Process for preparing high frequency high power ferrite material

A ferrite material, high-power technology, applied in the field of materials, can solve the problem of the material design system is not very perfect, not to mention design and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of 1~3MHz high-frequency high-power ferrite material of the present invention comprises the following steps:

[0030] The raw material adopts 51~55mol% Fe 2 o 3 , 5 ~ 10mol% ZnO, the balance is MnCO 3 ;

[0031] 1) Ball milling and mixing: mill the above powder in a ball mill for 1 to 6 hours to make the powder evenly mixed;

[0032] 2) Pre-burning: Pre-burning the ball abrasive obtained in step 1 in a furnace at 800-1000°C for 1-5 hours;

[0033] 3) Doping: Add the following additives to the powder obtained in step 2 by weight: 0.01-0.4wt% CaO, 0.00-0.5wt% TiO 2 , 0.00~0.3wt%SnO 2 , 0.01~0.2wt% Nb 2 o 5 And 0.01~0.1wt% K 2 CO 3 ;

[0034] 4) secondary ball milling: milling the powder obtained in step 3 in a planetary ball mill for 10 to 20 hours;

[0035] 5) Molding: add 8-12wt% organic binder to the powder obtained in step 4 according to the weight ratio, mix well, and after granulation, press the granular powder on a press to form a ...

example 1~15

[0039] 1) Using 53mol% Fe 2 o 3 , 8.5mol% ZnO, the balance is MnCO 3 ; Mill the above powder in a ball mill for 4 hours to make the powder evenly mixed;

[0040] 2) Pre-burning: Pre-burning the ball abrasive obtained in step 1) in a furnace at 950°C for 1.5 hours;

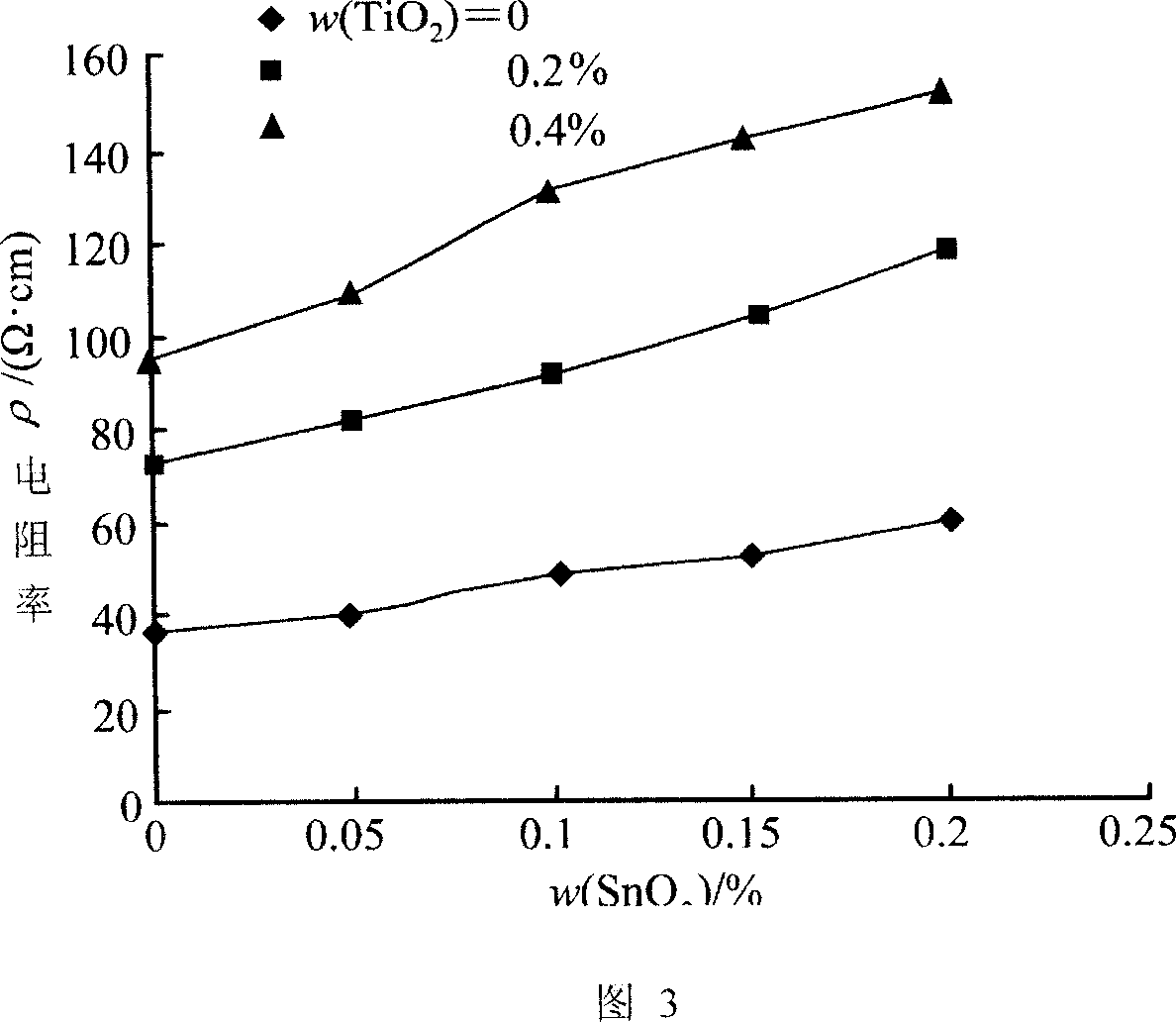

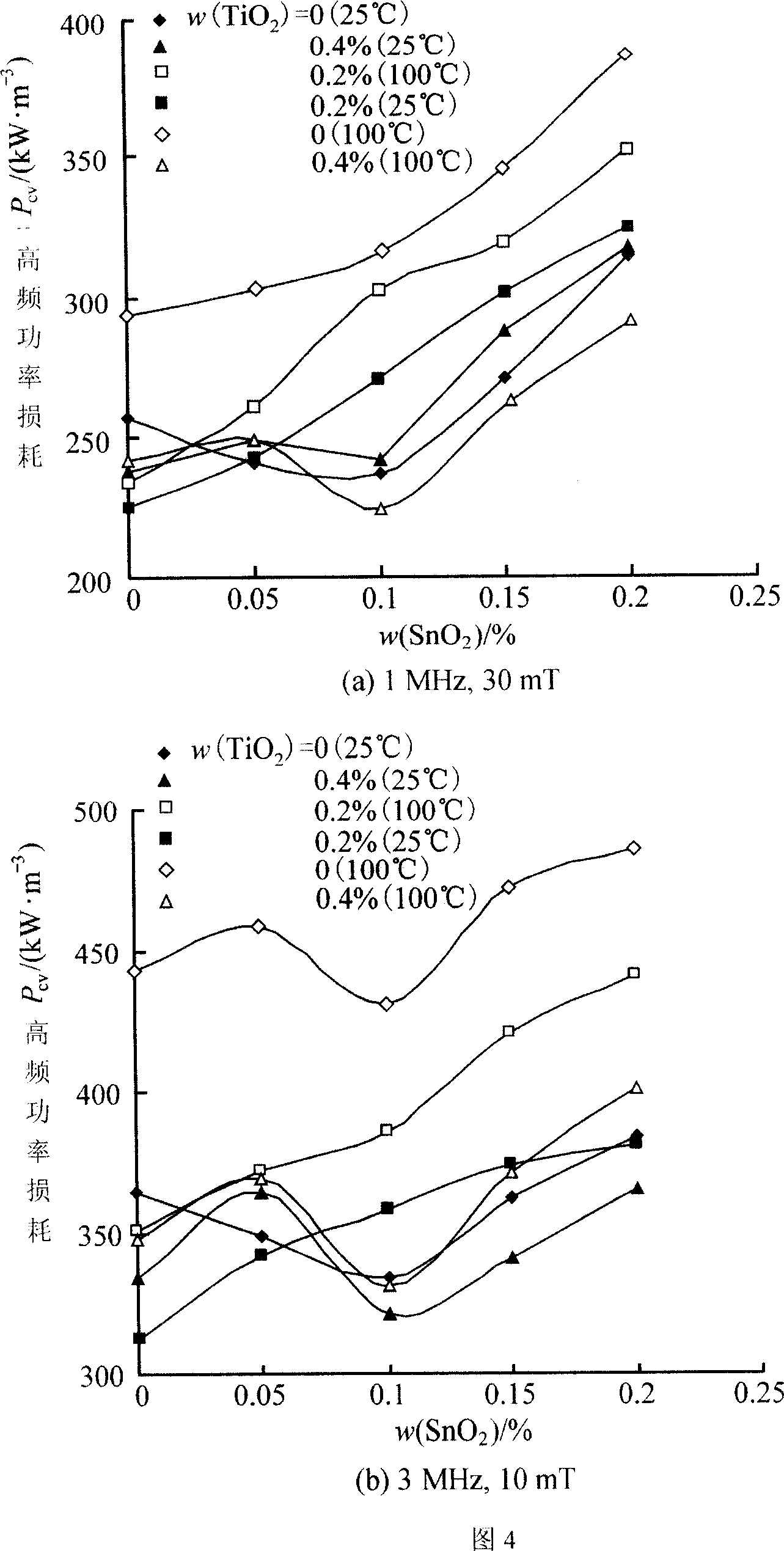

[0041] 3) Doping: Add the following additives to the powder obtained in step 2) by weight: 0.3wt% CaO, 0.025wt% Nb 2 o 5 , 0.05wt% K 2 CO 3 and different amounts of TiO 2 and SnO 2 , where TiO 2 and SnO 2 The corresponding addition amount is shown in Table 1 (corresponding to Examples 1-15); the material powder is ball-milled in a planetary ball mill for 16 hours;

[0042] Table 1

[0043]

example

CaO(wt%)

Nb 2 o 5 (wt%)

K 2 CO 3 (wt%)

TiO 2 (wt%)

SnO 2 (wt%)

1

0.3

0.025

0.05

0

0

2

0.3

0.025

0.05

0

0.05

3

0.3

0.025

0.05

0

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com