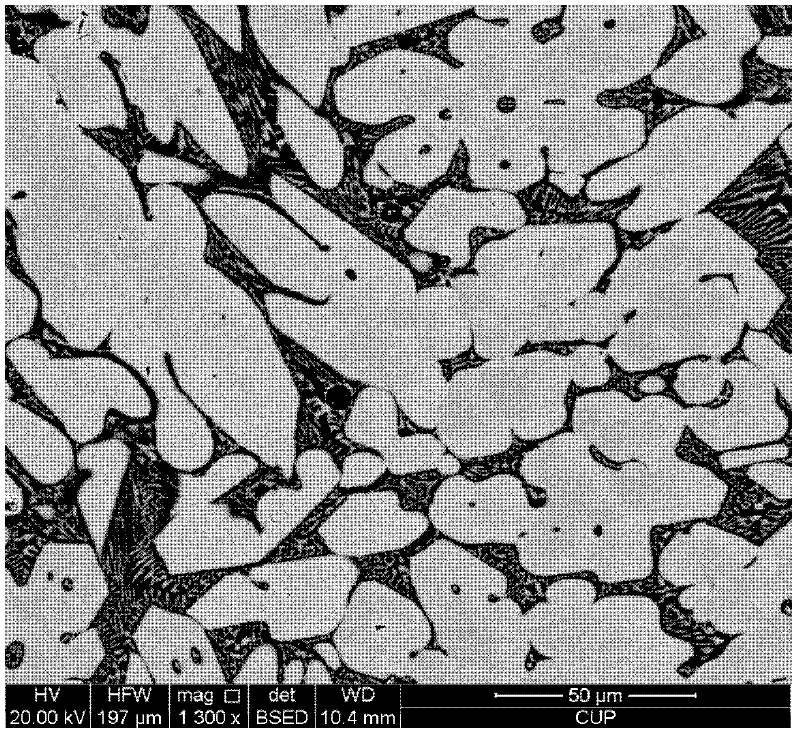

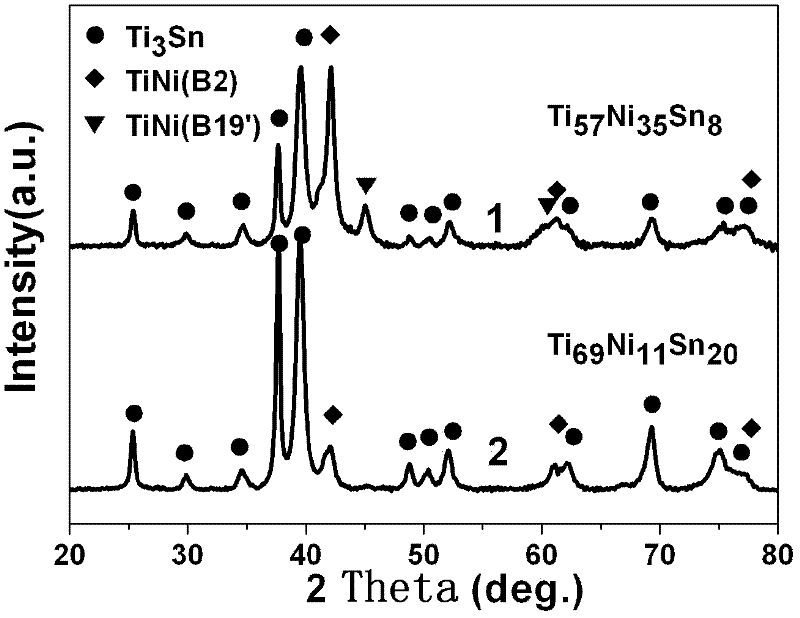

High-strength and high-damping Ti3Sn/TiNi memory alloy composite material

InactiveCN102358925AInterface is well integratedImprove the bonding strength of the interfaceHigh strainHigh intensity

The present invention relates to a novel high-strength and high-damping Ti3Sn / TiNi memory alloy composite material. The Ti3Sn / TiNi memory alloy composite material comprises a Ti element, a Sn element and a Ni element, wherein an atomic ratio of the three elements is (0.25x+y):0.25x:(100-y-0.5x), x comprises one selected from 16-84, y comprises one selected from 45.333-53.818. The memory alloy composite material of the present invention has unique functions of high strength, high plasticity, high strain strengthening, unobvious yielding, low frequency internal friction, high frequency acoustic attenuation and the like. The present invention further provides a preparation method for the Ti3Sn / TiNi memory alloy composite material. The preparation method comprises the following steps: selecting elementary substances of tin, titanium and nickel according to the component ratio of the Ti3Sn / TiNi memory alloy composite material, wherein the purities of the three elementary substances are more than 99 wt.%; placing the three elementary substances to a melting furnace with the vacuum degree more than 10<-1> Pa or under the protection of inert gas to carry out melting to obtain the Ti3Sn / TiNi memory alloy composite material.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method of phenol-formaldehyde resin based composite material sleeper

InactiveCN102744753AOvercome the shortcomingsAvoid disadvantagesFlat articlesDomestic articlesMaterials preparationArchitectural engineering

The invention provides a preparation method of a sleeper, which solves a problem that a composite material sleeper is not available in the prior art. A preparation method of a phenol-formaldehyde resin based composite material sleeper comprises processes of prereg preparation, surface material preparation and composite material preparation in sequence. According to the invention, as a large quantity of wood residues are utilized, low cost and good use performance are achieved, defects of a cement sleeper are overcome, saving and substitution of woods are developed, the wood consumption structure is optimized, the situation of domestic wood resource shortage is relieved to a certain degree, and sustainable utilization of forest resources and the ecological environment are improved.

Owner:NORTHEAST FORESTRY UNIVERSITY

Preparation method of ceramic-based electronic circuit

ActiveCN108558413AAvoid damageHigh dimensional accuracyCircuit susbtrate materialsLaser beam welding apparatusChemical platingMetallurgy

The invention discloses a preparation method of a ceramic-based electronic circuit, comprising the following steps: firstly, a ceramic matrix is prepared by using a conventional ceramic powder; then,a surface protective layer is deposited on the surface of the ceramic matrix; and a three-dimensional shape of the electronic circuit is engraved on the surface of the ceramic matrix by using a laserdevice; the ceramic matrix is immersed in a surface modifier liquid colloid to completely remove the residual surface protective layer; and finally, the electronic circuit itself is prepared by a conventional chemical plating and / or electroplating process. By optimizing combinational design of laser output power, laser engraving line spacing, engraving times and the engraving pattern, the surfaceof the ceramic matrix in the laser engraving area is roughened, thus being beneficial to interface bonding of the electronic circuit and the ceramic matrix and simultaneously reducing chippings generated during the engraving process to the maximum.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

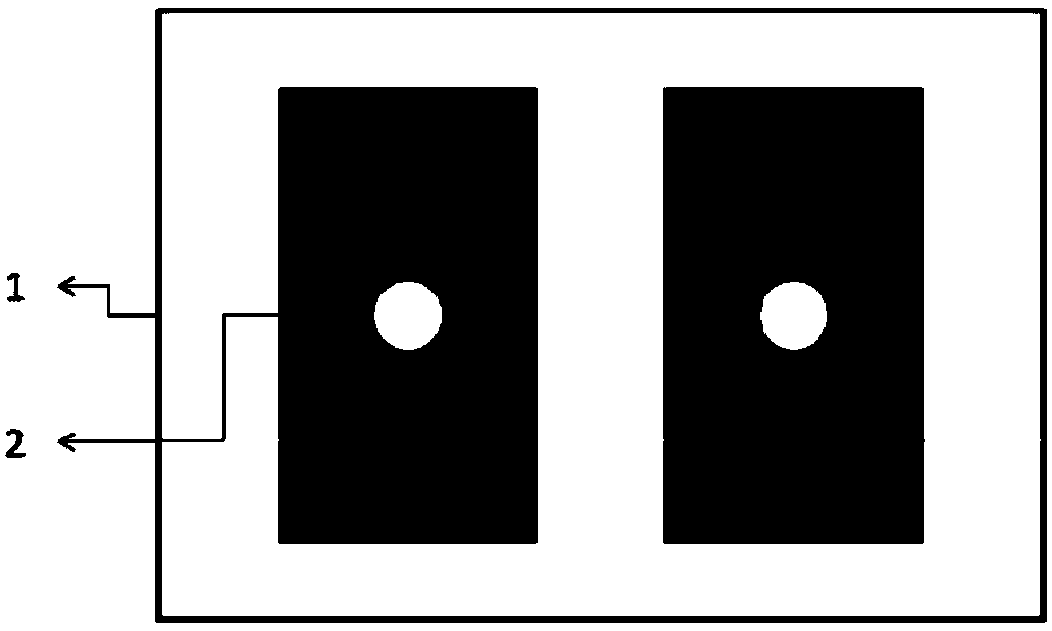

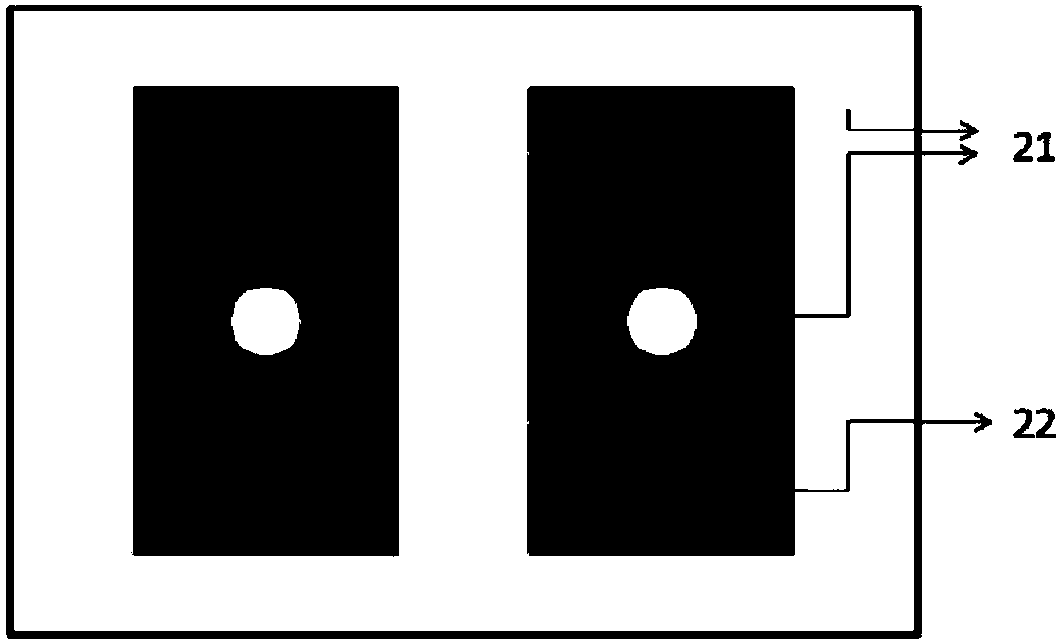

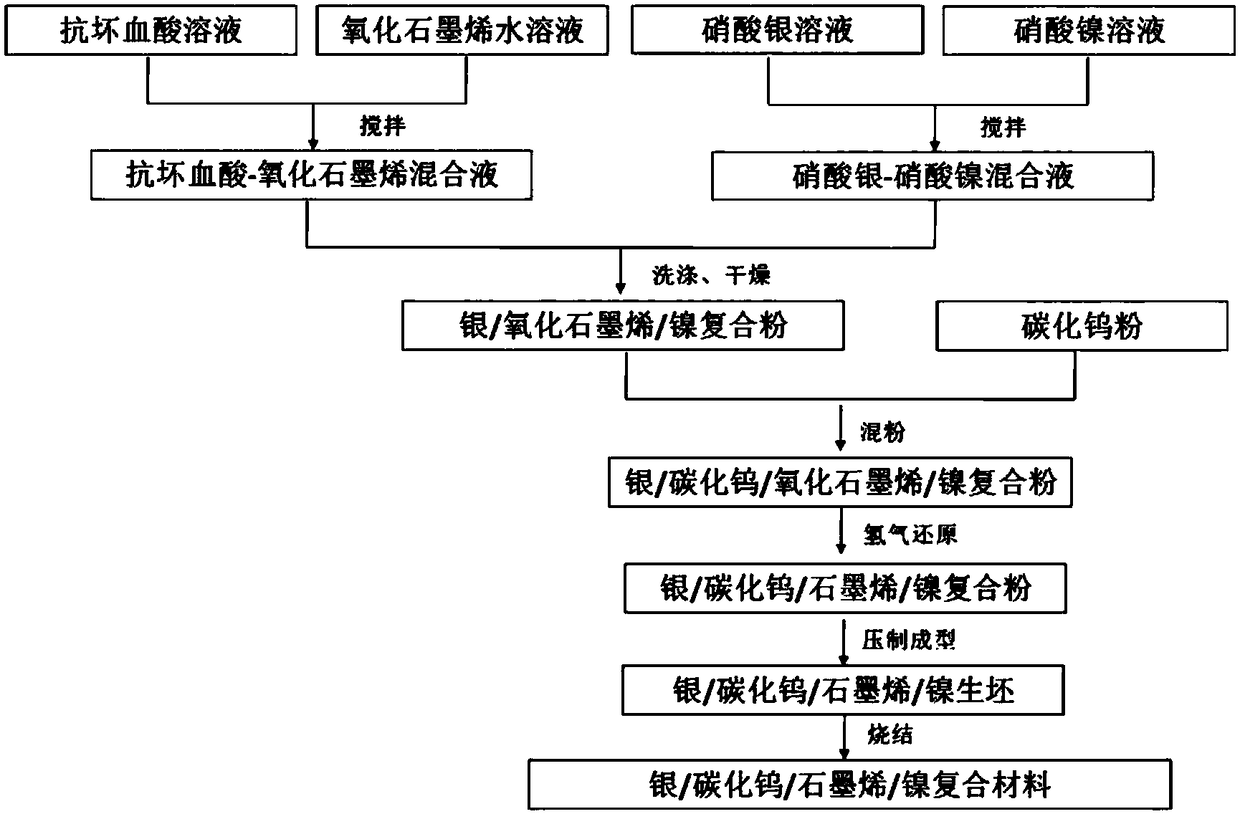

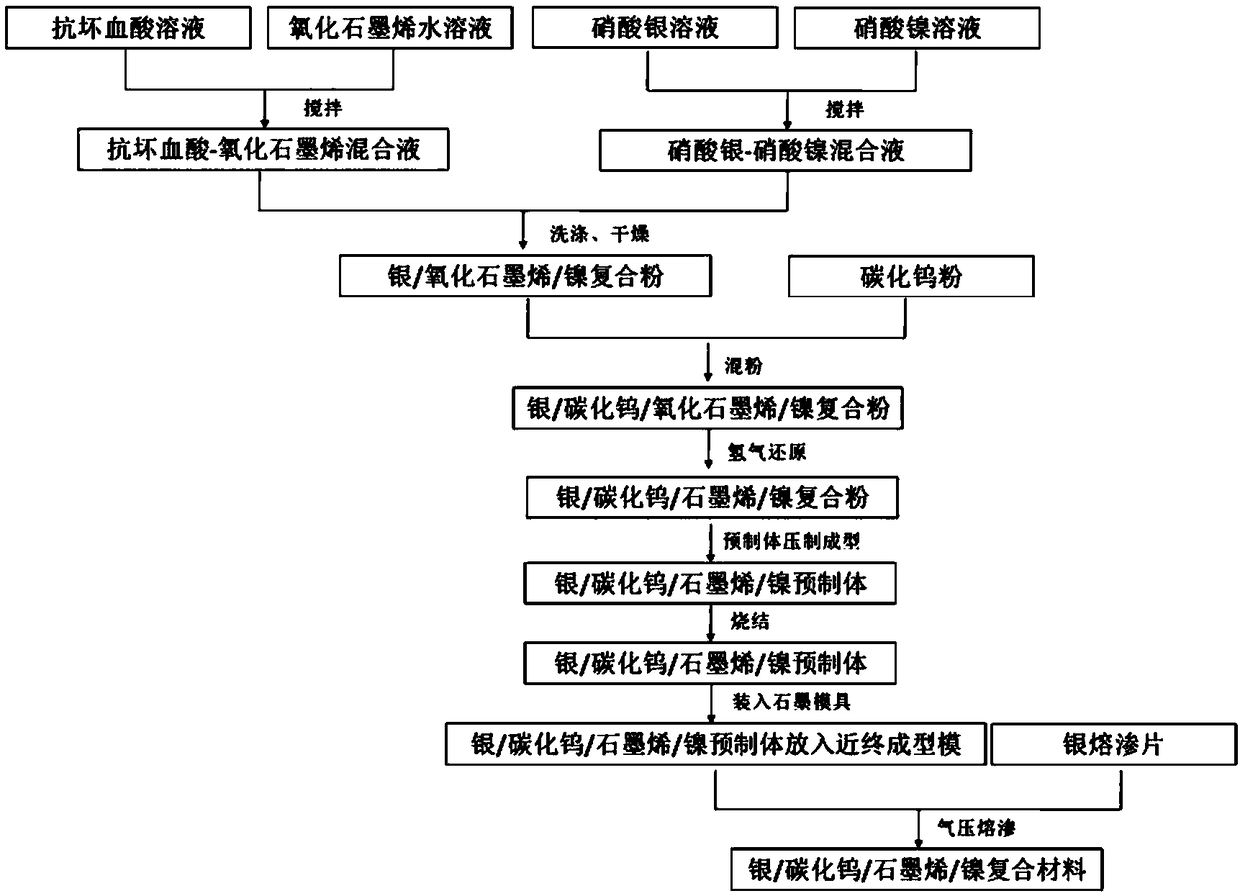

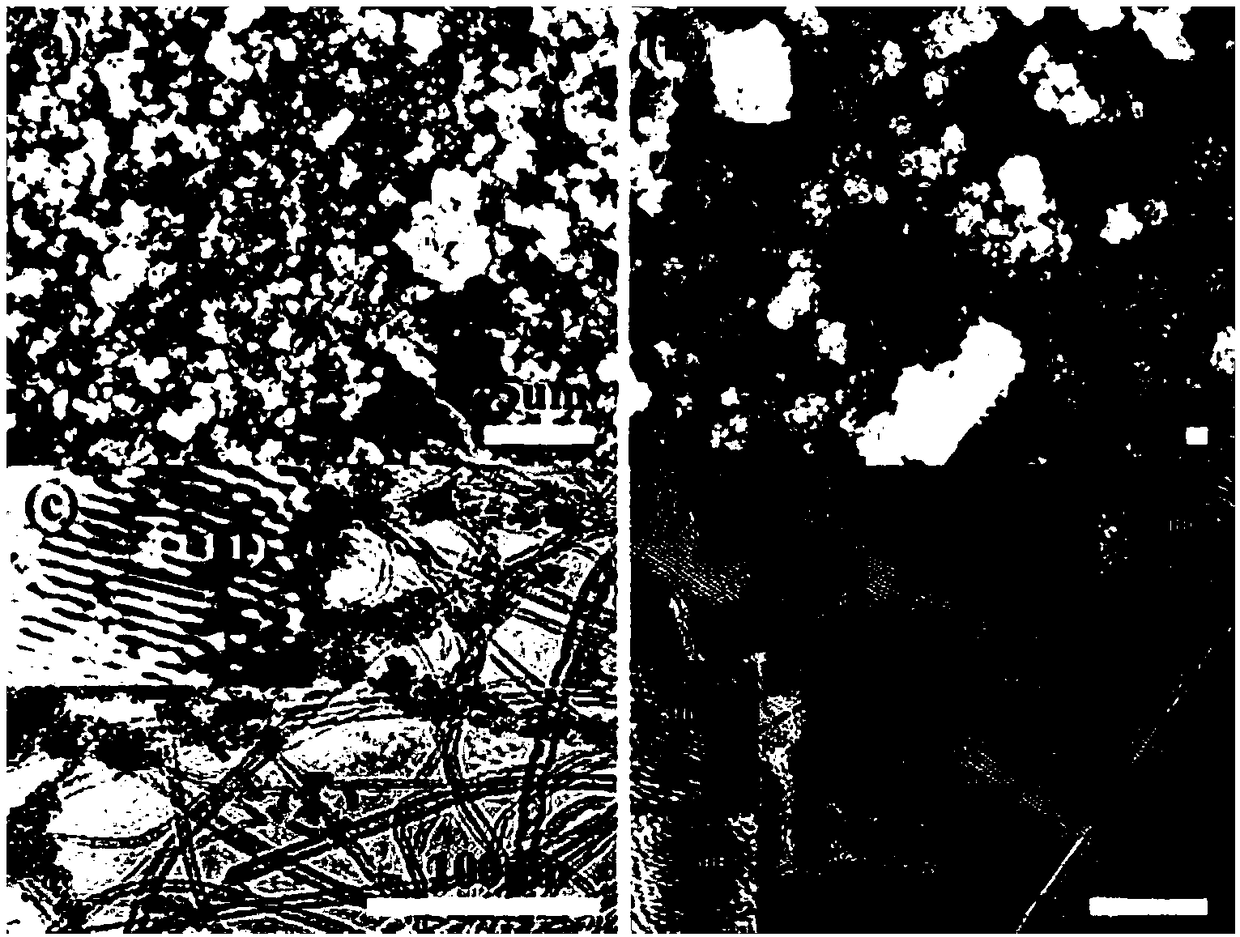

Silver tungsten carbide graphene electrical contact material and preparation method thereof

ActiveCN108531764AInterface is well integratedReduce contact resistanceCvd graphenePowder metallurgy

The invention discloses a silver tungsten carbide graphene electrical contact material and a preparation method of the silver tungsten carbide graphene electrical contact material. Silver is adopted as a base material, tungsten carbide serves as a first reinforcement phase, graphene serves as a second reinforcement phase, and nickel serves as a third reinforcement phase. The invention further discloses the preparation method of the material. Silver / graphene oxide / nickel compound powder is prepared through a chemical method; tungsten carbide powder is subjected to ball milling compounding withthe silver / graphene oxide / nickel compound powder, a silver / tungsten carbide / graphene oxide / nickel compound powder body is obtained, then the compound powder body is subjected to reduction treatment, and a silver / tungsten carbide / graphene / nickel compound powder body is obtained; and the material is prepared through a powder metallurgy technology or prefabricated body pressing and forming or an airpressure infiltration technology. The nickel element is introduced through a chemical coprecipitation method, then through ball milling and powder mixing, the silver, nickel and tungsten carbide forma mechanical alloying structure, good combination between the tungsten carbide and a base body is guaranteed, operation is simple, the process is easy to control, and scaled production is realized easily.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

Preparing method for high-toughness and heat resisting TiC/TiN steel bond hard alloy

The invention relates to a preparing method for a high-toughness and heat resisting TiC / TiN steel bond hard alloy. The preparing method is characterized that one of TiO2 powder, TiH2 powder and Ti powder and colloidal graphite powder are prepared according to the C / Ti atomic ratio of 0.7-1.1, one of the TiO2 powder, the TiH2 powder and the Ti powder and urea ((NH2)2CO) are prepared according to the N / Ti atomic ratio of 0.4-1.1, and accordingly in-situ synthesized TiN mixed powder is prepared; ferro-molybdenum powder, ferro-vanadium powder, ferro-chromium powder, ferro-manganese powder, ferro-silicon powder, iron powder, ferro-boron powder, nickel powder, colloidal graphite and rare earth raw materials are prepared according to the needed proportion for the bonding phase metal chemical component mass ratio to be arranged into a steel ball mill, absolute ethyl alcohol serving as a medium and PVA are added, after ball milling and slurry drying, pressing forming is conducted, and the steel bond alloy is obtained through sintering. The in-situ reaction synthesizing technology and the liquid phase sintering technology are combined, reinforced particles are fine in size, the surfaces are free of sharp corners, base body interface bonding is good, and the interface is clean. Through the method for preparing the steel bond alloy, the comprehensive mechanical performance of the alloy can be improved, cost is low, and the technology is easy and convenient to conduct.

Owner:JIANGSU HUICHENG MACHINERY MFG

Coppered carborundum particle reinforced Mg-based compound material

InactiveCN1667149ASilicon carbide particles are evenly distributedInterface is well integratedCopper platingStructure and function

This invention is coppered silicon carbide particle reinforcing magnesium group composite material used in composite material technique field. Matrix is made by 70~ 95% pure magnesium powders or magnesium alloy powder and 5~30% chemical copper plate silicon carbide particles. The chemical copper plate is one layer copper coat though chemical copper on silicon carbide durface, weight percent of copper is 10~50%, silicon carbide 50~90%. New type magnesium group composite material made in this invention by controlling appropriate copper coat thickness, silicon carbide particle volume portion and powder metallurgical technology and assistant hot extrusion technique, its silicon carbide particle distributed uniformly, interface bonding is good, and it has good mechanical properties and damping capability. High intension, high damping structure and function integrated magnesium group composite material is got and it has wide application prospect.

Owner:NINGBO AODA COPPER PRODS

High-ring-stiffness internal rib-reinforced corrugated pipe and preparation method thereof

The invention relates to a high-ring-stiffness internal rib-reinforced corrugated pipe. The high-ring-stiffness internal rib-reinforced corrugated pipe is prepared by extruding and shaping outer materials and inner materials with an extruder, wherein the outer materials is composed of, by weight part, 85-100 parts of high-density polyethylene, 15-25 parts of polypropylene, 5-15 parts of filler, 1-2 parts of bulking agent and 1-3 parts of color masterbatch; the inner materials is composed of 85-100 parts of high-density polyethylene, 15-25 parts of polypropylene, 1-2 parts of bulking agent and1-3 parts of color masterbatch. Compared with the prior art, the high-ring-stiffness internal rib-reinforced corrugated pipe is higher in ring stiffness, light in weigh per meter and capable of greatly reducing the costs of raw materials.

Owner:湖北盈禄塑胶制品有限公司

Aqueous heat-insulating flame-retardant coating nanomaterial

InactiveCN109401494AExcellent high temperature resistance and heat insulation performanceGood heat insulationCoatingsSodium BentoniteAcrylic resin

The invention provides an aqueous heat-insulating flame-retardant coating nanomaterial. The aqueous heat-insulating flame-retardant coating nanomaterial comprises the following ingredients in parts byweight: 70-80 parts of silicone acrylic resin, 4-8 parts of modified nano silicon carbide, 1-3 parts of silicon dioxide aerogel, 12-18 parts of hollow glass beads, 3-6 parts of Mg-Al hydrotalcite, 1-3 parts of wetting dispersant, 1-3 parts of diatomite, 3-6 parts of potassium titanate whiskers, 0.2-1 part of antifoamer and 30-40 parts of water, wherein the modified nano silicon carbide is mainlyprepared from nano silicon carbide, bentonite and a silane coupler. The coating material has excellent high-temperature resisting and heat-insulating properties and is good in flame retardance and long in service life.

Owner:合肥晓拂新能源有限公司

Molybdenum platinum porous composite material as well as preparation method and application thereof

InactiveCN108220996ASmall particle sizeMany active sitesElectrolytic coatingsElectrodesNew energyCarbon nanotube

The invention provides a molybdenum platinum porous composite material as well as a preparation method and application thereof. The preparation method comprises the following steps that a carbon nanotube is added into a solvent; turbid liquid is formed through ultrasound, and is then dripped on the surface of a pretreated glassy carbon electrode; a carbon nanotube thin layer is formed; a glassy carbon electrode is obtained; the glassy carbon electrode modified by the carbon nanotube is put into electroplating liquid to implement the electroplating; cleaning and natural drying are performed; then, the glassy carbon electrode containing a molybdenum sulfide carbon nanotube composite material is put into a sulfuric acid solution; pt is used as a counter electrode; a saturated calomel electrode is used as a reference electrode; under the certain condition, the glassy carbon electrode coated with a molybdenum platinum / carbon nanotube composite material is obtained; the glassy carbon electrode is cleaned by water and is naturally dried at normal temperature; the composite material is scrapped from the surface of the glassy carbon electrode to obtain a final product. The operation of themethod is simple; the prepared composite material has great advantages in the aspects of electrocatalysis hydrogen production, electrocatalysis oxygen evolution, electrocatalysis oxygen reduction andenergy conversion; the composite material can be applied to the fields of fuel battery and new energy source conversion.

Owner:WENZHOU UNIVERSITY

Nanocrystalline spinel-carbon composite powder and preparation method thereof

The invention relates to nanocrystalline spinel-carbon composite powder and a preparation method thereof. The preparation method comprises the following steps of: mixing magnesium carbonate and metal aluminum powder serving as raw materials in a molar ratio of 3:4 or mixing basic magnesium carbonate and the metal aluminum powder serving as the raw materials in a molar ratio of 3:28 to form mixed raw materials respectively, and adding metallic nickel powder, metallic iron powder and hydroxy-nickel powder in an amount which are respectively 0 to 10 weight percent of the mixed raw materials into the mixed raw materials to form a mixture; and loading the mixture and steel balls into a stainless steel ball-milling tank in a mass ratio of 1:(40-60) for sealing, vacuumizing to reach -0.1 MPa, and putting on a planetary ball mill for ball milling for 2 to 50 hours or vacuumizing to reach -0.1 MPa, introducing one of high-purity nitrogen, high-purity argon and CO2 gas, and putting on the planetary ball mill for the ball milling for 2 to 50 hours. The nanocrystalline spinel-carbon composite powder has the advantages of simple process, easy industrialization, direct preparation, good interface combination and high dispersity.

Owner:WUHAN UNIV OF SCI & TECH

Nano SiO2 modified PTFE needle blend filter material and preparation thereof and application thereof

InactiveCN109157911ASmall sizeLarge specific surface areaDispersed particle filtrationMembrane filtersFiberNano sio2

The invention relates to a nano SiO2 modified PTFE needle blend filter material and a preparation thereof and application thereof. The nano SiO2 modified PTFE needle blend filter material is obtainedby opening, mixing, combing, lapping, pre-needling and main-needling nano SiO2 modified PTFE short fibers and fibers A. The preparation method comprises the steps of preparing the nano SiO2 modified PTFE short fibers and preparing the nano SiO2 modified PTFE needle blend filter material. The nano SiO2 modified PTFE needle blend filter material possesses excellent friction electrification auxiliaryperformance so that fine particulate matters can be effectively captured; and the nano SiO2 modified PTFE needle blend filter material has the advantages of high efficiency, low resistance, stable physical and chemical property, long service life and the like.

Owner:DONGHUA UNIV

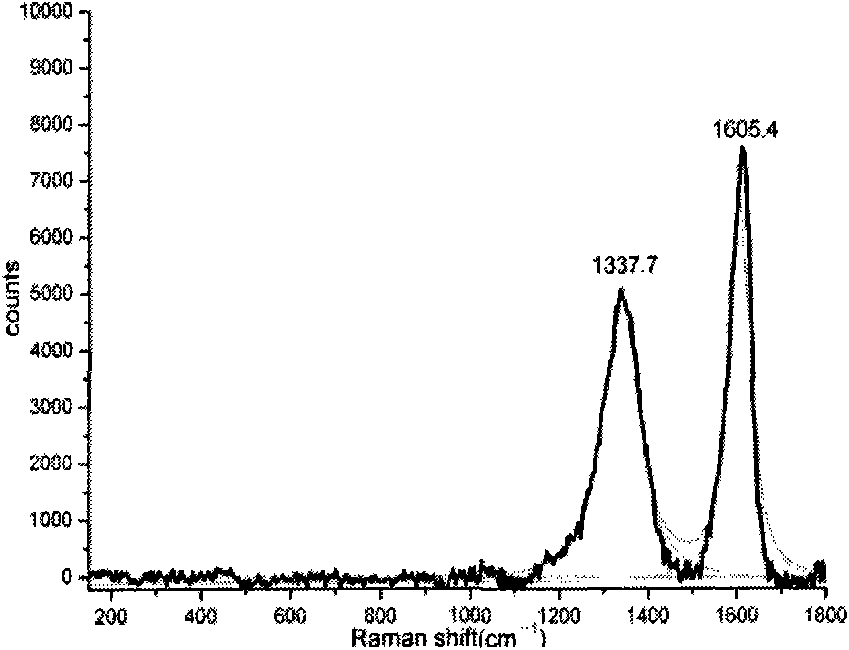

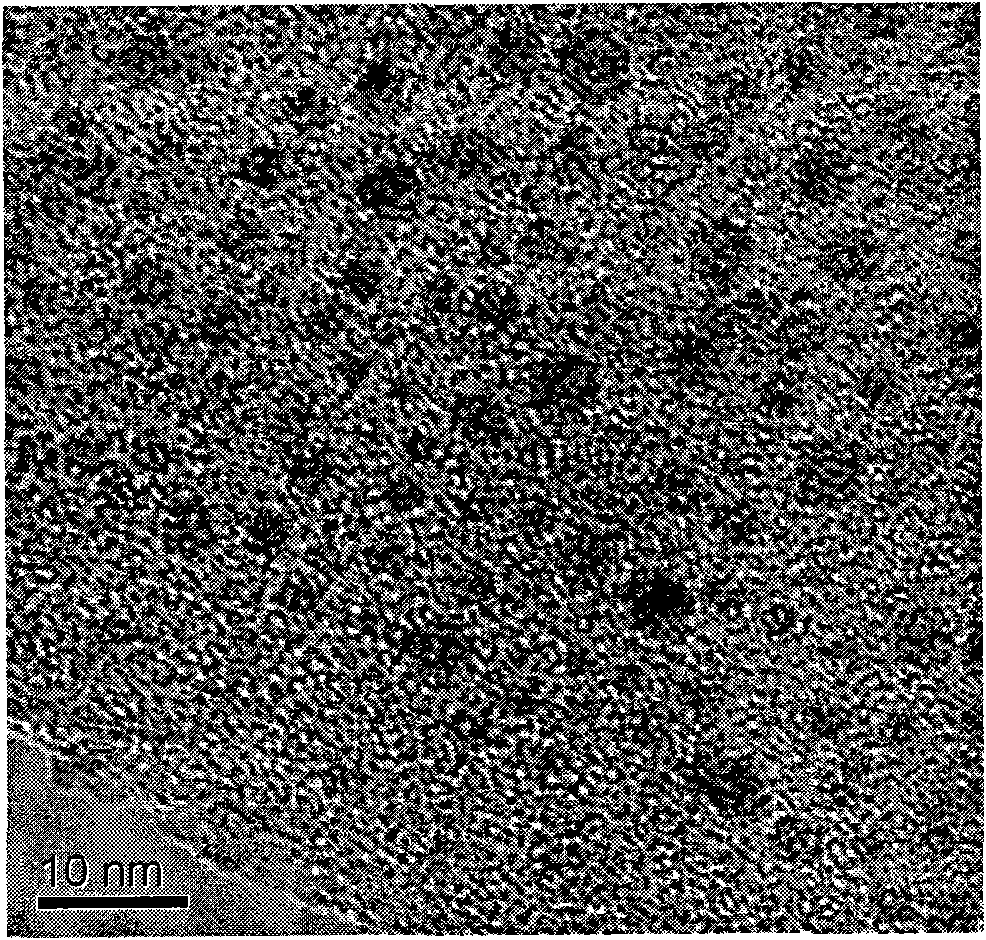

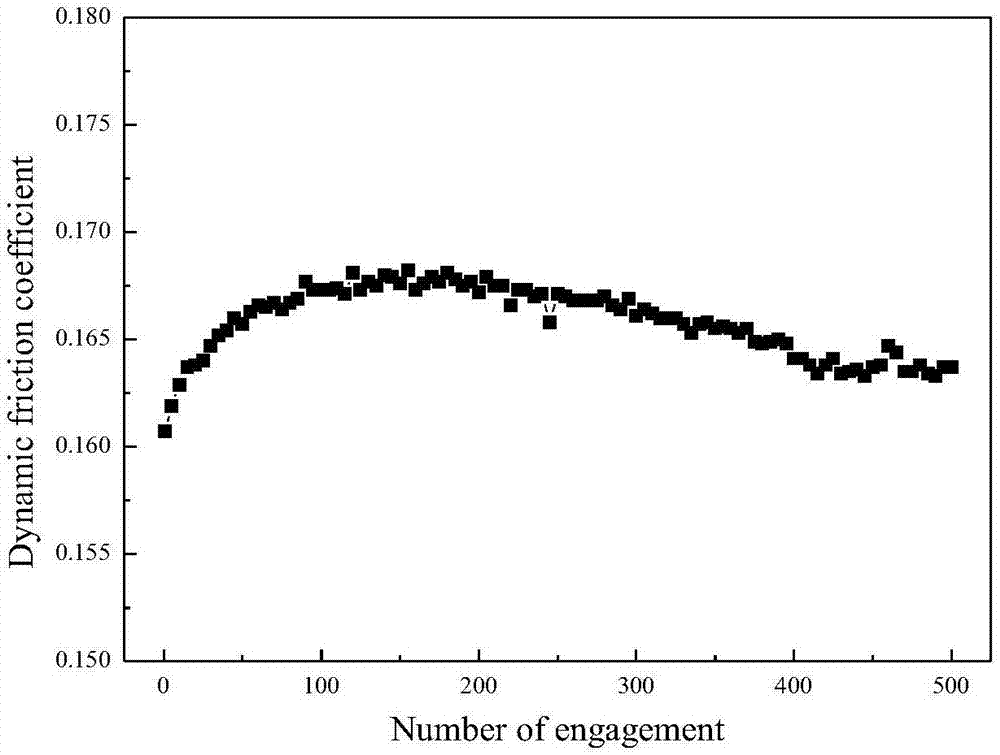

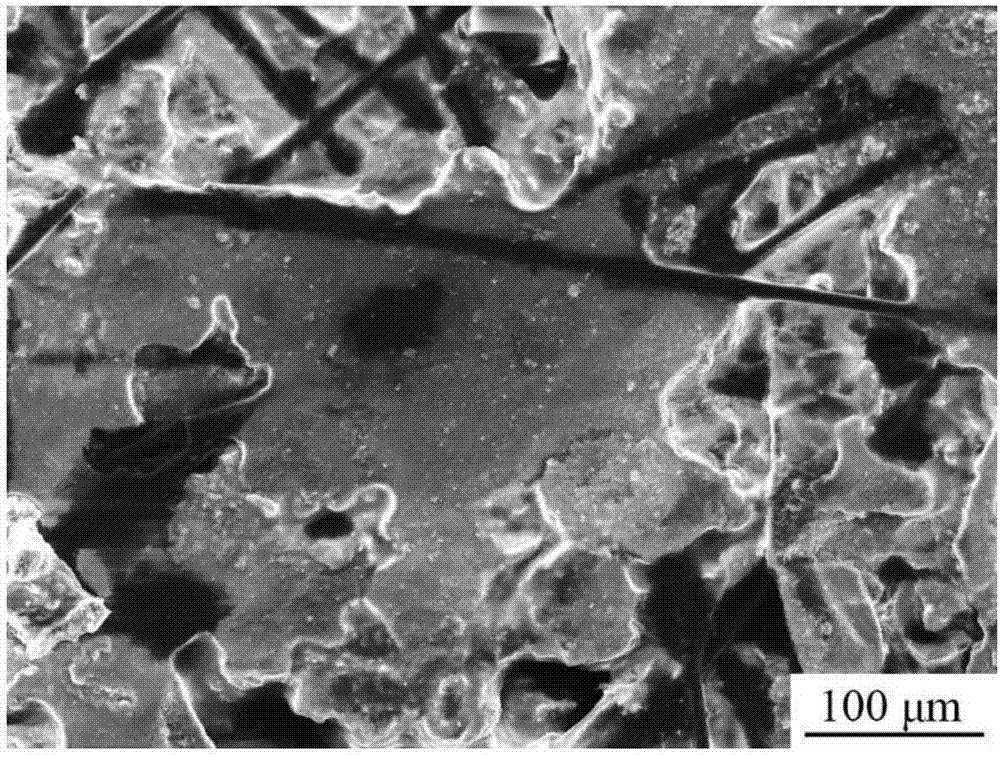

Graphene modified paper-based friction material and preparation method

InactiveCN106930138AIncrease frictionImprove wear performancePaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperState of artFiber

The invention relates to a graphene modified paper-based friction material and a preparation method. Graphene is introduced into a formula system in a friction performance modifier manner, and components of the paper-based friction material comprise, by weight, 15-35% of reinforced fibers, 10-20% of filling materials, 15-25% of friction performance modifiers, 25-45% of binders, and 1-3% of grapheme. The preparation method comprises the steps of evenly dispersing the reinforced fibers, the friction performance modifiers and the filling materials into water, obtaining a friction material prefab in a papermaking moulding manner and drying the friction material prefab, and obtaining a paper-based friction piece through resin impregnation and hot-pressing solidification. Compared with a traditional preparation method, according to the prepared paper-based friction material, friction performance and abrasion performance of the paper-based friction material can be both promoted, the dynamic friction coefficient is increased from 0.08-0.12 to 0.15-0.17, and the wear rate is reduced from <=6*10<-8>cm<3> / J of the prior art to <=3*10<-8>cm<3> / J.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

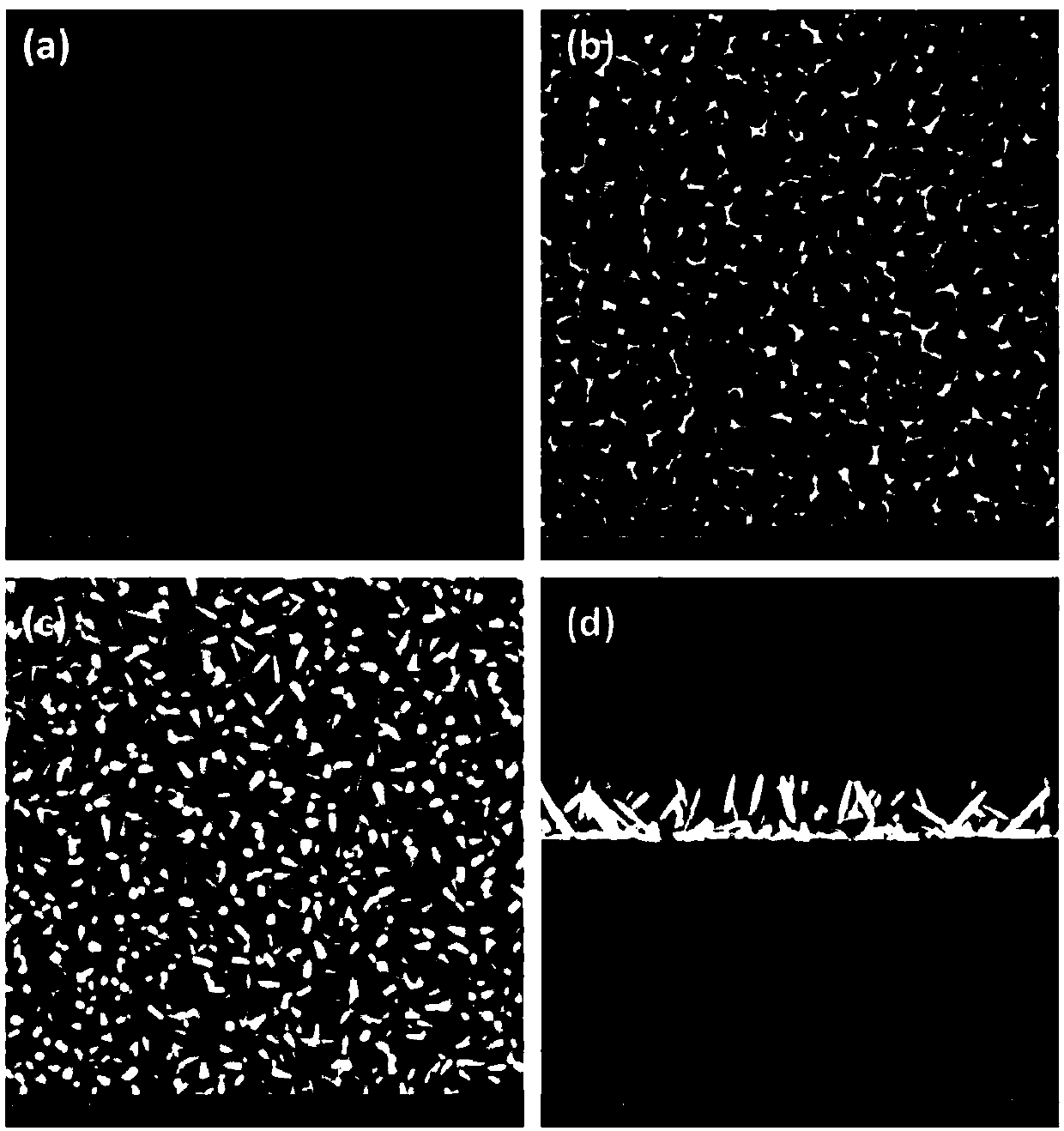

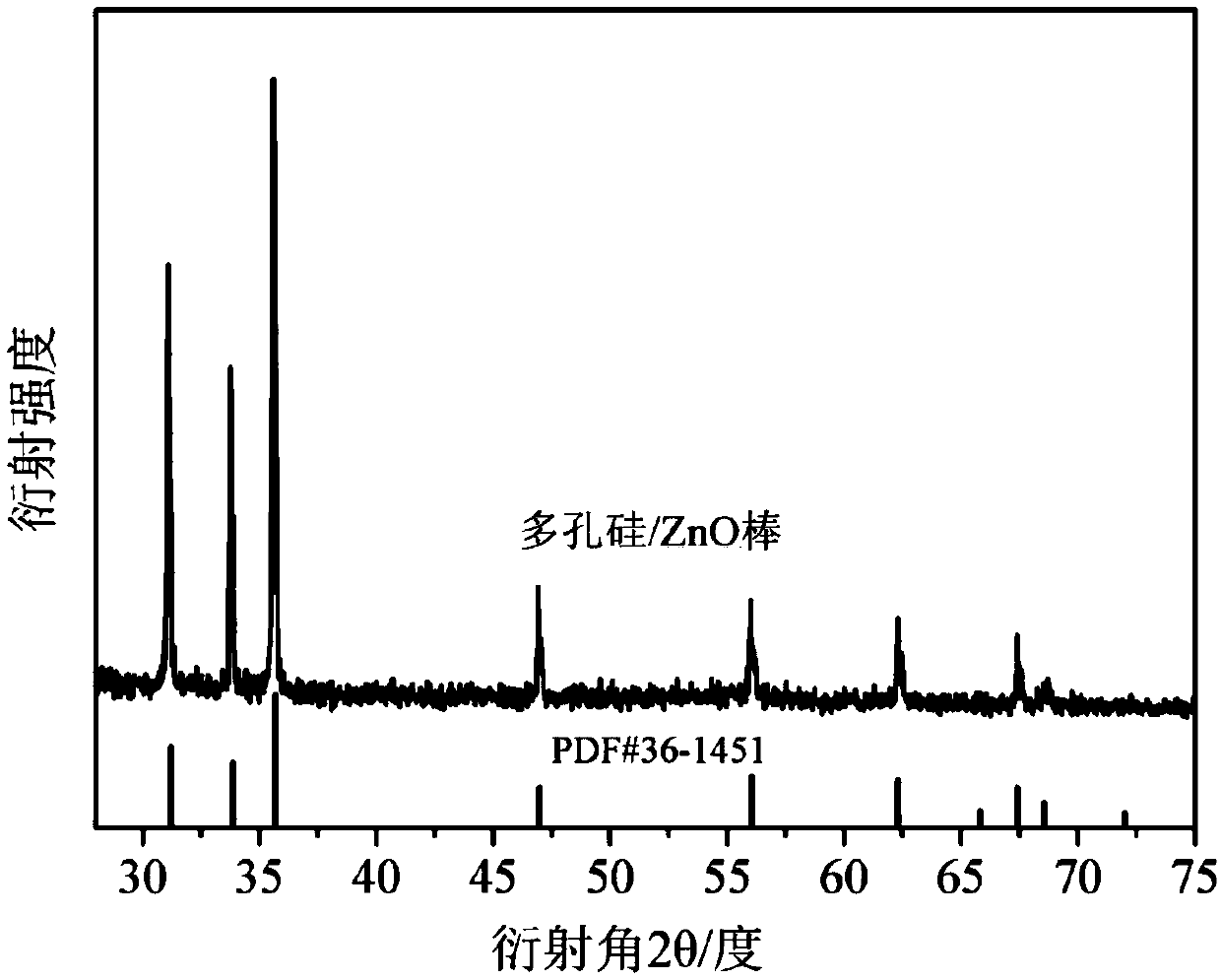

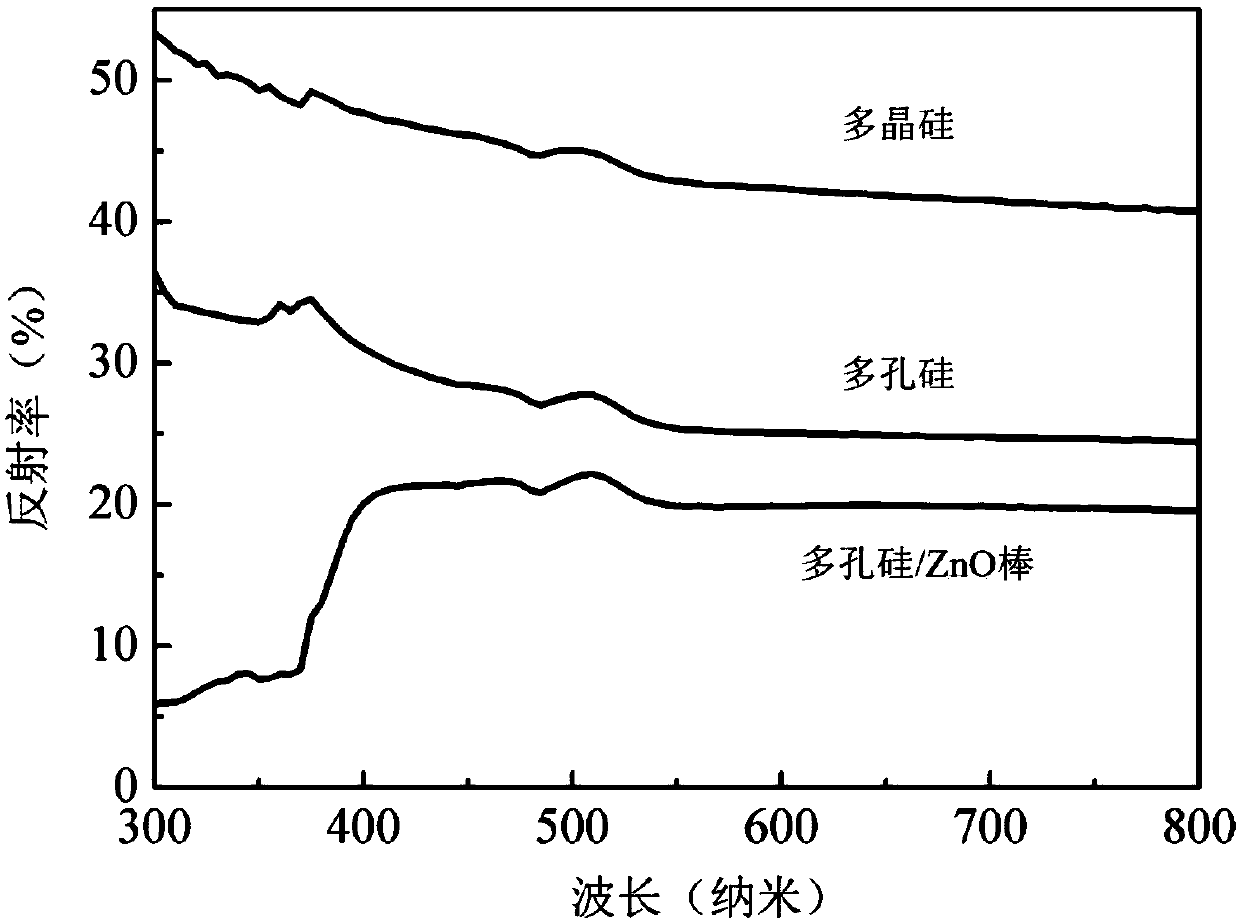

Preparation method for porous silicon/ZnO nanorod composite photo-anode

InactiveCN109569563APromote absorptionImprove photoelectric performanceMetal/metal-oxides/metal-hydroxide catalystsWater bathsZinc nitrate

The invention relates to a preparation method for a porous silicon / ZnO nanorod composite photo-anode. The preparation method comprises the following steps: (1) ultrasonic-washing a porous silicon substrate successively in acetone, absolute ethyl alcohol and deionized water, and treating by using potassium permanganate solution, washing, to obtain the completely washed porous silicon substrate; (2)preparing uniform aqueous solution of zinc nitrate hexahydrate, adding hexamine, stirring, to obtain uniformly mixed solution; and (3) enabling the porous silicon substrate to be vertically immergedin the mixed solution, performing a water bath reaction, washing, and airing, to obtain the porous silicon / ZnO nanorod composite photo-anode. The preparation method is simple, and low in cost. A ZnO seed crystal is not needed, and porous silicon is selected as the substrate. An obtained sample has very high light current density.

Owner:DONGHUA UNIV

Brazing method and solder preparation method for high-volume-fraction SiCp/Al composite

InactiveCN106825984AInterface is well integratedClosely connectedWelding/cutting media/materialsSoldering mediaMelt spinningBrazing

The invention relates to a brazing method and a solder preparation method for a high-volume-fraction SiCp / Al composite. A solder is an Al-Cu-Si-Mg quenched foil-like solder, the solder preparation method comprises the steps as follows: 1, material mixing; 2, preparation of a solder blank; 3, refinement of the solder into an alloy column; 4, quick melt-spinning of the alloy column for preparation of the quenched foil-like solder. The brazing method of the high-volume-fraction SiCp / Al composite comprises the steps as follows: 1, the surface of the SiCp / Al composite is pretreated; 2, a Ti active layer is formed on the pretreated surface of the SiCp / Al composite through magnetron sputtering; 3, a to-be-brazed surface is pretreated; 4, vacuum brazing is performed. The quenched foil-like solder and the Ti active layer can be subjected to a metallurgical reaction to form a compact reaction layer, brazing seams are well formed, joints are higher in shear strength and air tightness, and the brazing method can be widely applied to the welding field of the high-volume-fraction SiCp / Al composite.

Owner:HENAN POLYTECHNIC UNIV

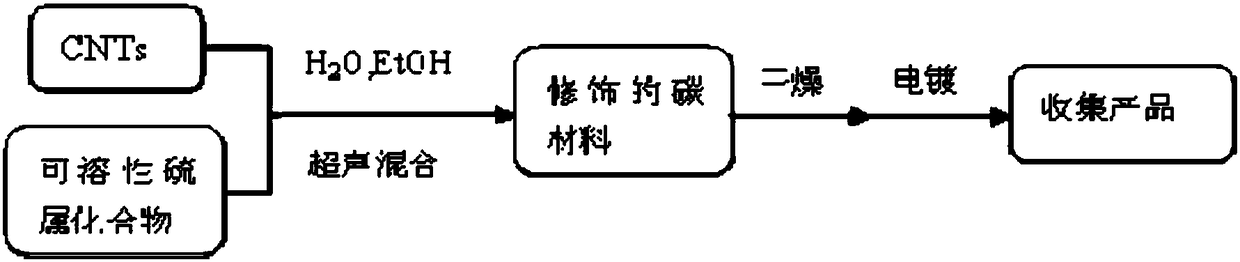

Carbon composite material modified by chalcogen compound and transition metal as well as preparation method and application of carbon composite material

ActiveCN108273524AUniform shapeThe size is easy to controlCell electrodesCatalyst activation/preparationSupporting electrolyteCarbon composites

The invention provides a carbon composite material modified by a chalcogen compound and a transition metal as well as a preparation method and application of the carbon composite material. The preparation method comprises the following steps: adding a mixture of carbon nanotubes and the soluble chalcogen compound into a solvent, performing ultrasonic treatment to form a suspension liquid, adding the suspension liquid dropwise to the surface of a pretreated glassy carbon electrode, and performing natural drying to form a uniform carbon nanotube thin layer, so as to obtain a glassy carbon electrode modified by a mixture of the carbon nanotubes and the chalcogen compound; adding a transition metal salt and a supporting electrolyte into deionized water, and adjusting the pH to 0-13 by using sulfuric acid to obtain an electroplating solution; and placing the glassy carbon electrode modified with the mixture of the carbon nanotubes and the chalcogen compound into the electroplating solution,performing electroplating, performing washing by using water, and performing natural drying at normal temperature to obtain the final product. The method provided by the invention is simple in operation, and the obtained composite material has great advantages in catalysis of hydrogen evolution and energy conversion, and can be applied to the fields of electro-catalyzing water decomposition for hydrogen production and photoelectric conversion.

Owner:WENZHOU UNIVERSITY

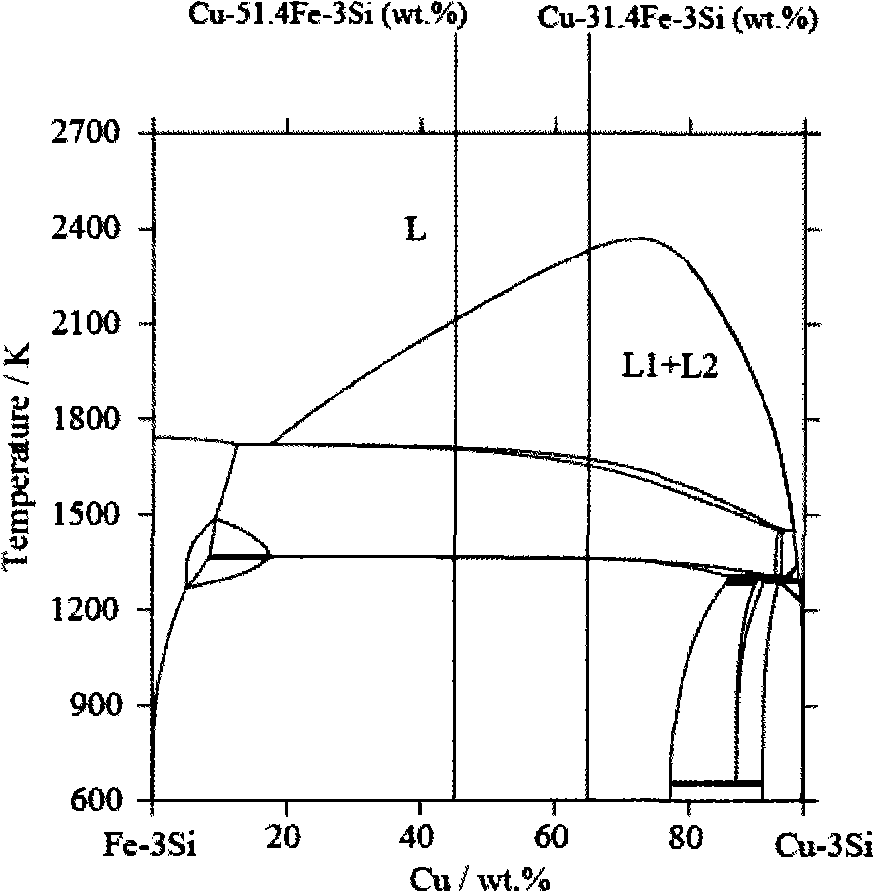

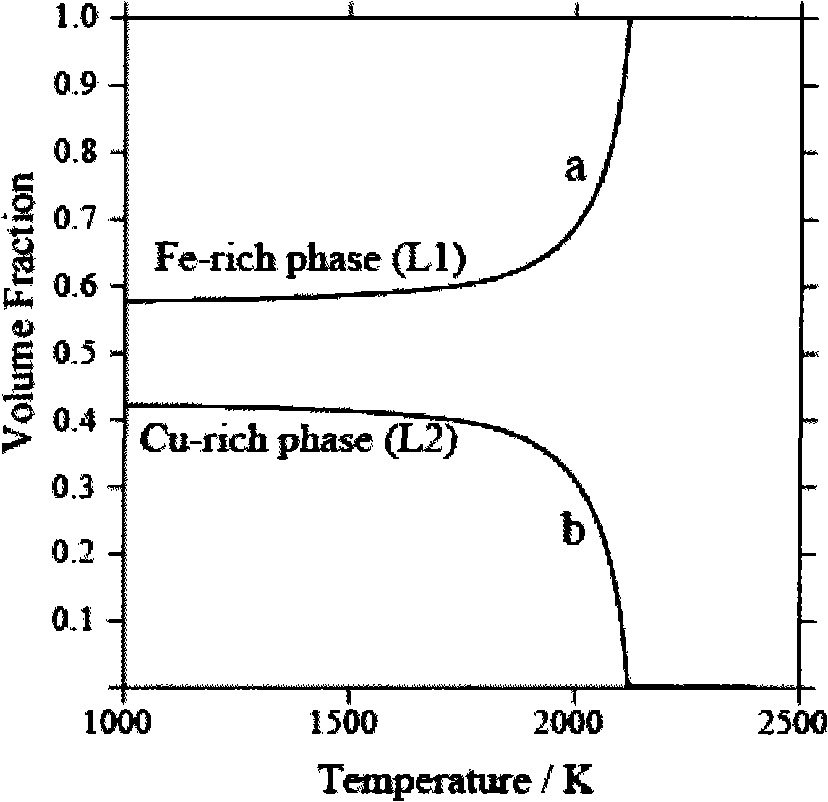

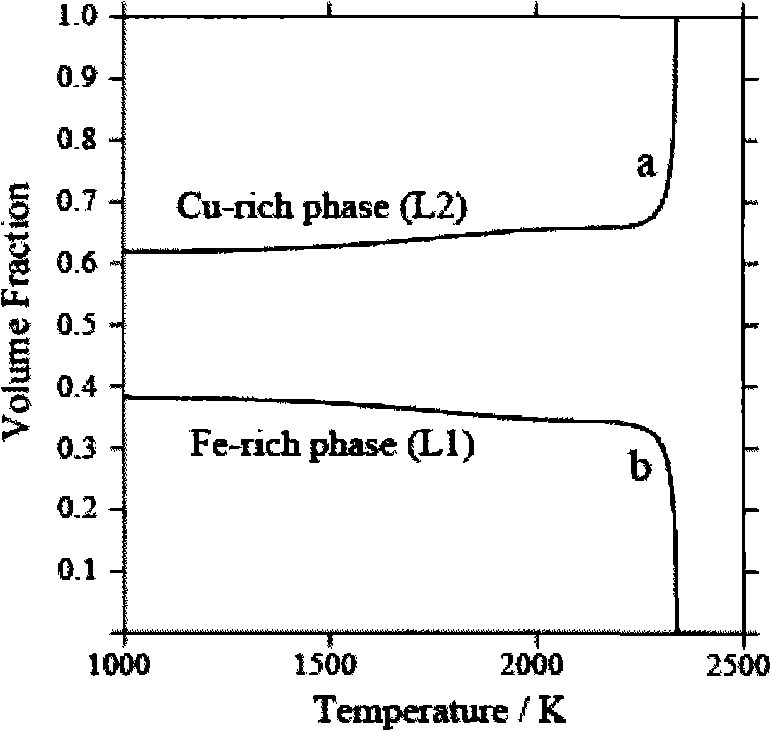

Copper-base alloy/iron-base martensite alloy composite powder and method of preparing the same

InactiveCN101274369AInterface is well integratedEnhanced interface bindingMetal layered productsCopperAlloy composite

The invention provides a copper-based alloy / iron-based martensitic alloy compound powder and a preparation method thereof, which relate to a compound powder material. The copper-based alloy / iron-based martensitic alloy compound powder which is simple and cheap and the preparation method thereof are provided. The compound powder comprises an inner core and an outer layer, wherein, the inner core is an iron-based martensitic alloy inner core or a copper-based alloy inner core, the outer layer is a copper-based alloy layer or a compound layer of an iron-based martensitic alloy layer and the copper-based alloy layer. The compound layer of the iron-based martensitic alloy layer and the copper-based alloy layer is composed by compounding the iron-based martensitic alloy layer and the copper-based alloy layer, wherein, the iron-based martensitic alloy layer is arranged at the inner layer of the compound layer and the copper-based alloy layer is arranged at the outer layer of the compound layer. Metals of copper, iron and silicon are weighted according to the preset composition of the copper-based alloy / iron-based martensitic alloy compound powder to be put into a vacuum induction furnace for being smelted to obtain alloy liquid; the smelted alloy liquid is poured into a liquid receiving bucket and inert gas is used for blowing the liquid at the instant when the liquid inflows into an atomizing chamber, and then the copper-based alloy / iron-based martensitic alloy compound powder is obtained.

Owner:XIAMEN UNIV

Composite encapsulating material with high heat conduction activity and preparation method thereof

ActiveCN107841669AImprove thermal conductivitySmall expansion coefficientSemiconductor/solid-state device detailsSolid-state devicesThermal expansionMetal matrix composite

The invention discloses a composite encapsulating material with high heat conduction activity and a preparation method thereof, and belongs to the field of metal based composite materials. The composite material consists of SnAg4Ti4 alloy powder, aluminum powder and diamond particle reinforcer, wherein volume percentage of diamond particles is 50%-70%, volume percentage of aluminum powder is 25%-49%, and volume percentage of SnAg4Ti4T alloy powder is 1%-5%. A preparation method for the composite encapsulating material comprises the following steps: preparing active brazing filler metal SnAg4Ti4 alloy powder through a vacuum gas-atomization powdering furnace, mechanically mixing powder, and putting mixed powder into a discharge plasma sintering furnace to prepare a diamond / aluminum composite material. The sintered composite material is relatively good in interface bonding, is relatively high in compactness, has heat conductivity of 703W / m.K, has a thermal expansion coefficient reduced to 7.9*10<-6> / K, and has compactness of 97.8% or more. The preparation method is strong in operability, is simple in process, and can be used for the fields of electronic encapsulating and the like.

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com