Patents

Literature

504 results about "Material Design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material Design (codenamed Quantum Paper) is a design language that Google developed in 2014. Expanding on the "card" motifs that debuted in Google Now, Material Design uses more grid-based layouts, responsive animations and transitions, padding, and depth effects such as lighting and shadows.

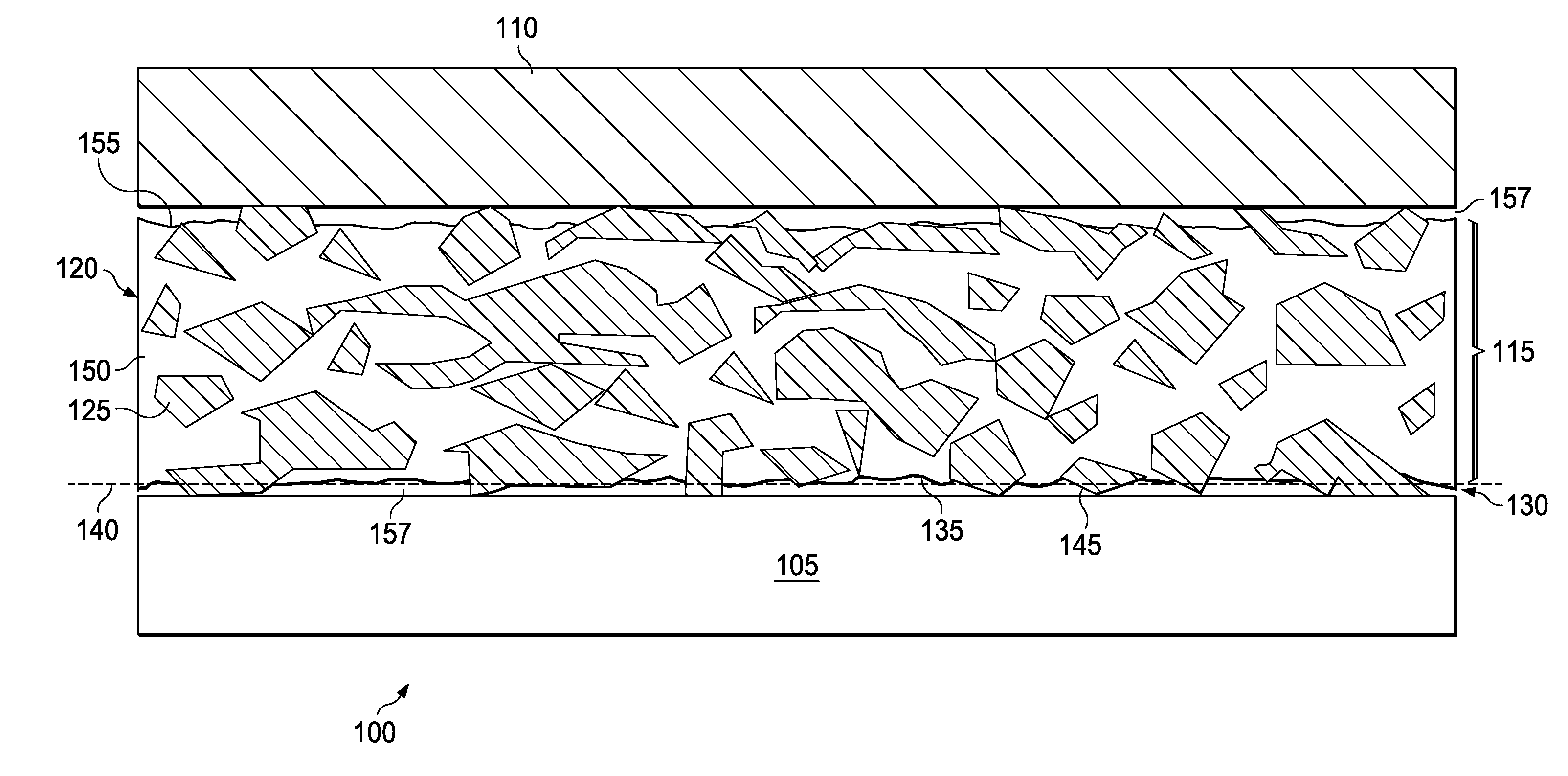

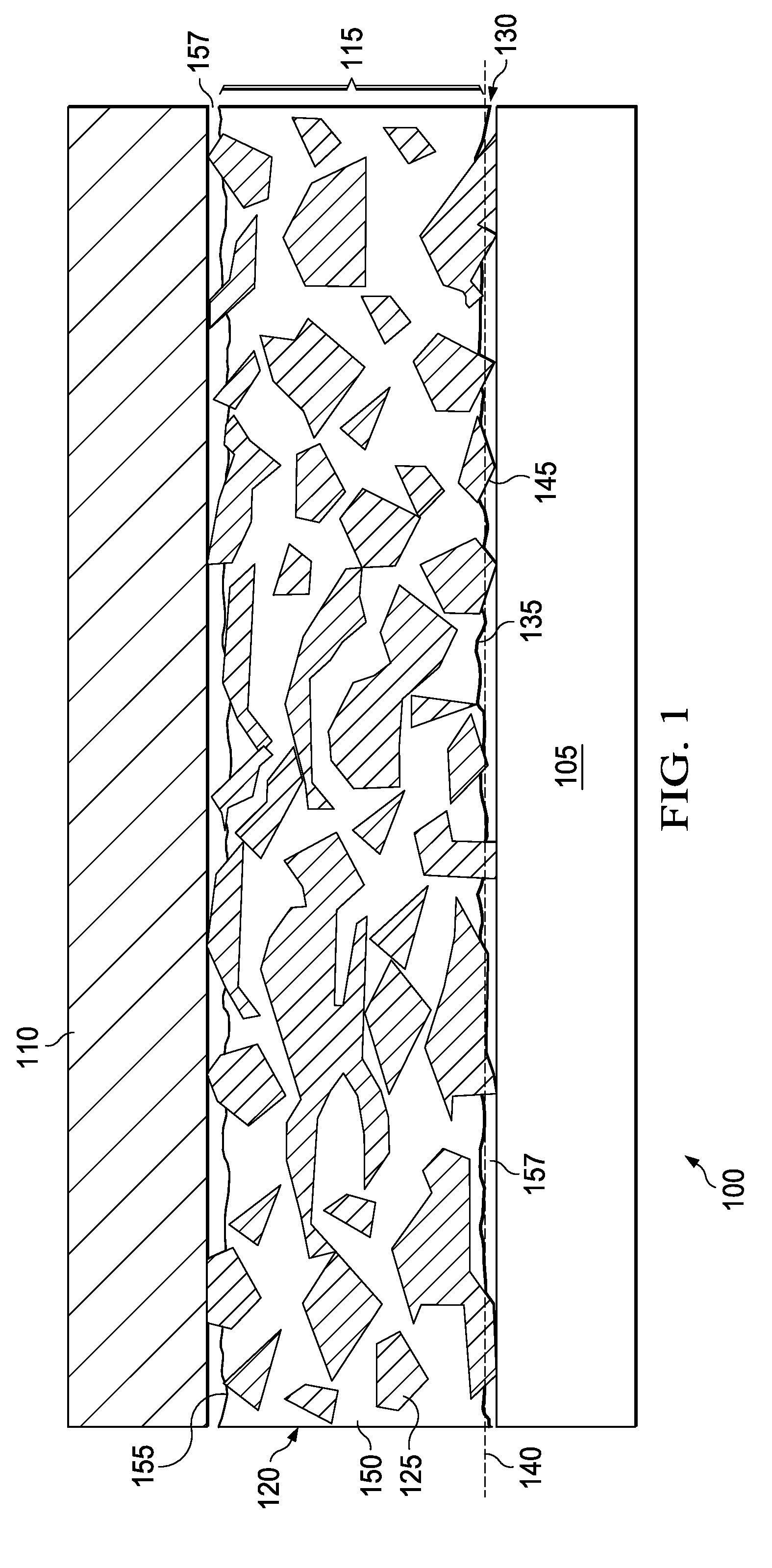

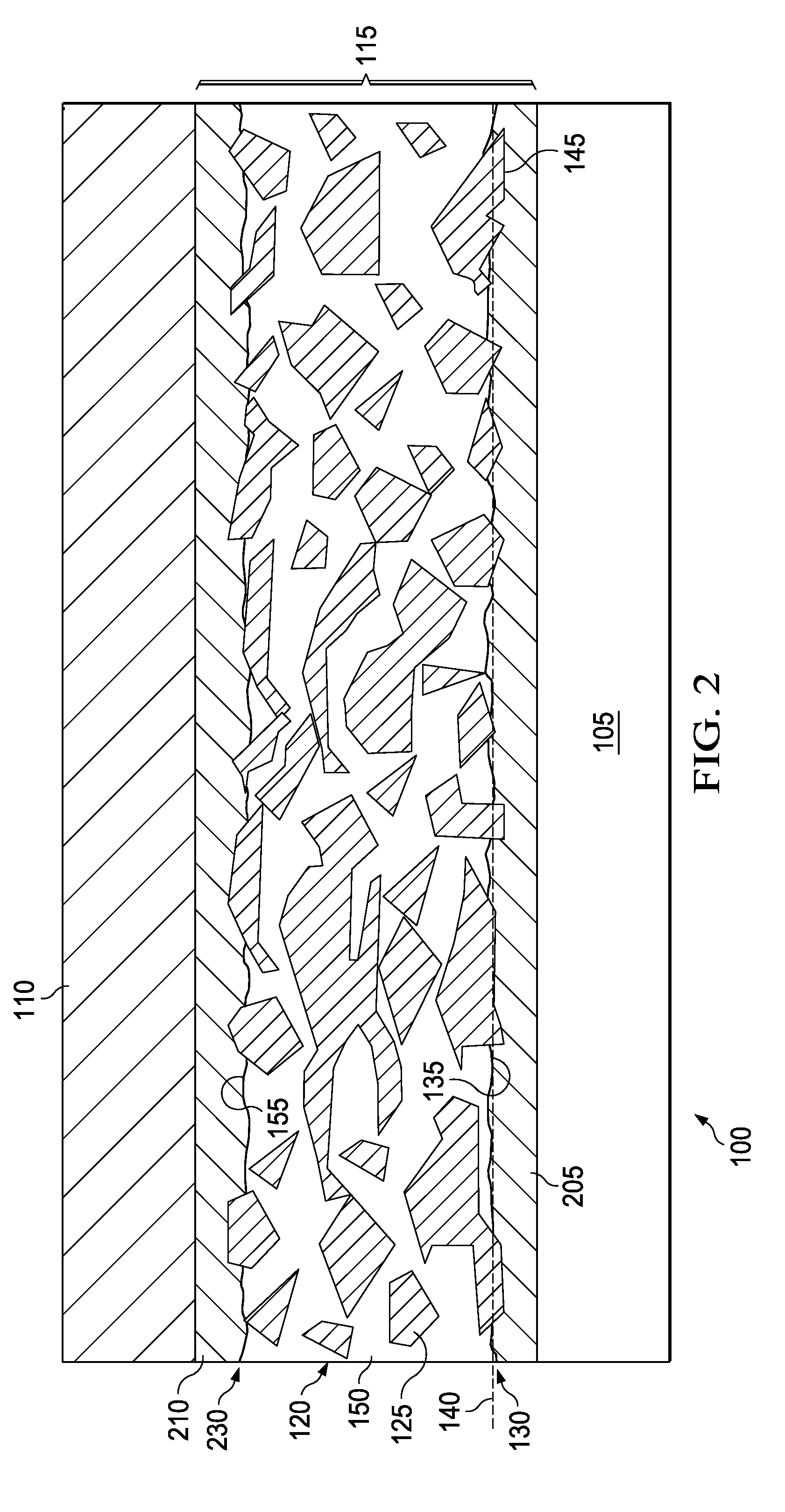

Vented, layered-wall deepwater conduit and method

A flexible conduit constructed of overlapping layers of sealing and strengthening materials designed to resist tensile, compressive, and axial forces is employed as a submerged flow line carrying pressurized fluid. Sealing material layers disposed radially on either side of the strengthening layers isolate the strengthening layers from the liquids that contact the internal and external conduit walls. The innermost seal layer is positioned within a burst layer that protects the external strengthening layers from pressure-induced damage. The annular area between the strengthening layers is continuously vented to the atmosphere to prevent pressure damage to the strengthening layers caused by gases leaking or permeating into the annular area through the seal layers. End connectors join sections of the conduit together and connect the vents of the sections to each other to form a continuous vent passage that vents the annulus gas at the water surface.

Owner:GE OIL & GAS UK LTD

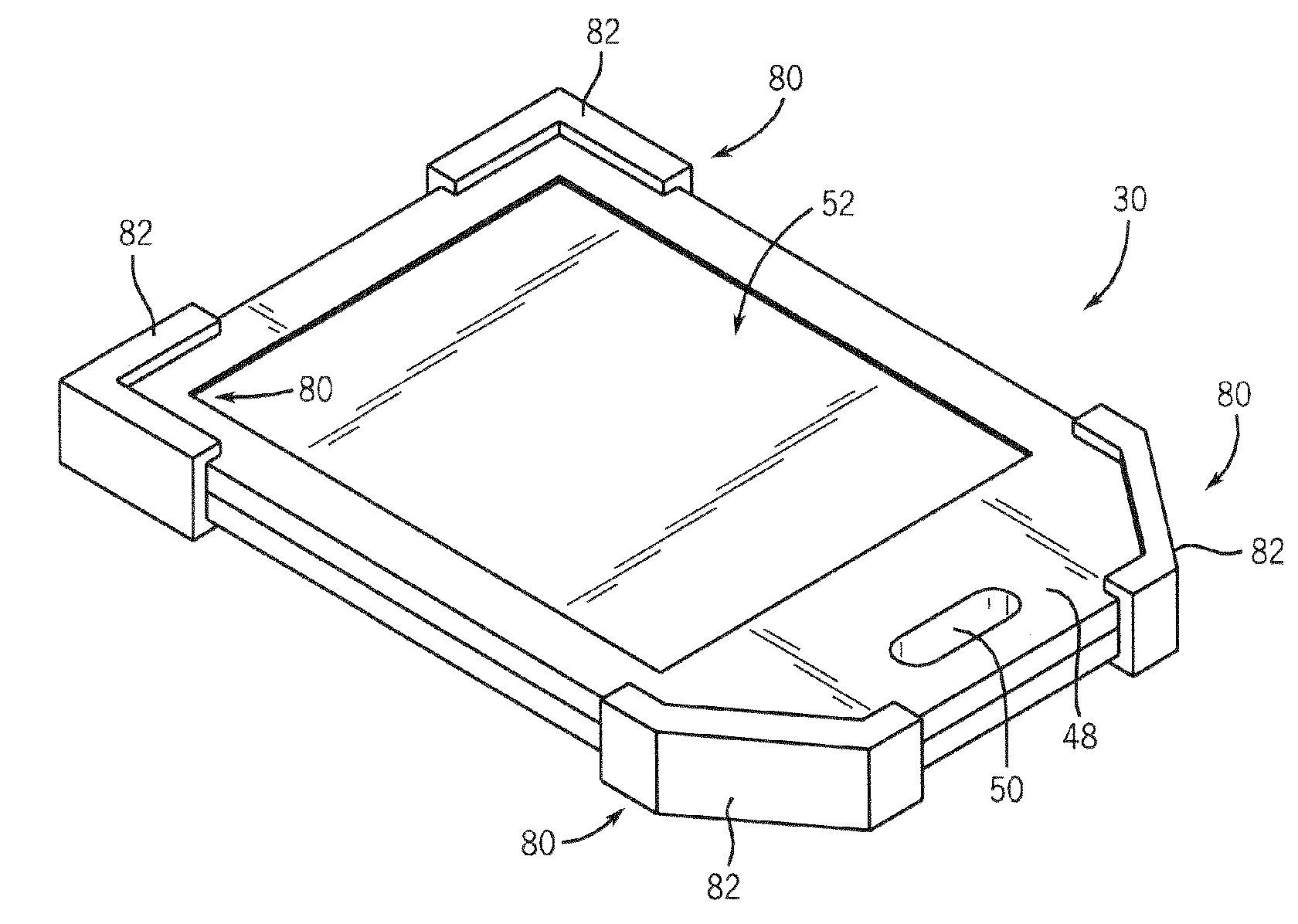

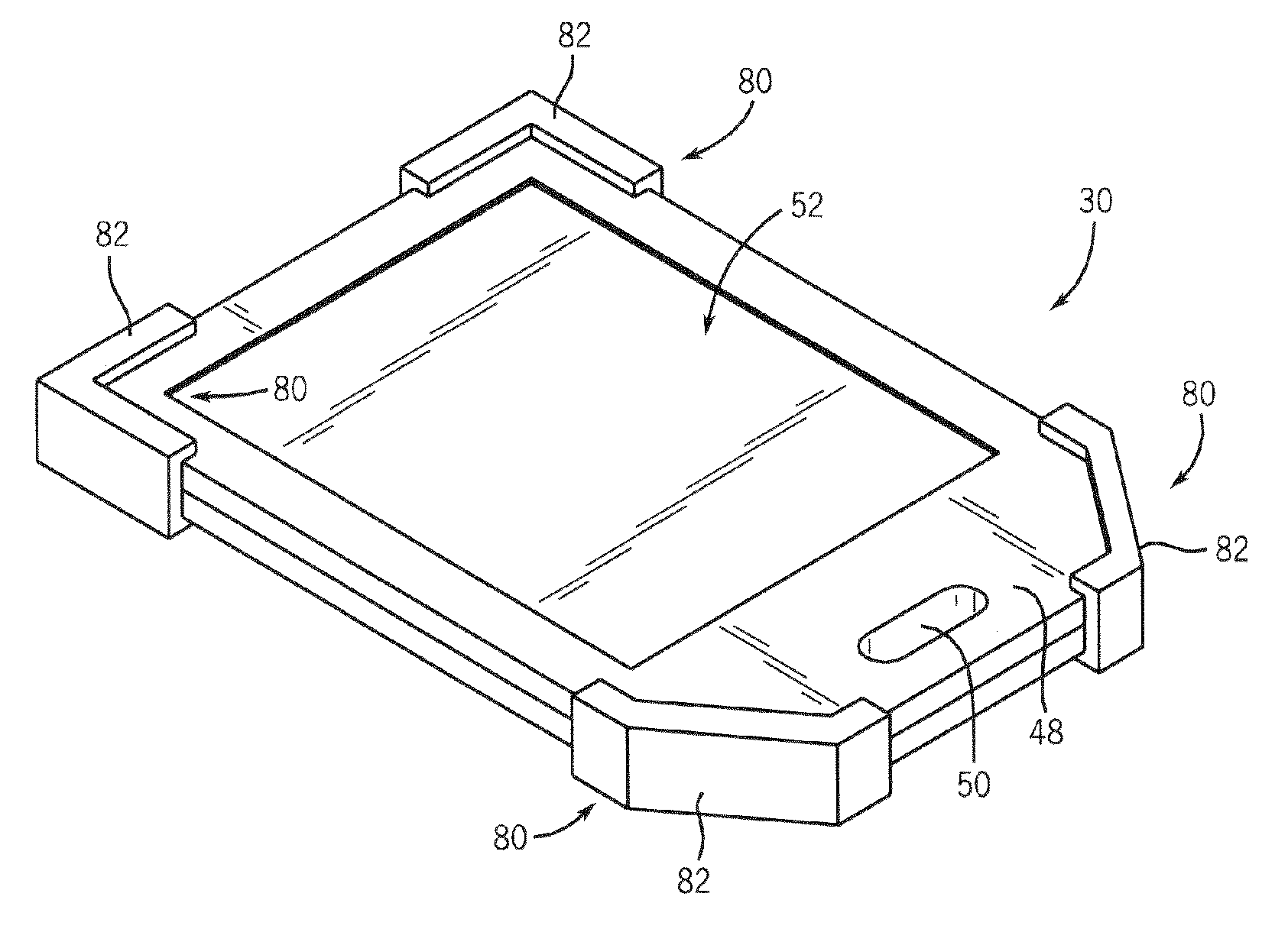

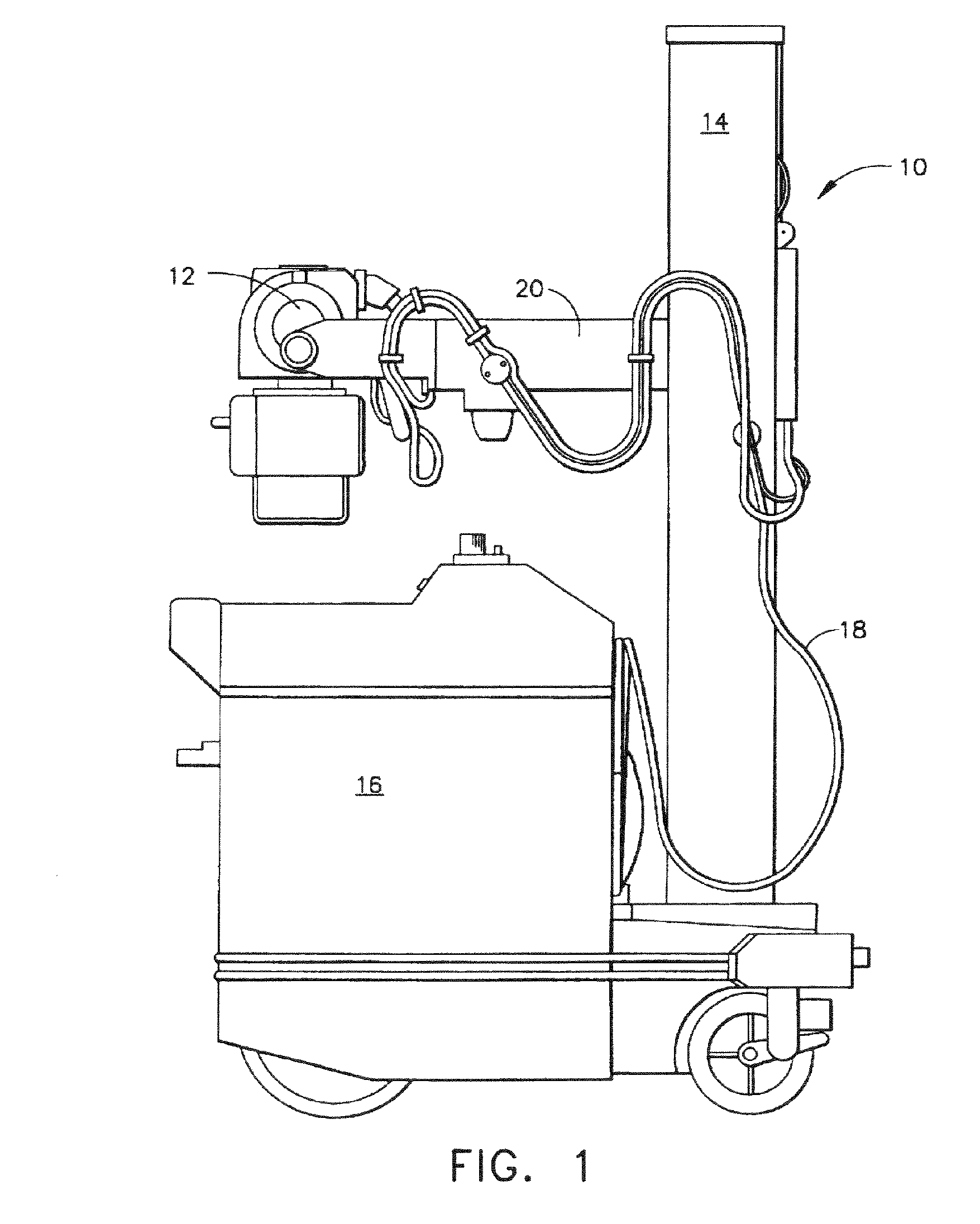

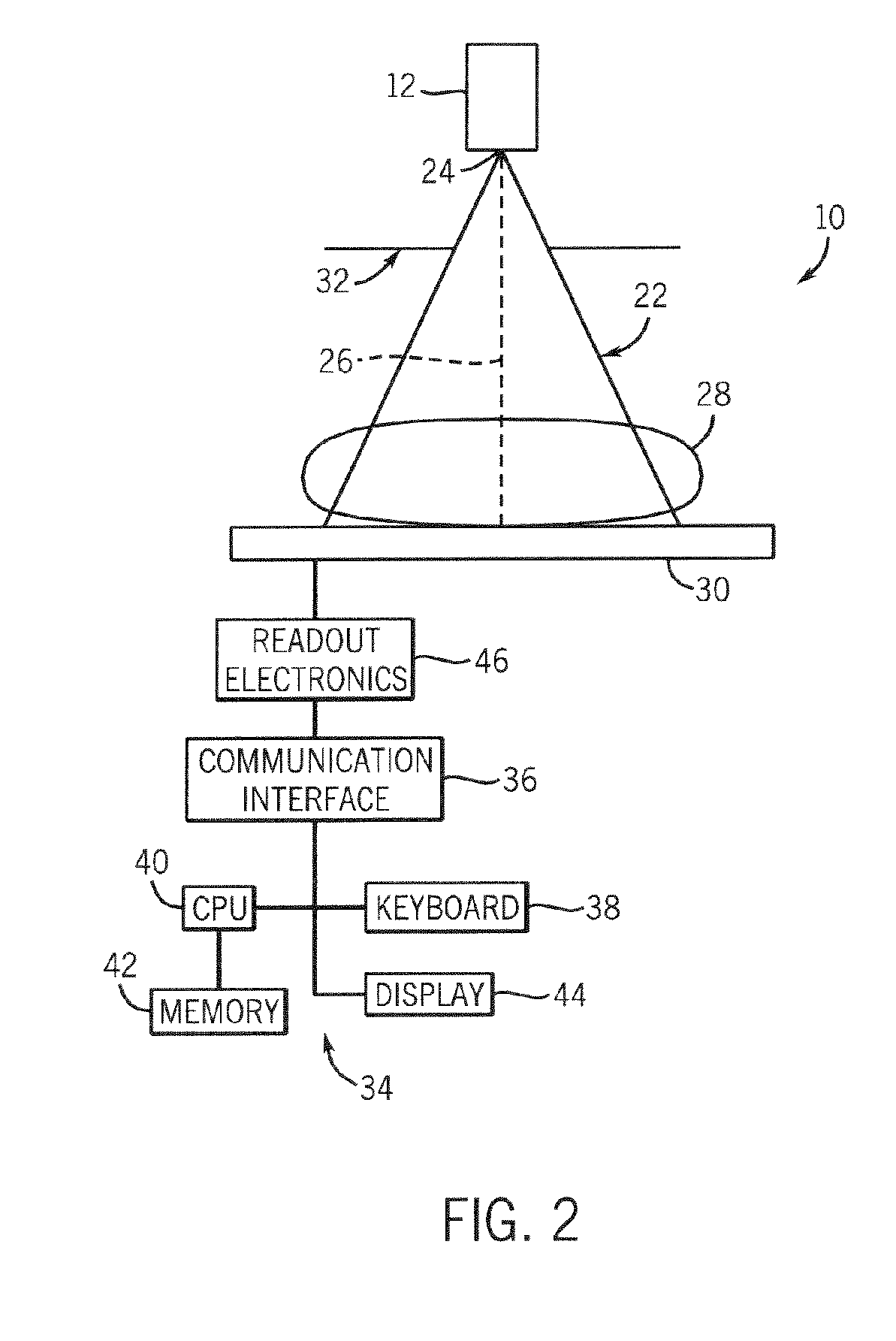

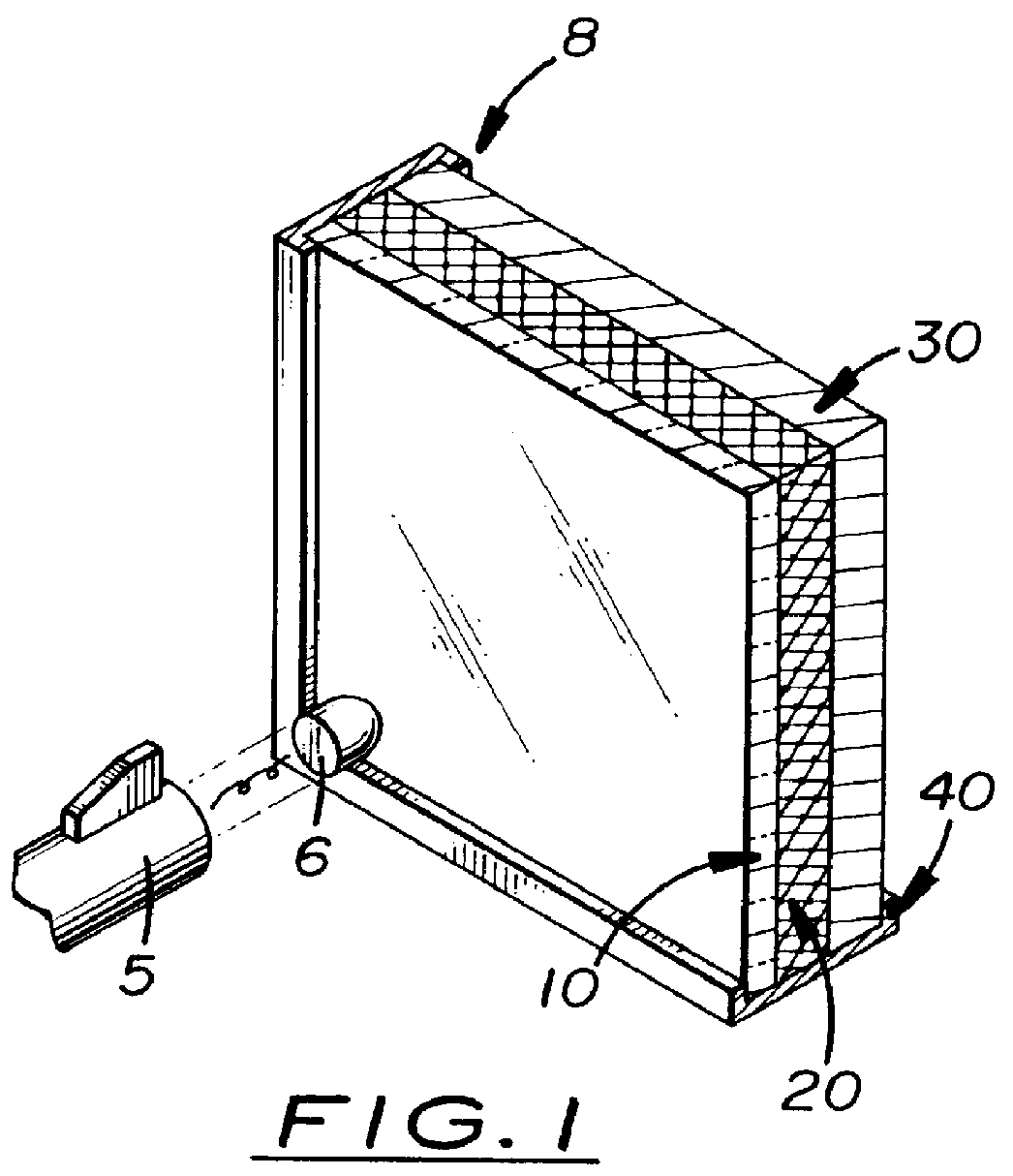

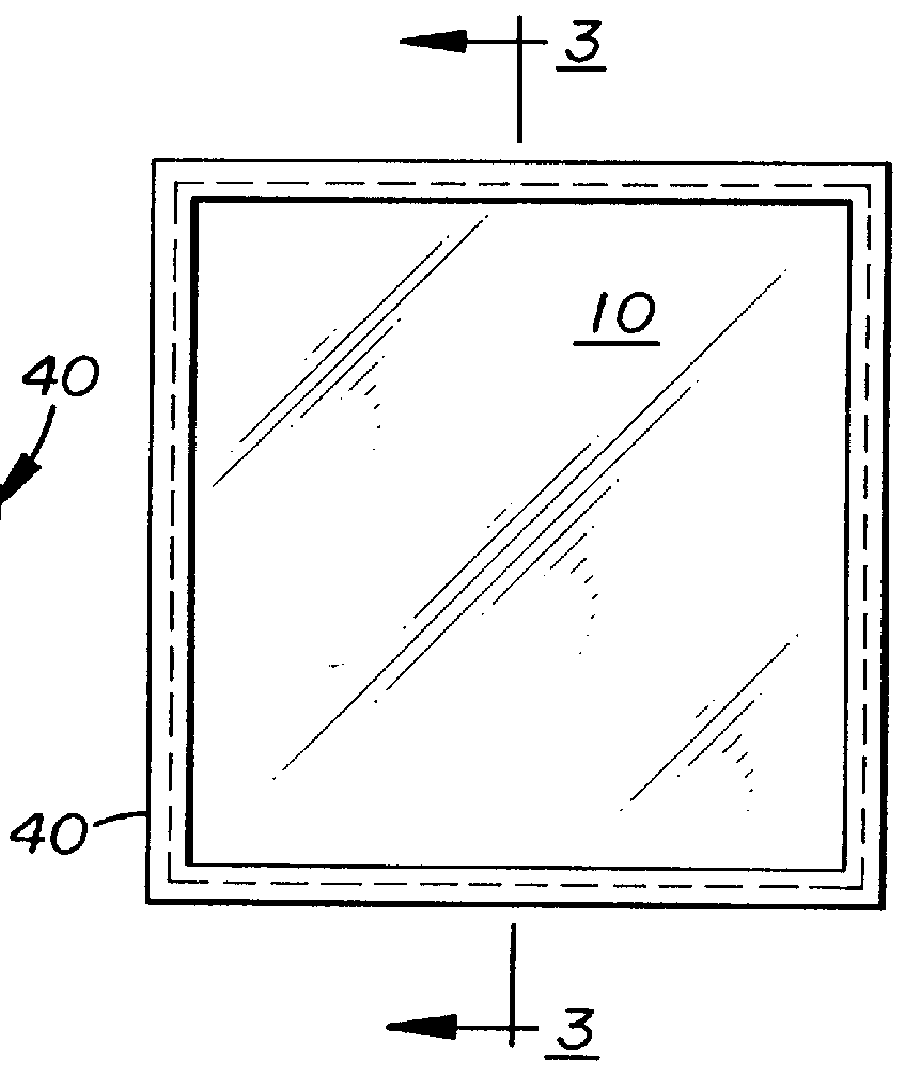

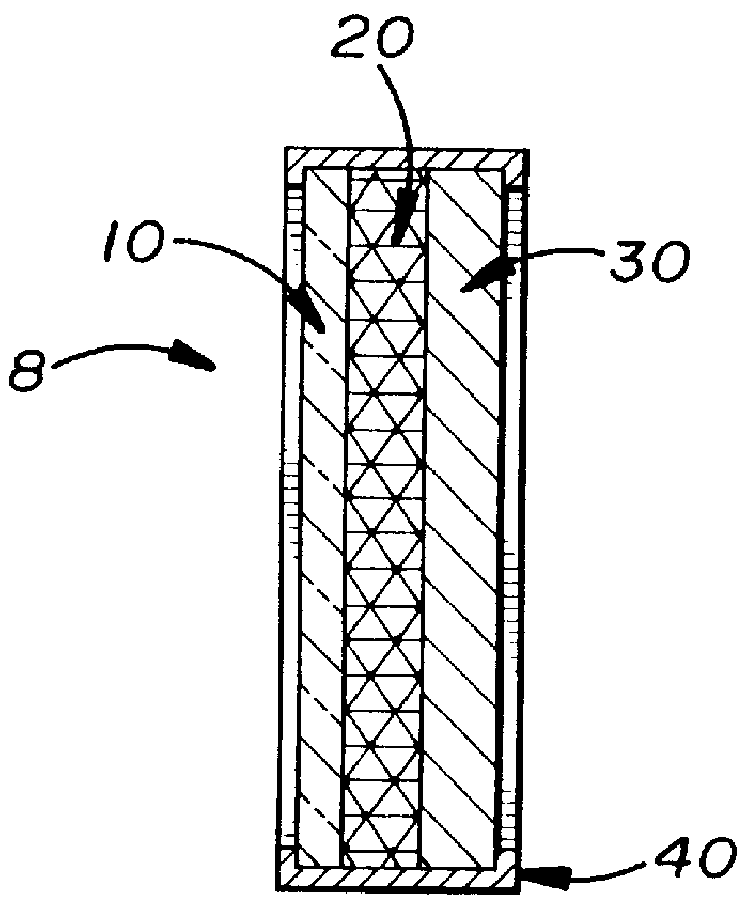

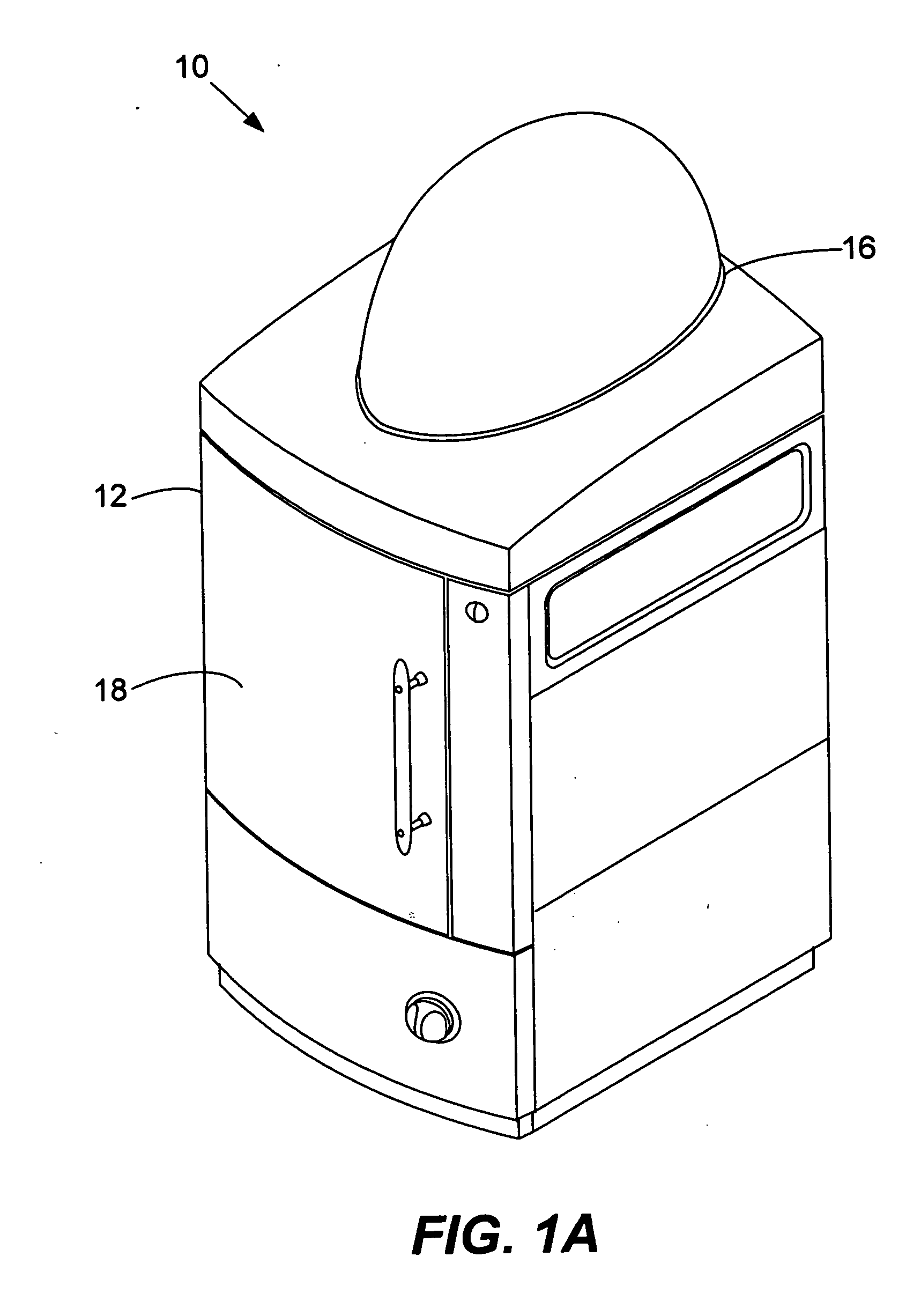

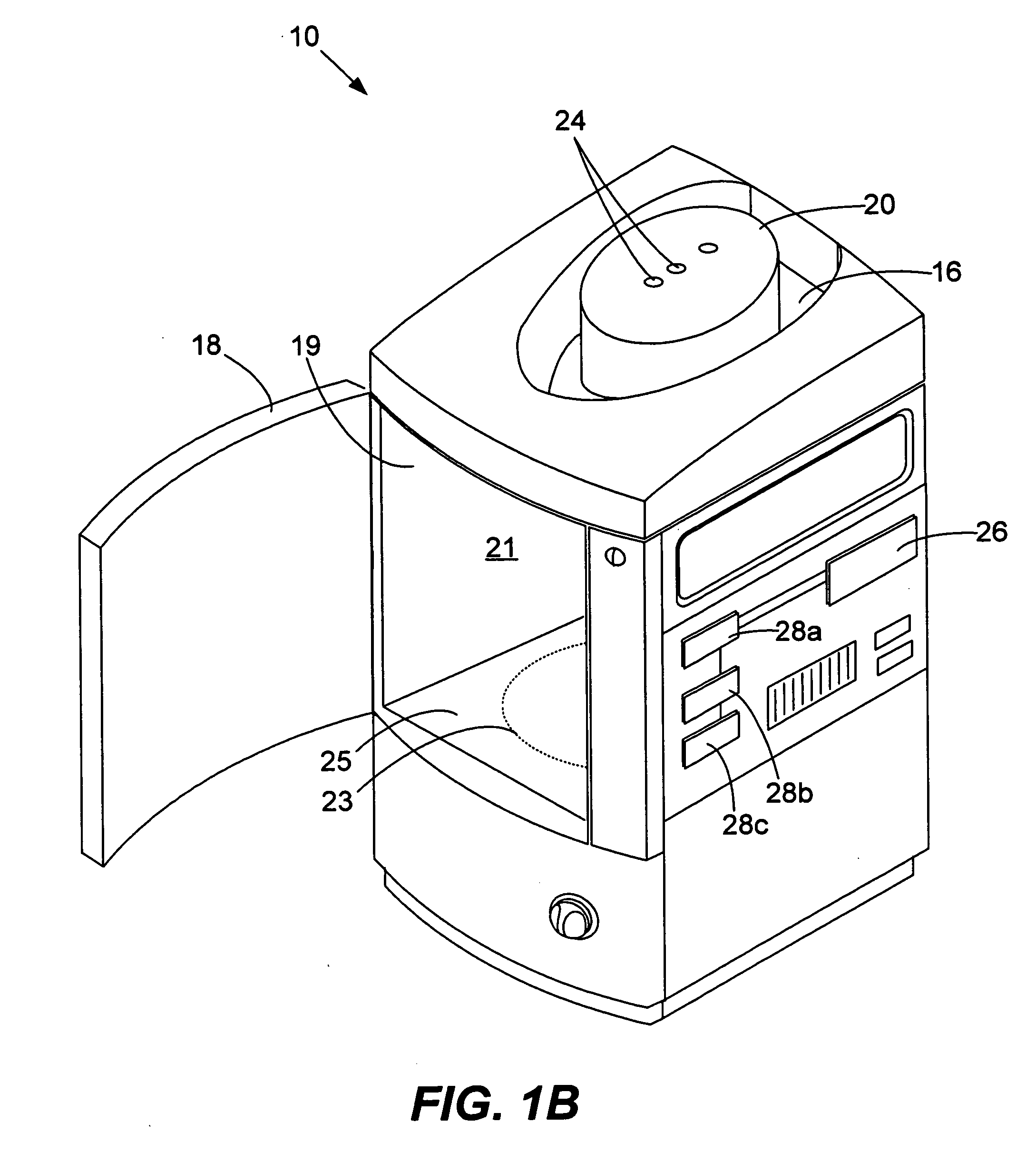

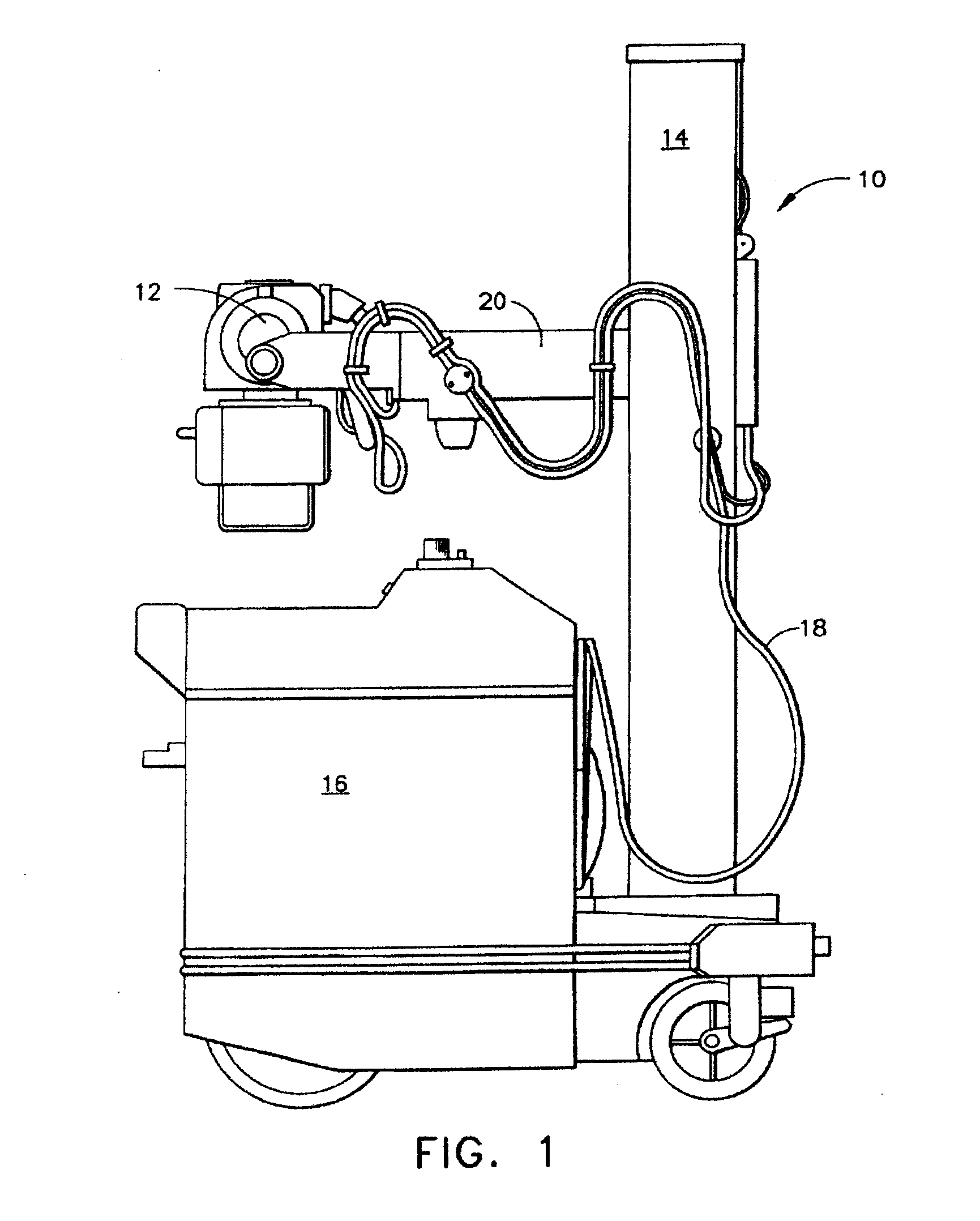

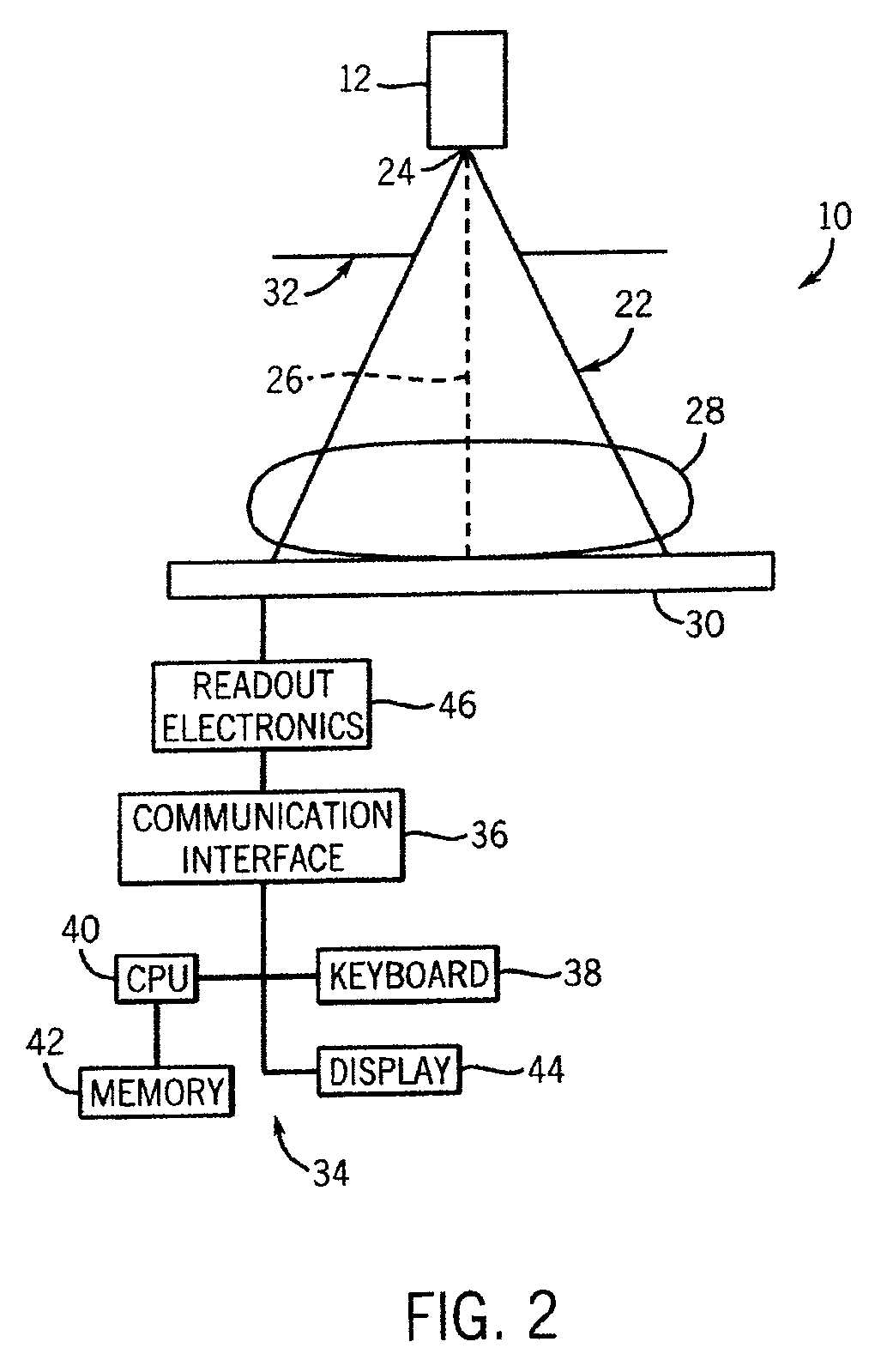

X-ray detector with impact absorbing cover

ActiveUS7189972B2Solid-state devicesMaterial analysis by optical meansMaterial DesignMaterials design

The present invention is a directed to a cover assembly for an x-ray detector that incorporates impact-absorbing material designed to absorb the shock, vibration, stress, and strain placed on the detector when dropped or subjected to a load. The cover assembly may include a layer or inserts of impact-absorbing material. Bumpers of impact-absorbing material may also be secured to the x-ray detector cover. Viscoelastic foam or other plastics may be used as the impact-absorbing material.

Owner:GENERAL ELECTRIC CO

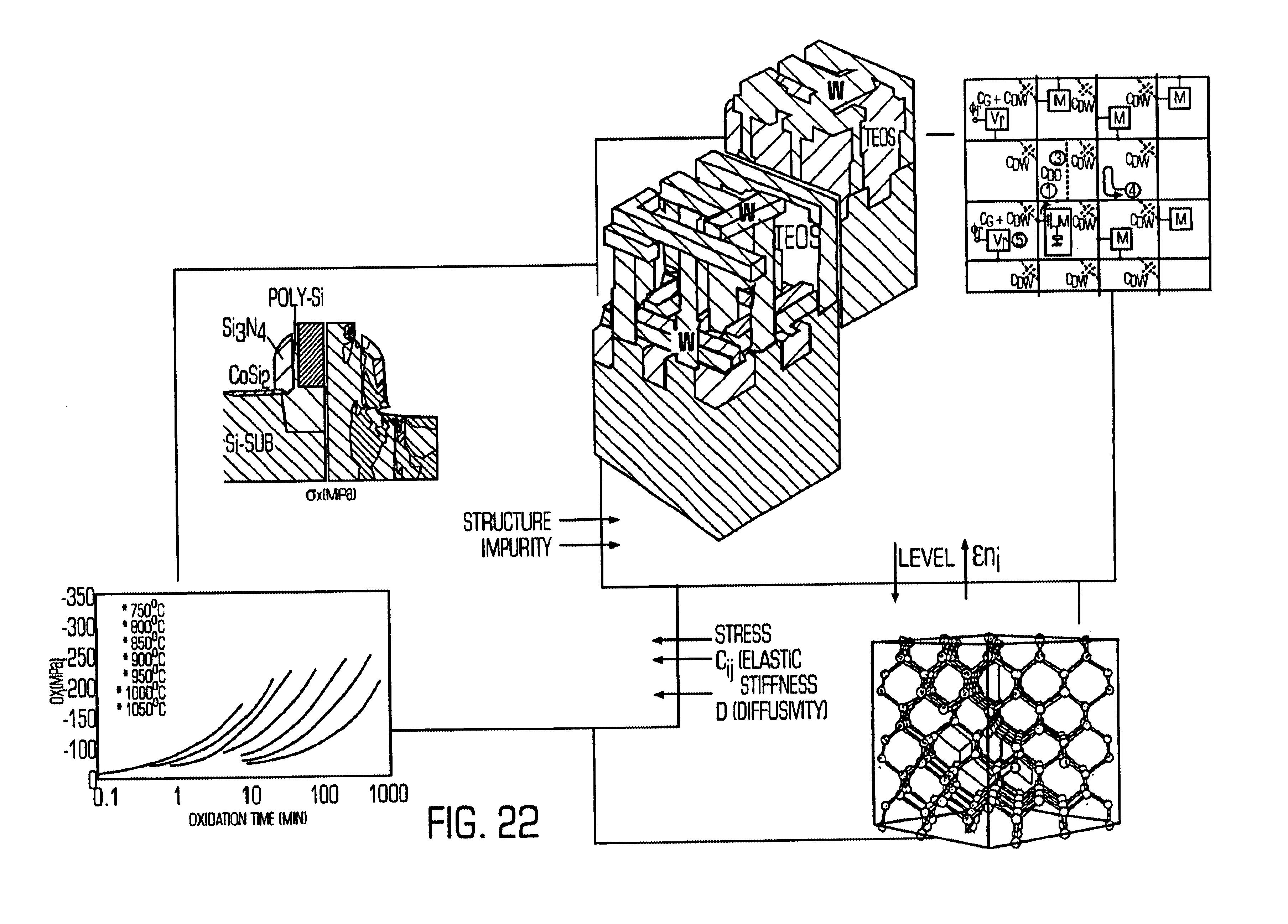

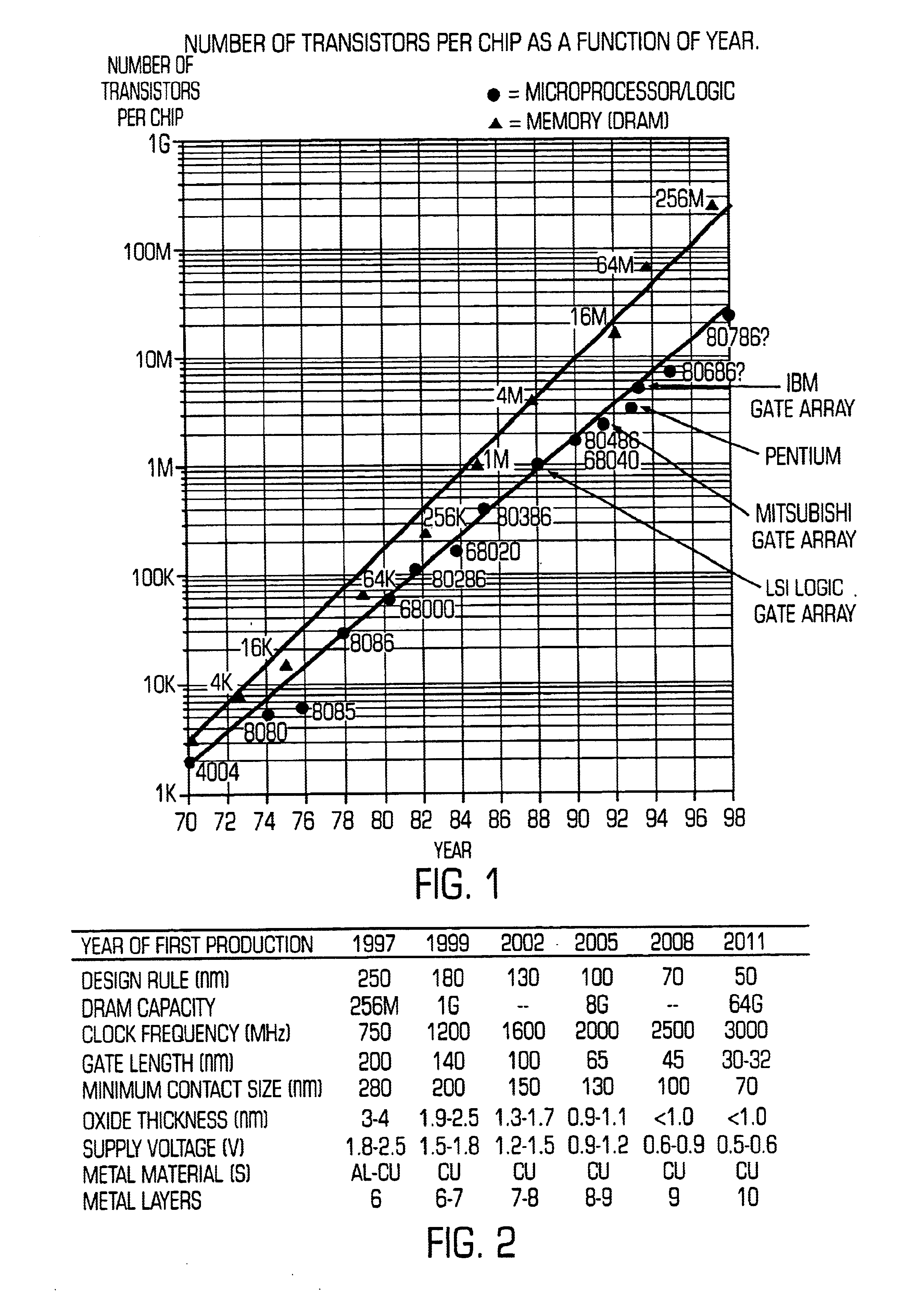

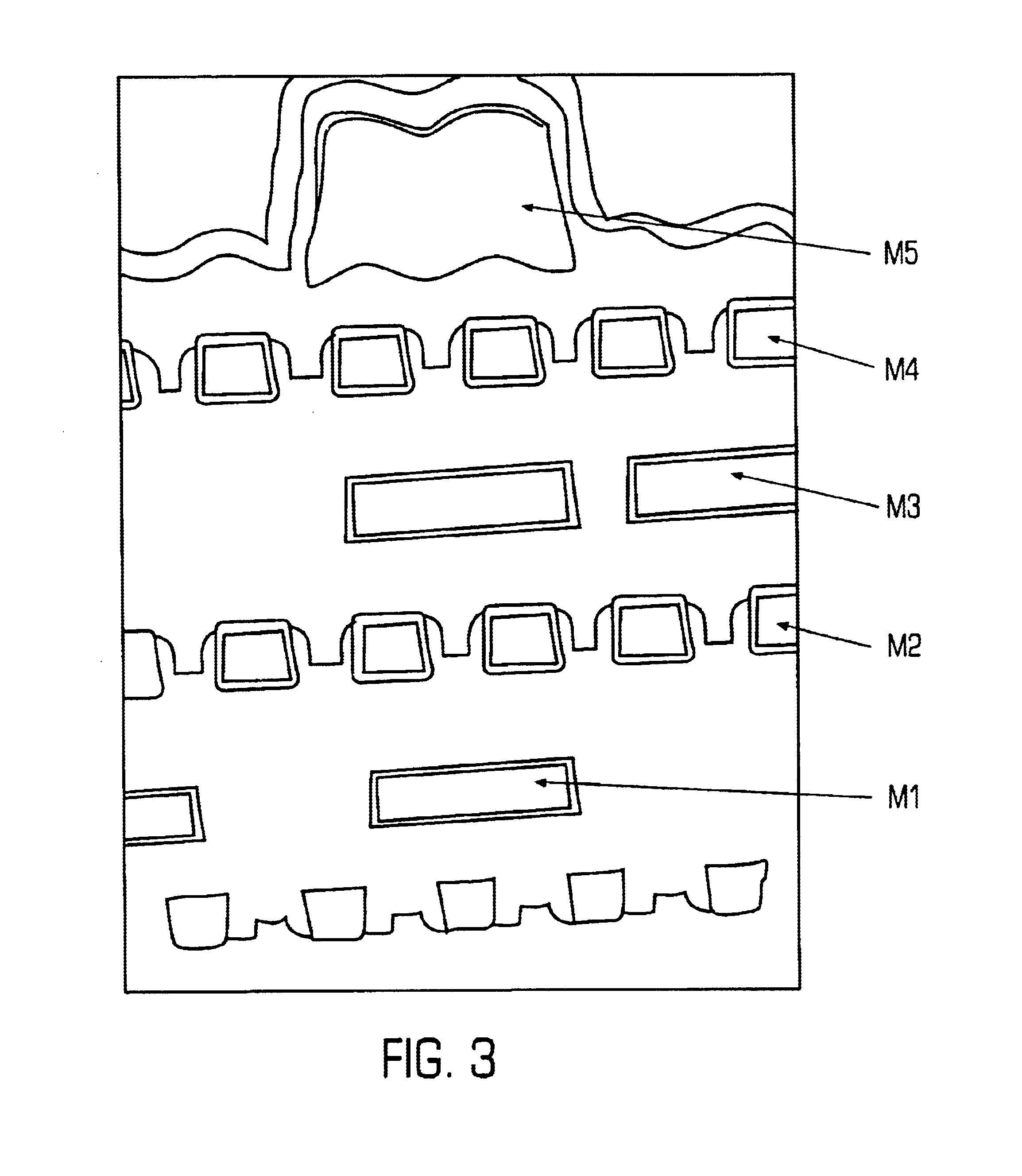

Method and apparatus for simulating manufacturing, electrical and physical characteristics of a semiconductor device

InactiveUS6826517B2Semiconductor/solid-state device detailsDetecting faulty computer hardwareElement modelMaterial Design

An electronic device simulator includes a three-dimensional lumped device model, a three-dimensional visco-elastic process simulation model and a material design model that are interlinked with each other. The three-dimensional lumped device element model comprises a Poisson's equation model, an electron continuity equation model, a hole continuity equation model, a Maxwell's equations model, an eddy current equation model, and an Ohm's law equation model. The simulator accounts for the three dimensional characteristics of the circuit to determine circuit performance.

Owner:KK TOSHIBA

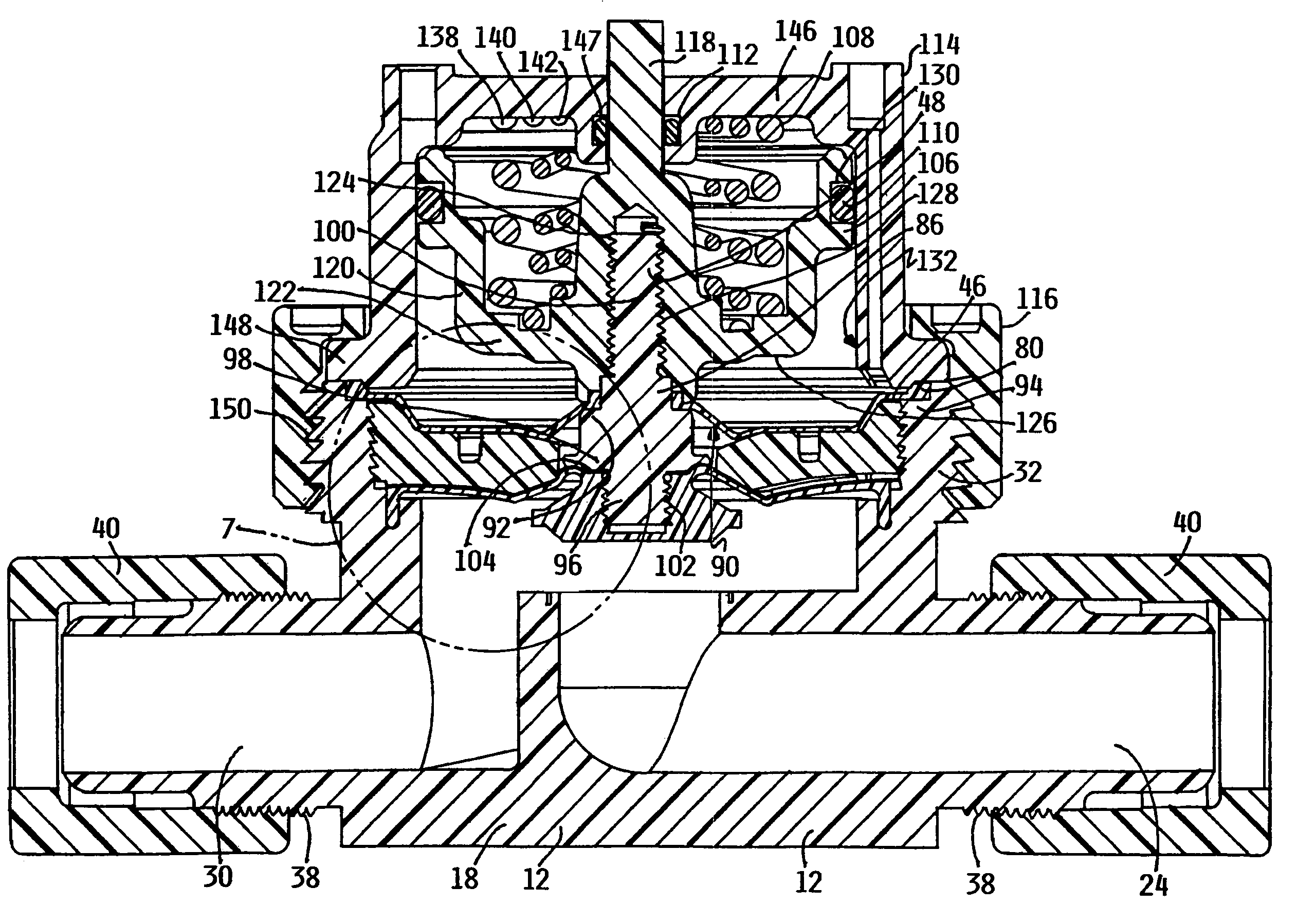

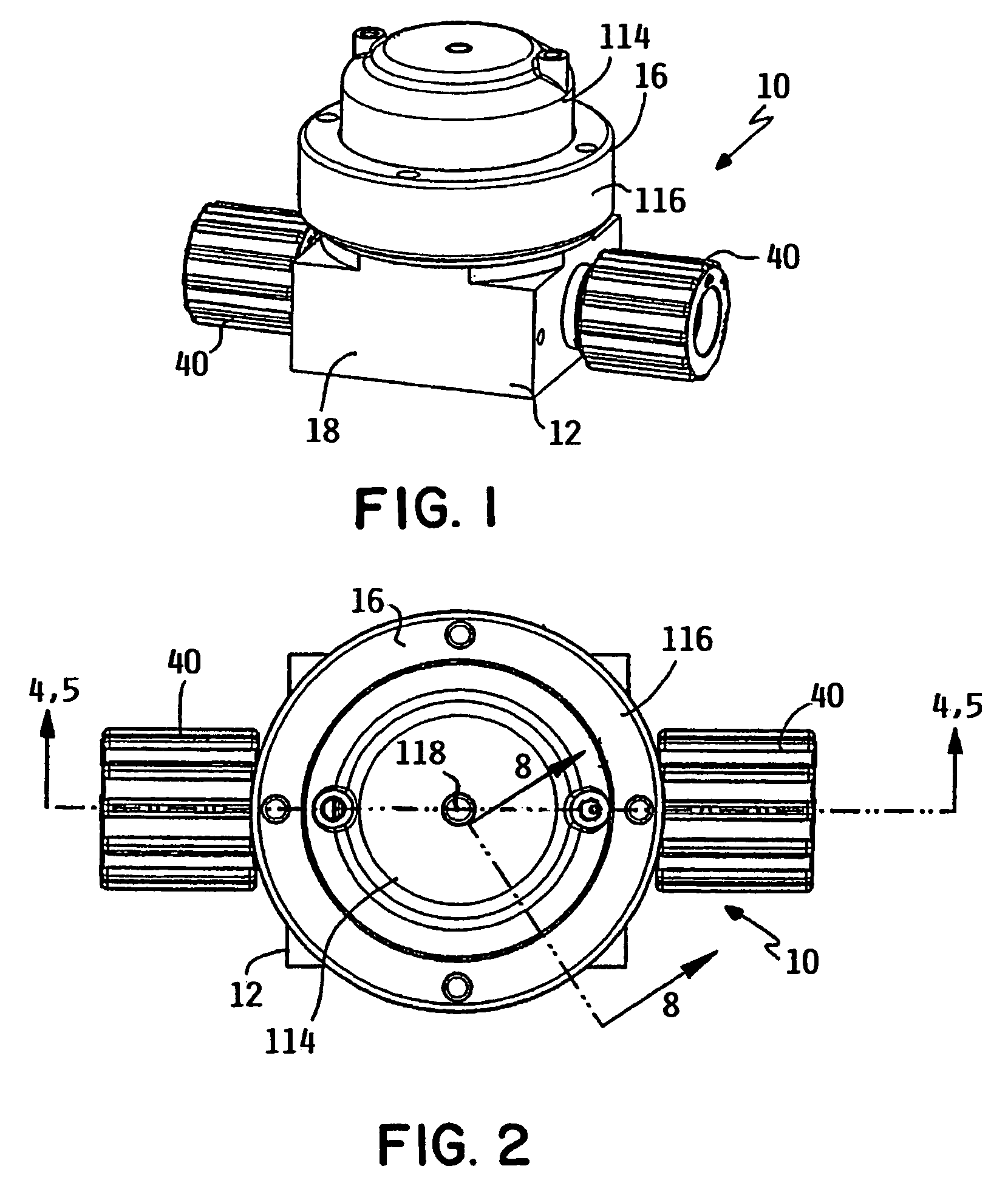

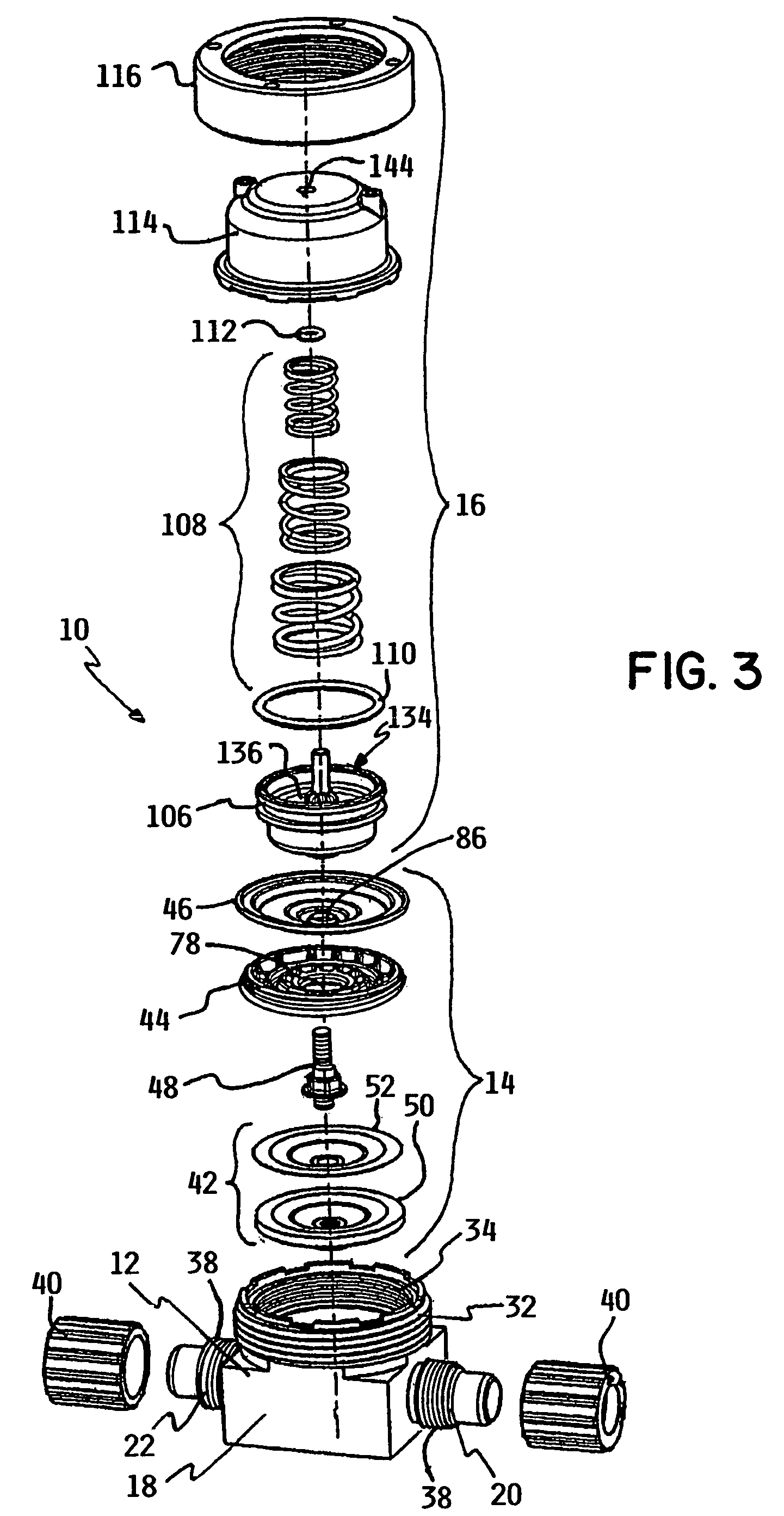

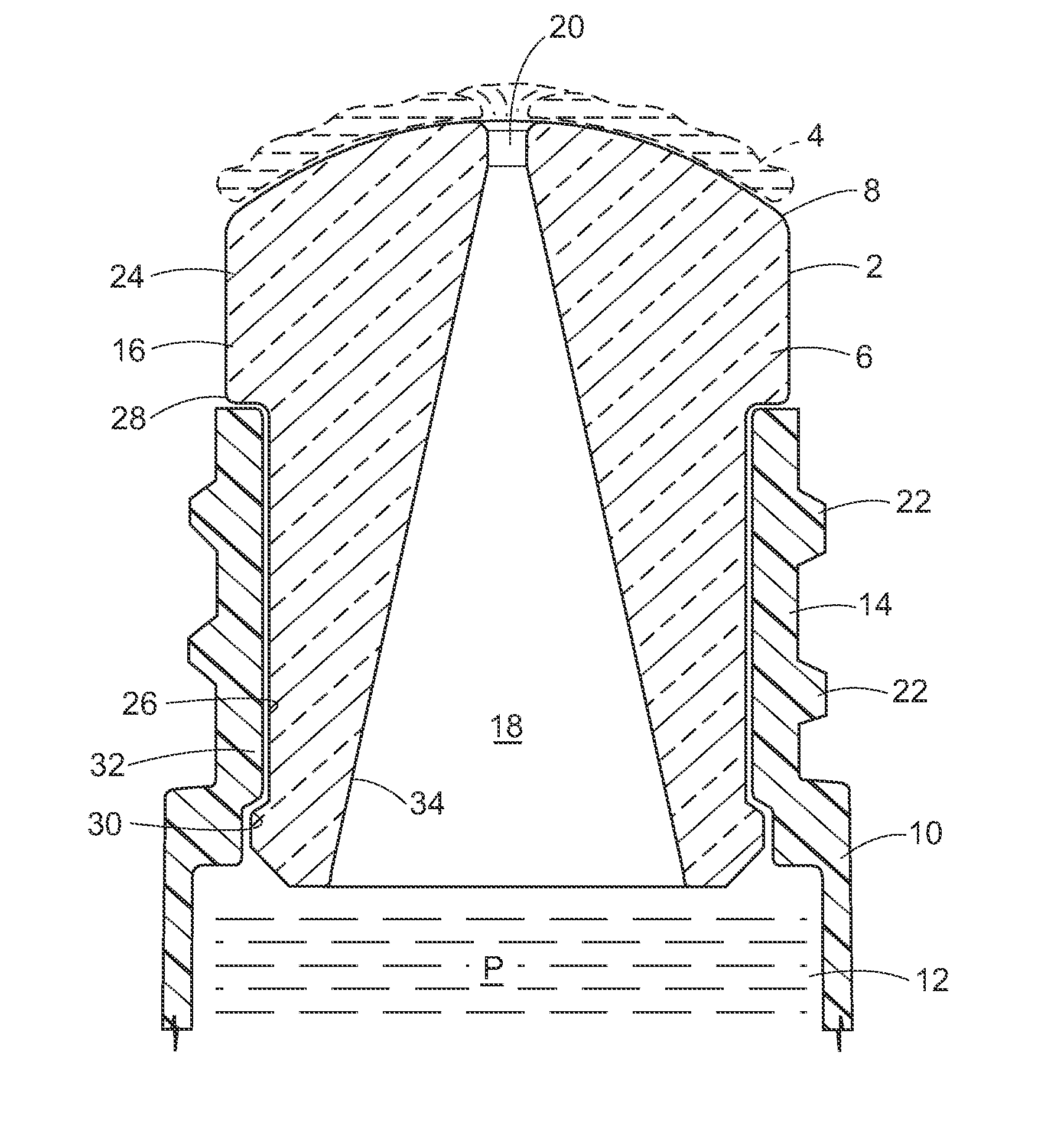

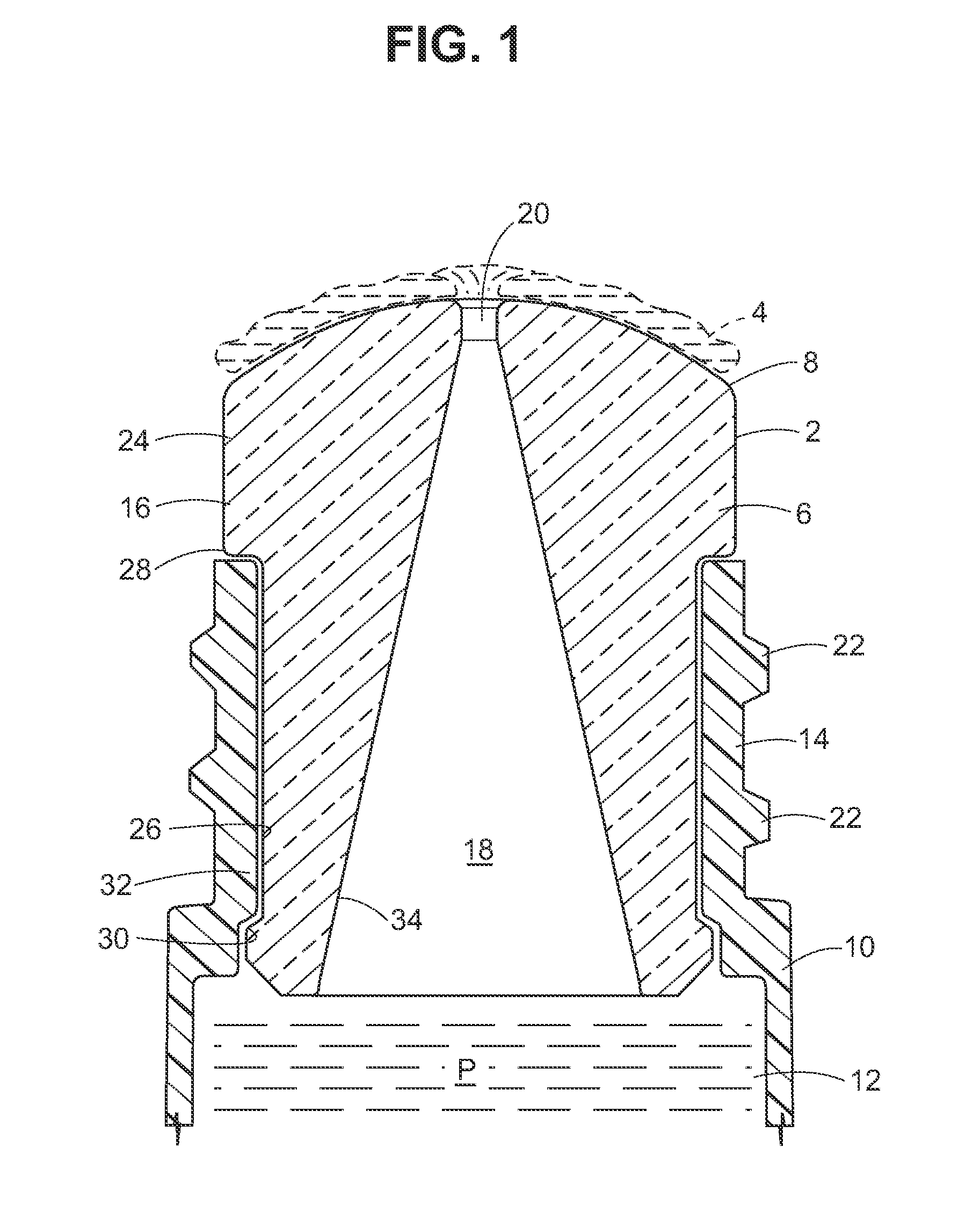

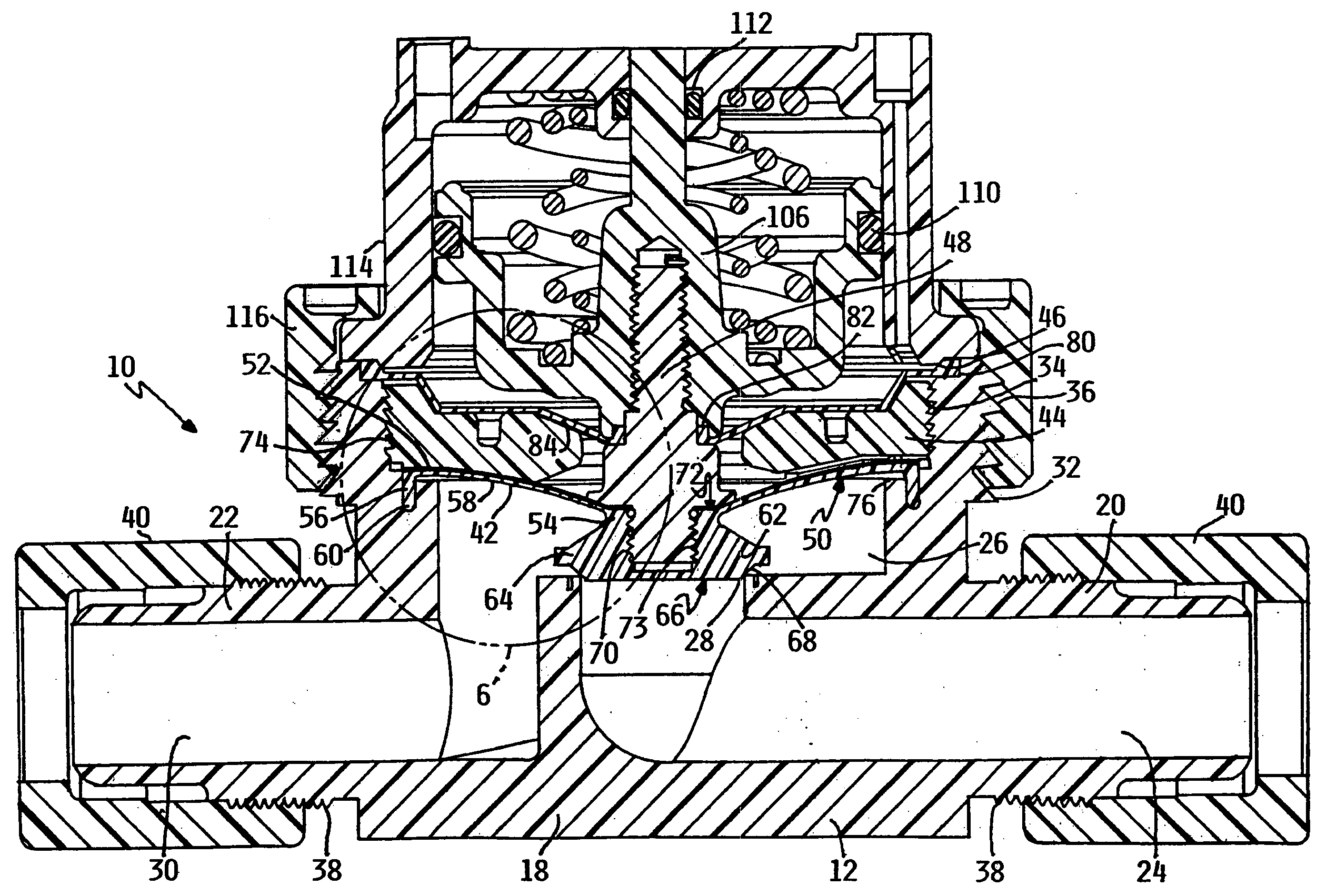

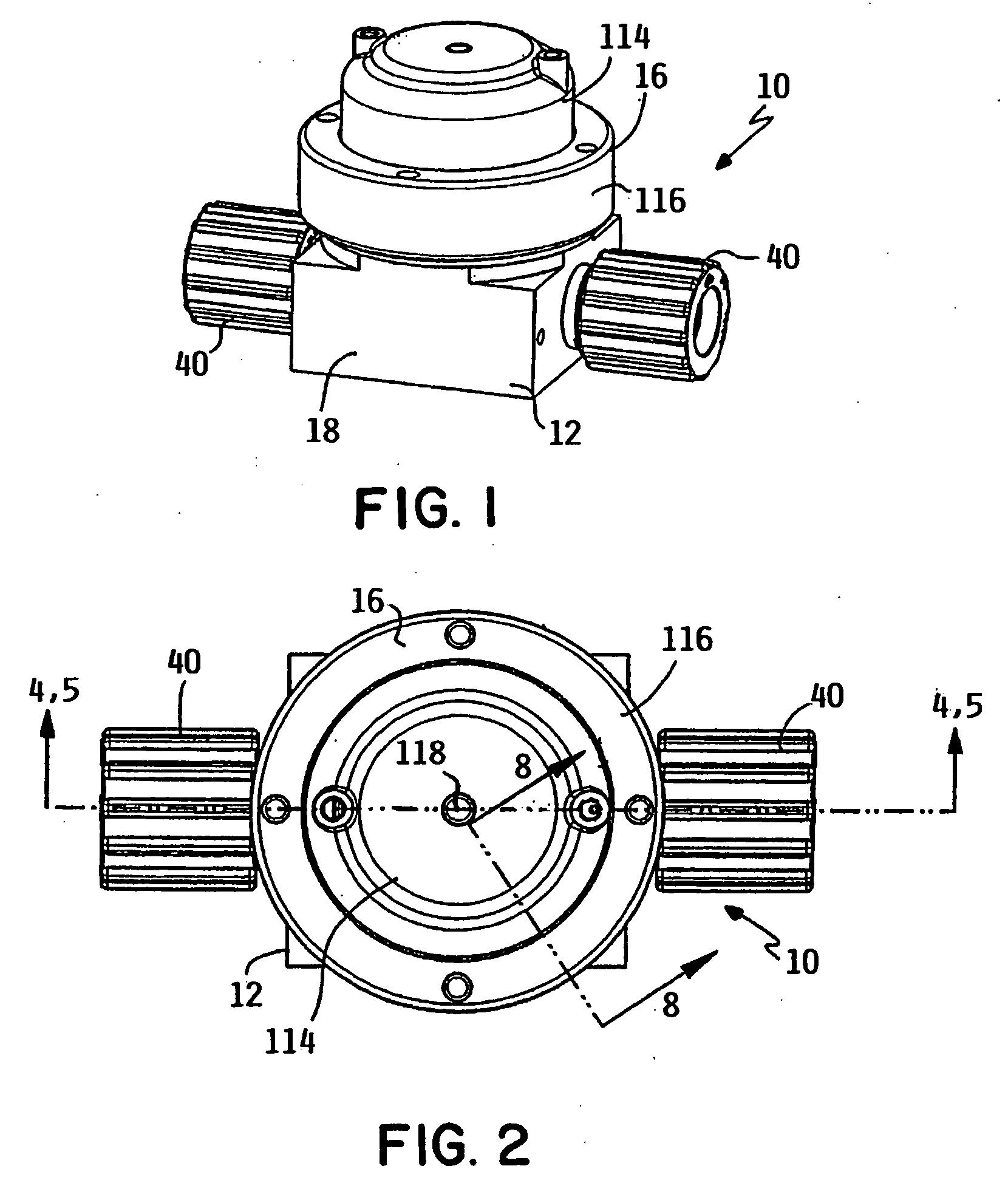

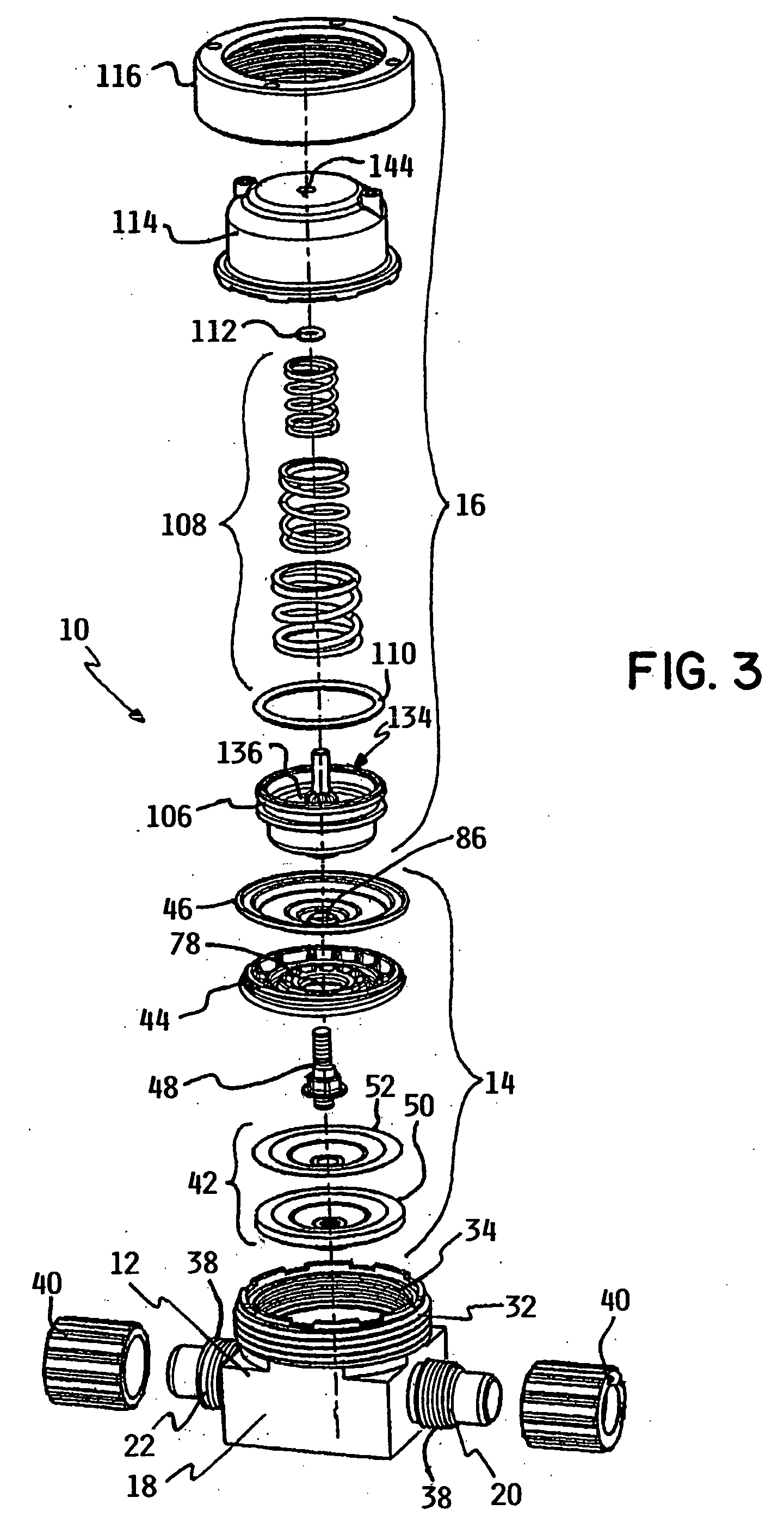

Extended stroke valve and diaphragm

ActiveUS7063304B2Extended service lifeHigh strengthDiaphragm valvesOperating means/releasing devices for valvesMaterial DesignEngineering

An extended stroke poppet valve particularly suited for handling caustic fluids and having features enabling an extended service life for the valve. The valve includes a two part primary diaphragm assembly with a wetted diaphragm made from highly fatigue resistant fluoropolymer material, and a diaphragm backer made from high strength fluoropolymer material designed to withstand the high stress loads imposed by an extended valve stroke. The combination of these two layers in a single primary diaphragm assembly yields a highly durable, caustic chemical resistant, diaphragm capable of use in a long stroke poppet valve and having a relatively long service life.

Owner:ENTEGRIS INC

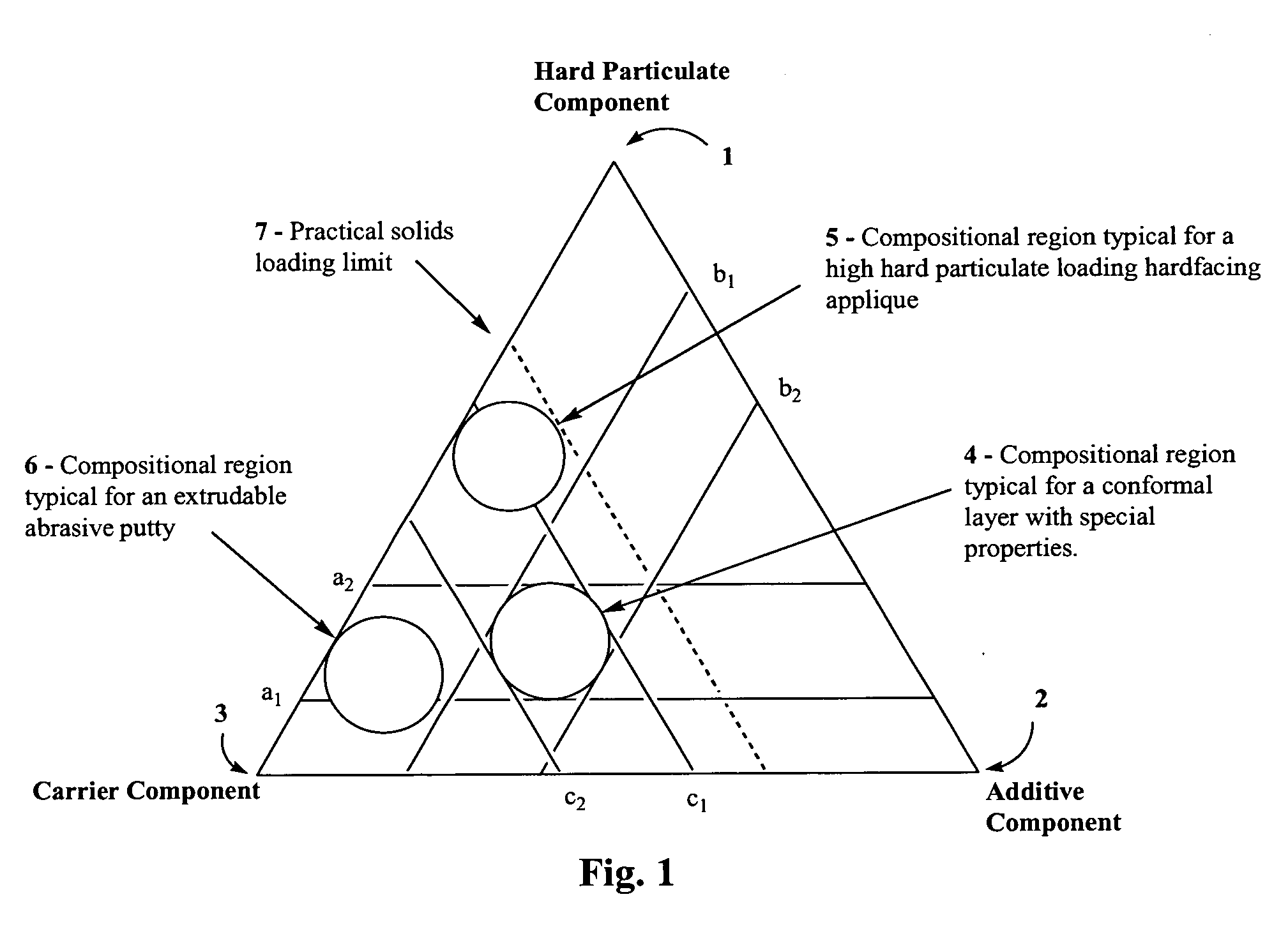

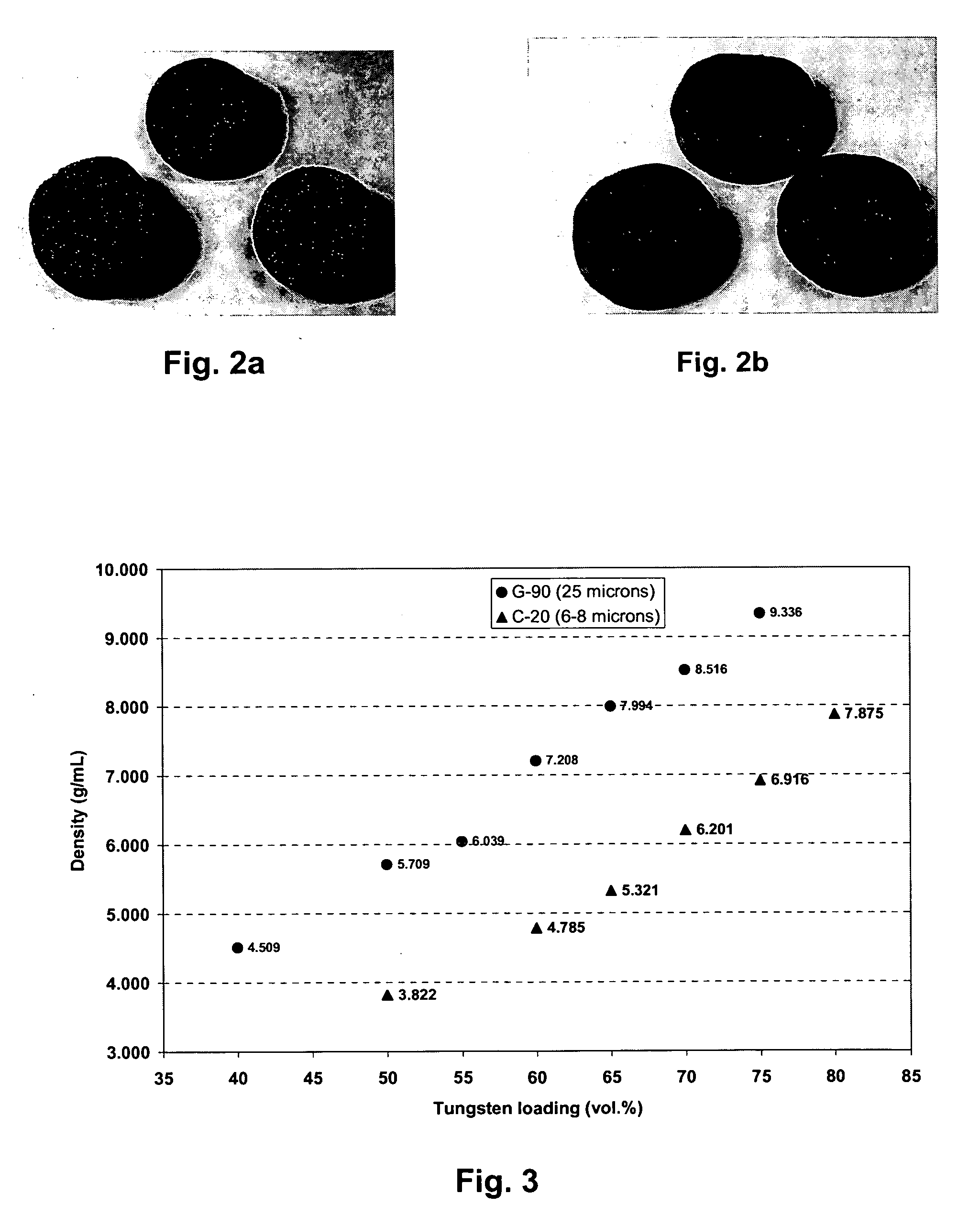

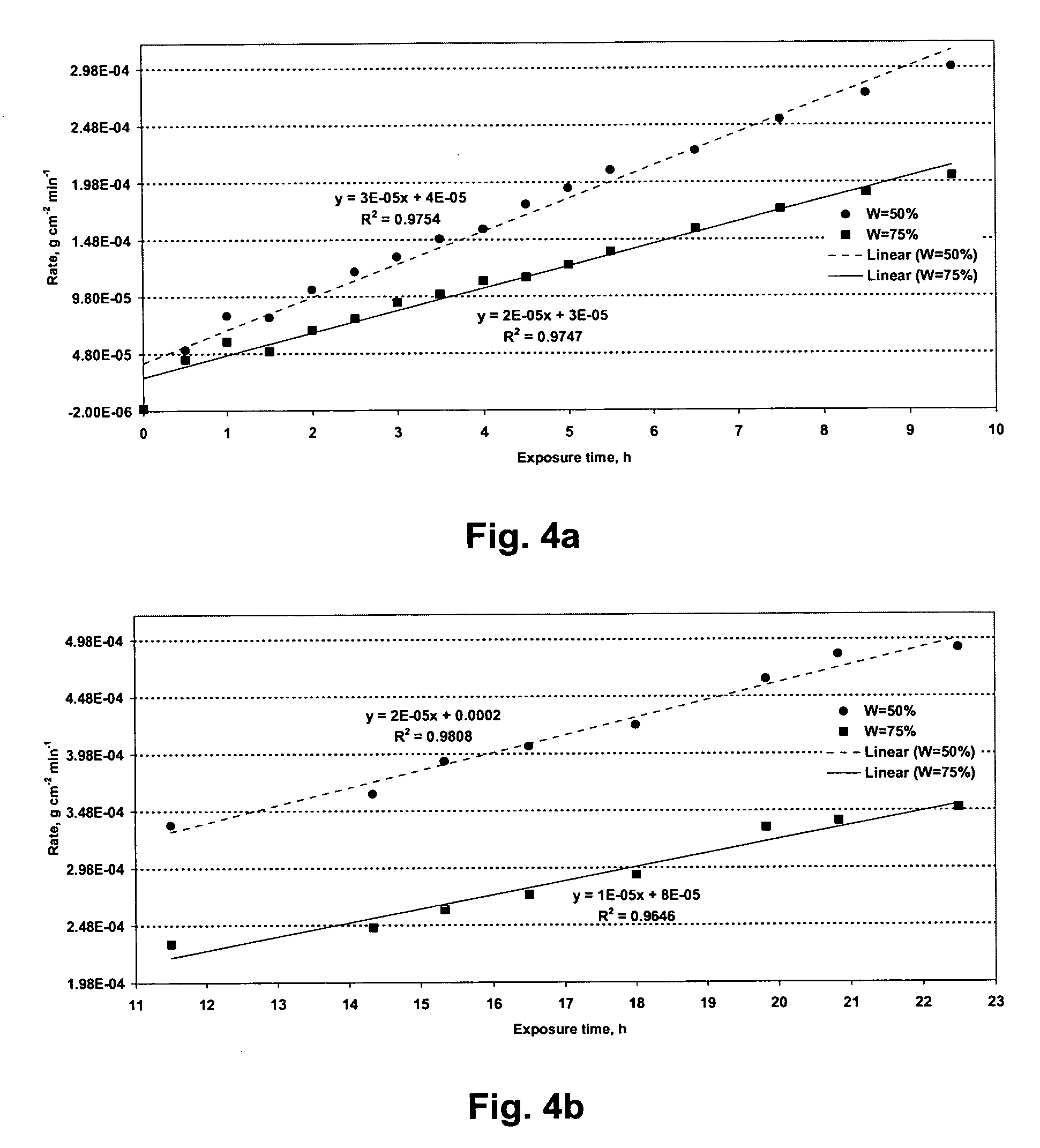

Composite materials and method for making same

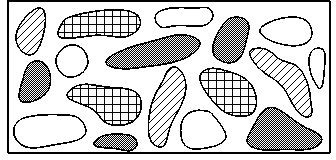

Certain non-limiting embodiments of the present disclosure comprise a family of composite materials targeting specific applications through a materials design approach involving; 1) a hard particulate; 2) a carrier or binder phase; and 3) one or more additives for property enhancement and / or hardness adjustment. According to certain embodiments, the composite material may be one of flexible conformal sheet; a rigid machinable molded preform; and an extrudable putty. Methods of manufacture of the composite materials are also disclosed.

Owner:ATI PROPERTIES

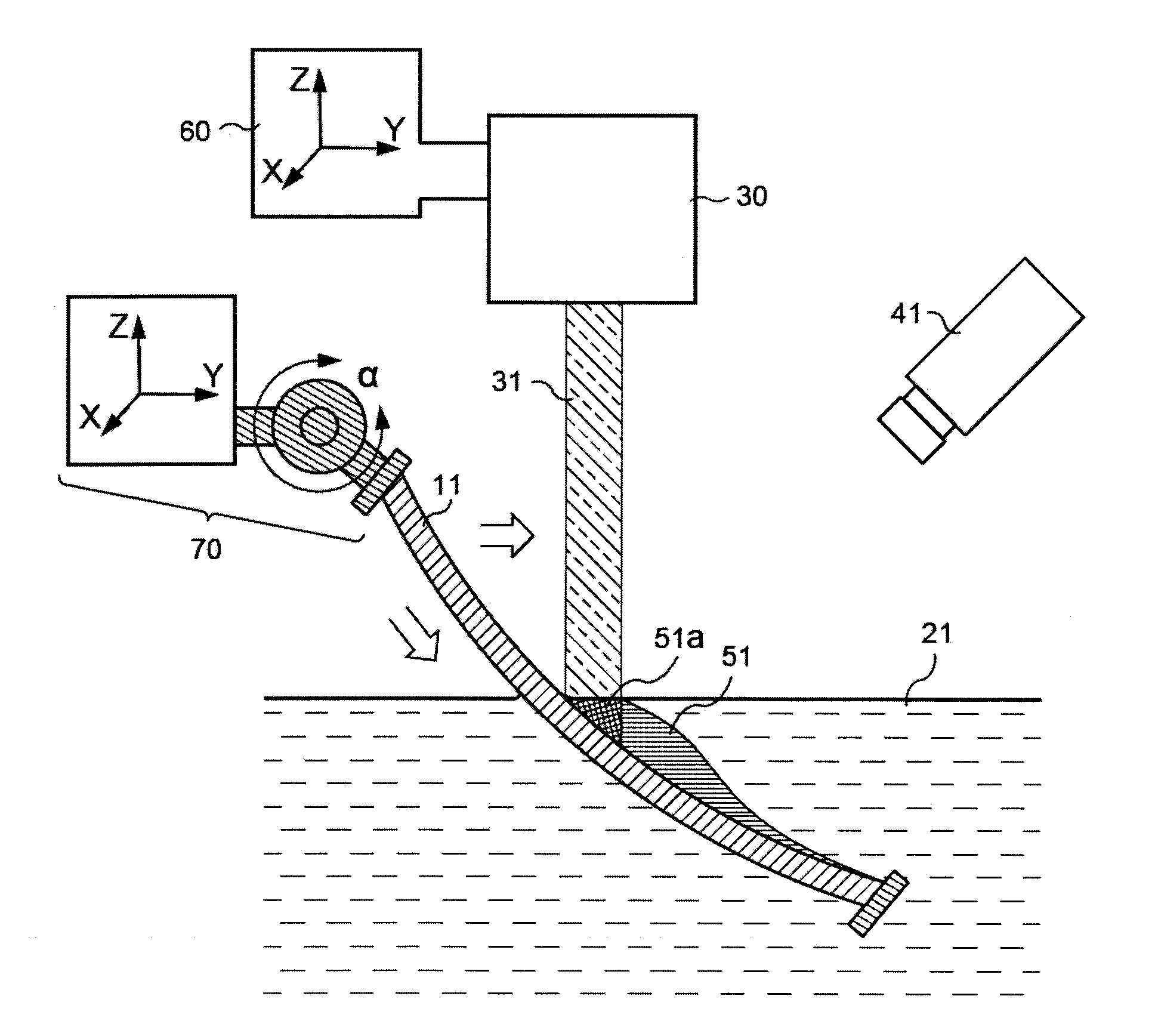

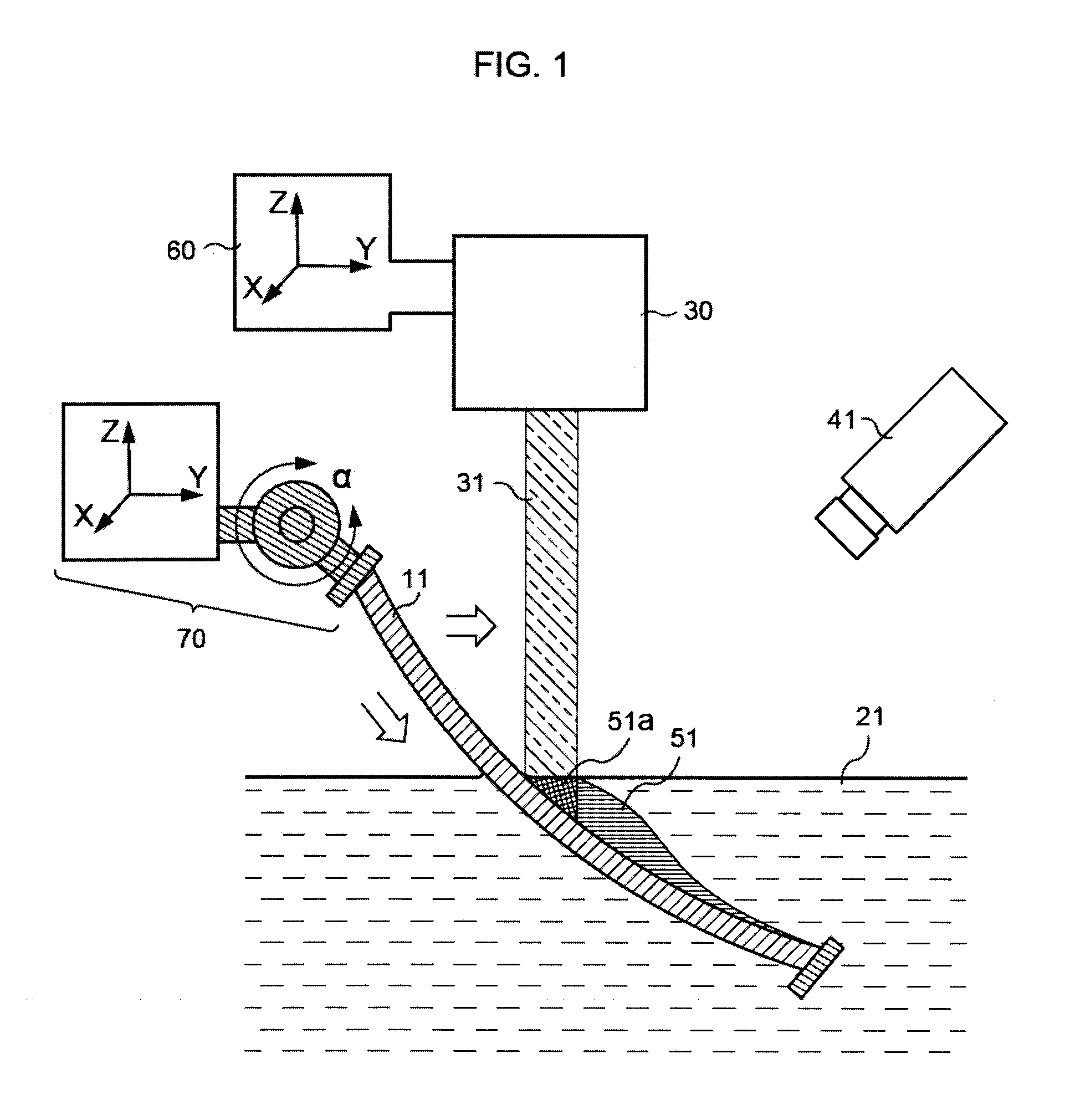

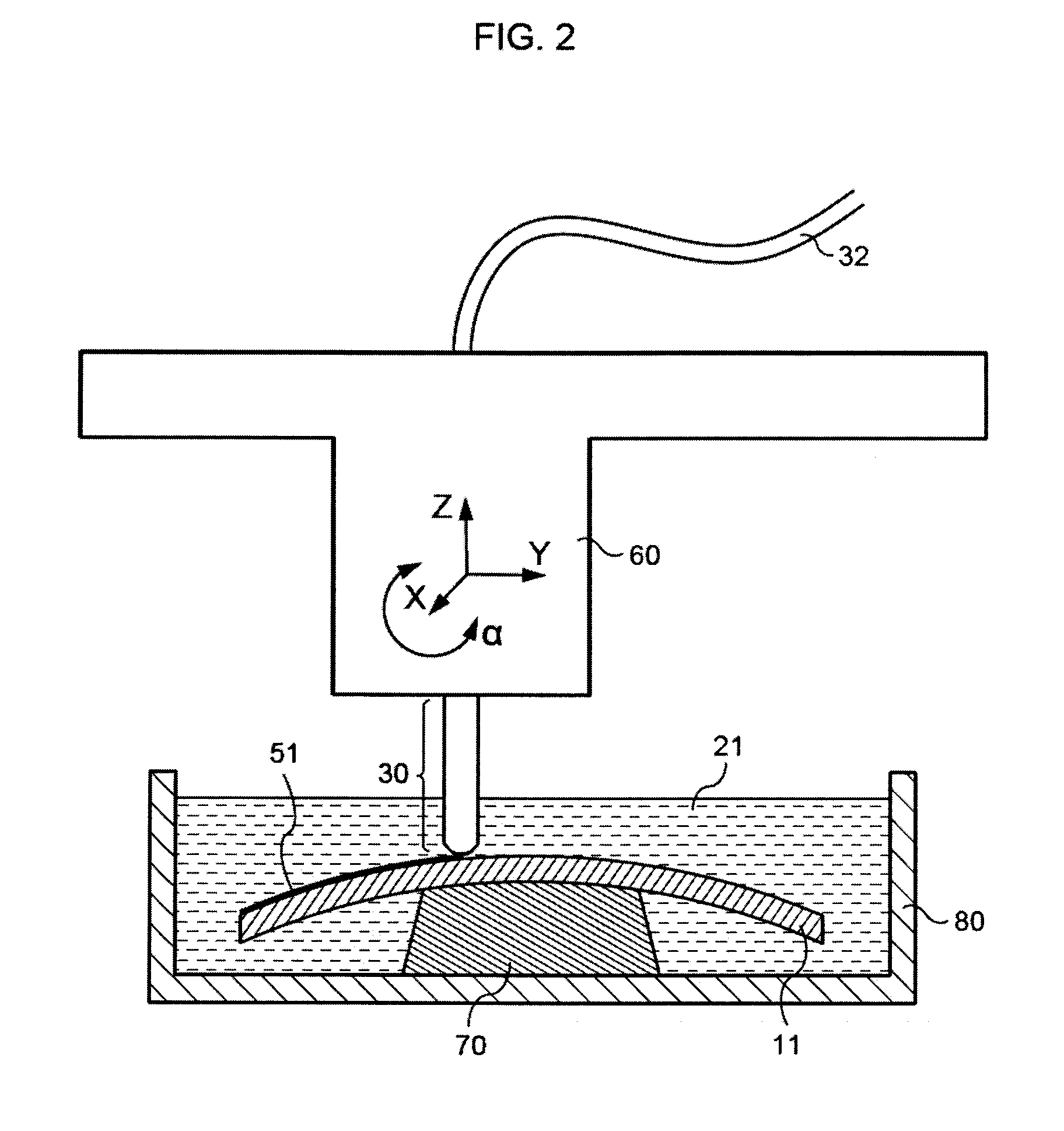

Eyewear lens production by additive techniques

ActiveUS20150277146A1Different optical propertyDifferent physical propertyAdditive manufacturing apparatusOptical articlesMaterial DesignEyewear

A method that adds material selectively to a lens substrate and is used to produce a customized eyewear lens with optical power that is discernibly different from the optical power of the lens substrate. The method involves obtaining the lens substrate, calculating and generating an added material design to convert the lens substrate's optical power to a desired optical power for the customized eyewear lens, contacting the lens substrate with a bulk source of flowable radiation-polymerizable material, and irradiating the material with radiation that is controlled for wavelength range, energy and spatial distribution to polymerize the radiation-polymerizable material only in a selected area according to the added material design. The method does not require the use of external shaping structures to form the customized lens on the lens substrate, and the added material is integrally bonded to the substrate.

Owner:INDIZEN OPTICAL TECH

X-ray detector with impact absorbing cover

ActiveUS20060071172A1Material analysis by optical meansRadiation intensity measurementMaterial DesignPhysics

The present invention is a directed to a cover assembly for an x-ray detector that incorporates impact-absorbing material designed to absorb the shock, vibration, stress, and strain placed on the detector when dropped or subjected to a load. The cover assembly may include a layer or inserts of impact-absorbing material. Bumpers of impact-absorbing material may also be secured to the x-ray detector cover. Viscoelastic foam or other plastics may be used as the impact-absorbing material.

Owner:GENERAL ELECTRIC CO

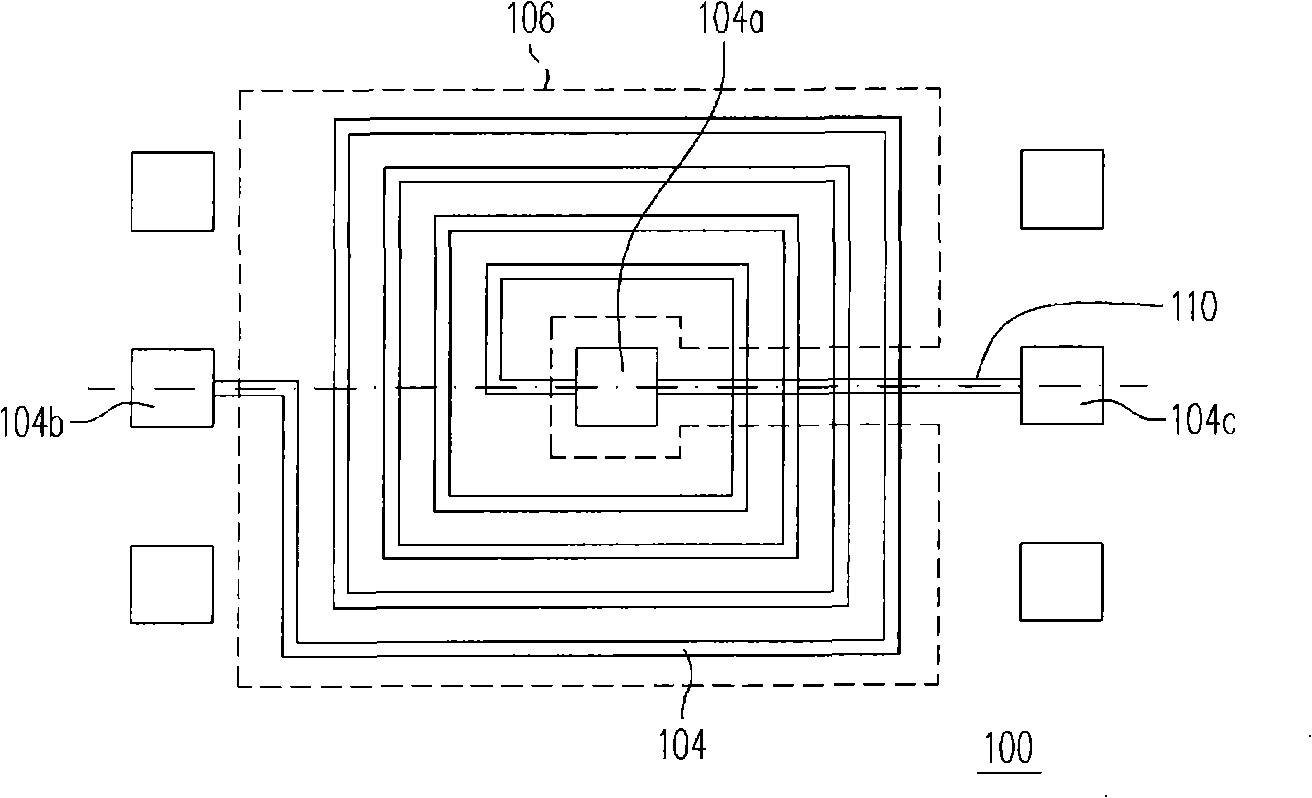

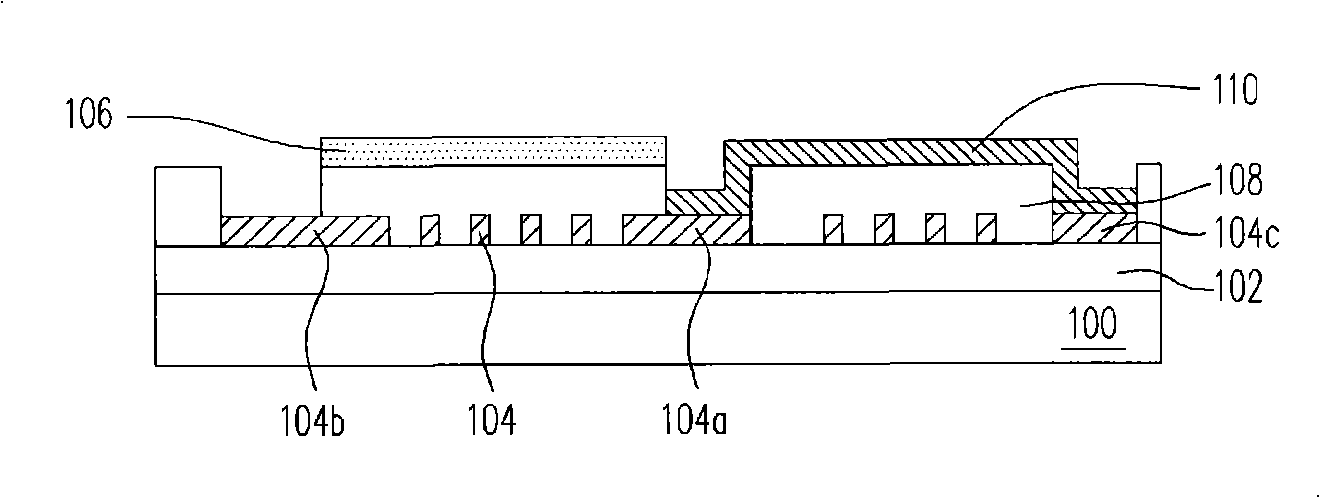

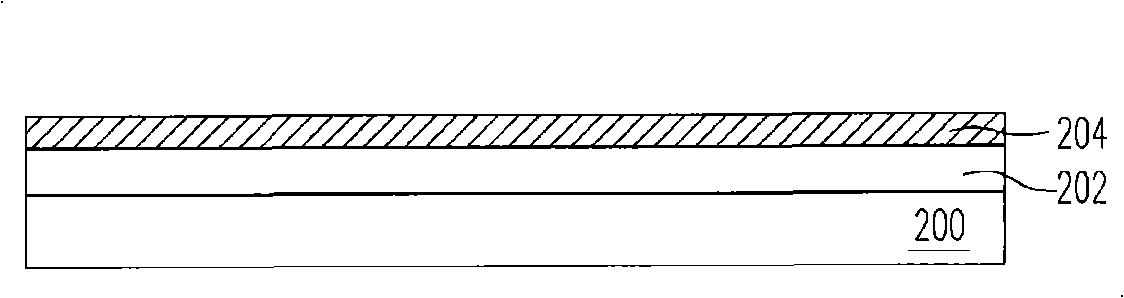

Thermal interface material design for enhanced thermal performance and improved package structural integrity

An electronic package comprising a semiconductor device, a heat spreader layer, and a thermal interface material layer located between the semiconductor device and the heat spreader layer. The thermal interface material layer includes a resin layer having heat conductive particles suspended therein. A portion of the particles are exposed on at least one non-planar surface of the resin layer such that the portion of exposed particles occupies a majority of a total area of a horizontal plane of the non-planar surface.

Owner:TEXAS INSTR INC

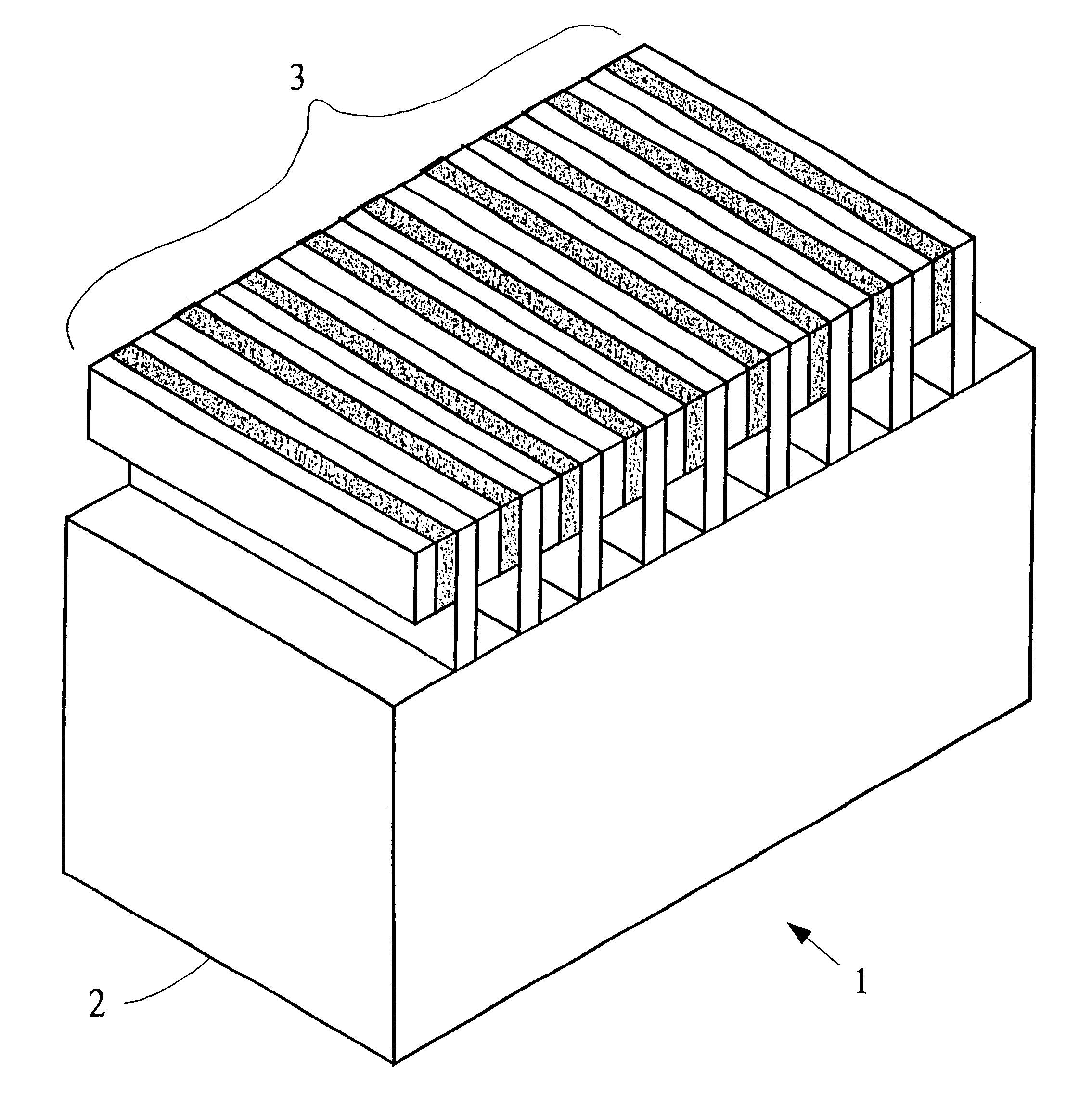

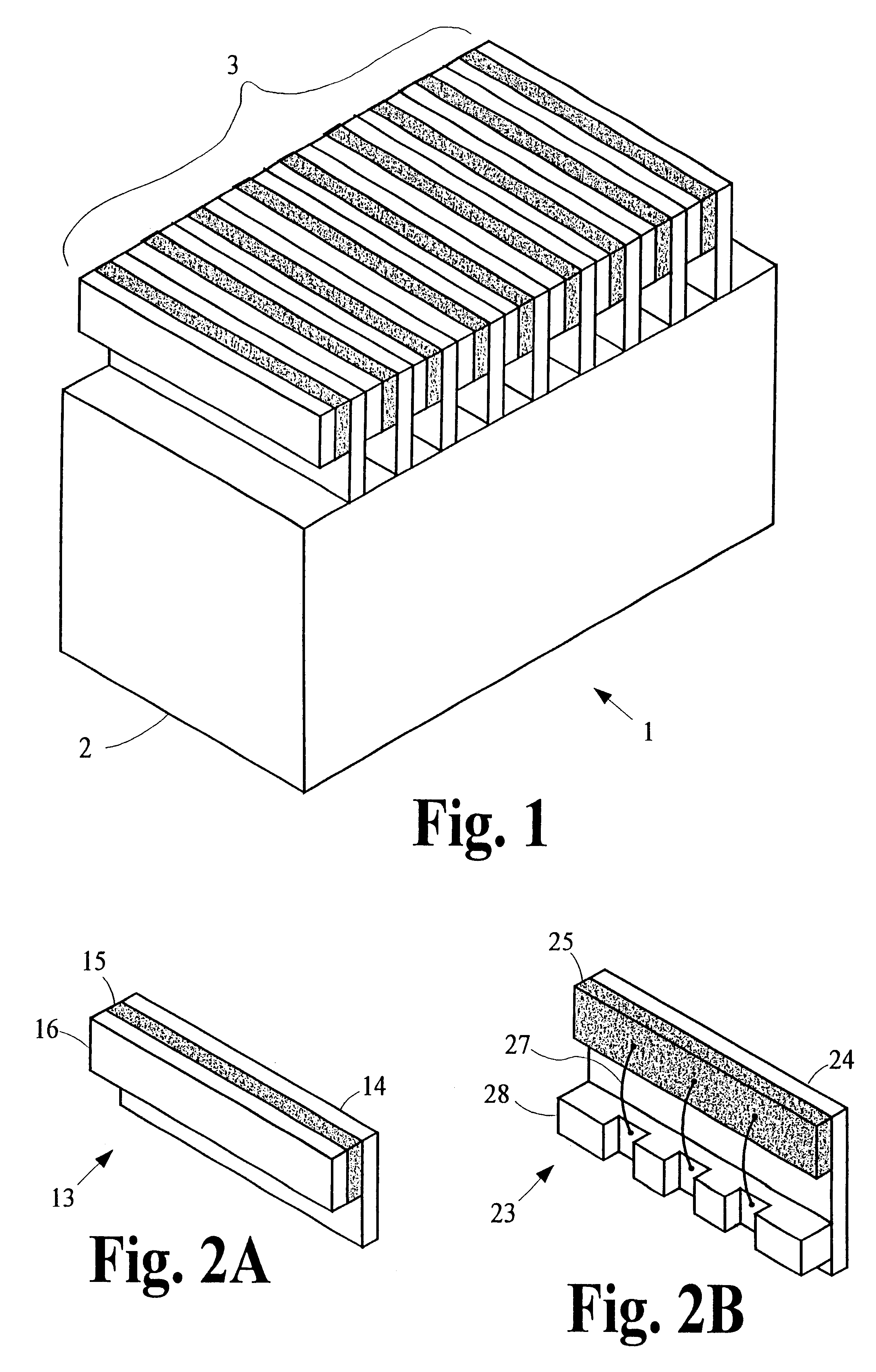

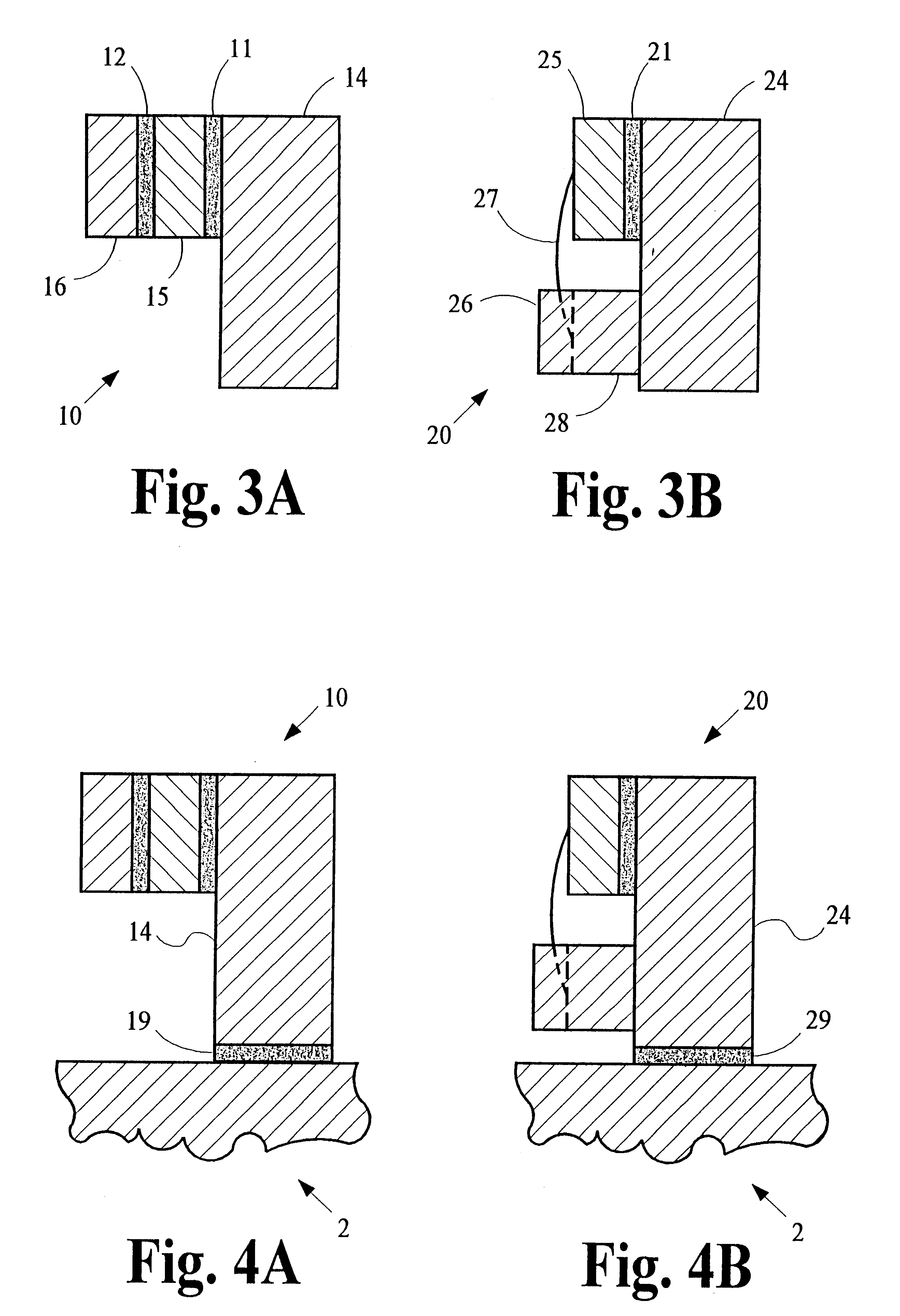

Solder and material designs to improve resistance to cycling fatigue in laser diode stacks

InactiveUS6424667B1Improve resistance to cycling fatigueReduce mechanical strainOptical wave guidanceSemiconductor laser arrangementsMaterial DesignThermal expansion

Laser modules that are operated intermittently are prone to stop operating after only a few thousand cycles or less. The laser modules sometimes experience a significant increase in operating temperature before they stop operating and, in some cases, manifest an opening of the electrical circuit that connects the laser diodes in the stack of laser subassemblies. In extreme cases, the laser module disintegrates into component subassemblies. These problems arise from structural failures in affixing agents like solder that are used to affix component parts to each other. The structural failures are caused by cyclical thermal expansion and contraction of component parts that exceed the elastic limit of the solder. Resistance to global plastic deformation (creep) and to local plastic deformation (fatigue) is improved by selecting materials to reduce mechanical strain and increase resistance to creep and fatigue, by altering the structural design of the laser module to reduce mechanical strain induced into the affixing agents, and by altering operational practices to reduce the range of temperatures imposed on laser module components. One design method improves resistance to creep and fatigue by controlling the thickness of the affixing agents used to affix component parts to each other.

Owner:JDS UNIPHASE CORP

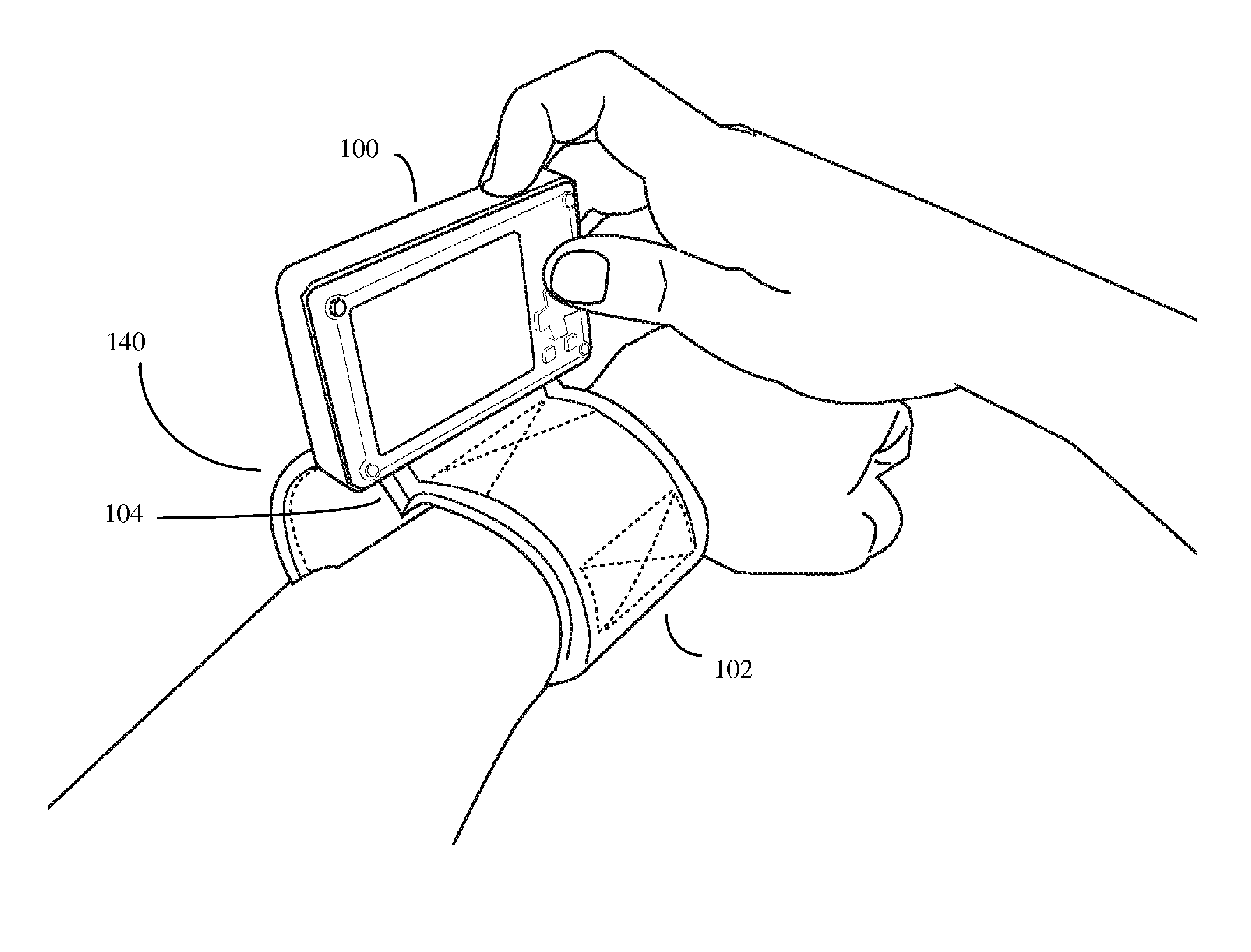

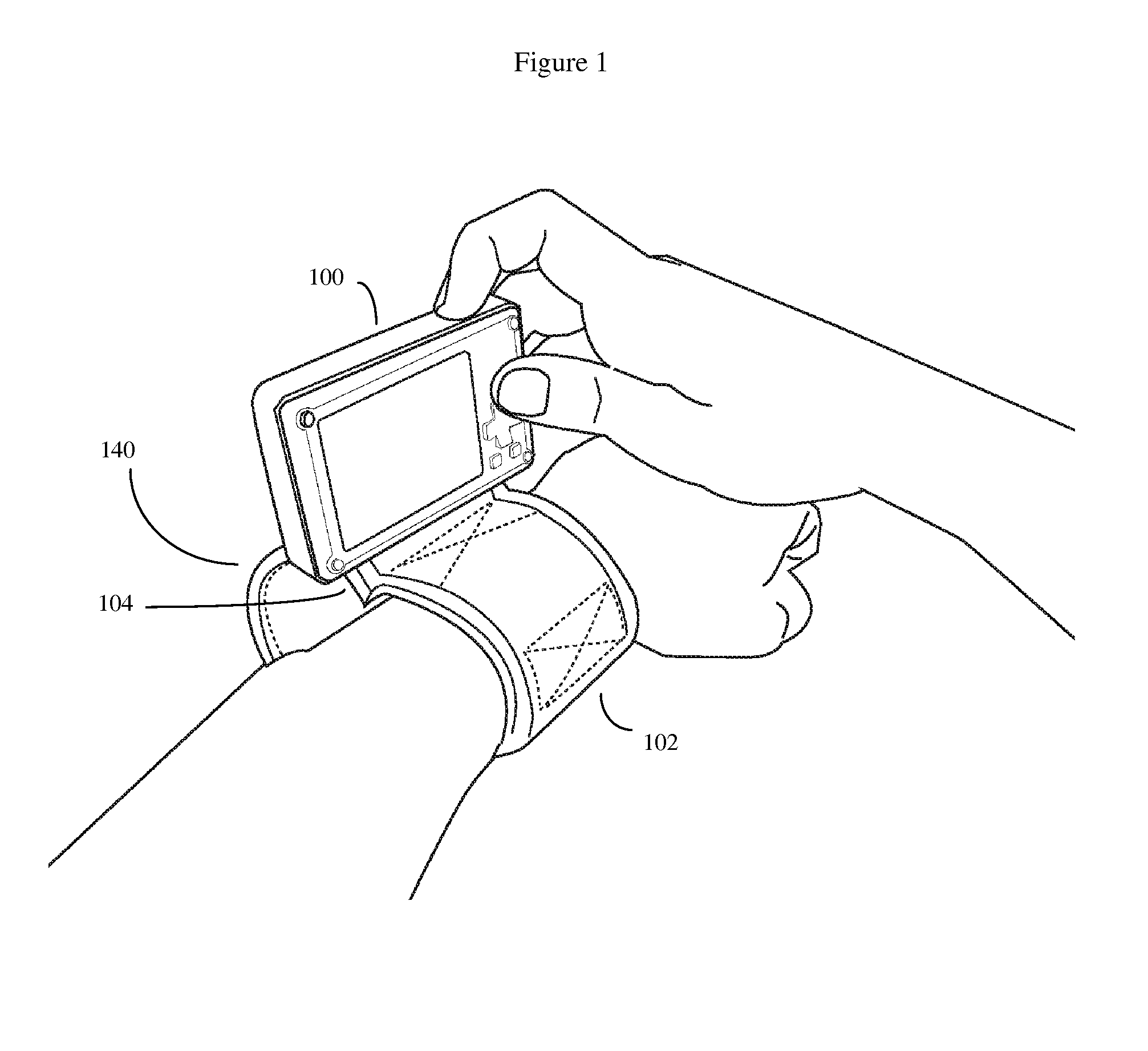

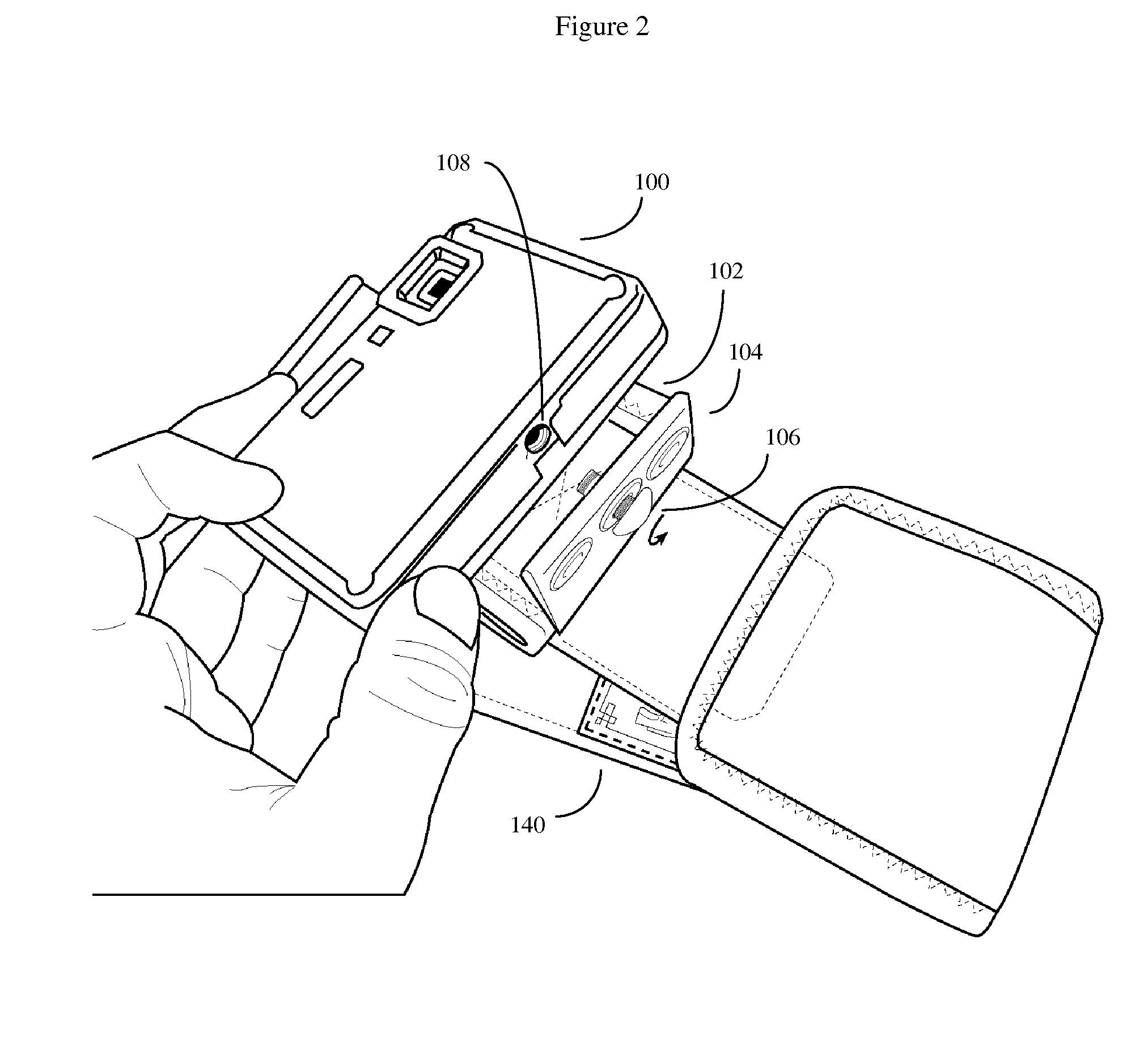

Wrist or arm strap with hinged mount for camera

InactiveUS20100316369A1Easy to controlAvoid accidental damageTravelling sacksOther accessoriesMaterial DesignHand arm

A device capable of attaching a portable handheld camera to the wrist or arm of a human user is disclosed. The device is a multi-component detachable band of fabric or other material designed to encircle a user's wrist or arm, and hold a small handheld camera to the user's arm by way a camera mounting screw that attaches, by way of a rigid or semi-rigid hinged camera mounting bracket affixed to the band, to the camera's tripod socket. The device will often additionally contain a built-in second band of fabric or other material that can be positioned over the majority of the camera's front, and both hold the camera tightly to the user's wrist or arm when photography is not desired, as well as help protect the camera from accidental damage. The device is particularly useful for action sports photography.

Owner:PYLE COLIN JAMES

Method and apparatus for simulating manufacturing, electrical and physical characteristics of a semiconductor device

InactiveUS20020123872A1Semiconductor/solid-state device detailsSolid-state devicesElement modelMaterial Design

An electronic device simulator includes a three-dimensional lumped device model, a three-dimensional visco-elastic process simulation model and a material design model that are interlinked with each other. The three-dimensional lumped device element model comprises a Poisson's equation model, an electron continuity equation model, a hole continuity equation model, a Maxwell's equations model, an eddy current equation model, and an Ohm's law equation model. The simulator accounts for the three dimensional characteristics of the circuit to determine circuit performance.

Owner:KK TOSHIBA

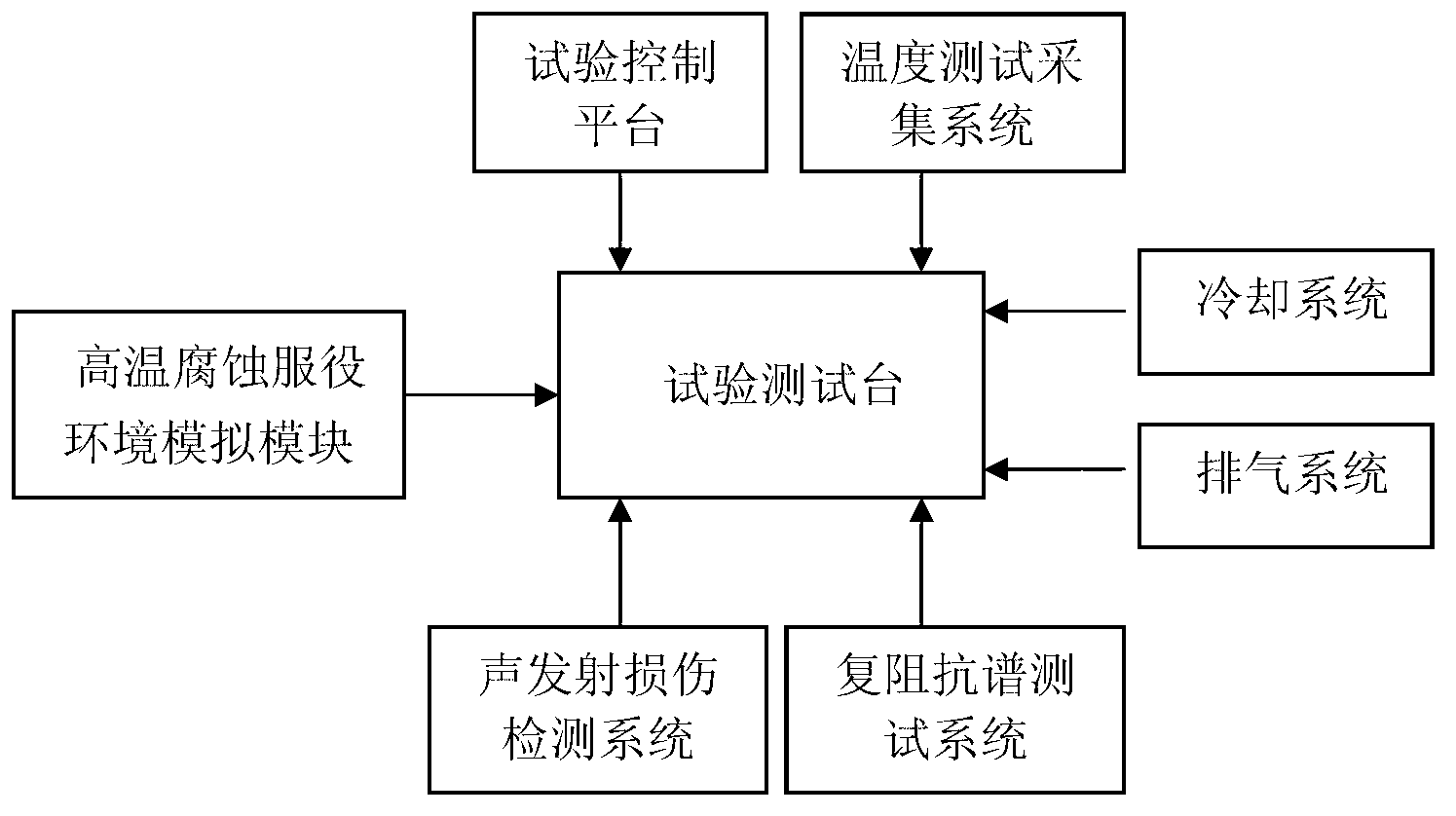

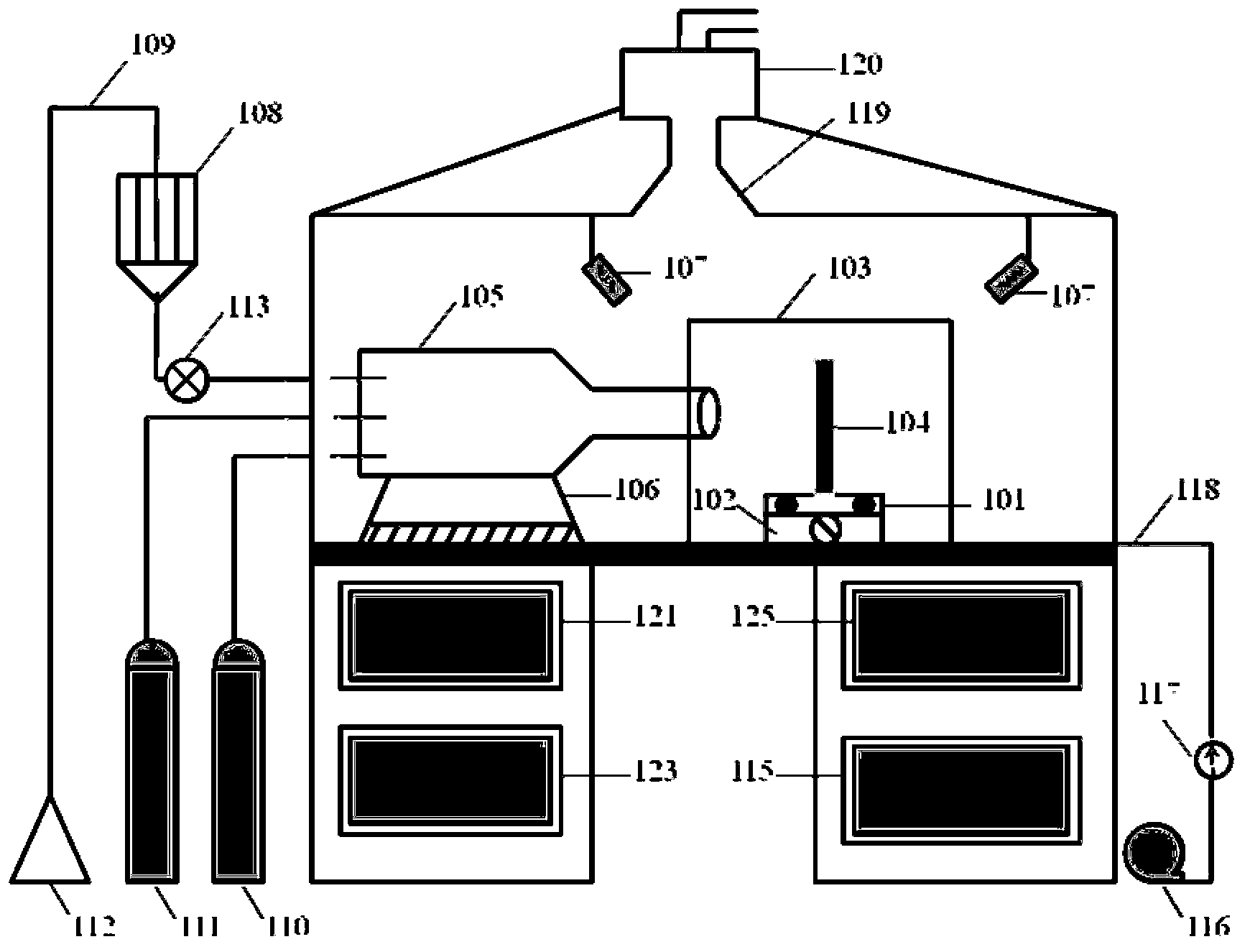

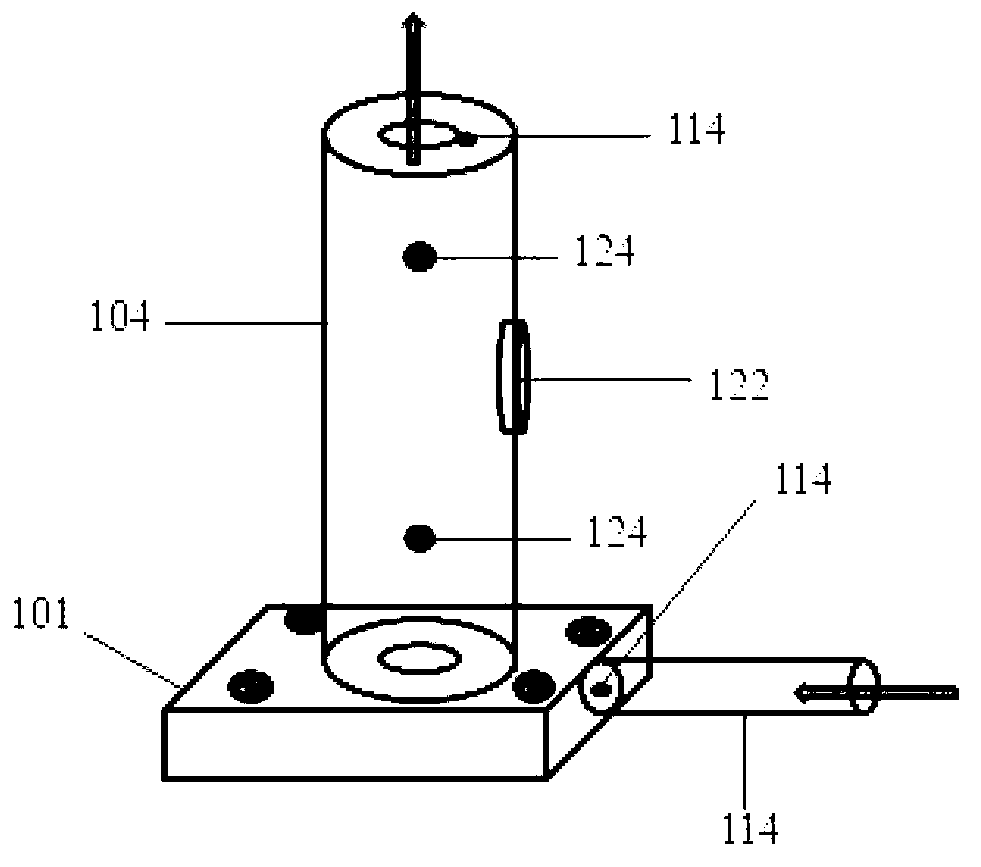

Testing device for simulation and real-time detection of high-temperature deposition corrosion of thermal barrier coatings

ActiveCN103063563AConcentration adjustableIngredients adjustableWeather/light/corrosion resistanceComplex impedance spectraMaterial Design

The invention discloses a testing device for simulation and real-time detection of high-temperature deposition corrosion of thermal barrier coatings, belonging to the field of simulation devices in a special service environment. The testing device comprises a test board which is equipped with a sample fixture and a fixture fixing device, a cooling system, a high-temperature corrosion service environment simulation module, an exhaust system, a complex impedance spectroscopy measuring system, an acoustic emission testing system and a test control and display platform, wherein the complex impedance spectroscopy measuring system and the acoustic emission testing system are integrated together. The device can be used for adjusting the parameters such as variety, concentration, corrosive temperature of corrosive medium. The change of coating impedance and damaged acoustic emission signals when a sample is corroded can be periodically detected by the complex impedance spectroscopy measuring system and the acoustic emission testing system, the high-temperature corrosion of various impurity particles, such as Ca, Mg, Al, Si and Na of thermal barrier coatings of aero-engine turbine blades in actual service temperature environment is actually simulated; in addition, the corrosion failure process is periodically detected; and an important test platform is provided for correctly understanding the high-temperature corrosion mechanism of thermal barrier coatings and optimizing the material design thereof.

Owner:XIANGTAN UNIV

Ceramic Cosmetic Applicator

InactiveUS20110103878A1Remarkable effectLower skin temperatureLiquid surface applicatorsBall-point pensAbsorption capacityMaterial Design

A cosmetic applicator formed from ceramic material designed to provide a product chilling effect when applying creams, lotions, treatment products, etc. The applicator is provided with a relatively substantial mass so that it has a greater thermal capacity than the dose of cosmetic and the application area combined. The applicator is in the form of a molded-ceramic applicator head or applicator tip designed to provide a relatively larger product-chilling effect to both the dose of cosmetic applied and to the user's skin in the application area when applying creams, lotions, treatment products, etc. The applicator provides an application device which will deliver the creams, lotions, treatment products, etc. such that the temperature of the product being delivered is lower than the temperature of the skin, and to provide a means of lowering the temperature of the skin by virtue of the thermal absorption capacity of the applicator head or tip, and to provide a vehicle by which formulations may be activated or enhanced by specific compounds in the ceramic material from which the applicator tip is comprised.

Owner:ELC MANAGEMENT LLC

Method for establishing composite pavement temperature field model of underground road

ActiveCN103031801ARoads maintainenceSpecial data processing applicationsTemperature stressMaterial Design

The invention relates to composite pavement temperature measurement of an underground road. The purposes of the invention are to make a research on a method for predicating the temperature of a pavement at any time and in any position and preferably instruct pavement structural and material design of the underground road. In order to achieve the purposes, a technical scheme adopted in the invention is as follows: a method for establishing a composite pavement temperature field model of the underground road is characterized by comprising the following steps: actually measuring a composite pavement temperature field of the underground road; carrying out heat transfer theoretical analysis, air convection heat exchange and air radiation heat exchange on the composite pavement temperature field of the underground road; from basic principles of climatology and heat transfer theory, analyzing the temperature field and temperature stress of the underground road pavement by using a two-dimensional elastic layer theory system according to actual situations of a pavement structure; and making the following basic assumptions. The method is mainly applied to the temperature measurement of the composite pavement of the underground road.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

Single-use, bullet-proof shield

InactiveUS6009790AReduce manufacturing costEasy to useArmour platesBullet catchersMaterial DesignMetallic materials

Owner:TEKORIUS PAUL

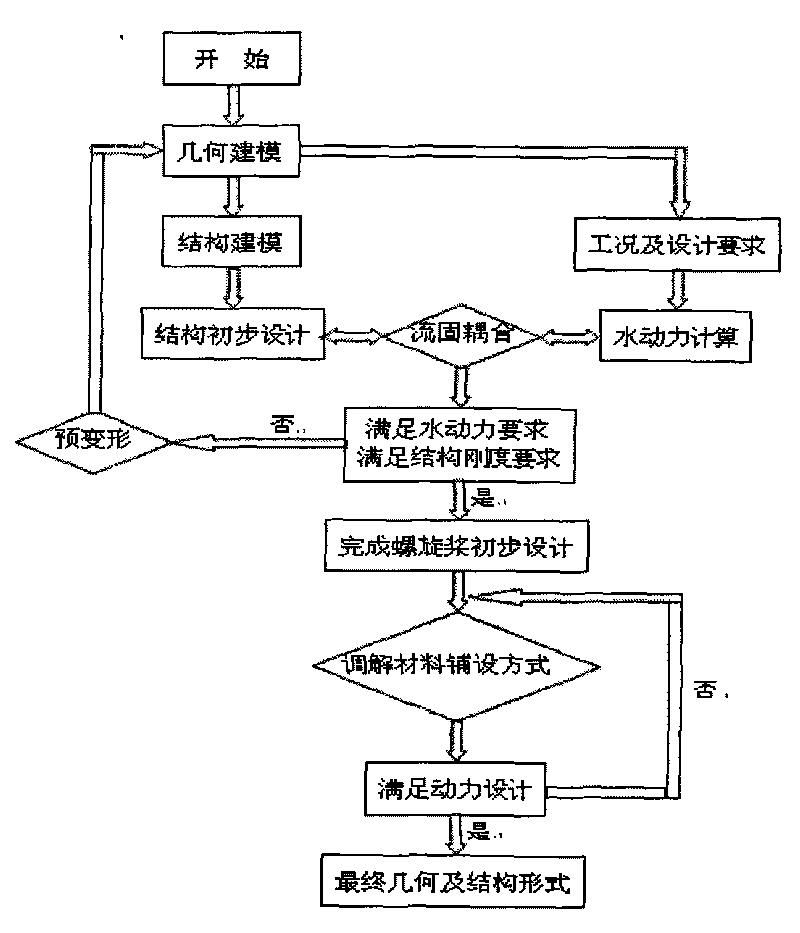

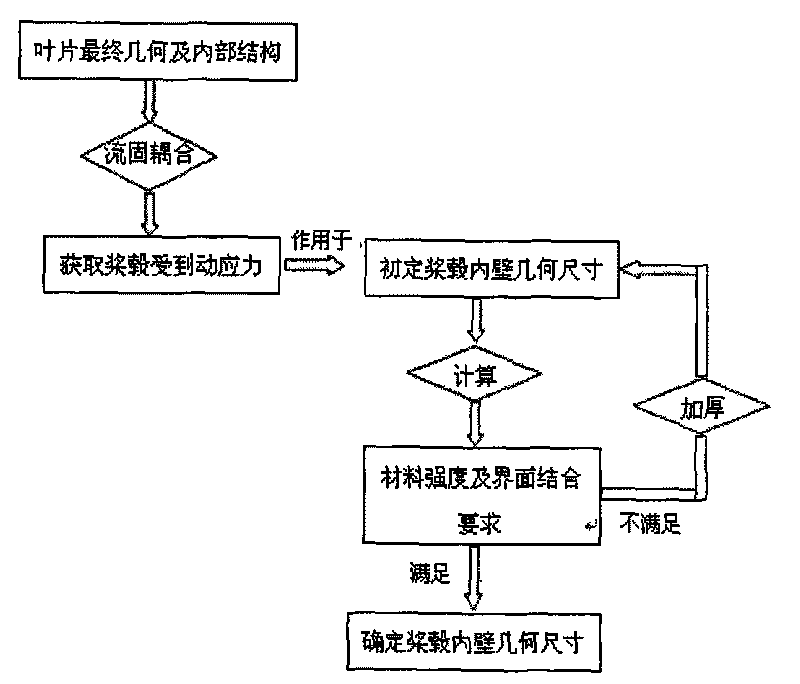

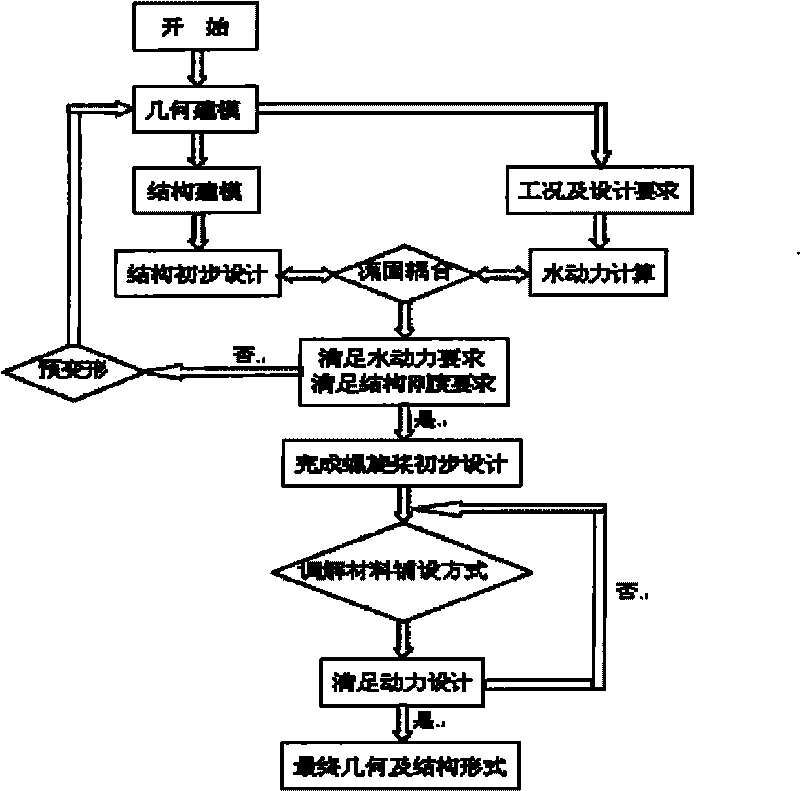

Design method for marine propeller made of carbon fiber composite material

InactiveCN101706833AImprove flow elasticityMeet propulsion performance requirementsRotary propellersSpecial data processing applicationsMaterial DesignPre deformation

A design method for marine propeller made of carbon fiber composite material relates to a design method for a propeller. The invention solves the problem that the current design method for the marine propeller made of carbon fiber composite material is imperfect. The geometrical appearance of the blade by the design method for marine propeller made of carbon fiber composite material is calculated by fully using the flexibility and designable performance of the composite material on the basis of the value data of the original MAU metal propeller blade and combining the fluid-structure coupling method with the implementation of the pre-deformation tactics; and the outside of the propeller hub is wrapped by the carbon fiber composite material. The marine propeller made of carbon fiber composite material designed by the method has the geometrical appearance and the internal structure more suitable for the propeller made of carbon fiber composite material, thereby being capable of effectively improving the fluid elasticity of the propeller and improving the propulsive efficiency.

Owner:HARBIN INST OF TECH

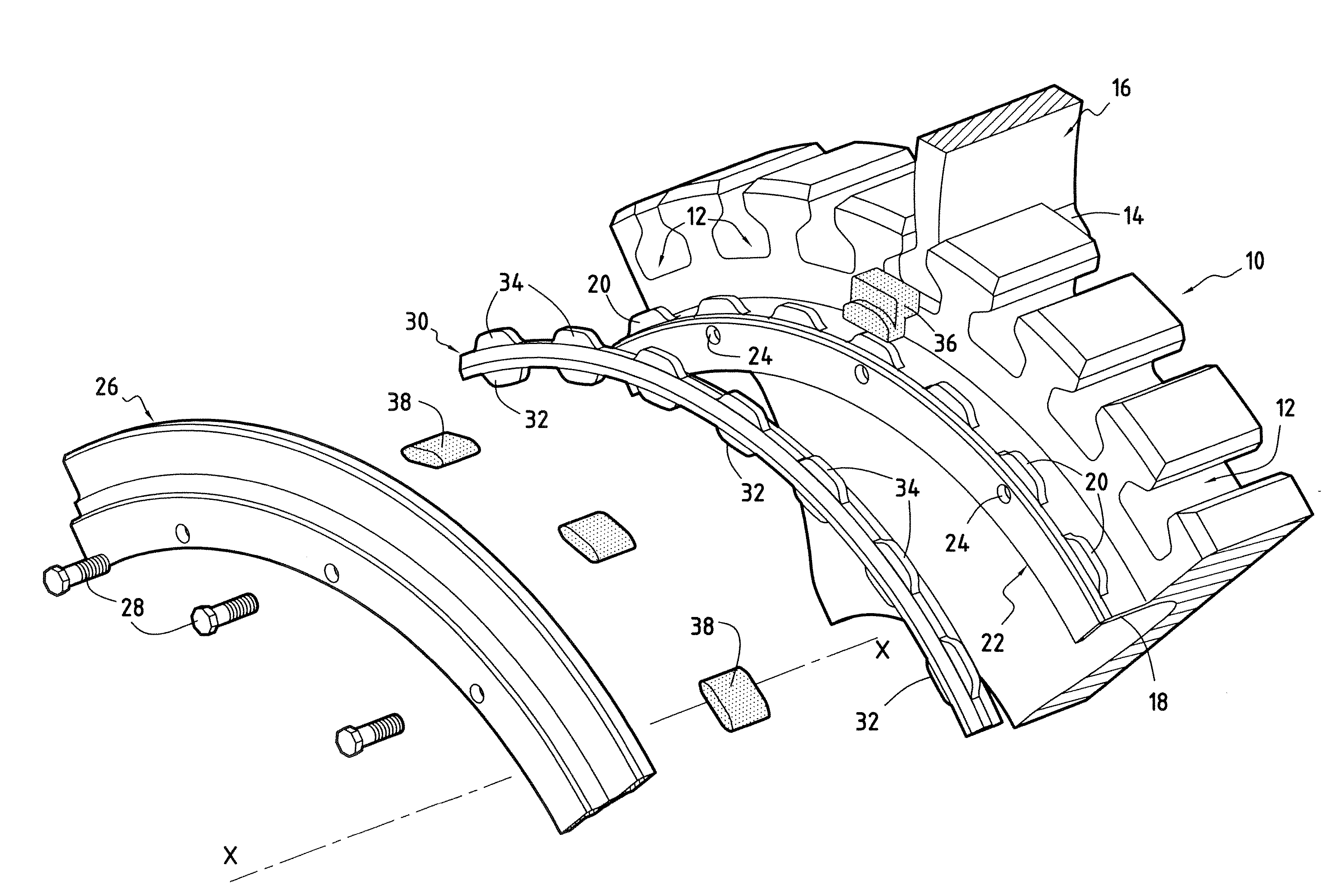

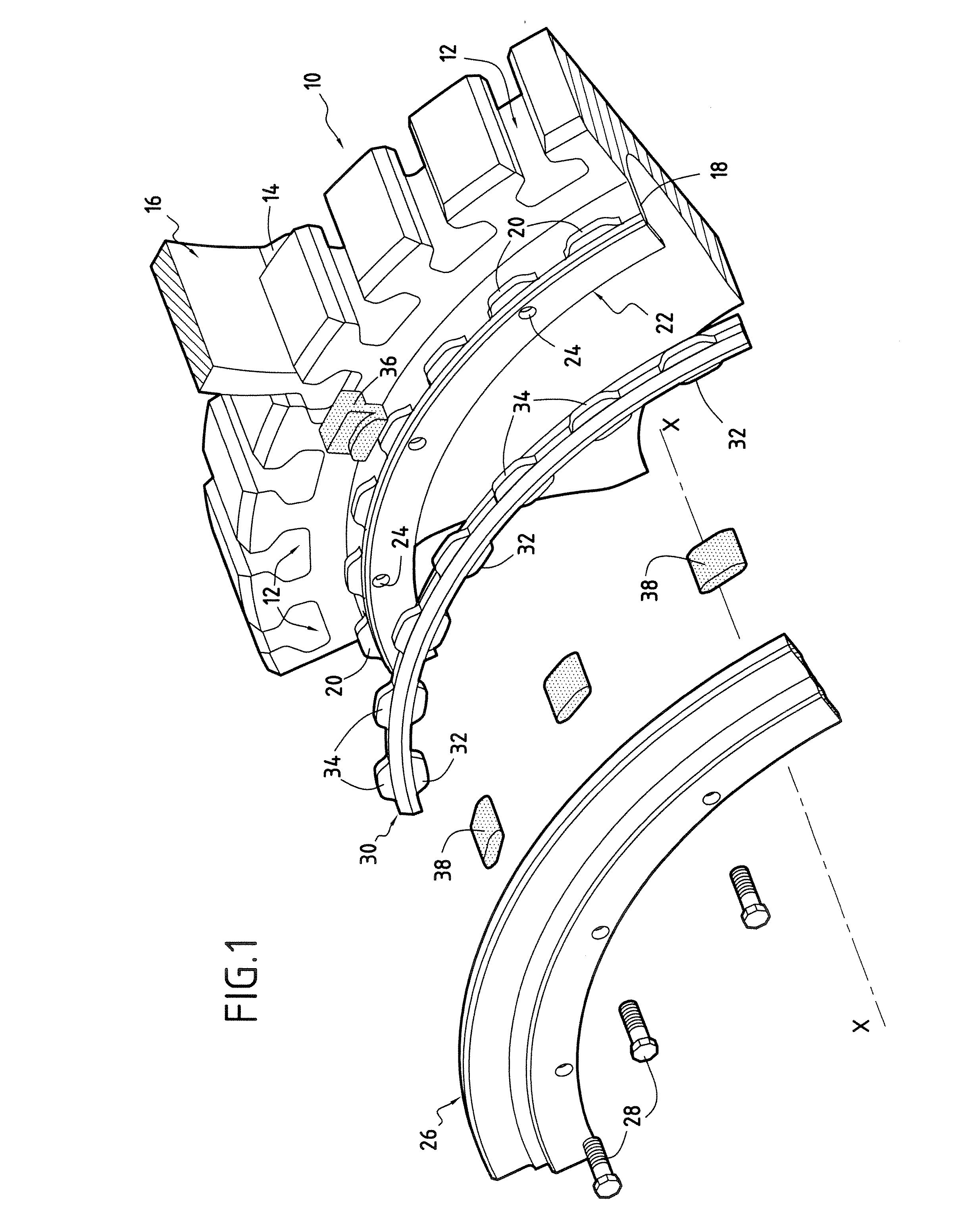

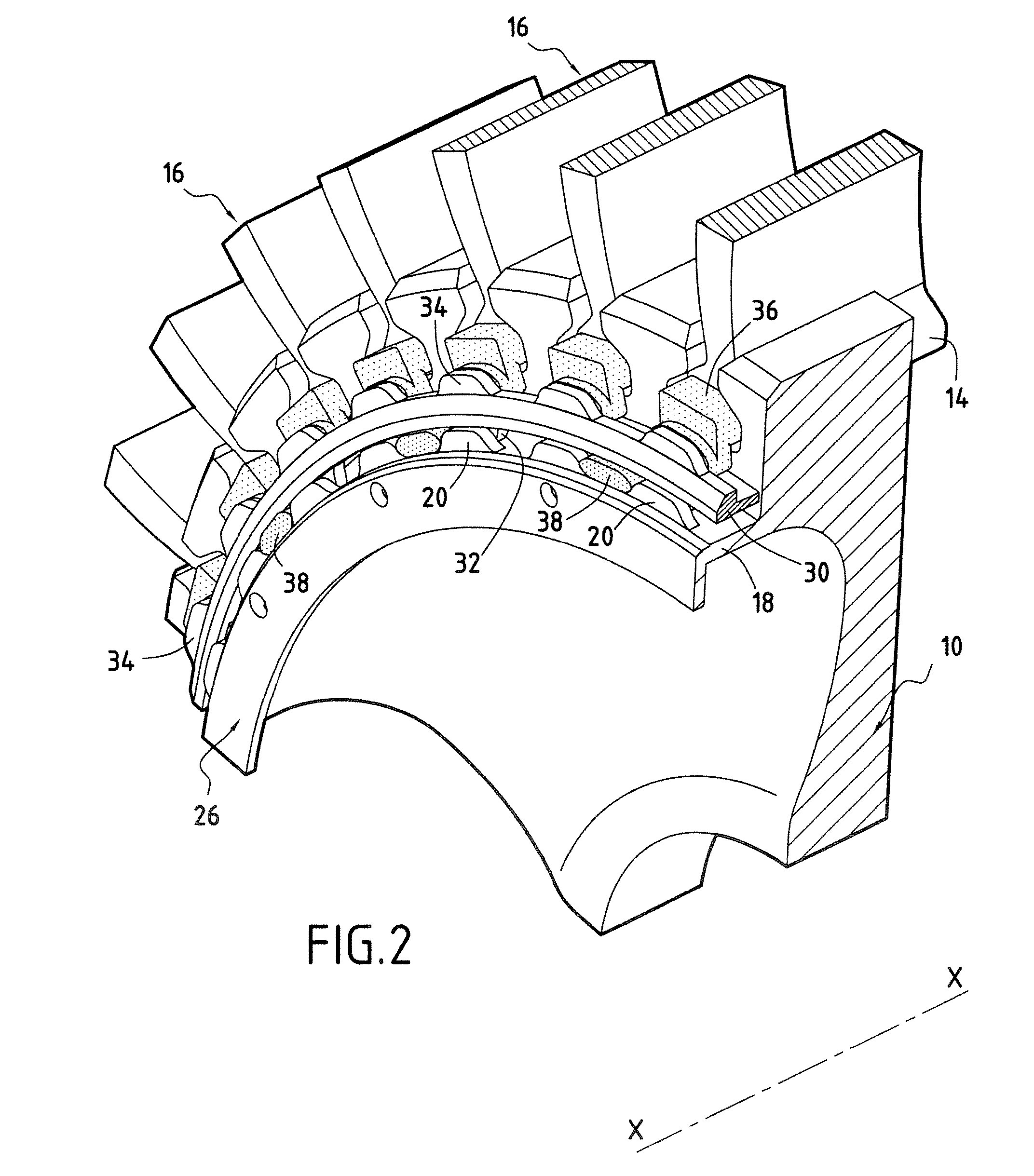

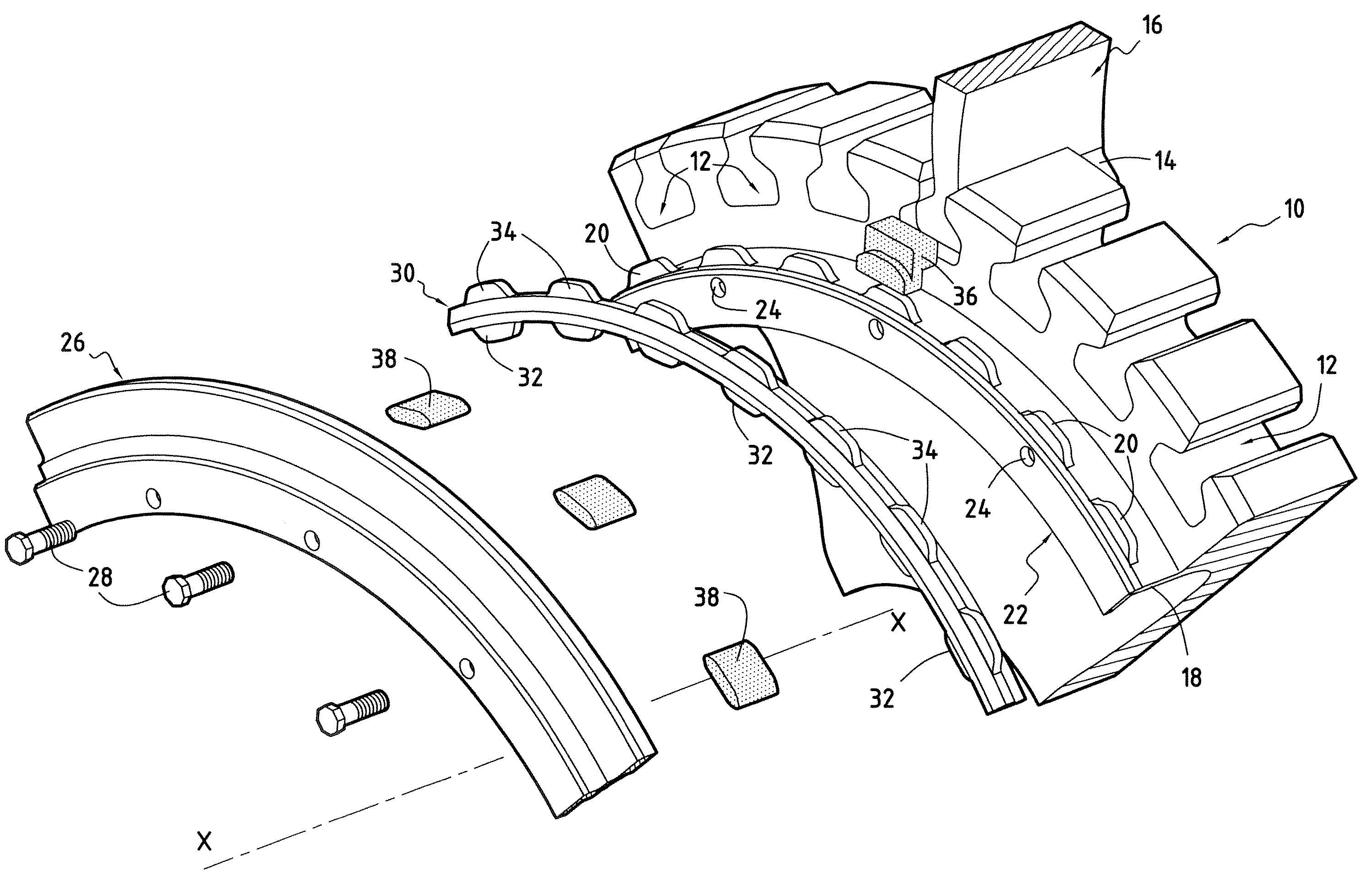

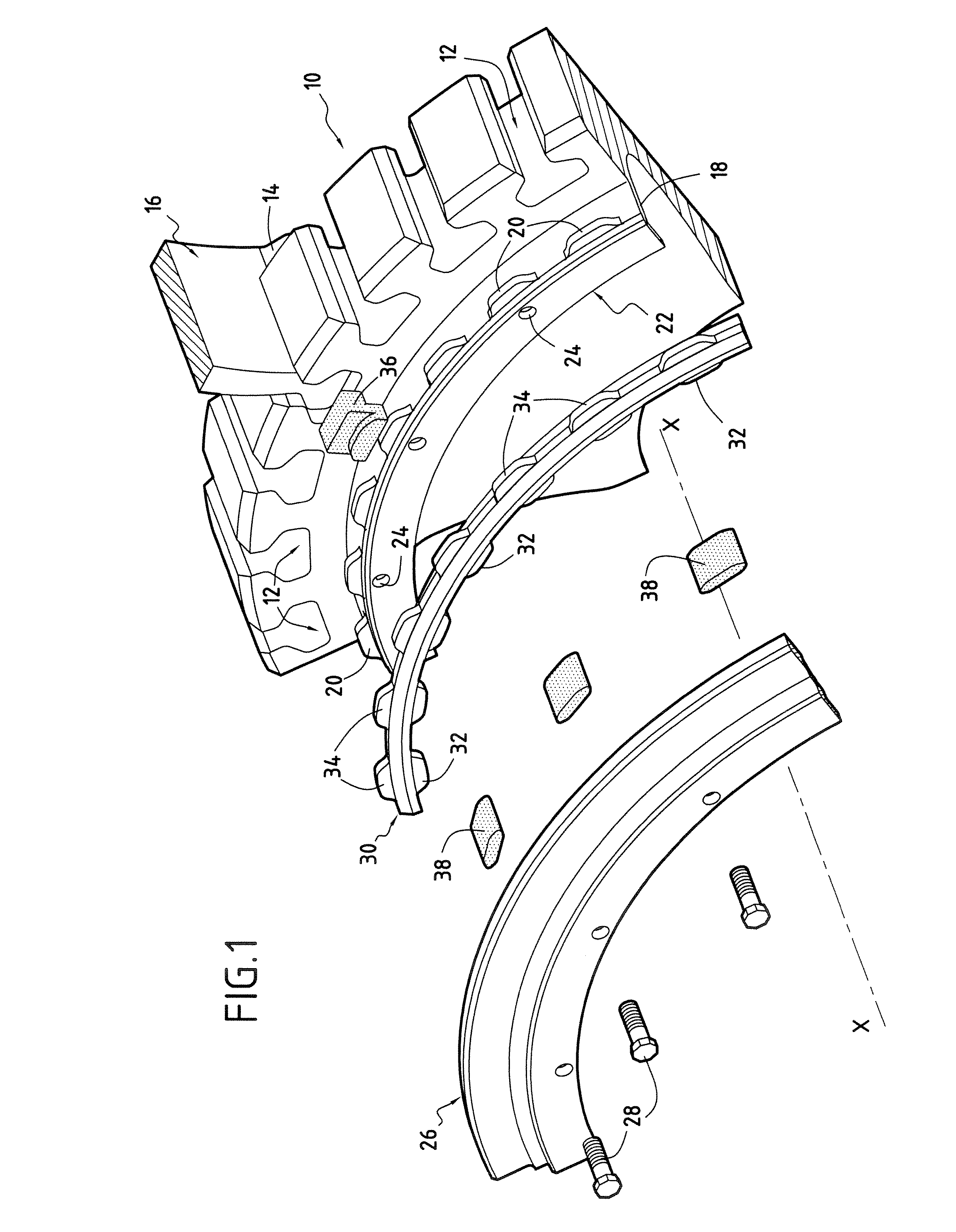

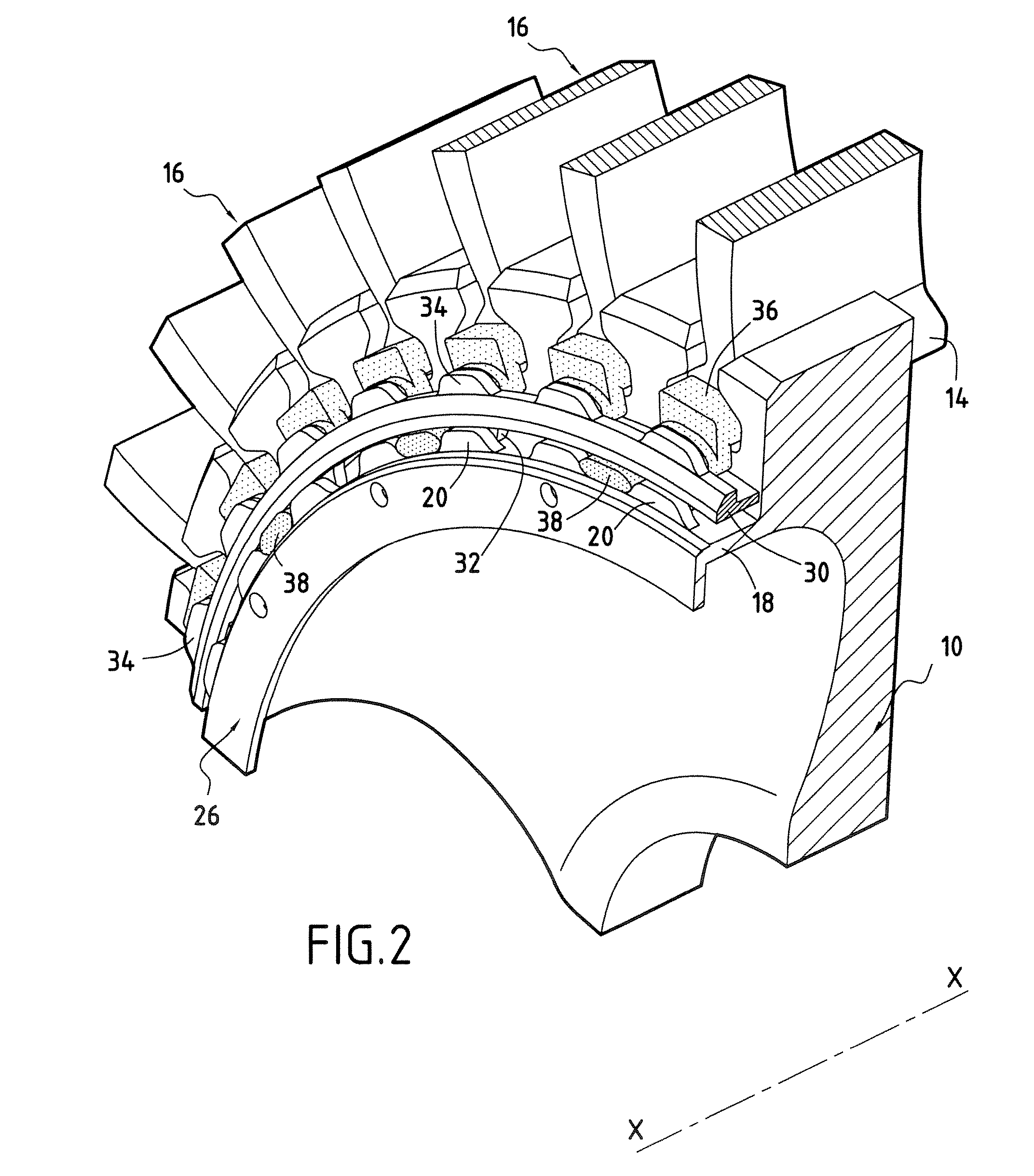

A device for damping vibration of a ring for axially retaining turbomachine fan blades

ActiveUS20070020089A1Mitigate such drawbackReduce riskEngine manufacturePump componentsElastomerMaterial Design

A device for damping vibration of a retention ring for axially retaining turbomachine fan blades, the blades being designed to be mounted via their roots on a rotary disk having an annular flange extending axially and provided with a plurality of radial crenellations for coming into contact with a plurality of complementary radial crenellations of a retention ring designed to be mounted around the disk flange, the device comprising an abutment element of elastomer material designed to be received axially between two adjacent crenellations of the flange and two adjacent complementary crenellations of the retention ring, and radially between the flange of the rotary disk and the retention ring, said abutment element presenting contact surfaces for coming into contact with the adjacent crenellations, with the retention ring, and with the flange of the rotary disk.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Extended stroke valve and diaphragm

ActiveUS20050006617A1Low costExtended service lifeDiaphragm valvesOperating means/releasing devices for valvesMaterial DesignCompound (substance)

An extended stroke poppet valve particularly suited for handling caustic fluids and having features enabling an extended service life for the valve. The valve includes a two part primary diaphragm assembly with a wetted diaphragm made from highly fatigue resistant fluoropolymer material, and a diaphragm backer made from high strength fluoropolymer material designed to withstand the high stress loads imposed by an extended valve stroke. The combination of these two layers in a single primary diaphragm assembly yields a highly durable, caustic chemical resistant, diaphragm capable of use in a long stroke poppet valve and having a relatively long service life.

Owner:ENTEGRIS INC

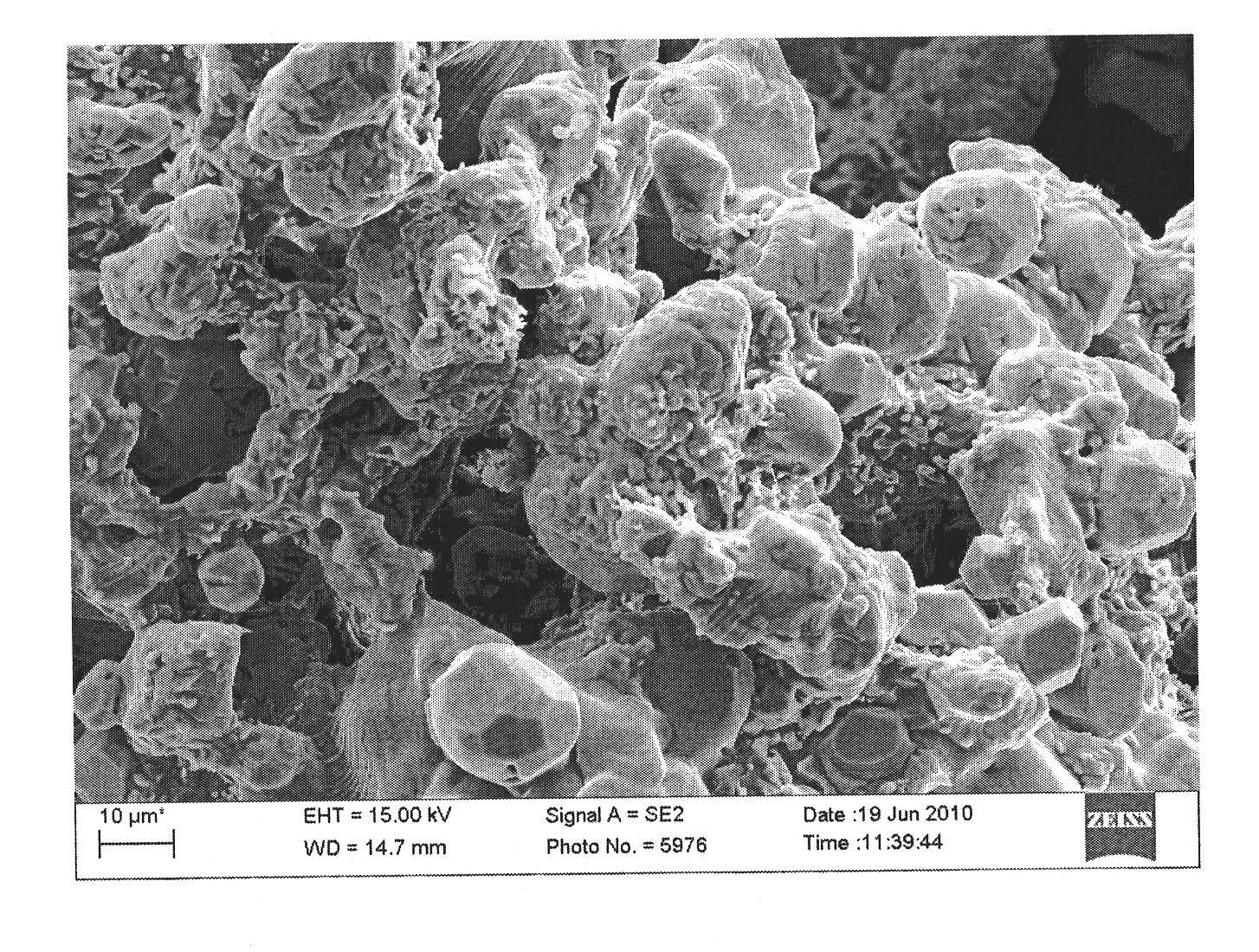

Preparation method of gradient pore porous high-niobium titanium-aluminum alloy

InactiveCN101967578AHigh porosityFree adjustment of porosity gradient changeMaterial DesignVacuum drying

The invention belongs to the field of porous metal materials and particularly relates to a preparation method of a gradient pore porous high-niobium titanium-aluminum alloy. The method comprises the following steps of: mixing pure titanium powder, pure aluminum powder and pure niobium powder and sintering the mixture by a Kerkendill effect reaction pore-forming method and a pore-forming agent physical pore-forming method; adding a plurality of ingredients; compacting the ingredients which contain different pore-forming agents and have different content into single blanks respectively; rolling a plurality of single blanks with different pore-forming agent content into the total blank; and performing a vacuum drying degreasing pore-foaming and high-temperature sintering reaction pore-forming process so as to finally obtain a porous high-niobium titanium-aluminum alloy material with a gradient hole structural characteristic and adjustable porosity. The material has gradient porosity change, optionally-adjustable pore structural characteristic, adjustable stress cross section, light weight, high specific stiffness and high heat insulation performance; simultaneously, the material has high material design flexibility and can be widely applied to the industrial fields of high temperature heat insulation, filtering separation, catalysis and the like.

Owner:UNIV OF SCI & TECH BEIJING

Soft magnetic film inductor and magnetic multi-component alloy thin film

InactiveCN101320617AIncrease disorderHigh nanocrystalline structureInductances/transformers/magnets manufactureMagnetic layersMaterial DesignHigh entropy alloys

A magnetic complex alloy film is suitable for high frequency operation. This magnetic complex alloy film is used for improving the quality factors of the film inductance under high frequency operation and improving the inductance value. This magnetic complex alloy film achieves that the magnetic complex alloy film still has good soft magnetic property when under high frequency operation mainly through leading the materials design concept of complex high-entropy alloy and utilizing some material properties of the complex high-entropy alloy, such as high randomness, nano microcrystalline structure, low coercive field and high resistivity.

Owner:IND TECH RES INST

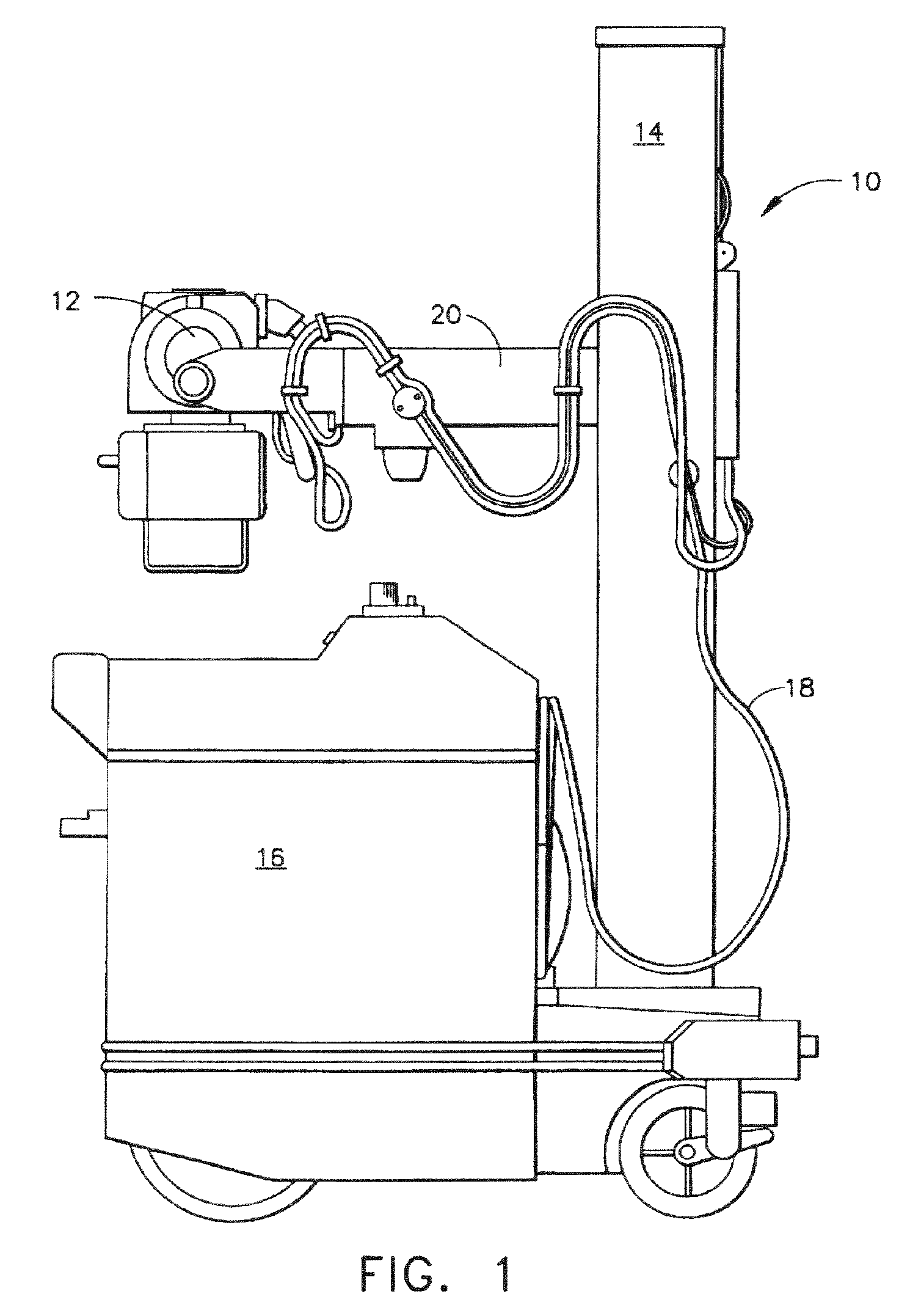

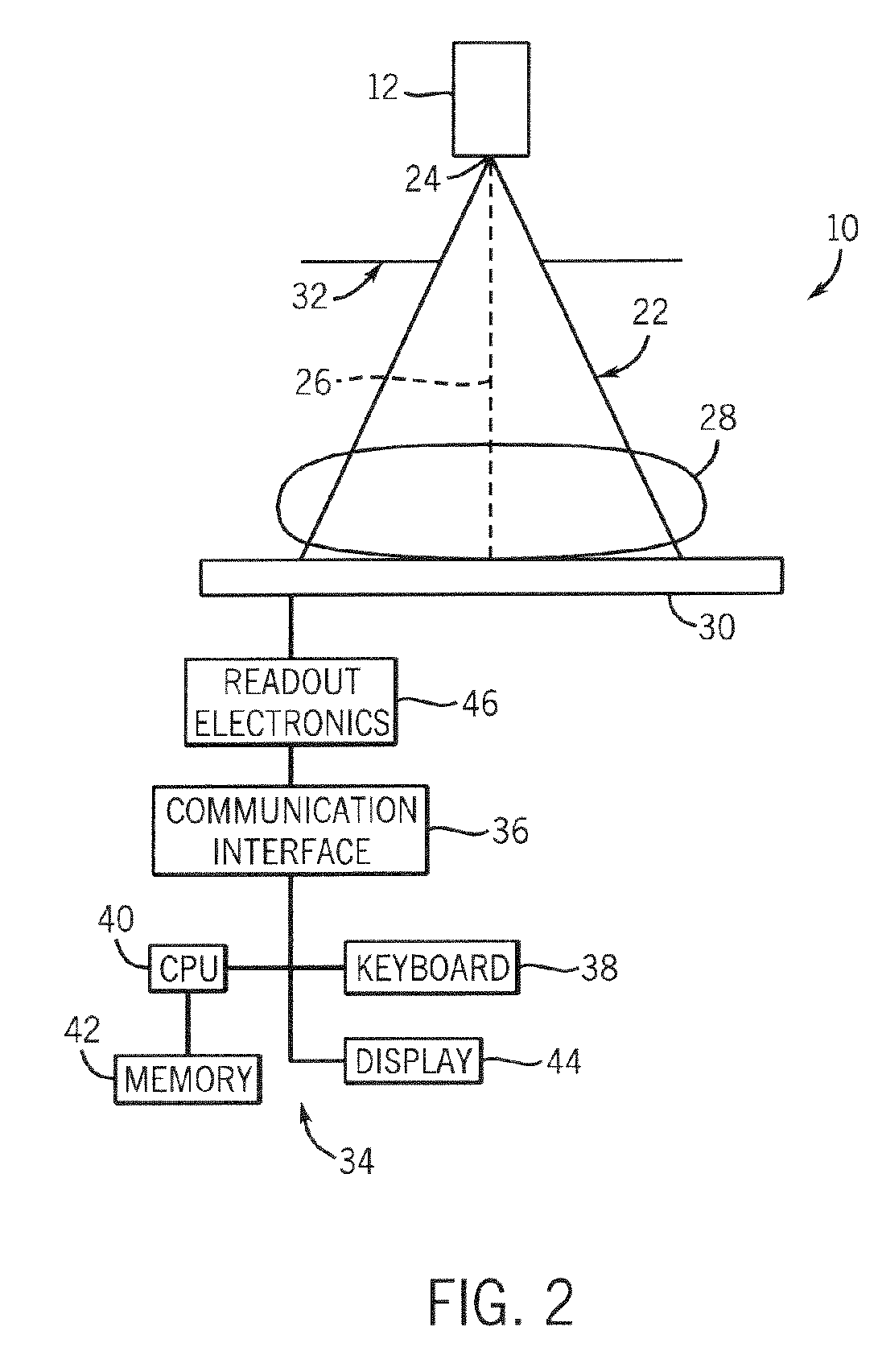

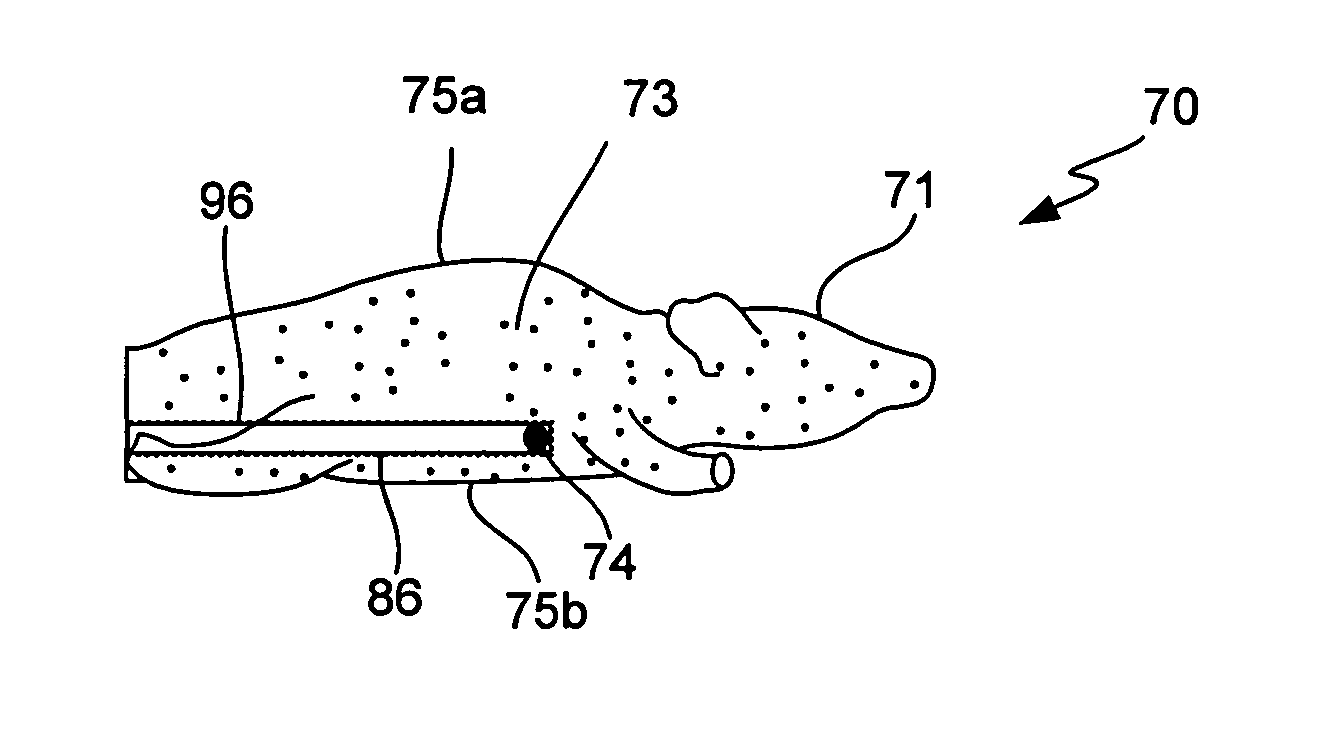

Phantom calibration device for low level light imaging systems

ActiveUS20050145786A1Simplifies usageEasy to testBioreactor/fermenter combinationsBiological substance pretreatmentsLow intensity lightMaterial Design

The present invention relates to a phantom device that simplifies usage and testing of a low intensity light imaging system. The phantom device includes a body and a light source internal to the body. The body comprises an optically selective material designed to at least partially resemble the optical behavior of mammalian tissue. Imaging the light source or phantom device may incorporate known properties of the optically selective material. Testing methods described herein assess the performance of a low-level light imaging system (such as the software) by processing light output by the phantom device and comparing the output against known results. The assessment builds a digital representation of the light source or test device and compares one or more components of the digital representation against one or more known properties for the light source or the test device.

Owner:XENOGEN CORP

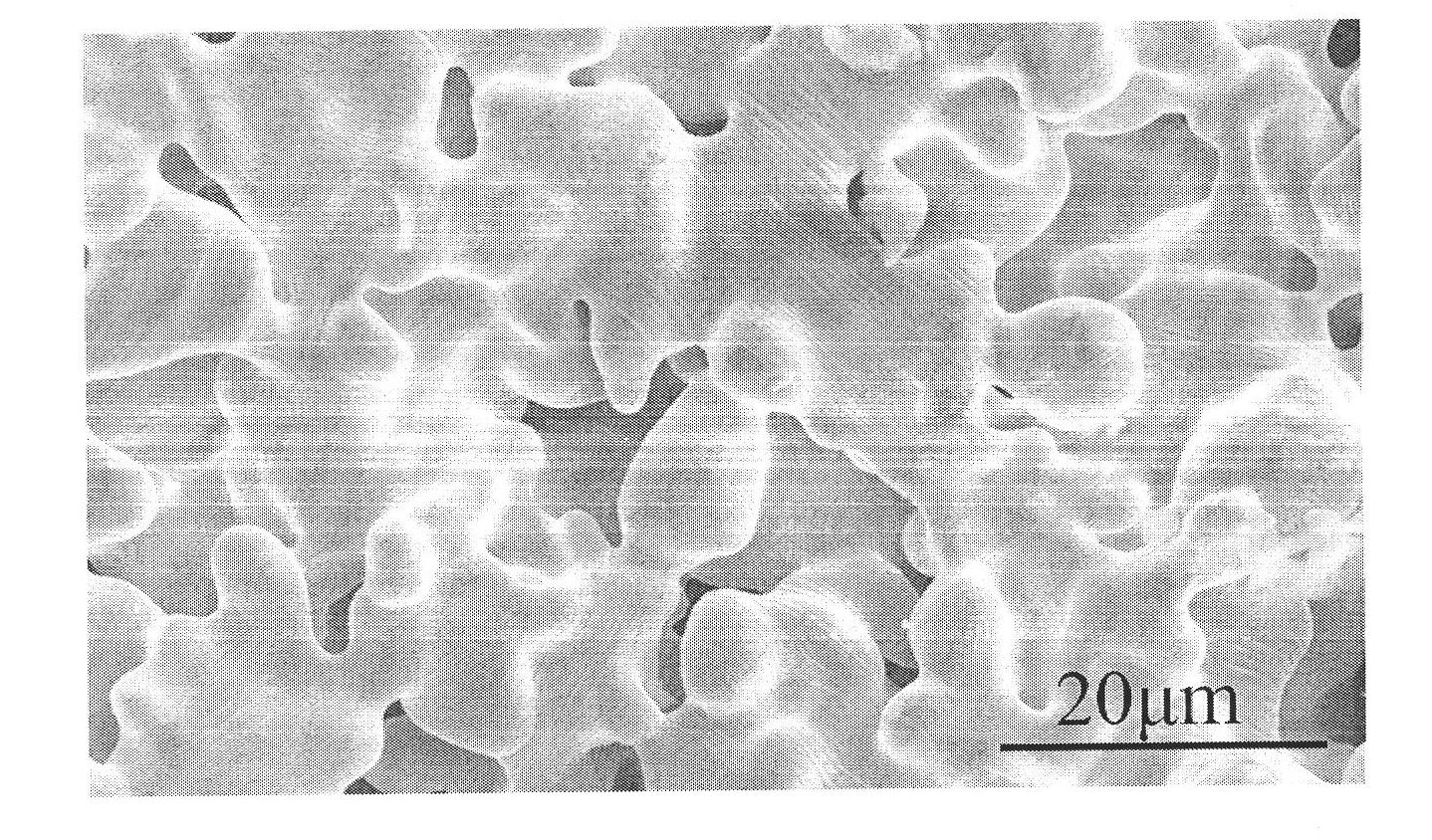

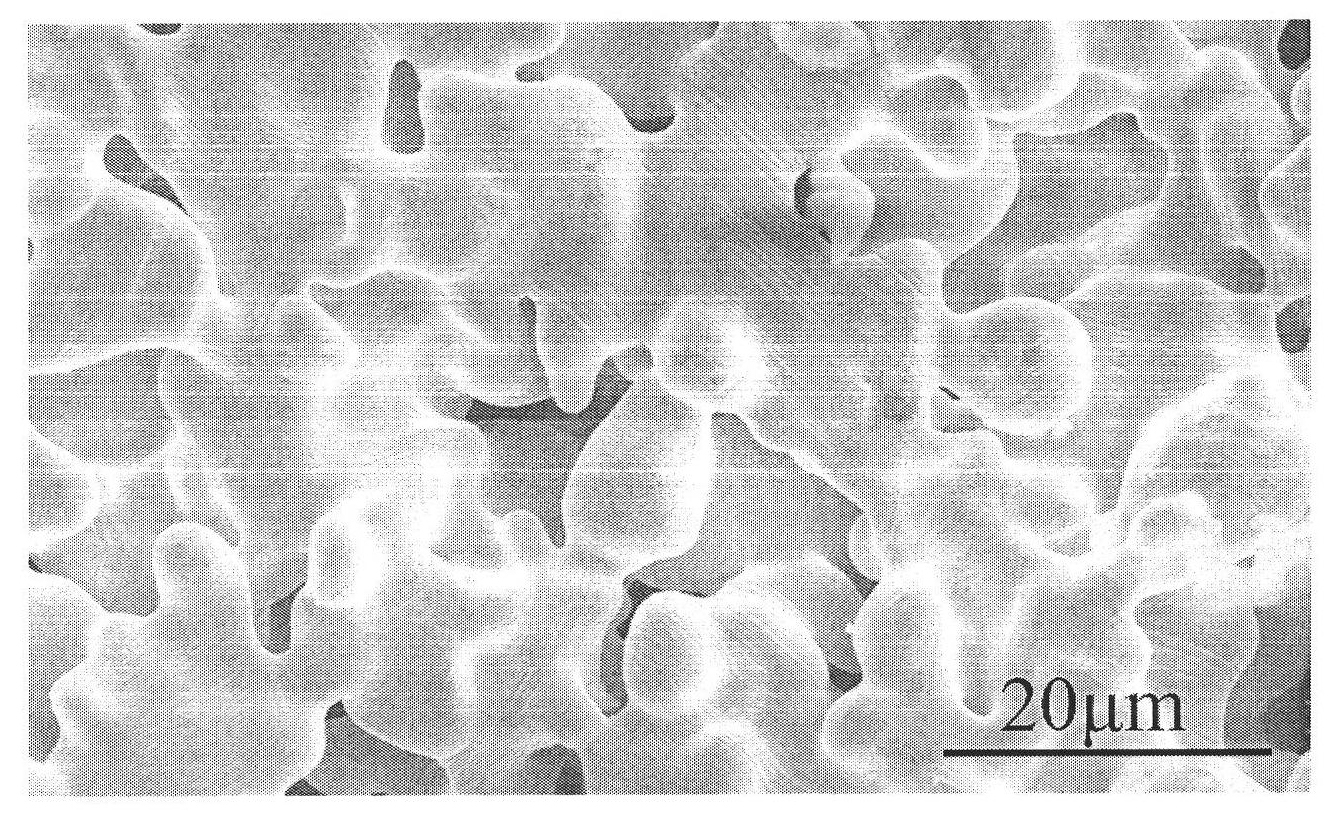

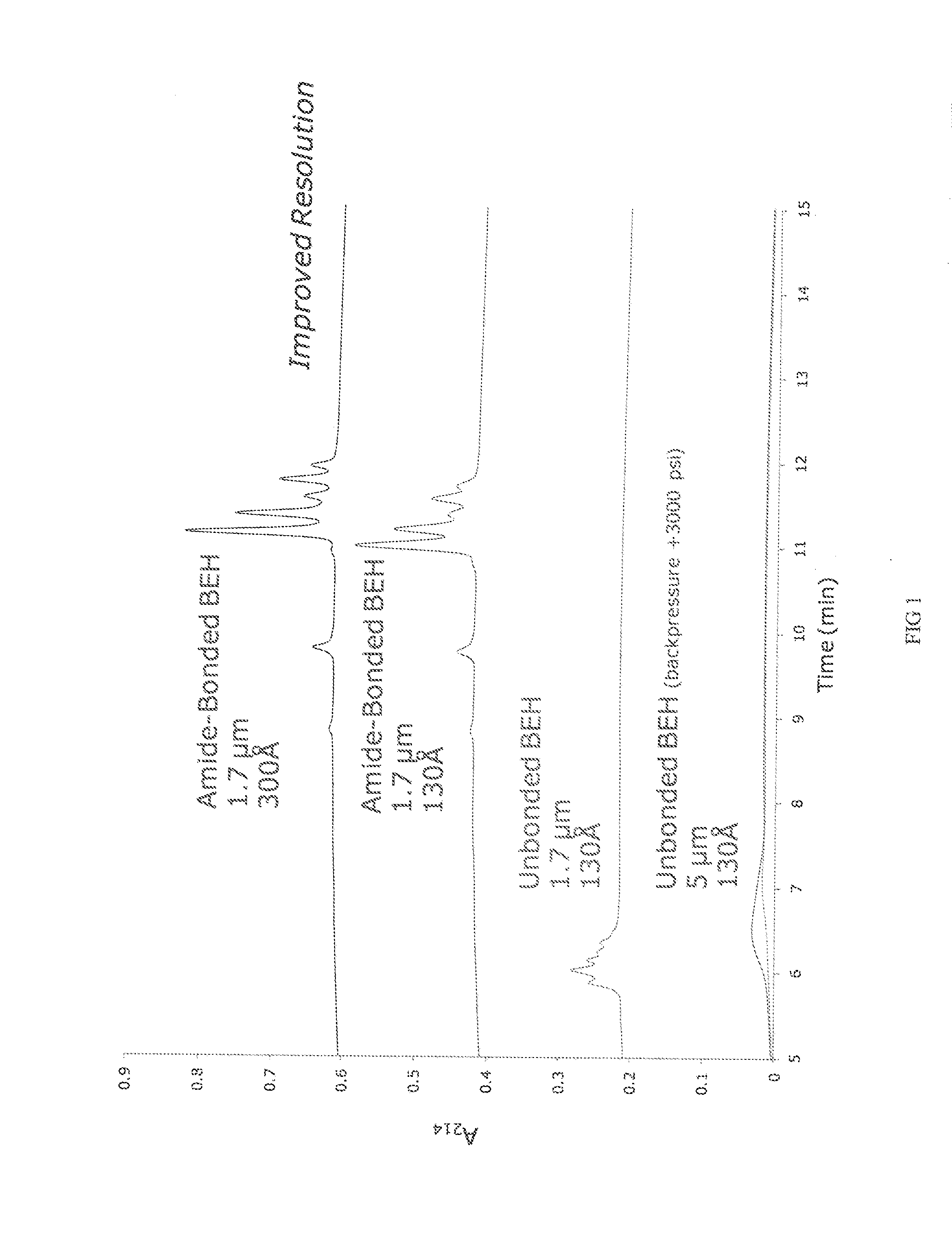

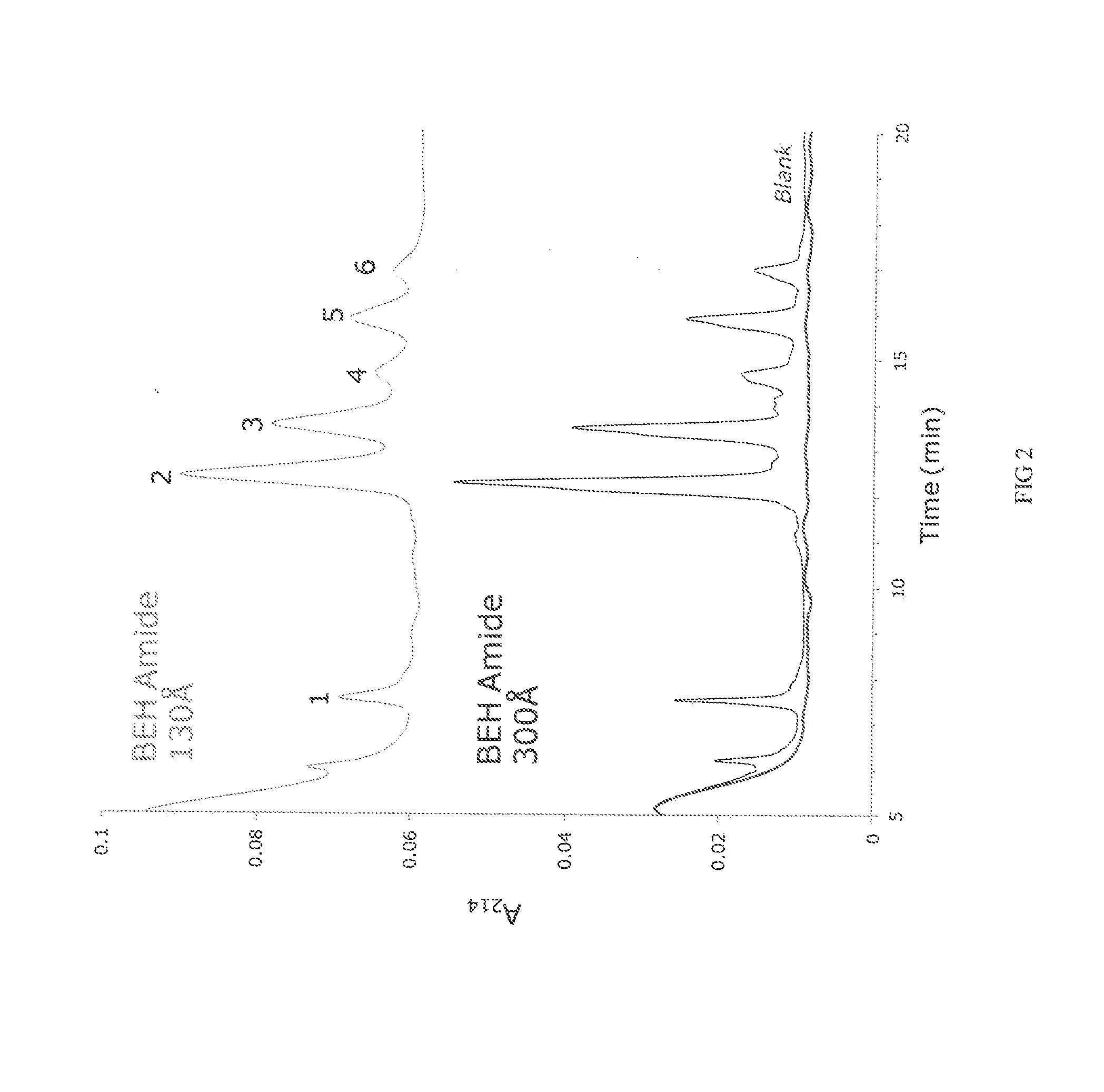

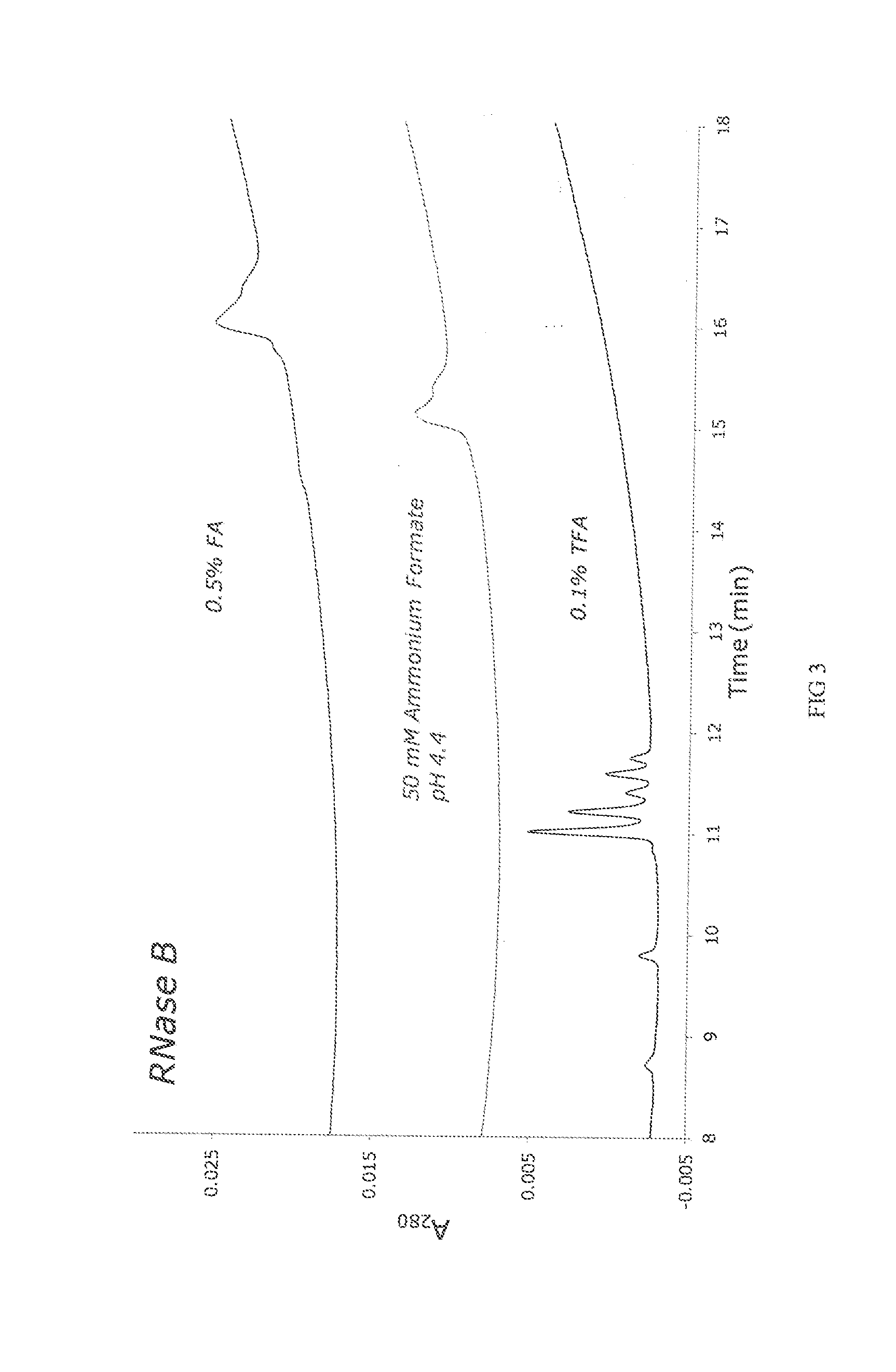

Materials for hydrophilic interaction chromatography and processes for preparation and use thereof for analysis of glycoproteins and glycopeptides

ActiveUS20150204824A1High resolutionDesirable retentivityComponent separationSurface/boundary effectMaterial DesignGlycan

The invention relates to poly-amide bonded hydrophilic interaction chromatography (HILIC) stationary phases and novel HILIC methods for use in the characterization of large biological molecules modified with polar groups, known to those skilled in the art as glycans. The invention particularly provides novel, poly-amide bonded materials designed for efficient separation of large biomolecules, e.g. materials having a large percentage of larger pores (i.e. wide pores). Furthermore, the invention advantageously provides novel HILIC methods that can be used in combination with the stationary phase materials described herein to effectively separate protein and peptide glycoforms by eliminating previously unsolved problems, such as on-column aggregation of protein samples, low sensitivity of chromatographic detection of the glycan moieties, and low resolution of peaks due to restricted pore diffusion and long intra / inter-particle diffusion distances.

Owner:WATERS TECH CORP

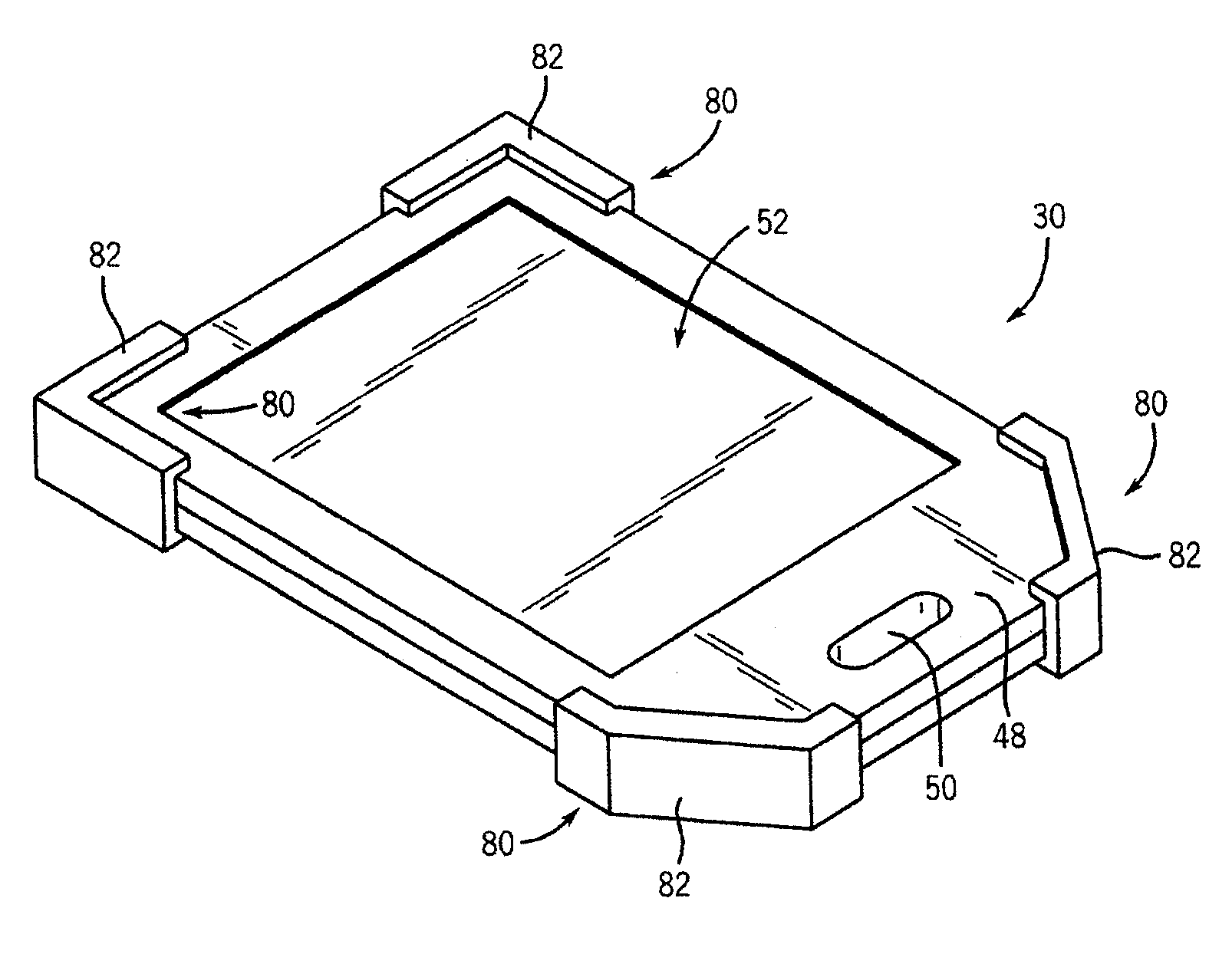

X-ray detector with impact absorbing cover

The present invention is a directed to a cover assembly for an x-ray detector that incorporates impact-absorbing material designed to absorb the shock, vibration, stress, and strain placed on the detector when dropped or subjected to a load. The cover assembly may include a layer or inserts of impact-absorbing material. Bumpers of impact-absorbing material may also be secured to the x-ray detector cover. Viscoelastic foam or other plastics may be used as the impact-absorbing material.

Owner:GENERAL ELECTRIC CO

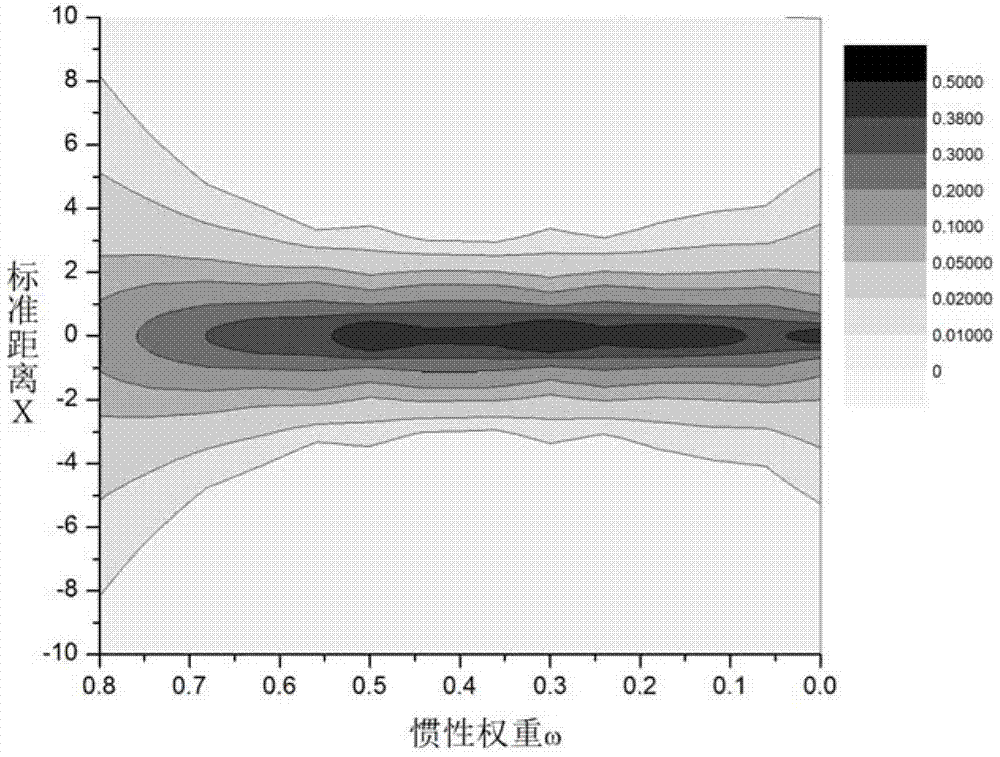

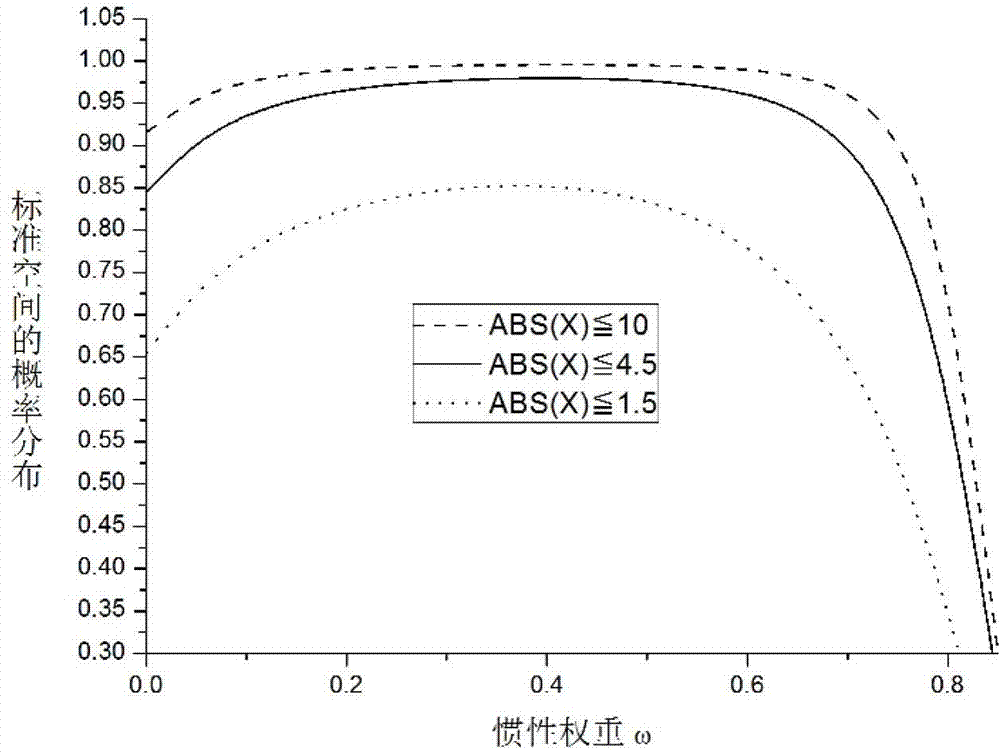

Method for determining ply angle direction and thickness of laminated board composite material

ActiveCN103034766AReduce weightHigh precisionSpecial data processing applicationsMaterial DesignEngineering

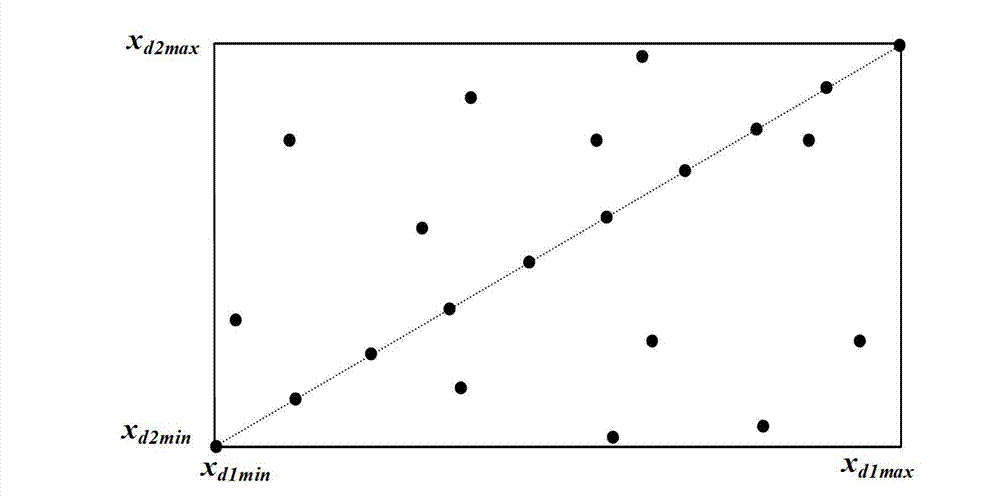

The invention relates to a method for determining the ply angle direction and thickness of a laminated board composite material. The method comprises the following steps of: (1) establishing a laminated board composite material design model, converting discrete variable in the model into continuous variable, adding corresponding restraints and generating a plurality of particles according to a specific initialization scheme, wherein the coordinate value of each particle is a design scheme; (2) recording the initial coordinate value of each particle as an individual optimal scheme to further obtain a global optimal design scheme; (3) updating positions of the particles first by using a particle swarm design method, and carrying out different maximum-iterations mathematical programming designs according to different types of the particles; (4) obtaining a new potential design scheme of the laminated board composite material and updating the individual and global optimal design schemes; (5) judging whether convergence conditions are met, and if not, turning to the step (3); and (6) taking the ply thickness in the global optimal design scheme and the ply direction of the rounded laminated board composite material as a final design scheme of the laminated composite material.

Owner:BEIHANG UNIV

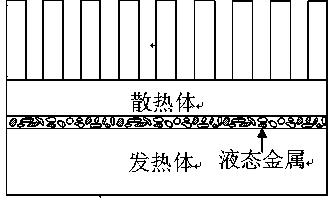

Zinc-containing multiphase liquid metal thermal interface material and preparation method thereof

The invention discloses a zinc-containing multiphase liquid metal thermal interface material and a preparation method thereof. The zinc-containing multiphase liquid metal thermal interface material comprises the following components: by weight, 30-40% of bismuth, 10-20% of tin, 10-20% of zinc, and the balance of indium. The multiphase structure liquid metal thermal interface material designed by the invention is a quaternary alloy, is completely in a solid structure at room temperature and rolling temperature, and in a liquid-solid state at working temperature. In the working status, the solid content is about 60%. The multiphase structure liquid metal thermal interface material can maintain the liquid-solid state in a large range of working temperature, can fully inhibit the heated melting fluidity of a low melting point alloy foil, and can eliminate the liquid droplet leak problem. In addition, the thermal interface material thickness remains in the vicinity of 0.04mm, and the liquid phase surface tension can be further used to achieve the anti leakage effect..

Owner:NINGBO SYRNMA METAL MATERIALS CO LTD

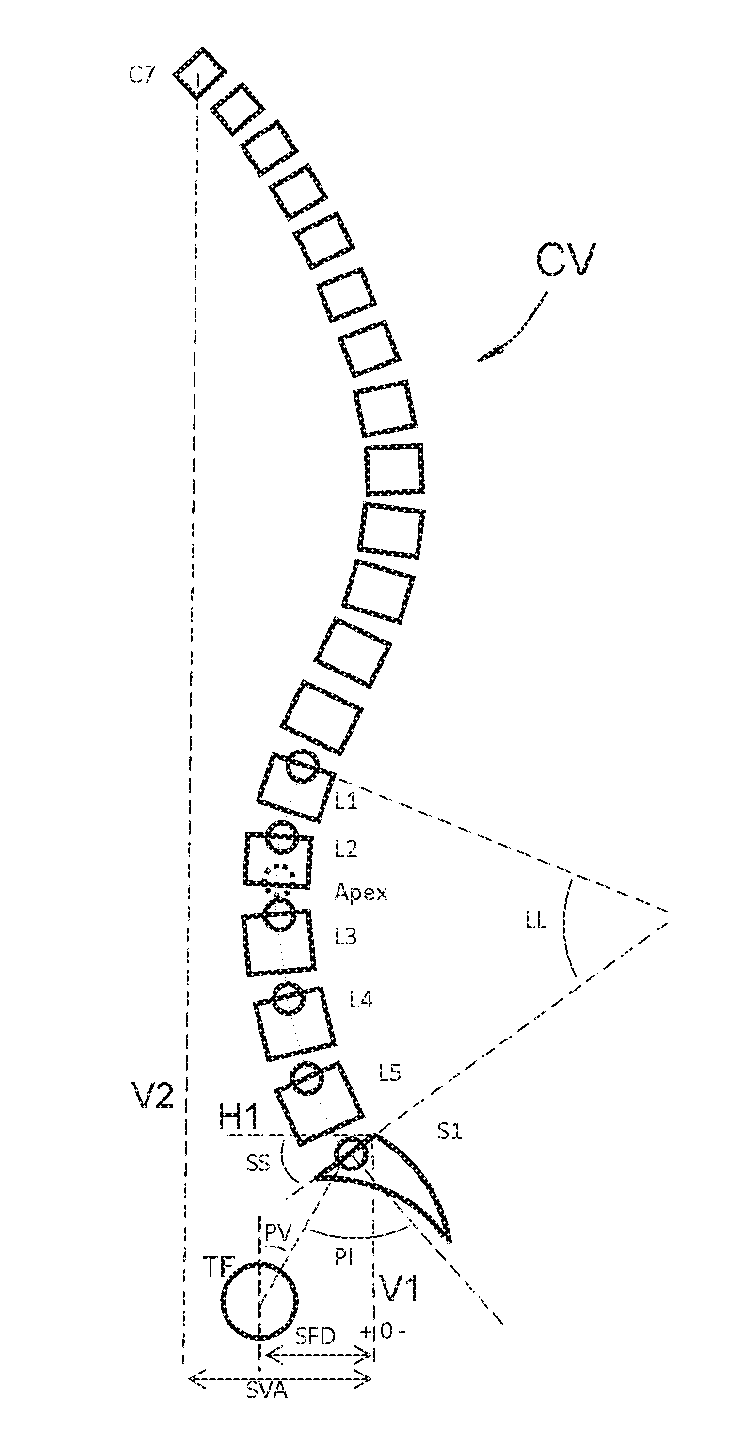

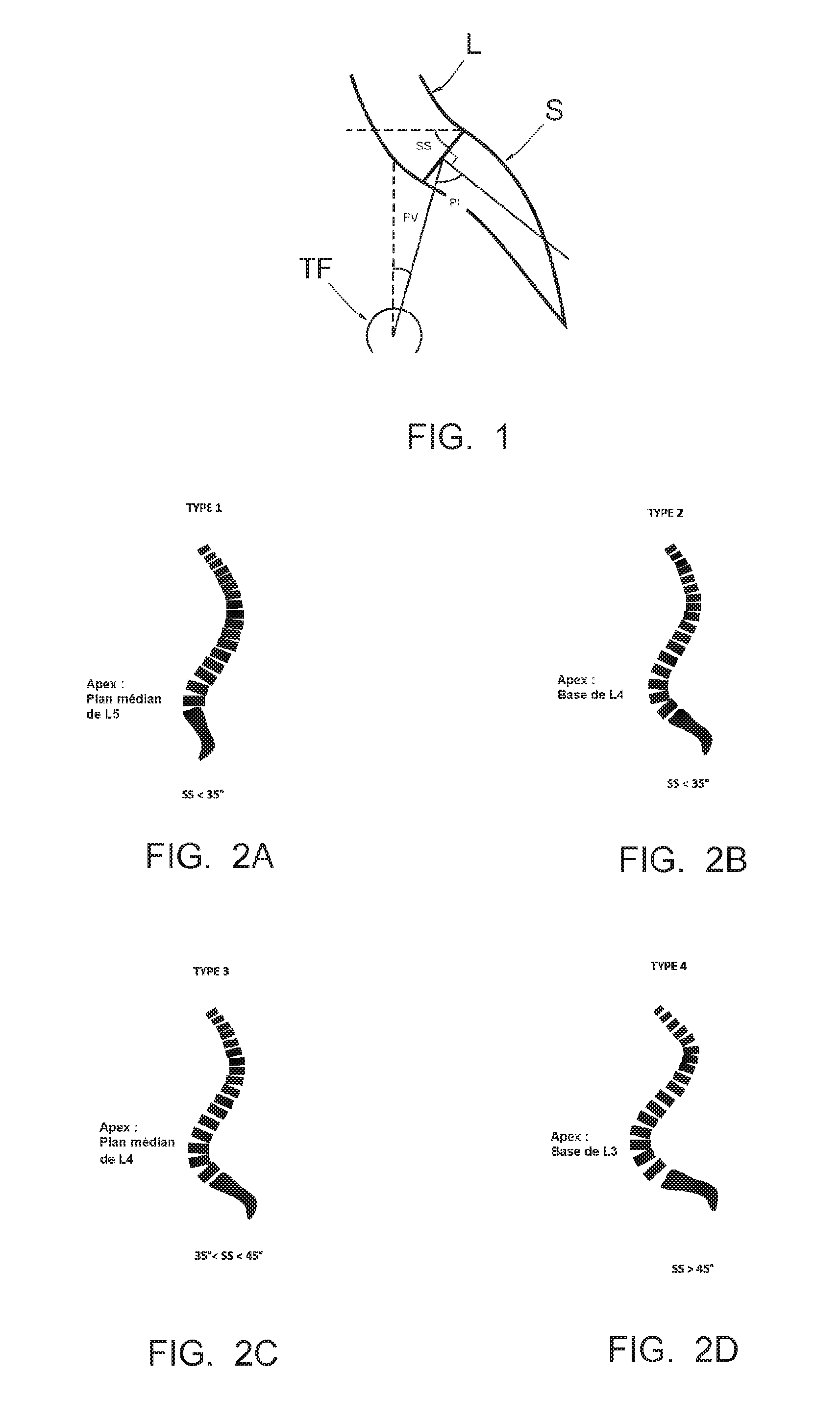

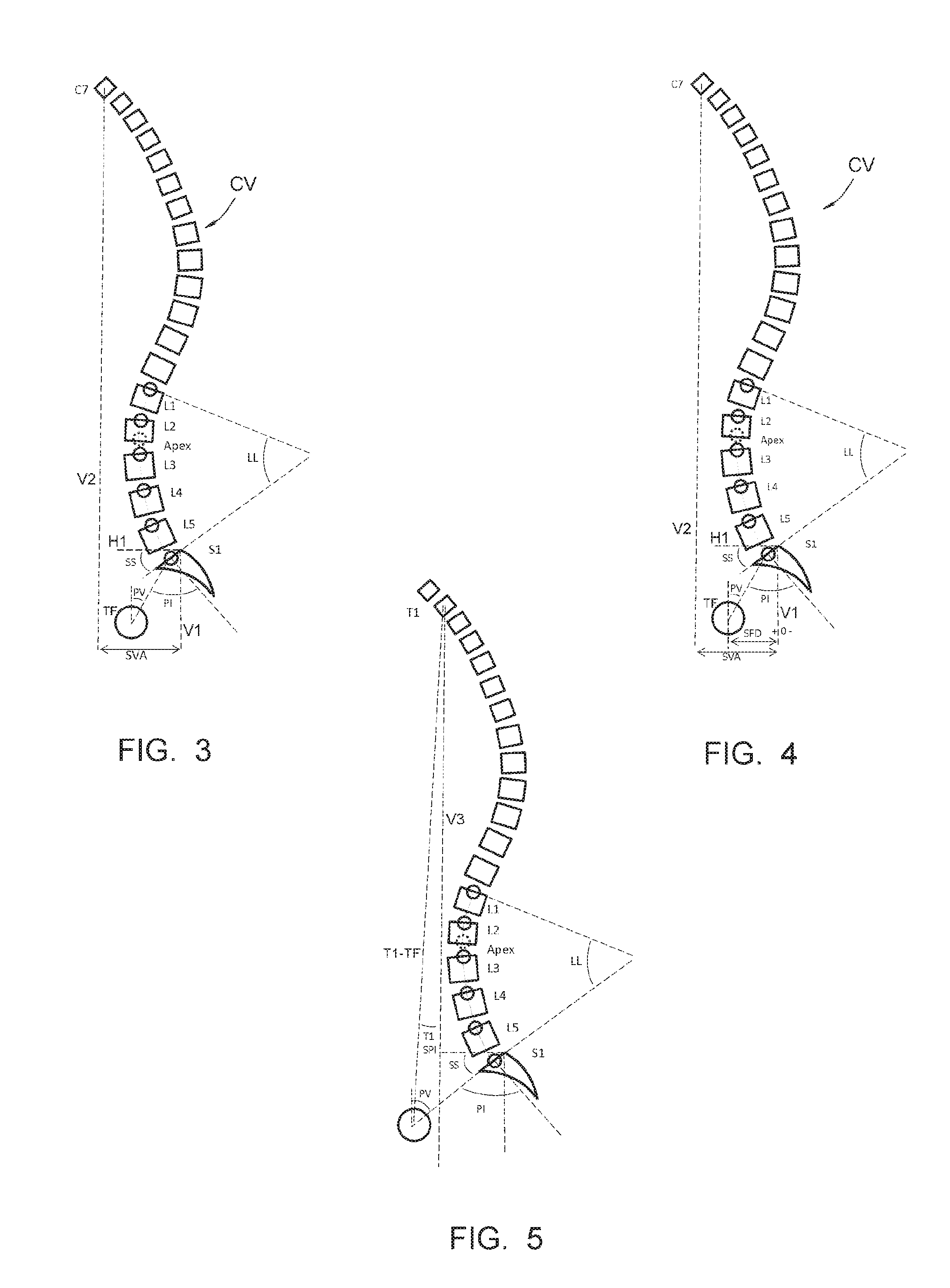

Method making it possible to produce the ideal curvature of a rod of vertebral osteosynthesis material designed to support a patient's vertebral column

ActiveUS20160210374A1Internal osteosythesisComputer-aided planning/modellingSpinal columnRight femoral head

The method according the the invention comprises the following steps: a) taking a sagittal preoperative x-ray of the vertebral column of the patient to be treated, extending from the cervical vertebrae to the femoral heads; b) on that x-ray, identifying the pelvic parameters, the lumbar lordosis, the position of the apical lumbar vertebra, distances called SVA and SFD and a cloud of points; c) deducing, among predetermined morphotypes, the morphotype to which the treated vertebral column corresponds and deducing therefrom the desired postoperative apex point; d) positioning the different points of the cloud of points in a reference centered at the plate of S1; e) simulating the correction to be applied to the lumbar segment to be treated, by defining co-radial arcs situated below and above the desired postoperative apex point; defining two arcs concentric to the two curvatures obtained, which are tangent to each other at the apex point; f) translating these arcs away from the mean line of the vertebral column and defining a two- or three-dimensional model of the rod to be implanted, curved along the arcs.

Owner:MEDICREA INT SA

Degradable lamellar Zn-Mg composite material and preparation method thereof

ActiveCN108237214AGood biocompatibilityPromote degradationSurgeryMetallic material coating processesMg compositeMaterial Design

The invention discloses a degradable lamellar Zn-Mg composite material and a preparation method thereof. The outer layer of a lamellar medical metal composite material is made of pure zinc or zinc alloy, and the core part of the lamellar medical metal composite material is made of pure magnesium or magnesium alloy; the ratio of zinc or zinc alloy and magnesium or magnesium alloy is calculated according to volume percentage, zinc or zinc alloy accounts for 20%-50% of the total volume of the material, and the balance is magnesium or magnesium alloy. The lamellar composite material is prepared bycombining layered casting with nested extruding. The degradable lamellar Zn-Mg composite material has the advantages that: the selected magnesium alloy and the selected zinc alloy have good biocompatibility and degradability; mechanical properties and a degradation rate of the integral composite material are controlled by controlling a relative thickness of a Zn layer to a Mg layer, so that the composite material adapts to a service environment, and therefore, a condition that single metal is too quick or too slow in degradation is solved. The material design and the preparation method are simple and convenient, and the cost is low, so that industrial production is facilitated.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Polycell collaborative coupling acoustic meta-material design method

InactiveCN109754777AImproved sound insulationImprove sound insulationSound producing devicesLow noiseMaterial Design

The invention discloses a polycell collaborative coupling acoustic meta-material design method. The method comprises a structure design method with insufficient localization rigidity and a structure design method with sufficient localization rigidity, wherein the structure design method with insufficient localization rigidity adopts a separating framework with localization rigidity lower than thinplate rigidity to separate local area resonance cells, so that strong coupling resonance behaviors of a single cell is generated, and a polycell combined structure with lumped coupling resonance effect is formed; the structure design method with sufficient localization rigidity adopts the separating framework with localization rigidity higher than thin plate rigidity, so that resonance of a single cell is not mutually affected within a design frequency band; and cells with gradient distribution of multiple thin plate widths, thin plate thicknesses or additionally mass block weight structure parameters define a polycell combined structure. The polycell collaborative structure can be applied to various transfer tools and various building decorations, and provides a brand-new denoising scheme for creating a low-noise environment.

Owner:XI AN JIAOTONG UNIV

Device for damping vibration of a ring for axially retaining turbomachine fan blades

ActiveUS7458769B2Mitigate such drawbackReduce riskPropellersEngine manufactureElastomerMaterial Design

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

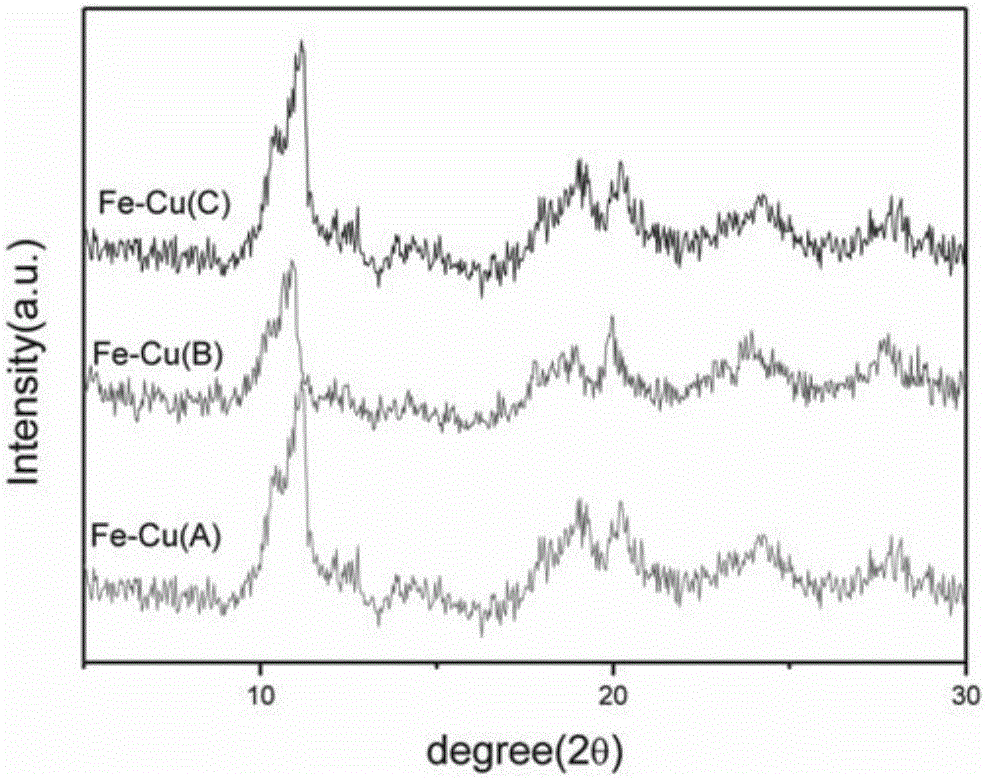

Method for preparing supported bimetal organic framework material MIL-100(Fe-Cu) and denitration application

InactiveCN106268952ACheap sourceUniform crystal formOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationDispersityMaterial Design

The invention provides a method for preparing a supported bimetal organic framework material MIL-100(Fe-Cu) and denitration application, and belongs to the field of novel material design and preparation. By means of the post-synthesis modification method, the Cu element is successfully introduced into an original MOFs framework, and a novel MOFs material with bimetal active sites is constructed. The method is characterized in that the hydrothermal technology is used, a metal precursor solution is prepared by means of stabilizer to be effectively combined with Fe-MOFs, and the material MIL-100(Fe-Cu) is prepared and used for denitration reaction. Compared with an original monometal catalyst, a catalyst prepared through the method has unsaturated active sites of Fe3+ and Cu+, denitration activity is improved by about 15%, and the material is good in dispersity, high in yield and good in catalytic activity.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com