NiCuZn ferrite material and preparation method thereof

A technology of ferrite material and raw material, applied in the field of magnetic isolation sheet NiCuZn ferrite material and its preparation, can solve the problems of poor electromagnetic compatibility, large leakage inductance, low conversion efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

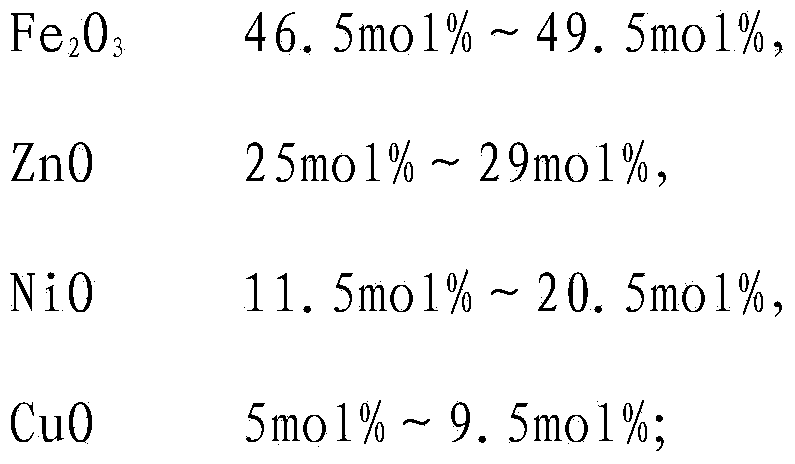

[0024] 1) Formulation: Fe 2 o 3 48.5 mol%, ZnO 29 mol%, NiO 16 mol%, CuO 6.5 mol%.

[0025] 2) One-time ball milling: put the weighed raw materials into a ball milling tank, add deionized water, wherein the mass ratio of raw materials and deionized water is 1:1.5 for ball milling, and the time is 2.5 hours.

[0026] 3) Pre-burning: Dry the ball abrasive obtained in the previous step, and pre-fire in a furnace at 900°C for 2.5 hours, and cool naturally in the furnace after pre-burning.

[0027] 4) Secondary ball milling: put the above-mentioned obtained materials into a ball milling tank, add deionized water, wherein the ratio of material to water is 1:1.5, and perform secondary ball milling for 2.5 hours.

[0028] 5) Granulation molding: add 6wt% polyvinyl alcohol to the dried material after secondary ball milling, mix evenly, carry out granulation, and finally press molding.

[0029] 6) Sintering: Put the molded ferrite material into a furnace whose atmosphere is air, set ...

Embodiment 2

[0031] 1) Formulation: Fe 2 o 3 is 48.5mol%, ZnO is 29mol%, NiO is 14.5mol%, CuO is 8mol%, dopant V 2 o 5 0.05wt%.

[0032] 2) Primary ball milling: Put the weighed raw materials into a ball milling tank, add deionized water, wherein the mass ratio of raw materials to deionized water is 1:2, and perform ball milling for 2 hours.

[0033] 3) Pre-burning: Dry the ball abrasive obtained in the previous step, and pre-fire in a furnace at 840°C for 3 hours, and cool naturally in the furnace after pre-burning.

[0034] 4) Doping: Add 0.05wt% V to the powder obtained in step 3) by mass percentage 2 o 5 .

[0035] 5) Secondary ball milling: Put the above-mentioned materials into a ball mill tank, add deionized water, and the mass ratio of material to water is 1:2. Perform secondary ball milling for 4 hours.

[0036] 6) Granulation molding: add 8wt% polyvinyl alcohol to the dried material after secondary ball milling, mix evenly, carry out granulation, and finally press molding...

Embodiment 3

[0039] 1) Formulation: Fe 2 o 3 is 48.5mol%, ZnO is 29mol%, NiO is 14.5mol%, CuO is 8mol%, dopant V 2 o 5 0.1 wt%.

[0040] 2) Primary ball milling: Put the weighed raw materials into a ball milling tank, add deionized water, wherein the mass ratio of raw materials to deionized water is 1:1, and perform ball milling for 3 hours.

[0041] 3) Pre-burning: Dry the ball abrasive obtained in the previous step, and pre-fire in a furnace at 880°C for 2 hours, and cool naturally in the furnace after pre-burning.

[0042] 4) Doping: Add 0.1wt% V to the powder obtained in step 3) by mass percentage 2 o 5 .

[0043] 5) Secondary ball milling: put the above-mentioned obtained materials into a ball milling tank, add deionized water, wherein the mass ratio of material to water is 1:1, and perform secondary ball milling for 3 hours.

[0044] 6) Granulation molding: add 7.5wt% polyvinyl alcohol to the dried material after the secondary ball milling, mix evenly, carry out granulation, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com