Patents

Literature

398 results about "Initial permeability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

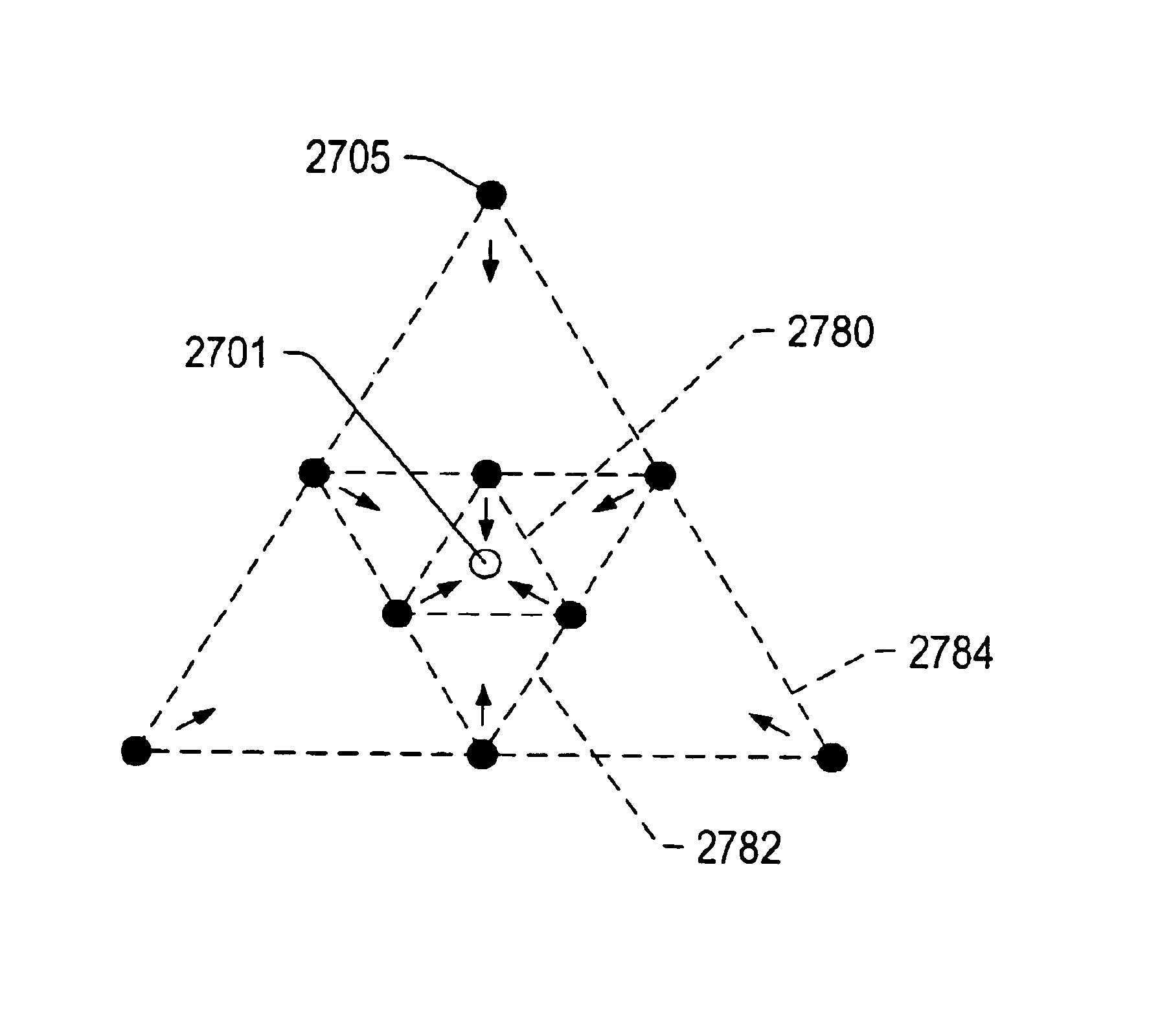

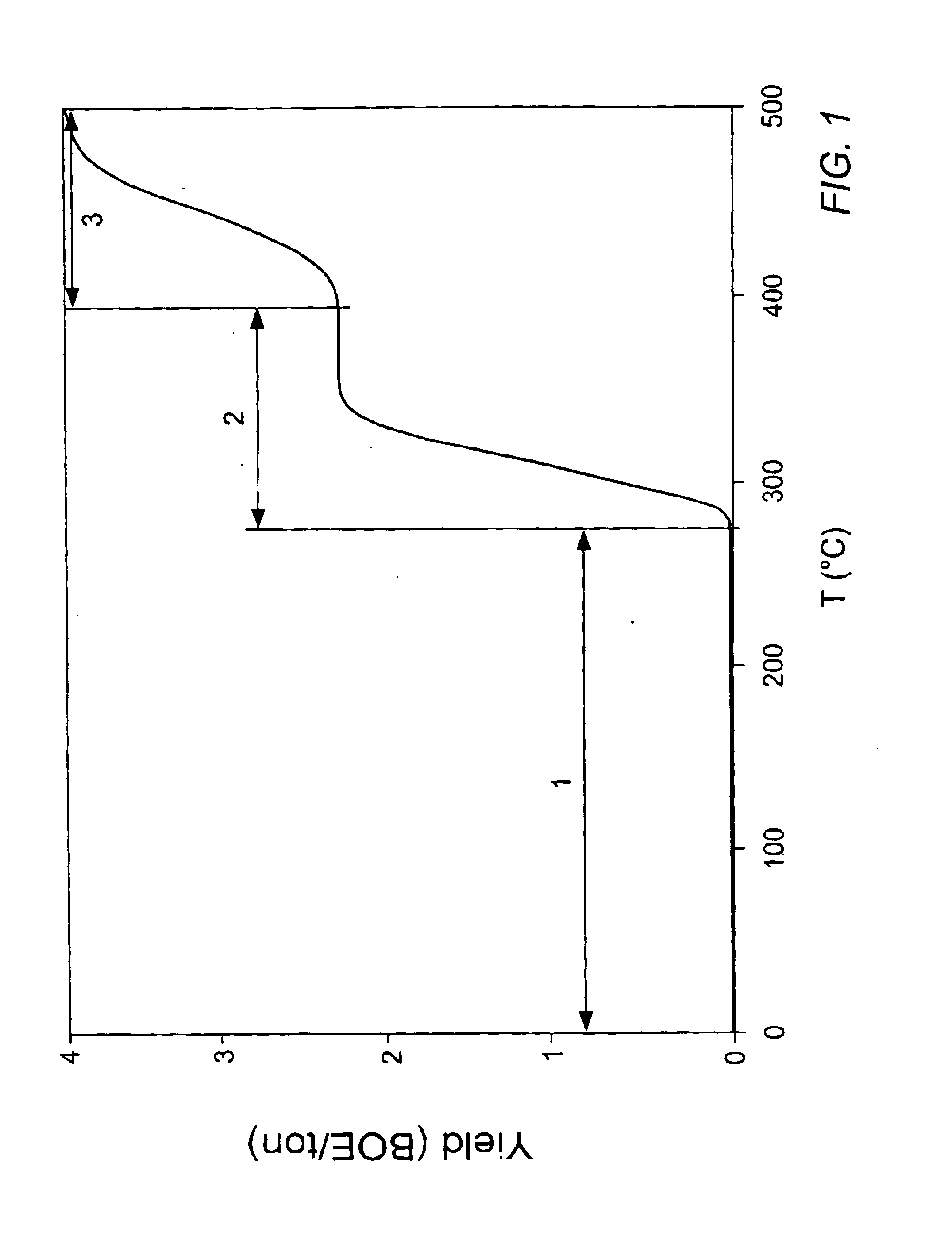

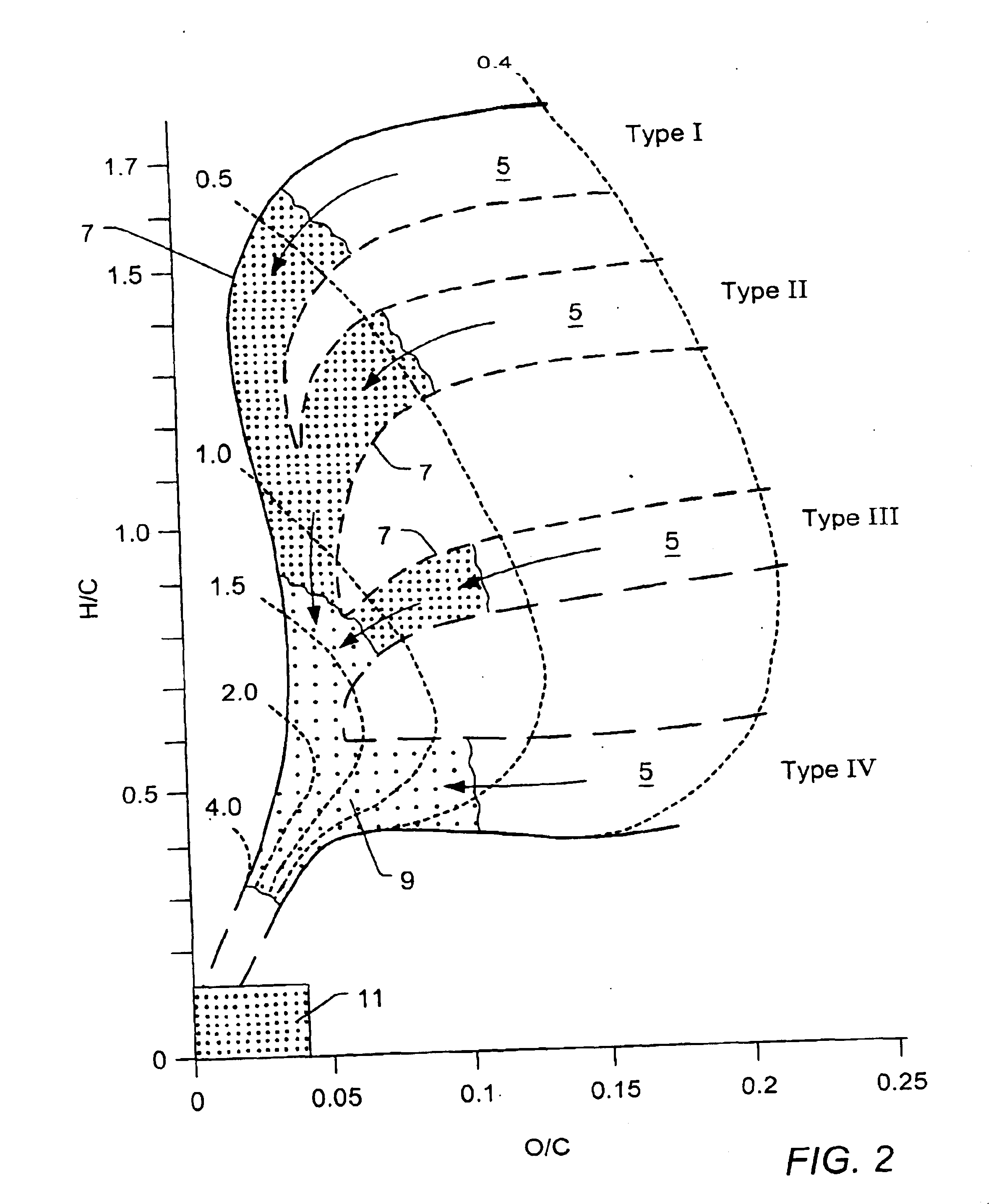

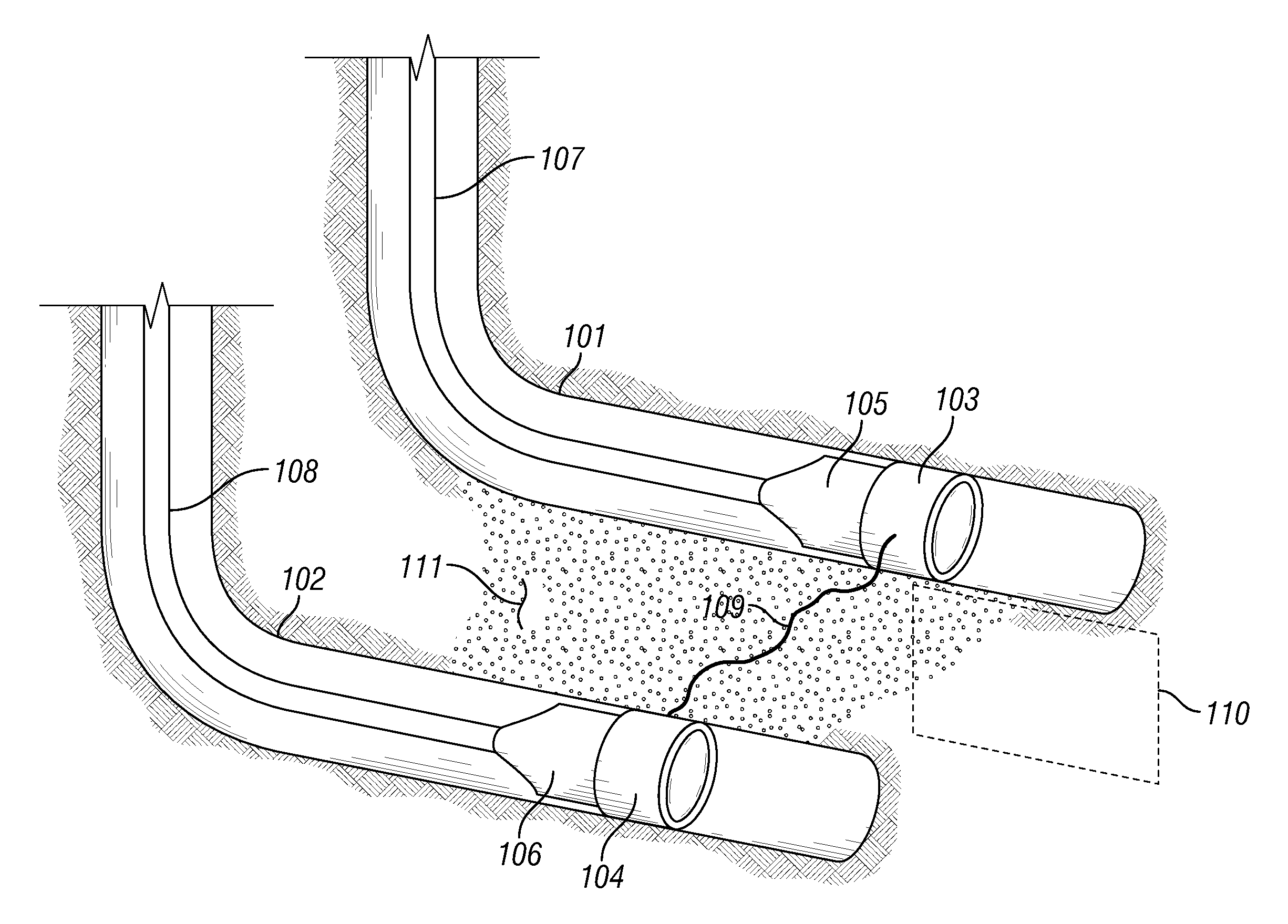

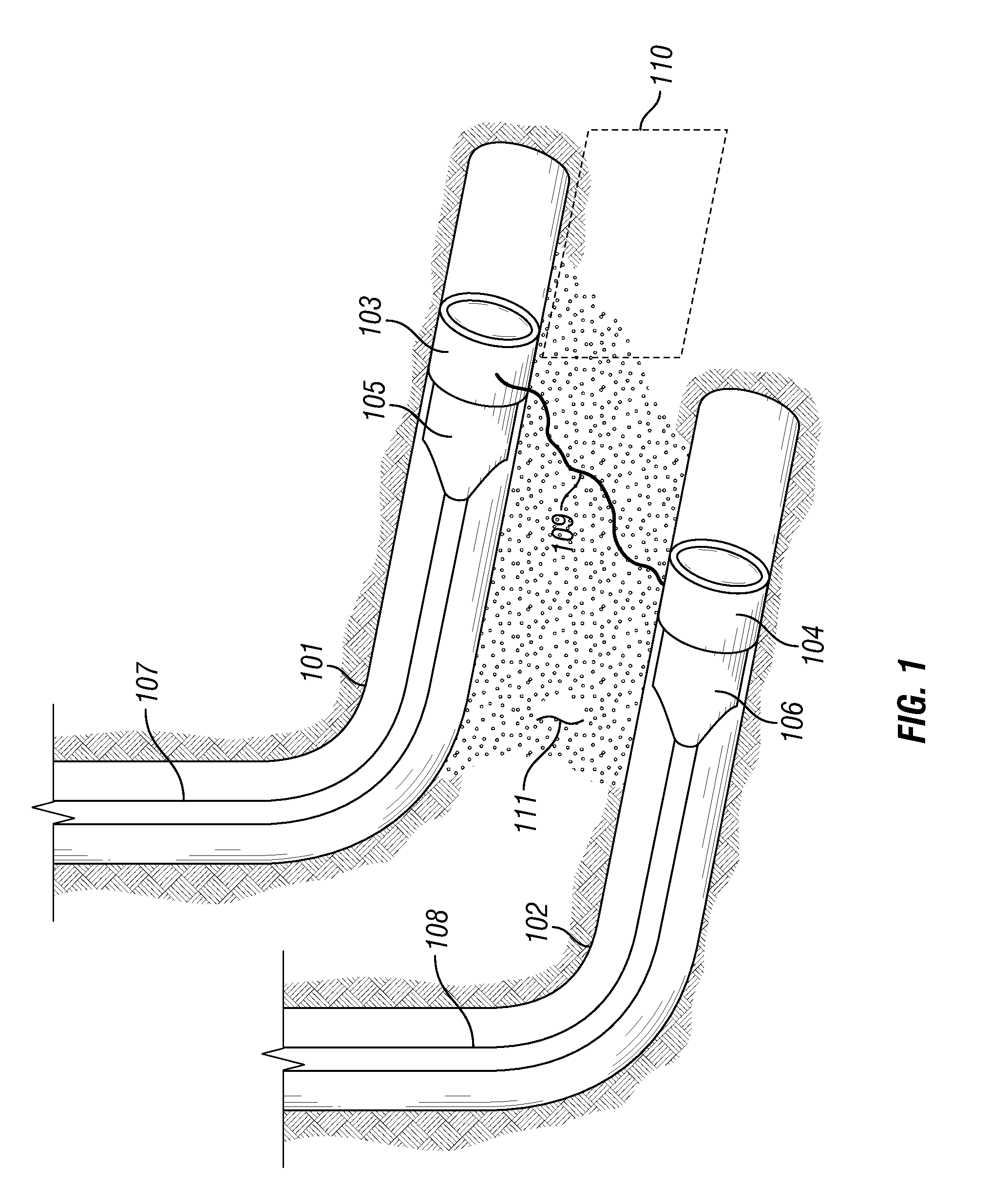

In situ thermal processing of a coal formation to increase a permeability/porosity of the formation

InactiveUS6866097B2Reduce the temperatureHigh strengthSurveyCombustion processPorosityInitial permeability

Owner:SHELL OIL CO

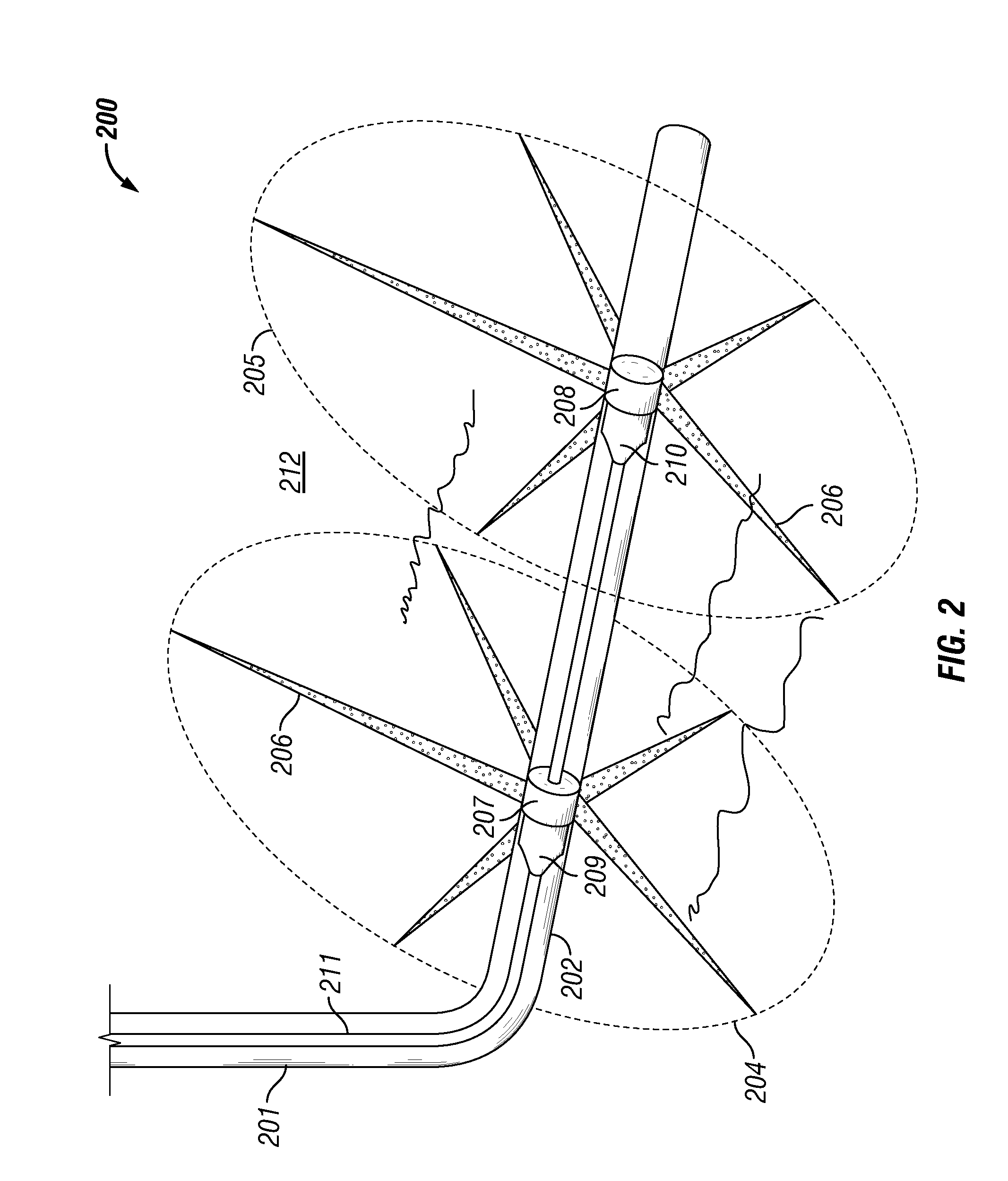

Electrofracturing formations

InactiveUS20130255936A1Reduction of formation stressDisloding machinesFluid removalElectricityInitial permeability

A method is provided to produce hydrocarbons from a formation, the method includes the steps of: placing a pair of electrodes within a formation; applying differential voltages between pairs of electrodes wherein the voltage differences between the electrodes is greater than at least 10,000 volts; and producing hydrocarbons from the formation or an adjacent formation wherein the formation has an initial permeability of less than ten millidarcy. The invention also includes an apparatus effective to release pulses of electrical energy into the formation as this frequency and voltage at least until the formation has reached a point where the electrical potential arcs from one electrode to at least one other electrode.

Owner:SHELL OIL CO

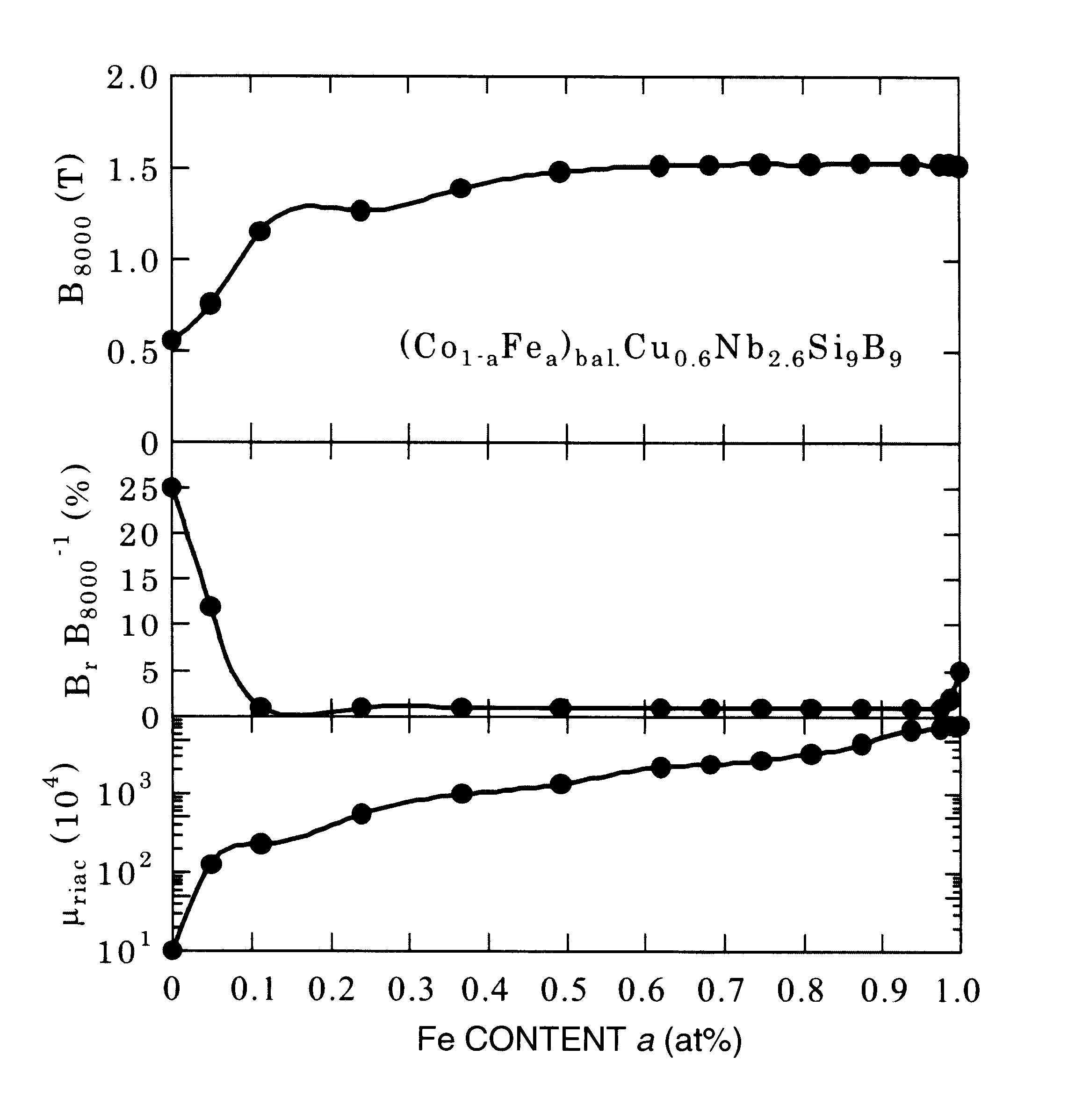

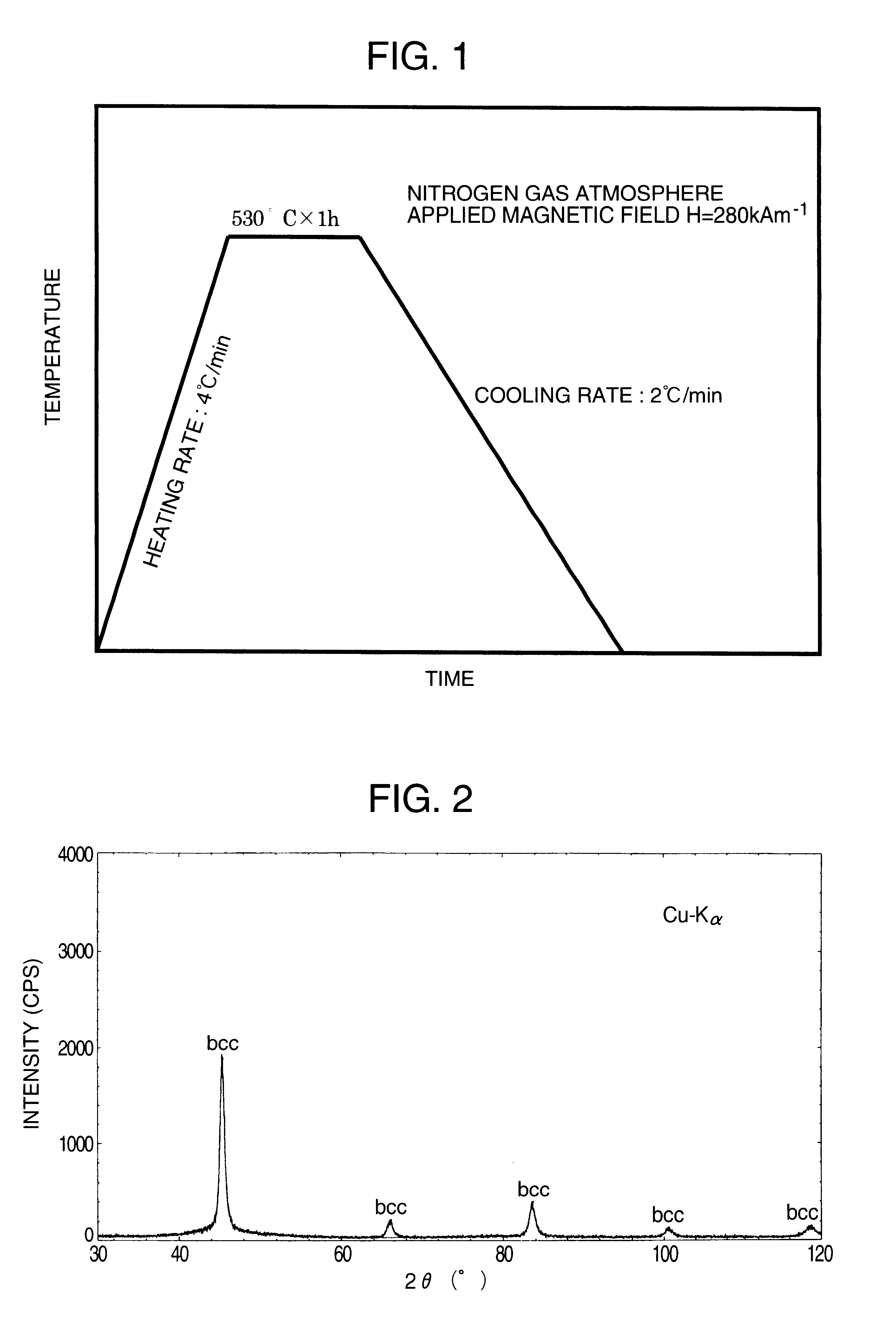

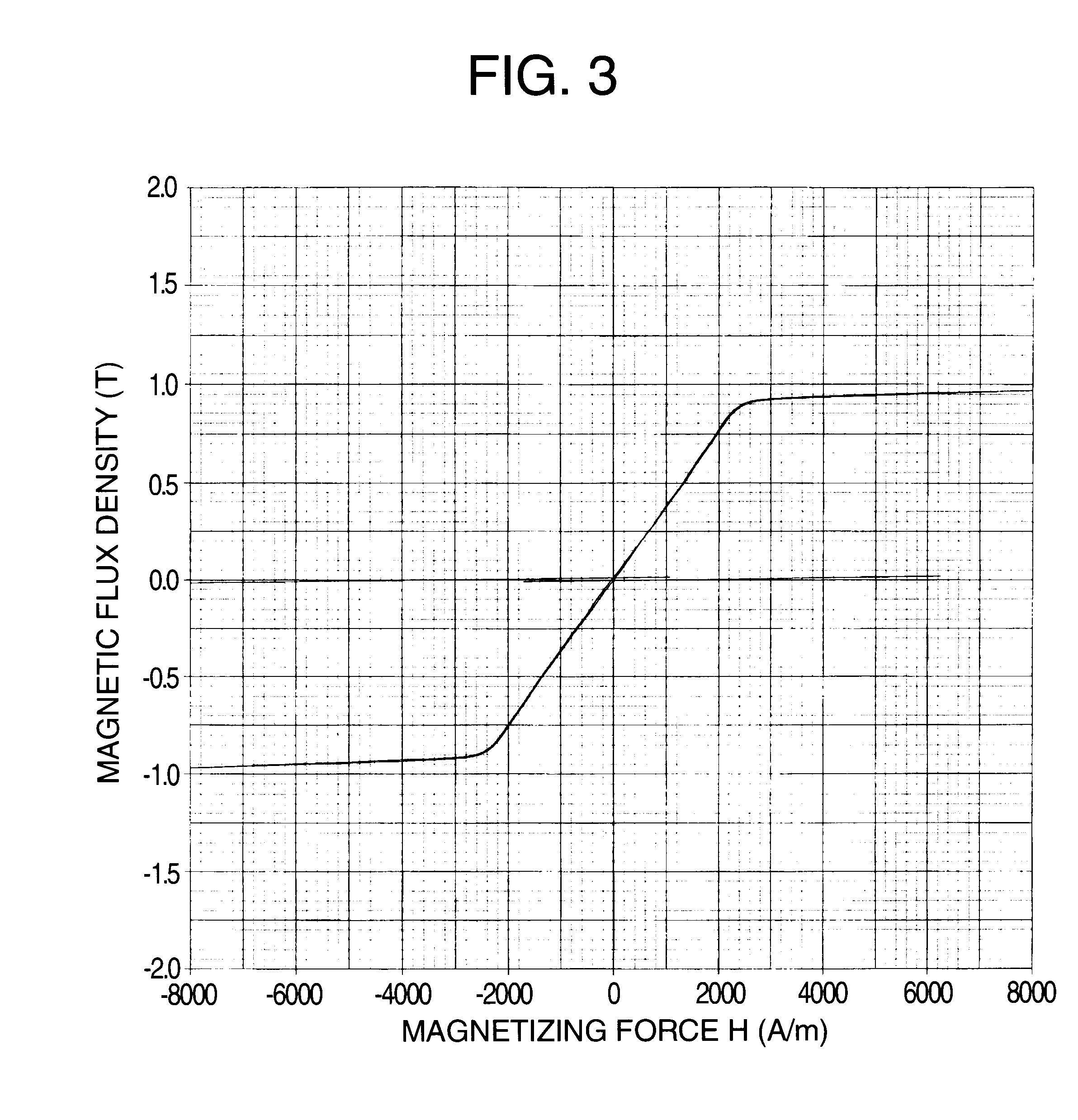

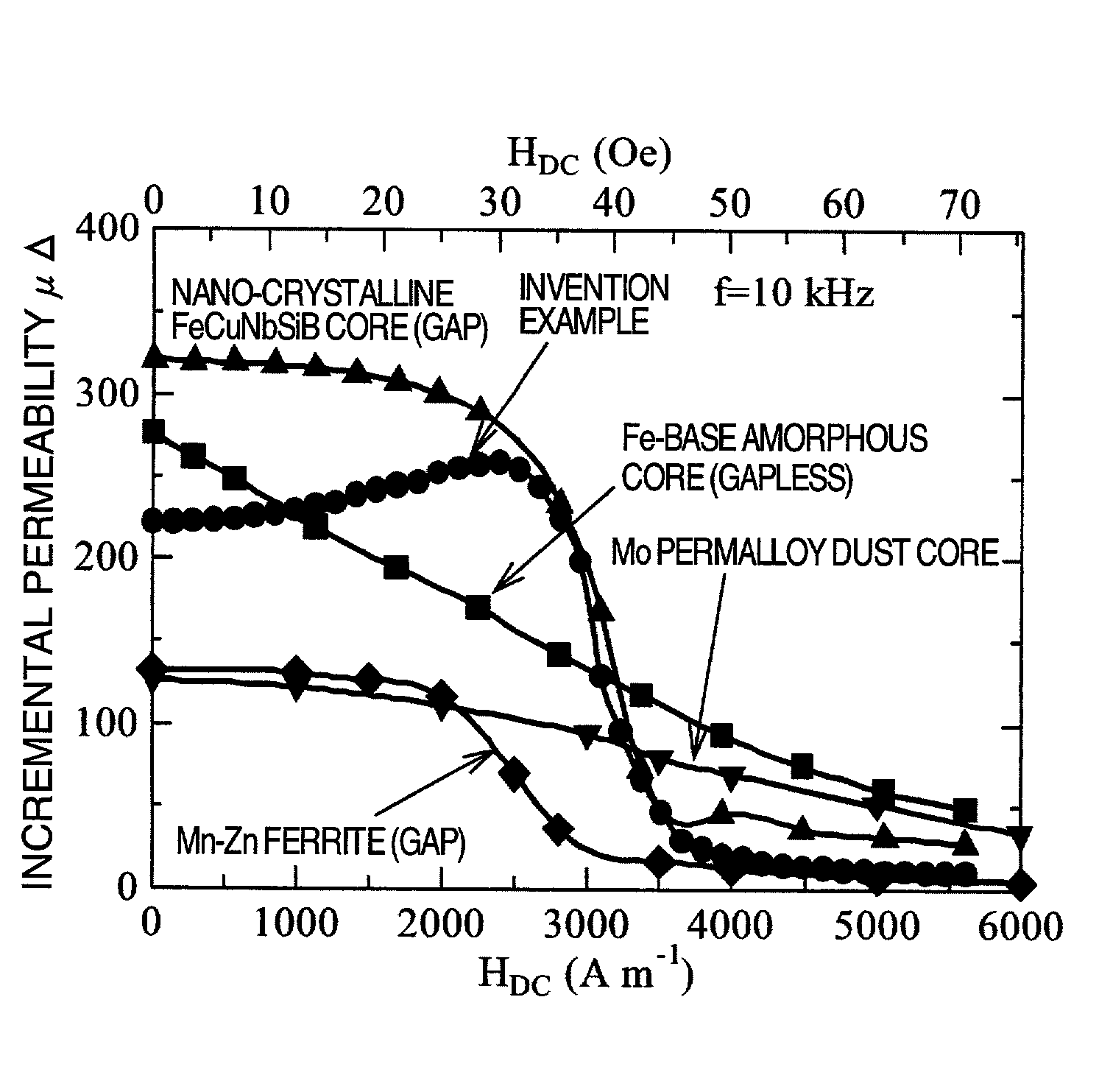

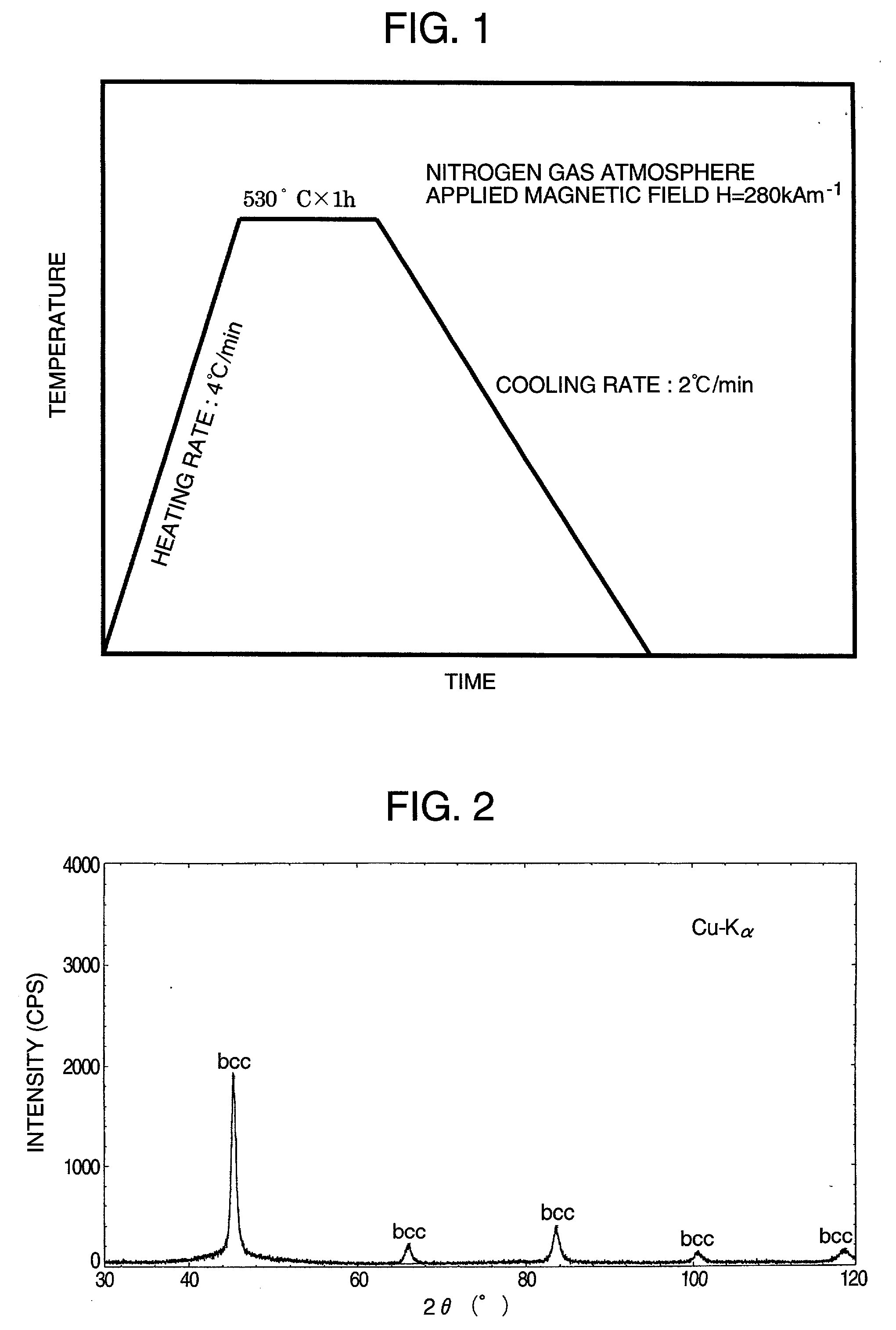

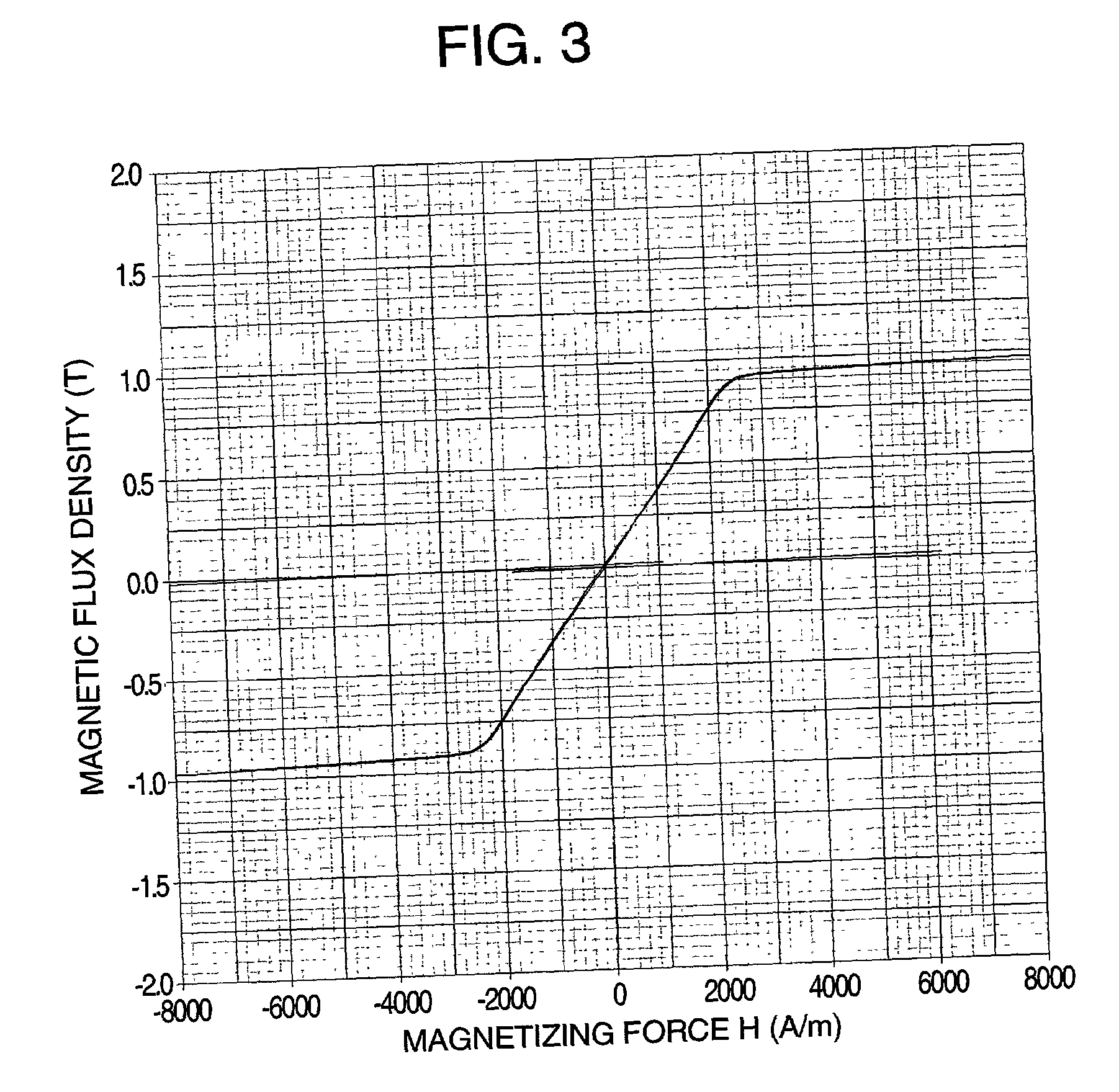

Co-based magnetic alloy and magnetic members made of the same

Disclosed is a Co-base magnetic alloy excellent in high-frequency magnetic properties, of which chemical composition is represented by the following general formula, by atomic %, (Co1-aFea)100-y-cM'yX'c, where M' is at least one element selected from the group consisting of V, Ti, Zr, Nb, Mo, Hf, Sc, Ta and W; X' is at least one element selected from the group consisting of Si and B; and a, y and c are defined by the formulas of a<0.35, 1.5<=y<=15, and 4<=c<=30, respectively. At least a part of the alloy structure of the alloy consists of crystal grains having an average grain size of not more than 50 nm. The alloy has a relative initial permeability of not more than 2000. It is suitably used for members of countermeasure against noise such as zero phase reactors for large current and electromagnetic shielding materials, inverter transformers, choke coils for active filters, antennas, smoothing choke coils, power supplies for lasers, pulse power magnetic members for accelerators.

Owner:HITACHI METALS LTD

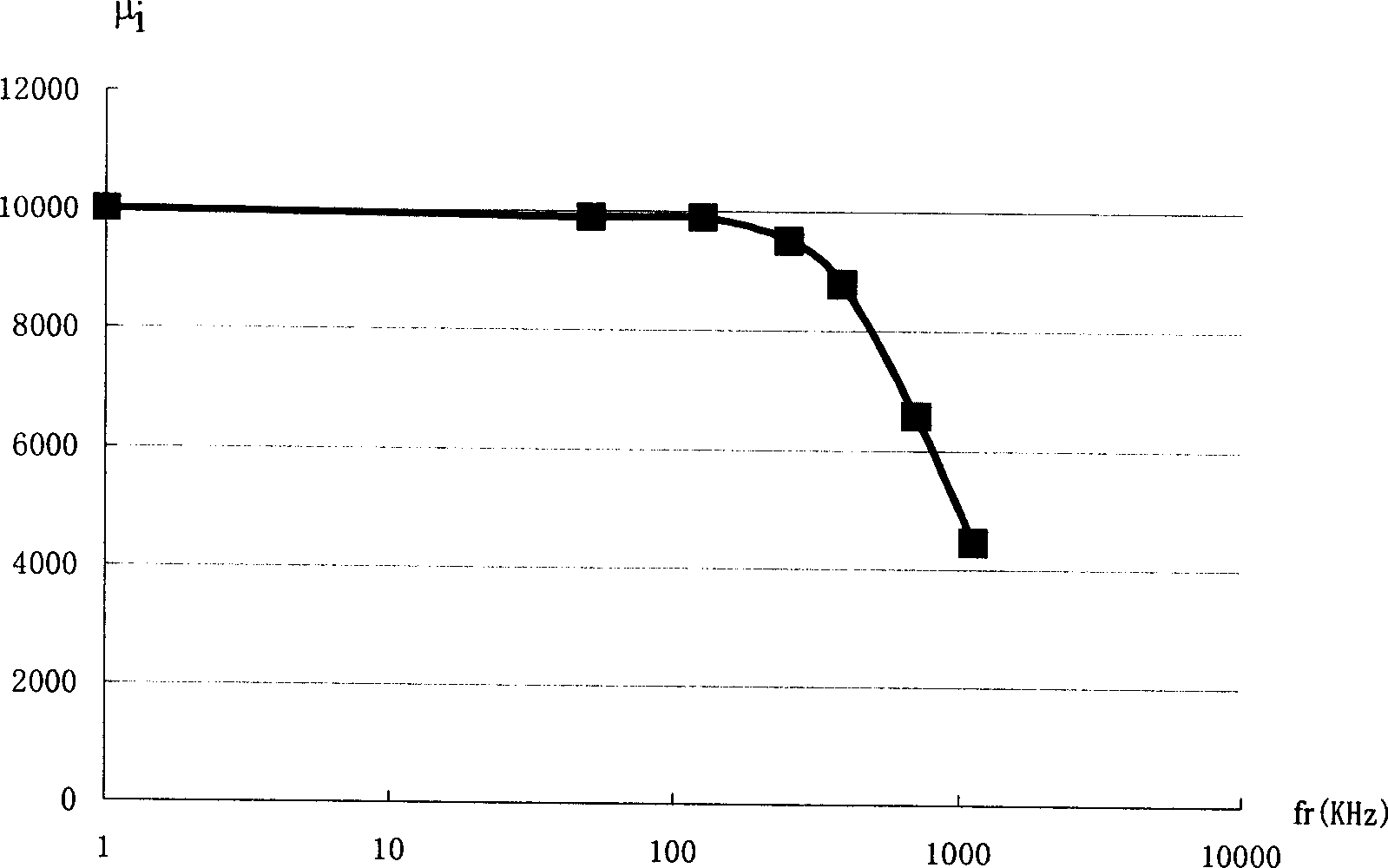

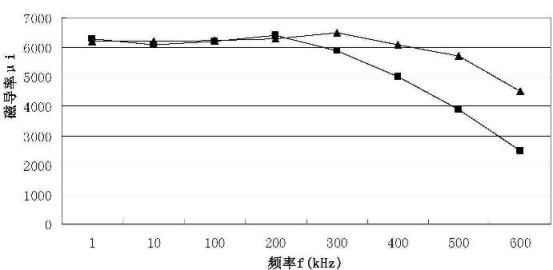

Wide-band manganese-zinc series high-magnetic-conductivity soft magnet oxysome material

ActiveCN1677579AHigh initial permeabilityRaise the cutoff frequencyInorganic material magnetismInitial permeabilitySoft magnet

The material of soft-magnetic ferrite comprises 50 - 55mol% Fe, 20 - 30mol% MnO, and 20 - 30mol% ZnO. initial permeability Mui is greater than or equal to 10000, and cut-off frequency fr is greater than or equal to 400 kHz. Features are low cost and applicable to fabricating filters, inductance transformer, digital transformer, chokes and current transformers etc.

Owner:广东肇庆微硕电子有限公司 +1

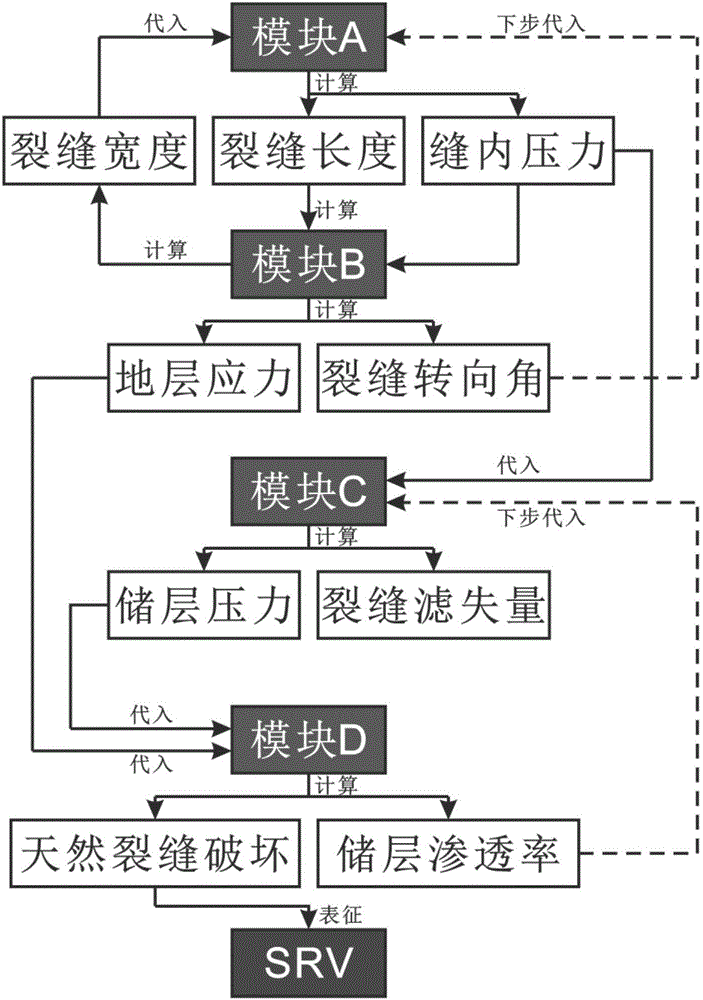

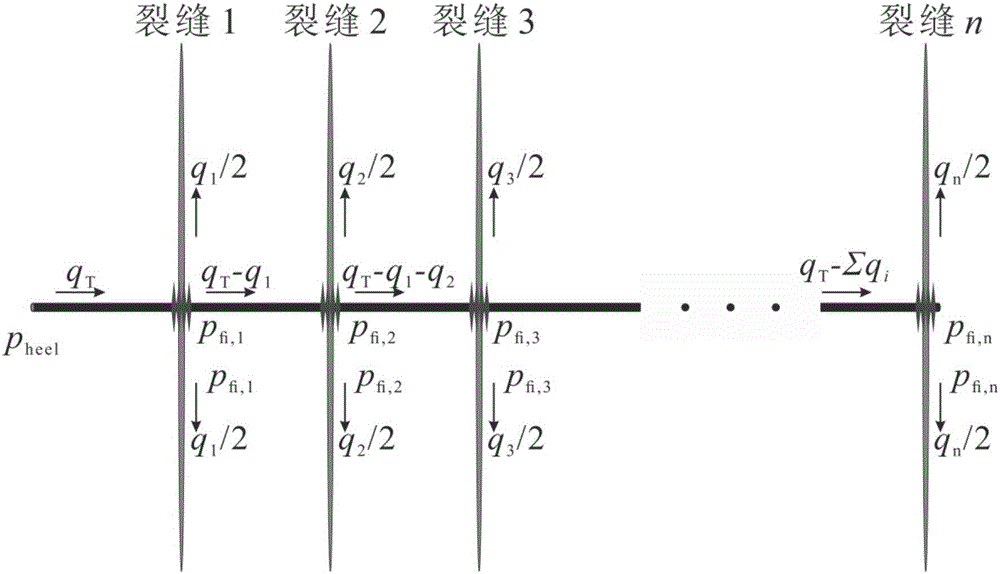

Method for calculating tight reservoir fracturing transformation volume area

ActiveCN106844909AFastSolve the problem of failure to widely promote and apply in the mining fieldGeometric CADDesign optimisation/simulationReservoir pressureChange model

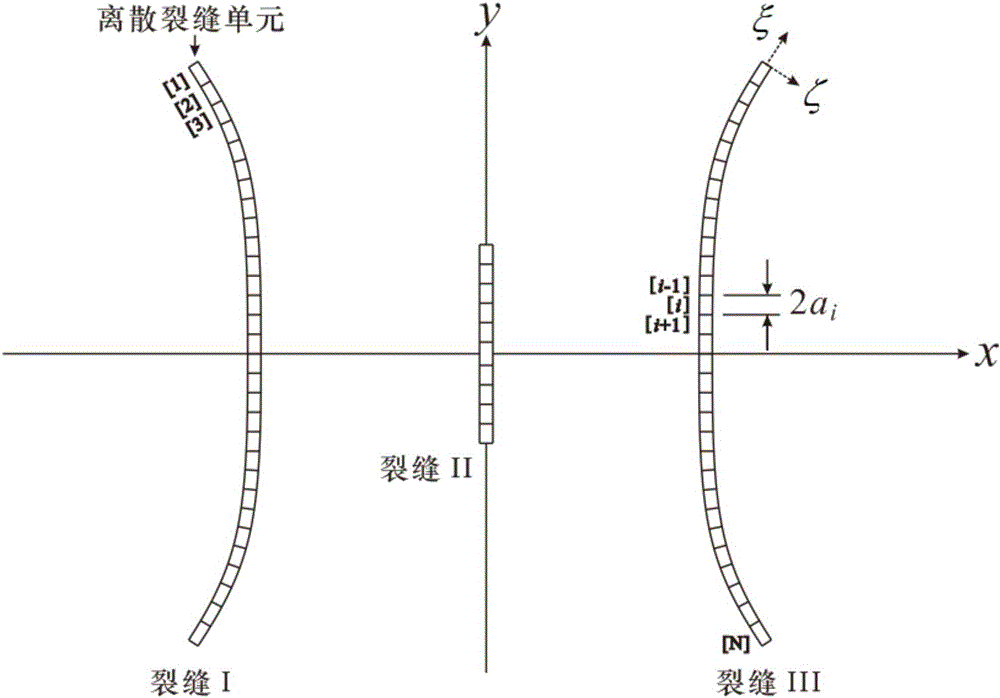

The invention discloses a method for calculating a tight reservoir fracturing transformation volume area. The method comprises the following steps that multiple hydraulic fracture non-planar turning extension models, a formation stress field change model, a reservoir pressure file change model and a natural fracture failure criterion in the tight reservoir horizontal well fracturing process are established, geological parameters, horizontal well fracturing construction parameters and the total fracturing time are obtained, an initial fracture filter loss value, an initial fracture half-length value, an initial in-fracture pressure value, an initial fracture extension turning angle, initial permeability and an initial fracturing time value are endowed, all the models are calculated, and natural fracture failure point coordinate data is calculated; a spatial and numerical integration method is utilized to calculate tension failure transformation area volume and shear failure transformation area volume in a reservoir respectively, and the spaces of the two parts are united and regarded as a total transformation volume area. By adopting the method, accurate, economic and rapid tight reservoir horizontal well fracturing evaluation can be achieved, and the problem that effort, money and time are wasted in the existing tight reservoir horizontal well fracturing transformation volume area calculating process is solved.

Owner:SOUTHWEST PETROLEUM UNIV

Hydraulic pulse-assisted reservoir chemical remedial treatment experiment device and method

ActiveCN101985875AEfficient chemical plugging removal experimentRapid chemical plugging removal experimentFluid removalPermeability/surface area analysisInjection pressureInitial permeability

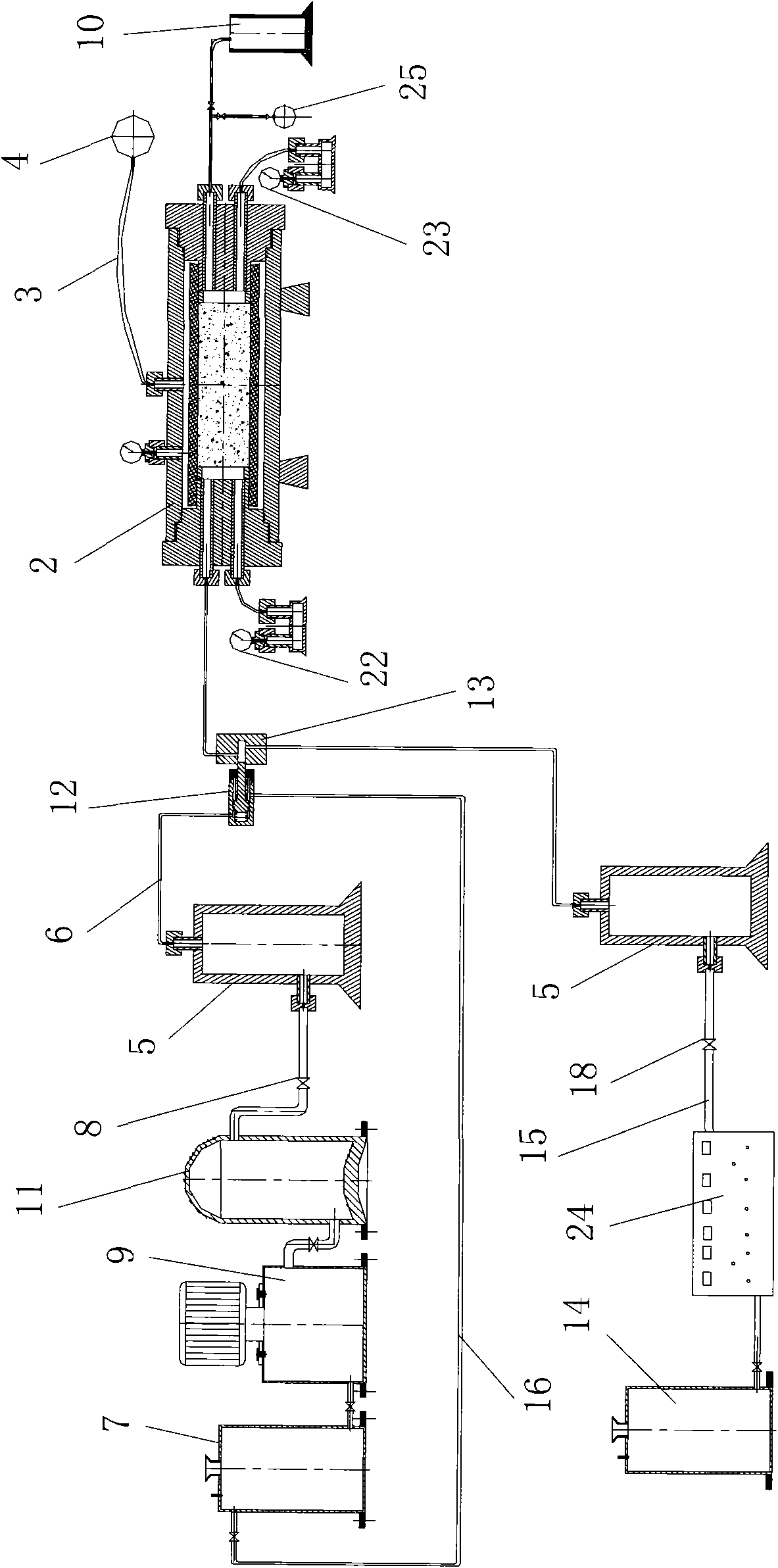

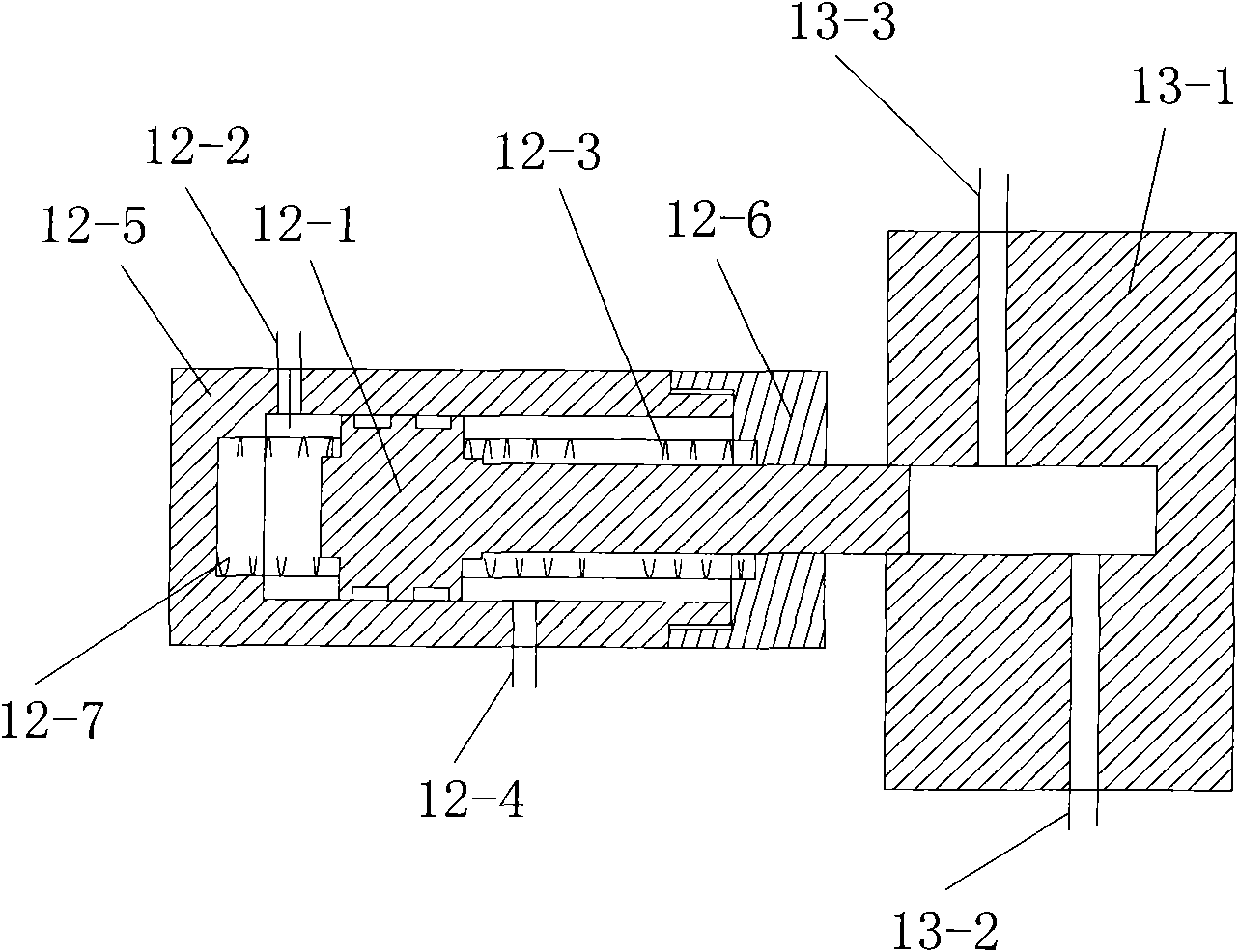

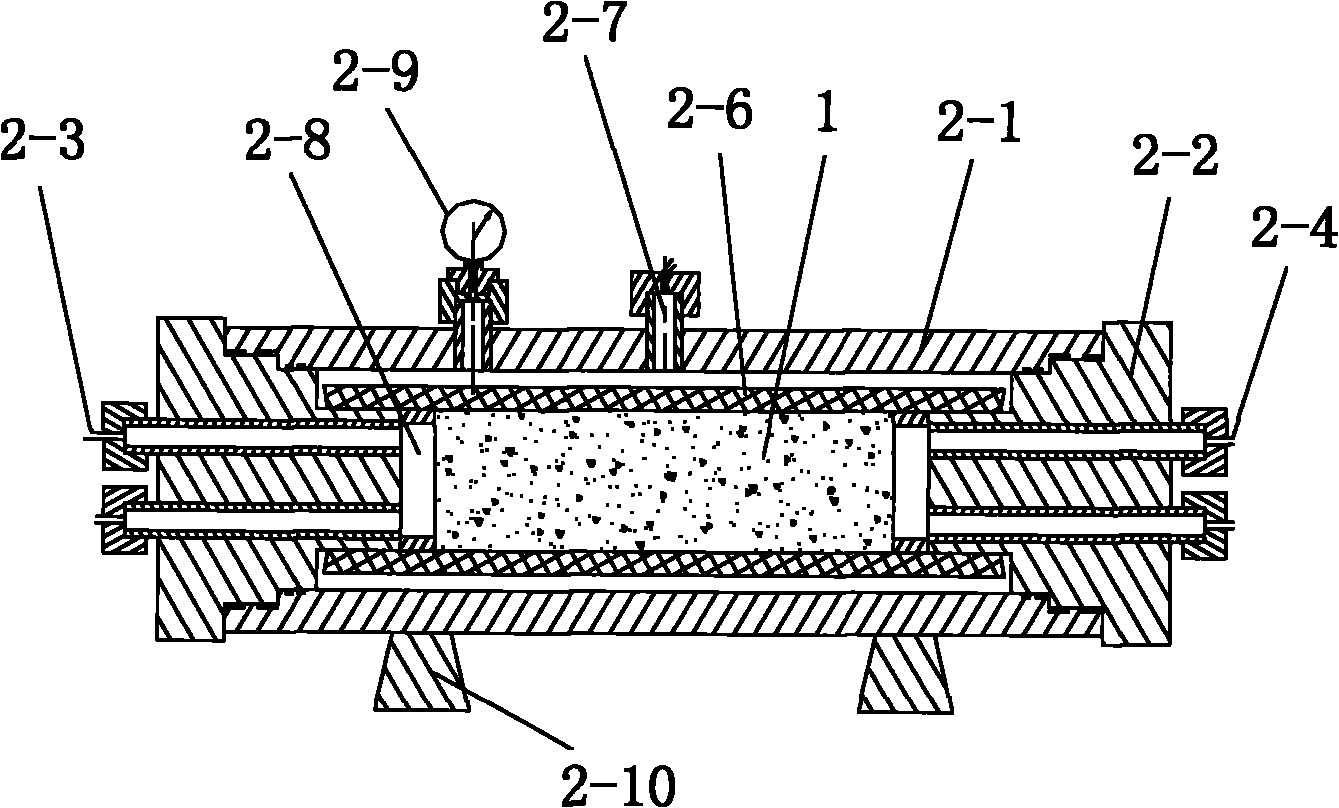

The invention discloses a hydraulic pulse-assisted reservoir chemical remedial treatment experiment device and a hydraulic pulse-assisted reservoir chemical remedial treatment experiment method. The experiment device comprises a core holder, an annular pressure supply device, a chemical reagent storage tank, a water storage tank, an oil storage tank and a liquid container, wherein the chemical reagent storage tank, the water storage tank and the oil storage tank are connected with a liquid inlet of the core holder through delivery pipes; the liquid container is connected with a liquid outlet of the core holder; and a hydraulic pulse generating device is arranged on each delivery pipe. The experiment method comprises the following steps of: 1, preprocessing a tested core; 2, measuring the initial permeability of the core by water drive; 3, polluting the core; 4, measuring the permeability of the core by water drive after pollution; 5, performing a hydraulic pulse-assisting chemical reagent remedial treatment experiment; 6, measuring the permeability of the core by water drive after remedial treatment; 7, performing the hydraulic pulse-assisted chemical reagent remedial treatment experiment under the conditions of different frequencies and different amplitudes; and 8, arranging data. The device is rational in design, convenient to arrange, complete in function, simple to operateand good in using effect and can realize pulse fluctuation of the chemical remedial treatment under the action of an injection pressure.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

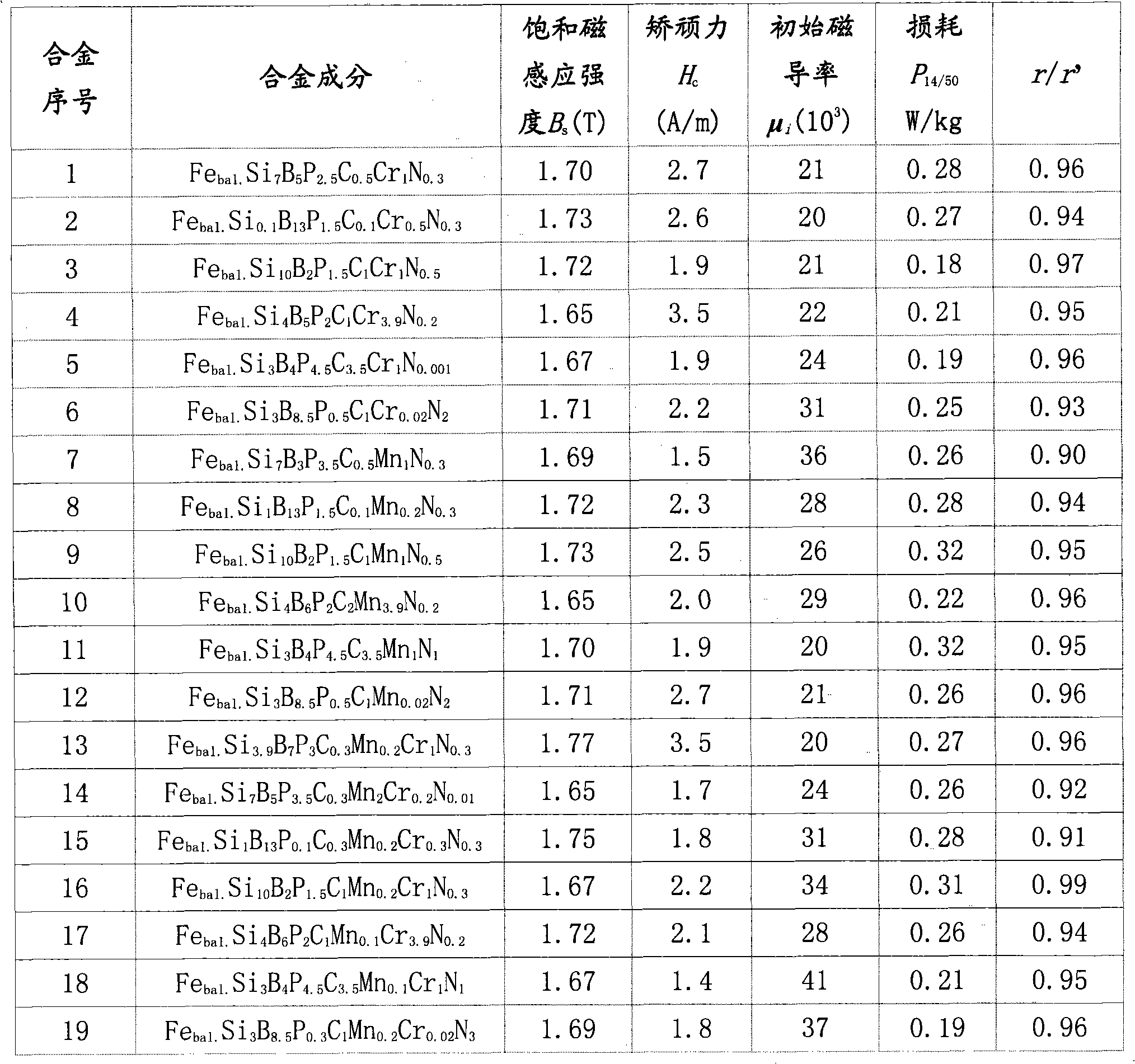

Iron-based amorphous soft magnetic alloy with high saturation magnetic induction and preparation method thereof

The invention provides iron-based amorphous soft magnetic alloy with high saturation magnetic induction and a preparation method thereof. The alloy is characterized by being melted and prepared by adopting high-pressure N2 as a protective atmosphere, , the atom percentage composition of the alloy satisfies the relation: FeSiaBbPcCdNeMf, wherein M is Mn or / and Cr, subscripts from a to f in the relation express atom percentage and satisfy the following conditions that a is not less than 0.02 and is less than 20, b is not less than 1 and is less than 20, c is not less than 0.002 and is not more than 8, d is not less than 0.002 and is not more than 10, e is not less than 0.001 and is not more than 3, f is not less than 0.002 and is not more than 4, and a+b+c+d+e+f is not more than 20; and thebalance is Fe and inevitable impurities. The soft magnetic alloy has the advantages of full elimination of stress during annealing, high saturation magnetic induction, high initial permeability and the like. The alloy has the saturation magnetic induction of above 1.65T and the initial permeability of above 20 thousand after annealing.

Owner:AT&M AMORPHOUS TECH CO LTD

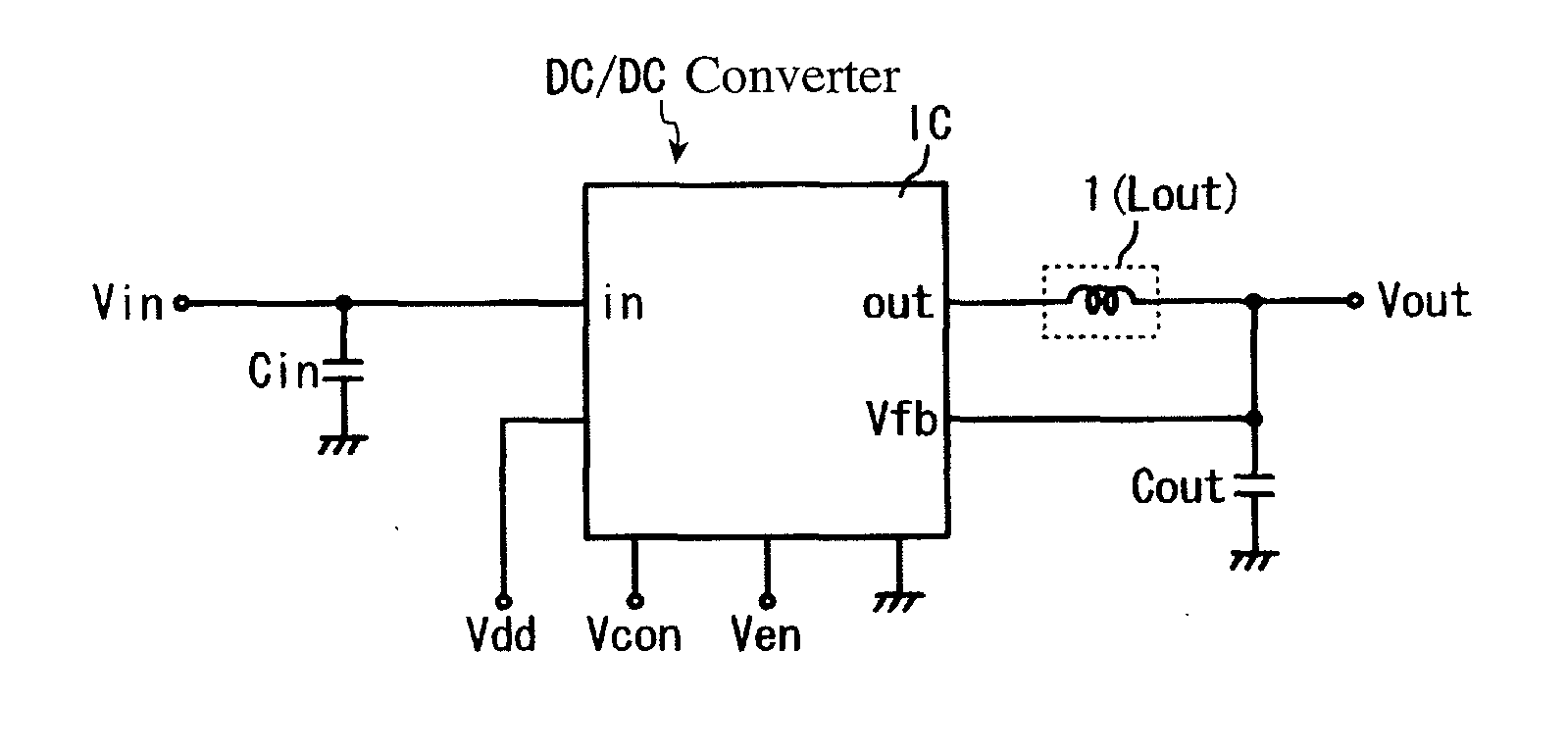

Multilayer inductor and power converter comprising it

ActiveUS20100283447A1Little changeGood temperature characteristicsTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureInitial permeabilityCurie temperature

A multilayer inductor comprising a coil embedded in a magnetic portion, and a magnetic gap formed by a non-magnetic portion in part of a magnetic path, the magnetic portion being made of Ni ferrite, whose relative temperature coefficient αμir of initial permeability at a frequency of 1 MHz is more than +10 ppm / ° C. and +40 ppm / ° C. or less between −40° C. and +80° C., the non-magnetic portion being made of Zn ferrite containing more Zn than in the magnetic portion and having a Curie temperature Tc of −50° C. or lower, and the Zn content changing continuously in boundary regions between the non-magnetic portion and the magnetic portion, whereby the thickness of the magnetic gap changes with the temperature.

Owner:HITACHI METALS LTD

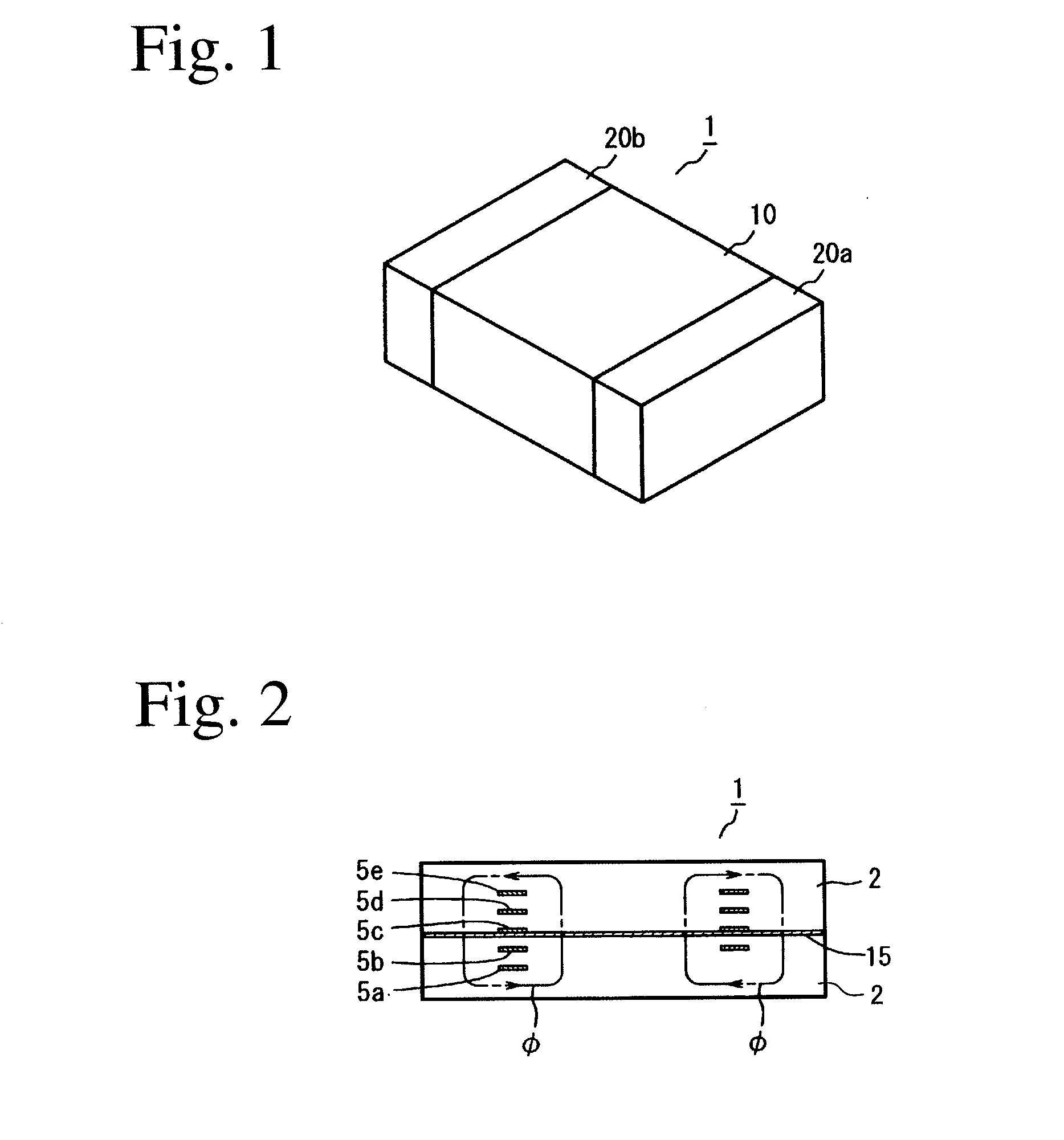

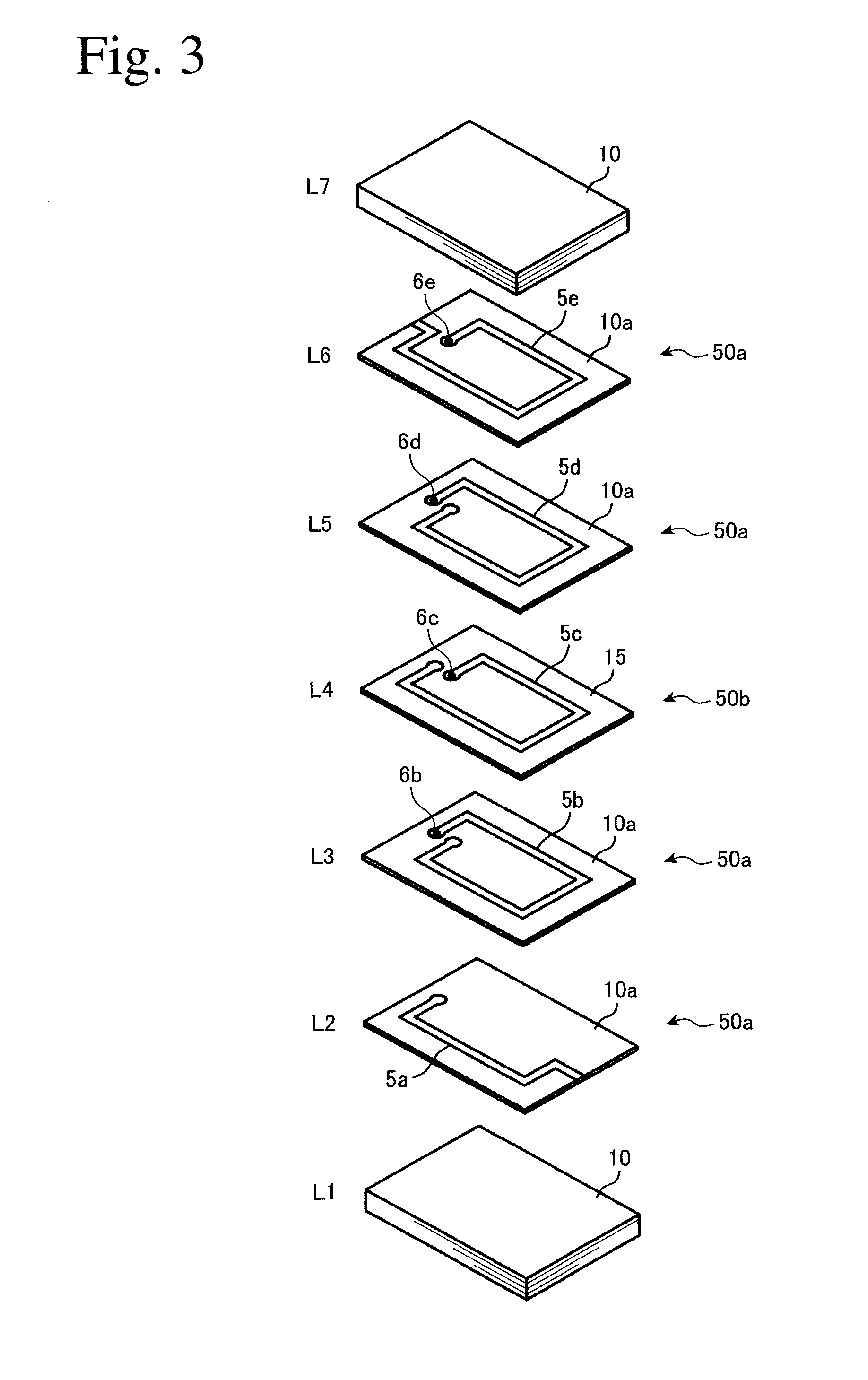

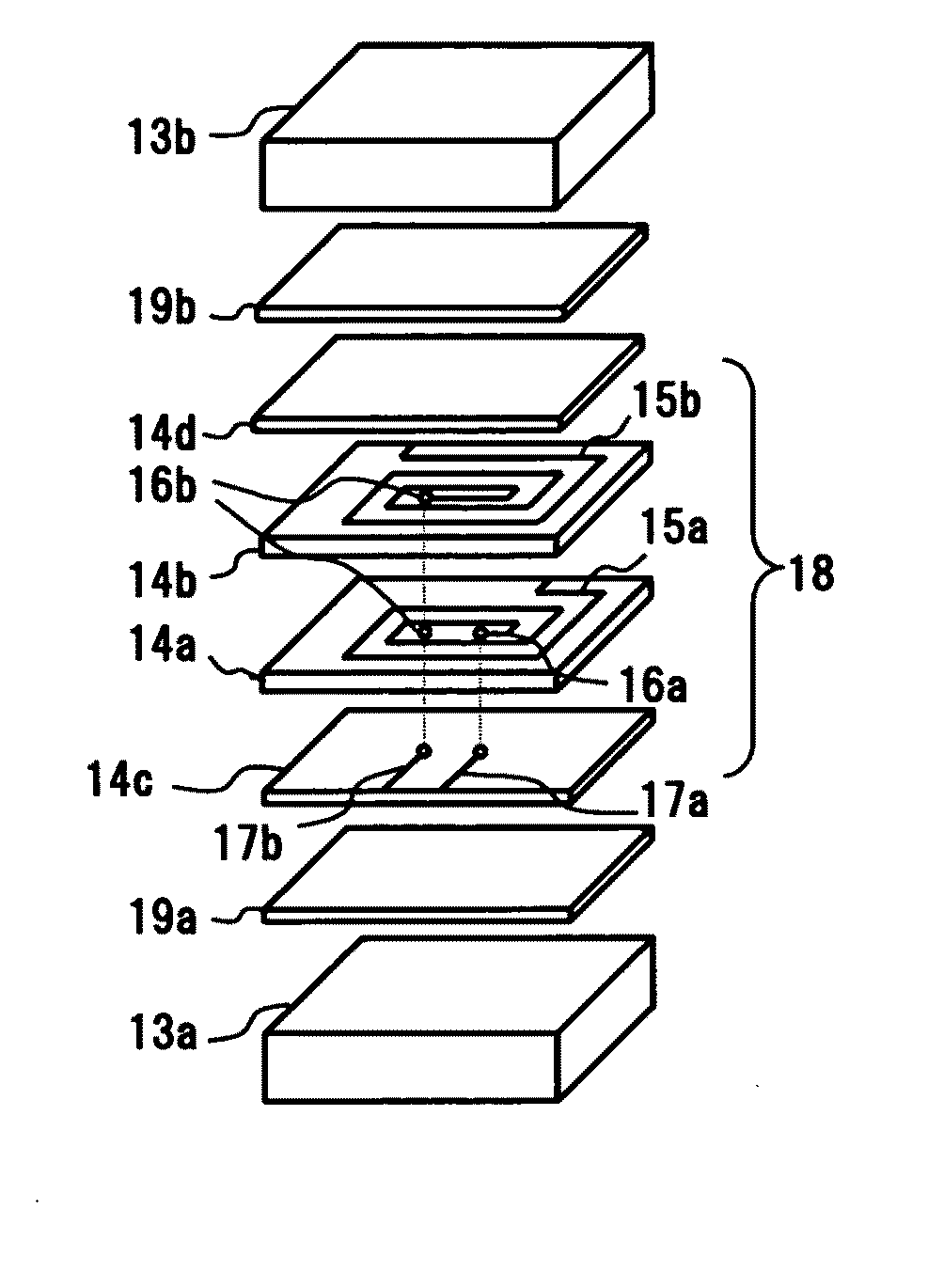

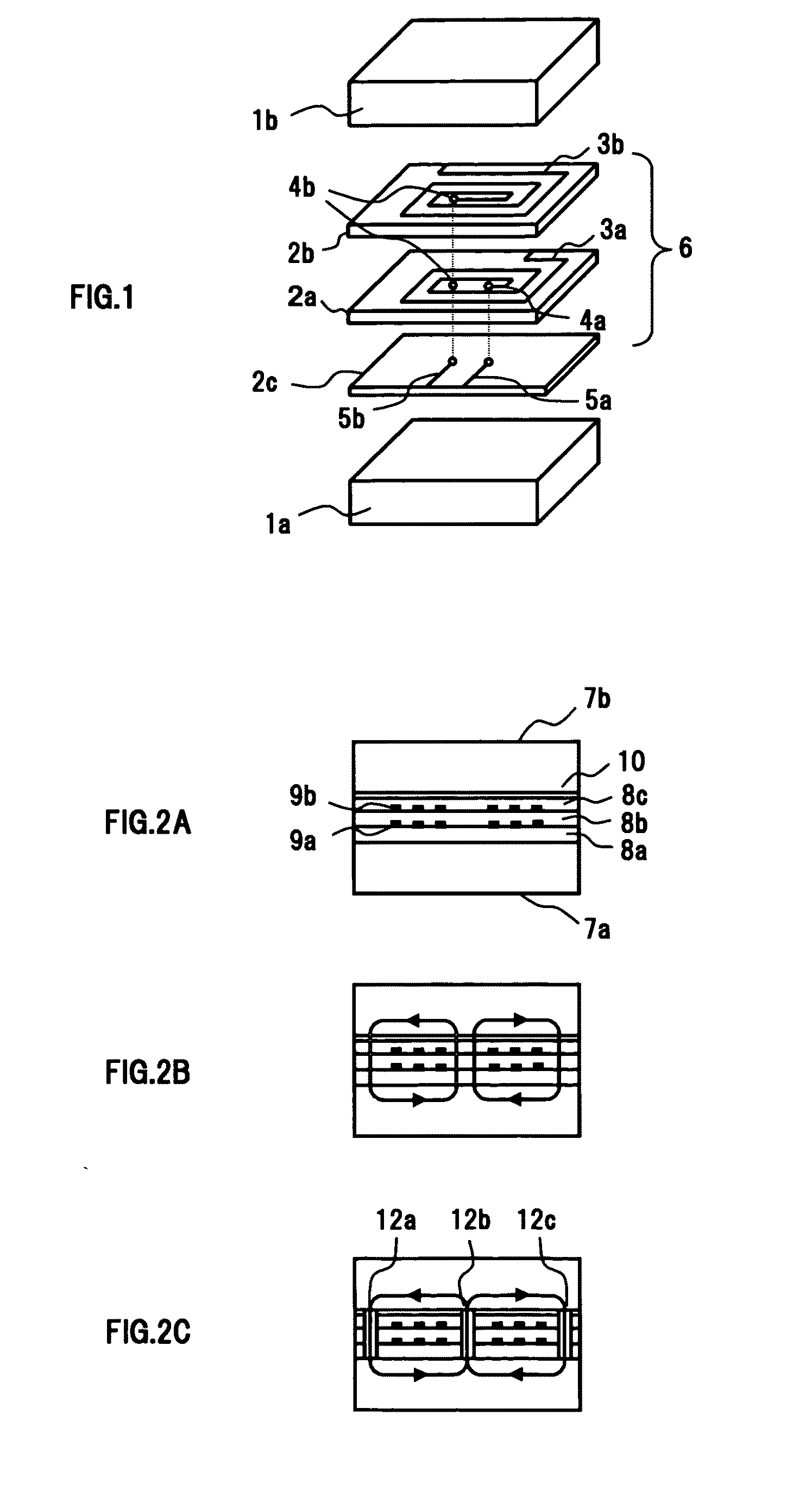

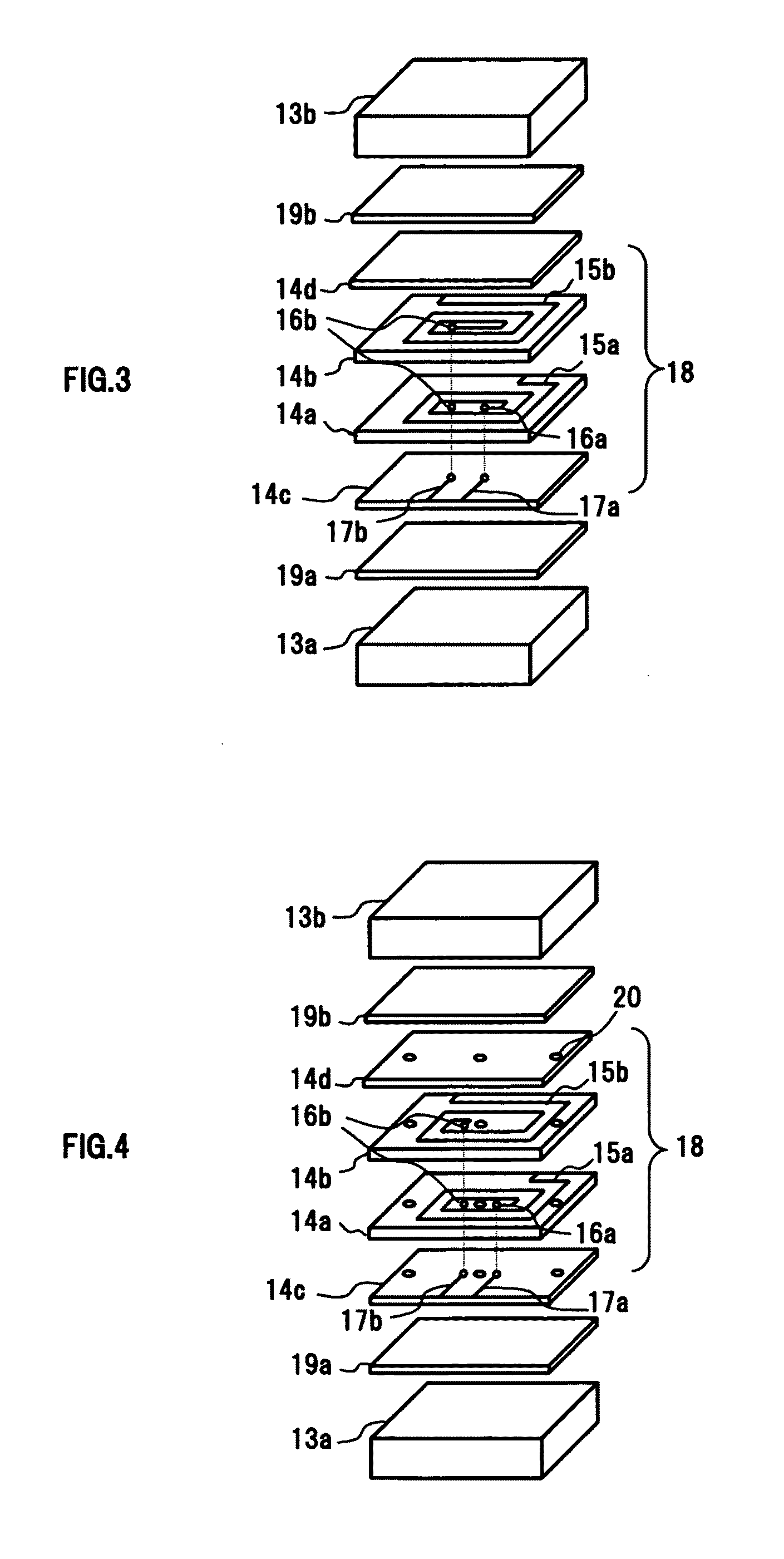

Coil Component and Its Manufacturing Method

InactiveUS20090295526A1Maintain initial magnetic permeabilityEasy magnetization planeTransformers/inductances coils/windings/connectionsIron compoundsInitial permeabilityCrystal orientation

In a coil component of the present invention, a coil member having a plurality of coil lines laminated through an insulating layer is sandwiched by hexagonal ferrite substrates, and the hexagonal ferrite substrate has anisotropy. To have the “anisotropy” means that alignment of the crystal orientation is different according to a direction of the substrate, in other words, that anisotropy is provided in the c-axis orientation of ferrite crystal grains of the hexagonal ferrite substrate. As the result of the “anisotropy”, an initial magnetic permeability is also different according to direction. By using the hexagonal ferrite substrate as a magnetic substrate to sandwich the coil member so as to form a magnetic path, the initial magnetic permeability can be maintained up to a high frequency, and a high-frequency characteristic of impedance generated by the coil lines can be improved.

Owner:HITACHI METALS LTD

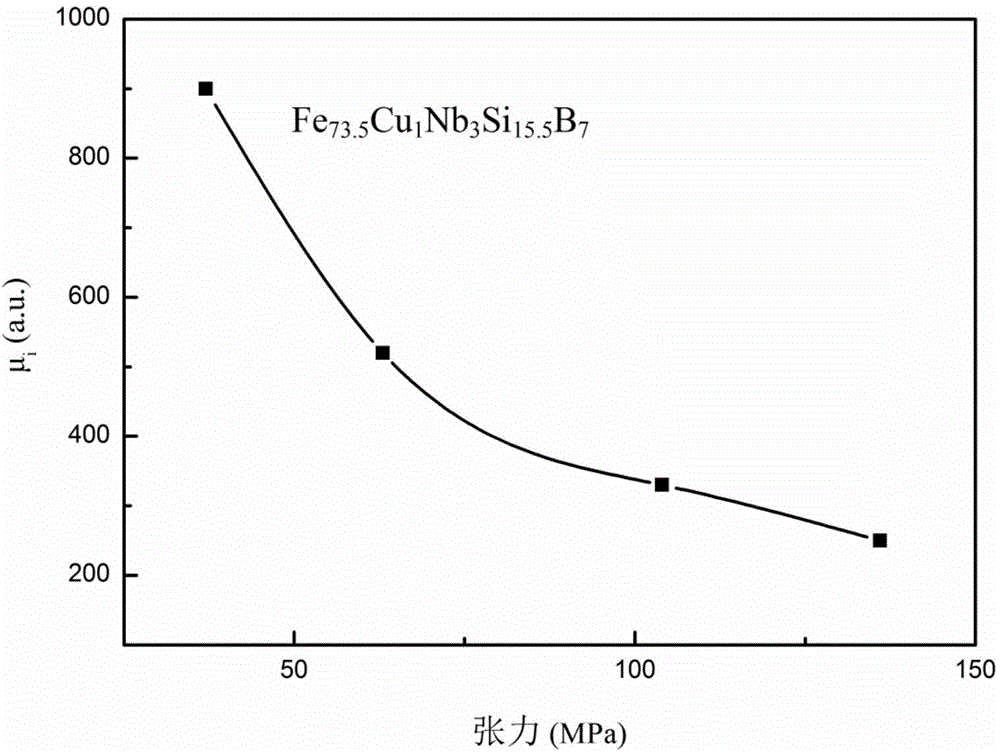

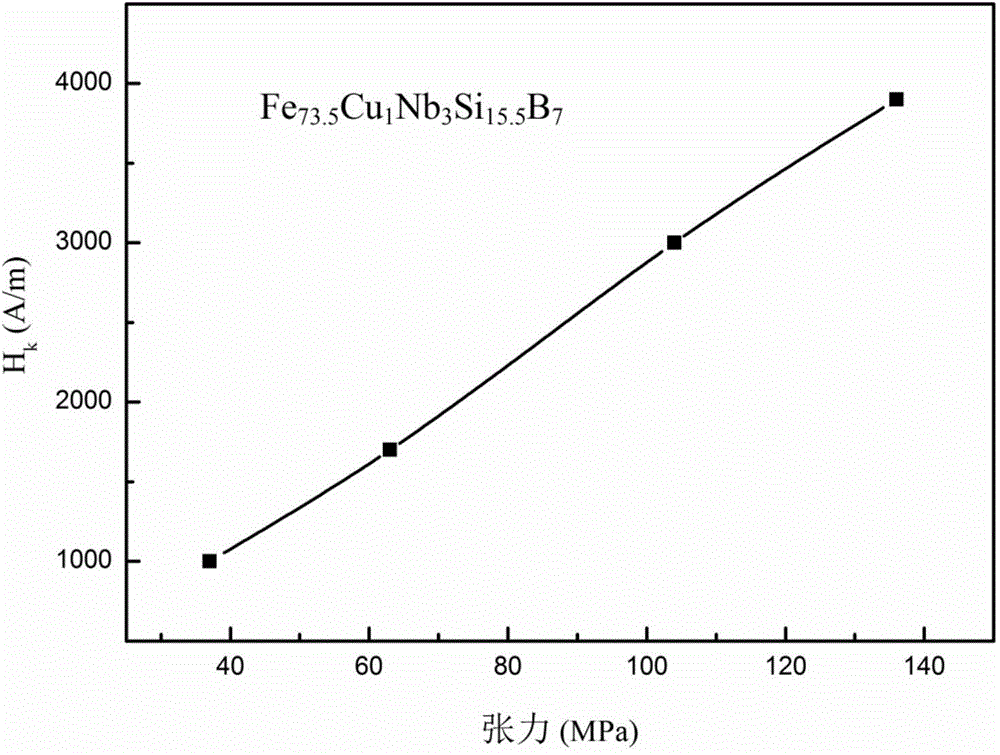

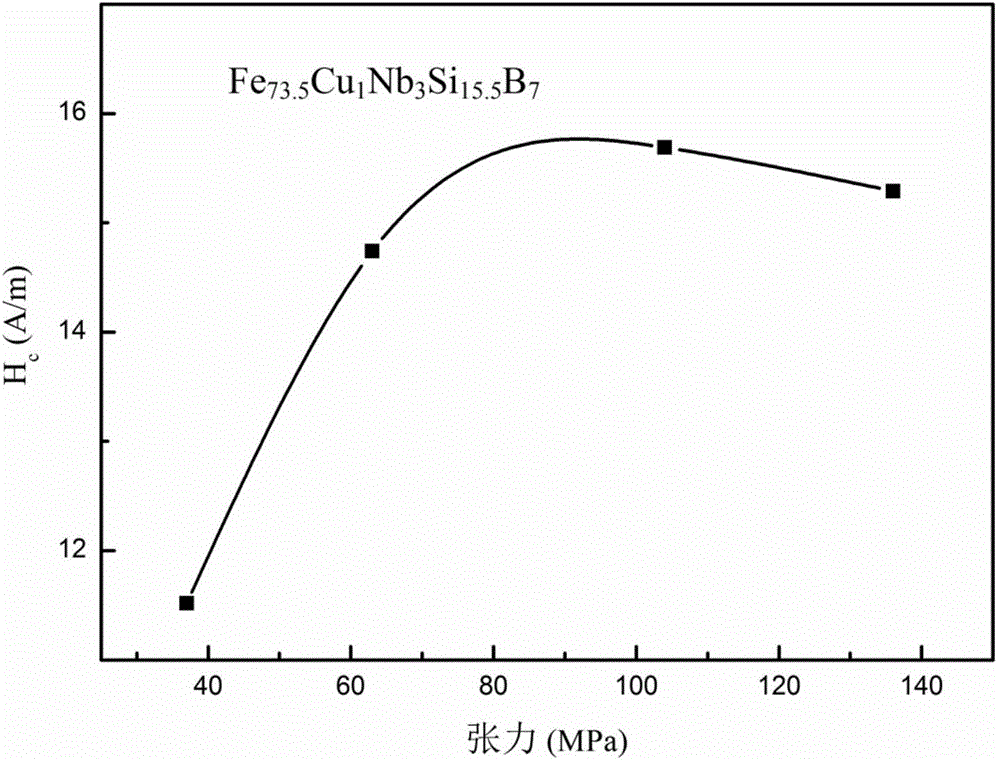

Iron-based constant-permeability nano crystal magnetic core and production method thereof

ActiveCN104376950ALow remanence flux densityLow coercivityTransformersTransformers/inductances detailsAlternating currentImpurity

The invention discloses an iron-based constant-permeability nano crystal magnetic core and a production method thereof. The magnetic core is made of iron-based alloy. The molecular formula of the iron-based alloy is FeaCubNbcSidBeMfXg, wherein M is at least one of V, Ti, Mn, Cr and Mo and X is at least one of C, Ge, P and impurities. The production method includes: thermally processing an amorphous alloy thin strip while applying tensile stress along the length direction of the strip; winding the strip to produce the magnetic core of a certain size. The method has the advantages that the magnetic domain structure and distribution in the strip during crystallization can be adjusted by adjusting the process parameters such as tension magnitude and temperature during thermal processing according to different components and final performance requirements so as to obtain the constant-permeability magnetic core, and the height of the permeability is adjustable under direct currents and alternating currents. In addition, the relative initial permeability of the magnetic core is 50-2000 under a direct current condition and by the aid of simulation impact method testing.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

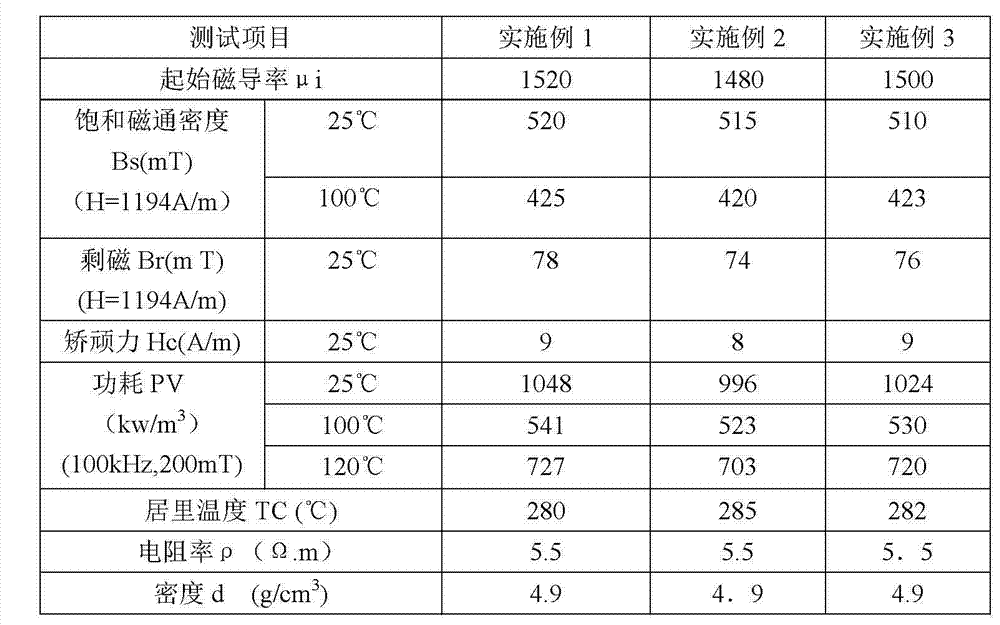

High-Curie-temperature low-loss high-strength ferrite magnetic block and preparation method thereof

InactiveCN103117146AReasonable choiceReasonable ratioPermanent magnetsInorganic material magnetismSilicon oxideCopper oxide

The invention discloses a high-Curie-temperature low-loss high-strength ferrite magnetic block and a preparation method thereof and belongs to the technical field of Mn-Zn serial ferrite. Main raw materials include ferric oxide, manganese oxide and zinc oxide, auxiliary raw materials include calcium carbonate, titanium oxide, cobalt oxide, silicon oxide, chromium oxide, niobium oxide, nickle oxide and copper oxide, the ferrite magnetic block is composed of the main raw materials, 55-61mol% of ferric oxide calculated according to Fe2O3, 33-40mol% of manganese oxide calculated according to MnO and 5-10% of zinc oxide calculated according to ZnO, and the adding amount of the auxiliary raw materials relative to the total weight of the main raw materials is 500-3000ppm of CaCO3, 80-3000ppm of TiO2, 50-1200ppm of Co2O3, 20-200ppm of superfine SiO2, 100-1500ppm of Cr2O3, 100-1500ppm of Nb2O5, 600-2000ppm of NiO and 600-2000ppm of CuO. The high-Curie-temperature low-loss high-strength ferrite magnetic block has the advantages that initial magnetic permeability can be lowered to be maintained at 1400+ / -25%, power consumption is lower than 550kw / m3 under the condition of 100KHz200mT and at the temperature of 100 DEG C, saturation magnetic flux density at 100 DEG C is larger than 410mT, the Curie temperature is larger than 275 DEG C, and strength of the magnetic block can meet the strength detection standard (F)40N).

Owner:SUZHOU GUANDA MAGNET

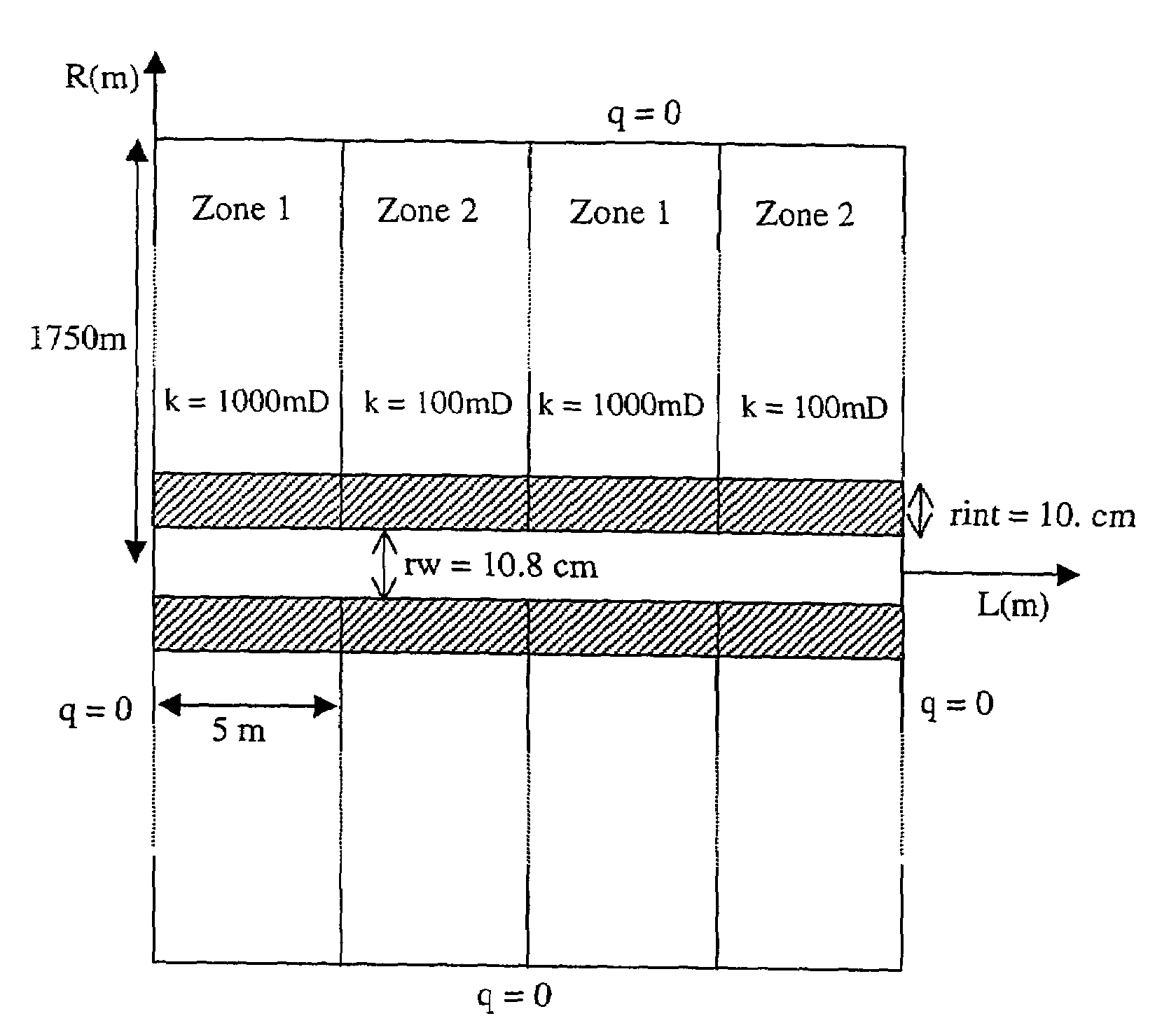

Method of determining by numerical simulation the restoration conditions, by the fluids of a reservoir, of a complex well damaged by drilling operations

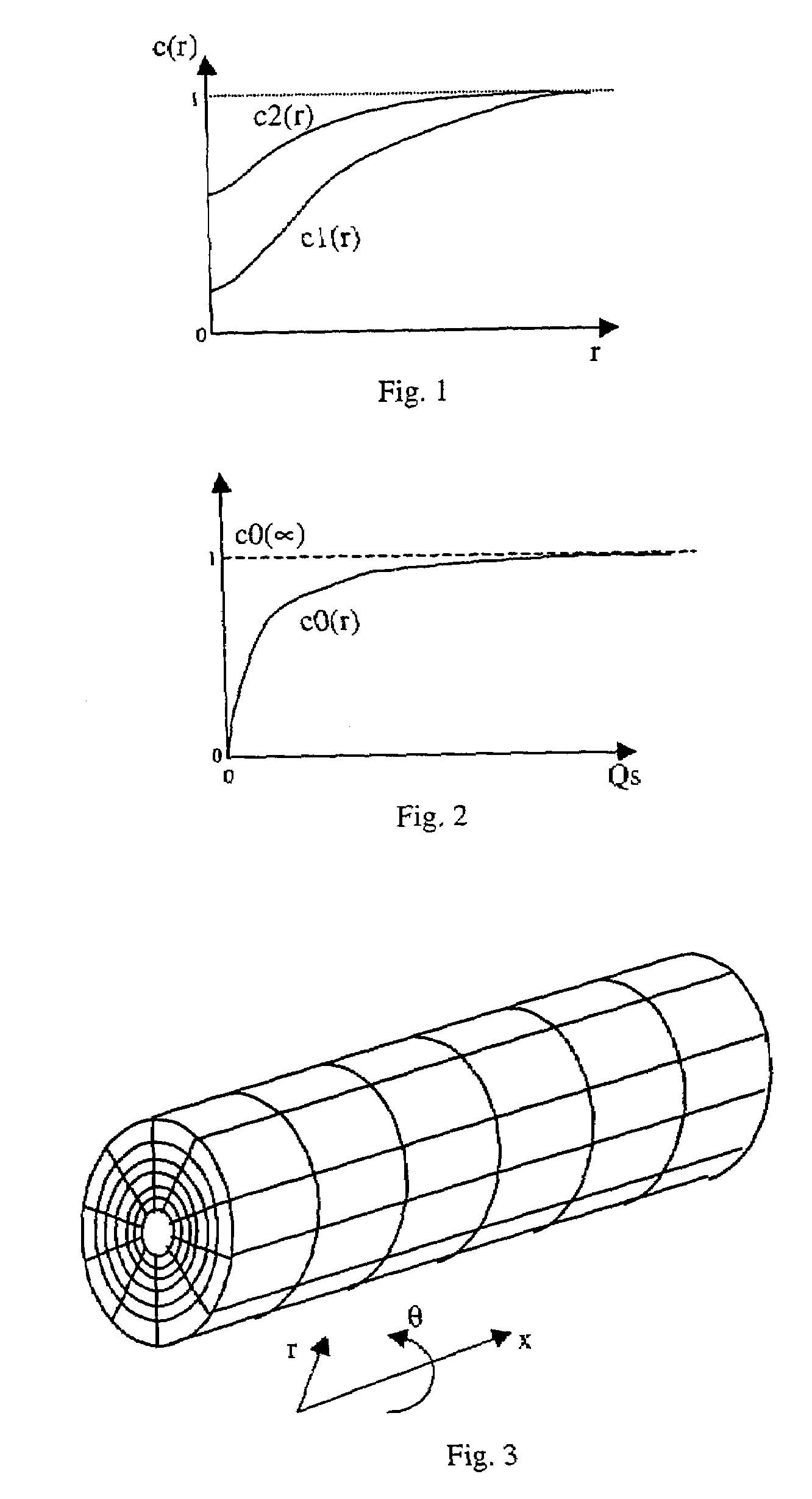

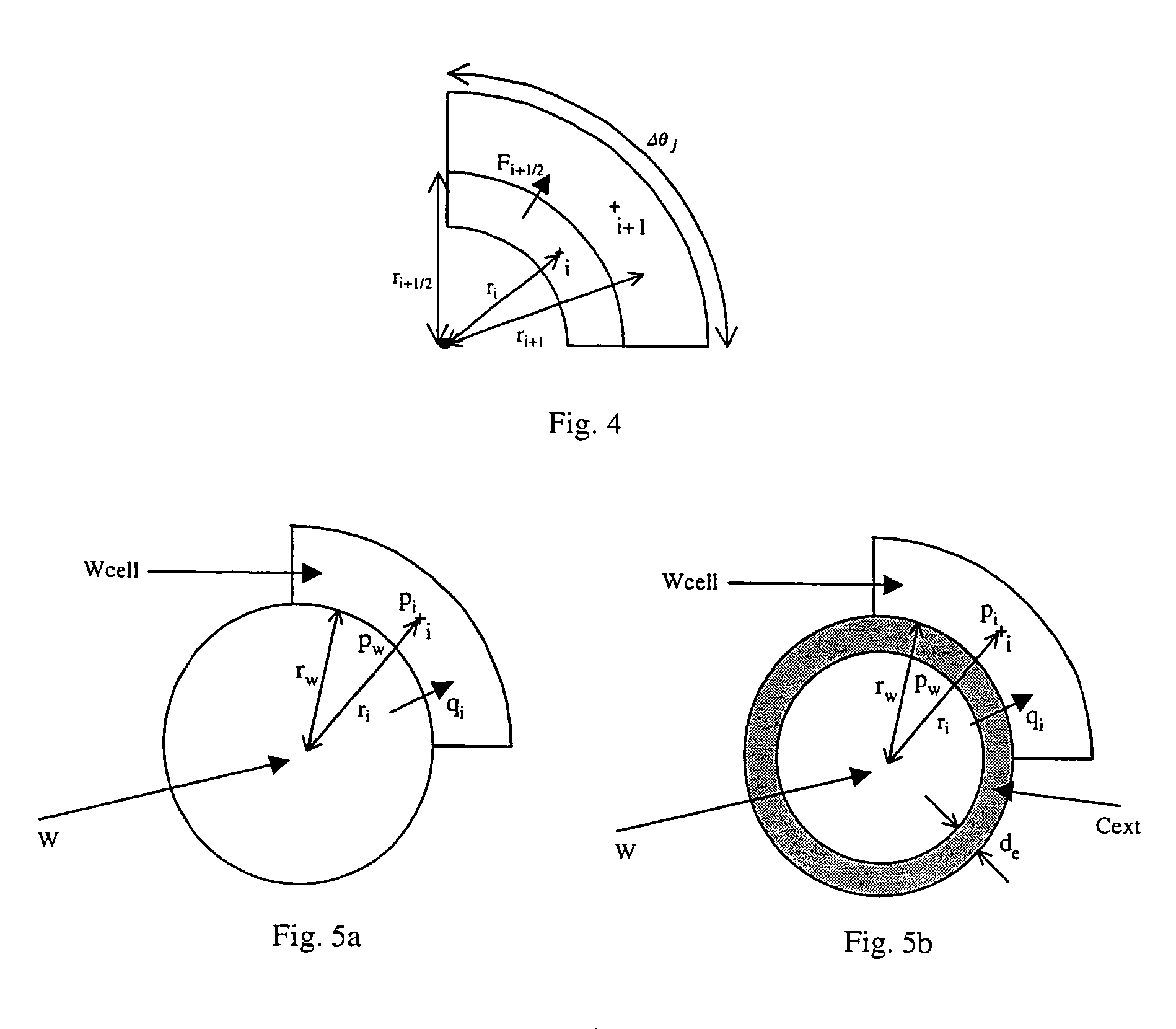

The method essentially comprises acquiring initial data obtained by laboratory measurements of the values, according to the initial permeability of the formations surrounding the well, of the thickness of the cakes and of the damaged permeability and restored permeability values of this zone, as a function of the distance to the wall of the well. Then the damaged zone is discretized by a 3D cylindrical grid pattern forming blocks of small radial thickness in relation to the diameter of the well, and the diffusivity equation, modelling the flow of the fluids through the cakes, is solved in this grid pattern by taking account of the measured initial data. Finally, the evolution of the permeability is modelled as a function of the flow rates of fluids flowing through the cakes, so as to deduce therefrom the optimum conditions to be applied for producing the well.

Owner:INST FR DU PETROLE

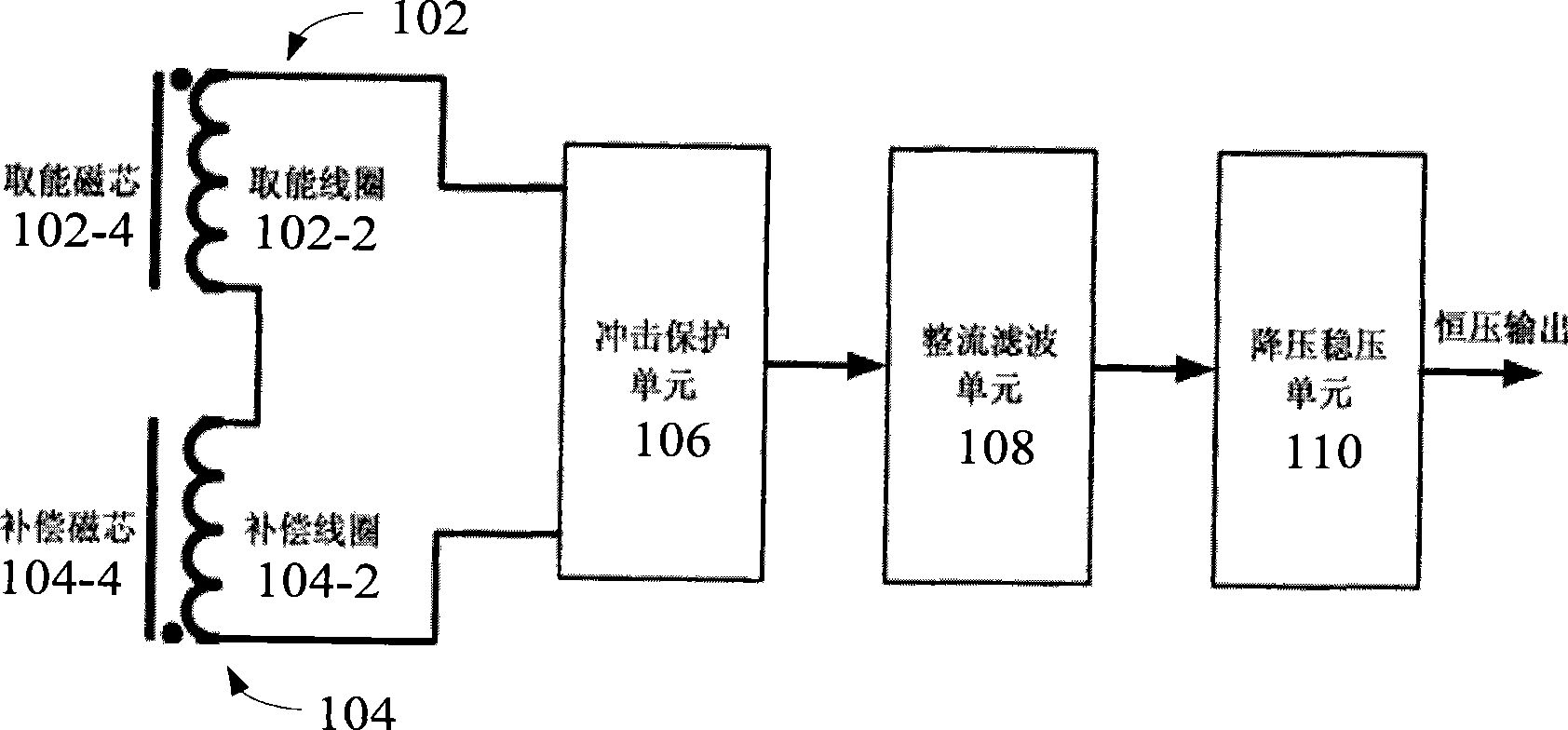

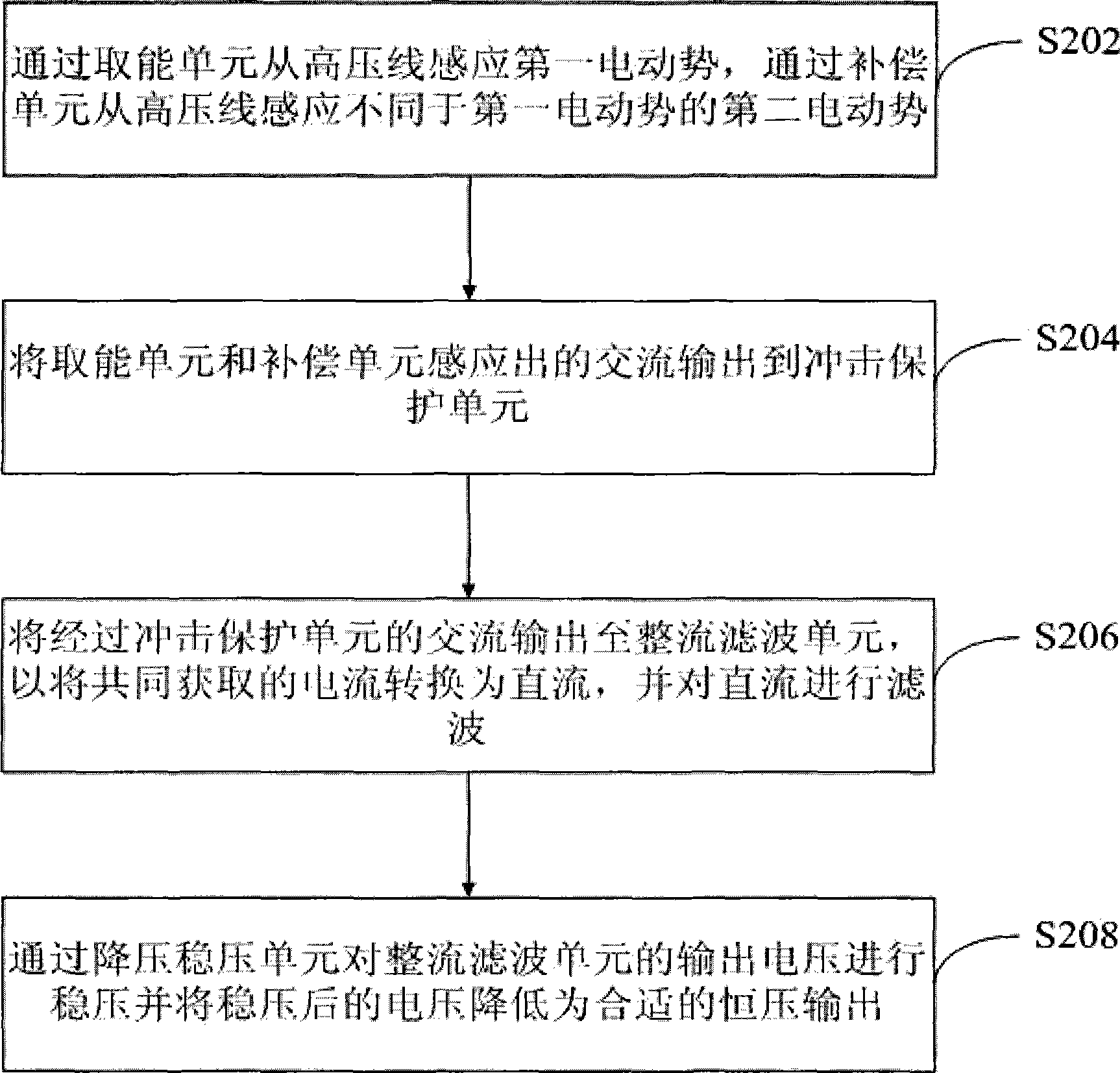

High voltage induction energy fetching power supply and method for obtaining power from high voltage line

InactiveCN101442222AAc-dc conversion without reversalElectromagnetic wave systemInitial permeabilityHigh tension line

The invention provides a high-voltage inductive energy acquiring power supply and a method for acquiring the power supply from a high-voltage wire. The high-voltage inductive energy acquiring power supply comprises an energy acquiring unit for inducing a first electromotive force from the high-voltage wire, a compensating unit for inducing a second electromotive force different from the first electromotive force from the high-voltage wire and reversely compensating a part of the first electromotive force through the second electromotive force to finally balance output voltage, a surge protection unit connected to the energy acquiring unit and the compensating unit respectively, a rectifying filter unit connected to the surge protection unit and used for converting alternating current acquired by the energy acquiring unit and the compensating unit together into direct current and filtering the direct current, and a voltage reducing and stabilizing unit for stabilizing output voltage of the rectifying filter unit and reducing the stabilized voltage to be proper constant pressure output. Through introducing a compensating coil, the method uses difference of initial permeability of different magnetic materials to generate different electromotive forces to be reversely counteracted, so as to achieve wide-range compensation, output steady power, simplify circuits and reduce heat consumption.

Owner:梁明

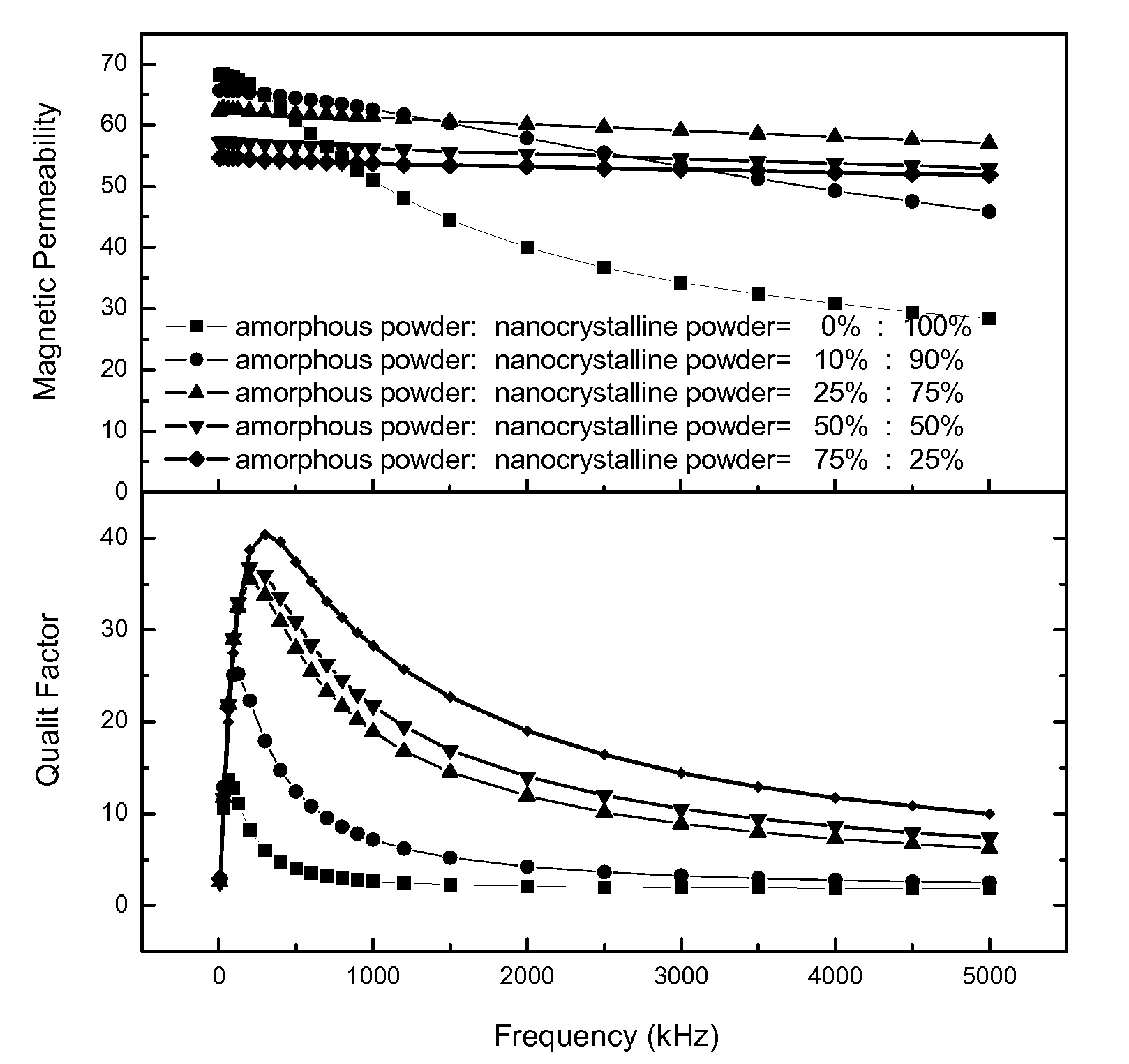

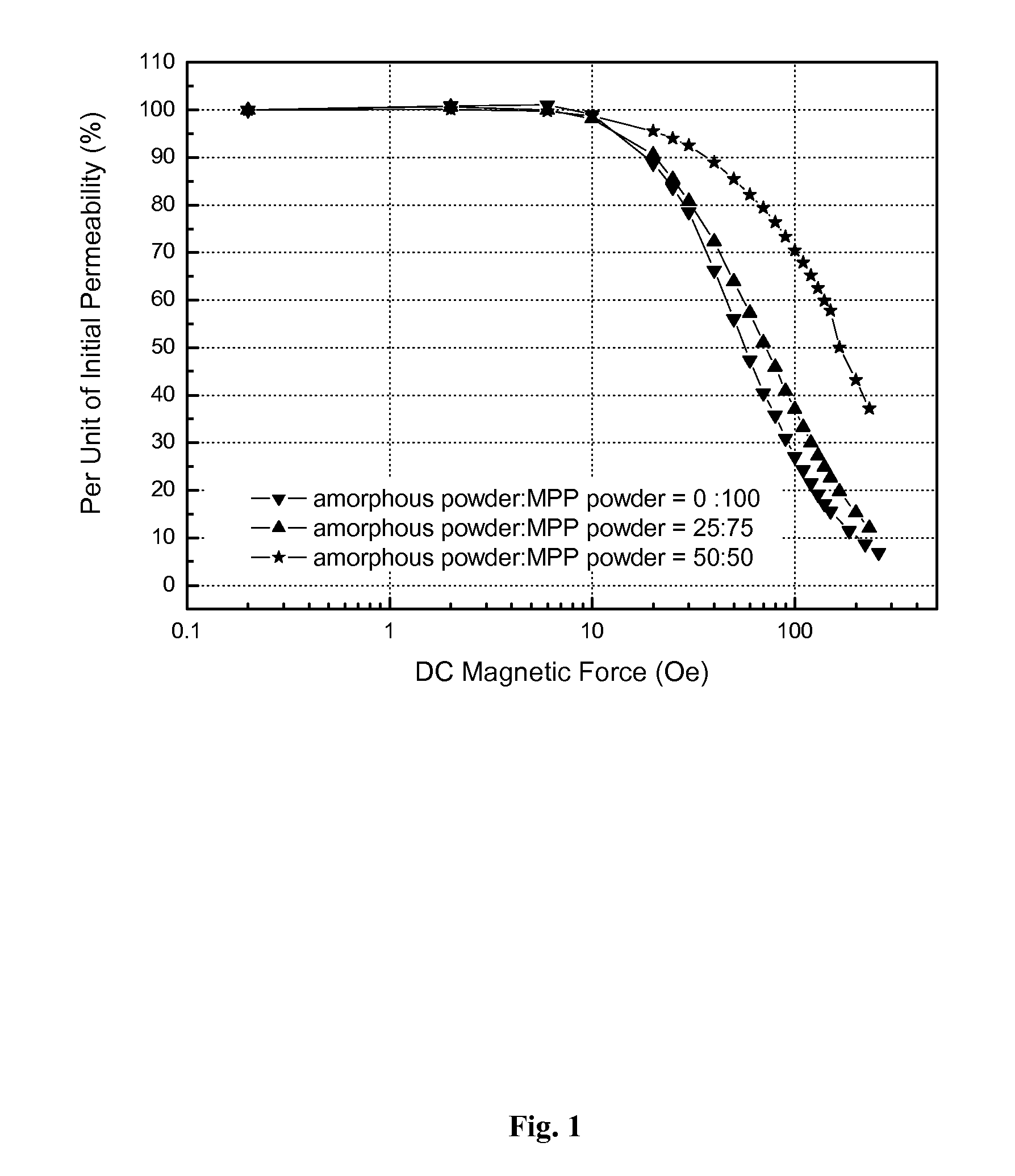

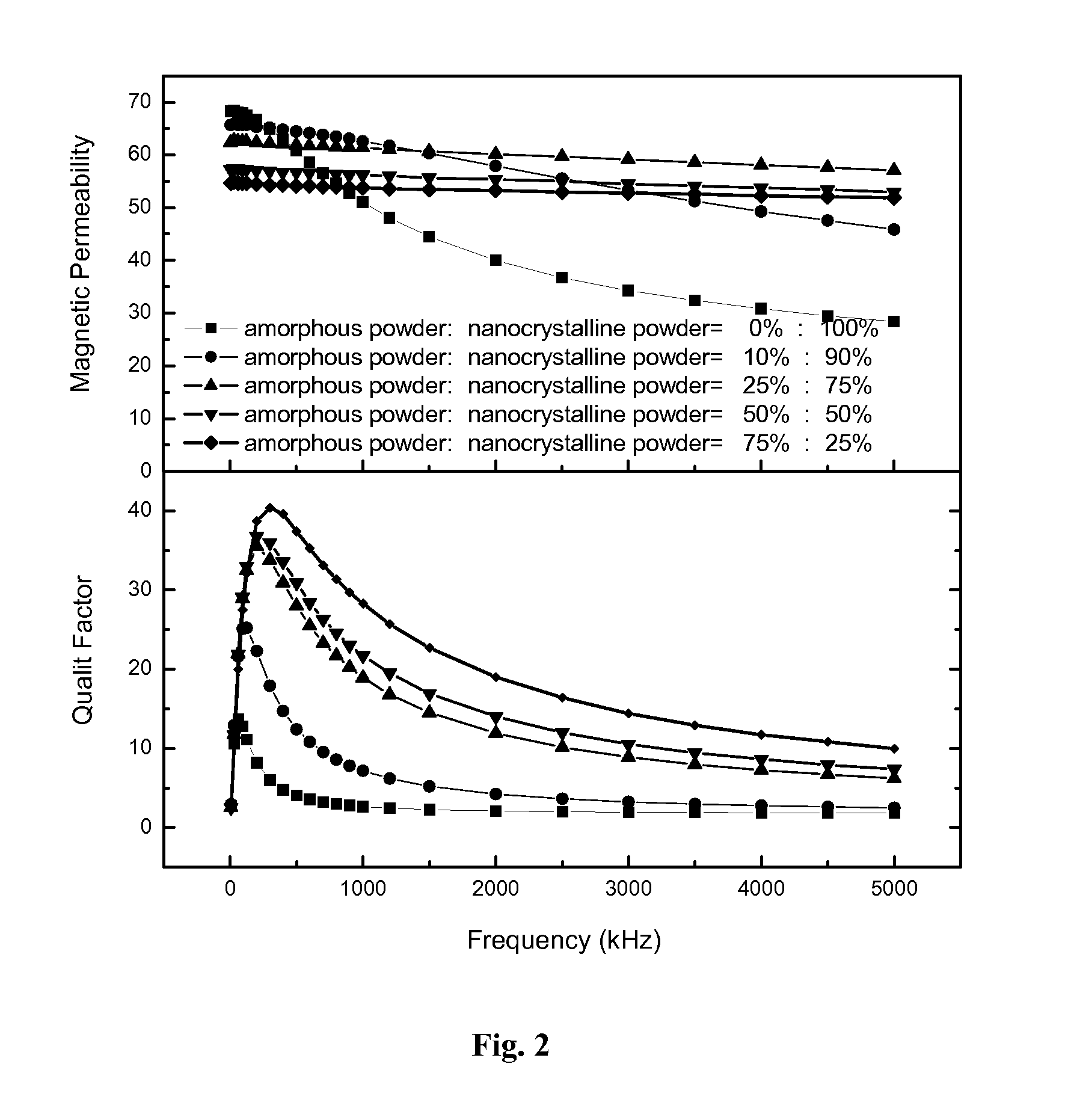

Compound magnetic powder and magnetic powder cores, and methods for making them thereof

ActiveUS20070144614A1Reduce penetrationLow core lossTransportation and packagingMetal-working apparatusAl powderIron powder

The present invention provides a compound powder for making magnetic powder cores, a kind of magnetic powder core, and a process for making them. Said compound powder is a mixture composing of powder A and powder B, the content of powder A is 50-96 wt % and the content of powder B is 4-50 wt %, wherein powder A is at least one selected from iron powder, Fe—Si powder, Fe—Si—Al powder, Fe-based nanocrystalline powder, Fe-based amorphous powder, Fe—Ni powder and Fe—Ni—Mo powder; powder B bears different requirement characteristics from powder A and is at least one selected from iron powder, Fe—Si powder, Fe—Si—Al powder, Fe-based nanocrystalline powder, Fe-based amorphous powder, Fe—Ni powder and Fe—Ni—Mo powder. Said powder B adopts Fe-based amorphous soft magnetic powder with good insulation property as insulating agent and thus core loss of magnetic powder core decreases. The decrease of magnetic permeability of magnetic powder core resulting from a traditional insulating agent is remedied and the initial magnetic permeability of magnetic powder core is improved by taking advantage of soft magnetic properties of Fe-based amorphous powder.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

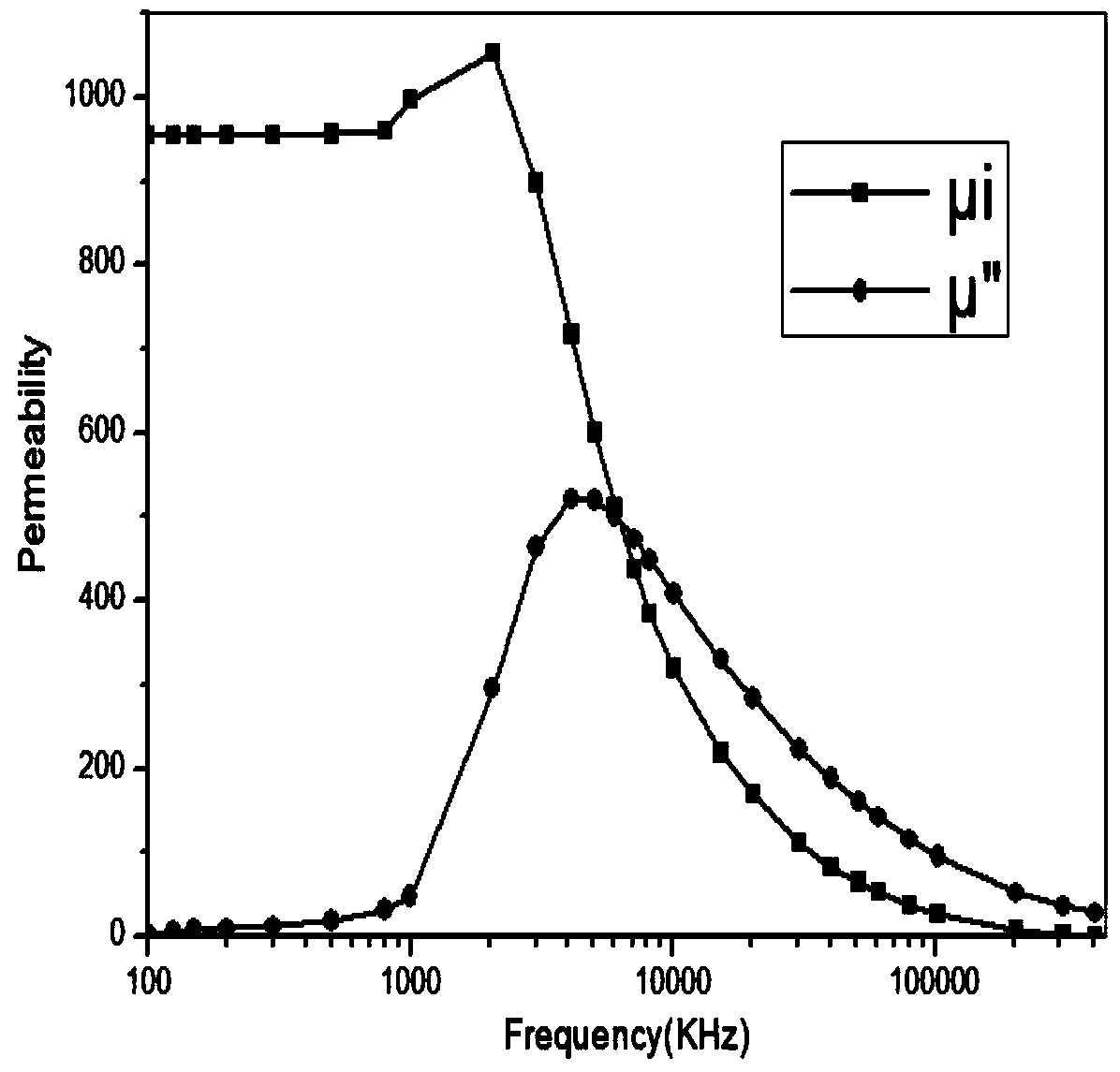

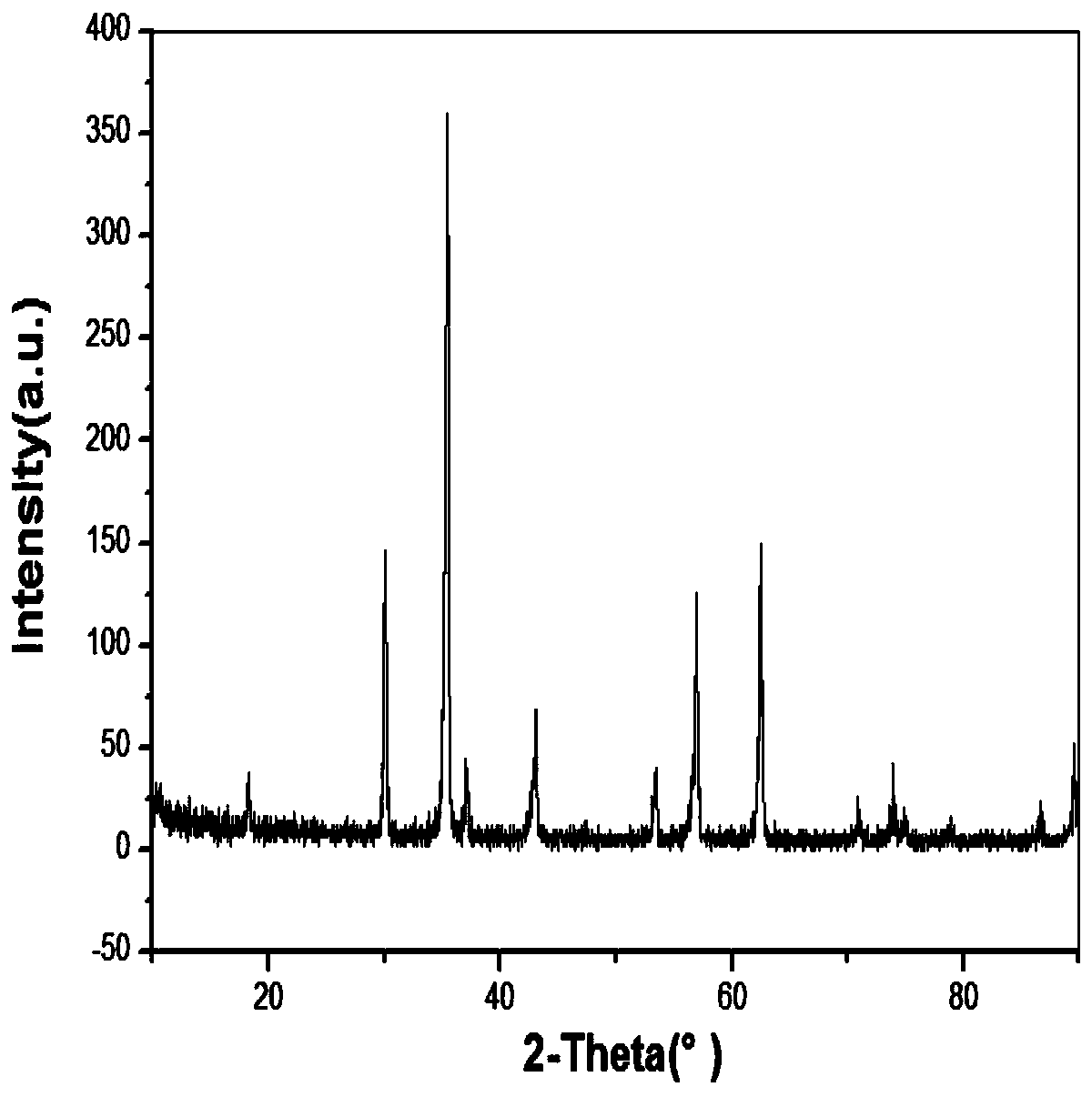

NiCuZn ferrite material and preparation method thereof

The invention relates to a NiCuZn ferrite material under the application background of being taken as a shielding material in wireless charging and a preparation method of the NiCuZn ferrite material. The NiCuZn ferrite material comprises main components and doping components based on oxide, the main components in molar percentage are as follows: 48.5-49.5mol% of Fe2O3, 25-29mol% of ZnO, 11.5-20.5mol% of NiO and 5-9.5mol% of CuO; the percentage by mass of the doping component V2O5 is more than or equal to 0 and less than or equal to 0.12wt%. The preparation method adopts the traditional oxide sintering preparation process and comprises the following steps: (1) mixing raw materials, (2) presintering, (3) doping, (4) carrying out secondary ball milling, (5) pelletizing and moulding, and (6) sintering. The prepared NiCuZn ferrite material has the advantages that initial permeability mu i is 950-1000 in frequency interval of 100-200KHz, power loss Pcv at 100KHz, 100mT and 25 DEG C is 460-500mW / cc, saturation induction density Bs is more than or equal to 360mT, and coercive force Hc is less than 32A / m; requirements of the ferrite material taken as the shielding material during the wireless charging of low power loss Pcv, low Hc, high mu i and high Bs can be met.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

A nickel-copper-zinc ferrite and its making method

InactiveCN101236819AUniform grain sizeUniform sizeInorganic material magnetismCurie temperatureVanadium oxide

The invention relates to a nickel-copper-zinc ferrite and a manufacturing method thereof. The ferrite of the invention comprises principal constituents and auxiliary constituents, wherein, the principal constituents are respectively iron oxides, nickel protoxide, zinc oxides and cupric oxides; the contents of the principal constituents calculated by respective reference substances are that: 48 mol percent to 50 mol percent Fe2O3, 13 mol percent to 16 mol percent NiO, 29 mol percent to 31.5 mol percent ZnO and 4.5 mol percent to 6.5 mol percent CuO; the auxiliary constituents comprise vanadium oxides, molybdenum oxides and titanium oxides; compared with the gross of the principal constituents, the total content of the auxiliary constituents calculated by respective reference substances V2O5, MoO3 and TiO2 is 0.01 weight percent to 0.08 weight percent. The nickel-copper-zinc ferrite has higher Curie temperature and high initial permeability, high saturation magnetic flux density and low loss under the condition of wide-temperature range, thereby comprehensive performance requirements of development of electric equipment towards directions of miniaturization, mobilization, integration and multifunction can be better met.

Owner:RUYUAN DONGYANGGUANG MAGNETIC MATERIAL

Low-total harmonic distortion (THD) wideband high-permeability MnZn ferrite material and manufacturing method thereof

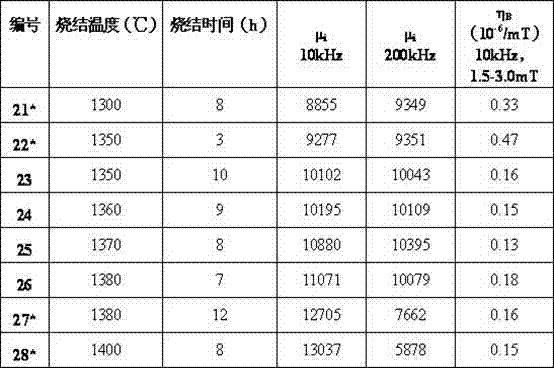

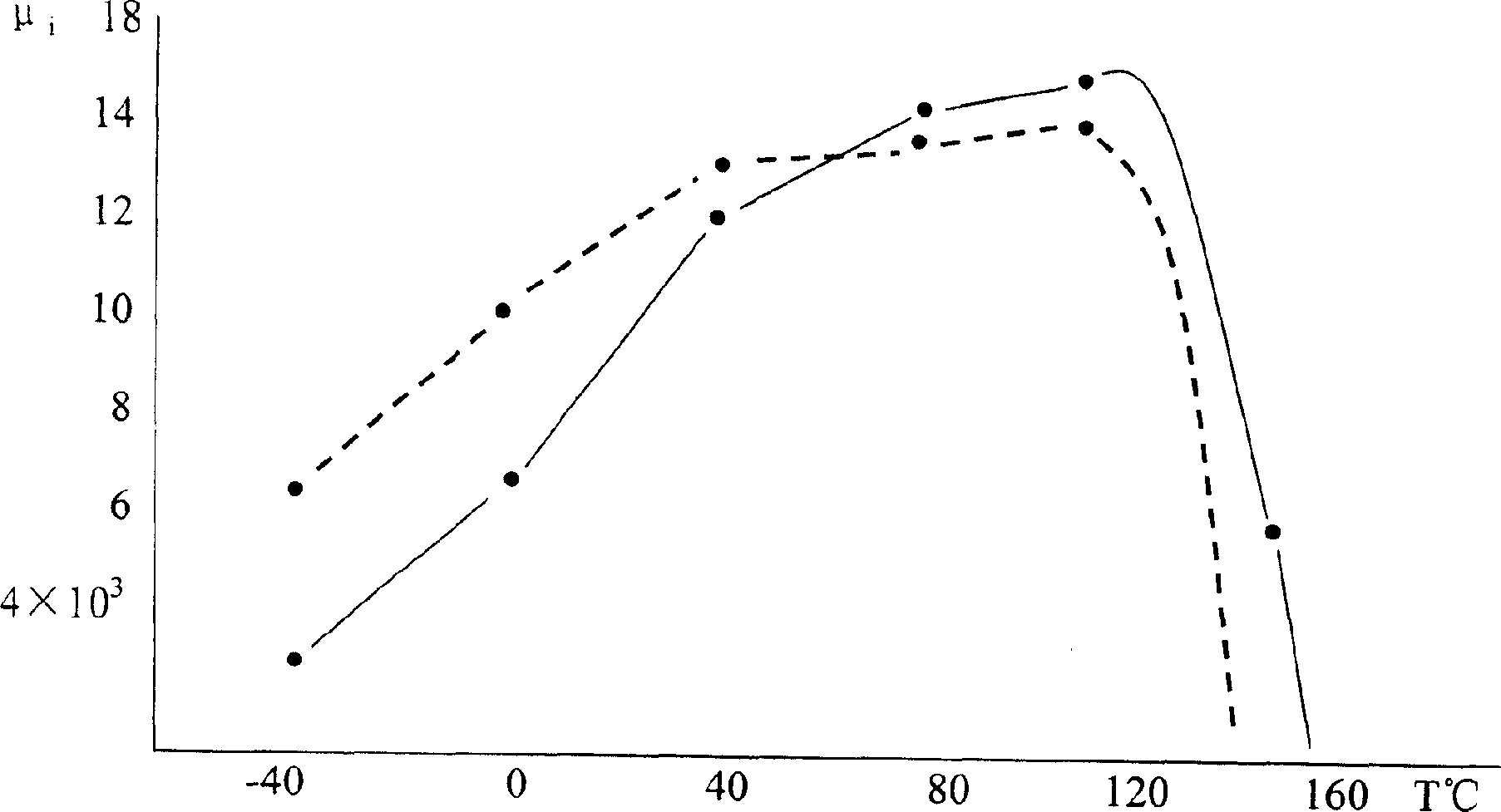

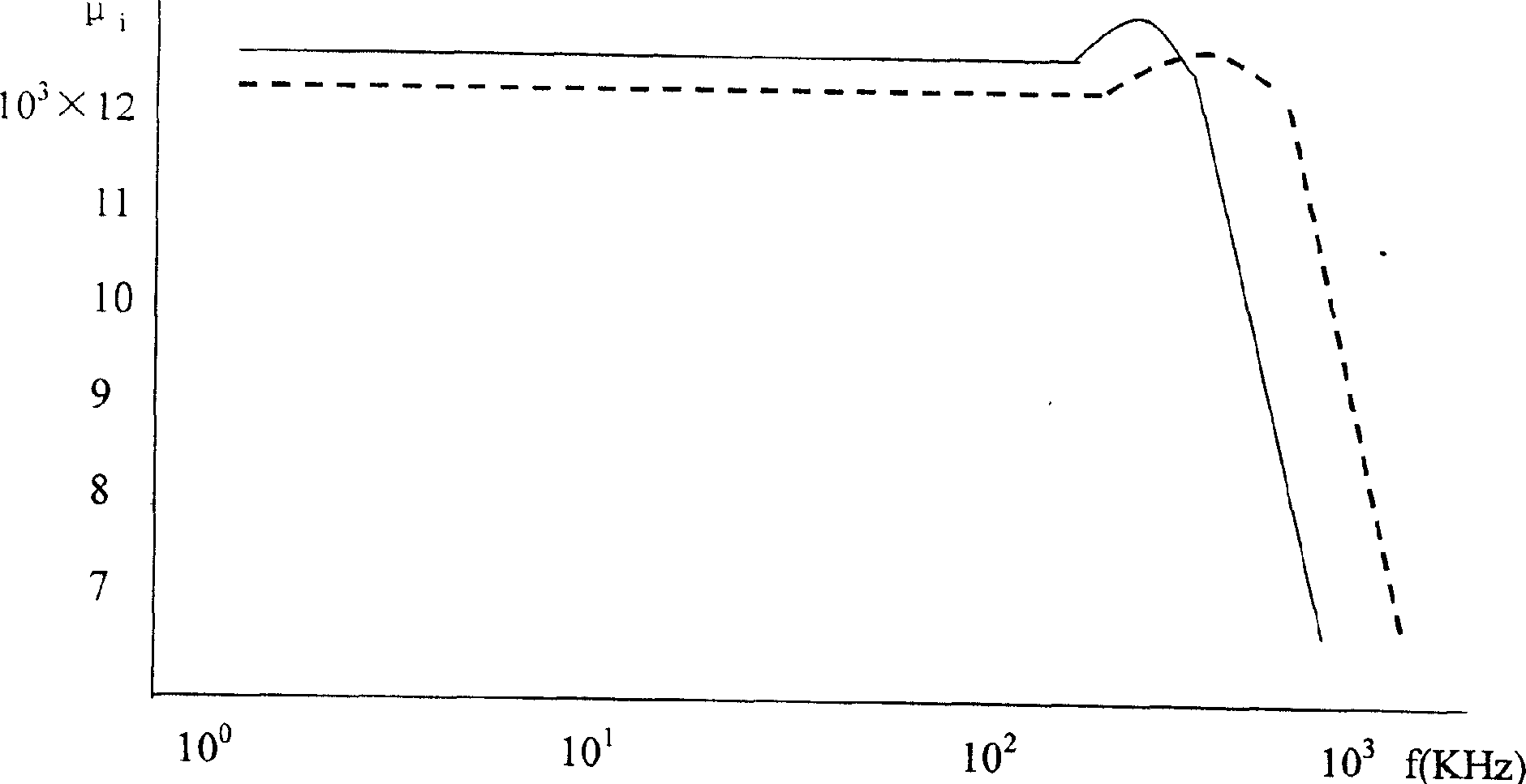

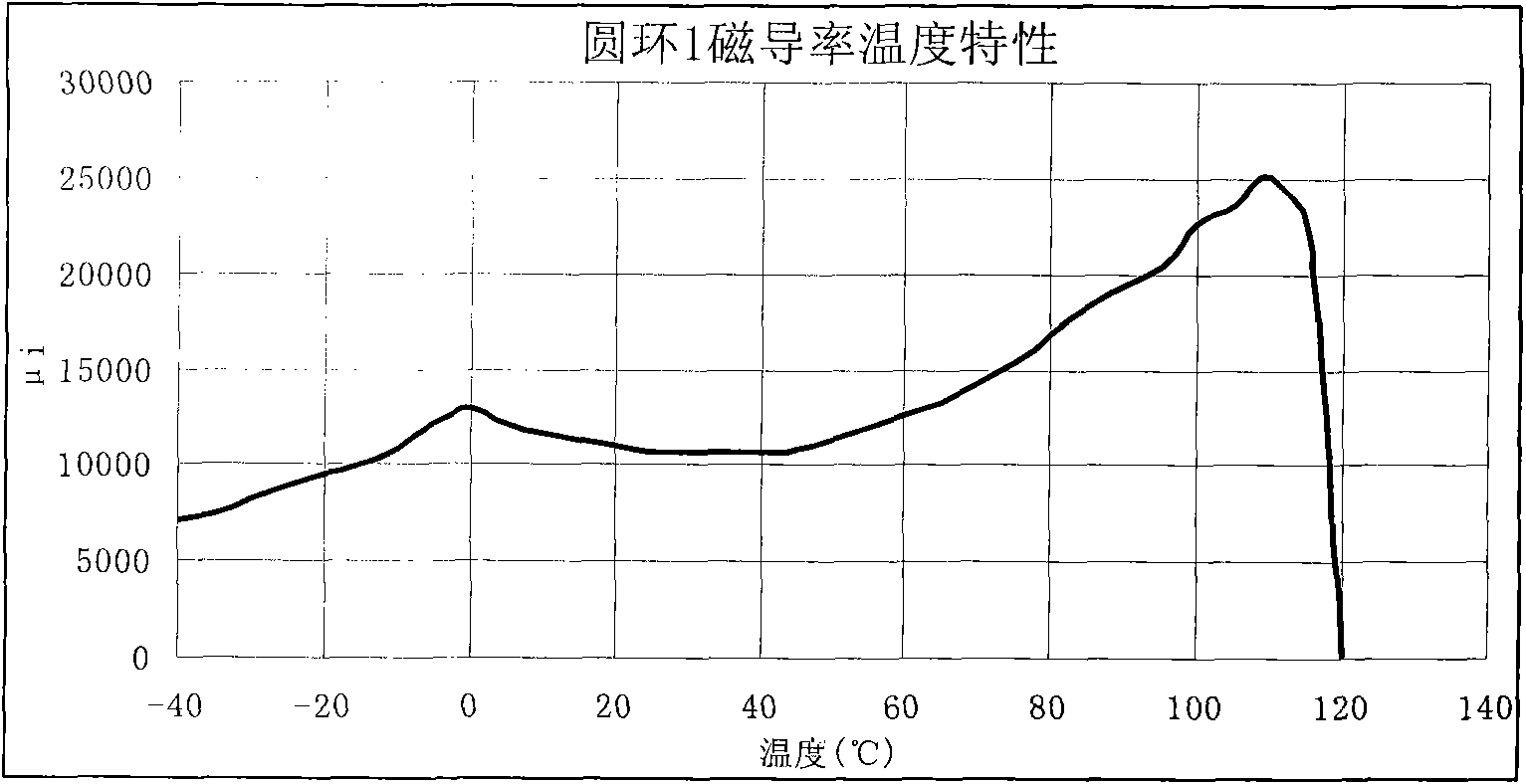

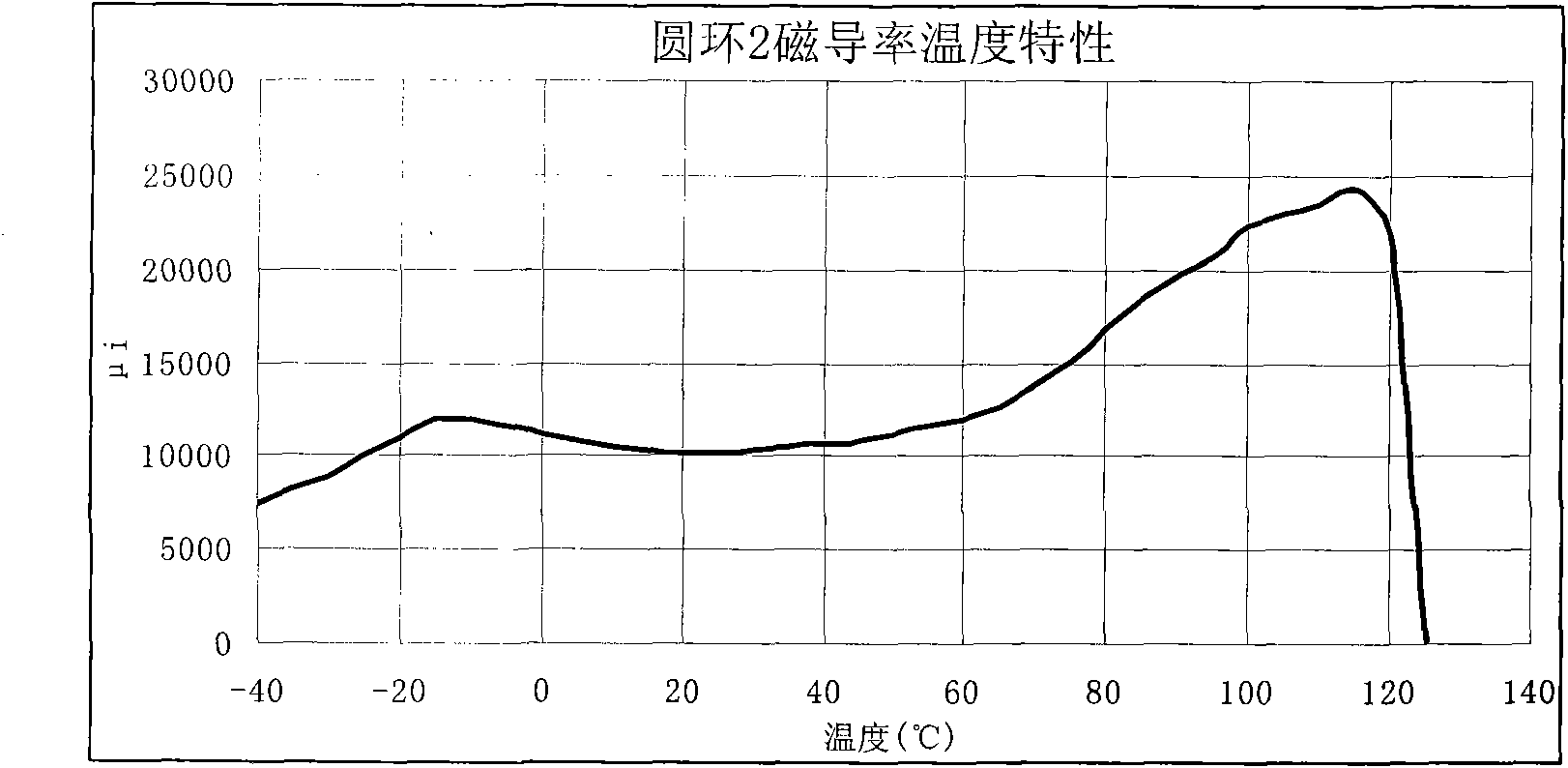

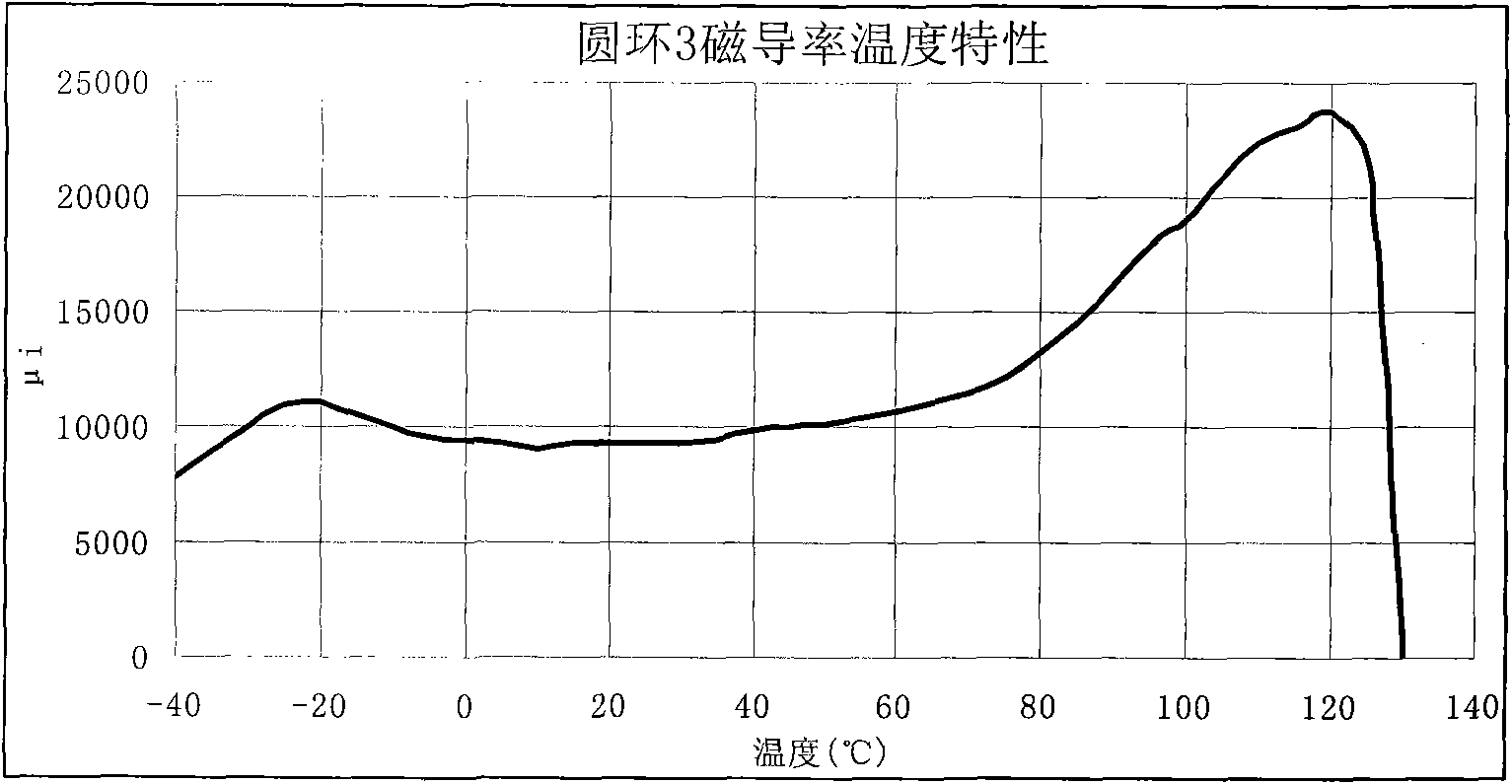

InactiveCN102231312AAccurate and efficient establishmentGood temperature characteristicsInorganic material magnetismHysteresisCompression molding

The invention provides a low-total harmonic distortion (THD) wideband high-permeability MnZn ferrite material, which comprises the following principal components of: 51.5 to 53 mol percent of Fe2O3, 22 to 27.5 mol percent of Mn3O4 based on MnO, and 20 to 25 mol percent of ZnO; and auxiliary components are at least four of TiO2 (or SnO2), Co2O3, MoO3, Bi2O3, SiO2, CaCO3 and Nb2O5, wherein the total weight of the auxiliary components is 0.02 to 0.04 weight percent of that of the principal components. In the low-THD wideband high-permeability MnZn ferrite material, an initial permeability at a low frequency of 10kHz and a high frequency of 200kHz at the temperature of 25 DEG C is not less than 10,000, and a hysteresis constant etaB is less than 0.2*10<-6> / mT. The invention also provides a method for manufacturing the low-THD wideband high-permeability MnZn ferrite material, which comprises the following steps of: mixing, drying, presintering, ball milling, pelleting, compression molding and sintering. The method has the advantages of simple process and low cost.

Owner:江门安磁电子有限公司

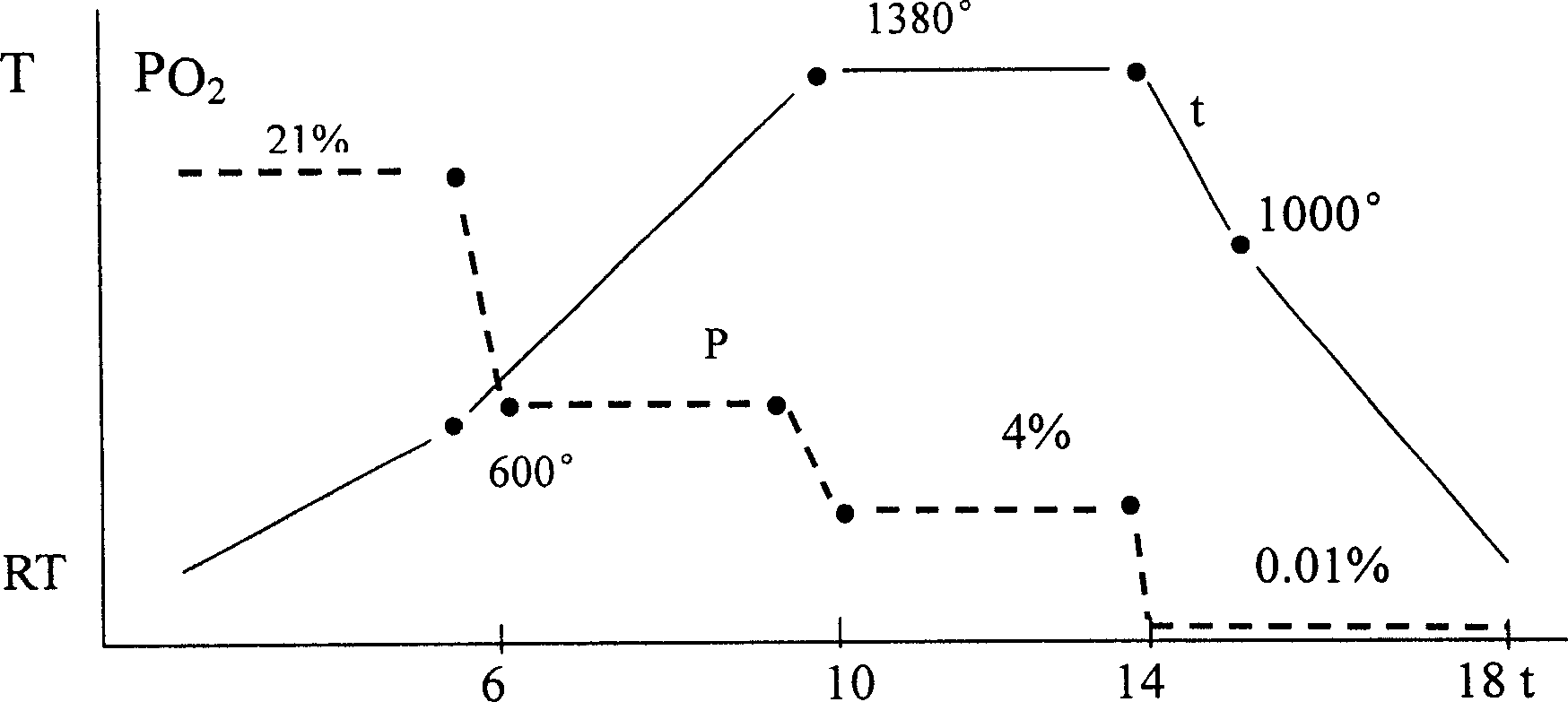

Ferrite magnet material of manganese-zinc, and Method for preparing high conductive ferrite of manganese-zinc from material

ActiveCN1697094AIncrease temperatureImprove performanceInorganic material magnetismManganese oxideTitanium oxide

Mixed main material including 51.5-52.8 mol% ferric oxide, 23.3-26.0 mol% manganese oxide, and 22.5-24.0 mol% zinc oxide is processed through shake grinding and pre-burning procedures. Next, auxiliary materials including 500-1000ppm calcium oxide, 300-1500ppm titanium oxide and 100-400ppm bismuth oxide are added to the said processed main material. Then, procedures including sand mill, granulation, body blank and burning are carried out in sequence to produce products. Advantages are: reasonable compounding ratio between main and auxiliary materials provides precondition for producing the disclosed product in high magnetic permeability and low coefficient of specific loss; optimized curve of agglomeration technology prevents oxidation of products, and improves temperature and even atmosphere in kiln. The product shows preferred initial permeability, coefficient of specific loss and coefficient of specific temperature.

Owner:SUZHOU GUANDA MAGNET

Coating method of winding amorphous iron core insulating coating

ActiveCN103128039AWith strengthUniform thicknessPretreated surfacesInductances/transformers/magnets manufactureEpoxyCoated surface

The invention relates to a coating method of a winding amorphous iron core insulating coating. The coating method comprises a first step that a whole amorphous iron core is arranged in epoxy glue to conduct vacuum impregnation, a second step that the surface of the amorphous iron core is coated with epoxy resin, and a third step of heating and solidifying after the amorphous iron core is coated with the modified epoxy glue coating. Gaps between amorphous strips are sealed and have certain strength after the epoxy glue impregnation, the coating is neat in surface and uniform in thickness, vibration and noises of the iron core are reduced, and integrated installation is convenient. The coating is thinner than general coating technique and solidifying time is shortened. The epoxy glue enables solidifying contraction percentage to be low, the epoxy glue coating has good adhesiveness and elasticity and has little stress to the iron core, and the coating has little influence on initial magnet conductivity and inductance of the amorphous iron core. The amorphous iron core dealt with the coating method can greatly reduce no-load loss.

Owner:SHANGHAI ELECTRICGROUP CORP

Co-based magnetic alloy and magnetic members made of the same

Disclosed is a Co-base magnetic alloy excellent in high-frequency magnetic properties, of which chemical composition is represented by the following general formula, by atomic %, (Co1-aFea)100-y-cM'yX'c, where M' is at least one element selected from the group consisting of V, Ti, Zr, Nb, Mo, Hf, Sc, Ta and W; X' is at least one element selected from the group consisting of Si and B; and a, y and c are defined by the formulas of a<0.35, 1.5<=y<=15, and 4<=c<=30, respectively. At least a part of the alloy structure of the alloy consists of crystal grains having an average grain size of not more than 50 nm. The alloy has a relative initial permeability of not more than 2000. It is suitably used for members of countermeasure against noise such as zero phase reactors for large current and electromagnetic shielding materials, inverter transformers, choke coils for active filters, antennas, smoothing choke coils, power supplies for lasers, pulse power magnetic members for accelerators.

Owner:HITACHI METALS LTD

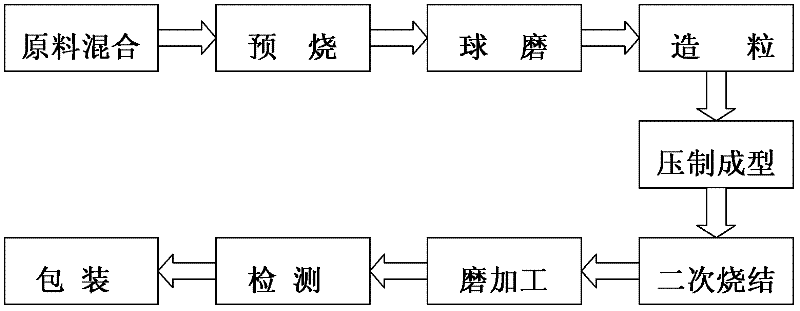

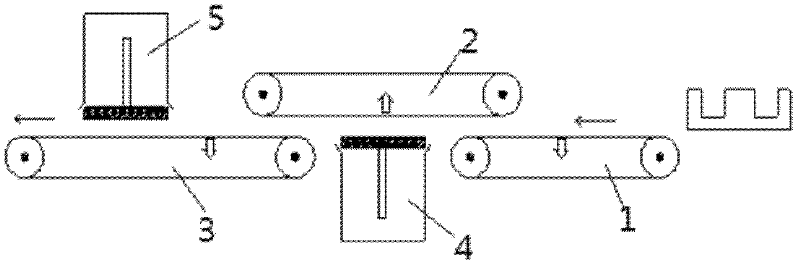

Method for producing soft magnetic ferrite core

InactiveCN102643083AImprove permeabilityLow dissipation factorEdge grinding machinesPolishing machinesInitial permeabilitySoft magnet

The invention discloses a method for producing a soft magnetic ferrite core. The method comprises the following steps of: mixing of raw materials, pre-sintering, ball milling, compression moulding, secondary sintering, grinding and detection, wherein an integral magnetic-attraction double-sided grinding machine is adopted in the grinding process. The magnetic core produced by the method has high magnetic conductivity and low loss factor, and energy sources can be saved; the magnetic core has uniform color, flat end surface and bright and clean surface; the ball milling as well as the uniformity and sphericity of the mixed material are improved; a low-temperature sintering technology is adopted, the heating rate and cooling rate of each stage are adjusted, the ferrite transformation of the material is promoted, and the grain size can be effectively controlled; and the initial permeability and temperature characteristic are improved.

Owner:ANHUI TAIDE ELECTRONICS TECH

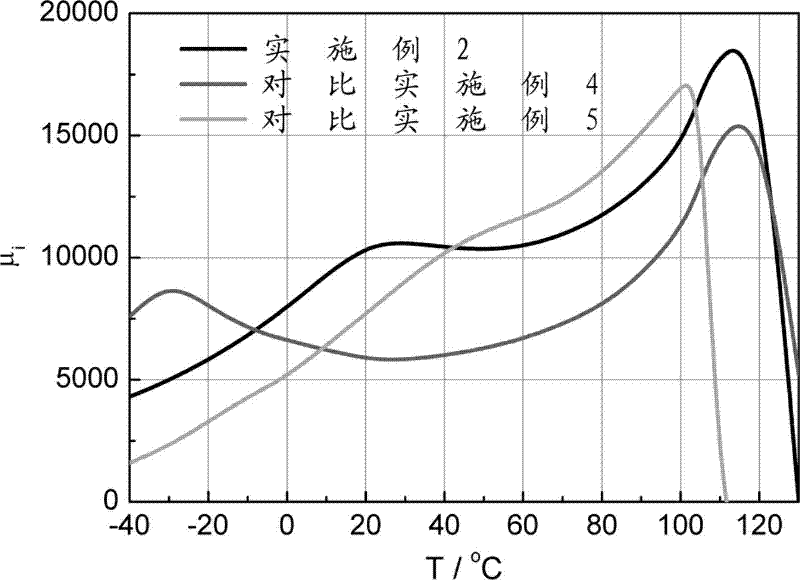

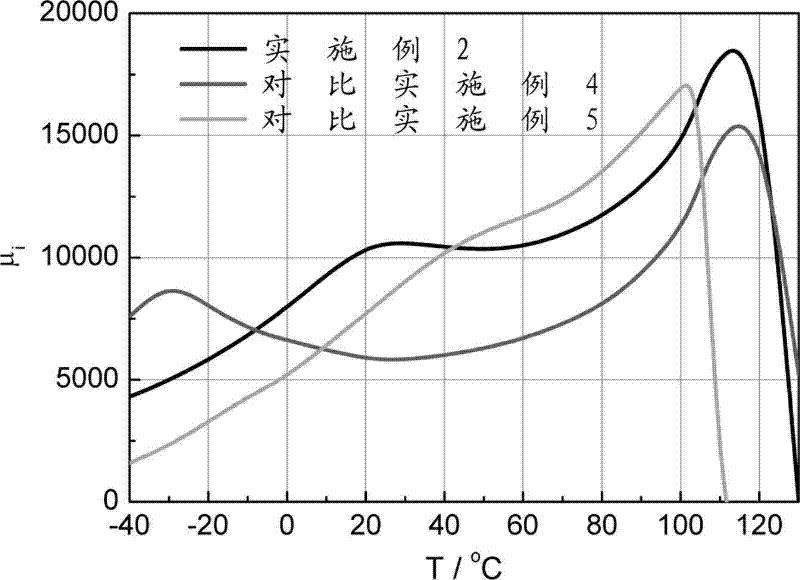

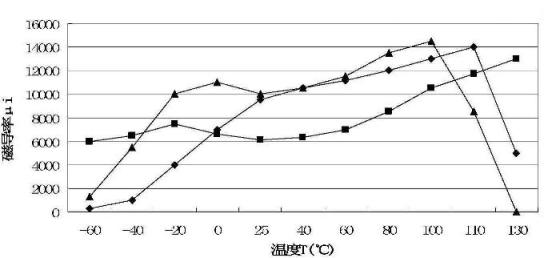

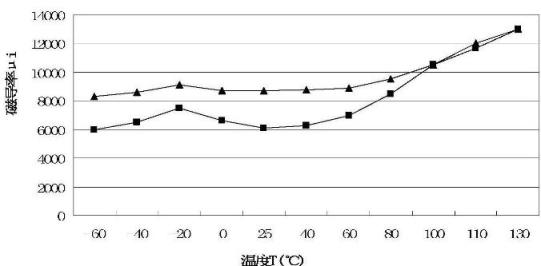

Mn-Zn ferrite material with wide temperature and high initial magnetoconductivity and preparation method thereof

The invention belongs to the field of soft magnetic ferrite, particularly relates to a Mn-Zn ferrite material and provides a Mn-Zn ferrite material with a high initial magnetoconductivity in a wide temperature scope. The Mn-Zn ferrite material is prepared by main components and auxiliary components. The main components are as follows: 51-56 mol% of ferric oxide, 16-26 mol% of zinc oxide and the balance manganese oxide; the auxiliary components comprise one or a combination of more of 50-500ppm of calcium oxide, 50-1000ppm of bismuth oxide, 50-800ppm of molybdenum oxide, 50-800ppm of vanadium oxide or 50-800ppm of indium oxide based on the total weight amount of the main components. In a preferred proposal, one or a combination of more of zirconium oxide, titanium oxide, cobalt oxide or niobium oxide is further added in the auxiliary components. The Mn-Zn ferrite material of the invention is prepared according to a production process of a conventional drying method, and has the characteristic that the initial magnetoconductivity mui is above 5000 within a temperature zone of minus 60 DEG C-130 DEG C, thereby meeting the requirement of electronic devices on a magnetic core with high magnetoconductivity at a lower temperature.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

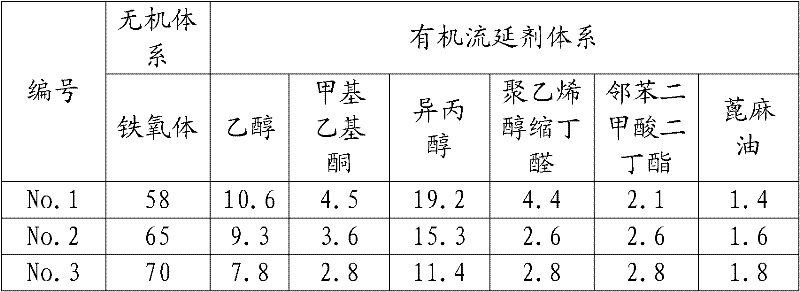

Soft magnetic iron core press formed from powdered iron in automobile ignition coil and its manufacturing method

InactiveCN1414577AHigh densityHigh strengthInorganic material magnetismTransformers/inductances magnetic coresAlcoholInitial permeability

A method to produce soft magnetic core formed by iron powder pressed in ignition coil of automobile uses iron powder and phenolic resin as a raw materials and the iron core is made in the shape of cylinders and rings which are formed by pressing with its manufacturing flow process as preparing iron magnetic powder to be formed by mould pressing-solidifying treatment. The detail process includes putting iron powder into alcohol solution of phenolic resin for obtaining the iron magnetic powder by granulating with sticking and cladding, putting the iron magnetic powder into a mould for obtainingthe primary piece by cold or warm pressing, carrying out the secondary solidifying as well as the treatments of antirust and insulation after the primary piece being processed by solidifying with thetemperature rising step by step.

Owner:李延军

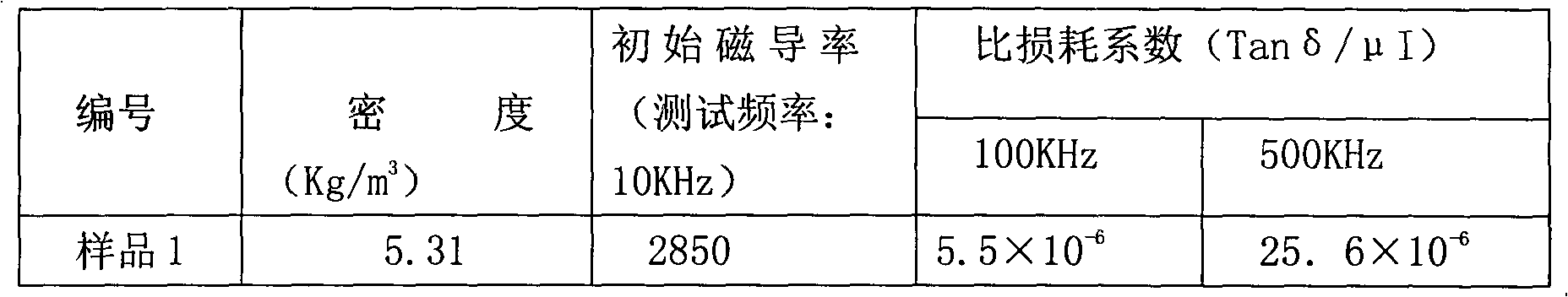

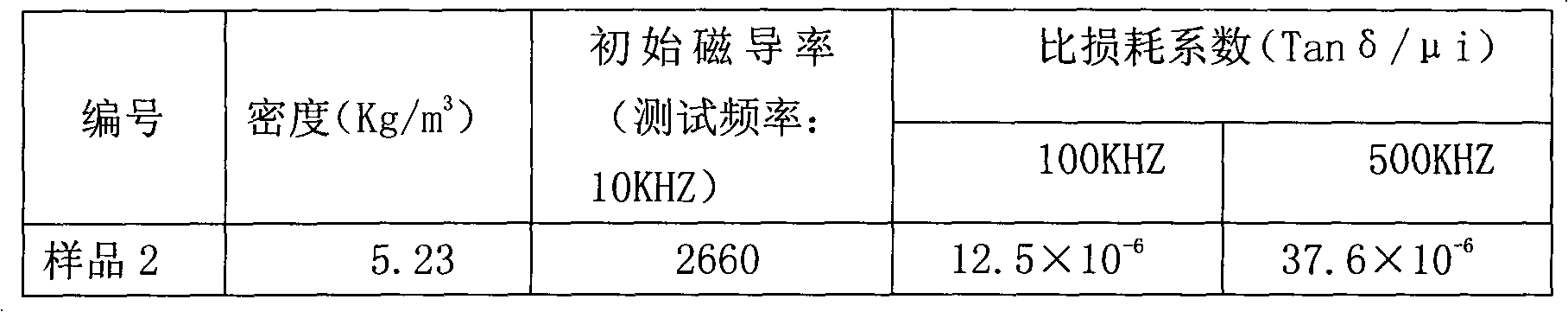

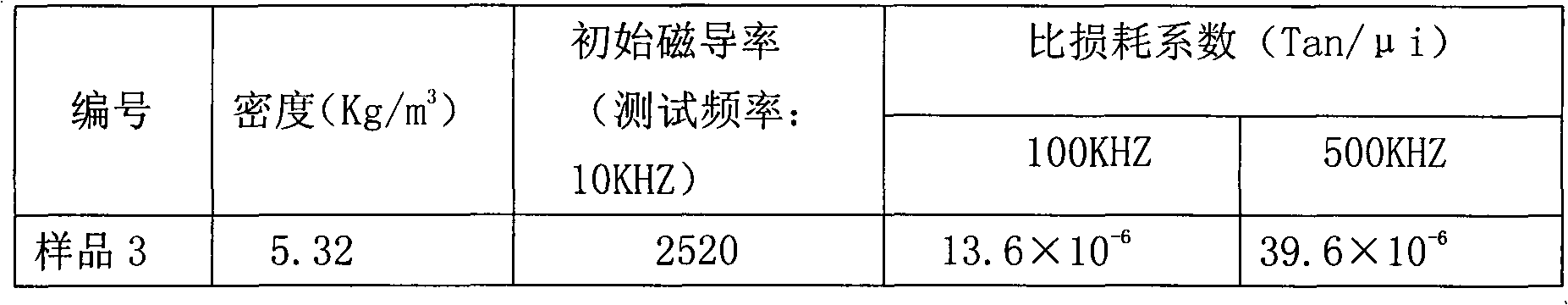

Low-temperature sintered high-permeability NiCuZn ferrite material

The invention discloses a low-temperature sintered high-permeability NiCuZn ferrite material for a wire wound chip inductor and a preparation method of the ferrite material. The ferrite material comprises the following main components based on oxide content: 40.5 to 49.6 moles percent of Fe2O3, 30 to 47 moles percent of ZnO, 5 to 20 moles percent of CuO and the balance of NiO. The preparation method comprises the following steps of: (1) mixing raw materials, (2) performing primary sanding, (3) performing primary spray drying and granulation, (4) pre-sintering, (5) adding trace elements, (6) performing secondary sanding, (7) performing secondary spray drying and granulation, (8) molding and (9) sintering. By adding auxiliary components such as NaCO3, B2O3, Ta2O5 and the like, the sintering temperature is greatly reduced, the sintering temperature is below 900 DEG C, the high-frequency electromagnetic performance of the material is greatly improved, the sintering density of the material is improved, the mechanical strength of the material is improved, and the manufacturing process requirement of the wire wound chip inductor is met; and on the other hand, energy is saved, and the producing and manufacturing costs are greatly reduced. The initial permeability of the material is 2,850; the specific loss coefficient of the material is less than 5.5*10<-6> under the test conditions of 100 kHz and 0.25mT; and the specific loss coefficient of the material is less than 25.6*10<-6> under the test conditions of 500 kHz and 0.25mT.

Owner:TAIXING ZHONGHENG BUILDING DECORATION ENGCO

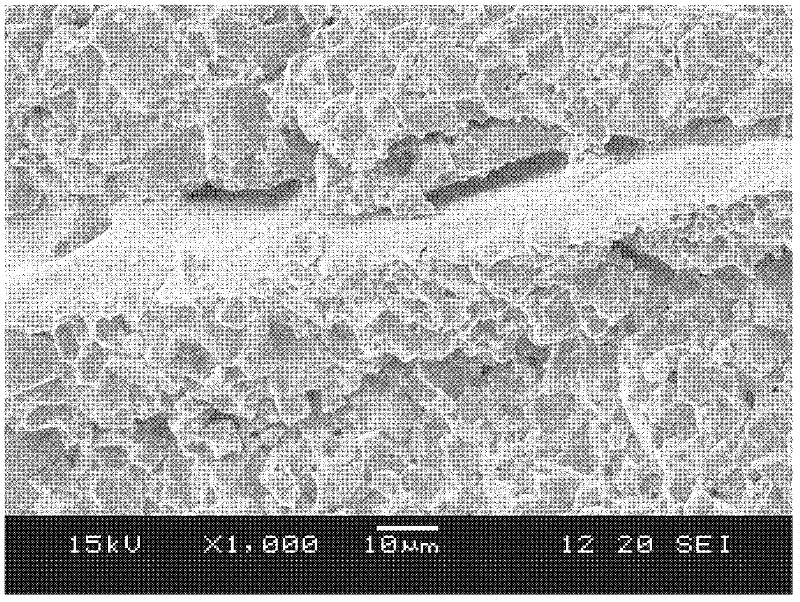

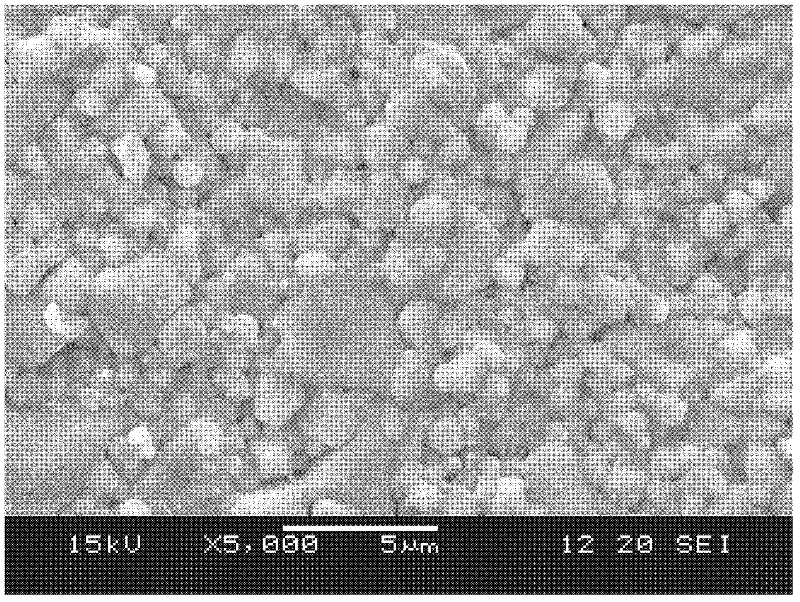

Broadband and high-magnetic-permeability ferrite teflon tape and production method thereof

The invention relates to a broadband and high-magnetic-permeability ferrite teflon tape and a production method thereof. The teflon tape comprises pre-burned ferrite powder and an organic tape casting system, wherein the pre-burned ferrite powder comprises ferric oxide, nickel oxide, copper oxide, zinc oxide, bismuth oxide and an additive, and the organic tape casting system comprises a solvent, a dispersant, a binder and a plasticizer. The LTCF (Low Temperature Cofired Ferrite) teflon tape prepared in the invention has a flat surface, is sintered at 900 DEG C for compactness, and a sintered body has an excellent performances: the initial permeability is not smaller than 450H / m at 100kHz, and the resistivity is not smaller than 109 ohm.cm. A chip inductor element manfauctured by using theteflon tape has high inductance and high quality factors, meanwhile, a low-temperature glass protective coating is coated in a silver paste circuit printing process of the inductor element, so that adevice failure caused by Ag diffusion when the device is used is prevented. Therefore, the broadband and high-magnetic-permeability ferrite teflon tape and the production method thereof have huge application prospect.

Owner:JIANGSU HUAXING ELECTRONICS CO LTD

High-frequency nickel-copper-zinc ferrite and preparation thereof

The invention relates to a high frequency nickel-copper-zinc ferrite and a method for preparing the same, which belong to the technical field of nickel series soft magnetism ferrite. The main components of the ferrite are ferric oxide, nickel oxide, zinc oxide, and copper oxide, the accessory components comprise cobalt oxide, bismuth oxide, and silicon oxide, and the ferrite is prepared by an oxide method. The invention adopts an iron deficiency formulation, a low calcination temperature, and a low sintering temperature so that the prepared high frequency nickel-copper-zinc ferrite has good performances of low initial permeability, low relative dissipation factor between 50MHz and 200MHz, and high Curie temperature, and can better satisfy the use requirement of communication electronic parts and components; besides, the preparation process is stable, and the production process has low energy consumption.

Owner:TDG HLDG CO LTD

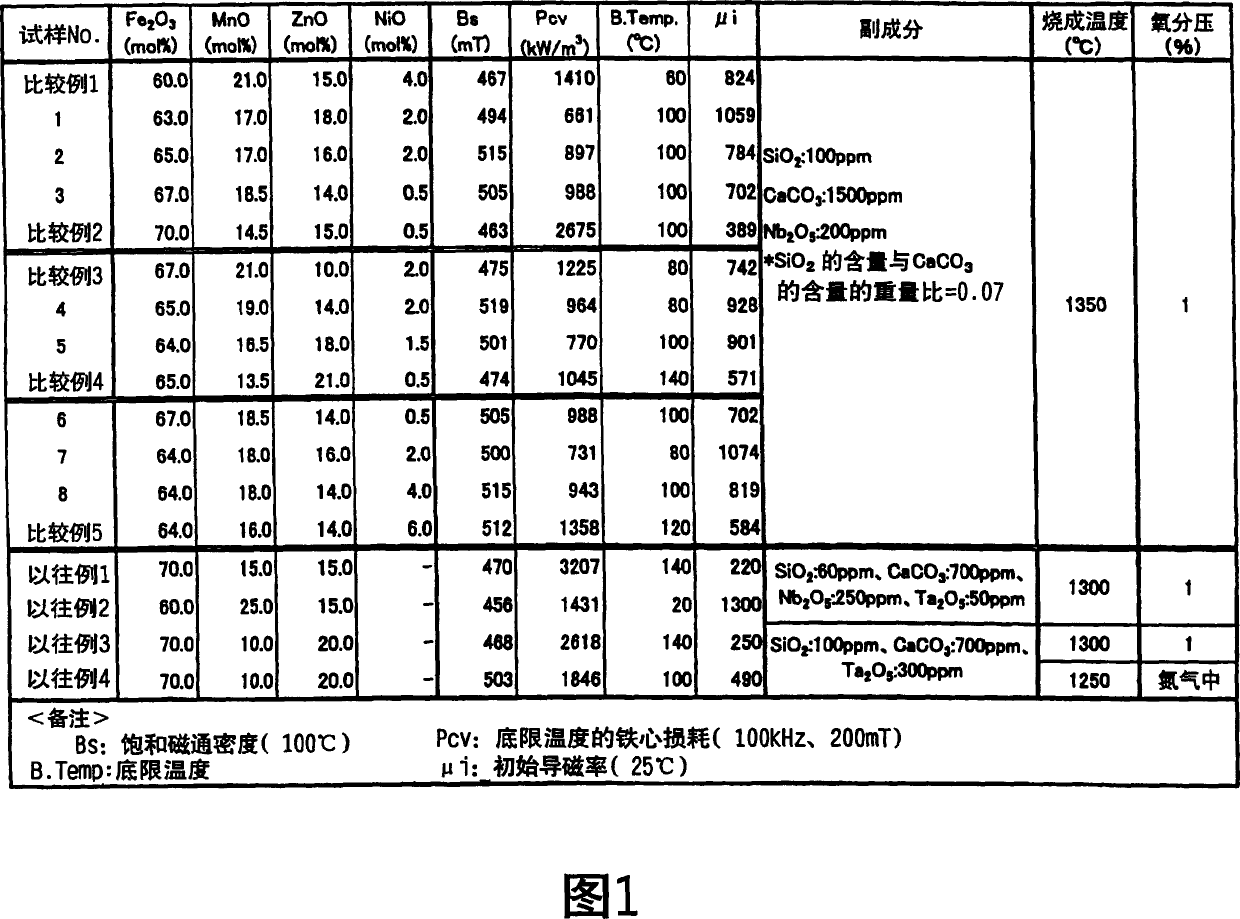

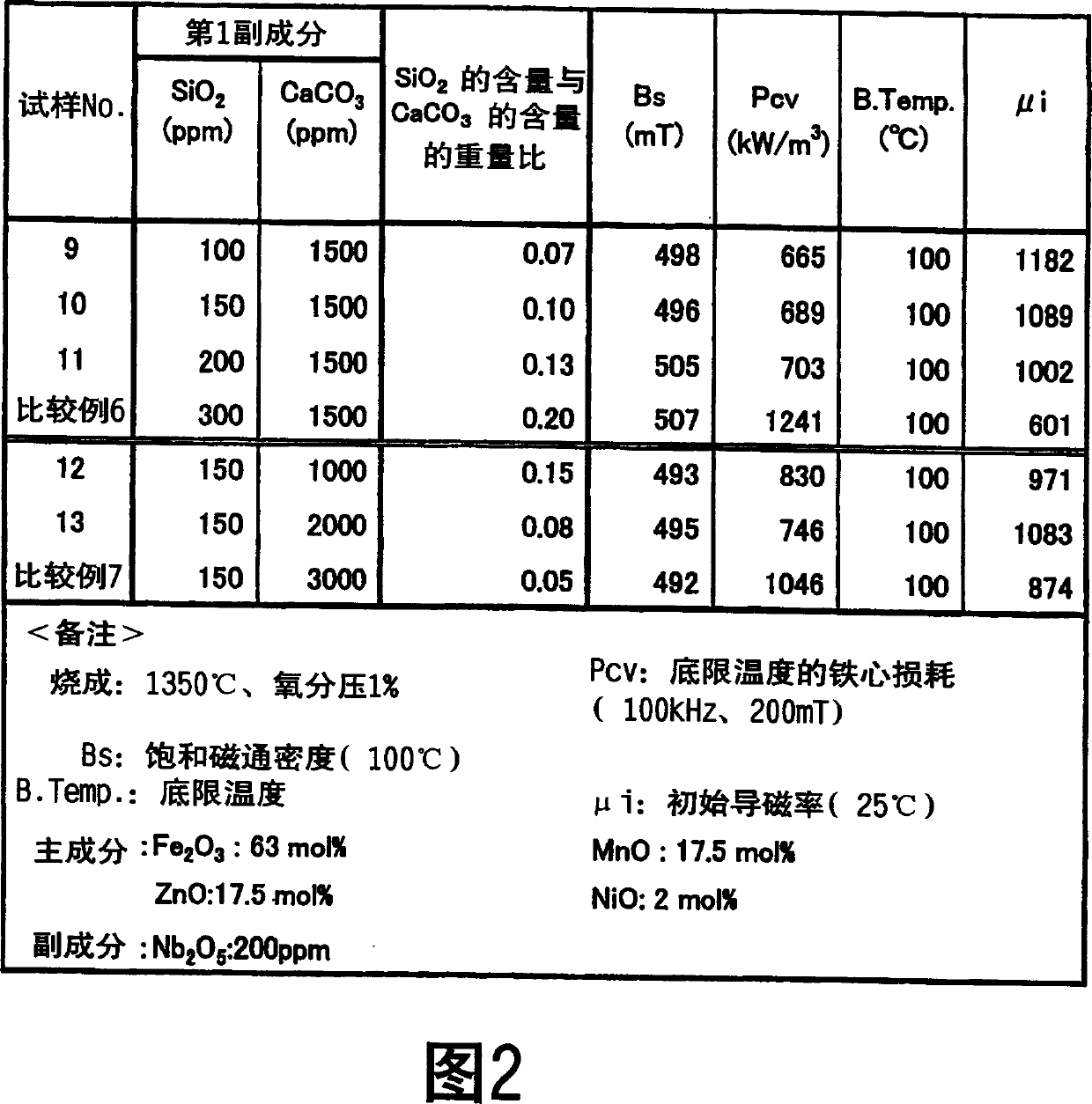

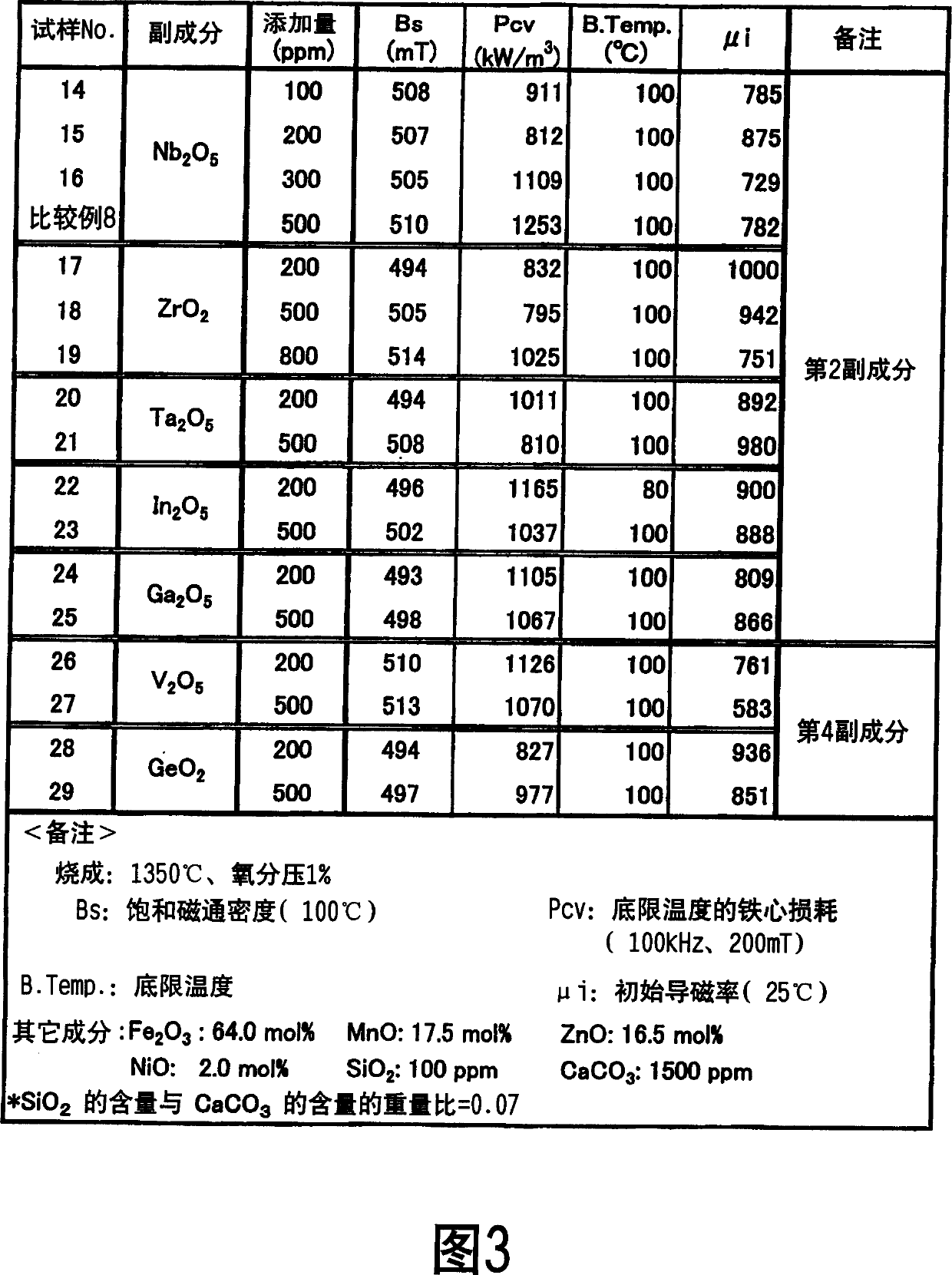

Ferrite material

InactiveCN1662470AHigh densityInorganic material magnetismIron compoundsInitial permeabilityRoom temperature

Owner:TDK CORPARATION

Wide-temperature high-permeability Mn-Zn soft magnetic ferrite material and magnetic core prepared therefrom as well as preparation method thereof

InactiveCN101913851AImprove featuresGood temperature characteristicsInorganic material magnetismCores/yokesInitial permeabilityMetallurgy

The invention discloses a wide-temperature high-permeability Mn-Zn soft magnetic ferrite material, of which a main formula comprises 50.5-52.5mol% of Fe2O3, 24.5-26.5mol% of MnO, and 21-25mol% of ZnO and simultaneously comprises the following auxiliary materials of a first auxiliary material group including one or a mixture of more than two of CaCO3, CuO, and Nb2O5 with the content of 100-500ppm, and a second auxiliary material group including one or a mixture of more than two of MoO3, BiO3 and SiO2 with the content of 100-2000ppm. At least one component in the first auxiliary material group and the second auxiliary material group forms a liquid state under high temperature, thereby reducing the sintering temperature, greatly accelerating the sintering solid-phase reaction, increasing the magnetic core density and improving the initial permeability of the material. A soft magnetic core prepared from the material has favorable temperature characteristics and very high permeability from low temperature to high temperature, and can be used for but not limited to a series of fields of external facilities of modern communication equipment, common communication equipment, and the like.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +2

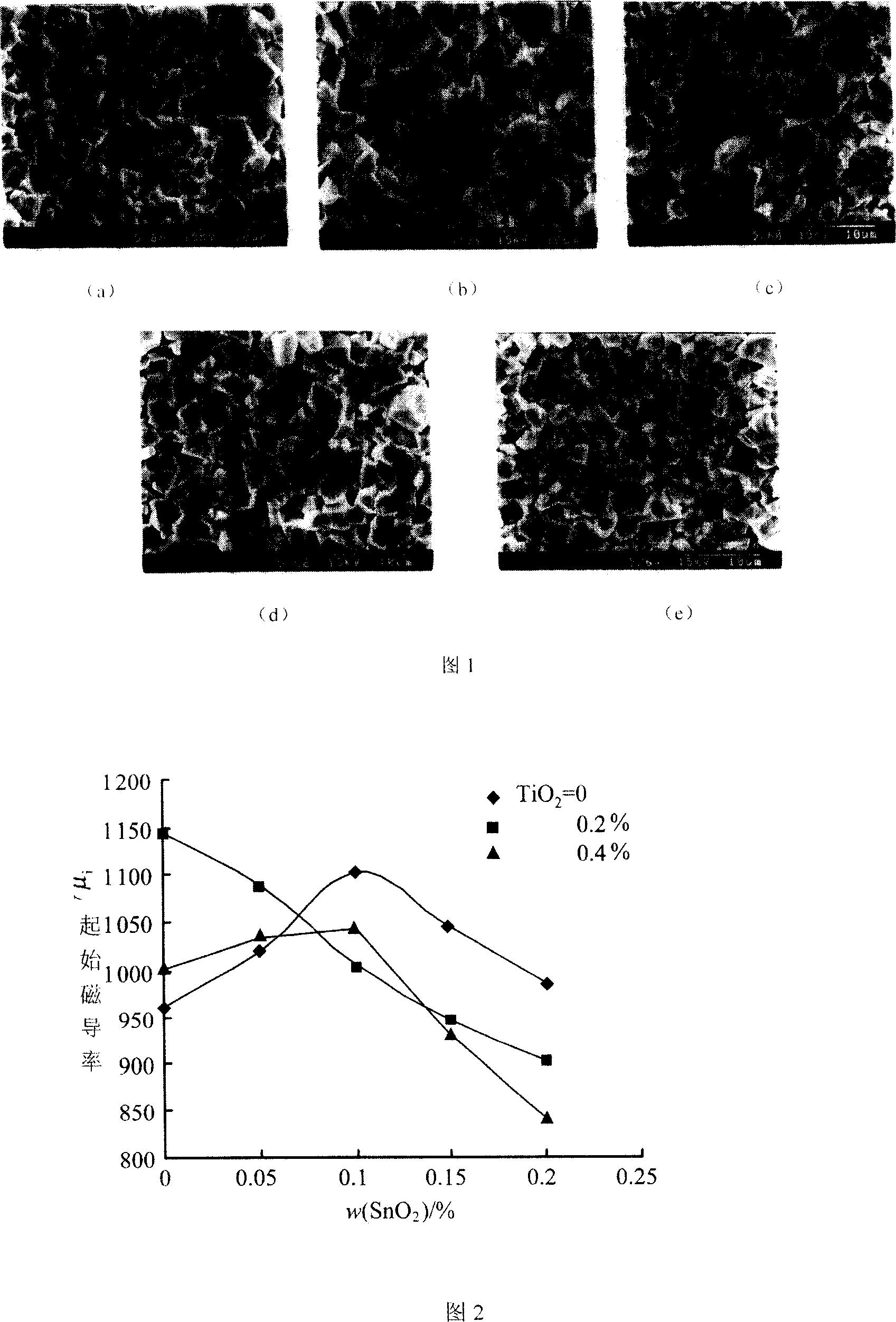

Process for preparing high frequency high power ferrite material

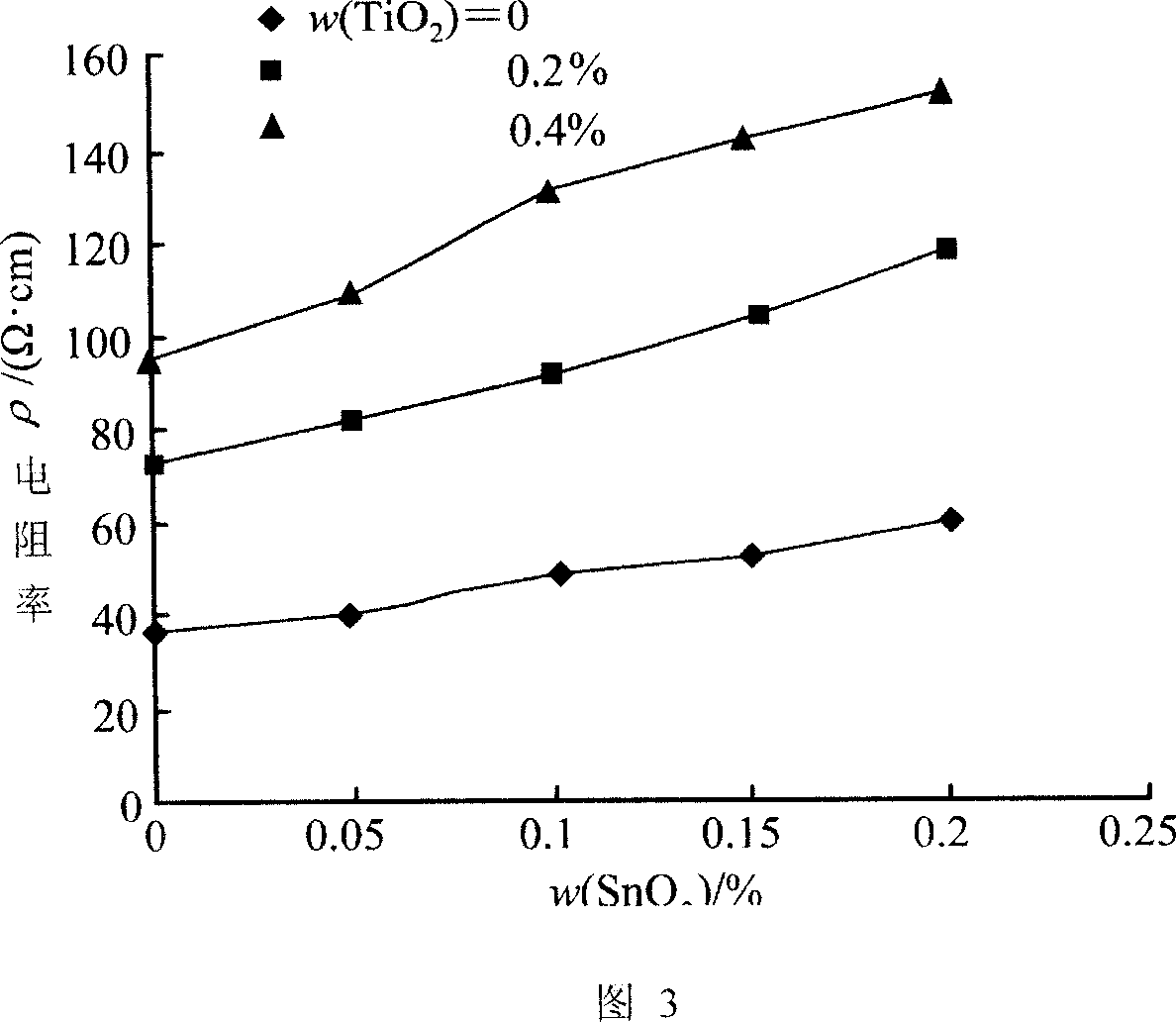

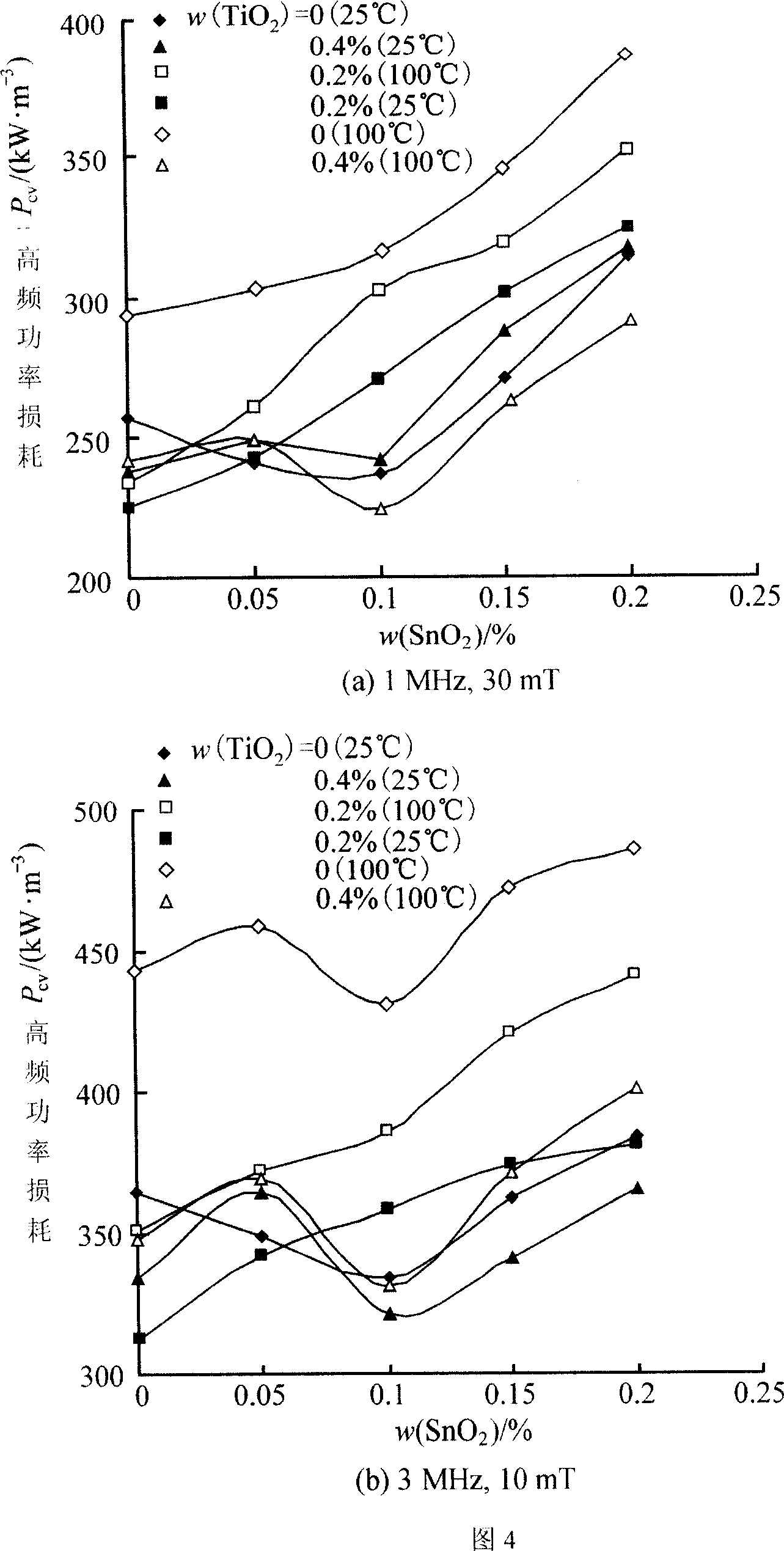

The method includes following steps: (1) mixing step, mixing powder materials 51-55 mol% Fe2O3, 5-10mol% ZnO, and residual MnCO3 uniformly; (2) preburning step, preburning mixture obtained from step (1); (3) doping step, adding additives according to following mass ratios to the mixture: 0.01-0.4wt% CaO, 0.01-0.2wt% Nb2O5, 0.01-0.1wt% K2CO3, and not exceeding 0.5wt% TiO2, and not exceeding 0.3wt% SnO2; (4) second ball milling step, ball milling powder material obtained from step (3) again; (5) molding step, adding 8-12wt% organic binding agent to powder material obtained from step (4), and after mixing and granulating, pressing powder material to blank; (6) aura sintering, placing blanks into sintering furnace to be sintered. Advantages of the MnZn power ferrite material are: fine microstructure, high initial permeability, and lower power loss under high frequency.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A kind of nickel-zinc-copper soft ferrite and preparation method thereof

InactiveCN102262950AHigh initial permeabilityHigh densityInorganic material magnetismInitial permeabilitySecondary component

The invention provides a nickel-zinc-copper soft ferrite and a preparation method thereof. The nickel-zinc-copper soft ferrite includes main components and auxiliary components, and the main components are iron oxide, nickelous oxide, zinc oxide, oxide Copper, characterized in that the content of the main components is as follows: iron oxide 65.05wt-66.35wt%; zinc oxide 20.66wt-22.20wt%; nickelous oxide 9.55wt-10.06wt%; copper oxide 2.91wt-3.17wt% ; The secondary component includes tungsten trioxide, and the content of the tungsten trioxide is 0.003wt-0.03wt%. The electromagnetic properties of the material in the invention reduce the loss performance of the product under the premise of maintaining high initial magnetic permeability and saturation magnetic flux density.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com