Zinc-containing multiphase liquid metal thermal interface material and preparation method thereof

A technology of thermal interface material and liquid metal, which is applied in the field of heat dissipation materials, can solve problems such as short circuits of microelectronic devices and circuit boards, and achieve the effect of inhibiting fluidity and eliminating droplet leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

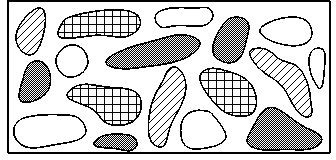

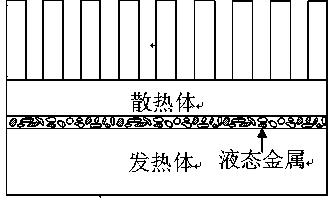

Image

Examples

Embodiment 1

[0016] A multi-phase liquid metal thermal interface material is composed of indium, bismuth, tin and zinc, and the weight ratio of each component is 30% bismuth, 10% tin, 20% zinc and 40% indium. The melting point is between 70-120°C. The alloy prepared according to the formula is melted in a vacuum induction furnace and then cast into a casting with a thickness of about 1 mm. Carry out rough rolling, intermediate rolling and finish rolling at lower than 60°C according to the rolling process mentioned above, lubricated with rolling oil, the reduction pass of rough rolling is: 1mm-0.4mm-0.2mm-0.1mm; Rolling: Intermediate rolling of rough-rolled wool, lubricated with rolling oil, and the next pass of intermediate rolling: 0.1mm-0.06mm; Finish rolling: Put the material after intermediate rolling into the finishing mill, and use rolling oil for rolling. Lubricating, the reduction pass of finish rolling is 0.06mm-0.04mm; the alloy foil with a thickness of 0.04mm is finally produce...

Embodiment 2

[0018] A multi-phase liquid metal thermal interface material is composed of indium, bismuth, tin and zinc, and the weight ratio of each component is 40% bismuth, 20% tin, 10% zinc and 30% indium. The melting point is between 70-120°C. The alloy prepared according to the formula is melted in a vacuum induction furnace and then cast into a casting with a thickness of about 1 mm. Carry out rough rolling, intermediate rolling and finish rolling at lower than 60°C according to the rolling process mentioned above, lubricated with rolling oil, the reduction pass of rough rolling is: 1mm-0.4mm-0.2mm-0.1mm; Rolling: Intermediate rolling of rough-rolled wool, lubricated with rolling oil, and the next pass of intermediate rolling: 0.1mm-0.06mm; Finish rolling: Put the material after intermediate rolling into the finishing mill, and use rolling oil for rolling. Lubricating, the reduction pass of finish rolling is 0.06mm-0.04mm; the alloy foil with a thickness of 0.04mm is finally produce...

Embodiment 3

[0020] A multi-phase liquid metal thermal interface material is composed of indium, bismuth, tin and zinc, and the weight ratio of each component is 35% bismuth, 15% tin, 15% zinc and 35% indium. The melting point is between 70-120°C. The alloy prepared according to the formula is melted in a vacuum induction furnace and then cast into a casting with a thickness of about 1 mm. Carry out rough rolling, intermediate rolling and finish rolling at lower than 60°C according to the rolling process mentioned above, lubricated with rolling oil, the reduction pass of rough rolling is: 1mm-0.4mm-0.2mm-0.1mm; Rolling: Intermediate rolling of rough-rolled wool, lubricated with rolling oil, and the next pass of intermediate rolling: 0.1mm-0.06mm; Finish rolling: Put the material after intermediate rolling into the finishing mill, and use rolling oil for rolling. Lubricating, the reduction pass of finish rolling is 0.06mm-0.04mm; the alloy foil with a thickness of 0.04mm is finally produce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com