Preparation method for porous silicon/ZnO nanorod composite photo-anode

A technology of porous silicon and nanorods is applied in the field of preparation of porous silicon/ZnO nanorod composite photoanode, and achieves the effects of easy availability of raw materials, simple preparation method and improved absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Polycrystalline silicon is etched by metal-assisted wet method to obtain porous silicon; the porous silicon substrate is ultrasonically washed in acetone, absolute ethanol, and deionized water in sequence, and 0.1580 g of potassium permanganate is added to 100 ml of water to form a 0.01 mol / L uniform solution, then put the porous silicon into the solution for 30 minutes and then clean it.

[0028] (2) Add 1.4875 g of zinc nitrate hexahydrate to 100 ml of water to form a uniform solution of 0.05 mol / L, then add 0.7009 g of hexamethylenetetramine and stir to form a mixed uniform solution.

[0029] (3) Vertically immerse the porous silicon in step (1) into the mixed solution of step (2), and react in a water bath at 90°C for 2 hours. After the reaction, wash the porous silicon with deionized water and dry it to obtain porous silicon / ZnO nanometer Rod composite photoanode.

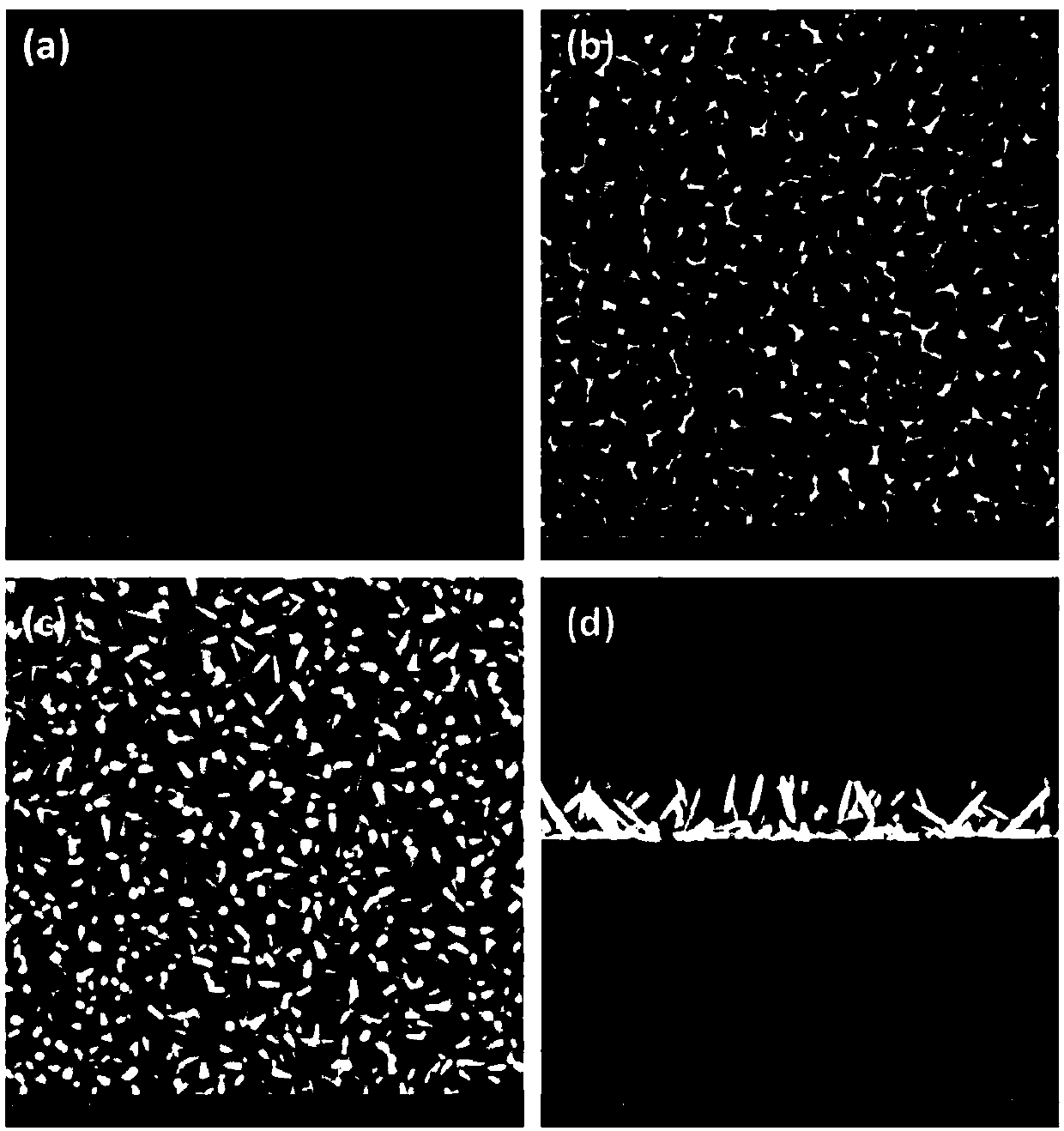

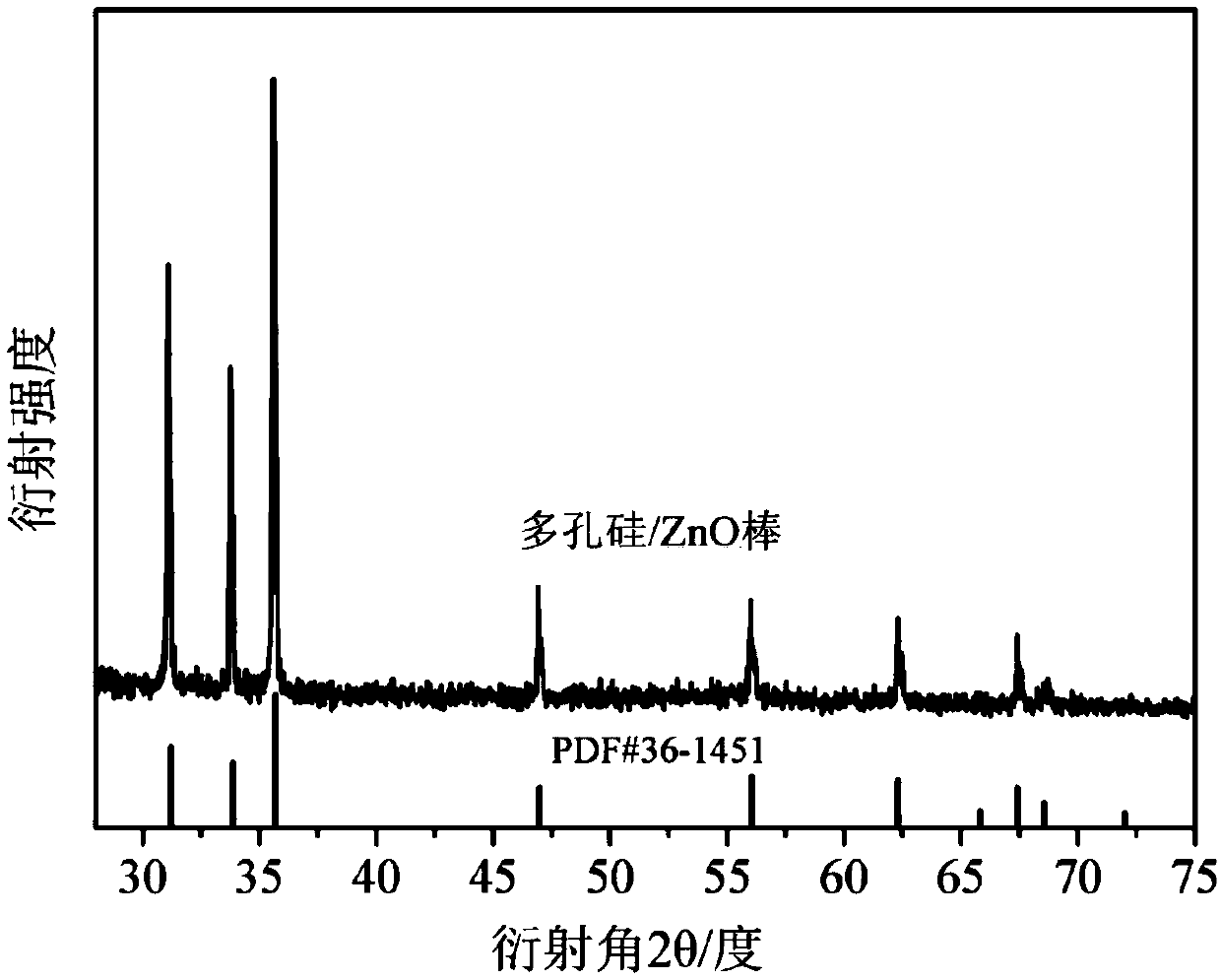

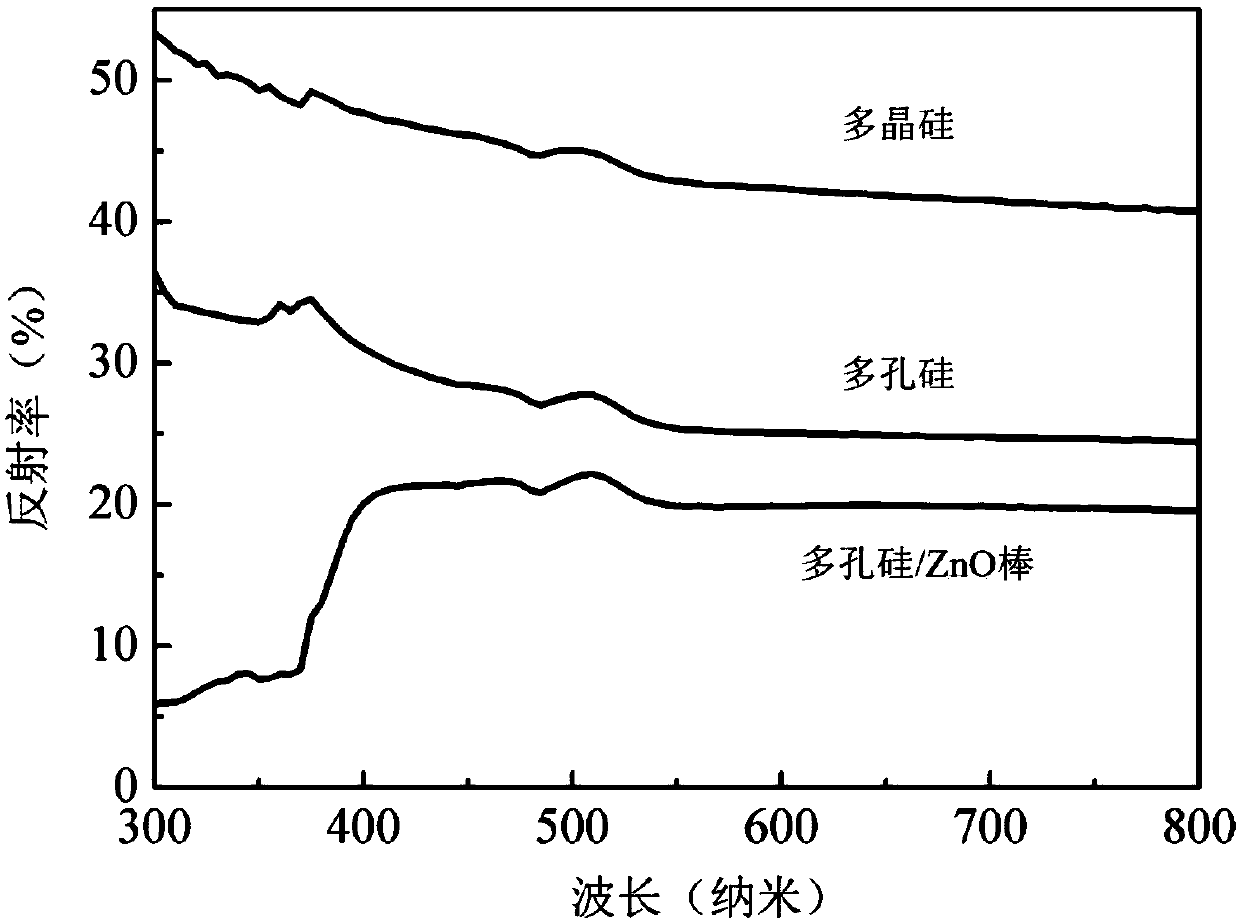

[0030] The SEM photos of polysilicon in this embodiment before and after metal-assisted wet et...

Embodiment 2

[0036] (1) Polycrystalline silicon is etched by metal-assisted wet method to obtain porous silicon; the porous silicon substrate is ultrasonically washed in acetone, absolute ethanol, and deionized water in sequence, and 1.5803 potassium permanganate is added to 100ml of water to form a 0.1mol / L homogeneous solution, then put the porous silicon into the solution for 20min and then clean it.

[0037] (2) Add 0.2975g of zinc nitrate hexahydrate to 100ml of water to form a uniform solution of 0.01mol / L, then add 0.1402g of hexamethylenetetramine and stir to form a mixed uniform solution.

[0038] (3) Vertically immerse the porous silicon of step (1) into the mixed solution of step (2), and react in a water bath at 70°C for 6 hours. After the reaction, the porous silicon is washed with deionized water and dried to obtain porous silicon / ZnO nanometer Rod composite photoanode.

[0039] The sample of this embodiment is used as the working electrode, the Pt sheet is used as the coun...

Embodiment 3

[0041] (1) Polysilicon is etched by metal-assisted wet method to obtain porous silicon; the porous silicon substrate is ultrasonically washed in acetone, absolute ethanol, and deionized water in sequence. Add 0.0790g of potassium permanganate into 100ml of water to form a uniform solution of 0.005mol / L, then put the porous silicon into the solution for 40min and then clean it.

[0042] (2) Add 5.9500 g of zinc nitrate hexahydrate to 100 ml of water to form a uniform solution of 0.2 mol / L, then add 2.8036 g of hexamethylenetetramine and stir to form a mixed uniform solution.

[0043](3) Vertically immerse the porous silicon in step (1) into the above solution, and react in a water bath at 95° C. for 1 h. After the reaction, the porous silicon was washed with deionized water and dried to obtain a porous silicon / ZnO nanorod composite photoanode.

[0044] The sample of this embodiment is used as the working electrode, the Pt sheet is used as the counter electrode, the saturated c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com