Composite tank, manufacturing method therefor, and wing

A technology of composite material tank and manufacturing method, which is applied in the direction of wings, fuel tank safety measures, power plant fuel tanks, etc., can solve the problems of CFRP strength degradation and achieve the effect of suppressing flow electrification and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

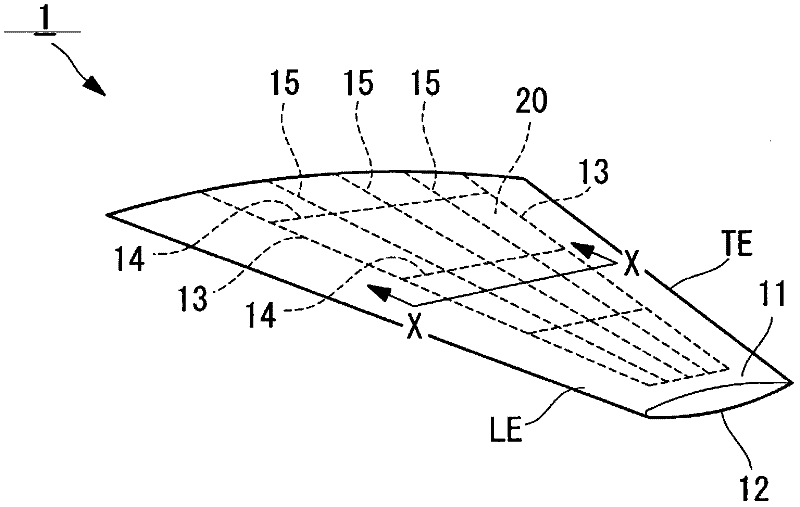

[0048] refer to Figure 1 ~ Figure 4 A main wing according to one embodiment of the present invention will be described.

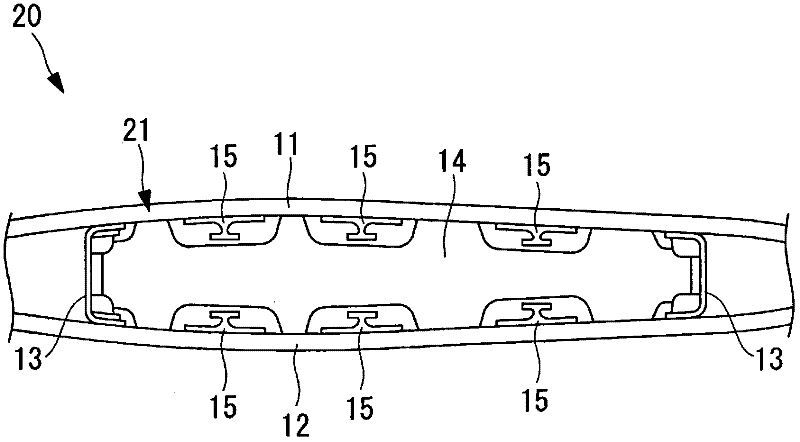

[0049] figure 1 It is a perspective view explaining the structure of the main wing provided with the fuel tank of this embodiment. figure 2 is description figure 1 X-X sectional view of the composition of the fuel tank.

[0050] In this embodiment, a structure in which a fuel tank (composite material tank) 20 is integrally formed inside is applied to a main wing (wing) 1 of an aircraft made of a composite material such as CFRP and described.

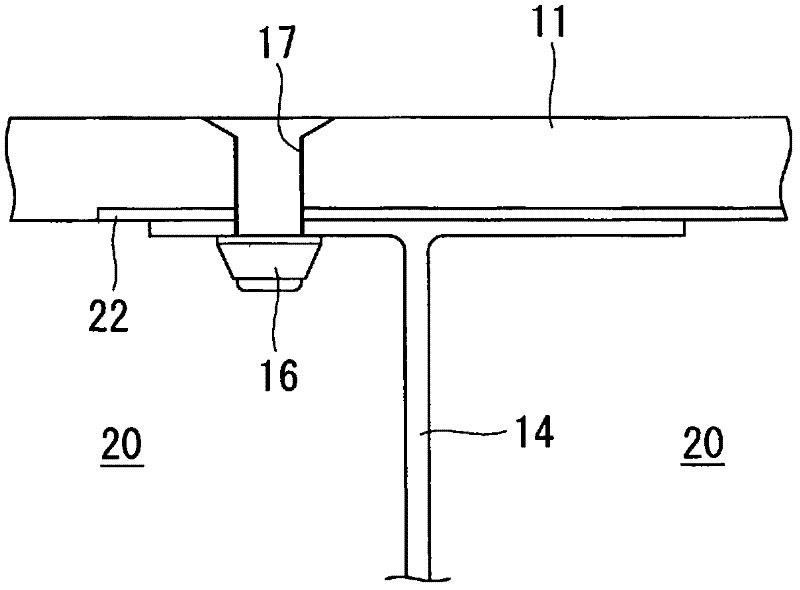

[0051] like figure 1 and figure 2 As shown, the main wing 1 is mainly provided with an upper wing outer panel 11 , a lower wing outer panel 12 , a spar 13 , a rib 14 , and a longitudinal beam 15 . These upper wing outer panels 11 , lower wing outer panels 12 , spars 13 , ribs 14 , and longitudinal beams 15 constitute the main structural parts of the main wing 1 , that is, wing boxes.

[0052] Furthermore, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com